Patents

Literature

143 results about "Ceiling temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ceiling temperature (Tc) is a measure of the tendency of a polymer to revert to its constituent monomers. When a polymer is at its ceiling temperature, the rate of polymerization and depolymerization of the polymer are equal. Generally, the ceiling temperature of a given polymer is correlated to the steric hindrance of the polymer’s monomers. Polymers with high ceiling temperatures are often commercially useful.

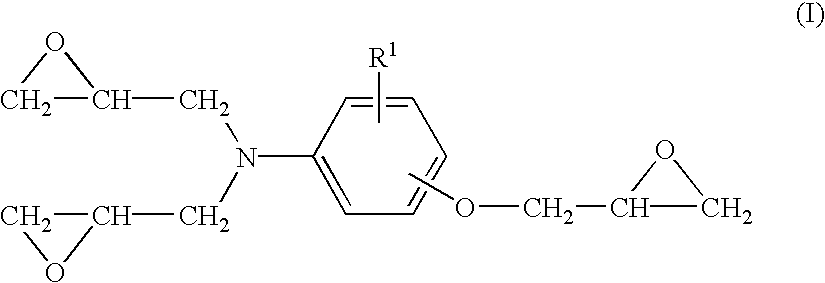

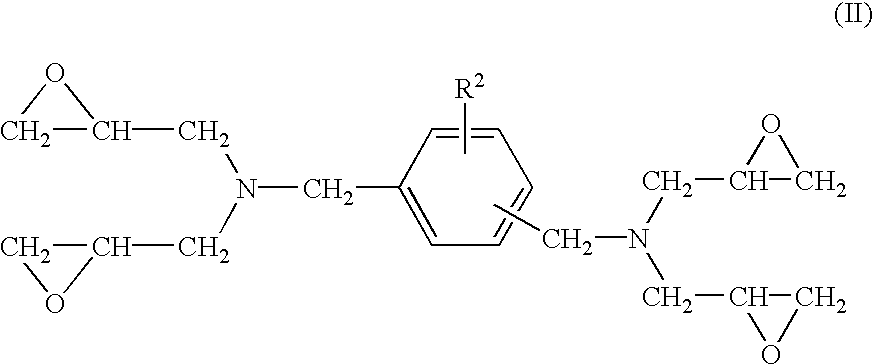

Epoxy resin compositions, epoxy resin compositions for fiber-reinforced composite materials, and fiber-reinforced composite materials comprising the same

InactiveUS6410127B1Improve heat resistanceImprove mechanical propertiesSynthetic resin layered productsYarnEpoxyCeiling temperature

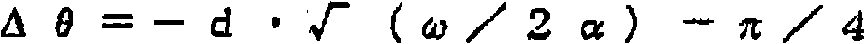

An epoxy resin composition having a low viscosity around a room temperature and excellent reinforcing fiber impregnating properties provides a composite material having excellent heat resistance and mechanical properties including compressive strength. The epoxy resin composition includes an aromatic epoxy resin having at least di-functionality, an aromatic amine compound and / or an alicyclic amine compound, wherein 5 minutes after the main agent comprising the epoxy resin and the curing agent comprising the aromatic amine compound and / or the alicyclic amine compound are mixed, the composition shows a viscosity at 25° C. in the range of from 1 to 1500 mPa sec, and Tc, tc, and Tg satisfy the following equation (1):wherein k=0 when 60<=Tc<90 and k=0.35 when 90<=Tc<=200;Tc is the highest temperature (°C.) during the curing process and is defined by the formula 60<=Tc<=200;tc is the retention time (min) at the highest temperature and is defined by the formula 1<=tc<=120; andTg is the glass transition temperature of the epoxy resin composition after a lapse of tc (min) at Tc (°C.).

Owner:TORAY IND INC

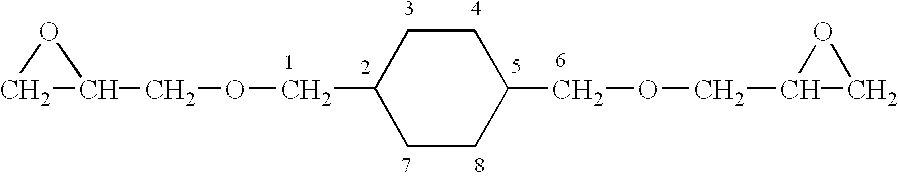

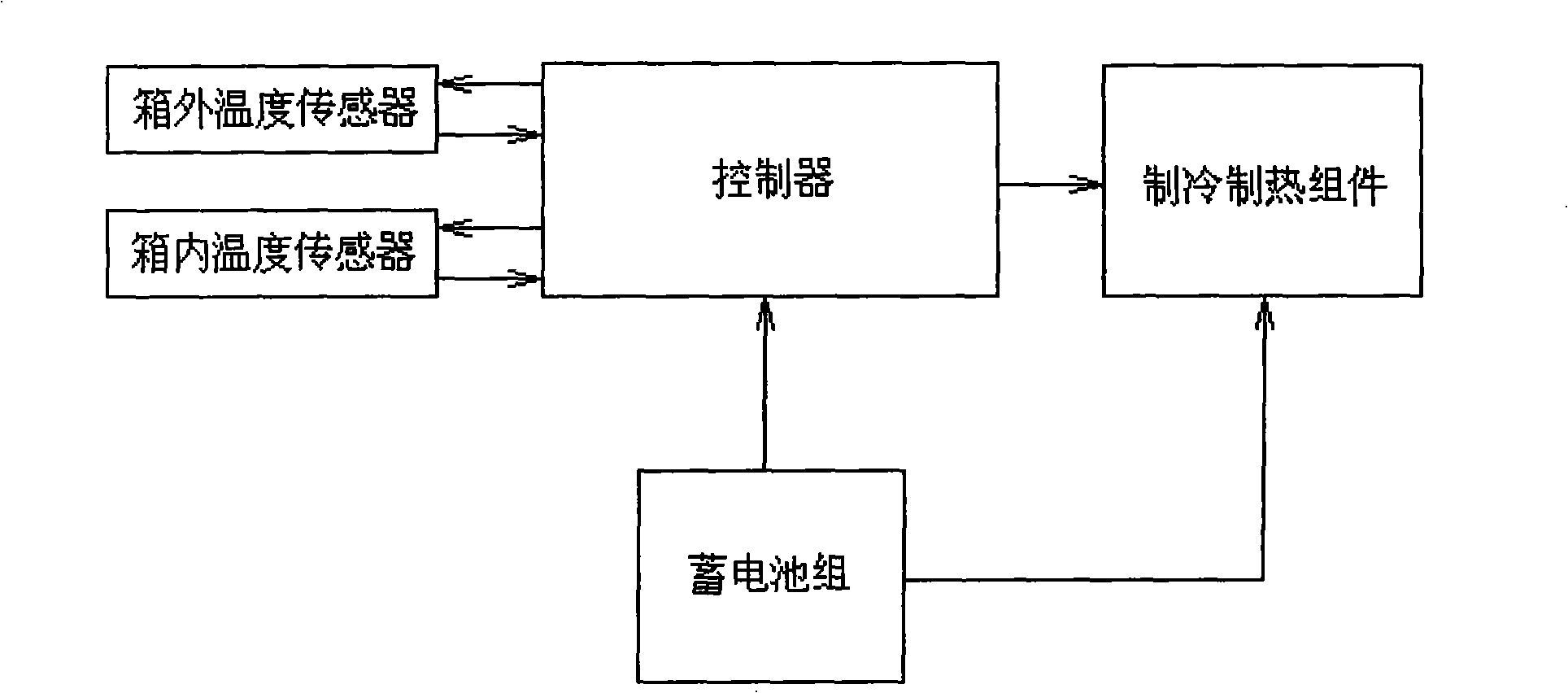

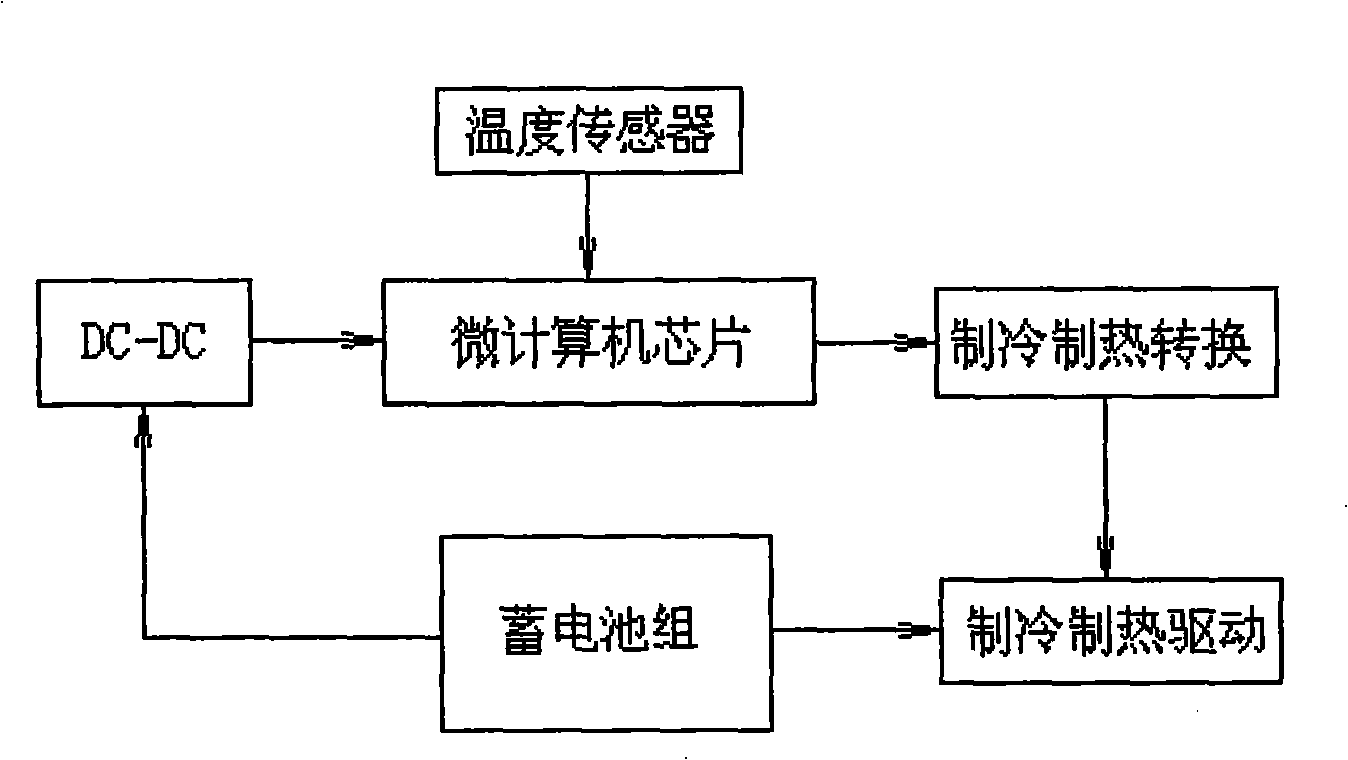

Constant temperature cabinet for accumulator and temperature-controlling method thereof

InactiveCN101409374AAvoid consumptionSatisfy consumptionTemperatue controlSecondary cellsTemperature controlAutomatic control

The invention relates to a thermotank and a temperature control method thereof, in particular to a thermotank of a storage battery and a temperature control method thereof. The thermotank comprises a thermotank body, heating and refrigerating components and a controller; the heating and refrigerating components comprise an air course outside the thermotank, an air course inside the thermotank, a radiator of the air course outside the thermotank, a radiator of the air course inside the thermotank, an air inlet door, an air outlet door, a ventilator of the air course outside the thermotank, a ventilator of the air course inside the thermotank, a cold clapboard and a hot clapboard as well as a semiconductor refrigerating device and a semiconductor heating device. When the temperature inside the thermotank is higher than the ceiling temperature for constant-temperature starting, then the temperature outside the thermotank is judged; if the temperature outside the thermotank is higher than the refrigerating starting temperature, then the refrigerating function is started; if the temperature outside the thermotank is lower than the refrigerating starting temperature, the ventilation is carried out; when the temperature inside the thermotank is lower than the floor temperature for constant-temperature starting, then the working condition is opposite. The invention is used for movable communication bases, uninterruptible power supply, and the like and has the advantages of automatic temperature control and regulation, energy saving, safety and convenient operation.

