Patents

Literature

127 results about "Blend time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

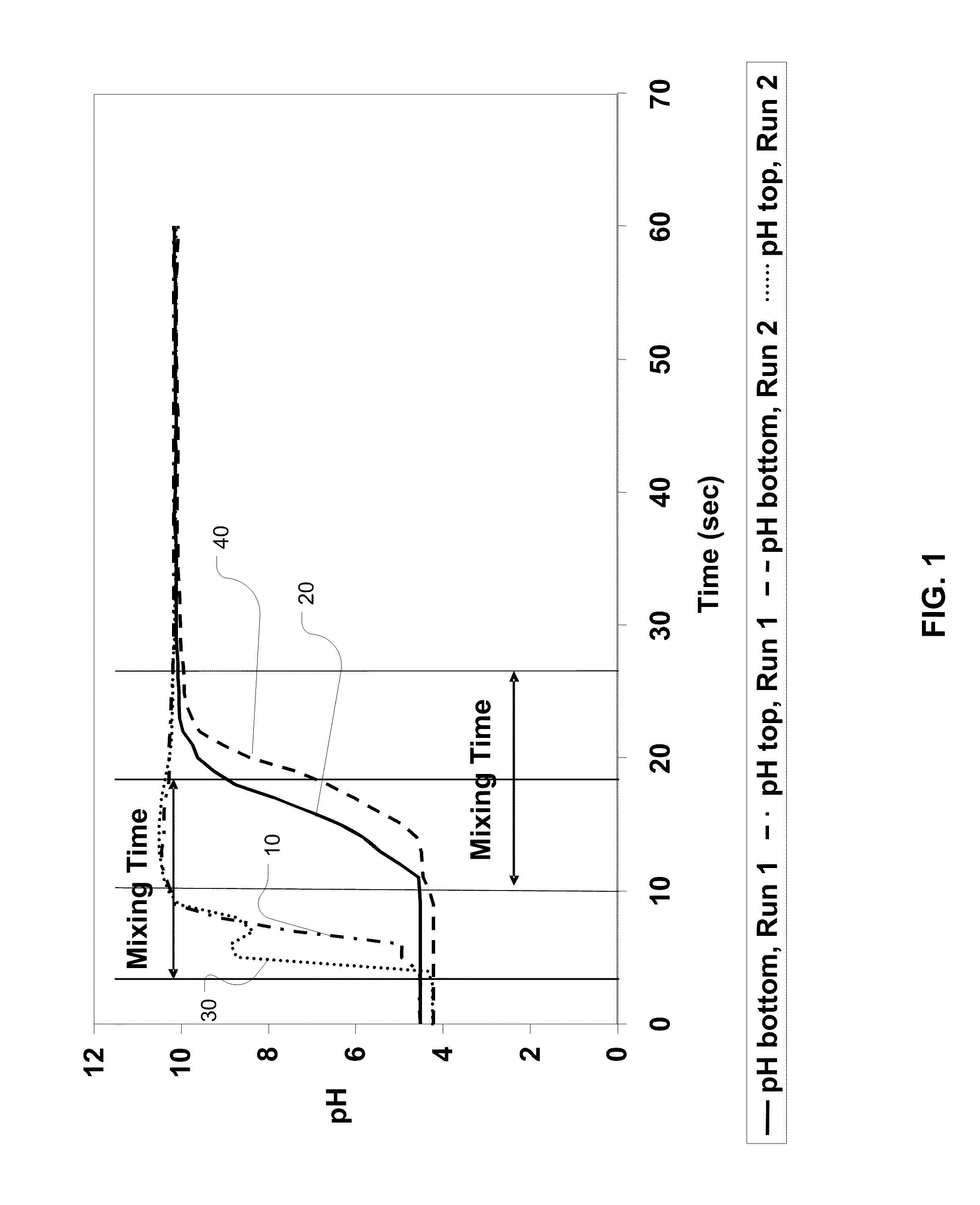

Blend time, sometimes termed mixing time, is the time to achieve a predefined level of homogeneity of a tracer in a mixing vessel. Blend time is an important parameter to evaluate the mixing efficiency of mixing devices. In order to make this definition valid, the tracer should be in the same physical phase (e.g. liquid) as the bulk material.

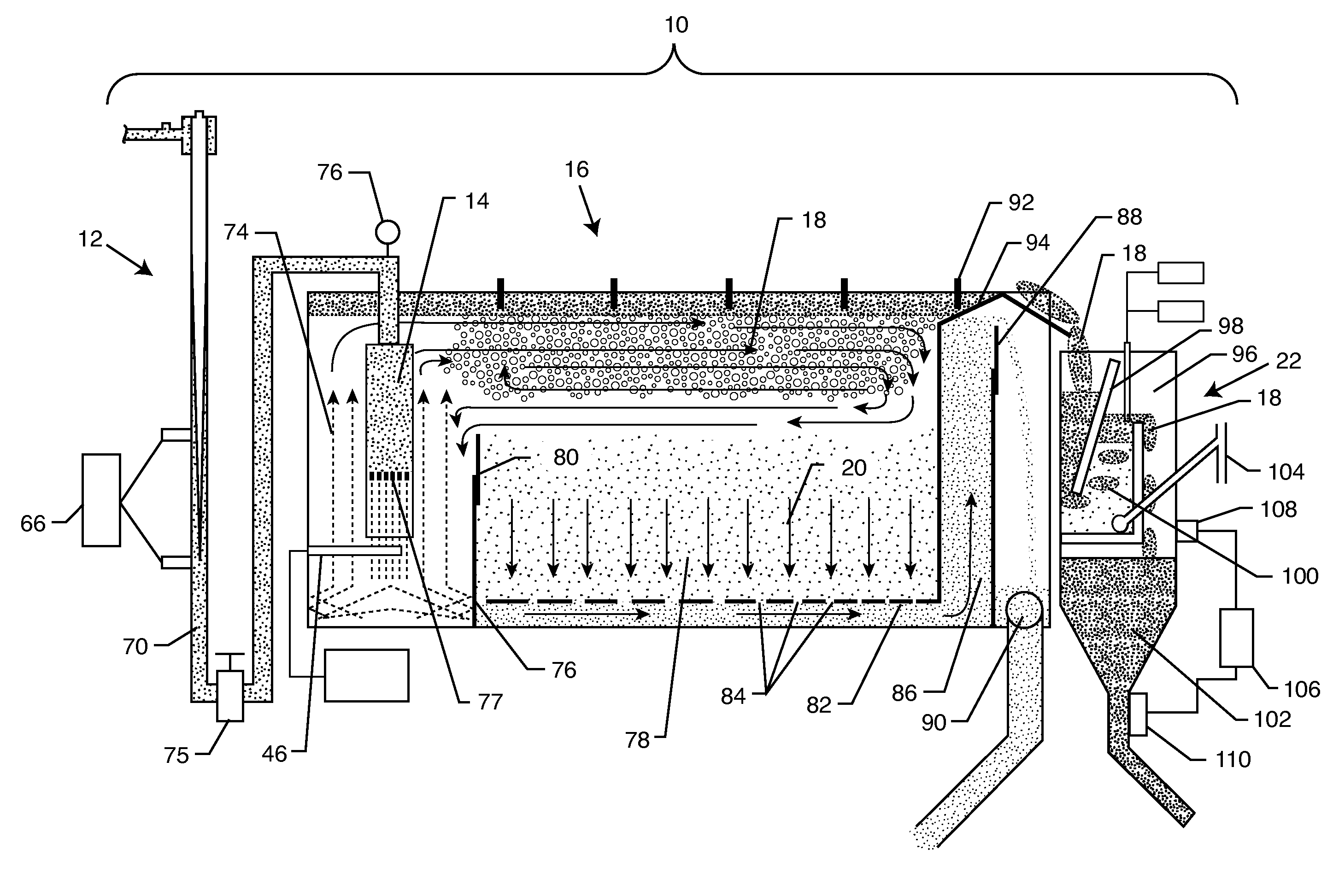

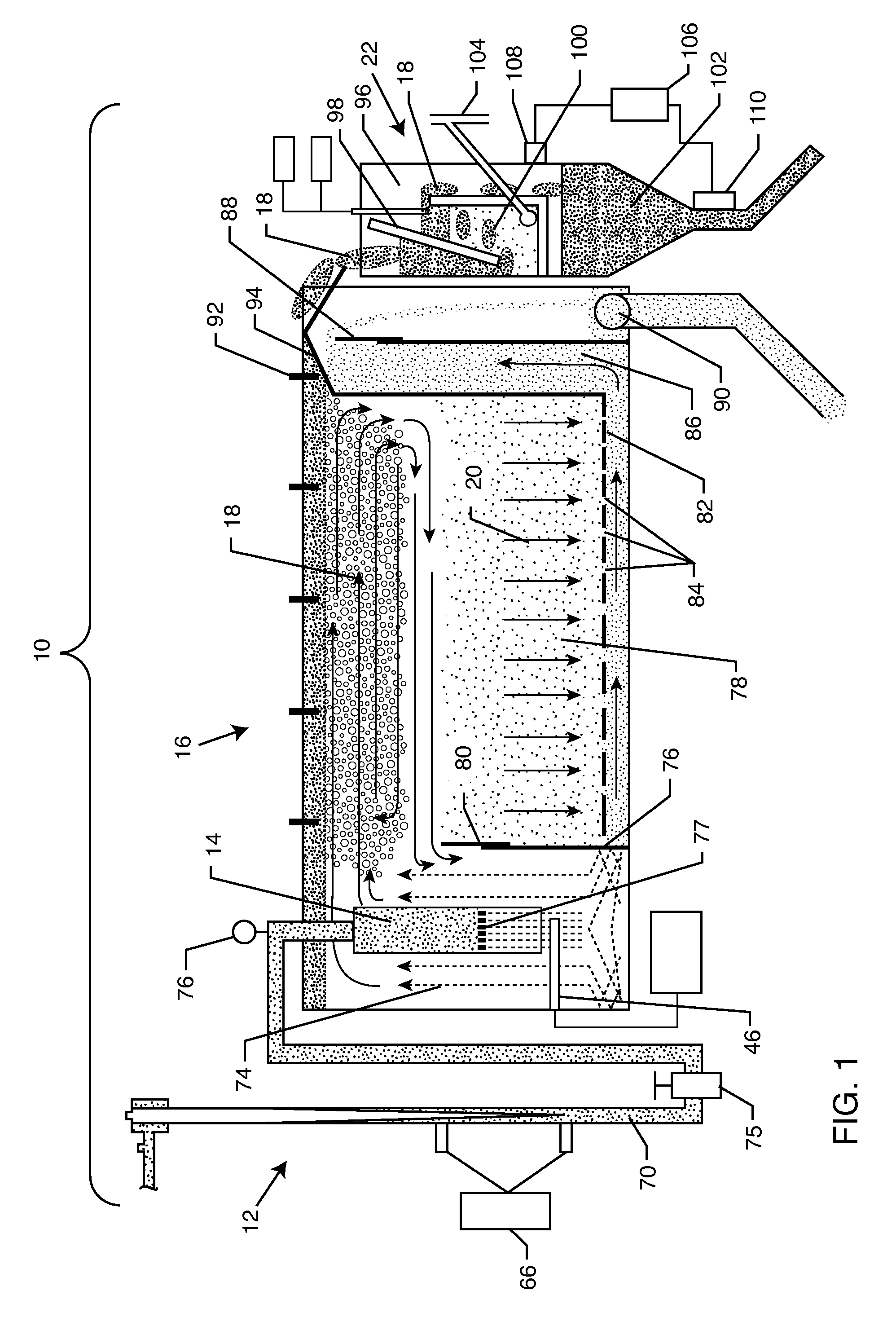

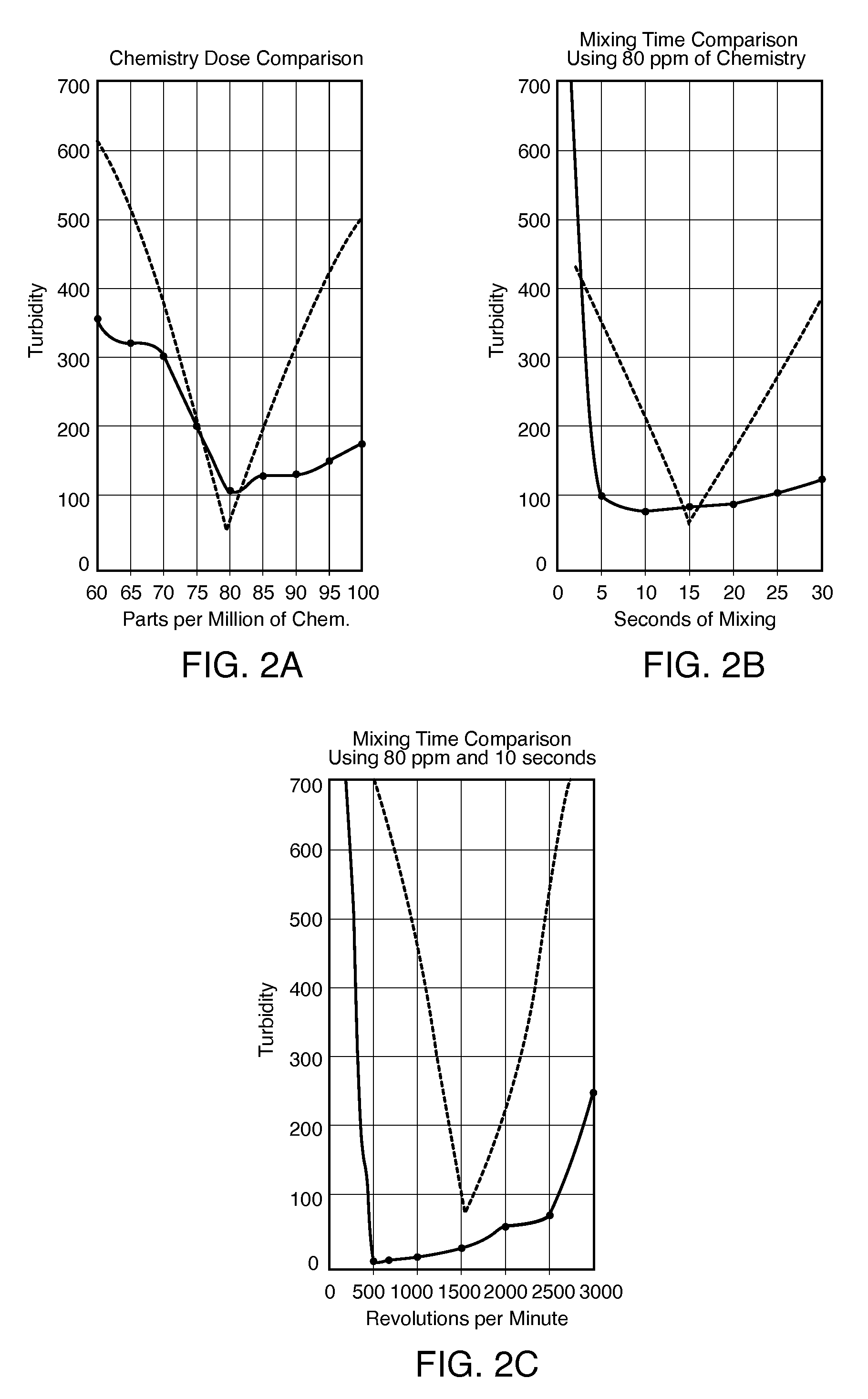

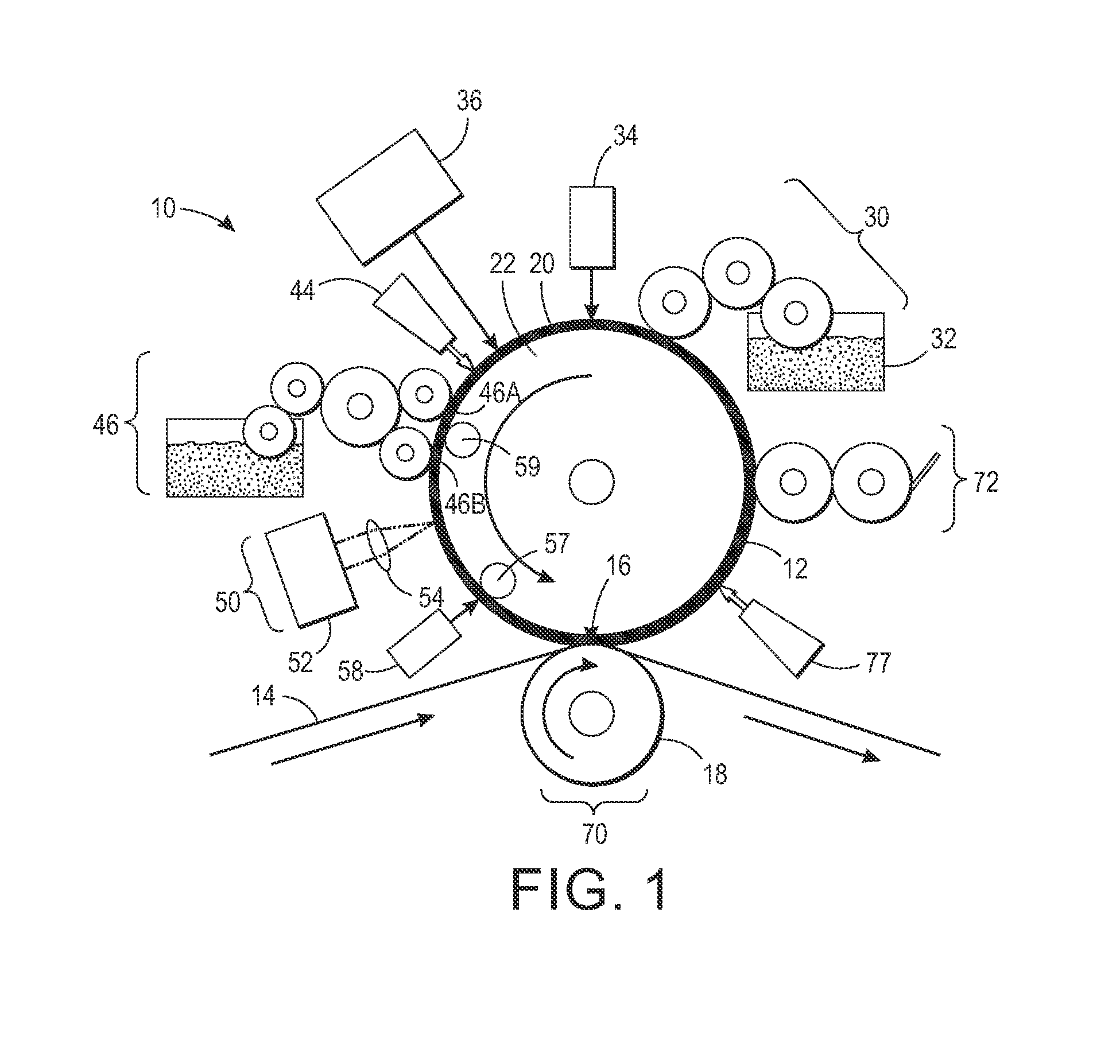

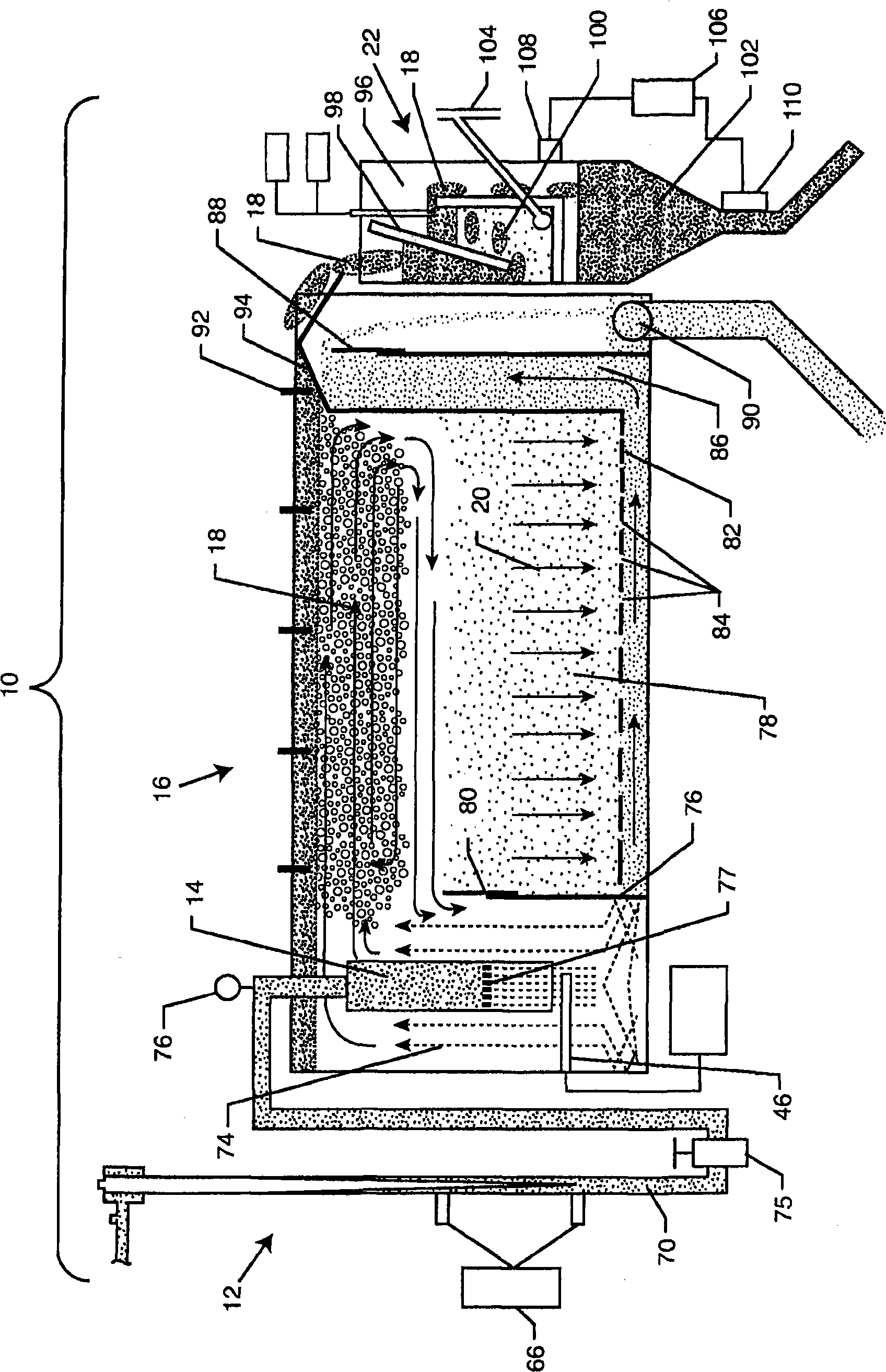

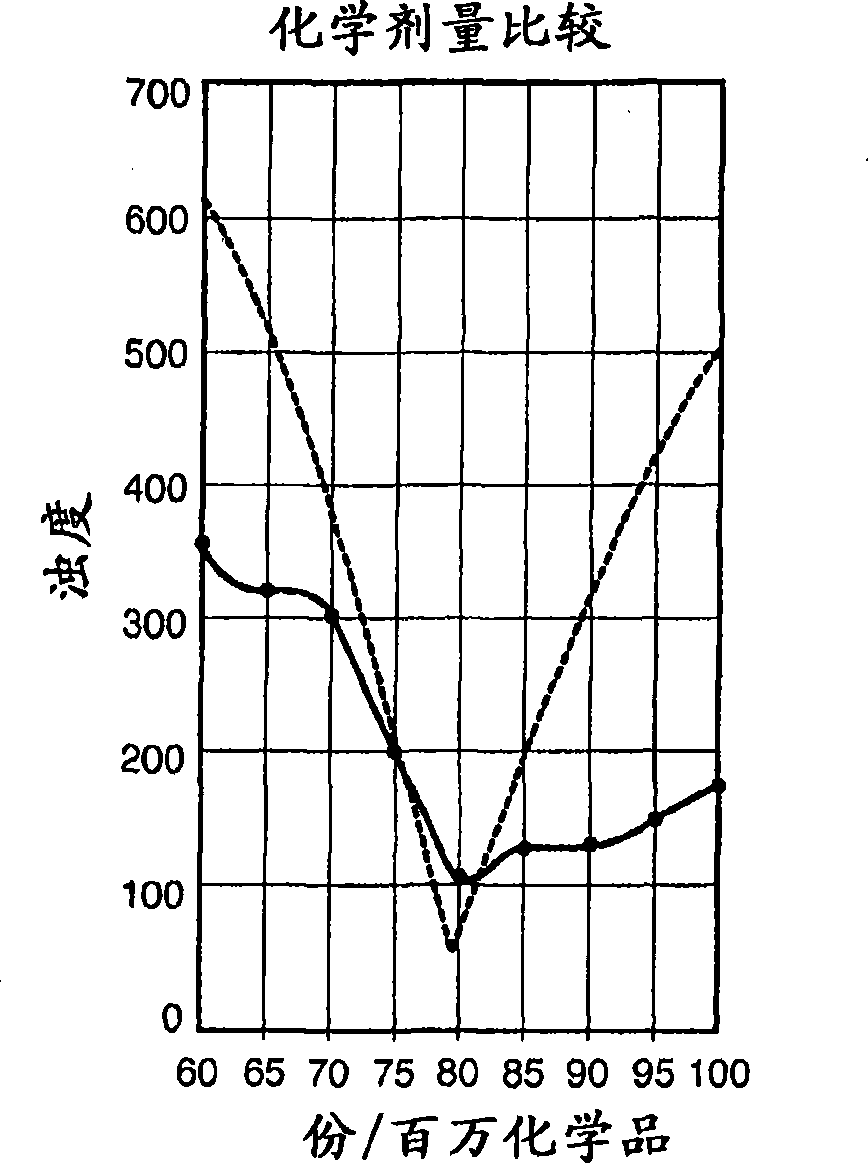

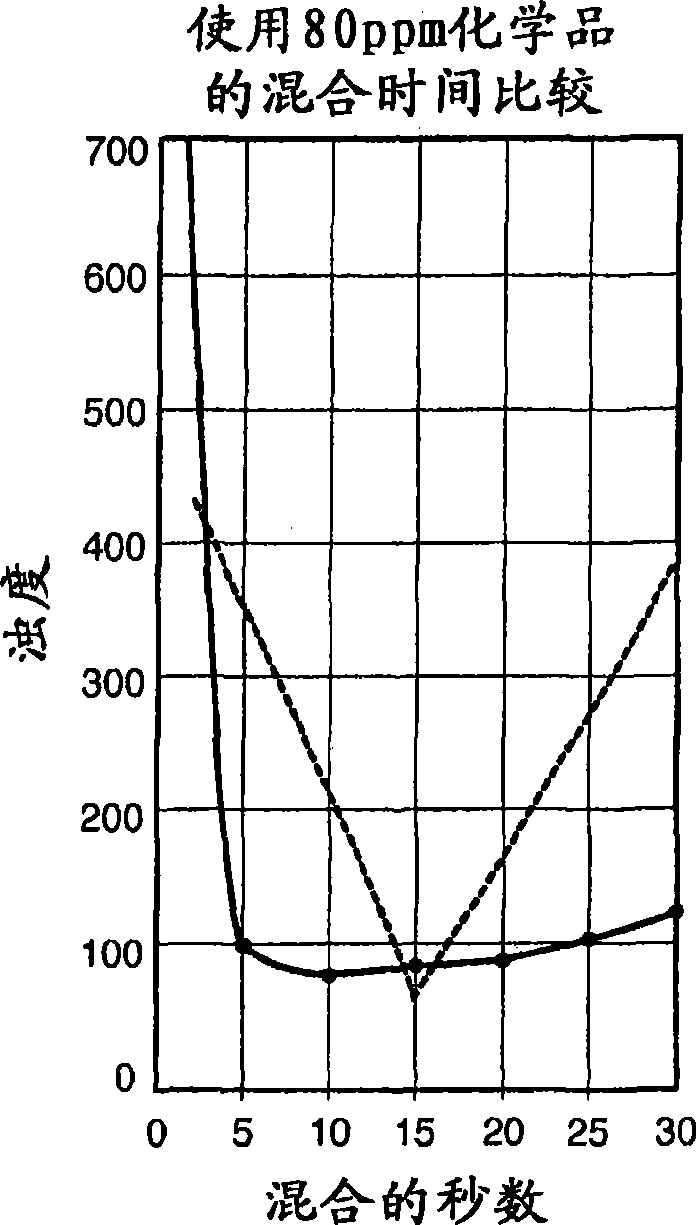

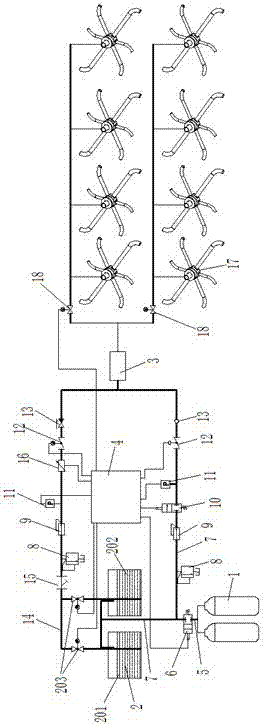

Control system and process for wastewater treatment

InactiveUS20080047903A1Effective positioningEasy to drainWater treatment parameter controlFlow mixersControl systemWastewater

A system and process is provided for optimizing chemical additions, mixing energy, mixing time, and other variables while treating a contaminated liquid stream. Samples from the contaminated liquid stream are tested to determine the optimal parameter for each variable, including type and amount of the chemicals to be added, chemical sequence, mixing energy, mixing time, temperature, and pressurization. A system of mixers, a flotation chamber, and a dewatering subsystem are designed to achieve optimal turbidity of the wastewater stream. The system can be modified in real-time in response to a continually changing contaminated liquid stream via a controller and set of sensors, valves, and ports.

