Patents

Literature

383 results about "Metallurgical slag" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Industrial waste slag-doped composite silicate cement and production method thereof

InactiveCN102101757ABlending amount increasedImprove early strengthCement productionMetallurgical slagAlloy

The invention discloses industrial waste slag-doped composite silicate cement and a production method thereof. The industrial waste slag-doped composite silicate cement comprises the following material components: 45-58 percent of silicate cement clinker, 3-5 percent of desulfurization gypsum, 1.5-4 percent of lime stone, 0.2-0.3 percent of cement grinding additive, 10-29 percent of granulated blast furnace slag, 2-10 percent of coal slag, 4-10 percent of pulverized fuel ash, 2-10 percent of ferroalloy slag, 2-10 percent of zinc metallurgical slag and 0.2-0.25 percent of waste slag grinding aid active excitant. The production method comprises the following steps of: taking and mixing the first four materials according to the proportion and grinding into 300-350m<2> / kg of powder; taking and mixing the rest six materials according to the proportion and grinding into 420-450m<2> / kg of superfine powder; and then combining the two kinds of powder, stirring and homogenizing. By adopting respective grinding of clinker and waste slag, the waste slag fineness reaches an optical value for stimulating the activity, the hydration progress and the cement clinker reach synchronization, and the doping amount and doping category of waste slag are also improved.

Owner:王明贵

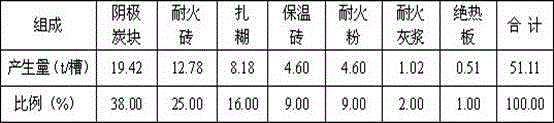

Deep comprehensive resource utilization method for electrolytic cell overhaul slag

ActiveCN102978659AHigh purityAchieve recyclingElectrolysis componentsSolid waste disposalMetallurgical slagBrick

The invention discloses a deep comprehensive resource utilization method for electrolytic cell overhaul slag. The method is characterized by comprising the following steps of: sorting electrolytic cell overhaul slag, respectively obtaining electrolyte blocks, cathode bars, waste cathode carbon blocks, waste refractory bricks, waste insulating bricks, waste heat-insulating plates, waste paste and residual mixed slag charge; respectively leaching the sorted blocks in water, crushing and leaching after the blocks are selected, recovering the selected blocks, grinding and floating the residual powder, selecting carbon powder and refractory material powder, and manufacturing a metallurgical slag former from the residual powder. According to the method, fluoride salts which are difficultly removed in the electrolytic cell overhaul slag are separated, the recycling value of the electrolytic cell overhaul slag is improved, waste materials are changed into valuable materials, economic and pollution-free recovery of the electrolytic cell overhaul slag is realized, and the pollution hidden danger is fundamentally eliminated.

Owner:周俊和 +1

Slag asphalt concrete pavement material composition for microwave heating

InactiveCN101774786ASimple preparation processIncreased heating rate by microwave heatingSolid waste managementMetallurgical slagMicrowave

The invention discloses a slag road asphalt concrete pavement material composition suitable for microwave heating. In the preparation process of road asphalt concrete, magnetic powder is added and is used for fully or partially replacing the lime stone powdered ore in the traditional asphalt concrete raw material, magnetic metallurgical slag is used for replacing the natural coarse aggregate in the traditional asphalt concrete raw material, and thus the finally obtained composition comprises magnetic powder, lime stone powdered ore, asphalt, magnetic metallurgical slag and natural coarse aggregate. Compared with the traditional asphalt concrete for microwave heating, the slag asphalt concrete of the invention improves the heating rate by several times to dozens of times, has lower cost, can greatly improve ice removing and snow melting efficiency by microwaves, and is widely applied to various asphalt concrete highway pavements, airports, factories, offices, schools, armies and other organizations.

Owner:CHANGAN UNIV

Method for comprehensively recovering mercury and selenium from metallurgical slag

InactiveCN104498722ALow costNo emissionsProcess efficiency improvementElemental selenium/telluriumMetallurgical slagHydroxylamine

The invention discloses a method for comprehensively recovering mercury and selenium from metallurgical slag and belongs to the field of metallurgy. The method comprises following steps: grinding the metallurgical slag to the range of 130-150 microns, blending the metallurgical slag with quick lime accounting for 10-30% of the metallurgical slag and roasting at a temperature ranging from 750 to 900 DEG C for 6-8 hours; collecting dust from mercury-containing vapor firstly by use of a cloth bag and then by virtue of cyclone, condensing the mercury vapor by use of a two-stage condensation apparatus to recovery the mercury, and returning mercurial soot and a tail gas adsorption filler to the metallurgical slag for reutilization, wherein no pollutant is emitted in the process; next, leaching selenium-containing slag by use of an oxidation solution prepared from hydrochloric acid and sodium chlorate in the ratio of 2:1, analyzing the contents of Hg<2+>, Fe<2+>, Ca<2+> and Mg<2+> in the leachate in the liquid-solid ratio of 2:1, respectively, precipitating the ions by use of sodium sulfide in the ratio of 1:1 to the total content of the ions and then filtering to remove the irons, and reducing for 2 hours by use of hydroxylamine hydrochloride, thereby obtaining the elemental selenium after washing the precipitate. The method for comprehensively recovering mercury and selenium from the metallurgical slag is high in extraction rate and prone to industrial production.

