Patents

Literature

839 results about "Energy materials" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Energy materials encompass a broad class of materials that may have applications in energy conversion or transmission. Examples include: Materials for photovoltaic cells (convert photons to a charge current) Thermoelectric materials (turn a temperature gradient into a voltage or vis versa)

Method for preparing nanometer ferrous phosphate lithium /carbon composite material

InactiveCN101582498ARich sourcesLow priceElectrode manufacturing processesCapacitanceCarbon composites

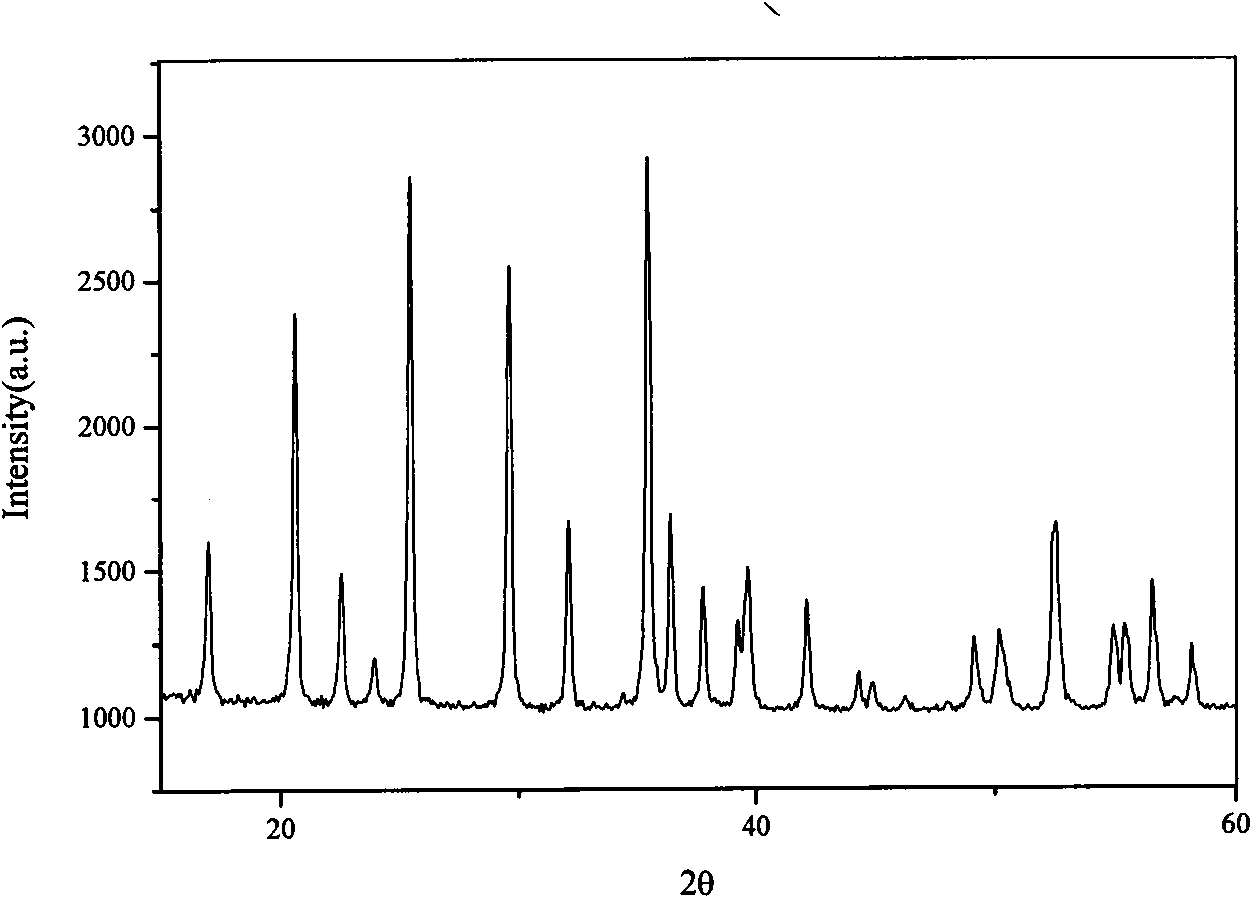

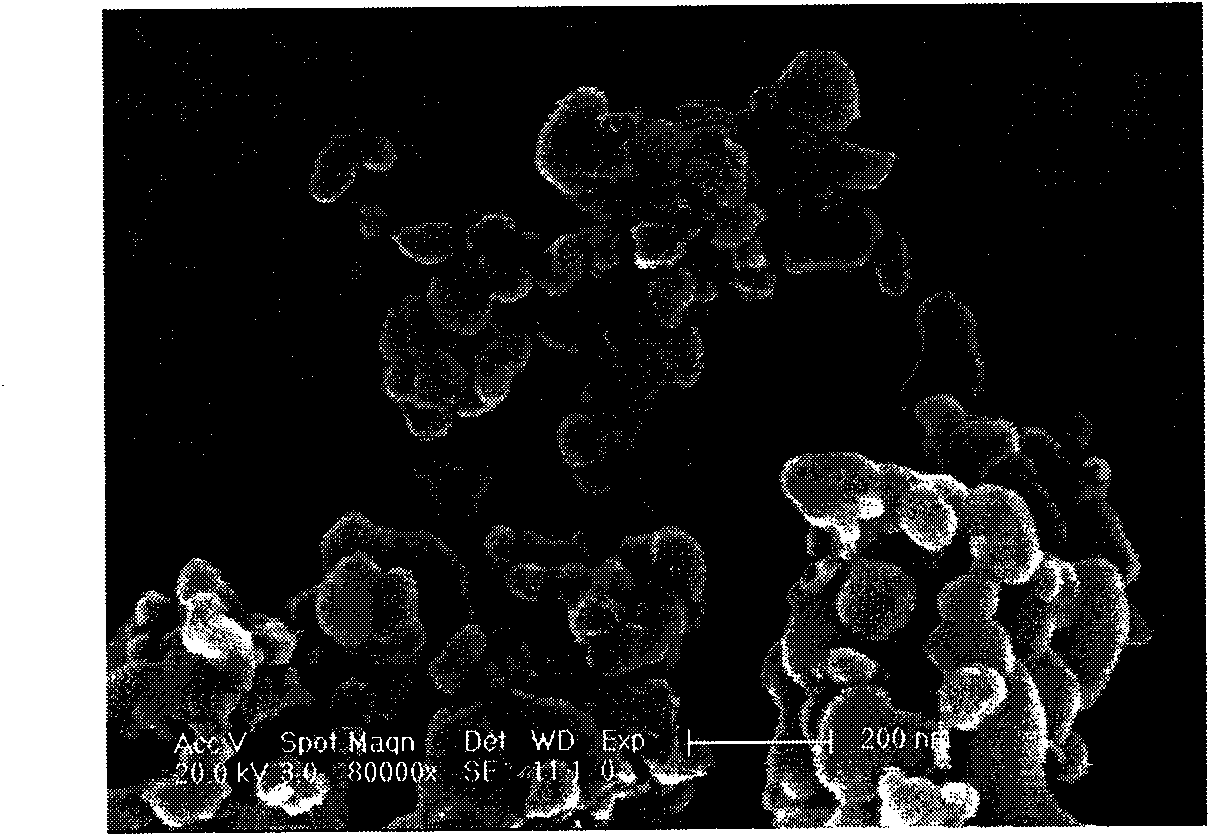

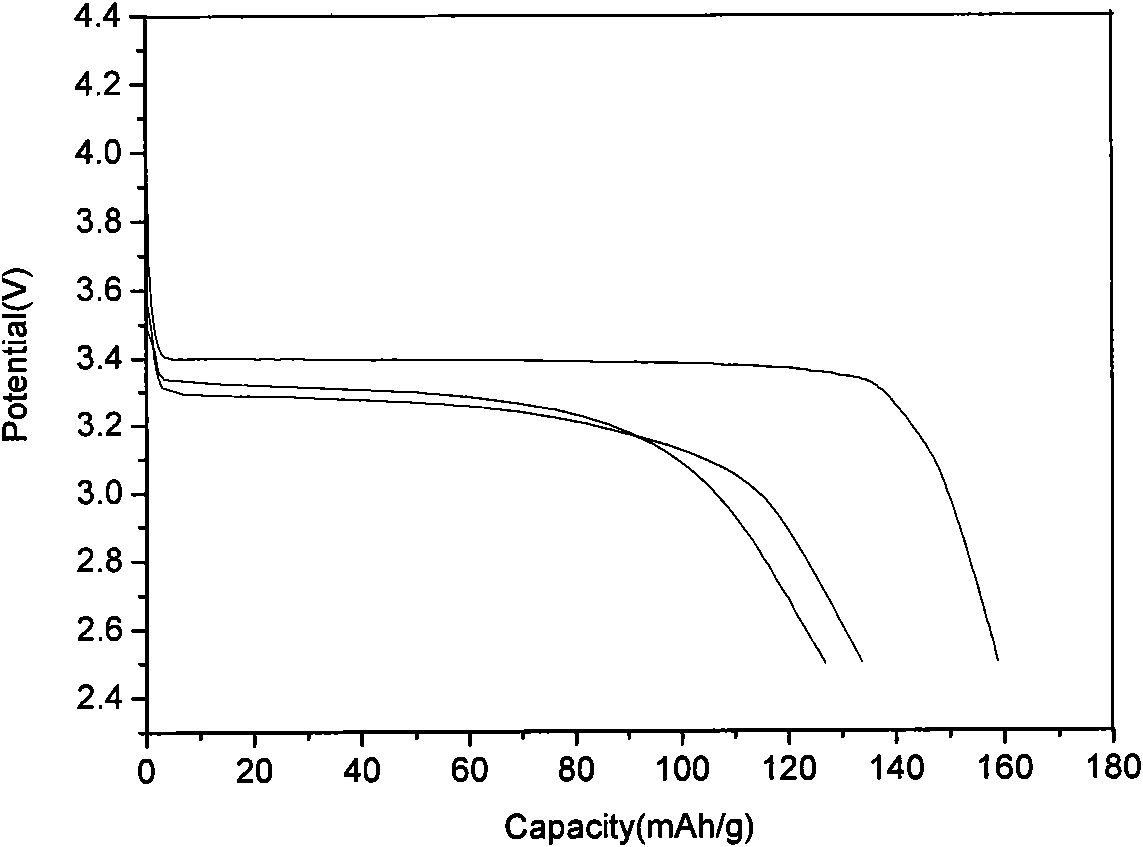

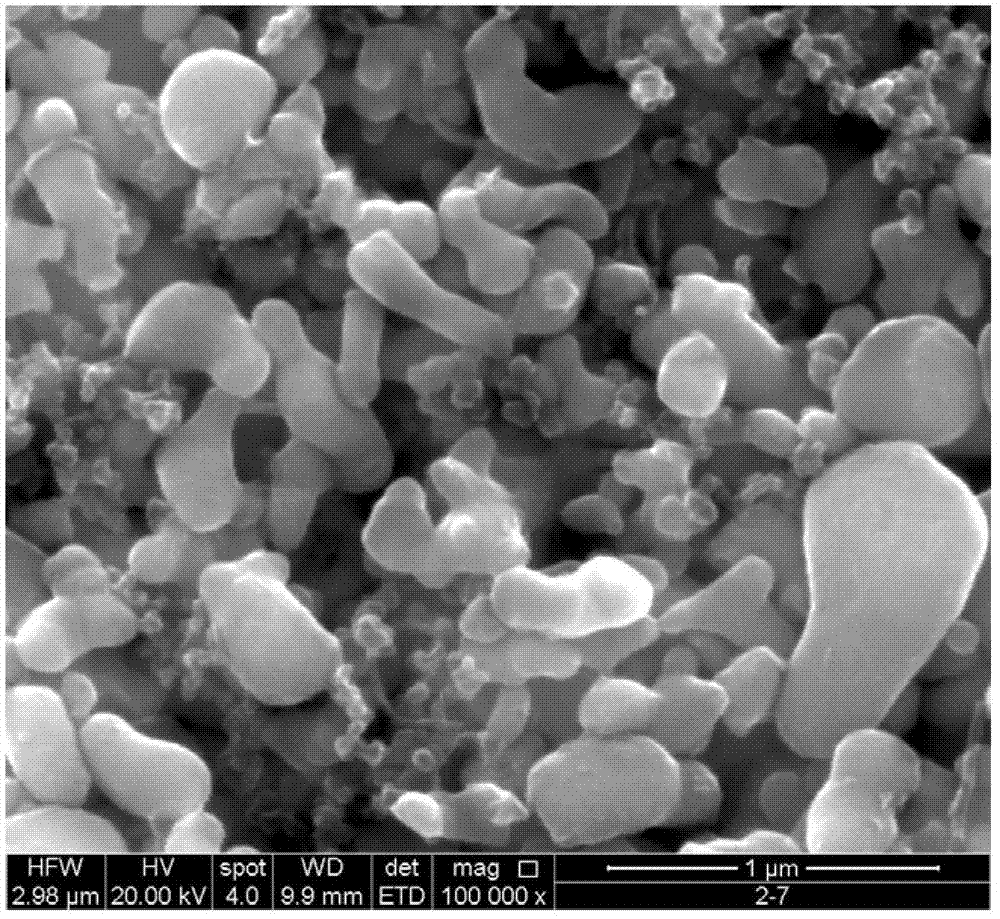

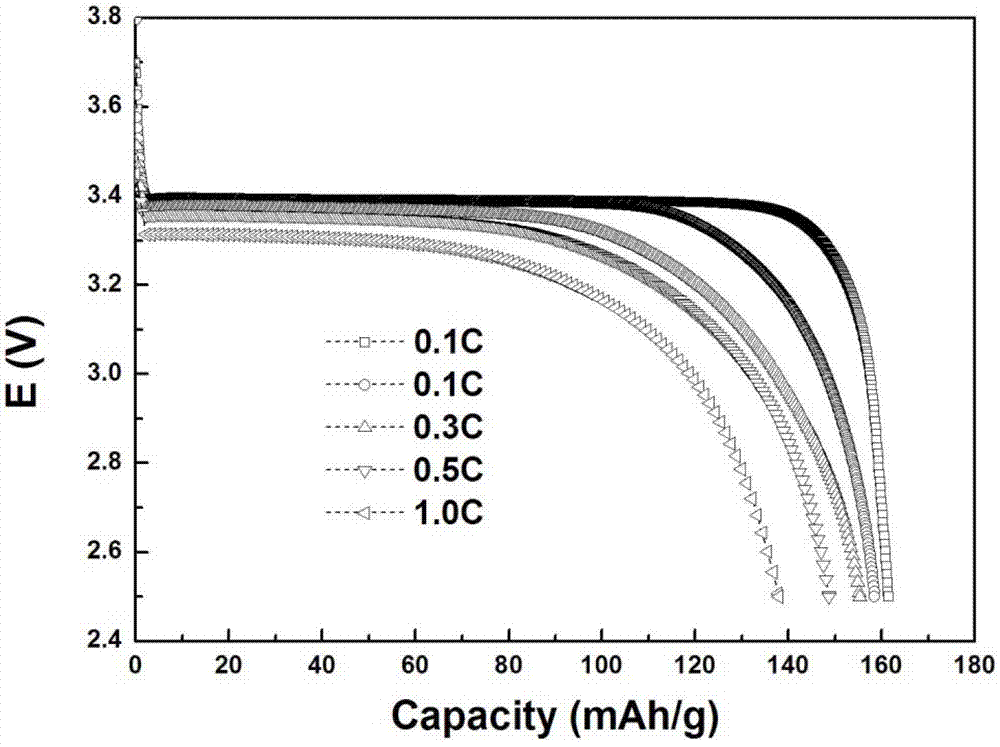

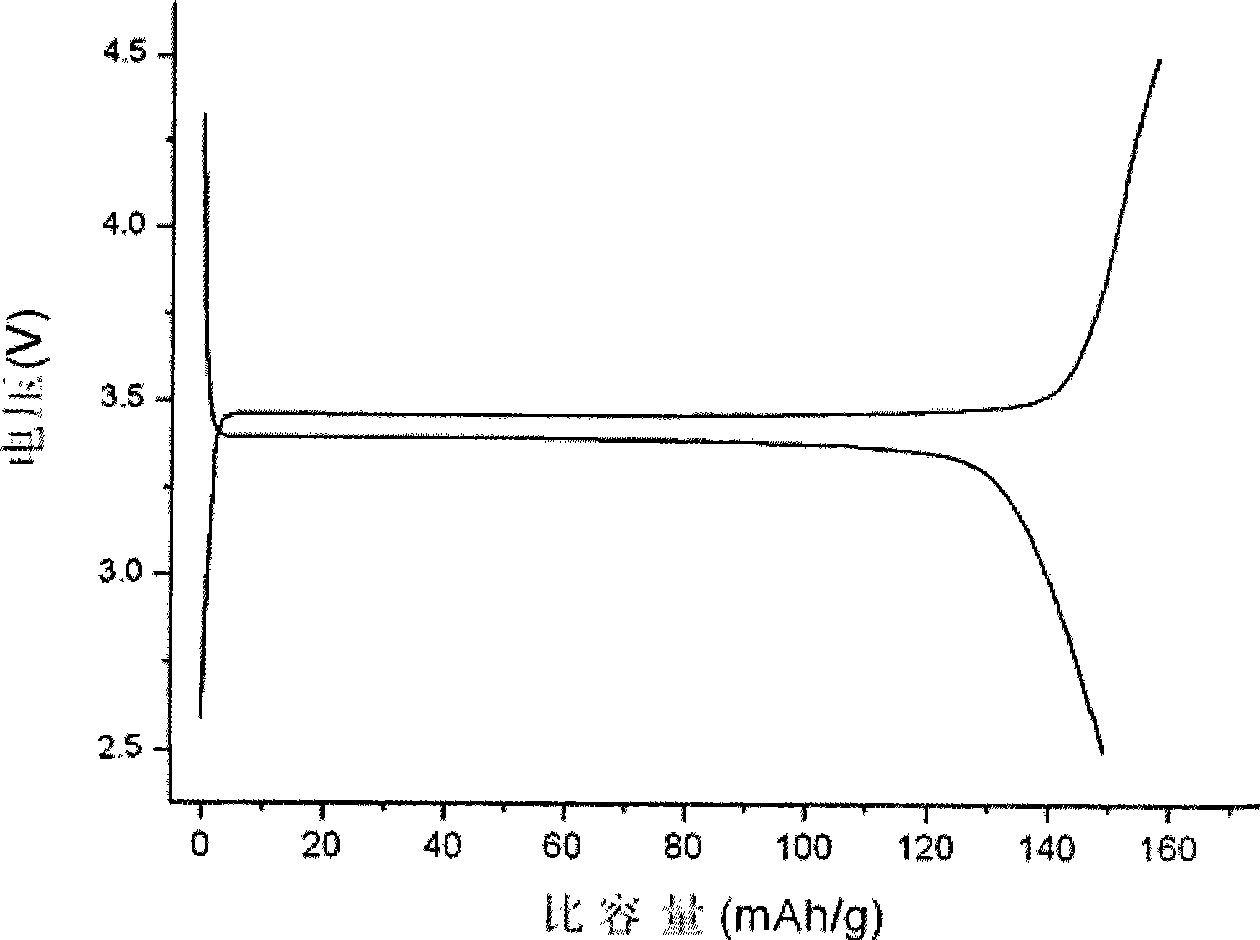

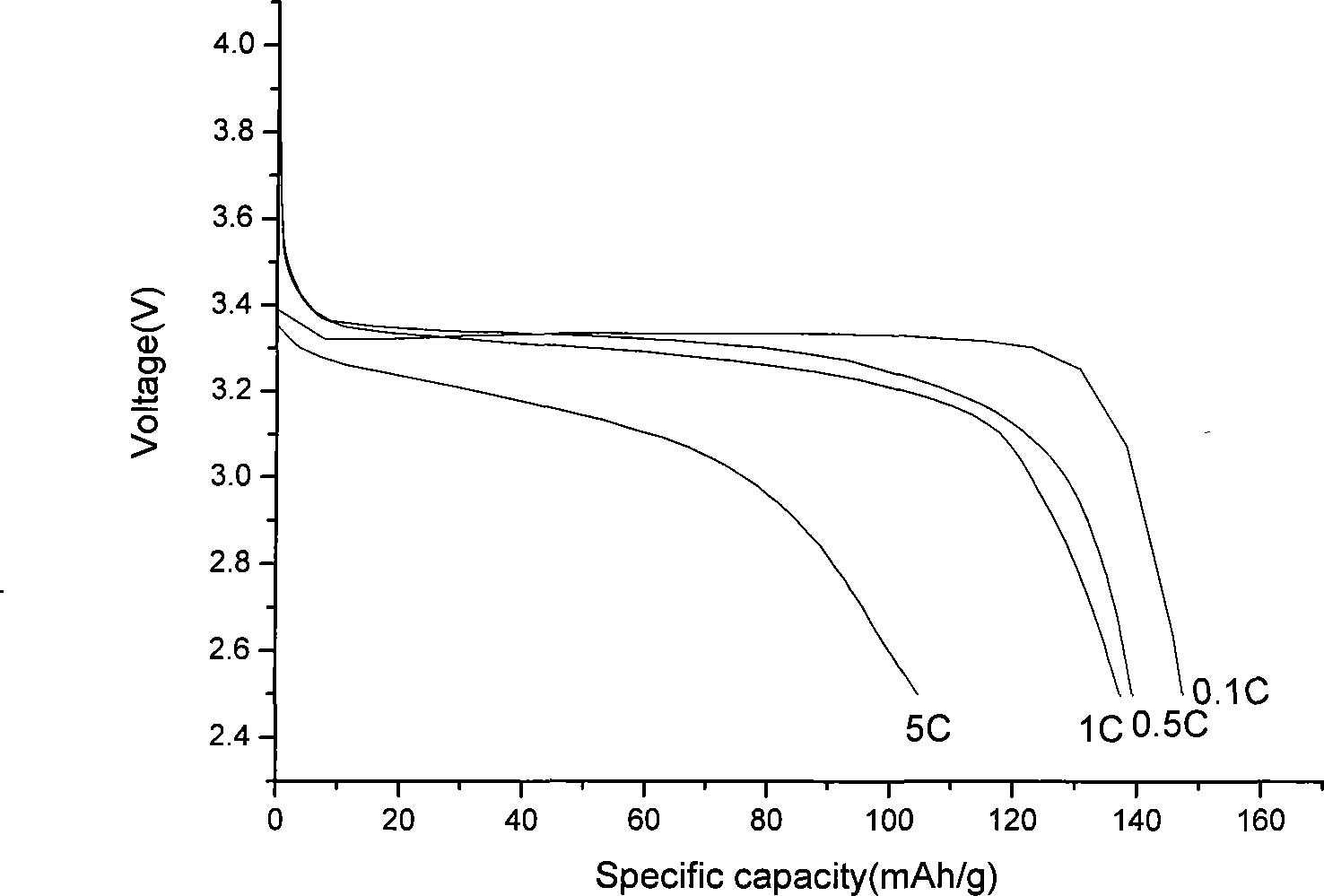

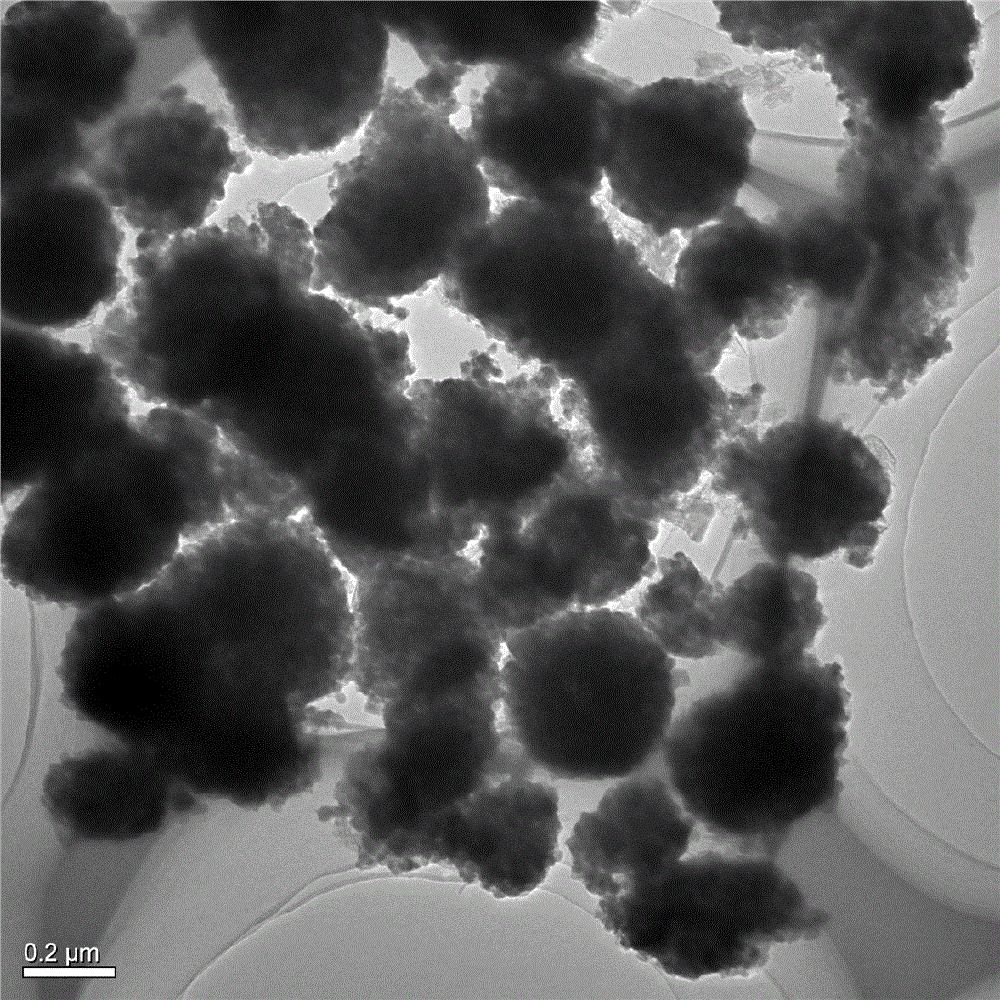

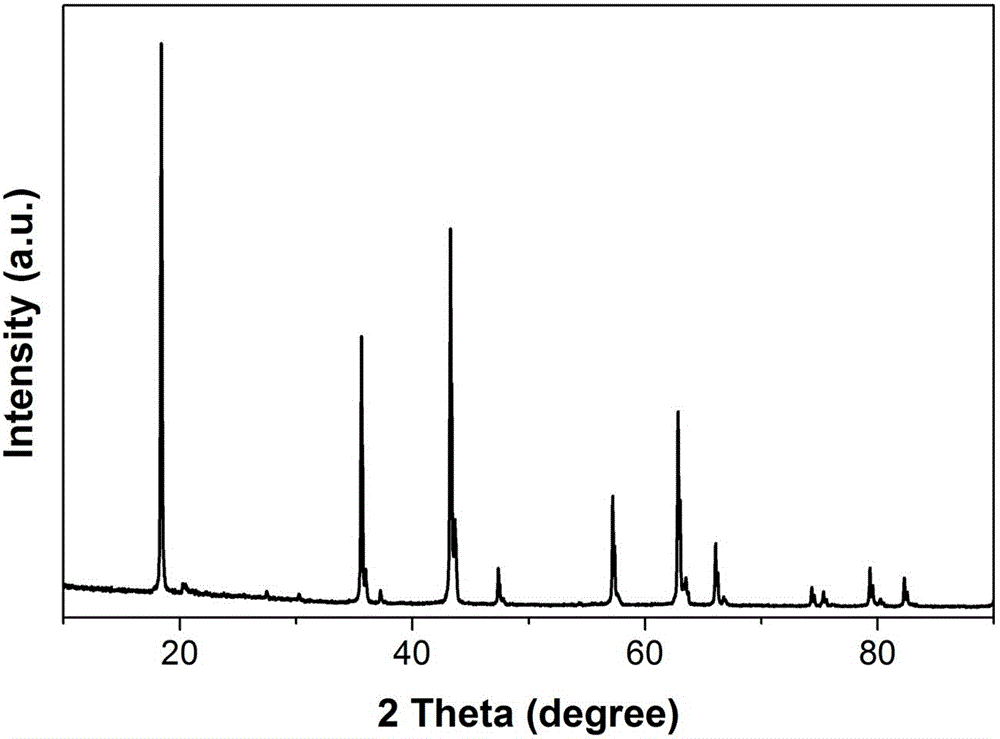

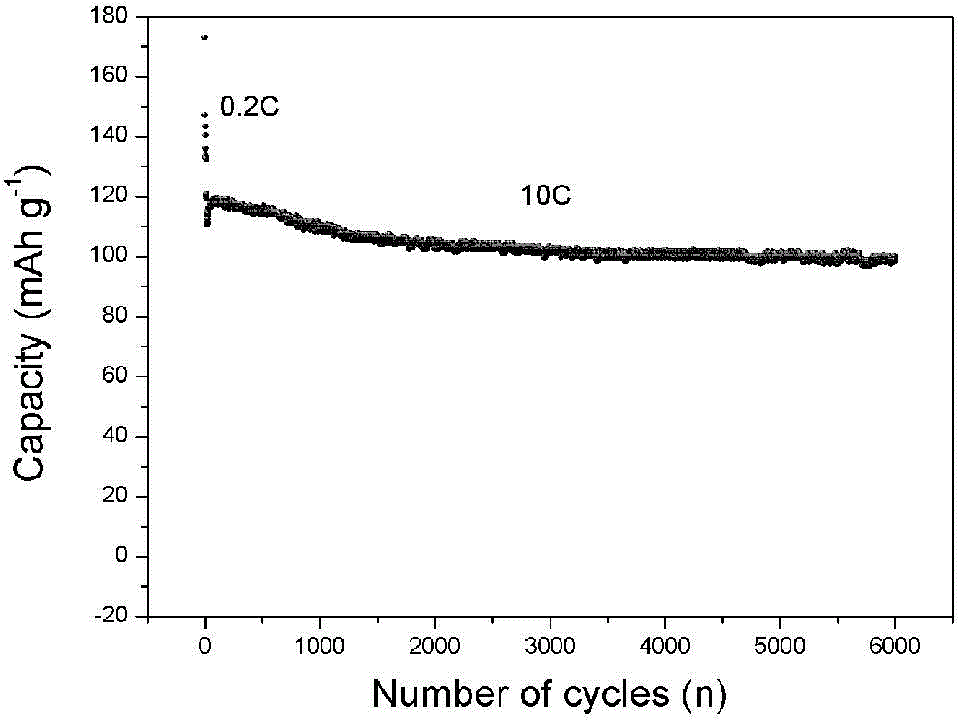

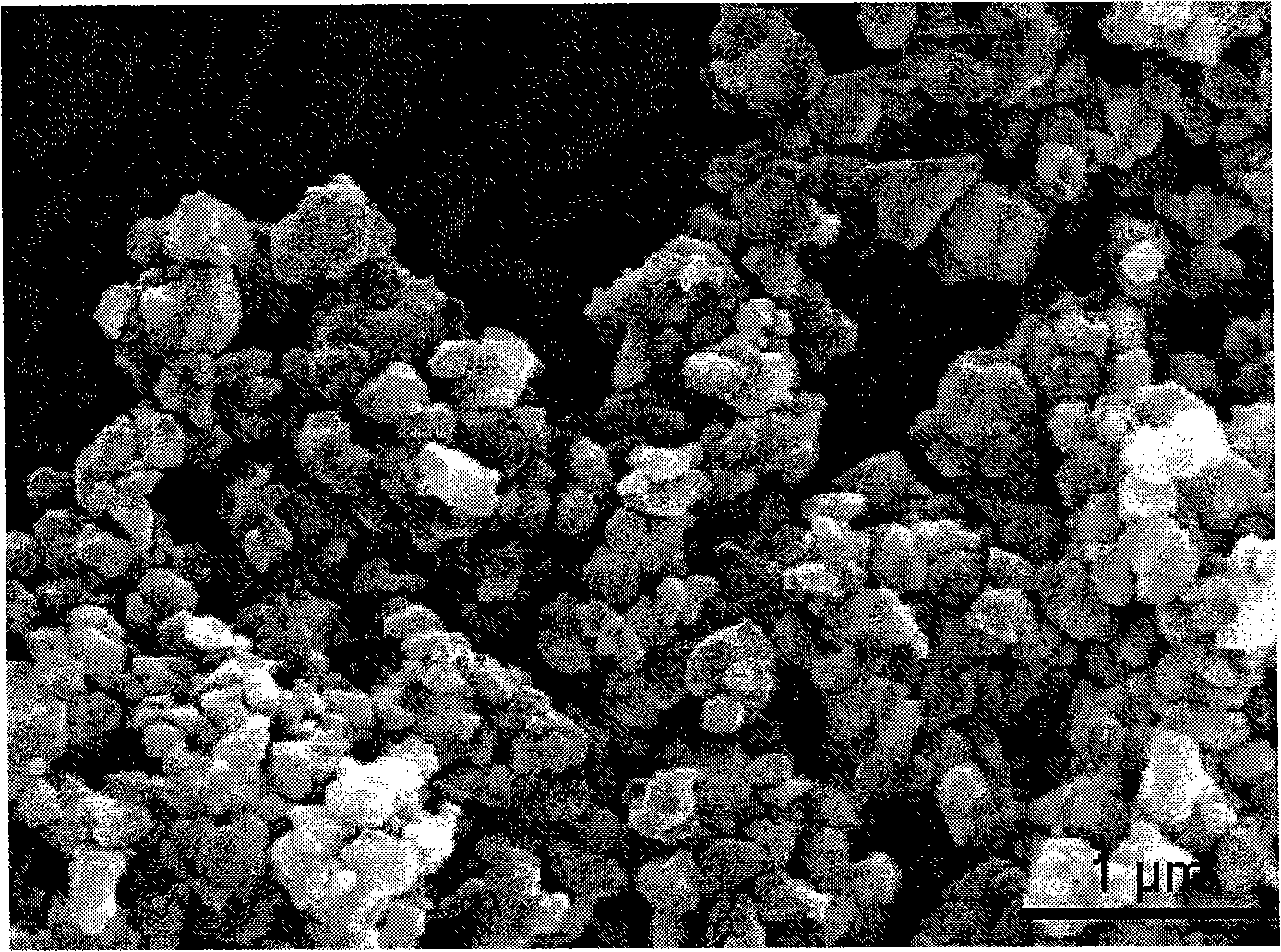

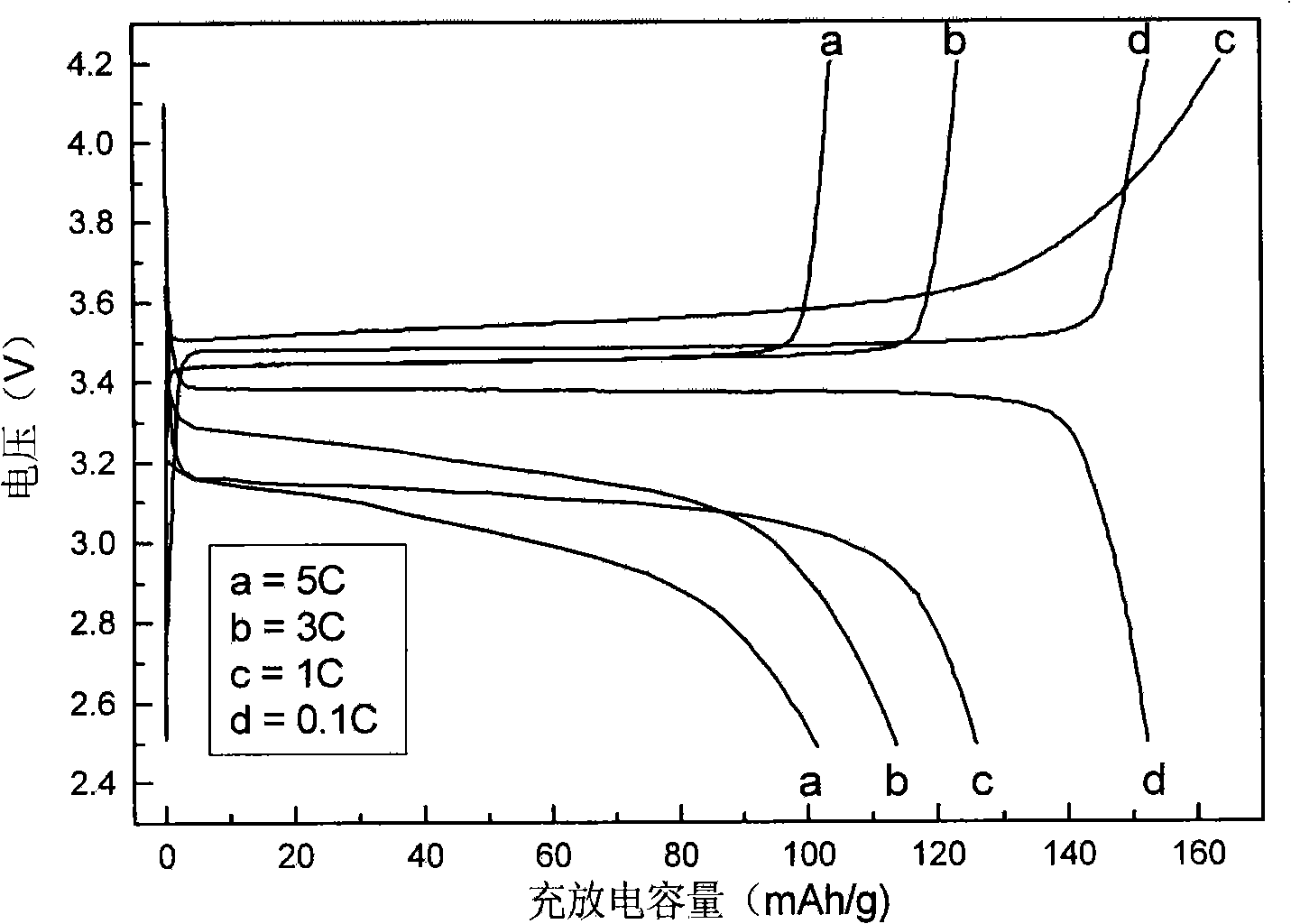

The invention belongs to energy materials, particularly relating to a method for preparing nanometer ferrous phosphate lithium / carbon composite material. In the invention, ferrous source, lithium source, phosphorus source are mixed with a small quantity of doped metal salt and organic macromolecular polymer carbon source according to certain ratio followed by the steps of ball milling, parching and calcining. High temperature sintering is carried out on the above mixture in the atmosphere of non-oxidation gas to obtain nanometer lithium iron phosphate LiMxFe(1-x)PO4 / C coated with carbon and LiFe(1-x)NxPO4 / C material, and the particle sizes of which are remarkably reduced and are less than 100nm. When the material is applied to battery assemble, 0.2C multiplying power discharge capacity can reach above 160mAh / g at room temperature, 1C multiplying power discharge capacity can be 140-155mAh / g, and 5C multiplying power discharge capacity is 130-150mAh / g. the initial capacity is 120-140mAh / g under the large multiplying power of 10C, and remains more than 90% through thousands of cycles, demonstrating good multiplying power and cycle properties. The invention features low cost, simple production process and fine safety. The prepared nanometer ferrous phosphate lithium / carbon composite material can be widely applied into manufacturing of convenient and fast equipment, electric vehicles and the like.

