Patents

Literature

1066results about How to "Achieve hybrid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

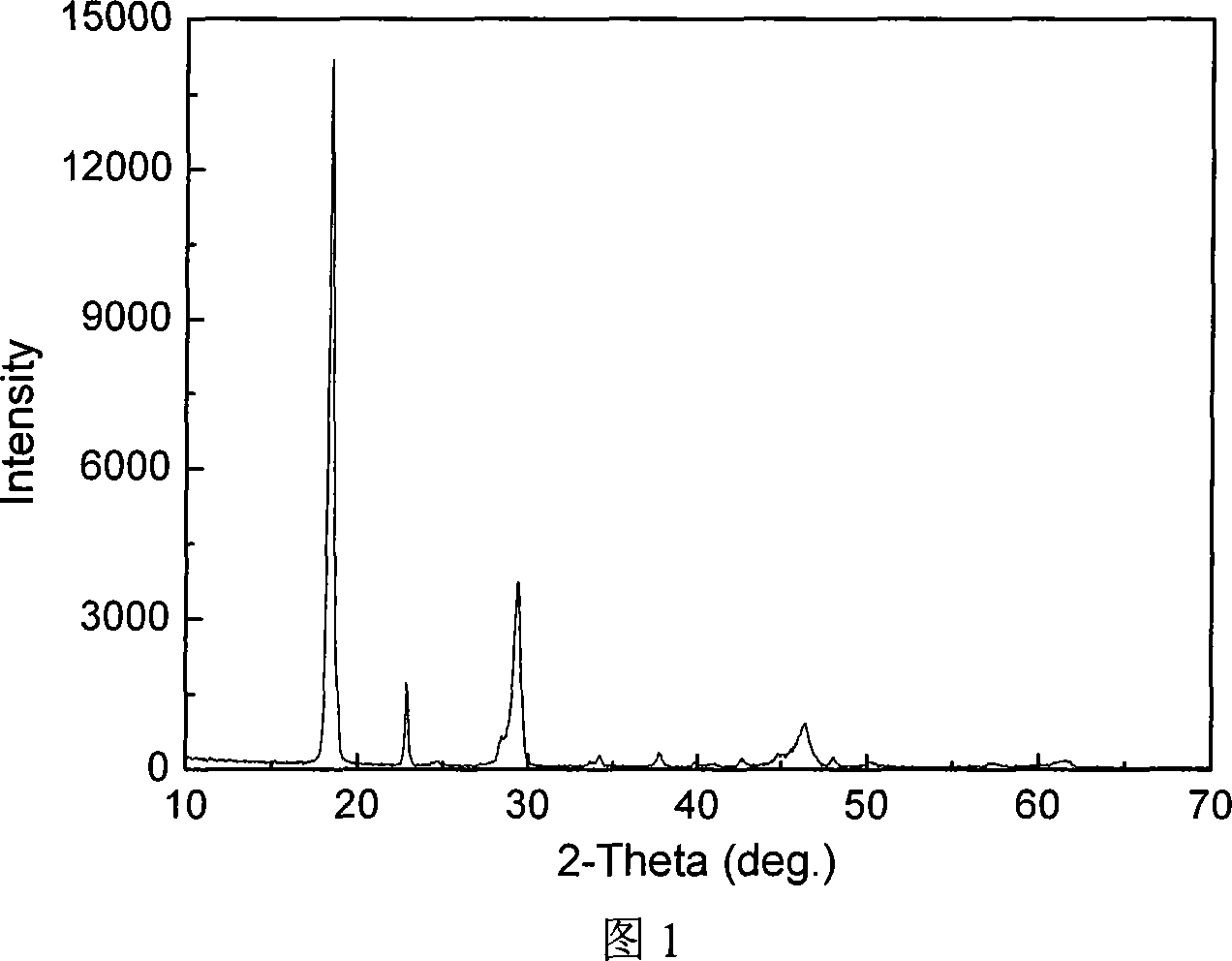

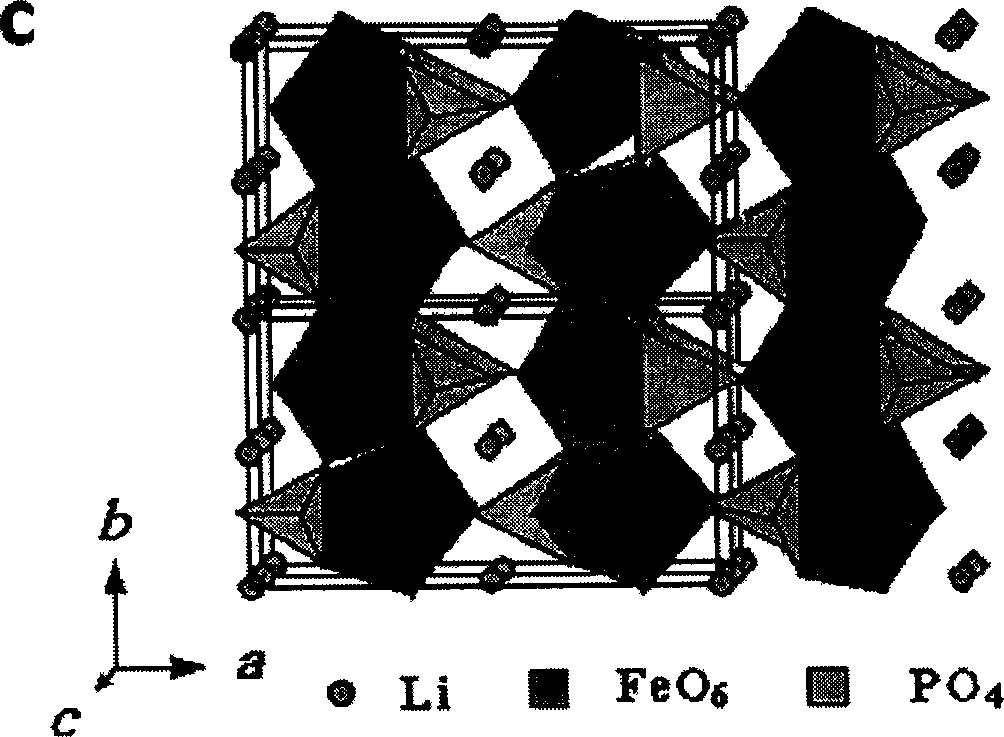

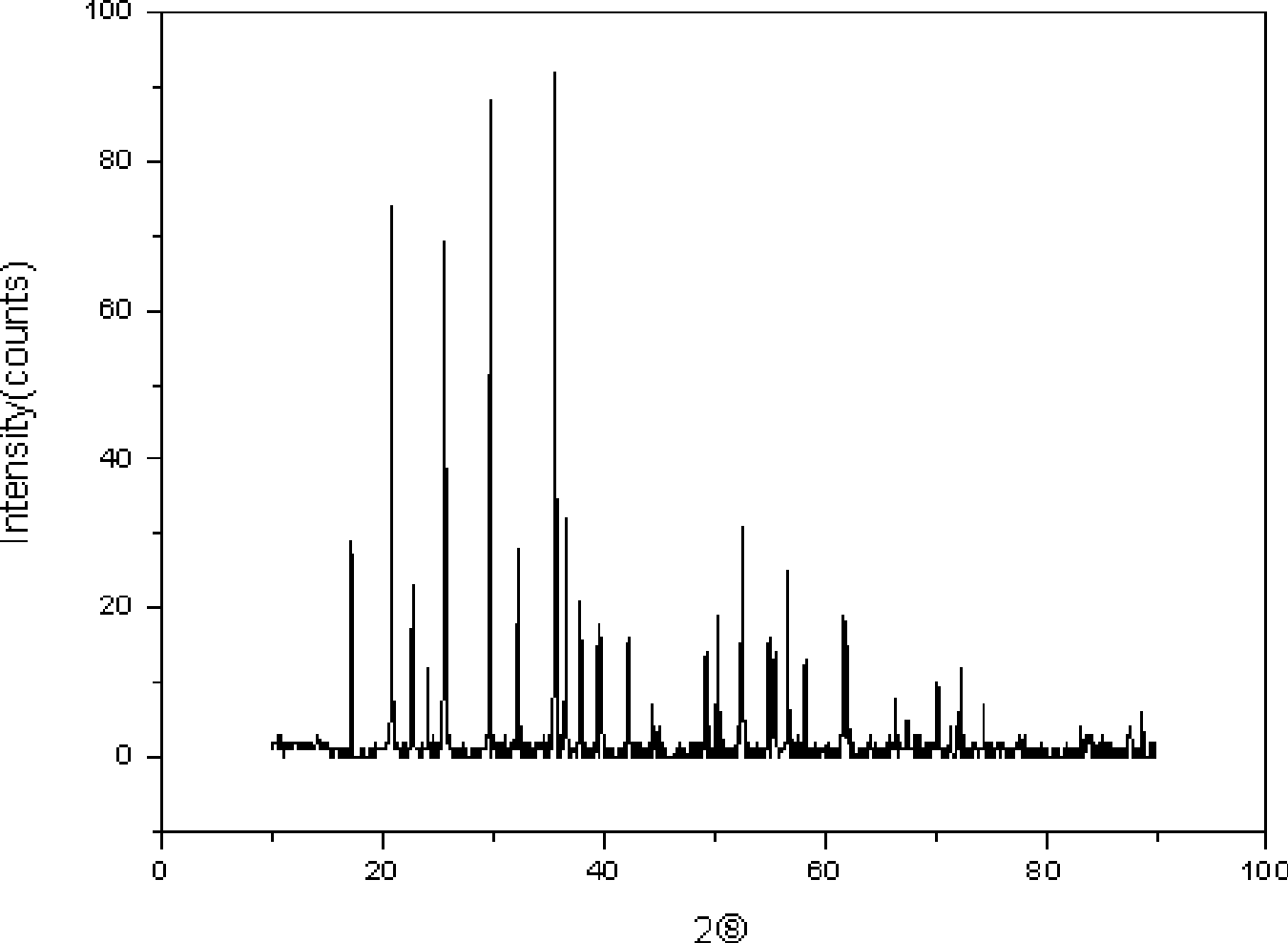

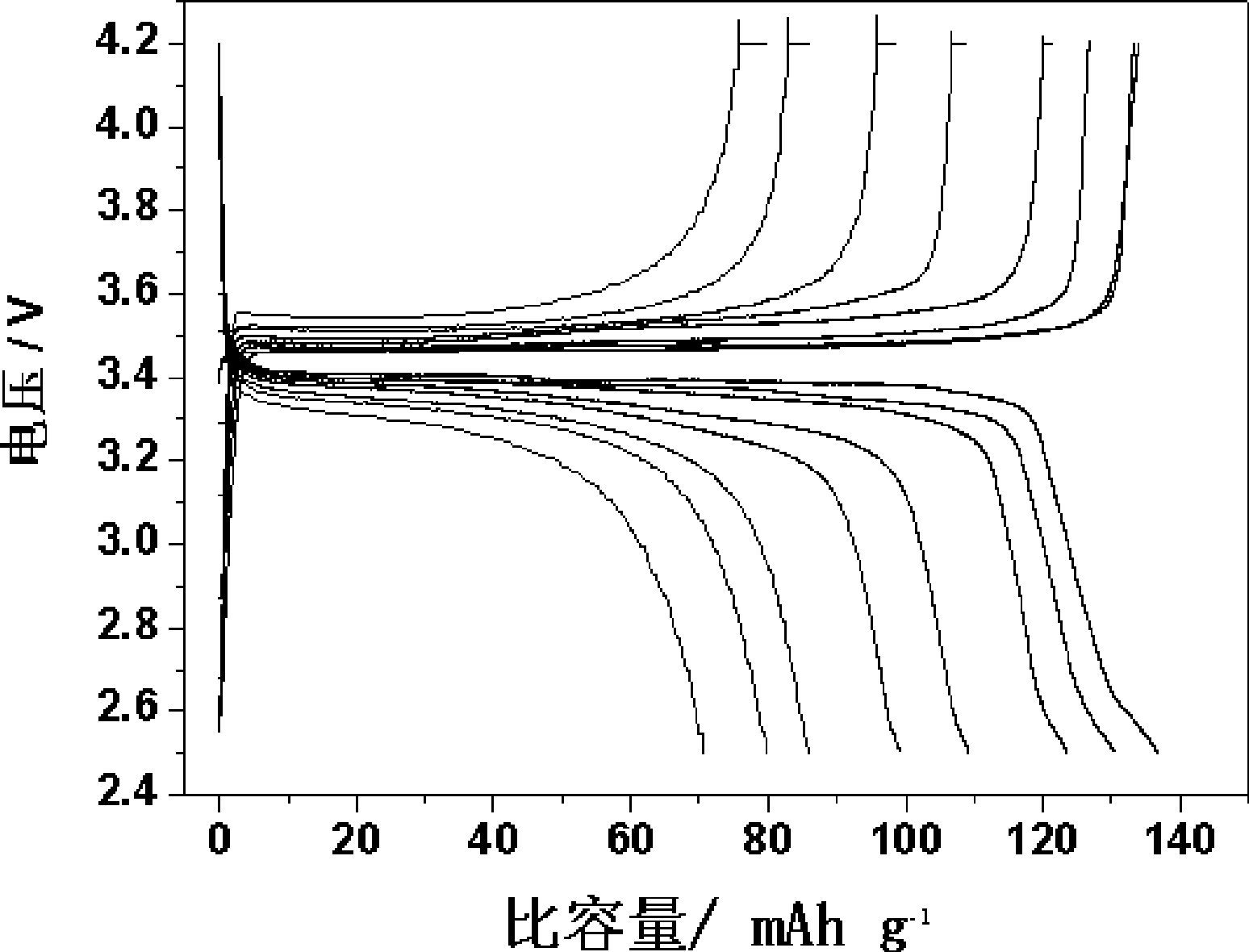

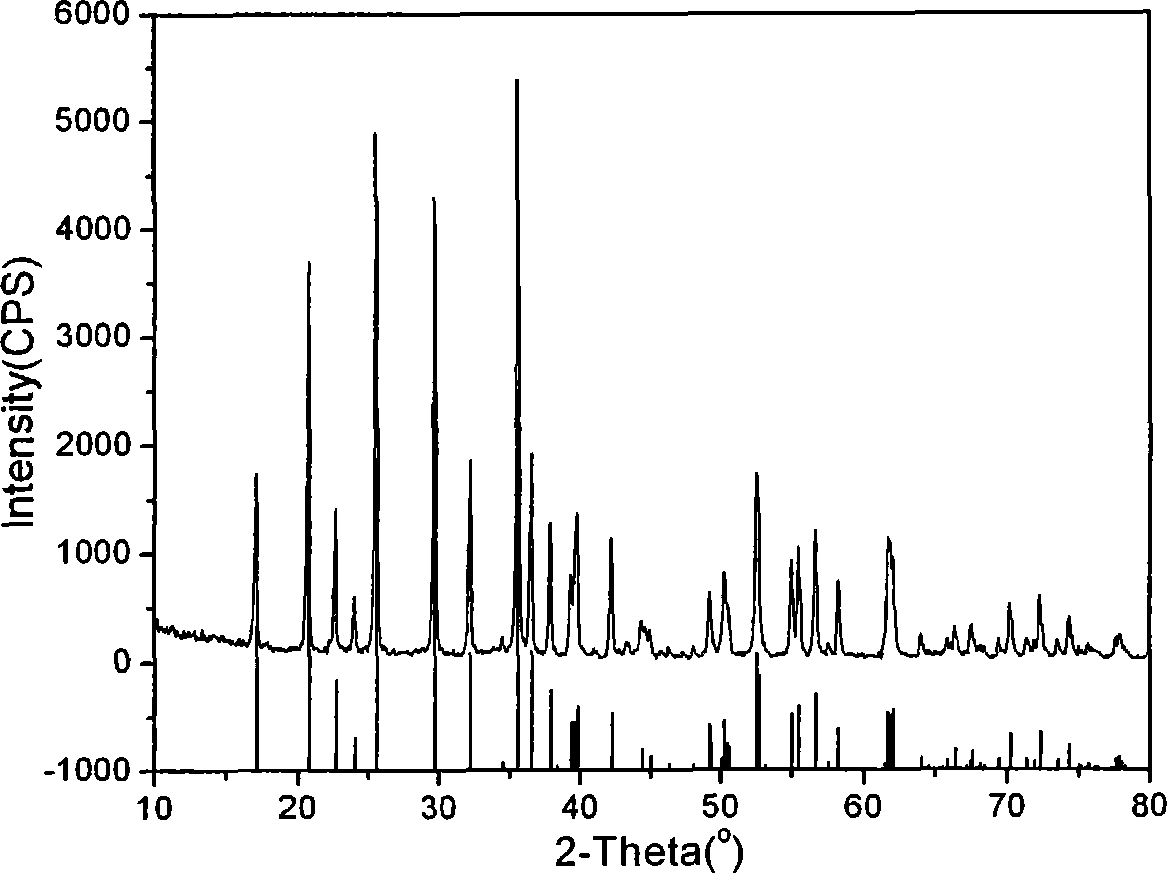

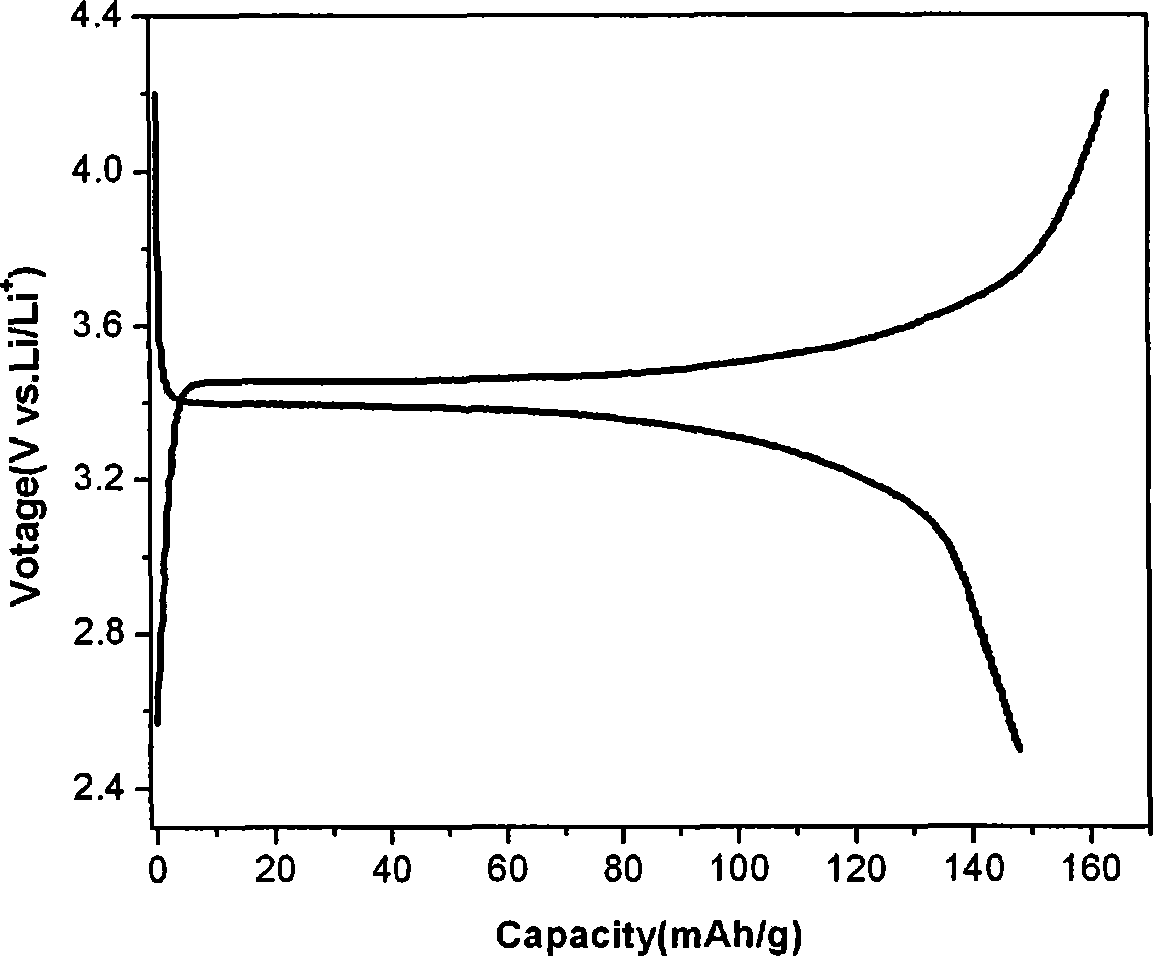

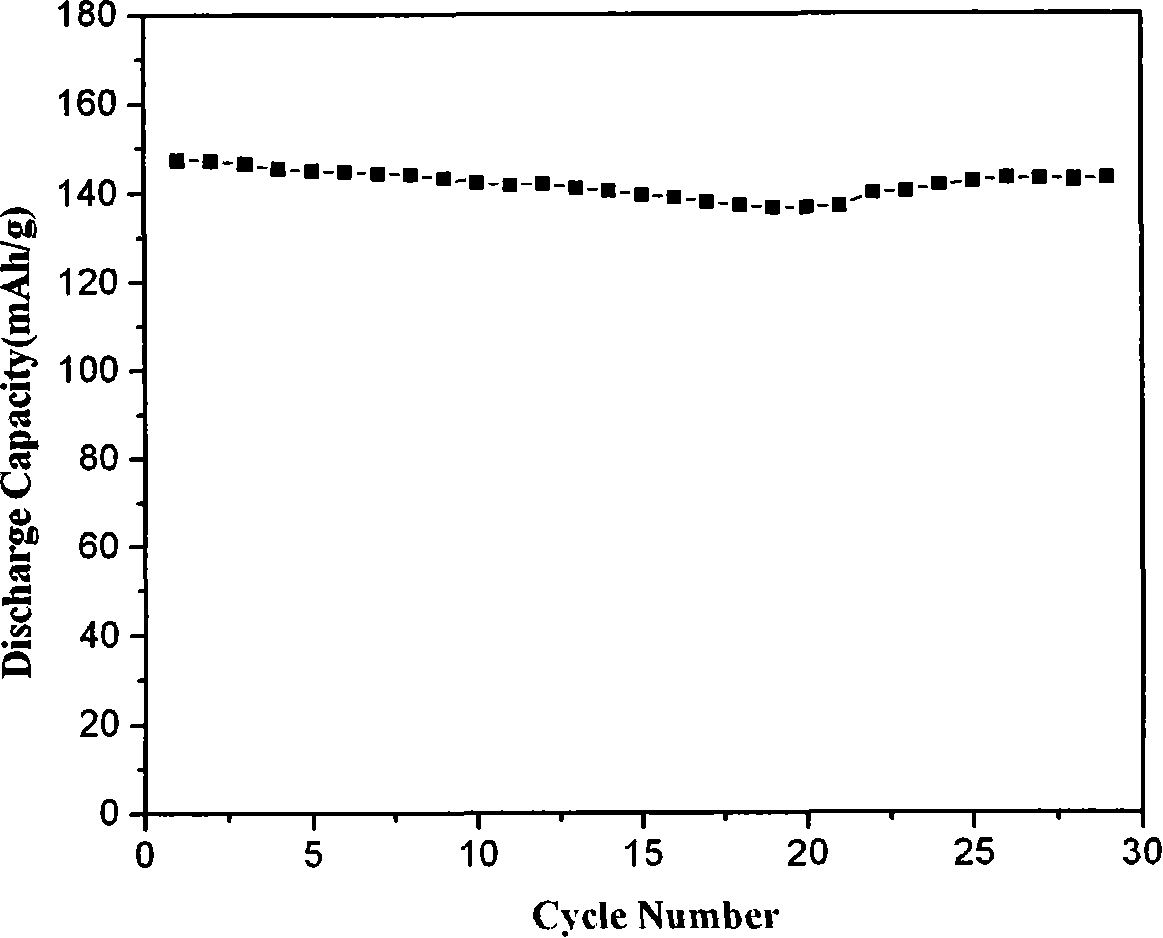

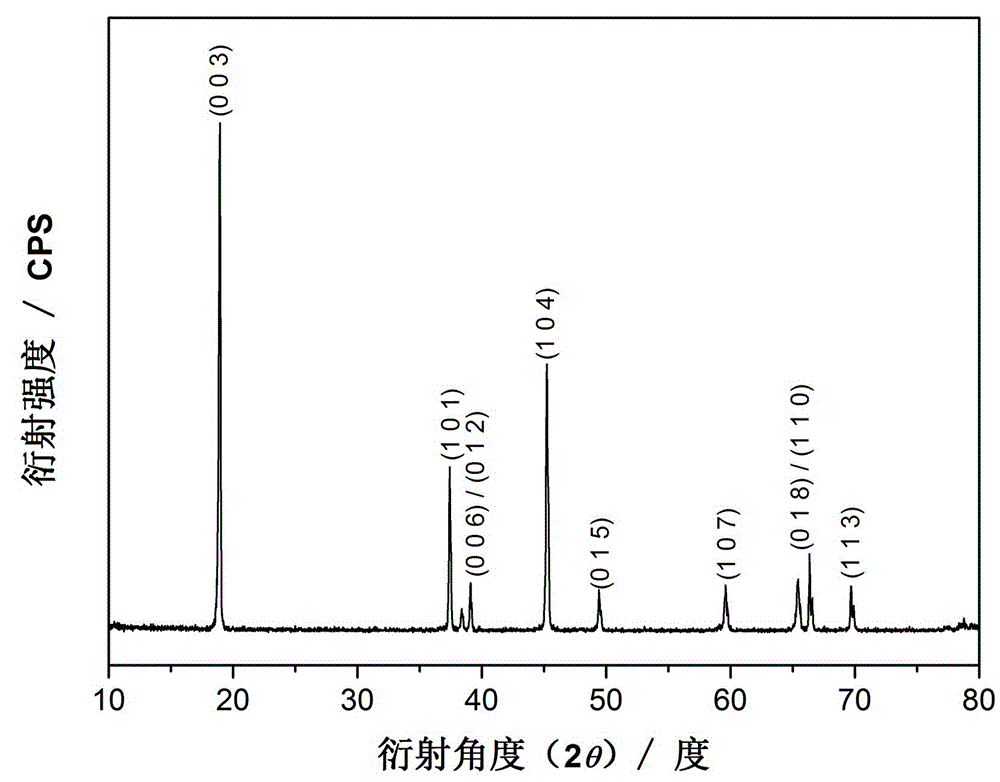

Method for preparing anode material of lithium ion battery in series of phosphate of olivine type

InactiveCN101049922AAchieve hybridEvenly distributedCell electrodesPhosphorus compoundsAluminium-ion batteryPhosphate

This invention relates to a method for preparing olivine-type phosphate-series lithium ion battery anode material. The method comprises: mixing one or more of ferrous salt solution, cobalt salt solution and manganese salt solution with oxalic acid or oxalate (precipitating agent) aqueous solution to obtain composite oxalate precursor, uniformly mixing with lithium source and phosphorus source by ball milling, and reacting in inert or weak-reductive atmosphere to obtain olivine-type phosphate-series lithium ion battery anode material. The method utilizes co-precipitation method for metal ion doping, and realizes molecular level uniform mixing among different ions. The obtained olivine-type phosphate-series lithium ion battery anode material has uniform chemical and physical compositions. The average particle size can be controlled within 0.3-10 mu.m. The first charge and discharge cycle specific capacity can reach 150 mAh / g at 0.1 C rate and room temperature. The livine-type phosphate-series lithium ion battery anode material has such advantages as high cycle performance and high charge / discharge performance.