Owner:贵州重力科技环保股份有限公司

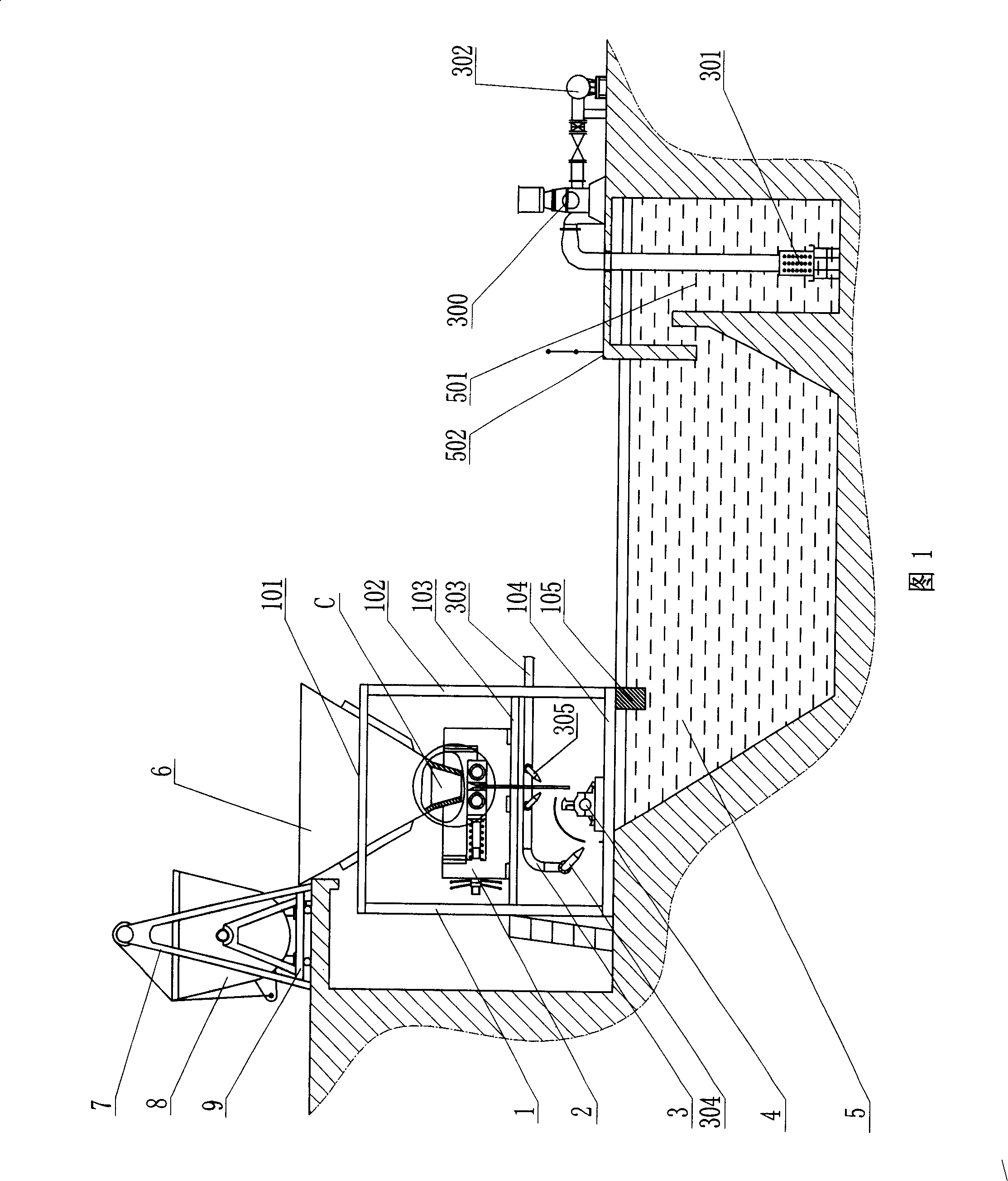

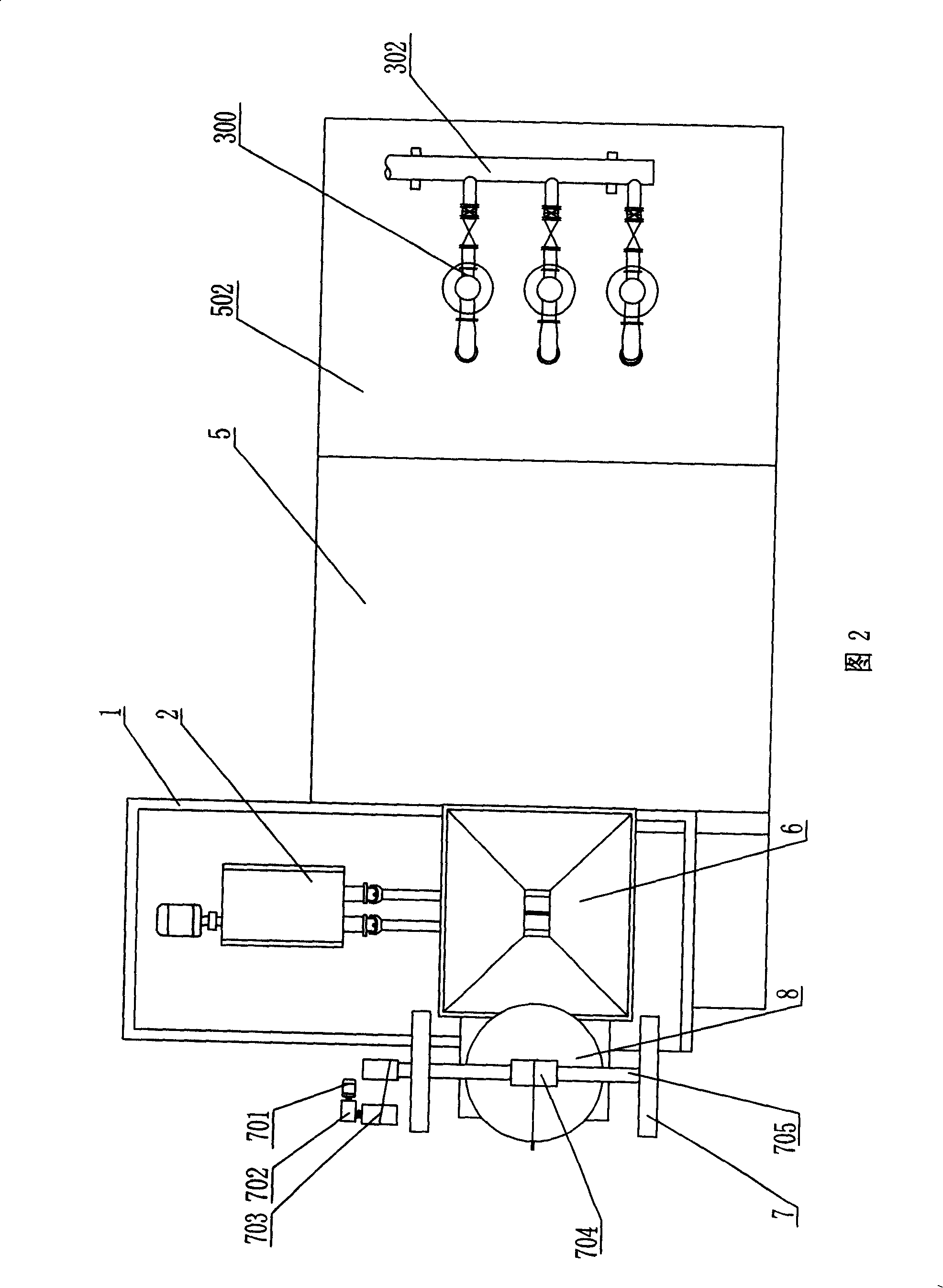

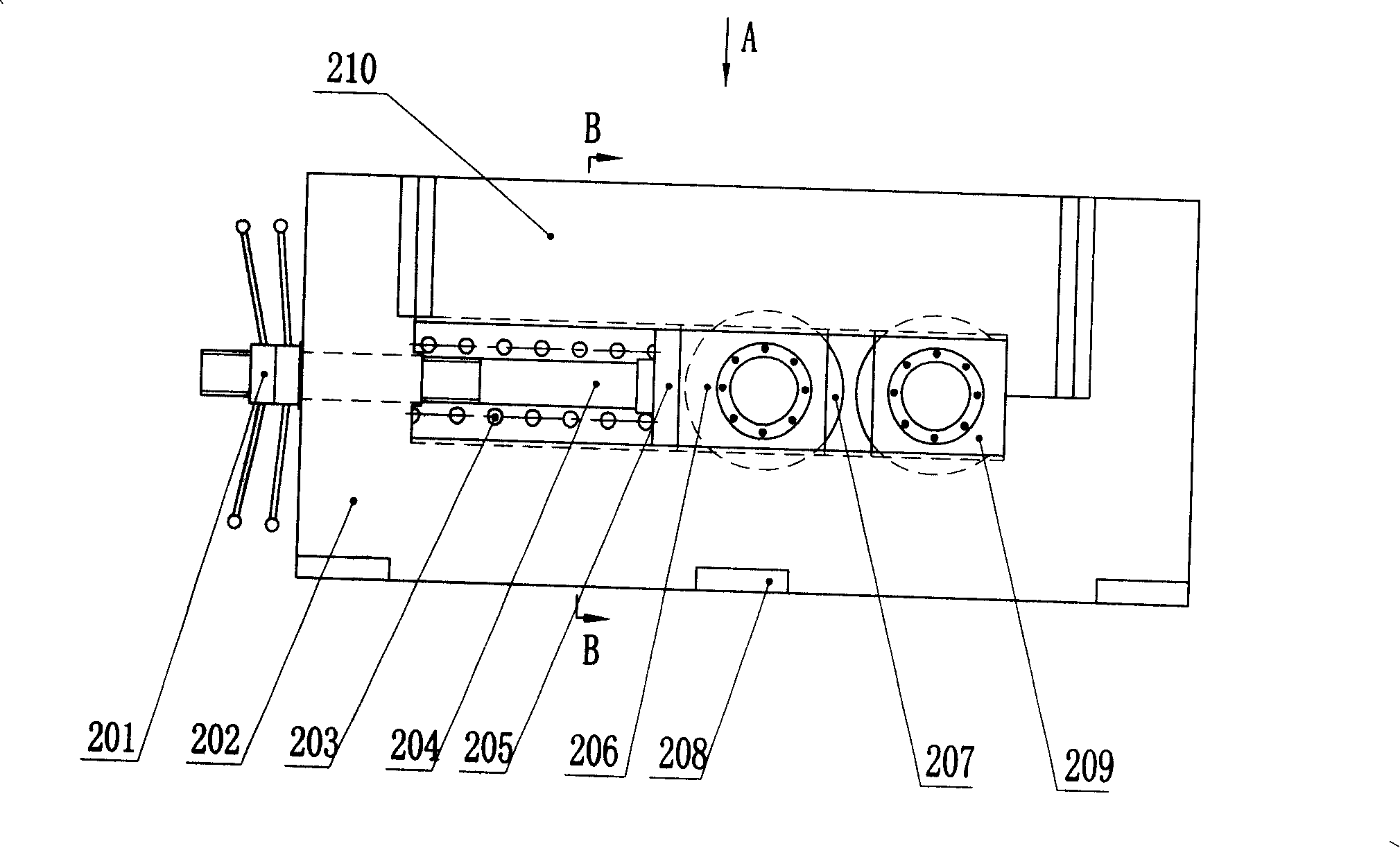

Metallurgical slag treatment method and treatment apparatus

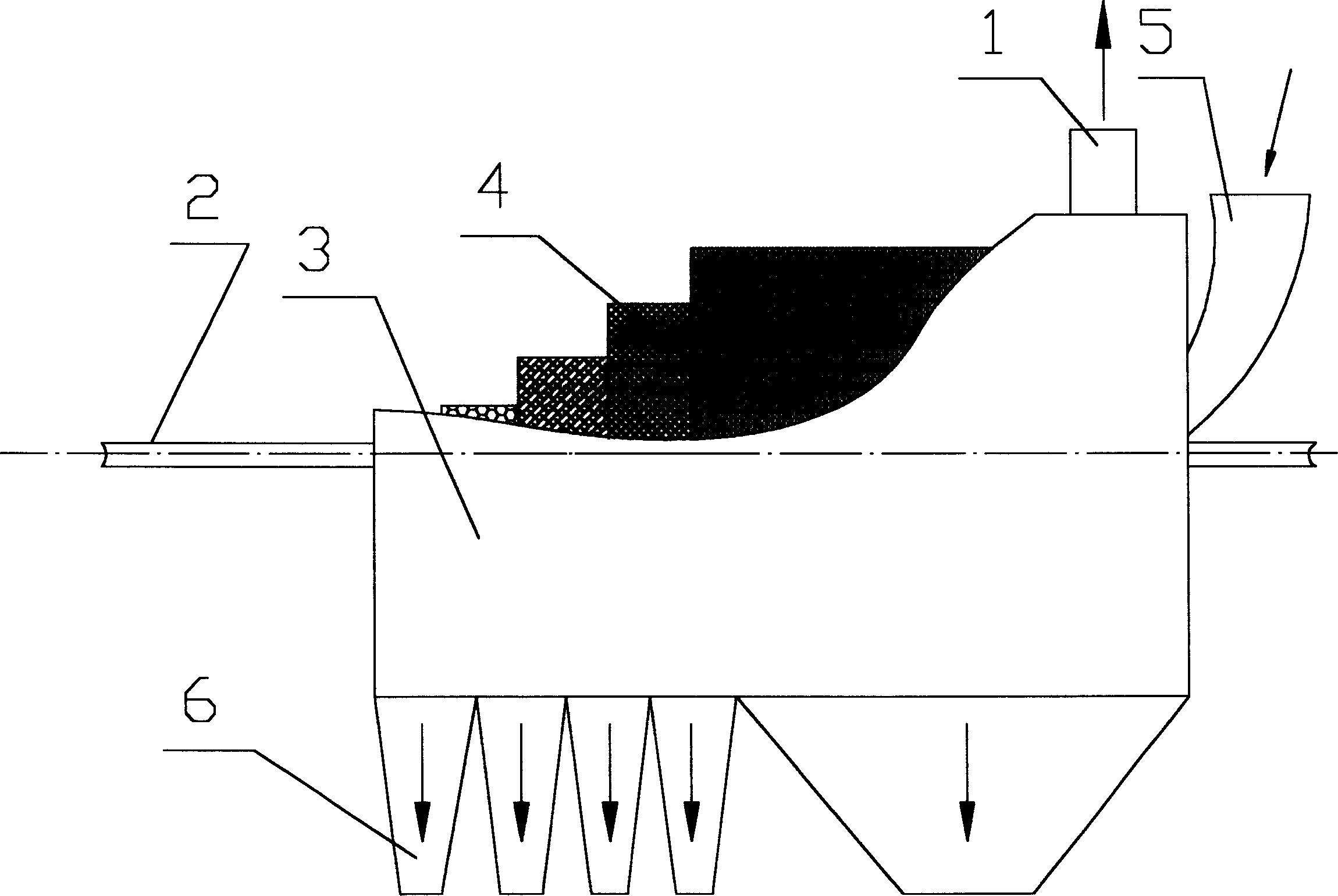

The invention relates to a metallurgical slag treatment method, wherein, the metallurgical slag in a smelting furnace is collected in a slag tank, which is delivered to a tipping device through delivery equipment; the tipping device tips the metallurgical slag into a slag rolling device which comprises a hopper, an outlet at the bottom of the hopper is provided with a pair of rotating rollers which roll the metallurgical slag into sheet shaped slag material, and continuously output outwards; the sheet shaped material continuously passes through a water spray cooling device and is made quick cooling treatment; the sheet shaped slag material enters into a crushing device and is made granulating treatment and forms slag grains by the crushing device which comprises a rotating crushing roller which is provided with a plurality of crushing teeth; the slag grains are thrown into a cooling bay for completely cooling.

Owner:张维田

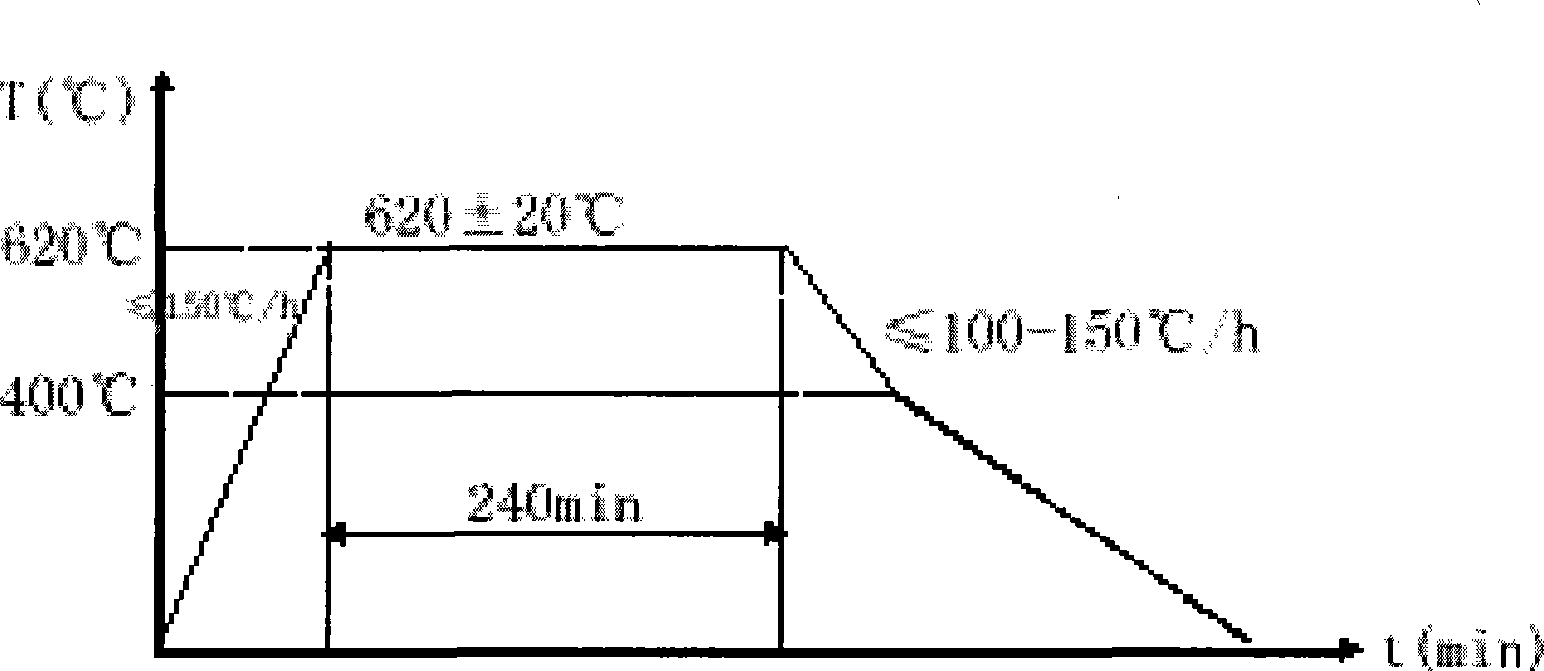

Preparation method of forging aluminum alloy for wheel hub swaging

ActiveCN102373352AImprove wear resistanceExcellent machinabilityTemperature controlMetallurgical slag

The invention discloses a preparation method of a forging aluminum alloy for wheel hub swaging. The forging aluminum alloy comprises 0.705-0.795 wt% of Si, 0.905-1.005 wt% of Mg, 0.2163 wt% of Fe, 0.0705 wt% of Mn, and the balance consisting of Al. The preparation method comprises the following steps: weighing and putting Al, Si, Mg, Fe and Mn in a melting furnace for melting, removing slag with a metallurgical slag removal device when the temperature reaches to 745-755 DEG C to obtain an aluminium alloy liquid; introducing the aluminium alloy liquid in a standing furnace, adding No.2 ground flux and refining, then standing the aluminium alloy liquid in the standing furnace for 30 min at the standing temperature of 735-745 DEG C; carrying out casting and molding on the aluminium alloy liquid through a hot-top casting machine, keeping the temperature of the aluminium alloy liquid within 735-745 DEG C, putting the molded aluminium alloy rods in a 800 kw homogenization furnace for homogenizing with controlling the temperature within 566-574 DEG C, keeping warm for no shorter than 8 h; putting the homogenized aluminium alloy rods in a cooling chamber, and cooling through a blower fan to obtain the forging aluminum alloy for wheel hub swaging.

Owner:秦皇岛开发区美铝合金有限公司

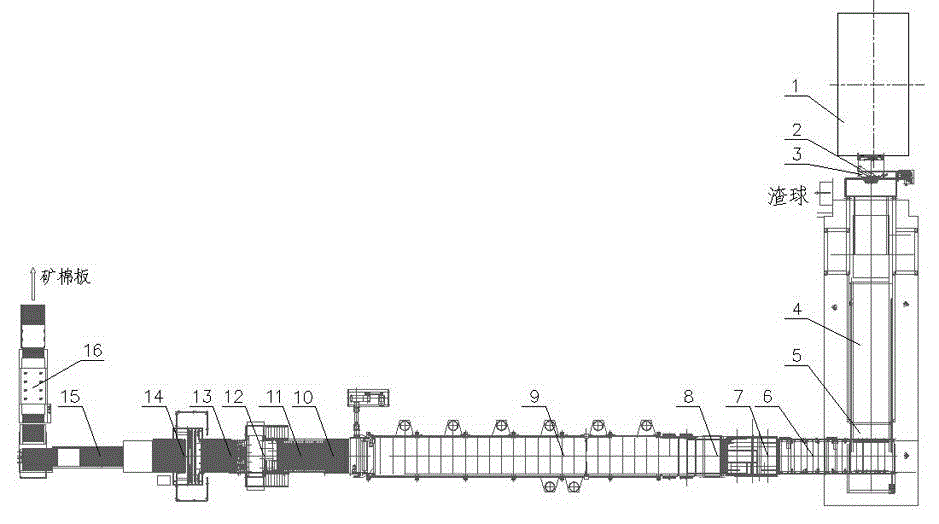

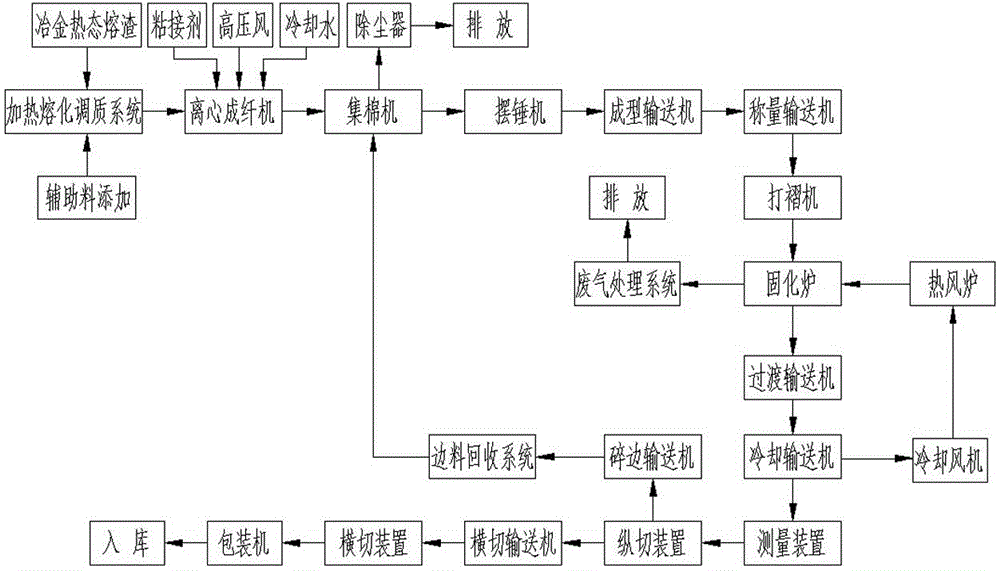

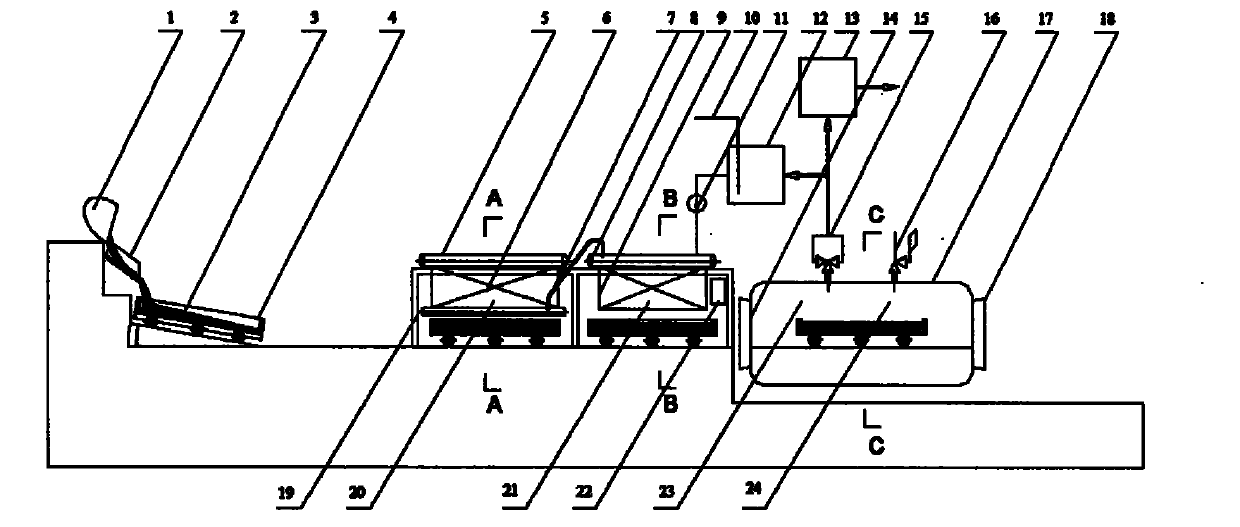

System and method for manufacturing mineral wool board or felt through hot slag

InactiveCN104890110AAvoid energy consumptionReduce energy consumptionCeramic shaping plantsFeeding arrangmentsMetallurgical slagFiber

The invention discloses a system and method for manufacturing a mineral wool board or felt through hot slag. The system comprises a heating and melting conditioning system, a chute system, a centrifugal fiber forming machine, a cotton collecting machine, a pendulum bob machine, a forming conveyor, a weighing conveyor, a pleating machine, a curing oven, a cooling conveyor, a measuring device, a slitting machine, a first conveyor, a transverse cutting machine, a second conveyor and a packager. The method is a technological process implemented through the system. According to the system and method, deep utilization that the metallurgical molten slag is directly manufactured into the mineral wool board or the felt or other products in the subsequent process of hot slag utilization is achieved, sensible heat recovery of the metallurgical hot slag is fully achieved, consumption of mineral resources and environmental pollution are reduced, and the system and method are closer to the target of achieving high value-added utilization and zero release of the metallurgical slag.

