Patents

Literature

297 results about "Vibration fatigue" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Vibration fatigue is a mechanical engineering term describing material fatigue, caused by forced vibration of random nature. An excited structure responds according to its natural-dynamics modes, which results in a dynamic stress load in the material points. The process of material fatigue is thus governed largely by the shape of the excitation profile and the response it produces. As the profiles of excitation and response are preferably analyzed in the frequency domain it is practical to use fatigue life evaluation methods, that can operate on the data in frequency-domain, such as power spectral density (PSD).

Vibration fatigue life predication method and system for micro-packaging assembly

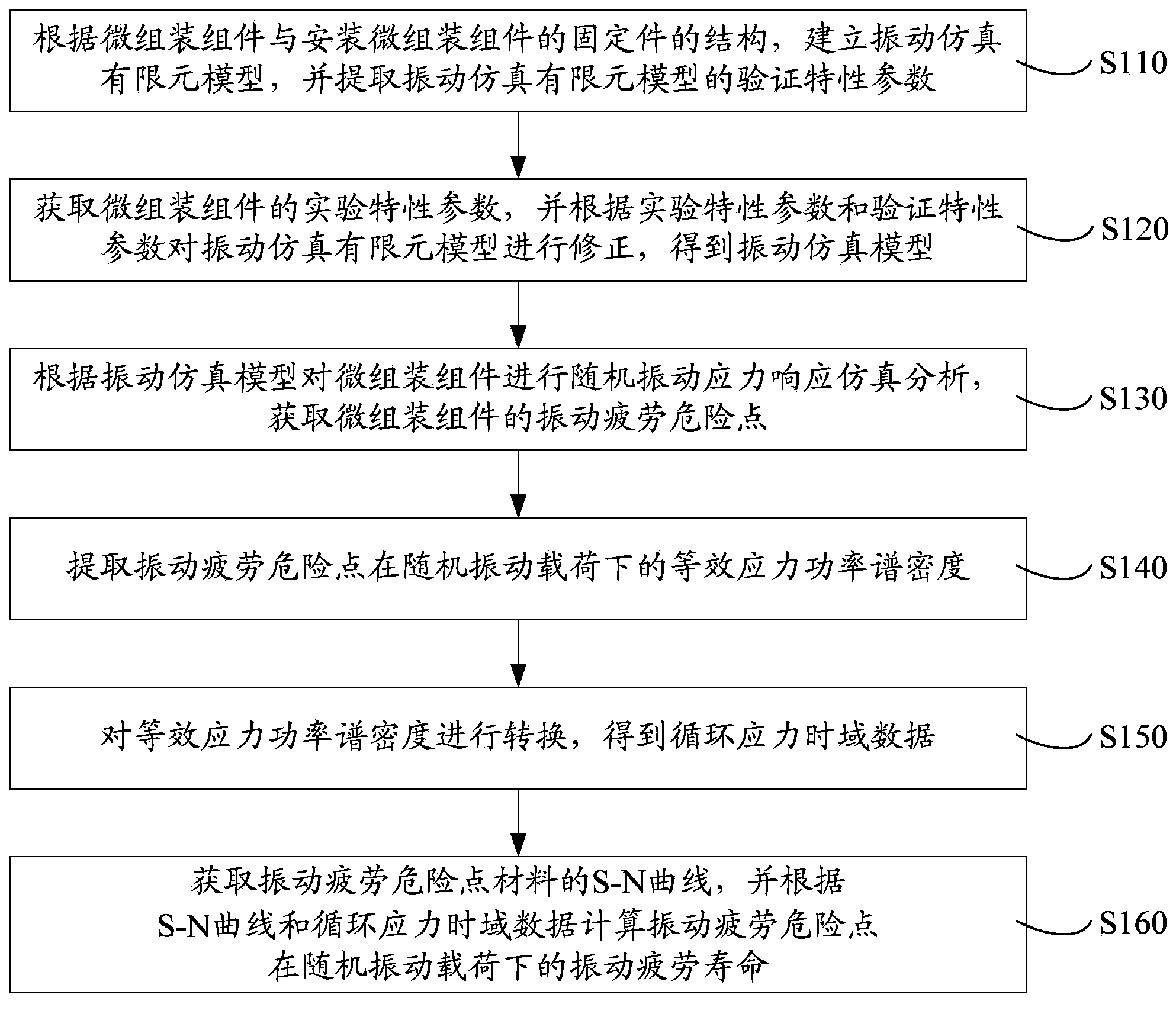

ActiveCN104268335ASolving the Difficulty of Vibration Fatigue Life PredictionAvoid data difficultiesSpecial data processing applicationsTime domainElement model

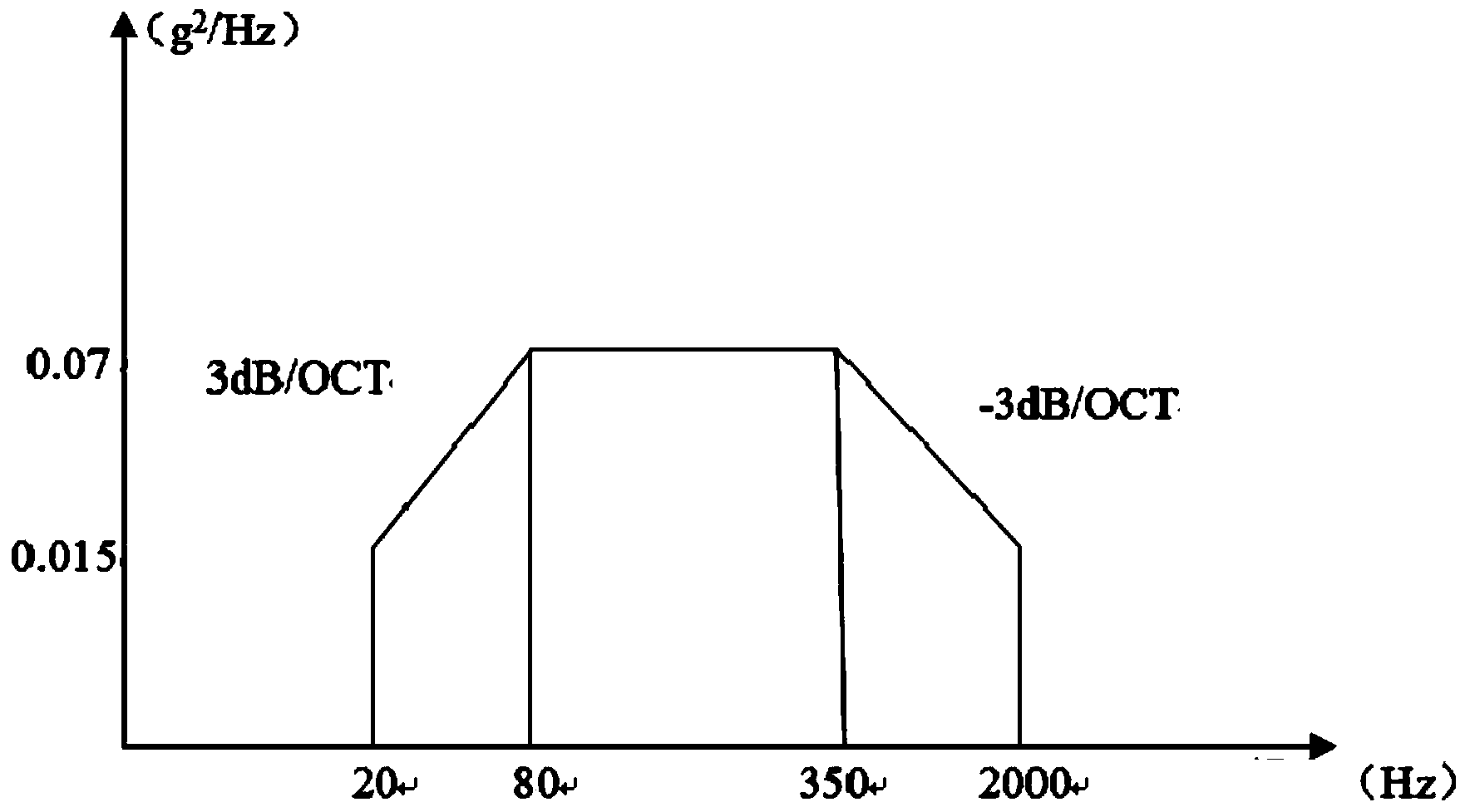

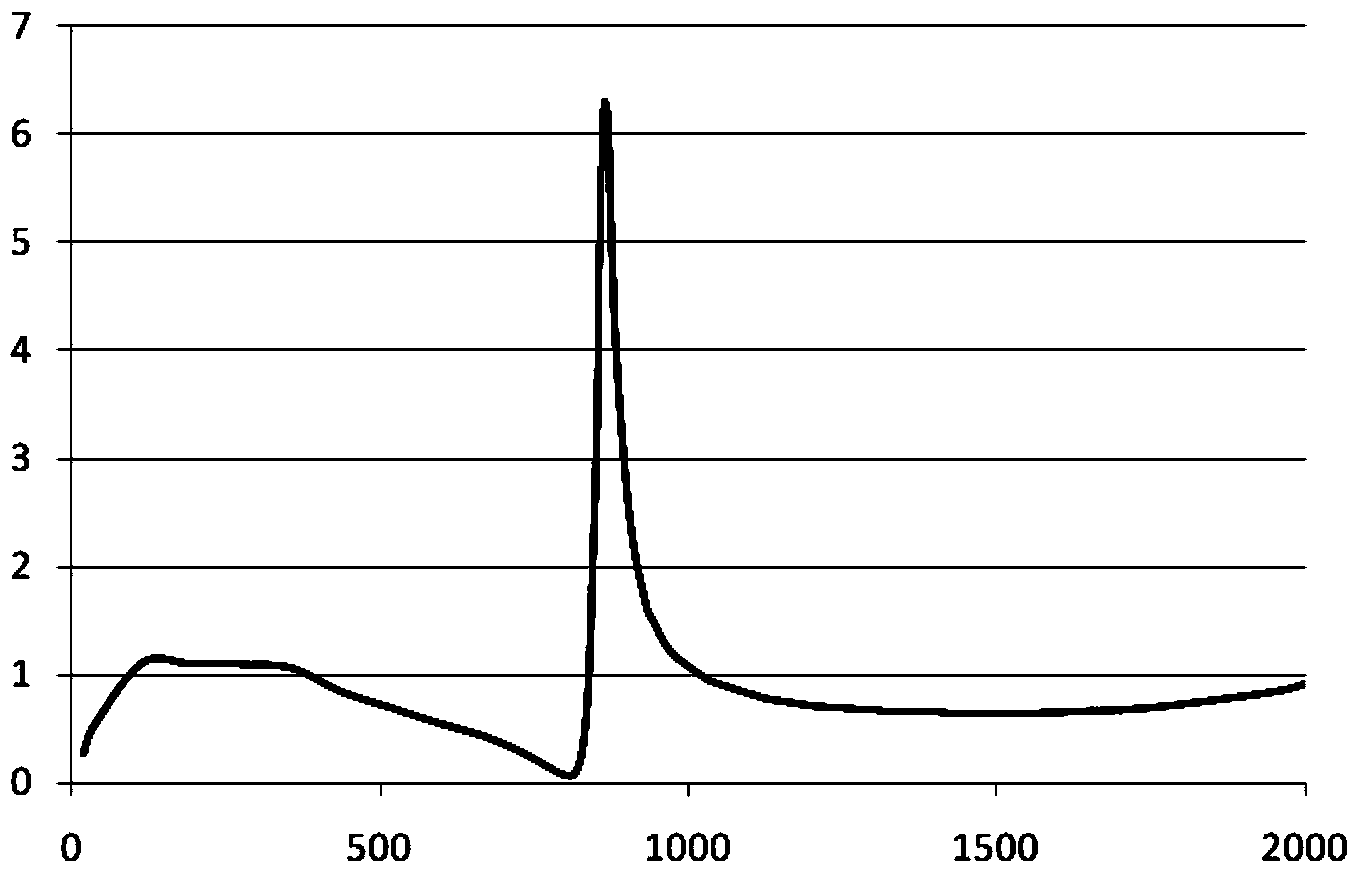

The invention provides a vibration fatigue life predication method and system for a micro-packaging assembly. The method comprises the following steps: creating a vibration simulating finite element model according to the structures of the micro-packaging assembly and a fixing part; extracting the verification characteristics parameters; modifying the vibration simulating finite element model according to the verification characteristics parameters and the experimental characteristics parameters of the micro-packaging assembly to obtain a vibration simulating model; performing random vibration stress response simulation analysis for the micro-packaging assembly according to the vibration simulation model to obtain a dangerous vibration fatigue point; extracting equivalent stress power spectrum density of the dangerous vibration fatigue point under the random vibration load; converting the equivalent stress power spectrum density to obtain cyclic stress time domain data; calculating the vibration fatigue life of the dangerous vibration fatigue point under the random vibration load according to an S-N curve and the cyclic stress time domain data of the dangerous vibration fatigue point; predicating the vibration fatigue life of the micro-packaging assembly by the method of synchronously extracting the response data of the fixing part and the micro-packaging assembly. With the adoption of the method and system, the testing accuracy is improved.

Owner:FIFTH ELECTRONICS RES INST OF MINIST OF IND & INFORMATION TECH

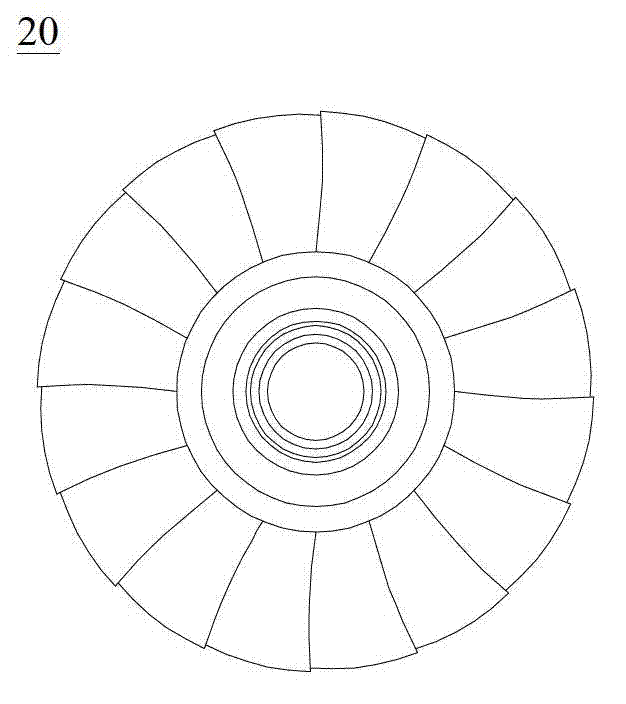

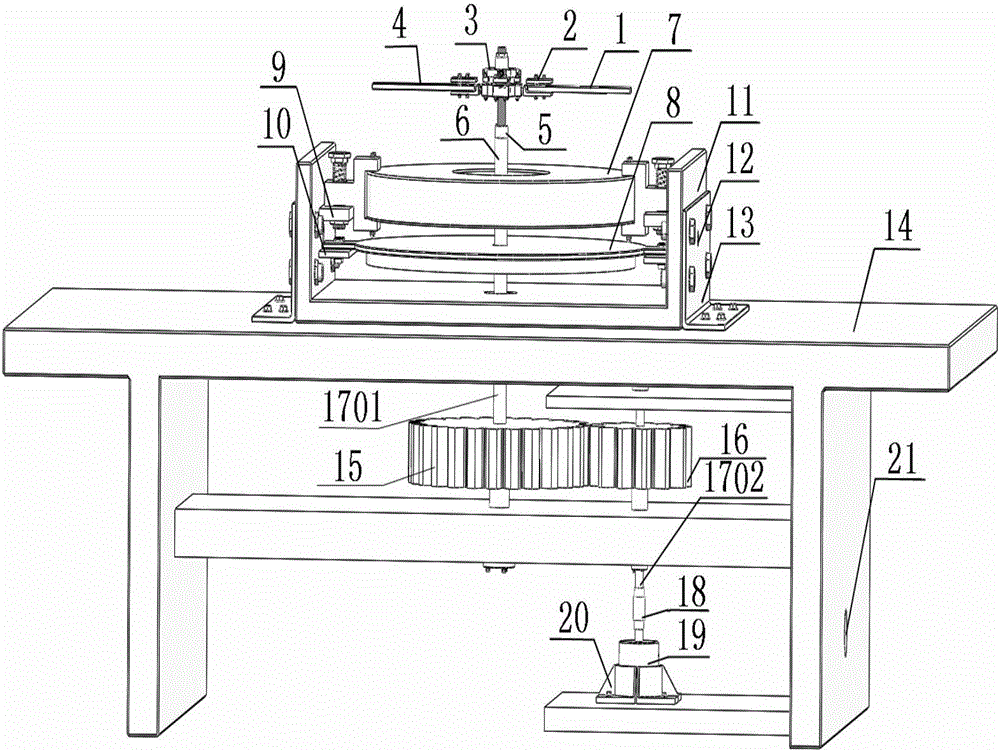

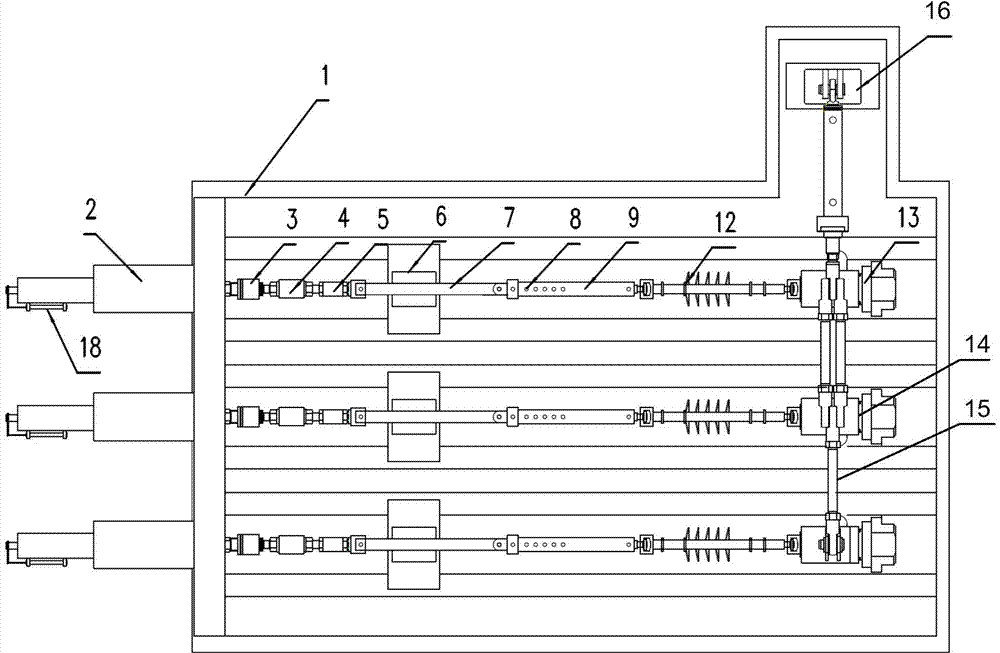

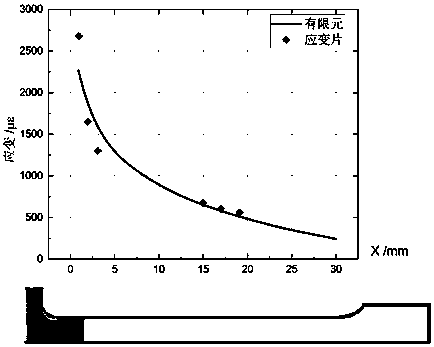

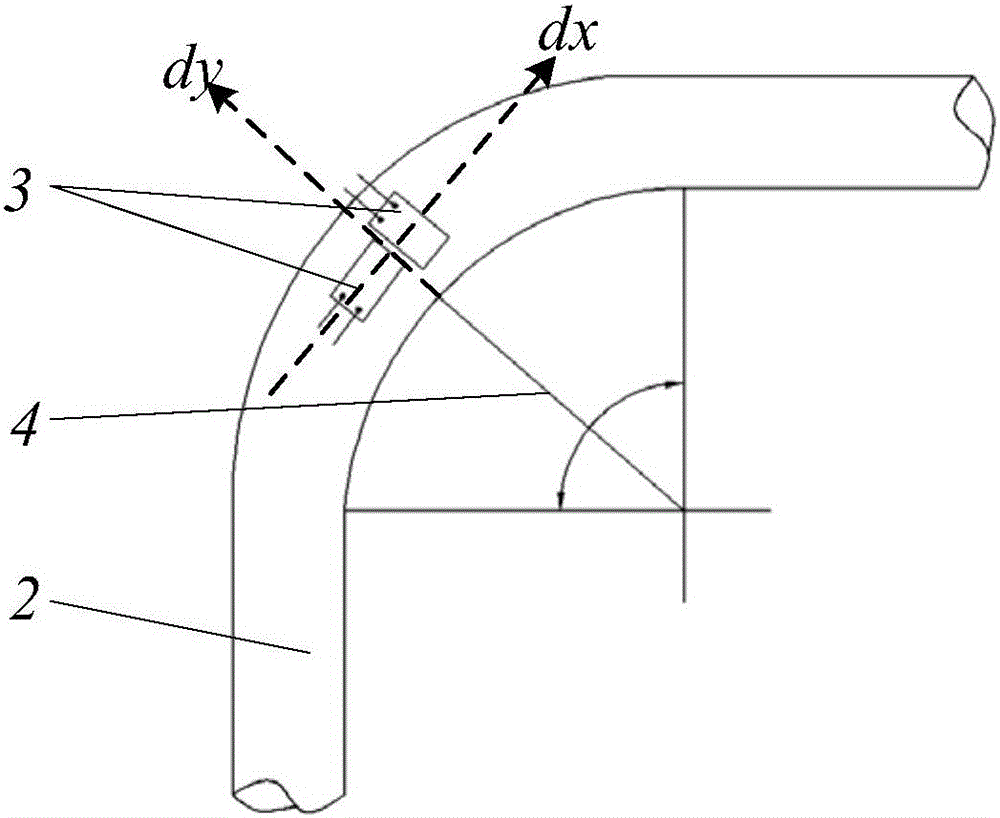

Testing device and testing method of integral-impeller blade vibration fatigue

ActiveCN103196644AChange natural frequencyAvoid the hassle of cutting in equal partsVibration testingImpellerEngineering

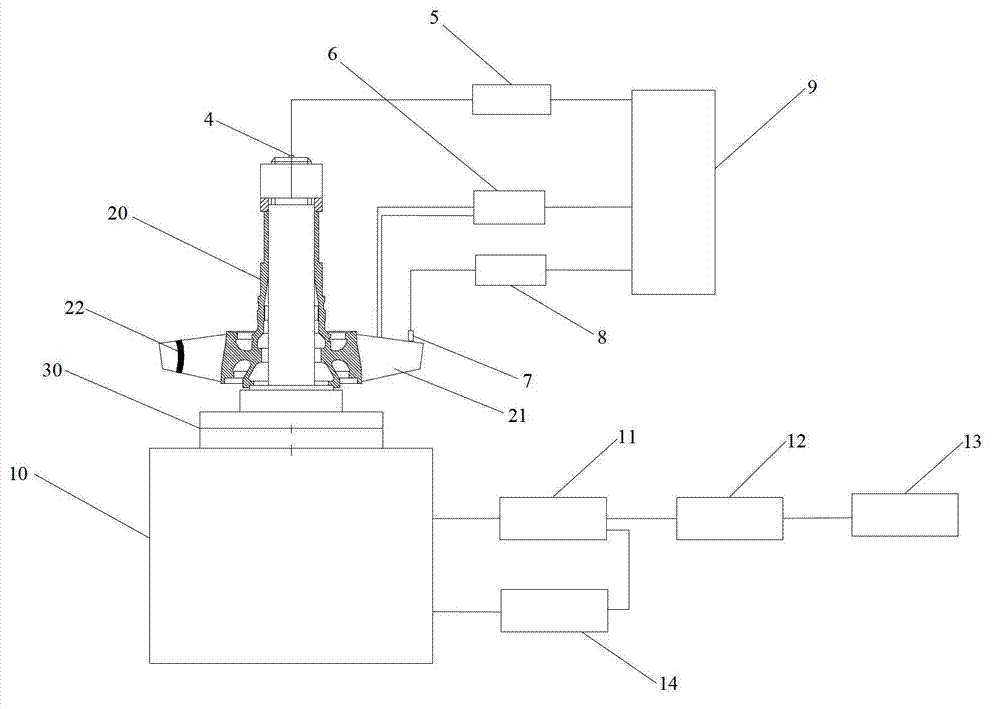

The invention discloses a testing device and a testing method of integral-impeller blade vibration fatigue. The testing device comprises a vibration testing platform and an integral impeller, wherein the integral impeller is axially pressed through a fixture and is fixed on the vibration testing platform; the vibration testing platform is connected with a vibration device used for starting oscillation; the integral impeller is connected with a detection device used for detecting and recording testing parameters; and a rubber damping block enabling adjacent blades to be mutually damped is installed between the adjacent blades of the integral impeller. According to the testing device and the testing method, each rubber damping block is installed between the adjacent blades of the integral impeller to enable the adjacent blades to be mutually damped, the fact that other blades cannot vibrate freely when vibration fatigue testing is conducted on a single blade of the integral impeller is guaranteed, troubles caused by equal division of the integral impeller are avoided, rigidity change of a wheel disc supporting the blades is prevented from leading to change of inherent frequency of the blades, and therefore reliability of vibration fatigue testing results is guaranteed.

