Patents

Literature

555 results about "Nanofiber composites" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

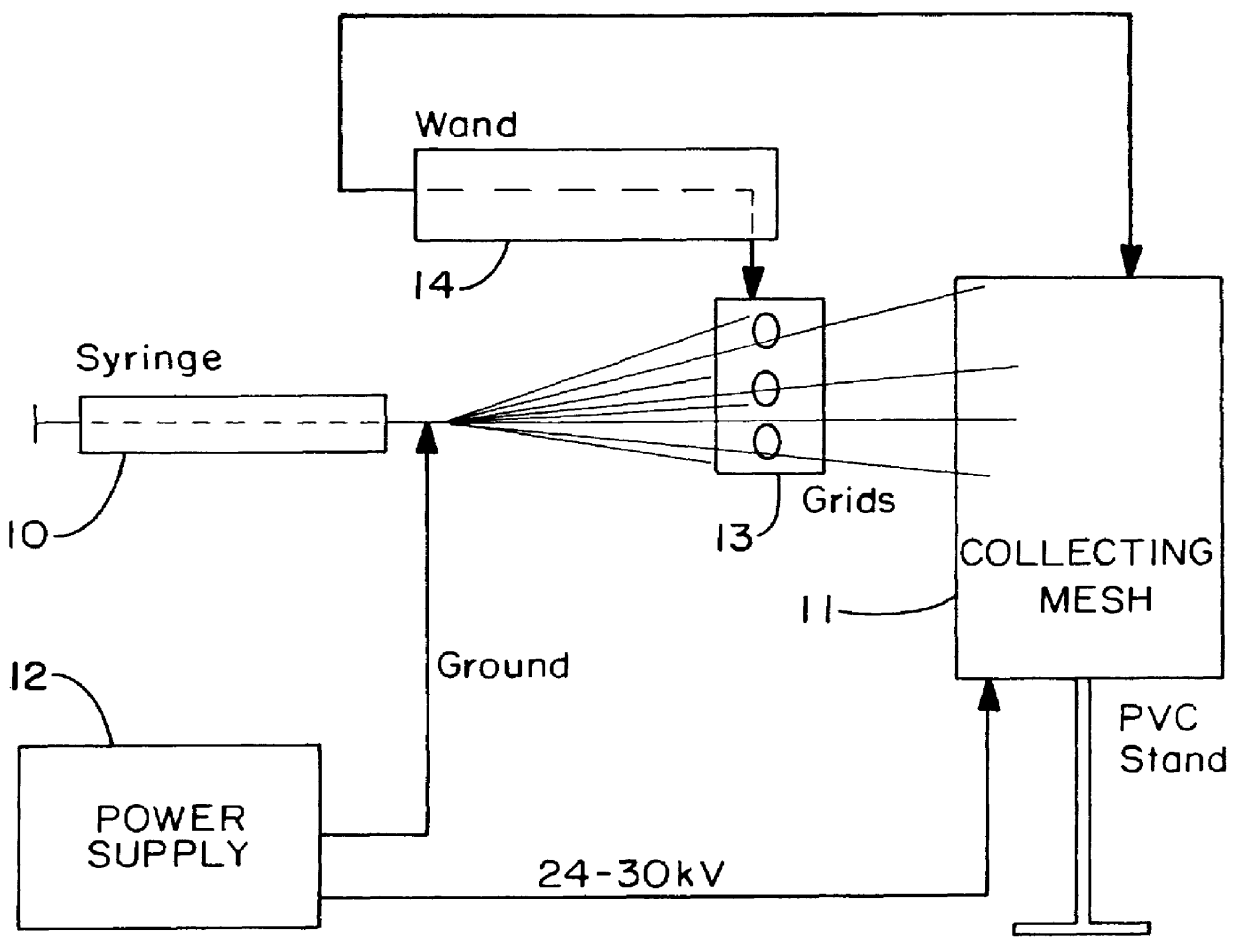

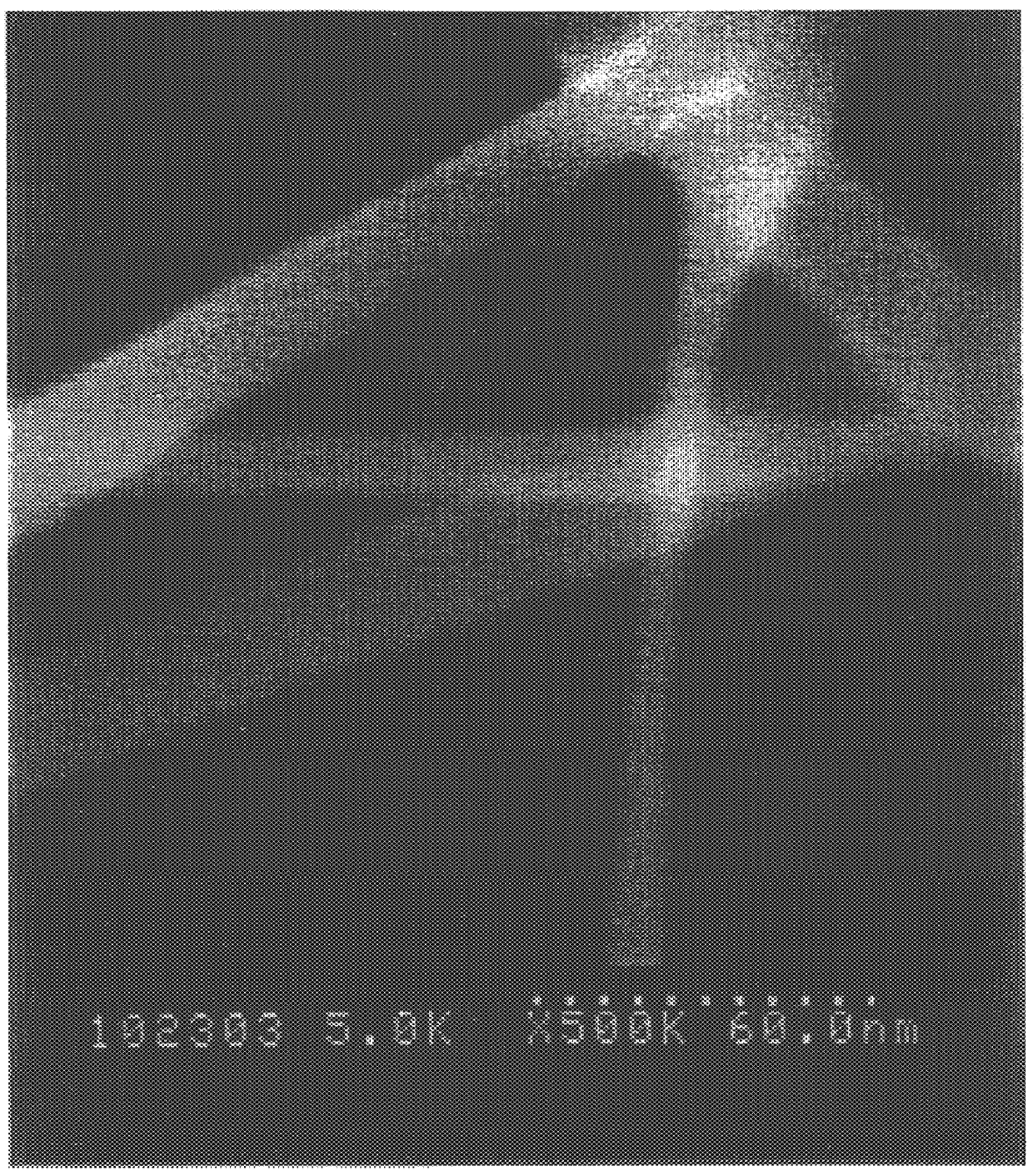

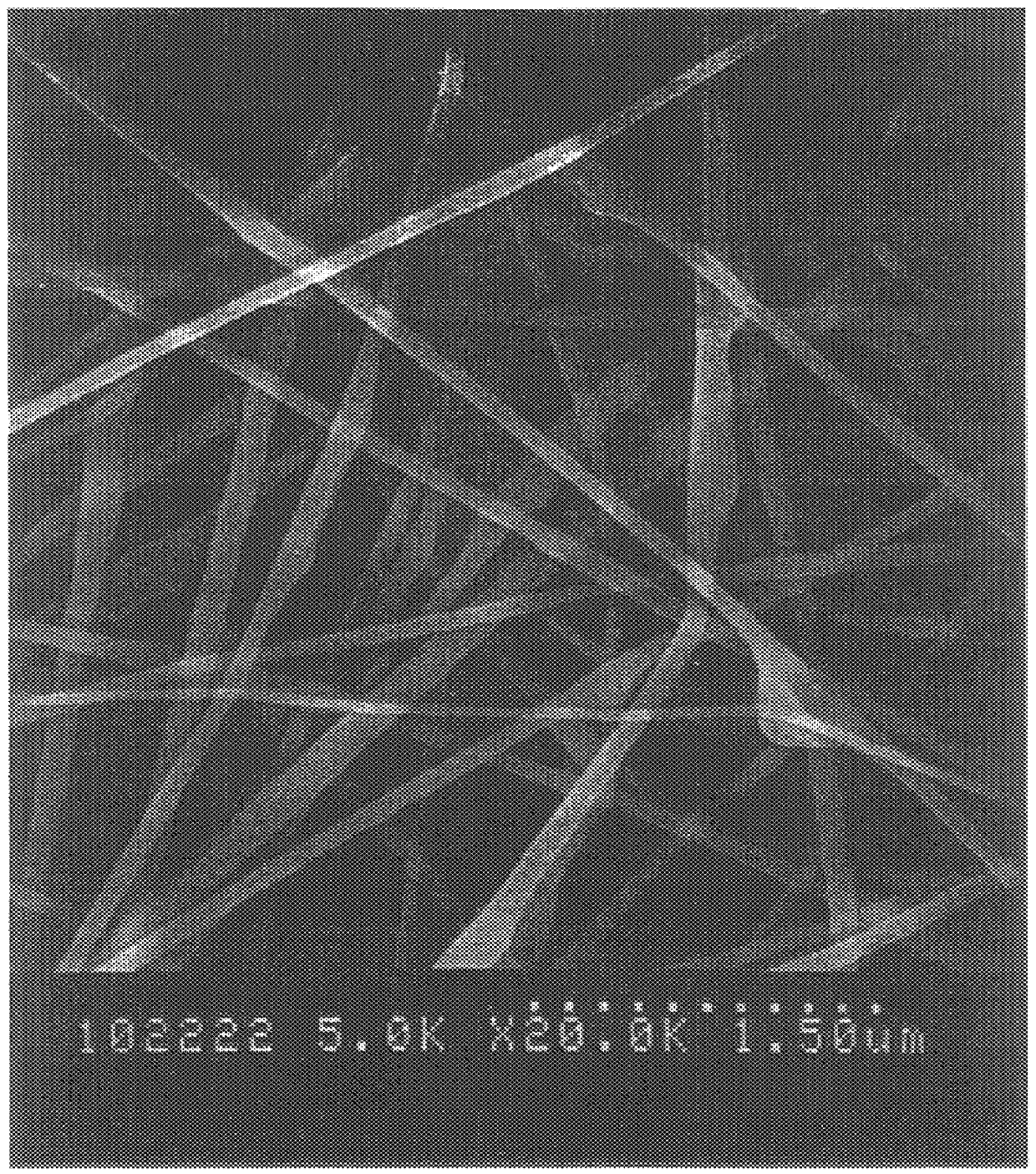

Synthetically spun silk nanofibers and a process for making the same

InactiveUS6110590AMonocomponent fibroin artificial filamentFilament/thread formingBombyx moriNanofiber

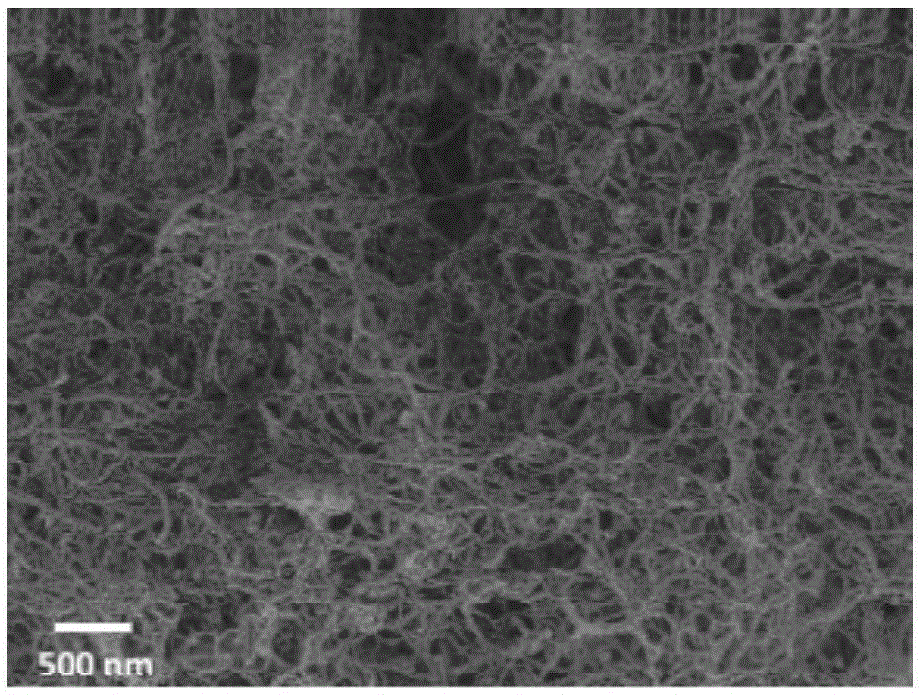

A silk nanofiber composite network produced by forming a solution of silk fiber and hexafluroisopropanol, wherein the step of forming is devoid of any acid treatment, where the silk solution has a concentration of about 0.2 to about 1.5 weight percent silk in hexafluroisopropanol, and where the silk is selected from Bombyx mori silk and Nephila clavipes silk; and electrospinning the solution, thereby forming a non-woven network of nanofibers having a diameter in the range from about 2 to about 2000 nanometers.

Owner:THE UNIVERSITY OF AKRON

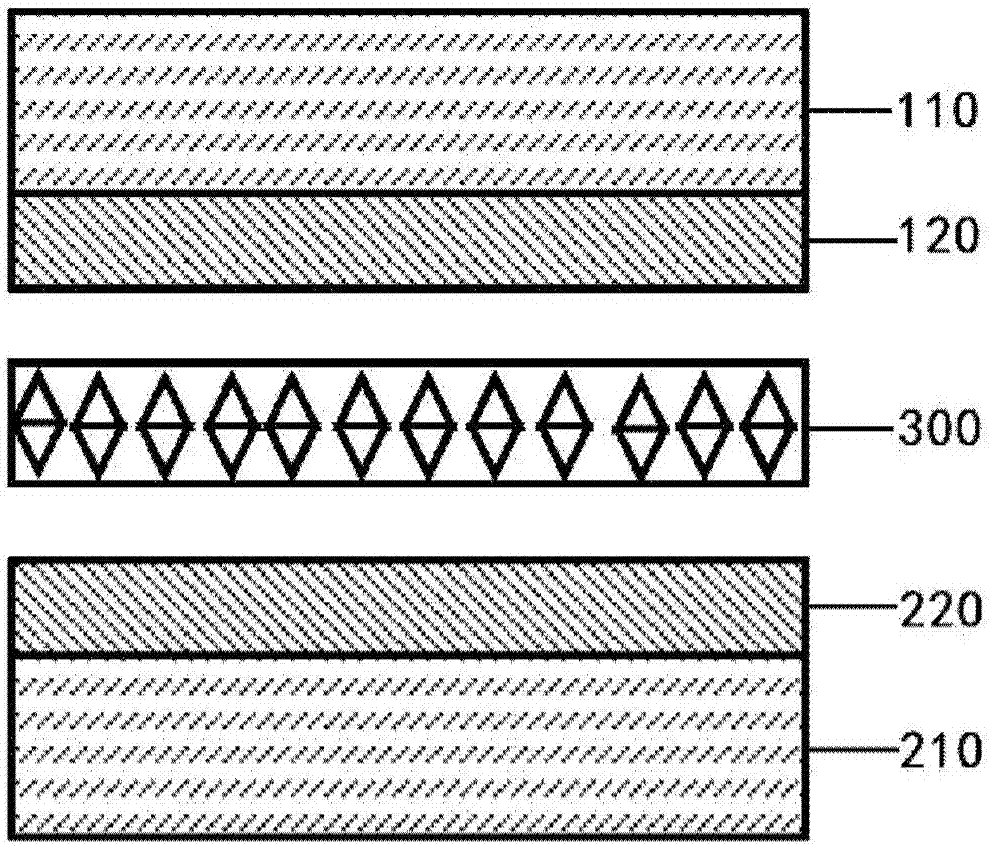

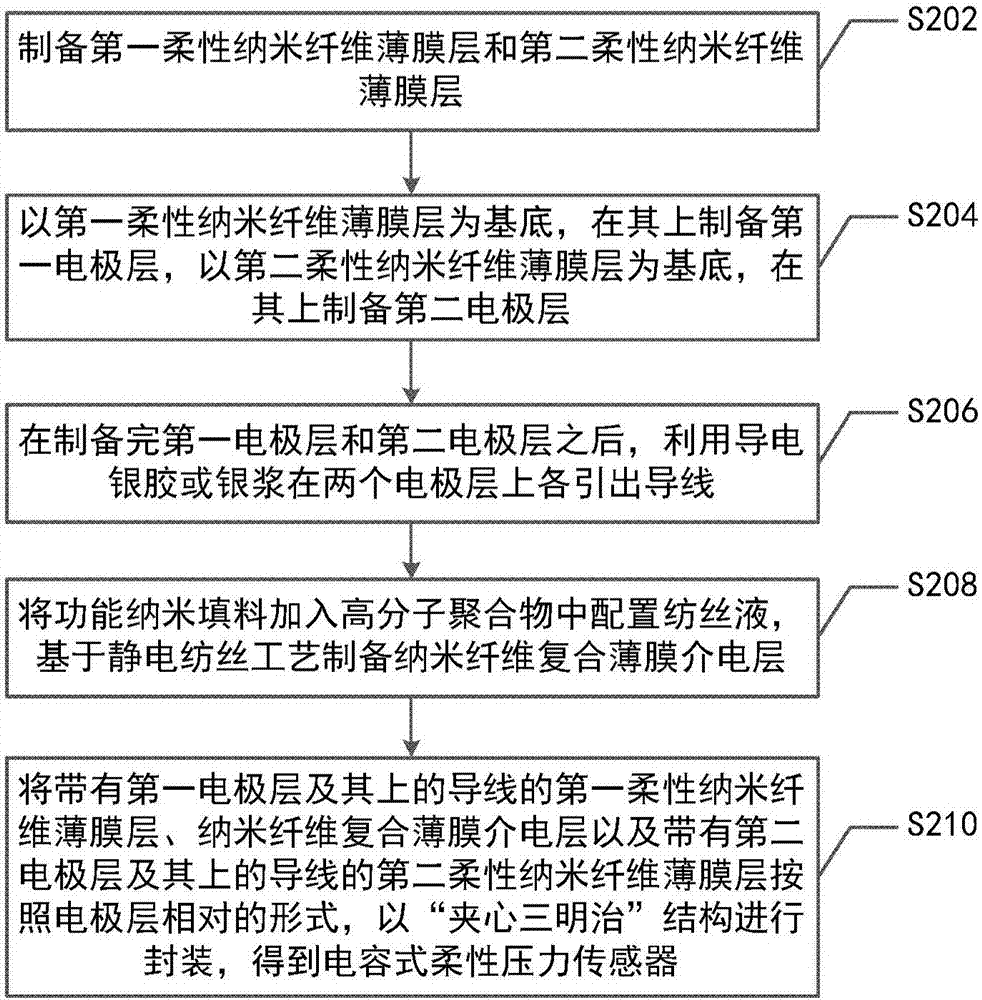

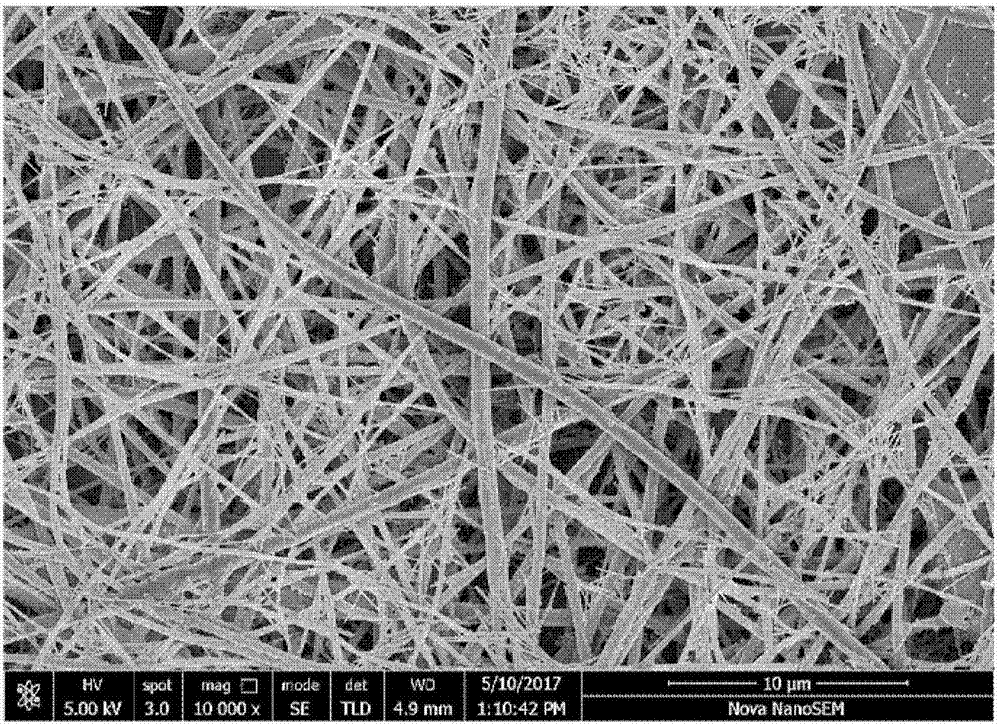

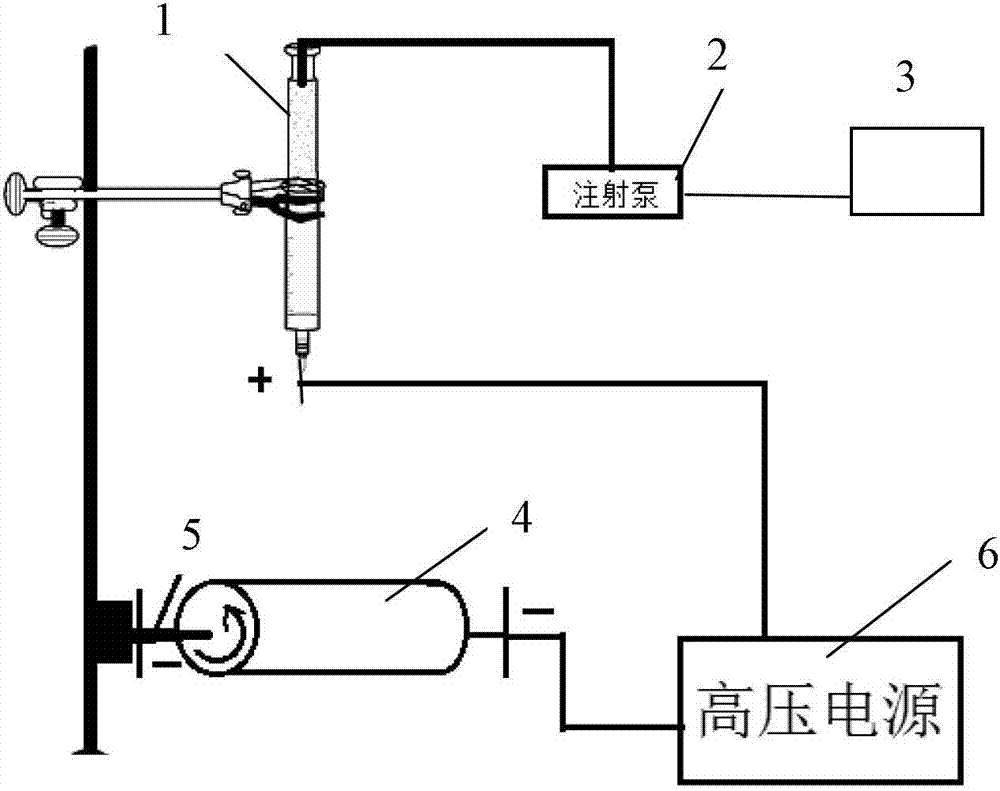

Capacitive flexible pressure sensor and preparation method thereof

The present invention discloses a capacitive flexible pressure sensor and a preparation method thereof. The capacitive flexible pressure sensor comprises: a first flexible nanofiber thin layer; a second flexible nanofiber thin layer which is oppositely arranged with the first flexible nanofiber thin layer; a first electrode layer attached to the internal side of the first flexible nanofiber thin layer; a second electrode layer attached to the internal side of the second flexible nanofiber thin layer; and a nanofiber composite film dielectric layer arranged between the first electrode layer and the second electrode layer. The nanofiber thin is utilized to each module of the capacitive flexible pressure sensor to allow the whole sensor to have good permeability and high sensitivity, and the addition of the functional nanofiber materials allow the sensor measuring range to be widened so as to facilitate human body long-time wearing to perform real-time monitoring of human body weak vital sign signals.

