Patents

Literature

490 results about "Sludge incineration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sludge incineration (German: Klärschlammverbrennung, Chinese: 污泥焚烧发电) is a sewage sludge treatment process using incineration. It generates thermal energy from sewage sludge produced in sewage treatment plants. The process is in operation in Germany where Klärschlammverbrennung GmbH in Hamburg incinerates 1.3m tonnes of sludge annually. The process has also been trialed in China, where it has been qualified as an environmental investment project. However the energy balance of the process is not high, as sludge needs drying before incinerating.

High-temperature melting treatment system and method for sludge

ActiveCN102537980ALow running costEmission reductionCombination devicesSludge treatment by pyrolysisAir preheaterCooling tower

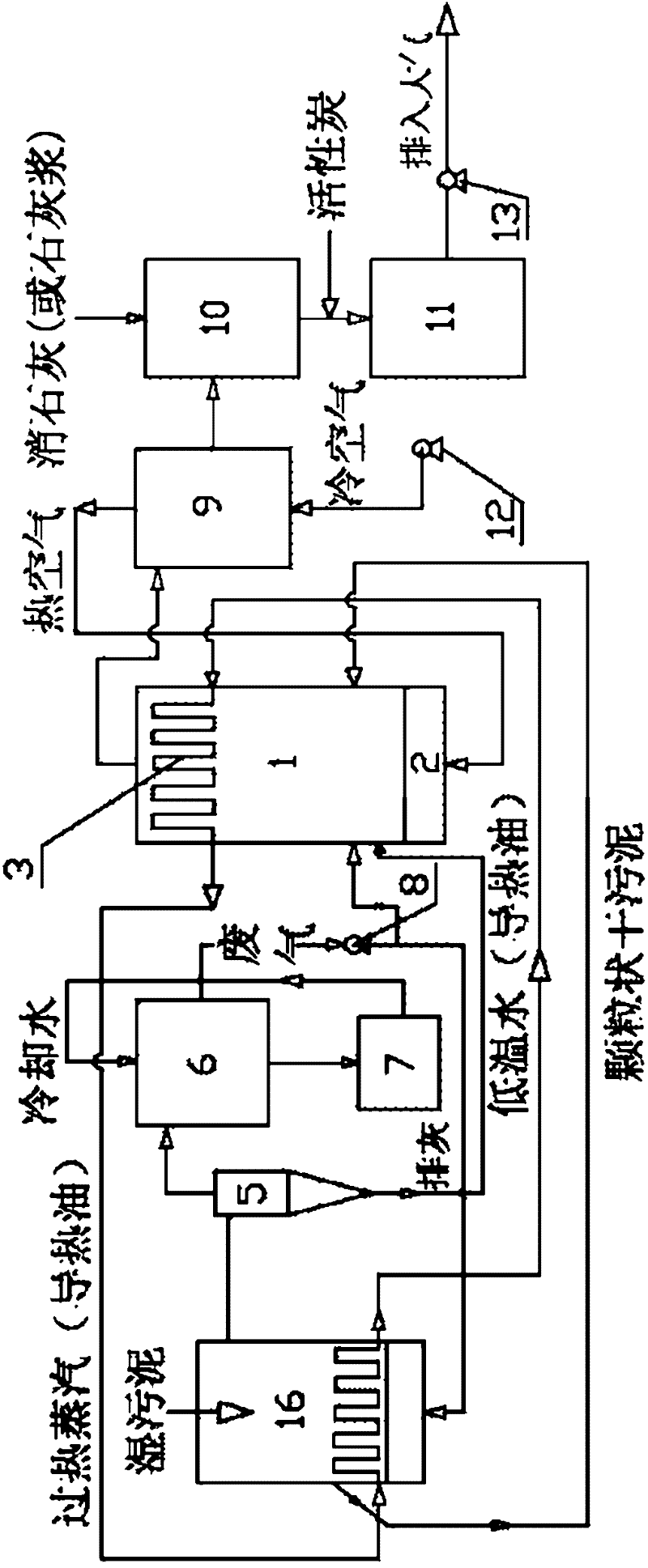

The invention discloses a high-temperature melting treatment system and a method for sludge, and relates to a sludge treatment system and a sludge treatment method. The system and the method solve the problem that dioxine exists in sludge incineration methods in prior arts. A first device comprises a melting chamber with a furnace body integrally manufactured from a lower side to an upper side, a shrinking section smoke outlet and a secondary combustor, high temperature and low temperature superheaters arranged in a smoke duct, high temperature and low temperature coal economizers, high temperature and low temperature air preheaters, and an SCR (selective catalytic reduction) denitration system, wherein the smoke duct is communicated with a smoke fast cooling tower, the smoke fast cooling tower is communicated with a bag-type dust collector, and the bag-type dust collector is communicated with a chimney by a smoke wet desulphurization system and a draught fan. The first method comprises the steps of feeding dry sludge powder into the melting chamber for burning to a high-temperature melting state, recycling liquid-state slag and reusing, treating high-temperature smoke after entering the smoke duct, and discharging. The differences between a system in a second scheme and the first device are as follows: the high temperature and low temperature superheaters and the high temperature and low temperature coal economizers are not arranged, and a steam heat exchanger is additionally arranged. A difference between a system in the third scheme and the second scheme is as follows: a multistage sludge dryer is additionally arranged. The high-temperature melting treatment system and method for the sludge are used for high-temperature melting treatment of the sludge.

Owner:HARBIN INST OF TECH

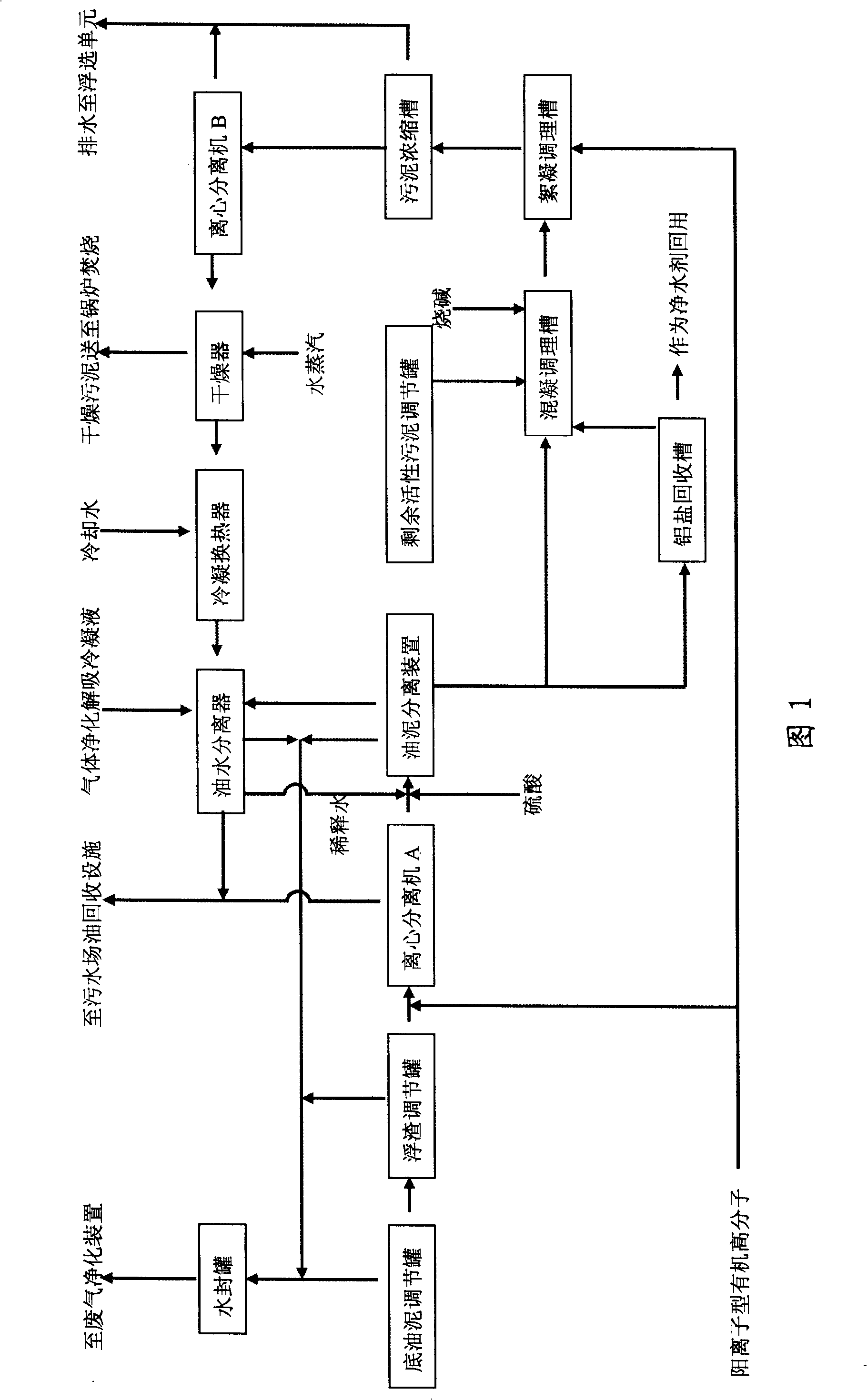

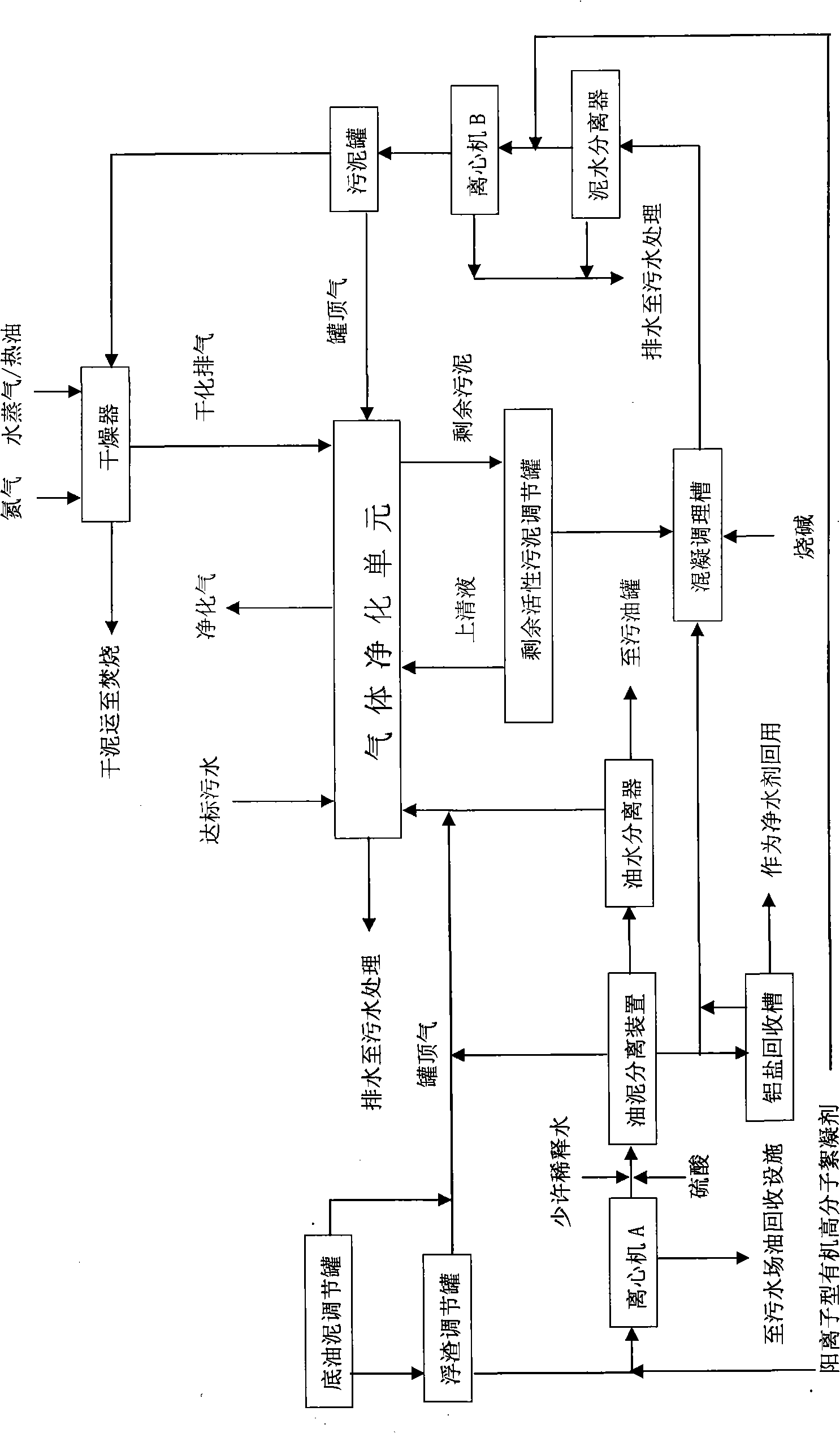

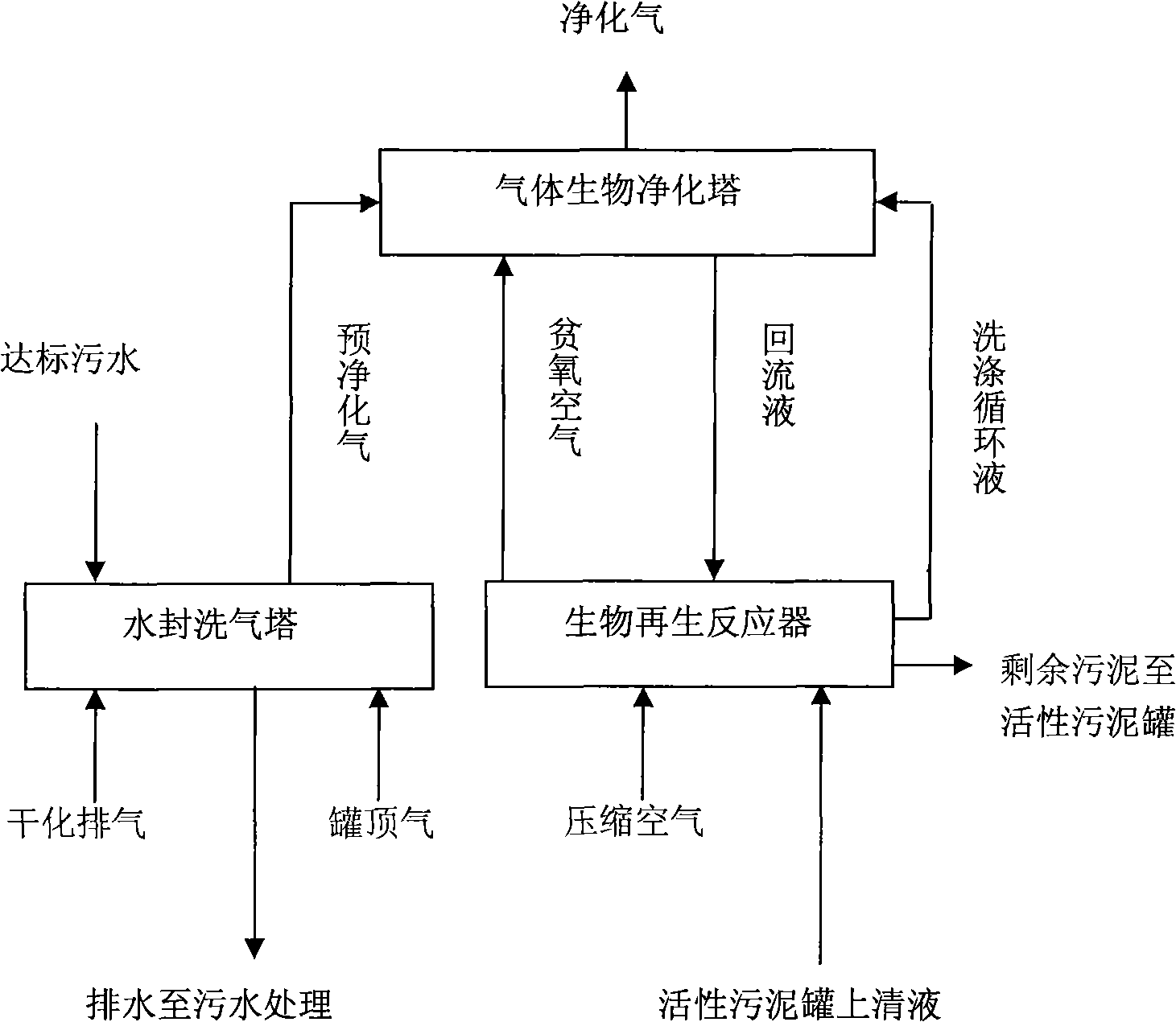

Method for innocent treatment of bottom oil sludge, scruff and active sludge in petro-chemical industry

InactiveCN101343137ASave resourcesReduce pollutionSludge treatment by de-watering/drying/thickeningIncinerator apparatusChemical industryActivated sludge

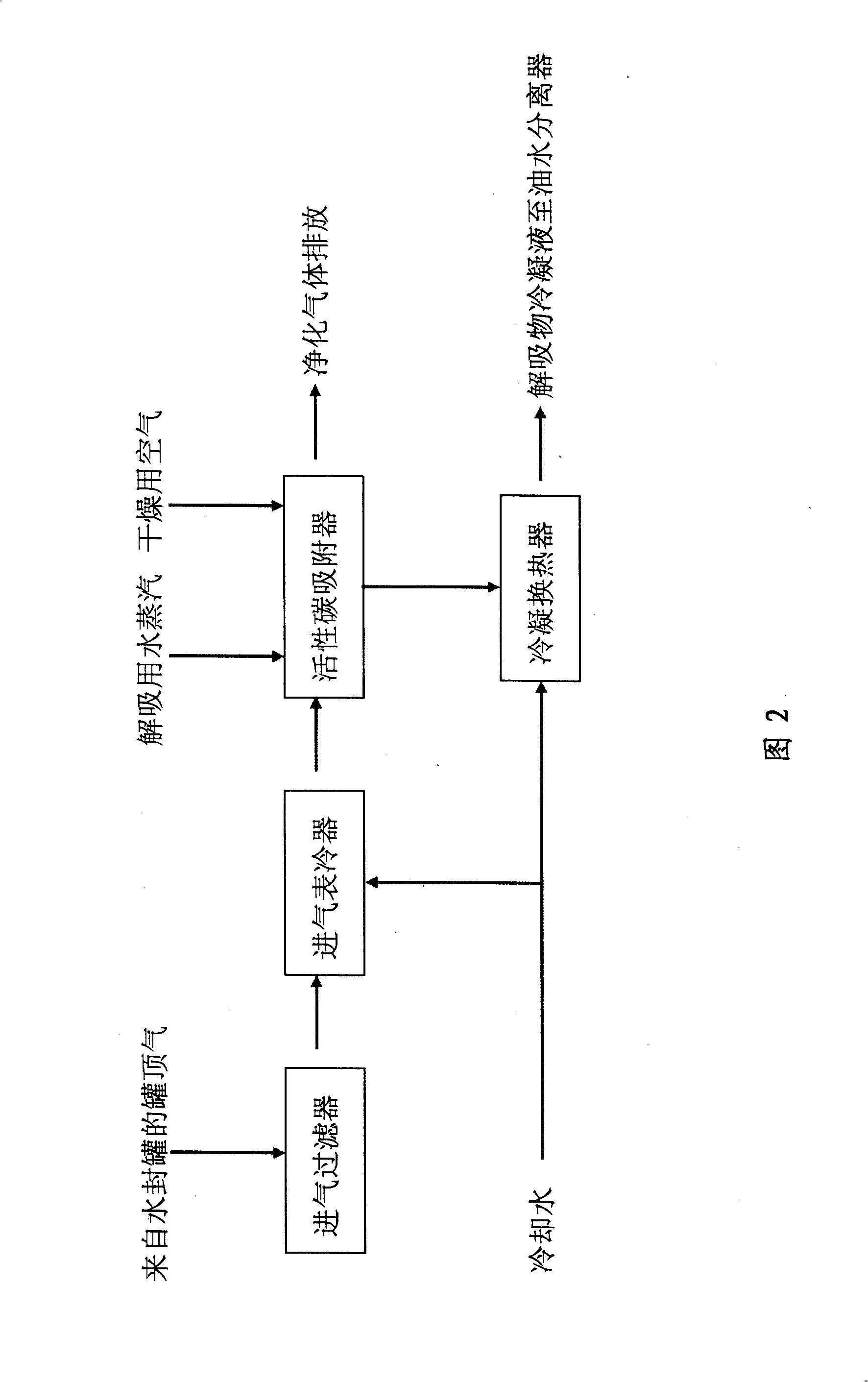

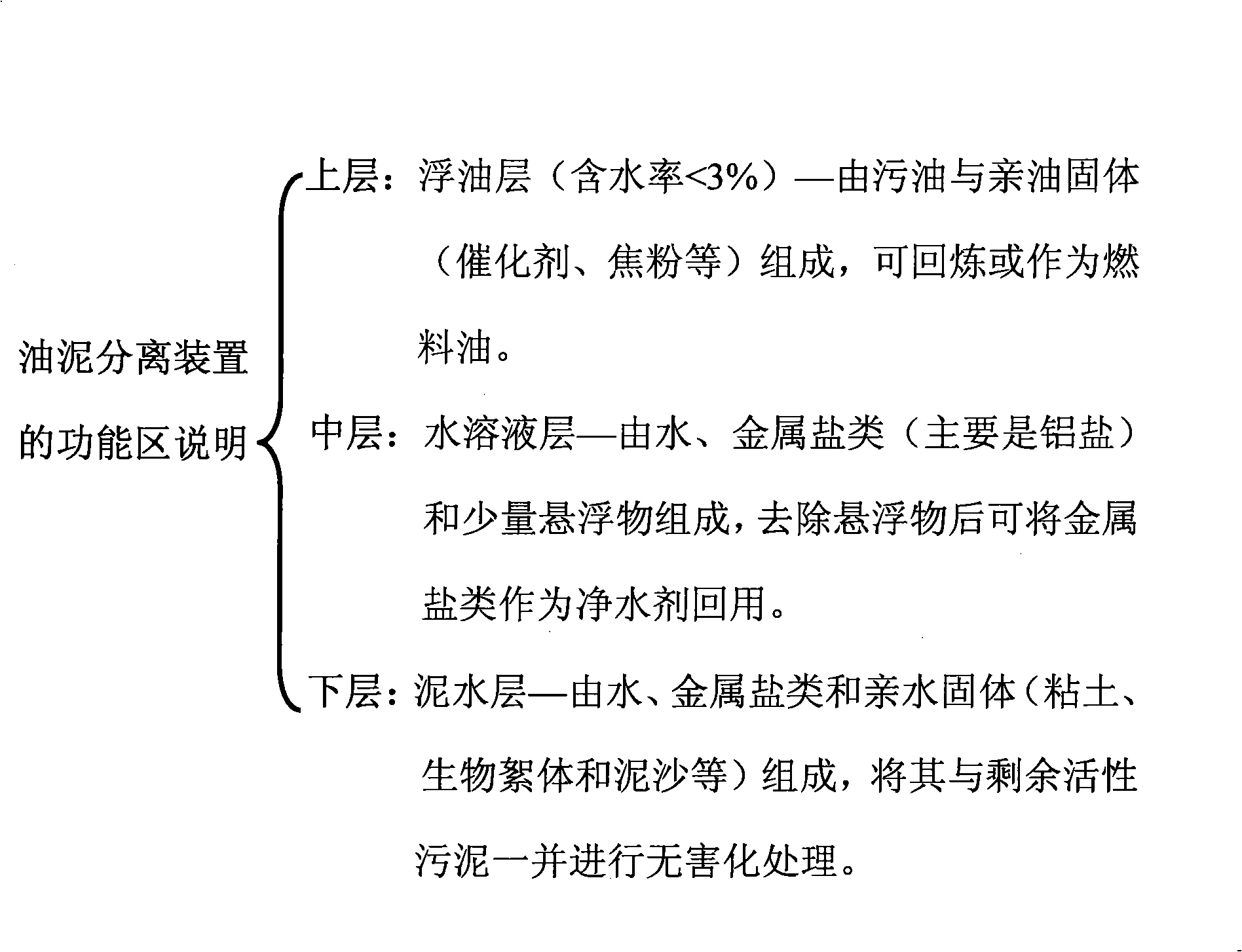

The invention discloses a method of harmless treatment to residual activated sludge produced by bottom sludge, scum and biochemical treatment units in the petrochemical industry, which comprises: emulsion breaking to the bottom sludge and scum; separation of oil, water and mud of products after emulsion breaking; and recovery of dirty oil at the upper part and sedimentation of mud-water mixture at the lower part, recovery of clear liquor at the upper part, and treatment of coagulation conditioning, flocculation conditioning, sludge concentration, sludge dewatering, sludge drying and sludge incineration to mud-water mixture at the bottom part and the residual activated sludge sequentially. The method can effectively recycle useful oil substances and aluminum-containing compounds in the bottom sludge and scum, purify possibly released malodorous gases in mud produced in the process of storage and disposal, and carry out the treatment such as sludge conditioning, dewatering and drying sequentially to the residual mass hazardous wastes after the recycling treatment, then utilize the current boilers in enterprises to implement the direct incineration treatment. The method has advantages of simple operation and running, safety and reliability, complete resource recovery, controllable water removal, and maximally reducing the environmental pollution.

