Patents

Literature

296 results about "Gaseous ammonia" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

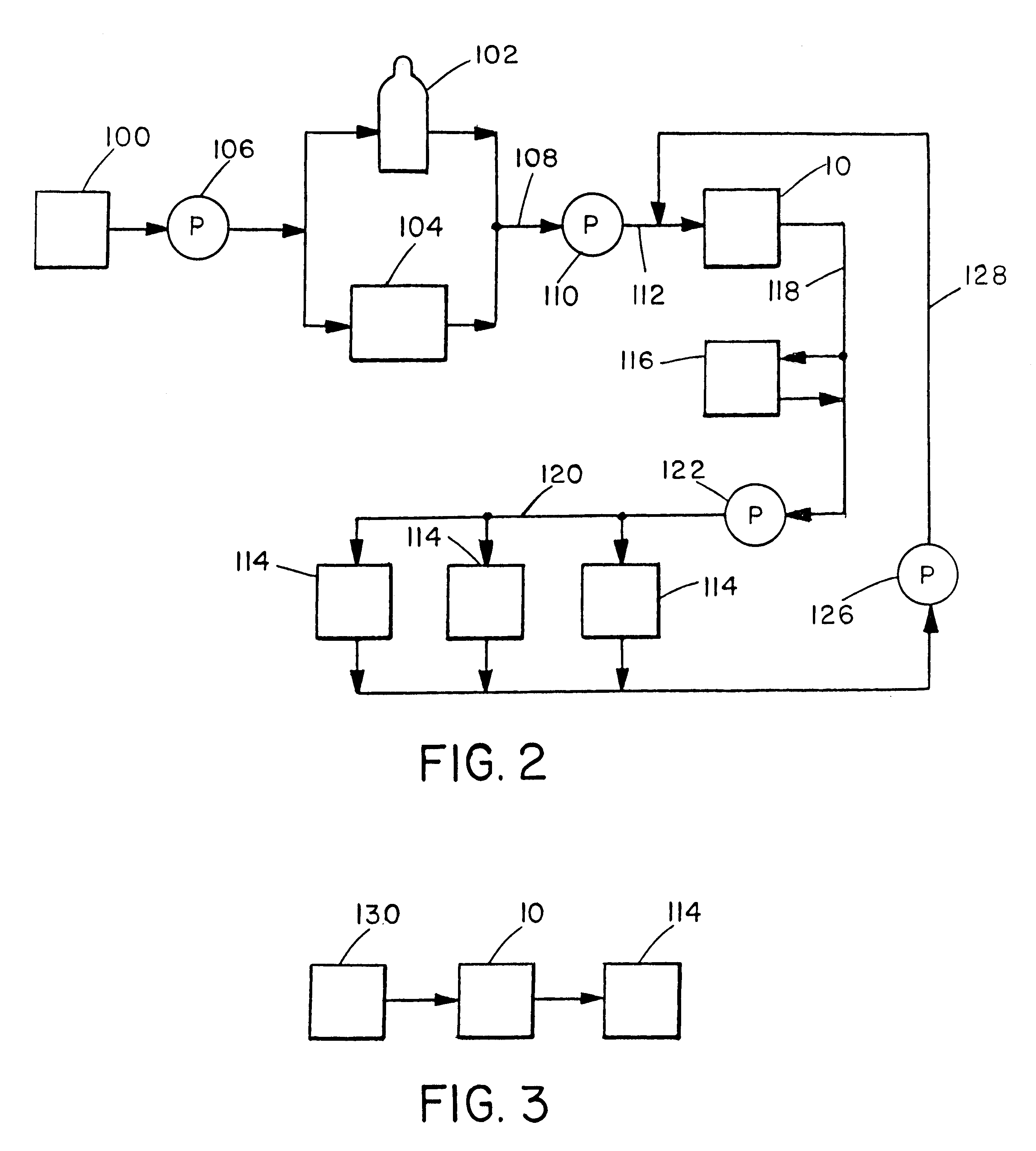

Systems and Methods of Urea Processing to Reduce Sorbent Load

InactiveUS20100184198A1Bioreactor/fermenter combinationsBiological substance pretreatmentsAmmonium compoundsSorbent

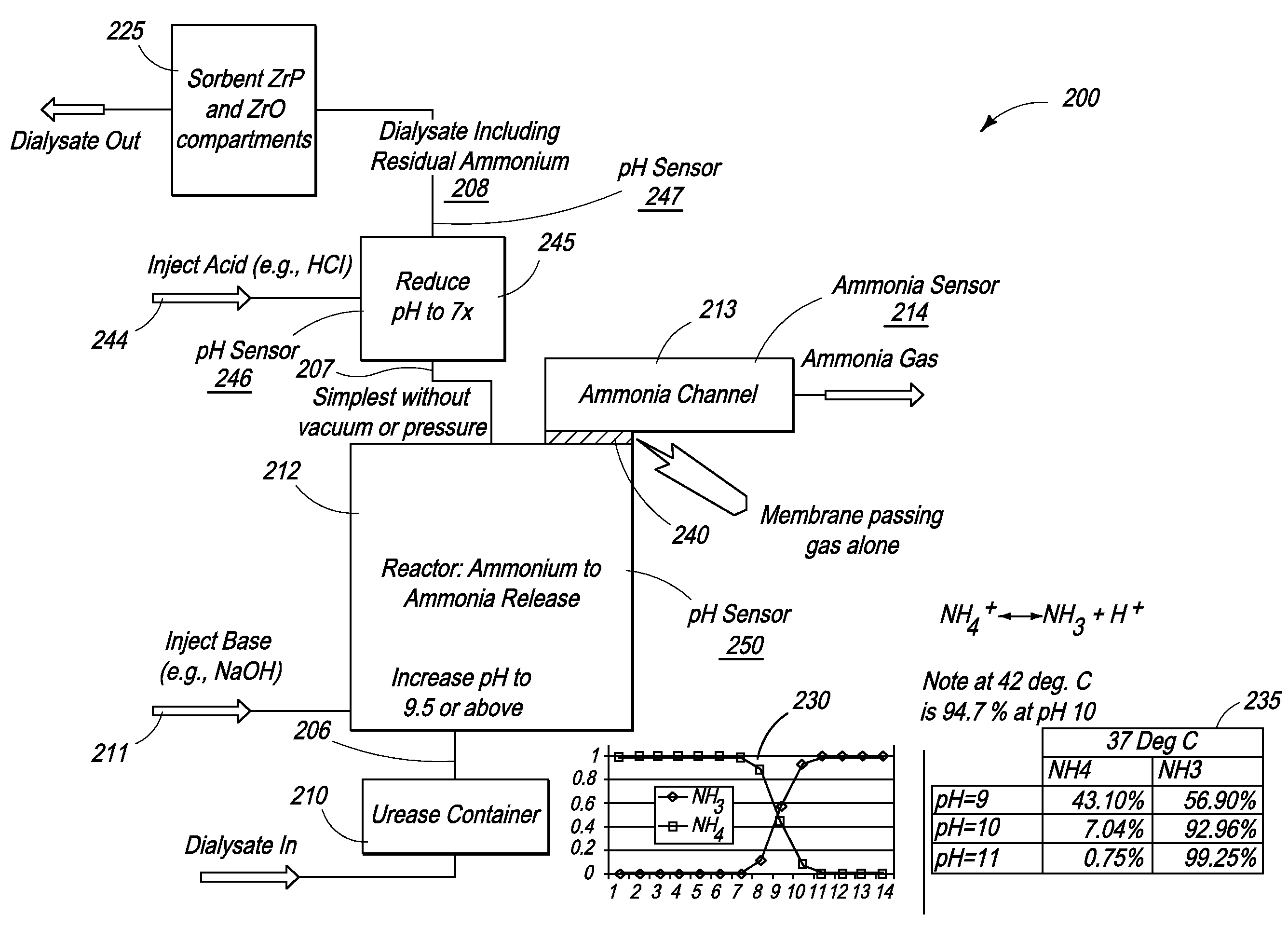

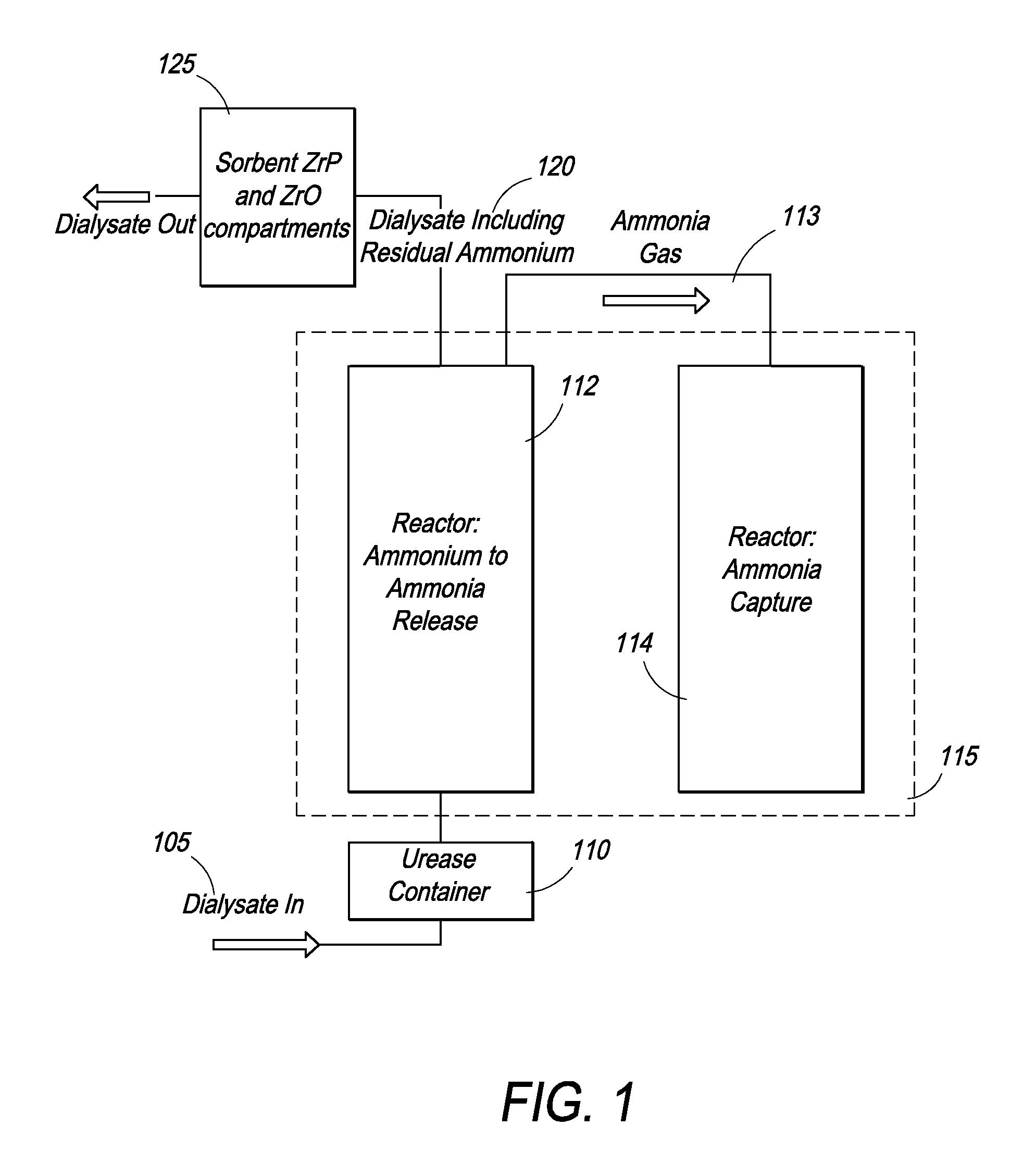

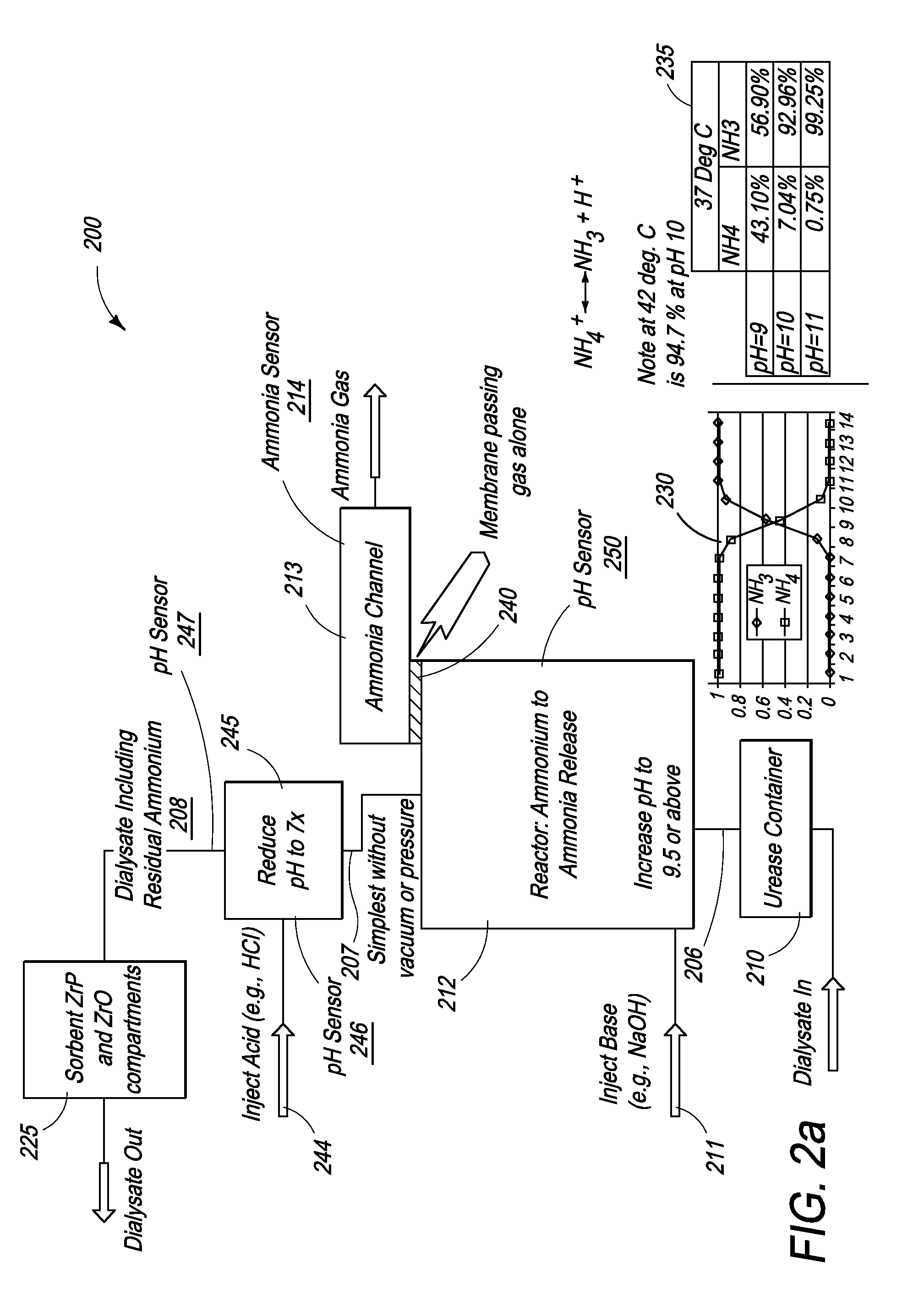

The present invention provides novel methods for removal and disposal of ammonia from spent dialysate in a dialysis system. Ammonium ions present in spent dialysate are converted into gaseous ammonia by raising the pH of the spent dialysate solution in a first reactor. Gaseous ammonia diffuses through a semi-permeable hydrophobic membrane at the outlet of the first reactor and into a second reactor via a gas channel. The second reactor converts gaseous ammonia into an ammonium compound for easy disposal.

Owner:FRESENIUS MEDICAL CARE HLDG INC

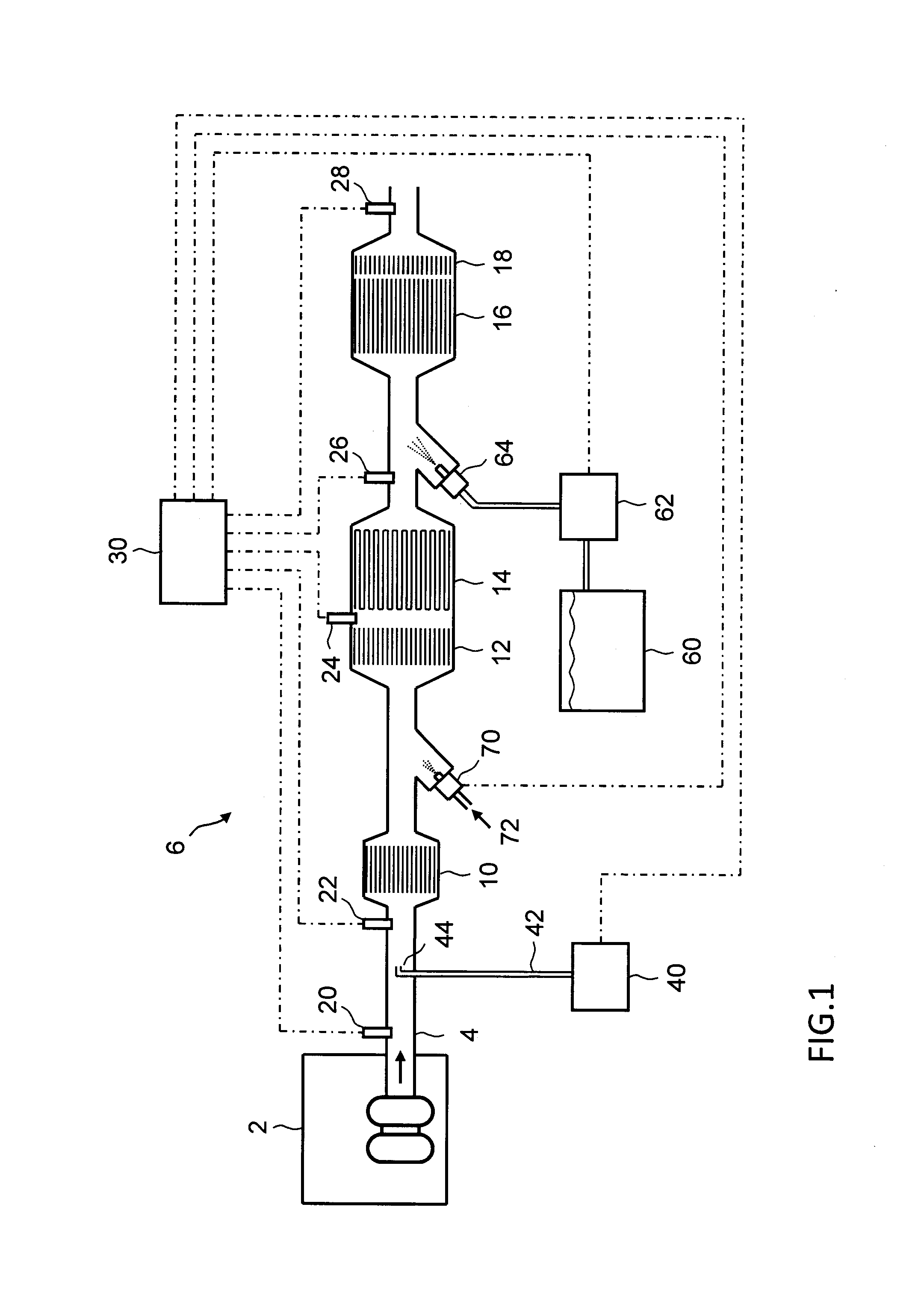

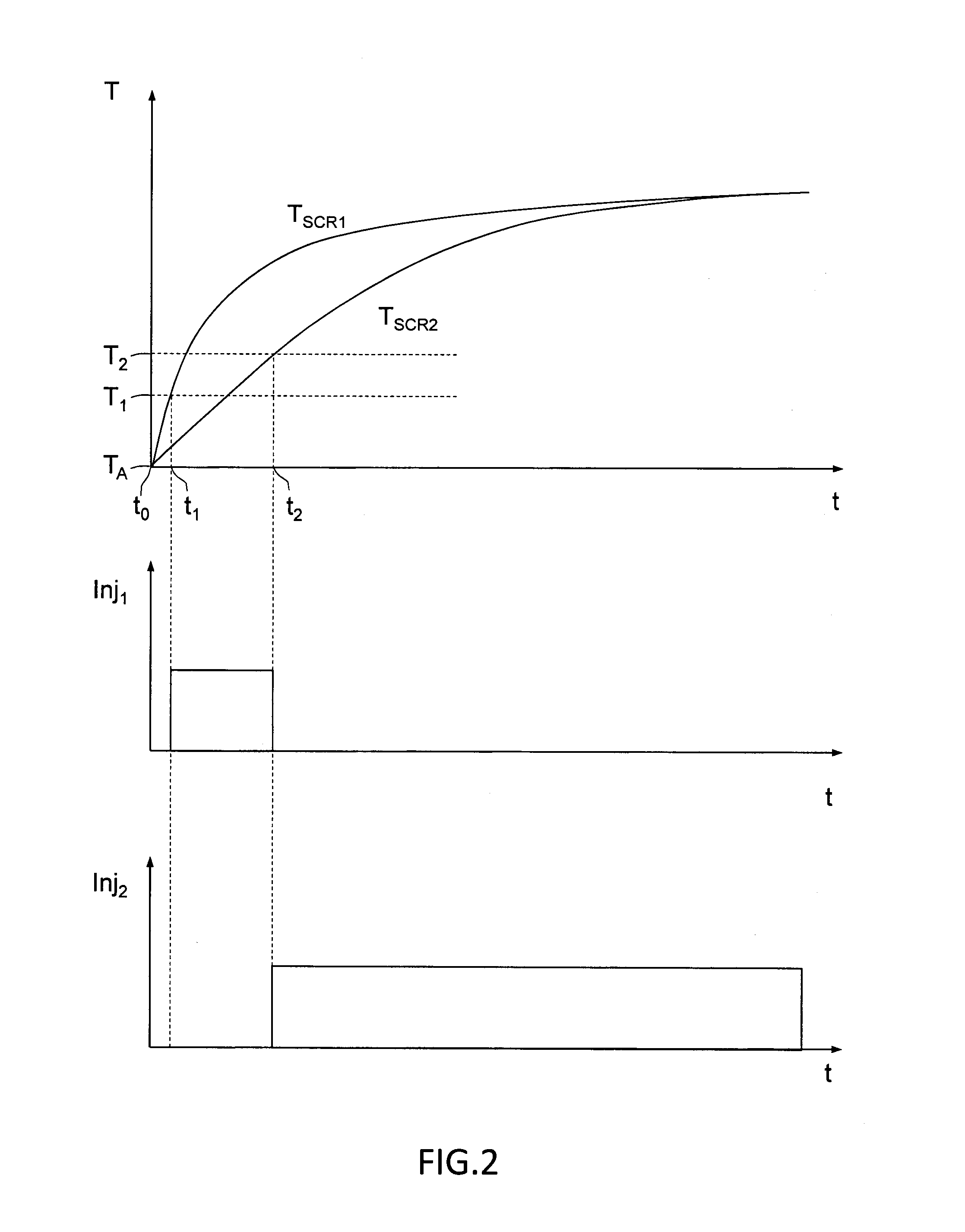

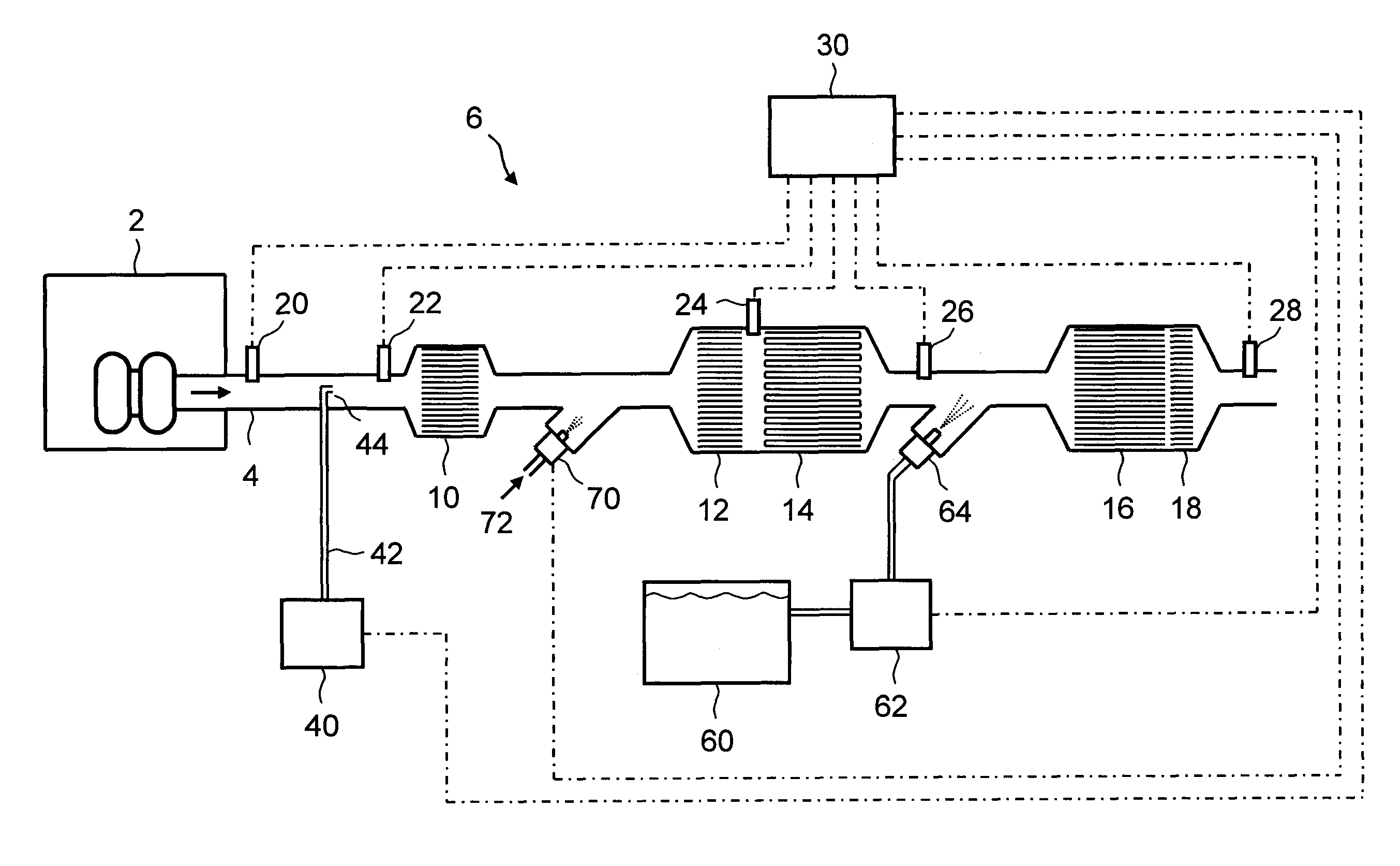

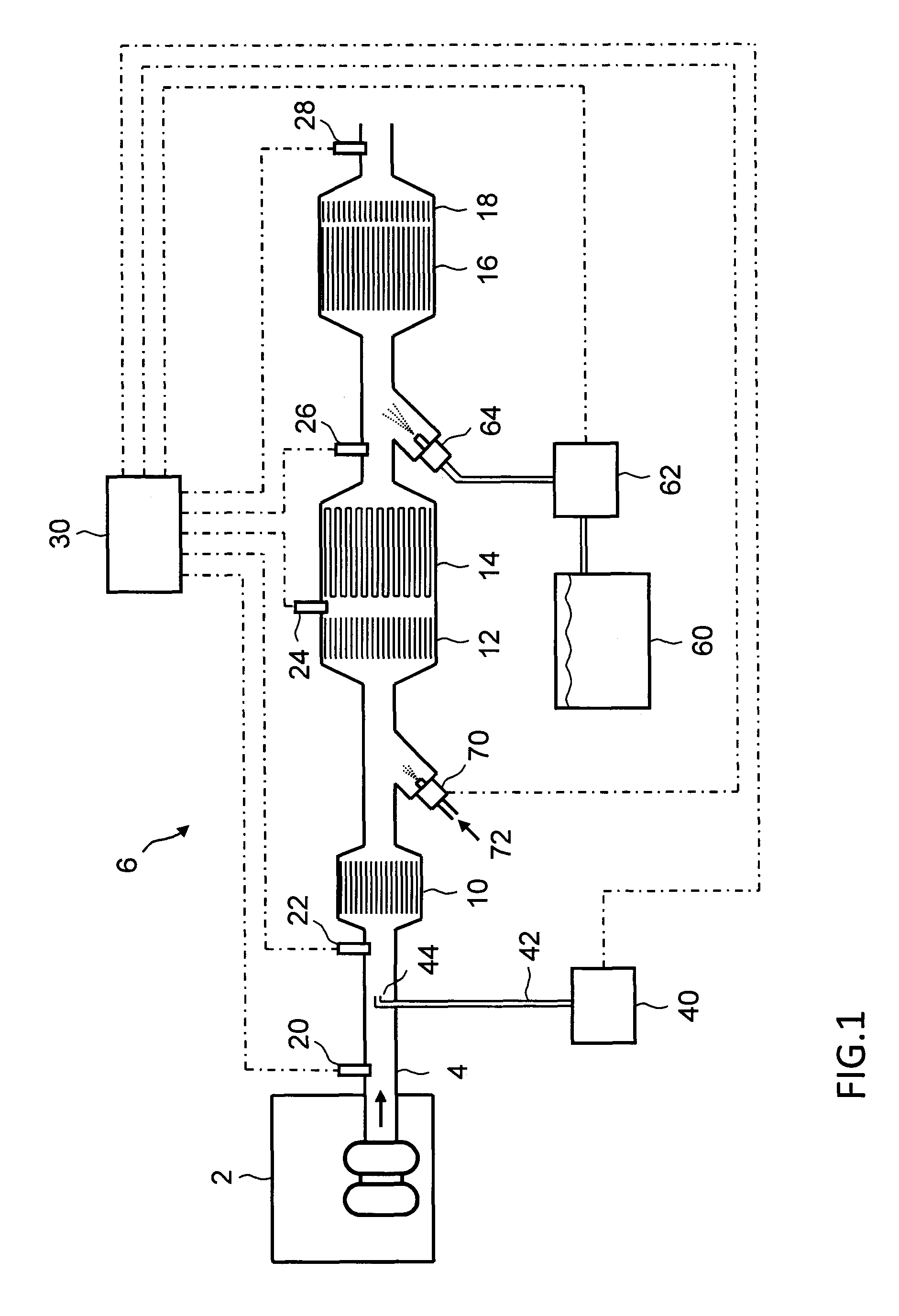

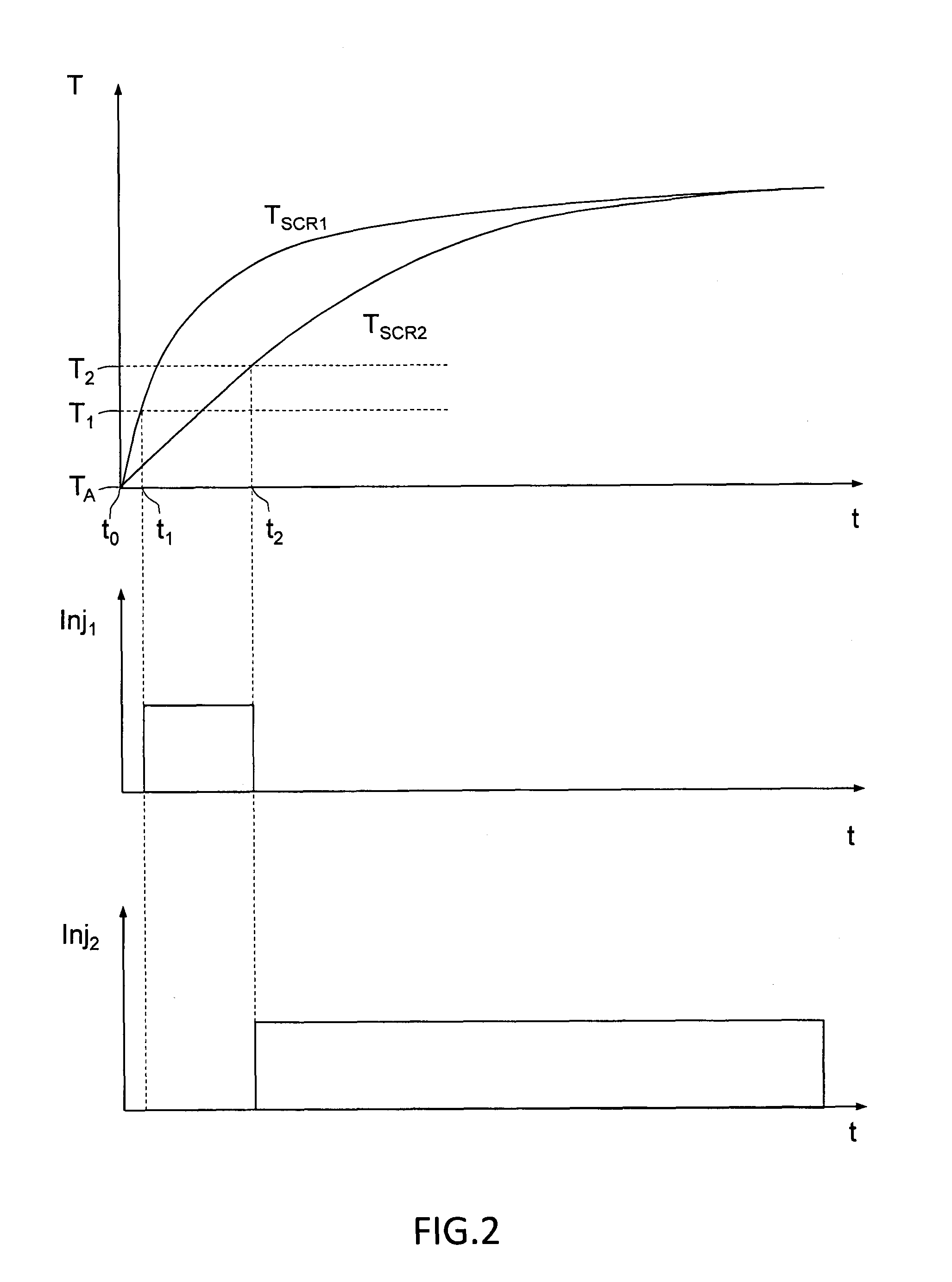

Exhaust aftertreatment system and method for operating the system

ActiveUS20140363358A1Fast warm-upFast and economical controlCombination devicesInternal combustion piston enginesEnvironmental engineeringGaseous ammonia

