Patents

Literature

1218 results about "Lithium cobalt oxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lithium cobalt oxide, sometimes called lithium cobaltate or lithium cobaltite, is a chemical compound with formula LiCoO₂. The cobalt atoms are formally in the +3 oxidation state, hence the IUPAC name lithium cobalt(III) oxide.

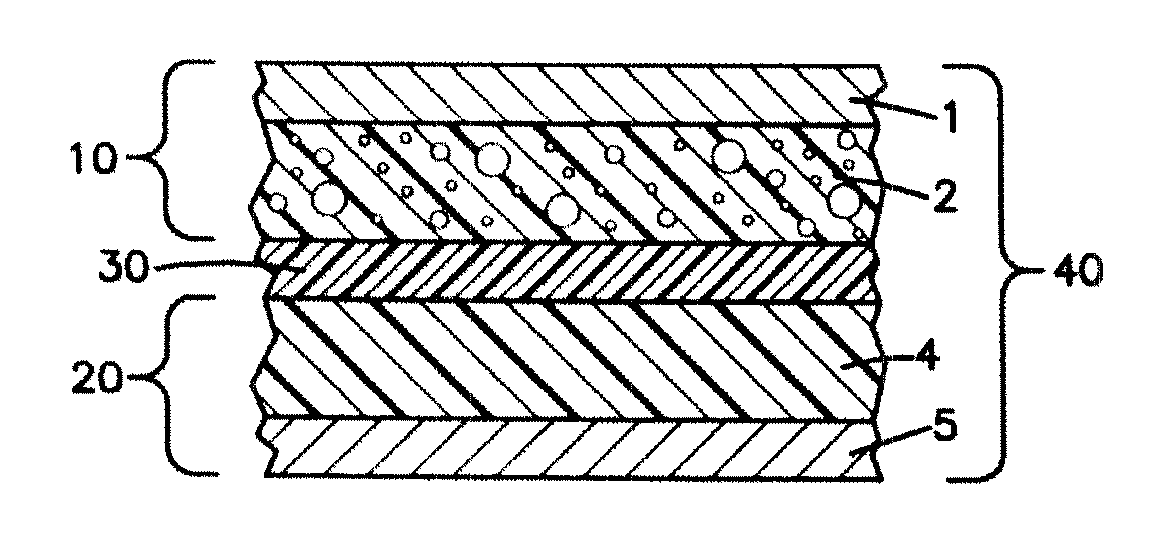

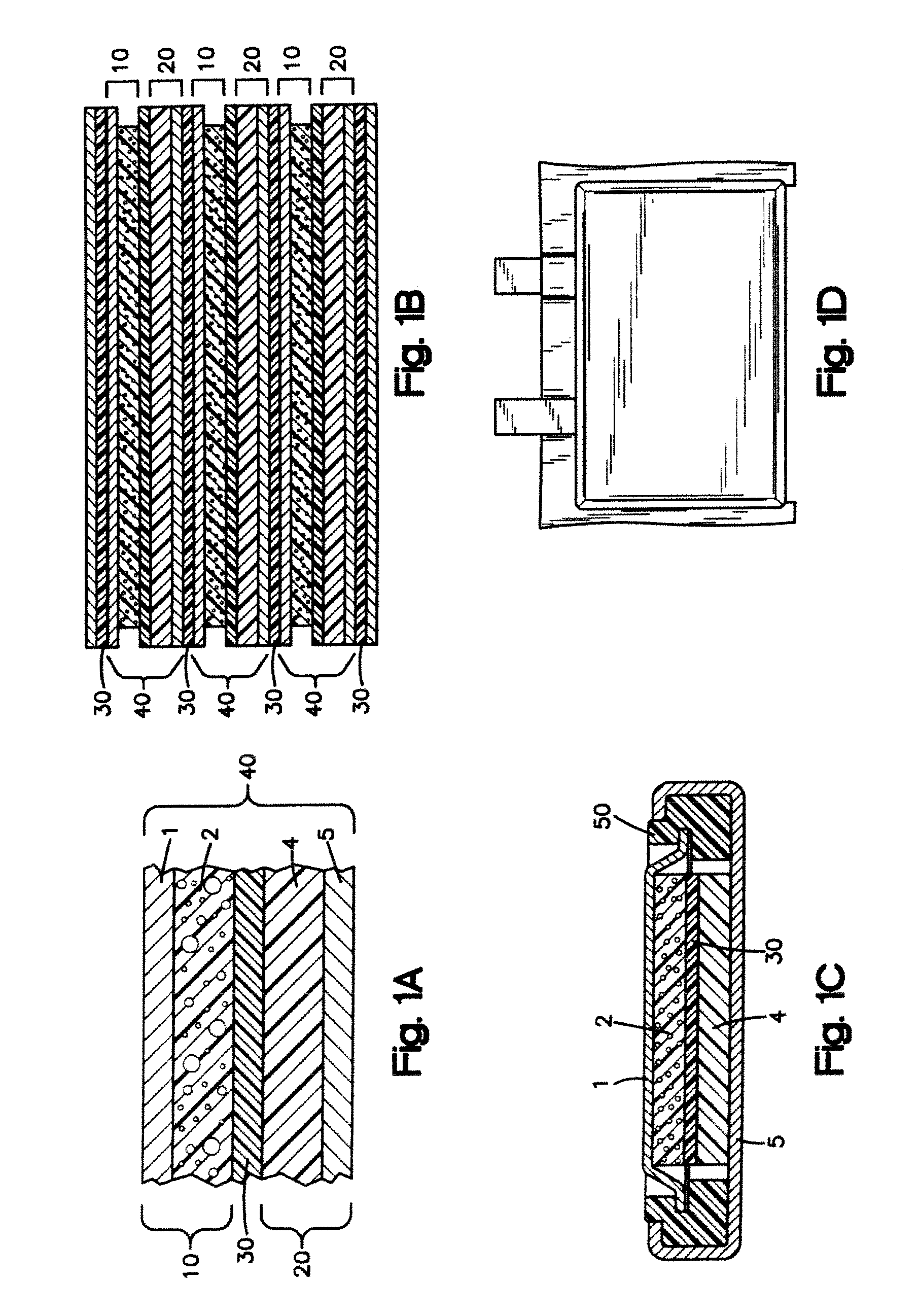

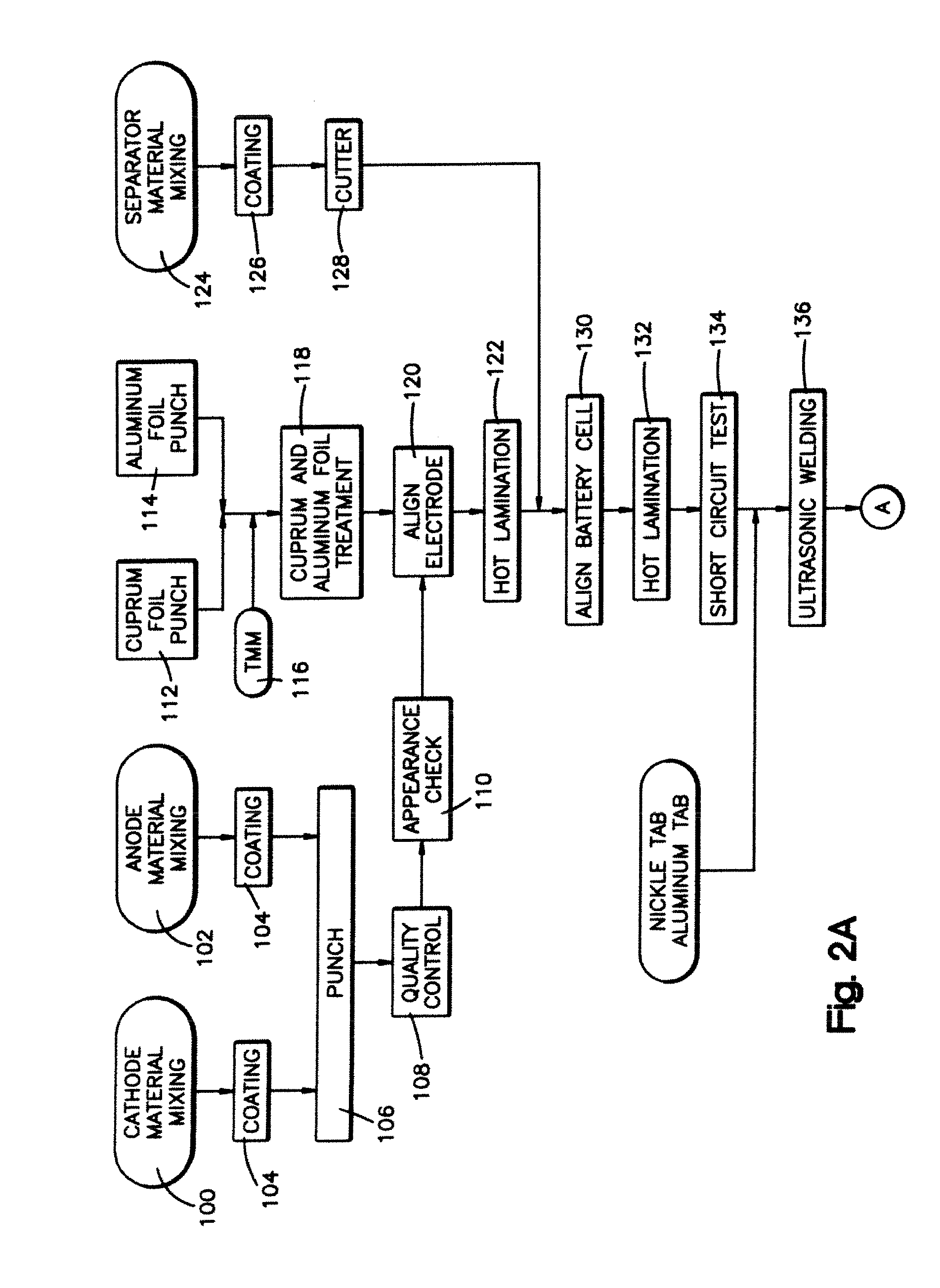

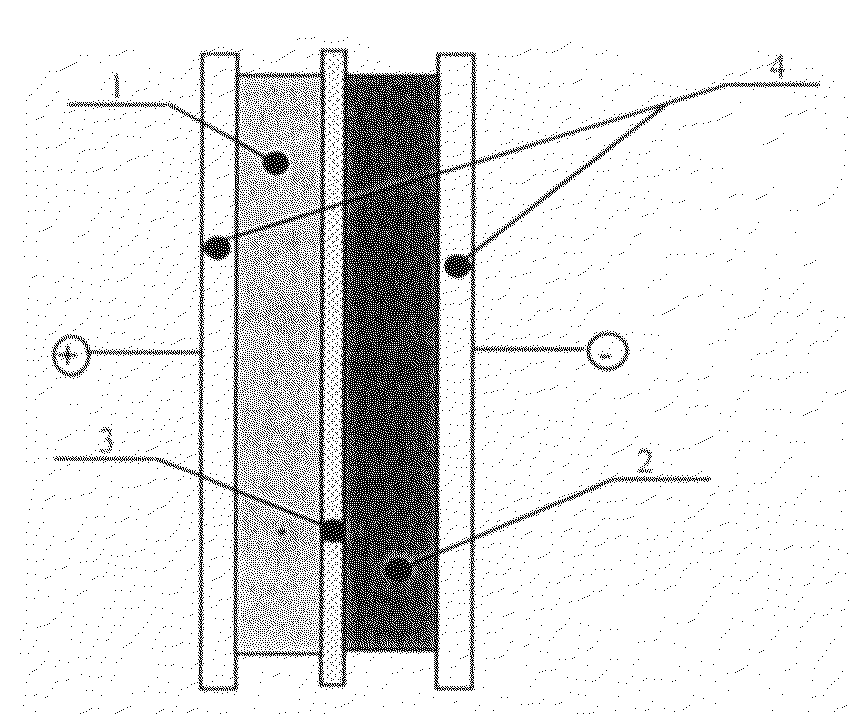

Nano-lithium-ion batteries and methos for manufacturing nano-lithium-ion batteries

The disclosure describes nano-lithium-ion batteries having a cathode, an anode including lithium titanium oxide nanoparticles, a separator including silicon dioxide nanoparticles and an electrolyte. In a preferred embodiment, the cathode is composed of 70-95 wt % lithium cobalt oxide, 1-6 wt % of a conductive carbon, and a synthetic resin including at least one thermoplastic; the anode is composed of 75-90 wt % lithium titanium oxide nanoparticles, 1-5 wt % of a conductive carbon, and a synthetic resin including at least one thermoplastic; and the separator is composed of silicon dioxide nanoparticles and a synthetic resin comprising at least one thermoplastic. The disclosure also describes methods of manufacturing the nano-lithium-ion batteries.

Owner:FU ZHIGUO +2

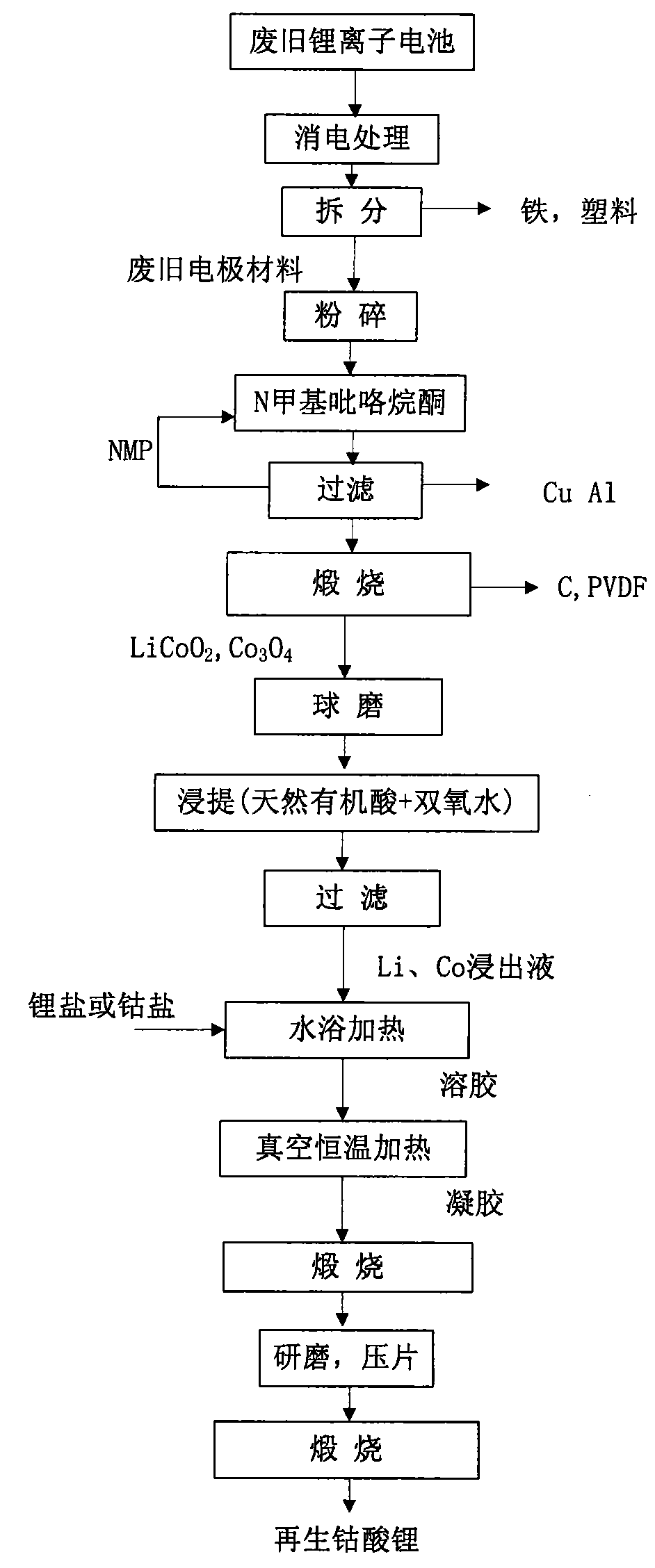

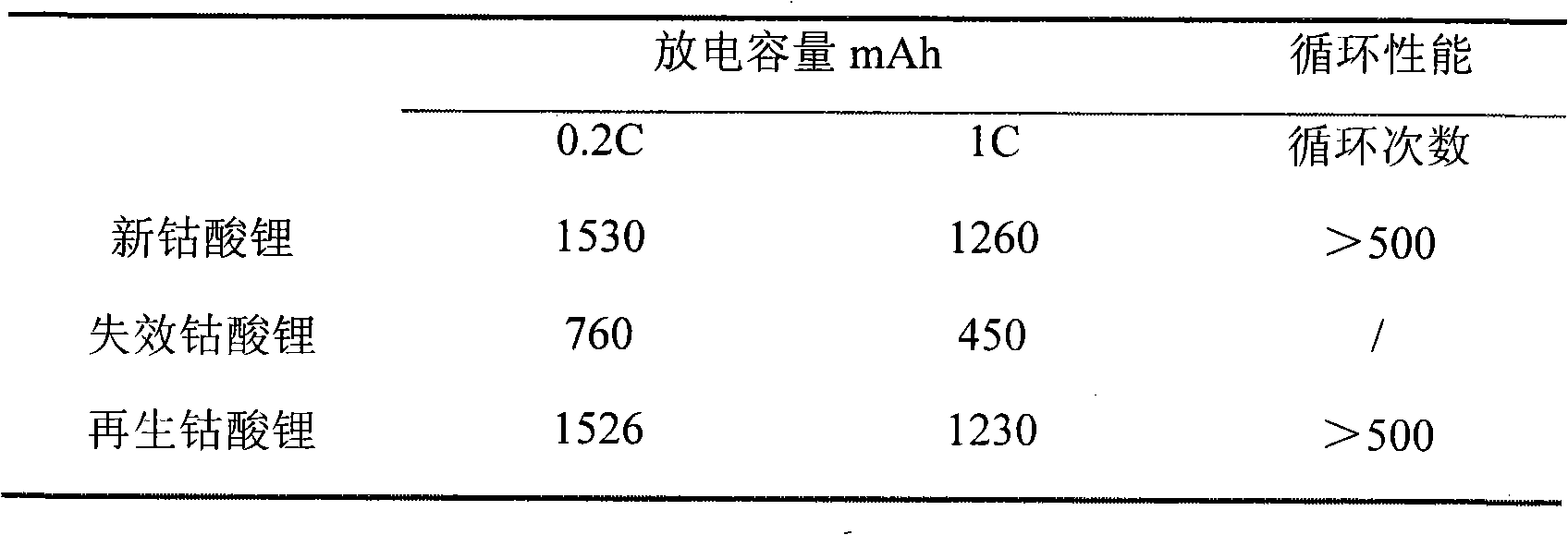

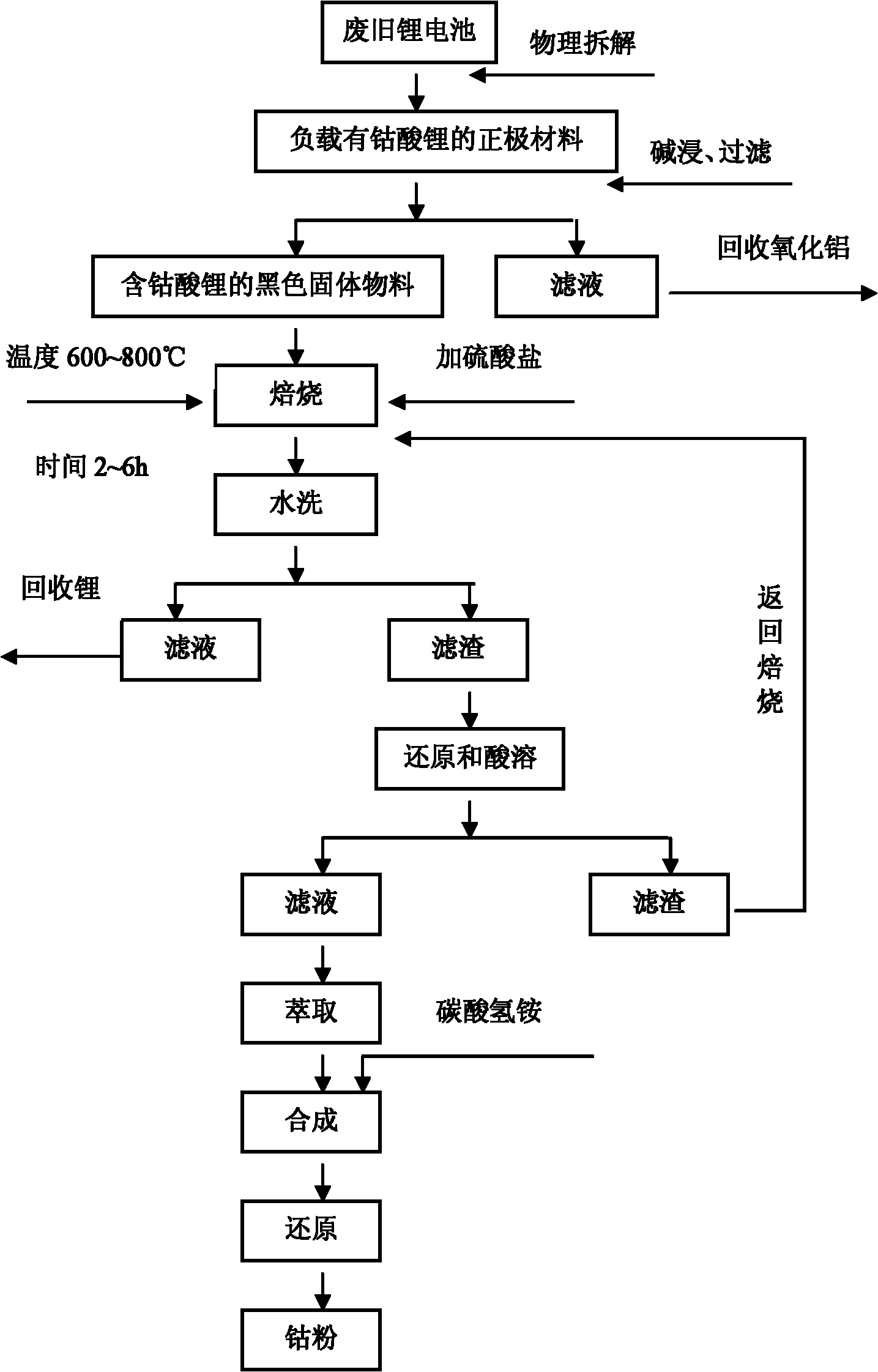

Method for recovering and preparing lithium cobalt oxide by using disused lithium battery

ActiveCN101673859ASolve the hazardSolve resource problemsLithium compoundsWaste accumulators reclaimingWater bathsOrganic acid

The invention relates to a method for recovering and preparing lithium cobalt oxide by using a disused lithium battery, belonging to the technical field of recovery and recycle of electrode materials.The method comprises the steps of: discharging, disassembling, smashing, NMP processing and burning a disused lithium battery sequentially, to obtain a disused LiCoO2 material; ball-milling the disused LiCoO2 material and adding natural organic acid and hydrogen peroxide to obtain a solution of Li<+> and Co<2+>; adding lithium salt or cobalt salt after filtering, and then heating by water bath; dropwise adding ammonia water in the solution to prepare a xerogel; and performing secondary burning to obtain an electrode material of lithium cobalt oxide. The method has the advantages that the electrochemical properties of the electrode material of the disused lithium battery can be recycled with obvious effect as well as simple and easy operation; the natural organic acid used in the process of acid dipping has small damage to apparatus; and the method is environment friendly and efficient, and has low cost, simple technique, high recovery rate and industrialized promotion.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

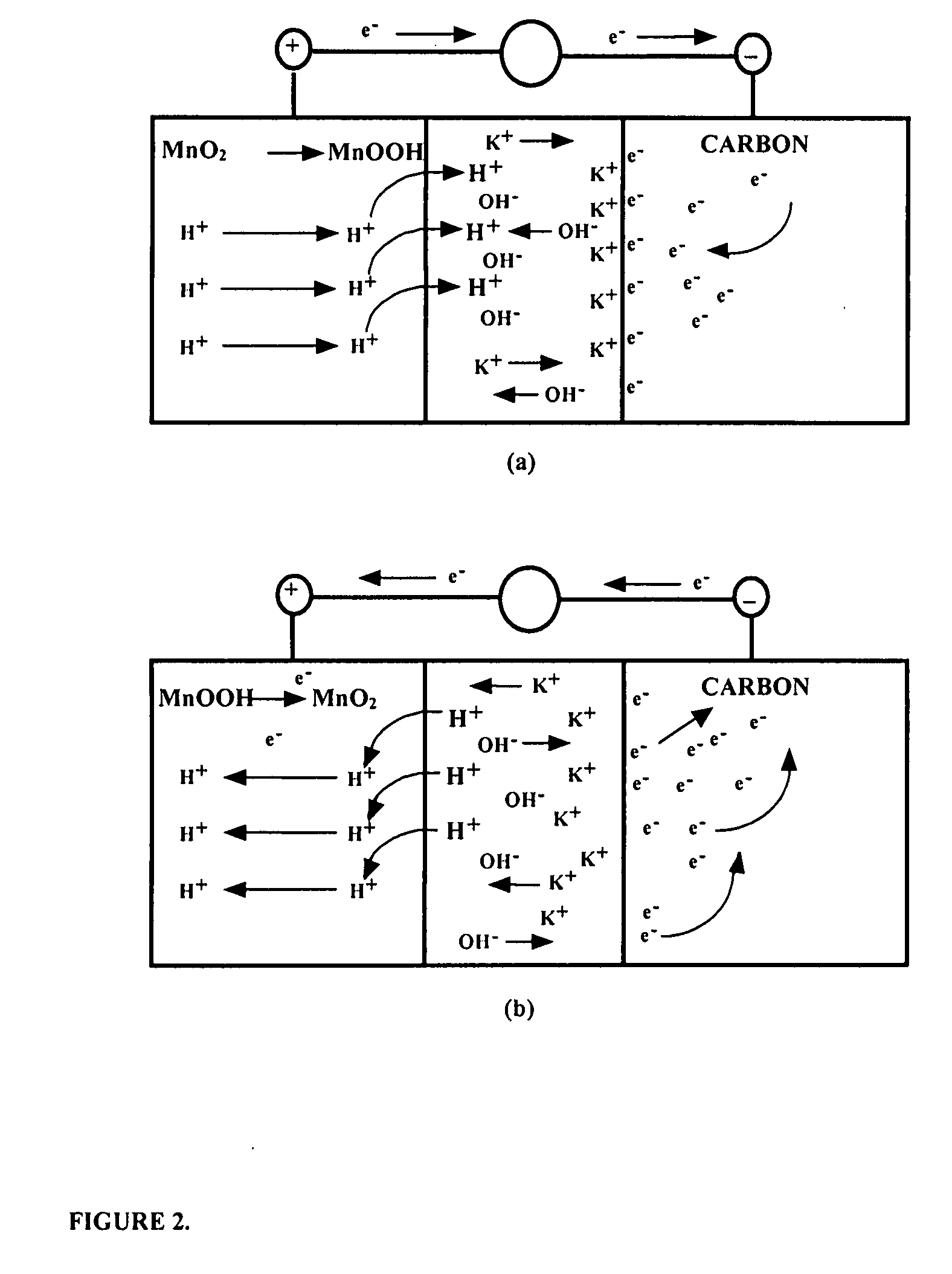

Asymmetric electrochemical supercapacitor and method of manufacture thereof

InactiveUS20080158778A1Increase energy densityImprove power densityHybrid capacitor electrodesLiquid electrolytic capacitorsAqueous electrolyteLithium manganese oxide

Asymmetric supercapacitors comprise: a positive electrode comprising a current collector and a first active material selected from the group consisting of manganese dioxide, silver oxide, iron sulfide, lithium manganese oxide, lithium cobalt oxide, lithium nickel oxide, lithium iron phosphate, and a combination comprising at least one of the foregoing active materials; a negative electrode comprising a carbonaceous active material; an aqueous electrolyte solution selected from the group consisting of aqueous solutions of hydroxides of alkali metals, aqueous solutions of carbonates of alkali metals, aqueous solutions of chlorides of alkali metals, aqueous solutions of sulfates of alkali metals, aqueous solutions of nitrates of alkali metals, and a combination comprising at least one of the foregoing aqueous solutions; and a separator plate. Alternatively, the electrolyte can be a non-aqueous ionic conducting electrolyte or a solid electrolyte.