Owner:罗德春

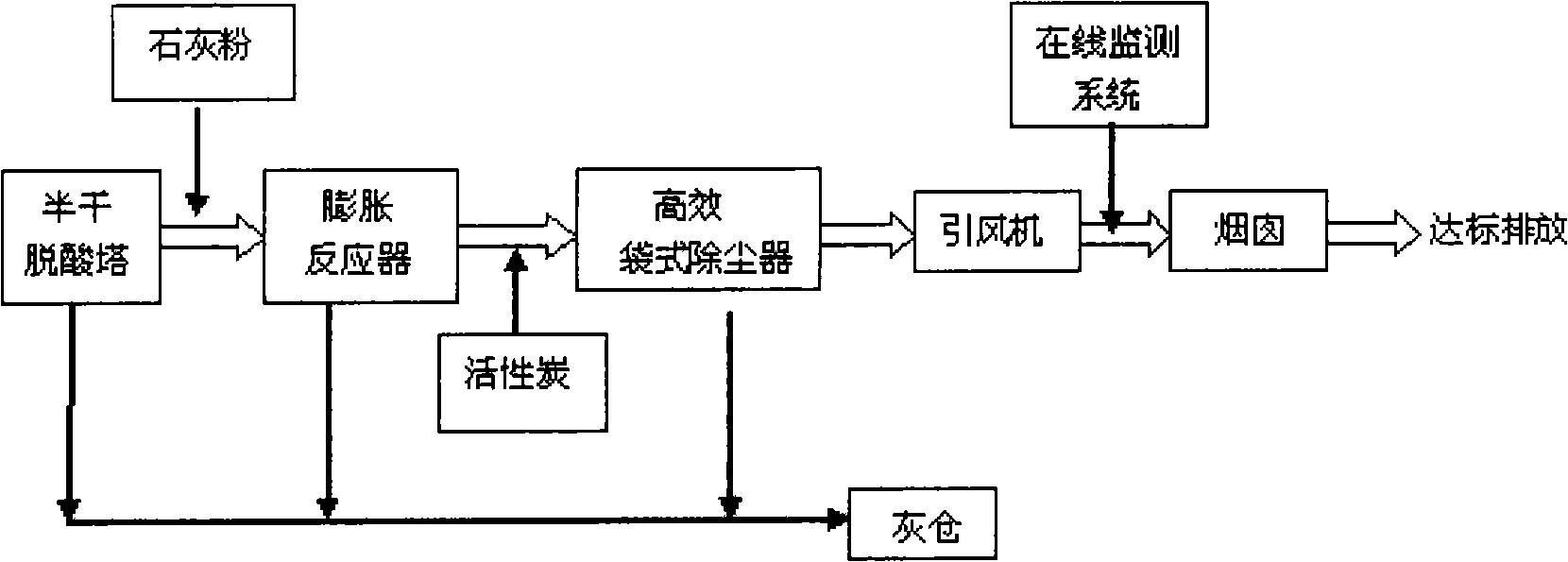

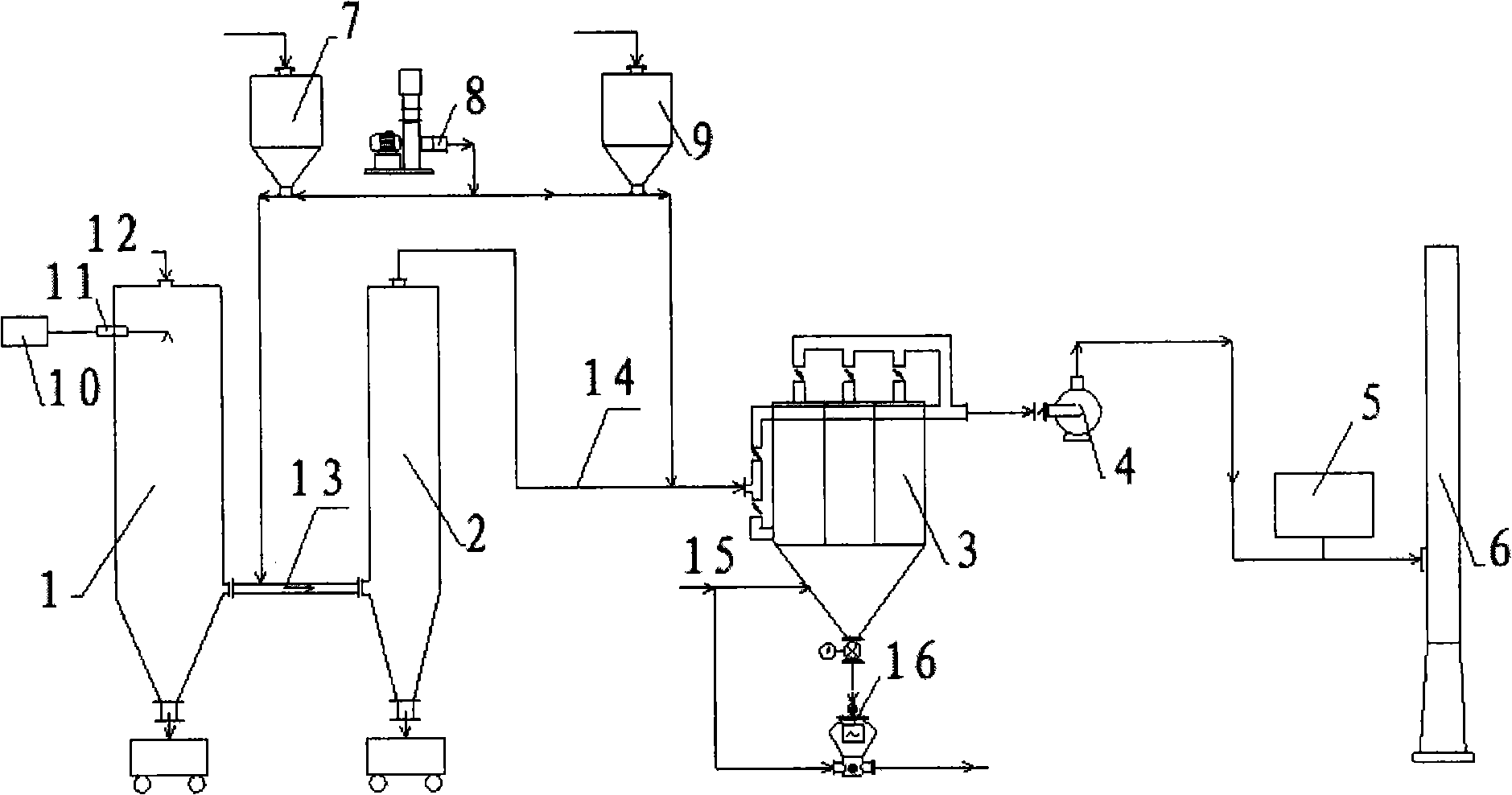

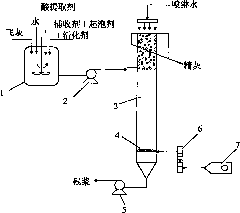

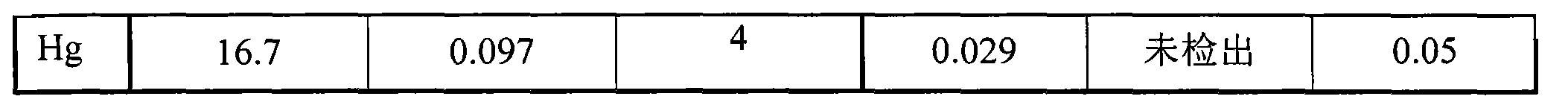

Complete set of device and method for treating tail gas from sludge incineration through semidry method

ActiveCN102120130AHigh removal rateEmission reductionDispersed particle separationChemical reactionSorbent

The invention relates to a device and a method for treating tail gas from sludge incineration through a semidry method, belonging to the field of solid wastes. The incineration tail gas passes through a semidry deacidification tower, thus the removing efficiency can reach about 90%, the use amount of chemicals is less, and sewage discharge is avoided; a flue in front of an expanded reactor is provided with a lime powder inlet, and the lime powder and the acid gas in the flue gas are subjected to full chemical reaction, thus the residue acid gas is removed; activated carbon serving as an adsorbent is injected, thus the removal rate of heavy metal and dioxin is further increased; an efficient bag filter is added to collect the Ca(OH)2 and powder of incomplete reaction, thus the removal rates of the heavy metal, dioxin and acid gas in the powder are effectively improved, the removal rate of the heavy metal (except mercury) reaches 99%, the emission of various pollutants can meet the environmental requirements, and the secondary pollution caused by incineration of the tail gas to the environment can be effectively solved.

Owner:BMEI

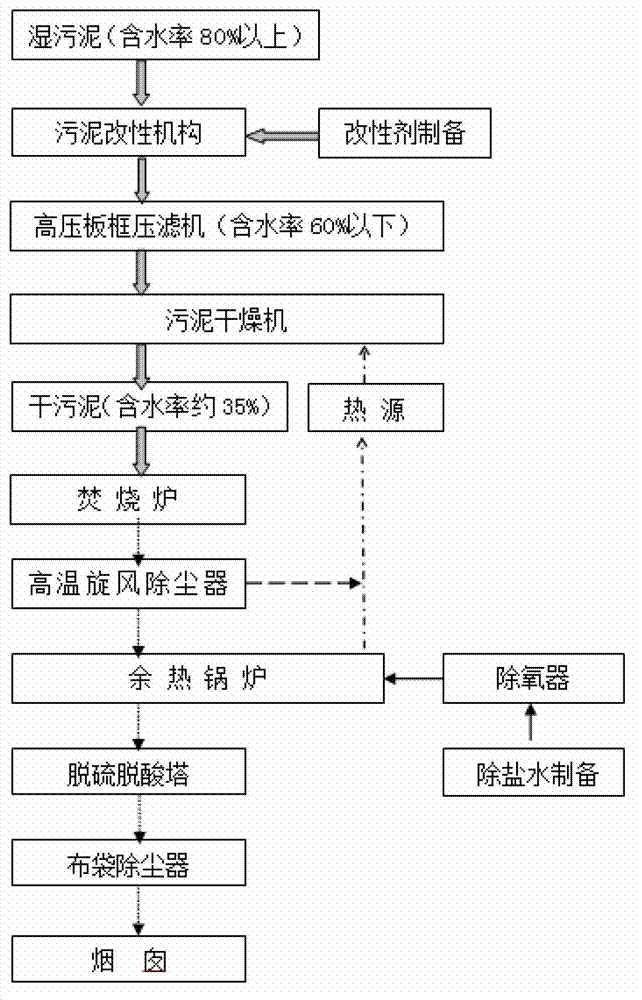

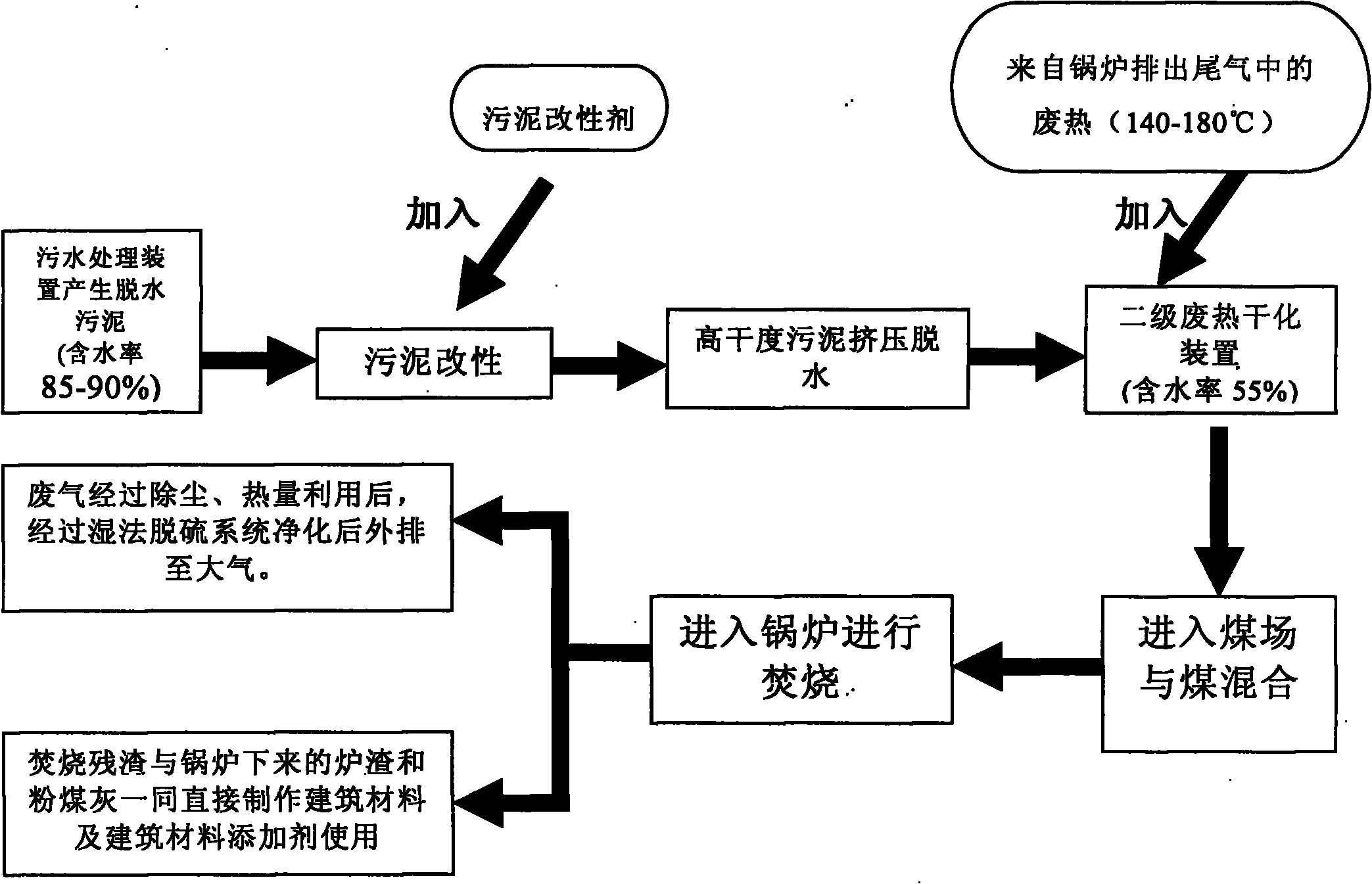

Two-stage drying and incineration method for sludge

InactiveCN103090396AStrong degree of harmlessnessReduce volumeSludge treatment by de-watering/drying/thickeningIncinerator apparatusEnvironmental resistanceFlue gas

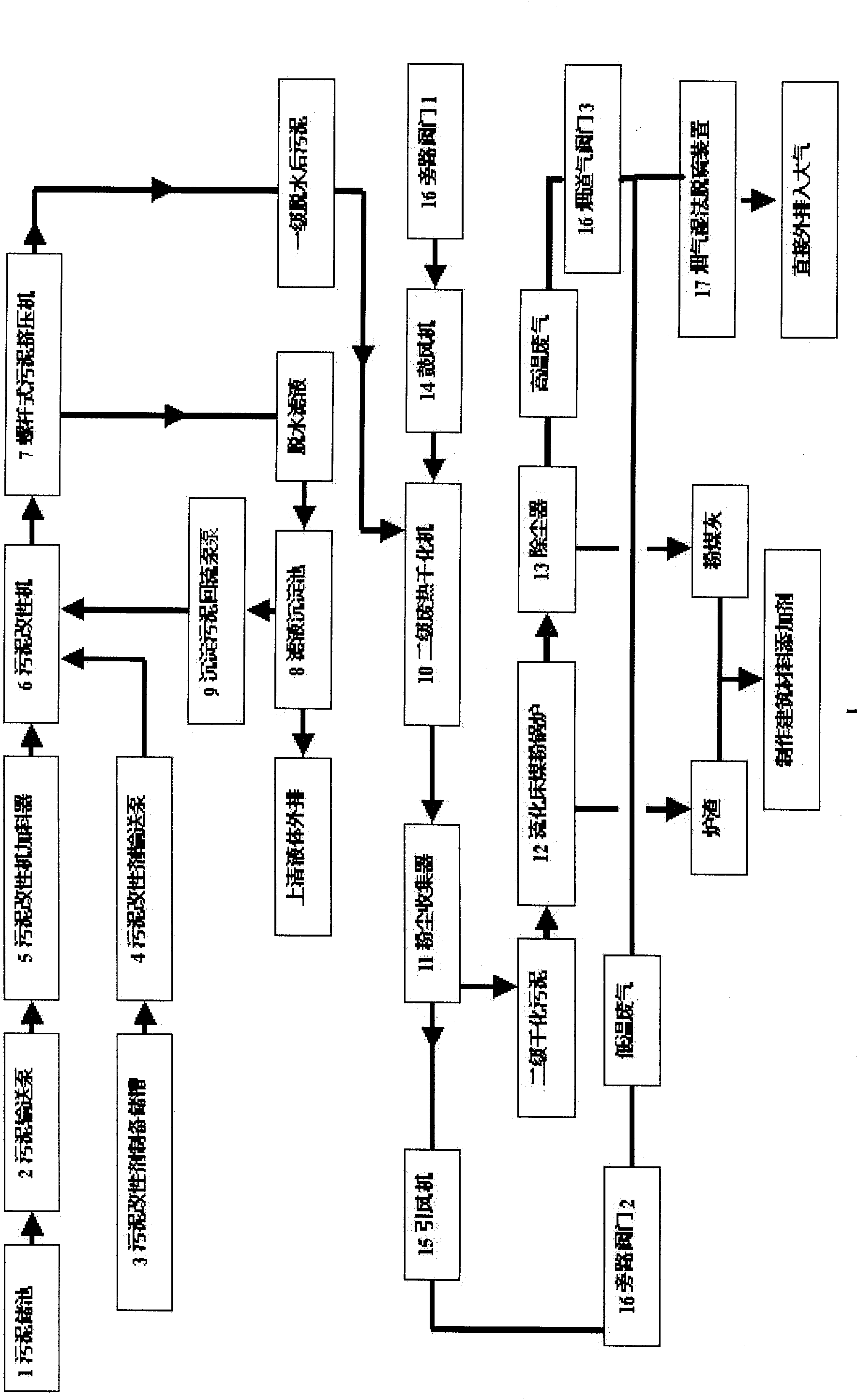

The invention discloses a two-stage drying and incineration method for sludge. The method comprises the following steps of: modifying and drying, namely adding a prepared modifier into a stirrer through an adding device, mixing the sludge and the modifier uniformly, then delivering the sludge into a modification mechanism, performing modification conditioning, delivering the sludge to a filter pressing system, performing deep dehydration, and reducing the water content of the modified and dried sludge to be 45 to 60 percent; drying with steam, namely reducing the water content of the dried sludge to be 35 percent; and incinerating the sludge and purifying flue gas. By adopting 'two-stage' drying and incineration, any auxiliary fuel is not required; the technology is advanced, the land occupation is low, and the investment cost and the operating cost are low; the volume of the sludge is minimized by incineration, and the reduction degree is highest; pathogens are killed at the high temperature of more than 850 DEG C, and the harmless degree is highest; the sludge incineration speed is high, and secondary pollution when the sludge is stored is avoided; and excellent environment-friendly performance is realized, and the incinerated ash can be recycled.