Owner:WORLD WATER TECH

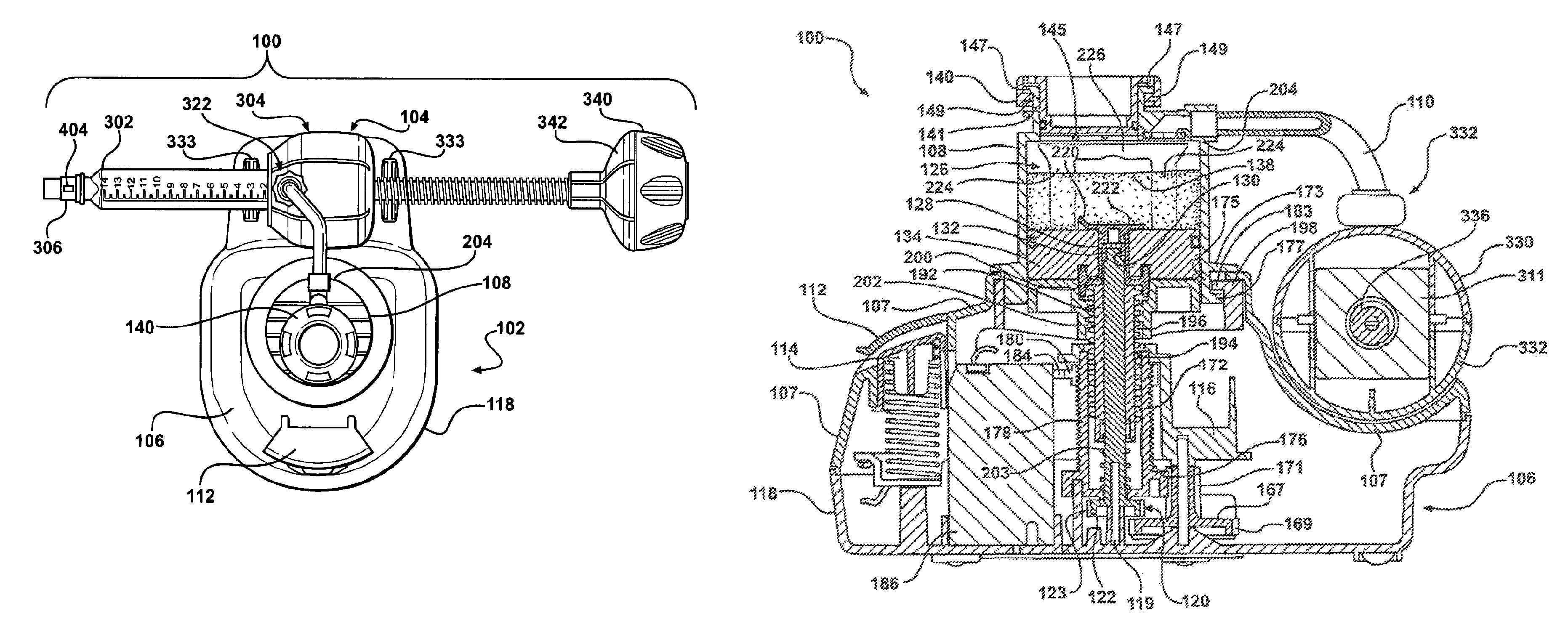

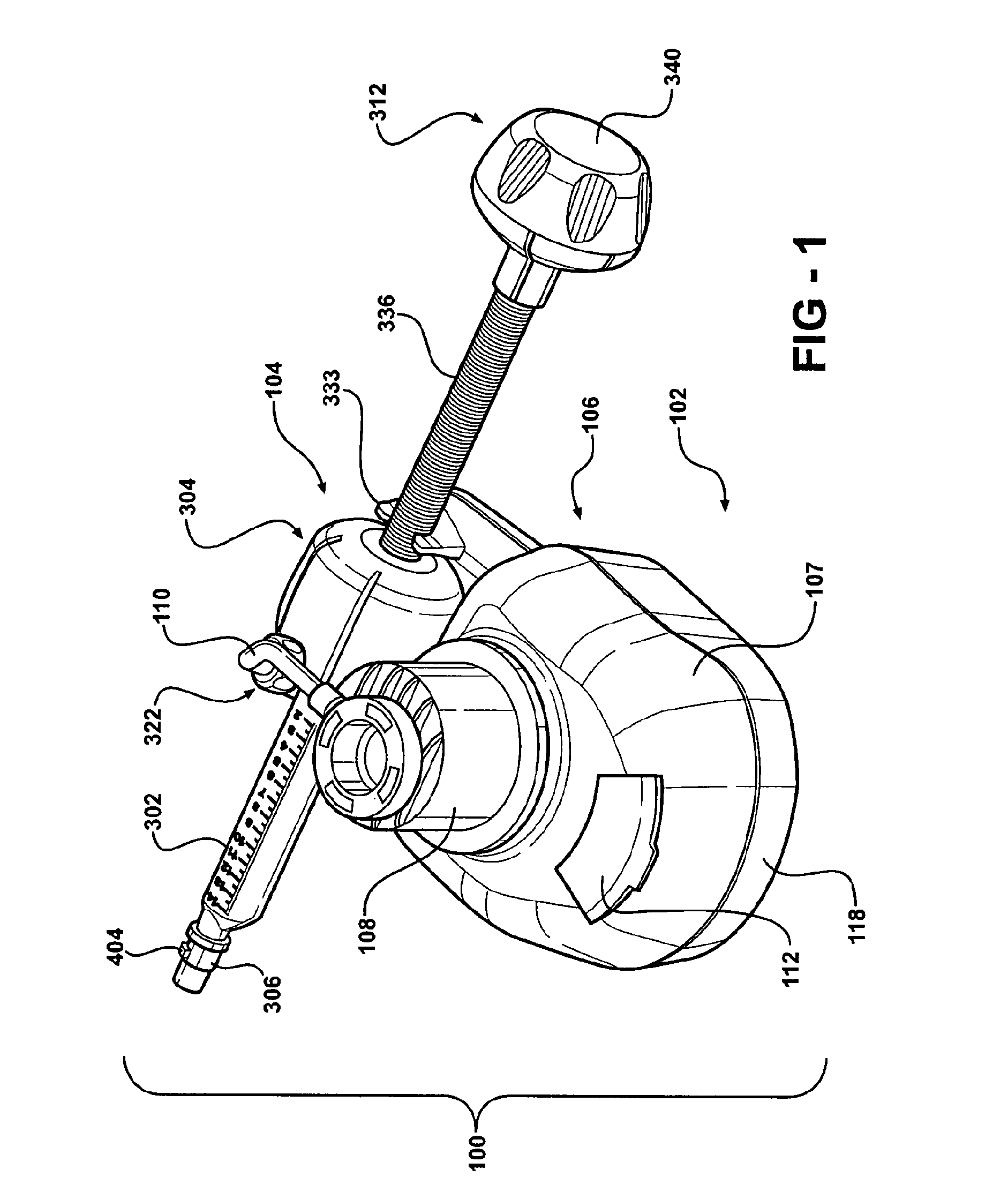

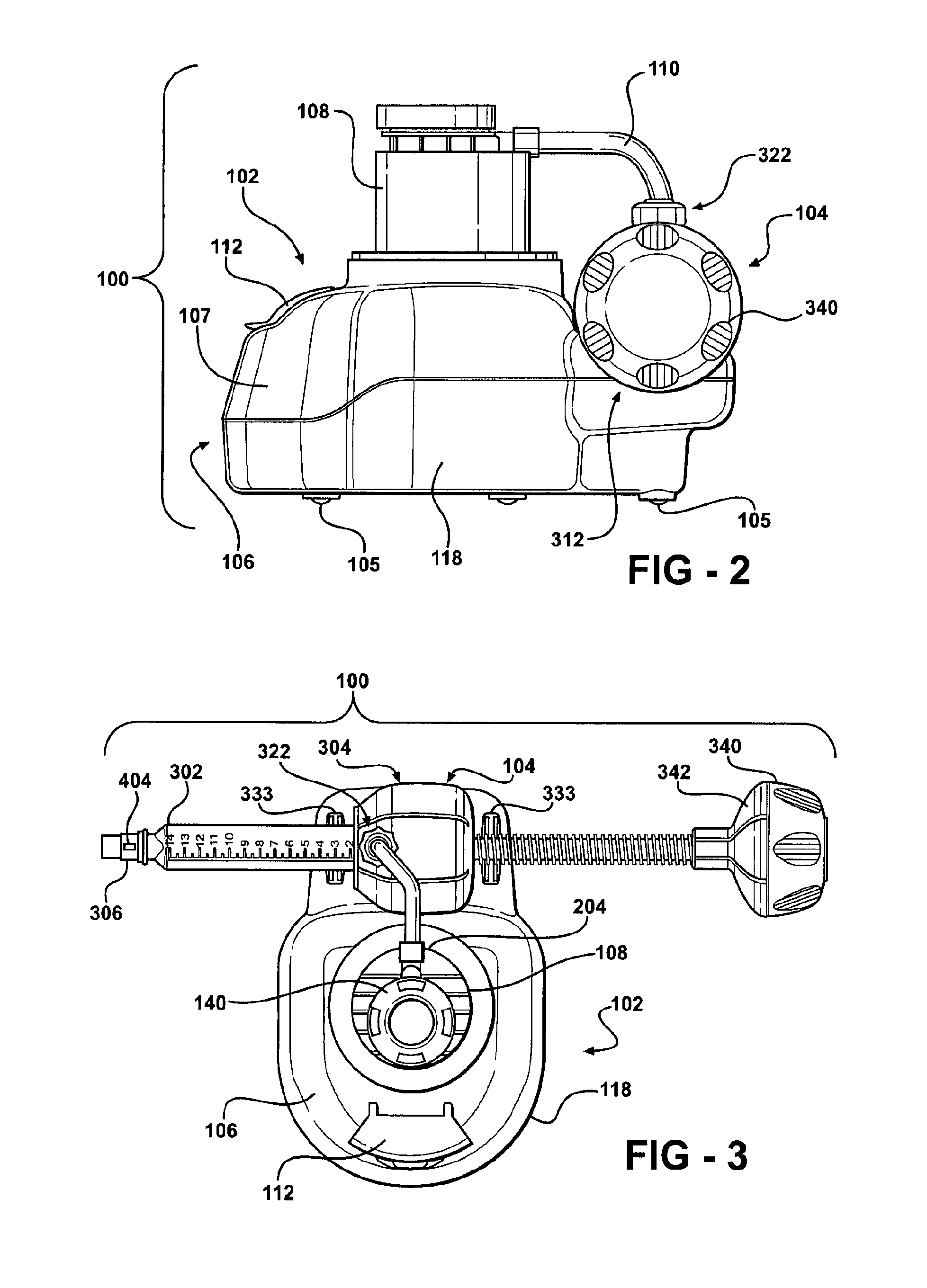

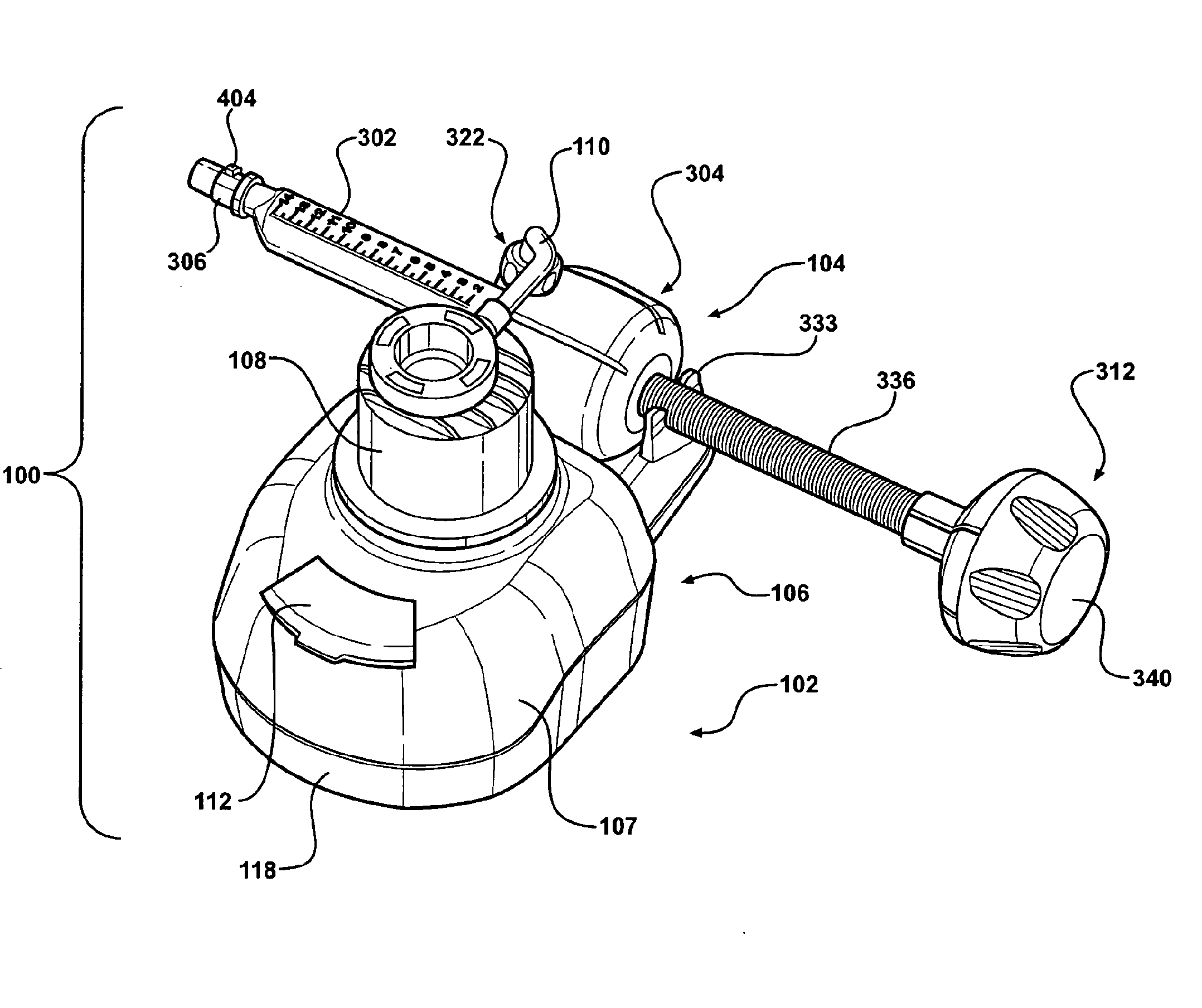

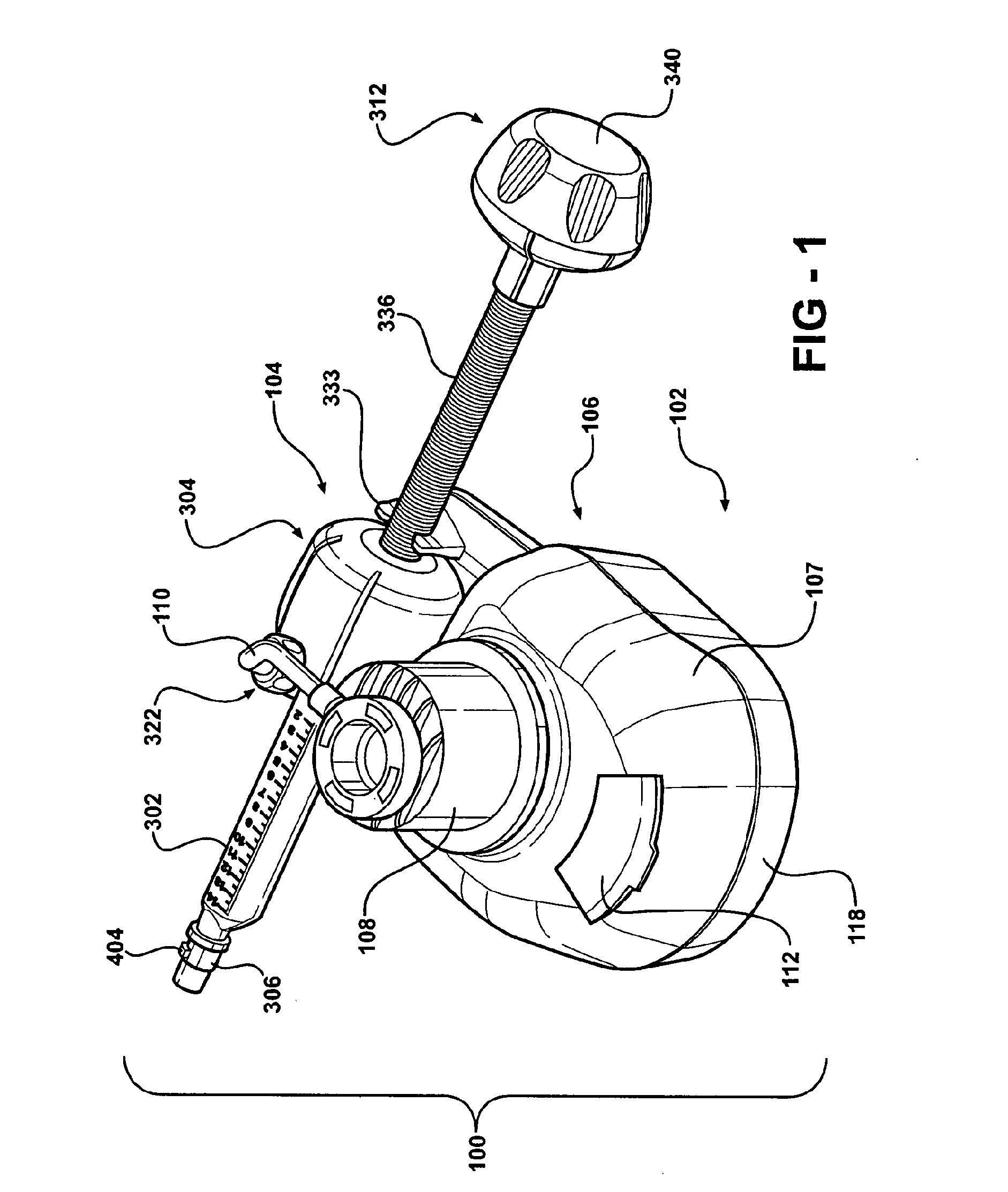

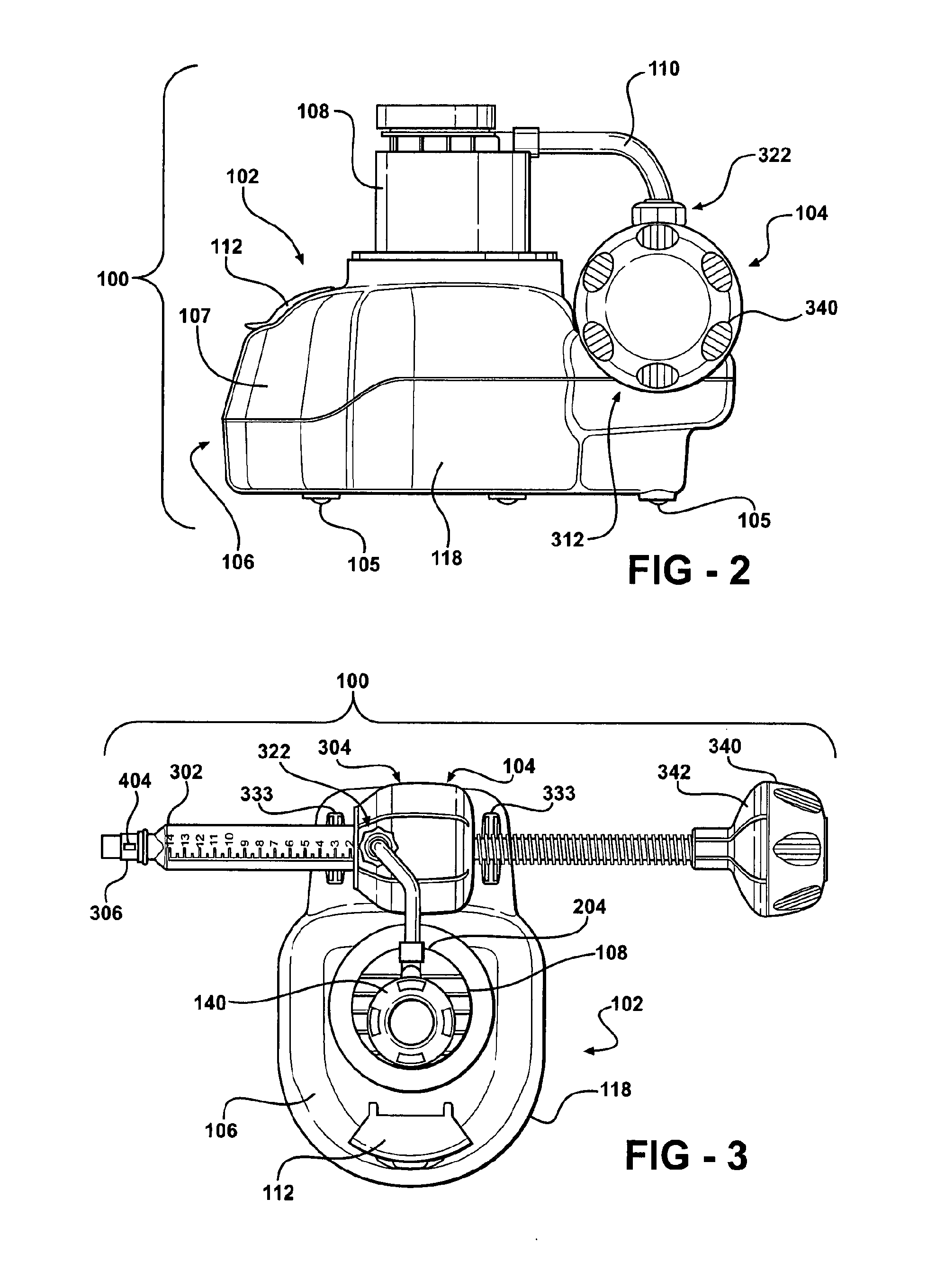

Bone cement mixing and delivery system with automated bone cement transfer between mixer and delivery device

ActiveUS7658537B2Reduce interactionSpeed up preparationRotating receptacle mixersRotary stirring mixersEngineeringTransfer mechanism

A bone cement mixing and delivery system is provided in which separate components of bone cement are mixed together in a mixer to form a bone cement mixture. The mixer includes a mixing paddle and a mixing shaft connected to the mixing paddle. A motor operatively engages the mixing shaft to rotate the mixing shaft and the mixing paddle to mix the components in a mixing chamber. The motor also operatively engages a transfer mechanism. After a predetermined mixing period has elapsed, the motor automatically actuates the transfer mechanism to transfer the mixture to a delivery device. The mixture is then delivered to a target site, such as a vertebral body of a patient or other anatomical site.

Owner:STRYKER CORP

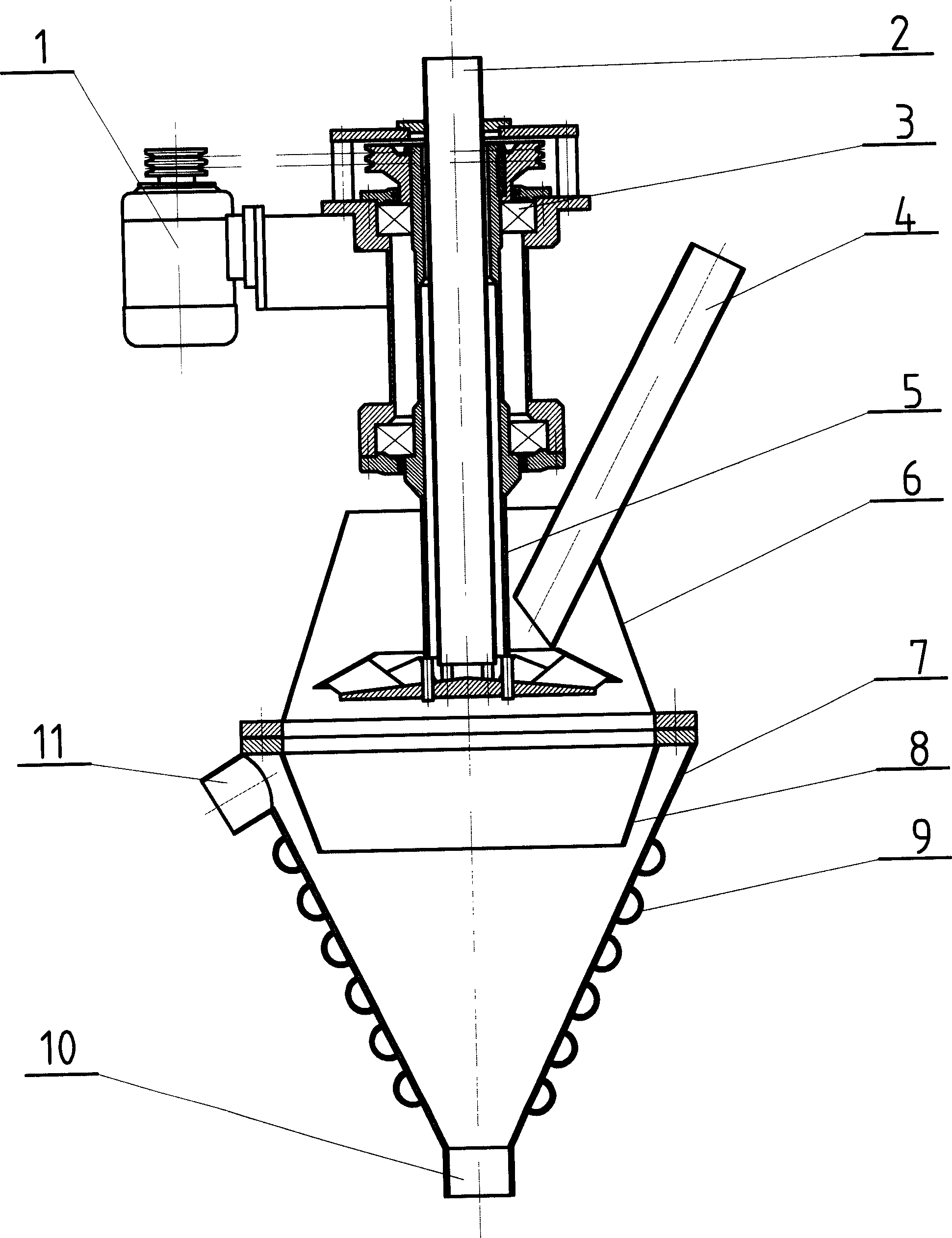

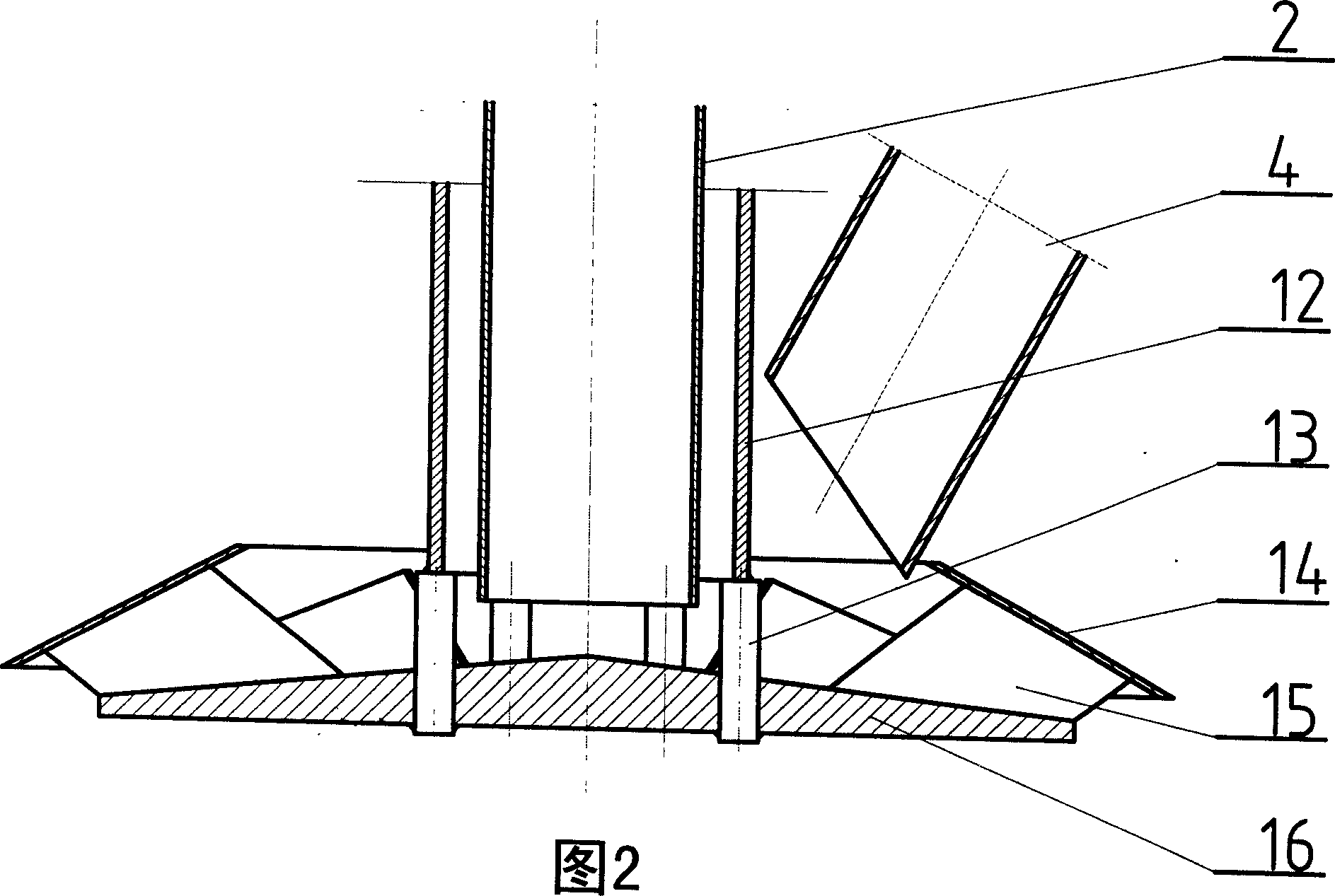

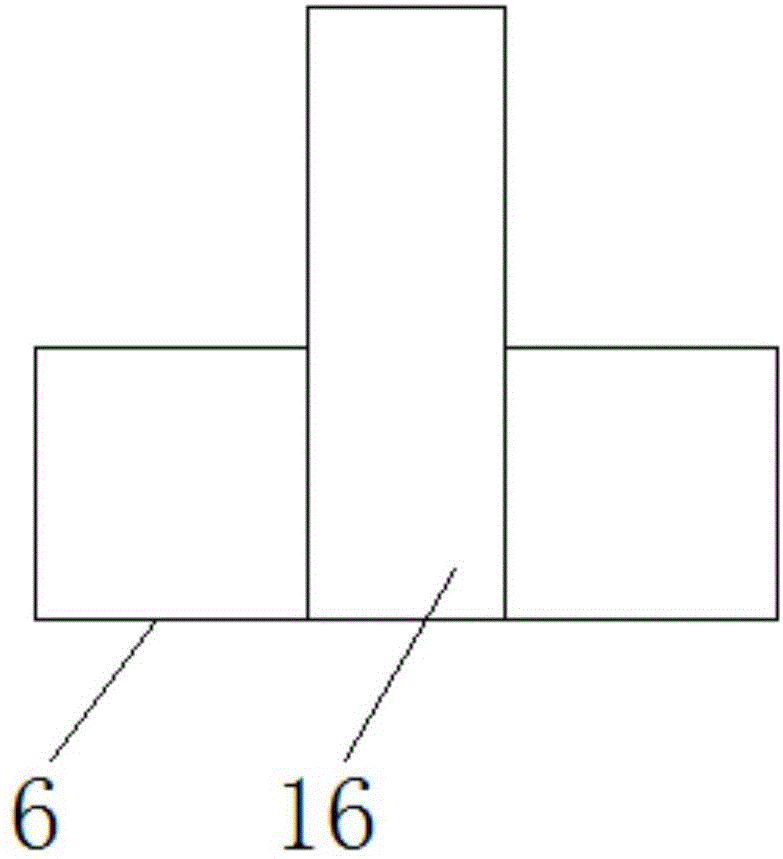

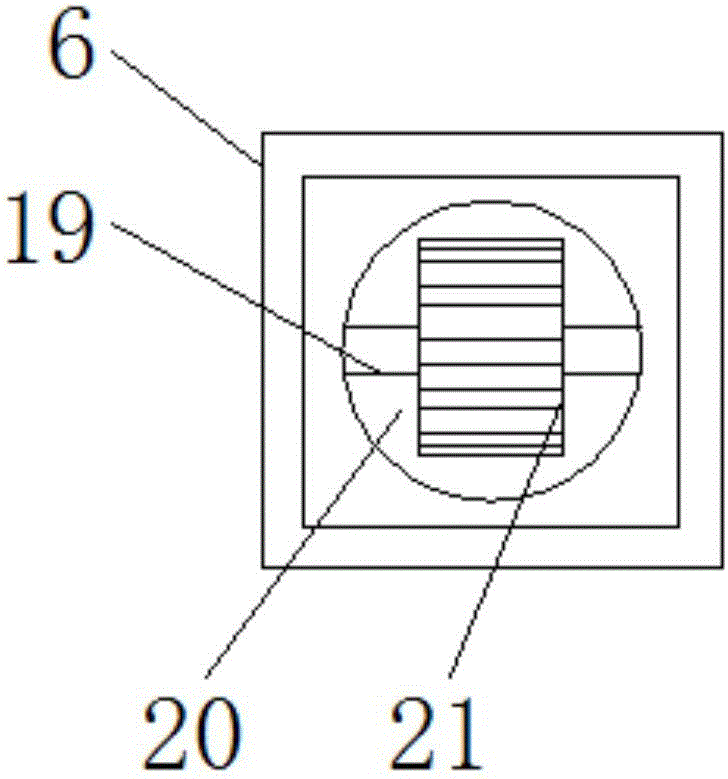

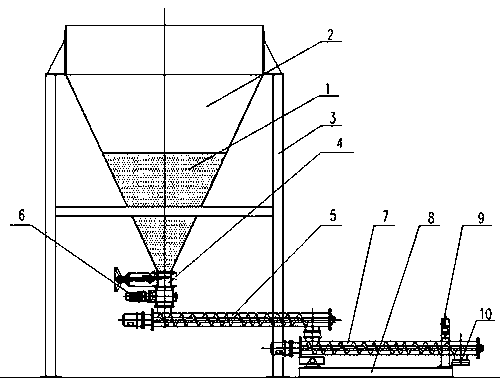

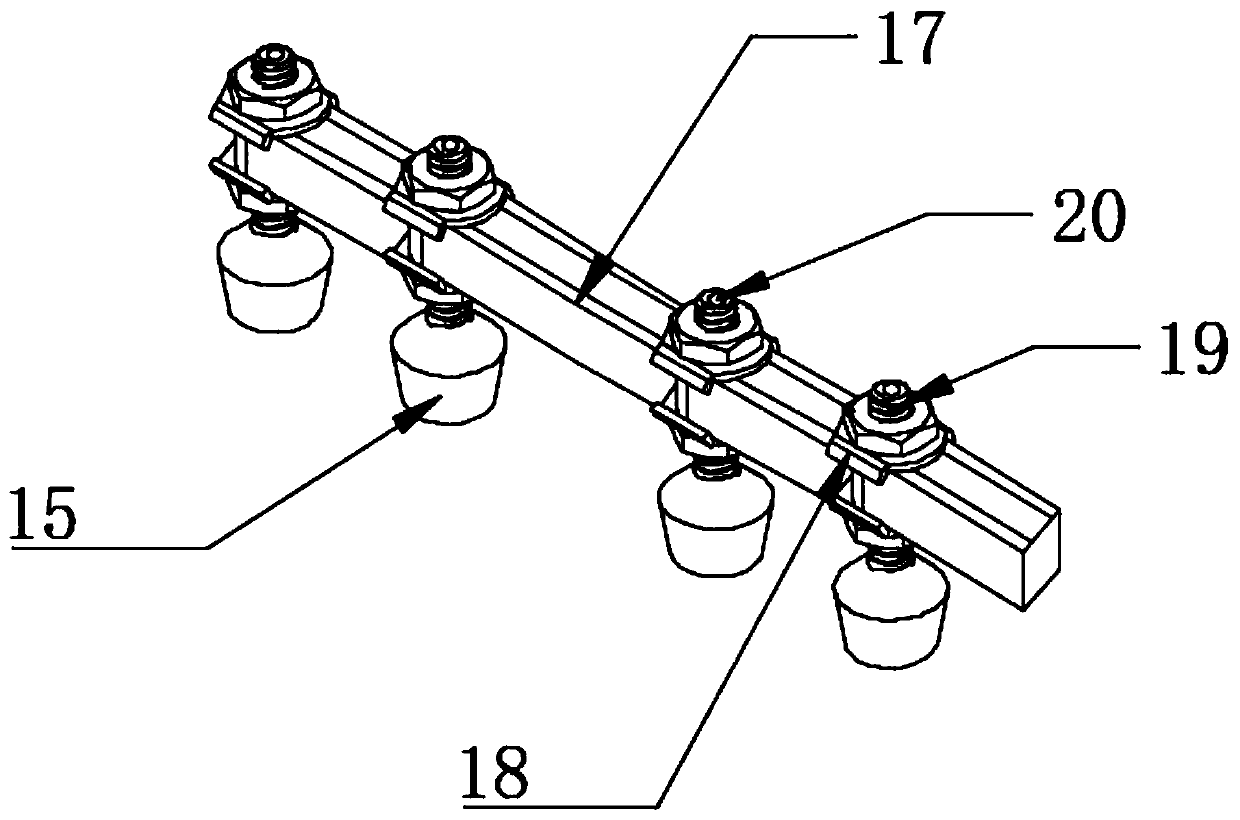

Apparatus for quickly mixing chemical melt and solid powder

InactiveCN1721051AAvoiding Agglomerate ProblemsParticle cavitation containmentFlow mixersTransportation and packagingEngineeringBlend time

Quick mixture device for chemical fuse-elements and solid power comprises mixture slot composed with fixed truncated cone upper mixed cone table laid narrow-end-up and lower mixed cone table laid narrow-end-down, and mixture impeller expended into and connected with the mixture table; discharge port; shaft extended into slot and drove by motor and gear mechanism; and inlet pipes for liquid and power expended and feed raw material into mixture impeller to make it rotate and finish the forced mixture depended on centrifuging motion. This invention can mix the raw material quickly and fully, and avoid the generation of new solid suspended matter.