Owner:CENT SOUTH UNIV

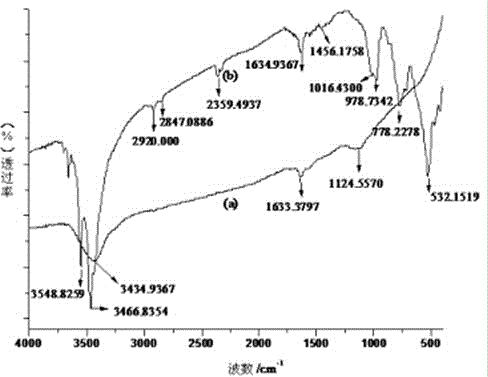

Surface modification method for carbon nano tube

InactiveCN102942810AGood for secondary modificationImprove thermal stabilityPigment treatment with organosilicon compoundsPigment treatment with non-polymer organic compoundsPtru catalystModified carbon

The invention provides a surface modification method for a carbon nano tube and belongs to the field of nanotechnology. The method includes step one, uniformly mixing a carbon nano tube which is subjected to acidification by a strong oxidizing acid with a silane coupling agent and deionized water, reacting under a certain condition, filtering, washing, and drying to obtain a primary modified carbon nano tube; step two, uniformly mixing the primary modified carbon nano tube with polyhydric alcohols and a concentrated sulfuric acid, reacting under a certain condition, filtering, washing to neutral, and drying to obtain a secondary modified carbon nano tube; uniformly mixing the secondary modified carbon nano tube with an organic carboxylic acid, an esterification reaction catalyst and N,N-dimethylformamide, reacting under a certain condition by the aid of the protection of inert gases, cooling to the room temperature, filtering, washing, and drying to obtain the surface modification carbon nano tube. When the prepared modified carbon nano tube which is provided with ester groups on the surface is mixed with a polyester resin, the interface-free mixing is achieved, and the heat stability and the mechanical property of the modified polyester resin can be improved.

Owner:TAIYUAN UNIV OF TECH

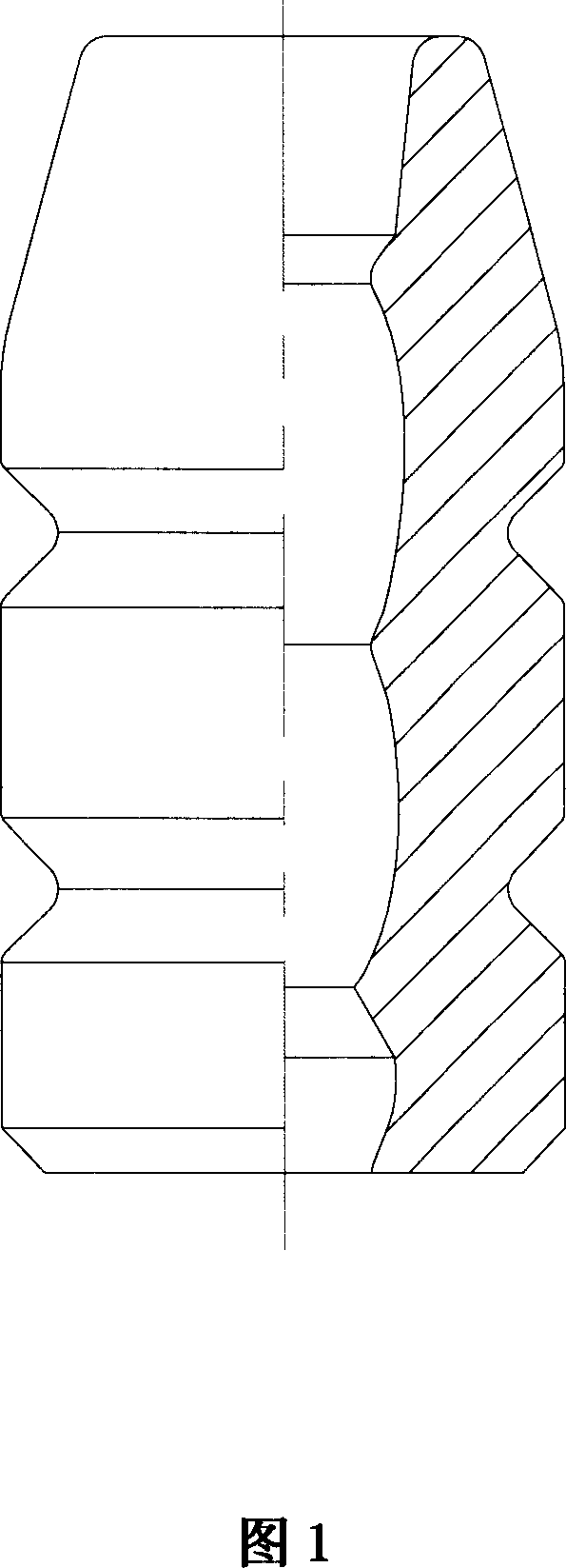

Production of NDI-polyurethane microporous elastomer

Production of NDI-base polyurethane micro-porous elastomer is carried out by preparing performed polymer, reacting excess polyisocyanate with polylol at 120-140degree to form NCO-base performed polymer, pouring, mixing performed polymer with chain extender proportionally, injecting reactive liquid into mould at 80-95degree, pre-curing, de-molding, and after-curing for de-molded product at 110degree for 13-16hrs. It has excellent weathering resistance and hydrolytic stability. It can be used for high-strength damping element, buffering component and shock-absorbing block.

Owner:上海凯众材料科技股份有限公司

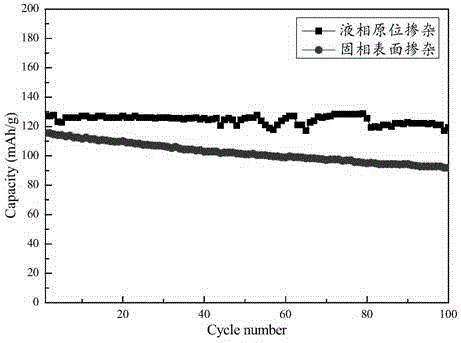

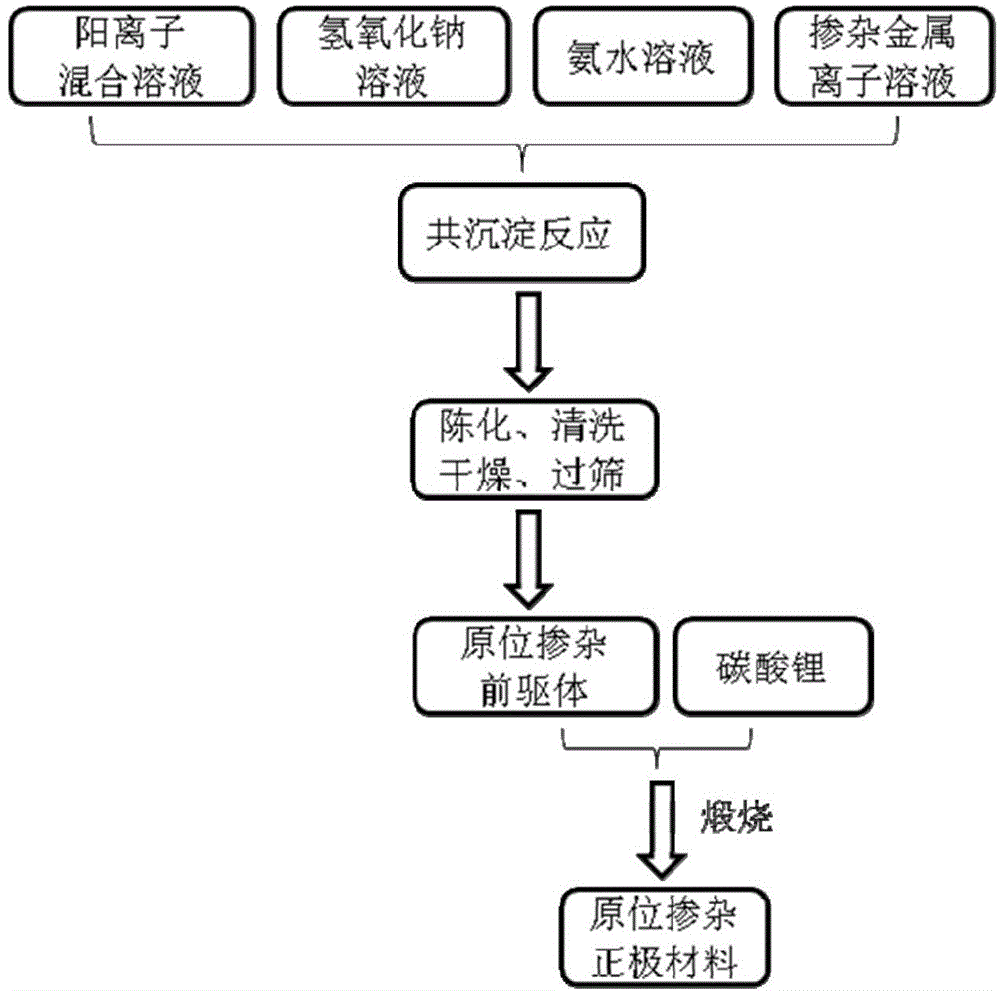

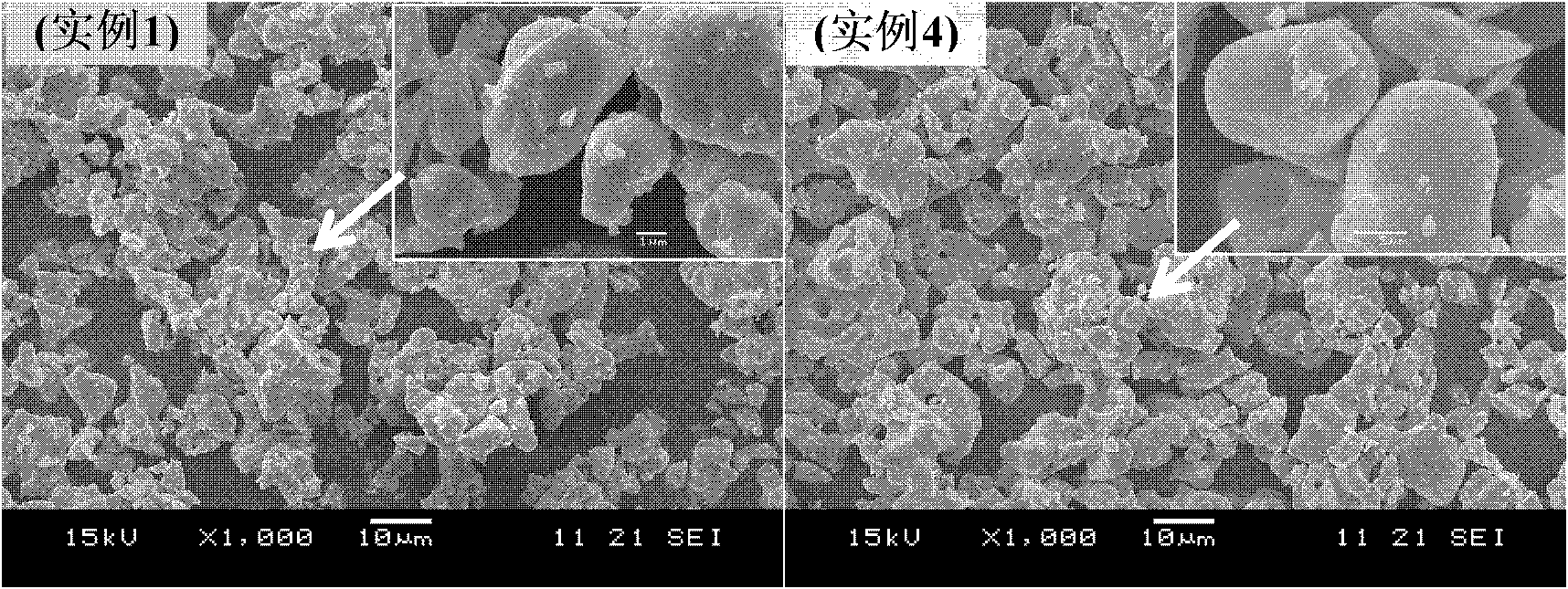

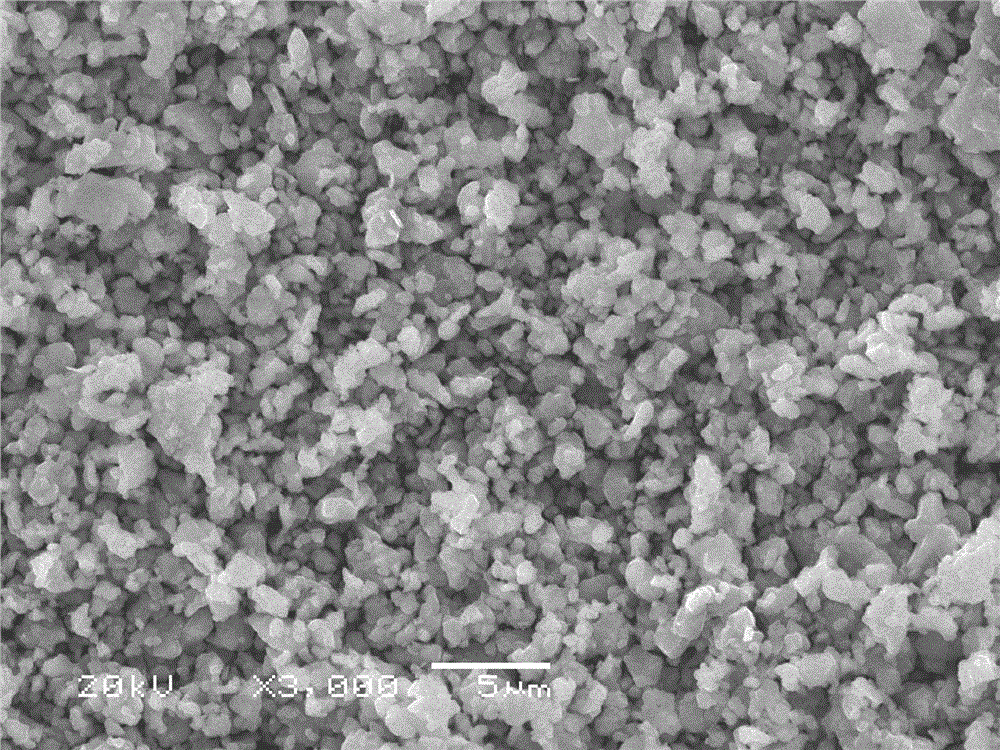

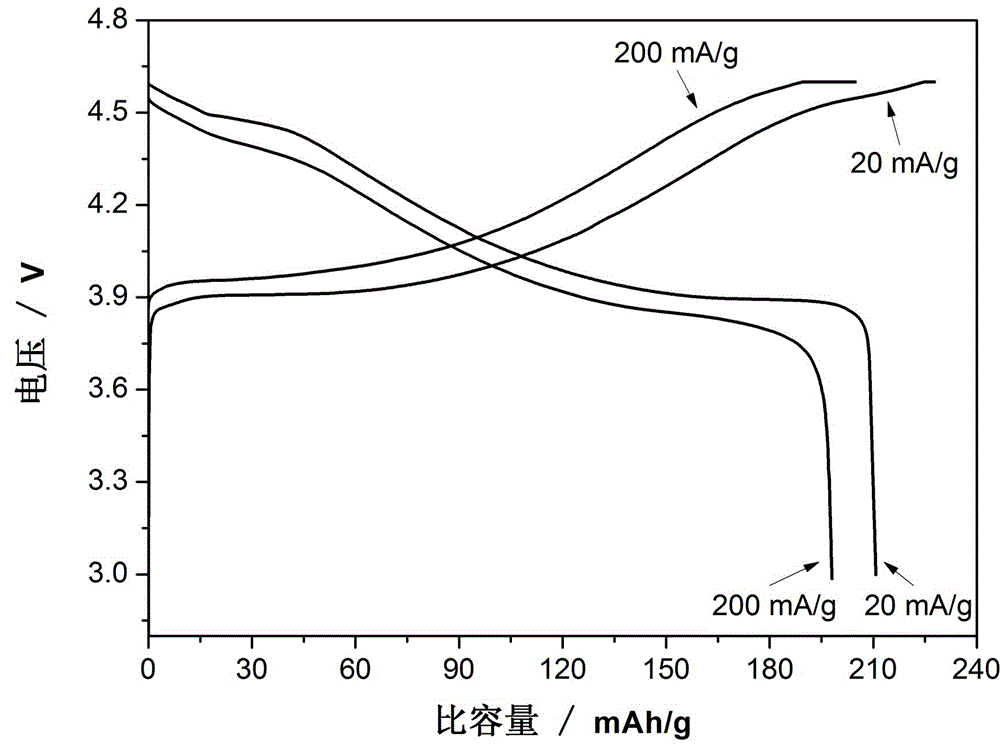

Preparation method of in-situ doped and modified nickel cobalt manganese lithium oxide positive material

InactiveCN104701530AStable structureImprove stabilitySecondary cellsPositive electrodesLithium oxideManganese

The invention discloses a preparation method of an in-situ doped and modified nickel cobalt manganese lithium oxide positive material. The preparation method of the in-situ doped and modified nickel cobalt manganese lithium oxide positive material is characterized by introducing metal elements in the process of preparing a nickel cobalt manganese precursor to stabilize the structure and implementing atom-scale mixing of doped elements and main elements in the process of preparing the precursor. Compared with the solid phase surface doping, the method can be used for stabilizing the material structure as a whole, so that the sintered positive material is relatively high in stability under the high voltage, thereby working under the relatively high voltage; the battery capacity is greatly improved; meanwhile, the cycle performance is greatly improved; by virtue of the preparation method of the positive material, a process of producing the precursor and a process of doping in the later period are integrated, so that the preparation process is simplified; the cost is saved; the raw materials are bulk chemical products; the industrialization is liable to implement.

Owner:TIANJIN B&M SCI & TECH

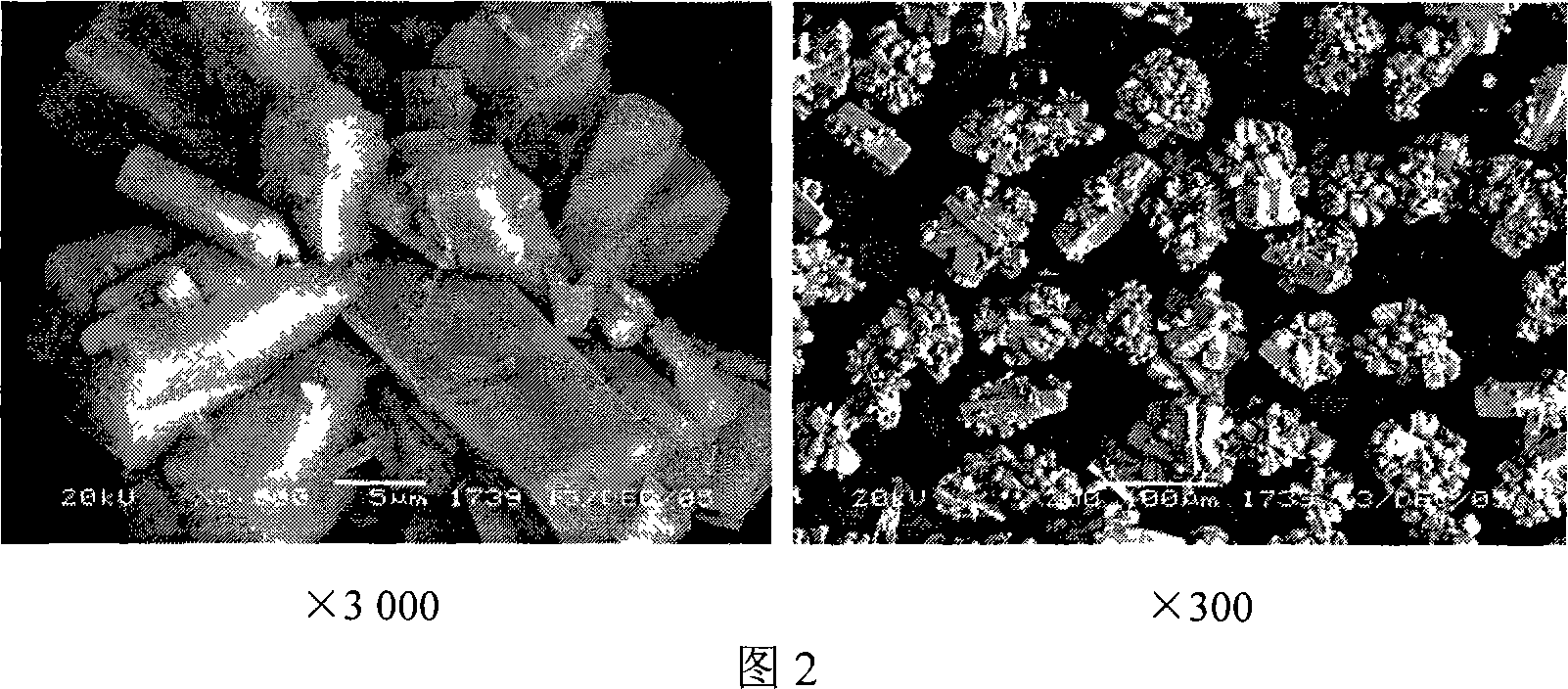

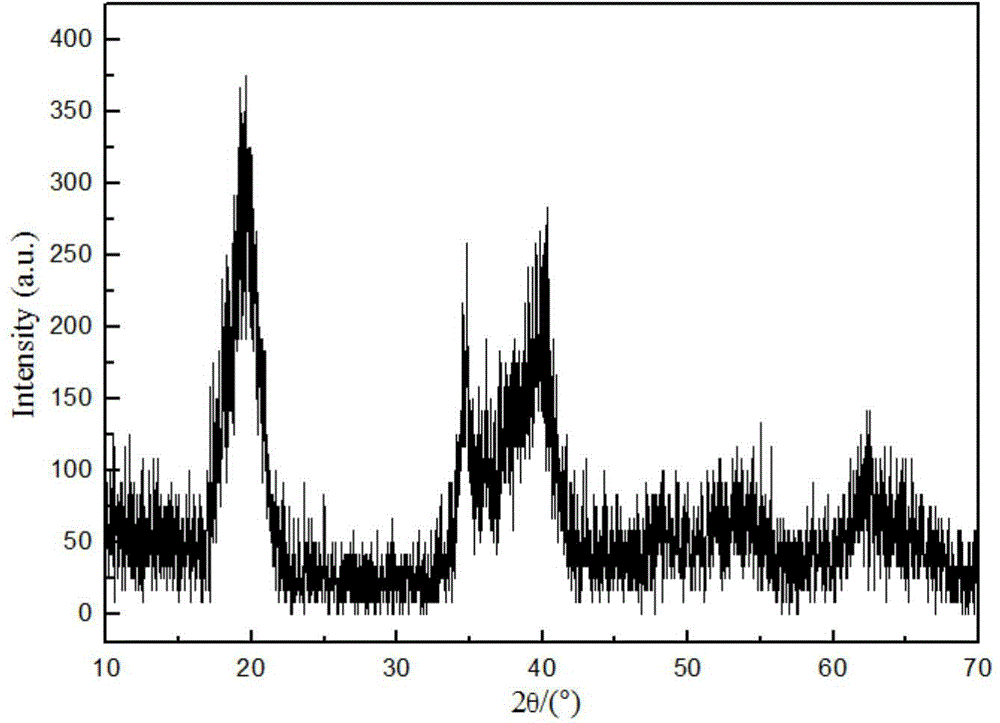

Ferrolithium phosphate and its compound metal phosphide electrode material and producing method thereof

InactiveCN1773754AProlong the fall timePromote growthCell electrodesPhosphorus compoundsLithium iron phosphateHigh density

An electrode material of Fe¿CLi phosphate and its composite metal phosphate is electrode material of LiFePO4 and LiFePO4 / MxP in high density spherical shape with diameter of 2micro m. The electrode material of LiFePO4 and LiFePO4 / MxP can be prepared by low ¿C temperature controllable one ¿C stage atomizing process in short flow.

