Patents

Literature

1025results about How to "High capacity retention" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

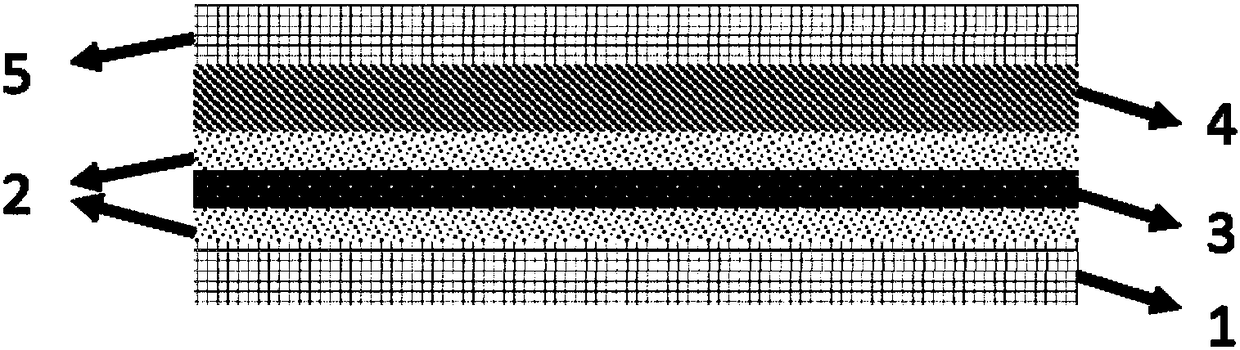

Organic-inorganic all-solid-state composite electrolyte as well as preparation and application methods thereof

PendingCN106785009AIncrease transport activityImprove wettabilitySolid electrolytesSecondary cellsElectrical conductorComposite electrolyte

The invention relates to organic-inorganic all-solid-state composite electrolyte as well as preparation and application methods thereof, belonging to the field of lithium ion batteries. According to the organic-inorganic all-solid-state composite electrolyte, a highly-ordered three-dimensional connection network skeleton is formed by an inorganic fast lithium ion conductor, and a three-dimensional connection network is filled with a polymer and lithium salt. The organic-inorganic all-solid-state composite electrolyte which is flexible and has a controllable three-dimensional connection network structure is prepared. The electrolyte is high in lithium ion conductivity, wide in electrochemical window, good in mechanical property and stable to lithium metal. A lithium ion secondary battery assembled by a composite electrolyte membrane prepared by the method is high in capacity, stable in cycle performance, low in interface impedance and good in interface stability.

Owner:UNIV OF SCI & TECH BEIJING

Electrodes Comprising Mixed Active Particles

InactiveUS20070141468A1High capacity retentionImprove cycle performanceLi-accumulatorsNon-aqueous electrolyte accumulator electrodesCharge carrierManganese

A battery containing a first electrode and a second electrode, and an electrolyte for transferring ionic charge-carriers there between, wherein the first electrode contains a first electrode active material represented by the formula A2eM4kM5mM6nM7oOg, and at least one second electrode active material selected from the group consisting of active materials represented by the formula A1aM1b(XY4)cZd, active materials represented by the formula A3hMniO4, and mixtures thereof.

Owner:VALENCE TECH INC

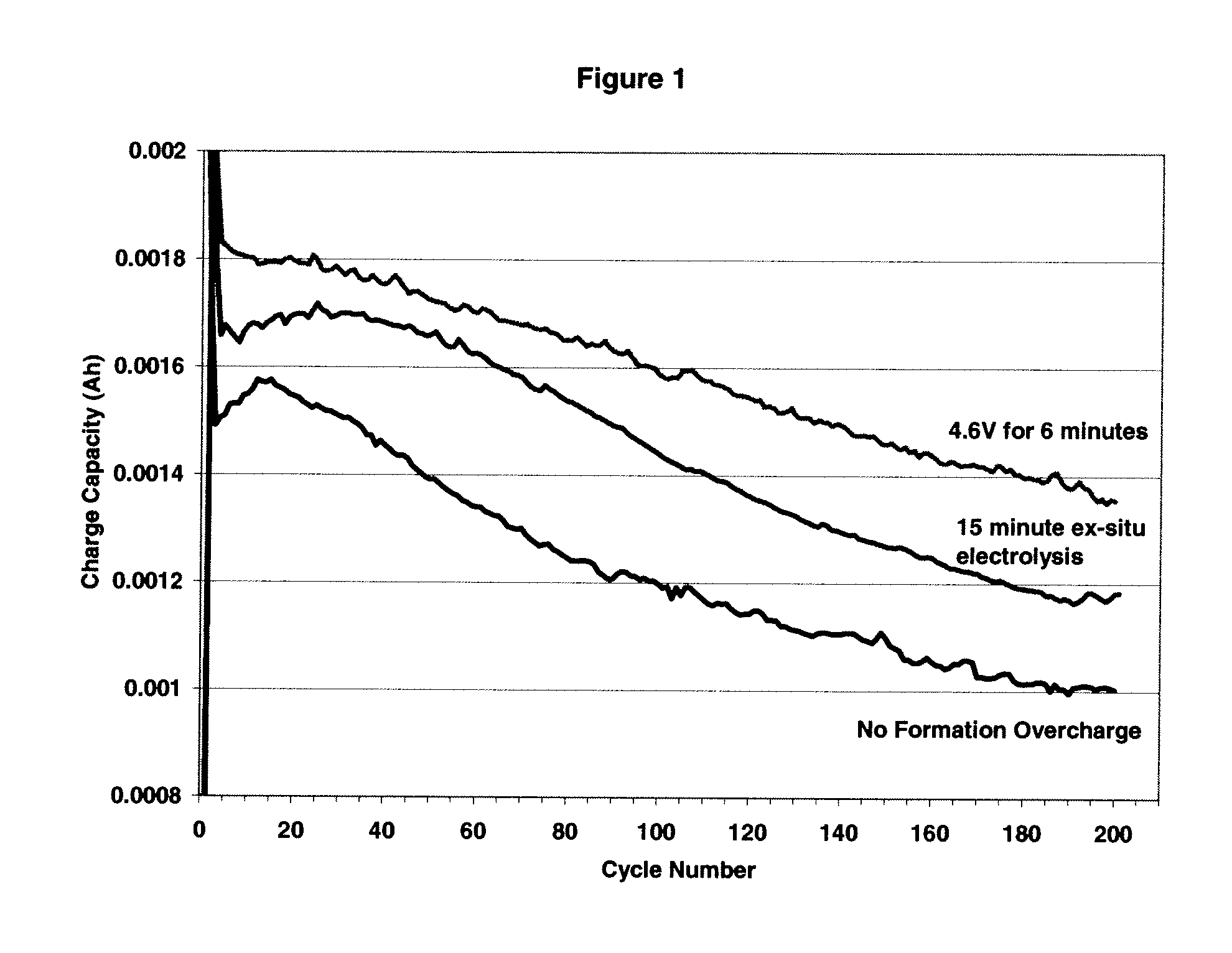

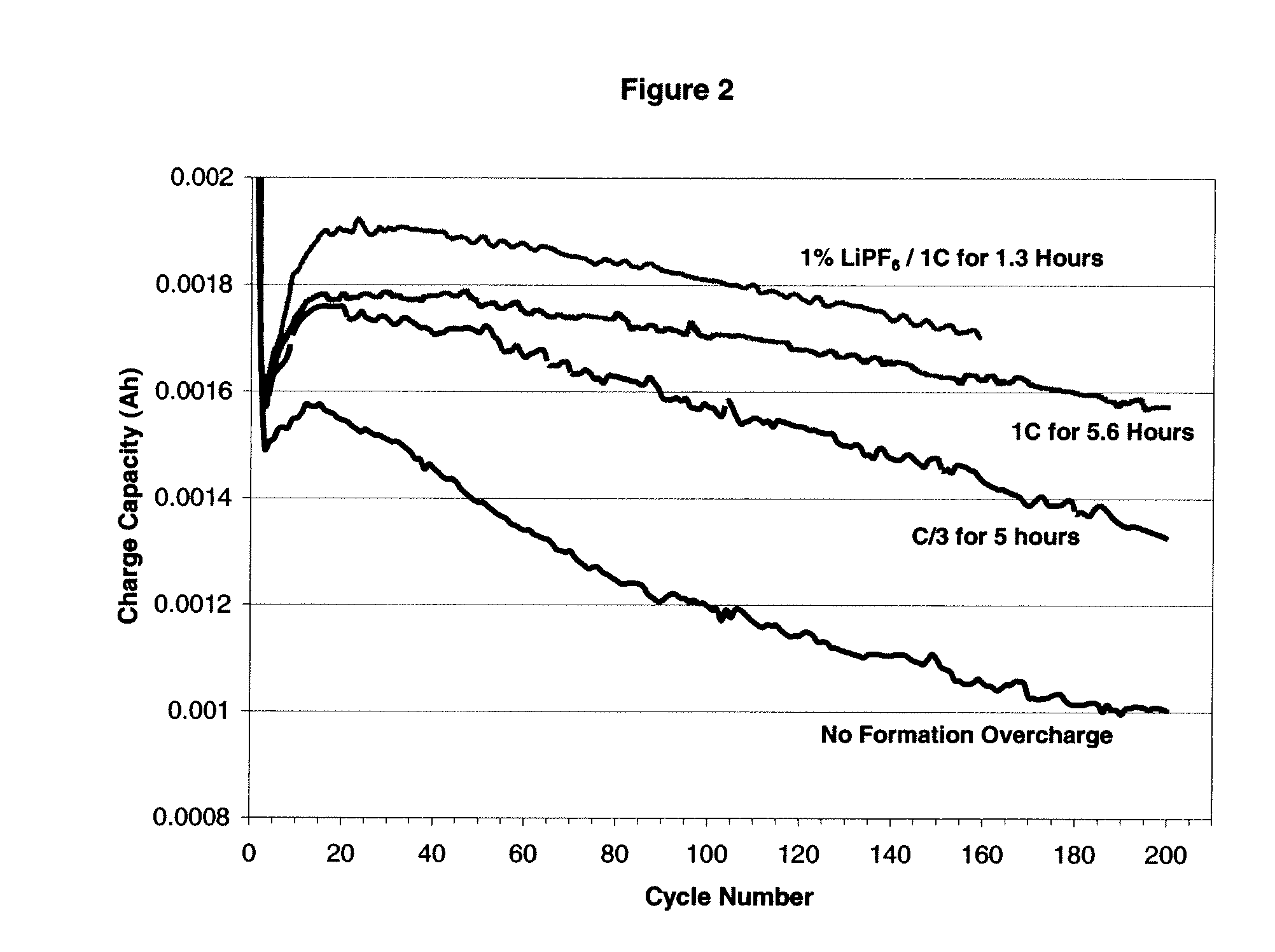

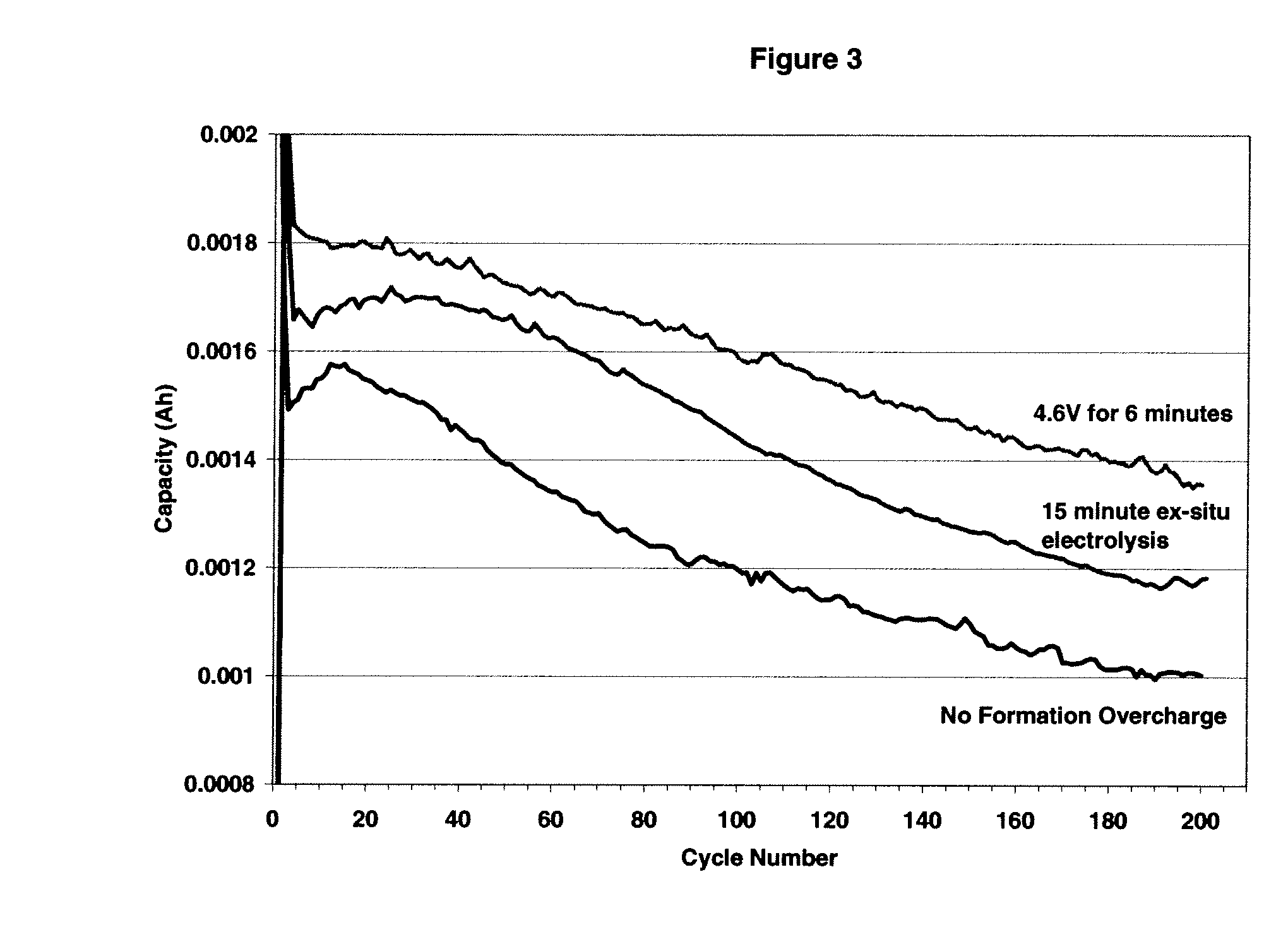

Electrolytes, electrolyte additives and cells

InactiveUS20080131772A1Improved leakage current characteristicHigh capacity retentionAlkaline accumulatorsCell electrodesElectrolyteChemistry

An electrolyte comprising a salt, which will not electrochemically passivate and at least two additives. A cell comprising a positive electrode, a negative electrode and an electrolyte comprising a salt, which will not electrochemically passivate and at least two additives.

Owner:AIR PROD & CHEM INC

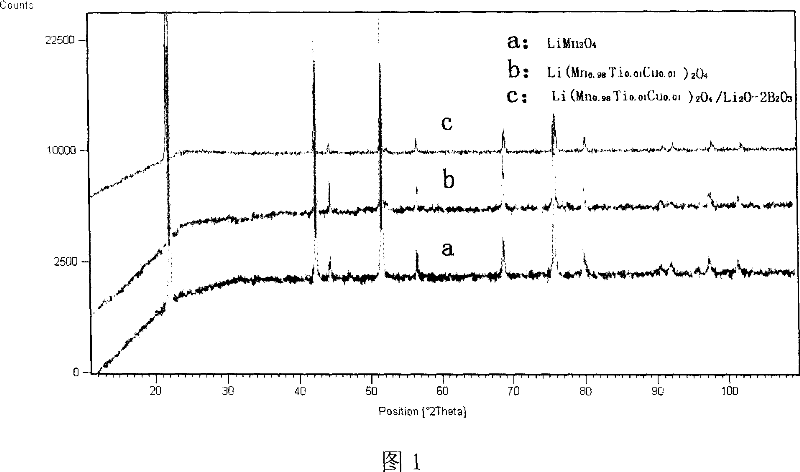

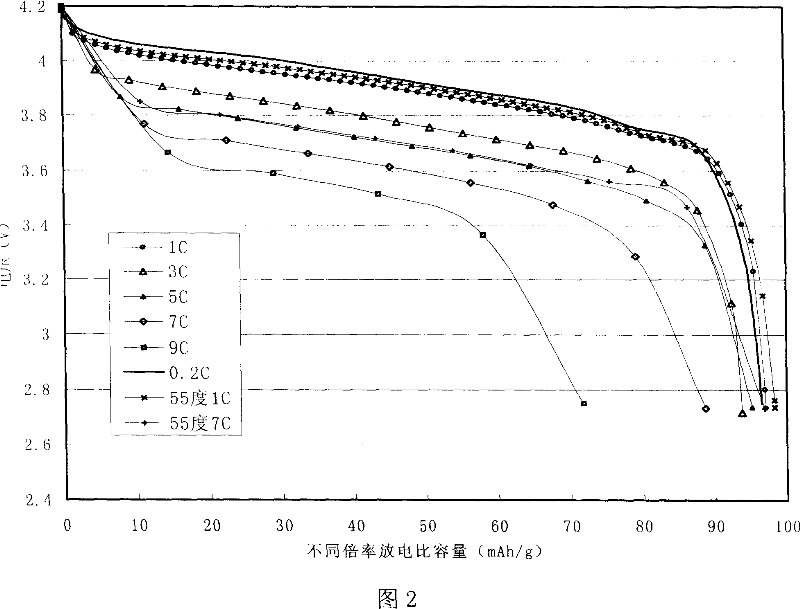

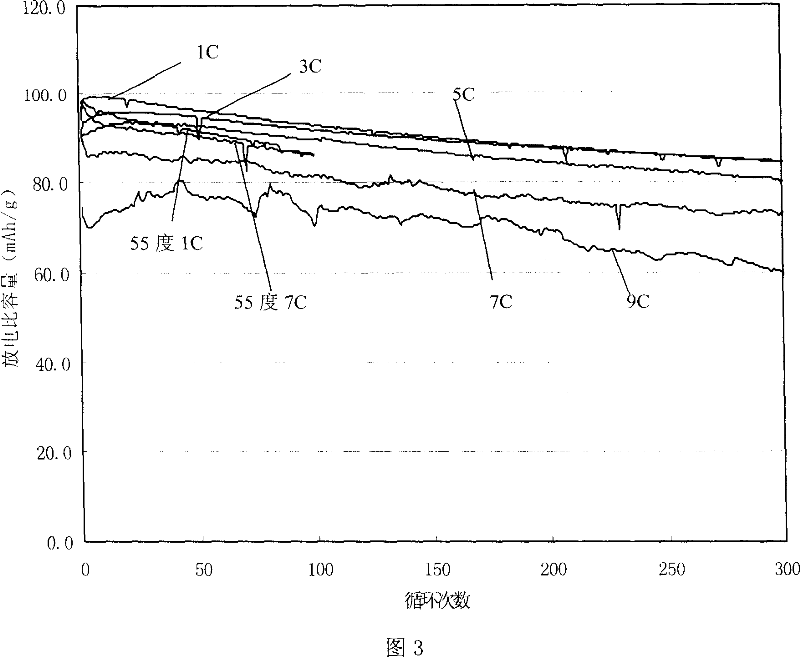

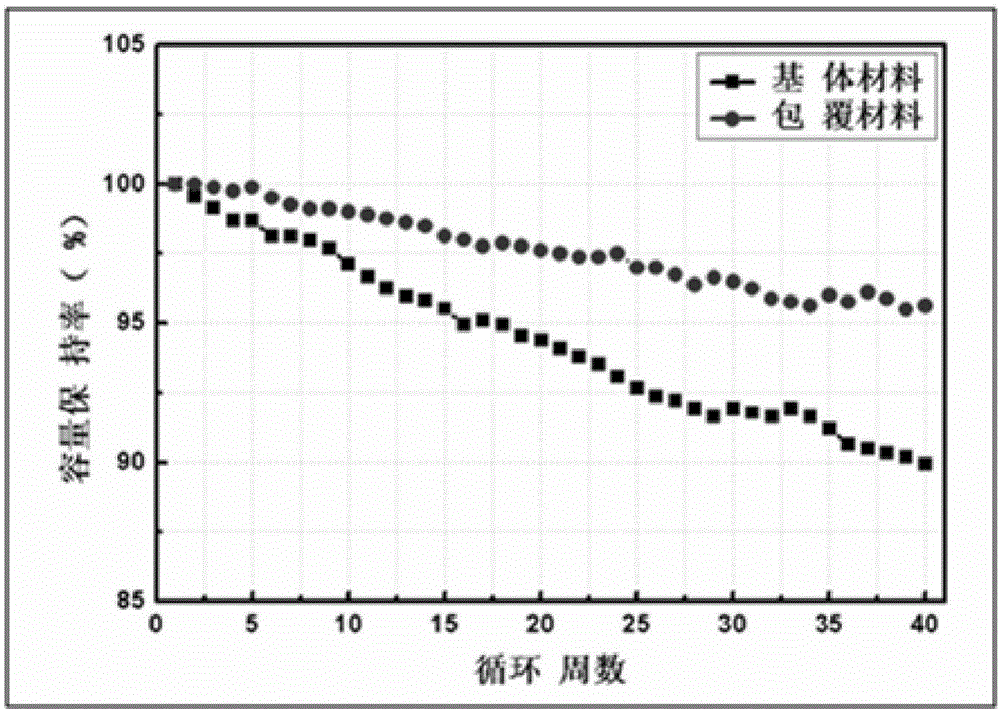

Method for preparing modified spinelle manganic acid lithium material and lithium secondary battery