Owner:BEIJING INST OF NANOENERGY & NANOSYST

Preparation method of multilayer sandwich type electrostatic-spinning polymer nanofiber composite membrane

ActiveCN103481624AIncrease the areaSimple structureLamination ancillary operationsLaminationFiberPolymer science

The invention discloses a preparation method of a multilayer sandwich type electrostatic-spinning polymer nanofiber composite membrane. The preparation method comprises the steps of firstly, spinning a polymer spinning liquid into a fiber membrane in an electrostatic manner, then spraying a spraying liquid containing inorganic nano-particles to the surface of the electrostatic-spinning fiber membrane by virtue of a jetting technique, continuously spinning the fiber membrane, and repeatedly carrying out the steps according to specific conditions so as to prepare the multilayer sandwich type composite membrane. As the inorganic nano-particles are adhered to the surface of the fiber membrane, not only can the ultrahigh specific area and the specific structural advantage of a nanofiber be brought into full play, but also the selectable ranges of the spraying liquid and the polymer spinning liquid are flexible, so that spraying liquids containing different inorganic nano-particles can be sprayed to electrostatic-spinning fiber membranes made from different raw materials according to actual demands so as to prepare sandwich type composite membranes with different functions, stable structures and good properties, and the application range of the electrostatic-spinning polymer nanofiber composite membranes is expanded.

Owner:河北立格新材料科技股份有限公司

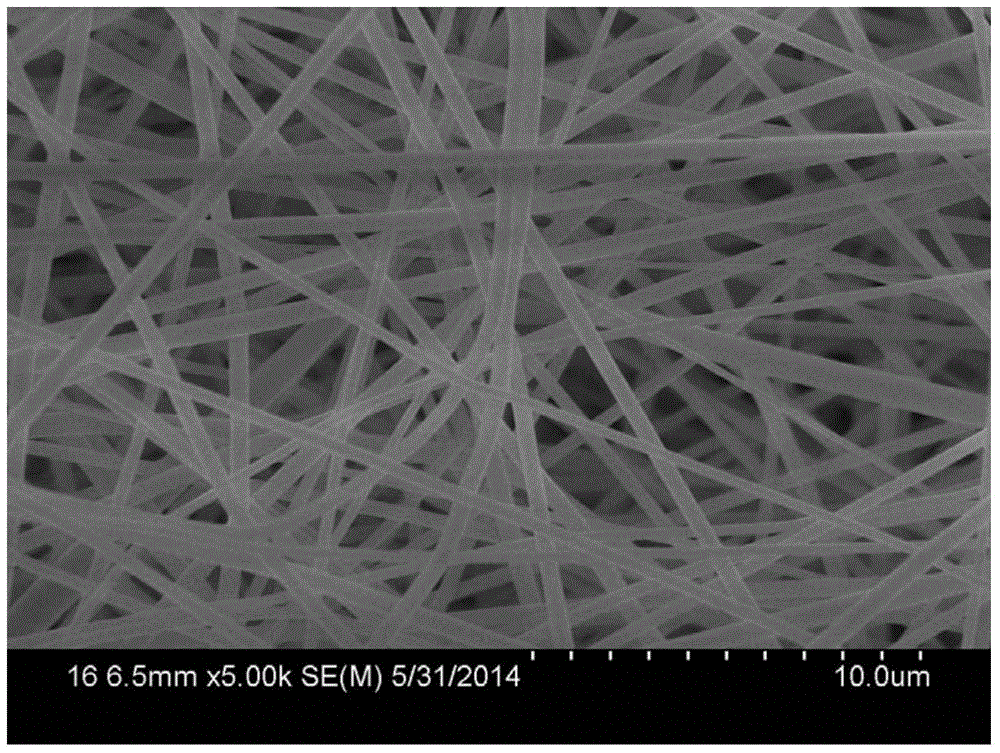

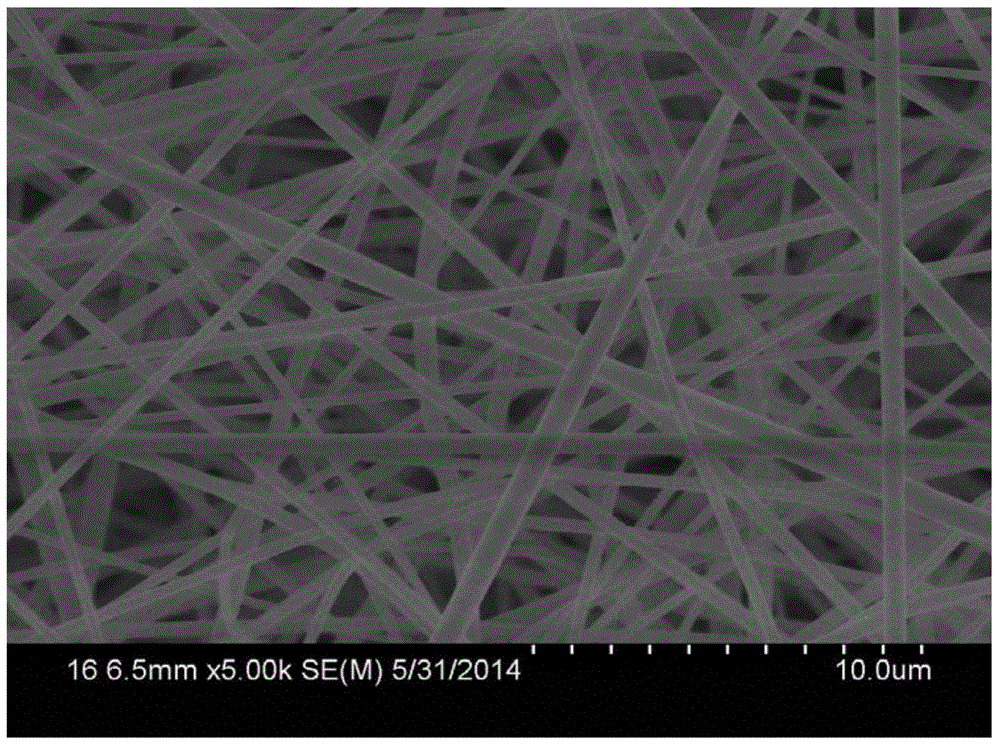

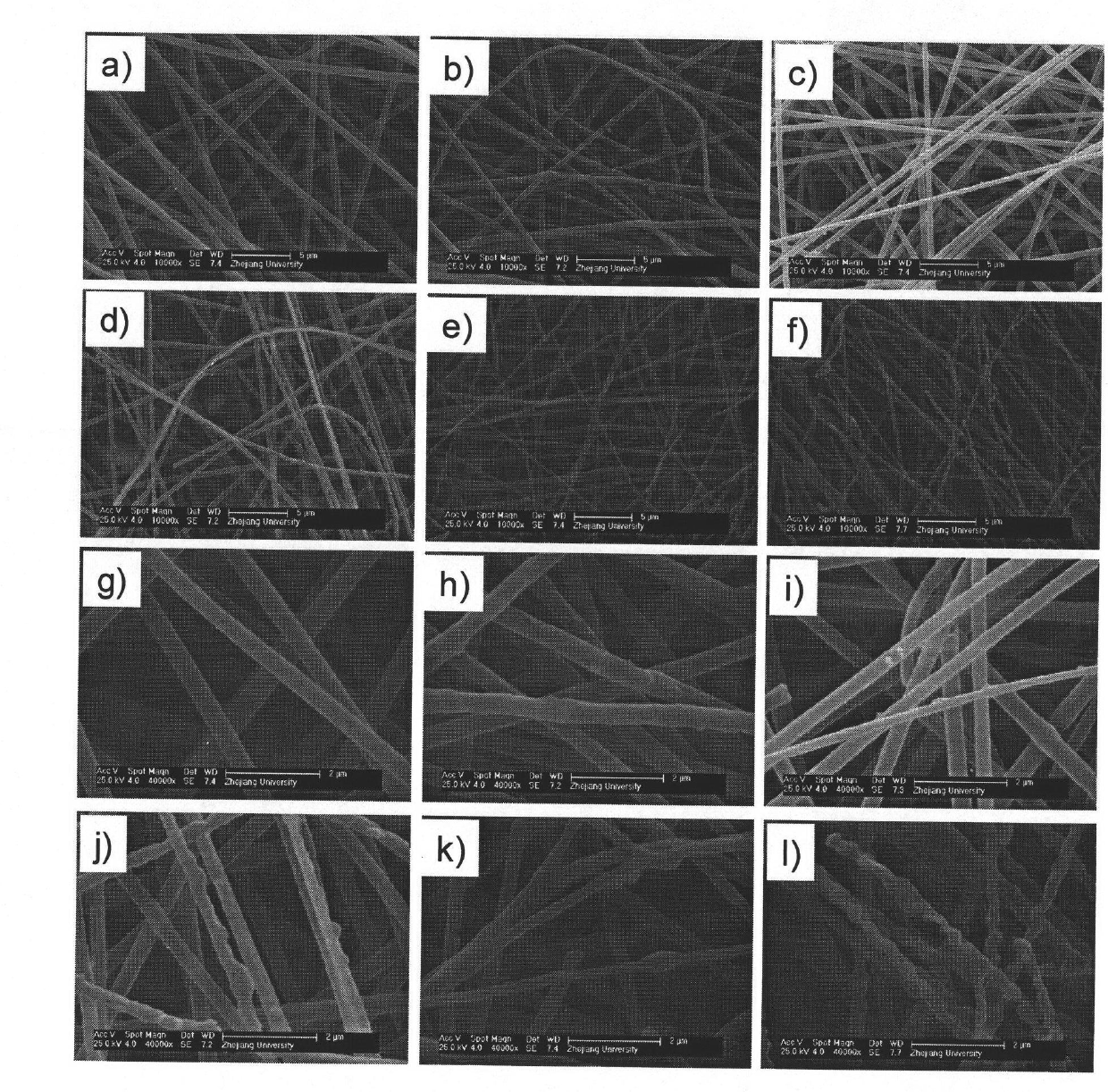

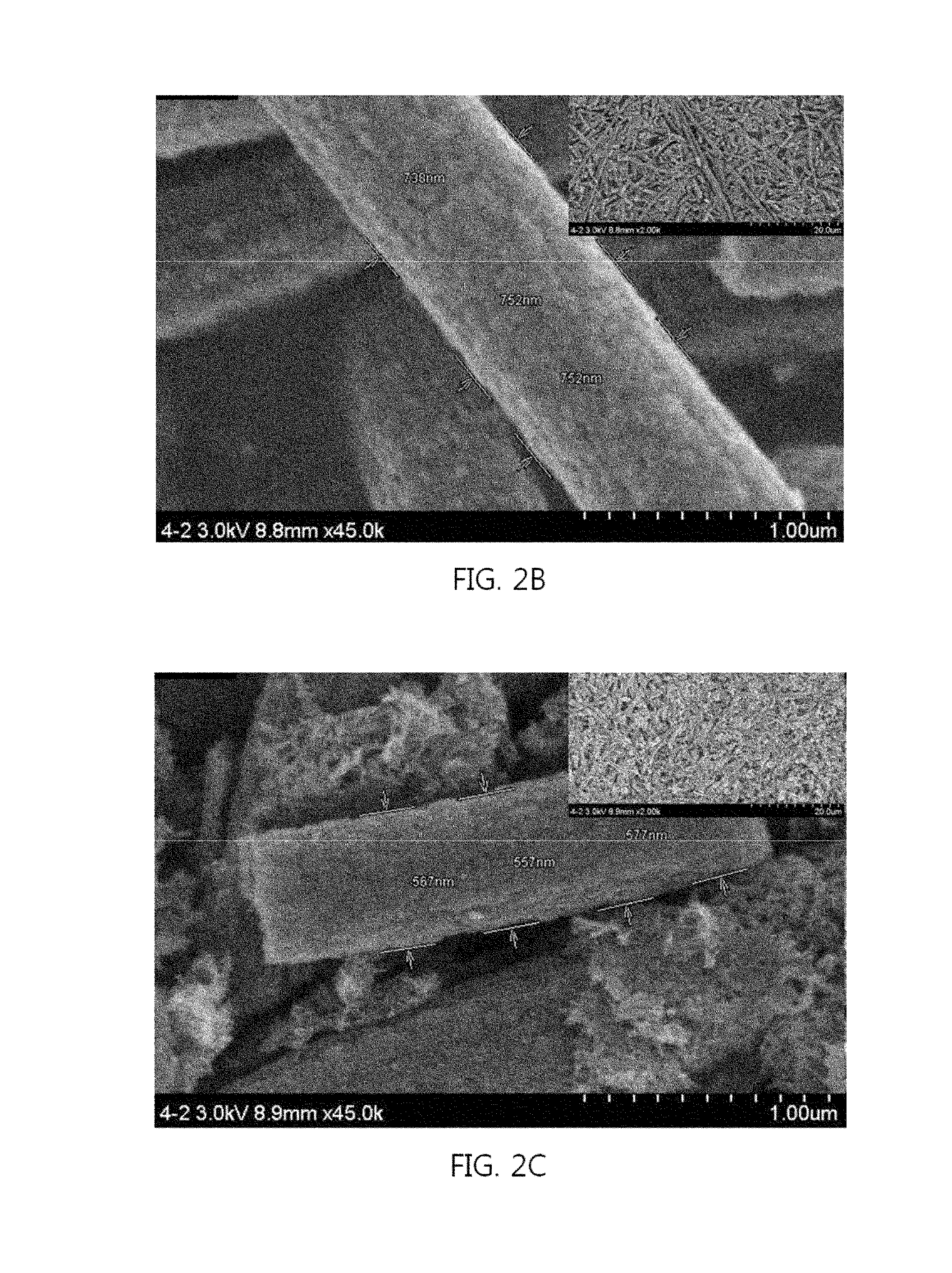

Polyimide nanofiber membrane with surface coated with nano titanium dioxide and preparation method for polyimide nanofiber membrane

The invention discloses a polyimide nanofiber membrane with the surface coated with nano titanium dioxide and a preparation method for the polyimide nanofiber membrane. The preparation method comprises the steps of synthesizing polyamide acid through diamine and binary anhydride to prepare a nanofiber membrane by an electrospinning technology, and then immersing the nanofiber membrane into titanium dioxide sol with different concentrations or partially cyclizing a polyamide acid nano fiber membrane, immersing the cyclized polyamide acid nano fiber membrane into the titanium dioxide sol, drying and preparing the polyimide nanofiber membrane with the surface coated with the nano titanium dioxide through gradient heating thermal imidization. The polyimide nanofiber composite membrane provided through the preparation method disclosed by the invention is formed by coating the surface of a polyimide nanofiber with titanium dioxide particles or a titanium dioxide layer; the particle size of the titanium dioxide particles is 10-150nm, and the titanium dioxide layer is 10-200nm; the diameter of the polyimide nanofiber is 30-600nm; the composite membrane is 10-90 microns thick; due to the coating of the titanium dioxide nano layer, the surface wettability, the size stability and the heat resistance performance of the polyimide nanofiber membrane are improved; the implementation process is simple and is easy to processize; the polyimide nanofiber membrane has a good application prospect.

