Patents

Literature

3119results about How to "Improve anti-aging properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ecological slope protection vegetation building blocks as well as making method and construction process

InactiveCN101200894APrevent collapseImprove the environmental landscapeSolid waste managementMixing operation control apparatusEngineeringLevee

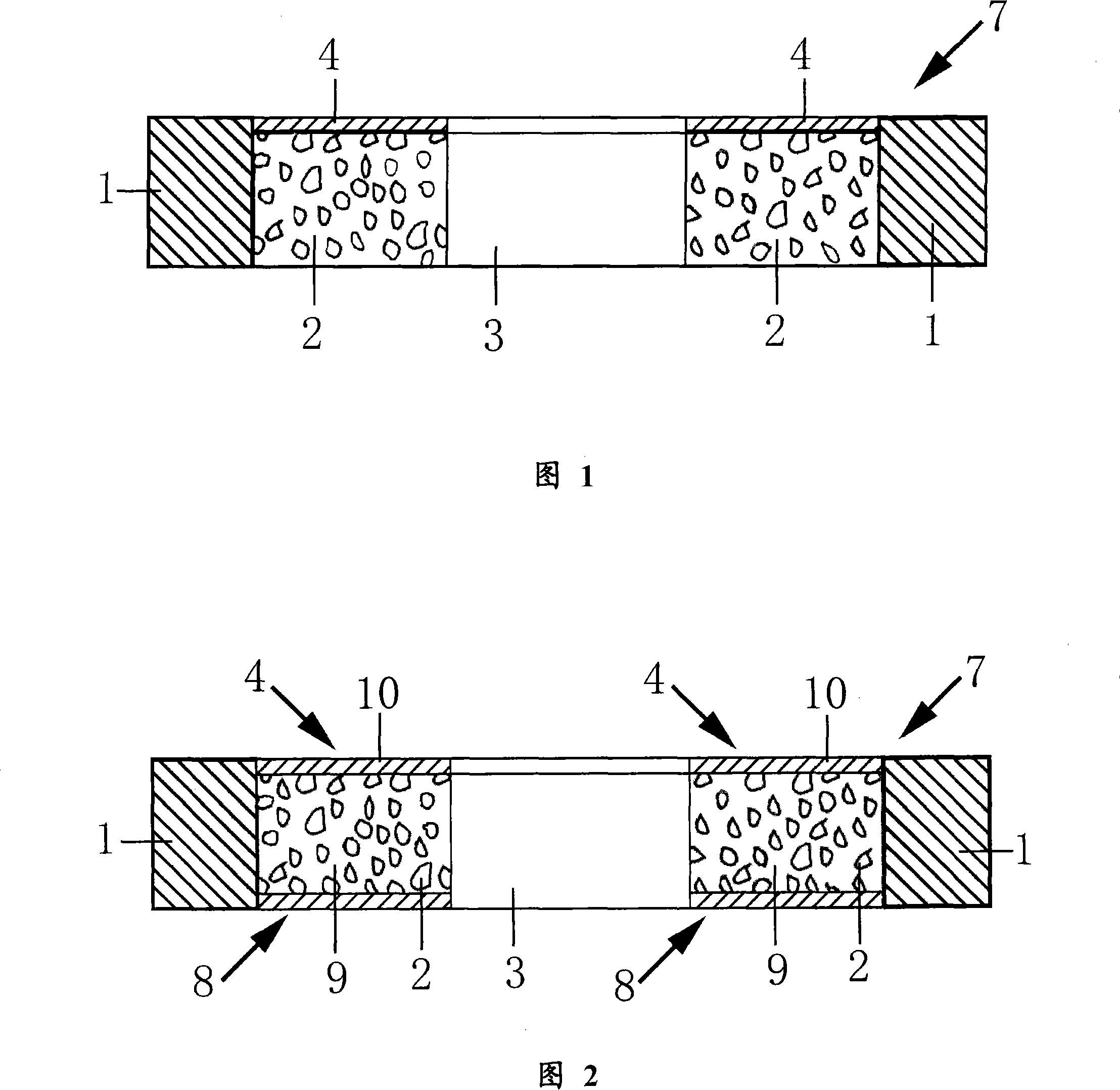

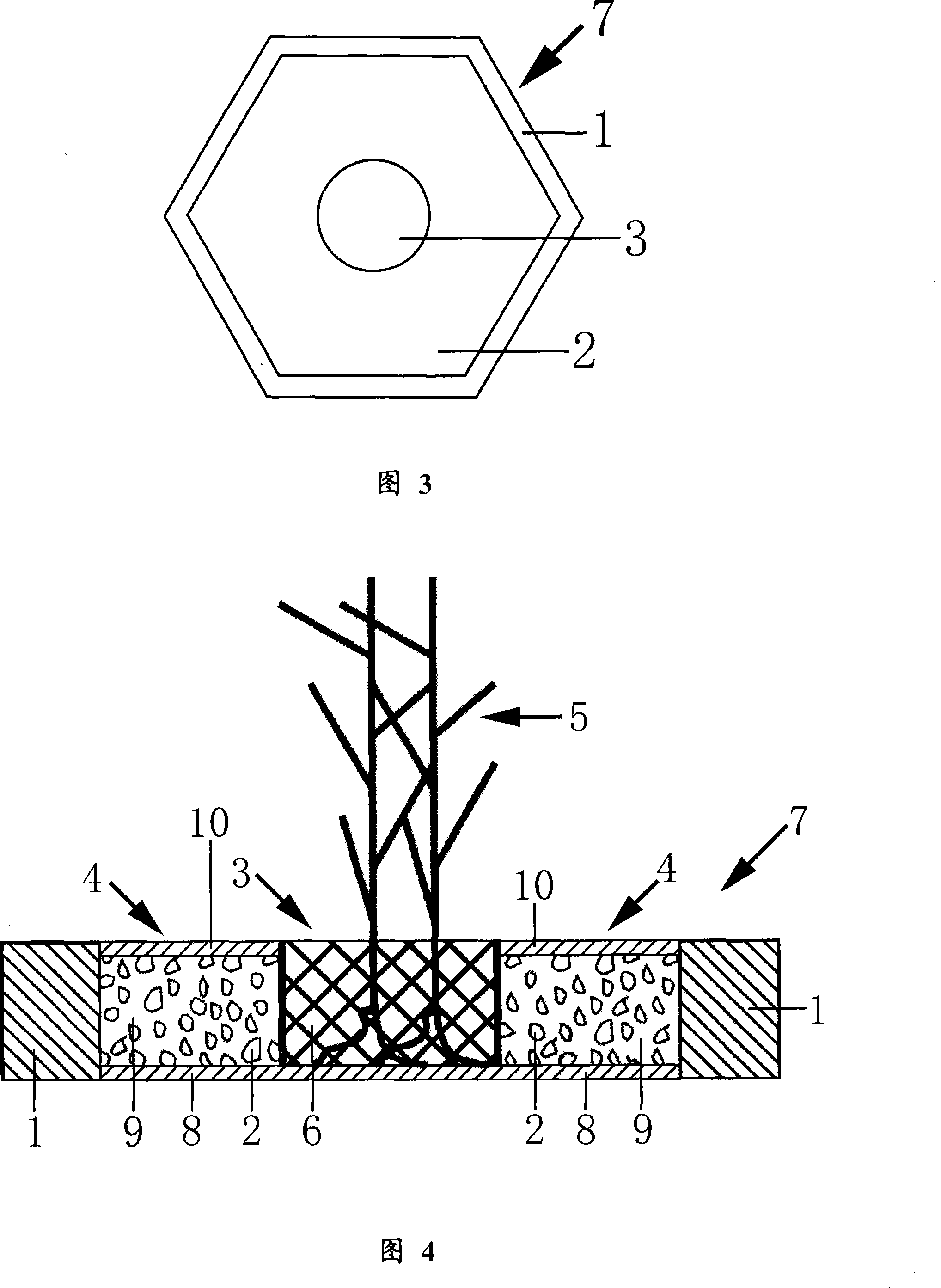

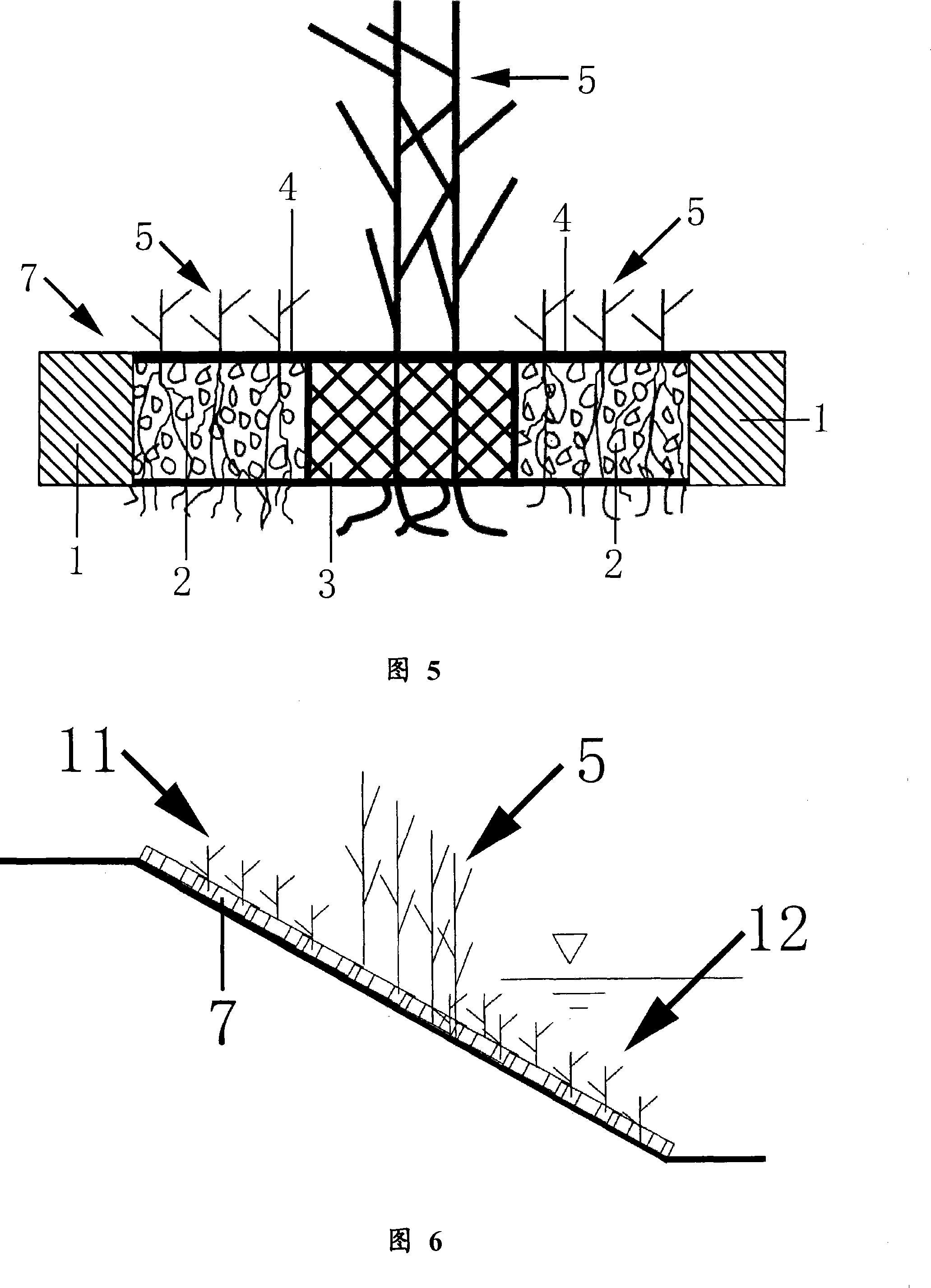

The present invention relates to a building block of ecological slope protection vegetation, a fabrication method and a construction technique. The building block is composed of a growing bed body, a lath crib, planting troughs, a vegetation layer and a plant, the lath crib wraps the circumference of the growing bed body, the upper plane of the growing bed body is lower than the upper plane of the lath crib and concave, the vegetation layer is formed on the growing bed body, which matches the inner walls of the sectional area of the lath crib to form an integral building block, and more than one planting troughs are arranged on and run through the growing bed body. The design of the present invention is scientific, the structure is reasonable, the restoration of water ecology can reduce the operating cost, environment is improved, ecology is reinstated, harmonious natural beauty is enhanced, and the present invention is suitable for the nidification of small living creatures and the habitation and the survival of aquatic fishes, so that the cutting-off continuity of water and land regions is restored. The present invention is widely applied to channel slope protection, levee slopes, roadsides, airports, parks, public lands, household lawns, sports grounds, etc. The present invention is suitable for cold regions, damp regions, warm and damp intermediate zone, etc.

Owner:TIANJIN WATER RESOURCES RES INST +2

Modified, weather resisting polypropylene material

This invention discloses a modified polypropylene material used as elements of home appliances, such as outdoor hulls of air-conditioners and panels of automobiles. The modified polypropylene material comprises: polypropylene resin 65-85 wt.%, toughening modifier 1-18 wt.%, mineral reinforcer 0-25 wt.%, coupler 0.1-0.8 wt.%, processing auxiliary 0.2-2 wt.%, photostabilizer 0.2-2 wt.% and colorant 0.1-1.5 wt.%. Compared with present polypropylene material, the modified polypropylene material has improved weathering resistance and anti-aging property.

Owner:CGN JUNER NEW MATERIALS

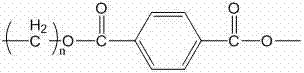

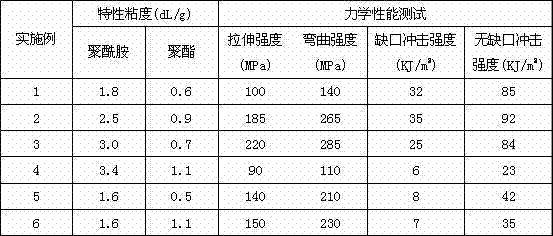

Glass fiber reinforced polyamide/polyester alloy and preparation method thereof

The invention discloses a glass fiber reinforced polyamide / polyester alloy and a preparation method thereof. The glass fiber reinforced polyamide / polyester alloy consists of the following components in percentage by weight: (A) 99-30 percent of resin component and (B) 70-1 percent of glass fiber, wherein the resin component (A) consists of the following components in percentage by weight: (1) 97-1 percent of polyamide of which the intrinsic viscosity is 1.8-3.0 dL / g, (2) 97-1 percent of polyester of which the intrinsic viscosity is 0.6-0.9 dL / g, (3) 1-20 percent of compatilizer and (4) 1 percent of other aids. The preparation method comprises the following steps of: weighing the materials with an electronic metering scale; feeding the materials into a dual-screw extruder respectively; and melting and mixing together to obtain a high-strength and high-toughness glass fiber reinforced polyamide / polyester alloy. The method is simple, and the performance of the obtained polyamide / polyester alloy is higher than that of a glass fiber reinforced nylon material.

