Ammonia-resistant fluoroplastic composite soft material

A soft material and fluoroplastic technology, applied in the field of ammonia-resistant fluoroplastic composite soft materials, can solve the problems of large volume and poor cooling conditions, and achieve the effects of good slot insulation and phase insulation performance and good ammonia resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

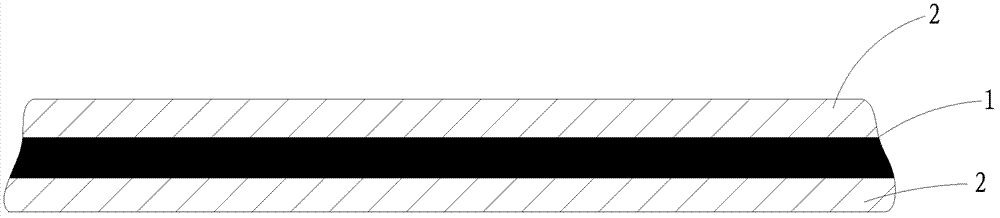

[0018] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

[0019] see figure 1 As shown, a kind of ammonium-resistant fluoroplastic composite soft material, comprises electrician non-alkali glass fiber cloth 1, and the two sides of electrician non-alkali glass fiber cloth 1 are all coated with fluoroplastic coating 2, in this embodiment, fluoroplastic coating Layer 2 is coated with FEP.

[0020] In this ammonia-resistant fluoroplastic composite soft material, fluoroplastics can work in liquid and gaseous ammonia environments without being damaged, but the mechanical strength of fluoroplastic films is not ideal, as long as there is a small crack in one direction , the film cracks very quickly, so it is not practical, so it is necessary to select a suitable material to strengthen it, and the electrician alkali-free glass fiber cloth 1 is the most suitable material selected from many tests as its reinfo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com