Patents

Literature

994 results about "Chemical reactor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A chemical reactor is an enclosed volume in which a chemical reaction takes place. In chemical engineering, it is generally understood to be a process vessel used to carry out a chemical reaction, which is one of the classic unit operations in chemical process analysis. The design of a chemical reactor deals with multiple aspects of chemical engineering. Chemical engineers design reactors to maximize net present value for the given reaction. Designers ensure that the reaction proceeds with the highest efficiency towards the desired output product, producing the highest yield of product while requiring the least amount of money to purchase and operate. Normal operating expenses include energy input, energy removal, raw material costs, labor, etc. Energy changes can come in the form of heating or cooling, pumping to increase pressure, frictional pressure loss or agitation.

Microfluidic chemical reactor for the manufacture of chemically-produced nanoparticles

InactiveUS20050129580A1Maintain propertiesMaterial nanotechnologyPolycrystalline material growthProcess functionNanoparticle

The present invention discloses microfluidic modules for making nanocrystalline materials in a continuous flow process. The microfluidic modules include one or more flow path with mixing structures and one or more controlled heat exchangers to process the nanocrystalline materials and reagents in the flow path. The microfluidic modules can be interconnected to form microfluidic reactors that incorporate one or more process functions such as nucleation, growth, and purification.

Owner:LAKE SHORE CRYOTRONICS INC

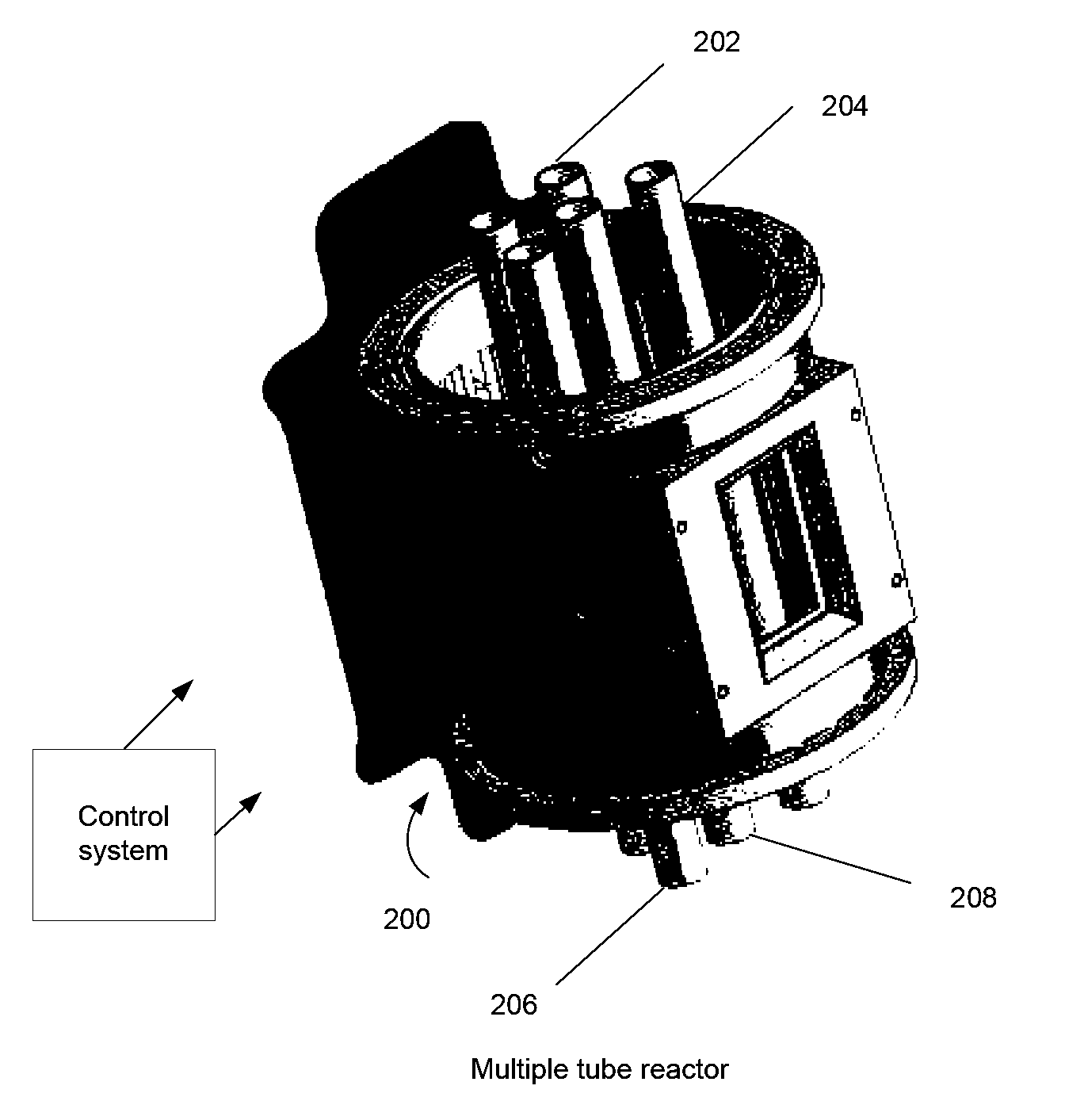

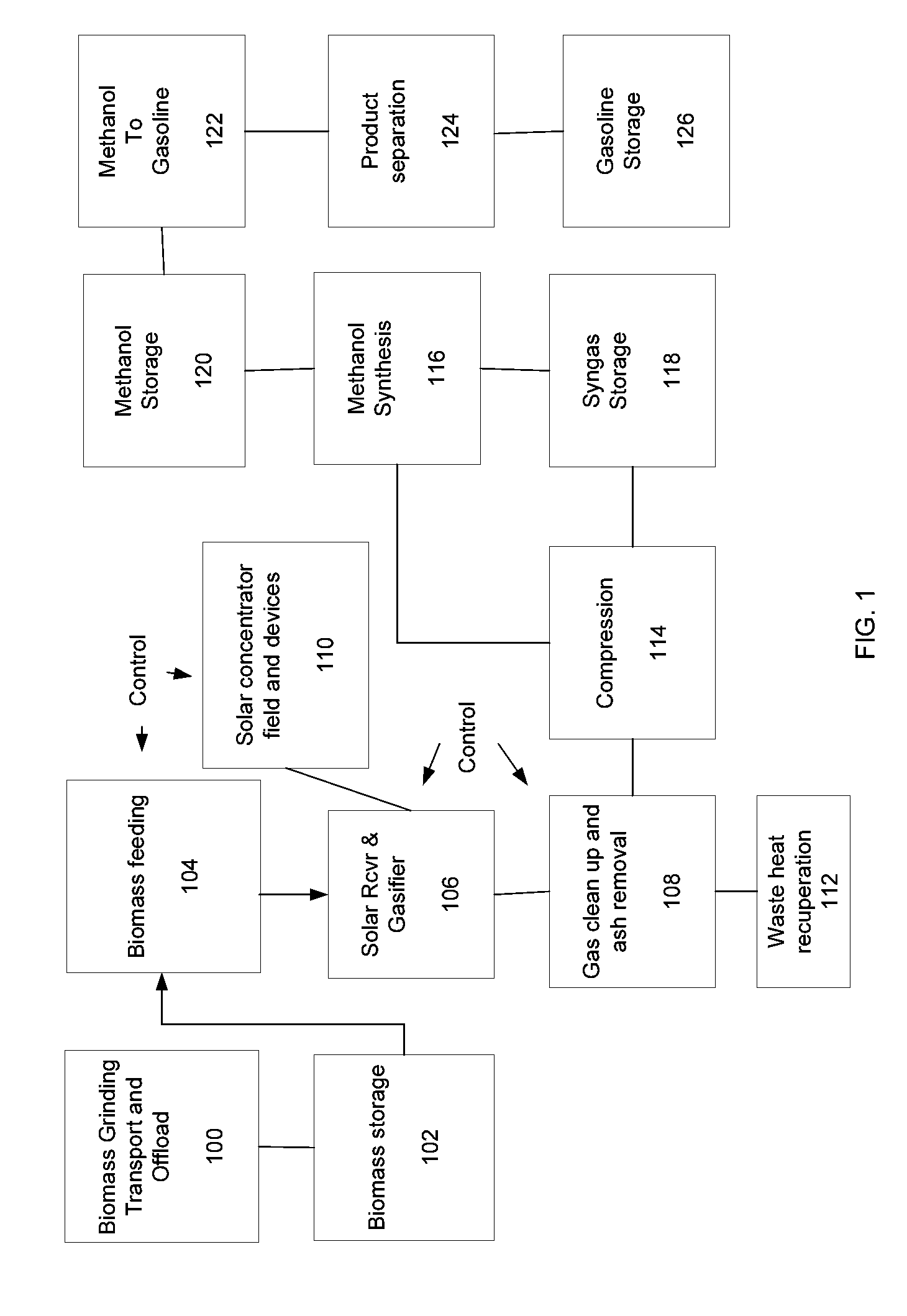

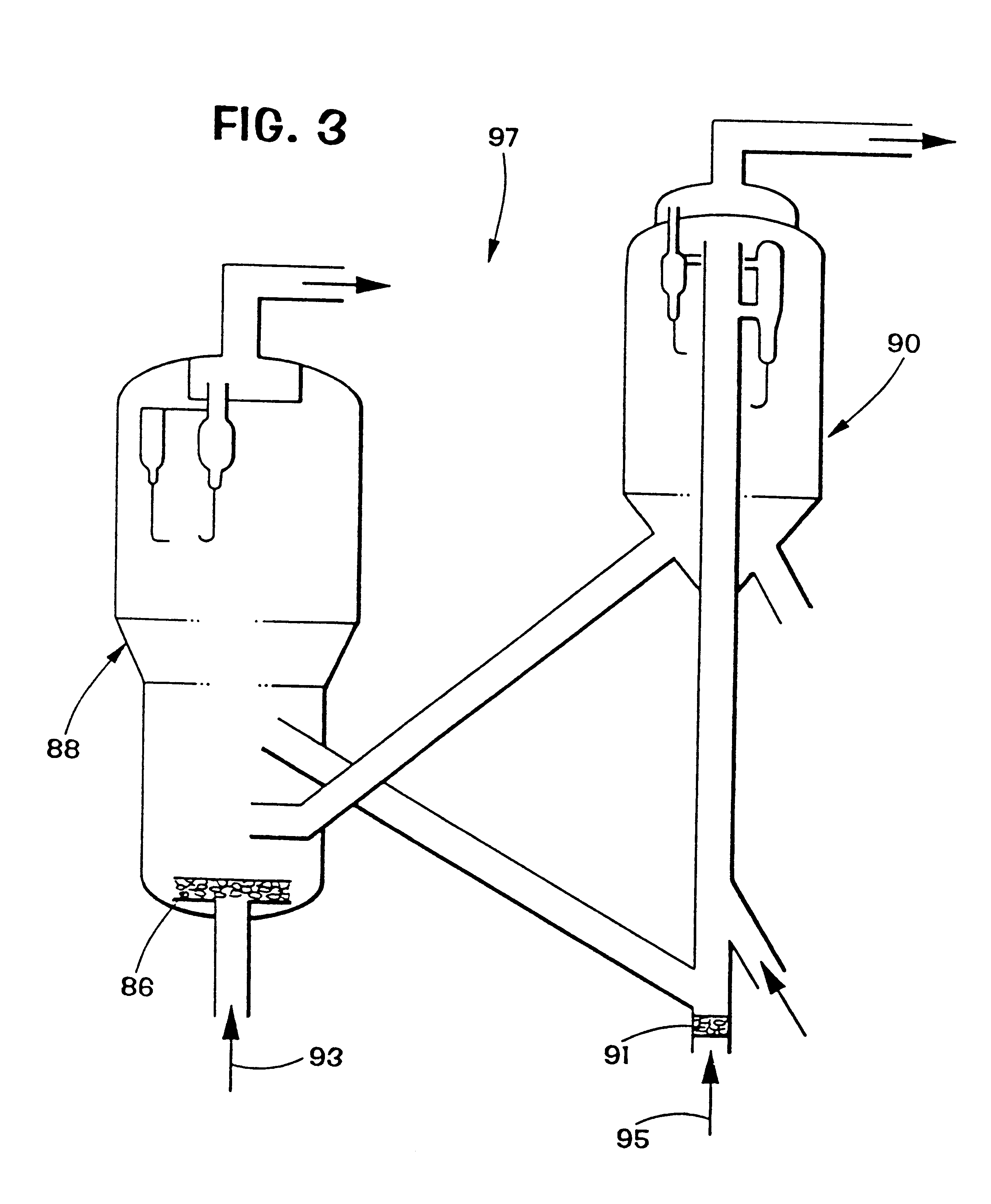

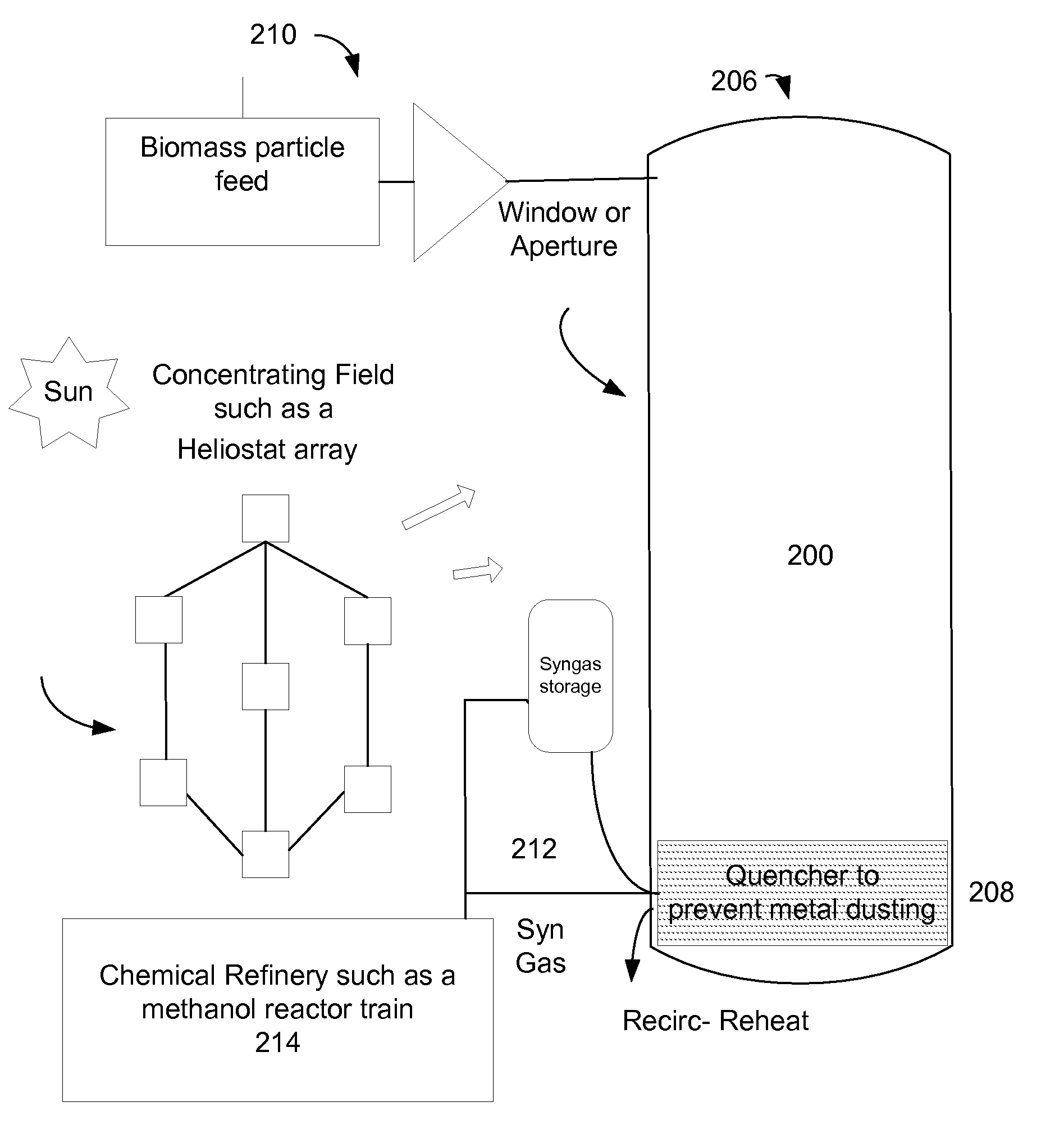

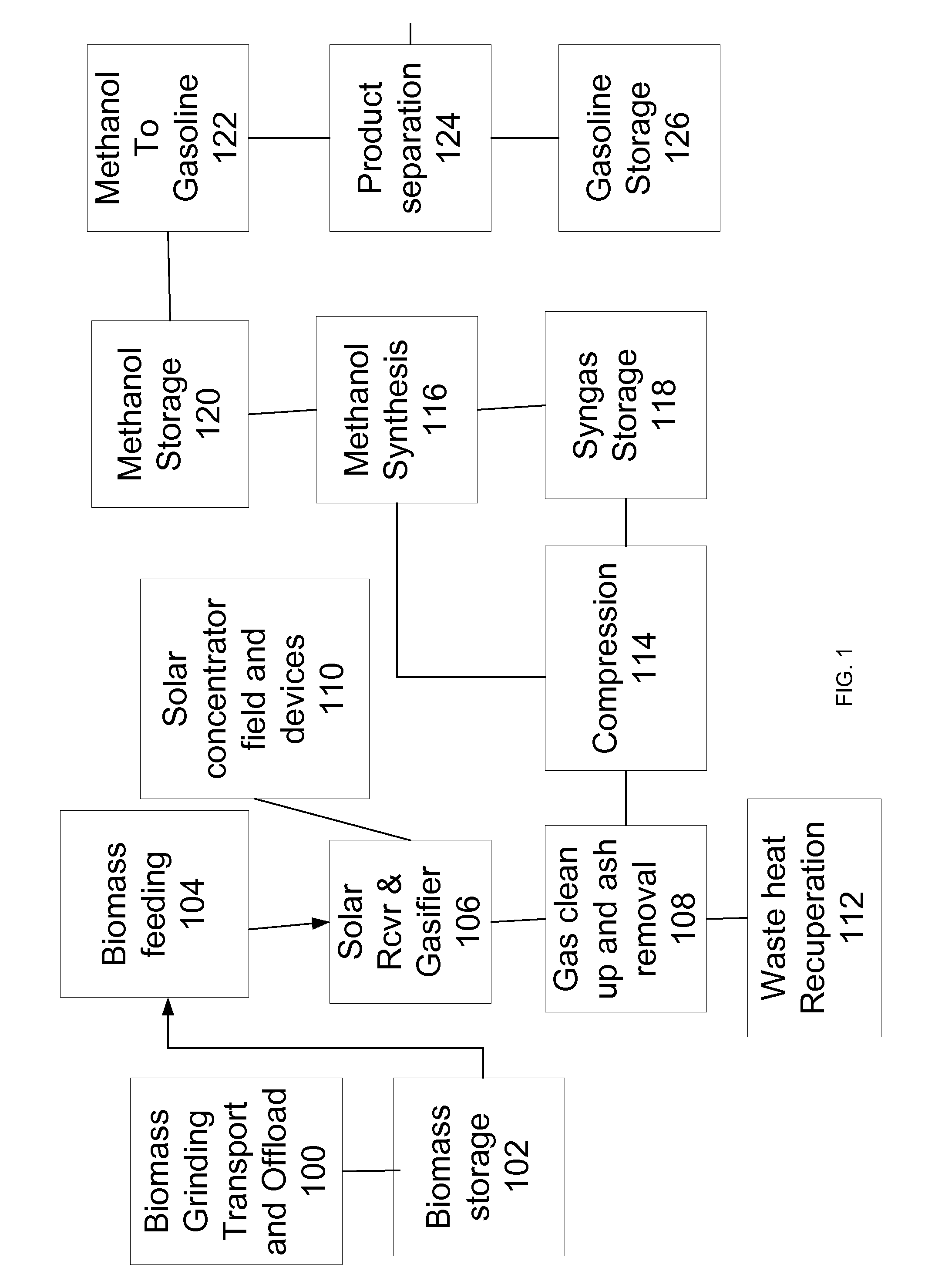

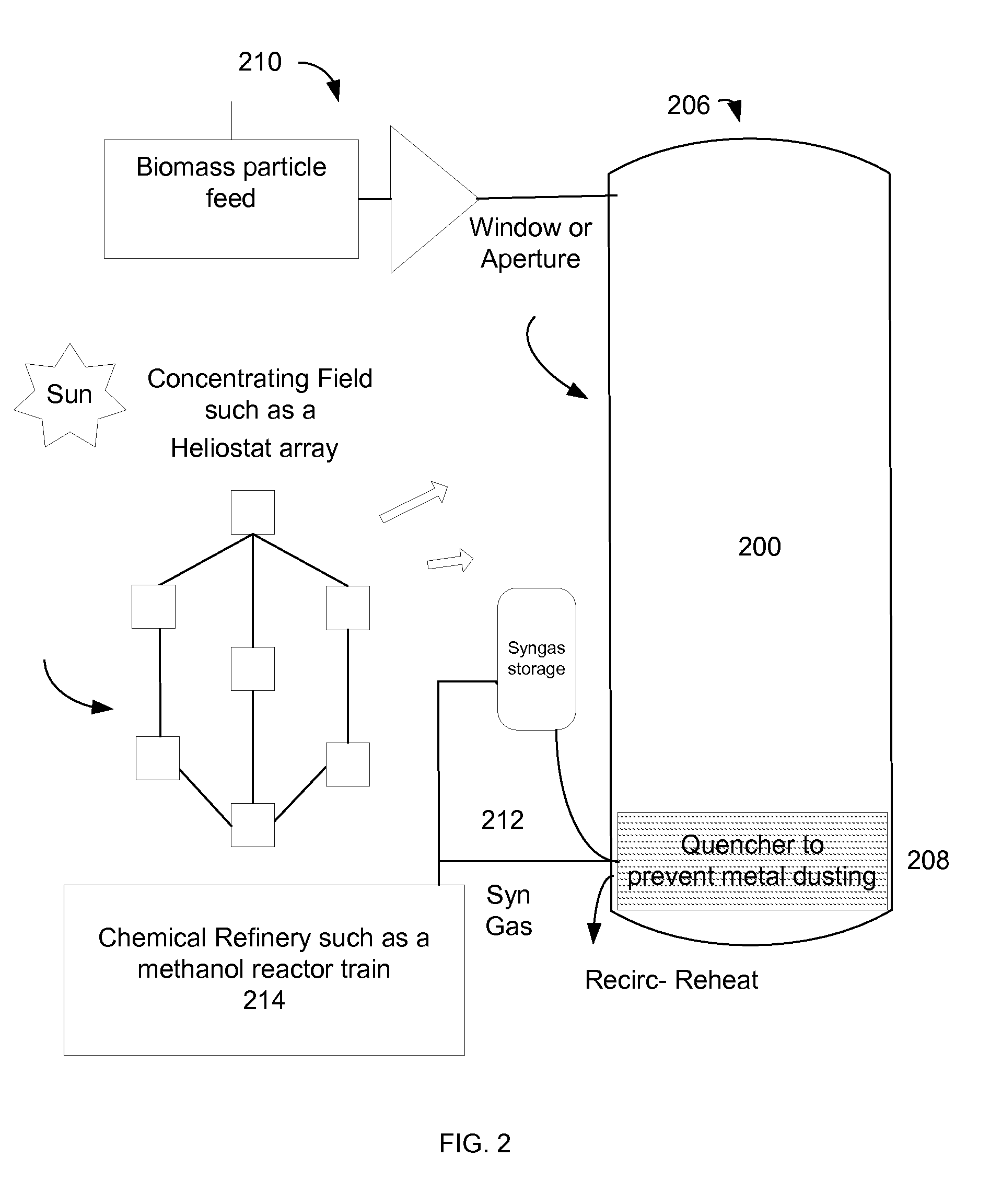

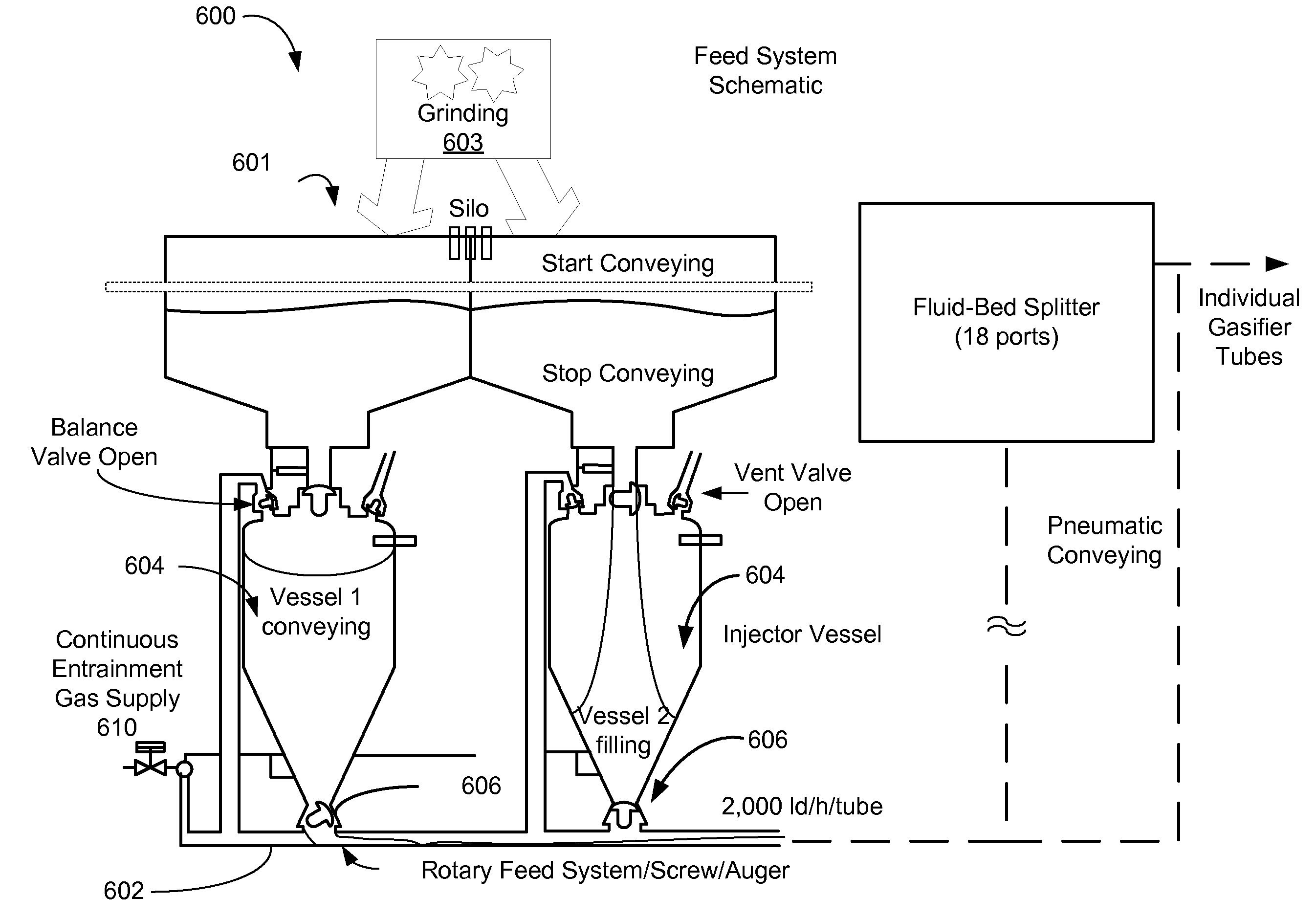

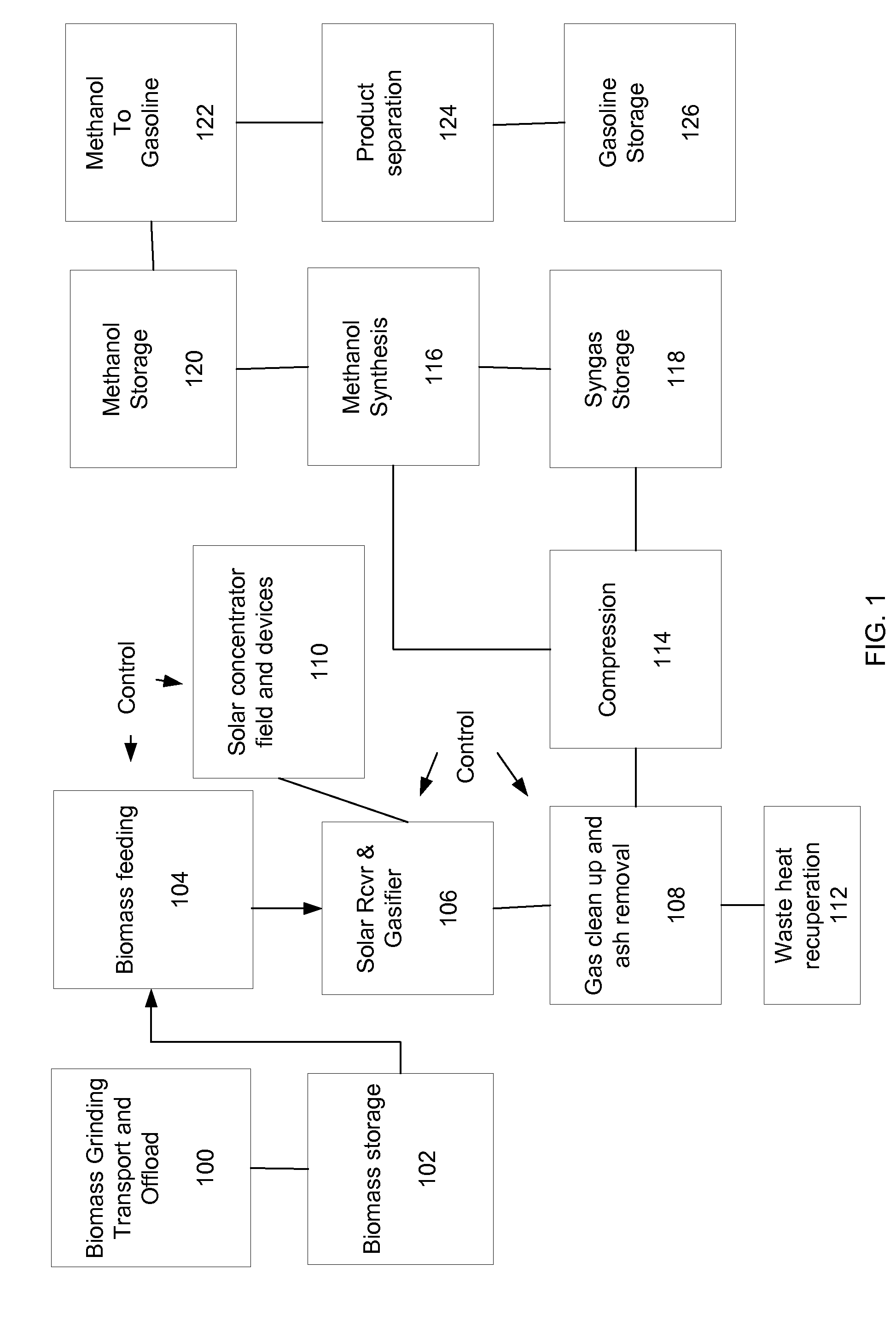

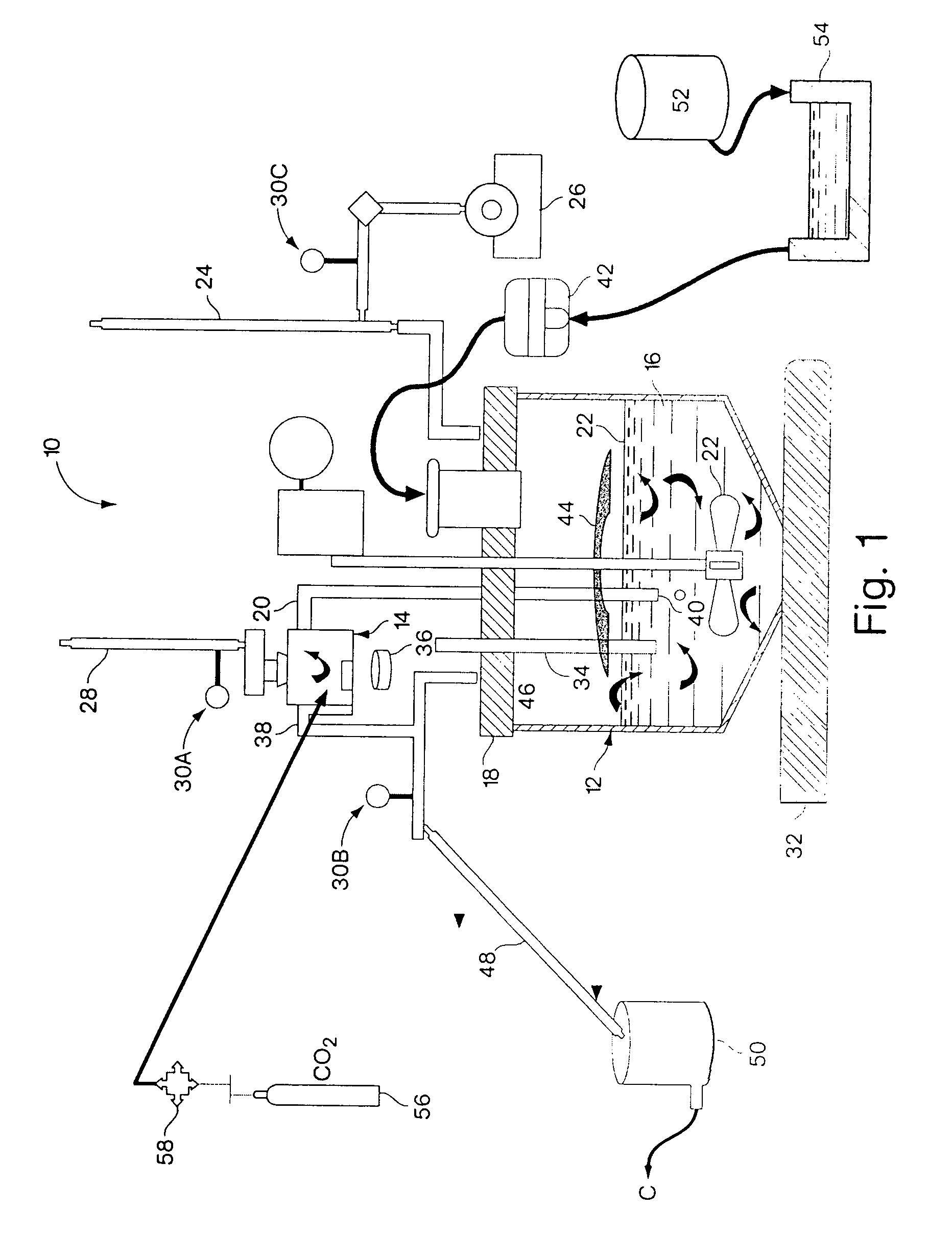

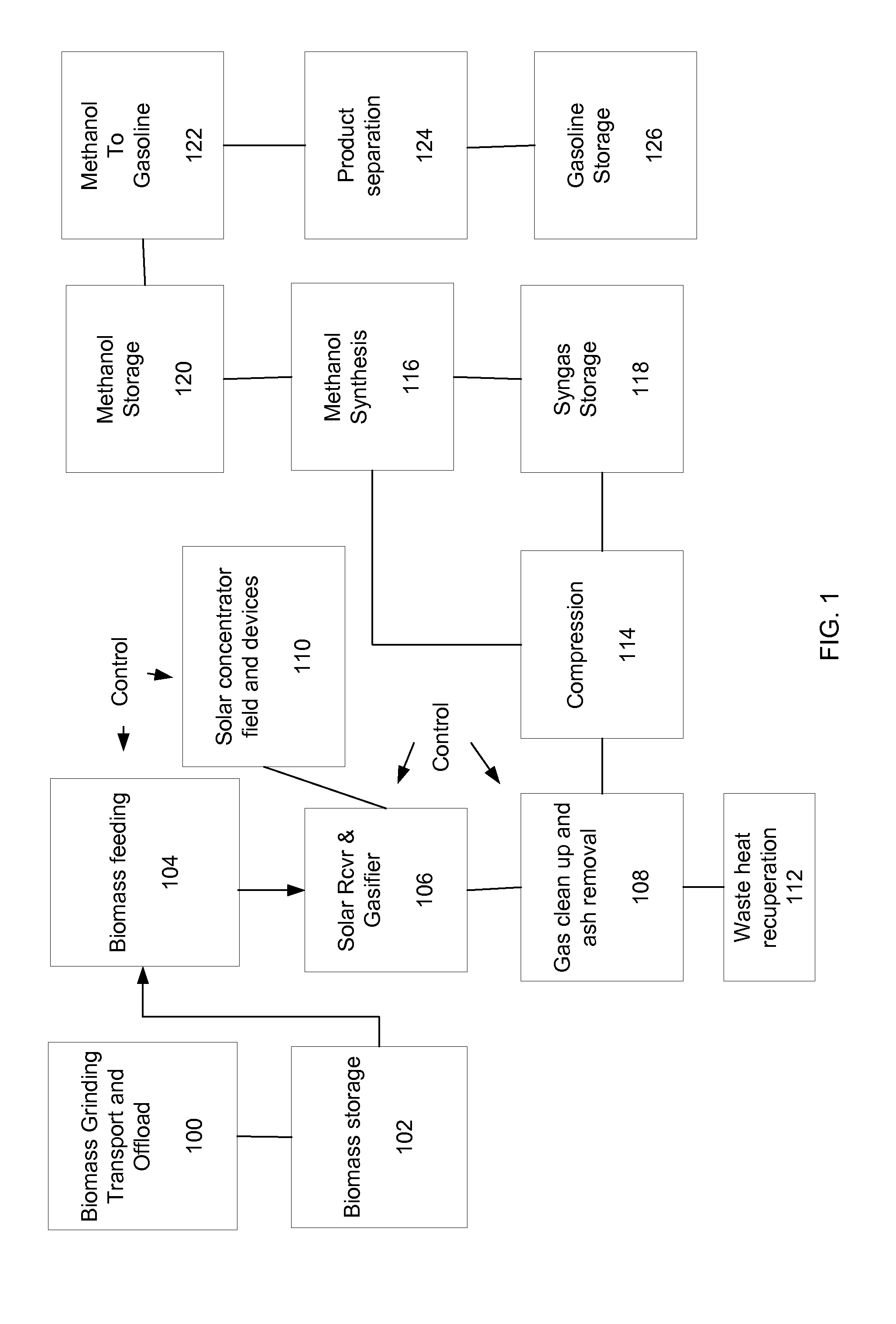

Systems and methods for solar-thermal gasification of biomass

InactiveUS20100237291A1Process control/regulationSolar heating energySteam reformingChemical reaction

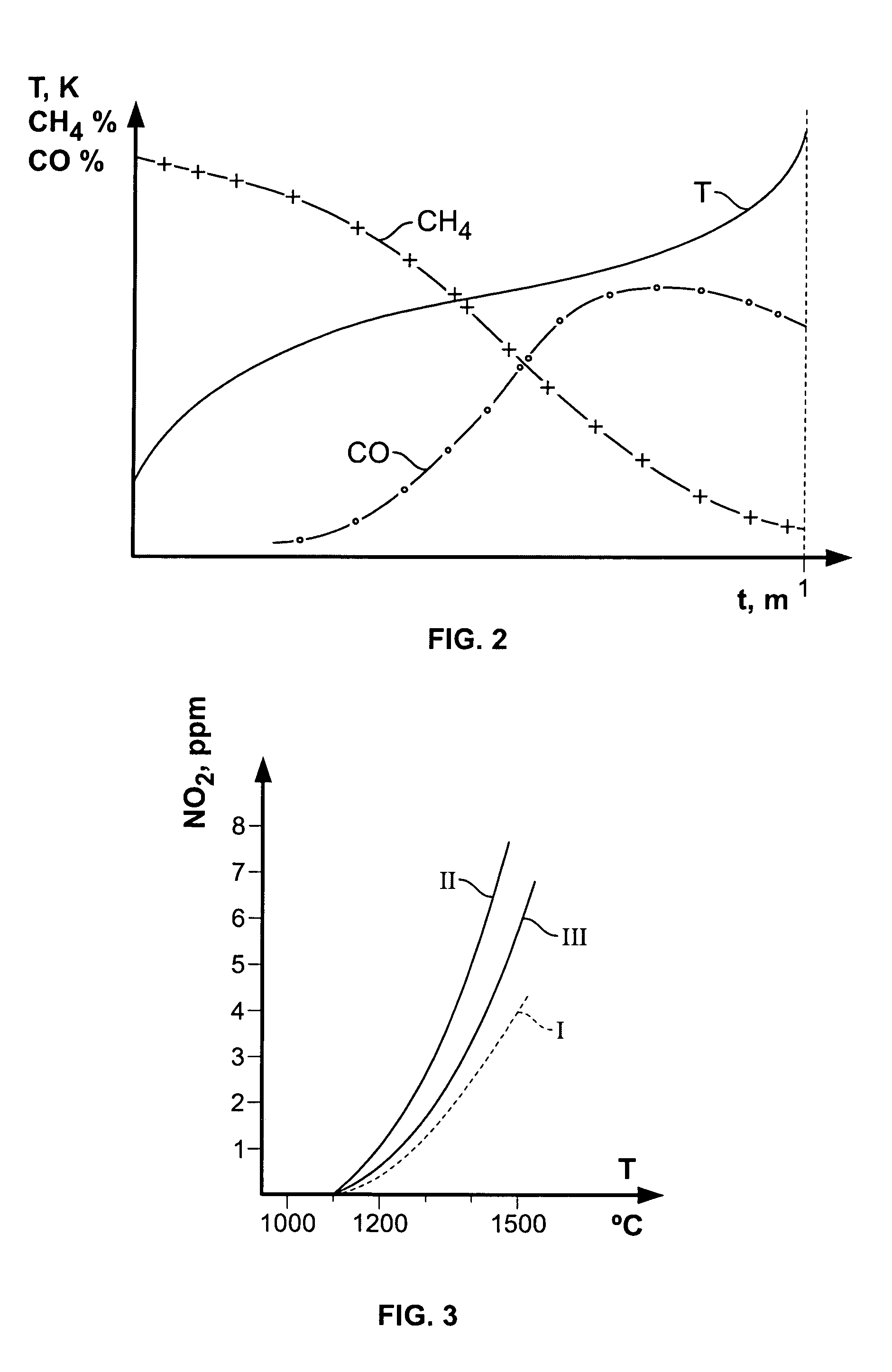

A method, apparatus, and system for a solar-driven chemical plant that may include a solar thermal receiver having a cavity with an inner wall, where the solar thermal receiver is aligned to absorb concentrated solar energy from one or more of 1) an array of heliostats, 2) solar concentrating dishes, and 3) any combination of the two. Some embodiments may include a solar-driven chemical reactor having multiple reactor tubes located inside the cavity of solar thermal receiver, wherein a chemical reaction driven by radiant heat occurs in the multiple reactor tubes, and wherein particles of biomass are gasified in the presence of a steam (H2O) carrier gas and methane (CH4) in a simultaneous steam reformation and steam biomass gasification reaction to produce reaction products that include hydrogen and carbon monoxide gas using the solar thermal energy from the absorbed concentrated solar energy in the multiple reactor tubes.