Owner:KINGFA SCI & TECH CO LTD +1

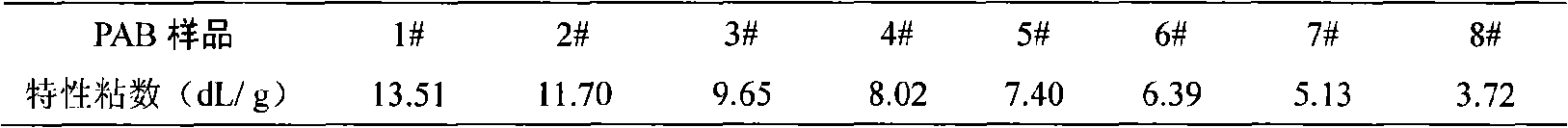

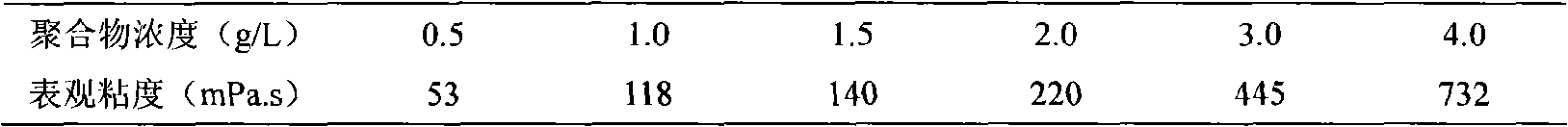

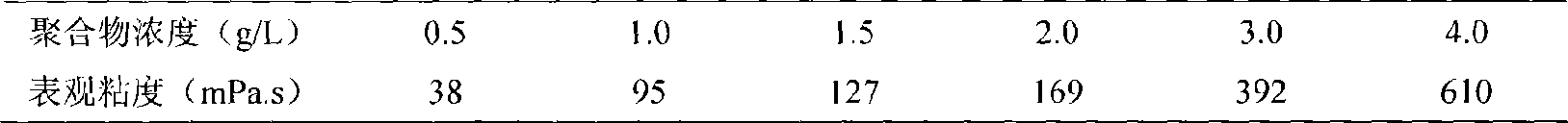

Acrylic amide modified graft copolymer, preparation method and application thereof

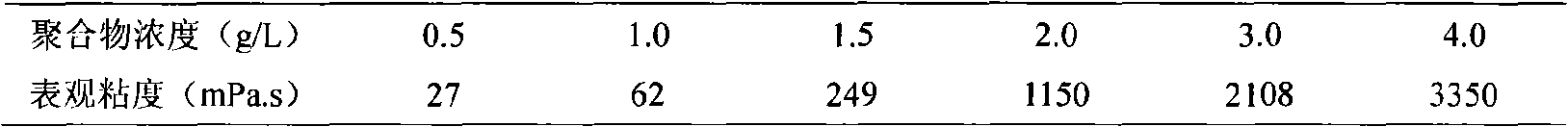

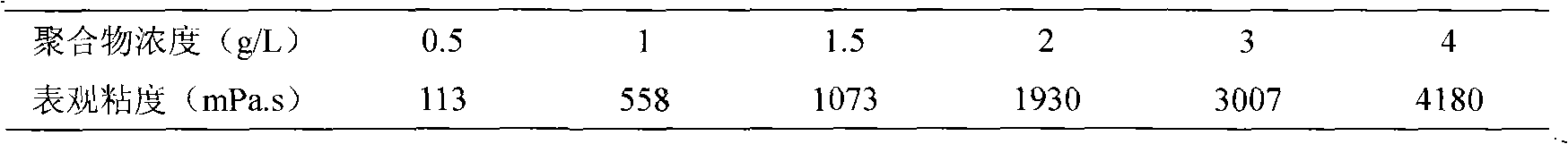

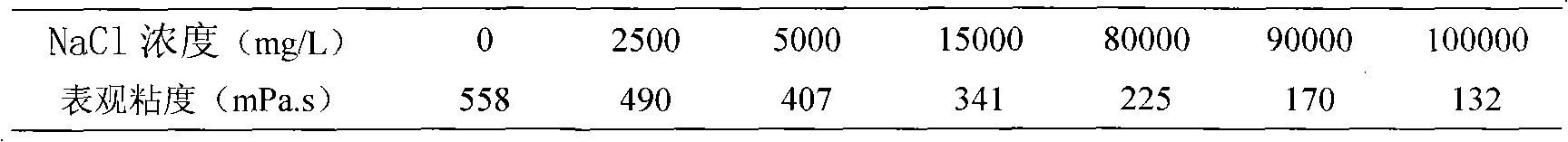

The invention discloses an acrylamide modified graft copolymer and a preparation method and usage thereof. The invention is characterized in that 20 parts of acrylamide, 1-20 anionic monomer and / or cationic monomer, 0.1-15 macromonomer, 0.05-10 ionic lyophobic monomer and 50-1000 deionized water are added into a three-necked reaction bottle, the pH value is adjusted to be 3-9, N2 is introduced for 30min, then 0.002-0.5 part of initiator persulfate is added at 30-75 DEG C, the reaction lasts 8-36h, then copolymer PAB is obtained, and finally water is used for dilution to obtain strong PAB solution. During polymerization, no surfactant is used, and the macromonomer with a long chain and the ionic lyophobic monomer with intermolecular association function are introduced into the copolymer PAB, so the capabilities of cooperative tackification and salt-resistance between the rigid conformation of a molecular chain and the intermolecular association can be played optimally, the PAB exhibits unique solution property and has higher colloidal viscosity in high saline solution than in fresh water, and the PAB obtains the capabilities of tackification, salt resistance, low surface tension and strong molecular association and can be used for the oil-displacing acrylamide modified graft copolymer. The copolymer is prepared into water solution with mass concentration of 0.2-3.0g / L and surfactant concentration of 0.01-2 mmol / L, then the water solution is added into a mixing vessel by a stirring device, and then a polymer oil-displacing agent with tackification, salt resistance and cutting resistance is obtained. The PAB has the functions of both a tackifier and a macromolecule surfactant. The copolymer PAB is prepared into water solution which has mass concentration of 0.05-7%, so the macromolecule surfactant with excellent surface activeness can be obtained and then applicable to an emulsifier, an emulsion splitter, a solubilizer and a wetting agent.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

High glowing filament environmental-friendly inflaming retarding reinforced polybutylece terephthalate (PBT)/acrylonitrile butadiene styrene (ABS) alloy material and preparation method thereof

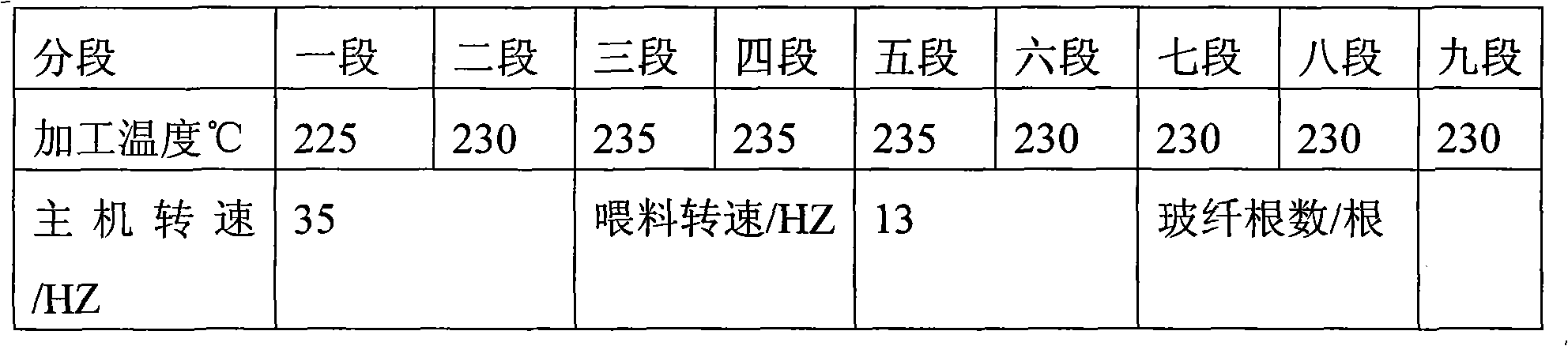

InactiveCN102108187AAvoid decompositionImprove impact performanceGlass fiberPolyethylene terephthalate

The invention relates to a high glowing filament environmental-friendly inflaming retarding reinforced polybutylece terephthalate (PBT) / acrylonitrile butadiene styrene (ABS) alloy material. The material comprises the following components in percentage by weight: 22.5-41% of PBT, 22.5-41% of ABS, 6-20% of complexing inflaming retardant, 3-15% of antimonous oxide, 20-30% of glass fiber, 2-10% of flexibilizer, 0.1-1% of antioxidant and 0.1-1% of lubrication dispersing agent. The preparation method comprises the following steps: putting raw materials weighed based on the weight proportion into a high mixer, mixing for 2-5 minutes, and then discharging; and then extruding and granulating by using an extruding machine at the processing temperature of 230-240 DEG C at the screw rotating speed of 30-40Hz. Compared with the alloy material prepared by the prior art, the high glowing filament environment-friendly inflaming retarding reinforced PBT / ABS alloy material has the advantages of high glowing filament temperature, environmental friendliness, balanced comprehensive performance and the like.

Owner:SHANGHAI SUNNY

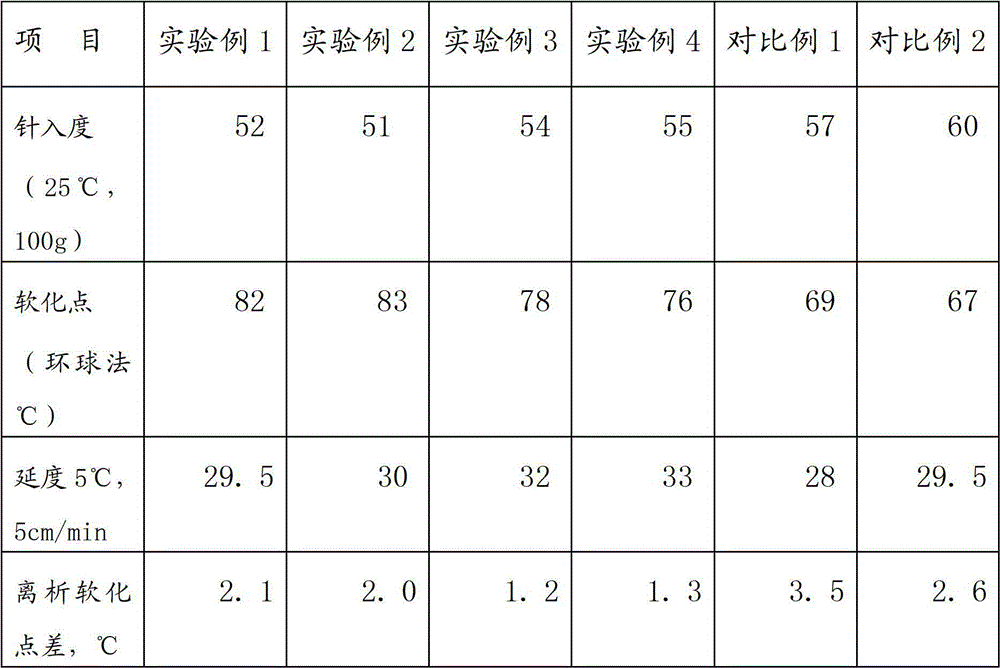

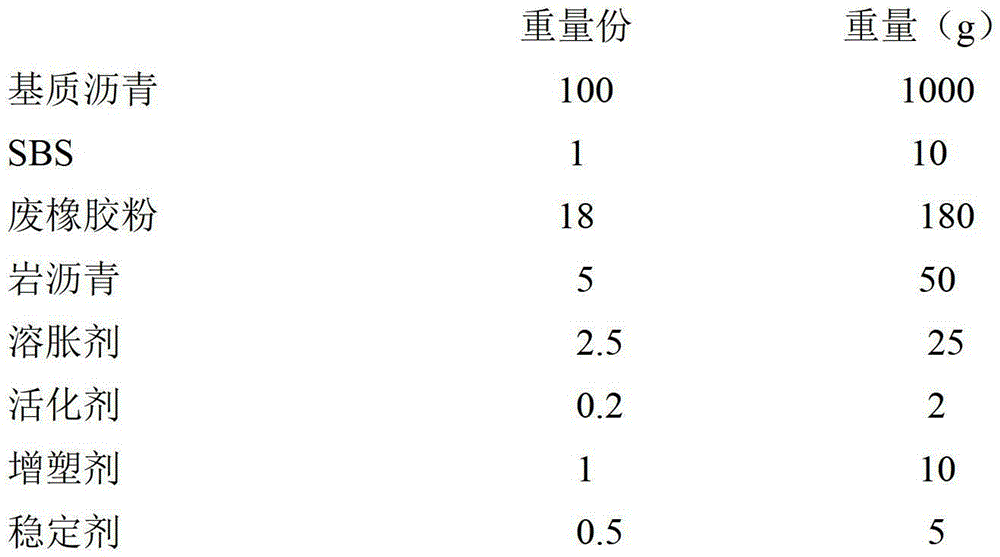

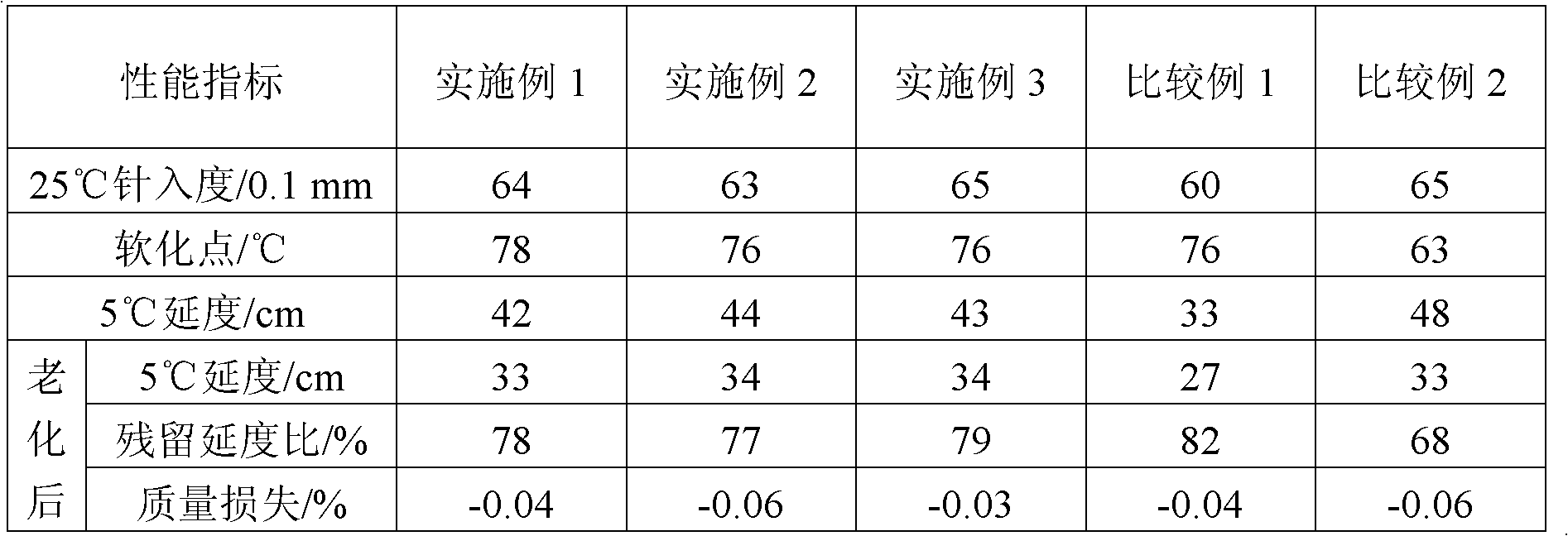

SBS (styrene-butadiene-styrene)/scrap rubber powder composite modified asphalt and preparation method thereof

