Patents

Literature

217 results about "Fluoroplast" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

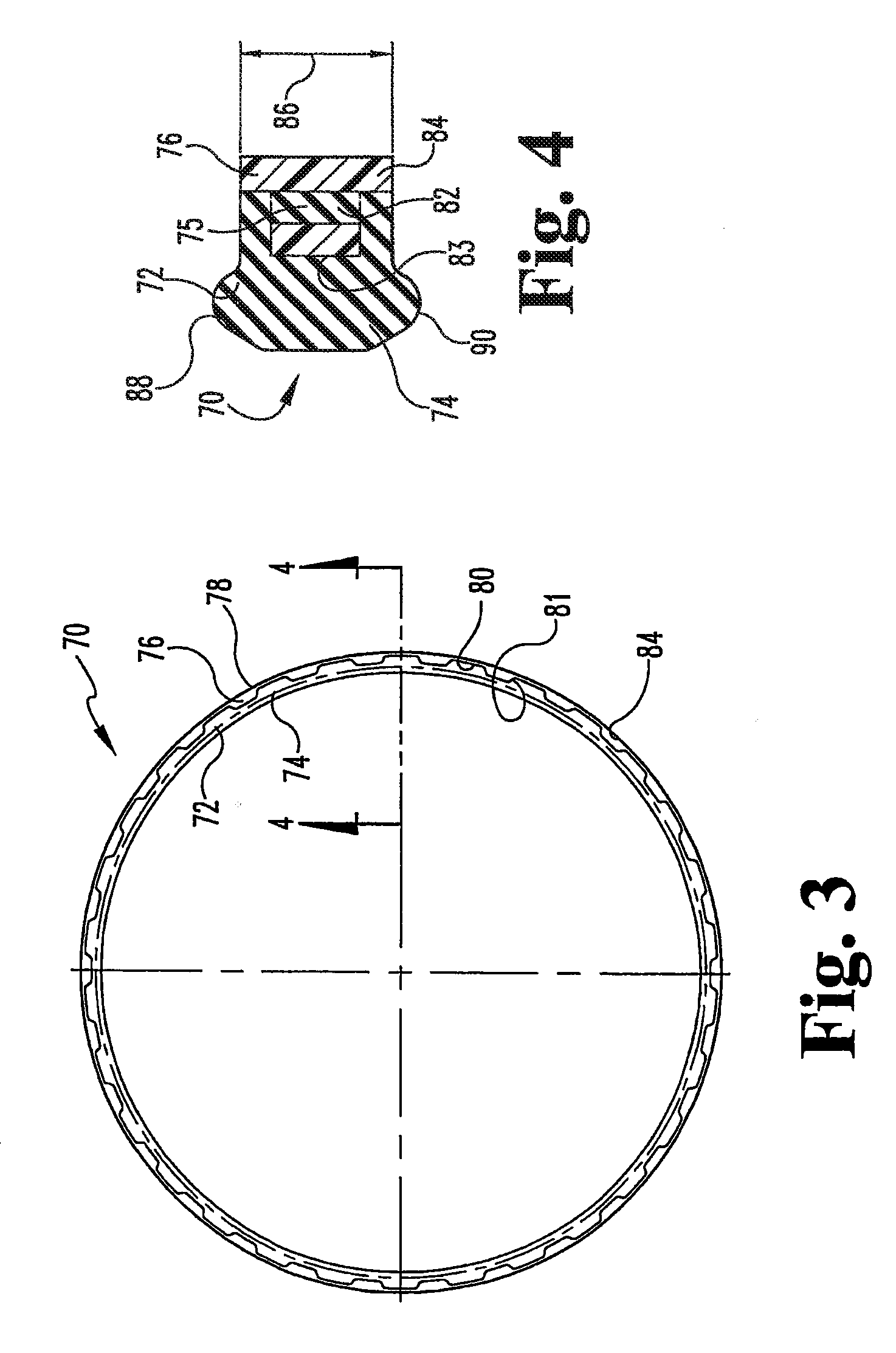

Fluoroplastic composite elastomer

InactiveUS20060018777A1Improve bending resistanceLow costEnvelopes/bags making machineryFlexible member pumpsElastomerFiber

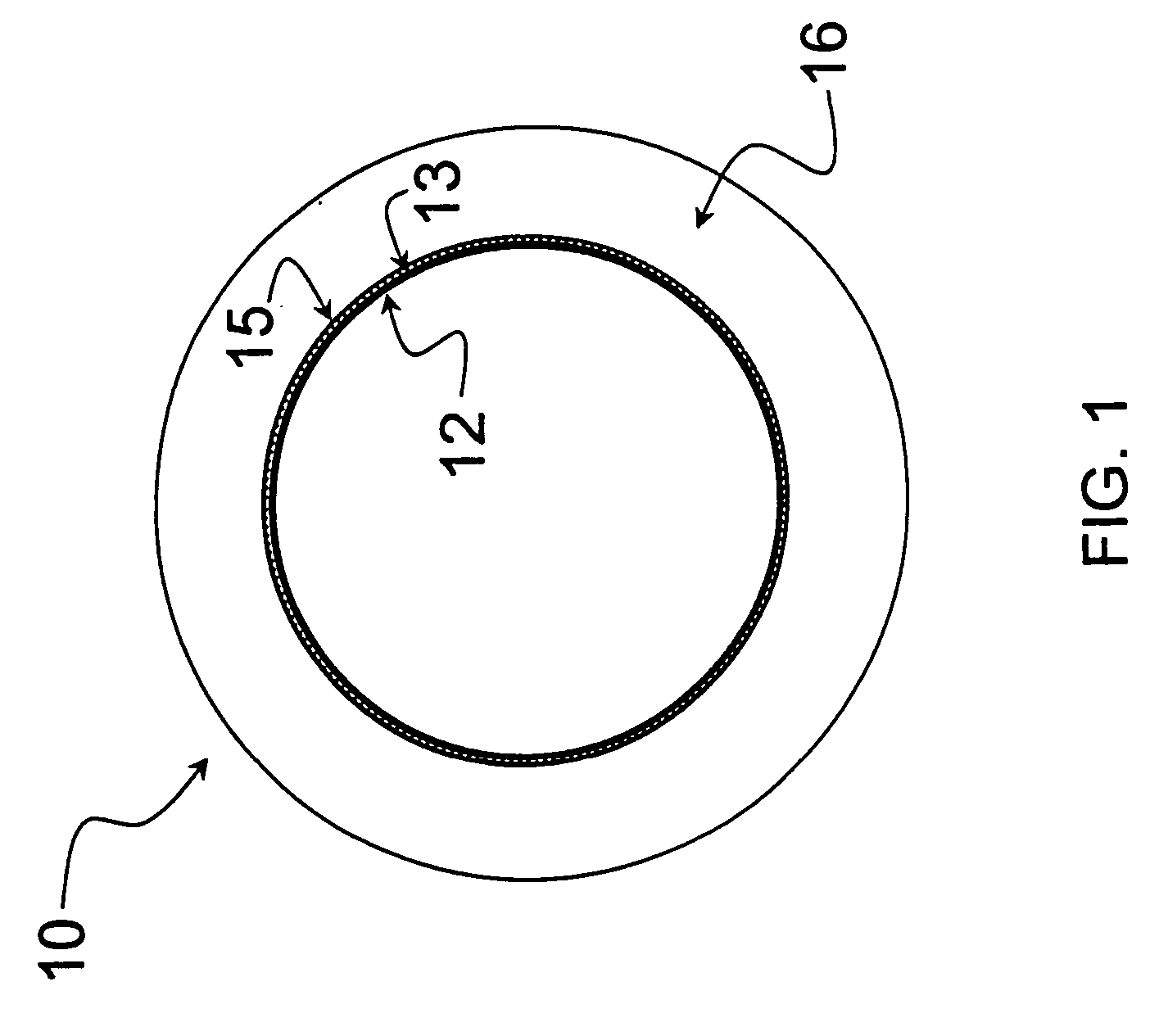

An improved fluoroplastic lined elastomeric tube that can maintain a stable flow rate while pumping aggressive chemicals in a peristaltic pump for an extended period of time and is fabricated in sizes ranging from 0.5 mm to 100 mm in inside diameter. The inner fluoroplastic liner comprises a composite of expanded polytetrafluoroethylene and a fluoroplastic polymer resulting in improved flex life over single component fluoroplastics. The inventive liner is bonded to either an unreinforced elastomer or a fiber reinforced elastomer for use in both low and high pressure peristaltic pump applications.

Owner:MAZTECH

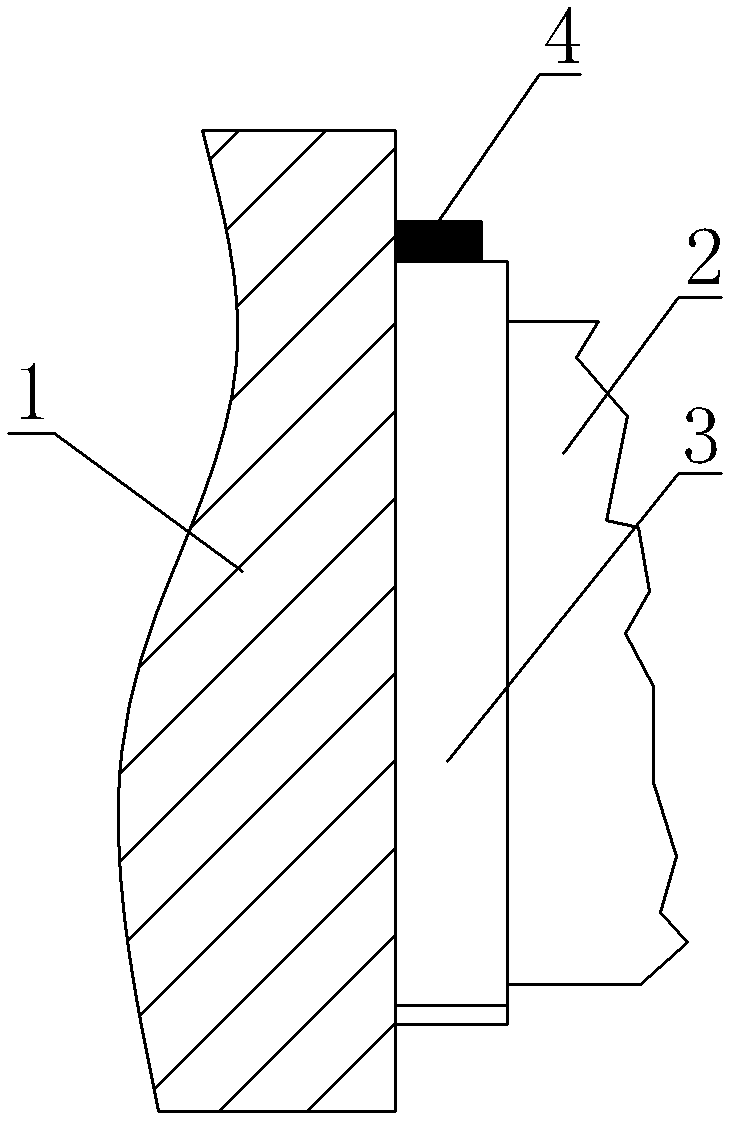

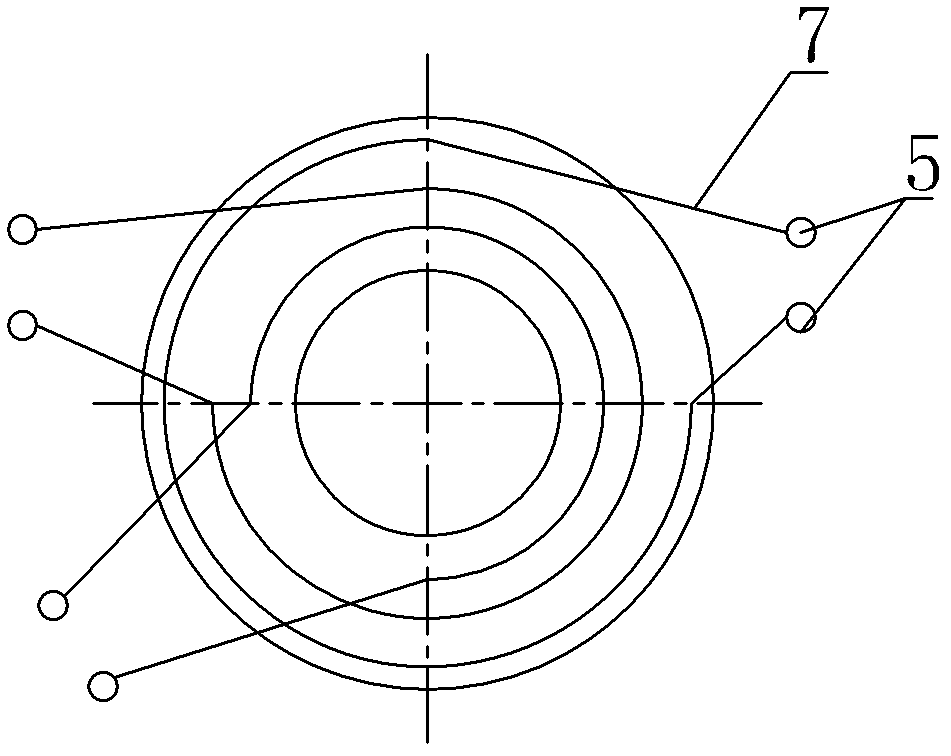

Self-lubricating wear-resistant coating swash plate and technique for producing the same

ActiveCN101503995AMeet the development requirements of lead-freeSimple production processLiquid surface applicatorsPositive displacement pump componentsWear resistantMolecular materials

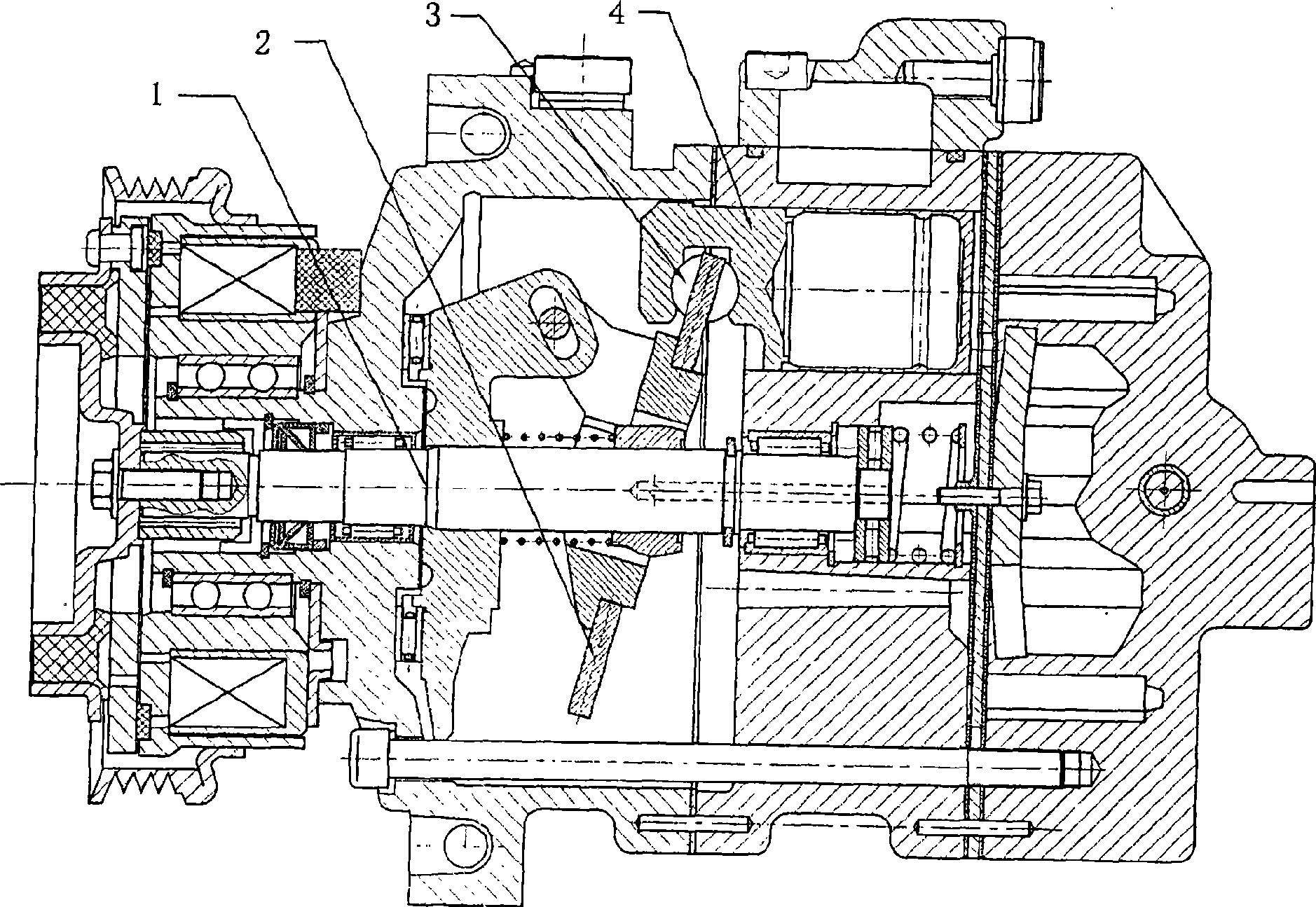

The invention relates to a self-lubricating wear-resistant coating swash plate, which consists of a metallic matrix and a self-lubricating wear-resistant coating, wherein annular planes on two sides of the metallic matrix are coated with the self-lubricating wear-resistant coating, and the components of the self-lubricating wear-resistant coating comprise a main material of high molecular materials, fluoroplastics, solid lubricants and inorganic matters. A process for producing the self-lubricating wear-resistant coating swash plate comprises that: the self-lubricating wear-resistant coating is coated on the swash plate after being prepared into a liquid coating, and a method for preparing the liquid coating comprises the steps of using a solvent of N-methyl pyrrolidone or dimethyl acetamide to dissolve the main material of the high molecular materials first, and then adding the fluoroplastics, the solid lubricants and the inorganic matters into the mixture to perform sufficient stirring and dispersion so as to prepare the liquid coating with certain solid content. The swash plate has the advantages of good self-lubricating and wear-resistant performance, simple production process and low production cost, and does not contain metallic lead which is harmful to human bodies and the environment.

