Graphene/polyaniline nano-fiber composite material and preparation method and application in super capacitor thereof

A technology of supercapacitors and nanofibers, applied in fibrous fillers, dyed low-molecular organic compounds, etc., can solve the problems of unguaranteed stability, affecting the conductivity of composite materials, and small capacitance of composite materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

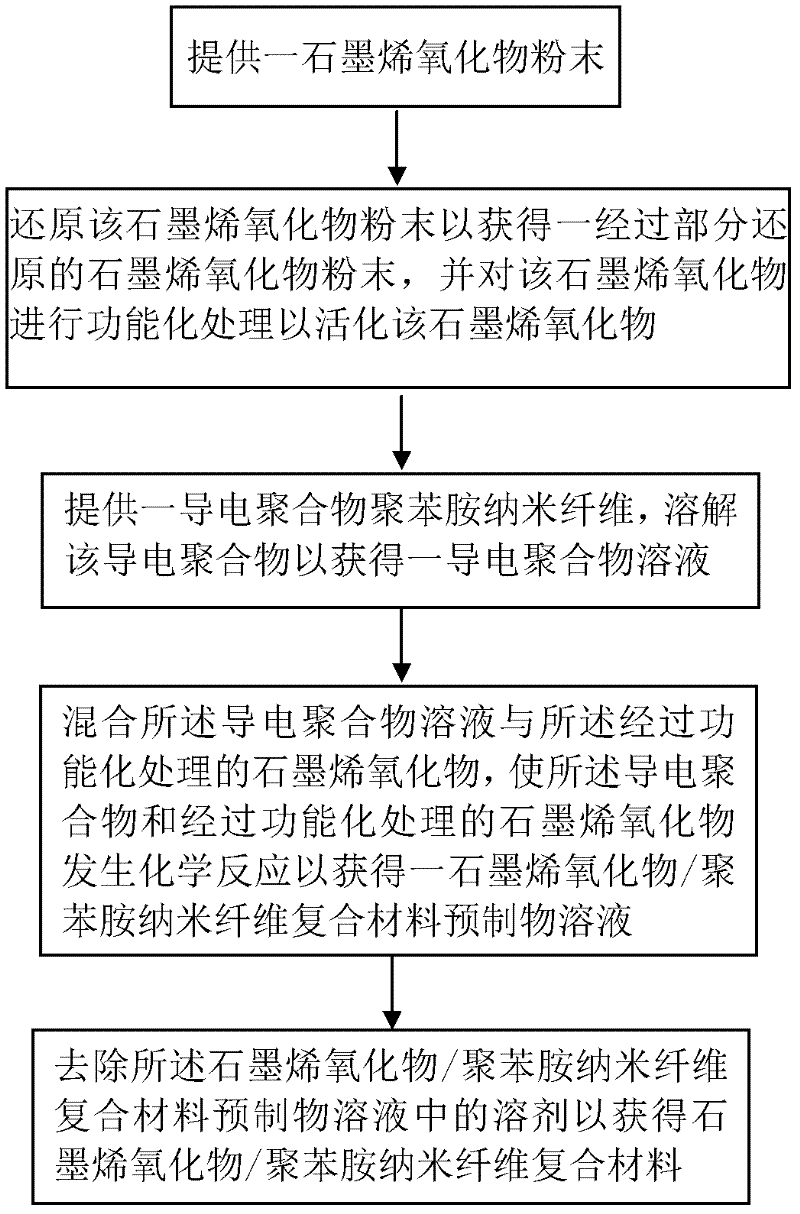

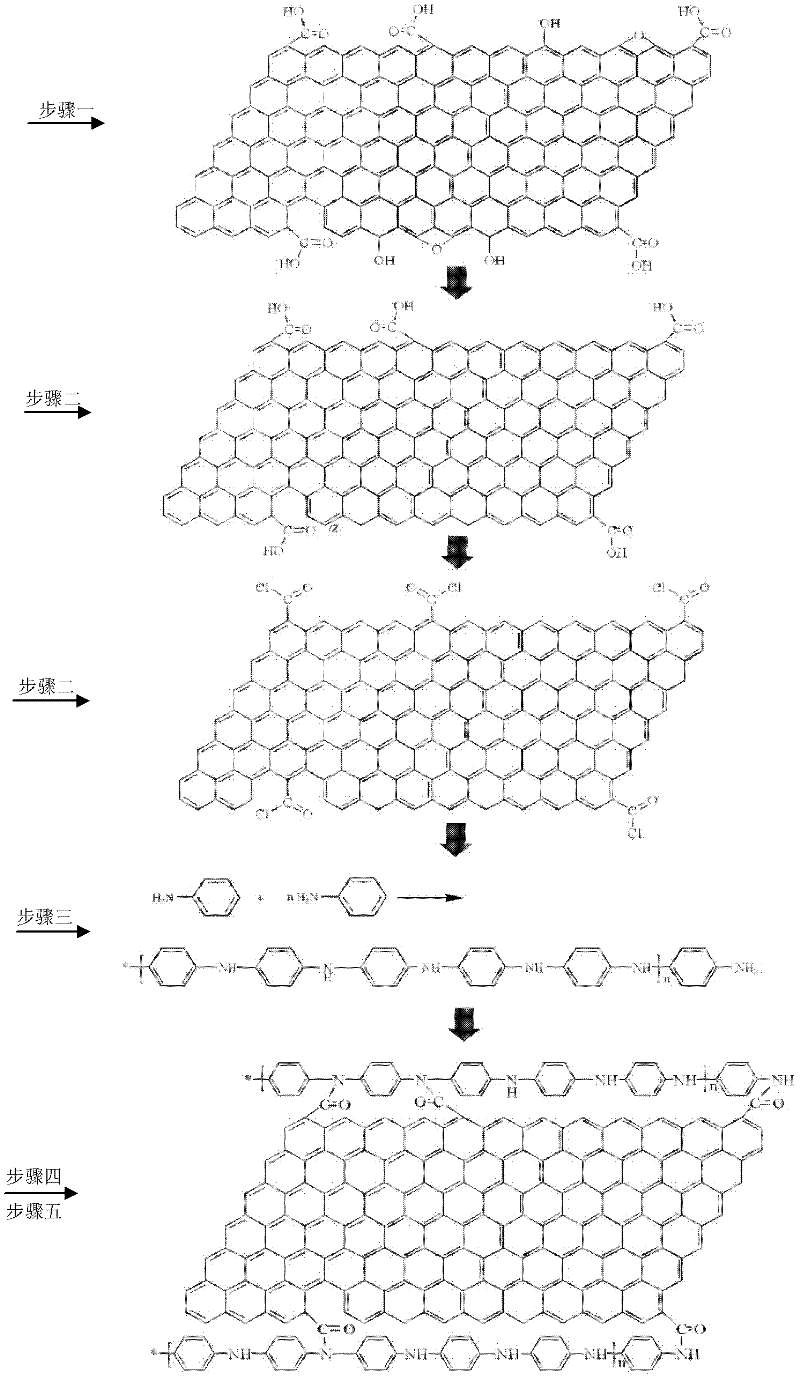

Method used

Image

Examples

Embodiment 1

[0086] Step 1: provide a graphene oxide powder; that is: disperse 5 grams of flake natural graphite into 100 milliliters of concentrated sulfuric acid to form a mixture, and stir the mixture at a high speed in the process; add 10 grams to the above mixture within 1 hour Potassium permanganate powder, keep the mixture mixed with potassium permanganate in ice bath to keep its temperature not exceeding 3°C; after the addition of potassium permanganate is completed, remove the ice bath and slowly add 400 ml of deionized water, then The solution is heated to raise the temperature of the solution to 100°C, and kept at the temperature of 100°C for 1 hour, so that the graphite powder, potassium permanganate powder and sulfuric acid fully react to form graphite oxide; after the reaction, dilute and filter And wash the graphite oxide, then the concentration of 5% Na 2 CO 3 The solution was added to the graphite oxide and stirred to become a homogeneous solution, by adding a concentrati...

Embodiment 2

[0092] step one:

[0093] First, disperse 5 grams of flaky natural graphite into 230 milliliters of concentrated sulfuric acid to form a mixture, and stir the mixture at a high speed during this process; add 30 grams of potassium permanganate powder to the above mixture within 1 hour, and continue the ice bath. Mix the mixture with potassium permanganate to keep its temperature not exceeding 3°C; after the addition of potassium permanganate is completed, remove the ice bath and slowly add 400 ml of deionized water, then heat the solution to increase the temperature of the solution to 100°C, kept at the temperature of 100°C for 1 hour, so that graphite powder, potassium permanganate powder and sulfuric acid fully reacted to form graphite oxide; after the reaction, dilute, filter and wash the graphite oxide, and then Graphite oxide is dissolved in water, then adding a concentration of 5% Na2CO3 solution makes its pH value 6, and the solution is ultrasonically treated for 30 min...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com