Vertically-oriented graphene/nanofiber composite membrane material and preparation method and application thereof

A nanofiber, vertical orientation technology, applied in the field of materials, can solve the problems of low efficiency and energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

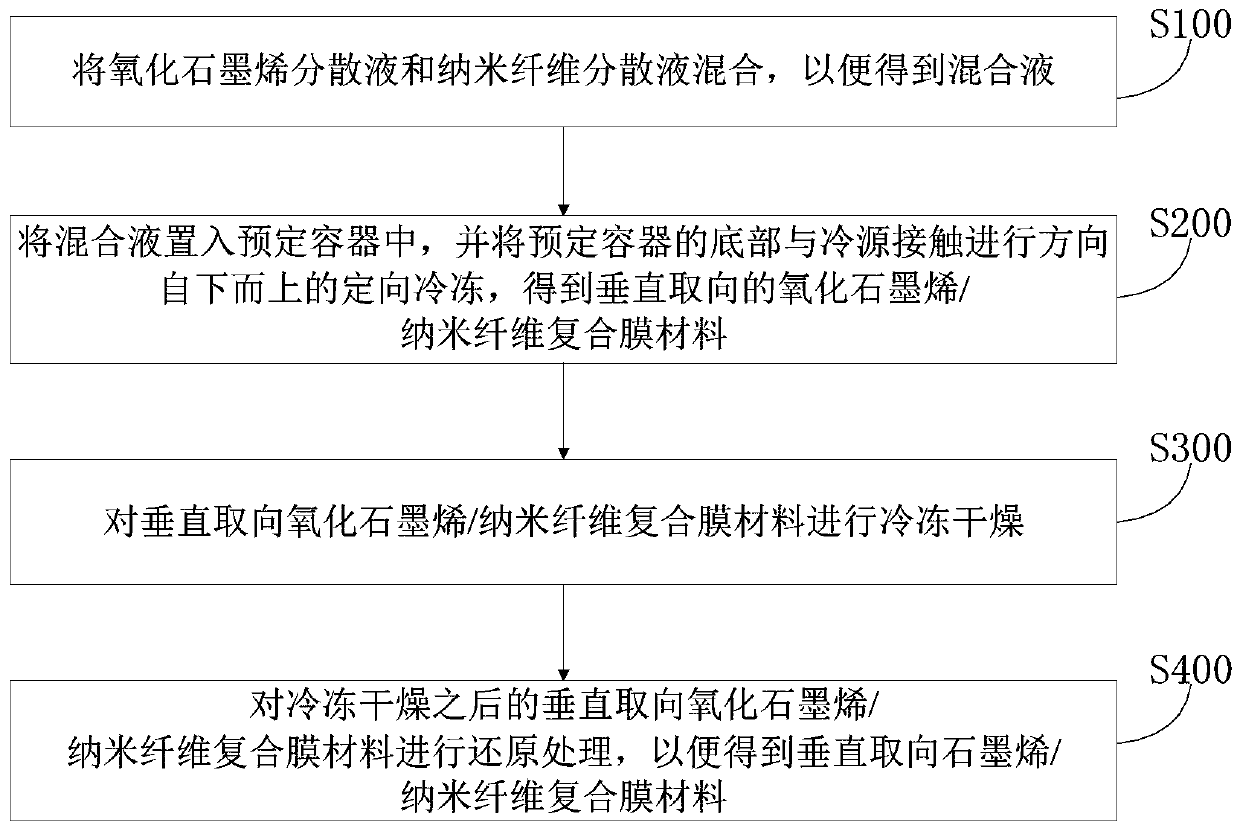

Method used

Image

Examples

preparation example Construction

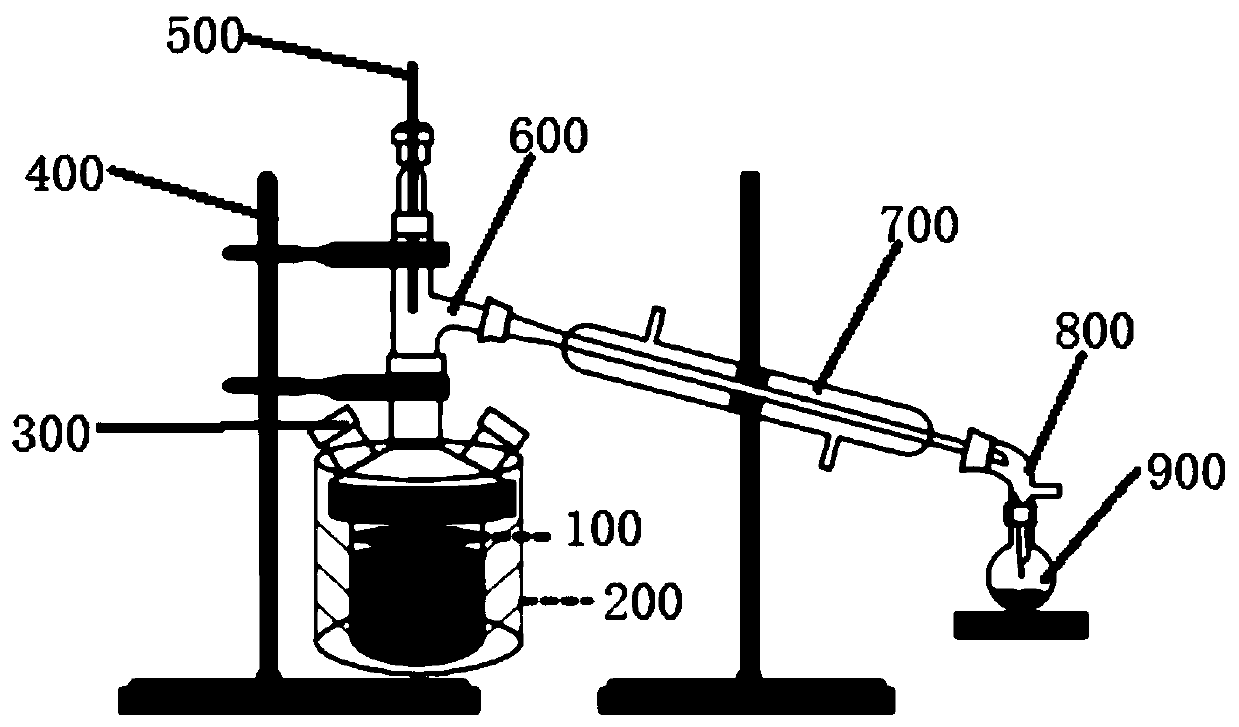

[0056] According to the embodiments of the present invention, there is no special requirement for the preparation method of the nanofibers, and those skilled in the art can choose flexibly according to the actual situation. In some embodiments, nanofibers can be prepared by electrospinning. Specifically, the preparation steps include: configuring an electrospinning precursor solution with a certain viscosity and fluidity, and the solution mass concentration can be 16%-25%. Use a needle tube to draw 5mL solution and fix it in the card slot of the electrospinning device, use a roller covered with aluminum foil as a receiving device, adjust the receiving distance between the needle and the receiving device, set the positive voltage at the needle, the negative voltage at the receiving device and the input voltage. Electrospinning was carried out at the feed speed. Among them, the inner diameter of the needle can be 0.16~3.0mm, the positive voltage of the needle can be 10~25kV, the...

Embodiment 1

[0090] Preparation of Vertically Oriented Graphene / Nanofiber Composite Membrane Material

[0091] 1. Use the Hummers method to prepare a concentration of 5mgmL -1 graphene oxide dispersion.