Owner:SHANDONG HOLLY PHARM CO LTD

Bone cement mixing and delivery system with automated bone cement transfer between mixer and delivery device and method of mixing and automated transfer of bone cement between mixer and delivery device and method of mixing and automated transfer of bone cement between mixer and delivery device

ActiveUS20090257306A1Minimize weightLow costRotating receptacle mixersRotary stirring mixersBlend timeTransfer mechanism

A bone cement mixing and delivery system is provided in which separate components of bone cement are mixed together in a mixer to form a bone cement mixture. The mixer includes a mixing paddle and a mixing shaft connected to the mixing paddle. A motor operatively engages the mixing shaft to rotate the mixing shaft and the mixing paddle to mix the components in a mixing chamber. The motor also operatively engages a transfer mechanism. After a predetermined mixing period has elapsed, the motor automatically actuates the transfer mechanism to transfer the mixture to a delivery device. The mixture is then delivered to a target site, such as a vertebral body of a patient or other anatomical site.

Owner:STRYKER CORP

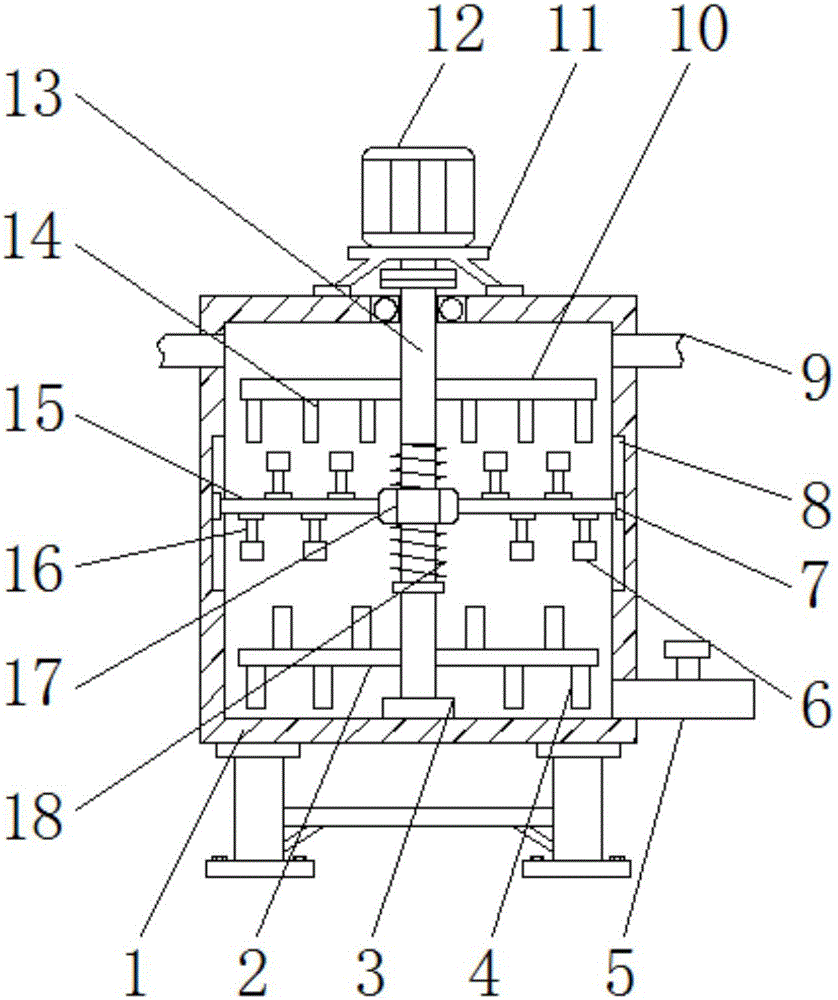

High-efficiency-stirring mixing device for chemical engineering

InactiveCN107433157AImprove stirring efficiencyEasy to useTransportation and packagingRotary stirring mixersBlend timeScrew thread

The invention discloses a high-efficiency-stirring mixing device for chemical engineering. The device comprises a box body, the tops at two sides of a box body inner cavity both communicate with a liquid inlet pipe, the bottom at the right side of the box body inner cavity communicates with a liquid outlet pipe, and the centers at the two sides of the box body inner cavity are separately provided with a sliding groove. According to the invention, stirring boxes, a forward / reverse rotation electrical machine, a stirring shaft, a connection rod, fixing rods, a thread sleeve, screw threads, fixing shafts, through holes and vane wheels are arranged in the device and are used in a cooperating manner, and a plurality of chemical mixed solutions can be stirred up and down, thus stirring efficiency of the mixing device for the chemical engineering is higher, problems that when a conventional mixing device for the chemical engineering is used, the conventional mixing device for the chemical engineering can just stir a plurality of the chemical mixed solutions left and right, and cannot stir a plurality of the chemical mixed solutions up and down and left and right at the same time, so that a condition that the uniform-mixing time of a plurality of the chemical mixed solutions is relatively long, and stirring efficiency of the conventional mixing device for the chemical engineering is relatively low are solved.

Owner:张家港保税区贤德国际贸易有限公司

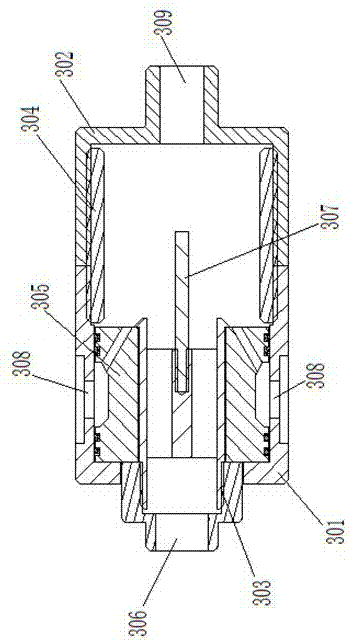

Fluid mixing method and device thereof

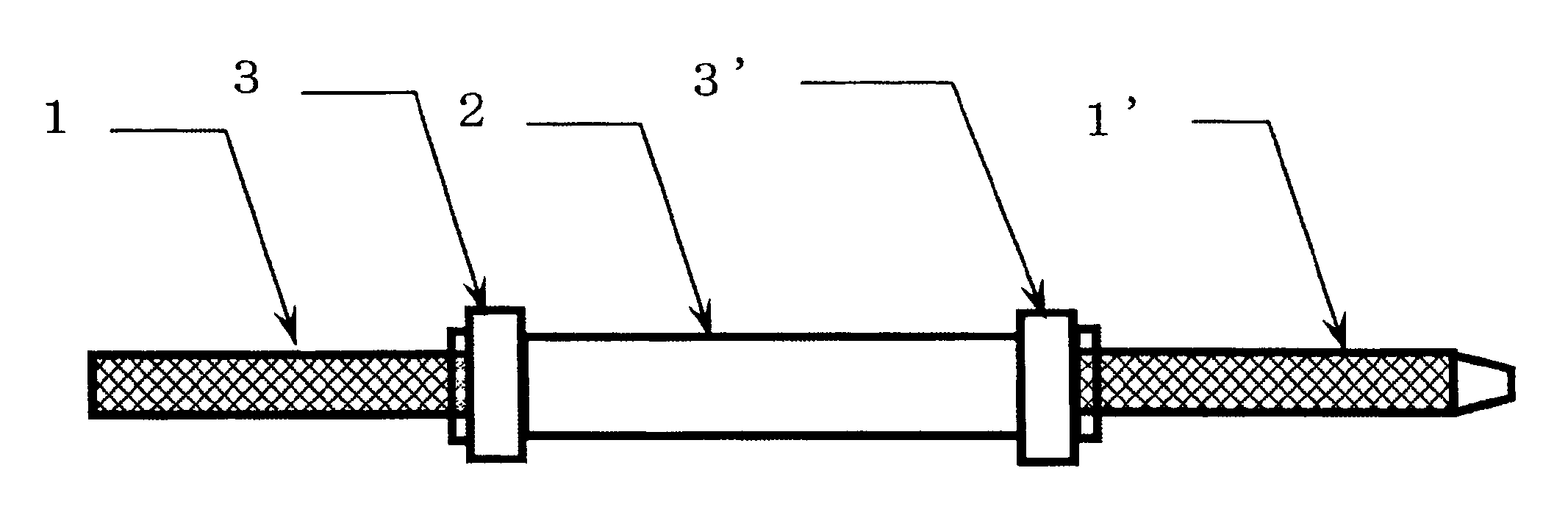

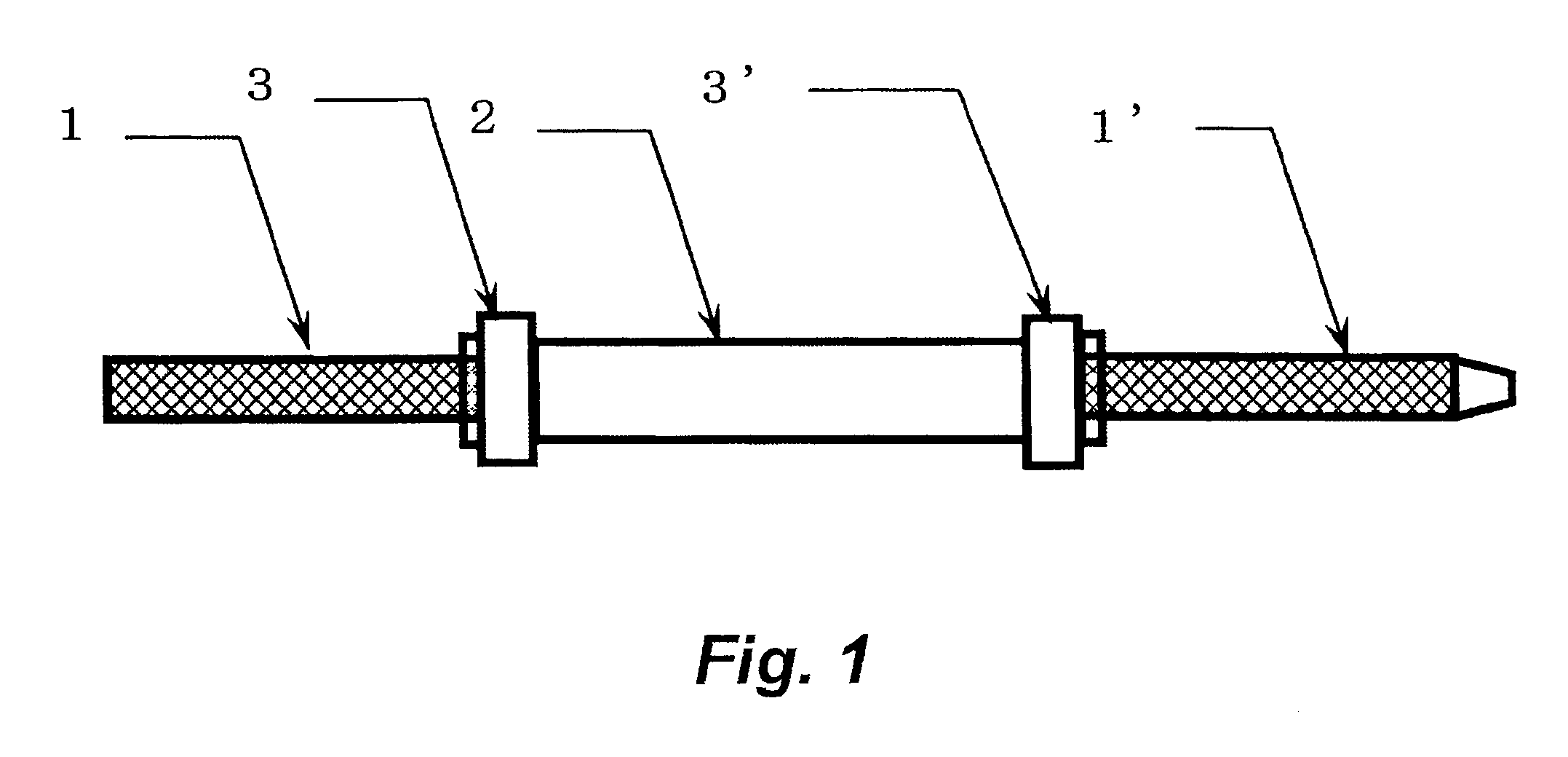

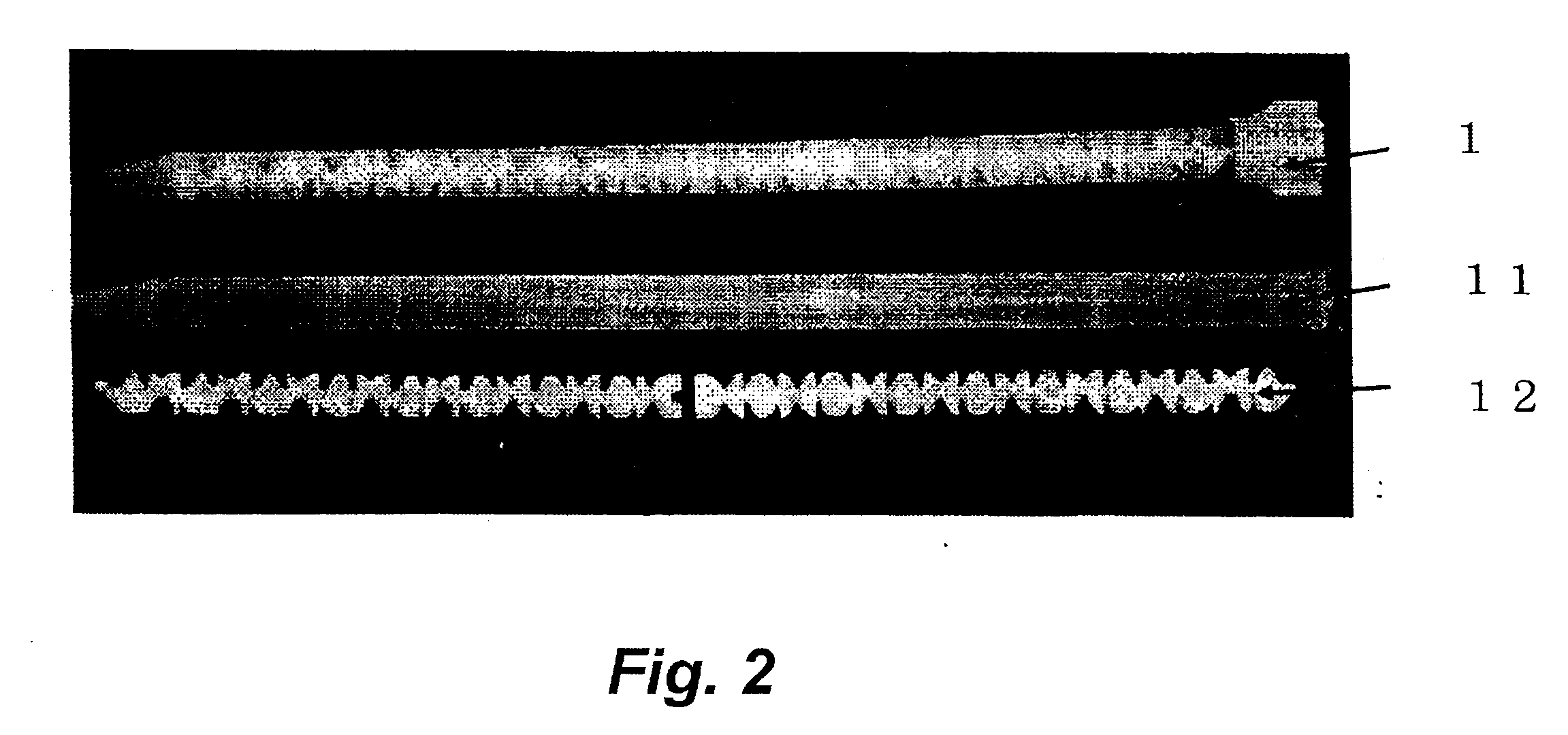

InactiveCN1456385AReduce consumptionFull macro mixShaking/oscillating/vibrating mixersCouplingEngineering

A fluid mixing method includes such steps as driving beater to rotate at high-speed, beating the rigid body of oscillator to generate high-frequency oscillation, and transferring the energy to two or more kinds of fluid around the rigid body to mix them together. Its equipment is composed of a beater consisting of flexible axle, axle coupling and beating head, and a rigid body of oscillator, which surrounds the high-speed beating head. Its advantages are short time and low energy consumption.

Owner:贡有成

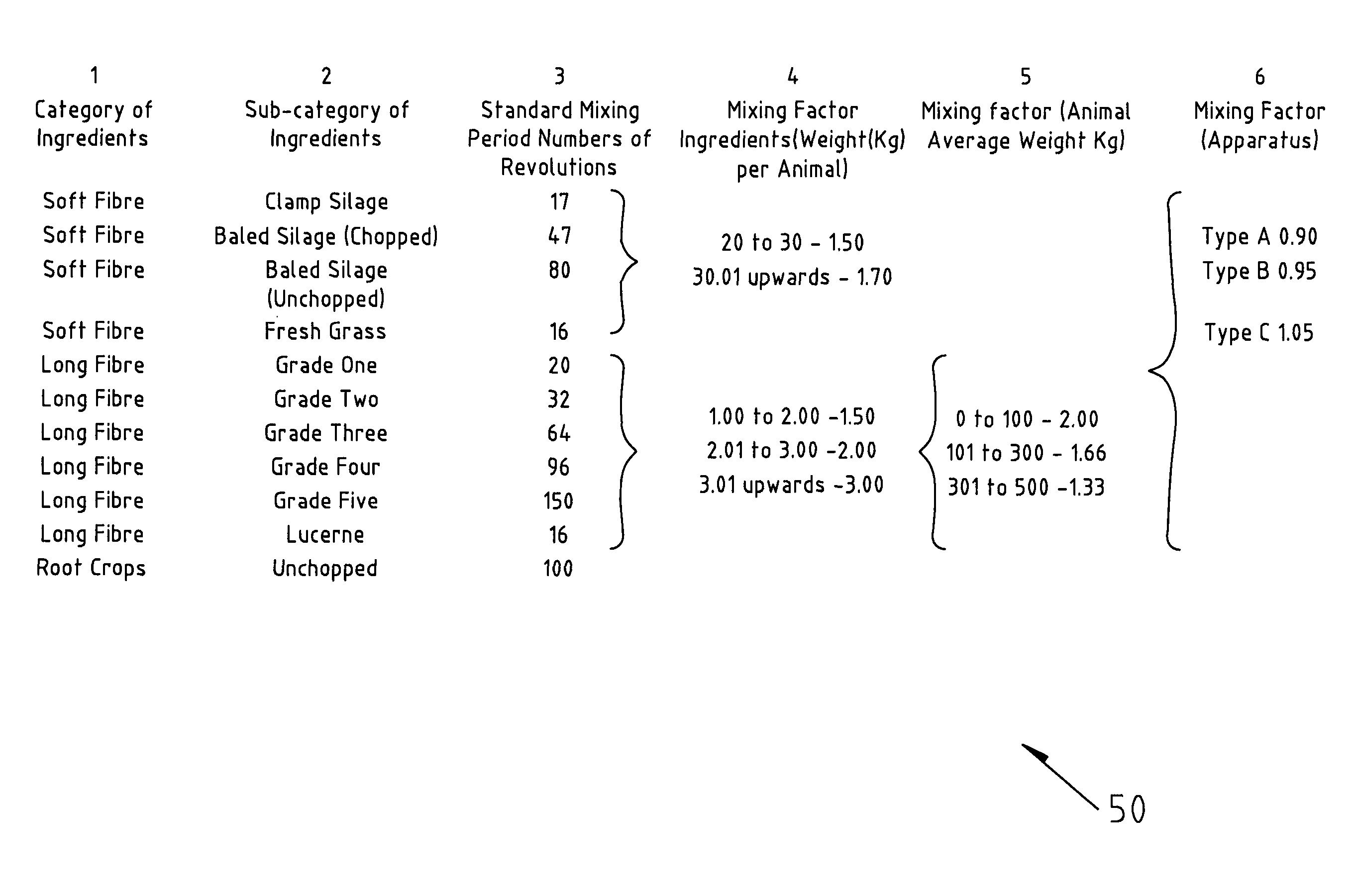

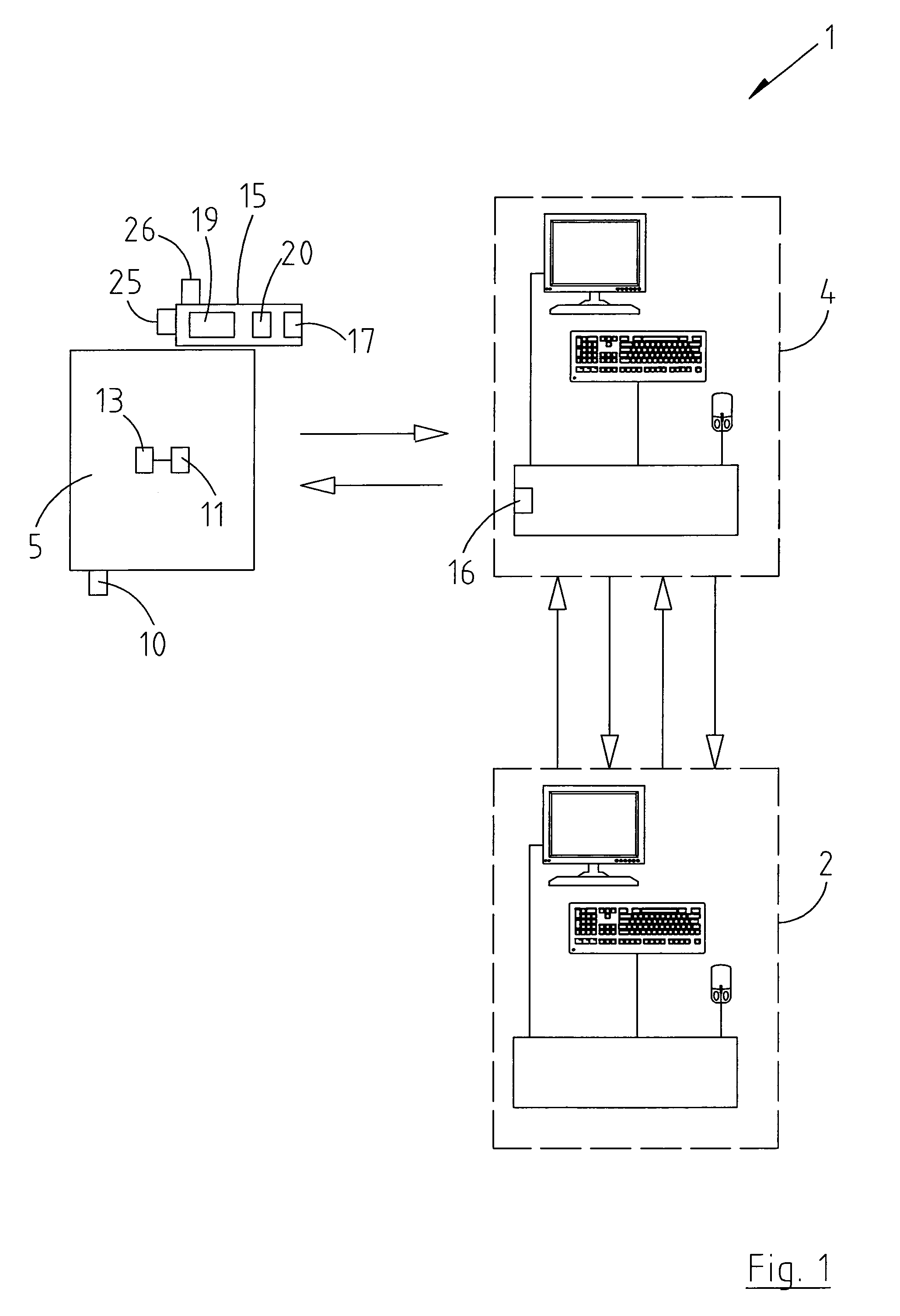

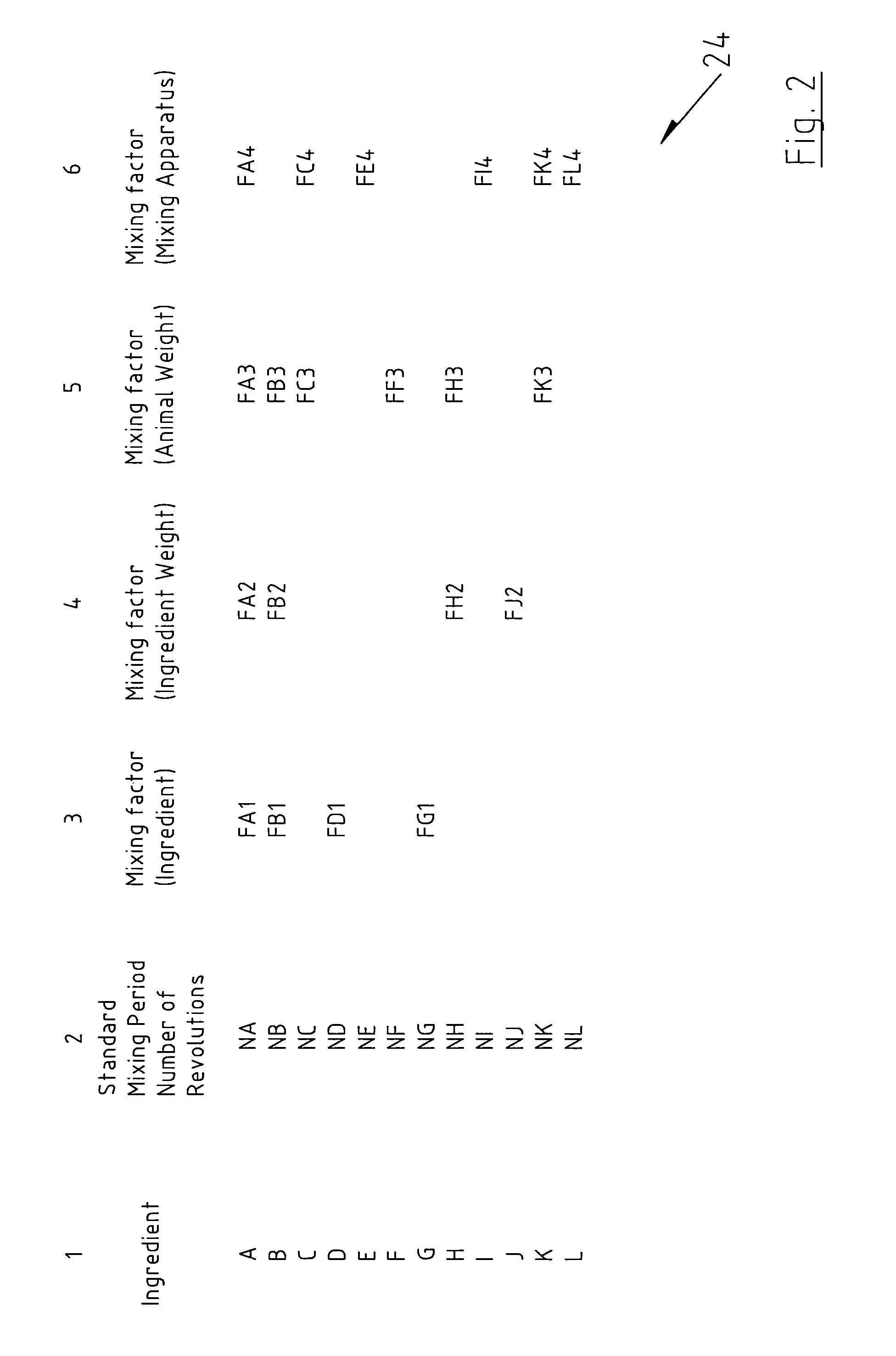

Method and apparatus for determining a mixing regime for use in the preparation of animal feed from a set of ingredients, and a system for producing the animal feed

ActiveUS8960996B2Optimal physical characteristicMaximize functionalitySampled-variable control systemsControlling ratio of multiple fluid flowsAdditive ingredientBlend time

A method and apparatus for determining a mixing regime for use in the preparation of an animal feed in which a main computer is programmed to store a master list of ingredients which are available to farmers and from which a farmer can select a specific set of ingredients for the preparation of animal feed. The main computer is programmed to store the ingredients in a look-up table cross-referenced with standard mixing periods to which the respective ingredients should be subjected during the mixing regime to produce an animal feed. Additionally, the look-up table contains mixing factors by which the standard mixing periods may be altered in order to take account of non-standard conditions, such as variations of the ingredients, the proportion of the particular ingredient, the average size or weight of the animals and the mixing apparatus and condition thereof in which the animal feed is to be mixed. The computer is programmed to determine the mixing period to which each ingredient is to be subjected in the mixing apparatus based on the corresponding standard mixing periods and any mixing factors which should be taken into account. The computer is programmed to then produce a sequence in which the ingredients are to be loaded into the mixing apparatus and the instants at which the respective ingredients are to be loaded into the mixing apparatus, so that each ingredient is subjected to the appropriate mixing period for that ingredient during the mixing cycle of the mixing regime, in order to avoid over-mixing and under-mixing of ingredients.