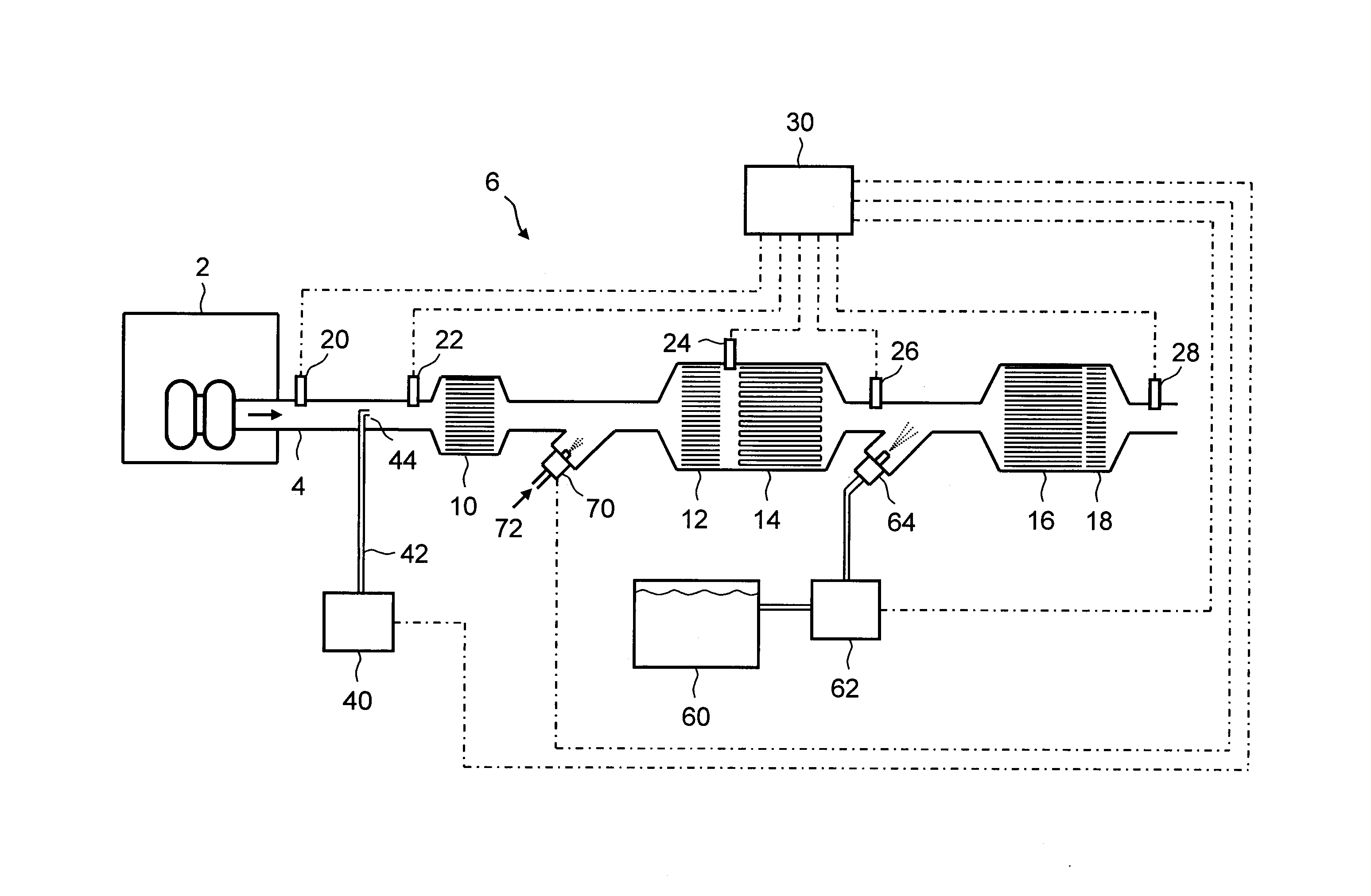

An exhaust system includes a first SCR catalyst and a second SCR catalyst positioned downstream of the first SCR catalyst. A first injector is provided upstream of the first SCR catalyst, and a second injector is provided upstream of the second SCR catalyst. The exhaust system further includes a gaseous ammonia supply device fluidly connected to the first injector for supplying gaseous ammonia to the exhaust gas by the first injector, and an ammonia-containing reductant reservoir fluidly connected to the second injector for supplying a fluid ammonia-containing reductant, such as urea, to the exhaust gas by the second injector. The first SCR catalyst has a smaller volume than the second SCR catalyst for a fast warm-up of the first SCR catalyst.

Owner:VOLVO LASTVAGNAR AB

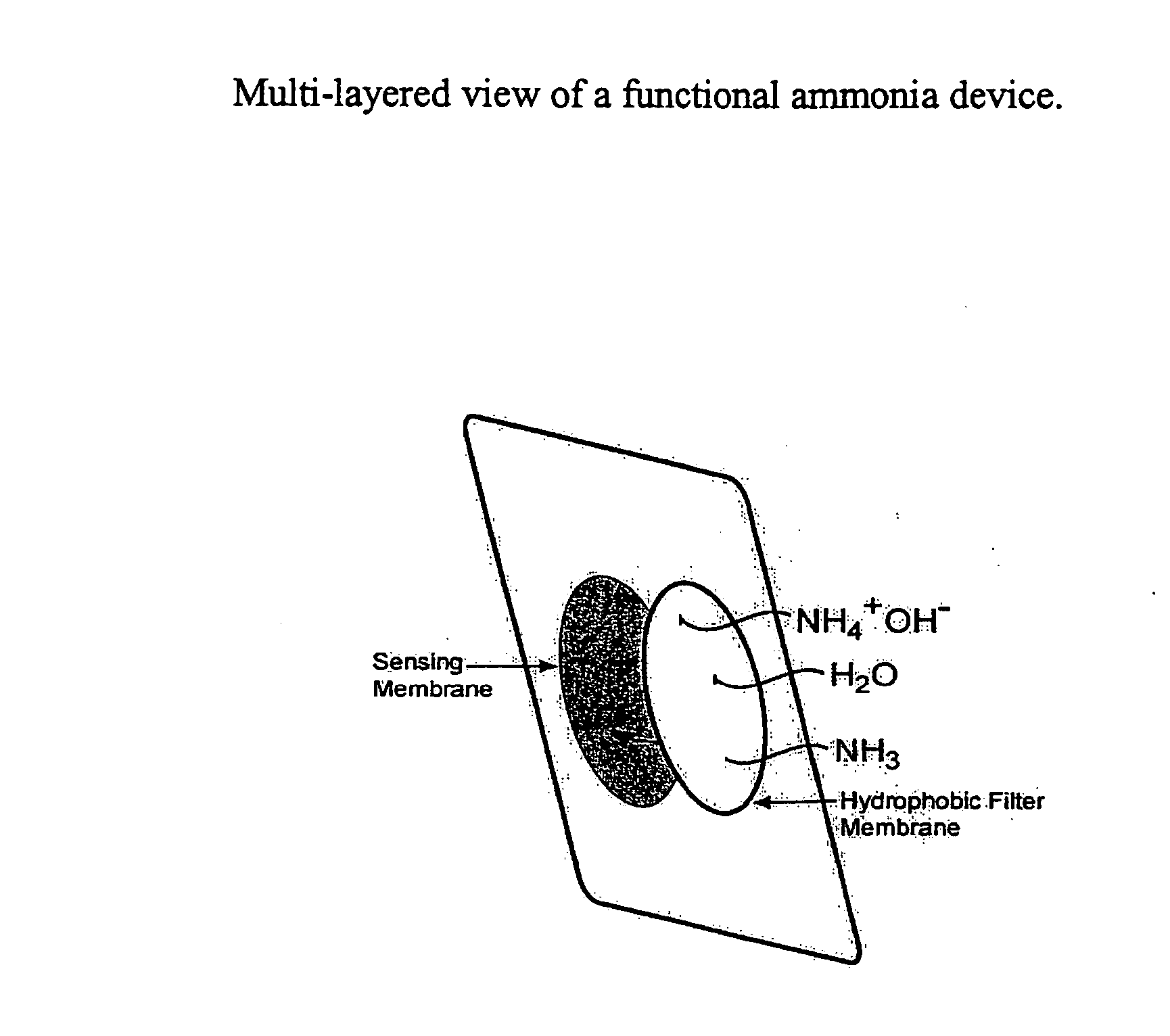

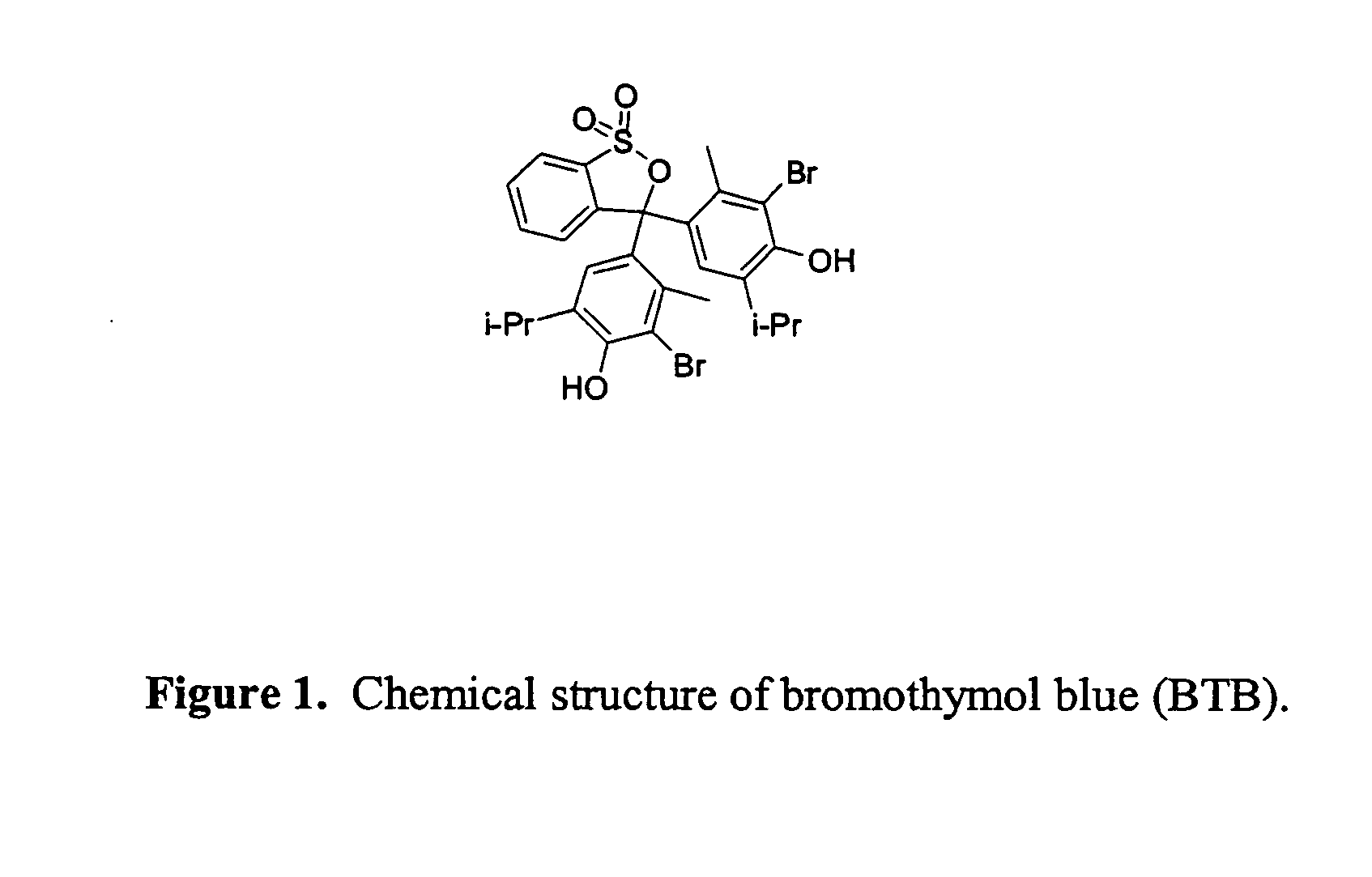

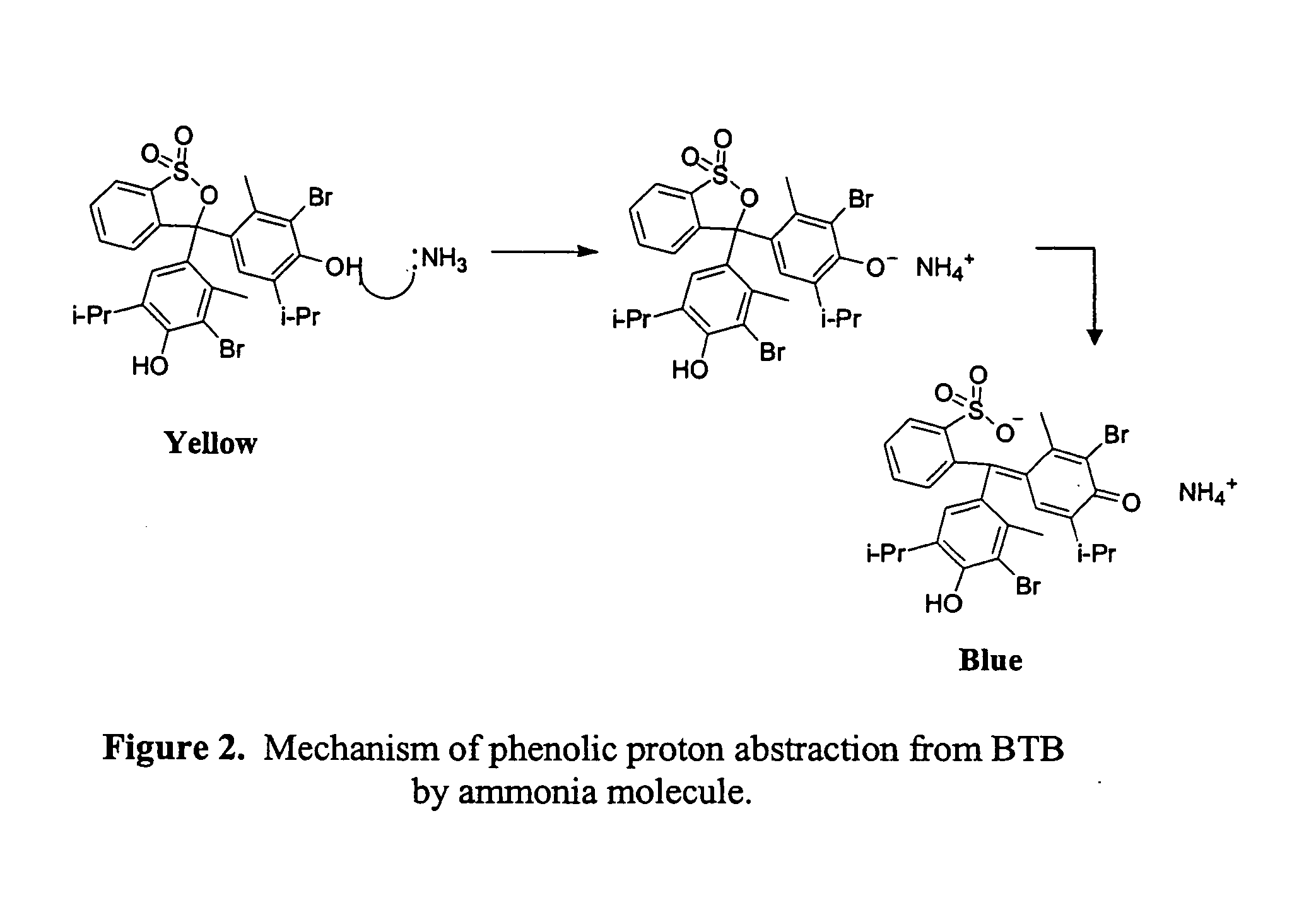

Ammonia detection device and related methods

InactiveUS20080041136A1Quickly and easily measuring and monitoring ammonia concentrationAnalysis using chemical indicatorsMaterial analysis by optical meansPolyamideGaseous ammonia

A reusable device for continuously monitoring gaseous ammonia concentration in a surrounding environment comprising a plurality of layers, including an active layer in which a dye (e.g., an indicator dye useful for measurement of pH) is immobilized to a membrane (e.g., polyamide membrane), and a hydrophobic filter layer capable of permitting contact between the active membrane and dissolved gaseous ammonia.

Owner:SERGEANTS PET CARE PRODS

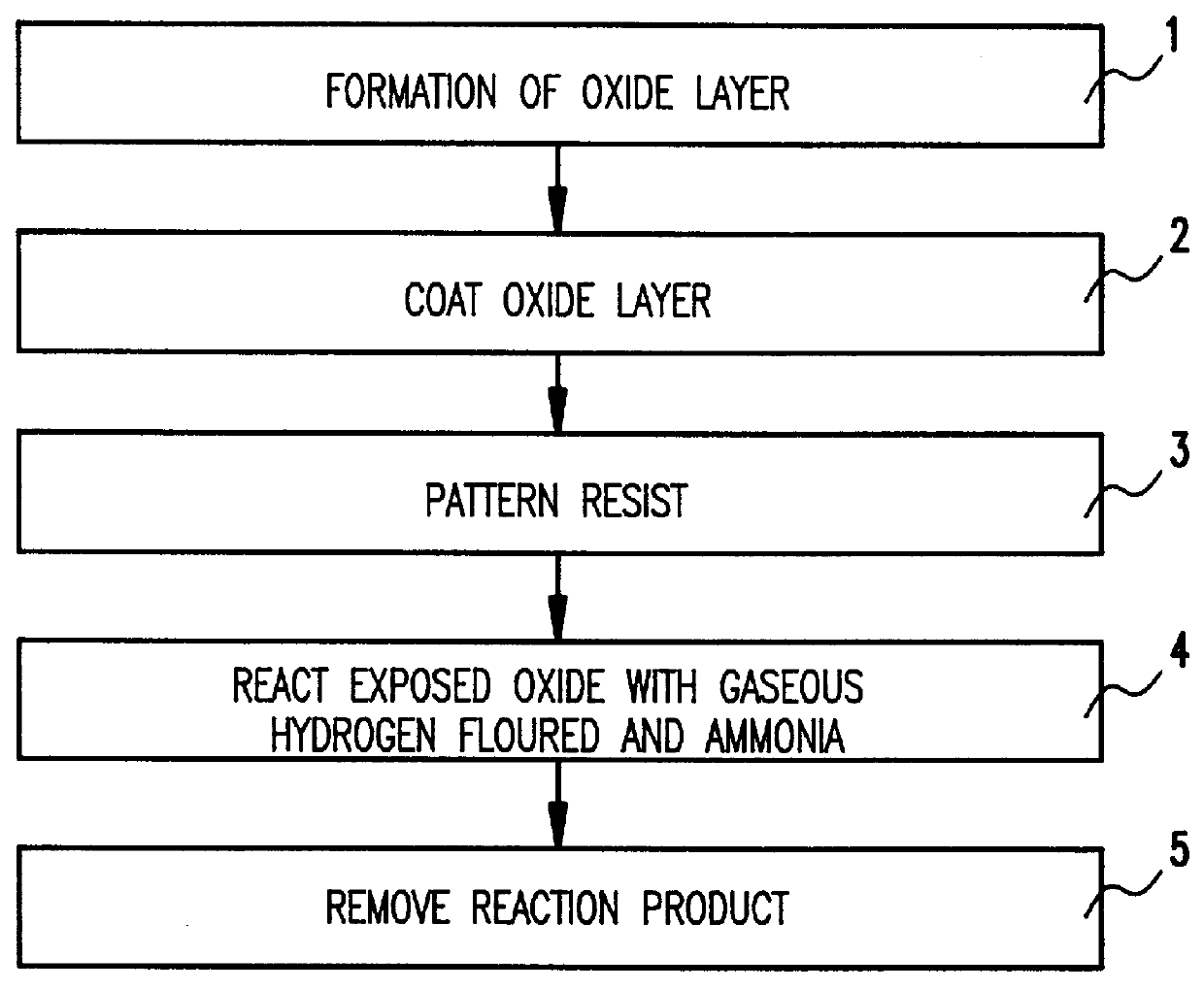

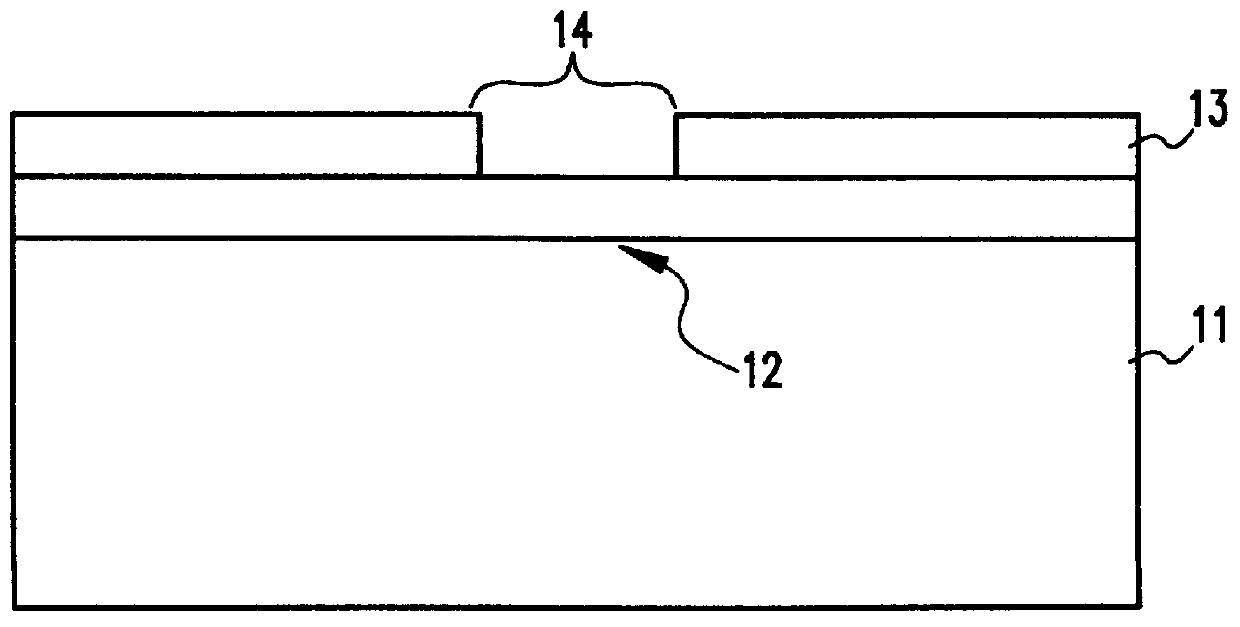

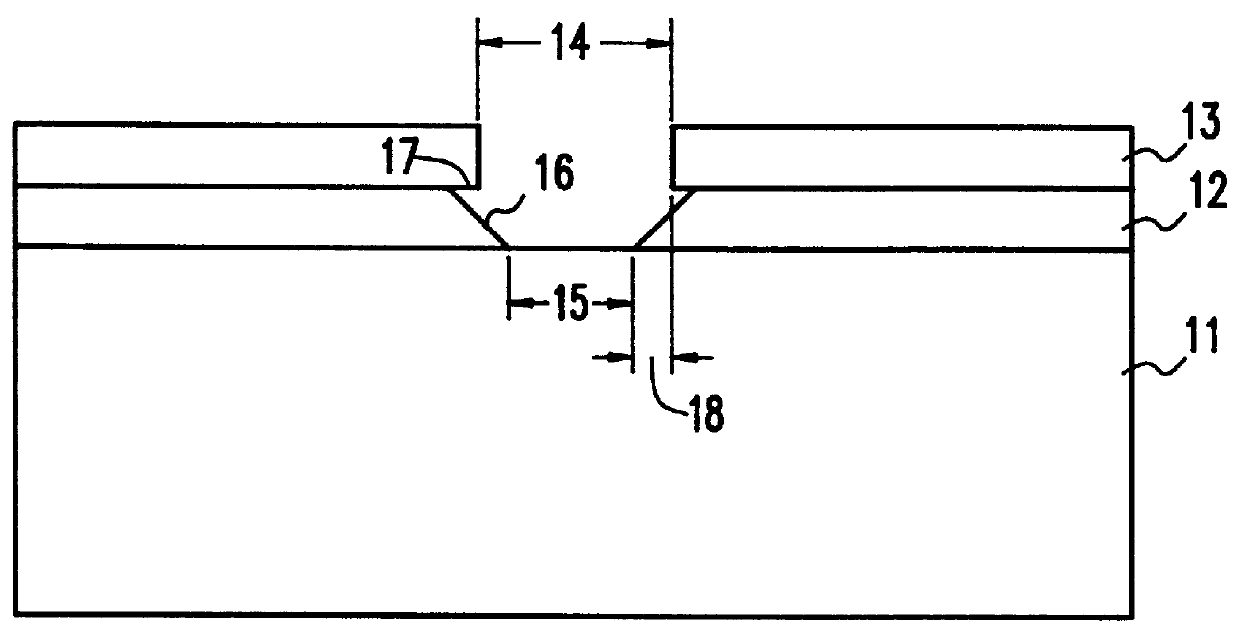

Vapor phase etching of oxide masked by resist or masking material

Hydrogen fluoride undercut of oxide layers may be reduced by using a low pressure mixture of gaseous hydrogen fluoride and gaseous ammonia mixture. Organic photoresists can be used as a masking material when using the gaseous hydrogen fluoride / ammonia mixture without resulting in an enhanced reaction rate. In addition, because of the reaction conditions, the dimensions in the oxide layer being etched can be specifically sized smaller than openings made in the overcoating masking material.

Owner:IBM CORP

Duplex coated steel composite products and method of manufacturing them

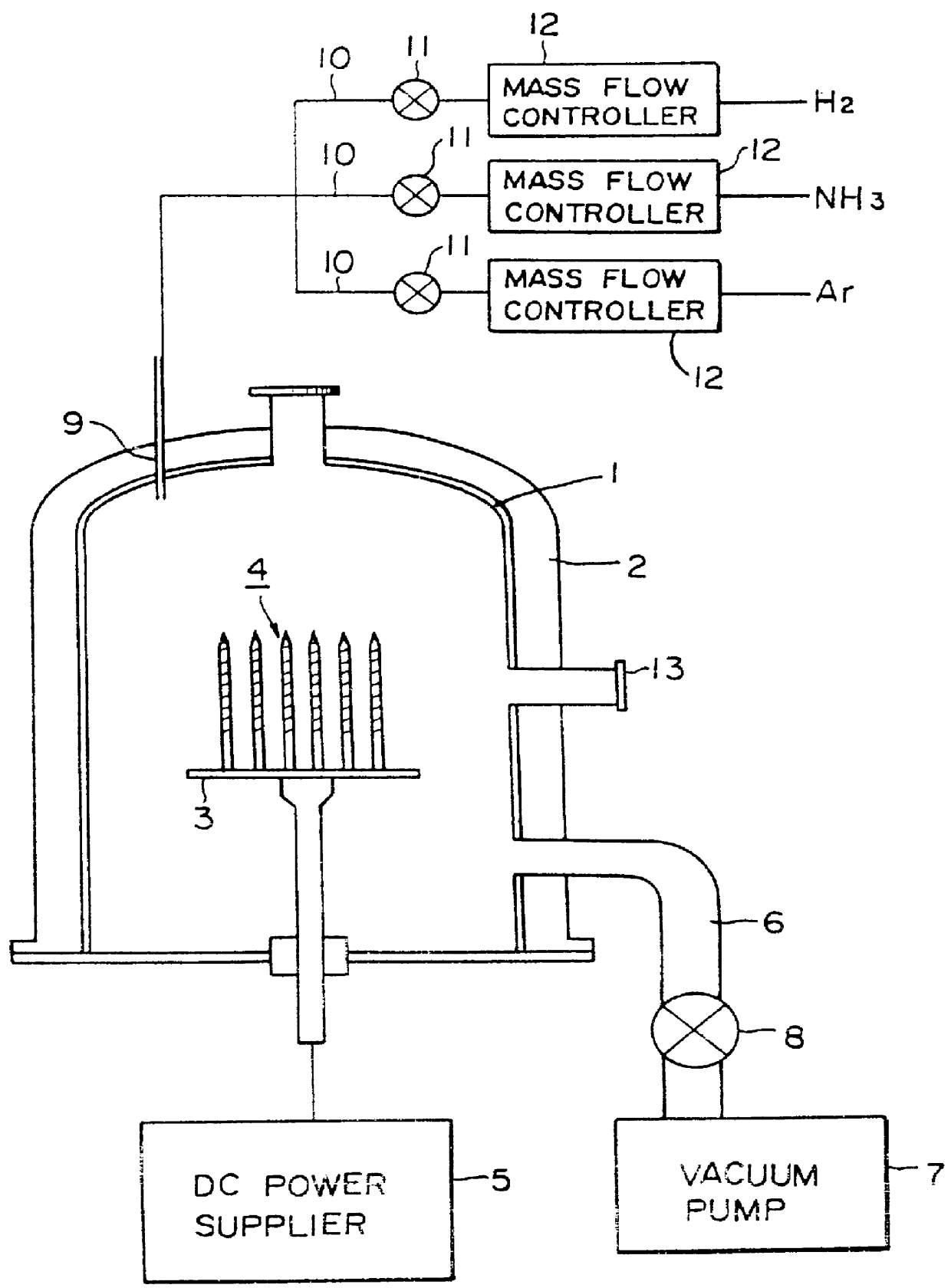

InactiveUS6110571AEasy to useElevation is easyVacuum evaporation coatingSputtering coatingCarbidePlasma nitridation

Duplex coated steel composite products comprising a first layer of a nitrided layer formed by applying glow discharge at a current density from 0.001 to 2.0 mA / cm2 to the surface of metal parts by using gaseous ammonia and gaseous hydrogen while maintaining the temperature of the metal parts at 300 to 650 DEG C., thereby applying plasma nitriding and a second layer comprising a hard film comprising a nitride, carbide and / or carbonitride of one or more of elements selected from Ti, Zr, Hf, V, Nb, Ta and Cr coated on the first layer by the PVD method of a laminate film or a gradient laminate film of such hard film. The treated products are excellent in adhesion with the substrate and durability and have both oxidation resistance and wear resistance.