Owner:上海金自天正信息技术有限公司

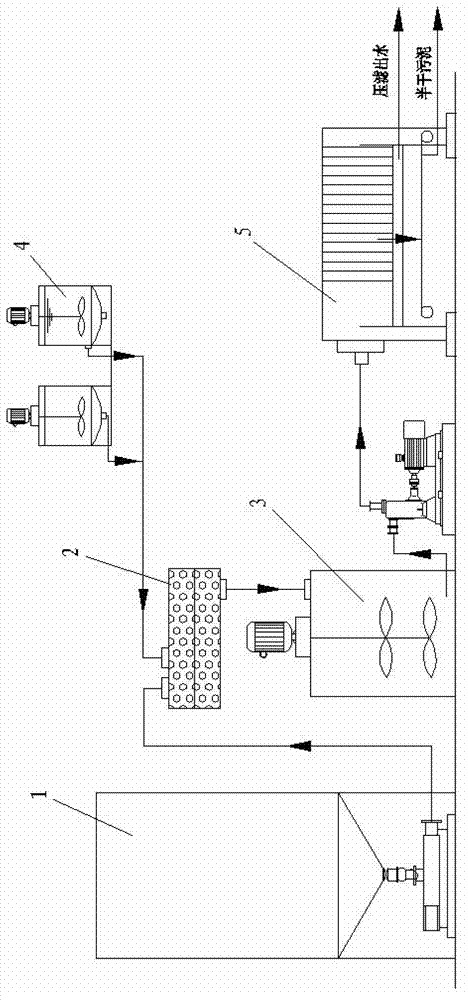

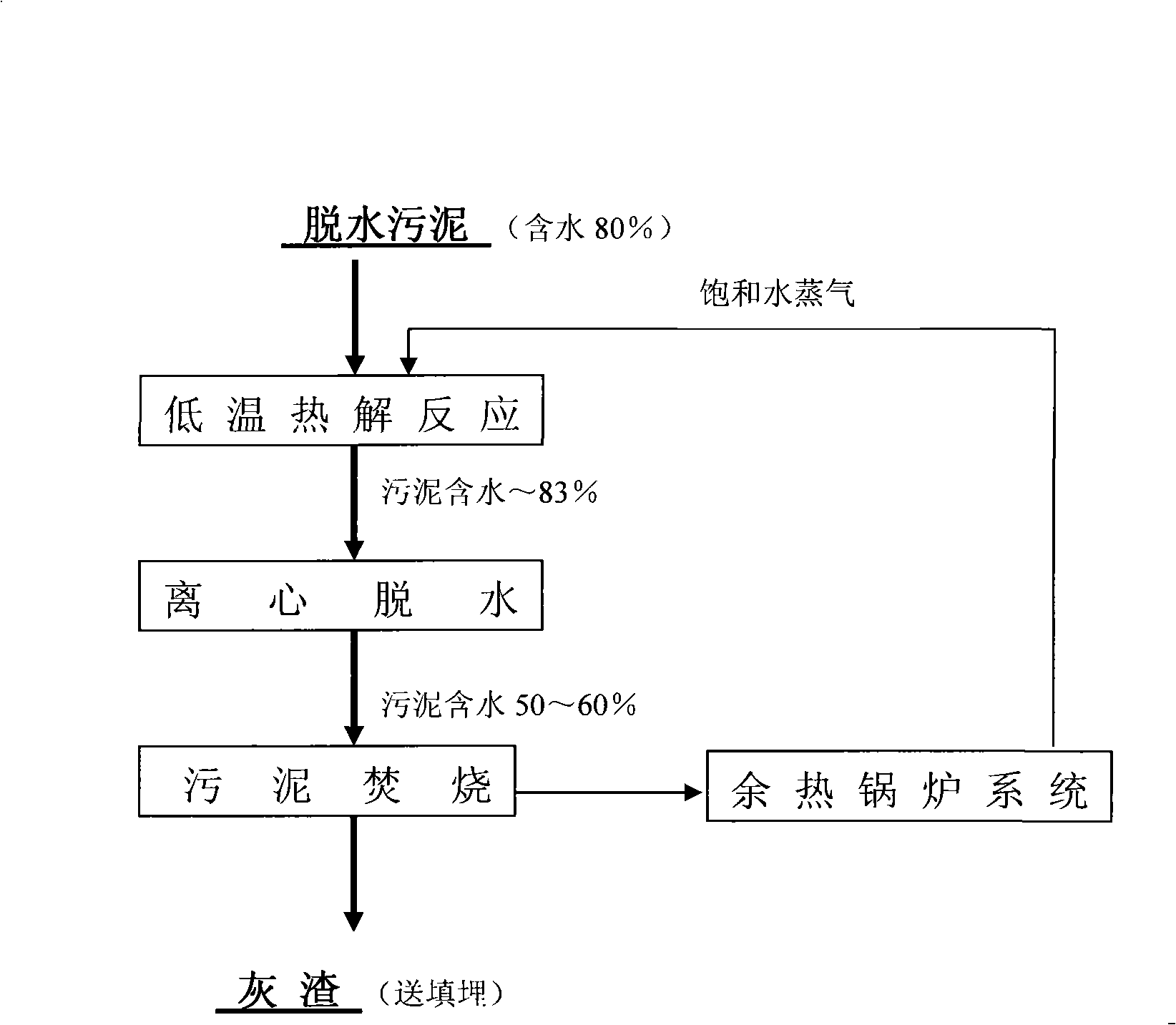

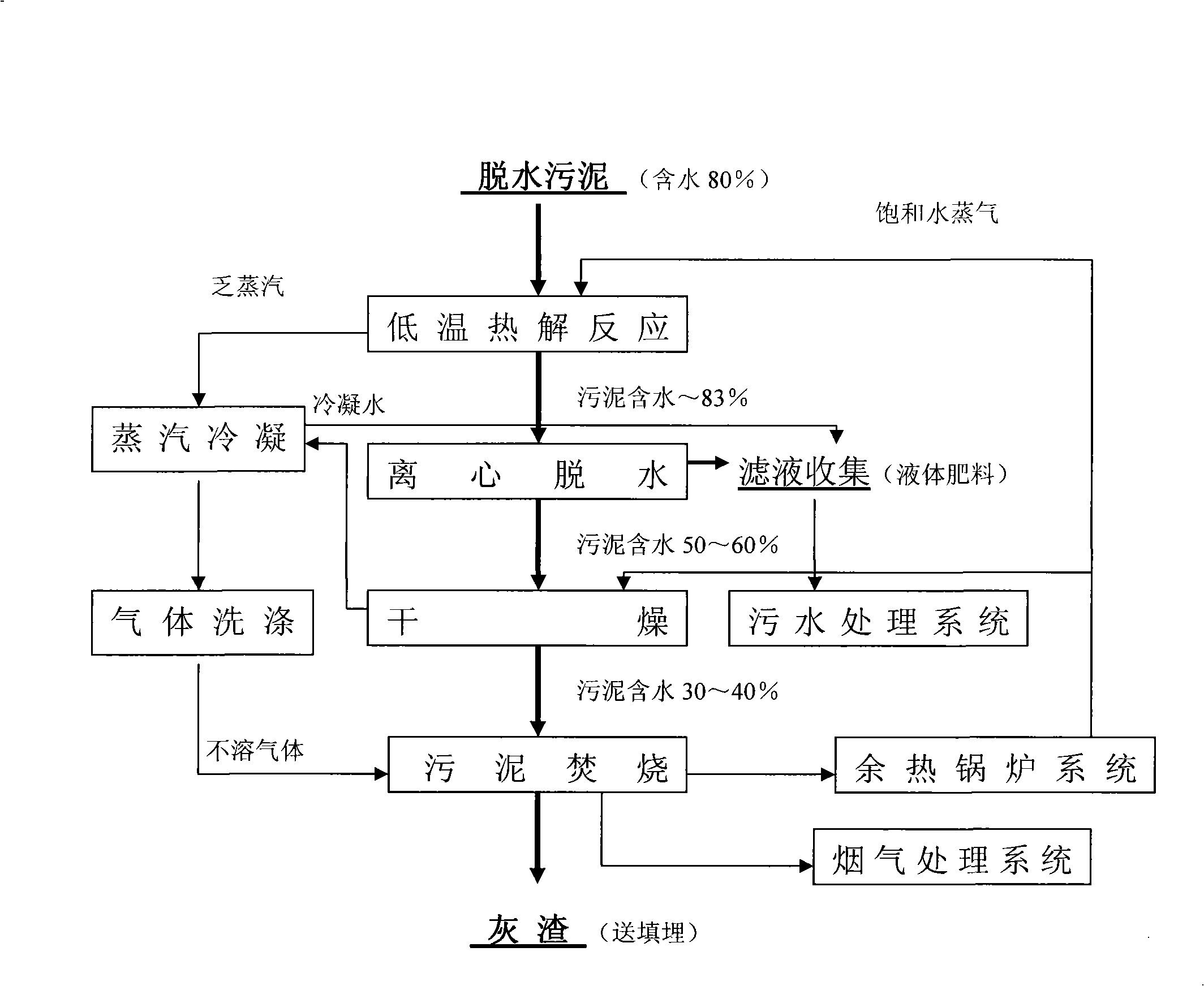

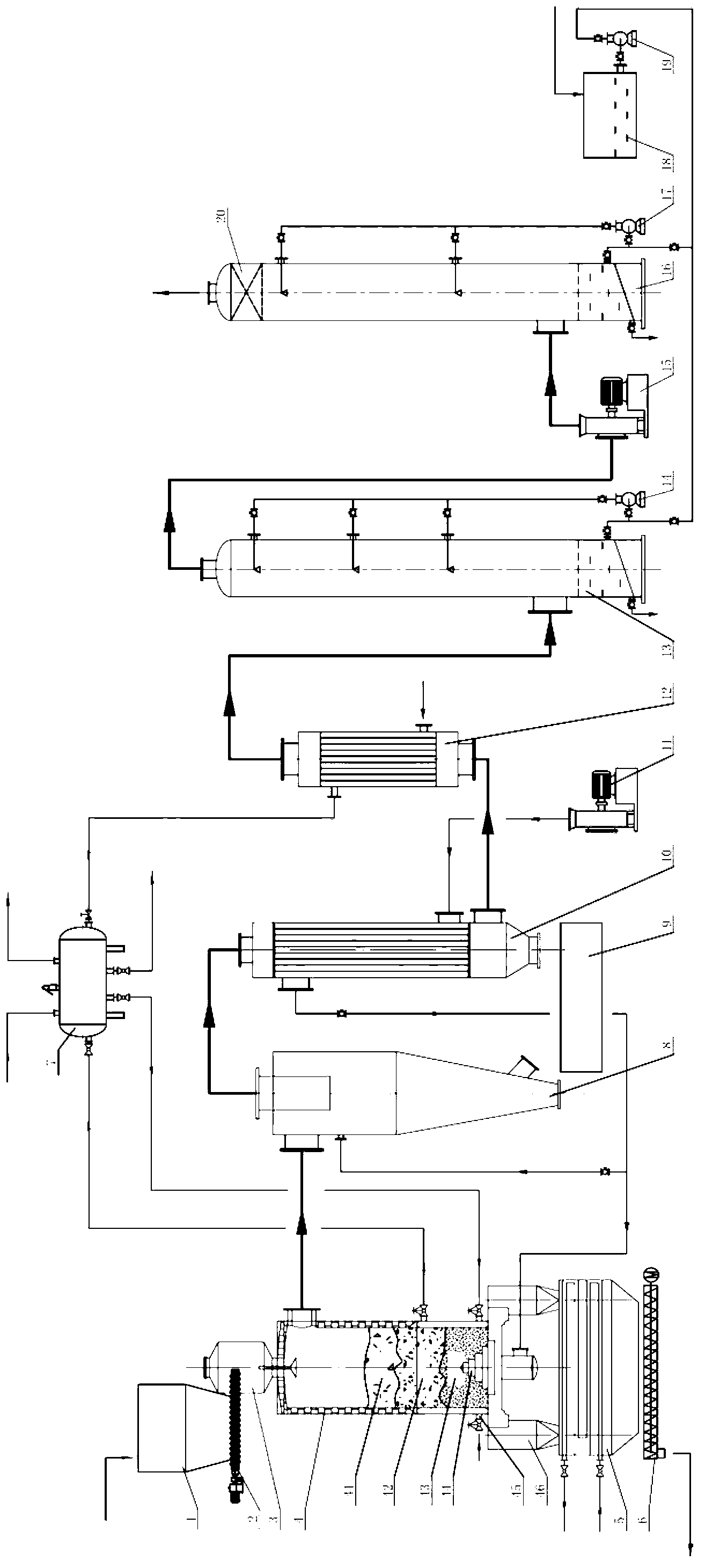

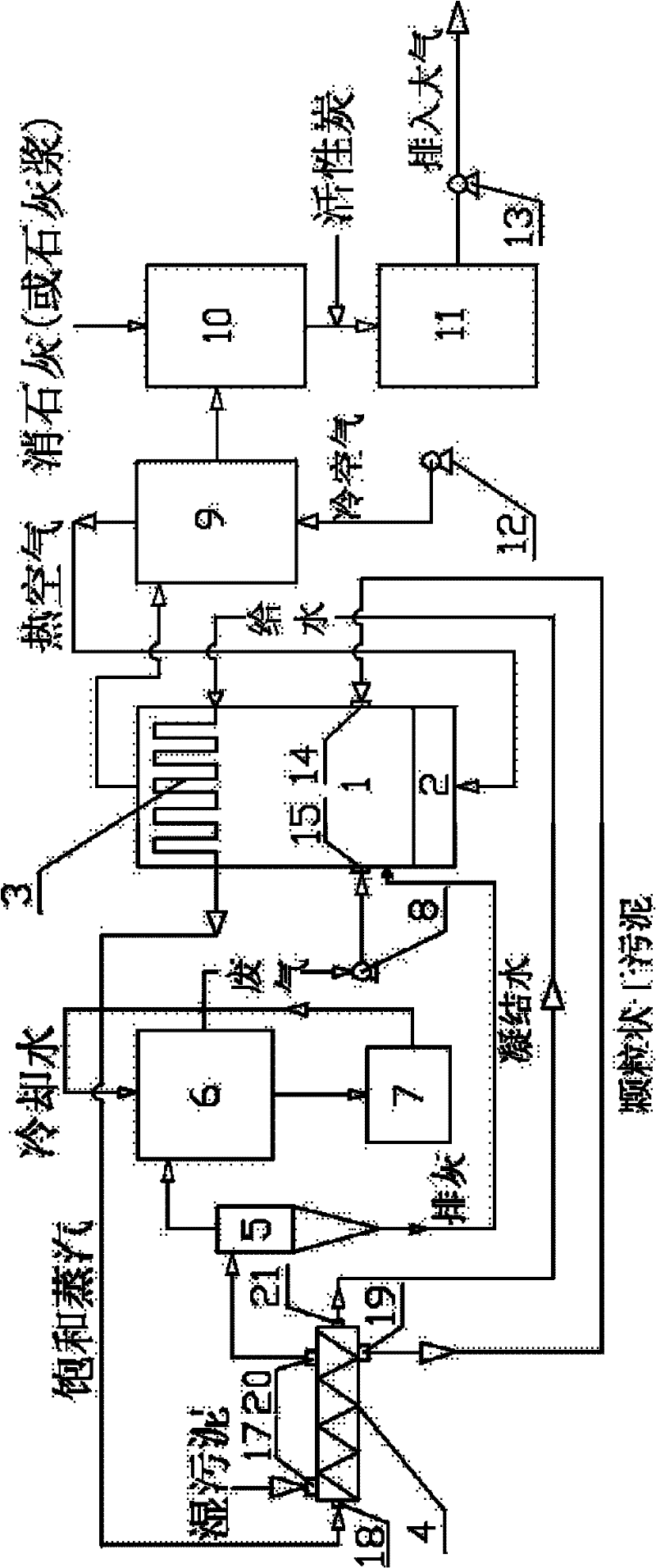

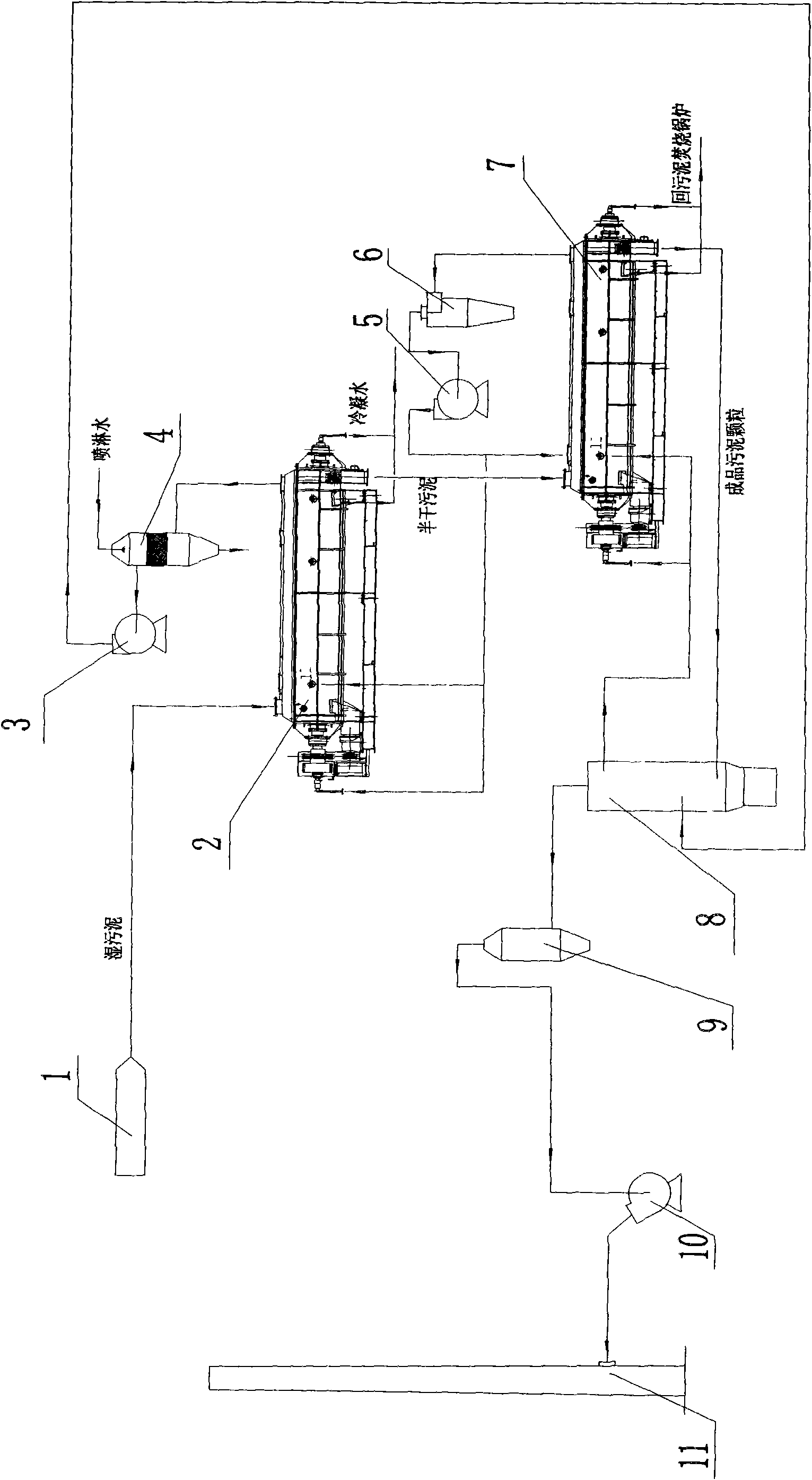

Wet sludge anhydration burning processing system and process

ActiveCN101290121AThoroughly deodorizedHarmlessDrying using combination processesSludge treatment by oxidationSteam condensationResource utilization

The invention relates to a wet sludge drying and incineration processing system. The system comprises a low-temperature pyrolytic reaction device, a centrifuging filtering device, a steam condensation device, a filtrate recovery device and a sludge incineration device; the low-temperature pyrolytic reaction device is used for carrying out low-temperature pyrolytic reaction between wet sludge and saturated steam in order to convert macromolecular organics in the wet sludge into low-molecular organics and destroy a sludge water-holding structure; the centrifuging device is used for carrying out centrifuging filtering to the wet sludge after pyrogenation; the steam condensation device is used for condensing and collecting bled steam converted from saturated steam in the low-temperature pyrolytic reaction device; the filtrate recovery device is used for collecting filtrate produced in the centrifuging device and for collecting condensed fluid from the steam condensation device; the sludge incineration device is used for incinerating semidry sludge after being dehydrated in the centrifuging device and insoluble gas remained in the steam condensation device as fuel. The system also relates to a process for carrying out the processing of wet sludge drying and incineration by adopting the processing system. The system and the process can solve the problem of sludge resource regeneration in a mode of environmental protection, energy conservation, high resource utilization rate and low operating cost.

Owner:SHENZHEN ECO SOLUTION TECH CORP

Flyash treatment method for waste incineration

InactiveCN101797575AReduce follow-up processing costsEfficient separationSolid waste disposalLiquid wasteCombustion chamber

The invention discloses a flyash treatment method for waste incineration, comprising the following steps: (1) mixing flyash produced in waste incineration with water to prepare into mortar, and adding acid extractant, collecting agent and foaming agent in the mortar to blend into grout; (2) performing foam flotation treament on the grout, and separating to obtain refined flyash and residual grout; (3) feeding the fined flyash in a secondary combustion chamber of a waste incinerator for supporting combustion, wherein carbon components enriched in the refined flyash are utilized in a combusted manner and dioxin in the refined flyash is decomposed at high temperature; (4) filtering the residual grout, separating to obtain tail flyash and filtrate, feeding the tail flyash in a domestic garbage landfill site for dumping; and (5) adding heavy metal precipitator in the filtrate, filtering once again, separating to obtain heavy metal precipitator salt and waste liquor, and discharging the waste liquor after sewage treament. The invention can effectively separate and recovery carbon components in high carbon and high chlorine waste incineration flyash, chloridion, dioxin and heavy metal at the same time.