Owner:U S NANOCORP

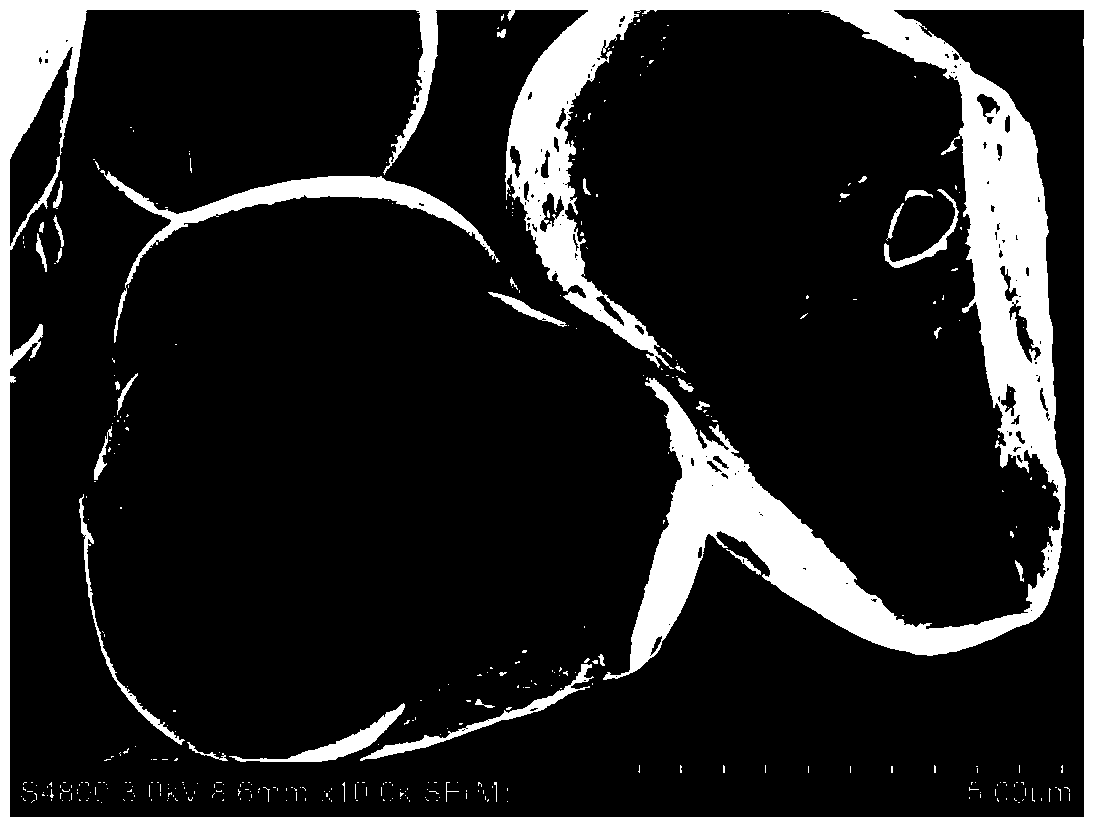

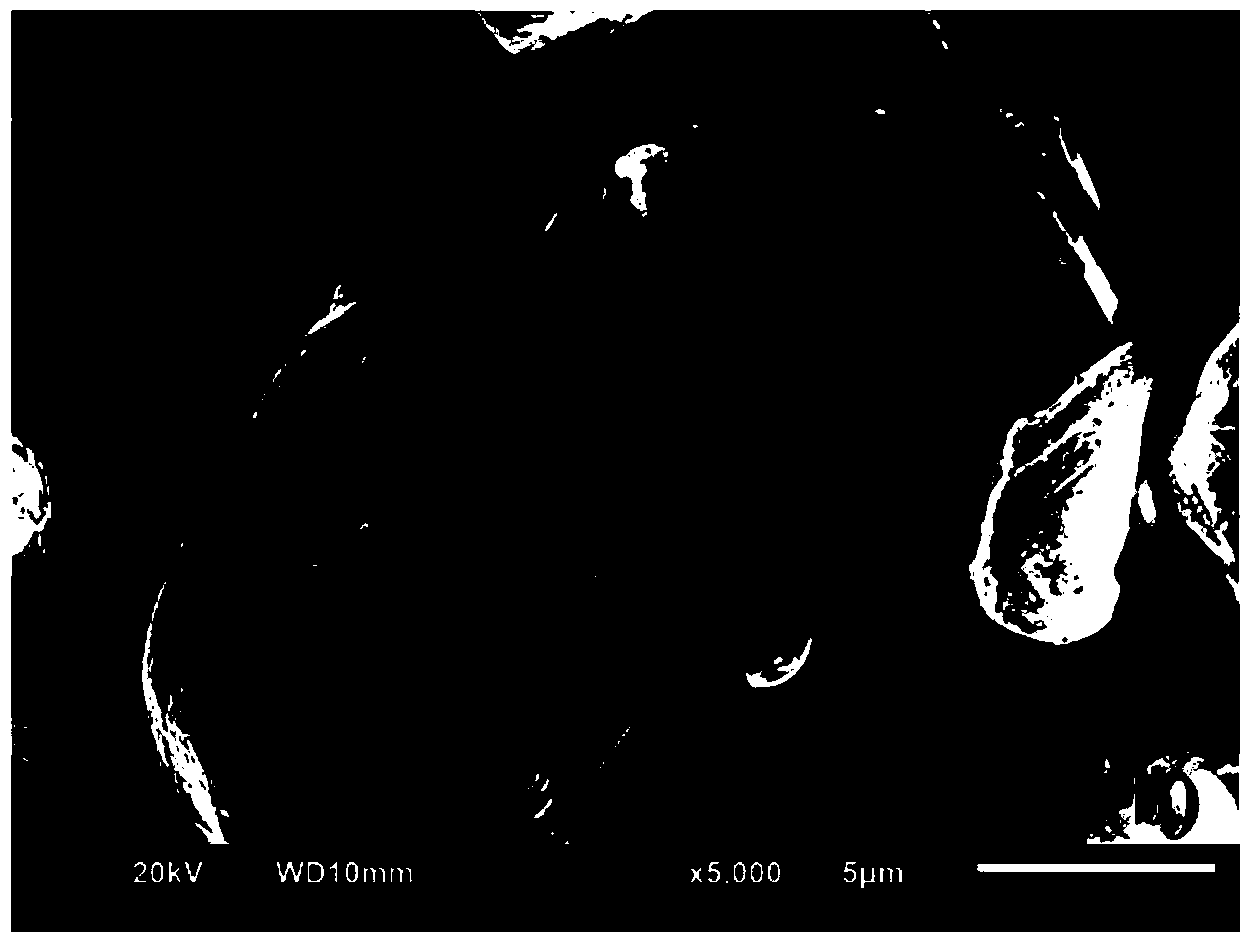

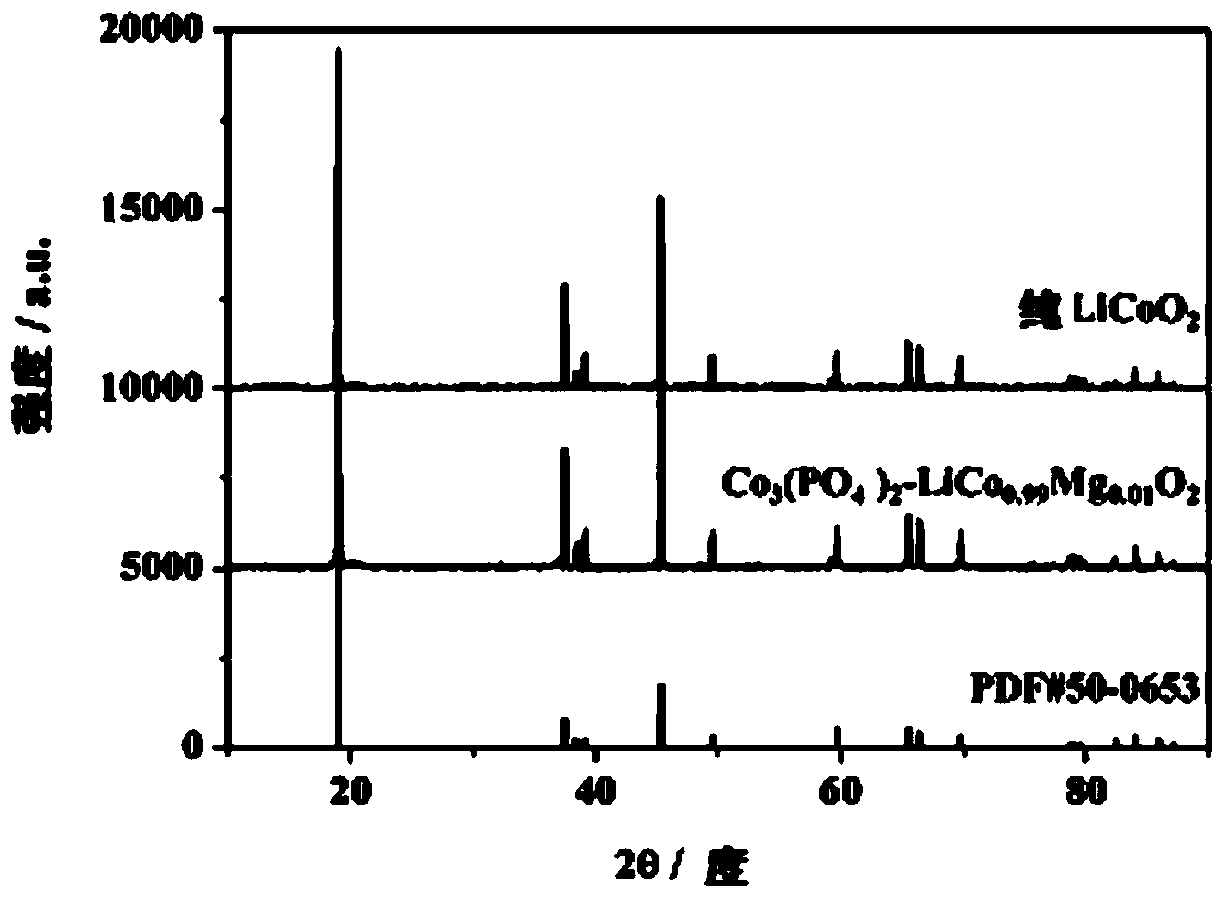

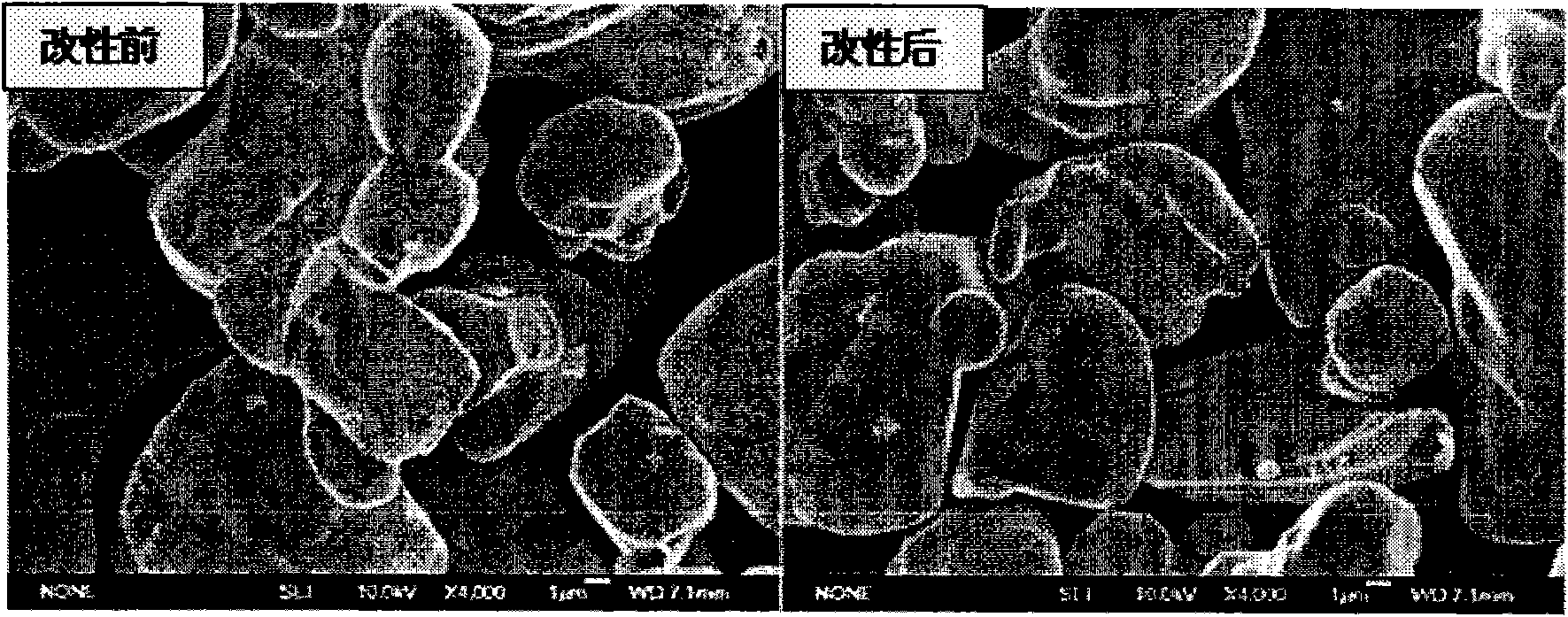

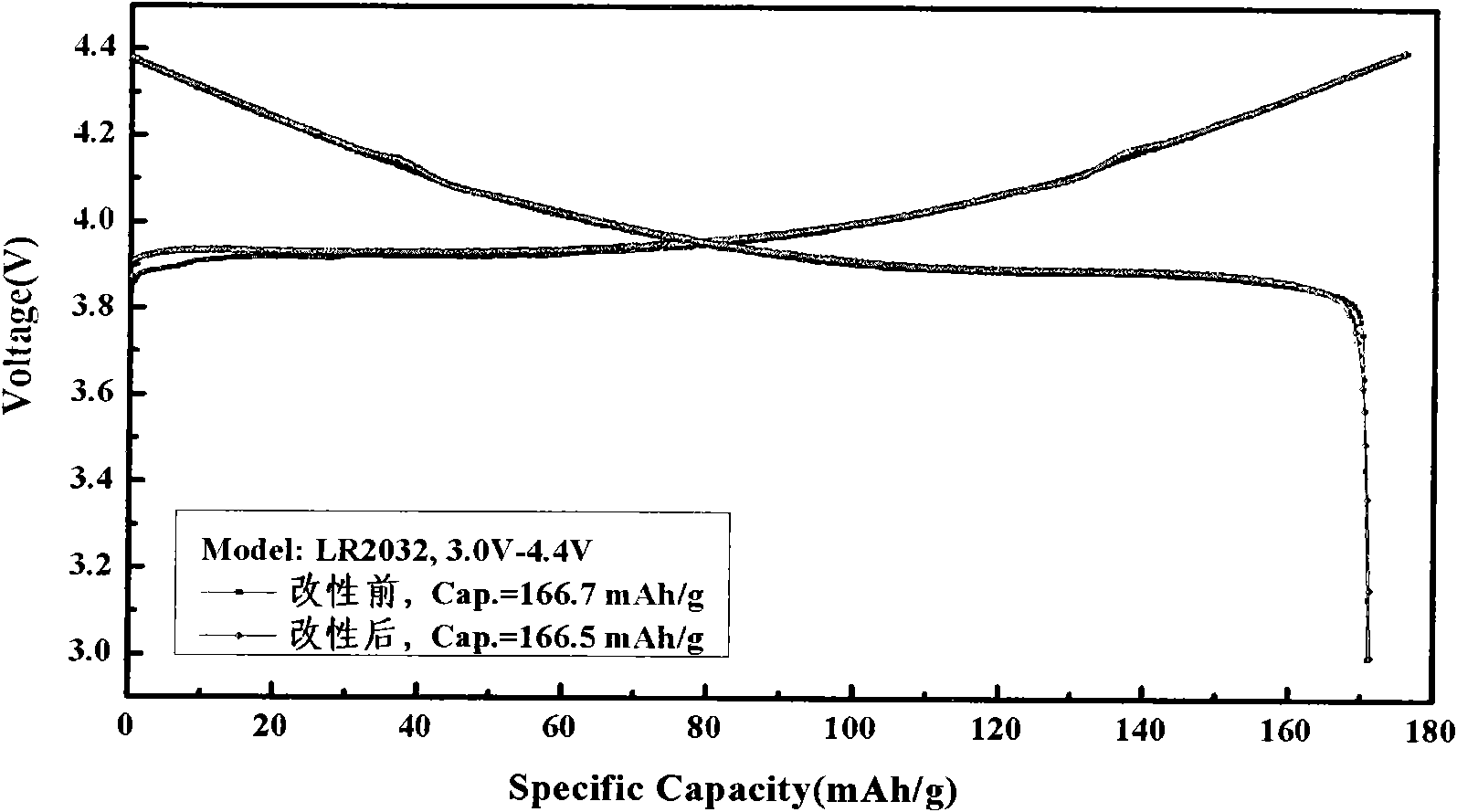

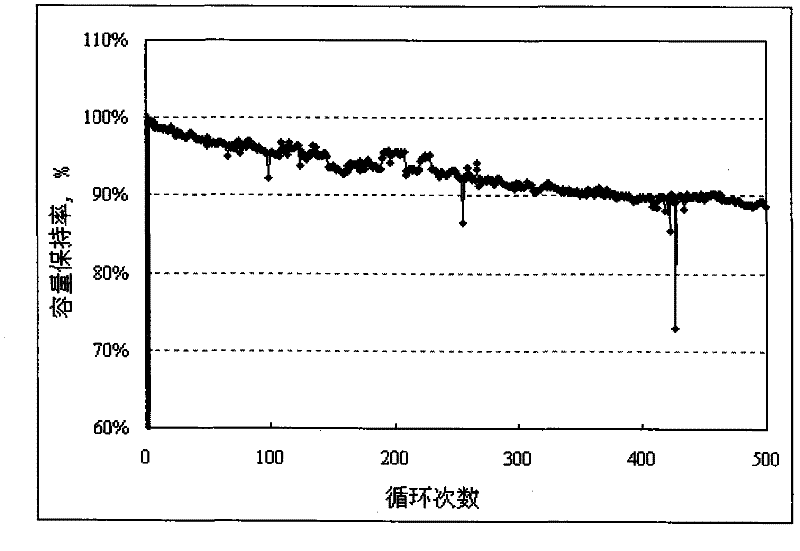

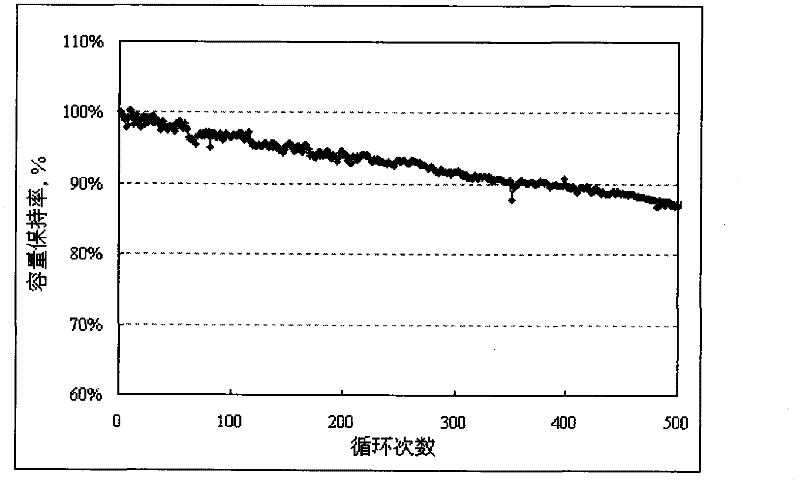

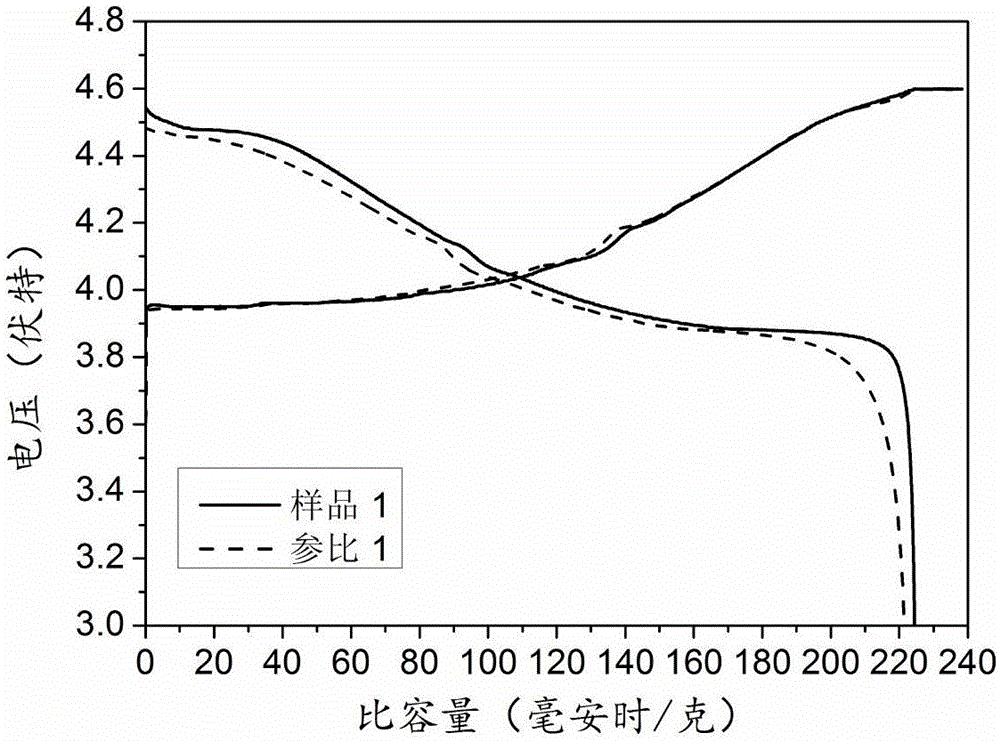

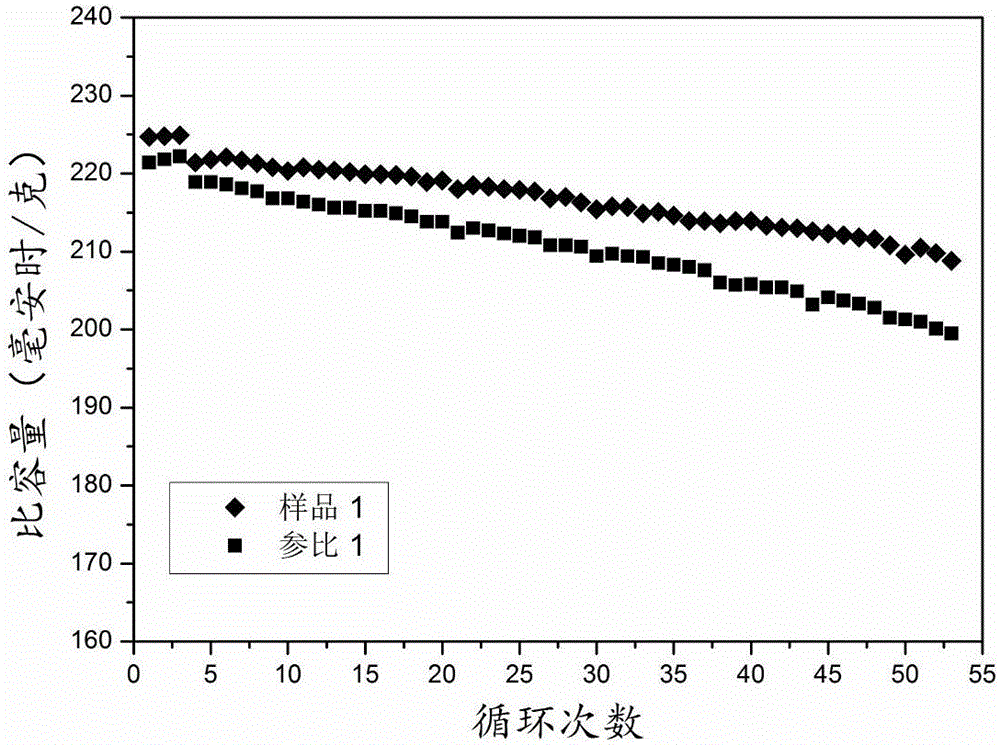

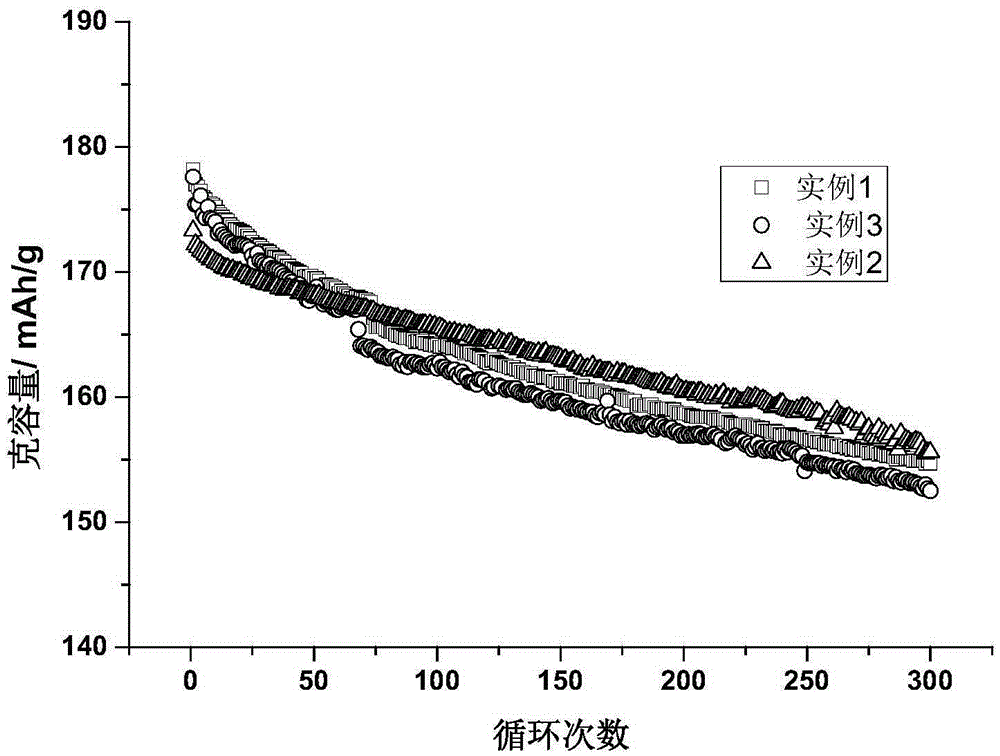

Doped and surface coating co-modified anode material for lithium ion battery and preparation method thereof

InactiveCN103779556APromote circulationEasy to operateSecondary cellsPositive electrodesEnvironmental resistancePhosphate

The invention discloses a doped and surface coating co-modified anode material for a lithium ion battery and a preparation method thereof. The anode material uses doped lithium cobalt oxide as a matrix, the surface of which is coated with Co3(PO4)2, AlPO4, Mn3(PO4)2, FePO4, Ni3(PO4)2, Mg3(PO4)2 and other phosphates, therefore, the electric conductivity, the circulating performance, the high temperature and high pressure resistance and other performances are improved. The preparation method has the advantages that the coating material is uniformly coated on the surface of the anode material to be beneficial to improving the electrochemical performance; the method is simple to operate, is green and environment-friendly and has industrial applicability.

Owner:北京盟固利新材料科技有限公司

All-solid state lithium ion battery composite positive electrode material and preparation method thereof, and all-solid state lithium ion battery

ActiveCN103633329AImprove cycle lifeImprove discharge capacityCell electrodesSecondary cellsSolid state electrolyteTitanium disulfide

Embodiments of the present invention provide an all-solid state lithium ion battery composite positive electrode material, which comprises a positive electrode active material and a cladding layer arranged on the surface of the positive electrode active material, the positive electrode active material is one or a plurality of materials selected from a lithium cobalt oxide, lithium nickelate, lithium manganate, lithium iron phosphate, lithium nickel cobalt manganese, vanadium pentoxide, molybdenum trioxide and titanium disulfide, and the cladding layer material is one or a plurality of lithium-containing transition metal oxides. According to the present invention, with the cladding layer, formation of the space charge layer can be effectively inhibited, the electrode / inorganic solid state electrolyte interface can be improved, and the interface resistance of the all-solid state lithium ion battery can be easily reduced so as to improve cycle stability and durability of the all-solid state lithium ion battery. Embodiments of the present invention further provide a preparation method for the all-solid state lithium ion battery composite positive electrode material, and an all-solid state lithium ion battery containing the all-solid state lithium ion battery composite positive electrode material.

