Patents

Literature

1203 results about "Ferrous salts" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Iron(II) sulfate (British English: iron(II) sulphate) or ferrous sulfate denotes a range of salts with the formula FeSO4·xH2O.

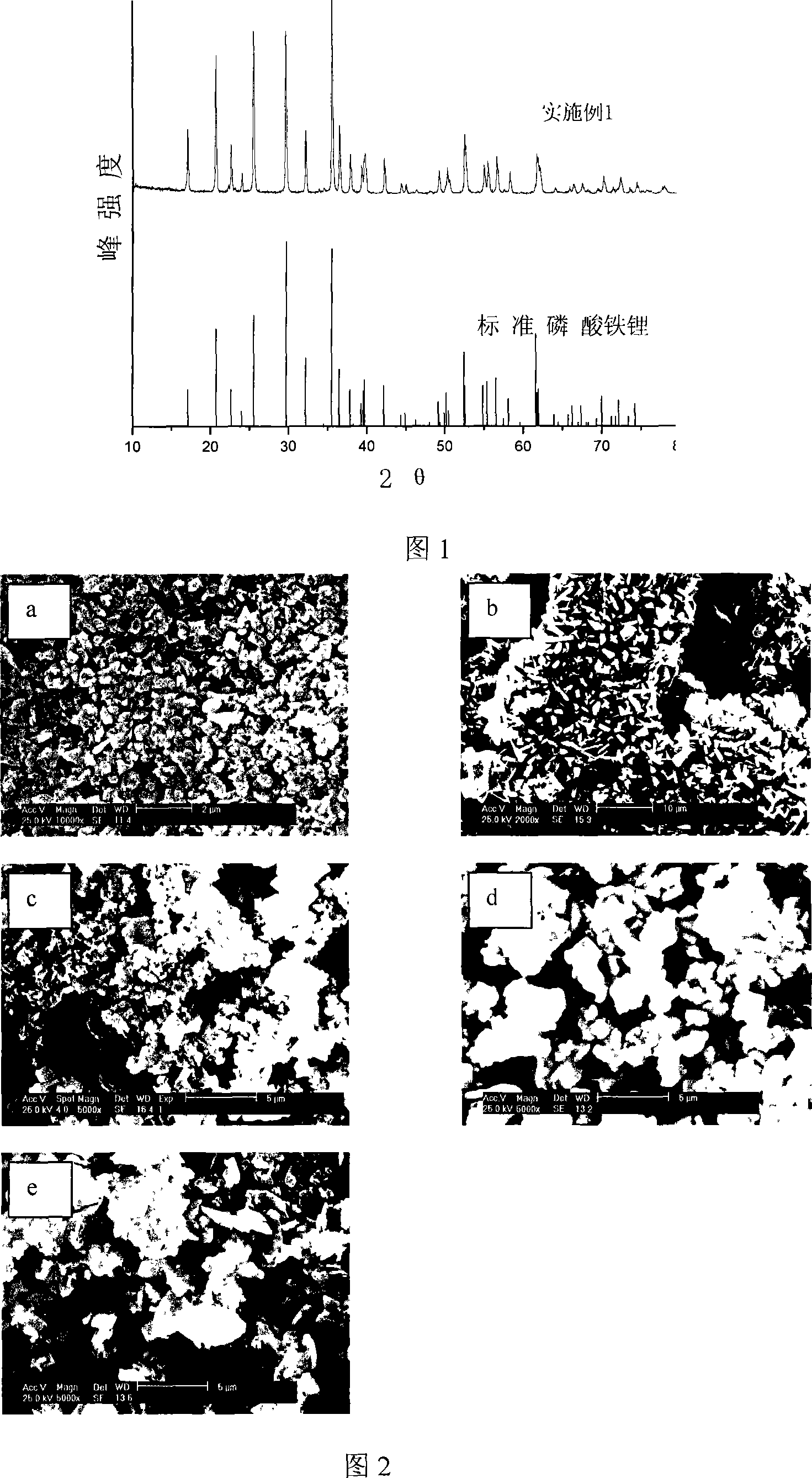

Hydrothermal synthesis method for lithium ion-cell anode material of ferric phosphate lithium

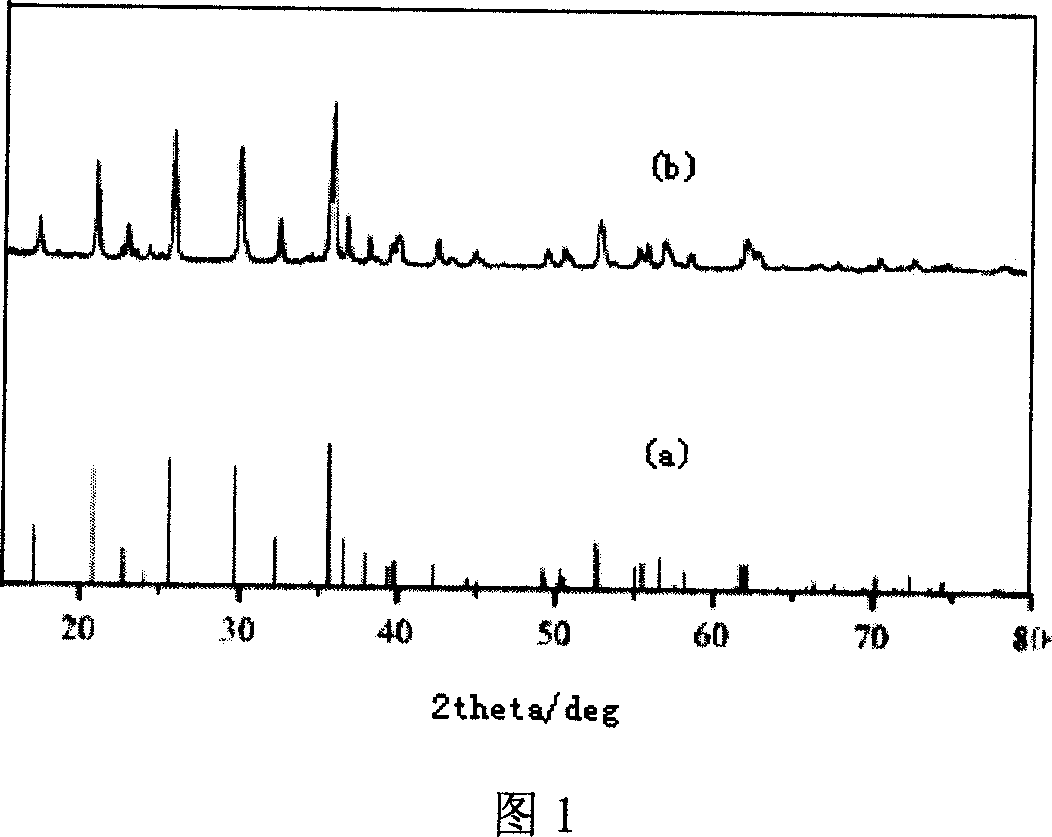

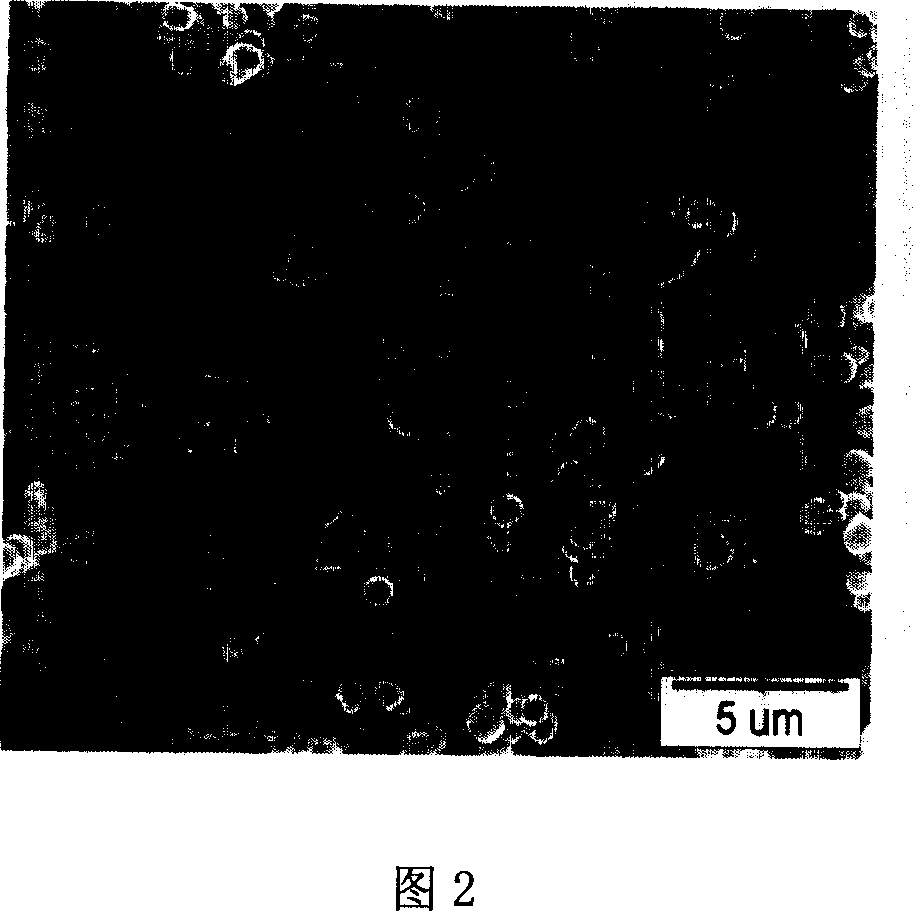

InactiveCN101117216AImprove electrochemical performanceShorten the diffusion pathCell electrodesPhosphorus compoundsExhaust valveDead volume

The invention discloses a hydrothermal synthesis method of lithium-ion battery anode material of lithium iron phosphate, relating two kinds of metal phosphate. The steps are as follows: lithium source and phosphorus source are dissolved in water or mixed with water, and added into the reaction autoclave, the quaternary cationic surfactants and the alkylphenols polyoxyethylene ethers nonionic surfactant is also added into the reaction autoclave, the air in the dead volume of the autoclave inside is purged by the inert gas, the autoclave is sealed and heated to 40-50 DEG C with stirring, a feed valve and an exhaust valve are opened, pure ferrous salting liquid is added into the autoclave, and then the autoclave is sealed for the reaction of the material at 140 to 180 DEG C for 30 to 480 minutes; the mixture ratio of the invention is set as follows: the molar ratio of Li, Fe and P is 3.0-3.15:1:1.0-1.15, and then the resultant is filtered, washed, dried and carbon-coated, thus the lithium iron phosphate is obtained. The lithium iron phosphate which is produced by the invention has the advantages that: the electrochemical performance is excellent, the particle size distribution of which the D50 is between 1.5 um to 2 um is even, the phase purity is above 99 percent and the electronic conductivity of the material is improved.

Owner:HEBEI LITAO BATTERY MATERIAL

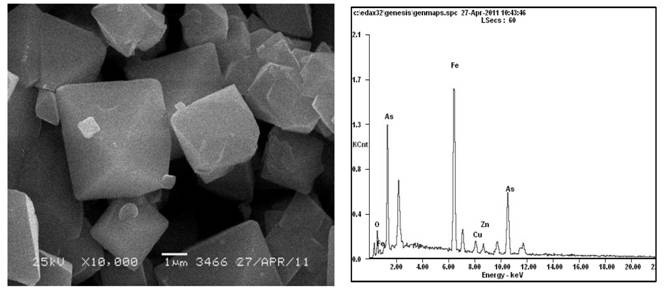

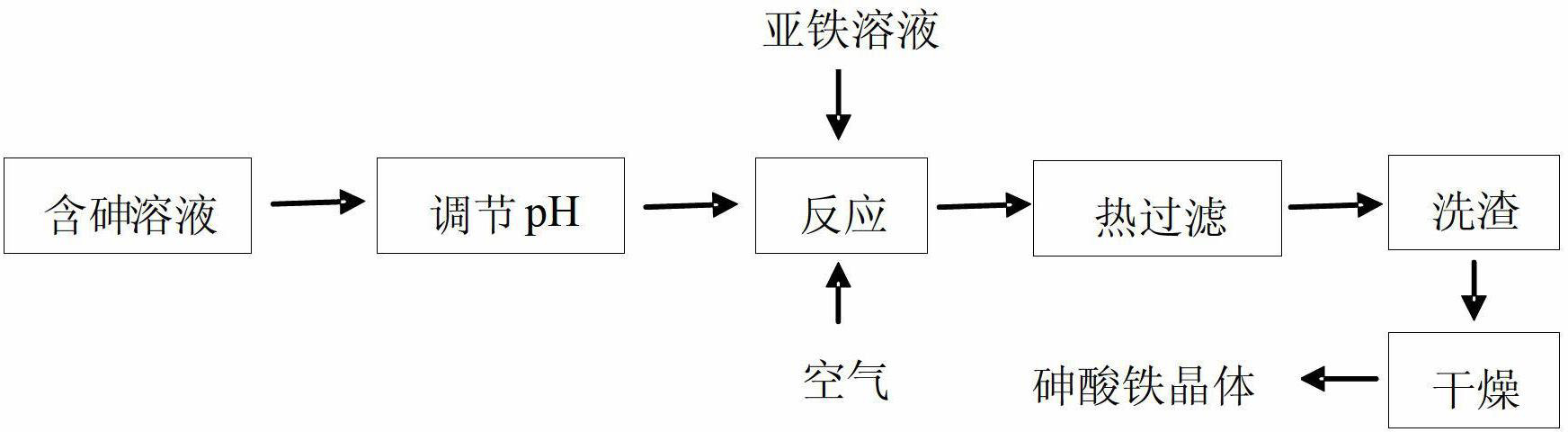

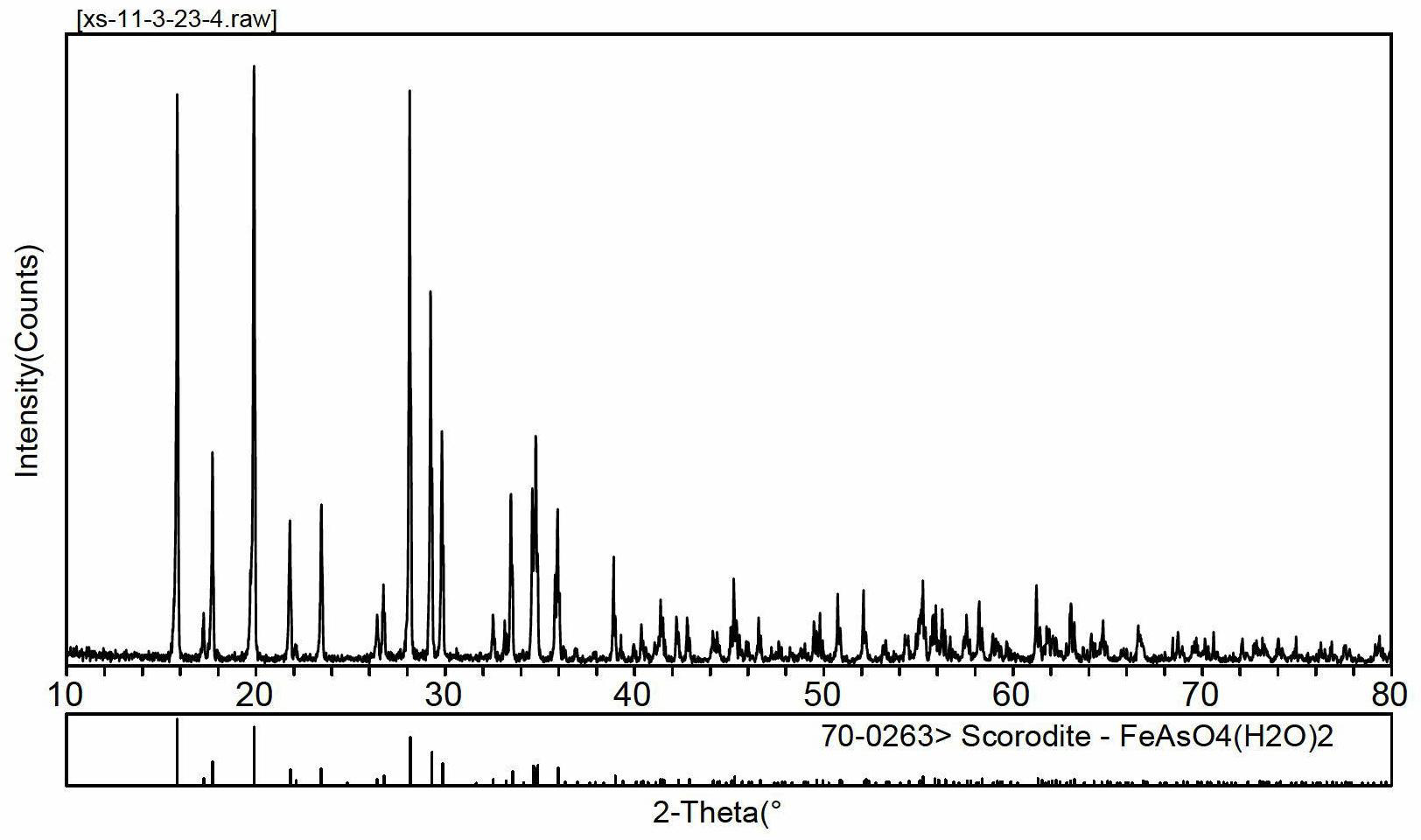

Method for precipitating and stabilizing As from As-containing solution

ActiveCN102674526ASimple preparation processLow equipment requirementsWater contaminantsWater/sewage treatment by oxidationFerrous saltsLimit value

The invention discloses a method for precipitating and stabilizing As from As-containing solution. According to the method, ferrous salt is used as As precipitator; through the air oxidation in the As-containing solution in a weak acid condition, Fe<2+> is oxidized into Fe<3+>; and Fe<3+> reacts with As to generate precipitate with high stability and low As leaching toxicity. The method is simple in technology, and generates the precipitate which is ferric arsenate crystalline compound-scorodite crystal FeAsO4. 2H2O under the conditions that the pH value is 4-6, the temperature is 70-95 DEG C, the molar ratio between Fe and As is 1-1.5, the air flow rate is 120-200L / h and the reaction time is 5-7h; the precipitate As has the leaching toxicity concentration of 1-2mg / L which is lower than the limit value of Identification Standards for Hazardous Wastes-Identification for Extraction Toxicity (GB 5085.3-2007); and the harmless stabilizing treatment for the As-containing solution can be realized.