Owner:NORTHEAST NORMAL UNIVERSITY

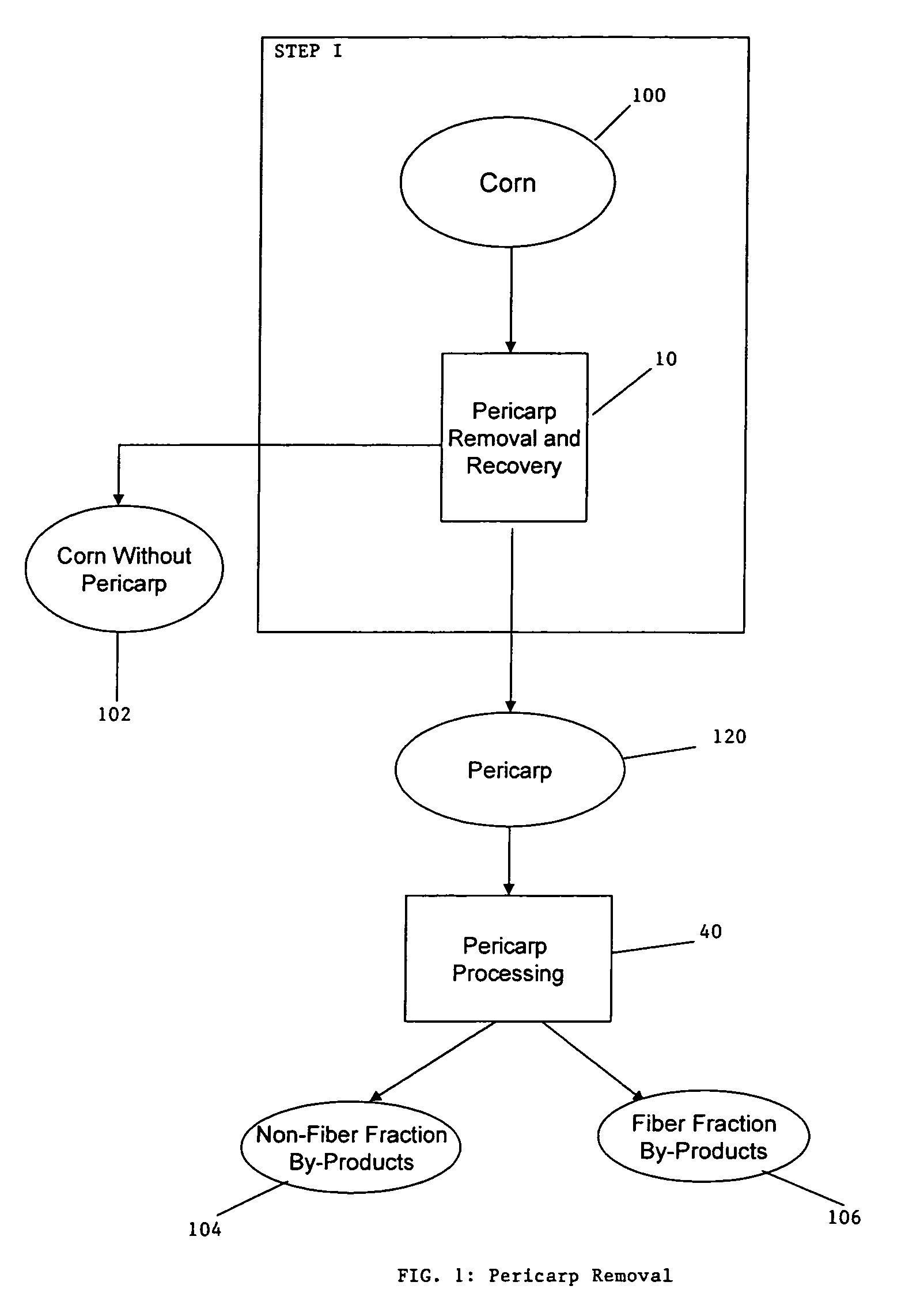

Process for the production of animal feed and ethanol and novel animal feed

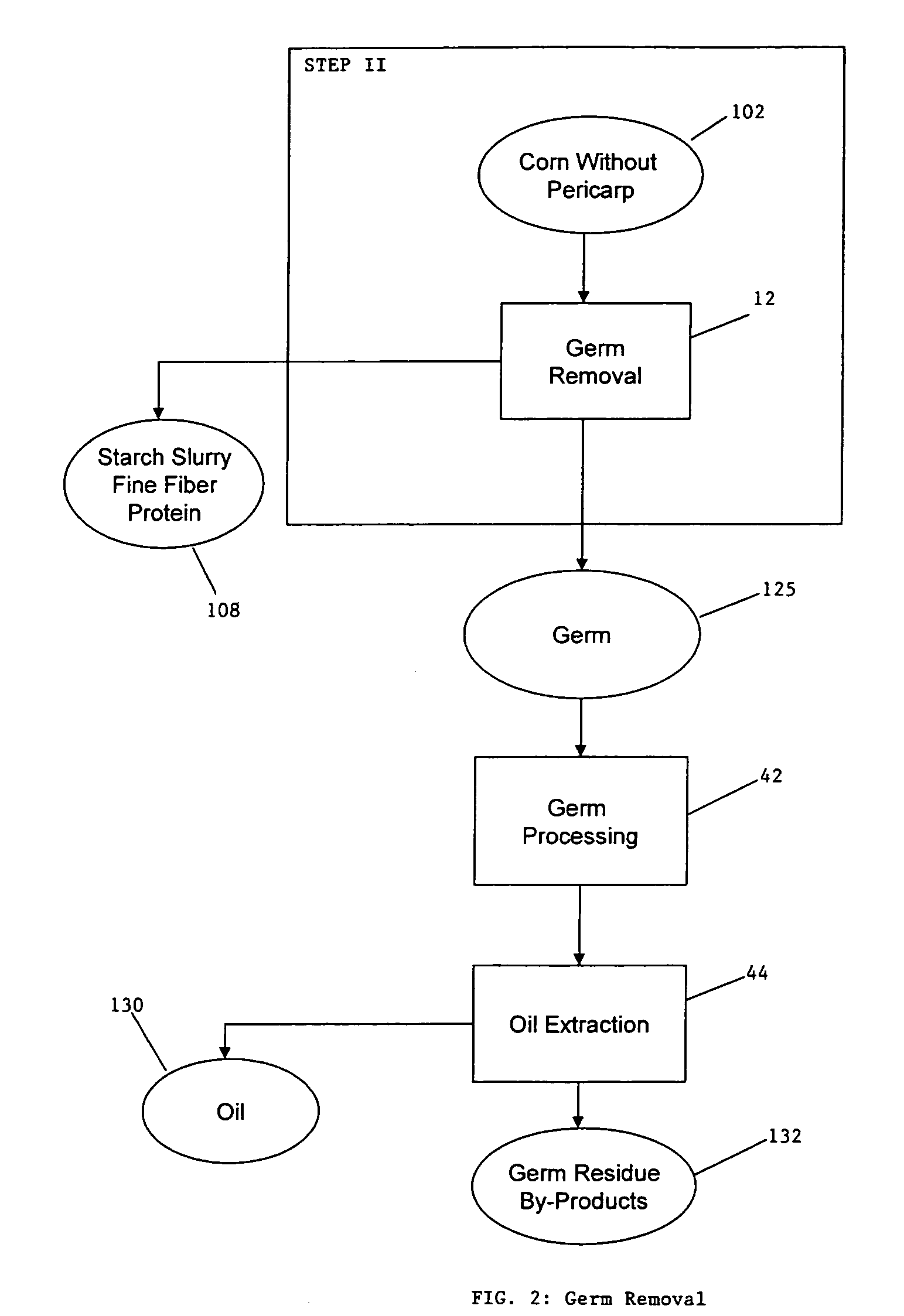

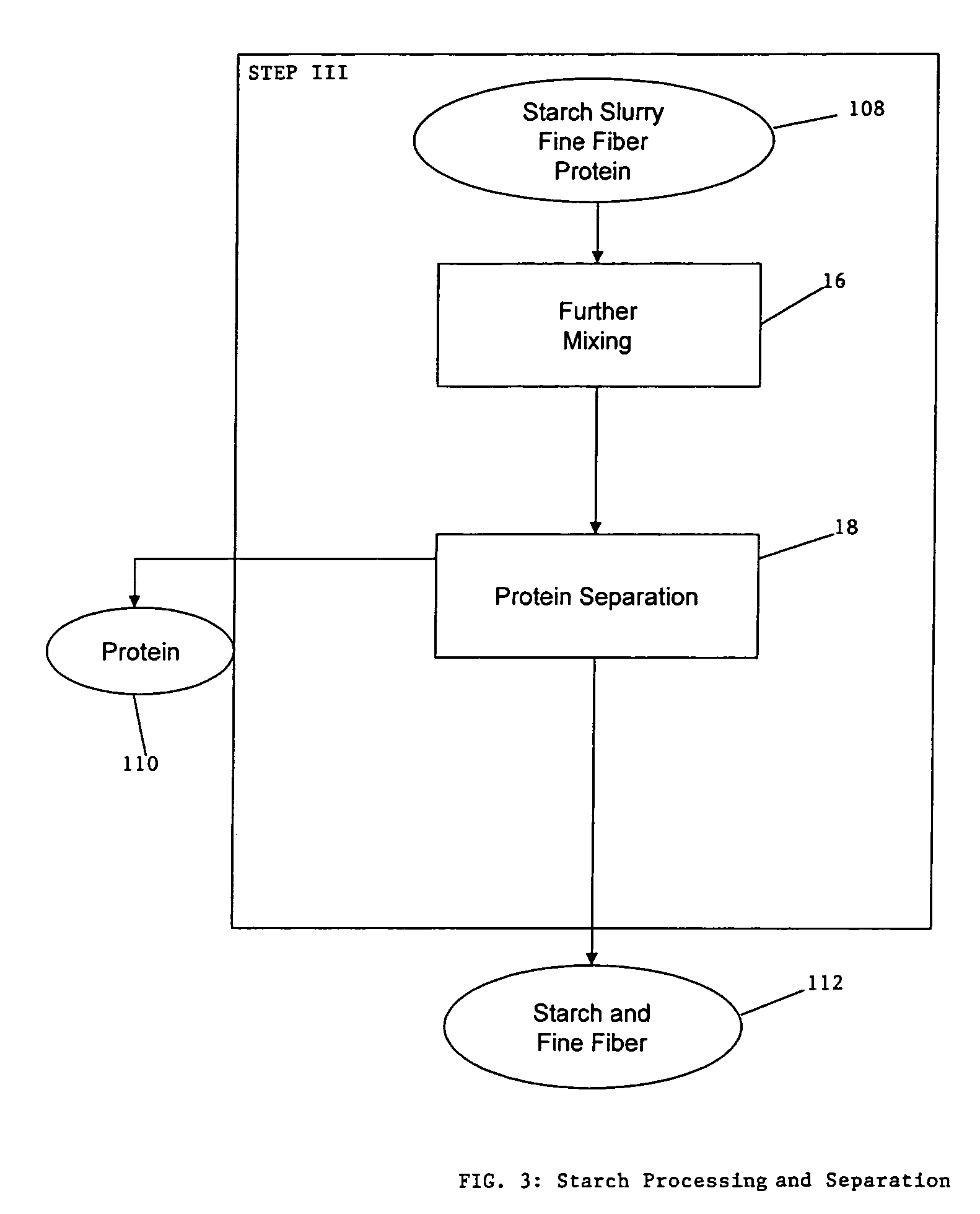

A method for the production of ethanol and a modified animal feed is provided. The method replaces the starch in known corn-based animal feed with biomass fiber treated to make it more digestible by animals. The process includes wherein the pericarp and germ are removed from the corn kernel and processed for by-products. The starch and protein are also removed and separated. The starch is then fermented and distilled to ethanol and stillage. The bioavailable modified animal feed comprises the pericarp and germ removed from corn kernels and optionally by-products of the pericarp and germ processing, and lignocellulosic materials. The modified animal feed may optionally include energy materials such as animal and vegetable fats, vegetable soapstocks, or glycerin, and combinations thereof.

Owner:ARCHER DANIELS MIDLAND CO

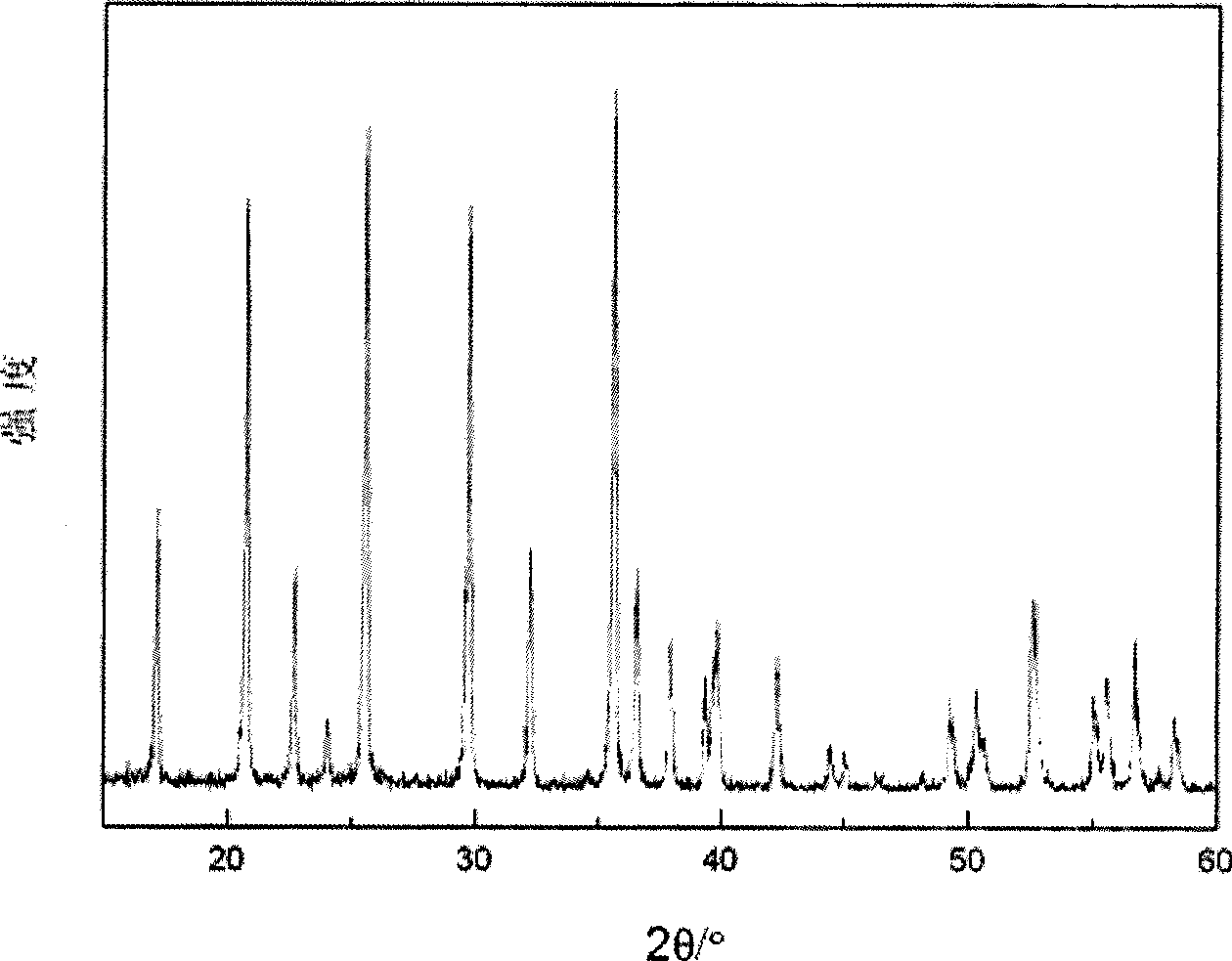

Method for preparing high-density spherical lithium iron phosphate and lithium iron manganese phosphate

InactiveCN1632970AWide variety of sourcesImprove conductivityElectrode manufacturing processesLithium compoundsFerrous ammonium phosphatePersulfate

This invention discloses a high-density ball ferric phosphate lithium and manganous phosphate iron lithium process method used in lithium ion battery positive electrode material in energy material process technique field. The process method comprises the following steps: to use ferric persulfate, phosphor or complex builder or manganese sulfate to process the mixture liquid; to react with the hartshorn solution to generate ball ferrous phosphate ammonium or manganese phosphate ferrous front driver; to mix it with lithium carbonate with mole proportion of one to one after washing and drying; under protection of nitrogen gas and after 600 to 900 degrees for 8 to 48 hours to get the ferric phosphate lithium or manganese phosphate ferrous.

Owner:TSINGHUA UNIV

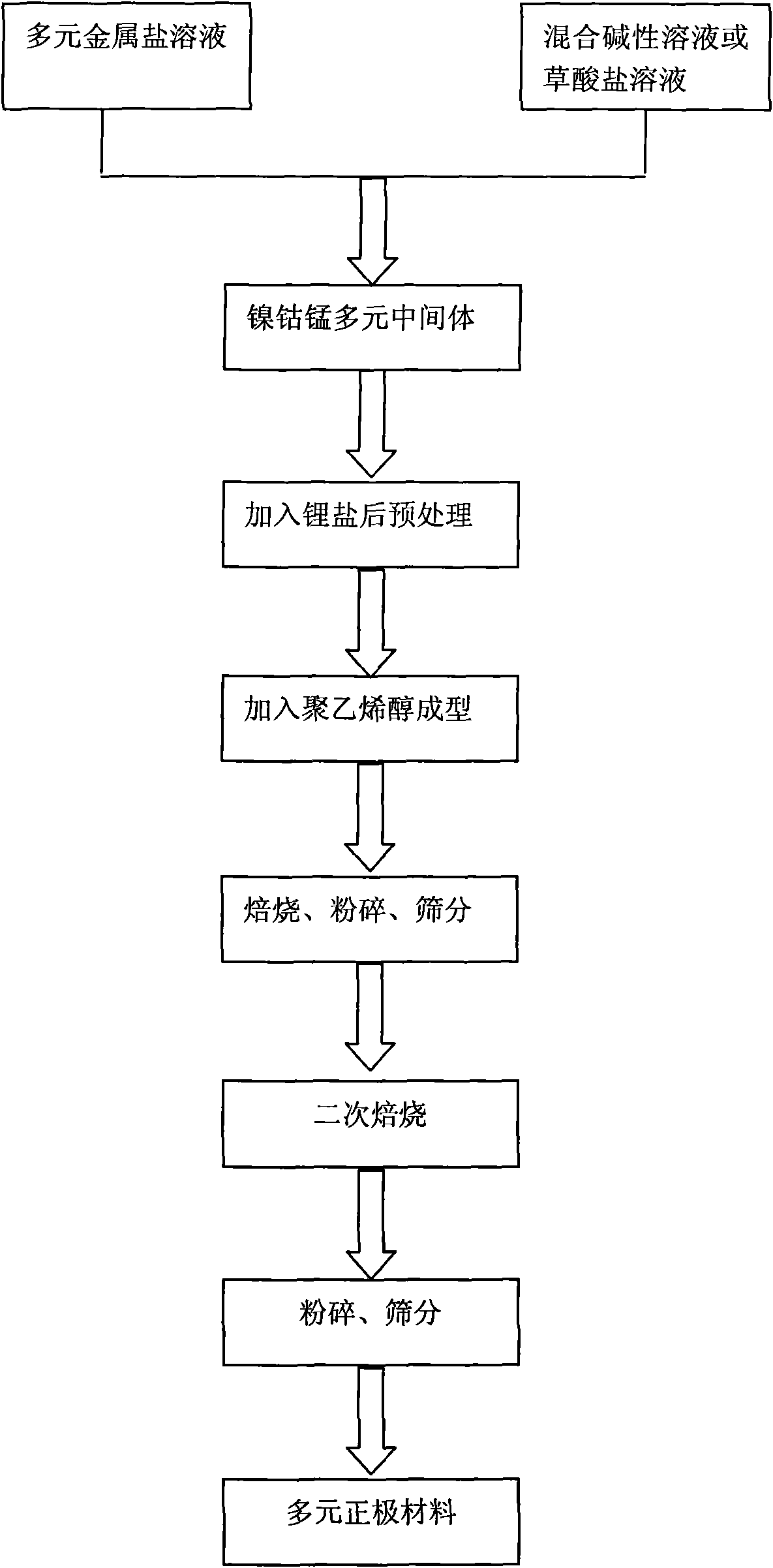

Nickel-cobalt-manganese multi-doped lithium ion battery cathode material and preparation method thereof

InactiveCN101621125AIncrease compaction densityLow hygroscopicityElectrode manufacturing processesSecondary cellsChemical synthesisPolyvinyl alcohol

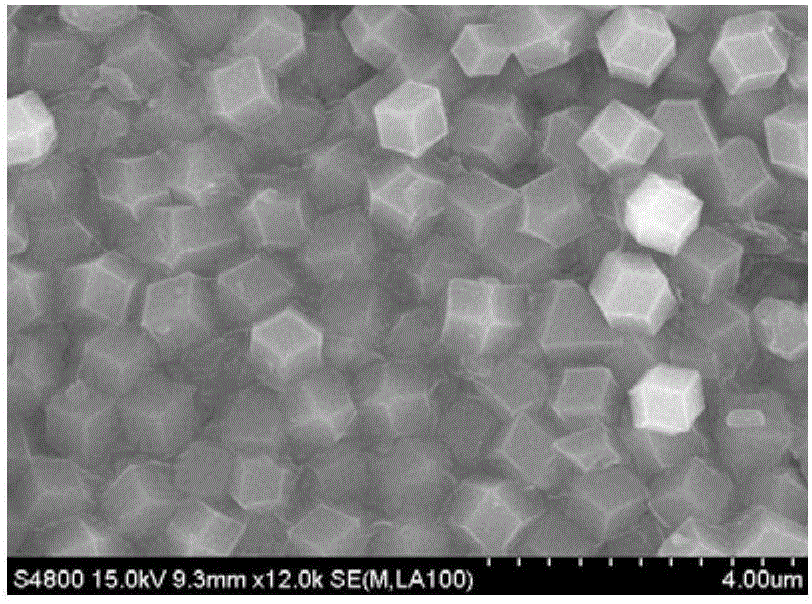

The invention discloses a nickel-cobalt-manganese multi-doped lithium ion battery cathode material with high compacted density and a preparation method thereof, belonging to the technical field of energy materials. The preparation method of the battery cathode material comprises the following steps: preparing a nickel-cobalt-manganese multi-doped intermediate by a coprecipitation method or a chemical synthesis method; mixing the multi-doped intermediate with lithium salts; after pretreatment, adding polyvinyl alcohol to the obtained mixture; uniformly mixing the polyvinyl alcohol and the mixture and then pressing the mixture into a cake; roasting the cake at 800-950 DEG C; taking the roasted cake out and carrying out cooling, pulverization and 400 meshes of sieving on the cake; then roasting obtained powder at 700-800 DEG C, taking the powder out and carrying out cooling, pulverization and sieving on the powder to obtain the battery cathode material. Granules of the battery cathode material are non-agglomerated single-crystal grains with a grain diameter of 0.6-30 microns, a chemical formula of LiNixCoyMnzM[(1-x-y-z)]O2, a degree of compaction of 3.5-3.7g / cm<3> and a primary discharge capacity of 150-165mAh / g, thus the battery cathode material has good cycle performance and higher safety performance.

Owner:CHENGDU JINGYUAN NEW MATERIALS TECH

Cathode material of lithium ion battery, preparation method of cathode, and lithium ion battery

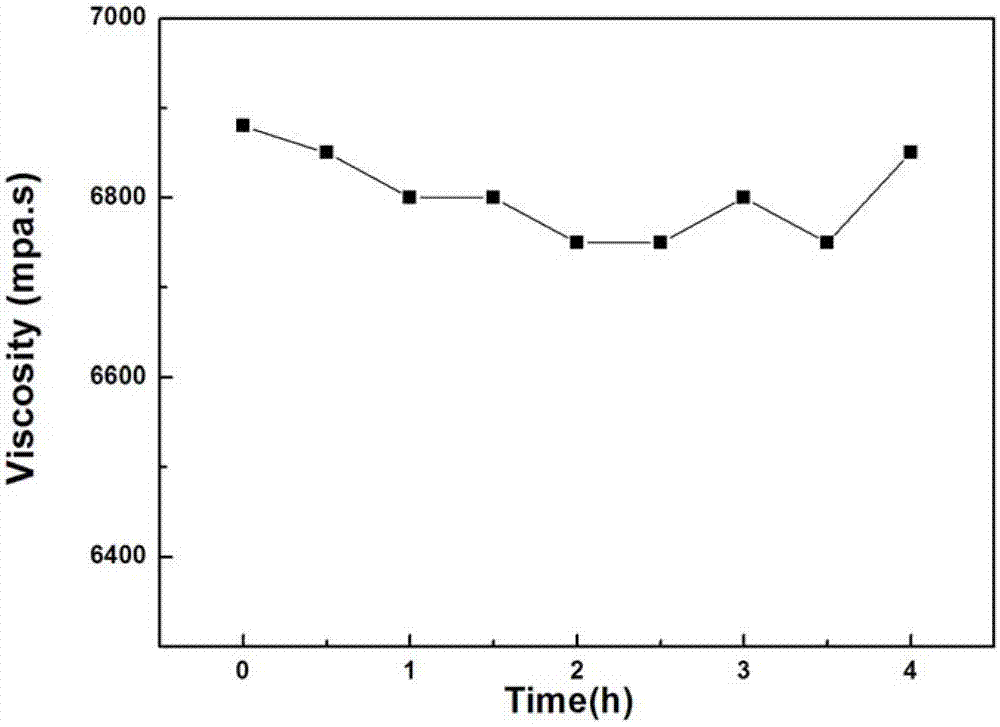

ActiveCN103199258APromote accumulationEvenly dispersedCell electrodesSecondary cellsSodium-ion batteryNano carbon

The invention discloses a cathode material of a lithium ion battery, a preparation method of the cathode, and the lithium ion battery using the cathode material, belonging to the technical field of energy material. According to the invention, a chemical dispersant is added into the cathode of an aqueous lithium-ion battery, thereby solving problems of uniform dispersion for active materials of positive electrode and a nano-carbon mixed conductive agent; and a mechanical dispersion method is combined, preferably with a revolution speed of the mechanical dispersion being 15-35 HZ and a rotation speed being 10-30 HZ, thereby realizing uniform dispersion of the nano-active substances in a relatively short time. The cathode material of a lithium ion battery and the preparation method provide technical approach for solving uniform dispersion of the aqueous nano-active substances, and are high in production efficiency and low in cost; the prepared battery is high in discharge capacity, and is significantly improved in low temperature, multiplying power and cycling performances; and a new approach is provided for a large scale application of the nanometer lithium batteries which are limited to a high cost and a high-polluting oil system in the field.

