Li2O-Al2O3-SiO2-B2O3, CaO-Al2O3-SiO2-B2O3 crystallizable glass low-temperature co-fired composite material and preparation method thereof

A composite material and low-temperature co-firing technology, which is applied in the field of electronic packaging materials, can solve the problems of difficulty in achieving complete crystallization, unfavorable sintering densification, and high dielectric loss, and achieve high densification, low thermal expansion coefficient, and low dielectric loss. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] In specific embodiments of the present invention,

[0023] Li in the composite 2 O-Al 2 o 3 -SiO 2 -B 2 o 3 Crystallizable glass and CaO-Al 2 o 3 -SiO 2 -B 2 o 3 The crystallizable glass is based on the total weight composition of the composite material, and its composition is as follows:

[0024]

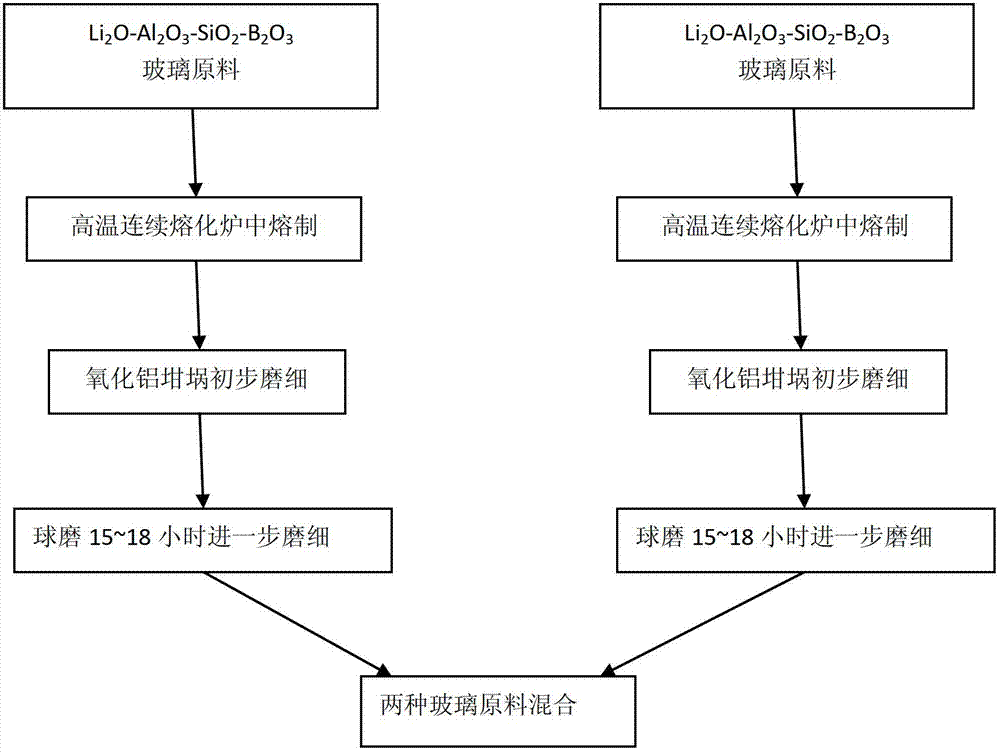

[0025] The preparation method of the low-temperature co-fired material in this embodiment comprises the following steps:

[0026] (1) Preparation of raw materials for crystallizable glass: press Li 2 O-Al 2 o 3 -SiO 2 -B 2 o 3 Glass and CaO-Al 2 o 3 -SiO 2 -B 2 o 3 The mass percent content of each oxide required for glass is taken by weighing the raw materials and mixed uniformly respectively;

[0027] (2)CaO-Al 2 o 3 -SiO 2 -B 2 o 3 Glass preparation: raise the high-temperature continuous melting furnace to 1550°C, and then mix evenly CaO-Al 2 o 3 -SiO 2 -B 2 o 3 The glass raw material is fed into the quartz crucible of the high-temperatur...

Embodiment 2

[0033] Li in the composite 2 O-Al 2 o 3 -SiO 2 -B 2 o 3 Crystallizable glass and CaO-Al 2 o 3 -SiO 2 -B 2 o 3 The crystallizable glass is based on the total weight composition of the composite material, and its composition is as follows:

[0034]

[0035] The preparation method of the low-temperature co-fired material in this embodiment comprises the following steps:

[0036] (1) Preparation of raw materials for crystallizable glass: press Li 2 O-Al 2 o 3 -SiO 2 -B 2 o 3 Glass and CaO-Al 2 o 3 -SiO 2 -B 2 o 3 The mass percent content of each oxide required for glass is taken by weighing the raw materials and mixed uniformly respectively;

[0037] (2)CaO-Al 2 o 3 -SiO 2 -B 2 o 3 Glass preparation: raise the high-temperature continuous melting furnace to 1550°C, and then mix evenly CaO-Al 2 o 3 -SiO 2 -B 2 o 3 The glass raw material is fed into the quartz crucible of the high-temperature continuous melting furnace at a rate of 10-20 g / min; the g...

Embodiment 3

[0043] Li in the composite 2 O-Al2 o 3 -SiO 2 -B 2 o 3 Crystallizable glass and CaO-Al 2 o 3 -SiO 2 -B 2 o 3 The crystallizable glass is based on the total weight composition of the composite material, and its composition is as follows:

[0044]

[0045] The preparation method of the low-temperature co-fired material in this embodiment comprises the following steps:

[0046] (1) Preparation of raw materials for crystallizable glass: press Li 2 O-Al 2 o 3 -SiO 2 -B 2 o 3 Glass and CaO-Al 2 o 3 -SiO 2 -B 2 o 3 The mass percent content of each oxide required for glass is taken by weighing the raw materials and mixed uniformly respectively;

[0047] (2)CaO-Al 2 o 3 -SiO 2 -B 2 o 3 Glass preparation: raise the high-temperature continuous melting furnace to 1550°C, and then mix evenly CaO-Al 2 o 3 -SiO 2 -B 2 o 3 The glass raw material is fed into the quartz crucible of the high-temperature continuous melting furnace at a rate of 10-20 g / min; the gla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| dielectric loss | aaaaa | aaaaa |

| dielectric loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com