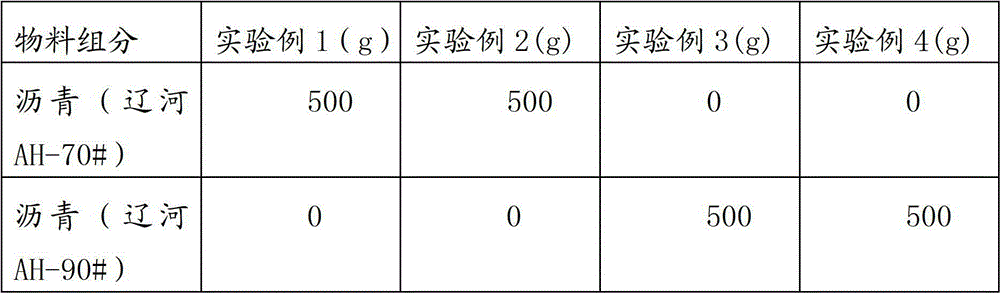

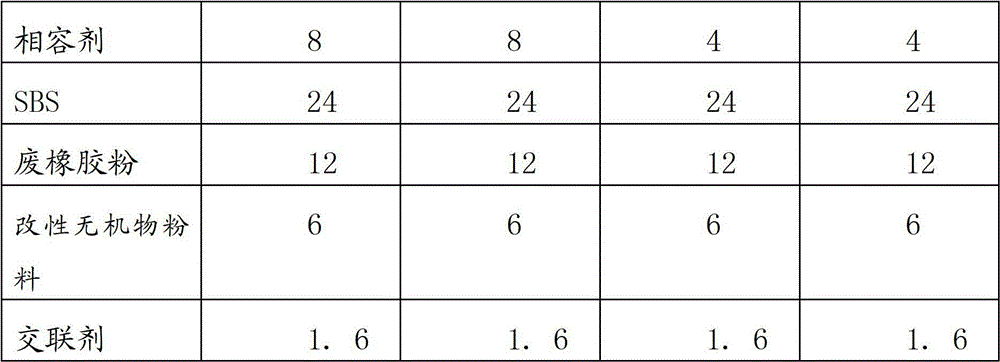

InactiveCN102977621AImprove anti-aging propertiesReduce material costsBuilding insulationsHigh temperature storagePolymer science

The invention relates to an SBS (styrene-butadiene-styrene) / scrap rubber powder composite modified asphalt which comprises the following components in parts by weight: 75-96 parts of matrix asphalt, 0.5-12 parts of scrap rubber powder, 0.5-6 parts of SBS, 0.2-8 parts of modified inorganic substance powder, 0.1-8 parts of compatilizer and 0.1-3 parts of crosslinking agent. The preparation method comprises the following steps: preparing the scrap rubber powder; heating the matrix asphalt to 160-180 DEG C, adding the compatilizer while stirring, and evenly mixing; adding the SBS scrap rubber powder and modified inorganic substance powder, stirring at the speed of 1000-5000 rpm for 5-125 minutes while keeping the temperature, and adding the crosslinking agent; and quickly stirring for 20-300 minutes while keeping the temperature. The key technical indexes of the product are higher than those of the SBS modified asphalt; and the invention enhances the high / low-temperature properties and aging resistance, prolongs the high-temperature storage stabilization period, and completely satisfies the property requirements for national high-grade roads.

Owner:TIANJIN HI TECH ENVIRONMENT DEV CO LTD

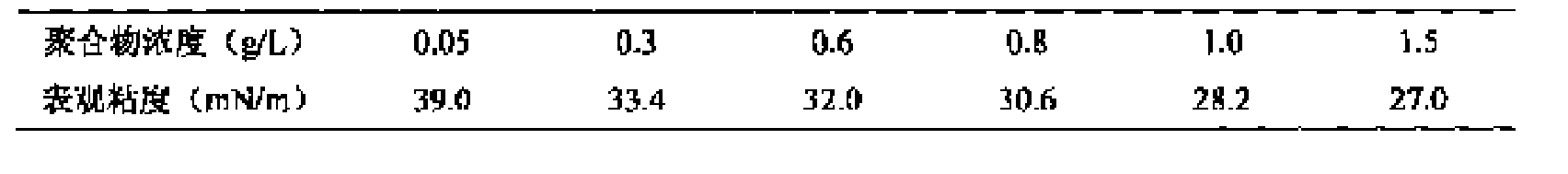

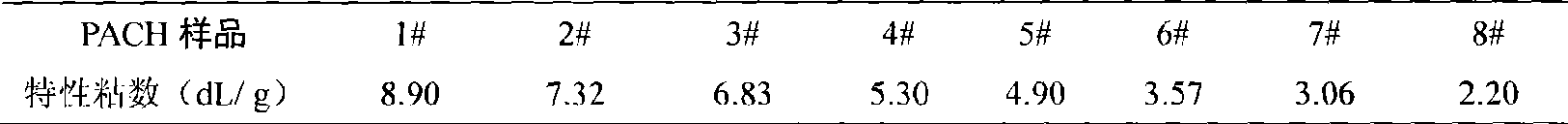

Non-linear associating water-soluble quadripolymer, and preparation and use thereof

InactiveCN101463116AImprove rigidityHigh temperature resistanceTransportation and packagingMixingIonChemistry

The invention discloses a non-linear associated water soluble quadripolymer as well as a preparation method and use thereof, comprising: adding 20 parts of acrylamide, 1-20 parts of nionic monomer or / and cationic monomer, 0.1-15 parts of macromonomer, 0.05-10 parts of hydrophobic monomer, 0.1-50 parts of surfactant and 60-1000 parts of deionized water to a three-necked reaction flask, adjusting the pH to be 3-9, adding 0.002-1 part of initiator (persulphate) at 30-75 DEG C after introducing N2 for 30min, reacting for 8-36h to obtain the quadripolymer PACH, diluting with water, and obtaining concentrated PACH solution. The macromonomer with a long chain and the hydrophobic monomer with a molecular association function are simultaneously introduced in a copolymer PACH, which can obtain the best synergistic viscosifying between rigid conformation of a molecular chain and molecular association and salt resistance. The non-linear associated water soluble quadripolymer is obtained. The copolymer is prepared into aqueous solution with the mass concentration of 0.2-3g / l and the surfactant concentration of 0.01-2mmol / l, added to a mixing vessel with a stirring device and evenly stirred at the room temperature to obtain a viscosified, salt-resistant and shear-resistant polymer oil displacement agent. The PACH has dual functions of a viscosifier and a high molecular surfactant; minute amount of a low molecular surfactant is added to the PACH solution, thus improving the apparent viscosity of the solution, reducing the surface tension of solution and the water-oil interfacial tension, and being beneficial to improving the crude oil recovery ratio. A copolymer PABE is prepared into the aqueous solution with the mass concentration of 0.05-7% to obtain high molecular surfactant with excellent surface activity, and the high molecular surfactant is used as an emulsifier, a demulsifier, a solubilizer and a wetting agent.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

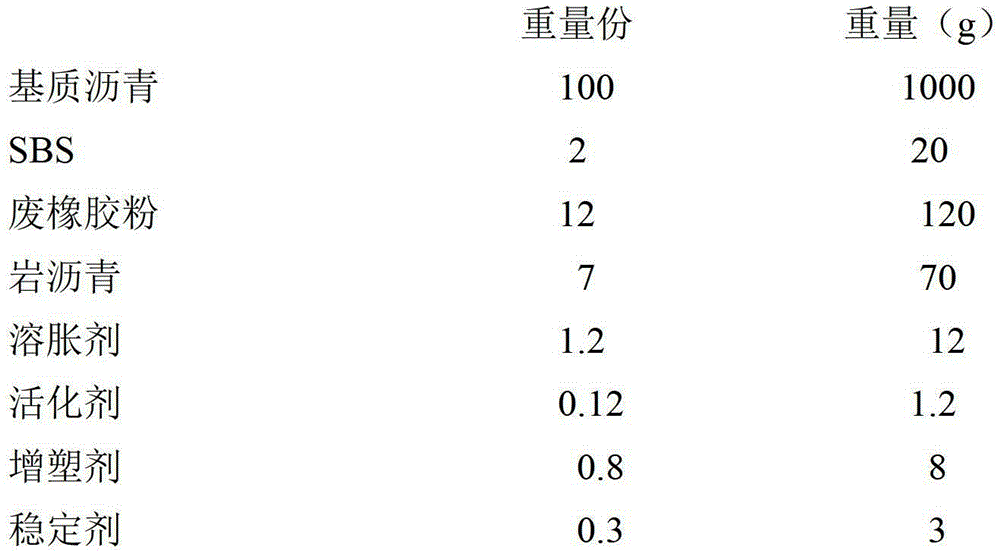

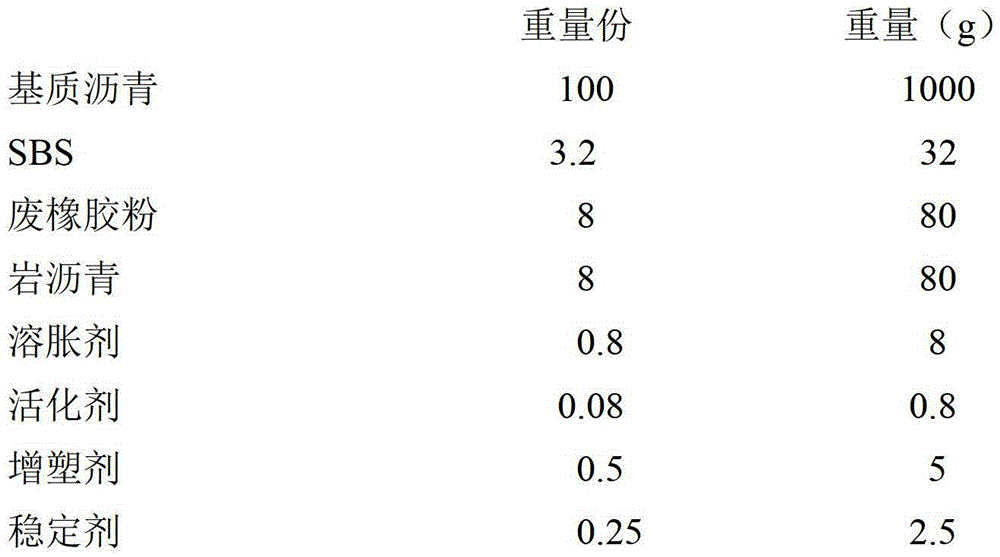

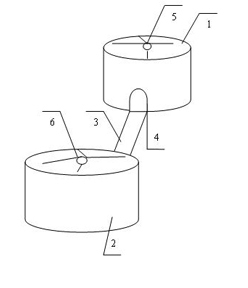

Ultraviolet aging-resistant compound modified asphalt and preparation method thereof

ActiveCN103146207AImprove anti-aging propertiesStop breakingTreatment with plural serial refining stagesBuilding insulationsPolymer modifiedPolymer science

The invention belongs to the technical field of road asphalt modification and relates to an ultraviolet aging-resistant compound modified asphalt, wherein on the basis of 100 parts by weight of matrix asphalt, in parts by weight, 1-6 parts of styrene-butadiene-styrene block copolymer, 3-18 parts of waste rubber powder, 5-10 parts of rock asphalt, 0.3-2.5 parts of sweller, 0.03-0.2 part of activator, 0.1-1 part of plasticizer and 0.2-0.5 part of stabilizer are further added, wherein the sweller is furfural extract oil which is subjected to dewaxing treatment previously; the furfural extract oil contains 60wt%-88wt% of aromatic components which contain 40-65wt% of heavy aromatic hydrocarbon; and the waste rubber powder is waste rubber tire tread rubber powder having the content of carbon black between 28wt% and 58wt% and the grain diameter between 45 and 80 meshes. The ultraviolet aging-resistant compound modified asphalt provided by the invention is up to the standard of the polymer modified asphalt in performance, and the ultraviolet aging resistance of the asphalt is improved to a large extent; and waste resources are utilized.

Owner:HUBEI GUOCHUANG HI TECH MATERIAL

High-impact-resistance less-fiber-floating long glass fiber reinforced polypropylene material

The invention discloses a high-impact-resistance less-fiber-floating long glass fiber reinforced polypropylene material which is prepared from the following components in parts by weight: 10-80% of long glass fiber reinforced polypropylene master batch and 20-90% of high-impact-resistance less-fiber-floating master batch. The long glass fiber reinforced polypropylene master batch is prepared from 8-80% of polypropylene copolymer, 0-80% of polypropylene homopolymer, 10-60% of glass fiber, 1-10% of grafted polypropylene, 0.1-2% of antioxidant and 0.2-2% of processing aid. The high-impact-resistance less-fiber-floating master batch is prepared from 20-80% of polypropylene copolymer, 0-50% of glass fiber, 0-30% of elastomer, 0-30% of grafted elastomer, 0-10% of low-viscosity polyamide resin, 0.1-2% of antioxidant and 0.2-5% of processing aid. The polypropylene material disclosed by the invention has the advantages of high glossiness and less fiber floatings; and the finished product made of the polypropylene material has the advantages of good drop resistance and processability, and can be used for replacing the parts made of engineering plastics.

Owner:WUHAN JINFA TECH CO LTD

Resin bendable grinding wheel and preparation method and device

InactiveCN101804602AAvoid carbonizationIncrease contentFlexible-parts wheelsGrinding devicesFiberglass meshCarbide silicon

The invention discloses a resin bendable grinding wheel and a preparation method and a device thereof. The resin bendable grinding wheel consists of brown aluminium oxide, calcined alumina, white alundum, black silicon carbide, phenolic resin powder, phenolic resin liquid, cryolite, barium sulphate, pyretic, iron oxide red, Hunori gel, alkali-free high tensile glass fiber mesh and non-woven black cloth. Compared with the prior art, through the optimization configuration on the aspect of the material selection and working procedures, the strength, the flexibility and the aging resistance of the grinding wheel are greatly improved, and at the same time, the resource and the energy are saved; and the strength of the grinding wheel is more than 80m / s, the grinding ratio is more than or equal to 1:15, the maximum bendable angle can reach 40 degrees, the tensile strength is greatly improved, the service life is prolonged by two times, the energy consumption is reduced by 5 to 10 percent, and the yield of the finished product can reach more than 99 percent.