Owner:CHINA AVIATION POWER MACHINE INST

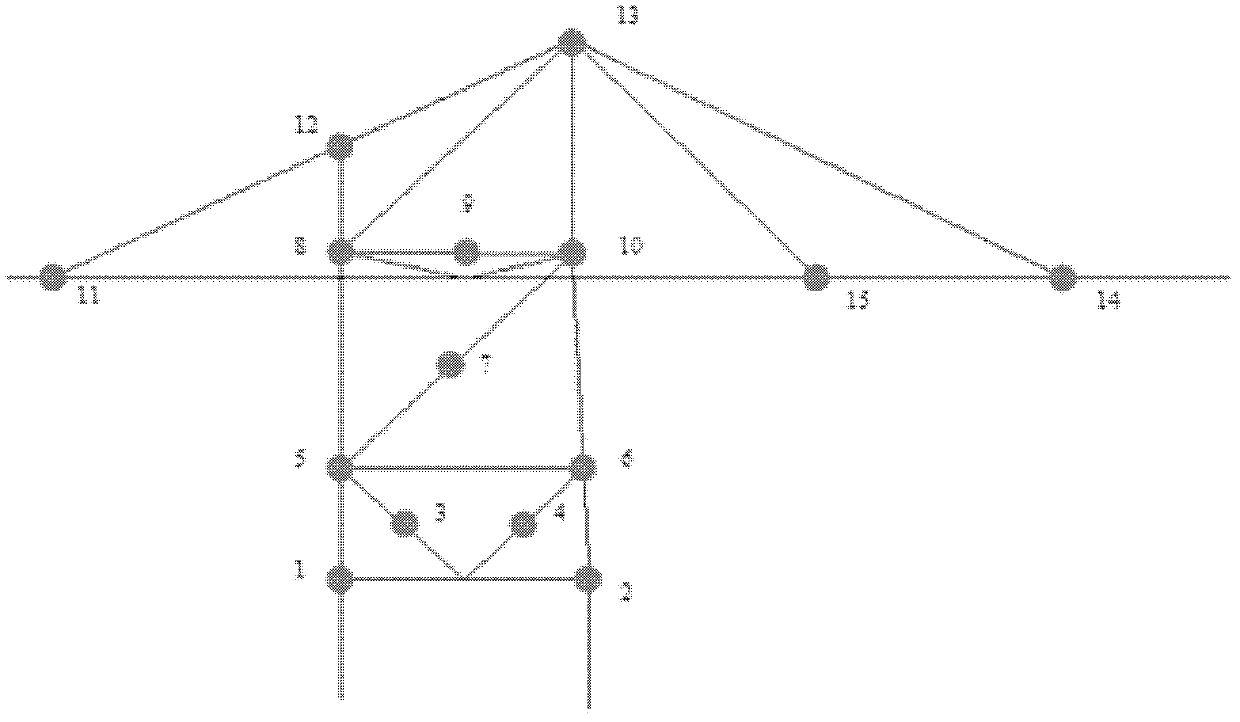

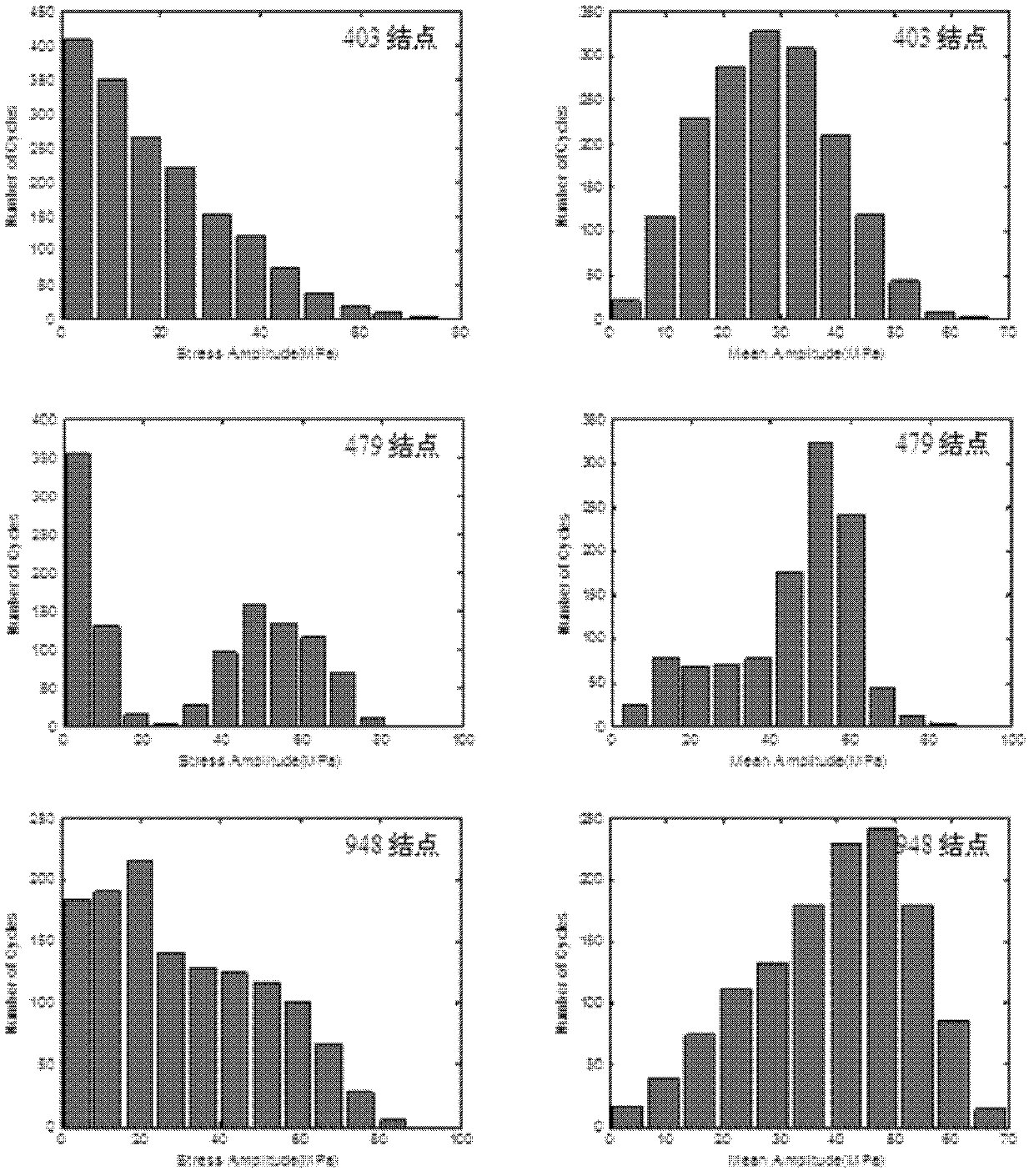

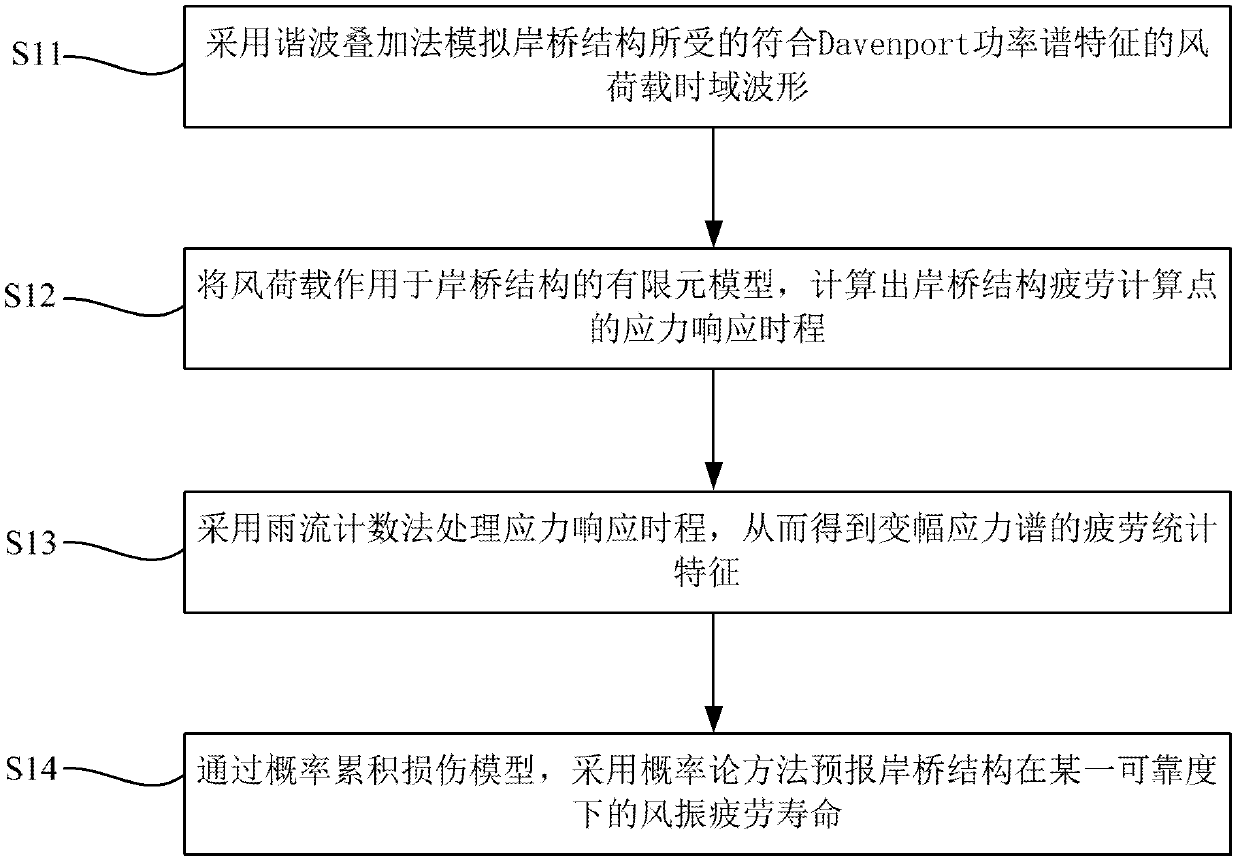

Shore bridge structure wind vibration fatigue life forecasting method based on accumulated damage of probability

InactiveCN102567632AImprove calculation accuracySpecial data processing applicationsElement modelStructural fatigue

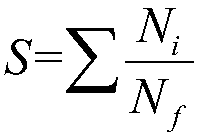

A shore bridge structure wind vibration fatigue life forecasting method based on accumulated damage of probability includes the following steps: step 1 adopting a harmonic superposition method to simulate time domain waveform of wind load borne by a shore bridge structure and according with davenport power spectrum characteristics; step 2 enabling the wind load to be acted on a finite element model of the shore bridge structure, and calculating a stress response time interval of fatigue calculation points of the shore bridge structure; step 3 adopting a rain flow counting process to deal with the stress response time interval so as to obtain fatigue statistical characteristics of amplitude stress spectrum; and step 4 adopting a probability accumulated damage model and a method of a probability theory to forecast wind vibration fatigue life of the shore bridge structure at a certain degree of reliability. The shore bridge structure wind vibration fatigue life forecasting method has the advantages of applying to a complex shore bridge structure, and being wide in scope of application, high in calculating accuracy and capable of calculating reliability fatigue life of a wind resisting structure under the action of any random wind load.

Owner:SHANGHAI JIAO TONG UNIV

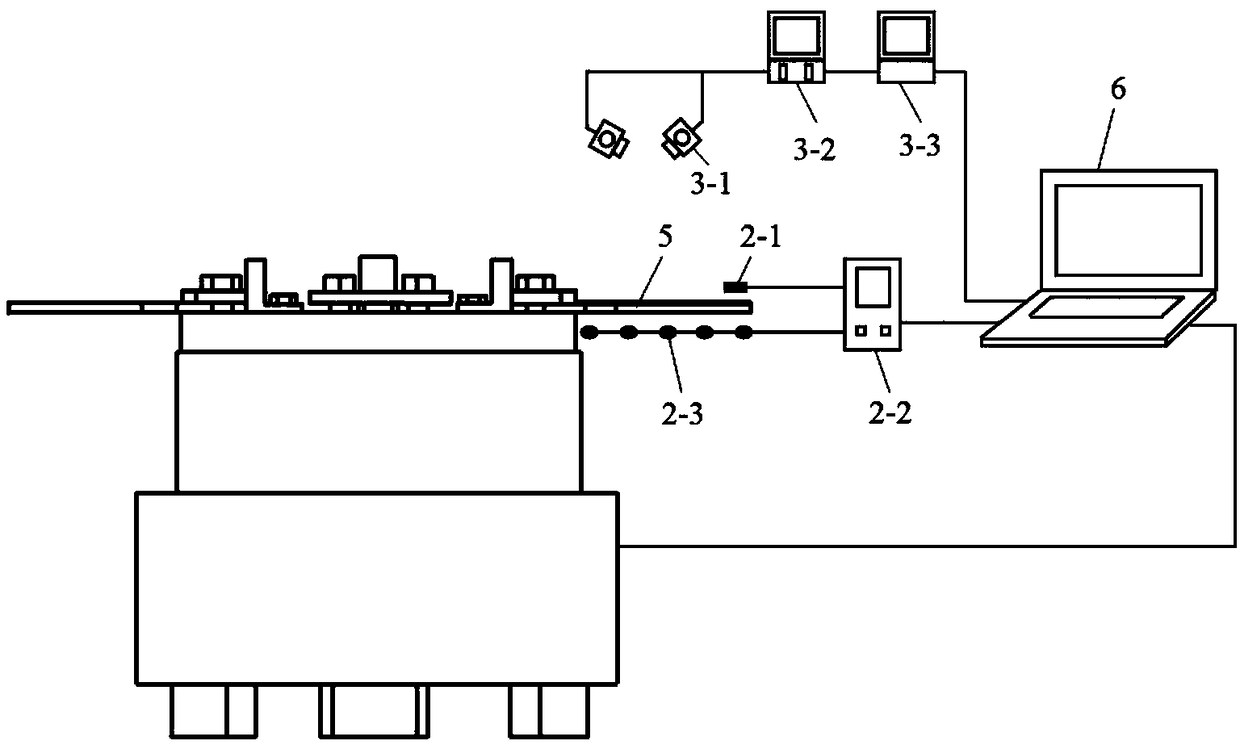

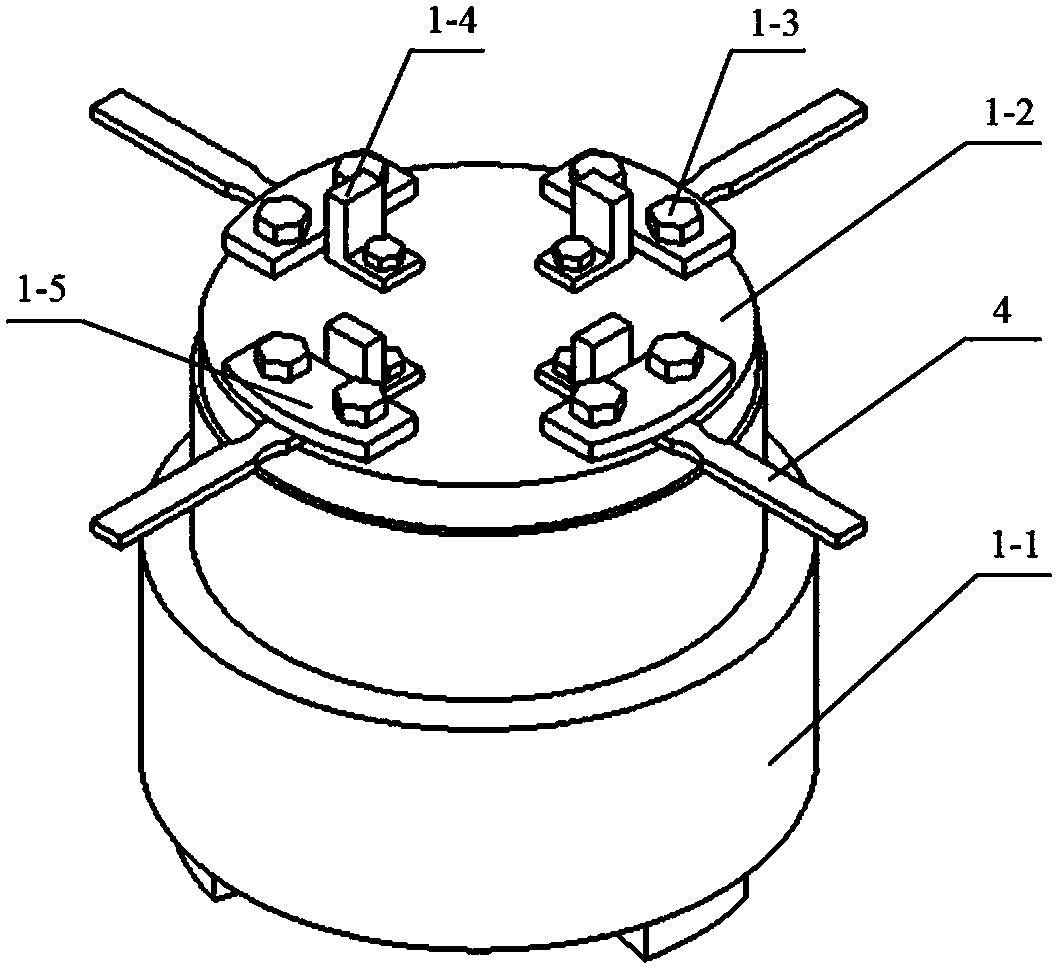

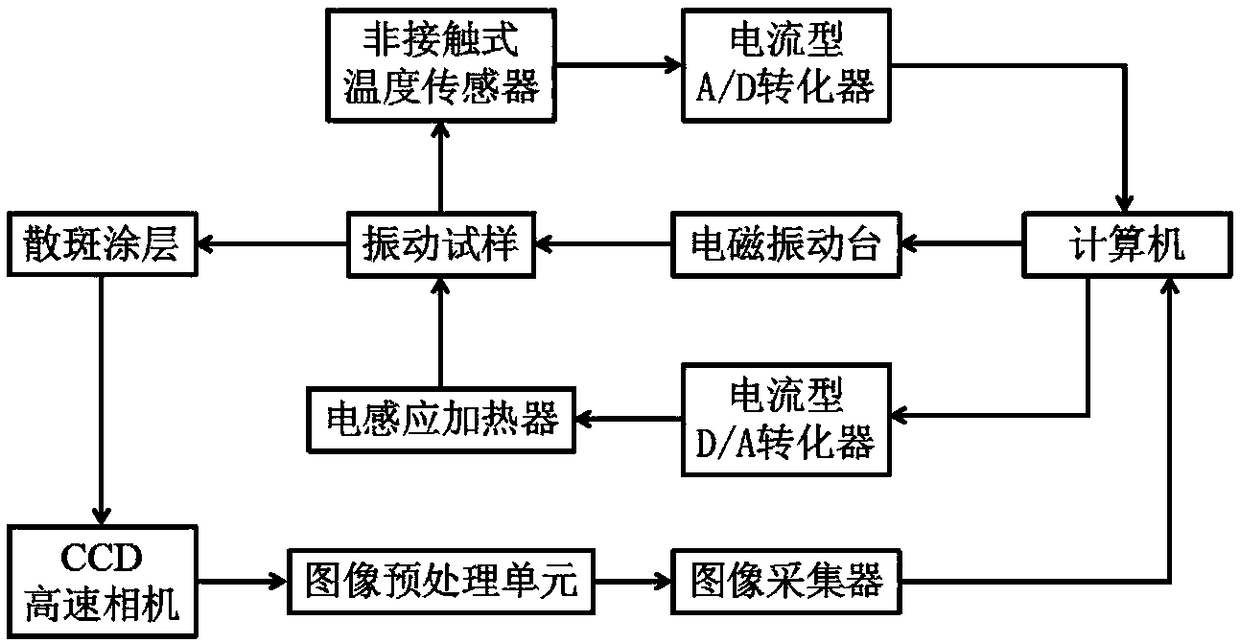

Device and method for detecting high-temperature vibration fatigue characteristics of aero-engine blade

ActiveCN108519225AMonitoring of Vibration Fatigue CharacteristicsGuaranteed accuracyMachine part testingVibration testingAviationFull field

The invention provides a device and a method for detecting high-temperature vibration fatigue characteristics of an aero-engine blade. A vibration loading system is used to apply a vibration load to an aero-engine blade, and the aero-engine blade is heated and controlled by an electric induction heating system; a three-dimensional digital image correlation method is utilized to detect and analyzethe vibration fatigue characteristics of the aero-engine blade under a high temperature vibration load. The invention utilizes the three-dimensional digital image correlation method of non-contact optical full-field deformation measurement, and can adapt to measurement under various scales and various conditions; the accuracy of the detection result is ensured; vibration fatigue monitoring of theaero-engine blade can be achieved at different temperatures and different frequencies; and the comprehensiveness of the experimental result can be ensured.

Owner:JIANGSU UNIV

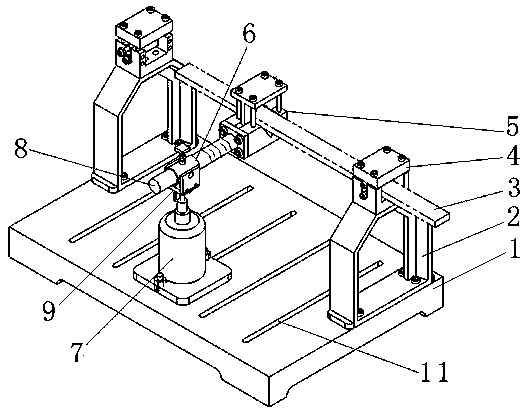

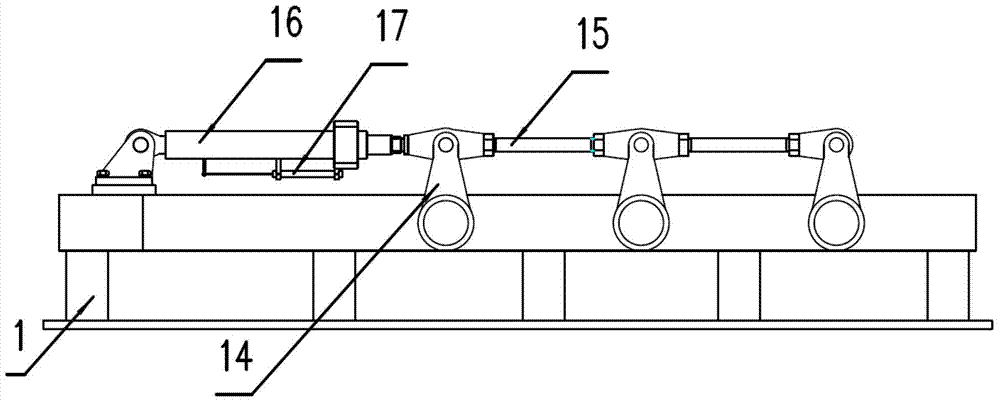

Loading device used for lateral-torsional vibration fatigue experiment and method thereof

ActiveCN108709793AGuaranteed stabilityMeet needsMaterial strength using steady bending forcesEngineeringLoading arm

The invention discloses a loading device used for a lateral-torsional vibration fatigue experiment and a method thereof. A sliding groove is formed in a base, brackets are installed at the two ends ofthe base, and a vibration exciter is connected to the sliding groove; the base body is connected with the brackets through bolts, rotary shafts are arranged on the two sides of a sliding sleeve, a clamping roller is installed above the sliding sleeve, and the rotary shafts are connected with a sliding seat and a shaft hole of a side plate; a guiding rod is sleeved with the sliding sleeve, and oneend of the guiding rod is connected with a loading arm; a clamping seat and a clamping head of the loading arm are opposite to each other, a V-shaped groove is formed in the clamping seat, and a second coupler is installed below the clamping seat. The loading device has adjustability and enough clamping force to ensure the stability of a platform, can provide pure torsion loading, torsion and transverse bending coupling loading, torsion and longitudinal bending coupling loading, torsion and oblique bending coupling loading and pure bending loading, has the advantages of high accuracy, high efficiency, low cost and multiple functions, and has important practical value regarding the completion of the vibration fatigue performance experiment for experimental piece materials with rectangularcross sections and circular cross sections.