ActiveCN101038965AImprove structural stabilityHigh capacity retentionElectrode manufacturing processesLithium compoundsComposite oxideChemistry

The invention discloses a modified spinel lithium manganate material used in anode material of lithium secondary battery, the lithium manganate is a kind of doped lithium manganate LiaMn2-bXbO4 with other metallic element X, wherein X is at least one element of chroumium, gallium, magnesium, titanium, cuprum, zincum, 0.97 <= a <= 1.07, 0 <= b <= 0.1; and the surface of the said doped lithium manganate LiaMn2-bXbO4 is provided with a coat which contains at least one kind of boron-lithium composite oxides, cobalt-lithium composite oxides, vanadium-lithium composite oxides or carbon layer. The invention also discloses a preparing method for the said material and the lithium secondary battery using the said material as anode material. The invention provided modified spinel lithium manganate material has relative good high rate deep discharge capacity in normal temperature or high temperature, in mean time, the preparing method is easy for control and operation and industrialisation, and production cost thereof is low.

Owner:SHENZHEN BAK POWER BATTERY CO LTD

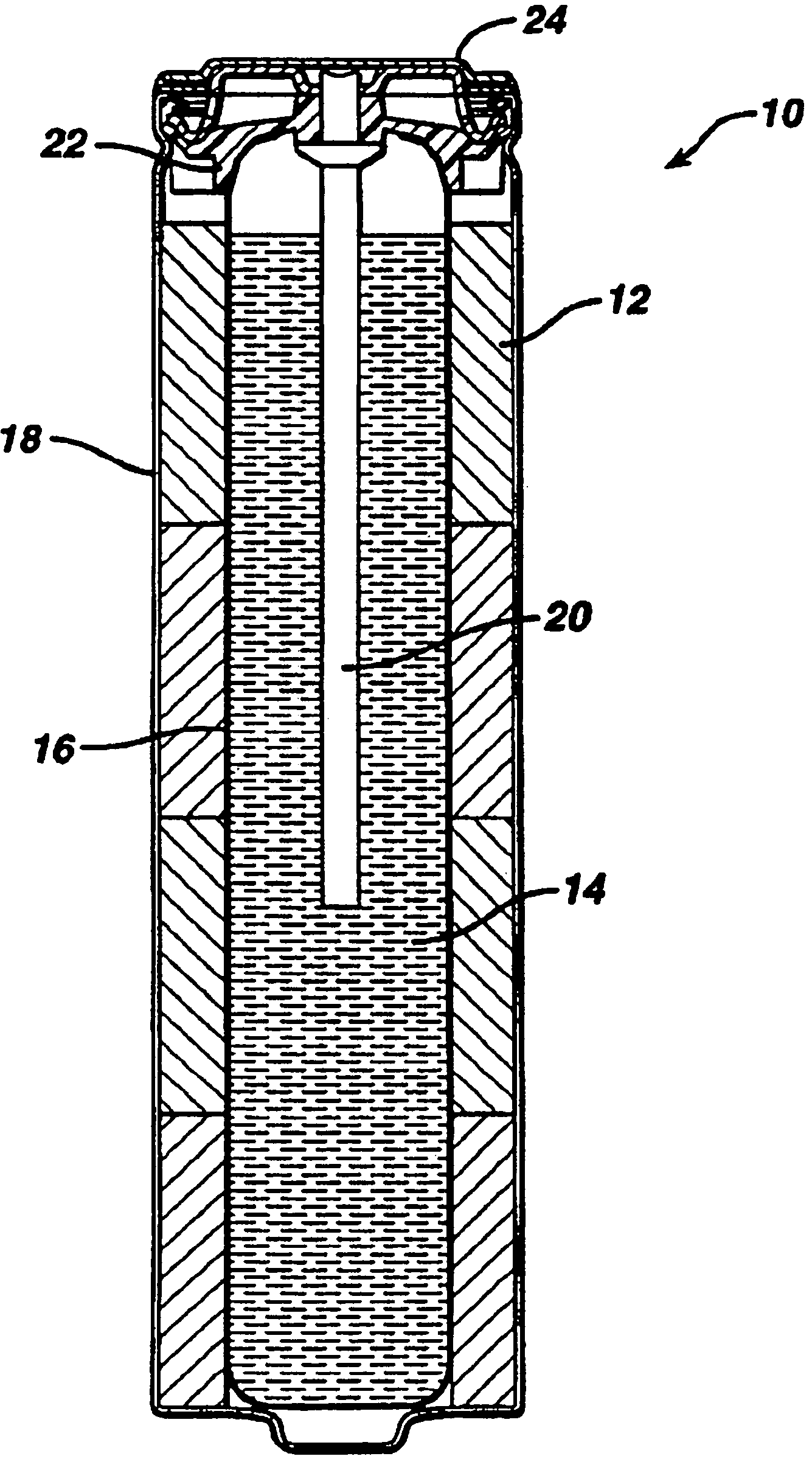

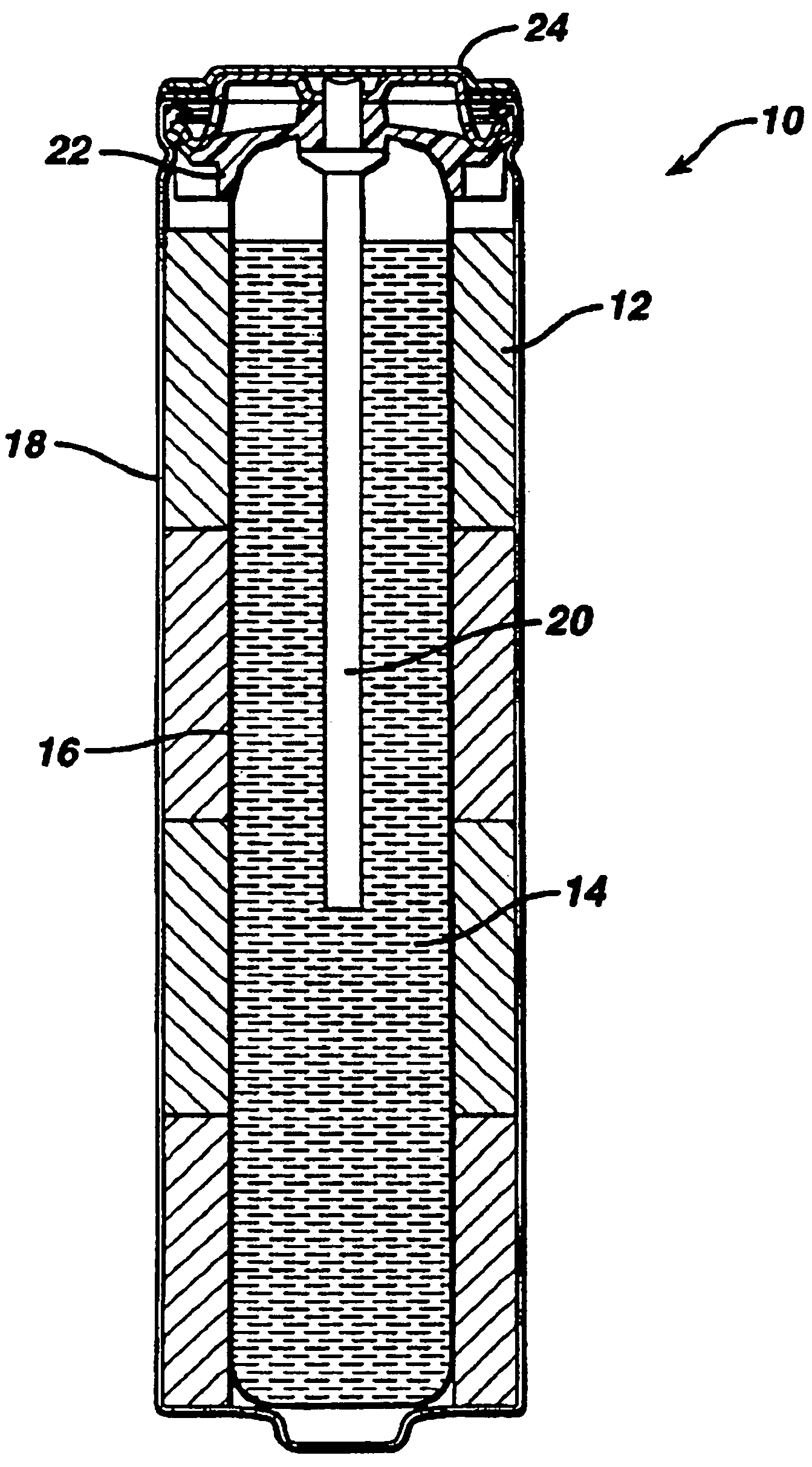

Alkaline battery including nickel oxyhydroxide cathode and zinc anode

ActiveUS7273680B2Improve discharge performanceHigh capacity retentionActive material electrodesJackets/cases materialsZinc alloysNickel

Owner:DURACELL U S OPERATIONS

Coating for separator or cathode of lithium-sulfur or silicon-sulfur battery

ActiveUS20140272569A1Improve cycle stabilitySatisfactory battery operationElectrode manufacturing processesSecondary cellsSulfurLithium sulfur

Owner:GM GLOBAL TECH OPERATIONS LLC

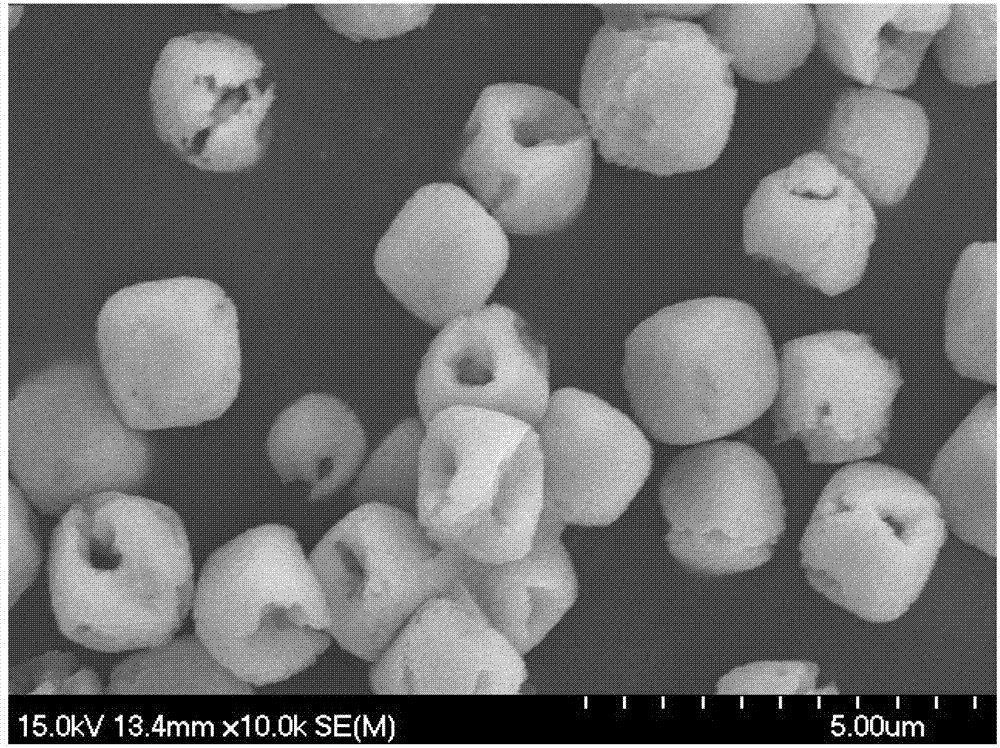

Cathode for secondary batteries, method for producing cathode for secondary batteries, and all-solid-state secondary battery

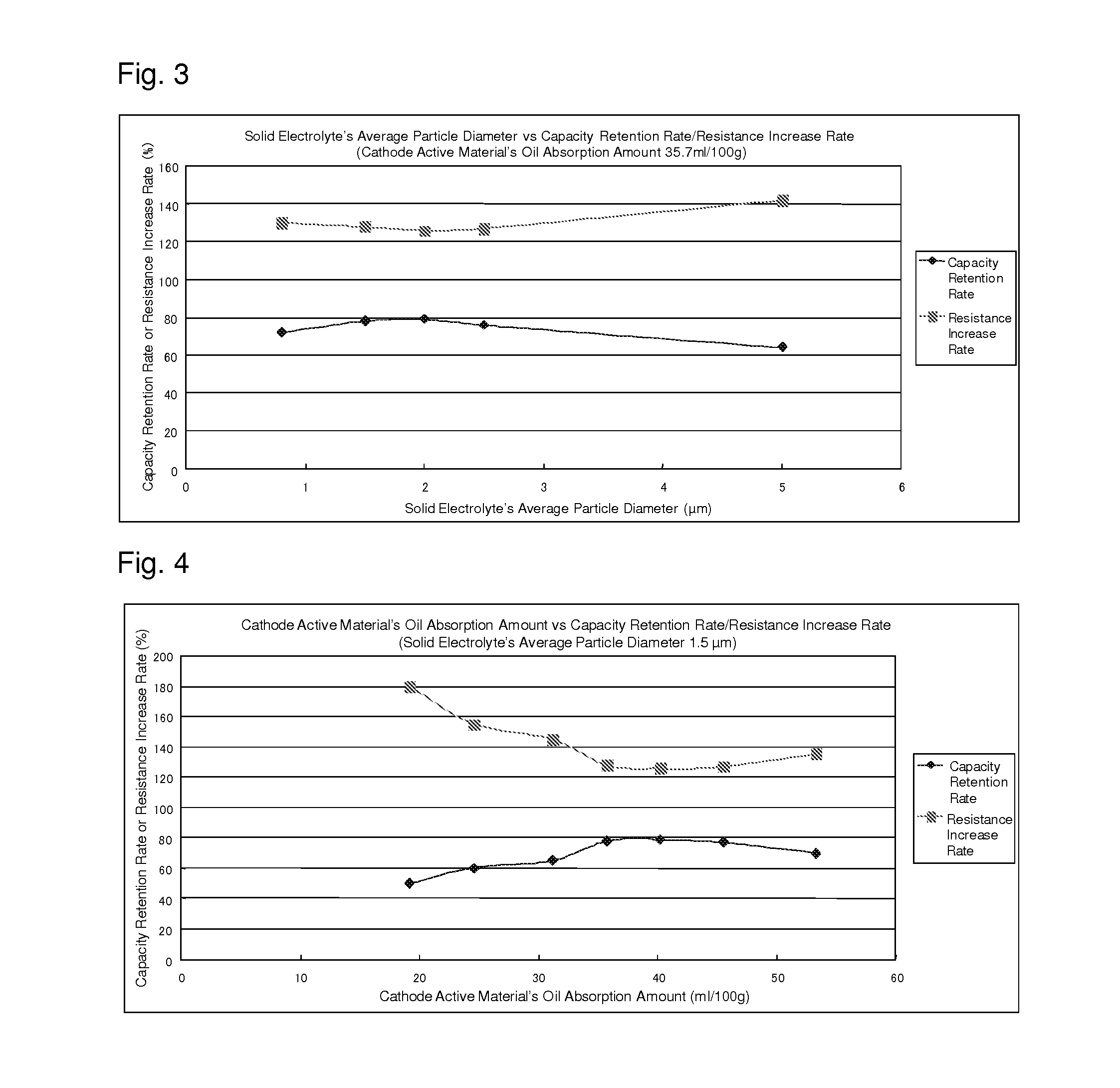

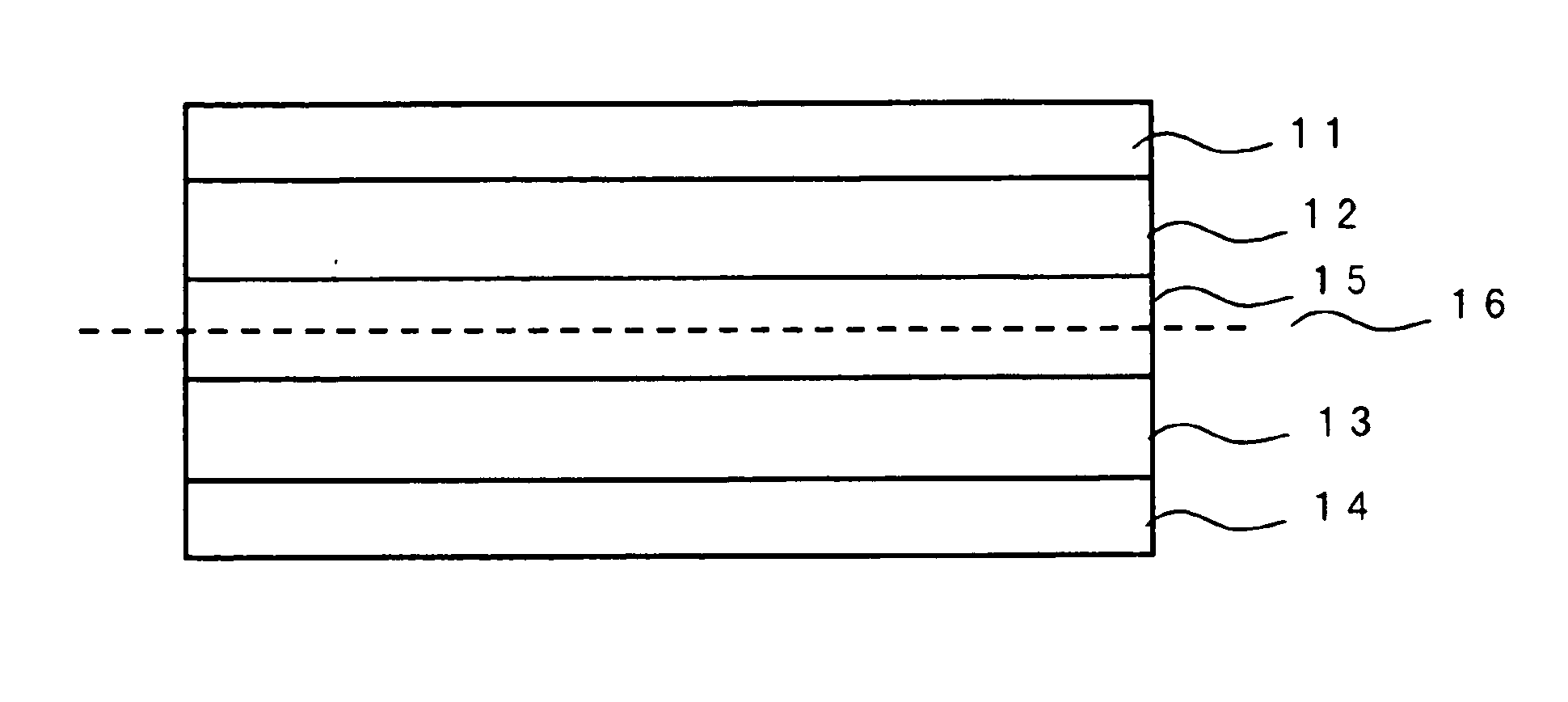

ActiveUS20150325844A1High capacity retentionSolid electrolytesFinal product manufactureAll solid stateEngineering