Owner:SUNDROP IP HLDG LLC

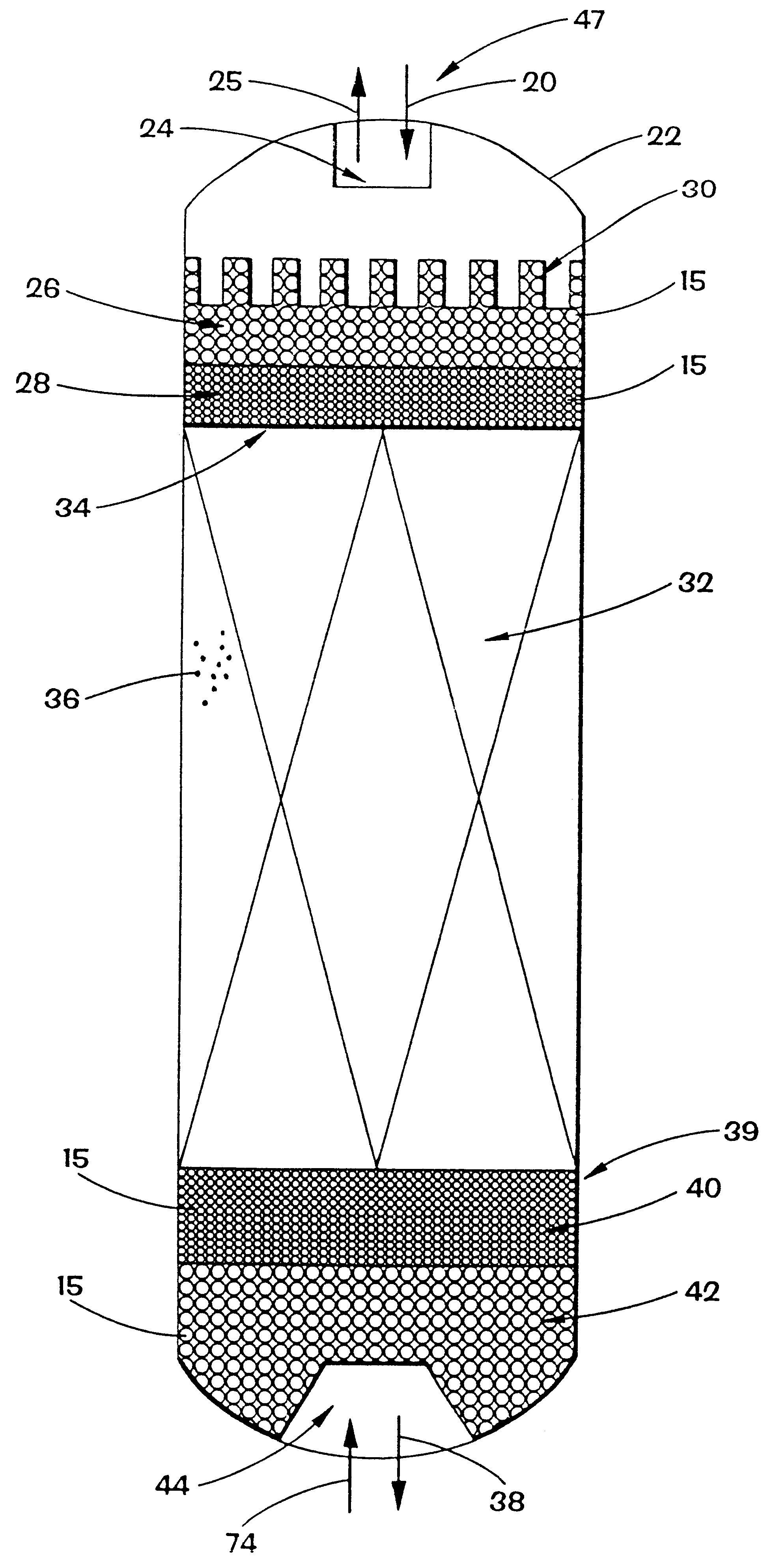

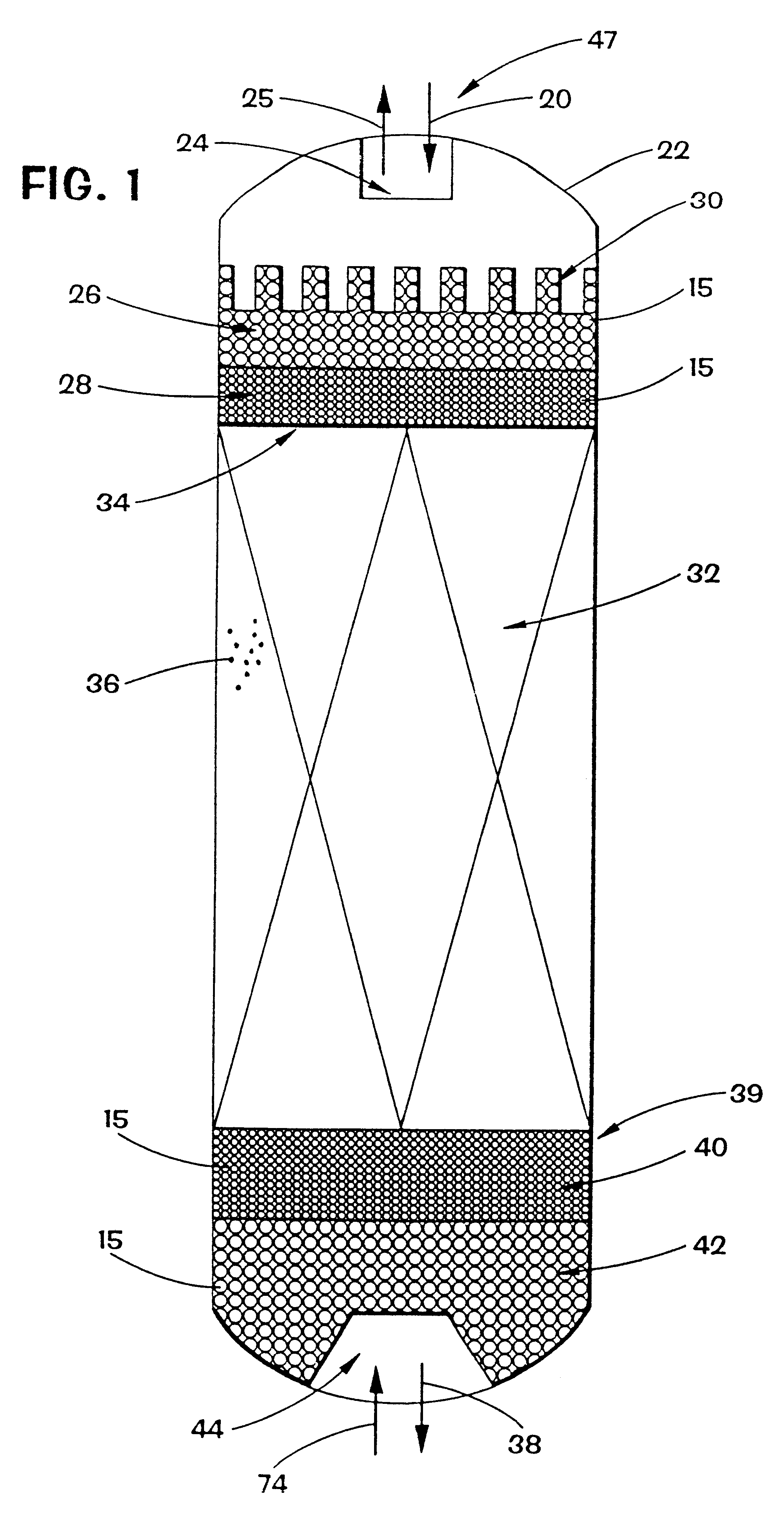

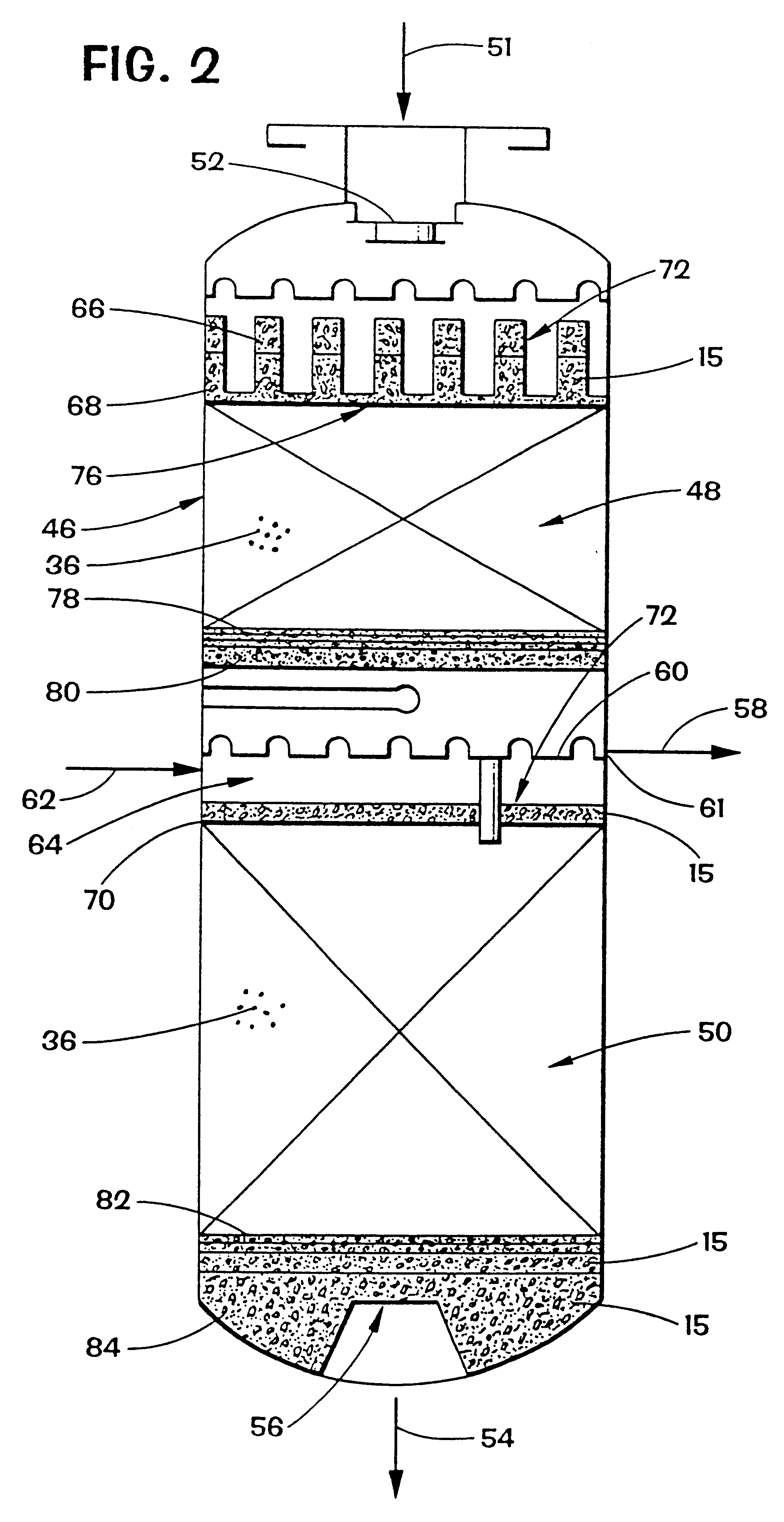

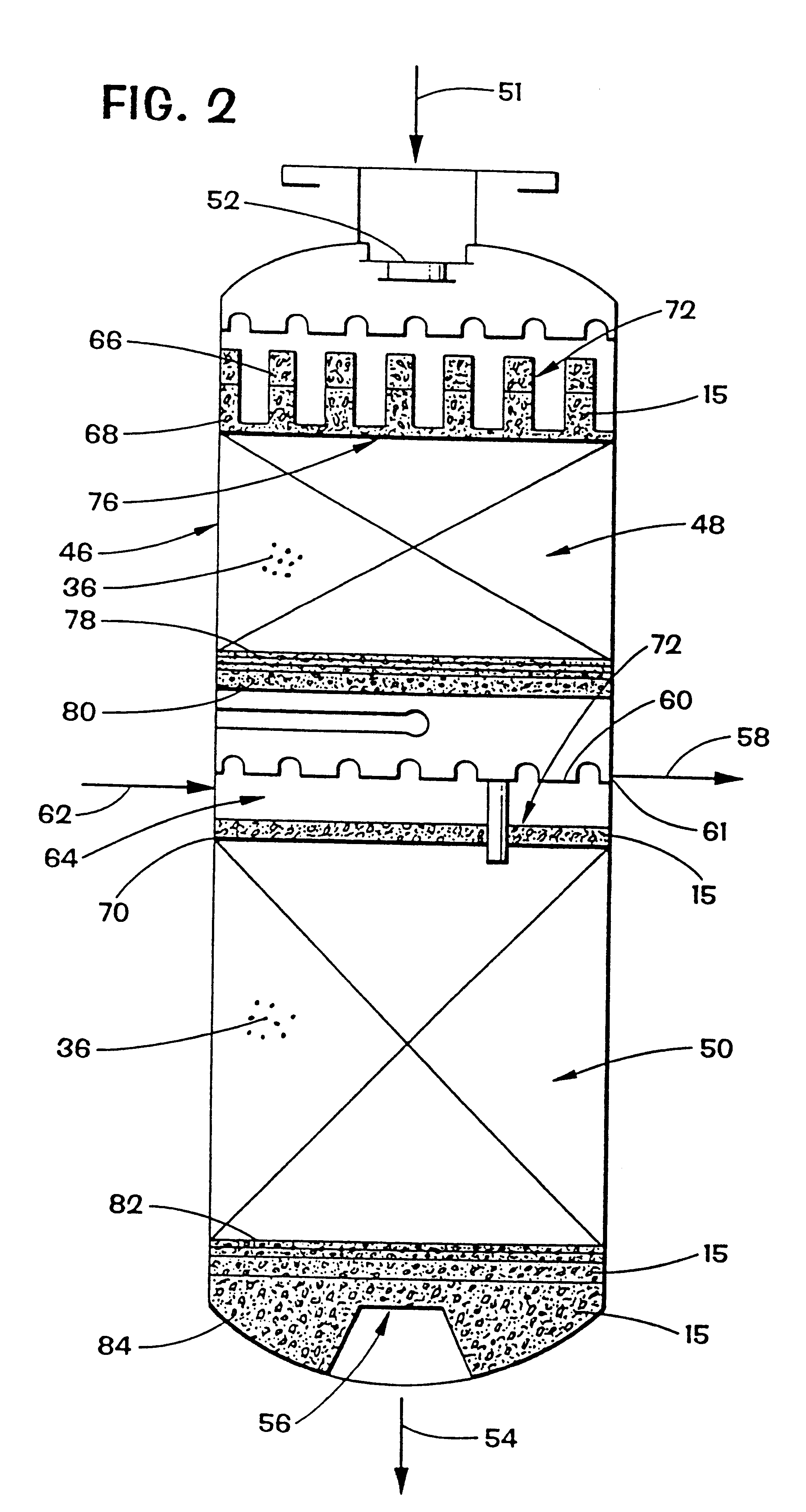

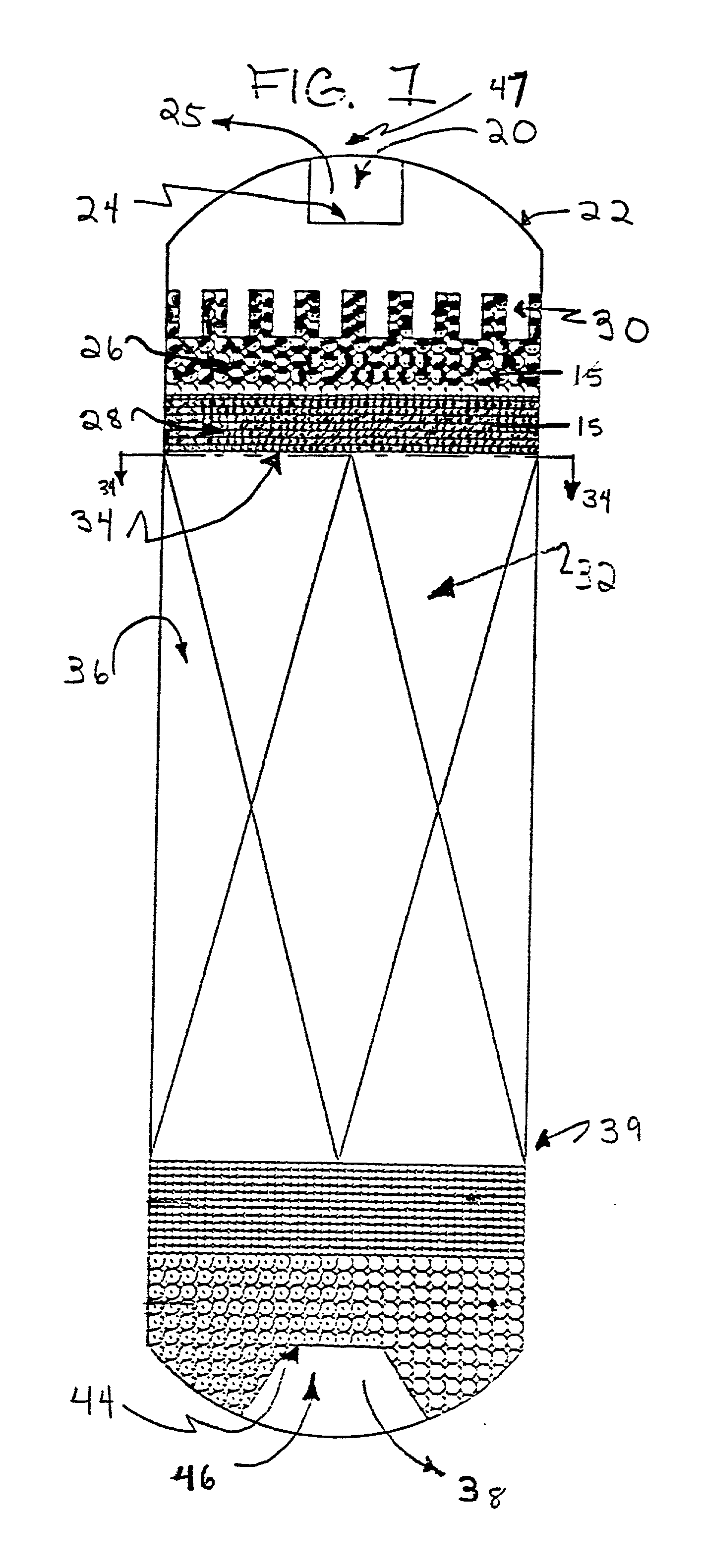

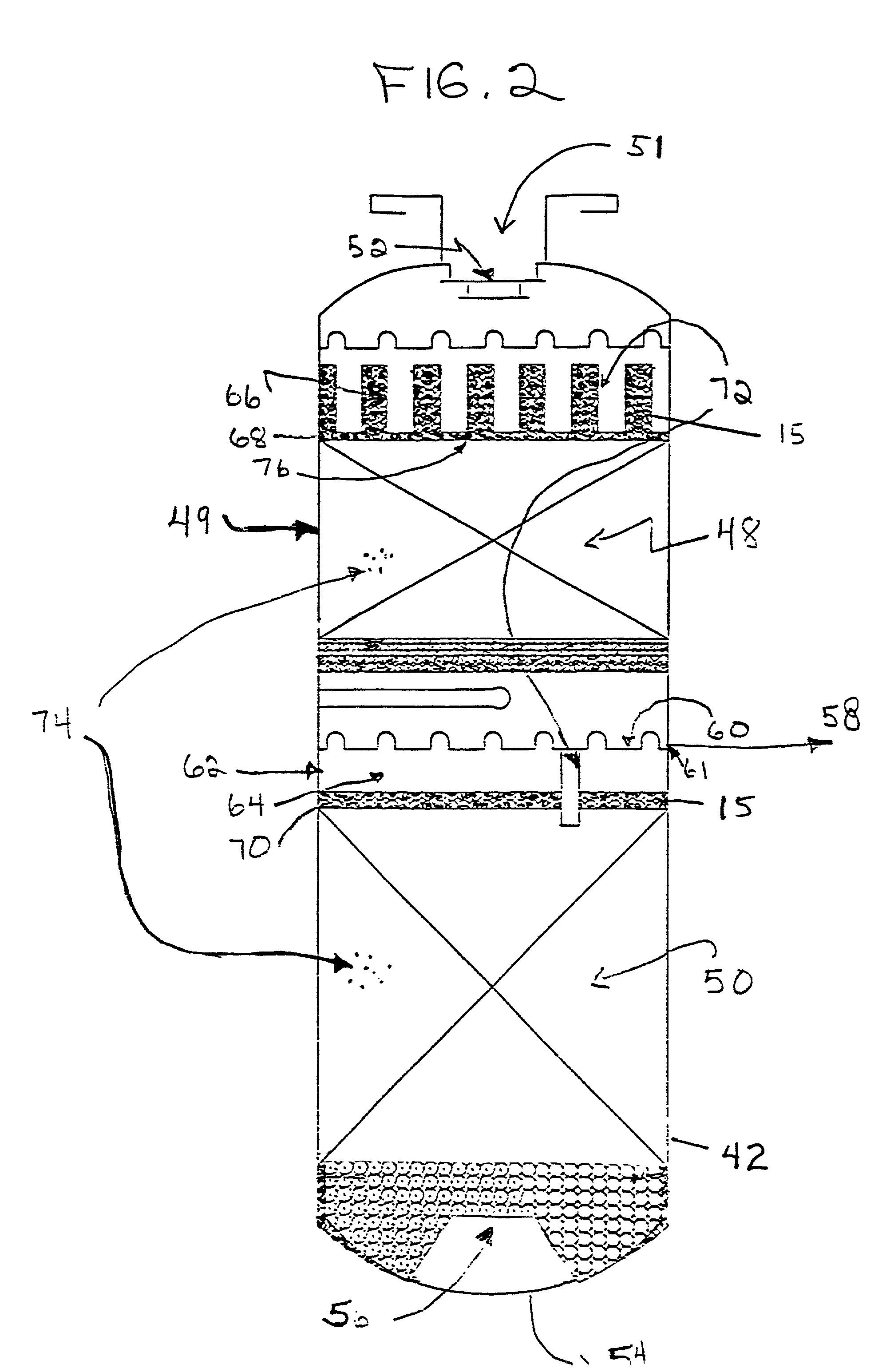

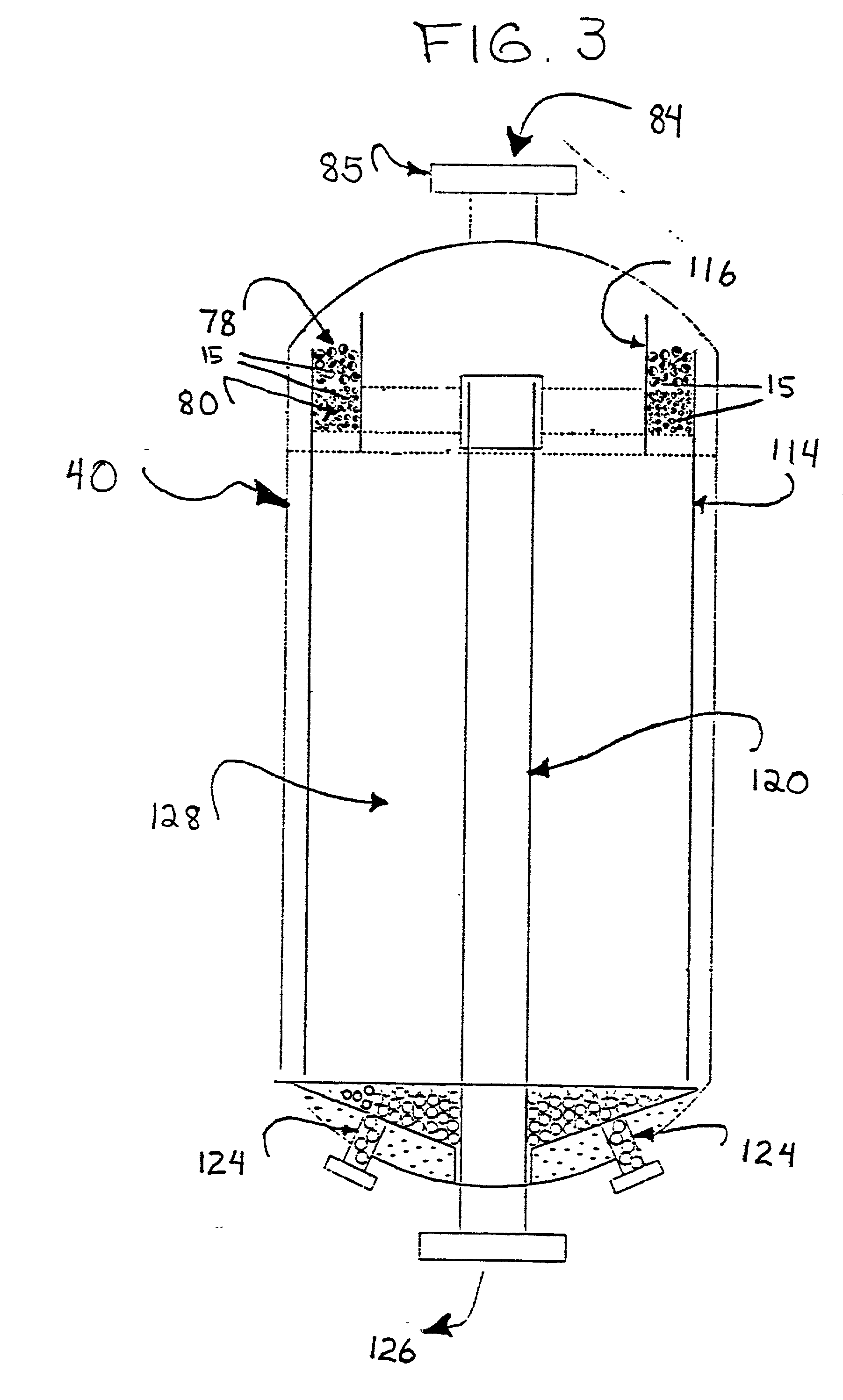

Filtration and flow distribution method for chemical reactors

InactiveUS6258900B1Reduce turbulenceHigh trafficCatalytic naphtha reformingMembrane filtersChemical reactorFiltration

