Low-temperature hydro-thermal synthesis for nano-lithium iron phosphate

A lithium iron phosphate, hydrothermal synthesis technology, applied in the direction of phosphorus compounds, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of poor performance consistency, long preparation time, complex process, etc., to achieve good application value, material particles The effect of uniform degree and easy process control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

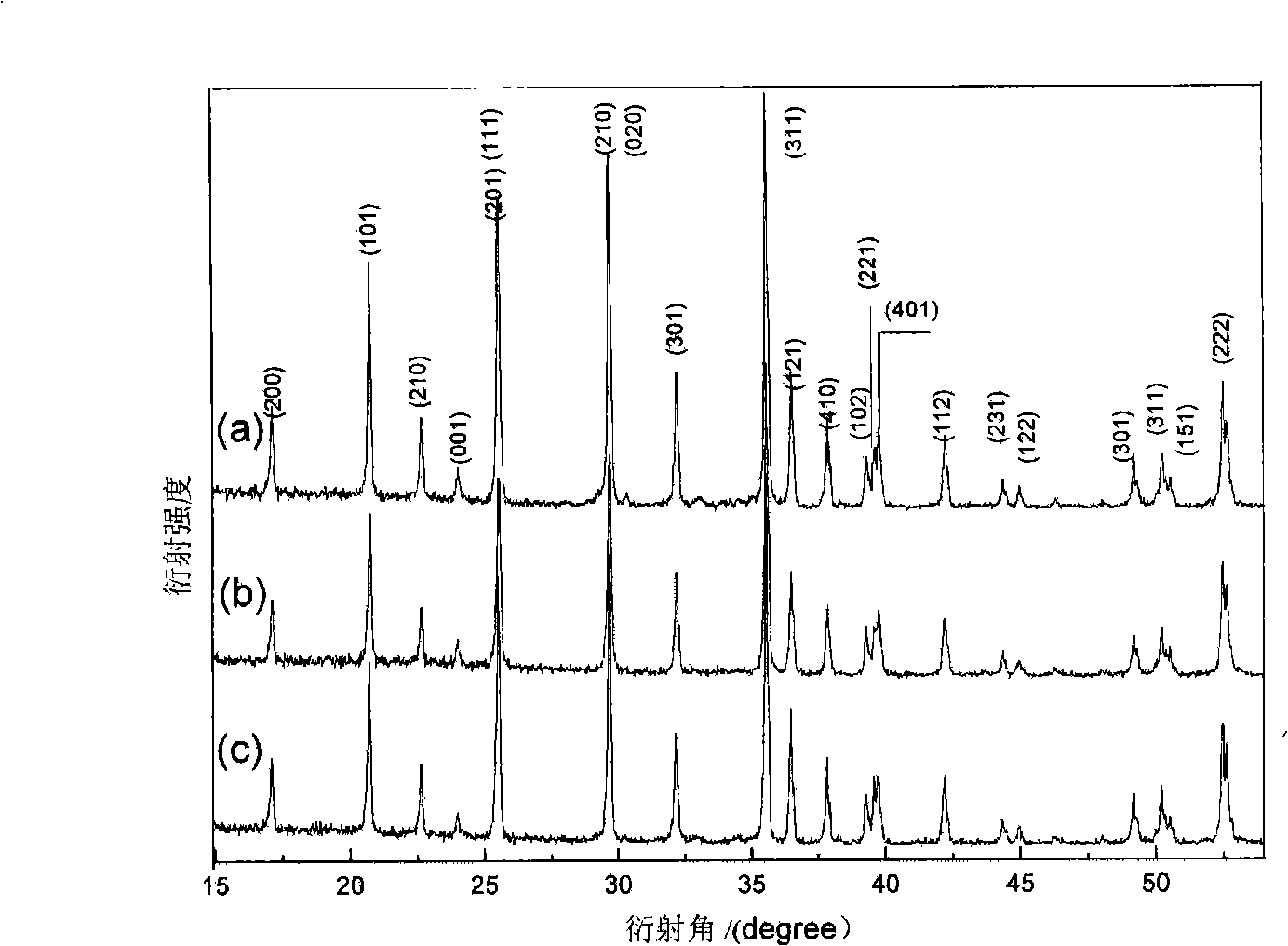

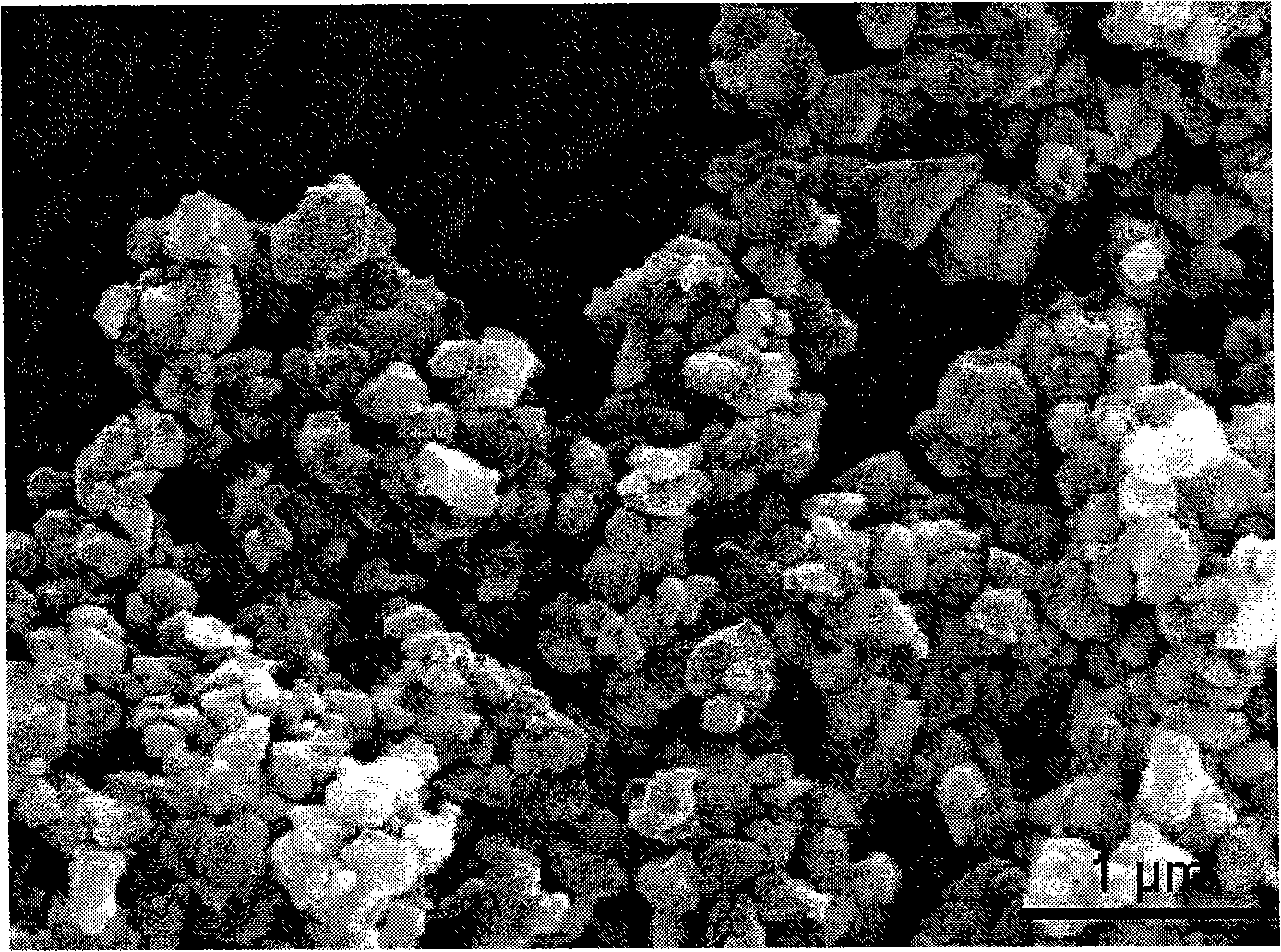

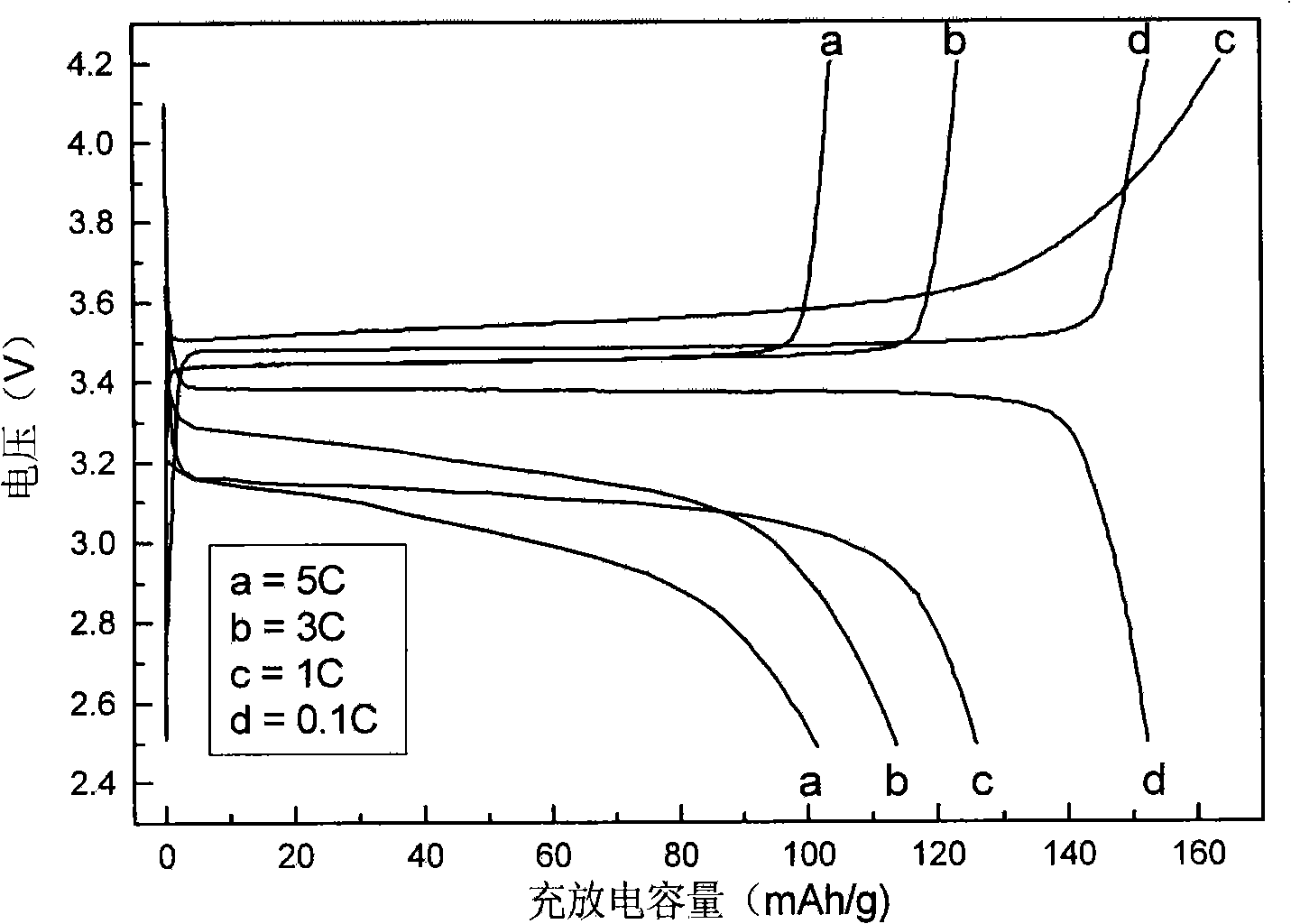

[0027] 27.8g FeSO 4 ·7H 2 O and 13.2g (NH 4 ) 2 HPO 4 Dissolve in aqueous solution and mix well, add 18.6g disodium edetate (complexing agent), then add 6.04g LiCl·H 2 O. Place the precursor solution in an ultrasonic oscillator and vibrate for 5 minutes, then transfer it into a 100mL stainless steel autoclave lined with a polytetrafluoroethylene tank, fill the solution with a volume of 90%, add 6 grams of urea, seal the autoclave, and keep it warm at 150°C for 10 hours Afterwards, the furnace was cooled, and the reaction product was taken out.