To provide: a cathode for secondary batteries, which has a high capacity retention rate; a method for producing a cathode for secondary batteries; and an all-solid-state secondary battery comprising the cathode. This object has been achieved providing by a cathode for secondary batteries, which is characterized by comprising a cathode active material layer containing at least a cathode active material and a solid electrolyte, wherein the cathode active material has an oil absorption amount of 35 to 50 ml per 100 g; wherein the solid electrolyte has an average particle diameter of 1.5 to 2.5 μm; and wherein the cathode active material layer is formed by mixing the cathode active material and the solid electrolyte in the absence of solvent and pressure-forming the resulting mixture.

Owner:TOYOTA JIDOSHA KK

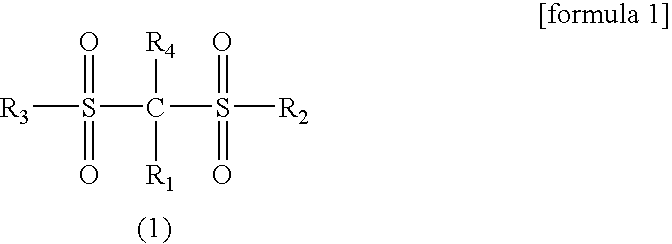

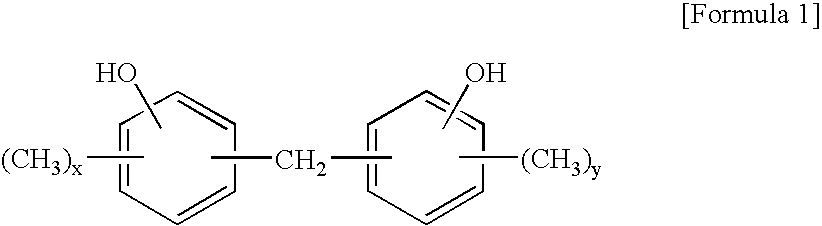

Electrolyte solution for secondary battery and secondary battery using same

ActiveUS20060292452A1Sufficient battery characteristicImprove efficiencyOrganic chemistryLight-sensitive devicesPhysical chemistrySolvent

There is provided a lithium secondary battery which has excellent characteristics such as energy density and electromotive force and is excellent in cycle life and storage stability. An electrolyte solution for secondary battery comprising at least an aprotic solvent having an electrolyte dissolved therein and a compound represented by the general formula (1).