Owner:ALLTECH FARMING SOLUTIONS LTD

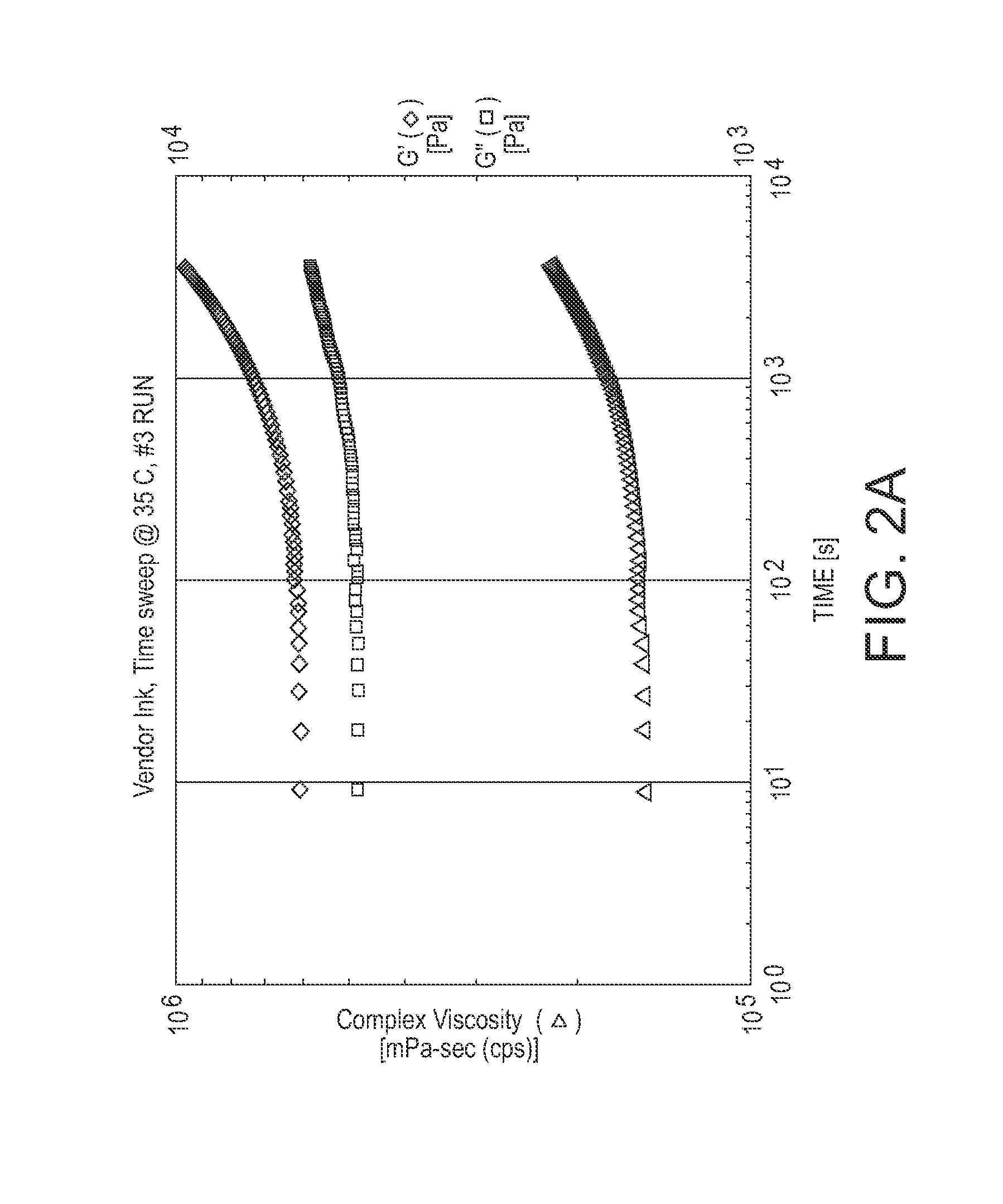

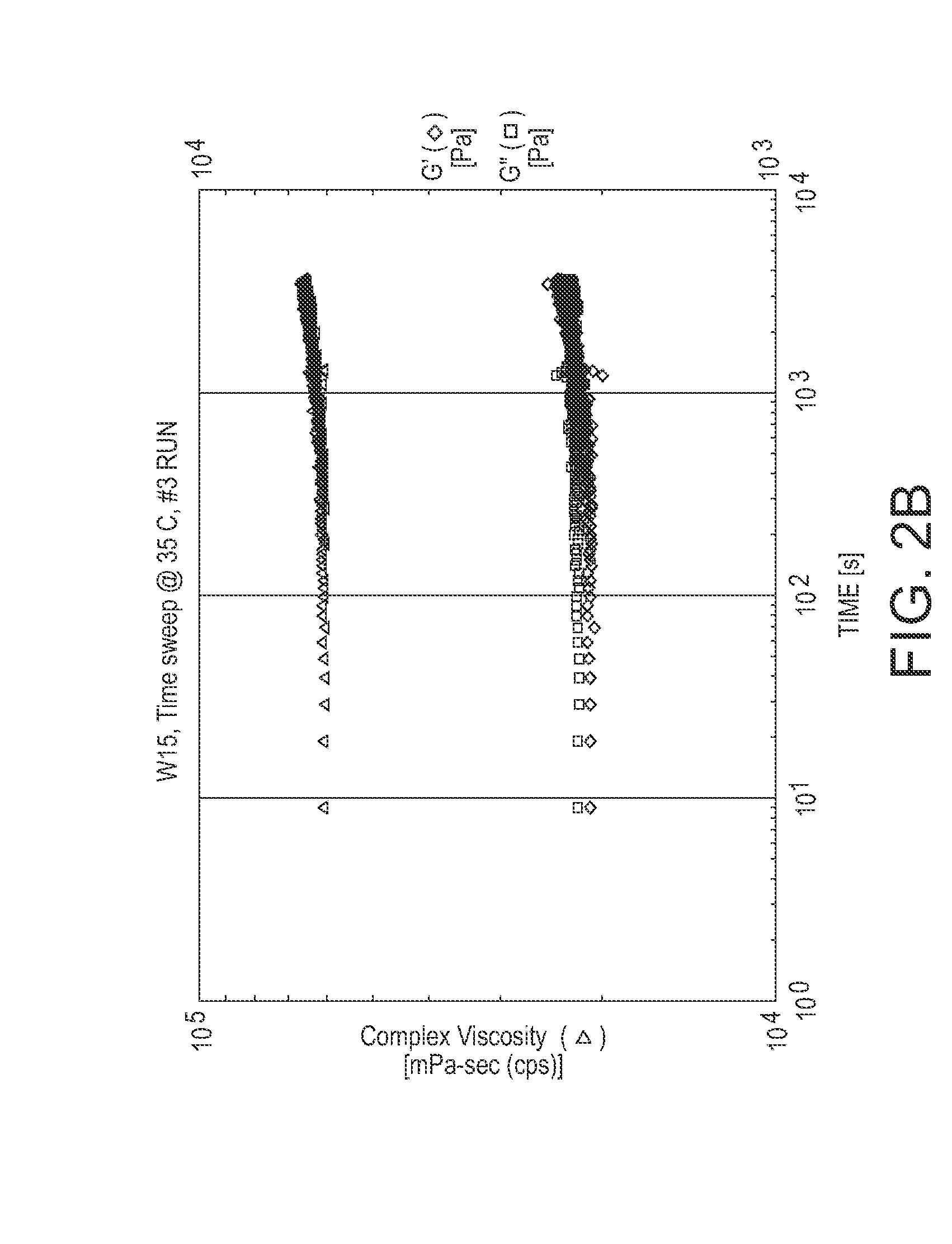

Methods for producing inks

Ink compositions are prepared by processes that include acoustically mixing a plurality of components at a resonance frequency. This encourages mixing of the components over a large range of viscosities with a minimal temperature rise and also shortens mixing time.

Owner:XEROX CORP

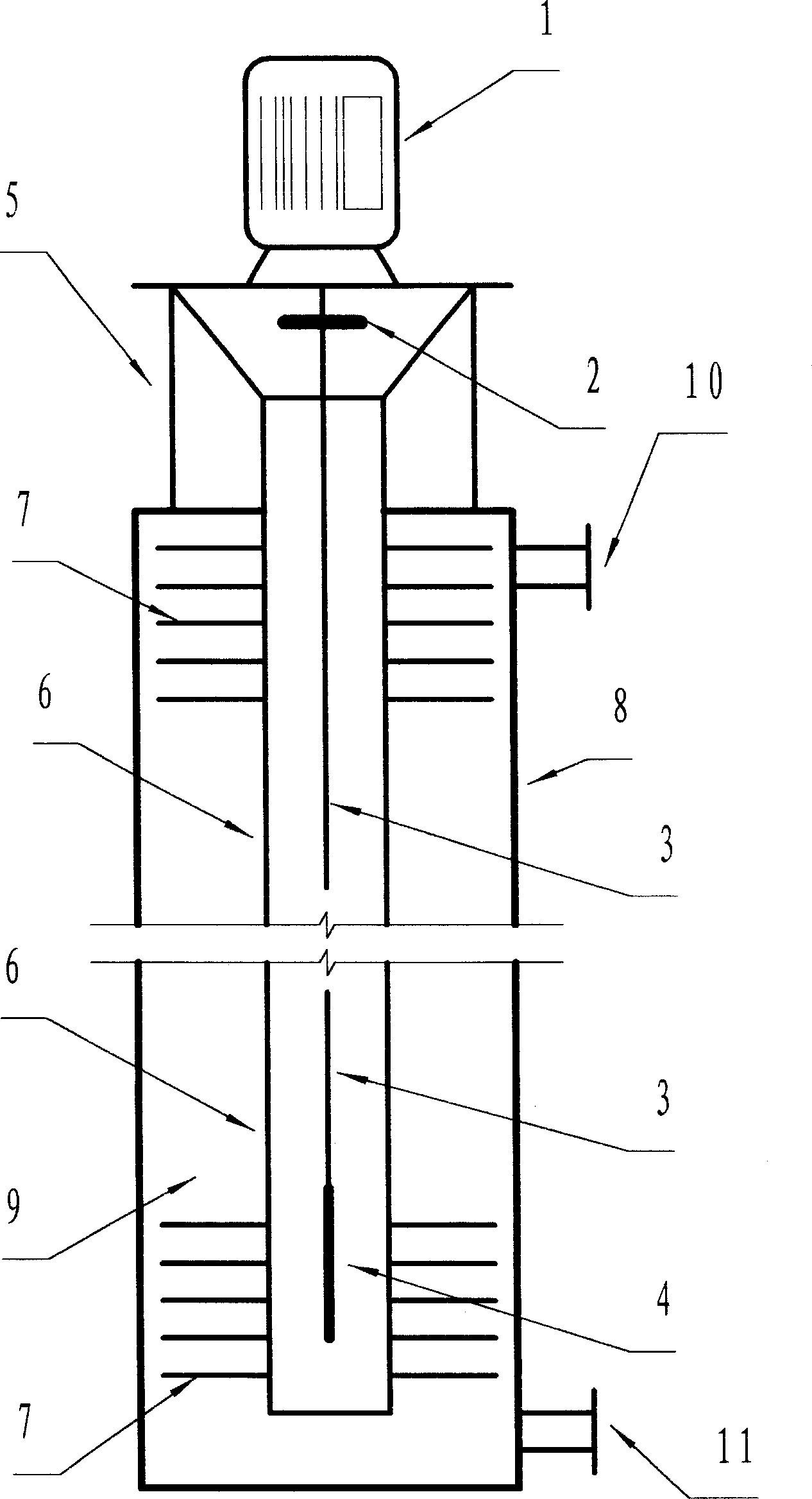

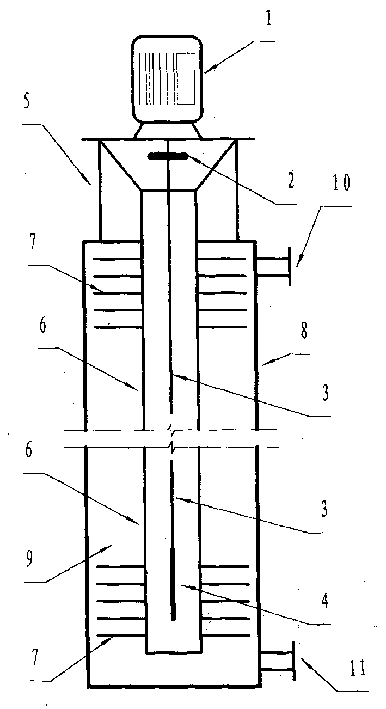

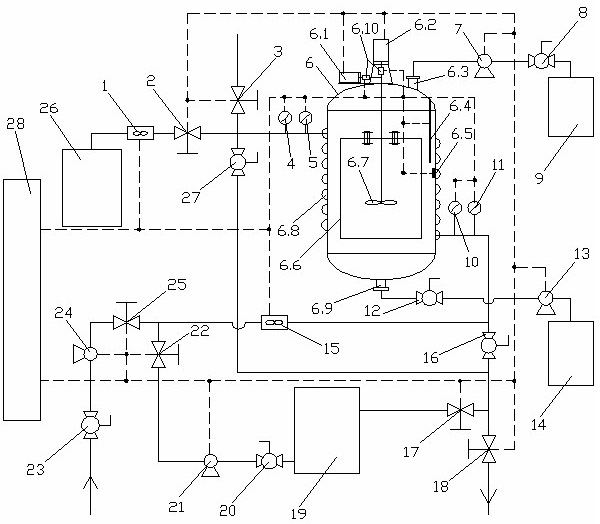

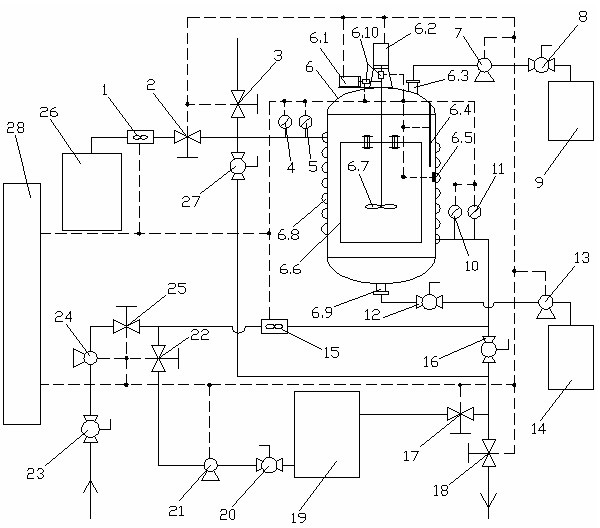

Performance test system of vertical type mechanical agitation equipment

InactiveCN102183379AProduce pollutionRealize automatic controlMaterial heat developmentStructural/machines measurementHeat conductingEngineering

The invention discloses a performance test system of vertical type mechanical agitation equipment. A spiral semicircular tube clamping sleeve is welded on the outer side of the agitation equipment; steam heating, heat conducting oil heating and cooling water cooling are realized by controlling a valve in a pipeline; a flow meter, a temperature meter and a pressure meter are arranged on an upper port and a lower port of the clamping sleeve; two driving systems are arranged at the upper end of the agitation equipment, so that dual-shaft agitation (having three motion modes, namely homodromous rotation, reverse rotation and single-shaft rotation) as well as frequency conversion and speed regulation are realized; torque sensors are arranged on agitation shafts at the output ends of two motors; a thermal resistance sensor is arranged on the surface of the inner wall of the agitation equipment; a thermocouple sensor is arranged in internal liquid; and the sensors are connected with a console. The performance test system can perform cold and hot die tests on low-viscosity fluid, middle-high-viscosity fluid, Newton fluid and non-Newton fluid under different operating parameters so as to obtain parameters such as a heat conducting coefficient, a mixing time, agitation power and the like, and evaluate the heat conducting performance, the mixing characteristic and the power consumption characteristic of various working conditions.

Owner:ZHEJIANG UNIV

Automatic control rubber mixing extruding device and control method

The invention discloses an automatic control rubber mixing extruding device and a control method. A reinforced rubber pre-mixing module is used for improving the machining quality of rubber mixing. Large rubber blocks are broken in a mechanical plastication room and are extruded through a pressing stone roller to enter a tablet press, tabletting is conducted through wheels, then slitting is conducted through a knife groove, finally, strips are cut into rubber particles through an automatic cutter, and even mixing is better facilitated through rubber refining. In addition, time and space are better saved through integrated design, a chemical throwing device conducts mobile batched scattering more evenly, the pre-mixing time is saved, a high-pressure water mist cooler is adopted in a cooling device of a mixing cylinder, compared with small force of cold air cooling and poor controllability of cold water cooling, the force of high-pressure water mist cooling is moderate, and regulation is convenient. In short, the automatic control rubber mixing and extruding device is reasonable in design, high in automation degree, high in production efficiency and high in machining quality.

Owner:WEIFANG UNIVERSITY

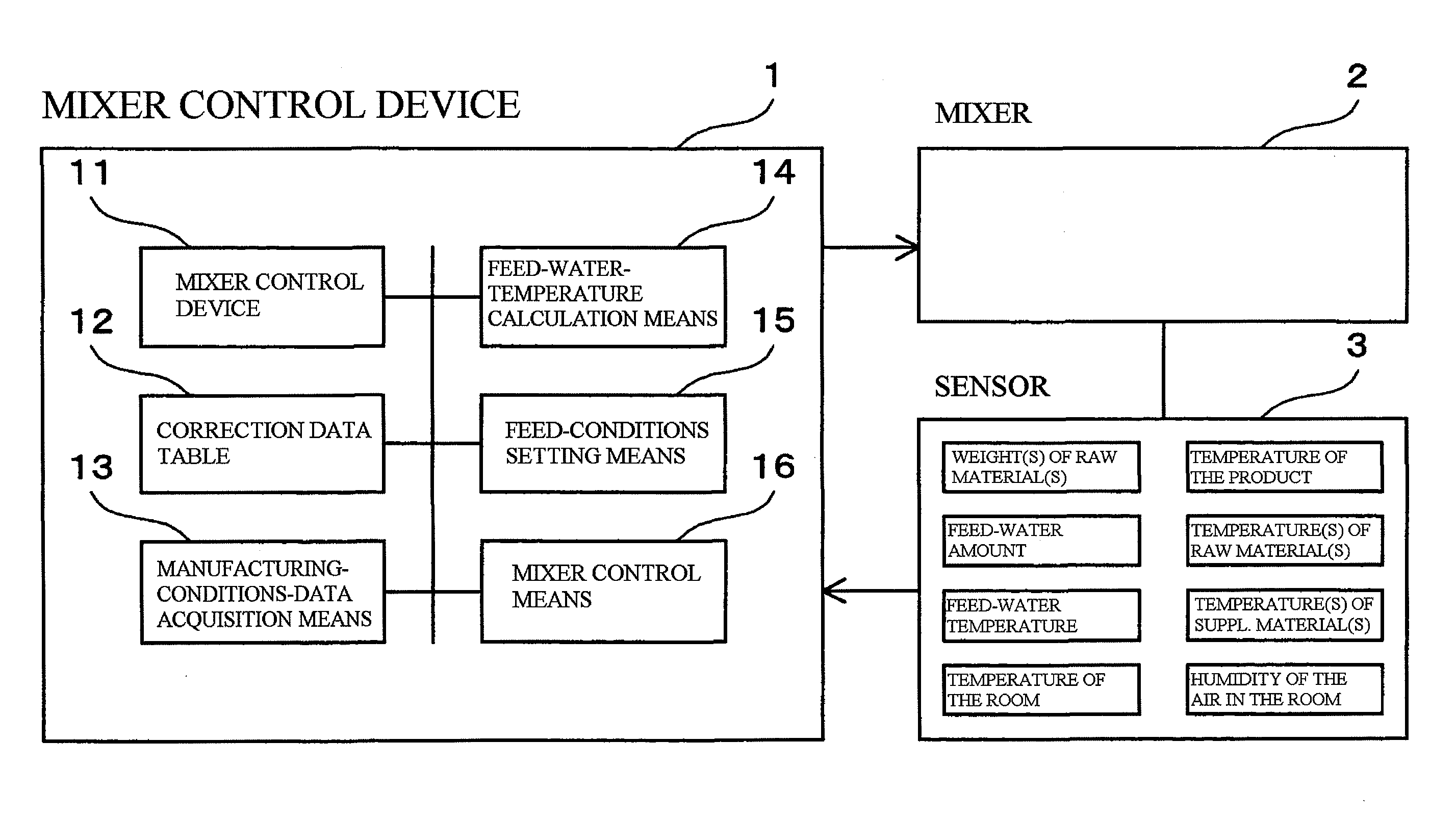

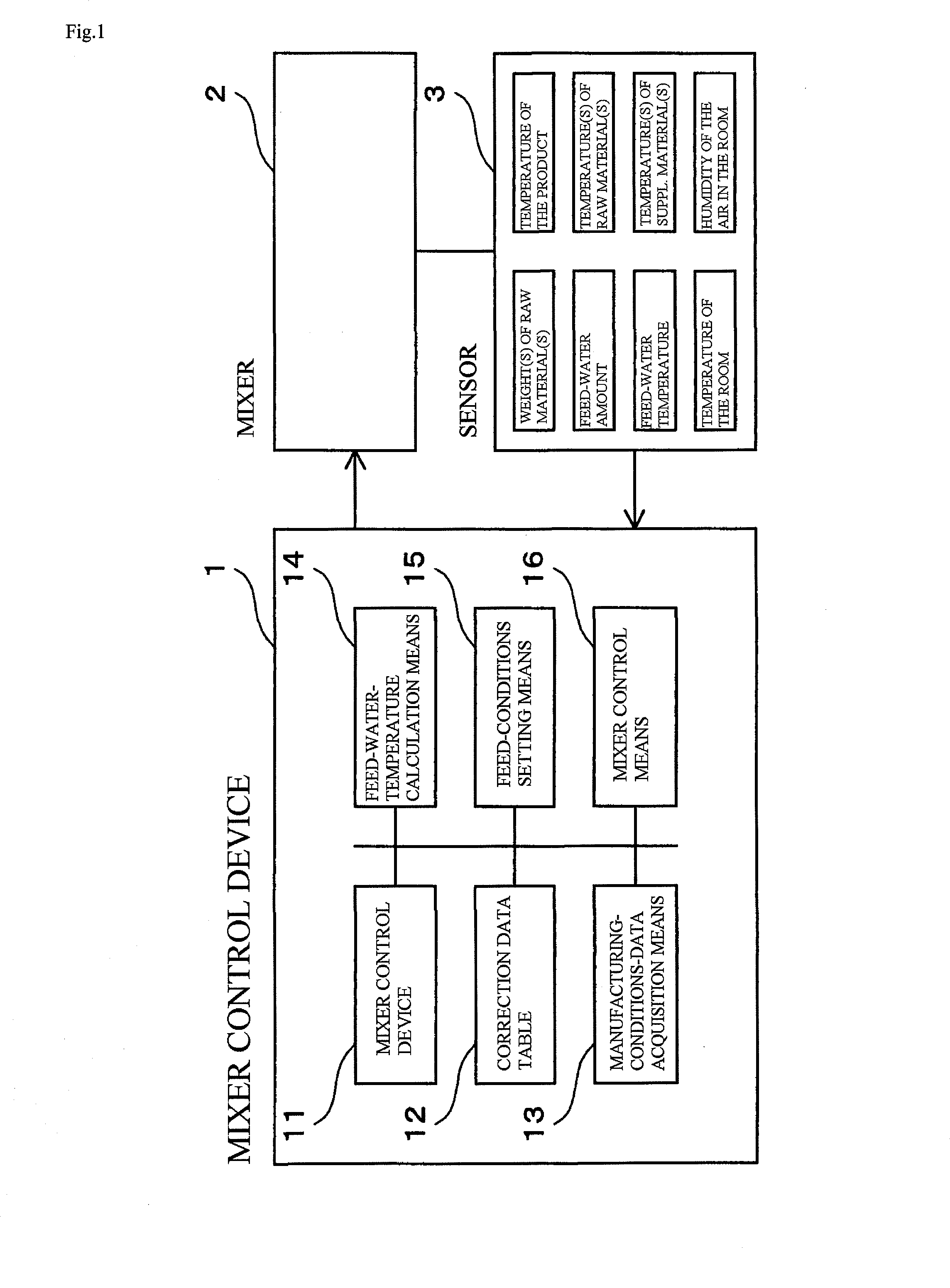

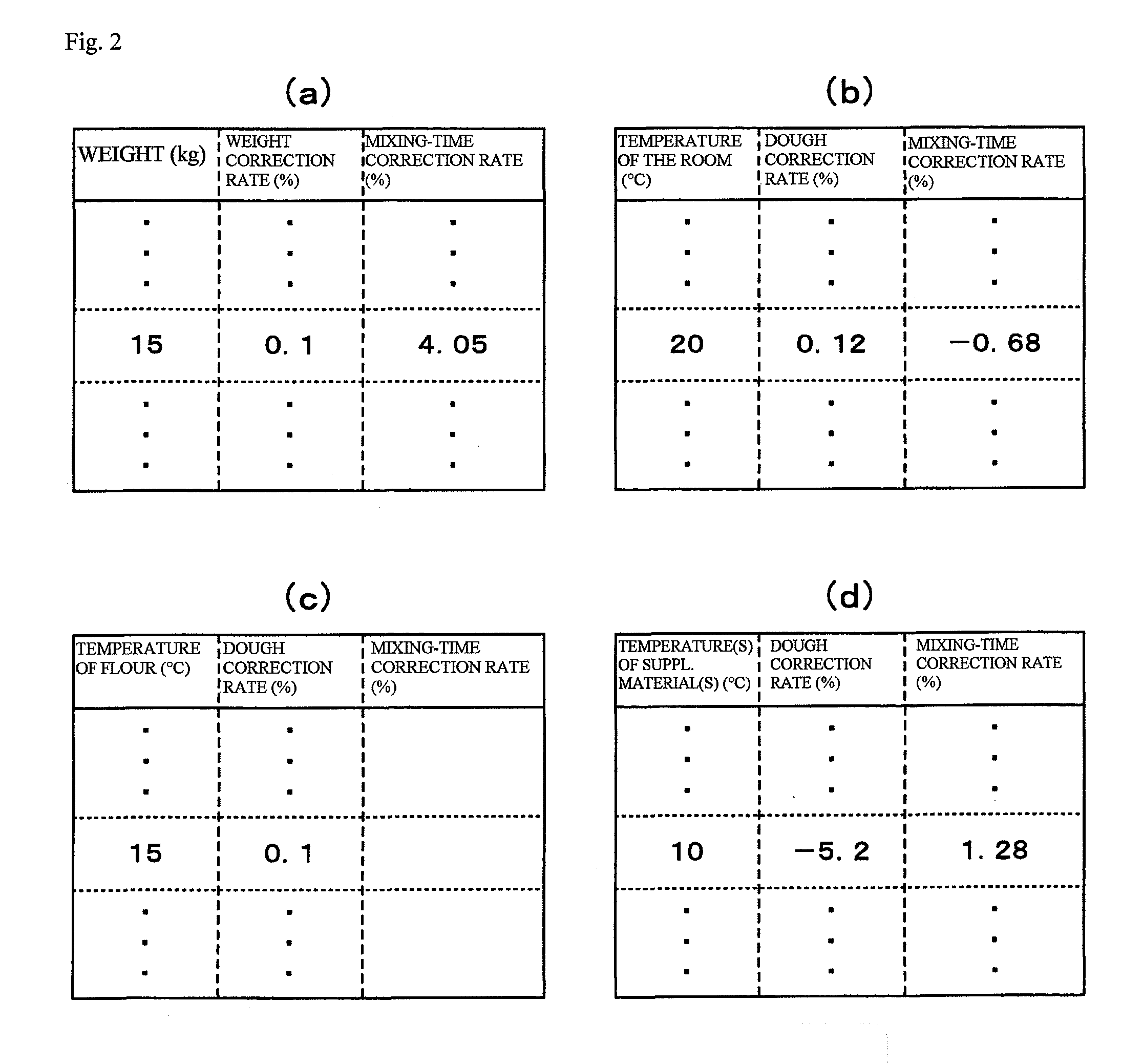

Mixer Control Device And System

InactiveUS20100061178A1Quality improvementRotary stirring mixersTransportation and packagingData acquisitionEngineering

A mixer control device capable of manufacturing products of consistent quality without skilled personnel is provided. Said mixer control device includes: (1) a sensor 3 for obtaining manufacturing-conditions data, including at least the temperatures of the raw materials, the temperature of the room in which the manufacturing occurs, and the temperature of the product being manufactured, along with changes in such manufacturing-conditions data; (2) a manufacturing-conditions-data acquisition means 13 for obtaining and maintaining the manufacturing-conditions data from said sensor; (3) correction data 12 for correcting the feed-water temperature based on said obtained manufacturing-conditions data; (4) a feed-conditions setting means 15 for setting the feed conditions, including at least the mixing time of the mixer and a product's feed-water temperature, according to the feed amounts of the raw materials based on said correction data; and (5) a mixer control means 16 for controlling said mixer, based on said feed conditions.

Owner:MIYAZATO YOSHIAKI +1

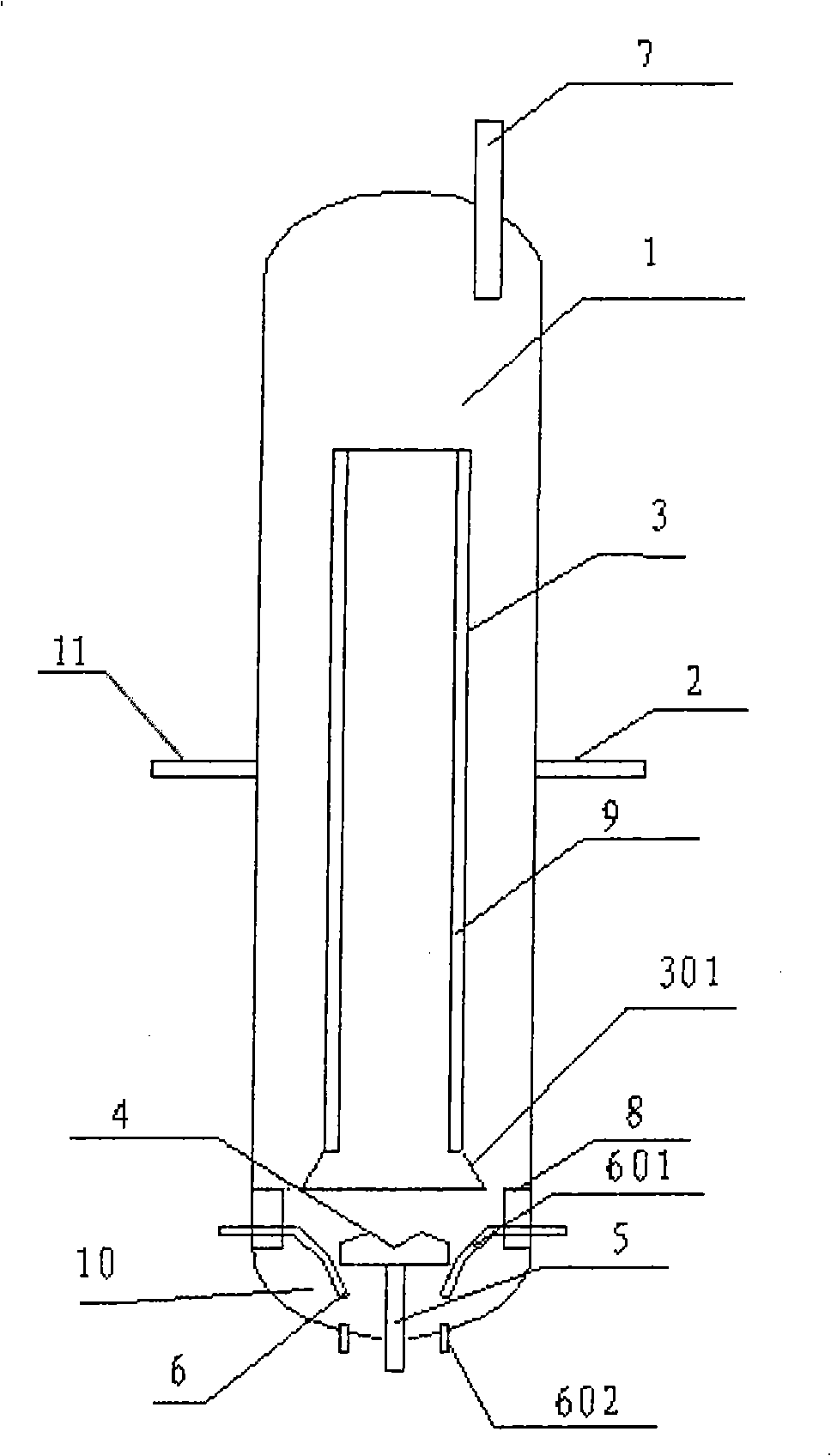

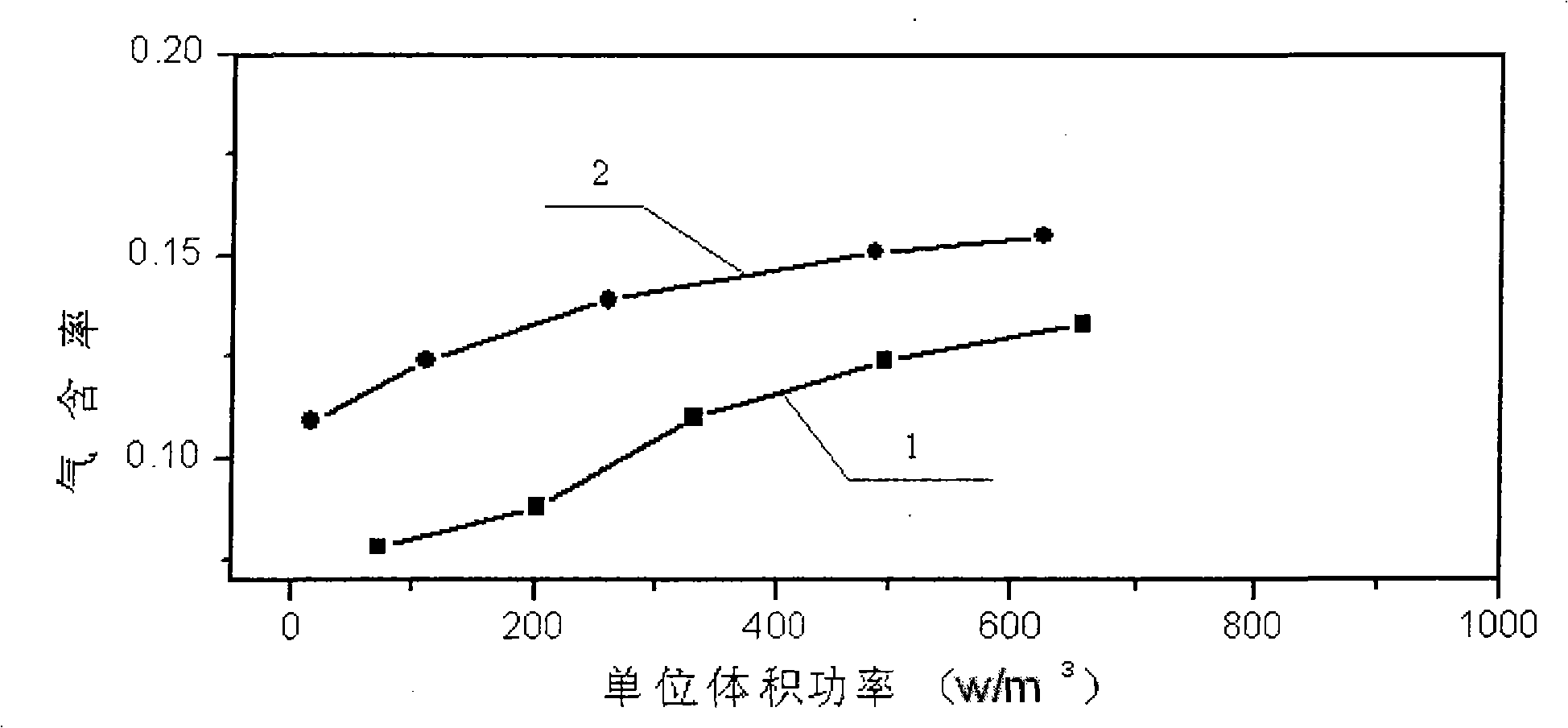

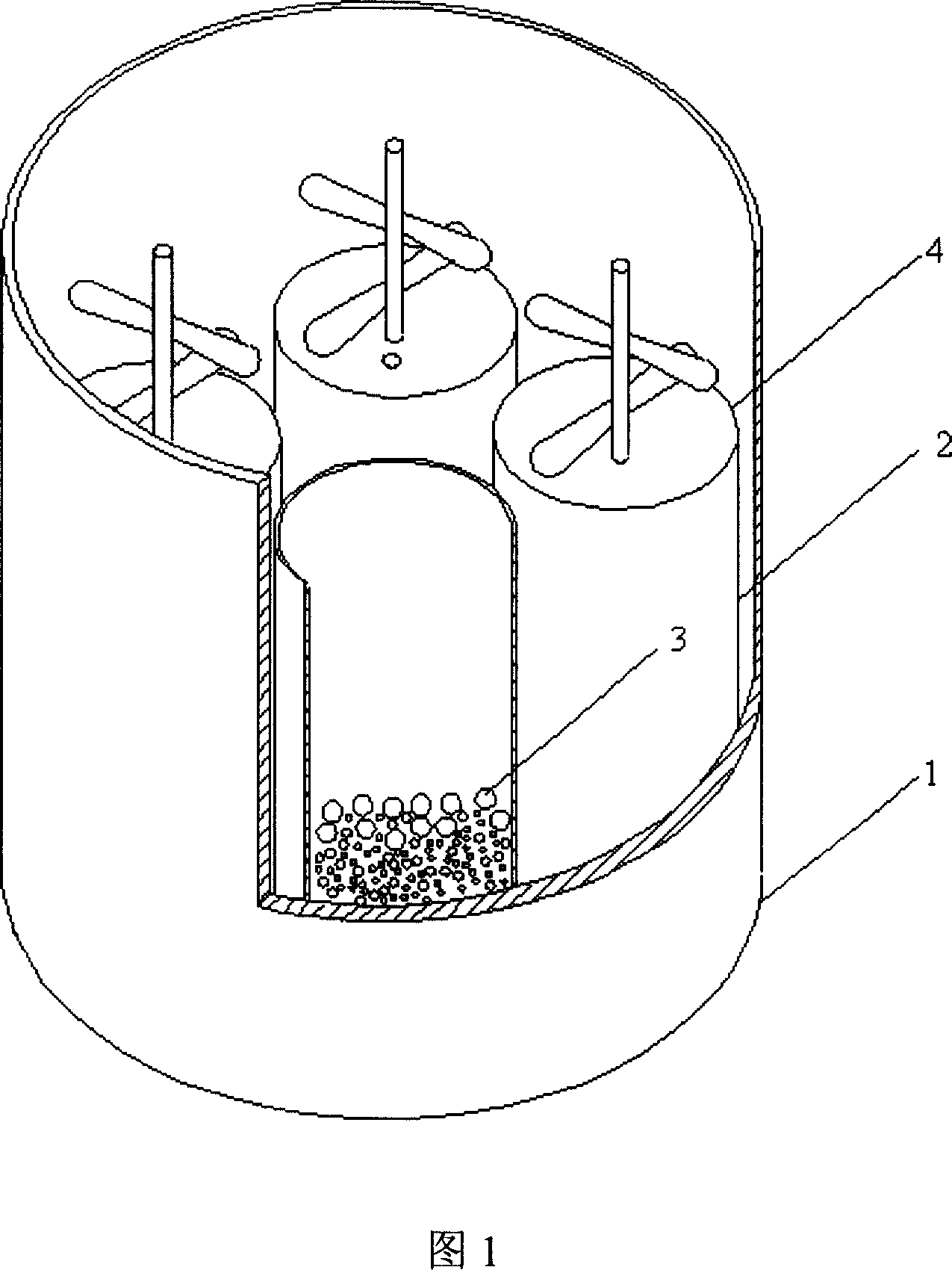

Stirring/flow-guiding multi-phase reactor

InactiveCN101293195ARaise the stirring shaftEasy to operateRotary stirring mixersChemical/physical/physico-chemical stationary reactorsBiochemical engineeringBlend time