Owner:NANCHANG HANGKONG UNIVERSITY

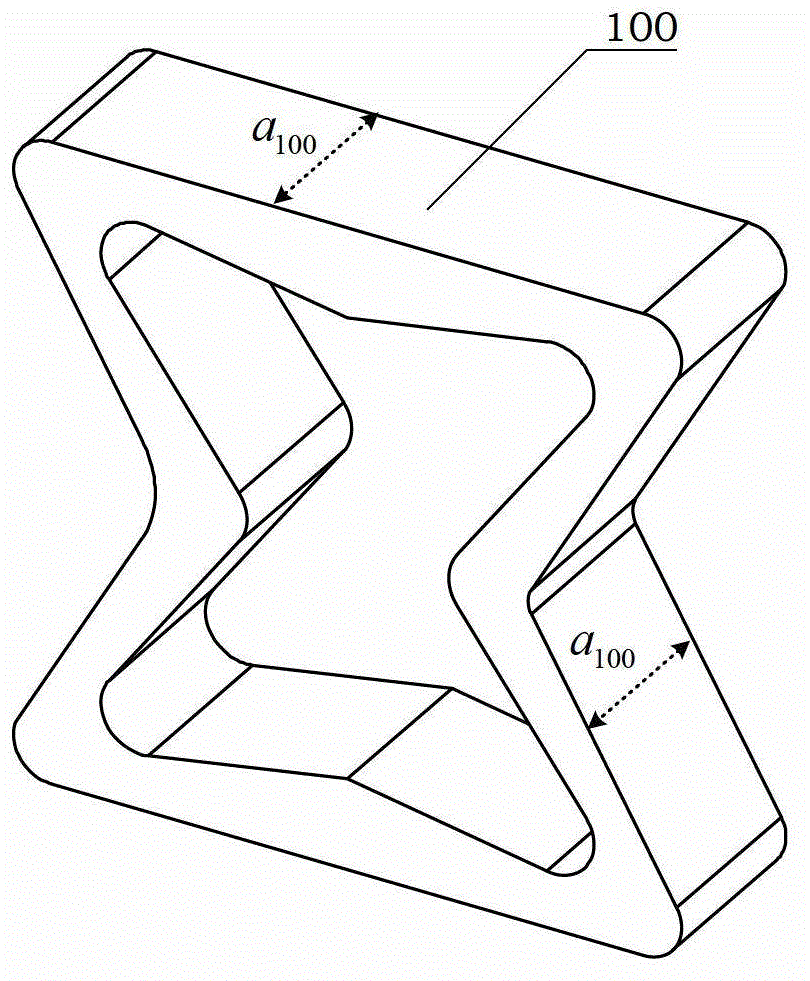

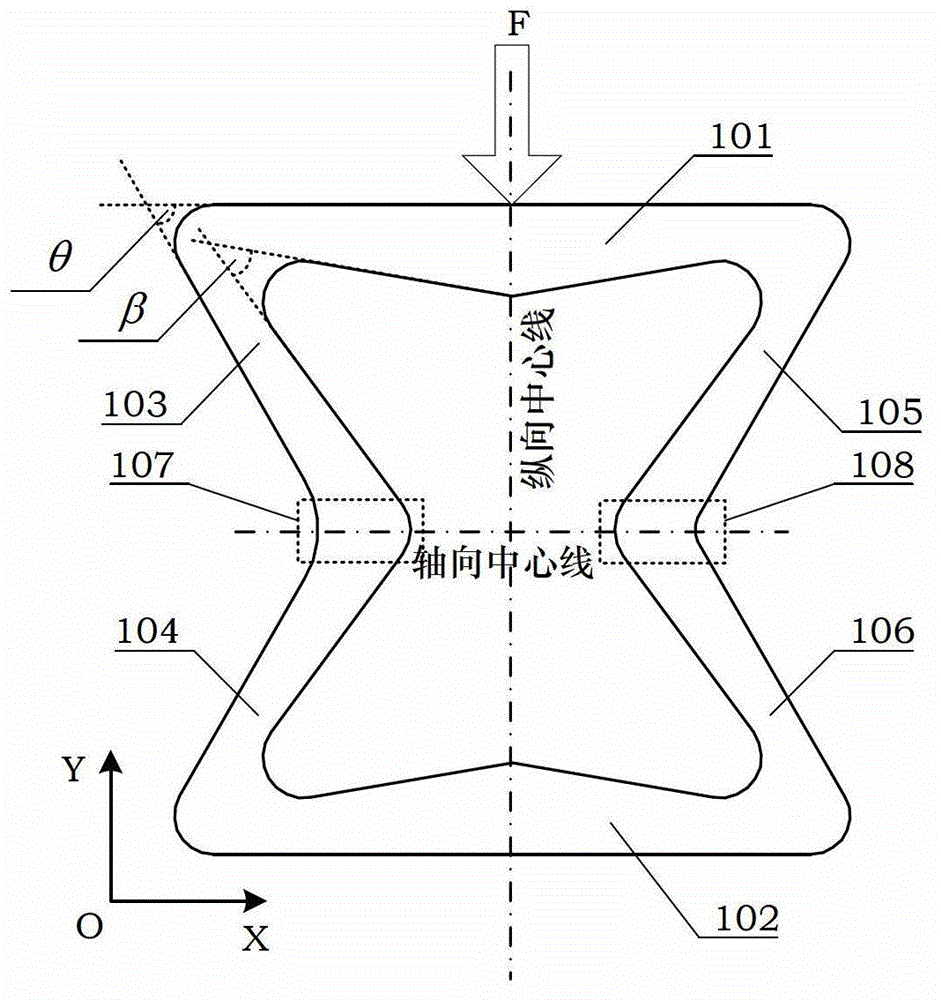

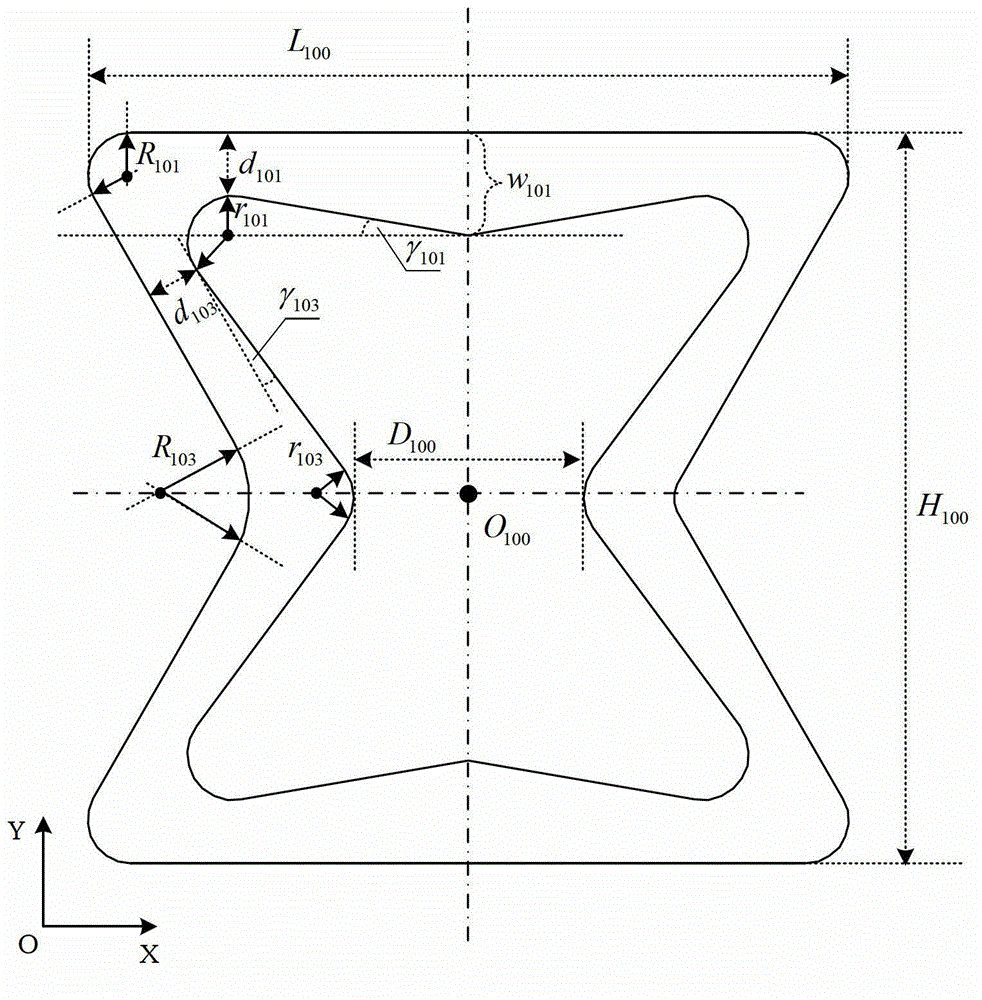

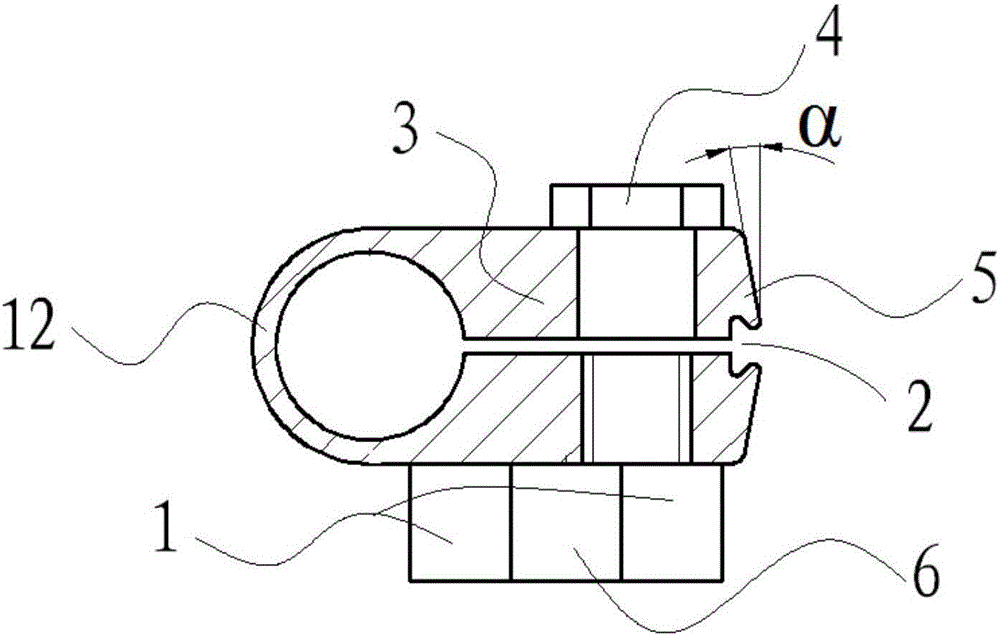

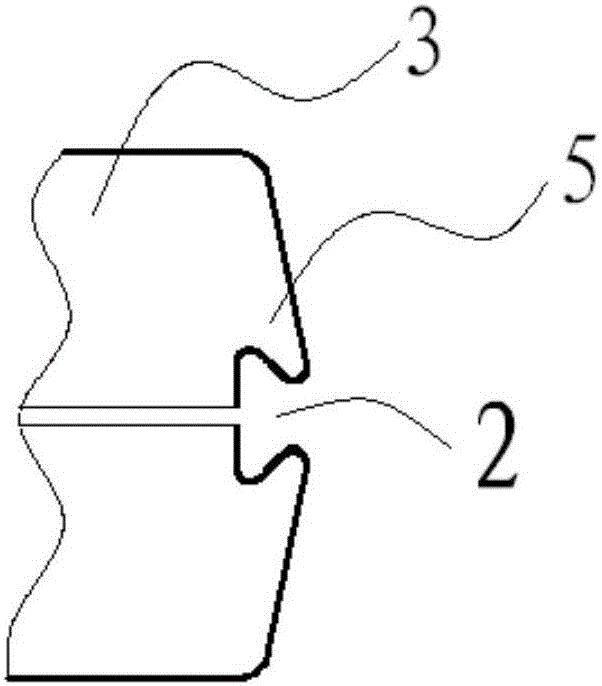

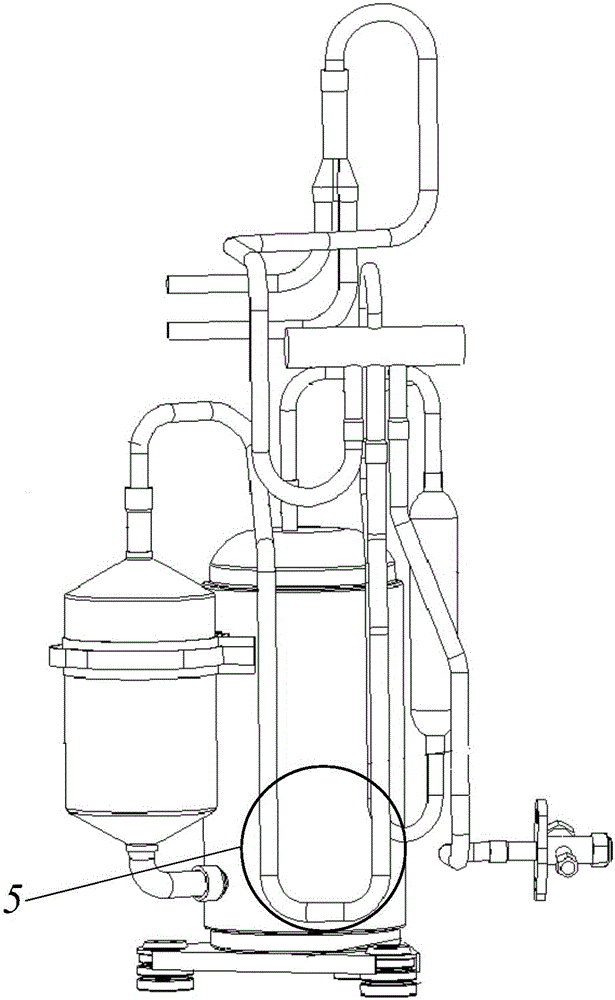

Internally hollow metal rubber vibration isolator with negative Poisson's ratio characteristic

InactiveCN102720785AEnough carrying capacitySufficient structural rigidityLow internal friction springsLoad resistanceMetal rubber

The invention discloses an internally hollow metal rubber vibration isolator with a negative Poisson's ratio characteristic. The internally hollow metal rubber vibration isolator comprises a plurality of complete unit bodies (100) with the same structure and a plurality of complementary unit bodies (200) with the same structure, which are arranged in an overlapped way. Each of the complementary unit bodies is half of each of the complete unit bodies in structure. The overlapped arrangement comprises a middle arrangement part (1), a left-end arrangement part (2), a right-end arrangement part (3), a left complementary arrangement part (4) and a right complementary arrangement part (5), wherein the middle arrangement part (1) is arranged in the middle, the left complementary arrangement part (4) and the right complementary arrangement part (5) are arranged on two sides of the middle arrangement part (1) respectively, the left-end arrangement part (2) is arranged on the left side of the left complementary arrangement part (4), and the right-end arrangement part (3) is arranged on the right side of the right complementary arrangement part (5). According to the internally hollow metal rubber vibration isolator, the problems of vibration fatigue and impact failure of the vibration isolator are solved by utilizing good damping performance of a metal rubber structure damping material on one hand, and the impact load resistance of the vibration isolator is improved through the negative Poisson's ratio characteristic of the stagger arrangement structure of the complete unit bodies and the complementary unit bodies on the other hand.

Owner:BEIHANG UNIV

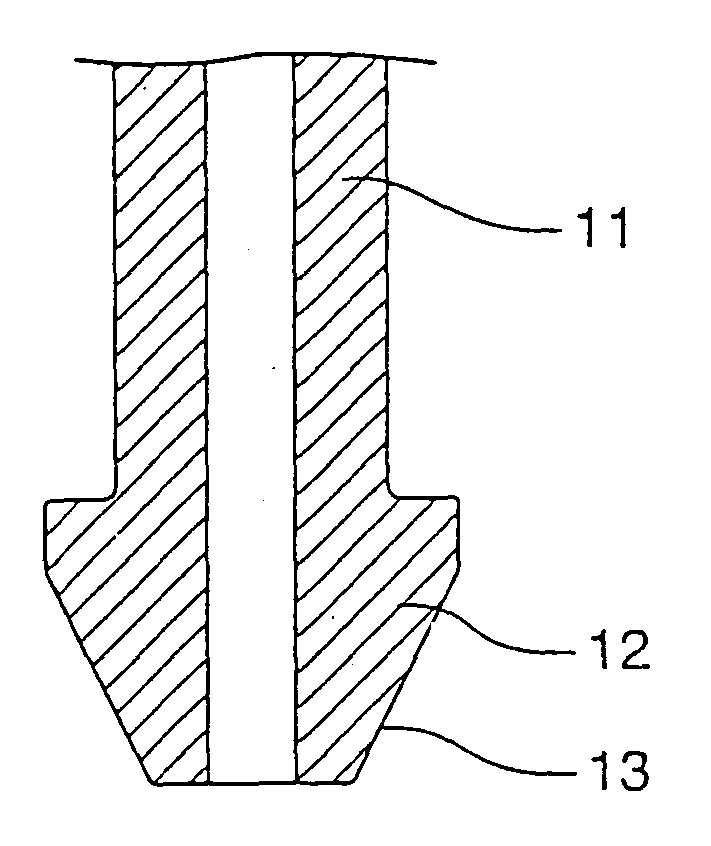

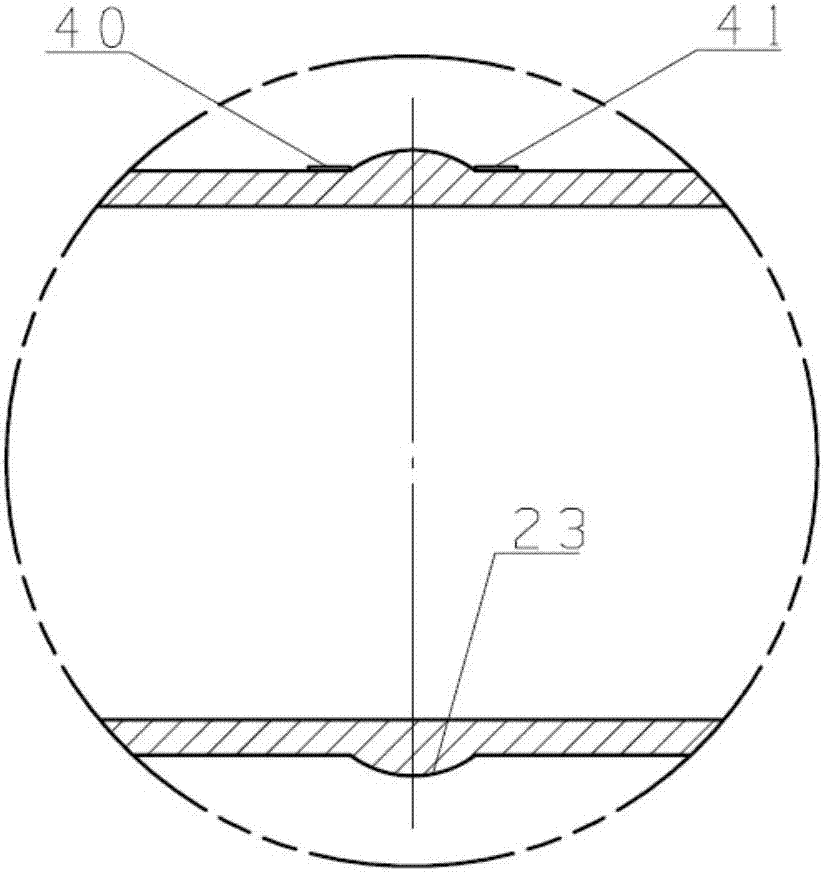

High-pressure fuel injection pipe

InactiveUS20050005913A1Improve fatigue strengthIncrease internal pressureMachines/enginesSpecial fuel injection apparatusInternal pressureCavitation

A high pressure fuel injection pipe is provided for a diesel engine and has excellent internal pressure fatigue resisting characteristics, vibrational fatigue resisting characteristics and cavitation resisting property and sheet face flawing resisting property, and can be made thin and light in weight. In the high pressure fuel injection pipe, pipe extension and heat treatment are repeated by using a header manufactured by transformation induced plastic type strength steel, and processing for depositing residual austenite is then performed and final pipe extension processing is performed, and a joint portion is molded and bending processing is performed without performing perfect annealing at the size of a product.

Owner:USUI KOKUSAI SANGYO KAISHA LTD

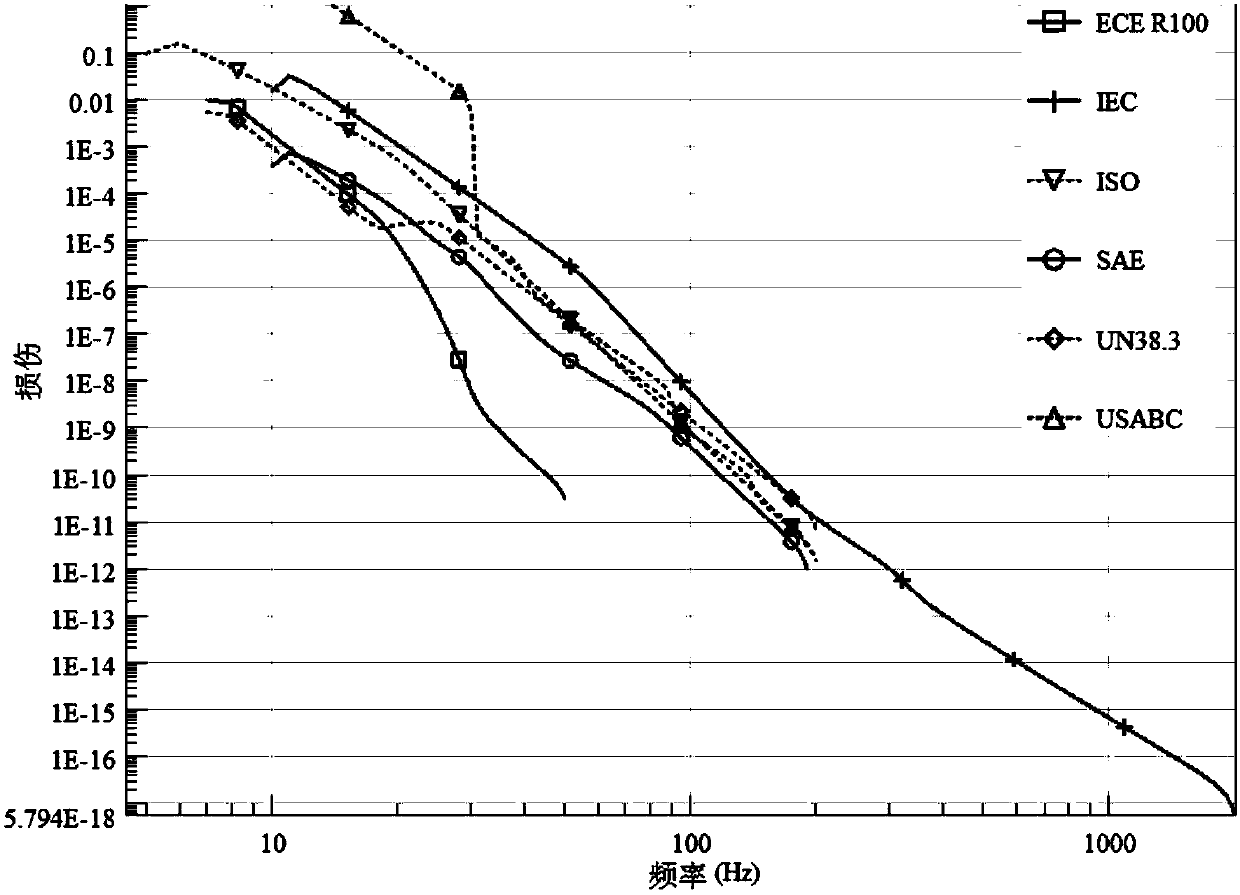

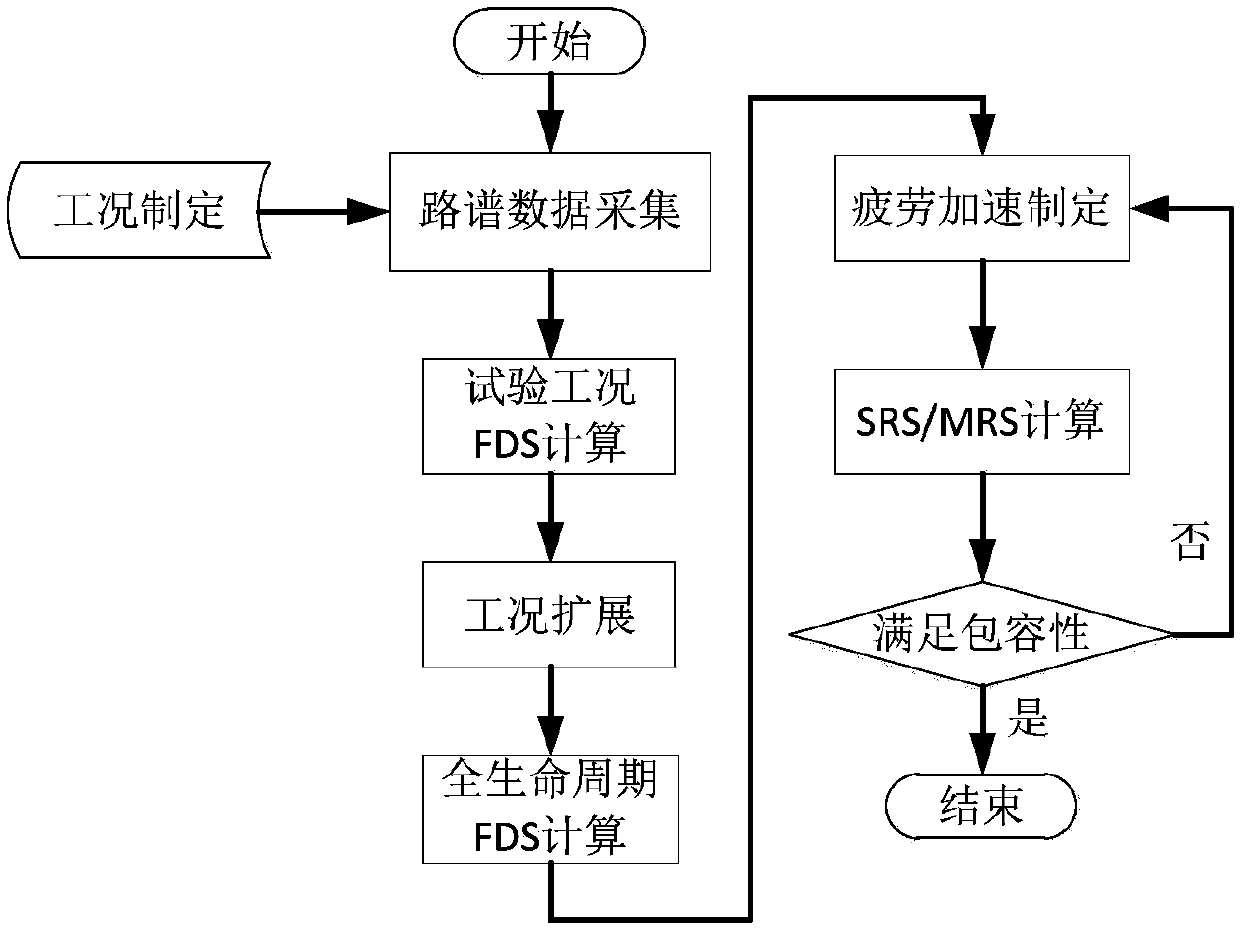

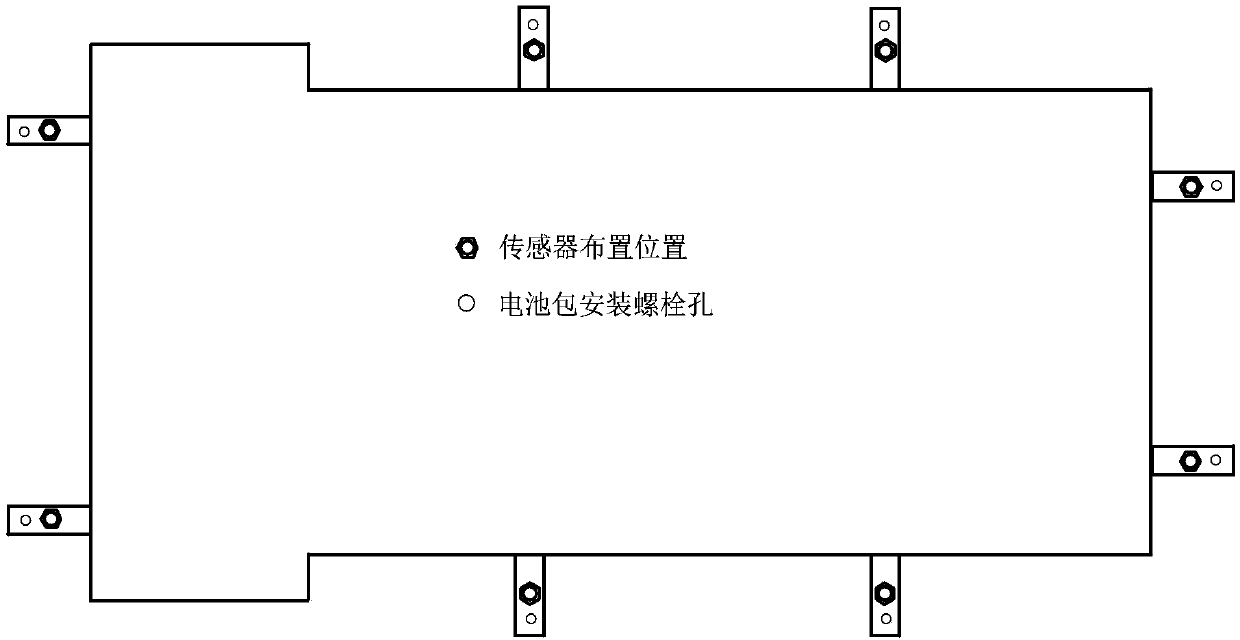

Electric automobile battery pack random vibration fatigue acceleration method based on real road spectrum

InactiveCN108036908AGuaranteed accuracyStrong engineering practicabilityVibration testingShock testingFatigue damageCar driving

The invention discloses an electric automobile battery pack random vibration fatigue acceleration method based on a real road spectrum. The method comprises the steps of (1) acquisition and analysis of the road load spectrum; (2) calculation of full life circle fatigue damage spectrum of the battery pack; and (3) formation of battery pack vibration fatigue acceleration (laboratory standard). Electric automobile battery pack laboratory stand vibration fatigue acceleration is performed for different installing positions of different automobile battery packs according to the actually measured road spectrum of the electric automobile driving so that the problem of single evaluation standard can be solved, and the China's electric automobile operation condition can be further met on the basis of the domestic road condition and the battery manufacturing level of the domestic enterprise.