Owner:NEC CORP

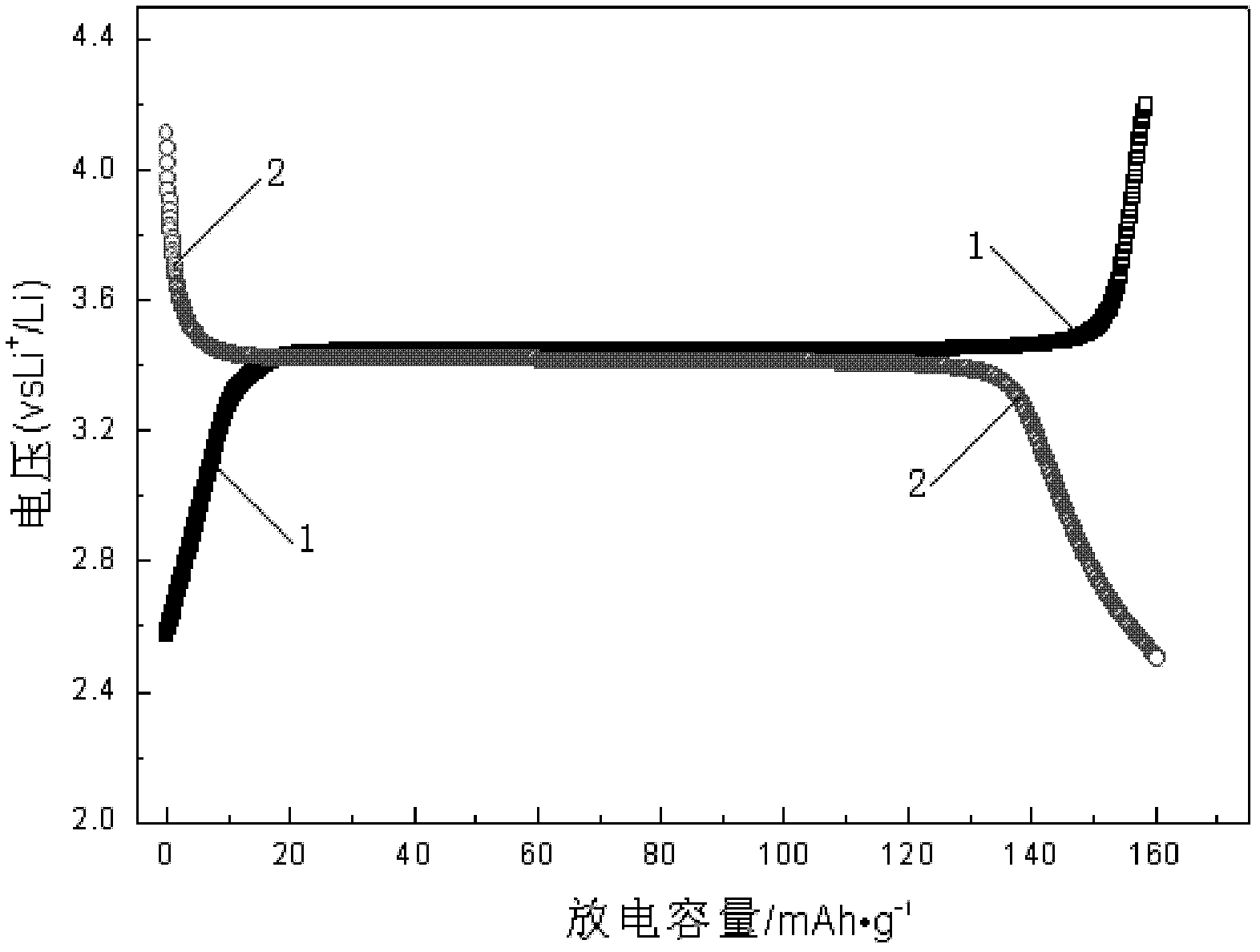

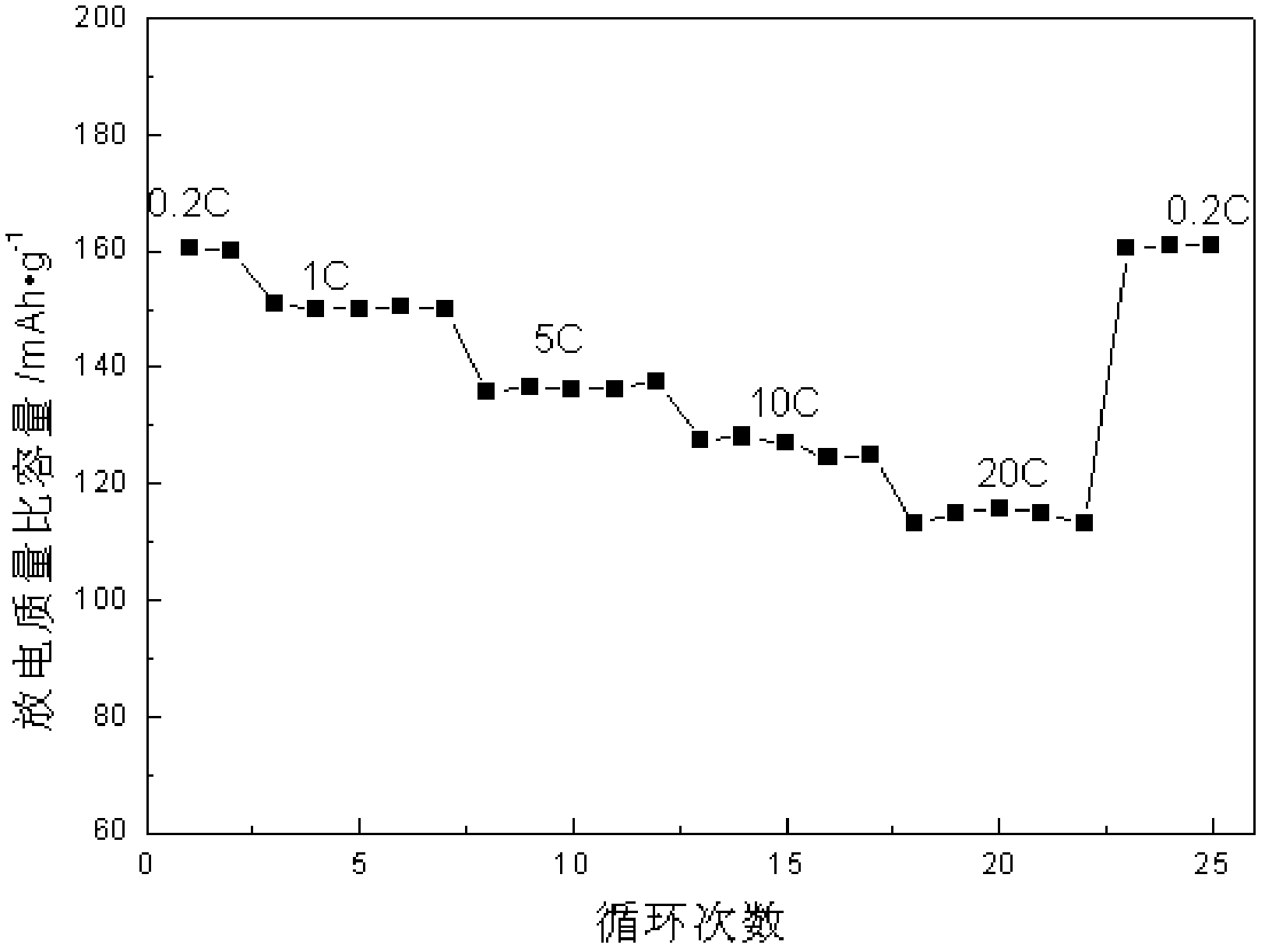

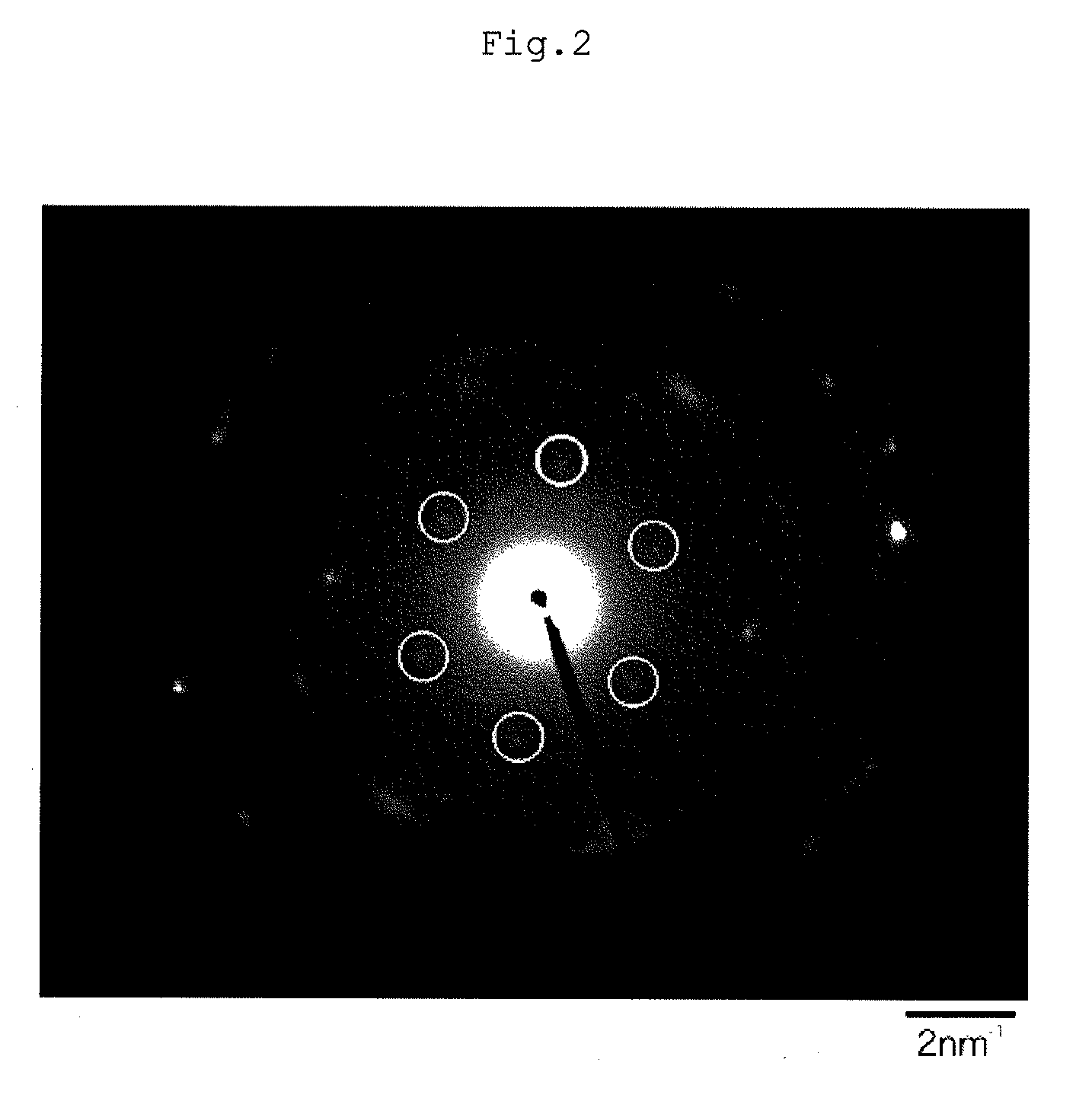

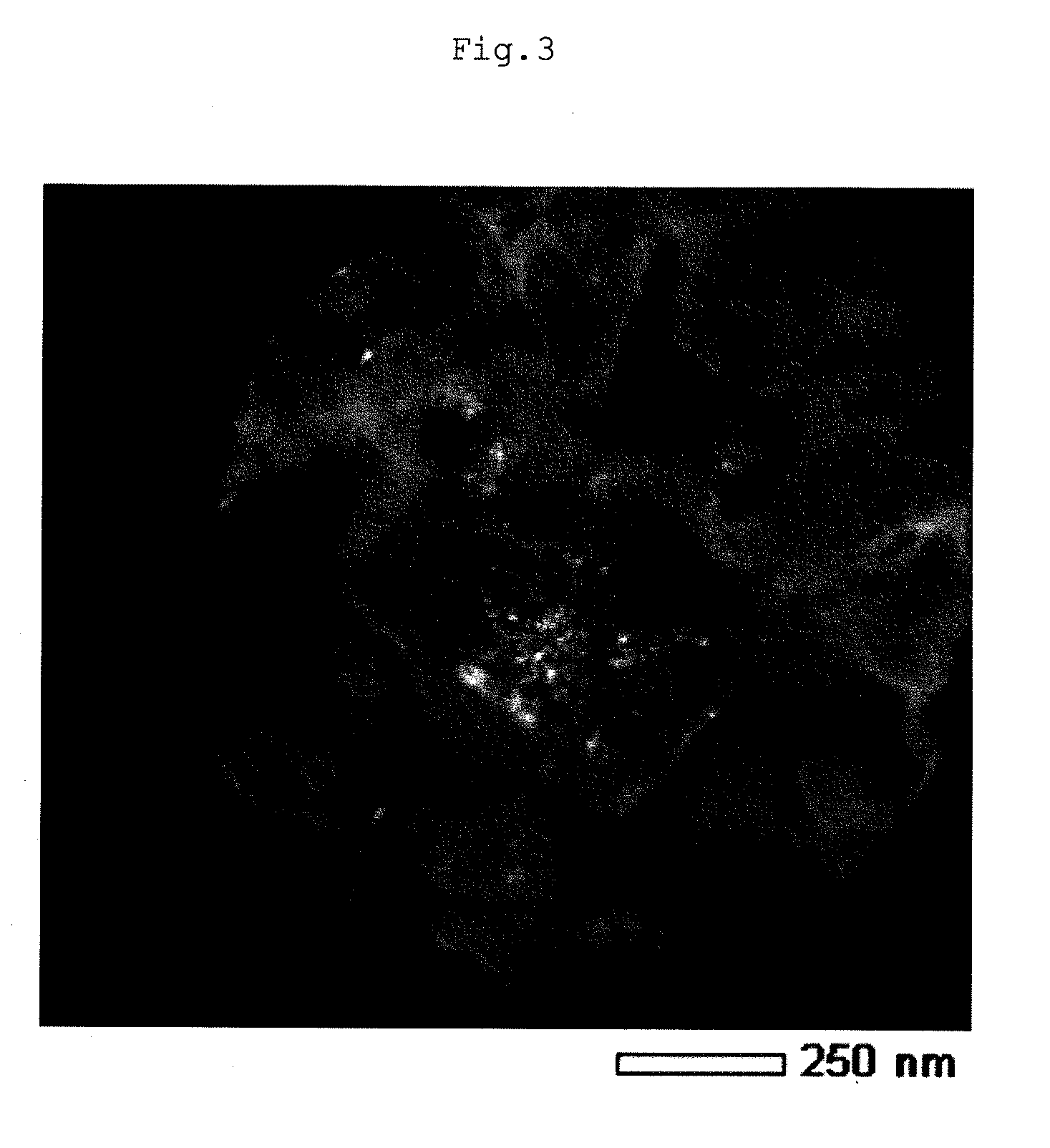

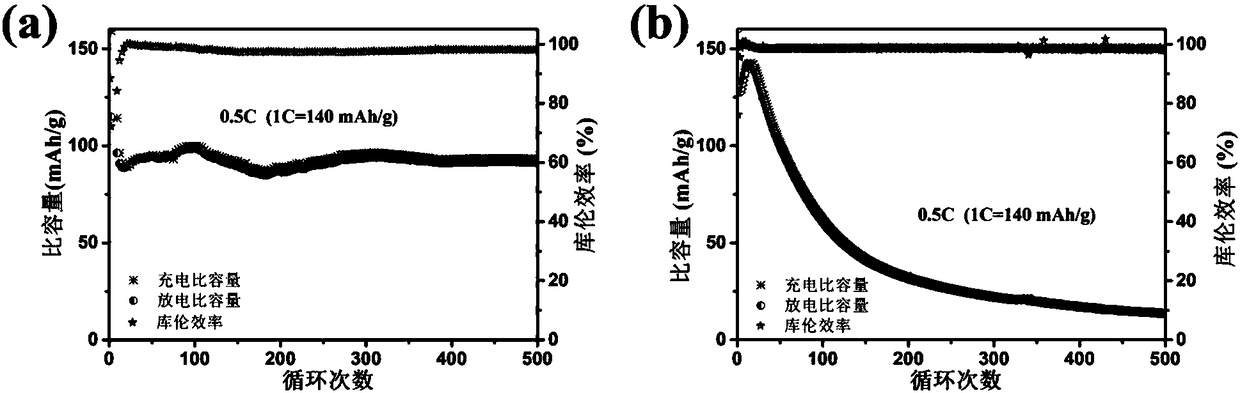

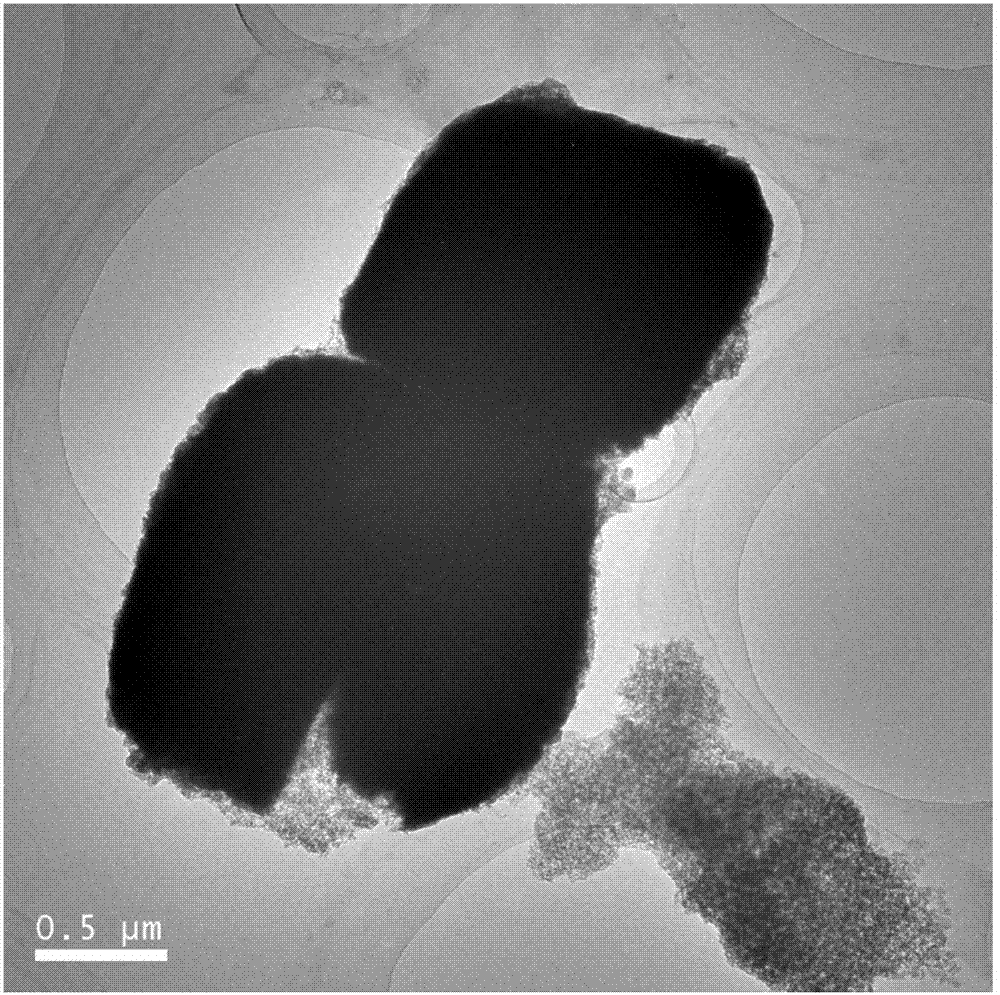

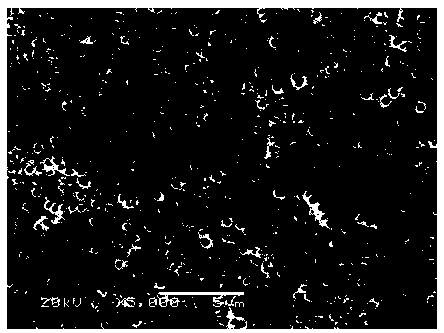

Multi-layer graphene/lithium iron phosphate intercalated composite material, preparation method thereof, and lithium ion battery adopting multi-layer grapheme/lithium iron phosphate intercalated composite material as anode material

InactiveCN102306783AImprove electronic conductivityReduced Diffusion ResistanceCell electrodesSecondary cellsHigh rateSlurry

The invention relates to a lithium iron phosphate intercalated composite material, a preparation method thereof and a lithium ion battery adopting the multi-layer graphene / lithium iron phosphate intercalated composite material as an anode material. In the prior art, the electronic conductivity of the lithium iron phosphate material is poor, high-rate charging / discharging capacity of the lithium ion battery adopting the lithium iron phosphate material as the anode material is poor. The purpose of the present invention is to solve the problems in the prior art, and improve the rapid charging capacity of the power lithium ion battery so as to meet the requirements of the pure electrocar. The composite material is prepared through the following steps that: a rheological phase reaction method is adopted for multi-layer graphene, a trivalent iron salt, a phosphorus compound, a lithium compound and carbon source of small organic molecule to obtain a composite precursor, then the precursor is sintered to obtain the multi-layer graphene / lithium iron phosphate intercalated composite material. The anode slurry of the lithium ion battery anode plate comprises the composite material, a conductive agent and polyvinylidene difluoride. The composite material is an intercalated structure, wherein the lithium iron phosphate particles are intercalated between the multi-layer graphene to form the intercalated structure. The trivalent iron salt is adopted as the raw material, such that the cost is reduced. The lithium ion battery has good charging / discharging cycle performance, wherein the specific capacity is more than 60 mA.h.g<-1> at the rate of 20C.

Owner:HARBIN INST OF TECH

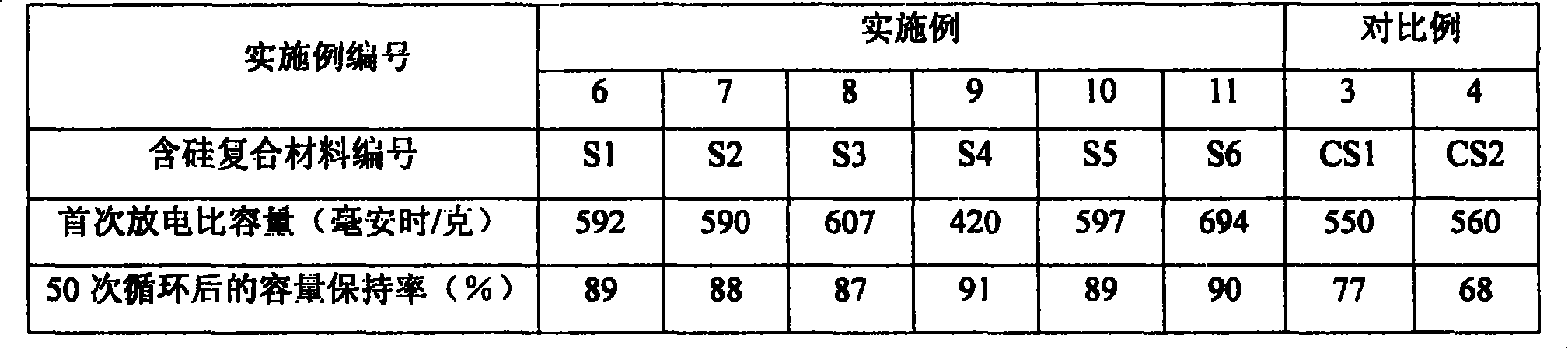

Method for preparation of composite material containing silicon

ActiveCN101207198AHigh specific capacityRelief of mechanical stressElectrode manufacturing processesCarbon nanotubeGraphite

The invention relates to siliceous composite material, which comprises silicon, graphite and formless carbon; wherein, the material also comprises carbon nanotube, the silicon is nanometer silicon, and at least part of the formless carbon is coated on the surfaces of the silicon, the graphite and the carbon nanotube. The siliceous composite material provided by the invention has higher specific capacity even in the condition of lower silicon content, and in addition, the siliceous composite material can ensure the battery which adopts the siliceous composite material as negative pole active substance to have good circulation stability.

Owner:BYD CO LTD

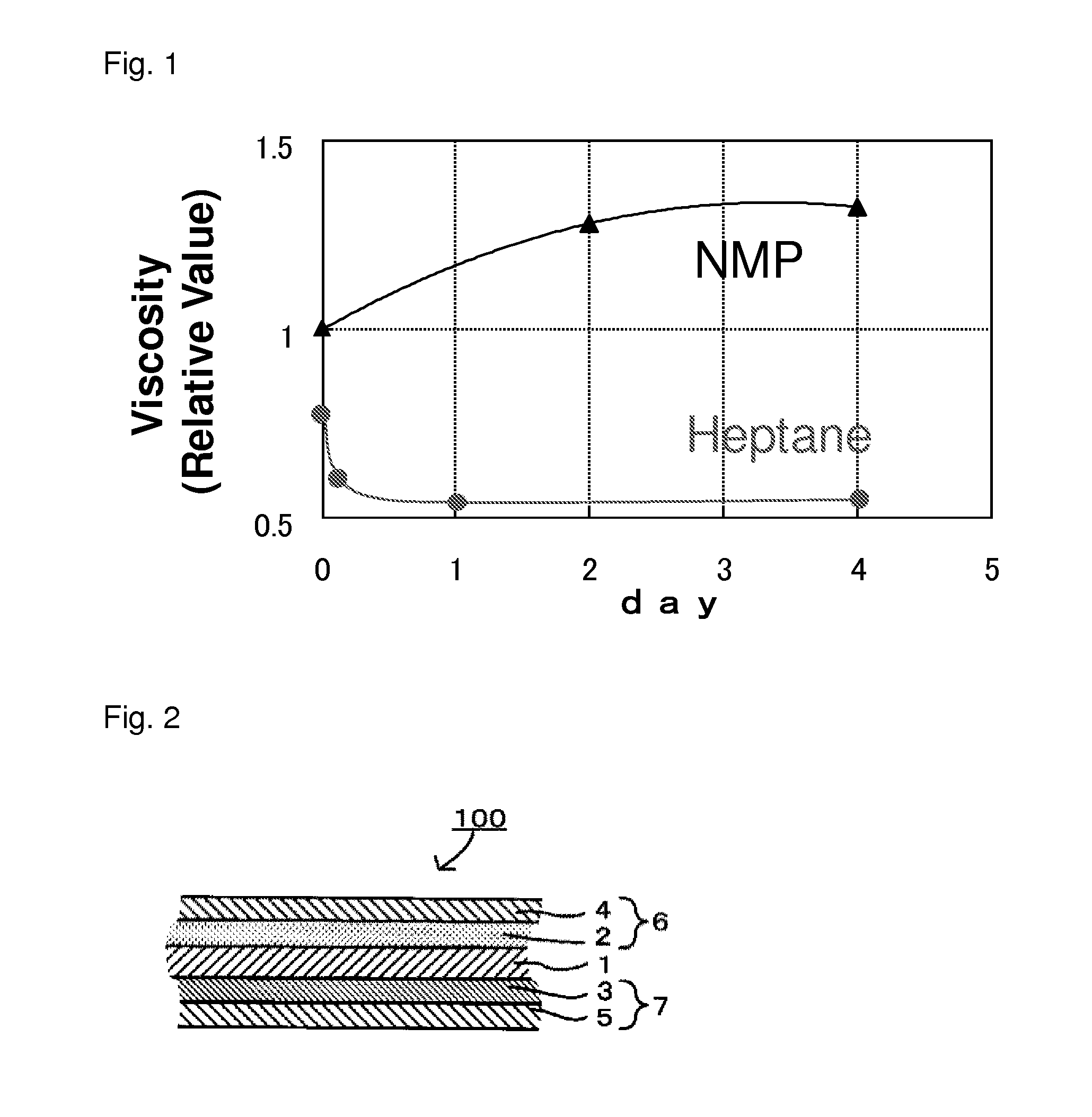

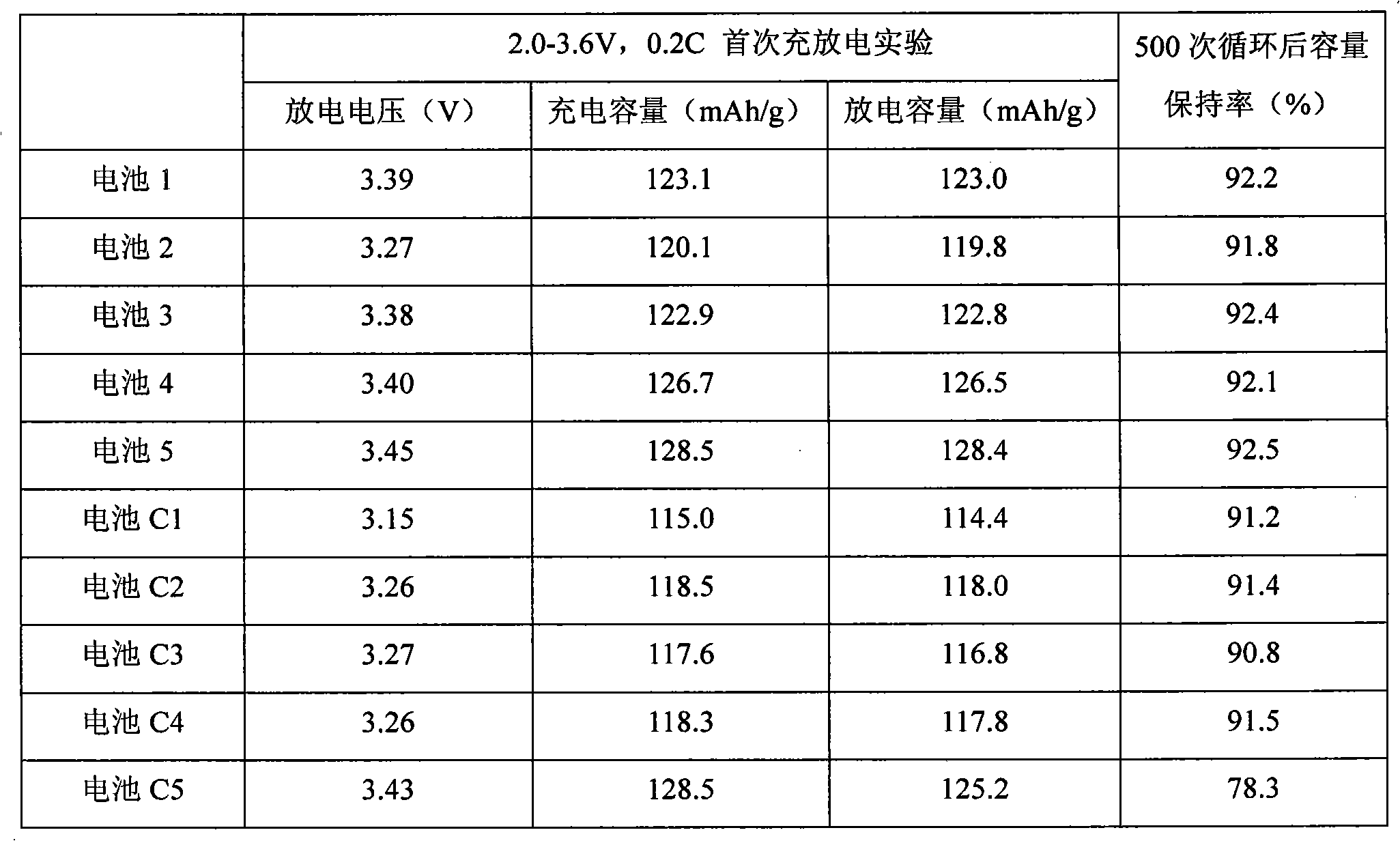

Lithium battery positive electrode slurry and preparation method thereof

ActiveCN103208631AGood high temperature performanceHigh capacity retentionNon-aqueous electrolyte accumulator electrodesOrganic solventSlurry

The invention discloses lithium battery positive electrode slurry. The lithium battery positive electrode slurry is a mixture of a positive electrode material and an organic solvent. The positive electrode material is composed of, by mass, 60-97% of a positive electrode active material, 1-30% of a binding agent, 0-10% of a conductive agent, 1-5% of a conductive reinforcing agent and 0.1-3% of a dispersing agent. A lithium battery prepared by the lithium battery positive electrode slurry provided by the invention has the advantages of excellent high temperature performance, high capacity conservation rate, good cycle performance, long service life and the like. The invention also provides a preparation method of the lithium battery positive electrode slurry, enabling solid materials such as the conductive reinforcing agent to be distributed in the organic solvent uniformly and stably and to be directly stirred and mixed in a common stirring apparatus, so that the operation is convenient and the method can realize large-scale production.