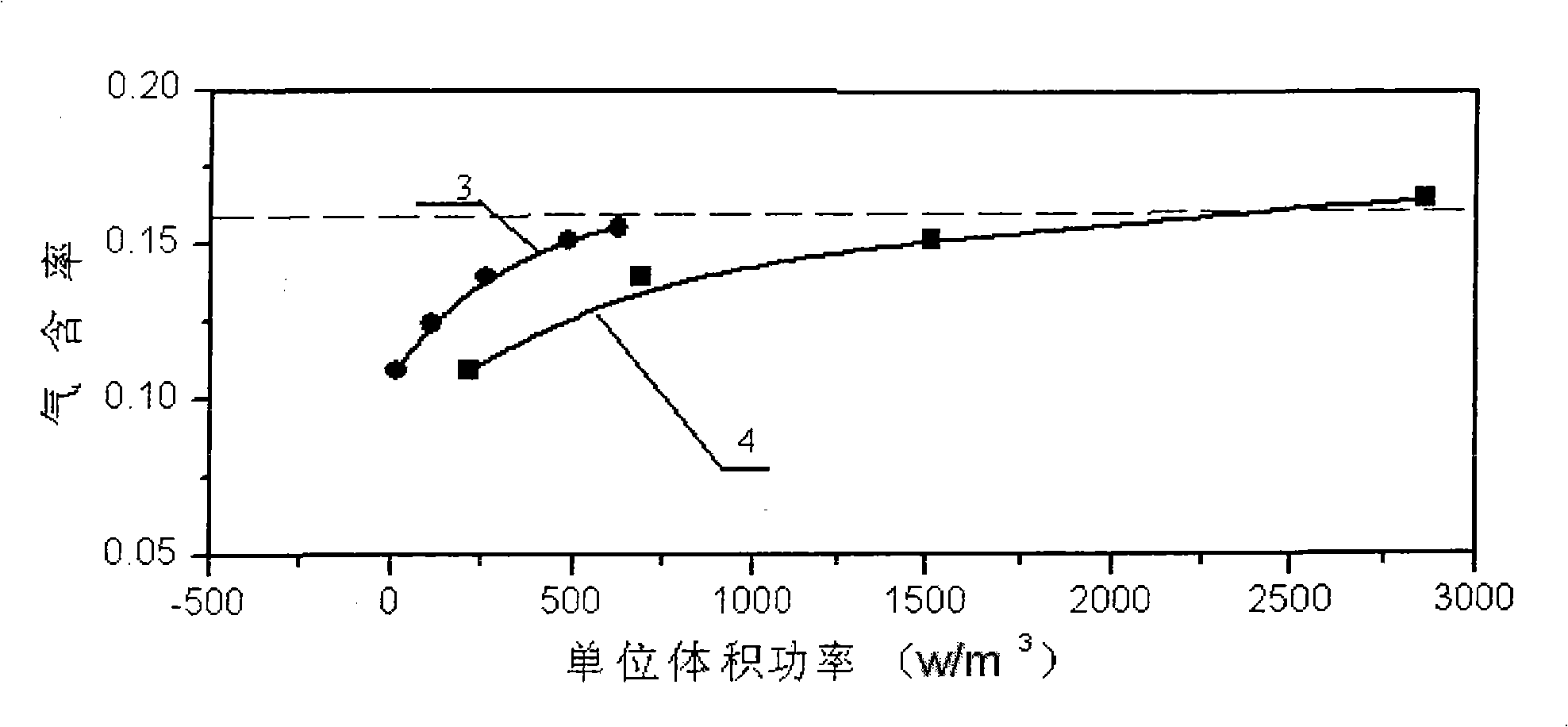

The present invention provides a stirring / guide multi-phase reactor, comprising a cylindrical sealed shell, a guide cylinder, a stirring device, air inlet device and an air outlet device; wherein, the cylindrical sealed shell is provided with a material inlet and outlet device; the lower part inside the shell is provided with the guide cylinder with an external diameter smaller than the internal diameter of the shell, a clearance is left between the guide cylinder and the shell bottom; the stirring device is arranged in the clearance between the guide cylinder and the shell bottom and comprises a stirring shaft and a blade fixed on the stirring shaft; the stirring shaft passes through the shell bottom and extends out of the shell; the air inlet device is arranged on the shell bottom and / or a lateral wall and the air outlet of the air inlet device is arranged below the blade; the air outlet device is arranged on the shell top. The stirring / guide multi-phase reactor provided by the present invention, which adopts the combination of the bottom-type stirring device and the guide cylinder, only needs comparatively low energy consumption to reach and even surpass the air rate the multi-layer or single-layer stirring reactor requires a plurality of times of energy consumption. Due to short mixing period and high effective energy utilization, the reactor is suitable for various industrial processes.

Owner:SINOPEC OILFIELD SERVICE CORPORATION +1

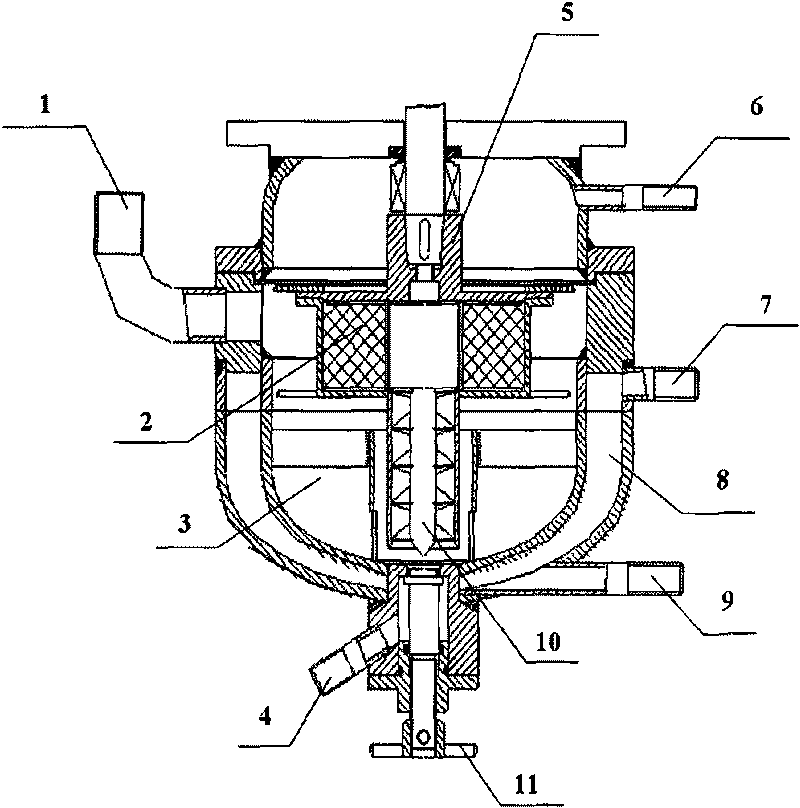

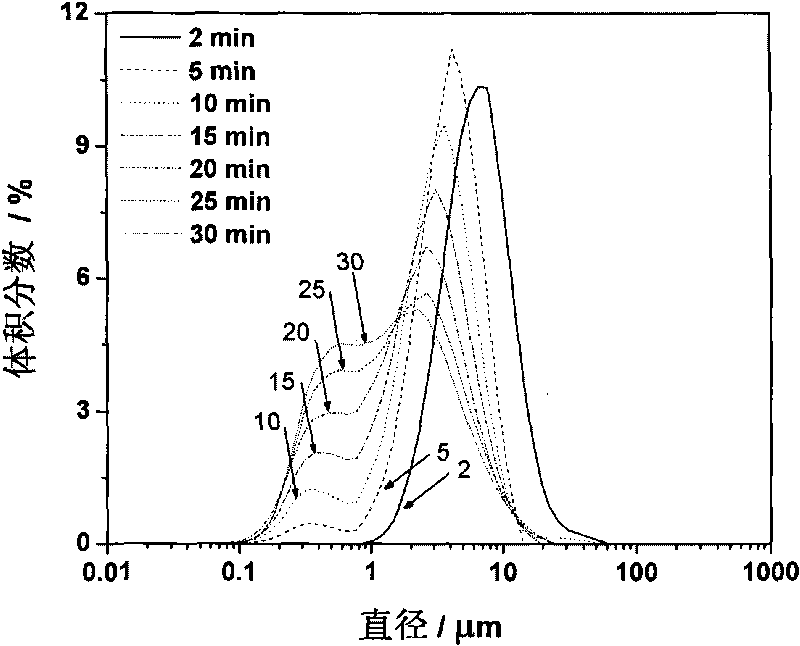

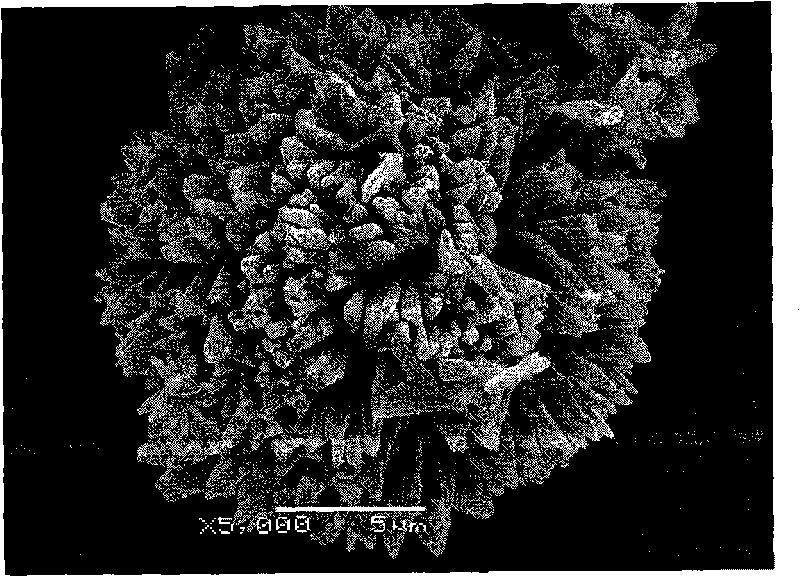

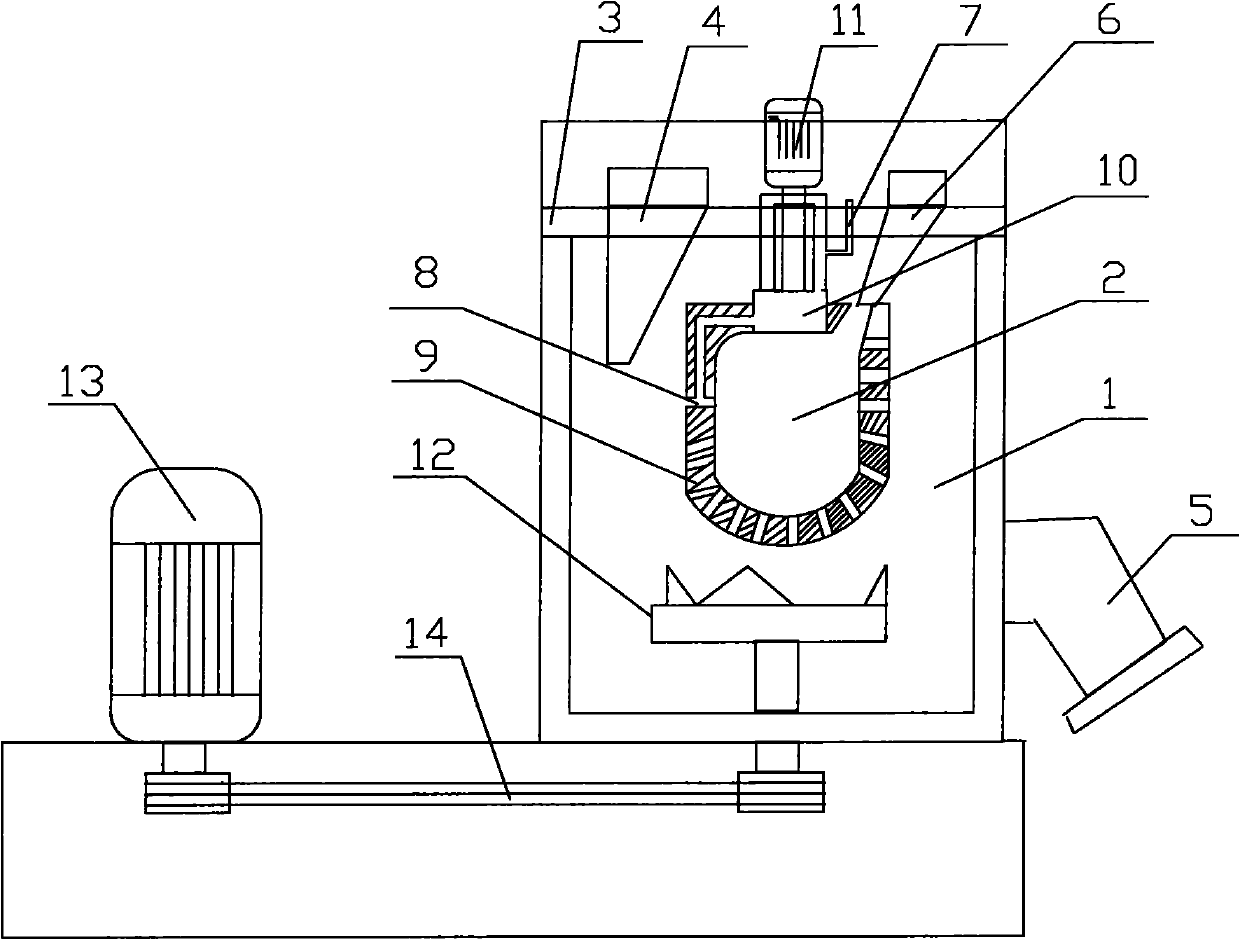

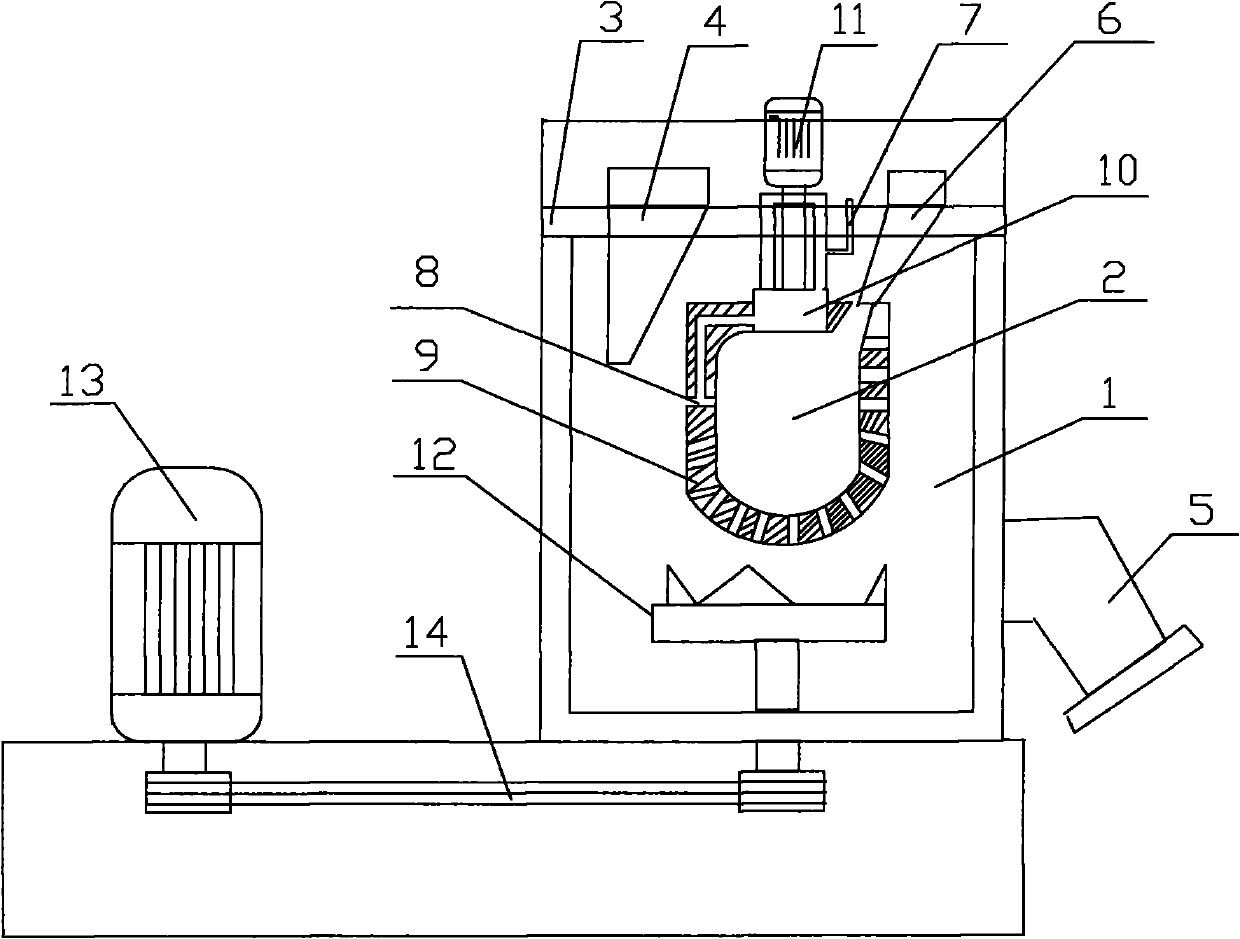

Method and device for preparing medicament particles with nano-micro structure

ActiveCN101721312ASimple operation processReduce energy consumptionPharmaceutical product form changeMicro structureCrystallization temperature

The invention provides a method and a device for preparing medicament particles with a nano-micro structure and belongs to the field of medicament preparation. The method comprises the following steps that: an internal circulation rotary filling bed is used as a precipitation-crystallization device; and in a cavity, liquid materials are lifted from the bottom to the inner wall of a rotor by a lifter, and the rotor is driven to rotate by a motor to generate centrifugal force, so that the material liquid passes a material filling layer, is thrown out from the outer wall of the rotor and then isreturned to the bottom of the cavity under the gravity action. The steps are cycled. The volume ratio of two kinds of material liquid is 1:2 to 1:100, and the two kinds of material liquid are fully mixed on the material filling layer to form crystallization suspension; the frequency of the motor is 25 to 50Hz, the mixed time is 5 to 20 minutes, and the crystallization temperature is 0 and 25 DEG C; and the crystallization suspension is filtered, washed and dried to form the medicament powder with the nano-micro structure. In the method, by adjusting the volume ratio, crystallization temperature, mixed time, frequency of the motor and the like of the two crystallization systems and the two kinds of material liquid, the medicament particles, which have the uniform nano-micro structure and of which the average grain size is controllable, can be obtained; and the method also has the advantages of simple process, safe operation, energy conservation, low cost and the like.

Owner:BEIJING UNIV OF CHEM TECH

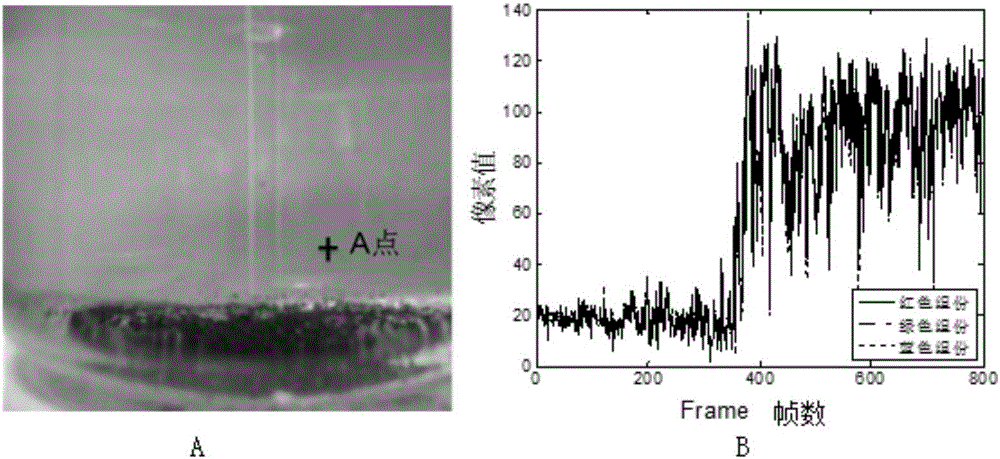

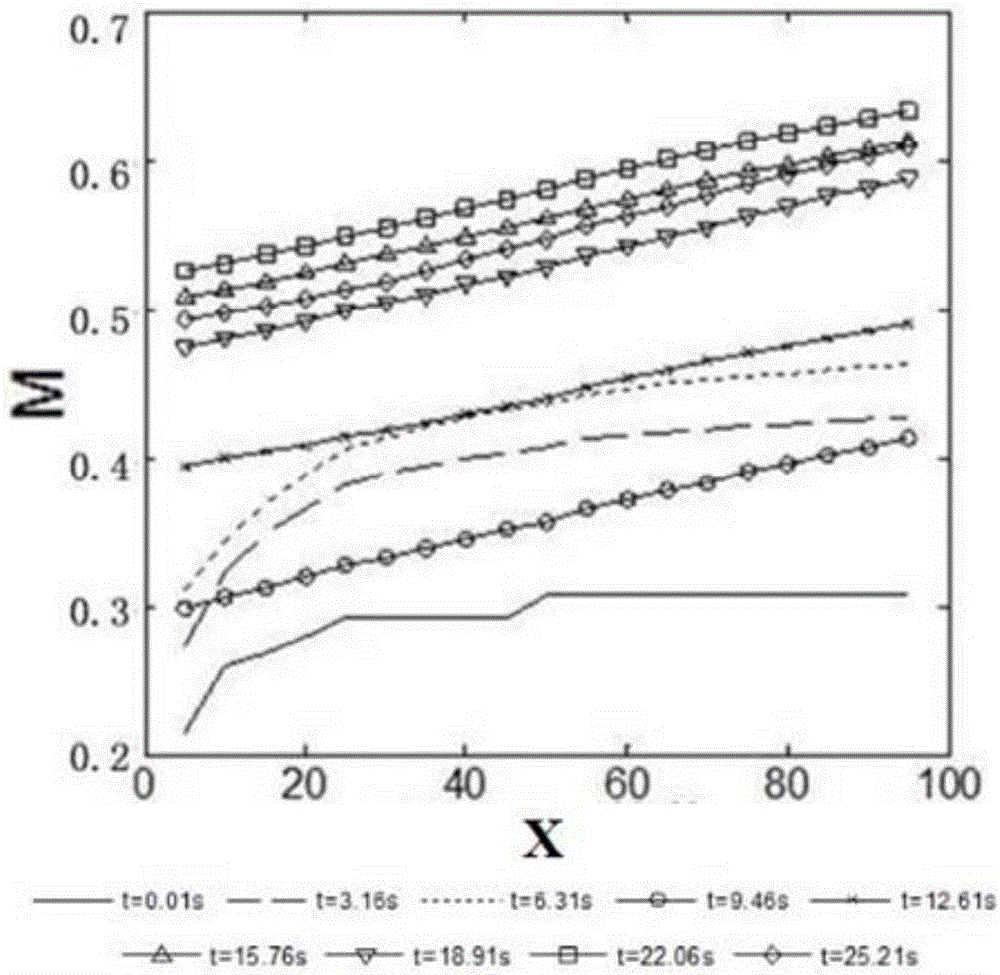

Method for determining mixing time of multiphase flow by using RGB color model

InactiveCN105910996AAccurately select the number of mixed uniform pixelsAccurately determineColor/spectral properties measurementsImaging processingBlend time

The invention discloses a method for determining mixing time of multiphase flow by using a RGB color model, belonging to the technical field of metallurgical energy engineering. The method determines macroscopic mixing time of multiphase flow on the basis of statistical mean square deviation, average change rate and the RGB color model for image processing and is mainly applied to chemical engineering for determination of the mixing time of multiphase flow and evaluation of mixing effect. The method is simple and convenient, has high practical value and provides a reliable and practical method for evaluation of mixing time of chemical and metallurgical stirring equipment and theoretical guidance of designing of a stirring reactor.