Owner:泰州市海通资产管理有限公司

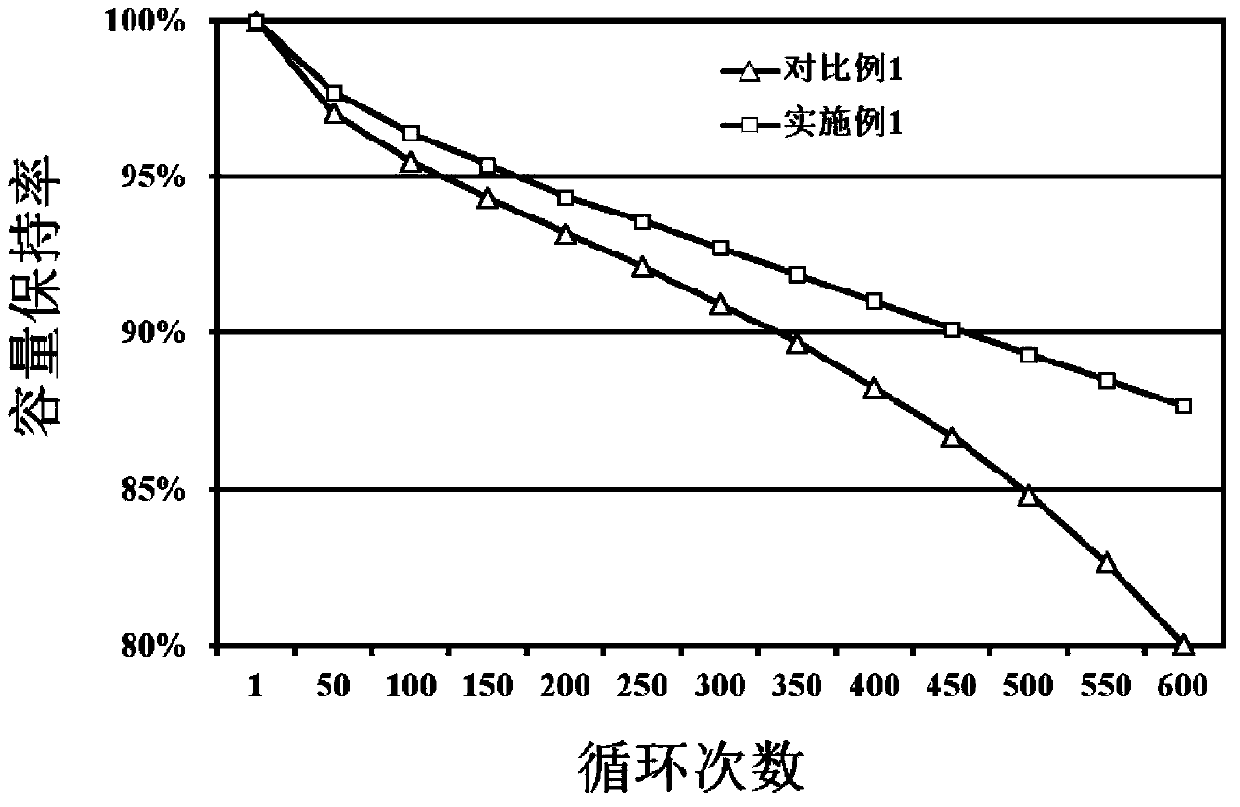

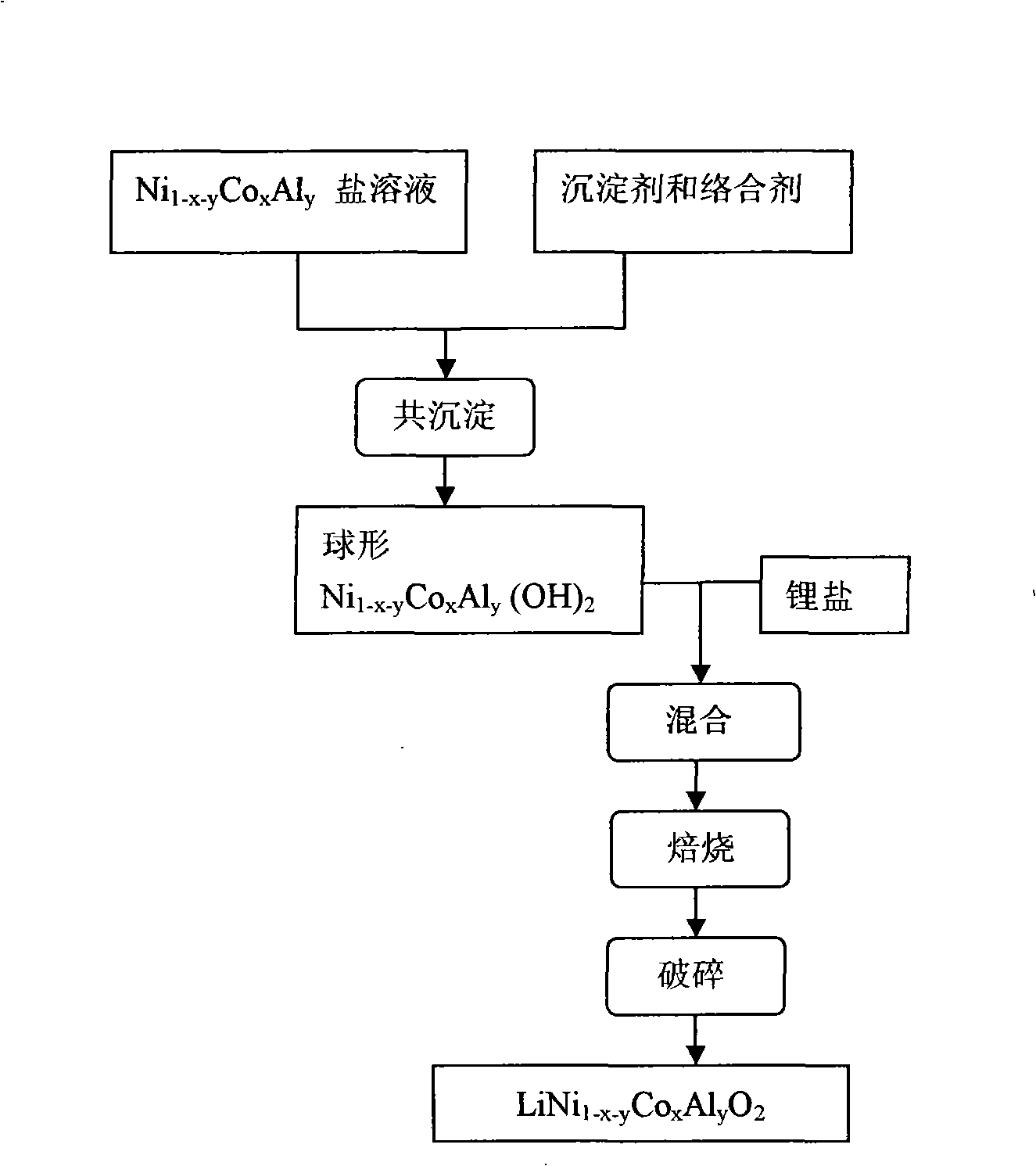

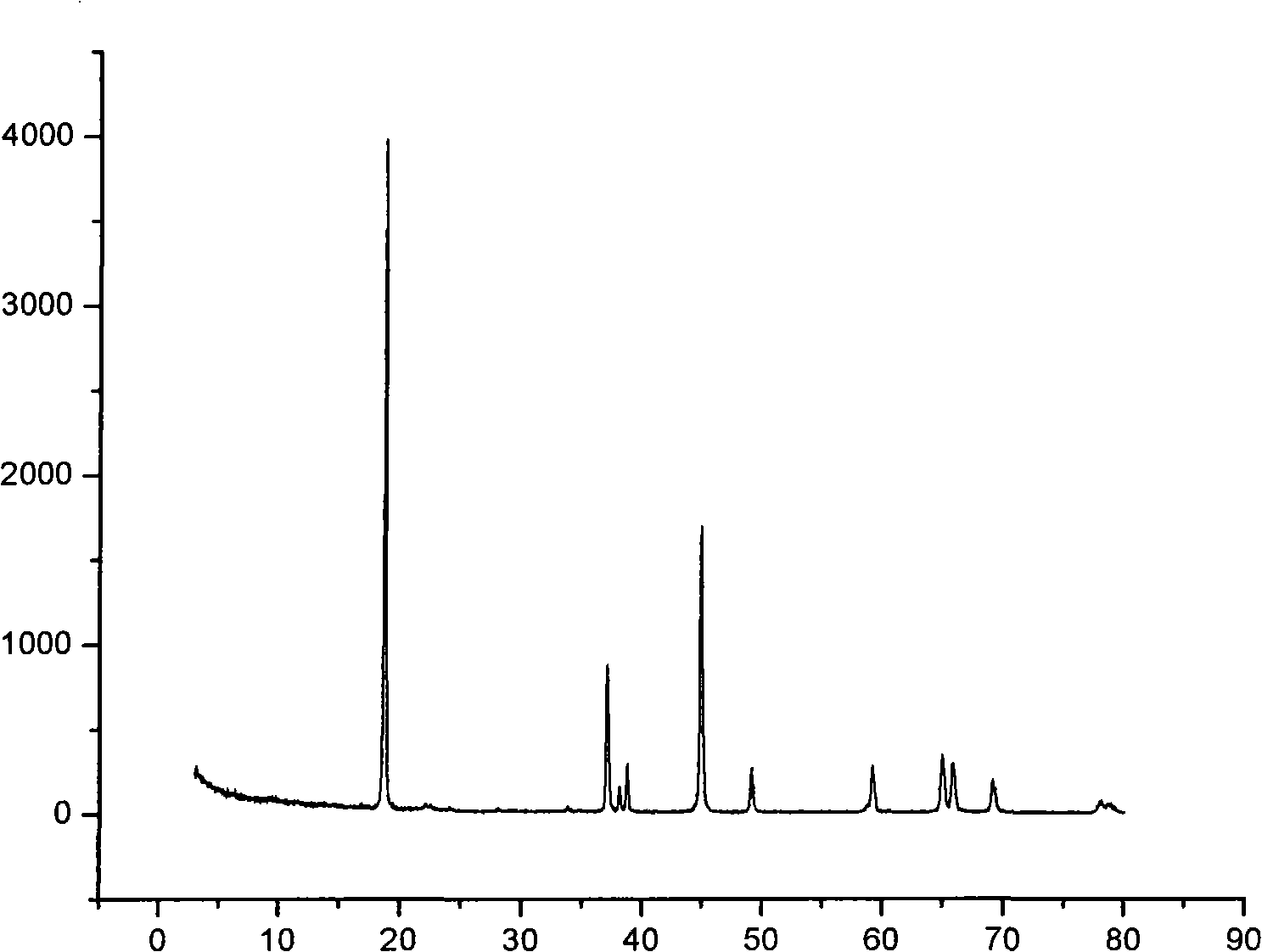

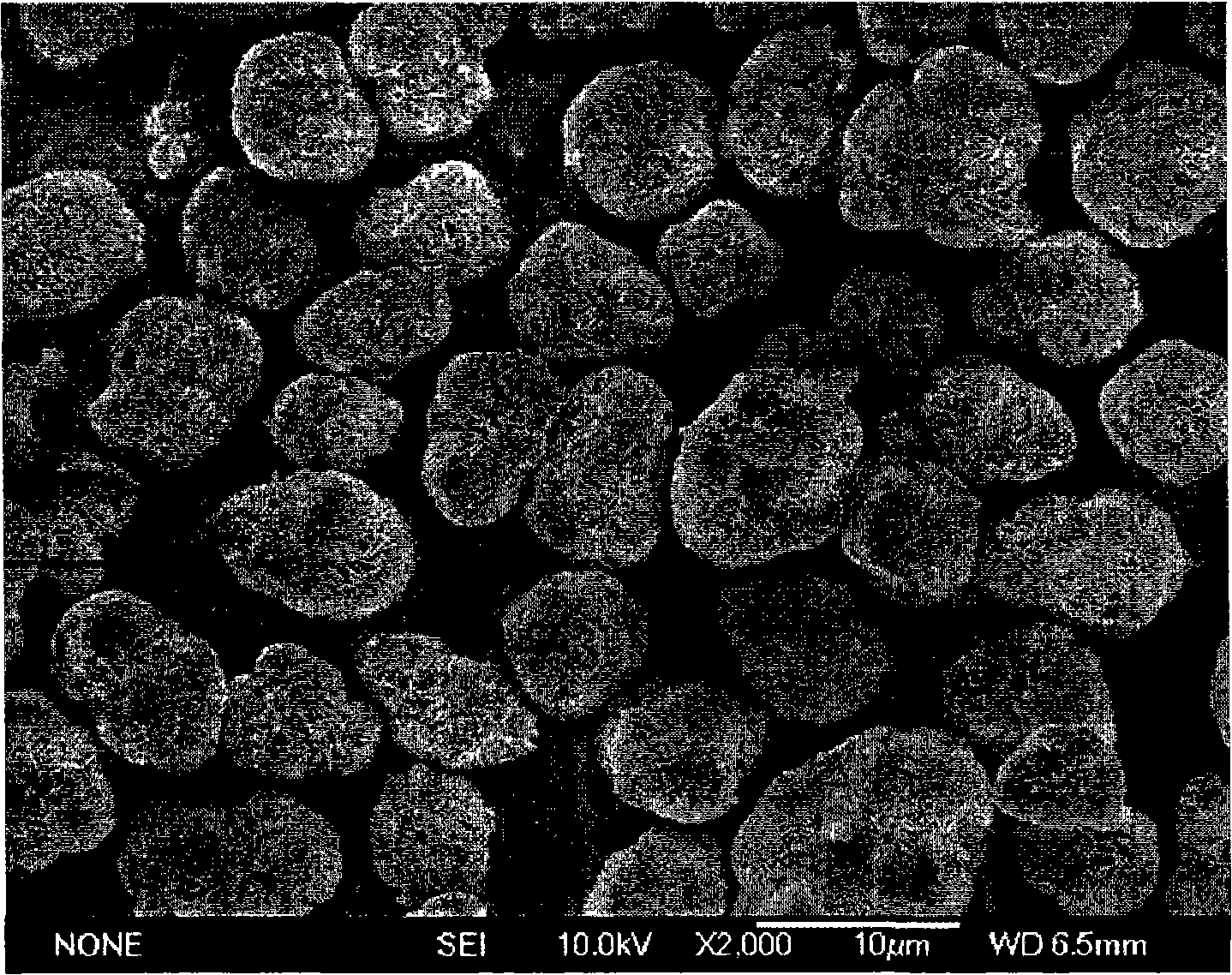

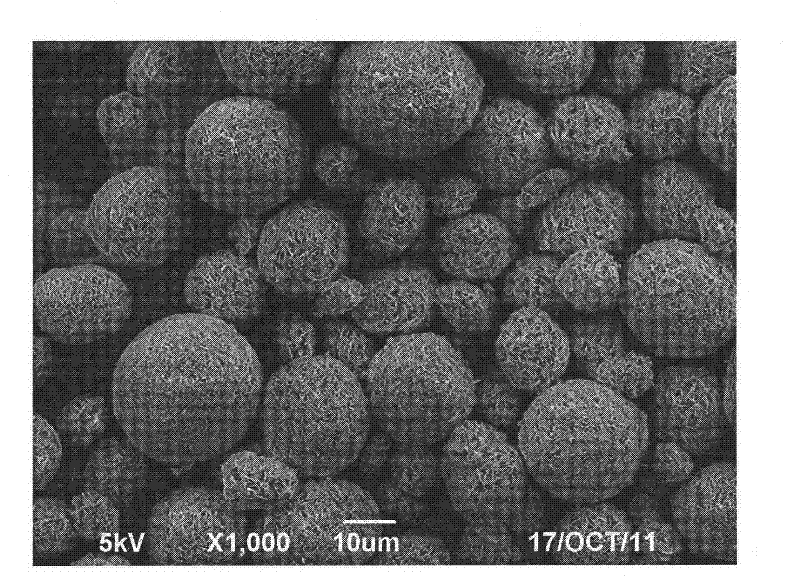

Spherical aluminum-doped nickel cobalt lithium for lithium ion battery and its making method

ActiveCN101262061AImprove liquidityImprove charge and discharge cycle stabilityElectrode manufacturing processesLithium compoundsDischarge efficiencyHigh rate

The invention discloses a preparation method of a spherical doped Al-Ni lithium cobalt oxide for lithium-ion battery. The preparation steps are that: first, sulfate, nitrate or chlorate of Al-Ni-Co react with strong alkali that is added with complex agent in liquid phase; the pH value, the temperature and the feeding speed of the reaction solution are controlled so as to produce a spherical precursor of Al-Ni-Co hydroxide; then the spherical precursor of Al-Ni-Co hydroxide is dried and evenly mixed with lithium hydroxide, lithium nitrate or lithium carbonate and dried; the obtained mixture is roasted into a spherical doped Al-Ni lithium cobalt oxide. The spherical doped Al-Ni lithium cobalt oxide has comparatively high tap density and remarkable cycle stability in the process of high-rate charge / discharge cycle, which improves over charge performance of Ni-Co substance and first obviously enhances charge / discharge efficiency; in addition, the preparation method of the spherical doped Al-Ni lithium cobalt oxide has the advantages of being simple, controllable and suitable for industrialized production with low energy consumption, high efficiency, short reaction time and low cost.

Owner:成都巴莫科技有限责任公司

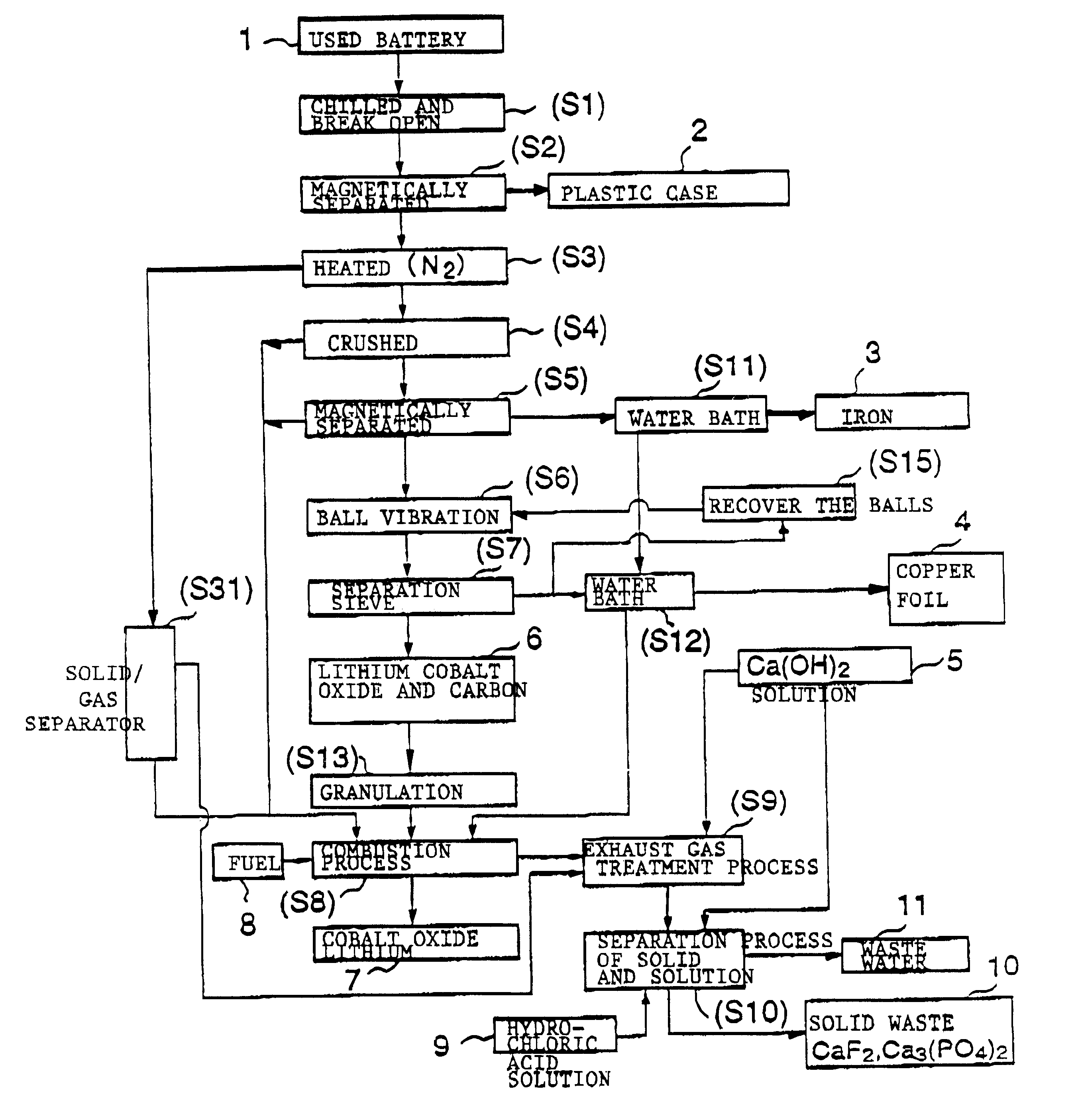

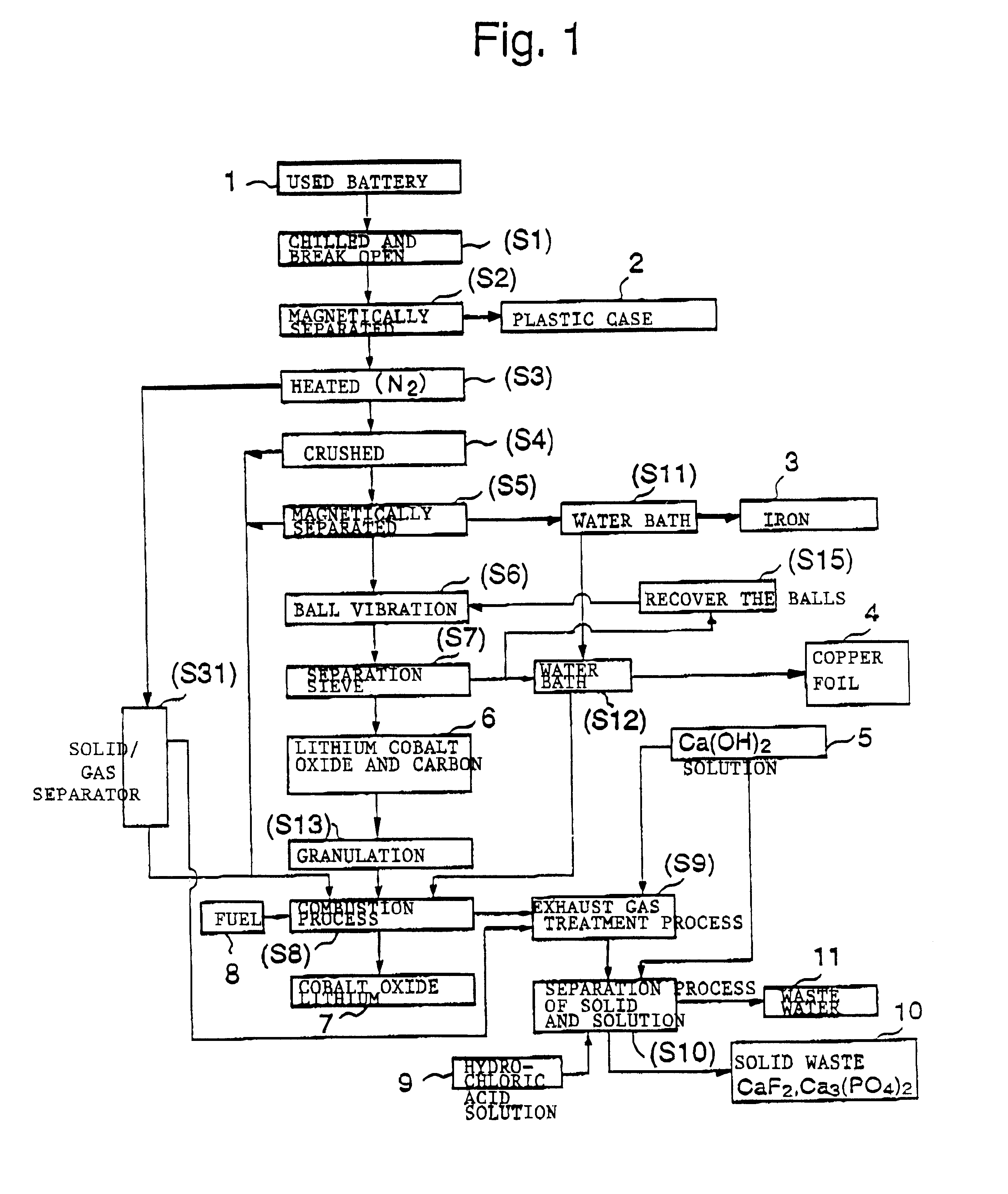

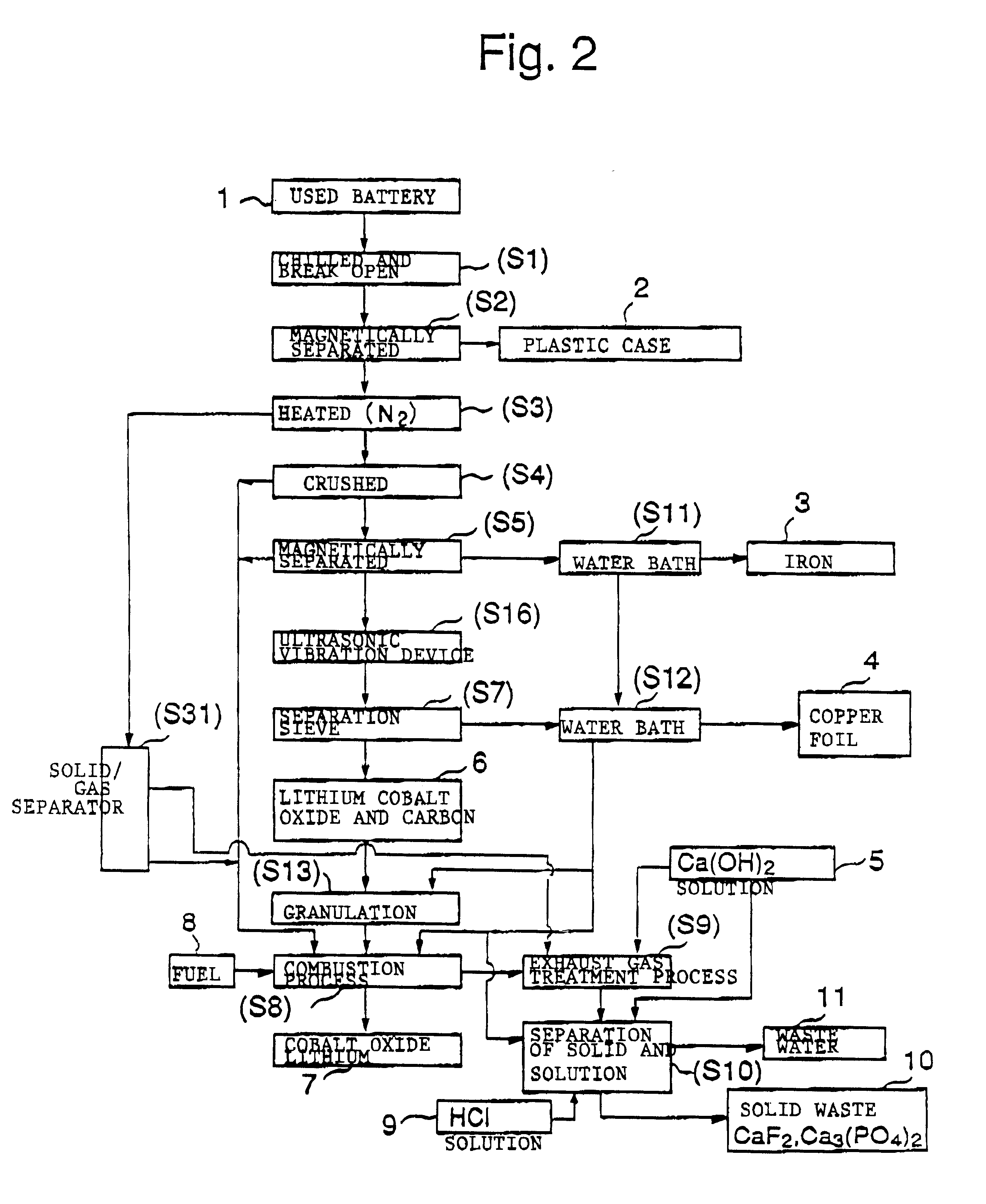

Method for crushing cell

InactiveUS6524737B1Non-aqueous electrolyte accumulatorsPrimary cell maintainance/servicingEngineeringCopper

This invention provides a safe and efficient method of dismantling used lithium ion batteries. More specifically, the plastic cases which protect sealed battery cells are removed from the system in a stable and reliable fashion. Valuable materials such as lithium cobalt oxide, an oxide of a lithium-transition metal compound, aluminum and copper must be separated and recovered. The invention is distinguished by the fact that it entails the following processes. In the crushing process, the batteries are chilled to a temperature of -50° C. or lower. In this state they are repeatedly subjected to vibration and pressure by a number of objects whose rigidity and specific gravity are greater than those of the plastic. In this way the batteries are separated into sealed battery cells and plastic cases. In the heating process, the sealed battery cells separated in the process are heated to a temperature of at least 200° C. in a non-oxidizing atmosphere to separate mainly the organic materials. Finally, in one or more separation processes, the useless materials are removed and the targeted valuable materials are separated in a sequential fashion from the crushed fragments produced in the crushing process.