Owner:CENT SOUTH UNIV

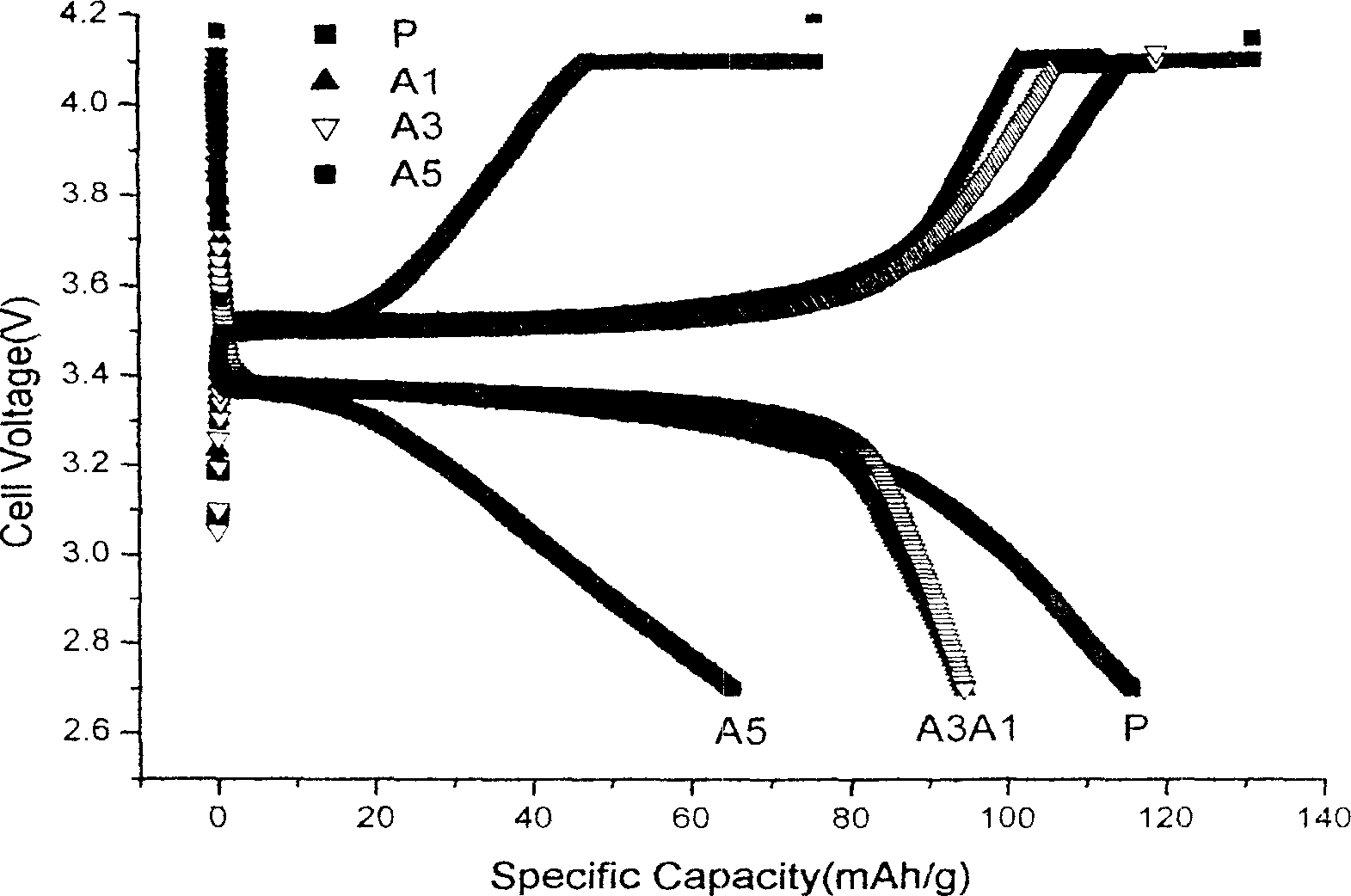

Preparation method of transition element doped iron lithium phosphate powder

InactiveCN1785799AIncrease capacityImprove capacity cycling performancePhosphorus compoundsMaterials preparationLithium iron phosphate

The present invention discloses a preparation method of transition element Mn, Co and Ni doped iron lithium phosphate powder body, belonging to the field of electrochemical power supply material preparation technology. Its molecular formula is Li1-x TRxFePO4, and its preparation method includes the following steps: weighting lithium salt, ferrous salt, phosphate and adulterant according to mole ratio, mixing them, drying, low-temperature prebaking and high-temperature secondary calcining so as to obtain the invented product which can be used as positive electrode material of lithium ion cell.

Owner:TSINGHUA UNIV

Methods for the preparation and use of ferric pyrophosphate citrate chelate compositions

A highly water soluble ferric pyrophosphate citrate chelate useful for treating iron deficiency contains 2% or less phosphate by weight. These chelate compositions are easily milled and / or processed into dosage forms using conventional techniques, and are expected to exhibit advantageous biocompatibility as compared to conventional soluble ferric pyrophosphates, ferric salts, ferric polysaccharide complexes and ferrous salts.

Owner:ROCKWELL MEDICAL INC

Method for preparing equal dispersion ferric phosphate lithium nano crystal by hydrothermal synthetis method

InactiveCN101047242AExcellent inert environmentElectrode manufacturing processesPhosphateFerrous salts

A method for preparing uniformly scattered nanocrystal of iron-lithium phosphate by hydrothermal synthesis includes using ferrous salt and phosphoric acid as well as lithium hydroxide as raw materials to obtain reaction pioneer matter under temperature of 40-100deg.c first, then reacting on obtained pioneer matter in high pressure reactor with temperature of 150-200deg.c under hydrothermal condition and processing obtained product by high temperature under protection of inert gas to finally obtain said uniformly scattered nanocrystal with average particle diameter of 0.2-0.5micron.

Owner:胜利油田华鑫石油材料有限公司

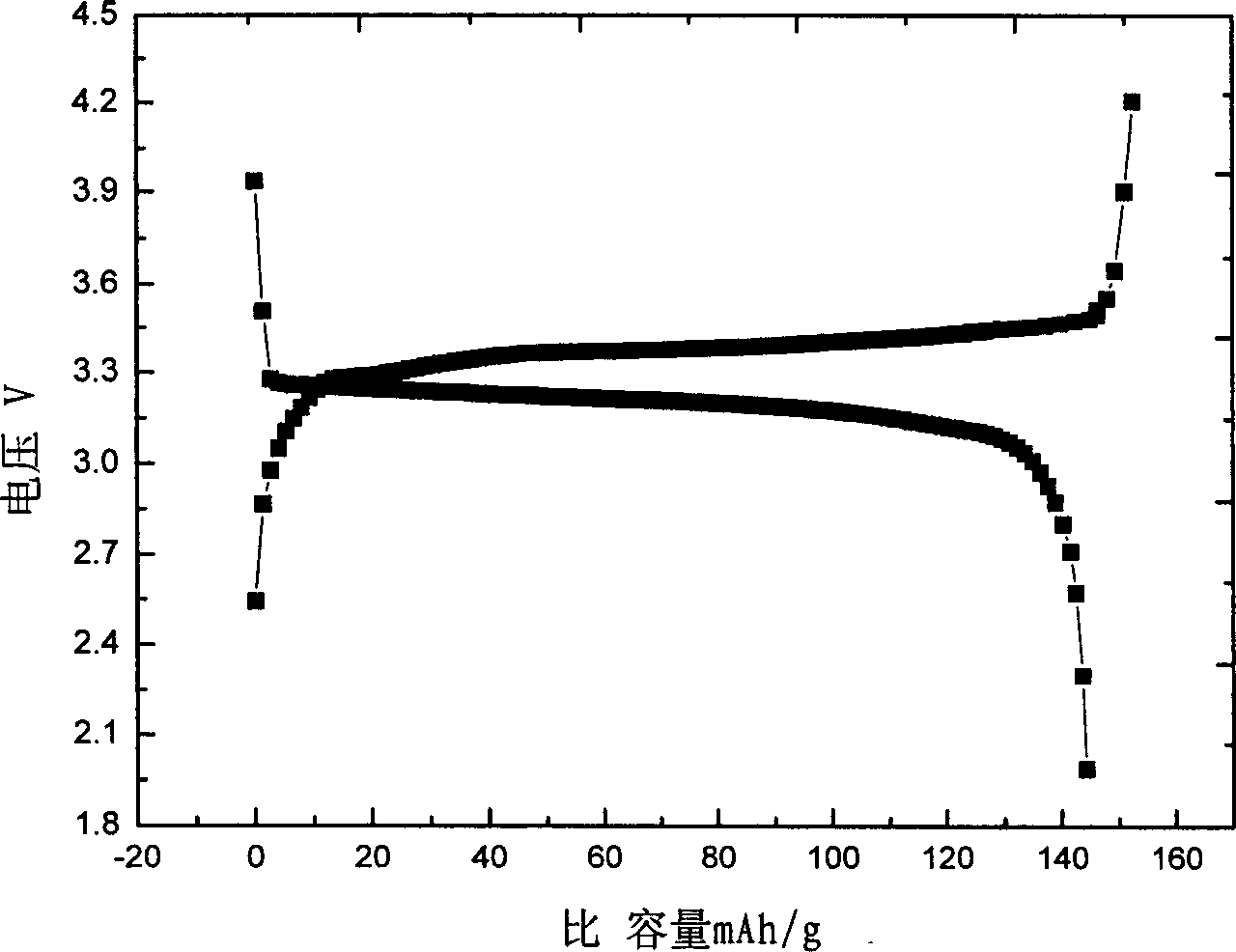

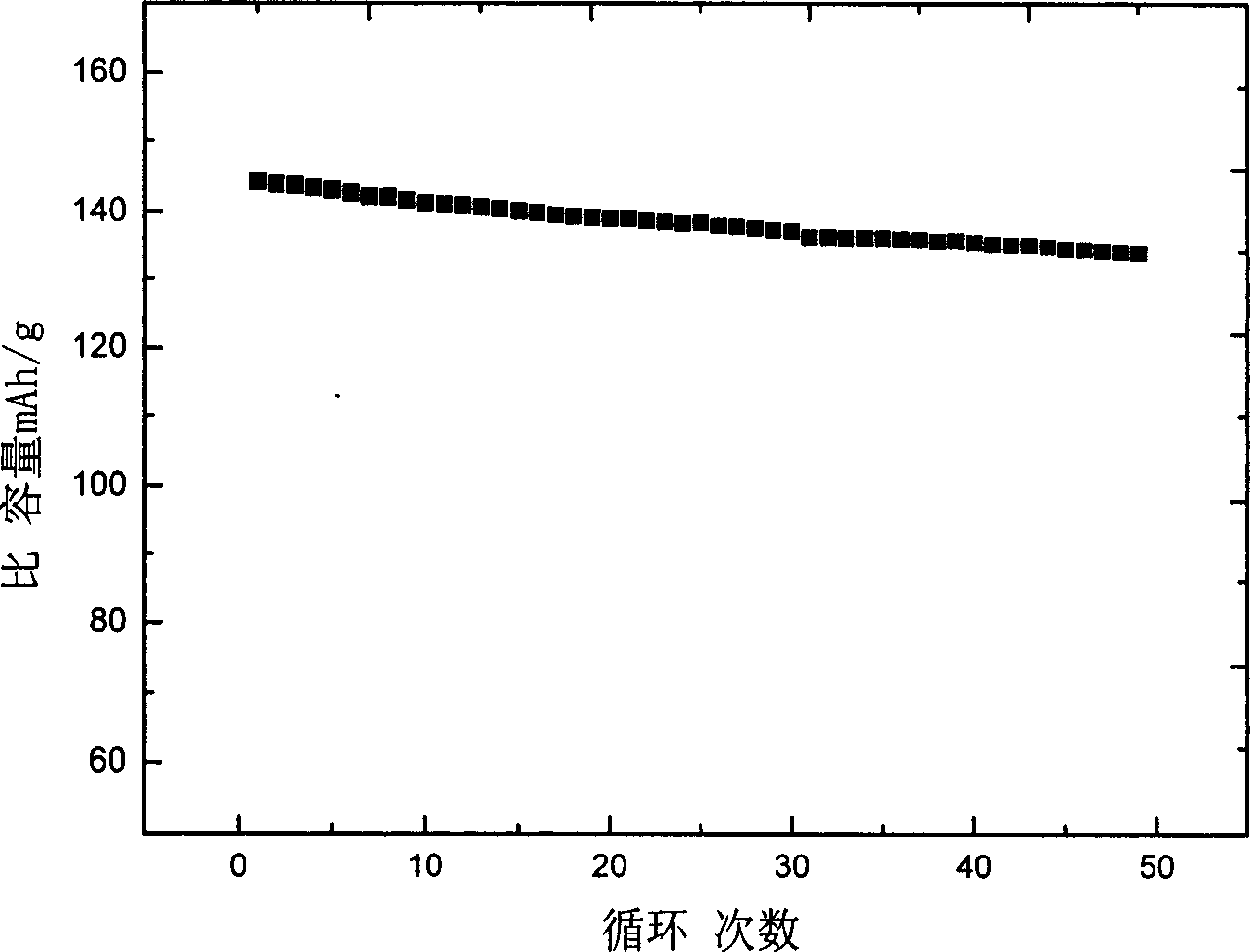

Method for preparing anode material of lithium ion battery in series of phosphate of olivine type

InactiveCN101049922AAchieve hybridEvenly distributedCell electrodesPhosphorus compoundsAluminium-ion batteryPhosphate

This invention relates to a method for preparing olivine-type phosphate-series lithium ion battery anode material. The method comprises: mixing one or more of ferrous salt solution, cobalt salt solution and manganese salt solution with oxalic acid or oxalate (precipitating agent) aqueous solution to obtain composite oxalate precursor, uniformly mixing with lithium source and phosphorus source by ball milling, and reacting in inert or weak-reductive atmosphere to obtain olivine-type phosphate-series lithium ion battery anode material. The method utilizes co-precipitation method for metal ion doping, and realizes molecular level uniform mixing among different ions. The obtained olivine-type phosphate-series lithium ion battery anode material has uniform chemical and physical compositions. The average particle size can be controlled within 0.3-10 mu.m. The first charge and discharge cycle specific capacity can reach 150 mAh / g at 0.1 C rate and room temperature. The livine-type phosphate-series lithium ion battery anode material has such advantages as high cycle performance and high charge / discharge performance.

Owner:CENT SOUTH UNIV

Natural hair dyeing agent prepared by plant pigment catechu and hair dyeing method thereof

The present invention relates to a hair-dying agent, in particular, it relates to a natural hair-dying agent prepared by adopting plant colour matter catechu and its hair-dying method. Said hair-dying agent includes agent A and agent B. The agent A includes (by wt%) 3-10% of plant colour matter catechu, 10-50% of organic solvent and the rest is water; and the agent B includes (by wt%) 1-5% of ferrous salt mordant, 0.2-1.0% of reduced iron powder, 1-10% of surfactant, 1-5% of thickening agent, proper quantity of acidifying agent, 0.1-0.3% of natural essence and the rest is water. The catechu is a traditional Chinese medicinal material, and has the functions of clearing away heat, astringing dampness, resisting bacteria and inhibiting bacteria.

Owner:JIANGNAN UNIV

Preparation method of rare earth doped iron lithium phosphate powder

InactiveCN1785800AIncrease capacityHigh crystallinityPhosphorus compoundsRare-earth elementMaterials preparation

The present invention discloses a preparation method of rare earth doped iron lithium phosphate powder body, belonging to the field of electrochemical power supply material preparation technology. Its molecular formula is Li1-xRExFePO4, and its preparation method includes the following steps: mixing lithium salt, ferrous salt, phosphate and adulterant according to a certain mole ratio, drying, low-temperature prebaking and high-temperature secondary calcining so as to obtain the invented product which can be used as positive electrode material of secondary lithium ion cell and power energy source cell. Said invention uses lanthanide series rare earth element compound as adulterant.

Owner:TSINGHUA UNIV

Nitrobacteria culture promoter

ActiveCN1986444ALow costHigh removal rateTreatment using aerobic processesBacteriaFerrous saltsSulfate

The nitrobacteria culture promoter consists of molasses 100 weight portions, ferrous salt 0.2-2.5 weight portions and adsorbent 1-8 weight portions. The ferrous salt includes is sulfate or hydrochloride. The adsorbent is zeolite powder, diatomite, powdered active carbon, fly ash or their mixture. The nitrobacteria culture promoter is used in biological nitrification process of eliminating ammonia nitrogen and thrown into sewage directly to promote the propagation and growth of nitrobacteria in sewage. Through combination with sewage temperature regulation, dissolving oxygen, regulating pH, etc, the nitrification may be completed in short period. It has raised ammonia nitrogen eliminating rate and low cost.

Owner:SINOPEC SHANGHAI PETROCHEMICAL CO LTD

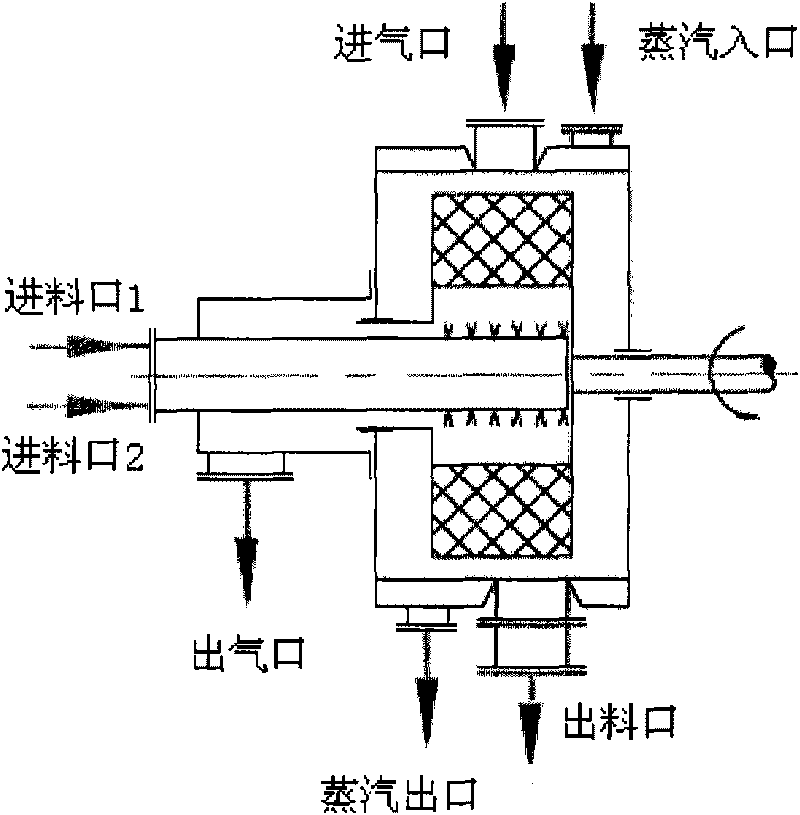

Method for preparing nano iron phosphate

InactiveCN101693531AReduce volumeReduce energy consumptionNanostructure manufacturePhosphorus compoundsPhosphateFerrous salts

The invention relates to a method for preparing nano iron phosphate, belonging to the technical field of the preparation of lithium ion battery cathode materials. The method is characterized by comprising the following steps: inputting an alkaline aqueous solution and a mixed solution formed by one of phosphoric acid or a soluble phosphate solution, one of a water-soluble ferrous salt solution and an oxidant or a ferric salt solution and a water-soluble dispersing agent into a rotating packed bed layer by a metering pump at a certain feeding speed; regulating the rotating speed of the rotating packed bed and controlling the pH value of the reaction system by an alkaline solution; discharging nano iron phosphate particles generated by reaction crystallization from a discharge hole of the rotating packed bed along with the mixed solution; and filtering, washing and drying the nano iron phosphate particles to obtain nano iron phosphate (FePO4.2H2O) powder. The method is simple and has easy operation and high efficiency, and the prepared iron phosphate reaches the nano grade, has uniform particle size and narrow distribution range and is suitable for industrialized production. The nano iron phosphate is a good precursor material for preparing lithium iron phosphate which is used as a cathode material of high-power type lithium ion batteries.