Owner:开沃新能源汽车集团股份有限公司

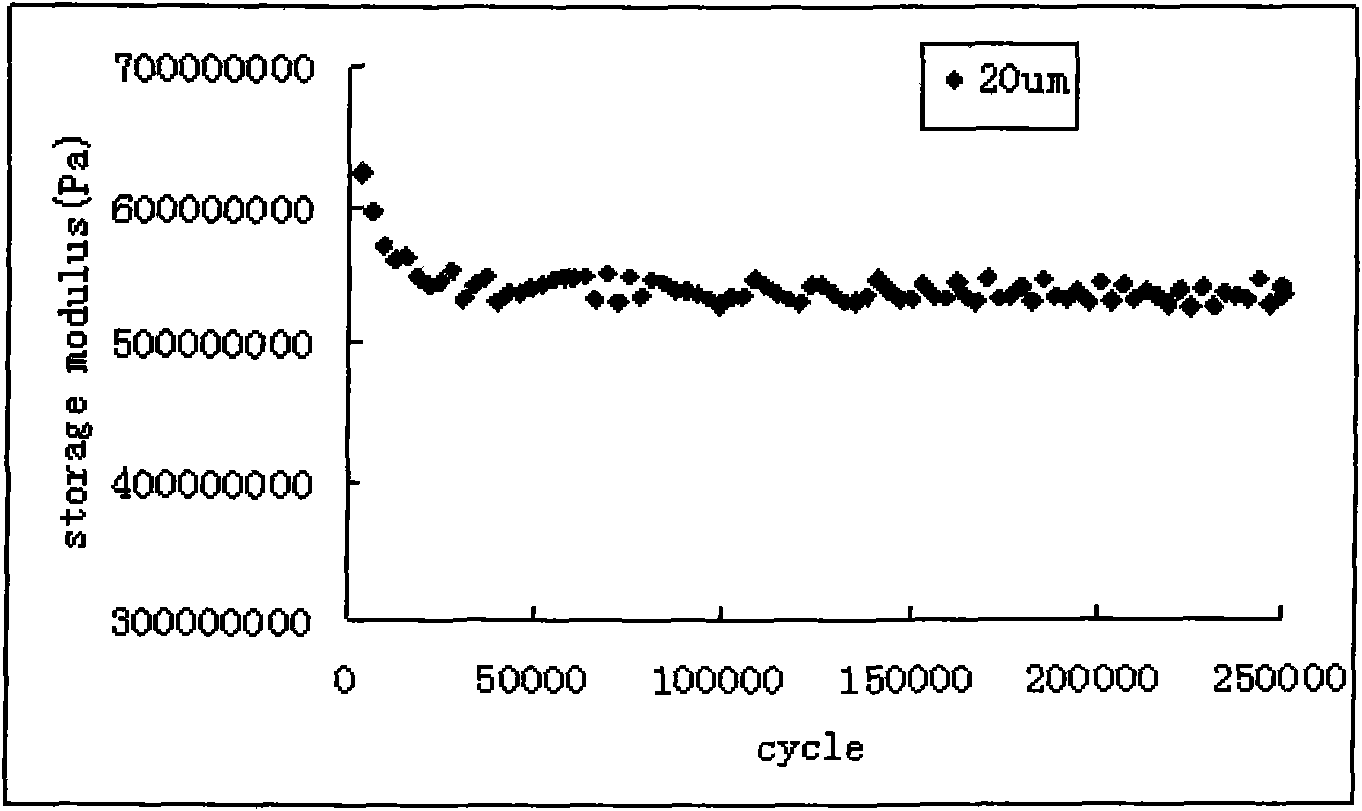

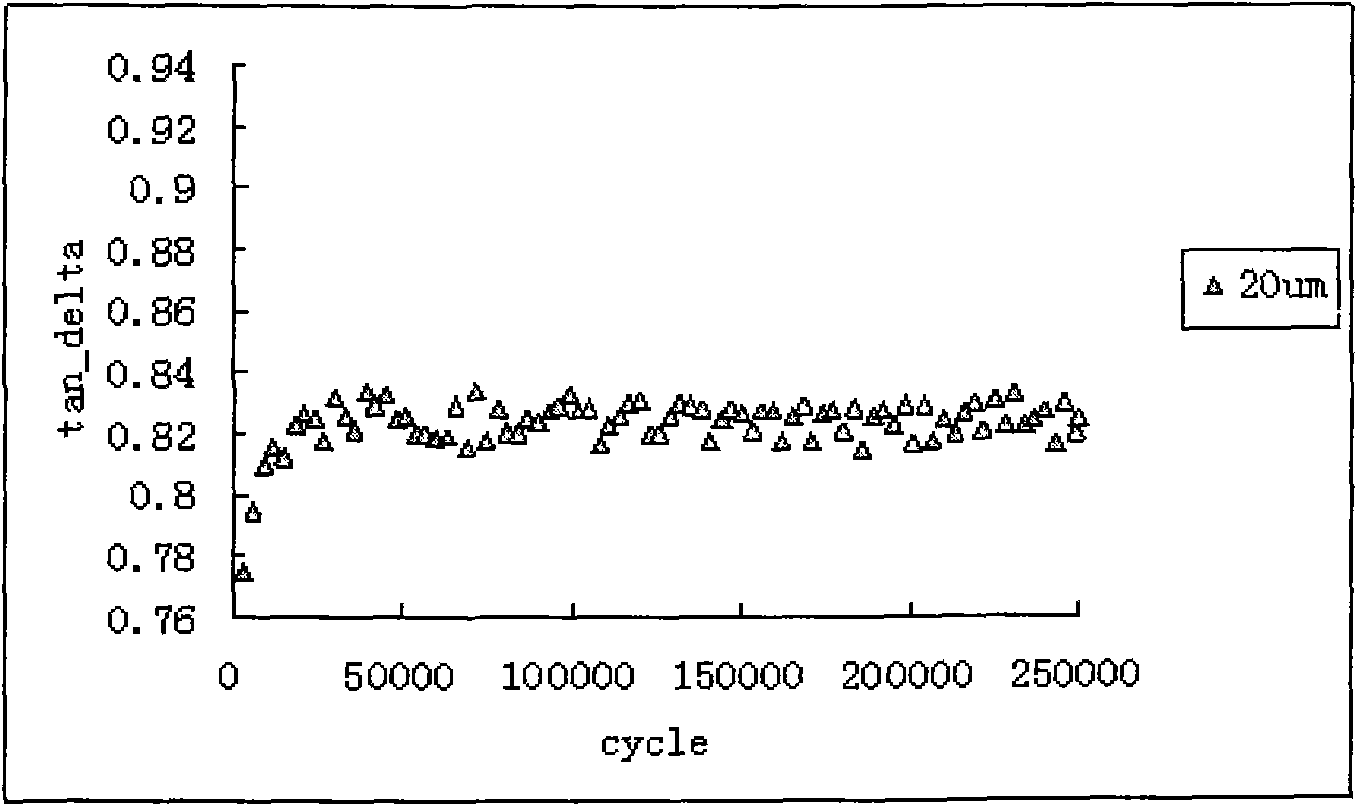

Method for predicting vibration fatigue performance of viscoelastic material

ActiveCN101975704AObtaining Vibration Fatigue PropertiesPredictable long-term performanceMaterial strength using repeated/pulsating forcesVibration amplitudeTest sample

The invention discloses a method for predicting the vibration fatigue performance of a viscoelastic material. The method comprises the following steps of: processing the viscoelastic material of which the vibration fatigue performance is to be predicted to a material with the size needed by a viscoelastometer; determining the stress mode, temperature, deformation vibration amplitude and the like of a vibration fatigue test sample according to the state of the material in the actual service environment; performing a vibration fatigue test; acquiring various performance parameters of the material after every fixed cycle fatigue period; analyzing the acquired performance parameters of the viscoelastic material; and predicting the long-term performance and life cycle of the material. By the method, the vibration fatigue performance of the viscoelastic material can be acquired and the long-term performance of the viscoelastic material under vibration fatigue and service life can be predicted.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

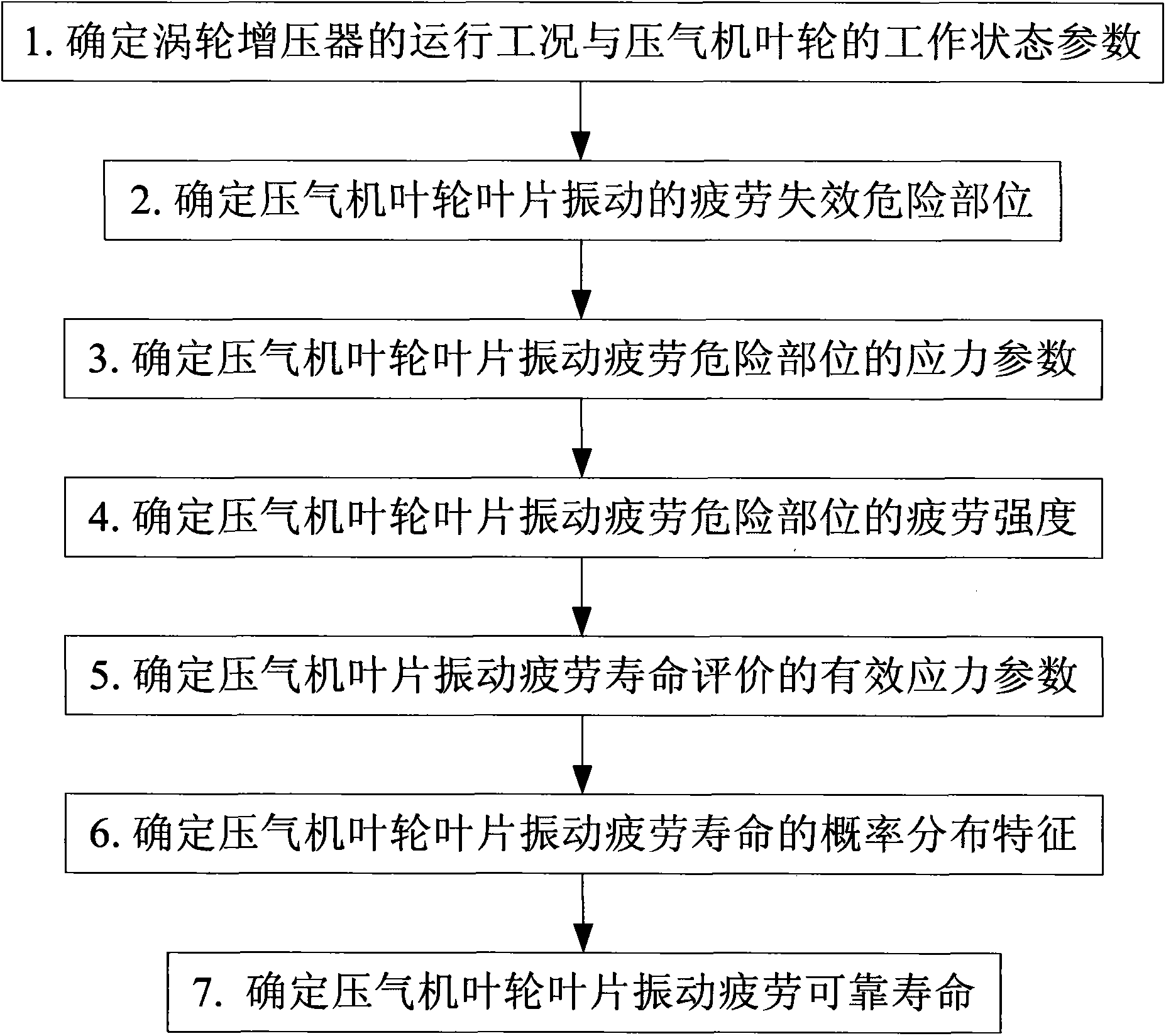

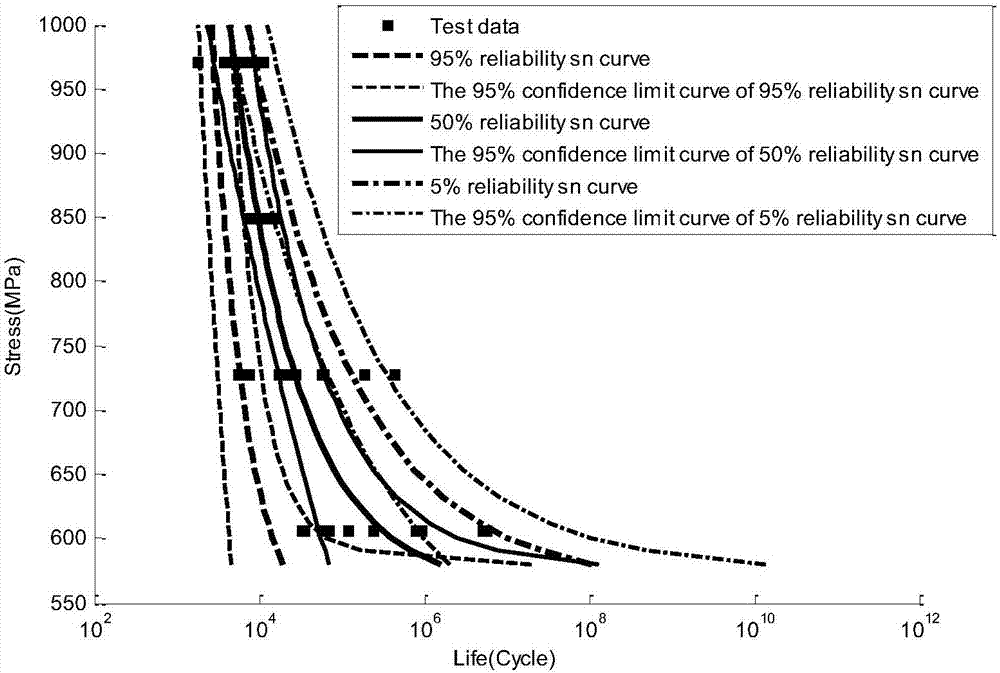

Evaluation method for reliable life of blade vibration fatigue of gas compressor impeller of supercharger

The invention relates to an evaluation method for reliable life of blade vibration fatigue of a gas compressor impeller of an automotive turbosupercharger. The method comprises the following steps: firstly, the operation condition of the automotive turbosupercharger and the working state parameters of the gas compressor impeller are determined; then, the dangerous parts of the blade vibration fatigue of the gas compressor impeller and the stress parameters of every corresponding working condition are determined; then, the fatigue strength of the dangerous parts of the blade vibration fatigue of the gas compressor impeller is determined by adopting a test method to compare the magnitude relation between the equivalent stress of the dangerous parts of the blade vibration fatigue of the gas compressor impeller and the fatigue limit of the blades under different working conditions and determine the effective stress parameters for evaluating the blade vibration fatigue life of the gas compressor impeller; the probability distribution characteristics of the blade vibration fatigue life of the gas compressor impeller and the reliable life meeting different reliability requirements are determined. The method can evaluate the reliable life of the blade vibration fatigue of the gas compressor impeller in the development stage of the turbosupercharger, and can preferably guide the structural design and reasonable use of the gas compressor impeller.

Owner:CHINA NORTH ENGINE INST TIANJIN

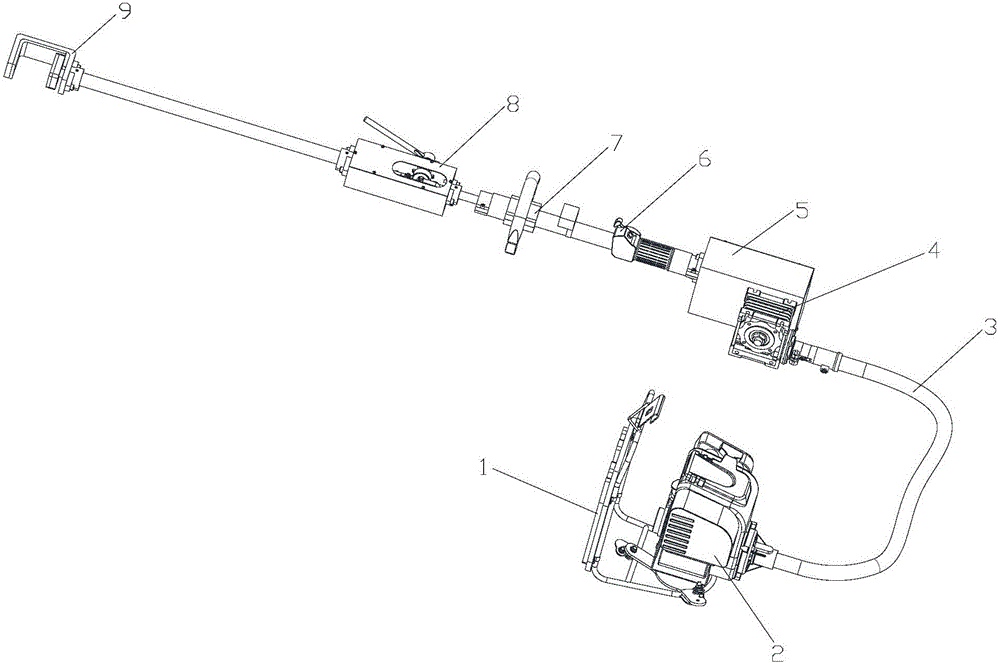

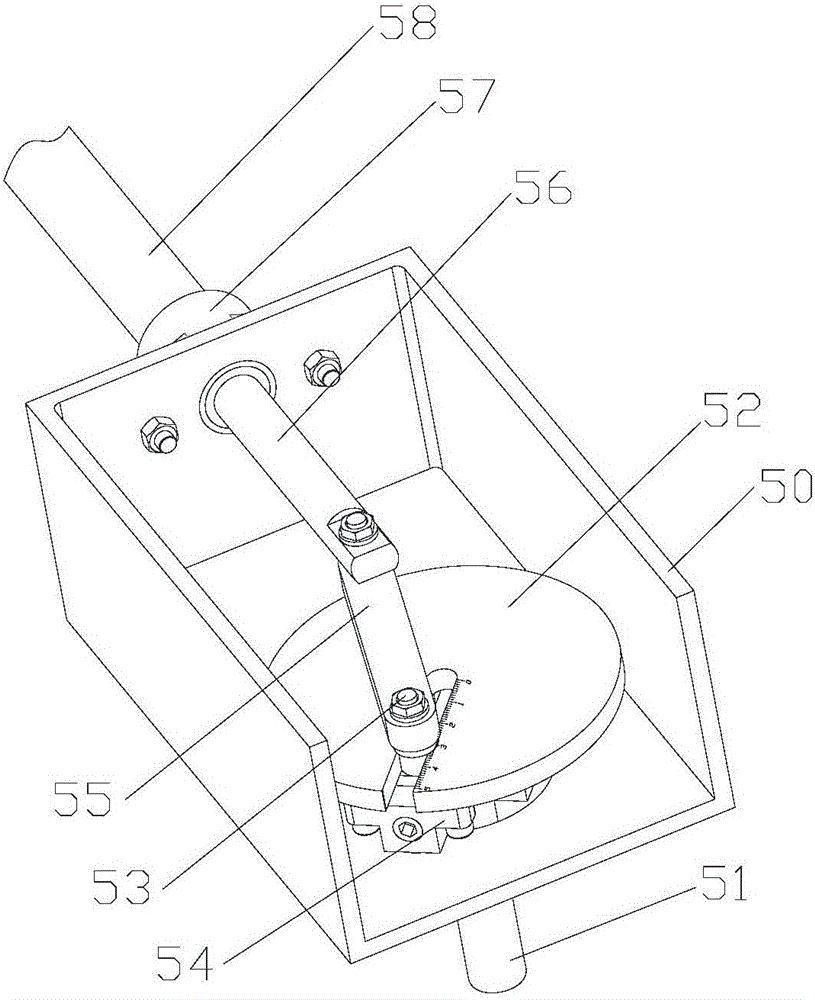

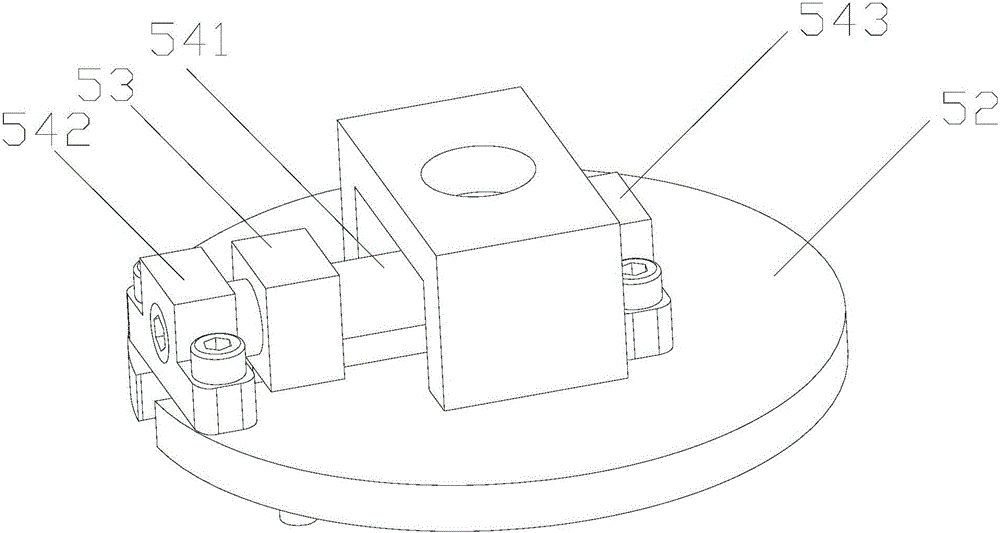

Handheld type branch vibration and fruit harvesting device

The invention relates to a handheld type branch vibration and fruit harvesting device and belongs to the technical field of fruit harvesting. The handheld type branch vibration and fruit harvesting device comprises a driving mechanism, a transmission mechanism, a vibration mechanism, a vibration-reducing handheld mechanism, a manual clamping mechanism, a branch clamping head and a ratchet wheel locking mechanism. The driving mechanism, a transmission mechanism, a vibration mechanism, a vibration-reducing handheld mechanism and a manual clamping mechanism are connected in sequence. The manual clamping mechanism comprises a crank push rod mechanism which controls clamping or loosening motions of the branch clamping head through forward direction or reverse rotation and is driven by a clamping handle. The ratchet wheel locking mechanism has a locking gear for controlling single forward direction rotation of the clamping handle and an unlocking gear for controlling forward direction or reverse direction rotation of the clamping handle. The handheld type branch vibration and fruit harvesting device can quickly clamp fruit tree branches and adjust vibration amplitude and frequency to perform vibration harvesting of fruits, improve fruit harvesting efficiency, reduce cost and alleviate damage to the fruit tree branches. The vibration-reducing handheld mechanism is adopted to prevent vibration fatigue damage to operators.

