Combined desulfurization and denitrification method implemented by using metallurgical slags

A metallurgical waste residue, desulfurization and denitrification technology, applied in the environmental field, can solve problems such as the need for catalysts, difficulties in industrial scale-up, and ammonia leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

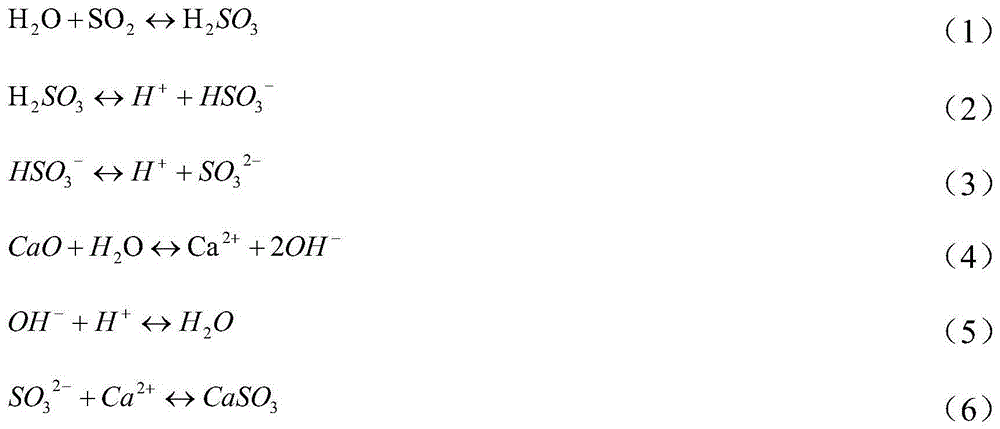

Method used

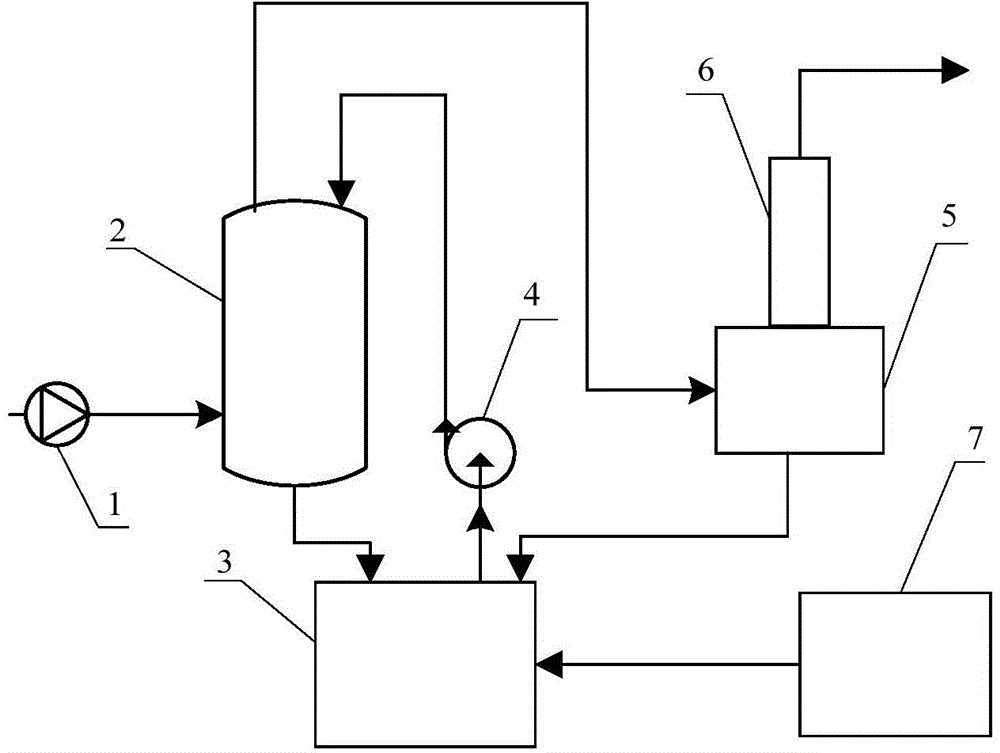

Image

Examples

Embodiment 1

[0063] In this embodiment, the metallurgical waste slag is selected from the converter steel slag produced in the steelmaking process, wherein the content of calcium oxide is 34wt%, and the simulated flue gas NO x (as NO) the content is 1000mg / Nm 3 , SO 2 Content at 400mg / Nm 3 , the oxygen content is about 5% (by volume).

[0064] (1) Prepare absorbent slurry: grind the steel slag to below 100 mesh, add water and stir in the batching tank to form a slurry, the content of steel slag is 1wt%, the stirring time is 5h, add sodium hypochlorite (0.3wt%) and hypochlorite Sodium bicarbonate (0.2 wt %) forms absorbent slurry;

[0065] (2) The flue gas enters the absorption tower 2 from the bottom of the absorption tower 2 after being pressurized by the centrifugal fan 1, and the absorbent slurry prepared in step (1) enters the absorption tower 2 from the top of the absorption tower 2 and flows countercurrently with the flue gas Contact, the temperature of the absorption tower 2 is ...

Embodiment 2

[0071] In this example, metallurgical waste slag is selected from blast furnace slag, in which the content of calcium oxide is 45wt%, and the simulated flue gas NO x(as NO) content at 500mg / Nm 3 , SO 2 Content at 2000mg / Nm 3 , the oxygen content is about 5% (by volume).

[0072] (1) Prepare absorbent slurry: grind the blast furnace slag to below 100 mesh, add water and stir in the batching tank to form a slurry, the blast furnace slag content is 30wt%, the stirring time is 7h, add potassium permanganate (2.5wt %) and hydrogen peroxide (0.5wt%) form absorbent slurry;

[0073] (2) The flue gas enters the absorption tower 2 from the bottom of the absorption tower 2 after being pressurized by the axial flow fan 1 with adjustable vanes, and the absorbent slurry prepared in step (1) enters the absorption tower 2 from the top of the absorption tower 2 And contact with the flue gas countercurrently, the temperature of the absorption tower 2 is controlled at 40-100°C; the liquid-ga...

Embodiment 3

[0079] In this example, the metallurgical waste slag is selected from the electric furnace refining slag produced in the steelmaking process, in which the calcium oxide content is 40wt%, and the simulated flue gas NO x (as NO) the content is 1000mg / Nm 3 , SO 2 Content at 1000mg / Nm 3 , the oxygen content is about 5% (by volume).

[0080] (1) Prepare absorbent slurry: grind the electric furnace refining slag to below 100 mesh, add water and stir in the batching tank to form a slurry, the content of the electric furnace refining slag is 15wt%, and the stirring time is 6h, adding calcium hypochlorite ( 8wt%) to form absorbent slurry;

[0081] (2) The flue gas enters the absorption tower 2 from the bottom of the absorption tower 2 after being pressurized by the movable blade adjustable axial flow fan 1, and the absorbent slurry prepared in step (1) enters the absorption tower 2 from the top of the absorption tower 2 And contact with the flue gas countercurrently, the temperatur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com