[0092] 2. Prepare the silica nanofiber precursor by electrospinning method, place the silica nanofiber precursor at room temperature for 24 hours to volatilize excess solvent, put it in a tube furnace and anneal at 850°C in air atmosphere for 2 hours , with a heating rate of 10°C min -1 . Subsequently, the silica nanofibers were shear dispersed in the aqueous solution with a homogenizer to obtain a concentration of 3mgmL -1 A dispersion of silica nanofibers with a diameter of 200nm;

[0093] 3. Under the condition of mechanical stirring, the prepared graphene oxide solution and the aqueous solution of silica nanofibers were uniformly mixed for 2 hours, and the mass ratio of graphene oxide and nanofibers was 1:1.

[0094] 4. After the above-mentioned mixed solution is poured into the ...

Embodiment 2

[0099] Preparation of Vertically Oriented Graphene / Nanofiber Composite Membrane Material

[0100] 1. Use the Hummers method to prepare a concentration of 3mgmL -1 graphene oxide dispersion.

[0101] 2. The polyimide nanofiber precursor was prepared by electrospinning, and the polyimide nanofiber precursor was placed at room temperature for 36 hours to volatilize the excess solvent, and then placed in a tube furnace for annealing in an inert atmosphere. The annealing conditions are from room temperature to 150°C for 30 minutes, to 200°C for 30 minutes, to 250°C for 30 minutes, to 300°C for 30 minutes, and finally to 300°C for 30 minutes, with a heating rate of 10°C min -1 , to obtain polyimide nanofiber membrane. Subsequently, the polyimide nanofibers were shear dispersed in the aqueous solution with a homogenizer to obtain a concentration of 5 mg mL -1 A polyimide nanofiber dispersion with a diameter of 350nm;

[0102] 3. Under the condition of mechanical stirring, the pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com