Owner:SUMITOMO METAL MINING CO LTD

Method for chemically modifying tobacco during curing

ActiveUS7293564B2Reducing nicotine contentReduce contentTobacco preparationTobacco treatmentCompound (substance)Gaseous ammonia

A method for chemically modifying a tobacco material during a curing process involves treating the tobacco material in a curing enclosure at a temperature and for a time sufficient to produce cured tobacco. The method also involves contacting the tobacco material with a chemical reagent before and / or during the time period that the tobacco material is cured so that the chemical reagent can interact with the tobacco material, thus resulting in further change in the chemical nature of the cured tobacco material. An exemplary chemical reagent is an ammonia source, which can be applied to a tobacco material in a variety of ways, including by spraying an aqueous ammonia source onto the tobacco or by introducing gaseous ammonia into the curing enclosure during the curing process.

Owner:R J REYNOLDS TOBACCO COMPANY

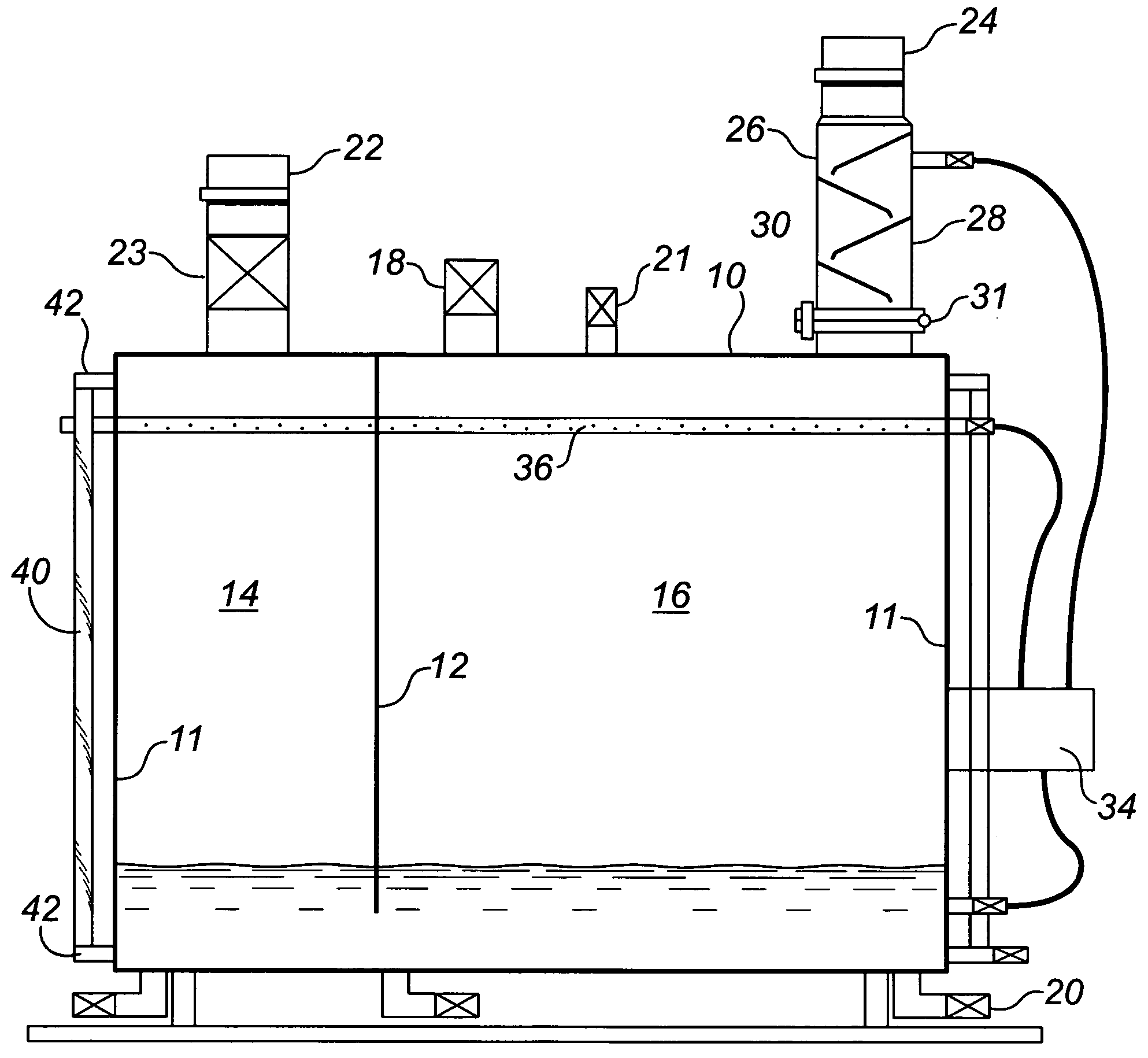

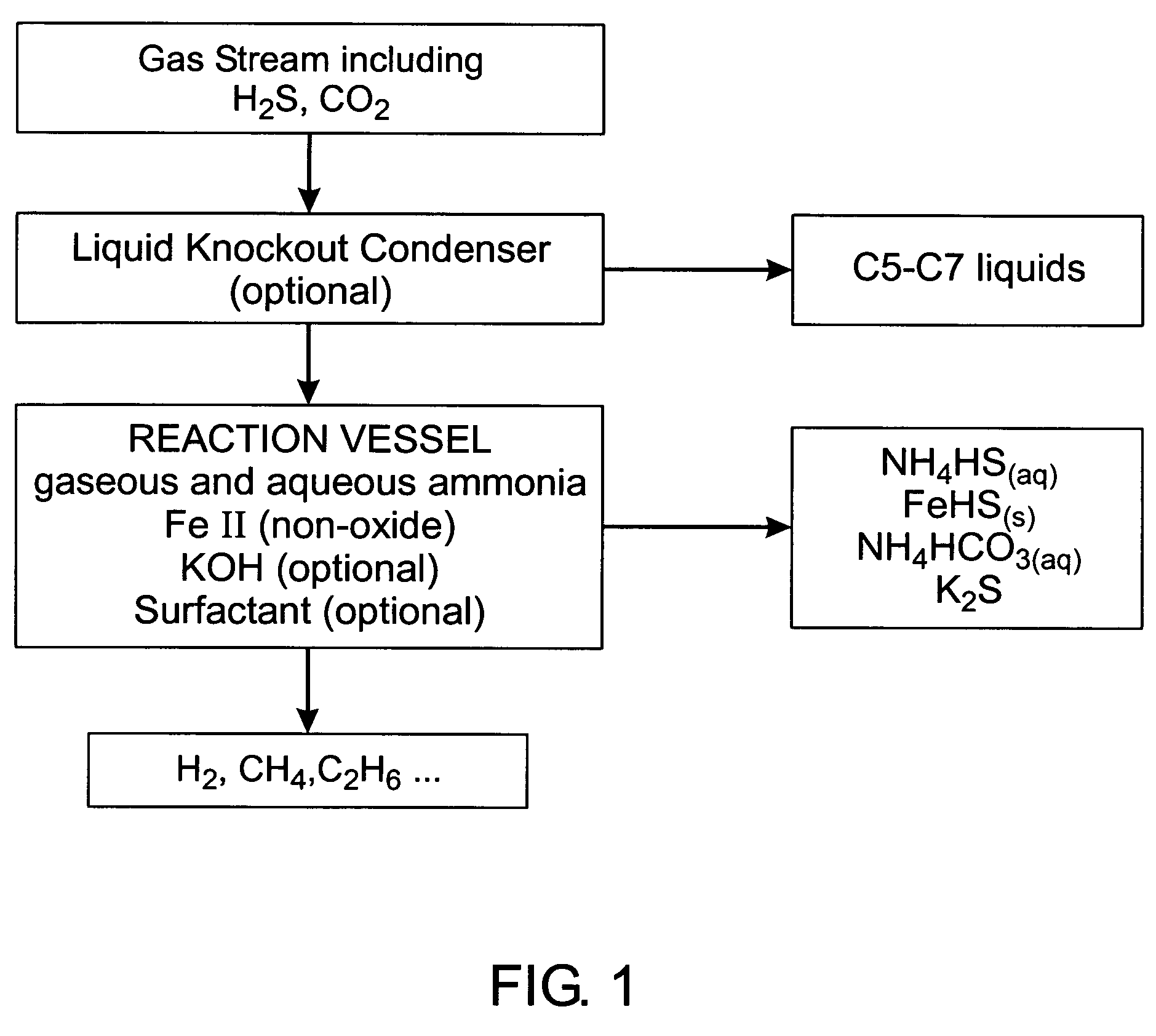

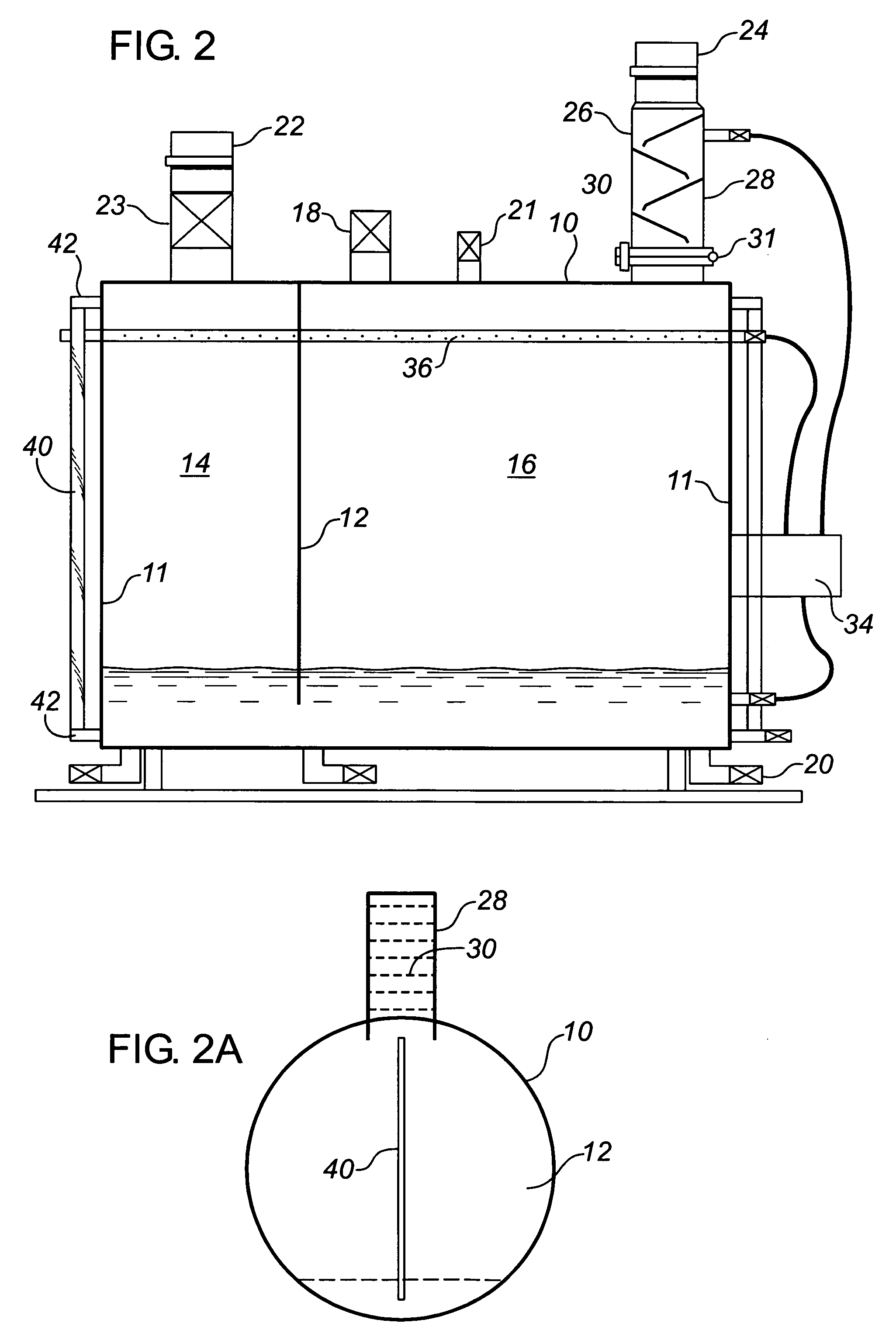

Method and apparatus for hydrogen sulphide removal

InactiveUS7144555B1Efficient and effectiveEfficiently and effectively accomplishedCombination devicesExhaust apparatusGaseous ammoniaFerric

A method for removing hydrogen sulphide and carbon dioxide from a gas stream includes the step of contacting the gas stream with aqueous and gaseous ammonia in a closed vessel in the presence of solid iron. An apparatus for removing hydrogen sulphide and carbon dioxide from a gas stream includes a closed vessel for containing aqueous and gaseous ammonia and an iron source. The vessel is partitioned into inlet and outlet chambers and may itself serve as the iron source.

Owner:WELL TO WIRE EMISSIONS CONTROL

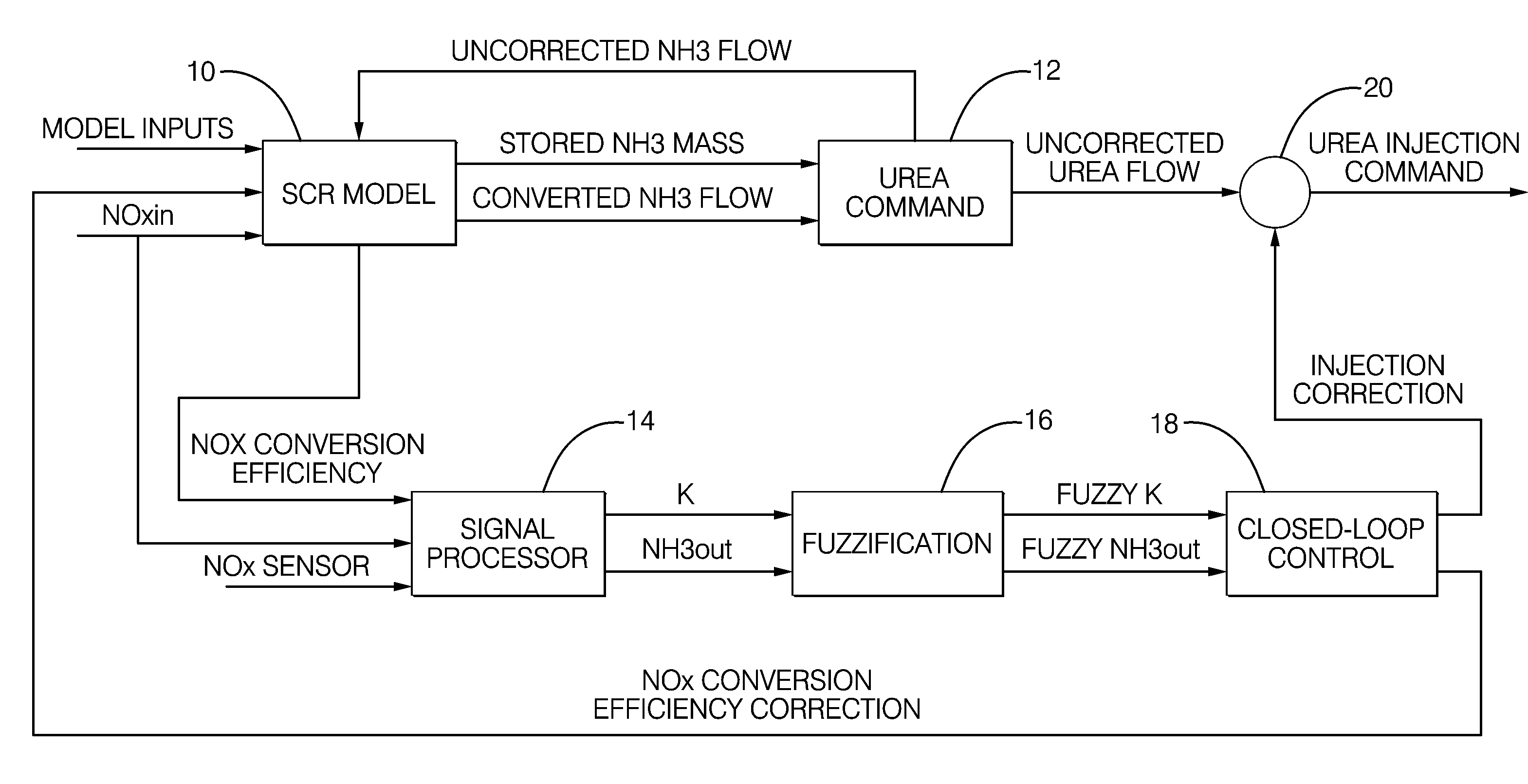

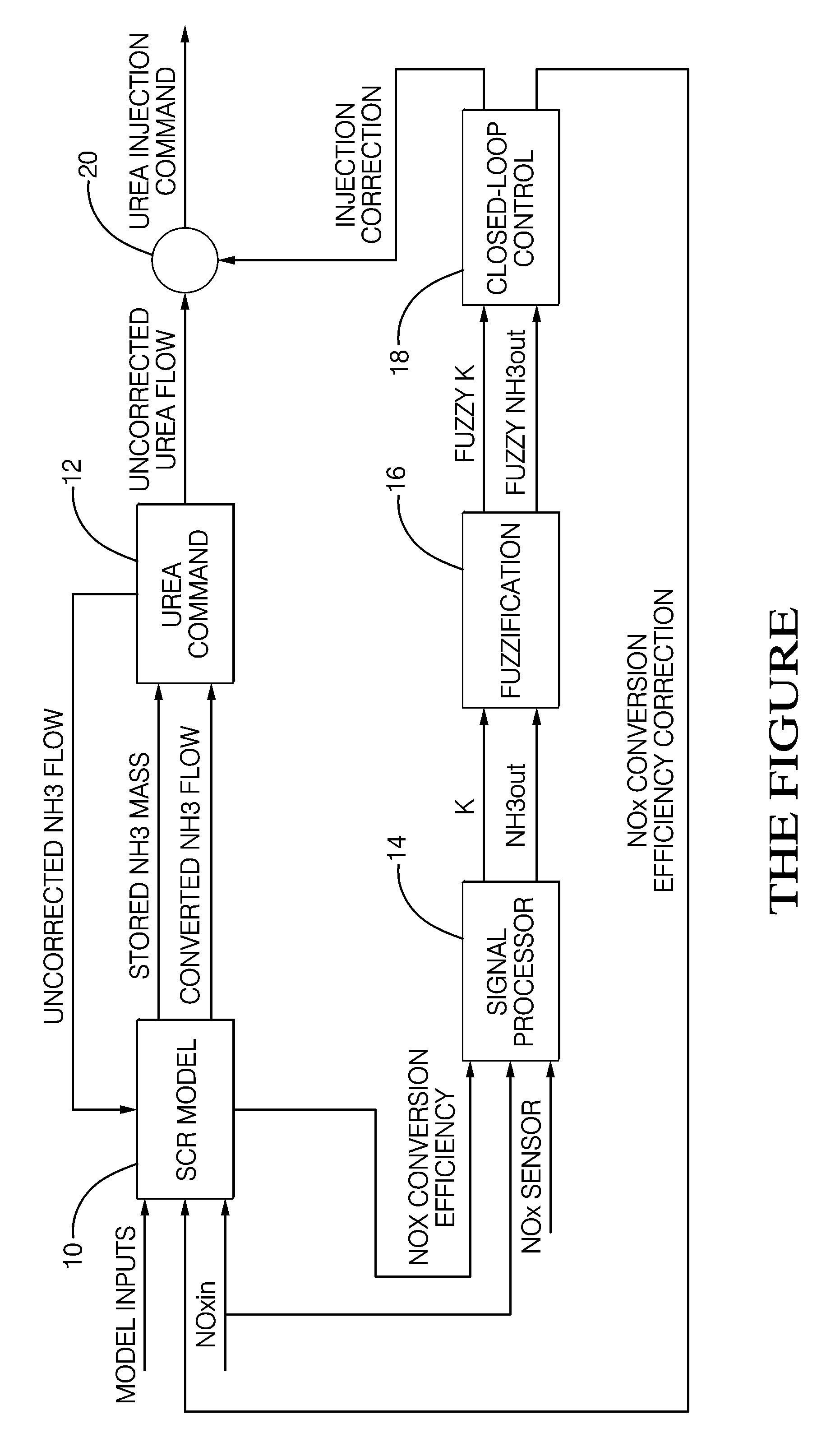

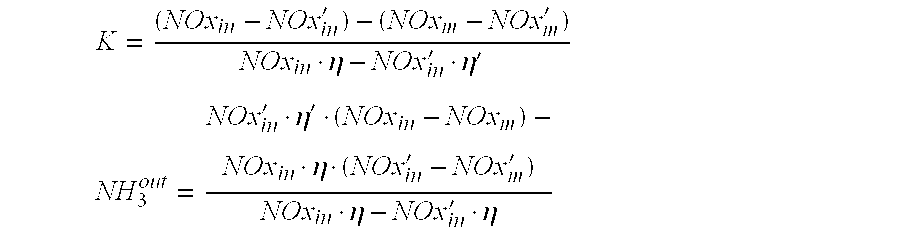

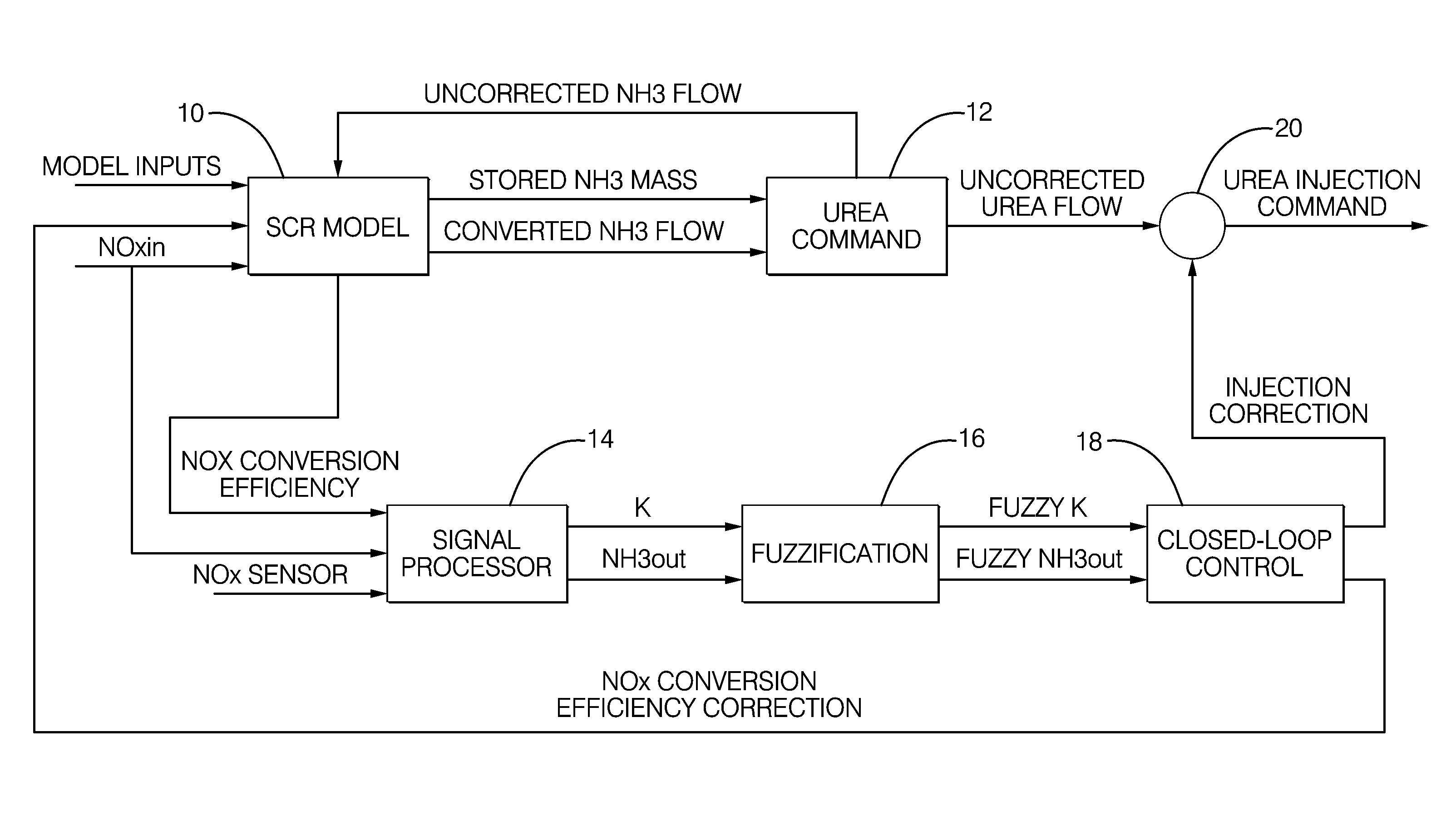

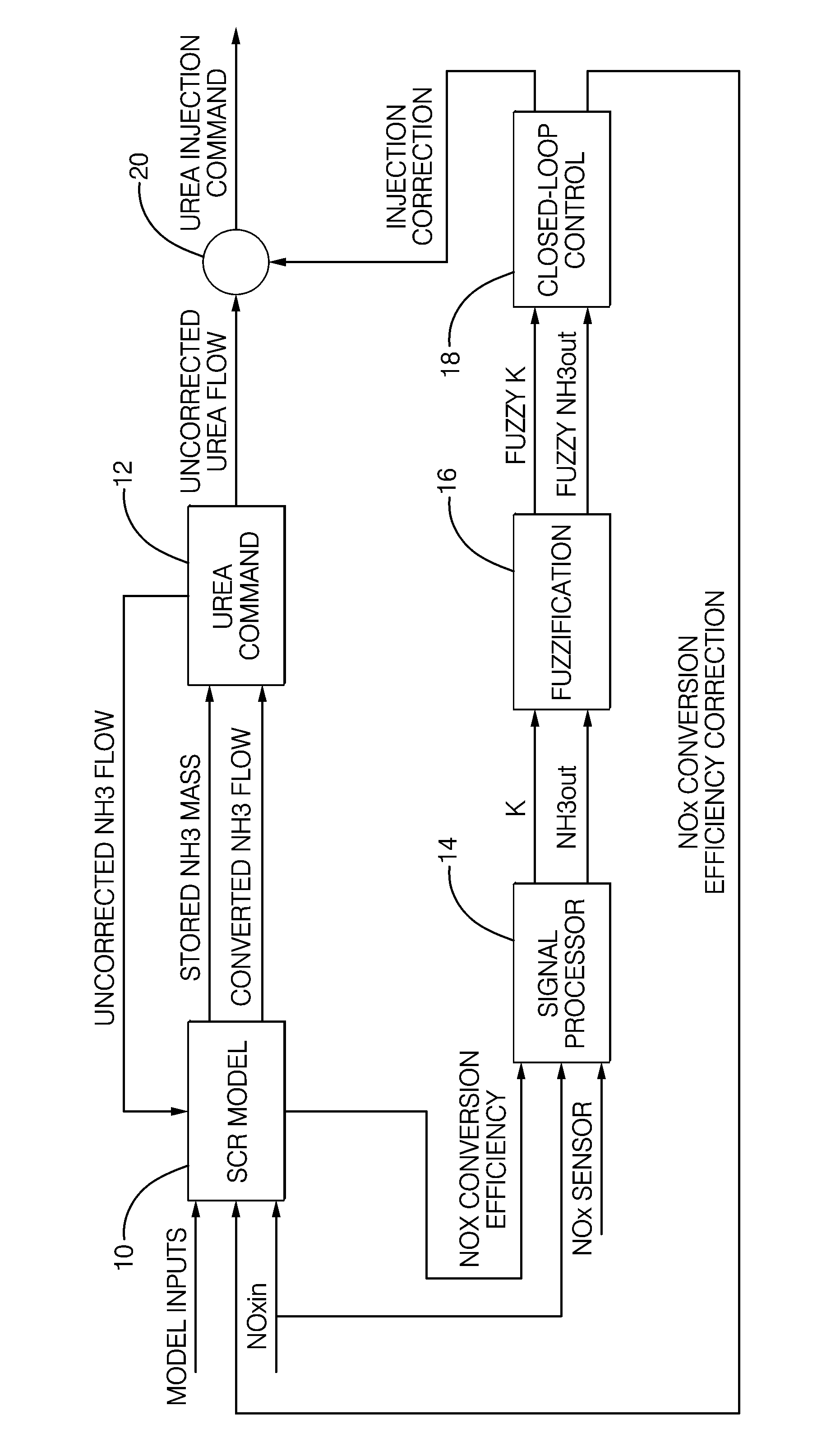

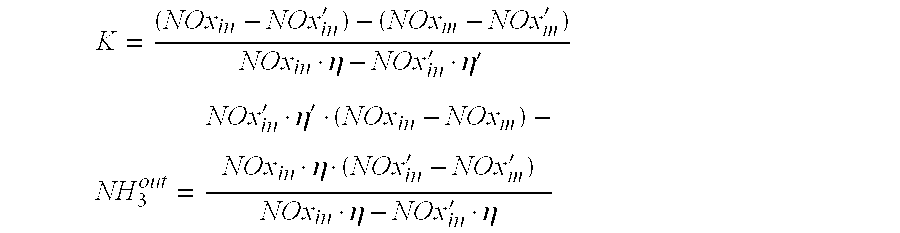

Method for controlling a scr catalyst

ActiveUS20100107609A1Reduce supplyNitrous oxide captureInternal combustion piston enginesClosed loopInternal combustion engine

A method for controlling a selective catalytic reduction catalyst in an exhaust line of an internal combustion engine is disclosed, wherein the supply of a quantity of a gaseous ammonia reductant to the SCR catalyst uses a closed-loop SCR catalyst model coupled to a SCR-out NOx sensor that measures a SCR-out NOx emission value. The closed-loop SCR catalyst model uses a relationship linking the measured SCR-out NOx value to the NOx conversion efficiency and the ammonia slip. The actual NH3 emission value and / or an actual SCR-out NOx indicative value are computed based upon differentiation of said relationship.