Owner:SOUTH CHINA AGRI UNIV

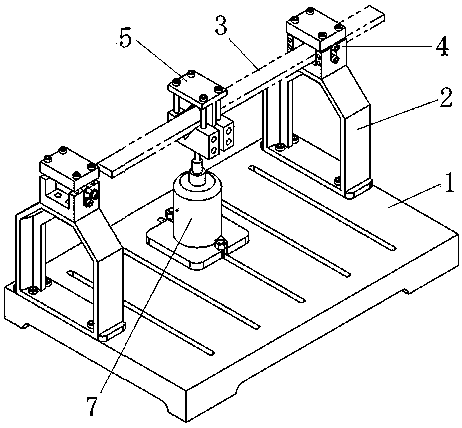

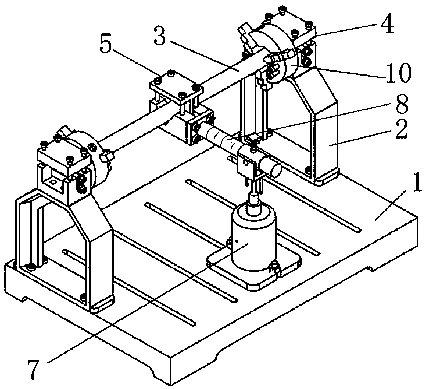

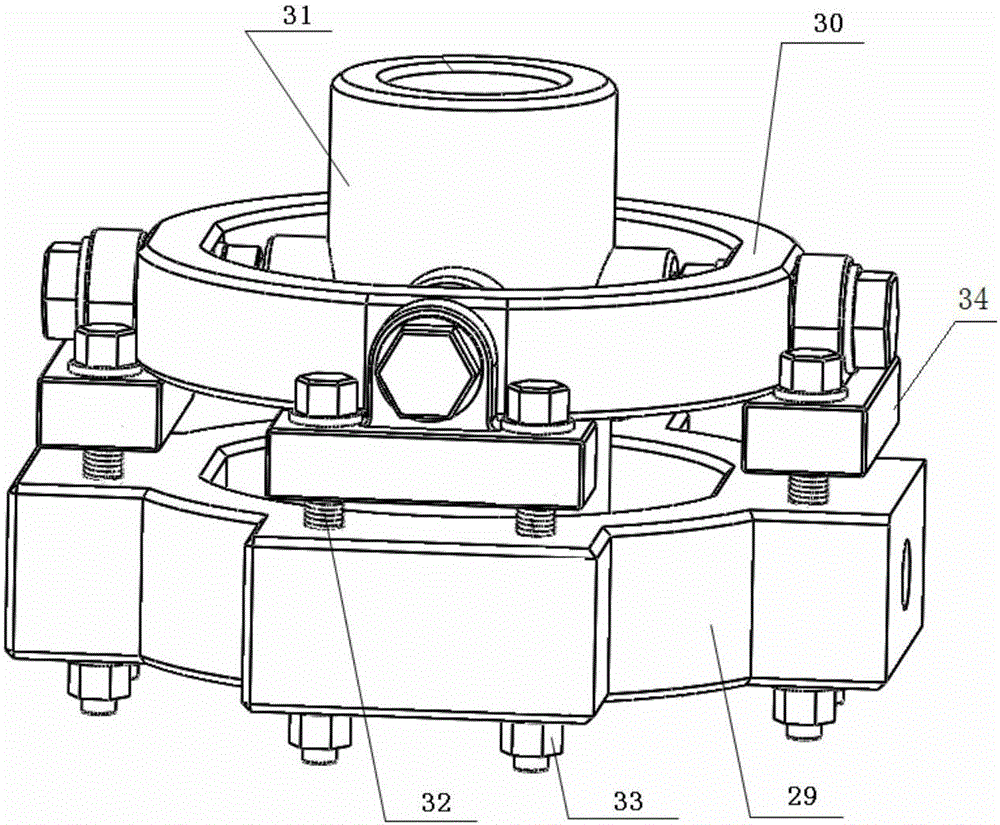

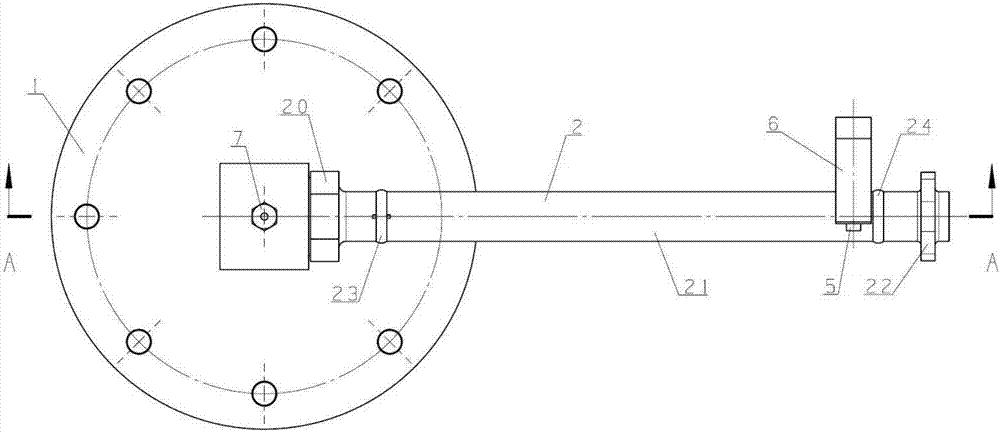

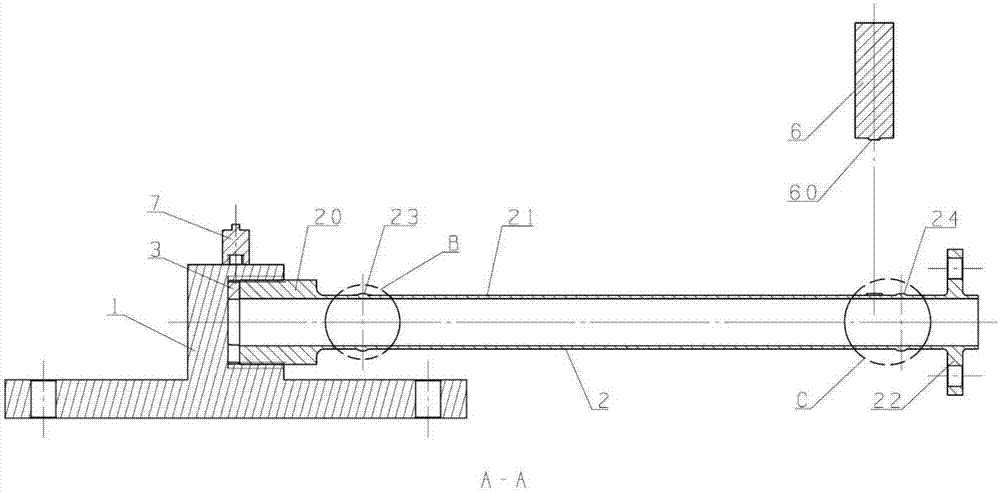

Accurate controllable non-contact test piece rotary magnetic field fatigue excitation and vibration test device

ActiveCN105910780AWide range of applicable objectsReduce the impactVibration testingVibration accelerationDynamic balance

The invention provides an accurate controllable non-contact test piece rotary magnetic field fatigue excitation and vibration test device. The device comprises a vibration damping insulation clamp, a vibration damper, a dynamic balance device, a vibration exciter, an electromagnetic piezoelectric coupling vibration sensor, a test station, a transmission device and an accurate control device. The excitation and vibration test device is suitable for rotary test pieces and especially suitable for vibration characteristic researches on a wind power blade, an engine, a turbine blade, a helicopter rotor and a tail rotor blade, the excitation and vibration test device can vividly simulate vibration fatigue states of rotary test pieces respectively under conditions of 360-DEG all directions, same rotating speed and different excitation forces, same excitation force and different rotating speeds, and different rotating speeds and different excitation forces, the excitation and vibration test device can monitor related vibration characteristic parameters such as the excitation force, the vibration displacement, the vibration speed and the vibration acceleration continuously, and the excitation and vibration test device is suitable for vibration fatigue characteristic analysis on stationary test pieces.

Owner:CHONGQING UNIV

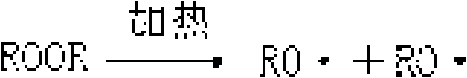

High temperature resistant vehicle radiator hose sizing compound formula

The invention provides a formula of sizing material of a high temperature-resistant hose of an automotive radiator. The sizing material is prepared by the mixture of ethylene propylene diene rubber, sulfur, dicumyl peroxide, antioxidant, a reinforcing agent and a plasticizer. The invention improves the heat resistance of the hose of the radiator by changing the formula of the sizing material of the hose of the automotive radiator and after being vulcanized and cross-linked, the sizing material can form a carbon-carbon cross link which has higher bond energy than a cross link formed after the sizing material taking sulfur as a vulcanization system is vulcanized, and can also meet the requirement of the working temperature of 150 DEG C (the instant highest temperature can reach 175 DEG C). Simutaneously, the properties of the hose such as tension strength at break, elongation at break, ozone ageing resistance, low-temperature resistance, vibration fatigue resistance, cooling fluid resistance, compression set, etc. can all meet the international requirements of the 150 DEG C level.

Owner:贵州戴斯威特橡胶有限公司 +1

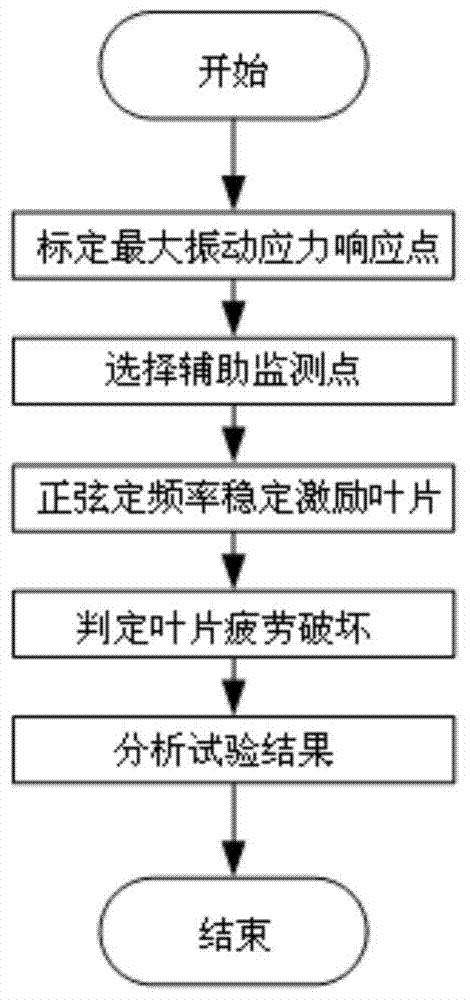

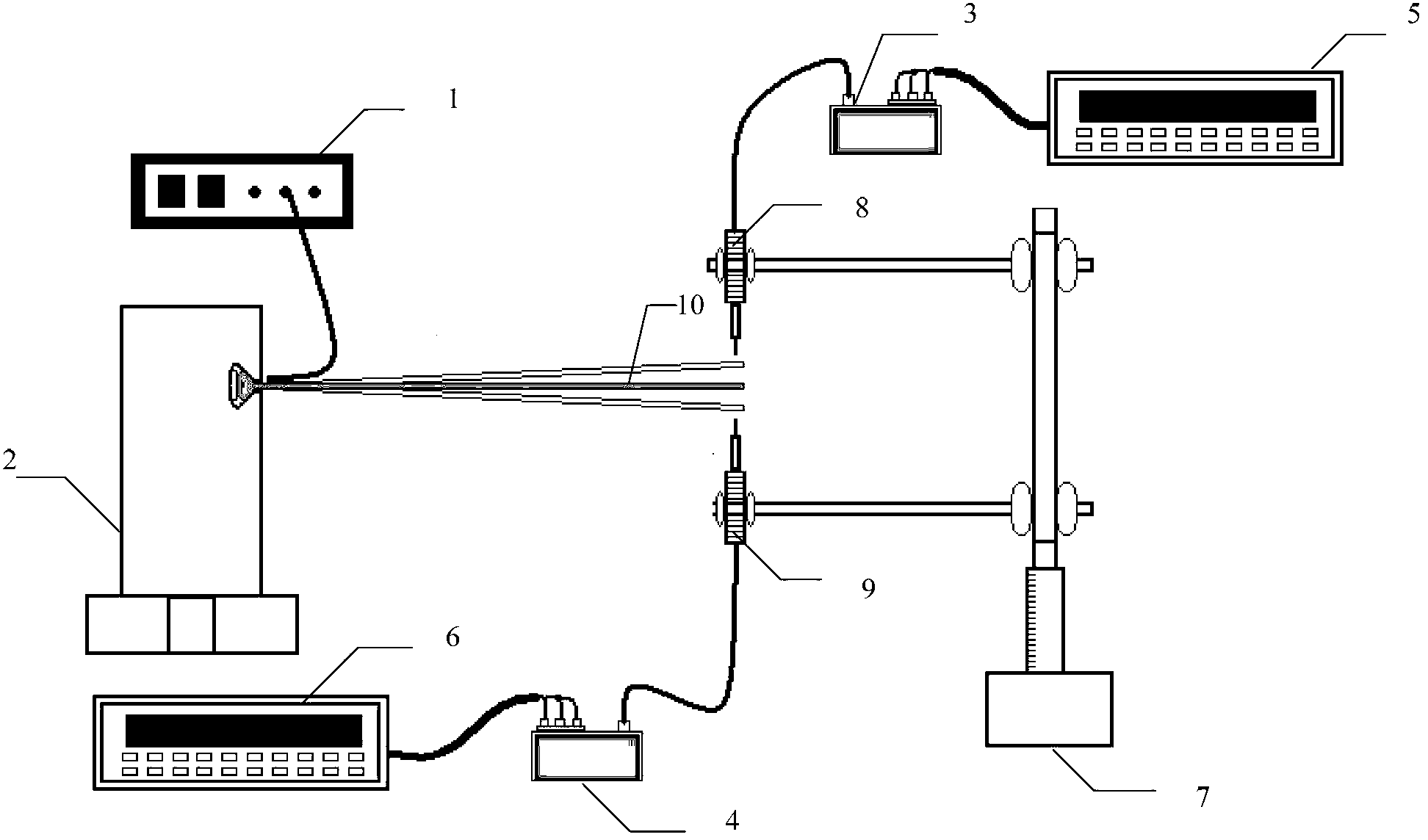

Vibratory fatigue testing method of aviation-engine blades based on electrodynamics vibration generator

InactiveCN104748928AStable Vibration Stress LevelGuaranteed test accuracyVibration testingAviationConstant frequency

Owner:TIANJIN AEROSPACE RELIA TECH +2

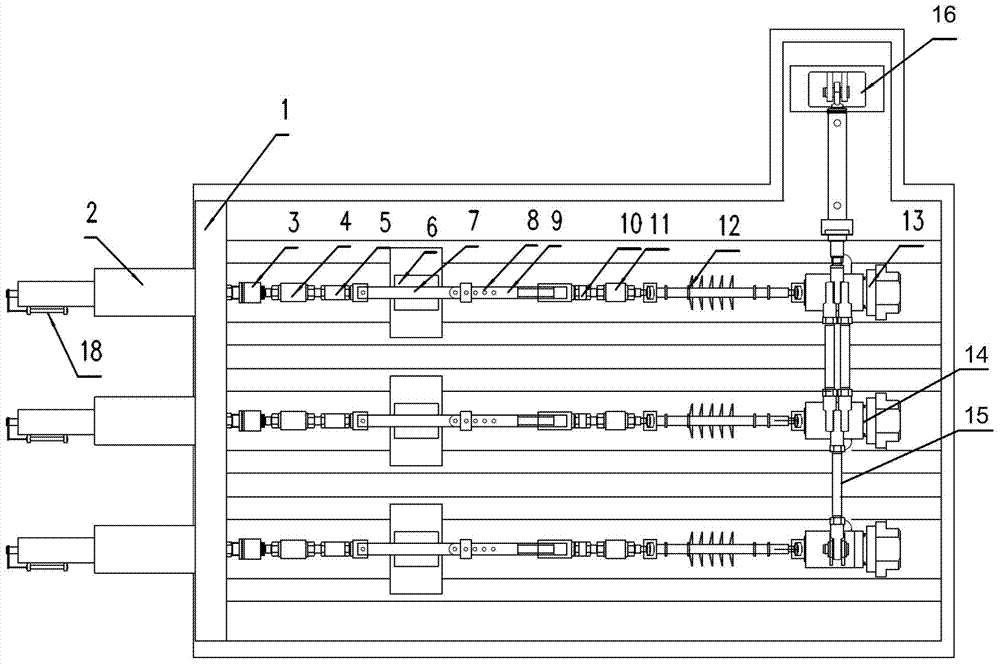

Tension-compression and torsion vibration fatigue test device

ActiveCN103616303AShorten test timeImprove test efficiencyMaterial strength using repeated/pulsating forcesTorsion fatigueTorsion test

The invention discloses a tension-compression and torsion vibration fatigue test device capable of simultaneously accomplishing tension-compression and torsion fatigue tests. The test device comprises a test device rack, a torsion test mechanism and a plurality of tension-compression test mechanisms. In each tension-compression test mechanism, a tension-compression actuating cylinder piston rod, a force sensor, a guide rod, an adjusting rod and a tested workpiece are sequentially connected end to end, wherein the adjusting rod is provided with a plurality of adjusting positions; according to the size of the tested workpiece, the guide rod is connected to the corresponding adjusting position of the adjusting rod; the guide rod does rectilinear movement under the limitation of a guide mechanism. In the torsion test mechanism, a rotating end of each bearing slewing mechanism is connected with the other end of the tested workpiece; oscillating rods of all the bearing slewing mechanisms are connected in series by a link mechanism, and the oscillating rod at one end is connected with the piston rod of a torsion actuating cylinder through a link mechanism. Tension-compression actuating cylinders, the bearing slewing mechanisms and the torsion actuating cylinder are all fixed on the test device rack.

Owner:北京乐冶液压气动设备技术有限公司 +1

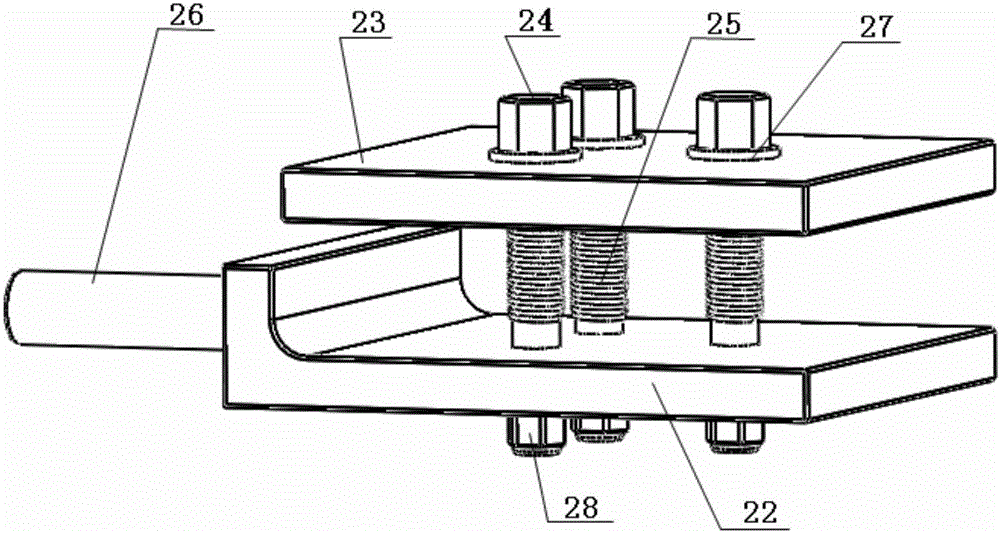

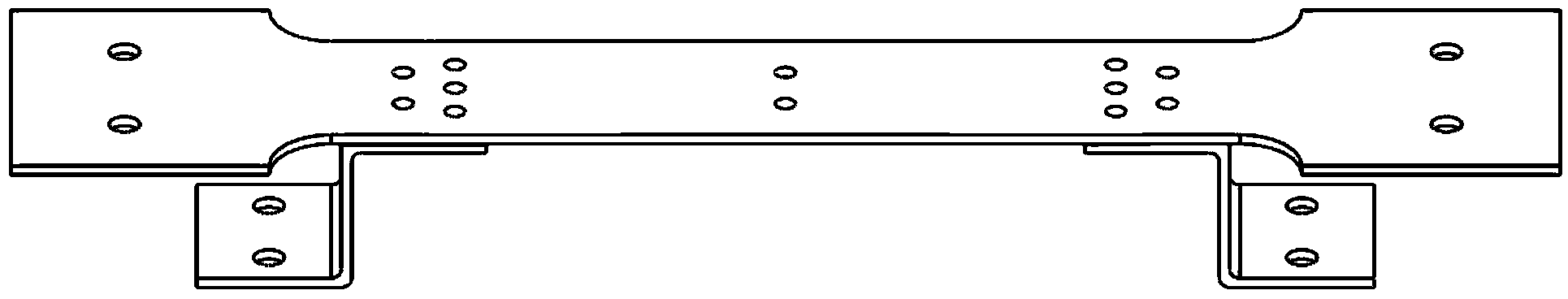

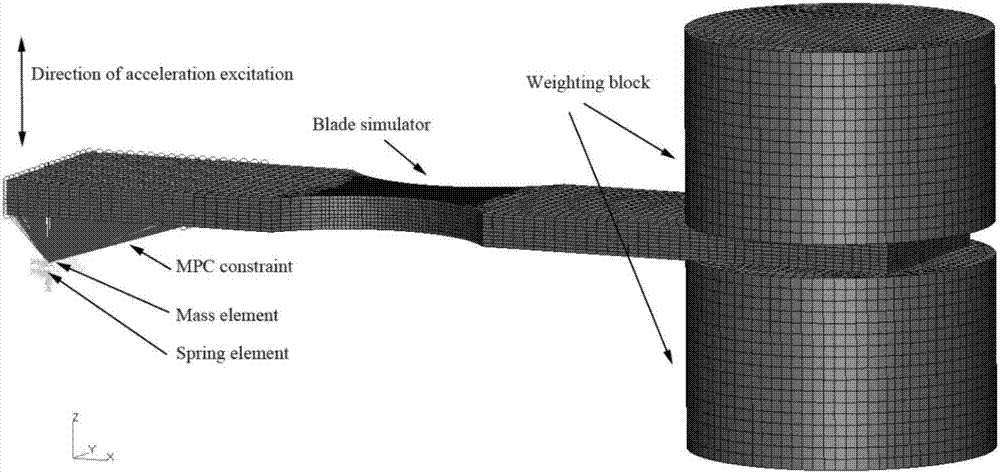

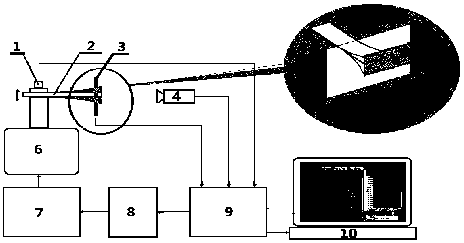

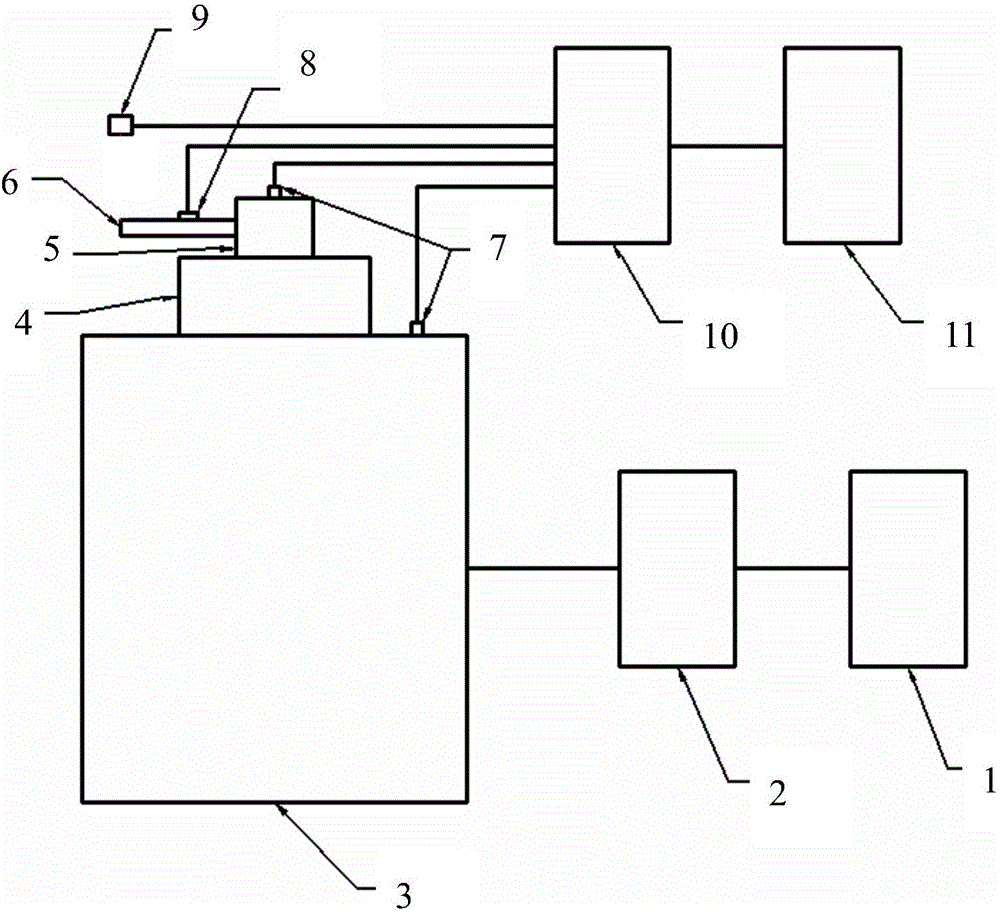

Testing system for testing vibration fatigue performance of aircraft fuel tank

InactiveCN104019950AEasy to operateHigh measurement accuracyVibration testingElectrical resistance and conductancePilot system

A testing system for testing vibration fatigue performance of an aircraft fuel tank is composed of an electromagnetic vibrator, a sample clamp, a signal output unit, a stabilized voltage supply, a frequency meter, a resistance strain gage, a dynamic resistance strain gauge, a sample and a clump weight. The clump weight is installed in the middle of the sample. The sample is mounted on the sample clamp, and pretension force can be applied by screwing studs on the sample clamp. The sample clamp is installed on the electromagnetic vibrator. The stabilized voltage supply is connected with the signal output unit. The signal output unit is connected with the electromagnetic vibrator so as to control the electromagnetic vibrator. The stabilized voltage supply is simultaneously connected with the frequency meter so as to monitor output excitation frequency. The resistance strain gage adhered to the sample is connected with a dynamic strain meter so as to monitor strain of the sample. The dynamic resistance strain gauge is connected with the frequency meter so as to monitor response frequency of the sample. The testing system has a simple structure, is convenient to operate and is used for testing vibration fatigue performance of an aircraft fuel tank. A test result has important engineering application value for evaluation of structure fatigue life.

