Application of metal-organic framework functional material

An organic framework and functionalization technology, which is used in radioactive purification, other chemical processes, chemical instruments and methods, etc., to achieve the effects of cheap synthetic raw materials, low price, and simple preparation methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

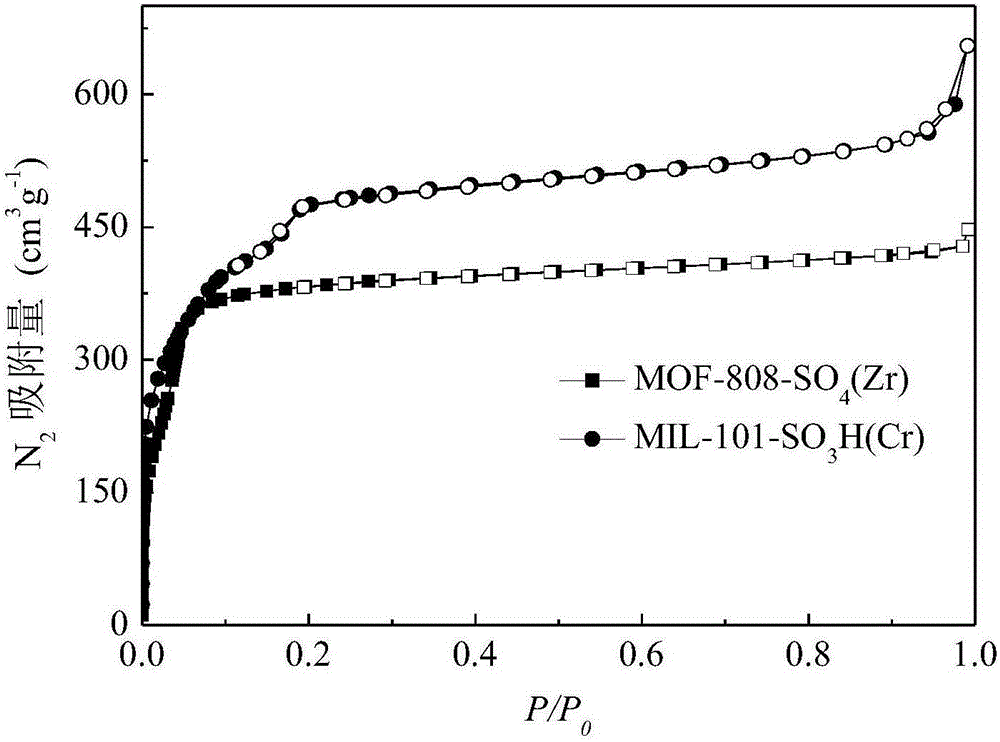

[0030] The MOF-808 (Zr) is synthesized as follows:

[0031]A certain amount of trimesic acid (2.1g, 10mmol) and zirconium oxychloride octahydrate (9.7g, 30mmol) were dissolved in N,N dimethylformamide / formic acid (450ml / 450ml) mixed solution, and the mixed solution was placed In a 1L glass pressure bottle, react at a constant temperature of 130°C for two days. Suction filter the obtained white product, rinse repeatedly with fresh N,N dimethylformamide, and soak the obtained product in anhydrous N,N dimethylformamide for three days, N,N dimethylformamide Change three times a day. The product activated by N,N dimethylformamide was suction filtered, rinsed repeatedly with deionized water and soaked for three days, the deionized water was replaced three times a day, the product activated by deionized water was repeatedly rinsed with anhydrous acetone, and the acetone It was replaced three times a day, and finally the acetone-activated product was vacuum-dried at room temperature...