Owner:中创新航科技(江苏)有限公司

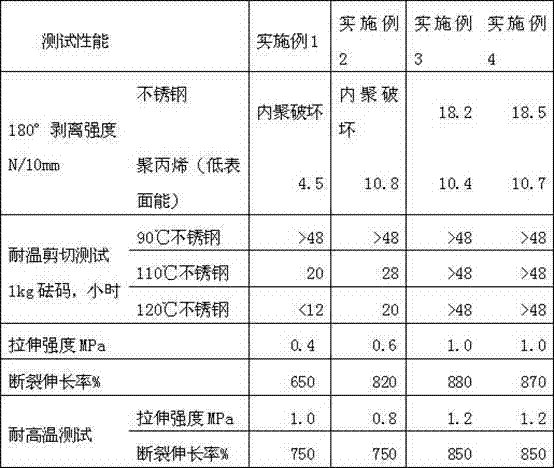

Ultraviolet-curable high temperature resistant pressure-sensitive adhesive and preparation method thereof

InactiveCN103484042AGood high temperature shear performanceHigh peel strengthFilm/foil adhesivesEster polymer adhesivesPolymer scienceFunctional monomer

The invention relates to an ultraviolet-curable high temperature resistant pressure-sensitive adhesive. The ultraviolet-curable high temperature resistant pressure-sensitive adhesive comprises: a solvent-free ultraviolet-curable prepolymer comprising 80-98wt% of a soft monomer and 2-20wt% of a hard monomer; one or more functional monomers comprising monofunctional monomers, bifunctional monomers or multi-functional monomers; one or more organosilicone having reactive groups or acrylates grafted by the organosilicone having reactive groups; and photoinitiators comprising a free radical cracking type photoinitiator, a hydride abstraction type photoinitiator and an ion type photoinitiator. The whole preparation process of the pressure-sensitive adhesive does not use any volatile organic solvents and is environmentally-friendly; a pressure-sensitive adhesive tape using the pressure-sensitive adhesive has a good high temperature shear resistance, has a high peeling strength on low-surface-energy materials, has a one-piece structure, and can be processed to prepare thick products without inner liner base materials.

Owner:TONSAN ADHESIVES INC

Method for preparing high-density spherical lithium iron phosphate

InactiveCN1632969AHigh bulk densitySimple processElectrode manufacturing processesPhosphatesKeroseneHexamethylenetetramine

This invention discloses a high density ball ferric phosphate lithium process method in energy material process technique, which comprises the following steps: to use ferric nitrate, phosphate chrome and acetic acid lithium as materials and to add deionized water to process solution A; to mix impurity metal compound or carbon source into the solution A; to make solution of hexamethylenetetramine and carbamide to process solution B; to make solution C by adding solution B into solution A; to drop solution C with kerosene and to heat it into gel for deposition; to get the ball dry gel front driver after centrifugal separation; to get the high volume proportion capacity high density ferric phosphate lithium through high temperature process.

Owner:TSINGHUA UNIV

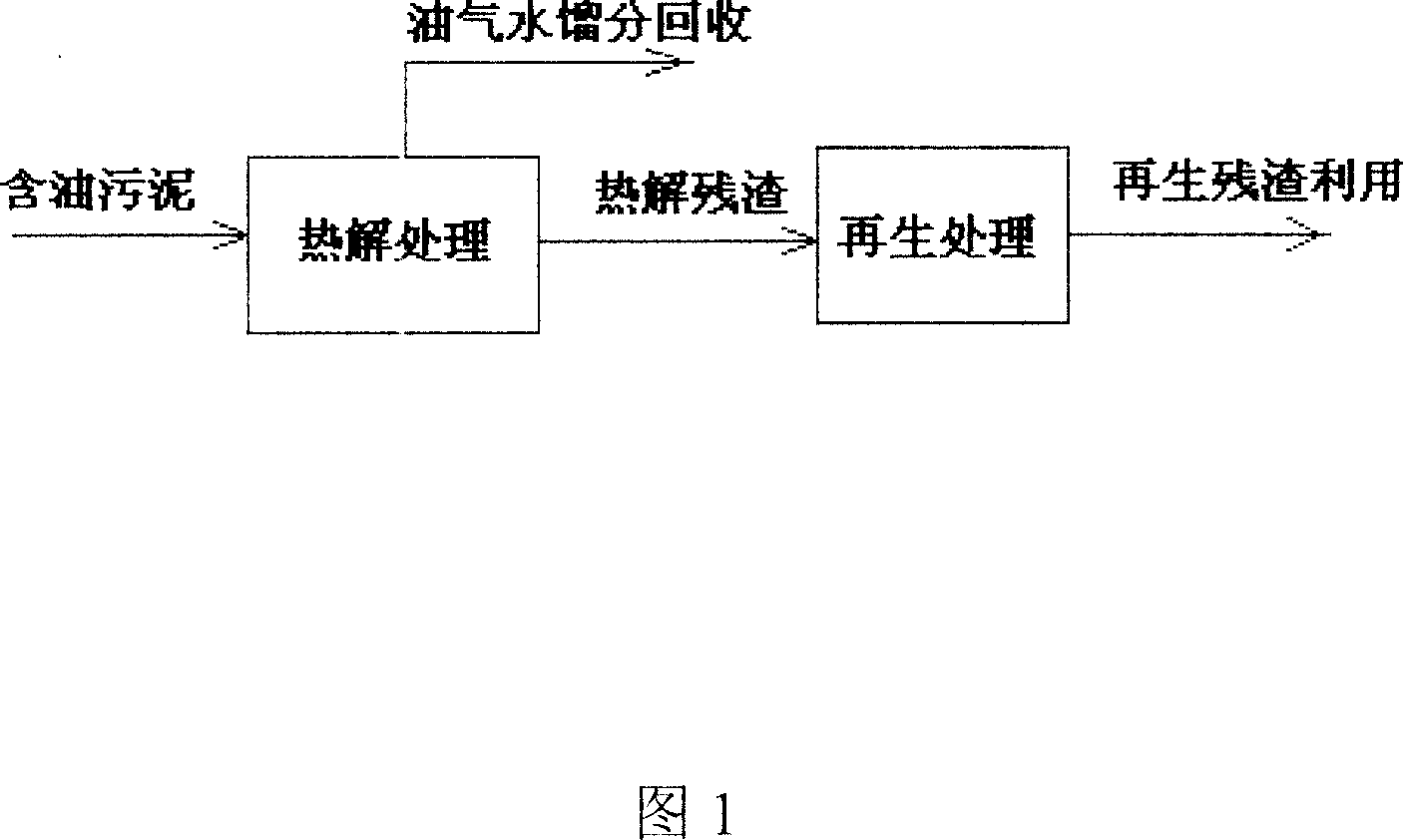

Resource treating method for oil-containing sludge

ActiveCN101113067ASolve pollutionReduce doseSludge treatment by pyrolysisByproduct vaporizationClay mineralsIron salts

The invention relates to a resource processing method for oily sludge. First, the oily sludge is sent to a closed retorting cracking furnace to be pyrolyzed, and the pyrolyzed period is 1-5 hours under 200-600 DEG C, then the oil, gas, and water are recovered. Second, sulfate or hydrochloride is put into the pyrobitumen of sludge containing inorganic aluminum salt or iron salt flocculant according to the chemical equivalent of the aluminum salt or iron salt 1 to 1-1.5 to do acid-soluble processing. The products after the two processes can be reclaimed and used as the flocculant of the sewage processing system, or reclaimed as the concentrating agent of sludge. The pyrobitumen containing mostly clay mineral can be used as decolorizing and absorbing material of waste water and oil, or used as absorbent for lube-oil complementing and refining process. The method used in oilfield gathering transportation and treatment system can realize zero discharge in course of the gathering transportation and treatment, and can effectively solve the pollution problem of the oily sludge and find the automate answer for the oily sludge. Meanwhile, by adopting the method, the cost for the treatment of sewage flocculation and for adding sludge concentration agent can be reduced and the energy material can be reclaimed from sludge and the wastage of oil can be reduced.

Owner:PETROCHINA CO LTD

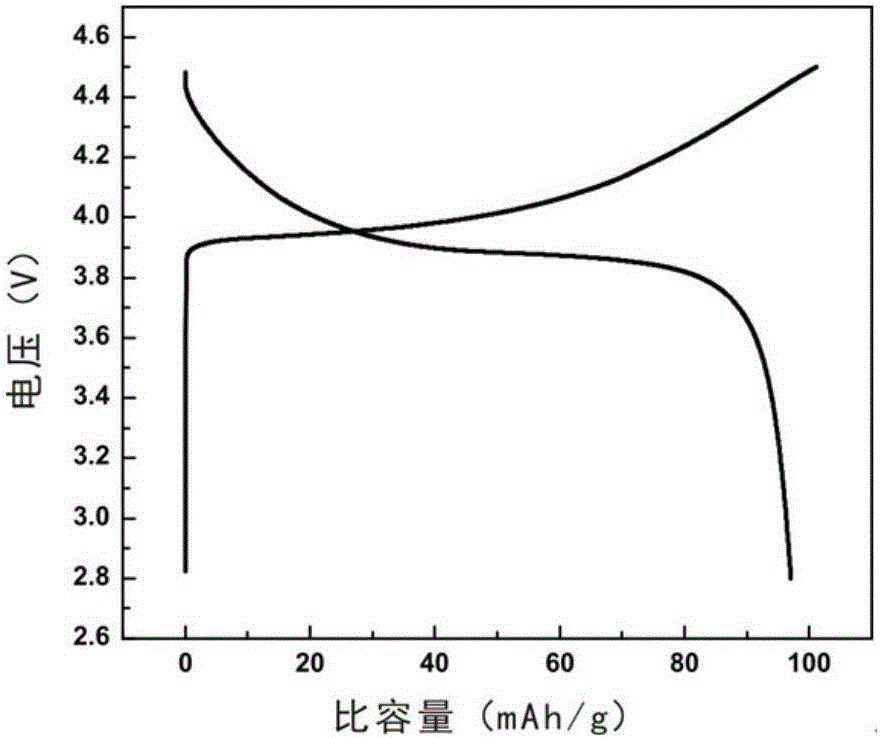

Preparing method of lithium ionic cell 5V anode material spherical LiNi*Mn*O*

InactiveCN101335348AImprove electrochemical performanceSimple processElectrode manufacturing processesLithium compoundsNickel saltHigh energy

The invention relates to a preparation method of 5V level anode material of a lithium ion battery, namely, ball LiNi0.5Mn1.5O4, and pertains to the energy material and novel material preparation technology field. The method includes the steps that: a liquid mixture of manganese salt and nickel salt which is prepared according to a molar ration of 3:1, reacts with dissoluble carbonate or bicarbonate water solution and ammonia or ethylene diamine water solution to obtain ball MnCO3-NiCO3, processes of centrifugal separation, washing and drying are carried out, ball Mn2O3-Ni2O3 powder is obtained by heat treatment at 400 DEG C to 600 DEG C, the ball Mn2O3-Ni2O3 powder is mixed with lithium salt compound, ball LiNi0.5Mn1.5O4 is obtained by heat treatment at 700 DEG C to 900 DEG C. The LiNi0.5Mn1.5O4 anode material obtained by the method has high purity and relatively high specific capacity; the product grain is a ball shape, with high tap density which can reach 2.2 to 2.5 g question mark cm <-3>; the ball grain can provide a beneficial condition to the further carrying out of surface coating and to the improvement of the cycle stability of the material, and has great practical value in the field of high energy density and high power lithium ion battery.

Owner:TSINGHUA UNIV

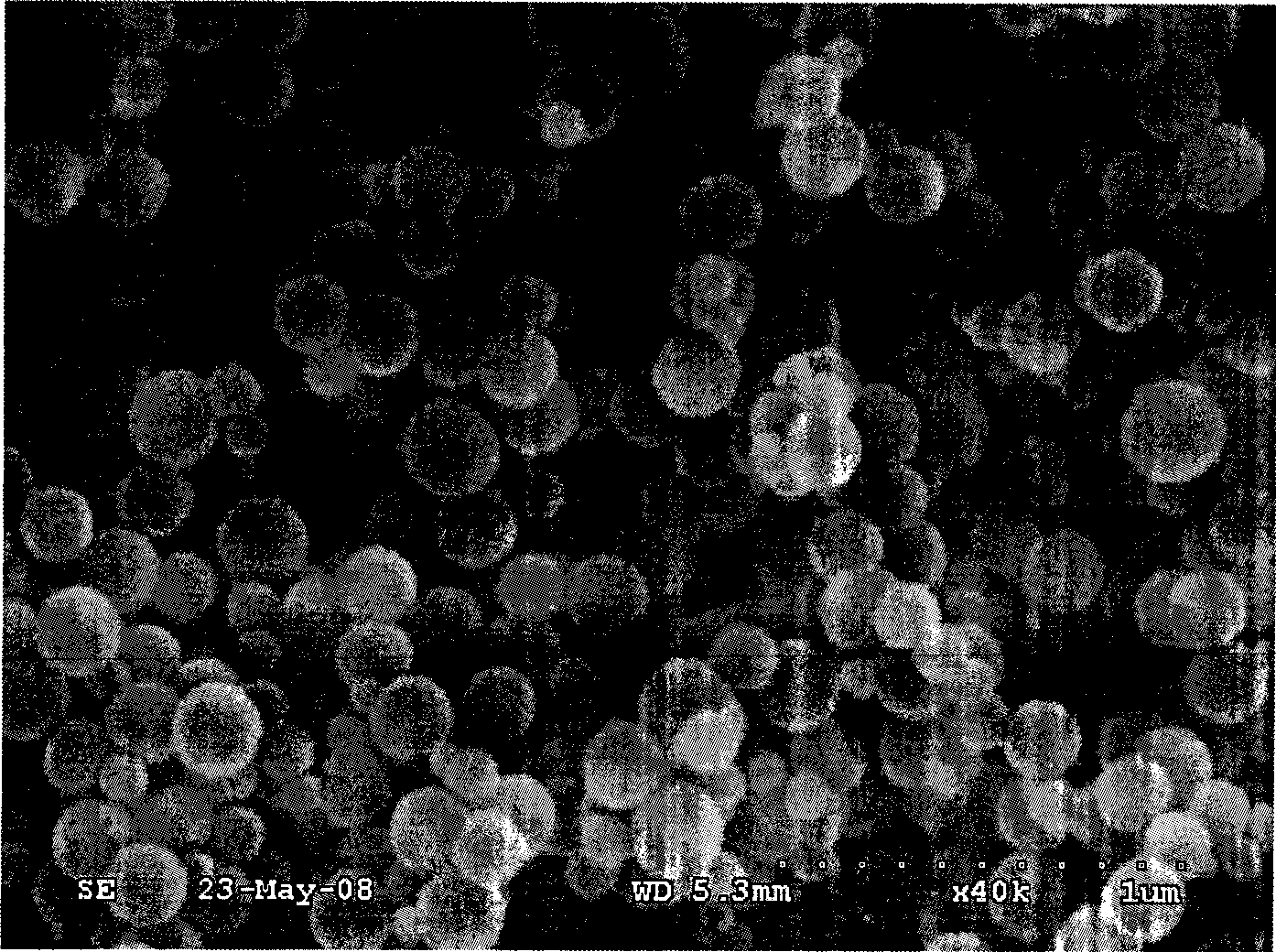

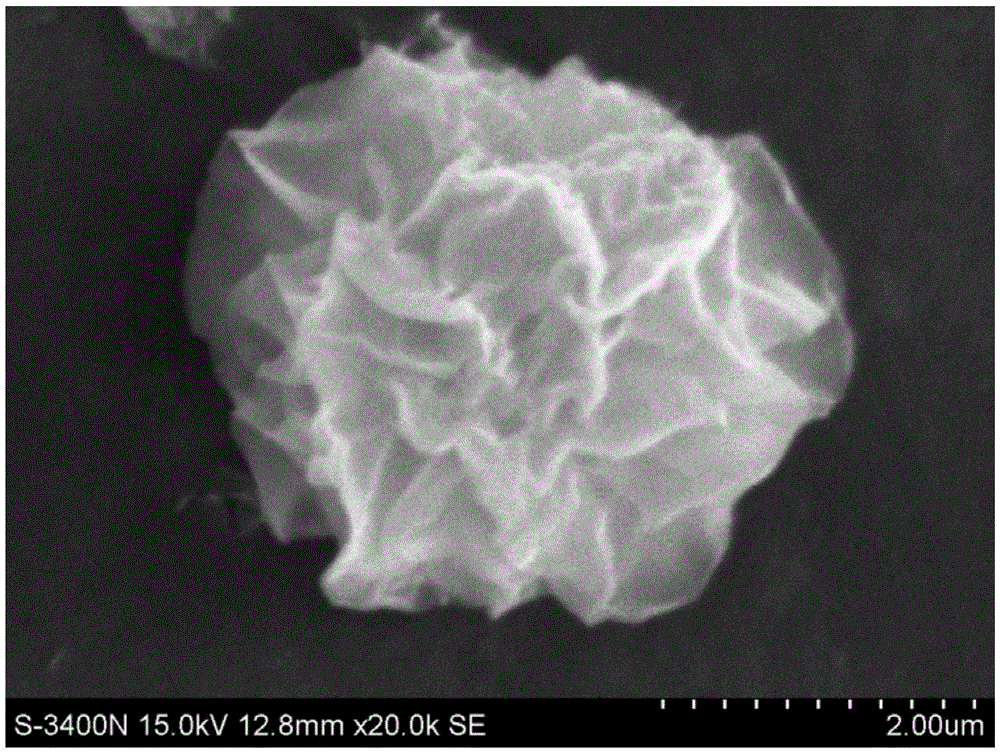

Process for producing homodisperse spherical iron lithium phosphate

InactiveCN101508431ALow costSimple process controlCell electrodesPhosphorus compoundsLithium iron phosphateRoom temperature

The invention relates to a method for preparing uniformly dispersed spherical lithium iron phosphate-an anode material for a lithium ion battery, and belongs to the field of green energy materials. The method comprises the following steps: firstly, preparing a spherical iron phosphate precursor through liquid-phase homogeneous precipitation; secondly, performing predecomposition on the spherical iron phosphate precursor at a temperature of between 350 and 450 DEG C for 2 to 8 hours under the protection of inert gas; and thirdly, performing reaction at the temperature of between 550 and 800 DEG C for 2 to 24 hours to obtain the uniformly dispersed spherical lithium iron phosphate. The particle diameter of the product is between 100 and 200 nanometers, the tap density is between 1.6 and 2.0 g / cm, and the specific capacity of initial discharge at the room temperature reaches 140 to 160 mAh / g. The method utilizes a liquid-phase spheroidization process to prepare the uniformly dispersed spherical lithium iron phosphate, has simple process, and is easy to realize industrialized production.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Method for making ferrous lithium phosphate/carbon compound material of high active disorderly ferric phosphate

InactiveCN101237043AHigh activitySmall particle sizeElectrode manufacturing processesPhosphorus compoundsCarbon compositesPhosphate

The present invention belongs to energy material, and in particular relates to a method of using high-activity disordered iron phosphate to prepare ferrous phosphate lithium / carbon composite material. A ferrous iron source is mixed with phosphorus source solution according to stoichiometric ratio, has hydrogen peroxide added in, has pH value controlled and is stirred so as to prepare high-activity disordered iron phosphate. iron phosphate, a lithium source and a carbon source are mixed pro rata, ball-milled uniformly, spray-dried and treated via high temperature under protective atmosphere, so as to obtain high specific capacity ferrous phosphate lithium / carbon composite material of which the average particle diameter is 200-500nm, 0.25C rate specific discharge capacity reaches 145-150mAh / g, 1C rate specific discharge capacity reaches 130-140mAh / g, and 5C rate specific discharge capacity reaches 105-110mAh / g. The method is low in cost and simple in process. Prepared material is good in electrochemical performance and especially excellent in rate performance, which is applicable to battery anode material of electric vehicles and other large-scale mobile devices.

