Complete set of device and method for treating tail gas from sludge incineration through semidry method

A technology of sludge incineration and semi-dry method, which is applied in separation methods, chemical instruments and methods, and separation of dispersed particles. The effect of emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

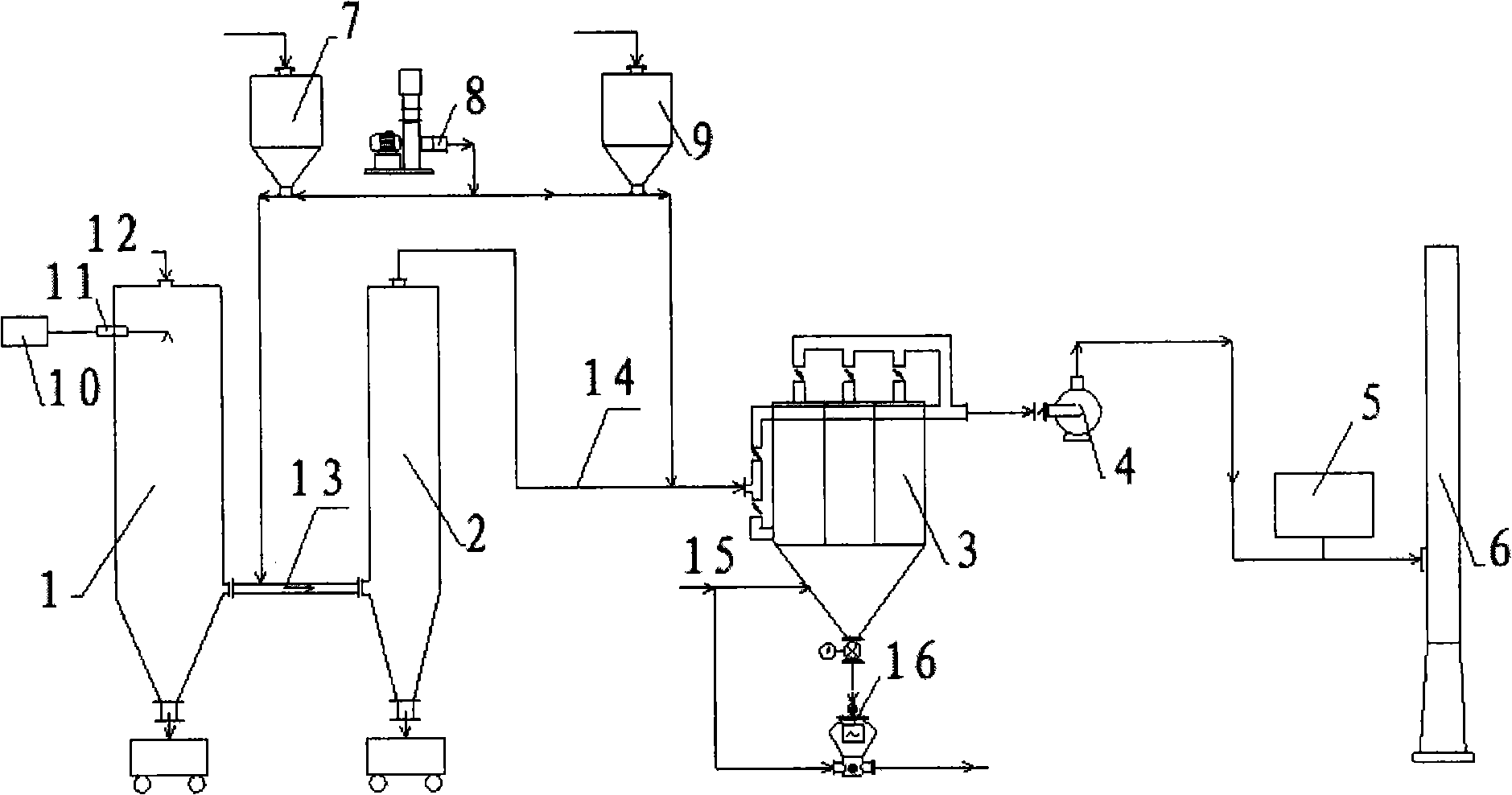

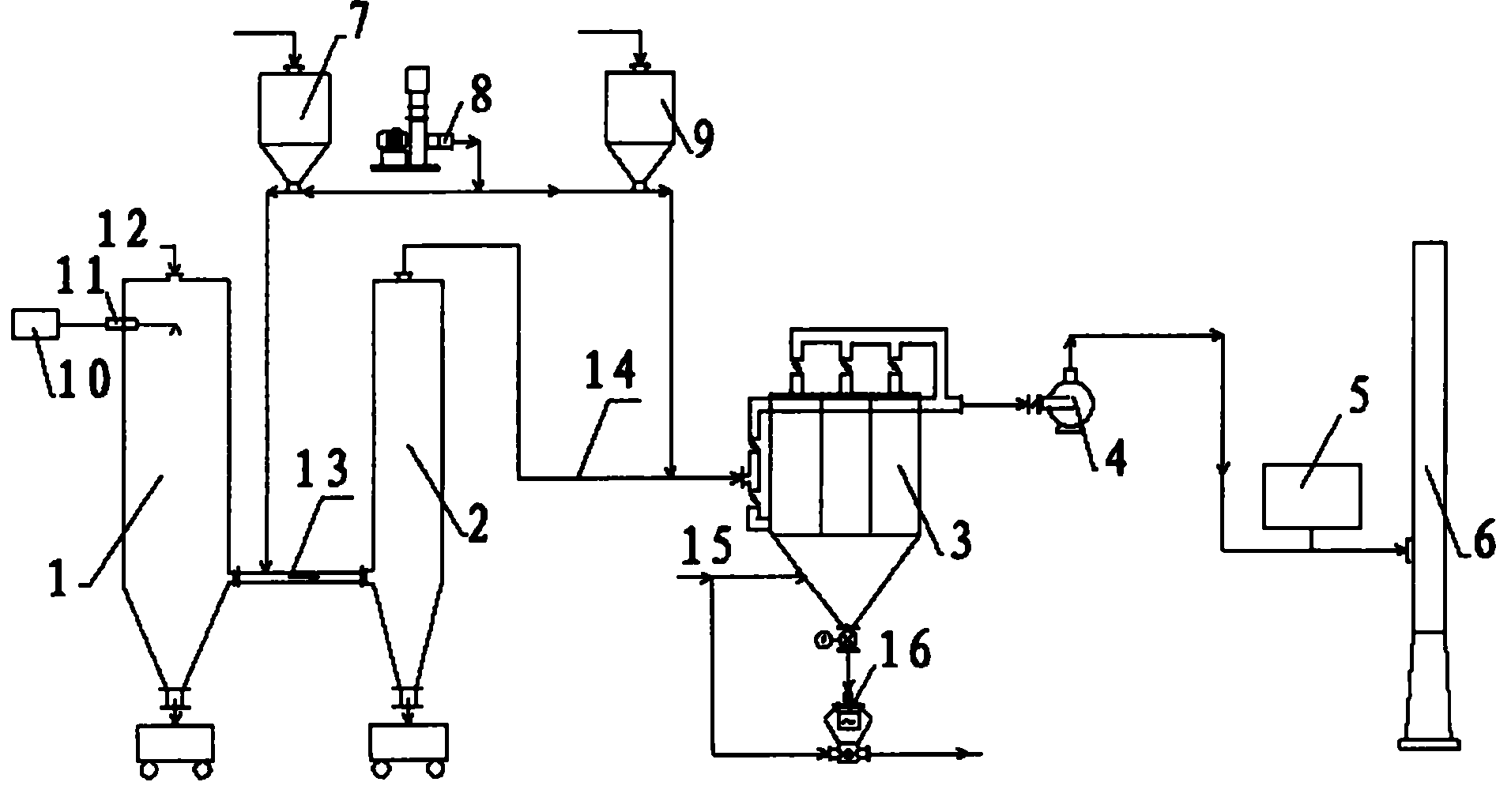

[0039] 1) The outlet of the lime slurry delivery pump 10, the atomizing spray gun 11, and the semi-dry deacidification tower 1 are sequentially connected through pipelines;

[0040] 2) The incineration tail gas delivery pipeline 12 is connected to the top entrance of the semi-dry deacidification tower 1;

[0041] 3) Semi-dry deacidification tower 1, expansion reactor 2, bag filter 3, induced draft fan 4, monitoring system 5, and chimney 6 are connected through pipelines in sequence;

[0042] 4) Roots blower 8, lime powder tank 7 and activated carbon sprayed into the flue 13 are connected through pipelines in sequence;

[0043] 5) The Roots blower 8, the activated carbon tank 9 and the activated carbon sprayed into the flue 14 are sequentially connected through pipelines;

[0044] 6) The pipeline 15 connected from the compressed air tank is connected with the bag filter 3;

[0045] 7) The ash hopper of the bag filter 3 is connected with the fly ash bin pump 16 through pipelin...