Owner:北京凯越嘉诚科技发展有限公司

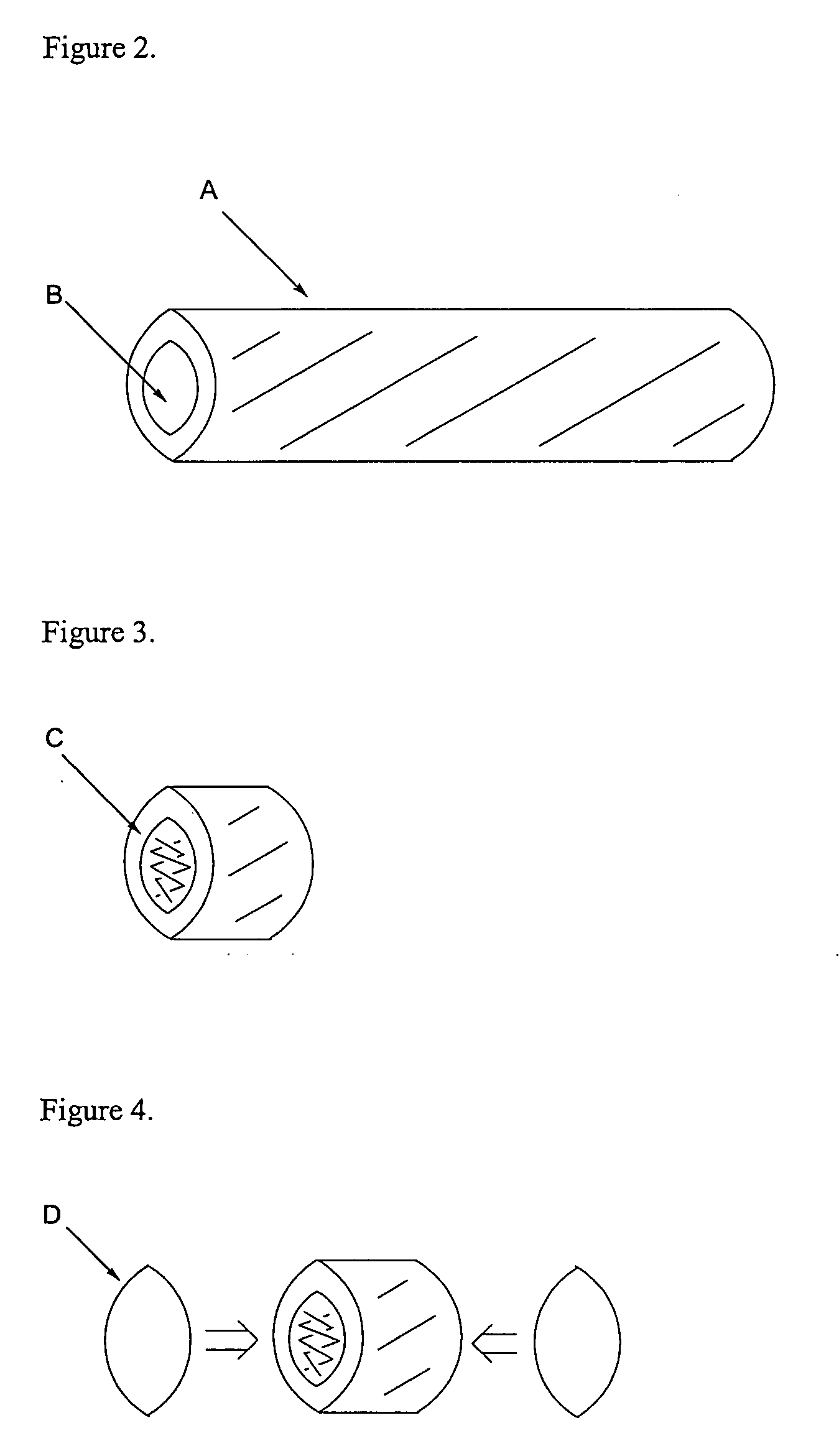

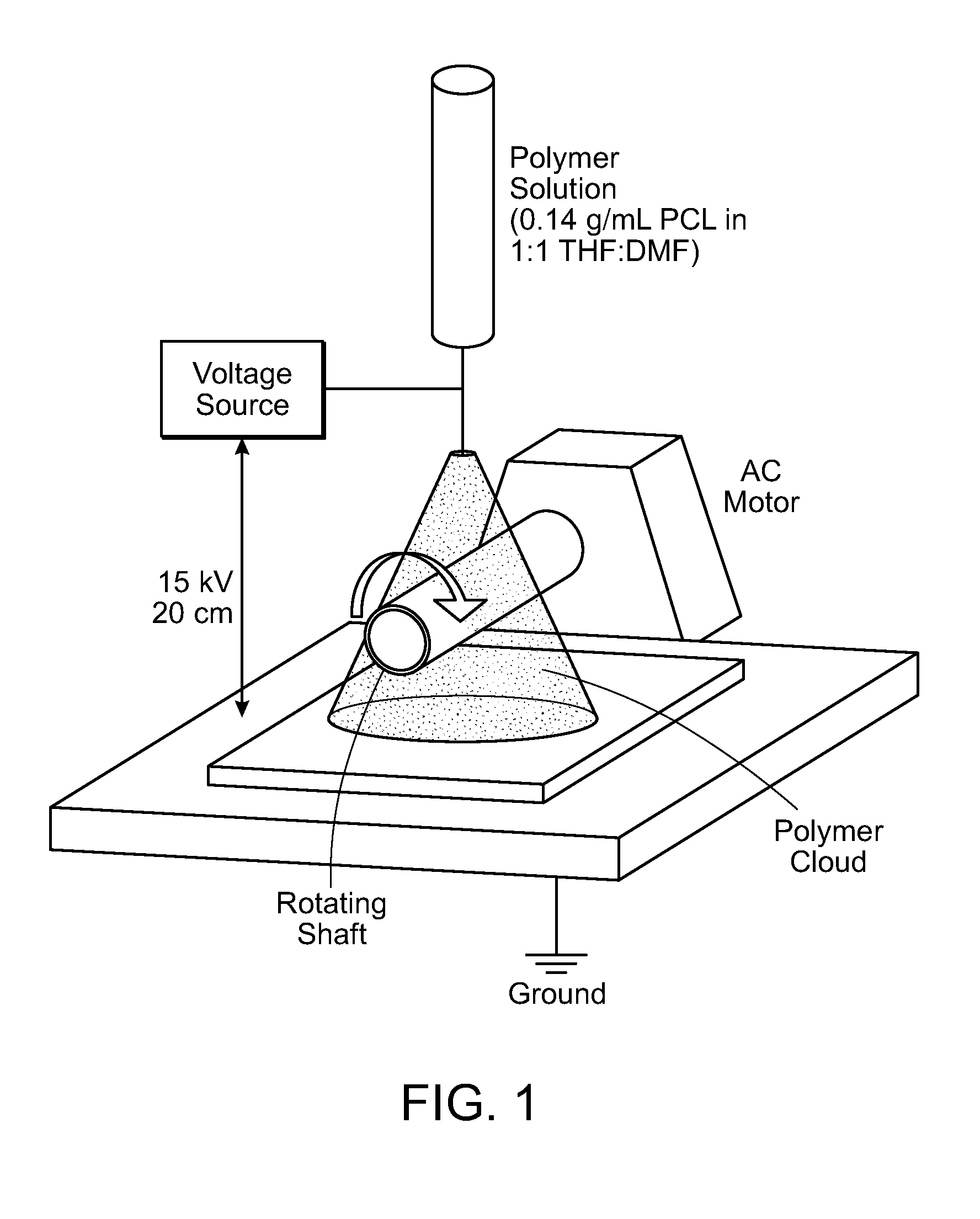

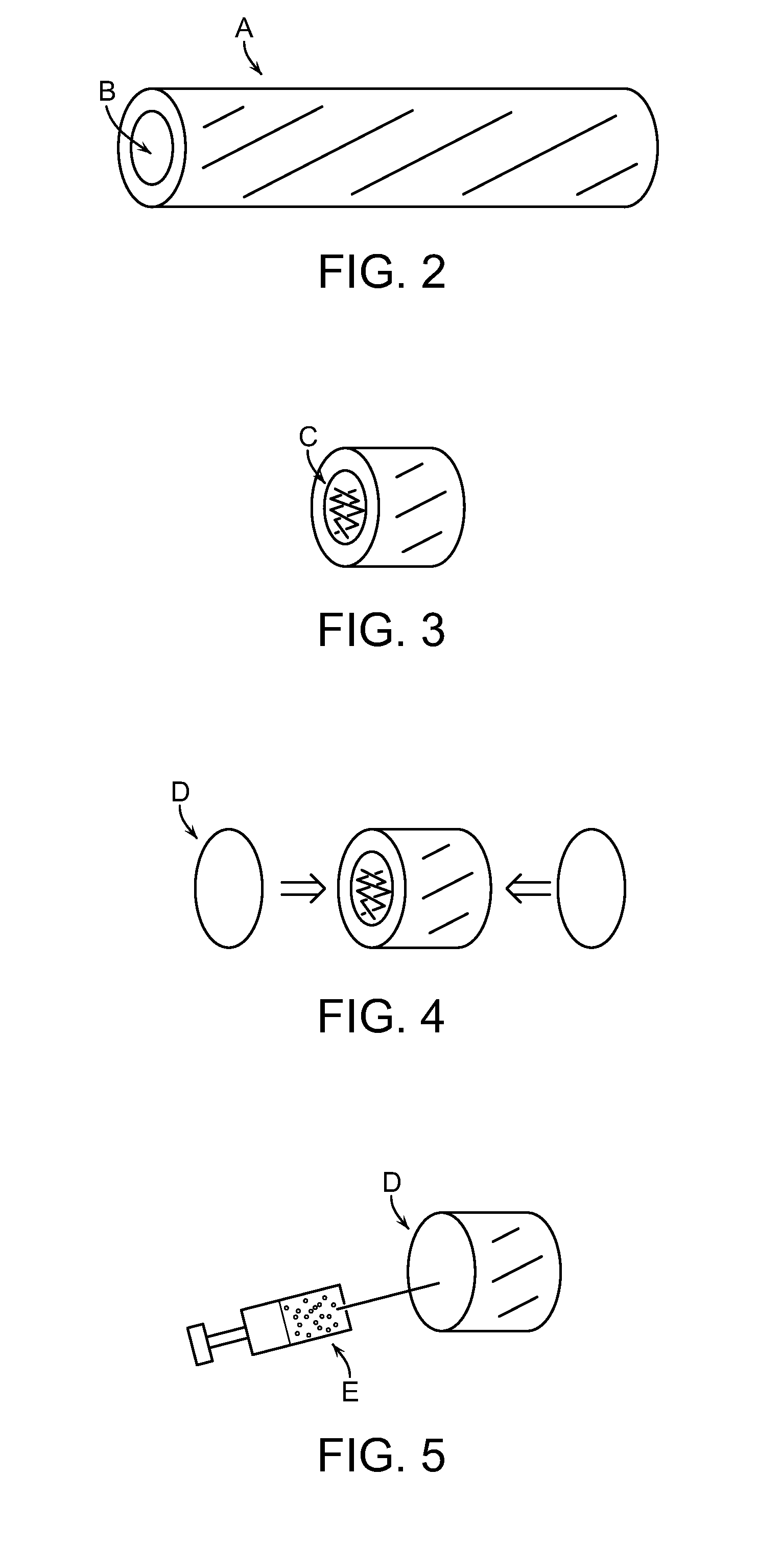

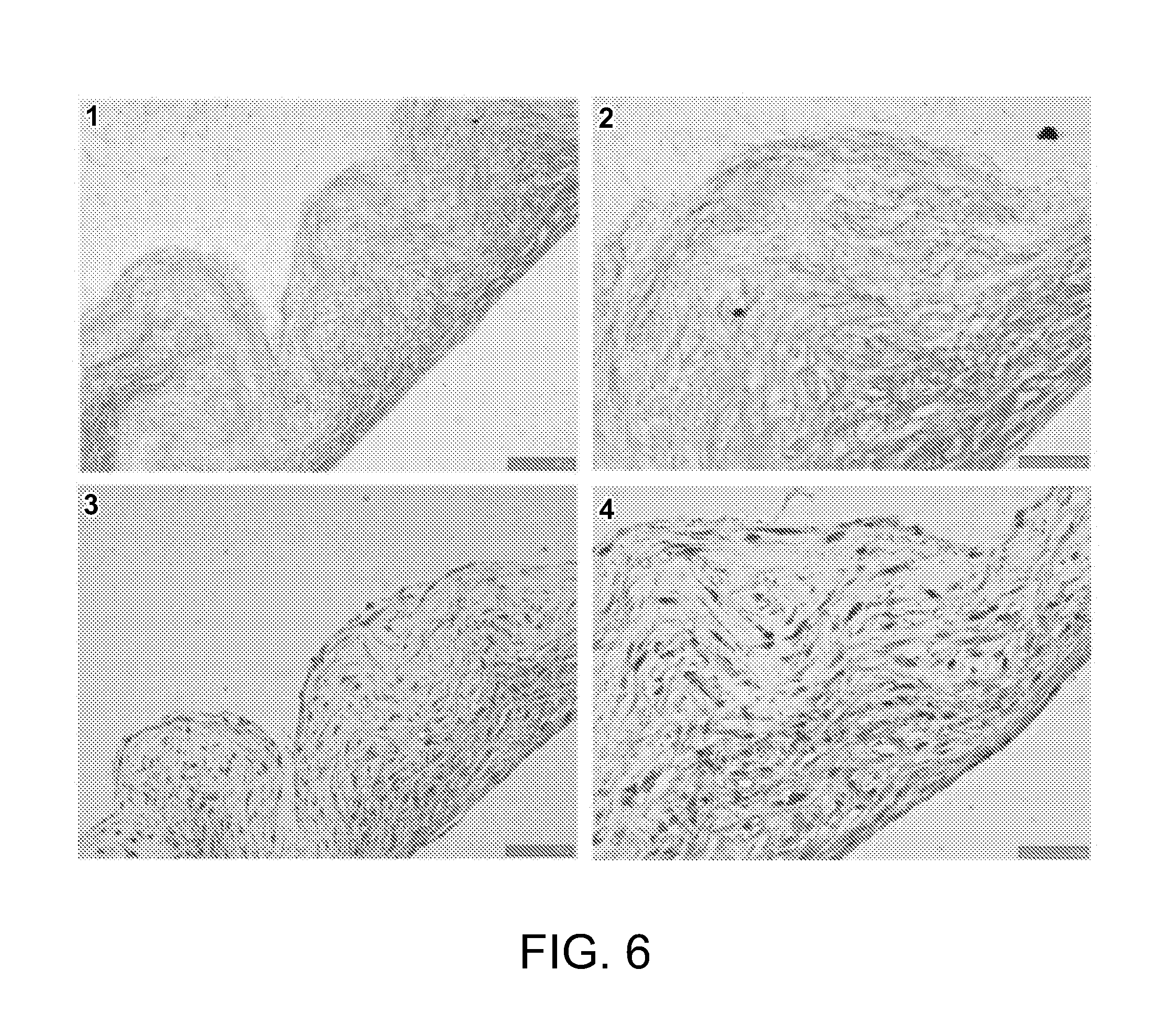

Cell-nanofiber composite and cell-nanofiber-hydrogel composite amalgam based engineered intervertebral disc

InactiveUS20100179659A1Promote differentiationPromote growthPharmaceutical delivery mechanismCell culture supports/coatingIntervertebral discNanofiber

The instant invention is directed to a tissue engineered intervertebral disc comprising at least one inner layer and an exterior layer, wherein: the exterior layer comprises a nanofibrous polymer support comprising one or more polymer nanofibers; the at least one inner layer comprises a hydrogel composition comprising at least one or more hydrogel materials and / or one or more polymer nanofibers; and a plurality of cells which are dispersed throughout the tissue engineered intervertebral disc. Additionally, the instant invention is directed to methods of making such intervertebral discs and methods of treating intervertebral disc damage.

Owner:HEALTH & HUMAN SERVICES GOVERNMENT OF THE US SEC DEPT OF

High performance super-amphiphobic conductive multi-functional corrosion-resistant coating and preparation method thereof

InactiveCN105238207AHigh aspect ratioIncrease the effective specific surface areaEpoxy resin coatingsPigment treatment with organosilicon compoundsFiberFirming agent

The invention relates to a high performance super-amphiphobic conductive multi-functional corrosion-resistant coating, which is characterized by comprising a bottom layer component and a surface layer component, wherein the bottom layer component is epoxy resins, epoxy curing agents, organic fluorines, polyaniline / carbon nanofibers composite materials, the surface layer component is organic fluorines, low surface energy modified nanofillers and fluorine silane coupling agents. The high performance super-amphiphobic conductive multi-functional corrosion-resistant coating can have the advantages of superamphiphobic, drag reduction, abrasion resistance and pit corrosion resistance, and is low in cost. The invention further provides a method for preparing the high performance super-amphiphobic conductive multi-functional corrosion-resistant coating.

Owner:NORTHEAST GASOLINEEUM UNIV

Nanofiber membrane and preparation method thereof, nanofiber composite and preparation method thereof

ActiveCN104099725AStrong air purification abilityImprove waterproof performanceSynthetic resin layered productsNon-woven fabricsSorbentNanofiber

The invention provides a nanofiber membrane. The nanofiber membrane is made of mixture by spinning. The mixture includes polymers and nanofiber materials in the mass ratio of 1:(0.01-0.2). The nanofiber materials are composed of photocatalyst and adsorbent. The adsorbent and the photocatalyst are used in the nanofiber membrane, the adsorbent can adsorb harmful gas in an adsorption chamber, the photocatalyst is capable of degrading and adsorbing harmful organics in holes of the adsorbent into carbon dioxide and water under the condition of indoor light rays and irradiation of a daylight lamp, and activates and regenerates the adsorbent in situ when decomposing the harmful organics on the adsorbent in the meantime, so that the adsorbent and the photocatalyst are reusable, and the nanofiber membrane has excellent air purification capacity. The invention further provides a preparation method of the nanofiber membrane and a nanofiber composite and a preparation method thereof.

Owner:ZHEJIANG WEIXING IND DEV

Nanofiber composite membrane containing plant source antibacterial agents, preparation method and application of nanofiber composite membrane

InactiveCN103266424AGood water solubilityGood biocompatibilityFilament/thread formingMonocomponent synthetic polymer artificial filamentEscherichia coliPolyvinyl alcohol

The invention belongs to the field of nanometer materials and food packaging materials, and discloses a nanofiber composite membrane containing plant source antibacterial agents, a preparation method and application of the nanofiber composite membrane. The preparation method of the nanofiber composite membrane includes a first step of preparing 6%-10%, by mass, of polyving akohol solution, a second step of cooling the obtained polyving akohol solution down to 30-50 DEG C, adding 1%-3% of beta-cyclodextrin, carrying out magnetic stirring for 0.5-1 hour, and then cooling the mixtures down to indoor temperatures, a third step of adding 2%-8% of cinnamon essential oil to the solution of the second step, carrying out magnetic stirring for 1-2 hours at 25-40 DEG C, and obtaining spinning solution, and a fourth step of carrying out electrostatic spinning on the obtained spinning solution, carrying out vacuum drying, and obtaining the nanofiber composite membrane containing the plant source antibacterial agents. The sterilizing rate of the nanofiber composite membrane for staphylococcus aureus and escherichia coli is larger than or equal to 90%, and the nanofiber composite membrane has good tenacity, biocompatibility and degradability, and has wide application prospect in the field of the food packaging materials.

Owner:SOUTH CHINA UNIV OF TECH

Nanofiber composite membrane and preparation method thereof

InactiveCN104727016AWide range of usesHigh hydrostatic pressure resistanceNon-woven fabricsAdhesivesPolymer scienceNanofiber

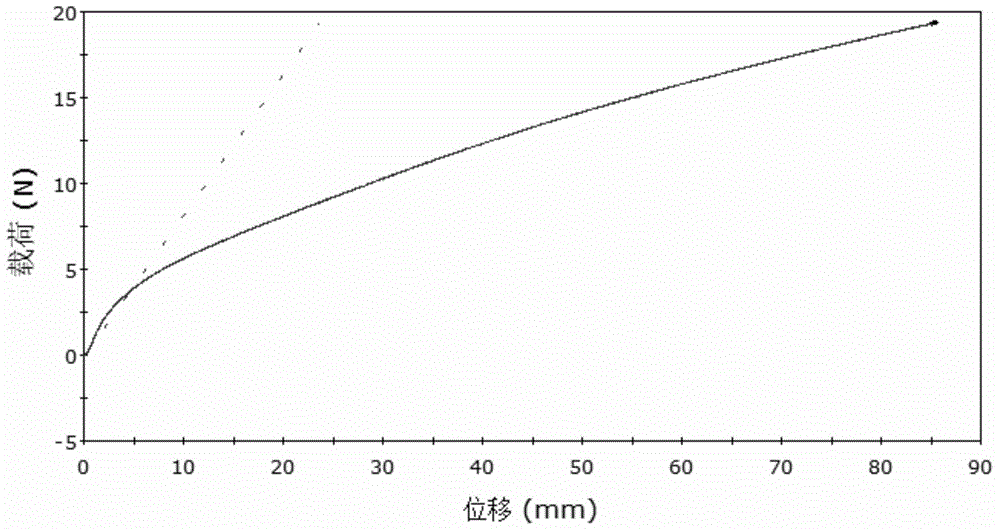

The invention provides a preparation method of a nanofiber composite membrane. The method includes the steps that a spinning solution and melt of a high-melting-point polymer are provided, a spinning solution and melt of a low-melting-point polymer are provided, and the melting point difference of the high-melting-point polymer and the low-melting-point polymer is not smaller than 10 DEG C; the spinning solution of the high-melting-point polymer and the spinning solution of the low-melting-point polymer are subjected to electrostatic spinning, and accordingly an electrostatic spinning high-melting-point polymer fiber membrane and an electrostatic spinning low-melting-point polymer fiber membrane are obtained; the low-melting-point polymer melt and the high-melting-point polymer melt are subjected to melt-blowing spinning, so that a melt-blowing spinning low-melting-point polymer fiber membrane and a melt-blowing spinning high-melting-point polymer fiber membrane are obtained; the melt-blowing spinning high-melting-point polymer fiber membrane and the electrostatic spinning low-melting-point polymer fiber membrane undergo composite hot pressing, or the melt-blowing spinning low-melting-point polymer fiber membrane and the electrostatic spinning high-melting-point polymer fiber membrane undergo composite hot pressing, and thus the nanofiber composite membrane is obtained. The nanofiber composite membrane has high tensile strength which reaches up to 22 MPa-32 MPa.