Owner:CRYSTAPHASE PRODS

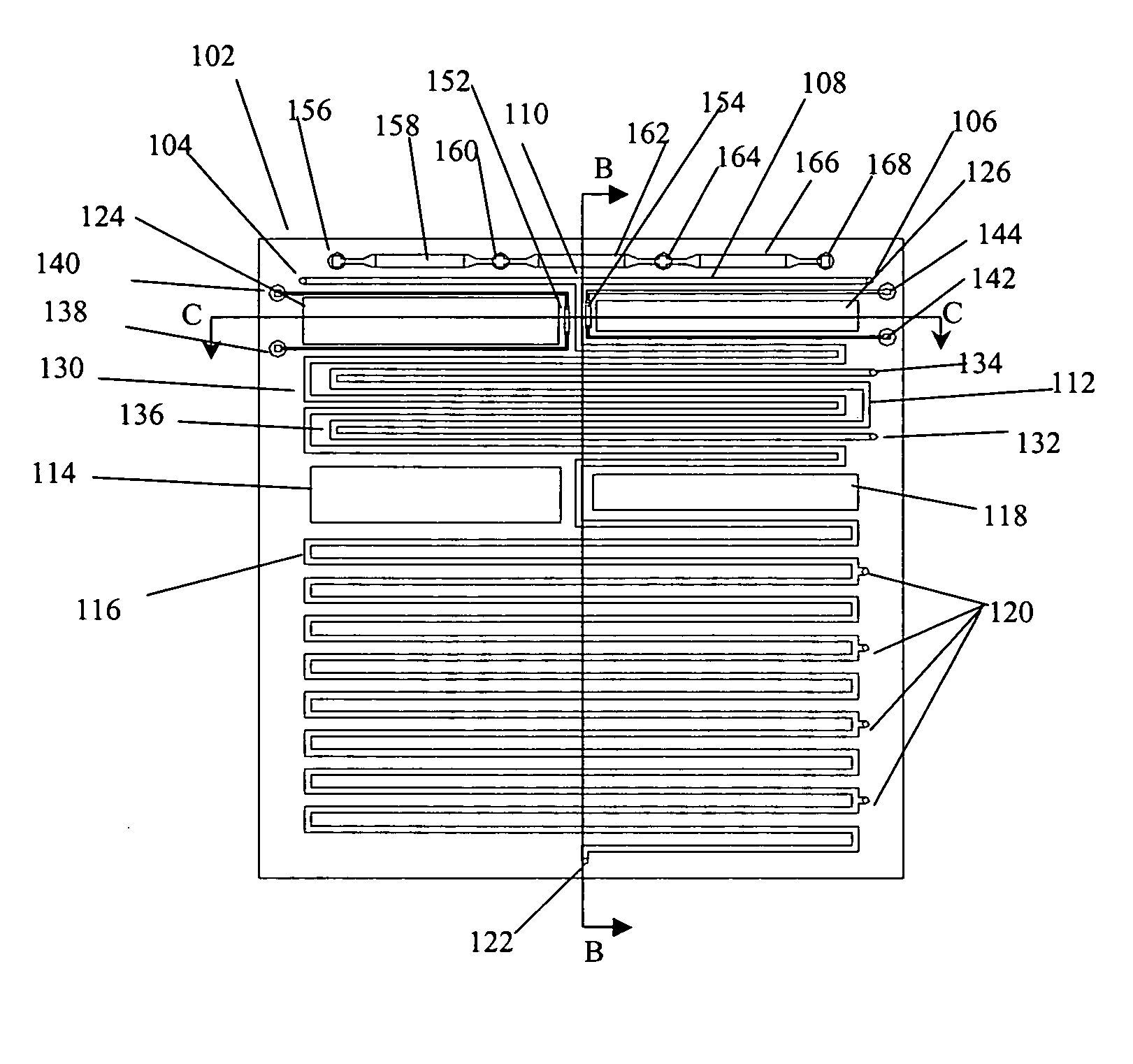

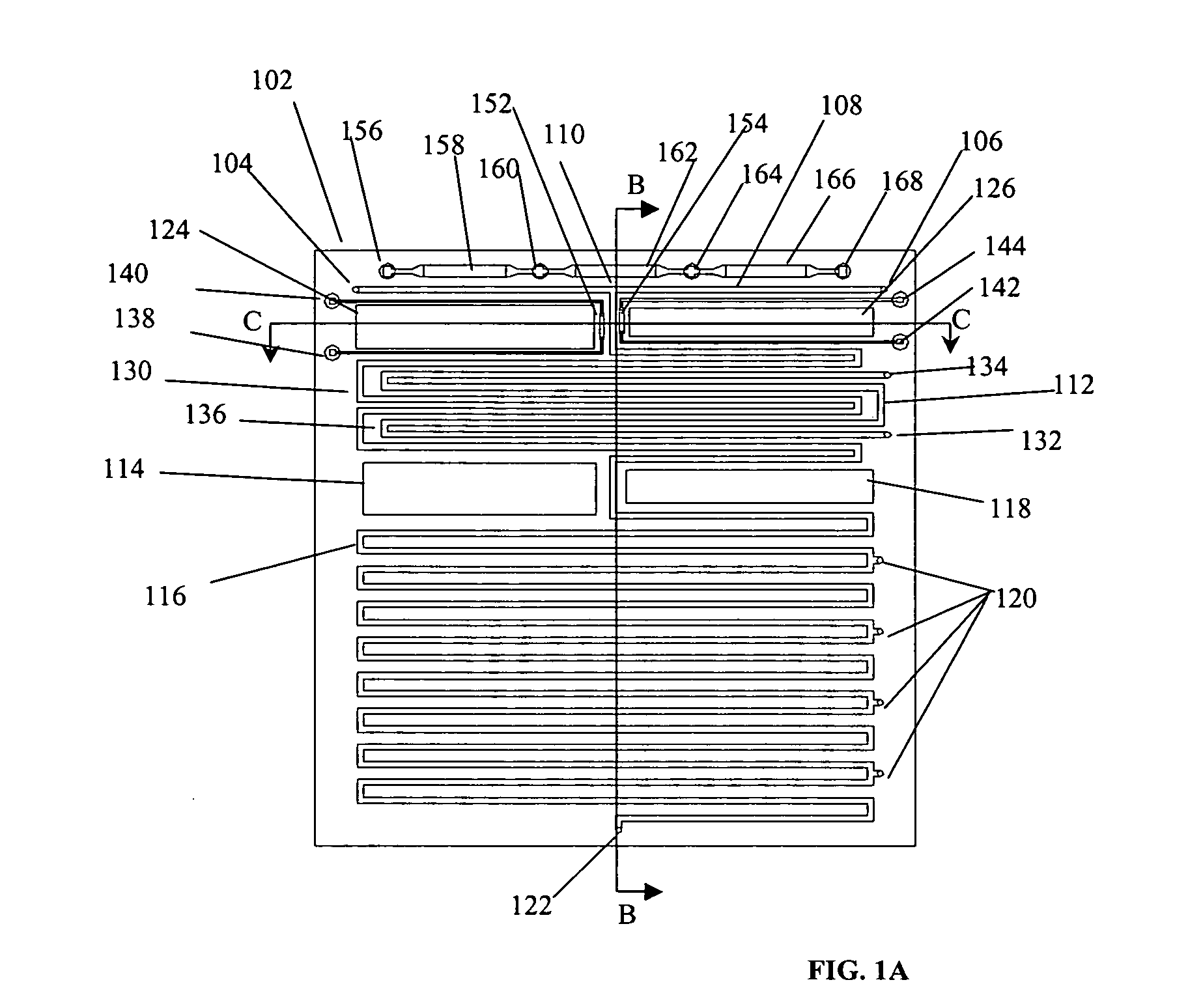

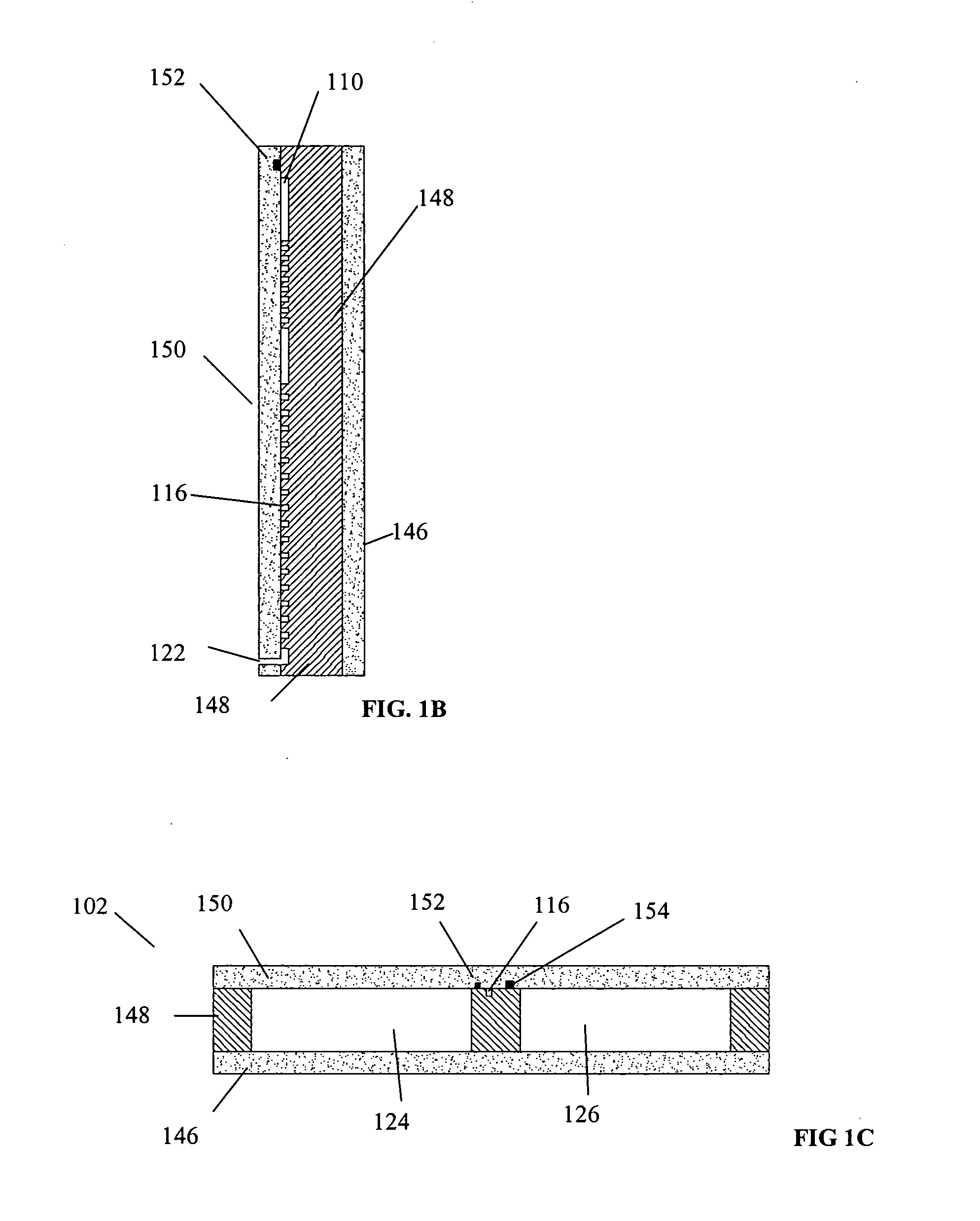

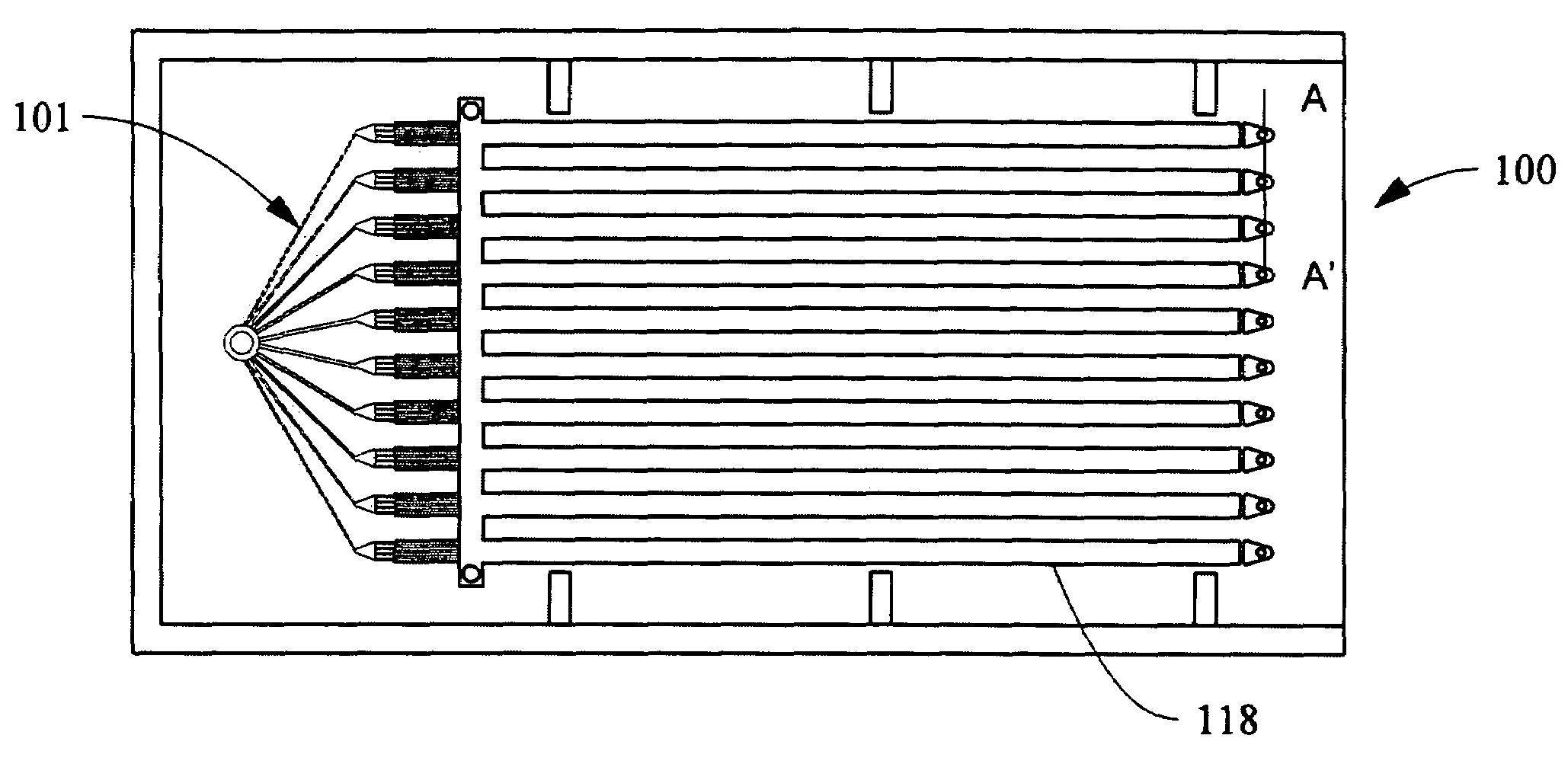

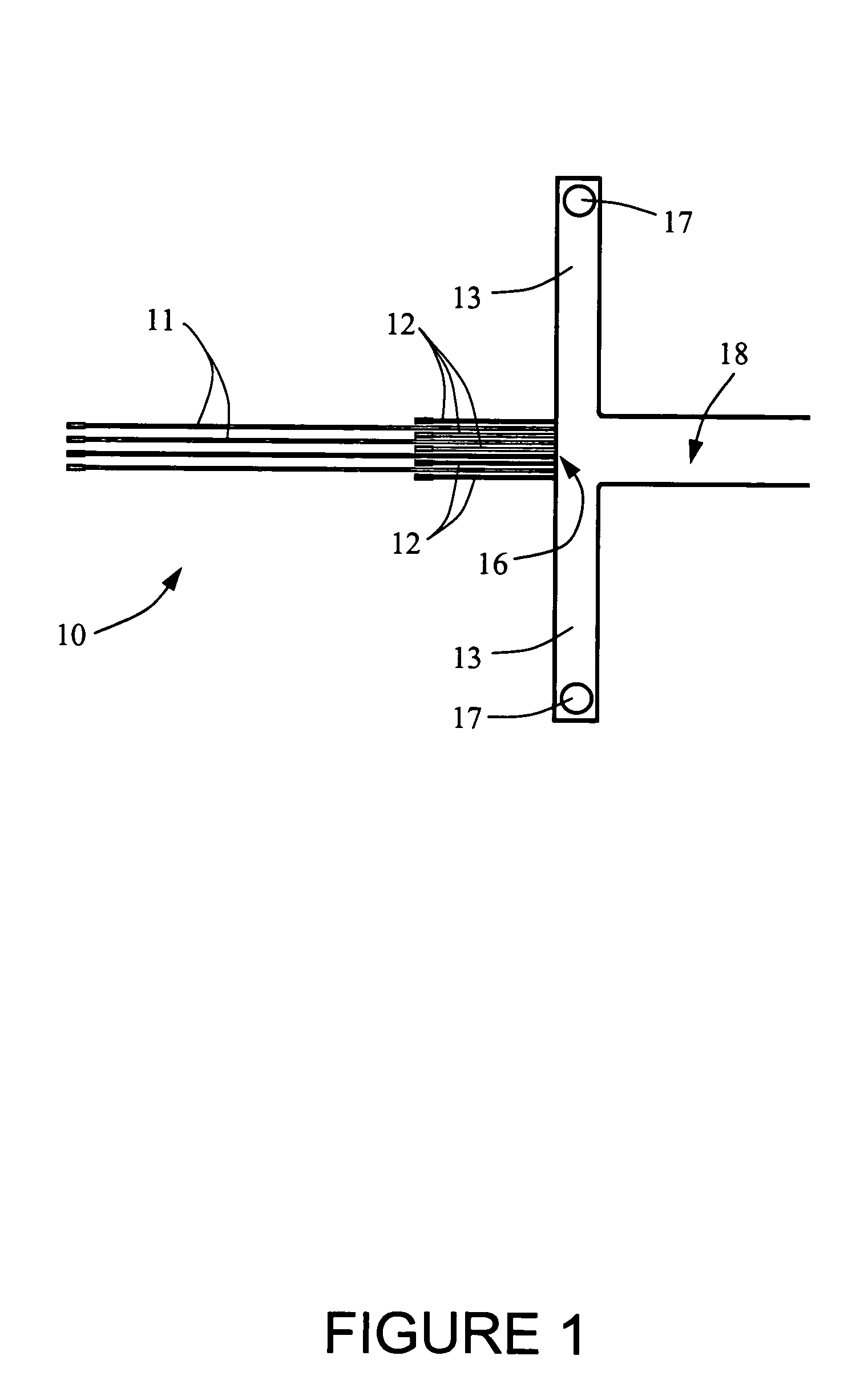

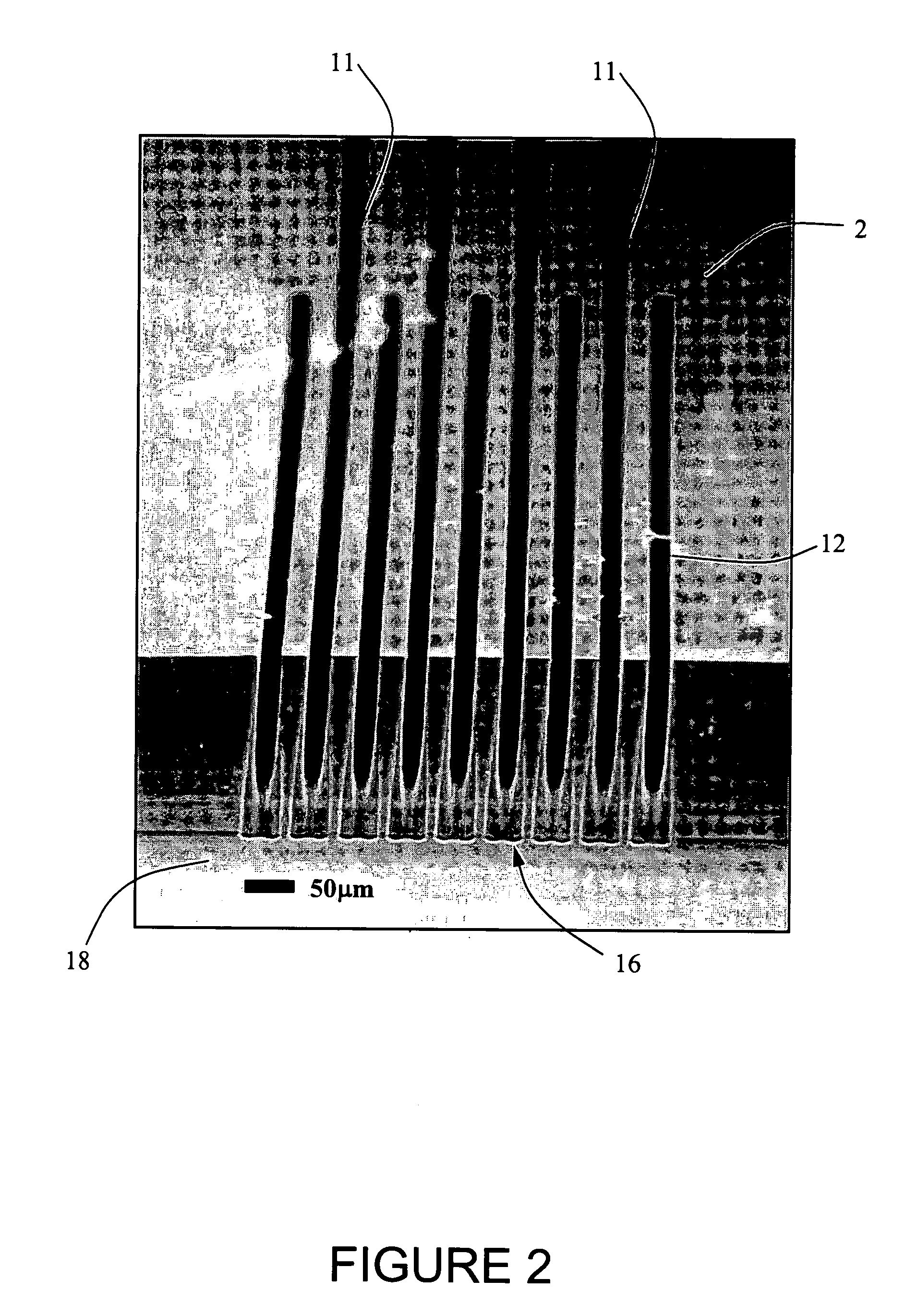

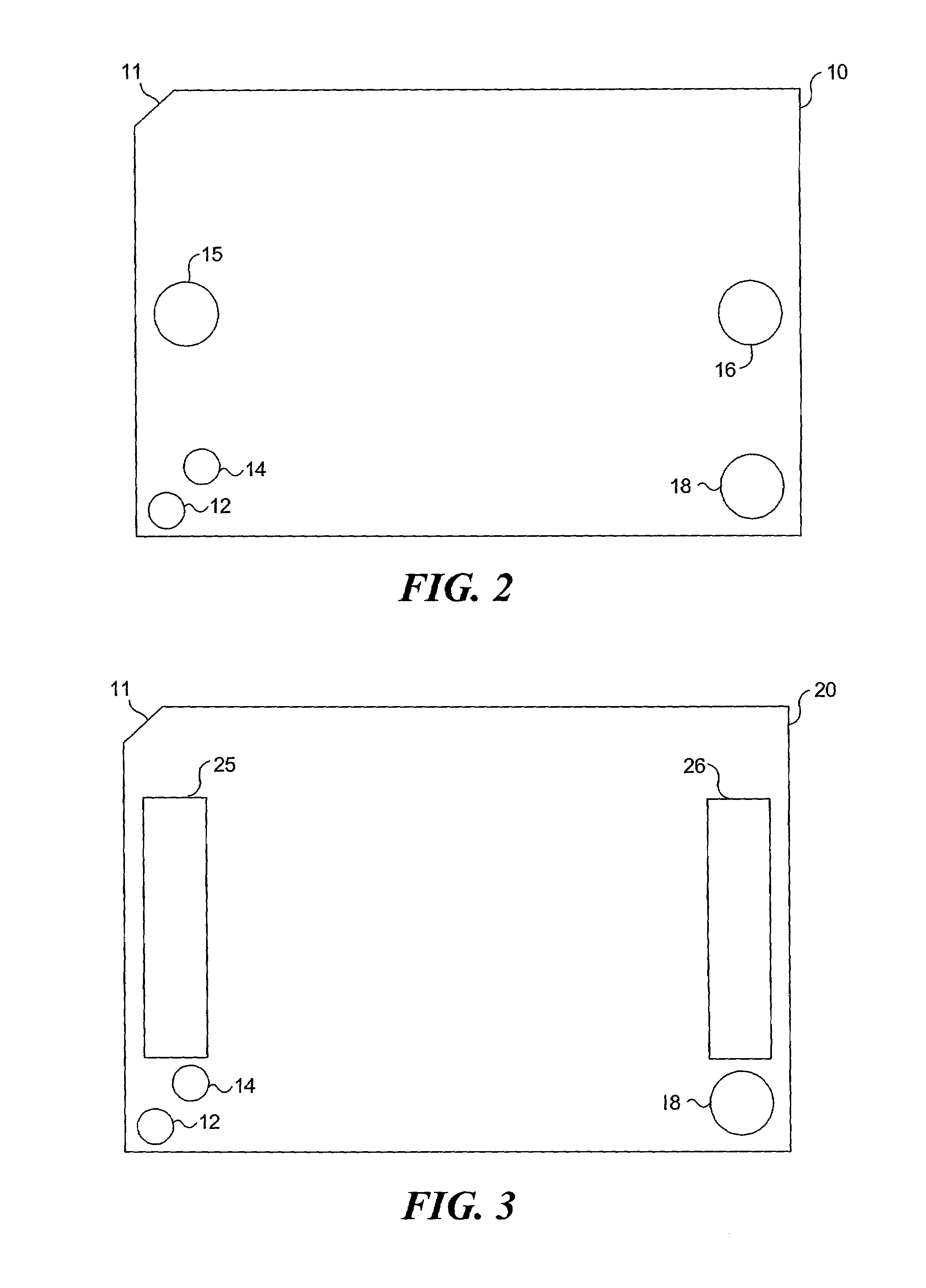

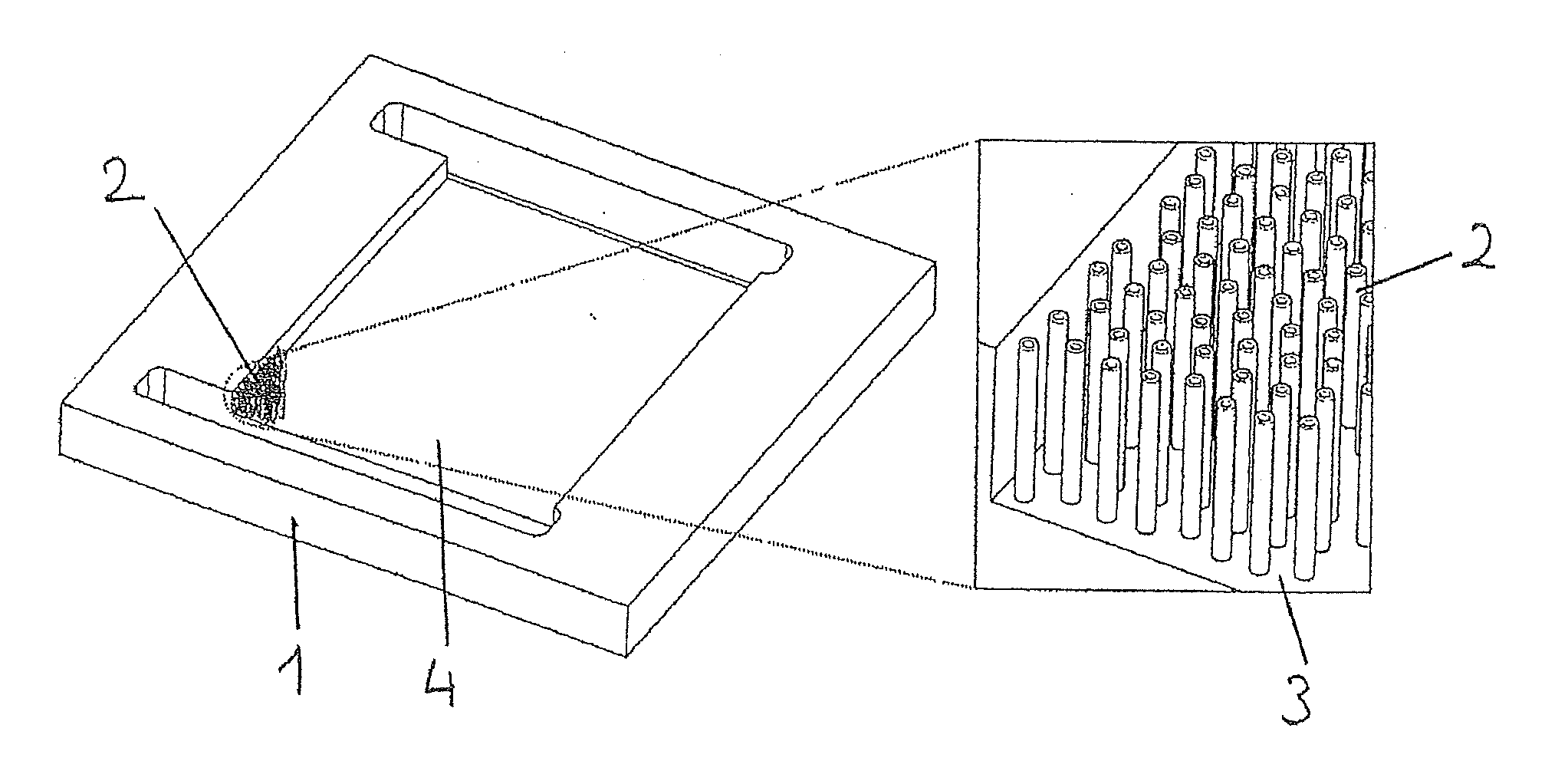

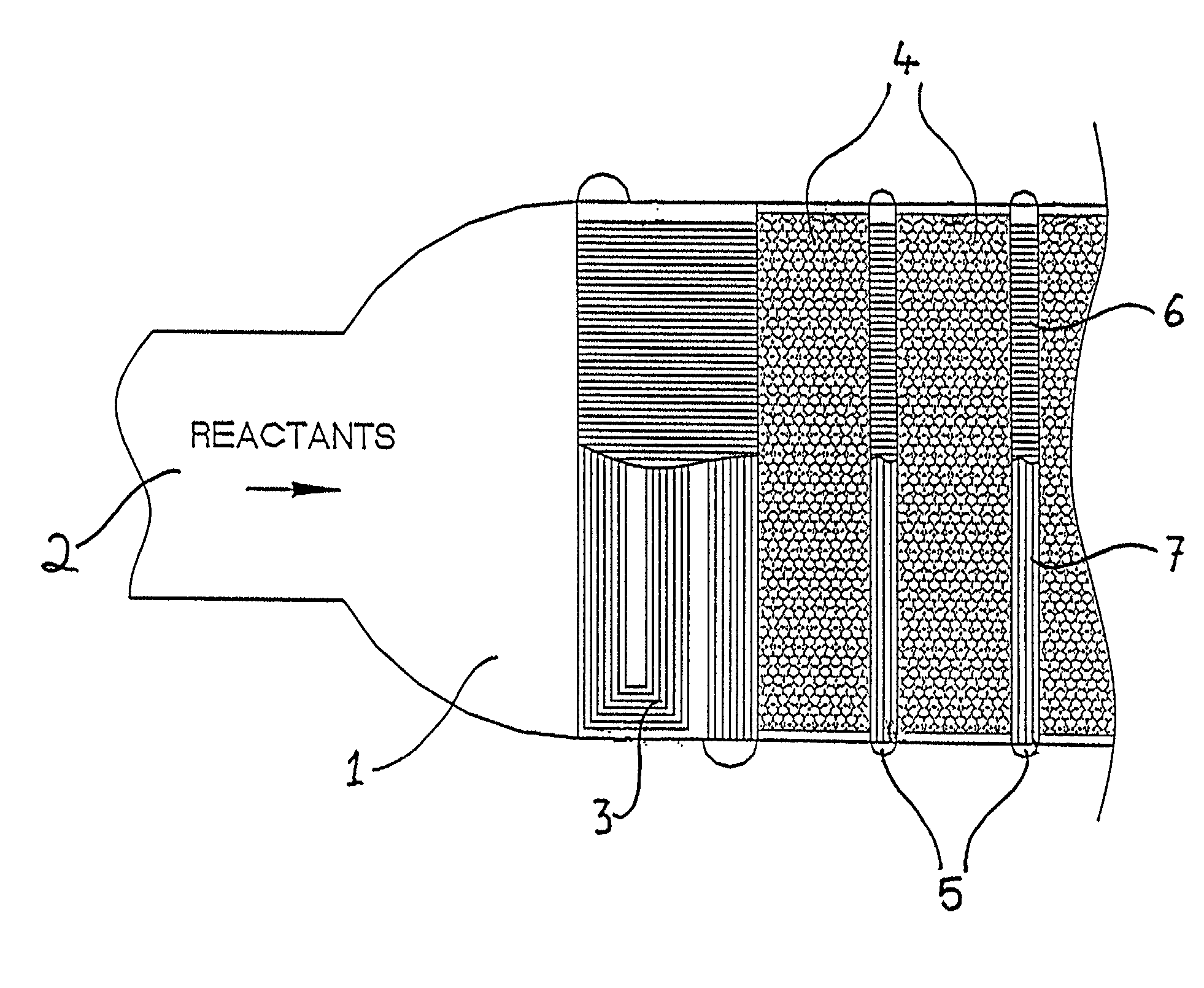