Owner:GUIZHOU FUSUN INDAL

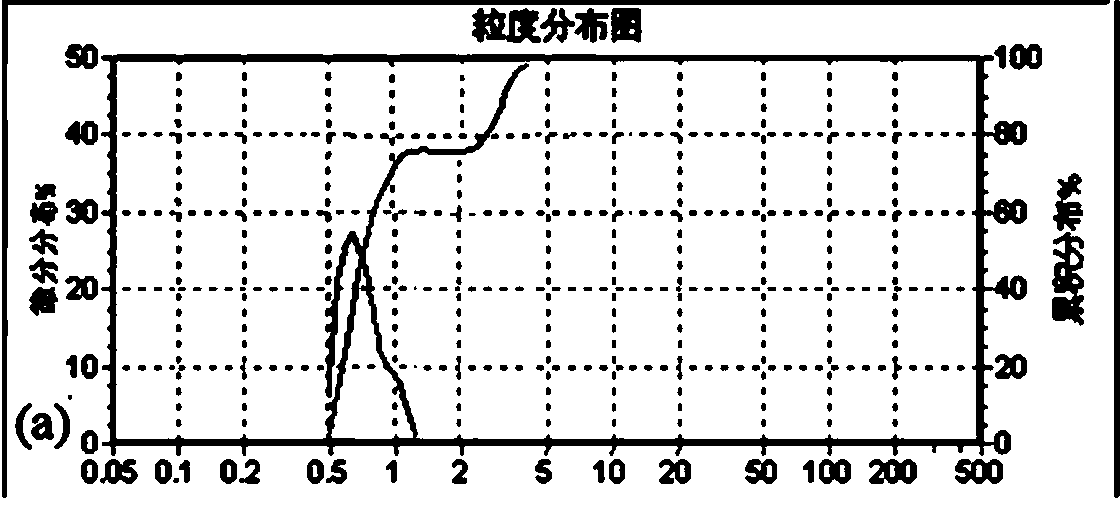

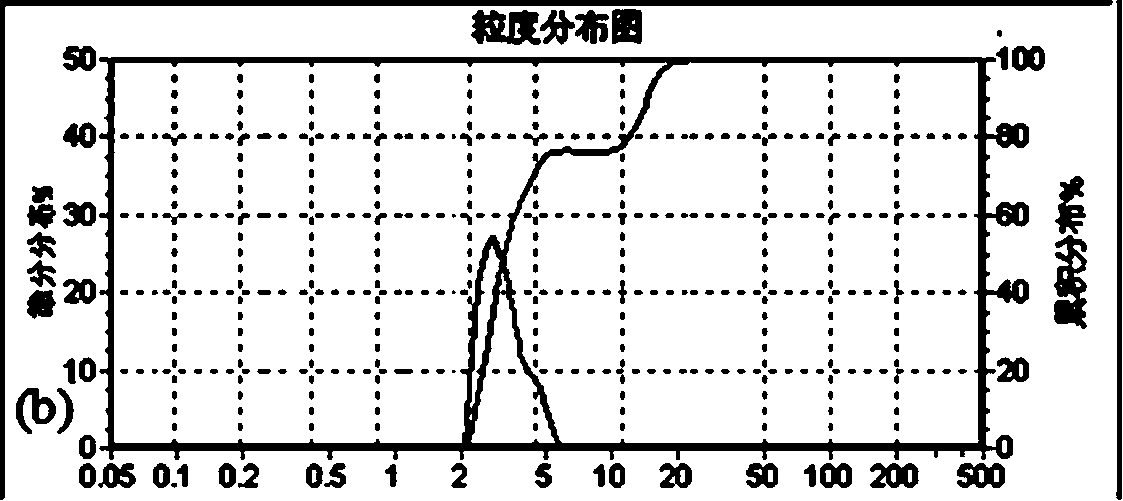

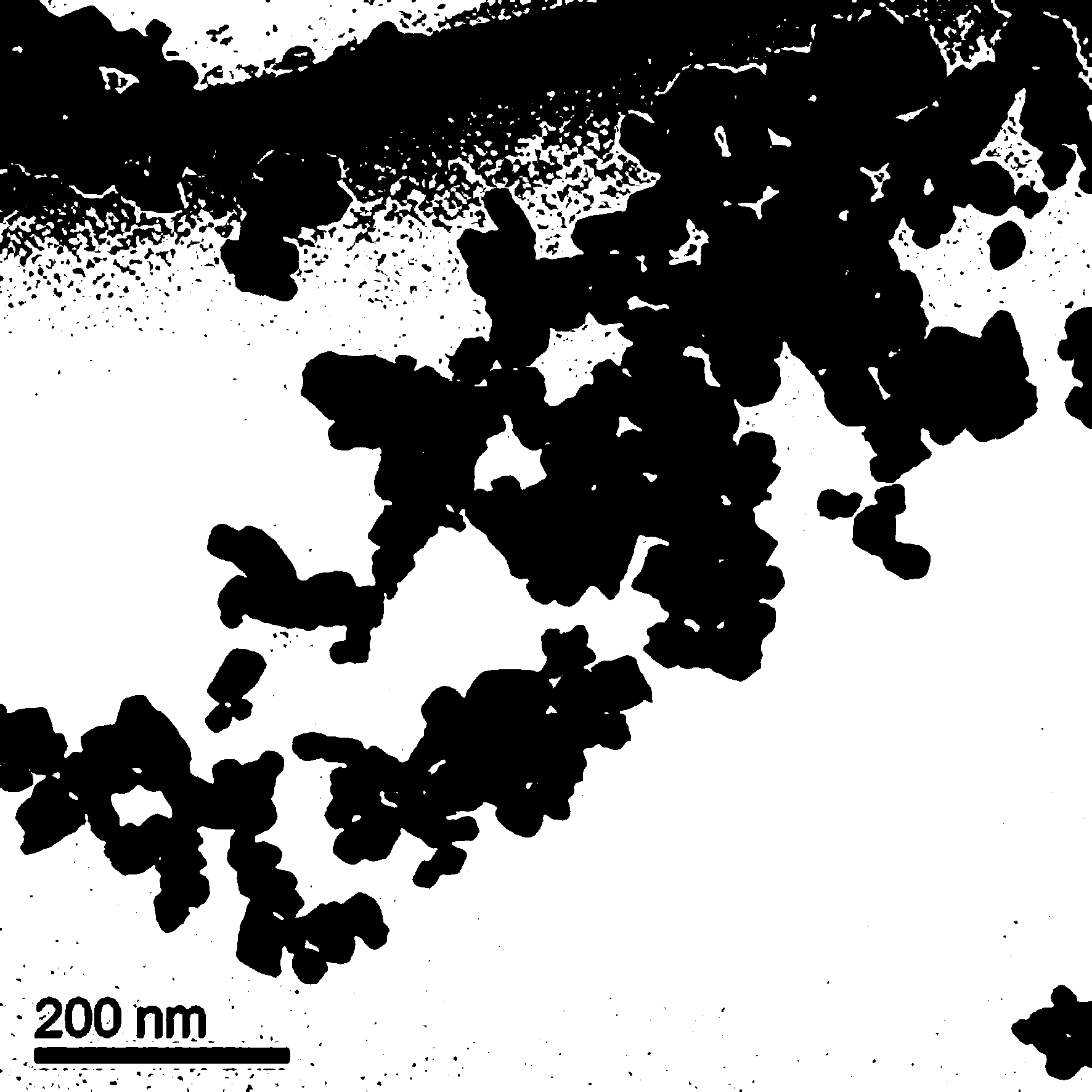

Yttria-stabilized zirconia powder and preparation method thereof

The invention relates to yttria-stabilized zirconia powder and a preparation method thereof. The yttria-stabilized zirconia powder has the composition characteristics that yttria is taken as a stabilizer of a zirconia material; the powder comprises a doping system formed by one or more following third components: alumina, ceria, lanthana, copper oxide, magnesium oxide and calcium oxide, wherein the weight of the yttria is 2-8mol%, and the total doping weight of the alumina, the ceria, the lanthana, the copper oxide, the magnesium oxide and the calcium oxide is 0-5wt%. According to the yttria-stabilized zirconia powder and the preparation method, the deficiencies of an existing liquid phase preparation process of nanometer zirconia powder are overcome, and the prepared nanometer ZrO2 composite powder has the performance of uniformity in dispersion of components, uniform grain size, super-fineness, high sintering activity, good liquidity and the like. Furthermore, the preparation method is simple in process and low in cost and is easy to industrialize.

Owner:YAAN YUANCHUANG CERAMIC

Electroluminescence wire

InactiveCN1798459AIncrease brightnessWith repeated useElectroluminescent light sourcesCeramicsDielectric layerLight-emitting diode

The invention consists of a baseline body, a metal decorating layer covering on outside of the baseline body, a dielectric layer covering on the metal decorating layer, a light emitting layer covering on the dielectric layer, a transparent conducting layer covering on the light emitting layer and connected to an out-guard wire. All layers are sealed by fluoroplast.

Owner:SHANGHAI KERUN PHOSPHOR TECH

Vitamin powder and preparation method thereof

ActiveCN102716087AHigh mechanical strengthGood dispersionPowder deliveryHydroxy compound active ingredientsEmbedding rateAntioxidant

The invention mainly discloses vitamin powder and a preparation method of the vitamin powder. The vitamin comprises the following components in mass percentage: 5-60% of fat soluble vitamin, 30-70% of wall material, 5-30% of assistant wall material, 0.5-2% of emulsifier, 0.1-2% of antioxidant and 0.1-3% of cross linking agent. The invention further relates to a preparation method of the vitamin powder. By using a microencapsulation technique, the fat soluble vitamin oil (e.g. vitamin A, vitamin D3, vitamin E and vitamin K) is embedded to a micro-capsule, the wall material used in the embeeding process is starch sodium octenylsuccinate, the vitamin oil is embeeded in the wall and then the micro-capsule is subjected to cross linkage, mist spraying and drying are carried out to form the vitamin powder, and the embedding rate of the vitamin is more than 95.3%. According to the invention, the process is simple, the cost is low, the obtained vitamin powder is not soluble in water, high in oil loading amount and good in flowability, and can be used in the fields such as foods, daily-used industrial chemicals and medicines.

Owner:ZHEJIANG ZHONGTONG TECH

Polyethylene wood plastic and preparation method thereof

The invention relates to a polyethylene wood plastic and a preparation method thereof and belongs to the technical field of plastic compound modifying processing. The invention provides a formula of the polyethylene wood plastic and a preparation method for a section bar; extruding temperature and extruding speed are increased; a polyethylene wood plastic section bar produced according to the preparation method has excellent high-temperature resistance; and according to the technical scheme, the polyethylene wood plastic comprises the following raw materials in parts by weight: 30-40 parts of polyethylene, 50-70 parts of wood flour, 0.5-2 parts of maleic anhydride grafted polyethylene, 0.8-1.5 parts of polyethylene wax, 1-3 parts of zinc stearate, 2-6 parts of toner, 0.5-1 part of antioxidant, 0.4-0.9 part of anti-ultraviolet light absorber UV-531 and 0.5-1.2 parts of stearic acids. The preparation method provided by the invention is suitable for the extruding molding of the polyethylene wood plastic section bar.

Owner:山西峰岩新型建材股份有限公司

High heat resisting and high abrasion resistant polyvinyl chloride (PVC) modified material and preparation method thereof

ActiveCN103059465AImprove wear resistance and heat resistanceImprove surface gloss and surface smoothnessPelletizingPlasticizer

The invention relates to the technical field of polyvinyl chloride composite materials, in particular to high heat resisting and high abrasion resistant polyvinyl chloride (PVC) modified materials and a preparation method of the high heat resisting and high abrasion resistant PVC modified materials. The modified materials comprise the following raw materials, by weight, 80-120 parts of PVC resin, 25-60 parts of stuffing bulking agents, 21-60 parts of plasticizer, 1-10 parts of chlorinated polyvinyl chloride, 1-10 parts of fire retardant, 1-10 parts of stabilizer, 1-10 parts of impact modifier and 0.2-2 parts of lubricating agents. The raw materials are weighed according to parts by weight and are blended. After being blended, the raw materials are extruded out to be granulated through a double-screw extruder to produce the modified materials. The modified materials are good in heat resisting property and abrasion resistant property, environment-friendly, high in strength, good in flame retardant effect, strong in compressing property and toughness, good in processing property and good in comprehensive property. The preparation method is simple in craft, convenient to operate and control, stable in quality and high in production efficiency, and can be produced in a large scale industrialization mode.

Owner:广东祺龙科技有限公司

Preparation process, product and application of new plastic

ActiveCN101982495AImprove thermal stabilityImprove toughnessInsulated cablesInsulated conductorsTemperature controlHigh resistance

The invention provides a process for preparing a new plastic, which comprises the following steps: (1) preparing raw materials; (2) weighing and proportioning the raw materials; (3) mixing PVC powder, stabilizers, packing, plasticizers and other additives, then carrying out high-speed kneading on the obtained mixture, and preplasticizing the mixture so as to obtain a pre-plasticized mixture; (4) mixing the pre-plasticized mixture with TPU particles, carrying out banbury mixing on the obtained mixture under the condition of gradient temperature control so as to obtain colloidal products; (5) carrying out double-screw granulation on the obtained colloidal products; and (6) carrying out sorting, dehydration and packing on the granular products obtained in step 5 so as to obtain the new plastic. The process is simple, the conditions of the process are easy to control, and the process is suitable for large-scale production. The invention also provides a new plastic, which has the characteristics of high resistance to wear and scrape, high elasticity, easy recovery, high flame retardance, ultraviolet resistance, freezing damage (caused by low temperature in the north) resistance, environmental protection, soft handfeel and stick resistance, and the like; and the new plastic can be applicable to wire and cable compound.