Owner:DELPHI INT OPERATIONS LUXEMBOURG S A R L +1

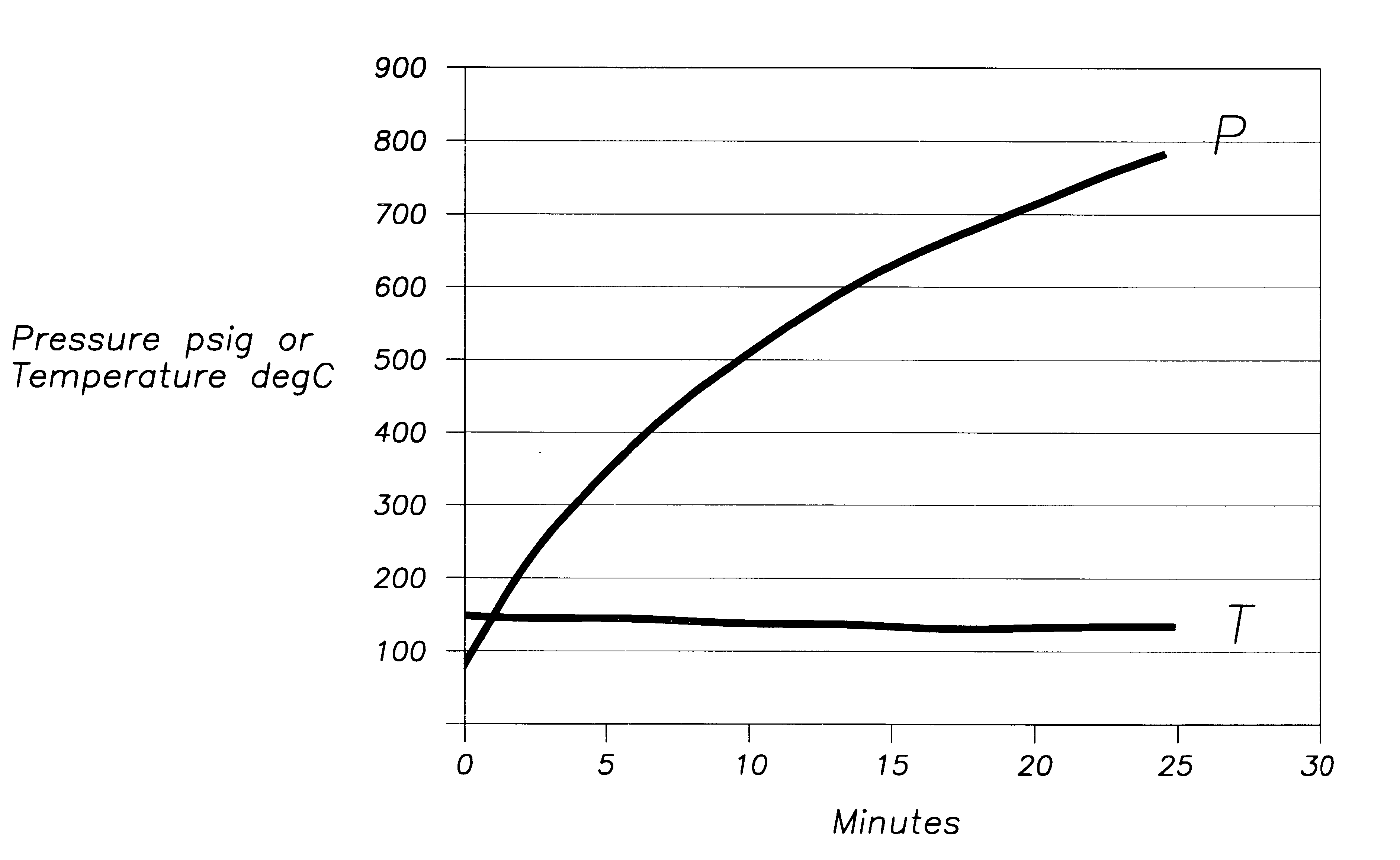

Method for controlling the production of ammonia from urea for NOx scrubbing

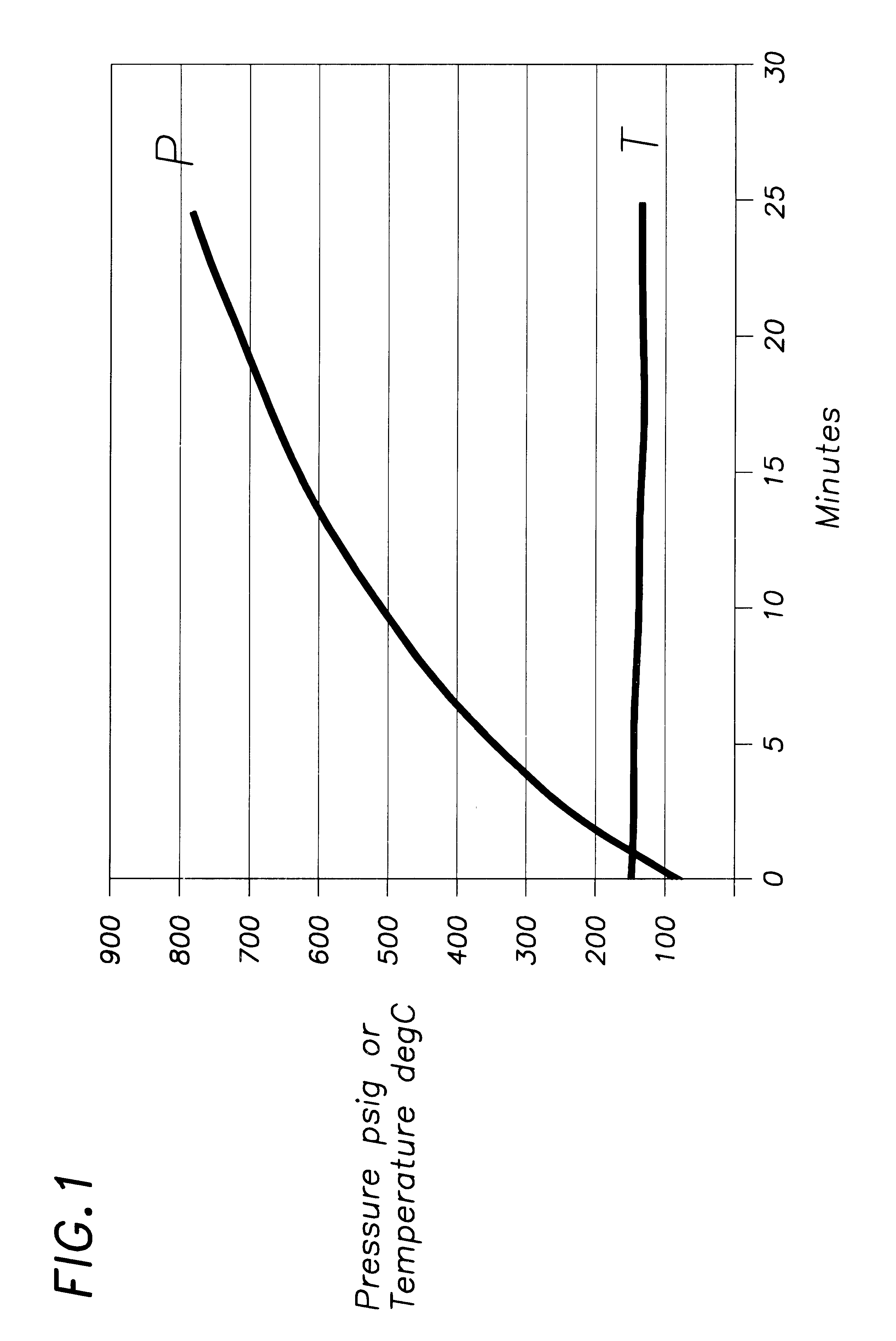

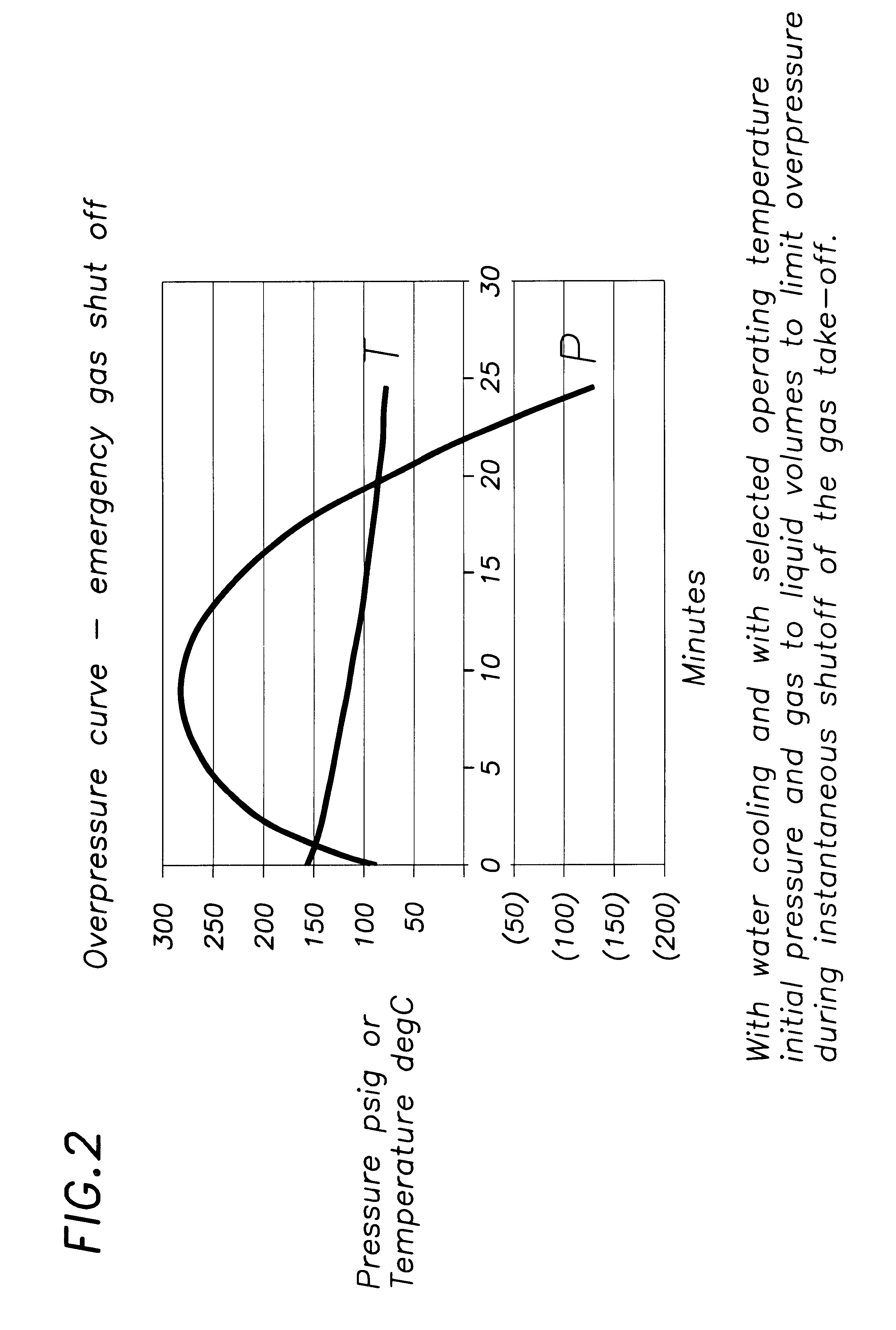

A process to provide a pressurized gas stream useful for removing nitrogen oxides from a combustion gas stream by hydrolyzing urea in aqueous solution in a closed reactor to evolve gaseous ammonia at a rate essentially balanced to the amount required from the combustion gas stream. The improvement resides in maintaining the pressure in the reactor within a preselected range when the demand for ammonia for external use suddenly drops by cooling the solution within the hydrolysis reactor by heat exchange either within or external to the reactor in response to rapid changes in demand for ammonia required to remove said nitrogen oxides.

Owner:EC&C TECH

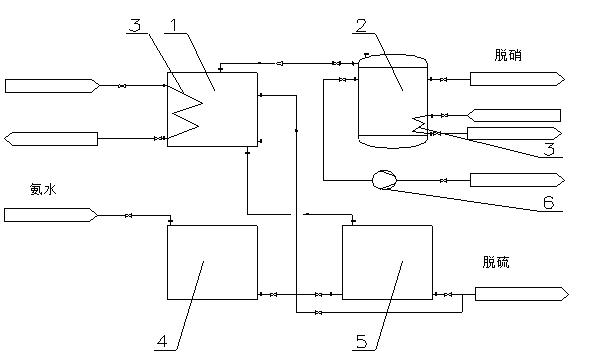

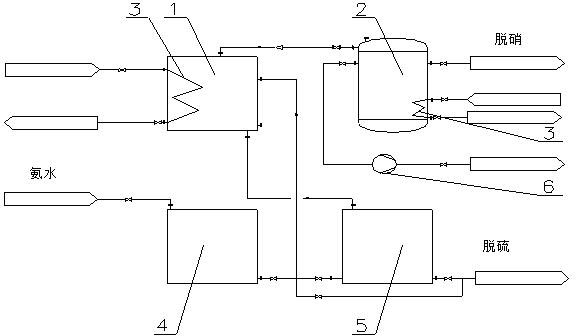

Flue gas desulphurization and denitration reactant integrated supply method and apparatus

ActiveCN102489140ARealize joint desulfurization and denitrificationMeet regional planning requirementsDispersed particle separationWater storageFlue gas

Owner:JIANGSU NEW CENTURY JIANGNAN ENVIRONMENTAL PROTECTION

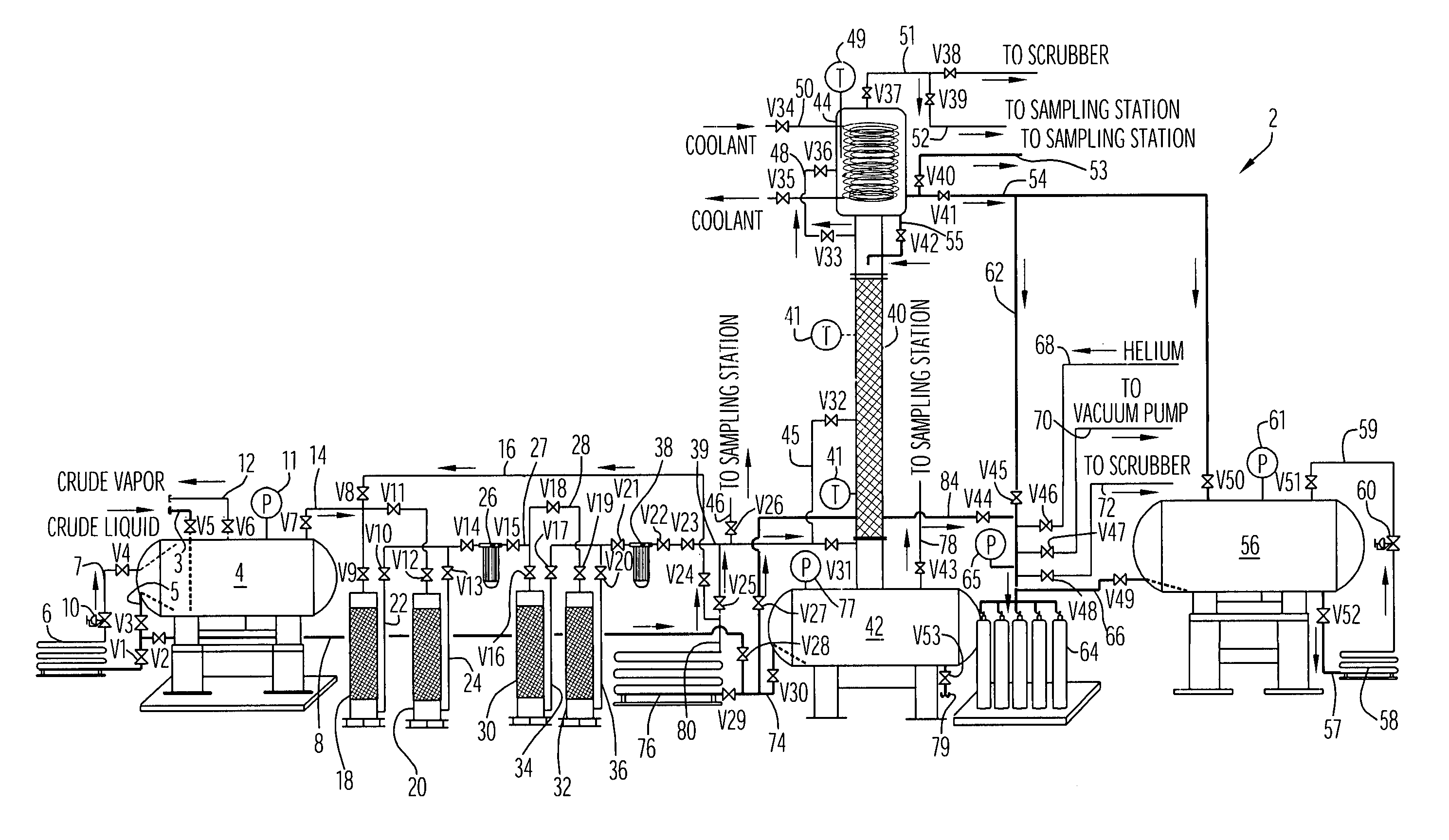

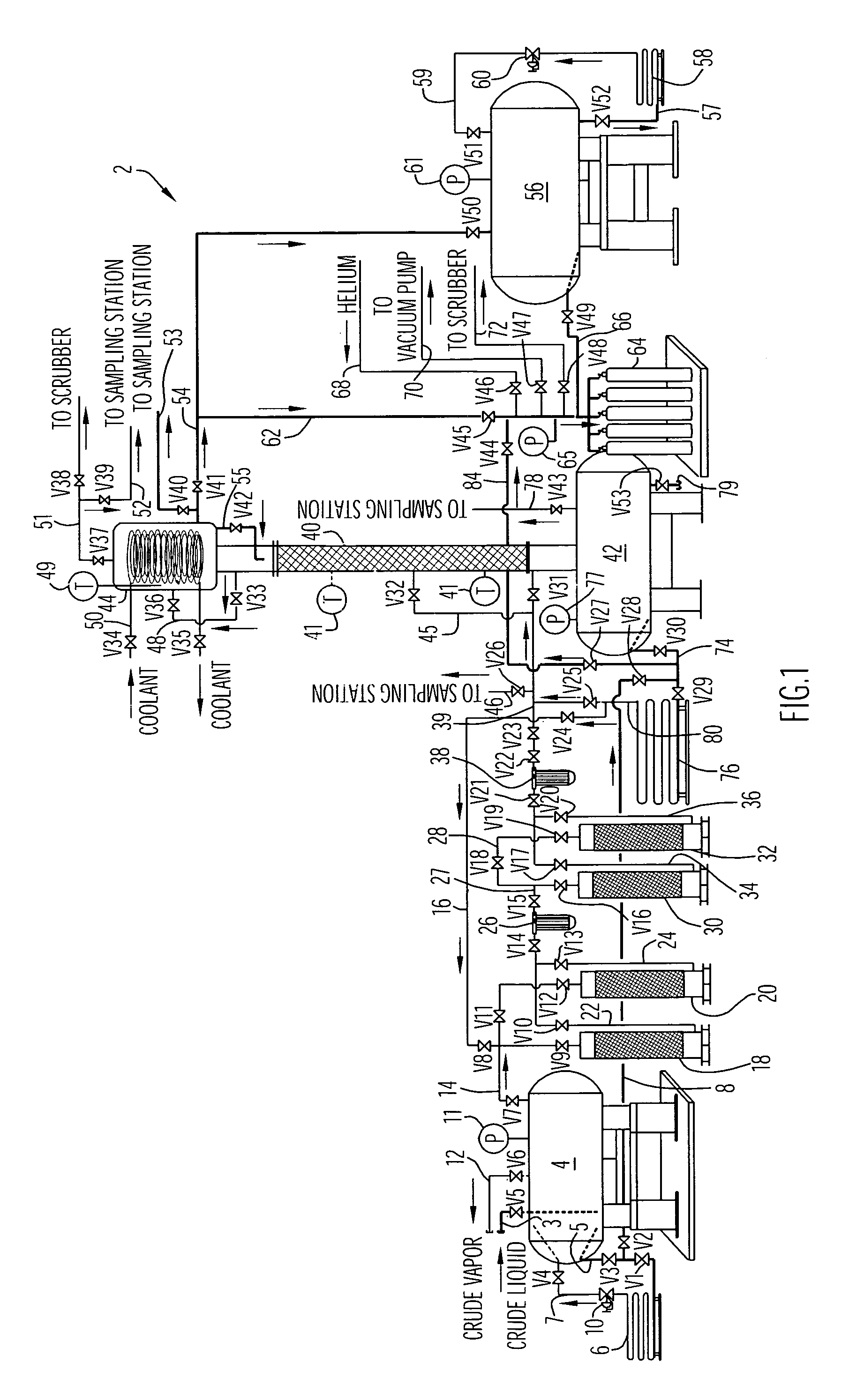

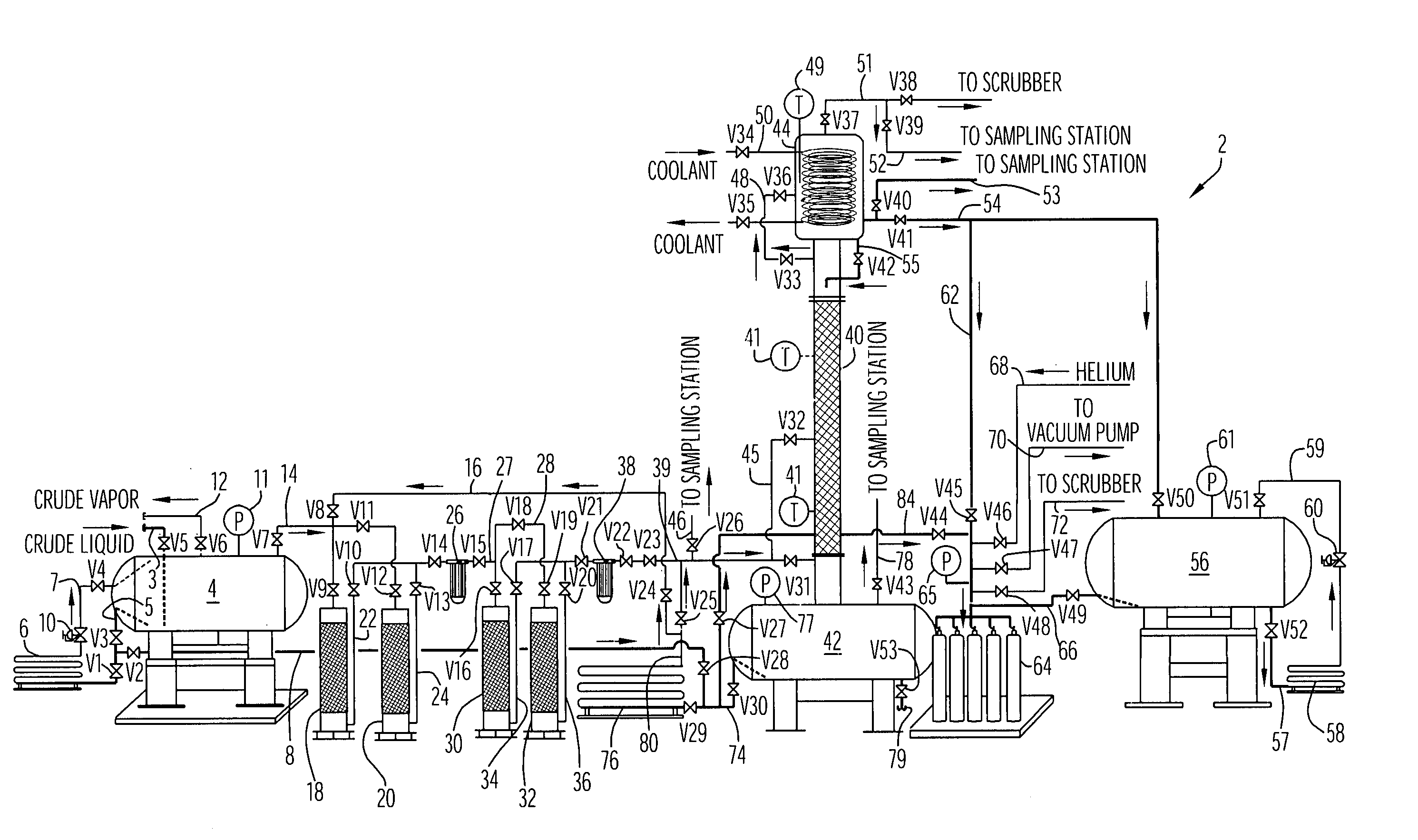

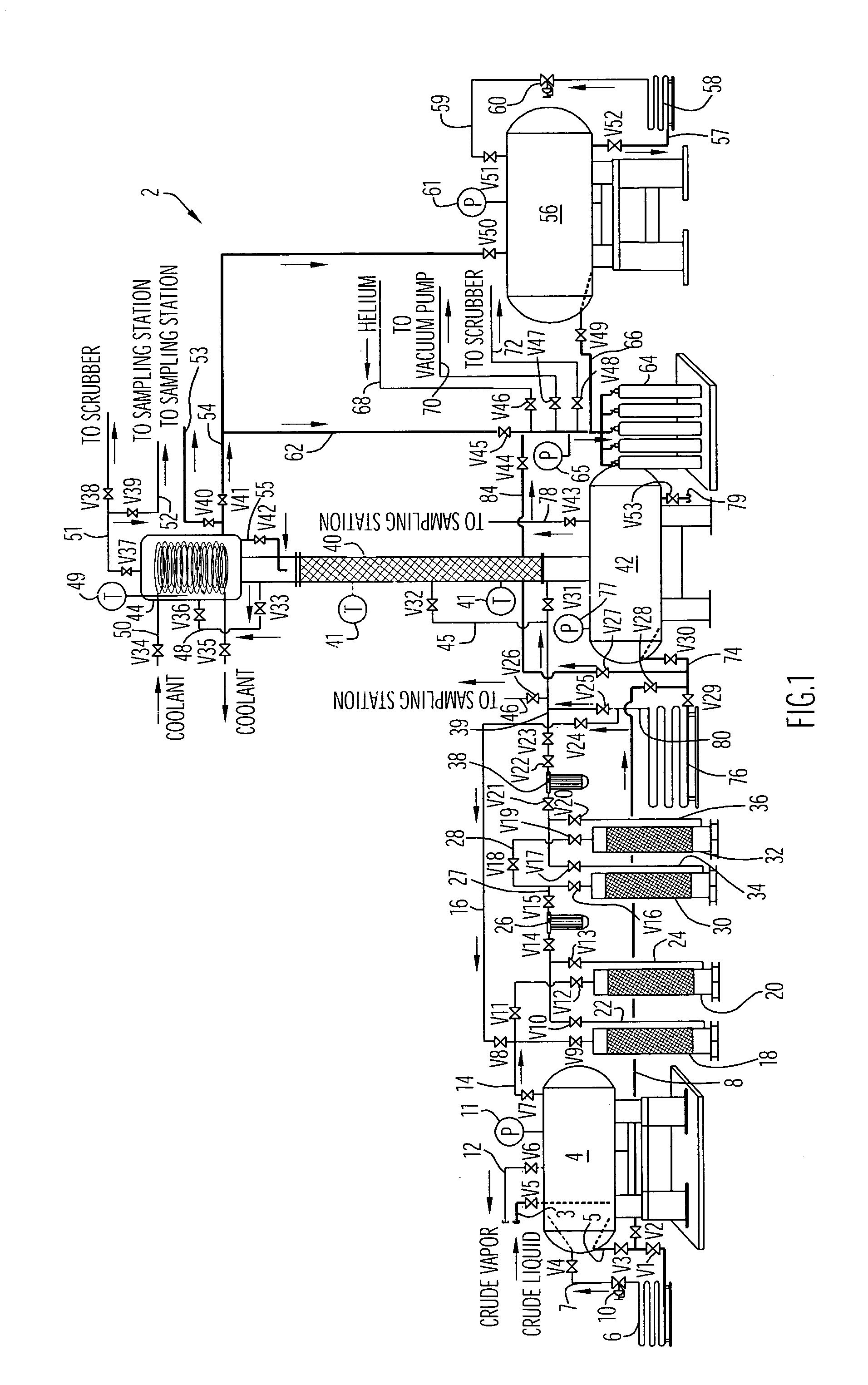

Purification and transfilling of ammonia

InactiveUS7297181B2Ultra-high purity levelsEfficient and economicalSolidificationLiquefactionFractionating columnGaseous ammonia

An ammonia purification system includes a hydrocarbon removal station that removes hydrocarbons from gaseous ammonia via adsorption, a moisture removal station that removes water from gaseous ammonia via adsorption, and a distillation station including a distillation column connected with a condenser to facilitate removal of impurities from ammonia and condensation of gaseous ammonia to form a purified liquid ammonia product. The system further includes a storage tank to receive purified ammonia, a remote station connected with the storage tank, and a vaporizer connected with the storage tank. The vaporizer is configured to receive and vaporize liquid ammonia from the storage tank and deliver gaseous ammonia back to the storage tank so as to facilitate pumping of the ammonia to the remote station based upon a vapor pressure established within the storage tank.