Owner:SHANGHAI BAOSTEEL ENERGY TECH

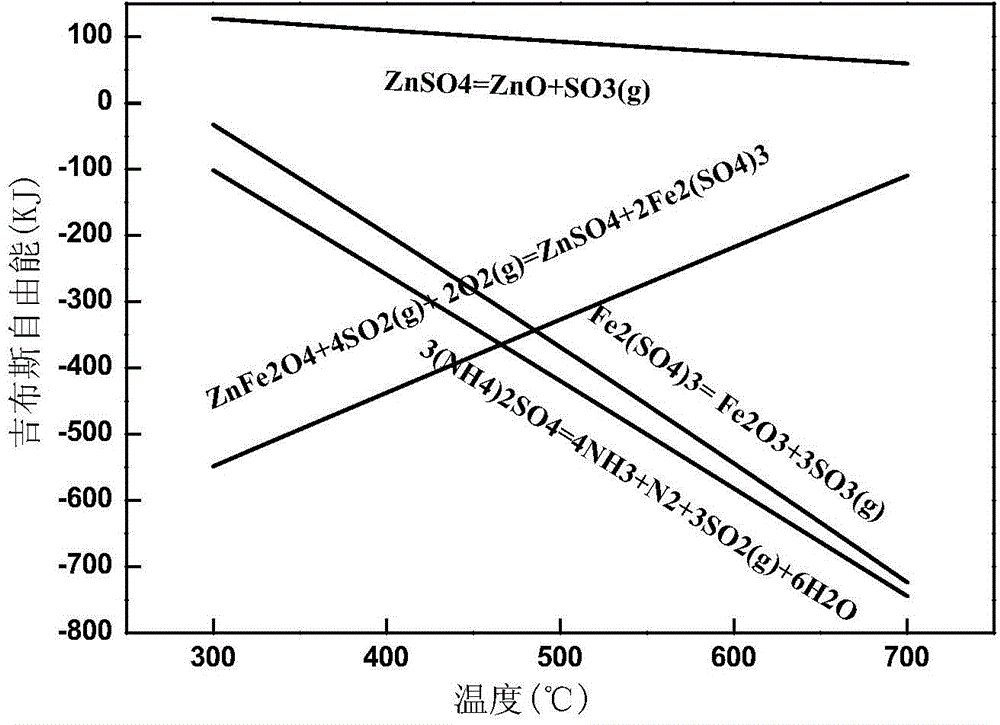

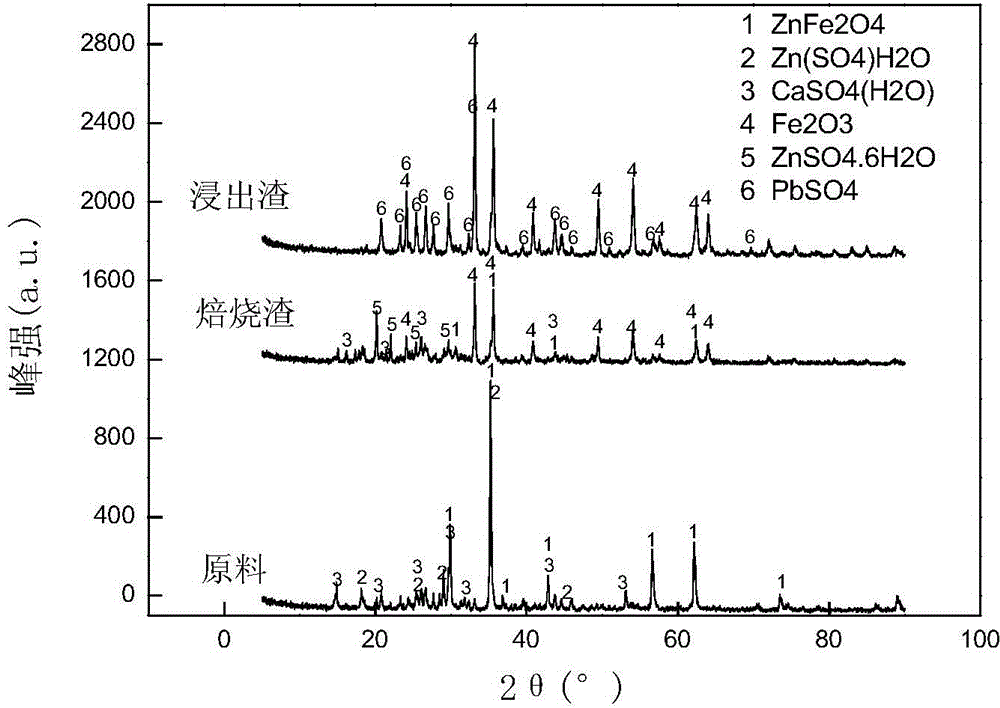

Method for zinc-iron separation by carrying out activated roasting and phase control on zinc ferrite

ActiveCN104087754AReduce contentLow firing temperatureProcess efficiency improvementMetallurgical slagPhase control

The invention discloses a method for zinc-iron separation by carrying out activated roasting and phase control on zinc ferrite. The method comprises the following steps: adding ammonium sulfate to zinc ferrite metallurgical slag, and carrying out activated roasting to decompose zinc ferrite at 300-470 DEG C; roasting and controlling the phase of iron to be Fe2O3 at 480-670 DEG C; selectively leaching zinc in the leaching process to obtain zinc-rich liquid; and gathering iron into the slag to obtain an iron-rich material, wherein the zinc-rich liquid contains 20g / L of zinc and less than 0.5g / L of iron; the leaching rate of zinc under the optimal condition is greater than 92%; the leaching rate of iron is smaller than 0.8%; the iron-rich material contains less than 1% of zinc; the slagging rate of iron can be up to over 99%. By adopting the method, zinc and iron in the zinc ferrite metallurgical waste can be effectively recovered, and the method has good economic significance and environmental significance.

Owner:CENT SOUTH UNIV

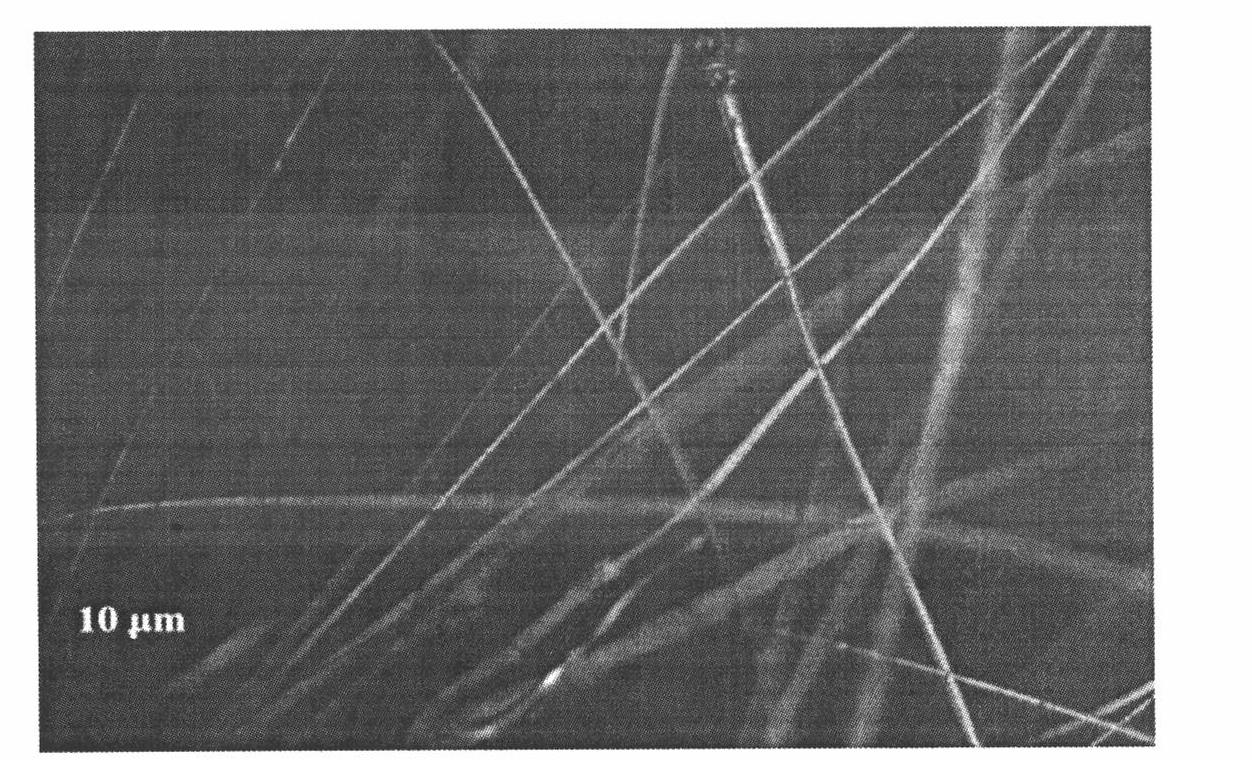

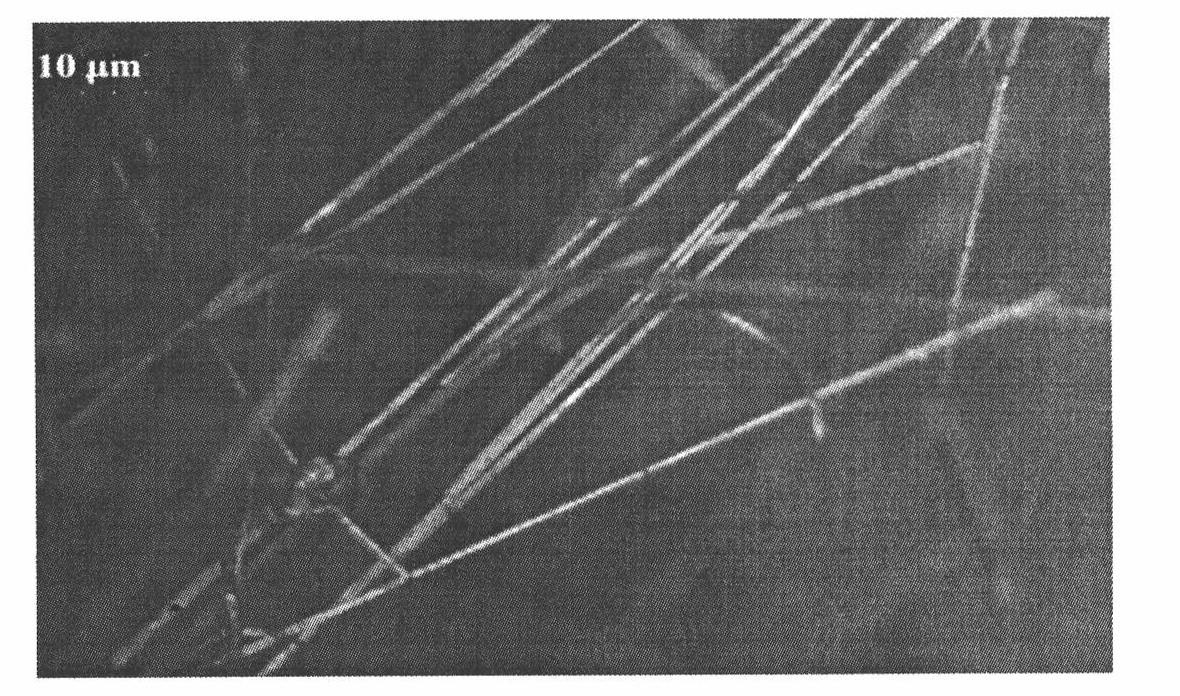

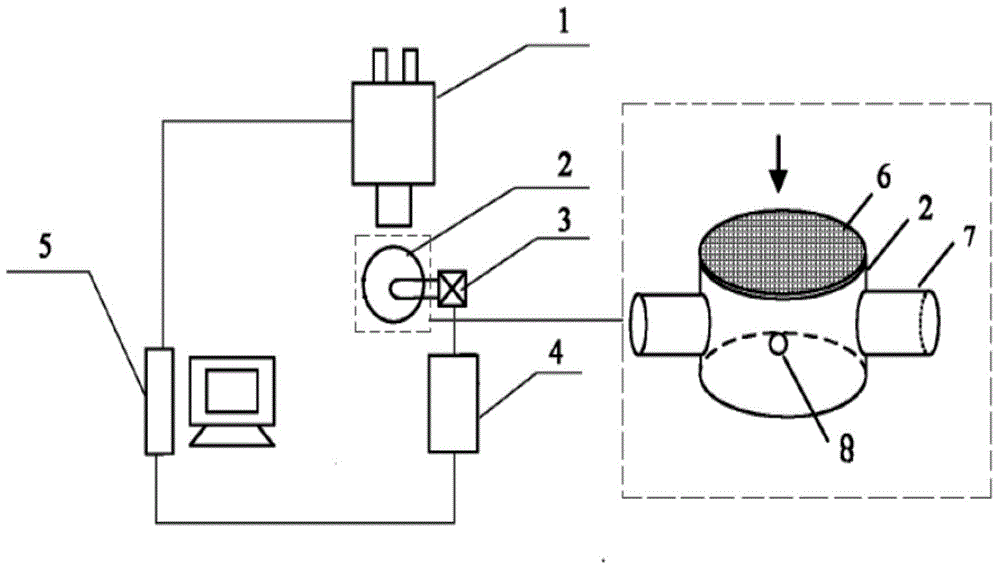

Method for determining melting behavior and melting point of slag-like material

ActiveCN102495096AThe test result is accurateDynamic and intuitive testing processInvestigating phase/state changeMetallurgical slagTemperature testing

The invention relates to a method for determining a melting behavior and a melting point of a slag-like material, belonging to the technical field of detection of metallurgical slag-like material. The process comprises slag sample preparation, slag sample formation, high-temperature laser sample filling, experimental parameter setting, melting process observation and data and image processing. The method provided by the invention has the advantages that the defect of low accuracy of the slag column deformation method, i.e. the hemisphere point temperature testing method, in the traditional melting point testing can be overcome, and the limitations of difficulties in control of the stability of testing conditions and high testing costs in the method of slag melting in liquid steel can be eliminated. The initial melting temperature of the slag sample from the solid phase to the liquid phase and the melting temperature of the slag sample to the full liquid phase can be captured promptly so as to accurately determine the melting point of the slag sample; and the liquid phase nucleation, growth and other melting changes and behaviors of the slag sample in the heating process can also be analyzed, the direct theoretical basis and technical support can be provided for the curing of liquid slag and the control of metallurgical reaction in the steel-making and iron-making process, and different characteristics of different slag samples in the melting process can be used as an important means for evaluation of high-temperature properties of different slag samples.