Owner:WANXIANG 123 CO LTD

Electrodes Comprising Mixed Active Particles

ActiveUS20060194112A1High capacity retentionImprove cycle performanceConductive materialOxide conductorsChemical compositionActive particles

Electrode active materials comprising two or more groups of particles having differing chemical compositions, wherein each group of particles comprises a material selected from: (a) materials of the formula A1aM1b(XY4)cZd; and (b) materials of the formula A2eM2fOg; and wherein (i) A1, A2, and A3 are Li, Na, or K; (ii) M1 and M3 comprise a transition metal; (iv) XY4 a phosphate or similar moiety; and (v) Z is OH, or halogen.

Owner:RIL USA INC +1

Lithium composite metal oxide and nonaqueous electrolyte secondary battery

ActiveUS20090280412A1High capacity retentionIncrease productionActive material electrodesNon-aqueous electrolyte accumulator electrodesLithiumX-ray

The present invention provides a lithium composite metal oxide containing Li and at least one transition metal element, wherein at least one lithium composite metal oxide particle constituting the lithium composite metal oxide has both hexagonal and monoclinic crystal structures. Further, the present invention also provides a lithium composite metal oxide containing Li, Ni and M (where, M represents one or more kinds of transition metal elements selected from the group consisting of Mn, Co and Fe), having a diffraction peak (diffraction peak A) at an angle 2θ in a range from 20° to 23° in a powder X-ray diffraction pattern of a lithium composite metal oxide which is obtained by powder X-ray diffraction measurement made in the condition that CuKα is used as a radiation source and the measurement range of diffraction angle 2θ is in a range from 10° to 90°.

Owner:SUMITOMO CHEM CO LTD

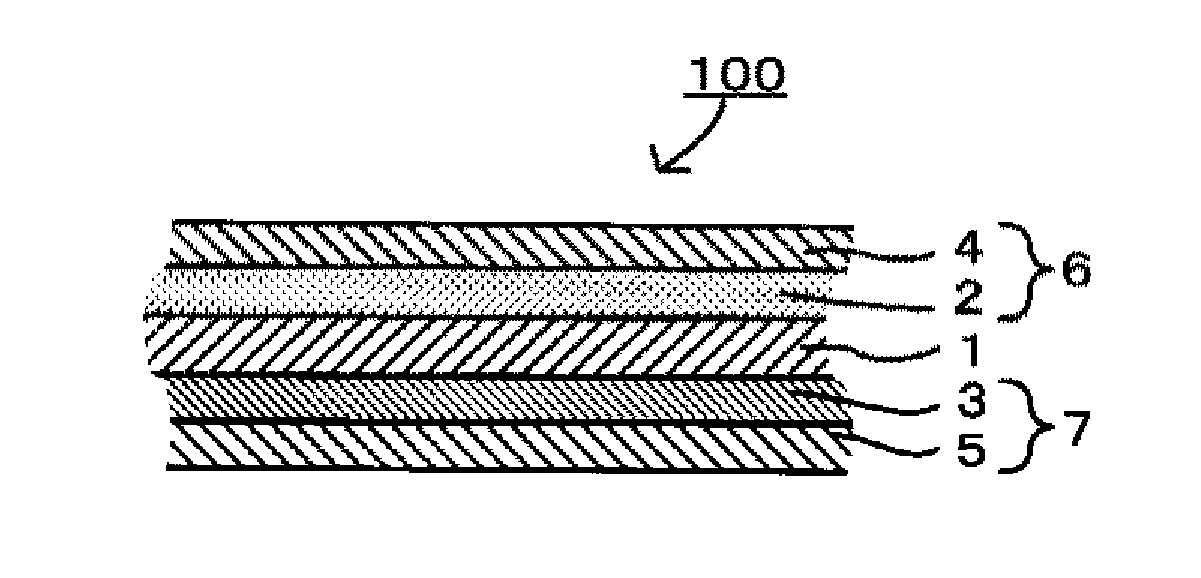

Negative electrode material for lithium ion secondary battery, composite negative electrode material for lithium ion secondary battery, resin composition for lithium ion secondary battery negative electrode for lithium ion secondary battery, and lithium ion secondary battery

ActiveUS20150325848A1High capacity retentionImprove initial efficiencyNegative electrodesSecondary cellsLithiumPhysical chemistry

The present invention provides a negative electrode material for a lithium ion secondary battery, a composite negative electrode material for a lithium ion secondary battery, a resin composition for a lithium ion secondary battery negative electrode, and a negative electrode for a lithium ion secondary electrode, which may provide high charge / discharge capacity, and excellent initial charge-discharge characteristics and capacity retention. The surfaces of core particles of silicon of 5 nm or more and 100 nm or less in average particle size are coated with a coating layer to use a negative electrode material containing substantially no silicon oxide in the coating layer, or a composite negative electrode material for a lithium ion secondary battery, which includes the negative electrode material and a matrix material, further with the use of a polyimide resin or a precursor thereof as a bonding resin, thereby making it possible to achieve high charge / discharge capacity and excellent capacity retention, as well as high initial efficiency.

Owner:TORAY IND INC

Application of high-molecular coating in aluminium negative electrode, aluminium negative electrode, preparation method thereof and secondary battery

ActiveCN108155363AAvoid erosionAvoid reactionCell electrodesSecondary cellsElectrochemistryElectrochemical energy storage

The invention discloses application of a high-molecular coating in an aluminium negative electrode, the aluminium negative electrode, a preparation method thereof and a secondary battery and relates to the field of electrochemical energy storage devices. For the application of the high-molecular coating in the aluminium negative electrode, the aluminium negative electrode is used as a negative current collector and a negative active material simultaneously. The aluminium negative electrode is used as the negative current collector and the negative active material simultaneously and is coated with the high-molecular coating; the secondary battery comprises the aluminium negative electrode. The application disclosed by the invention has the beneficial effects that the problems that the volume of the aluminium negative electrode used as the negative current collector and the negative active material is expanded and the capacity is attenuated due to an unstable solid electrolyte membrane are relieved; after the high-molecular coating is applied on the aluminium negative electrode, electrolytic solution and the aluminium negative electrode can be effectively isolated, the aluminium negative electrode can be prevented from being eroded and reacted, the coulombic efficiency is effectively improved, the irreversible capacity can be reduced, the cyclic stability of the battery can be improved, simultaneously certain role is played in inhibiting powdering of the aluminium negative electrode in the process of volume expansion, and the integrity of the aluminium negative electrode structure can be ensured.

Owner:SHENZHEN INST OF ADVANCED TECH

High voltage electrolyte considering high and low temperature performance and lithium ion battery using the electrolyte

InactiveCN105576283AImprove wettabilityImprove cycle performanceSecondary cellsElectrolytesElectrolytic agentCarboxylic acid

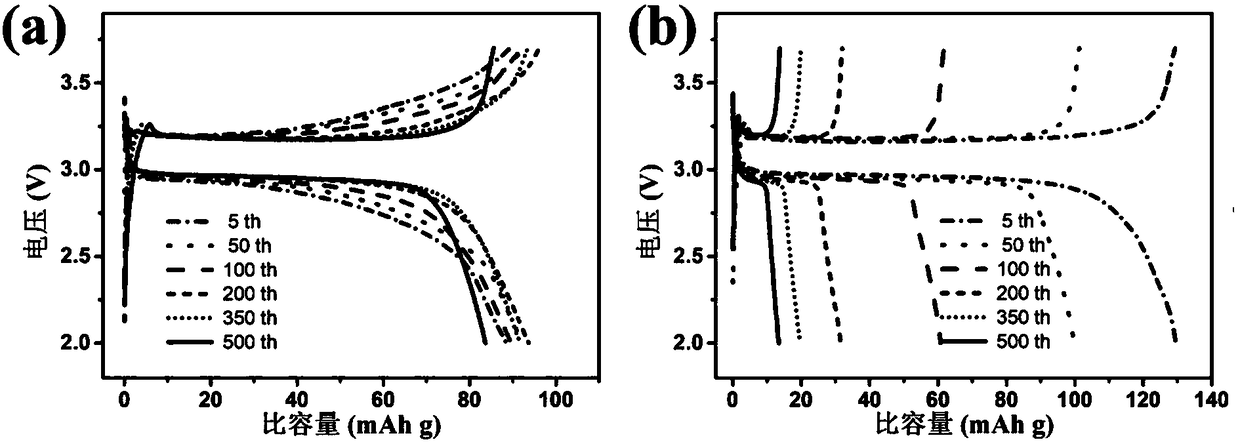

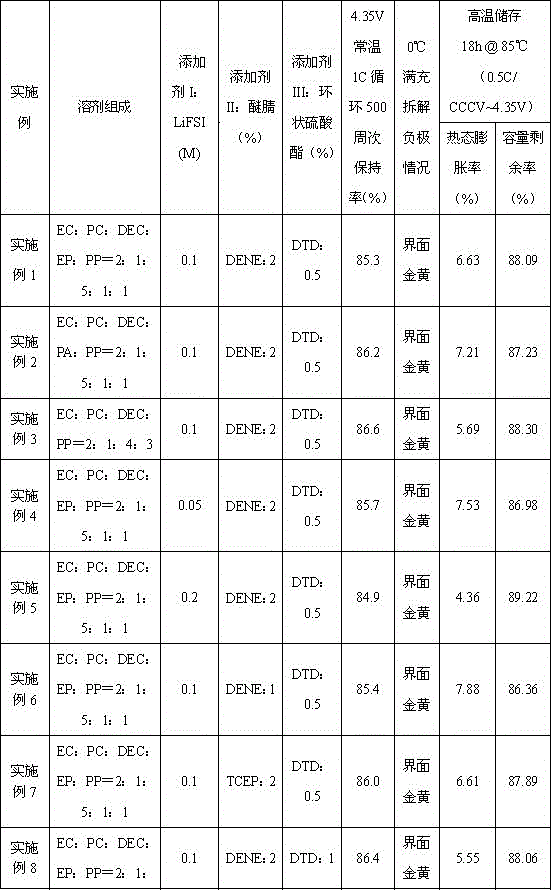

The invention discloses high voltage electrolyte considering high and low temperature performance and a lithium ion battery using the electrolyte. The high voltage electrolyte comprises a non-aqueous organic solvent, an electrolyte lithium salt, an ether nitrile compound and a low impedance additive, wherein the non-aqueous organic solvent comprises a carbonate solvent and a linear carboxylic acid ester solvent with a wide liquid range; the electrolyte lithium salt is a combination of lithium hexafluorophate and lithium triflurosulfimide according to a molar ratio of 0.01-0.5; and the low impedance additive is a cyclic sulfate compound. The linear carboxylic acid ester solvent for perfecting the electrode / electrolyte interface is contained in the high voltage electrolyte, by means of the optimized combination of the ether nitrile compound, the lithium triflurosulfimide and the cyclic sulfate compound and other additives, a high voltage battery can be guaranteed to have excellent circulation performance, and meanwhile, the excellent high and low temperature performance of the high voltage battery of storage for 18 h in a full charge state at 85 DEG C and no lithium separation in the full charge state at 0 DEG C is considered.