Owner:NORTHEAST NORMAL UNIVERSITY

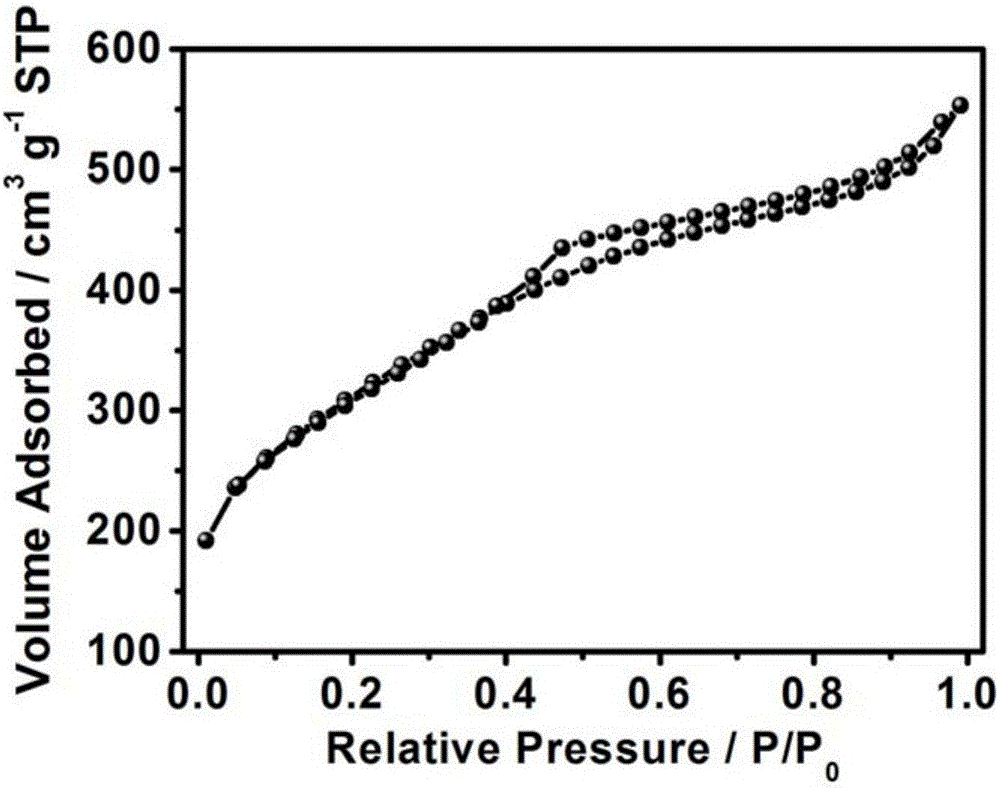

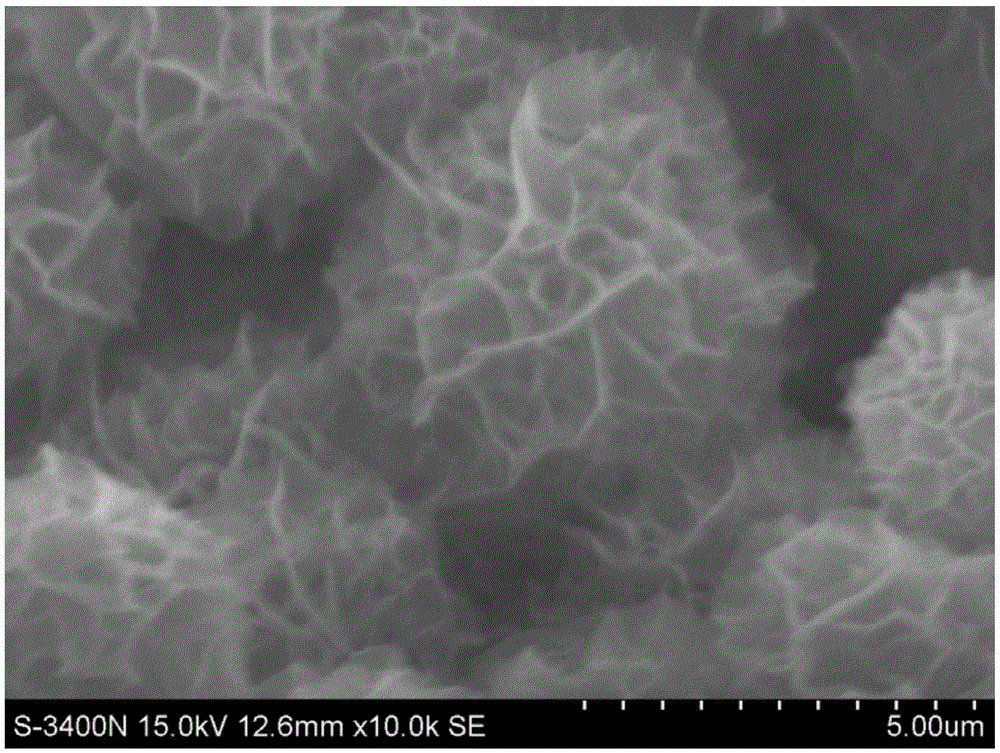

Nitrogen-doped porous carbon and preparation method as well as application of nitrogen-doped porous carbon to super-capacitor electrode material

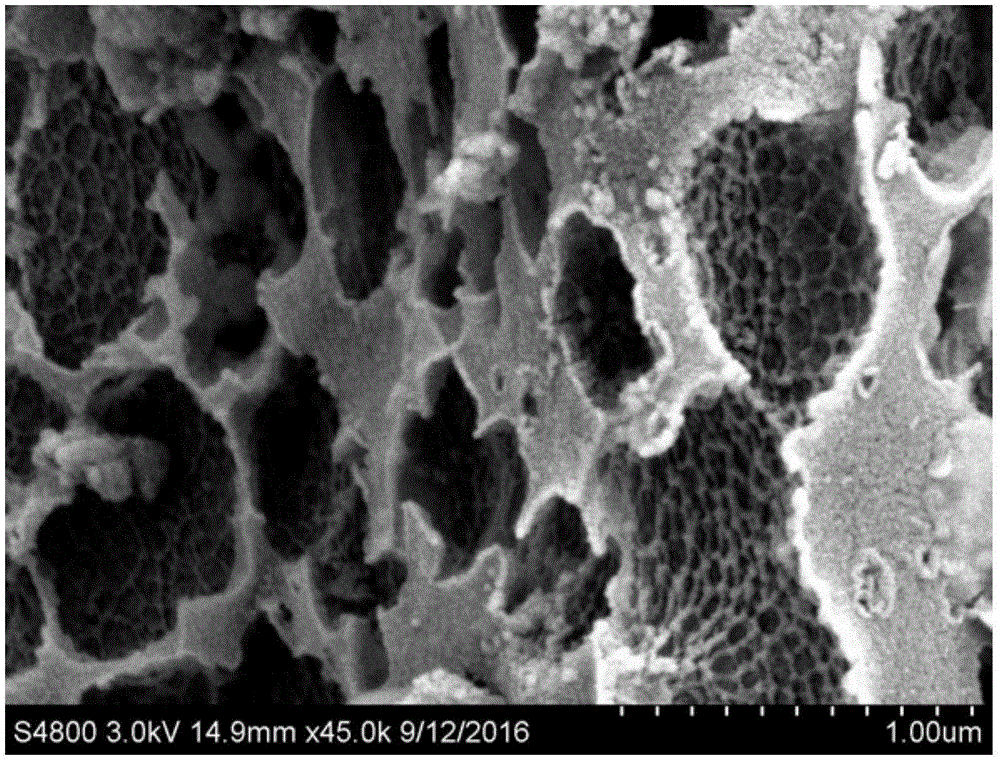

ActiveCN106629724ALarge specific surface areaImprove pore utilizationCarbon compoundsHybrid capacitor electrodesCapacitancePorous carbon

The invention discloses nitrogen-doped porous carbon and a preparation method as well as application of the nitrogen-doped porous carbon to a super-capacitor electrode material and belongs to the technical field of energy source materials and application. The nitrogen-doped porous carbon is prepared by taking natural waste products, namely peanut shells, as raw materials through steps of carrying out ball milling, sieving, carrying out high-temperature activation and washing. The nitrogen-doped porous carbon prepared by the invention has graded pores including micro-pores and medium pores; a main pore diameter range is 2nm to 5nm, the specific surface area is 1000 square meters per gram to 1200 square meters per gram, the nitrogen mass ratio is 8 percent to 10 percent and the mass specific capacitance is 290 Faraday per gram to 310 Faraday per gram; the mass energy density of a nitrogen-doped porous carbon based super-capacitor prepared from the nitrogen-doped porous carbon is 40 watt-hour per kilogram to 43 watt-hour per kilogram; the nitrogen-doped porous carbon has excellent circulating stability so that the nitrogen-doped porous carbon can be better applied to the field of super-capacitor electrodes.

Owner:ANHUI UNIVERSITY

Ni-Mn layered double hydroxide@nickel foam@carbon three-dimensional hierarchically-structured electrode material and preparation method thereof

InactiveCN105655152AGood flexibilityLow reaction temperatureHybrid capacitor electrodesCell electrodesReaction temperatureCarbonization

The invention discloses a Ni-Mn layered double hydroxide@nickel foam@carbon three-dimensional hierarchically-structured electrode material and a preparation method thereof. The preparation method comprises the following steps: firstly carrying out one-step hydrothermal treatment by respectively taking nickel chloride hexahydrate, anhydrous manganese chloride and nickel foam as a nickel source, a manganese source and a substrate, so as to obtain Ni-Mn LDH@NF; and coating Ni-Mn LDH@NF by virtue of glucose or graphene as a carbon source, and carrying out hydrothermal treatment, so as to obtain Ni-Mn LDH@NF@C. According to the preparation method, by virtue of a stepwise hydrothermal-drying method, the preparation process and the required equipment are simple, raw material sources are rich, the reaction temperature is relatively low, the high temperature carbonization is not needed, and the large-scale production is easy to realize; and the Ni-Mn LDH@NF@C composite material is good in thermal stability, high in crystalline degree, large in specific surface area and strong in shape controllability and is one of ideal energy source materials.

Owner:SHANGHAI INST OF TECH

Method for solving flatulence of lithium titanate cathode of lithium battery by using double-boundary wrapping

ActiveCN103187562AImprove cycle stabilityImprove cycle lifeCell electrodesNickel–lithium batteryFlatulence

The invention relates to a method for solving flatulence of a lithium titanate cathode of a lithium battery by using double-boundary wrapping, and belongs to the technical field of energy materials. The method is characterized in that firstly, boundary stabilizing layer wrapping is carried out on a nitride of a lithium titanate cathode material, so as to establish an electrochemistry stable boundary between an electrode material and electrolyte, and subsequently hydrophobic surface layer wrapping is carried out by adopting a nitrogen-containing compound so as to establish a hydrophobic electrode boundary and prevent the crystal water in the electrode material from entering electrolyte; and at the same time the trace moisture of an electrolyte system is prevented from diffusing to the electrode boundary to cause catalysis reaction, and the electrolyte is prevented from decomposing to generate gas in the charging and discharging process, so that the problem that a lithium ion battery is swelled is solved, and the circulation service life of the battery is prolonged.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

Solid electrolyte material for lithium battery and preparation method and application of solid electrolyte material

InactiveCN106532112ASimple methodSimple post-processingSolid electrolytesFuel and secondary cellsSolid state electrolyteHeat stability

The invention discloses a solid electrolyte material for a lithium battery and a preparation method and application of the solid electrolyte material, and belongs to the field of energy material preparation. The solid electrolyte material comprises a metal organic framework compound, a lithium salt, a film-forming additive and a filling. The solid electrolyte material for the lithium battery does not need polyoxyethylene or a derivative thereof; and compared with other inorganic solid electrolytes, the solid electrolyte material has the advantages of higher lithium ion containing capability, higher ionic conductivity and better heat stability, and the security of the battery can be greatly improved. The lithium-ion all-solid-state battery prepared by the method has the electrochemical properties equivalent to a liquid electrolyte. The solid electrolyte material for the lithium battery can be used for a lithium-ion battery, can be suitable for the systems of a lithium-sulfur battery, a lithium-air battery and the like, and is wide in application.

Owner:XIAMEN UNIV

Process for preparing high density spherical lithium ferric phosphate

InactiveCN1821065AHigh yieldWide variety of sourcesCell electrodesPhosphorus compoundsFerrous ammonium phosphateEnergy source

The present invention is microwave synthesis process of high density spherical lithium ferric phosphate as the positive electrode material of lithium ion cell, and belongs to the field of energy source material preparing technology. Spherical lithium ferric phosphate is prepared through mixing ferrous sulfate and solid phosphorus in the required Fe / P ratio; adding in certain speed into deionized water; adding alkali matter to regulate pH value to form the precursor ammonium ferrous phosphate; drying the precursor, mixing with lithium acetate in the same ratio, adding proper amount of conducting agent, and high temperature treatment at 600-800 deg.c for 3-30 hr in the protecting atmosphere. Thus prepared spherical lithium ferric phosphate has average grain size of 5-10 microns, tap density 2.0-2.3 g / cu cm, and room temperature initial specific discharge capacity of 140-160 mA / g. The process is simple, low in cost, high in yield and suitable for industrial production.

Owner:TSINGHUA UNIV

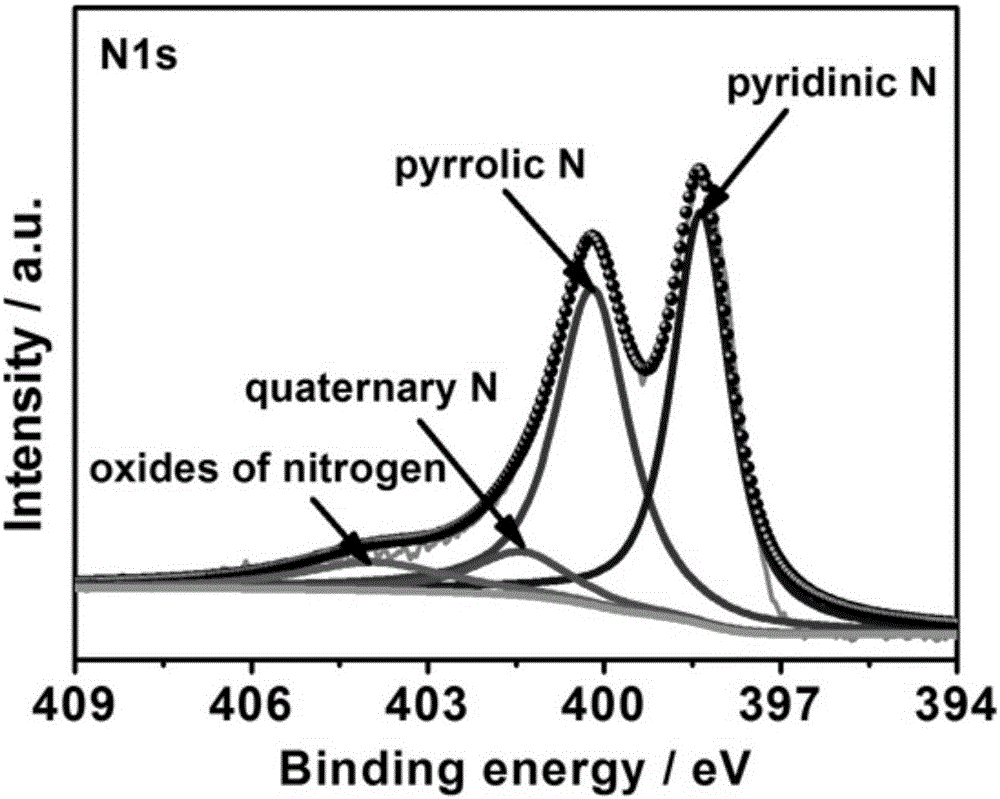

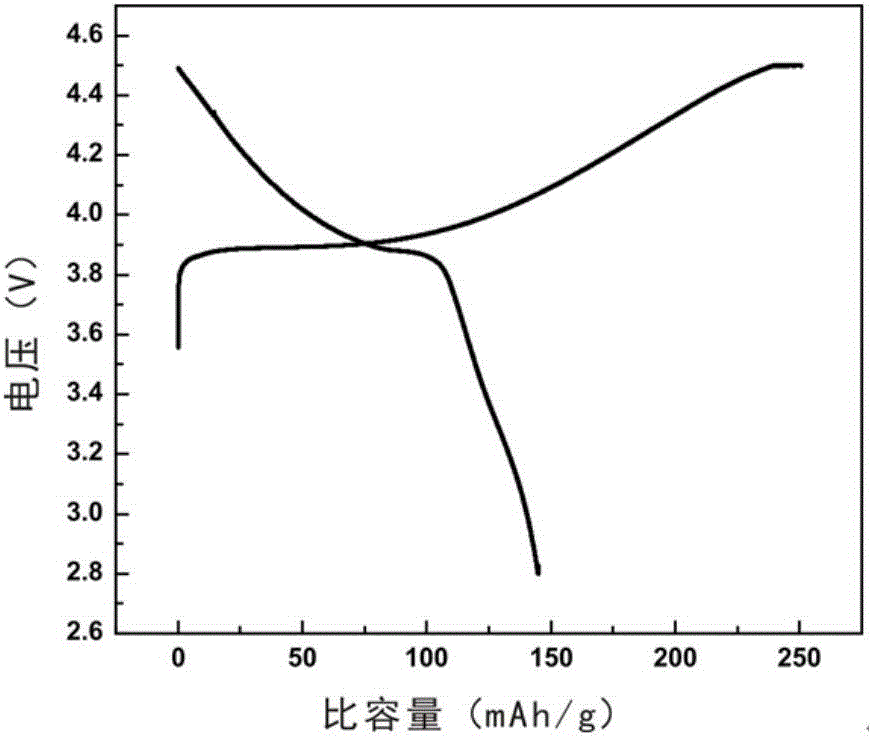

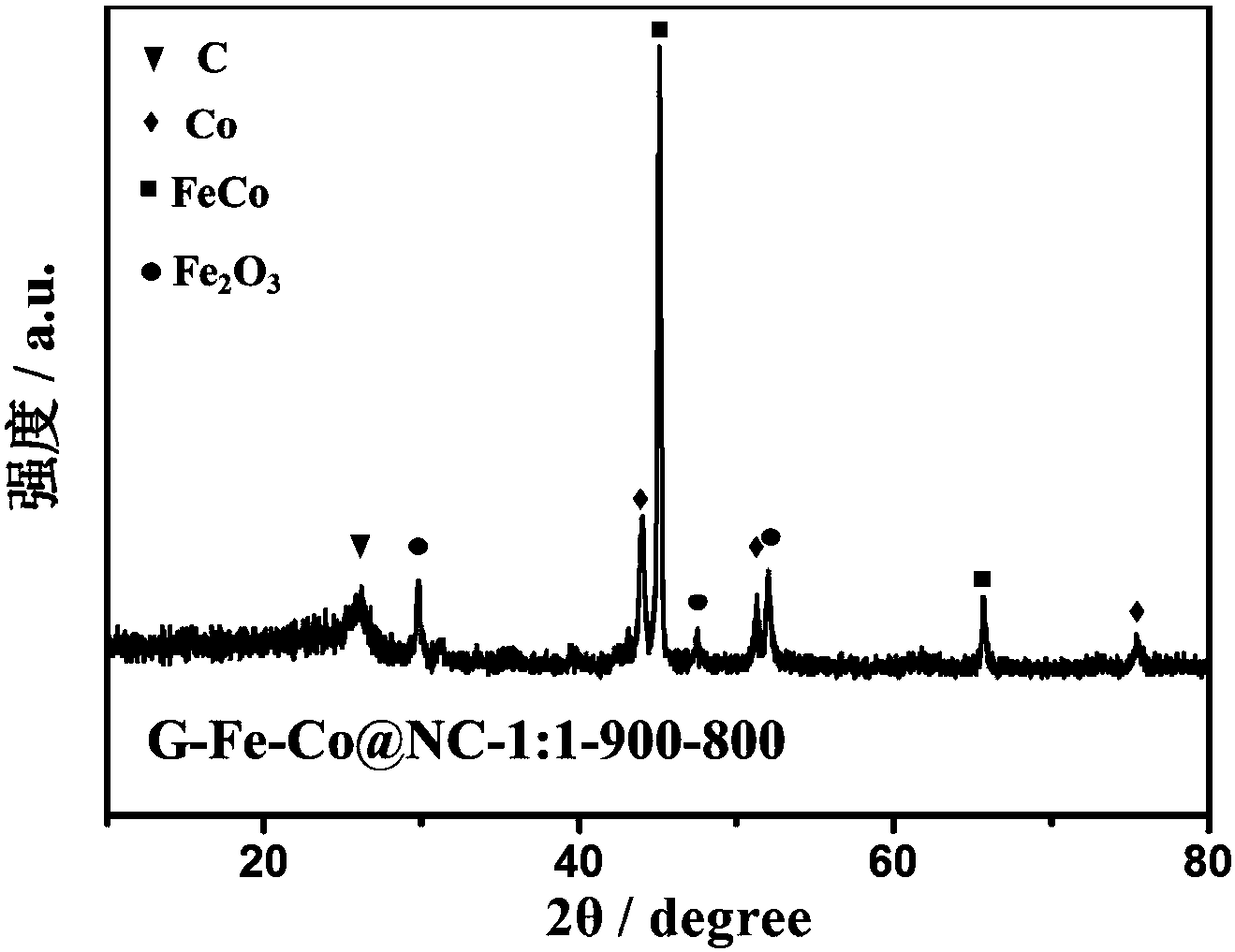

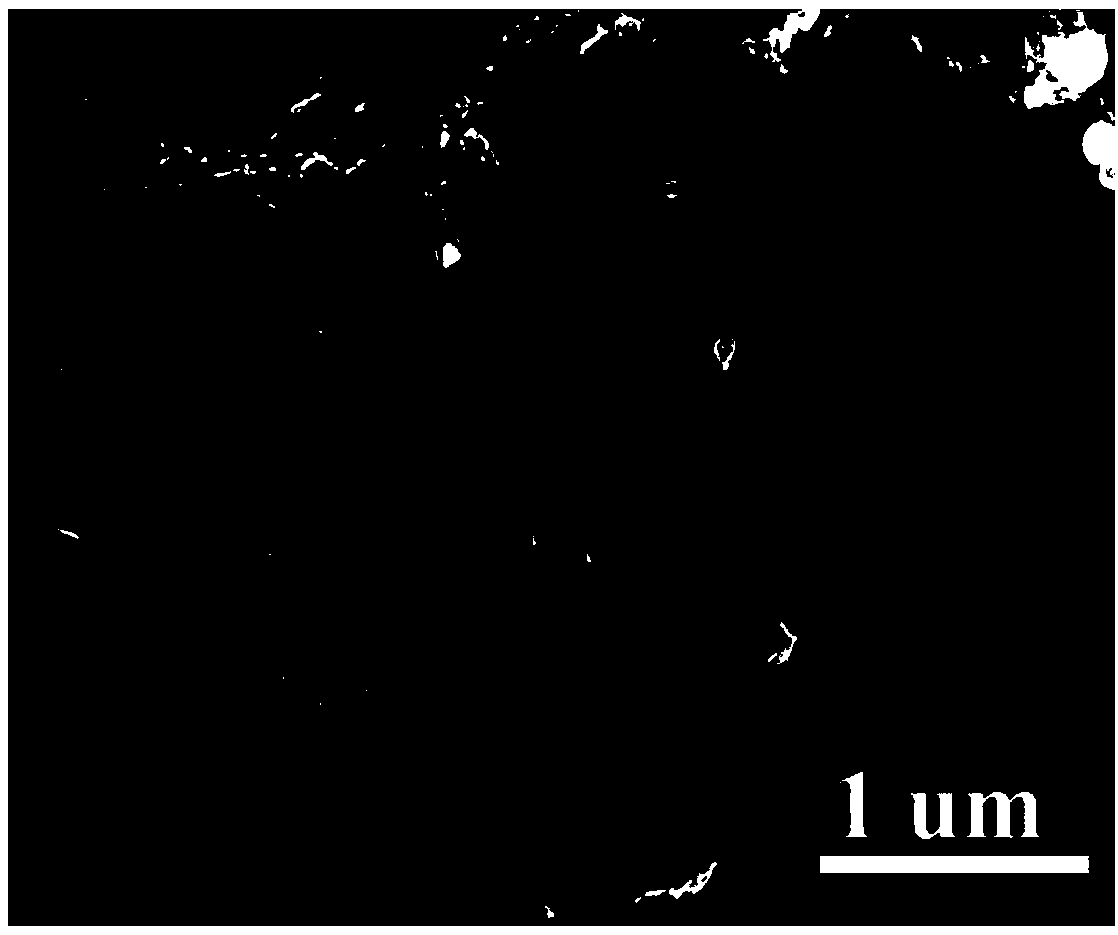

N-doped porous carbon coated Fe and Co bi-metal nanoparticle catalyst and preparation method thereof