Owner:SHOUGANG CORPORATION

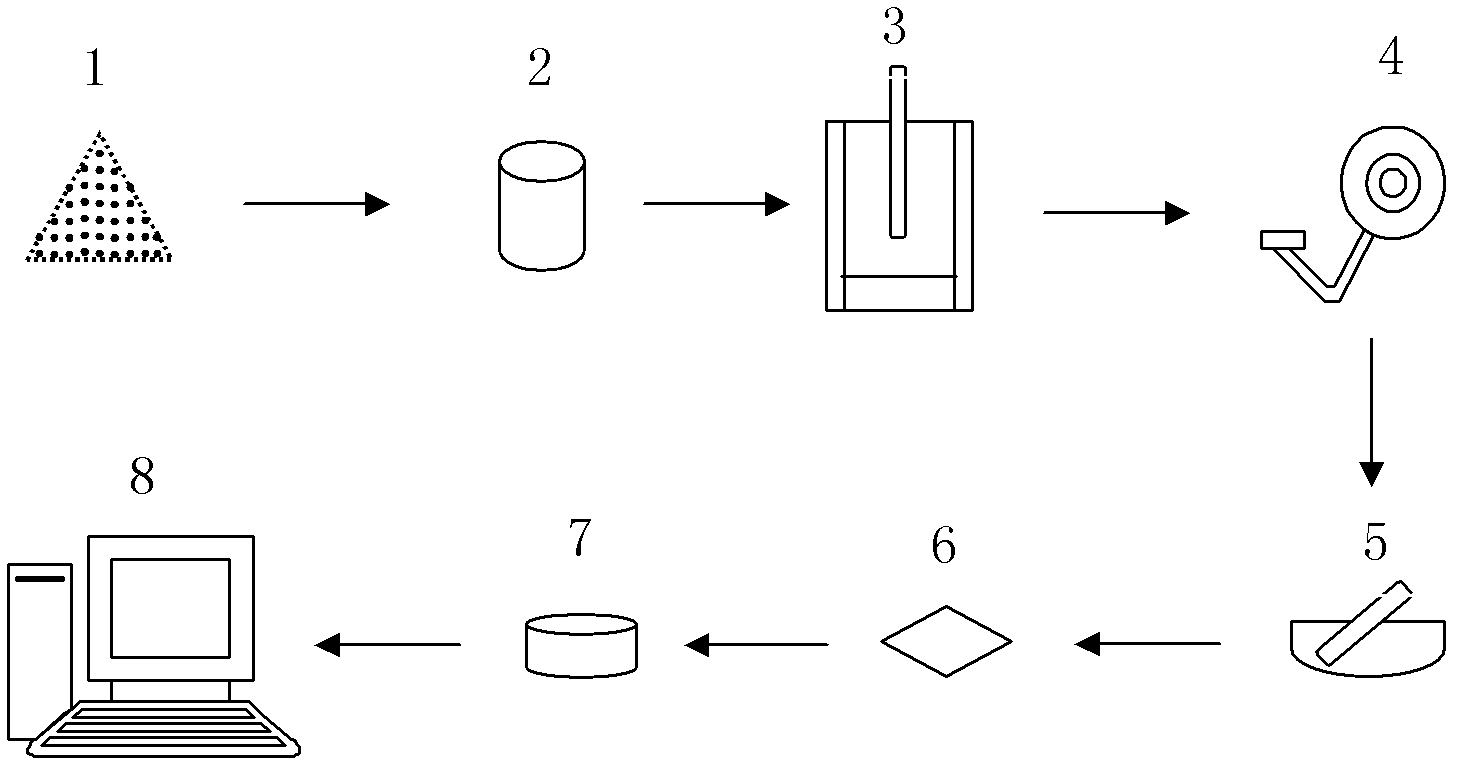

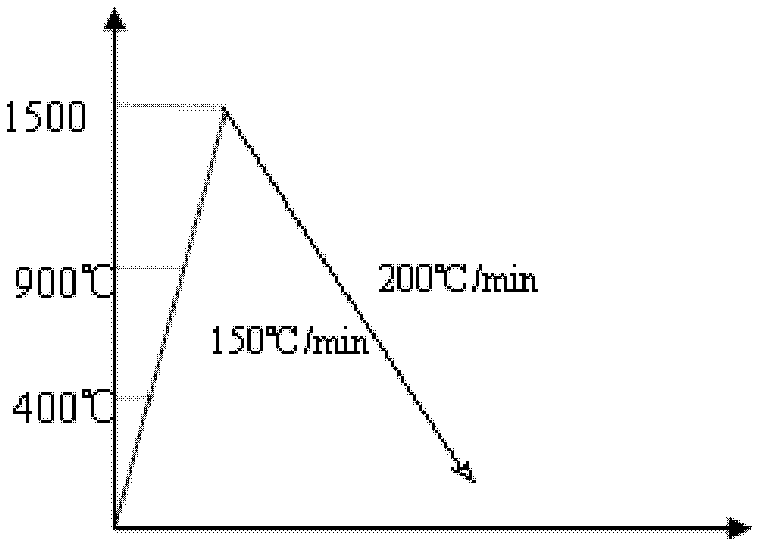

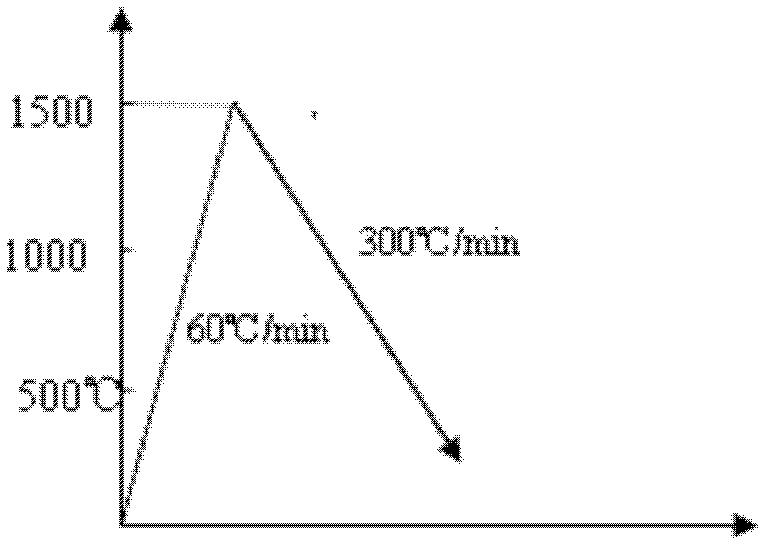

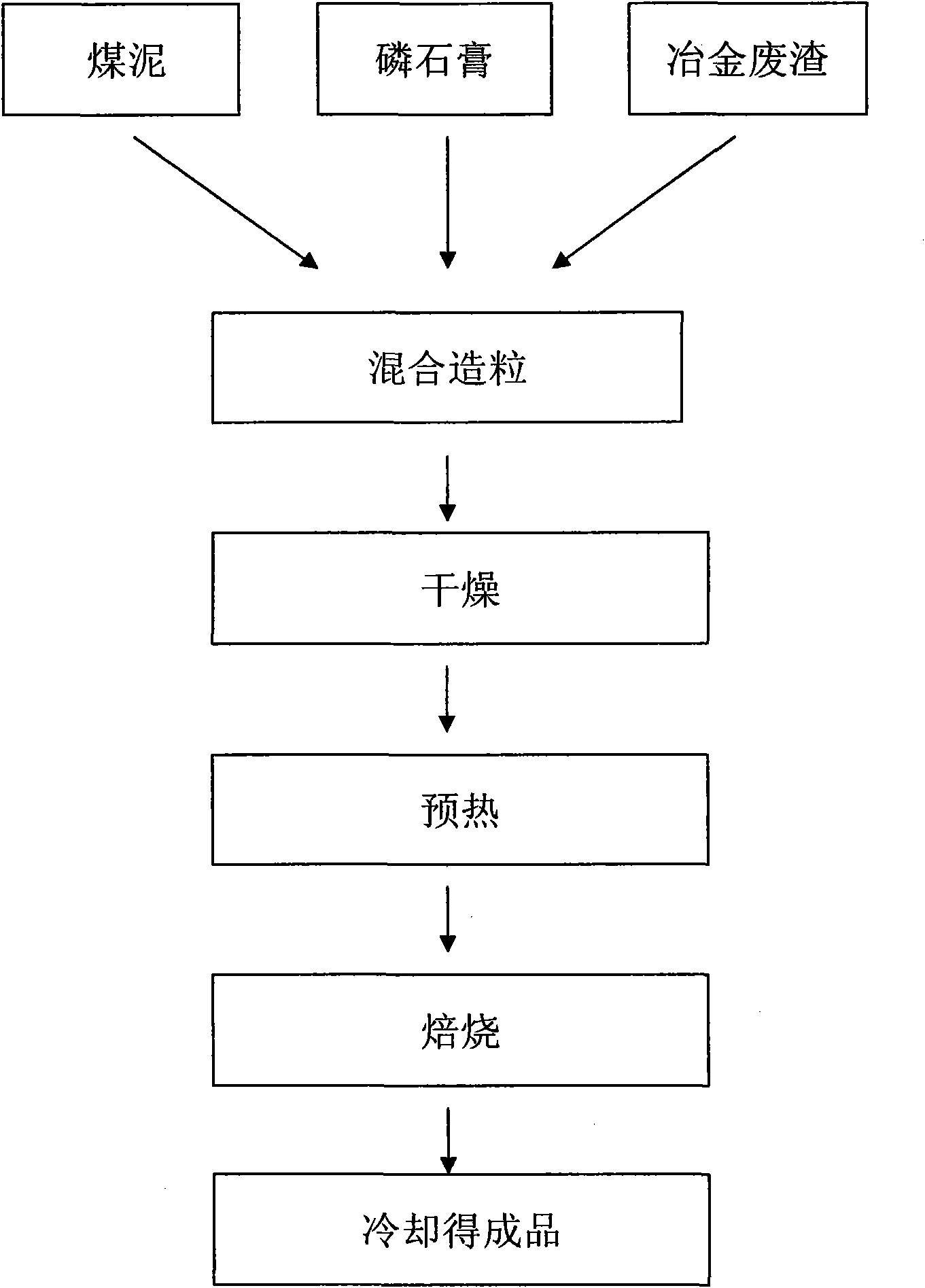

Method for synthesizing ceramsite by coal slurry, ardealite and metallurgical slag

InactiveCN101913846APan sourceHigh strengthCeramic materials productionClaywaresMetallurgical slagExpanded clay aggregate

The invention relates to a method for synthesizing ceramsite by coal slurry, ardealite and metallurgical slag. The method comprises the following steps of: mixing the coal slurry serving as a main raw material and the ardealite and the metallurgical slag serving as auxiliary materials; pelletizing the mixture; baking the particles; and naturally cooling the baked particles to the room temperature to obtain the ceramsite. The water absorption rate of the finished ceramsite is less than or equal to 15 percent, the bulk density range is less than or equal to 500 kg / m<3> and the cylinder compressive strength is more than or equal to 0.3 MPa. The technical index of the ceramsite can reach the standard of GBT17431.1-1998 Lightweight Aggregates and Its Test Methods.

Owner:KUNMING UNIV OF SCI & TECH

All-solid-waste ecological cementing material

InactiveCN110041015AIncrease alkali concentrationFacilitate dissociationMetallurgical slagDefoaming Agents

The invention provides an all-solid-waste ecological cementing material and relates to the field of building materials. The all-solid-waste ecological cementing material is prepared from raw materialsin parts by mass as follows: 100 parts of solid waste, 1-5 parts of a chemical activator, 0.5-1 part of a water reducing agent and 0.5-1 part of a defoaming agent, wherein the solid waste is preparedfrom 50%-70% by mass of ferro-nickel residues, 10%-30% of slag, 5%-10% of fly ash, 0-10% of gypsum and 5%-10% of steel slag. According to the all-solid-waste ecological cementing material, the ferro-nickel residues, the slag and the steel slag are taken as raw materials, utilized as a clinker source of the cementing material and supplemented with industrial solid waste such as industrial byproducts gypsum and fly ash, and one low-hydration-heat ecological cementing material capable of partially replacing Portland cement is prepared by mechanical excitation and chemical excitation. Efficient recycling of the industrial metallurgical slag such as the ferro-nickel residues, the slag and the steel slag is realized, and usage amount of Portland cement clinker is effectively reduced. Compared with the Portland cement, the all-solid-waste ecological cementing material has the characteristics of low hydration heat and good sulfate corrosion resistance.

Owner:GUANGDONG TSINGDA TONGKE ENVIRONMENTAL PROTECTION TECH CO LTD

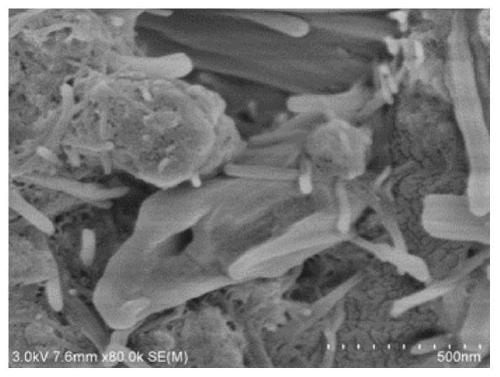

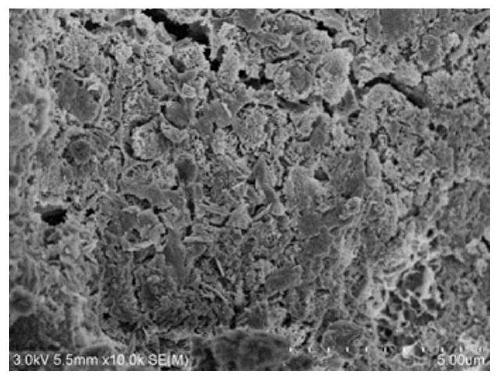

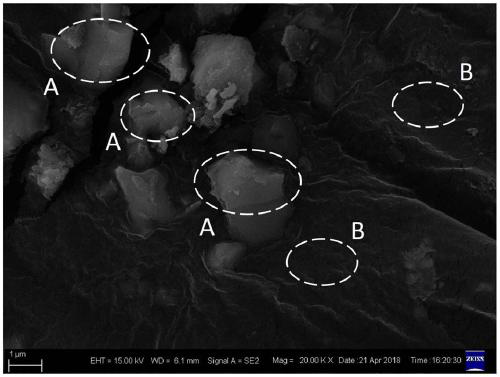

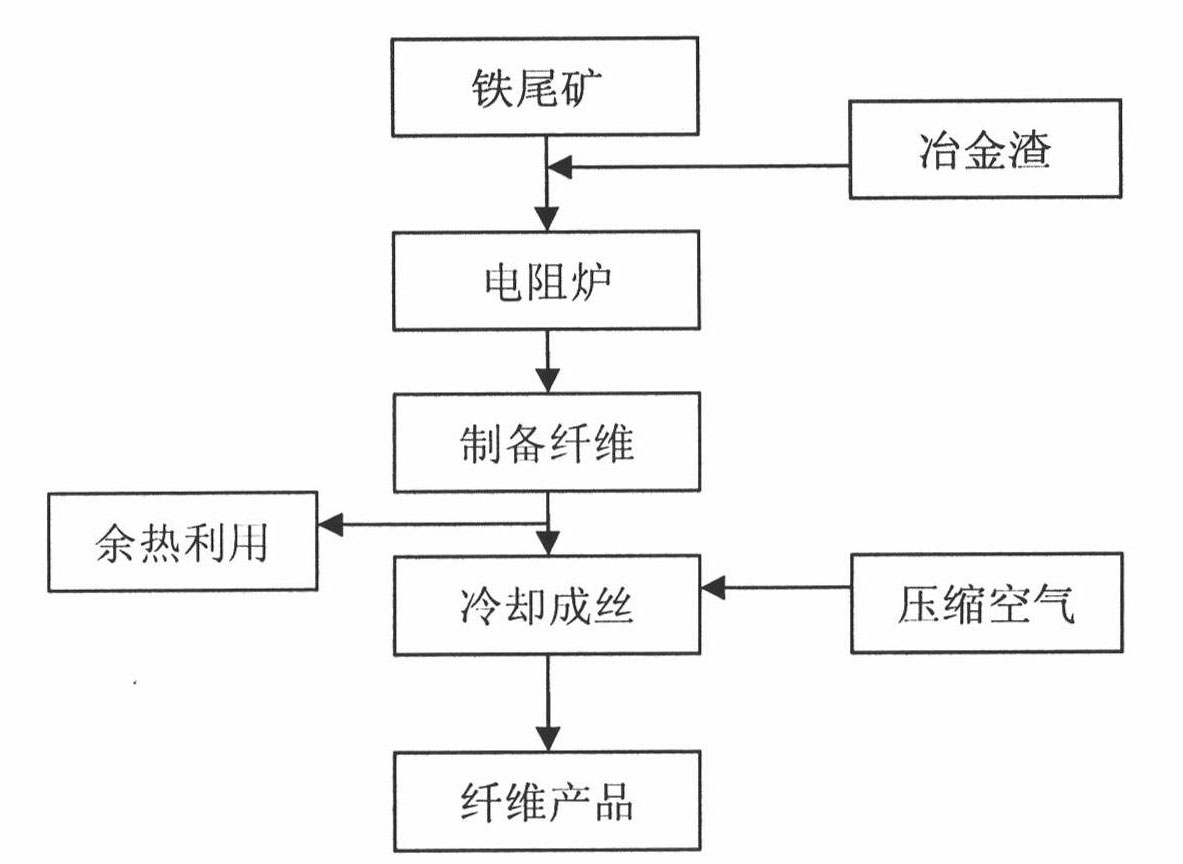

Method for preparing inorganic slag fibers by using iron tailings

ActiveCN102010122ARealize comprehensive utilizationIncrease added valueGlass making apparatusFiberMetallurgical slag

The invention discloses a method for preparing inorganic slag fibers by using iron tailings, and belongs to the technical field of inorganic nonmetallic material preparation. The method comprises the following steps of: mixing the iron tailings and metallurgical slag, heating the mixture to be a melted state, and preparing the inorganic slag fibers by blowing or throwing, wherein the mixture in the melted state contains 30 to 90 weight percent of iron tailings and 70 to 10 weight percent of blast furnace slag. The method has simple and feasible process, is convenient to implement, realizes comprehensive utilization of different industrial wastes such as the iron tailings, the metallurgical slag and the like, improves the additional value of the comprehensive utilization of the iron tailings, and has good economic and environmental benefits.