Owner:TSINGHUA UNIV

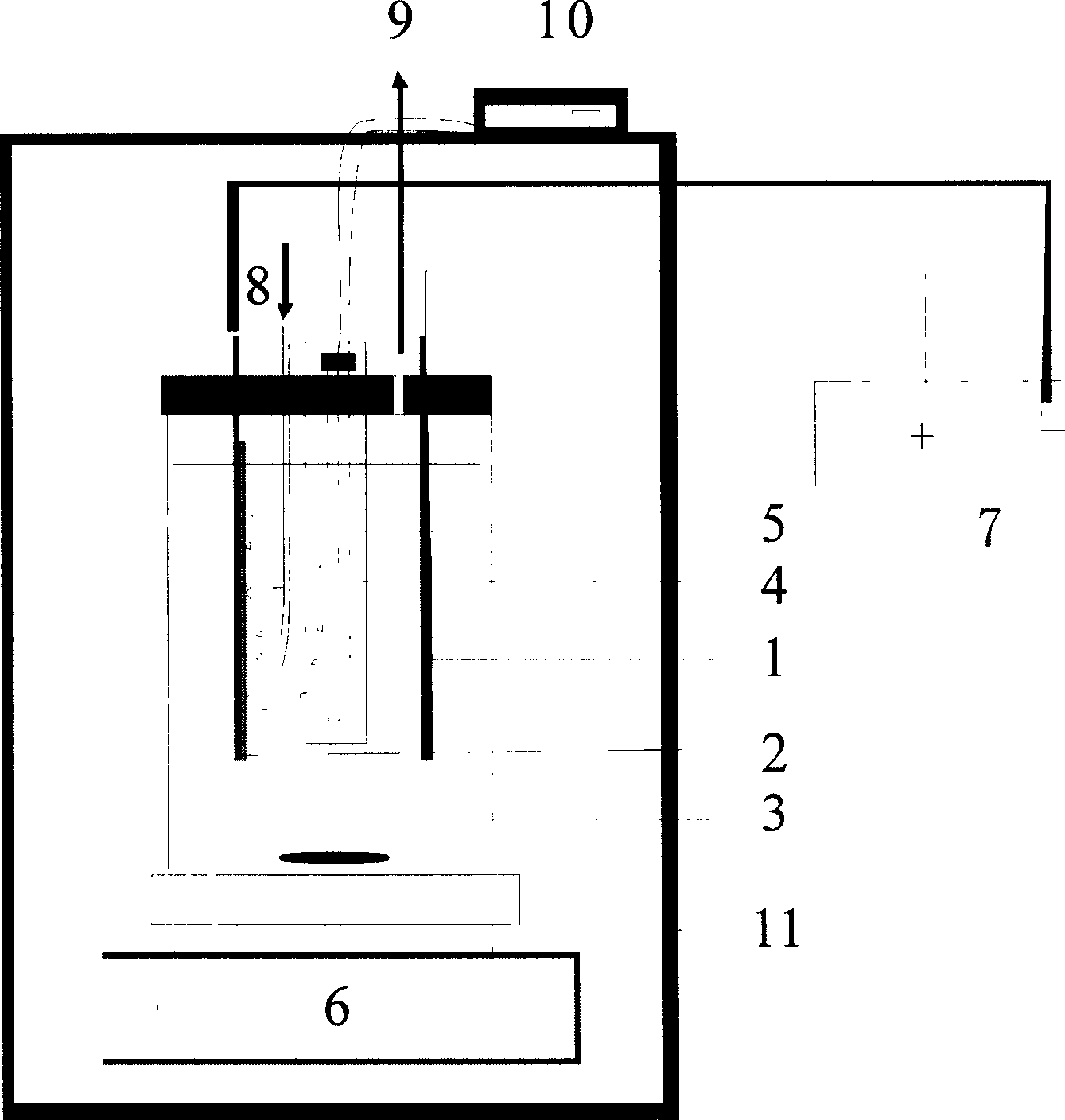

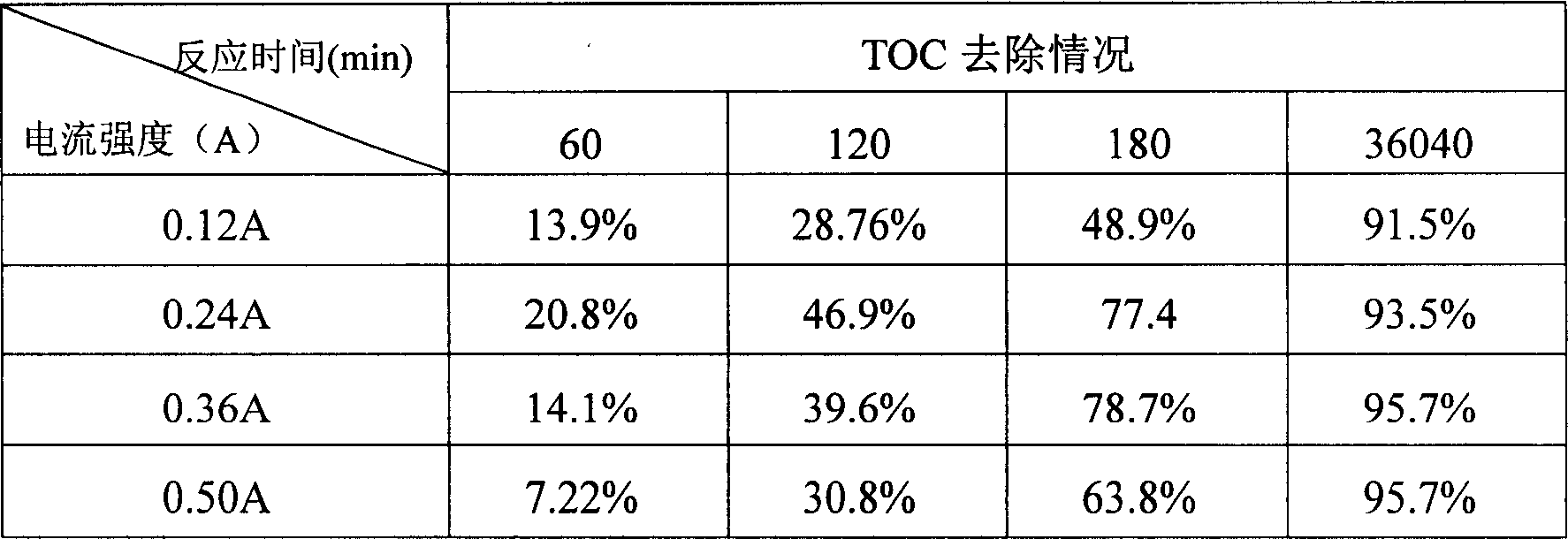

Method and apparatus for highly efficient removal of water organisms by utilizing photoelectric Fenton reaction

The invention provides a photoelectrical FenDun method for removing the non-degradable organic substance in water, which combines photochemistry reaction and electrical FenDun reaction to co-treat the organic substance effectively with multiple actions. The invention also provides a device applying the photoelectrical FenDUN reaction to remove organic substance in water, which comprises: the reactor employing shape stable electrode (DSA) as anode, employing activated charcoal as cathode, putting the low pressure mercury vapor lamp closed in the quartz glass tube vertically between the anode and cathode and venting a certain quantity of oxygen to the cathode surface, adding marginal ferrous salt into the organic wastewater with pH being about 3 as catalyst and importing current flow for electrolysis to remove pollutant. The invention oxides and degrades organic substance by using the hydroxyl free radical generated by photochemical reaction and electrical FenDun reaction, the hydroxyl free radical possesses strong oxidability which can oxide organic substance without selection, and is characterized by the complete, fast and effective oxidation and no secondary pollution.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

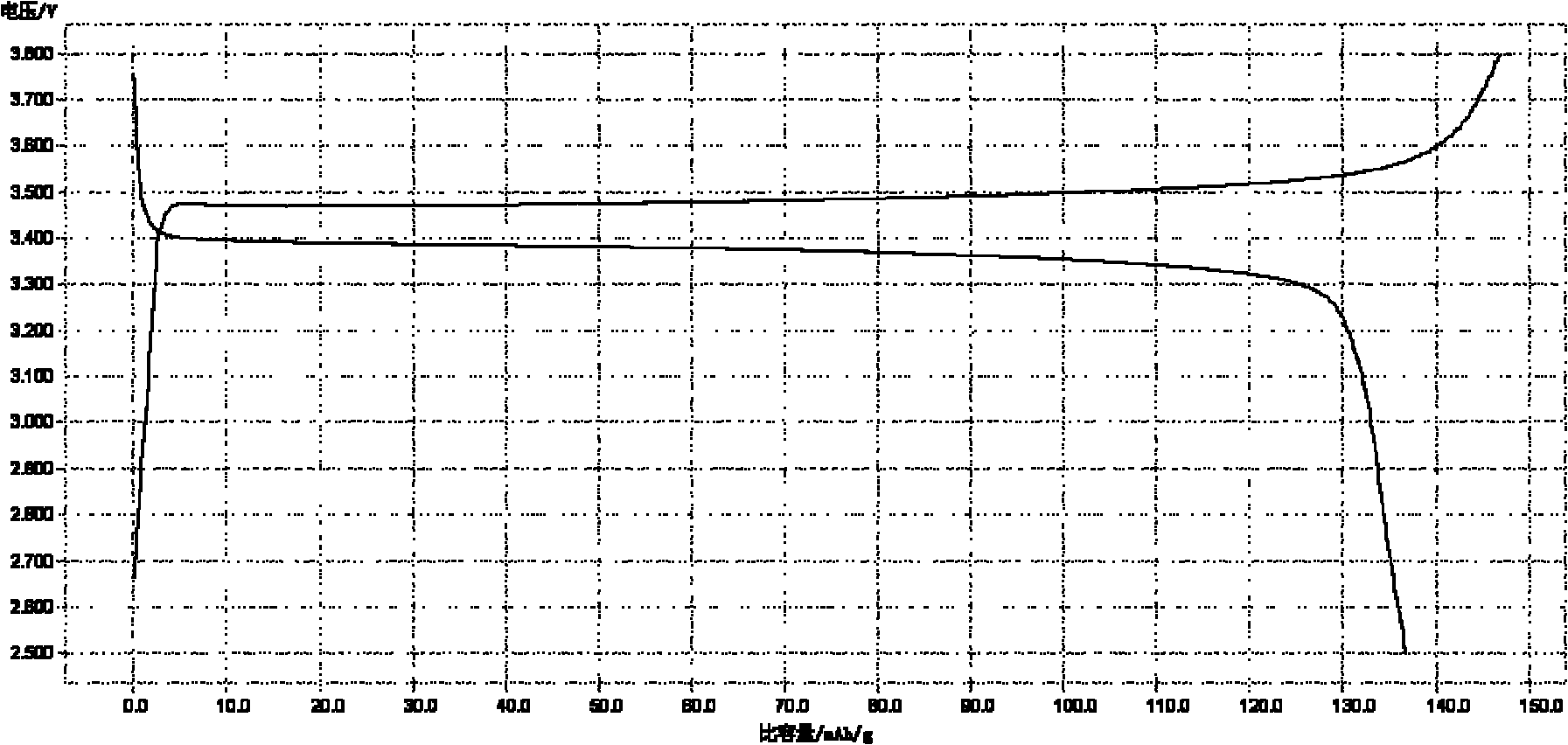

Anode material of lithium ion cell and preparation method thereof

ActiveCN1790782AAddressing deficiencies in ion diffusion performanceWide variety of sourcesPhosphatesCell electrodesLithiumPhosphate

The invention relates to prepare composite anode material LiFePO4 / C for lithium-ion cell with solid-phase method. Wherein, selecting lithium salt, ferrous salt and phosphate as material with mole proportion of Li, Fe and P as 1-1.1:1-1.02:1, putting mixture into ball grinding tank to grind for 8-24h, holding temperature at 150-400Deg for 4-24h, thermostatic baking at 500-800Deg for 10-30h, and obtaining the final product. This invention has wide material source with low cost, convenient to control. The product has well evenness and compatibility with electrolyte.

Owner:GUANGZHOU GREAT POWER ENERGY & TECH CO LTD

Lithium iron phosphate anode material and its preparing method

InactiveCN1767238AImprove conductivityHigh tap densityElectrode manufacturing processesCalcium/strontium/barium compoundsBorideAlcohol

The invention relates to ferric phosphate lithium anode material and its preparing method, which relates to a cell anode material, especially to a ferric phosphate lithium anode material used in lithium ion cell second time. It provides a cell anode material and ití»s preparing method which can elevate the LiFePO4 conductivity and tap density at the same time. It is formed by ferric phosphate lithium and calcium boride (by weight rate): ferric phosphate lithium: calcium boride=100í† (1.01- 5.26). It first syntheses pure ferric phosphate lithium: it balls the ferrous salt, microcosmic salt and lithium salt by alcohol grease, heats the mixed material and uses inactive gas as preserving gas. It balls the synthesis ferric phosphate lithium anode and calcium boride, burns the mixed material and adds inactive gas as preserving gas to obtain the object product.

Owner:河南天科科技有限公司

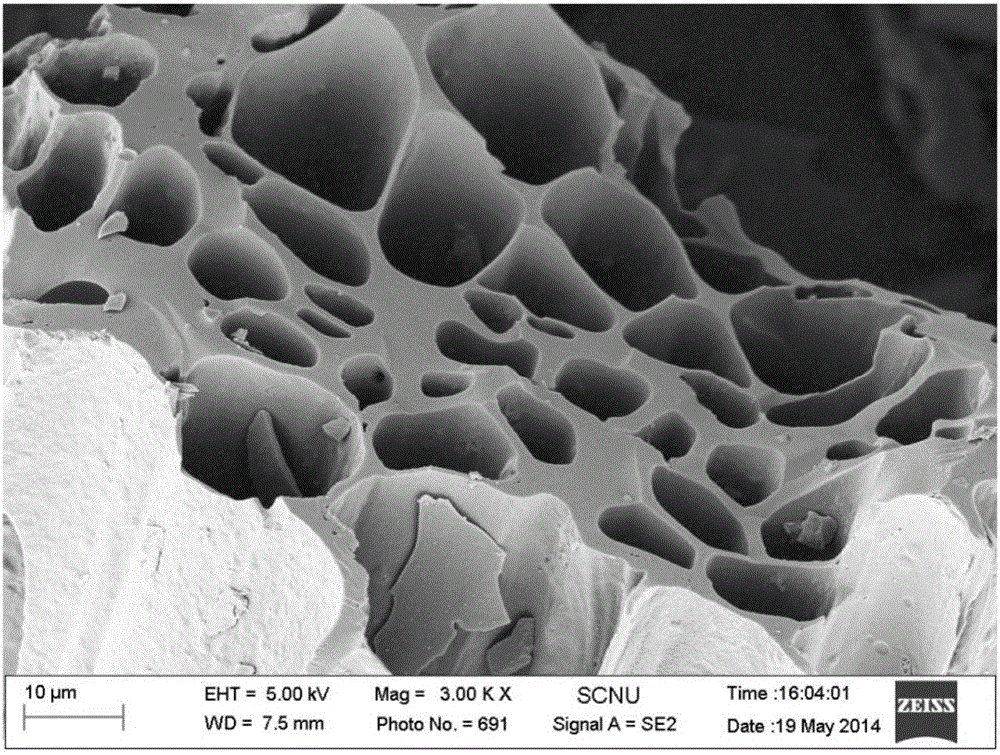

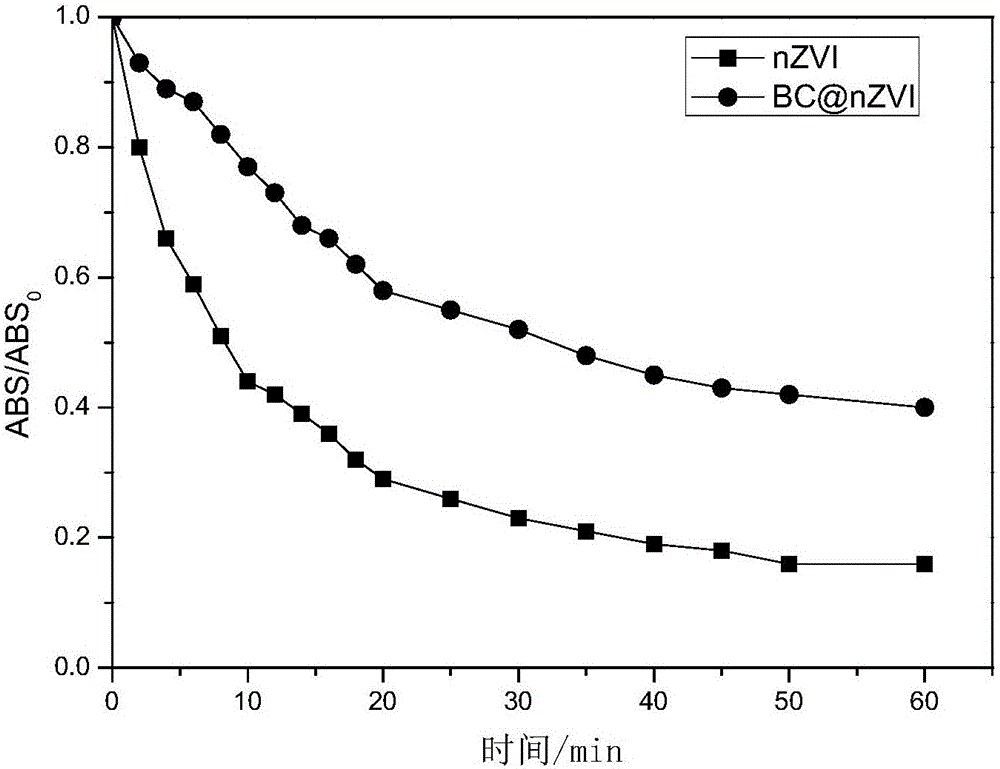

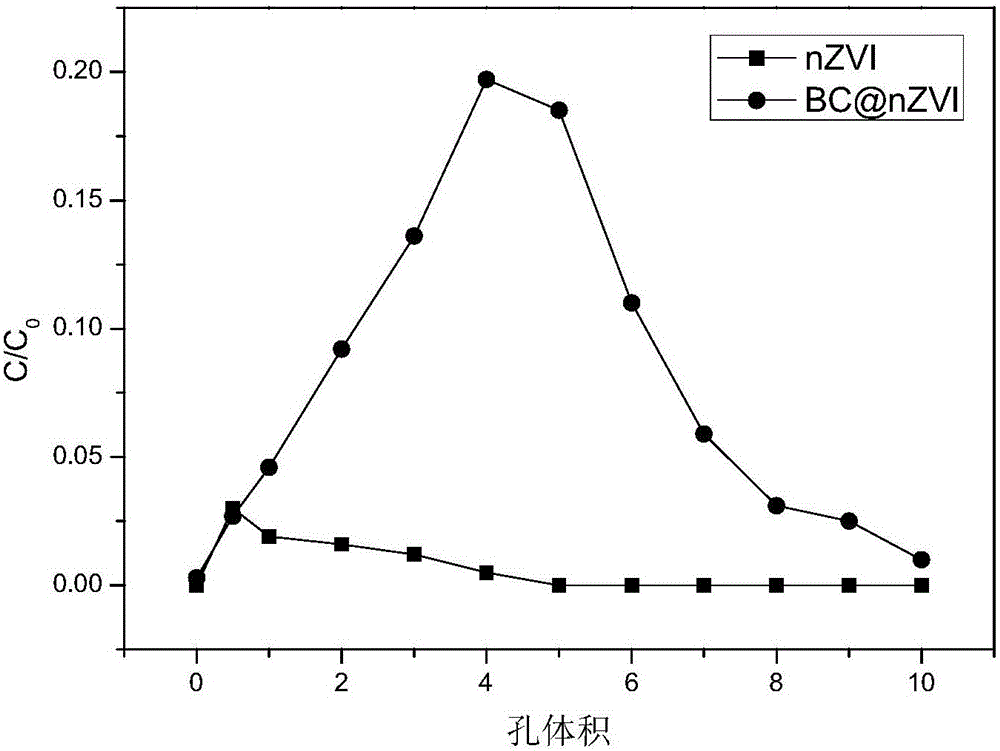

Preparation and application for heavy metal chromium contaminated soil remediation material

ActiveCN105013811AImprove repair efficiencyImprove stabilityContaminated soil reclamationOrganic fertilisersFerrous saltsCarbon particle

The invention discloses preparation and an application for a heavy metal chromium contaminated soil remediation material. Preparation for biological carbon particles comprises the following steps: 1) cleaning, drying and crushing agriculture waste to obtain a substance A; and 2) placing the substance A under a protective atmosphere to deoxidize and carbonize, and grinding and sieving carbonize products to obtain the biological carbon particles. Preparation for supported type nano zero-valent iron particles comprises the following steps: 1) preparing ferrite into a solution; 2) adding biological carbon particles into the solution, and uniformly mixing the biological carbon particles with the solution; and 3) dissolving a reducing agent into a solvent to obtain a mixture, adding the mixture into the system in the last step under the protective atmosphere, stirring the mixture, sufficiently reacting the mixture, separating nano zero-valent iron, washing, drying and grinding the nano zero-valent iron to obtain the supported type nano zero-valent iron particles. The invention further discloses the application of the supported type nano zero-valent iron particles to remediating chromium contaminated soil in situ. The in-situ remediation method for the heavy metal chromium contaminated soil comprises the following steps: adding the supported type nano zero-valent iron particles into soil, uniformly mixing the supported type nano zero-valent iron particles, adding deoxygenated water, and carrying out remediation. The remediation material prepared by the preparation disclosed by the invention is high in efficiency of remediating the chromium contaminated soil, and capable of improving the soil structure and improving the soil fertility.