Owner:GUANGDONG OMG TRANSMITTING TECH CO

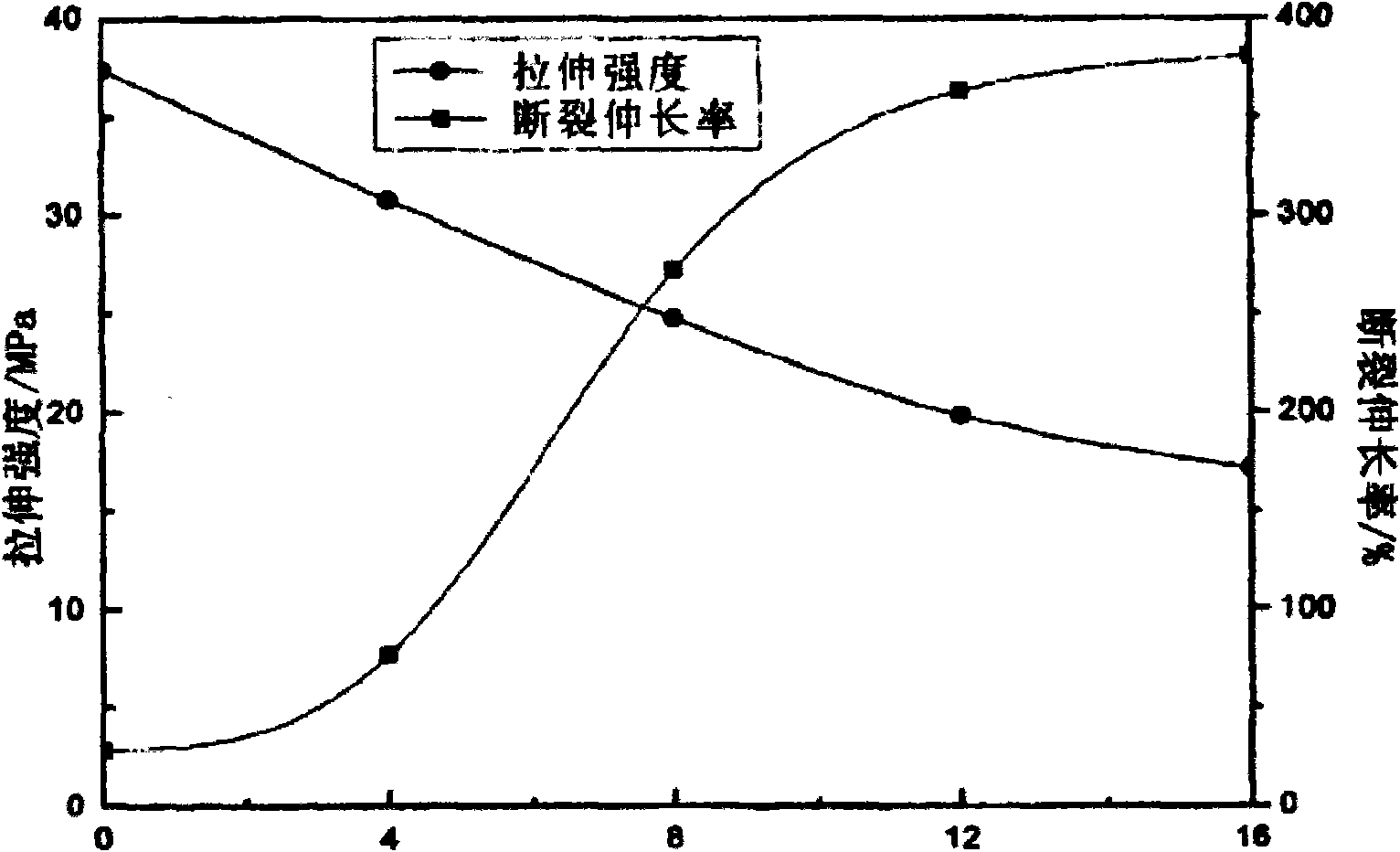

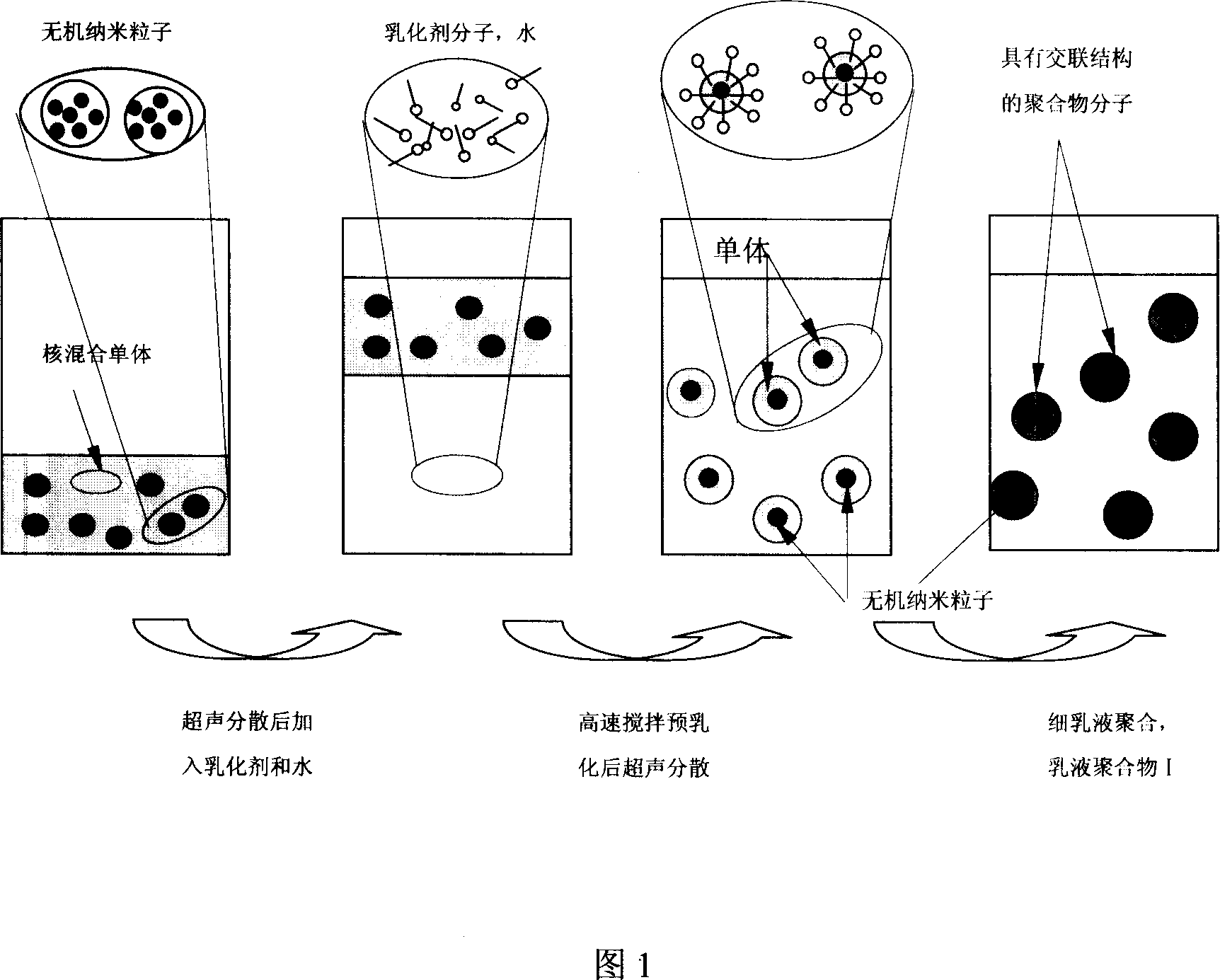

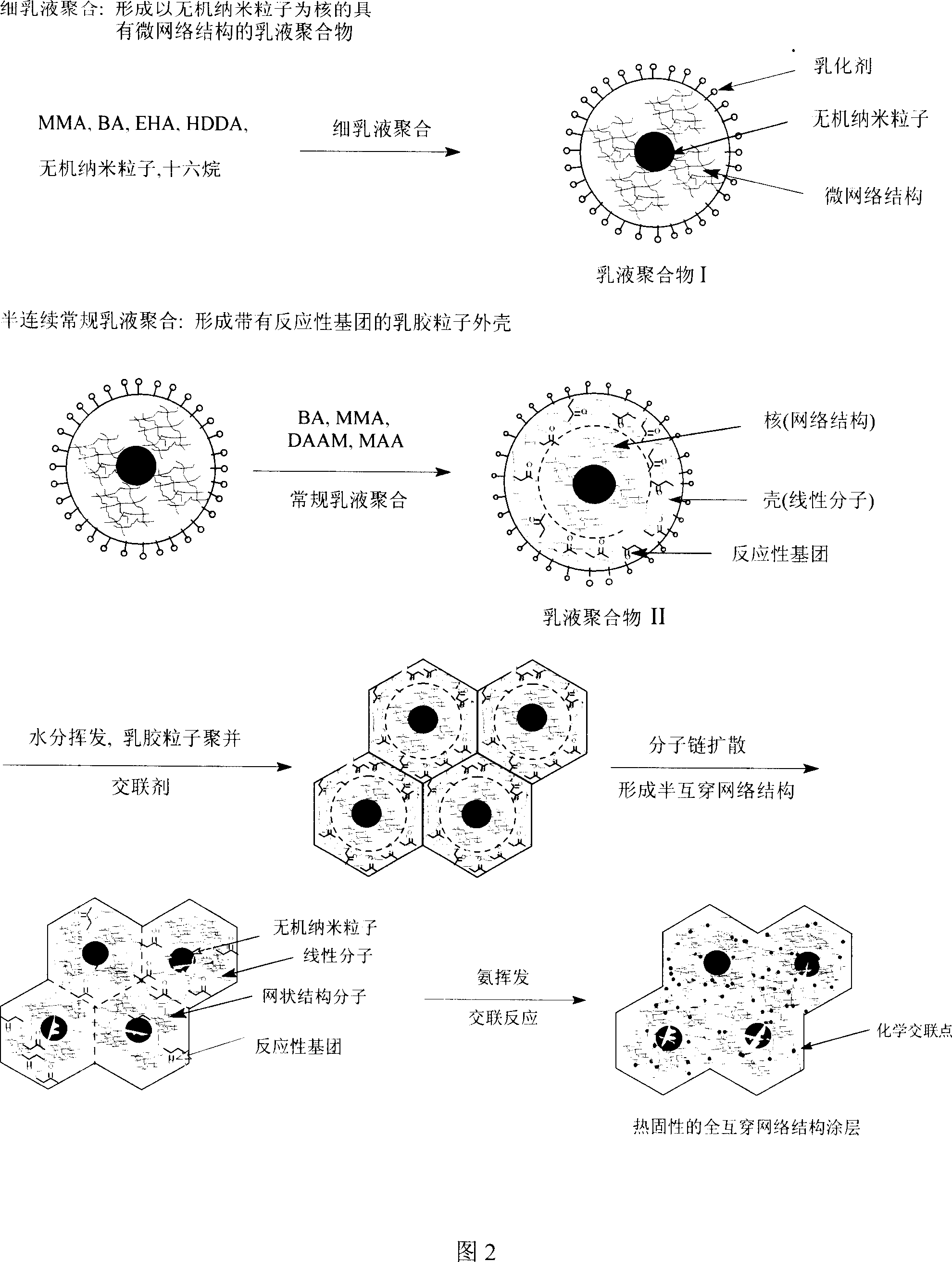

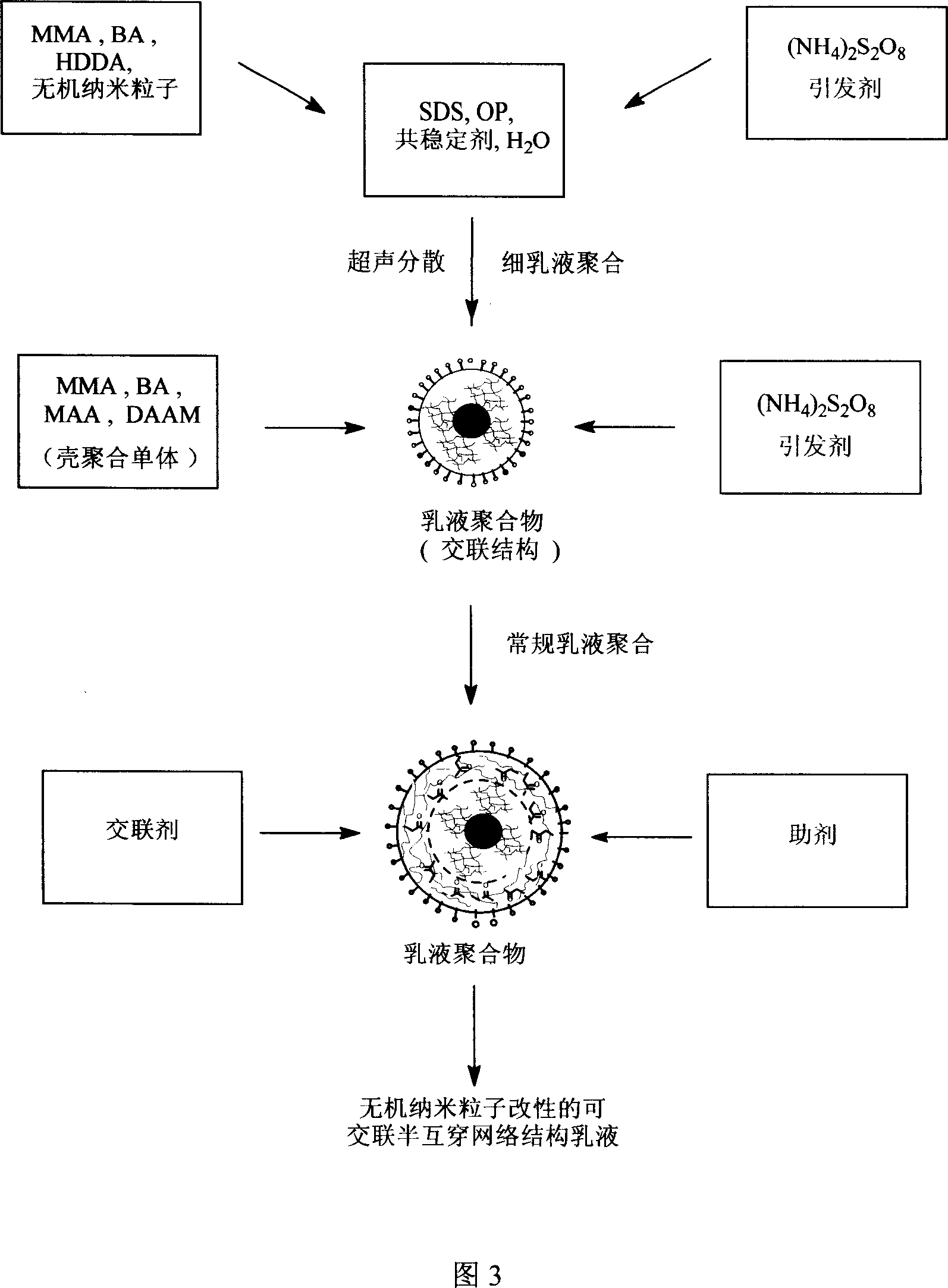

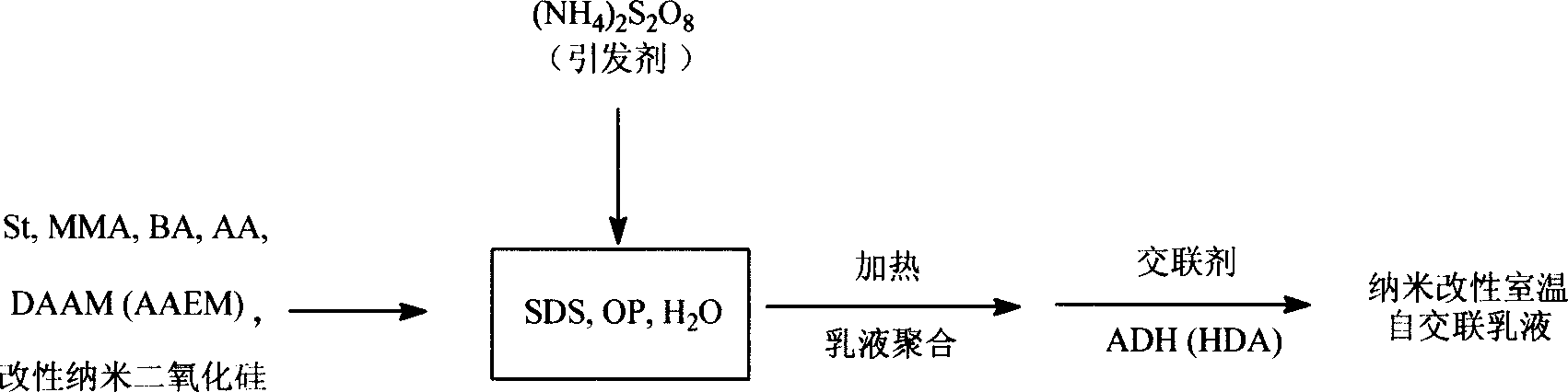

Method of preparing organic/inorganic hybridization reactivity semi-interpenetrating network structure emulsion

The invention discloses a new method for manufacturing Interpenetrating Polymer Network of organic or inorganic reaction latex, which belongs to macromolecule manufacturing polymer synthesis. The emulsion has excellent storage stability. Its coating with a high pencil hardness, excellent scratch resistance, water-resistance, stain resistance, chemical resistance and aging resistance, can be used for wood, metal and surface decoration and construction exterior paint, The water emulsion polymer can be made through the following steps: (a) At least two unsaturated compounds, allyl monomer and inorganic nano particle are polymerized to the cross-linked structure seed emulsion. (b) The unsaturated compounds with reaction and allyl monomer are polymerized to core / shell structure emulsion on the basis of the seed emulsion. (c) In the core / shell structure emulsion, organic / inorganic hybrid with cross-linked structure semi-IPN emulsion can be got for adding cross-linker.