Owner:CHANGZHI HUAXING ENVIRONMENTAL PROTECTION ENG CO LTD +1

Method for determining melting temperature interval and melting behavior of metallurgical slag

InactiveCN104407007AReal dataThe result is accurateInvestigating phase/state changeTime rangeMetallurgical slag

Owner:CENT SOUTH UNIV

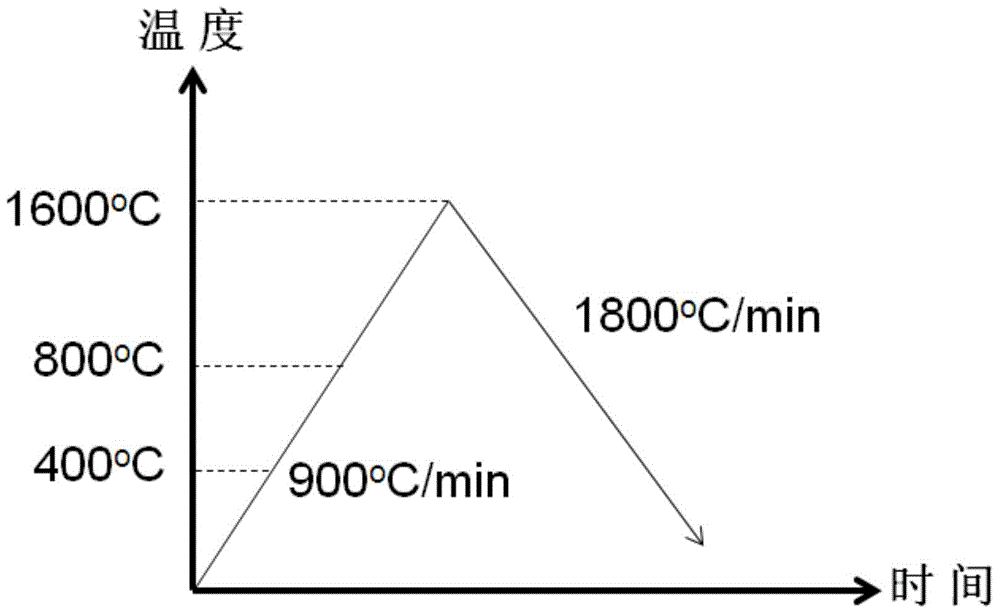

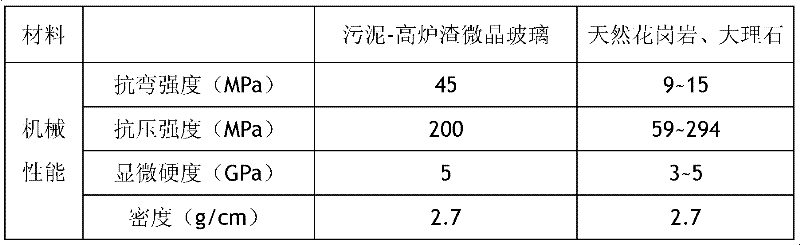

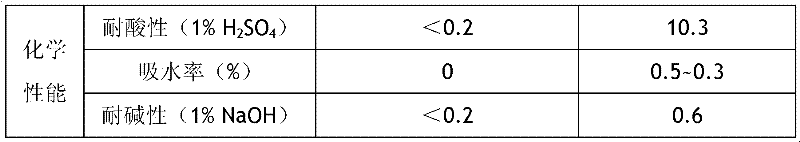

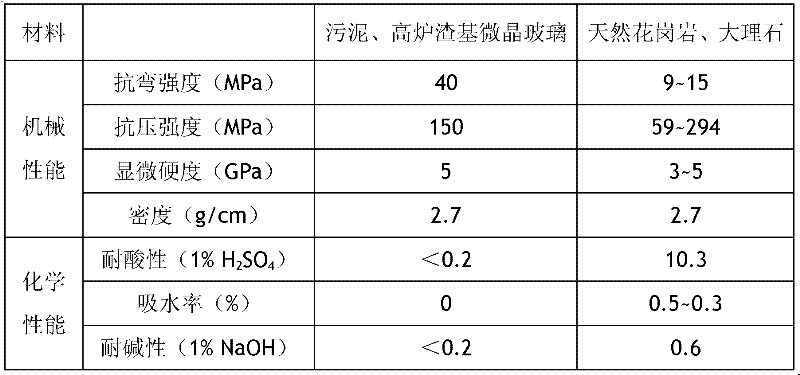

Method for preparing microcrystalline glass by synergetically processing municipal sludge through utilizing metallurgical slag

The invention which relates to a method for preparing microcrystalline glass by synergetically processing municipal sludge through utilizing metallurgical slag belongs to the technical field of resource utilization and environment protection. The method is characterized in that the microcrystalline glass is prepared from main raw materials of two solid wastes of sludge burning ash and the metallurgical slag without other nucleating agents, fluxing agents, and the like. The microcrystalline glass concretely comprises, by mass, 30-65% of the sludge burning ash, 35-60% of the metallurgical slag, and 0-25% of a component regulator. The method of the invention, which treats municipal sludge and the metallurgical slag as the main raw materials and fully utilizes complementation characteristics of components and physicochemical properties of the sludge and the metallurgical slag, transmits heavy metal elements in the sludge and the metallurgical slag into beneficial nucleating agents and fluxing agents, needs no other additives, and substantially reduce the cost in the manufacturing process of the microcrystalline glass; and the method has the advantages of simple preparation process, low manufacturing cost, and possessing of substantial economic and social benefits.

Owner:UNIV OF SCI & TECH BEIJING

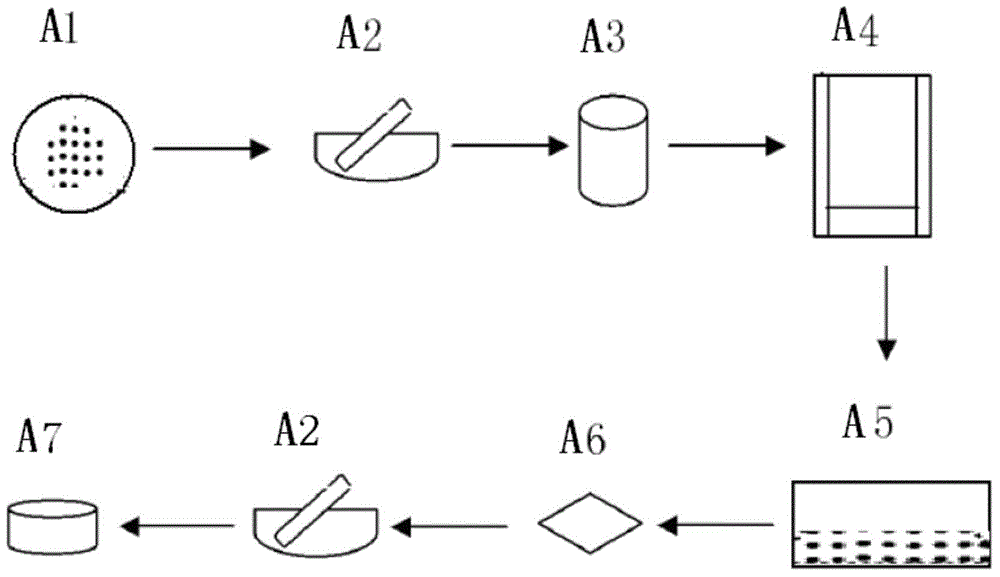

A process for washing and removing boron from polysilicon slag by metallurgical method

ActiveCN102259865AFully evenly dispersedImprovement of poor wettability conditionsSilicon compoundsMetallurgical slagMedium frequency

The invention relates to the technical field of metallurgical polycrystalline silicon purification, and in particular relates to a slag washing process for removing boron from metallurgical polycrystalline silicon. The technical schemes are as follows: a metallurgical slag-washing boron removing method is adopted, the same two composite slag agents are pre-melted into a slag agent molten pool, then industrial silicon is added for melting, boron (B) in molten silicon performs oxidation reaction with the slag agent so that boron (B) forms a multi-element slag phase, and boron (B) impurities in silicon are removed by slag-metal separation to obtain solar-grade high-purity polycrystalline silicon with a boron content being 0.15 ppmw. The process provided by the invention has the advantages that: the process is simple to operate, the cost is low, the used devices are formed by combination and transformation of traditional medium-frequency furnaces, the used slag agent can be used repeatedly after adding new SiO2 and CaO, and the process is conducive to large-scale industrial promotion.

Owner:宁夏高创特能源科技有限公司

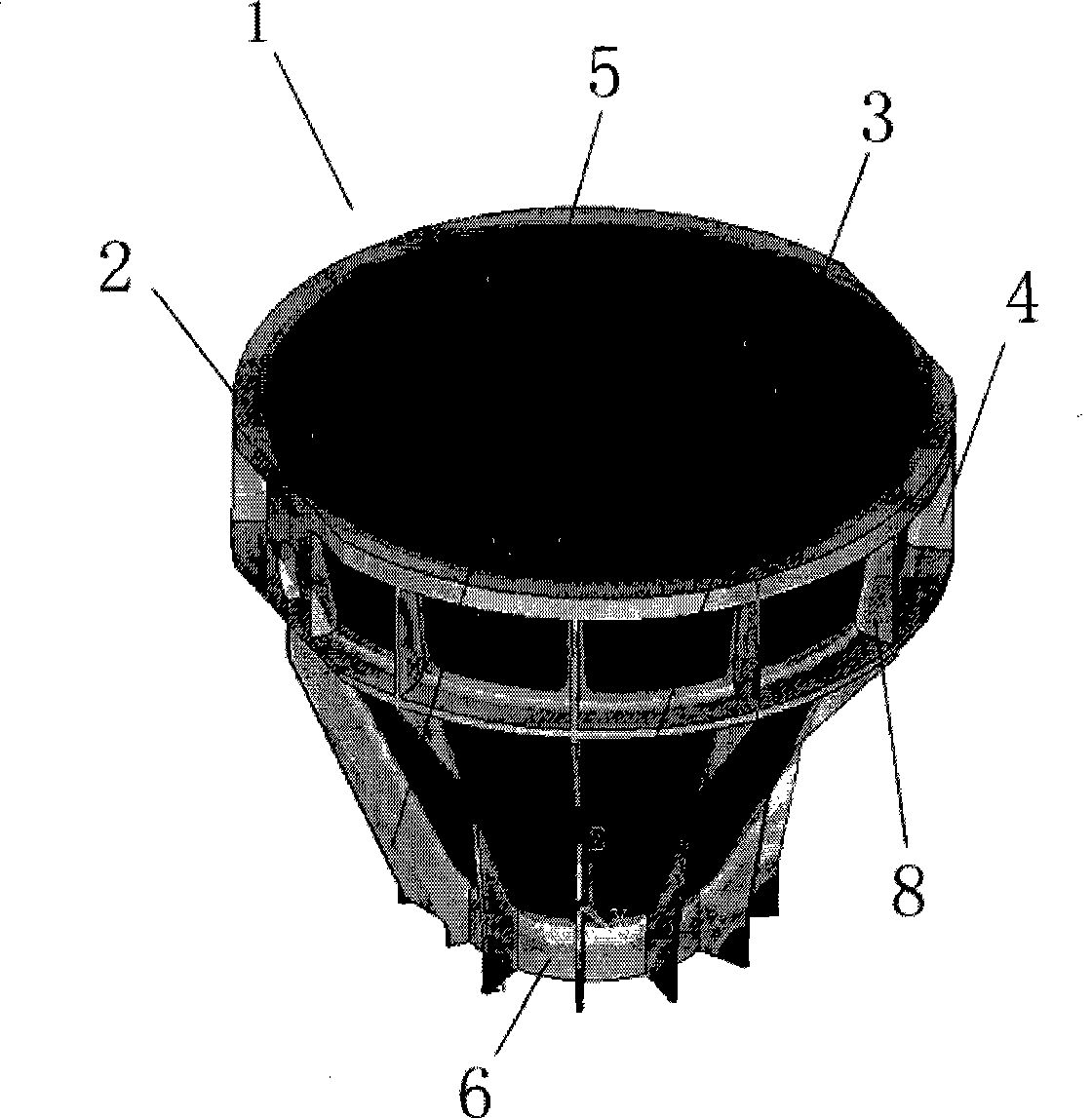

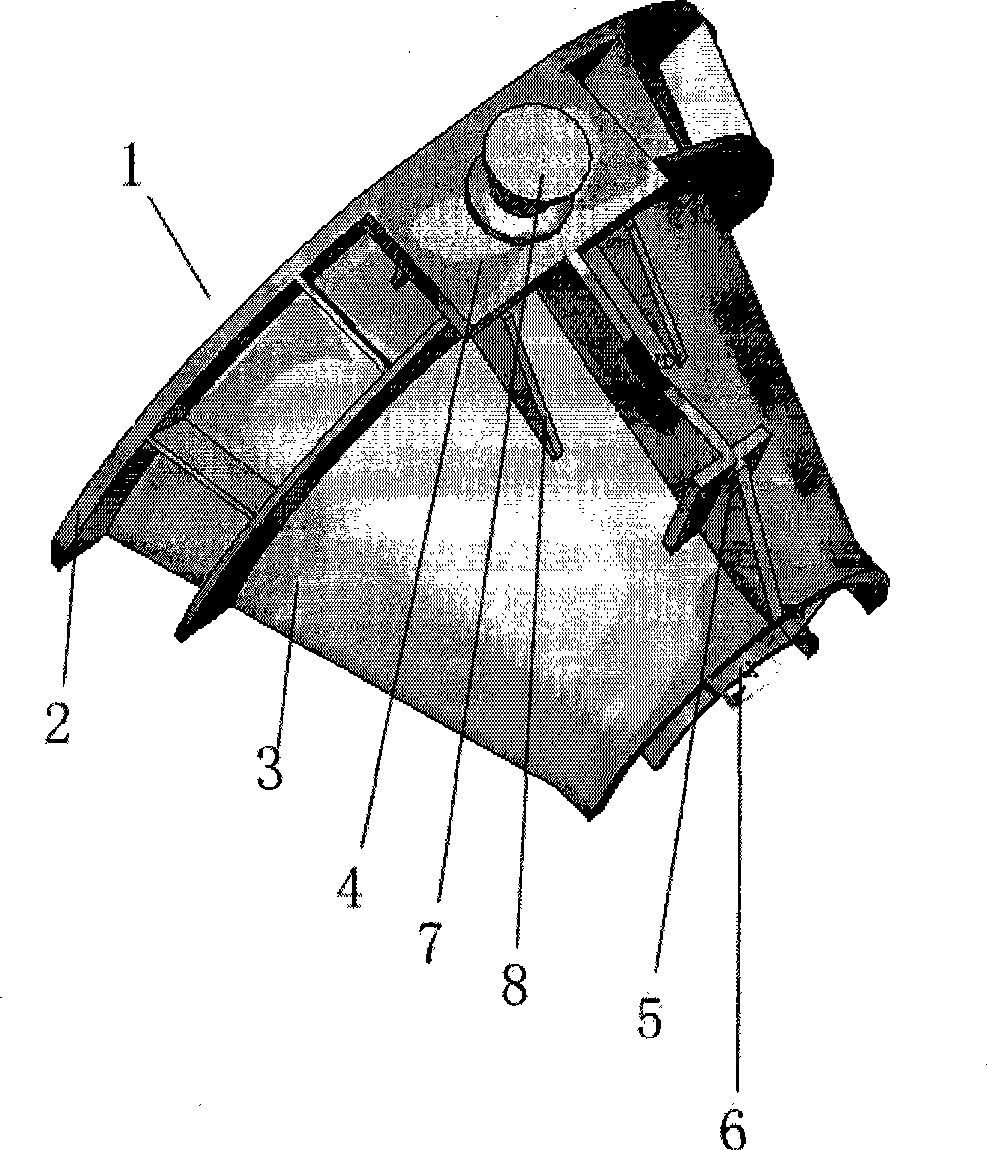

Novel structured metallurgy cinder ladle and method of producing the same

ActiveCN101368220AImprove solderabilityImprove repairabilityWorkpiece edge portionsMetallurgical slagSheet steel

The invention discloses a metallurgical slag tank with a novel structure which is a tank-shaped container used for holding melting steel (iron) slag with a bottom diameter larger than a mouth diameter. The invention is characterized in that the metallurgical slag tank is welded by steel plates. According to the metallurgical slag tank of a novel structure, a welding technique is used to weld the steel plates into the tank, thus reducing the environment pollution to a large extent. As the crystal grains of the steel plates forming the wall of the metallurgical slag tank are uniform in thickness and almost does not have the defects of shrinkage cavity, shrinkage porosity, air hole, segregation, crack, non metallic inclusion, thermal fragment, cold cracking, and the like; and as the crystal grains of the steel plates forming the wall of the metallurgical slag tank are like common rolling steel, the solderability and the maintainability of the slag tank are good; the service life of the slag tank can be greatly prolonged; the safety troubles often appeared in a production field like the cracking of the slag tank can be eliminated; the cost is reduced to a large extent.

Owner:BAOSHAN IRON & STEEL CO LTD +1

Technology for producing cement pipe bar product by using jevigating metallurgy slag and coal ash as doping material

InactiveCN101041582AReduce dosageImprove early strengthSolid waste managementCeramic shaping apparatusMetallurgical slagLate stage

The invention discloses a making method of cement pipe rod based on grinded metallurgical slag and coal powder as doped material, which is characterized by the following: blending grinded metallurgical slag and coal powder according to certain proportion to replace 5%-60% cement over 32.5 grade; reducing doped quantity of cement; improving early-stage and late-stage strength of cement pipe rod.