Owner:MITSUBISHI HEAVY IND LTD

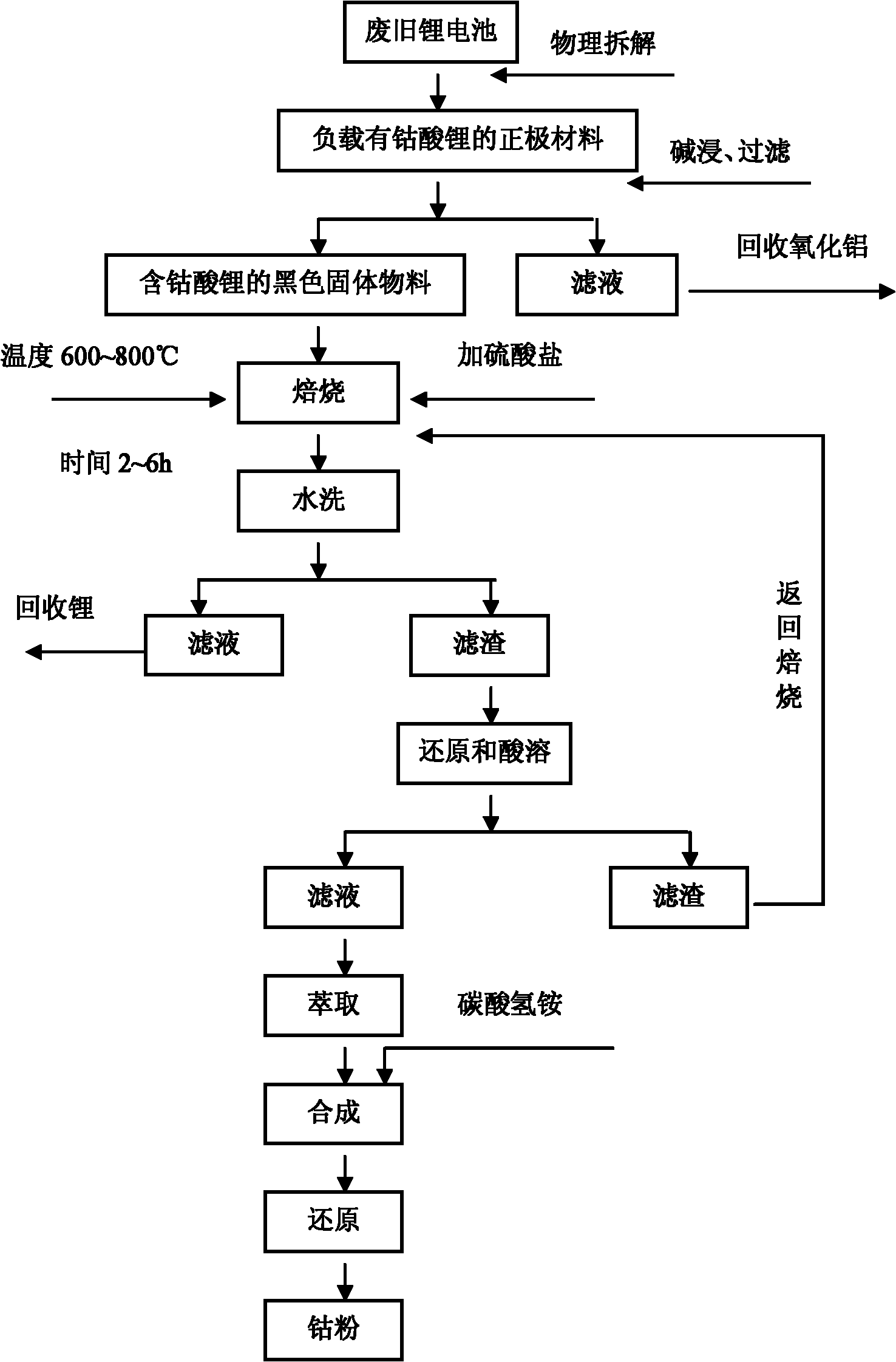

Method for separating and recovering lithium and cobalt from positive electrode material of lithium battery

ActiveCN102163760AAchieve recyclingReduce or eliminate adverse effectsWaste accumulators reclaimingProcess efficiency improvementLithiumSocial benefits

The invention provides a method for separating and recovering lithium and cobalt from a positive electrode material of a lithium battery. The method comprises the following: (1) a step of physical disassembly and alkaline leaching; (2) a step of roasting and washing, namely adding sulfate into a black solid material containing lithium cobalt oxide obtained in the step (1) in the weight ratio of the black solid material to the sulfate being 1:(0.8-1.2), mixing, roasting for 2 to 6 hours at a temperature of between 600 and 800 DEG C, cooling, adding a cleaning solution in terms of the ratio of solid to liquid being 1:(3-5) to wash, agitating for 1 to 2 hours at a temperature of between 60 and 80 DEG C and filtering to obtain Li<+>-containing filtrate and filter residue containing lithium and a small amount of cobalt; (3) a step of reducing and acid saluting; and (4) a step of extracting the cobalt to obtain pure Co2<+> solution. By the method, high recovery ratios of the metal lithium and the metal cobalt are achieved, the recovery ratio of the lithium is over 90 percent, the obtained lithium and the obtained cobalt have high purity, the content of the lithium mixed in the cobalt isgreatly reduced, and the purity of the cobalt can reach over 99.5 percent. Therefore, the method has higher economic benefits and social benefits.

Owner:JINGMEN GEM NEW MATERIAL +1

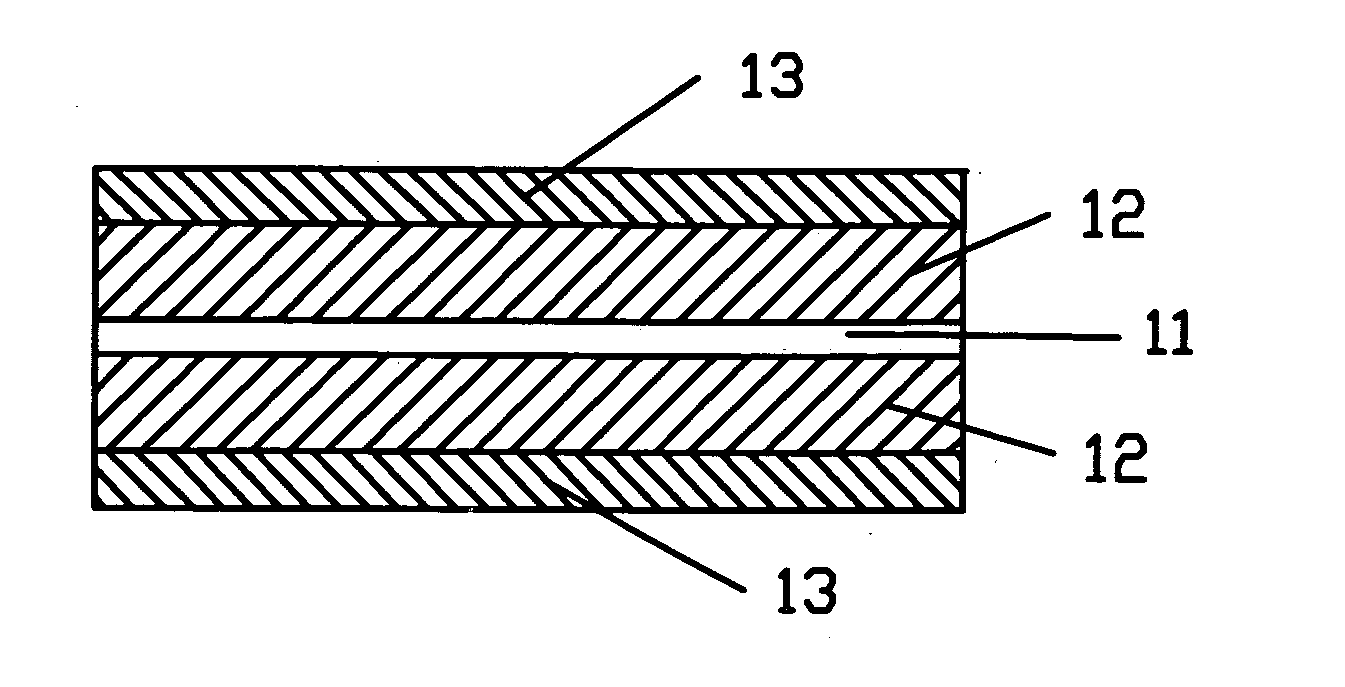

Positive electrodes for lithium batteries and their methods of fabrication

InactiveUS20050186474A1Low costImprove cycle performanceSecondary cellsPositive electrodesSpinelLithium manganese oxide

The present invention discloses positive electrodes and their methods of fabrication. These electrodes are low in cost. Lithium rechargeable batteries that use these positive electrodes have excellent cycling properties at high temperature. The positive electrode of the embodiments of this invention comprises of a current collector coated by two layers of active materials for positive electrodes. The active material for the first layer of coating is one or more active materials selected from the following: spinel lithium manganese oxide, and spinel lithium manganese oxide derivatives. The active material for the second layer of coating is one or more active material selected from the following: lithium cobalt oxide, lithium cobalt oxide derivatives, lithium nickel oxide, and lithium nickel oxide derivatives. To fabricate these positive electrodes, a first layer of coating comprising of the active materials stated above is applied onto a current collector and then dried before a second layer of coating is applied onto the surface of the first layer of coating. The positive electrode is obtained after the current collector with the two layers of coating is dried a second time and then pressed to form a slice.

Owner:BYD AMERICA CORP

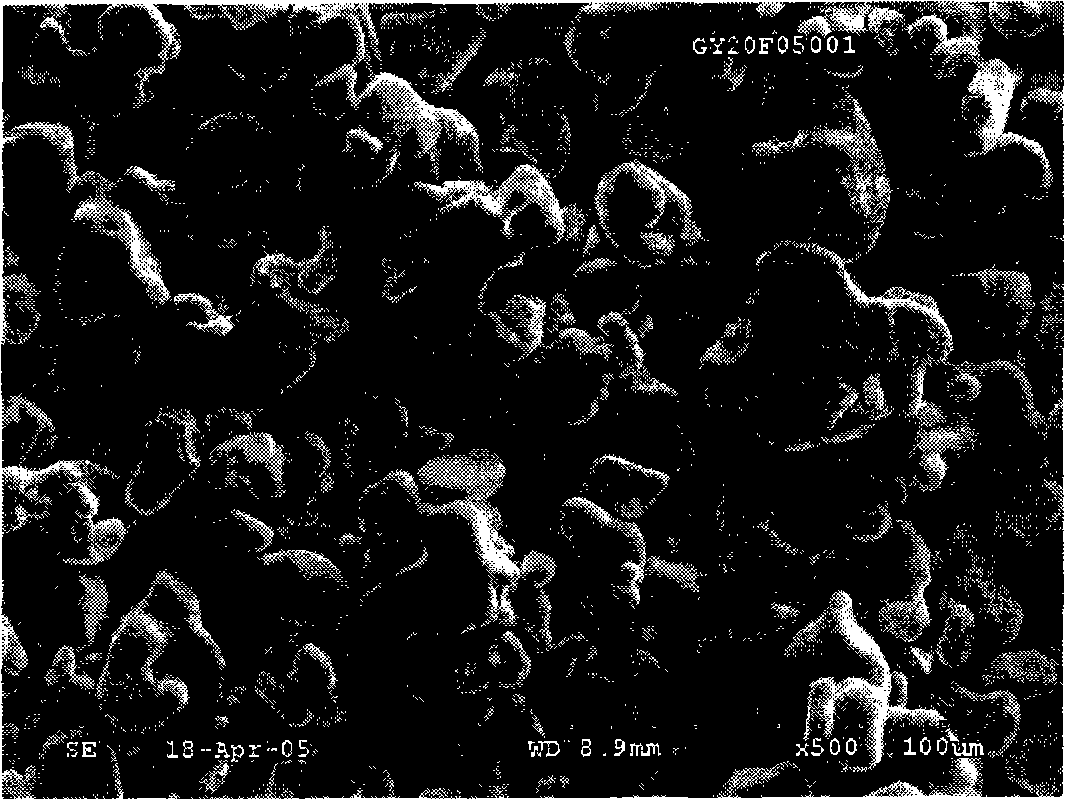

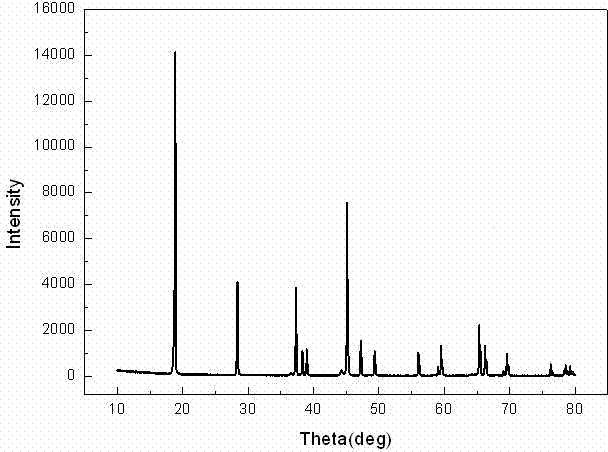

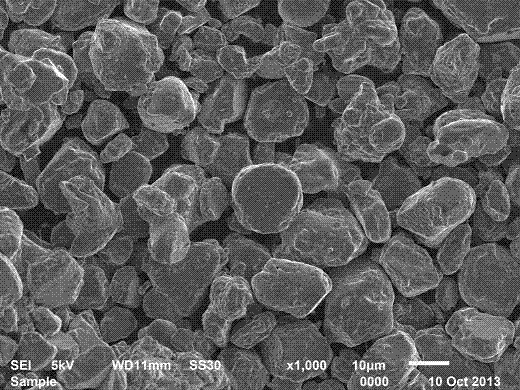

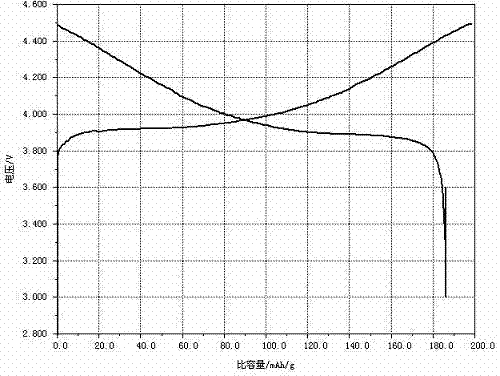

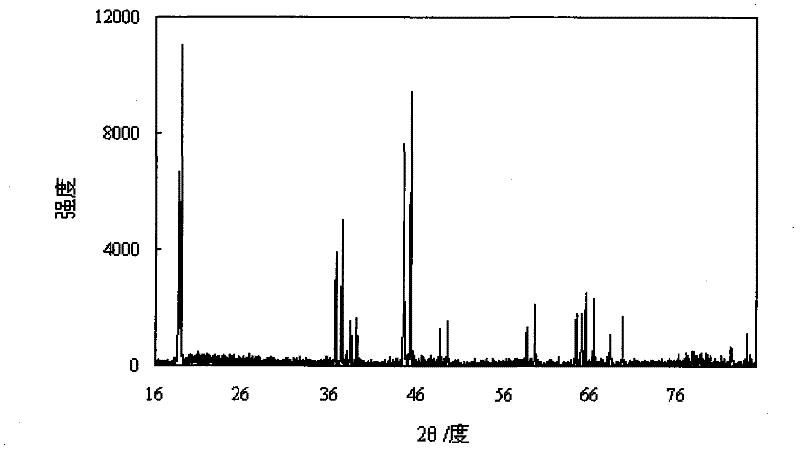

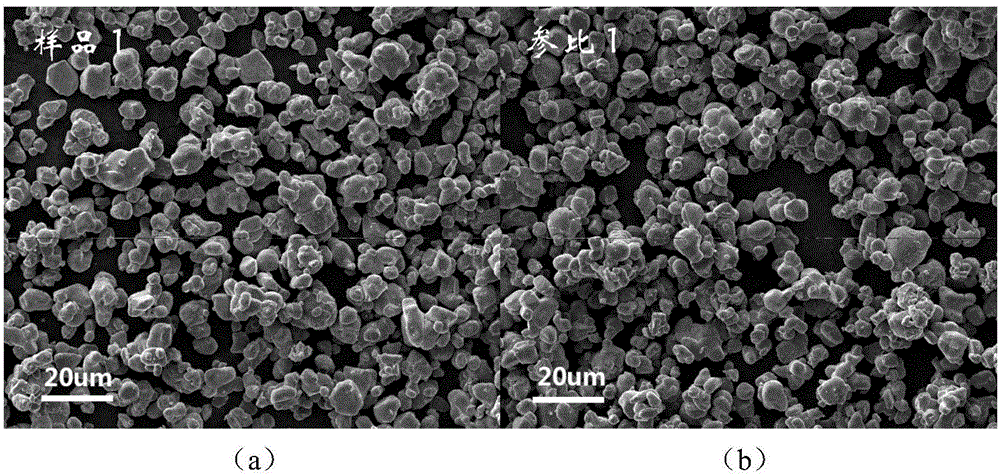

Super-size and high-density lithium cobalt oxide and method for preparing the same

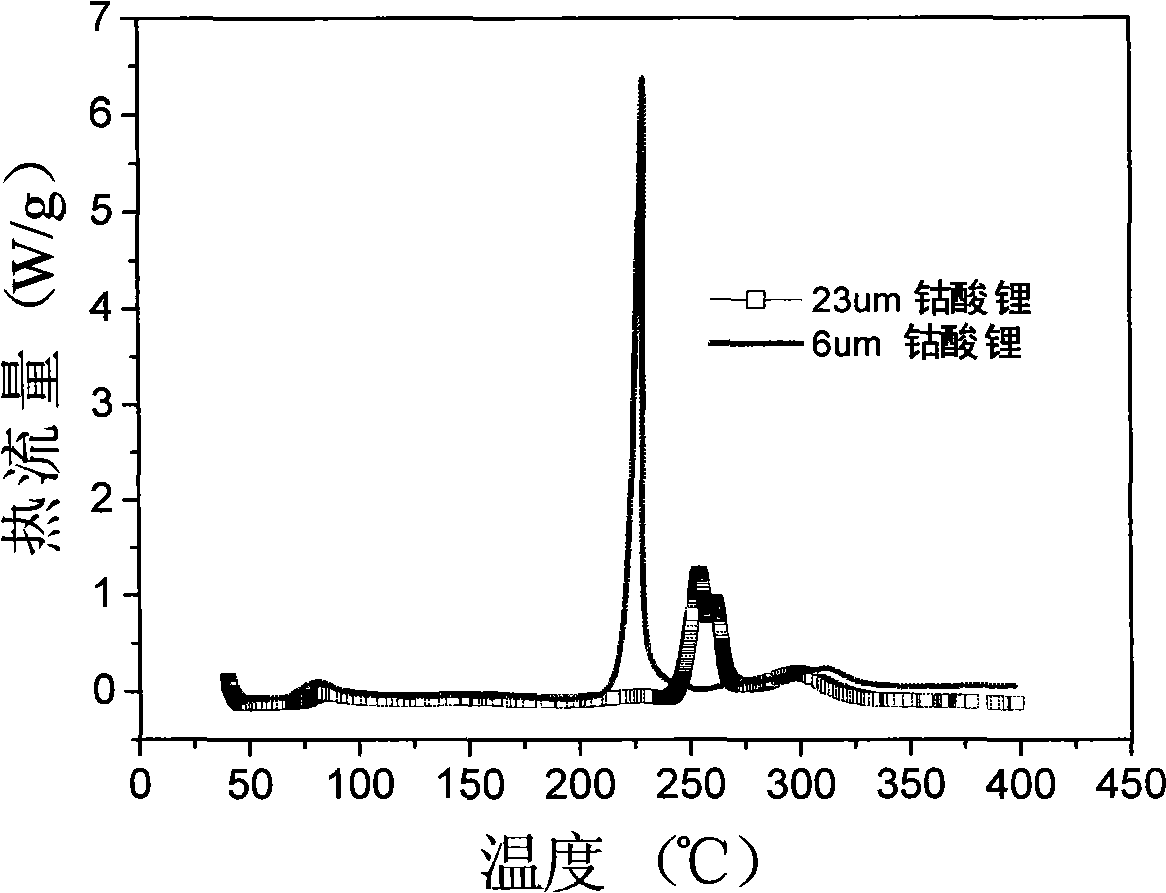

ActiveCN101284681ALarge particle sizeHigh tap densityCell electrodesLithium compoundsHigh densityThermal impact

The invention relates to a high-density lithium cobalt oxide power material with a super-large grain diameter. The method comprises the steps of mixing a cobalt compound, a lithium compound or meanwhile a small amount of doping element compounds; sintering for 3 to 30 hours at the high temperature of 950 to 1,100 DEG C to form a block sintered product; crushing and grading the product to obtain the lithium cobalt oxide power material (molecular formula is LiaCo1-bMbO2), wherein, when b is not equal to 0, the middle diameter of the lithium cobalt oxide containing the doping elements is larger than or equal to 15 Mum, and the tap density is higher than or equal to 2.5g / cm<3>; when b is equal to 0, the middle diameter of the lithium cobalt oxide without the doping elements is larger than 20 Mum, and the tap density is higher than or equal to 2.6g / cm<3>. the 3.6V platform capacity rate of the material as the anode active substance for a lithium battery is higher than or equal to 75%; in the thermal impact test in a 150 DEG C thermotank, the lithium battery with the material is free from leakage and does not catch fire or explode for 60 minutes; the 1C5A specific capacity of the material in the battery is larger than or equal to 135mAh / g.

Owner:BEIJING EASPRING MATERIAL TECH CO LTD

Method for directly roasting and processing spent lithium ion batteries and recycling valuable metals

InactiveCN101519726AImprove leaching rateEasily brokenProcess efficiency improvementCobaltSodium sulfate

The invention relates to a method for directly roasting and treating spent lithium ion batteries and recycling valuable metals, in particular to a method for recycling and treating spent lithium ion batteries using lithium cobalt oxide as an anode material. The method comprises the following steps: firstly, remove organic binder on an organic diaphragm material and an electrode material in the batteries by roasting at a temperature of 500 DEG C to 850 DEG C; crushing and mixing the roasted battery material with sodium sulfate (or potassium sulfate) and concentrated sulfuric acid before size mixing; carrying out secondary heat treatment in an electric stove at a temperature of 350 DEG C to 600 DEG C to convert metals in the spent lithium ion batteries, such as cobalt, copper, lithium, and the like into easily water-soluble sulfate which is leached by water or a dilute sulphuric acid solution; then, using an organic extracting agent to respectively extract the cobalt and the copper from a leaching solution and obtain a cobalt product and a copper product; using sodium carbonate to precipitate the metal lithium from the leaching solution after the cobalt and the copper are removed; and enabling the leaching solution to return treatment heat so as to secondarily treat materials. The invention has a metal leaching rate higher than 99.5 percent and a metal recovery rate higher than 99 percent.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

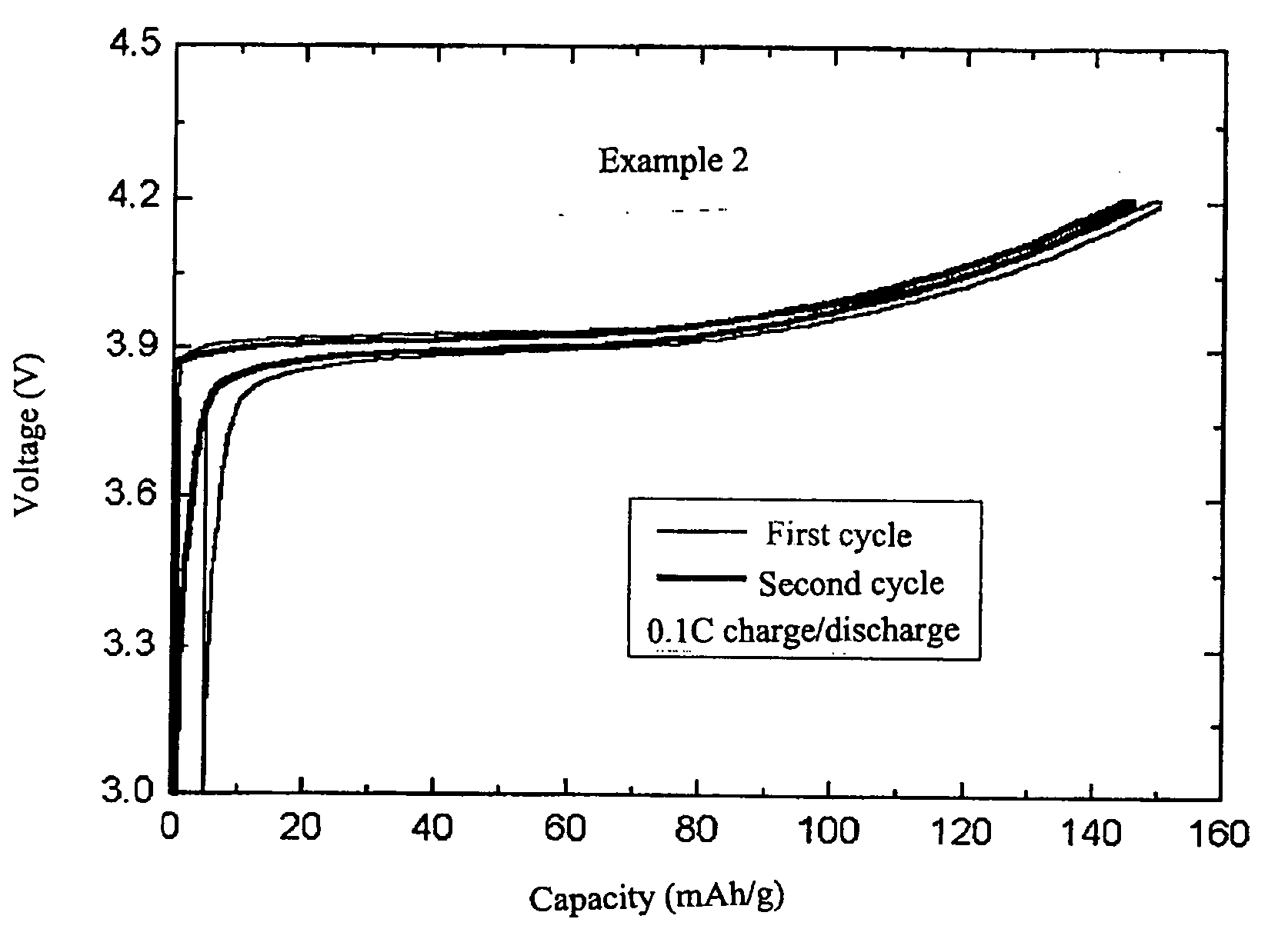

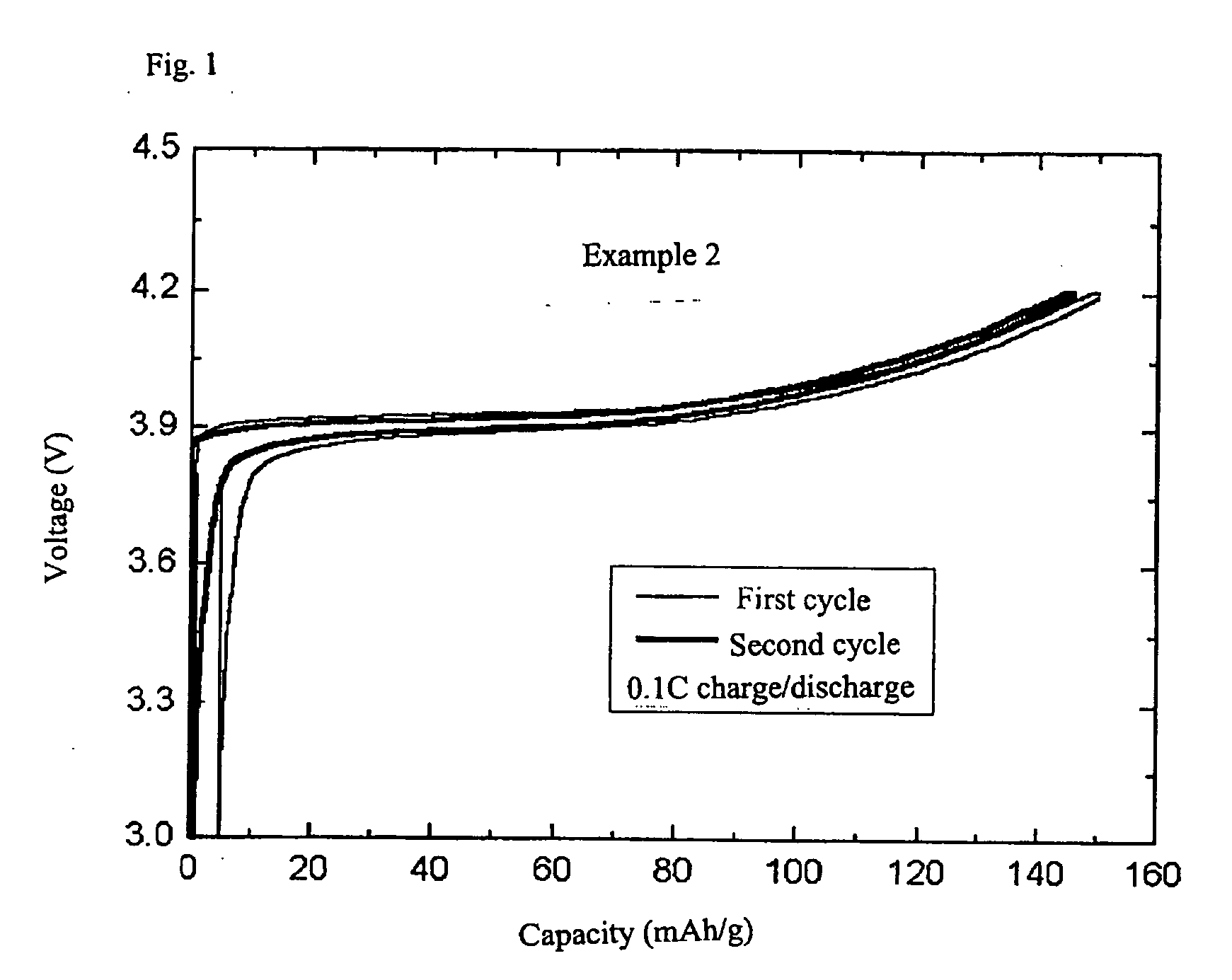

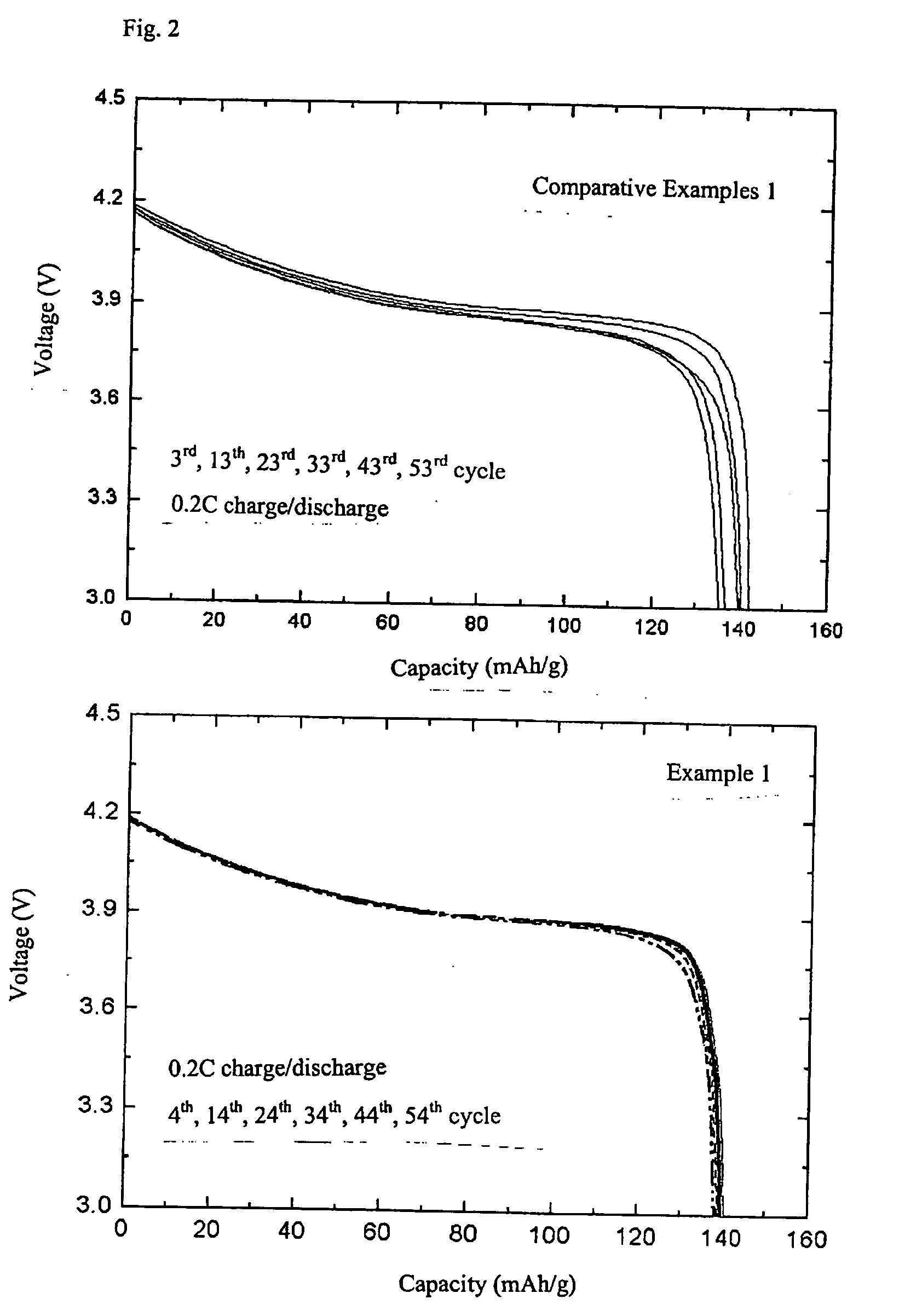

Complex lithium metal oxides with enhanced cycle life and safety and a process for preparation thereof

ActiveUS20040200998A1Improve cycle lifeImprove securityElectrode manufacturing processesConductive materialHigh temperature storageLithium metal

This invention relates to complex lithium metal oxides, which are cathode active materials of a lithium or lithium ion secondary battery with enhanced cycle life and safety, and a process for preparation thereof. The core particles are complex lithium metal oxides capable of absorbing, storing and emitting lithium ions, and a coating layer comprised of amorphous complex lithium cobalt oxides that are formed on the surface of the core particle, which is structurally stable and inactive with electrolytes. Because the amorphous complex lithium cobalt oxides are inactive with electrolytes, the oxides stabilize the surface structure of the complex lithium metal oxide and improve on high temperature storage properties, as well as safety and cycle life.