Owner:ZHEJIANG CHANGSHENG SLIDING BEARINGS

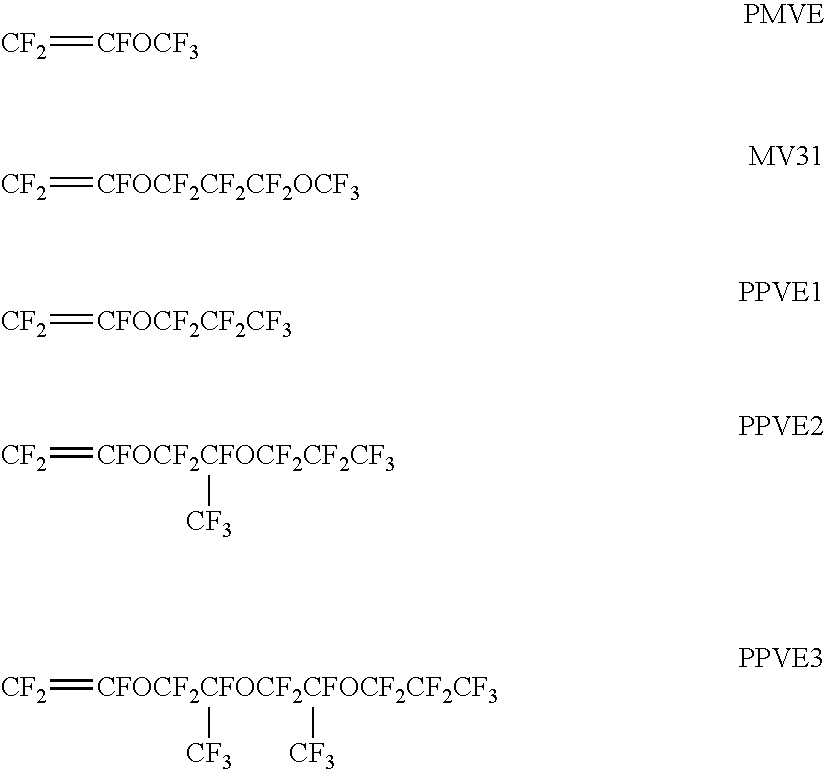

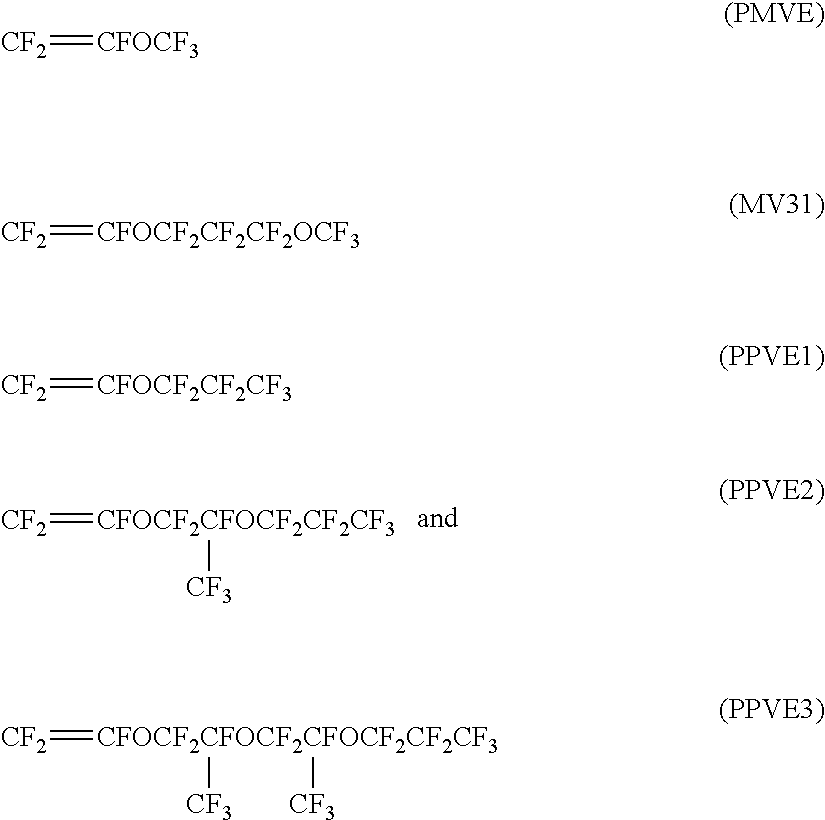

Blends of perfluoroelastomers and fluoroplastics

Cured articles are prepared from a composition that comprises a blend of a perfluoroelastomer and 51-300 phr of a semi-crystalline thermoplastic copolymer comprising copolymerized units of tetrafluoroethylene and 5-12 weight percent of a perfluoro(alkyl vinyl ether). The semi-crystalline copolymer is present as particles having an average particle size greater than 100 nm.

Owner:DUPONT POLYMERS INC

Closed ammonia-resistant motor with ammonia-resistant insulation system

InactiveCN103138451AImprove leakageImprove efficiencyWindings insulation materialWindings insulation shape/form/constructionEpoxyRefrigeration compressor

The invention relates to a closed ammonia-resistant motor with an ammonia-resistant insulation system. The closed ammonia-resistant motor with the ammonia-resistant insulation system comprises a stator core, a stator winding, slot insulation and a slot wedge, wherein the stator winding is wound inside a stator core slot, the slot insulation is used for insulating and isolating the stator winding, and the slot wedge is used for fixing the stator winding. The stator winding is aluminum conductor electromagnetic wires coated with polyphenylene sulfide; the slot insulation is compound insulation cloth which is alkali-free glass fiber cloth coated with fluoroplastic; and the slot wedge is a lamination of epoxy resin and glass fiber. The closed ammonia-resistant motor with the ammonia-resistant insulation system enable an ammonia-resistant motor to work in an environment full of ammonia refrigerant, the same with a freon-resistant motor; and is a novel motor for a closed ammonia refrigeration compressor.

Owner:SUZHOU BETTER TECH

Fluorocarbon rubber with enhanced low temperature properties

Processable rubber compositions containing a vulcanized elastomeric material dispersed in a matrix of a thermoplastic polymeric material. The vulcanized elastomeric material is a peroxide cure polymeric material containing repeating units derived from fluorine-containing monomers and at least one peroxide cure site monomer. In one embodiment the matrix forms a continuous phase and the vulcanized elastomeric material is in the form of particles forming a non-continuous phase. The compositions are made by combining a radical curing system, a fluorocarbon elastomer material, and a fluoroplastic material, and heating the mixture at a temperature and for a time sufficient to effect vulcanization of the elastomeric material, while mechanical energy is applied to mix the mixture during the heating step. Shaped articles may be readily formed from the rubber compositions according to conventional thermoplastic processes such as blow molding, injection molding, and extrusion. Examples of useful articles include seals, gaskets, O-rings, and hoses.

Owner:FREUDENBERG NOK GEN PARTNERSHIP

Recoating of optical fiber

InactiveUS20040036188A1Long-term useFast and reliable recoatingTailstocks/centresConfectioneryFiberUV curing