Owner:ZHEJIANG WEIXING IND DEV

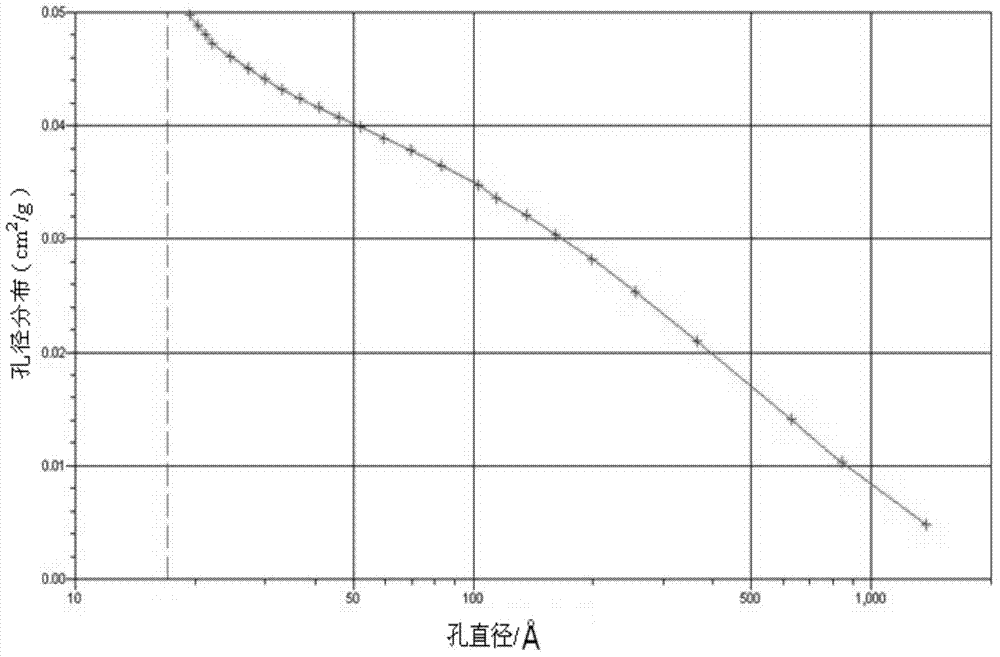

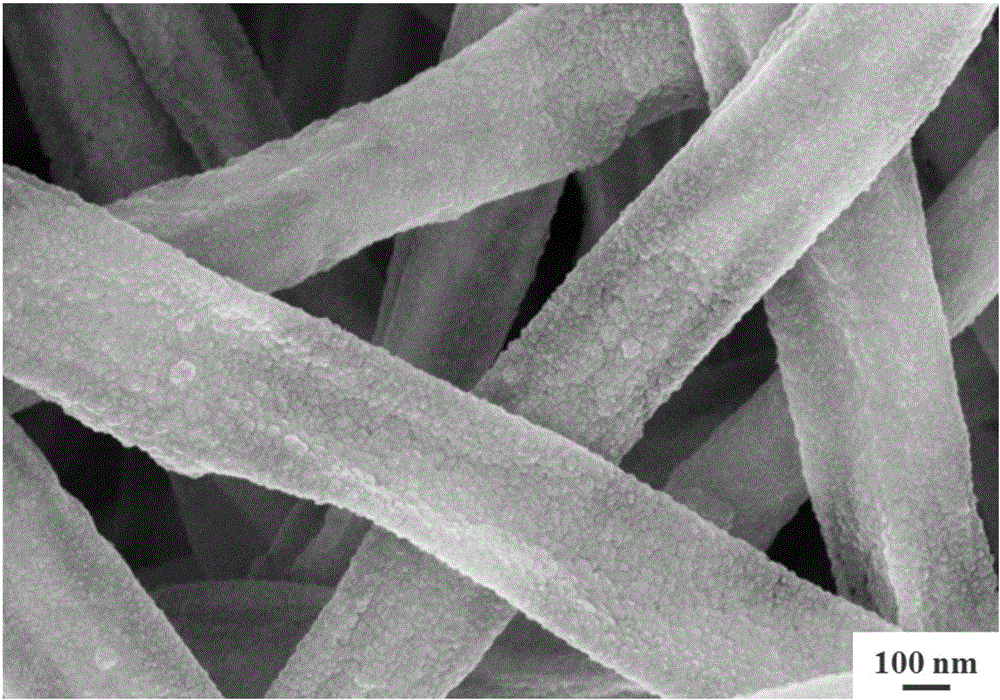

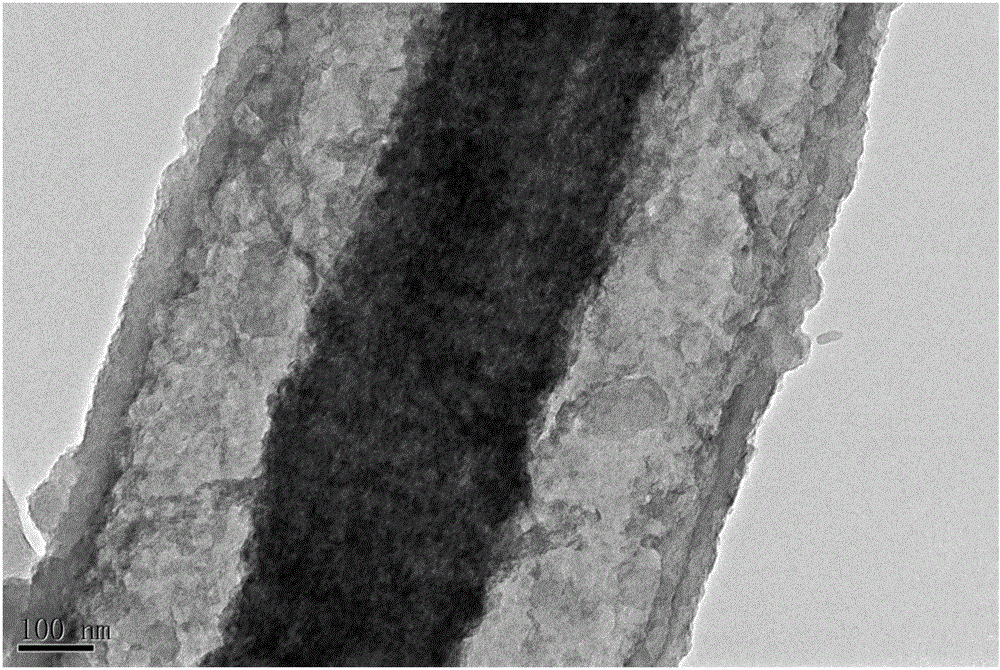

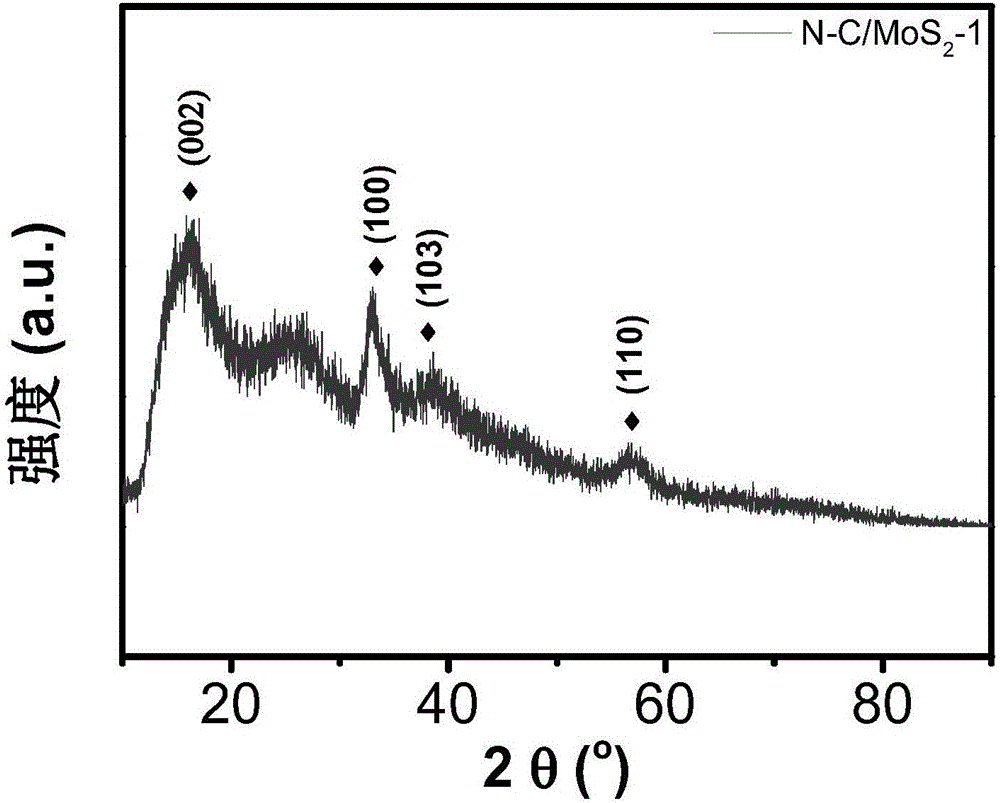

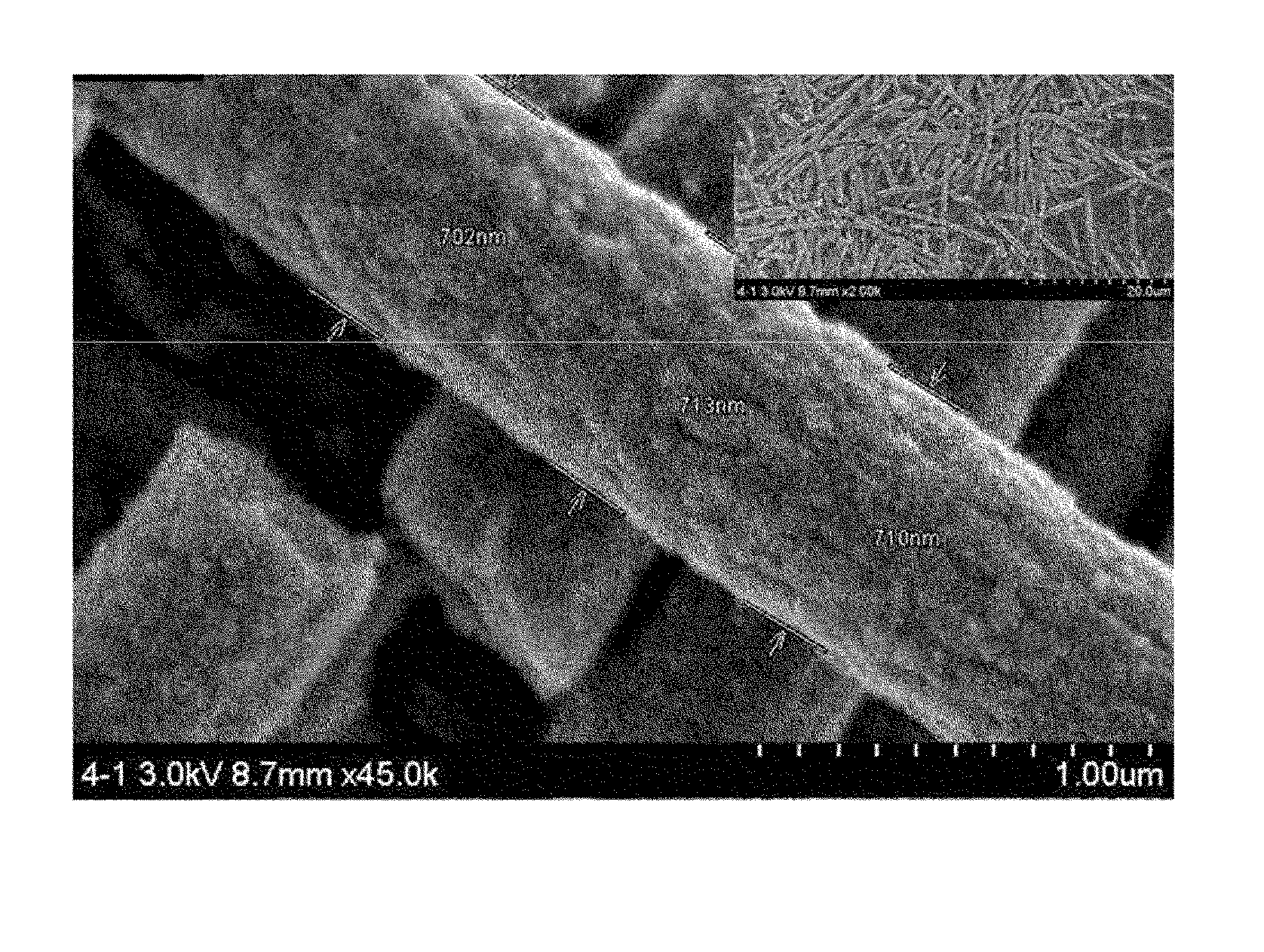

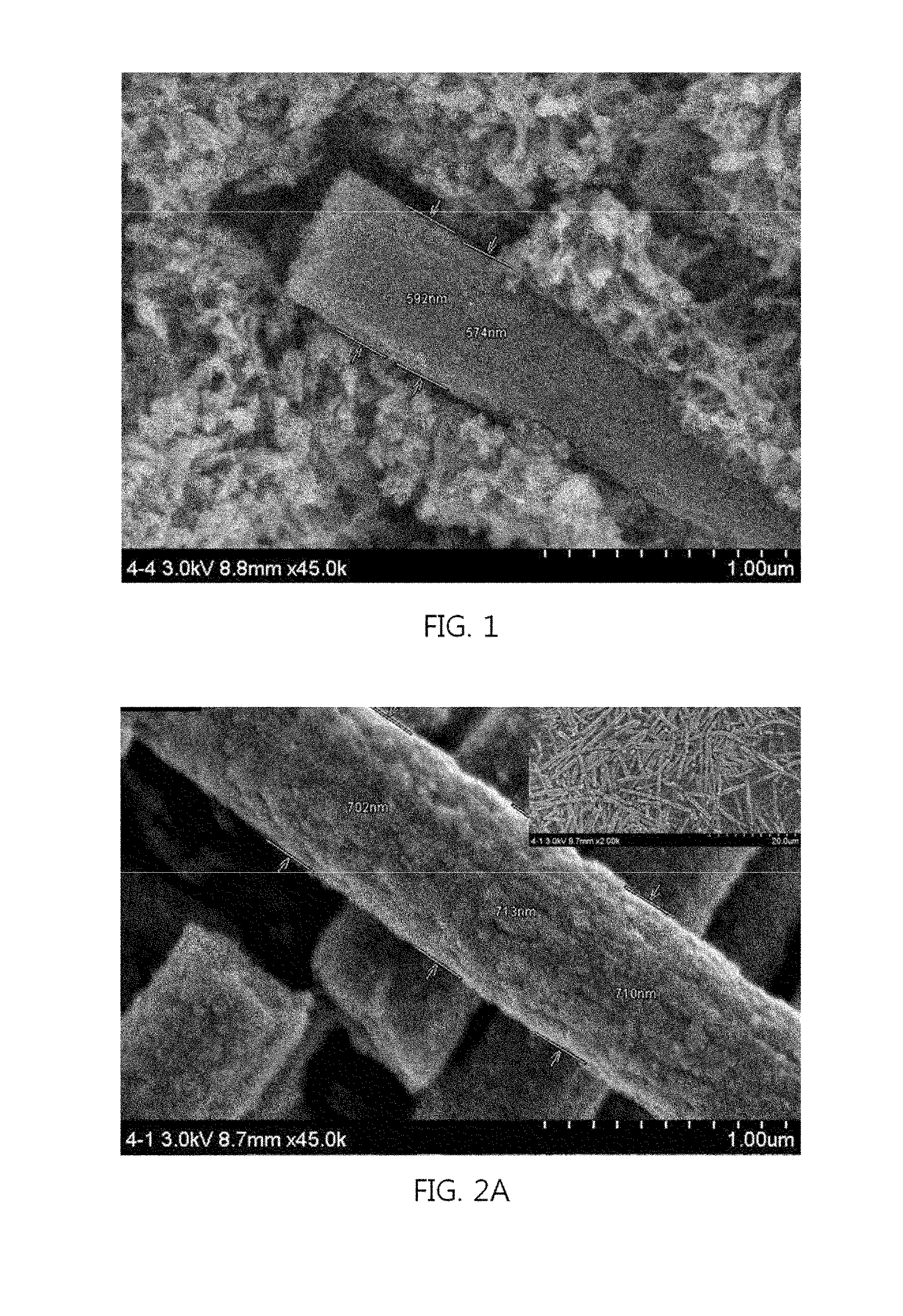

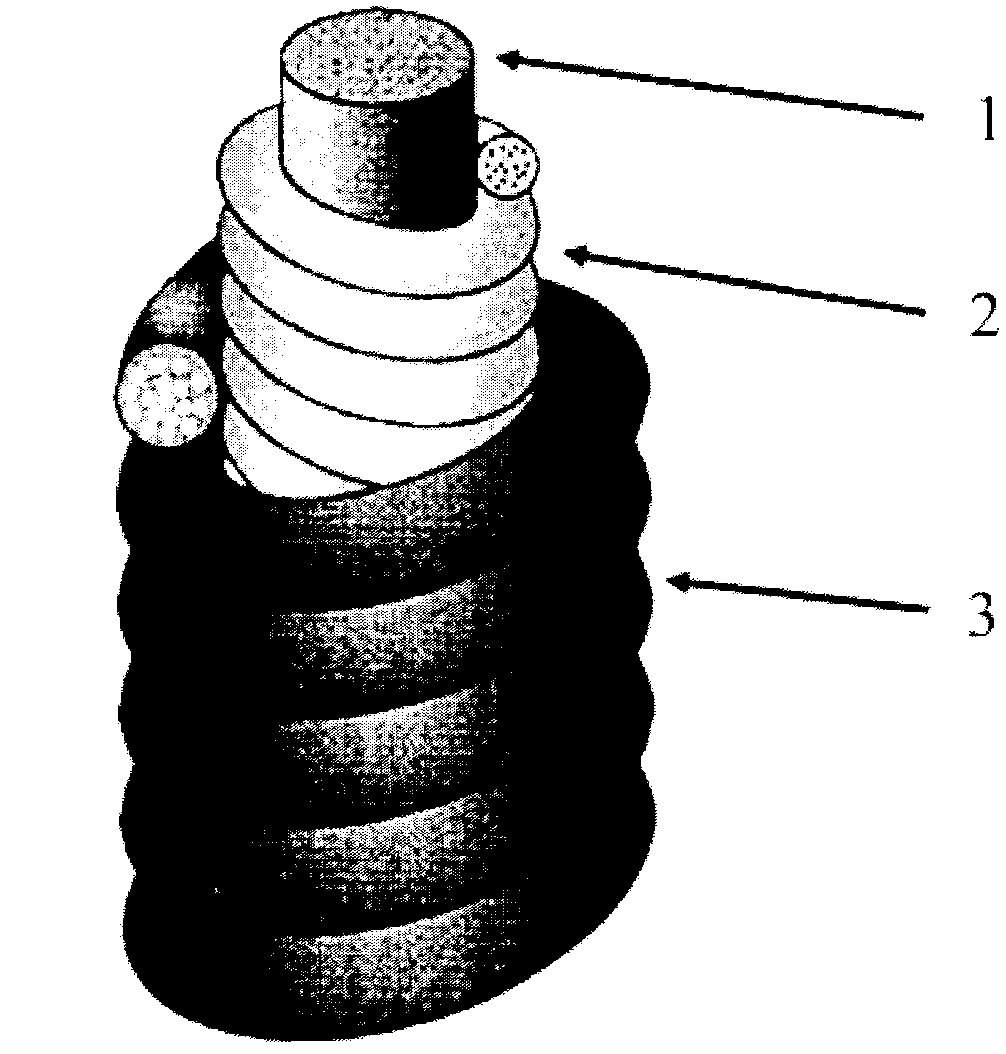

Molybdenum disulfide/nitrogen-doped carbon nanofiber composite material and preparation method and application thereof

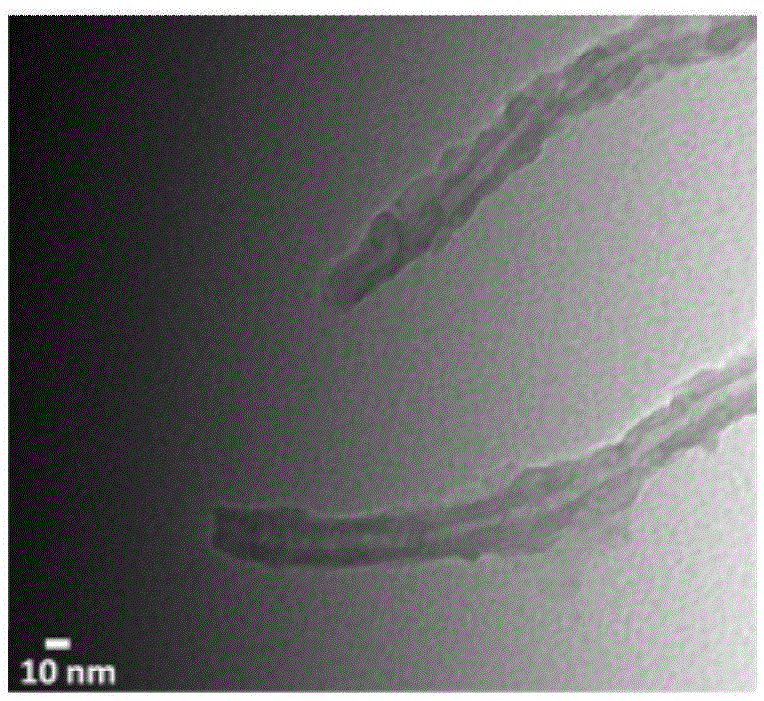

ActiveCN106450181AHigh specific capacityImprove cycle stabilityCell electrodesSecondary cellsFiberIn situ polymerization

The invention relates to a molybdenum disulfide / nitrogen-doped carbon nanofiber composite material and a preparation method and an application thereof. The composite material is of a pipe sleeving structure, a molybdenum disulfide fiber core is arranged in the composite material and a nitrogen-doped carbon nanofiber shell is arranged outside the composite material; and a gap is arranged between the molybdenum disulfide fiber core and the nitrogen-doped carbon nanofiber shell. The preparation method comprises the steps of dissolving ammonium thiomolybdate and polymethyl methacrylate into a solvent and carrying out electrostatic spinning to obtain a polymethyl methacrylate / ammonium thiomolybdate nanofiber; carrying out drying and surface treatment, immersing the nanofiber into a pyrrole / hydrochloric acid solution, dropwise adding a ferric chloride / hydrochloric acid solution and carrying out in-situ polymerization to obtain the fiber coated with polypyrrole on the surface; and washing and drying the fiber, carrying out high-temperature reduction under the condition of taking an argon / hydrogen mixed gas as a protective atmosphere and then carrying out high-temperature carbonization under an argon condition. The composite material has high specific capacity and good cycle stability, and can be used as an efficient and safe novel negative electrode material of a lithium-ion battery.

Owner:DONGHUA UNIV

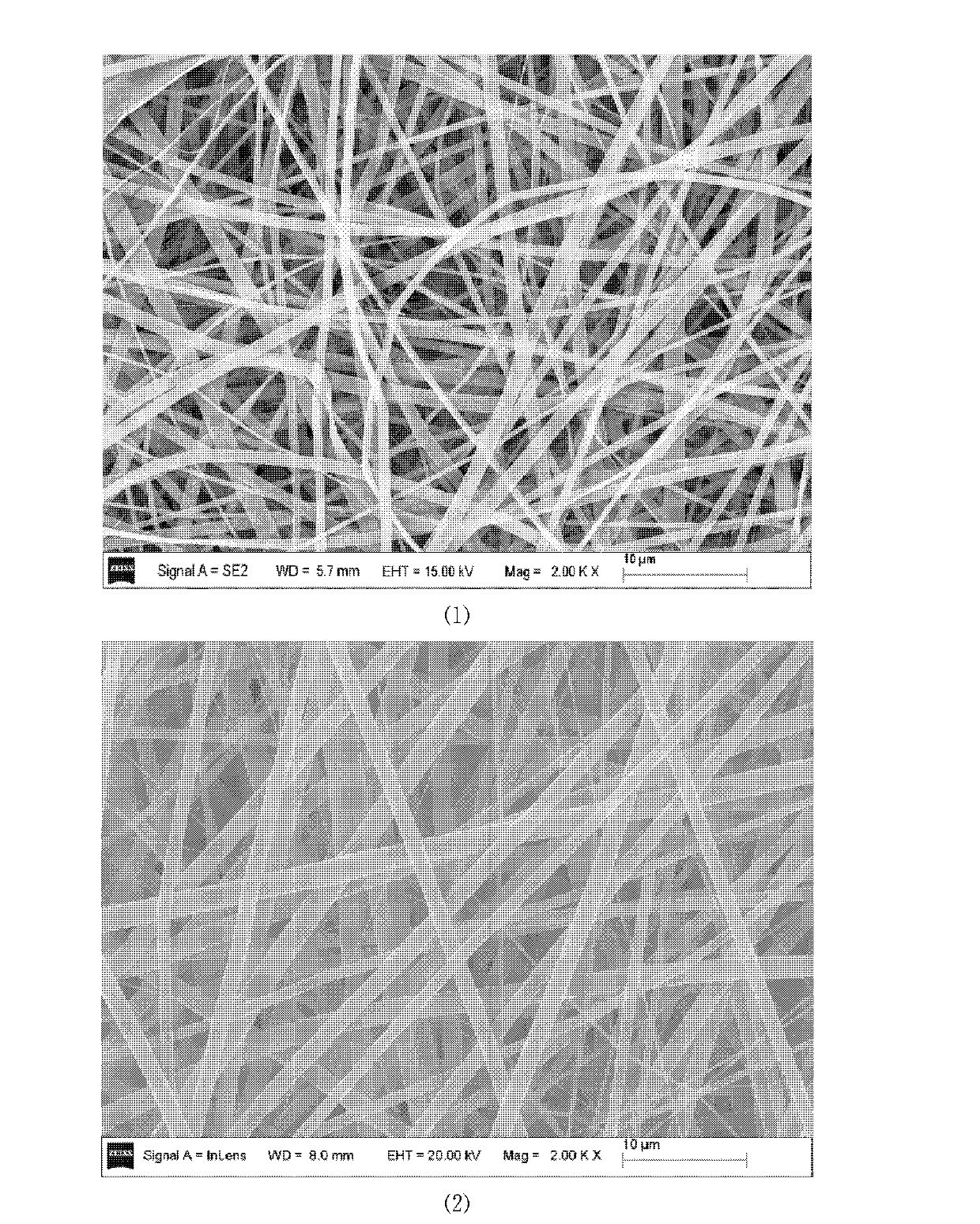

Preparation method for super-hydrophobic and super-hydrophilic electrostatic spinning nanofiber composite membranes

InactiveCN102605554AEasy to prepareSpinning process is stableFibre typesNon-woven fabricsFiberNanofiber

A preparation method for super-hydrophobic and super-hydrophilic electrostatic spinning nanofiber composite membranes belongs to the field of the nanofiber composite membranes. For the method, the raw materials are easy to obtain, the process is simple, and the operation is convenient and quick. In the method, the electrostatic spinning technology is mainly adopted to prepare the polymer nanofiber composite membranes, different solvents and different treatment methods are adopted, the nanofiber composite membranes are super-hydrophobic or super-hydrophilic, and the mechanical property is improved. The preparation method is simple, the spinning process is stable, the fiber is small in diameter and light in weight, no pollution is caused, and the preparation method is widely applied to the fields of filter materials, construction paint, mineral floatation and the like.

Owner:BEIJING UNIV OF CHEM TECH

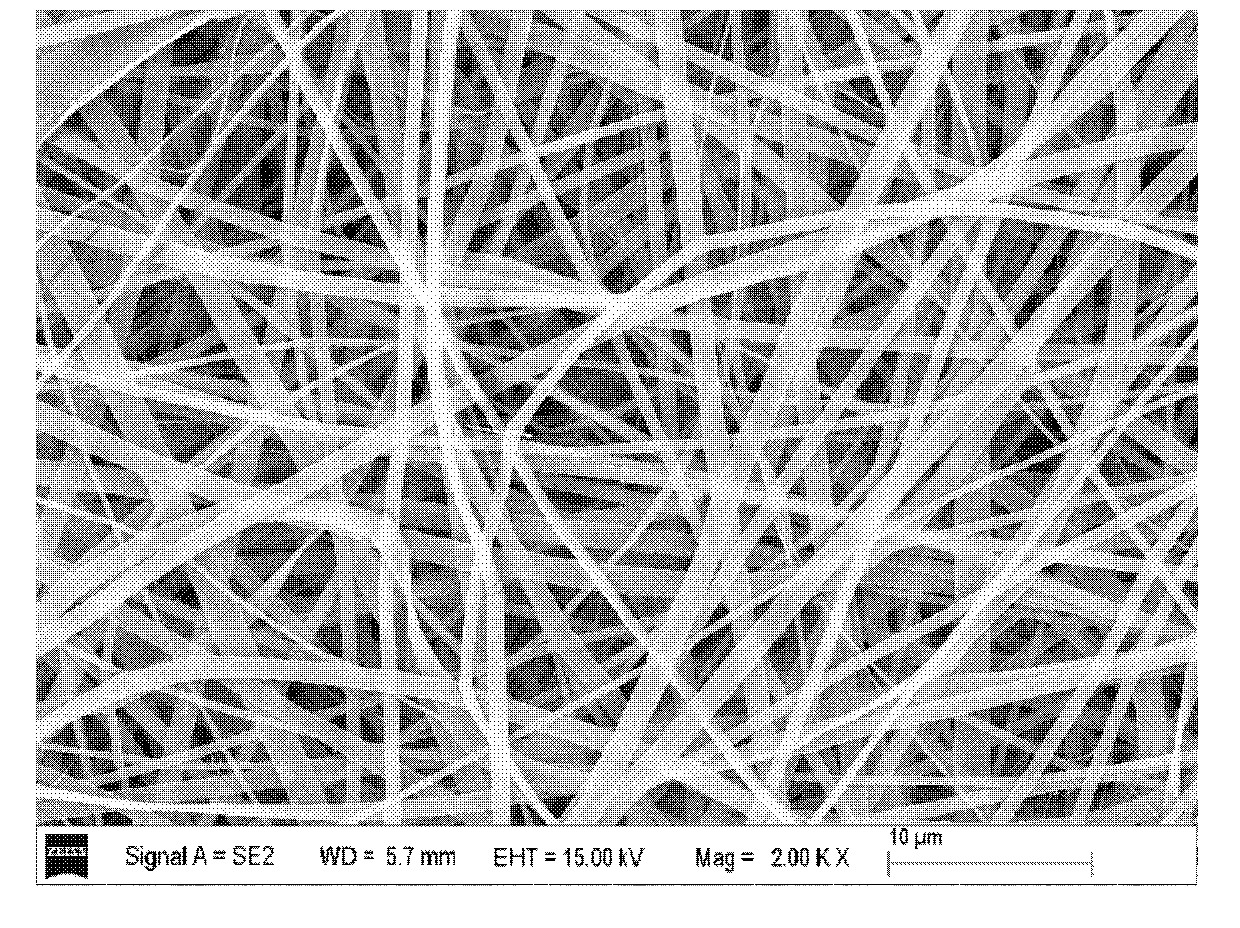

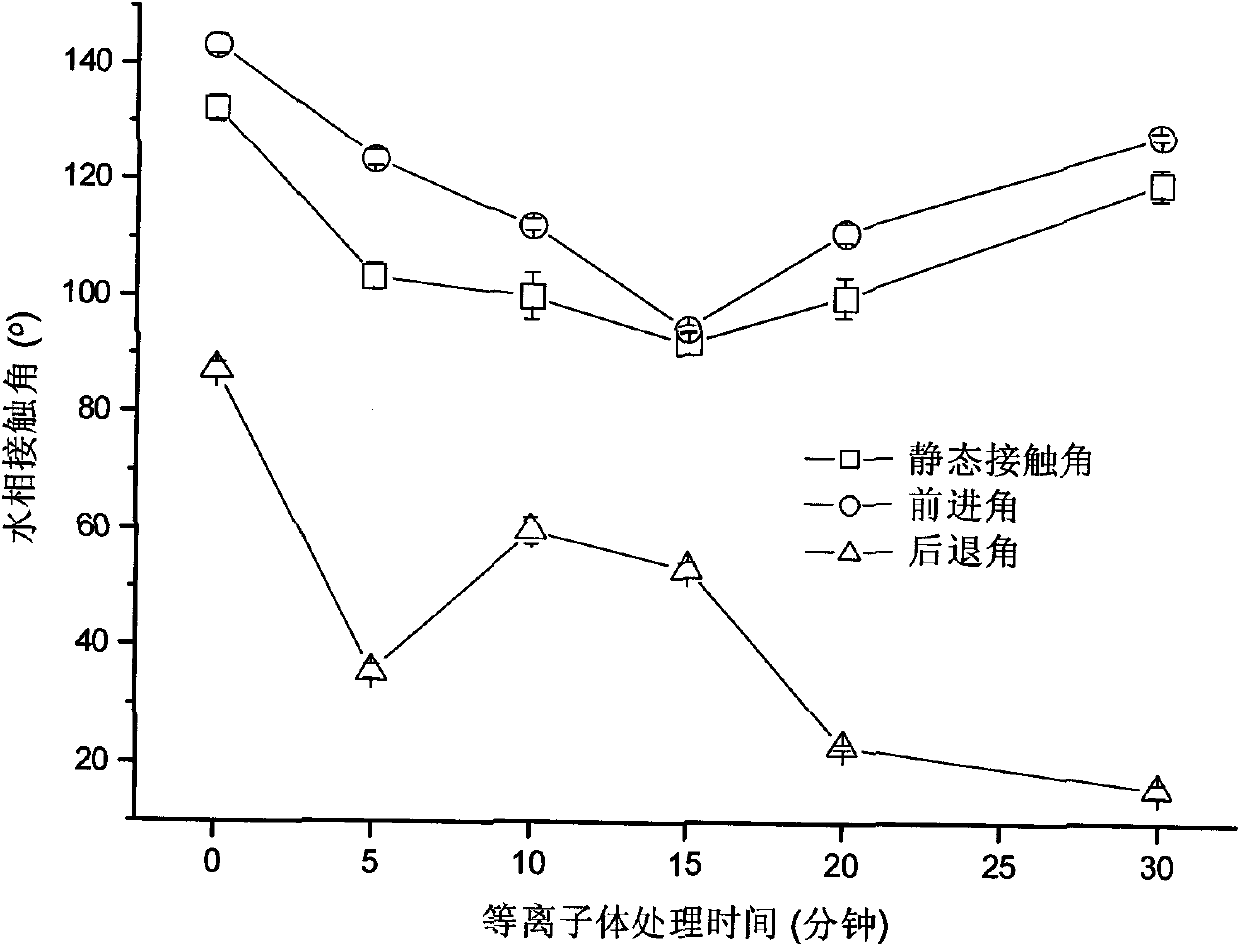

Method for preparing bioactive poly(lactic-co-glycolic acid)/collagen/hydroxyapatite composite fiber membrane for bone repair

The invention discloses a method for preparing a bioactive poly (lactic-co-glycolic acid) / collagen / hydroxyapatite composite fiber membrane for bone repair. The method comprises the following steps of: treating a poly (lactic-co-glycolic acid) electrospun nanofiber membrane by using plasma, coating collagen, and immersing the poly (lactic-co-glycolic acid) electrospun nanofiber membrane into a simulated human physiologic body fluid to mineralize to obtain the poly (lactic-co-glycolic acid) / collagen / hydroxyapatite composite fiber membrane. The preparation method of the invention has the advantages of simpleness, high speed and wide material sources. By adopting the method of plasma treatment and coating, the highly-bionic nanofiber composite membrane is prepared by the steps of introducing collagen with osteocyte epimatrix into the poly (lactic-co-glycolic acid) electrospun nanofiber membrane and depositing active hydroxyapatite onto the fiber membrane, thereby obtaining. The composite fiber membrane has the advantages of favorable combination properties and convenient operation, can effectively promote the capabilities of adherence, growth and calcification osteogenesis of osteoblasts and stem cells, and is hopeful to become an ideal active bracket for bone repair.