Owner:NANKAI UNIV

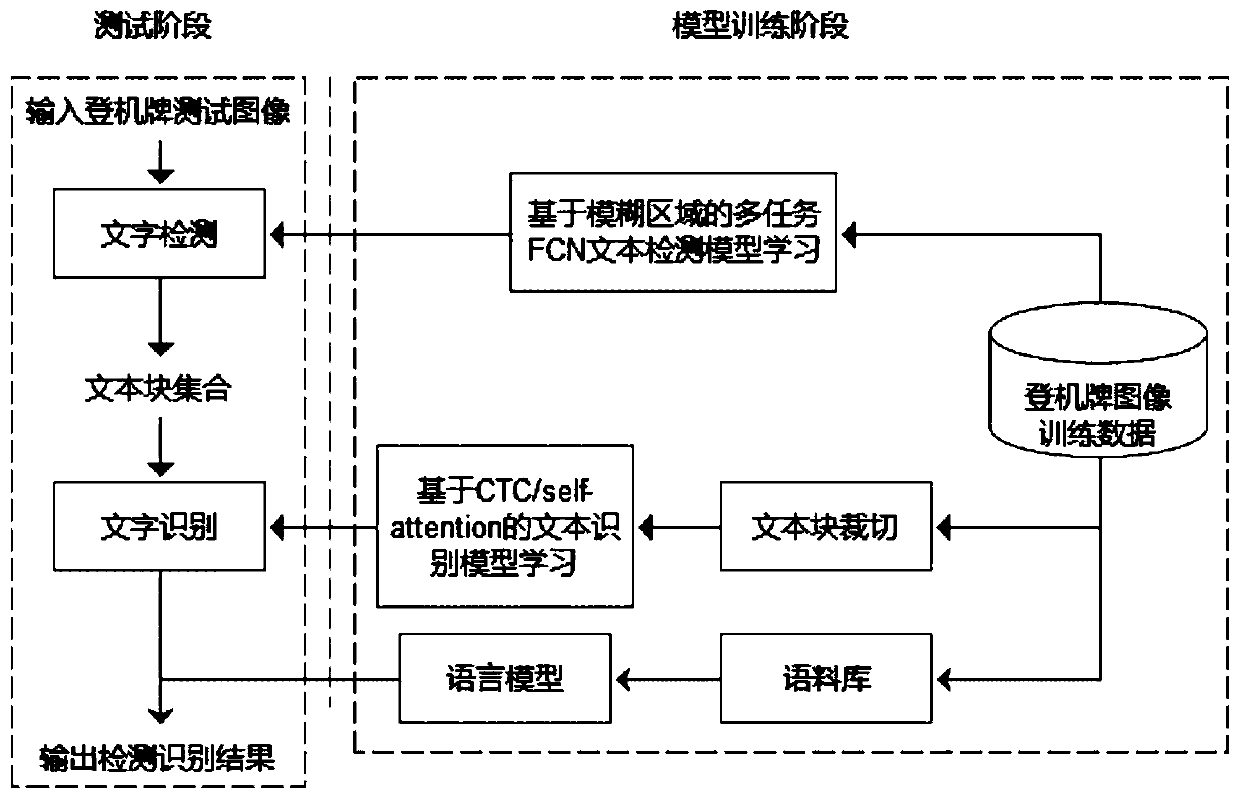

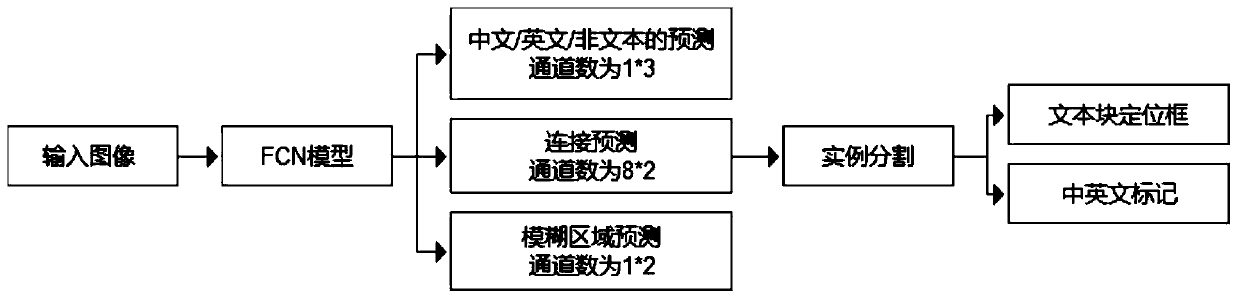

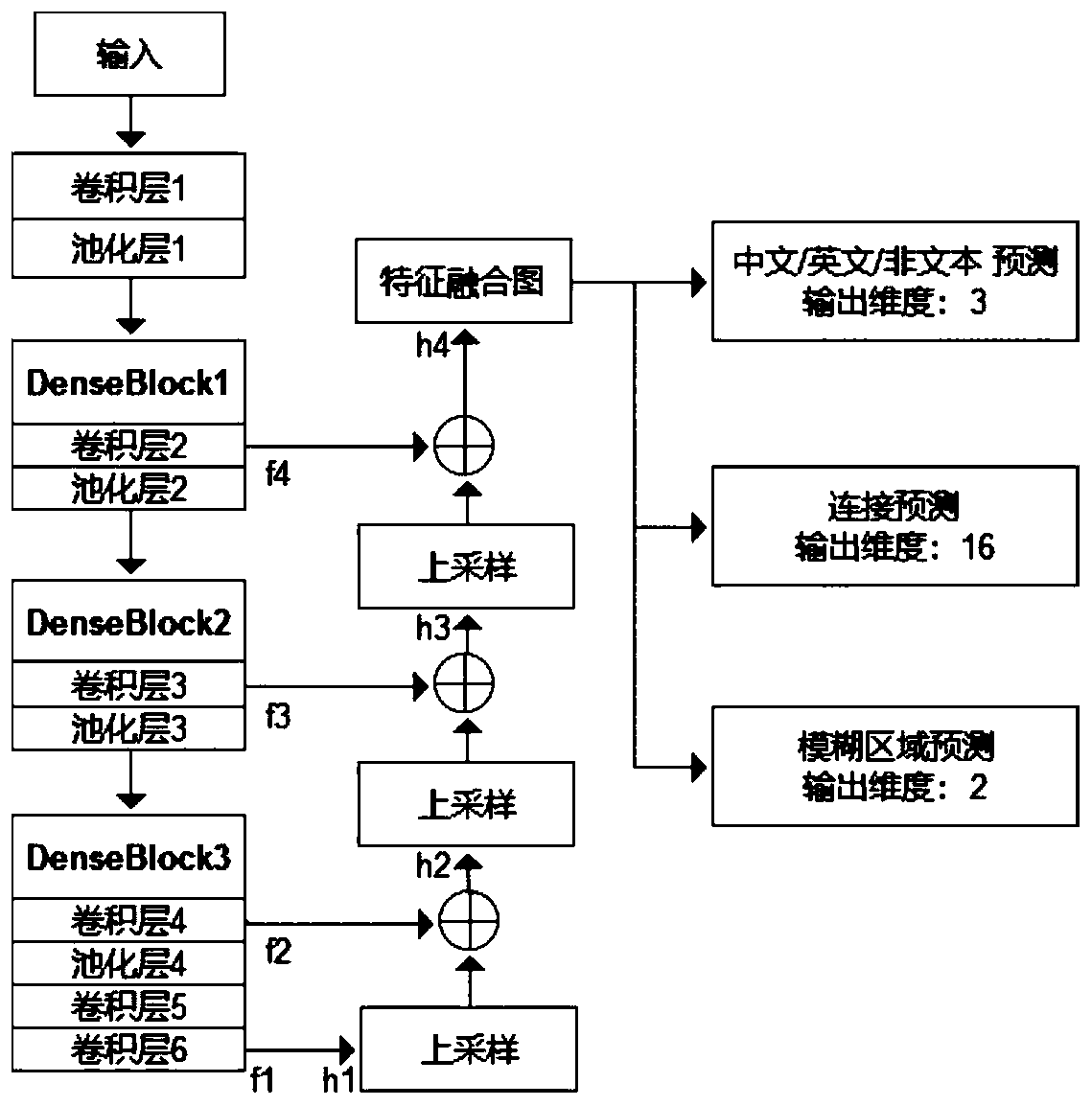

A character detection and recognition method for boarding pass information verification

ActiveCN109902622AOptimize text line recognition resultsComprehensive personal informationCharacter and pattern recognitionNeural architecturesModel learningSelf attention

The invention relates to a character detection and recognition method for boarding pass information verification, and belongs to the field of computer vision. The method comprises the following steps:S1, reading a boarding pass image, and obtaining a boarding pass test image and a training image; S2, positioning each text block through a text line detection method of a multi-task full convolutional neural network model based on a fuzzy region; S3, through text recognition model learning based on a CTC and a self-attention mechanism, realizing recognition of a text line, namely a positioned text block; S4, establishing a boarding pass common text library so as to learn an n-gram language model, and assisting in optimizing a text line recognition result. The boarding pass character information is automatically detected and recognized, Chinese and English mixed text line recognition is achieved, and more comprehensive personal information is obtained.