Owner:GUANGZHOU TINCI MATERIALS TECH

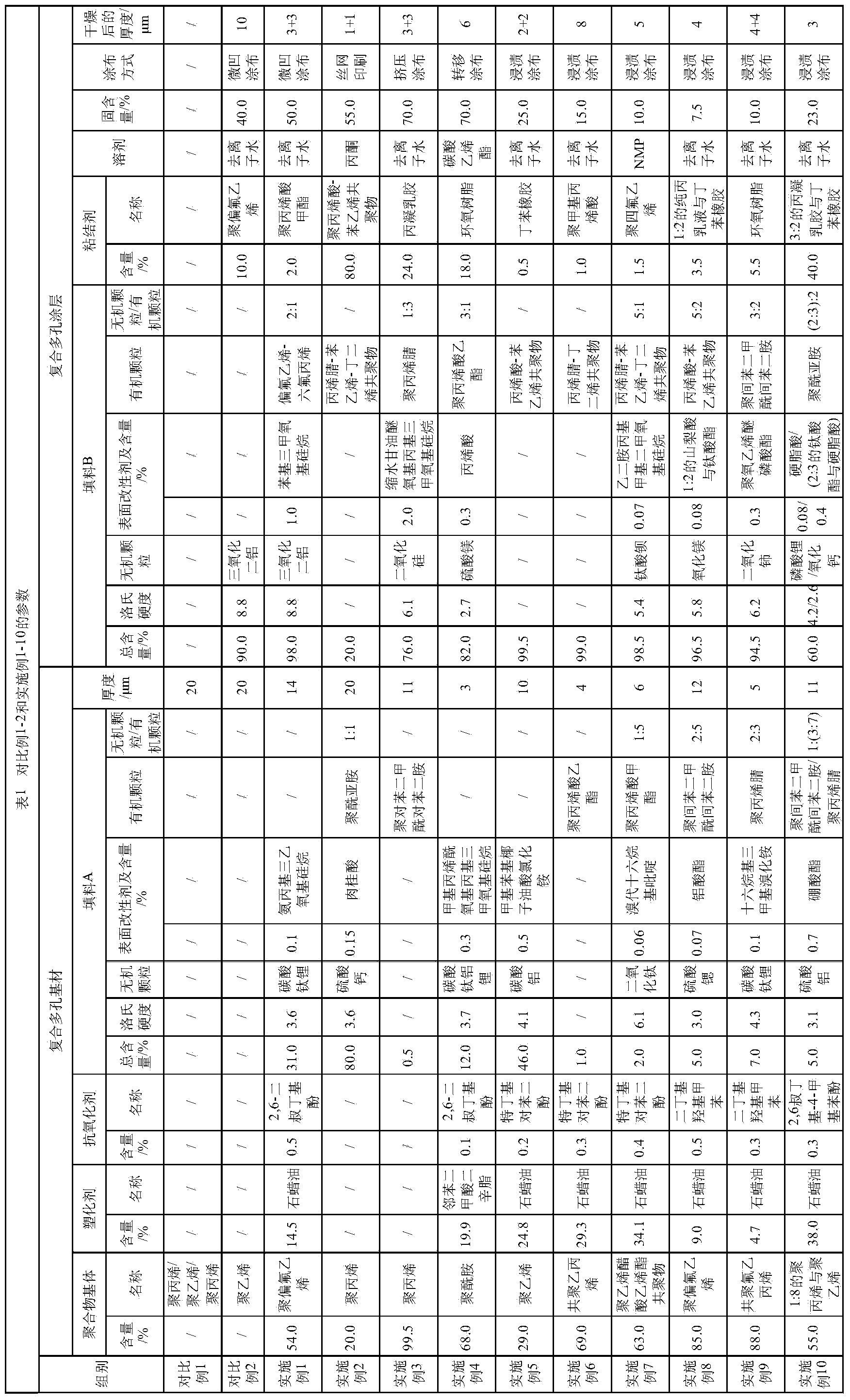

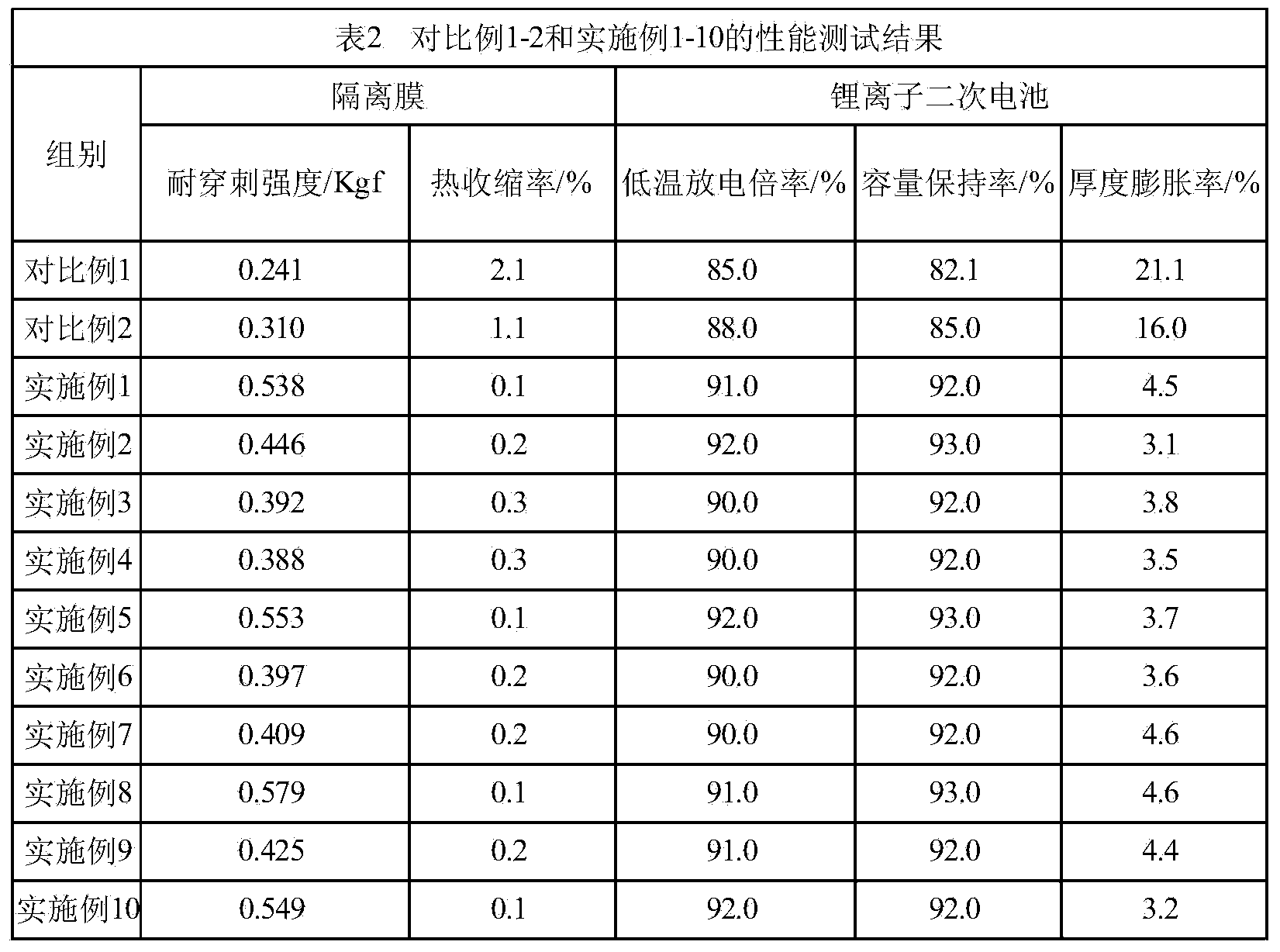

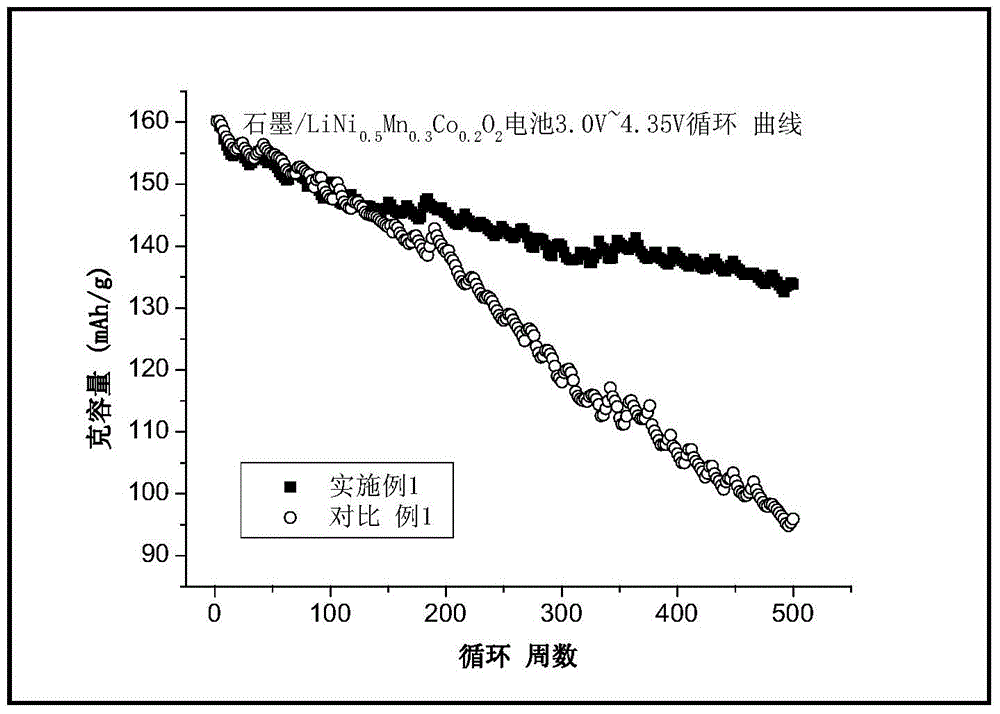

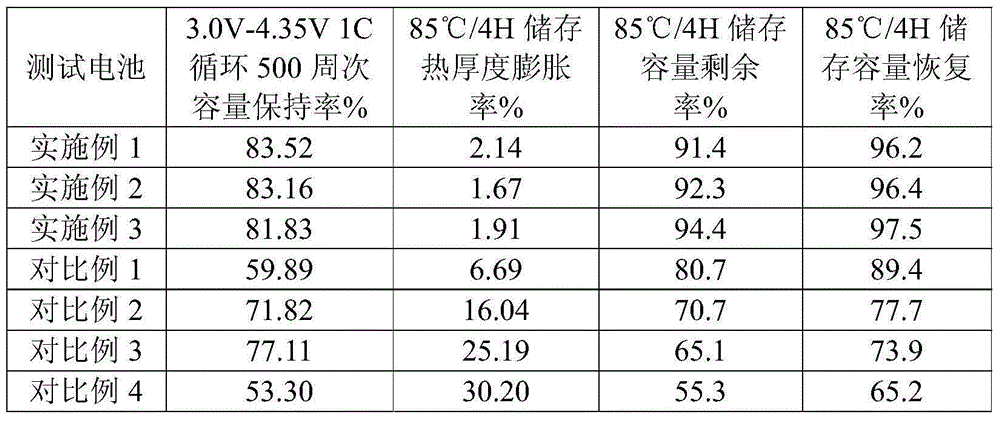

Composite porous isolating film and electrochemical device

ActiveCN103904276AImprove puncture strengthImprove thermal stabilitySecondary cellsCell component detailsPorous substratePorous coating

The invention provides a composite porous isolating film and an electrochemical device. The composite porous isolating film comprises a composite porous base material and a composite porous coating which is coated on at least one surface of the composite porous base material. The composite porous base material comprises filler A and a polymer substrate, and the filler A is selected from at least one of inorganic particles and organic particles; the composite porous coating comprises filler B and an adhesive, and the filler B is selected from at least one of inorganic particles and organic particles. The electrochemical device has a composite porous isolating film. By adopting the composite porous isolating film, the heat stability of the composite porous isolating film is improved, the deformation resistance and the capacity maintaining rate of the electrochemical device can be improved, and the cycling performance and low-temperature kinetic performance of the electrochemical device can be improved.

Owner:DONGGUAN AMPEREX TECH

Quinone compound anode material for aqueous lithium ion battery and aqueous lithium ion battery

ActiveCN105047932APolymer designabilityHigh discharge specific capacityCell electrodesFinal product manufactureElectrode potentialCarbon nanotube

The invention relates to a quinone compound anode material for an aqueous lithium ion battery. The quinone compound anode material is quinone polymers directly connected through C-C bonds or connected through N atoms or S atoms, or is a quinone compound formed by in-situ composition of a quinone compound monomer with a high-conductivity carbon material during the polymerization process, and the high-conductivity carbon material is selected from one or more of graphite oxide, carbon black, carbon nano tube and expanded graphite. The material has the advantages of high molecule designability, high discharging specific capacity (the maximum can reach 200mAh g<-1>, appropriate electrode potential (2-2.8V to Li / Li<+>), high rate capability and cycle performance and the like, and the aqueous lithium ion battery prepared from the material has the advantages of long cycle life, high efficiency, safety, low cost, environmental friendliness and the like.

Owner:中国人民解放军军事科学院防化研究院

Lithium-ion battery electrolyte for high-voltage ternary positive electrode material system

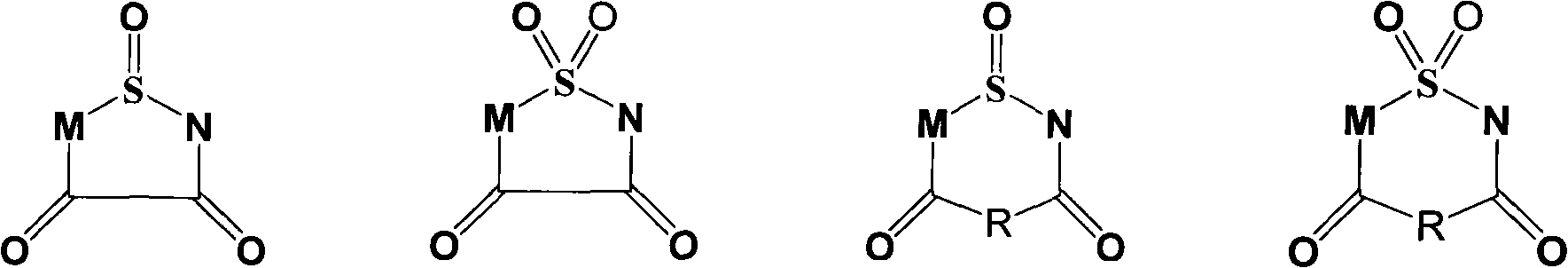

ActiveCN105140564AImprove cycle performanceImprove high temperature performanceSecondary cellsOrganic electrolytesSolventStructural formula

The invention provides a lithium-ion battery electrolyte for a high-voltage ternary positive electrode material system. The lithium-ion battery electrolyte comprises a non-aqueous solvent, lithium hexafluorophate and a functional additive; the functional additive comprises a cyclic anhydride compound, a lithium salt type additive and methylene methanedisulfonate; the general structural formula of the cyclic anhydride compound is as shown in the description, wherein R1, R2, R3 and R4 are independently selected from any one of hydrogen atom, fluorine atom, or straight chain or branched chain alkyl with the number of carbon atoms of 1-4. The cyclic anhydride compound used in the lithium-ion battery electrolyte is higher in reduction potential (the reduction potential of succinic anhydride is 1.50 V vs Li+ / Li) on the negative electrode surface, so that other components in the electrolyte can be preferably reduced into films in the first charging process of the battery, the formed SEI film is high in stability. The cyclic anhydride compound used in the lithium-ion battery electrolyte is capable of effectively improving the cycle performance and high-temperature performance of the battery; and compared with fluoroethylene carbonate, the cyclic anhydride compound has excellent high-temperature performance as well as capability of improving the cycle performance.

Owner:GUANGZHOU TINCI MATERIALS TECH

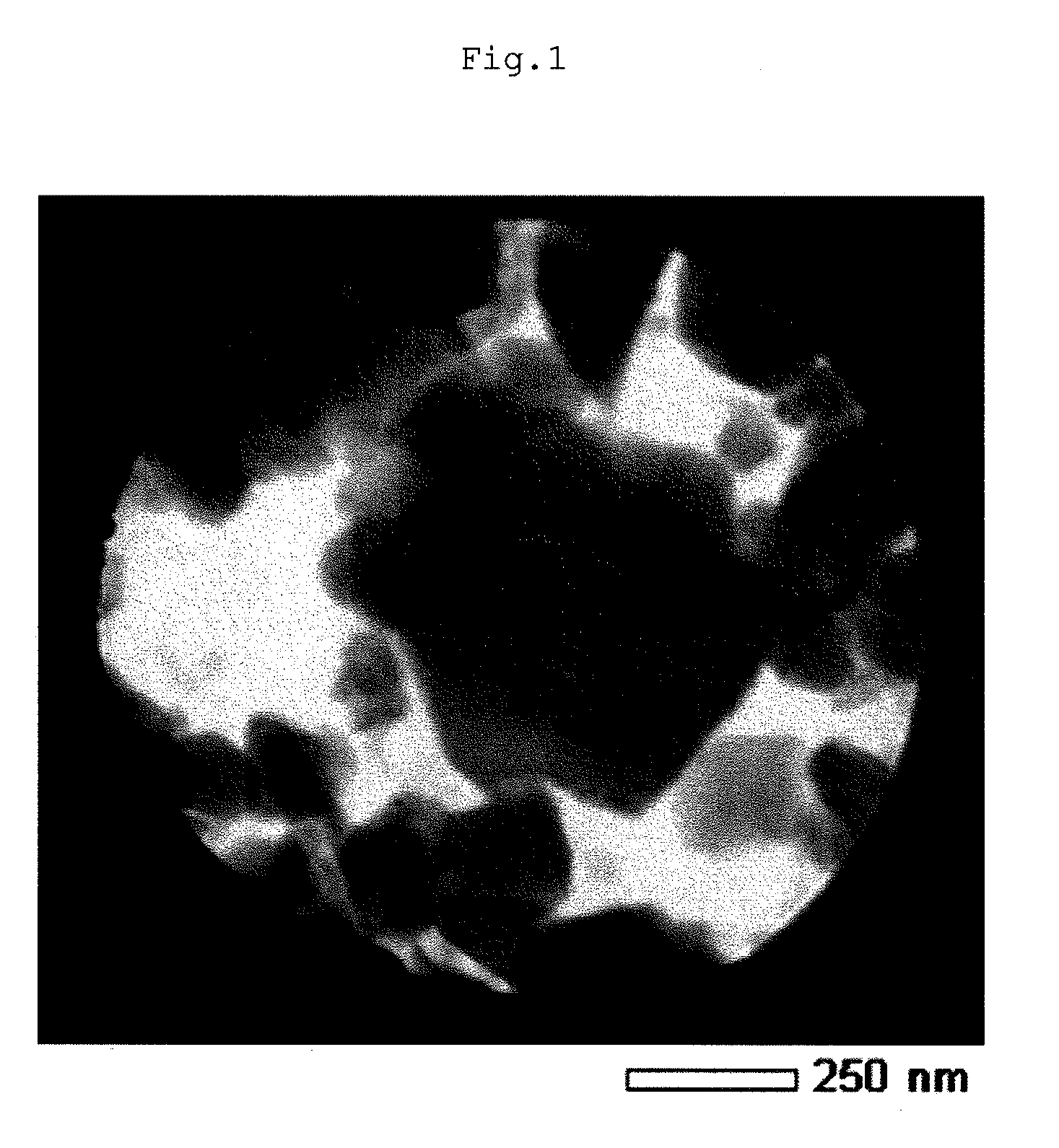

Sponge-like silicon graphene and carbon nano-tube composite negative electrode material preparation method

ActiveCN105185956AUnique pore network structureImprove conductivityCell electrodesSecondary cellsSupercritical dryingFreeze-drying

The present invention discloses a sponge-like silicon graphene and carbon nano-tube composite negative electrode material preparation method, which comprises, by weight, 50-90% of silicon powder, 2-35% of graphene, and 1-25% of carbon nano-tubes. According to the present invention, the composite material prepared by using the freeze-drying or supercritical drying method retains the original skeleton structure, the carbon nano-tubes are adopted as the skeleton support unit and the graphene is adopted as the frame pore structure surface to co-support the three-dimensional electric conduction network composite structure having innumerable pores, and the silicon powder is adsorbed inside the pores; the composite material has characteristics of high conductivity, high structure elasticity, strong adsorption, effective inhibition of the volume expansion effect of the silicon during the charge and discharge process, and improvement of the cycle stability of the material; and the process is simple and environmental protection, and is suitable for industrial production.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

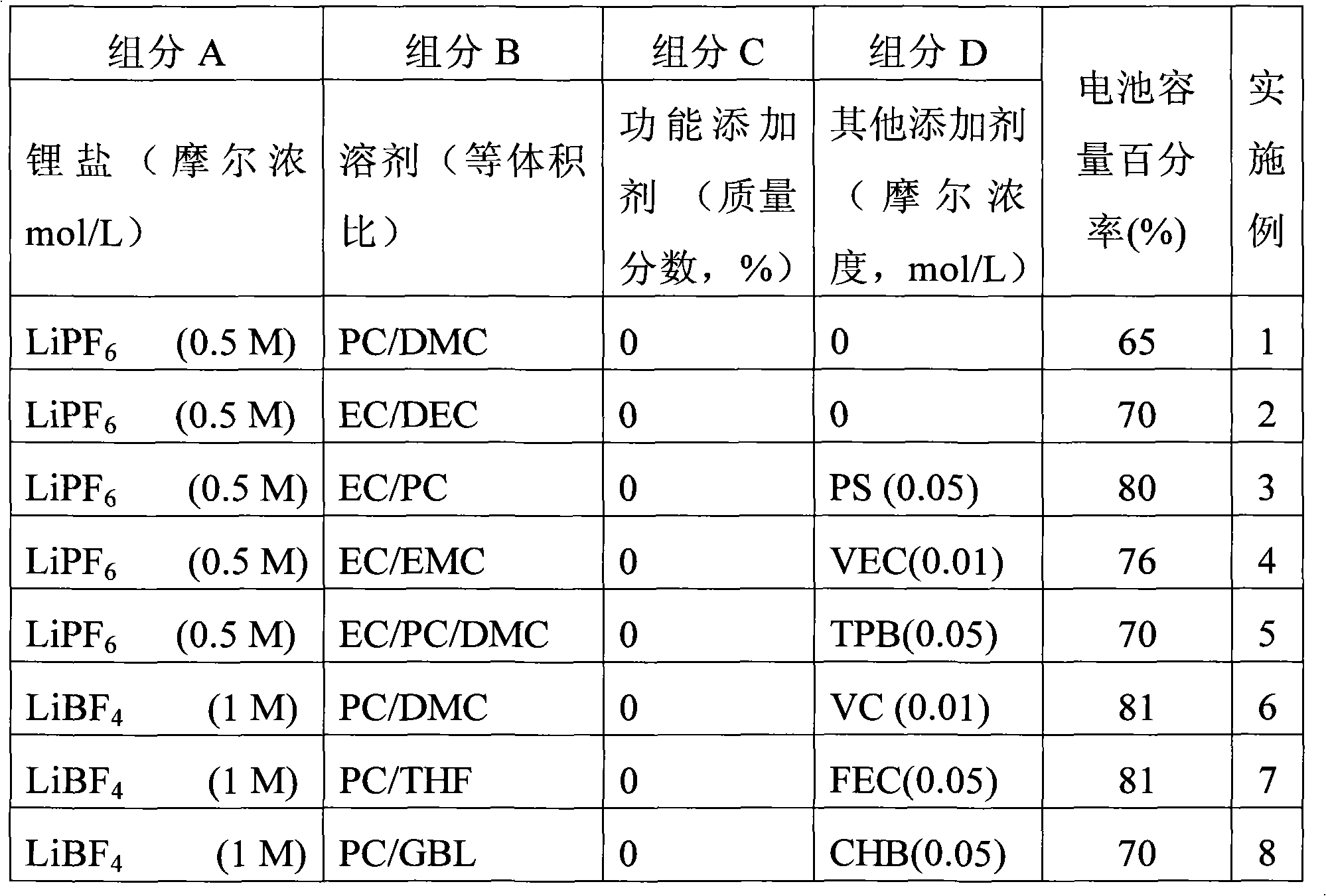

Non-aqueous electrolyte solution and application thereof

InactiveCN102074738AAvoid decompositionLower resistanceFinal product manufactureNon-aqueous electrolyte cellsOrganic solventDecomposition

The invention provides a non-aqueous electrolyte solution and application thereof. The electrolyte solution comprises the following four components: lithium salt, a carbonic ester and / or ether organic solvent, a function additive and other additives, wherein the molar concentration range of lithium salt in the electrolyte is 0.001-2 mol / L; the mass proportion range of the function additive in the electrolyte is 0.01-20 percent; and the molar concentration range of the other additives in the electrolyte is 0-0.5 mol / L. The non-aqueous electrolyte solution provided by the invention can inhibit the decomposition of the solvent, prolong the cycle life and service life of a lithium battery, inhibit the resistance increase of the battery, improve the volume maintenance rate of the battery and prolong the volume maintenance rate and cycle life of the battery in a high-temperature environment and can be applied to the manufacture of a primary lithium battery, a secondary lithium battery or a lithium ion battery.