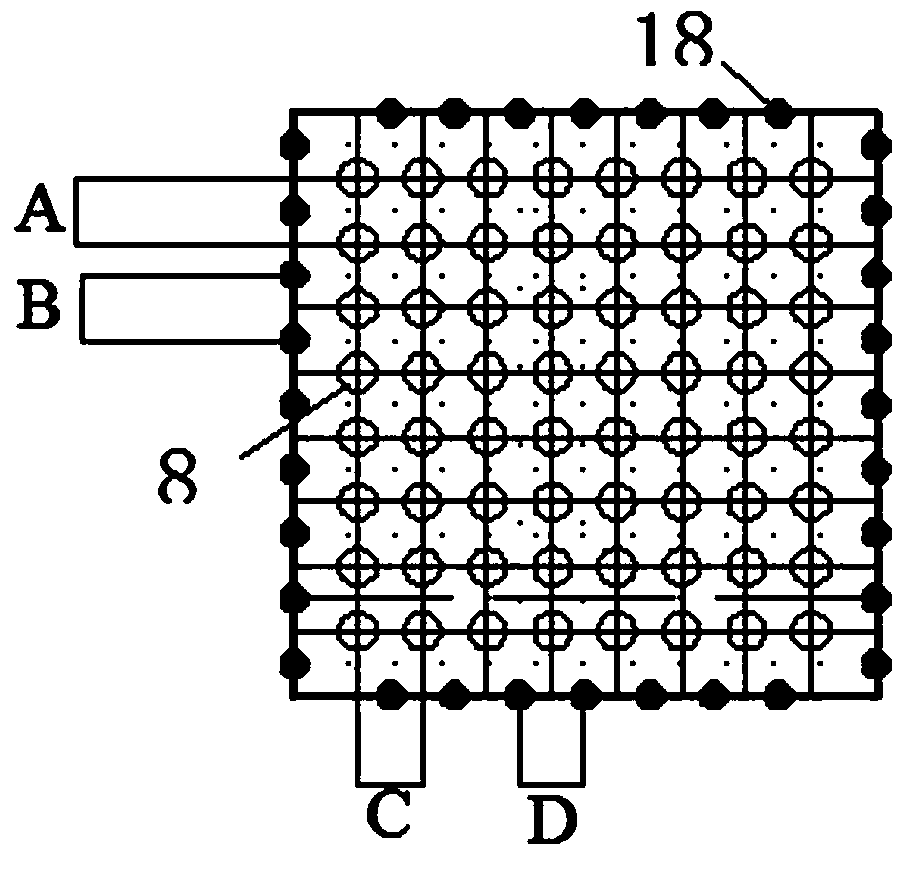

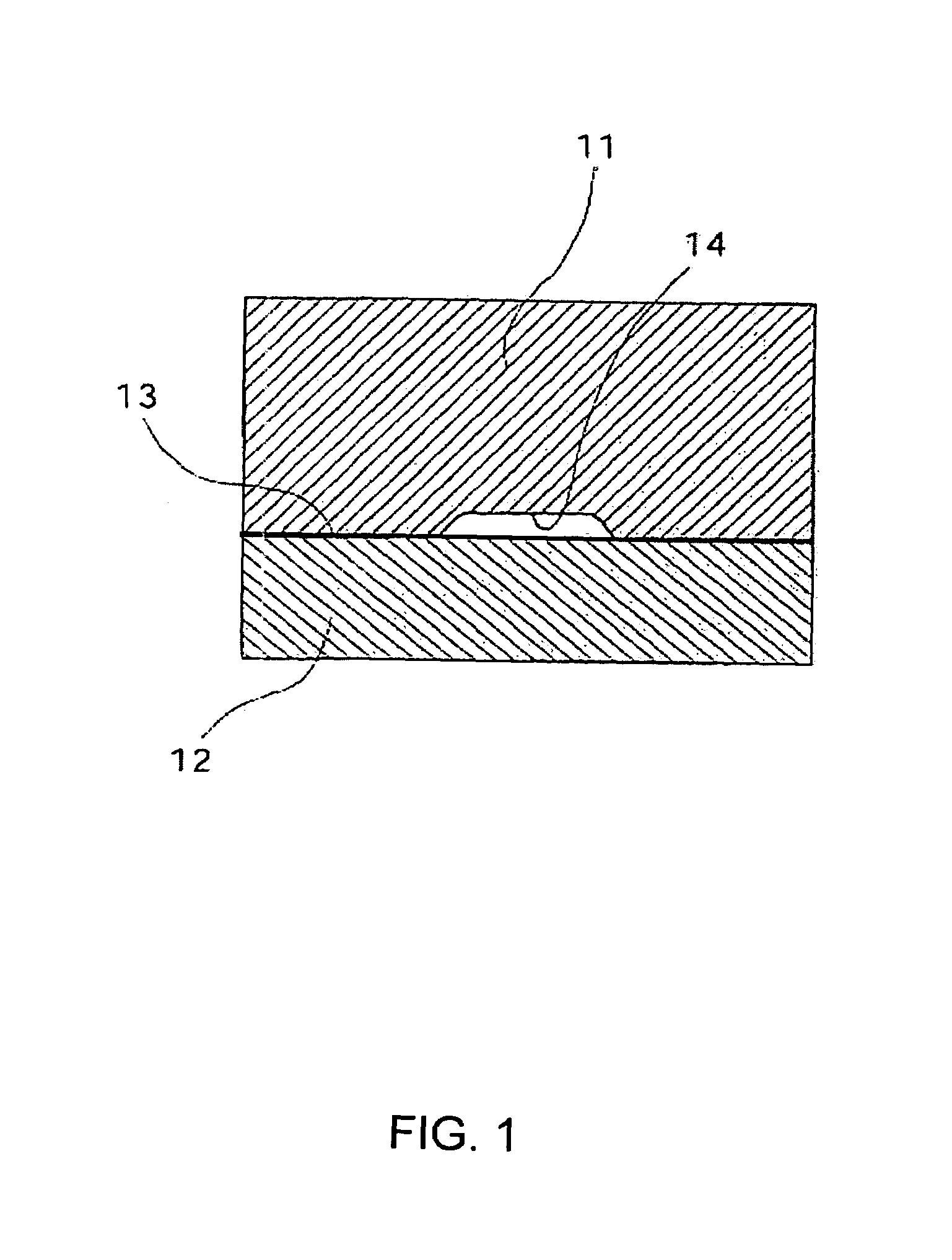

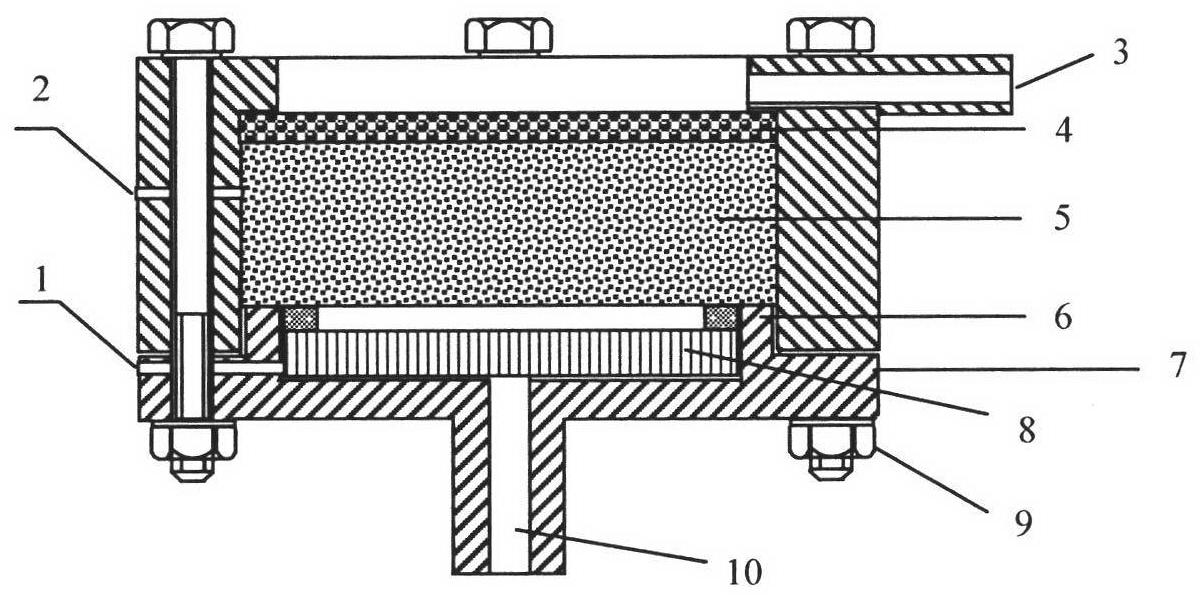

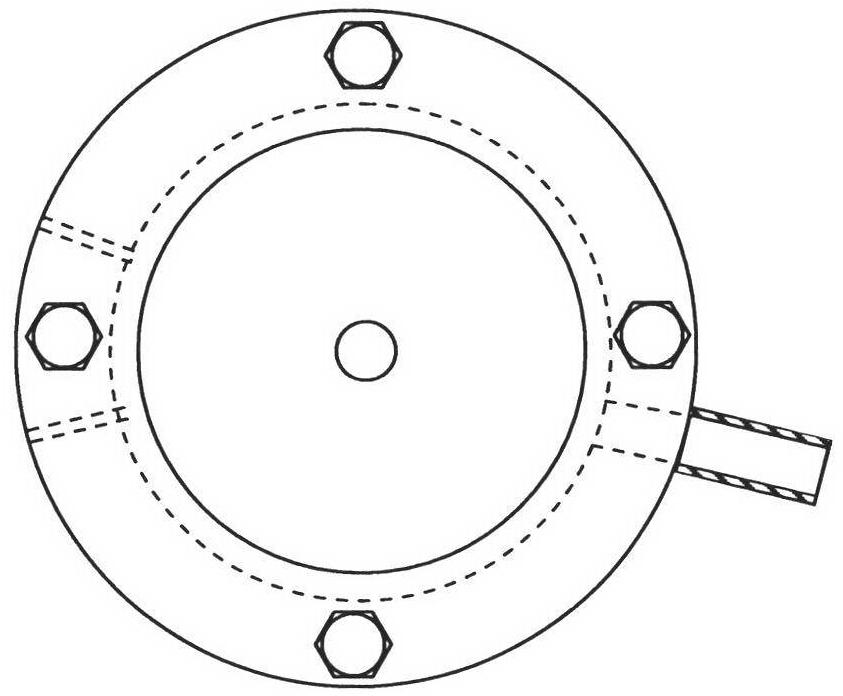

Microfabricated chemical reactor

InactiveUS6932951B1Components is relatively effectiveLower overall pressure dropChemical/physical/physico-chemical microreactorsMetal/metal-oxides/metal-hydroxide catalystsChemical reactorEngineering