Owner:TIANJIN URBAN CONSTR COLLEGE

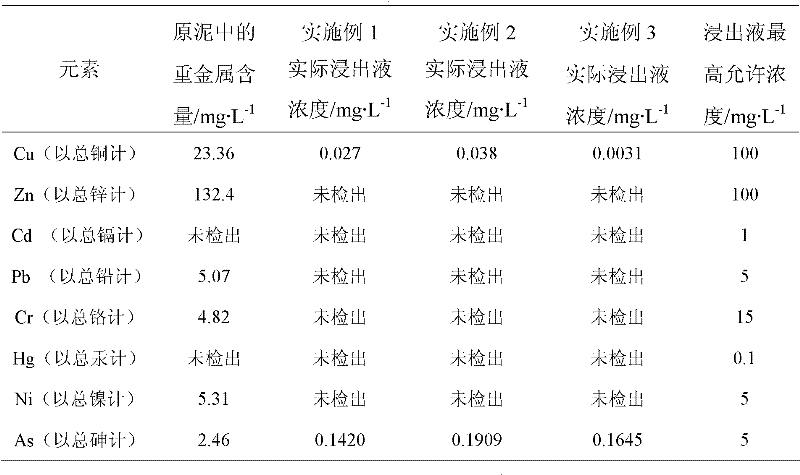

Method for preparing haydite from sludge incineration ash in chemical industry

ActiveCN102249730AAchieve reductionRealize resourcesSludge treatmentCeramicwareChemical industryDry mixing

The invention relates to recycling of industrial solid waste, and discloses a method for preparing haydite from sludge incineration ash in chemical industry. The method comprises the following steps: drying sludge subjected to mechanical dewatering, incinerating at high temperature, proportioning, carrying out dry mixing, adding water, evenly mixing, granulating to obtain fresh pellets, drying the fresh pellets, and roasting at 1050-1150 DEG C to form sludge haydite. The leaching concentration of heavy metals is far below GB 5085.3-2007 (Identification Standards for Hazardous Wastes-Identification for Extraction Toxicity). The method has the advantages of low energy consumption and low production cost, develops a new way for recycling sludge in the fields of waste treatment with waste andcyclic utilization of waste, and has obvious environmental benefit and economic benefit.

Owner:江苏江淮环保科技有限公司

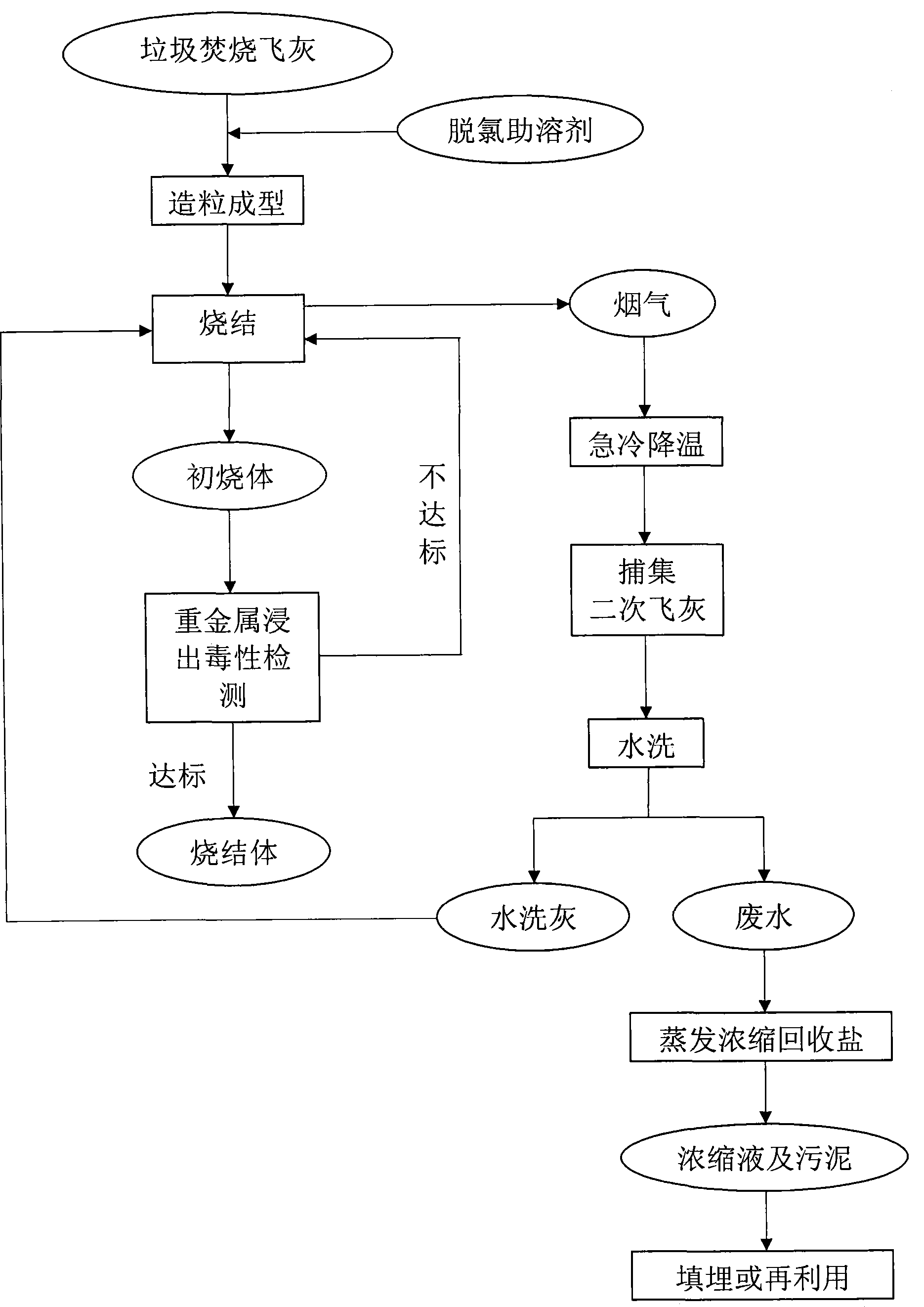

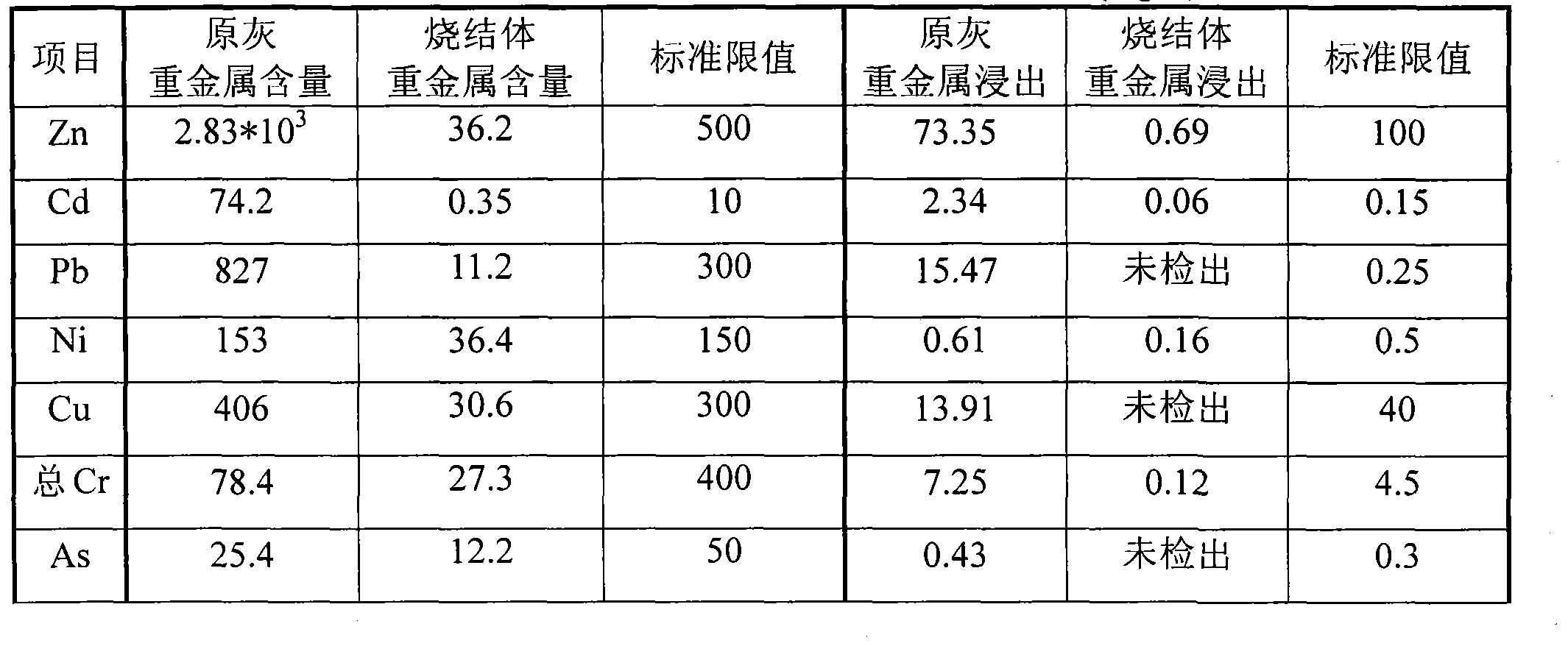

Waste incineration fly ash sintering reduction treatment technique

ActiveCN104070054AAccelerate evaporationPromote decompositionSolid waste disposalReduction treatmentDecomposition

The invention relates to a waste incineration fly ash sintering reduction treatment technique which is especially applicable to treatment and disposition of waste incineration fly ash of which the salt content is lower than 20%. The fly ash is added with a dechloridation fusing assistant to intensify the volatilization of heavy metals and the decomposition of dioxin, heavy metals and chlorine salt are intensively concentrated in secondary fly ash within a relatively low temperature range, and then the secondary fly ash is washed by water so as to further realize concentration of pollutants and reduction of the fly ash. The water-washed fly ash is returned to a rapid sintering device so as to completely degrade dioxin type pollutants; water-washing liquid is evaporated and concentrated to recycle the salt by using the afterheat of a sintering system, the concentrated liquid and mud obtained by evaporation and the obtained sintered body are safely buried or recycled. The treatment technique disclosed by the invention is relatively simple in overall process and equipment, the energy consumption and the treatment cost are relatively low, the environmental friendliness of the obtained end product is improved, and the long-term potential impacts of the fly ash on the environment are minimized.

Owner:TIANJIN YIMING ENVIRONMENTAL TECH CO LTD

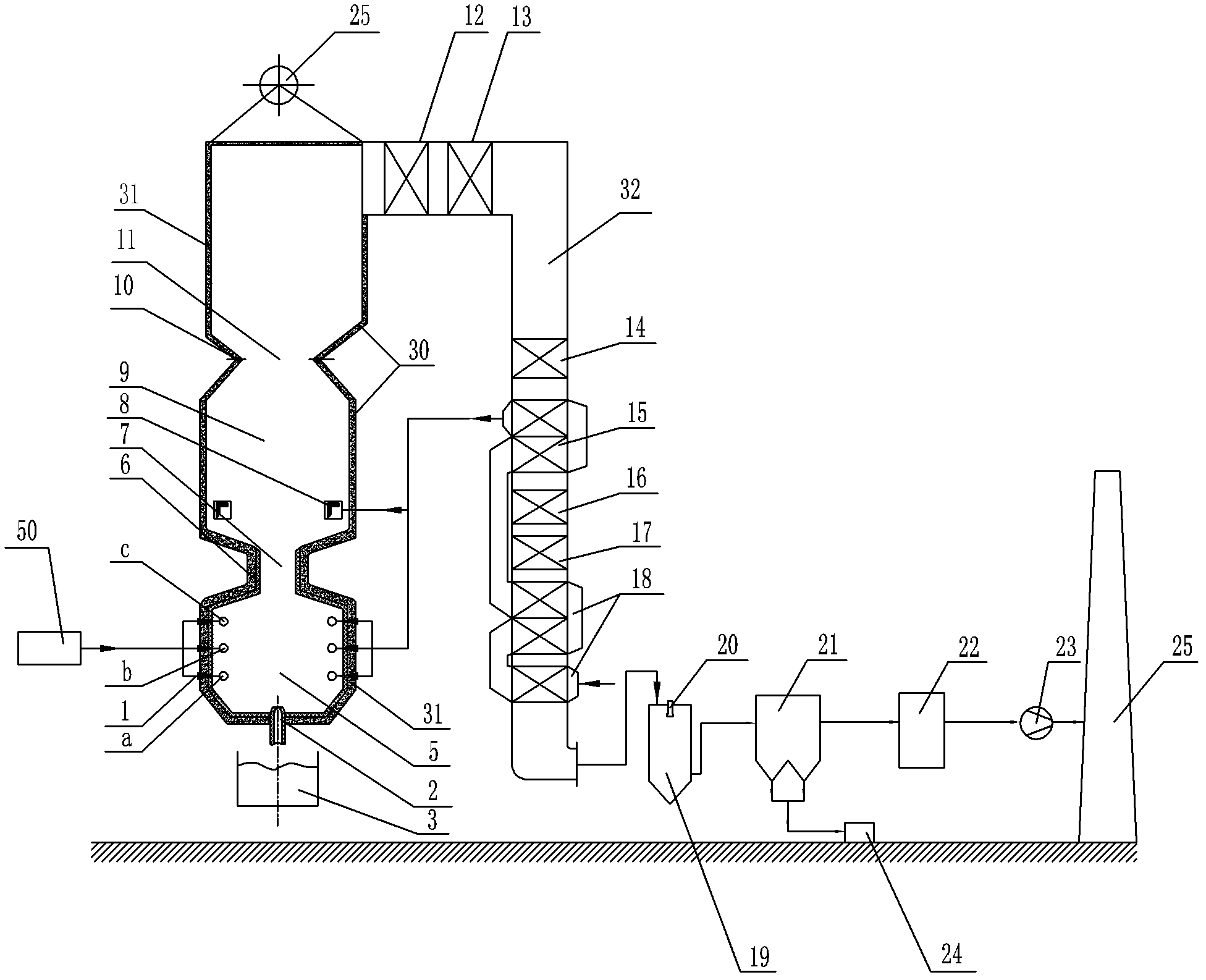

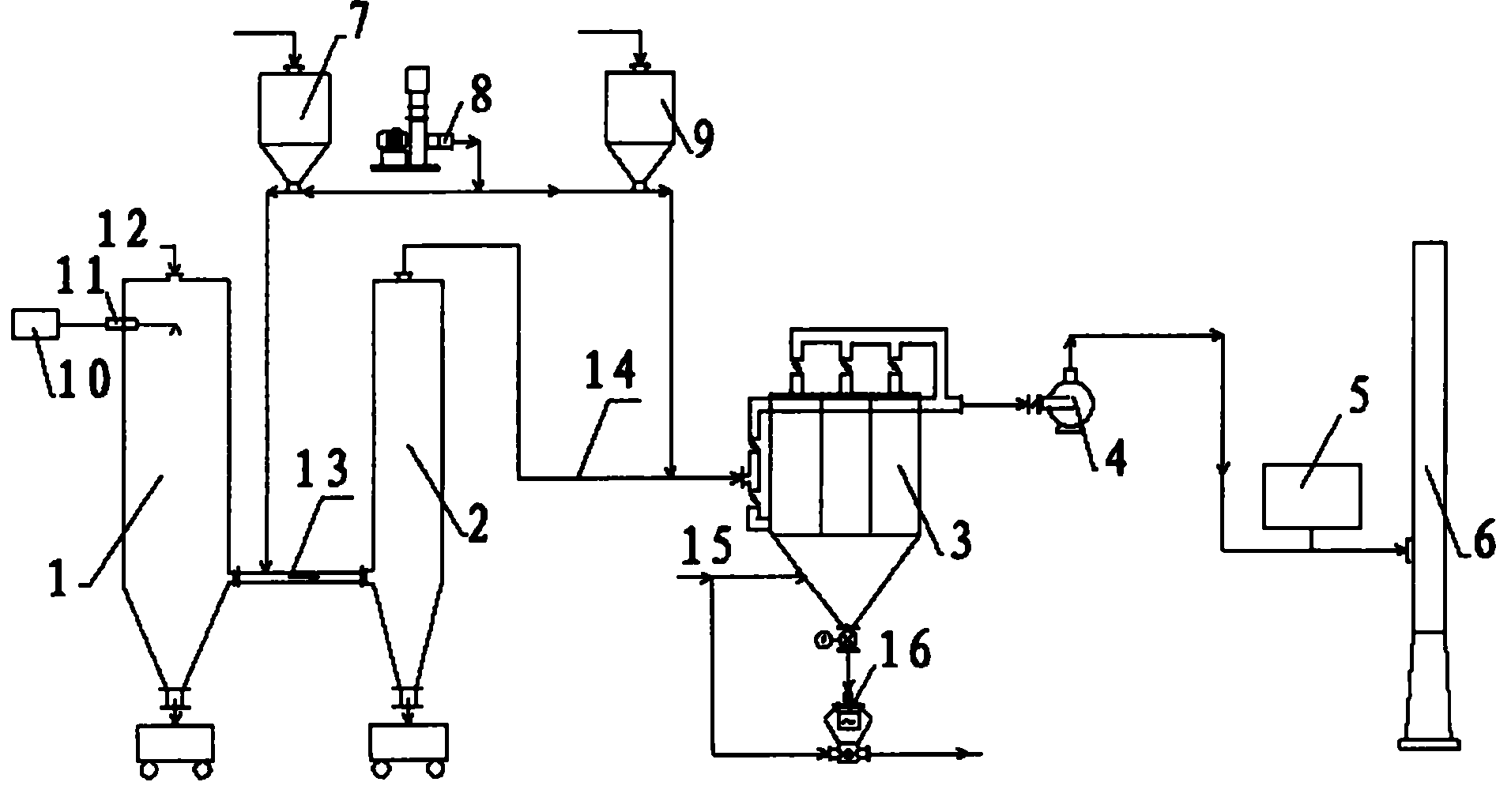

Sludge roller external heat drying and circulating fluidized bed incineration integration and tail gas cleanup device

ActiveCN106287747AReduce emission concentrationAchieve self-sufficiencySludge treatment by de-watering/drying/thickeningIncinerator apparatusAir preheaterActivated carbon

The invention discloses a sludge roller external heat drying and circulating fluidized bed incineration integration and tail gas cleanup device, and belongs to the technical field of sludge incineration treatment. The problem existing in an existing sludge drying and incineration technology is solved. The device comprises a circulating fluidized bed, a drying system and a tail gas cleanup system. The drying system comprises a rotary kiln roller, a fan and a condenser. The rotary kiln roller is inserted into a tail flue of the circulating fluidized bed in a penetrating mode. After water vapor and bed smell generated in the sludge drying process are condensed and water is removed, the water vapor and bed smell are supplied to a hearth of the circulating fluidized bed to be combusted for deodorization; two air preheaters are arranged inside the tail flue and connected with a primary tuyere and a secondary tuyere arranged in the hearth of the circulating fluidized bed respectively. The tail gas cleanup system comprises an activated carbon injection device, a cloth bag dust remover and a wet desulphurization system which are sequentially arranged behind the air preheaters. A gas conveying pipe is arranged between the cloth bag dust remover and the wet desulphurization system to be connected with the primary tuyere. The device is used for sludge drying and incineration.