Owner:无锡贝迪生物工程股份有限公司

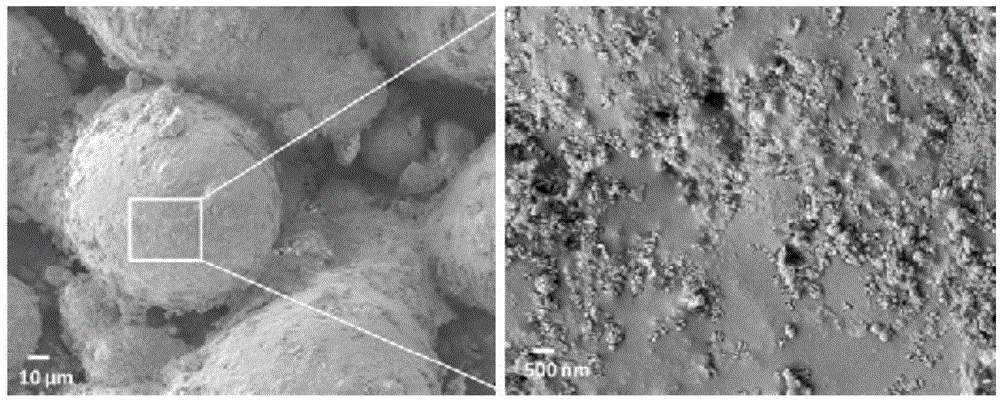

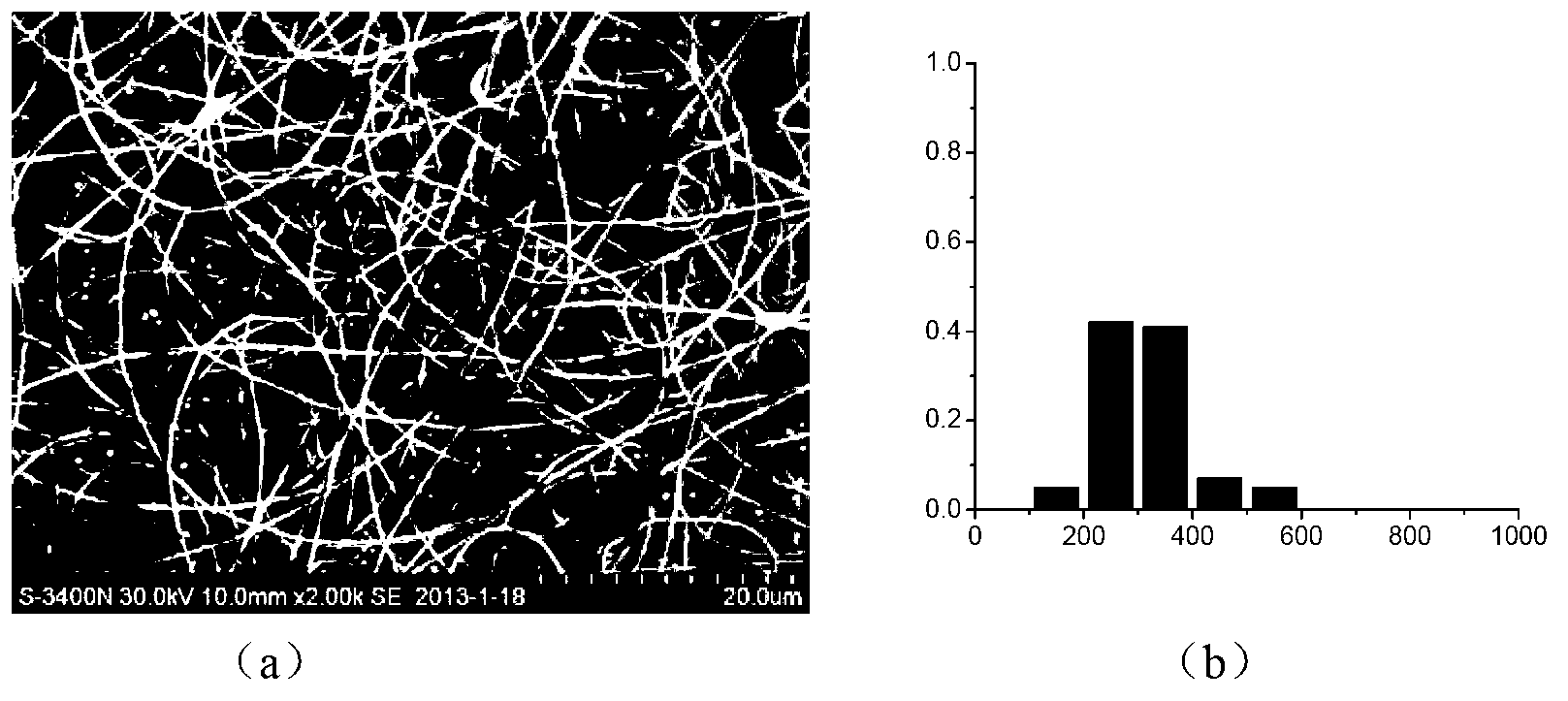

Modified silicon dioxide powder/silicon dioxide nanofiber composite aerogel material and preparation method thereof

The invention provides a modified silicon dioxide powder / silicon dioxide nanofiber cross-gradient composite aerogel material and a preparation method thereof. The modified silicon dioxide powder / silicon dioxide nano fiber cross-gradient composite aerogel material is characterized in that silicon dioxide nano fibers serve as a three-dimensional framework structure of aerogel, modified nano silicondioxide powder is uniformly filled in gaps formed among single nano fibers, the whole composite material is divided into three layers of different nano silicon dioxide powder filling densities in thickness, and by the three-dimensional framework formed by the silicon dioxide nanofibers, good compression resilience and strength are achieved. The three-dimensional silicon dioxide powder / silicon dioxide nanofiber aerogel material has a bulk density of 10-1000 mg / cm<3> and the average pore size of 0.05-1000 mu m, a tensile strength of 20-50 kPa, and a compression resilience is greater than or equal to 85%. According to the inner structure of the obtained aerogel material, silicon dioxide powder is uniformly dispersed in meshes of a three-dimensional frame formed by silicon dioxide fibers, thefibers are mutually staggered and penetrated to form pores, the mechanical strength of the aerogel material is improved, meanwhile, the aerogel material has a high porosity and small pore size structure, and has wide application prospects in the fields of heat insulation, sound absorption, noise reduction and the like.

Owner:黄金龙

Method for preparing carbon nano-tube modified polyaniline nano fiber composite material

InactiveCN101235199ALarger than surfaceImprove conductivityNon-conductive material with dispersed conductive materialFiberCarbon nanotube

The invention discloses a preparation process of carbon nano-tube modification polyaniline nano fiber conductivity composite material. The characteristics of the invention are that conducting acid treatment for carbon nano-tube with concentrated mixed acid, adding carbon nano-tube which is treated with acid and aniline monomer into perchloric acid water solution according to the weight ratio of 1:6-1-32, and evenly dispersing through ultrasonic processing, using ammonium persulphate as oxidation agent, controlling the molar ratio of ammonium persulphate and aniline monomer within 1:2-1:8, and reacting under the ambient temperature to obtain polyaniline nano fiber / conductivity composite material of polyaniline coating carbon nano-tube coexisting structure. The process has simple art, and is easy to be controlled. The composite material which is prepared has the characteristics of high electricity conductivity ratio and small influence by system pH valve, large specific surface and excellent electrochemistry property and the like, which is expected to be used on electrode material such as second lithium ion cell and super capacitor and the like.

Owner:EAST CHINA UNIV OF SCI & TECH

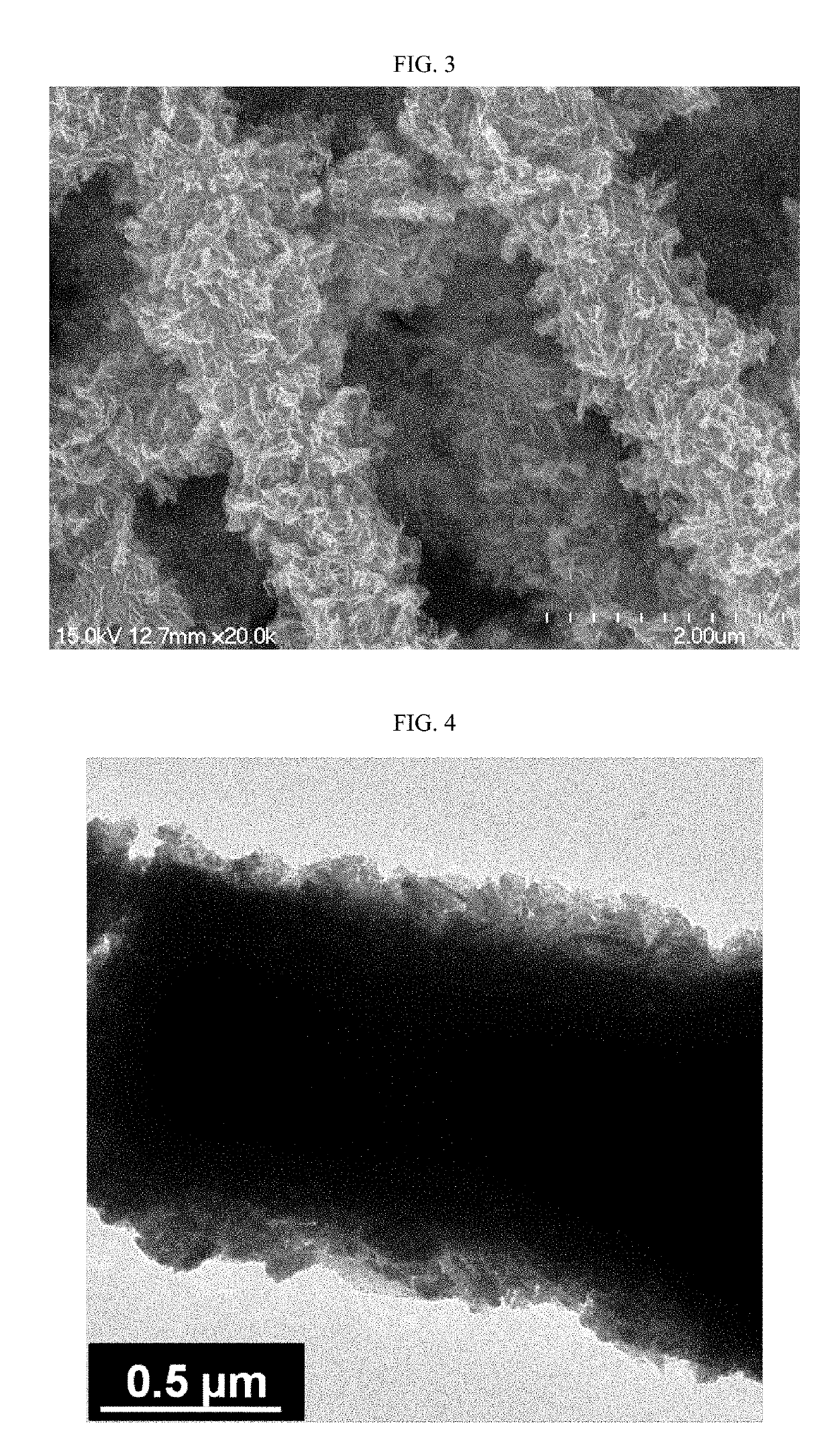

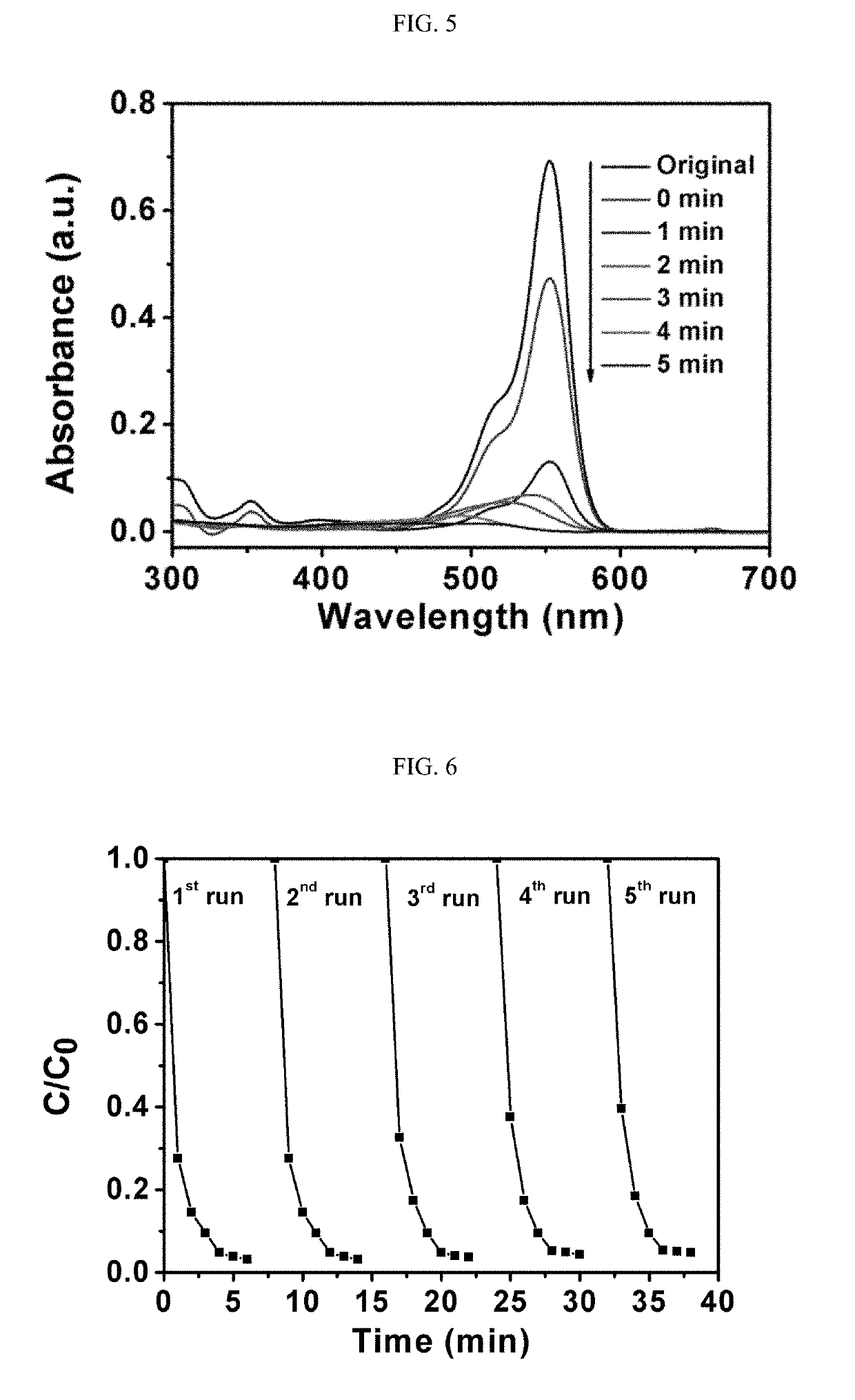

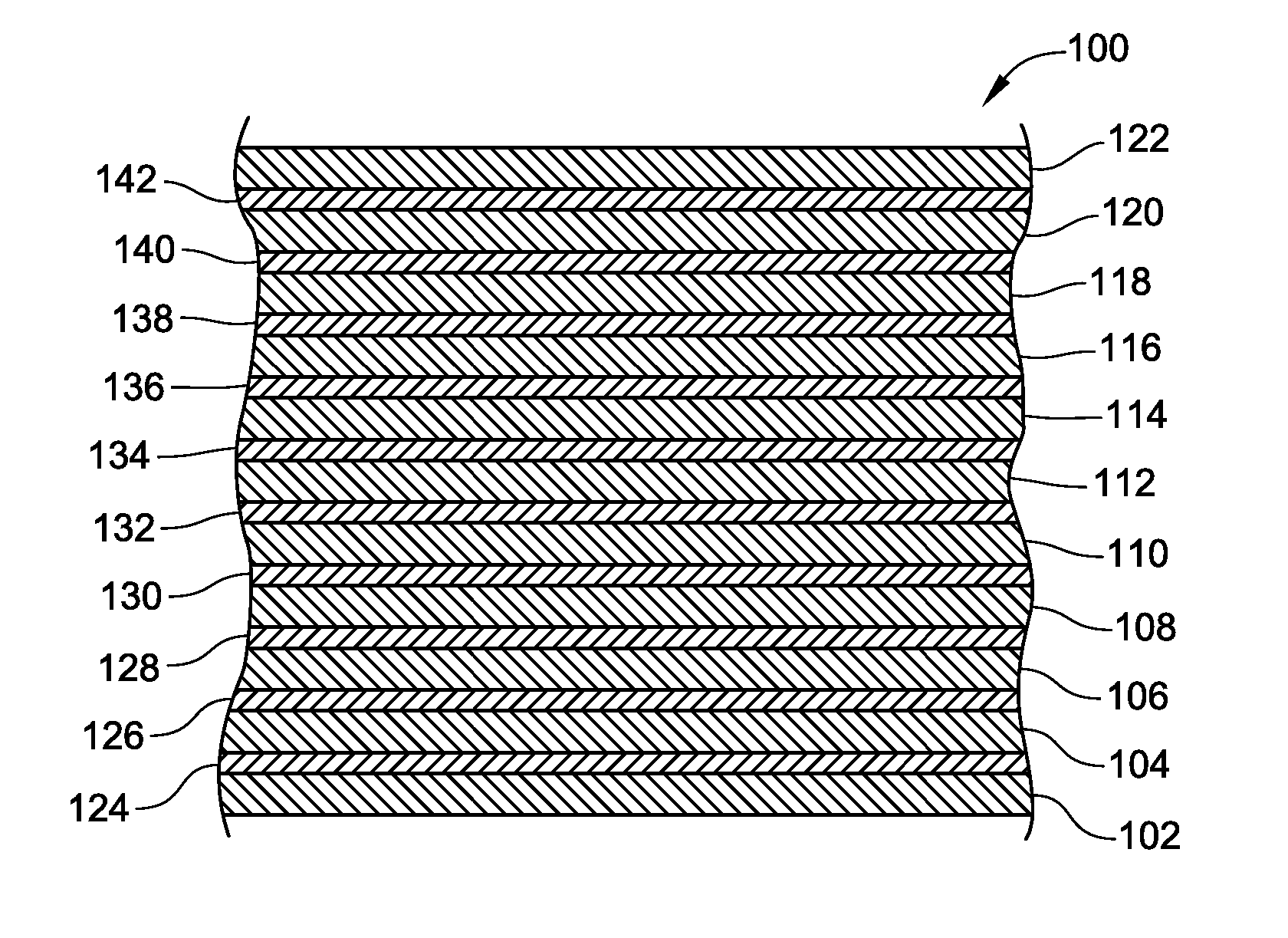

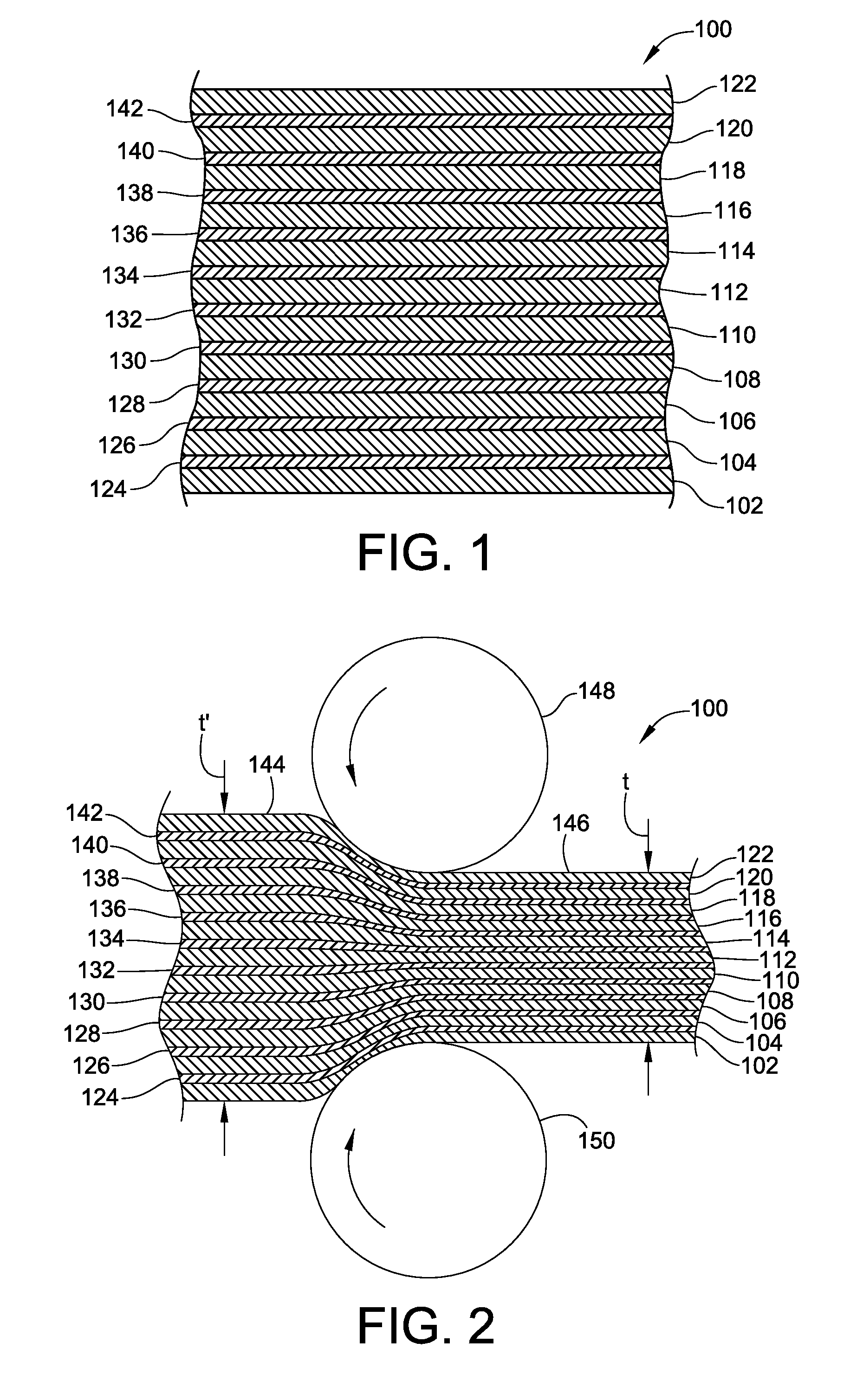

Iodine doped bismuthyl carbonate nanosheet and molybdenum disulfide modified carbon nanofiber composites, preparation method and application thereof

ActiveUS20190127883A1Low costEasy to operateFullerenesArtificial filament washing/dryingFiberSodium iodide

Iodine doped bismuthyl carbonate nanosheet and molybdenum disulfide modified carbon nanofiber composites, preparation method and its application in wastewater treatment are disclosed. Bismuth citrate and sodium carbonate as precursors, sodium carbonate as a precipitating agent, dispersed in a mixed solution of water and ethylene glycol, sodium iodide as a iodine source, nano carbon fiber membrane act as the carrier, to synthesis carbon fiber membrane that modified by iodine-doped Bi2O2CO3 nanosheets; then sodium molybdate and thioacetamide as precursors, dispersed in water to react to obtain iodine doped bismuthyl carbonate nanosheet and molybdenum disulfide modified carbon nanofiber composites. The composite material synthesized through a series of steps exhibit excellent photocatalytic activity for the degradation of Rhodamine B and can be recycled for many times. And this invention has the advantages of simple preparation process, easy recovery and multiple use, etc., and has industrial application prospect in water pollution treatment.