Owner:南京科迅科技有限公司 +1

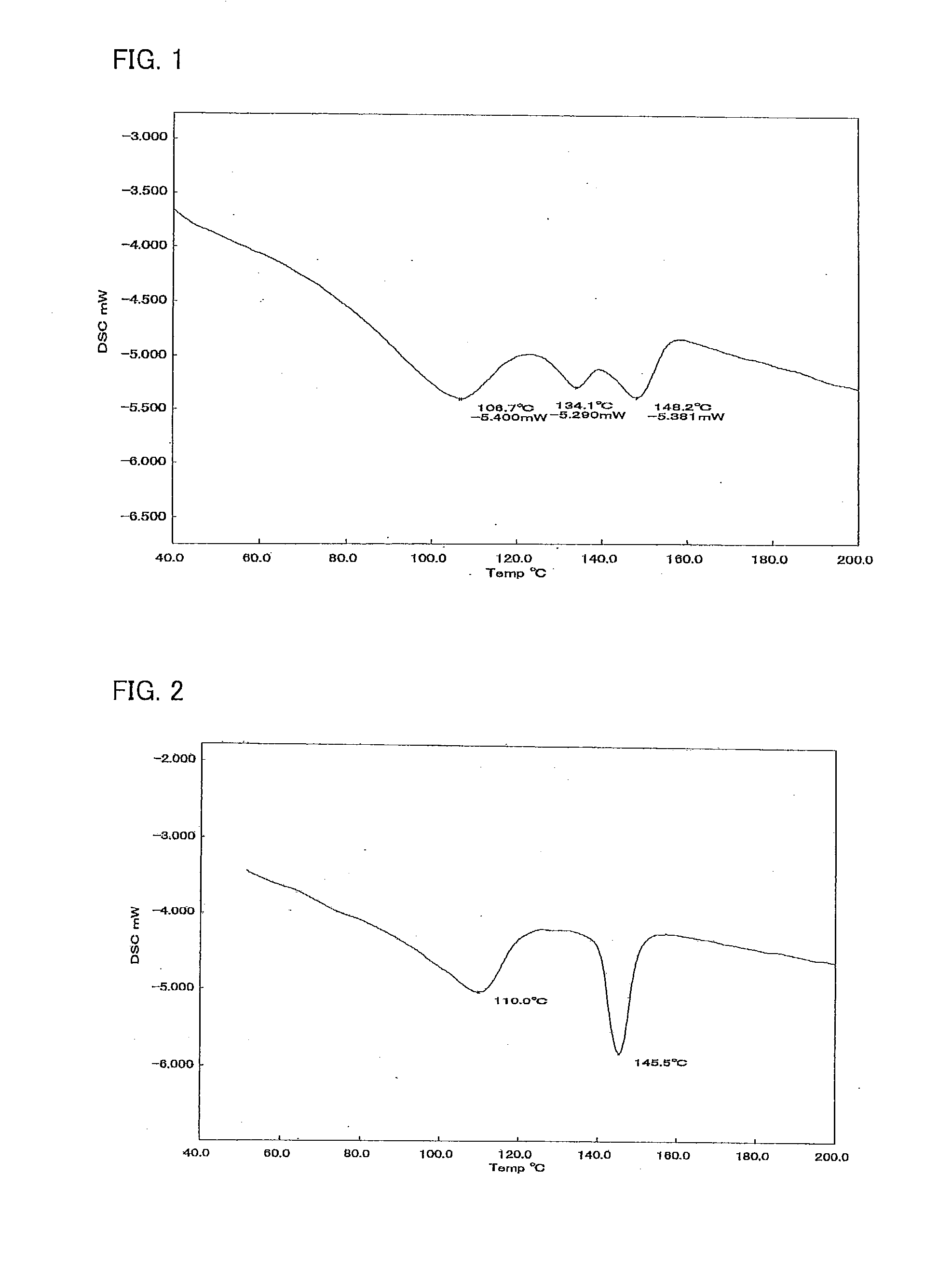

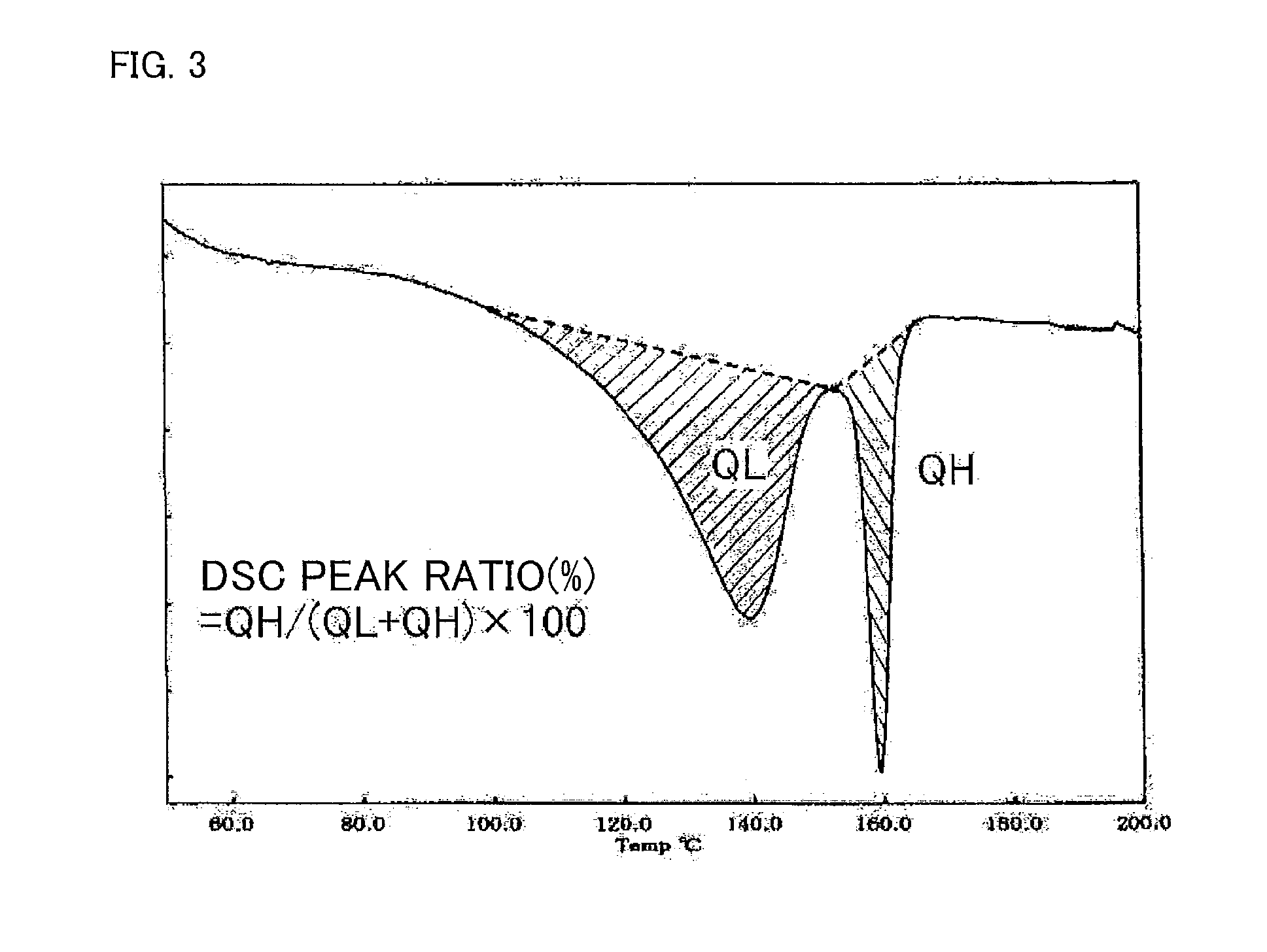

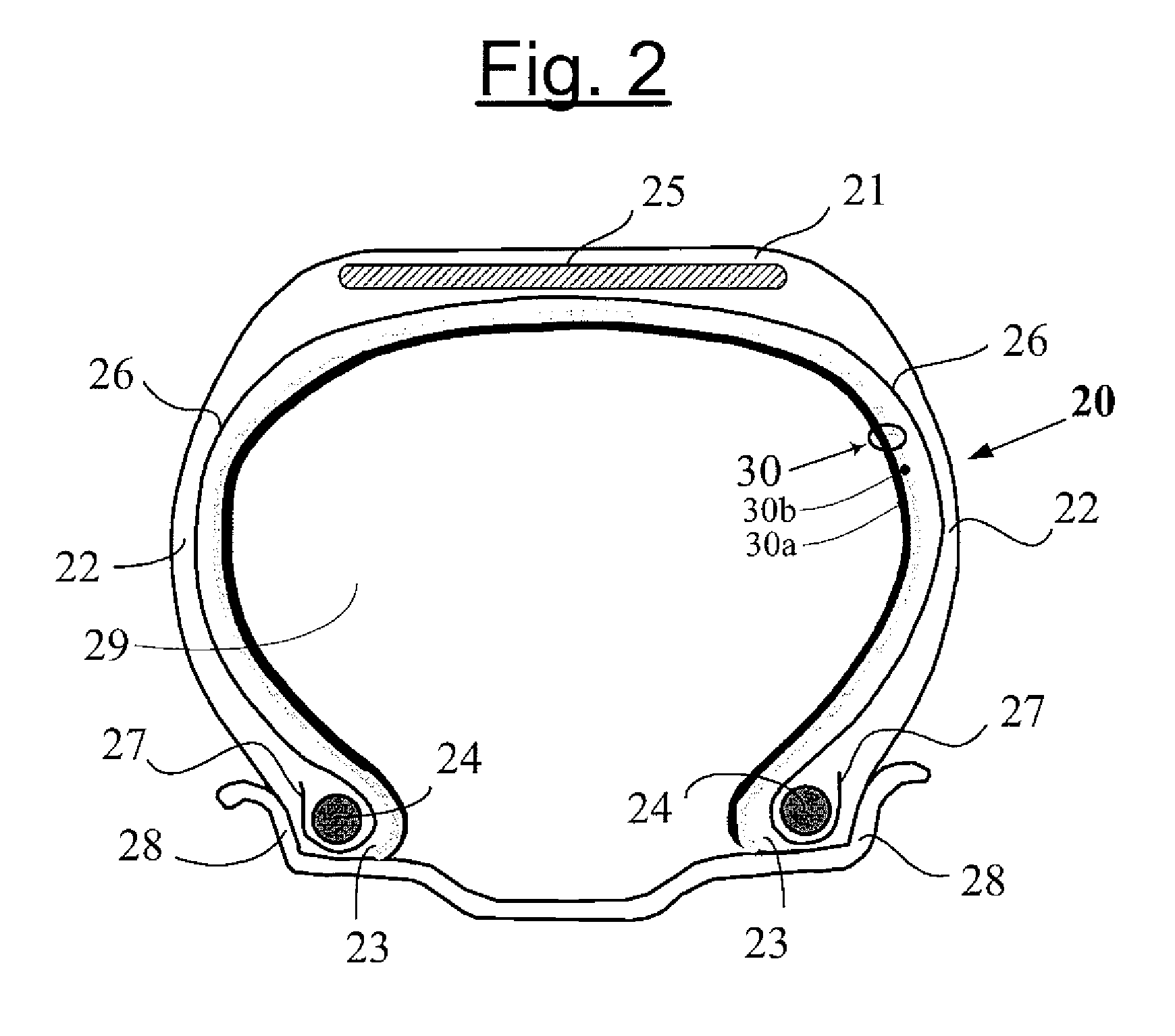

Polypropylene resin expanded particles and polypropylene resin in-mold foaming molded body

ActiveUS20120214890A1Wide range of heating conditionSatisfactory moldabilityLow distortionSteam pressure

Polypropylene resin expanded particles include polypropylene resin as base material resin having at least two melting peaks on a DSC curve, the at least two melting peaks including (i) a lowest-temperature melting peak of 100° C. or more but 130° C. or less and (ii) a highest-temperature melting peak of 140° C. or more but 160° C. or less, so that the expanded particles: produce an in-mold foaming molded product at a very low mold heating steam pressure; exhibit low distortion, low shrinkage, and a wide range of heating condition for molding, even if the mold heating steam pressure is increased; have satisfactory moldability when the expanded particles are molded by using a mold having a complicated shape or a large mold; and maintain properties such as compressive strength, substantially unimpaired, when the expanded particles make the in-mold foaming molded product.

Owner:KANEKA CORP

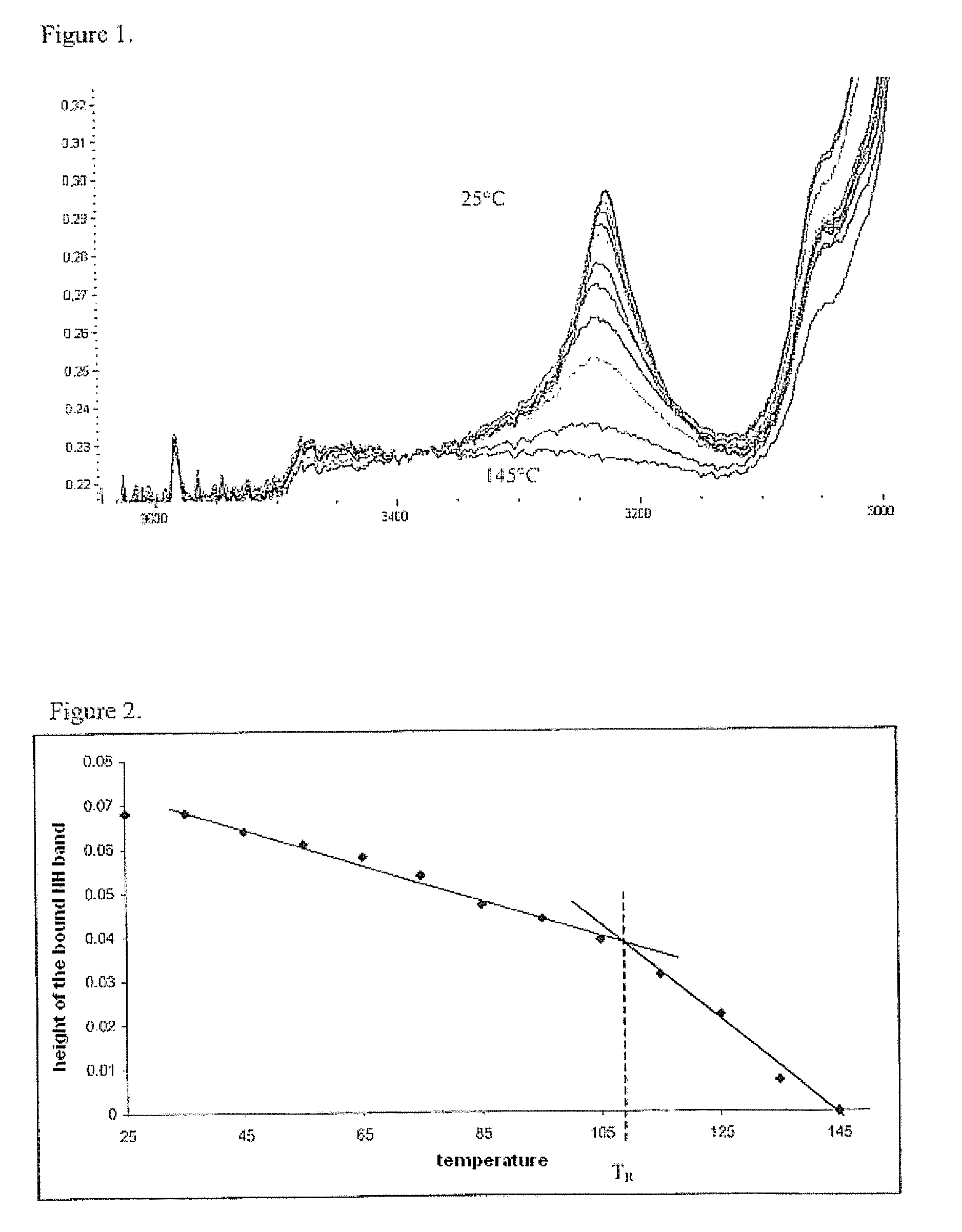

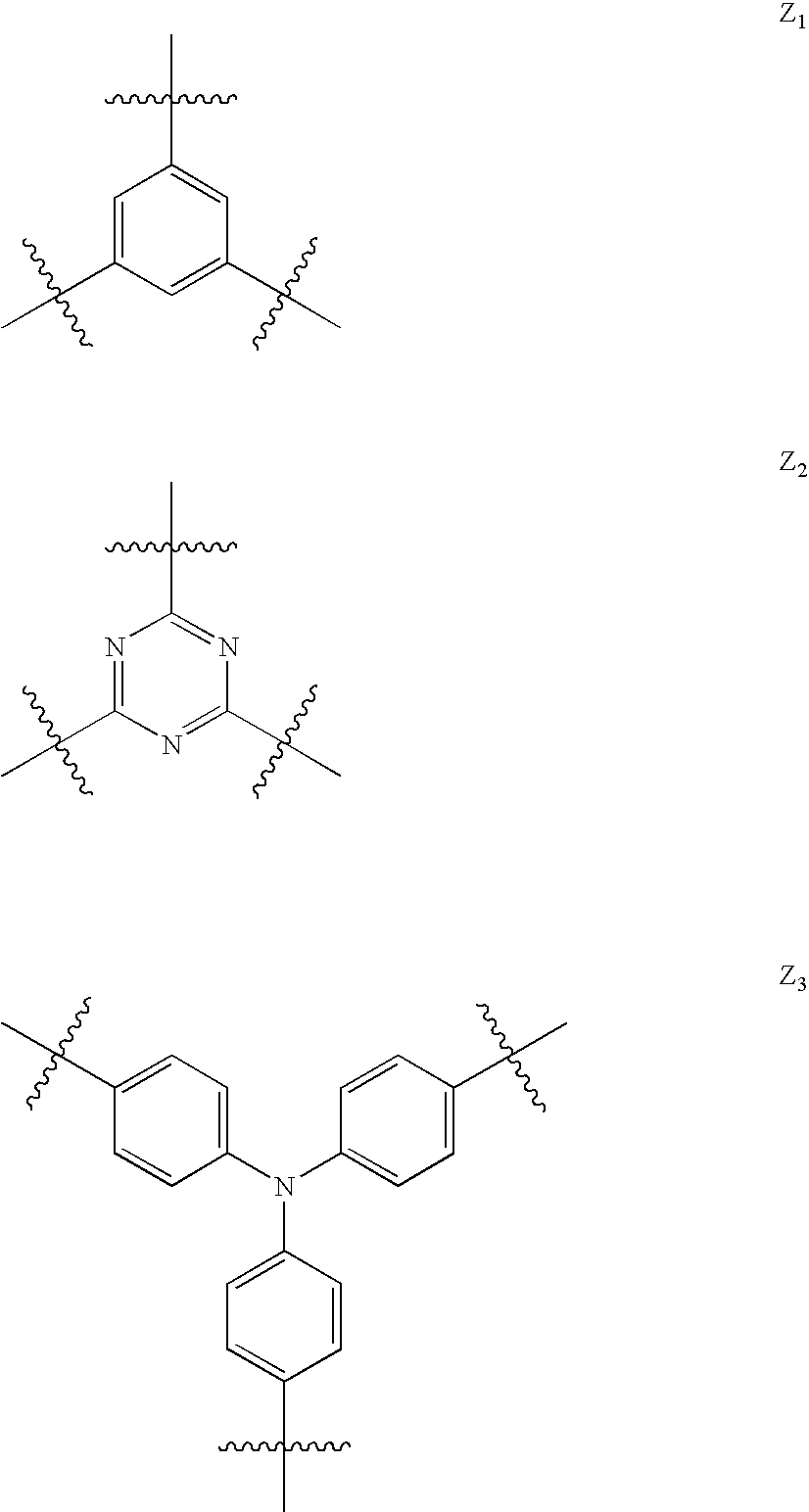

Bituminous composition with thermoreversible properties

InactiveUS20100192804A1High viscosityBuilding insulationsBituminous coatingsHydrogenMaximum temperature

The invention relates to a bituminous composition that comprises a major portion of at least one bitumen and a minor portion of at least one chemical additive, said additive being an organogelling agent that generates a network of hydrogen bonds between the organogelling molecules constituting the same, and trapping the bitumen phase up to a maximum temperature TR of between 40 and 120° C. The invention also relates to the use of these bitumen compositions in the field of road applications, particularly in the production of road binders, as well as in industrial applications. The invention also relates to a method for preparing these bituminous compositions.

Owner:TOTAL RAFFINAGE MARKETING +1

Preparation method and product of low-roughness polyimide film and application of product

ActiveCN104672477AReduce roughnessReduce surface roughnessPhotovoltaic energy generationSemiconductor devicesCeiling temperaturePolyamide

The invention discloses a preparation method and a product of a low-roughness polyimide film and application of the product. The preparation method comprises four steps, including synthesis and treatment of polyamide acid, curtain coating, pre-drying of the film and imidization, and the preparation method comprises the following concrete steps: taking biphenyl diamine and dianhydride as polyamide acid synthesizing monomers; controlling the temperature of a curtain coating substrate to be above 30 DEG C before film formation; drying and imidizing the film by adopting a programmable temperature increment mode, wherein the highest drying temperature is 130 DEG C; the highest imidization temperature is not lower than 450 DEG C. The prepared polyimide film is flat in surface, smaller than or equal to 10nm in surface roughness, larger than 300MPa in tensile strength, larger than 330 DEG C in glass-transition temperature, smaller than 1% in thermal shrinkage rate and smaller than 20ppm / DEG C in thermal expansion coefficient (CTE). The preparation method disclosed by the invention is safe in overall technological process, free of use of expensive equipment, simple in operation procedures and easy in control on surface appearance of the film.

Owner:CHINA LUCKY FILM CORP

1-Butene polymer and molded product consisting of the polymer

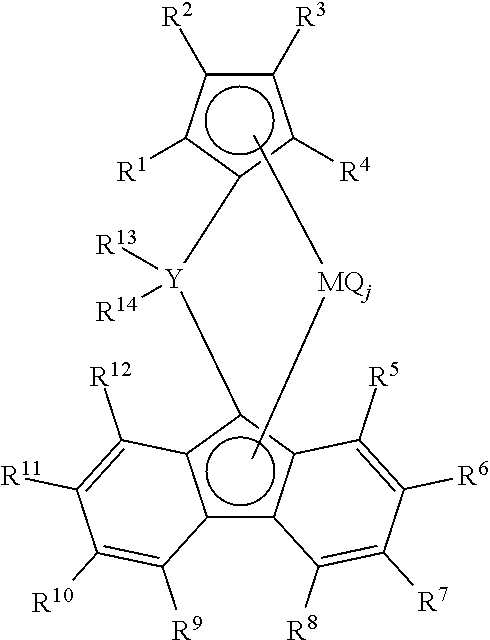

1-butene based polymer satisfying following requirements (1″) to (4″) provides formed product having low stickiness, superior flexibility and transparency.(1″) Crystalline resin having melting point (Tm−P), not observed or in the range of 0 to 100° C., wherein said melting point defined as the peak top of the peak observed in the highest temperature zone of the melting heat absorption curve obtained by heating a sample of said polymer at a rate of 10° C. / minute using Differential Scanning Calorimeter (DSC), after melting said sample in advance at 190° for 5 minutes under nitrogen atmosphere, followed by cooling it to −10° C. at a rate of 5° C. / minutes, and keeping it at −10° C. for 5 minutes.(2″) Stereoregularity index {(mmmm) / (mmrr+rmmr)} is at most 20.(3″) Molecular weight distribution (Mw / Mn) measured by Gel Permeation Chromatography (GPC) method is at most 4.0.(4″) Weight average molecular weight (Mw) measured by GPC method is in the range of 10,000 to 1,000,000.

Owner:IDEMITSU KOSAN CO LTD

High temperature resistant vehicle radiator hose sizing compound formula

The invention provides a formula of sizing material of a high temperature-resistant hose of an automotive radiator. The sizing material is prepared by the mixture of ethylene propylene diene rubber, sulfur, dicumyl peroxide, antioxidant, a reinforcing agent and a plasticizer. The invention improves the heat resistance of the hose of the radiator by changing the formula of the sizing material of the hose of the automotive radiator and after being vulcanized and cross-linked, the sizing material can form a carbon-carbon cross link which has higher bond energy than a cross link formed after the sizing material taking sulfur as a vulcanization system is vulcanized, and can also meet the requirement of the working temperature of 150 DEG C (the instant highest temperature can reach 175 DEG C). Simutaneously, the properties of the hose such as tension strength at break, elongation at break, ozone ageing resistance, low-temperature resistance, vibration fatigue resistance, cooling fluid resistance, compression set, etc. can all meet the international requirements of the 150 DEG C level.

