Zymohydrolysis lactoprotein ferrous complex compound microcapsule iron supplement agent and preparation thereof

A milk protein and complex technology, applied in the biological field, can solve the problems of low absorption and utilization rate, toxic and side effects, etc., and achieve the effect of improving absorption and utilization rate, no toxic and side effects, prevention and treatment of iron deficiency anemia

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

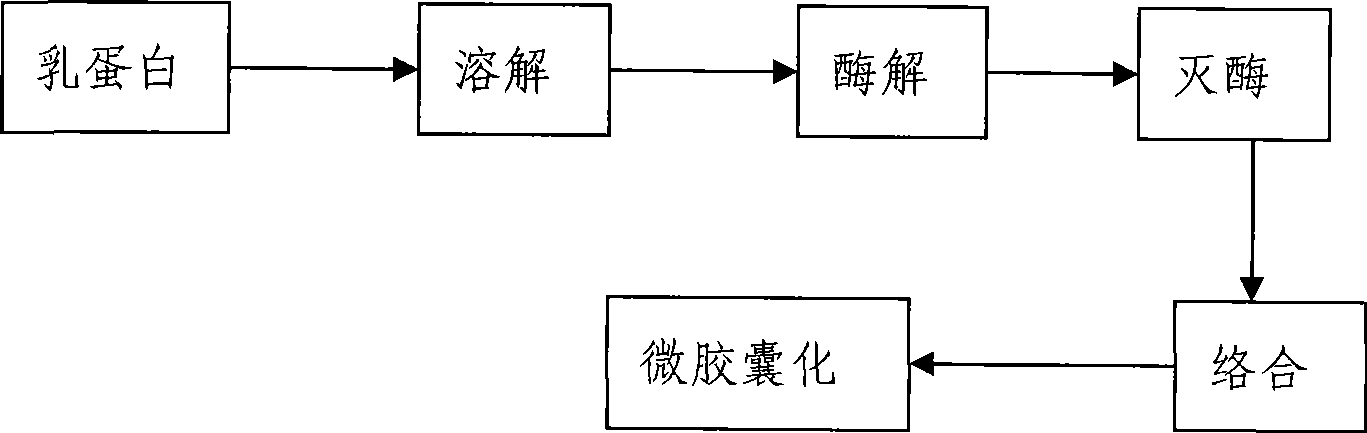

Method used

Image

Examples

Embodiment 1

[0041] Casein was purchased from Northwest Biotechnology Company; alkaline protease was purchased from Novozymes Biotechnology Co., Ltd.; sodium alginate was purchased from Beijing Aoboxing Biotechnology Co., Ltd. Whey protein was purchased from Beijing Yinhe Road Company.

[0042]Take 0.6 kg of casein, make it into a 6% (w / v) protein solution, add 0.6 g of alkaline protease, adjust the enzymolysis temperature to 42°C, enzymolysis time is 7 hours, and the pH value is 8.0 for enzymolysis. After the end of the enzymolysis, Inactivate the enzyme at 90°C for 10 minutes, and perform ultrafiltration with an ultrafiltration device (a blended ultrafiltration membrane with a molecular weight cut-off of 10 kDa) to obtain a relatively pure milk protein hydrolyzate, which is cooled to room temperature for later use.

[0043] Dissolve the hydrolyzate of milk protein with distilled water, according to the bioactive peptide and FeSO 4 The mass ratio (calculated by Fe) is 2:1, the reaction p...

Embodiment 2

[0046] Crude cheese was from Xinjiang; alkaline protease was purchased from Beijing Fangshan Enzyme Preparation Factory; chitosan was purchased from Beijing Aoboxing Biotechnology Co., Ltd.; whey protein was purchased from Beijing Yinhe Road Company.

[0047] Take 0.6kg of crude cheese and 0.1kg of whey protein, make it into a 3% (w / v) protein solution, add 0.25g of alkaline protease, adjust the enzymatic hydrolysis temperature to 55°C, enzymatic hydrolysis time for 9h, and pH value 7.0 for enzymatic After enzymatic hydrolysis, inactivate the enzyme at 60°C for 30 minutes, then cool to room temperature for later use.

[0048] Take the milk protein hydrolyzate solution, carry out the complexation reaction according to the mass ratio of bioactive peptide and ferrous lactate (calculated as Fe) is 4:1, the reaction pH value is 4.0, the reaction temperature is 40 ° C, and the complexation time is 55min. A solution containing milk protein bioactive peptide ferrous complex is prepare...

Embodiment 3

[0051] Casein: from Northwest Biotechnology Company; alkaline protease was purchased from Novozymes Biological Co., Ltd.; modified starch was purchased from National Starch Company; whey protein was purchased from Beijing Yinhe Road Company.

[0052] Take 0.6 kg of casein, make it into a 9% (w / v) protein solution, add 1.42 grams of alkaline protease, adjust the enzymolysis temperature to 25° C., enzymolysis time of 4 hours, and pH value 9.0 for enzymolysis. After the enzymolysis, Inactivate the enzyme at 75°C for 15 minutes, cool to room temperature, and set aside.

[0053] Use ultrafiltration equipment (ceramic ultrafiltration membrane with a molecular weight cut-off of 10kDa) for ultrafiltration, and use Sephadex G-25 for gel filtration chromatography to obtain a solution of higher purity milk protein hydrolyzate, and cool to room temperature spare.

[0054] Take the above-mentioned enzymatically hydrolyzed milk protein solution (after deactivating the enzyme) and dissolve ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com