Method for determining mixing time of multiphase flow by using RGB color model

A technology of mixing time and color models, applied in the field of chemical engineering, which can solve the problems of subjectivity of global measurement methods and unconvincing reliability of mixing time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Build an ISA furnace water model dynamics simulation experiment, use polystyrene particles to simulate the solid phase (matte), water is used to simulate the liquid phase (melt) in the chemical reactor, nitrogen is used to replace the top-blown gas phase (oxygen) . Nitrogen was sprayed down through a spray gun above the chemical reactor, and polystyrene pellets were spread flat on the bottom of the tank before the experiment, and agitation was achieved by nitrogen injection from the nozzle.

[0045] The specific operation steps of this embodiment are as follows:

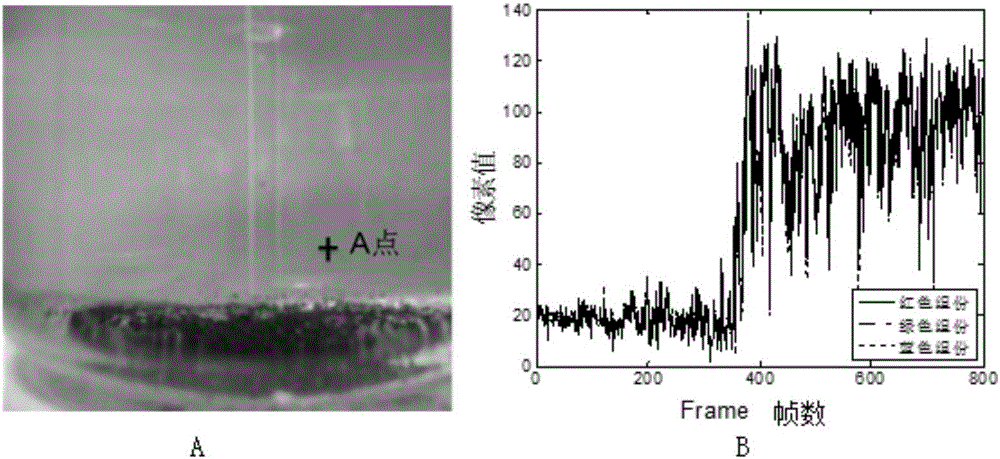

[0046] (1) Use a high-speed digital camera (AVI format, 30 frames per second) to shoot and record the entire process of the ISA furnace water model experiment, and use the video processing software KMPlayer to capture and store 800 images reflecting the distribution of polystyrene particles. Flow pattern (pattern format is bmp), the experimental pattern obtained is as follows figure 1 shown;

[0047] (2) Ob...

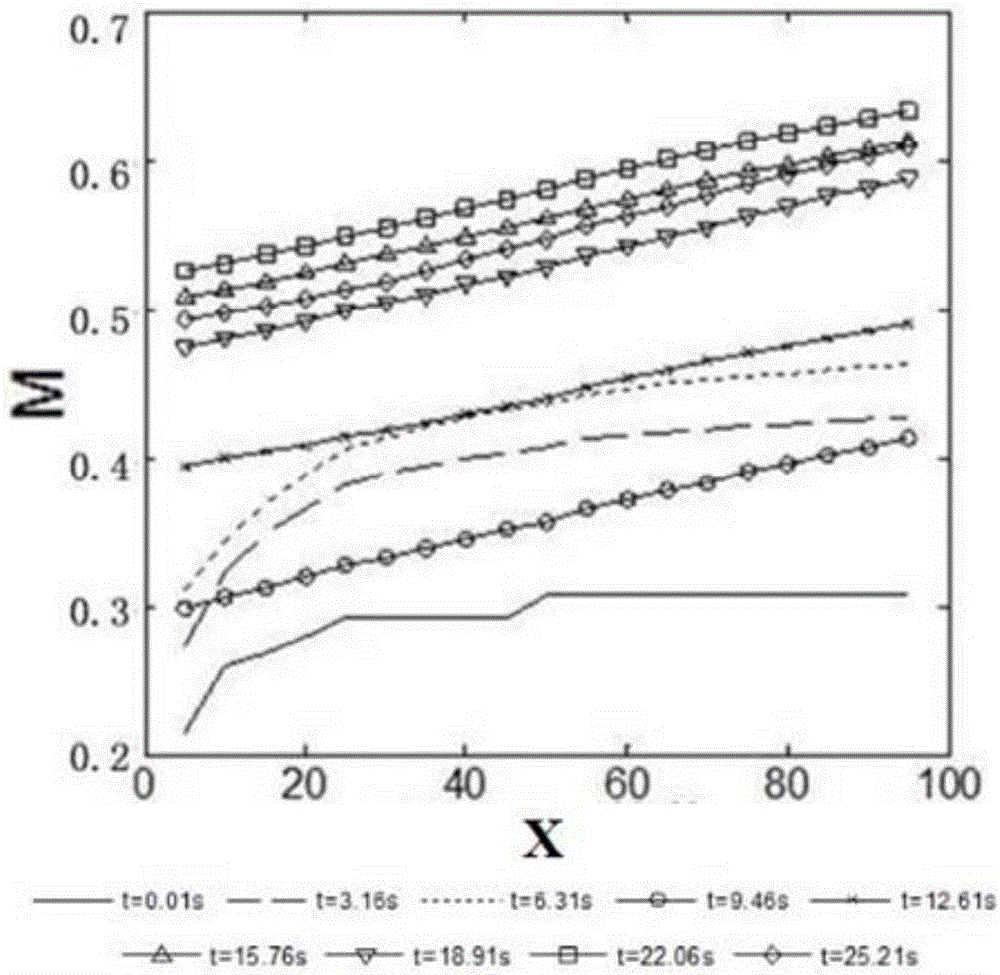

Embodiment 2

[0065] (1) The ORC direct contact steam generator test platform was built. According to the orthogonal test table, this test uses an orthogonal test with 4 factors and 3 levels. See Table 4 for details. During the test, a high-speed digital camera (AVI format, 30 frames per second) was used to shoot and record the heat transfer process of the dispersed phase droplet group in the continuous phase heat transfer oil through the visible window. Save 500 patterns of the behavior change of the droplet group during the direct contact heat transfer process (the pattern format is bmp), and obtain the experimental pattern as follows Figure 7 As shown in A. The experiment was carried out at night, and the fluorescent lamp was turned off during the experiment shooting process, and a high-power light source was used to illuminate the visible window. After such treatment, it was found that the photographed pattern was less affected by the outside world, and it could accurately reflect the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com