Polymer modified asphalt rubber material and preparation method thereof as well as waterproof coiled material

A modified asphalt and polymer technology, which is applied in asphalt coatings, building structures, building insulation materials, etc., can solve the problems of high temperature performance, low temperature performance and poor anti-aging performance, and achieve high temperature performance, low temperature performance, large The effect of chemical polarity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

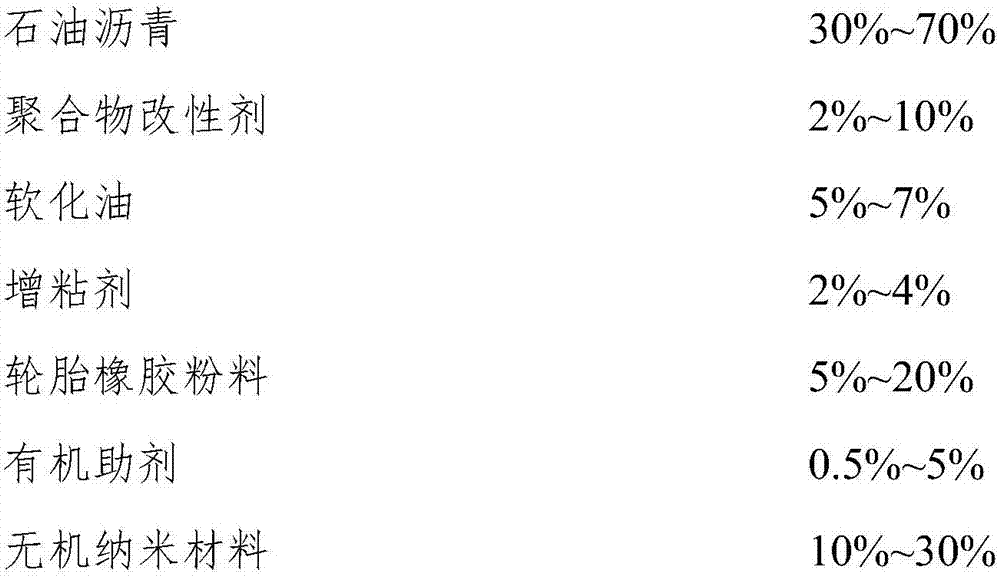

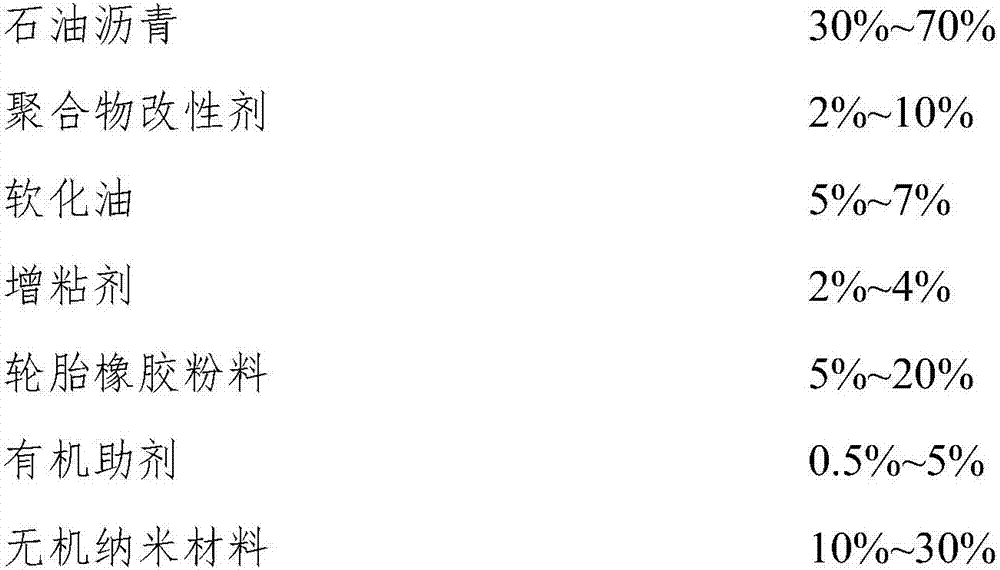

[0051] This embodiment provides a polymer modified asphalt compound, the raw material formula of the polymer modified asphalt compound includes the following components in mass fraction:

[0052]

[0053] Petroleum asphalt is No. 90 asphalt.

[0054] The polymer modifier is styrene-butadiene-styrene block copolymer and styrene-butadiene rubber (mass ratio is 2:1).

[0055] The softening oil is line reduction oil and aromatic oil (mass ratio is 1:1).