Owner:HUNAN UNIV OF TECH

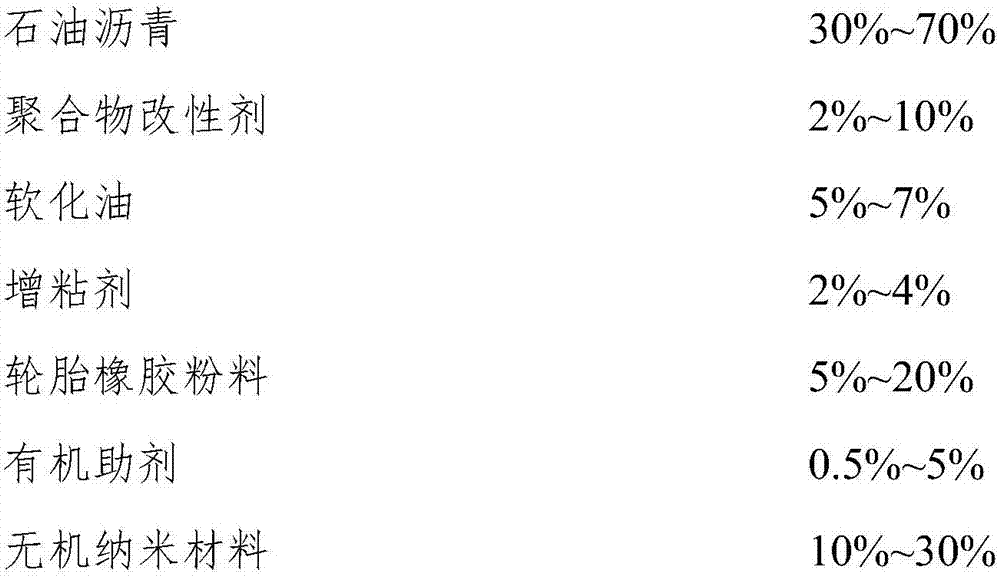

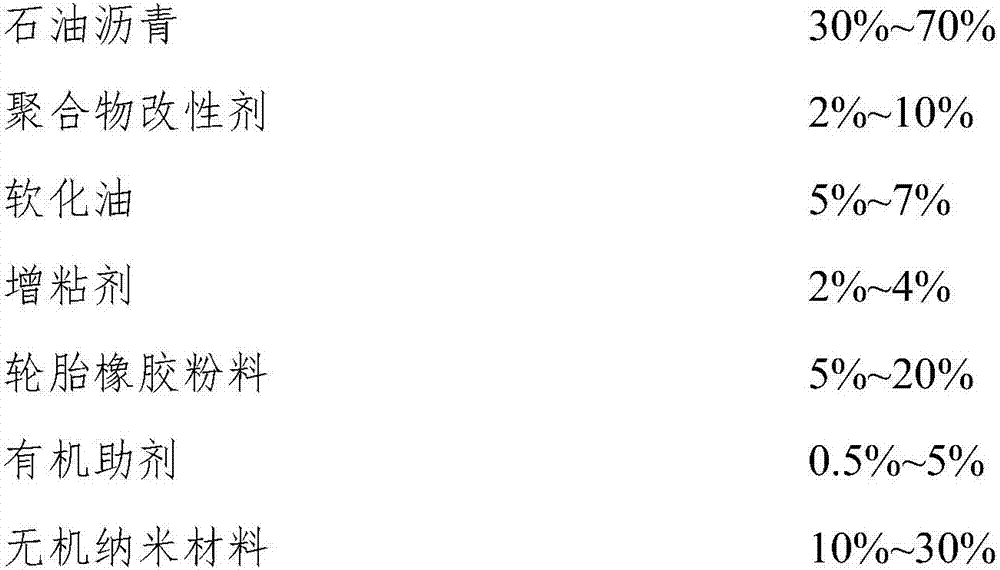

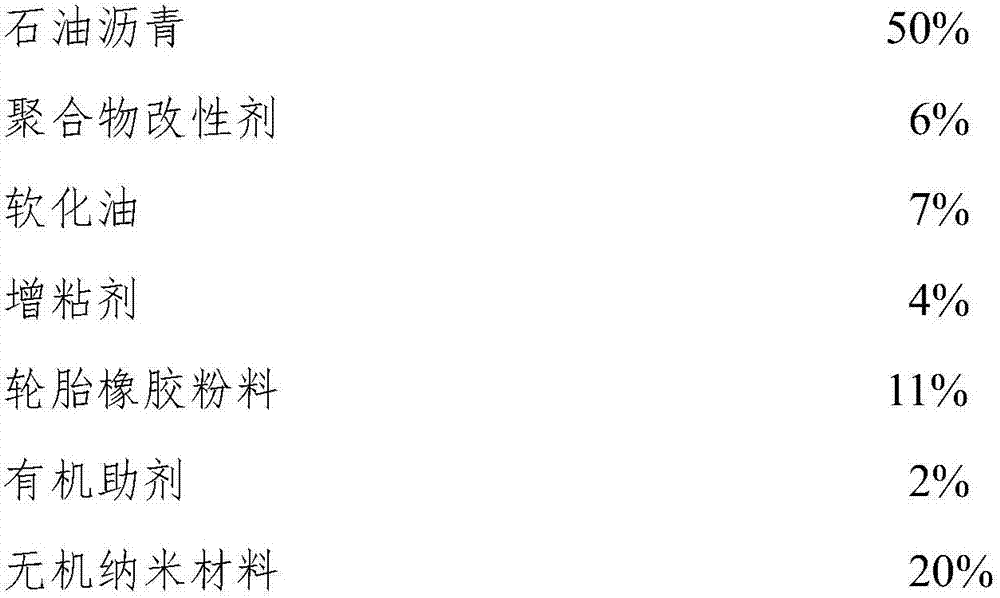

Polymer modified asphalt rubber material and preparation method thereof as well as waterproof coiled material

InactiveCN107286684AImprove high temperature performanceLarge chemical polarityBuilding insulationsBituminous coatingsBuilding materialPetroleum

The invention belongs to the technical field of building materials, and particularly relates to a polymer modified asphalt rubber material and a preparation method thereof as well as a waterproof coiled material. Aiming to solve the technical problems of poorer high temperature performance, low temperature performance and anti-aging performance of an existing modified asphalt rubber material, the polymer modified asphalt rubber material and the preparation method thereof are provided. A raw material formula the rubber material comprises petroleum asphalt, a polymer modifying agent, softening oil, a tackifier, tyre rubber powder, an organic additive and an inorganic nano-material. Meanwhile, the invention also discloses the preparation method of the polymer modified asphalt rubber material. The polymer modified asphalt rubber material provided by the invention has better high temperature performance and low temperature performance; moreover, according to the waterproof coiled material containing the polymer modified asphalt rubber material, the aging resistant performance is enhanced, and the service life of the waterproof coiled material is prolonged.

Owner:中油佳汇(广东)防水股份有限公司

Glass fiber impregnating agent for transparent plate

The invention discloses a glass fiber impregnating agent for a transparent plate, which basically comprises the following components in percentage by weight: 0.15-1.0 percent of silane coupling agent, 3.0-20.0 percent of binding agent, 0.02-1.0 percent of lubricating agent, 0.05-0.8 percent of antistatic agent, 0.1-2 percent of pH value adjusting agent and the balance of deionized water, wherein the binding agent is epoxy-ester emulsion or a mixture of PVAc emulsion and the epoxy-ester emulsion, and the contents of the PVAc emulsion and the epoxy-ester emulsion are calculated by respective solid content. The invention adopting the epoxy-ester emulsion or the mixture of the PVAc emulsion and the epoxy-ester emulsion as the binding agent can improve the glass fiber impregnating speed and the production efficiency; in addition, the light refractive rates of the impregnating agent and matrix resin are close, and the transmittance of the produced plate is high.

Owner:JUSHI GRP CO

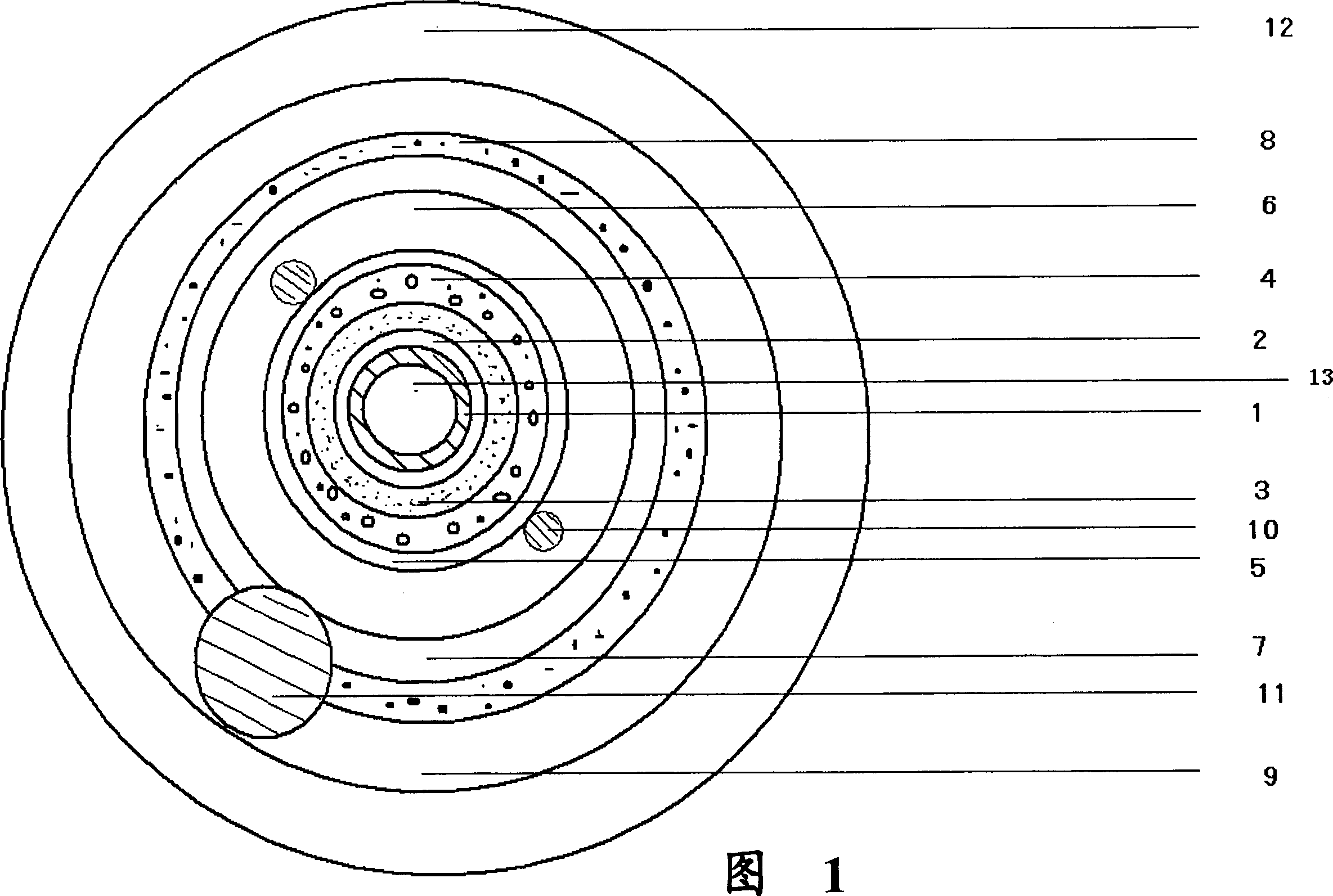

Cerium zirconium aluminum based multiple oxide material and preparing method thereof

ActiveCN101745375AImprove anti-aging propertiesHigh specific surface areaDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsCeriumCe element

The present invention provides cerium zirconium aluminum based multiple oxide material and a preparing method thereof, wherein on the basis of the total amount of the cerium zirconium aluminum based multiple oxide material, the cerium zirconium aluminum based multiple oxide material is composed of the following components by weight: 25 to 70 shares of aluminum oxide, 20 to 60 shares of cerium oxide, 5 to 25 shares of zirconium oxide, 2 to 4.9 shares of lanthanum oxide and 2 to 15 shares of stable addition agent which is one or more oxides selected from Y, Eu, Gd and Sm. The cerium zirconium aluminum based multiple oxide material has high specific surface area. After the cerium zirconium aluminum based multiple oxide material is roasted in 450 DEG C to 550 DEG C for two to four hours, the specific surface area is all larger than 100m2 / g; after the cerium zirconium aluminum based multiple oxide material is roasted in 1000 DEG C for ten hours, the specific surface area at least can reach60 m2 / g; after the cerium zirconium aluminum based multiple oxide material is roasted in 1100 DEG C for five hours, the specific surface area at least can reach 40m2 / g. thus, the cerium zirconium aluminum based multiple oxide material is superior to the anti-aging performance of multiple oxide material of the prior art, and can be used as an addition agent or carrier for vehicle tail gas purifying three-way catalyst.

Owner:苏州相城埭辰科技产业发展有限公司

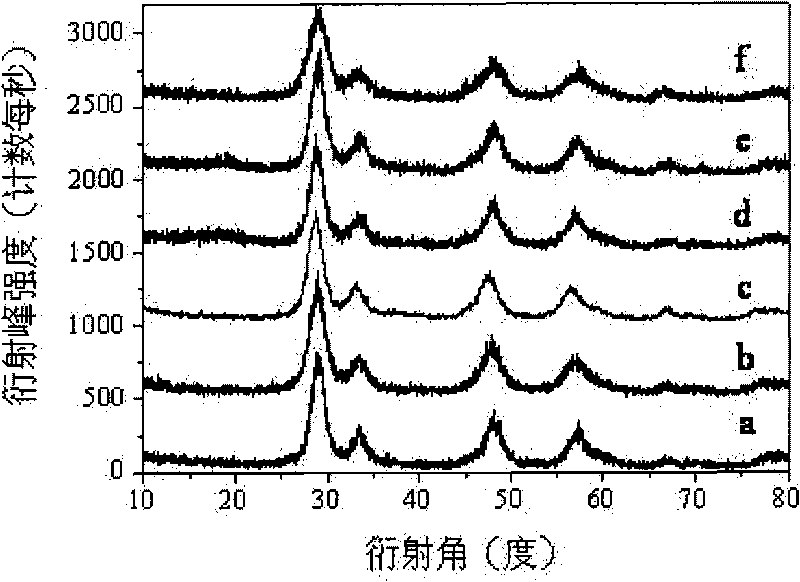

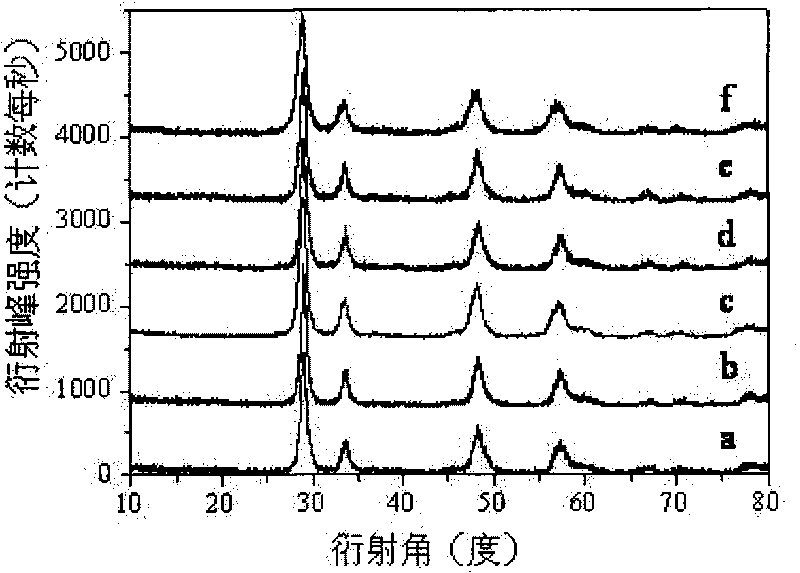

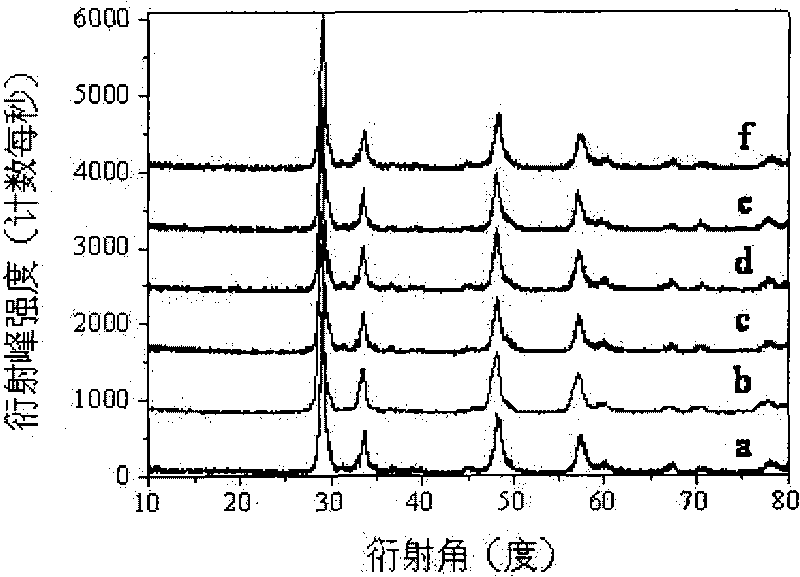

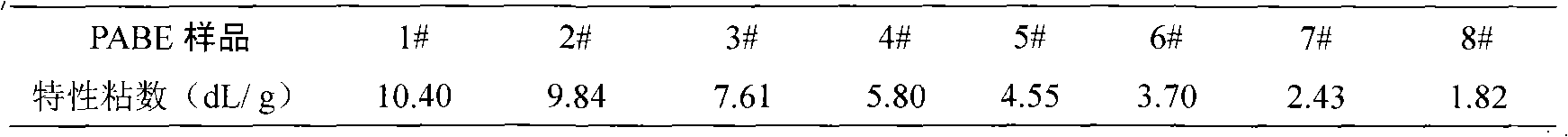

Comb-typed amphiphilic water-soluble co-polymer, method for preparing same and use