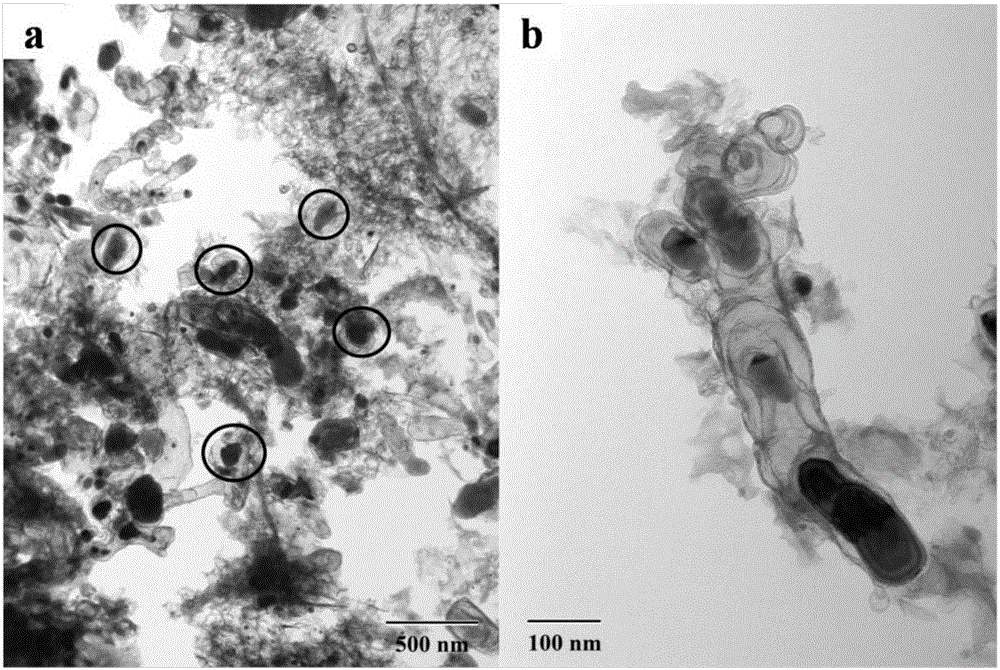

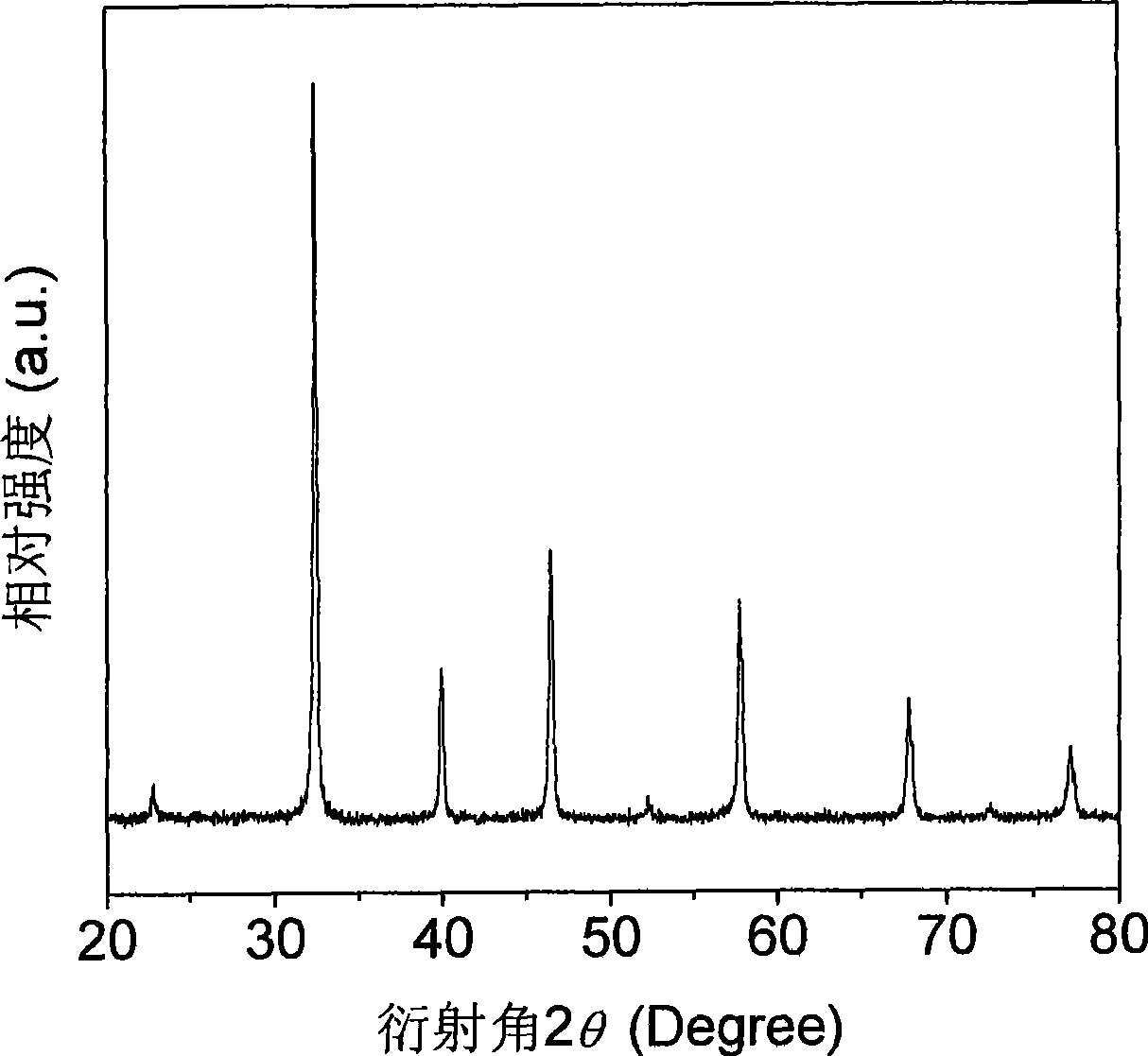

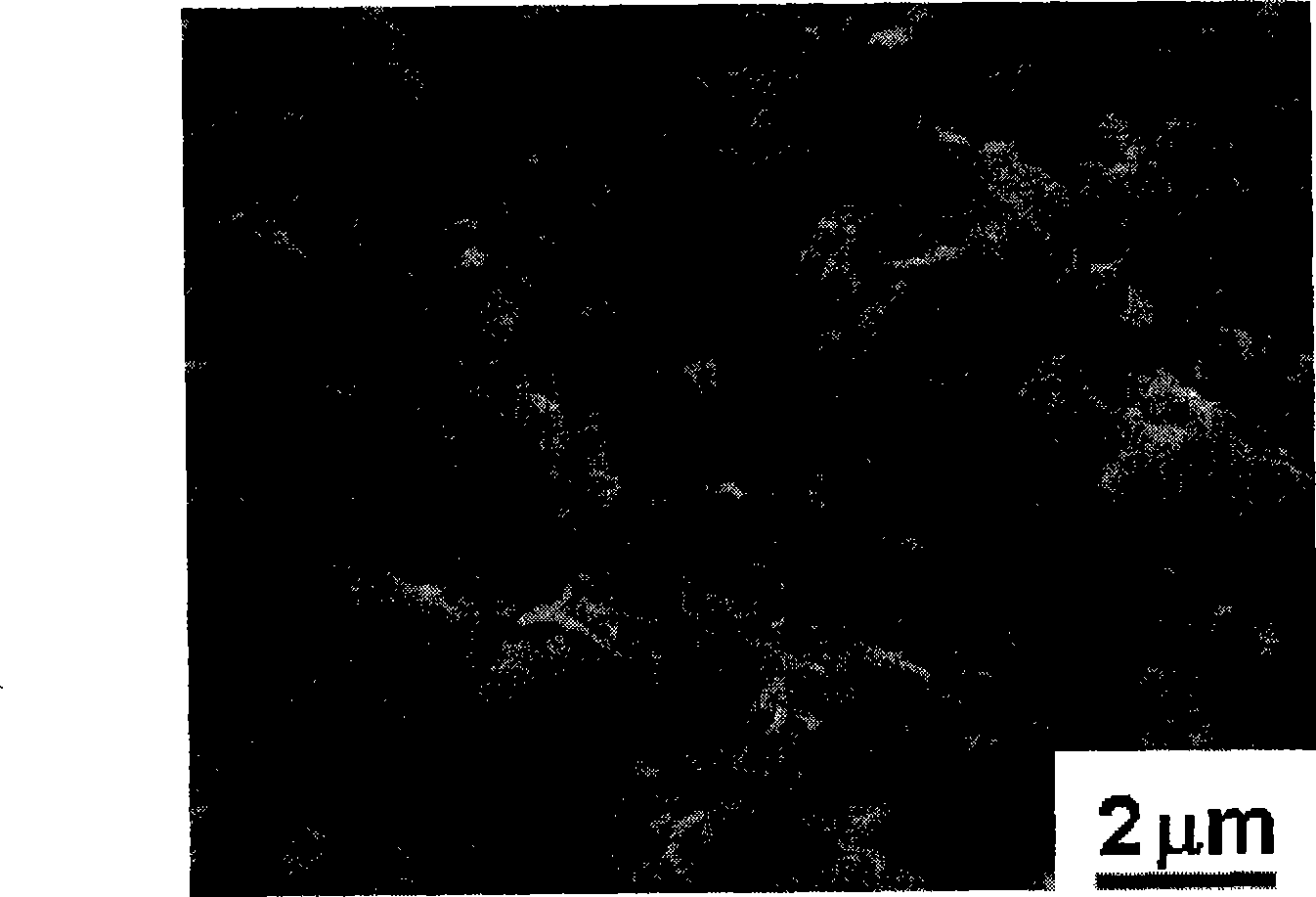

InactiveCN108493461AIncrease varietyInhibit aggregationMaterial nanotechnologyFinal product manufacturePorous carbonMetal alloy

The invention discloses a N-doped porous carbon coated Fe and Co bi-metal nanoparticle catalyst and a preparation method of the N-doped porous carbon coated Fe an Co bi-metal nanoparticle catalyst, and belongs to the field of energy materials and electrochemistry. The catalyst takes glucose as the C source, g-C3N4 as the N source, the C source and the template, F3Cl3.6H2O and Co(NO3)2.6H2O are metal sources, a high-temperature stepwise calcining method is used to prepare the N-doped porous carbon coated Fe and Co Fe-Co@NC catalyst, and the catalyst is in a three-dimensional porous unordered stacking structure. Fe and Co exists in the forms of Fe0.3Co0.7, Fe2O3, and Co, and is evenly coated in the N-doped porous carbon. Compared with the commonly used Pt-based catalyst, the ORR (Overall Response Rate) performance in an alkaline medium is not much different from that of the commercial Pt / C catalysis, the OER (Oxygen Enhancement Ratio) performance is far better than that of the Pt / C catalyst, and the stability and the methanol tolerant property are better. Compared with the commonly seen bi-metal alloy catalyst, the catalyst has more active species, and the specific surface area is larger. In addition, the cost of the raw materials of the catalyst is low, the source of the raw materials is wide, the preparation process is simple and is favorable for large-scale production, and thecatalyst has a higher practical value.

Owner:DALIAN UNIV OF TECH

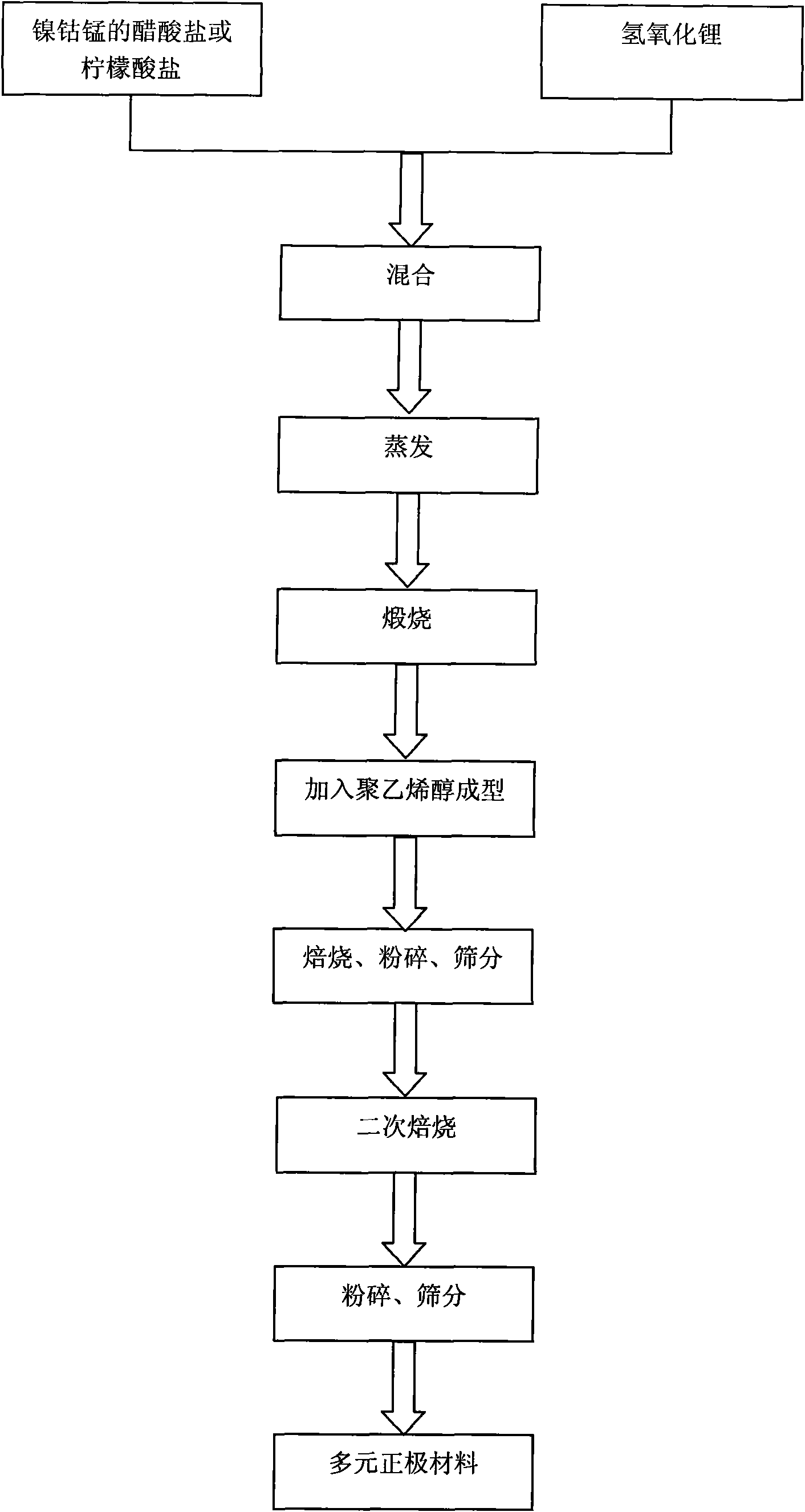

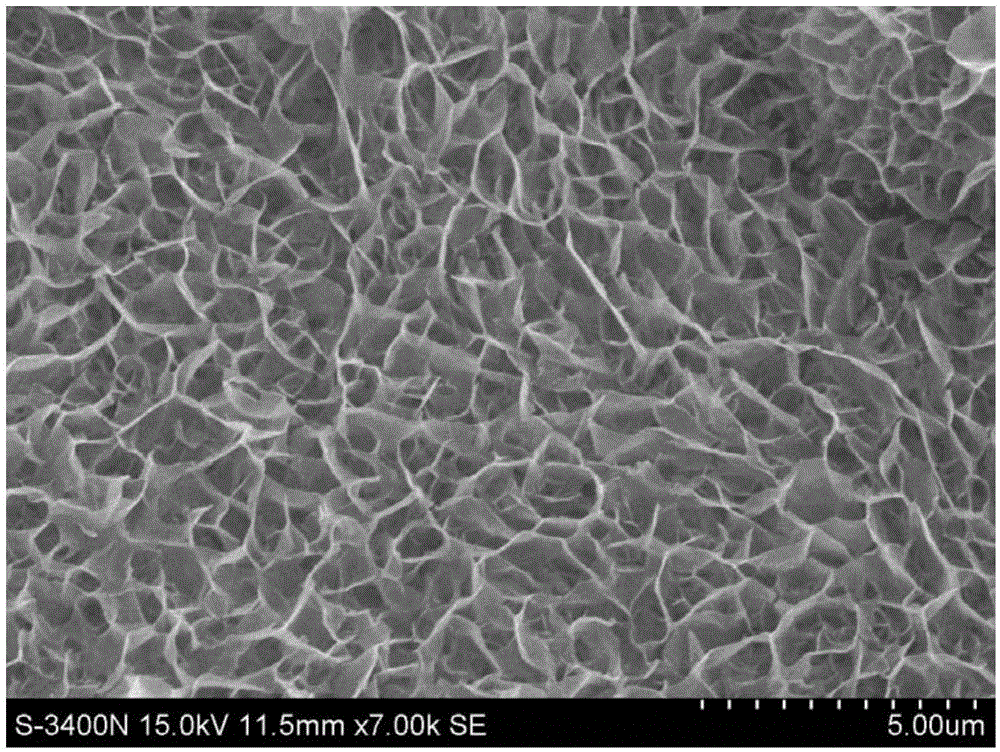

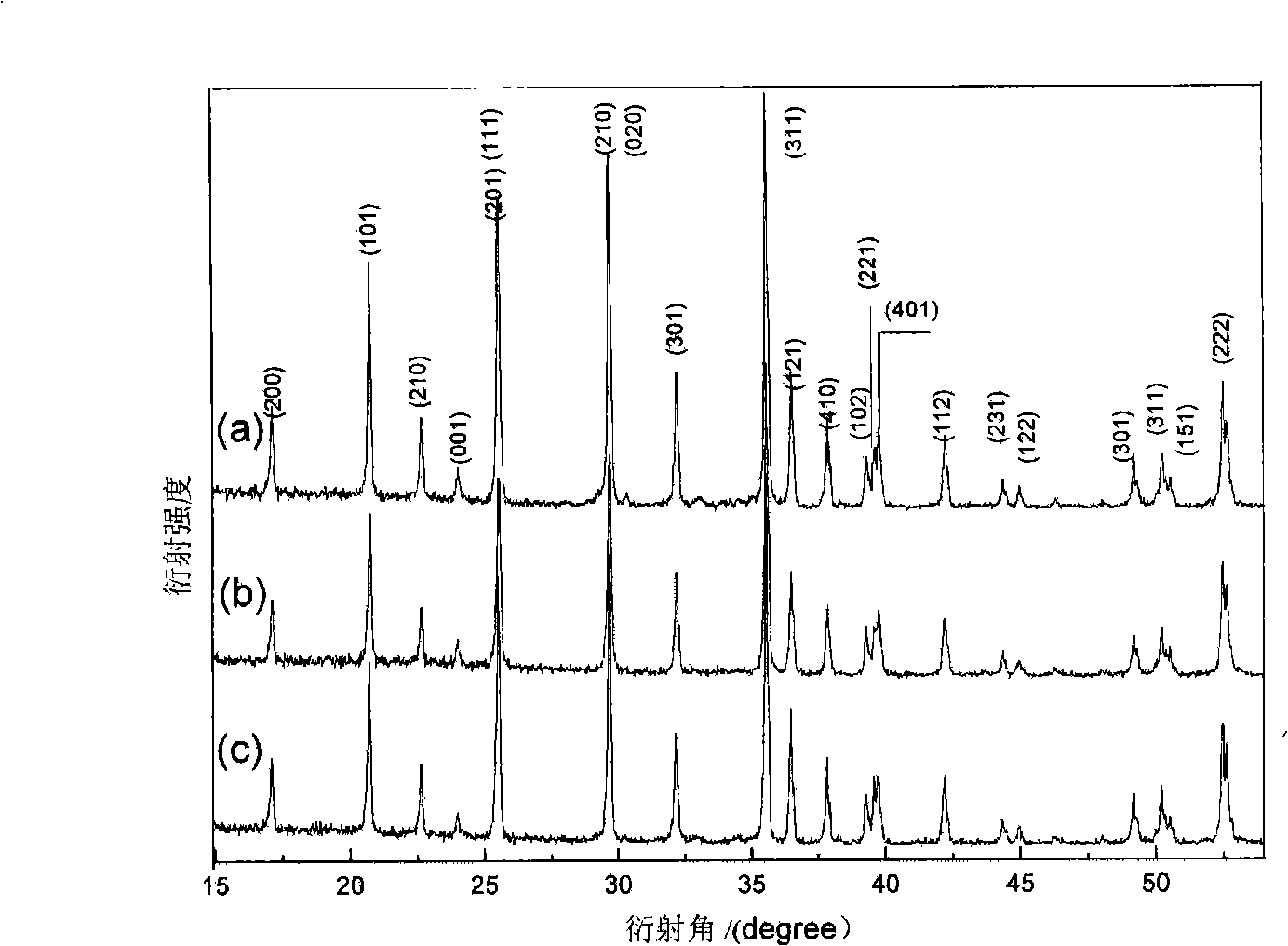

Monocrystal Ni-Co-Mn battery positive pole material and preparing method thereof

ActiveCN103746111AThe size is easy to controlPromote growthCell electrodesSecondary cellsAcetic acidLithium

