High temperature resistant vehicle radiator hose sizing compound formula

A technology of automobile radiator and rubber compound formulation, which is applied in the direction of hose, pipe, pipe/pipe joint/pipe fitting, etc. The effect of heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

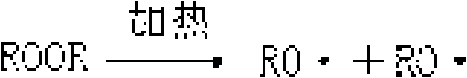

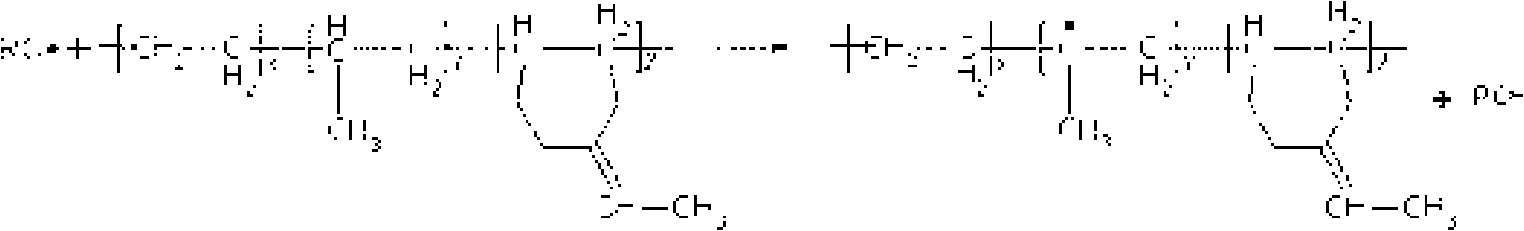

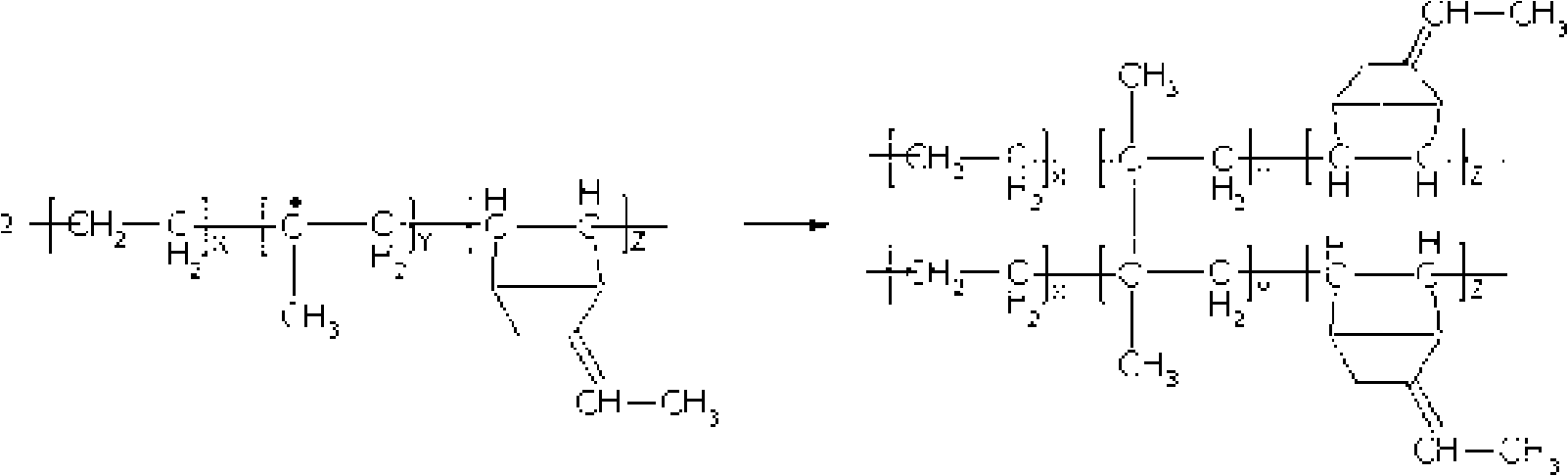

Method used

Image

Examples

Embodiment Construction

[0030] Raw materials: according to the proportioning of the following embodiments, the prescription is carried out: (unit: kilogram)

[0031]

[0032] Preparation:

[0033] 1. Material shape

[0034] 1. The EPDM rubber should be selected from products with high Mooney, medium-high ethylene content, medium-low ethylene and norbornene content. This specific implementation mode uses MG47085 produced by DuPont Copper in the United States;

[0035] 2, paraffin oil should select the product of high flash point, high viscosity, low volatility for use, and this embodiment selects domestic 500# paraffin oil for use;

[0036] 3, anti-aging agent selects quinoline anti-aging agent, what this specific implementation mode selects is anti-aging agent RD, in order to enhance the protective effect, the protective system of RD+MB can be used in combination;

[0037] 4. Other materials can be shaped as usual.

[0038] 2. Preparation

[0039] 1. Rubber mixing

[0040] The rubber material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com