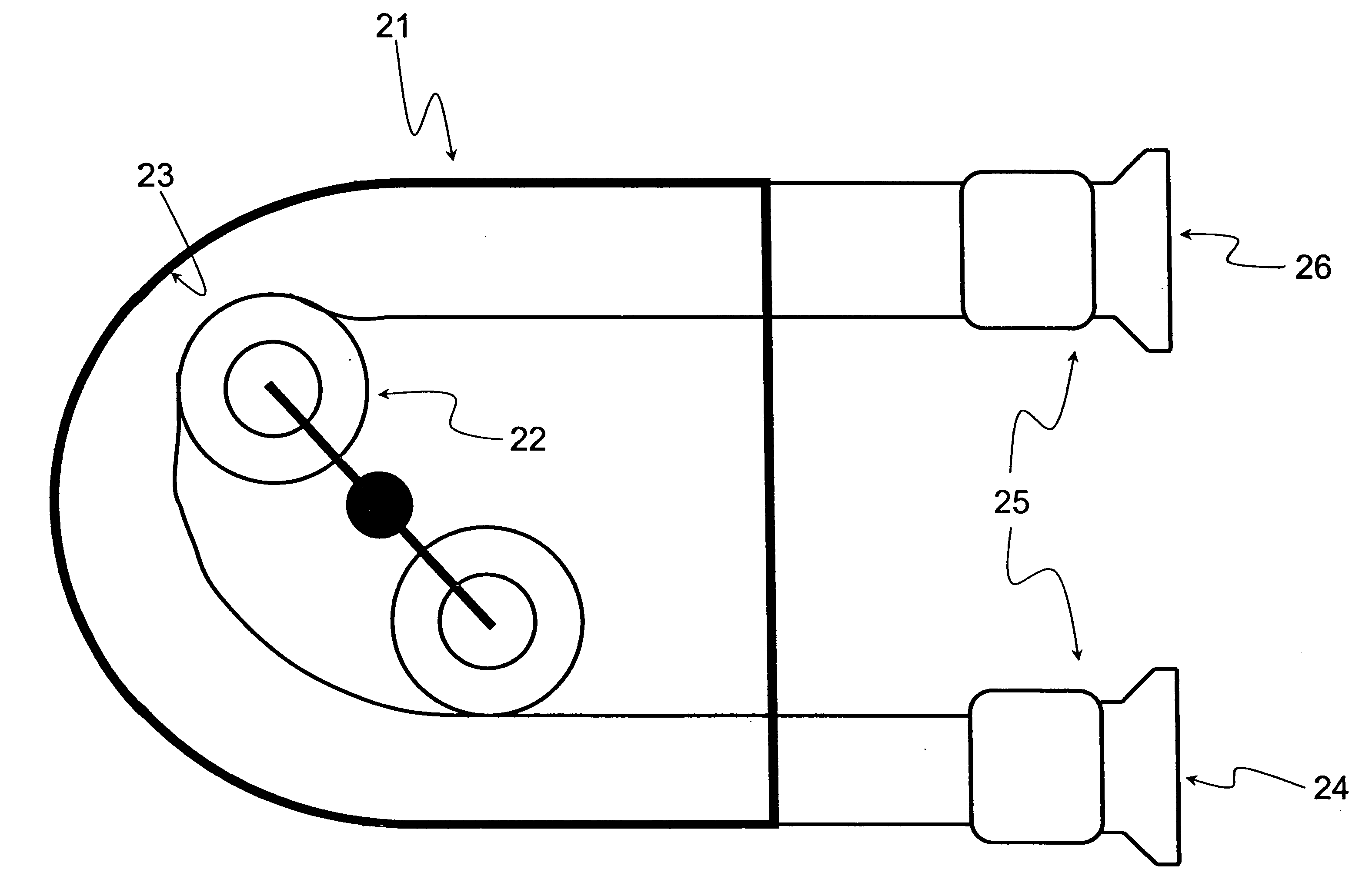

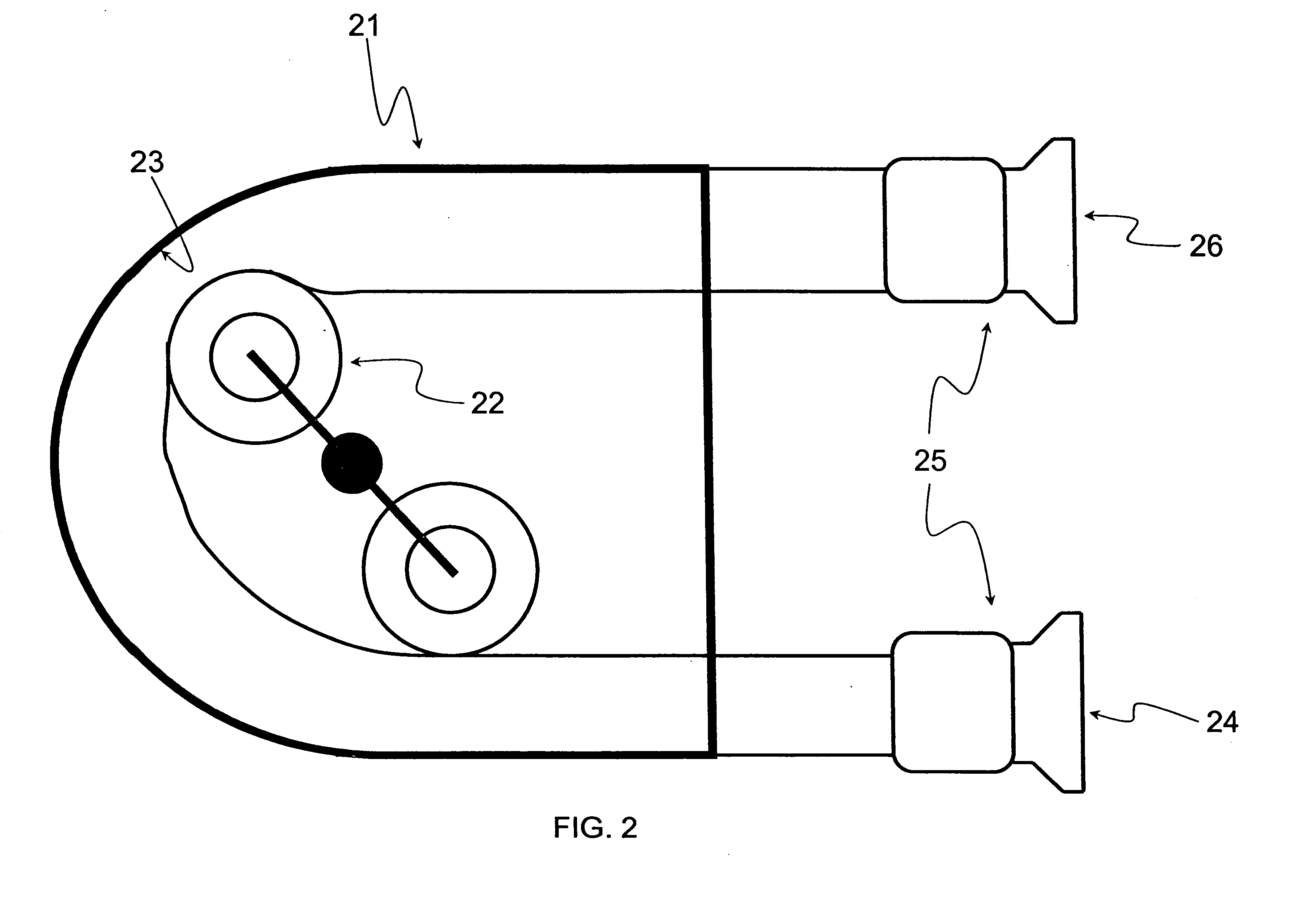

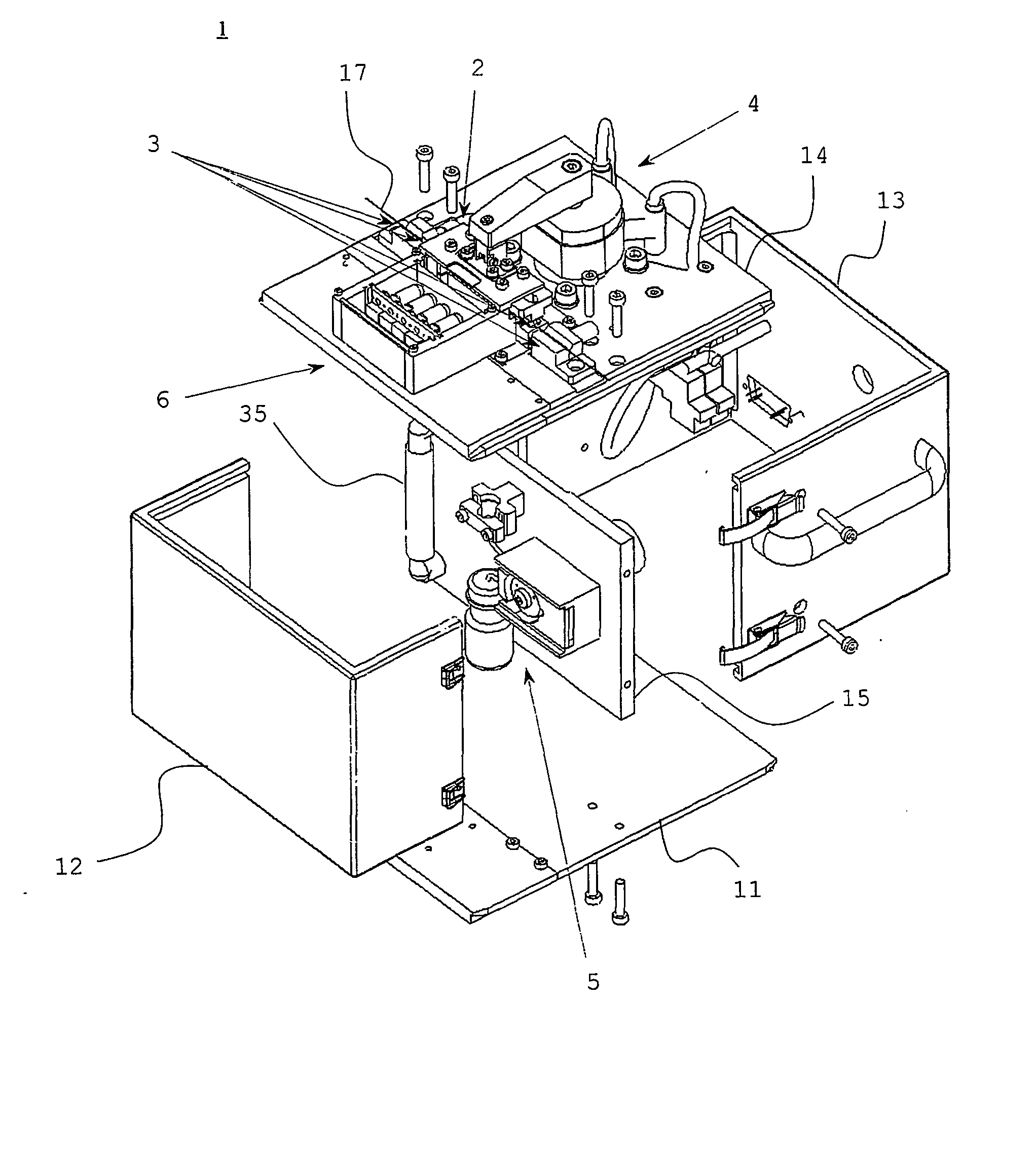

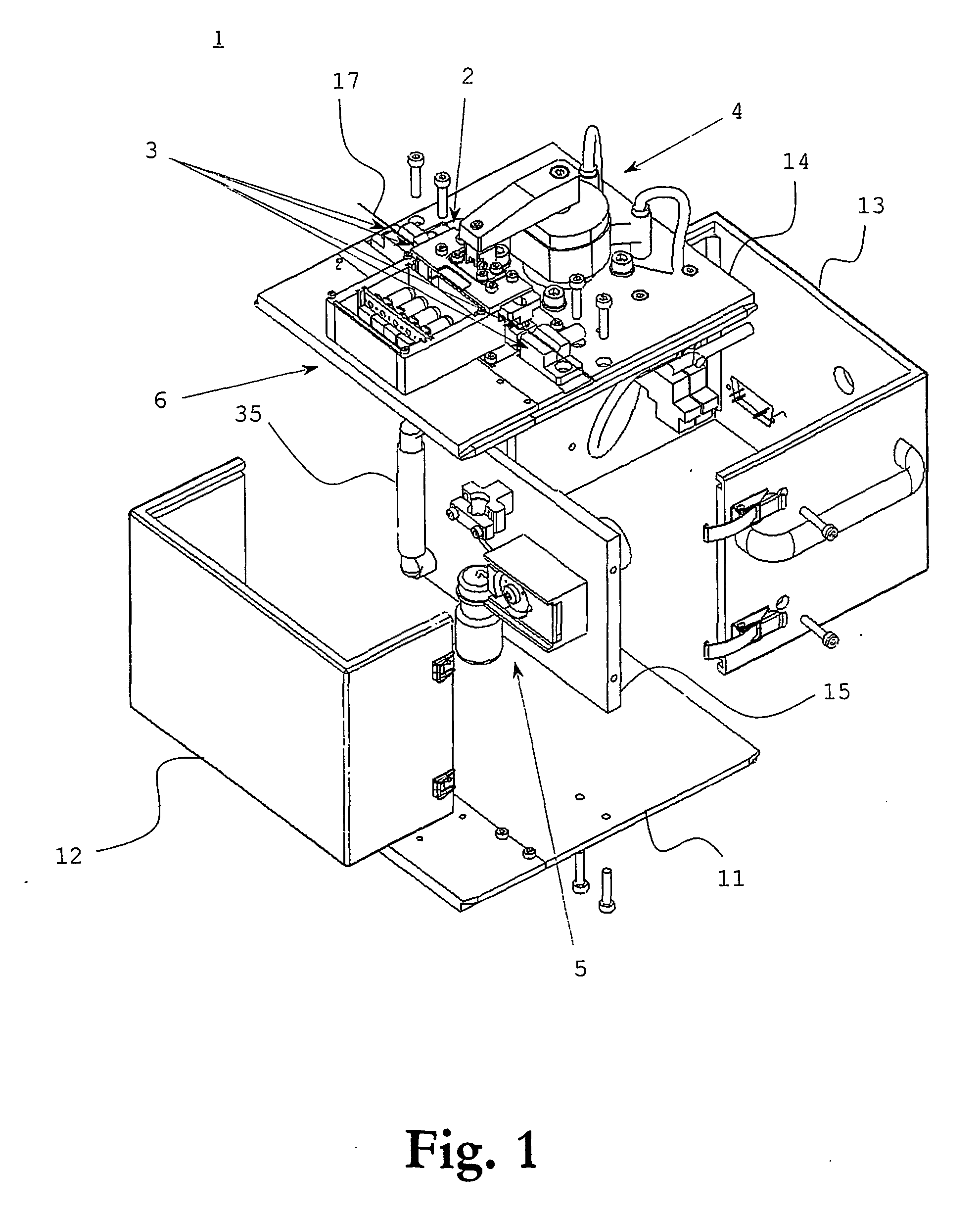

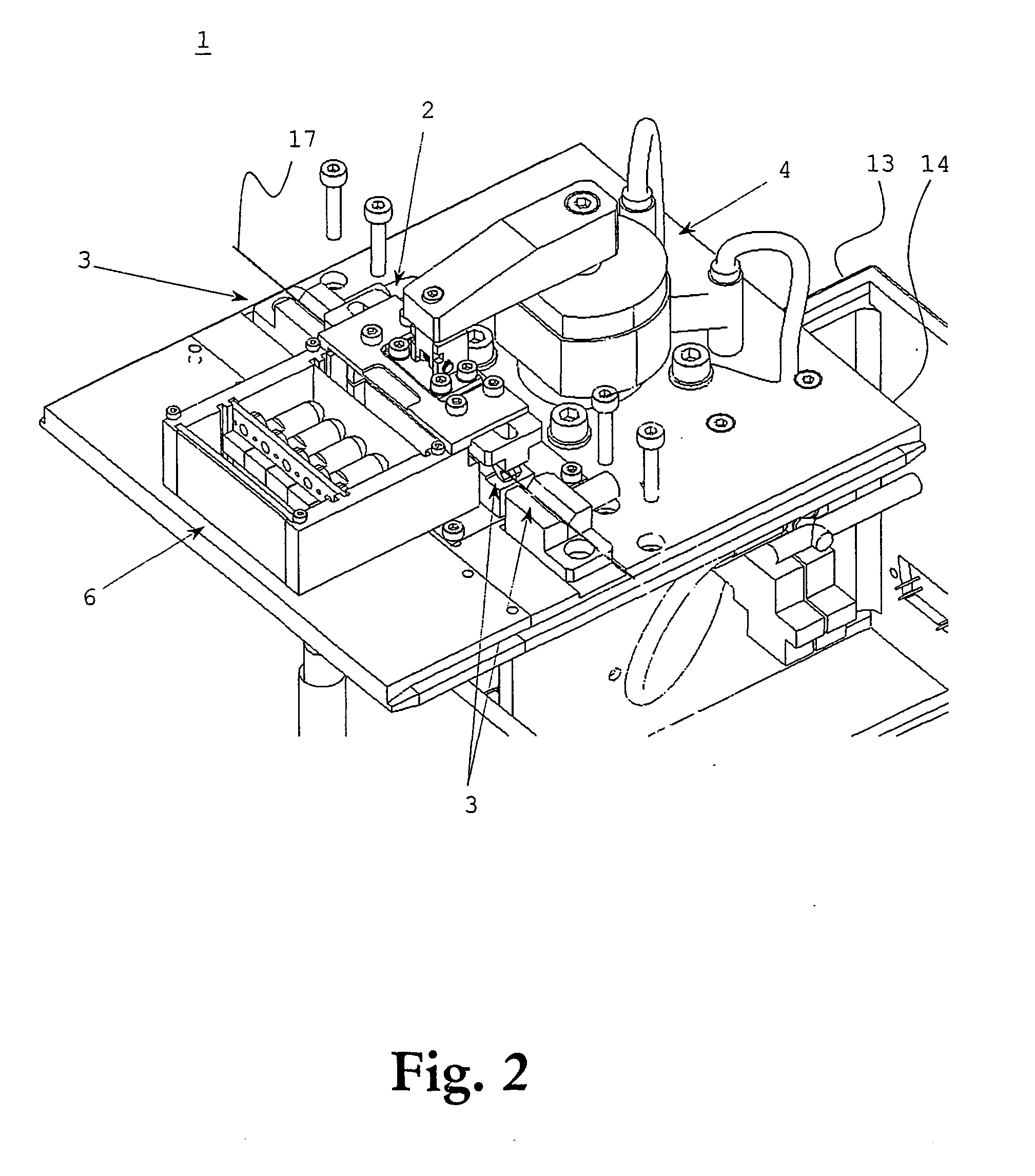

An apparatus (1) for recoating uncoated and spliced end portions of optical fibers (17) comprises two mold blocks (21a, 22b), each of which includes a groove (22a, 22b), the mold blocks being arrangable in a closed state, wherein the grooves cooperate to form a mold cavity for the fiber end portions, and in an open state, wherein the fiber end portions are insertable into the grooves. The apparatus further includes an injection system (5) for injecting a recoating material into the mold cavity, and a UV curing system (6) for irradiating the recoating material with UV light, thus curing the recoating material. At least one mold block is made of a plastic material comprising a fluoroplastic, e.g. PCTFE, the plastic material being at least partly transparent to UV light to enable the curing system to irradiate the UV curable recoating material with UV light through this mold block.

Owner:ARBOIX ESTEBAN +1

High temperature-resistant adhesive tape used for photovoltaic assembly battery piece positioning, and production method thereof

InactiveCN106590459AImprove yellowingHas a release effectNon-macromolecular adhesive additivesFilm/foil adhesivesPolyesterAdhesive

The invention discloses a high temperature-resistant adhesive tape used for photovoltaic assembly battery piece positioning. The adhesive tape sequentially comprises an adhesive layer, a substrate layer and an f coating layer from top to bottom, wherein the f coating layer comprises organic resin, a curing agent and an inorganic filler, and the substrate layer is a fluoroplastic film or a polyester film. The invention also provides a production method of the adhesive tape. An acrylic acid adhesive is specially modified, that is, an antioxidant and an ultraviolet absorbent are introduced to an adhesive system in order to greatly improve the yellow stain performance of the adhesive tape. The back side of the substrate layer is coated with the transparent f coating layer, so the substrate layer does not yellow, and makes the stability of the bonding force between the f coating layer surface and the adhesive film good; and the f coating layer has a certain release effect, so the unsmooth operating phenomenon caused by large bonding force between the adhesive surface and the f coating layer surface in the adhesive tape use process of a user is avoided.

Owner:CYBRID TECHNOLOGIES INC

Heat fixing rolls

InactiveUS6111221AIncrease resistanceDecorative surface effectsLayered productsPolymer scienceFluoroplast

A heat fixing roll includes a silicone rubber layer on a cylindrical metal mandrel having a penetration of at least 10 according to ASTM D1403 and a fluoroplastic layer thereon. The silicone rubber layer is obtained by molding and curing an addition reaction type liquid silicone rubber composition to the mandrel. The roll provides a sufficient nip width under low pressure, improved abrasion resistance, long-lasting toner release, and a satisfactory fixing function even at a high speed over a long period of time.

Owner:SHIN ETSU CHEM IND CO LTD

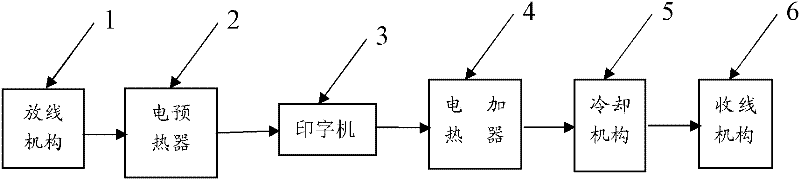

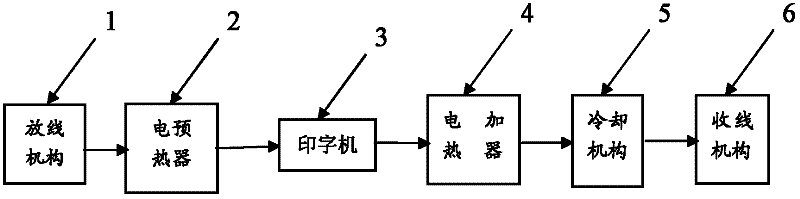

Fluoroplastic electric wire and cable surface lettering method and device

The invention provides a fluoroplastic electric wire and cable surface lettering method. The method comprises the following steps of: preheating a fluoroplastic electric wire in an electrical heating preheater, lettering on a high-temperature printing ink lettering wheel, heating the lettered electric wire in an electric heater, cooling the electric wire and the like. The invention also provides a corresponding lettering device which comprises a paying-out mechanism, the electric preheater, a high-temperature printing ink roll wheel lettering machine, the electric heater, a cooling mechanism and a cable coiling mechanism through which the electric wire successively passes. The method has the beneficial effects that the fluoroplastic surface of the electric wire is preheated to a required temperature firstly, then lettering is carried out on the fluoroplastic surface of the electric wire by use of high temperature printing ink, then the lettered fluoroplastic surface of the electric wire is heated to the required temperature so as to be firmly adhered to the fluoroplastic surface of the electric wire and cable, and subsequently, and cooling is performed, so that the lettering is firm and clear, the price is economic and cheap. Thus, the method and device provided by the invention are suitable for national conditions of China.

Owner:TIANJIN DAILY PROSPERITY SCI & TECH GROUP

Inkjet printing identification process for fluorine plastic sheath phase-stabilized cable

InactiveCN104021894AImprove marking resistance to abrasion testHigh fastnessConductor/cable markingPolymer scienceFluoroplast

The invention discloses an inkjet printing identification process for a fluorine plastic sheath phase-stabilized cable. The process includes the first step of carrying out plasma treatment on a fluorine plastic sheath so that ink can be easily immersed in scattered molecular structures of treated materials, the second step of adopting an inkjet printer with high ink adhesive force to carry out inkjet printing on the surface of the fluorine plastic sheath of the fluorine plastic sheath phase-stabilized cable, and the third step of adopting an electric heater to heat and solidify ink inkjet printing identifications on the surface of the fluorine plastic sheath after inkjet printing is conducted on the surface of the fluorine plastic sheath of the fluorine plastic sheath phase-stabilized cable. A plasma treatment machine is utilized, so that ink is prone to adhering to the surface of the sheath of the fluorine plastic sheath phase-stabilized cable; the electric heater is used for heating and solidifying, so that firmness and productivity of the identifications are improved.