Owner:贵州戴斯威特橡胶有限公司 +1

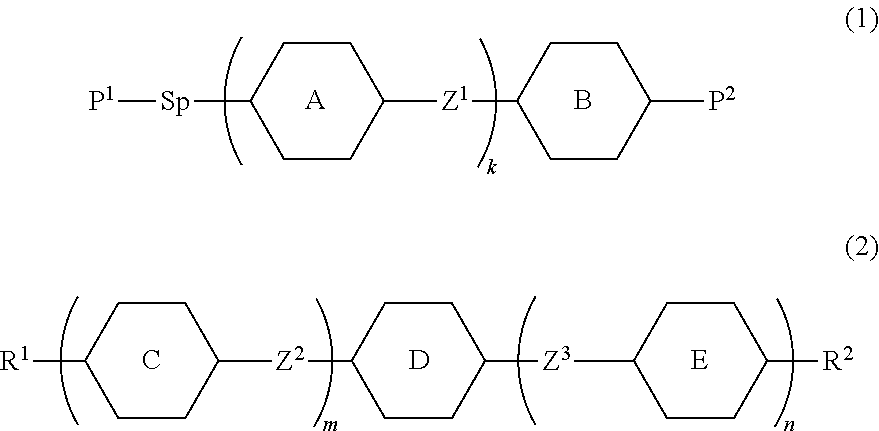

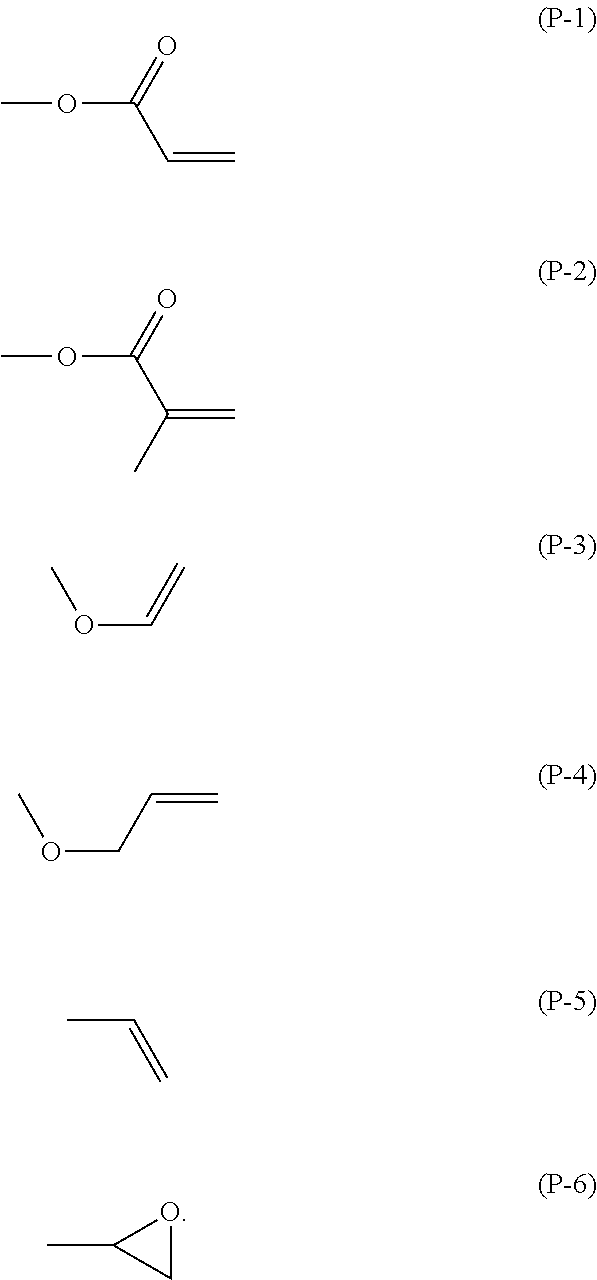

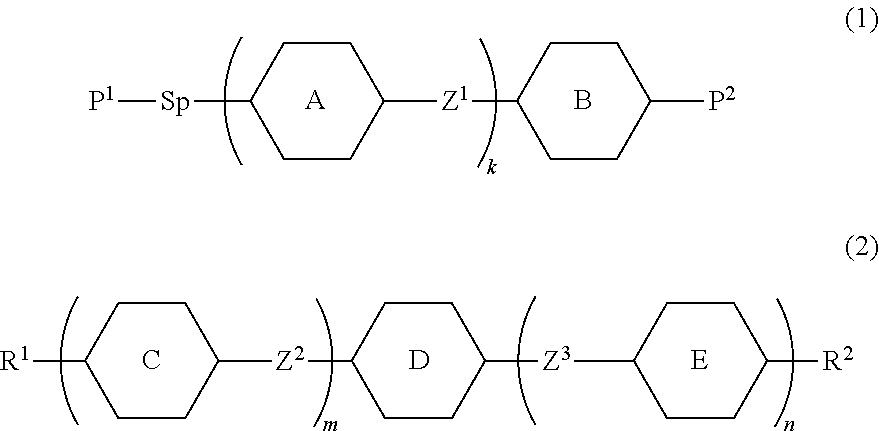

Liquid crystal composition and liquid crystal display device

ActiveUS20130135575A1Improve stabilityShort response timeLiquid crystal compositionsNon-linear opticsSolubilityDisplay device

To provide a highly reactive polymerizable compound having a high solubility in a liquid crystal compound; a liquid crystal composition satisfying at least one characteristic such as a high maximum temperature of a nematic phase, a low minimum temperature thereof, a small viscosity, a suitable optical anisotropy, a large negative dielectric anisotropy and specific resistance, a high stability to ultraviolet light and heat, and having a suitable balance regarding at least two characteristics; a PSA device having a short response time, a large pretilt angle, a small residual monomer concentration, a large voltage holding ratio and contrast ratio and a long life; a polymerizable compound into which one bonding group or nonidentical reaction group is introduced by constructing a polymer structure having a high polymerization degree in a PSA device manufacturing process to obtain a stable display, a liquid crystal composition containing thereof, and a liquid crystal device including thereof.

Owner:JNC CORP +1

Method for manufacturing a polyester composition having improved impact properties

InactiveUS20120271004A1Increase impactViscosityCeramic shaping apparatusPolymer scienceCeiling temperature

The invention relates to a method for manufacturing a thermoplastic composition including: a polyester resin (c); a mixture including a copolymer (a) of an α-olefin and of a monomer having an ethylenic unsaturation and an epoxy function, as well as a core-shell compound (b); characterized in that said method includes a first step of manufacture the mixture of (a) and (b) by extrusion at a temperature at which the copolymer (a) is in the molten state and at a maximum temperature of 60 to 180° C.; a second step of manufacturing the thermoplastic composition by extrusion or by mixing the polyester resin (c) with the mixture of (a) and (b) produced in the first step.

Owner:ARKEMA FRANCE SA

Preparation method of radiation-heatable MXene/polymer composite material

PendingCN113024871AThe preparation method is simple and safeMild conditionsFibre typesChemical industryCeiling temperaturePolymer composites

The invention relates to the field of flexible wearable heating materials, in particular to a preparation method of a radiation-heatable MXene / polymer composite material. The preparation method comprises the following steps: carrying out surface hydroxylation treatment or polarity modification treatment on a polymer material, washing with deionized water, and drying to obtain a pretreated polymer material; and uniformly spraying an MXene solution on the pretreated polymer material, and drying to obtain the radiation-heatable MXene / polymer composite material. The preparation method is simple and safe, conditions are mild, and large-scale batch preparation can be achieved; the prepared MXene / polymer composite material has three heating modes of radiation heating, electric heating and light heating, the highest temperature in the radiation heating mode can reach 45.2 DEG C, the highest temperature in the electric heating mode can reach 85.0 DEG C, the highest temperature in the light heating mode can reach 90.0 DEG C, and the method has huge application value in the field of new-generation energy-saving heating flexible heat preservation fabrics or films.

Owner:ZHENGZHOU UNIV

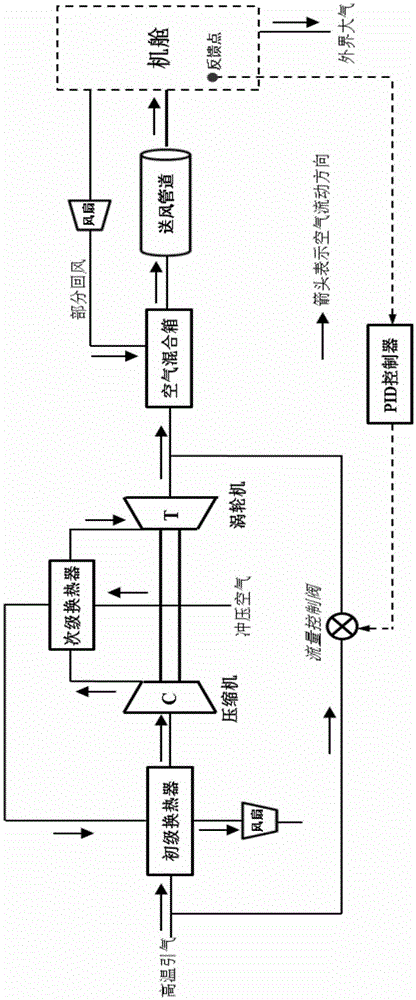

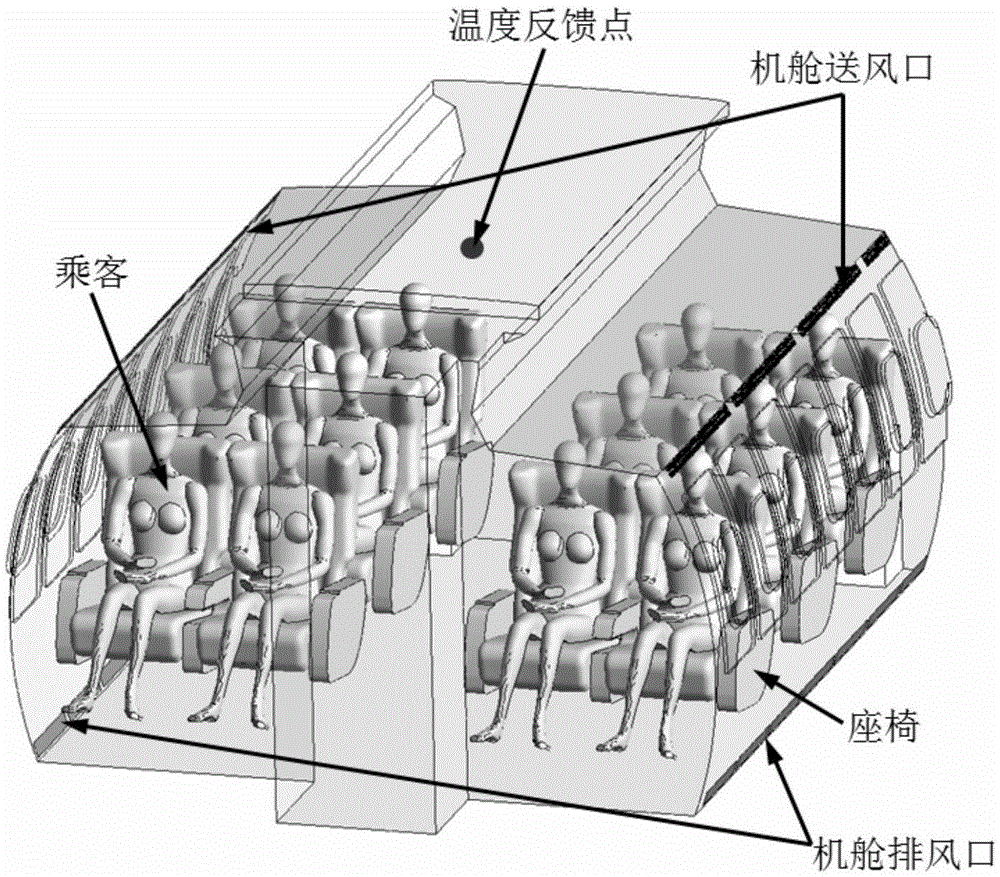

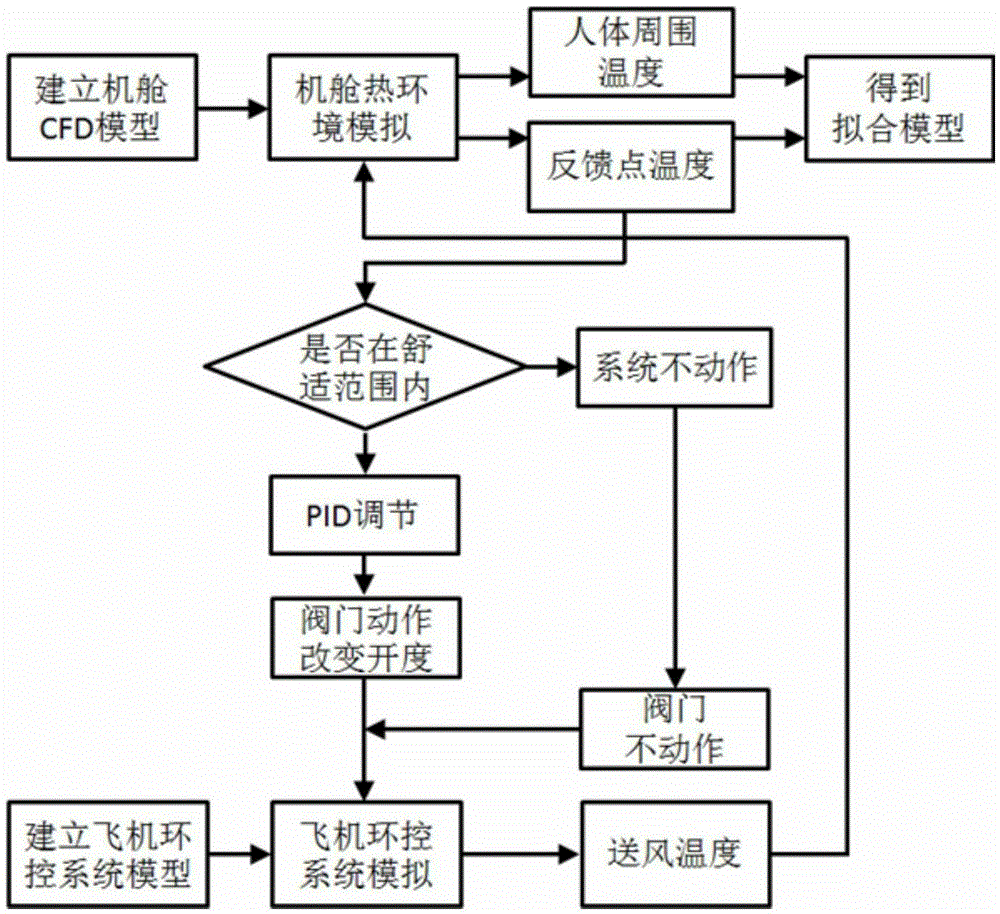

CFD simulation and system simulation model combination based airplane cabin environment control method

InactiveCN105260518AOvercoming the limitations of settingsAccurately obtain the temperature valueGeometric CADDesign optimisation/simulationHuman bodyControl system

The invention discloses a CFD simulation and system simulation model combination based airplane cabin environment control method. Mainly, an airplane environment control system simulation model and an airplane cabin heat environment CFD model are subjected to combined simulation to accurately obtain temperature field parameters of all points in an airplane cabin space under the control of an airplane environment control system, wherein the temperature field parameters include a temperature value around personnel taking an airplane under dynamic control regulation, so that the limitation problem in position setting of a temperature sensor in the prior art is solved. By fitting temperature change of a ceiling temperature feedback point with temperature change around the personnel taking the airplane, the temperature around the personnel taking the airplane can be quickly obtained, and the timeliness of control and the accuracy of control effect are improved; and meanwhile, the optimization control is equivalent to the control on the temperature around a human body, so that the heat comfort level of the personnel taking the airplane is improved and the problems of high error of control on a heat environment in an airplane cabin and incapability of ensuring heat comfort of the personnel in the prior art are solved.

Owner:TIANJIN UNIV

Adsorption agent for removing iodide from organic medium and preparation and application

ActiveCN101209428AOrganic cation exchangersCarboxylic compound separation/purificationCarboxyl radicalIodide

The invention provides a sorbent used for removing iodide in organic medium, in particular to macroporous crosslinking ion exchange resin loaded with one or a plurality of metal ions. The metal ions loaded is one of silver, Hg and Pd, and mol loading of the metal ions is 1-90 percent of active sites of the ion exchange resin; the macroporous crosslinking ion exchange resin comprises two functional groups containing sulfonic group and carboxyl. A preparation method of the invention is that: through the initiation of azo-bis-iso-heptonitrile, acrylonitrile is suspension copolymerized with divinylbenzene monomer to obtain corsslinking polymer beads, pore-forming agent of which is extracted and washed out by solvent, thus obtaining the invention through sulfonation and ion exchange loading metal ions; the mol loading of the metal ions is 1-90 percent of the active sites of the ion exchange resin. Ceiling temperature used by the sorbent is 90 DEG C, liquid hourly space velocity is 1-15hr<-1> when ion-exchange column is used for removing iondine. The sorbent can remove the iondine ions in acetic acid below 5ppb.

Owner:JIANGSU SOPO CHEM +1

Process for producing flexible polyurethane foam and seat

InactiveUS20120252916A1Improve mechanical propertiesShrinkage of a foam can be reducedCyanide compoundPolymer science

A process for producing a flexible polyurethane foam excellent in mechanical strength, and exhibiting reduced shrinkage. The foam is produced using a polyol (A) containing from 40 to 100 mass % of a polyoxyalkylene polyol (A1). The polyoxyalkylene polyol (A1) is produced through an initial step of adding, to a reaction liquid containing an initiator and a double metal cyanide complex catalyst, 5 to 20 mass % of an alkylene oxide, based on the content of the initiator. After the initial step, an alkylene oxide is newly supplied to carry out polymerization. In the initial step, the temperature of the reaction system when addition of the alkylene oxide is started is from 120 to 165° C., and the maximum temperature of the reaction system after the alkylene oxide has been added in the initial step is higher by 15 to 50° C. than the temperature when addition of the alkylene oxide was started.