Owner:HARBIN INST OF TECH

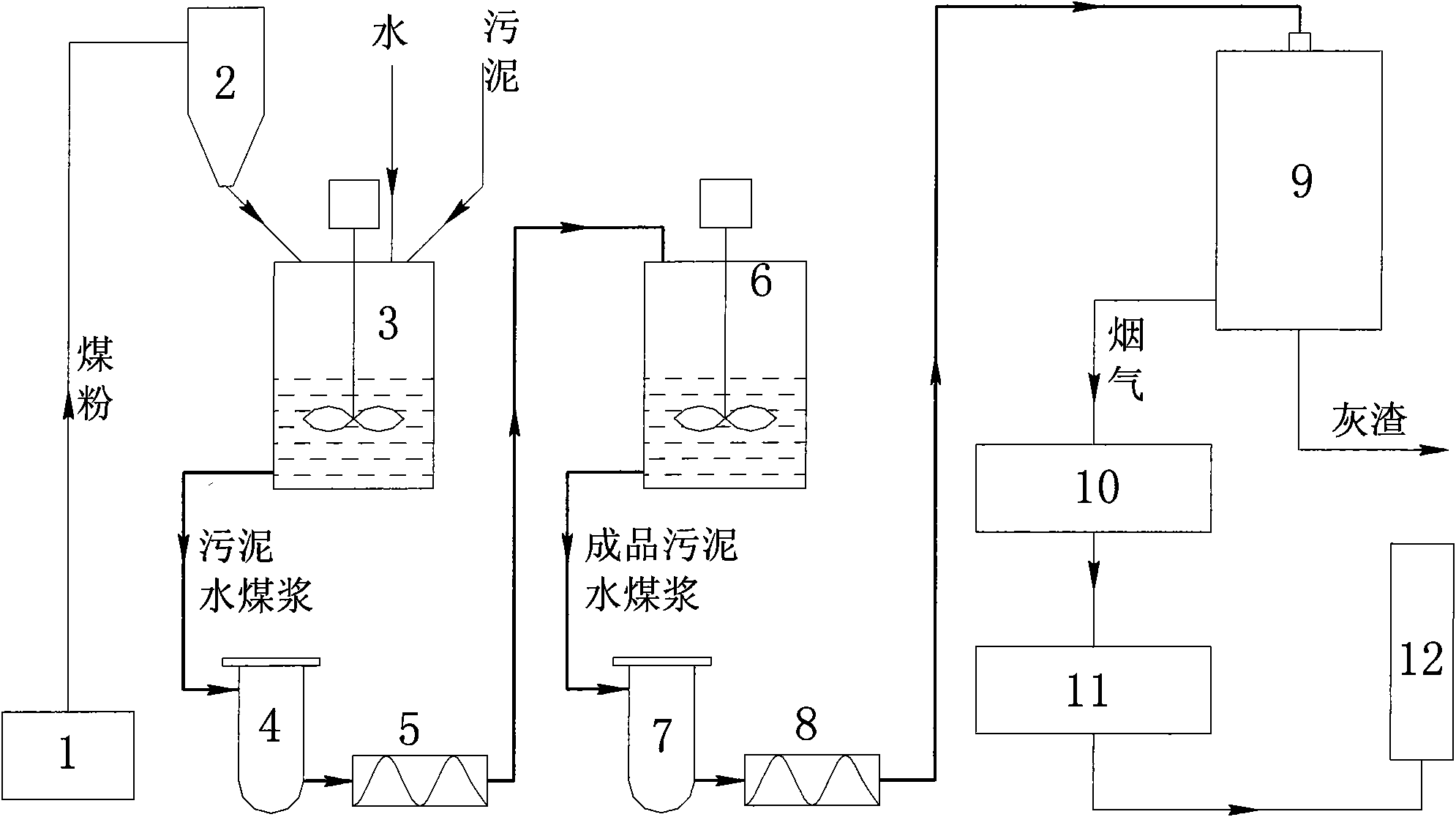

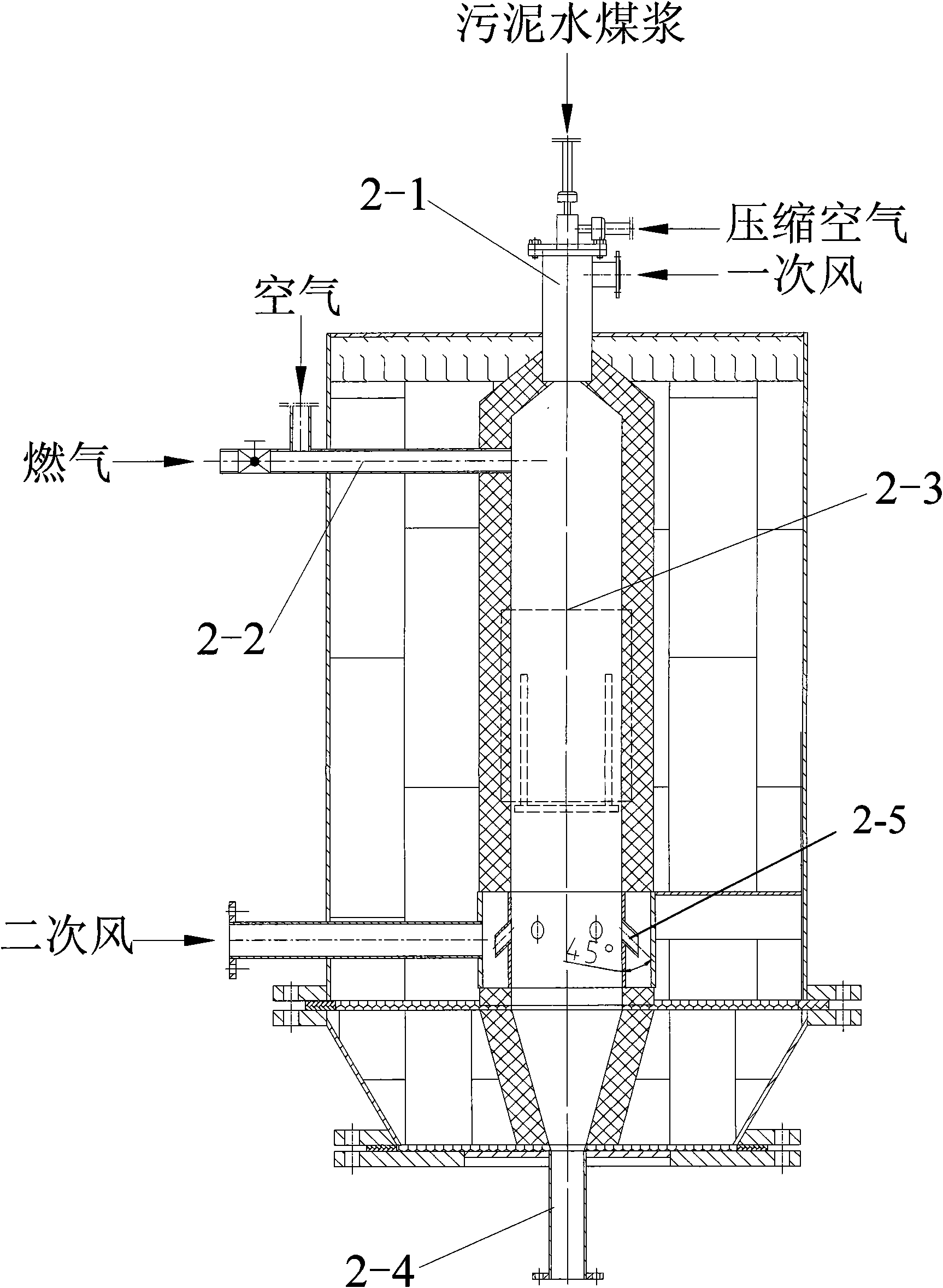

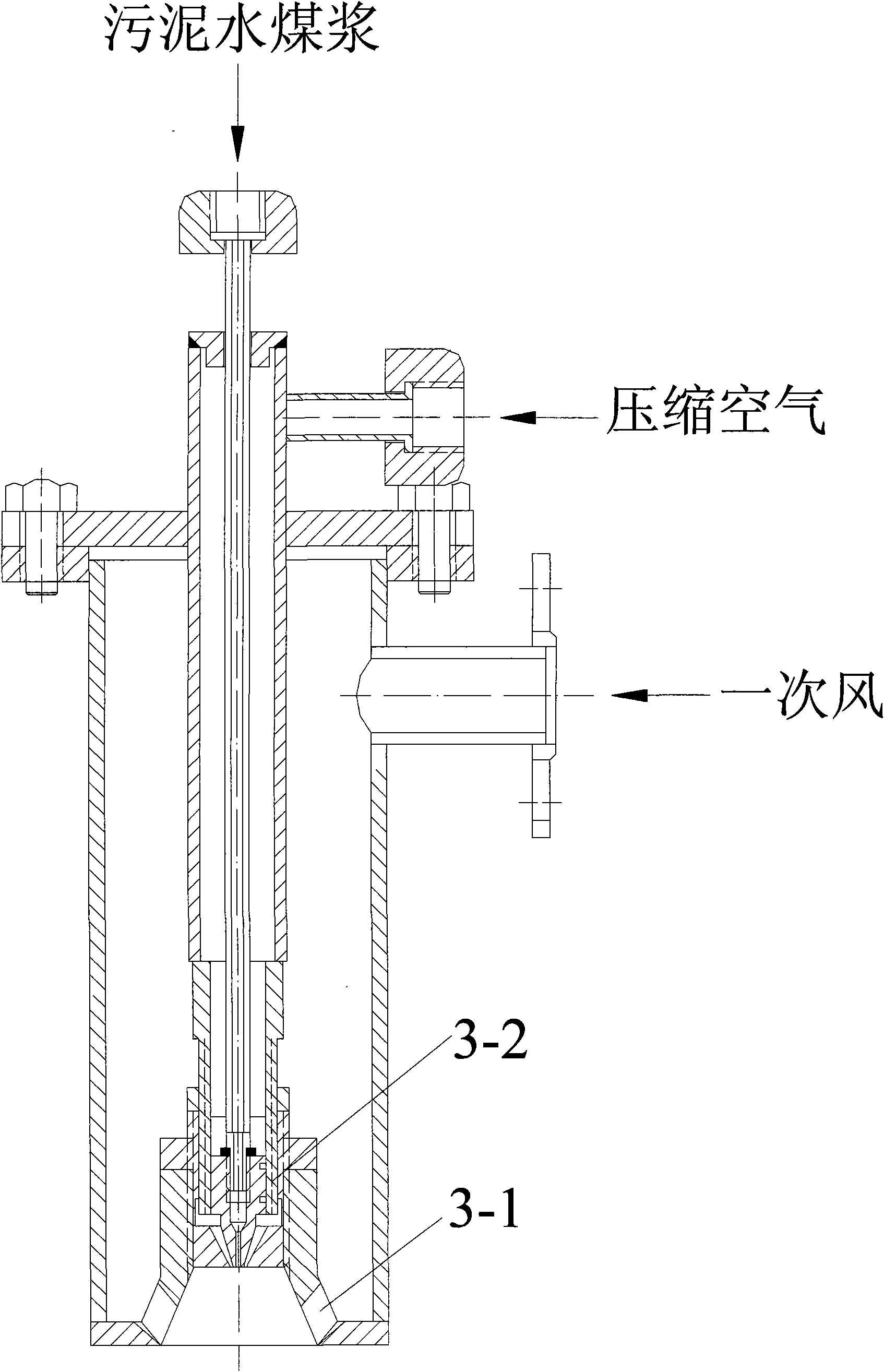

Incineration treatment method of municipal sludge and device thereof

InactiveCN101551108AReduce collectionSave storageIncinerator apparatusCombustion chamberAtmospheric air

The invention relates to an incineration treatment method of municipal sludge and a device thereof. The method comprises the steps of directly mixing powdered coal with average particle diameter of 75 to 90 micrometers, municipal sludge with water content of 95 wt percent and water according to the mass ratio of 60:25:15, then stirring for two times and filtering to manufacture finished sludge water-coal-slurry, directly adopting a screw pump for pressurizing, feeding the sludge water-coal-slurry into a sludge water-coal-slurry atomizing nozzle, and simultaneously feeding compressed air and primary air into the atomizing nozzle to ensure that the sludge water-coal-slurry is injected into a combustion chamber in a good spray pattern. Generated high-temperature flue gas is discharged into atmosphere after heat is recycled by a waste-heat boiler, and clinker is recycled. The device mainly consists of a coal grinding mill, a powder storage bin, an agitator tank, a first filter, a first screw pump, a storage tank, a second filter, a second screw pump, a combustion chamber, a waste-heat boiler and a bag-type dust collector. The disadvantages in the conventional sludge incineration method that the process is complex and the energy consumption during the sludge drying is high are overcome, and the low pollution emission of the flue gas and the comprehensive utilization of the clinker are realized.

Owner:SOUTHEAST UNIV

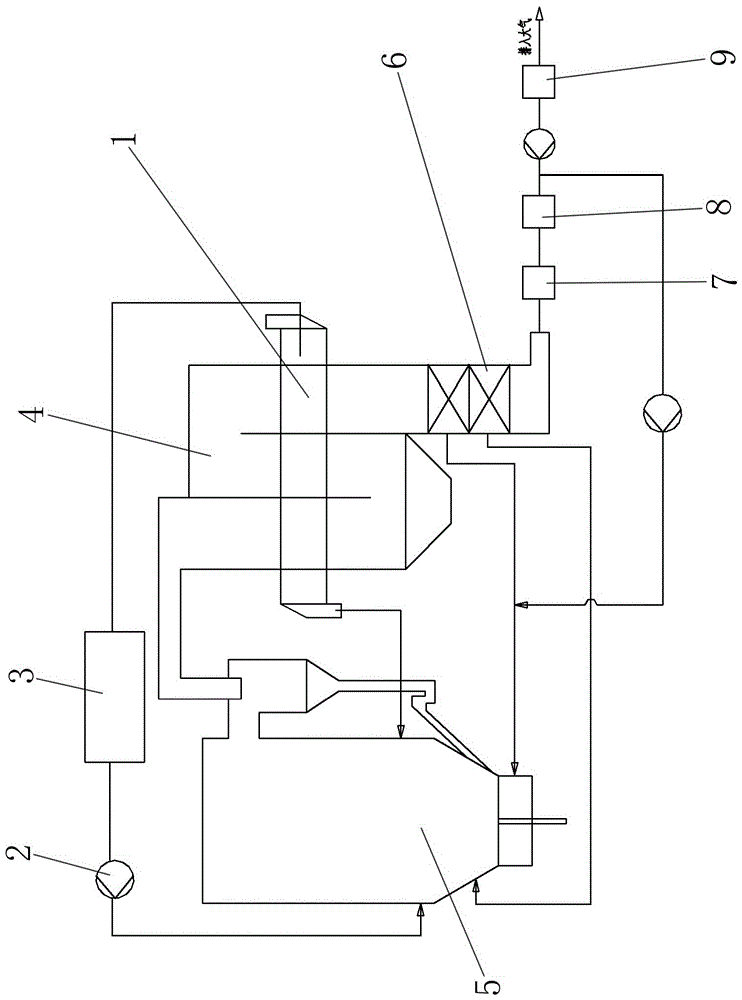

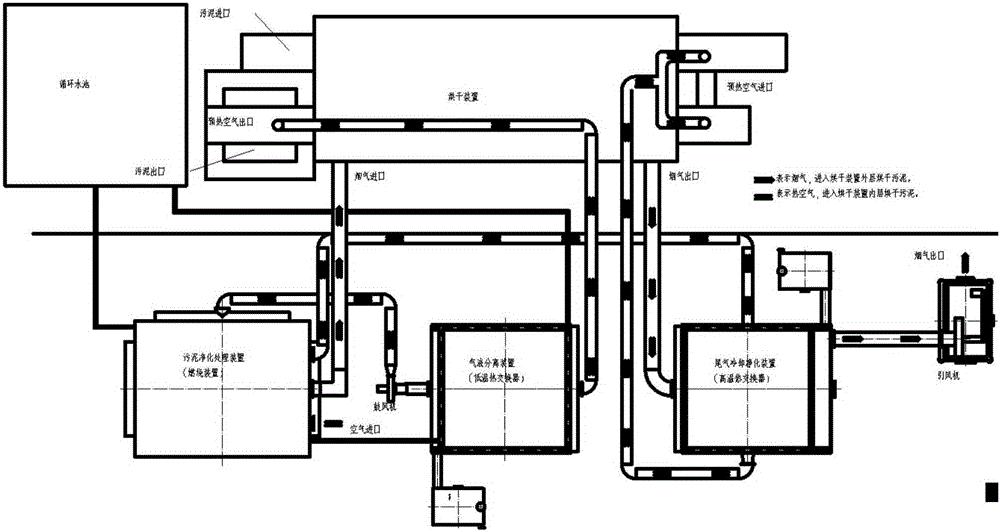

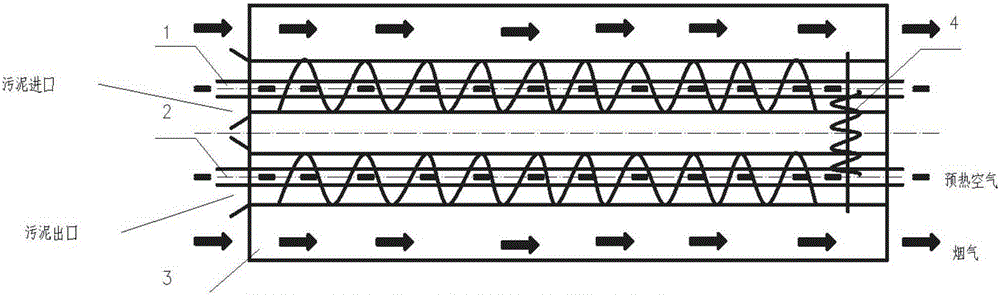

Sludge incineration treatment system

InactiveCN105198185AEmission reductionRealize harmless dischargeSludge treatment by de-watering/drying/thickeningEngineeringTreatment system

The invention relates to a sludge incineration treatment system which comprises a sludge purification treatment device, a gas-liquid separation device, a tail gas purification device, a drying device, a blower and an induced draft fan. The sludge incineration treatment system is characterized in that the drying device and the tail gas purification device respectively comprise an inner layer and an outer layer, smoke generated by the sludge purification treatment device enters the outer layer of the drying device, so as to indirectly dry sludge, and the smoke which enters the outer layer of the drying device enters the outer layer of the tail gas purification device from an outlet of the outer layer of the drying device; hot air generated by the sludge purification treatment device enters the inner layer of the tail gas purification device for preheating, preheated air enters the inner layer of the drying device from an outlet of the inner layer of the tail gas purification device, so as to directly dry the sludge, and the preheated air enters the gas-liquid separation device from an outlet of the inner layer of the drying device and is blown in the sludge purification treatment device by the blower for burning.

Owner:WEIMING BIOLOGY ENVIRONMENT TECH GRP

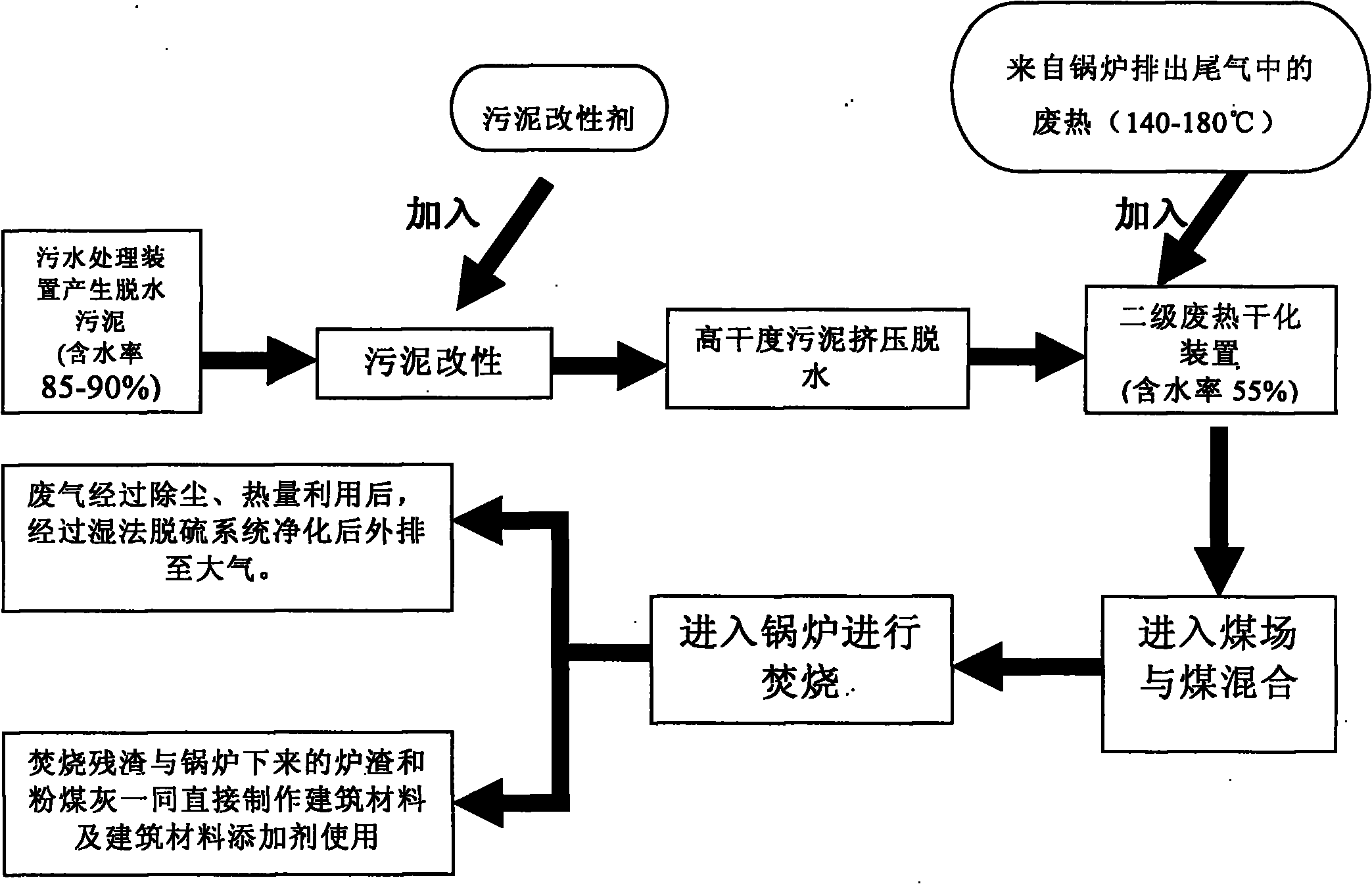

Closed machinery incineration treatment method for half-dry sludge

InactiveCN102140002AChange high viscosityChange the characteristics of high viscosity and difficult separation of mud and waterHuman health protectionSludge treatment by de-watering/drying/thickeningSlagPulverized fuel ash

The invention relates to the technical field of residual sludge treatment after sewage is treated, in particular relates to a sludge incineration treatment method. The closed machinery incineration treatment method for half-dry sludge is characterized by comprising the following steps: step 1, modifying the sludge, the adhesiveness of the sludge, the bonding force of water between the sludge and the sludge and the strength of sludge particles are reduced by utilizing a modifier; step 2, extruding the sludge for dewatering, so that the moisture content of the sludge is reduced to 75%, and the incompact particle-shaped sludge is formed; step 3, further drying the sludge by using waste heat, so that the moisture content of the sludge is reduced to 55%; step 4, mixing the sludge with the moisture content of 55% from the step 3 with coal; step 5, feeding a sludge-coal mixture obtained in the step 4 to a boiler for combustion, dedusting and desulfurizing tail gas to be used as a secondary waste heat source; and step 6, taking slag and coal ash remained by combustion in the step 5 as building materials and additives. The method is low in cost, efficient and environment-friendly.

Owner:HEFEI GUOHUI ENVIRONMENTAL PROTECTION TECH

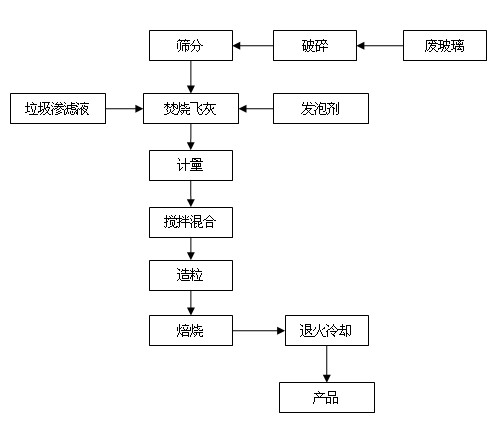

Method for preparing ceramsite by using waste incineration fly ash and waste glass

InactiveCN102643109ACause secondary pollutionEfficient curingSolid waste disposalCeramicwareFoaming agentHardness

The invention relates to a method for preparing ceramsite by using waste incineration fly ash and waste glass. The method includes the steps that waste glass is broken and ball ground to 200 meshes, and then waste incineration fly ash, rubbish leachate and a foaming agent are added according to certain proportion; and the mixture is stirred evenly, granulated and placed in a furnace to go through a pre-heating stage, a temperature rising stage and a heat preservation anneal stage to obtain the glass ceramsite. The glass ceramsite prepared through the preparation method is good in structural strength, low in water absorbing rate, large in hardness, good in chemical stability and wide in an application range. Simultaneously, dioxin pollutant in raw materials can be decomposed and damaged, heavy metal is cured in firing products, a toxic leaching standard of our country is met, and a purpose of disposing the rubbish leachate and the waste incineration fly ash is achieved simultaneously. The glass ceramsite produced through the method meets requirements of building aggregate, and the method not only turns waste into wealth, but also protects environment.