Owner:KUNMING UNIV OF SCI & TECH

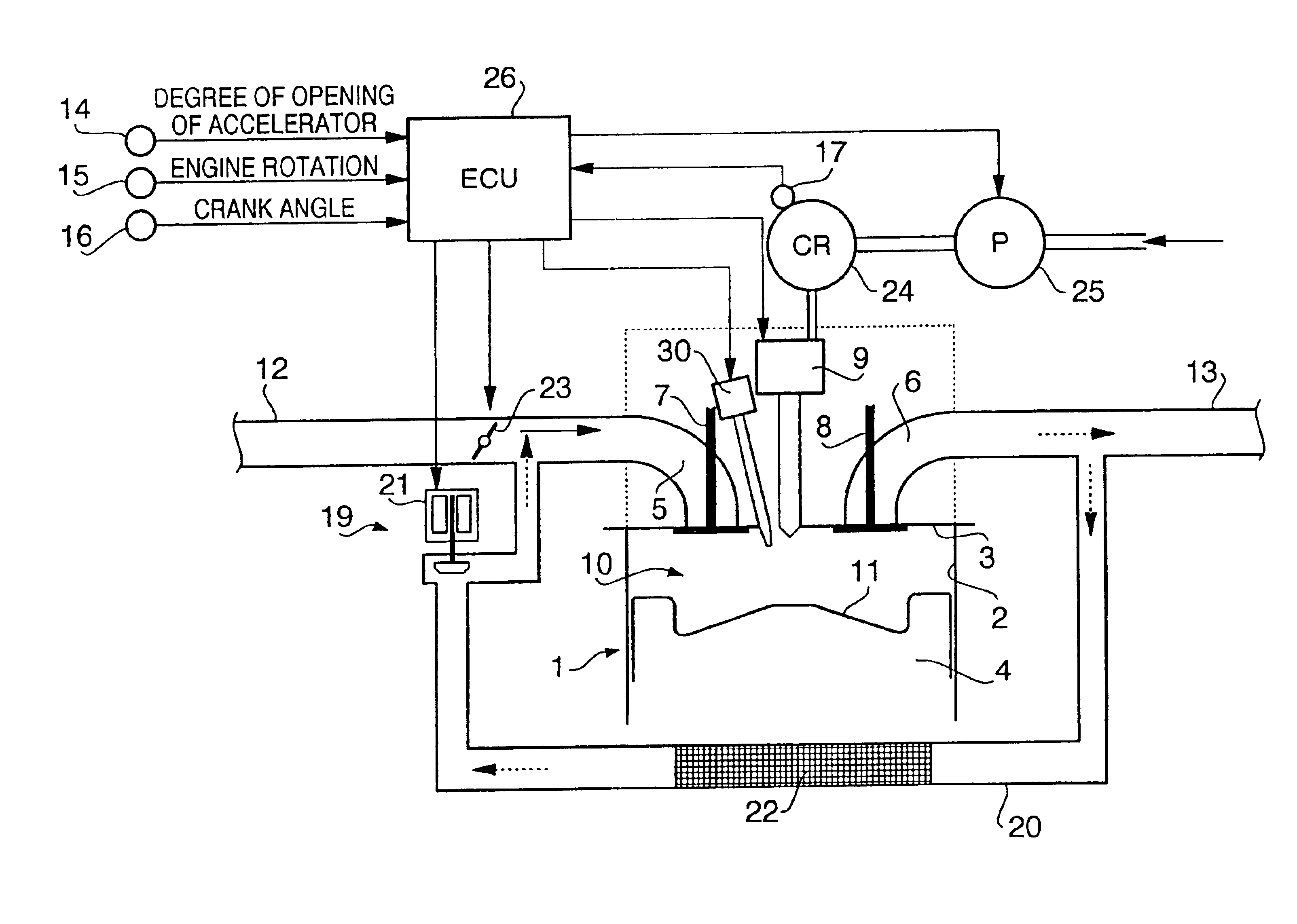

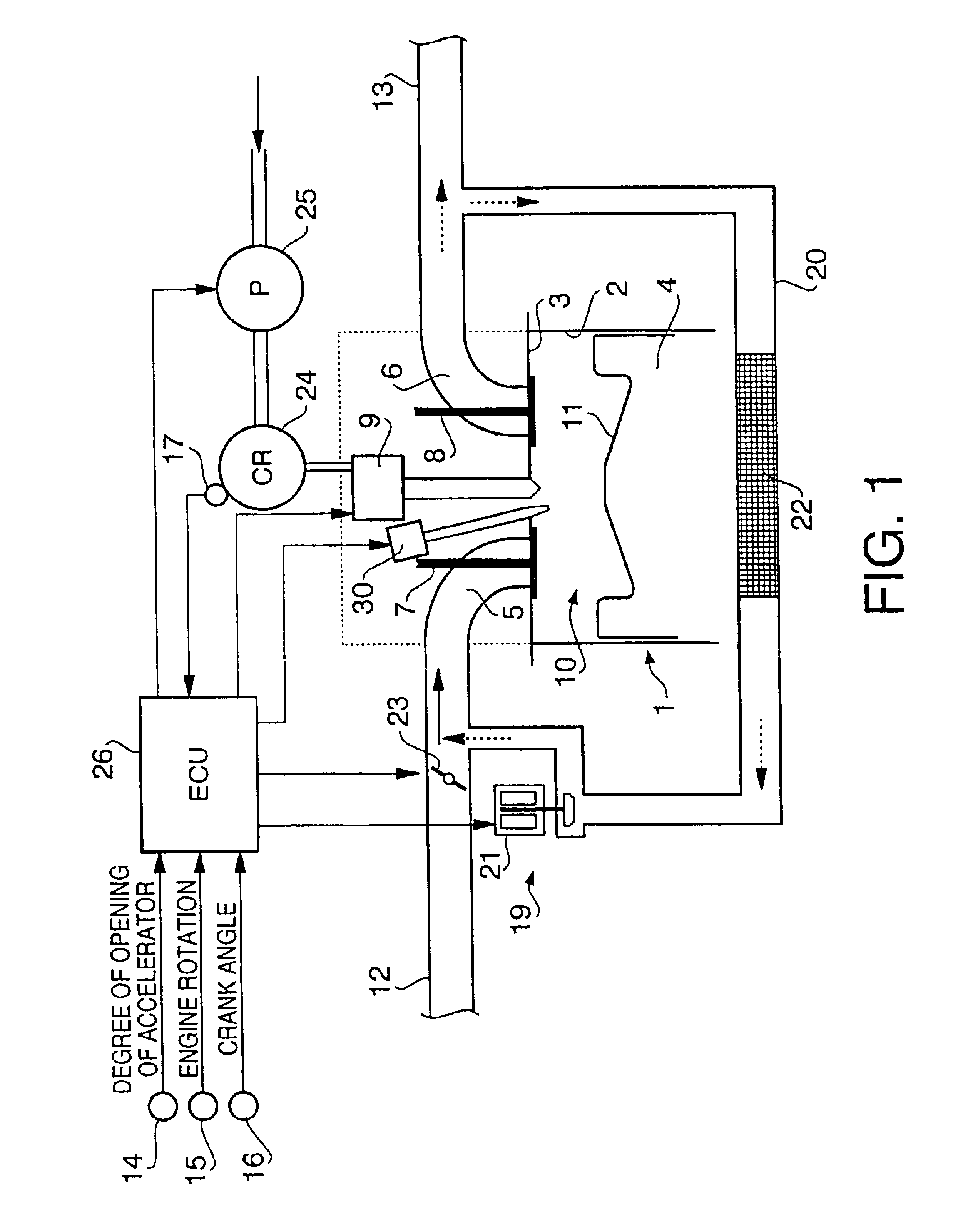

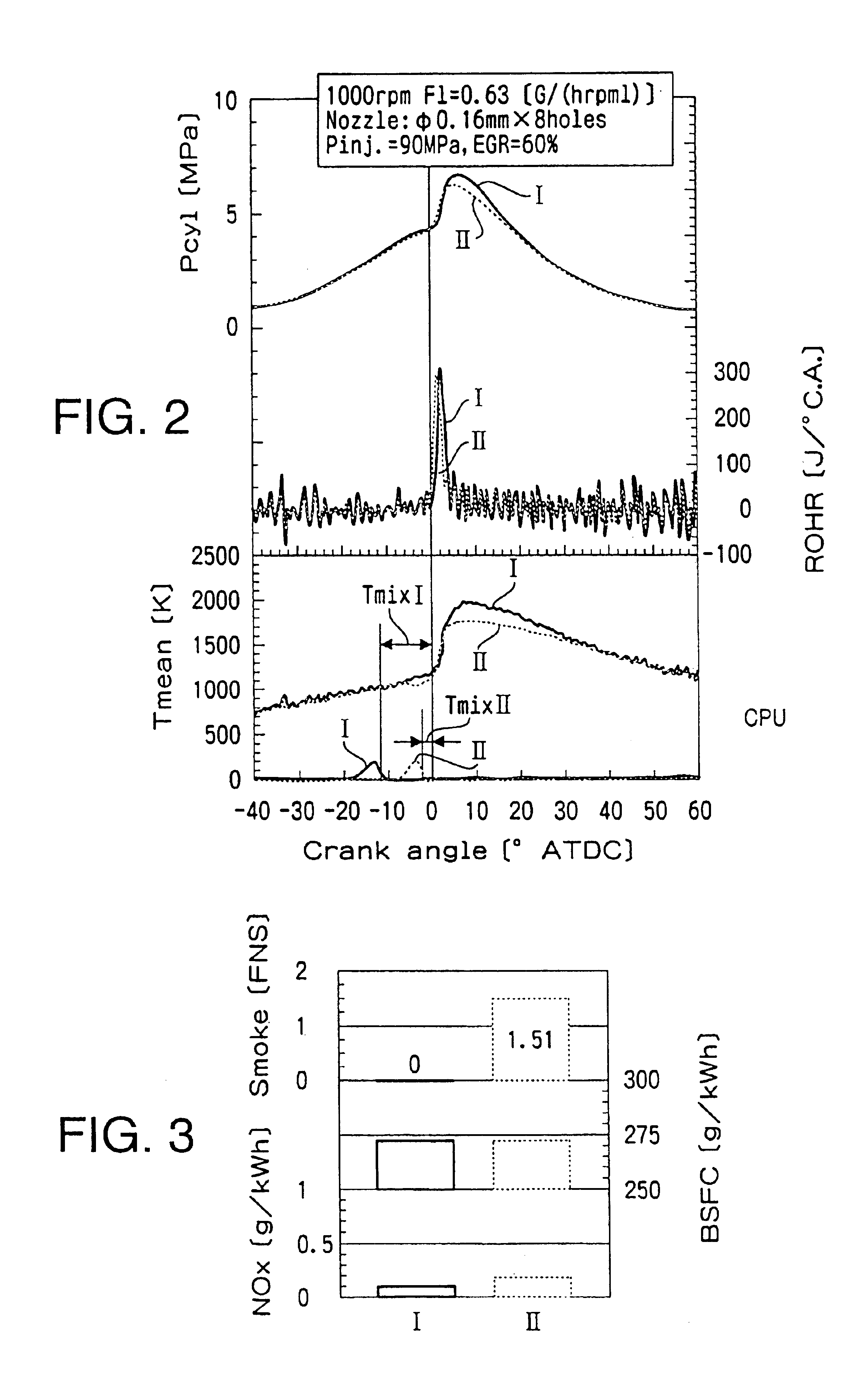

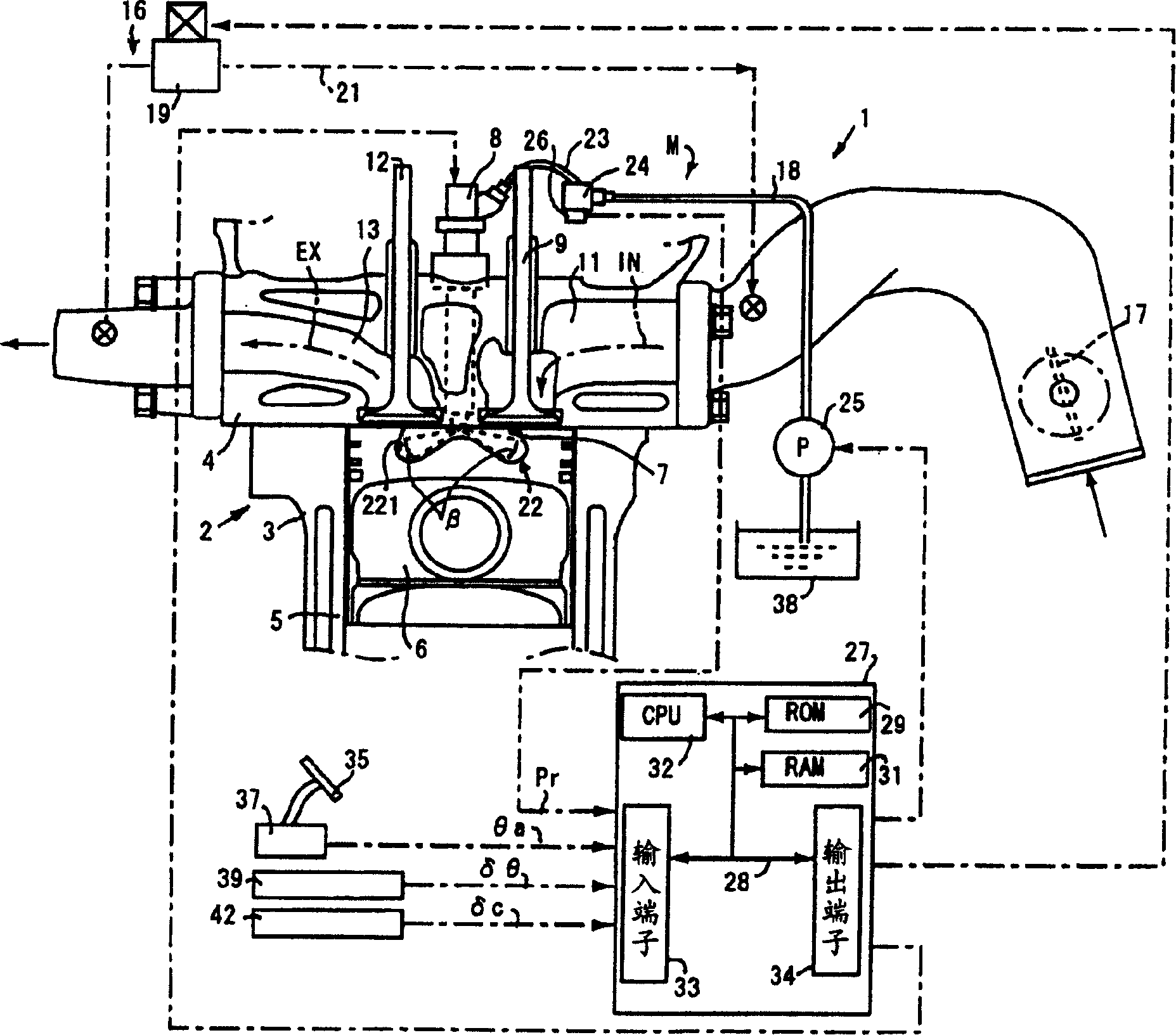

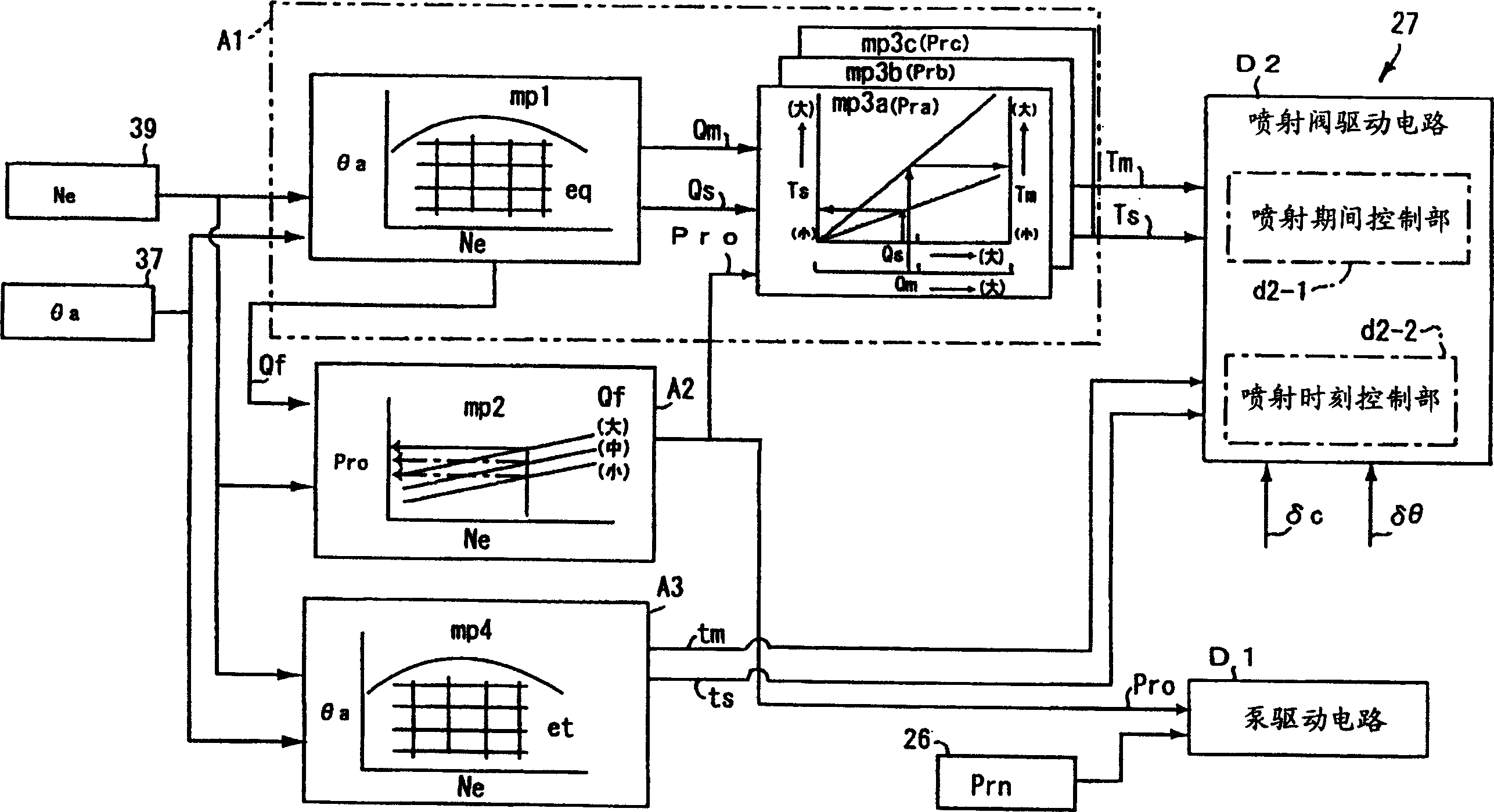

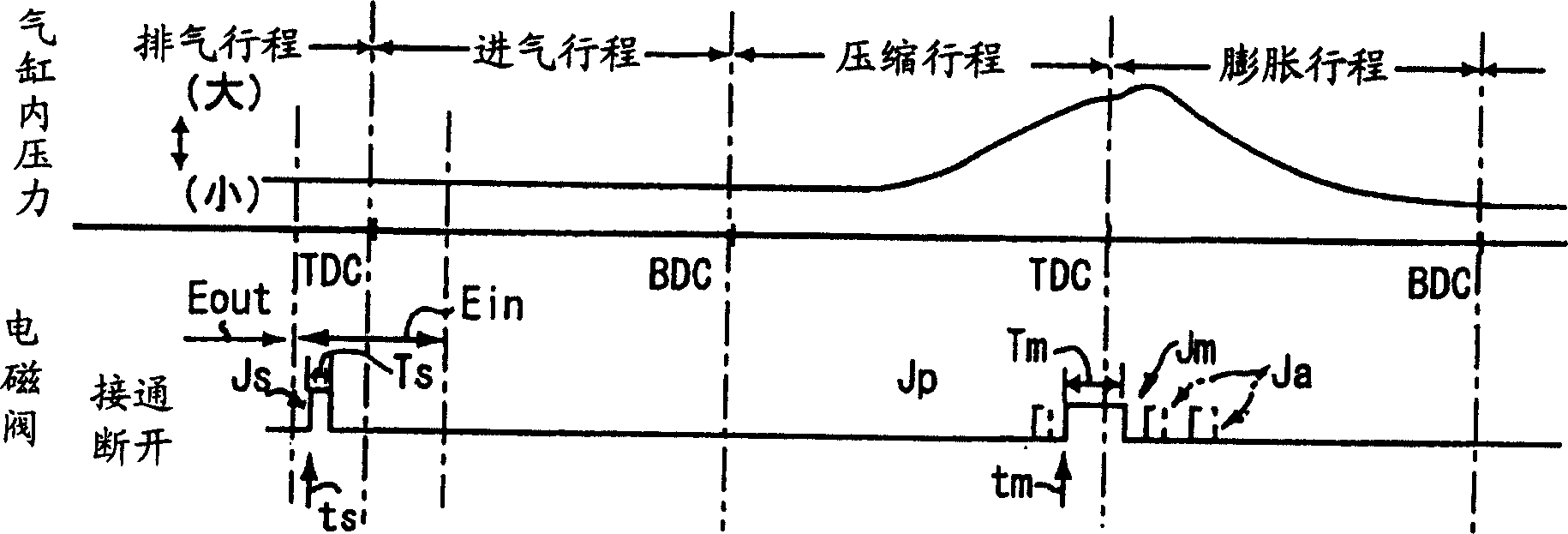

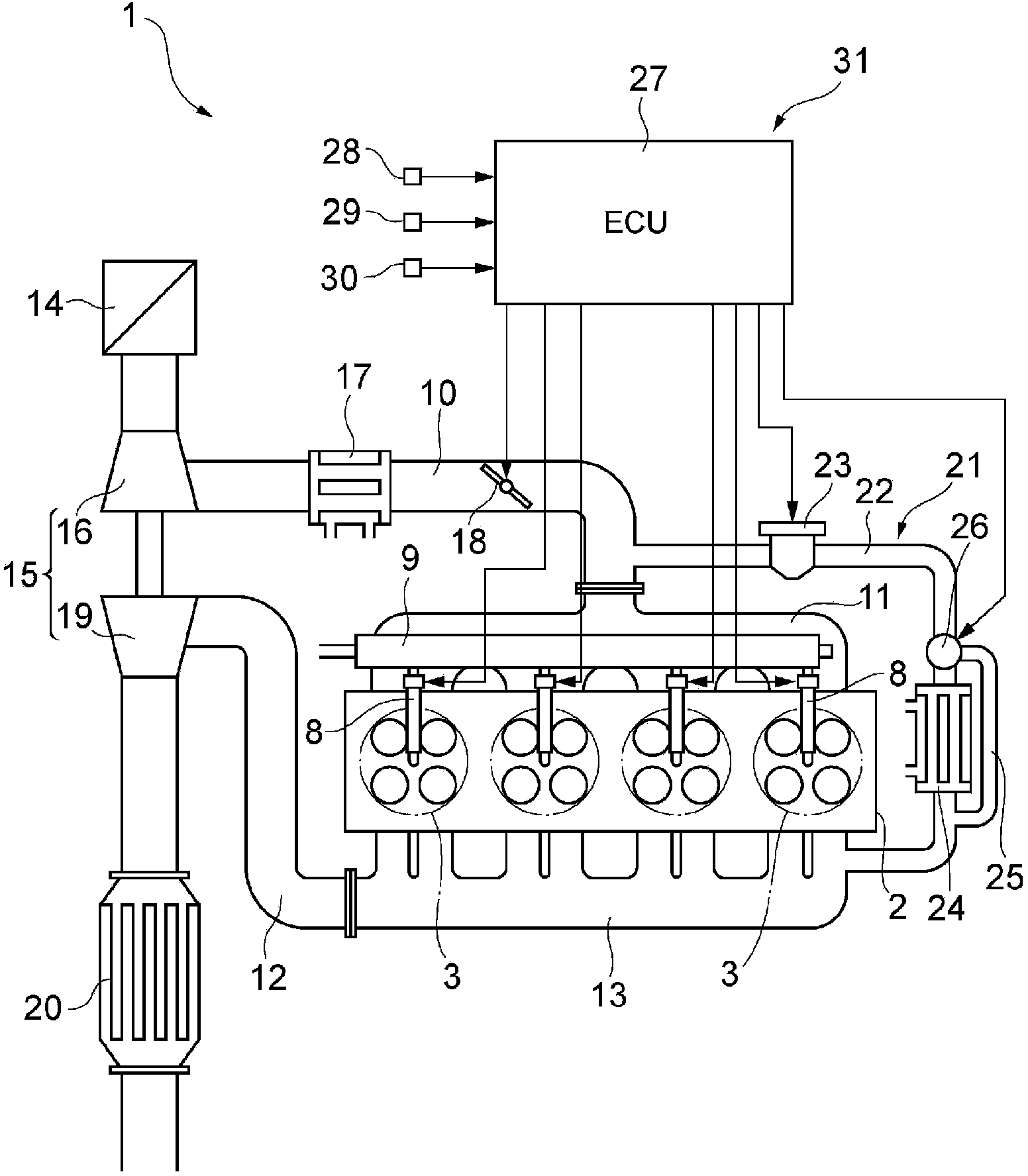

Fuel injection control device

InactiveUS6918371B2Easy to optimizeImprovement of exhaust gasElectrical controlInternal combustion piston enginesCombustion chamberBlend time

A fuel injection control device in which fuel injected into the combustion chamber is ignited after a pre-mixing period has elapsed following the completion of the injection of the fuel, includes target pre-mixing period determining unit for determining the target pre-mixing period on the basis of the engine operating conditions, actual pre-mixing period detection unit for detecting the actual pre-mixing period, and pre-mixing period adjustment means for adjusting the pre-mixing period of the fuel so that the actual pre-mixing period approaches the target pre-mixing period. With this device, the pre-mixing period of the fuel can be appropriately controlled, and the exhaust gas can be reliably improved.

Owner:ISUZU MOTORS LTD

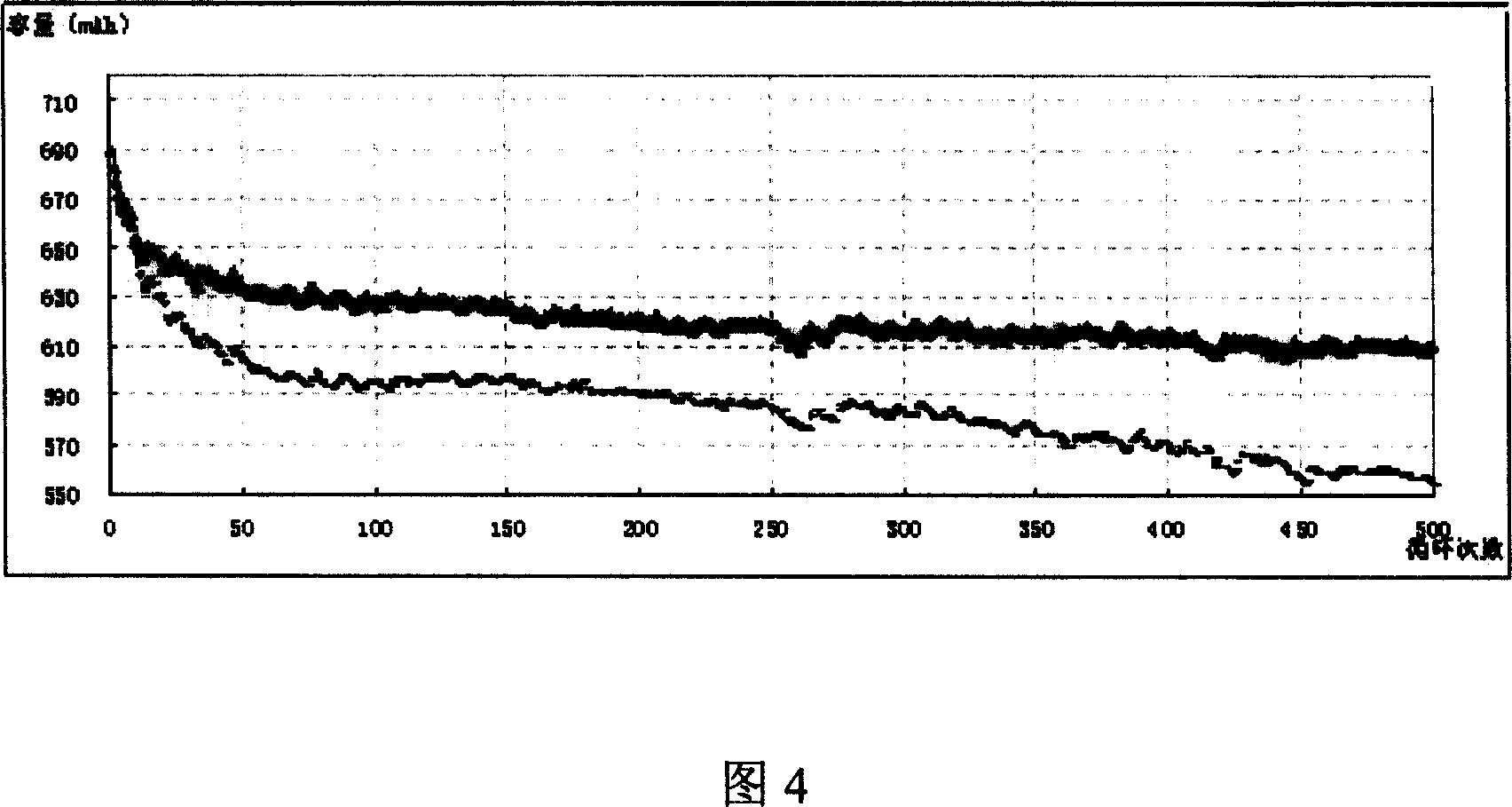

Electrode slurry mixing process

InactiveCN1986067AWell mixedShorten mixing timeRotating receptacle mixersGrain treatmentsEngineeringSlurry

The electrode slurry mixing process is to mix materials constituting electrode slurry in a planetary ball mill. The electrode slurry mixing process can produce electrode slurry capable of raising the great current discharge performance, capacity and cycle performance of cell, and can shorten the electrode slurry mixing time and raise production efficiency greatly.

Owner:BYD CO LTD

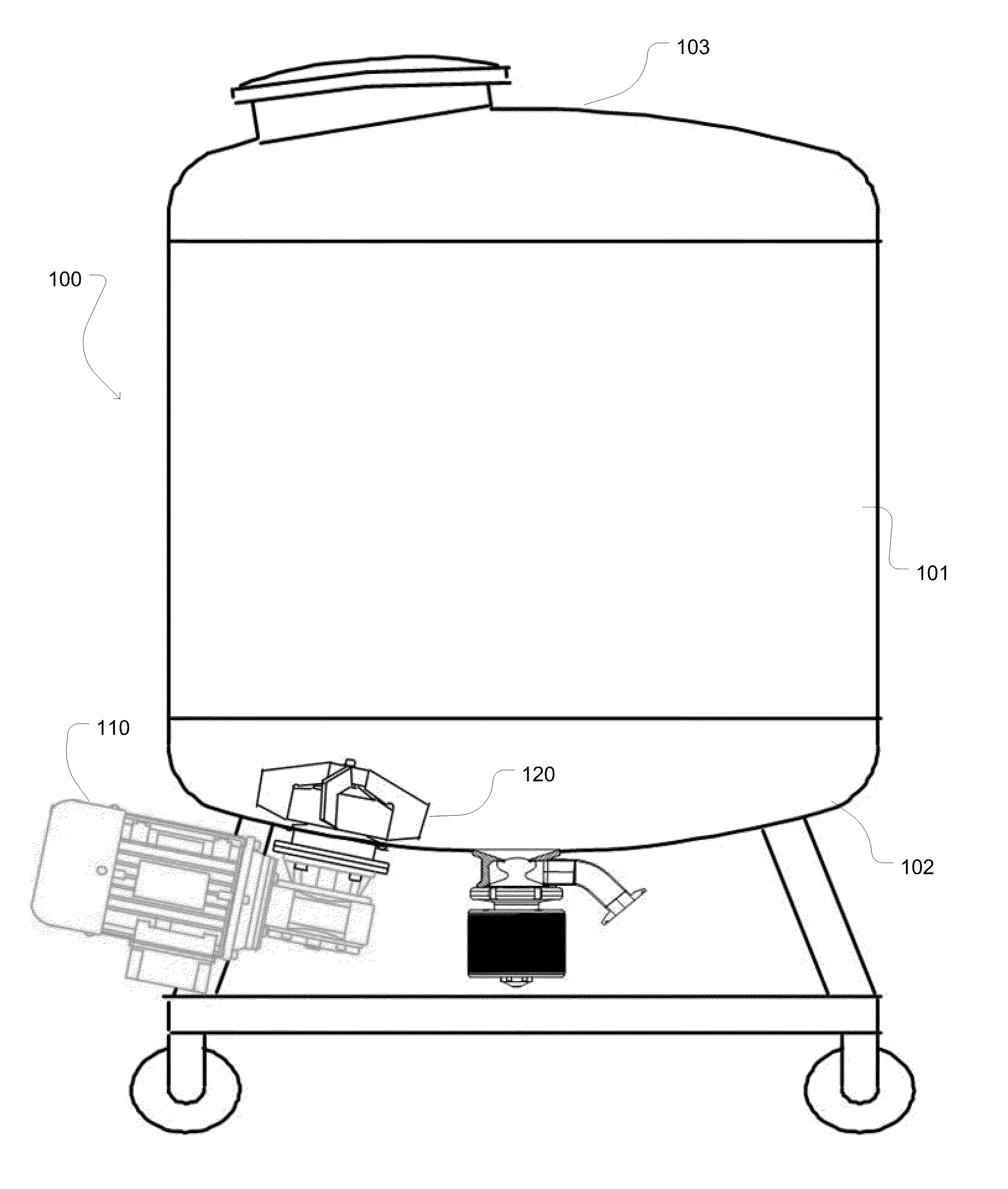

Control system and process for wastewater treatment

A system and process is provided for optimizing chemical additions, mixing energy, mixing time, and other variables while treating a contaminated liquid stream. Samples from the contaminated liquid stream are tested to determine the optimal parameter for each variable, including type and amount of the chemicals to be added, chemical sequence, mixing energy, mixing time, temperature, and pressurization. A system of mixers, a flotation chamber, and a dewatering subsystem are designed to achieve optimal turbidity of the wastewater stream. The system can be modified in real-time in response to a continually changing contaminated liquid stream via a controller and set of sensors, valves, and ports.