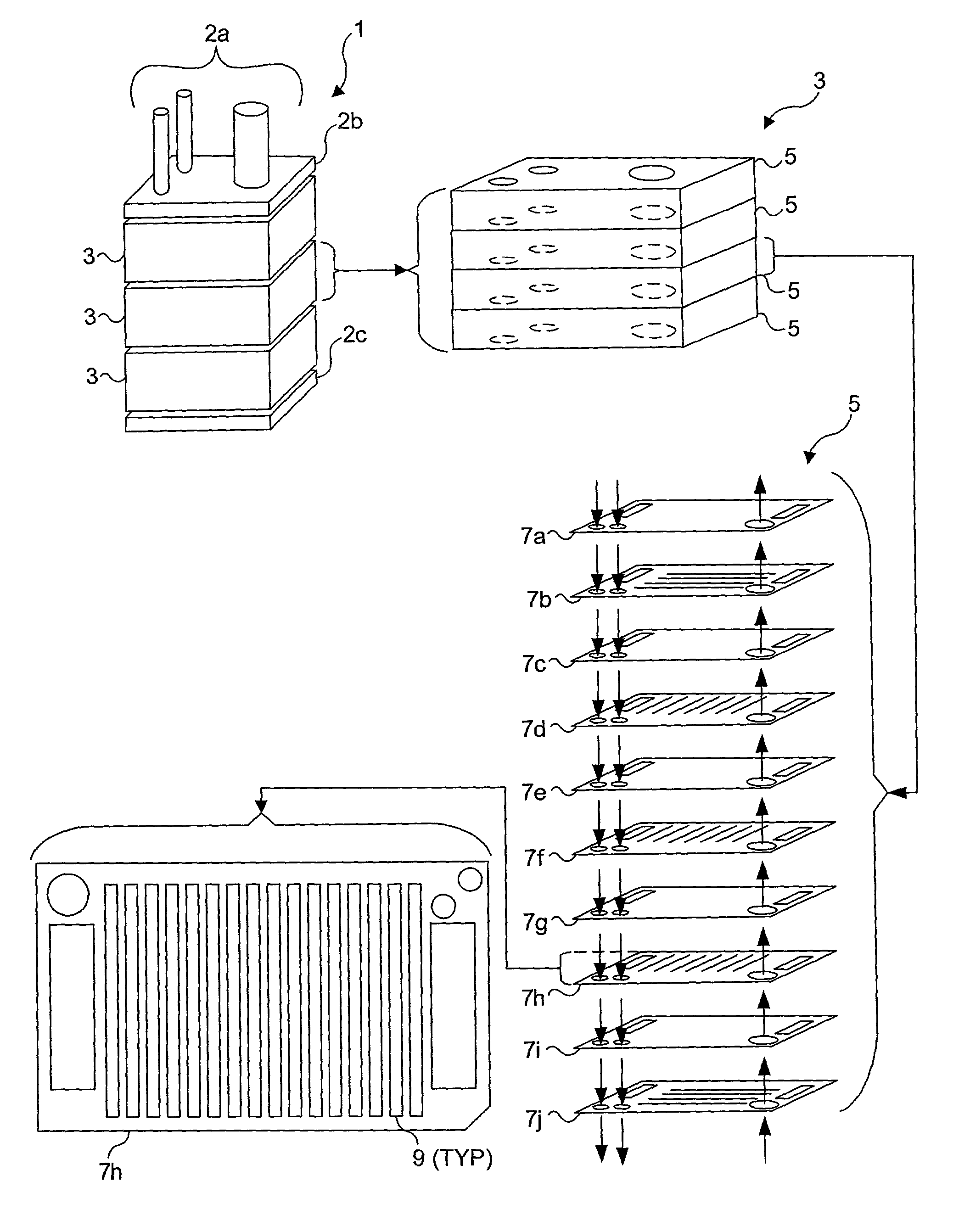

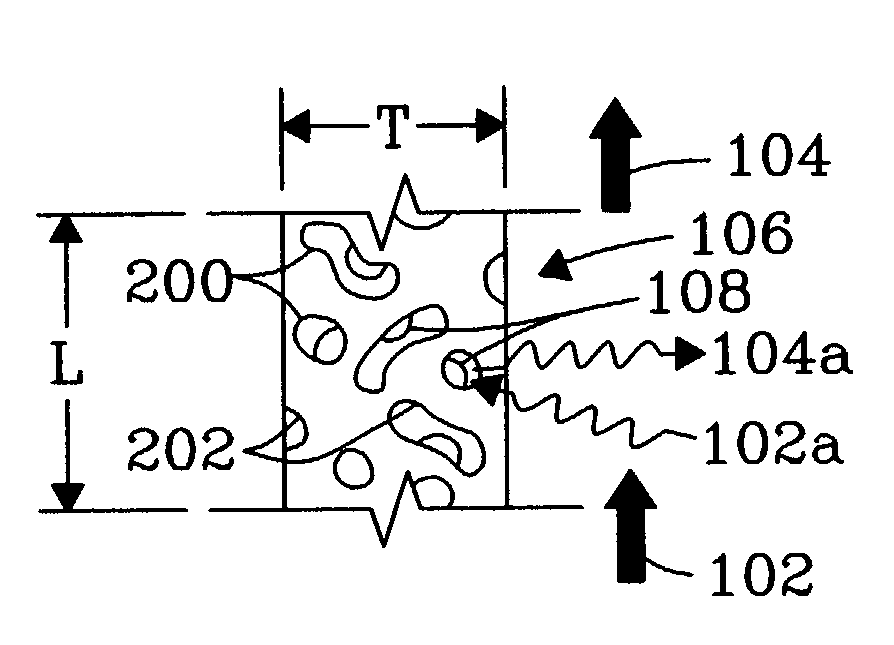

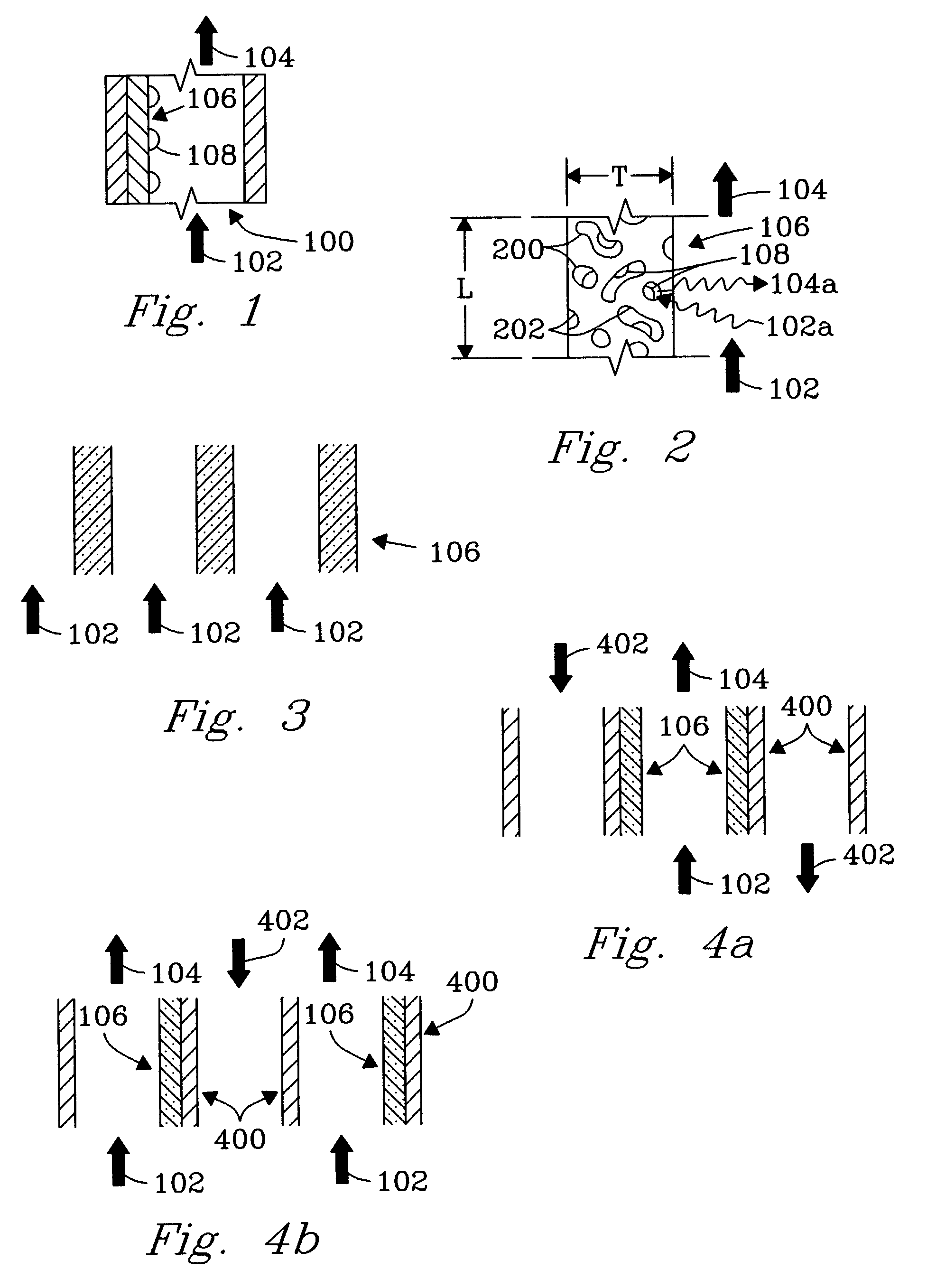

A microfabricated chemical reactor includes a plurality of lamina, an inlet port formed in at least one of the lamina, and an outlet port formed in at least one of the lamina. A continuous channel is formed in at least one of the lamina and provides fluid communication between the inlet port and the outlet port. In one configuration of the microfabricated chemical reactor, the reactor includes a particle filter disposed in the continuous channel and formed by one of the lamina, wherein the particle filter restricts flow through the continuous channel and retains catalyst or other particles within the continuous channel.

Owner:MASSACHUSETTS INST OF TECH

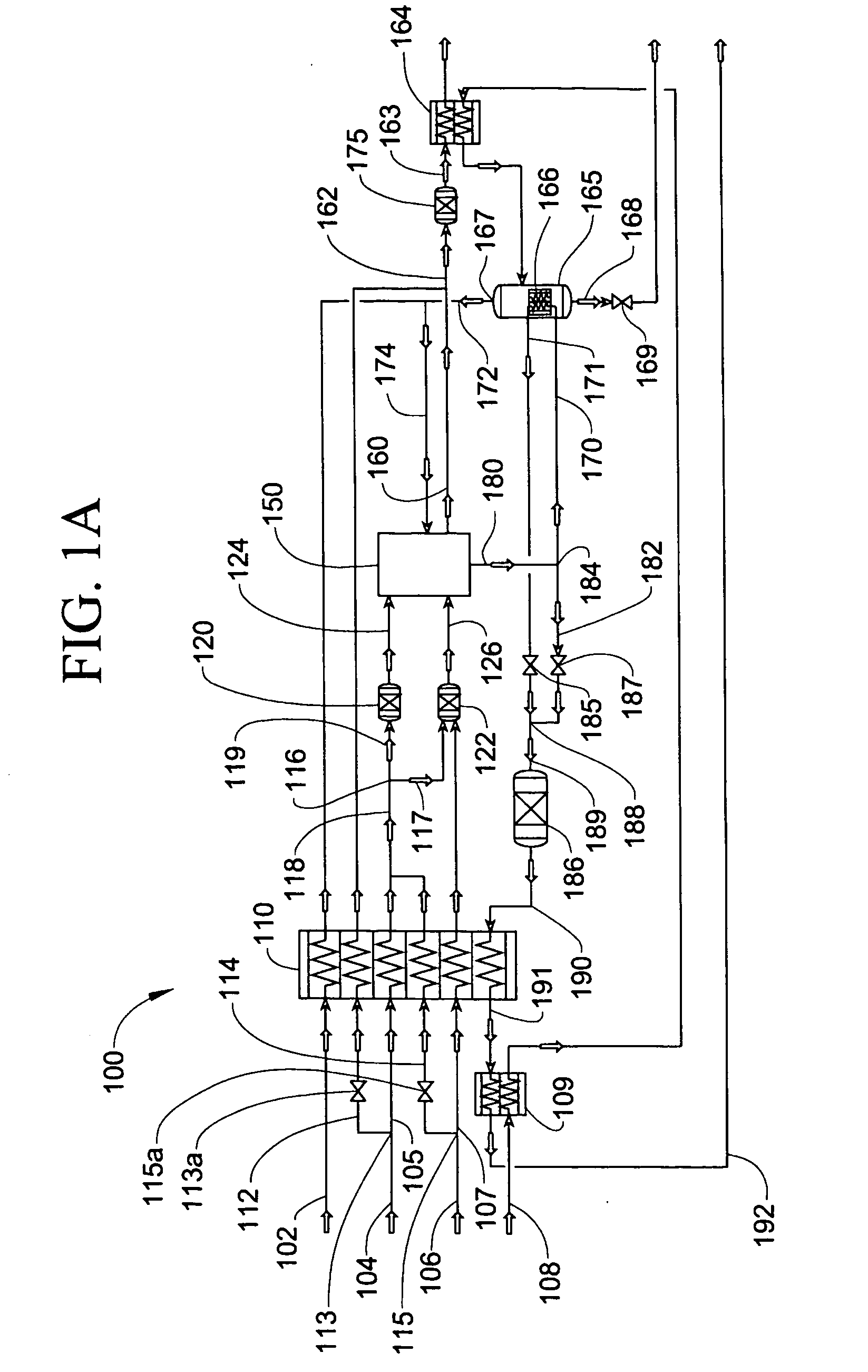

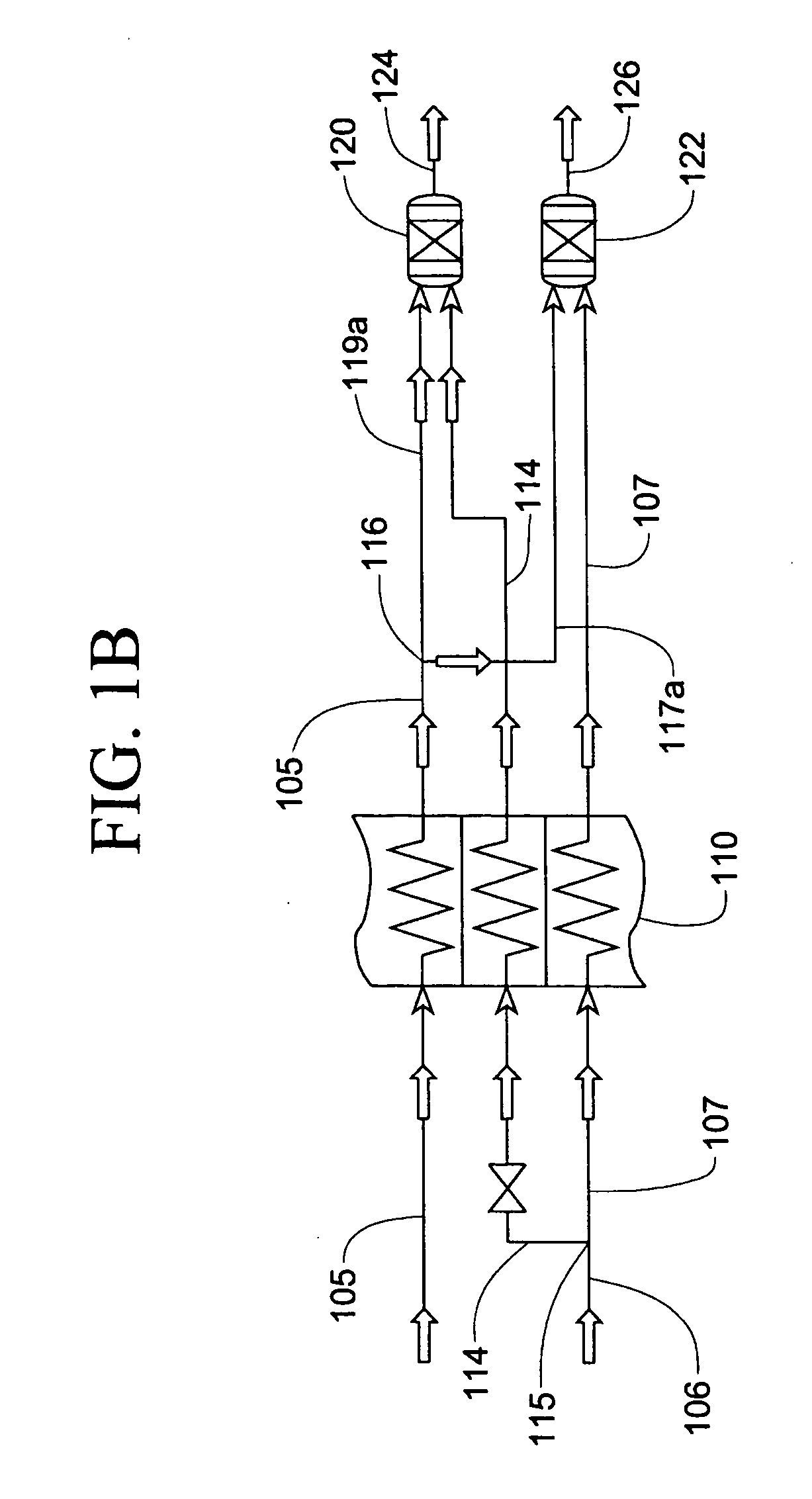

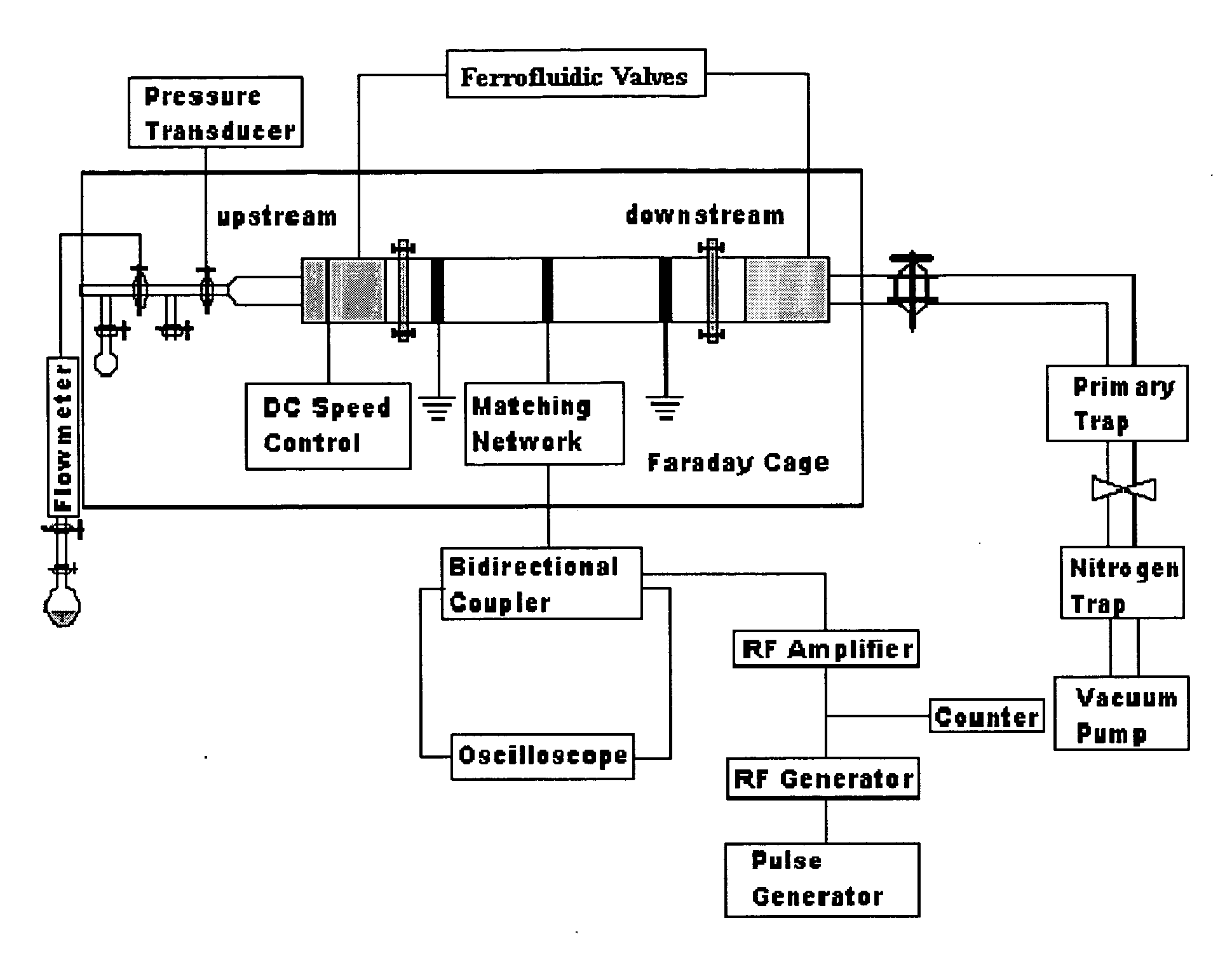

Chemical reactor with pressure swing adsorption

InactiveUS20070253872A1Improve energy efficiencyCompact machineryGas treatmentHydrocarbon from carbon oxidesChemical reactionChemical reactor

A chemical reaction is performed with separation of the product(s) and reactant(s) by pressure swing adsorption (PSA), using an apparatus having a plurality of adsorbers cooperating with first and second valve assemblies in a PSA module. The PSA cycle is characterized by multiple intermediate pressure levels between higher and lower pressures of the PSA cycle. Gas flows enter or exit the PSA module at the intermediate pressure levels as well as the higher and lower pressure levels, entering from compressor stage(s) or exiting into exhauster or expander stages, under substantially steady conditions of flow and pressure. The PSA module comprises a rotor containing the adsorbers and rotating within a stator, with ported valve faces between the rotor and stator to control the timing of the flows entering or exiting the adsorbers in the rotor. The reaction may be performed within a portion of the rotor containing a catalyst.

Owner:AIR PROD & CHEM INC

Filtration and flow distribution method for chemical reactors using reticulated ceramics with uniform pore distributions

InactiveUS6291603B1Reduce turbulenceEntrance losses may be reducedCatalytic naphtha reformingMembrane filtersPore distributionFiltration

Owner:CRYSTAPHASE PRODS

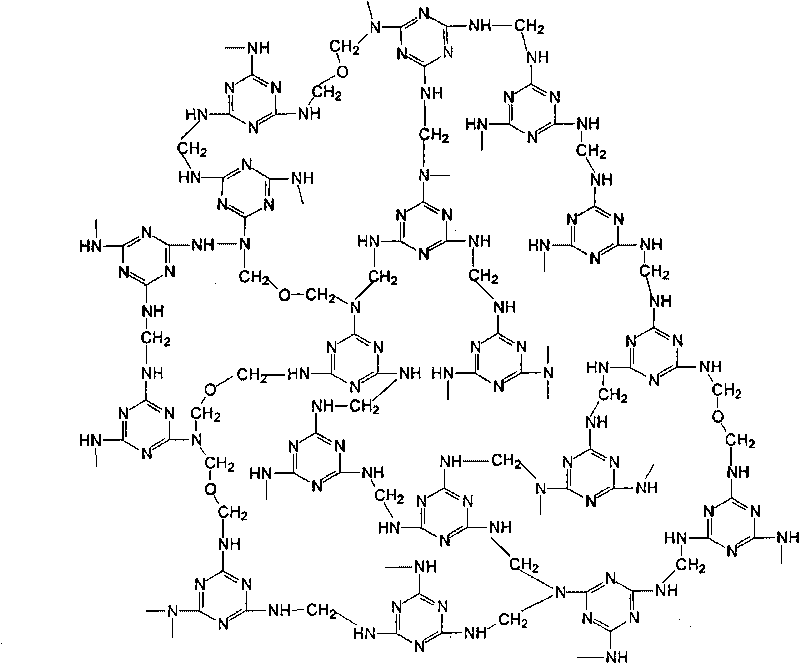

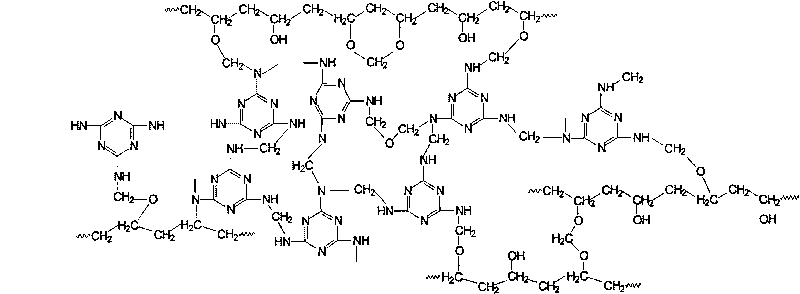

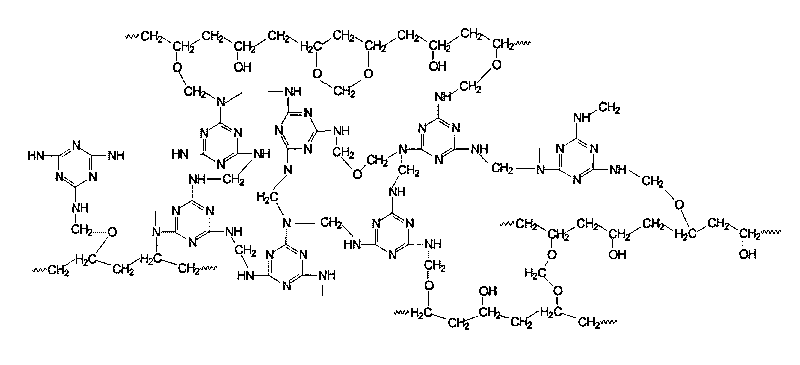

High-flexibility melamino-formaldehyde foam material and preparation method thereof

The invention discloses a high-flexibility melamino-formaldehyde foam material and a preparation method thereof. The preparation method comprises: firstly, preparing melamino-formaldehyde prepolymer modified by polyol into aqueous solution with definite weight concentration; weighting 100 parts by weight of prepolymer aqueous solution; adding 0-15 parts by weight of surfactant, 1-20 parts by weight of foaming agent, 0-10 parts by weight of accelerator and 0-10 parts by weight of curing agent to be fully stirred and mixed to prepare foaming liquid; filling foaming liquid into a microwave chemical reactor or a high-temperature oven; and foaming for 30s-15min at the temperature of 100-300 DEG C to prepare the foam material. The melamino-formaldehyde foam material disclosed by the invention solves the problems of big brittleness, poor flexibility, easy duslting of foam, complex preparation technology, high production cost and the like of the existing melamino-formaldehyde foam material and has wide application prospect.