Owner:师大清远环境修复科技有限公司

Method for uniformly coating carbon on nano lithium iron phosphate

The invention discloses a method for uniformly coating carbon on nano lithium iron phosphate, which is characterized by comprising the following steps of: 1) weighting soluble ferrous salt and phosphoric acid according to a proportion, dissolving the ferrous salt and the phosphoric acid in deionized water, adding a complexing agent into the mixture, and slowly adding lithium salt solution into the mixture under continuous stirring; 2) continuously stirring the solution in an oil bath until a green precipitate is generated, and performing suction filtration and washing to obtain a solid product; 3) drying the solid product in a vacuum drying oven, and performing ball milling on the dried solid product to obtain precursor powder; 4) dissolving the precursor powder and nano amorphous carbon in the deionized water, uniformly dispersing and mixing the precursor powder and the nano amorphous carbon, and drying the mixture to obtain a nano carbon-coated precursor; and 5) grinding and breaking the nano carbon-coated precursor, and sintering to obtain the uniform carbon-coated nano lithium iron phosphate. By adopting method, the nano-size carbon is fully dispersed in the solution and is uniformly coated on lithium iron phosphate granules through the surface acting force among nano granules, and the transmission rate of ions and electrons, thereby improving the electric conductivity of the nano lithium iron phosphate.

Owner:IRICO

Advanced treatment method for arsenic-containing wastewater

InactiveCN103043812AImprove removal efficiencyConducive to aggregation and settlementMultistage water/sewage treatmentWater/sewage treatment by flocculation/precipitationSludgeFerrous salts

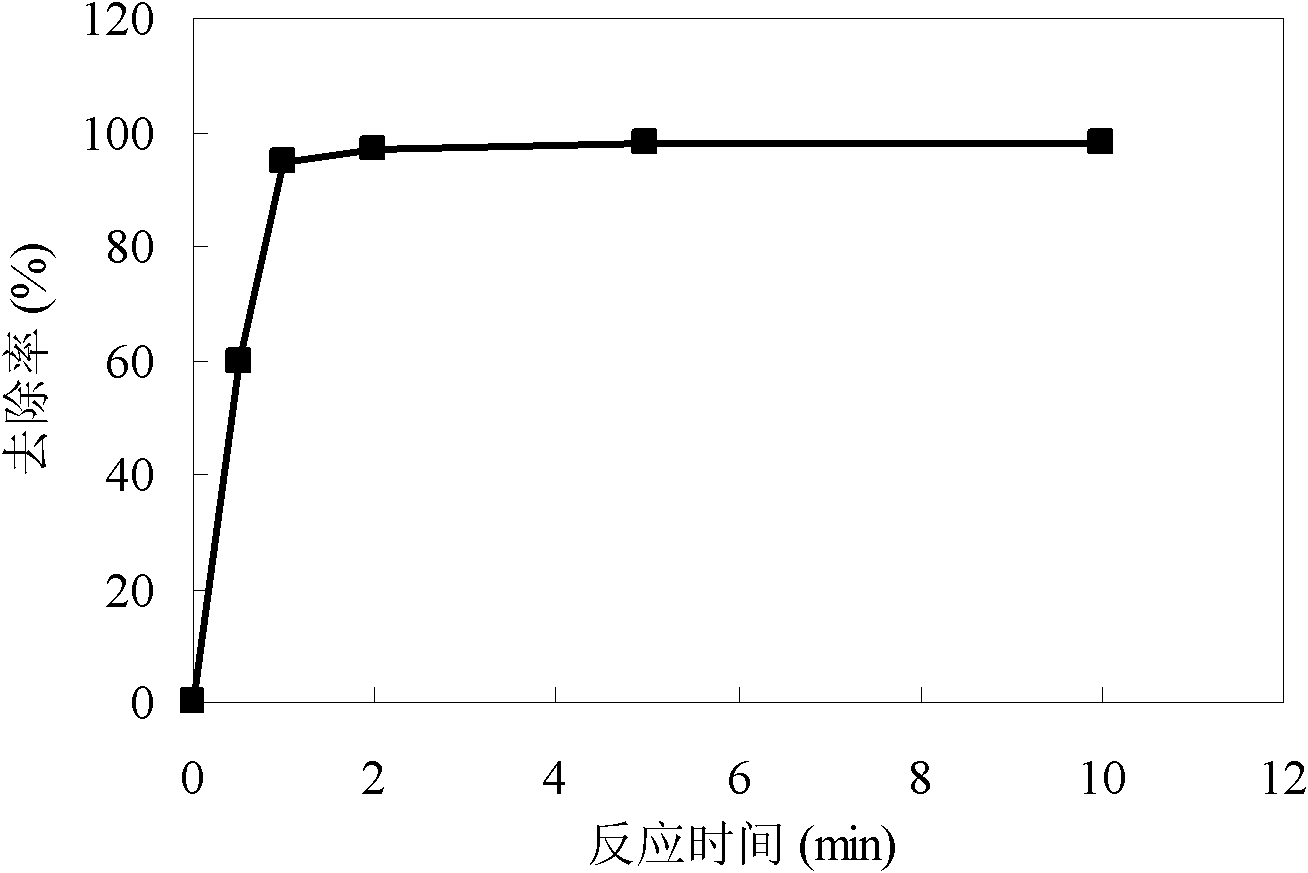

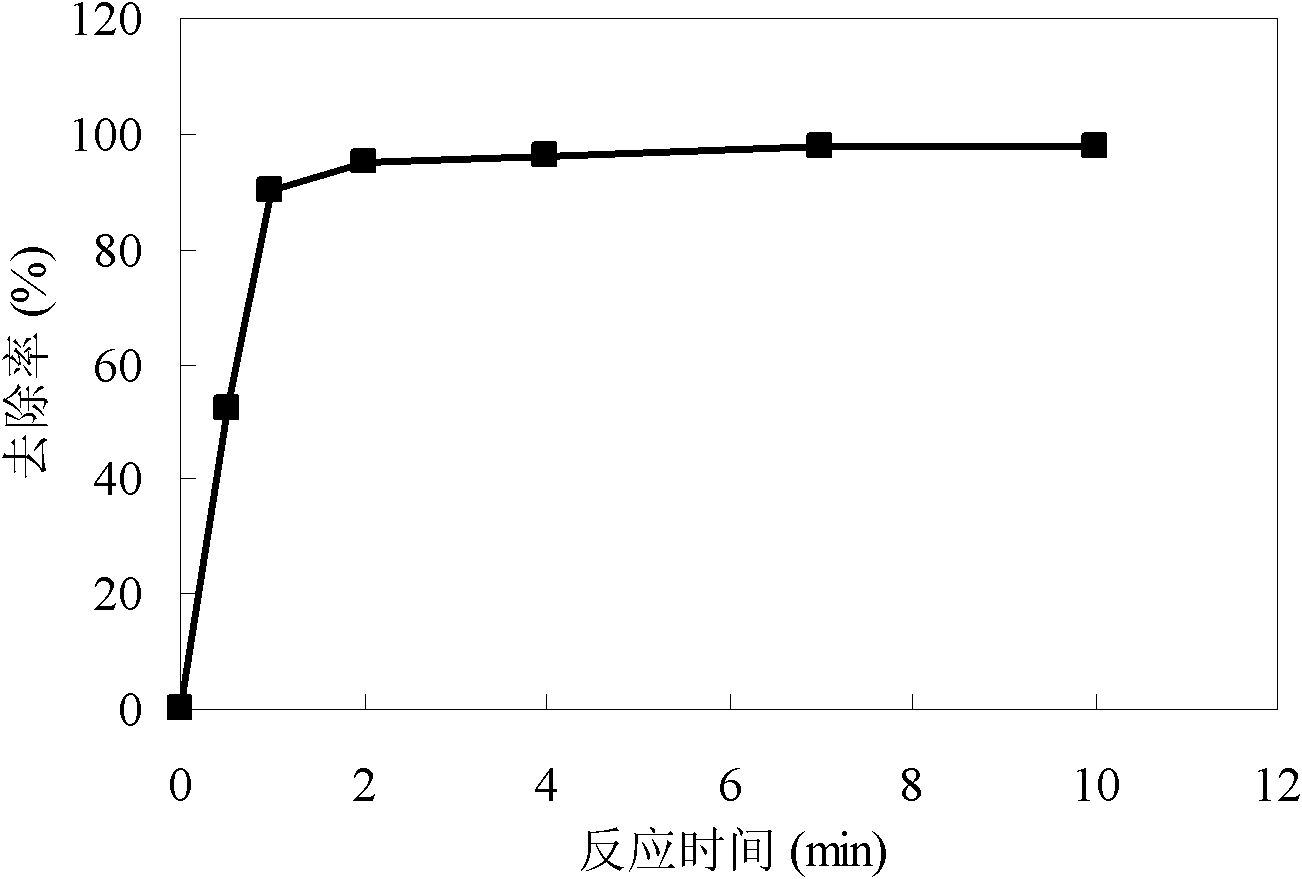

The invention relates to a method for treating arsenic-containing wastewater by a process of preoxidation-composite coagulation deposition-filtering, and belongs to the technical field of wastewater treatment. The method comprises the steps of adding a certain amount of an oxidizing agent in a reaction tank for preoxidation in a condition that the wastewater contains trivalent arsenic so as to transform the trivalent arsenic into pentavalent arsenic completely, while for the wastewater only contains the pentavalent arsenic, the preoxidation process is not needed; adding a certain amount of a ferrous salt water solution; controlling a molar ration of Fe to As being 5-50; adding acid or alkali to adjust a pH value being 6-8; stirring for 0.1-1 min rapidly, so that a ferric arsenate precipitate is formed, at the same time, the ferrous salt is hydrolyzed into ferrous carbonyl to promote coagulation deposition of the ferric arsenate; adding a solution of 0.1-10 mg / L organic polymer flocculant; stirring for 0.1-1 min rapidly; stirring for 5-10 min slowly, precipitating for 10-30 min, discharging sludge from the bottom, introducing supernatant into a sand filter tank, a filter film or a filter bag, filtering and discharging the effluent. Arsenic content in water after treatment is lower than that of a drinking water standard (less than 10 [mu]g / L) regulated by the world health organization. The method has low sludge production and low cost, and can be used for advanced treatment of the arsenic-containing industrial wastewater and treatment of arsenic polluted underground water and drinking water.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Method for preparing magnetic oxide iron and magnetic oxide iron desulfurizer prepared thereby

ActiveCN101585557AGuaranteed temperatureGuaranteed firing temperatureIron oxides/hydroxidesFerrous saltsSulfur

The invention relates to a method for preparing magnetic oxide iron Fe21.333O32, which comprises the following steps: (a) mixing solid soluble ferrous salt and solid hydroxid according to a molar ratio of iron to hydroxyl being between 1:2 and 1:3; (b) completing reaction of a mixed material prepared in step (a) by kneading, and controlling the temperature of the material not to exceed 70 DEG C in the kneading process; (c) drying a reaction product obtained in step (b) in air; (d) washing and filtering a material obtained in step (c); (e) naturally drying or baking a solid obtained in step (d); and (f) roasting a product obtained in step (e) at a temperature of between 150 and 500 DEG C. The invention further discloses a magnetic oxide iron Fe21.333O32 desulfurizer prepared by the preparation method. Tests show that the desulfurizer has high sulfur capacity reaching 62.0 percent.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