Owner:CHONGQING INST OF GREEN & INTELLIGENT TECH CHINESE ACADEMY OF SCI

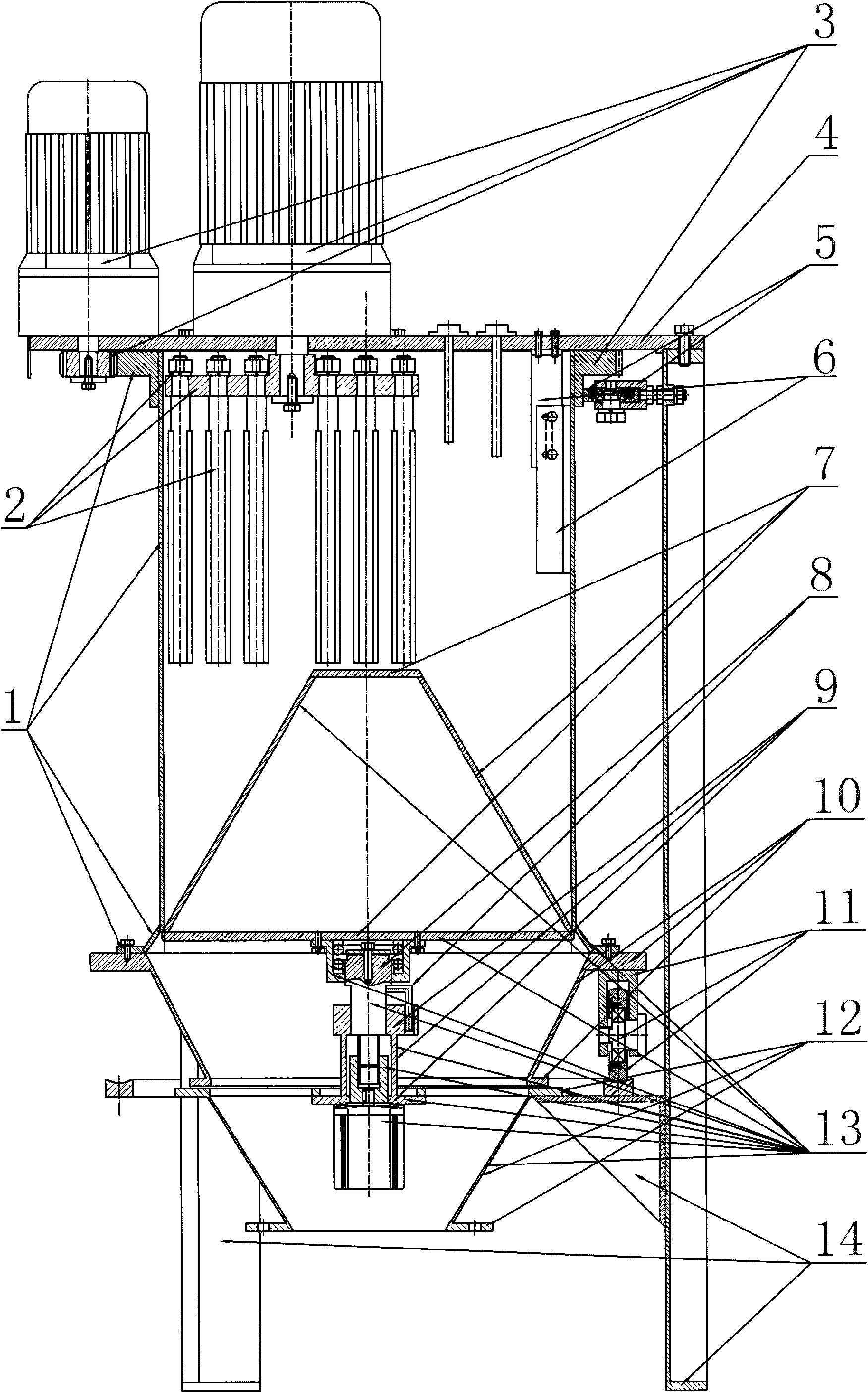

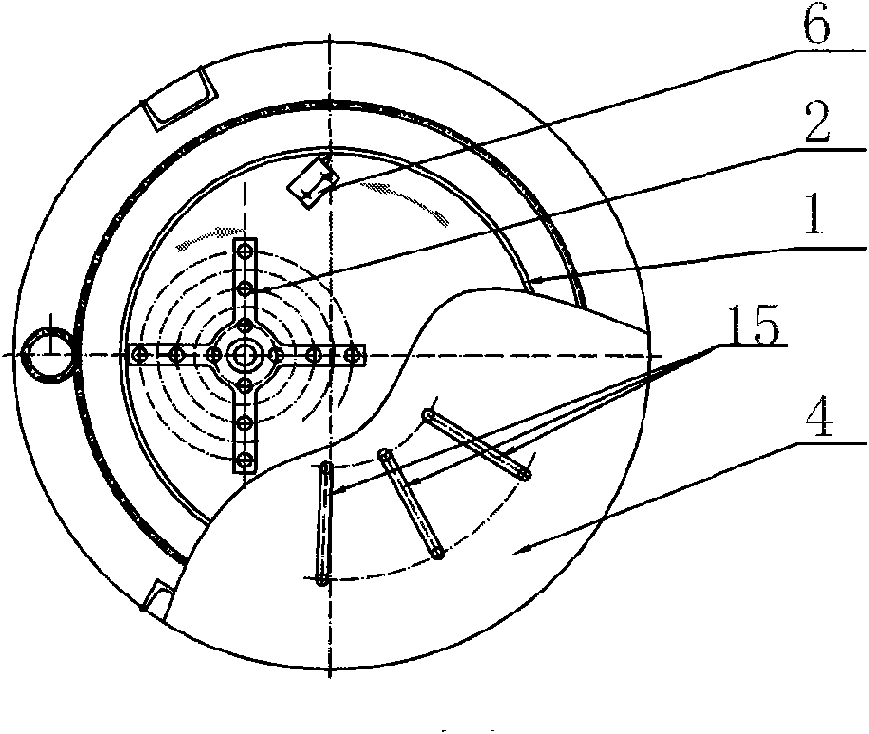

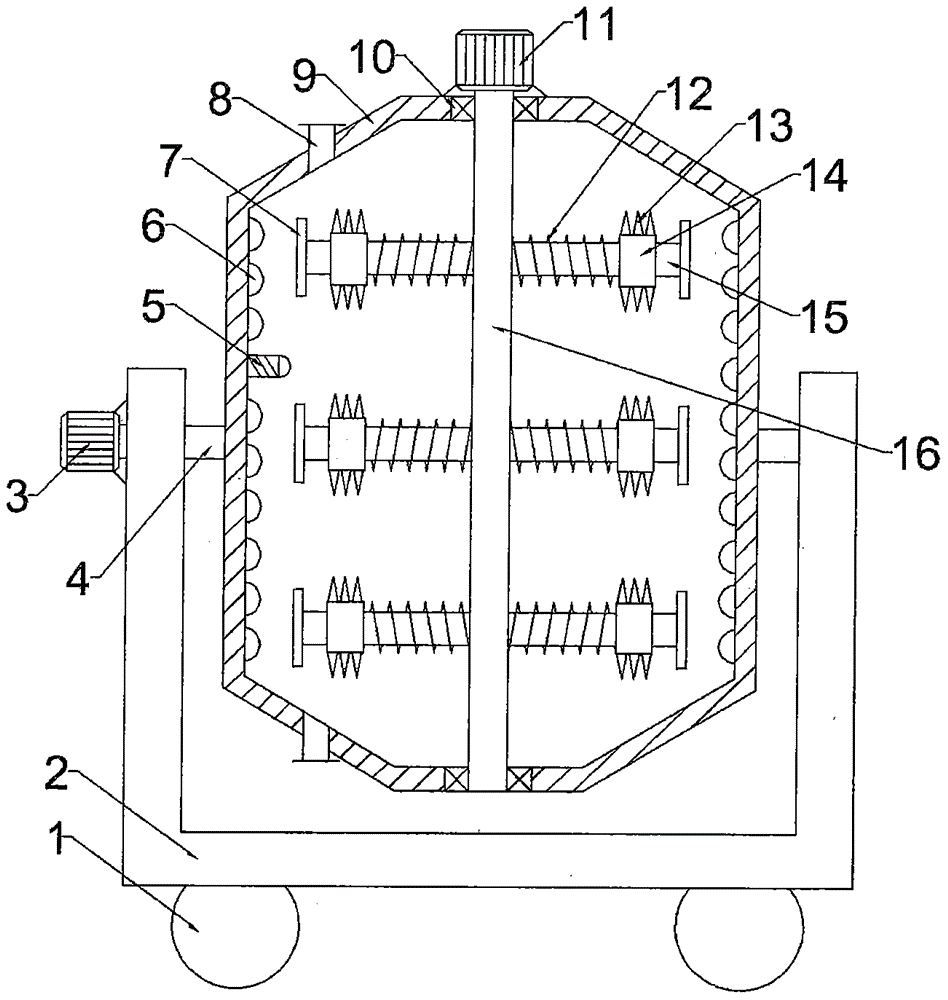

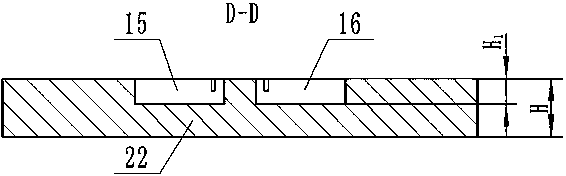

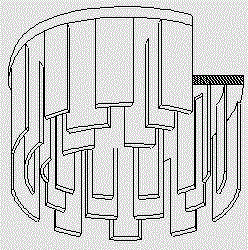

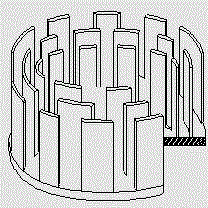

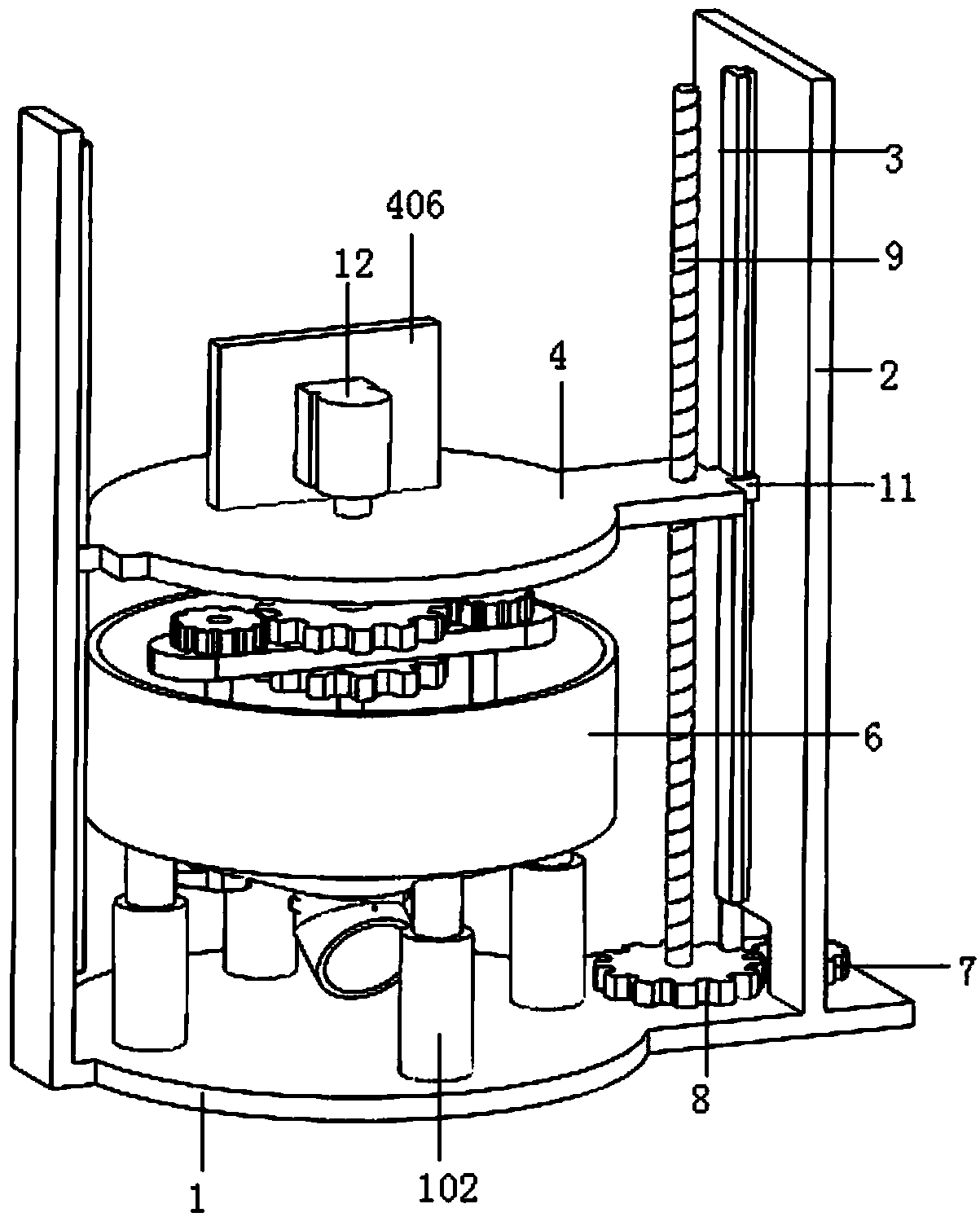

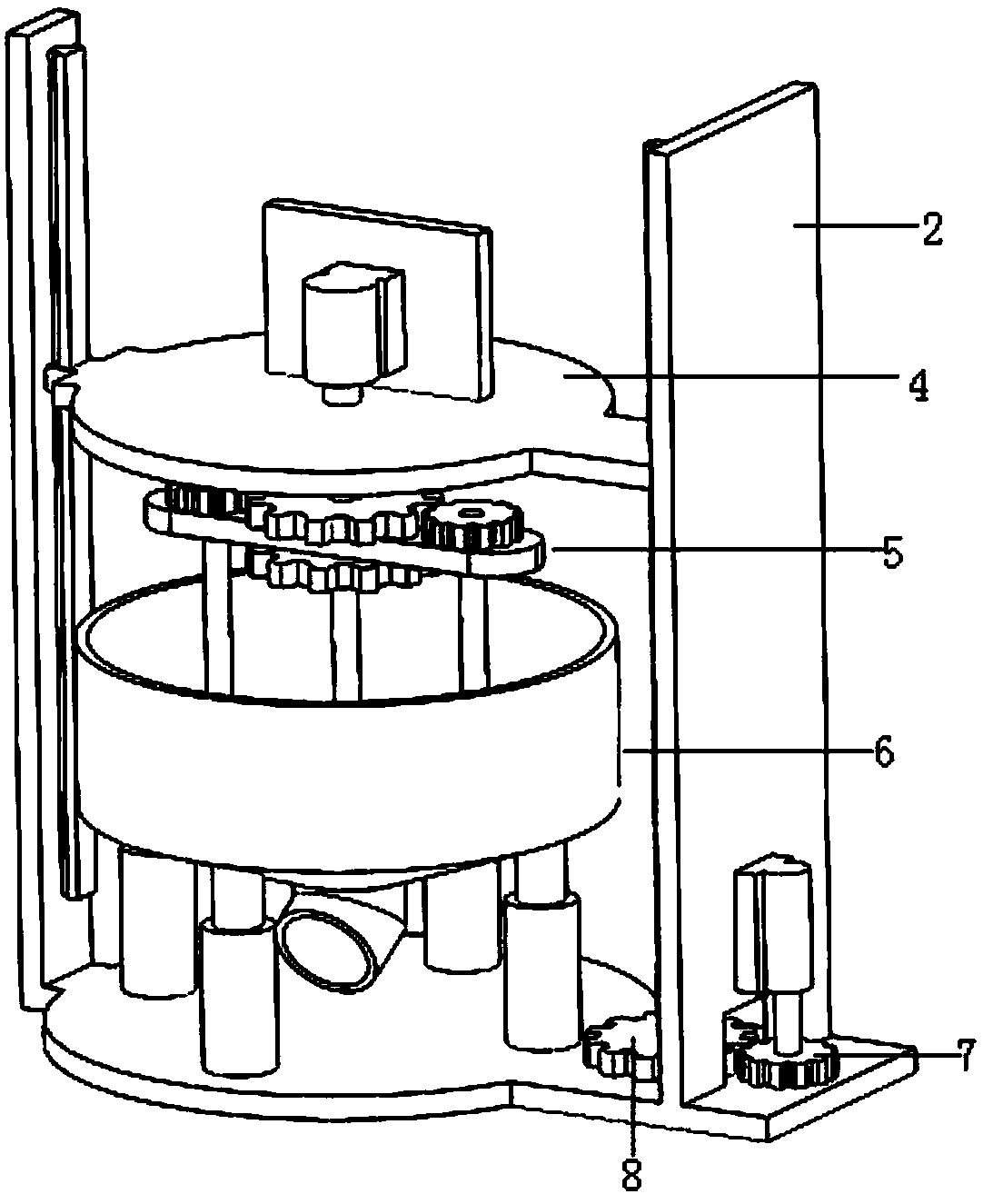

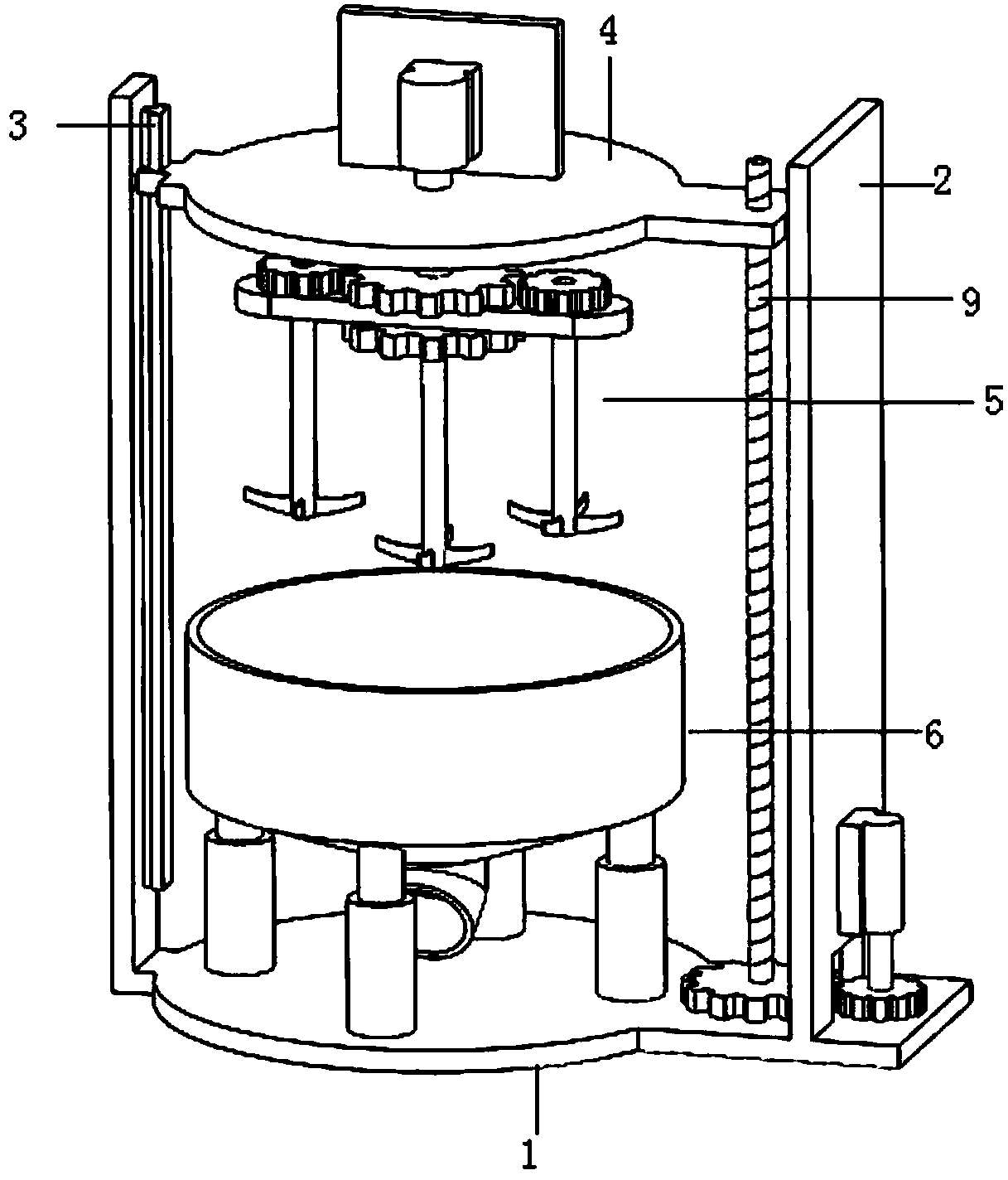

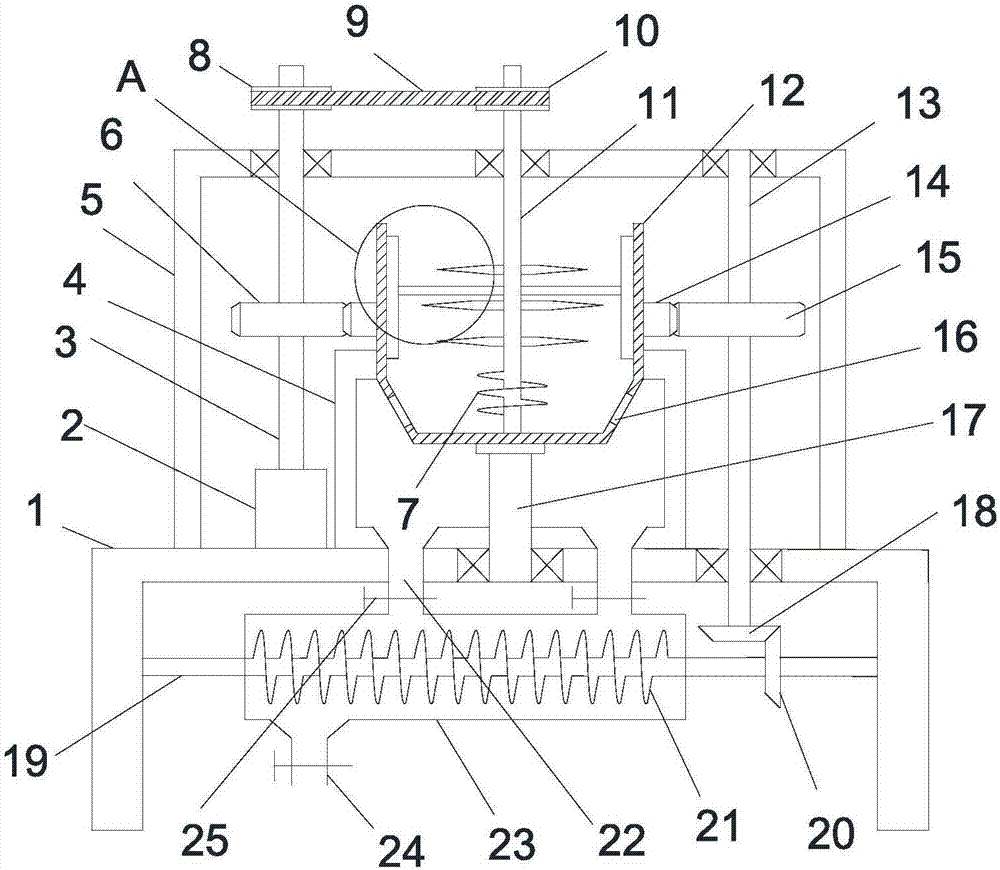

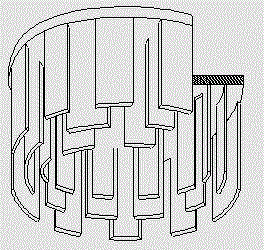

Multifunctional stirring machine

InactiveCN101658771AImprove work efficiencyImprove the quality of workRotating receptacle mixersTransportation and packagingAutomatic controlPulp and paper industry

The invention relates to a multifunctional stirring machine which consists of a rotatable vertical cylindrical container and a stirrer capable of rotating in reverse direction in the container. The structural design that a rotating shaft center of the container and the rotating shaft center of the stirrer are eccentric and a scraper mechanism which is specially arranged can ensure that the multifunctional stirring machine has no stirring dead angles during the work, and an electrical material level automatic control device can ensure the discharge flow of materials by relying on the self-gravity and simultaneously maintain the stable material level in the container. The multifunctional stirring machine can have a plurality of functions of mixing, peeling, clearing, polishing, dampening andthe like by being matched with stirring rods with different structures. When the multifunctional stirring machine is used as a mixing machine, the multifunctional stirring machine has the advantagesof simple structure, low cost, fast mixing speed, high mixing uniformity, small segregation tendency, low energy consumption, simple use and maintenance, long service life and the like. When the multifunctional stirring machine is used as a peeling machine, a clearing machine or a polishing machine, the multifunctional stirring machine has the advantages of high peeling efficiency or good clearingeffect, no production of crushed particles, low energy consumption and the like. When the multifunctional stirring machine is used as a dampening machine, the multifunctional stirring machine has theadvantages of uniform dampening, low energy consumption and the like.

Owner:王洪福

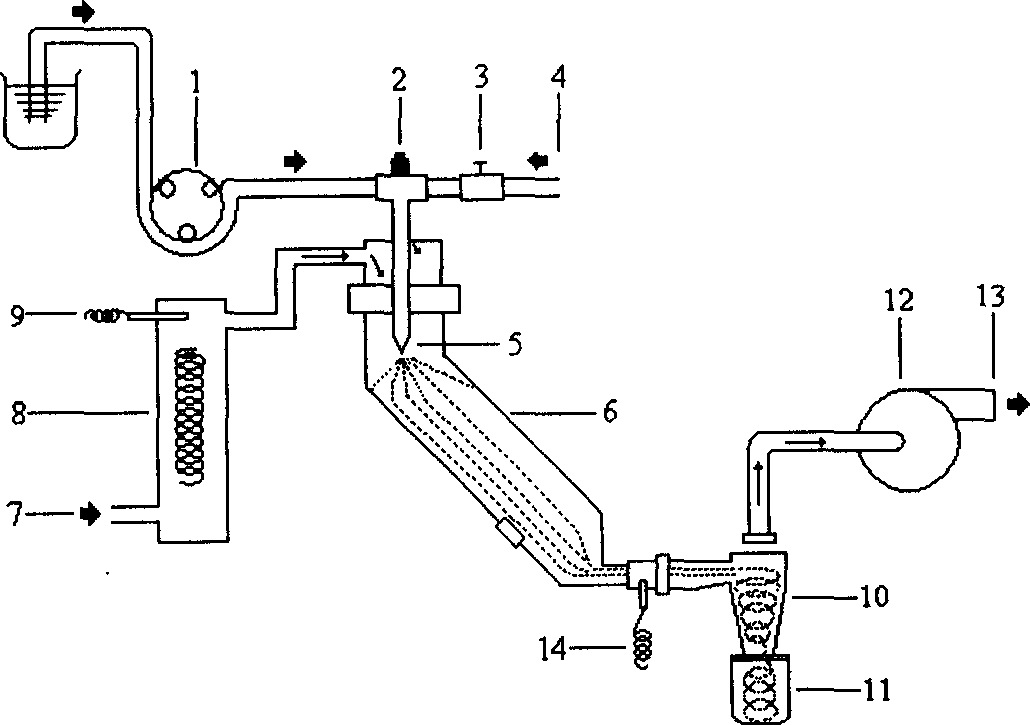

Carbon coated granularity controllable spherical lithium ferric phosphate composite positive pole material and preparation thereof

InactiveCN101420034AWide variety of sourcesThe synthesis process is simpleElectrode manufacturing processesChemical/physical/physico-chemical processesLithium iron phosphateGranularity

The invention discloses a carbon-coated granularity controllable sphere lithium iron phosphate compound anode material and a preparation method thereof, the steps of the preparation method is as follows: 1) the Fe<3> compound is weighted according to mol ratios as below: 1.95-2.05 of the Fe<3> compound, 1.95-2.05 of lithium source compound, 0.01-0.2 of phosphorus source compound and 2 of carbon source; 2) defined amount water is added into the Fe<3> compound, the lithium source compound, the phosphorus source compound and the carbon source, and is mixed and placed into a stirring grinder for grinding, thus obtaining precursor solution; 3) a precursor solution is granulated by spraying and drying for obtaining yellow precursor solution powder; 4) the precursor solution powder is calcined under the condition of atmosphere protection and is cooled. By adopting the spraying and drying, the obtained sphere powder granularity is evenly distributed and the size of the granularity can be adjustable; glucide is taken as the carbon source, thus achieving the purpose of thinning the particles and improving the product purity and performance; and the synthesis technique is simple, the source of the raw material is wide, thus greatly reducing the manufacturing cost.

Owner:李庆余 +2

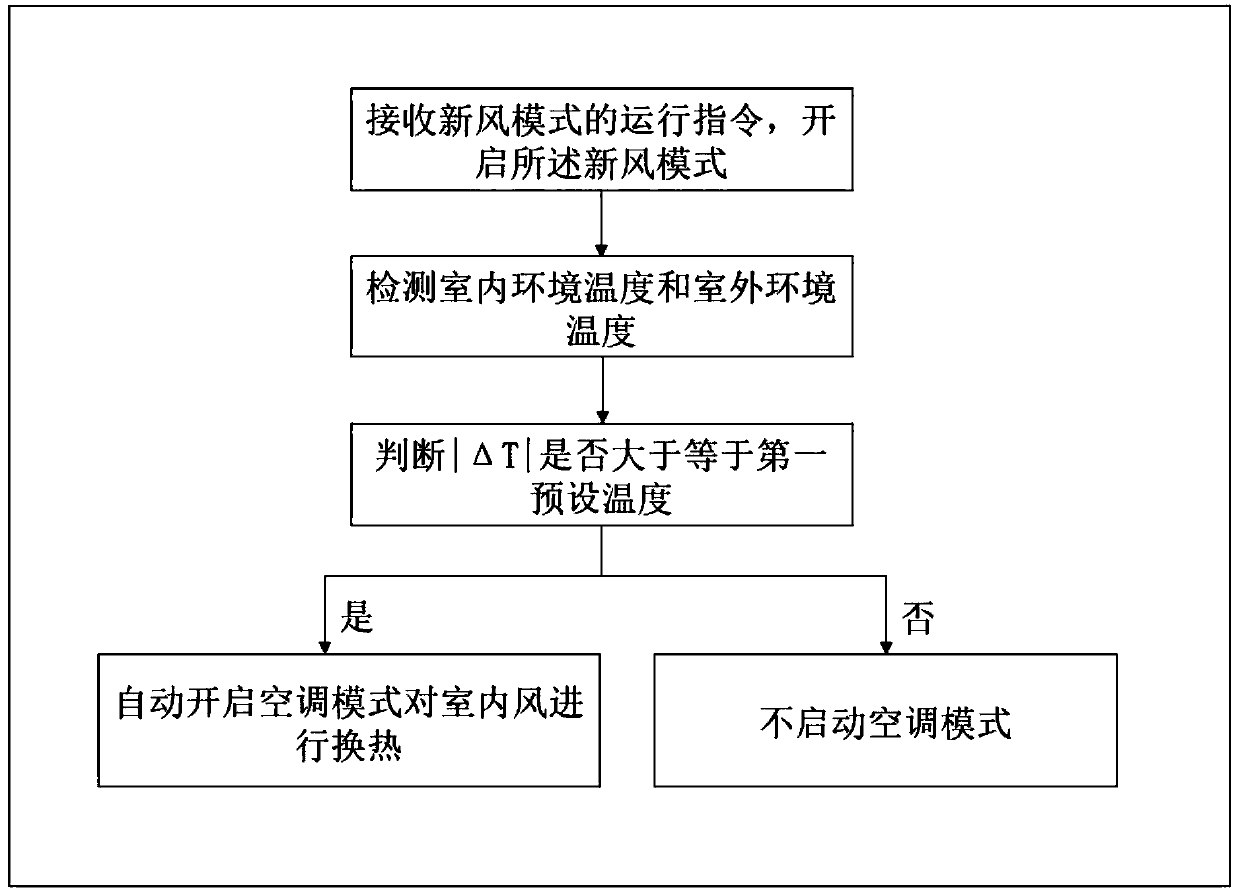

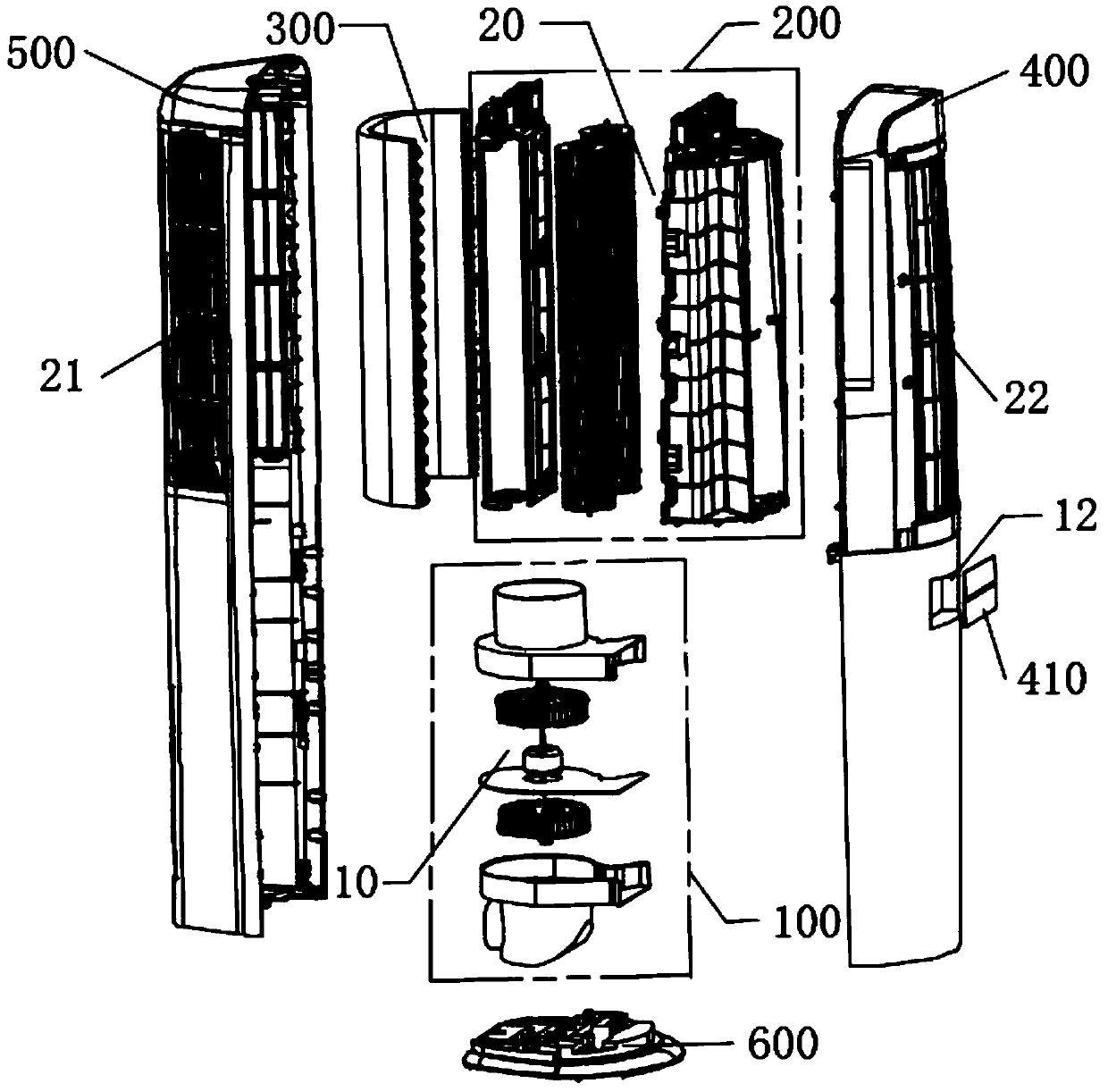

Fresh air conditioner and comfortable air supply control method thereof

InactiveCN111237876APrevent overcoolingAvoid overall overheatingMechanical apparatusSpace heating and ventilation safety systemsFresh airProcess engineering

The invention provides a fresh air conditioner and a comfortable air supply control method thereof. The comfortable air supply control method comprises the steps of receiving an operation instructionof a fresh air mode, and starting the fresh air mode; detecting an indoor environment temperature and an outdoor environment temperature; judging whether the absolute value |delta T| of the temperature difference between the indoor environment temperature and the outdoor environment temperature is greater than or equal to a first preset temperature or not; and if yes, automatically starting an airconditioner mode to exchange heat with indoor air, mixing the indoor air subjected to heat exchange with outdoor fresh air, and enabling mixed air to flow into a room. Under the condition that the indoor and outdoor temperature difference is large, the air conditioner mode is automatically started to exchange heat with indoor air, the indoor air subjected to heat exchange through the heat exchanger can be mixed with the introduced outdoor fresh air, the situation that the indoor temperature is too low or too high due to introduction of the outdoor fresh air is avoided, and the comfort degreeof a human body is improved; and no extra heat exchanger needs to be added for heat exchange of the outdoor fresh air, universality is good, and implementation is easy.

Owner:NINGBO AUX ELECTRIC +1

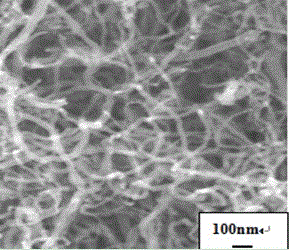

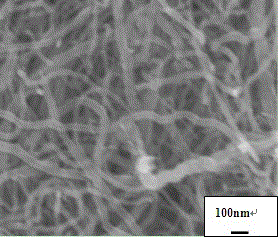

LiFePO4/C nano composite positive pole material and preparation method thereof

InactiveCN101159328AAchieve hybridControl chemical compositionElectrode manufacturing processesChemical industryPhosphateLithium-ion battery

The invention discloses a nano-composite positive material LiFePO4 / C and a fabrication method, relating to a fabrication method of positive material of a lithium-ion battery. The invention uses the method of liquid-phase coprecipitation, the certain amount of lithium resource, iron resource and phosphate resource is weighted as the quality mol ratio of Li:Fe:P = (3.0-3.3):(1.0-1.1):(1.0-1.1), and the appropriate amount of carbon-doped material and organic surfactant is added in the reaction vessel; by controlling the reaction conditions like concentration, temperature etc. of the reaction solution, precursor gels are fabricated, and the precursor gels are separated, cleaned, filtered and dried to obtain precursor powder; the precursor powder is tableted and put into the crucible with microwave absorbent, and then the crucible is placed in the microwave oven, with the microwave power controlled between 100 to 600W and heated for 30 min, to obtain nano-sized composite positive material LiFePO4 / C. The technique method in the invention has the advantages of short periods, saved energy consumption, ease to control the process, suitability for industrialization and so on. The composite positive material LiFePO4 / C fabricated in the invention is characterized by high purity, small particle size lower than 100 nm, and good electrochemical properties.

Owner:上海微纳科技有限公司

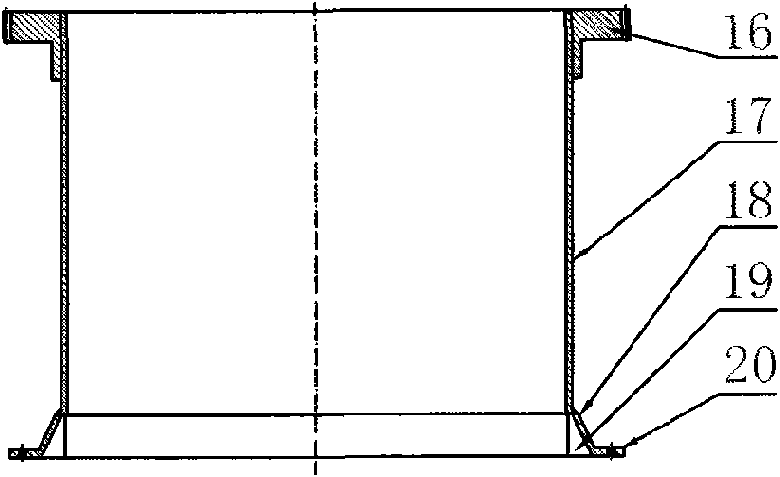

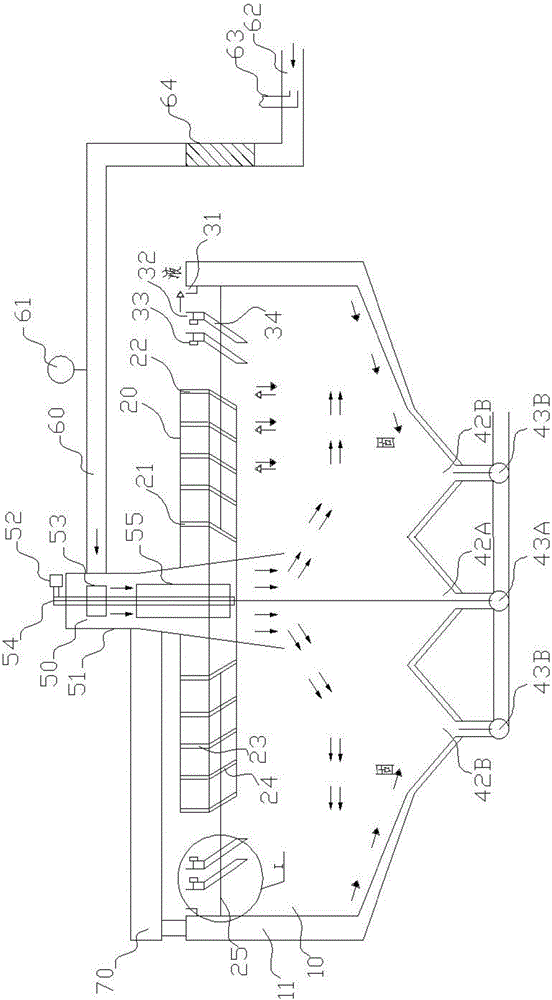

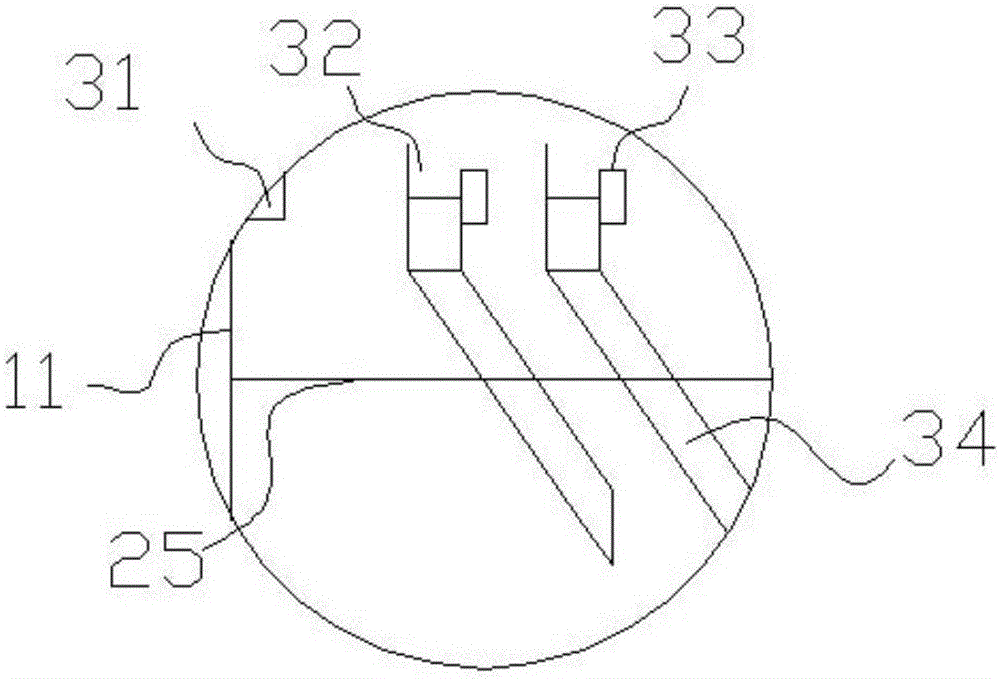

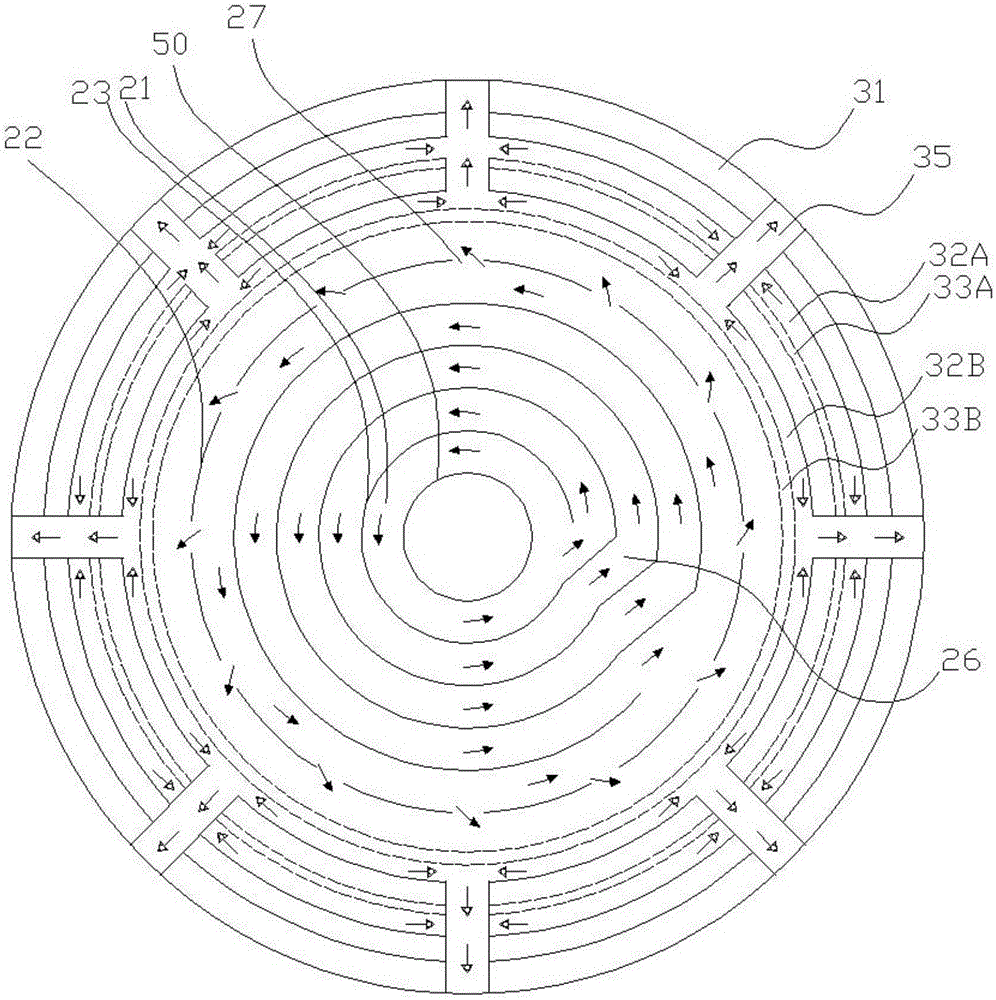

Rake-free thickener with rotary annular channels

ActiveCN105944407AEnsure stabilityImprove settlement performanceSedimentation regulating devicesSettling tanks feed/dischargeWater concentrationEngineering