The invention relates to a monocrystal Ni-Co-Mn battery positive pole material and a preparing method thereof and belongs to the technical field of energy materials. The chemical formula of the monocrystal Ni-Co-Mg battery positive pole material is LiNixCoyMn1-x-yO2, wherein 0.3 < x < 0.8, and 0.1 < y < 0.4. The preparing method of the monocrystal Ni-Co-Mn battery positive pole material comprises the following steps: (1) preparation of seed crystals: adding amino water of which the concentration is 0.5-1.5 mol / L to a carbonate or acetate solution of Ni-Co-Mn; then adding a 1-4 mol / L of LiOH solution; standing, filtering and drying; mixing with LiOH.H2O and forging; (2) preparation of a precursor: adding amino water of which the concentration is 0.5-1.5 mol / L to a carbonate or acetate solution of Ni-Co-Mn, and adding a 1-4 mol / L of LiOH solution; standing, ageing and vacuum drying; (3) preparation of the monocrystal Ni-Co-Mn battery positive pole material through sintering: mixing the precursor with a lithium source and the seed crystal according to a stoichiometric ratio, compacting into a block form, sintering, cooling and pulverizing. The monocrystal Ni-Co-Mn battery positive pole material and the preparing method thereof have the advantages of simplicity in operation, easiness in the control of grain size, narrow grain size distribution range, high product purity, excellent circulating performance, excellent safety performance and the like.

Owner:菏泽建数智能科技有限公司

Method for preparing manganese lithium phosphate/carbon composite material by manganese phosphate

ActiveCN101673819ALow costThe synthesis process is simpleElectrode manufacturing processesCarbon compositesManganese

The invention discloses a method for preparing manganese lithium phosphate / carbon composite material by manganese phosphate, belonging to the technical field of energy material, comprising the following steps: firstly, preparing active manganese phosphate (MnPO4), secondly mixing the active manganese phosphate with lithium source and adding carbon source, ball milling and spray drying the materials, conducting heat treatment on the dried powder in the presence of protective atmosphere, heating to 300-850 DEG C and roasting for 2-12 hours and naturally cooling to obtain the manganese lithium phosphate / carbon composite material. The preparation method has low cost and simple synthesis technology, is applied to industrial production; the prepared manganese lithium phosphate / carbon composite material has a primary particle average diameter of 40-500 nm; the synthetic manganese lithium phosphate / carbon composite material has good electrochemical property when taken as the anode material ofthe lithium battery, high specific capacity and nice circulating performance at the conditions of room temperature and large current density; and the specific discharge capacity with 0.1 C multiplyingpower is more than 130 mAh / g.

Owner:TSINGHUA UNIV

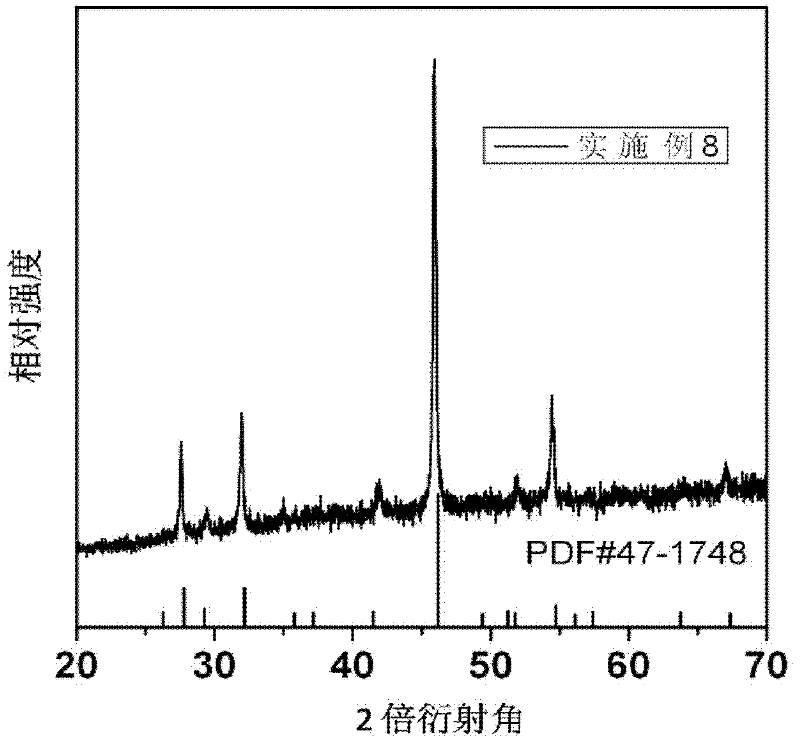

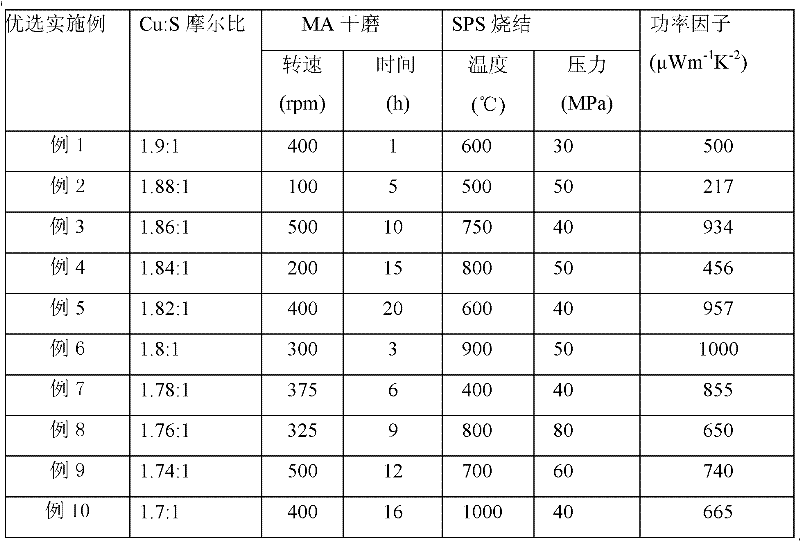

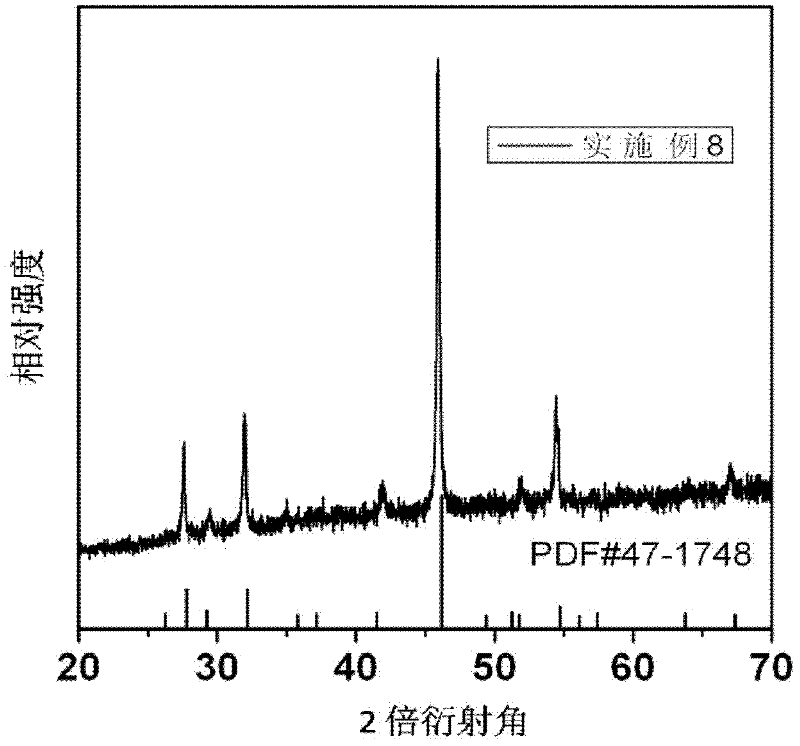

Preparation method of Cu1.8+xS binary thermoelectric material

InactiveCN102363530AShort preparation processShort timeNanotechnologyCopper sulfidesThermoelectric materialsSulfur

A preparation method of a Cu1.8+xS binary thermoelectric material belongs to the technical field of energy materials, and is characterized by comprising the following steps of: using an elemental copper powder (its mass fraction is greater than 99.9%) and an elemental sulfur powder (its mass fraction is greater than 99.8%) as raw materials, preparing a compound powder by a mechanical alloying method according to the ratio of Cu1.8+xS (x is less than or equal to 0.1 and greater than or equal to minus 0.1), and preparing the Cu1.8+xS bulk thermoelectric material which has a rhombohedral structure at room temperature by the adoption of a spark plasma sintering technology. The thermoelectric material has high conductivity and good mechanical properties. The raw materials required by the preparation method are cheap and easily available. The preparation method has advantages of no pollution and short technological process, and is convenient and fast.

Owner:UNIV OF SCI & TECH BEIJING

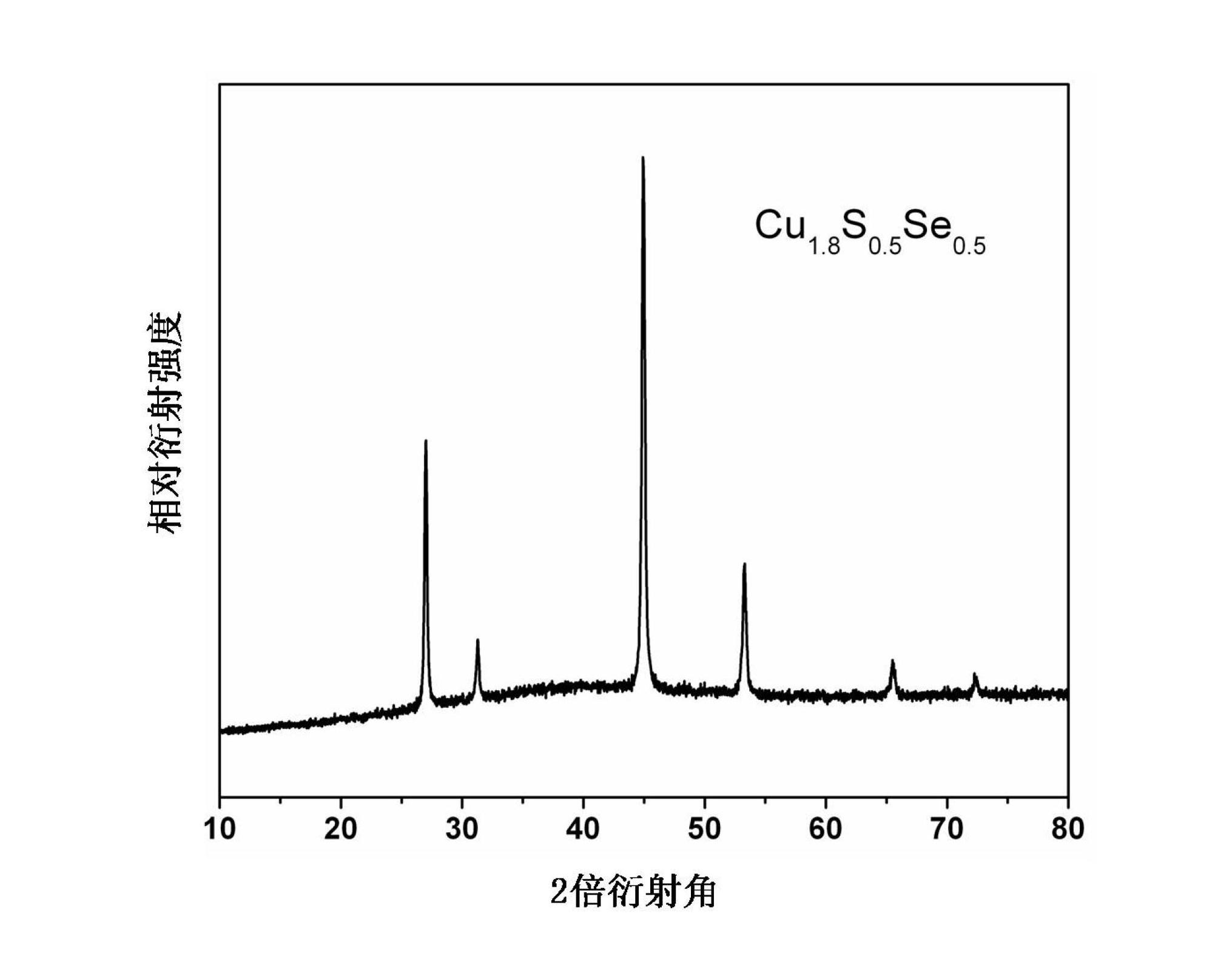

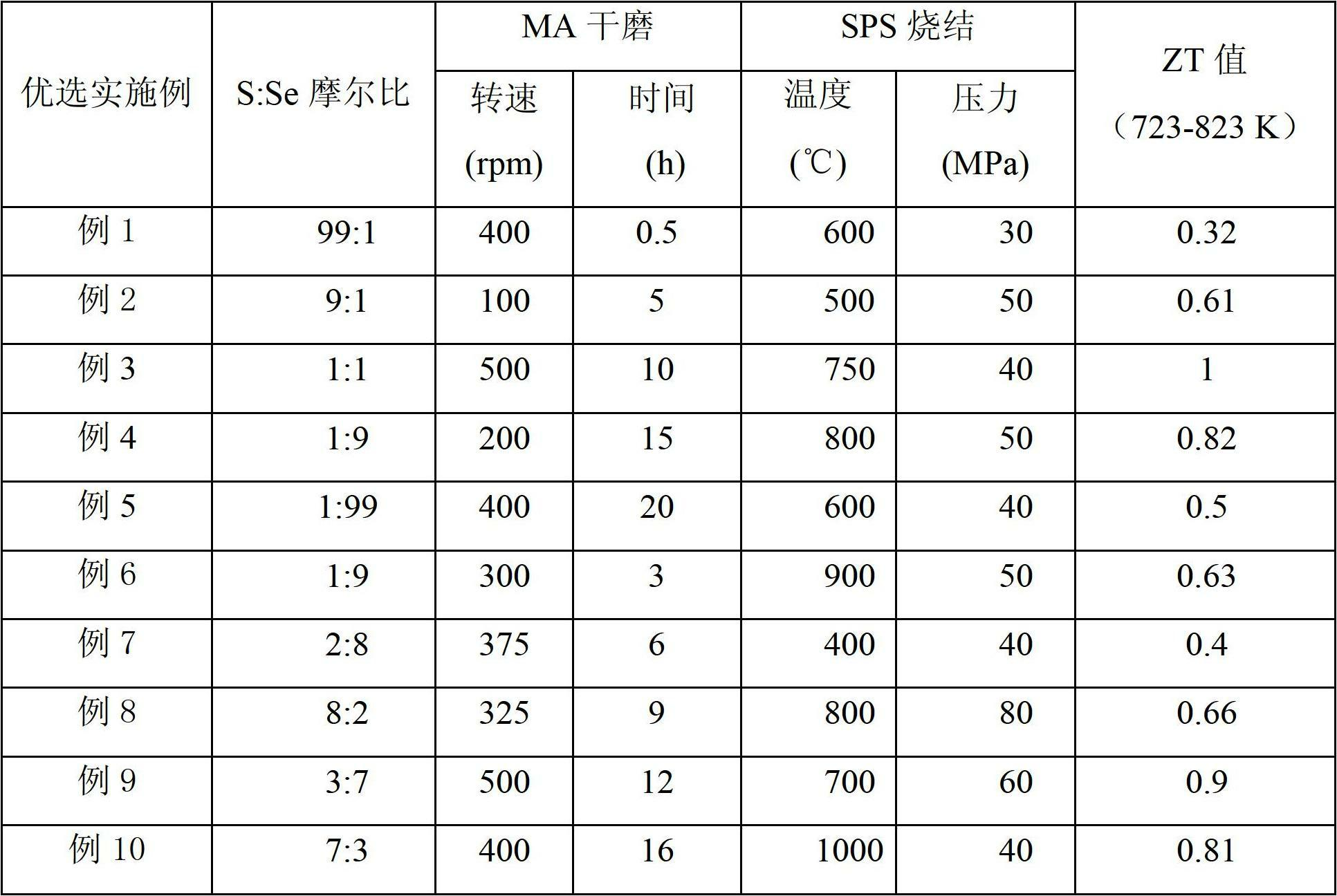

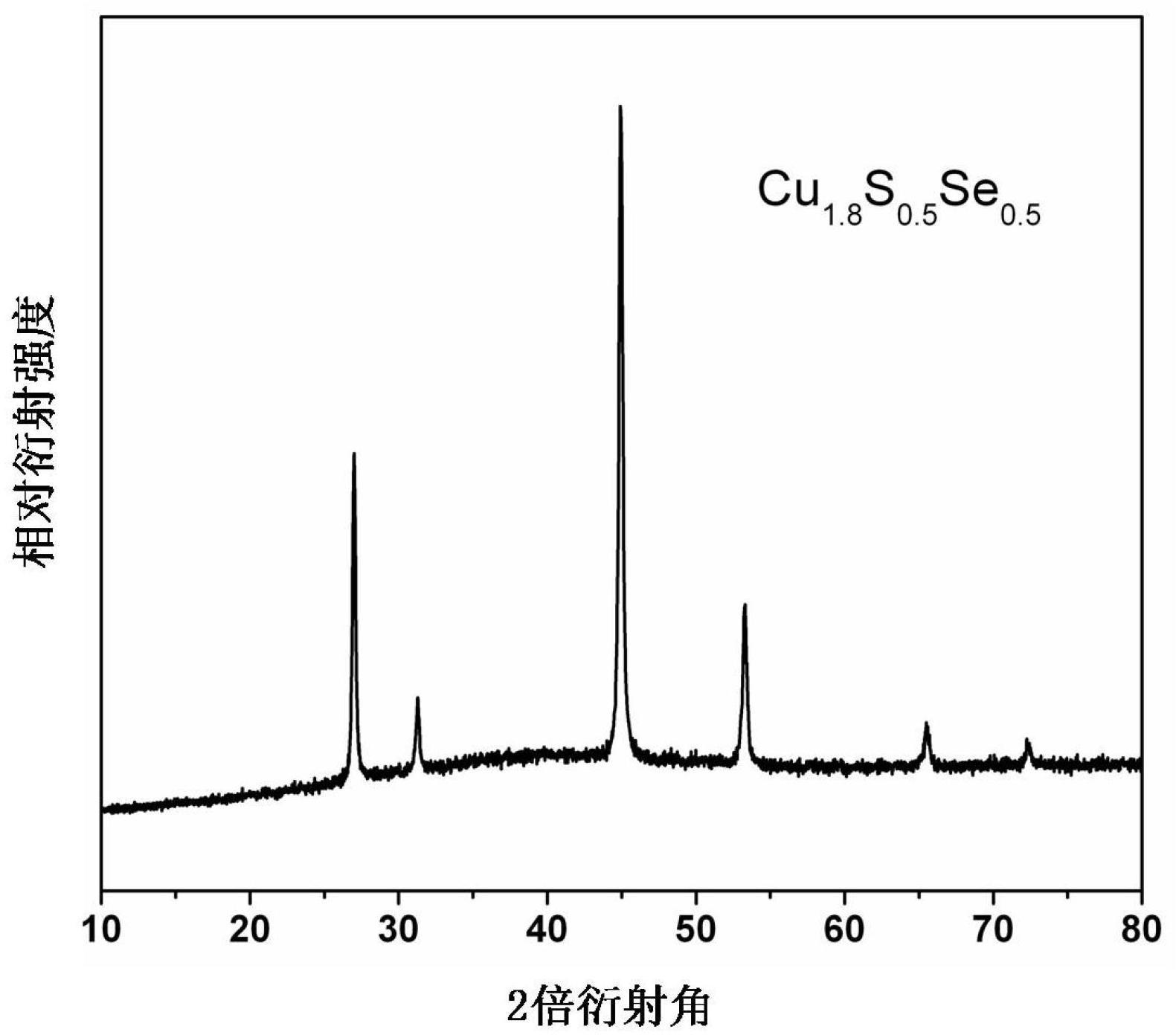

Cu-S-Se ternary thermoelectric material and preparation method thereof

InactiveCN102674842ARaise the average atomic massExcellent thermoelectric performance in the middle temperature regionThermoelectric materialsEnergy materials

The invention relates to a Cu-S-Se ternary thermoelectric material and a preparation method of the material, belonging to the technical field of energy material. The method for preparing the Cu-S-Se ternary thermoelectric material is characterized in that high-pure metal simple substance Cu powder, high-pure Se powder and high-pure S powder are taken as raw materials and are proportioned according to the chemical general formula Cu 1.8 S 1-x Se x (wherein x is the mole fraction of Se component element and is more than or equal to 0.01 and less than or equal to 0.99); and the compound powder is synthesized by a mechanical alloying method, and a block is prepared by spark plasma sintering. The method can be used for preparing the Cu-S-Se ternary thermoelectric material simply, conveniently and accurately, and the Cu-S-Se ternary thermoelectric material has the excellent thermoelectric property at the medium temperature area.