Owner:安徽宏源特种电缆集团有限公司

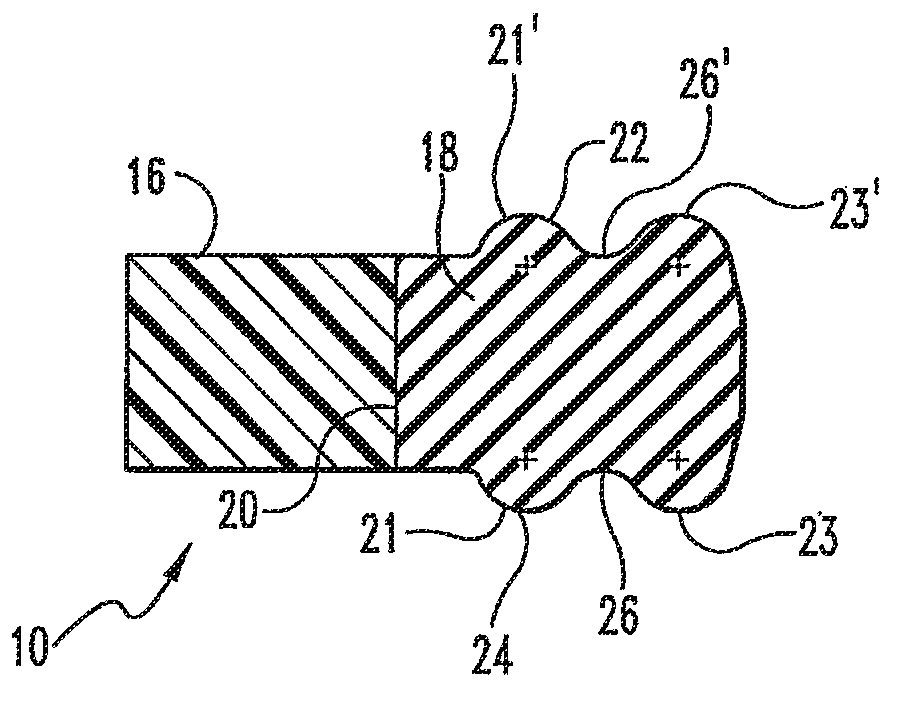

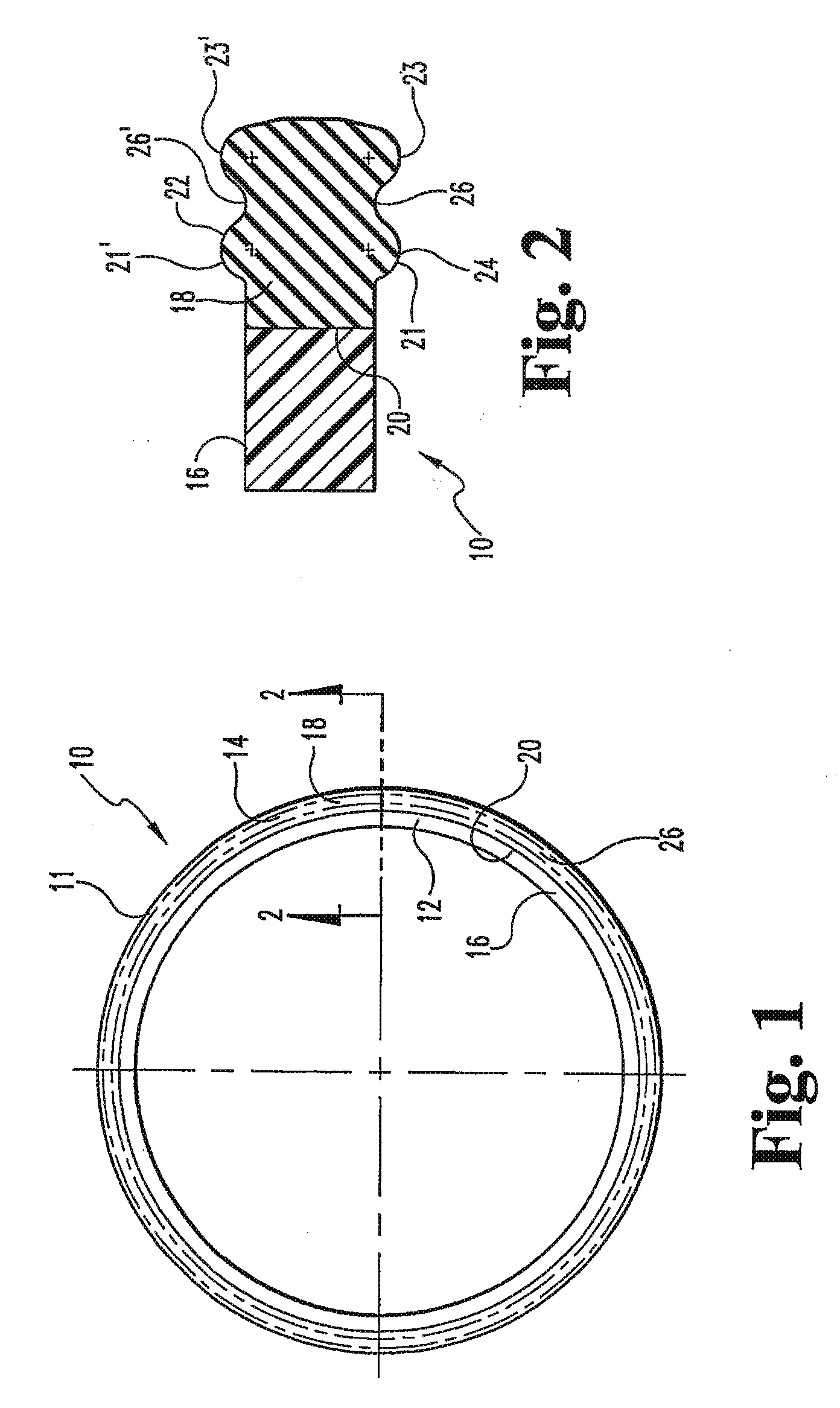

Composite fuel permeation barrier seal

Composite seal or gasket for inhibiting the release of a volatile organic compound such as fuel. The seal includes a deformable portion interconnected to a vapor barrier portion via a mechanical or adhesive interlocking connection. The deformable portion can be formed from an elastomeric material. The vapor barrier portion can be formed from a wide variety of materials that inhibit permeation of the organic vapor. Examples of the materials for the vapor barrier include ductile metals, plastic polymers, and fluoroplastic polymers. The gaskets and seals can be, but are not restricted to be, used between the connections of the components in an automotive or consumer product fuel system.

Owner:KENT JR EDWIN J +1

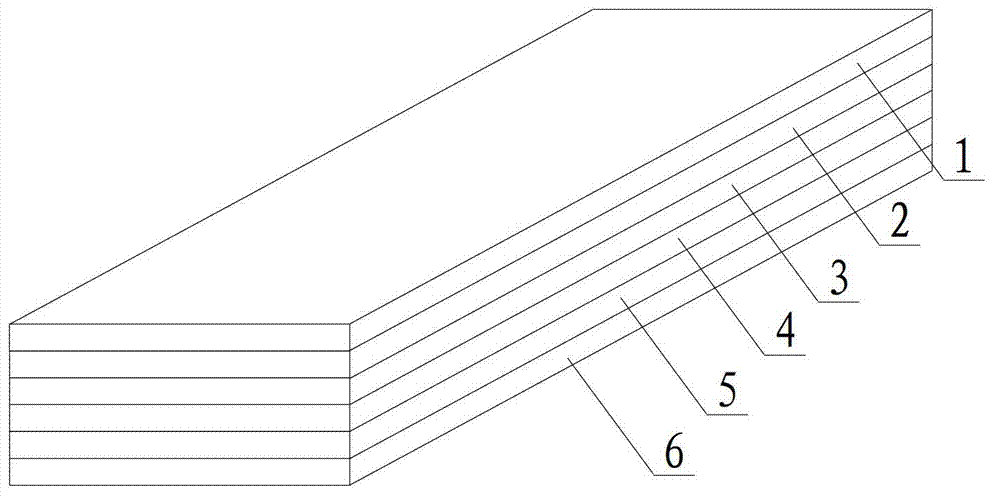

Front plate packaging structure of solar module

InactiveCN102738283AGood optical matching characteristicsImprove conversion efficiencySynthetic resin layered productsPhotovoltaicsSpectral responseEngineering

The invention relates to a front plate packaging structure of a solar module. An ETFE (Ethylene Tetra Fluoro Ethylene) fluoroplastic film (5), a first EVA (Ethylene-Vinyl Acetate) film (4), a cell slice (3), a second EVA film (2) and a back plate (1) are sequentially arranged on the upper surface of the solar cell module (6) from bottom to top. Compared with conventional tempered glass, the packaging structure disclosed by the invention has a better optical matched characteristic and not only has an excellent adsorption effect on main spectral response light of the cell slice, but also has a good light transmitting effect on light of which the wavelength is in the range of 320 to 1,200nm, so that the conversion efficiency of the solar module is improved and the packaging loss is reduced.

Owner:DONGFANG ELECTRIC YIXING MAGI SOLAR POWER TECH

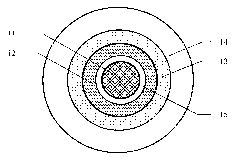

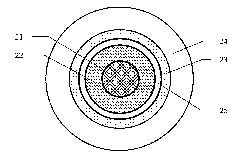

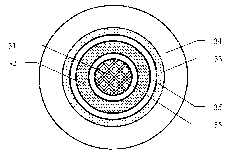

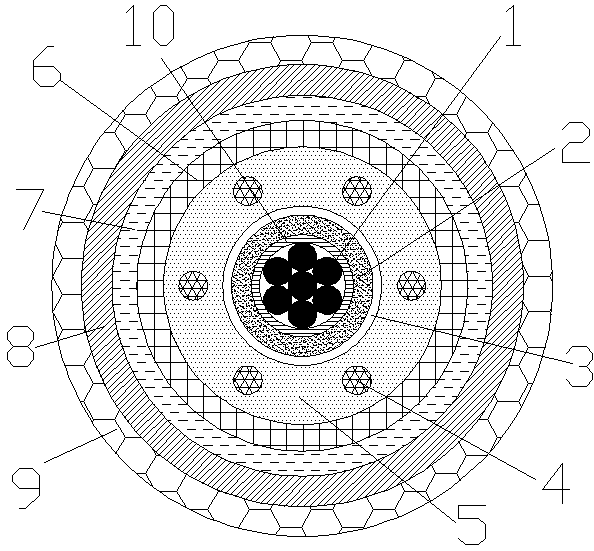

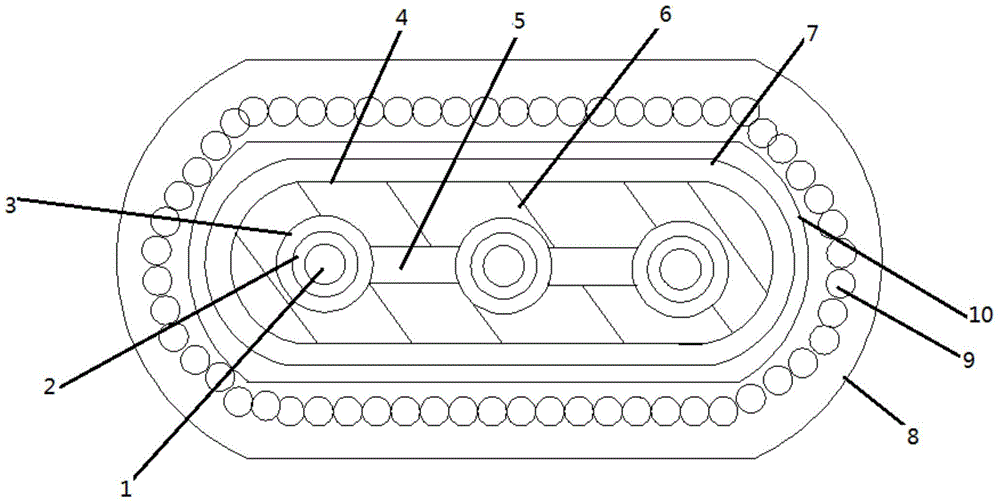

High-temperature and high-frequency foam fluorine plastic coaxial cable and production method thereof

ActiveCN101800097APrevent oxidationAvoid contactCoaxial cables/analogue cablesPlastic/resin/waxes insulatorsElectrical conductorCoaxial cable

The invention discloses a high-temperature and high-frequency foam fluorine plastic coaxial cable and a production method thereof, which relate to the technical field of coaxial cables and aim at improving the humidity resistance and enhancing the wear resistance and the mechanical strength of an insulating layer. The coaxial cable comprises a cable core conductor, a PTFE (Polytetrafluoroethylene) winding layer, a metal screen layer and a protective jacket in sequence from the inside to the outside. The coaxial cable is characterized in that a PFA (Polytetrafluoroethylene) layer is arranged between the cable core conductor and the PTFE winding layer or another PFA layer is arranged between the PTFE winding layer and the metal screen layer, or two PFA layers are respectively arranged between the cable core conductor and the PTFE winding layer and between the PTFE winding layer and the metal screen layer. The coaxial cable has the advantages of favorable humidity resistance, high power transmission performance and high wear resistance and mechanical strength of the insulating layer.

Owner:SHANGHAI NORGEIN COMM

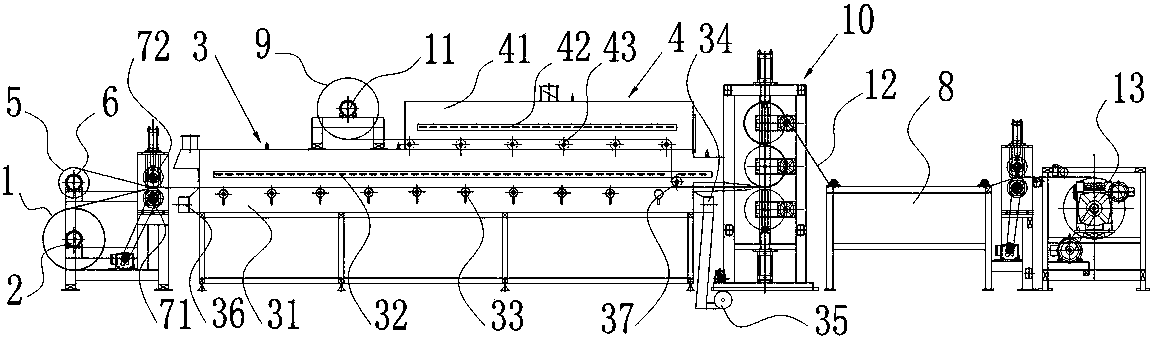

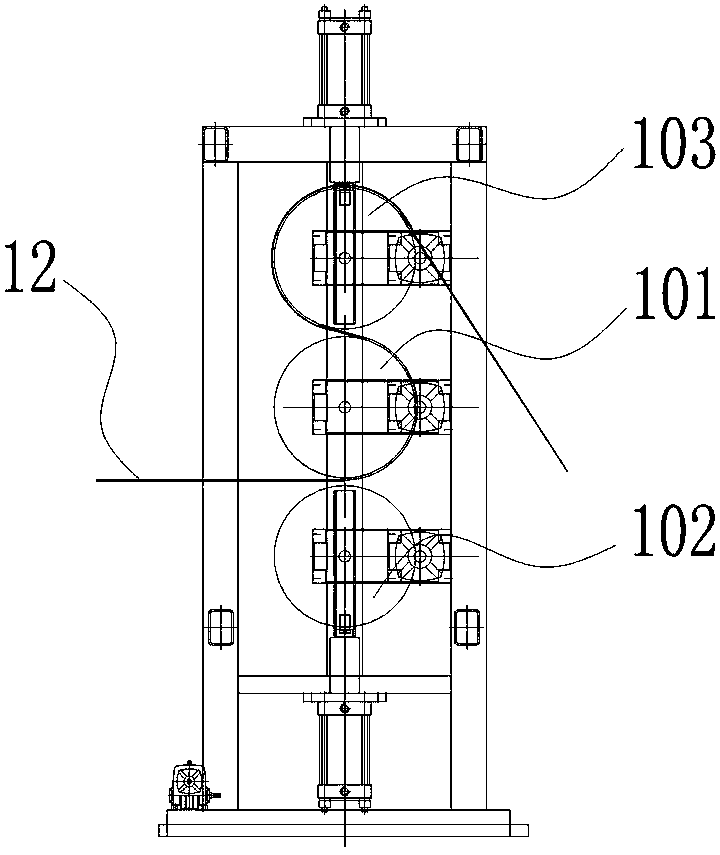

Fluoroplastic cable and production process thereof

InactiveCN110993155AImprove stabilityGood compression and impact resistancePlastic/resin/waxes insulatorsInsulated cablesGlass fiberVulcanization

Provided is a fluoroplastic cable. The cable comprises a cable core. The cable is characterized in that the cable core is formed by twisting a plurality of wires A, a high-temperature vulcanized silicone rubber layer is arranged outside the cable core, a rubber tube is arranged outside the high-temperature vulcanized silicone rubber layer, the rubber tube is also made of high-temperature vulcanized silicone rubber, non-Newtonian fluid is arranged between the high-temperature vulcanized silicone rubber layer and the rubber tube, a glass fiber layer is arranged outside the rubber tube, a plurality of wires B are evenly distributed in the glass fiber layer, a graphite fiber layer is arranged outside the glass fiber layer, a Kevlar fiber layer is arranged outside the graphite fiber layer, a polyurethane sheath layer is arranged outside the Kevlar fiber layer, and an aluminum tape armor layer is arranged outside the polyurethane sheath layer. The cable has the beneficial effects that the cable has excellent stability, compression resistance and impact resistance, and can be used for a longer time when an accident occurs.

Owner:金湖博通科技有限公司

Combining device and method of composite PTFE (polytetrafluoroethylene) plate

ActiveCN103612463ANo reduction in composite strengthComposite goodLaminationLamination apparatusGlass fiberFluoroplast

The invention discloses a fluoroplastic combining device and method and provides a combining device and method of a composite PTFE plate, which are capable of completely changing the non-sticky property of fluoroplastic and endowing the PTFE plate with excellent corrosion resistance and enable the PTFE plate to be spliced and combined with other materials. The technical problems that the PTFE plate treatment technology is only limited to surface treatment, and a lining layer is peeled and bulged and even worse, severe safety accidents are resulted because a surface activation layer easily loses effectiveness are solved. The combining device comprises a first drying tunnel and a second drying tunnel which are arranged side by side, wherein a PTFE plate unwinding machine and a composite film unwinding machine are arranged at the inlet end of the first drying tunnel side by side; the PTFE plate and a composite film are synchronously introduced into the first drying tunnel through a fixed-speed base material conveying mechanism after being superposed; a glass fiber cloth unwinding machine is arranged at the inlet end of the second drying tunnel; a plating press is arranged between the outlet ends of the first drying tunnel and the second drying tunnel; the PTFE plate and the composite film, which go out of the first drying tunnel, and glass fiber cloth going out of the second drying tunnel are superposed and then are extruded and combined through the plating press to form the composite PTFE plate; the composite PTFE plate winds a winding roller through a cooling mechanism.