The invention relates to the field of slime water concentration and clarification, in particular to a rake-free thickener with rotary annular channels. The rake-free thickener at least comprises a thickener body, and further comprises rotary annular channels, wherein the rotary annular channels are used for constraining upper-layer ore pulp inside the thickener to do reciprocatory motion; the rotary annular channels consist of a plurality groups of annular channels of which the diameters are increased gradually; adjacent annular channels are mutually communicated through connecting channels; each group of the annular channels comprises an upper annular partitioning plate and a lower inclined settlement plate; overflowing ore pulp is discharged out from overflow weirs; the overflow weirs comprise annular overflow weirs and composite overflow weirs; settled granules are fed into a bottom flow discharge system; the bottom flow discharge system consist of bottom flow collecting cabins, bottom flow holes and corresponding bottom flow pumps; the rake-free thickener further comprises a feeding pipeline and a driving stirring mechanism; a stirring machine is driven by residual power of the feeding pipeline conveying the ore pulp to rotate so as to uniformly mix the ore pulp with medicines. The rake-free thickener has the characteristics of being low in energy consumption, low in repairing workload, low in medicine consumption and free of rake.

Owner:ANHUI UNIV OF SCI & TECH

Asphalt stirring device for building construction

InactiveCN105664769AAchieve flippingAchieve hybridRotating receptacle mixersTransportation and packagingArchitectural engineeringAsphalt

The invention relates to an asphalt stirring device for building construction. The asphalt stirring device comprises a stander and a stirring tank, wherein two support shafts are symmetrically arranged in the middle of the outer surface of the stirring tank and are rotatably connected with support arms on two sides of the stander, and one support shaft is connected with an inverted motor; a stirring shaft is arranged in the stirring tank, the upper end of the stirring shaft is connected with a variable frequency motor located above the stirring tank, a plurality of stirring device are uniformly distributed on the stirring shaft and comprise mounting rods, one ends of the mounting rods are fixedly connected with the stirring shaft, the mounting rods are sleeved by reset springs, one ends of the reset springs are fixedly connected with the stirring shaft, sliding blocks are fixedly connected to the other ends of the reset springs, and the mounting rods are sleeved by the sliding blocks. The asphalt stirring device has the beneficial effects that the inverted motor can drive the stirring tank to rotate by 180 degrees, and then materials at the bottom of the stirring tank are transferred to the top, so that the substantial overturning of the materials is realized, and the effective mixing of the materials is realized.

Owner:杨露萍

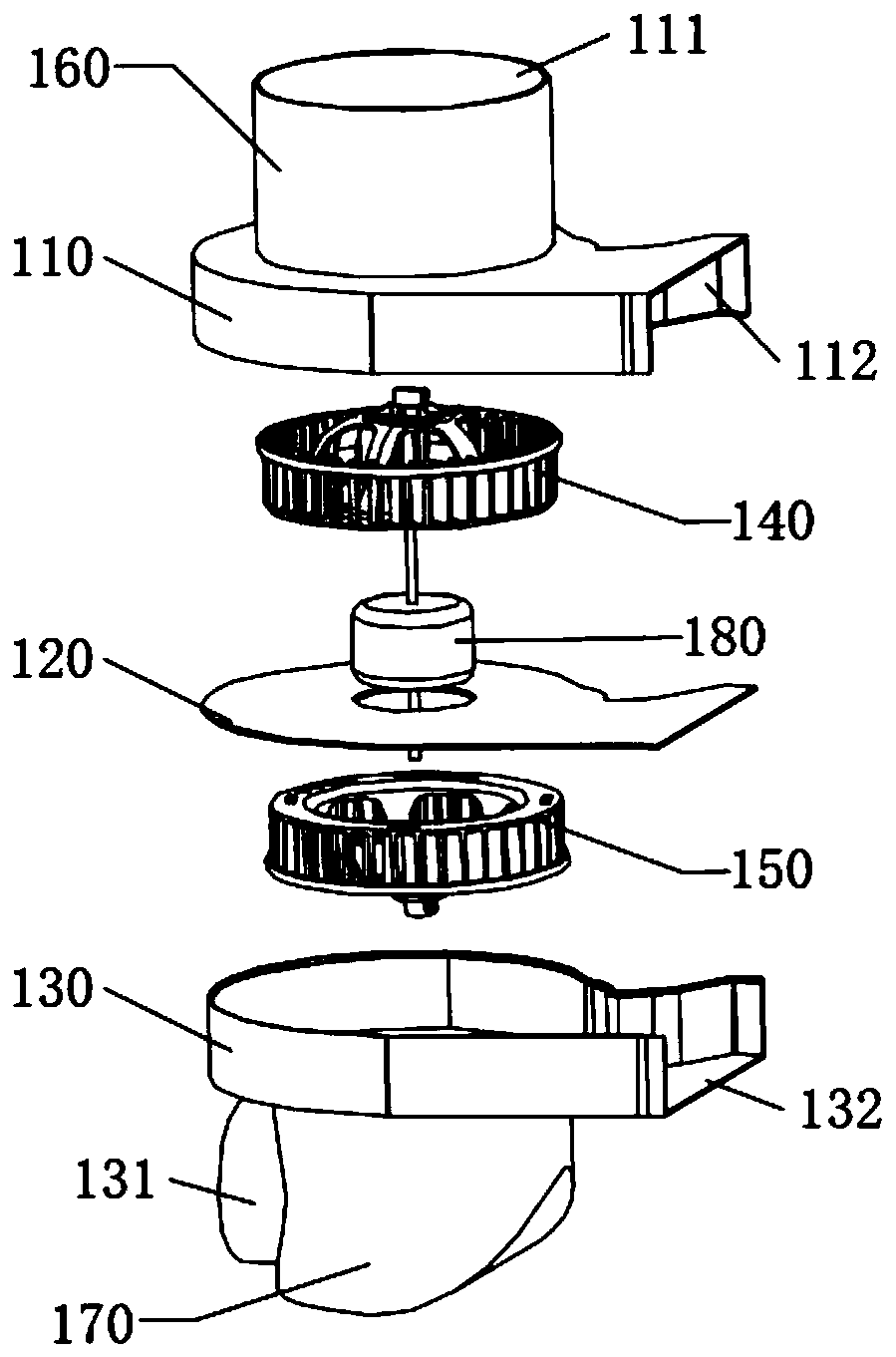

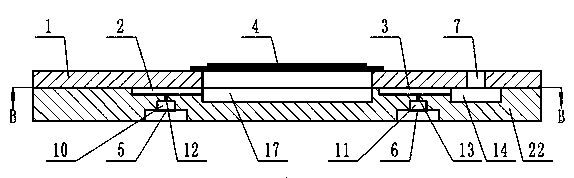

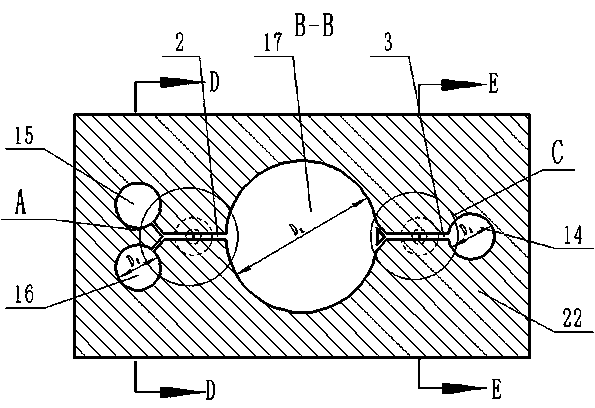

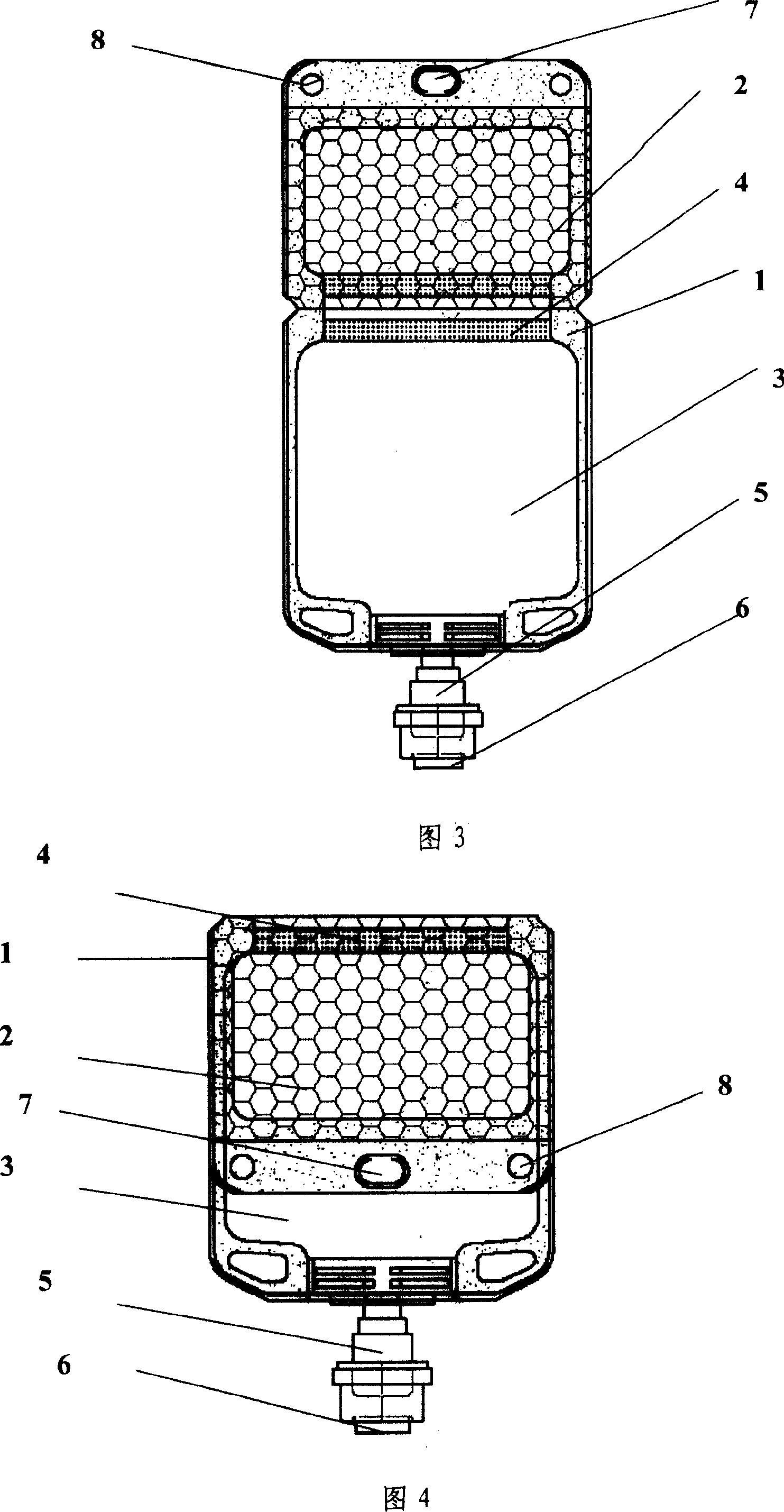

Valveless piezoelectric micromixer for synthesizing jet

The invention discloses a valveless piezoelectric micromixer for synthesizing jet, comprising a pump cover and a pump body which are bonded together, wherein two synthesis jet chambers are communicated with a relative inlet mixing flow path and a outlet mixing flow path, a first piezoelectric vibrator is fixed right above the pump cover, each of a second piezoelectric vibrator and a third piezoelectric vibrator is fixed right below the two synthesis jet chambers respectively, the inlet mixing flow channel and the outlet mixing flow channel are Y-type mixing flow channels each of which is composed of two shunting flow channels and a shunting flow channel, a jet synthesis exciter is arranged on the bottom of the mixing flow channel of the micromixer, fluid flow in the mixing flow channel is interfered by periodically ejecting and absorbing fluid by synthesis jet, and alternating voltage signal applied on the piezoelectric oscillator is regulated to implement large-range controllable mixing of mixed effect and mixed time.

Owner:JIANGSU UNIV

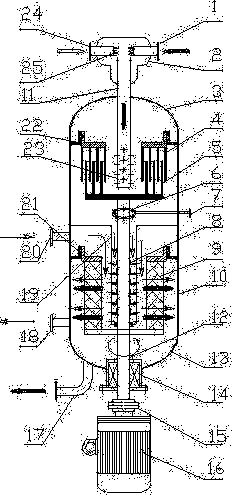

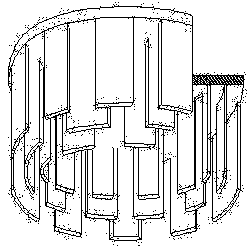

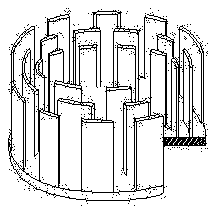

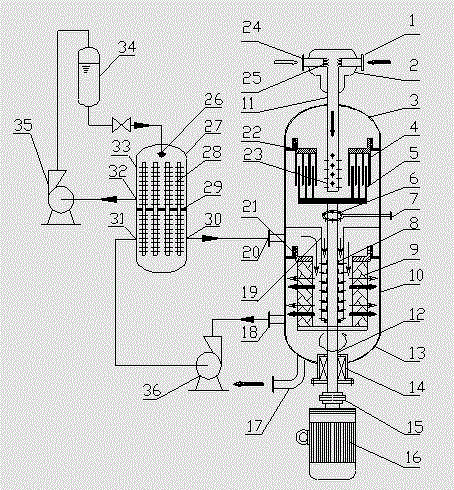

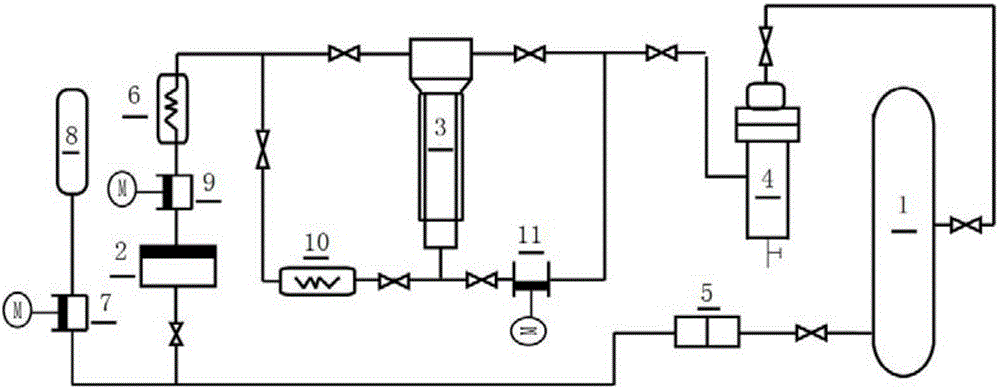

Alkylation reactor and alkylation reaction method

ActiveCN104549110ALow powerFully dispersedLiquid hydrocarbon mixtures productionChemical/physical/physico-chemical nozzle-type rreactorsPtru catalystProcess engineering

The invention discloses an alkylation reactor and an alkylation reaction method. The reactor comprises a reactor tube body, closure heads, a revolving bed, a charging pipe, a charge distribution pipe, a discharging opening, a circulating cooling gas inlet, a circulating cooling gas outlet and a circulating cooling gas refrigeration system, wherein a shell body is formed by the reactor tube body and the closure heads, the revolving bed is arranged at the internal middle part of the shell body and is connected with a driving device through a revolving shaft, the charge distribution pipe is arranged in a hollow tube structure of the center of the revolving bed and is communicated with the charging pipe, the discharging opening is formed in the lower part of the shell body of the reactor, a sealing member is arranged between the upper part of the revolving bed and the shell body, static components and revolving components are sequentially arranged at the radial outer side of the revolving bed, and the circulating cooling gas refrigeration system is located between the circulating cooling gas inlet and the circulating cooling gas outlet. According to the alkylation reaction method disclosed by the invention, alkylation reaction is carried out by taking concentrated sulfuric acid as a catalyst and taking isobutane and alkene as raw materials. According to the alkylation reactor and the alkylation reaction method, the alkylation reaction can be carried out at relatively low temperature, the acid consumption is low, the quality of products is high, and the equipment scale is small.