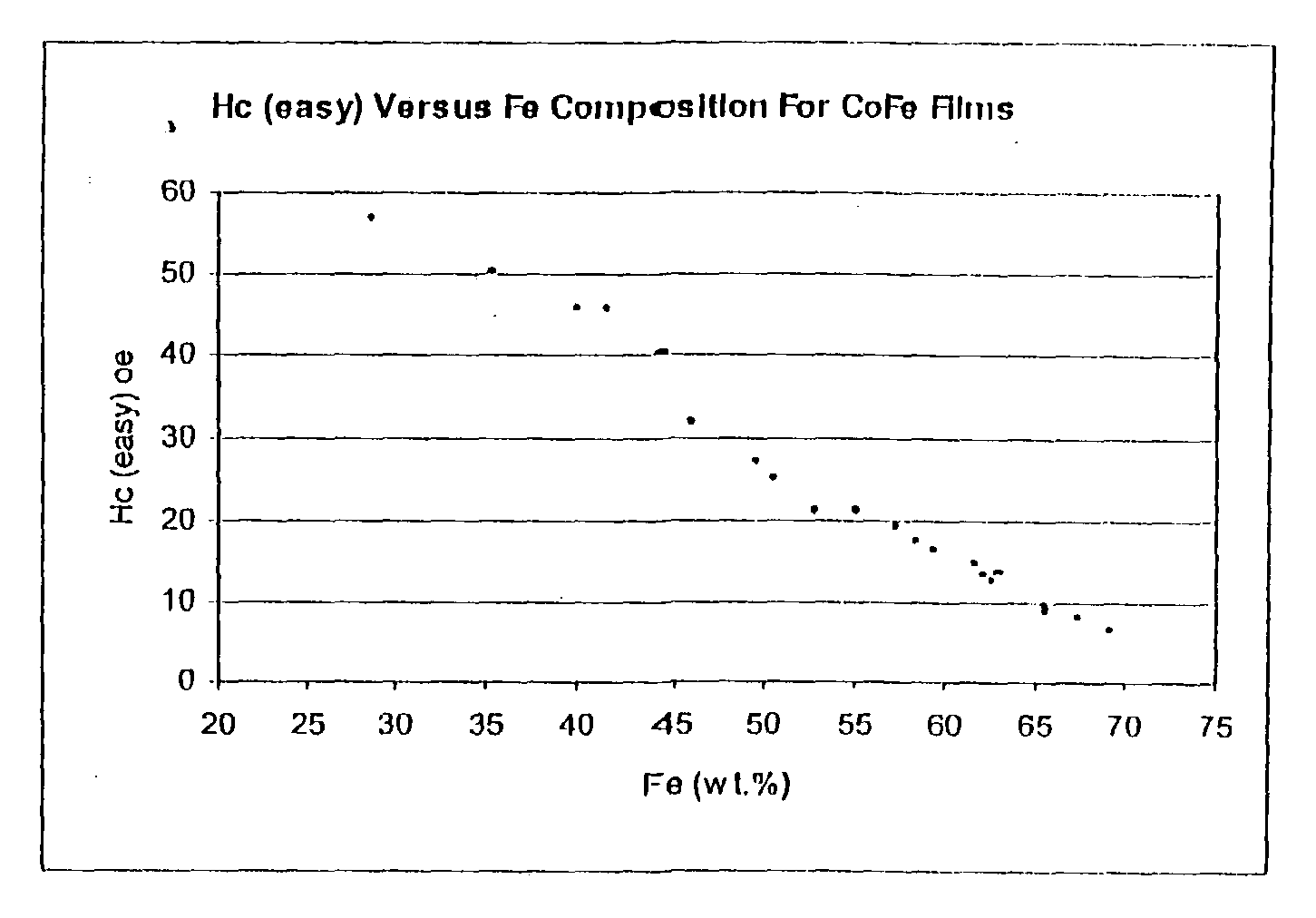

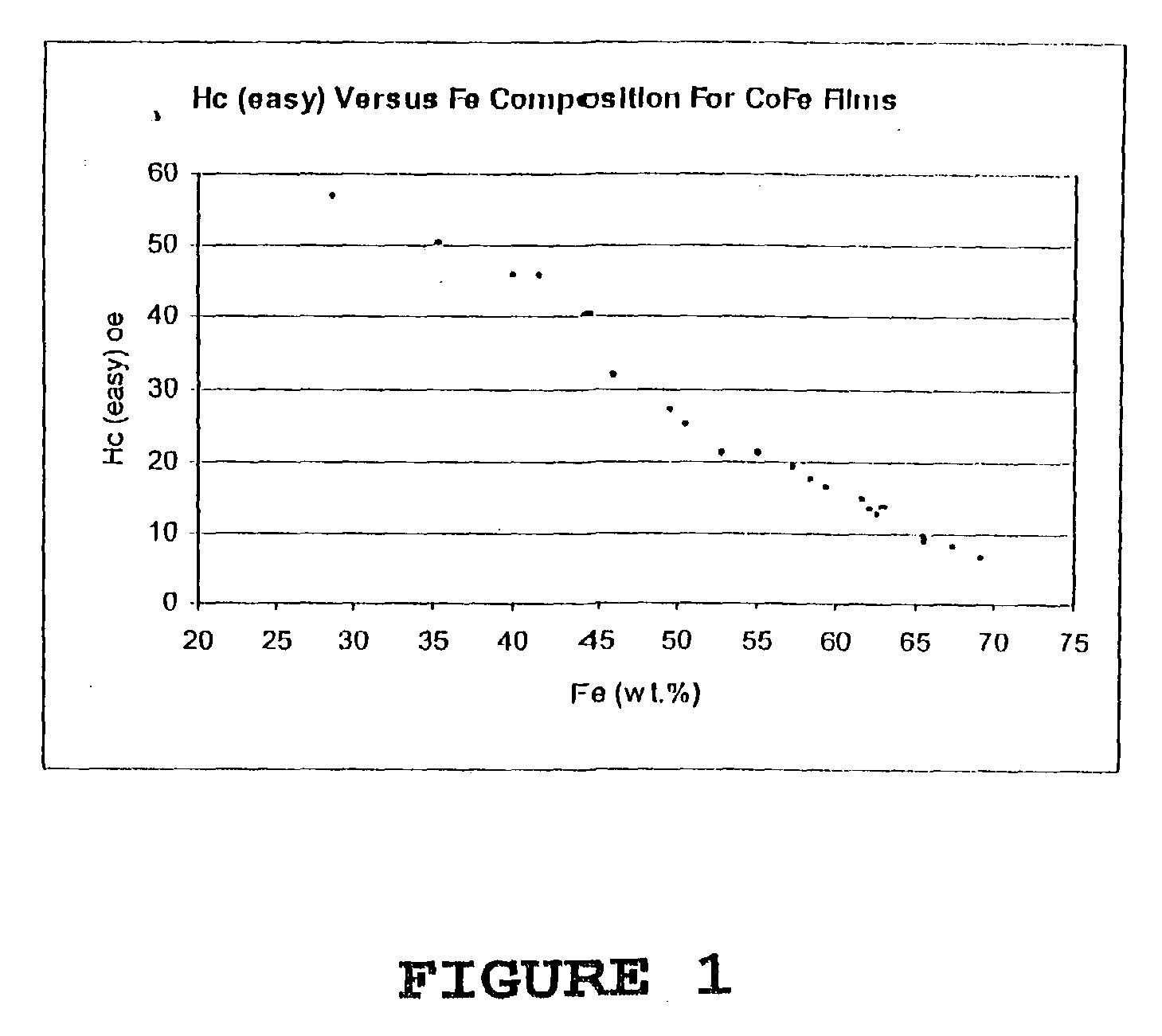

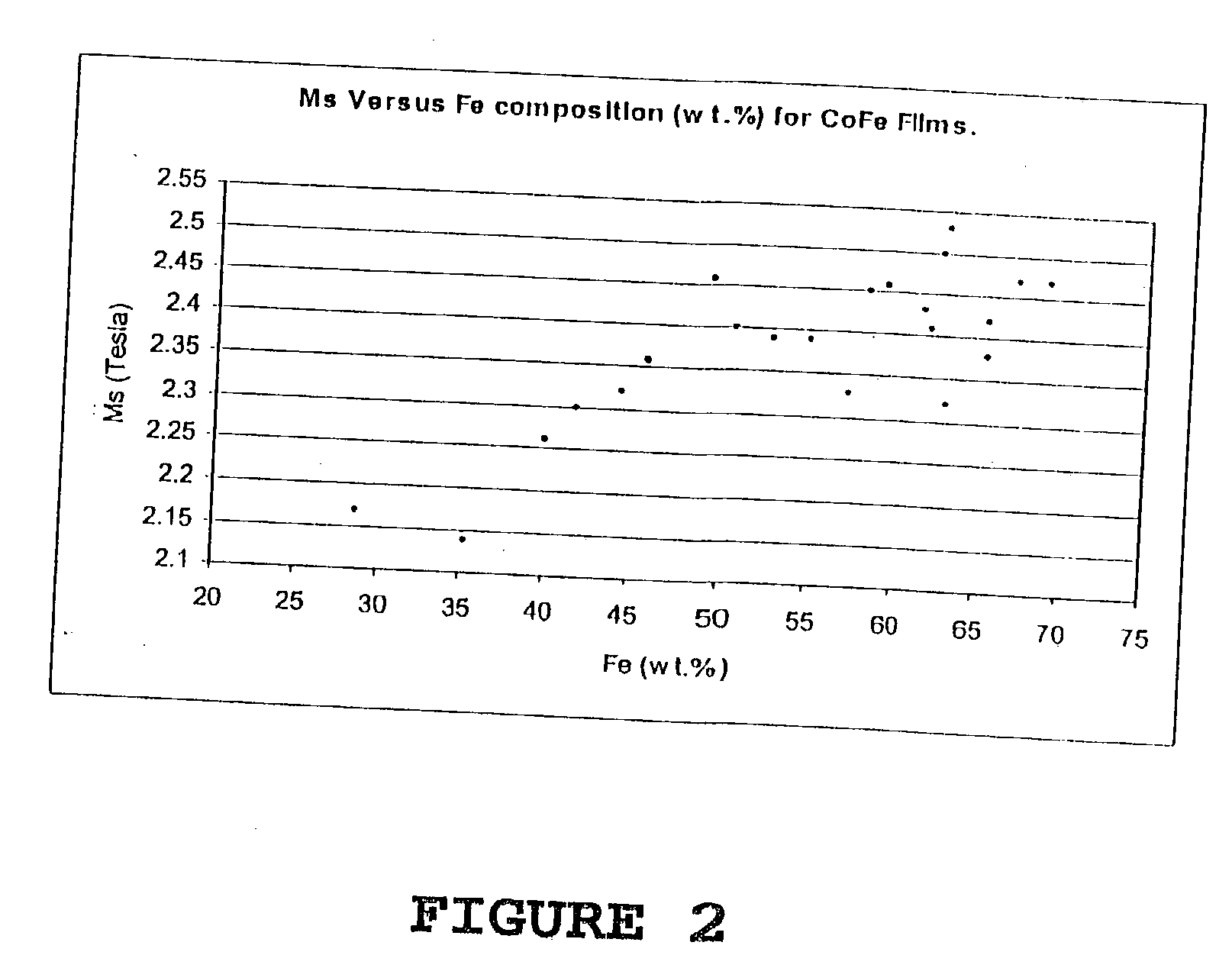

CoFe alloy film and process of making same

A cobalt-iron alloy film having saturation magnetization of at least about 2.30 Telsa. The film alloy includes about 55 wt % to about 75 wt. % iron and the remainder cobalt. The film is made by a process in which the film is electrodeposited from an aqueous medium which includes one or more ferrous salts, one or more cobaltous salts, a buffer having a pKa of about 6 to about 8, at least one carboxylic acid having a pKa of between about 3.5 and about 5.5, an aromatic sulfinic acid or its salt and optionally, a halide salt and / or a surfactant. The alloy film is useful as a write head in magnetic recording.

Owner:HITACHI GLOBAL STORAGE TECH NETHERLANDS BV

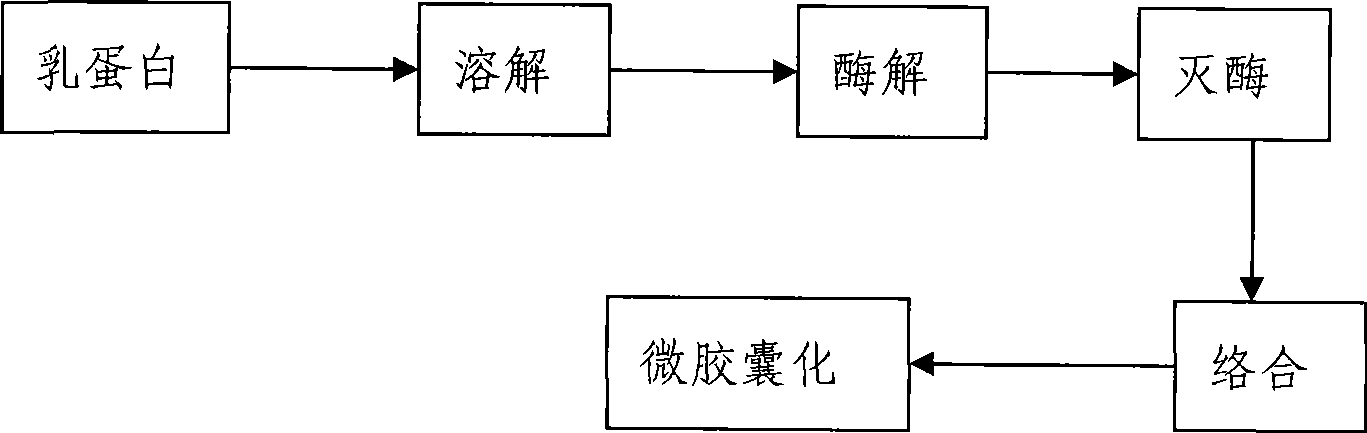

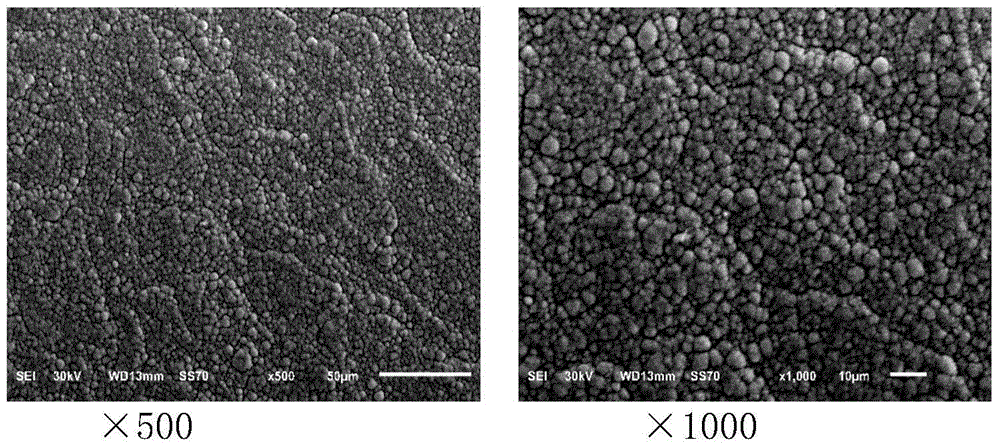

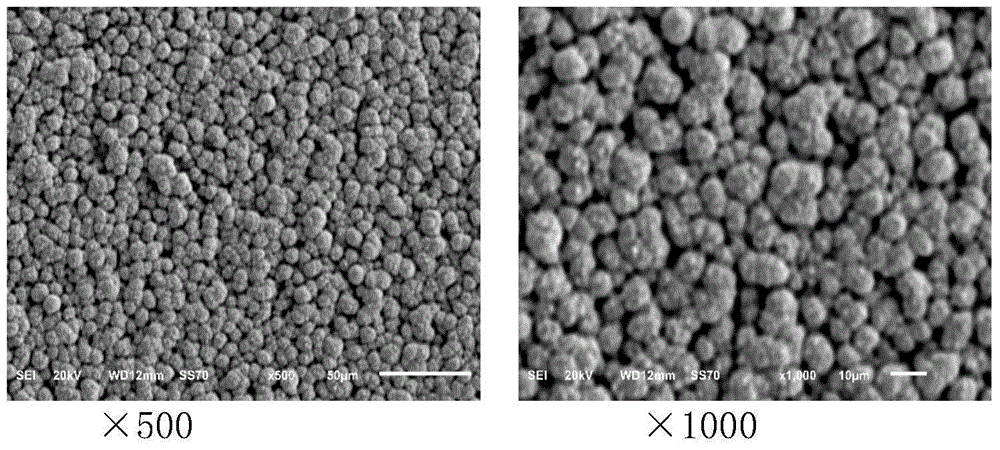

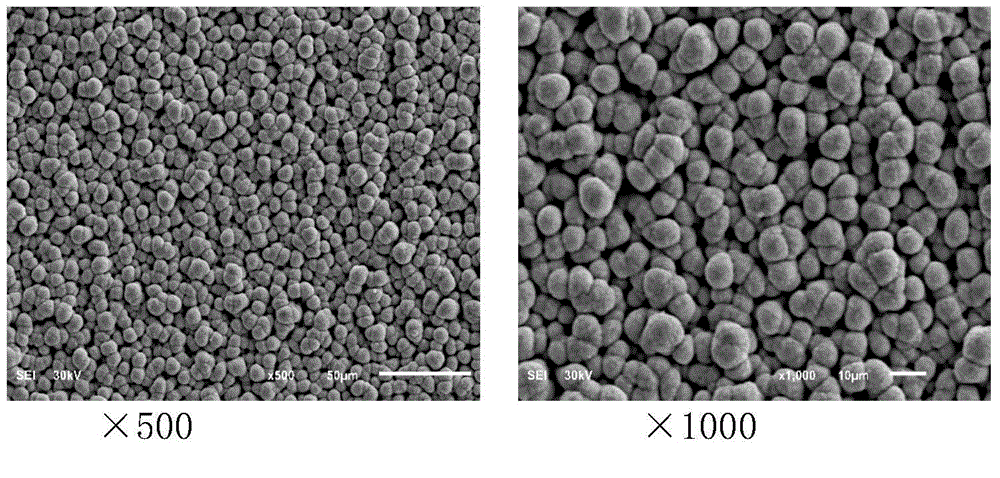

Zymohydrolysis lactoprotein ferrous complex compound microcapsule iron supplement agent and preparation thereof

InactiveCN101481404AReduce solubilityImprove bioabsorption and utilizationPeptide/protein ingredientsMetabolism disorderSolubilitySide effect

The invention relates to an enzymolytic lactoprotein ferrous complex, a microcapsule iron supplement and a preparation method thereof. In the preparation method, ferrous salt is complexed with an enzymolysis product of lactoprotein, which can improve solubility of iron salt under an alkalescent intestinal condition, improves absorptivity and availability of iron and ensures a safe and pollution-free preparation process; a proper coating material is adopted for microencapsulating the enzymolytic lactoprotein ferrous complex to prepare the microcapsule iron supplement agent of the enzymolytic lactoprotein ferrous complex; the iron supplement agent can mask self-odor of the ferrous salt, prevent the ferrous iron from oxidation, gradually release Fe under the alkalescent intestinal condition to ensure high biological absorptivity and biological availability of the Fe, and has no toxic and side effect; and the enzymolytic lactoprotein can prevent and treat iron-deficiency anemia, and has physiological functions of resisting oxidation, adjusting immunity, lowering blood pressure and the like.

Owner:CHINA AGRI UNIV

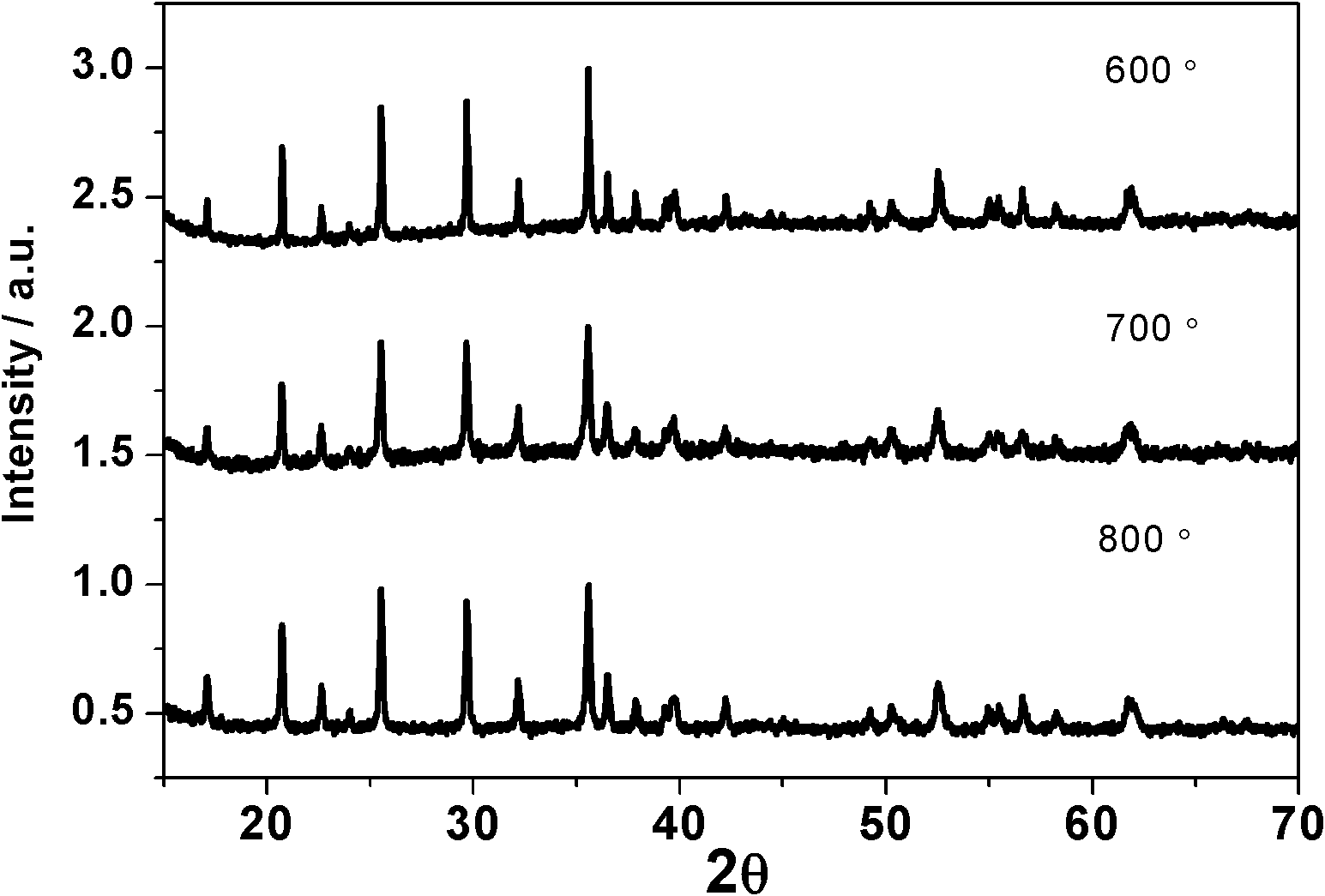

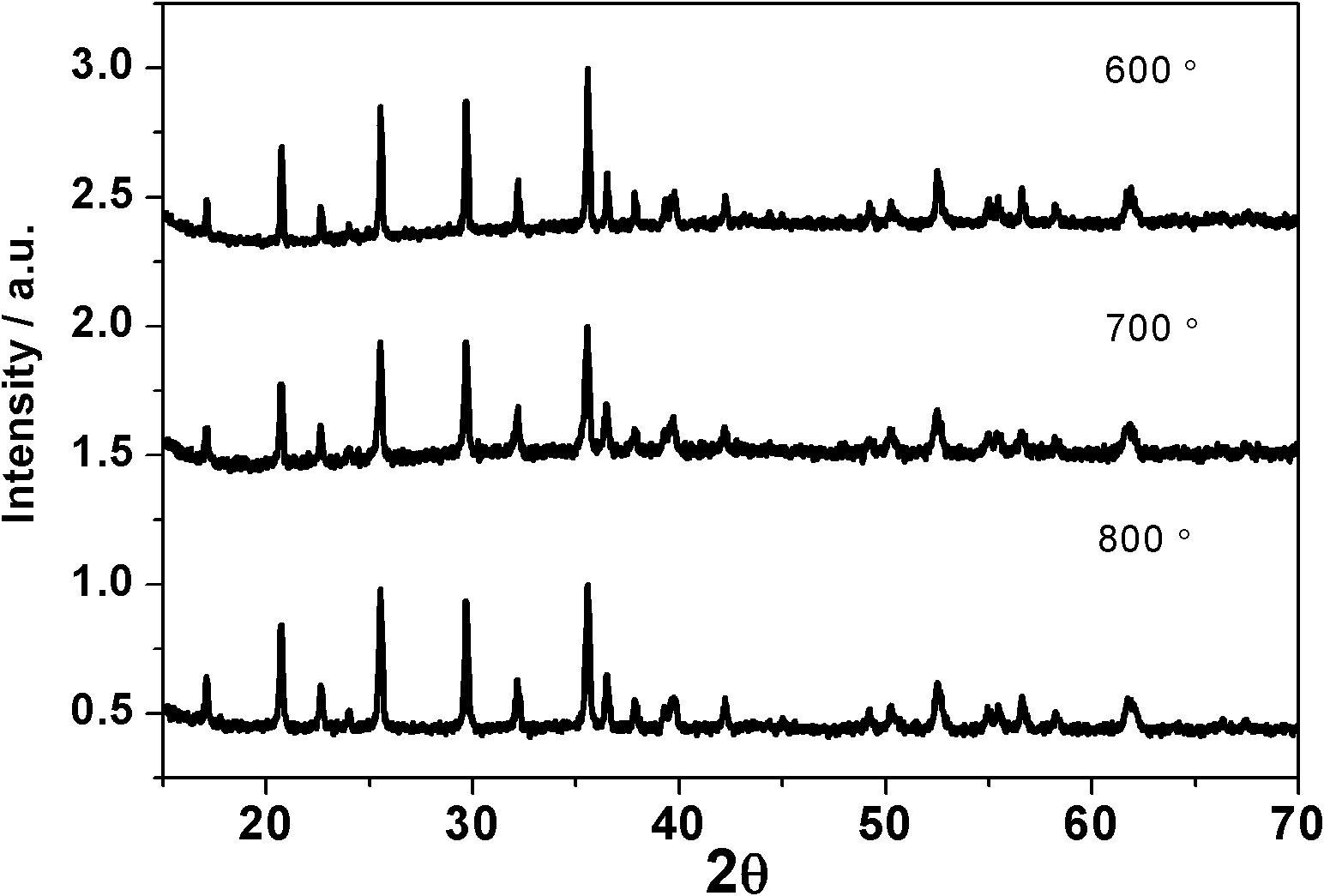

Preparation method of Li2FeSiO4 cathode material used for controlling Fe3P

InactiveCN101734675ALow costWide variety of sourcesCell electrodesAlkali metal silicatesPhosphorous acidWater baths

The invention relates to a preparation method of Li2FeSiO4 cathode material used for controlling Fe3P. The technical scheme comprises the following steps: weighting lithium salt or hydrate of lithium salt, ferrous salt or hydrate of ferrous salt, silicon compound and phosphorous acid or aqueous solution of phosphorous acid according to a molar ratio of the reactants that Li<+>:Fe<2+>:Si:H3PO3=0.95-1.10:0.95-1.10:0.70-0.999:0.001-0.429, mixing the reactants, then adding carbon-containing compound which accounts for 1wt%-20wt% of anhydrous reactants and wet grinding medium which accounts for 0.10-10 times of anhydrous reactants by volume, mixing with a ball mill, heating with water bath, mixing with a ball mill again, heating and drying in vacuum, and then using the two-stage sintering process or temperature programmed two-stage sintering process to prepare Li2FeSiO4 with controllable Fe3P under inert atmosphere or weak reduction atmosphere. The material prepared by the method of the invention has better discharge performance, the discharge capacity is significantly increased in 2.9V zone and the cycle performance is good under 0.3C current.