Owner:ZHEJIANG DONGFU PLASTIC SCI & TECH

Injection-moldable conductive heat-conduction modified fluoroplastic material and preparation method and application thereof

ActiveCN104927271AGood electrical and thermal conductivityWide range of applicationsIn situ polymerizationInjection moulding

The invention relates to an injection-moldable conductive heat-conduction modified fluoroplastic material which is prepared from the following components in parts by weight: 50 to 100 parts of conductive heat-conduction modified basic fluoroplastic, 10 to 30 parts of an auxiliary material, 0 to 20 parts of a filling material and 5 to 30 parts of a processing auxiliary. The conductive heat conduction modified basic fluoroplastic is formed by performing in-situ polymerization on tetrafluoroethylene, perfluoro propyl vinyl ether, a conductive heat-conduction medium material and the auxiliary. The injection-moldable conductive heat-conduction modified fluoroplastic material has the beneficial effects that according to the prepared fluoroplastic, the conductive heat-conduction medium material is added in the polymerization process; by adoption of an in-situ polymerization technology, the volume resistivity (about 103 to 104) of the material is greatly reduced, and the heat conduction performance is improved (the heat conduction coefficient is greater than 3W / (m.K)), so that the injection-moldable conductive heat-conduction modified fluoroplastic material is higher in conductivity and heat conduction performance on the basis of chemical resistance and aging resistance. The technology is simple, the production efficiency is high, and no pollution waste is produced.

Owner:青岛科凯达橡塑有限公司

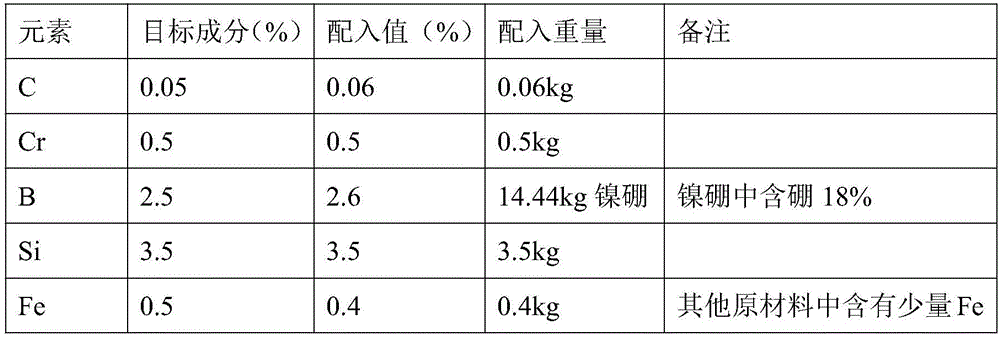

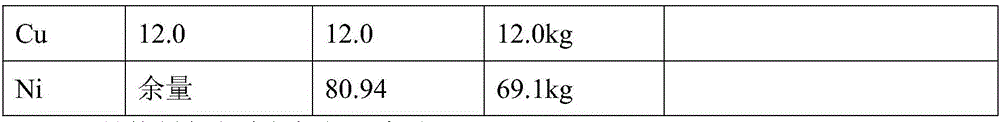

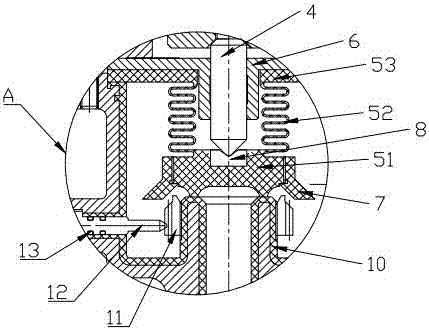

Nickel base alloy material resisting abrasion and hydrofluoric acid corrosion and preparing method of nickel base alloy material

The invention discloses a nickel base alloy material resisting abrasion and hydrofluoric acid corrosion and manufacturing fluoroplastic machining components and a preparing method of the nickel base alloy material. The nickel base alloy material comprises, by weight percent, 0.03%-0.10% of C, 0.2%-1.0% of Cr, 1.5%-2.5% of B, 2.0%-3.5% of Si, smaller than or equal to 2.0% of Fe, 12%-26% of Cu and the balance Ni. Induction heating smelting is mainly adopted, then direct forming is achieved through pouring, or powder is obtained through atomizing, and then, a powder metallurgy forming method is used for manufacturing the fluoroplastic machining components. Compared with a hastelloy C, the nickel base alloy material resisting abrasion and hydrofluoric acid corrosion and manufactured through the method has better hydrofluoric acid corrosion resisting performance and abrasion resisting performance, the manufactured fluoroplastic machining components meet the requirements of abrasion resistance and corrosion resistance of the fluoroplastic machining components, the service life is greatly prolonged, and component replacing cost is saved.

Owner:苏州艾盾合金材料有限公司

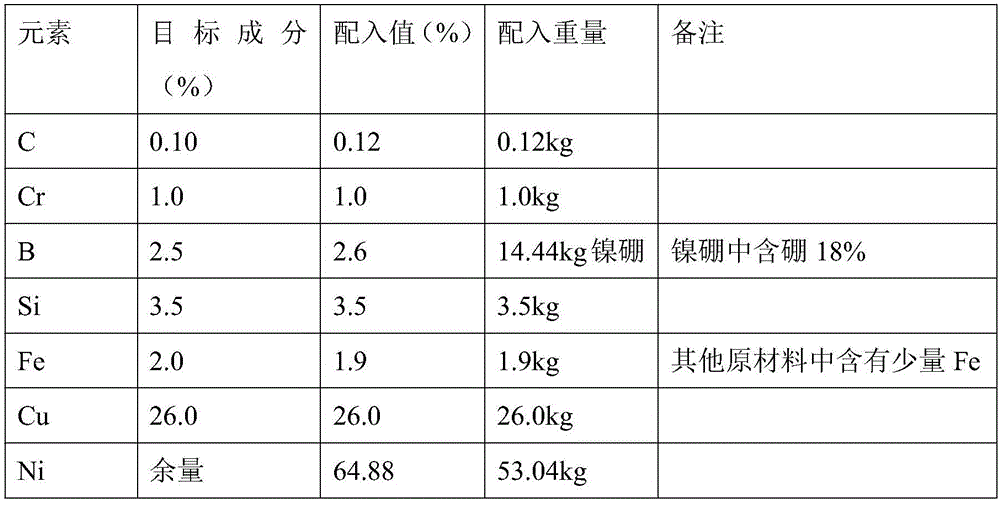

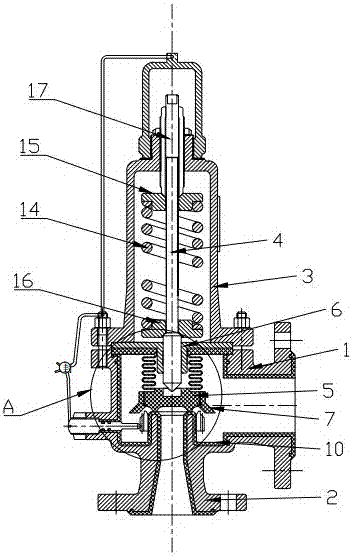

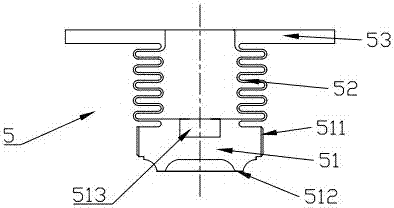

Spring-loaded type fluorine lining safety valve and valve clack assembly thereof as well as processing method of valve clack assembly

ActiveCN107202170AImprove corrosion resistanceNo gapSpindle sealingsEqualizing valvesFluoroplastStructural engineering

The invention relates to a spring-loaded type fluorine lining safety valve and a valve clack assembly thereof as well as a processing method of the valve clack assembly, which mainly aim to solve the problems of easiness in leakage, high price and high cost of a bellows of an existing spring-loaded type fluorine lining safety valve. The spring-loaded type fluorine lining safety valve and the valve clack assembly are characterized in that the valve clack assembly comprises a valve clack, a bellows and an installation disc and is integrally processed and formed by adopting fluoroplastics. The spring-loaded type fluorine lining safety valve and the valve clack assembly have the advantages that the valve clack assembly is integrally processed and formed, and compared with a separated structure, the integrated structure has the advantages of no gap, good sealing effect and zero leakage; additionally, the fluoroplastics which have the advantages of good corrosion resistant performance and low price are adopted, so that the manufacturing cost is greatly reduced.

Owner:ZHEJIANG TIANHE VALVE CO LTD

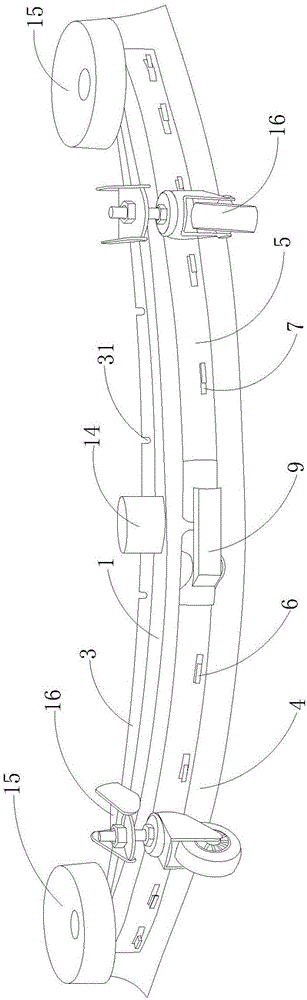

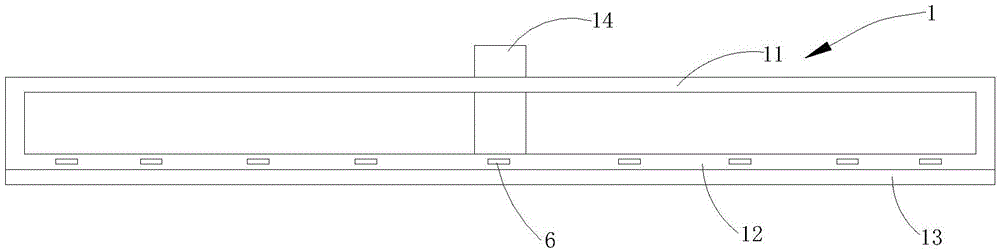

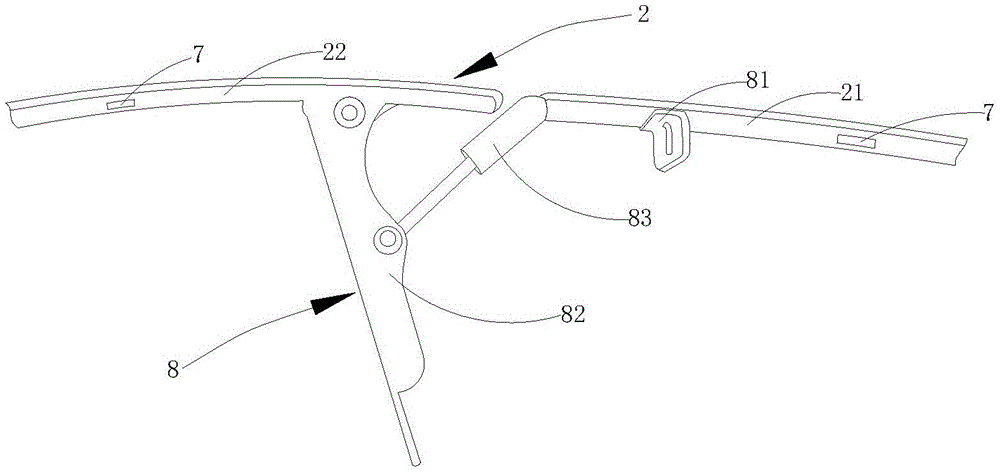

Water absorption rake structure of automatic ground washing machine

ActiveCN105125145AEasy to assemble and disassembleNo air leakageMachine detailsFloor-scrubbing machinesFluoroplastStructural engineering

The invention discloses a water absorption rake structure of an automatic ground washing machine. The water absorption rake structure of the automatic ground washing machine comprises a front pressing bar, a front rubber sheet, a main body support, a rear rubber sheet and a rear pressing bar which are sequentially arranged in the front and rear direction. The main body support comprises an upper side plate and a lower side plate, the front side face and the rear side face of the lower side plate are each provided with inserting connection heads, and the front pressing bar, the front rubber sheet, the rear rubber sheet and the rear pressing bar are each correspondingly provided with inserting holes matched with the inserting connection heads; the main body support further comprises a seal plate which is arranged under the lower side plate and used for preventing air leakage occurring between the inserting connection heads and the inserting holes in the water absorption process of the water absorption rake. Due to the fact that the sealing plate is additionally arranged, in the water absorption process of the water absorption rake, the air leakage does not occur between gaps of the inserting connection heads and the inserting holes, and the water absorption capacity of the water absorption rake is improved; meanwhile, the main body support is made of ferrous materials coated with fluoroplastic, and the main body support is low in manufacturing cost, good in anti-corrosion effect and long in service life.

Owner:张家港高格清洁设备有限公司

Thermally conductive fuser coating

InactiveUS20120164570A1Electrographic process apparatusElectrographic processes using charge patternOptoelectronicsInorganic particle

The present invention is directed towards a fuser member having as its outermost layer, a cured composite comprising: a) a continuous phase of an elastomer; and b) thermally conductive particles dispersed in the elastomer, where the conductive particles comprise inorganic particles coated with a layer of fluoroplastic.

Owner:EASTMAN KODAK CO

Flat-shaped power cable connected through frame

ActiveCN103985472AEasy to useImprove toughnessPower cables with screens/conductive layersFlat/ribbon cablesLow smoke zero halogenFiber

The invention discloses a flat-shaped power cable connected through a frame. The power cable comprises a plurality of lead wires which are arrayed side by side horizontally. Polyethylene insulation layers and low-smoke-zero-halogen flame retardant belt outer taped covering layers are wrapped outside the lead wires in sequence respectively. A flat-shaped structure inner protecting sleeve layer is wrapped outside all the low-smoke-zero-halogen flame retardant belt outer taped covering layers. The rubber frame is arranged in the inner protecting sleeve layer. Adjacent lead wires are connected together through the rubber frame. The inner portions of the low-smoke-zero-halogen flame retardant belt outer taped covering layers are filled with high-temperature-resistant fiber filaments. A flat-shaped structure copper belt shielding layer, an armor layer formed by steel wires which are twisted to form beams and a fluoroplastic outer protecting sleeve layer are wrapped outside the low-smoke-zero-halogen flame retardant belt outer taped covering layers in sequence. A fire-resistant mica layer is arranged between the copper belt shielding layer and the armor layer. The structure improvement is simple and practical, the whole pressure-resisting mechanical performance is improved, meanwhile, an inflaming-retarding fire-resistant structure layer is arranged, and practicability is good.

Owner:ANHUI SAIHUA CABLE

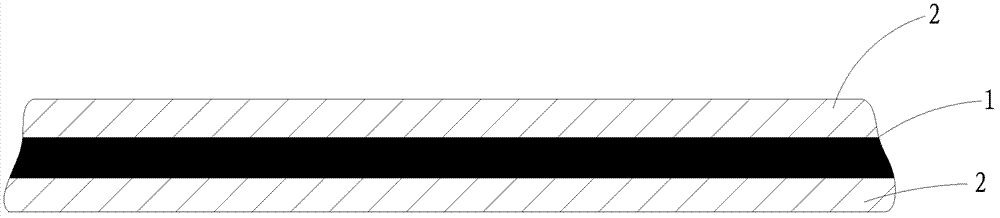

Ammonia-resistant fluoroplastic composite soft material

InactiveCN103085391AWith strengthGood ammonia resistanceWindings insulation shape/form/constructionGlass/slag layered productsGlass fiberRefrigeration compressor

The invention discloses an ammonia-resistant fluoroplastic composite soft material. The ammonia-resistant fluoroplastic composite soft material comprises an electrical alkali-free glass fiber cloth. Fluoroplastic coatings are coated on two surfaces of the electrical alkali-free glass fiber cloth. The ammonia-resistant fluoroplastic composite soft material has good ammonia resistance and certain strength, can be used for a refrigerating fluid-resistant motor and is not damaged so that good slot insulation and phase insulation performances of the refrigerating fluid-resistant motor are guaranteed, and the refrigerating fluid-resistant motor adopting the ammonia-resistant fluoroplastic composite soft material satisfies slot insulation and phase insulation requirements in an ammonia refrigerating environment and works for a long time. Through the ammonia-resistant fluoroplastic composite soft material, the refrigerating fluid-resistant motor can be used in a closed refrigeration compressor system adopting ammonia as a refrigerating fluid.

Owner:SUZHOU BETTER TECH

Mining cable of flat structure

InactiveCN103985447AImprove stress resistanceImprove practicalityFlat/ribbon cablesInsulated conductorsPolyesterFluoroplast

The invention discloses a mining cable of a flat structure. The mining cable comprises a plurality of wires. The wires are twisted and bundled into multiple sets. An isolating layer wraps each set of wires. Insulating layers wrap the isolating layers of the multiple sets of wires respectively. The multiple sets of wires are horizontally arrayed in parallel. An aluminum-polyethylene bonding layer wraps all the insulating layers of the multiple sets of wires. Vertical nylon fiber frameworks are arranged at the portions, between the adjacent sets of wires, in the aluminum-polyethylene bonding layer. High-temperature-resistant filaments are wound around the outer surfaces of the nylon fiber frameworks. A ceramic silicone rubber flame-retardant layer, a medal shielding layer, a tear-resistant layer and a fluoroplastic protective sleeve layer sequentially wrap the aluminum-polyethylene bonding layer, wherein the tear-resistant layer is formed by weaving polyester silks. The metal shielding layer is filled with magnesium oxide powder, and steel ropes are arranged in the magnesium oxide powder. The mining cable is simple in structure; the frameworks are added to the mining cable of the flat structure, and therefore pressure resistance of the whole cable is improved, practicability is higher, and meanwhile flame retardance and high temperature resistance are high.

