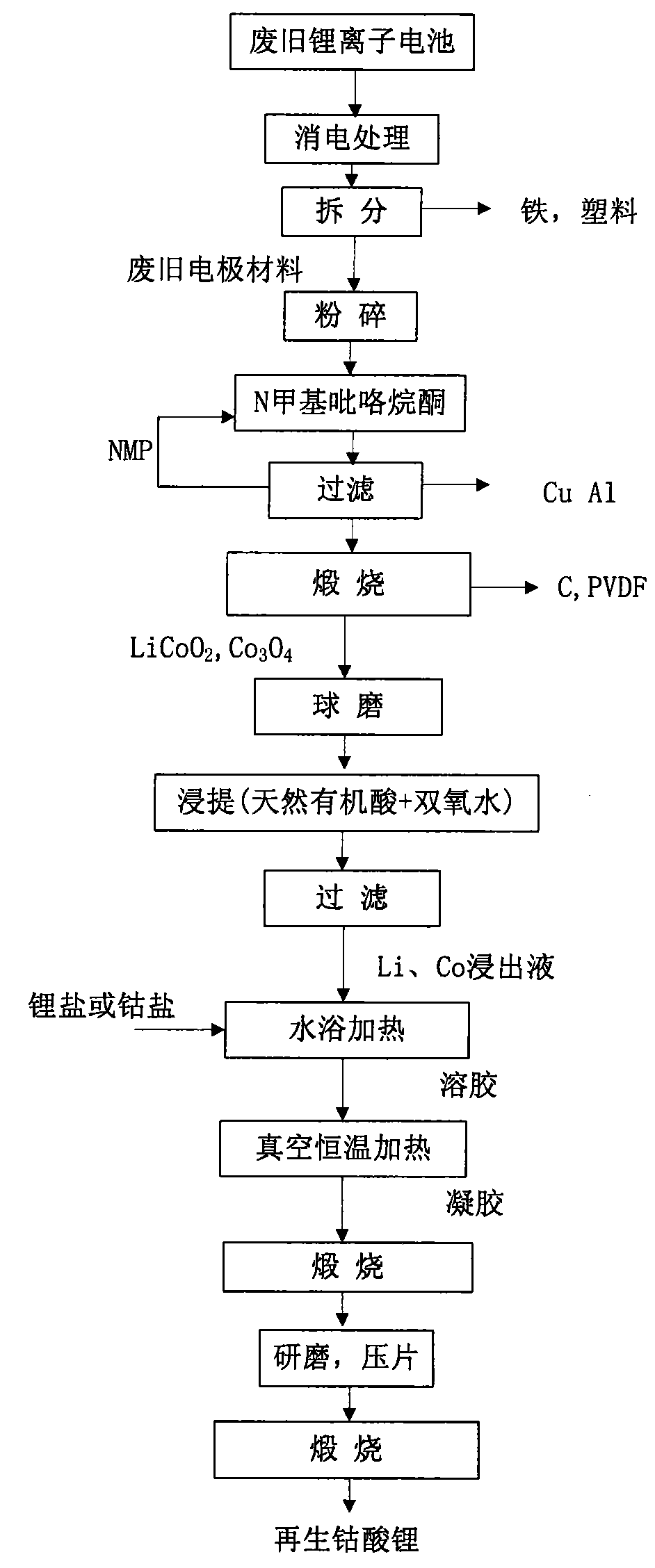

Method for recovering and preparing lithium cobalt oxide by using disused lithium battery