Owner:FUJIAN NORMAL UNIV

Chemical copper plating solution and chemical copper plating method

InactiveCN104651814AImprove stabilitySmall particle sizeLiquid/solution decomposition chemical coatingCopper platingOrganic matter

The invention discloses a chemical copper plating solution and a chemical copper plating method. The chemical copper plating solution is characterized by being a water solution comprising 5-30g / L of copper salt, 5-20ml / L of a reducing agent, 10-40g / L of a complexing agent, 8-20g / L of a pH adjustor, 5-15g / L of a pH buffer, 5-50mg / L of organic matter Q, 0-1g / L of ferrite, 0-5g / L of a surfactant, 1-100mg / L of a stabilizer, 5-3mg / L of an accelerator and 10-20ml / L of methanol; the pH value of the chemical thick copper plating solution is 12.0-13.5. The chemical thick copper plating solution is used in the chemical copper plating process of circuit board direct metallization, the stability of the plating solution is good and the appearance of the plating is bright with a metallic luster and the impurity content is few, the thickness of the plating layer is more than 30 nm and the thickness of the plating layer is greatly increased. The plating speed of the chemical copper plating solution can be quickened to reach 20nm / hr.

Owner:广东致卓环保科技有限公司

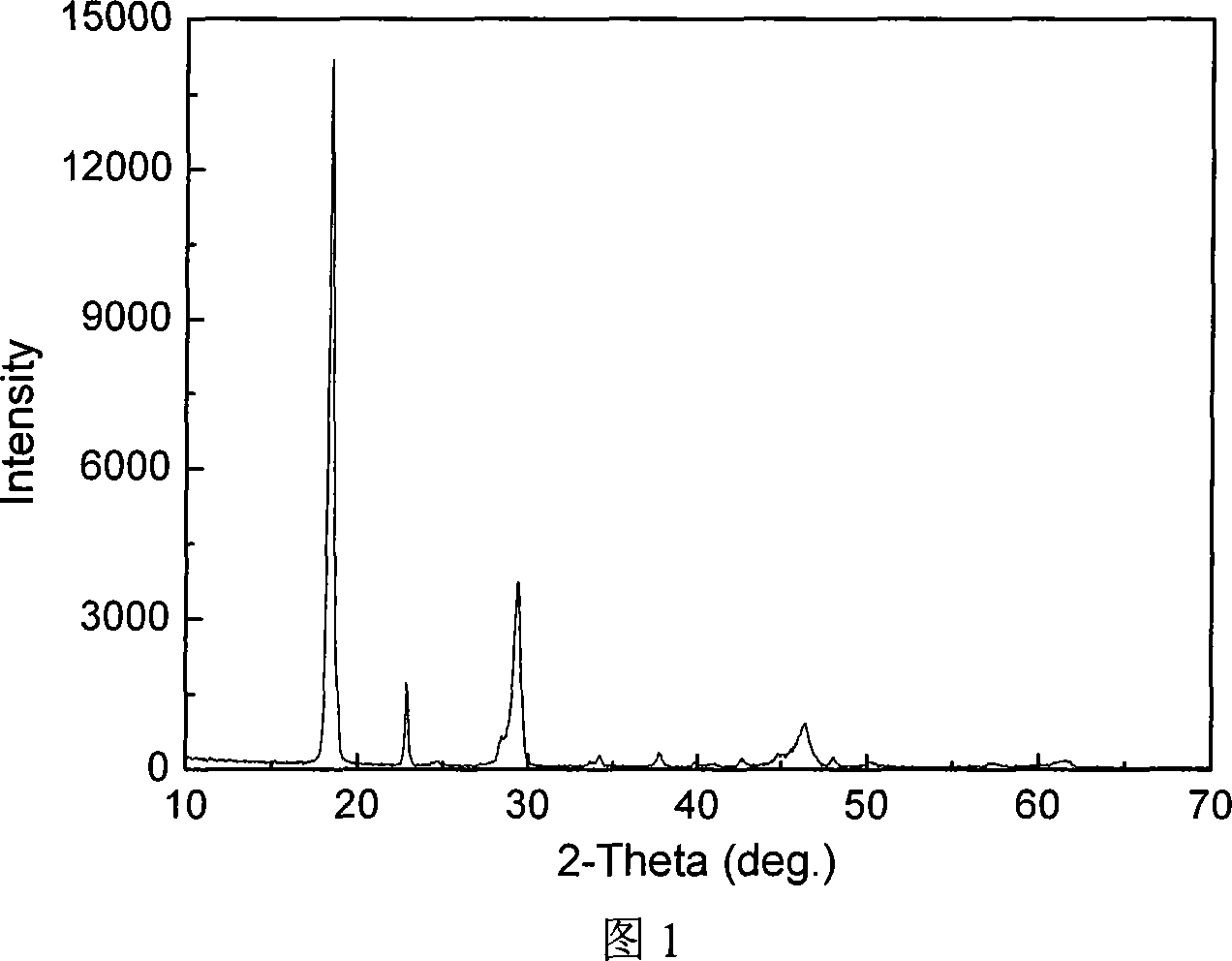

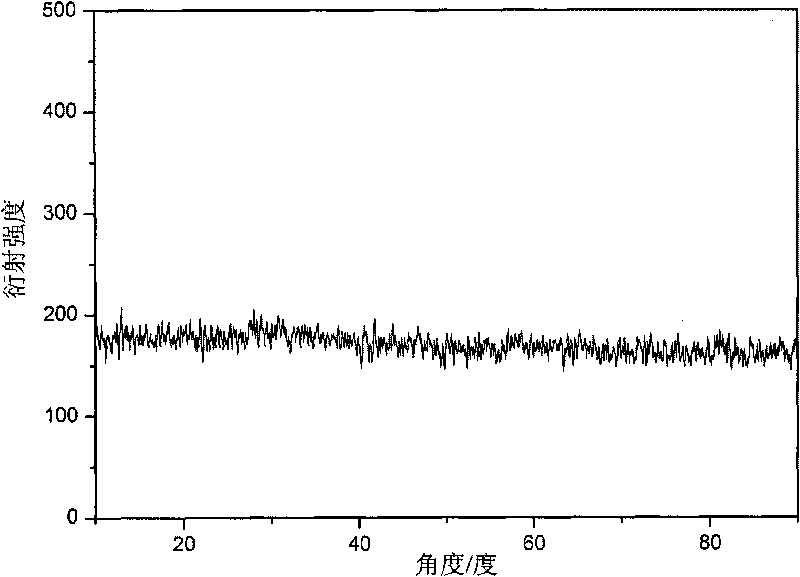

Battery-grade anhydrous iron phosphate and preparation method thereof

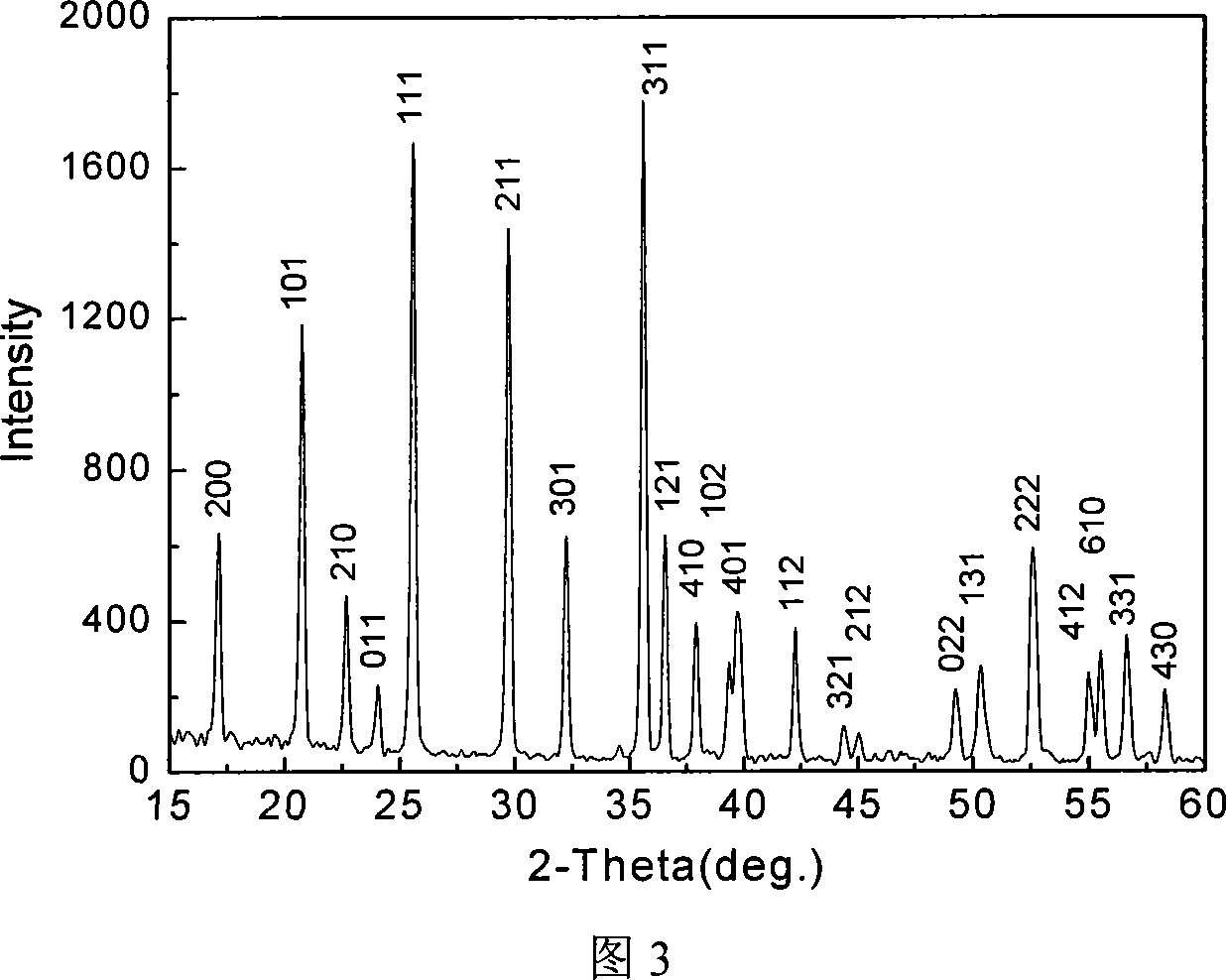

The invention relates to a battery grade anhydrous iron phosphate and a preparation method thereof. The battery grade anhydrous iron phosphate is in an orthorhombic type. The preparation method of the battery grade anhydrous iron phosphate is an oxidation precipitation method using air as oxidant and includes steps: adding pH value modifier solution into aqueous solution of mixture of ferrous salt with phosphoric acid or phosphate, feeding air and stirring for reaction to generate a crystalline-state composite containing ammonium, hydroxyl and water of crystallization; and obtaining the battery grade anhydrous iron phosphate after solid-liquid separating, washing, drying and roasting. The battery grade anhydrous iron phosphate is an ideal material for preparation of lithium iron phosphate which is the material of anodes of lithium ion batteries. The preparation method is suitable for large-scale, economical, stable and reliable production of high-quality battery grade anhydrous iron phosphate, and has evident advantages and practical value.

Owner:HUBEI WANRUN NEW ENERGY TECH DEV

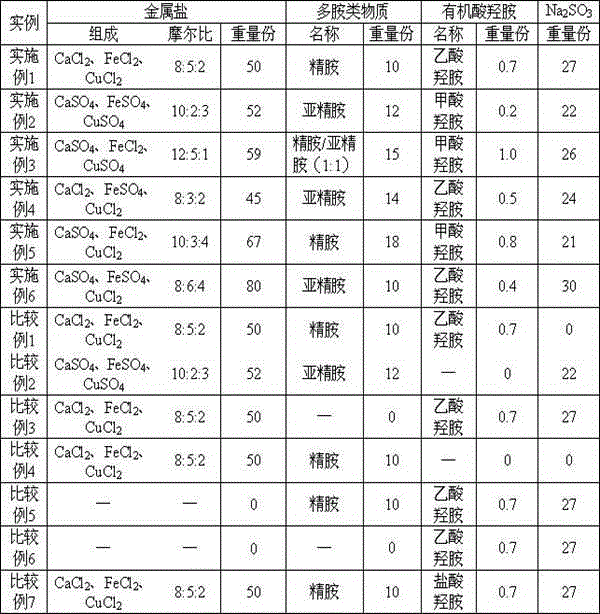

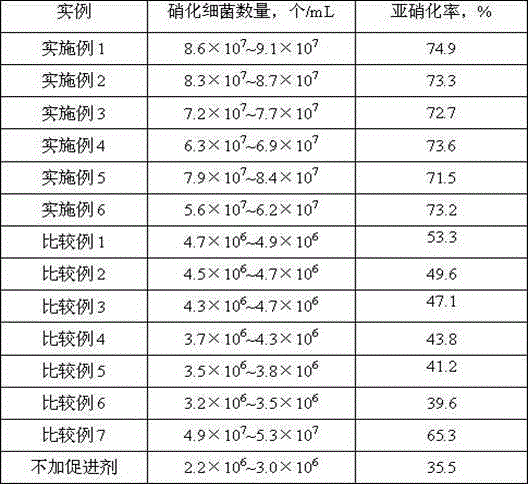

Nitrite bacteria growth promoter and preparation method thereof

ActiveCN105621625AImprove settlement performanceImprove stabilityBiological water/sewage treatmentBacteroidesHydroxylamine

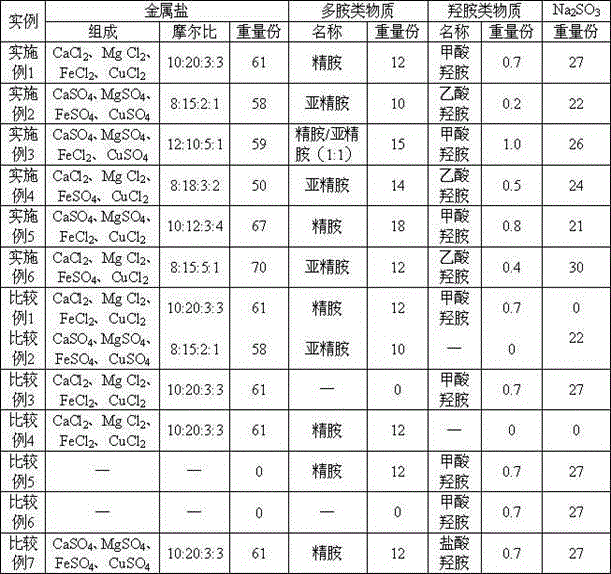

The invention discloses a nitrite bacteria growth promoter including the components: 40-100 parts by weight, preferably 50-80 parts by weight, of metal salts; 5-30 parts by weight, preferably 10-20 parts by weight, of an amine substance; 0.05-1.5 parts by weight, preferably 0.1-1.0 part by weight, of organic acid hydroxylamine; and 10-40 parts by weight, preferably 20-30 parts by weight, of Na2SO3; the metal salts comprise a calcium salt, a magnesium salt, a ferrous salt and a copper salt, and the molar ratio of Ca<2+> to Mg<2+> to Fe<2+> to Cu<2+> is (5-15) to (5-25) to (1-8) to (0.5-5), preferably (8-12) to (10-20) to (2-6) to (1-4). The promoter has the advantages of simple formula and easy preparation, can be used in the cultivation process of nitrite bacteria, can also be directly added into a sewage treatment system, accelerates starting of short-cut nitrification-denitrification and short-cut nitrification-anaerobic ammonium oxidation processes and achieves stable operation.