Owner:ANHUI SAIHUA CABLE

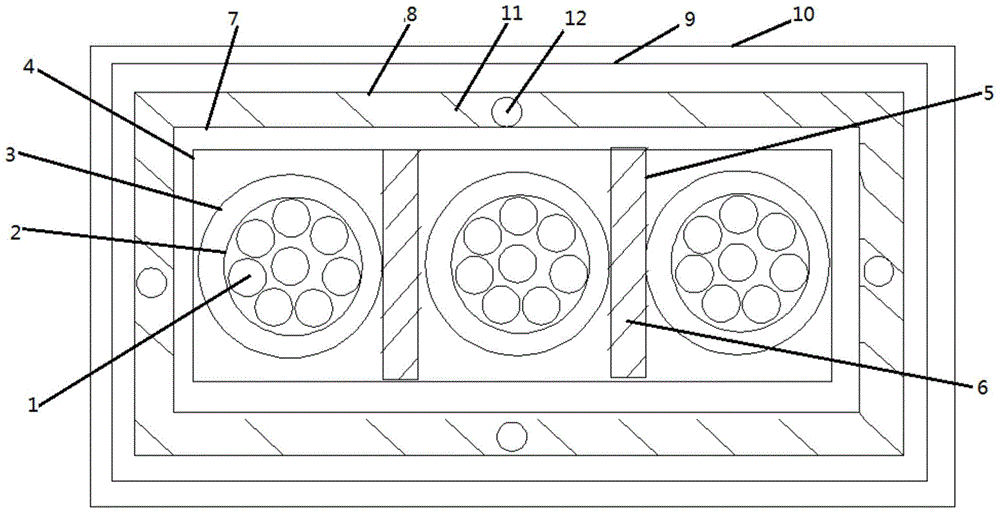

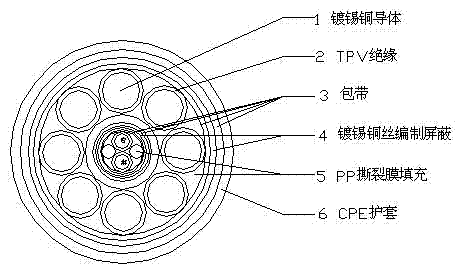

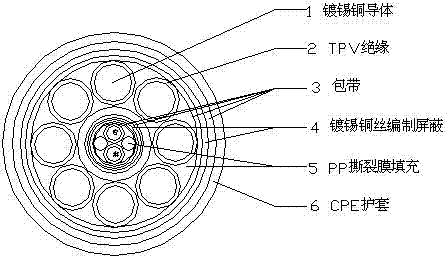

Fluoroplastic or elastic body insulation chlorinated polyethylene jacket feeding and signal cable

InactiveCN102412009AHigh tensile strengthImprove electrical performanceFlexible cablesFlexible conductorsPolyesterElastomer

The invention discloses fluoroplastic or elastic body insulation chlorinated polyethylene jacket feeding and signal cable, and the cable is composed of a cable core, a communication core and an electroline cores. The communication core forms an insulated core through guide and external package of an insulated material, the insulated core is twisted to package a polyester film, and a metal shielding layer is arranged outside the polyester film, a non-woven fabric is packaged outside the metal shielding layer so as to serve as a protective layer; 6 lectroline cores are concentrically twisted on the periphery of the communication core, a PP (parcel post) laniating strap is filled in a gap, and two layer of polyester films are packaged on the periphery of the twisted cable core; and the metal shielding layer is knitted outside the polyester film, a low-smoke no-halogen antiflaming strap is packaged outside the metal shielding layer, and a CPE ( chlorinated poly ethylene) material of an outer package of the antiflaming strap is utilized as an outer sheath. The cable provided by the invention has the advantages that the cable is suitable for being used in a field moving condition, the operating temperature range is minus 40-90 DEG C, the wearability is good, the circumnutating resisting property is strong, ultraviolet radiation is resisted, the core and skin can not be broken after being repeatedly circumnutated, and a drag chain cable used for an abrasion-resistant and circumnutating-resisting port machinery has long service life.

Owner:吴洪明

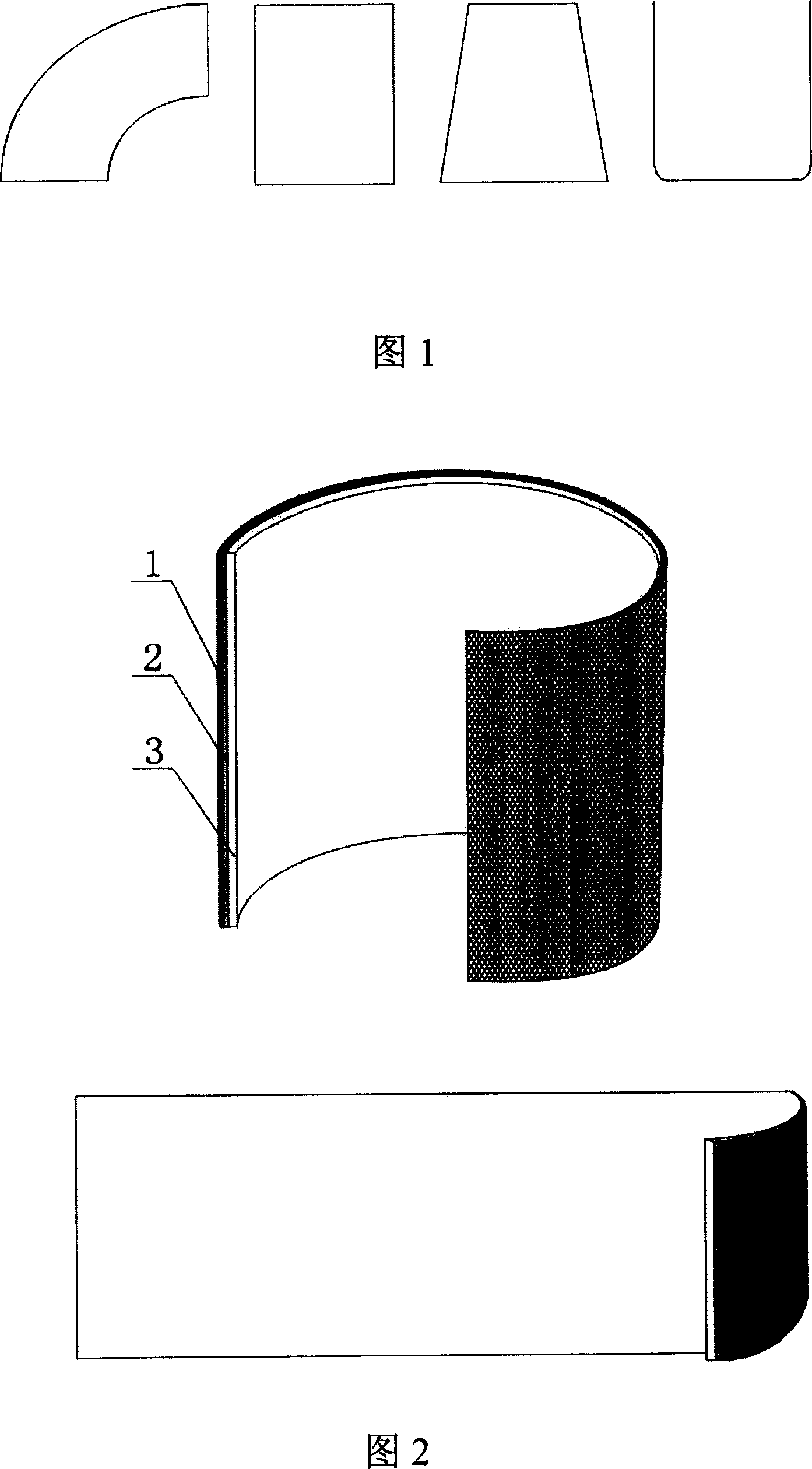

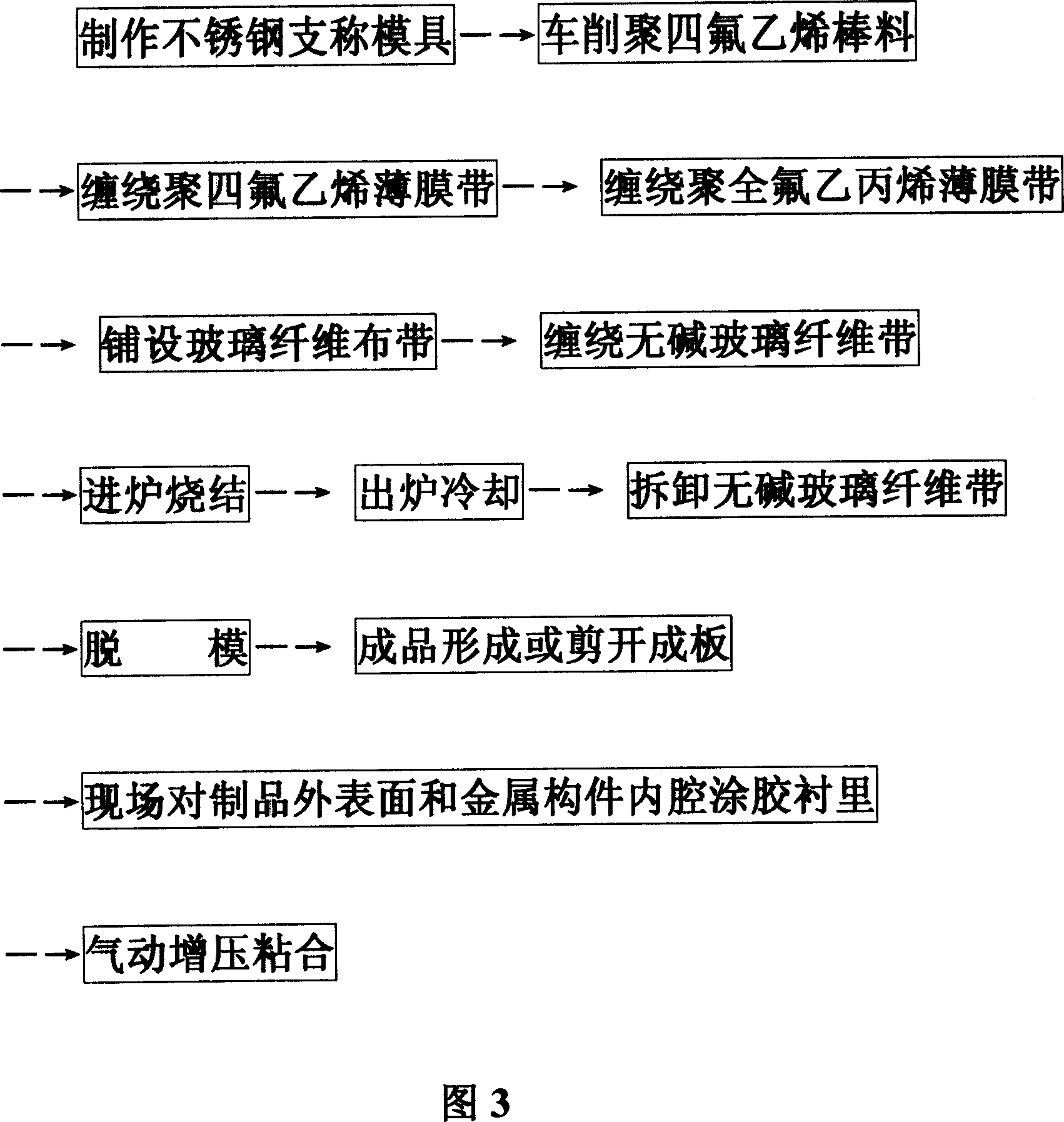

Fluoroplastic compound product and its making method

InactiveCN101007453ASolve the technical problem that the lining cannot be constructed on siteReduce energy costsSynthetic resin layered productsLaminationGlass fiberTetrafluoroethylene

The invention involves fluorine plastic liner manufacturing and application technology, particularly a fluorine plastic lining composite product and its manufacturing method. Its characteristic is: it contains glass fibers, fluorinated ethylenepropylene copolymer and PTFE, they are coiled on stainless steel supporting mold consecutively, then the out surface is coiled with alkali-free glass fiber belts, it is pressed and sintered in high-temperature and molten condition, fluorinated ethylenepropylene copolymer permeates into the glass fiber gap laid on surface, cooling out furnace, disassembling the alkali-free glass fiber belts and demolding, then the product is completed or is sheared into sheets. It aims at designing a fluorine plastic composite product which can process the fluorine plastic and metal components with lining on site and its production method. The invention fills the technology gap of large equipment can not process PTFE with lining, reduces a lot of costs of electricity, coal energy and transportation, greatly expands PTFE lining equipment application scope, and plays a positive role of replacing the products made by expensive rare metals materials.

Owner:董秀峰

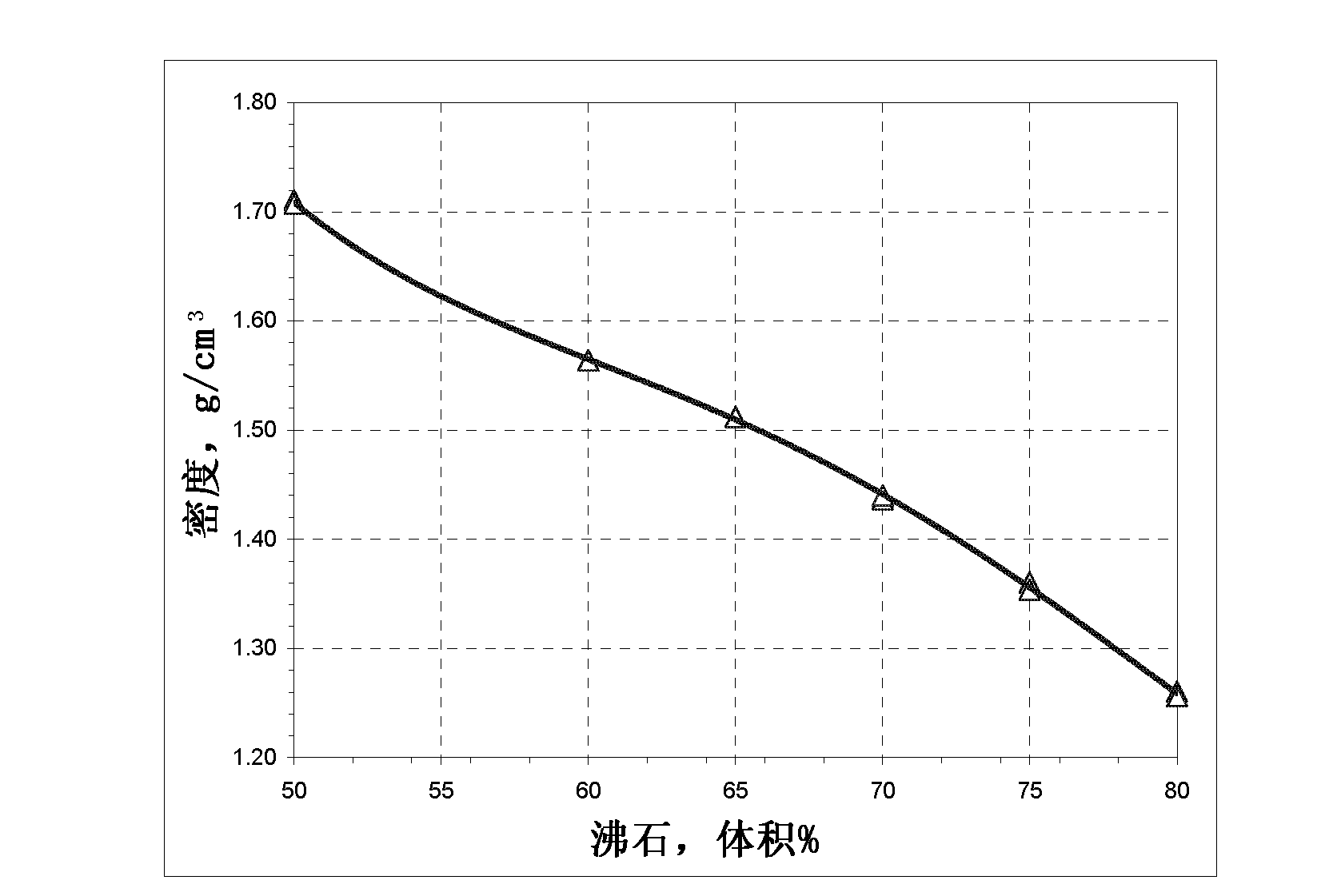

Composite material, moulding, electronic unit comprising moulding, and process for producing a moulding

InactiveCN103153454AMeasurement apparatus componentsOther chemical processesPolymer scienceFluoroplast