Owner:BEIHANG UNIV

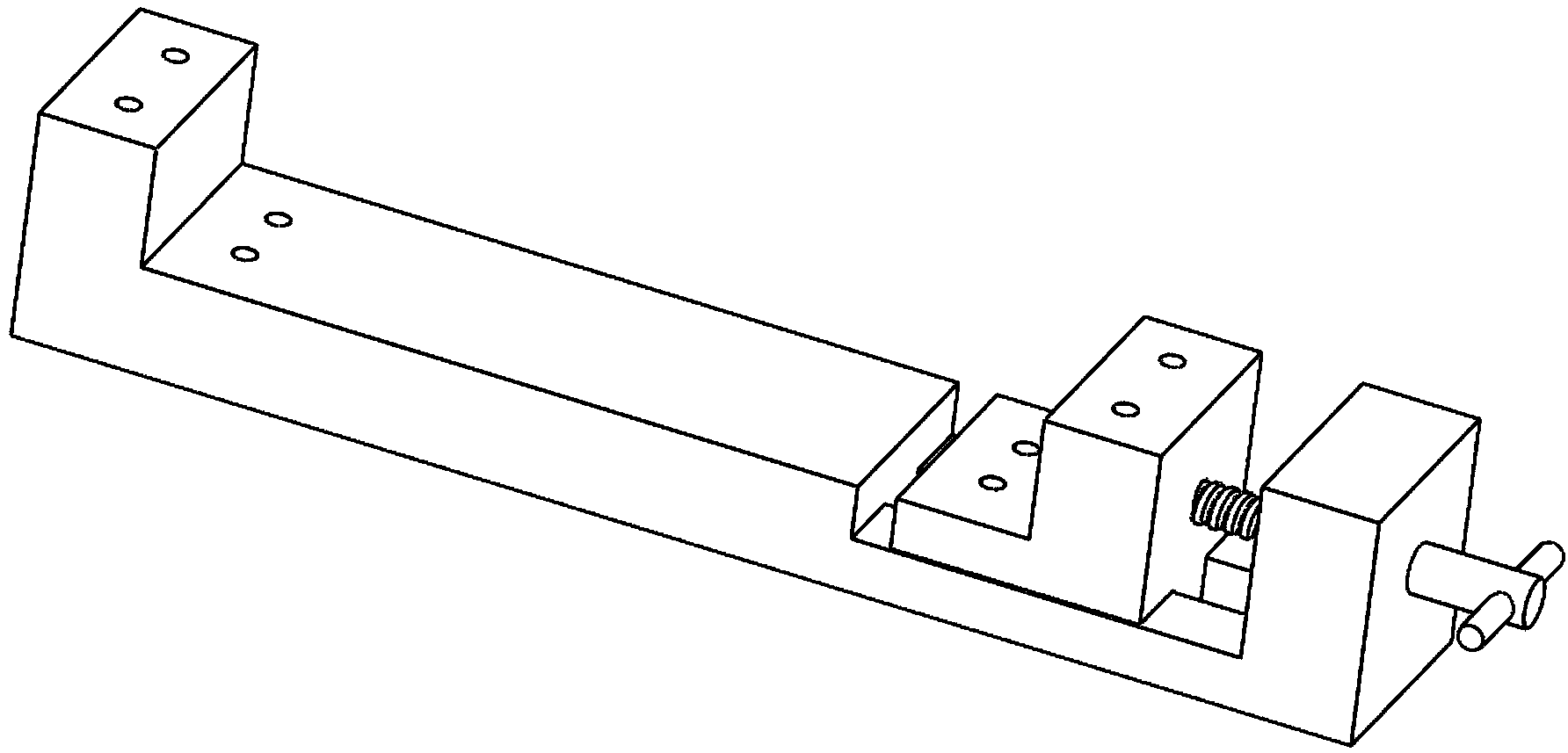

Integrated clamp for dovetail tenon turbine blade vibration fatigue test and test method

The invention discloses an integrated clamp for a dovetail tenon turbine blade vibration fatigue test and a test method. The integrated clamp comprises an integrated clamp body dovetail tenon turbine blade, wherein one end of the integrated clamp body dovetail tenon turbine blade is provided with a groove clamp port dovetail tenon turbine blade, an outer side surface of the groove clamp port dovetail tenon turbine blade is provided with a groove which is identical to a dovetail tenon in shape and can accommodate the dovetail tenon, and the top portion of the integrated clamp body dovetail tenon turbine blade is provided with an adjusting fastening bolt. The integrated clamp is advantaged in that the blade is prevented from breaking at an R portion of a throat portion of the tenon, the test can be smoothly accomplished, a test target is realized, the quantity of test parts is reduced, and test cost is reduced.

Owner:AECC AVIATION POWER CO LTD

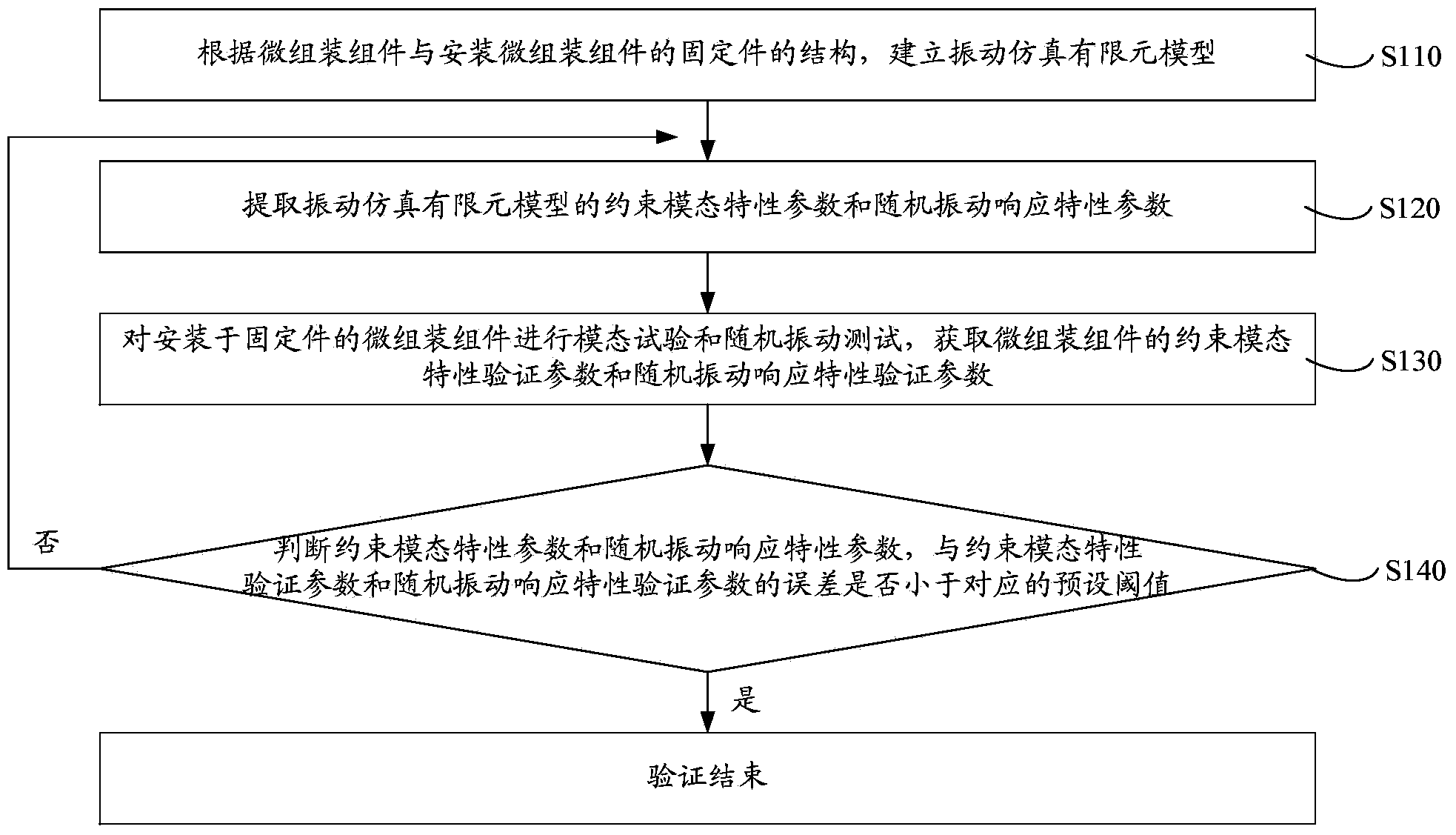

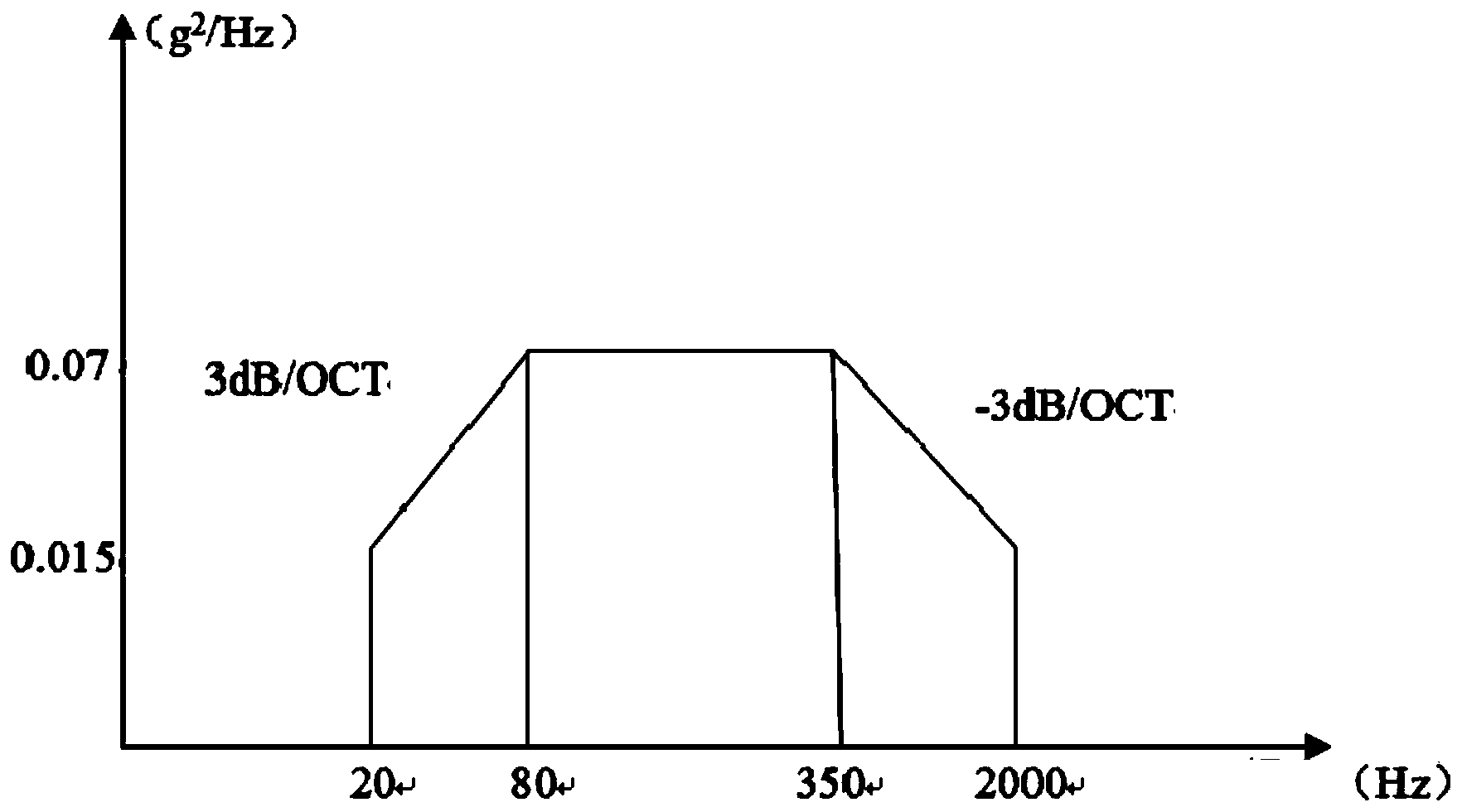

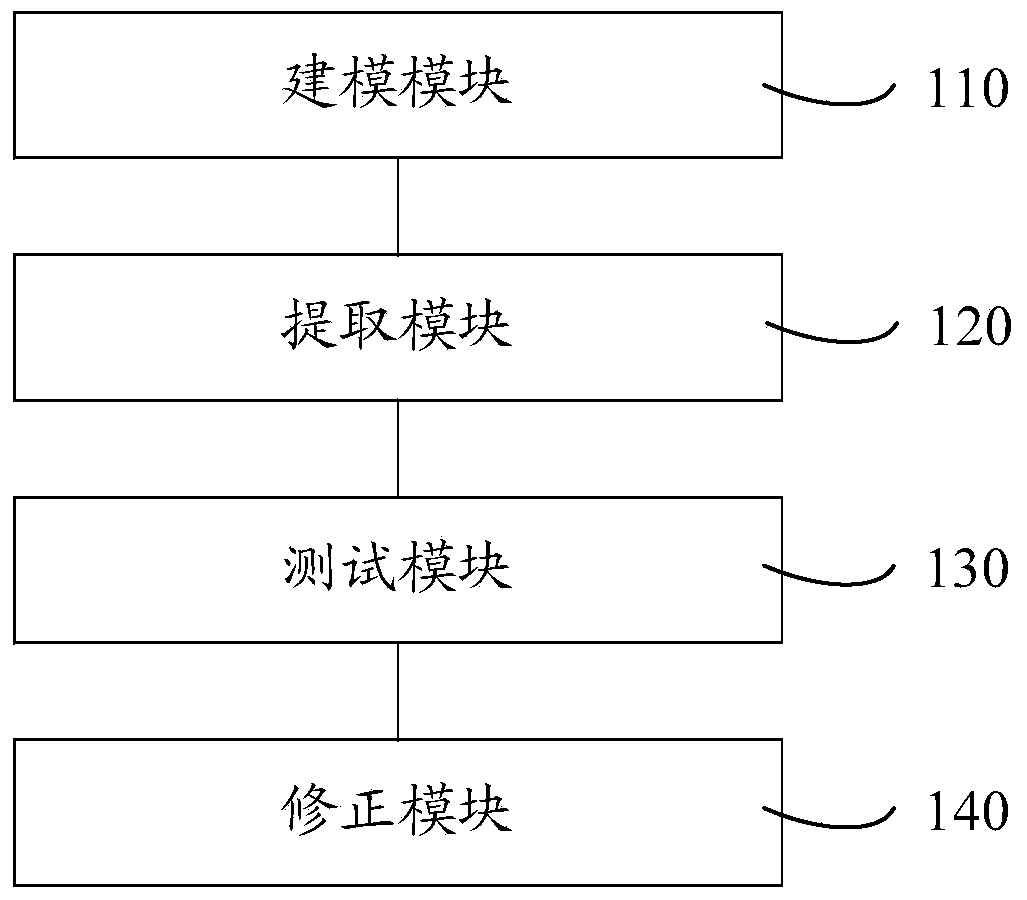

Method and system for verifying forecast simulation model of vibration fatigue life of micro assembly component

ActiveCN104239646AImprove accuracyImprove test accuracySpecial data processing applicationsElement modelEngineering

The invention relates to a method and a system for verifying a forecast simulation model of the vibration fatigue life of a micro assembly component. The method comprises the following steps of building a vibration simulation finite element model according to the structures of the micro assembly component and a fixed part; extracting constraint mode characteristic parameters and random vibration response characteristic parameters of the vibration simulation finite element model, carrying out a mode test and a random vibration test on the micro assembly component, and acquiring constraint mode characteristic verification parameters and random vibration response characteristic verification parameters of the micro assembly component; judging whether the error of the acquired two groups of parameters is less than a corresponding preset threshold value, if yes, finishing the verification, if not, correcting the vibration simulation finite element model, and extracting constraint mode characteristic parameters and random vibration response characteristic parameters of the corrected vibration simulation finite element model again. According to the method, the random vibration response characteristic verification which has a load with the same magnitude as the fatigue life forecast random vibration is increased, so that the vibration simulation finite element model obtained through verification is closer to an actual use status, and the accuracy of model verification is improved.

Owner:FIFTH ELECTRONICS RES INST OF MINIST OF IND & INFORMATION TECH

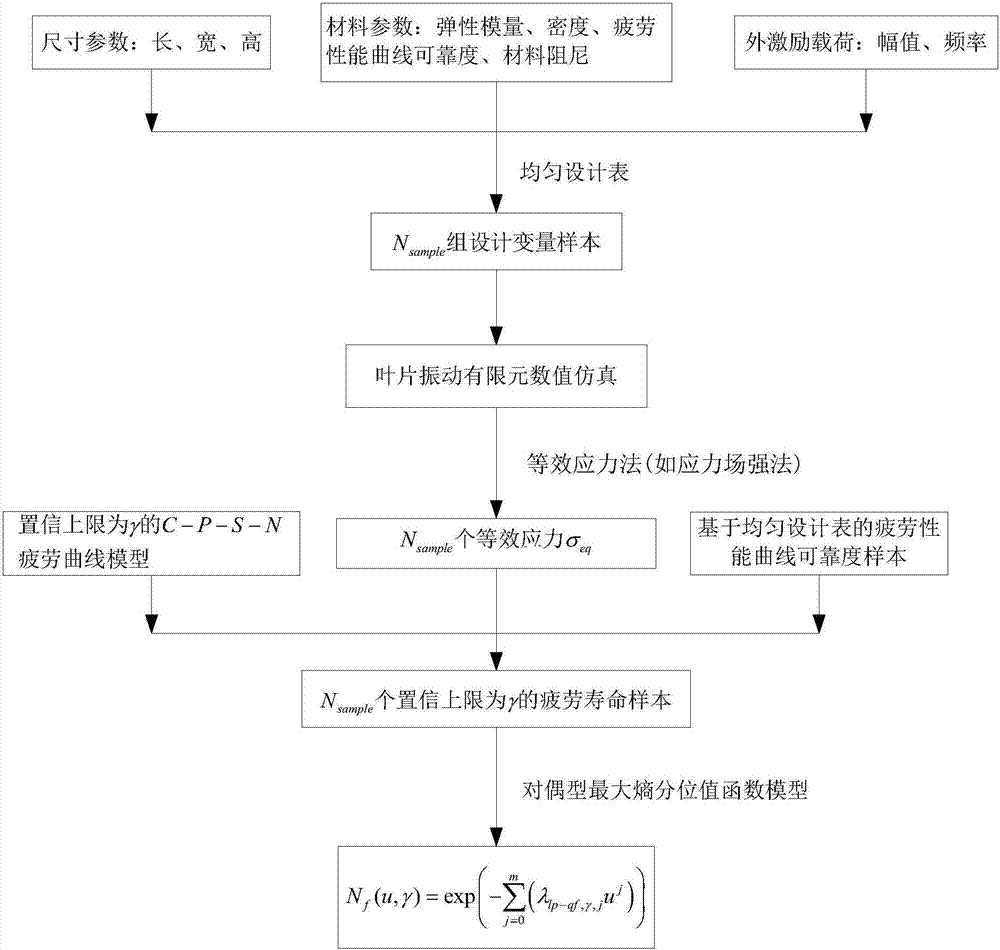

Method for predicting blade vibration fatigue probability life

ActiveCN107145641AImprove calculation accuracyRaise the confidence levelGeometric CADSustainable transportationEngineeringAero engine

The invention provides a method for predicting blade vibration fatigue probability life. The method comprises the steps of (1) establishing a C-P-S-N fatigue curve model of a material; (2) establishing a dual maximum entropy tantile function model; and (3) establishing a blade vibration fatigue probability life prediction model and a blade vibration fatigue probability life prediction method based on the C-P-S-N fatigue curve model and the dual maximum entropy tantile function model. The blade vibration fatigue probability life prediction model and the blade vibration fatigue probability life prediction method established by the invention can be successfully applied to prediction of blade vibration fatigue probability life of an aircraft engine. Compared with an existing prediction method, the method for predicting the blade vibration fatigue probability life has the advantages of high calculation accuracy, confidence level and calculation efficiency.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Amplitude control based aviation engine blade vibration fatigue testing method

InactiveCN108195537AAmplitude real-time monitoringEliminate errorsVibration testingAviationDriving current

The invention discloses an amplitude control based aviation engine blade vibration fatigue testing method. A non-contact laser amplitude monitoring system is adopted. The amplitude of the end parts ofblades of an engine is monitored in real time. The amplitude of the end parts of the blades of the engine is taken as feedback signals. If that the dynamic amplitude deviates from a test preset valueis detected, a measurement and control system sends a modification command in real time. The amplitude constancy of the end parts of the blades of the engine is maintained through adjusting the magnitude of excitation drive current or adjusting excitation frequency. The amplitude control precision is superior to 1%. Therefore, a reliable blade vibration fatigue testing result can be acquired.