Owner:SOUTH CHINA INST OF ENVIRONMENTAL SCI MEP

Sludge incineration method

ActiveCN103256608ALow costAvoid affecting the combustion effectIncinerator apparatusBrickResource utilization

The invention relates to a sludge incineration method which comprises the following steps: incineration, secondary incineration, incinerator bottom blast, cooling, ash discharging, waste-heat utilization, desulfuration and dedusting treatment. According to the sludge incineration method, sludge burns off completely through the methods of high temperature and multiple incineration, and germs, causative agents and the like in the sludge are killed. The waste heat produced in incineration can be further used for producing steam, and the ash after incineration can be used for making building materials such as bricks and cement. Therefore, the sludge incineration method provides an effective path for follow-up resource utilization of the sludge.

Owner:杭州国泰环保科技股份有限公司

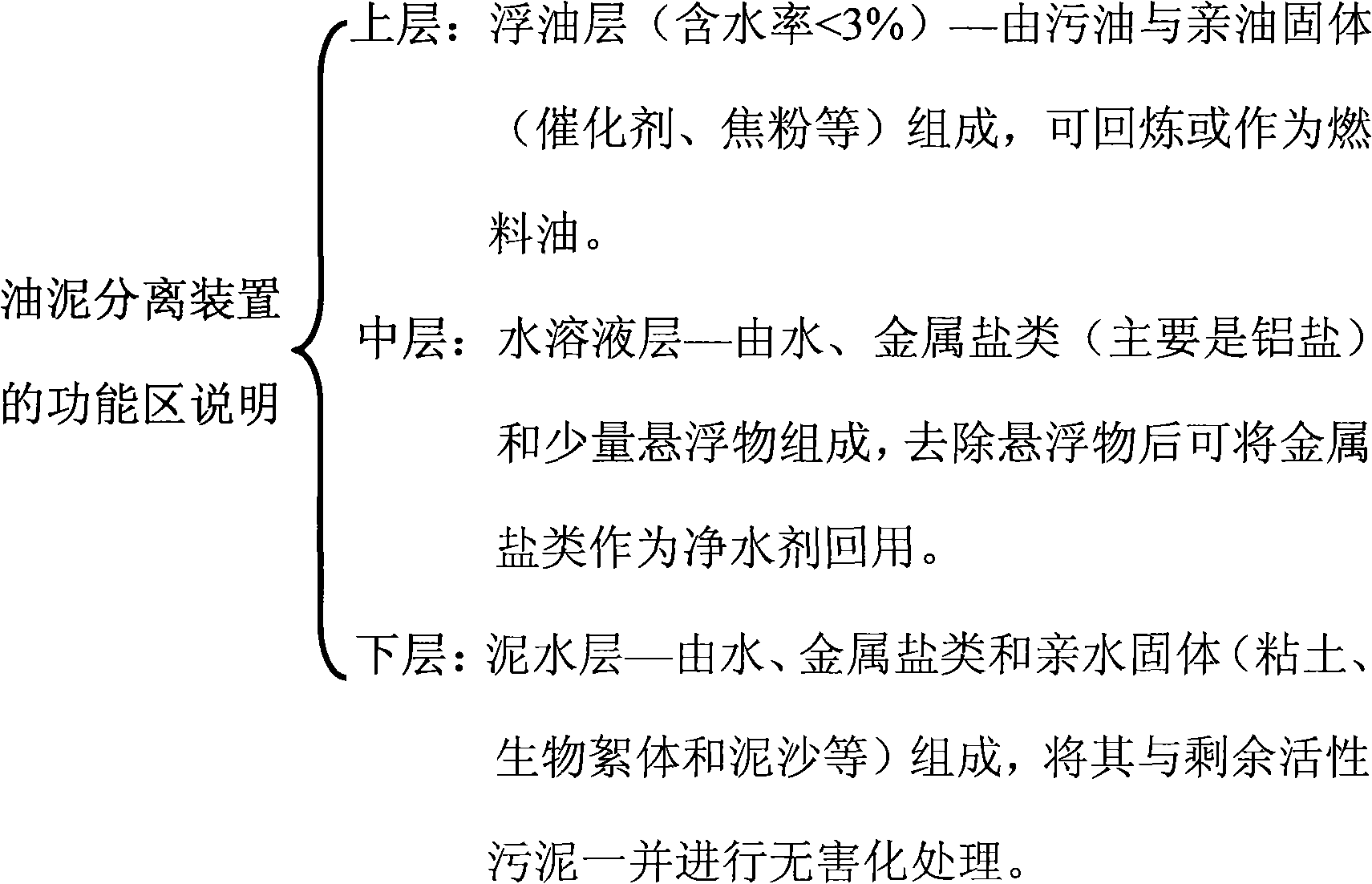

Method for innocent treatment of bottom oil sludge, scruff and active sludge in petro-chemical industry

ActiveCN101492231AControllable removalReduce pollutionWaste water treatment from quariesSludge treatment by de-watering/drying/thickeningActivated sludgeChemical industry

The invention discloses a method for harmlessly treating bottom oil sludge, floating slag and activated sludge in petrochemical industry, which comprises the following steps: performing emulsion breaking on the bottom oil sludge and the floating slag in a special oil-sludge separation device; separating oil, water and sludge of the products after the emulsion breaking in the oil-sludge separation device; and reclaiming dirty oil on the upper part, performing sedimentation on sludge-water mixture on the lower part, reclaiming a supernatant liquid, and sequentially performing treatments of coagulation conditioning, sedimentation separation, mechanical dehydration, sludge drying and sludge incineration on the sludge-water mixture on the bottom and the remaining activated sludge. The method can effectively recycle useful petroleum substances and aluminiferous compounds, effectively purify the gas generated in the processes of the storage and the treatment of the three types of sludge, and sequentially perform the treatments of sludge conditioning, dehydration, drying, and the like and then perform incineration treatment on the residual hazardous wastes after the recycling treatment. The method has the advantages of simple running, safety and reliability, complete resources recovery and controllable moisture elimination, and reduces the pollution to the environment to the utmost extent.

Owner:湖北汇丰方圆环保科技有限公司

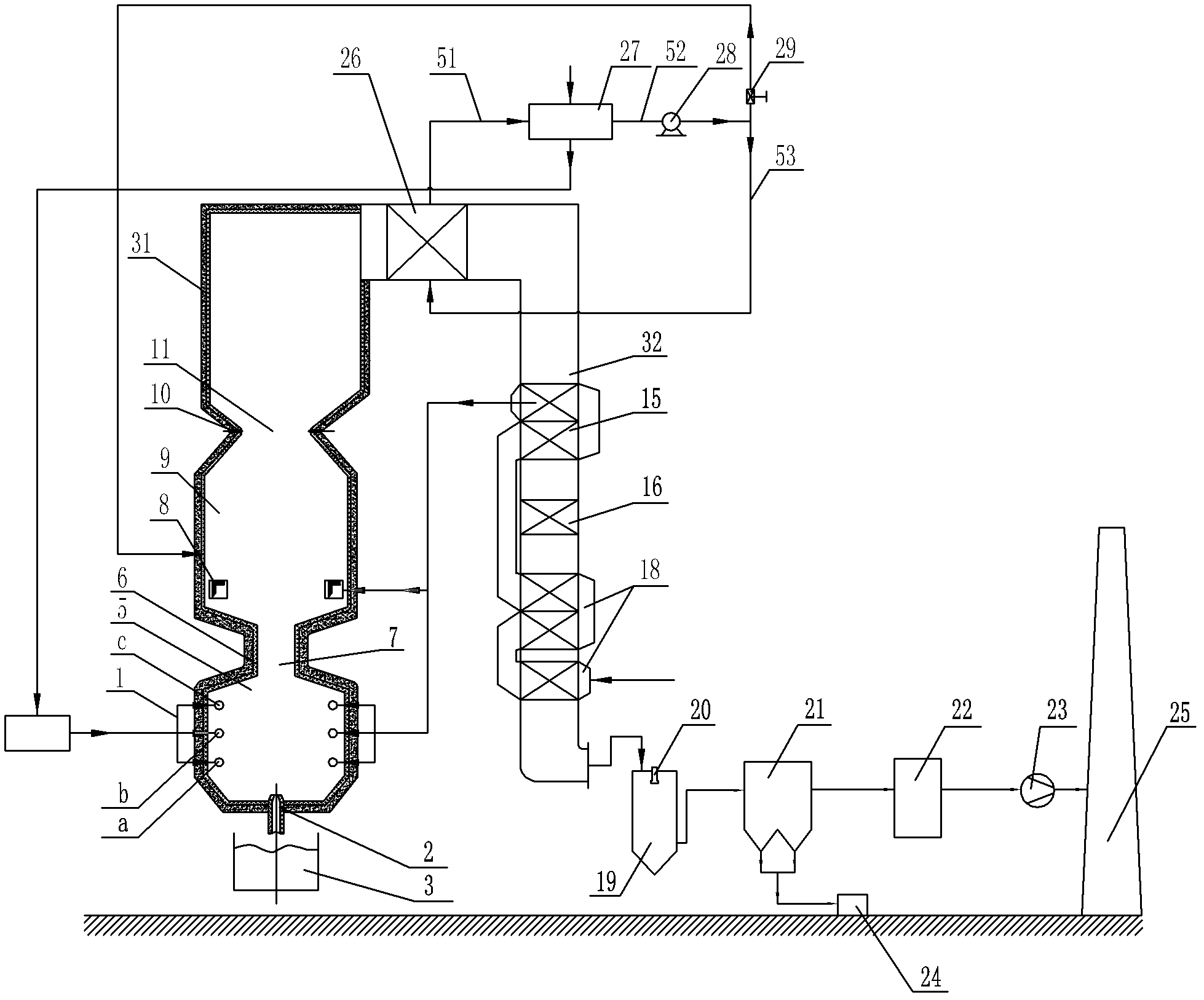

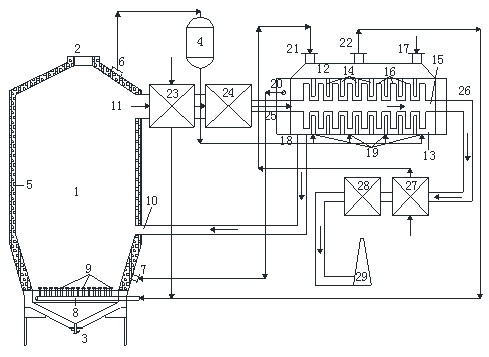

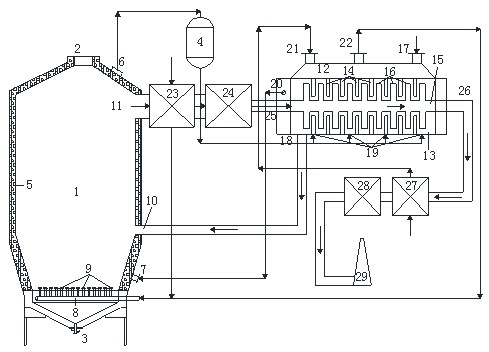

Energy self-feed type fluidized bed sludge incineration and tail gas pollution control system

ActiveCN102252331AAchieve self-sufficiencyAchieve balanceSludge treatment by de-watering/drying/thickeningIndirect carbon-dioxide mitigationAir preheaterWater vapor

The invention relates to an energy self-feed type fluidized bed sludge incineration and tail gas pollution control system. The system comprises a fluidized bed incinerator, a waste heat boiler, a sludge dryer, a separator, a spray dehydrating tower, a sewage treatment pool, an air preheater, an acid air absorption tower, a bag-type dust collector, an air blower and an induced draft fan. Wet sludge is dried in the dryer (a heat source is steam produced through combustion of dried sludge), and the dried sludge (granular) is conveyed into a fluidized bed and combusted; as the calorific value of the dried sludge is high, the normal combustion can be kept, and the heat produced through combustion is used for drying the wet sludge, so that an energy conversion process is finished. Waste air which contains water vapor and comes from the dryer is sprayed and dehydrated by a spray condensation tower and then is conveyed into a fluidized bed and is combusted. The self feed of sludge incineration energy can be realized, the waste water and waste air produced at each treatment section can be subjected to deodorization and innocent treatment, and the system has the advantages of high energy utilization rate, good treatment effect, and the like, and a small amount of pollutant is discharged.

Owner:BRIGHT THERMAL EQUIP CO LTD

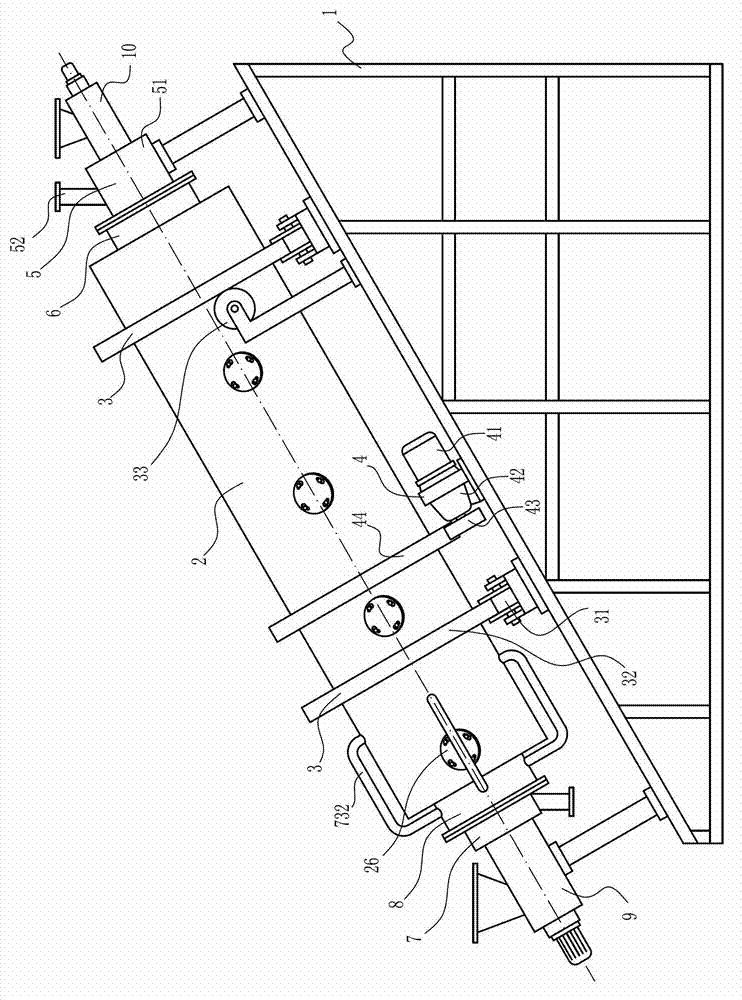

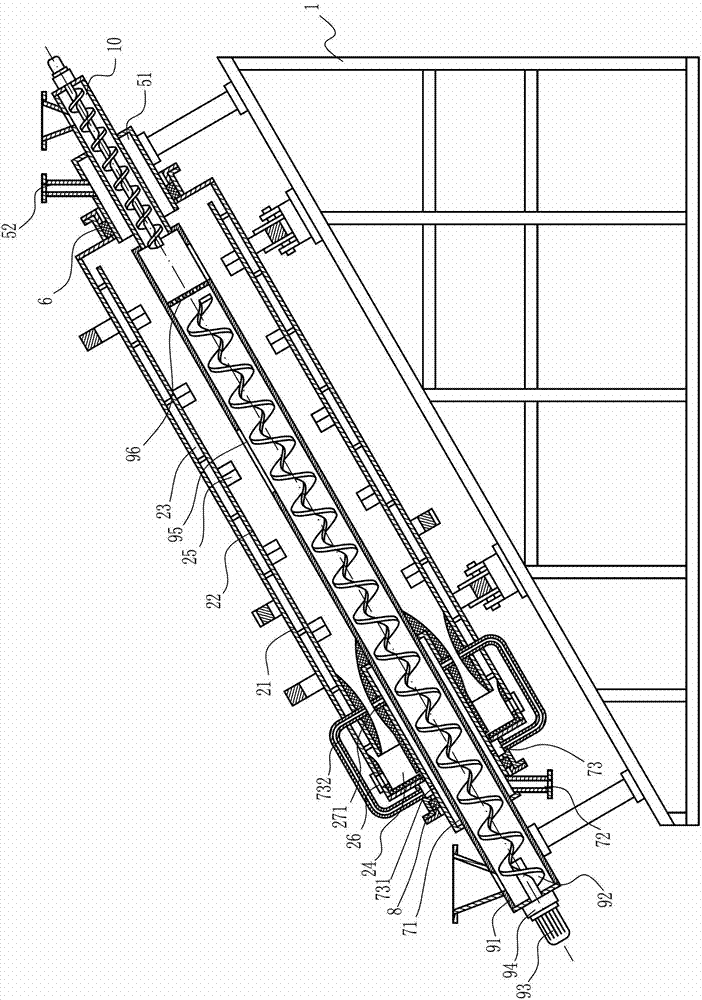

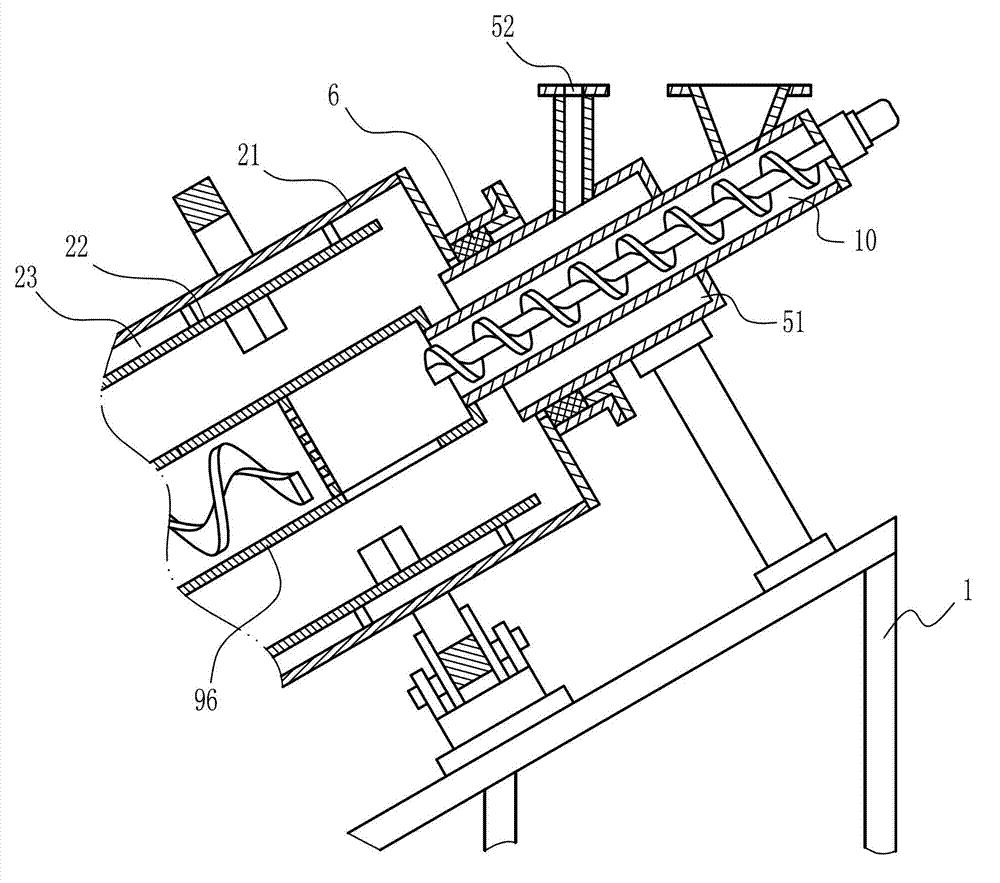

Sludge drying and incinerating integrated treatment system and process thereof

ActiveCN102635865AHarm reductionReduce energy consumptionSludge treatment by de-watering/drying/thickeningIncinerator apparatusHeat carrierEmission standard

The invention discloses a sludge drying and incinerating integrated treatment system and a process thereof. A sludge incinerator is formed by externally laying a fire resistant material on a membrane wall; through the high-temperature smoke generated by sludge incineration, a part of heat is transferred to the membrane wall to generate steam which serves as a heat source together with the discharged smoke so as to dry the sludge; a sludge drying unit mainly consist of a hollow rotation shaft, a rotatable blade which is arranged on the shaft, a hollow outer wall and a fixed blade which is arranged on the hollow outer water; smoke and steam are used together for heat exchange; the hollow rotation shaft is arranged on a sludge incineration smoke pipe, serves as a part of the smoke pipe and asmoke heat source flows in the hollow rotation shaft; a steam heat source flows in the hollow outer wall; and after transferring heat to the sludge, the smoke heat source is treated to reach the emission standard and then is emitted. According to the sludge drying and incinerating integrated treatment system and the process thereof, the sludge drying and incinerating processes are closely integrated, the energies of various heat carriers in the sludge drying and incinerating processes are fully utilized, the system energy consumption is greatly reduced and good economical efficiency is provided.

Owner:ZHEJIANG UNIV

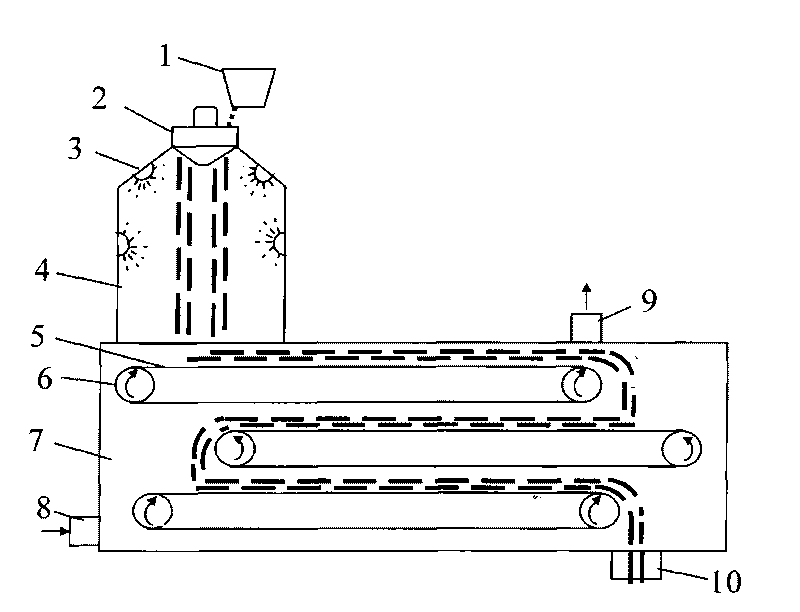

Sludge drying processing method and equipment

InactiveCN101708944AReduce drying costsHigh porositySludge treatment by de-watering/drying/thickeningSludge treatment by oxidationInfrared lampFilter press

The invention discloses a sludge drying processing method; firstly, the filter-pressed sludge and combustible material are mixed, the mixed sludge is extruded into sludge string by a sludge string extrusion machine at the top part of a pre-baking tank, in the dropping process of the sludge string, an infrared lamp on the inner wall of the pre-baking tank is used for shadowless irradiation, and a layer of soft shell is formed at the outer surface of the sludge string after the heat is adsorbed; the invention further discloses equipment for realizing the method; the equipment solves the problems that the traditional belt drier has short distance of the sludge strings, so as to cause caking, and the distance is long, the unit treatment capacity is low, hot air heat is hard to be utilized effectively and the drying speed is low; the equipment is particularly suitable for sludge dry treatment for sludge incineration; the invention can promote the industrialization progress of the sludge drying incineration.