The invention discloses a comb-type amphipathicity water-solubility multipolymer and a method for making the same as well as an application. The method is characterized in that: 20 portions of acrylamide, 0.1 to 10 portions of negative ion monomer, 0.5 to 15 portions of at least one of the surface activity macromolecular monomer 4-vinyl benzyl alkylphenol polyoxyethylene ether or / and allyl alkylphenol polyoxyethylene ether and 30 to 600 portions of deionized water are added into a three-necked reaction bulb, the pH value of the solution is adjusted to between 4 and 9, N2 is introduced into the solution for 30 minutes, 0.002 to 0.3 portion of evocating agent sulphate is added at the temperature of between 30 and 70 DEG C to react 12 to 36 hours in order to prepare PABE which is diluted by water to obtain the PABE strong solution; the comb-type amphipathicity water-solubility multipolymer which can viscosify, has salt resistance and the low surface tension as well as the molecular association ability and can be used for the fuel scavenge. The multipolymer is prepared into a water solution with a mass concentration between 0.3 and 3g / L and a surface active agent concentration between 0.01 and 2mmol / L, the water solution is added into a blending container with a stirring device and is stirred evenly at room temperature so that the polymer oil-displacing agent which can viscosify and shear-resistant and has excellent anti-aging performance in a hyperhaline state and at the temperature of 70 DEG C. The PABE has the double function of a tackifier and a macromolecule surfactant. Infinitesimal low molecular surface active reagent is added into the PABE solution, thereby evidently increasing the apparent viscosity of the solution, reducing the surface tension and the oil-water boundary tension of the solution and contributing to improving the recovery ratio.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

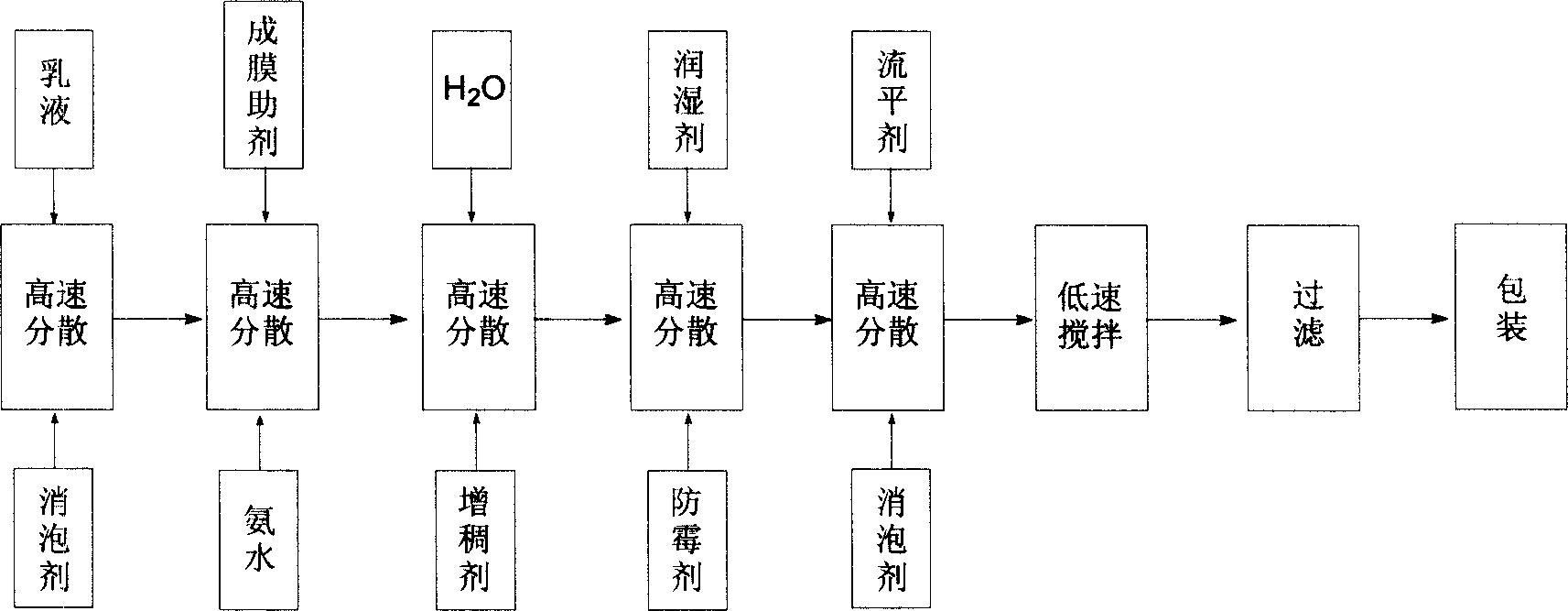

Nano composite latex paint and preparing method thereof

The composition of the invented nano composite latex paint comprises (wt%) 0.3-1% of moistening dipersant, 2-70% of nano pulp, 1-4% of film-forming adjuvant, 0.5-2% of anti-sedimentation agent, 0.8-15% of antifreeze agent, 0.5-3% of defoaming agent, 5-30% of pigment, 0-30% of filling material, 10-45% of emulsion, 0.2-2% of thickening agent, 0.2-2% of leveling agent, 0-2% of pH regulating agent, 0-2% of microbiocide and 2-35% of water. Its preparation method includes two steps: firstly, preparing dispersion stable nano material pulp, then adding said nano material pulp into the latex component according to a certain process so as to obtain the invented high-performance product.

Owner:中科纳米涂料技术(苏州)有限公司

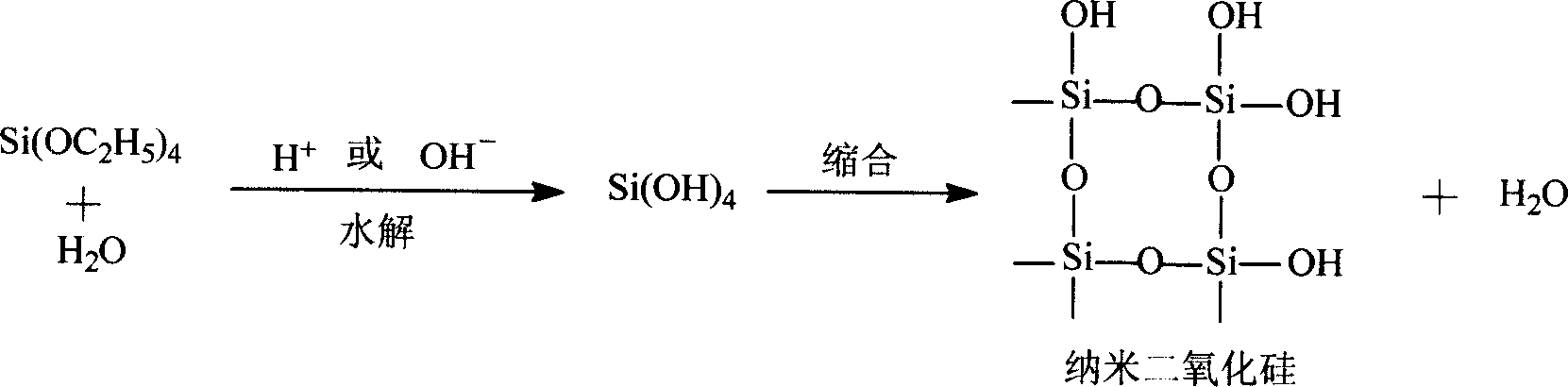

Process for preparing room temperature self-crosslinking acrylic ester emulsion modified by inorganic nano particle

InactiveCN1908022AHigh hardnessImproved resistance to water and chemicalsCoatingsDouble bondEmulsion

the invention discloses a preparing method of modified indoor temperature self-cross-linking acrylate emulsion of inorganic nanometer particle in the macromolecular synthetic manufacturing industry, which comprises the following steps: (1) adopting ethyl silicic acid; preparing different grains and contents of nanometer silica particle; hydrolyzing under catalyst with unsaturated double-bond siloxane; condensing with silicon hydroxyl group of nanometer silica surface; obtaining nanometer silica with unsaturated double-bond; (2) diffusing the material in the emulsifier; blending with acrylic ester and polymeric monomer; obtaining self-cross-linking acrylate emulsion; (3) adding cross linker in the self-cross-linking acrylate emulsion to obtain the product.

Owner:东莞市才智坊新材料有限公司

Preparation method of biodegradable polyester with low carboxyl end group content

The invention relates to a preparation method of biodegradable polyester, and specifically relates to a preparation method of biodegradable polyester with a low carboxyl end group content. The method comprises esterification reactions and condensation and polymerization reactions: after the esterification reaction, polycyclic oxy-compounds are directly added into the reaction products to carry out reactions, and the reaction products are subjected to carry out condensation and polymerization reactions so as to obtain the biodegradable polyester with a low carboxyl end group content, wherein the carboxyl end group content is 5 to 20 mmol / kg. The invention aims to solve the problem of high carboxyl end group content in biodegradable polyesters, namely aliphatic polyester / copolymer and aliphatic-aromatic copolyester materials. The method provided by the invention reduces the carboxyl end group content in the materials, improves the flux strength, shortens the reaction time, obtains a polyester material with a good color (low b value), improves the anti-aging ability of the biodegradable polyester material, and prolongs the service life of the biodegradable polyester material. The preparation method has the advantages of controllable reaction conditions, low cost, and suitability for industrial production.

Owner:山东悦泰生物新材料有限公司

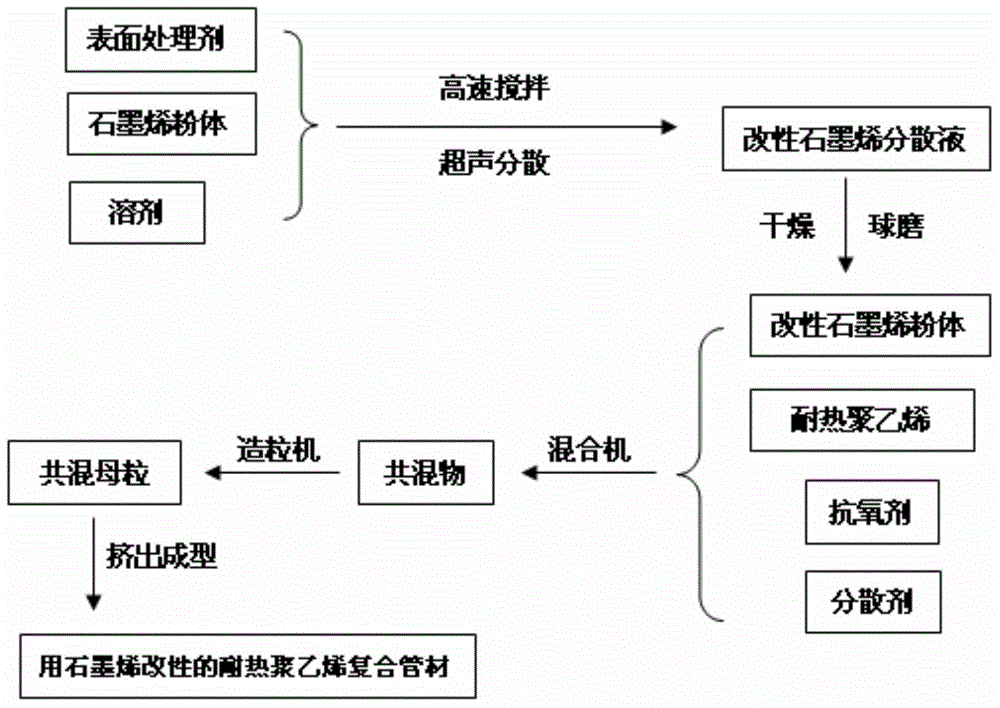

Preparation method of graphene-modified heat-resistant polyethylene composite tubing

ActiveCN104004251AImproved mechanical strength and anti-aging performanceLow costCvd grapheneAging resistance

The invention provides a preparation method of a graphene-modified heat-resistant polyethylene composite tubing. The preparation method comprises the following steps of 1, modified graphene powder preparation, 2, modified graphene powder / heat-resistant polyethylene blended master batch preparation, and 3, graphene-modified heat-resistant polyethylene composite tubing preparation. The preparation method fully utilizes the existing equipment used in the heat-resistant polyethylene composite tubing industry, can obviously improve tubing conductivity, mechanical strength and aging resistance only by use of a small amount of modified graphene powder, and has a low cost, obvious effects and good practicality.