Owner:ASAHI GLASS CO LTD

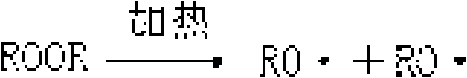

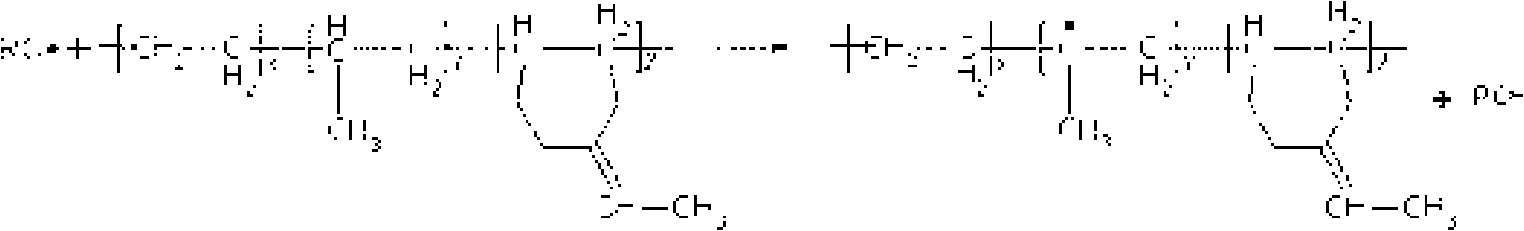

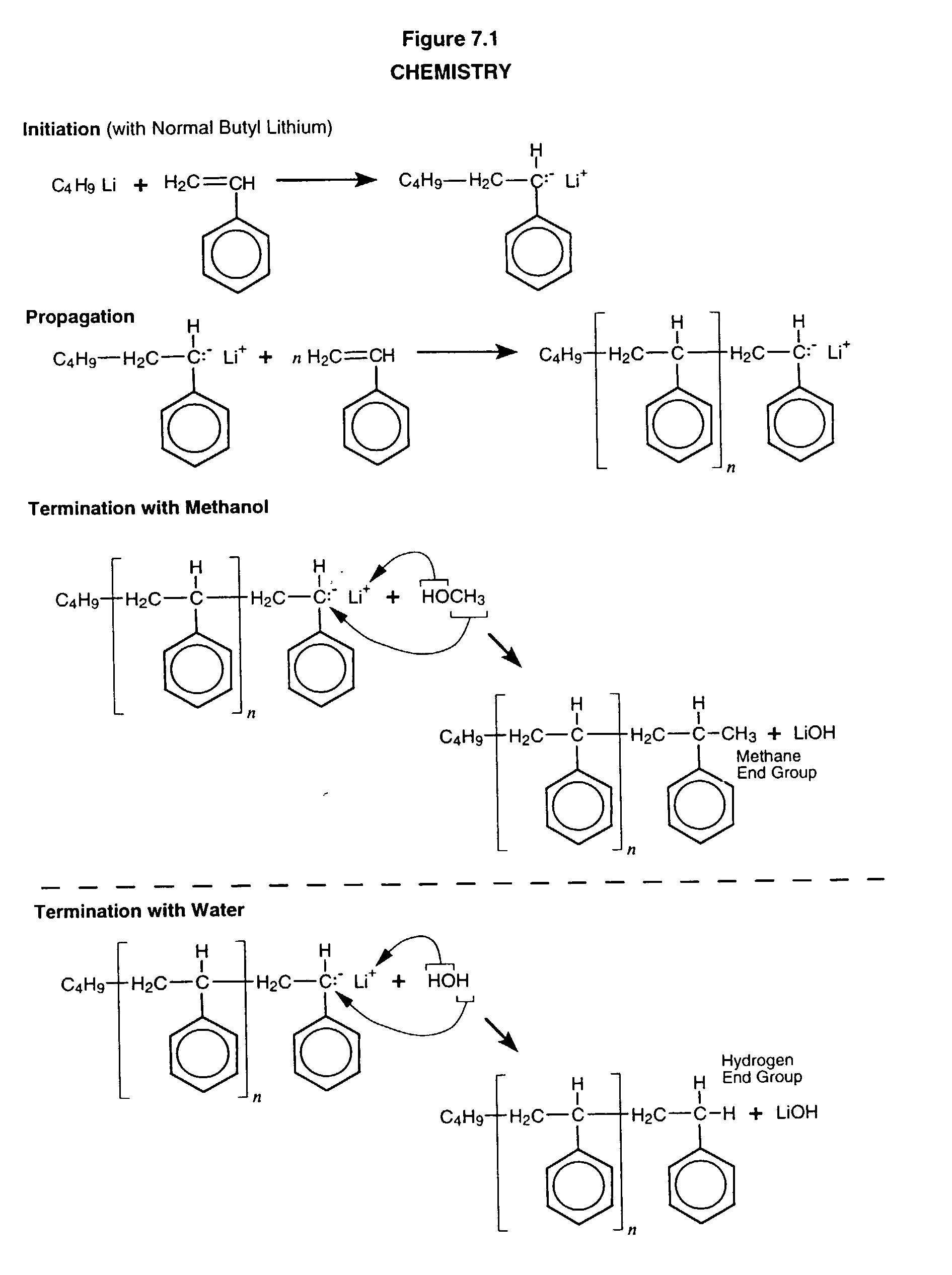

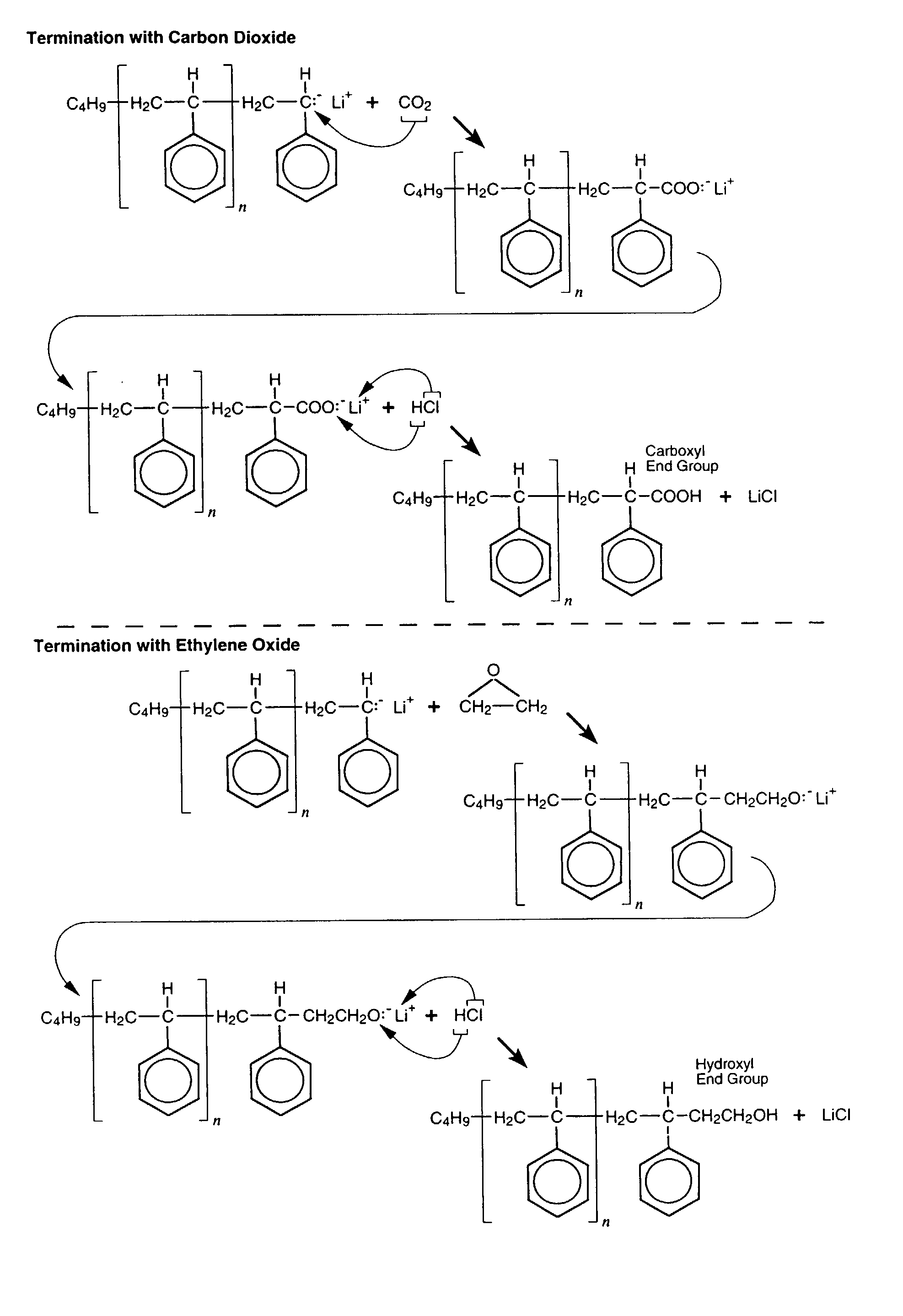

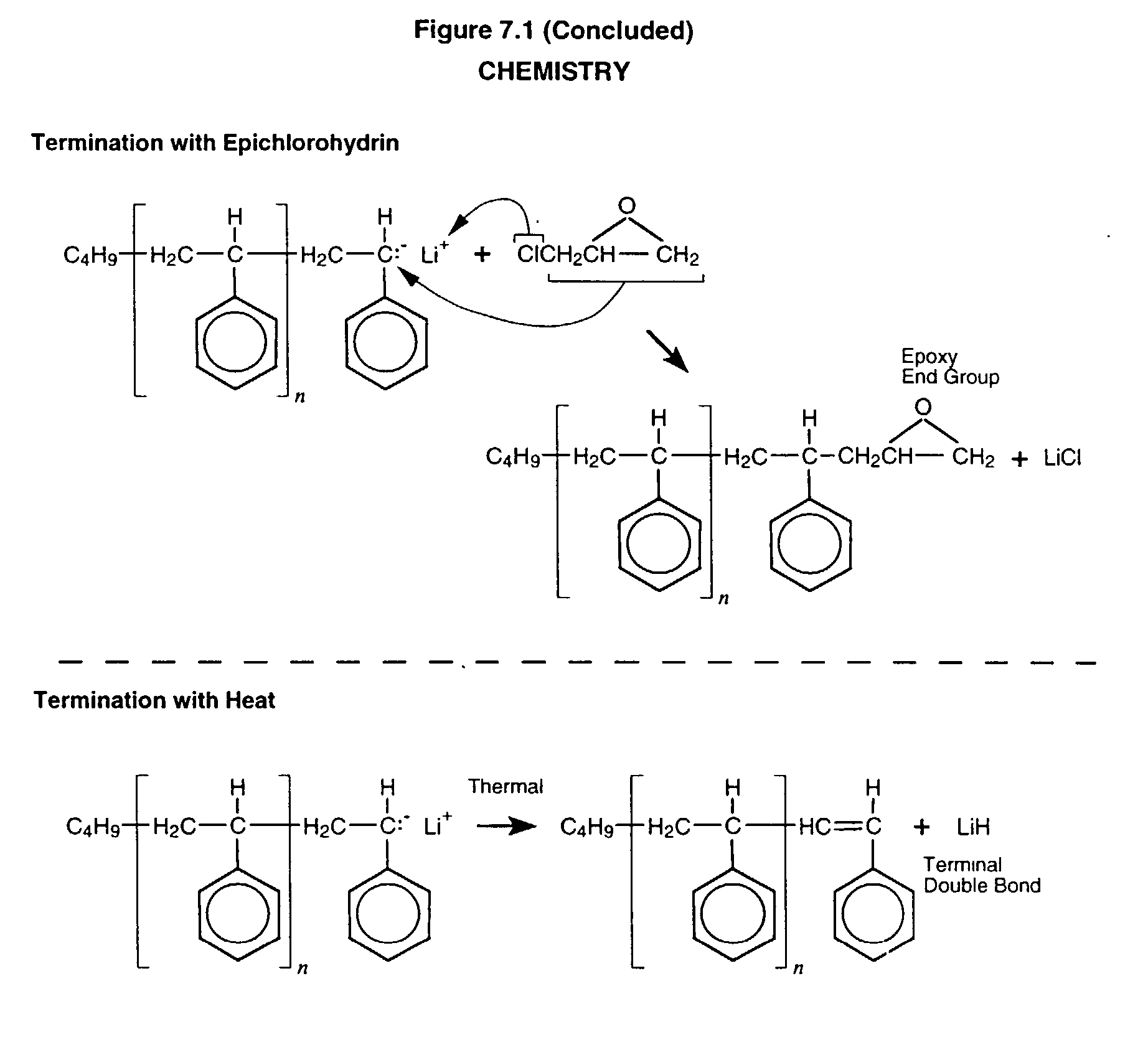

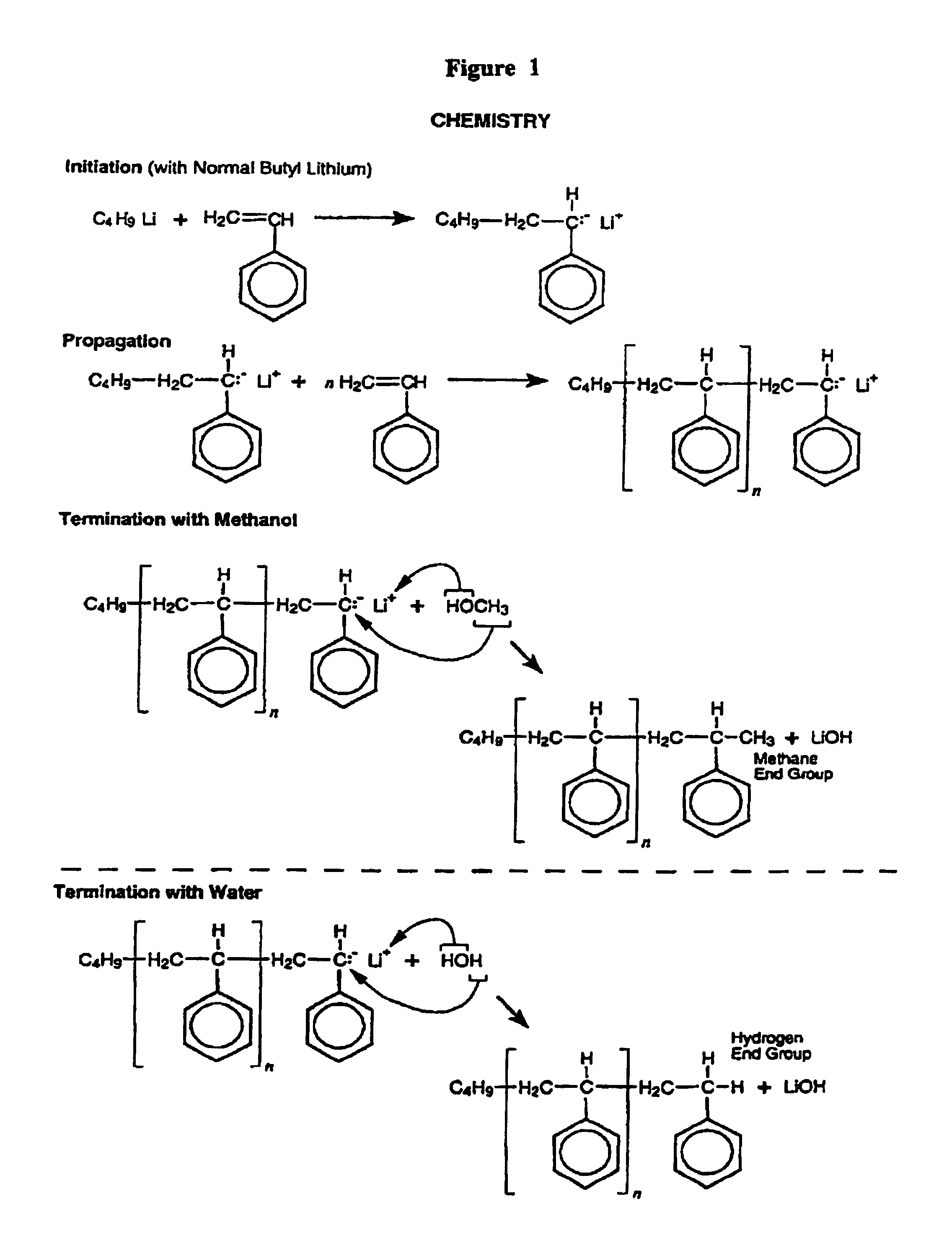

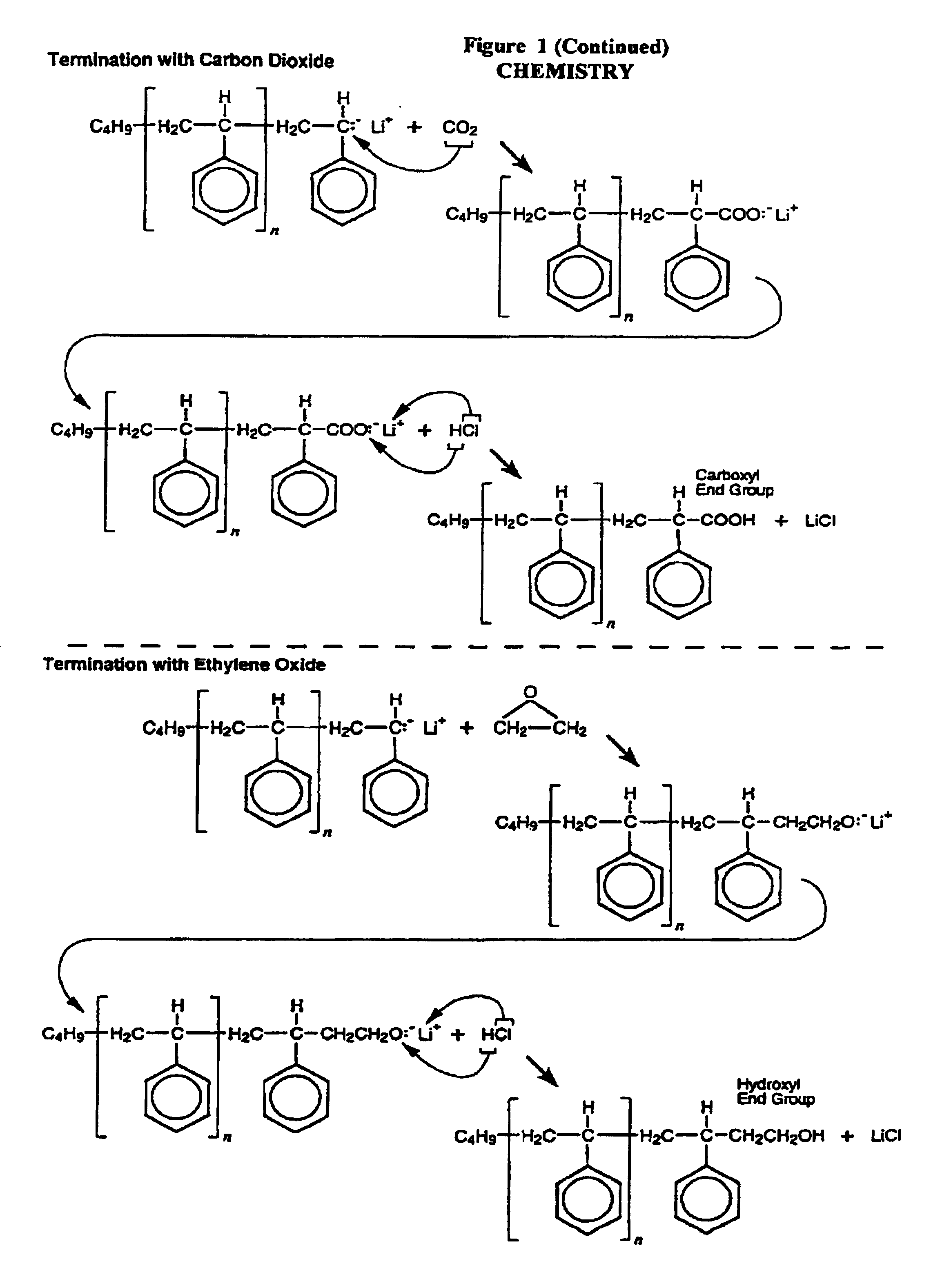

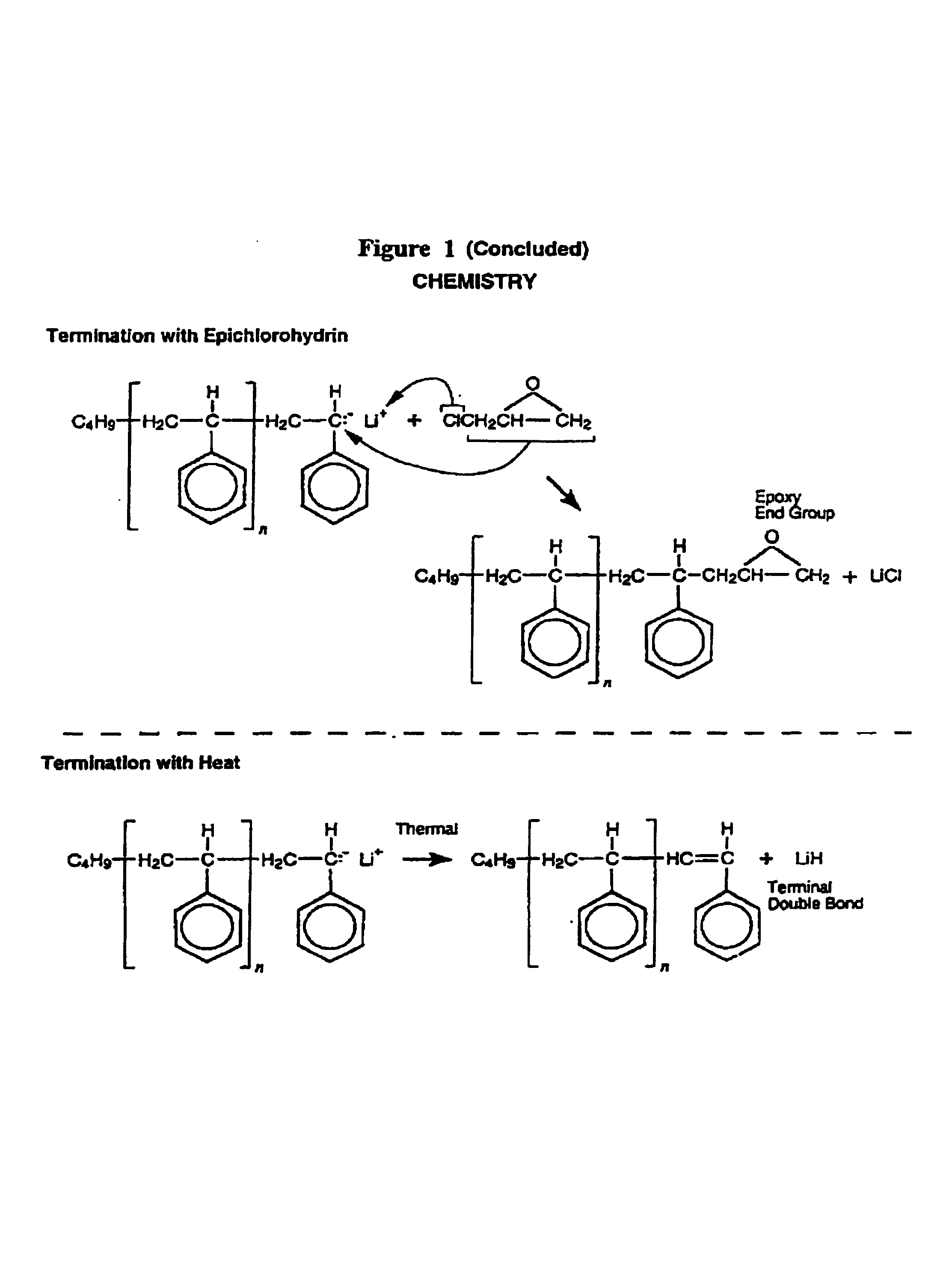

Anionic process design for rapid polymerization of polystyrene without gel formation and product produced there from

The extremely rapid anionic polymerization rate of polystyrene has made polymerization difficult to control and has prevented large-scale development. This invention uses batch polymerization to utilize the rapid rate of polymerization to complete polymerization from zero to 100% conversion in minutes and turns this rapid rate into an advantage. Polystyrene itself is used as a heat sink to limit and control the maximum temperature reached during polymerization. Adiabatic polymerization increases the polymer temperature to the desired processing temperature of the polymer for either removal of volatile compounds or for direct pellet formation when no solvent is employed. The polystyrene to be used as a heat sink is added either as pellets or is first formed at a low controllable temperature. Extremely low levels of residual monomer are found in the product. This invention also demonstrates techniques to prevent gel formation or to reduce formation to an acceptable level.