Owner:嘉兴学院管桩应用技术研究所

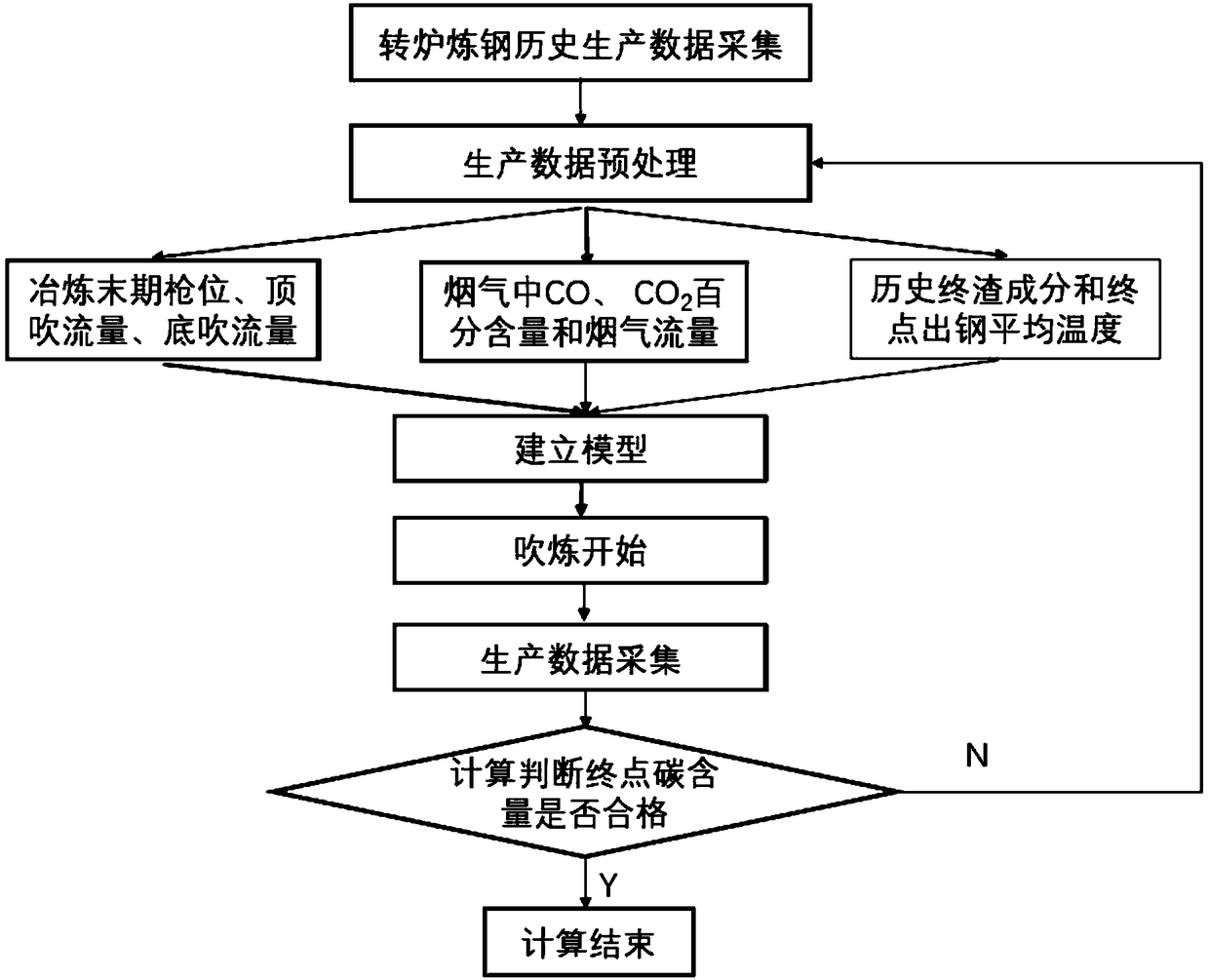

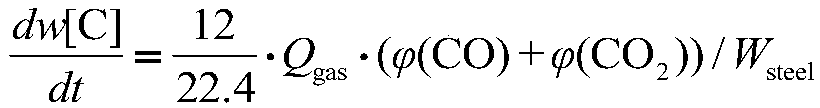

Carbon determination method for converter steelmaking flue gas analysis

ActiveCN108647407AImprove accuracyManufacturing convertersDesign optimisation/simulationMetallurgical slagSteelmaking

The invention provides a carbon determination method for converter steelmaking flue gas analysis, belonging to the field of iron and steel metallurgy. The method includes the following steps: firstly,according to the principle of mass conservation, calculating a decarburization rate of a molten pool in combination with the CO and CO2 percentage contents of the flue gas and the flue gas flow obtained by detection equipment in a converter smelting process; secondly, introducing a concept of molten pool mixing degree into an end point carbon curve fitting index model; and then, according to themolecular theory of metallurgical slags and the characteristics of steel grades produced, obtaining compositions of final smelting slags and the temperature of molten steel at a smelting end point, and calculating a limiting carbon content W[C]0 of the smelting molten pool; and finally, obtaining a carbon determination model for converter steelmaking flue gas analysis. The model in the method introduces the concept of molten pool mixing degree, and fully considers the influence of operating process parameters such as oxygen lance positions, top-blown oxygen flow and bottom-blown gas flow on the decarburization process of the converter molten pool; and the limiting carbon content W[C]0 of the molten pool can be calculated by using the activity of molten slags according to actual smelting steel grades, and higher accuracy can be realized.

Owner:UNIV OF SCI & TECH BEIJING

Method for recovering mercury from multi-element mercury-containing hazardous solid wastes by high-temperature rotary roasting

The invention discloses a method for recovering mercury from multi-element mercury-containing hazardous solid wastes by high-temperature rotary roasting, and belongs to the field of environmental protection and metallurgy. The method comprises the following steps: crushing multi-element mercury-containing solid wastes namely nonferrous metallurgy slag, flue dust and waste catalysts until the granularity is 130-150 microns; adding quicklime accounting for 20-40% of the total weight of the mercury-containing solid wastes, and stirring continuously at 70-90 DEG C for 2 hours to ensure that mercury compounds are converted into mercury oxide; roasting in a high-temperature rotary furnace at a roasting temperature of 75-850 DEG C for 2-8 hours to ensure that mercury oxide is decomposed into mercury vapor; performing cyclone dust collection, and then performing bag dust collection to remove dust from the mercury vapor; performing two-stage condensation recovery on the mercury vapor by adopting tubular condensing equipment, and condensing and collecting the mercury vapor in a mercury collecting tank; and recovering mercury-containing tail gas by adopting a filler adsorption tower. By adopting the method disclosed by the invention, the problems of difficult stacking of the multi-element mercury-containing solid wastes, environmental pollution and mercury recovery are solved, and the economic value of mercury is improved.

Owner:贵州重力科技环保股份有限公司

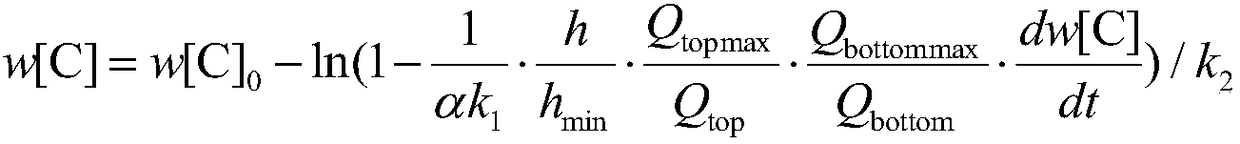

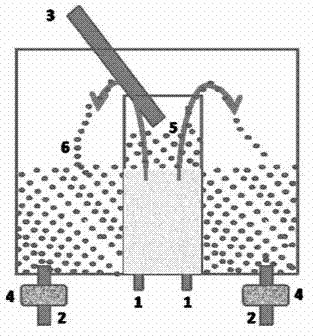

Method for preparing hydrogen by utilizing metallurgical slag waste heat to reform regenerative resources rich in methane

ActiveCN102826508AOvercome the problem of high costHydrogenEnergy inputMetallurgical slagChemical reaction

The invention discloses a method and a device thereof for preparing hydrogen by utilizing metallurgical slag waste heat to reform regenerative resources rich in methane. According to the method, through the chemical reactions of reforming methane and carbon dioxide to convert the methane and the carbon dioxide into the hydrogen, high-temperature waste heat which is difficult to utilize is converted into chemical energy, and high calorific value substances such as the hydrogen and the like are simultaneously obtained; the sizes of steel and iron slag granulated particles can be controlled through process conditions of mixed gas flow rate, subsequent ball milling and the like by the method; and because the steel and iron slag contains a large quantity of alkaline substances such as calcium oxide and the like, after the temperature of molten slag is reduced, excess carbon dioxide gas can be absorbed by the steel and iron slag in a ball milling device so as to have a fixing effect on the carbon dioxide, and the steel and iron slag after carbon fixing can be further used as a building material or a land reclamation material.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

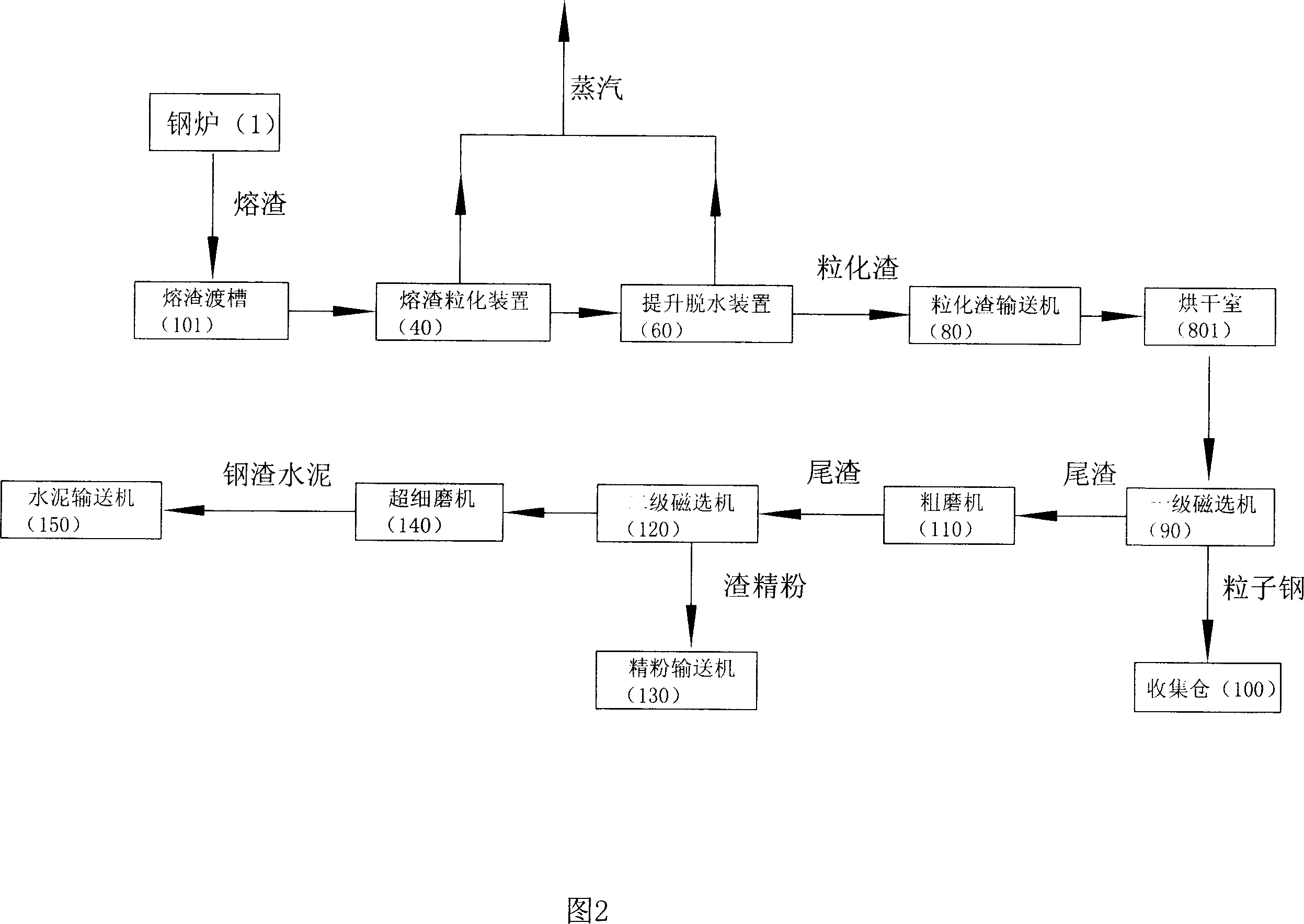

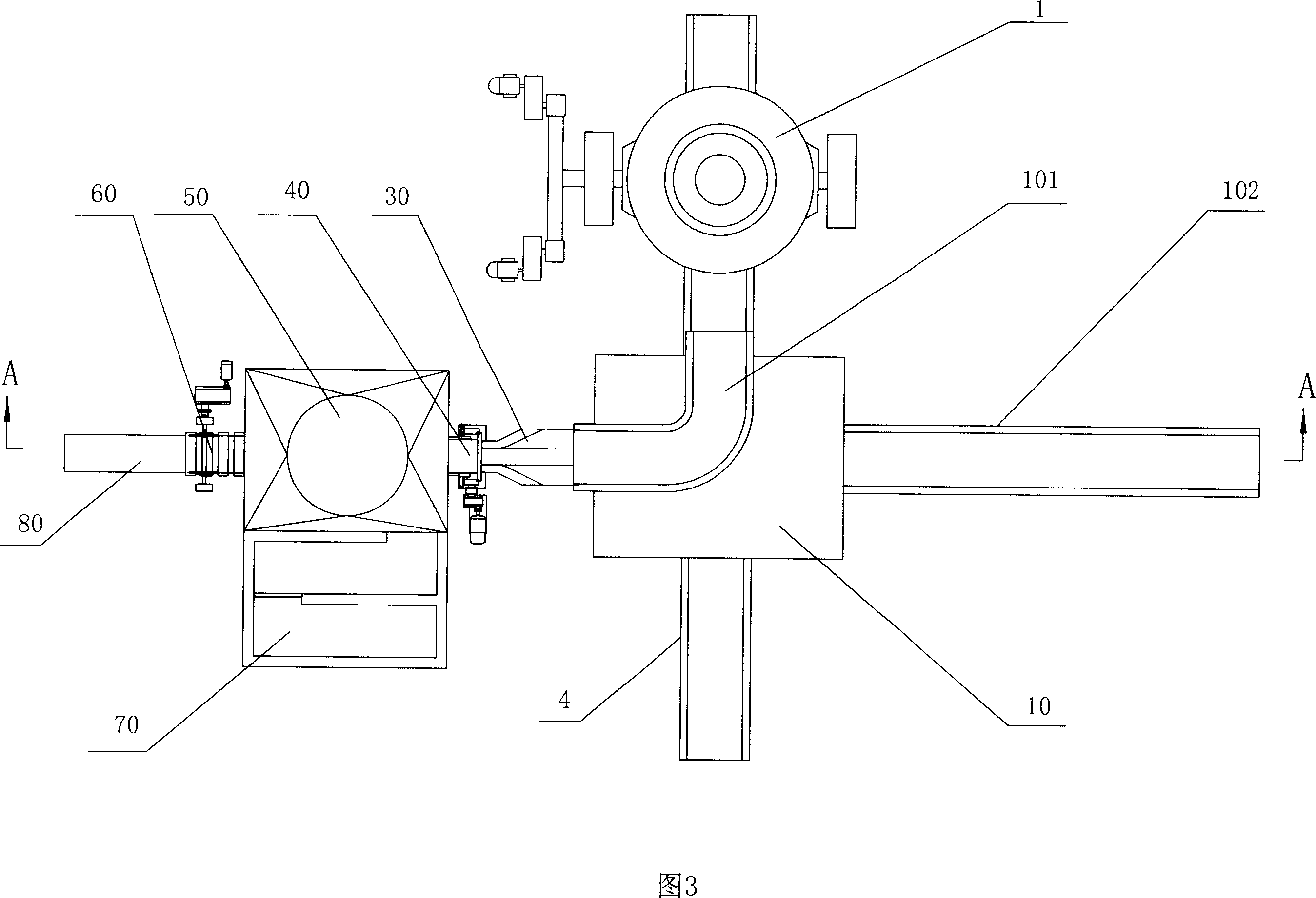

System and method for producing cement short flow-process with metallurgical furnace slag

ActiveCN101053975AShort process flowHigh recovery rateSolid waste managementCeramic shaping plantsMetallurgical slagMagnetic separator

The present invention relates to a short stage production system for metallurgical slag cement. A slag granulating device is arranged on one side of the traveling rail of slag car, a slag flume car traveling rail is arranged at the other side of the traveling rail of slag car, the slag flume car is provided with a slag flume, the inlet end of the slag flume is connected with the steel furnace slag hole by abutting joint, the outlet end of the slag flume is connected with the chute of the slag granulating device by abutting joint. A collecting basin with a grain slag lift and dewater unit therein is arranged at the granulating outlet of the slag granulating device, the discharge end of the lift and dewater unit is provided with a grain slag conveyor, the discharge end of the grain slag conveyor is arranged above the entrance of a first level magnetic separator, the tailings outlet of the magnetic separator is connected with the inlet end of a kibbling mill by means of a tailings conveyor, the discharge opening of the kibbling mill is connected with the inlet end of a second level magnetic separator, the slag fine powder outlet of the second level magnetic separator is connected with a fine powder conveyor, the tailings outlet of the second level magnetic separator is connected with the inlet end of a superfine mill, the outlet of the superfine mill is connected with a cement conveyor.