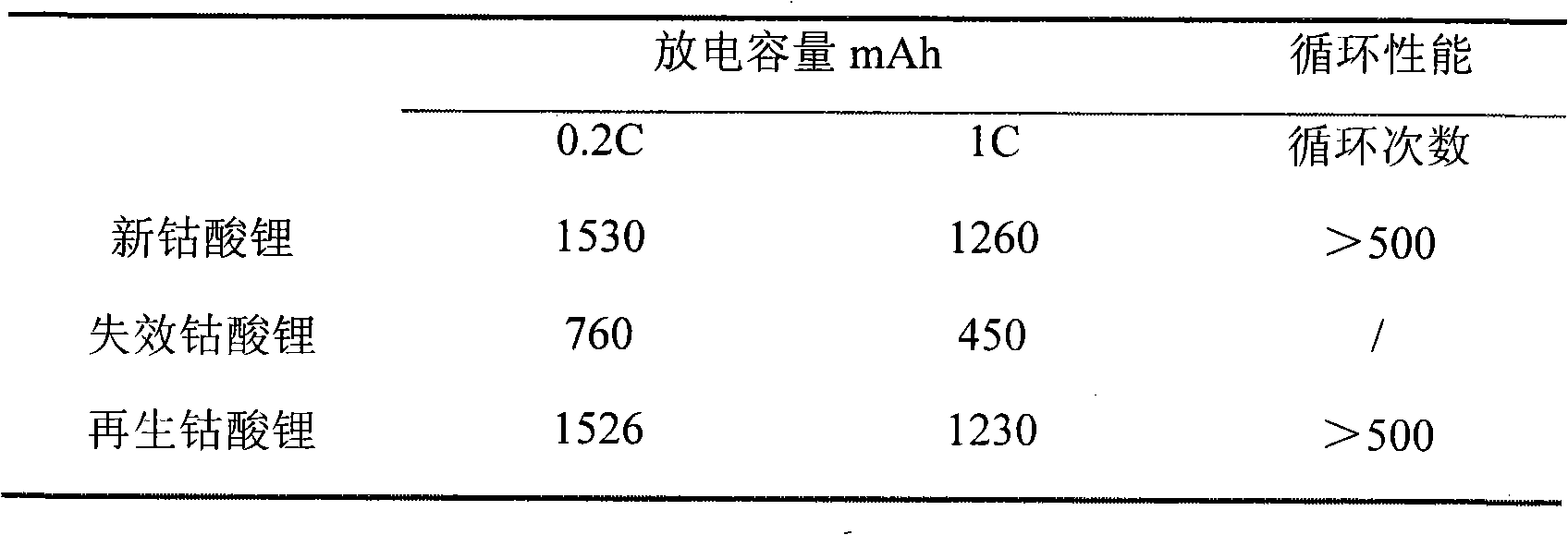

A technology for lithium-ion batteries and used batteries, applied in battery recycling, waste collector recycling, recycling technology, etc., can solve the problems of difficult disposal of waste liquid, high equipment requirements, secondary pollution, etc., to solve the problem of cobalt resource scarcity , the effect is obvious, the effect of high recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] A lithium-ion battery that has a charge-discharge cycle life of 1000 cycles and has a good consistency is used in the experiment of preparing lithium cobaltate by recycling the waste lithium-ion battery of the present invention. After the de-energization treatment, the battery is mechanically cut and dissected, and the iron shell and electrode materials are disassembled. Treat the pulverized positive and negative electrodes with NMP, filter and collect the fluid. The recovered electrode active material was dried and then calcined in a muffle furnace at 700°C to obtain LiCoO 2 Crude product (LiCoO 2 、Co 3 o 4 , C powder), under the condition of 80 ℃, the obtained electrode material crude product is immersed in the citric acid solution of 1.25M, and the hydrogen peroxide of 1.0vol.%. Fully react under the condition of condensation, and obtain leachate after filtration. Determination of Li in solution by atomic absorption spectrophotometer + 、Co 2+ content. Add 120...

Embodiment 2

[0020] A lithium-ion battery that has a charge-discharge cycle life of 1000 cycles and has a good consistency is used in the experiment of preparing lithium cobaltate by recycling the waste lithium-ion battery of the present invention. After the de-energization treatment, the battery is mechanically cut and dissected, and the iron shell and electrode materials are disassembled. Treat the pulverized positive and negative electrodes with NMP, filter and collect the fluid. The recovered electrode active material was dried and then calcined in a muffle furnace at 700°C to obtain LiCoO 2 Crude product (LiCoO 2 、Co 3 o 4 , C powder), under the condition of 90 ℃, the obtained electrode material crude product is immersed in the malic acid solution of 1.5M, and the hydrogen peroxide of 0.5vol.%. Fully react under the condition of condensation, and obtain leachate after filtration. Determination of Li in solution by atomic absorption spectrophotometer + 、Co 2+ content. Add 120ml...

Embodiment 3

[0022] A lithium-ion battery that has a charge-discharge cycle life of 1000 cycles and has a good consistency is used in the experiment of preparing lithium cobaltate by recycling the waste lithium-ion battery of the present invention. After the de-energization treatment, the battery is mechanically cut and dissected, and the iron shell and electrode materials are disassembled. Treat the pulverized positive and negative electrodes with NMP, filter and collect the fluid. The recovered electrode active material was dried and then calcined in a muffle furnace at 700°C to obtain LiCoO 2 Crude product (LiCoO 2 、Co 3 o 4 , C powder), under the condition of 90 DEG C, the obtained electrode material crude product is immersed in 0.5M succinic acid solution, and 0.1vol.%.% of hydrogen peroxide is added, and the solid-liquid ratio is S: L=10g / L. After stirring and Fully react under the condition of condensation, and obtain leachate after filtration. Determination of Li in solution b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com