Owner:TIANJIN TEDA ENVIRONMENTAL PROTECTION

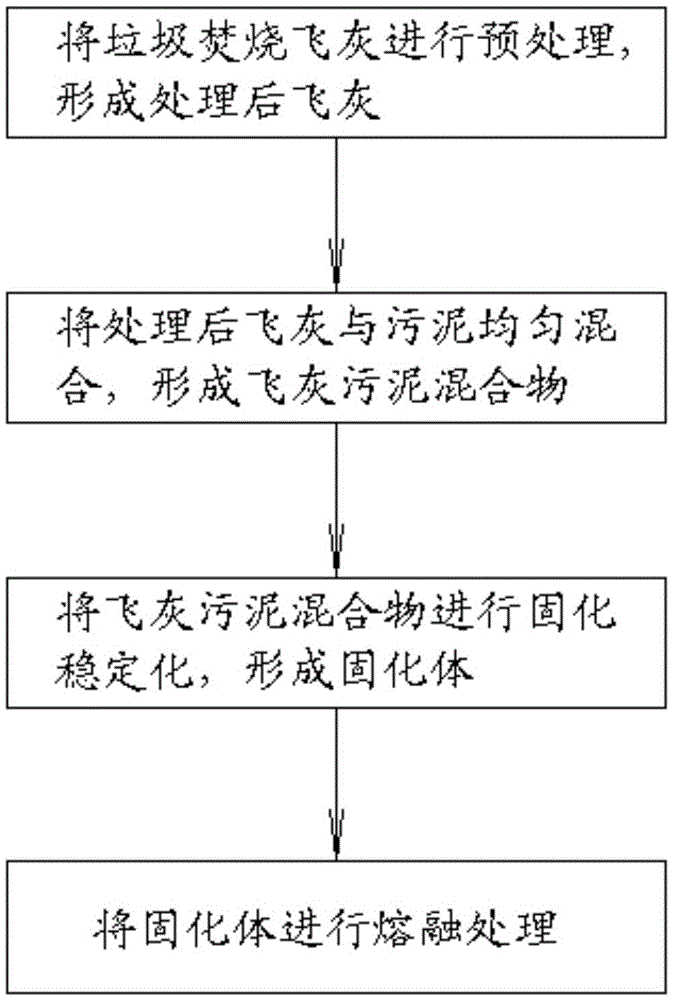

Melting treatment method for waste incineration flying ash

ActiveCN105562423AReduce volatilityPrevent volatilizationSolid waste disposalResource utilizationCaloric values

The invention relates to a melting treatment method for waste incineration flying ash, and belongs to the technical field of environmental engineering. The treatment method comprises the following steps of carrying out pretreatment on the waste incineration flying ash to form treated flying ash; uniformly mixing the treated flying ash with sludge to form a mixture of the flying ash and the sludge; carrying out solidification and stabilization on the mixture of the flying ash and the sludge to form a solidified body; and carrying out melting treatment on the solidified body. The treatment method can effectively solve the problems that the caloric value in the flying ash is relatively low, and heavy metals in the flying ash are liable to volatilize, so that pipeline blockage in a flying ash conveying process is avoided; and the melting treatment method is good in treatment effect, is low in cost, is free from secondary pollution, and is high in resource utilization.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI +1

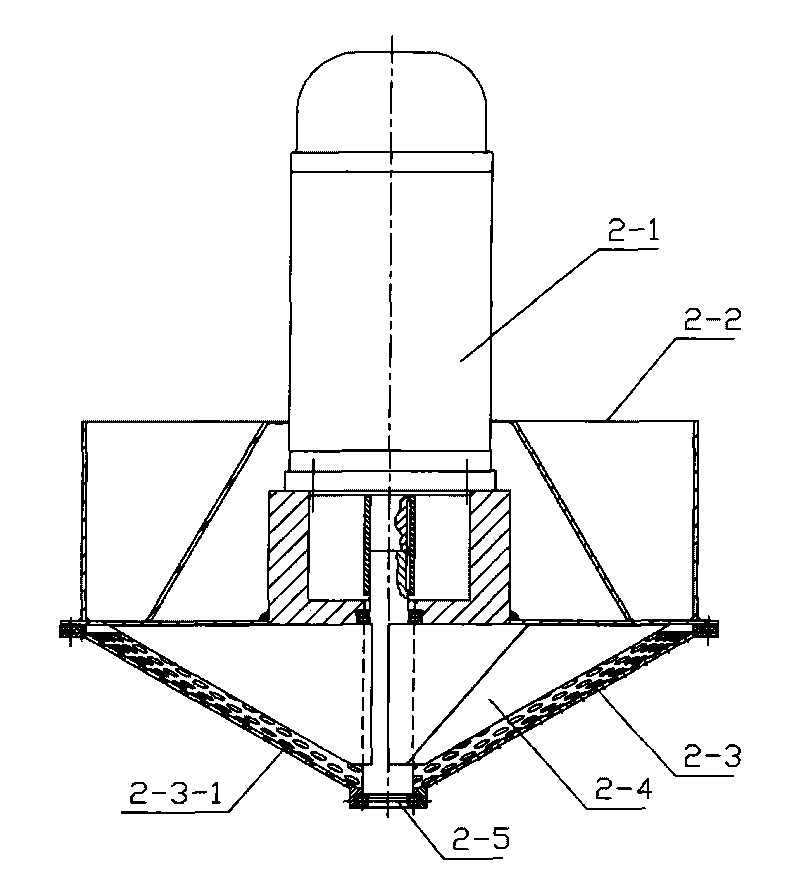

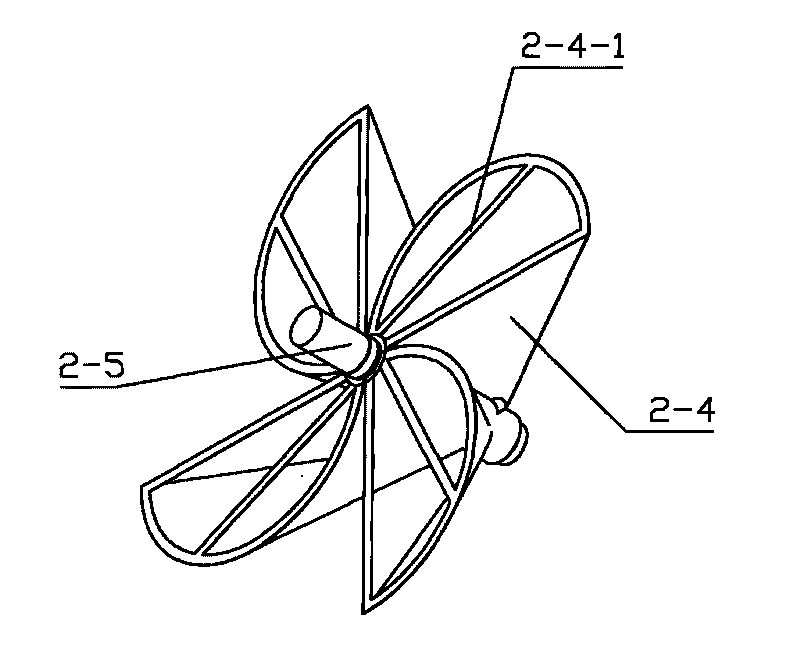

Wet sewage sludge combustion furnace

ActiveCN102889599AAchieve combustionConcentrated and dried with high efficiencyIncinerator apparatusSocial benefitsCombustion

The invention discloses a wet sewage sludge combustion furnace which comprises a machine frame, wherein the machine frame is provided with a barrel type furnace body in an inclining manner, and a riding wheel device and a furnace body revolution driving device are arranged between the barrel type furnace body and the machine frame; the machine frame is fixedly provided with a sludge granulation spiral conveyer, and a discharge end of the sludge granulation spiral conveyer stretches into the upper part of the interior of the barrel type furnace body; and the upper end of the sludge granulation spiral conveyer is provided with a steam exhausting device and a granulation discharge hole. The wet sewage sludge combustion furnace provided by the invention can concentrate the sludge in a sludge transport process, the subarid sludge is extruded and granulated through the granulation discharge hole, the sludge grains are driven by the revolving barrel type furnace body to continually roll and dry so as to move to a hearth position, and turn into flammable grains at the heart position, and the combustion of the sludgy is realized. The wet sewage sludge combustion furnace provided by the invention has the advantages that the structure is compact, the sludge concentration drying efficiency is high, an energy source is not wasted, the sludge incineration is thorough, the technical bottle neck of sludge incineration is fully solved, and the wet sewage sludge combustion furnace has great economic and social benefits and popularization and application values.

Owner:刘振亮

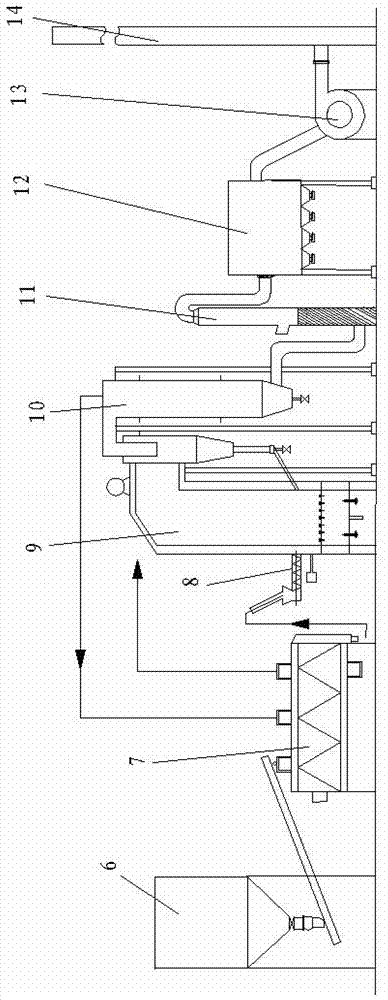

Sludge superheated vapor drying system of two-stage paddle dryer and drying process thereof

ActiveCN101565263AImprove drying efficiencyReduce consumptionSludge treatment by de-watering/drying/thickeningIncinerator apparatusCycloneBaghouse

The invention relates to a sludge superheated vapor drying system of a two-stage paddle dryer. In the system, a sludge pump is connected with a feed inlet of the primary-stage paddle dryer through a pipe, the discharge hole of the primary-stage paddle dryer is connected with the feed inlet of a secondary-stage paddle dryer, and the discharge hole of the secondary-stage paddle dryer is connected with the inlet of a sludge incineration boiler; the air outlet of the primary-stage paddle dryer is sequentially connected with a washer, a draught fan A and the sludge incineration boiler through pipes; the air outlet of the secondary-stage paddle dryer is connected with a dust collector cyclone which is connected with the air inlet of the secondary-stage paddle dryer and the air inlet of the primary-stage paddle dryer through a draught fan B respectively; and the vapor outlet of the sludge incineration boiler is connected with the air inlet of the secondary-stage paddle dryer and the tail gas outlet of the sludge incineration boiler is sequentially connected with a tail gas washer, a bag-type dust remover, a draught fan C and a chimney through pipes. The invention also discloses a sludge drying process using the system at the same time.

Owner:SHANDONG TIANLI DRYING TECH & EQUIP

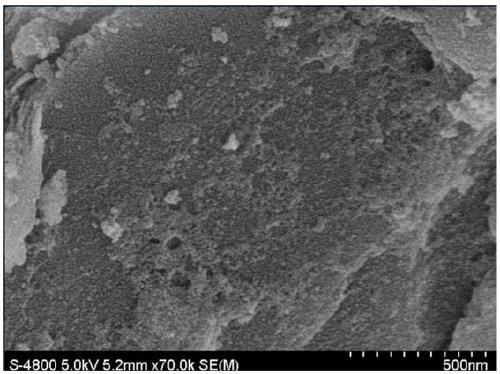

Carbon-based sludge composite regulating and dehydrating agent based on sludge incineration

ActiveCN102452781AImprove dehydration effectReduce moisture contentSludge treatment by de-watering/drying/thickeningBrown coalEngineering

The present invention discloses a carbon-based sludge composite regulating and dehydrating agent based on sludge incineration. The carbon-based sludge composite regulating and dehydrating agent comprises a carbon-based framework construct and a small amount of an assistant agent, wherein the addition amount of the carbon-based framework construct is 1-5% of the weight of the sludge, the addition amount of the assistant agent is 0.03-1.0% of the weight of the sludge, and the carbon-based framework construct is a material selected from wood chips, biological straws, brown coal and coal gangue, or a mixture comprising any materials selected from wood chips, biological straws, brown coal and coal gangue. According to the present invention, with the used carbon-based framework construct and the assistant agent, the electrostatic repulsion effect and the hydration effect between the sludge particles can be reduced; the porous granular structure of the carbon-based sludge composite regulating and dehydrating agent can absorb the partial sludge to form the penetrative and solid lattice structure, such that the permeability of the filter cake during the mechanical dehydration process is ensured, and the dehydration speed during the filtering stage and the compressing stage is improved; with the formed homogeneous framework, the water content of the compressed mud cake is uniform, and the compressed mud cake has good homogeneity; the carbon-based sludge composite regulating and dehydrating agent of the present invention has characteristics of less addition amount, good sludge filtering performance, high dehydration efficiency, high solid content of the mud cake, and the like; the components of the carbon-based sludge composite regulating and dehydrating agent comprise the carbon-based material, such that the heat value of the mud cake is improved so as to easily perform the follow-up cake incineration treatment.

Owner:UNIVERSTAR SCI & TECH SHENZHEN +1

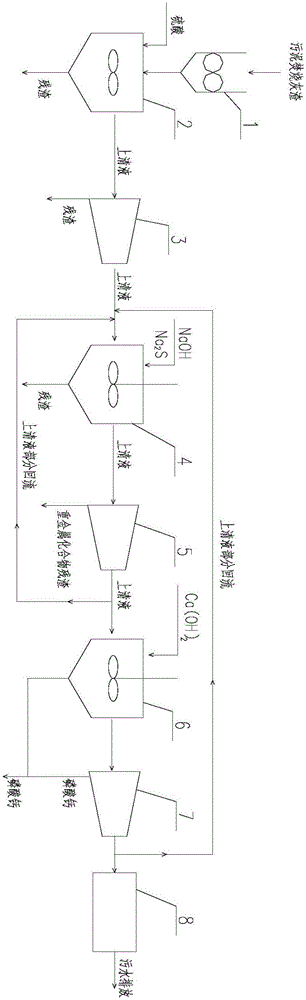

Method for recovering phosphorus and removing heavy metals from sludge separate incineration ash residues

ActiveCN106430136AReduce the scale of recycling processingReduce processingPhosphorus compoundsCalcium biphosphateDissolution

The invention relates to a method for recovering phosphorus and removing heavy metals from sludge separate incineration ash residues. The method comprises the following steps: taking sludge incineration ash residues from a sludge separate incineration plant; dissolving heavy metals and phosphorus-containing compounds in the sludge incineration ash residues into a solution by adopting a sulfuric acid dissolution method; performing solid-liquid separation on the mixed solution in a centrifugal separator, wherein residues after separation can be treated as general wastes; adding NaOH into supernatant to adjust the pH value to be 8-10; adding Na2S to form deposits with the heavy metals in the supernatant; performing centrifugal separation to achieve removal of the heavy metals; adding Ca(OH)2 into the supernatant after separation to adjust the pH value to be 10-12, wherein Ca<2+> and PO4<3-> in the solution form a calcium phosphate deposit; and performing centrifugal separation to obtain high-quality calcium phosphate, and then achieving an aim of recovering phosphorus in the solution. The method provided by the invention abandons a conventional method for extracting phosphorus from residual sludge, provides a new way of extracting phosphorus from the sludge separate incineration ash residues, and has the advantages of being high in phosphorus recovery efficiency, small in treatment scale, capable of removing heavy metals, and high in calcium phosphate quality.

Owner:张国闽

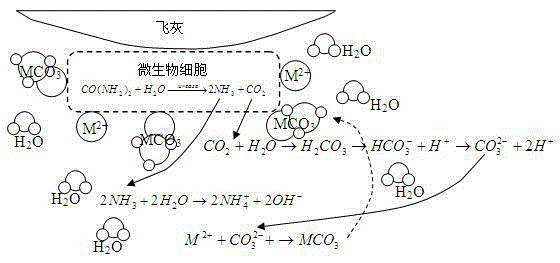

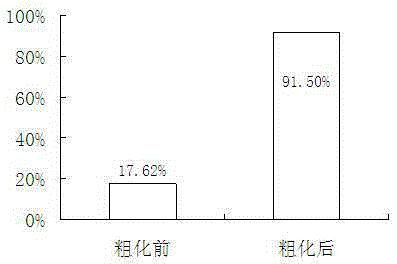

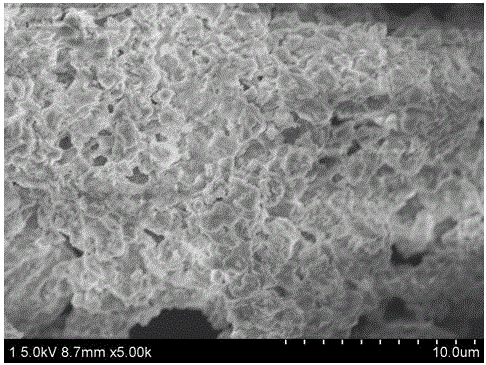

Method for achieving aggregation of waste incineration fly ash through microorganism mineralization

ActiveCN105268727AReduce leaching toxicityReduce consistencyTransportation and packagingSolid waste disposalPrillMass ratio

The invention discloses a method for achieving aggregation of waste incineration fly ash through microorganism mineralization. Peptone, meat extract and urea are placed in distilled water 200 mass folds of peptone according to the mass ratio for preparing a culture medium; after high-temperature and high-pressure sterilization, bacteria with mineralization are inoculated into the culture medium, shaking culture is carried out on a shaking table till bacterial liquid is completely turbid; the prepared bacterial liquid and the waste incineration fly ash are mixed and stirred evenly in proportion, and are horizontally laid on a corrosion-resistant plane; and a urea solution is sprayed, and aggregated waste incineration fly ash can be obtained. The characteristics that the waste incineration fly ash is rich in calcium ion and heavy metal ion and alkaline in lixivium are utilized, only the bacterial liquid of microorganisms with mineralization and the urea solution need to be added to the waste incineration fly ash, and the aggregated waste incineration fly ash can be obtained. The particle diameter of aggregated waste incineration fly ash is remarkably increased, and the mass of the aggregated waste incineration fly ash with the particle diameter large than 80 micrometers is increased to 90% to 95% from 15% to 20%.

Owner:ZHEJIANG SCI-TECH UNIV

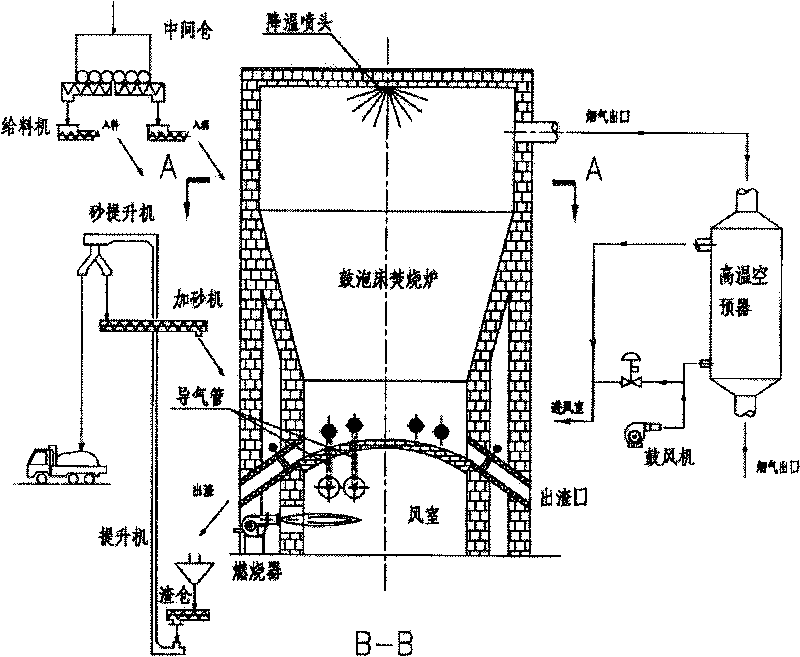

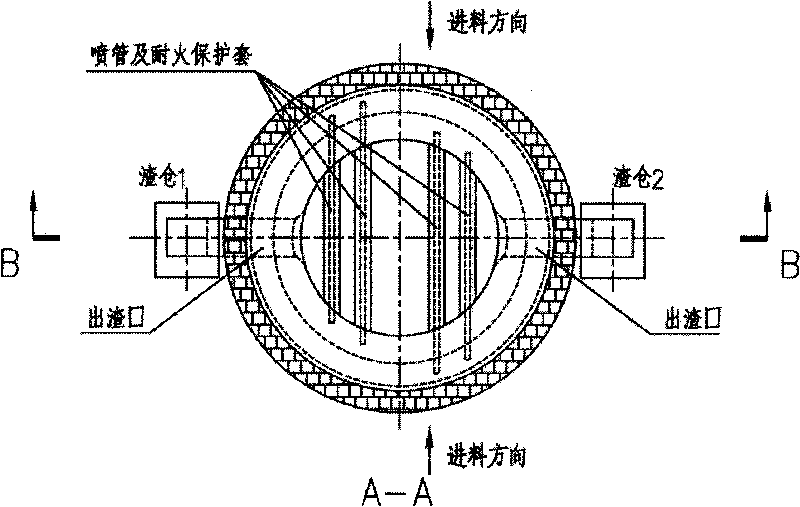

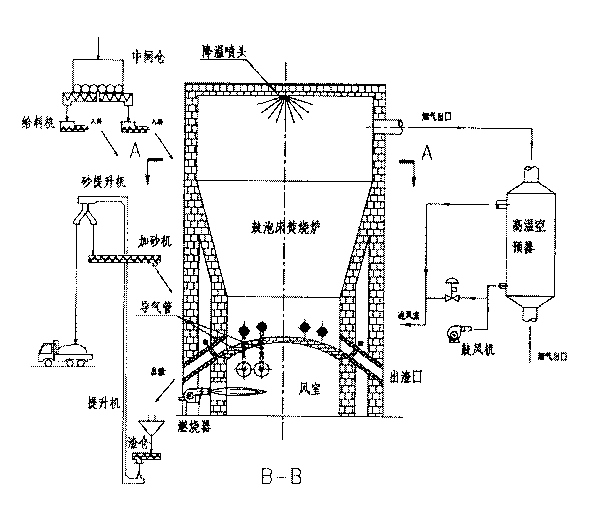

Sludge incinerator with no auxiliary fuel

InactiveCN101713543AIncineration stableMass transfer speedSludge treatment by oxidationByproduct vaporizationAir preheaterFailure rate

The invention relates to the field of environmental engineering, in particular to sludge incineration technology. The sludge incinerator with no auxiliary fuel overcomes the disadvantage that sludge incineration in the prior art requires the auxiliary fuel such as coal. The sludge incinerator with no auxiliary fuel mainly comprises a boiling section, a suspension chamber, a spray pipe, a gas-guide pipe, a support arch, a slag outlet, a cooling spray nozzle, a combustor, an air chamber and a high-temperature air pre-heater, a slag cabin, a sand hoisting machine, a sand feeder, a middle cabin and a feeding machine. The sludge incinerator with no auxiliary fuel has the following advantages that: the incinerator adopting the technology can realize stable incineration of the sludge under the condition of not adding the coal so as to achieve innocent treatment of the sludge; the sludge incinerator using the technology can store a large amount of heat inside, and a bed has a uniform reaction temperature, so that partial overheat phenomenon is prevented and the temperature in the bed is easy to be controlled; the sludge incinerator is also safe for treating sludge containing a lot of volatile substances (such as oil-containing sludge); a fluidized bed has a simple structure, a low failure rate and a low construction cost, and is provided with a mechanical transmission component; the sludge incinerator can lower the coefficient of excess air and can reduce power consumption; the sludge incinerator has wide fuel adaptability so as to realize controlling harmful gases, such as SO2, NOx and the like easily and to obtain higher combustion efficiency; and ash produced by sludge incineration has a plurality of applications.