Owner:CARTILAST

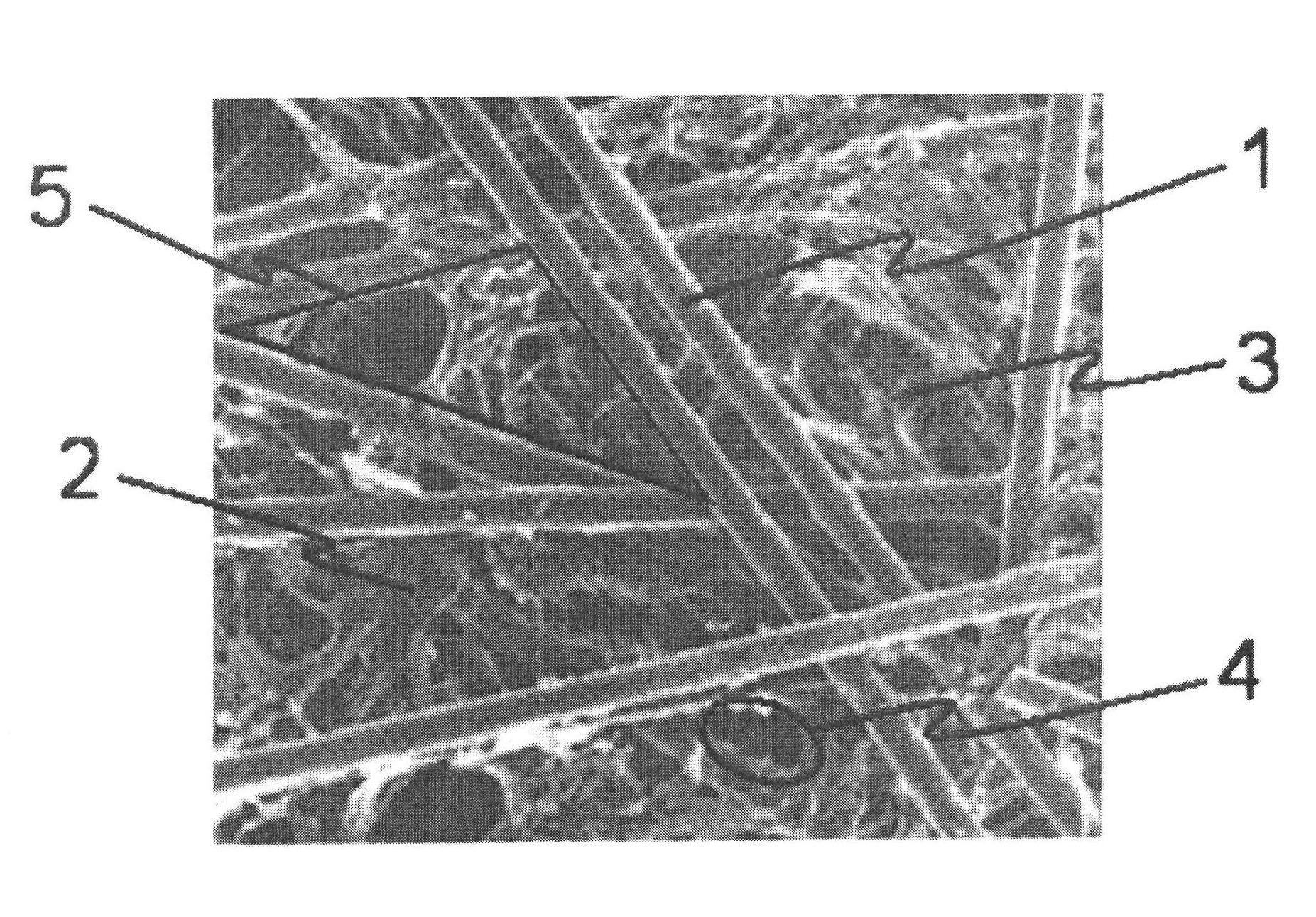

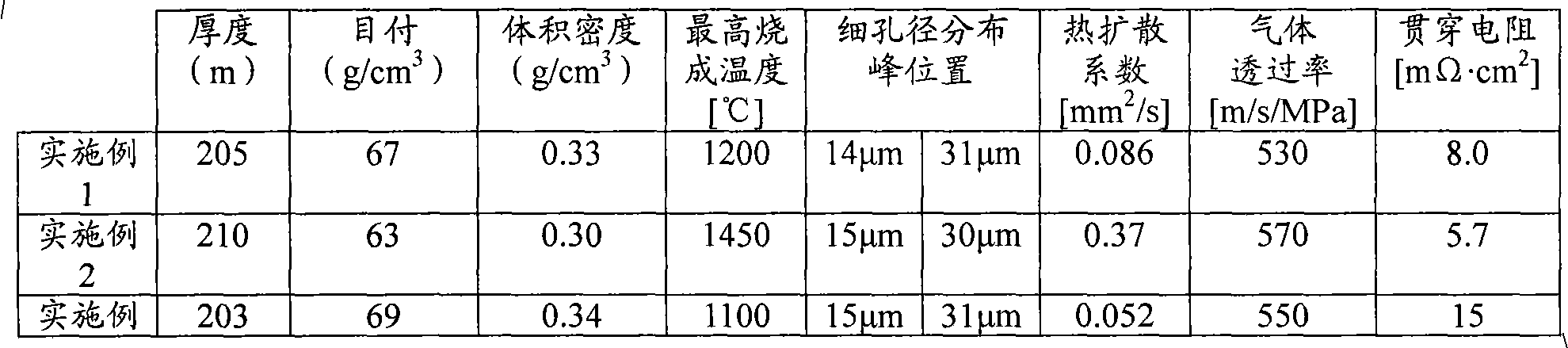

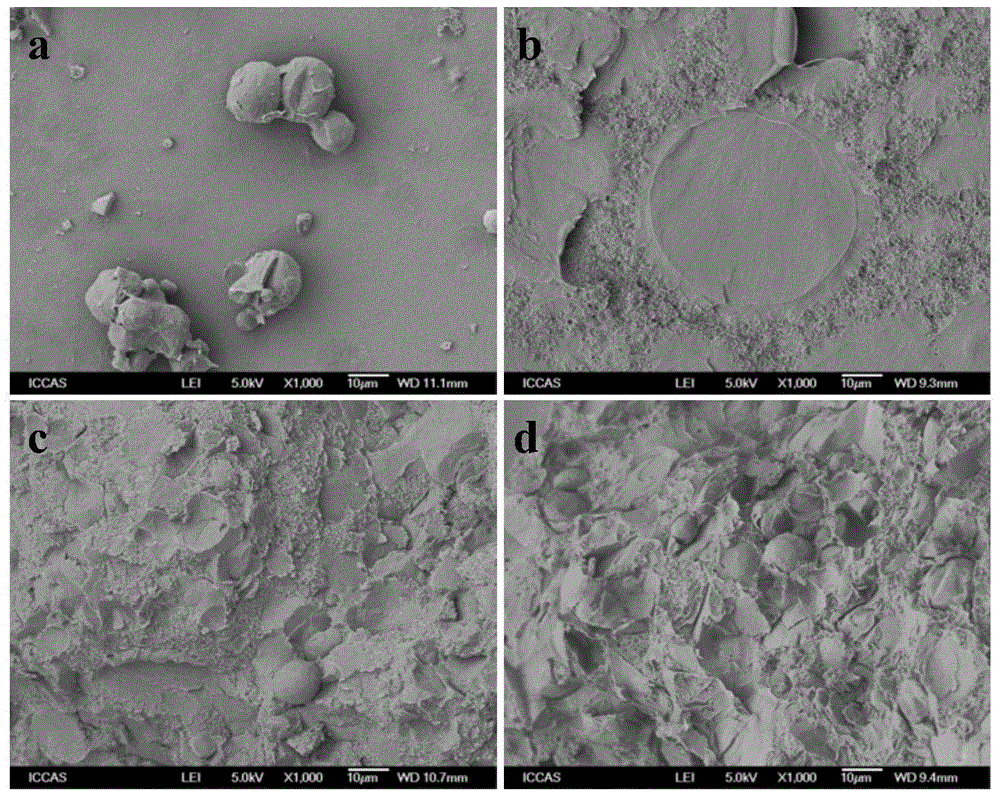

Porous electrode substrate and manufacturing method thereof, film-electrode combination and solid high-polymer fuel cell

ActiveCN102104152ALow apparent thermal diffusivityHigh flood toleranceCell electrodesFinal product manufactureHigh current densityCarbon fibers

The present invention provides a porous electrode substrate and a manufacturing method thereof, a film-electrode combination with the substrate and a solid high-polymer fuel cell. The invention provides the porous electrode substrate with the advantages of low thermal diffusion coefficient in a thickness direction and high flooding resistance at high moisture state or high current density area, and the film-electrode combination with the substrate, and the solid high-polymer fuel cell. The porous electrode substrate is prepared through the method which comprises the following steps: a step of obtaining a piece of carbon fiber paper which is adhered with the resin and is obtained through causing carbon precursor resin to adhere with the carbon fiber paper that comprises the planar scattered short carbon fibers with an average fiber diameter of 3-9 mu m and original fiber-shaped object; a step of performing hot pressing and solidifying the carbon fiber paper which is adhered with resin for obtaining an intermediate substrate; and heating the intermediate substrate with a maximum temperature of 1000-1800 DEG C and carbonizing the carbon precursor resin.

Owner:MITSUBISHI CHEM CORP

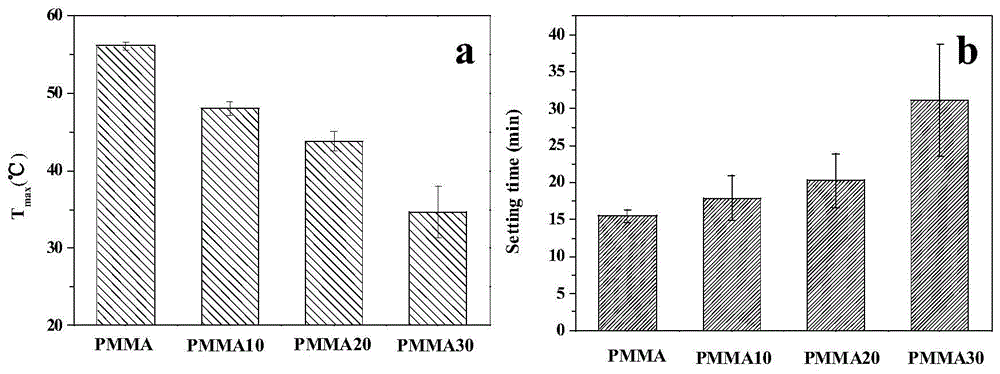

Compound bone cement with function of reducing thermal necrosis effect

ActiveCN104784753AReduce heat necrosisInjectableSurgical adhesivesProsthesisCeiling temperaturePhase change

The invention relates to low-heat type compound bone cement and a preparation method thereof. Raw materials of the bone cement include a solid-phase component and a liquid-phase component; the solid-phase component comprises an acrylic polymer and a phase-change microcapsule material (PCM). The preparation method of the bone cement comprises the following steps: uniformly stirring and mixing the solid-phase component and the liquid-phase component at a certain ratio, injecting a mixture into a mould, and performing curing to obtain the low-heat type compound bone cement. The compound bone cement is nontoxic and has injectable property, curing rate and mechanical property suitable for clinic; the highest temperature in a curing process is greatly reduced, so that a thermal necrosis effect can be reduced and the use safety of the acrylic polymer bone cement in a human body is improved.

Owner:PEKING UNIV THIRD HOSPITAL +1

Method for producing polyimide film

InactiveUS6264866B1Uneven qualityHigh bonding strengthFlat articlesCoatingsCeiling temperaturePolyimide membrane

A method for producing a polyimide film in which the imidation ratio and / or the amount of volatile constituent are controlled to improve the adhesive strength of the polyimide film. The method may also comprise controlling the highest temperature of heating the prefilm to improve the adhesive strength of the polyimide film.

Owner:KANEKA CORP

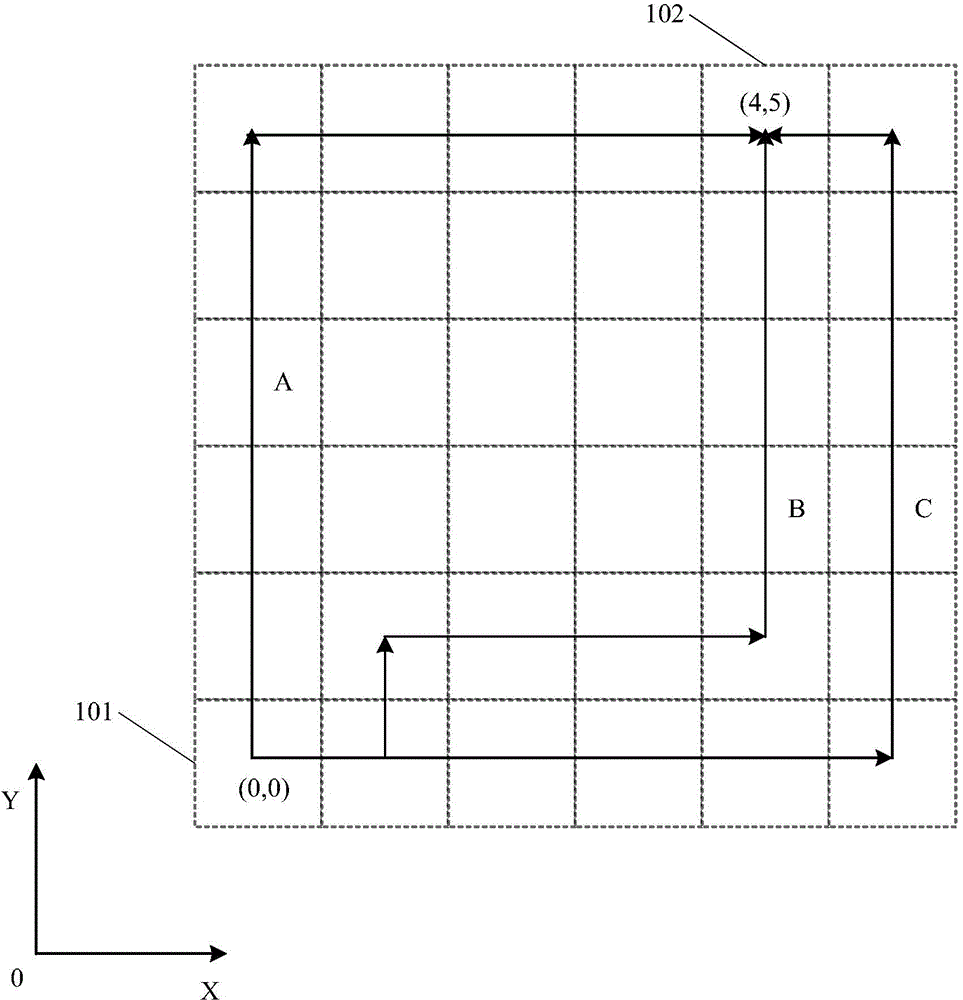

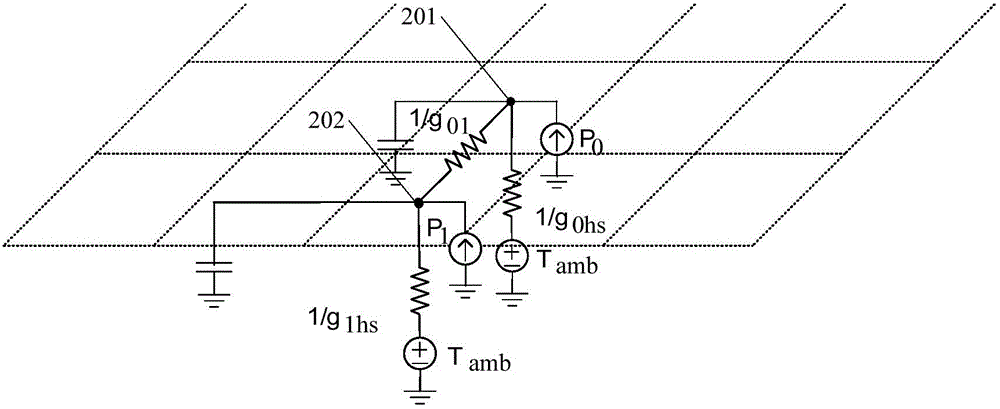

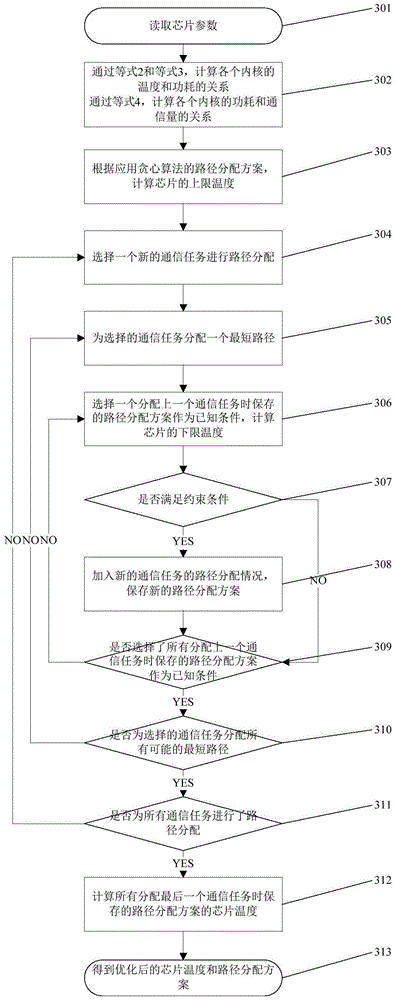

Network chip temperature optimization method applied to two-dimensional grid structure piece

ActiveCN104461732ACompact constraintsSmall amount of calculationResource allocationGreedy algorithmCeiling temperature

The invention relates to a network chip temperature optimization method applied to a two-dimensional grid structure piece. The network chip temperature optimization method includes the following steps that 1, the relation between the communication task load among all inner cores and the temperature is worked out by inputting chip parameters and conducting formula computing to serve as the relation equation for calculating the temperature of the chip; 2, path distribution of communication tasks among all the inner cores is conducted by the adoption of a greedy algorithm, the chip temperature caused by the path distribution scheme serves as the ceiling temperature in the optimizing process; 3, all possible shortest paths are distributed to the communication tasks to be combined to different path distribution schemes, and the computing amount is reduced by weeding out the path distribution schemes which cannot meet the constrain conditions while path distribution is conducted; 4, the path distribution scheme of the minimum temperature value is used as the optimized result by computing the chip temperature of the path distribution scheme stored when the last communication task is distributed. According to the network chip temperature optimization method, the lower chip temperature is obtained without changing the chip performance, more communication tasks are made to use the communication paths higher in heat dissipation efficiency, and thus the temperature of the chip is reduced.