Owner:LG ENERGY SOLUTION LTD

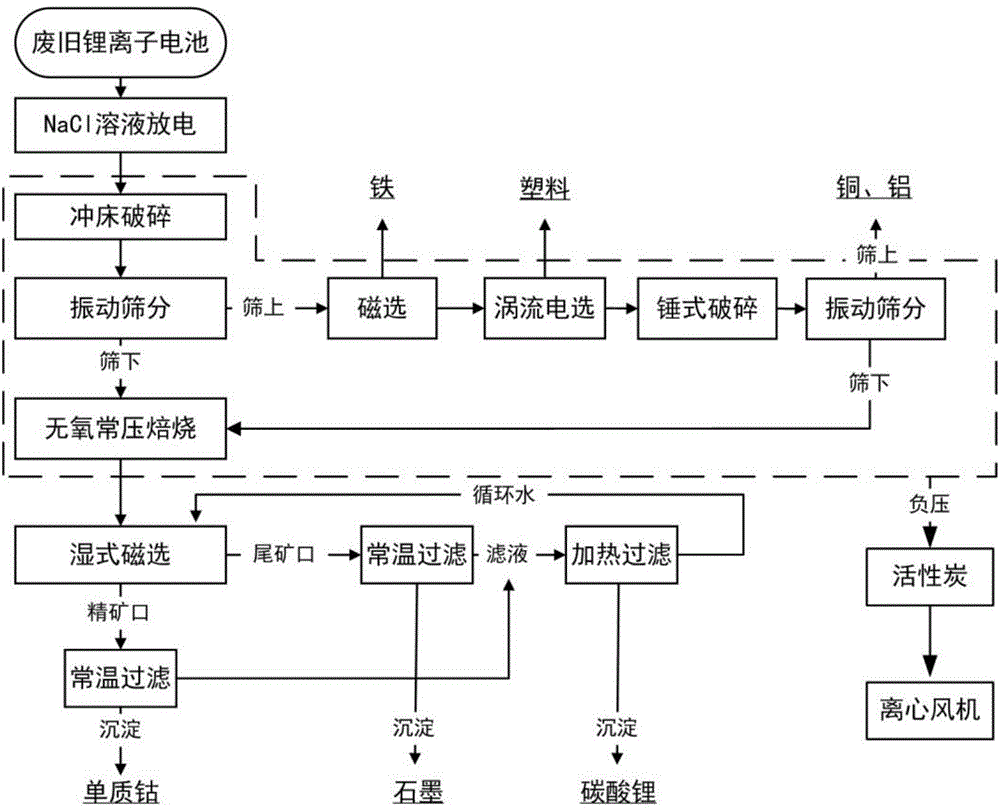

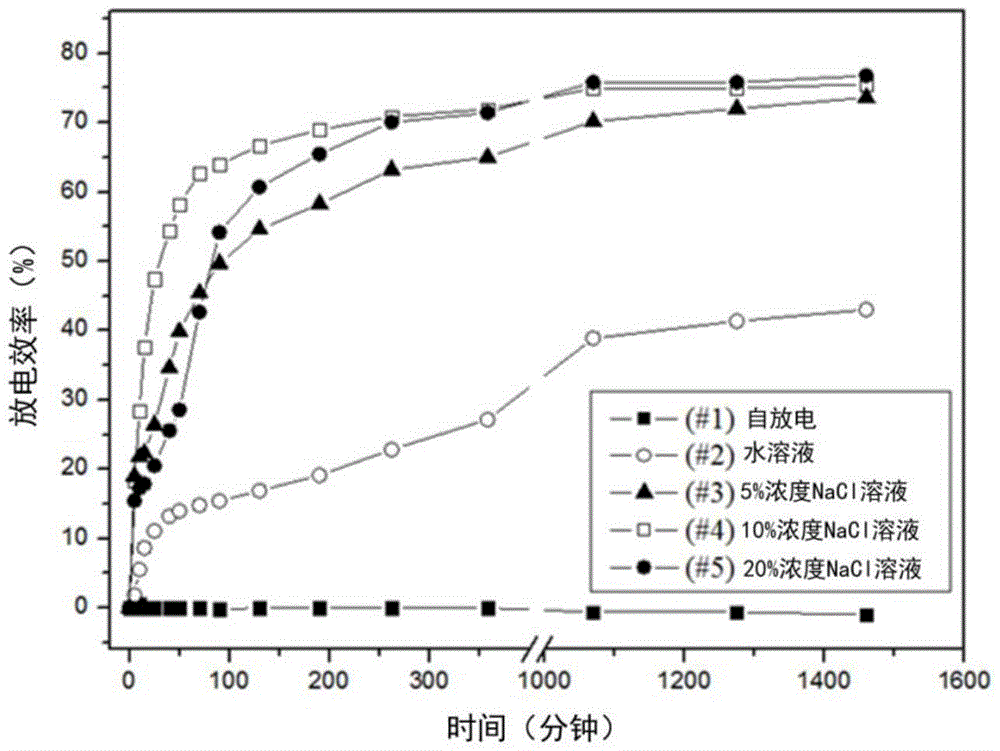

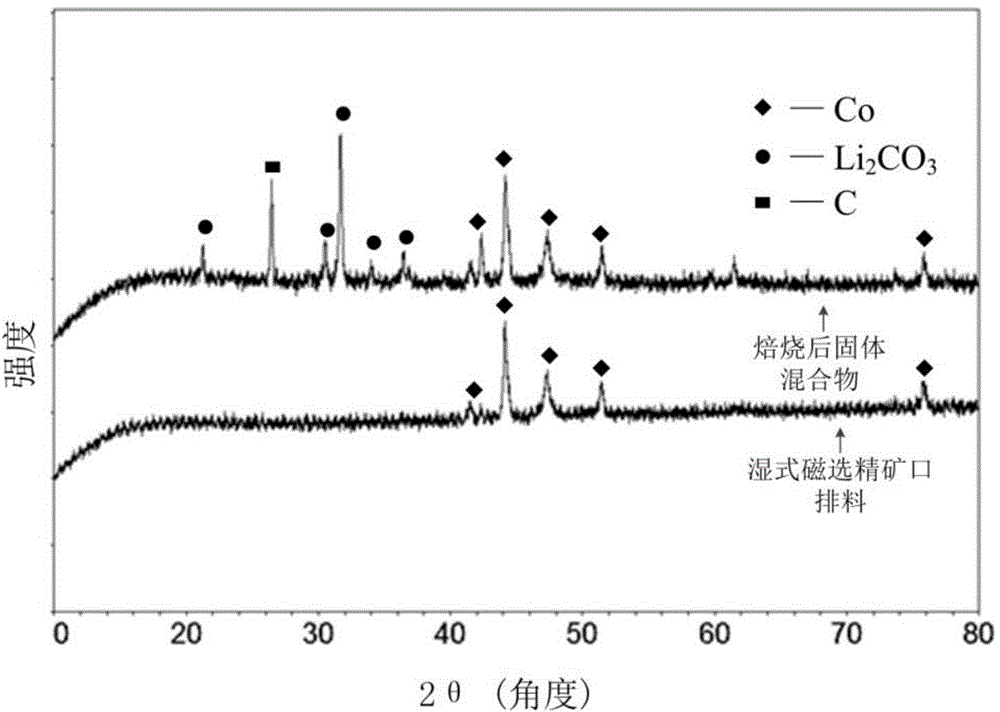

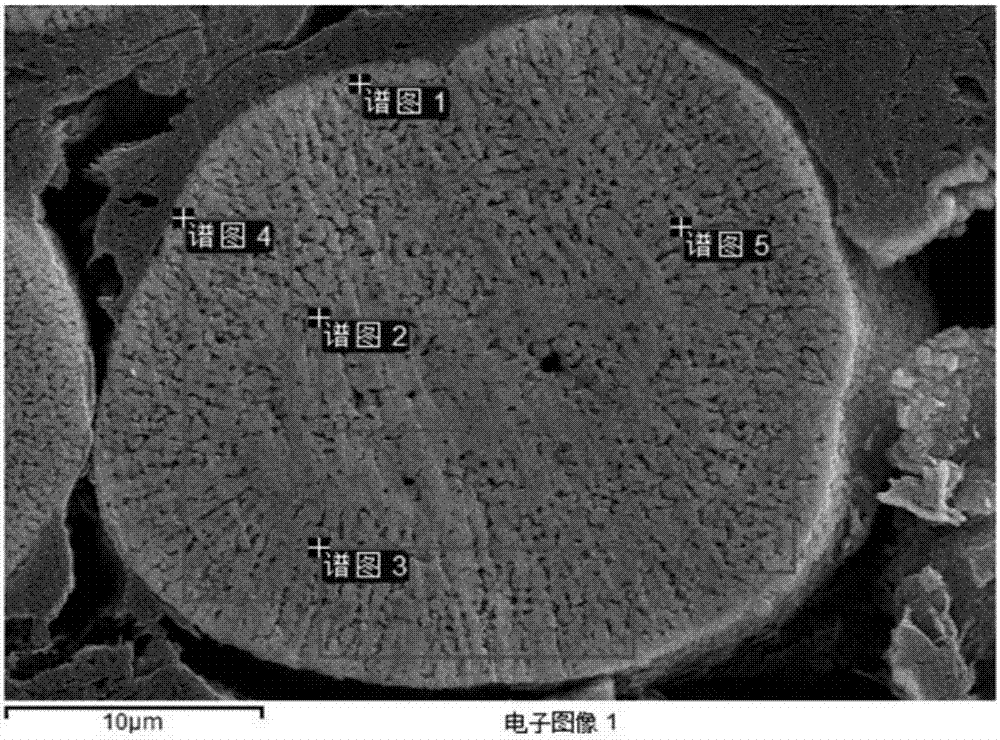

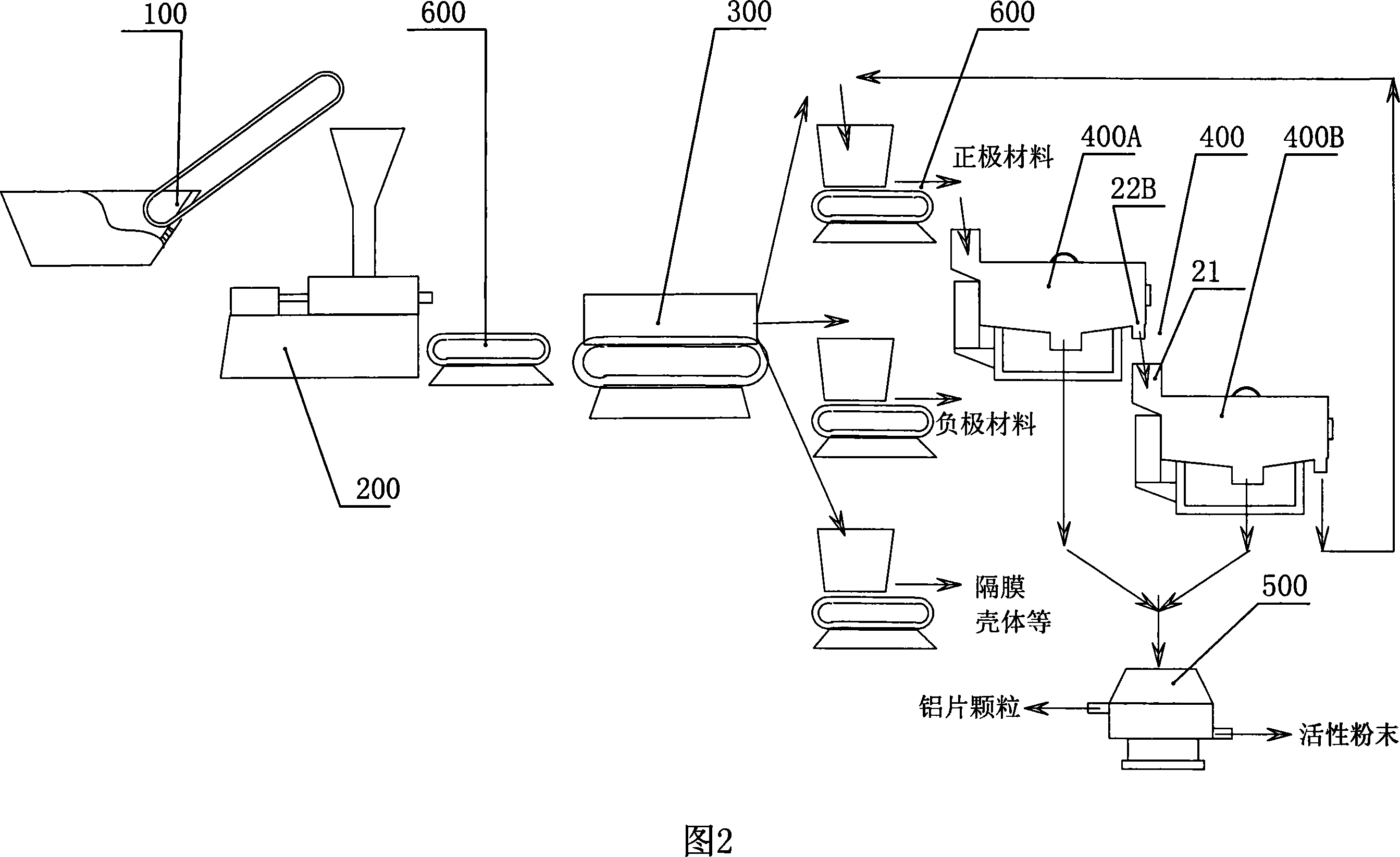

Method for recycling waste lithium cobalt oxide lithium ion battery

ActiveCN104577249AFully resourcedReduce lossesWaste accumulators reclaimingBattery recyclingPunch pressCobalt

The invention relates to a method for recycling waste lithium cobalt oxide lithium ion battery. The method is characterized in that valuable components in the waste lithium ion battery are completely recycled by integrating the processes of crushing by a punch press, magnetic separation, eddy current selection, anaerobic atmospheric roasting, temperature-variable filtering and the like, and products with the relatively high additional values, such as elemental crude cobalt, lithium carbonate, graphite, copper, aluminum, iron, and plastics are obtained. Manners of crushing by a punch press, magnetic separation, eddy current selection and the like are adopted for performing material separation, so that the original physical properties of materials are kept. Meanwhile, positive powder and negative powder of an electrode material are cooperatively treated, the negative graphite material is effectively utilized, the in-situ preparation of a resource can be realized, and the waste lithium ion battery can be relatively completely recycled. The anaerobic atmospheric roasting is adopted, so that the reaction condition is relatively loose, the loss of a graphite material is reduced, the cost is saved, the technological flow is simplified, and the industrial application practice can be facilitated.

Owner:SHANGHAI JIAO TONG UNIV

High-capacity lithium cobalt oxide-base lithium ion battery anode material and preparation method thereof

InactiveCN103682326AIncrease capacityGuaranteed stabilityCell electrodesSecondary cellsDopantLithium

The invention discloses a high-capacity lithium cobalt oxide-base lithium ion battery anode material. The material is a lithium cobalt oxide finished product which is obtained by mixing modified lithium cobalt oxide in different granularities and coating the lithium cobalt oxide, the anode material contains a cobalt-source substance, a lithium-source substance, a doping agent and a coating material, wherein the molar ratio of Li to Co is 0.95 to 1.2, the doping quantity of the doping agent is 0.01 to 10 percent by weight, and the doping quantity of the coating material is 0.01 to 20 percent by weight. The capacity of the lithium cobalt oxide material is improved by mixing the lithium cobalt oxide in different granularities, the stability, safety and electrochemical property of the material under the high voltage condition of more than 4.2V are improved through doping and coating, and the high-temperature circulating property is improved.

Owner:NANTONG RESHINE NEW MATERIAL

Preparation method of Co3O4 with large grain size and uniformly doped with aluminum

ActiveCN108011101AEvenly distributedUniform particle size distributionCell electrodesCobalt oxides/hydroxidesCobalt(II,III) oxideMicrometer

The invention relates to a preparation method of Co3O4 with large grain size and uniformly doped with aluminum. The invention provides the preparation method of the Co3O4 which is uniformly doped withaluminum and is large in grain size and uniform in particle distribution, and the obtained Co3O4 with the large grain size and uniformly doped with aluminum can completely conform to the requirementof preparation of 4.45V high-voltage lithium cobalt oxide. According to the method, the large-grain size and aluminum-doped cobalt carbonate is synthesized by a wet method, and the problems of difficulty in enlargement of cobalt hydroxide (or hydroxyl cobalt) system grain size and non-uniform particle distribution are solved; with the regard to the problem of uniform aluminum doping of a cobalt carbonate system, a parameter is set from principle, an aluminum compound is prevented from being independently separated out and gathered, the doped Al element can be uniformly distributed in the Co3O4, the grain size reaches 15 micrometers or above, and the particle distribution is uniform; and the lithium cobalt oxide prepared from the aluminum-doped Co3O4 has high specific capacity and excellentcycle property under 4.45V.

Owner:취저우화여우코발트뉴머터리얼컴퍼니리미티드

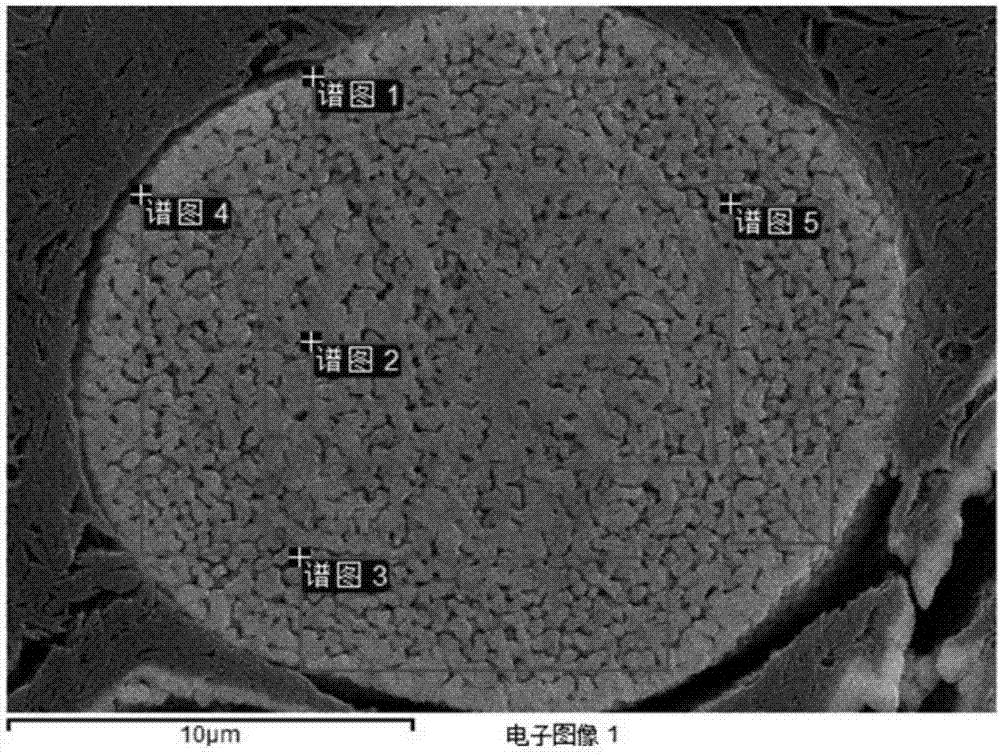

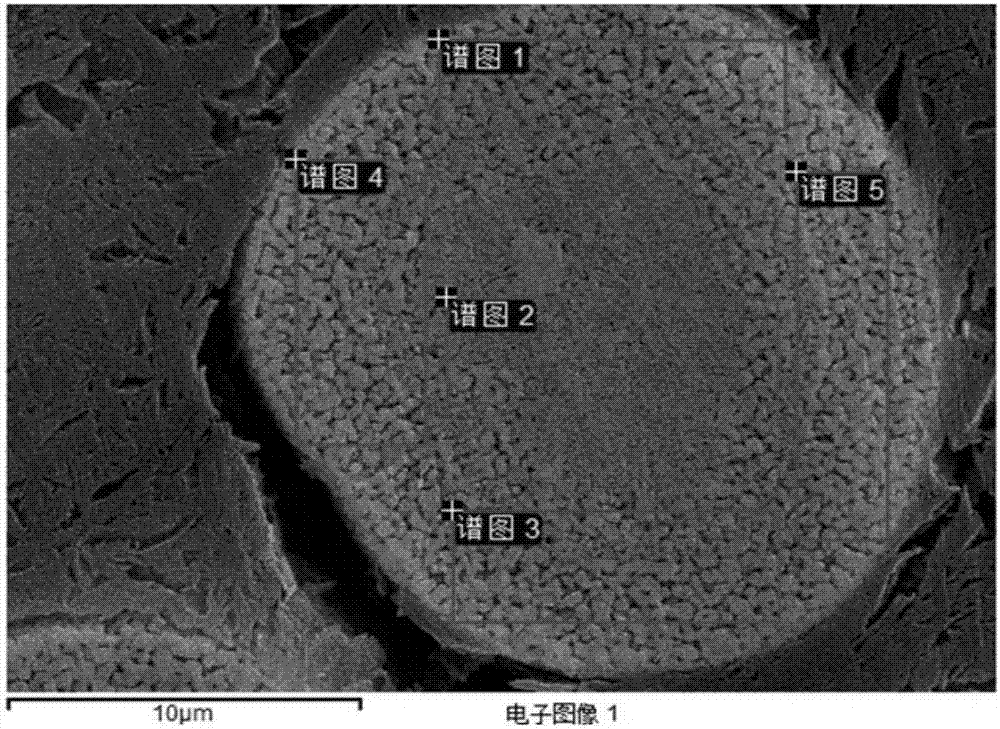

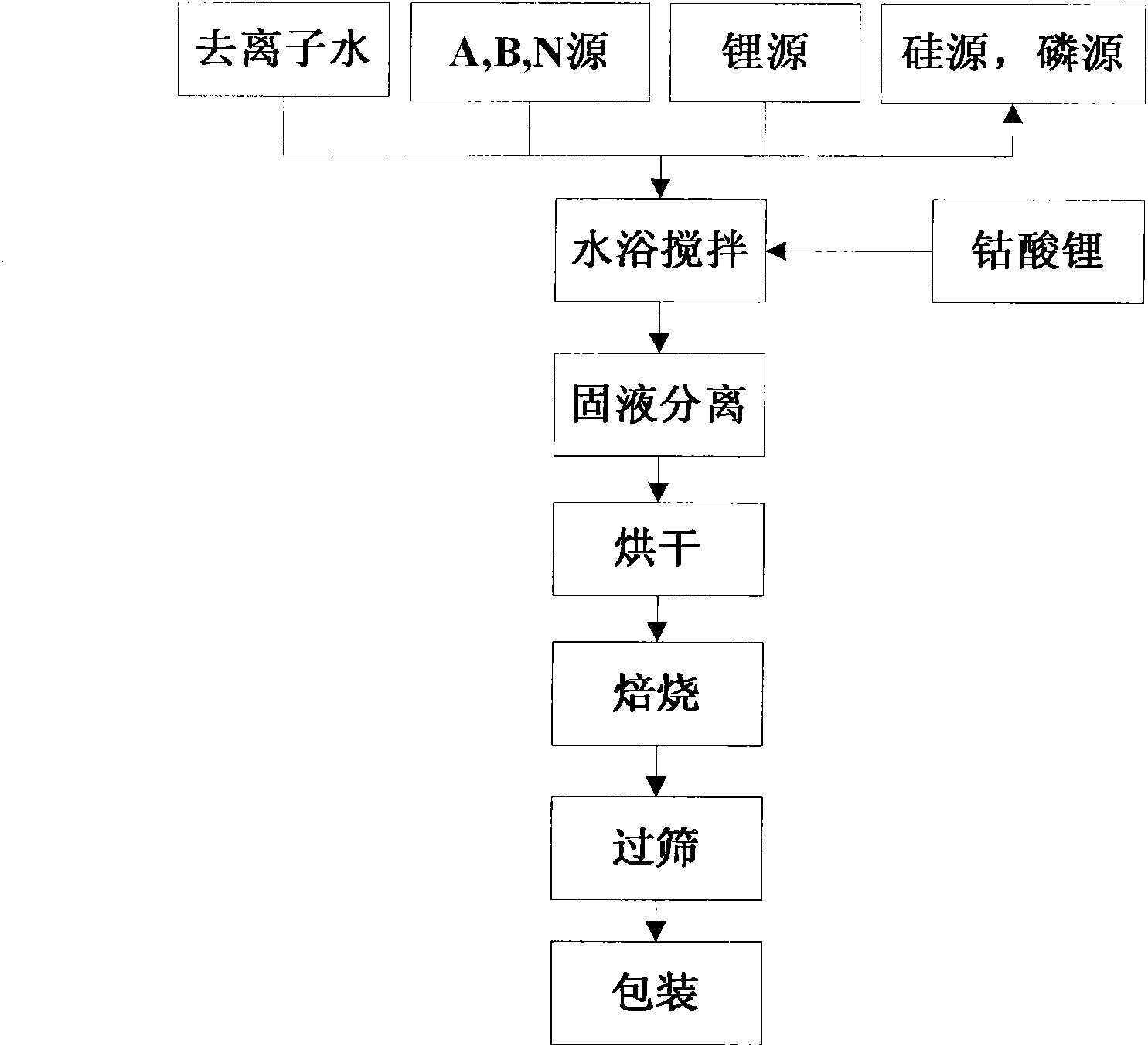

Fast ion conductor modified lithium ion battery cathode material lithium cobalt oxide with fast ion conductor and preparation method

InactiveCN101969110AIncrease capacityAvoid direct contactCell electrodesElectrical conductorPhosphate

The invention discloses a fast ion conductor modified lithium ion battery anode material lithium cobalt oxide comprising lithium cobalt oxide and a lithium fast ion conductor layer coating the outer surface of the lithium cobalt oxide. The lithium fast ion conductor layer comprises the components of Li1+x+yAxB2-xSiyP3-yO12-eN, wherein A is one or more than one of Al, Sc, La, Cr, Fe, Tl, Eu and In, B is one or more than one of Ti, Zr and Hf, N is one or more than one of Li2O, MgO and Y2O3, and x, y and e are all not less than 0 and not more than 2. The preparation method of the fast ion conductor modified lithium ion battery anode material lithium cobalt oxide comprises the following steps of: evenly mixing A, B an N sources, lithium salt, a silicon source, a phosphorus source and a lithium ion battery anode material to be modified, carrying out the processes of drying, roasting, crushing, screening and the like to prepare the lithium ion battery anode material coated with a phosphate system on the surface. The modified anode material lithium cobalt oxide not only can work under a higher voltage and greatly improve the battery capacity, but also greatly improves the cycle performance, the multiplying power performance, the overcharging performance and the safety performance thereof.

