Flue gas desulphurization and denitration reactant integrated supply method and apparatus

A technology for desulfurization, denitrification, and supply devices, which is applied in chemical instruments and methods, separation methods, and dispersed particle separation. It can solve the problems of catalyst poisoning, accumulation of evaporators, and high energy, and achieve mild operating parameters, low investment, and no secondary problems. The effect of pollution

Active Publication Date: 2012-06-13

JIANGSU NEW CENTURY JIANGNAN ENVIRONMENTAL PROTECTION

View PDF4 Cites 38 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Moreover, many chemical and fertilizer enterprises in China have by-product ammonia water. If the complete evaporation method commonly used abroad is used to evaporate all the ammonia water, not only will the energy be high, but also part of the impurities in the ammonia

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

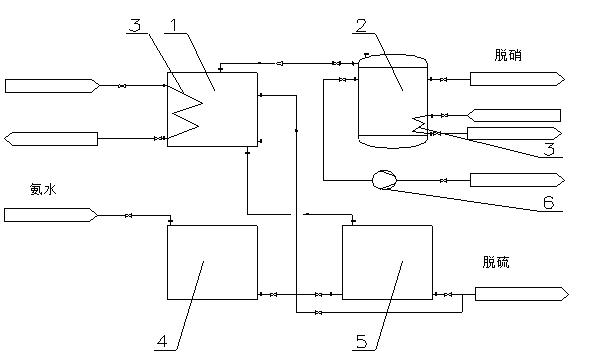

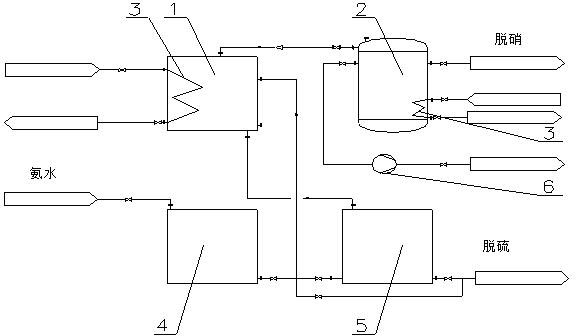

An integrated supply method by using ammonia water as a desulphurization and denitration reactant contains the following steps of: 1) ammonia water evaporation: part of ammonia in inputted concentrated ammonia water is evaporated by controlling the temperature and pressure of an evaporator and other components are remained in the ammonia water; 2) gaseous ammonia storage and its use for denitration: a buffer tank is configured to store the gaseous ammonia generated from the ammonia water evaporation under a certain pressure so as to supply ammonia for a denitration apparatus and stabilize the operation of the evaporator; and 3) dilute ammonia water storage and its use for desulphurization: a dilute ammonia water groove is correspondingly configured to store the ammonia water, the concentration of which is reduced after the original ammonia water is evaporated into the gaseous ammonia, and the dilute ammonia water is used for flue gas desulphurization. The operation pressure and concentration of the evaporator are stabilized by extraction of the dilute ammonia water from the evaporator, and simultaneously ammonia water is stably supplied for the flue gas desulphurization apparatus. The inputted concentrated ammonia water is stored in a concentrated ammonia water groove and enters into the evaporator from the concentrated ammonia water groove. Ammonia is evaporated into a gas phase after being heated by a heater of the evaporator. The gaseous ammonia is used for denitration and the dilute ammonia water is used for desulphurization.

Description

technical field [0001] The present invention relates to an integrated supply process and device for desulfurization and denitrification reactants of coal-fired flue gas in the field of environmental protection. After treatment, it can be used as a reactant for desulfurization and denitrification to realize an integrated process with no residue and energy saving. Background technique [0002] my country is a developing country with coal as the main fuel, and the environmental pollution caused by coal combustion is becoming more and more serious. 2 , NO x very important. [0003] Due to the advantages of high desulfurization efficiency, no secondary pollution, low operating costs, and high device feasibility, ammonia flue gas desulfurization technology is more and more widely used in China. The reactants of ammonia desulfurization can be liquid ammonia, ammonia water, carbon Ammonium, urea and other alkaline substances containing ammonia. [0004] At present, flue gas deni...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B01D53/78B01D53/60

Inventor 徐长香罗静徐延忠许祥俊薛玉业陈任远

Owner JIANGSU NEW CENTURY JIANGNAN ENVIRONMENTAL PROTECTION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com