Embodiment 2

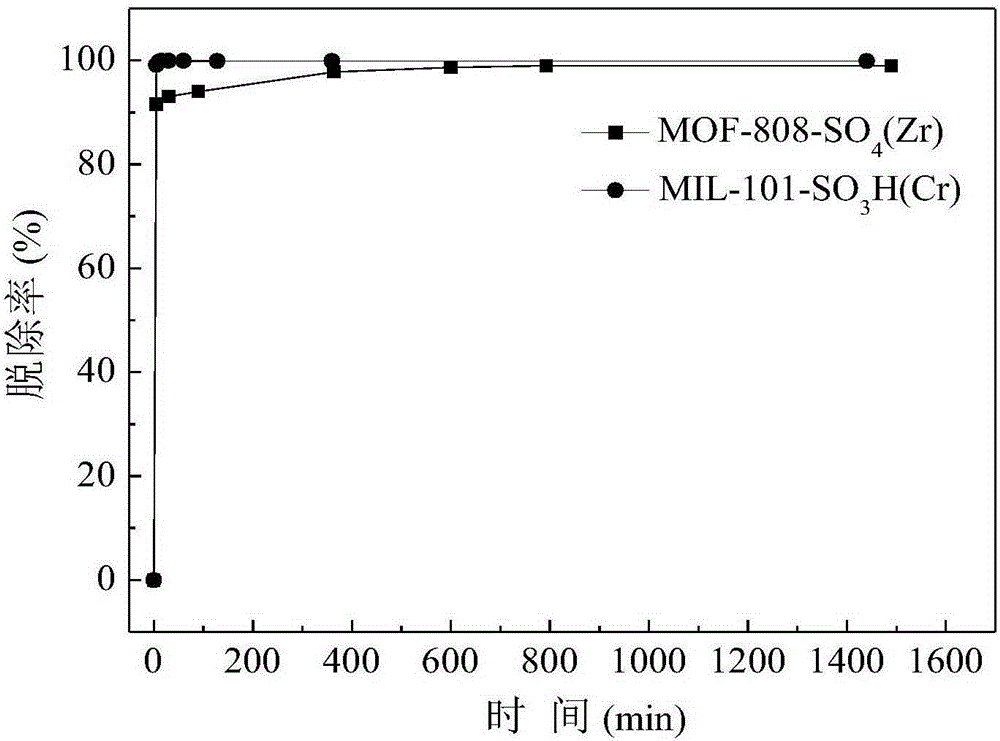

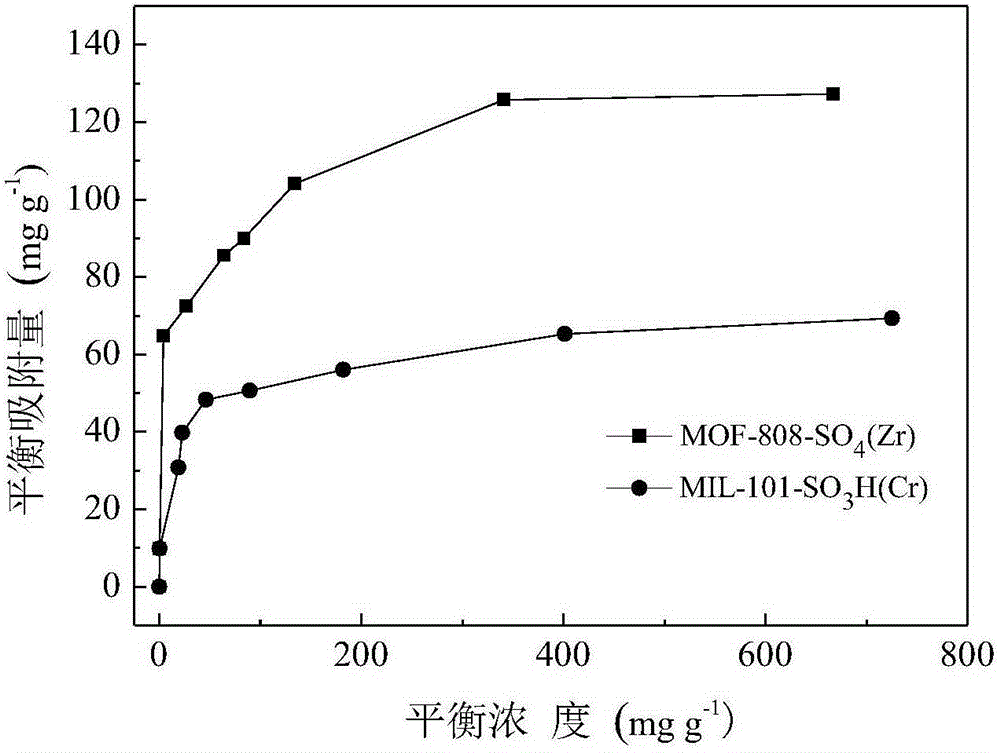

[0051] MOF-808-SO 4 (Zr) Adsorption of Ba 2+

[0052] Take 10mg MOF-808-SO 4 (Zr), configure 10ml of Ba with a certain initial concentration 2+ Aqueous solution, add 10mg of MOF-808-SO to the solution 4 (Zr), the whole system was carried out in a stoppered Erlenmeyer flask, which was placed in a shaker for 24 hours. Subsequently, the suspension was filtered using a microporous syringe and a 0.22 μm microporous filter membrane (PTFE), and the filtered supernatant was tested for the metal ion concentration of the solution using an inductively coupled plasma spectrometer, and the removal rate reached 99%. %.

Embodiment 3

[0054] MIL-101-SO 3 H(Cr) Adsorption of Ba 2+

[0055] Take 10mg MIL-101-SO 3 H(Cr), configure 10ml of Ba with a certain initial concentration 2+ Aqueous solution, add 10mg of MIL-101-SO to the solution 3 H(Cr), the whole system was carried out in a stoppered Erlenmeyer flask, which was placed in a shaker for 24 hours. Subsequently, the suspension was filtered using a microporous syringe and a 0.22 μm microporous filter membrane (PTFE), and the filtered supernatant was tested for the metal ion concentration of the solution using an inductively coupled plasma spectrometer. The removal rate was measured to be 99%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com