Owner:刘沪滨

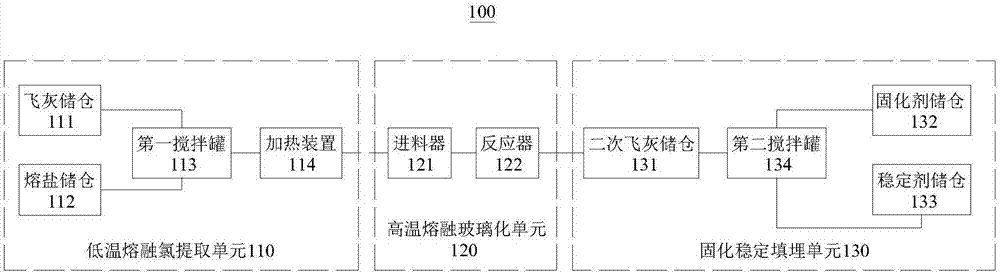

Waste incineration fly ash treatment and recycling method and device

InactiveCN107999520AAchieve permanent cureHigh degree of harmlessnessSolid waste disposalTransportation and packagingWaste treatmentHazardous waste treatment

The invention relates to the field of hazardous waste treatment and recycling, in particular to a waste incineration fly ash treatment and recycling method and device. According to the waste incineration fly ash treatment and recycling method, waste incineration fly ash is mixed with fused salt, and low-temperature fusing is conducted for 20-120 min in the environment at the temperature of 400-900DEG C; lower-layer solid products are mixed with a mineral auxiliary material, high-temperature fusing is conducted in the environment at the temperature of 1000-5000 DEG C, and then a vitrified formis obtained. By the adoption of the waste incineration fly ash treatment and recycling method, permanent solidification of heavy metal is achieved, recycling is also achieved, and good market prospect and application value are achieved. A low-temperature fusion chlorine extracting unit of the waste incineration fly ash treatment and recycling device comprises a flying ash storage bin, a fused salt storage bin, a first stirring tank, a heating device, a fused salt storage bin and a flying ash storage bin are connected with a first stirring tank. The first stirring tank is connected with a heating device. A high-temperature fusion vitrification unit comprises a feeding device and a reactor, wherein the feeding device is connected with the reactor. According to the waste incineration fly ashtreatment and recycling method and device, equipment is easy and convenient to use, and popularization is easy.

Owner:CHINA CITY ENVIRONMENT PROTECTION ENGINEERING LIMITED COMPANY

Treatment method of oil-containing sludge

InactiveCN108314290AHigh surface tension reduction abilityStrong flocculationDewatering/demulsification with chemical meansSludge treatment by de-watering/drying/thickeningAlkylphenolOil sludge

The invention discloses a treatment method of oil-containing sludge and belongs to the field of environmental engineering. The treatment method comprises the following steps of: introducing the oil-containing sludge into a separating groove, discharging into a deemulsifying groove for deemulsification after initially separating, and carrying out oil-water-sludge separation on deemulsified productsin an oil-sludge separating device; recovering dirt oil at the upper part, settling sludge-water mixture at the lower part, recovering clear liquor, and carrying out coagulation treatment, settling separation, mechanical dewatering, sludge drying and sludge incineration treatment in sequence on the sludge-water mixture at the bottom part and residual active sludge. Composite deemulsifying agentspreferred by the invention include a polyethylene polyamine blocked polyether deemulsifying agent, a silicon-containing deemulsifying agent, a phenolic-resin deemulsifying agent, an alkylphenol polyoxyethylene ether deemulsifying agent, a polyphosphoester deemulsifying agent or a polyaluminium-chloride deemulsifying agent. The deemulsifying method disclosed by the invention has the beneficial effects that the safe and environment-friendly effects are achieved, the water content of oil sludge can be reduced, most crude oil in the oil sludge can be recovered, and the difficulty of the followingtreatment of the sludge can be reduced.

Owner:YANGZHOU DAYANG WATER SUPPLY EQUIP

Bubbling bed sludge incineration boiler and sludge incineration method

ActiveCN102235677AImprove efficiencyGuaranteed afterburnIncinerator apparatusAir preheaterCombustion

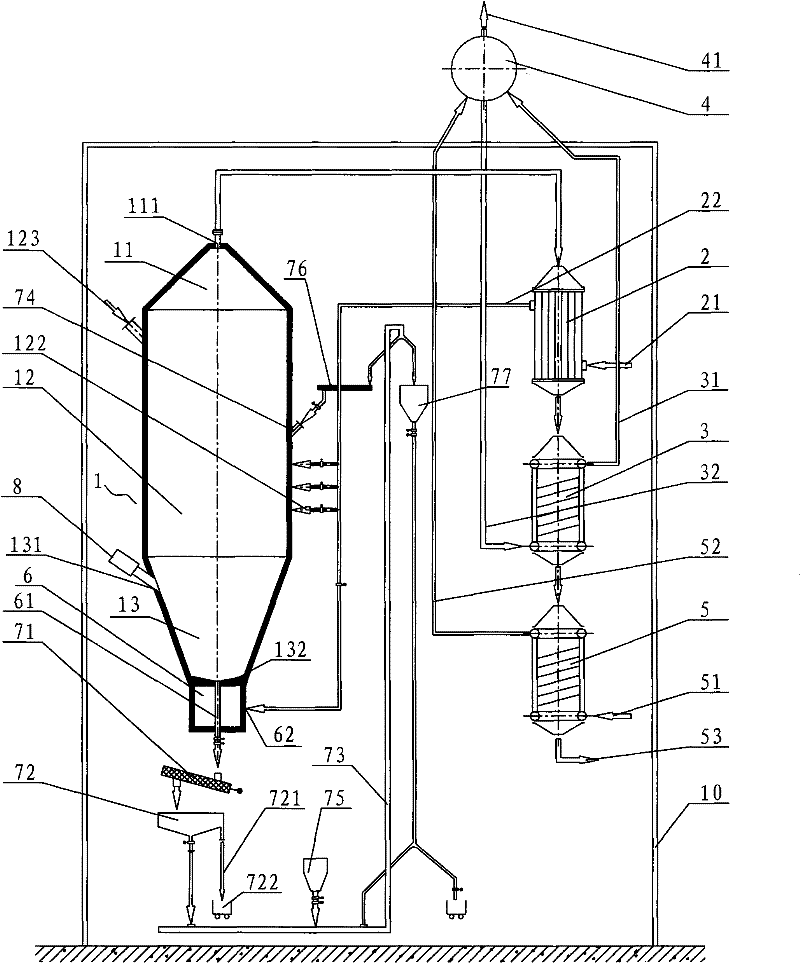

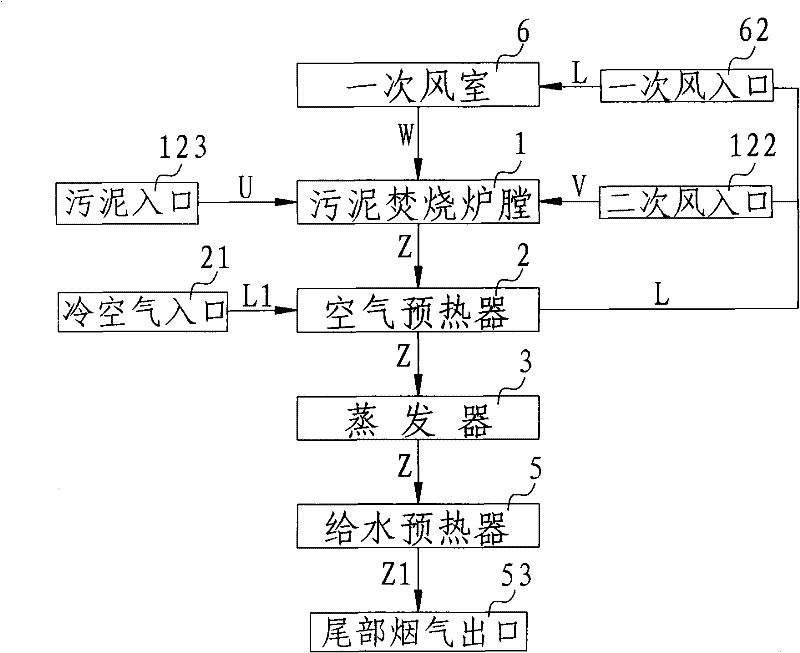

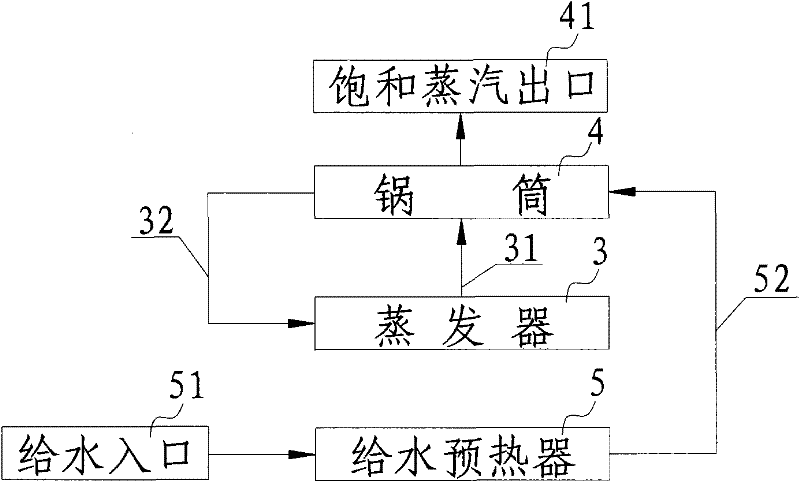

The invention relates to a bubbling bed sludge incineration boiler and a sludge incineration method. The bubbling bed sludge incineration boiler comprises a steel framework, and a sludge incineration hearth, an air preheater, an evaporator, a feed water preheater, a primary air chamber and a boiler barrel which are arranged on the steel framework, wherein the primary air chamber is connected withthe lower port of the sludge incineration hearth; the sludge incineration hearth is a heat-insulating hearth, so that heat generated by sludge incineration is completely used for drying sludge; the air preheater is communicated with a flue gas outlet and a secondary air inlet of the hearth and the primary air chamber through a pipeline respectively, and is used for generating high-temperature airto supplement heat required by drying the sludge and providing oxygen required by ignition and preliminary combustion; the evaporator is connected with the air preheater; the feed water preheater is connected with the evaporator; and the evaporator and the feed water preheater are connected with the boiler barrel respectively to generate saturated steam for drying the sludge.

Owner:烟台鑫丰源电站设备有限公司

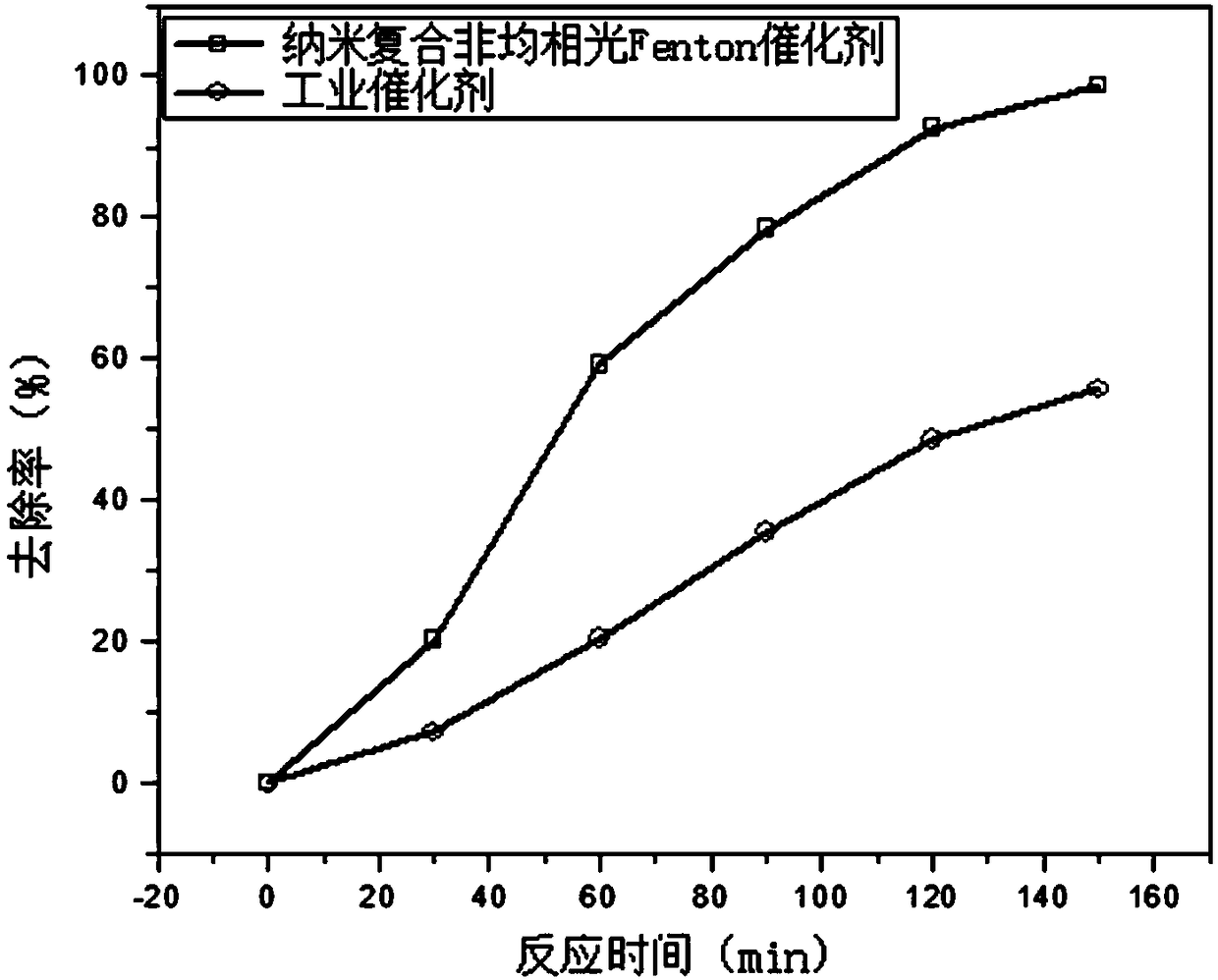

Nanocomposite heterogeneous photo-Fenton catalyst and preparation method and application thereof

ActiveCN108993518AWide range of sourcesWide range of sources and cheapWater/sewage treatment by irradiationWater contaminantsHigh concentrationActive component

The invention provides a nanocomposite heterogeneous photo-Fenton catalyst and a preparation method and application thereof. The catalyst is composed of a carrier and a catalytically active componentimmobilized in the carrier. The carrier comprises sludge incineration residues. The catalytically active component comprises nanocomposite metals. The nanocomposite metals comprise two or three of Fe2O3, MnO2, Ag2O, In2O3, Bi2O3, SrO and V2O5. The nanocomposite heterogeneous photo-Fenton catalyst has the advantages of high activity, low active component load, mature technology, good stability andlow cost in photocatalytic oxidation. The catalyst carrier has a large surface area and strong adsorption properties. The loaded active component does not easily fall off. The method has a TOC removalrate of 95% or more in high concentration and refractory organic wastewater. The nanocomposite heterogeneous photo-Fenton catalyst has high catalytic performances and a stable structure, and is conducive to promotion in the photocatalytic oxidation industry.

Owner:NANJING UNIV OF TECH

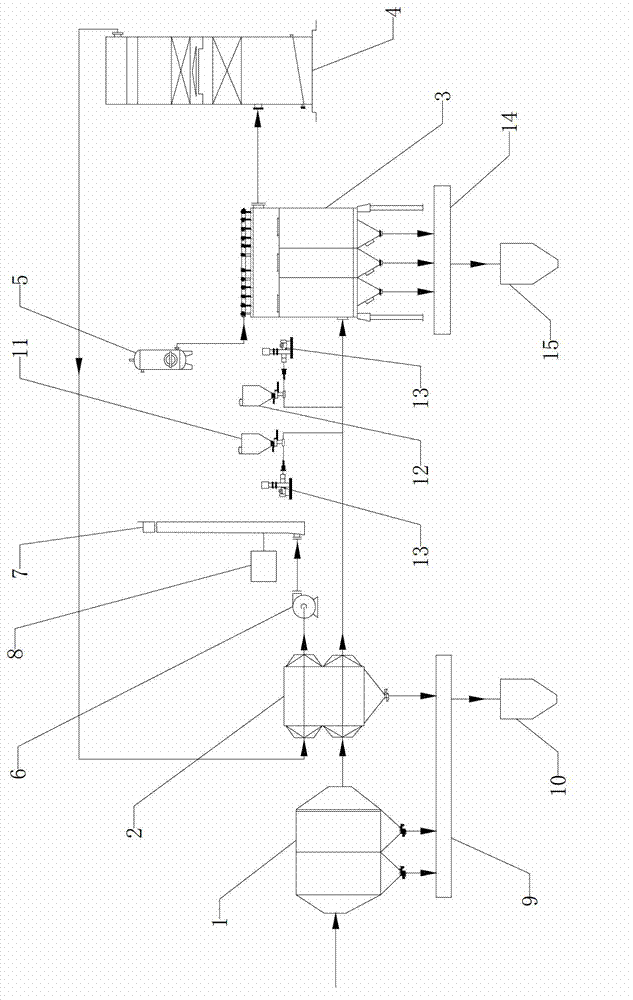

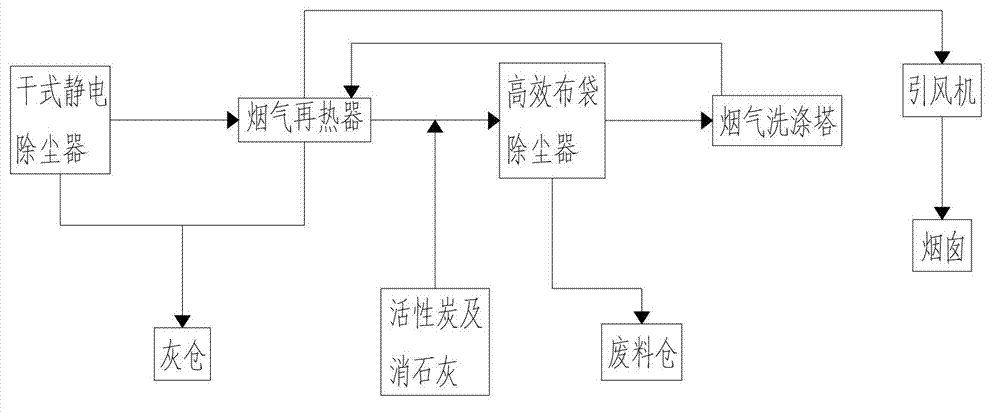

Complete equipment and method for wet processing of sludge incineration offgas

InactiveCN102824837AAvoid Expensive Processing CostsImprove dust removal effectCombination devicesGas heaterBaghouse

The invention relates to complete equipment and a method for wet processing of sludge incineration offgas. The complete equipment comprises a dry electrostatic cleaner, a flue gas reheater, a bag-type dust collector and a flue gas washing tower, wherein one end of the dry electrostatic cleaner is connected with a sludge incineration offgas pipe, and the other end of the dry electrostatic cleaner is connected with the flue gas reheater through a pipe; the bag-type dust collector is connected with the right side wall, which is close to the bottom end, of the flue gas reheater through the pipe; the top of the bag-type dust collector is connected with a compressed air tank through the pipe; the flue gas washing tower is connected with the right side wall, which is close to the top, of the bag-type dust collector through the pipe; the flue gas reheater is connected with the right side wall, which is close to the top, of the flue gas washing tower through the pipe; an induced draft fan is connected with the right side wall, which is close to the top end of the flue gas reheater, of the gas heater through the pipe; and an online monitoring system is arranged on the side wall of a chimney. The complete equipment realizes equipment localization, and the automation and intellectualization of sludge offgas cleanup process control are realized.

Owner:BMEI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com