Owner:CHINA PETROLEUM & CHEM CORP +1

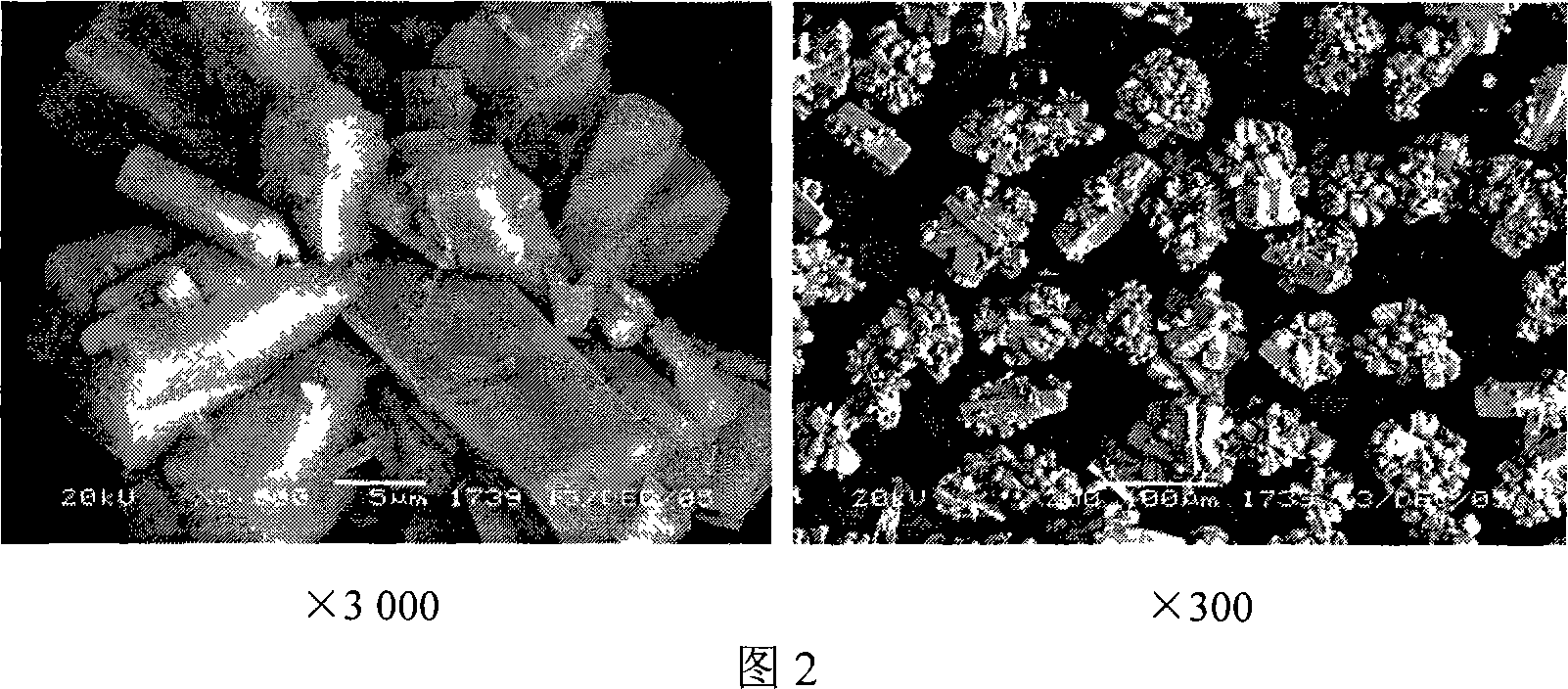

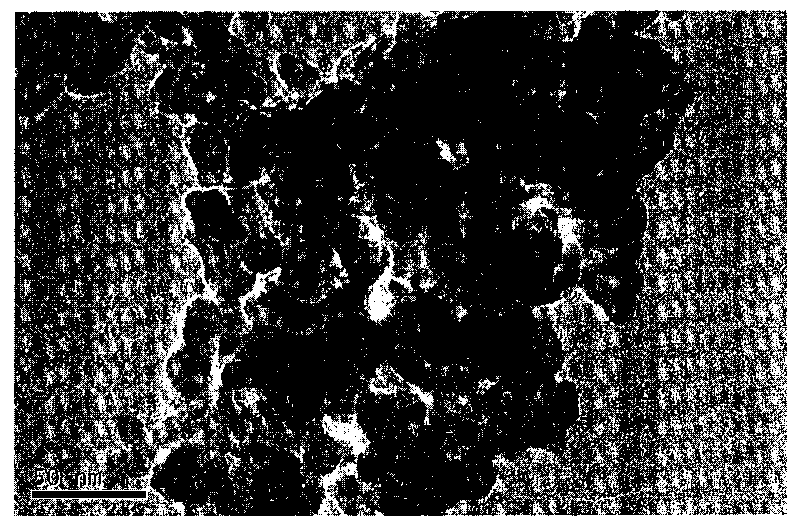

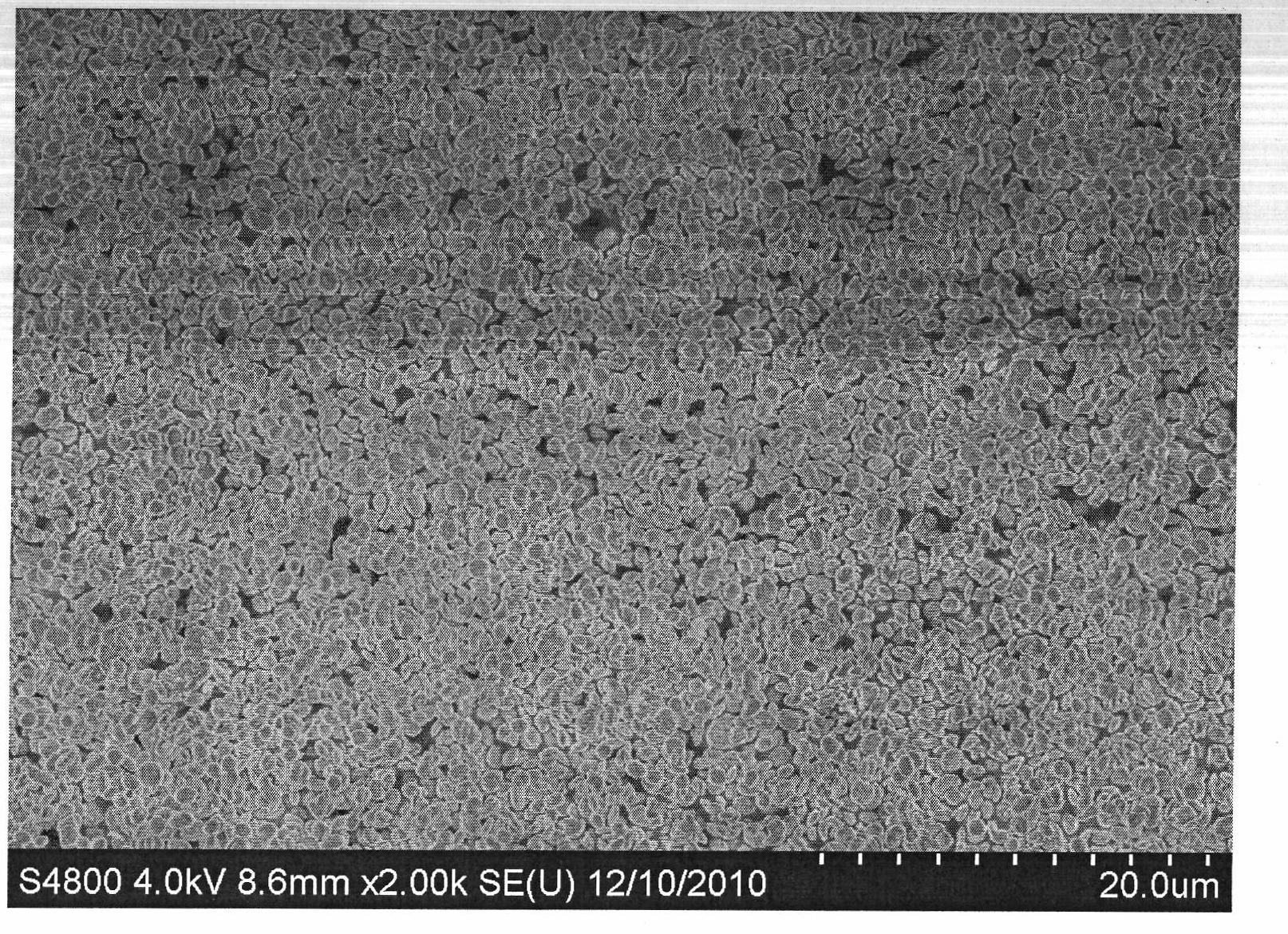

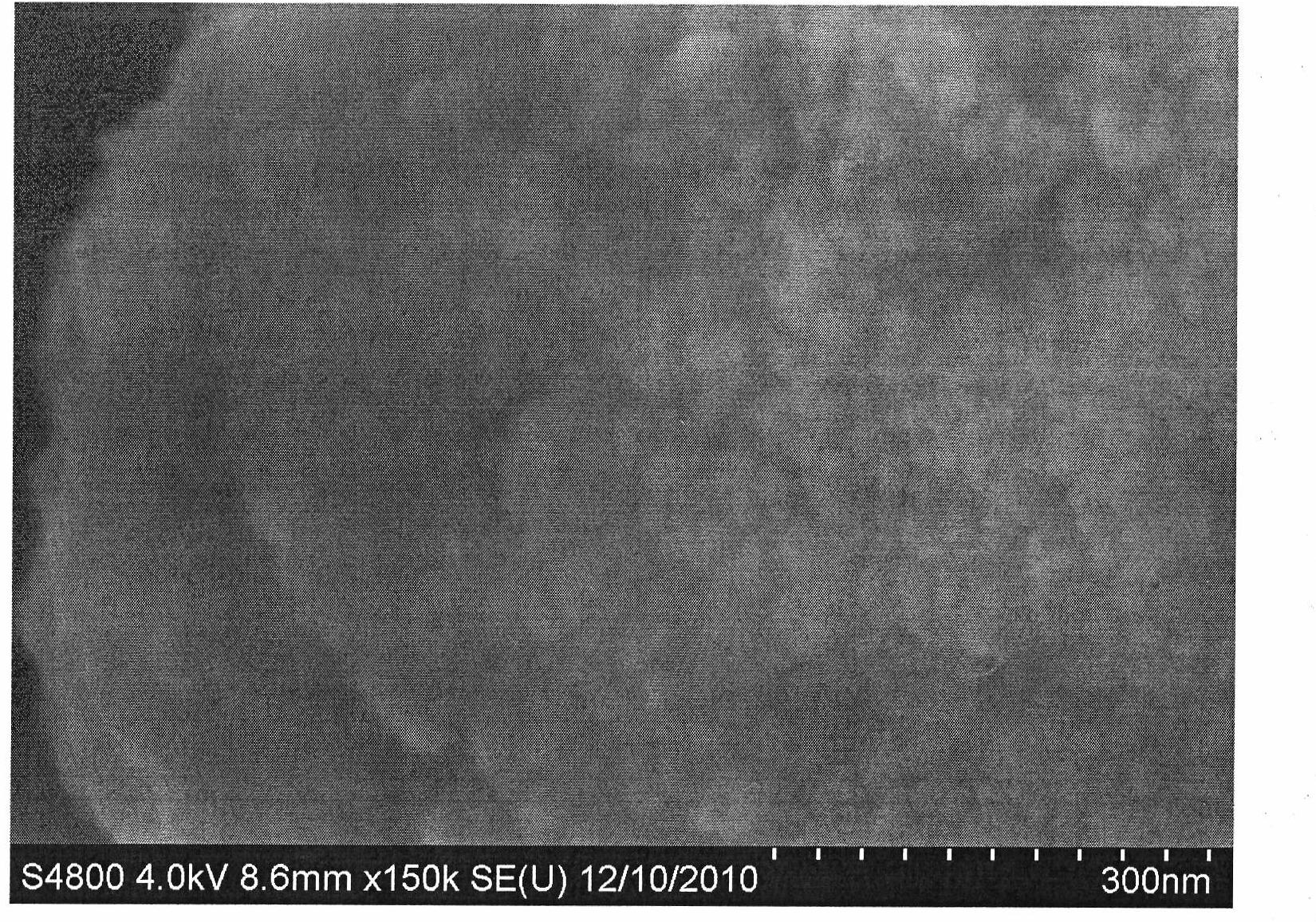

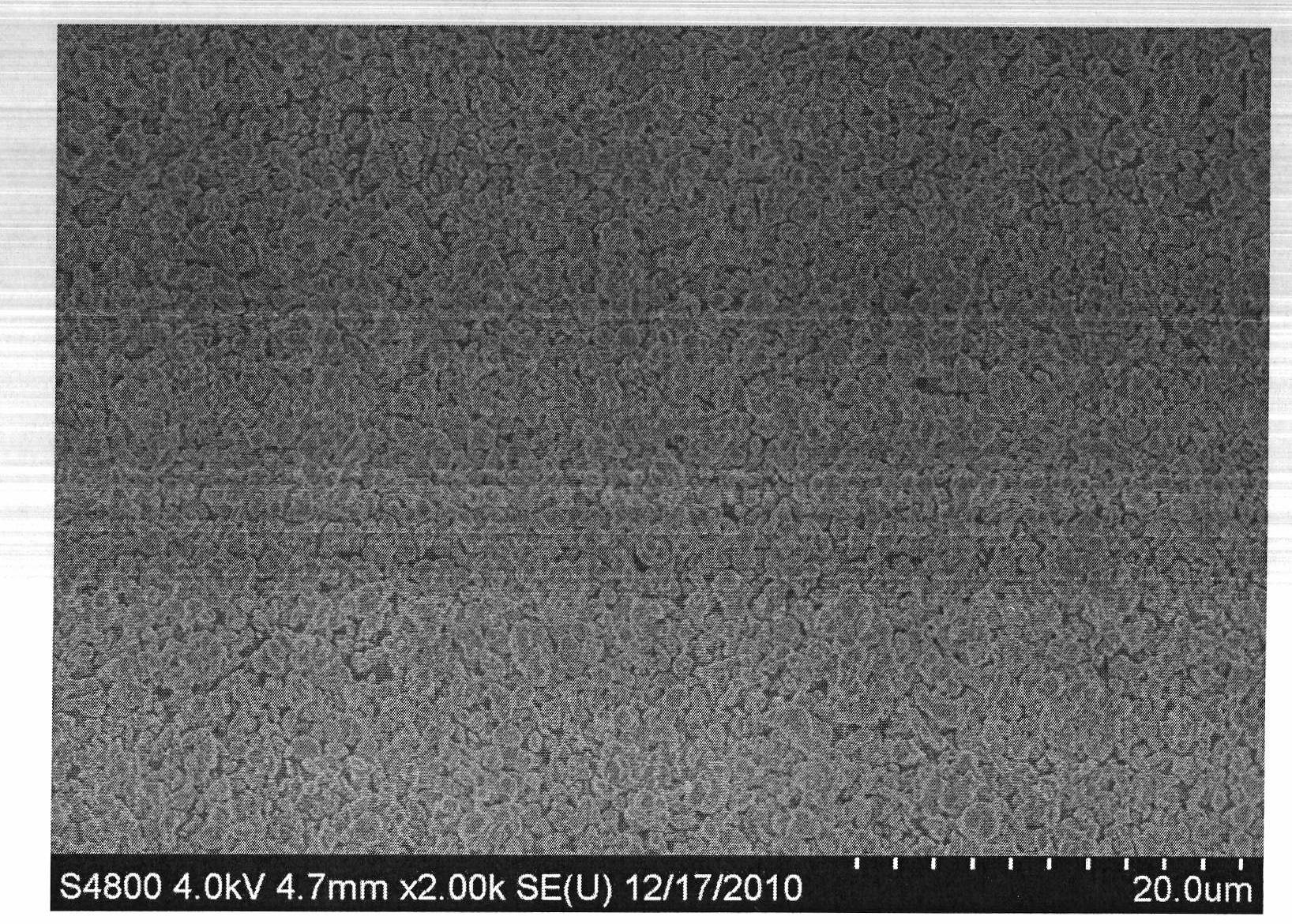

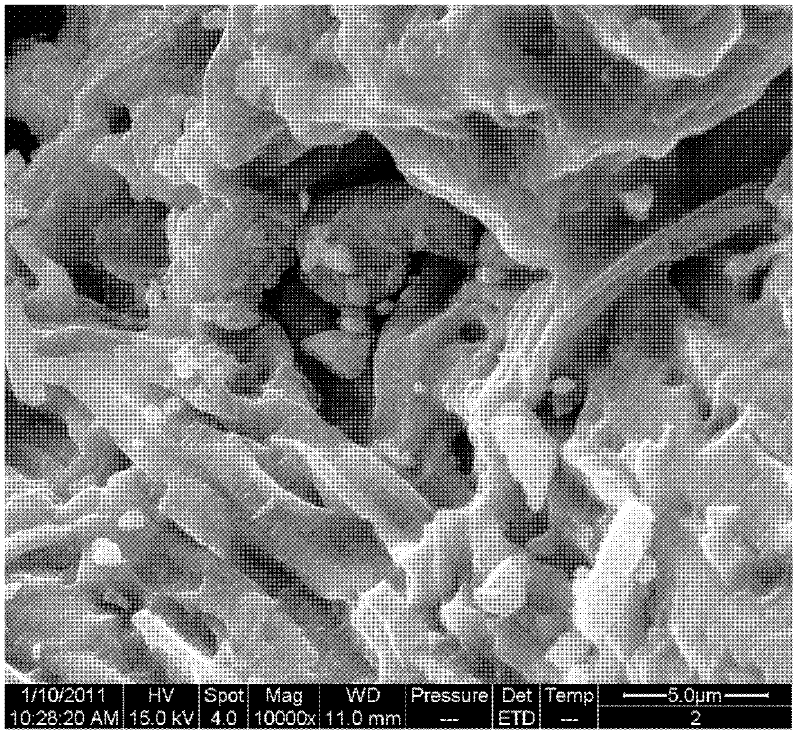

Ferric phosphate having micro-nano structure and preparation method thereof as well as lithium iron phosphate material

ActiveCN102583292AOptimal Control StructureShape is easy to controlMaterial nanotechnologyCell electrodesMicro nanoFerrous salts

The invention relates to ferric phosphate having a micro-nano structure and a preparation method thereof as well as a lithium iron phosphate material. At least one dimension of a primary particle size of the ferric phosphate having the micro-nano structure in a three-dimensional space stays within a nanosecond range, an average size of the primary particles is 1nm to 100nm, and the size of a secondary particle consisting of the primary particles ranges between 0.5 to 10 micrometers. The preparation process is that: a phosphorus source is added into ferrous salt aqueous solution, oxidant is added under a blending condition, aqueous ammonia is used for controlling the systematic pH value to be 1 to 5, and a micro-nano structural particle with given grain fineness distribution is formed after being gathered and after the reaction for 2 to 72 hours under the temperature of 20 to 90 DEG C, and the micro-nano structure particles are washed, dried and roasted to obtain the ferric phosphate having the micro-nano structure. The preparation method has characteristics of simple process flow, good and stable product quality, low cost and the like. The lithium iron phosphate positive material which is prepared by utilizing the ferric phosphate having the micro-nano structure has excellent performance and has characteristics of high vibration density, good specific capacity, good circulation performance and the like.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Nitrite bacterium culture promoter and preparation method thereof

ActiveCN105624093AImprove settlement performanceImprove stabilityBacteriaTreatment with aerobic and anaerobic processesHydroxylamineFerrous salts

The invention discloses a nitrite bacterium culture promoter, which consists of metal salts, polyamine substances, organic acid hydroxylamine and Na2SO3, wherein in parts by weight, the content of the metal salts is 40-100 parts by weight, preferably 50-80 parts by weight; the content of the polyamine substances is 5-30 parts by weight, preferably 10-20 parts by weight; the content of the organic acid hydroxylamine is 0.05-1.5 parts by weight, preferably 0.1-1.0 part by weight; and the content of the Na2SO3 is 10-40 parts by weight, preferably 20-30 parts by weight; the metal salts include calcium salt, ferrous salt and copper salt; and the molar ratio of Ca<2+> to Fe<2+> to Cu<2+> is (5-15) to (1-8) to (0.5-5), and preferably (8-12) to (2-6) to (1-4). The promoter is simple in formula and easy for preparing; and the promoter can be applied to the culture process of the nitrite bacteria and the promoter can be also directly added to a sewage treatment system, so that the starting of partial nitrification-denitrification and partial nitrification-anaerobic ammonia oxidation processes is accelerated and the stable running of the processes is achieved.

Owner:CHINA PETROLEUM & CHEM CORP +1

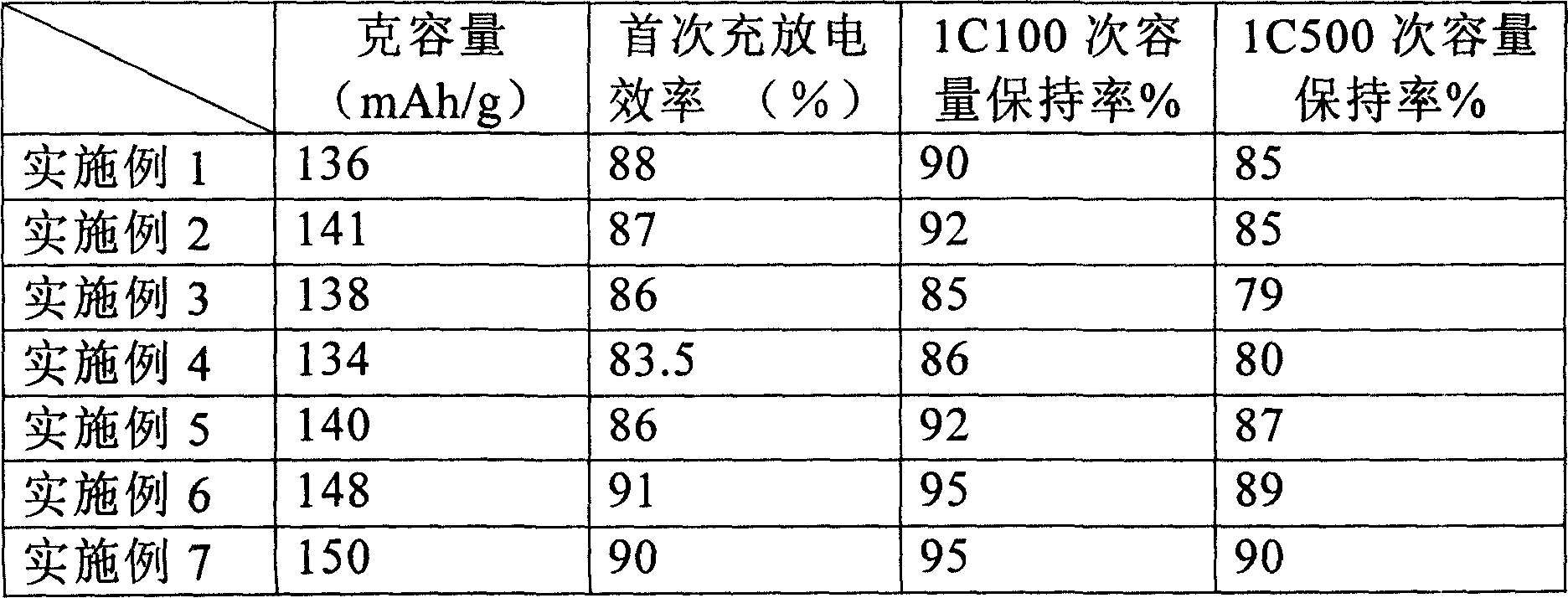

Ferrous phosphate doping lithium anode material and preparation process

InactiveCN1921187AImprove discharge capacityLow costElectrode manufacturing processesPhosphorus compoundsPhosphateFerrous salts

The invention relates to a lithium anode material doped with phosphate ferrous iron, and relative preparation. Wherein, the product has common advantages of lithium battery, while its discharge capacity can reach 150mAh / g, the 500-circled capacity is over 90%, with low cost. The invention is characterized in that: its formula is LiFe0.99M0.01PO4 / C; M is Cr, Zn, and Ca; the preparation comprises that (1) mixing and grinding lithium carbonate, ferrous salt, chromate salt, zinc salt, calcium salt, phosphorus source and glucose; (2), preheating the powder material in step (1) in inertia gas and low temperature; (3), grinding the material in step (2), under inertia gas, to be burnt, cooled and screened at 300-deal screen. The invention can be used in the anode of lithium battery.