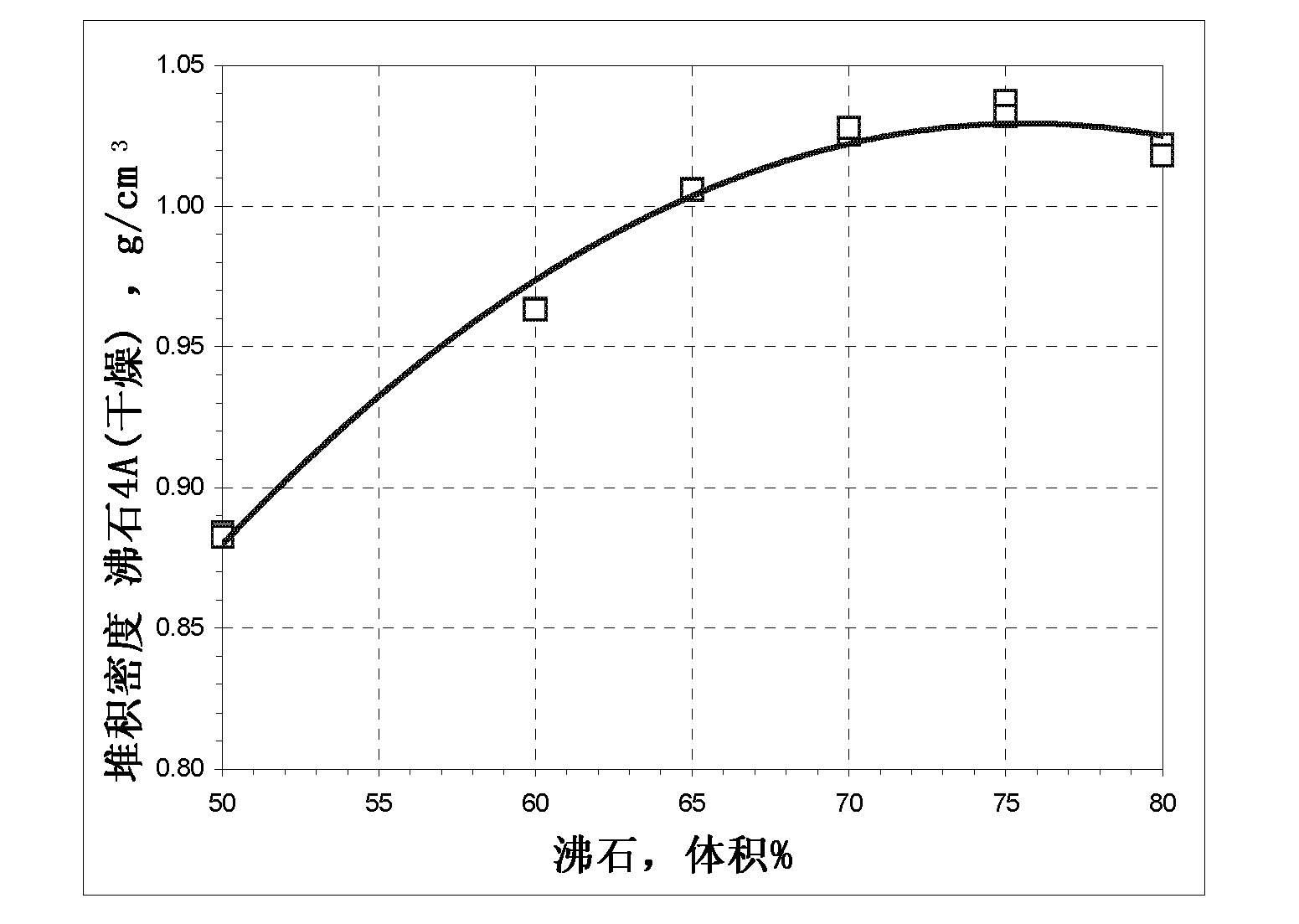

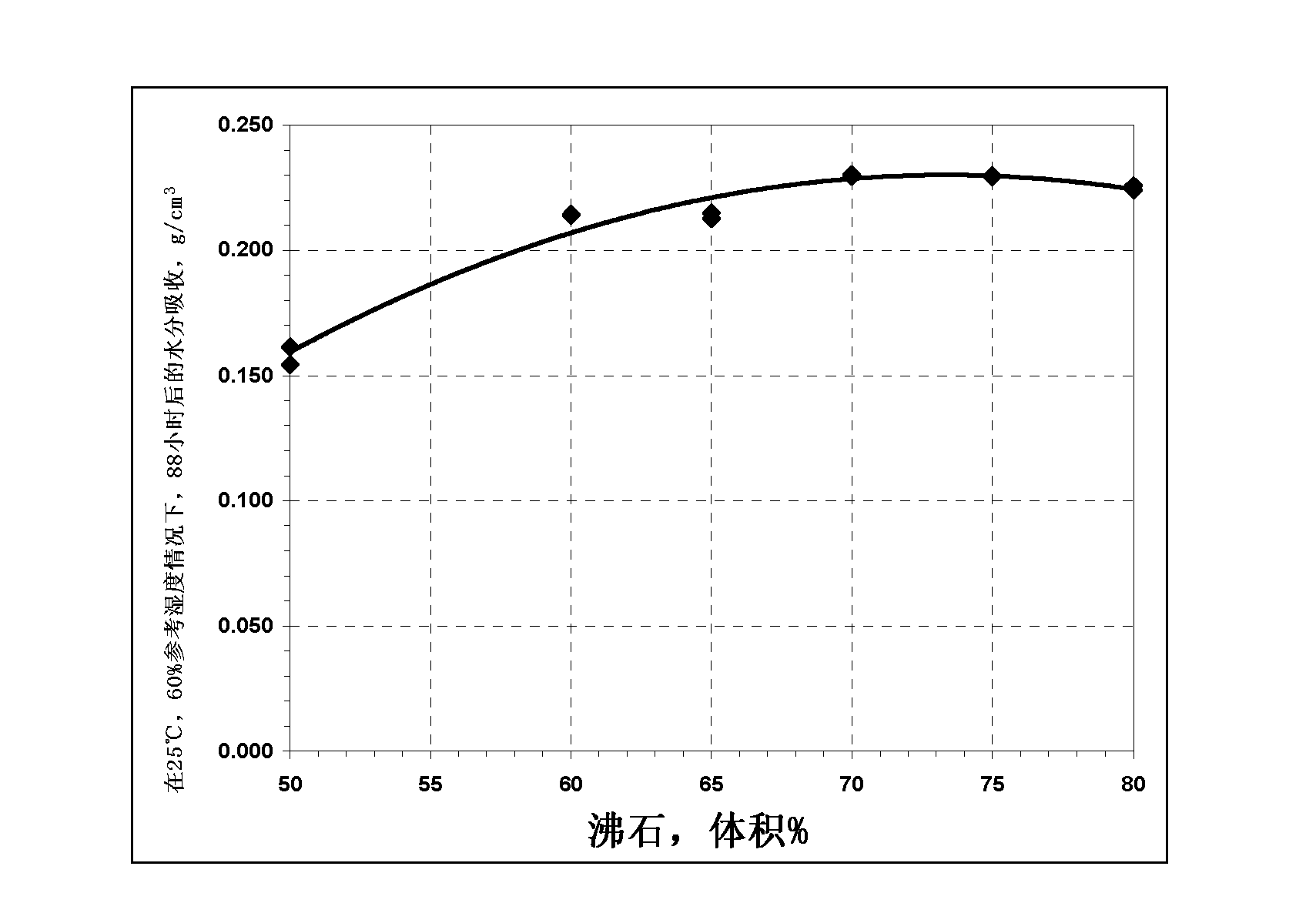

A composite material comprises a polymer matrix; and zeolite bound within the polymer matrix; where the proportion by volume of the zeolite in the volume of the composite material is at least 50%, especially at least 65%. The polymer matrix may especially comprise a polymer selected from a group of polymers consisting of fluoropolymers, polyaryl ether ketones, sulphur polymers and polymers of high heat resistance. The zeolite comprises especially a type A zeolite, especially a 4A or 3A zeolite.

Owner:EHNDRESS KHAUZER GMBKH KO KG

Back plate film of solar cell

InactiveCN102416740AExtended service lifeGuaranteed bonding effectSynthetic resin layered productsPhotovoltaic energy generationPolymer scienceFluoroplast

The invention discloses a back plate film of a solar cell. The back plate film comprises fluoroplastic films on the inner and outer layers adhered by an adhesive and a moisture resisting film on a middle layer, wherein the fluoroplastic films are grafted with acrylate substances. The fluoroplastic films are grafted with acrylate substances through irradiation, and the grafting chain is connected with the fluoroplastic through a chemical bond, being relatively stable and not weakening with the time lasting; and therefore, the sticking property between the prepared back plate film of the solar cell and an EVA (ethylene vinyl acetute) adhesive film as well as the stability of the back plate film is ensured, and the service life of the prepared back plate of the solar cell is long.

Owner:FSPG HI TECH

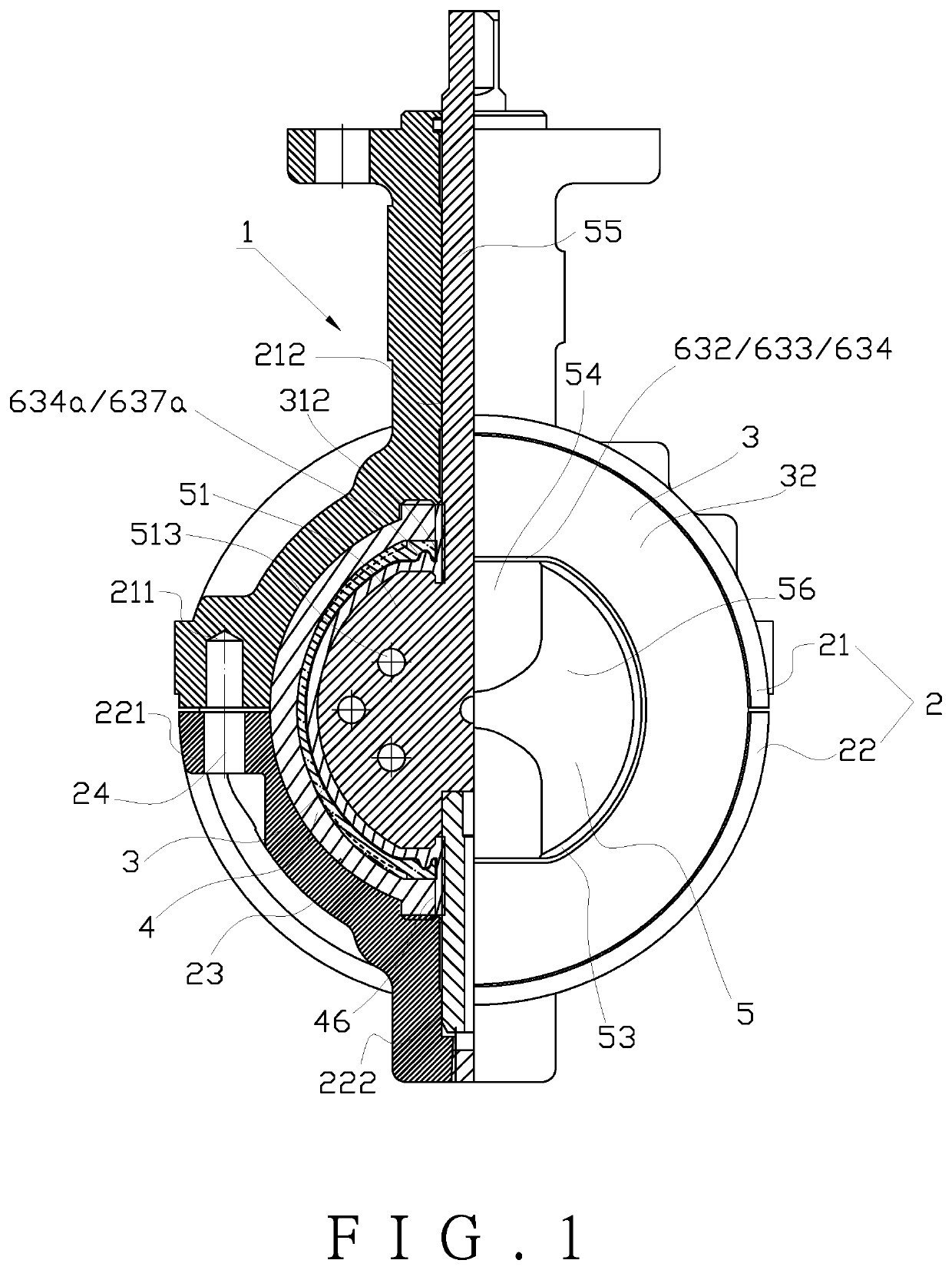

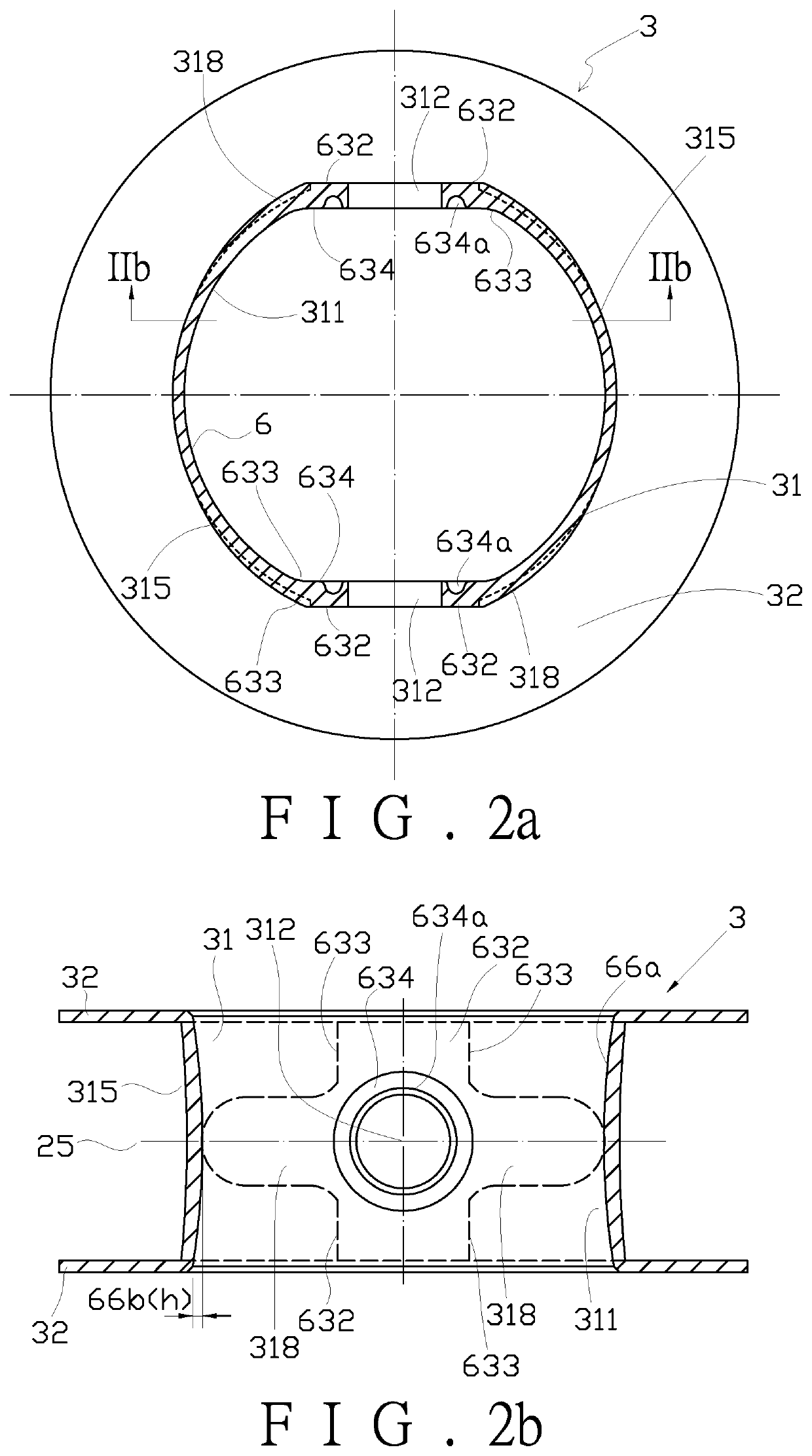

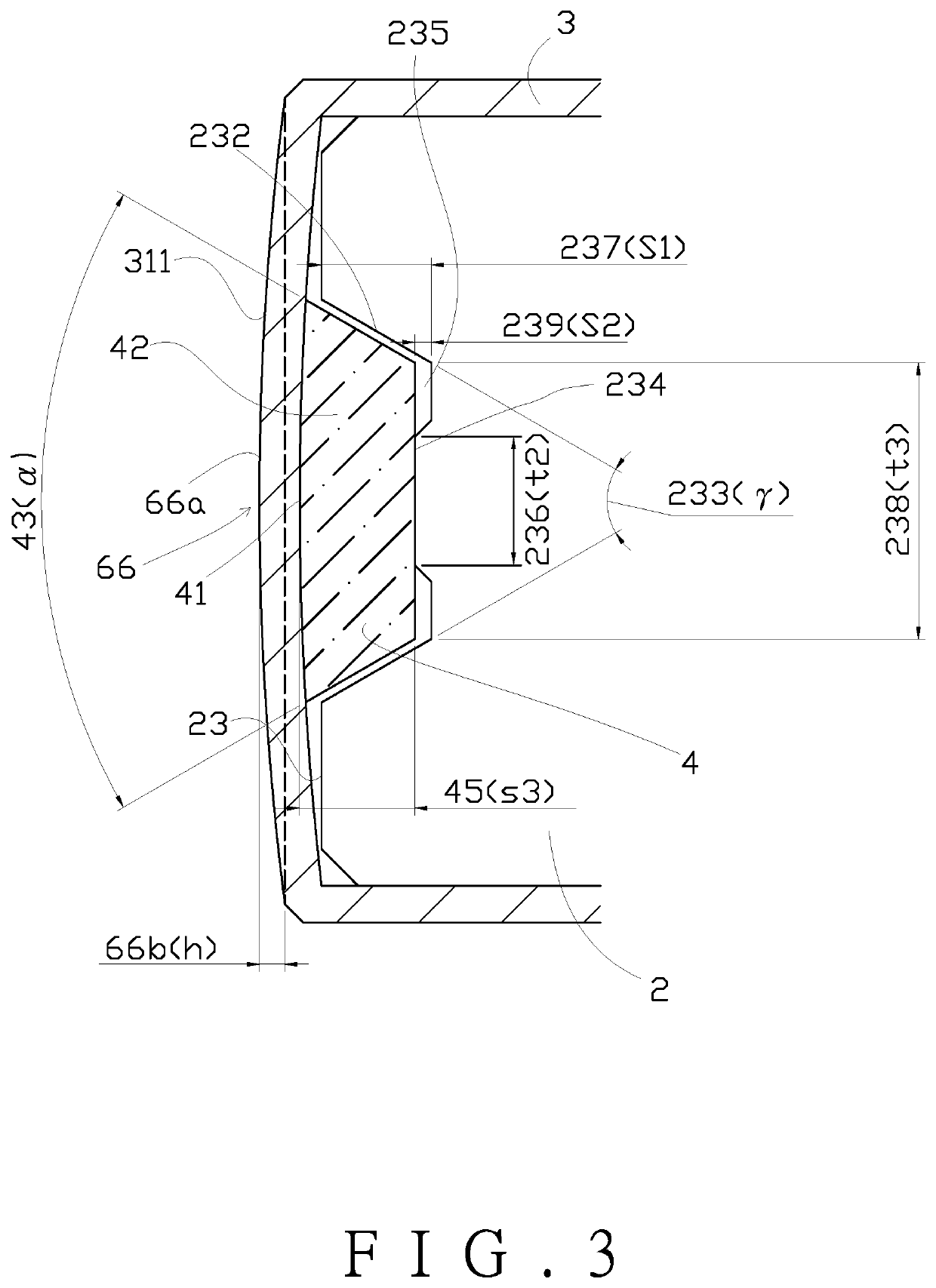

Fluoroplastic butterfly valve structure

ActiveUS20200072359A1Improve the immunityReduce trafficLift valveValve housingsInterference fitFluoroplast