Owner:AIR LIQUIDE AMERICA INC

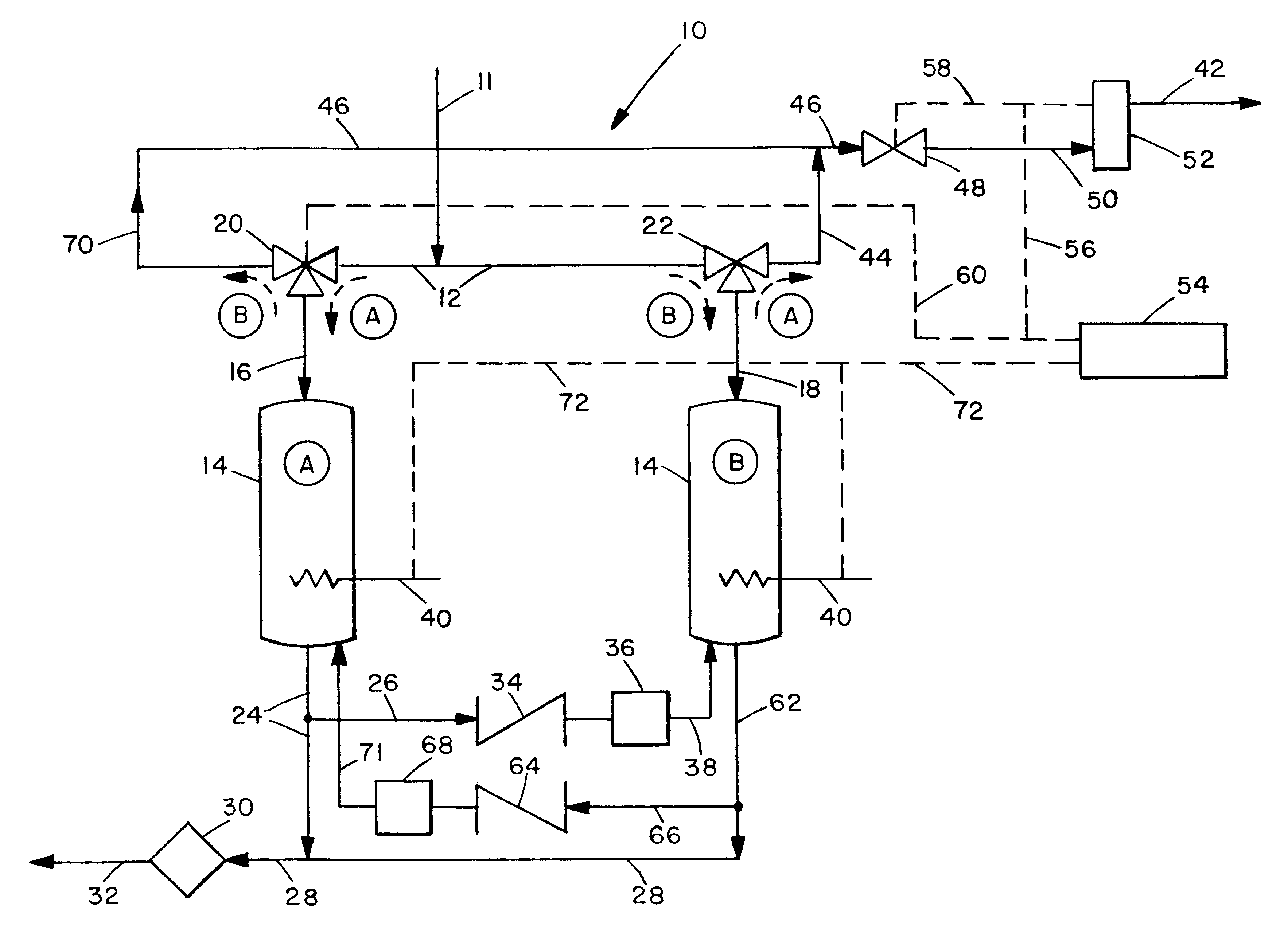

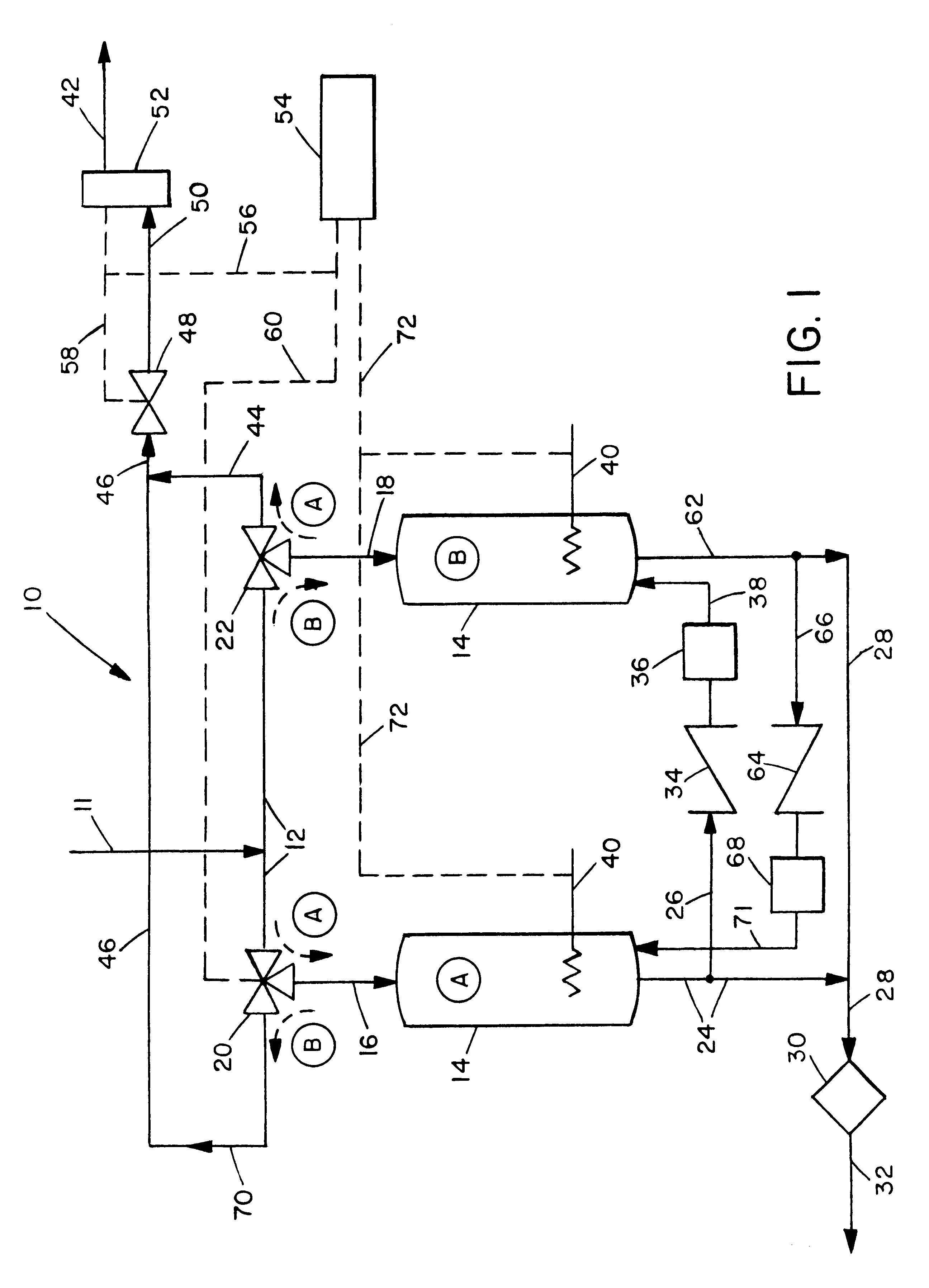

Self-regenerative process for contaminant removal from ammonia

A method and apparatus for the decontamination of fluid ammonia are described. Liquid or gaseous ammonia is purified of contaminants by passage through an adsorbent bed, the contaminants accumulating in the bed. A portion of the purified ammonia discharged from the bed is decomposed to hydrogen and nitrogen. The hydrogen is used to regenerate an adsorbent bed which has accumulated sufficient contaminants to reduce its ability to further decontaminate incoming ammonia satisfactorily. Preferably there are a plurality of interconnected adsorbent beds, with some being operated for ammonia decontamination while others are being regenerated, with their operations being reversed as needed to maintain a continual production of decontaminated ammonia from the plurality of beds. Computers or other controllers can be used to control such bed operations and interchanges. Internal production of hydrogen makes the system self-contained and no addition of hydrogen is needed.

Owner:ENTEGRIS INC

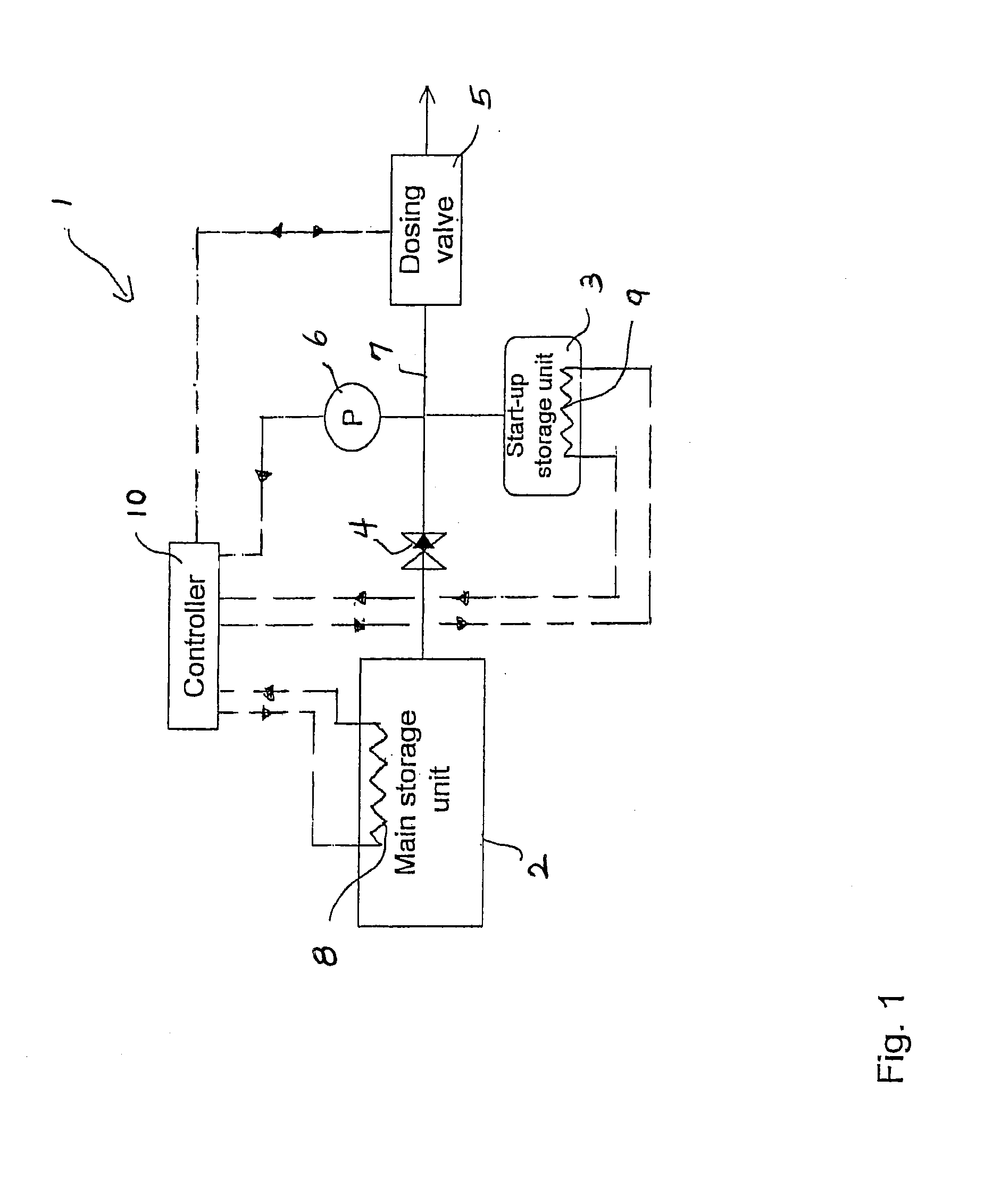

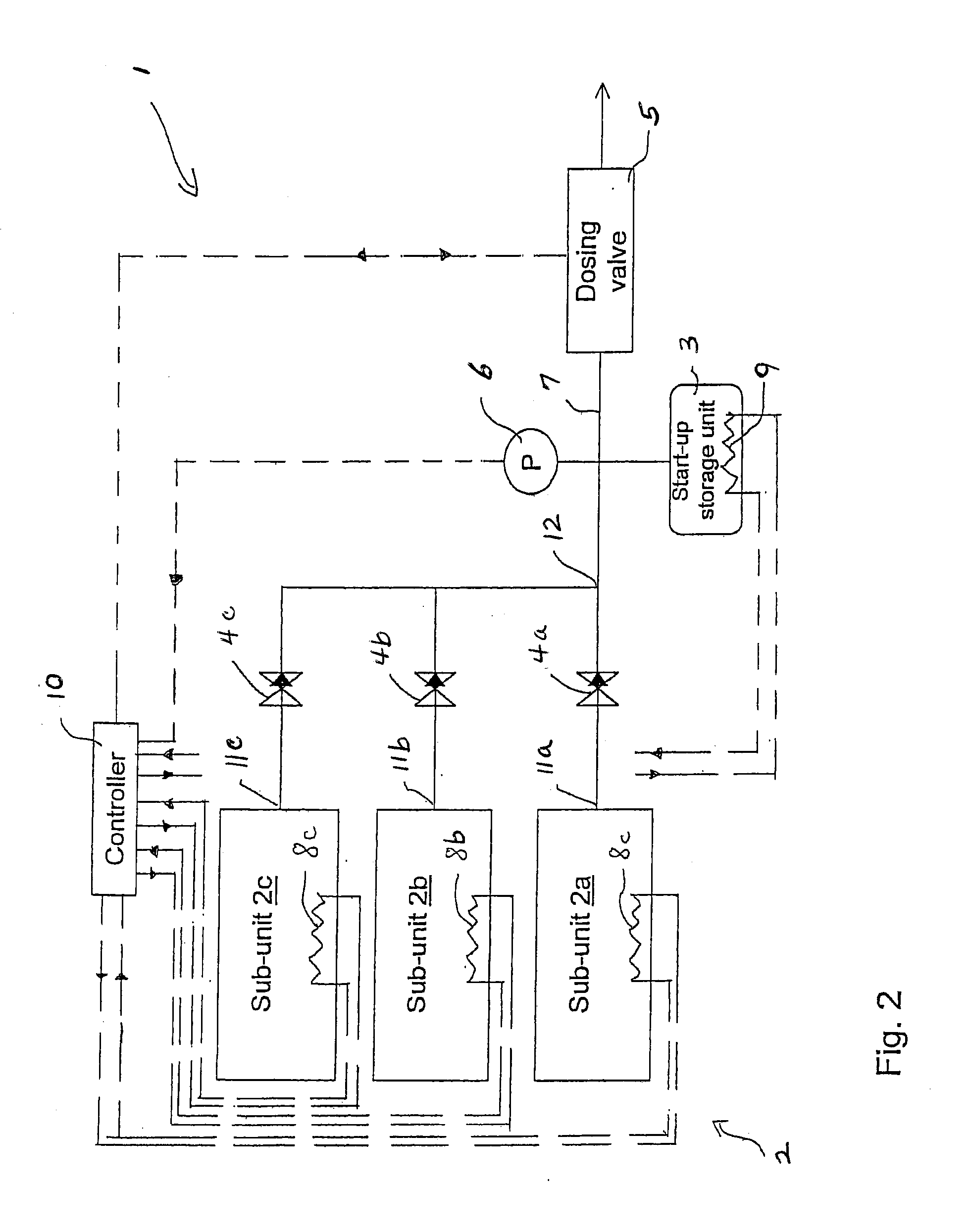

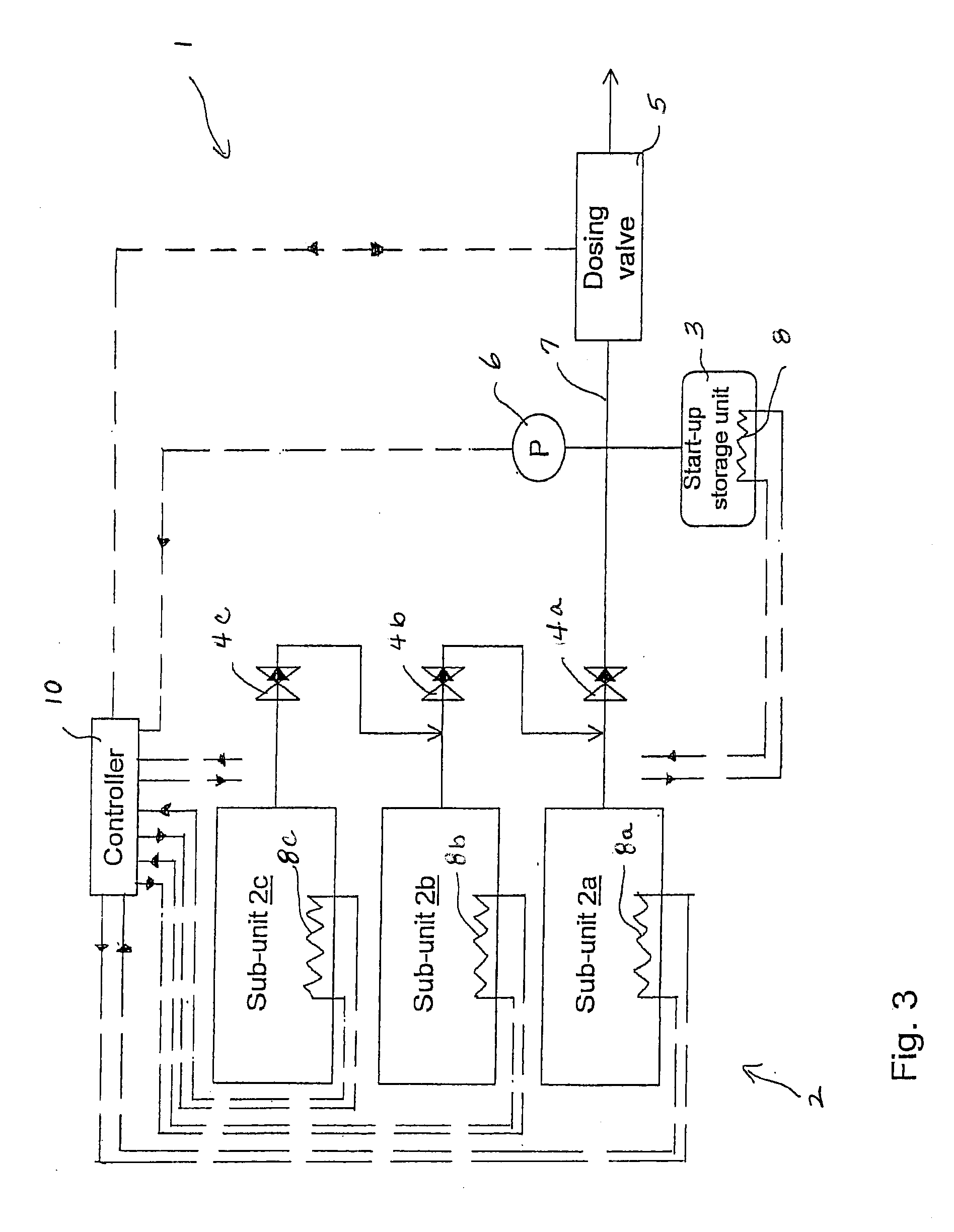

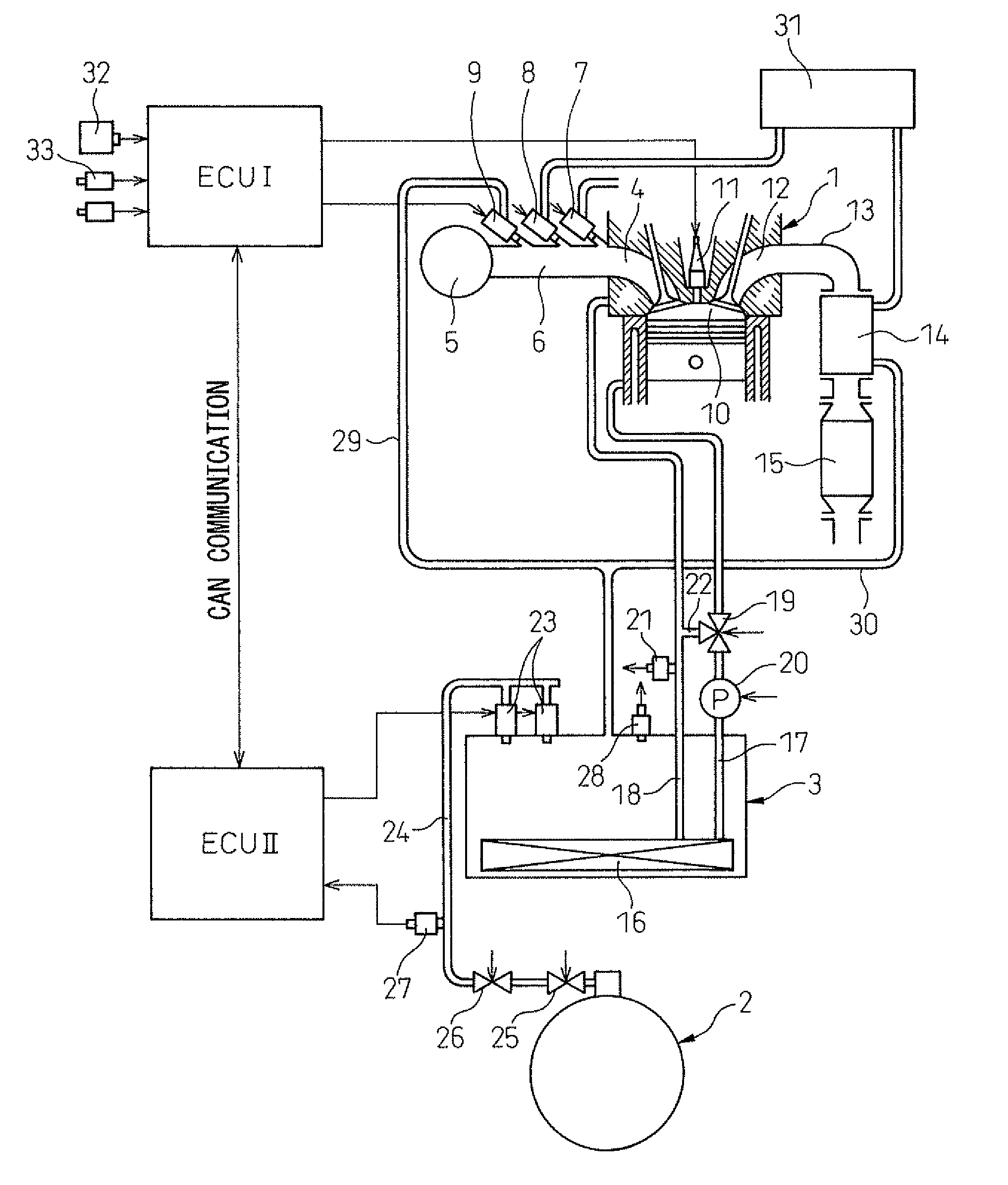

Release of Stored Ammonia at Start-Up

ActiveUS20100086467A1Demand for it variesPrevent backflowInternal combustion piston enginesExhaust apparatusAmmonia storageGaseous ammonia

A system for storage and dosing of ammonia, including a solid ammonia storage material capable of binding and releasing ammonia reversibly by adsorption / absorption. The system is able to release ammonia gradually according to a demand that can vary over time with intermediate periods of no ammonia demand. A main storage unit and a start-up storage unit are provided. The storage units hold ammonia storage material. At least one one-way valve is provided via which the one main storage unit is in communication with the start-up storage unit. The one-way valve prevents any back-flow of ammonia from the start-up storage unit to the main storage unit. Heating devices are arranged to heat the main storage unit and the start-up storage unit separately to generate gaseous ammonia by thermal desorption from the solid storage material. A controller controls the heating power of the main storage unit and the start-up storage unit, thereby enabling ammonia release from at least one of the start-up and / or the main storage unit. A dosing valve controls ammonia flow from the storage units according to a demand.

Owner:AMMINEX EMISSIONS TECH

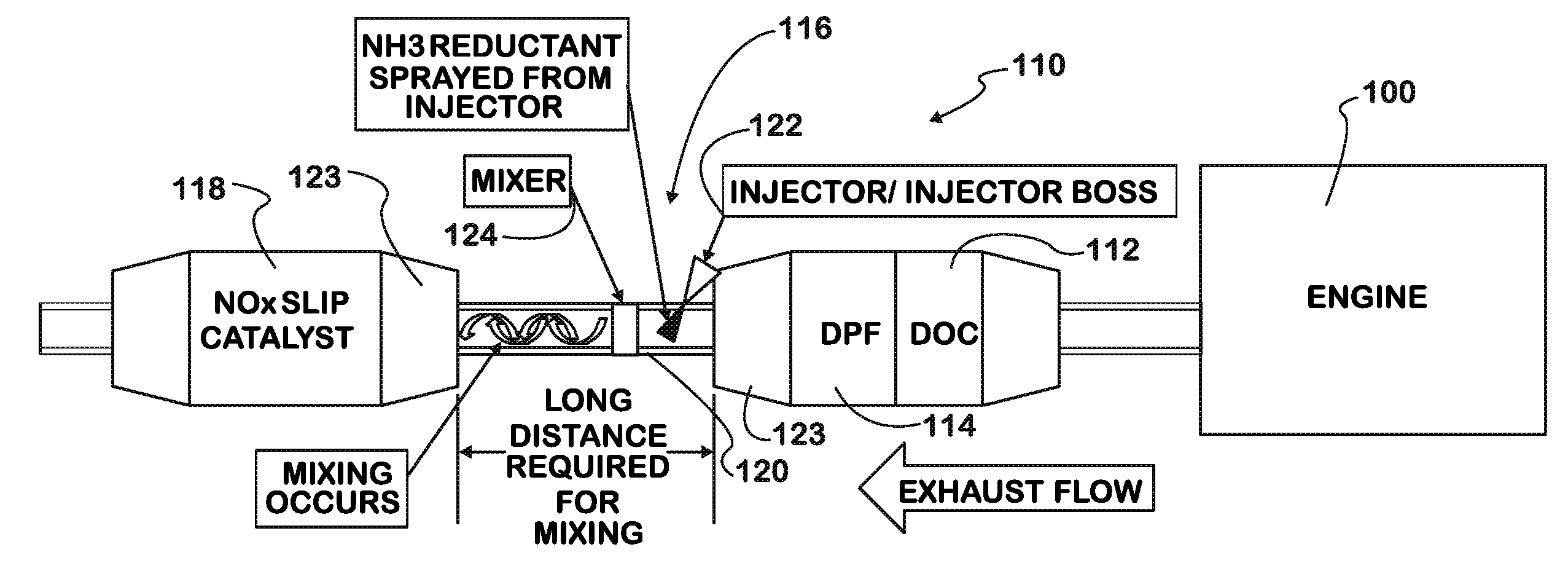

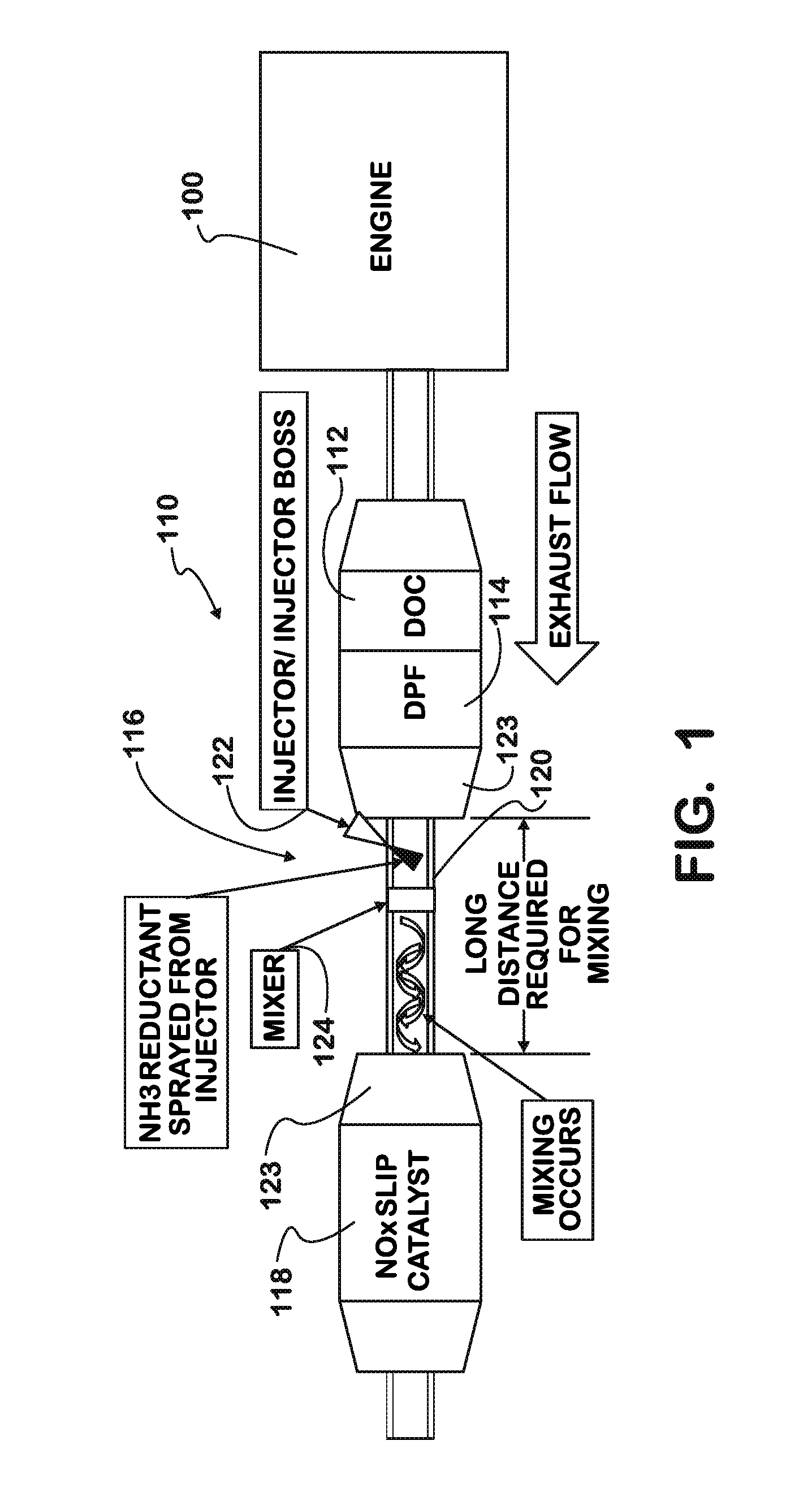

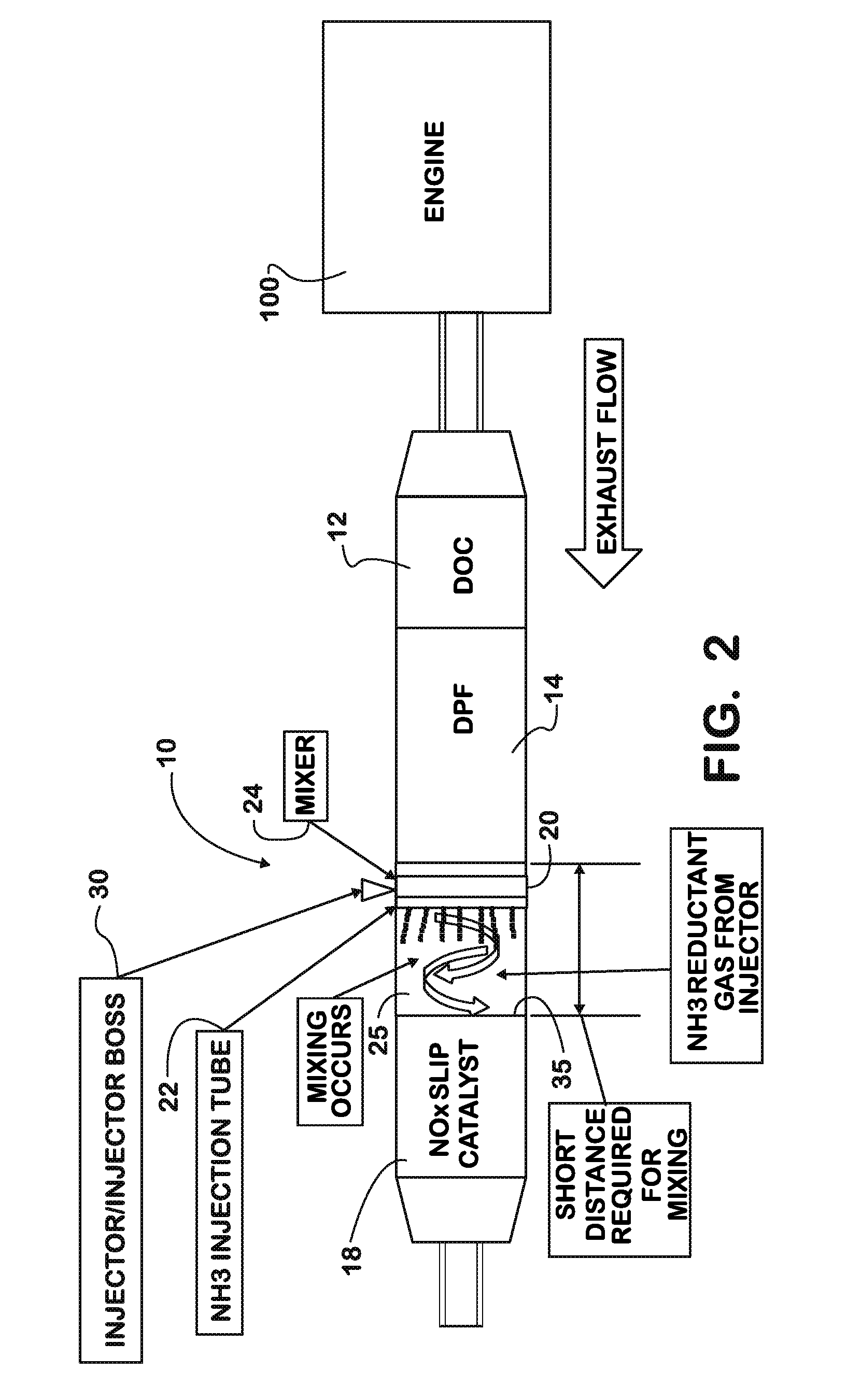

Method and apparatus for gaseous mixing in a diesel exhaust system

InactiveUS20110219745A1Simple structureAdditional operating advantageFlow mixersExhaust apparatusStream flowInjection point

A mixing device and method for a diesel exhaust system is disclosed having a chamber, a mixer within the chamber, and an injection tube supported on the mixer within the chamber. The mixer is positioned within the chamber adjacent an inlet and includes a plurality of angled blades to effect turbulent flow in a diesel exhaust stream entering the chamber through the inlet. The injection tube includes a plurality of injection points (e.g., openings) for discharging a reagent, such as gaseous ammonia (NH3), into the exhaust stream. The injection tube is curved, and more specifically it is coiled with the injection points spread along the length of the tube in order to deliver reagent across a section of the chamber perpendicular to the exhaust stream flow.