Owner:SOUTHEAST UNIV

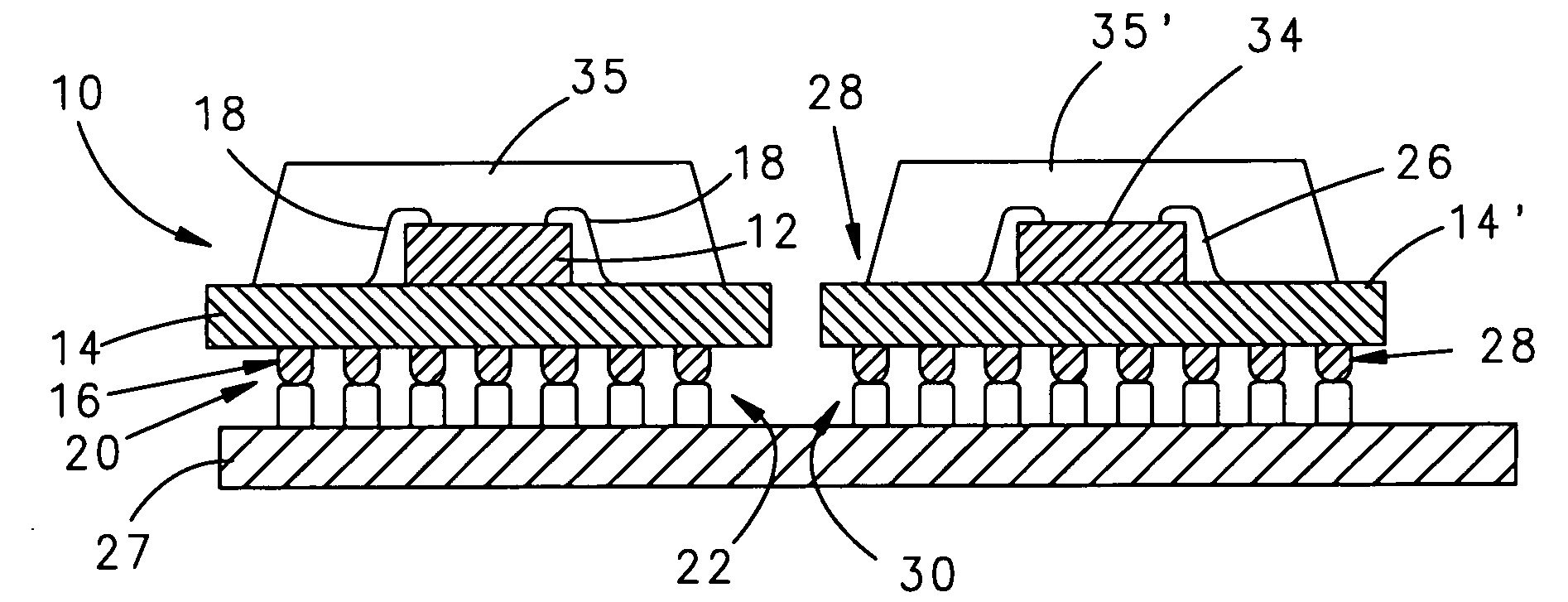

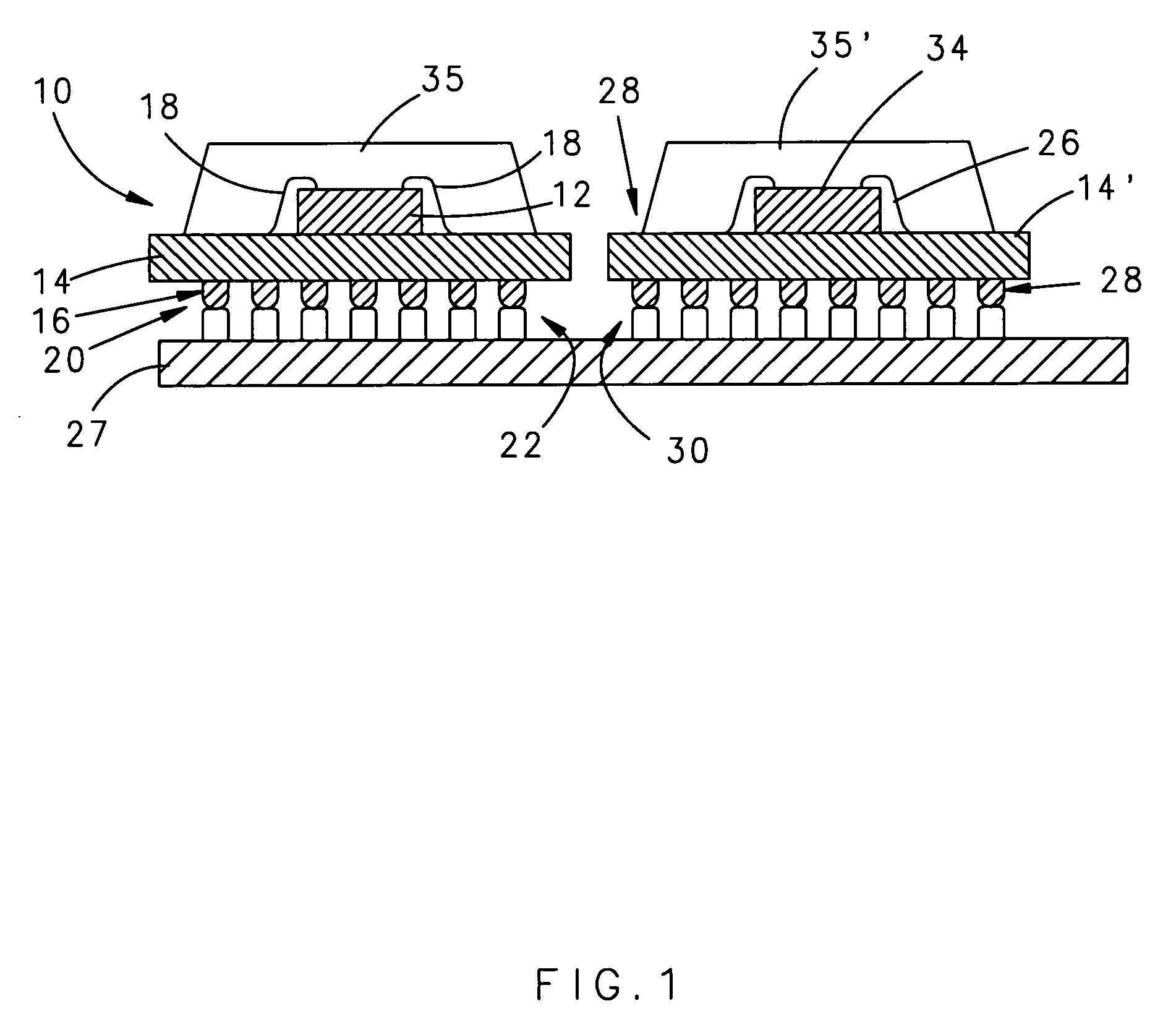

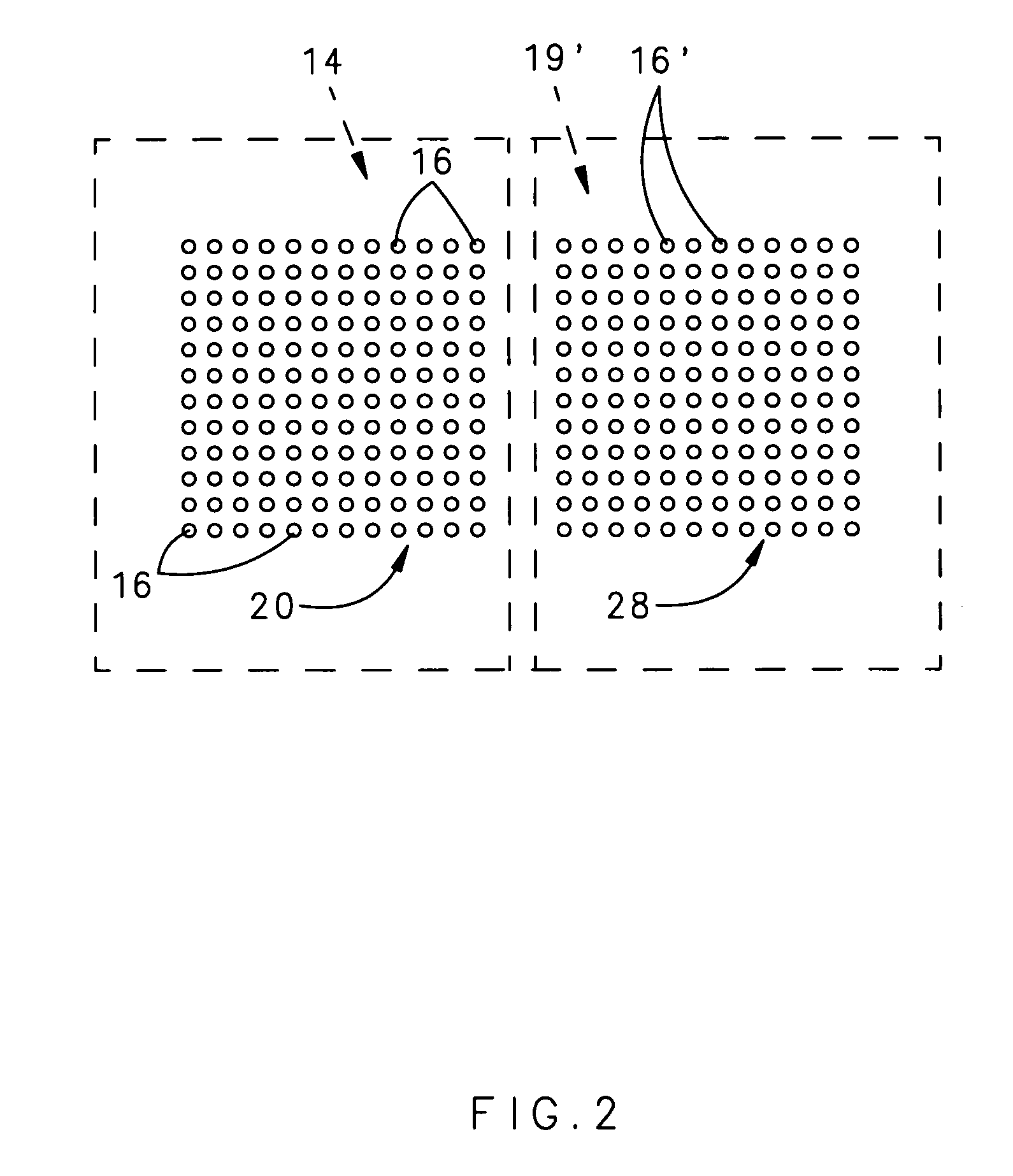

In-situ monitoring and method to determine accumulated printed wiring board thermal and/or vibration stress fatigue using a mirrored monitor chip and continuity circuit

InactiveUS20070296068A1Easy to calculateImprove the level ofSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsMonitoring systemEngineering

A monitoring system includes a monitor chip or chips soldered to a printed wiring board. By mirroring a function IC chip interface with the monitor chip, the consumed and remaining thermal / and or vibration-fatigue life of the function IC chip based on the life-environment actually experienced through monitoring of the monitor chip is readily determined. The monitor chip includes monitoring interconnections and / or circuitry which determines the number and / or location of failed-open solder terminations of the monitor chip.

Owner:HAMILTON SUNDSTRAND CORP

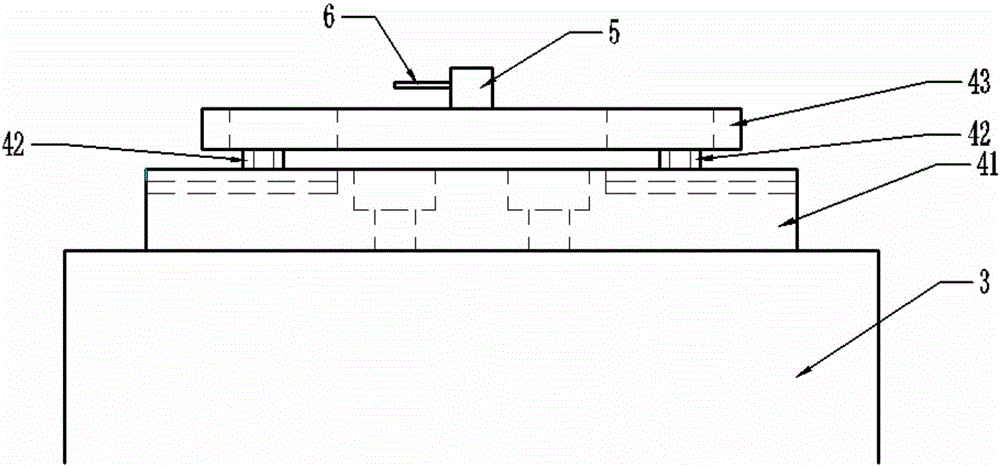

Engine blade fatigue testing device

InactiveCN106441761ALow costEffectively completedMachine part testingEngine testingAudio power amplifierSignal generator

The invention discloses an engine blade fatigue testing device which comprises a vibration test table (3). The vibration test table (3) is connected with a power amplifier (2) through a signal line, the power amplifier (2) is connected with a signal generator through a signal line, an amplification tool (4) is fixedly connected to the top of the vibration test table (3), a clamping tool (5) is fixedly connected to the top of the amplification tool (4), and the left end of the clamping tool (5) is fixedly connected with a blade (6) needing a vibration fatigue test. The engine blade fatigue testing device can reduce the load of the vibration test table under the situation that the blade vibration fatigue test is effectively completed at high quality, ensures that the vibration test table works for a long time and does not easily break down, the service life of the vibration test table is remarkably prolonged, and further the cost for the vibration fatigue test of engine blades is reduced.

Owner:TIANJIN AEROSPACE RELIA TECH +2

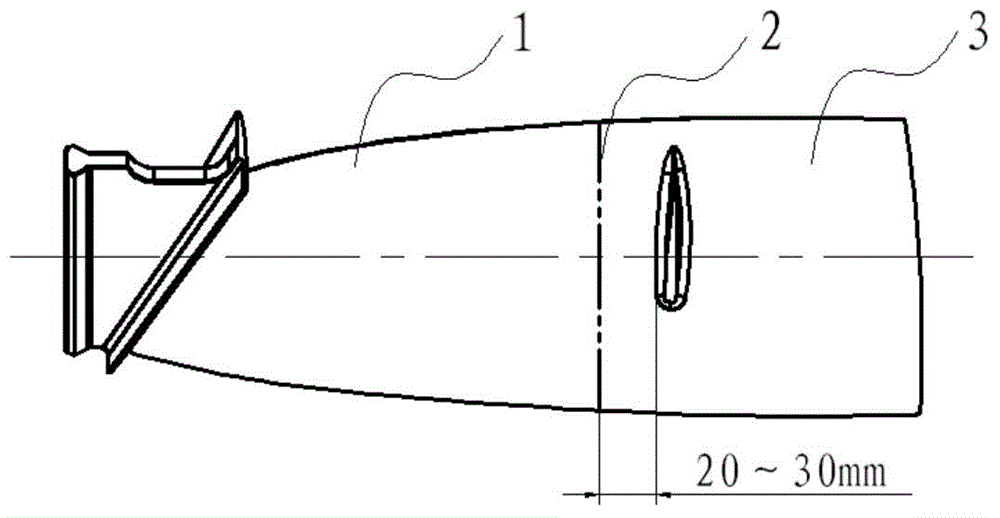

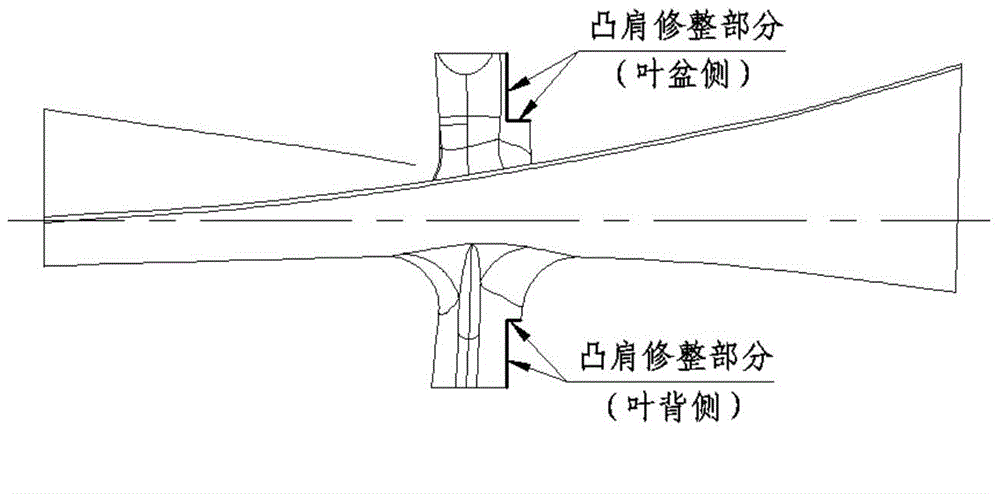

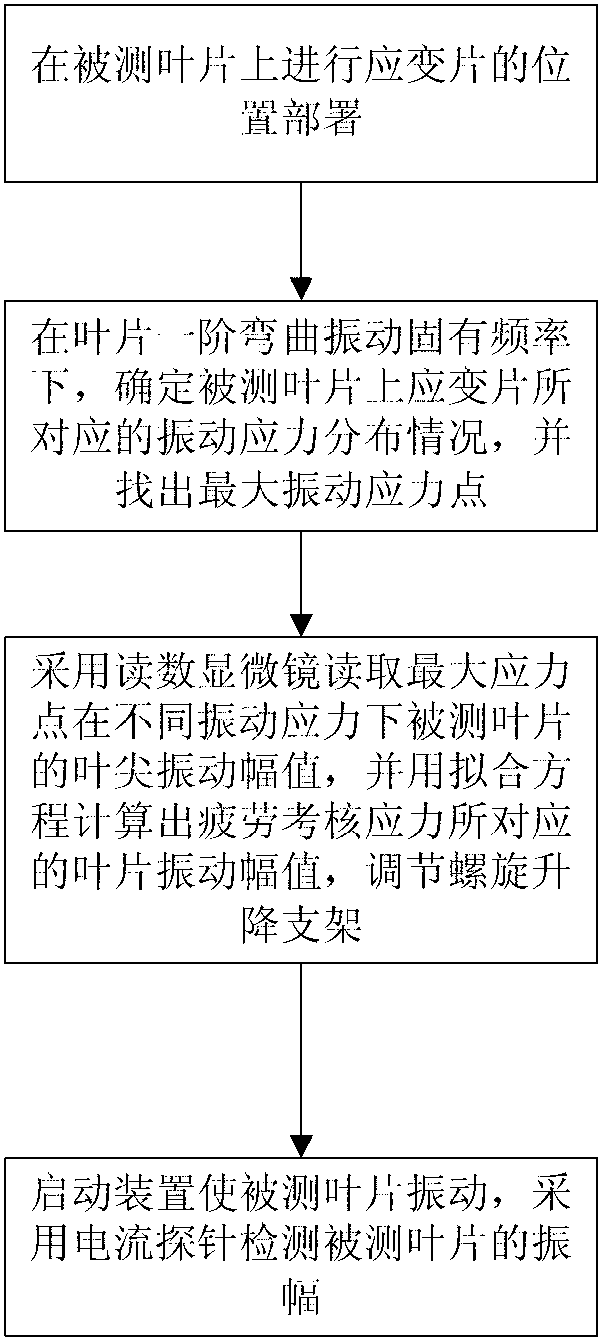

Vibration fatigue testing method for large-bypass-ratio engine fan blade with shoulder

The invention belongs to the technology of aviation engine blade testing, and provides a vibration fatigue testing method for a large-bypass-ratio engine fan blade with a shoulder. The method comprises the steps: (1) laterally cutting the fan blade with the shoulder; (2) machining the top of the shoulder into two parallel platforms; (3) enabling a clamp pedestal to be fixedly connected with a vibrating platform; (4) binding strain gages on the blade body; (5) enabling a testing blade with the strain gages to be placed on an inner clamping surface of a dedicated clamping block; (6) enabling the dedicated clamping block with the testing blade to be placed into a frame of the clamp pedestal for compression; (7) enabling the lead of each strain gage on the testing piece to be connected with a corresponding channel of a deformeter; (8) controlling the vibration sweep frequency of a small load of the vibration platform, and finding a first-order bending resonance frequency of the blade; (9) recording the strain value of each channel and the amplitude of a blade tip through the deformeter, determining the maximum stress position, and carrying out the fitting of the relation between the maximum stress and the amplitude of the blade tip; (10) solving a required testing load value, and completing the vibration fatigue testing.

Owner:AECC AVIATION POWER CO LTD

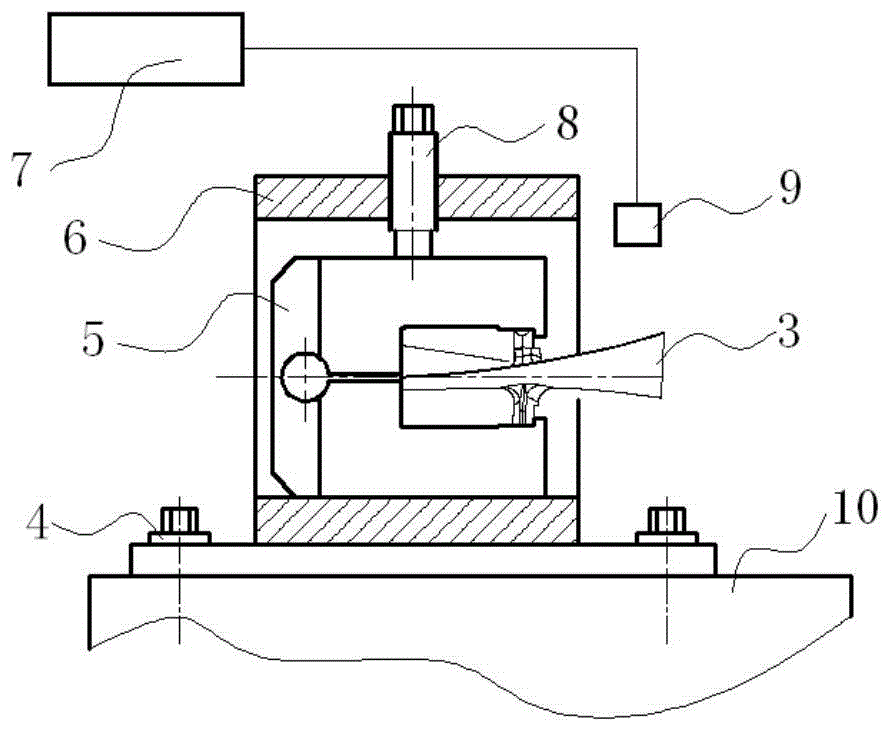

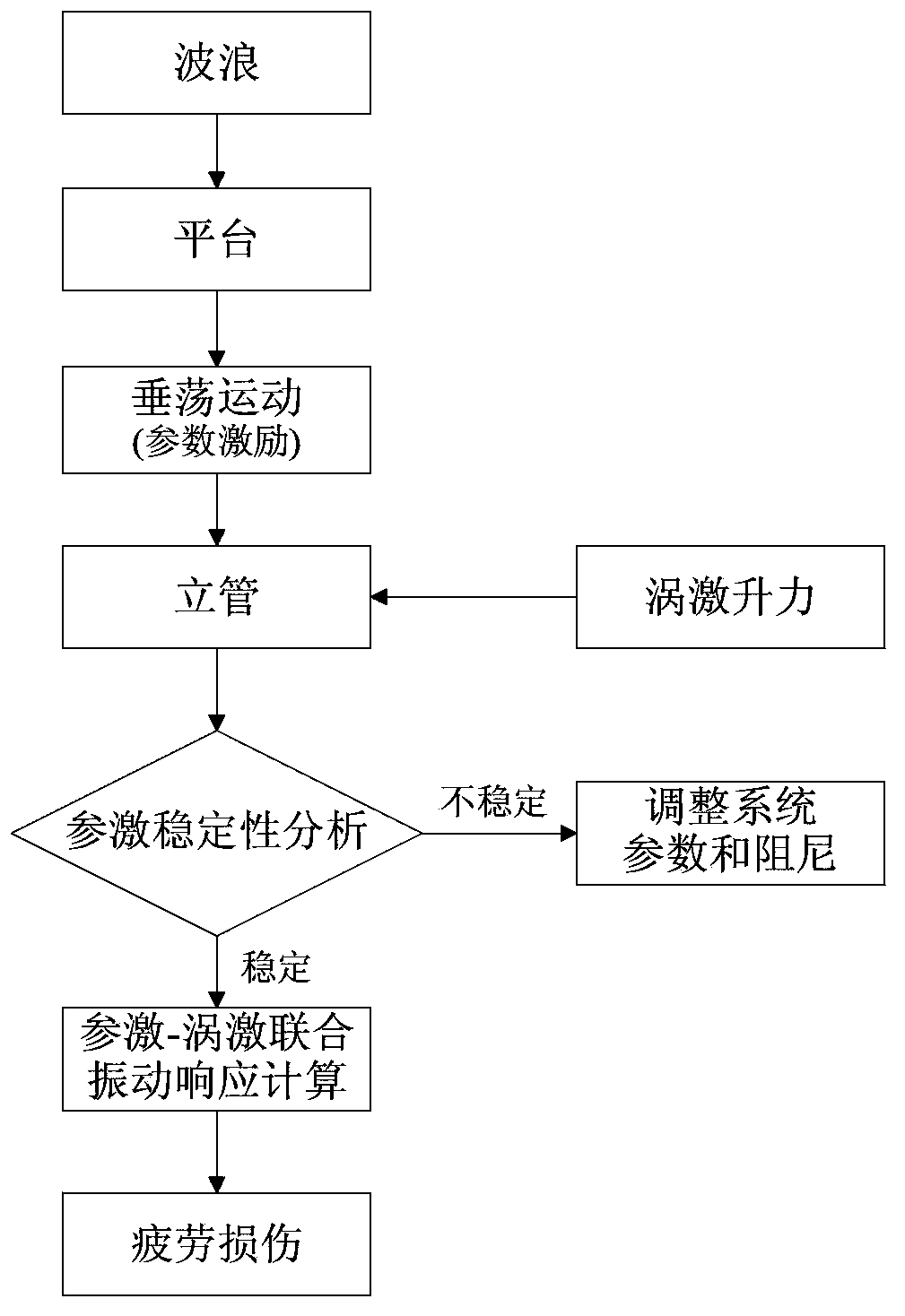

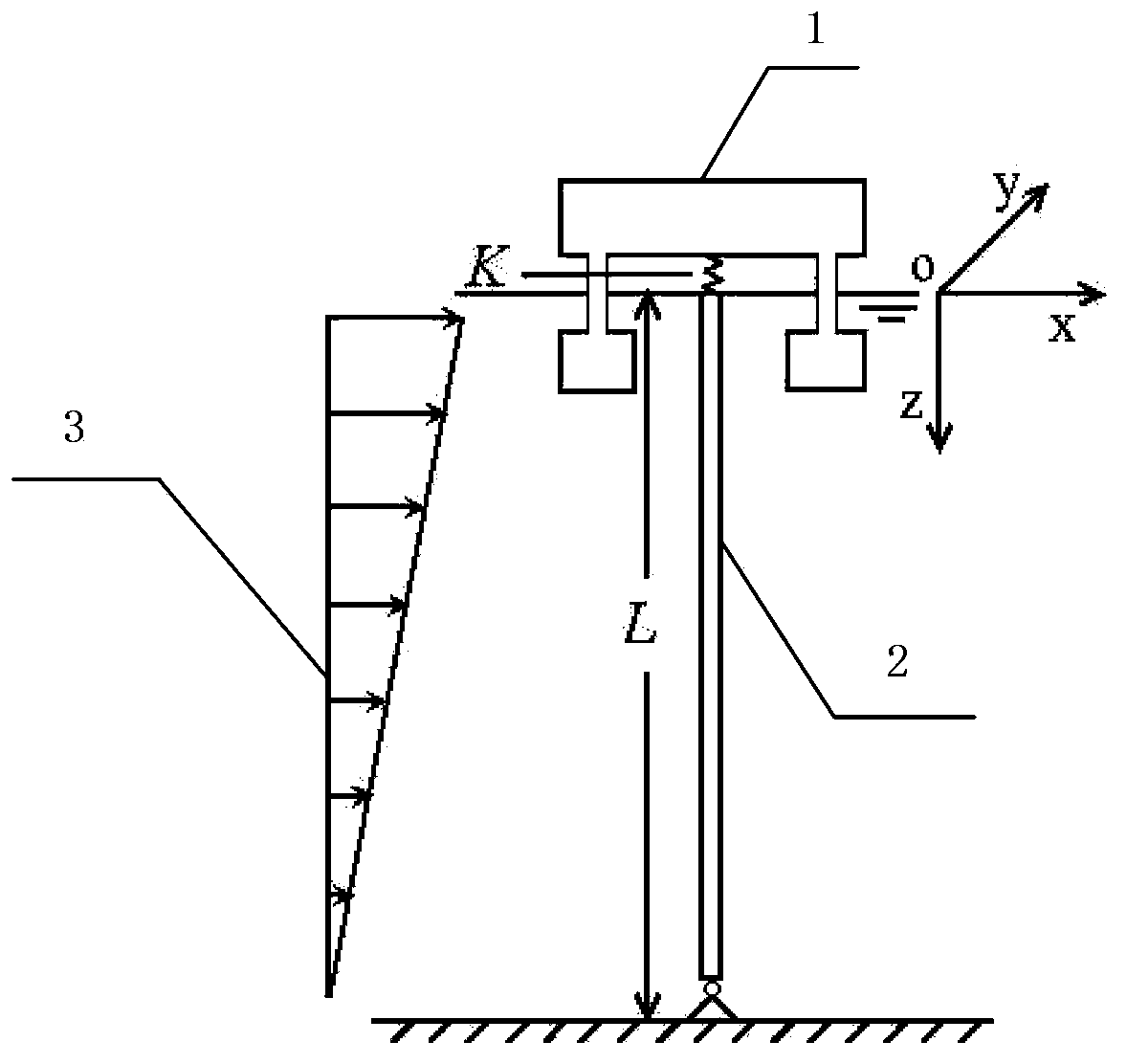

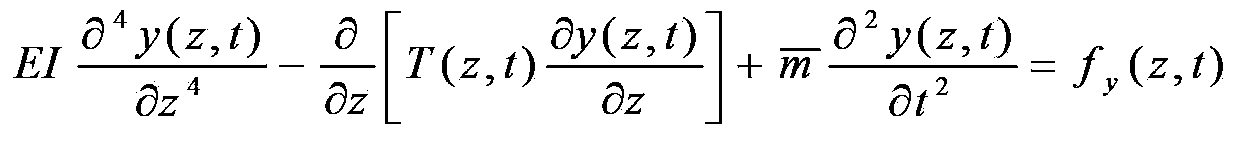

Analyzing method for parametric-excitation and vortex-induced vibratory fatigue of deep-ocean top tension riser