Owner:SICHUAN UNIV

Thermally conductive honeycombs for chemical reactors

InactiveUS6881703B2Good catalyst compatibilityImprove thermal conductivityHydrogenChemical/physical/physico-chemical stationary reactorsChemical reactorHoneycomb

Monolithic metallic catalyst substrates offering improved heat conductivity are provided from metal powder extrusion batches of copper, tin, zinc, aluminum, iron, silver, nickel, and mixtures and alloys thereof by extrusion through a honeycomb extrusion die followed by drying and firing in a two stage firing process to oxidize organic extrusion batch components, remove residual oxides from the porous wall structure, and consolidate the metal powders to strong, integral honeycomb support structures.

Owner:CORNING INC

Systems and methods for quenching, gas clean up, and ash removal

A method, apparatus, and system for a solar-driven chemical plant are disclosed. An embodiment may include a solar thermal receiver aligned to absorb concentrated solar energy from one or more solar energy concentrating fields. A solar driven chemical reactor may include multiple reactor tubes located inside the solar thermal receiver. The multiple reactor tubes can be used to gasify particles of biomass in the presence of a carrier gas. The gasification reaction may produce reaction products that include hydrogen and carbon monoxide gas having an exit temperature from the tubes exceeding 1000 degrees C. An embodiment can include a quench zone immediately downstream of an exit of the chemical reactor. The quench zone may immediately quench via rapid cooling of at least the hydrogen and carbon monoxide reaction products within 0.1-10 seconds of exiting the chemical reactor to a temperature of 800 degrees C. or less.

Owner:SUNDROP IP HLDG LLC

Combustion method and apparatus for carrying out same

InactiveUS7086854B2Increase speedTransfer is bulkyContinuous combustion chamberGas turbine plantsChemical reactionCombustor

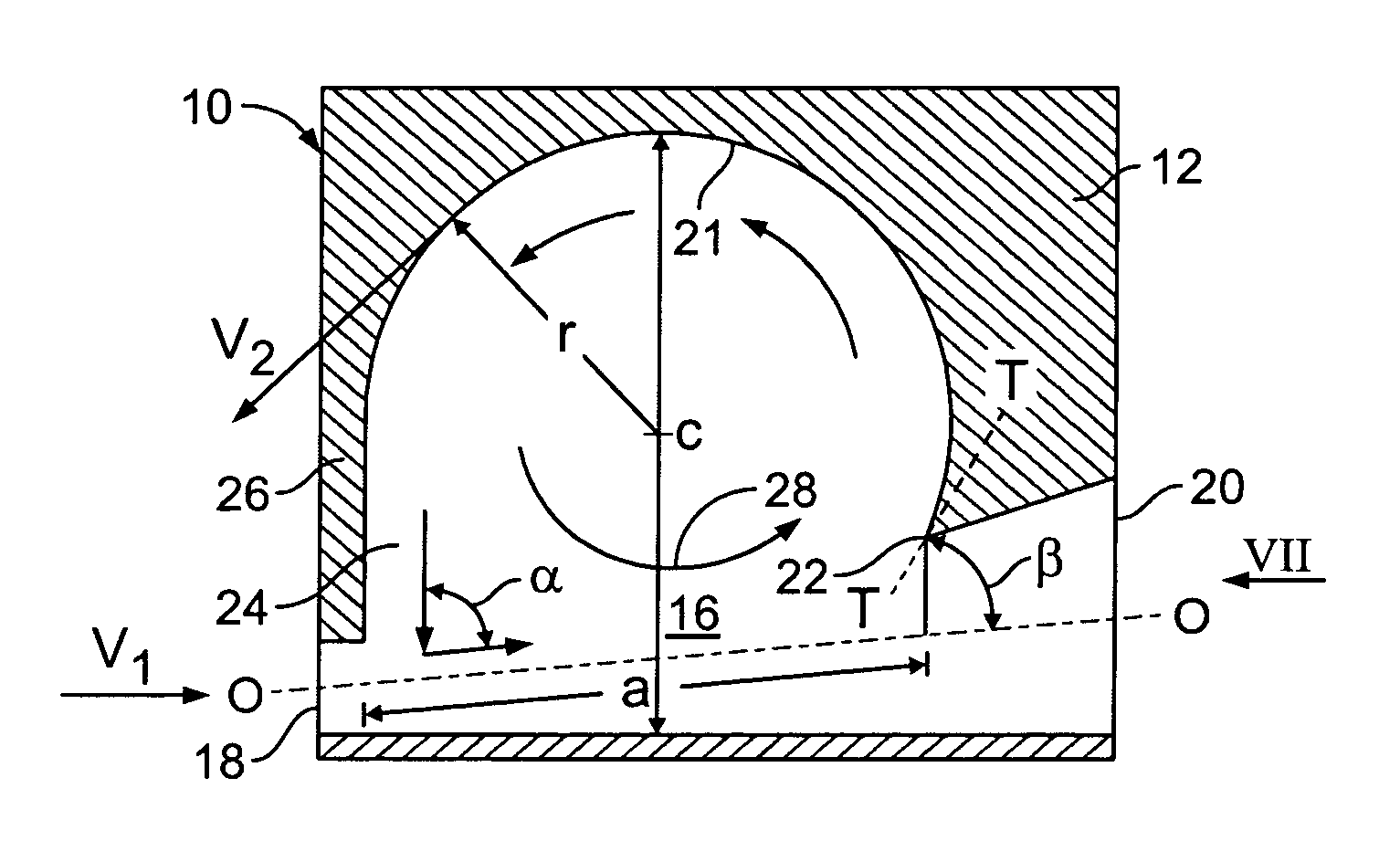

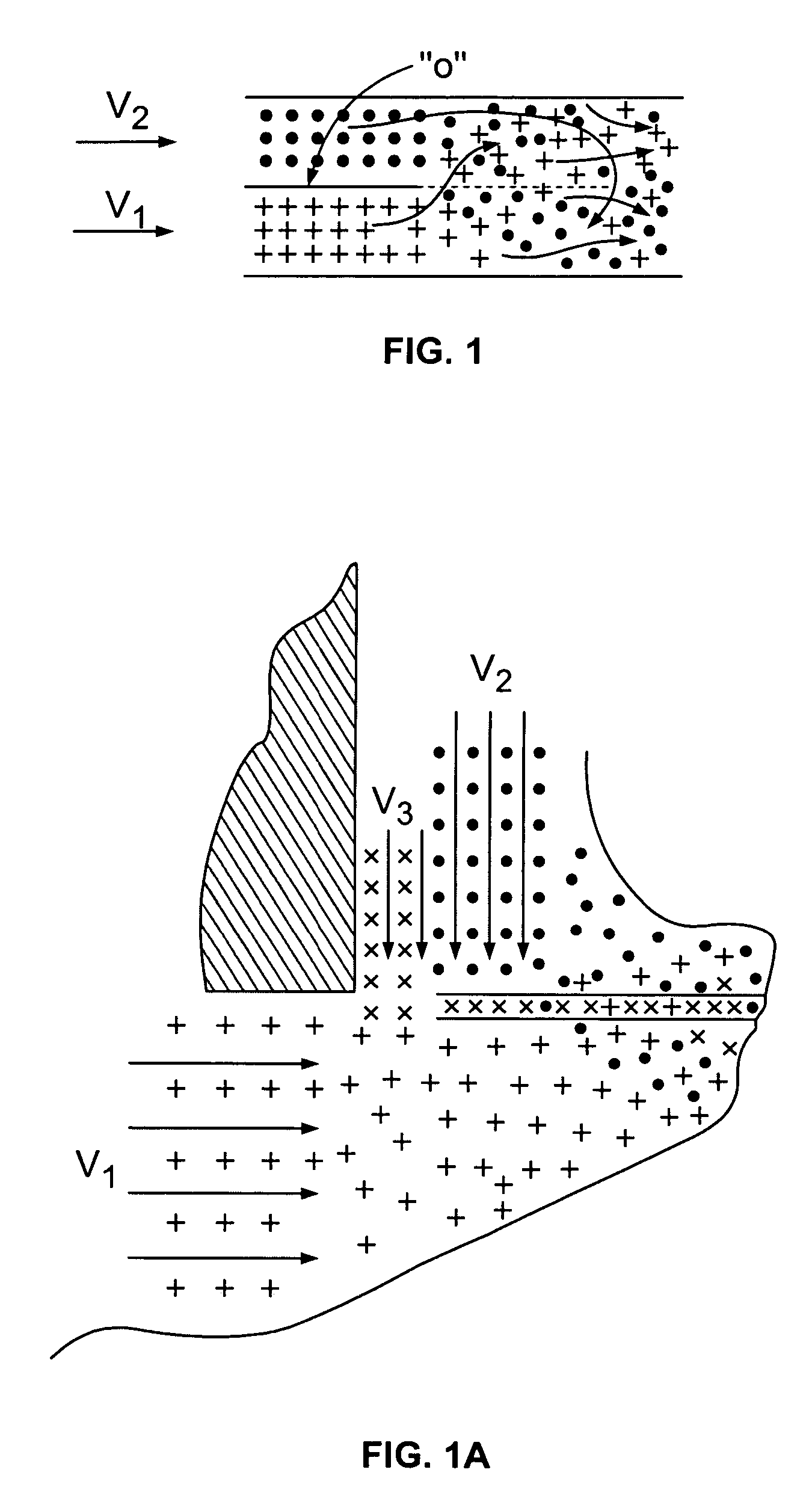

The invention relates to recirculation flow combustors having a generally curved recirculation chamber and unobstructed flow along the periphery of the boundary layer of the vortex flow in this chamber, and methods of operating such combustors. Such combustors further have a border interface area of low turbulence between the vortex flow and the main flow in the combustor, in which chemical reactions take place which are highly advantageous to the combustion process, and which promote a thermal nozzle effect within the combustor. A combustor of this type may be used for burning lean and super-lean fuel and air mixtures for use in gas turbine engines, jet and rocket engines and thermal plants such as boilers, heat exchanges plants, chemical reactors, and the like. The apparatus and methods of the invention may also be operated under conditions that favor fuel reformation rather than combustion, where such a reaction is desired.

Owner:LEAN FLAME INC

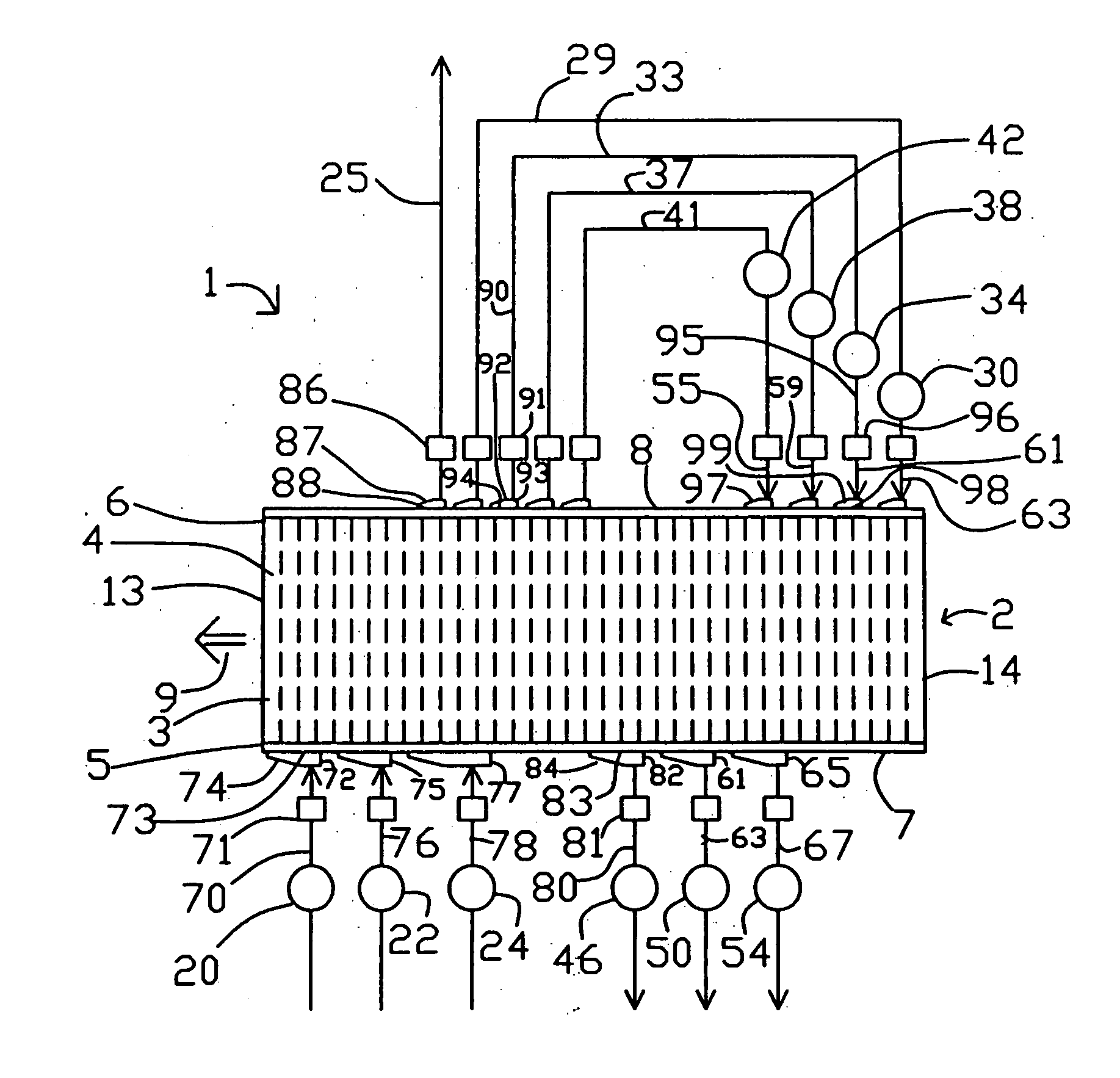

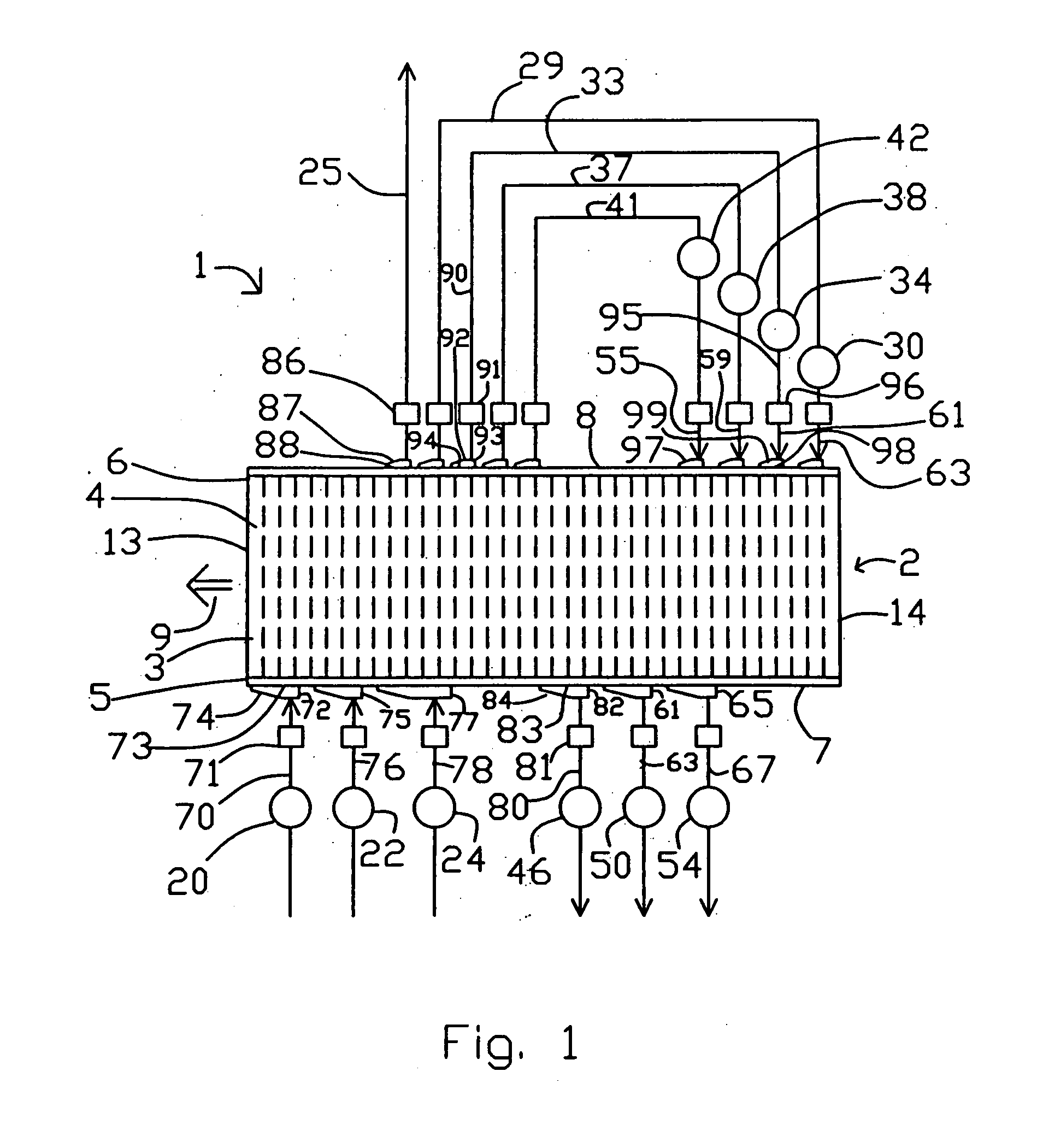

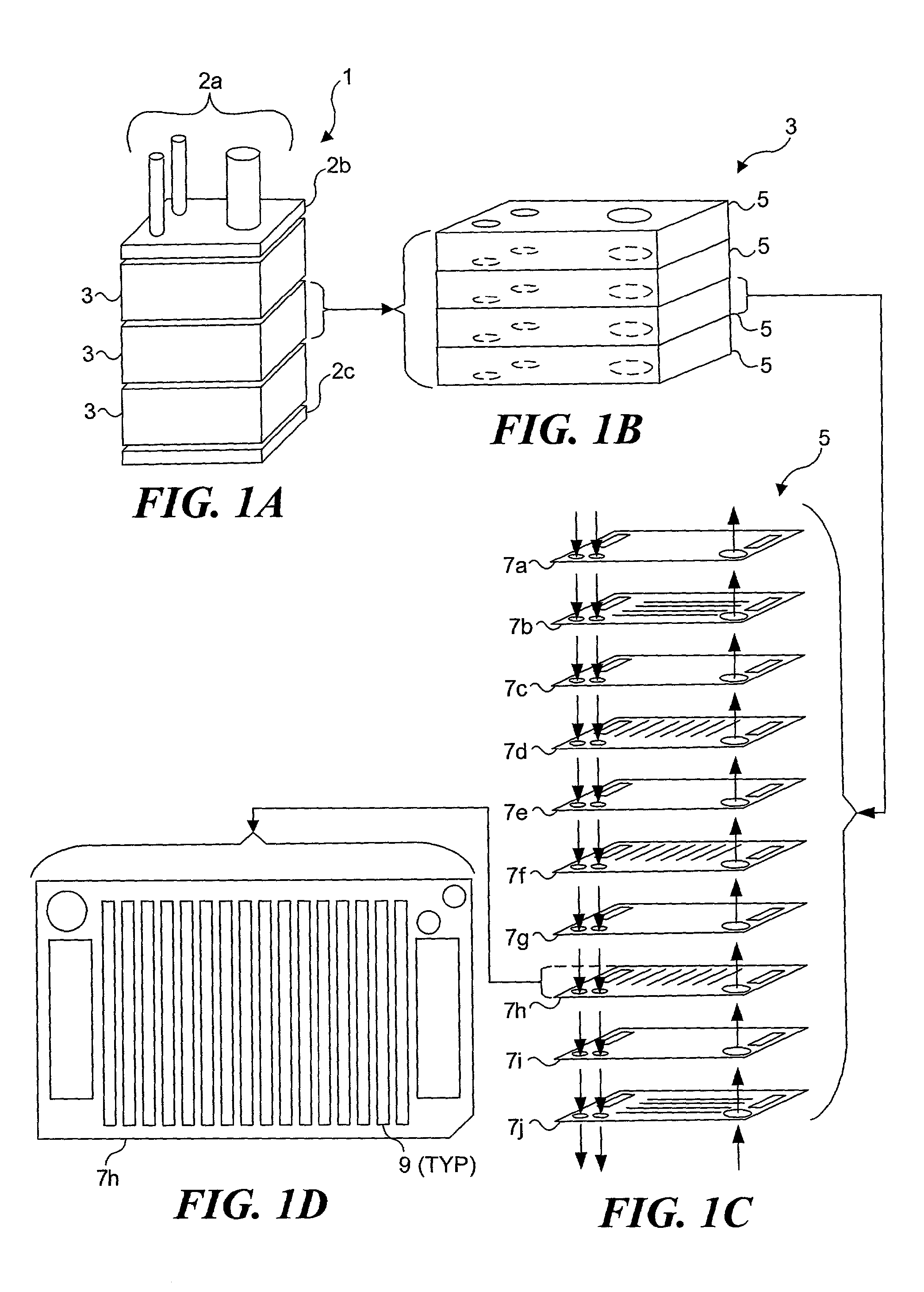

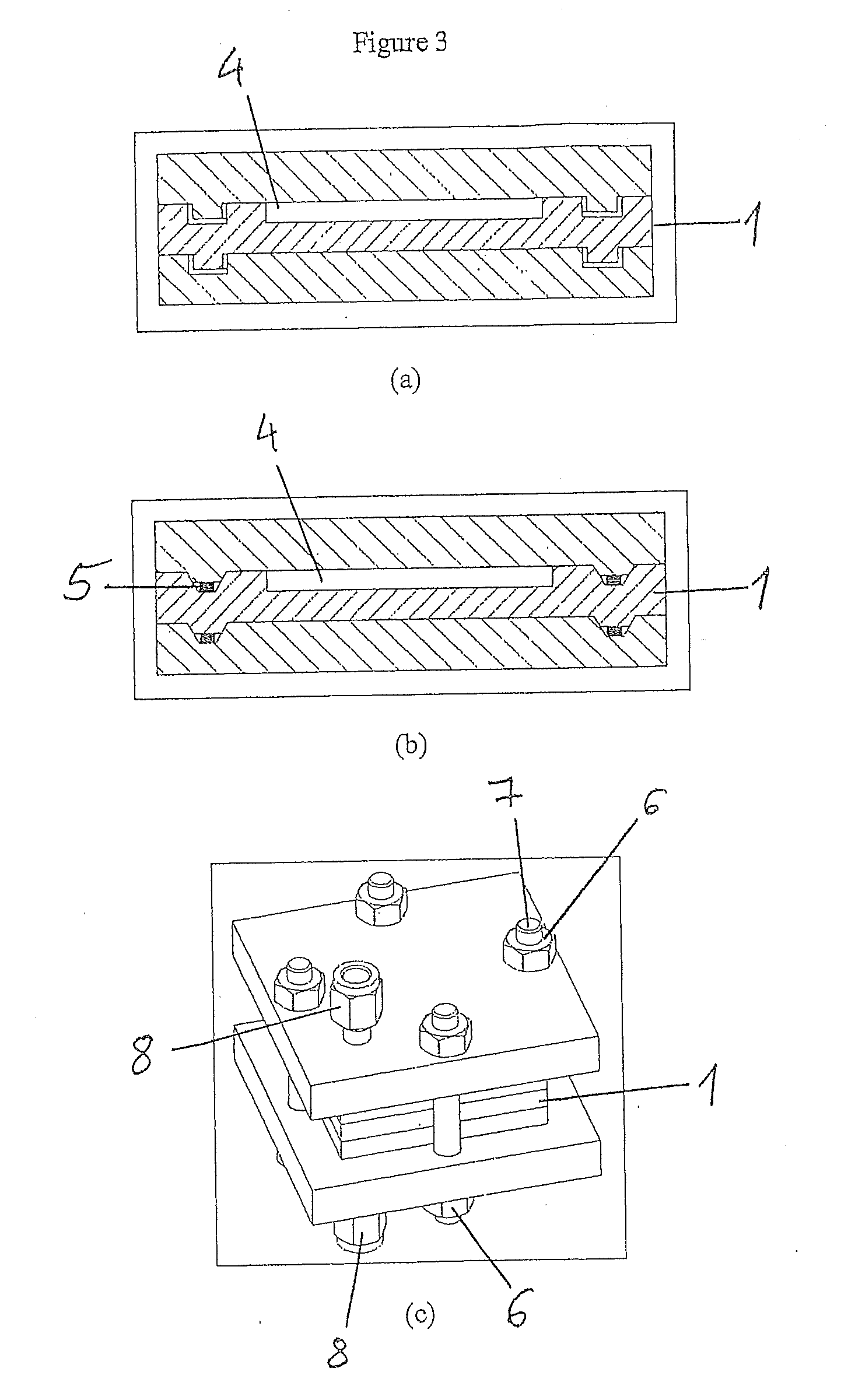

Enhancing fluid flow in a stacked plate microreactor

InactiveUS7241423B2Easy to reconfigureFree of scratchesFlow mixersTransportation and packagingMicroreactorChemical reaction

A stacked plate chemical reactor in which simple plates are stacked together to form the reactor. When openings in adjacent plates are properly aligned, fluid pathways and processing volumes are defined for chemical reactants, heat transfer medium, and a product. In one embodiment of the invention, an n-fold internal array is achieved by providing a first group of simple plates defining a reaction unit that includes bypass fluid channels and reaction fluid channels for each reactant, such that a portion of each reactant is directed to subsequent groups of simple plates defining additional reaction units. A chemical reactor with variable output is obtained in a preferred embodiment by reversibly joining reactor stacks comprising irreversibly joined reaction units, these reaction units consisting of a plurality of simple plates. Other embodiments employ at least one of an array of parallel fluid channels having different widths, bifurcated fluid distribution channels to achieve a substantially even flow equipartition for fluids with varying viscosities flowing within the fluid channels of each reaction unit.