Owner:INT ENGINE INTPROP CO LLC

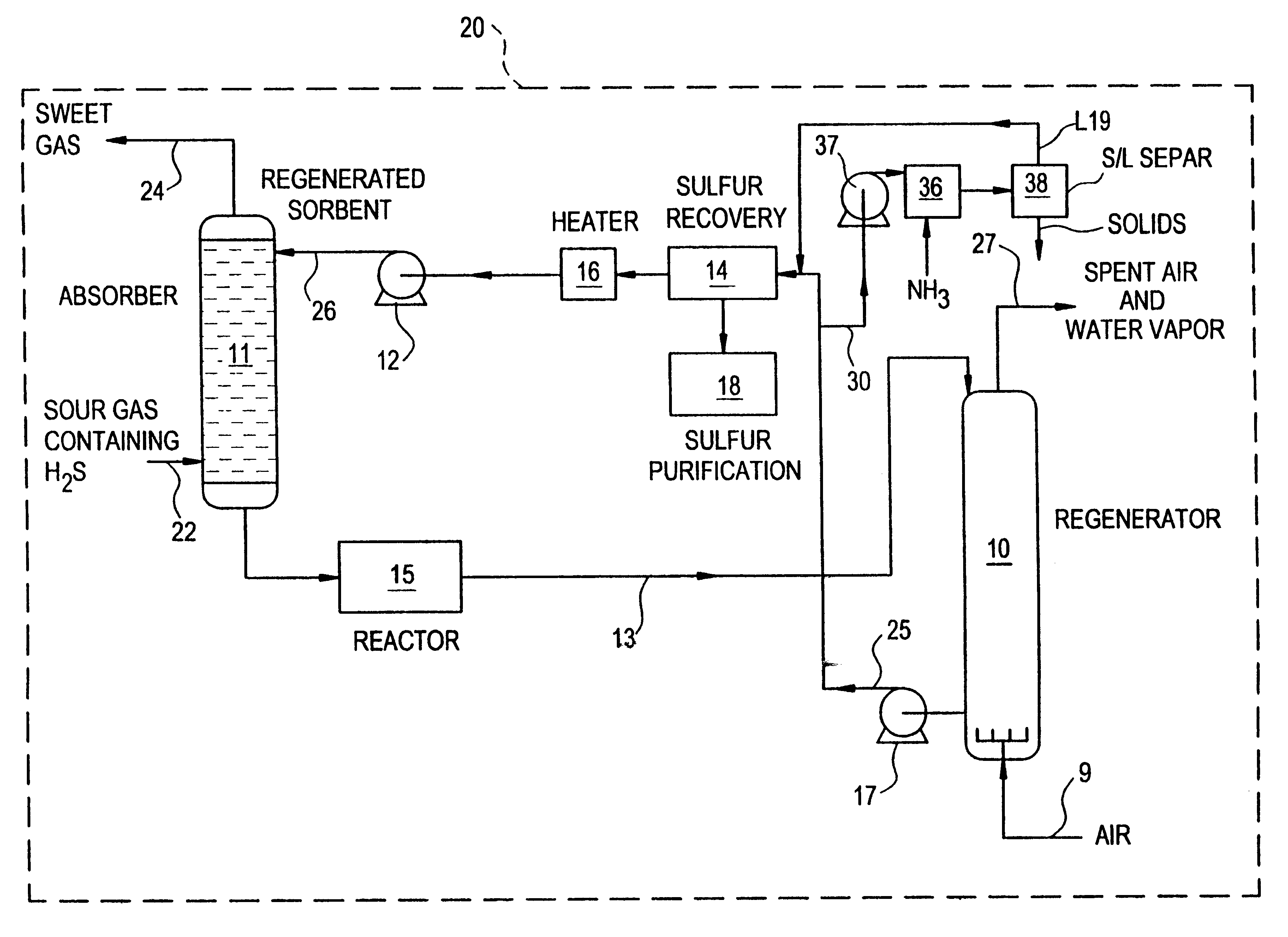

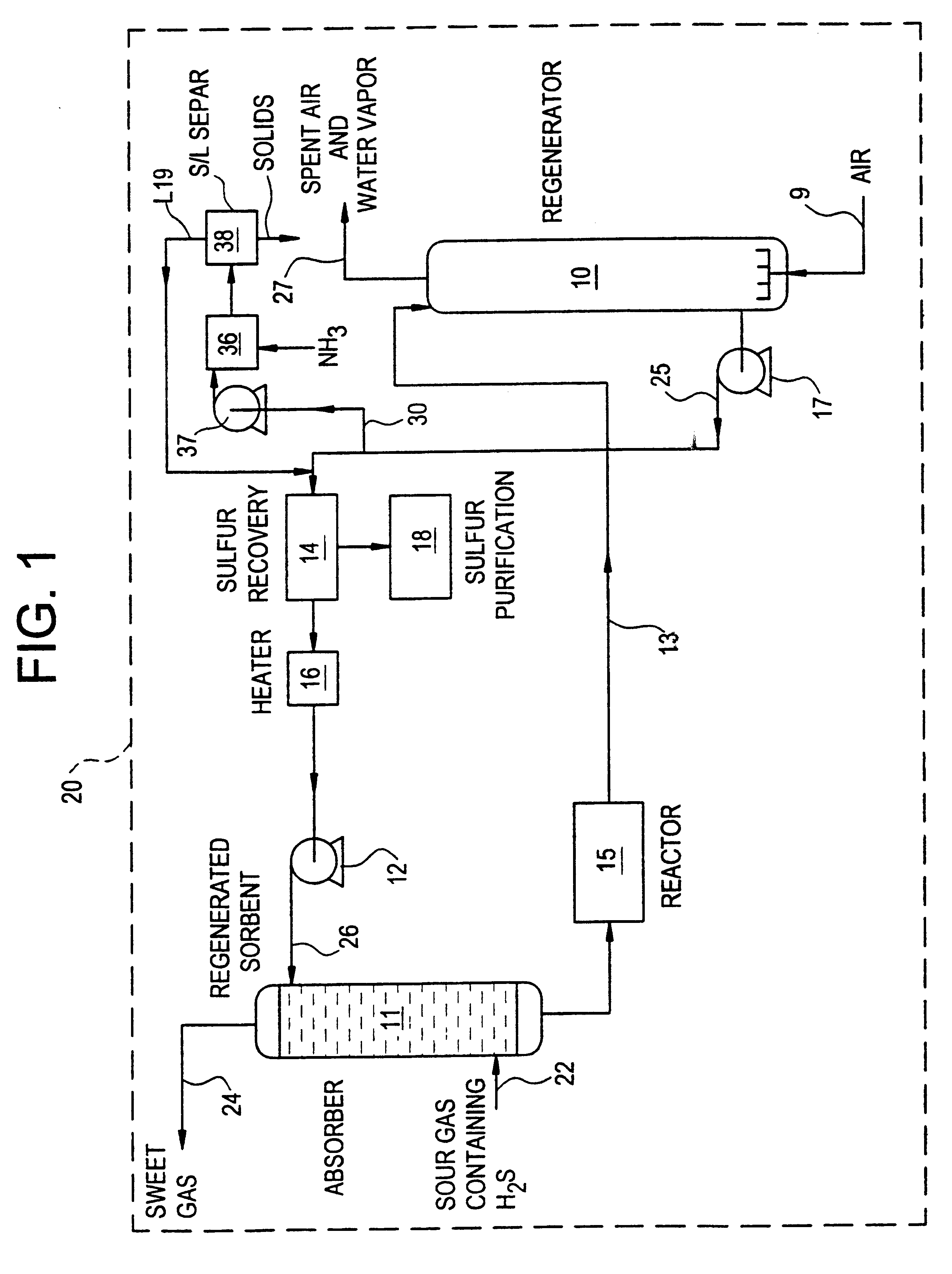

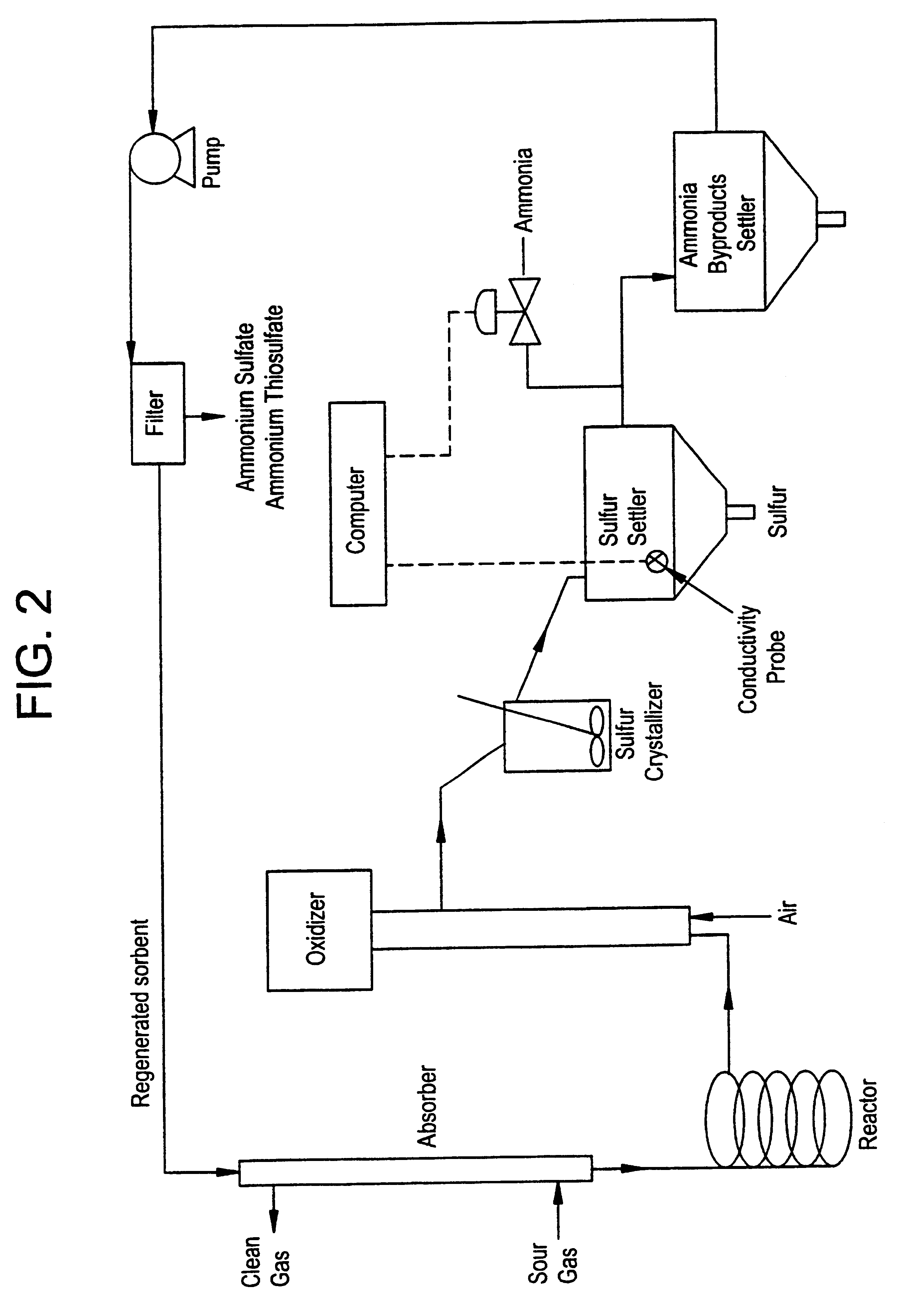

Regeneration method for process which removes hydrogen sulfide from gas streams

InactiveUS6544492B1Removal process is favorableAvoid problemsThiosulfates/dithionites/polythionitesHydrogen sulfidesThio-Sulfide

A process is provided for the removal of hydrogen sulfide out of a gaseous stream (22), such as a natural gas, by contacting the hydrogen sulfide containing gas with a sorbing liquid (26) containing a tertiary amine so that the hydrogen sulfide is sorbed into the liquid in absorber (11) and transferring the sorbing liquid / hydrogen sulfide mixture to a reactor (15) where the tertiary amine promotes the conversion of the hydrogen sulfide into polysulfide via reaction with sulfur; transferring the polysulfide solution from the reactor (15) to a regenerator (10) where polysulfide is converted into elemental sulfur via reaction with air (9); transferring at least a portion of the solution (25) containing elemental sulfur, as well as sulfate and thiosulfate species, into a mixture (36) where it is contacted with gaseous ammonia which reacts with the sulfate and thiosulfate species to produce ammonium sulfate and ammonium thiosulfate which are removed from the solution while the remaining portion of solution (25) is transferred to a sulfur recovery unit (14). That portion of the solution which has been subjected to ammonium sulfate and ammonium thiosulfate removal is rejoined with that portion of the solution (25) being forwarded to sulfur recovery unit (14). The solution from the sulfur recovery unit (14) is recycled back to the absorber (11).

Owner:URS

Ammonium/ammonia removal from a stream

In one embodiment, an ammonium removal method can comprise: removing a multivalent cation from a stream comprising ammonium to form a treated stream; converting the ammonium in the stream to ammonia by increasing the pH of the stream; and separating the ammonia from the treated stream to form a separated stream and gaseous ammonia. In another embodiment, an ammonium removal method can comprise: a multivalent cation from a stream comprising ammonium to form a treated stream comprising a total of less than or equal to about 50 ppm by weight of multivalent cations; increasing the pH of the stream to a conversion pH; converting the ammonium to ammonia; and separating the ammonia from the treated stream to form a separated stream and gaseous ammonia.

Owner:THERMOENERGY CORP

Method for preparing high-purity acetonitrile from acetic acid and ammonia by two steps

ActiveCN101891648AReduce typesReduce contentPreparation by ammonia-carboxylic acid reactionCarboxylic acid nitrile purification/separationChemical treatmentSynthesis methods

The invention discloses a method for preparing high-purity acetonitrile from acetic acid and ammonia by two steps, which comprises the following steps of: (1) neutralizing acetic acid and ammonia to generate ammonium acetate; (2) mixing aqueous solution of ammonium acetate and gaseous ammonia, preheating, and making the mixture enter a fixed bed reactor filled with a catalyst aluminium oxide for reaction to generate acetonitrile-containing mixed gas; and (3) continuously refining the mixed gas to obtain the acetonitrile. The 70 to 80 weight percent acetic acid is taken as a raw material, and the produced acetonitrile product has the advantages of less varieties and low content of impurities, high purity of over 99.9 percent, simple separation process, shorter flow, low energy consumption only about 40 percent of that of a byproduct method in unit product, and lower cost. The separation process is a physical separation method, and avoids generating a great amount of wastewater and waste gas in the chemical treatment process of the byproduct method. Meanwhile, a synthesis method is adopted, so the limitation that the yield is limited by a main product can be radically eliminated.

Owner:SHANDONG HEYI GAS CO LTD DONGYING CITY

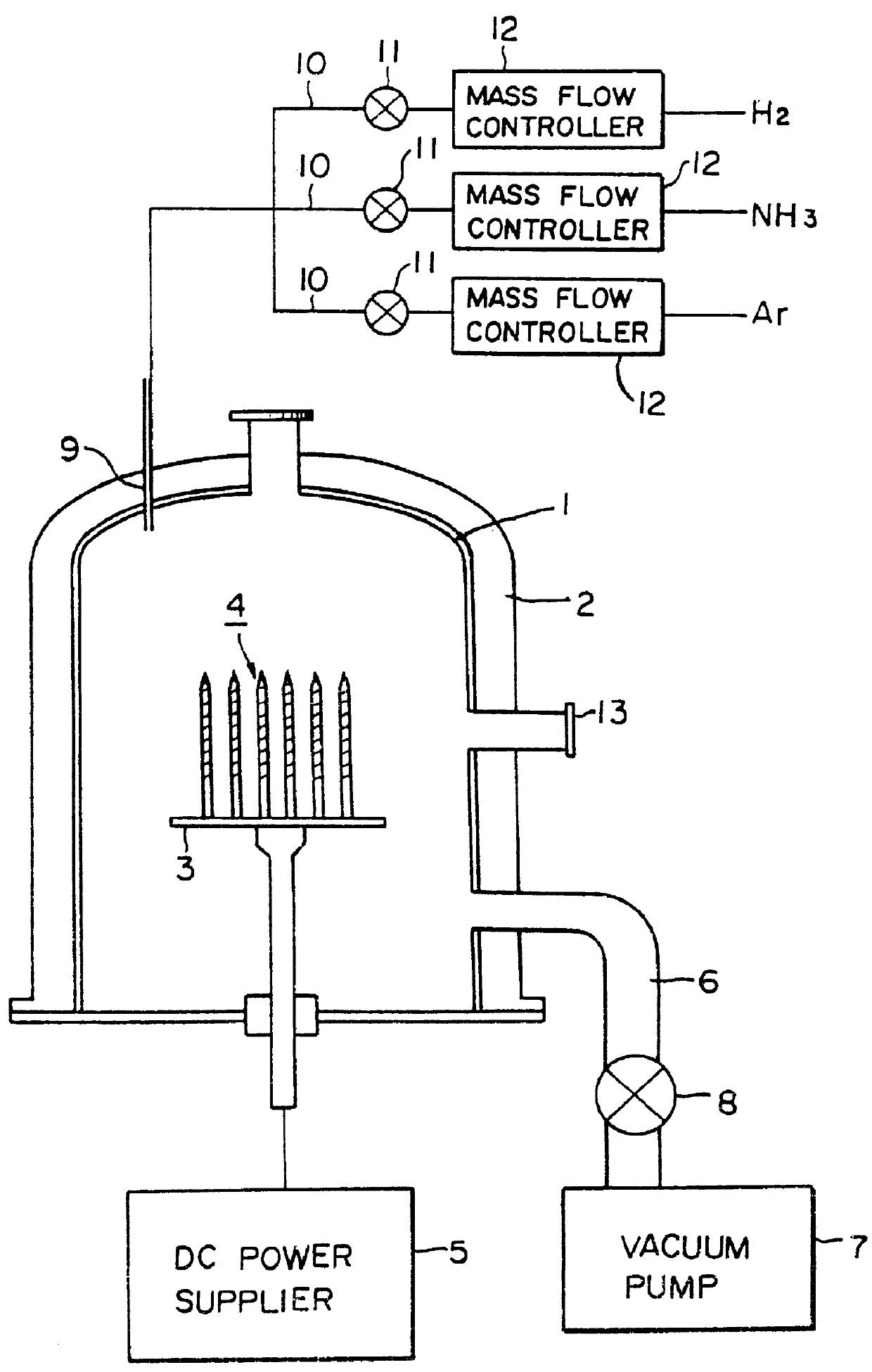

Duplex coated steel composite products and method of manufacturing them

InactiveUS6117280AHigh adhesion and durabilityIncreased durabilityVacuum evaporation coatingSputtering coatingCarbidePlasma nitridation

Duplex coated steel composite products comprising a first layer of a nitrided layer formed by applying glow discharge at a current density from 0.001 to 2.0 mA / cm2 to the surface of metal parts by using gaseous ammonia and gaseous hydrogen while maintaining the temperature of the metal parts at 300 to 650 DEG C., thereby applying plasma nitriding and a second layer comprising a hard film comprising a nitride, carbide and / or carbonitride of one or more of elements selected from Ti, Zr, Hf, V, Nb, Ta and Cr coated on the first layer by the PVD method of a laminate film or a gradient laminate film of such hard film. The treated products are excellent in adhesion with the substrate and durability and have both oxidation resistance and wear resistance.

Owner:SUMITOMO METAL MINING CO LTD

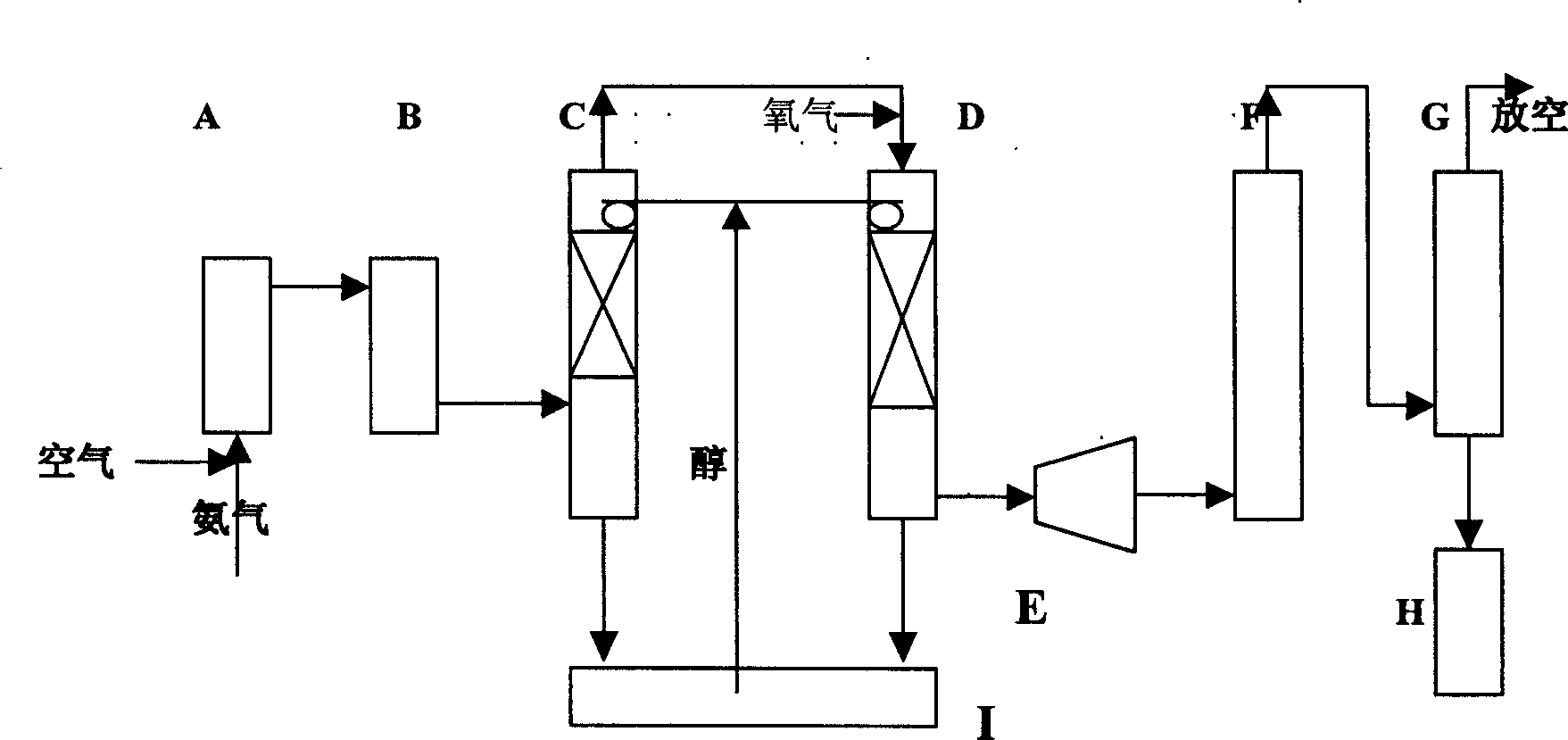

Production process of No gas for synthesizing oxalate

The production process of NO gas for synthesizing oxalate belongs to the field of chemical and environment protection technology. The production process includes ammoxidation of air to produce NOx as the NO gas for synthesizing oxalate, or utilizing the NOx in nitric acid producing tail gas as the NO gas for synthesizing oxalate, absorbing nitrite with alcohols and compression and condensation to recover alcohols and nitrite from the tail gas. The production process has liquid ammonia or gaseous ammonia of concentration 1-30 vol%, oxygen of concentration 1-30 vol%, alcohol concentration of 50-100 wt%, pressure of 0.1-10 MPa, and condensation temperature of ¿C20 to 100 deg.c. The present invention has high economic utility and social utility.

Owner:TONGLIAO GOLD COAL CHEM

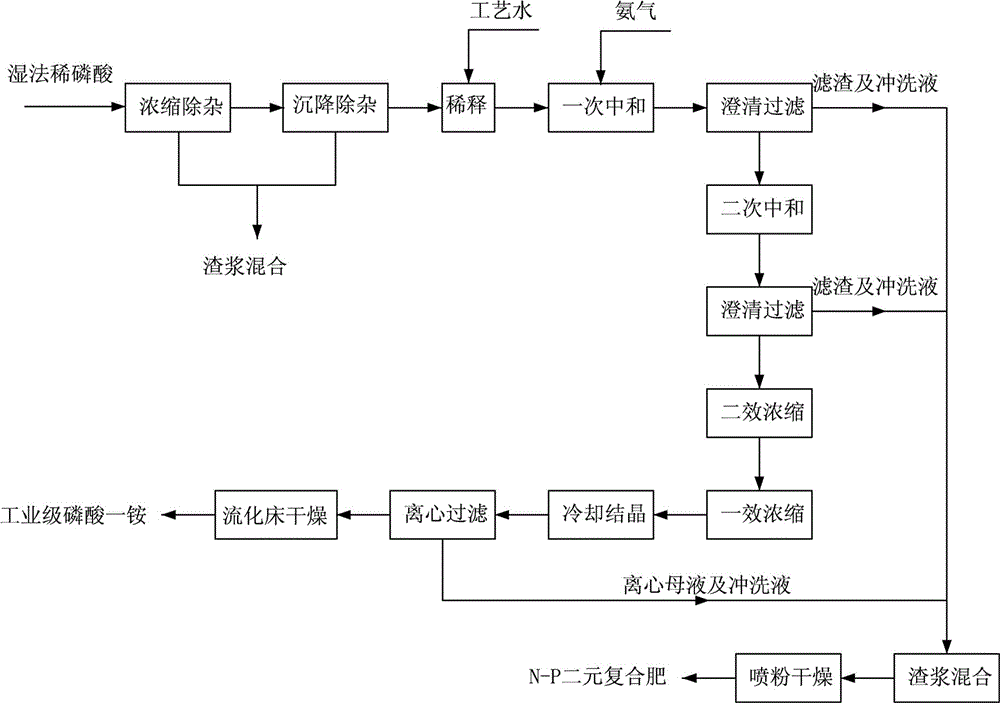

Method for producing monoammonium phosphate and coproducing N-P binary compound fertilizer by using wet-process phosphoric acid

ActiveCN102863267AReduce cleaning costsSimple processEnergy inputFertilizer mixturesLow gradedGaseous ammonia

The invention discloses a method for producing monoammonium phosphate and coproducing an N-P binary compound fertilizer by using wet-process phosphoric acid. According to the method, wet-process phosphoric acid prepared from low-grade phosphate ores is used as a raw material. The method comprises the following steps: concentrating and setting the wet-process phosphoric acid to remove impurities; diluting with process water; neutralizing with ammonia twice; filtering twice; concentrating; cooling for crystallization; centrifugally separating; drying to obtain the industrial grade monoammonium phosphate finished product; and mixing acid sludge, the centrifugalized mother liquor, residue and the flushing fluid in a slurry mixing tank, performing spray drying to obtain the N-P binary compound fertilizer. According to the method, wet-process phosphoric acid and gaseous ammonia are directly used as raw materials and the existing related devices in the phosphoric acid industry and resources such as waste heat steam and self power can be utilized, thus the yield of industrial grade monoammonium phosphate can be increased, the output of the byproduct N-P binary compound fertilizer can be reduced, the production cost of industrial grade monoammonium phosphate can be greatly reduced, the industry scale can be enlarged, the adaptability of the equipment can be enhanced, the market demands can be met, the stepped comprehensive utilization of the phosphorus resource can be realized and the economic benefit is higher.