The present invention relates to a fluoroplastic butterfly valve structure, including a valve body, a butterfly disc, a lining, and a back-up ring. The butterfly disc has a disc-like structure and includes an inner metallic butterfly disc and an outer fluoroplastic material enclosing the metallic butterfly disc. The butterfly disc is provided with a valve shaft and includes two bulging portions for connecting with the valve shaft. The butterfly disc has a board-like or cone-like cross section. The valve shaft is mounted in a shaft hole portion of the valve body, enabling rotation of the butterfly disc for adjusting flow amount or opening / closing the valve. The back-up ring and the fluoroplastic lining are mounted on an inner peripheral surface of the valve body. An outer rim of the butterfly disc and an inner surface of the lining are tightly pressed against each other by interference fit. The back-up ring is provided between the inner peripheral surface of the valve body and the lining and is made of high temperature resistance rubber in order for bearing the pressing pressure of deformation resulted from said interference fit, thereby meeting the requirement of working with a high-temperature (200 degree Celsius) and high-pressure fluid. The butterfly disc has a complex sealing structure, which includes an unequal-width conical surface and an unequal-width curved surface. The unequal-width curved surface is disposed in a closing direction of the butterfly disc for preventing interference sliding thereof with respect to the inner surface of the lining, thereby reducing deformation of lining and reducing torque. The unequal-width curved surface is composed of arc curves. A portion of the unequal-width curved surface which is at a position near the valve shaft has a longer arc, while a portion of the unequal-width conical surface which is at a position near the valve shaft has a smaller width, said smaller width exceeding 50 percent of a thickness of the outer rim of the inner metallic butterfly disc. Take a 3-inch butterfly disc as an example, where a thickness of the butterfly disc is 8 mm, a sealing width of the butterfly disc is greater than 4 mm. A portion of the unequal-width curved surface which is at a largest-diameter region of a central of the butterfly disc has a shortest arc, while a portion of the unequal-width conical surface which is at the largest-diameter region of the central of the butterfly disc has a largest width, said largest width exceeding 70 percent of the thickness of an outer rim of the inner metallic butterfly disc of the butterfly disc.

Owner:BUENO TECH

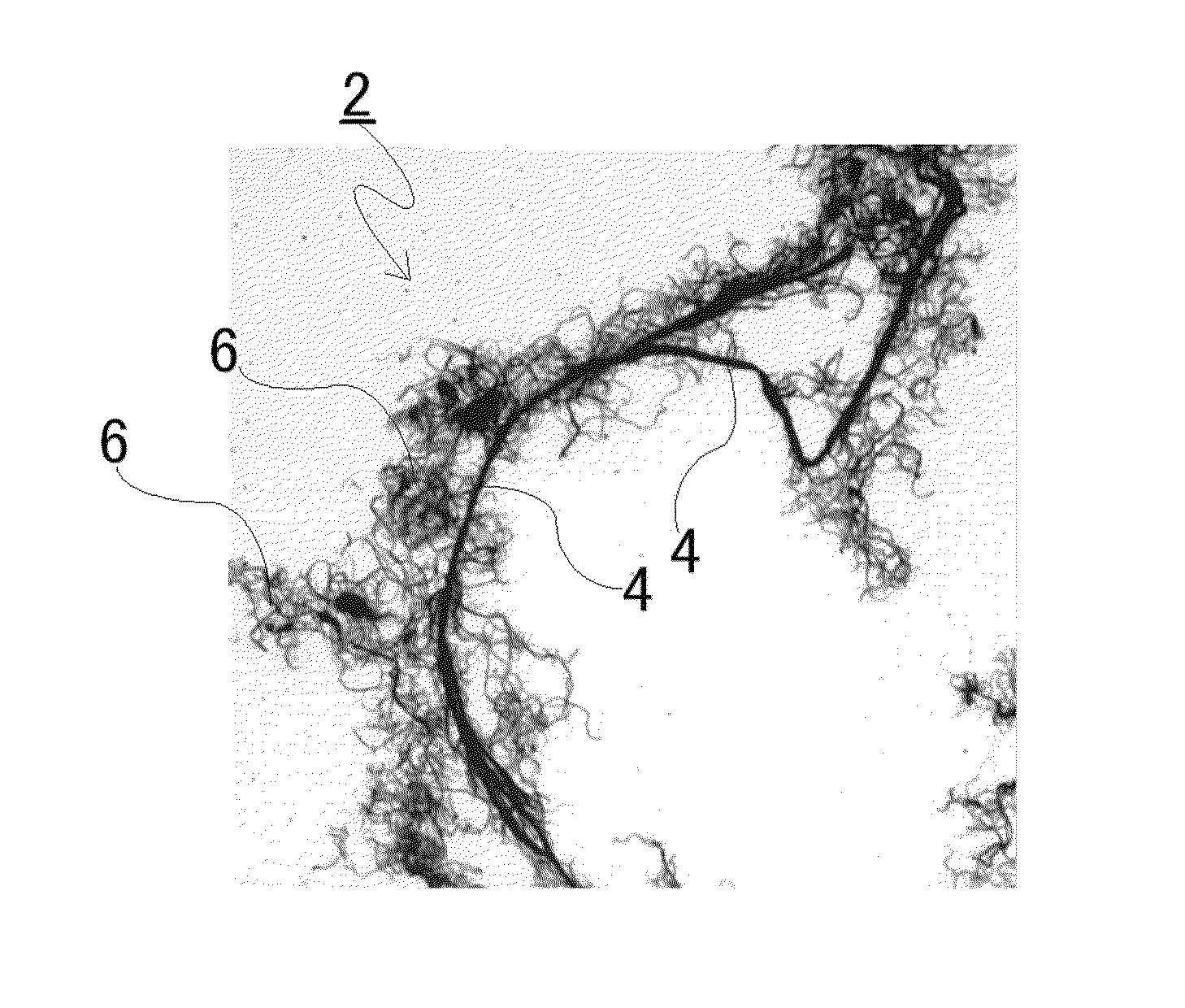

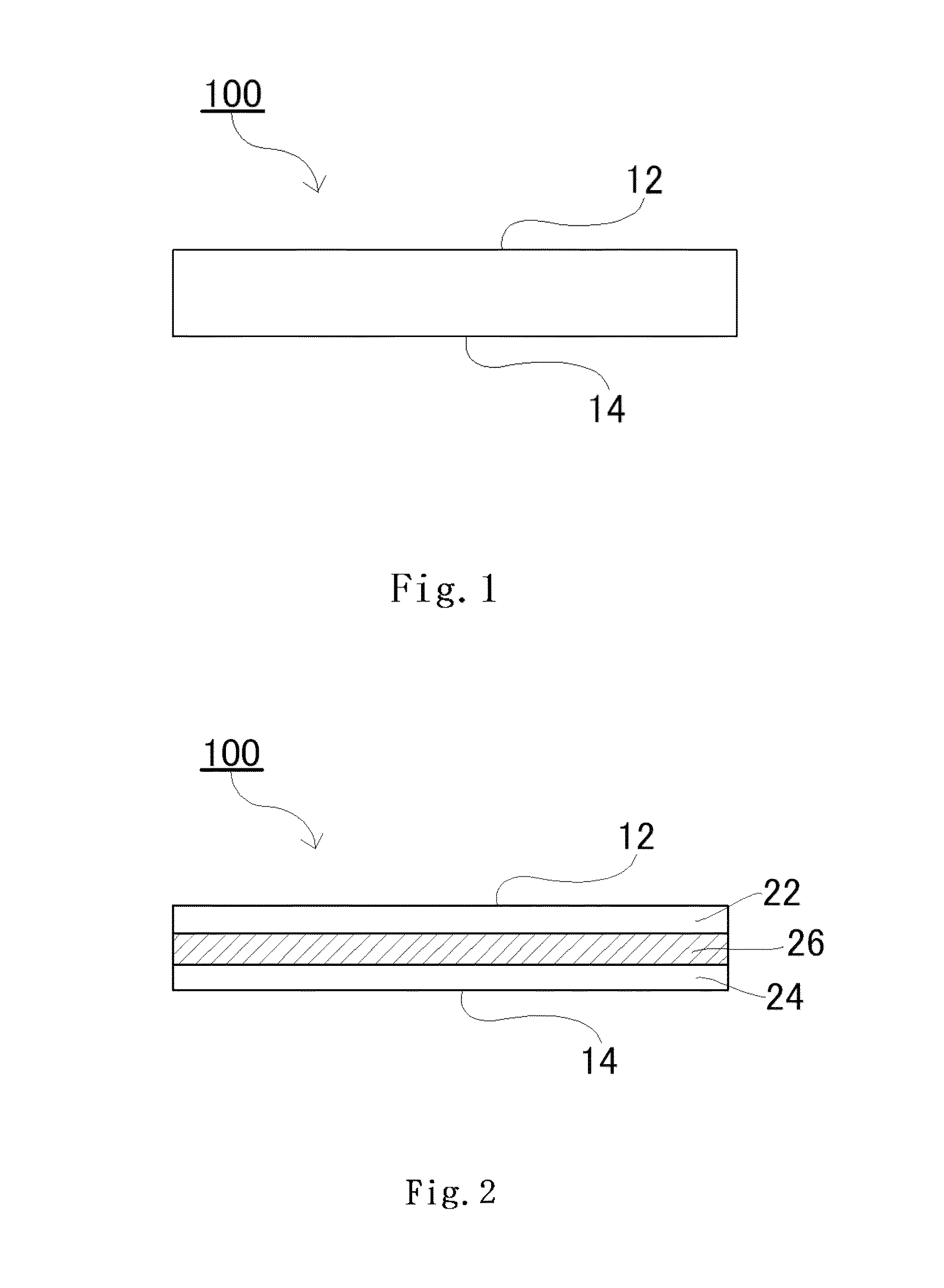

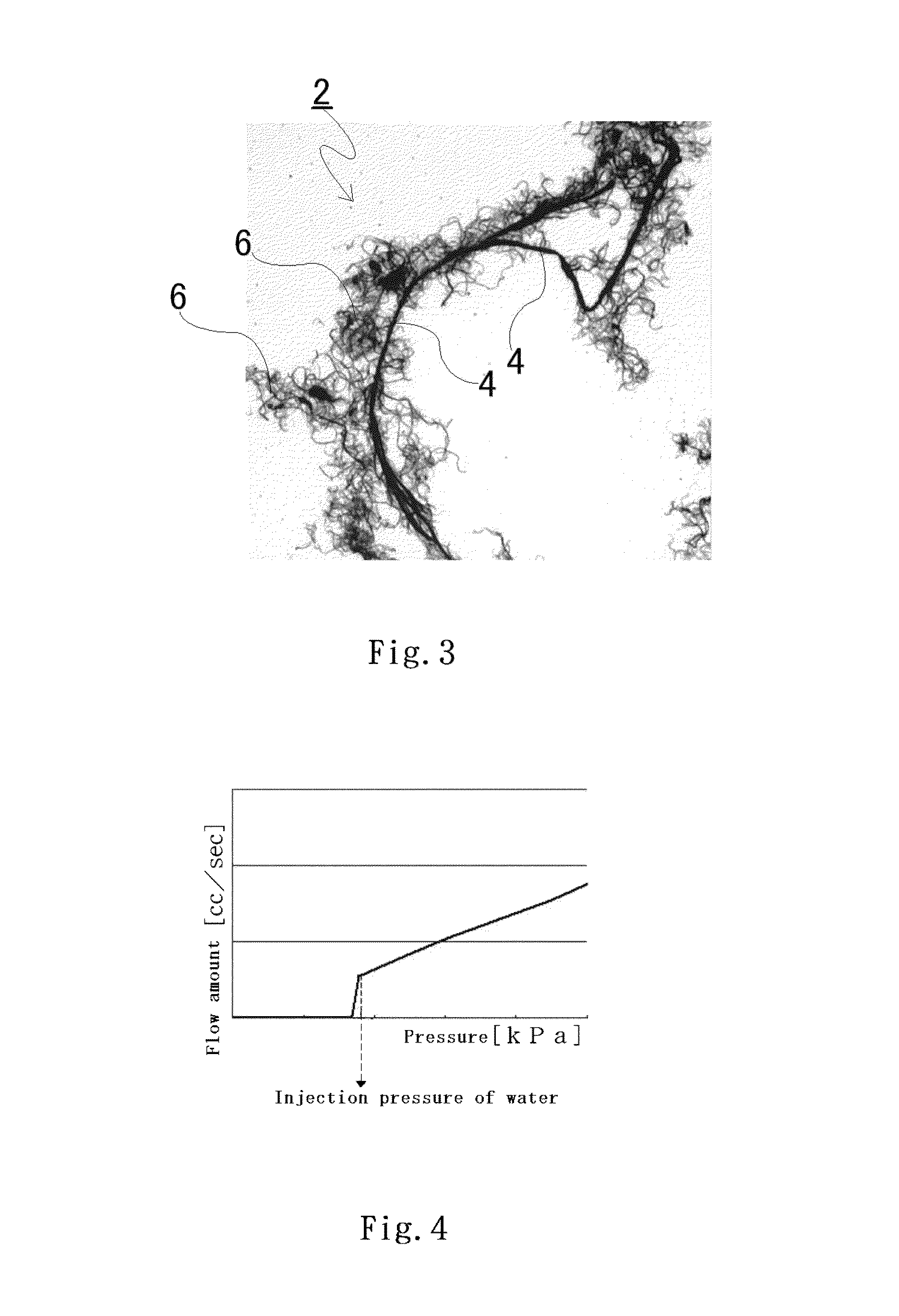

Conductive sheet and production method for same

ActiveUS8916310B2Maintain good propertiesUse of materialFinal product manufactureActive material electrodesInjection pressureAramides

A conductive sheet comprises an aromatic polyamide pulp, a fluoroplastic fused to the aromatic polyamide pulp, and a carbon-based conductive material; wherein the conductive sheet has a static contact angle of water on a first surface that is greater than the static contact angle of water on a second surface that in the opposite surface to the first surface, and the difference between the static contact angle of water on the first surface and the static contact angle of water on the second surface is 20°-180°; or wherein the injection pressure of water on the first surface of the conductive sheet is less than the injection pressure of water on the second surface that is the opposite surface to the first surface, and the difference between the injection pressure of water on the first surface and the injection pressure of water on the second surface is 20-50 kPa.

Owner:TOHO TAYON CO LTD

ETFE thin film panel for perovskite flexible solar panel and preparation method

The invention belongs to the field of ETFE films, and discloses an ETFE film panel for a perovskite flexible solar panel, which comprises the following raw materials: ETFE resin, a functional additive, graphene, an antistatic agent, a tensile agent and a flame retardant, and is characterized in that the melt index of ETFE is 15-25; the functional additive comprises any one or more of a conventional fluoroplastic additive and a conventional engineering additive, and the weight ratio of the ETFE resin to the functional additive to the graphene to the antistatic agent to the tensile agent to theflame retardant is 100: (10-20): (3-5): (1.5-2.5): (5-8): (4-6). The preparation method is simple to operate, the thickness and quality of the product are controllable, the preparation technology is easy to master, the obtained ETFE thin film panel for the perovskite flexible solar panel has high temperature resistance, good chemical property, weather resistance, light transmittance, tensile resistance, non-stick property and insulativity, and the thin film panel does not contain impurities such as dust and is good in product quality.

Owner:银金达(上海)新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com