Owner:CHINA PETROLEUM & CHEM CORP +1

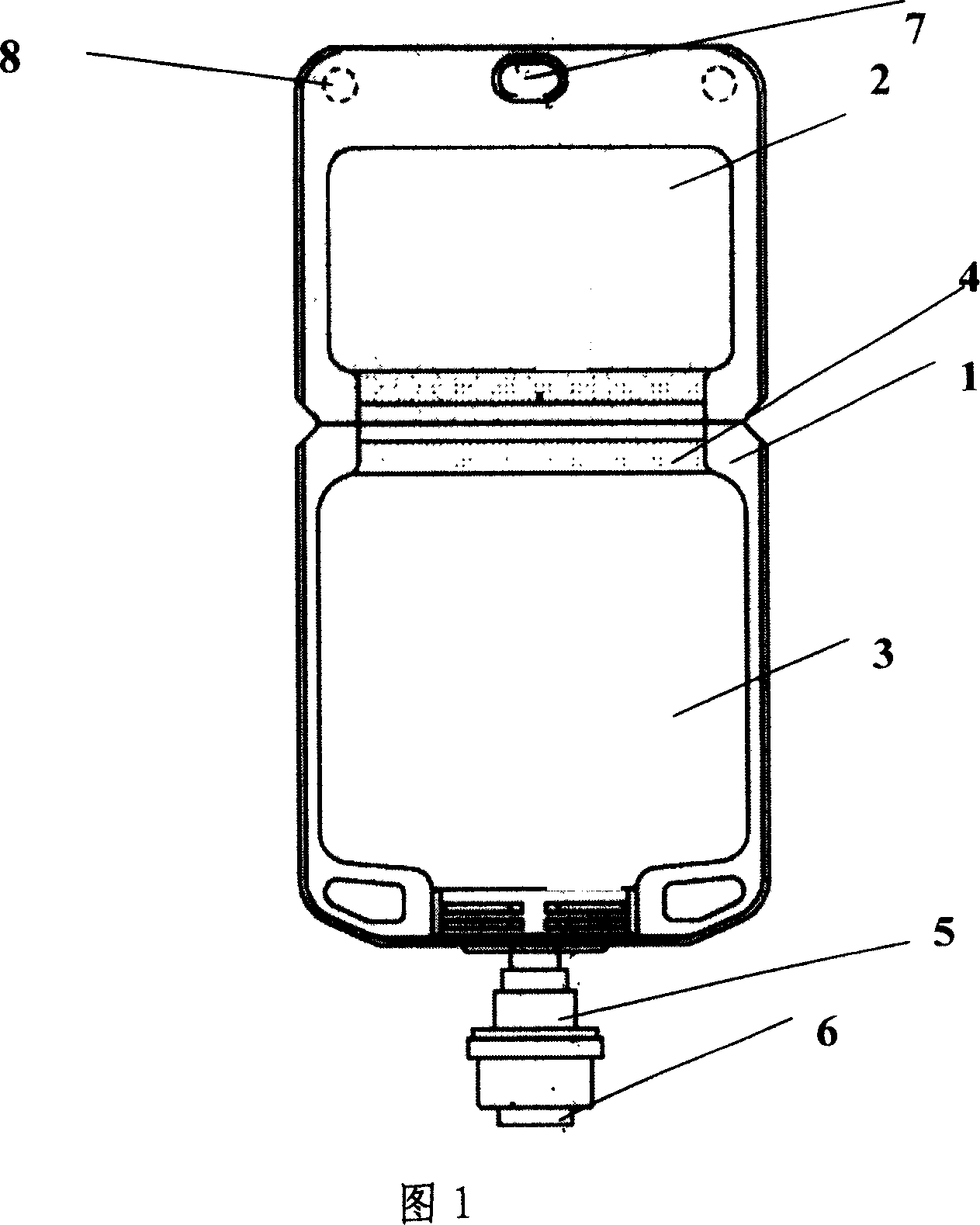

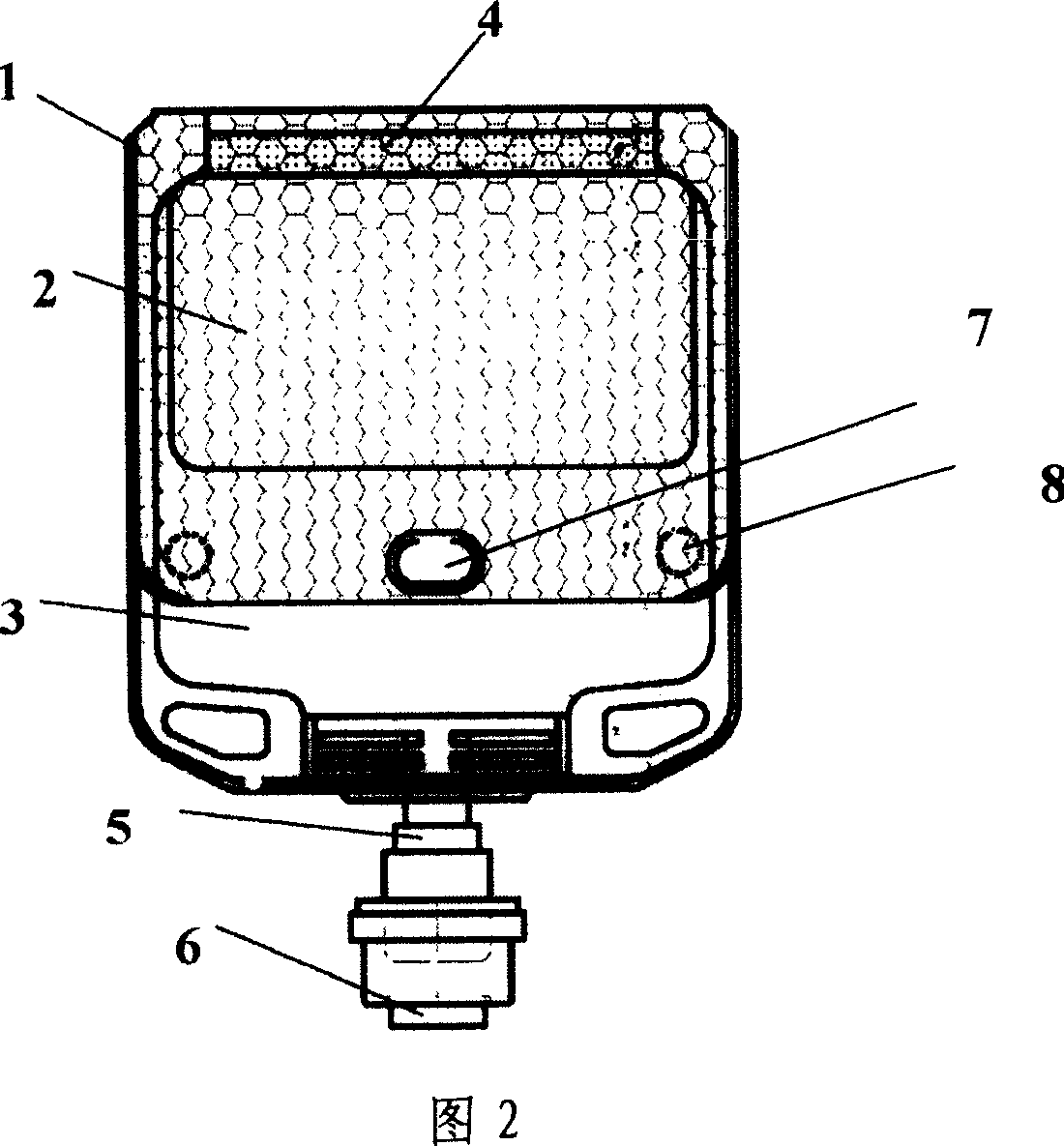

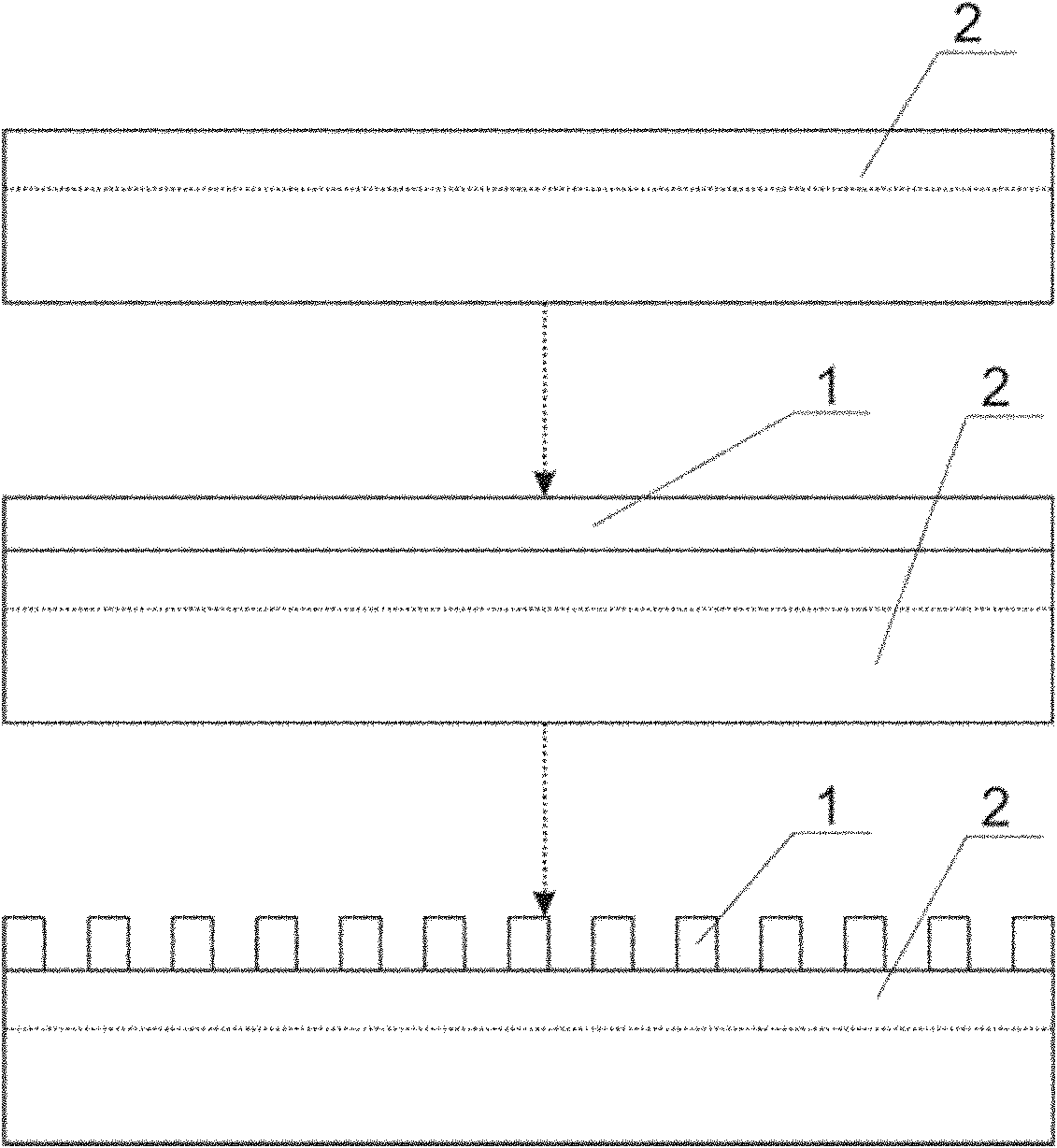

Powder and liquid bag and preparation method thereof

The invention discloses a powder-liquid container and manufacturing method, which is composed of sealed bag with two bag film on the periphery, wherein the bag possesses at least one powder chamber with antibiotics and liquid chamber with aseptic solution, which is separated by separating part, the separating part is connected by bag film through strippable welding structure, two external sides of bag film of powder chamber possesses a layer of baffle film.

Owner:SHANGHAI WUBIN PACKAGING PRODS

Sectional feeding type alkylation reactor and alkylation reaction method

ActiveCN104549087AEliminate concentration differencesImprove product qualityLiquid hydrocarbon mixtures productionMixersEmulsionSulfuric acid

The invention discloses a sectional feeding type alkylation reactor and an alkylation reaction method. The reactor comprises a reactor barrel body, a seal head, a separating plate, an upper bed layer, a lower bed layer, a feeding pipe, a fed material distributing pipe, a rotating shaft, a supplementing material inlet, a discharging opening, a circulating cooling air inlet and a circulating cooling air outlet. The invention further provides the alkylation reaction method adopting the sectional feeding type alkylation reactor. The alkylation reaction method comprises the following steps: preparing acid hydrocarbon emulsion through iso-butane and concentrated sulfuric acid in the upper bed layer, and then entering a rotating bed at the lower bed layer together with mixed hydrocarbon which enters through a supplemented material inlet, so as to perform alkylation reaction.

Owner:CHINA PETROLEUM & CHEM CORP +1

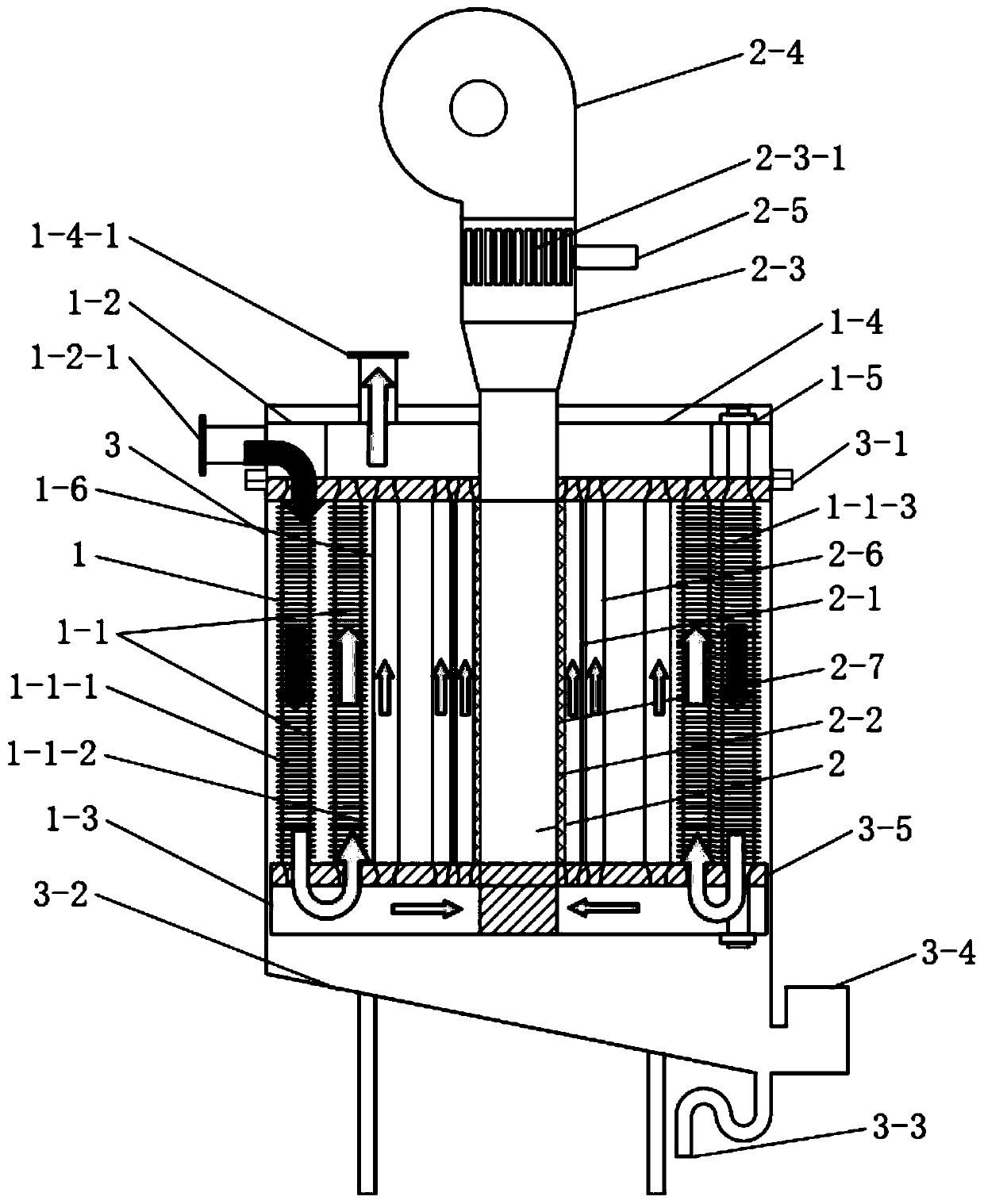

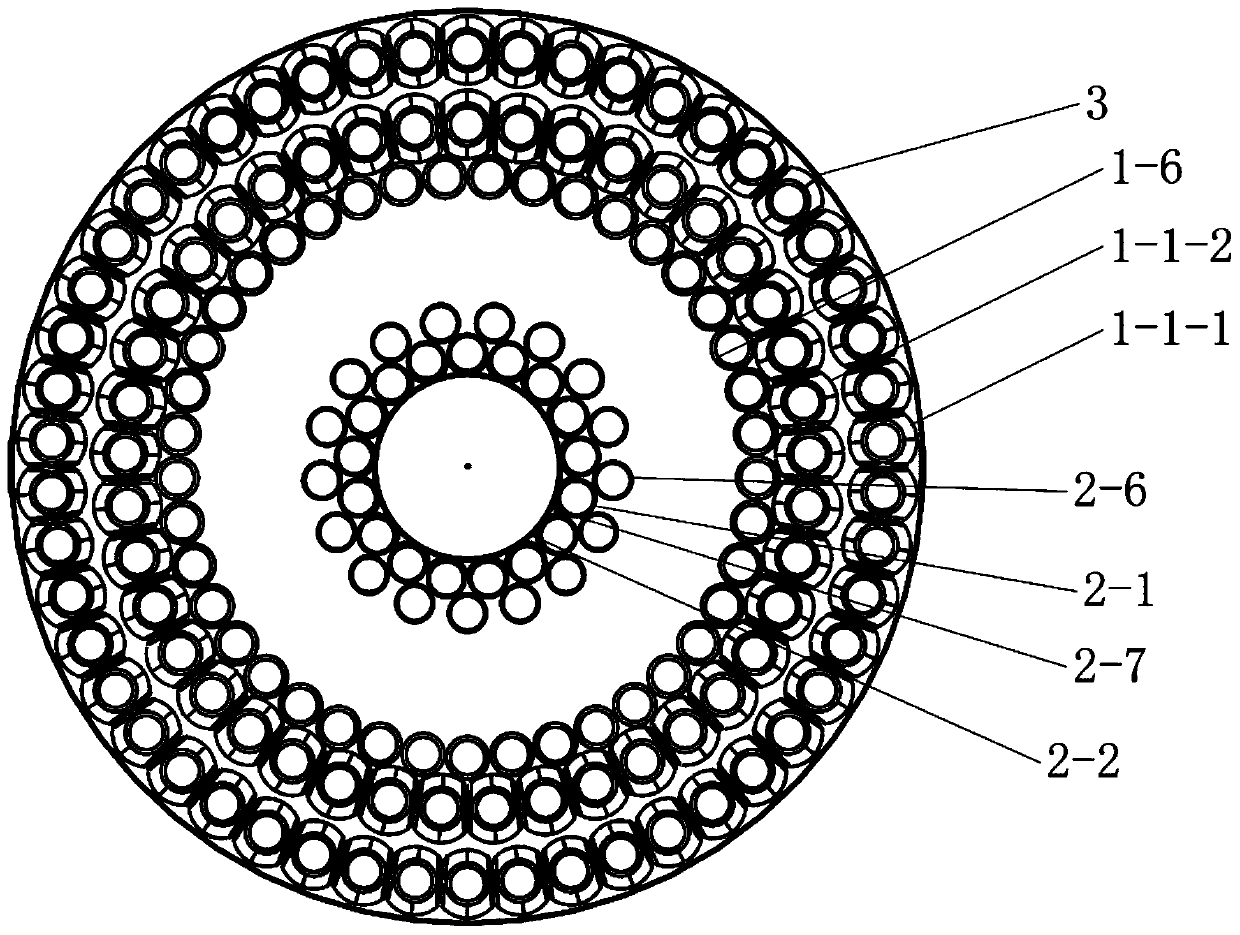

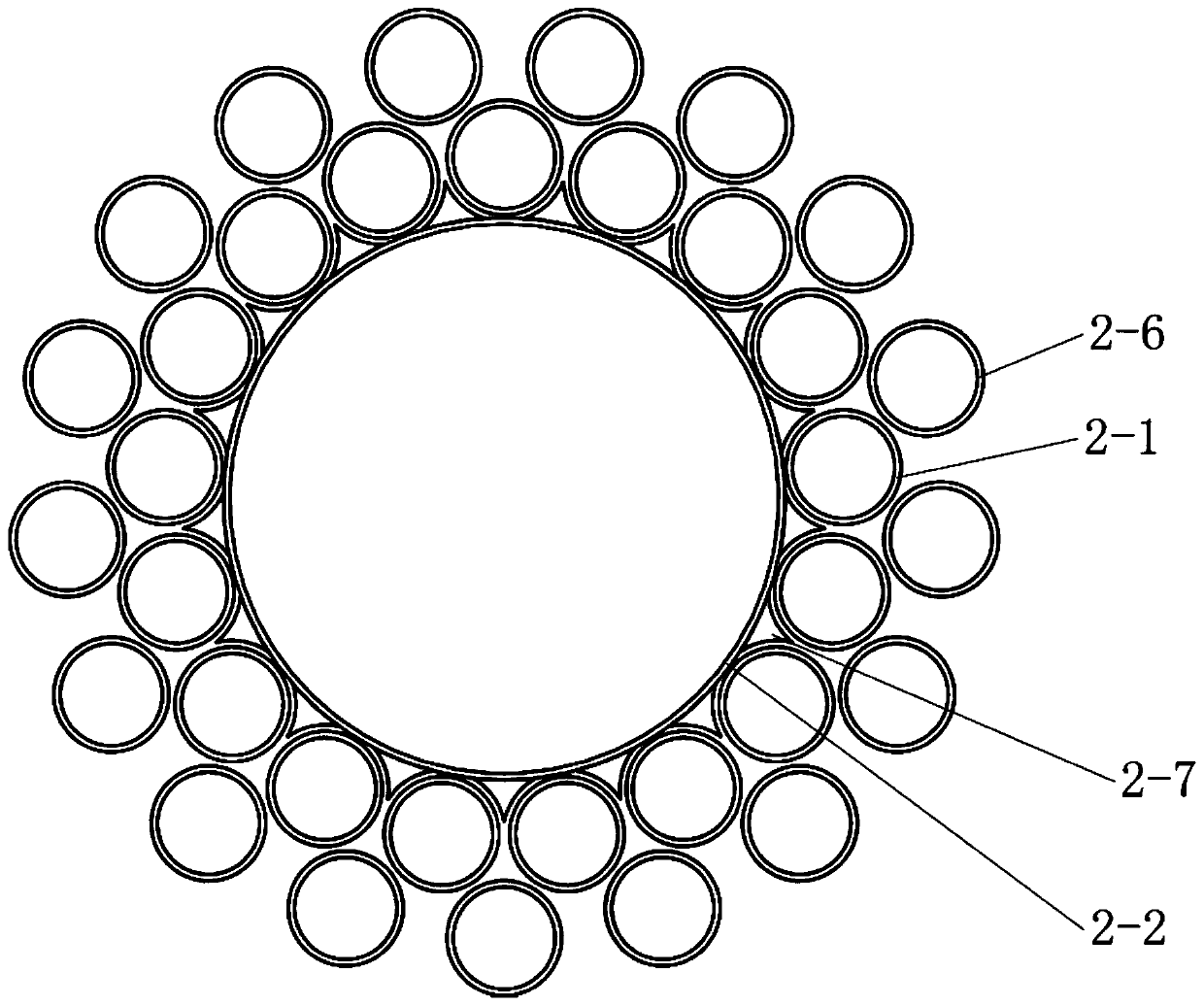

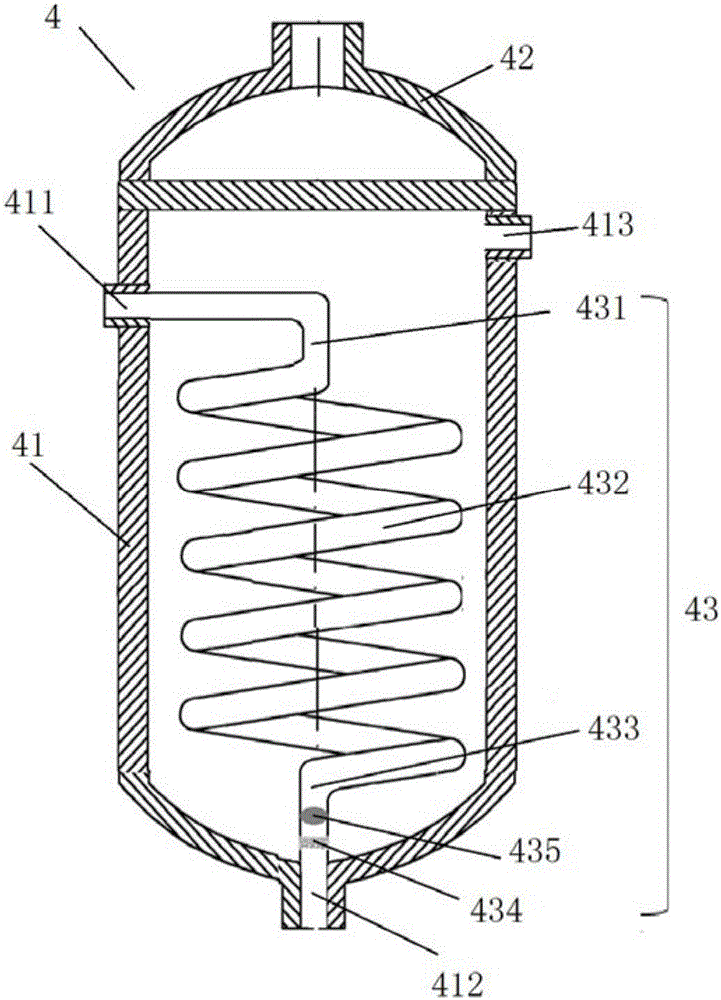

High-adjustment-ratio water-cooling premixed combustion high-strength heat exchange gas condensation boiler

PendingCN111141028AFully absorb radiation heat transferEnhanced radiation heat transferAir heatersGaseous fuel burnerCombustorAir blower

The invention provides a high-adjustment-ratio water-cooling premixed combustion high-strength heat exchange gas condensation boiler. The high-adjustment-ratio water-cooling premixed combustion high-strength heat exchange gas condensation boiler comprises a combustor and a heat exchanger, wherein the full-premixed combustor mounted in the center of a boiler top plate consists of a booster fan, a premixing chamber and a water-cooling combustion head; a flame stabilizing pipe and an anti-tempering column of the water-cooling combustion head can realize high-adjustment-ratio water-cooling premixed combustion; the heat exchanger consists of a lap of water-cooling wall and one or more laps of fins uniformly arranged in the peripheral direction by bent edge folding fin pipes; an air blower feedsair into the premixing chamber for fully mixing with gas to enter an inner cavity of a hole plate of the combustion head; the air flows out from a fire hole, and is sprayed out from narrow gaps amongthe water-cooling pipes distributed in the peripheral direction; after the air flows out from the flame stabilizing pipe, the air is ignited to uniformly combust in the peripheral direction and the axial direction, and radiates and releases heat to an inner pipe ring; smoke flushes base pipes and fins of inner and outer ring fin pipes in sequence to reinforce heat exchange; and the smoke downwards flows into a dew bearing disc through gaps between a housing and an outer layer fin pipe, and is exhausted into atmosphere from a smoke outlet. The high-adjustment-ratio water-cooling premixed combustion high-strength heat exchange gas condensation boiler is high in combustion load adjustment ratio, compact in heat exchange, low in nitrogen emission and high in heat efficiency.

Owner:XI AN JIAOTONG UNIV +1

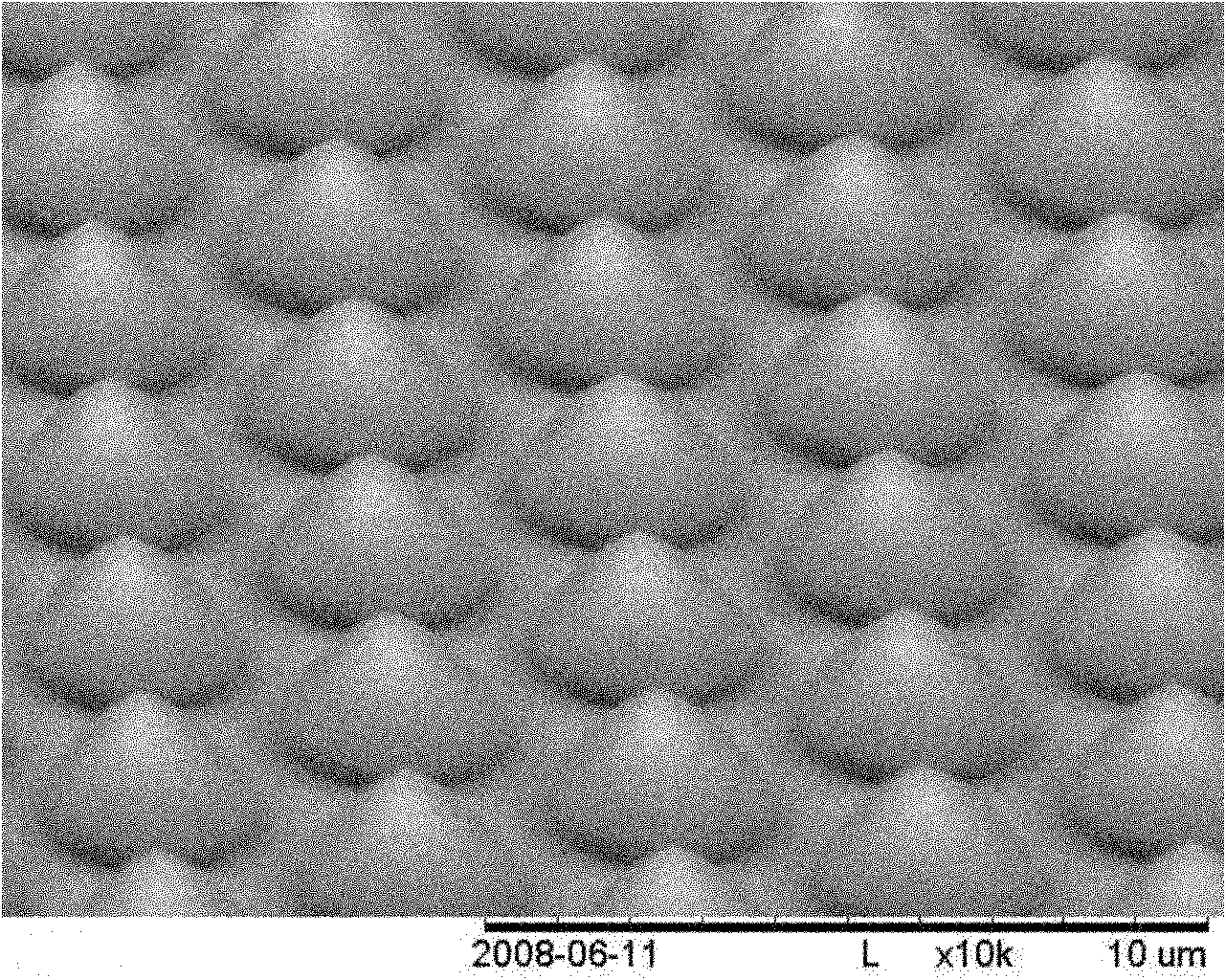

Method for preparing graphical GaN substrate

ActiveCN102142487AImprove light extraction efficiency and thermal conductivityExcellent performanceSemiconductor/solid-state device manufacturingSemiconductor devicesNanometreSubmicron scale

The invention provides a method for preparing a graph on a GaN substrate, which can greatly improve internal quantum efficiency, light emitting efficiency and heat conductivity of a light emitting diode (LED) chip. The method comprises the following steps of: generating a graph template on the surface layer of the GaN substrate by using a mask of a micro / nano graph, a lithographic technology, a nano impression technology or an aluminum oxide graph transfer technology, and then preparing a graphical structure capable of realizing stable micro and submicron scales and favorable for emitting light by using a graphical etching technology. The substrate can greatly improve the light emitting efficiency and the heat conductivity of the LED chip and has excellent performance.

Owner:广东中图半导体科技股份有限公司

High-efficiency coating stirring and mixing machine

InactiveCN107617360AAchieve hybridEasy accessRotary stirring mixersMixer accessoriesEngineeringCoating

The invention discloses a high-efficiency coating stirring and mixing machine. The high-efficiency coating stirring and mixing machine comprises a fixed base, wherein two corresponding locating guideplates are vertically and fixedly arranged at both ends of the surface of the fixed base; two corresponding slide rails are fixedly arranged at the inside surfaces of the two locating guide plates; aslide support base is fixedly arranged on the two slide rails, and a stirring mechanism is vertically and fixedly arranged at the lower end of the slide support base; a stirring tank is fixedly arranged at the surface of the fixed base, a first gear and a second gear are fixedly arranged on the fixed base, and are engaged together, a screw rod is fixedly arranged on the second gear and penetratesthrough the slide support base, and the screw rod drives the slide support base to move up and down along the slide rails in the vertical direction. The high-efficiency coating stirring and mixing machine has the advantages that by arranging the stirring mechanism, stirring rods are respectively arranged in the middle part and both sides of the stirring mechanism, and the stirring rods at the twosides can rotate around the center, and can also rotate around the self axis, so that the stirring efficiency is improved; the materials in the middle part and both sides of the stirring tank can be simultaneously mixed, so that the materials can be more uniformly mixed.