Owner:SHANGHAI INFOTM MICROELECTRONICS

Highly flowable 1-butene polymer and process for producing the same

A 1-butene polymer satisfying the following (1), (2) and either (3) or (3′): a process for producing the polymer; a resin modifier comprising the polymer; and a hot-melt adhesive containing the polymer. (1) The intrinsic viscosity [η] as measured in tetralin solvent at 135° C. is 0.01 to 0.5 dL / g. (2) The polymer is a crystalline resin having a melting point (Tm-D) of 0 to 100° C., the melting point being defined as the top of the peak observed on the highest-temperature side in a melting endothermic curve obtained with a differential scanning calorimeter (DSC) in a test in which a sample is held in a nitrogen atmosphere at −10° C. for 5 min and then heated at a rate of 10° C. / min. (3) The stereoregularity index {(mmmm) / (mmrr+rmmr)} is 30 or lower. (3′) The mesopentad content (mmmm) determined from a nuclear magnetic resonance (NMR) spectrum is 68 to 73%.

Owner:IDEMITSU KOSAN CO LTD

1-butene polymer and molded product consisting of the polymer

1-butene based polymer satisfying following requirements (1″) to (4″) provides formed product having low stickiness, superior flexibility and transparency.(1″) Crystalline resin having melting point (Tm−P), not observed or in the range of 0 to 100° C., wherein said melting point defined as the peak top of the peak observed in the highest temperature zone of the melting heat absorption curve obtained by heating a sample of said polymer at a rate of 10° C. / minute using Differential Scanning Calorimeter (DSC), after melting said sample in advance at 190° for 5 minutes under nitrogen atmosphere, followed by cooling it to −10° C. at a rate of 5° C. / minutes, and keeping it at −10° C. for 5 minutes.(2″) Stereoregularity index {(mmmm) / (mmrr+rmmr)} is at most 20.(3″) Molecular weight distribution (Mw / Mn) measured by Gel Permeation Chromatography (GPC) method is at most 4.0.(4″) Weight average molecular weight (Mw) measured by GPC method is in the range of 10,000 to 1,000,000.

Owner:IDEMITSU KOSAN CO LTD

Anionic process design for rapid polymerization of polystyrene without gel formation and product produced there from

Owner:CARTILAST

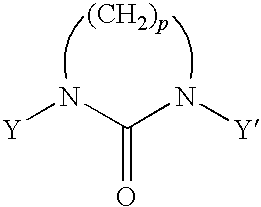

Process for manufacturing a self-sealing composition

Process for manufacturing a self-sealing elastomer composition, wherein the process comprises the following steps: firstly a masterbatch comprising at least one diene elastomer and a thermoplastic plasticizing hydrocarbon resin with a content greater than 30 phr is manufactured by compounding these various components in a mixer at a temperature or up to a temperature called the “hot compounding temperature” which is above the softening point of the hydrocarbon resin; and then at least one crosslinking system is incorporated into the masterbatch thus prepared, by compounding everything, in the same mixer or in a different mixer, at a temperature or up to a maximum temperature which is kept below 100° C., in order to obtain said self-sealing composition, and wherein at least one liquid plasticizer having a glass transition temperature (Tg) below −20° C. is furthermore incorporated in an amount of less than 60 phr into said masterbatch or into said composition.

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN

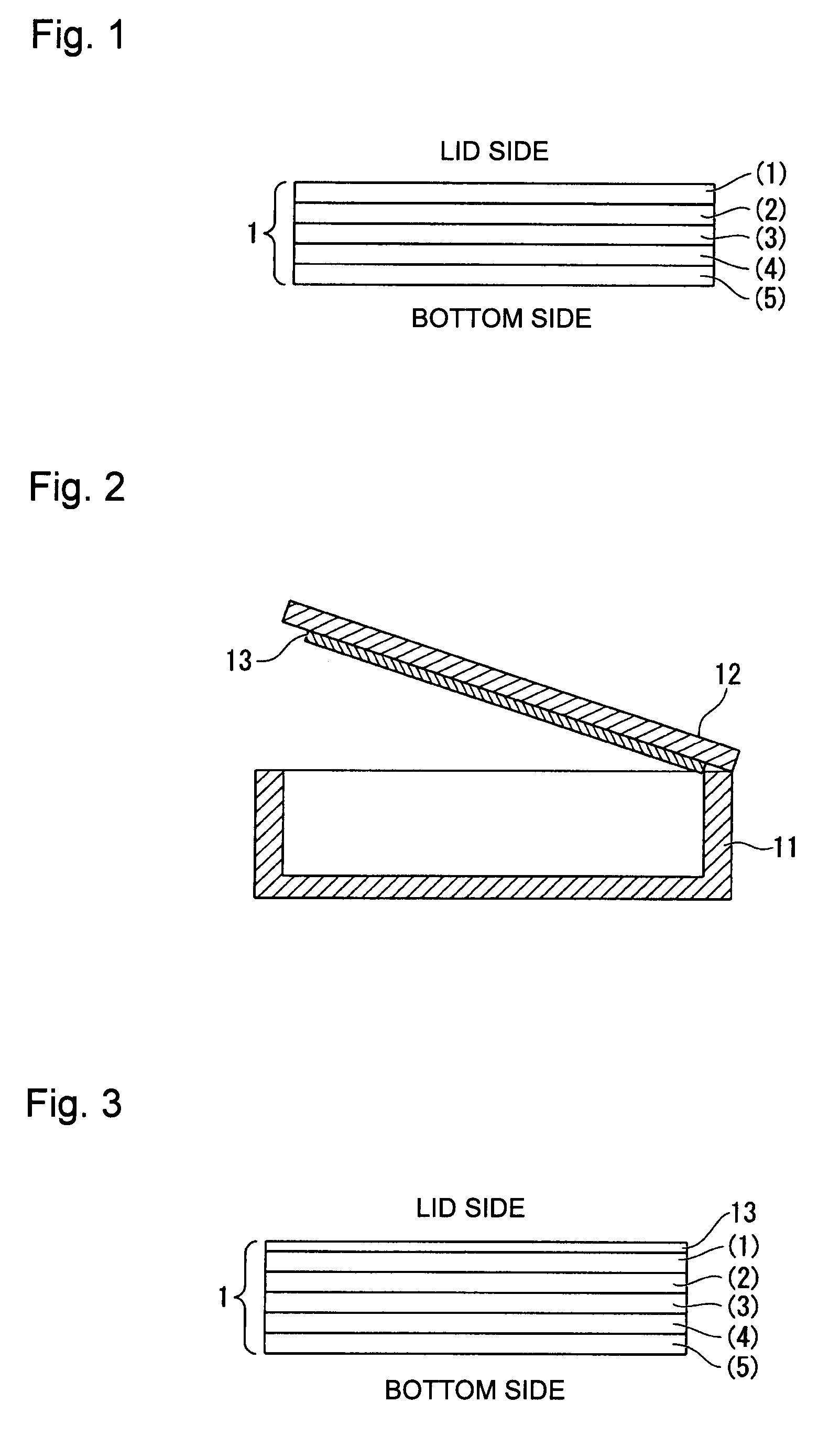

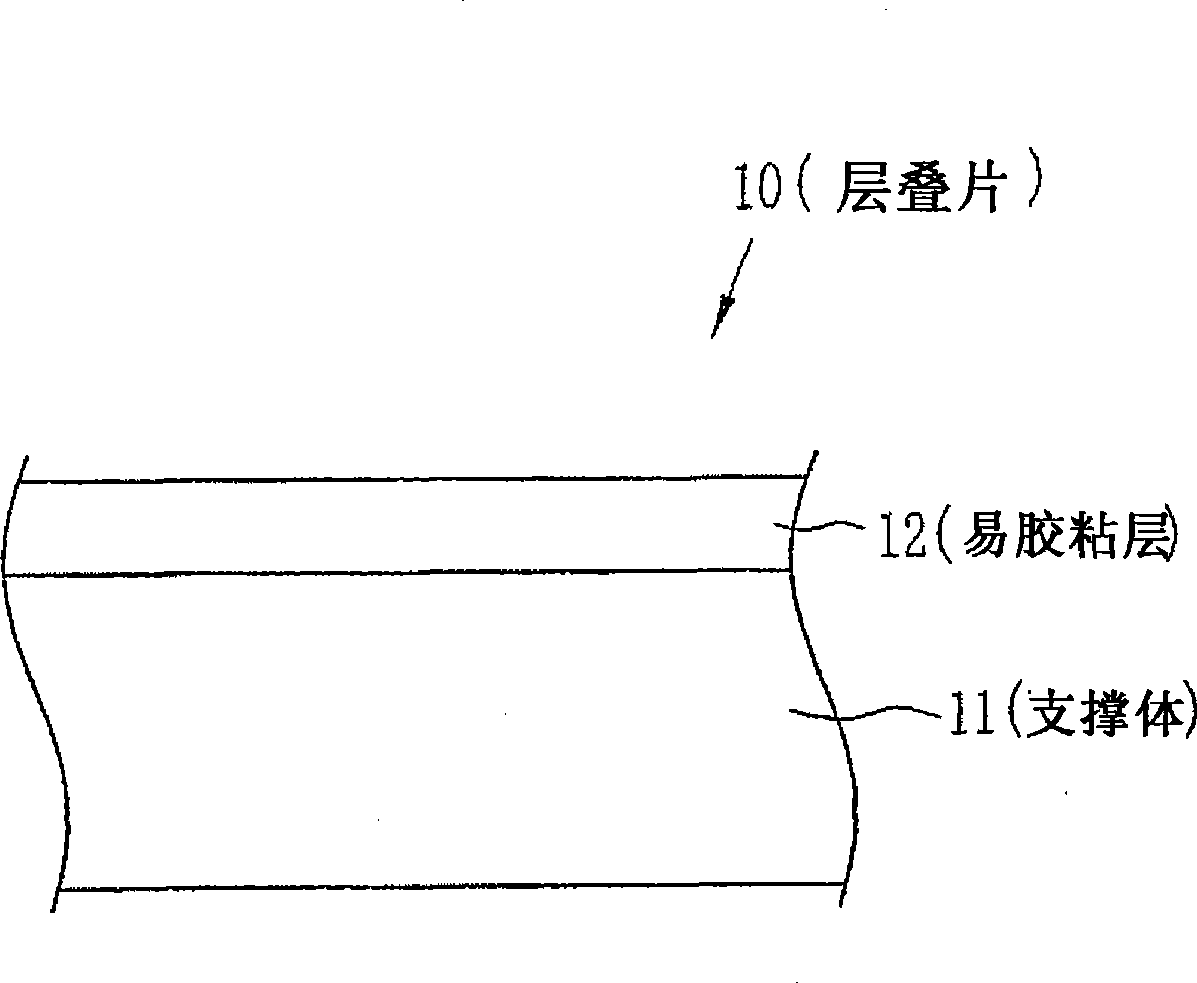

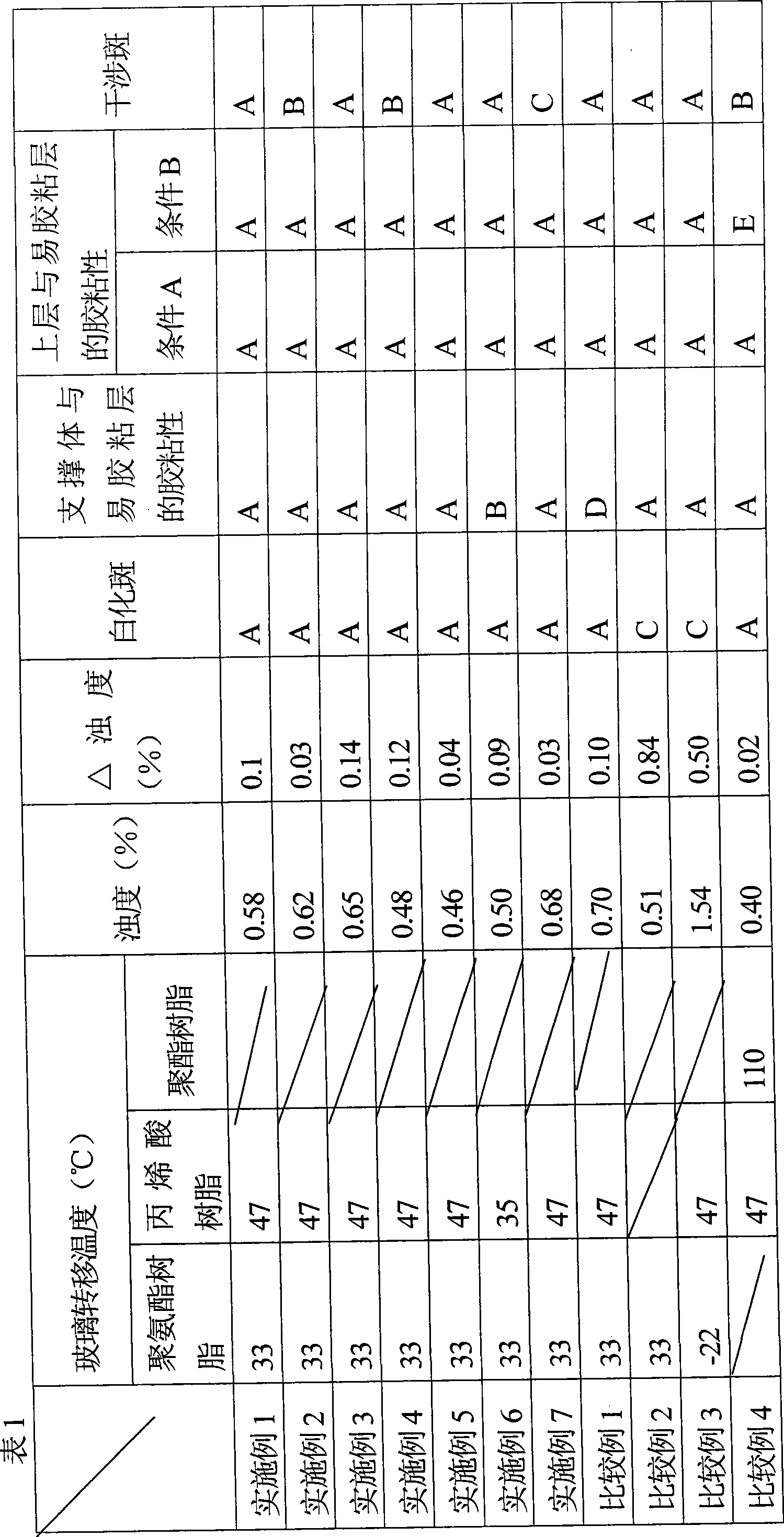

Optical layer pieces and manufacture method thereof

InactiveCN101452094AGood adhesivenessSuppresses turbidity riseSynthetic resin layered productsOptical light guidesCross-linkPolyester

A support body formed with polyester 11 is biaxially stretched. An adhesive layer 12 is formed on at least a surface of the biaxially stretched polyester 11. The adhesive layer 12 contains both urethane resin and acrylic resin with glass transition point higher than 30DEG C, and carbodiimide cross-linking agent. The weight ratio of the urethane resin and acrylic resin is of 95:5 to 50:50. The thickness of the adhesive layer 12 is 30nm-200nm. The adhesive layer 12 is formed by coating water soluble coating fluid then drying. The max temperature in drying is from 120 to 170 DEG C. The adhesive layer 12 contains organic or inorganic fine particle and lubricant.

Owner:FUJIFILM CORP

Preparation of thermal stabilizing manganese oxide molecular sieve catalyst for reducing CO and NO of cigarette smoke and application

InactiveCN101606754AThermally stableReduce COTobacco treatmentManganese oxides/hydroxidesMolecular sieveCeiling temperature

The invention relates to a preparation of a thermal stabilizing manganese oxide molecular sieve catalyst for reducing CO and NO of cigarette smoke and an application, and the manganese oxide molecular sieve is used as a catalytic material for reducing CO and NO of cigarette smoke. The manganese oxide molecular sieve is doped with metal ions. The catalyst is a thermal stabilizing material which can reach to be 600 to 700 DEG C, has catalytic activity in longer distance along the burning direction of the cigarette and has more advantages than the former catalyst; in addition, the material has high catalytic activity at the temperature of about 200 DEG C. The catalyst powder has thermal stability which leads the catalyst powder to be cracked only at the highest temperature point in a cigarette burning area, thus guaranteeing that CO and NO can be effectively reduced in a bigger area of the cigarette section of the cigarette and wider temperature range (200 to 600 DEG C).

Owner:CHINA TOBACCO HUNAN INDAL CORP

Acrylamide polymer, its preparation method and its application

ActiveCN103864986AHigh viscosity average molecular weightHigh apparent viscosityDrilling compositionCeiling temperatureTemperature difference

The invention discloses an acrylamide polymer, its preparation method and its application, the method is characterized that under the condition of aqueous solution polymerization, under the protection of inert gas, an acrylamide-containing monomer aqueous solution and an initiator are contacted, wherein, the aqueous solution polymerization condition comprises: the polymerization initial temperature is -10-15 DEG C, the polymerization time is 4-15 hours, and the temperature difference of the highest temperature and the lowest temperature in a polymerization process is 10-50 DEG C. The product performance of the polyacrylamide polymer is greatly better than that of the current products.