specific Embodiment approach

[0046] The semi-dry process for treating sludge incineration tail gas is not only suitable for large and medium-sized sludge incineration plants in the field of sludge treatment, but also can be applied in other incineration fields such as solid waste, hazardous waste treatment, and domestic garbage. In conjunction with the accompanying drawings, the specific implementation is as follows:

[0047] (1) First, the incineration tail gas enters the semi-dry deacidification tower 1 through the incineration tail gas conveying pipeline 12, fully mixes with the absorbent (lime slurry) sprayed from the atomizing spray gun 11, and is rapidly cooled to about 150-170°C, reducing two The chance of oxin repolymerization creates favorable process conditions for efficient deacidification at the back end. Among them, the amount of sprayed water is automatically adjusted according to the temperature of the flue gas at the inlet of the tower to ensure the economy of the amount of liquid used. T...

Embodiment 2

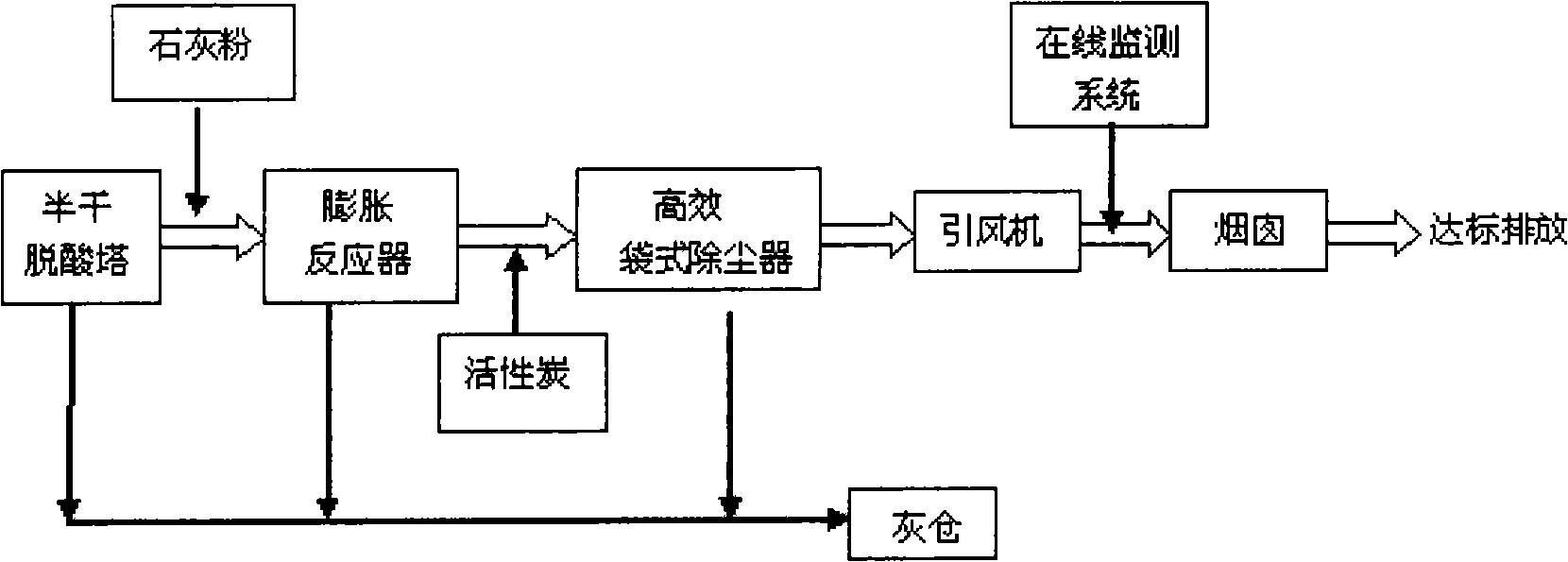

[0057] A complete set of semi-dry method for treating sludge incineration tail gas, which mainly includes: removal of acid gas by semi-dry deacidification tower and expansion reactor; removal of organic matter (dioxin) and heavy metal by activated carbon; high-efficiency bag dust removal Capture dust, dioxins, volatile heavy metals and other organic pollutants on activated carbon particles. Contains the following steps:

[0058] (1) The incineration tail gas first enters the semi-dry deacidification tower, Ca(OH) 2 The solution is generally sprayed into the reactor by a nozzle or a rotary sprayer to form a lime slurry with extremely fine particle size. By means of the volatilization of water, the temperature of the tail gas is reduced and its humidity is increased, so that the acid gas in the tail gas reacts chemically with the absorbent to form Salts fall to the bottom of the tower and are discharged through the ash hopper.

[0059] A lime slurry preparation step is also in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com