Owner:HUBEI SANNING CHEM

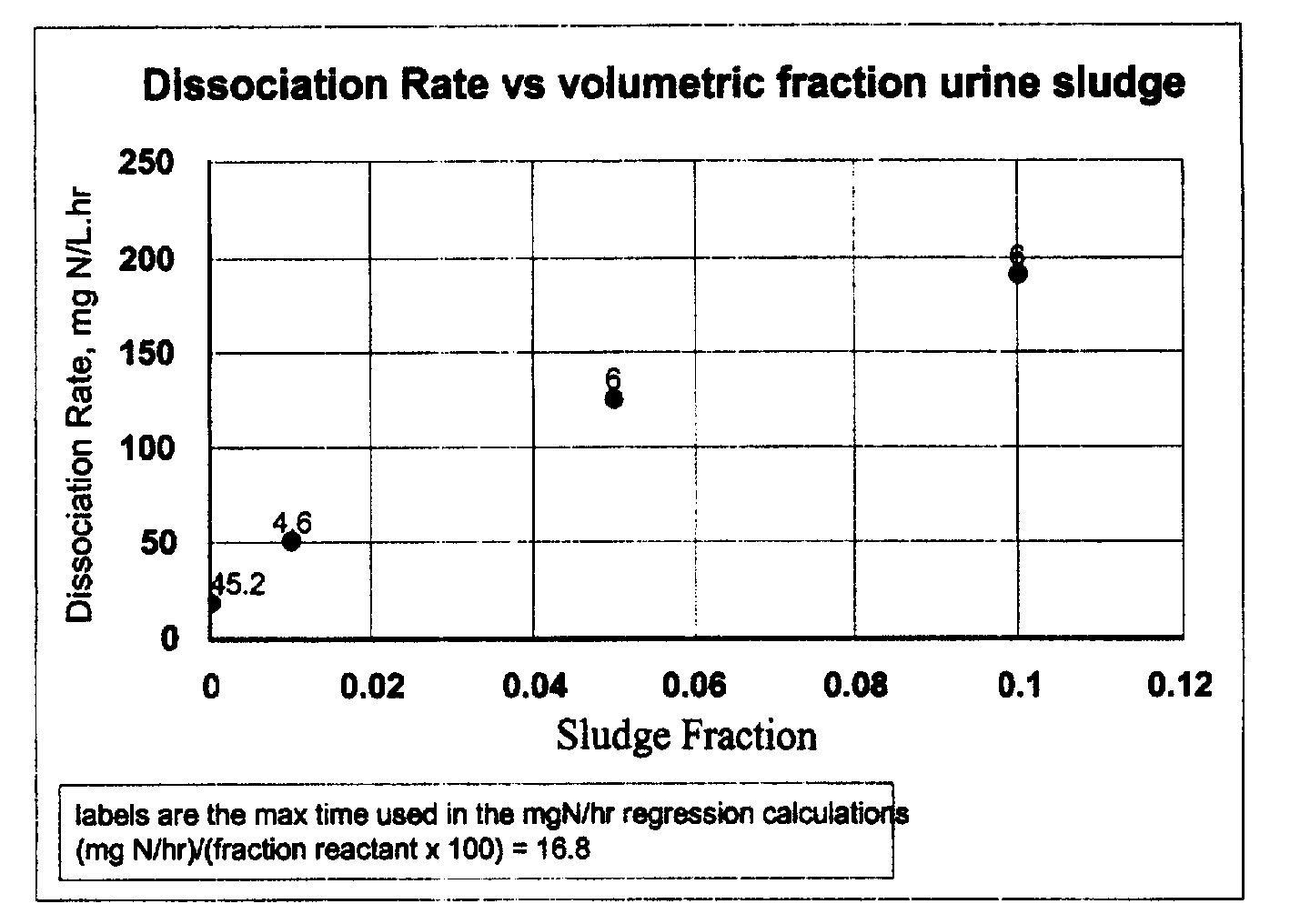

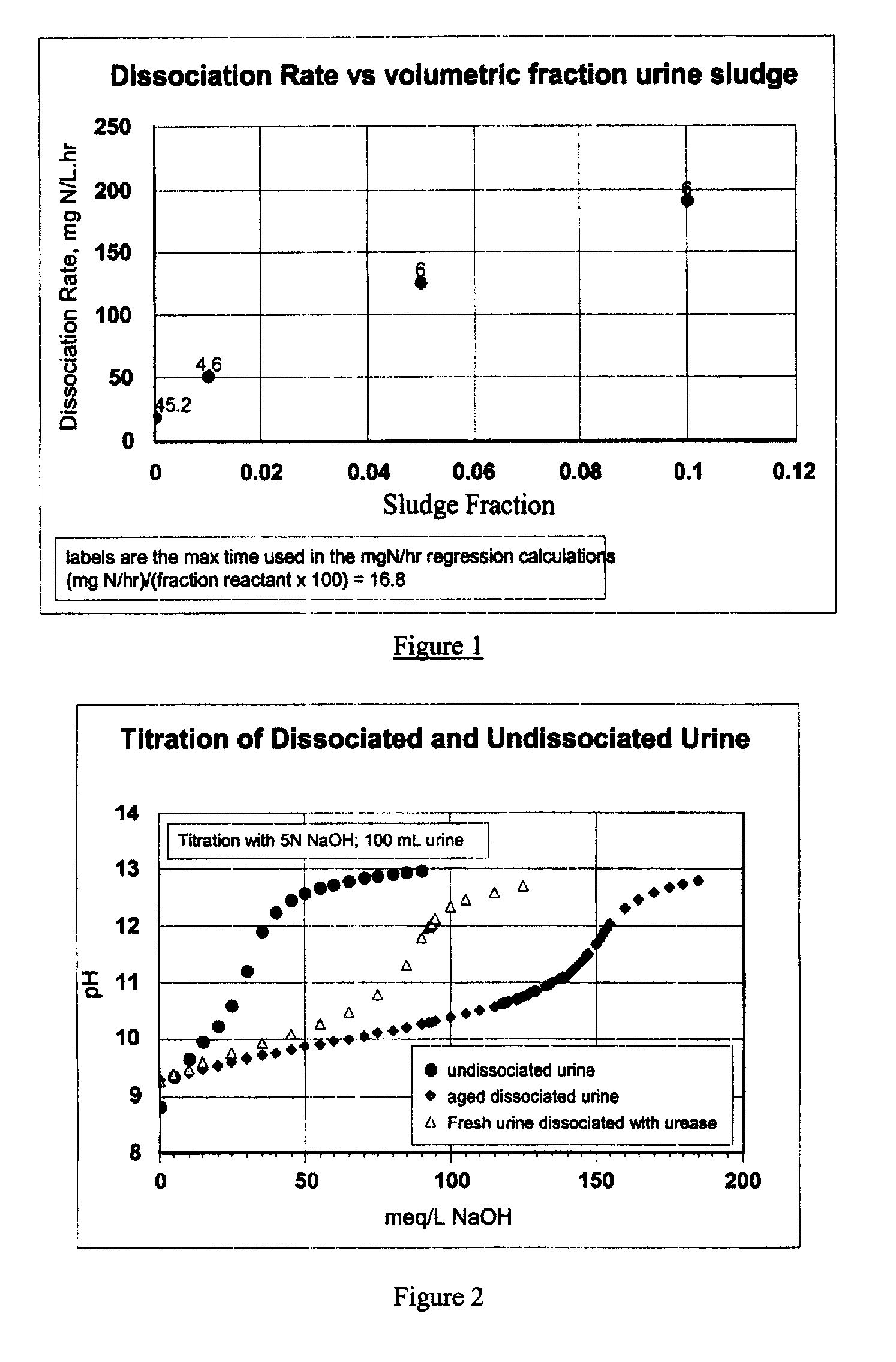

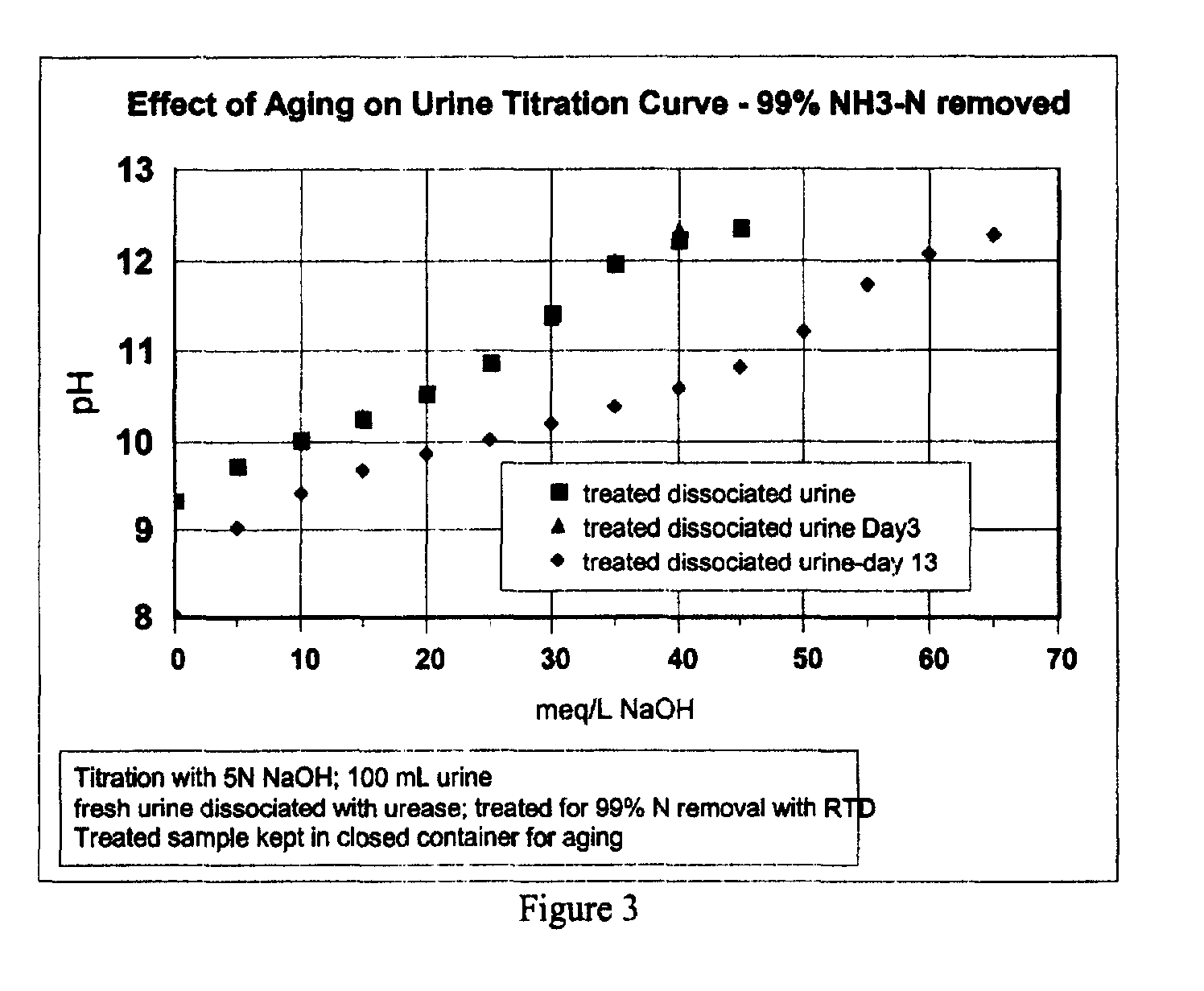

Process for recovery of nutrients from wastewater

InactiveUS7135116B2Less producedNew technologyExcrement fertilisersSedimentation separationGaseous ammoniaNutrient

The present invention relates to a process for treating a wastewater comprising an ammonium ion species and a phosphorus ion species. The process comprises the steps of: (i) treating the effluent in a first stage of the process to convert the phosphorus to a phosphorus-containing salt; (ii) treating the wastewater in a second stage of the process to convert the ammonium ion species to gaseous ammonia; (iii) removing the struvite and / or other phosphorous containing salts from the effluent; and (iv) removing the gaseous ammonia from the wastewater.

Owner:HAGGERTY KENNETH

Exhaust aftertreatment system and method for operating the system

ActiveUS9132386B2Reduce the amount requiredLimited efficiencyInternal combustion piston enginesExhaust apparatusEnvironmental engineeringGaseous ammonia

An exhaust system includes a first SCR catalyst and a second SCR catalyst positioned downstream of the first SCR catalyst. A first injector is provided upstream of the first SCR catalyst, and a second injector is provided upstream of the second SCR catalyst. The exhaust system further includes a gaseous ammonia supply device fluidly connected to the first injector for supplying gaseous ammonia to the exhaust gas by the first injector, and an ammonia-containing reductant reservoir fluidly connected to the second injector for supplying a fluid ammonia-containing reductant, such as urea, to the exhaust gas by the second injector. The first SCR catalyst has a smaller volume than the second SCR catalyst for a fast warm-up of the first SCR catalyst.

Owner:VOLVO TRUCK CORP

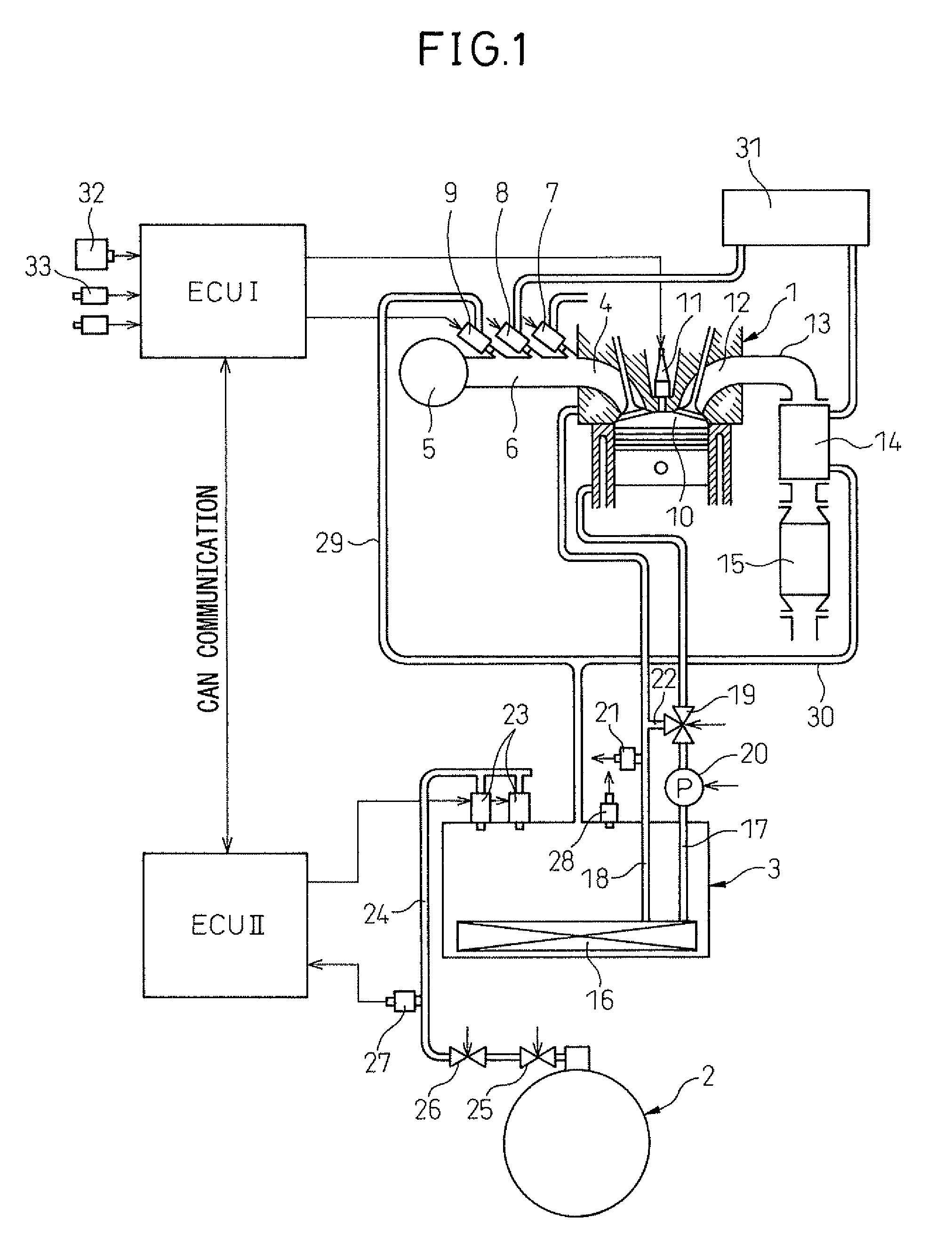

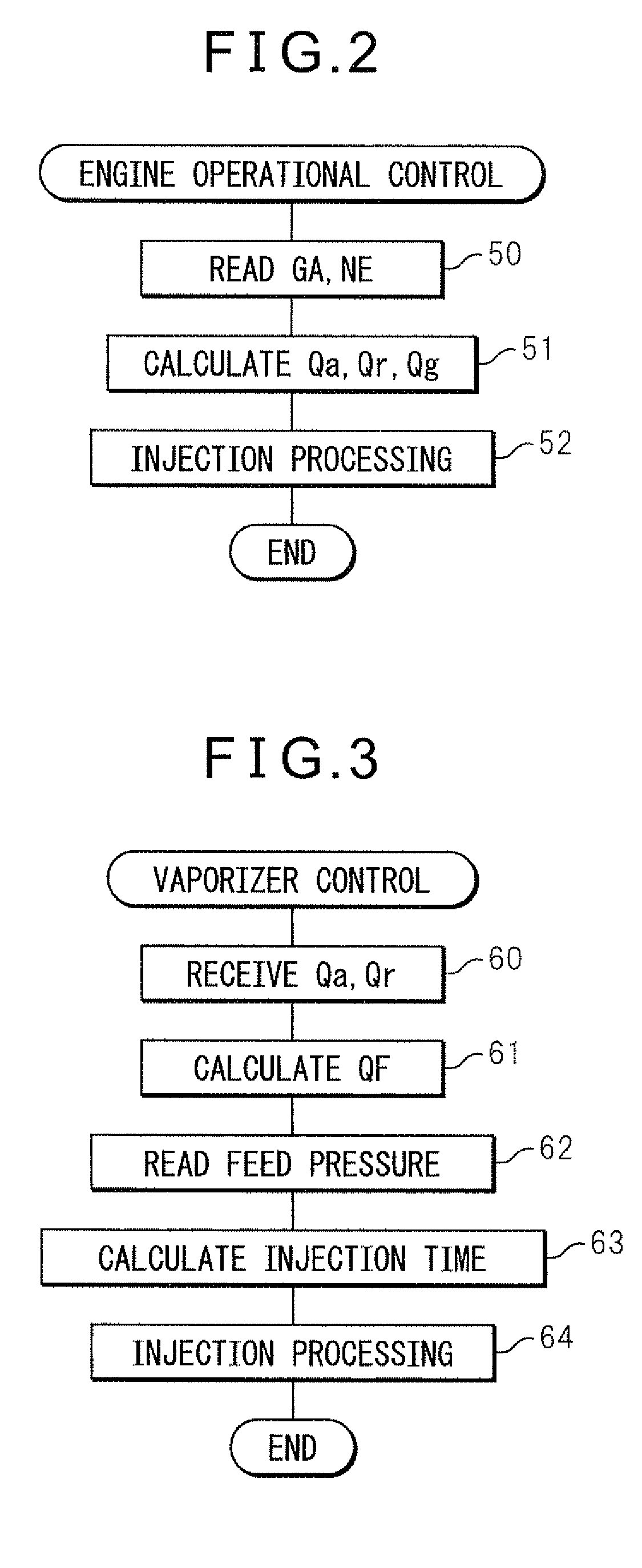

Control device of an internal combustion engine

ActiveUS8151779B1Smooth feedingStablyInternal combustion piston enginesFuel supply apparatusExternal combustion engineAmmonia storage

Liquid ammonia is fed from an ammonia storage tank to a vaporizer where it is vaporized. Gaseous ammonia vaporized inside the vaporizer is on the one hand injected from an ammonia injector and on the other hand reformed by a reformer, then injected from a reformed gas injector. The amount of liquid ammonia fed into the vaporizer is made to become equal to the amount of ammonia fed into the combustion chamber in the form of gaseous fuel by control of the amount of feed of the liquid ammonia to the vaporizer.

Owner:TOYOTA JIDOSHA KK

Purification and transfilling of ammonia

InactiveUS20060005704A1Increasing adsorbent capacityLarge average pore sizeSolidificationLiquefactionDistillationHydrocotyle bowlesioides

An ammonia purification system includes a hydrocarbon removal station that removes hydrocarbons from gaseous ammonia via adsorption, a moisture removal station that removes water from gaseous ammonia via adsorption, and a distillation station including a distillation column connected with a condenser to facilitate removal of impurities from ammonia and condensation of gaseous ammonia to form a purified liquid ammonia product. The system further includes a storage tank to receive purified ammonia, a remote station connected with the storage tank, and a vaporizer connected with the storage tank. The vaporizer is configured to receive and vaporize liquid ammonia from the storage tank and deliver gaseous ammonia back to the storage tank so as to facilitate pumping of the ammonia to the remote station based upon a vapor pressure established within the storage tank.

Owner:AIR LIQUIDE AMERICA INC

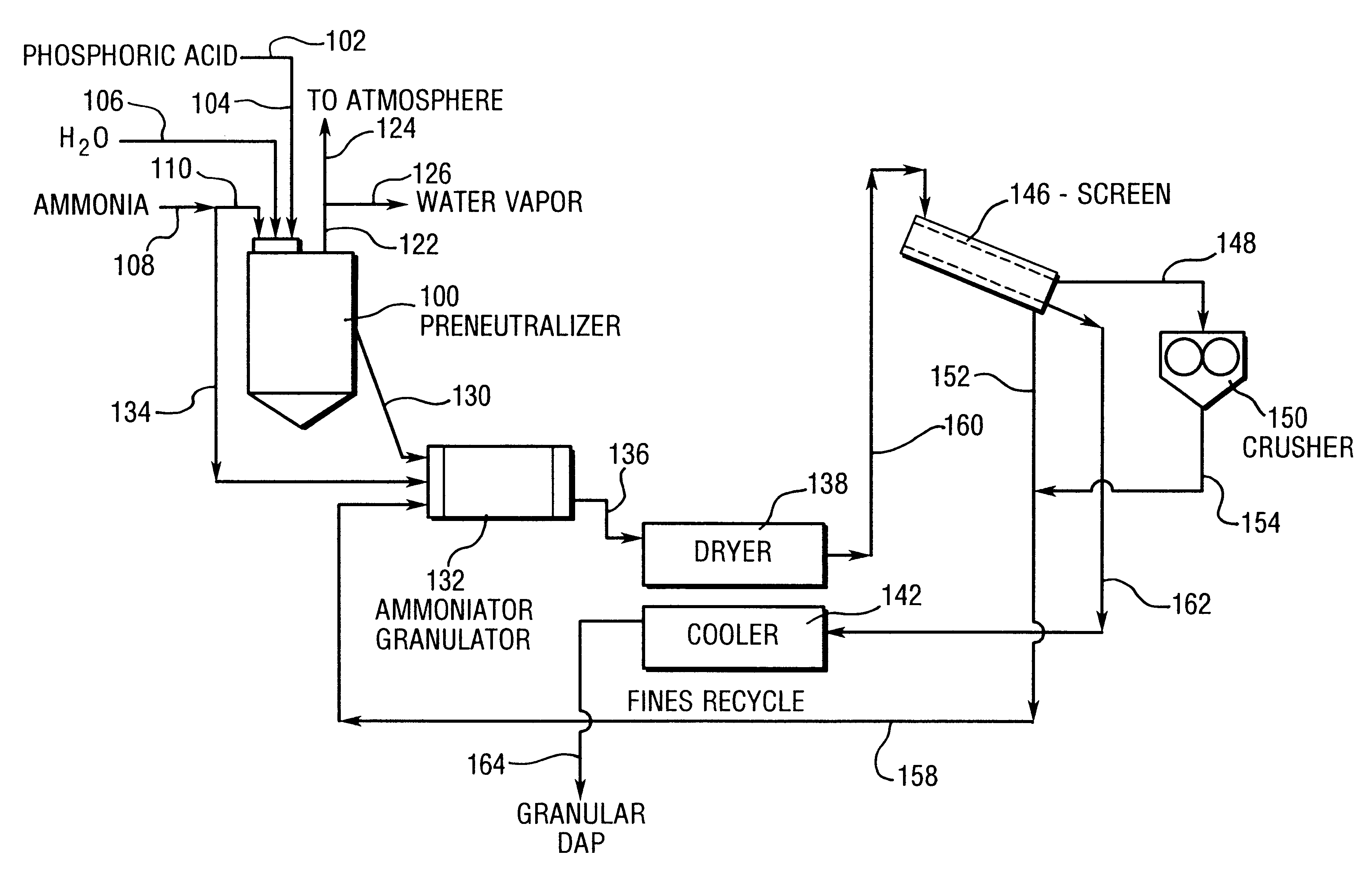

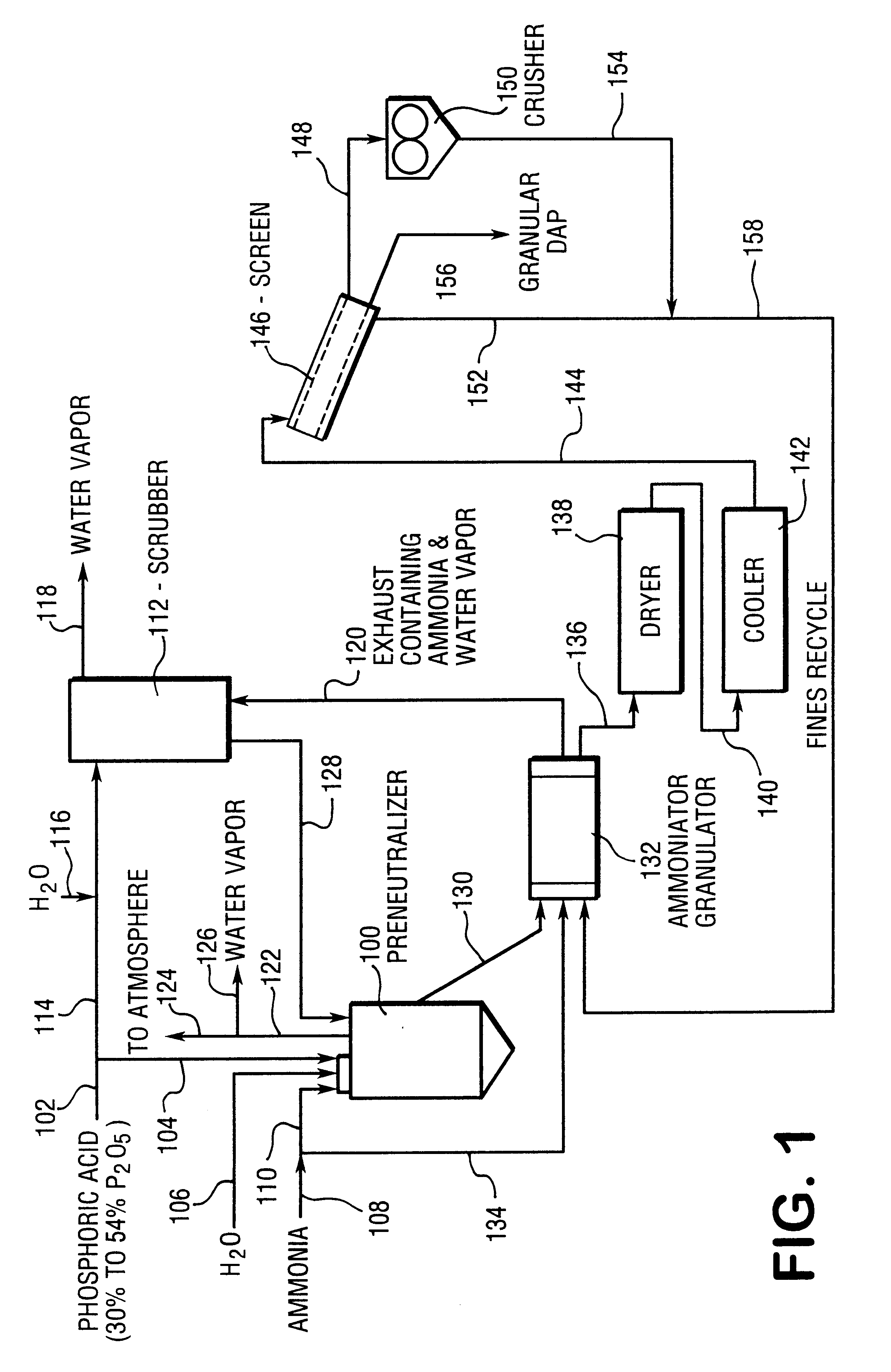

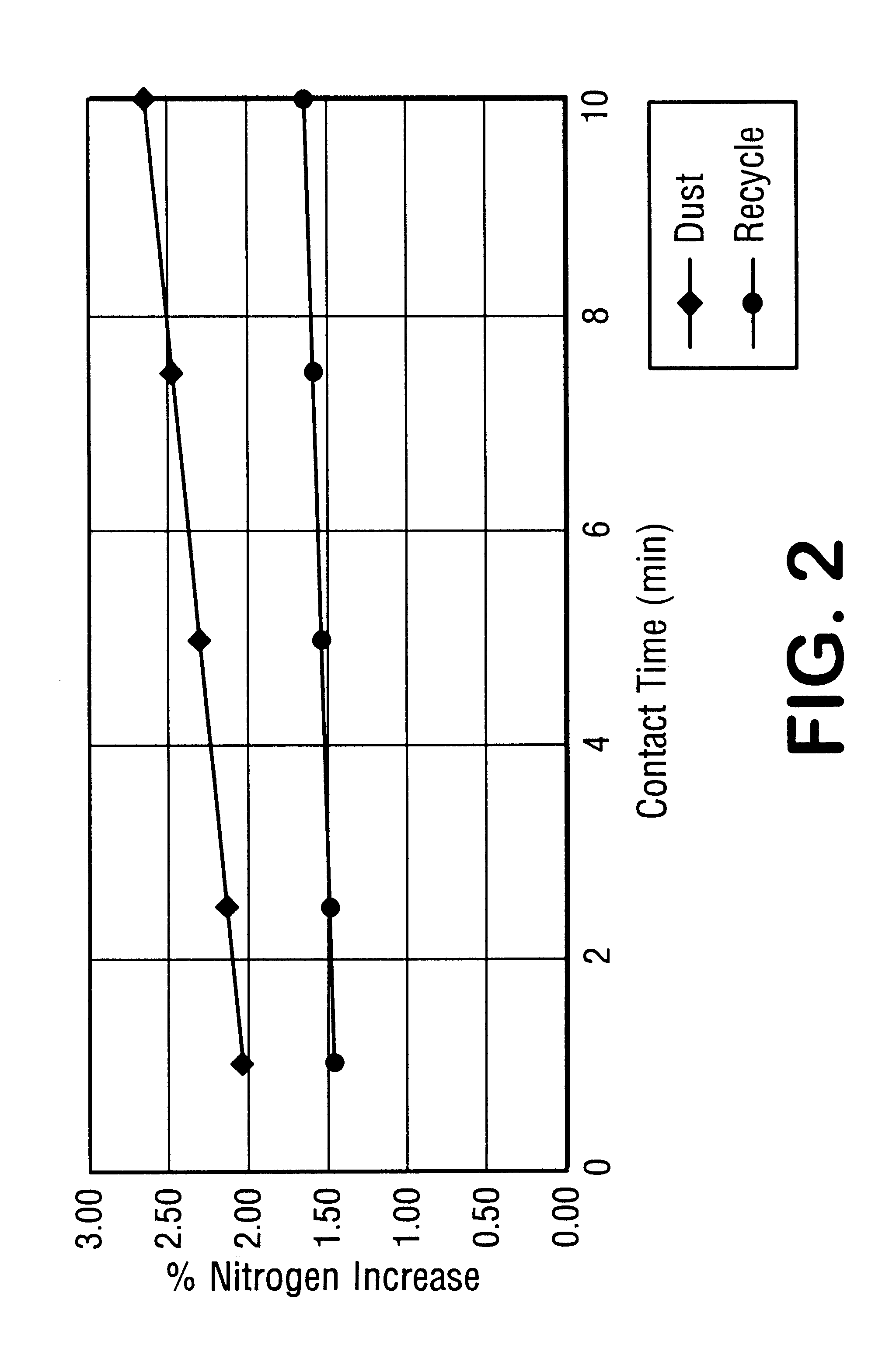

Method for producing fertilizer grade DAP having an increased nitrogen concentration from recycle

InactiveUS6241796B1Small particle sizeEnhancing ammoniacal nitrogen concentrationPhosphatesPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesAmmoniacal nitrogenContact time

A process for the preparation of granular fertilizer grade DAP (a product composed of ammonium phosphates, principally diammonium phosphate, resulting from the ammoniation of phosphoric acid, as defined in Official Publication No. 52 of the Association of American Plant Food Officials, dated 1999) comprising partially preneutralizing orthophosphoric acid with ammonia, completing the ammoniation of the orthophosphoric acid with ammonia in a rotary ammoniator-granulator to provide granular DAP, sizing the granular DAP to provide the granular DAP product, reducing the particle size of the oversized granular DAP, and recycling the undersized granular DAP and the sized-reduced oversized granular DAP to the ammoniator-granulator. The ammoniacal nitrogen concentration of the granular DAP recycle, hence the granular DAP product, is enhanced by subjecting the finely-divided recycled granular DAP to anhydrous gaseous ammonia which is at a super atmospheric pressure and which is at a temperature sufficient to maintain said anhydrous ammonia in the gaseous state. The increase in the ammoniacal nitrogen concentration is a function of the absolute ammonia pressure, the initial moisture content of the granular DAP recycle, and the contact time of the ammonium with the granular DAP recycle.