Owner:CHINA PETROLEUM & CHEM CORP +1

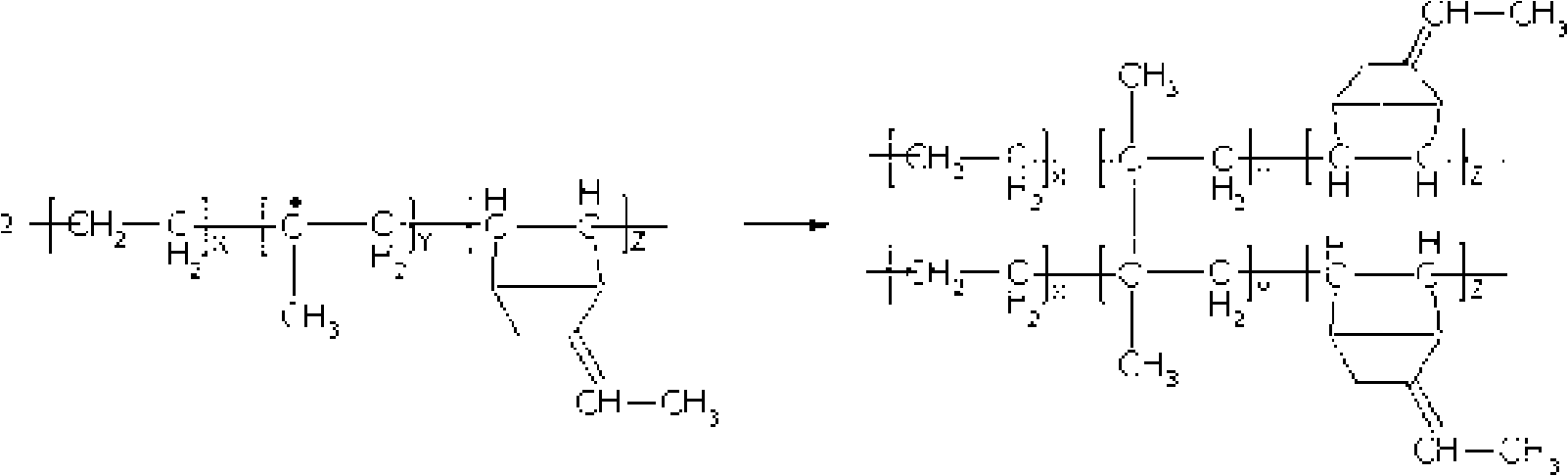

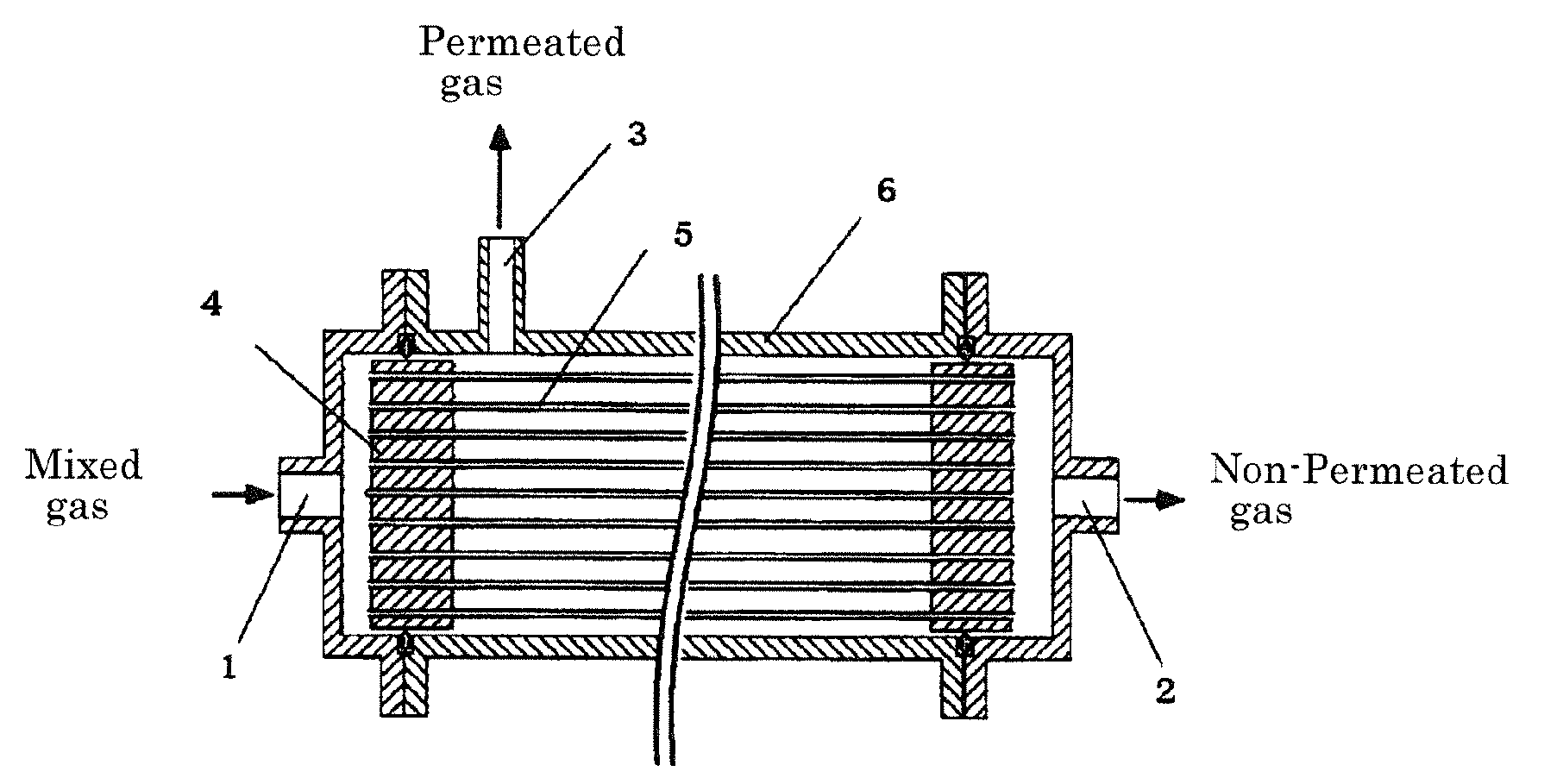

Solvent-resistant asymmetric hollow fiber gas separation membrane, and method for production thereof

InactiveUS20110048229A1Improve ductilityHigh mechanical strengthSemi-permeable membranesMembranesPolymer scienceSolvent

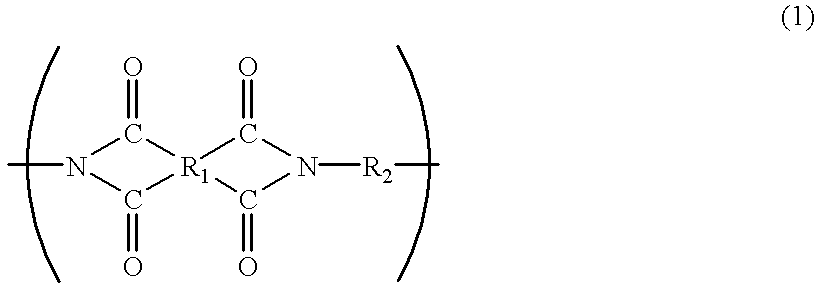

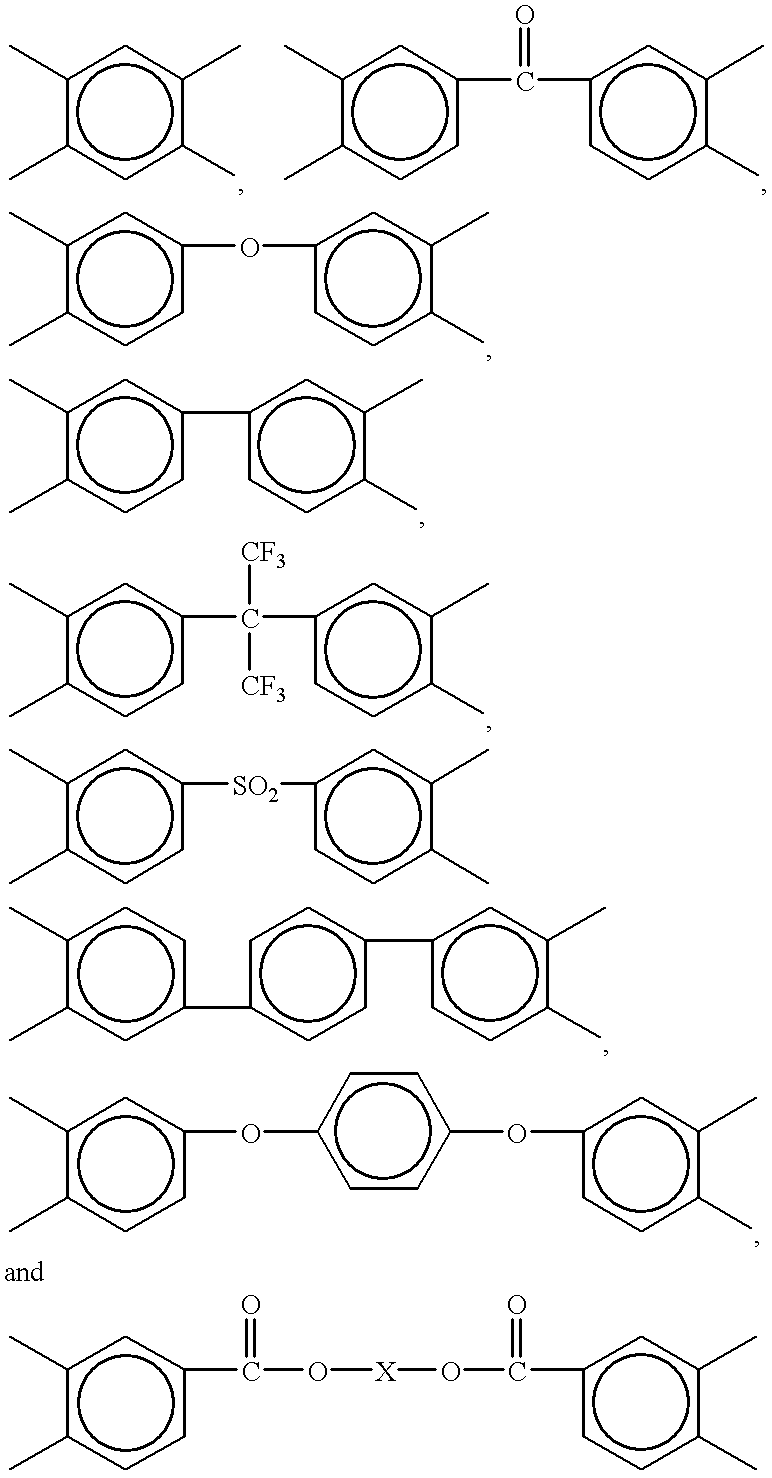

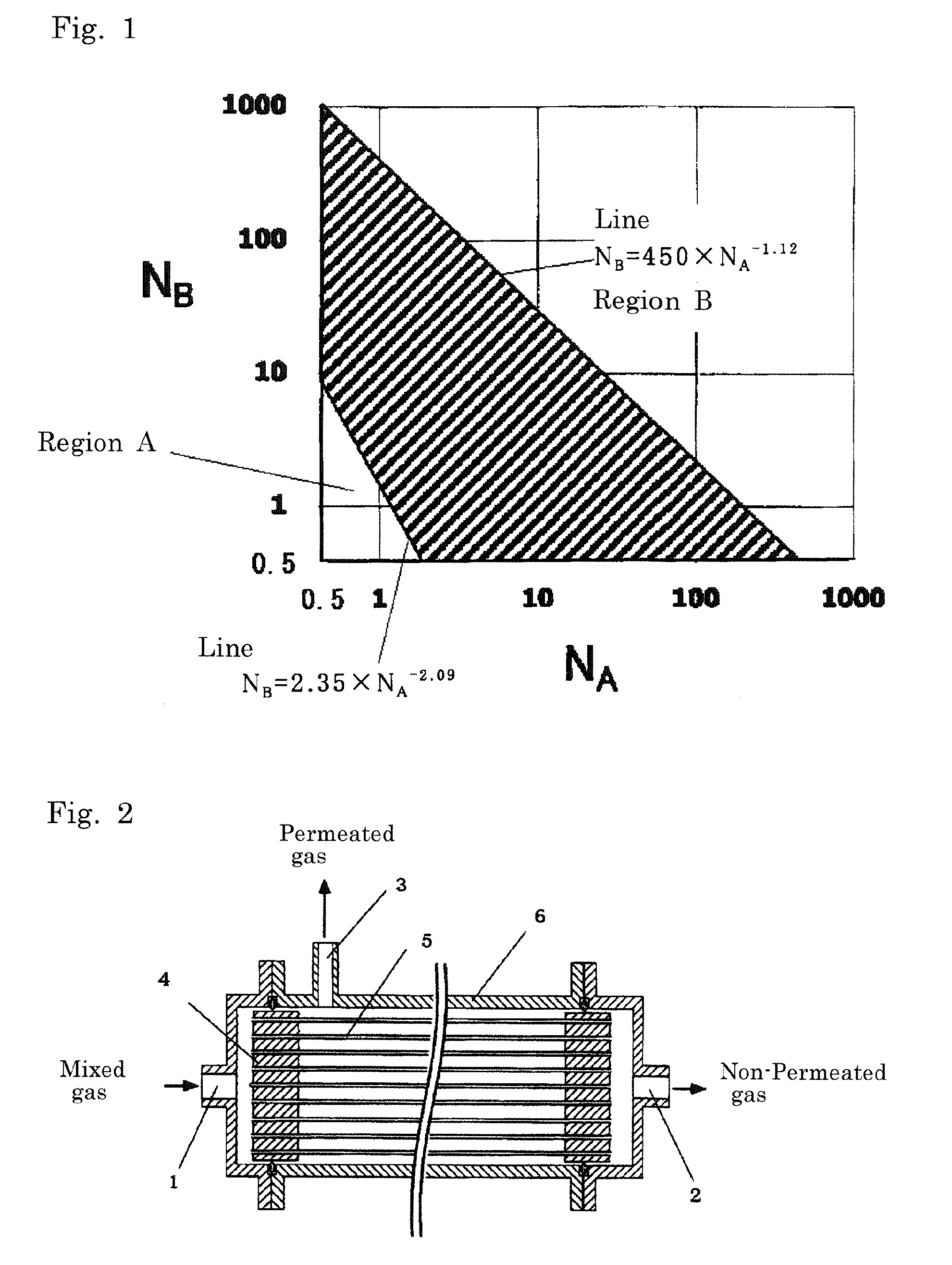

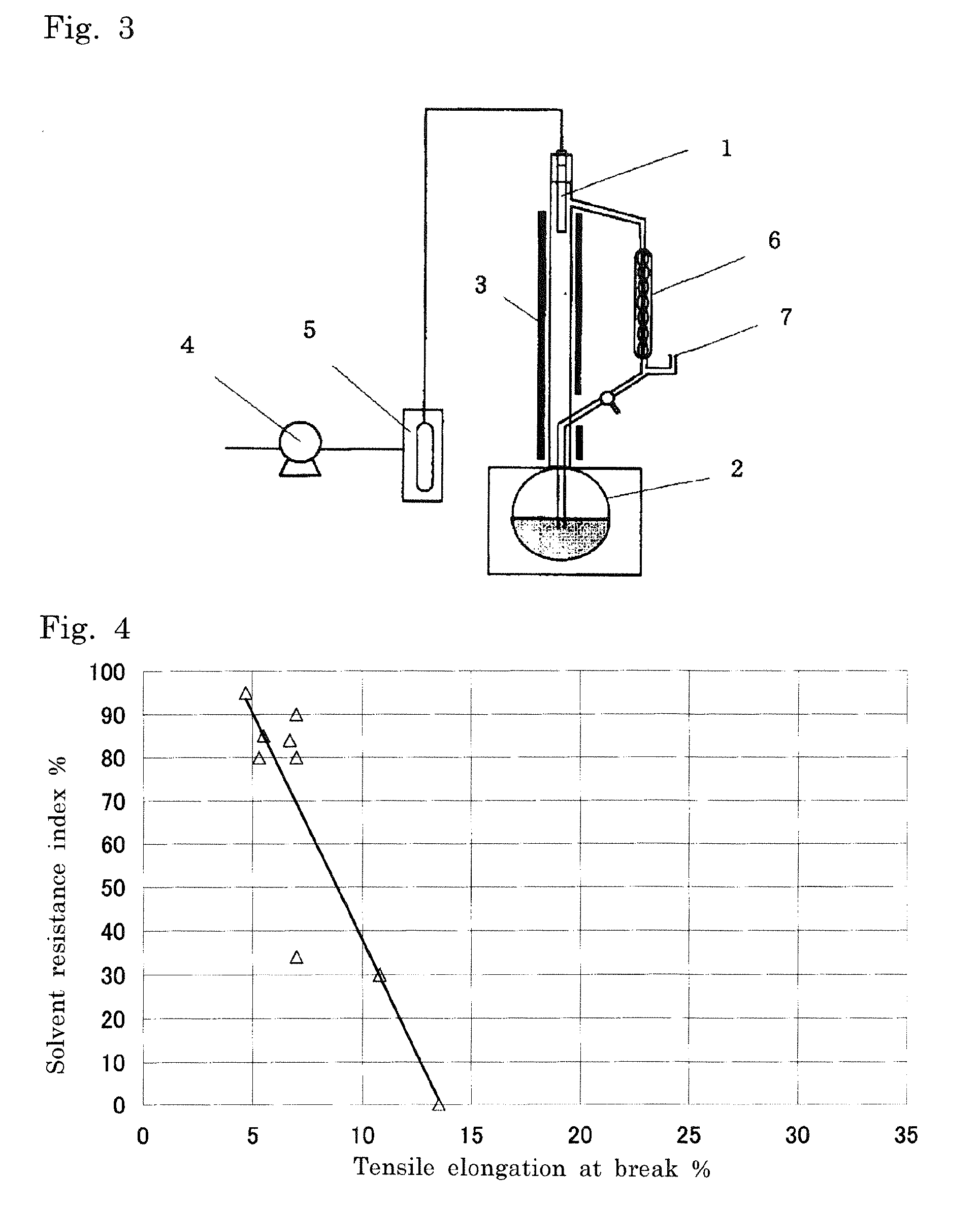

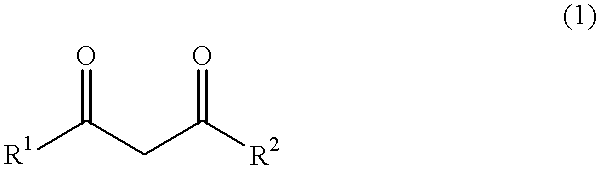

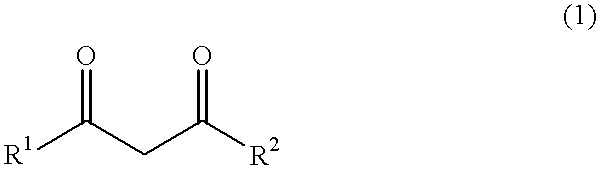

An asymmetric hollow fiber gas separation membrane obtained by subjecting an asymmetric hollow fiber polyimide membrane to a heat treatment having a maximum temperature of from 350 to 450° C., wherein the asymmetric hollow fiber polyimide membrane is formed with a polyimide essentially having a repeating unit represented by a general formula (1);is excellent in a solvent resistance and a thermal stability, and as well has such a mechanical strength that a tensile elongation at break is not less than 10% as a hollow fiber membrane. In the general formula (1), 20 to 80 mol % of A is a tetravalent unit based on a biphenyl structure represented by formula (2), 20 to 80 mol % of A is a tetravalent unit based on a diphenylhexafluoropropane structure represented by formula (3), and 0 to 30 mol % of A is a tetravalent unit based on a phenyl structure represented by formula (4); and in the general formula (1), 30 to 70 mol % of R is a divalent unit represented by formula (5) and / or formula (6), and 30 to 70 mol % of R is a divalent unit having one or two other aromatic rings than formula (5) or (6),wherein, R1 and R2 are a hydrogen atom or an organic group, and n is 0, 1 or 2,wherein, R1 and R2 are a hydrogen atom or an organic group, X is —CH2— or —CO—, and n is 0, 1 or 2.

Owner:UBE IND LTD

Process for the preparation of alkaline earth metal salts of beta-diketo compounds

InactiveUS6376719B1High purityLow purityOrganic compound preparationCarboxylic acid esters preparationAcetoacetatesAlkaline earth metal

An alkaline earth metal salt of beta-diketo compound is produced using 1 mol of a powdery alkaline earth metal compound and 2.04 mol or more of an aliphatic beta-diketo compound. The reaction may be carried out while supplying both components to a reactor continuously or intermittently, or may be carried out by adding one component to the other continuously or intermittently. The highest temperature during the reaction may be at 50° C. or higher. The reaction mixture may be aged, and then dried at a temperature of at 100 to 180° C. in an atmosphere of an inert gas. The alkaline earth metal compound may be calcium hydroxide, magnesium hydroxide, or barium hydroxide. The aliphatic beta-diketo compound may be represented by the following formula, particularly an acetoacetic acid ester or acetylacetone.According to the production method as mentioned above, highly stable alkaline earth metal salts of beta-diketo compounds of high quality can be produced.