Owner:SUZHOU UNIV

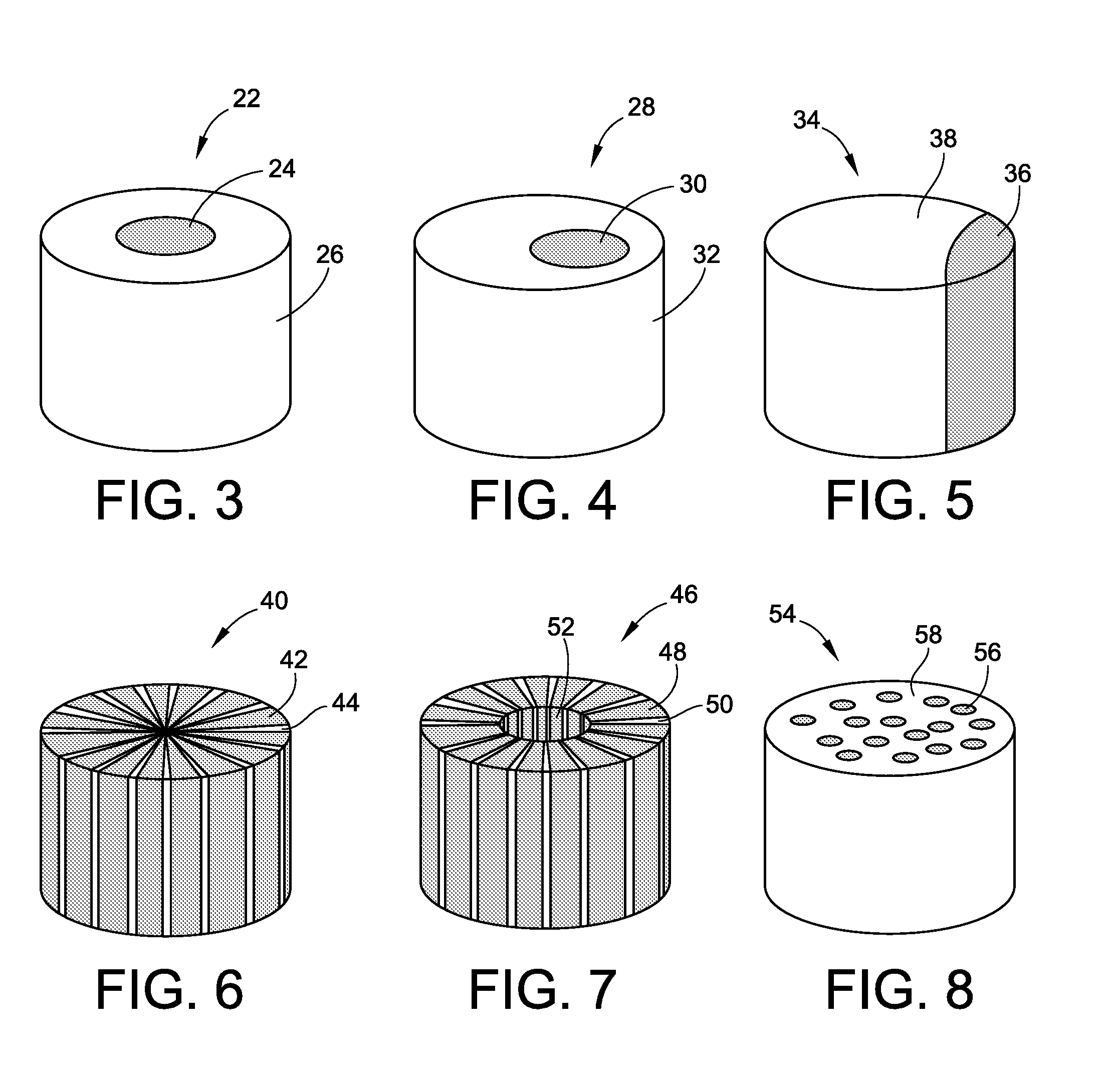

Compressed nanofiber composite media

InactiveUS20110210061A1Good suitHeavy total coverageMaterial nanotechnologySemi-permeable membranesComposite filterMaterials science

A coalescing media includes a compressed composite filter media comprising substrate layers and hydrophilic fine fiber layers for separating free water emulsified in fuels.

Owner:CLARCOR INC

Preparation method of waterproof moisture-permeable nanofiber composite membrane

InactiveCN110438659AImprove performanceSmall fiber diameterSilicaElectro-spinningWater vaporLiquid water

The invention relates to a preparation method of a waterproof moisture-permeable nanofiber composite membrane, and belongs to the technical field of textile materials. According to the preparation method, polyacrylonitrile is taken as a main raw material, polyvinylidene fluoride and polyurethane are added, the waterproof and moisture-permeable nanofiber composite membrane is prepared, and the waterproof and moisture-permeable membrane prepared from polyacrylonitrile nanofibers has the characteristics of high porosity, fine fiber diameter and small pore diameter. The waterproof and moisture-permeable effect of the fiber membrane is effectively improved, the hydrophobic microporous membrane is preliminarily obtained by blending polyacrylonitrile, polyvinylidene fluoride and polyurethane through a solution, the waterproof moisture-permeable membrane with a certain welding structure is obtained in combination with heat treatment, penetration of liquid water is effectively prevented, polyurethane is a block polymer, polar groups such as hydrophilic groups which exist on a macromolecular chain segment provide a carrier for water vapor transfer, meanwhile, the polyurethane has a certain hydrophobic property by the hydrophobic group on the chain segment, and by addition of the polyurethane, the nanofiber composite membrane has excellent comprehensive performance.

Owner:欧名龙

High-wear-resistant anti-stripping electrostatic spinning nanofiber composite filter material and spinning method thereof

ActiveCN104028047ACompact structurePrecise control of bulk densitySynthetic resin layered productsLaminationFiberWear resistant

The invention relates to a high-wear-resistant anti-stripping electrostatic spinning nanofiber composite filter material and a spinning method thereof. The preparation method comprises the following step: in the electrostatic spinning process, performing one-step forming by controlling and regulating the solvent concentration / pressure difference / melting points of two different polymers / an electrostatic spray solvent, so as to obtain dense three-dimensional arc-hole structural composite filter material fully adhered to fiber lapping points, wherein the gram weight of a fiber layer is 0.01 to 30 g / m<2>, the wear resistance of the composite filter material is 600 to 3,000 circles, the anti-stripping intensity is 5 to 100 MPa, the filter efficiency to 0.008-2-mircon particles reaches more than 99.99%, the resistance pressure drop is below 25 Pa, and the clogging capacity is 100 to 3,000 g / m<2>. The spinning method has the advantages of simple preparation process and low cost, and the prepared composite filter material has wide application prospects in the fields of engine filtration, air compressor filtration, gas turbine filtration, indoor air purification and filtration, high-efficiency filtration and the like.

Owner:上海迅江科技有限公司

Cell-nanofiber composite and cell-nanofiber-hydrogel composite amalgam based engineered intervertebral disc

InactiveUS20160106548A1Promote differentiationPromote growthPharmaceutical delivery mechanismCell culture supports/coatingIntervertebral discNanofiber

The instant invention is directed to a tissue engineered intervertebral disc comprising at least one inner layer and an exterior layer, wherein: the exterior layer comprises a nanofibrous polymer support comprising one or more polymer nanofibers; the at least one inner layer comprises a hydrogel composition comprising at least one or more hydrogel materials and / or one or more polymer nanofibers; and a plurality of cells which are dispersed throughout the tissue engineered intervertebral disc. Additionally, the instant invention is directed to methods of making such intervertebral discs and methods of treating intervertebral disc damage.

Owner:UNITED STATES OF AMERICA

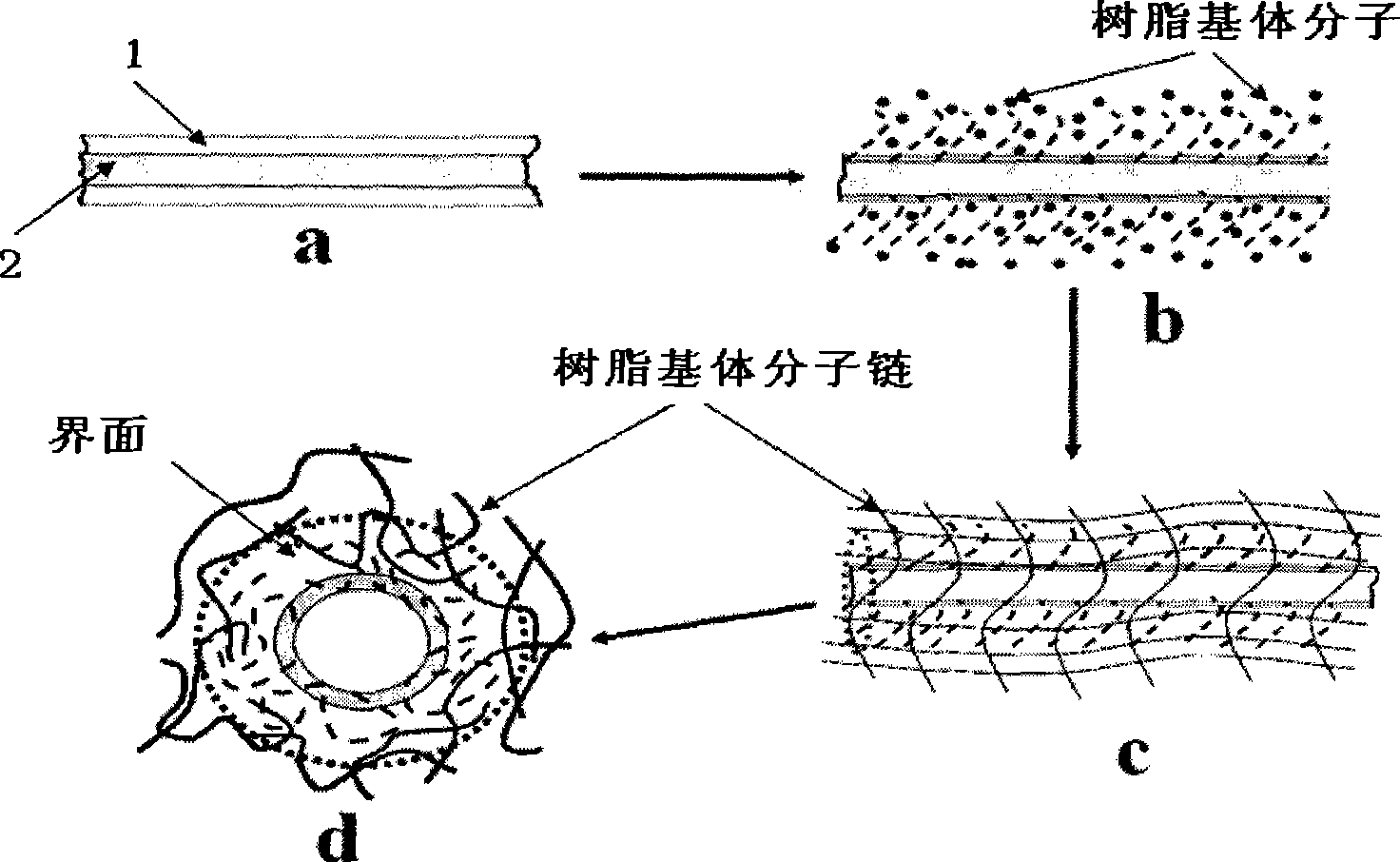

Method for preparing nano fiber reinforcement toughening resin base composite material

ActiveCN101397372ASolve the problem of poor interface compatibilityImprove interface performanceFilament/thread formingSolubilityResin matrix

Owner:BEIJING UNIV OF CHEM TECH

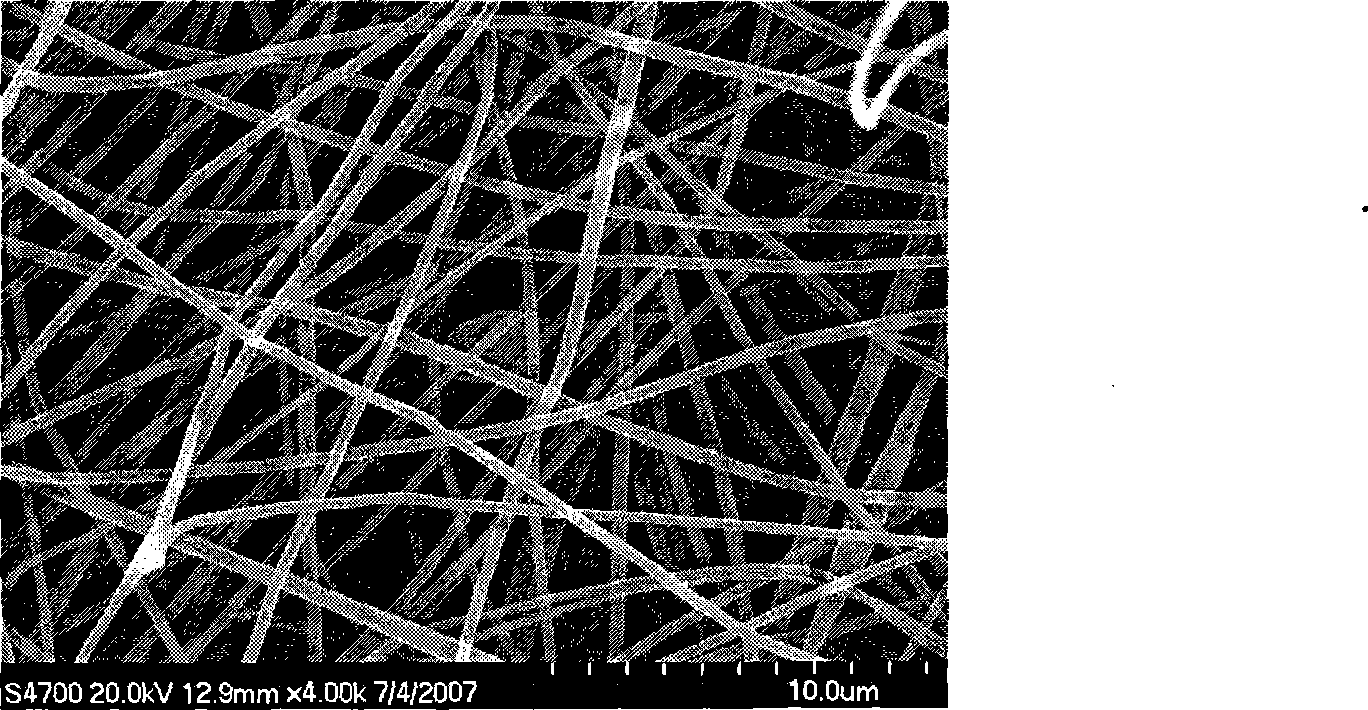

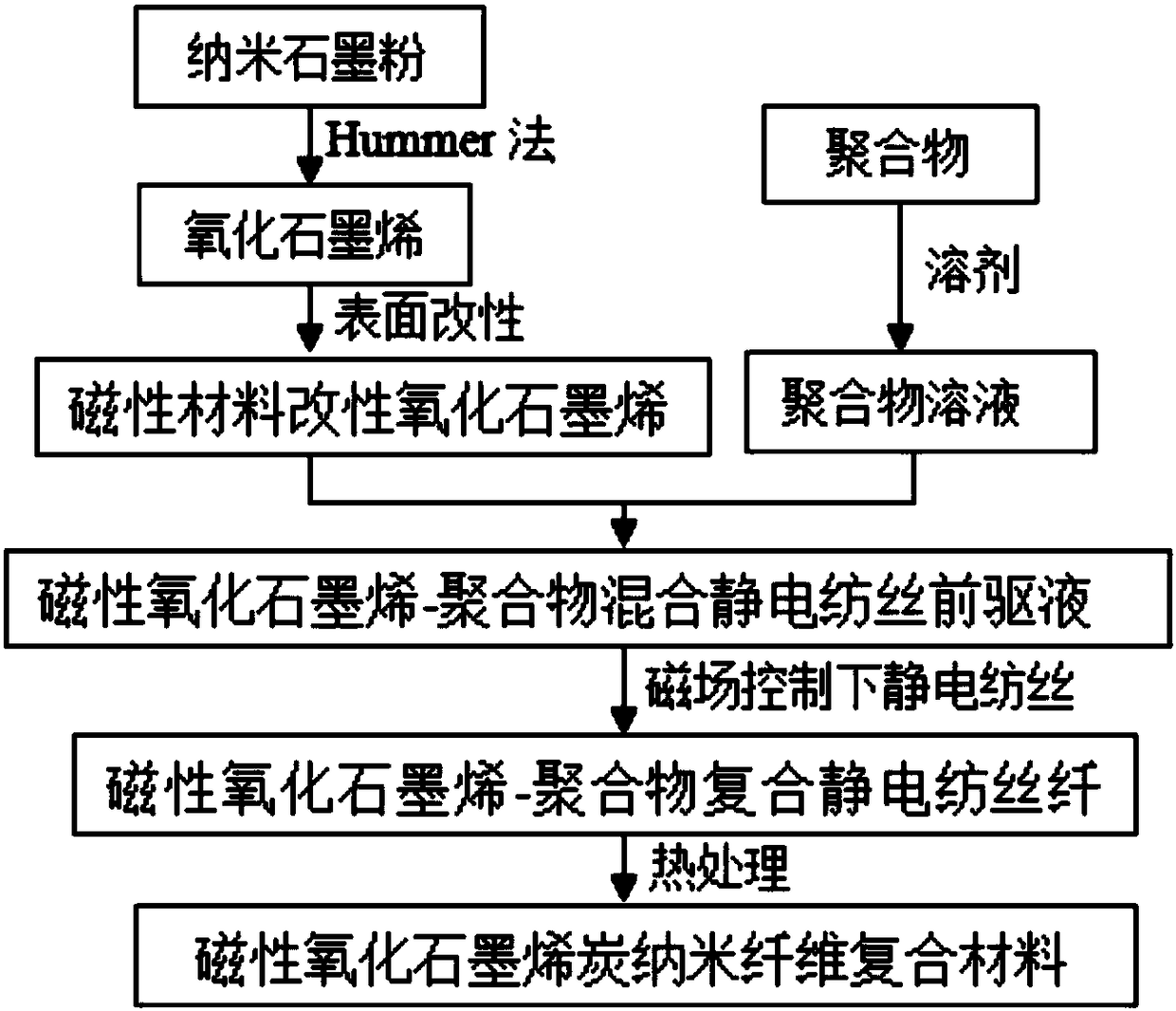

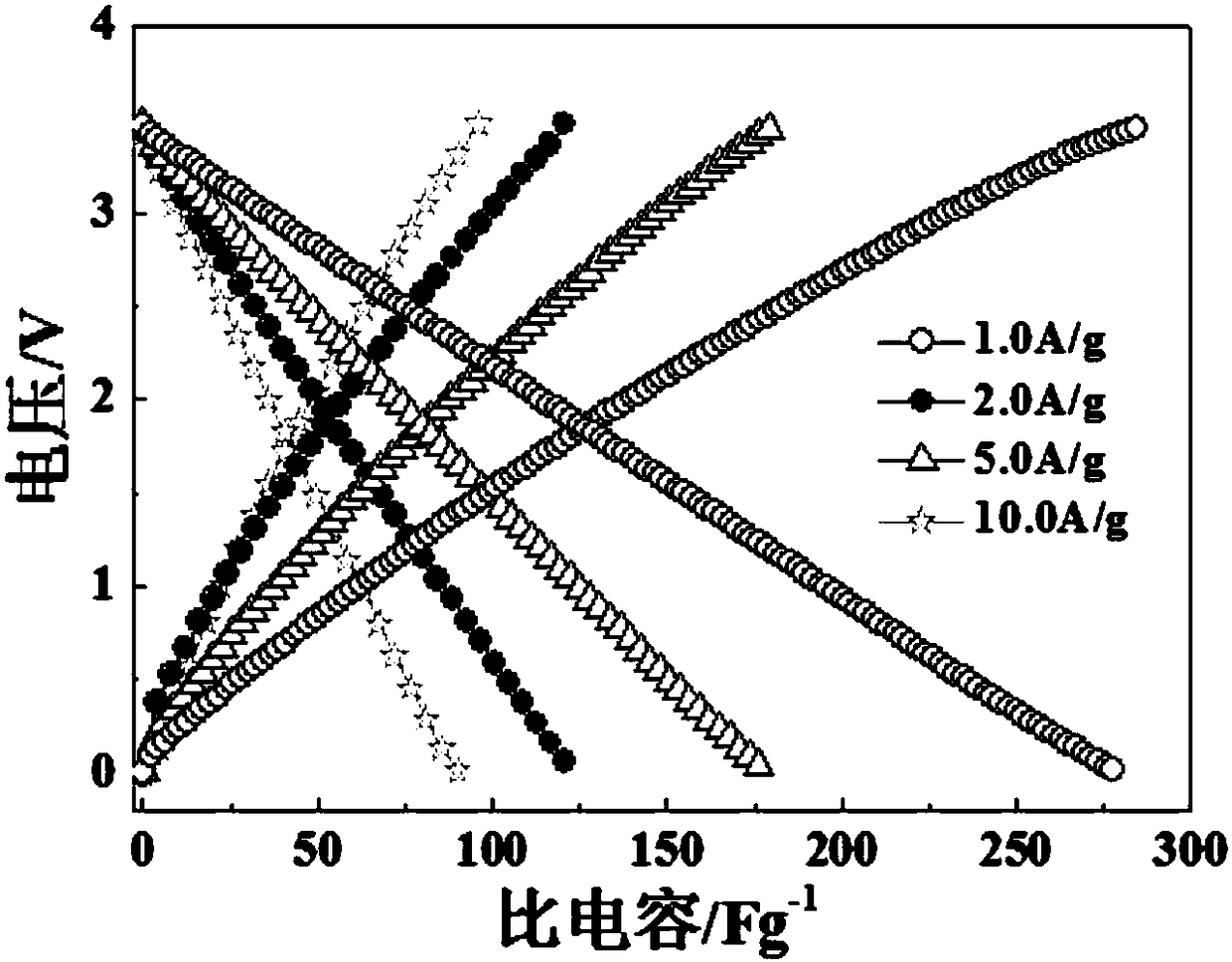

Preparation method of array magnetic reduced graphene oxide-carbon nanofiber

ActiveCN108315834AEasy to manufactureIncrease load capacityHybrid capacitor electrodesCell electrodesCapacitanceCharge discharge

The invention discloses a preparation method of array magnetic reduced graphene oxide-carbon nanofiber. The method comprises the following steps: taking flake graphite as a raw material, and preparinggraphene oxide with a Hummer method, so as to obtain the graphene oxide; preparing the graphene oxide and magnetic material precursor into magnetic material modified graphene oxide with a hydrothermal / solvothermal method, preparing the magnetic material modified graphene oxide, polymer and a solvent into a magnetic graphene oxide-polymer mixed electrostatic spinning precursor solution, preparingmagnetic graphene oxide-polymer compounded electrostatic spinning fiber, and performing heat treatment, so as to obtain a magnetic graphene oxide carbon nanofiber composite material. The method has the advantages that an RGO surface loaded nano metal oxide particle has a pseudocapacitor characteristic, can improve the charge energy storage density of the composite material, and is suitable for high-capacity power supercapacitors, with the specific capacitance being 240.3CP / F*g<-1>-254.1CP / F*g<-1> and the charge discharge efficiency being 99.1% to 99.6%.

Owner:锦州凯美能源有限公司

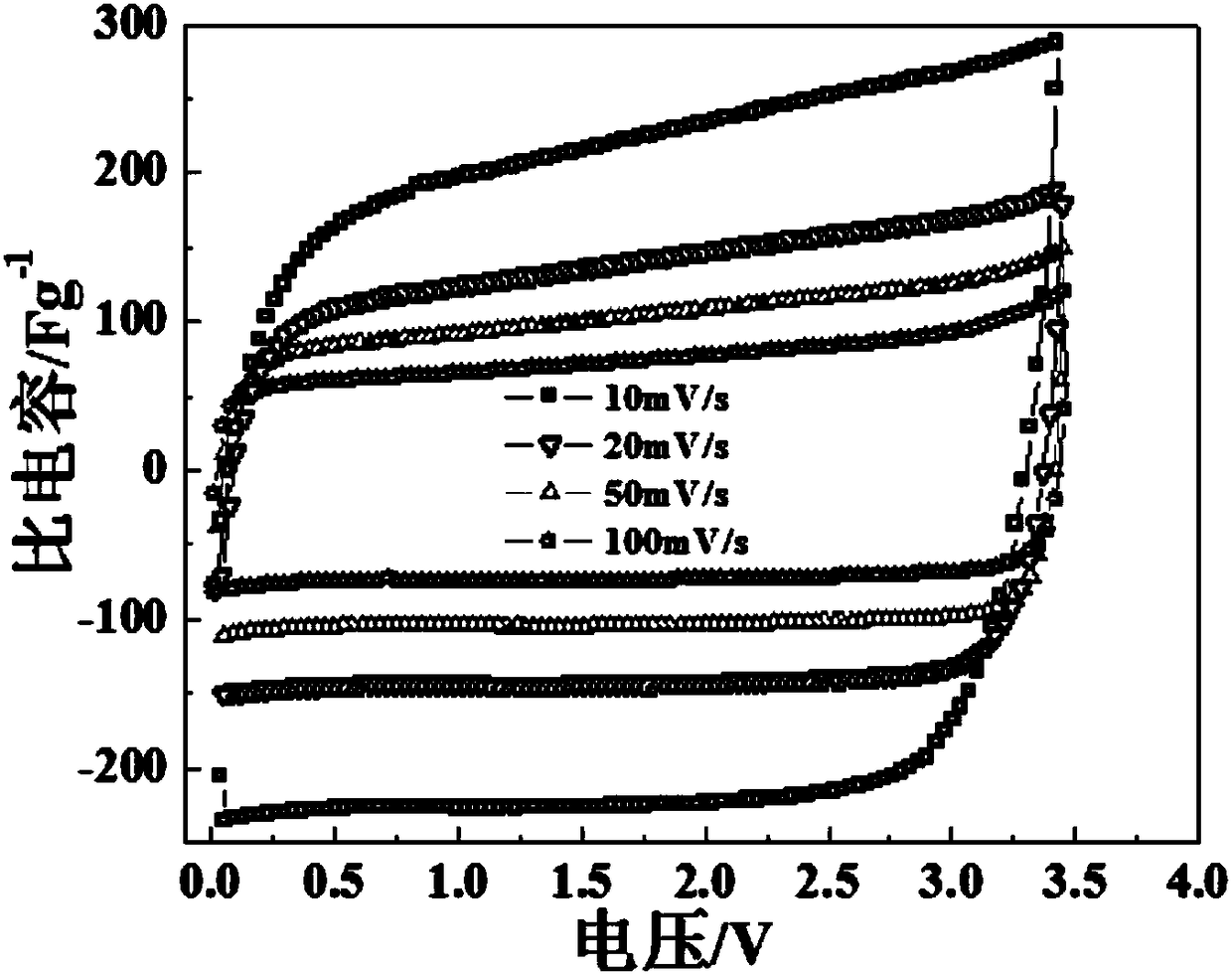

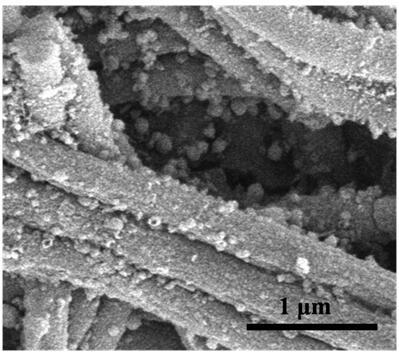

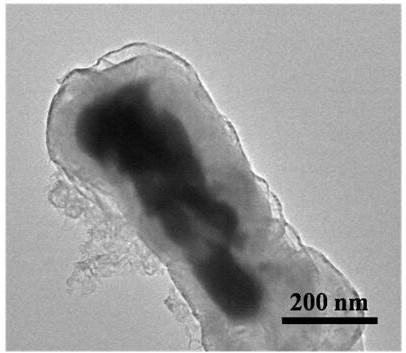

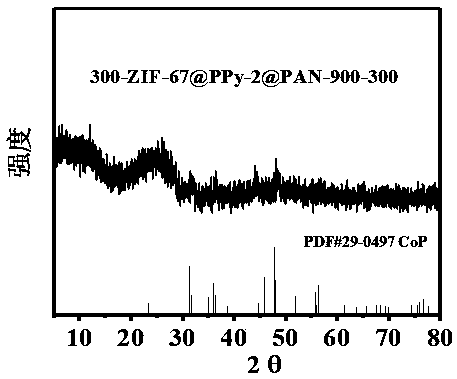

Preparation and application of transition metal phosphide/core-shell nitrogen-doped carbon nanofiber composite material

ActiveCN110052282AImprove conductivityImprove stabilityPhysical/chemical process catalystsElectrodesFiberElectrolysis

The invention provides a preparation method of a transition metal phosphide / core-shell nitrogen-doped carbon nanofiber composite material. The preparation method includes preparing a carbon nanofiberaccording to an electrospinning technique by taking a carbon-containing high-molecular polymer as a carbon source, coating the carbon nanofiber with an electroconductive polymer through surface polymerization, loading an MOF material onto the surface of the carbon nanofiber coated with the electroconductive polymer according to an in-situ growth method to obtain a precursor, and subjecting the precursor to high-temperature carbonizing and phosphating to obtain the transition metal phosphide / core-shell nitrogen-doped carbon nanofiber composite material. Activity test results show that the transition metal phosphide / core-shell nitrogen-doped carbon nanofiber composite material prepared by the preparation method has high electrocatalytic activity for total decomposition reaction of HER, OER and water and has high stability in acid-base media, thereby being a dual-functional catalyst that can replace precious metal and having a good development prospect in water electrolysis reaction.