[0028] The above reaction product was washed with ethanol, then washed with distilled water, and centrifuged with a high-speed centrifuge (10 min each time, rotating speed 8000 rpm), repeated 3 times. The obtained solid was dried in a vacuum oven at a temperature of 60° C. for 4 hours. After drying, place it in a tube furnace with nitrogen protection, raise the temperature to 400°C at a heating rate of 5°C / min, and cool naturall...

Embodiment 2

[0030] 39.2g (NH 4 )2Fe(SO 4 ) 2 ·6H 2 O and 11.53g of phosphoric acid were dissolved in the aqueous solution and mixed uniformly, after adding 18.6g of disodium edetate (complexing agent), 7.4g of Li 2 CO 3 ·H 2 O. Place the precursor solution in an ultrasonic oscillator and vibrate for 5 minutes, then transfer it into a 100mL stainless steel autoclave lined with a polytetrafluoroethylene tank, fill the solution with a volume of 90%, add 9 grams of urea, seal the autoclave, and keep it warm at 170°C for 10 hours Afterwards, the furnace was cooled, and the reaction product was taken out.

[0031] The above reaction product was washed with ethanol, then washed with distilled water, and centrifuged with a high-speed centrifuge (10 min each time, rotating speed 8000 rpm), repeated 3 times. The obtained solid was dried in a vacuum oven at a temperature of 60° C. for 4 hours. After drying, place it in a tube furnace with nitrogen protection, raise the temperature to 400 deg...

Embodiment 3

[0033] 27.8g FeSO 4 ·7H 2 O and 11.53g of phosphoric acid with a concentration of 85% were dissolved in an aqueous solution and mixed uniformly. After adding 18.6g of disodium edetate (complexing agent), 6.04g of LiCl·H was added under constant stirring. 2 O. Place the precursor solution in an ultrasonic oscillator and vibrate for 5 minutes, then transfer it into a 100mL stainless steel autoclave lined with a polytetrafluoroethylene tank, fill the solution with a volume of 90%, add 9 grams of urea, seal the autoclave, and keep it warm at 170°C for 10 hours Afterwards, the furnace was cooled, and the reaction product was taken out.

[0034] The above reaction product was washed with ethanol, then washed with distilled water, and centrifuged with a high-speed centrifuge (10 min each time, rotating speed 8000 rpm), repeated 3 times. The obtained solid was dried in a vacuum oven at a temperature of 60° C. for 4 hours. After drying, place it in a tube furnace with nitrogen prot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com