Owner:DAICEL CHEM IND LTD

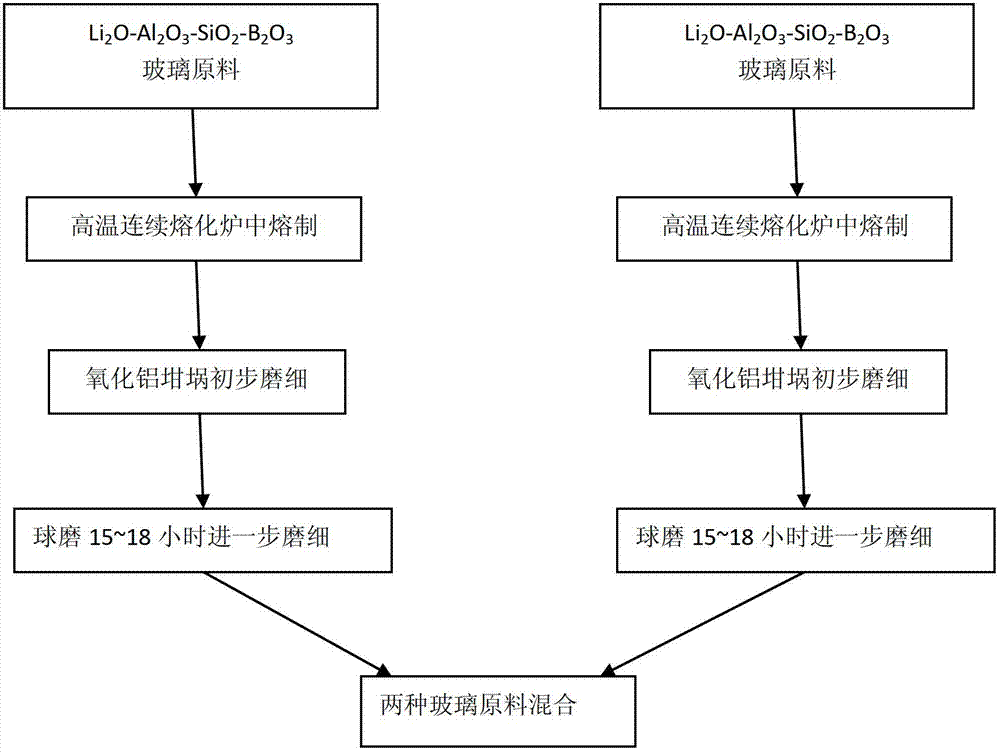

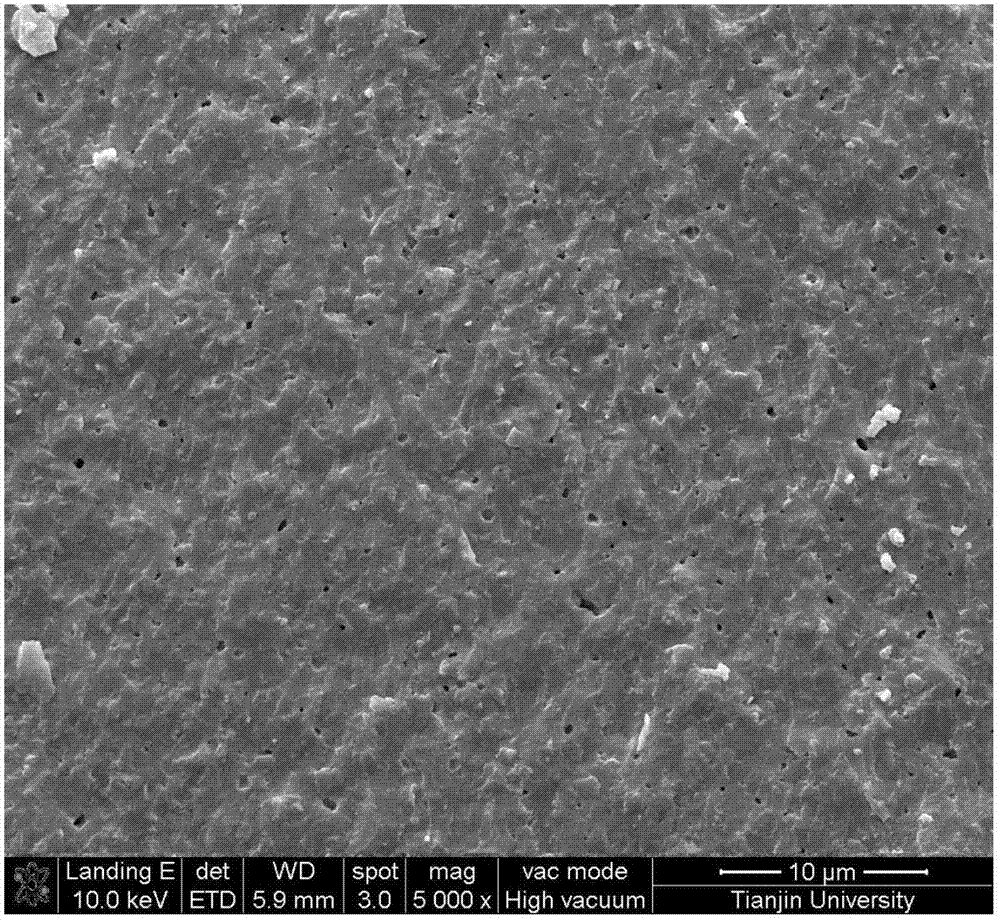

Li2O-Al2O3-SiO2-B2O3, CaO-Al2O3-SiO2-B2O3 crystallizable glass low-temperature co-fired composite material and preparation method thereof

InactiveCN102898145ALower sintering temperatureSmall coefficient of thermal expansionPorosityLithium oxide

The invention relates to a Li2O-Al2O3-SiO2-B2O3, CaO-Al2O3-SiO2-B2O3 crystallizable glass low-temperature co-fired composite material and a preparation method thereof. The composite material disclosed herein is characterized in that: the composite material comprises 40-60wt% of CaO-Al2O3-SiO2-B2O3 crystallizable glass and 60-40wt% of Li2O-Al2O3-SiO2-B2O3 crystallizable glass; composite material has a low sintering temperature and can be sintered at 800-900 DEG C that is greatly lower than the ceiling temperature (950 DEG C) of existing LTCC material sintering; the thermal expansion coefficient of the composite material (less than 6.7*10<-6> / DEG C) is low, and the medium loss (less than 0.02) is low; and the composite material has high densification degree and low porosity. According to the invention, the process is simple, the cost is low, and the obtained composite material has low thermal expansion coefficient.

Owner:TIANJIN UNIV

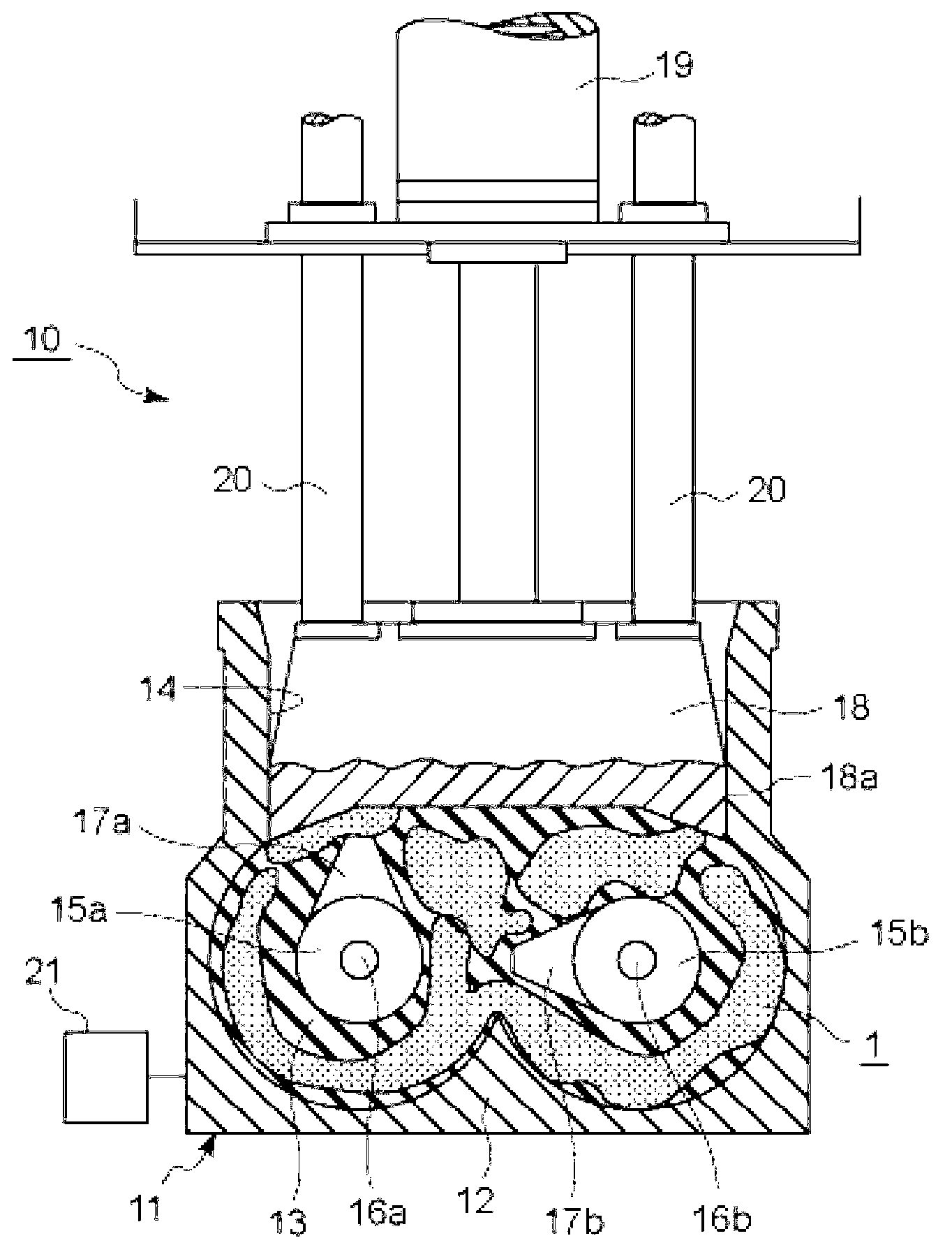

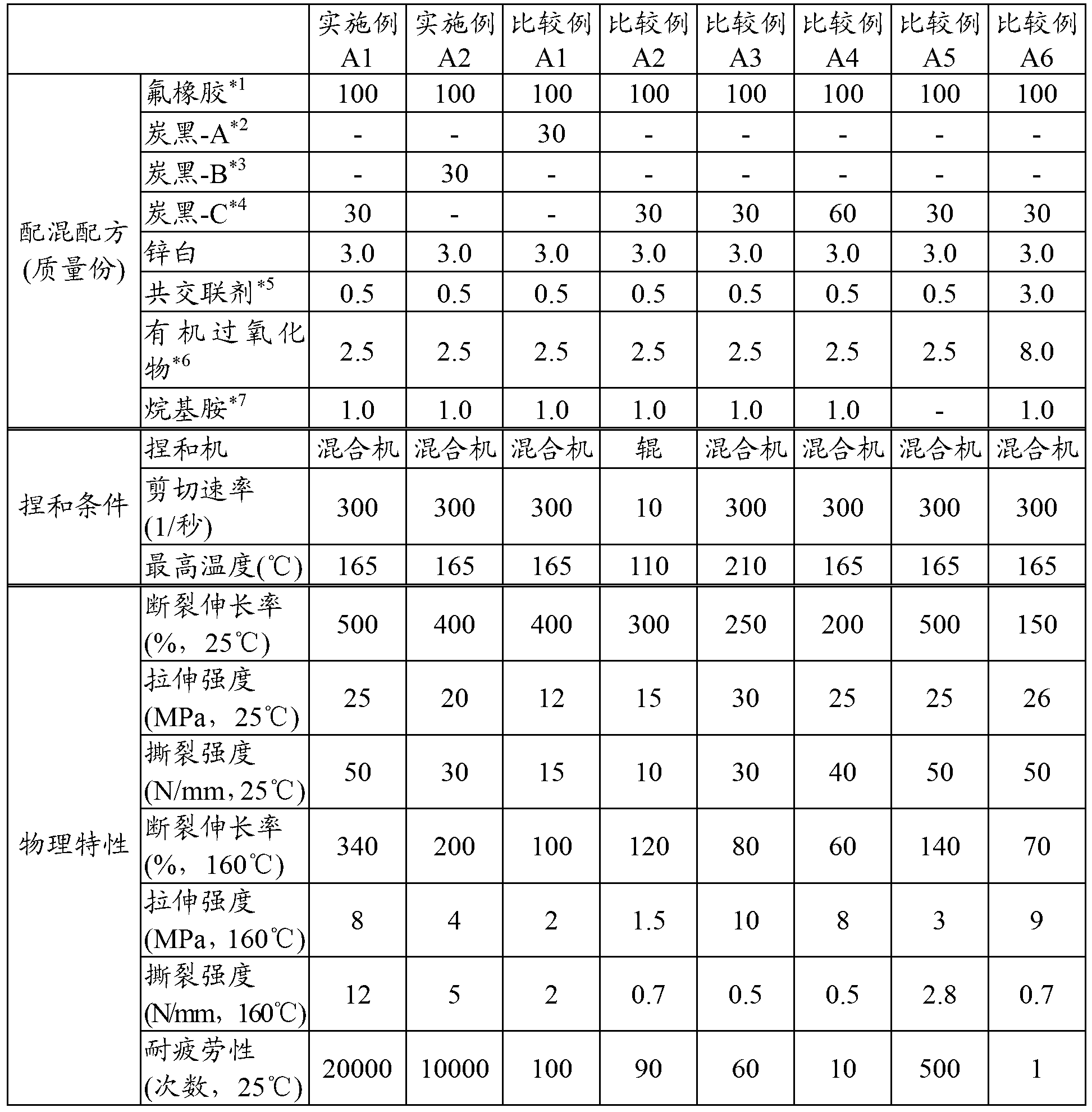

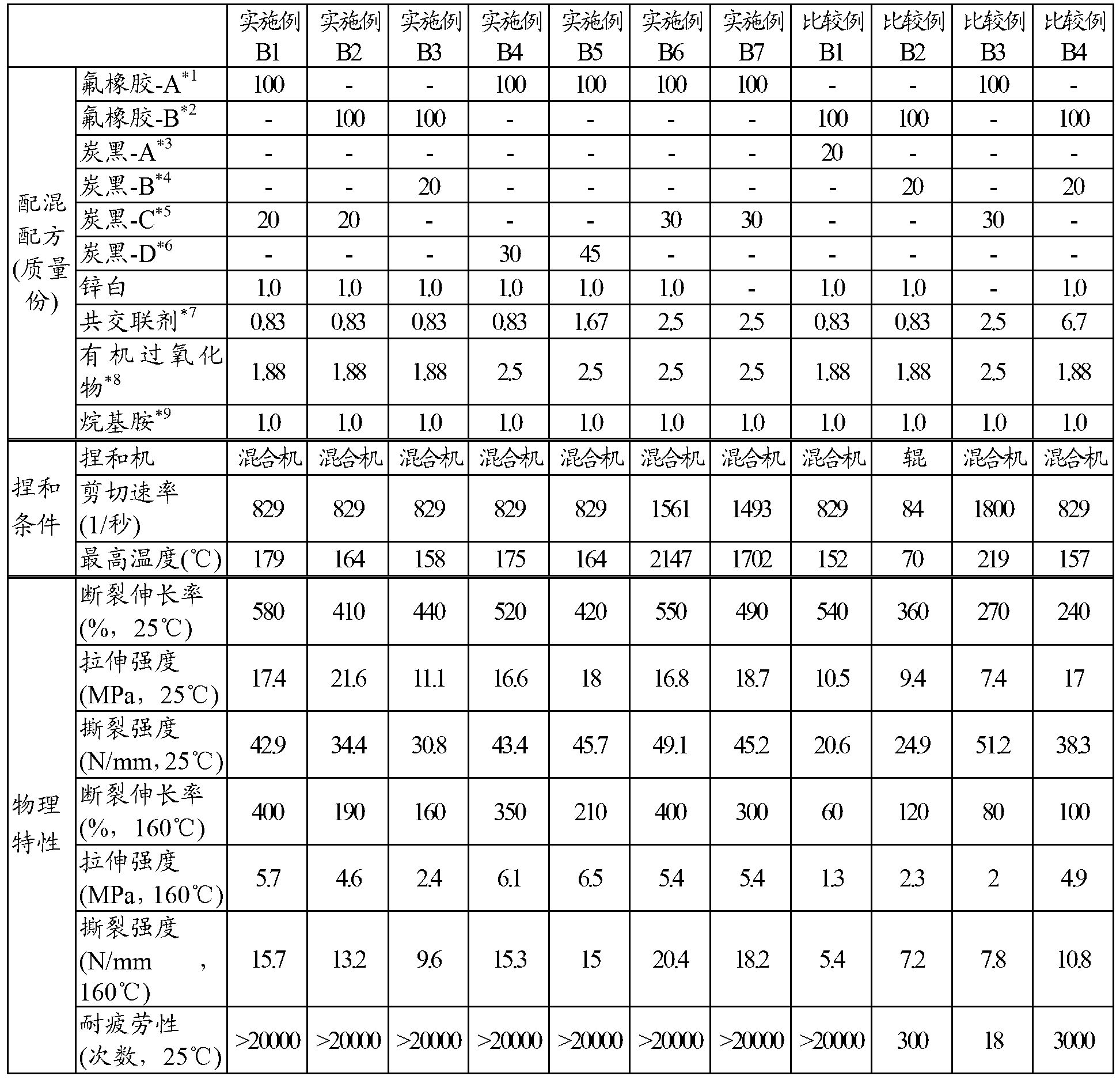

Fluorine rubber composition and bladder for tire production

ActiveCN103298877AHigh tensile strengthHigh elongation at breakTyresHollow articlesPolymer scienceVulcanization

Owner:BRIDGESTONE CORP +2

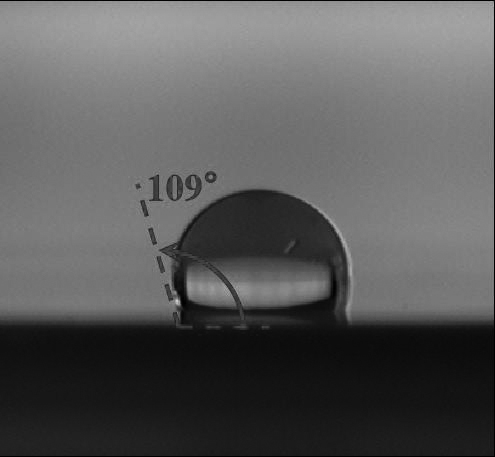

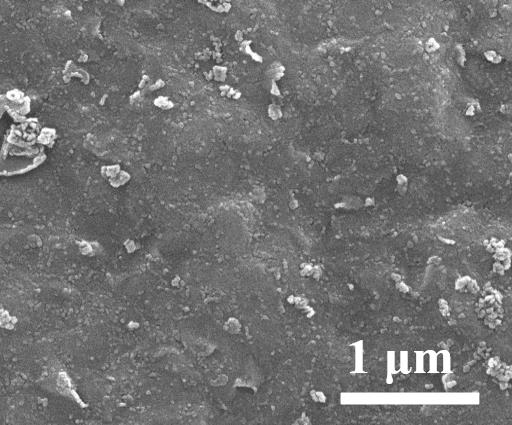

Light-blocking articles with spacer functional composition

ActiveUS20190390027A1Less pollutionReduce decreaseCurtain accessoriesFibre treatmentCeiling temperatureMaterials science

A foamed, opacifying element useful as a light-blocking article has a substrate; an opacifying layer disposed on the substrate, and a functional composition disposed over the opacifying layer. The functional composition comprises: (i) inorganic or organic spacer particles having a mode particle size of at least 1 μm and up to and including 100 μm, and which inorganic or organic spacer particles resist melt flow at a pressure of up to and including 100 psi (689.5 kPa) and a temperature of up to and including 220° C.

Owner:EASTMAN KODAK CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com