Owner:TIANJIN B&M SCI & TECH

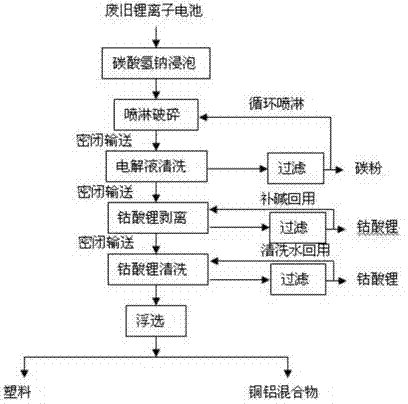

Method for comprehensively recycling waste lithium ion batteries

ActiveCN103943911AAccelerated corrosionAffect healthWaste accumulators reclaimingBattery recyclingSocial benefitsEconomic benefits

The invention discloses a method for comprehensively recycling waste lithium ion batteries, and belongs to the field of recycling of regeneration resource. The method comprises the following steps: a, performing discharging processing on waste lithium ion batteries; b, fragmenting waste lithium ion batteries into sheets with a diameter of 10-20 mm in a closed shearing-type crusher, and spraying during fragmentation to dissolve lithium hexafluorophosphate in the waste lithium ion batteries into a spraying solution; c, peeling carbon powder on the surface of aluminium foils through stirring, dissolving electrolyte into the spraying solution, and recovering carbon powder; d, sending the sheets into a sodium hydroxide solution, peeling lithium cobalt oxide powder on the surface of aluminium foils through stirring, and recovering lithium cobalt oxide powder; e, cleaning the sheets, and recovering lithium cobalt oxide powder; and f, separating and recovering plastic and a copper-aluminium mixture. The method realizes recovery of carbon powder, lithium cobalt oxide powder, the copper-aluminium mixture and plastic through a simple environment-friendly process, and has certain economic benefit and social benefit.

Owner:SICHUAN CHANGHONG ELECTRIC CO LTD

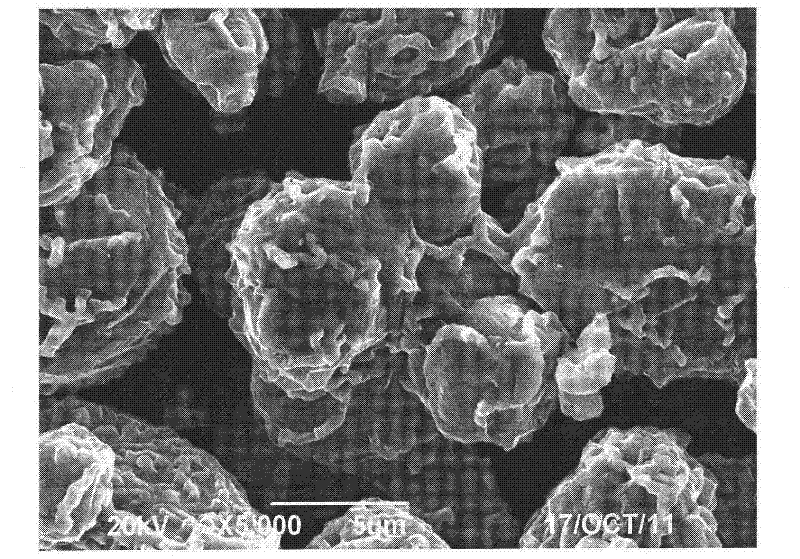

Preparation method for spherical cobalt oxyhydroxide

ActiveCN103904323AHigh densityGood sphericityCell electrodesSecondary cellsHigh densityPhysical chemistry

The invention discloses a preparation method for spherical cobalt oxyhydroxide. Prepared spherical cobalt oxyhydroxide can be directly used as a raw material for preparation of lithium cobalt oxide. According to the invention, wet processing and doping of trace metal elements are adopted to improve related performance like cycle and voltage of the product; the method is simple and produces no pollution; and the product has the advantages of uniform distribution of doped elements, high density and a good sphericity degree.

Owner:BEIJING EASPRING MATERIAL TECH CO LTD

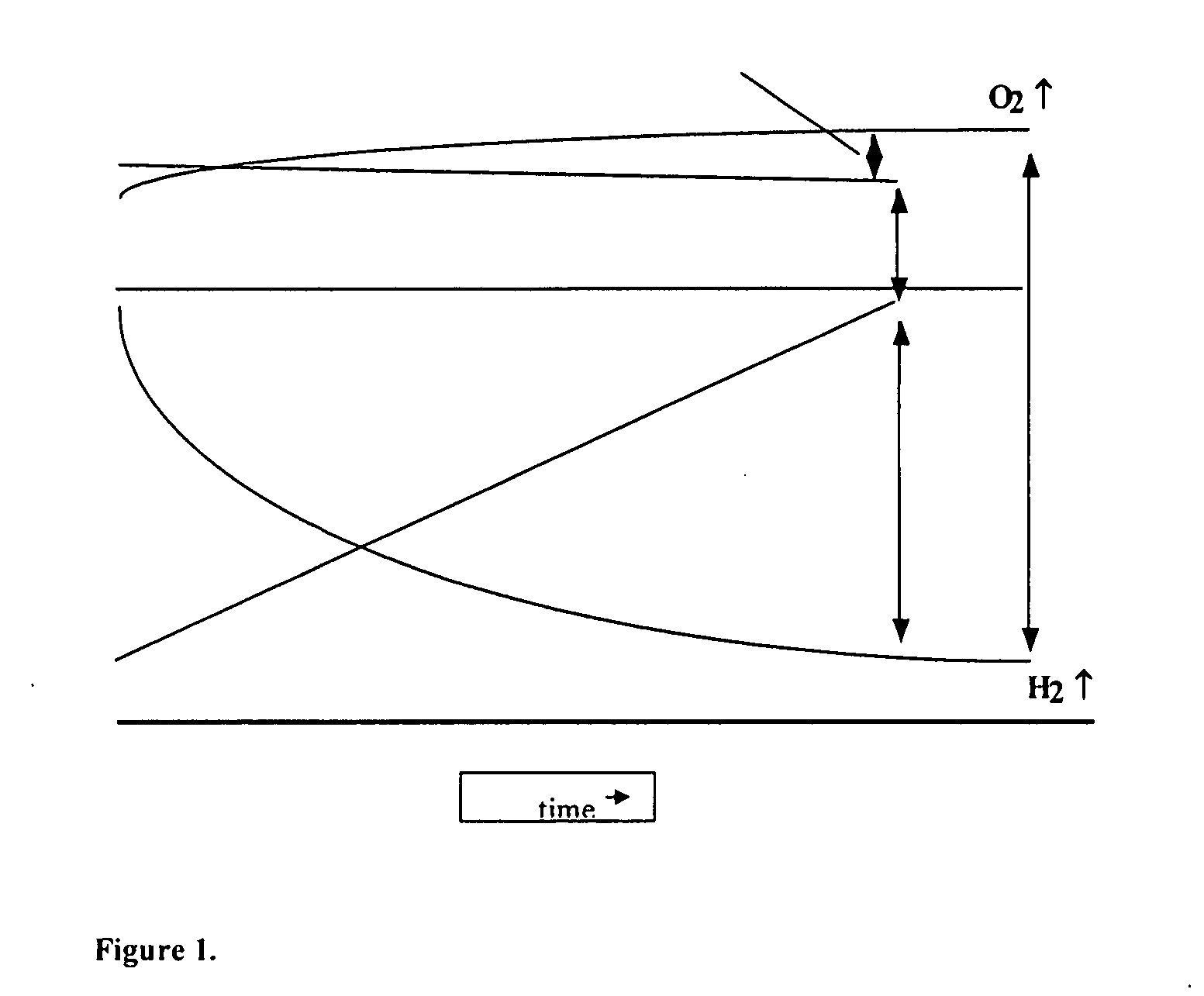

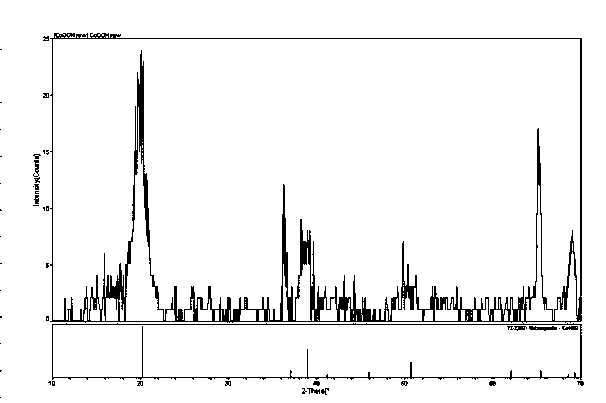

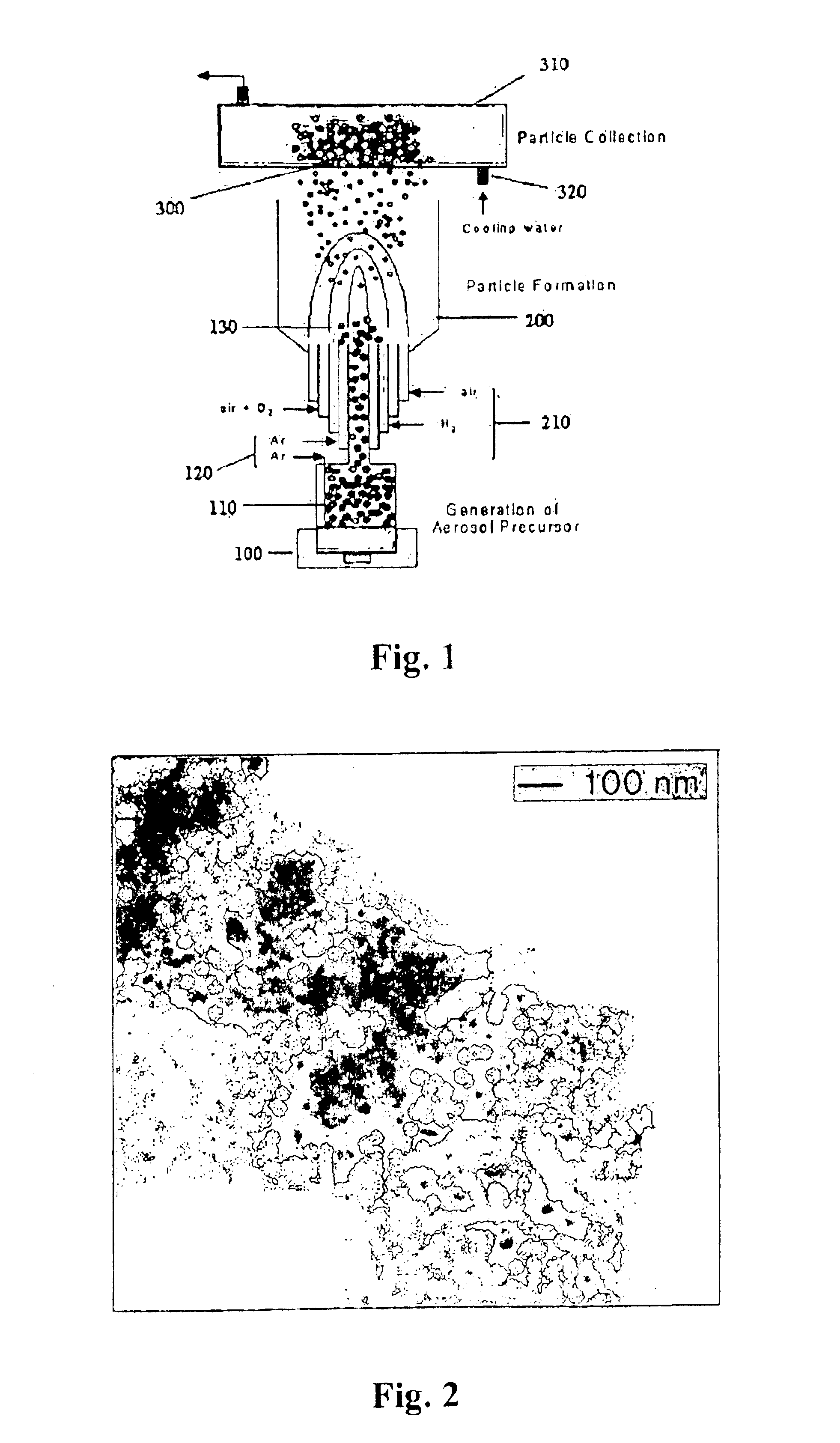

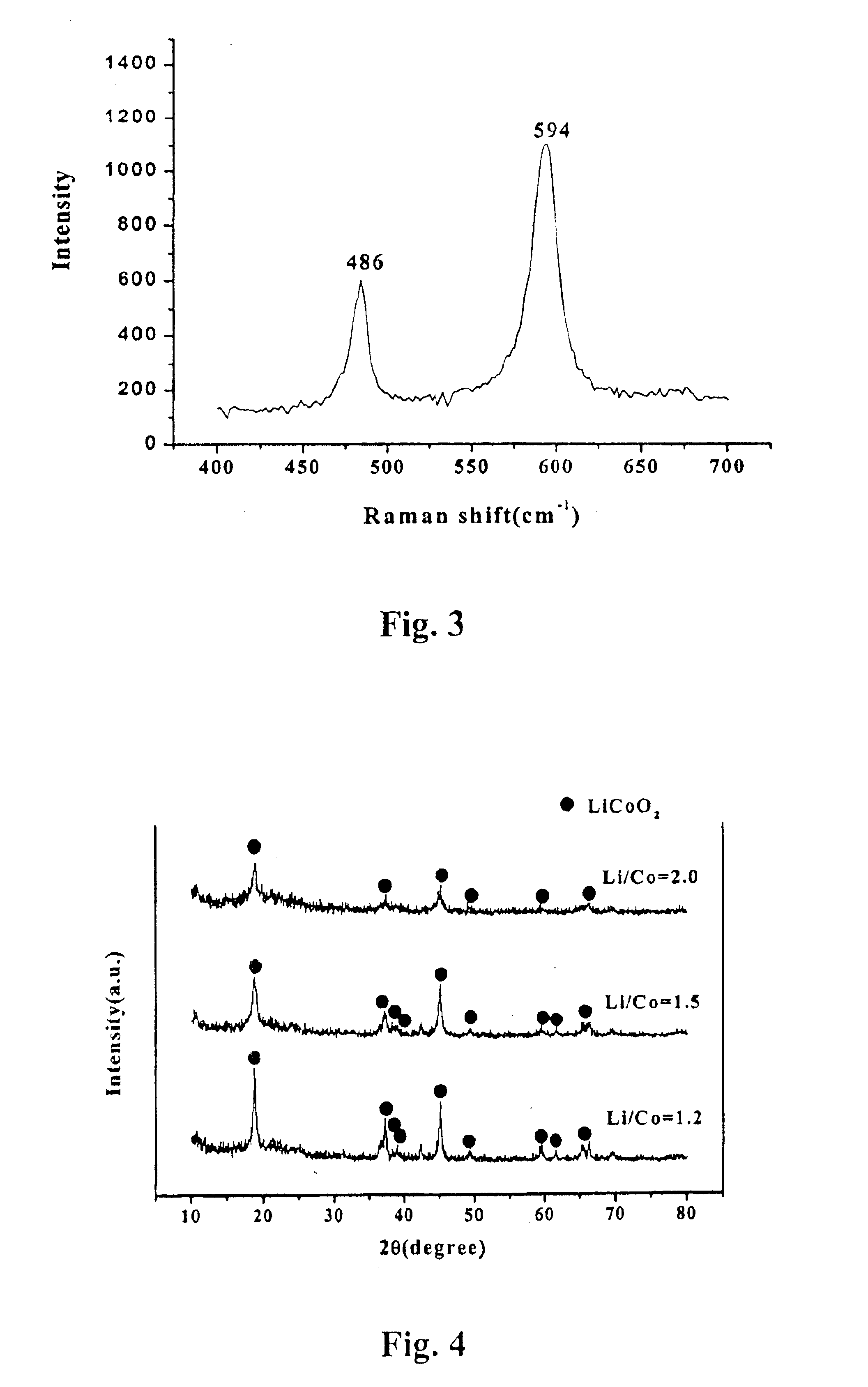

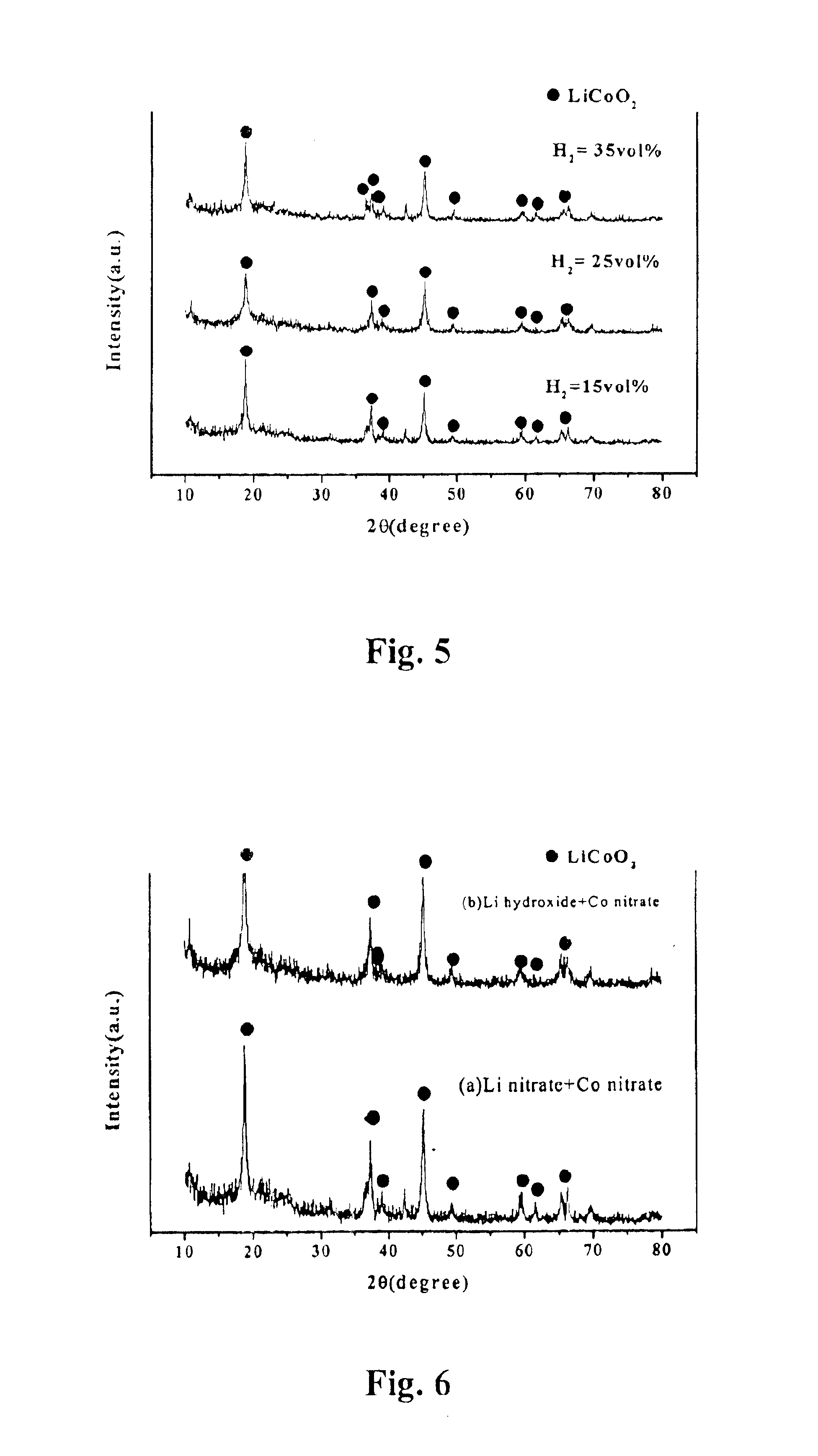

Method of manufacturing nano-sized lithium-cobalt oxides by flame spraying pyrolysis

InactiveUS6902745B2Extend your lifeImprove efficiencyHeavy metal active ingredientsMaterial nanotechnologyGas phaseOxygen

A method for producing nano-sized lithium-cobalt oxide is provided by using flame-spray pyrolysis. The method comprises the steps of: spraying minute droplets, which is a solution dissolved lithium salt with cobalt salt at room temperature; atomizing the minute droplets through rapid expansion into a high temperature environment generated by combusting oxygen and hydrogen; decomposing and oxidizing the atomized minute droplets thermally at high temperature to produce nano-sized oxides in gaseous phase: and collecting the produced nano-sized composite oxides particles. The produced nano-sized lithium-cobalt oxide can be applied to a highly efficient lithium battery as the electrode materials and a thin film type of battery as well as to a miniaturized battery.

Owner:KWAK YOUNG HOON

High-voltage high-capacity anode material for lithium ion battery and preparation method of anode material

InactiveCN103618081AGuaranteed stabilityImprove electrochemical performanceCell electrodesSecondary cellsDopantElectrical battery

The invention discloses a high-voltage high-capacity anode material for a lithium ion battery. The anode material contains a cobalt source substance, a lithium source substance, a dopant M and a coating material, wherein the molar ratio of Li to Co is 0.95-1.2, the doping amount of the dopant M is 0.01-10wt%, and the total doping amount of the coating material is 0.01-20wt%. The structural stability of lithium cobalt oxide is enhanced by means of doping, the advantages of the lithium cobalt oxide in a base layer and the active material in a coating layer are complemented mutually by means of coating with an active substance, so that the electrochemical performance of the anode material is enhanced; stable cycling can be achieved under the condition of high voltage of 3.0-4.5V and the anode material has excellent electrochemical performance. In a word, the anode material has the advantages of high voltage platform, high reversible specific capacity, excellent thermal cycling performance, stable structure, good safety and the like; the problem that the calcination temperature of the base layer and the coating layer cannot be unified is solved and the anode material has excellent uniformity.

Owner:NANTONG RESHINE NEW MATERIAL

Lithium ion battery and anode material thereof

ActiveCN102332577AStable structureImprove electrochemical performanceCell electrodesSecondary cellsHigh energyGranularity

The invention belongs to the technical field of a lithium ion battery, and particularly relates to a lithium ion battery and an anode material thereof. A nickel-cobalt-manganese ternary material with a suitable granularity and a lithium cobalt oxide anode material are selected and mixed, the ratio of the two materials is strictly controlled and the compound anode material after being mixed is subjected to cladding treatment, thereby acquiring the material with a greatly increased gram-capacity relative to pure lithium cobalt oxide, greatly increasing the space use ratio of an anode diaphragm and acquiring the anode diaphragm with a compaction density of over 4.0g / cm<3>. The compound anode material can be used for preparing the lithium ion battery with excellent electrochemical property, excellent safety performance and higher energy density, and meanwhile, the high-temperature memory property of the lithium ion battery is obviously improved and the circulating property is excellent.

Owner:DONGGUAN AMPEREX TECH

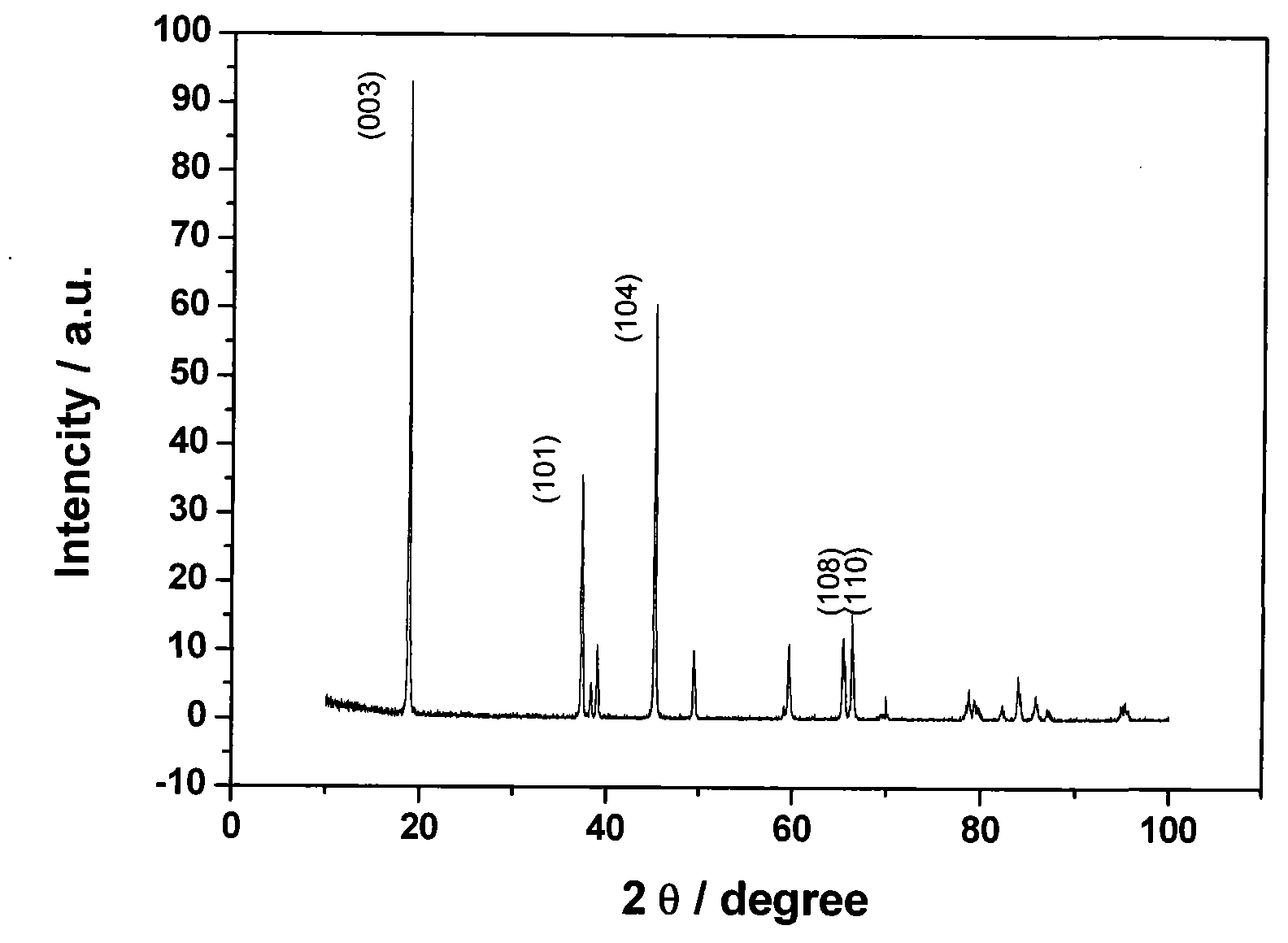

Method for recovering and preparing lithium cobaltate from waste lithium ionic cell

ActiveCN101383442ASimultaneous recyclingLow priceLithium compoundsWaste accumulators reclaimingCobaltMuffle furnace

The invention discloses a method for reclaiming and preparing lithium cobalt oxide from waste lithium ion batteries. The method is characterized in that the waste lithium batteries are disassembled and the shells are removed to select positive plates with the anode made of lithium cobalt oxide; the positive plates are crushed and screened to obtain minus sieve containing waste lithium cobalt oxide as the main component; in a constant-temperature resistance furnace, caking agent and conductive agent acetylene black in the minus sieve are removed in high temperature, sodium hydroxide is adopted to remove aluminum, and filtering, washing and drying are performed to obtain inactive lithium cobalt oxide containing little impurity; the content of lithium and cobalt is detected in the inactive lithium, then lithium carbonate with proper proportion is mixed in, at last, active lithium cobalt oxide battery material is synthesized by high-temperature agglomeration in a muffle furnace. Through the application of the method, the coefficient of recovery of cobalt in waste lithium ion batteries can reach more than 95.0 percent, and the coefficient of recovery of lithium can reach more than 97.0 percent.