Owner:ZHANGJIAGANG GUOTAI HUARONG NEW CHEM MATERIALS CO LTD

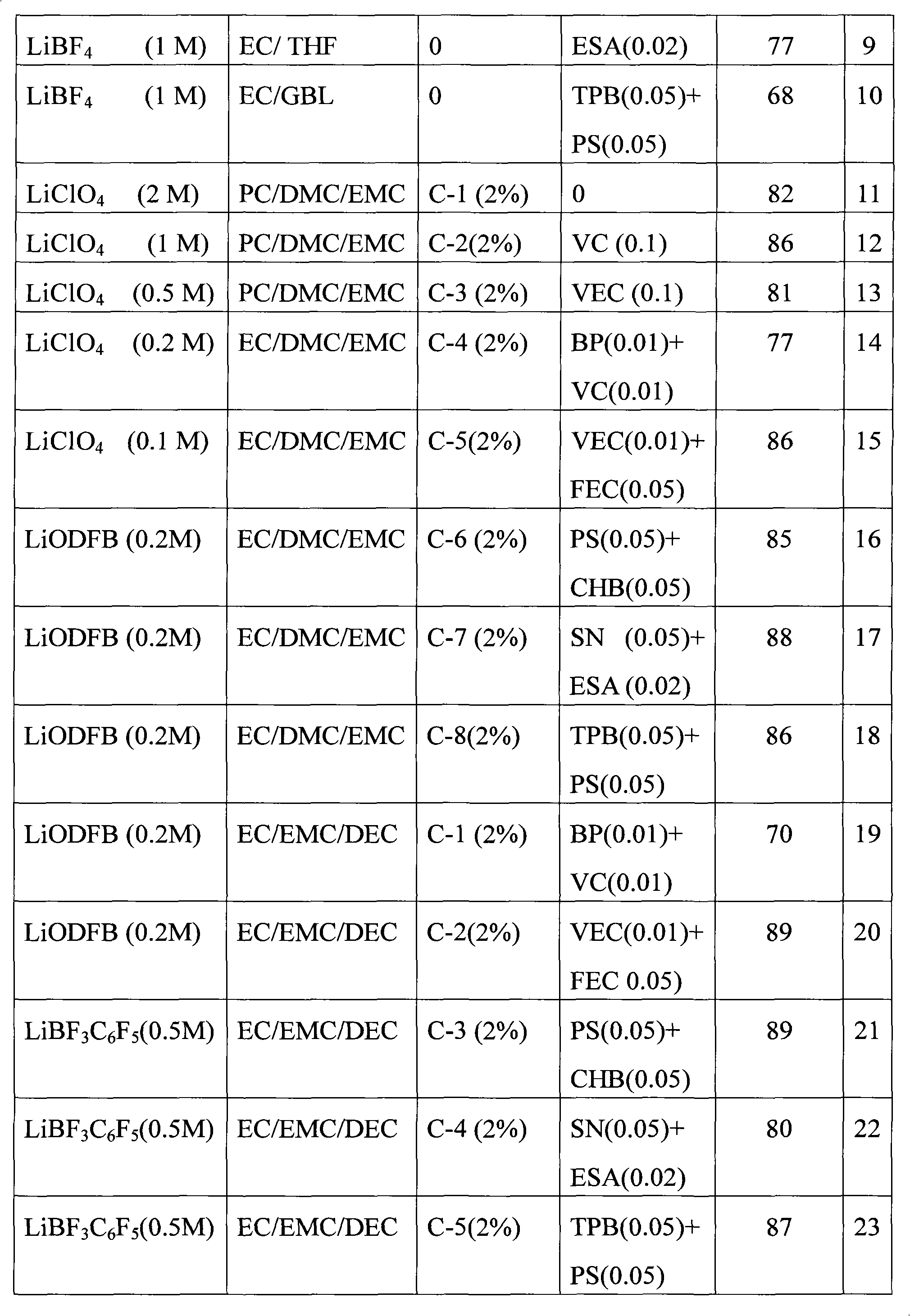

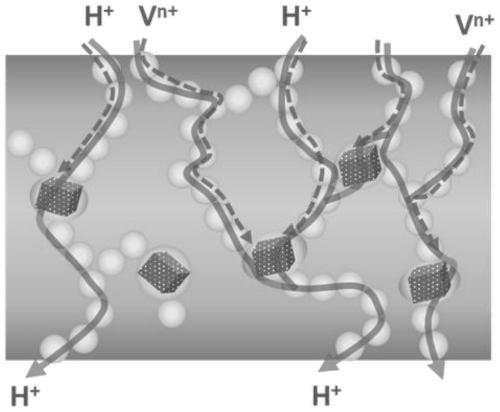

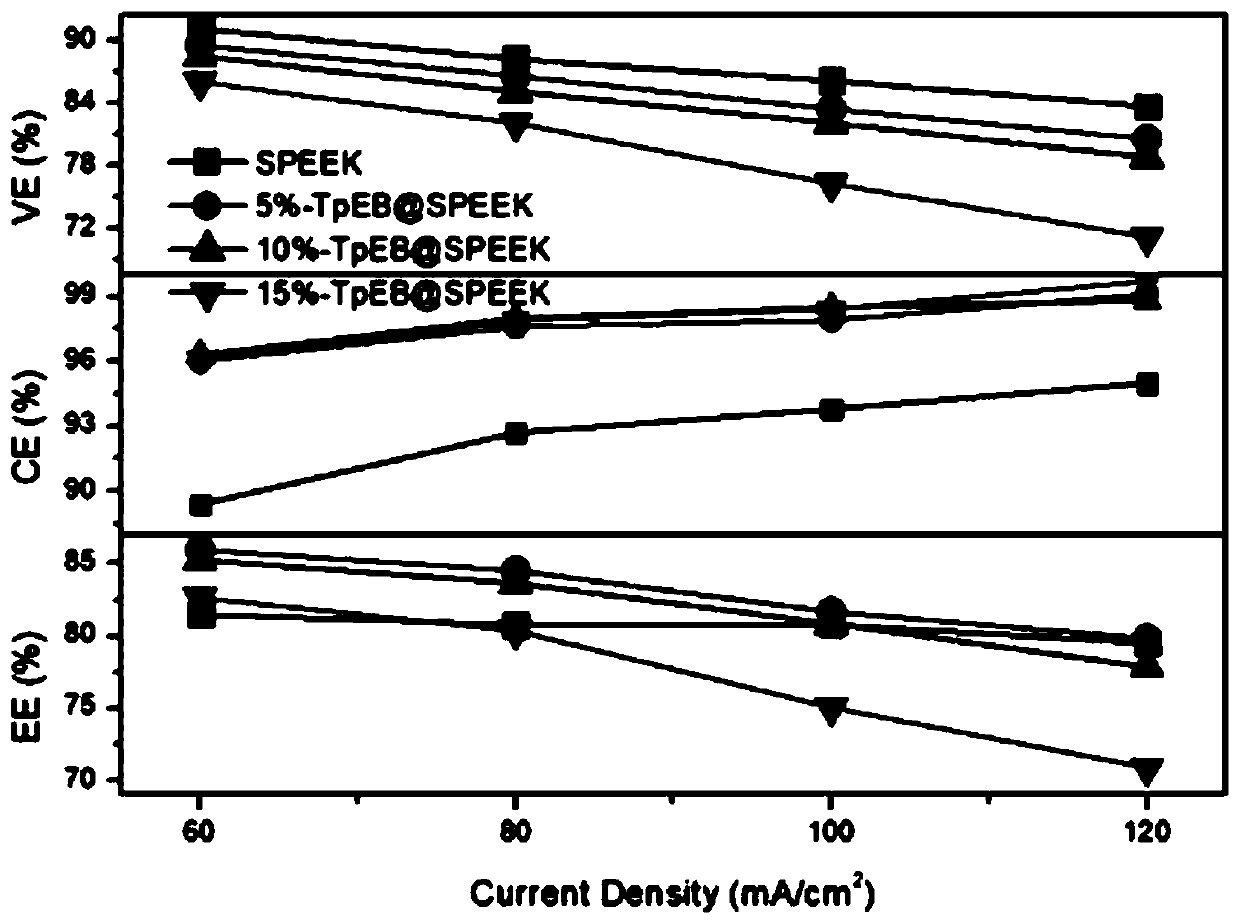

Mixed matrix type cation exchange membrane and preparation method thereof

ActiveCN110336052AInhibit water swellingImprove tensile propertiesRegenerative fuel cellsOrganic structureFunctional modification

The invention relates to a mixed matrix type cation exchange membrane and a preparation method thereof. The cation exchange membrane takes a sulfonated modified polymer material as a substrate and isdoped with Schiff base type covalent organic framework materials loaded with different functional groups. The preparation method comprises the following steps of: sequentially performing monomer preparation and polymerization of a covalent organic framework material, sulfonation modification of a polymer, uniform mixing of the covalent organic framework material and a sulfonated polymer, and flow-spreading film formation; and finally, performing acid treatment to obtain the cation exchange membrane. The covalent organic framework material can effectively improve the vanadium resistance of themembrane based on the rigid porous structure; the organic porous structure of the covalent organic framework and the different functional modifications can partially compensate the loss of membrane proton conductivity caused by the introduction of particles; the rigid framework can obviously inhibit the swelling in the membrane and can improve the tensile strength of the membrane; COFs is composedof organic structures and can promote compatibility between sulfonated polymers and covalent organic framework materials; and moreover, the polymer as the substrate can improve the film forming performance of the covalent organic framework material, so that the covalent organic framework material has the better mechanical strength.

Owner:DALIAN UNIV OF TECH

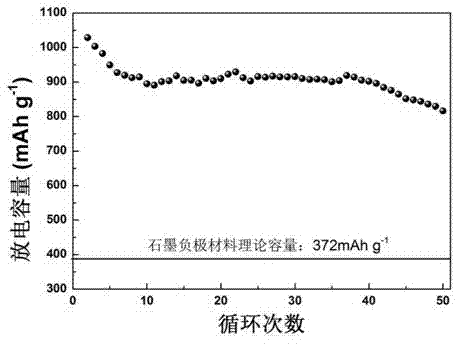

Carbon-coated hollow ferriferrous oxide and application thereof

The invention discloses carbon-coated hollow ferriferrous oxide and an application thereof. The preparation method of the carbon-coated hollow ferriferrous oxide comprises the following steps of: (1) adding a ferric salt into a solvent and dissolving the ferric salt, wherein the solvent is a mixture of water and ethanol; implementing a hydrothermal reaction in a sealed hydrothermal kettle for 20-30hours at 100-250 DEG C, and separating to obtain a ferric oxide deposit; and (2) uniformly mixing the ferric oxide deposit with a reducing carbon source, wherein the reducing carbon source is one substance or a combination of multiple substances selected from carbon powder, glucose, polyethylene, acetylene black and starch; and implementing an insulating reaction for 0.5-4hours in a muffle at 200-1000 DEG C, to obtain the carbon-coated hollow ferriferrous oxide. The carbon-coated hollow ferriferrous oxide, used as a lithium ion battery negative electrode material, can remarkably improve electrical conductivity and keeps a stable structure, so that a comparatively high capacity retention ratio is still guaranteed after several charge-discharge cycles.

Owner:ZHEJIANG UNIV OF TECH

Preparation method of functional diaphragm of lithium sulfur battery

ActiveCN105514482AHigh capacity retentionImprove Coulombic efficiencyCell seperators/membranes/diaphragms/spacersFinal product manufactureSolventPolyvinylidene fluoride

The invention discloses a preparation method of a functional diaphragm of a lithium sulfur battery. The preparation method comprises the following steps: dissolving oxidized graphene into deionized water, performing ultrasonic treatment to obtain an oxidized graphene solution, then adding lithium hydroxide and monochloro acetic acid into the oxidized graphene solution, and performing ultrasonic treatment to obtain a carboxylic oxidized graphene solution; mixing polyvinylidene fluoride, a lithium conducting polymer, a perforation additive, deionized water, a solvent for dissolving the polymer and the carboxylic oxidized graphene according to a ratio, curing and stirring at 70 DEG C, and stewing and defoaming at a normal temperature to obtain a membrane casting solution; scraping the membrane casting solution into a wet membrane; pre-steaming the wet membrane, putting the membrane into a mixed coagulating bath, and immersing in the deionized water to form a preliminary membrane; treating the preliminary membrane to obtain the functional diaphragm. According to the diaphragm of the lithium sulfur battery, the capacity retention ratio and the coulombic efficiency of the battery can be obviously improved; the density of a carboxyl group on the surface of the diaphragm can be obviously increased, thus enhancing the permselectivity function of the diaphragm.

Owner:CENT SOUTH UNIV

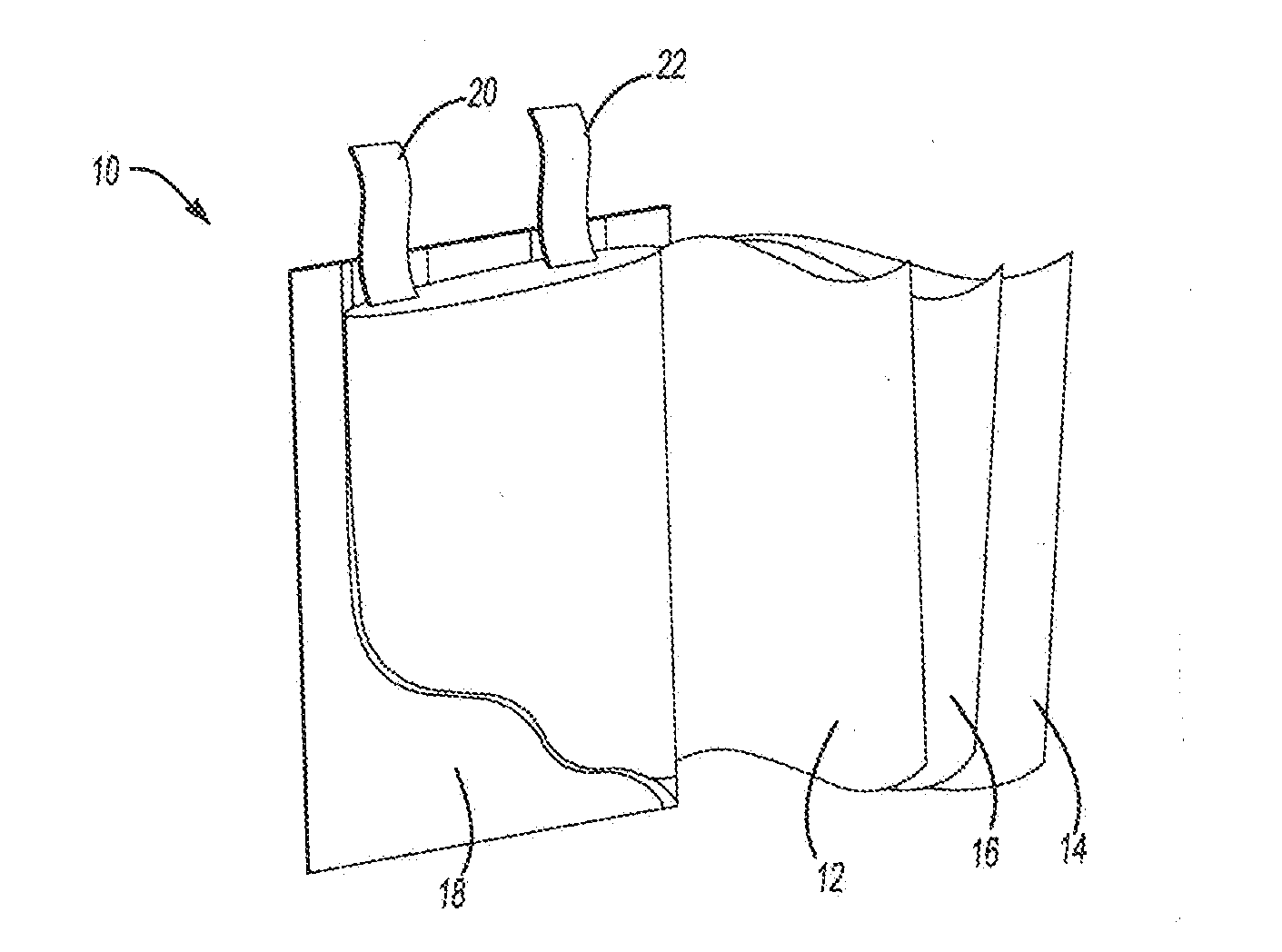

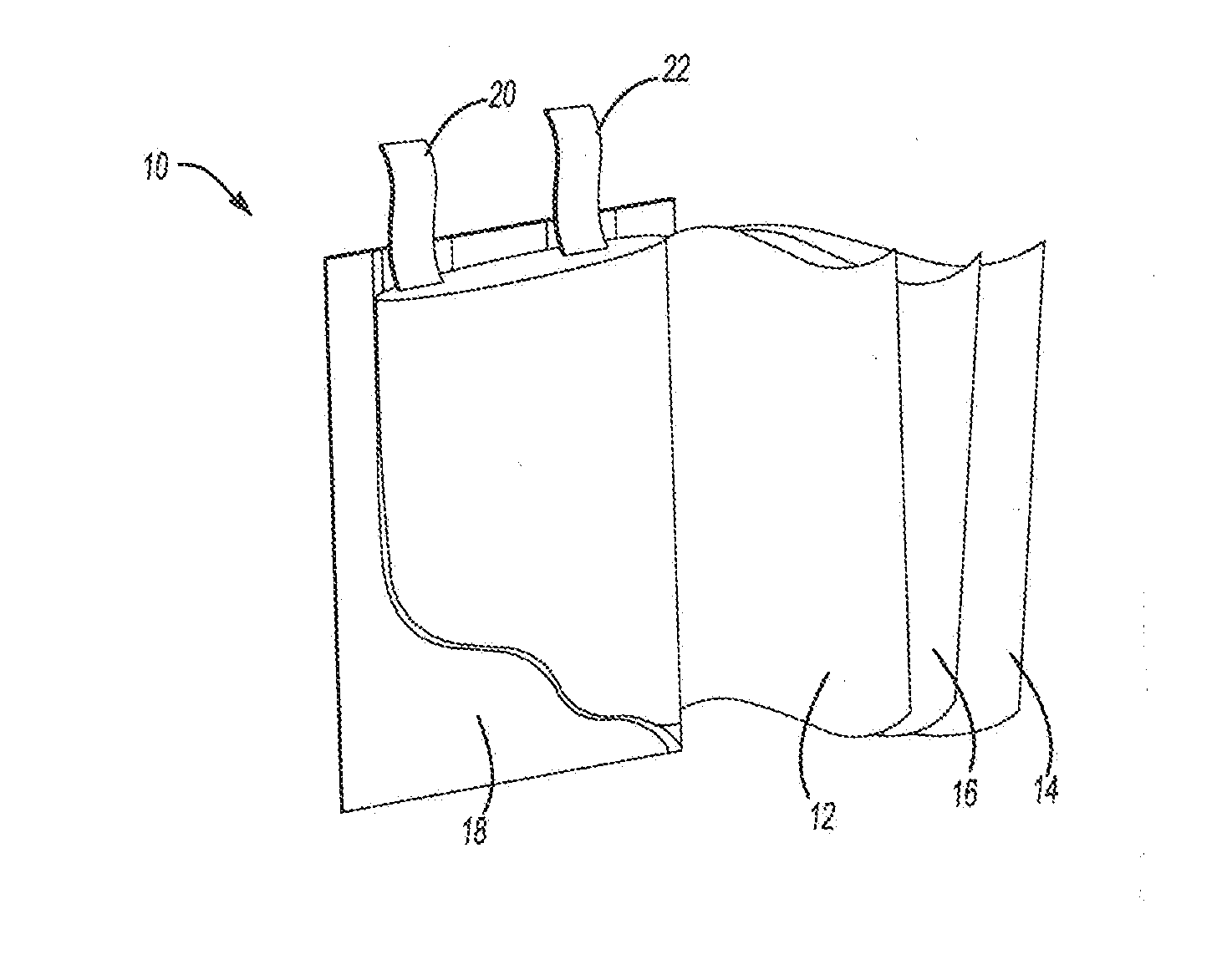

Lithium-ion capacitor

ActiveUS20080055819A1Increased durabilityHigh capacity retentionHybrid capacitor electrolytesLiquid electrolytic capacitorsOrganic solventHigh energy

A lithium-ion capacitor excellent in durability, which has high energy density and high capacity retention ratio when the capacitor is charged and discharged at a high load, is disclosed. The lithium-ion capacitor includes a positive electrode, a negative electrode and an aprotic organic solvent of a lithium salt as an electrolyte solution. In the lithium-ion capacitor, a positive electrode active material allows lithium ions and / or anions to be doped thereinto and de-doped therefrom, and a negative electrode active material allows lithium ions to be doped thereinto and de-doped therefrom. At least one of the negative electrode and the positive electrode is pre-doped with lithium ions so that after the positive electrode and the negative electrode are shortcircuited, a potential of the positive electrode is 2 V (relative to Li / Li+) or lower. A thickness of a positive electrode layer of the positive electrode is within a range from 18 to 108 μm.

