Preparation method of functional diaphragm of lithium sulfur battery

A lithium-sulfur battery and functional technology, applied in the direction of lithium battery, electrolyte battery manufacturing, battery pack components, etc., can solve the problem of unable to suppress the shuttle effect, etc., to improve the selective permeability function of the separator, improve the density, and improve the Coulomb efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

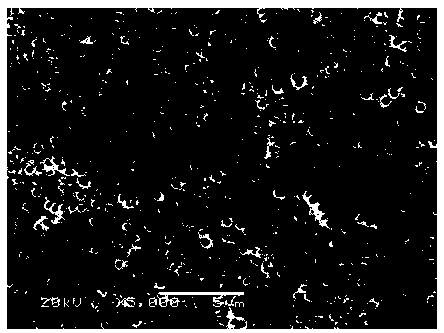

Image

Examples

Embodiment 1

[0025] Example 1: Add 100mg of graphene oxide to 100mL of deionized water, and ultrasonically disperse for 0.5h, then continue to sonicate and slowly add 10g of lithium hydroxide, 8g of monochloroacetic acid, and finally ultrasonic for 5h to complete the graphene oxide carboxylation reaction. A carboxylated graphene oxide solution is obtained. The carboxylated graphene oxide solution was vacuum dried at 50°C. Mix 8g polyvinylidene fluoride, 8g sulfonated polyethersulfone, 0.004g polyvinylpyrrolidone, 0.004g sodium nitrate, 1g deionized water, 78g dimethylformamide and 1g carboxylated graphene oxide in an Erlenmeyer flask. , Aging at 70℃ for 48h, stirring at 70℃ for 12h, and standing at room temperature for 48h to defoam to obtain casting liquid. Pour the casting liquid on the glass plate and scrape it to make a wet film. After the wet film was pre-evaporated in the air for 5 seconds, it was quickly placed in the coagulation bath for 1 min to initially replace the solvent. The...

Embodiment 2

[0026] Example 2: Add 50 mg of graphene oxide to 100 mL of deionized water, and ultrasonically disperse for 2 hours, continue to sonicate and slowly add 3 g of lithium hydroxide, 2 g of monochloroacetic acid, and finally ultrasonic for 3 hours to complete the graphene oxide carboxylation reaction. Carboxylated graphene oxide solution. The carboxylated graphene oxide solution was vacuum dried at 20°C. Mix 8g polyvinylidene fluoride, 0.4g polyacrylic acid, 1g polyethylene glycol, 0.008g deionized water, 25g N-methylpyrrolidone, 25g dimethyl sulfoxide and 1.2g carboxylated graphene oxide in an Erlenmeyer flask It is uniform, matured at 70°C for 24h, stirred at 70°C for 36h, and allowed to stand at room temperature for 8h to defoam to obtain a casting solution. Pour the casting liquid on the glass plate and scrape it to make a wet film. After the wet film was pre-evaporated in the air for 10 minutes, it was quickly placed in a coagulation bath for 30 minutes to initially replace ...

Embodiment 3

[0027] Example 3: Add 0.5g of graphene oxide to 100mL of deionized water, ultrasonically disperse for 3h, continue to sonicate and slowly add 10g of lithium hydroxide, 5g of monochloroacetic acid, and finally ultrasonic for 1h to complete the carboxylation of graphene oxide. A carboxylated graphene oxide solution is obtained. The carboxylated graphene oxide solution was vacuum dried at 30°C. Mix 8g polyvinylidene fluoride, 5g polymethyl methacrylate, 0.3g polyvinylpyrrolidone, 1g deionized water, 67g dimethylacetamide and 0.75g carboxylated graphene oxide in an Erlenmeyer flask. Maturation at ℃ for 24h, stirring at 70℃ for 24h, and standing at room temperature for 12h to defoam to obtain casting liquid. Pour the casting liquid on the glass plate and scrape it to make a wet film. After the wet film was pre-evaporated in the air for 30 seconds, it was quickly placed in a coagulation bath for 20 minutes to initially replace the solvent. The coagulation bath was a deionized aqueo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com