Owner:GUANGDONG BRUNP RECYCLING TECH +1

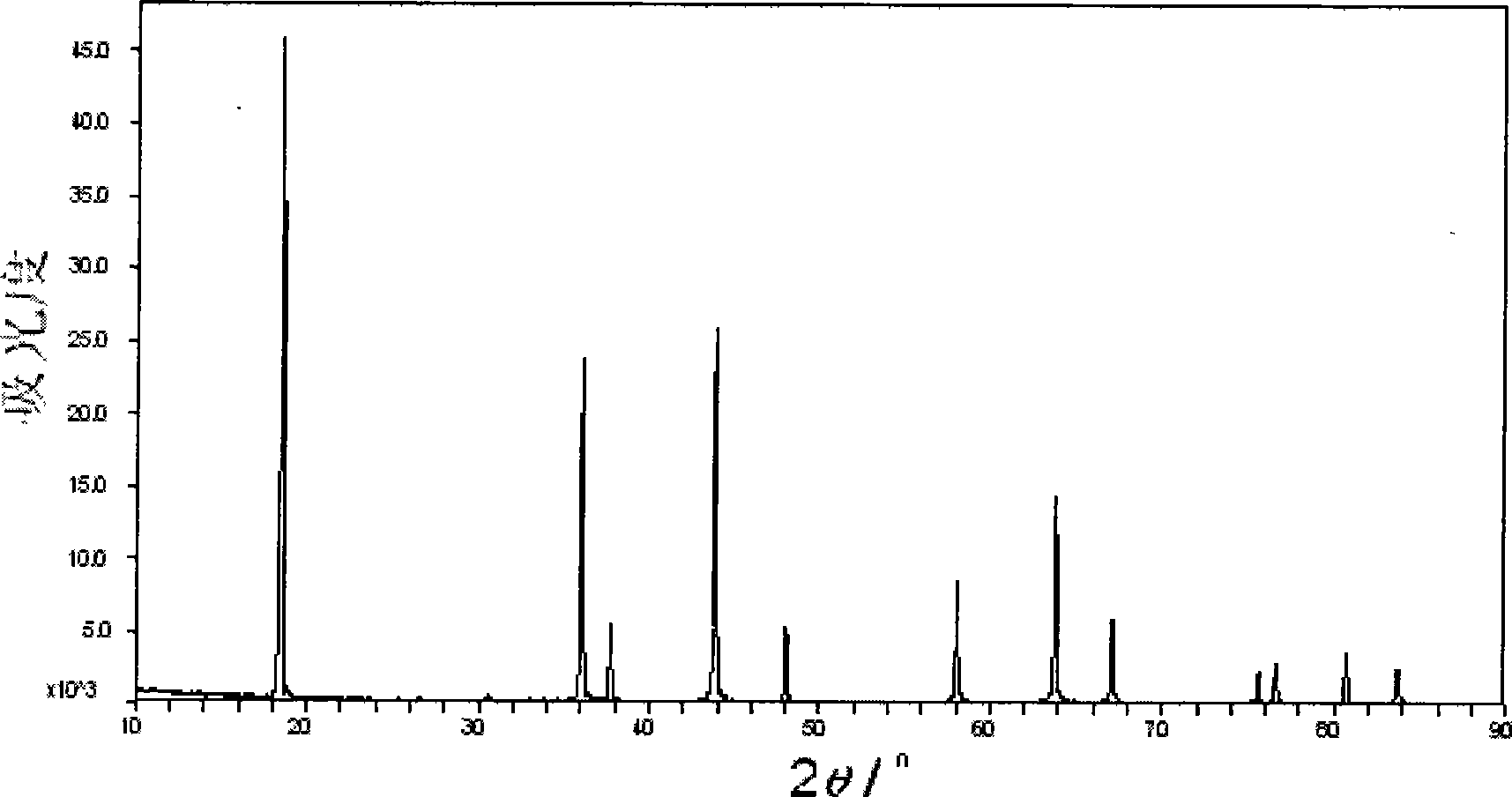

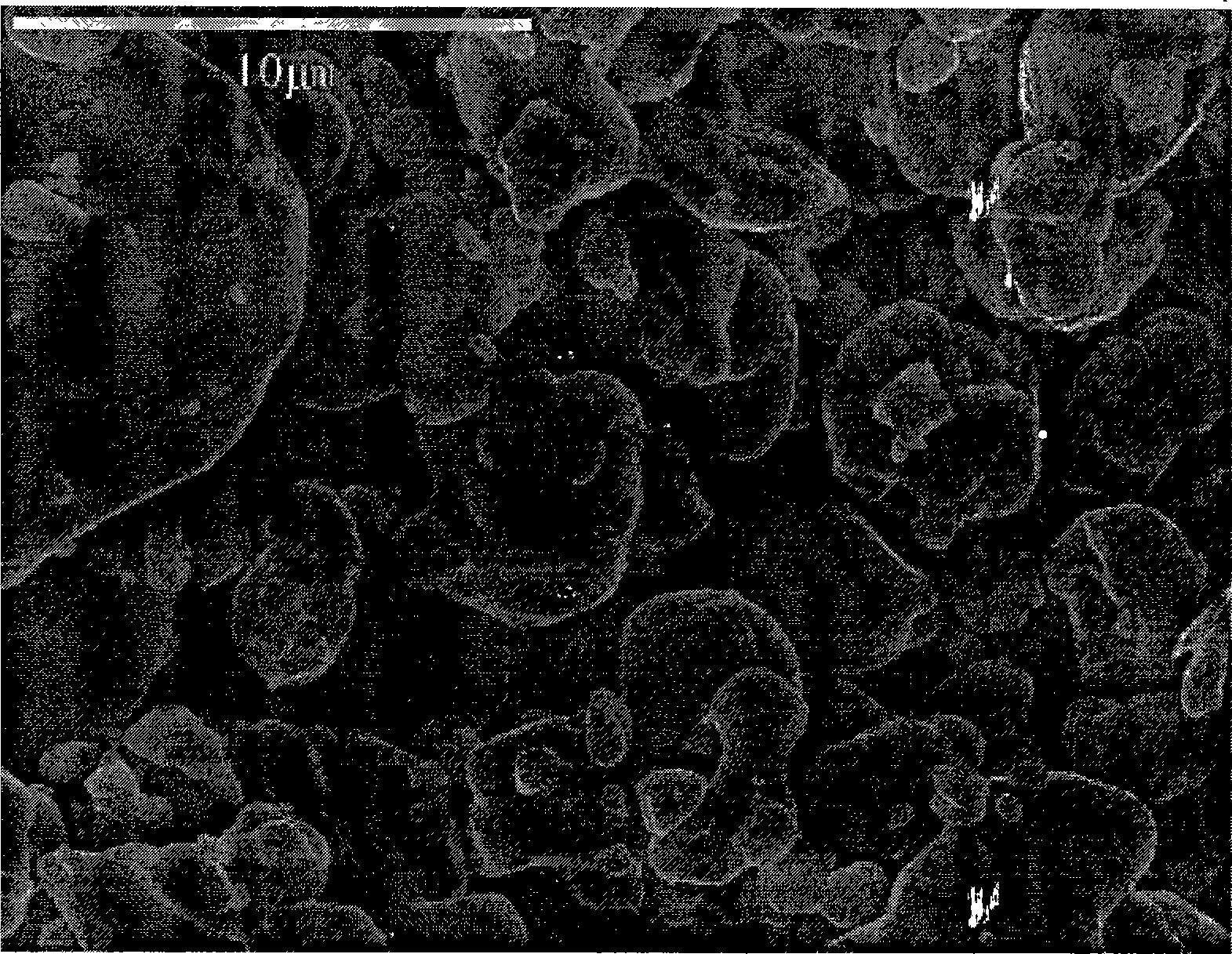

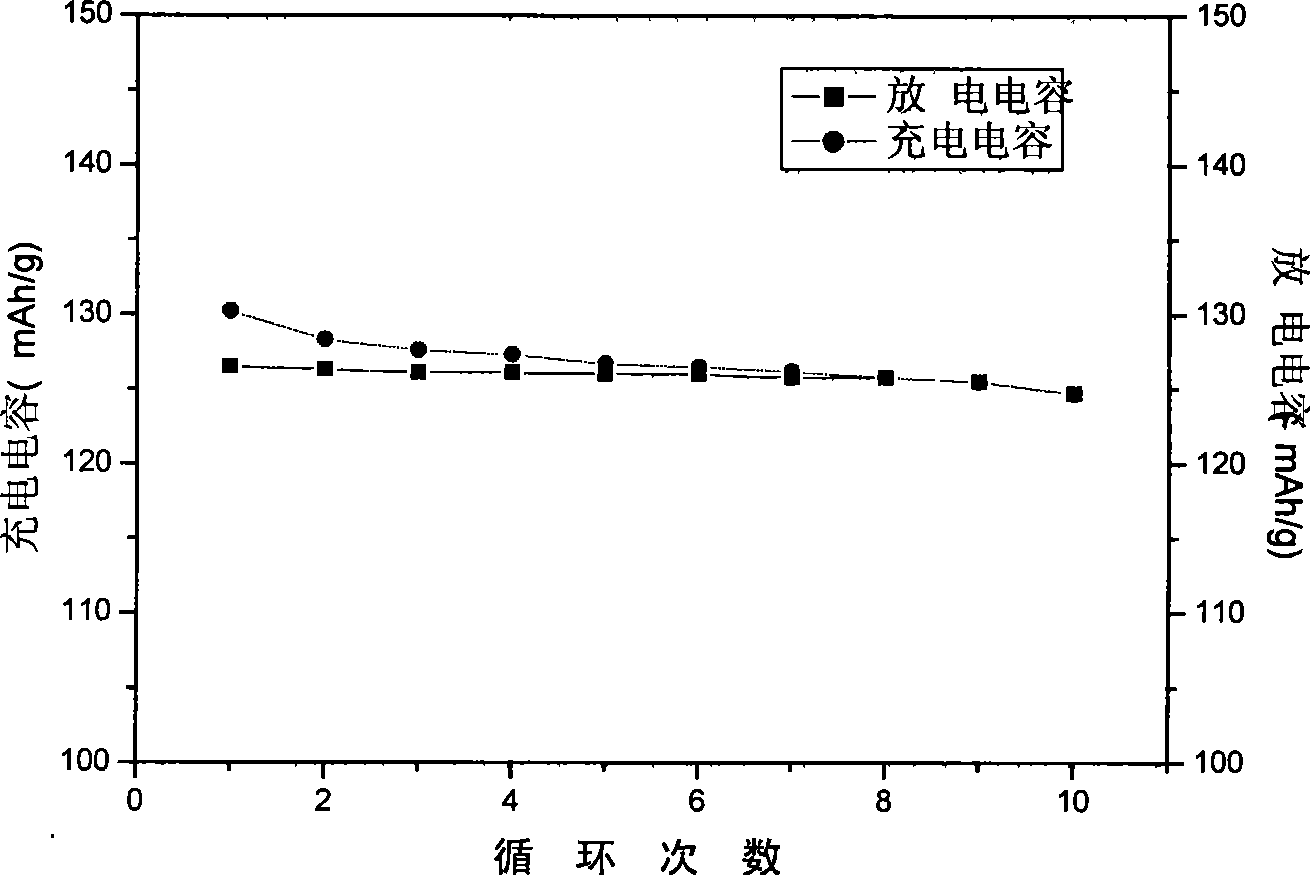

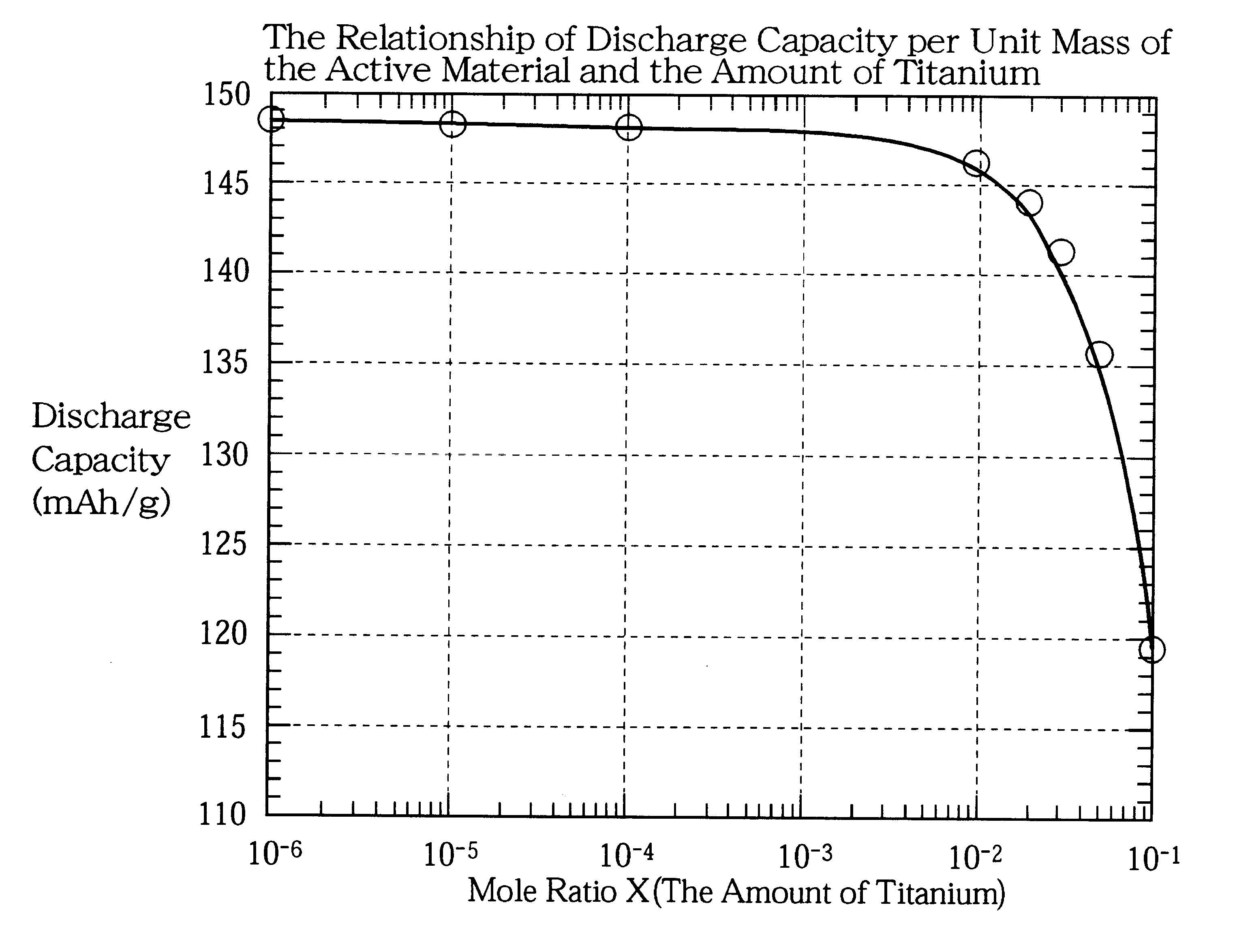

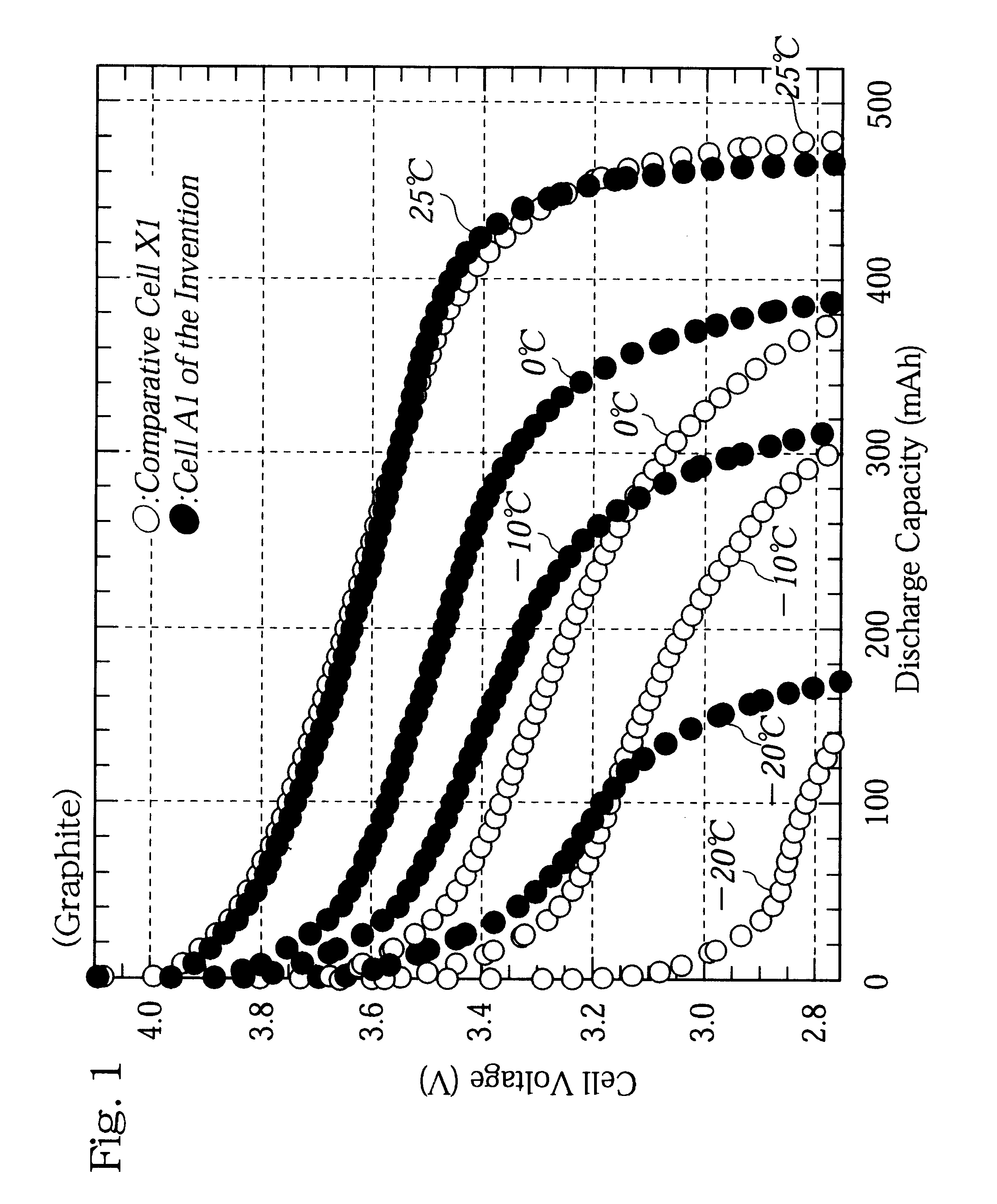

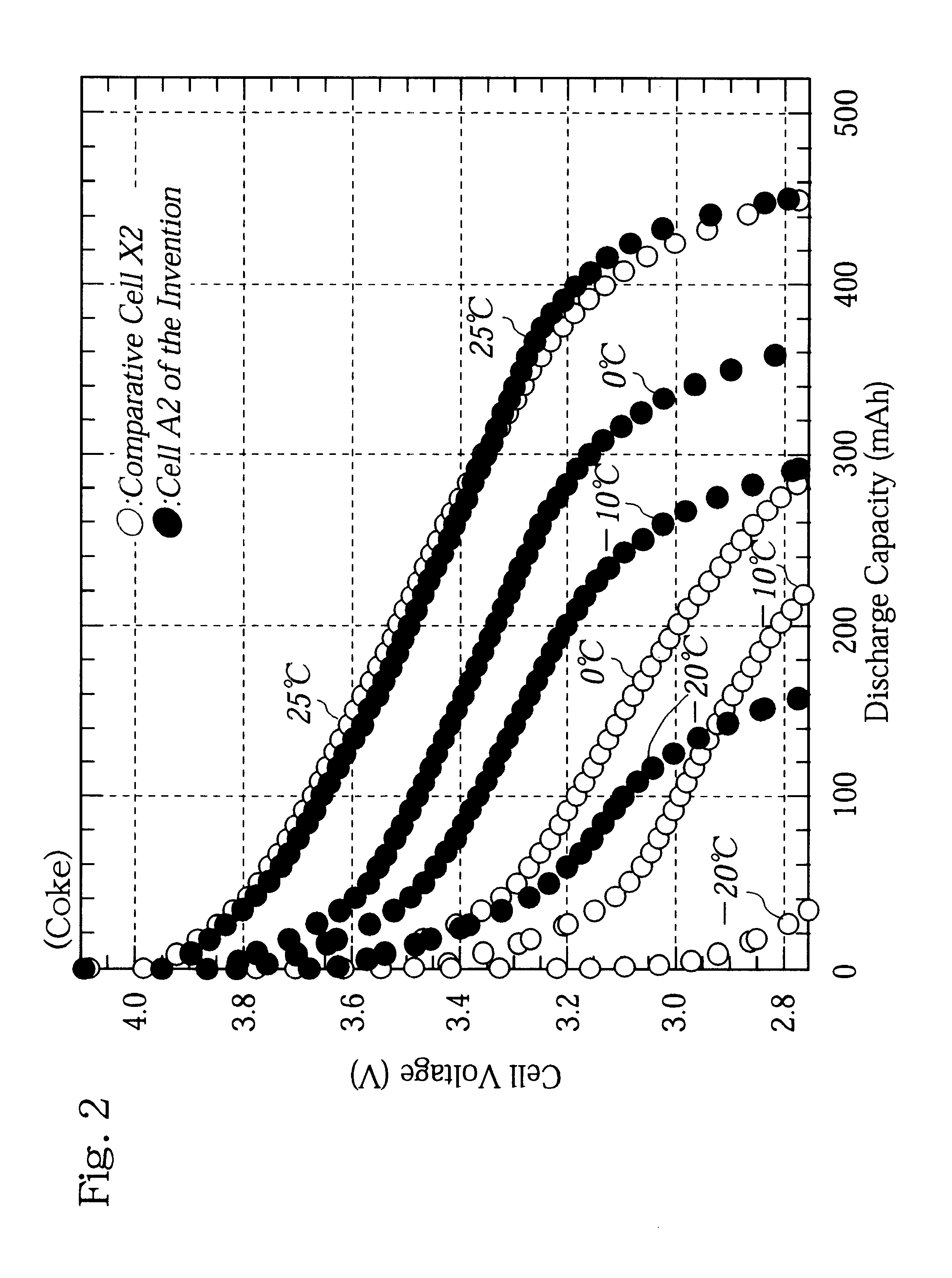

Non-aqueous electrolyte cell having a positive electrode with Ti-attached LiCoO2

InactiveUS6395426B1Easy to transformImprove reliabilityNon-aqueous electrolyte accumulatorsFinal product manufactureTitaniumPropylene carbonate

The invention provides a non-aqueous electrolyte cell having a high working voltage in a low temperature range of 0° C. or below and thereby attaining excellent low temperature discharge characteristics, a reduced internally-generated gas, and an excellent safety against heat. This is achieved by a cell comprising a non-aqueous electrolyte containing propylene carbonate and LiN(SO2C2F5)2 as an electrolyte salt, a graphite negative electrode, and a positive electrode having a positive electrode active material comprising a Ti-attached LiCoO2 in which a particle of titanium and / or titanium compound is attached on a surface of a particle of lithium cobalt oxide and a mole ratio of titanium and / or titanium compound in the Ti-attached LiCoO2 is within the range of from 0.00001 to 0.02.

Owner:SANYO ELECTRIC CO LTD

Lithium ion secondary battery positive electrode material and preparation method thereof

ActiveCN105118991AImprove electrochemical performanceProtect structural stabilityPositive electrodesBatteriesCyclic processOxygen

The invention discloses a lithium ion secondary battery positive electrode material and a preparation method thereof. Doping of a lithium secondary battery positive electrode active substance is carried out by virtue of the synergistic effect among specific elements so as to realize simultaneous protection for a lithium-oxygen layer and a transitional metal-oxygen layer in a lithium cobalt oxide layered structure. By virtue of the optimal design of a secondary sintering technology, gradient doping or wrapping of the specific elements can be realized, so that the structural stability of large-particle lithium cobalt oxide of the material in a circulating process, particularly under a high-voltage condition, is better protected, and more excellent electrochemical performance is obtained; therefore, the lithium ion secondary battery positive electrode material can simultaneously meet the requirements on a high-discharge-voltage platform, high capacity and good circulating performance.

Owner:QINGHAI TAIFENG XIANXING LITHIUM ENERGY TECH CO LTD

Preparation technology for spherical lithium cobalt oxide doped with Ti, Mg and Al

InactiveCN102583585ASimple processReaction is easy to controlCell electrodesCobalt carbonatesSlurryCarbonate

The invention relates to the field of lithium ion battery materials and particularly relates to a preparation technology for spherical lithium cobalt oxide doped with Ti, Mg and Al. According to the preparation technology, pure water serves as base solution under the conditions that temperature ranges from 40 DEG C to 80 DEG C and a stirring speed is controlled to 60-180 r / min, ammonium bicarbonate is added into the base solution to adjust the alkalinity of the base solution to range from 5 to 30, cobalt-salt mixed solution and ammonium bicarbonate solution are continuously pumped into the base solution in parallel flow and are subjected to sedimentation reaction under the temperature of 40-80 DEG C, the solid content and the alkalinity of slurry in a reaction system are controlled, reaction feed liquid flows out continuously from an overflow gate at the upper part of a reaction kettle to enter into an ageing kettle and then is washed by a washing press and dried by a vacuum drier, spherical cobalt carbonate is subjected to primary calcination to obtain cobaltosic oxide, and the cobaltosic oxide and a lithium source are subjected to secondary calcination to obtain the spherical lithium cobalt oxide doped with Ti, Mg and Al. According to the invention, the process is simple, the reaction is easy to control, the production cost is low, the product application range is wide, and thus, the method is relatively large in production value; and the spherical lithium cobalt oxide is stable in performance and better in overcharging prevention performance.

Owner:ANHUI ALAND NEW ENERGY MATERIALS

High density lithium ion battery cathode material lithium cobalt oxide and preparation method thereof

InactiveCN102447107AIncrease compaction densityIncrease volumetric energy densityCell electrodesCobalt compoundsManufacturing technologySodium-ion battery

The invention relates to a manufacture technology of a lithium ion battery cathode material and specifically provides a high density lithium ion battery cathode material lithium cobalt oxide and a preparation method thereof. The high density lithium ion battery cathode material lithium cobalt oxide of the invention has a chemical formula of Li1+xCo(1-a-b-c) MgaTibAlcFdO(2-d), wherein a, b, c, d and x satisfy relations of: 0<=a<=0.03, 0.001<=b<=0.02, 0<=c<=0.01, 0<=d<=0.02 and 0<=x<=0.08; and a preferable value of a, a preferable value of b, a preferable value of c and a preferable value of d satisfy relations of: 0.005<=a<=0.01, 0.002<=b<=0.01, 0<=c<=0.005 and 0<=d<=0.005; and a cation M is doped or cladded by one or a composition of several selected from magnesium, titanium and aluminium. The invention can enhance stability of material structure, cycle performance and safety performance of the lithium ion battery as well as effectively increase space utilization rate of the material and compacted density of the cathode material, thereby substantially raising volume energy density of the material.