Owner:NORTHWEST NORMAL UNIVERSITY

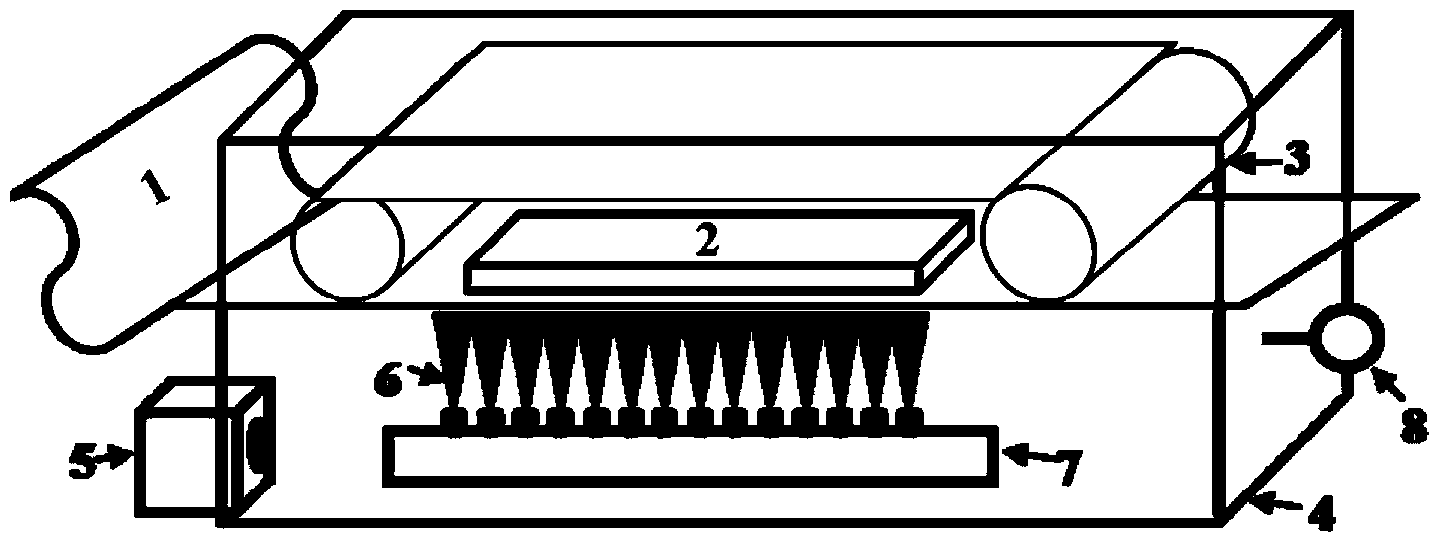

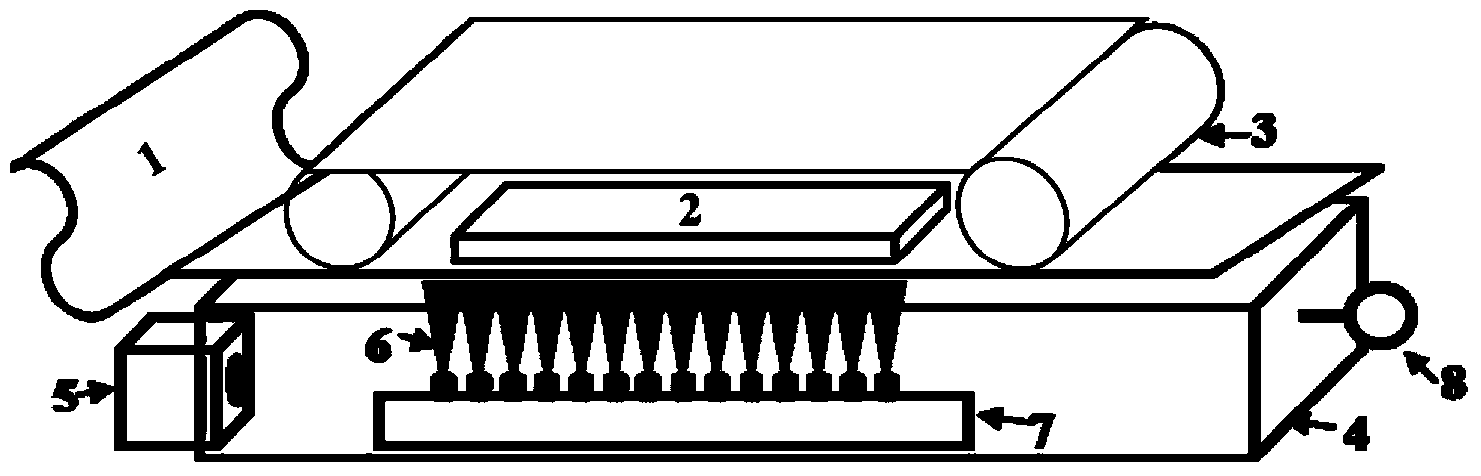

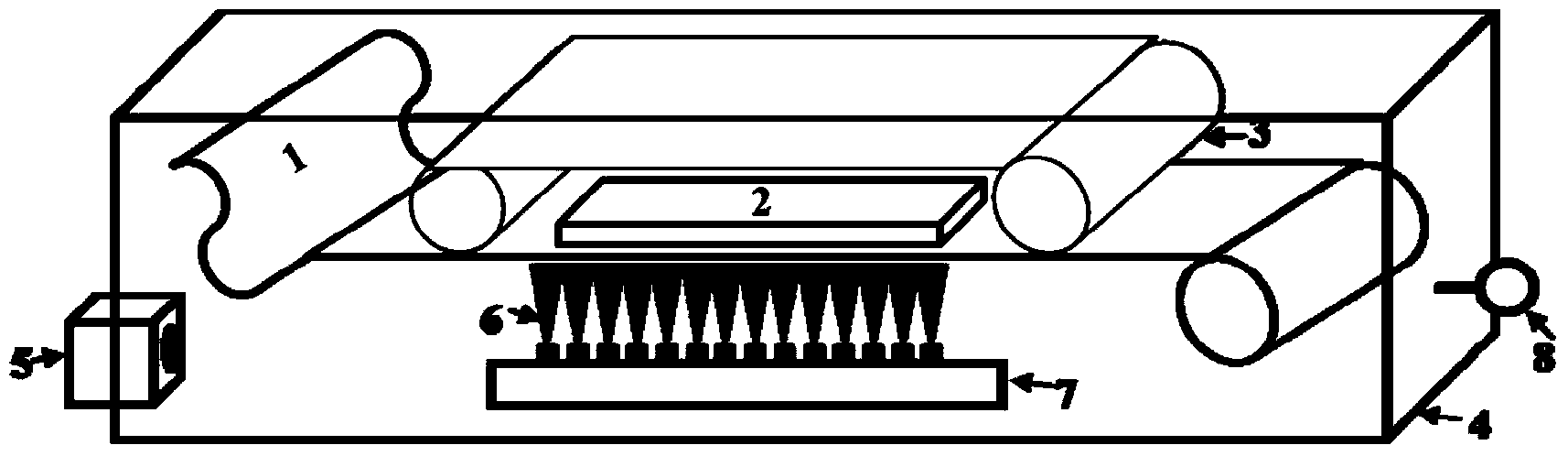

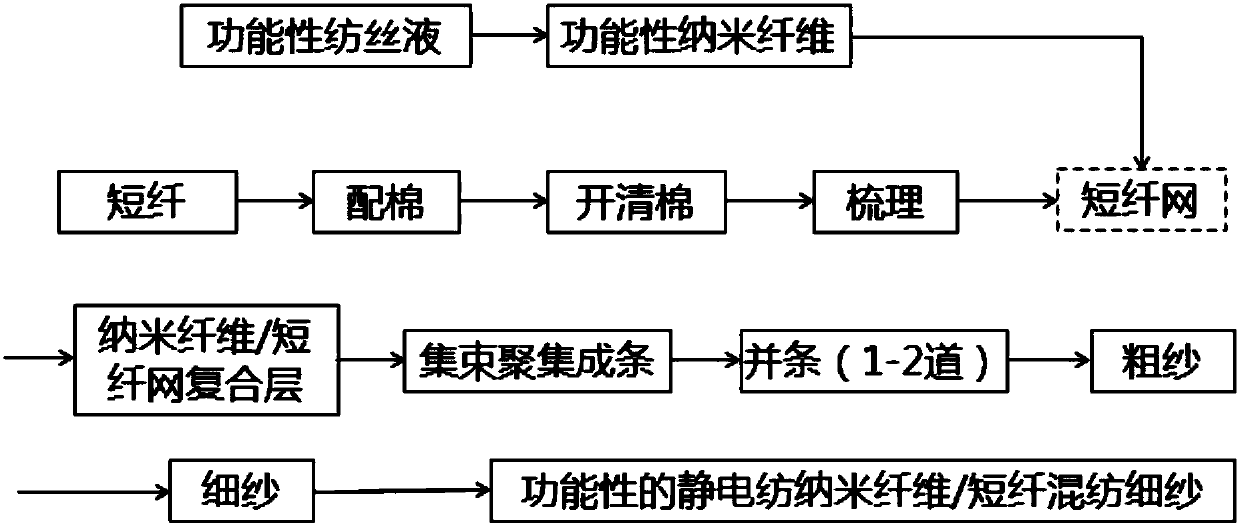

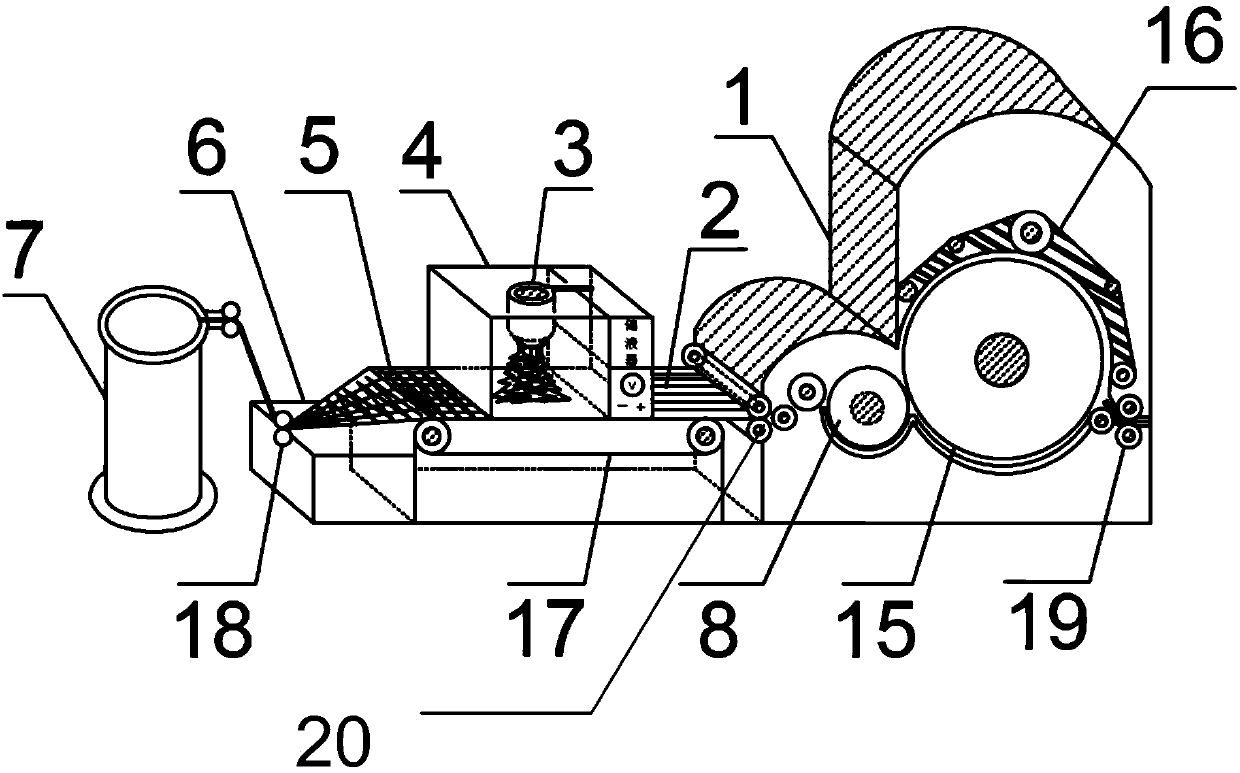

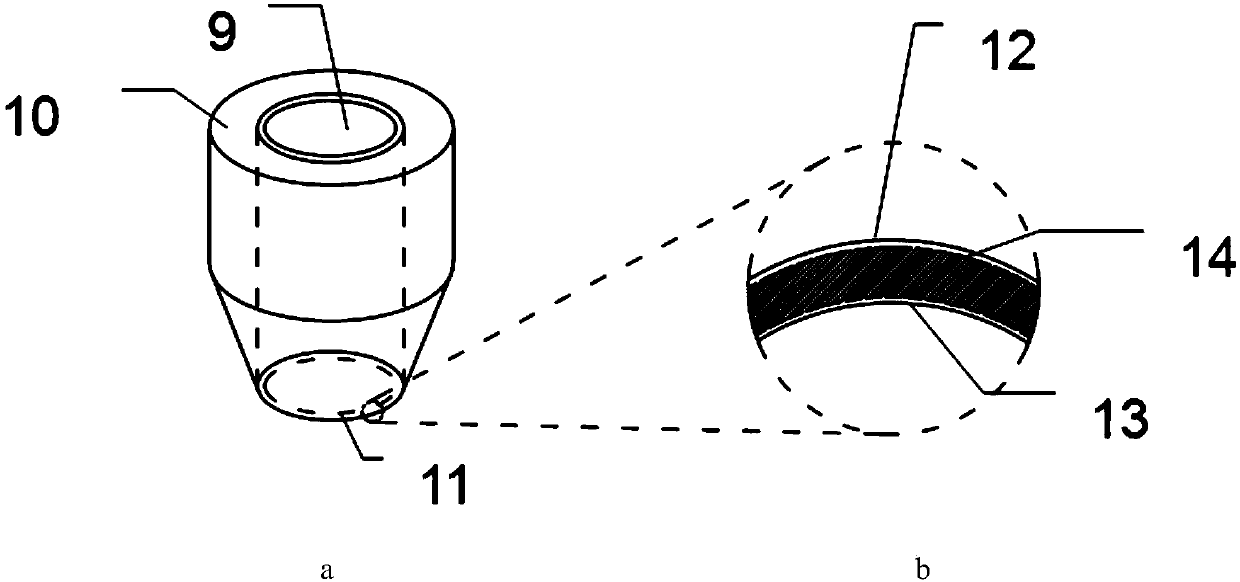

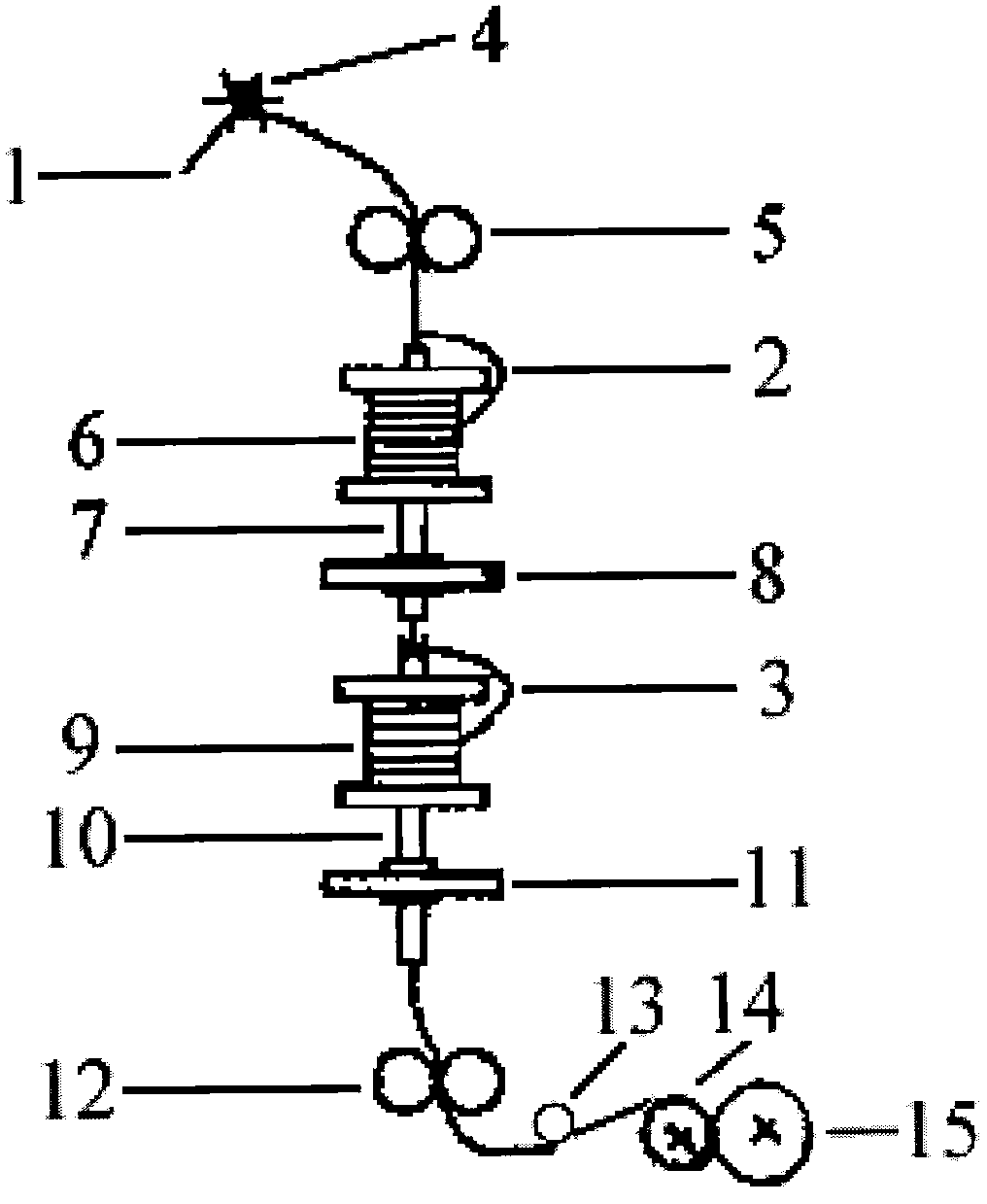

Device and method for batch preparation of blended yarn with electrostatic spinning nanofiber composite short fiber network

The invention relates to a device and a method for batch preparation of blended yarn with an electrostatic spinning nanofiber composite short fiber network. The device is that a conveyor belt (17) isarranged on one side of a carding machine (1), an electrostatic spinning device (4) is arranged on the conveying belt (17), a bell mouth fixing device (6) is arranged on the other side of the conveying belt (17), a bell mouth (18) is arranged on the bell fixing device (6), a cylinder (7) is arranged on the other side of the bell fixing device (6). The method comprises preparation of functional spinning solution, preparation of functional nanofibers, preparation of a composite layer of nanofiber / short fiber network and preparation of electrostatic spinning nanofiber / short fiber blended yarn.The device is simple in processing, the operation is feasible, the prepared nanofibers / short fiber blended yarn has better functionality and nanofiber distribution uniformity, the grades and added value of traditional textiles are significantly improved, and the device and the method have a good application prospect of industrialization.