Owner:EHRFELD MIKROTECHNIK BTS GMBH

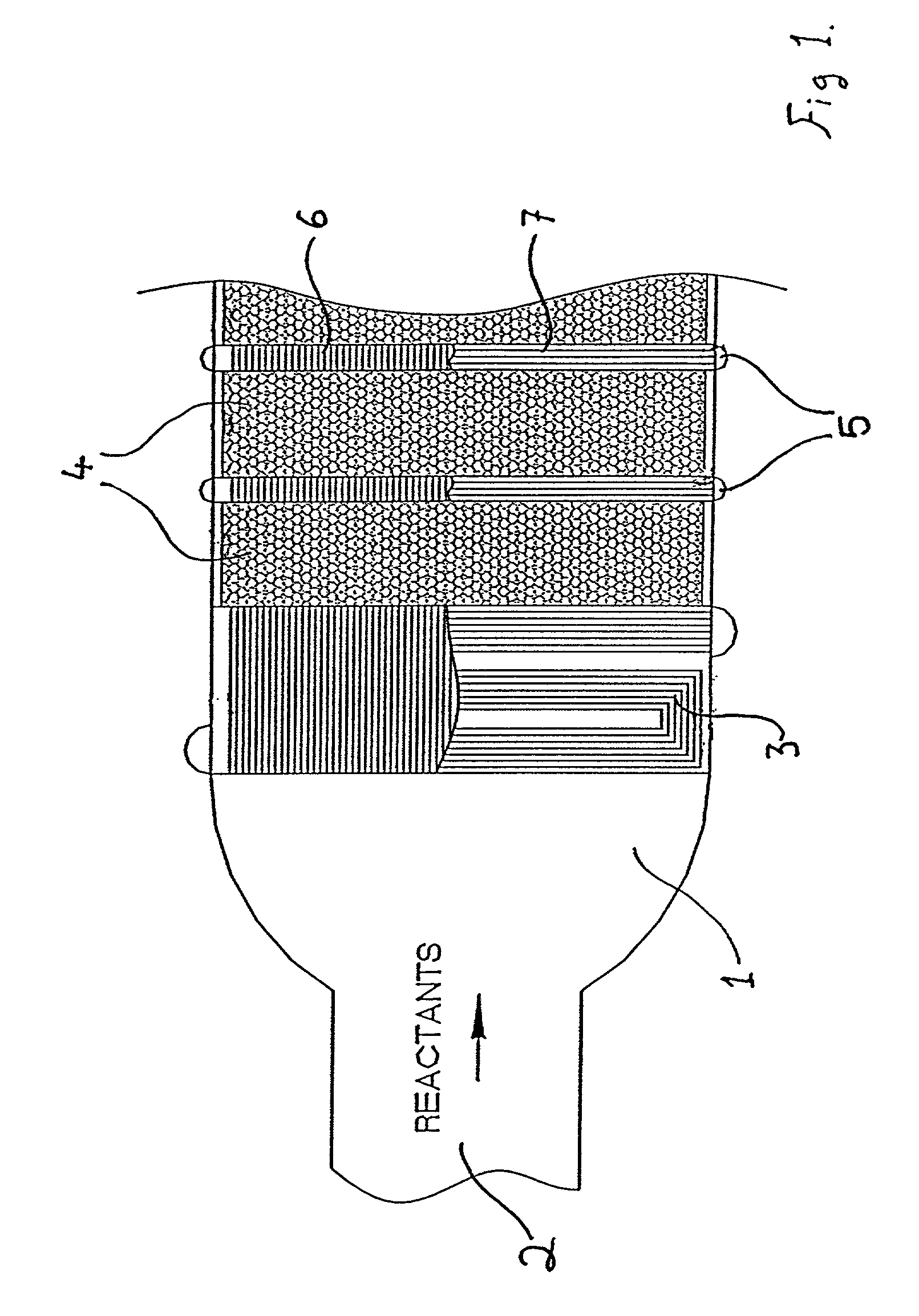

Chemical reactor

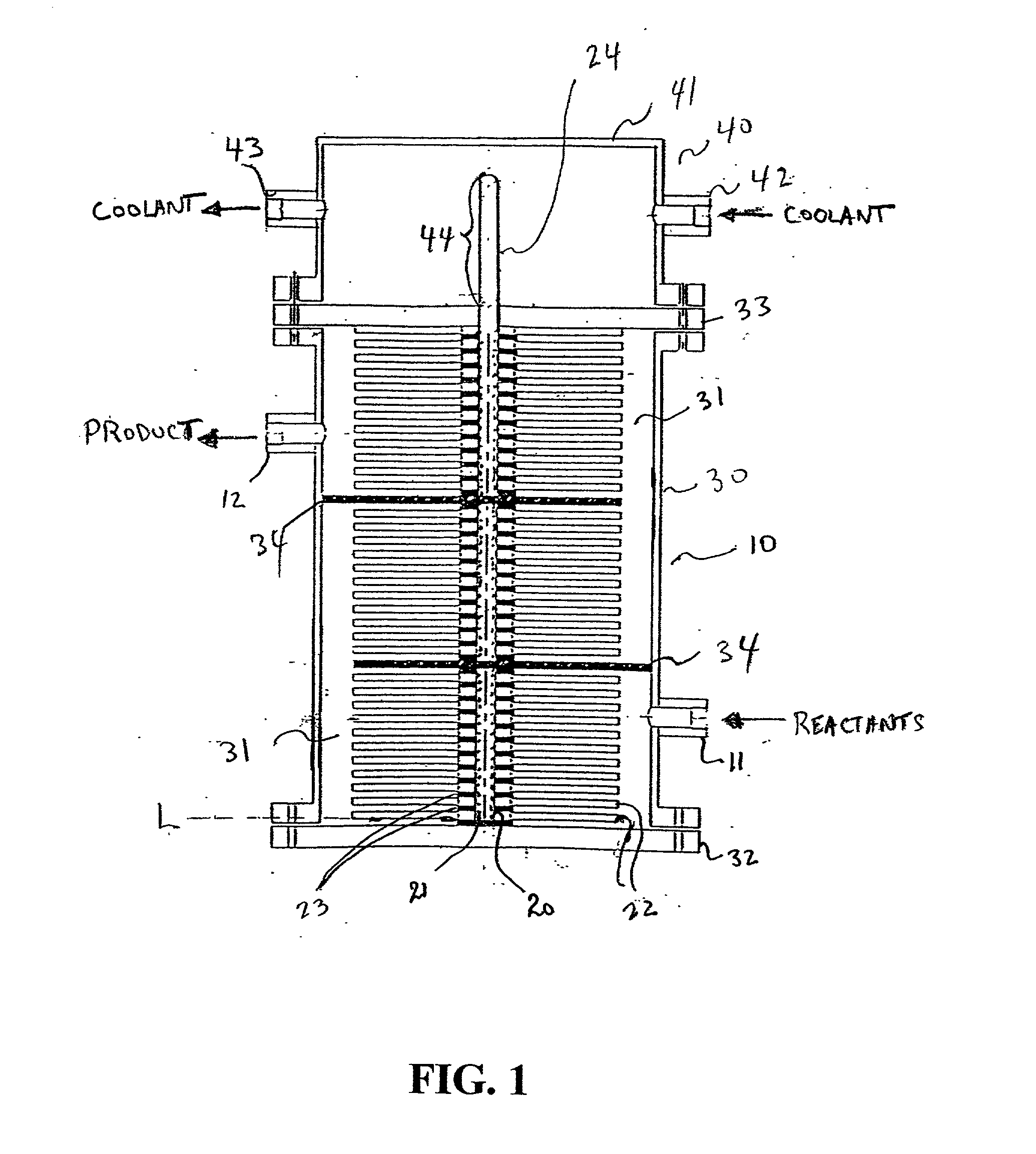

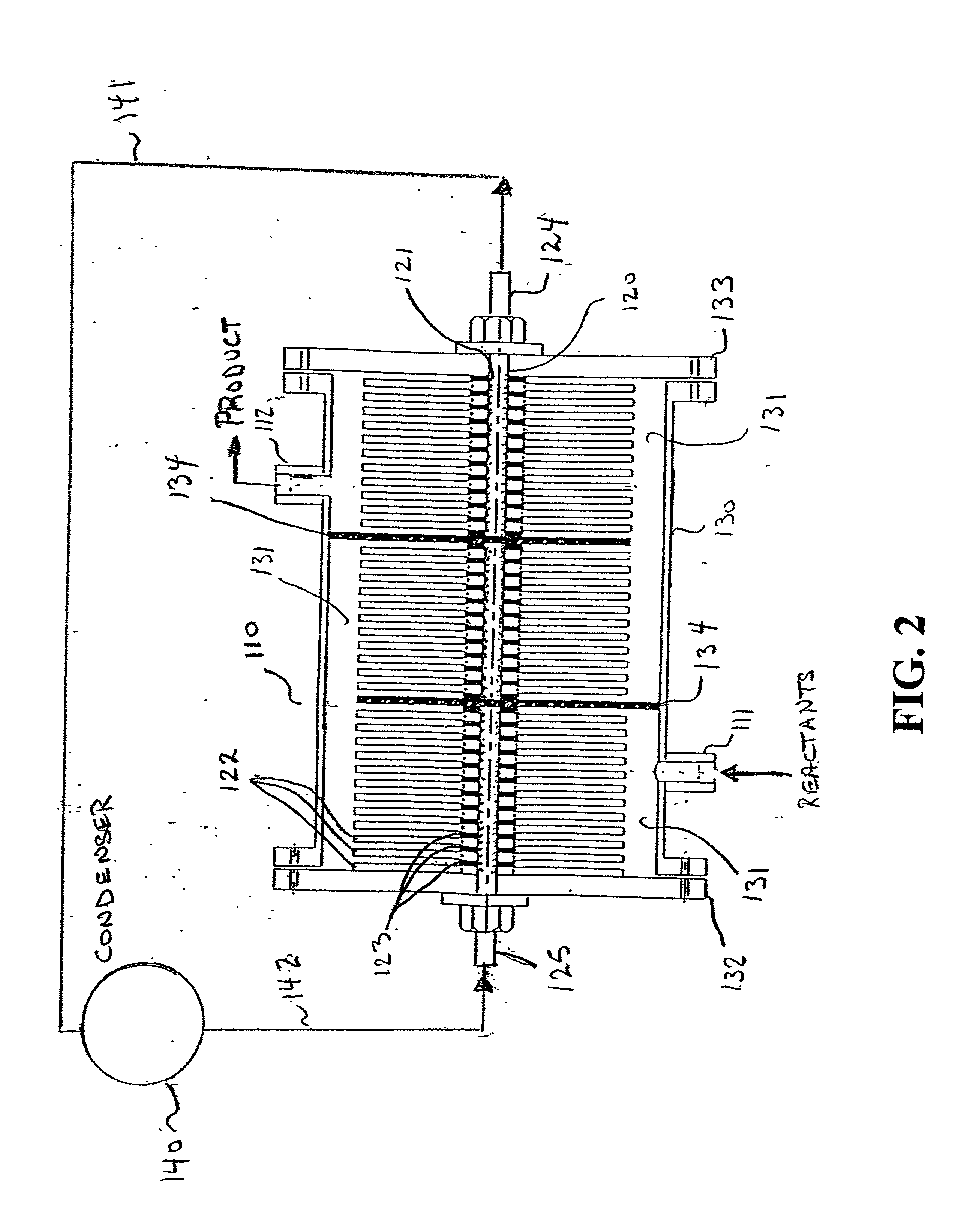

InactiveUS6921518B2Significant changeAvoid mixingLiquid surface applicatorsVapor condensationChemical reactorProcess engineering

A reactor of the staged adiabatic reactor type, comprises at least one heat exchanger panel, preferably a printed circuit heat exchange (PCHE) panel, interposes between adiabatic beds of catalyst, wherein the facial area of the panels and the superficial facial area of the corresponding catalyst are substantially similar, and the panels include means defining discrete passages for handling of reactants and heat transfer media, wherein the means defining passages for heat transfer media provide for at least two differing flow path directions for the heat transfer media through the heat exchanger panel whereby the occurrence of temperature bias or differentials is reduced.

Owner:MEGGIT (UK) LTD

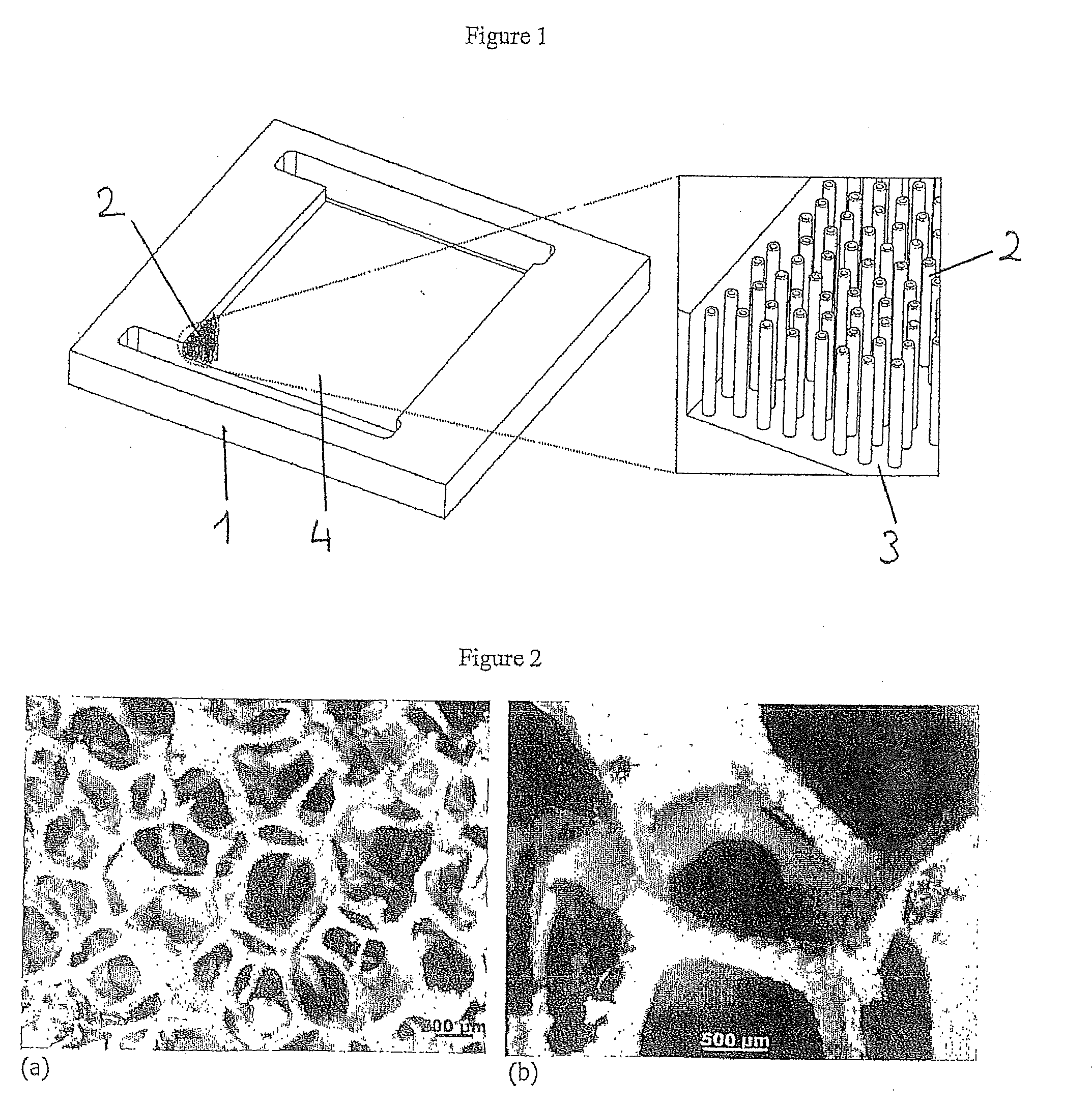

Chemical reactor with nanometric superstructure

InactiveUS20110123409A1Good choiceInhibition formationAnodisationMaterial nanotechnologyGlass fiberCarbon fibers

The invention relates to a chemical reactor with a nanometric superstructure, comprising at least one member wherein at least one reaction chamber is arranged, and said reaction chamber being filled at least partially with a high specific surface area material having a specific surface area greater than 5 m2 / g, and characterised in that said high specific surface area material is selected from nanotubes or nanofibres.These nanotubes or nanofibres are preferably selected in the group consisting of carbon nanofibres or nanotubes, β-SiC nanofibres or nanotubes, TiO2 nanofibres or nanotubes.They may be deposited on an intermediate structure selected in the group consisting of glass fibres, carbon fibres, SiC foams, carbon foams, alveolar β-SiC foams, said intermediate structure filling the reaction chamber of said reactor at least partially.

Owner:CENT NAT DE LA RECHERCHE SCI +1

Stratified flow chemical reactor

InactiveUS20030133856A1Maximum effectivenessImprove thermal efficiencyFlow mixersTransportation and packagingReaction rateRates reactions

A polymerization reactor for exothermic liquid phase reactions comprises a reaction zone which is divided into a plurality of channels by thermally conductive heat transfer fins which are conductively mounted on one or more heat pipes for the removal of heat of reaction from reactants and reaction products flowing between the heat transfer fins. The reactor of the invention is capable of maintaining essentially isothermal conditions without the use of complicated and maintenance intensive agitators. The reactor is particularly useful when viscosity of the reactants and / or reaction products is high, when the reaction conducted has a fast reaction rate and when consistent polymer properties are desired.