Owner:XINXIANG ZHONGKE SCI&TECH

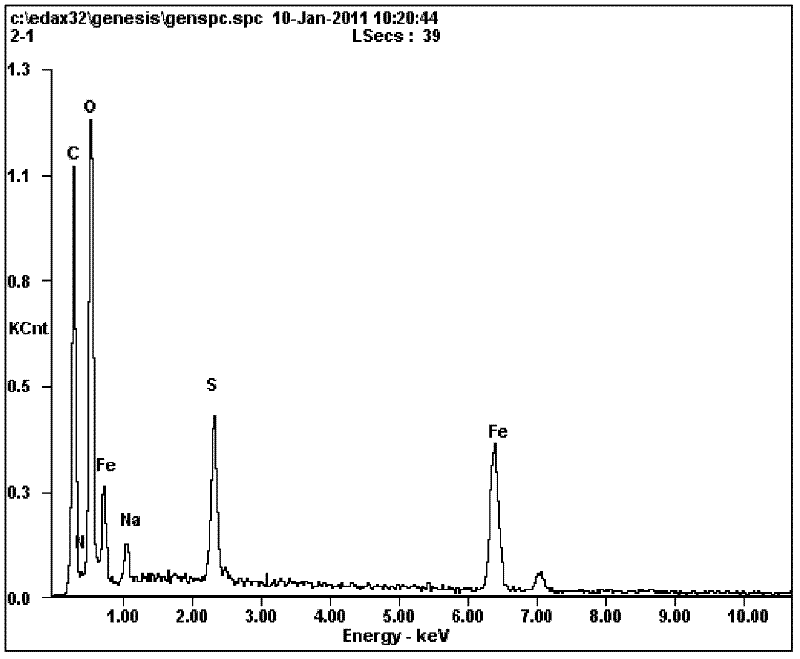

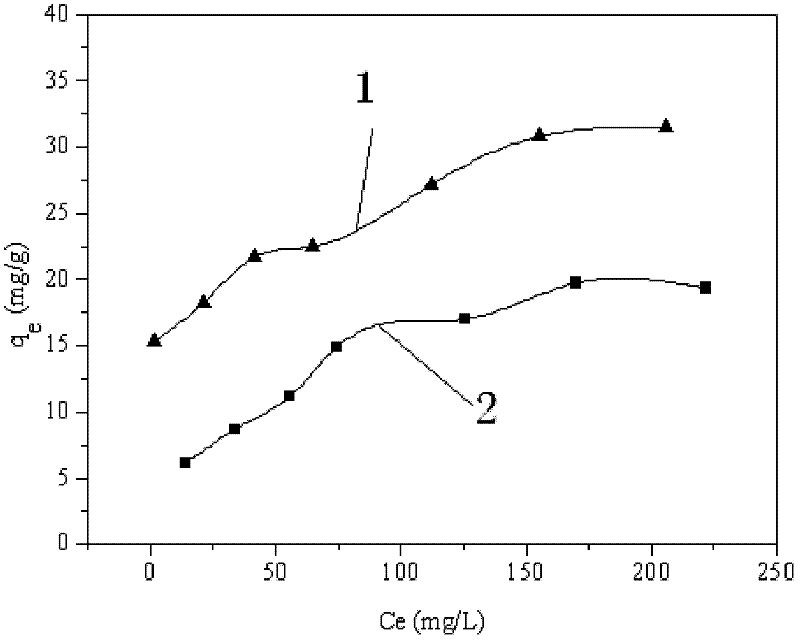

Preparation of sulfur-modified magnetic chitosan and method for treating heavy metal wastewater

InactiveCN102258980AHigh adsorption capacityEasy to prepareOther chemical processesWater contaminantsMaterials preparationVulcanization

The invention discloses a method for preparing sulfured magnetic chitosan and a method for treating waste water containing heavy metals by using the sulfured magnetic chitosan, which belong to the technical field of material preparation. The method for preparing the sulfured magnetic chitosan comprises: dispersing a ferrous salt and a ferric salt in acetic acid solution of chitosan in advance; dripping the mixed solution into alkaline solution by using an injector to form magnetic chitosan spheres; crosslinking the spheres by using glutaraldehyde to form crosslinked magnetic chitosan spheres;and drying under vacuum, grinding into powder and obtaining the sulfured magnetic chitosan. The prepared material is used for treating waste water containing heavy metals.

Owner:TSINGHUA UNIV

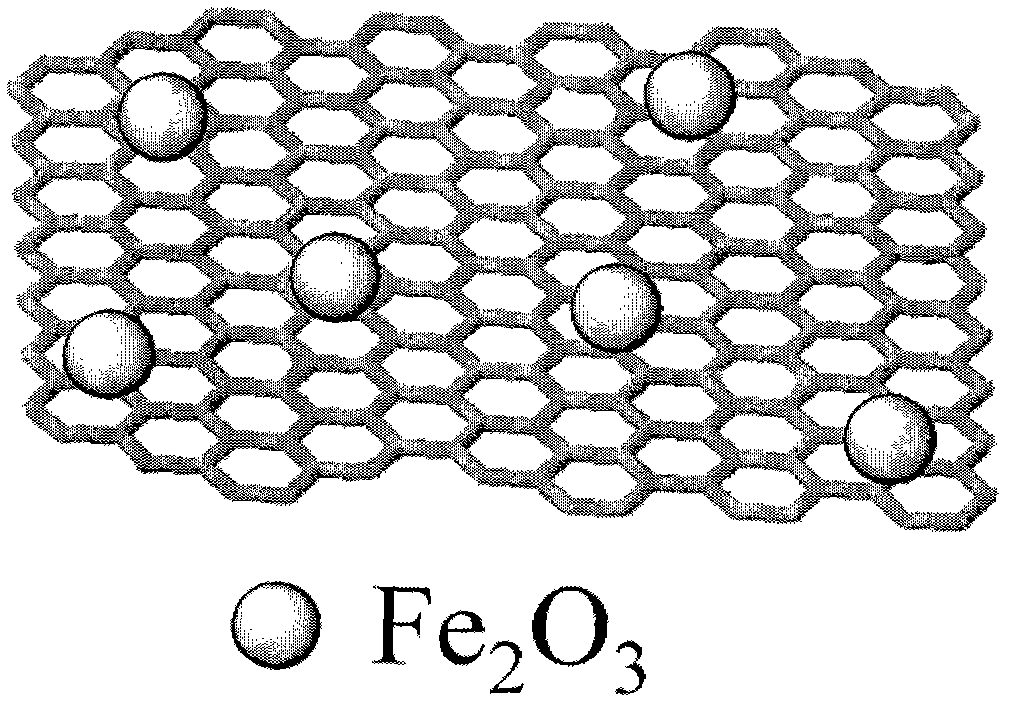

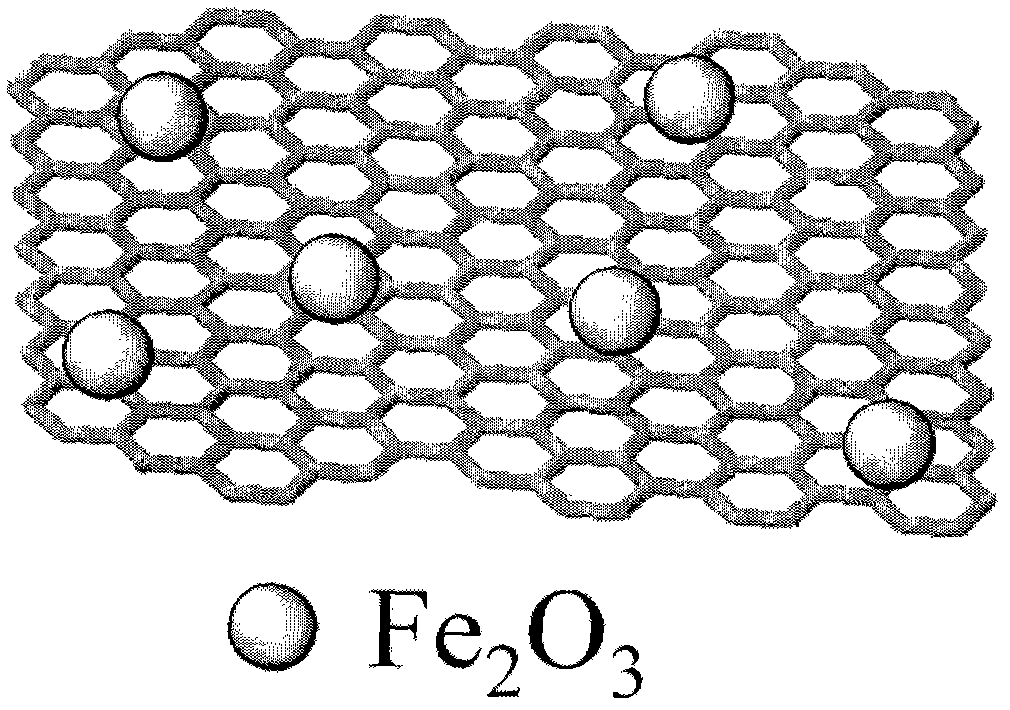

Environment-friendly and efficient method for preparing iron sesquioxide/graphene composite material

The invention relates to an environment-friendly and efficient method for preparing an iron sesquioxide / graphene composite material. In the method, cheap and abundant soluble ferrous salt serves as an iron source and reducing agent, graphene oxide is quickly reduced into the graphene by the characteristics of microwave heating, and ferrous is oxidized and converted into iron sesquioxide so as to obtain a sesquioxide / graphene composite material. The environment-friendly and efficient method fully utilizes the characteristics of ferrite, has the advantages of simple and efficient preparation technology, no industrial three-waste pollution and stable product performance and is favorable for producing on a large scale, and a product has a wide application prospect in the cathode material of a lithium-ion secondary battery.

Owner:BEIJING ZHONGKE MICRO NANO NETWORKING SCI TECH

Water treatment method for removing Tl<+> and/or Cd2<+> by producing nanometer iron and manganese oxides in situ

ActiveCN102145947AHigh electronegativityLarge specific surface areaWater contaminantsMultistage water/sewage treatmentFerric hydroxideWater source

The invention discloses a water treatment method for removing Tl<+> and / or Cd2<+> by producing nanometer iron and manganese oxides in situ, relating to a water treatment method of thallium and / or cadmium-containing source water and solving the problems of complex process, high running cost and low removing efficiency of thallium and / or cadmium existing in the conventional water treatment technology specific to thallium and / or cadmium-polluted source water. The method comprises the following steps of: adding permanganate and ferrous salt into Tl<+> and / or Cd2<+>-containing water; stirring to obtain a mixed solution; adding a coagulant; and performing conventional water treatment. A nanometer ferric hydroxide-manganese dioxide oxide composite adsorbent which has a large specific surface area and high electronegativity and is easy for precipitation separation is produced in situ by making permanganate react with the ferrous salt, so that Tl<+> and / or Cd2<+> can be removed effectively andspecifications in the national Sanitary Standard for Drinking Water are met. The method has the advantages of high removing efficiency, simple process, flexibility and convenience for operation, no change of the original treatment process of a water plant, low running cost and the like, and can be applied to emergency treatment of a water pollution event.

Owner:HARBIN INST OF TECH

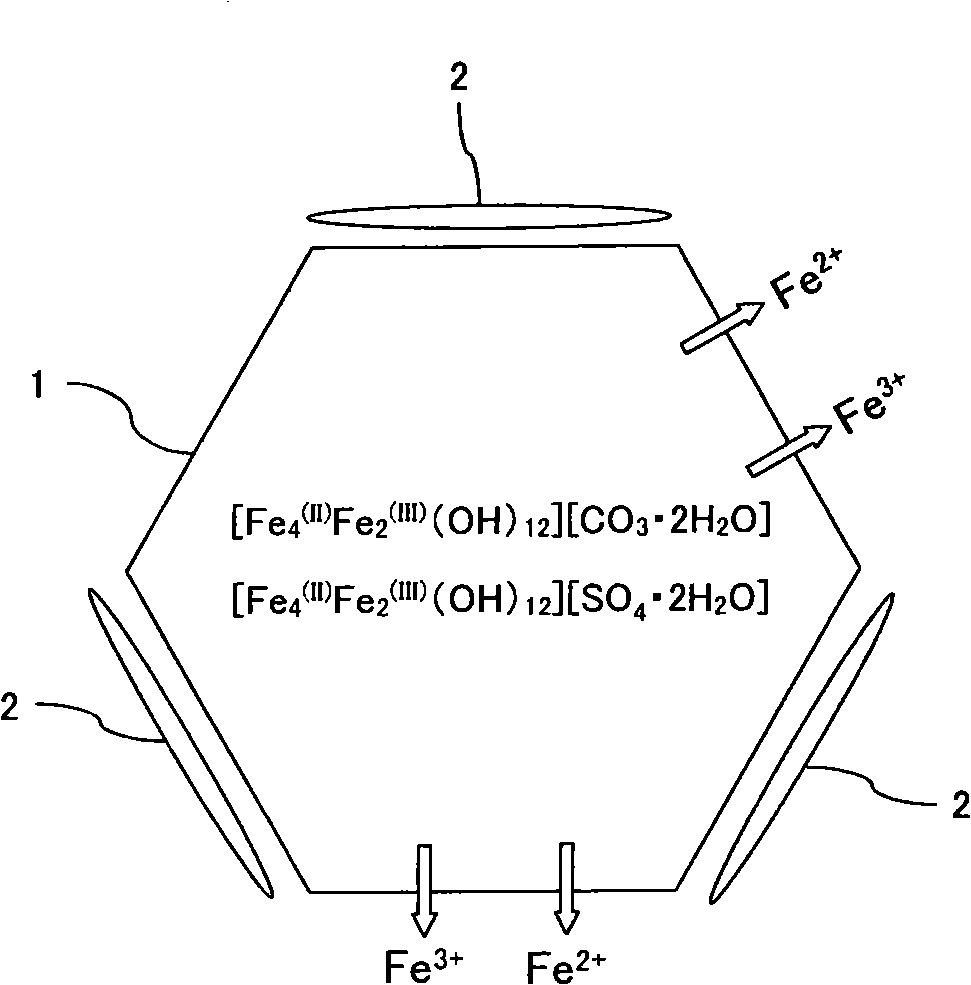

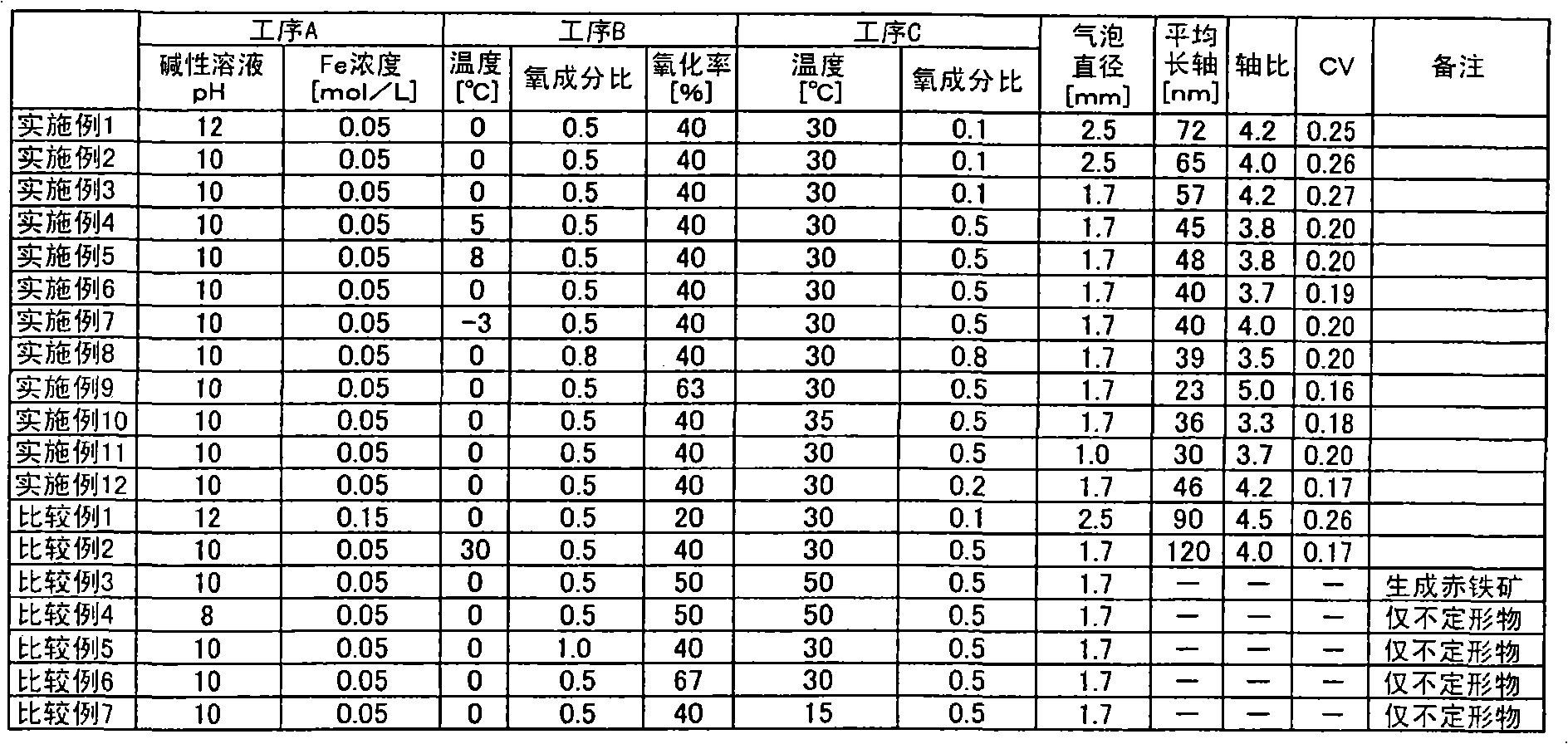

Method for producing iron oxyhydroxide particle

Owner:TDK CORPARATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com