Owner:重庆彩润建材有限公司

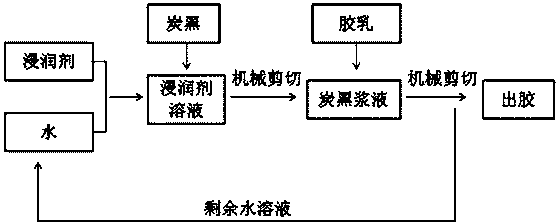

Process method for preparing high-performance carbon black masterbatch

The invention provides a process method for preparing high-performance carbon black masterbatch, relating to the technical field of carbon black masterbatch preparation processes. The wet-method carbon black masterbatch preparation process method provided by the invention is simple in process, low in energy consumption and excellent in performance. The method comprises the steps: soaking non-granulated carbon black powder in an aqueous solution of a micromolecular volatile solvent, so as to prepare uniformly-dispersed carbon black slurry; flocculating out masterbatch and carbon black at a certain stirring linear speed without adding other flocculating agents, filtrating and drying. The carbon black in the masterbatch prepared by the method disclosed by the invention reaches nano dispersion, vulcanized rubber has the advantages of excellent mechanical property, good resilience, low heat generation and high wear resistance, the preparation process is simple, the equipment investment is small, the energy consumption is low, the cost is low, the method is environmental-friendly, and the influence on the performance of the rubber and the pollution to the environment, caused by a surfactant, a flocculating agent and the like, are avoided.

Owner:BEIJING UNIV OF CHEM TECH

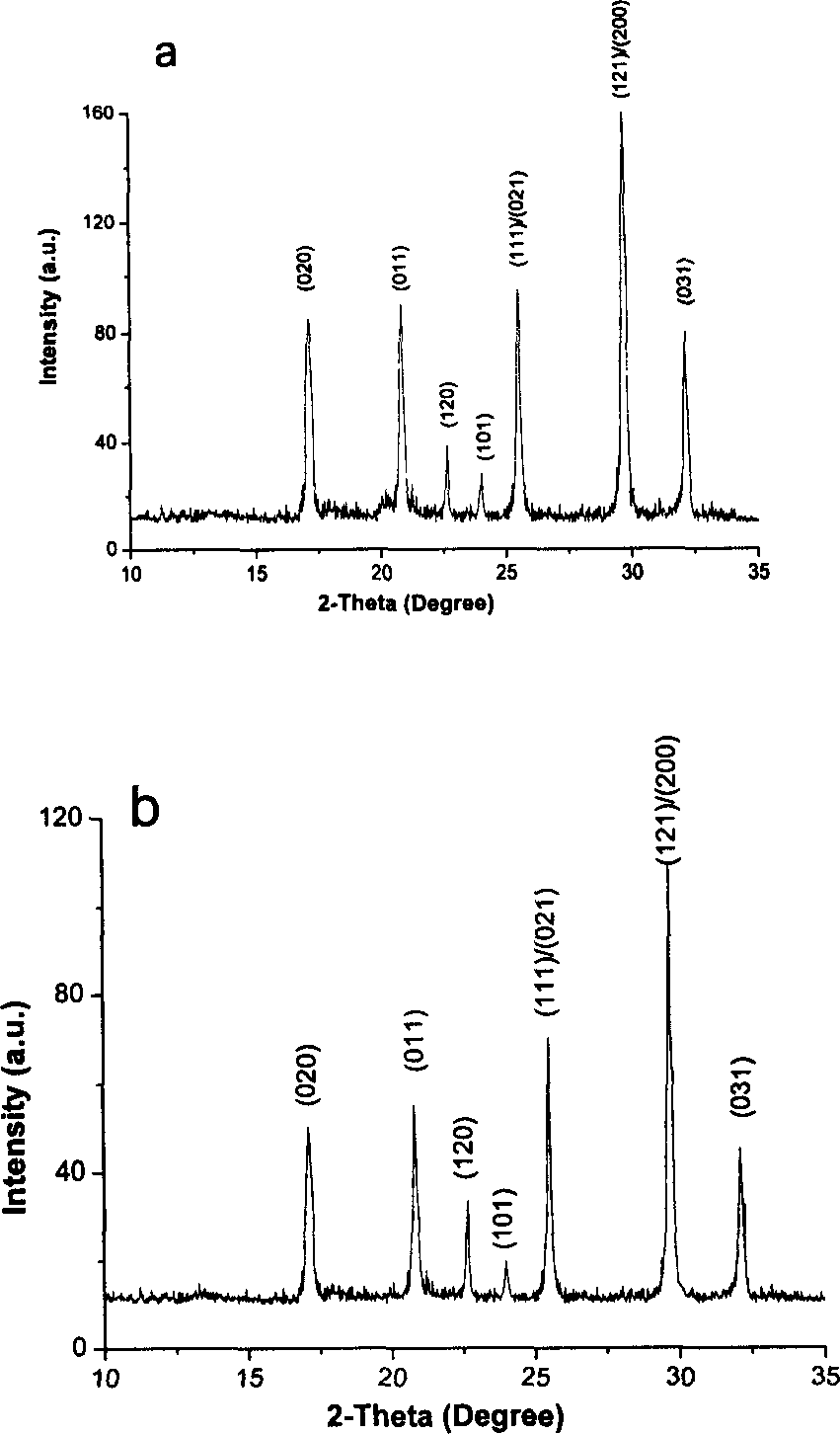

Doped small-particle size lithium nickel cobalt manganese oxide positive electrode material and precursor thereof and preparation methods of doped small-particle size lithium nickel cobalt manganese oxide positive electrode material and precursor

InactiveCN108258201AStable structureImprove stabilityCell electrodesSecondary cellsManganese oxideCobalt

The invention relates to a doped small-particle size lithium nickel cobalt manganese oxide positive electrode material and a precursor thereof and preparation methods of the doped small-particle sizelithium nickel cobalt manganese oxide positive electrode material and the precursor. A small-particle size hydroxide precursor is produced by adopting a nucleation coprecipitation method; a chemical general formula of the precursor is mA / Ni<x>Co<y>Mn<1-x-y>(OH)<2>, wherein x is smaller than or equal to 0.5 and greater than or equal to 0.3; y is smaller than 0.5 and greater than or equal to 0.1; Ais one or more of zirconium, magnesium, titanium and aluminum; m represents the mass fraction m% of the element A in the total mass of the nickel cobalt manganese hydroxide precursor; m is smaller than or equal to 0.5 and greater than or equal to 0.05; the particle size D10 is greater than or equal to 1.5 microns and smaller than or equal to 4.0 microns; the particle size D50 is greater than or equal to 2.0 microns and smaller than or equal to 5.0 microns; the particle size D90 is smaller than or equal to 8 microns; the specific surface area is smaller than or equal to 30m<2> / g; and the tap density TD is greater than or equal to 1.3g / cm<3> and smaller than or equal to 2.0g / cm<3>. The precursor has the characteristics that the elements are uniformly distributed, the shapes of the particlesare spherical or quasi-spherical, the specific surface area is controllable, the tap density is relatively high and the precursor is high in cycle life after being sintered and high in capacity.

Owner:HENAN KELONG NEW ENERGY CO LTD

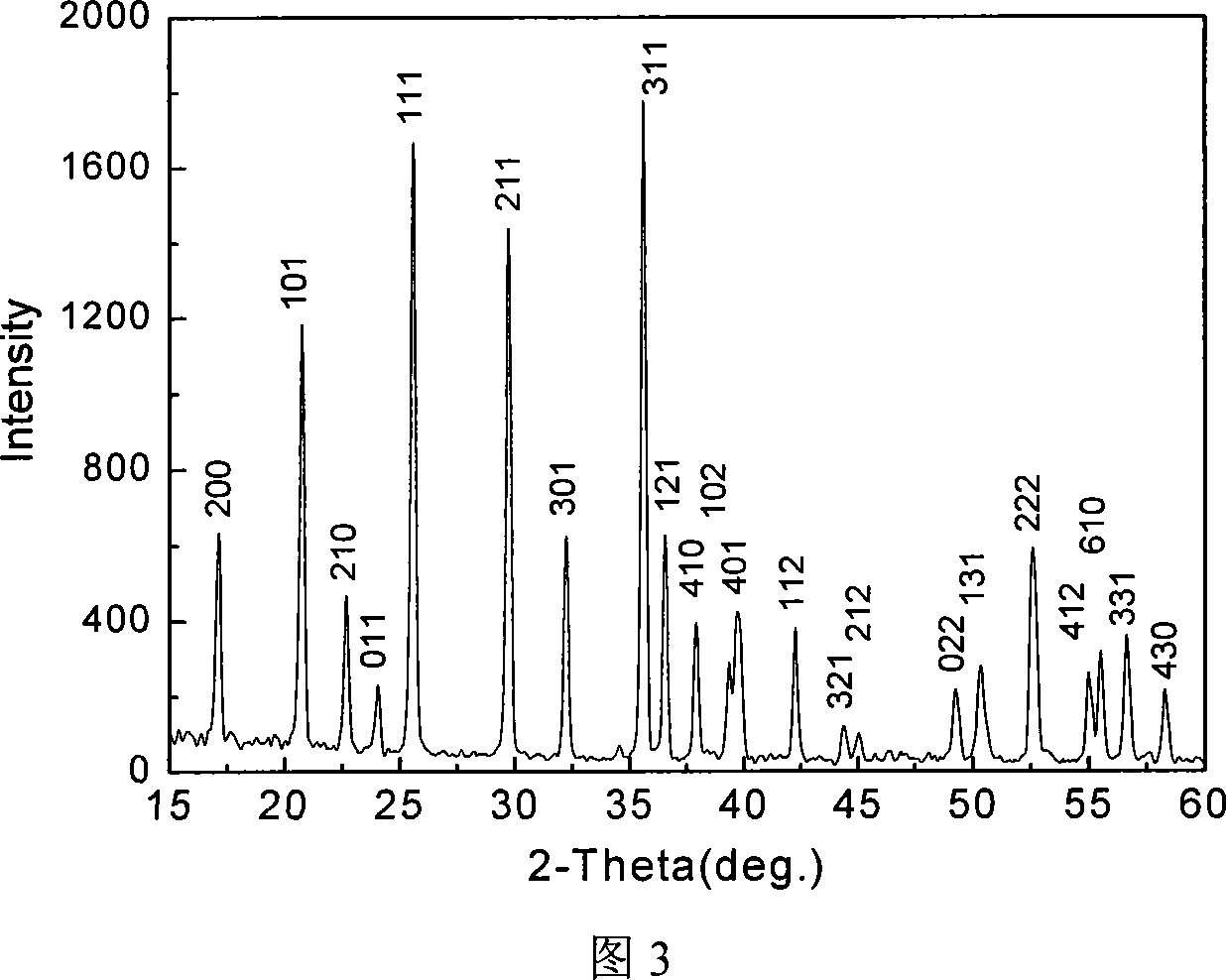

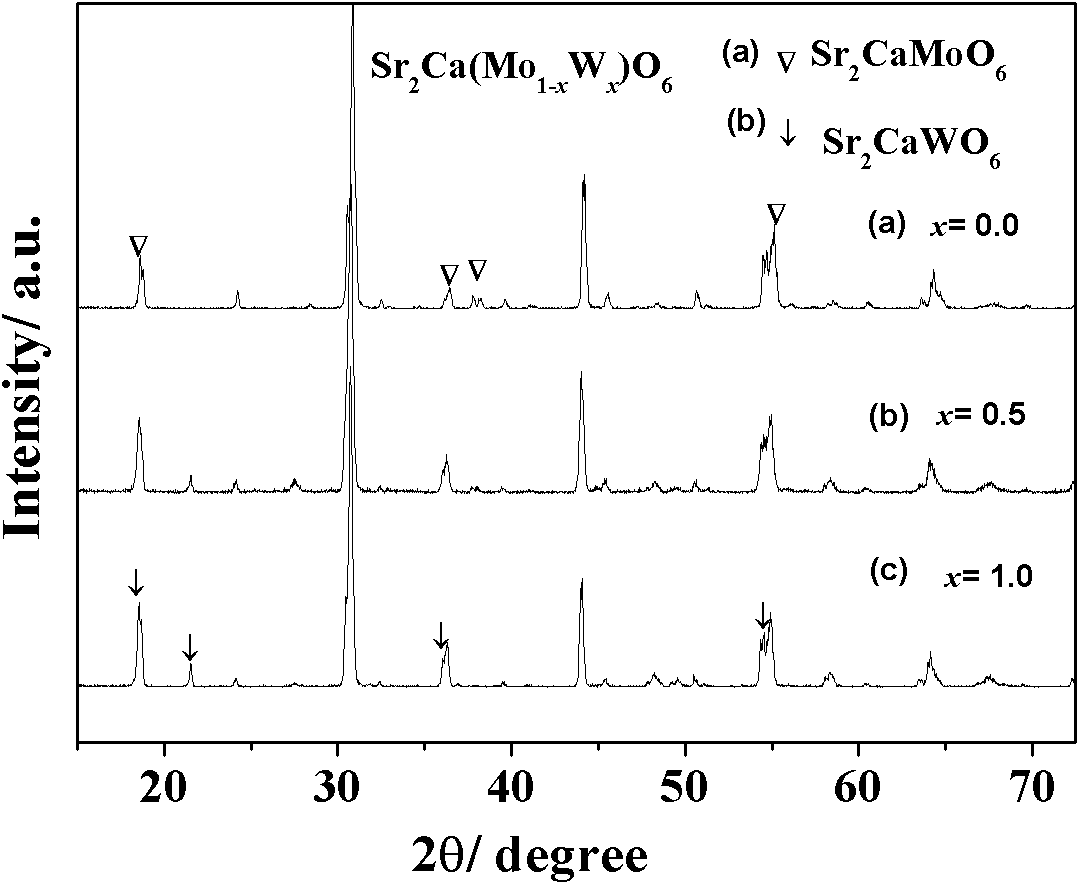

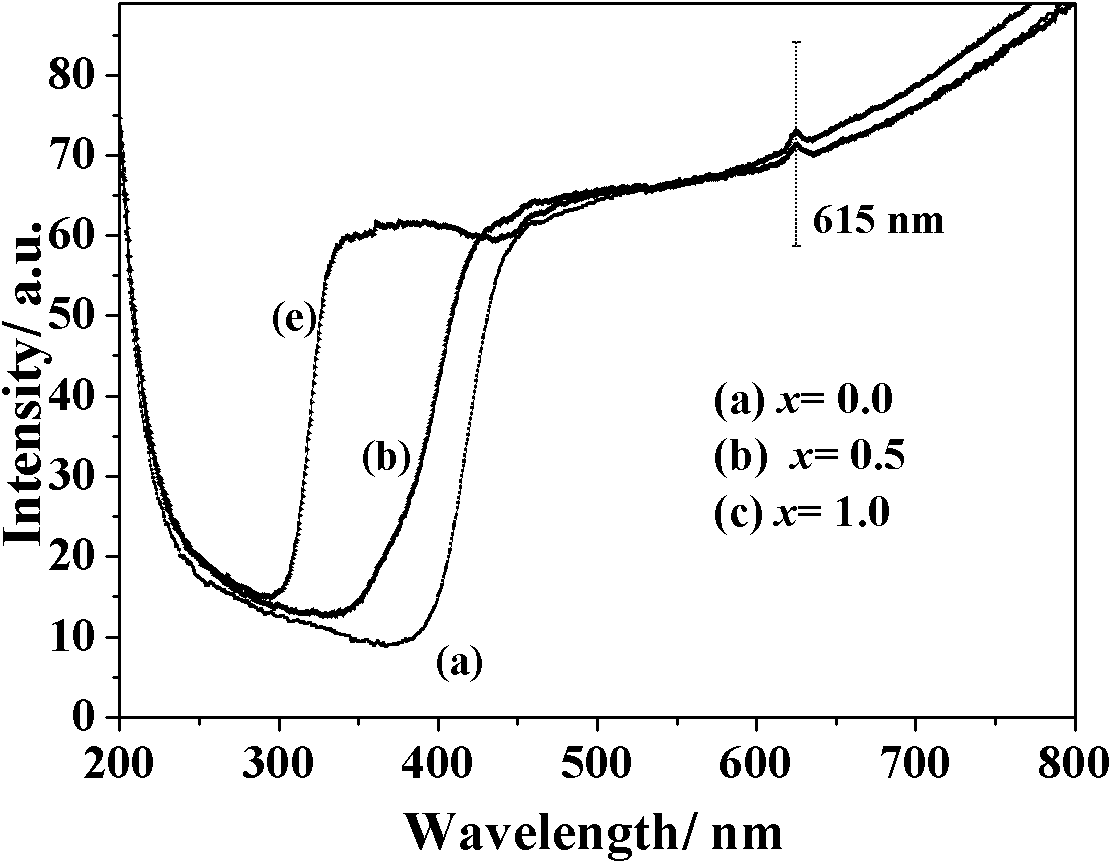

Preparation method of ion-doped double perovskite structure tungsten molybdate oxide powder

The invention relates to a preparation method of ion-doped double perovskite structure tungsten molybdate oxide powder. The preparation method is implemented through gelatinization and redox reaction of metal nitrate, tungsten ammonium molybdate, citric acid and ethylene diamine tetraacetic acid (EDTA) by a sol gel combustion synthesis method, wherein the citric acid and the EDTA serve as complexing agents. The prepared powder is a double perovskite component shown in the following formula: (A1-xMex)2B(Mo1-yWy)O6 or A2(B1-xMex)(Mo1-yWy)O6, wherein A is at least one of Ba, Sr or Ca; B is one of Ca, Mg, Ni, Fe, Co or Zn; A and B are not Ca at the same time; Me is one or two of rare elements or transition metal elements; x is more than or equal to 0.0 and less than or equal to 0.5; and y is more than or equal to 0 and less than or equal to 1. According to the prepared powder, single-phase ion-doped tungsten molybdenum substituted double perovskite oxide powder can be obtained under the conditions of low temperature and short heat-preserving time; test period is greatly shortened; cost is greatly reduced; and the method is particularly suitable for preparing rare earth-doped luminescent materials, magnetic resistance materials and the like with the structure type.

Owner:NANJING UNIV OF TECH

Concrete stirring device applied to construction

InactiveCN107953455AImproves thorough mixingAchieve hybridDischarging apparatusCement mixing apparatusEngineeringLeather belt

The invention discloses a concrete mixing device for construction, which comprises a support platform, on which a portal frame is vertically and fixedly installed, a driving pulley is fixedly installed on the upper end of the driving shaft, and a flat belt and The flat belt connected by the driving pulley transmission; the bottom of the support platform is horizontally fixed with a cylindrical conveying barrel, and a conveying shaft is installed horizontally in the cylindrical conveying barrel, and a conveying pipe is installed between the cylindrical conveying barrel and the sleeve barrel. There is a valve, the invention realizes the full mixing of the concrete through the reverse rotation of the mixing bucket and the mixing blade, and the spiral lifting blade lifts and flips the concrete at the bottom of the mixing bucket, which promotes the full mixing effect of the concrete; the rotation of the scraper impacts the inner wall of the mixing bucket The adhered concrete is scraped off to realize the comprehensive mixing of the concrete. The spiral blade can transport the concrete and play the role of rotating and mixing again, making the concrete more fine and uniform.

Owner:HENAN GAOSHENG ENTERPRISE MANAGEMENT CONSULTING CO LTD

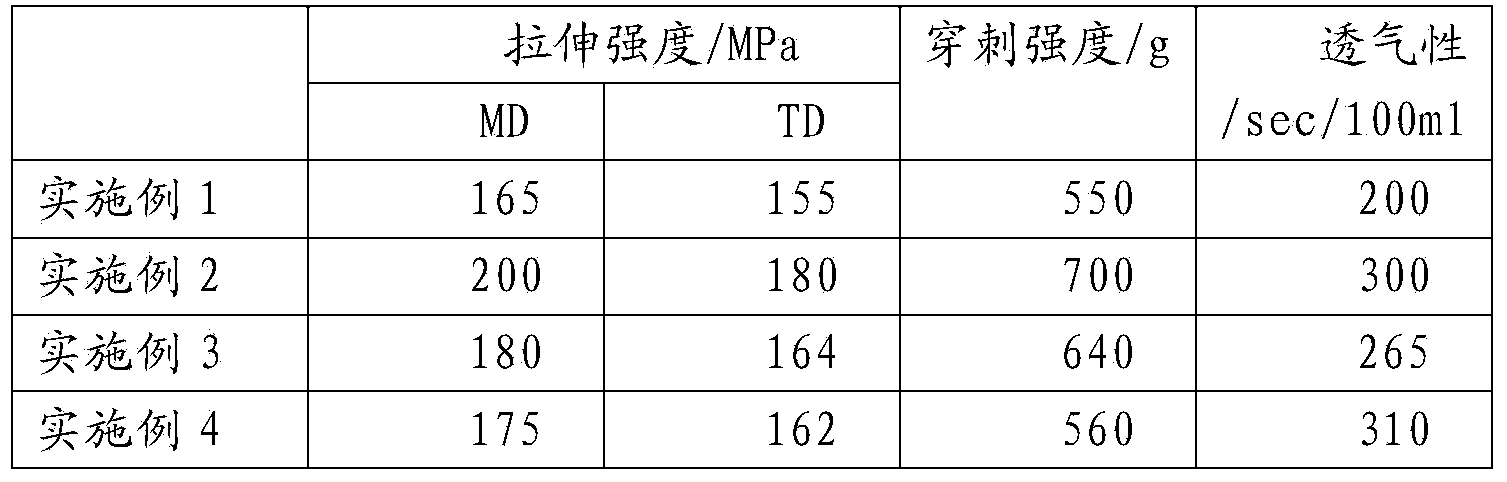

Ultrathin high-strength polyolefin microporous film and preparation method thereof

The invention discloses a preparation method of an ultrathin high-strength polyolefin microporous film. Polyolefin resin is used as a raw material, and the polyolefin microporous film is prepared by a thermally induced phase separation principle. The method comprises the following steps: a. polyolefin swelling dissolving; b. sheet casting; c. stretching a polyolefin cast film once; and d. stretching the polyolefin cast film secondarily. The invention also discloses the polyolefin microporous film prepared by the method. The method has the advantages of semi-continuous production convenience, simple process flow and simplicity in operation.

Owner:SHENZHEN SENIOR TECH MATERIAL

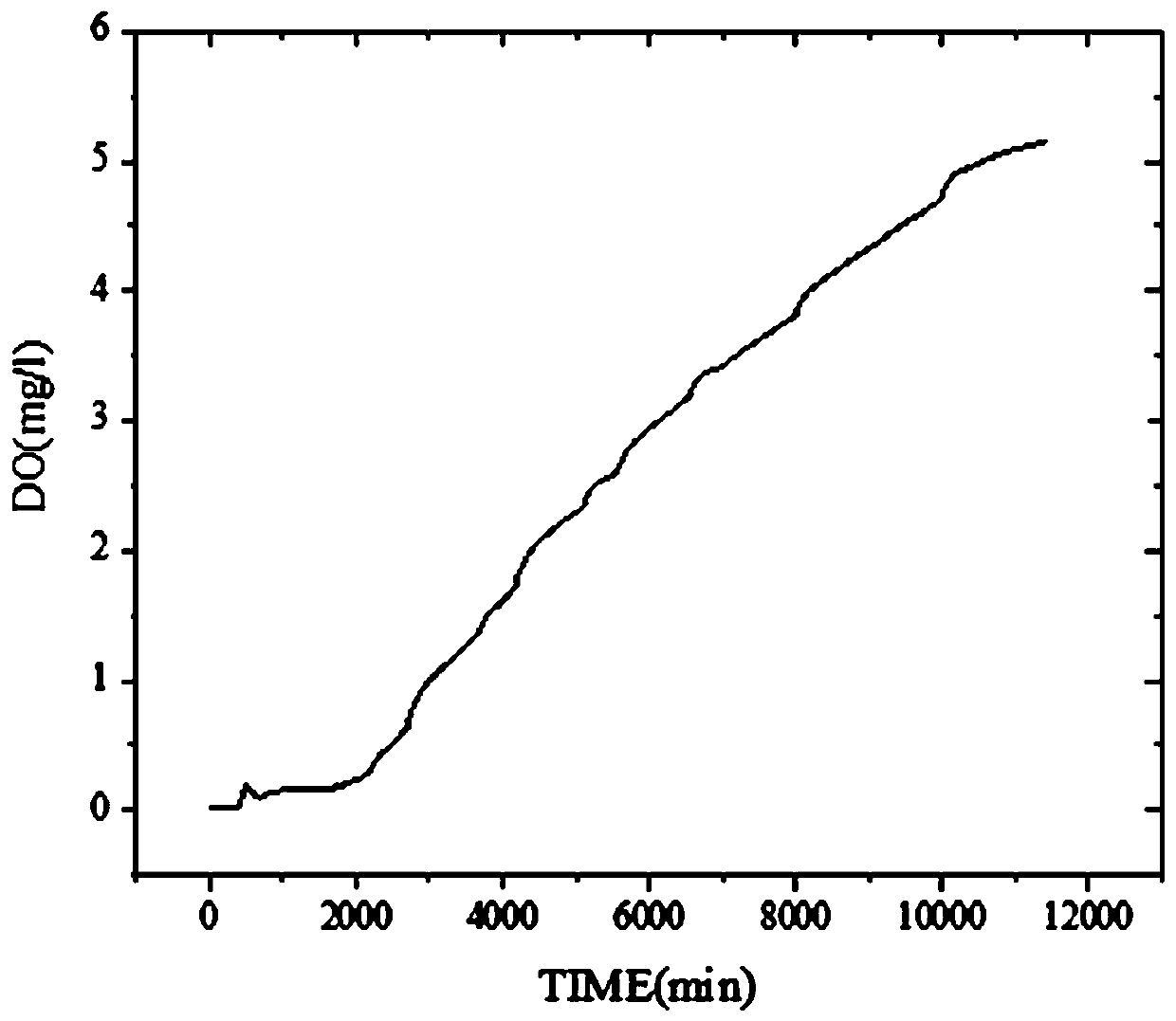

Production method of calcium peroxide particles for slowly releasing oxygen

InactiveCN110184072AAchieve hybridControl oxygen release rateContaminated soil reclamationWater/sewage treatmentSemi solidOxygen

The invention discloses a production method of calcium peroxide particles for slowly releasing oxygen. The production method of the calcium peroxide particles for slowly releasing the oxygen comprisesthe steps of using calcium peroxide powder as an oxygen releasing agent, using polylactic acid particles as an embedding medium, using dichloromethane as an intermediate medium for dissolving the polylactic acid particles, after the dissolved polylactic acid particles and the calcium peroxide powder are completely mixed, conducting volatilizing under a ventilation condition to remove the dichloromethane, placing an obtained mixture in a tubular mold after the mixture is in a gelatinous semi-solid state, and conducting extrusion molding and shearing balling to finally obtain the calcium peroxide particles for slowly releasing the oxygen after the dichloromethane is completely volatilized. By means of the production method of the calcium peroxide particles for slowly releasing the oxygen, the calcium peroxide powder and the polylactic acid particles can be completely mixed and embedded, the oxygen release speed of the calcium peroxide in water can be effectively controlled, and in the production process, loss, due to contact between the calcium peroxide and the water, of an oxygen releasing component is avoided. The produced calcium peroxide particles for slowly releasing the oxygencan slowly and continuously release the oxygen in the water, and meanwhile, due to the biodegradability of the PLA, no secondary pollution is generated during material use.

