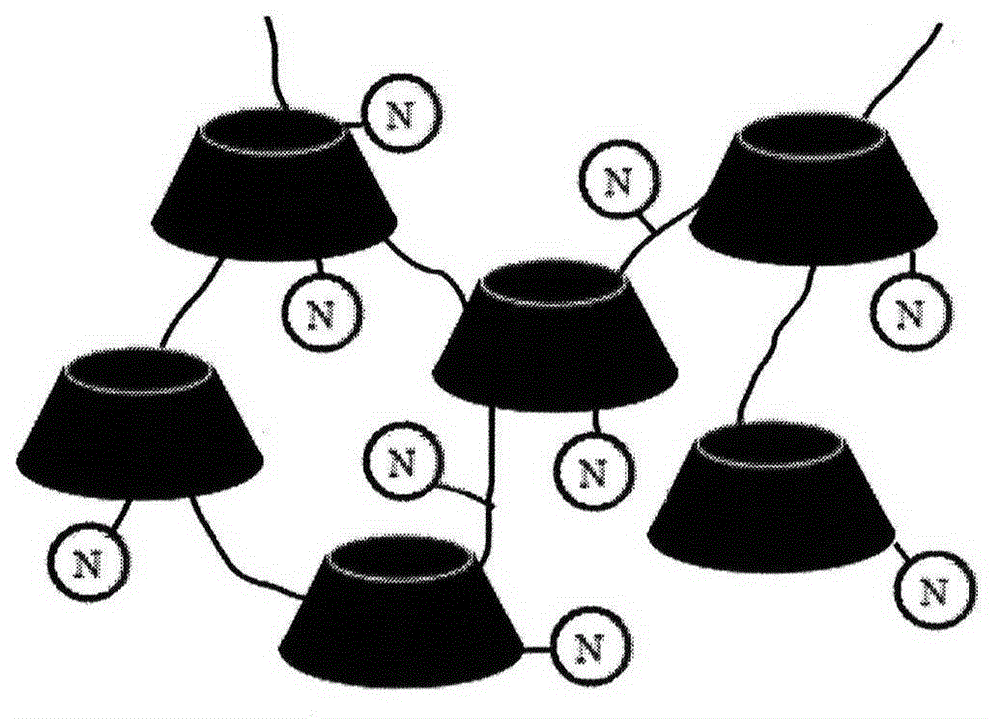

Nitrogen-containing binder for sulfur-lithium batteries and preparation method thereof

A lithium-sulfur battery and binder technology, which is used in battery electrodes, cyclodextrin adhesives, circuits, etc., can solve the problems of low cyclodextrin solubility, capacity decay, and low viscosity, and achieve inhibition of dissolution and shuttle effect. , the effect of maintaining stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

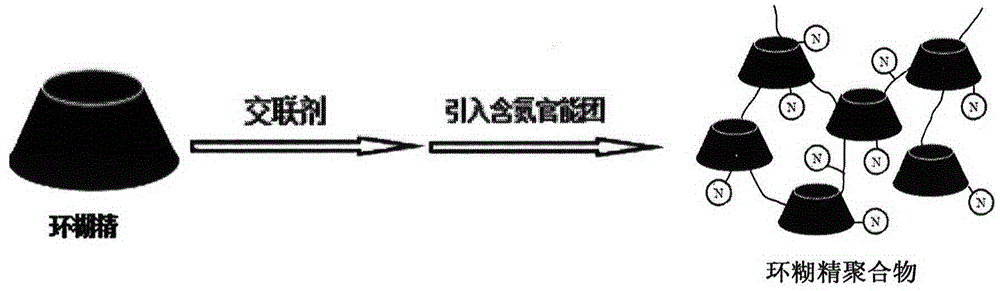

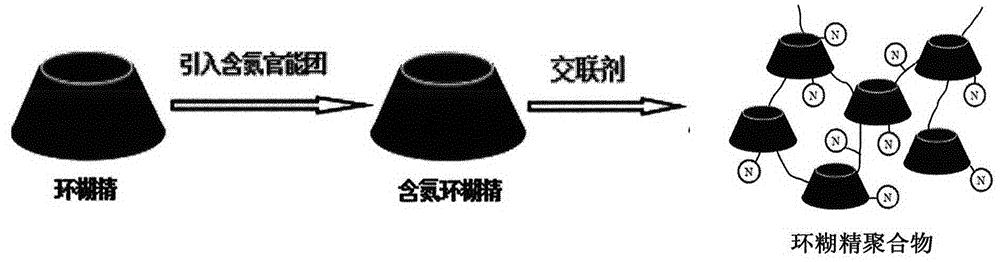

Method used

Image

Examples

Embodiment 1

[0041] Add 25g of β-cyclodextrin, 50ml of water, and 15g of sodium hydroxide into the reaction flask, stir vigorously at room temperature for 4 hours, add 20.35g of epichlorohydrin, continue stirring for 4 hours at room temperature, add acetone to stop the reaction, chromatograph, and neutralize with hydrochloric acid , dialyzed, and concentrated to obtain the β-cyclodextrin polymer.

Embodiment 2

[0043] Weigh 15g of the product of Example 1 into a reaction flask, add 15g of sodium hydroxide, 65ml of N,N-dimethylformamide (DMF), stir at 20°C for 30min, add 4.04g of 4-methyl-benzene dissolved in The solution of sulfonyl chloride in 15ml DMF was stirred at 20°C for 3h, neutralized with HCl, dialyzed, concentrated, and freeze-dried to obtain p-toluenesulfonylated β-cyclodextrin polymer.

Embodiment 3

[0045] Dissolve 5 g of the dried product in Example 2 in 100 ml of N, N-dimethylformamide (DMF), add anhydrous 3 g of NaI, and react for 5 hours under magnetic stirring at 90 ° C. After cooling, rotary evaporation removes the solvent. Wash with acetone to remove excess NaI, dissolve the precipitate in a small amount of water, filter, and wash the filtrate with acetone to obtain a white powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com