InactiveCN103353382AAnalysis meets realityOvercome the disadvantage of unsafe vortex induced vibration fatigue analysisVibration testingFatigue damageAnalysis method

The invention provides an analyzing method for parametric-excitation and vortex-induced vibratory fatigue of a deep-ocean top tension riser. The analyzing method comprises 1) taking regard of vortex induced lift caused by ocean current and parametric excitation caused by platform heave, and establishing a parametric-excitation and vortex-induced vibration model for the riser; 2) calculating heaving movement of a platform under wave effects according to on-site measuring results or a numerical method, and determining the parametric excitation of the riser; 3) analyzing stability of the parametric excitation of the riser, and ensuring that the parametric excitation of the riser is within a stable range; 4) calculating parametric-excitation and vortex-induced vibration response of the riser, and obtaining a time-history stress curve for each point of the riser; 5) calculating a stress cycle index of each point of the riser in a rain-flow counting method; and 6) calculating a fatigue life of the riser via a Miner damage cumulating theory and an S-N curve method. The analyzing method of the invention overcomes the disadvantage that present fatigue analysis based on vortex induced vibration tends to be unsafe, and enables fatigue damage analysis of the riser to satisfy practicality better.

Owner:TIANJIN UNIV

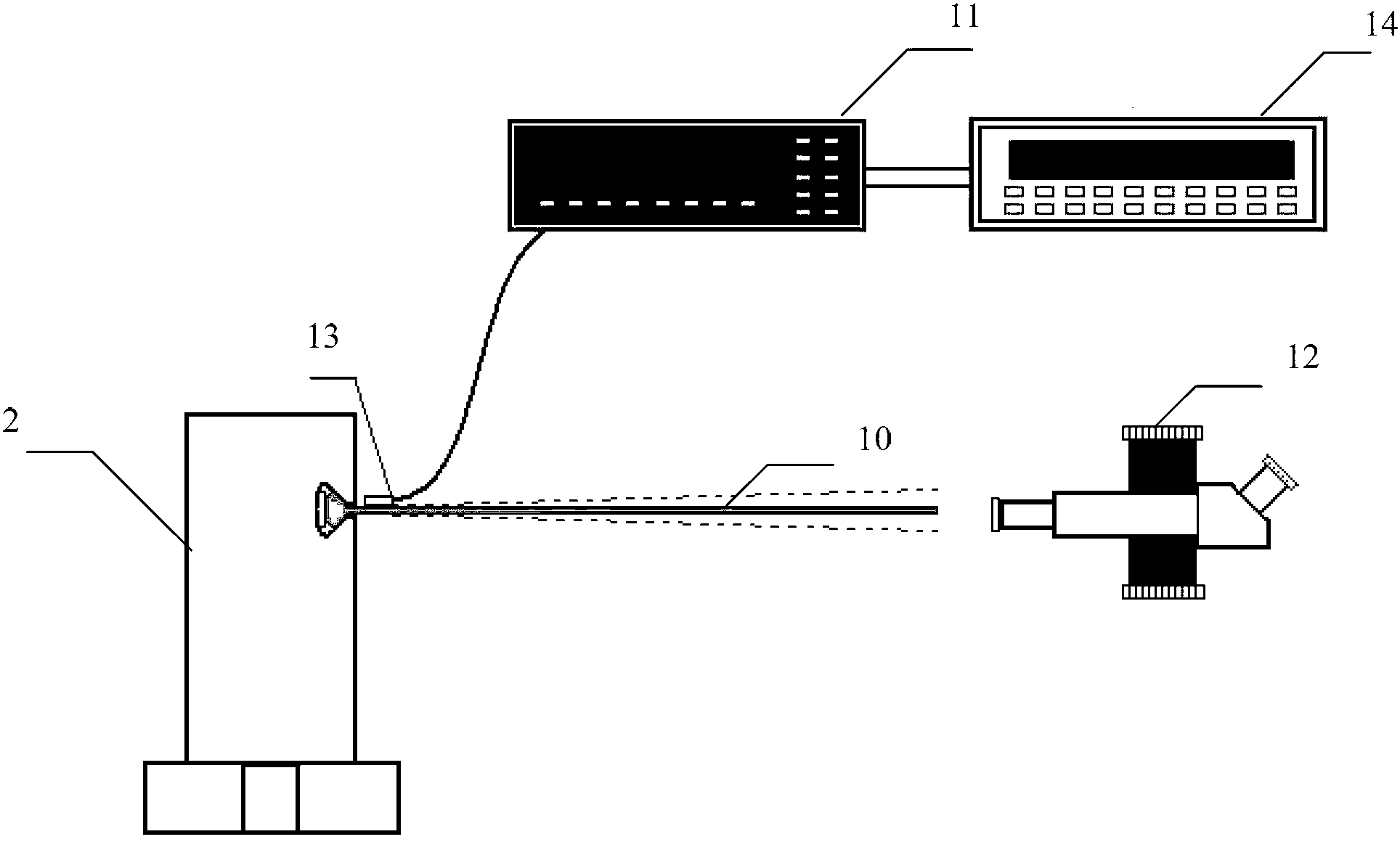

Detection device and detection method for wide-range vibration amplitude of blade of aviation engine

InactiveCN102840968ASolve the problem of difficult vibration amplitude monitoringExpansion of Vibration Stress Testing TechnologyMachine part testingSubsonic/sonic/ultrasonic wave measurementAviationVibration amplitude

The invention provides a detection device and a detection method for wide-range vibration amplitude of a blade of an aviation engine. The detection device comprises a power supply, a fixture, bridge circuit boxes, millivoltmeters, a reading microscope, a spiral lifting support and current probes, wherein two transverse fixing supports for fixing the current probes are arranged on the spiral lifting support. An output end of a first current probe is connected with an input end of a first bridge circuit box. An output end of the first bridge circuit box is connected with an input end of a first millivoltmeter. An output end of a second current probe is connected with an input end of a second bridge circuit box. An output end of the second circuit box is connected with an input end of a second millivoltmeter. The power supply is connected with a detected blade which is fixed on the fixture. The detection device and the detection method solve the problem of difficult monitoring of the wide-range vibration amplitude in a blade fatigue test, provide a completely novel test method for monitoring technology of blade and blade tip vibration amplitude in the vibration fatigue test, and expand test technology of vibration stress in the blade fatigue test.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

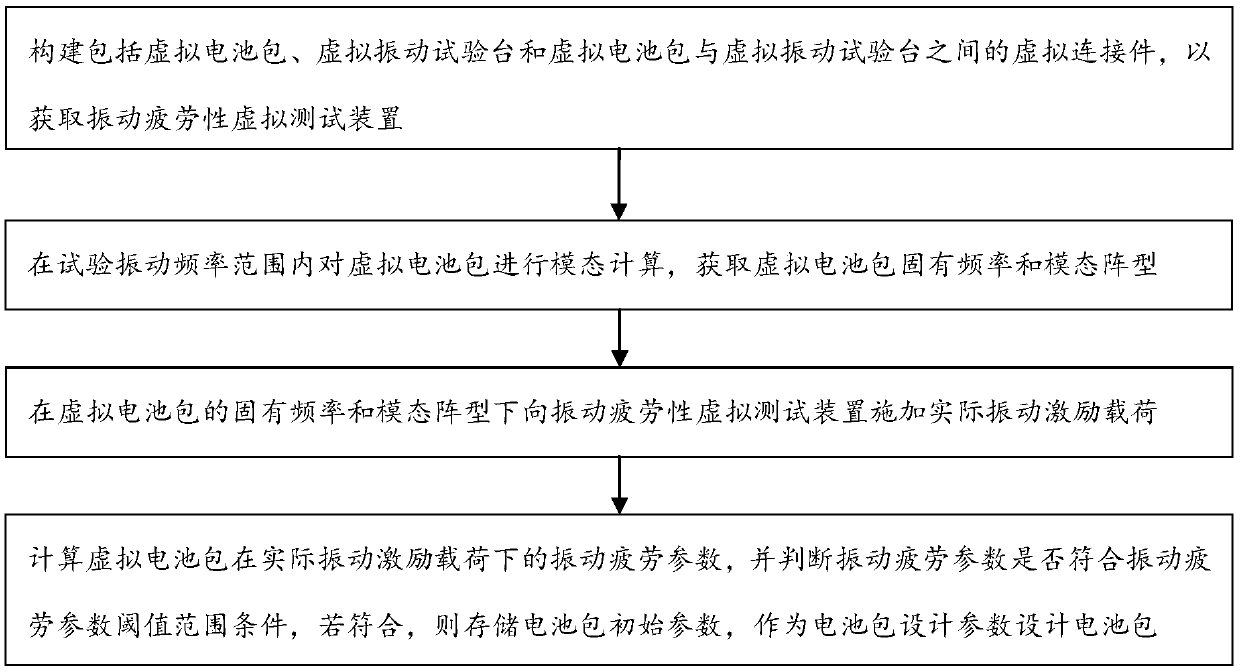

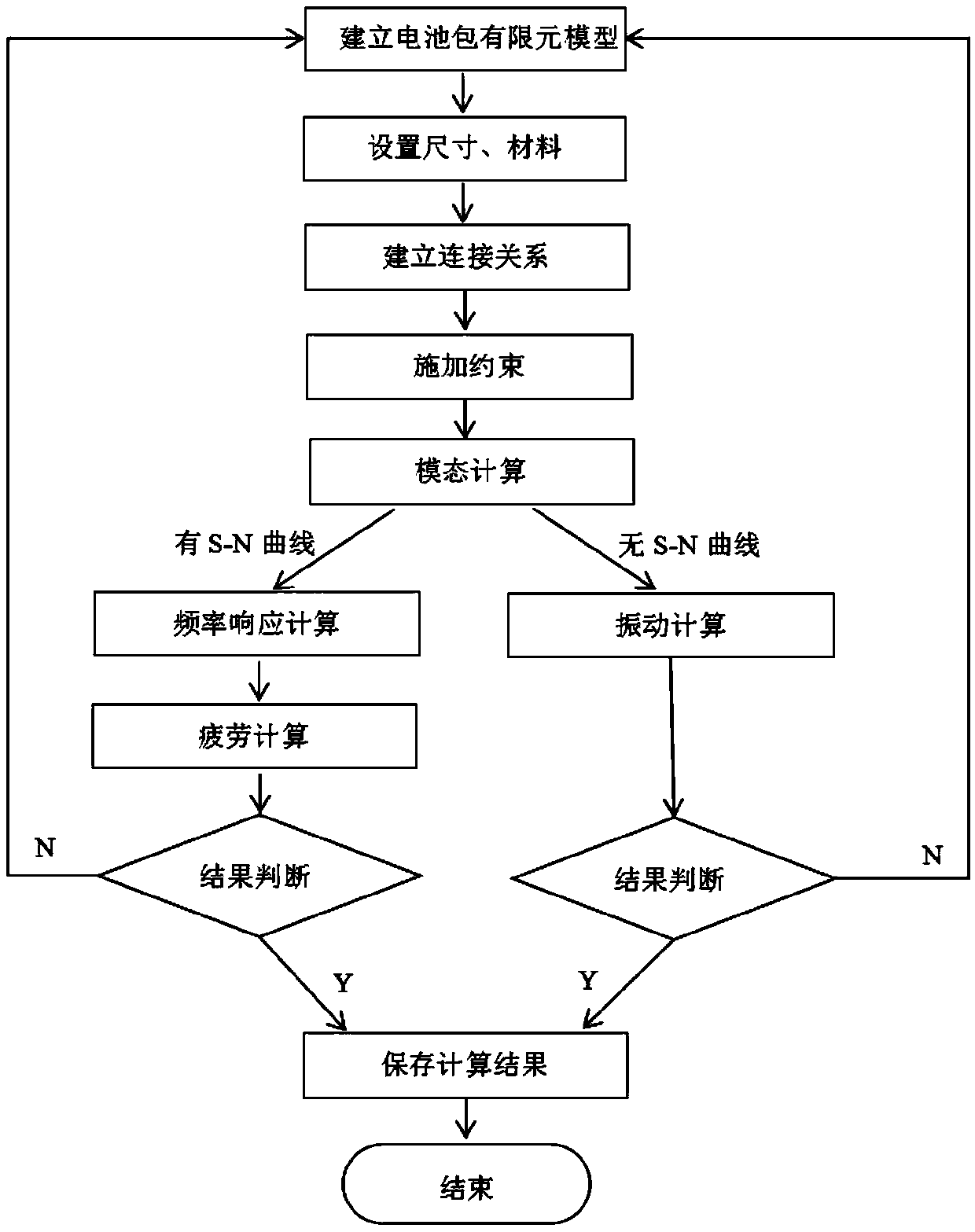

CAE-based vibration fatigue simulation test method of new energy vehicle battery pack

The invention relates to a CAE-based vibration fatigue simulation test method of a new energy vehicle battery pack.The CAE-based vibration fatigue simulation test method comprises the steps that virtual connection parts among a virtual battery pack, a virtual vibration test bench and a virtual battery pack and a virtual vibration test bench areconstructed to obtain a vibration fatigue virtual testdevice; modal calculation is performed on the virtual battery pack within the test vibration frequency range, and the natural frequency and modal matrix of the virtual battery pack are obtained; andactual vibration excitation load is applied to the vibration fatigue virtual test device under the natural frequency and modal matrix of the virtual battery pack; and the vibration fatigue parametersof the virtual battery pack under the actual vibration excitation load are calculated, whether the vibration fatigue parameters meet the vibration fatigue parameter threshold range conditions or not is determined, and if so, the initial parameters of the battery pack are stored to be taken as the design parameters of the battery pack for designing the battery pack. The CAE-based vibration fatiguesimulation test method evaluates whether the virtual battery pack is subjected to vibration fatigue damage or not during the test, and reduces the test cost of the battery pack design.

Owner:BEIDOU AEROSPACE AUTOMOBILE BEIJING CO LTD

Shore bridge structure wind vibration fatigue reliability forecasting method based on probability accumulated damage

InactiveCN102567633AImprove calculation accuracySpecial data processing applicationsTime domainStructural fatigue

A shore bridge structure wind vibration fatigue reliability forecasting method based on probability accumulated damage comprises the following steps of 1 adopting a harmonic superposition method to simulate wind load time domain wave forms endured by a shore bridge structure and accorded with Davenport power spectrum characteristics; 2 enabling the wind load to act on a finite element model of the shore bridge structure and calculating a stress response time interval of a fatigued calculation point of the shore bridge structure; 3 adopting a rain flow counting method to process the stress response time interval so as to obtain the fatigue statistics characteristics of amplitude stress spectral; and 4 adopting a probability theory method to forecast the wind vibration fatigue reliability of the shore bridge structure in a certain serving period through a probability accumulated damage model. The shore bridge structure wind vibration fatigue reliability forecasting method has the advantages of being applicable to the complex shore bridge structure, wide in application scope, high in computational accuracy, and capable of calculating the fatigue reliability of a wind resisting structure under any random wind load effects.

Owner:SHANGHAI JIAO TONG UNIV

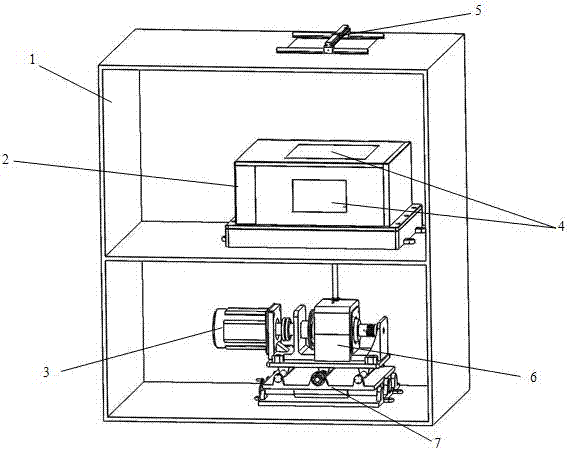

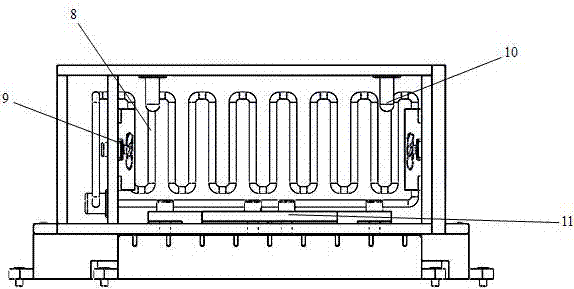

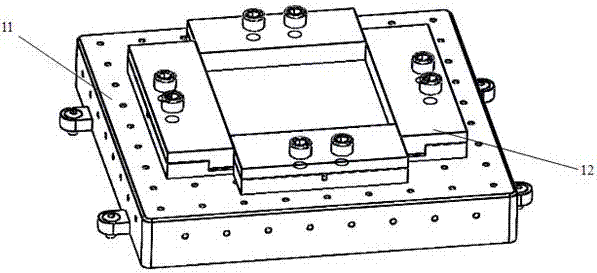

Impact and thermal compounding test device for fiber-reinforced compound thin-walled component

InactiveCN107966259AImpact speed is easy to controlImpact Speed ControlVibration testingElectric machineEngineering

The invention relates to an impact and thermal compounding test device for a fiber-reinforced compound thin-walled component, which belongs to the technical field of vibration fatigue test. The devicecomprises an outer box, a base and a test box arranged in the outer box, and a motor, a rotation accelerator and a guide pipe arranged on the base, wherein the shell of the motor is fixed on the base; the output shaft of the motor is connected with the power input shaft of the rotation accelerator; the rotation accelerator comprises a housing fixed on the base and a drive rotor and a driven rotorwhich are arranged in the housing; the drive rotor fixedly sleeves the power input shaft; the driven rotor can axially slide relative to the drive rotor; an electromagnetic separator is arranged on adriven rotor shaft; meshed teeth are arranged on the drive rotor and the driven rotor; the lower end of the guide pipe is corresponding to the edge of the drive rotor; the test box is arranged abovethe guide pipe; the lower part of the test box is provided with an opening corresponding to the guide pipe; and the test box is internally provided with a rotating fan, a carbon fiber heating pipe, acooling system, a temperature sensor and a test rig.

Owner:NORTHEASTERN UNIV

Method for calculating pipeline vibration fatigue life of frequency conversion air conditioner

InactiveCN106033498ACalculate Vibration Fatigue LifeAccurate calculationInformaticsSpecial data processing applicationsFatigue damageFrequency conversion

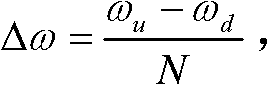

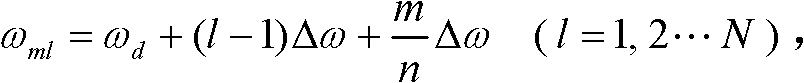

The invention relates to an air conditioner and provides a method for calculating the pipeline vibration fatigue life of a frequency conversion air conditioner. The working conditions of the frequency conversion air conditioner in the refrigerating season and the heating season every year and actual contributions of all frequency points to pipeline vibration need to be combined to estimate the pipeline vibration fatigue life of the frequency conversion air conditioner. The average operating frequency of the frequency conversion air conditioner is calculated through weighting, the working conditions of the frequency conversion air conditioner and the weights of all operating frequency points are determined, fatigue damage of pipelines of the frequency conversion air conditioner in a starting state, an operating state and a halt state within a year is calculated according to fatigue features of pipeline materials and tested vibration maximum stress values at all the frequency points, and the pipeline system vibration fatigue life of the frequency conversion air conditioner is calculated through accumulation of the fatigue damage. The method is suitable for the frequency conversion air conditioner.

Owner:四川长虹空调有限公司

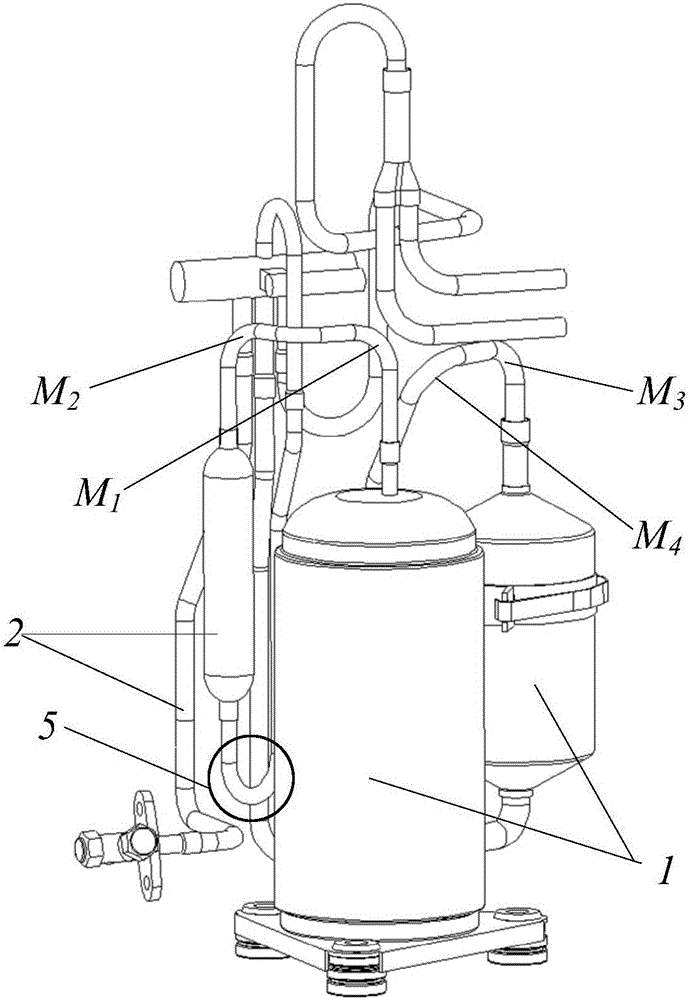

Test apparatus, system and method for obtaining vibration fatigue limit of welded pipe

The invention provides a test apparatus, system and method for obtaining a vibration fatigue limit of a welded pipe. The test apparatus comprises a mounting seat having a receiving part; a pipe having a pipe joint, a pipe body and an installation section, the pipe body being located between the pipe joint and the installation section; a plurality of strain gauges adhered to the pipe body and used for measuring the vibration stress of the pipe and converting it into a dynamic strain signal; a displacement measuring sensor disposed above the pipe body and keeping a distance from the pipe body for measuring the displacement of the pipe during vibration and converting it into a vibration displacement signal; a vibration acceleration sensor which is fixedly arranged above the housing portion for acquiring the vibration acceleration signal of the pipe and converting the vibration acceleration signal into a dynamic analog voltage signal. The pipe joint is fixed in the housing portion. The test apparatus of the invention is reasonable in design and stable and reliable in system operation, and the fatigue test method is correct and feasible.

Owner:AECC HUNAN AVIATION POWERPLANT RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com