Method for preparing microcrystalline glass by synergetically processing municipal sludge through utilizing metallurgical slag

A technology of glass-ceramics and synergistic processing, applied in the fields of resource utilization and environmental protection, achieving significant economic and social benefits, simple preparation process, and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] The sludge discharged from a sewage treatment plant was placed in a heating furnace and calcined at 700°C for 2 hours. The color of the sludge changed from black to light yellow. After cooling, it was taken out and ground to less than 1mm; after chemical composition analysis, the results (wt% )as follows:

[0019] Raw material CaO SiO 2 al 2 o 3 MgOSO 3 Fe 2 o 3 TiO 2 K 2 O Na 2 OP 2 o 5

[0020] Sludge incineration ash 8.32 41.27 13.05 5.72 1.53 6.01 0.80 4.19 0.97 17.49

[0021] The blast furnace slag of a steel plant was finely ground to less than 1mm, and the chemical composition analysis results (wt%) were as follows:

[0022] Raw material CaO SiO 2 al 2 o 3 MgOSO 3 Fe 2 o 3 TiO 2 K 2 o

[0023] Metallurgical blast furnace slag 42.21 31.40 11.73 8.70 2.61 1.30 0.69 0.45

[0024] Sludge incineration ash and metallurgical blast furnace slag are weighed and mixed uniformly according to the mass percentage: sludge incinerat...

Embodiment 2

[0030] The incineration of sludge, the treatment of blast furnace slag and the chemical composition are the same as in Example 1.

[0031] Raw materials are proportioned by mass percentage: 41% of sludge incineration ash, 55% of metallurgical blast furnace slag, and 4% of quartz sand. Concrete technological process and technological parameter are with embodiment 1.

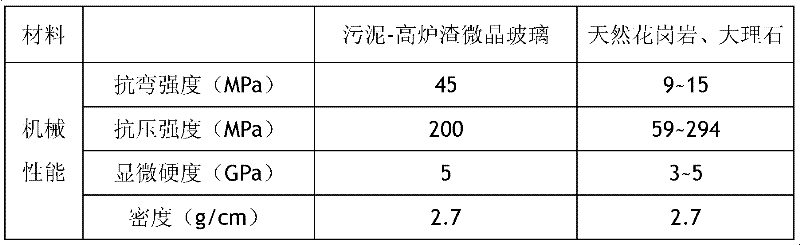

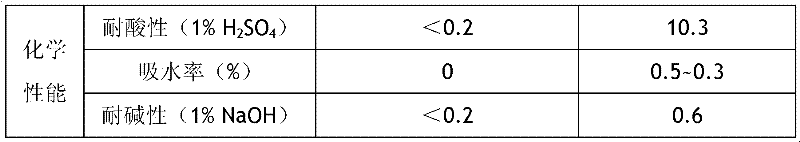

[0032] According to relevant standards, after testing, its performance indicators are as follows:

[0033]

Embodiment 3

[0035] The incineration and chemical composition of sludge are with embodiment 1;

[0036] The steel slag of a steel plant is finely ground to less than 1mm, and the chemical composition analysis results (wt%) are as follows:

[0037] Raw material CaO SiO 2 al 2 o 3 MgOSO 3 Fe 2 o 3 TiO 2 K 2 O Na 2 OP 2 o 5

[0038] Metallurgical steel slag 44.81 16.69 2.04 5.62 0.29 24.05 0.77 0.06 0.93 2.01

[0039] Sludge incineration ash and metallurgical steel slag are weighed according to the mass percentage: sludge incineration ash 37%, metallurgical steel slag 42%, and quartz sand 21%. Mix them evenly, put them into a graphite crucible, and melt at 1400 ° C for 2 hour, take out the molten mixed glass liquid and carry out water quenching treatment to obtain basic glass granules;

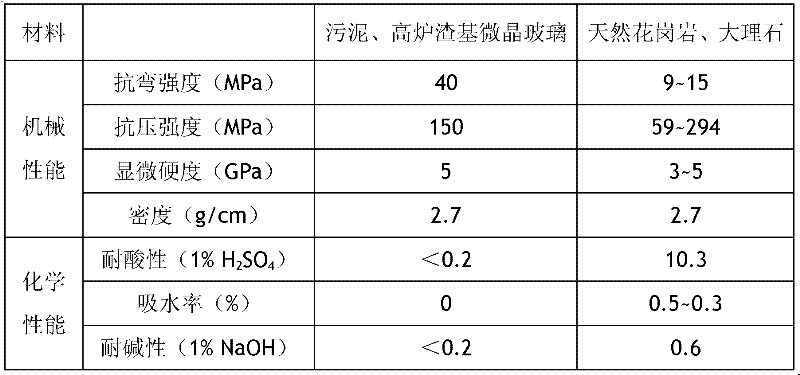

[0040] Finely grind the prepared basic glass granules to 200 meshes, press them into shape, put them into a heating furnace for nucleation and crystallization treatment, heat up to 90...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com