Owner:SHANGHAI MUNICIPAL ENG DESIGN INST GRP

Alkylation reactor and alkylation reaction method

ActiveCN104667856ASmall scaleFast scaleLiquid hydrocarbon mixtures productionChemical/physical/physico-chemical nozzle-type rreactorsPtru catalystEmulsion

The invention discloses a sectional feeding alkylation reactor and an alkylation reaction method. The reactor comprises a reactor barrel, seal heads, a partition plate, an upper bed layer, a lower bed layer, a feeding pipe, a feeding distributing pipe, a rotary shaft, a supplementing material inlet, a discharging opening, a circulating cooling gas inlet, a circulating cooling gas refrigerating system and a circulating cool gas outlet. The invention further provides the alkylation reaction method. The method comprises the following steps: as the sectional feeding alkylation reactor is adopted, firstly forming an acidic hydrocarbon emulsion in the upper bed layer from iso-butane and concentrated sulfuric acid; and then carrying alkylation reaction on the acidic hydrocarbon emulsion and mixed hydrocarbon entering from the supplementing material inlet in a lower bed layer rotary bed. According to the alkylation method disclosed by the invention, by taking the concentrated sulfuric acid as a catalyst and the iso-butane and olefin as raw materials, the alkylation reaction is carried out. The alkylation reaction disclosed by the invention can be carried out at a low temperature, so that the reactor is low in acid consumption and small in equipment scale.

Owner:CHINA PETROLEUM & CHEM CORP +1

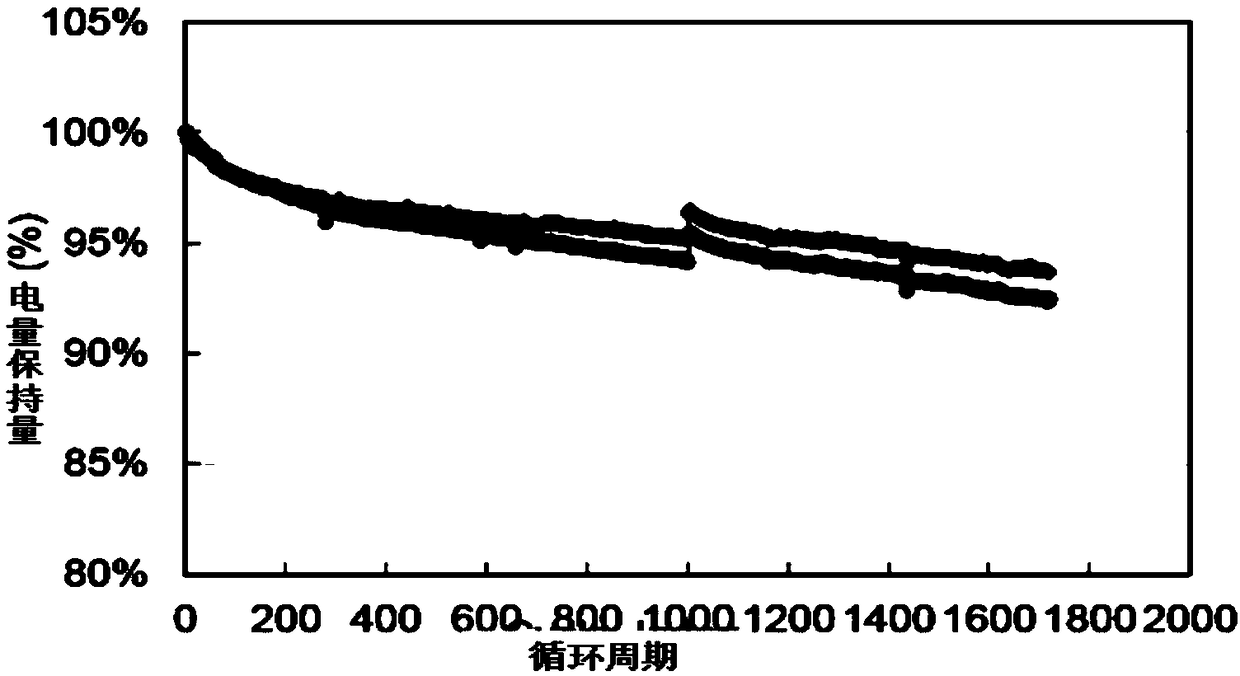

High-voltage lithium cobaltate based composite cathode material of lithium ion battery and preparation method of high-voltage lithium cobaltate based composite cathode material

ActiveCN104466099AInhibition of phase transitionGuaranteed stabilityCell electrodesSecondary cellsComposite cathodePhysical chemistry

The invention discloses a high-voltage lithium cobaltate based composite cathode material of a lithium ion battery. Metal element M is doped into lithium cobaltate; meanwhile, Li2MnO3 is introduced into lithium cobaltate to form the composite cathode material; the phase change of lithium cobaltate in a charging / discharging cyclic process under high voltage is inhibited, and the cyclic performance under high voltage (more than 4.5V) is improved; the molecular formula of the composite cathode material is xLi2MnO3.(1-x)LiCo(1-y)MyO2, wherein x is more than or equal to 0.01 and less than or equal to 0.20 and y is more than or equal to 0.005 and less than or equal to 0.10; and the doped metal element M is one or more of Mg, Ca, Ni, Mn, Cr, Fe, Al, Y, Ti, Zr, Cu, Zn, Ce, V, Nb and Mo. The lithium cobaltate based composite cathode material is prepared by a liquid phase mixing-spray drying-high temperature sintering combined method, and dual modification operations (material compounding and doping) are finished in one step, so that the preparation process of the material is simplified.

Owner:CENT SOUTH UNIV

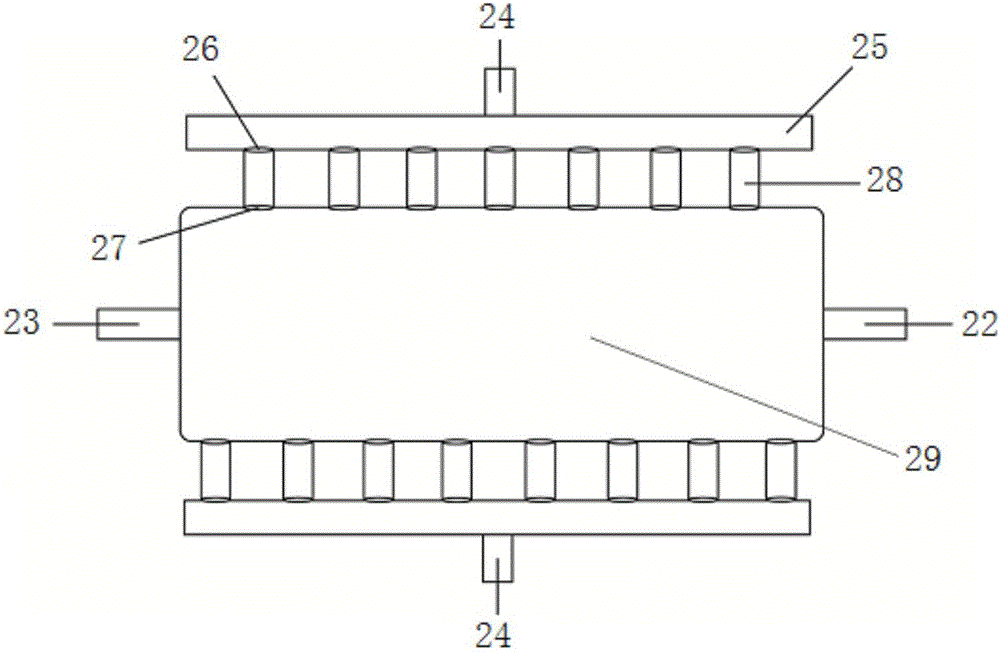

Flax thick yarn supercritical CO2 biological enzyme scouring device and scouring method thereof

ActiveCN106676788AReduce usageReflect the concept of modern lifeTextile treatment containersTextile treatment machine arrangementsYarnBreaking strength

The invention discloses a flax thick yarn supercritical CO2 biological enzyme scouring device and a scouring method thereof. Flax thick yarn is placed in supercritical CO2 fluid where a biological enzyme scouring agent is dissolved, flax fibers are swollen for 10-30 min at 30-40 DEG C and 8-15 MPa; the flax thick yarn is scoured for 30-60 min under dynamic conditions of a flow velocity of supercritical CO2 at 10-50 g / min at 40-60 DEG C and 15-25 MPa; the flax thick yarn is processed through a scouring-separation combined process for 10-30 min at 40-60 DEG C and 15-25 MPa; after the scouring, the weight loss rate of the flax thick yarn is 6-12%, the residual gum rate is 7-15%, the single fiber breaking strength is 6-13 cN / dtex, and the elongation at break is 4.5-8.5%. The whole scouring process is free of pollution and has zero release, requirements of commercialized production are met, and the modern life idea of fashionable bast fiber spinning and green bast fiber spinning is embodied.

Owner:YIXING SUNSHINE LINEN TEXTILE CO LTD

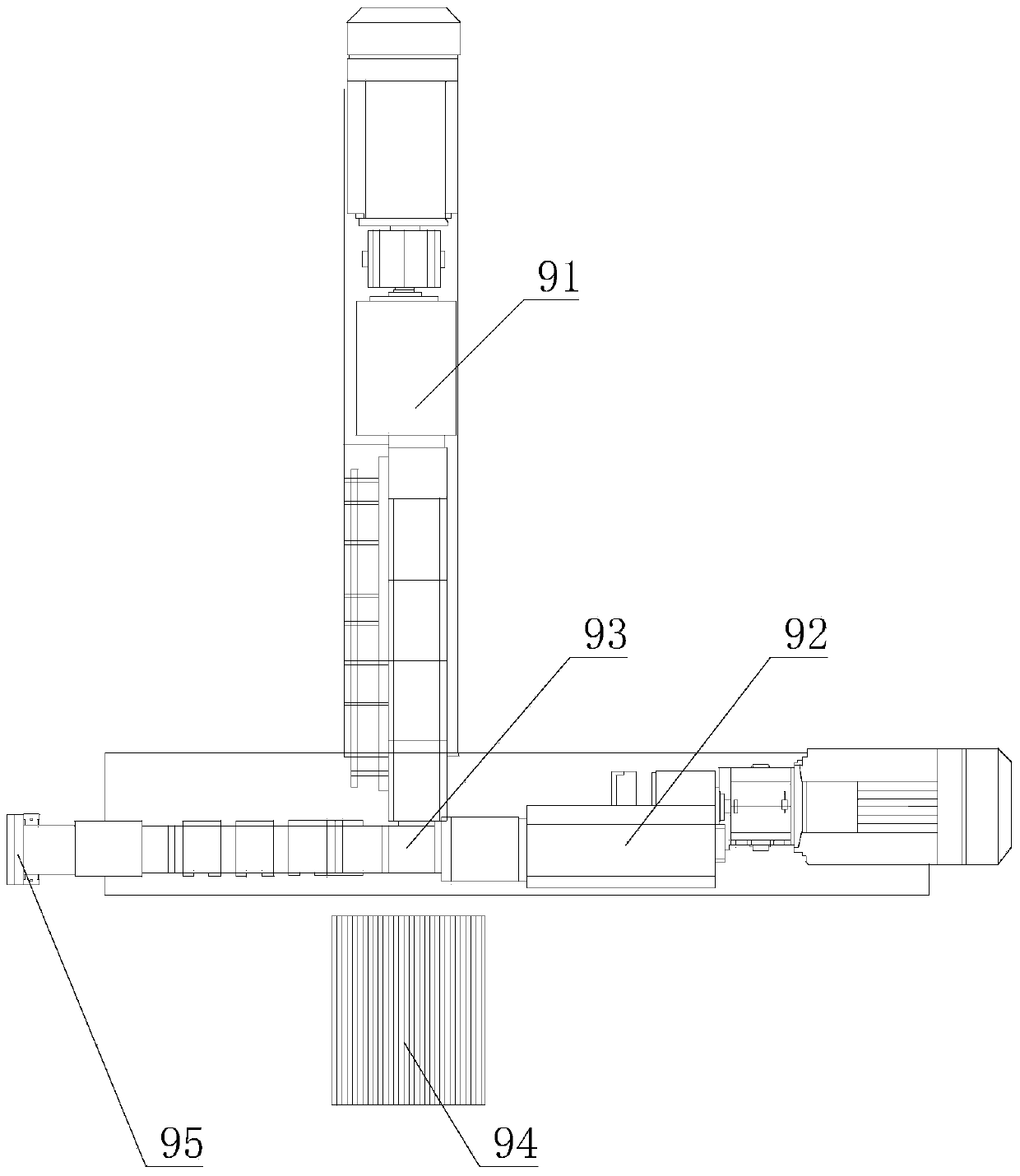

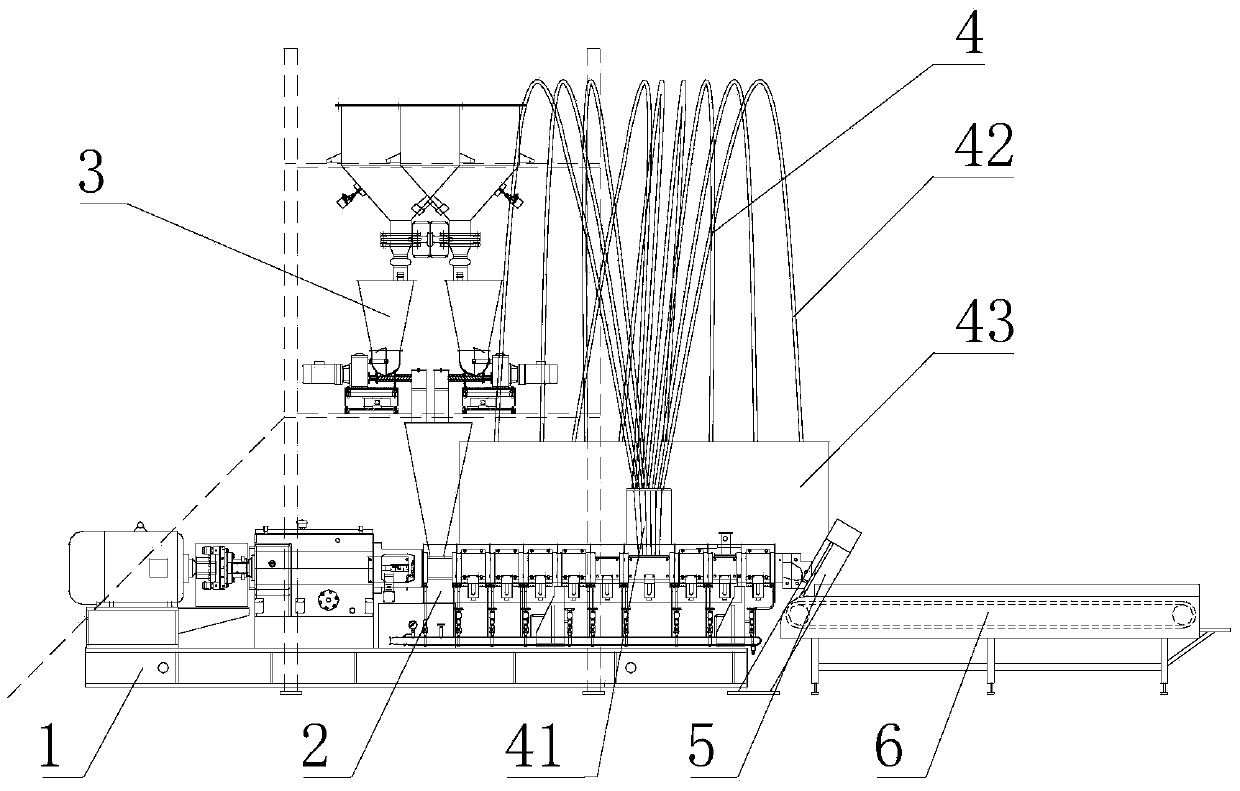

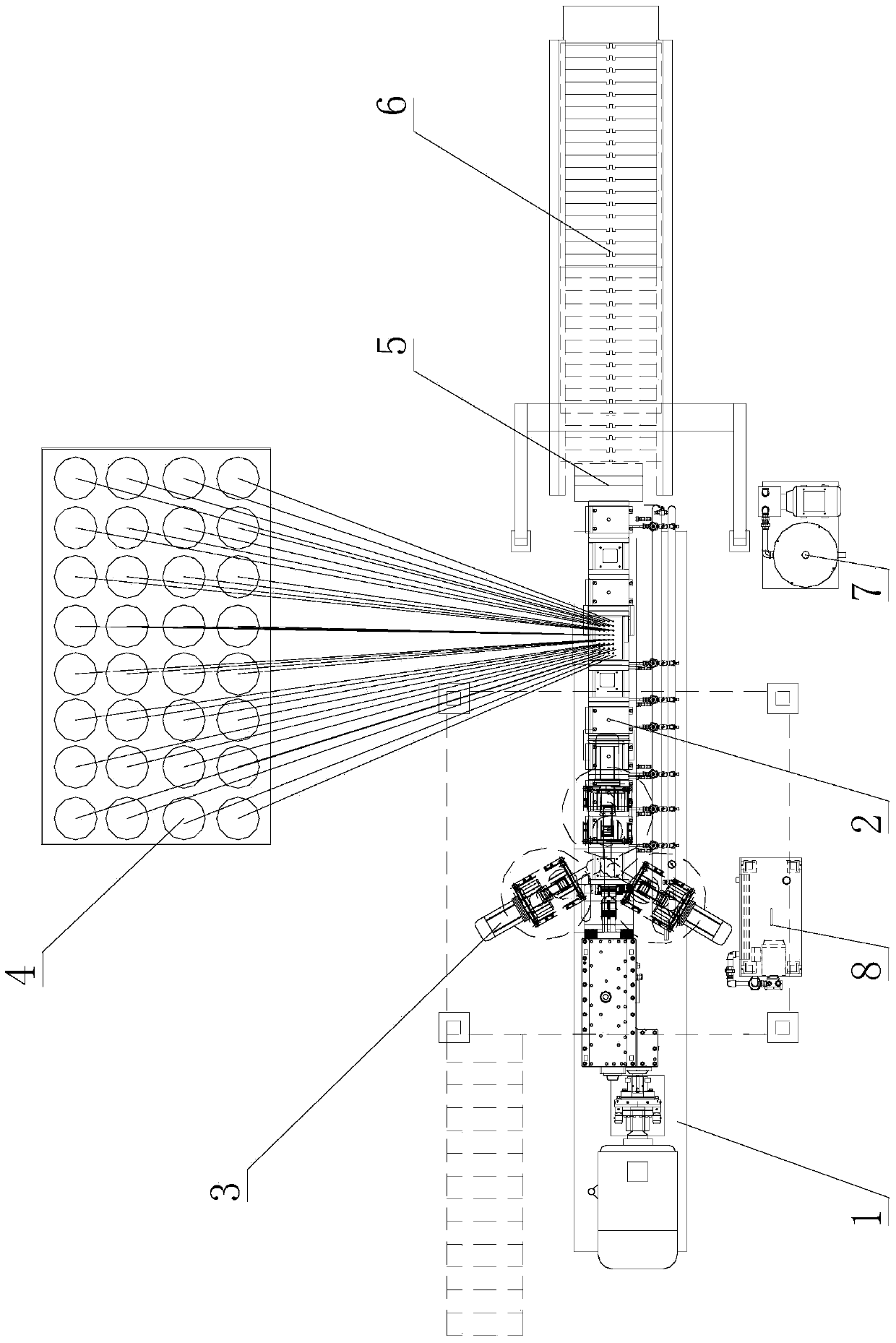

Direct on-line molding apparatus for long fiber-reinforced thermal plastics

The invention provides a direct on-line molding apparatus for long fiber-reinforced thermal plastics. The direct on-line molding apparatus comprises a steel platform, an extruding device, a metering feeding device and a glass fiber adding device, wherein the extruding device comprises an extruder, the central part of the extruding device is provided with a glass fiber introducing port, and the glass fiber adding device comprises a glass fiber heating device arranged above the glass fiber introducing port. According to the invention, only one extruder is arranged, a glass fiber enters the central part of the extruding device, is cut by a screw and is then directly mixed with a master batch, so intermediate transition distance does not exist; through additional installation of the glass fiber heating device, moisture in the glass fiber is removed and the glass fiber undergoes preheating treatment, which is more beneficial for mixing of the glass fiber and the master batch and for improvement of product quality; the addition amount of the glass fiber is controlled through the rotating speed of the screw of the main engine; when the amount of the introduced master batch is constant, the rotating speed of the screw is increased, the addition amount of the glass fiber is increased accordingly, so the content of the glass fiber is increased, or otherwise, the content of the glass fiber is decreased.

Owner:SICHUAN ADVANCE TECH CO LTD

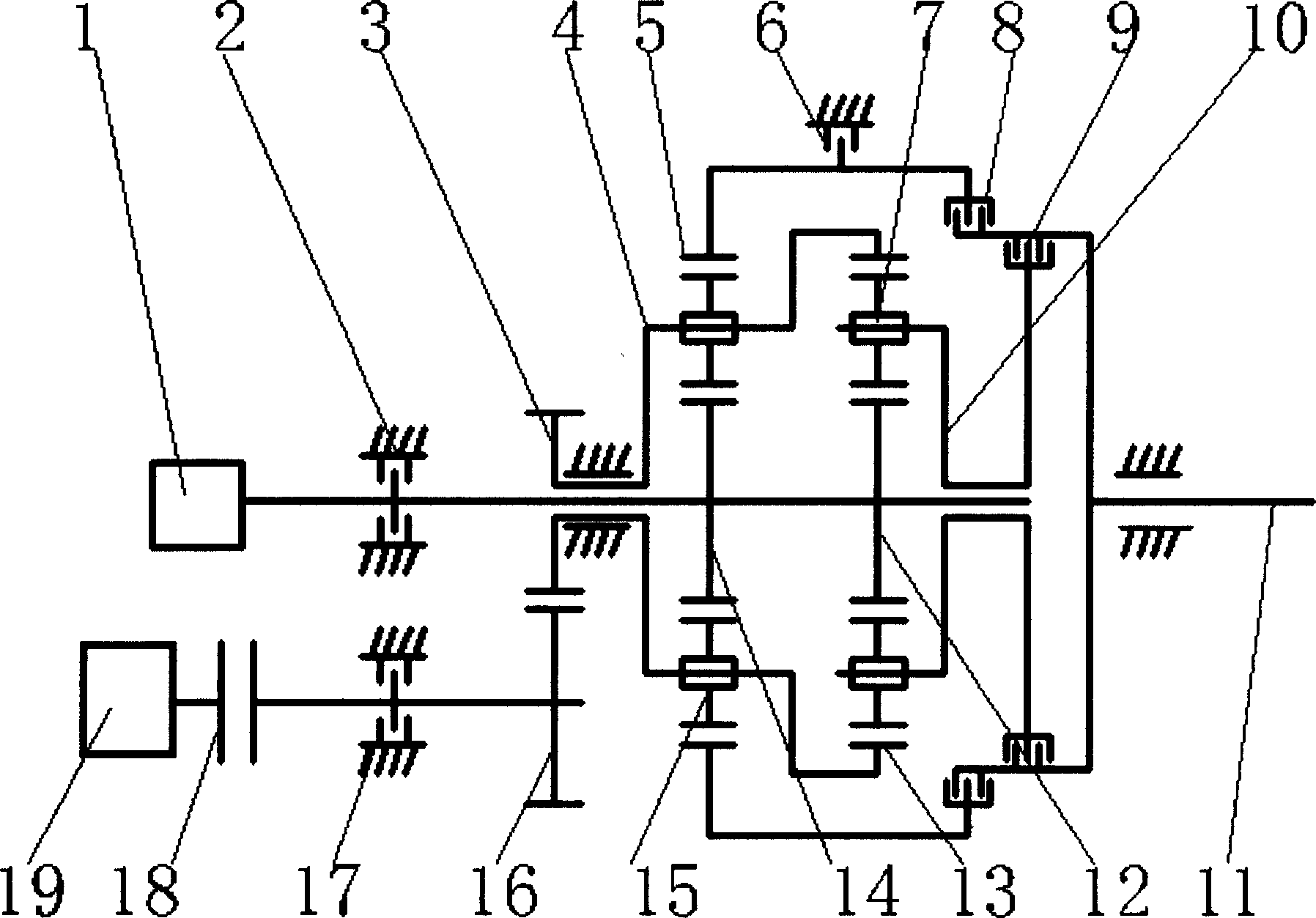

Electric coupling assembly of double-row planet gear apparatus of mixed dynamic vehicle

The invention consists of a motor, three clutches, three brakes, a pair of constant mesh gears, four front and back planet rows, an output shaft and an engine. The output shaft of the motor is connected with the front and back solar wheels. The engine is connected with the driving gear via the clutch of the engine, and the driven gear is integrated with the front planet frame and the back gear ring. The output shaft is connected with the front gear ring or the back planet frame via the front gear ring clutch and the back planet frame clutch. Using the different state combination of three clutches and three brakes can realize many kinds of working modes of the motor vehicles.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com