Owner:张维田 +1

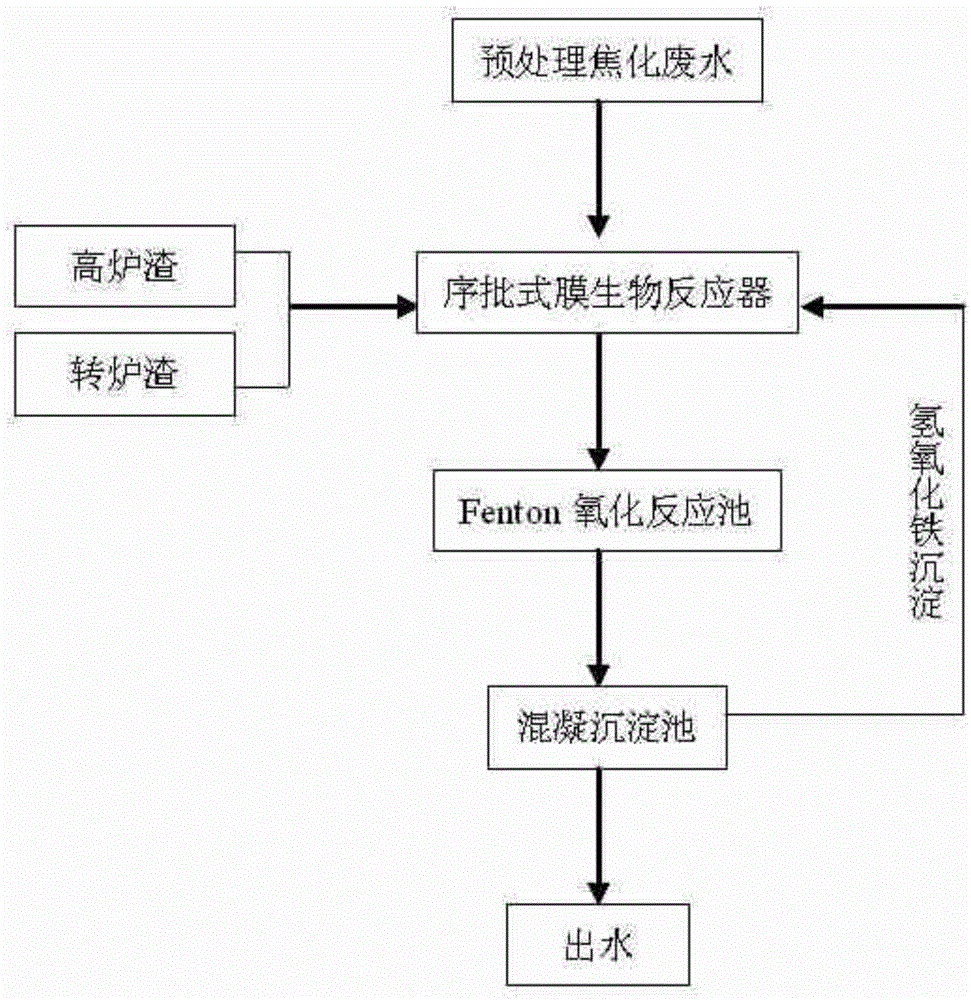

Coking wastewater treatment method

ActiveCN105271606APorosityMitigation capacityMultistage water/sewage treatmentSequencing batch reactorMetallurgical slag

A coking wastewater treatment method is as follows: coking wastewater pretreated by a gravity degreasing tank and an air flotation degreasing tank is treated by collaborative Fenton oxidation and coagulation precipitation by use of a sequencing batch membrane bioreactor, metallurgical slag with 1 / 8 to 1 / 6 of effective volume of the reactor are added into the sequencing batch membrane bioreactor, metallurgical slag accounted for 0.3%-0.8% of the metallurgical slag amount is supplemented into the sequencing batch membrane bioreactor every 10-15 days, iron mud precipitate produced by Fenton reaction is refluxed into the sequencing batch membrane bioreactor every 5-7 days, and the reflux amount is 6% to 8% of the reactor sludge amount; the sequencing batch membrane bioreactor is anoxically stirred for 7-8h in every cycle, aerobic aeration time is 15-17h, and the residence time is 70-73h. According to the method, by use of the flocculation effect of iron hydroxide floc, wastewater treatment effect is strengthened, alkalinity consumed in nitrification process can be mitigated, and the iron mud precipitate produced by the reaction can be recycled, meanwhile by taking advantage of adsorption precipitation performance of the metallurgical slag, purposes of improvement of wastewater treatment effect and reduction of wastewater treatment costs can be realized.

Owner:ANGANG STEEL CO LTD

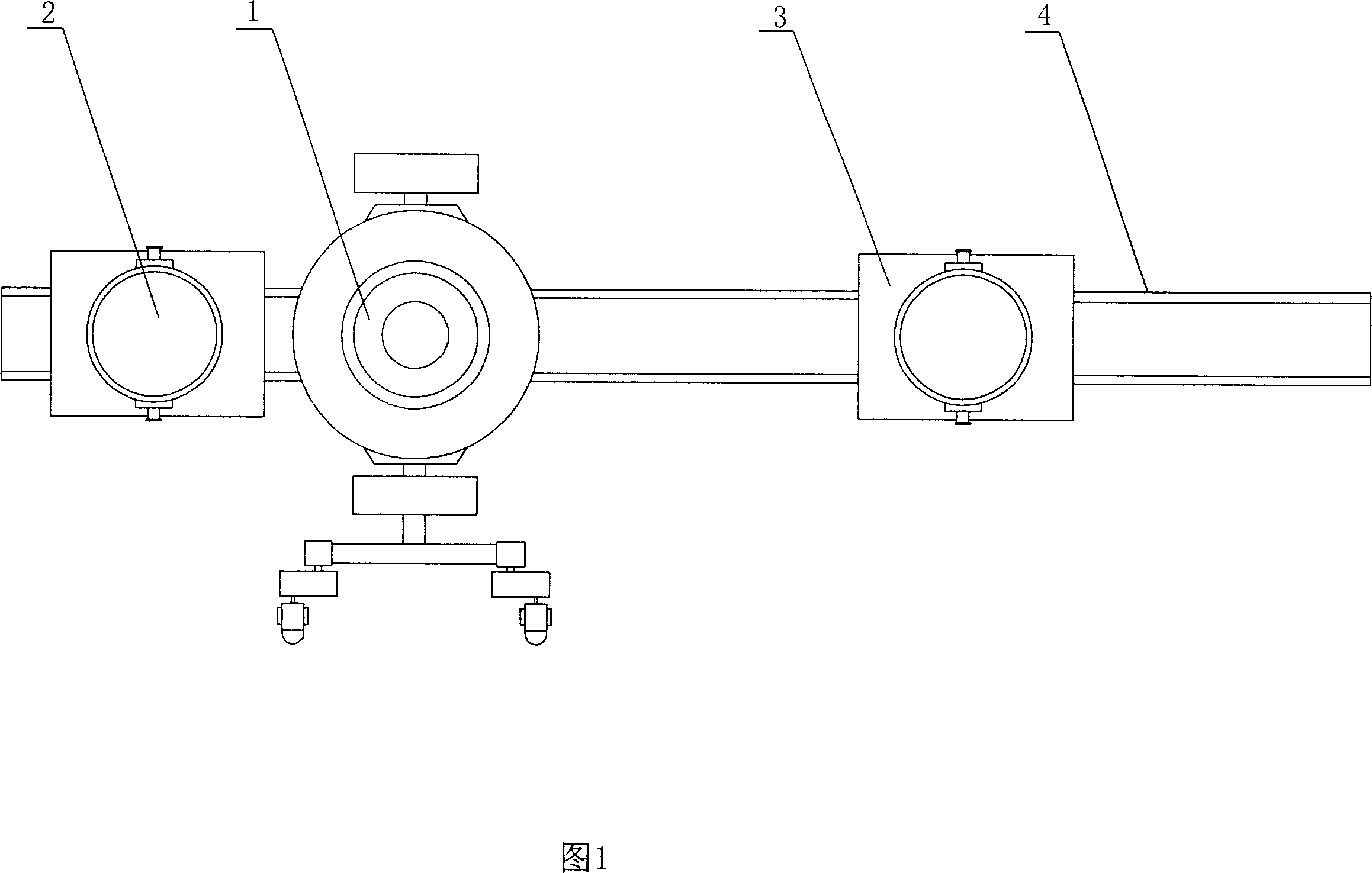

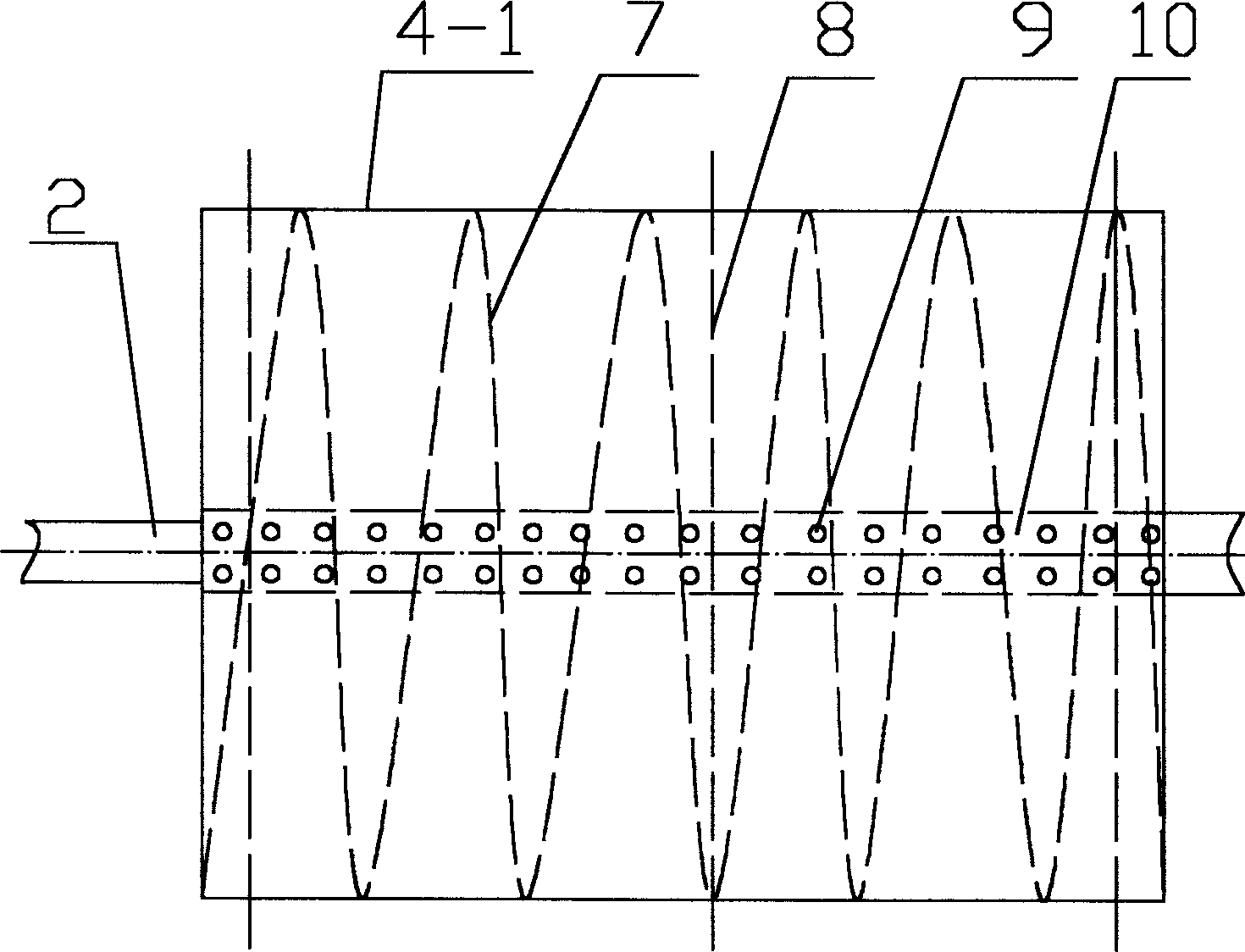

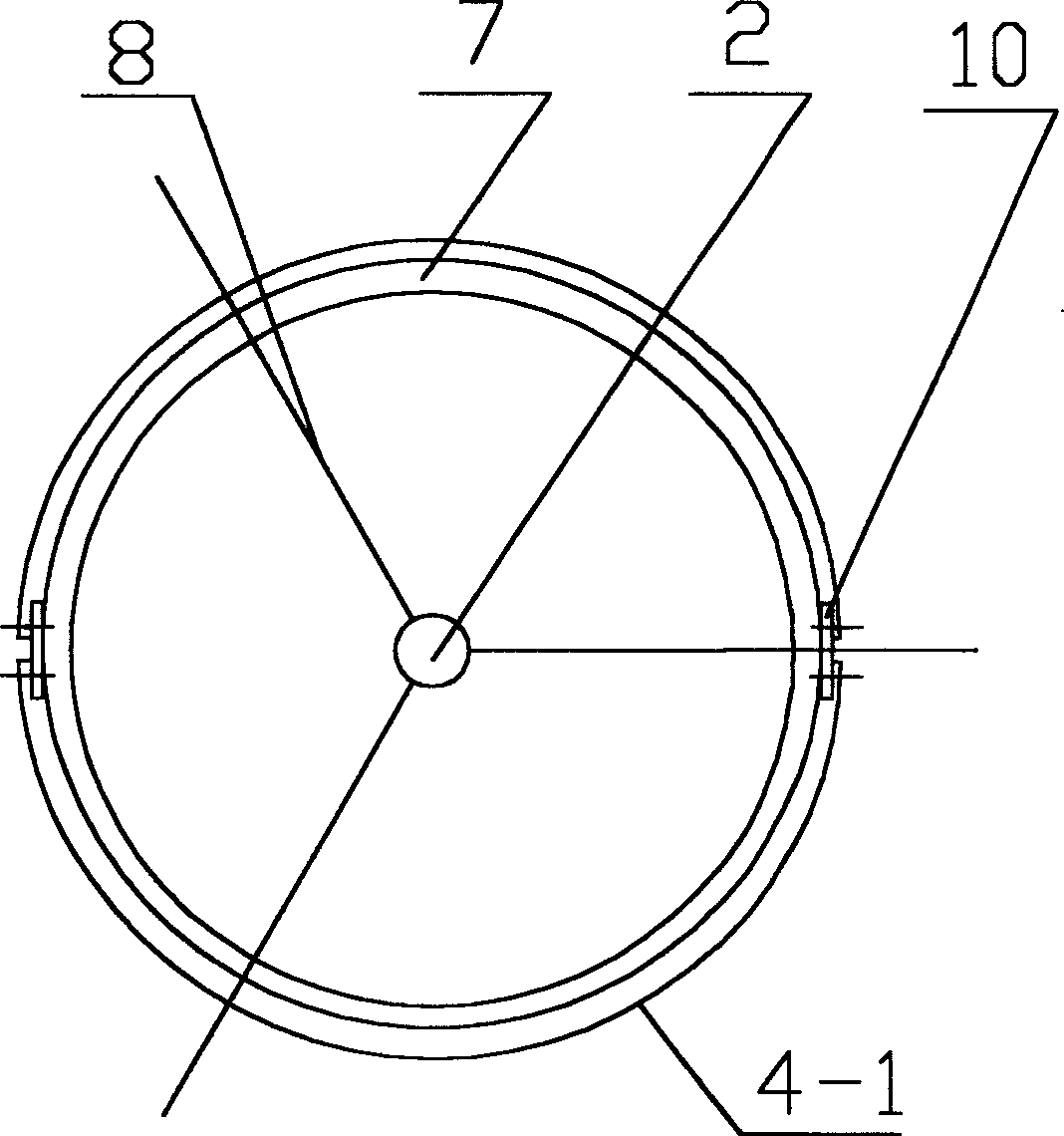

Multilayer coaxial rotating sieve

InactiveCN1557571AImprove sorting efficiencyImprove targetingSievingScreeningMetallurgical slagMechanical field

The present invention belongs to the field of material screening machinery, and is one kind of multi-layer coaxial rotary sieve for screening metallurgical slag. The multi-layer coaxial rotary sieve includes a multi-layer coaxial cylindrical screen rotating around one shaft inside the outer tank, with the screen layers having gradually increased diameters and gradually decreased mesh size; an outer tank with one material inlet in the top and several material outlets corresponding to different screen layers in the bottom; spiral pushing boards inside the screen layers with size matching the diameter of the cylindrical frame separately; and screen fixing rack to connect the screen layers and to connect the spiral pushing boards. The present invention may be used in screening metallurgical slag into several grades of different sizes.