Owner:DONGHUA UNIV

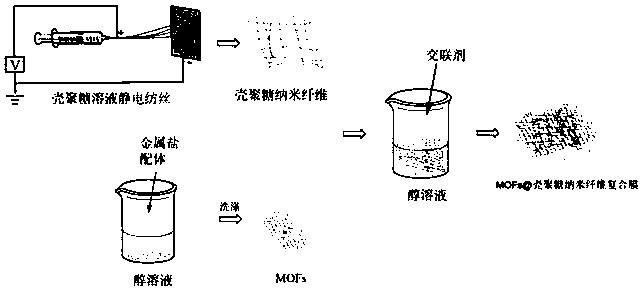

Preparation method of MOFs-chitosan nanofiber composite membrane

The invention belongs to the technical field of preparation of polymer materials and particularly relates to a preparation method of a MOFs-chitosan nanofiber composite membrane. The preparation method comprises: preparing chitosan nanofibers through an electrospinning method, and blending a synthesized MOFs material and the chitosan nanofibers so that the MOFs material and chitosan nanofibers arecompounded under the action of a cross-linking agent to form the MOFs-chitosan nanofiber composite membrane. The MOFs-chitosan nanofiber composite membrane effectively solves the problem of low strength, poor stability and poor dispersibility of the MOFs material in the chitosan fibers. The MOFs-chitosan nanofiber composite membrane has the advantages of high MOFs retention rate, high strength, excellent water resistance and excellent solvent resistance. The preparation method is simple and easy, the preparation conditions are mild, the preparation method is suitable for large-scale production, and the MOFs-chitosan nanofiber composite membrane can be used in the fields of dye adsorption, metal ion adsorption, gas adsorption and storage.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

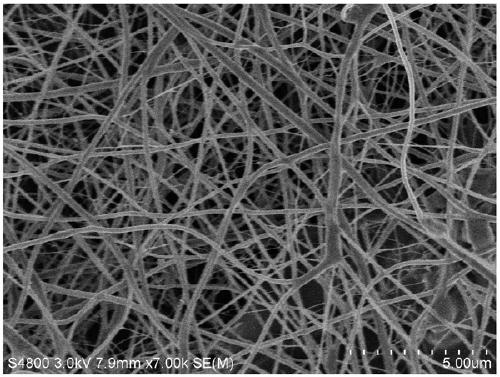

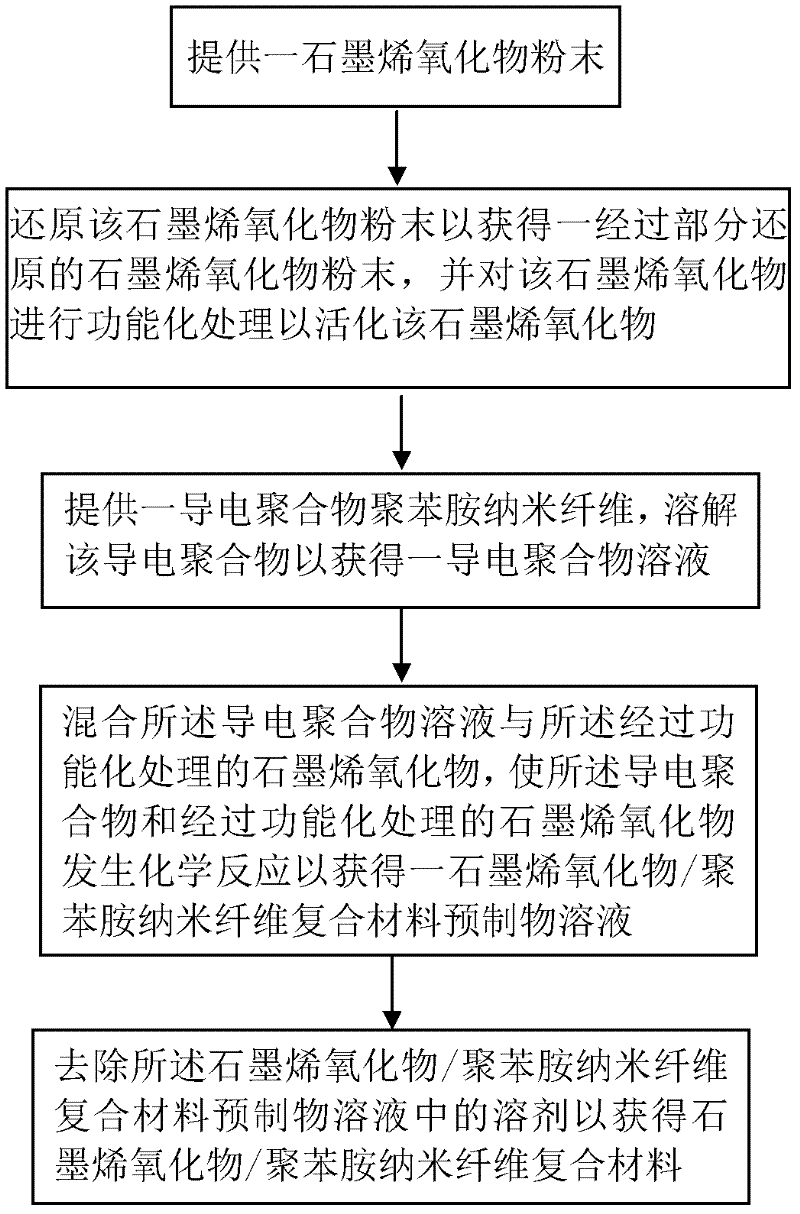

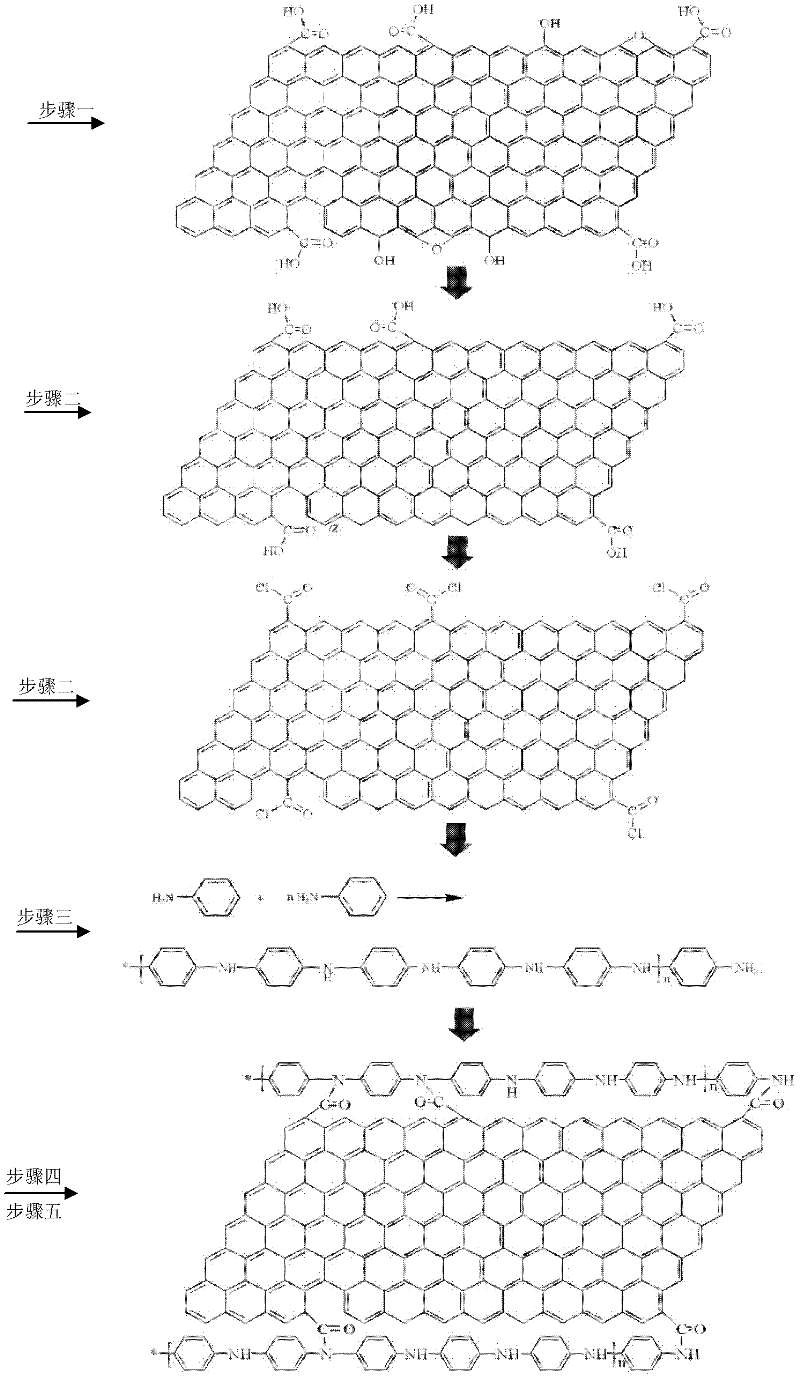

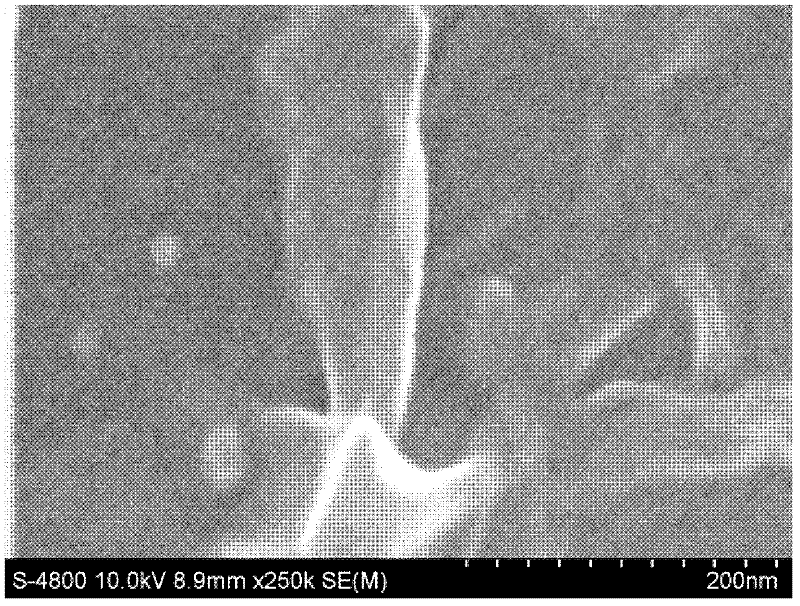

Graphene/polyaniline nano-fiber composite material and preparation method and application in super capacitor thereof

InactiveCN102532891AIncrease capacityHigh capacity retentionElectrolytic capacitorsPigment treatment with non-polymer organic compoundsFiberElectric capacity

The invention relates to a graphene / polyaniline nano-fiber composite material and a preparation method; an application of the composite material as an electrode material in a super capacitor; and a preparation method of the super capacitor. The composite material is obtained by chemical bond connection of functionally-treated graphene oxides with conductive polymer through amido groups; through reduction of the composite material, the conductivity is increased; combined with its inherent characteristic of structure stability, the composite material has higher electric capacity. The invention also relates to a super capacitor, which comprises a first electrode, a second electrode, a first current collector, a second current collector, a diaphragm, and an electrolytic solution; the first electrode and the second electrode are composed of the graphene oxide / polyaniline composite material, wherein the graphene / polyaniline nano-fiber composite material comprises graphene and conductive polymer which are in chemical bond connection through amido groups.

Owner:BEIHANG UNIV

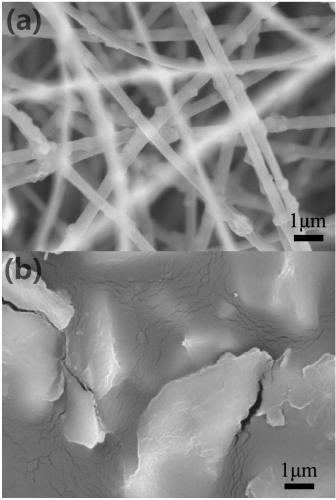

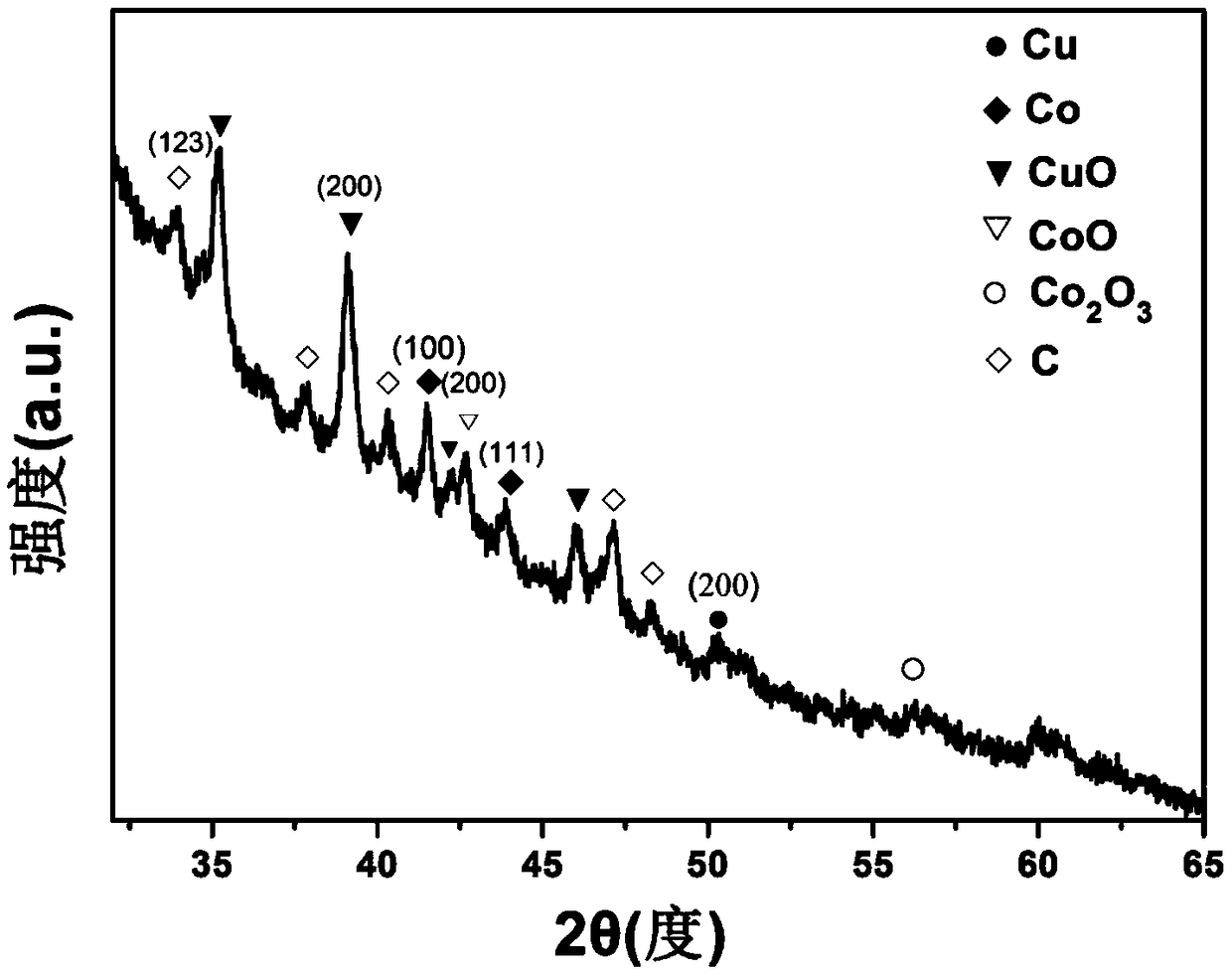

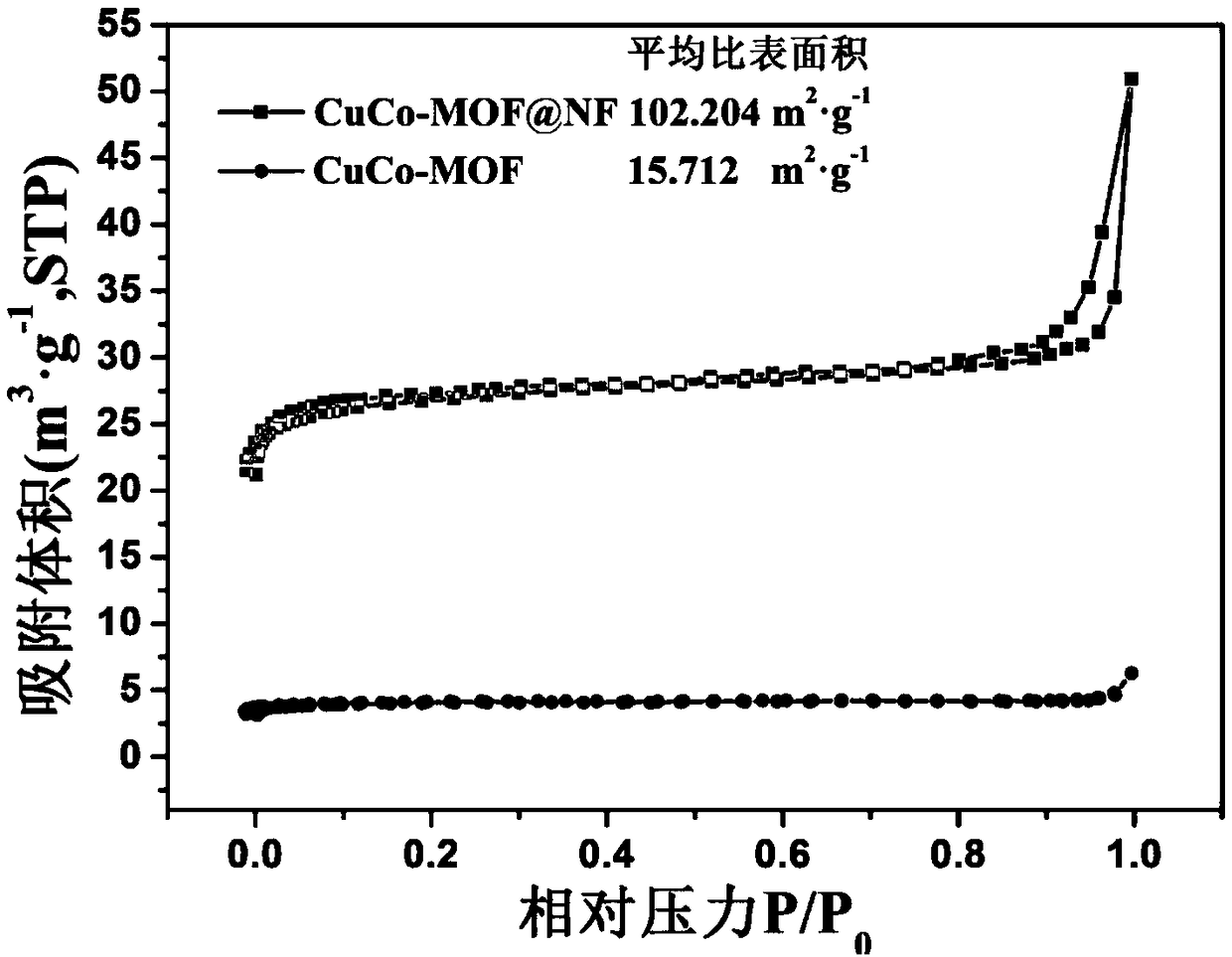

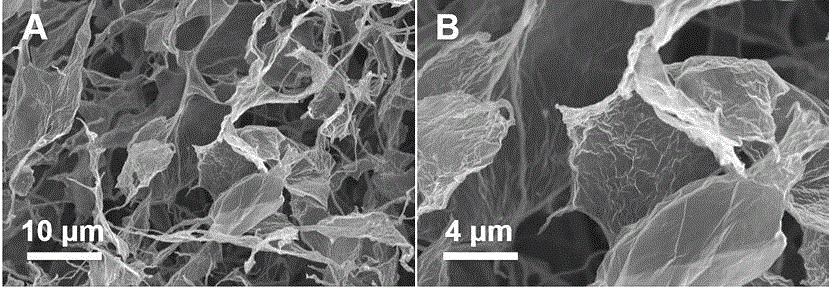

Copper-cobalt double-metal organic framework/nano-fiber composite material, preparation method thereof and application of composite material

InactiveCN109126885AImprove catalytic performanceImprove catalytic stabilityOrganic-compounds/hydrides/coordination-complexes catalystsWater contaminantsFiberMetal-organic framework

The invention discloses a copper-cobalt double-metal organic framework / nano-fiber composite material (CuCo-MOF@NF). A preparation method of the composite material includes the steps: firstly, preparing a copper-cobalt double-metal organic framework by a solvothermal method; secondly, mixing the copper-cobalt double-metal organic framework and a high-molecular polymer to prepare the copper-cobalt double-metal organic framework / nano-fiber composite material by an electrostatic spinning method. The composite material has excellent catalytic effects on azo-dyes such as rhodamine B (cationic dyes)and acid red 1 (anionic dyes) at normal pressure and temperature. The preparation method of the composite material is simple, a catalyst is convenient to operate and recycle, high in catalytic efficiency, good in stability and less in dosage, mass production of the composite material is easily achieved, and the composite material has an excellent application prospect in respects of catalytic degradation of azo-dyes in industrial wastewater and control of other pollutants.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

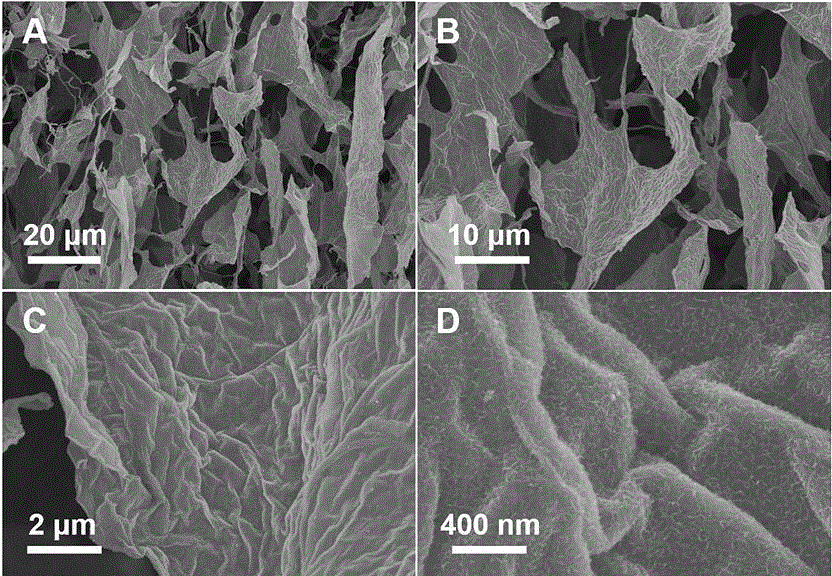

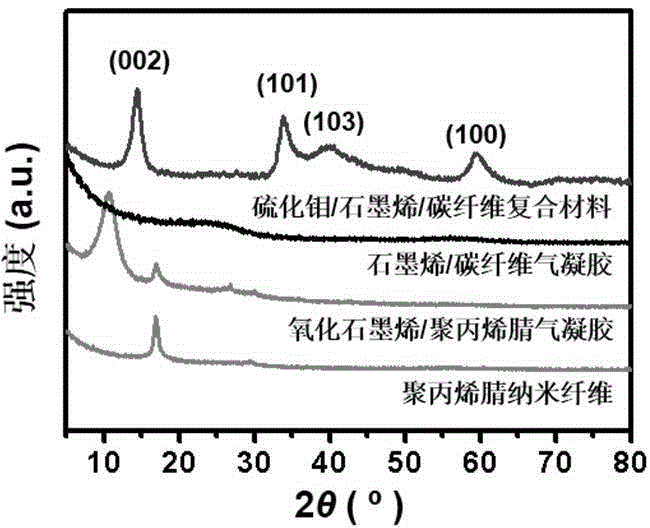

Molybdenum sulfide/graphene/carbon nano fiber composite material and preparation method thereof

InactiveCN105304876AEasy to makeEasy to operateHybrid capacitor electrodesCell electrodesSpinningNew energy

The invention belongs to the technical field of transition metal sulfide-carbon materials, and particularly relates to a molybdenum sulfide / graphene / carbon nano fiber composite material and a preparation method thereof. The preparation method includes the steps that polyacrylonitrile nano fibers are prepared through electrostatic spinning, oxidized graphene / polyacrylonitrile nano fiber aerogel is prepared through mechanical stirring and freezing drying, then graphene / carbon nano fiber aerogel is prepared through high-temperature carbonization, and finally, molybdenum sulfide nanosheets grow in situ on the graphene / carbon nano fiber aerogel through the one-step hydrothermal method. The molybdenum sulfide / graphene / carbon nano fiber composite material prepared through the method has the advantages that the material has a three-dimensional porous space structure, conductivity is good and chemical properties are stable, and can serve as an ideal high-performance electro-catalysis material and electrode materials of new energy devices such as lithium ion batteries and solar batteries.

Owner:FUDAN UNIV

Method for preparing carbon nanofiber composite and carbon nanofiber composite prepared thereby

ActiveUS20150243451A1Improve resolutionImprove production efficiencyElectric discharge heatingElectrolytic capacitorsFuel cellsDecomposition

The present invention relates to a method for preparing a carbon nanofiber composite, and a carbon nanofiber composite prepared thereby. The method for preparing a carbon nanofiber composite provided by the present invention has reduced costs and is economical and efficient compared with a convention method for preparing a carbon nanofiber composite. In addition, the carbon nanofiber composite of the present invention can provide remarkable decomposition performance of organic pollutants, and a carbon nanofiber composite prepared by the preparation method of the present invention can be used in an electrode for an electric double-layer supercapacitor, a fuel cell electrode, a filter, a hydrogen storage material, and the like.

Owner:DAEGU GYEONGBUK INST OF SCI & TECH

Cu-Ag-RE alloy in-situ nano fiber composite material

The invention relates to normal position nm fiber enhancing Cu basal compounding material of Cu-Ag-RE alloy that has high strength and high conductivity. The material uses Cu as basal body, and contains Ag less than 15%, RE less than 0.1%. The best performance of the compounding material is that: UTS is over 1.5GPa, relative conductivity is over 60% IACS. The invention could be used as high strength and high conductivity conductor material.

Owner:KUNMING INST OF PRECIOUS METALS

High-strength wear-resistant nanofiber composite yarn and preparation method thereof

The invention relates to a high-strength wear-resistant nanofiber composite yarn, which comprises a core yarn and a fasciated yarn, wherein an oriented nanofiber yarn or a nanofiber / filament covering yarn is adopted as the core yarn; and a water-soluble or alkali-soluble chemical fiber filament is adopted as the fasciated yarn. When the nanofiber covering yarn is used as the core yarn, a water-soluble vinylon or alkali-soluble polyester or other filament or yarn can be adopted as a core material, and a biocompatible or common filament or yarn can be also used as the core material. The preparation method of the high-strength wear-resistant nanofiber composite yarn comprises the following step of: adopting the high-strength nanofiber yarn or the nanofiber / filament covering yarn as the core yarn; winding the water-soluble vinylon or alkali-soluble polyester or other filament on the core yarn by using a hollow ingot form a composite yarn, wherein the nanofiber can be favorably cladded just by one or twice winding, therefore the composite yarn is favorable in strength and wear resistance for subsequent weaving and the fasciated yarn and the core yarn can be removed through posttreatment after weaving is finished. The composite yarn disclosed by the invention can be weaved and can be also prepared into various structures of materials, composite materials and materials with specific functions through combination and functionalization.

Owner:杨恩龙 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com