Owner:WORLD WATER TECH

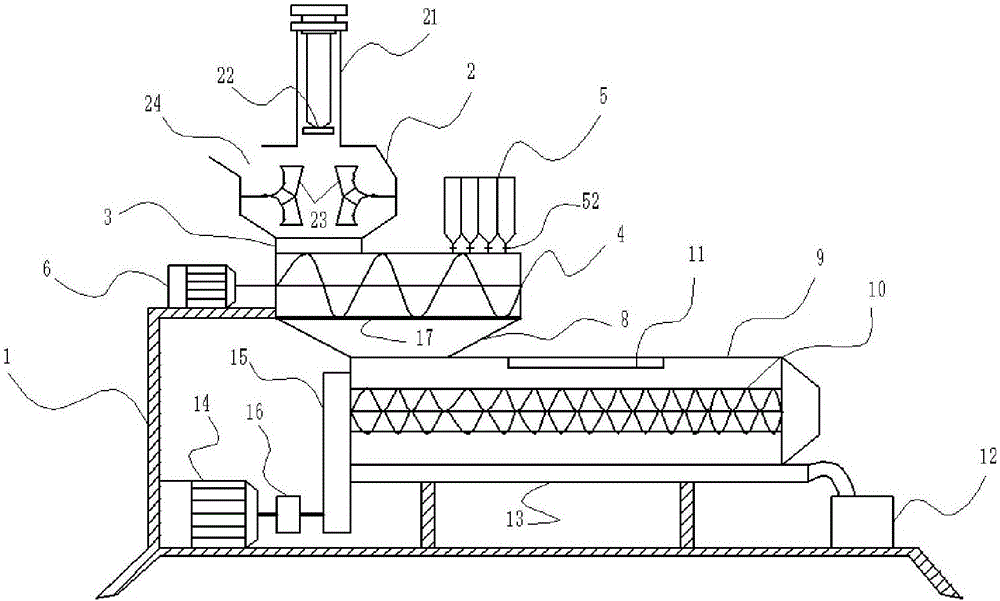

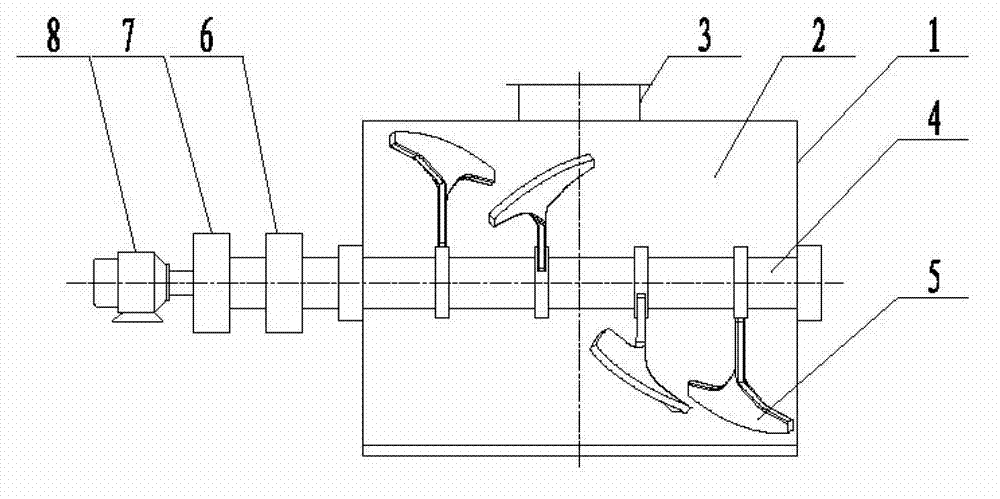

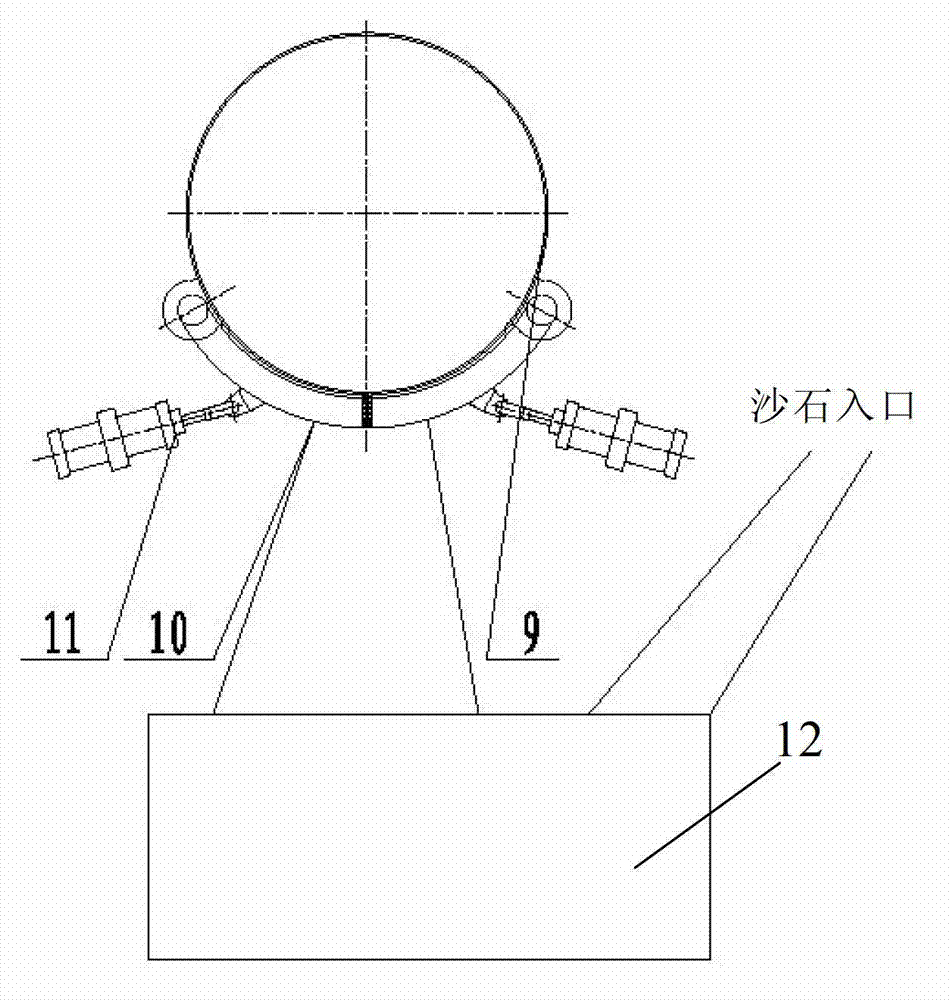

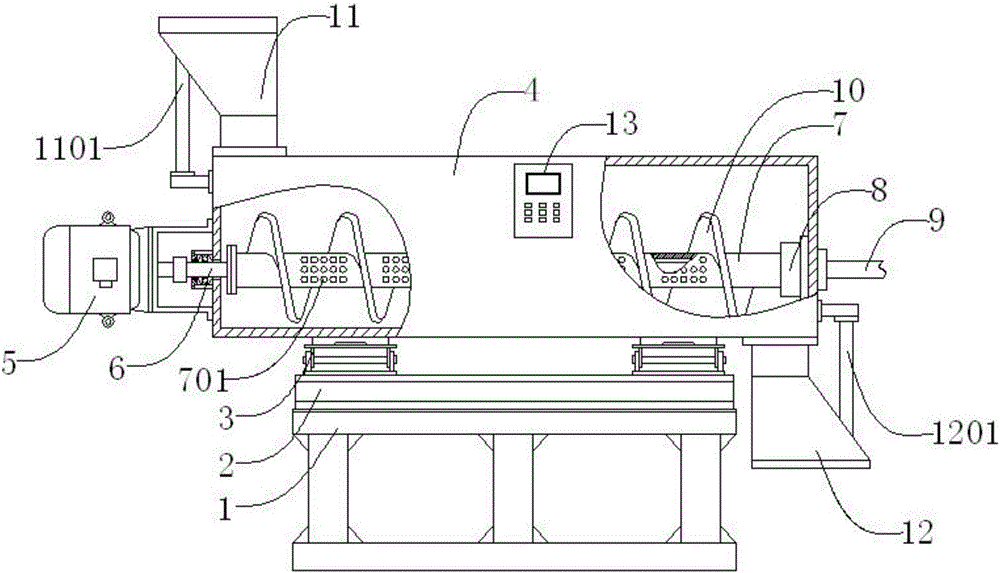

Fine powder mixing device as well as concrete mixing equipment and concrete mixing process using fine powder mixing device

The invention discloses a fine powder mixing device, comprising a shell main body, wherein a horizontal main shaft is arranged in the shell main body; a plurality of mixing blades are arranged on the main shaft; the main shaft is connected with a motor via a speed reducer outside the shell main body; and the charge port of the device is a vertical inlet. Concrete mixing equipment using the fine powder mixing device comprises a main mixing machine, wherein the main mixing machine is provided with two charge ports, one charge port is a sand inlet, and the other charge port is a powder inlet; and the powder inlet is connected with the discharge port of the fine powder mixing device. Concrete mixing process using the fine powder mixing device comprises the following steps of: firstly, uniformly mixing a powder in the fine powder mixing device; and then conveying the powder into the main mixing machine to mix together with sand in a ratio according to grade requirements. According to the invention, the requirements of rapidly and uniformly mixing and rapidly unloading can be met, few moving parts are provided, structure is simple, and maintenance is convenient. The fine powder mixing device is simple in structure, convenient to choose for a rotation speed, short in mixing time, and high in mixing efficiency.

Owner:XIAN DELONG NEW BUILDING MATERIALS TECH +2

Variable frequency low speed mixer and method for mixing materials with different stacking densities

ActiveCN101905131AAvoid uneven mixingReduce the chance of delaminationMixing methodsMixersLow speedMixed materials

The invention provides a variable frequency low speed mixer and a method for mixing materials with different stacking densities. The mixer comprises a main mixing chamber and an auxiliary mixing chamber, wherein the auxiliary mixing chamber is arranged in the main mixing chamber; a material mixing cover of the main mixing chamber is provided with a granular material feed port; the bottom of the main mixing chamber is provided with an impeller mechanism; the top of the auxiliary mixing chamber is provided with a powdery material feed port and a liquid material feed port; the wall of the auxiliary mixing chamber is provided with a liquid material discharge port and a plurality of powdery material discharge ports; the top of the auxiliary mixing chamber is provided with a liquid material temporary storage chamber which is communicated with the liquid material feed port and the liquid material discharge port; and by the method, the granular material or preliminarily mixed material is threw up by using the main mixing chamber and the powdery material or the liquid material is scattered in the main mixing chamber by using the auxiliary mixing chamber, so various materials with large stacking density difference are mixed uniformly. The mixer and the method can effectively prevent the phenomenon of non-uniform mixing of the materials, realize premixing with good effect and reduce the probability of demixing of the granular material and the powdery material while greatly shortening the mixing time.

Owner:合诚技术股份有限公司

Processing technology used for quantitatively mixed liquid media

InactiveCN105289343AShorten mixing timeHigh mixing precisionMixing methodsMixer accessoriesLiquid mediumControl engineering

The invention discloses a processing technology used for quantitatively mixed liquid media. By arranging a plurality of metering pumps and a controller used for controlling the rotation speeds of the metering pumps, various kinds of material liquid can be mixed strictly according to a set proportion, mixing time of material liquid is shortened, mixing precision is improved, and continuous production can be achieved.

Owner:JIANGSU NEWAMSTAR PACKAGING MACHINERY

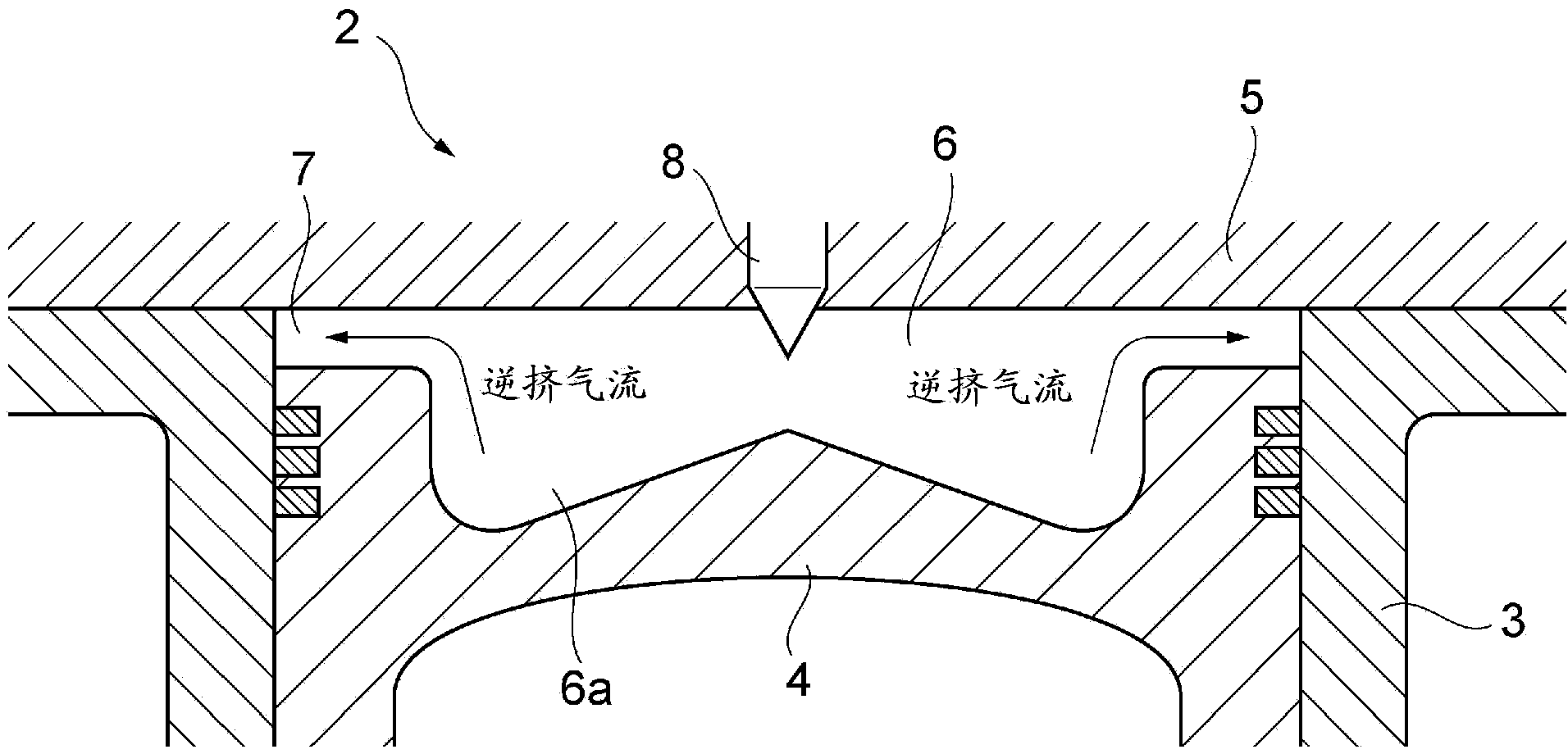

Diesel oil engine

InactiveCN1611758ASimplify Injection ControlPrevent adhesionElectrical controlInternal combustion piston enginesCombustion chamberTop dead center

The diesel engine 1 is provided with a fuel injection device M to conduct main injection Js of high-pressure fuel into the combustion chamber 7 near a compression top dead center, and conduct the preliminary injection Js before the main injection, and a controller 27 to control the fuel injection device M corresponding to the operation condition. The controller 27 controls the injection so as to conduct the preliminary injection before the opening position tintop of a suction valve in a latter part of the exhaust stroke. In the diesel engine in which the preliminary injection is made in an exhaust stroke range without the immediate ignition by obtaining a sufficient premixed time so that premixed combustion is promoted, and main injection fuel is quickly vaporized and burned in a combustion chamber raised in temperature so as to enable both the reductions in a formation amount of NOx and discharge of a smoke (PM).

Owner:MITSUBISHI MOTORS CORP

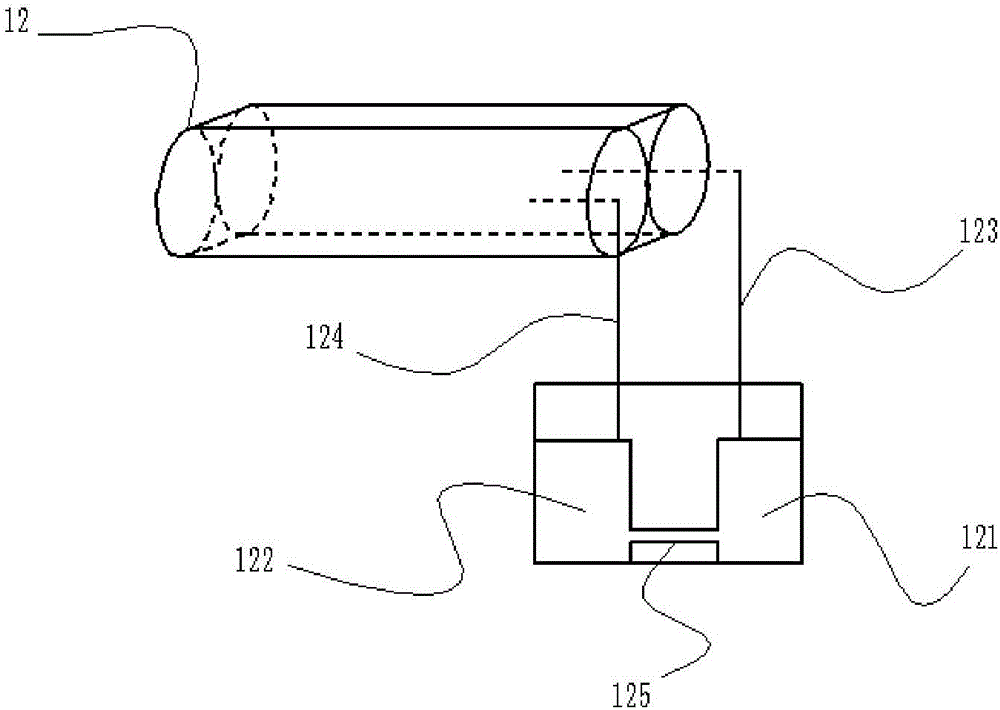

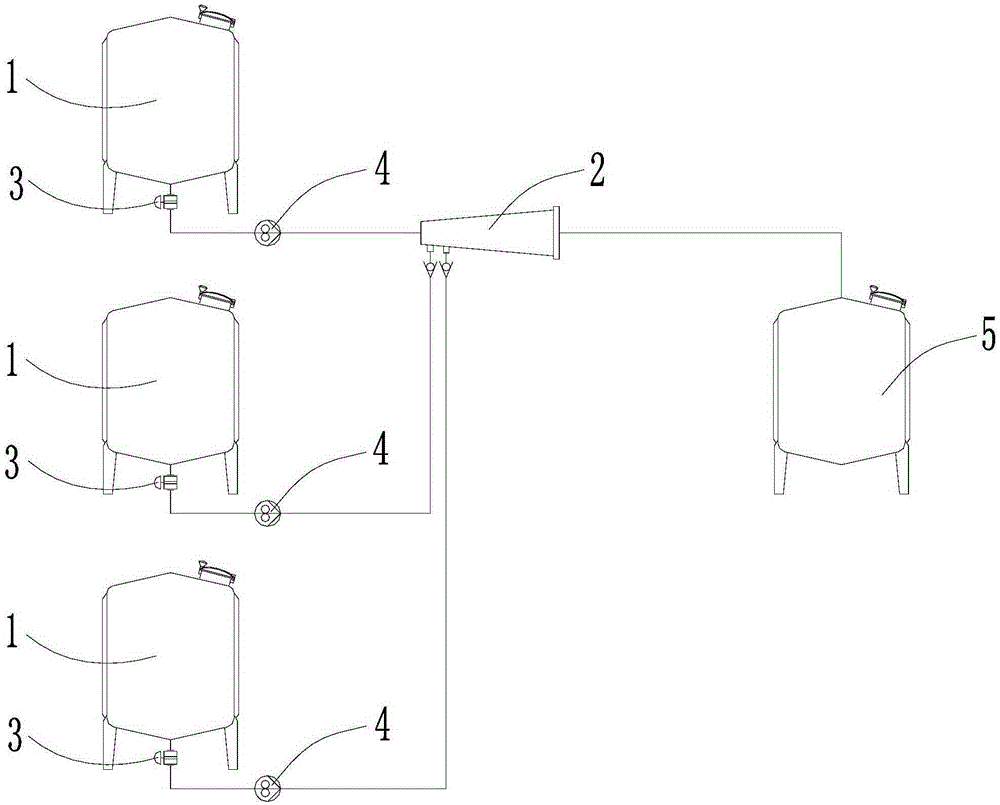

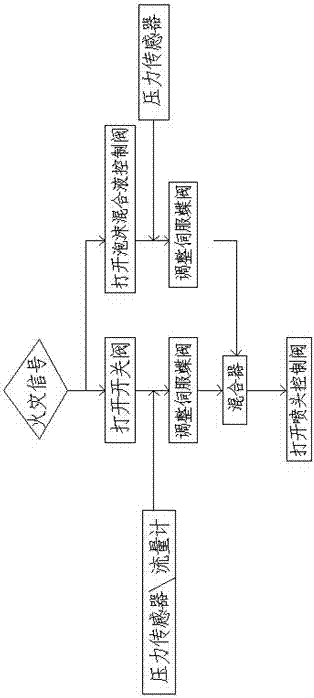

Compressed nitrogen rotation-type foam proportionally-mixed fire extinguishing system

The invention discloses a compressed nitrogen rotary foam proportional mixing fire extinguishing system, which relates to the technical field of fire extinguishing systems and mainly consists of a nitrogen cylinder group, a foam mixed liquid tank, a mixer, a control system, a rotary compressed nitrogen foam nozzle and the like. The compressed nitrogen rotary foam proportional mixing fire extinguishing system of the present invention does not need municipal electricity to open the fire fighting system, and has wide applicability, especially suitable for urban tunnel fire extinguishing. The system uses an independent mixer to mix nitrogen and foam liquid without mixing in any pipeline. The mixing is uniform and the mixing time is short. After the mixing is completed, it is sprayed out by each injection device on the pipeline system. There is no need for any suction device on the injection device, which simplifies the overall structure. The compressed nitrogen foam after mixing has strong fire extinguishing ability and time Short, can greatly reduce the combustion temperature of the fire scene, reduce the casualty rate of the fire.

Owner:安徽对称轴智能安全科技有限公司 +1

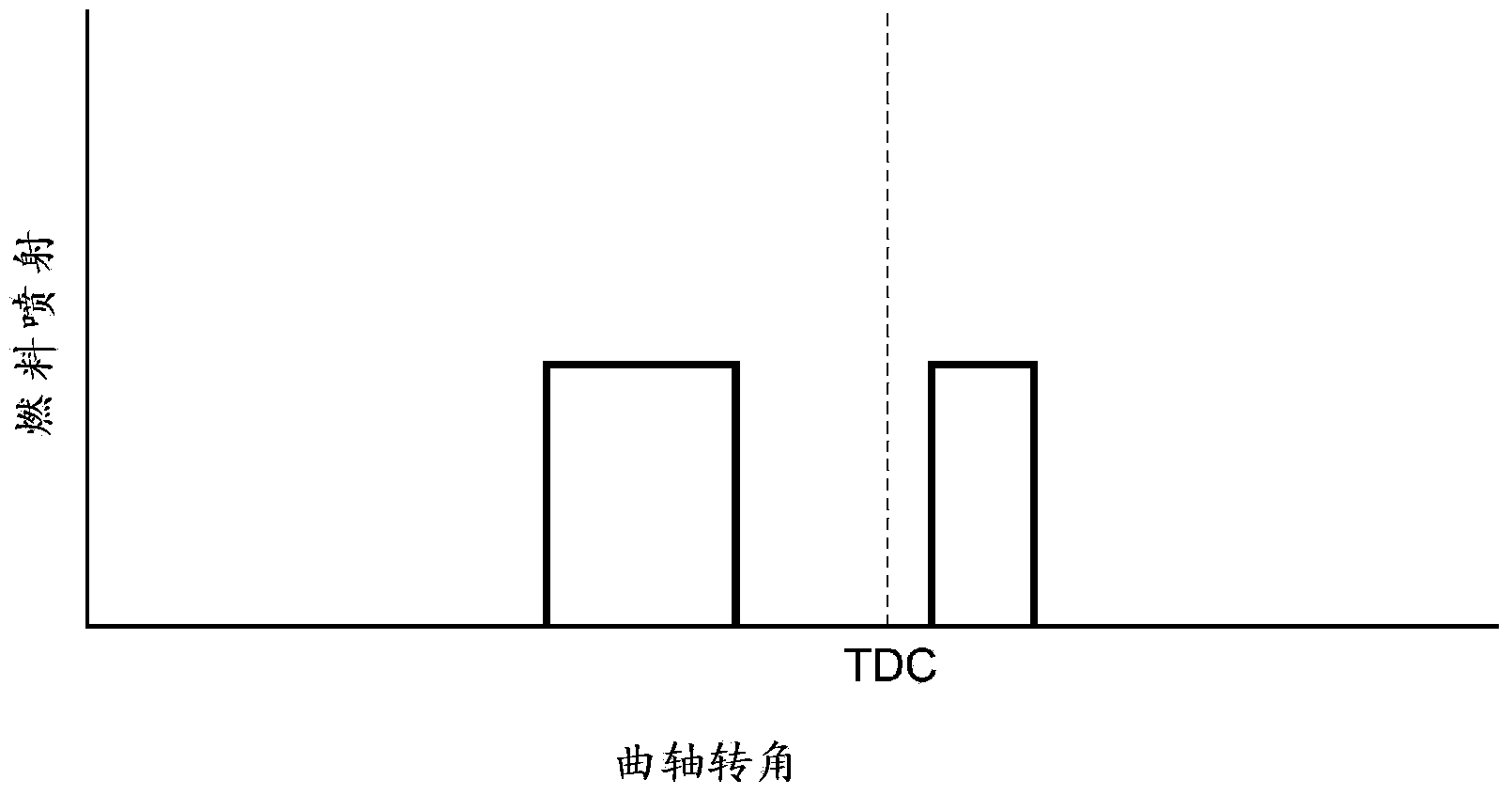

Fuel injection device

ActiveCN103415691AReduce combustion noiseElectrical controlInternal combustion piston enginesCombustion chamberBlend time

This fuel injection device is provided with a fuel injection valve that injects fuel into the combustion chamber of an engine; and an electronic control unit that operates the fuel injection valve in a manner so as to cause the fuel to be injected split into a plurality of instances. The electronic control unit controls the time of a first fuel injection by the fuel injection valve in a manner so that the first fuel injection is performed at the lagging side of the period at which the pre-mixing time immediately after the first injection is minimized, and controls the time of a second fuel injection by the fuel injection valve in a manner so that the heat release rate waveform generated by the first fuel injection and the subsequent second fuel injection is a double-peaked shape.

Owner:TOYOTA IND CORP

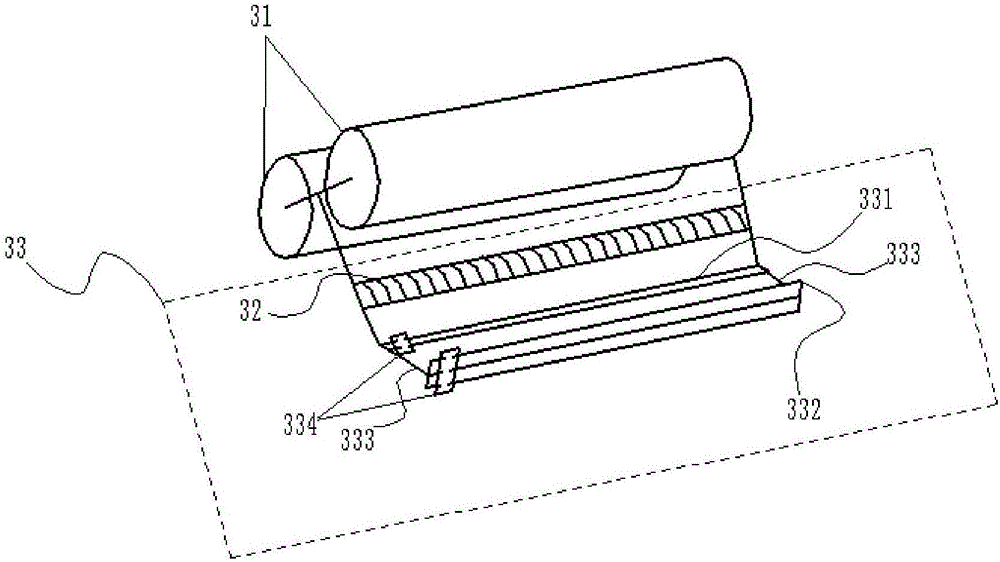

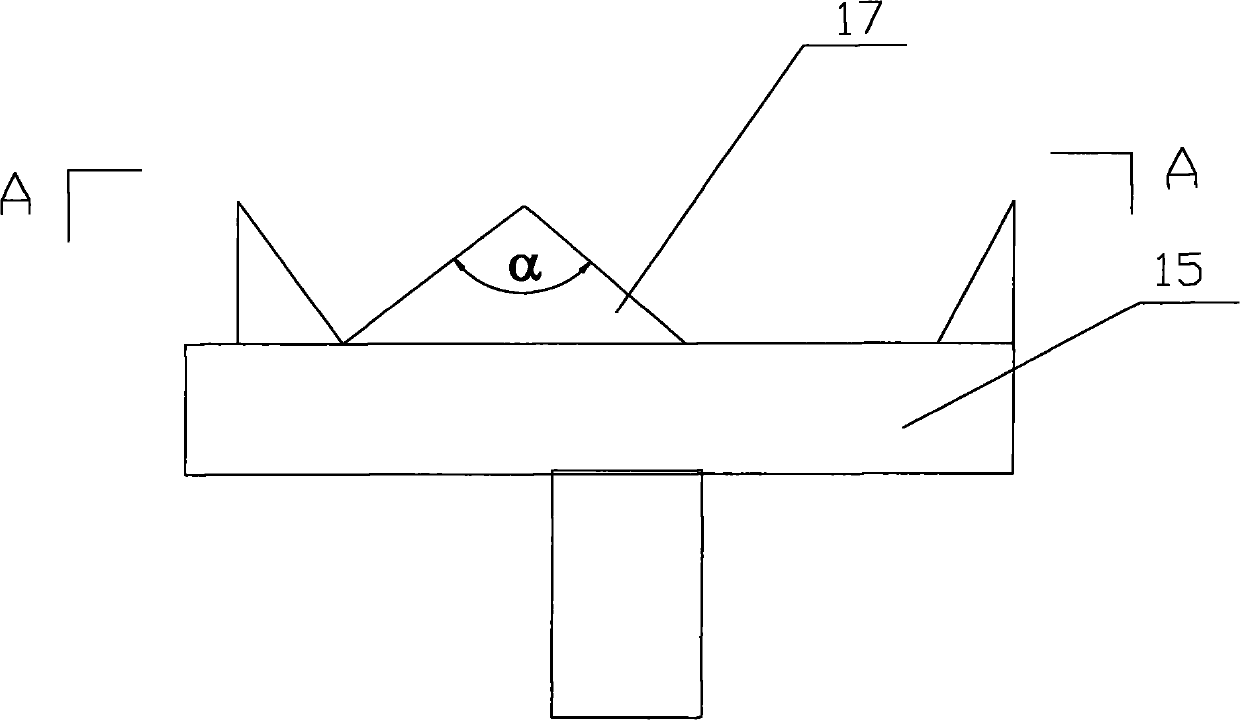

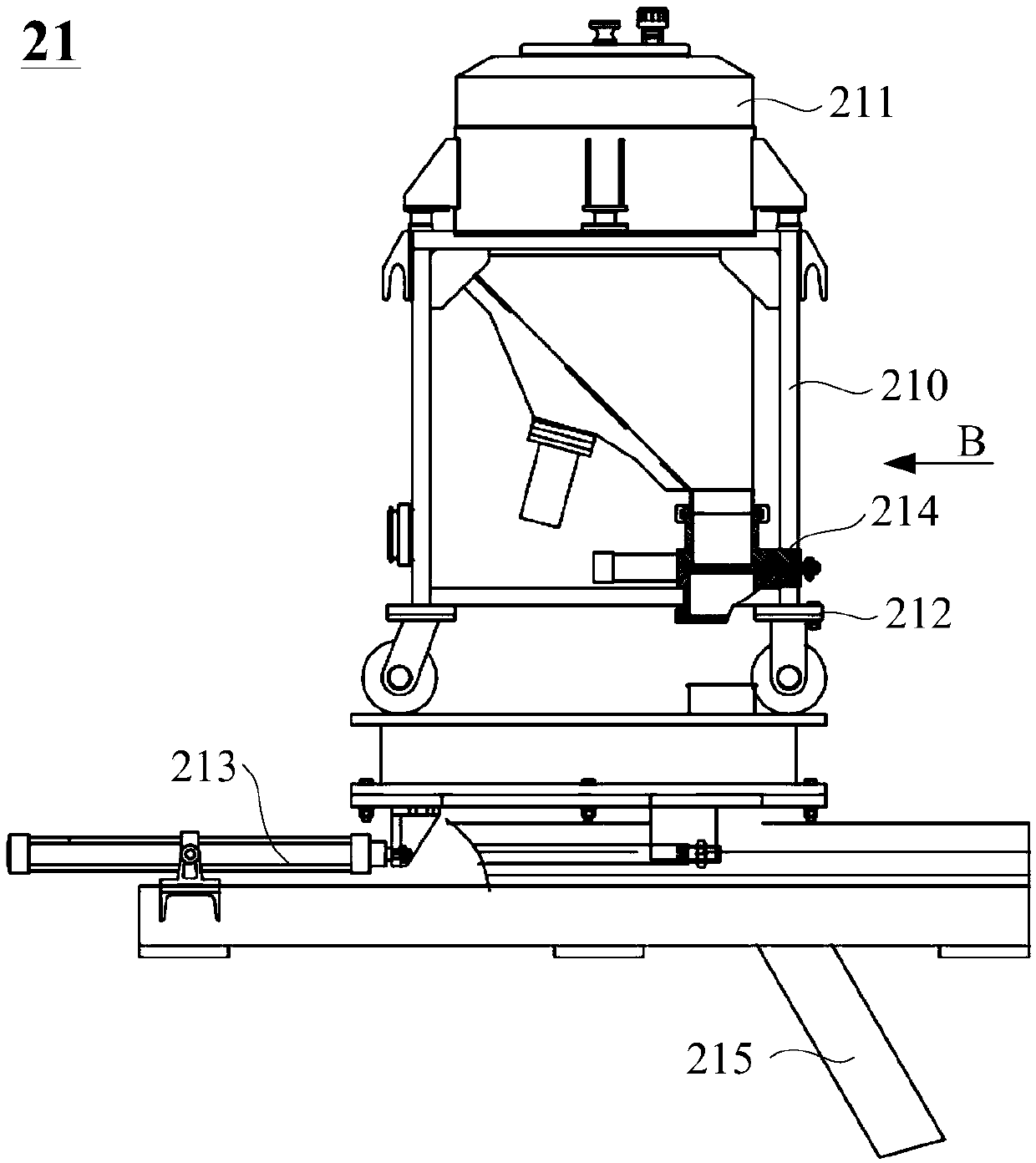

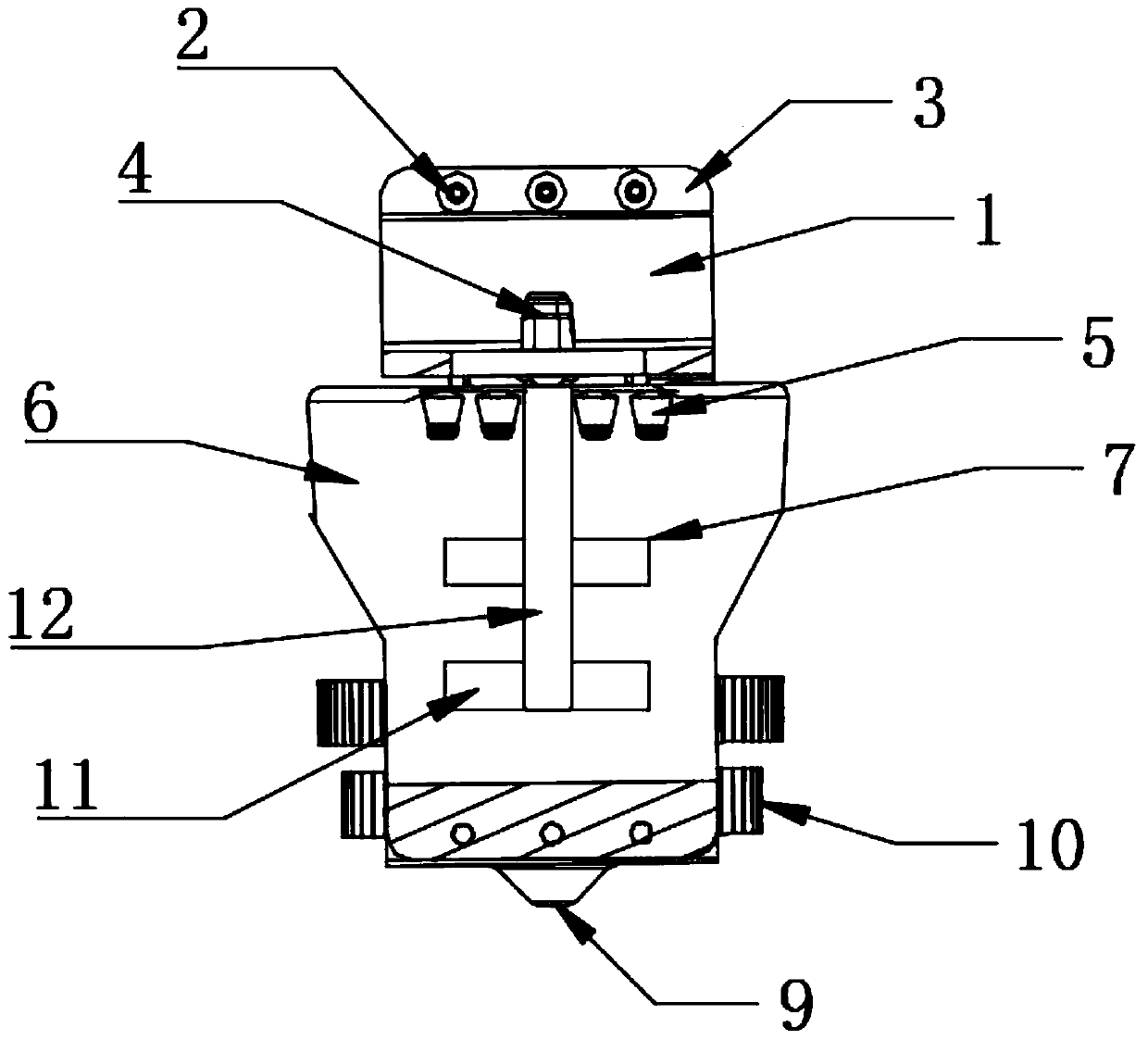

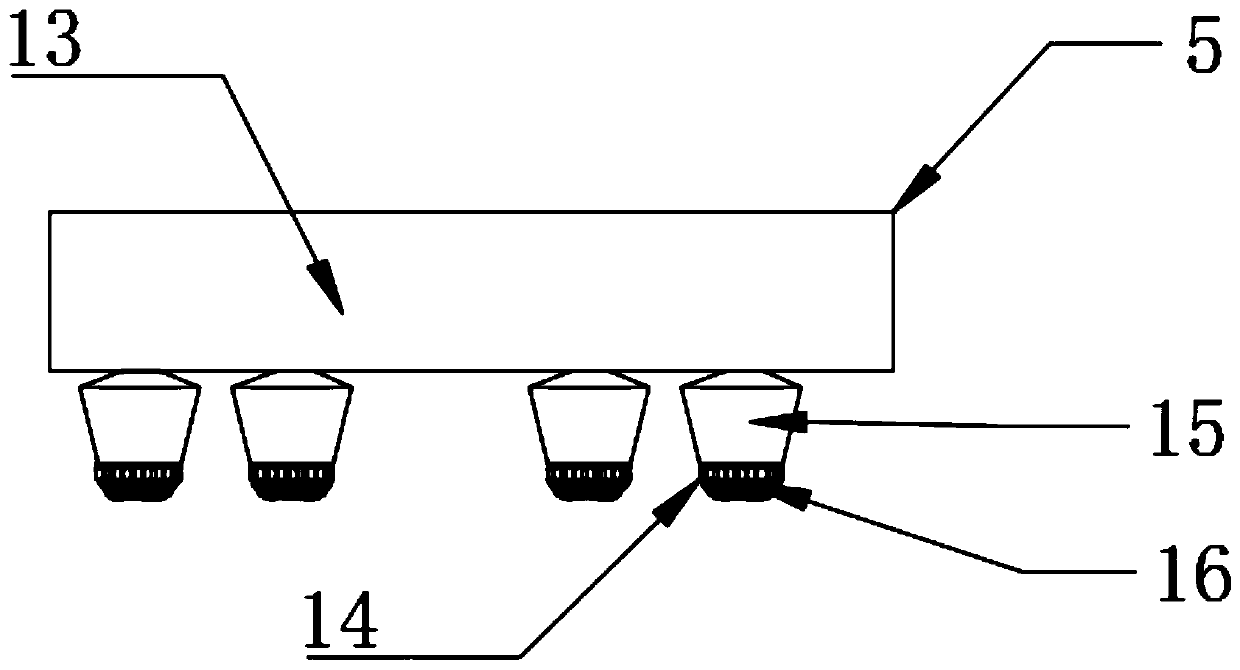

Pre-mixing type spiral powder feeding device

InactiveCN106672561APrecise output controlSimple structureMixer accessoriesPackagingBiochemical engineeringBlend time