[0056] The tackifier is C5 petroleum resin.

[0057] The organic additives are N,N'-methylenebisacrylamide and N,N'-ethylenebisstearamide (mass ratio 1:1).

[0058] Inorganic nanomaterials are organic montmorillonite and nano TiO 2 (The mass ratio is 3:1).

[0059] The preparation method of the polymer modified asphalt compound is as follows:

[0060] a. Compound petroleum asphalt and softened oil and heat to 170°C;

[0061] b. Add the polymer modifier and tackifier according to this and maintain the temperature at 180°C...

Embodiment 2

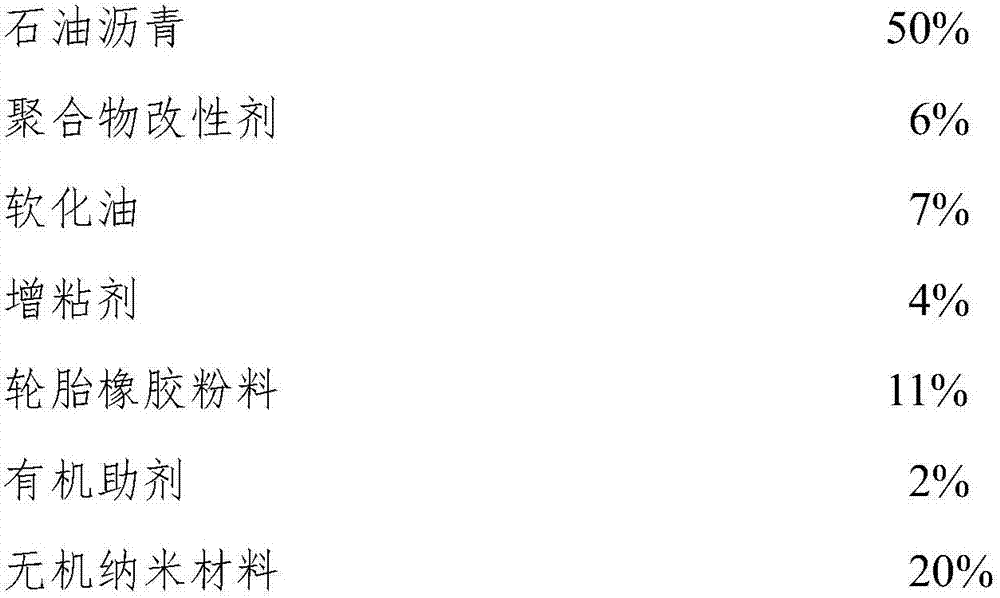

[0065] This embodiment provides a polymer modified asphalt compound, the raw material formula of the polymer modified asphalt compound includes the following components in mass fraction:

[0066]

[0067] The petroleum asphalt is No. 70 asphalt and No. 200 asphalt (mass ratio is 40:11).

[0068] The polymer modifier is styrene-butadiene-styrene block copolymer and styrene-butadiene rubber (the mass ratio is 1:1).

[0069] The softening oil is line reduction oil and aromatic oil (mass ratio is 1:1).

[0070] The tackifier is C5 petroleum resin.

[0071] The organic additives are N,N'-methylenebisacrylamide and N,N'-ethylenebisstearamide (mass ratio 1:1).

[0072] The inorganic nano material is organic montmorillonite and nano ZnO (mass ratio is 3:1).

[0073] The preparation method of the polymer modified asphalt compound is as follows:

[0074] a. Compound petroleum asphalt and softened oil and heat to 180°C;

[0075] b. Add the polymer modifier and tackifier according...

Embodiment 3

[0079] This embodiment provides a polymer modified asphalt compound, the raw material formula of the polymer modified asphalt compound includes the following components in mass fraction:

[0080]

[0081] The petroleum asphalt is No. 70 asphalt and No. 200 asphalt (mass ratio is 39:11).

[0082] The polymer modifier is styrene-butadiene-styrene block copolymer and styrene-butadiene rubber (the mass ratio is 1:1).

[0083] The softening oil is line reduction oil and aromatic oil (mass ratio is 1:1).

[0084] The tackifier is C5 petroleum resin.

[0085] The organic additives are N,N'-methylenebisacrylamide and N,N'-ethylenebisstearamide (mass ratio 1:1).

[0086] The inorganic nanomaterials are organic montmorillonite and nano ZnO (mass ratio 1:1).

[0087] The preparation method of the polymer modified asphalt compound is as follows:

[0088] a. Compound petroleum asphalt and softened oil and heat to 175°C;

[0089] b. Add the polymer modifier and tackifier according t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com