Owner:MCC BAOSTEEL TECH SERVICE

Physical heat recovery process of high-temperature material

InactiveCN102200267AImprove distributionIncrease heat dissipation surfaceSteam generation using hot heat carriersHot-water central heatingMetallurgical slagRadiant heat

The invention aims at recovering physical heat of liquid-state molten slag, and can be used for recovering waste heat of steel slag or blast furnace slag in a metallurgical process. A tunnel type boiler is established by using intermittent operation characteristic of the metallurgical process to convert physical sensible heat of the molten slag into a high-grade energy heat source for power generation or other technological processes. The process comprises the following steps of: firstly laying the molten liquid-state slag produced by a production process flakily, and setting a radiant heating surface to recover high-temperature heat by using high temperature characteristic of the slag so as to form a first heat absorbing stage; introducing flowing air by using an induced draught fan after the temperature of the surface is reduced to a certain value, and absorbing gas convective heat and a part of radiant heat by using a high-efficiency heat transfer element (such as a heat pipe) to form a second heat absorbing stage; and feeding the substantially solidified (at least surface solidified) slag into a water quenching chamber which can bear a certain pressure, gradually ejecting cold water to the slag body to blow up the cracked slag body into powder, performing subsequent cooling on the metallurgical slag, namely externally connecting a barrel type slag cooler to continuously recover the physical heat so as to form a third heat absorbing stage.

Owner:刘柏谦 +1

Method for recovering valuable metal from metallurgical slag materials

InactiveCN102534236AEfficient separationHigh recovery rateProcess efficiency improvementMetallurgical slagAlkaline earth metal

The invention relates to a method for recovering valuable metals from metallurgical slag materials. The invention adopts a technical scheme that the method comprises: mixing 100 mass parts of metallurgical slag with 0.1 to 100 mass parts of an activating agent; heating and activating the mixture at the activation temperature of 200 to 1,600 DEG C; and recovering the valuable metals by an ore dressing process or wet-process metallurgical process. The metallurgical slag materials may be more than one of copper slag, lead slag, zinc slag, titanium slag, vanadium slag, nickel slag and rare earth smelting slag; the chemical activating agent may be more than one of an alkali metal oxide, an alkaline earth metal oxide, an alkali metal hydroxide, an alkaline earth hydroxide, an alkali metal carbonate, an alkali metal silicate, an alkaline earth metal carbonate, an alkali metal bicarbonate, an alkali metal fluoride, an alkaline earth metal fluoride and ammonium fluoride. The method has the characteristics of simple process, high adaptability and high production efficiency, and can be widely used for recovering noble metals from metallurgical slag materials.

Owner:WUHAN UNIV OF SCI & TECH

Metallurgical slag sintered bricks and preparation method thereof

InactiveCN106431350AReduce energy consumptionImprove the exhaust effectCeramic materials productionClaywaresMetallurgical slagMineral Sources

The invention provides metallurgical slag sintered bricks and a preparation method thereof. The preparation method comprises the following steps: mixing metallurgical slag, clay and / or shale and an additive, which meet a preset condition, according to preset proportions; aging the mixture obtained after mixing, and then performing forming to obtain green bricks; and drying the green bricks, and then burning the green bricks in a kiln to obtain the sintered bricks. According to the preparation method provided by the invention, by controlling the preset condition of the metallurgical slag, the clay and the additive can be directly mixed with the metallurgical slag by stirring, and secondary breaking is not needed, so that the energy consumption of the preparation is greatly reduced; the metallurgical slag has a function of reducing the melting point, so that the temperature of a sintering reaction can be reduced; and by controlling factors including the content of ferric oxide in the metallurgical slag, the sintering temperature and the sintering atmosphere, sintered bricks with different colors can be obtained without adding an expensive coloring agent, so that large-scale utilization of the metallurgical slag is achieved, mineral resources are saved, and meanwhile, qualified sintered bricks are produced with low cost, low energy consumption and a high efficiency, thereby achieving comprehensive utilization of resources, and protecting the environment.

Owner:UNIV OF SCI & TECH BEIJING

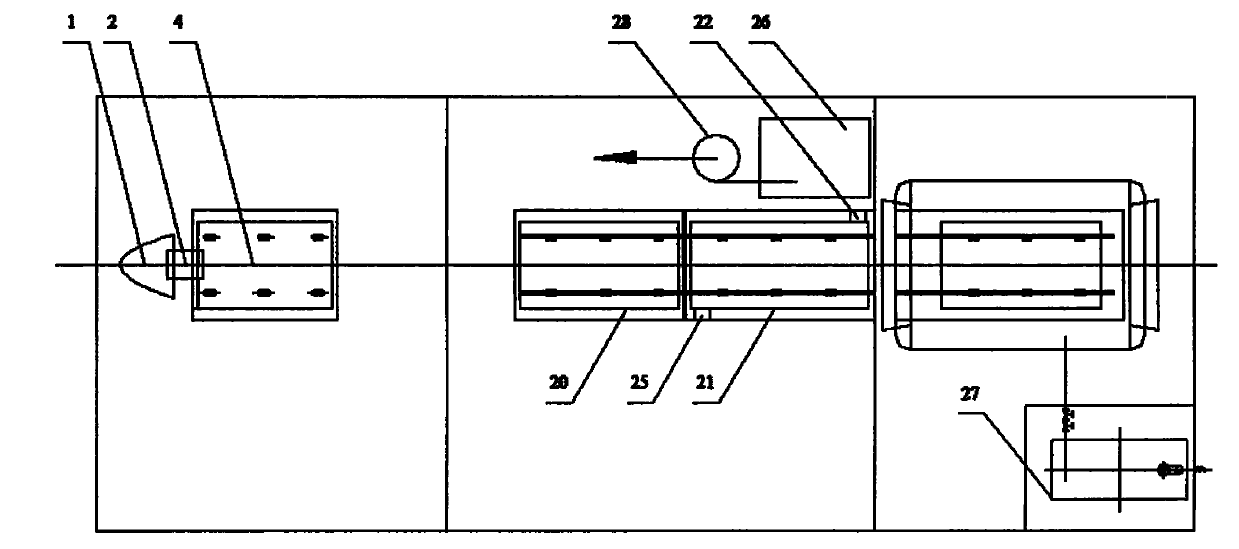

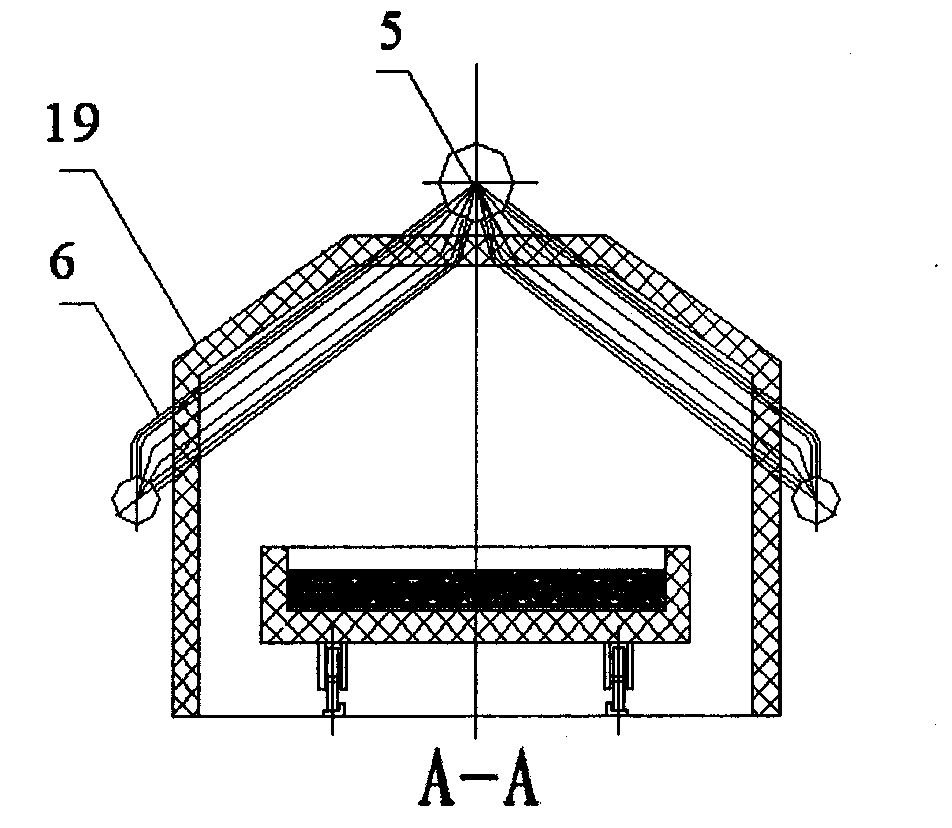

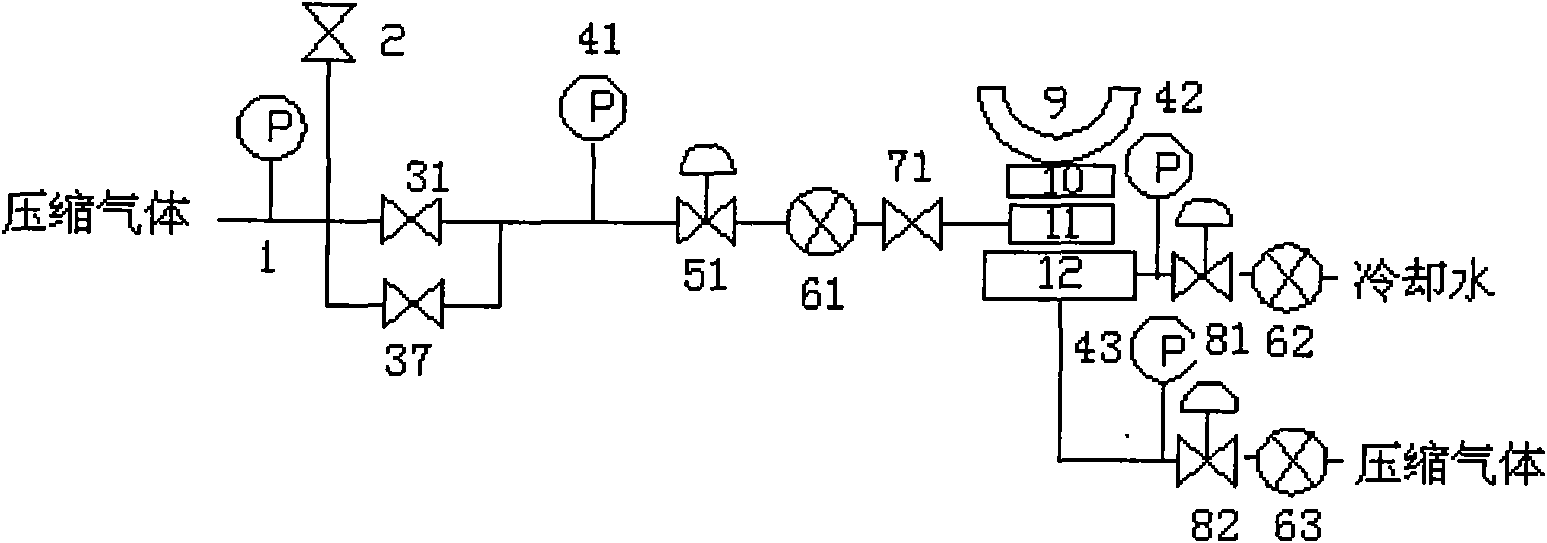

Anhydrous granulating technique of metallurgical slag or melted sulphonium and device thereof

ActiveCN101660012AAchieve the purpose of granulationSimple processRecycling and recovery technologiesMetallurgical slagPre cooling

The invention relates to the field of pyrometallurgy, in particular to an anhydrous granulating technique of metallurgical slag or melted sulphonium and a device thereof; the device comprises a granulating chamber, a dispersing device and cooling water spray heads, wherein an inner cavity of the granulating chamber is communicated with a slagging chute; a bottom slag hole corresponds to a feed bin; the dispersing device is arranged inside the granulating chamber and positioned under an outlet of the slagging chute; and the cooling water spray heads are also arranged inside the granulating chamber and positioned at the two sides of and under the dispersing device. Compressed gas is adopted in the granulating chamber to lead the melted slag to be dispersed into numerous tiny liquid drops, and the liquid drops are simultaneously pre-cooled in the air to become semi-molten or even solid granules which are then cooled by water mist, so that the aim of granulating can be achieved; finally, after being granulated and cooled, the slag can be settled into the feed bin by means of gravity. The invention has simple technique, convenient operation and a little investment, and overcomes the defects of the traditional water quench process.

Owner:YANGGU XIANGGUANG COPPER

Method for preparing MgALON-based compound material by using boron-rich slag

The invention provides a method for preparing an MgAlON base composite material by making use of boron-rich slag, which is characterized in that: in the first step, boron-rich slag containing 30 to 40 percent of MgO is taken as main material; the massive boron-rich slag is processed into boron-rich slag powder which is then fine-ground and sieved; the sieved boron-rich slag powder is mixed with an aluminum contained compound and carbon black and made into mixed blank which is then pressed to obtain round blank; the round blank is sintered to obtain MgAlON composite powder; in the second step, the prepared MgAlON composite powder is mixed with an additive and then pressed to obtain round blank which is then sintered to obtain the MgAlON base composite material. The preparation method of MgAlON base composite material of the invention is characterized in that: metallurgical slag is utilized as raw material to prepare the MgAlON base composite material, which reduces the production cost thereof; the synthesized MgAlON base composite material has various excellent performances and can be wildly applied in such fields as metallurgy and ceramics, etc. The preparation method of the invention has simple technique, low production cost and vital significance in comprehensive utilization of the boron-rich slag.

Owner:NORTHEASTERN UNIV

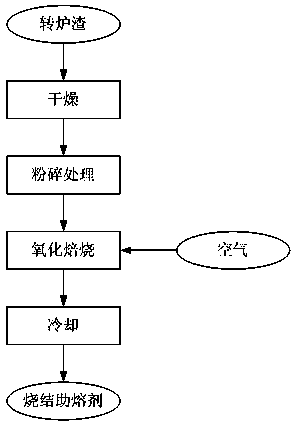

Preparation method of sintering flux for iron ore sintering

The invention provides a preparation method of a sintering flux for iron ore sintering, which can solve the problem of waste recycling of converter slags, also can produce a low-cost sintering flux, and reduces the damages of converter slags on the environment. According to the invention, converter slags and air are fully reacted at a high temperature of 800-1100 DEG C, a main ingredient SFCA (complex calcium ferrite) in an obtained sintering flux product can reduce the melting point of the flux, so that the formation of a liquid phase in the process of sintering is facilitated, therefore, the energy consumption is reduced, conditions are provided for the improvement of the efficiency of a blast furnace, the maximum value of converter slags is utilized as much as possible, the recycling of metallurgical slags is implemented, and the energy conservation and emissions reduction of enterprises are facilitated. The preparation method of a sintering flux for iron ore sintering disclosed by the invention provides products and technical supports for the reduction of ironmaking and steelmaking production costs and the implementation of energy conservation and emission reduction.

Owner:CHONGQING UNIV

Method for preparing polysilicon ferric sulfate water purifying agent from steel slag and water slag

InactiveCN101239721AReduce manufacturing costImprove water purification effectSolid waste disposalSilicon compoundsMetallurgical slagLiquid waste

The present invention provides a method of PFSS water clarified reagent using industry's steel slag and grain slag as main material. Al, Fe salting liquid is prepared by sulphuric acid resolving steel slag and grain slag, filtrate and filter residue are obtained by filtering; the filtrate is adjusted pH value to remove Al, adding H2O2 to oxidize ferrous iron being ferric can obtains Fe 3+ precursor; the filter residue is alkali resolved by NaOH solution to obtain Na2SiO3 precursor; the two precursors are added in H3PO4 as stabilizing agent, PFSS are prepared by polymerization reaction. The invention realizes resource regeneration of metallurgical slag, the prepared PFSS has lower cost, better water purifying effect, capable of widely use for purifying factory effluent and domestic sewage such as liquid waste and paper making, printing in steel factory.

Owner:朱成林 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com