The invention discloses a pre-mixing type spiral powder feeding device which comprises a rack, a plane table, weighing sensors, a box, a motor, a rotating shaft, a hollow shaft, a sealing seat, a blowing pipe, a spiral impeller, a feeding nozzle, a discharging nozzle and a controller. Raw materials and a modifier are fed into the box through the feeding nozzle, and the controller controls the motor to drive the spiral impeller fixedly connected with the hollow shaft to rotate through the rotating shaft, so that the raw materials and the modifier are continuously conveyed; meanwhile, compressed air is pumped into the hollow shaft through the blowing pipe, so that the raw materials and the modifier are blown up, and the raw materials and powder are mixed; and the raw materials and the modifier are mixed and pushed to move forwards by the spiral impeller at the same time till mixtures are discharged from the discharging nozzle, and the weighing sensors are used for weighing, so that the output amount of the raw materials and the modifier is precisely controlled. The pre-mixing type spiral powder feeding device is simple in structure, the raw materials and the modifier are mixed and pushed to move forwards by the spiral impeller at the same time so as to be mixed in advance, the subsequent modification mixing time is shortened, and modification efficiency is improved.

Owner:安徽金鼎新材料有限公司

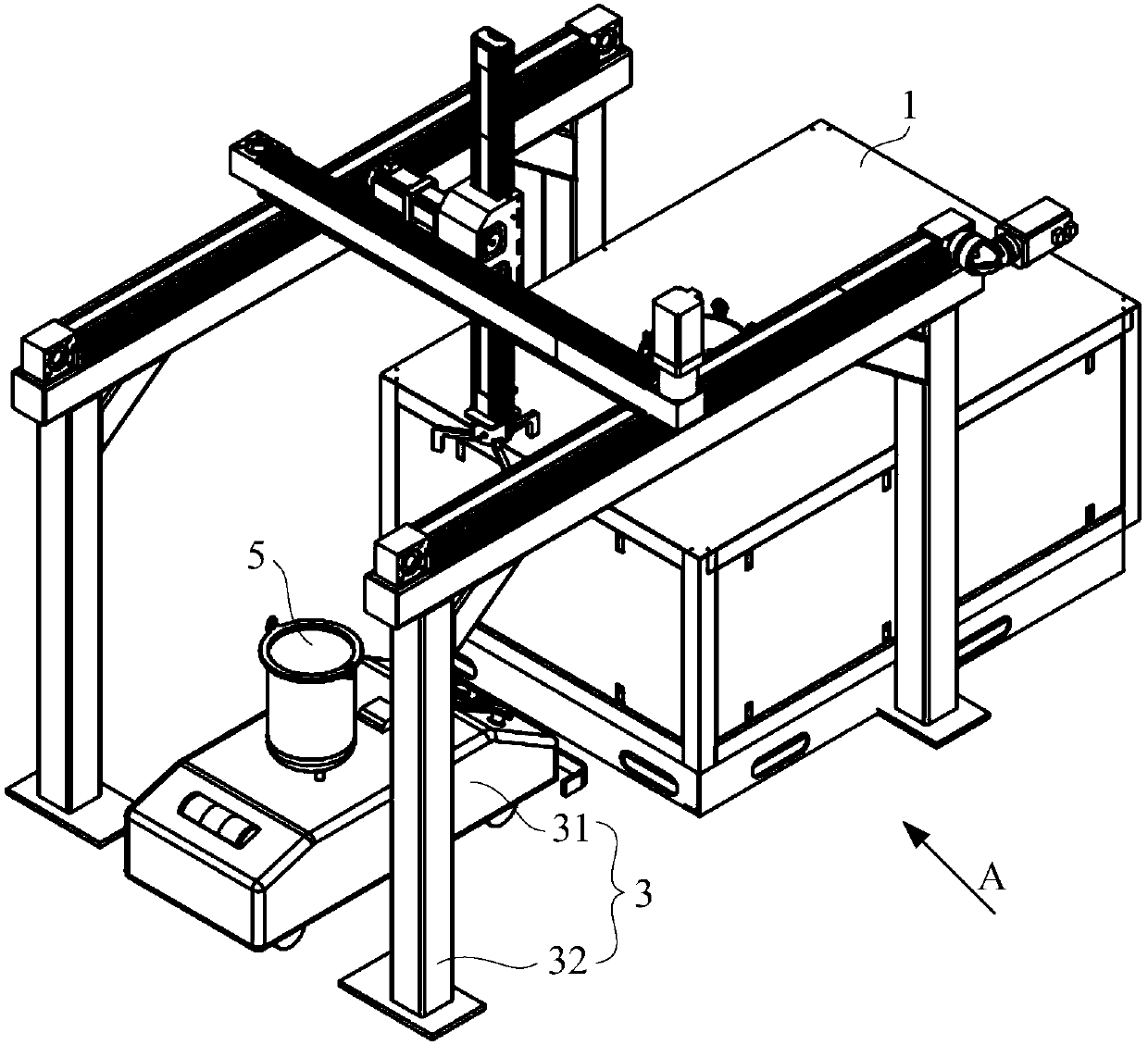

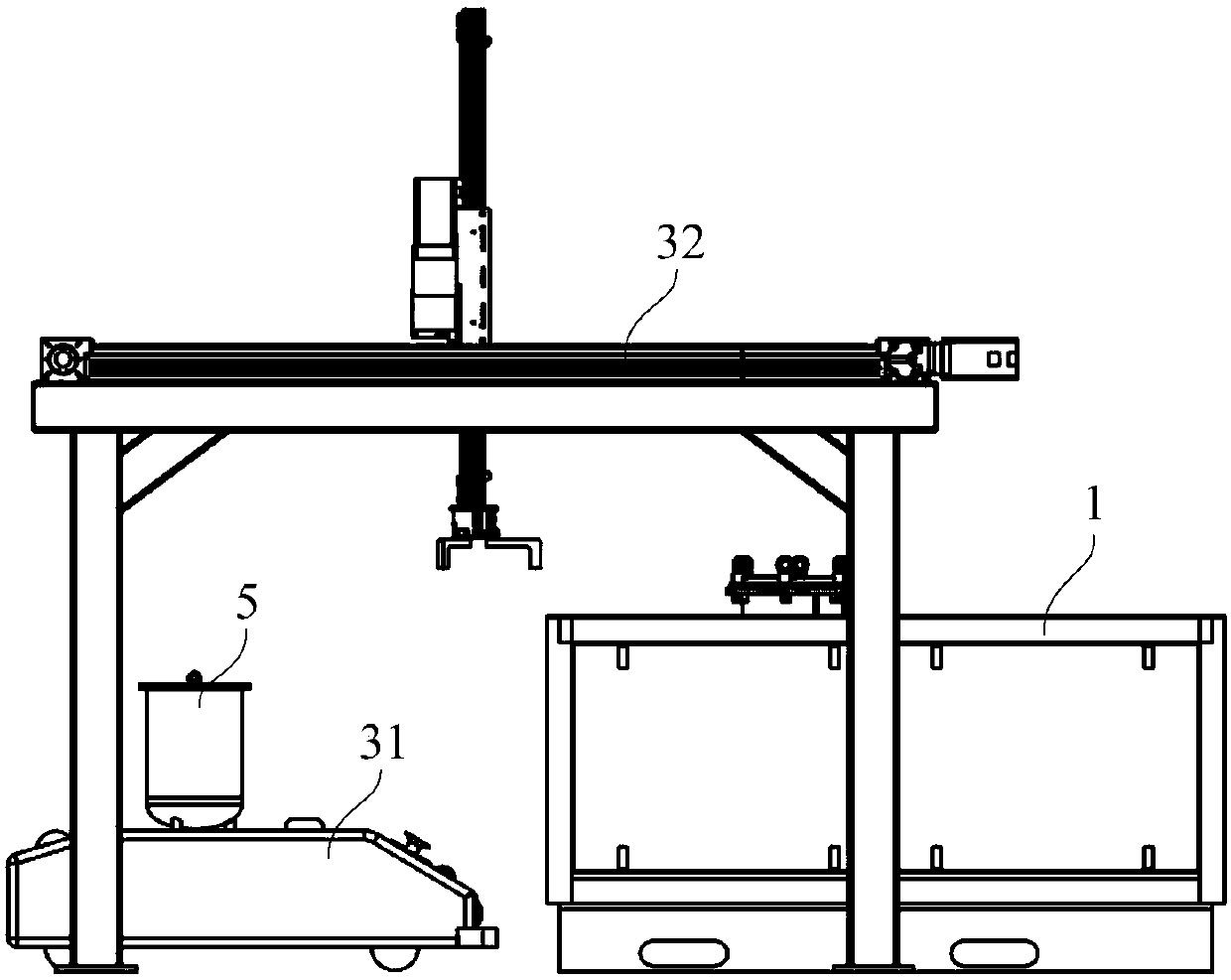

Explosive charging system and method

InactiveCN109092176AReduce lossesImprove mixing uniformityShaking/oscillating/vibrating mixersTransportation and packagingVibration accelerationMass ratio

An embodiment of the invention relates to the technical field of material mixing, in particular to an explosive charging system and method. the explosive charging system comprises a mixer, a mixing container, an automatic charging device, an automatic material transferring device and a control device, wherein the automatic charging device is used for charging a to-be-mixed material into the mixingcontainer in a preset mass ratio; the mixer is used for controlling the temperature, vacuum degree, vibration acceleration and mixing time of the mixing container containing the to-be-mixed material;the automatic material transferring device is used for conveying the mixing container among a charging station, a mixing station and a transfer station; the control device is in signal connection with the mixer, the automatic charging device and the automatic material transfer device and used for controlling actions of the mixer, the automatic charging device and the automatic material transferring device. The explosive charging system can solve the problems of long operation time and low production efficiency in the explosive charging process in the prior art.

Owner:HUBEI HANGPENG CHEM POWER TECH +1

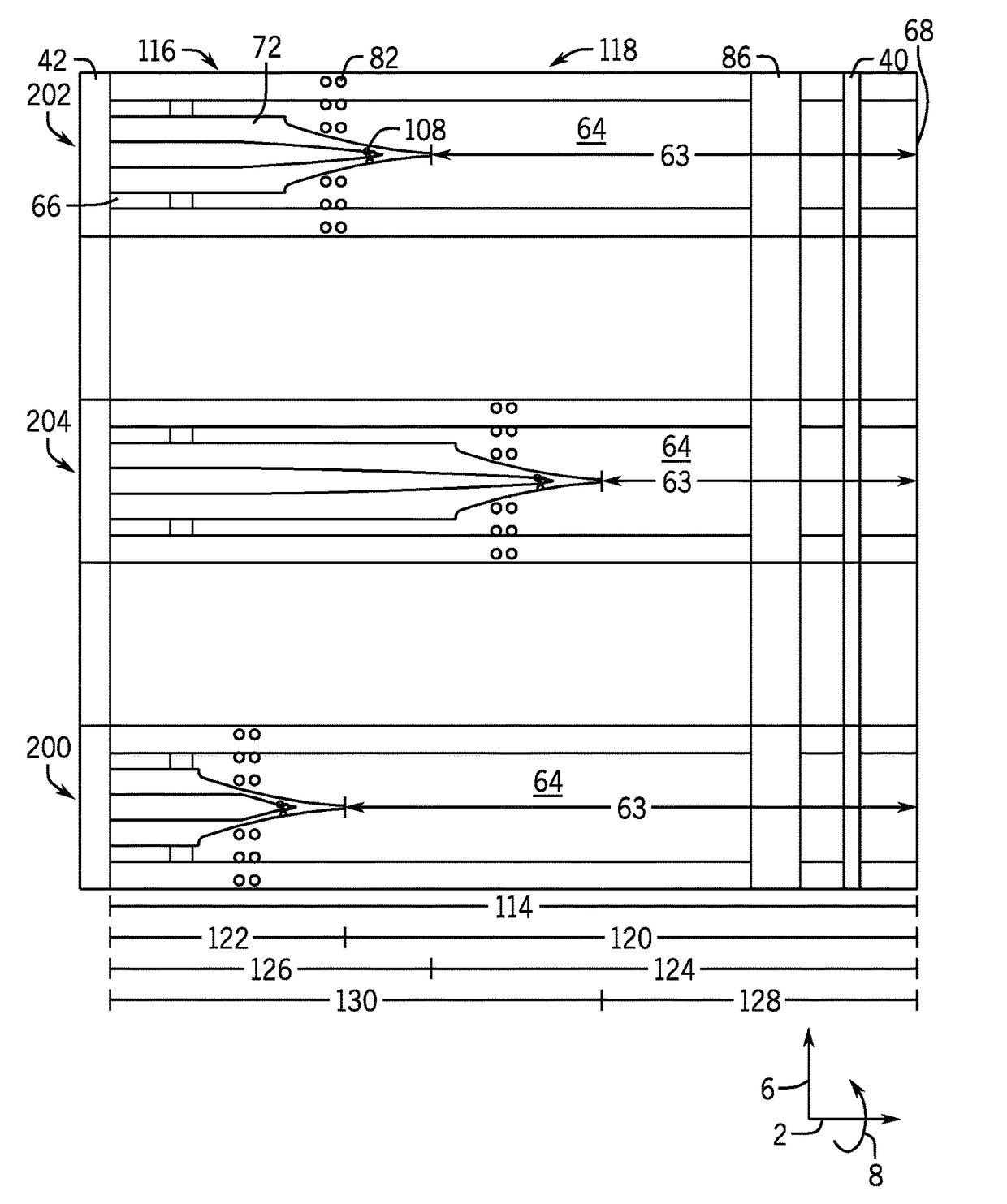

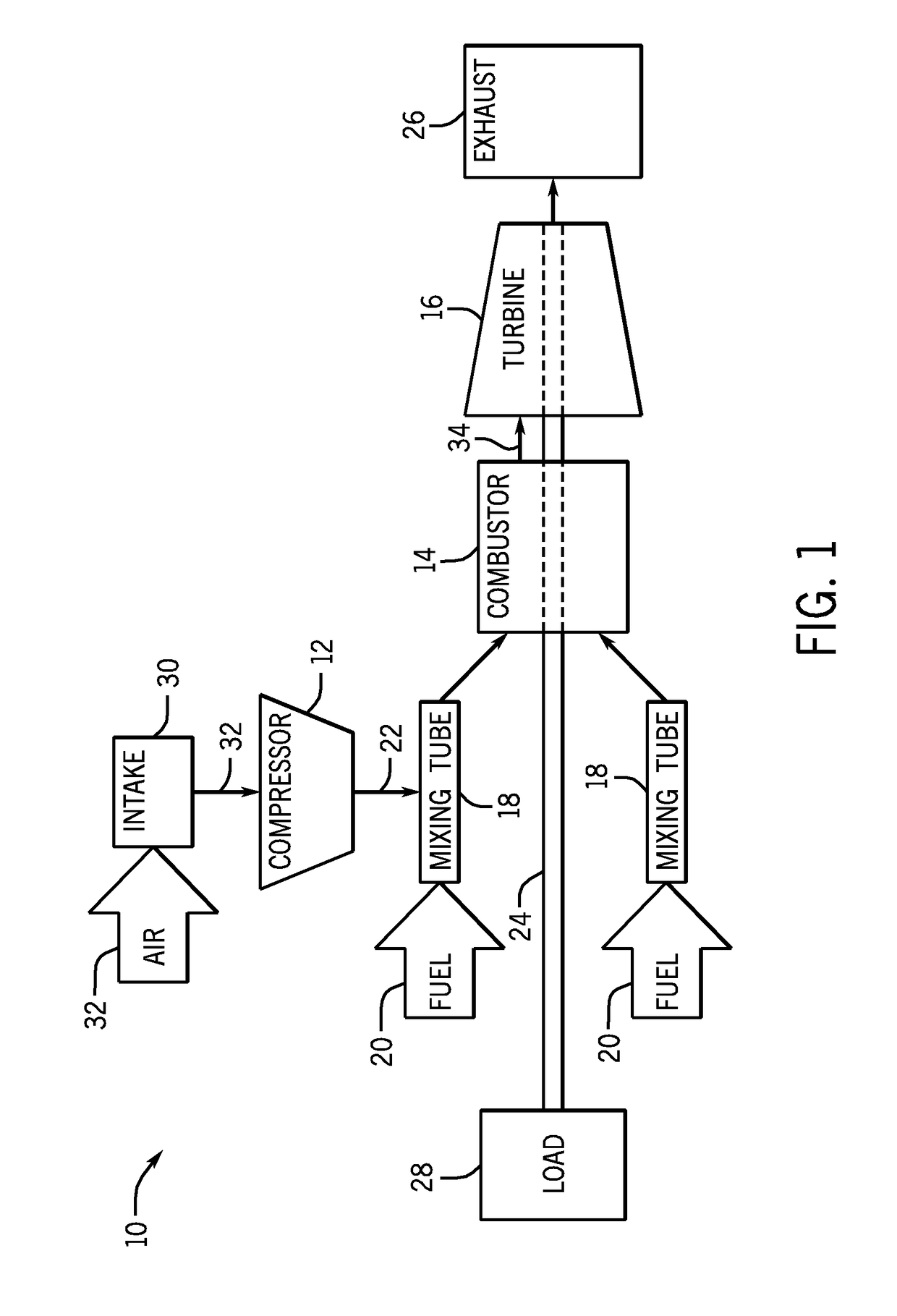

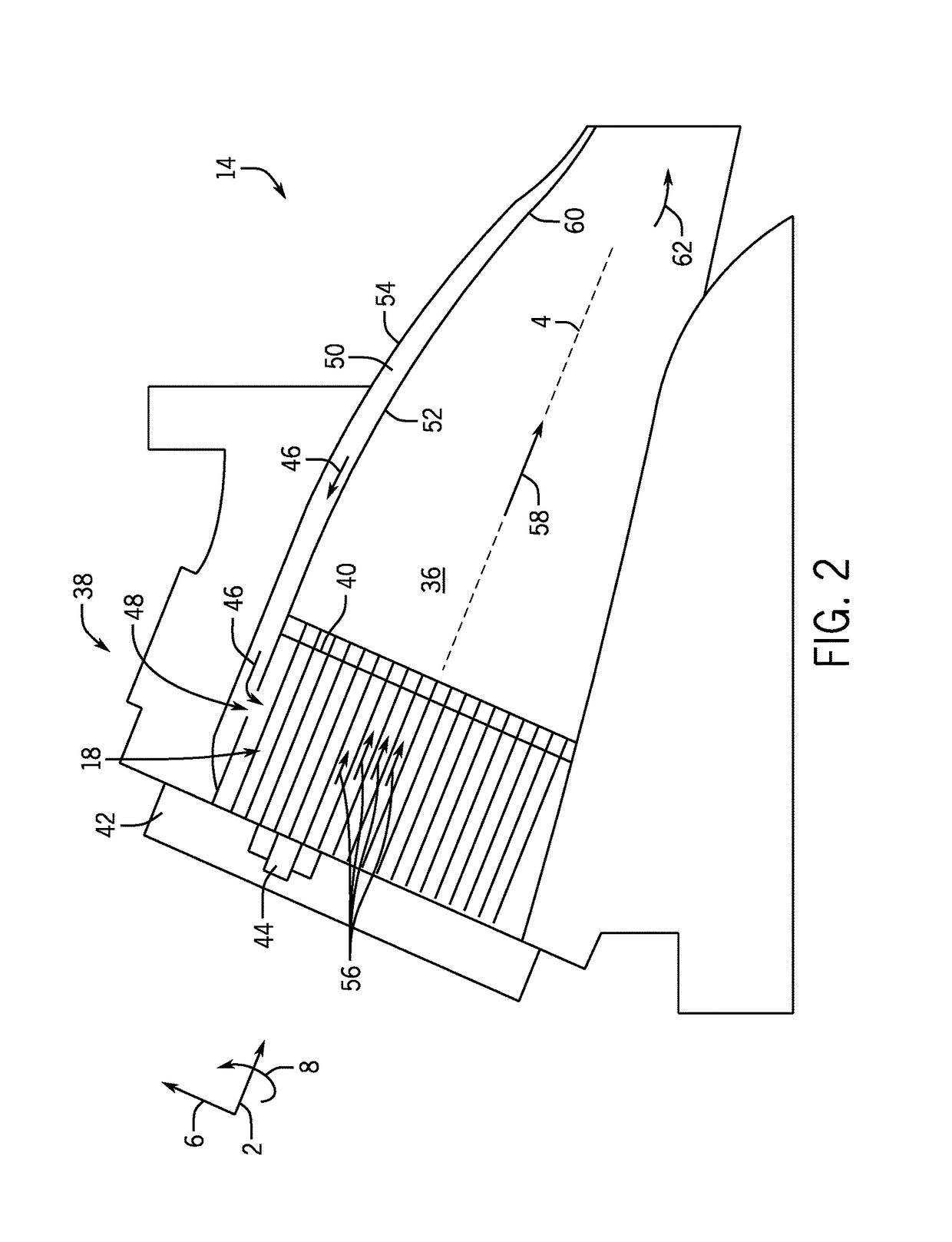

Fuel-air mixing system with mixing chambers of various lengths for gas turbine system

InactiveUS9650959B2Continuous combustion chamberTurbine/propulsion fuel supply systemsCombustion chamberHybrid system

Embodiments of the present disclosure are directed to systems and methods for premixing fuel and air prior to combustion within a combustion chamber. The system includes a plurality of fuel injectors and a plurality of mixing tubes, wherein each mixing tube has a first portion for receiving one of the plurality of fuel injectors and a second portion having a mixing chamber that is configured to mix fuel and air. The length of the mixing chamber varies among the plurality of mixing tubes to allow for different mixing times.

Owner:GENERAL ELECTRIC CO

Batching device for uniformly and continuously measuring microscale solid powder and particles

InactiveCN105366382AGuaranteed accuracyGuaranteed continuityConveyorsLoading/unloadingCycle controlProgrammable logic controller

The invention discloses a batching device for uniformly and continuously measuring microscale solid powder and particles and relates to the continuous and uniform measuring and batching device for metallurgy, construction materials, foods and other manufacturing fields. The batching device is characterized in that the device structurally comprises a feeding box, a variable-speed spiral conveyor connected with a discharging pipe of the feeding box, and a weighting spiral conveyor connected with a discharging outlet of the variable-speed spiral conveyor; an electronic scale is arranged on the weighting spiral conveyor, and the data of the electronic scale are connected with the control end of a variable-frequency and variable-speed motor of the variable-speed spiral conveyor through a programmable logic controller (PLC). According to the batching device for uniformly and continuously measuring the microscale solid powder and the particles, close-cycle control, continuous operation and sealed operation in the batching process are achieved, sufficient mixing time and mixing space of the microscale solid powder, the particles and materials are ensured; the precision, the continuity and the stability of adding the microscale solid powder and the particles are ensured, and the microscale solid powder and the particles are sufficiently dispersed and mixed in the materials.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Process for producing mixture of two-liquid mixing type curable resin and process for producing hollow-fiber membrane filter element

InactiveUS20100044908A1Easy curingReduce energy consumptionShaking/oscillating/vibrating mixersFlow mixersHybrid typeBlend time

An object of the present invention is to provide a process for producing a mixture of a two-liquid mixing type curable resin, which process is hard to generate curing unevenness, can be carried out with low energy consumption, and is suited for mixing even with a disposable static mixer.The present invention provides a process for producing a mixture of a two-liquid mixing type curable resin by mixing the constituents of the resin, wherein mixing operations of the constituents are performed multiple times and a non-mixing time is provided between at least one of the mixing operations and another one of the mixing operations subsequent thereto.

Owner:ASAHI KASEI CHEM CORP

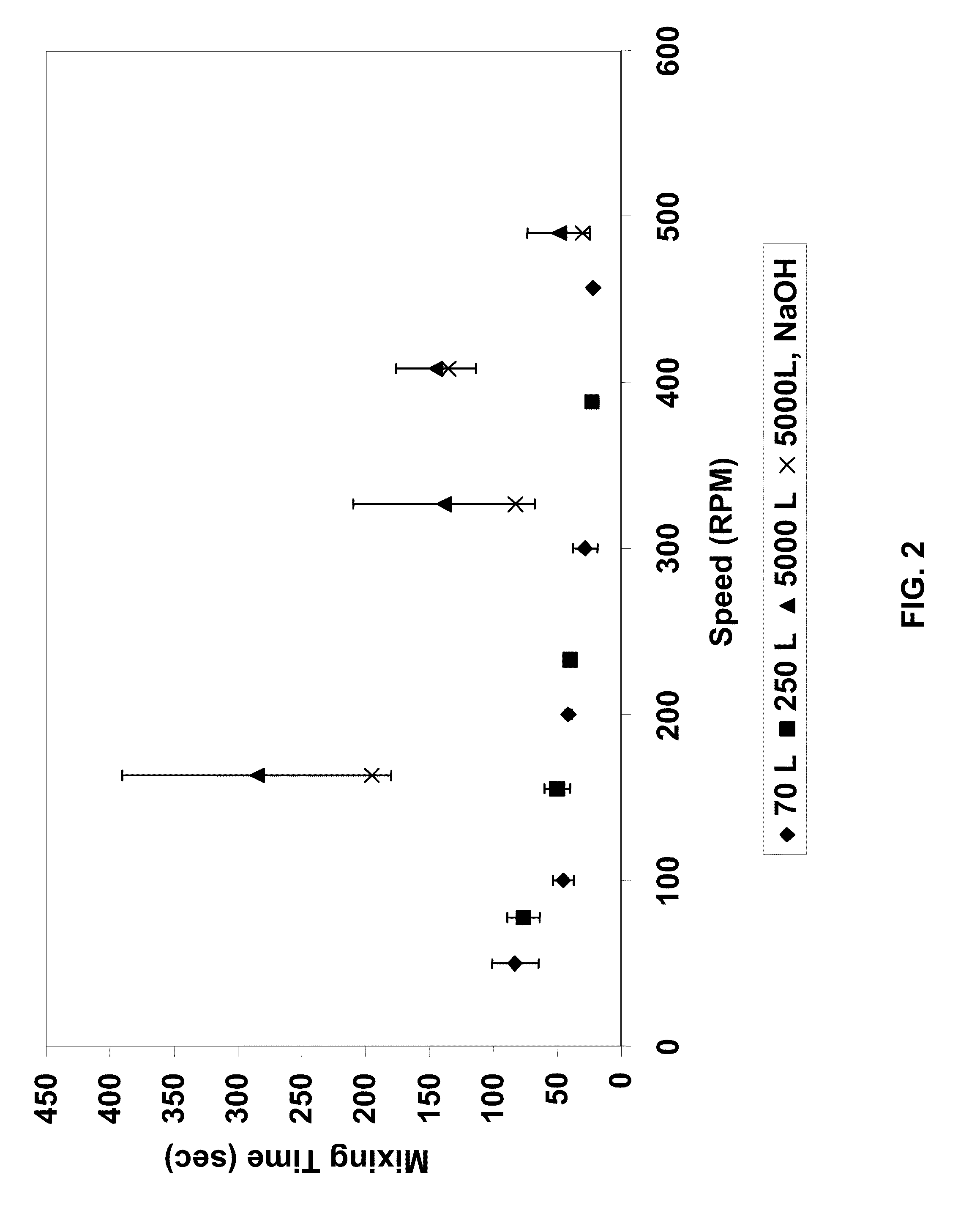

Method for scaling mixing operations

A method for determining mixing time for a variety of vessels is disclosed. This method utilizes information about the configuration, such as vessel diameter, impeller diameter and speed, fluid density and viscosity, and fluid height to determine the appropriate mixing time. In another embodiment, the parameters used to create small batches of material can be used to scale up to larger vessel sizes.

Owner:MILLIPORE CORP

Mixing device and chemical material storage equipment with same

InactiveCN111450731AAvoid mixingGuaranteed tightnessRotary stirring mixersTransportation and packagingEngineeringMechanical equipment

The invention is applicable to the field of chemical mechanical equipment and provides a mixing device and chemical material storage equipment with the same. The mixing device comprises a second shell, a stirring assembly, a driving mechanism and a first shell, wherein a feeding assembly used for conveying materials into the second shell is arranged in the first shell; and the feeding assembly comprises a third shell installed in the first shell, and a plurality of feeding parts capable of moving in the side line direction of the third shell are evenly arranged on one side of the third shell.Materials are stirred and mixed through the stirring assembly; since the feeding assembly is arranged, feeding can be realized while sealing performance is ensured; meanwhile, uniform spraying and feeding of the materials are realized through the plurality of feeding parts; the materials are mixed with the stirred materials again after being sprayed, so mixing time is shortened, granular impurities are prevented from being mixed in the feeding process, and the problems that granular impurities are easily mixed and materials are mixed only by stirring caused by direct feeding of materials of most of existing mixing devices are solved.

Owner:豆翠荣

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com