Owner:WUHAN KINGBULL ECONOMIC DEV

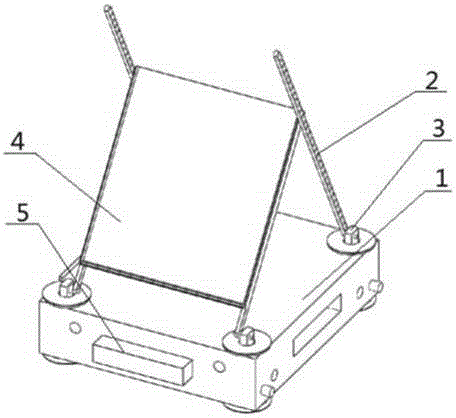

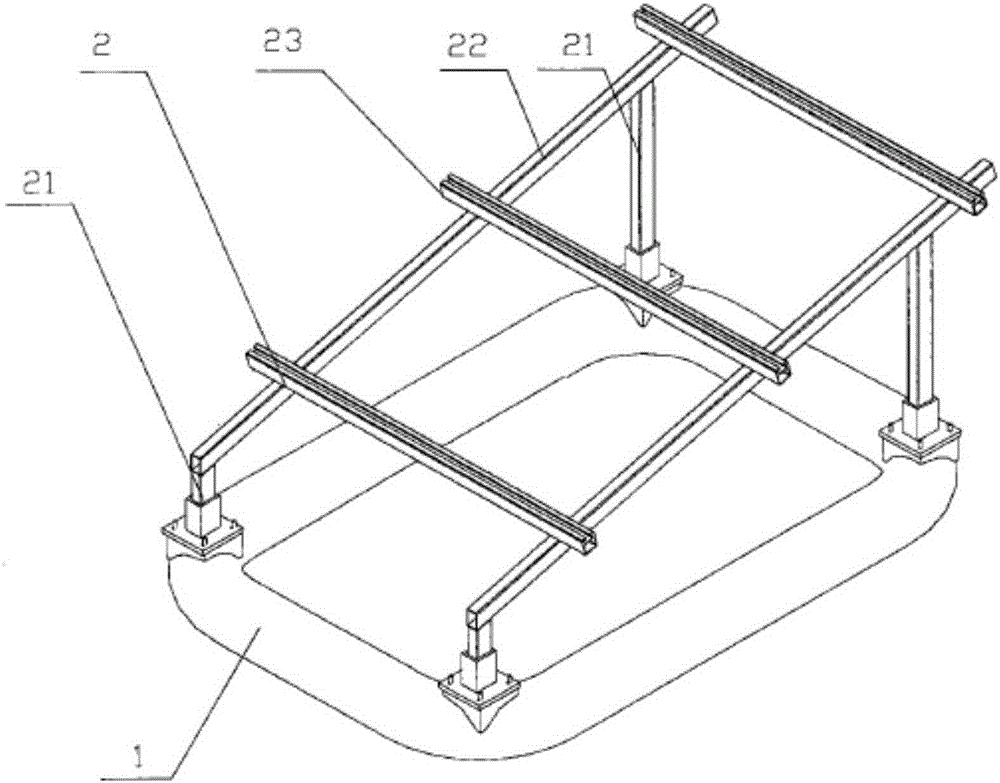

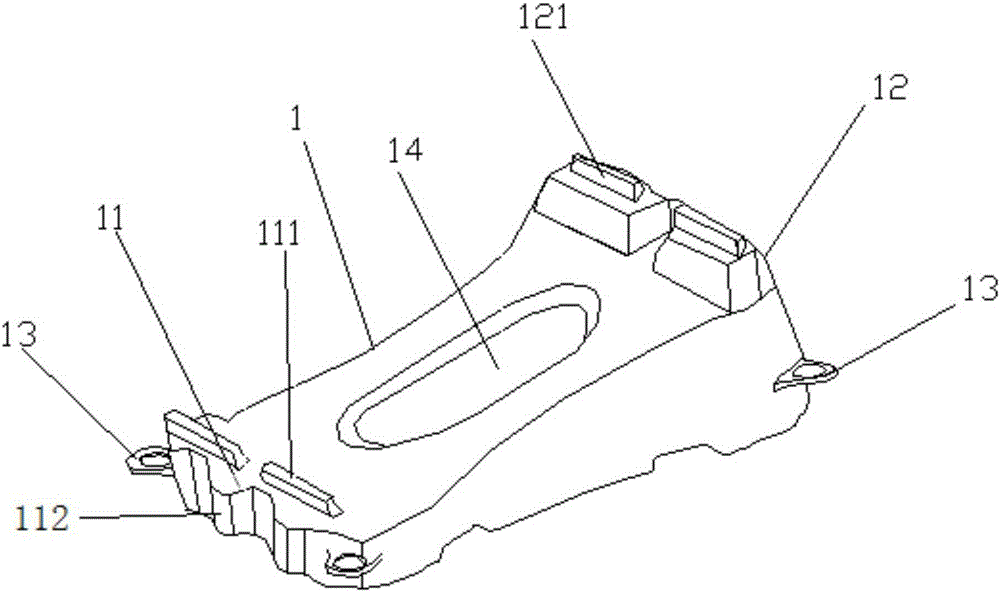

Floating member used for waterborne photovoltaic power station and connection method thereof

InactiveCN105186968ASimplify the installation processImprove stabilityPV power plantsPhotovoltaic energy generationPhotovoltaic power stationSurface level

The invention discloses a floating member used for a waterborne photovoltaic power station and a connection method thereof. The floating member at least comprises a floating member body which can be floated on water. The floating member body comprises a first end part and a second end part. Height of the upper surface of the first end part is lower than that of the upper surface of the second end part. The upper surface of the floating member body, which is close to the first end part, is provided with a first connection structure which is used for being detachably connected with the first connection piece of the back surface of a photovoltaic panel. The upper surface of the floating member body, which is close to the second end part, is provided with a second connection structure which is used for being detachably connected with the second connection piece of the back surface of the photovoltaic panel. Height of the upper surface of the first end part of the floating member body is set to be higher than that of the upper surface of the second end part, and the connection structures connected with the photovoltaic panel are directly arranged on the upper surface of the floating member body so that the installing technology of the photovoltaic power station can be greatly simplified, installing time can be saved and installing cost can be reduced.

Owner:SHANGHAI QIHUA WHARF ENG CO LTD

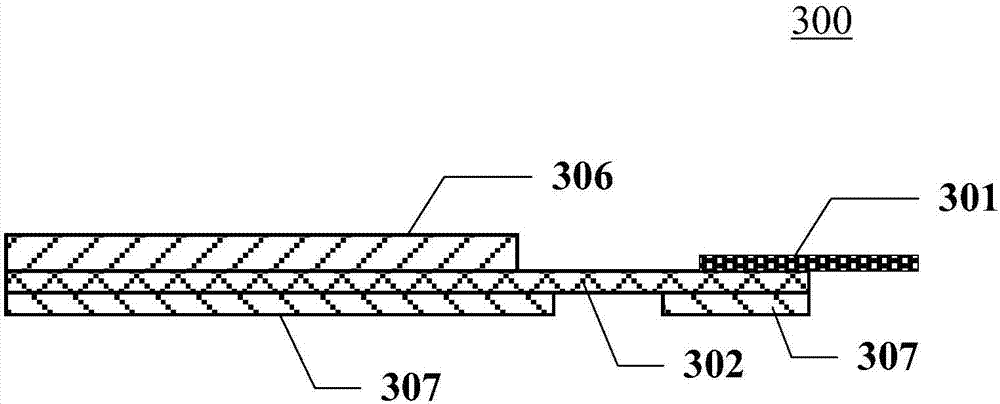

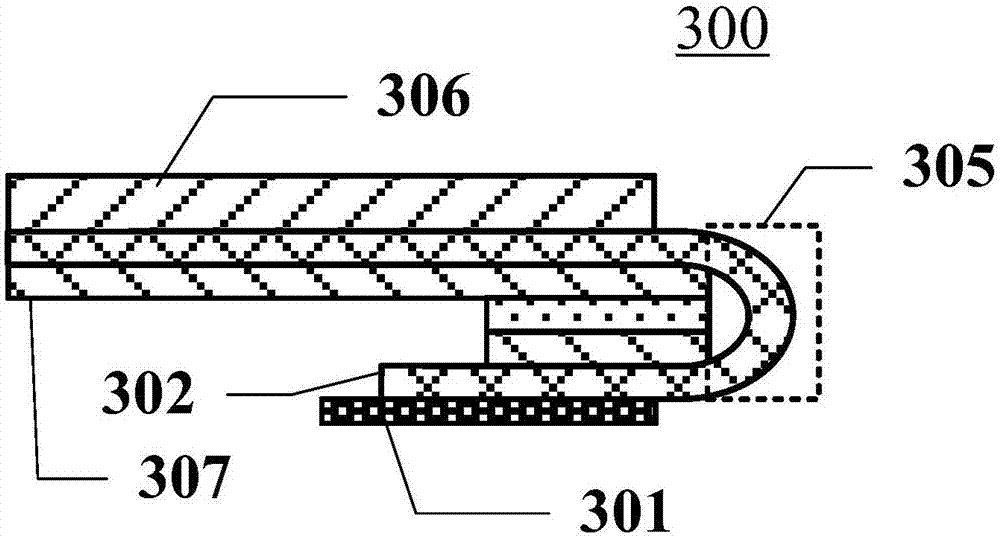

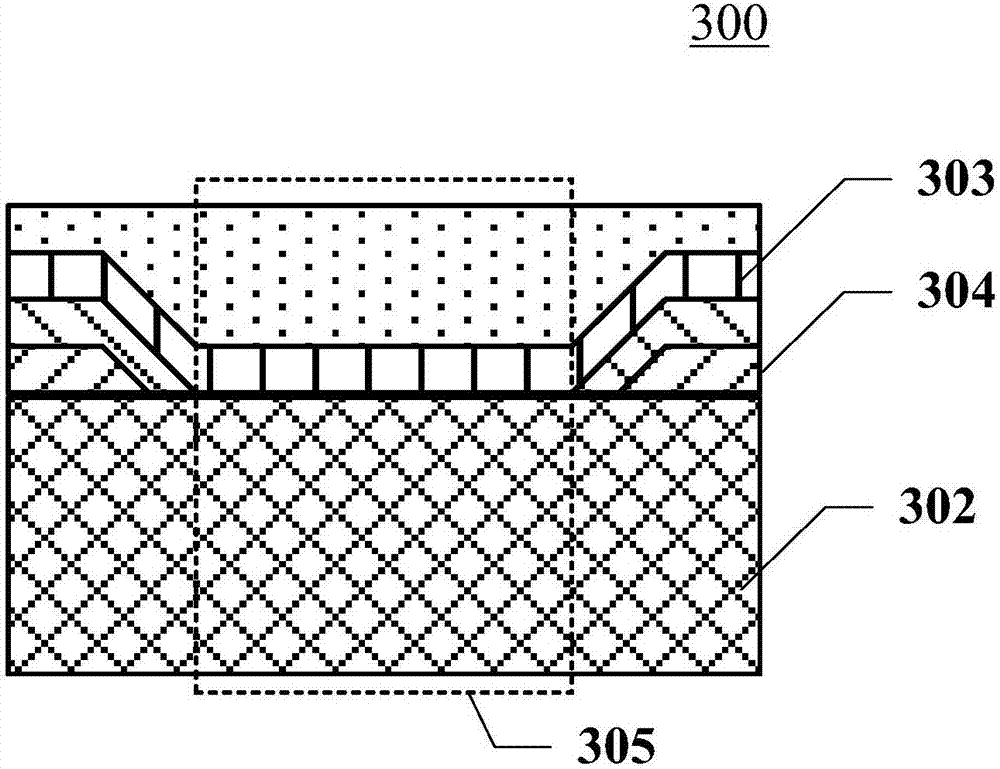

Flexible display panel and flexible display device

ActiveCN107424519AImprove anti-aging propertiesExtended service lifeIdentification meansFlexible displayComputer science

The invention discloses a flexible display panel and a flexible display device, and relates to the technical field of display. The flexible display panel comprises a flexible substrate, and the flexible substrate comprises a first flexible layer, a first inorganic layer and a second flexible layer which are arranged in sequence; the flexible substrate is divided into a display region and a non-display region surrounding the display region, the display region comprises a drive function layer and a light-emitting layer, the non-display region comprises a first region and at least two grooves, wherein the first region comprises a signal lead, a first buffering layer and a first packaging layer which are arranged in sequence, the grooves are located in the non-display region, the extending direction of the grooves is the same as that of the signal lead, the grooves penetrate through the second flexible layer and the first buffering layer, and the first packaging layer makes contact with the first inorganic layer through the grooves; in the first region, an annular closed space is formed by the first packaging layer and the first inorganic layer on the section vertical to the signal lead extending direction, and the signal lead is located in the closed space, which is beneficial for improving ageing resistance of the flexible display panel.

Owner:WUHAN TIANMA MICRO ELECTRONICS CO LTD

Composite modified asphalt and preparation method thereof

InactiveCN102153874AImprove low temperature performanceImprove anti-aging propertiesBuilding insulationsAging resistanceRoad surface

The invention discloses composite modified asphalt, which is prepared by mixing modifier and matrix asphalt, wherein the modifier consists of the following components in percentage by mass (based on 100 percent of the matrix asphalt): 1 to 10 percent of inorganic substance filler, 1 to 10 percent of polymer, 0.1 to 5 percent of stabilizer, and 0.1 to 5 percent of coupling agent. The prepared modified asphalt has good high and low temperature resistance and ageing resistance, can prolong the service life of roads and reduce the maintenance expense of pavements, and is suitable to be spread in the engineering of high-grade roads, airfield runways, parking lots, bridges and the like.

Owner:SHANDONG JIAOTONG UNIV

Linear low-density polyethylene composition

ActiveCN102477180AUniform viscosityEliminate cracksLow-density polyethyleneLinear low-density polyethylene

The invention relates to a linear low-density polyethylene composition comprising components of, by weight: 50-98 parts of linear low-density polyethylene with a density of 0.918-0.922g / cm<3> and a melt flow index of 0.1-10g / 10min, 0.5-45 parts of low-density polyethylene with a density of 0.910-0.925g / cm<3> and a melt flow index of 0.1-30g / 10min, 0.5-45 parts of high-density polyethylene with a density of 0.941-0.970g / cm<3> and a melt flow index of 0.5-10g / 10min, 0.5-45 parts of polypropylene with a density of 0.830-0.910g / cm<3> and a melt flow index of 0.5-50g / 10min, 0.1-20 parts of an ethylene-vinyl acetate copolymer with a density of 0.926-0.939g / cm<3>, 0.01-1 part of a rheology modifying agent, and 0.5-20 parts of a compatibilizing agent with a melt flow index of 0.5-50g / 10min. With the composition, extrusion processing performance can be effectively improved, a melt fracture phenomenon can be eliminated, and the compatibility can be improved. With the composition, the strength, flexibility and aging resistance of a product can be improved. The composition can be used for producing films, drip irrigation tapes, and pipes with various specifications.

Owner:XINJIANG TIANYE WATER SAVING IRRIGATION SYST

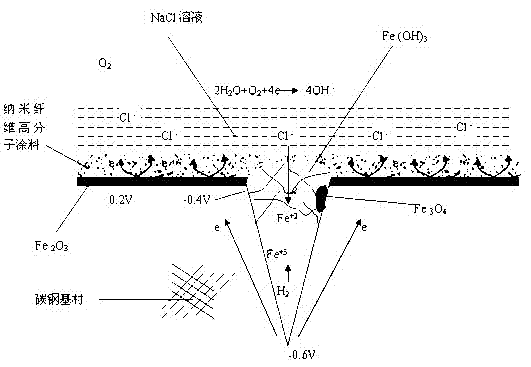

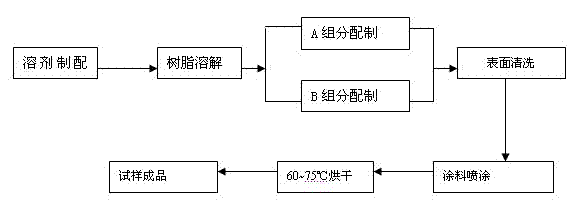

Nanofiber heavy-duty anti-corrosive coating, preparation method and spraying method of nanofiber heavy-duty anti-corrosive coating

ActiveCN102604509AStrong resistance to salt sprayStrong resistance to salt waterAnti-corrosive paintsPolyurea/polyurethane coatingsNanofiberPetrochemical

The invention discloses nanofiber heavy-duty anti-corrosive coating, a preparation method and a spraying method of the nanofiber heavy-duty anti-corrosive coating. The anti-corrosive coating comprises components C, A and B by mass ratio. The preparation method comprises the steps of preparing mixed solvent C, dissolving resin and preparing resin solution, pouring the dissolved resin solution into a ball mill for stirring and refluxing, then pouring the component A into the ball mill, uniformly stirring with a glass rod initially, performing ball milling and filtering, pouring the component B into the ball mill, uniformly stirring, adding the component B into the component A, and then uniformly stirring to obtain the nanofiber heavy-duty anti-corrosive coating. The spraying method comprises the steps of cleaning up the surface of an object to be sprayed, uniformly spraying the coating onto the surface of the object to be sprayed with a spray gun, and drying or naturally drying the sprayed surface. The nanofiber heavy-duty anti-corrosive coating has super-normal acid resistant, alkali resistant, salt resistant, water vapor corrosion resistant and harmful substances corrosion resistant capabilities, is non toxic, harmless, tasteless and environmentally friendly, and is applicable to the fields of ocean vessels, submarines, ocean engineering, drilling platforms, wharfs, water conservancy facilities, petrochemical equipment, bridge buildings, concrete facilities and the like.

Owner:西安华捷奥海新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com