Valveless piezoelectric micromixer for synthesizing jet

A technology of synthetic jet and micro-mixer, which is applied in mixers, chemical instruments and methods, dissolution, etc., can solve the problems of mixing controllability, poor mixing effect, low mixing efficiency, and failure of synthetic jet, etc. Control, improve mixing efficiency, and strengthen mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

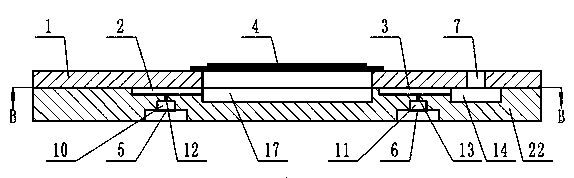

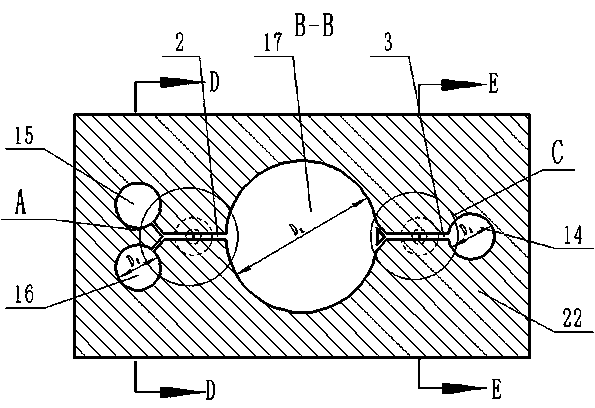

[0024] Such as figure 1 , 2 , 3, 4, 10, and 11, the present invention integrates a microfluidic driving unit (ie, a piezoelectric pump) and a microfluidic mixing unit (ie, a mixing channel). It includes a pump cover 1, a pump body 22, a synthetic jet actuator and a piezoelectric vibrator 4. The pump inlet 8, the pump inlet 9, the upper part of the pump cavity 17 and the pump outlet 7 are processed on the pump cover 1 by using MEMS technology. The pump inlet 8 and the pump inlet 9 are located at the left part of the pump cover 1, and are respectively connected with inlet pipelines. The pump outlet 7 is located at the right part of the pump cover 1, and is externally connected to the outlet pipeline. The upper half of the pump cavity 17 is in the middle of the pump cover 1 .

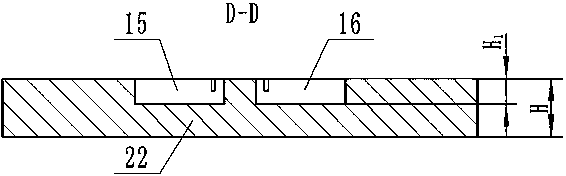

[0025]In the upper part of the pump body 22, the inlet mixing channel 2 and the outlet mixing channel 3 with the same structure, two inlet buffer chambers 15, 16 with the same structure, an outlet buff...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com