Owner:JIANGSU KING LITHIUM CELL

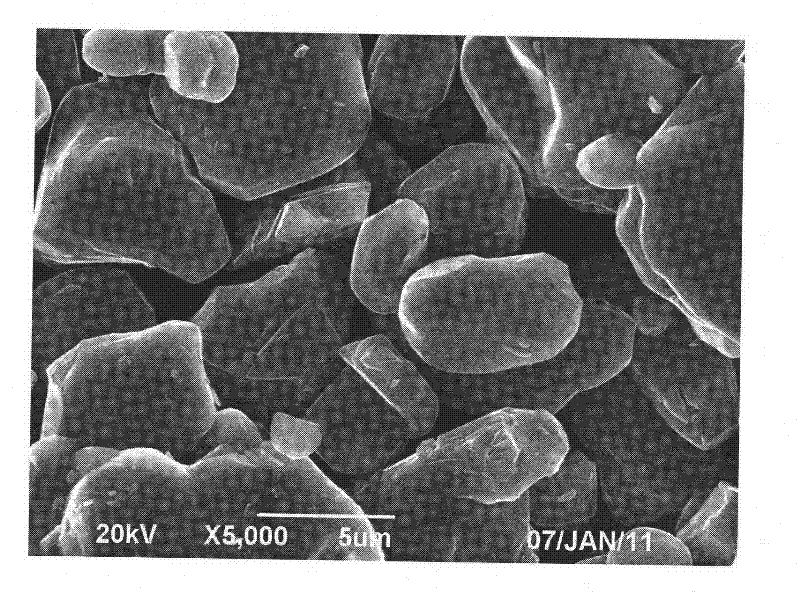

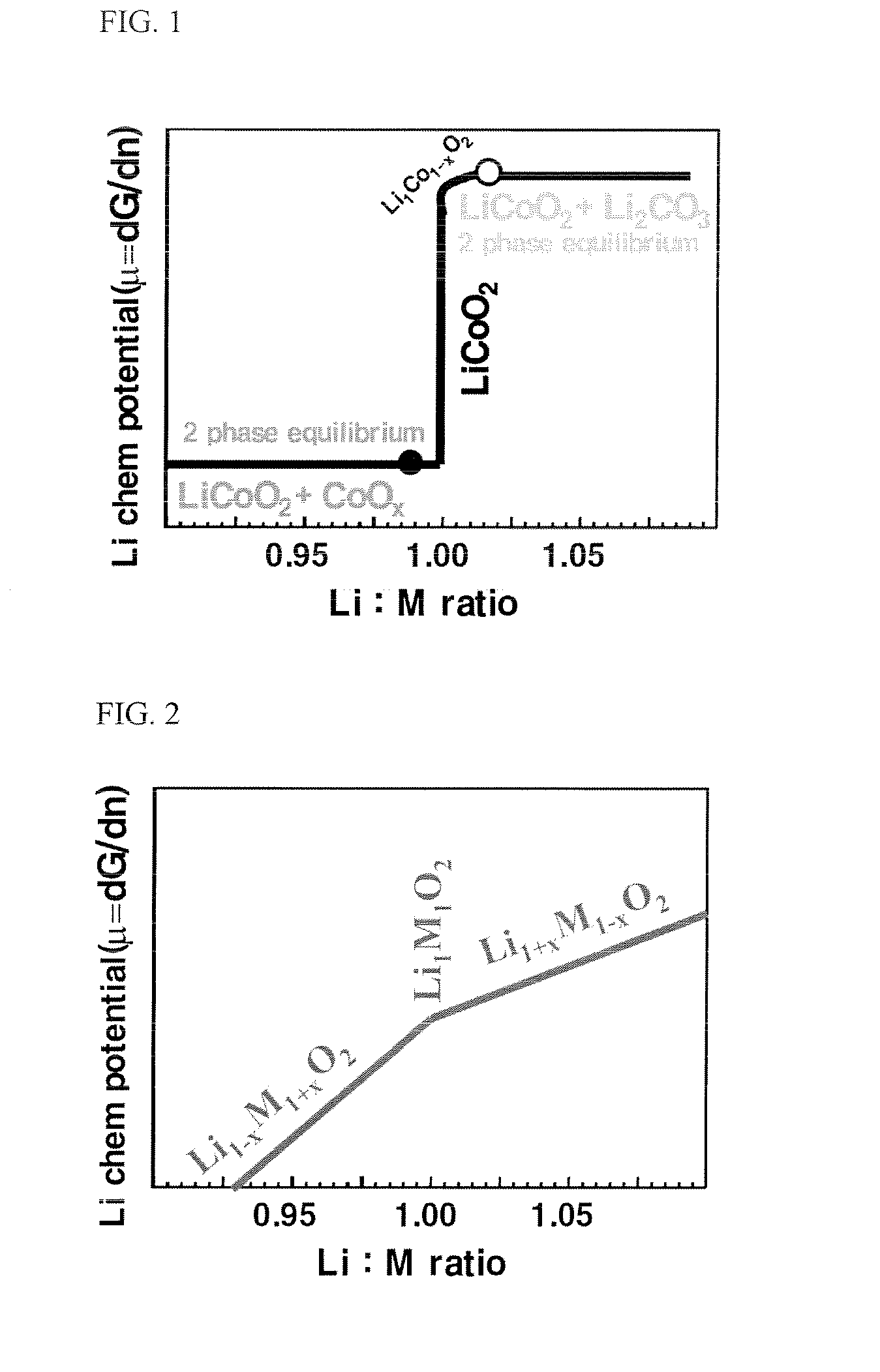

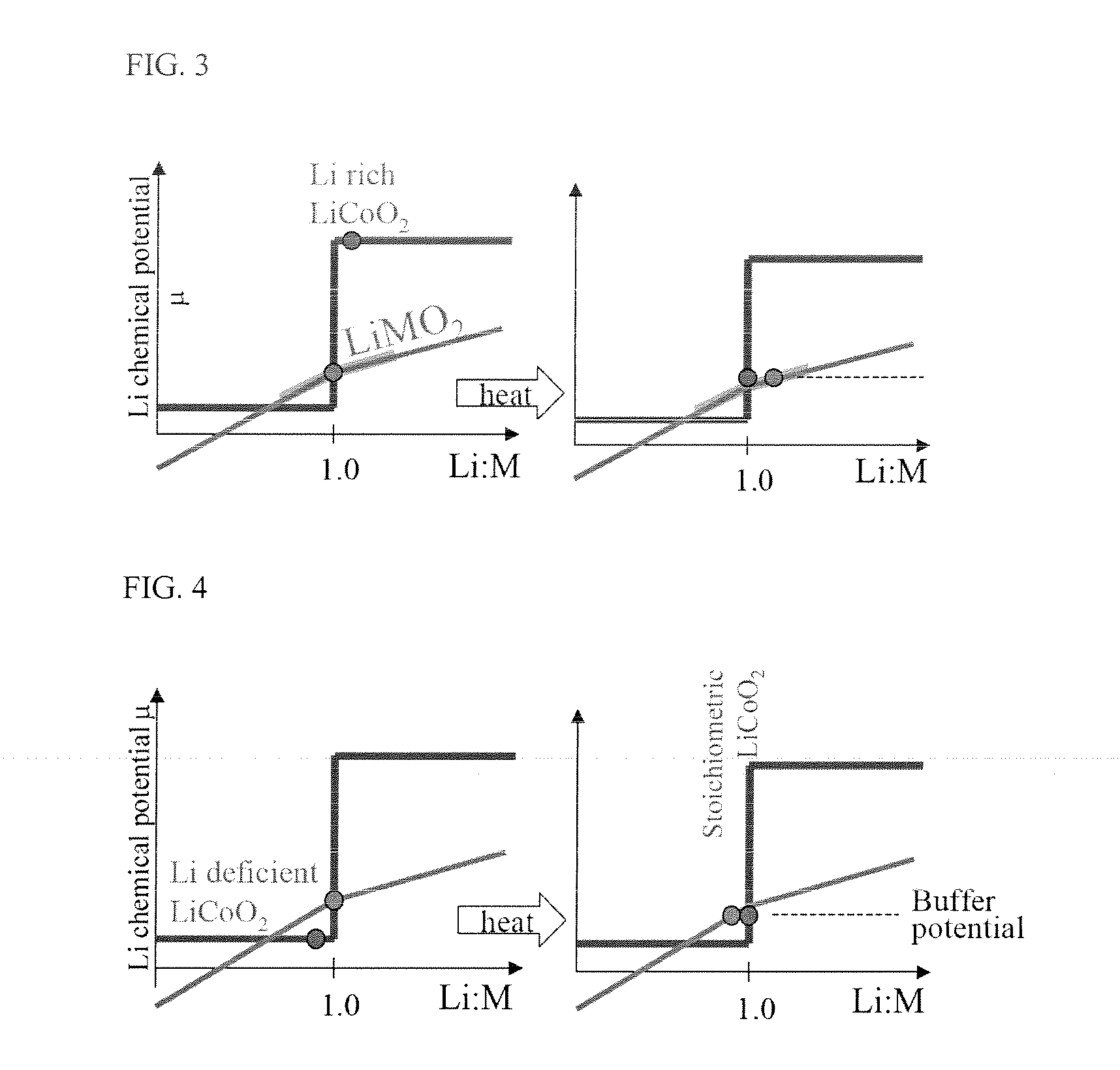

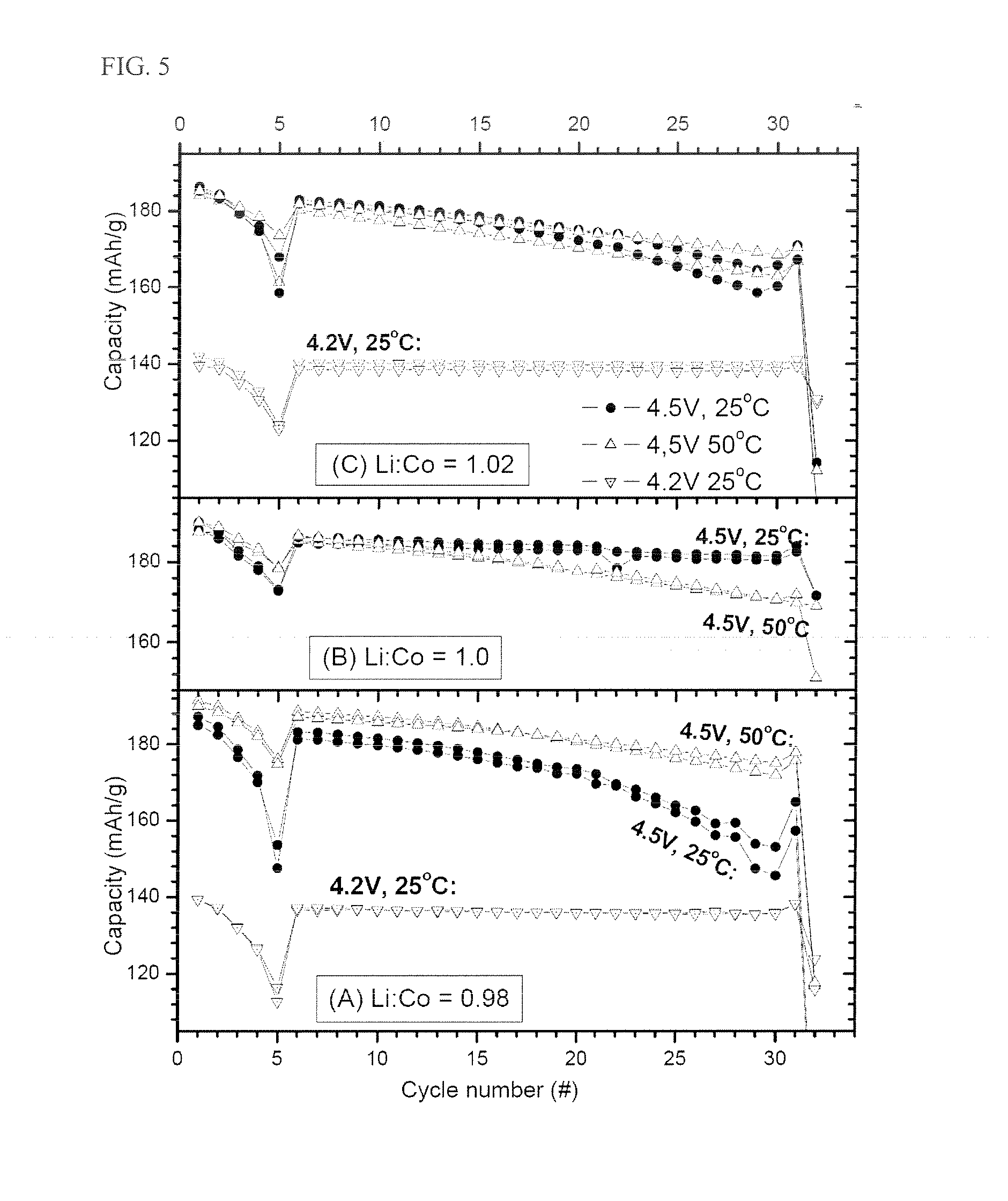

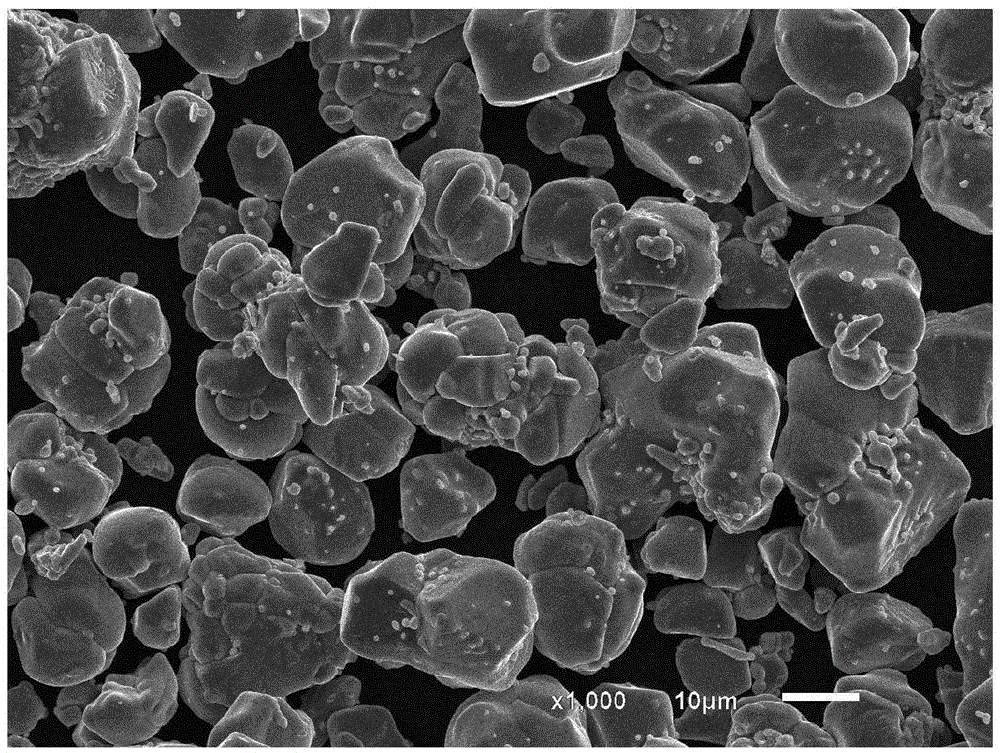

Stoichiometric Lithium Cobalt Oxide and Method for Preparation of the Same

ActiveUS20070218363A1Sensitive to process parameterLarge fluctuationsPrimary cell to battery groupingElectrode manufacturing processesHigh temperature storageLithium metal

The present invention provides a LiCoO2-containing powder comprising LiCoO2 having a stoichiometric composition via heat treatment of a lithium cobalt oxide and a lithium buffer material to make equilibrium of a lithium chemical potential therebetween: a lithium buffer material which acts as a Li acceptor or a Li donor to remove or supplement Li-excess or Li-deficiency, coexisting with a stoichiometric lithium metal oxide; and a method for preparing a LiCoO2-containing powder. Further, provided is an electrode comprising the above-mentioned LiCoO2-containing powder as an active material, and a rechargeable battery comprising the same electrode.The present invention enables production of a LiCoO2 electrode active material which has improved high-temperature storage properties and high-voltage cycling properties, and is robust in composition fluctuation in the production process. Therefore, the present invention provides advantages such as reduction of time and labor required for quality control and process management in the mass-production of the electrode active material, and decreased production costs of LiCoO2.

Owner:LG ENERGY SOLUTION LTD

High-voltage lithium cobalt oxide cathode material for lithium-ion battery and preparation method of high-voltage lithium cobalt oxide cathode material

ActiveCN105406036AIncrease volumetric energy densityImprove cycle performanceCell electrodesSecondary cellsPhysical chemistryHigh voltage

The invention discloses a high-voltage lithium cobalt oxide cathode material for a lithium-ion battery and a preparation method of the high-voltage lithium cobalt oxide cathode material. The high-voltage lithium cobalt oxide cathode material is prepared from a doped lithium cobalt oxide matrix and a coating on the surface of the doped lithium cobalt oxide matrix, wherein a general formula of the doped lithium cobalt oxide matrix is Li<x>Co<1-y>M<y>O<2-z>N<z>; the general formula of the coating is LiNi<x'>Co<y'>Al<z'>O<2>; and the preparation method comprises the following steps: firstly, obtaining the lithium cobalt oxide matrix Li<x>Co<1-y>M<y>O<2-z>N<z> through once sintering; secondly, preparing a lithium cobalt oxide cathode material precursor coated with Ni<x'>Co<y'>Al<z'>(OH)<2> on the surface by liquid-phase co-precipitation reaction; and finally obtaining the high-voltage lithium cobalt oxide cathode material through twice sintering. The high-voltage lithium cobalt oxide cathode material prepared by the method is good in processability and high in compaction density, has relatively high specific capacity and good cycle performance in a high-voltage state, and can be stably circulated at high voltage of 3.0V to 4.5V.

Owner:HUNAN CHANGYUAN LICO CO LTD +1

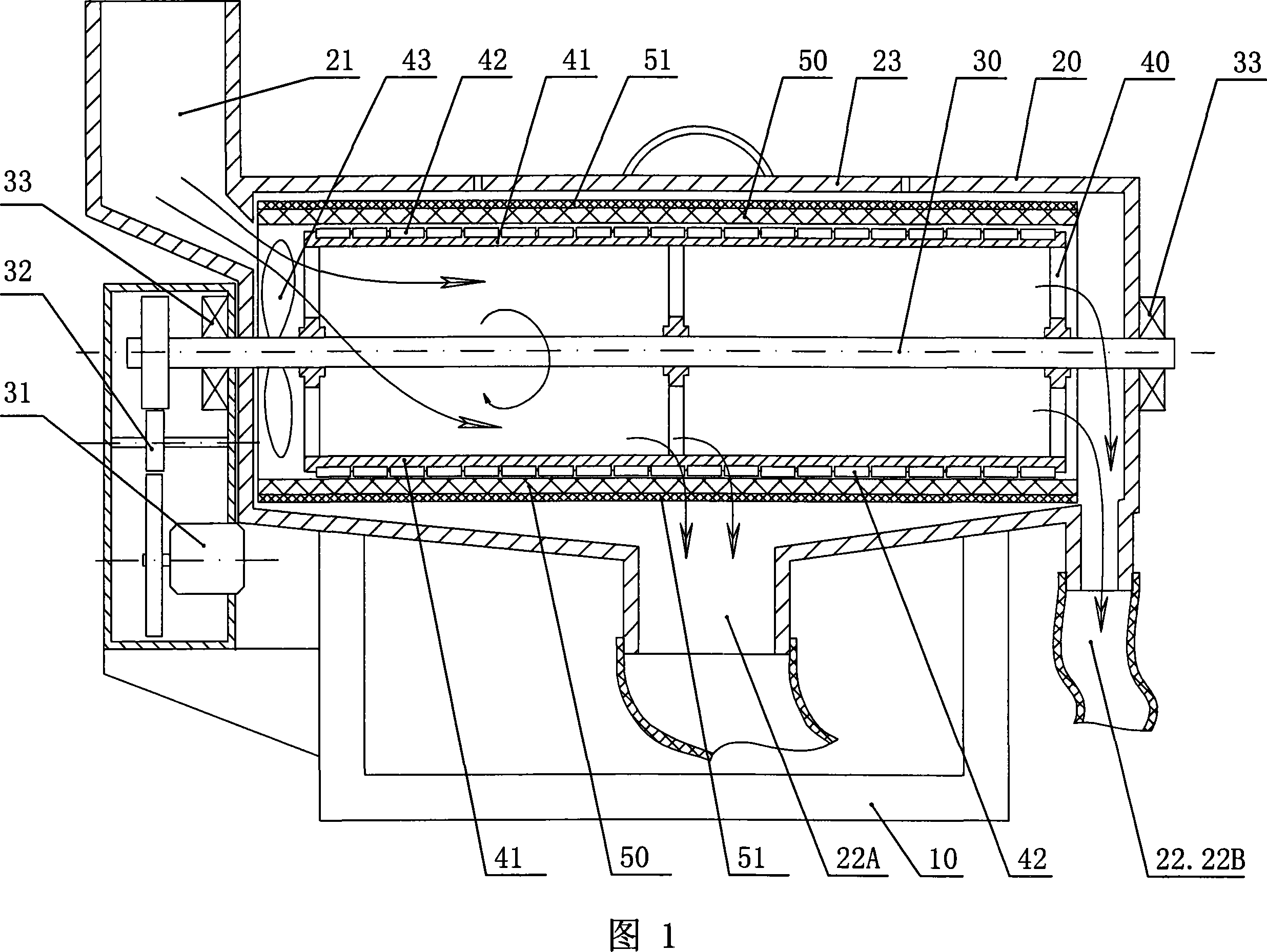

Method of controlling fragmentation and recovery of waste battery and system thereof

ActiveCN101183740AAppropriate spacingReduce pollutionSolid waste disposalReclaiming serviceable partsRecovery methodEngineering

The invention relates to a controllably-crushing recovery method and system of scrap batteries, comprising the following steps that: the scrap batteries are separated and classified to obtain a collection of lithium-ion batteries; the casings of the lithium-ion batteries are shelled by a scrap-battery rejuvenator to obtain a collection of lithium-ion battery content; the collected lithium-ion battery content is physically separated to obtain a collection of aluminium positive plates and positive active coatings on the positive plates; the aluminium positive plates and the positive active coatings on the positive plates are sent into a controllably-crushing device of scrap batteries and processed controllably-crushing to obtain a collection of mixture of aluminium granule and positive powder; the mixture of aluminium granule and positive powder is subtly sieved and separated to respectively obtain the aluminium granule and the positive powder. The invention has the advantages of greatly reducing environmental pollution of recovery process, less material-separating energy consumption, being close to 90% of intrinsic purity for the lithium cobalt oxide powder from recovery and facilitating economic running.

Owner:GEM CO LTD

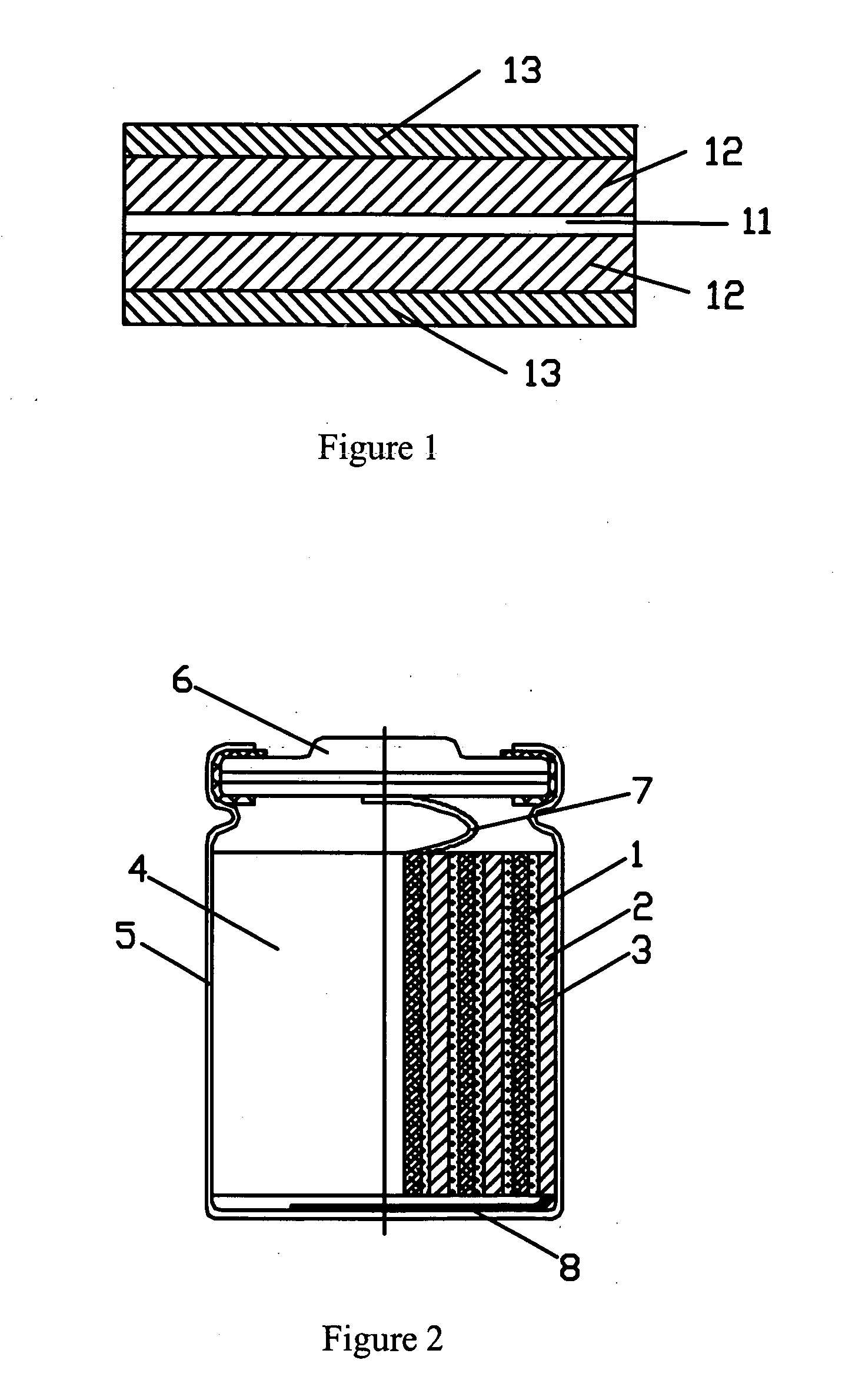

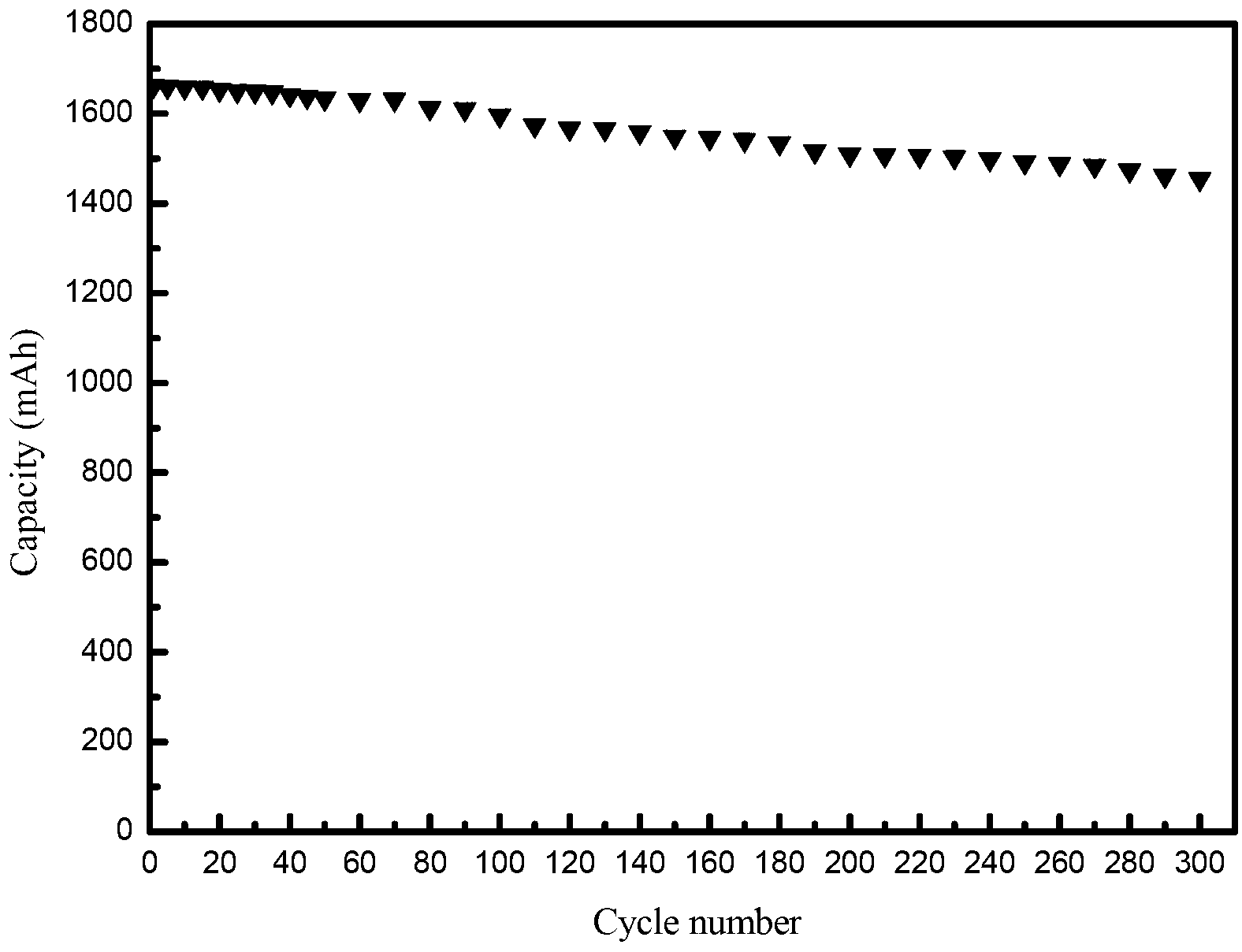

High-voltage high-energy-density lithium ion battery

InactiveCN103311539AIncrease energy densityHigh discharge platformFinal product manufactureElectrode carriers/collectorsElectrical batteryHigh energy

The invention discloses a high-voltage high-energy-density lithium ion battery which comprises a positive pole piece, a negative pole piece, a diaphragm, electrolyte and a shell, wherein the positive pole piece comprises a positive active material, a conducting agent, an adhesive and a current collector, and the weight percents of the positive active material, the conducting agent and the adhesion are 92 to 97%: 2 to 3.5%: 1 to 6%; the negative pole piece comprises a negative material, a conducting agent, an adhesive and a current collector, and the weight percents of the negative material, the conducting agent and the adhesive are respectively 90 to 96%, 1 to 5% and 4 to 10%; the lithium ion battery is prepared by adopting modified lithium cobalt oxides (LiCoO2) as the positive active material and the artificial graphite or natural graphite as the negative material and matching the corresponding ceramic diaphragm, high-voltage electrolyte, adhesive and conducting agent. The lithium ion battery not only has high energy density and high discharging platform, but also is good in chemical performance and safety performance and is applicable to the commercialized mass production.

Owner:SHENZHEN WISEWOD TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com