Centrifugal impeller optimal design method for preventing vibration localization for happening

An optimized design and centrifugal impeller technology, applied in mechanical equipment, machines/engines, liquid fuel engines, etc., can solve problems affecting the safe and reliable operation of fans, impeller vibration fatigue damage, impeller structure detuning, etc., to achieve safe and reliable long-term operation , reduce vibration and related hazards, and reduce the effect of failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

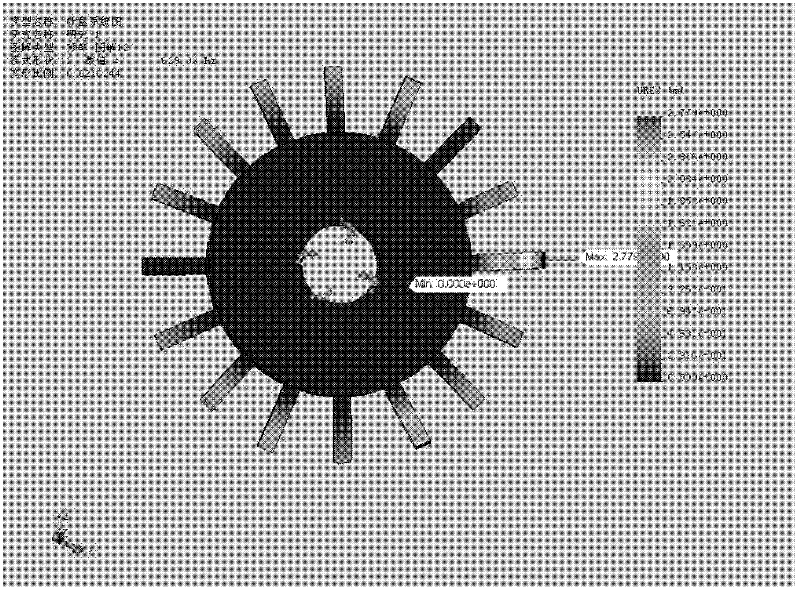

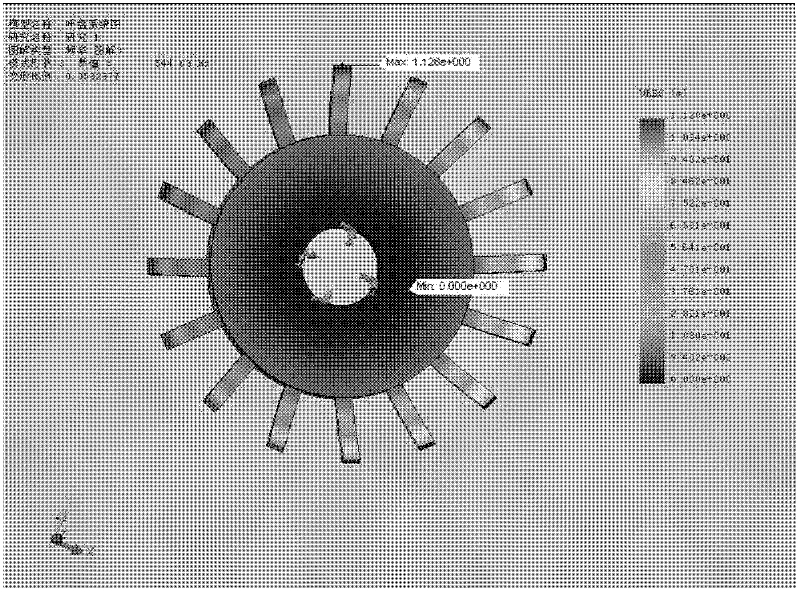

[0090] Example: a centrifugal impeller

[0091] Fault phenomenon: Cracks appear at the inlet ring of the impeller cover

[0092] Elimination method: adjust the number of blades of the inlet reflux to Z=14

[0093] The main dimensions and technical parameters of the impeller: diameter D = Φ1020mm, number of blades Z = 19, blade thickness δ = 8mm, working speed n = 5545r / min, material: alloy steel, yield limit σ s =8.50×108Pa, elastic modulus E=2.1×1011Pa, Poisson’s ratio v=0.28, material density ρ=7700kg / m 3 .

[0094] Relevant parameters of the compressor unit: the total number of stages: 3 stages, the stage number of the impeller: the third stage, the number of blades of the inlet blade reflux device Z 1 =18.

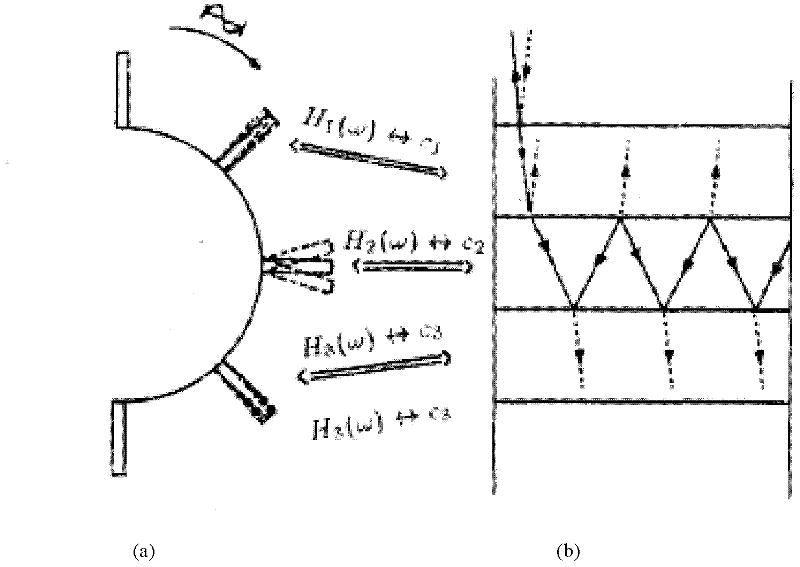

[0095] Excitation source: the frequency of the excitation force caused by the imported reflux The frequency of the exciting force caused by the blades at the exit of the impeller

[0096] Finite element model of the impeller: 10-node tetrahedral solid elements...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com