Owner:UNIV OF SCI & TECH BEIJING

Modified diaphragm for lithium-sulfur battery, preparation method thereof and lithium-sulfur battery with diaphragm

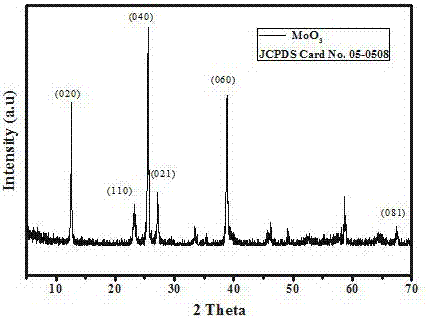

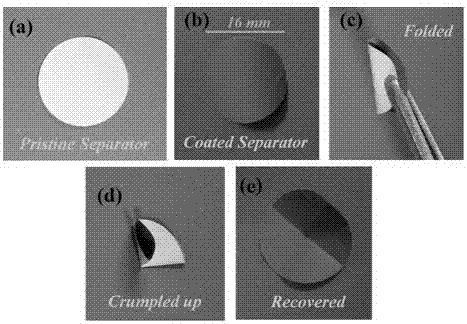

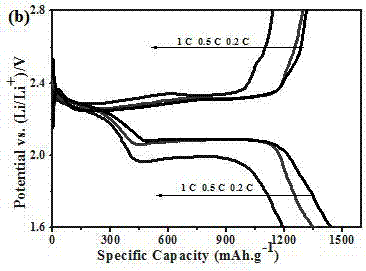

InactiveCN107359303AWide variety of sourcesLow costMaterial nanotechnologyCell electrodesInorganic particleSulfur

The invention belongs to the technical field of energy materials, and specifically relates to a modified diaphragm for a lithium-sulfur battery, a preparation method of the modified diaphragm and the lithium-sulfur battery with the diaphragm; the diaphragm adopts a diaphragm body of a commercial battery as a skeleton, and a decorative coating is coated on one side of the diaphragm body; and the decorative coating consists of nanometer inorganic particles containing molybdenum element, a conductive agent and a binder. Through the diaphragm for the commercial battery and the nanometer inorganic particles containing molybdenum element as raw material and a proportional relation among the raw materials, the composite diaphragm for the lithium-sulfur battery is formed through a simple technology, the technology is simple and controllable, a complex and energy-consuming sulfur-filling process is not needed, the raw materials are wide in sources, the cost is low, and the technology is beneficial for large-scale implementation. The lithium-sulfur assembled in the invention is high in capacity and good in cycle performance, and the preparation technology is simple and controllable, economical and environmentally-friendly, and is applicable for large-scale production.

Owner:UNIV OF JINAN

Method for preparing lithium ionic battery anode material spherical LiFePO4 /C

InactiveCN101330141AUniform carbon dopingImprove conductivityElectrode manufacturing processesChemical/physical/physico-chemical processesSucrosePolyvinyl alcohol

A process for preparing the high-density spherical LiFePO4 / C anode material of lithium ion batteries belongs to the technical field of the energy material. The process comprises the following steps: weighing Fe2O3, a phosphate compound and a lithium-source compound by a stoichiometric ratio; slowly adding to one or more aqueous solutions of hexane diacid, polyethylene glycol, polyacrylic acid or polyvinyl alcohol, and adding one or more of conductive carbon black, sucrose and glucose in a certain amount as well as the doping ions, heating, ball-milling and stirring to form an uniform suspension; spray-drying the obtained suspension to obtain the spherical mixed powder precursor; and carrying out the heat treatment of the precursor under the protection of the inert gas to obtain the high-density high-conductivity LiFePO4 / C anode material. The prepared LiFePO4 / C anode material granule is spherical, has a tap density as high as 1.35-1.45g*cm<-3>, a larger specific surface area and good conductivity, and has high application value in the field of the power-type lithium ion batteries.

Owner:TSINGHUA UNIV

Method for manufacturing metal surface self-cleaning high-protection film

ActiveCN104213112AGuaranteed protective effectWith self-cleaning functionMetallic material coating processesComposite filmMolybdate

The invention provides a method for manufacturing a metal surface self-cleaning high-protection film. The method comprises two steps of molybdate solution soaking treatment and plant corrosion inhibitor-low-surface-energy material collaborative modification treatment. According to the molybdate solution soaking treatment step, a composite film which is of a specific micro / nano coarse structure, has the good protection effect and is composed of metallic oxides, molybdenum oxide and metal molybdate can be formed on a metal surface, and therefore according to the plant corrosion inhibitor-low-surface-energy material collaborative modification treatment step, efficient green plant corrosion inhibitors can be introduced into the film, and the protection effect can be obviously improved. Due to the hydrophobization effect of the low-surface-energy material on the film, the film has the self-cleaning function, the pollution can be avoided, the probability of direct contact of metal materials and corrosive media can be reduced, and the protection effect of the film can be further improved. The method has the advantages of being environmentally friendly, simple in process, convenient to operate, capable of being easily and industrially produced in a large-scale mode and the like.

Owner:重庆中昆新材料科技有限公司

Low-temperature hydro-thermal synthesis for nano-lithium iron phosphate

InactiveCN101279727ANo pollution in the processEasy to controlCell electrodesPhosphorus compoundsPhosphate ionFerrous salts

The invention relates to a low temperature hydrothermal synthesis method for nano lithium ferrous iron phosphate and pertains to the technical field of production process of inorganic compound energy materials. In the method, aqueous solutions of ferrous salt and aqueous solutions of phosphate are mixed, proper amount of complexing agent is added, water-soluble lithium salt or lithium salt which is soluble in a weak acid environment is added, the ratio of lithium ion, ferrous ion and phosphate ion is 1-2:1:1 and the total concentration of the reaction system is 0.1-3.0mol / L; proper amount of pH regulator is added, resultant obtained after heating reaction in a high pressure reaction kettle is carried out washing, separating, drying and heat treatment to obtain nano lithium ferrous iron phosphate material. The method of the invention has simply controllable process, high yield of materials, no heavy metal pollution during the process, even particle of the materials and excellent electrochemical performance, which can be applied to electrode material of lithium-ion battery.

Owner:SHANGHAI UNIV

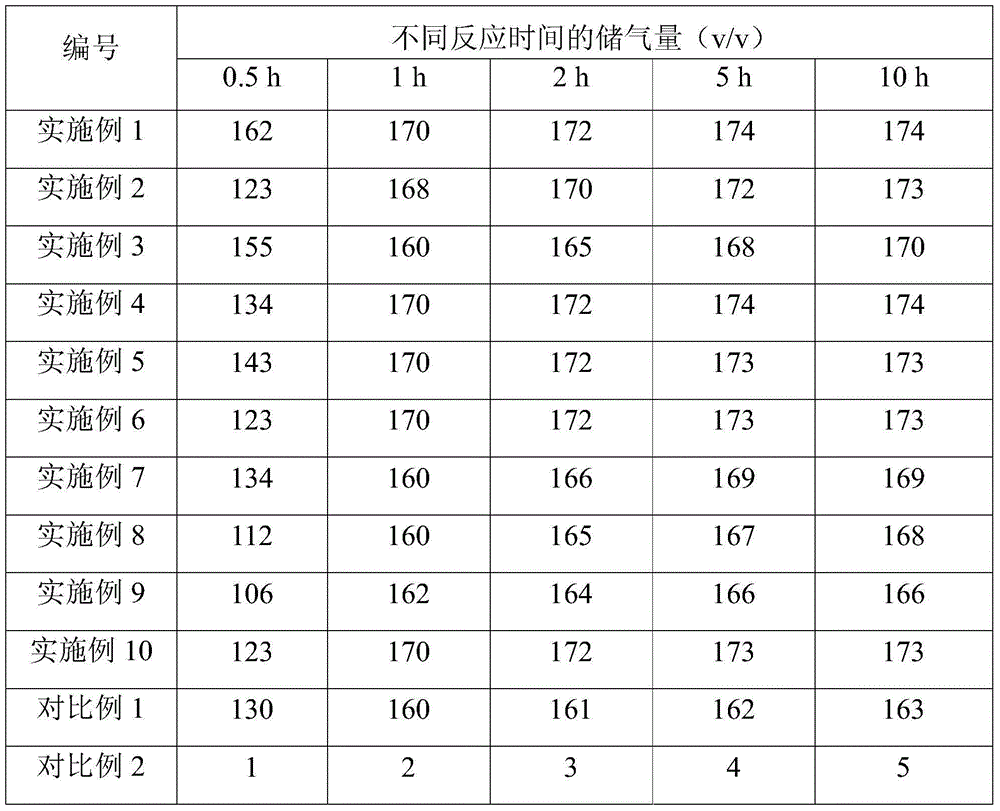

Hydrate accelerant and application thereof in preparing high-gas-storage-density gas hydrate

ActiveCN104974713ANon-toxicNo pollution in the processOther chemical processesGaseous fuelsVolumetric Mass DensityHigh pressure

The invention relates to the technical field of energy materials, and discloses a hydrate accelerator and an application thereof in preparing a high-gas-storage-density gas hydrate. The accelerant comprises amino acid and water, and is prepared by well mixing 100 parts by mass of water and 0.05-5 parts by mass of amino acid. The application comprises the specific steps that 100 parts by mass of water and 0.05-5 parts by mass of amino acid are well mixed, such that an accelerant water solution is obtained; the accelerant water solution is placed in an autoclave; high-pressure gas is delivered in under a low temperature; and a reaction is allowed for a period of time, such that the high-gas-storage-density solid gas hydrate is obtained. The accelerant provided by the invention is green and environment-friendly. With the accelerant, hydration induction time can be reduced, gas storage capacity can be increased, and gas storage density can be improved. The accelerant provided by the invention also has the advantages of low price, low dosage, and wide source. The accelerant is recyclable, and has no special requirement on temperature and pressure conditions. The method for preparing the high-gas-storage-density gas hydrate is fast, highly efficient, simple, and easy to realize.

Owner:SOUTH CHINA UNIV OF TECH

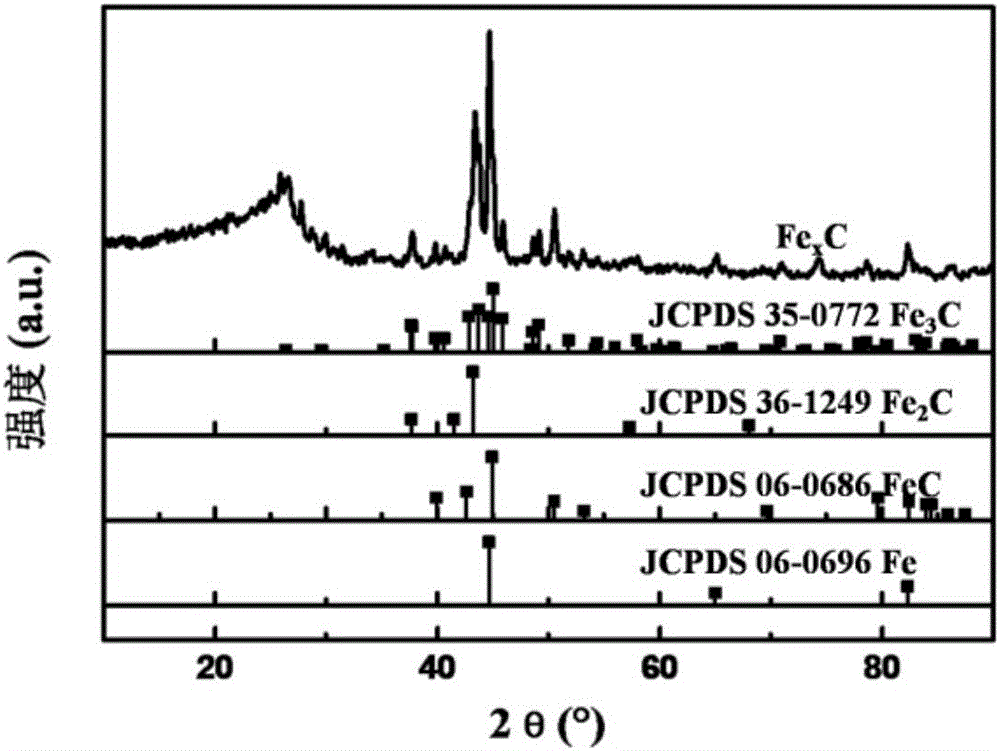

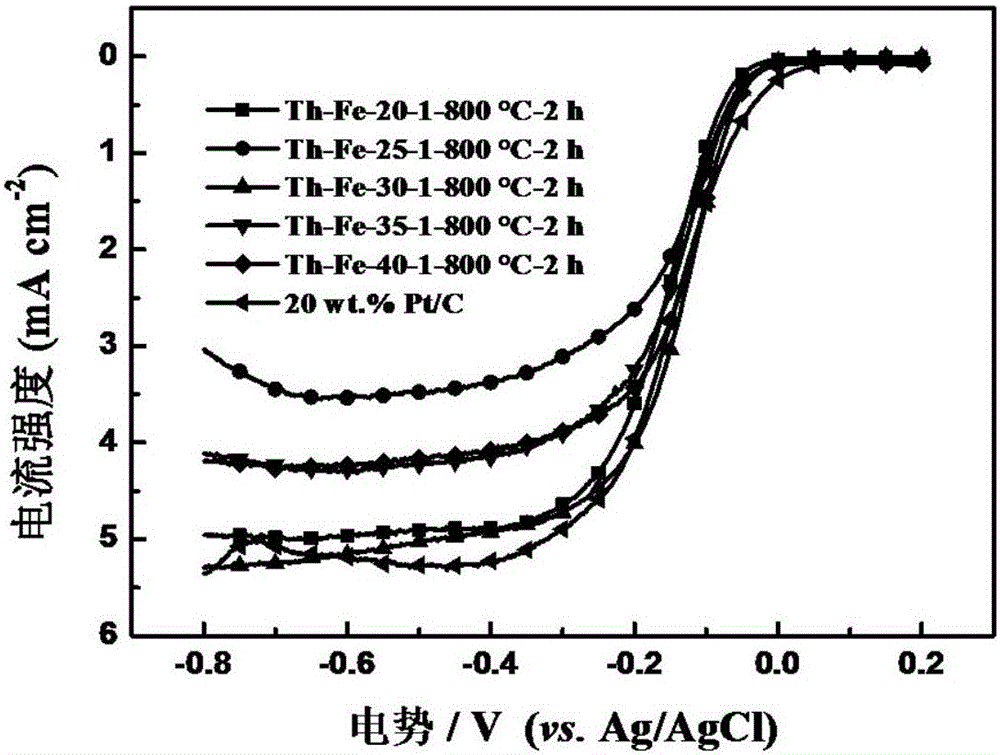

N and S dual-doped carbon nanotube-coated FexC catalyst and preparation method and application thereof

The invention provides a N and S dual-doped carbon nanotube-coated FexC catalyst and a preparation method, and belongs to the field of energy materials and electrochemistry. The N and S dual-doped carbon nanotube-coated FexC catalyst is prepared through pyrolysis in an inert atmosphere by taking thiourea as a C source, a N source and a S source, taking FeCl3.6H2O as a metal source and adopting a one-step method. According to the catalyst, metal particles are coated with N and S dual-doped carbon nanotubes, therefore, direction contact of the metal particles and an electrolyte solution in the reaction process can be effectively avoided, and the catalyst is beneficial for improving the material stability; the catalyst not only shows the oxygen reduction catalyzing performance equivalent to a Pt-C catalyst and the better stability and methanol tolerance under the alkaline condition, but also has the oxygen reduction catalyzing performance under the acidic condition; compared with a common coated-type FexC catalyst, the catalyst has the advantages that the preparation method is simple, the raw materials are easy to obtain, scale production is convenient to achieve, and the high practical value is achieved.

Owner:DALIAN UNIV OF TECH

La doped SrTiO3 base oxide pyroelectric material and preparation method

InactiveCN101423243AStoichiometric ratio is accurateUniform compositionTitanium compoundsThermoelectric materialsStrontium titanate

A La-doped strontium titanate (SrTiO3)-based oxide thermoelectric material and a preparation method thereof, belonging to the technical field of energy materials. The method is divided into two parts of powder synthesis and forming of bulk materials. The powder synthesis adopts the sol-gel method, takes tetrabutyl titanate, strontium nitrate and lanthanum nitrate as raw materials, takes deionized water and ethanol as solvents and takes acetic acid and glycerol as a catalyst and a chelating agent to prepare SrTiO3 gel with different La doping amount, and the temperature is kept at the temperature of 500-560 DEG C for 1-2 hours to obtain precursor powder. The bulk forming adopts the spark plasma sintering method, and the sintering conditions are as follows: the vacuum degree is 2-10Pa, the pressure is 40-50MPa, the heating rate is 100 DEG C / min, the sintering temperature is 900-1000 DEG C, and the holding time is 5-10min. The method synthesizes the La-doped SrTiO3-based bulk thermoelectric material with high chemical homogeneity, uniform and fine grains and single-phase perovskite structure under the conditions of lower reaction temperature and shorter reaction time. The preparation method has the advantages of simple and convenient process, short synthesis and forming time, and the like.

Owner:UNIV OF SCI & TECH BEIJING

Process for preparing super activated carbon from nut shell carbon and waste liquid activation treatment method of process

The invention discloses a process for preparing super activated carbon from nut shell carbon and a waste liquid activation treatment method of the process, belonging to the field of biochemical engineering and energy materials. The process comprises the following steps: soaking nut shell carbon which is subjected to pre-washing and thermal treatment A into an oxidization substance in a vacuum reaction kettle; performing thermal treatment B on the nut shell carbon soaked into the oxidization substance, and soaking into an alkali aquo-complex activating agent in the vacuum reaction kettle; in inert gas or reductive atmosphere, heating the nut shell carbon to perform thermal treatment C so as to obtain activated nut shell carbon; adding water to leach and separate the activated nut shell carbon so as to obtain alkali activated mother liquor A and a solid; adding water into the solid for leaching again so as to obtain carbonate mother liquor B and activated carbon slurry; performing multi-stage washing and acidization treatment on the activated carbon slurry, washing with water, and separating so as to obtain a crude activated carbon product; and performing thermal treatment D of different stages on the crude activated carbon product, thereby obtaining an activated carbon product. The super activated carbon with high yield and good properties can be prepared, and meanwhile useful byproducts such as bicarbonate and hydrated silica can be prepared.

Owner:BEIJING UNIV OF CHEM TECH

Method for recycling lithium in lithium iron phosphate through electrochemical method

InactiveCN105937038AGrade adjustableEasy to recyclePhotography auxillary processesWaste accumulators reclaimingWater basedLithium iron phosphate

The invention relates to a method for recycling lithium in lithium iron phosphate through an electrochemical method, and belongs to the technical field of energy materials. The method for recycling the lithium in the lithium iron phosphate through the electrochemical method is the technical purpose needing to be achieved. According to the method, the lithium iron phosphate serves as a positive electrode, a metal or carbon type electrode serves as a negative electrode, a water-based solution serves as an electrolyte, the electric potential is applied, and lithium ions in a positive electrode material of a lithium battery move into the electrolyte water solution to form a lithium-containing solution. By means of the method, the lithium can be extracted from the lithium iron phosphate at a time, the lithium solution is formed, the emigration rate of the lithium is high and can reach 90% or above and even reach up to 99%, the content of impurities in the obtained lithium solution is low, and therefore the lithium element can be easily and efficiently recycled from the lithium iron phosphate.

Owner:TIANQI LITHIUM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com