Owner:THE MOSAIC COMPANY

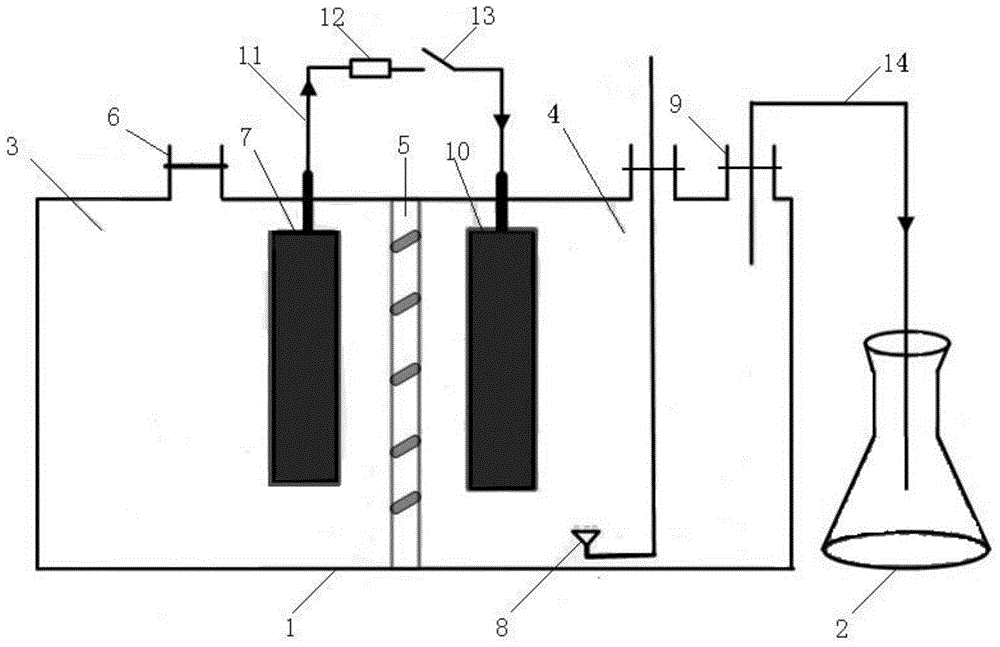

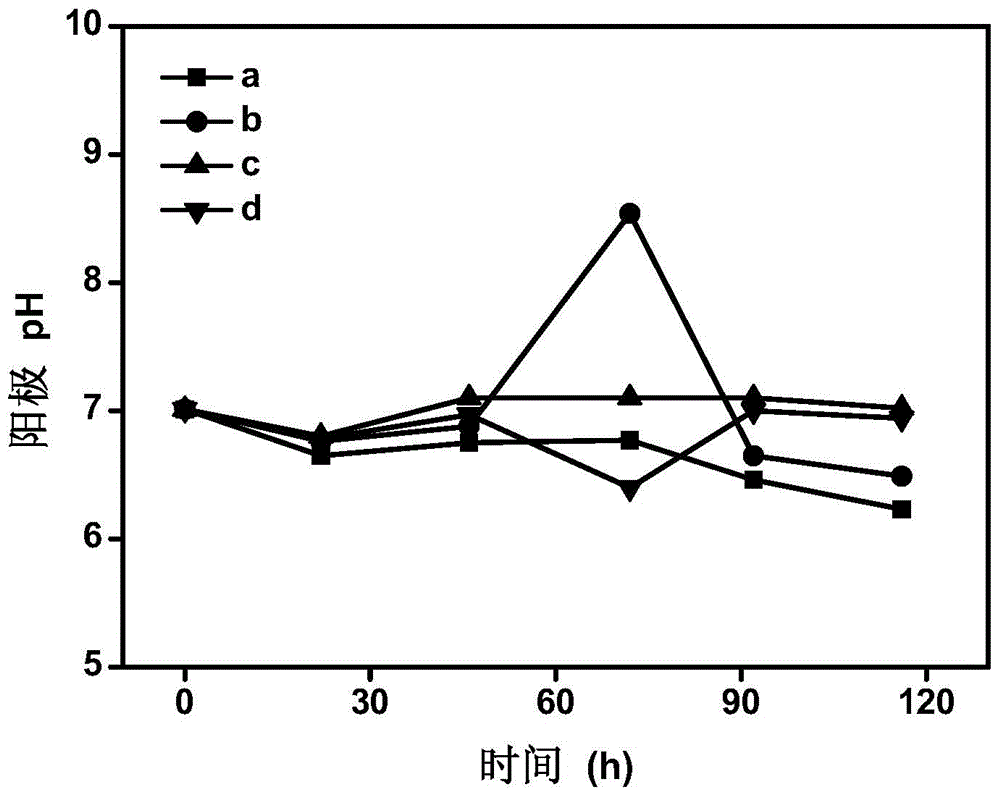

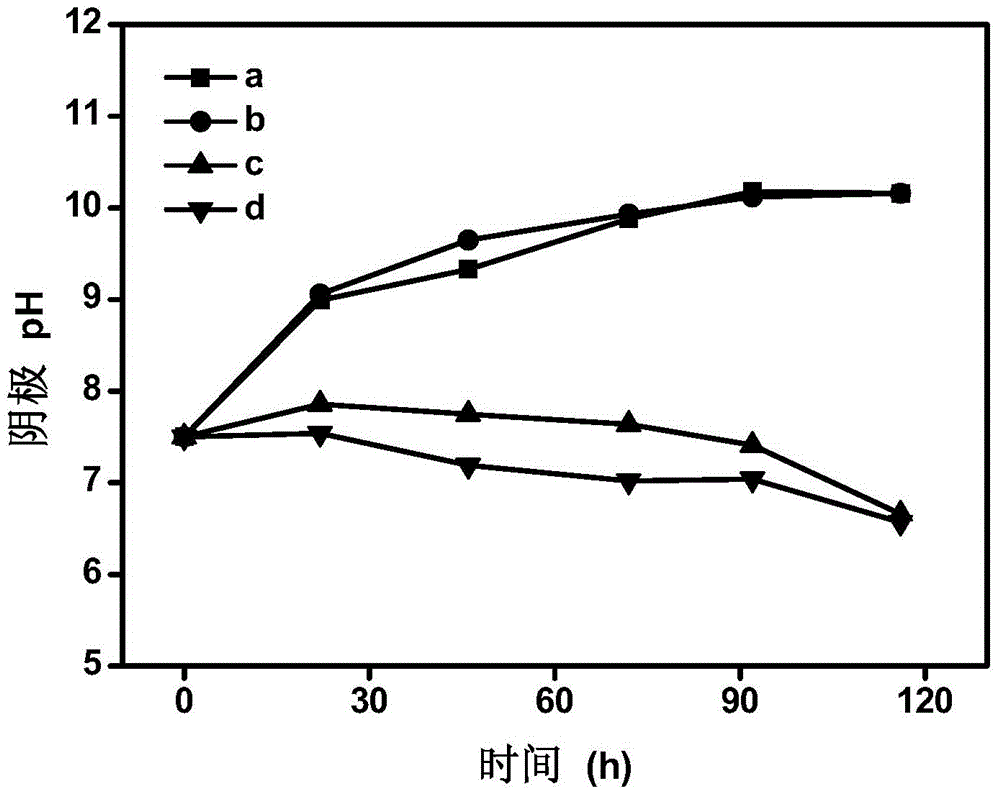

Device and method for removing and recycling ammonia nitrogen in sewage by means of microbial fuel cell

ActiveCN104143648AAchieve removalAchieve the function of recycling energy resourcesWater contaminantsBiochemical fuel cellsSodium acetateElectron donor

The invention belongs to the technical field of sewage processing, and discloses a device and method for removing and recycling ammonia nitrogen in sewage by means of a microbial fuel cell. A double-chamber microbial fuel cell system and an ammonia recycling device are built, an anode chamber is inoculated with domesticated electrogenesis mixed bacterium liquid, sodium acetate is added to serve as electron donors, and then phosphate buffered solutions with a PH value of 7.0 and nutrient solutions are added to the anode chamber until the anode chamber is full; the sewage containing the ammonia nitrogen is added to a cathode chamber, and air is led to the cathode chamber through an aeration device; H2SO4 of 0.1 mol*L<-1> is added to an ammonia recycling device, then the microbial fuel cell is started, and the ammonia nitrogen in the cathode chamber is converted into gaseous ammonia, removed from the sewage and recycled by the ammonia recycling device. The device and method are used for removing and recycling the ammonia nitrogen in the sewage and have good economic efficiency and environmental protection benefits.

Owner:SOUTH CHINA UNIV OF TECH

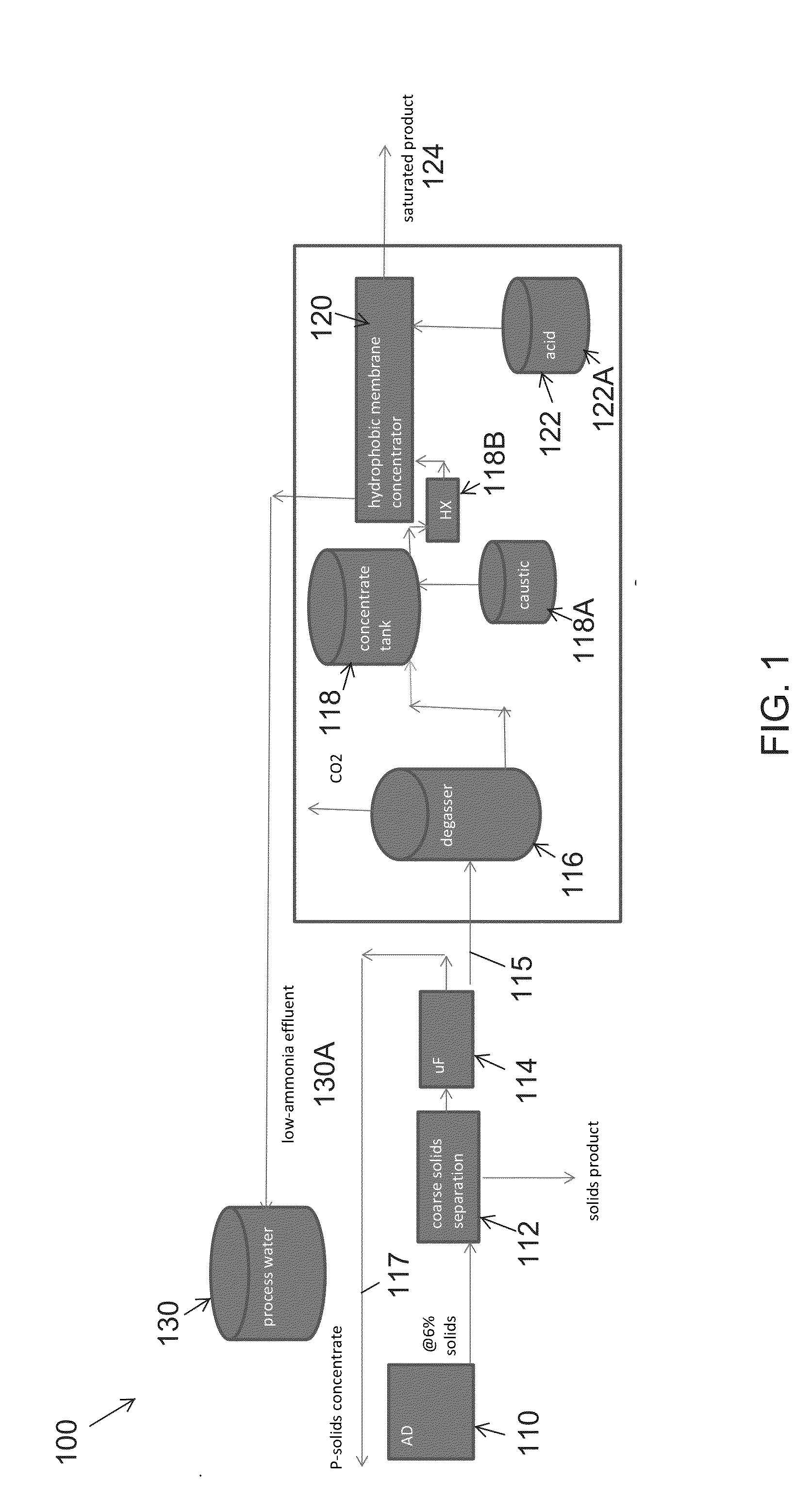

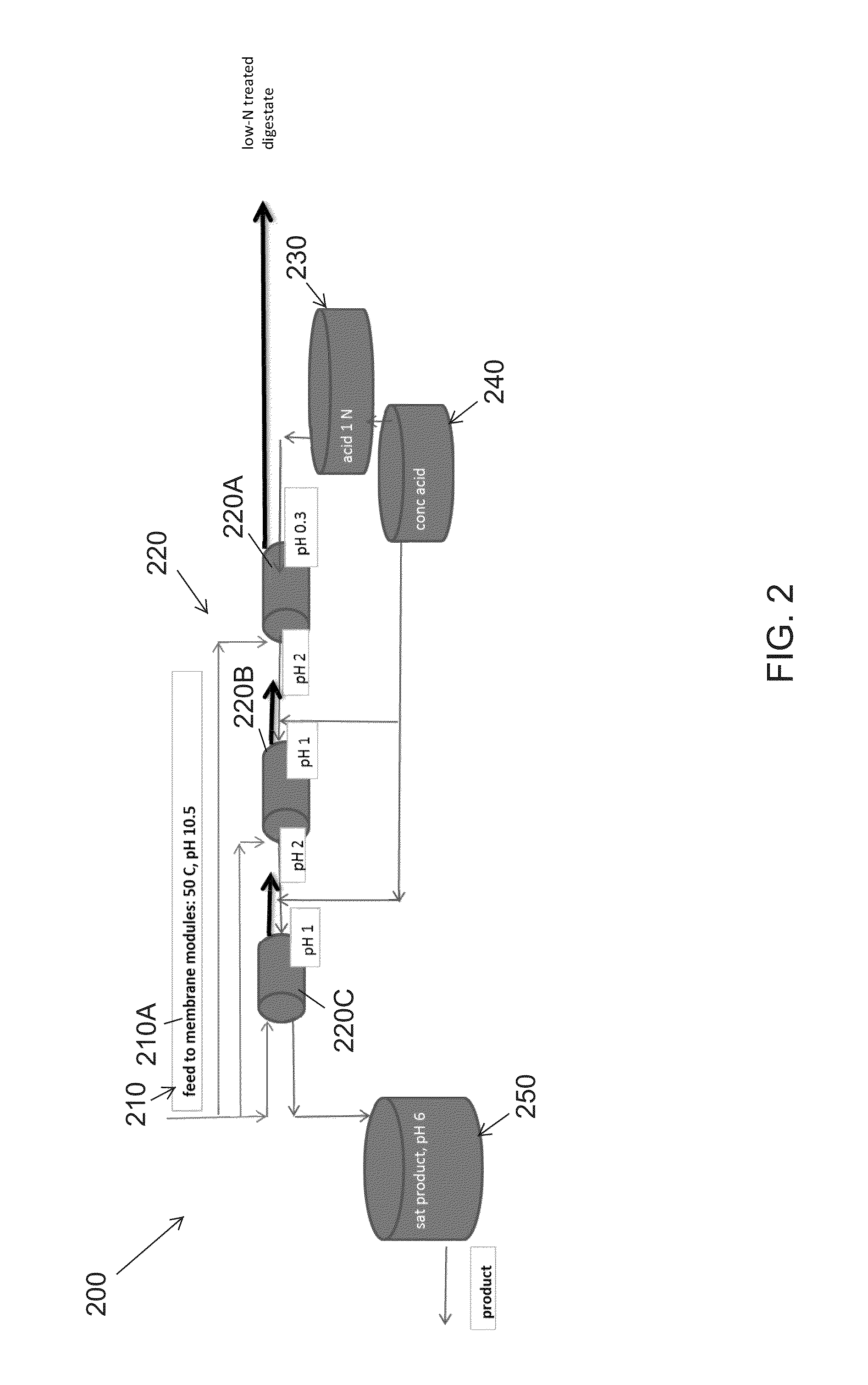

Ammonia capture recovery system

An ammonia capture recovery system is disclosed. The ammonia capture recovery system may include pretreatment with conventional solid removal devices and a single or a series of hydrophobic membrane concentrators receiving a heated ammonium containing influent either heated to a sufficient temperature to convert ammonia to ammonium or containing sufficient alkali to convert ammonia to ammonium in the influent. The heated ammonium containing liquid is pumped through the hydrophobic membrane concentrator and the hydrophobic membrane concentrator receives an acid. The acid then reacts with the extracted gaseous ammonia and ultimately forms a saturated ammonium salt product that is discharged from the hydrophobic membrane concentrator, the hydrophobic membrane concentrator includes a feed line, a plurality of hydrophobic membrane modules, a diluted acid source and a concentrated acid source and tanks to receive the saturated ammonium salt product and the low ammonia effluent.

Owner:ORENTLICHER MORTON +1

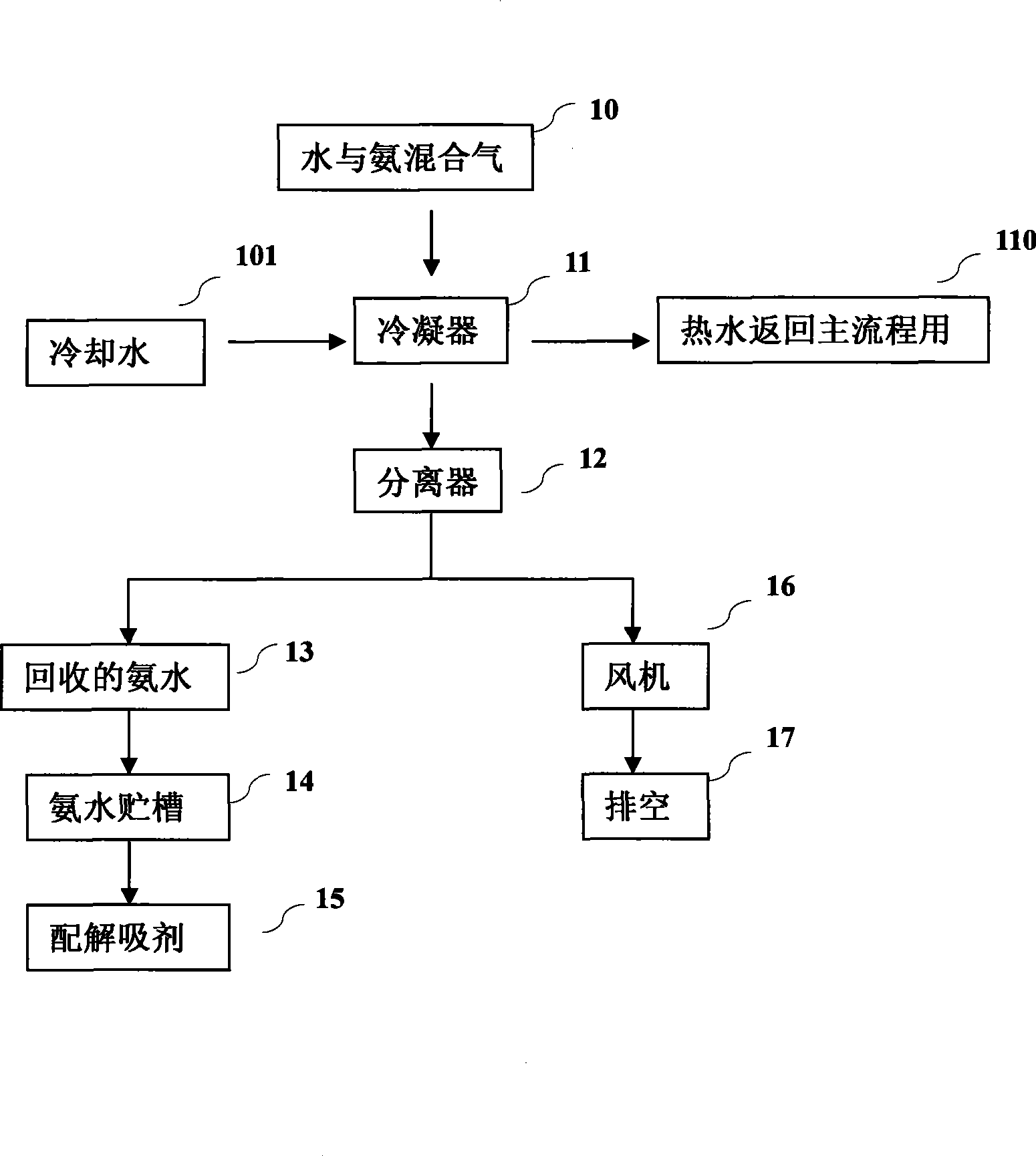

Method for recycling ammine in ammonium paratungstate production

InactiveCN101439865AReduce consumptionAchieve recyclingAmmonia preparation/separationAtmospheric emissionsAtmospheric air

The invention provides a method for recycling ammonia during the production of ammonium paratungstate. During the evaporation and crystallization of a solution for producing the ammonium paratungstate, free ammonia in the solution and ammonia released by the crystallization process can be volatilized in a gas state. Firstly, a closed vessel is used to collect gaseous ammonia; secondly, the ammonia is reclaimed through the mode of condensation and separation; and finally the reclaimed ammonia can be returned to the main production process and be used for preparing a strippant. The method reduces the consumption of liquid ammonia during the production of the ammonium paratungstate, thereby greatly reducing the production cost and having an ammonia reclamation rate of above 90 percent. Simultaneously, the method prevents the air pollution caused by a large amount of evaporated and overflowed ammonia gas; and the atmospheric emission reaches national standards. Therefore, the method reduces the corrosion of workshop equipment and realizes the reclamation of the ammonia, thereby not only realizing considerable economic benefits, but also realizing certain social and environmental benefits.

Owner:JIANGXI RARE EARTH & RARE METALS TUNGSTEN GRP

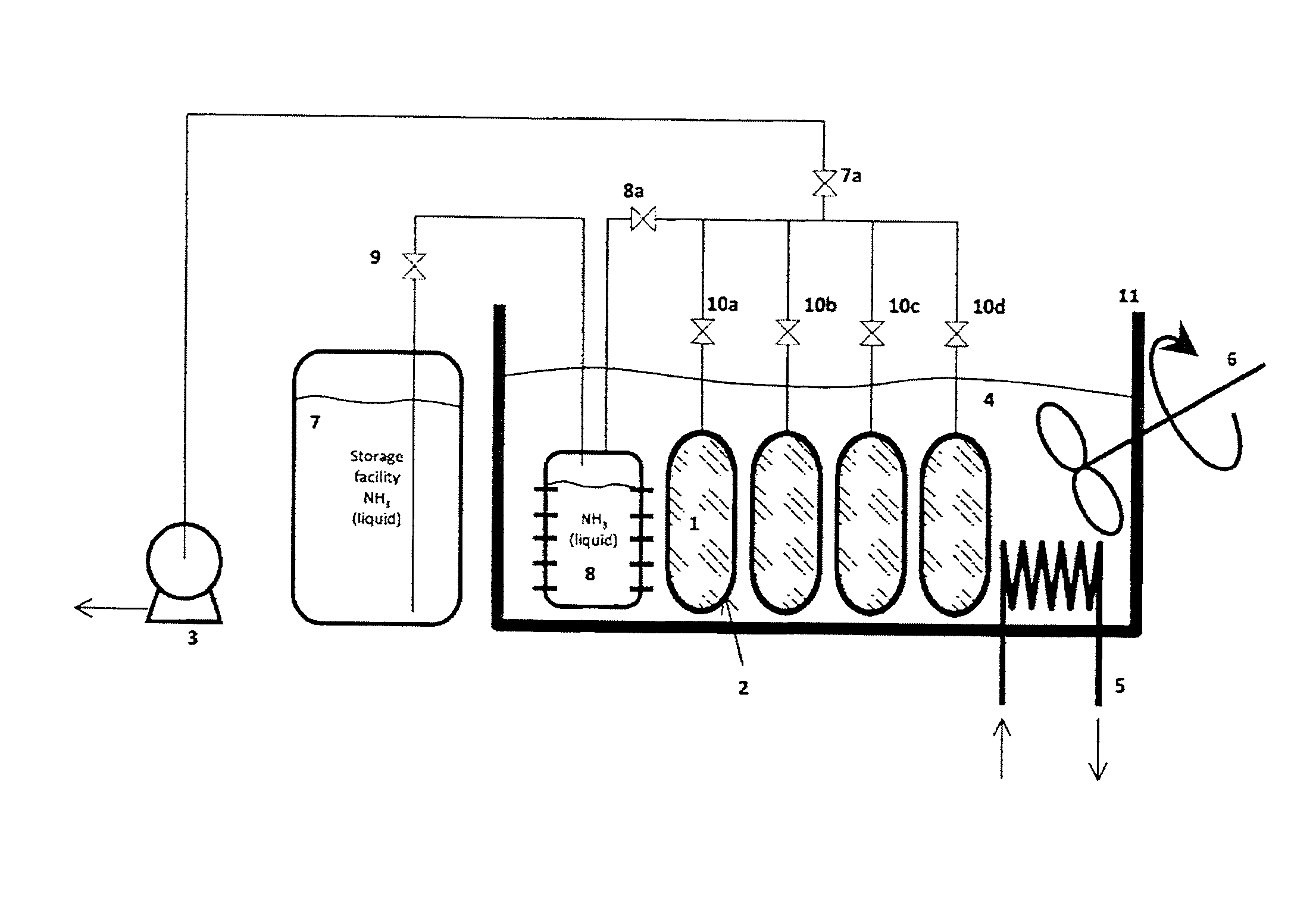

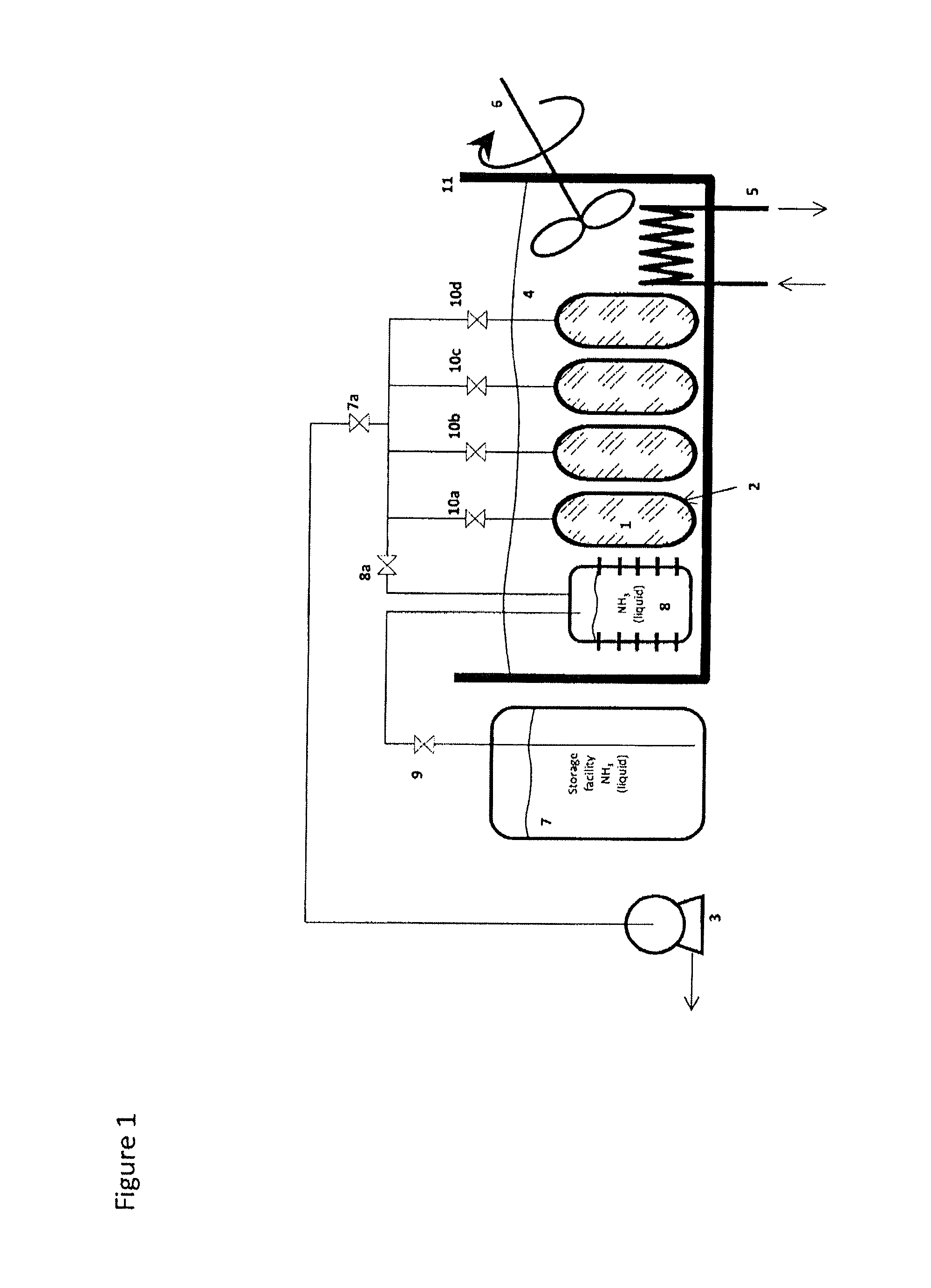

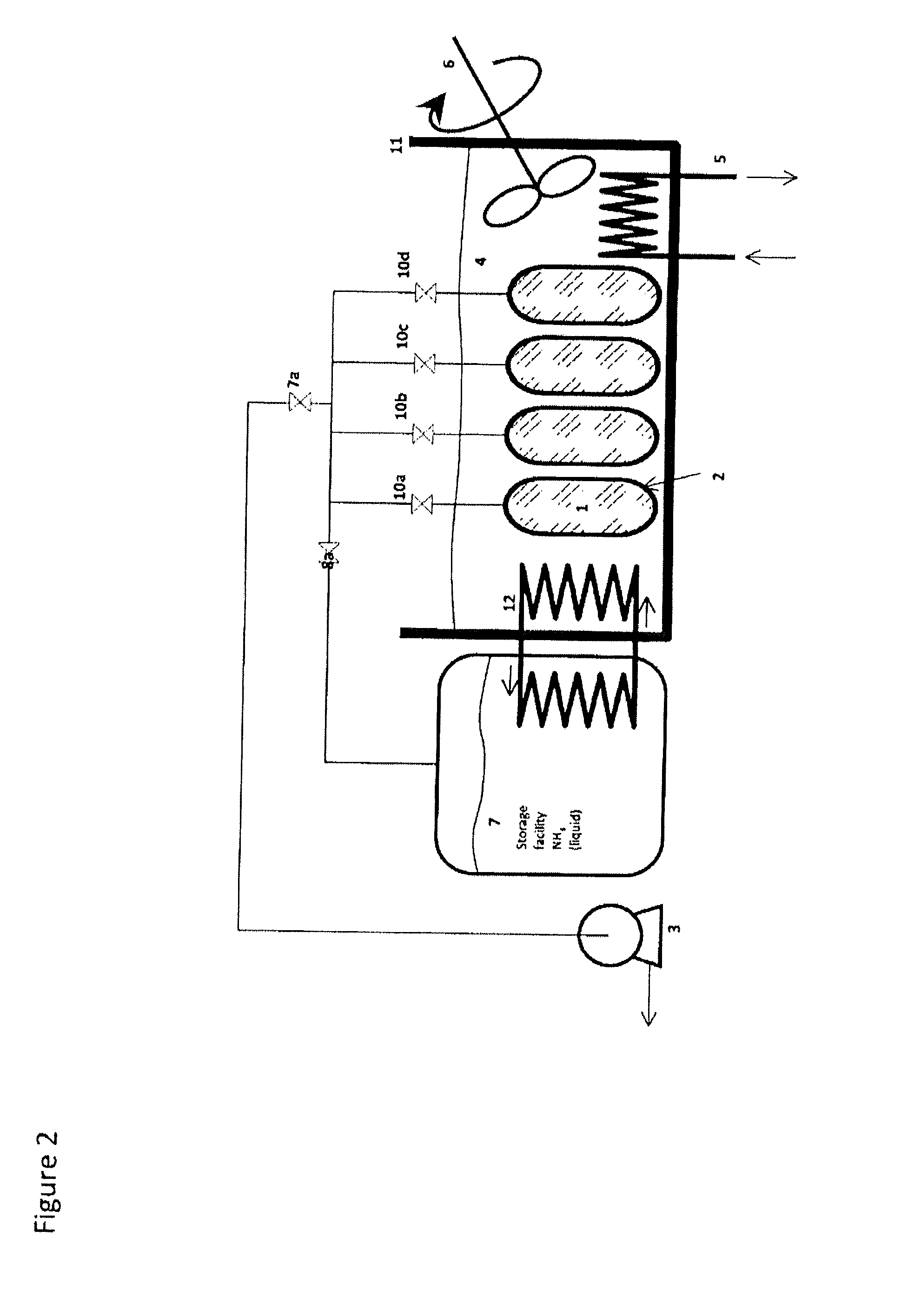

Method for Saturating and Re-Saturating Ammonia Storage Material in Containers

A method for saturating or re-saturating ammonia storage material (1) capable of reversibly absorbing and desorbing ammonia in one or more storage containers (2), wherein said material is partly or fully depleted of ammonia, with ammonia to a predetermined saturation degree comprises a. placing the storage container(s) (2) in direct or indirect contact with a thermostatting medium (4) at a temperature level TT≦ about 65° C.; and b. connecting the storage container(s) (2) to a source of gaseous ammonia wherein at least during a part of the method the gaseous ammonia during saturating or re-saturation of the ammonia storage material (1) is at a pressure PS≦ about PT, wherein PS is the ammonia pressure during saturating or re-saturating of the ammonia storage material (1) and PT is the equilibrium vapor pressure of liquid ammonia at the temperature level TT.

Owner:AMMINEX EMISSIONS TECH

Method for controlling a SCR catalyst

ActiveUS8387368B2Nitrous oxide captureInternal combustion piston enginesClosed loopInternal combustion engine

A method for controlling a selective catalytic reduction catalyst in an exhaust line of an internal combustion engine is disclosed, wherein the supply of a quantity of a gaseous ammonia reductant to the SCR catalyst uses a closed-loop SCR catalyst model coupled to a SCR-out NOx sensor that measures a SCR-out NOx emission value. The closed-loop SCR catalyst model uses a relationship linking the measured SCR-out NOx value to the NOx conversion efficiency and the ammonia slip. The actual NH3 emission value and / or an actual SCR-out NOx indicative value are computed based upon differentiation of said relationship.

Owner:DELPHI INT OPERATIONS LUXEMBOURG S A R L +1

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com