Owner:SUBARU CORP

Cathode material of lithium ion battery and battery

ActiveCN102487141ALower internal resistanceHigh specific capacityCell electrodesSecondary cellsFiberConductive polymer

The invention provides a cathode material of a lithium ion battery. The cathode material contains active substance and conductive agent, wherein the conductive agent comprises a first conductive agent and a second conductive agent; the first conductive agent is a conductive polymer containing polar groups, and the second conductive agent is one or more selected from carbon black, graphite, carbon fiber, carbon nanotube, nickel carbonyl powder, copper powder, iron powder, zinc powder and aluminium powder. The invention also provides a lithium ion battery. During a slurry preparation process, polar groups facilitate hydrogen bond formation on the second conductive agent and the anode active substance surface and enhance disperse degree of the second conductive agent and the anode active substance in a solvent, so that the slurry is more easily coated, and the coating thickness is uniform; and the prepared polar sheet has good consistency.

Owner:BYD CO LTD

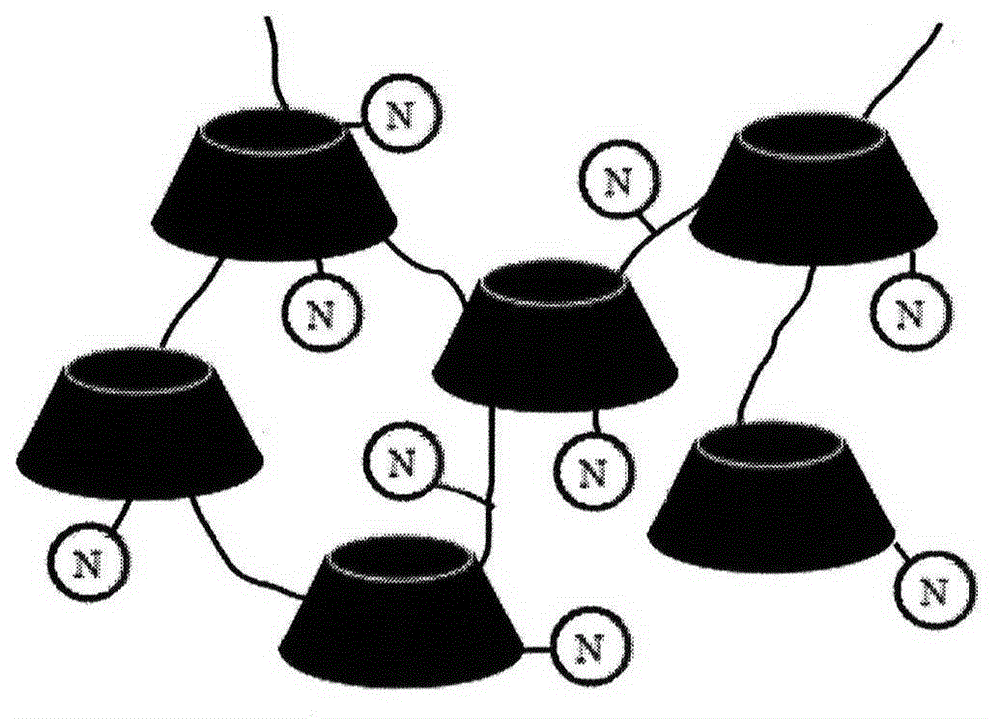

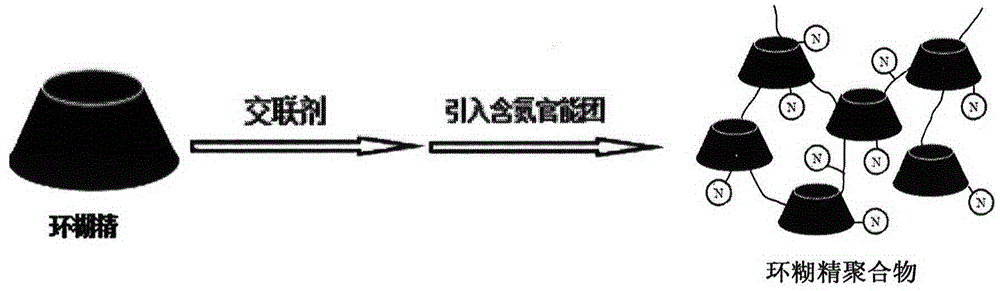

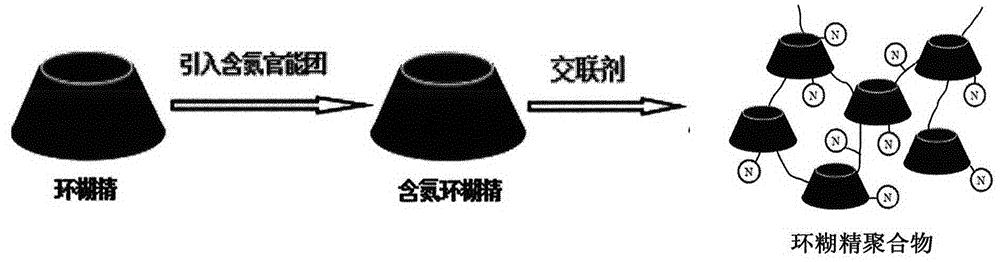

Nitrogen-containing binder for sulfur-lithium batteries and preparation method thereof

InactiveCN106159272AImprove adsorption capacityInhibition of dissolutionCell electrodesCyclodextrin adhesivesWater basedElectrical battery

The invention relates to a nitrogen-containing binder for sulfur-lithium batteries and a preparation method thereof. The binder is a nitrogen-containing cyclodextrin polymer water-based binder with a three-dimensional network structure. The existing three-dimensional network structure can well bear the mechanical pressure brought by sulfur-lithium batteries in the charging and discharging process due to volume change, introduced nitrogen-containing functional groups can effectively inhibit the problems of dissolution and shuttle effect of polysulfide ions in electrolyte, a number of hydroxyl groups exist in the cyclodextrin and have strong hydrogen-bond interaction with anode material particles, and the stability of pole pieces can be maintained. In addition, the binder also has a role of increasing guide ions. Therefore, the binder can effectively solve the problem that a positive polysulfide material in the sulfur-lithium batteries is unstable in organization structure, the utilization rate of composite material active matter and the rate capability of the active matter can be improved, and accordingly the specific power, specific energy and cyclicity of the batteries can be improved.

Owner:NO 63971 TROOPS PLA

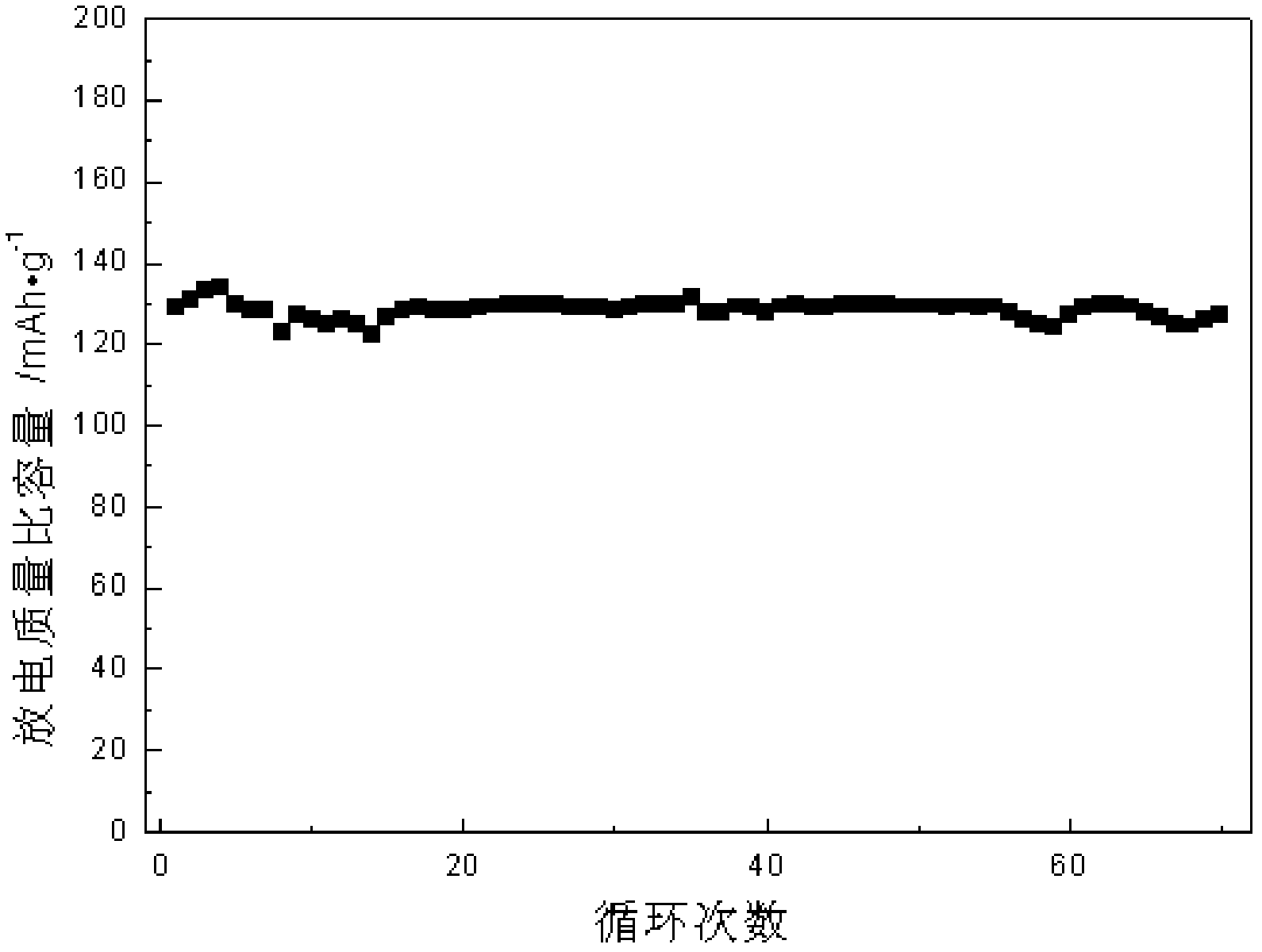

Composite carbon material, modified electrode material prepared from composite carbon material and lithium ion battery

ActiveCN107706403AImprove stabilityImprove coating uniformityCell electrodesCarbonizationSodium-ion battery

The invention discloses a composite carbon material, a modified electrode material prepared from the composite carbon material and a lithium ion battery. The composite carbon material contains a firstcarbon material, a second carbon material and a carbon source, wherein the first carbon material and the second carbon material are doped carbon materials. Compared with a conventional manner for firstly coating by virtue of a carbon source for carbonization to obtain a carbon material coating layer, the composite carbon material has the advantages that by introducing a proper amount of the firstcarbon materials and a proper amount of the second carbon materials, on one hand, the use amount of a common carbon source is reduced, and on the other hand, the electrochemical properties of structure stability, electrical conductivity, tap density, volume energy density, rate capability, cycle performance and the like of an electrode material modified by the composite carbon material can be cooperatively improved. By coating and modifying lithium iron phosphate by virtue of the composite carbon material, the rate capability and cycling stability of lithium iron phosphate can be substantially improved, the specific discharge capacity of lithium iron phosphate is more than or equal to 149mAh / g under a 6C rate condition, and the capacity retention ratio is more than or equal to 97% after 60 cycles.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

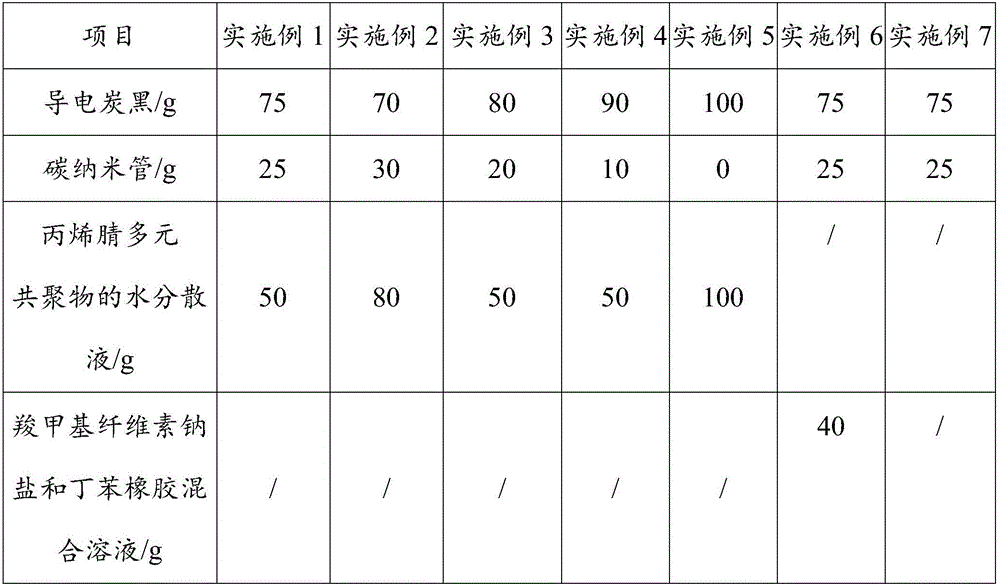

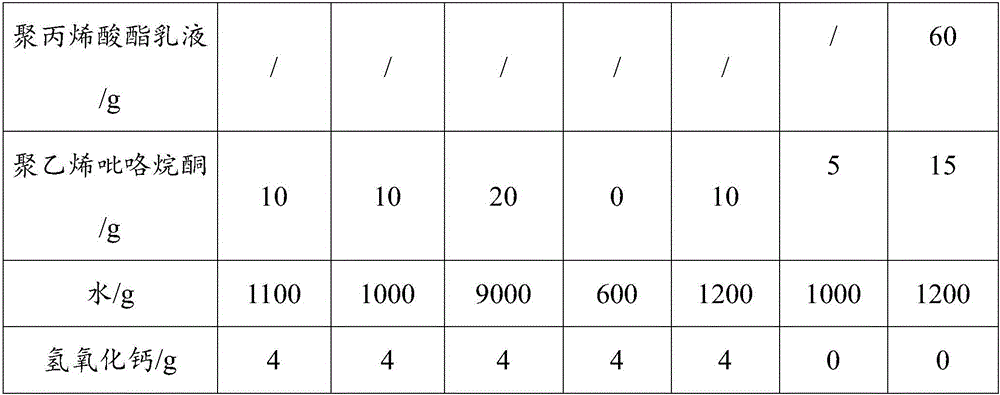

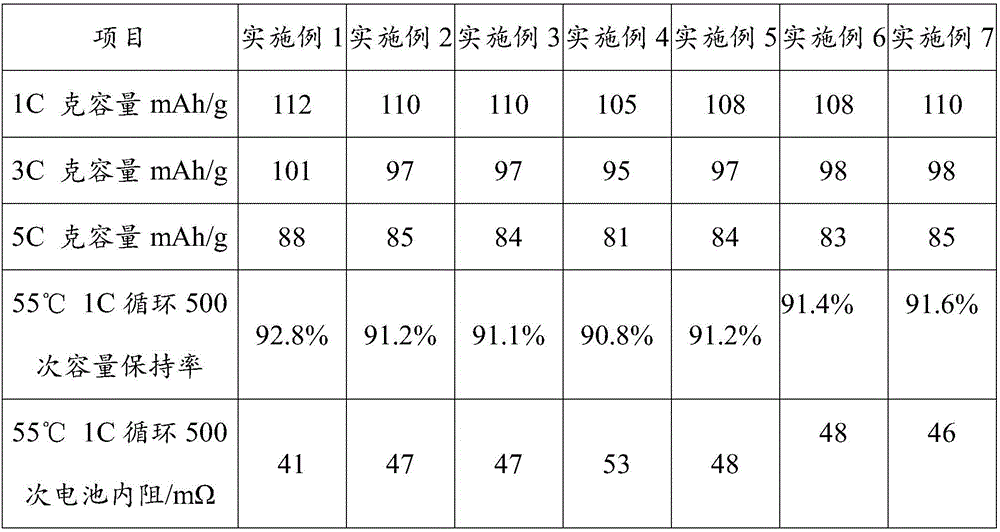

Conductive coating material for lithium ion battery, preparation method of conductive coating material and lithium ion battery

ActiveCN106047015ATake advantage of low pricesImprove stabilityCell electrodesConjugated diene hydrocarbon coatingsConductive coatingSodium-ion battery

The invention provides a conductive coating material for a lithium ion battery. The conductive coating material comprises components in parts by weight as follows: 100 parts of a conductive agent, 20-150 parts of a binding agent, 0-30 parts of polyvinylpyrrolidone and 500-10,000 parts of water, wherein in terms of 100 parts by weight of the conductive agent, the conductive coating material further comprises components of 70-100 parts by weight of conductive carbon black and 0-30 parts by weight of carbon nano-tubes. The invention further provides a preparation method of the conductive coating material and the lithium ion battery adopting the conductive coating material. The conductive coating material is safe and environment-friendly, has good stability after dispersed and can improve the electrochemical performance of the lithium ion battery remarkably.

Owner:宇锵新材料(湖北)有限公司

Electrode material surface coating method and application thereof

InactiveCN106099047ANovel and ideal encapsulation technologyIncrease coverageCell electrodesMetal clustersMetal-organic framework

The invention provides an electrode material surface coating method and application thereof. The method includes steps: (1) enabling in-situ growth of a metal organic skeleton on the surface of an electrode material; (2) subjecting the metal organic skeleton coated electrode material to heat treatment to obtain an oxide coated electrode material. Since the metal organic skeleton material with appropriate morphologic size and target ion metal clusters is designed as a precursor and converted into nanometer oxide after heat treatment, effective coating of the electrode material with the metal oxide and regulation of structure and coating amount of the metal oxide can be realized, more surface coating substances and structures difficult to realize by traditional methods can be introduced, and the electrode material surface coating method is a novel electrode material surface coating means.

Owner:SHENZHEN CITY BATTERY NANOMETER TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com