Owner:SAUDI BASIC IND CORP SA

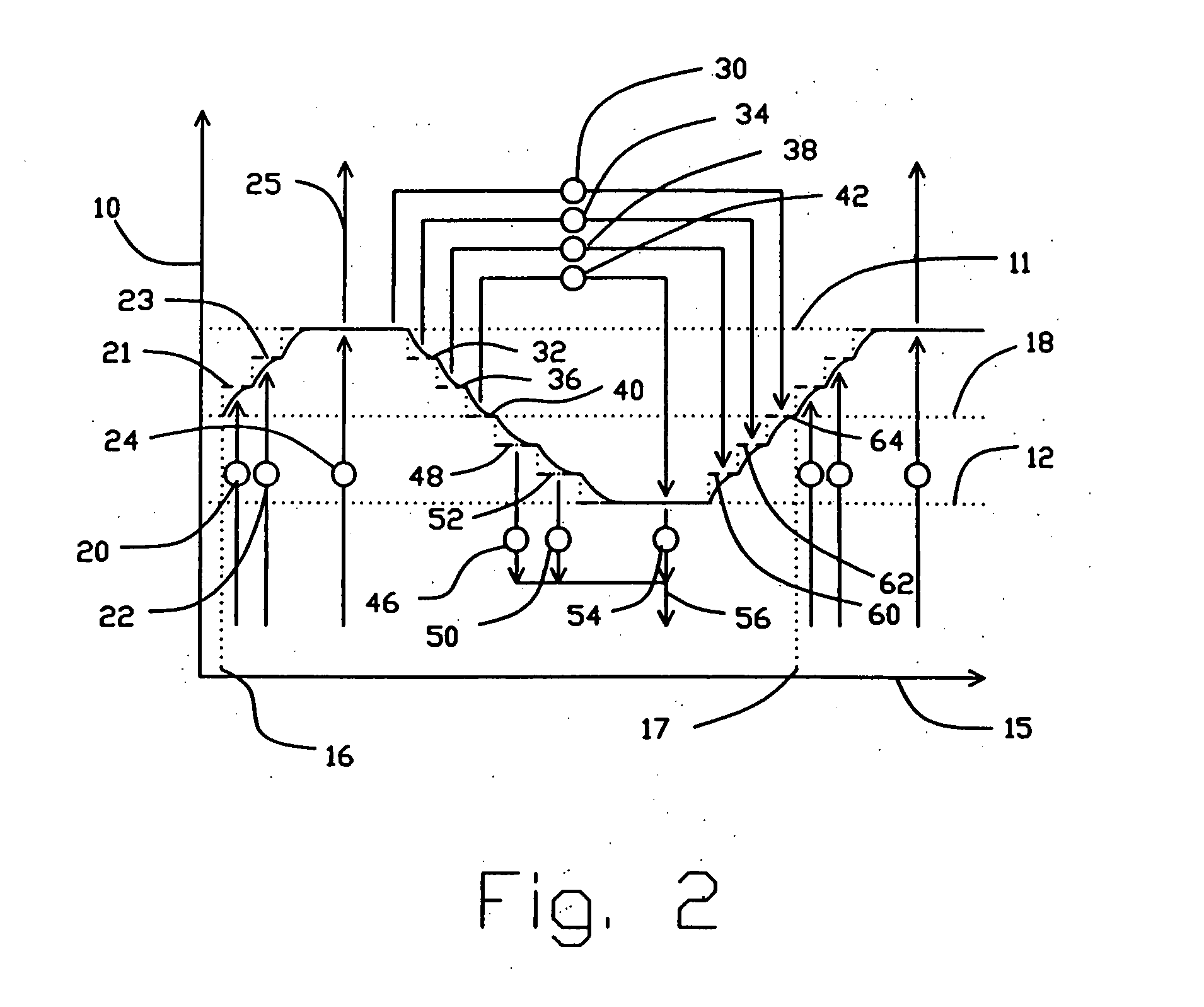

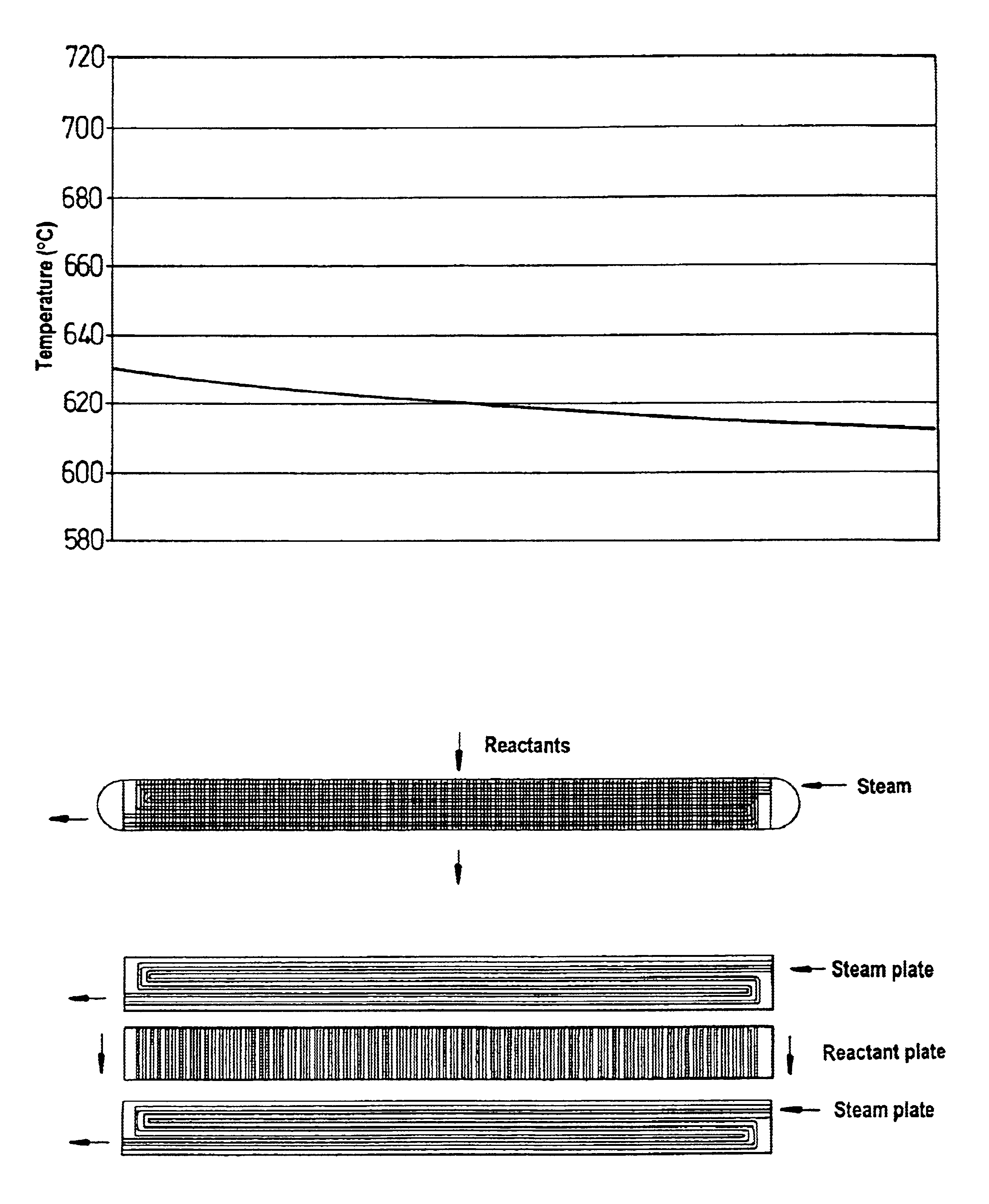

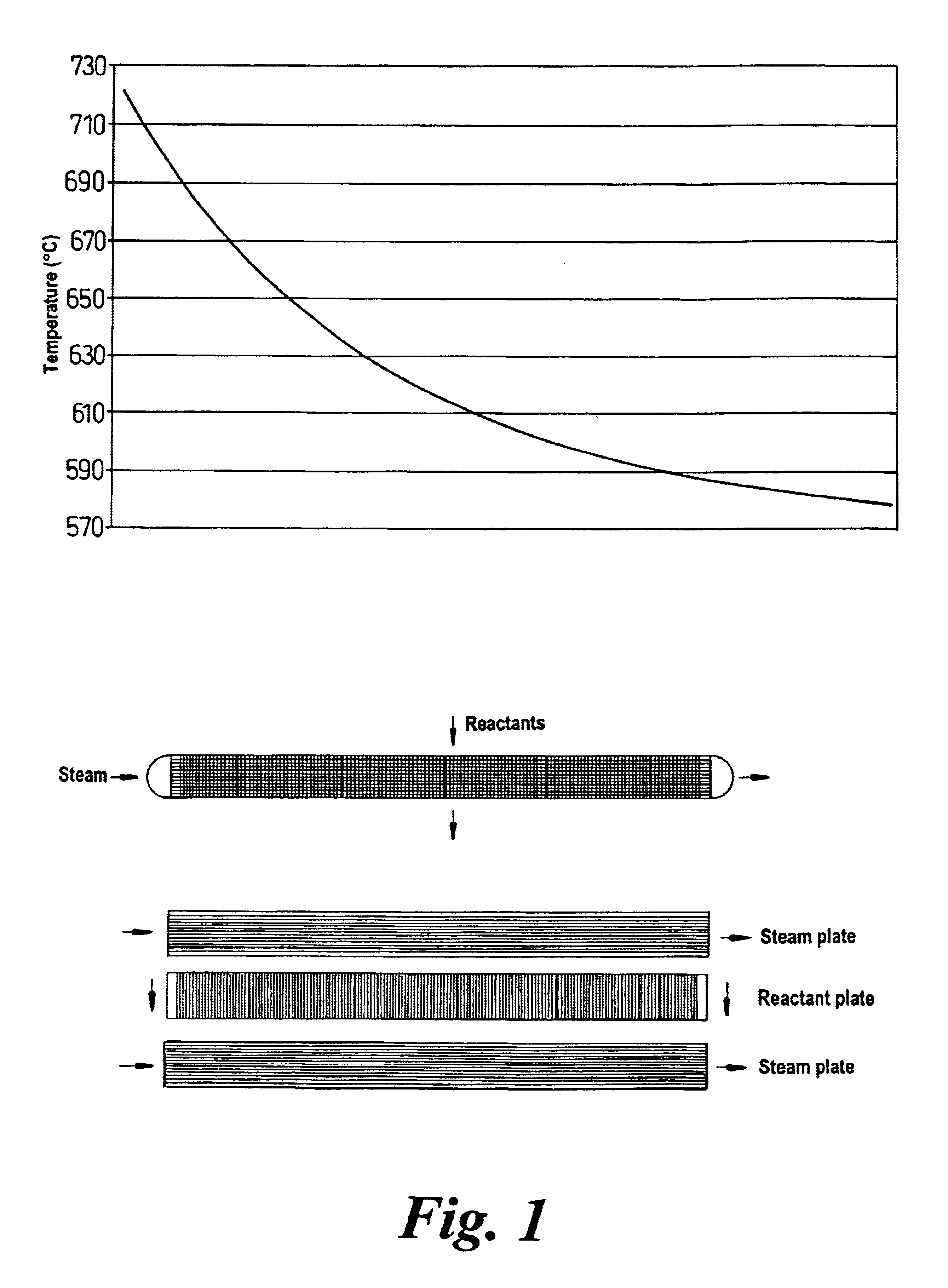

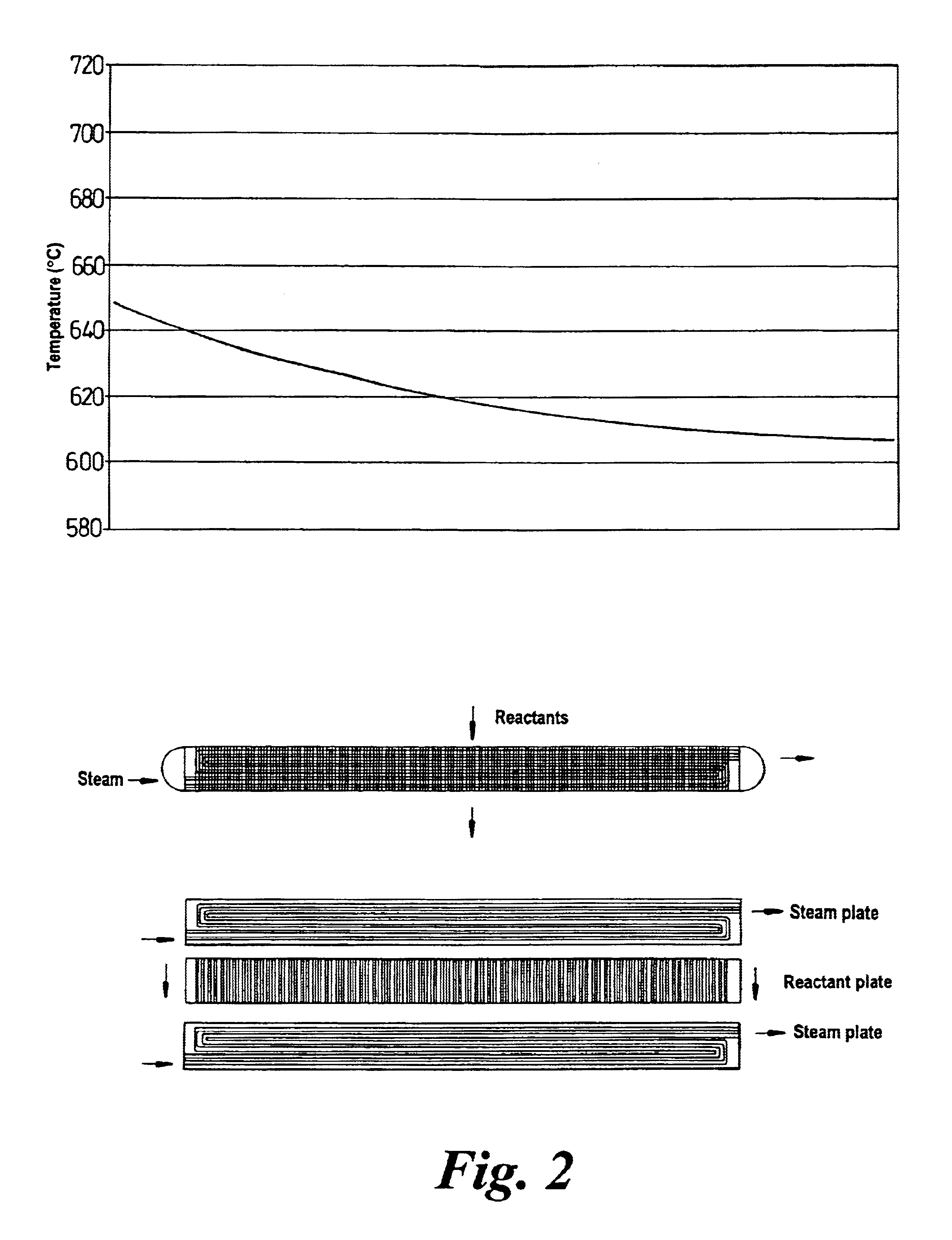

Reforming apparatus and method

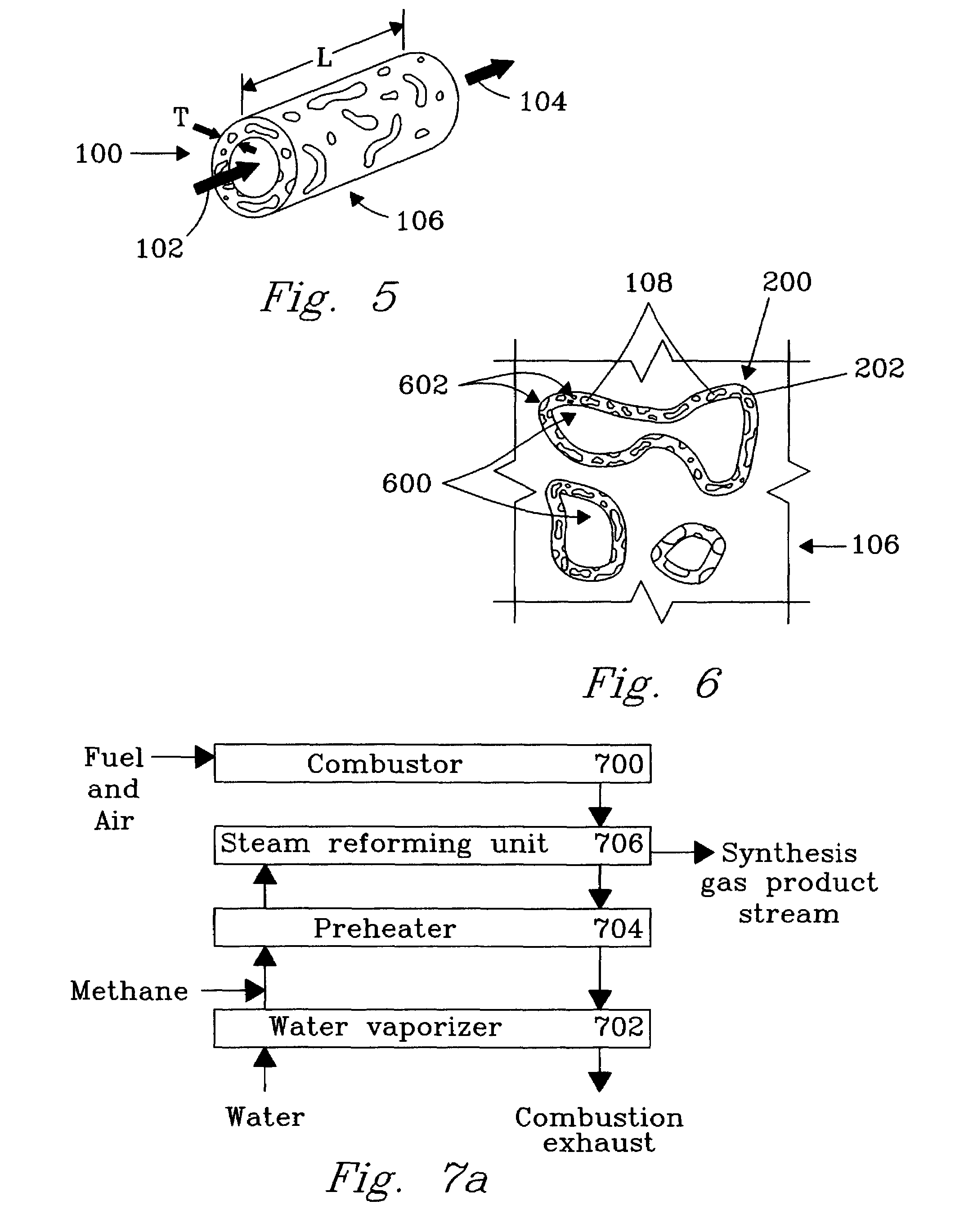

ActiveUS20080244975A1Avoid adjustmentMultiple metal hydridesHigh temperature gas-gas reactionSyngasMetal dusting

A multiple adiabatic bed reforming apparatus and process are disclosed in which stage-wise combustion, in combination with multiple reforming chambers with catalyst, utilize co-flow and cross-flow under laminar flow conditions, to provide a reformer suitable for smaller production situations as well as large scale production. A passive stage by stage fuel distribution network suitable for low pressure fuel is incorporated and the resistances in successive fuel distribution lines control the amount of fuel delivered to each combustion stage. The fuel distribution system allows relatively constant fuel and air flow during turn up or turn down conditions. High efficiency is achieved by capturing heat from reforming syngas product to preheat gases before entering the reformer. Conditions that would produce unwanted coking or metal dusting are also eliminated or localized to locations within the apparatus outside the heat exchangers, but which locations can be cost effectively protected. Also, a chemical reactor is disclosed and which has a core composed of a stack of metal plates that are diffusion bonded in face-to-face relationship. A plurality of reaction zones are located within the core, as are a plurality of catalyst receiving zones, and both the reaction zones and the catalyst receiving zones are defined by respective aligned apertures in the plates. First and second channel arrangements are provided in the plates for transporting first and second reactants to reaction zones. Portions of the first channel arrangement that interconnect the reaction zones are formed as heat exchange channels. A third channel arrangement is provided in the plates for transporting a third reactant to catalyst receiving zones. Portions of the third channel arrangement are formed as heat exchange channels in proximity to the heat exchange channels of the first channel arrangement.

Owner:MEGGIT (UK) LTD

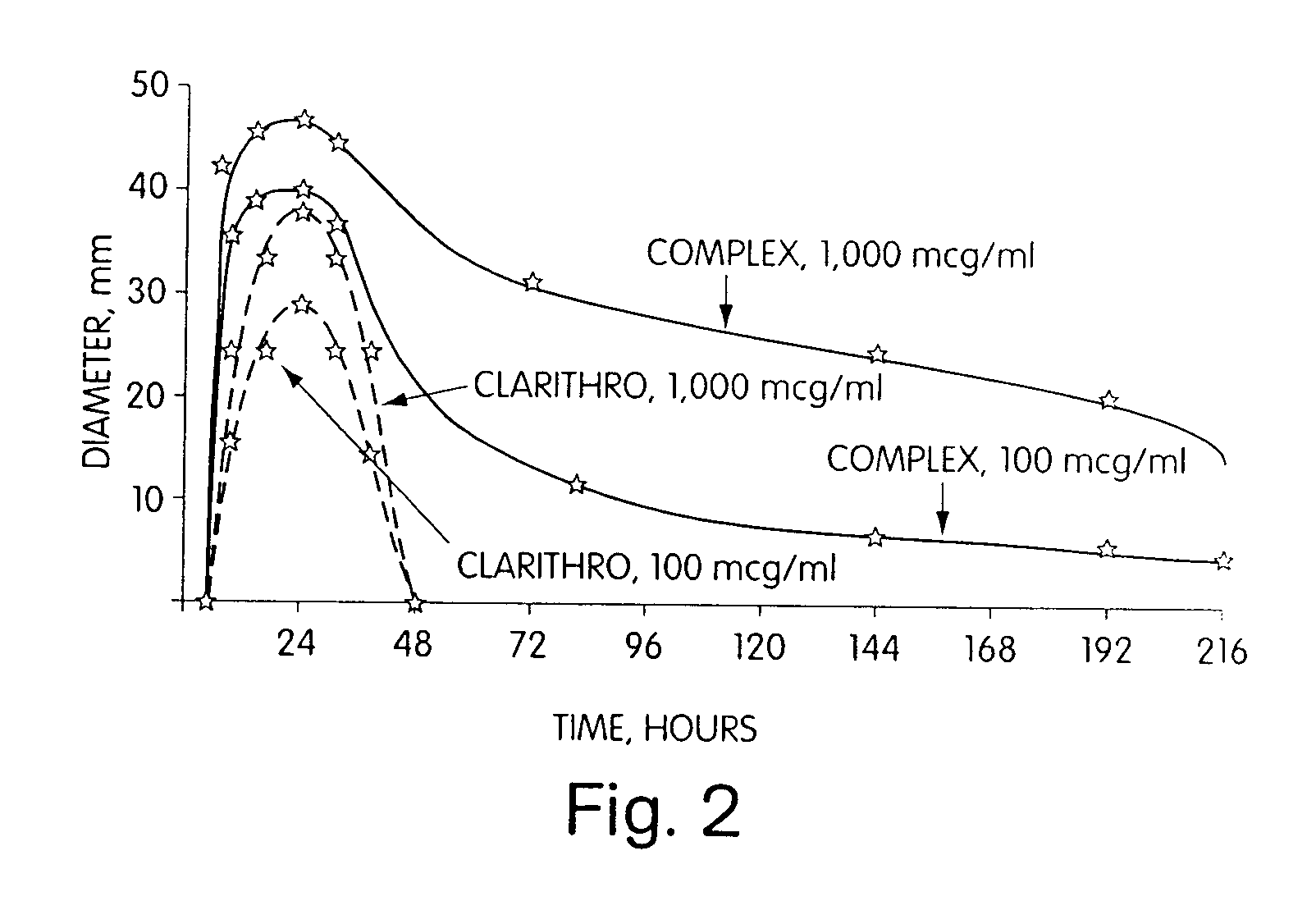

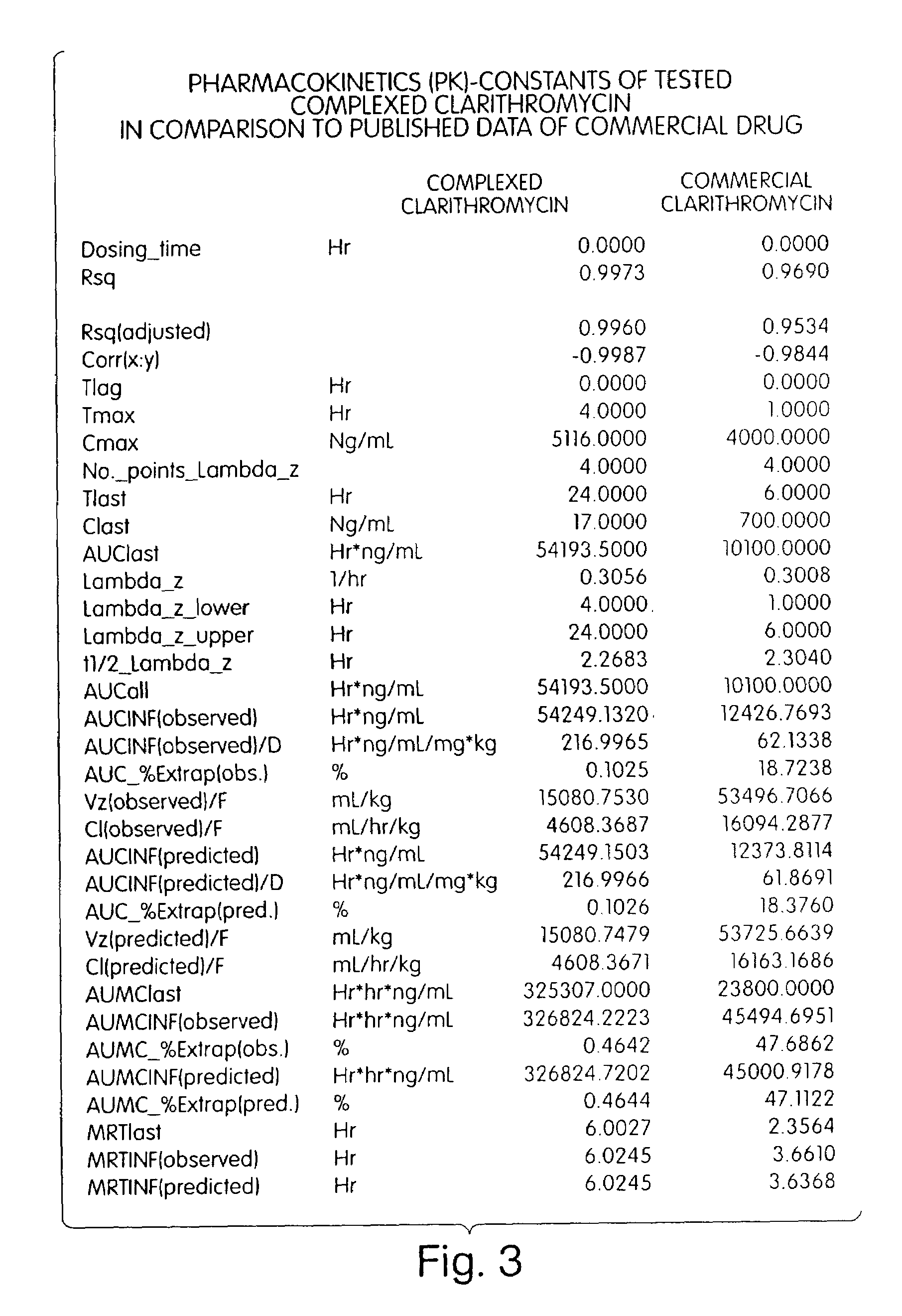

Hydrophilic complexes of lipophilic materials and an apparatus and method for their production

InactiveUS6878693B2Improve uniformitySimple processAntibacterial agentsPowder deliveryFood additiveWater insoluble

This invention provides a soluble inclusion complex formed of a water-insoluble lipophilic compound and an amphiphilic polymer and which demonstrated improved solubility and stability. The lipophilic compound within the inclusion complex may consist of pharmaceutical compounds, food additives, cosmetics, agricultural products and veterinary products. The invention also provides novel methods for preparing the inclusion complex, as well as a novel chemical reactor for forming the inclusion complex.

Owner:SOLUBEST

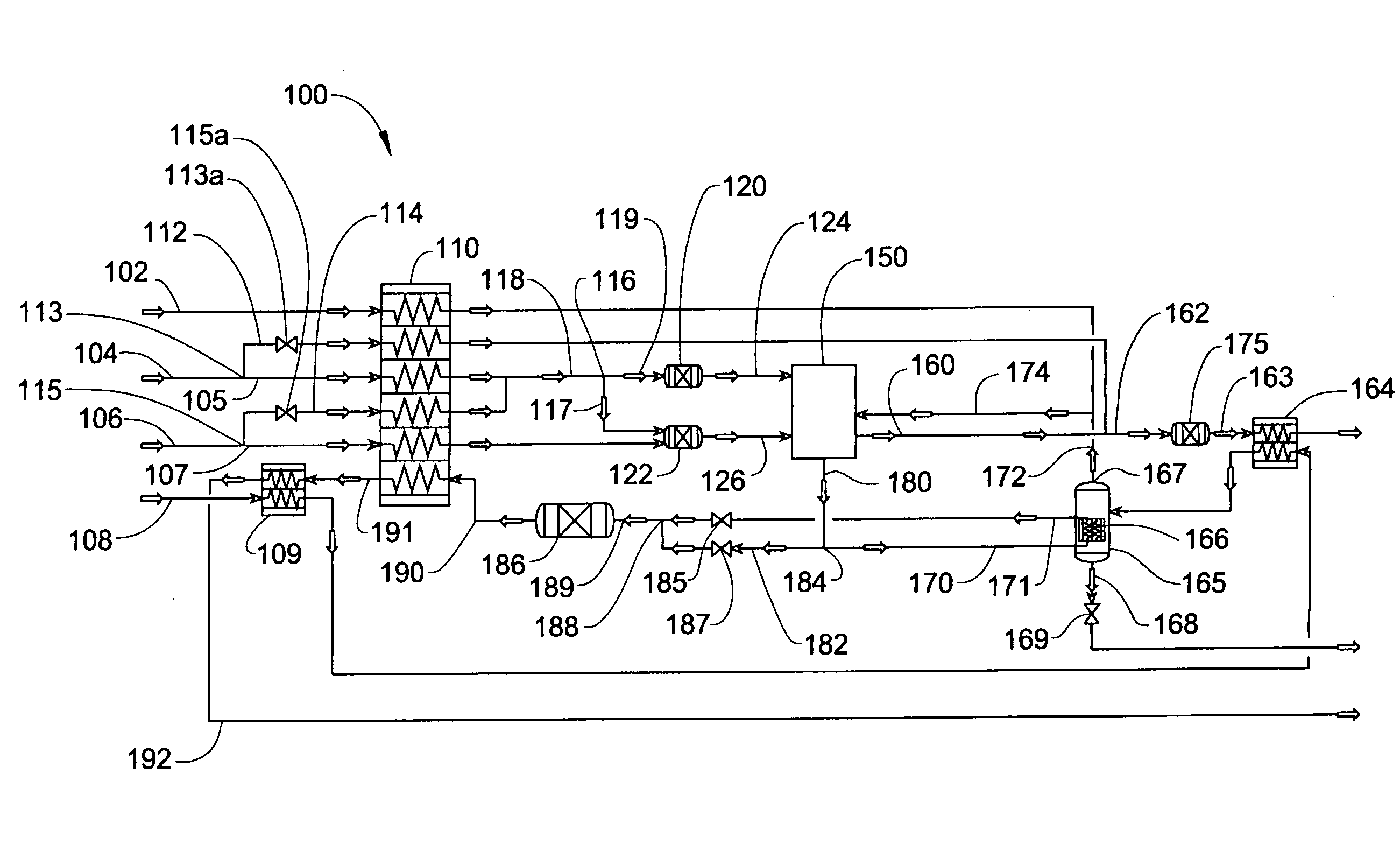

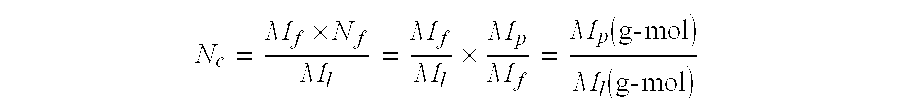

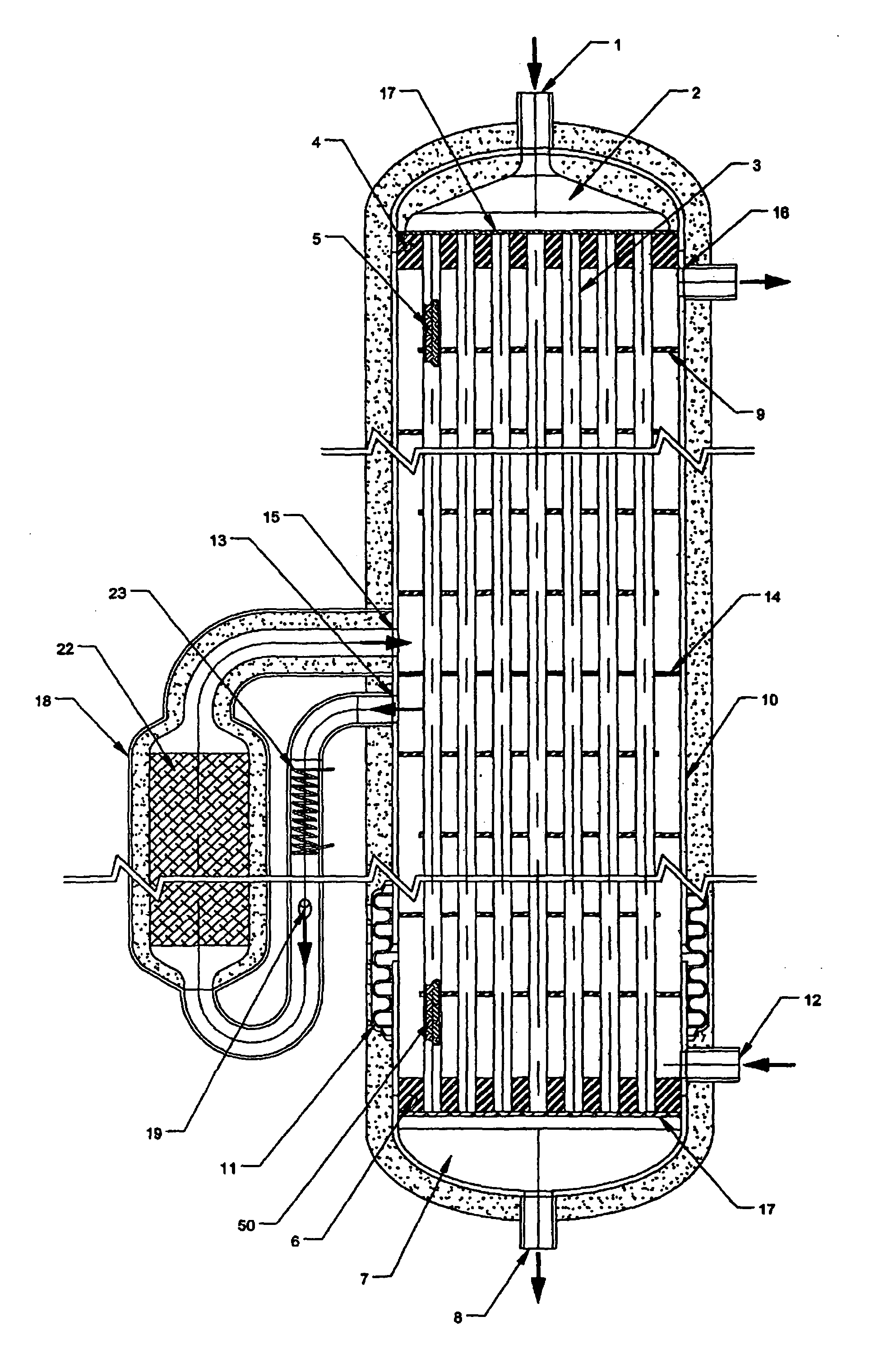

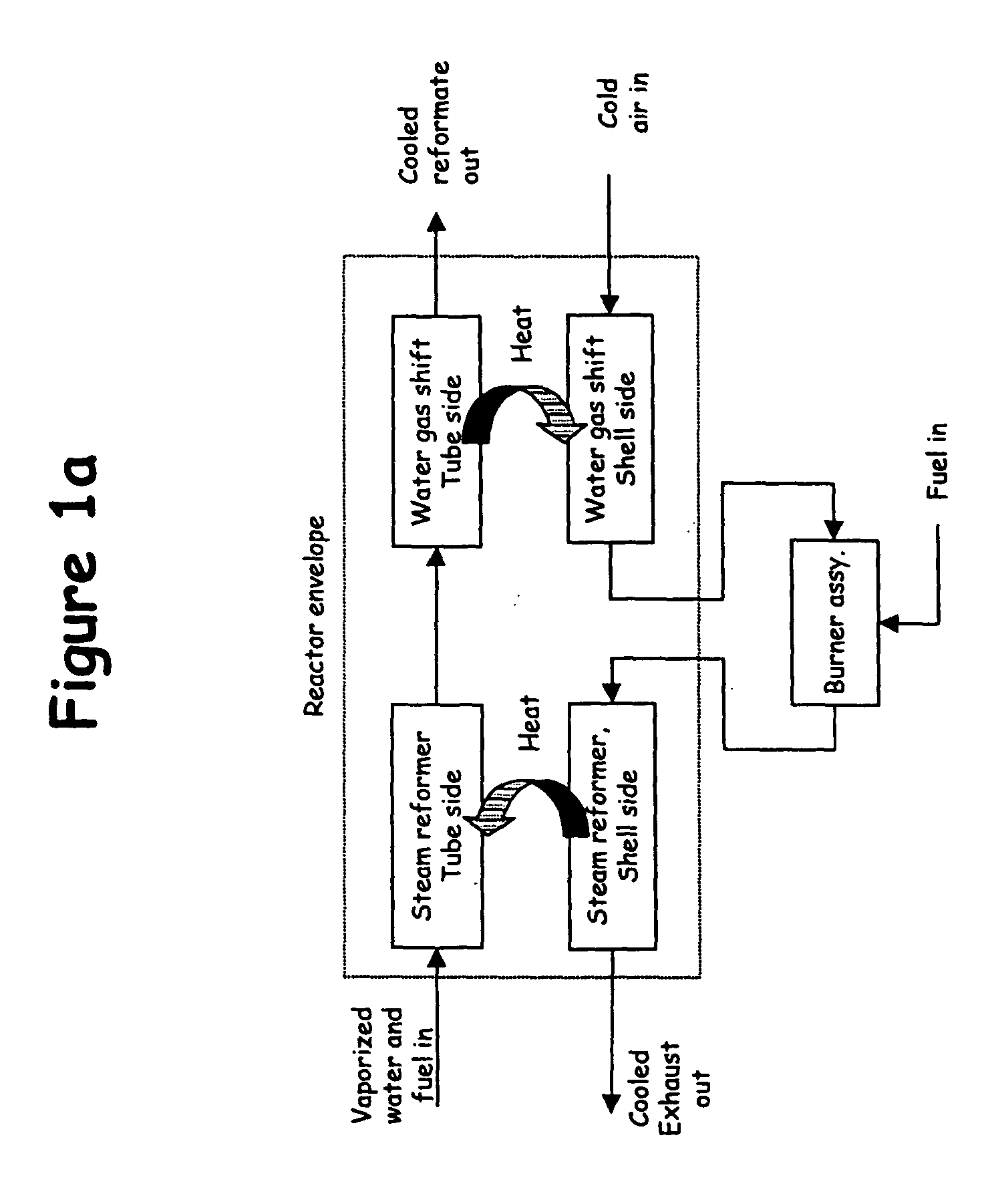

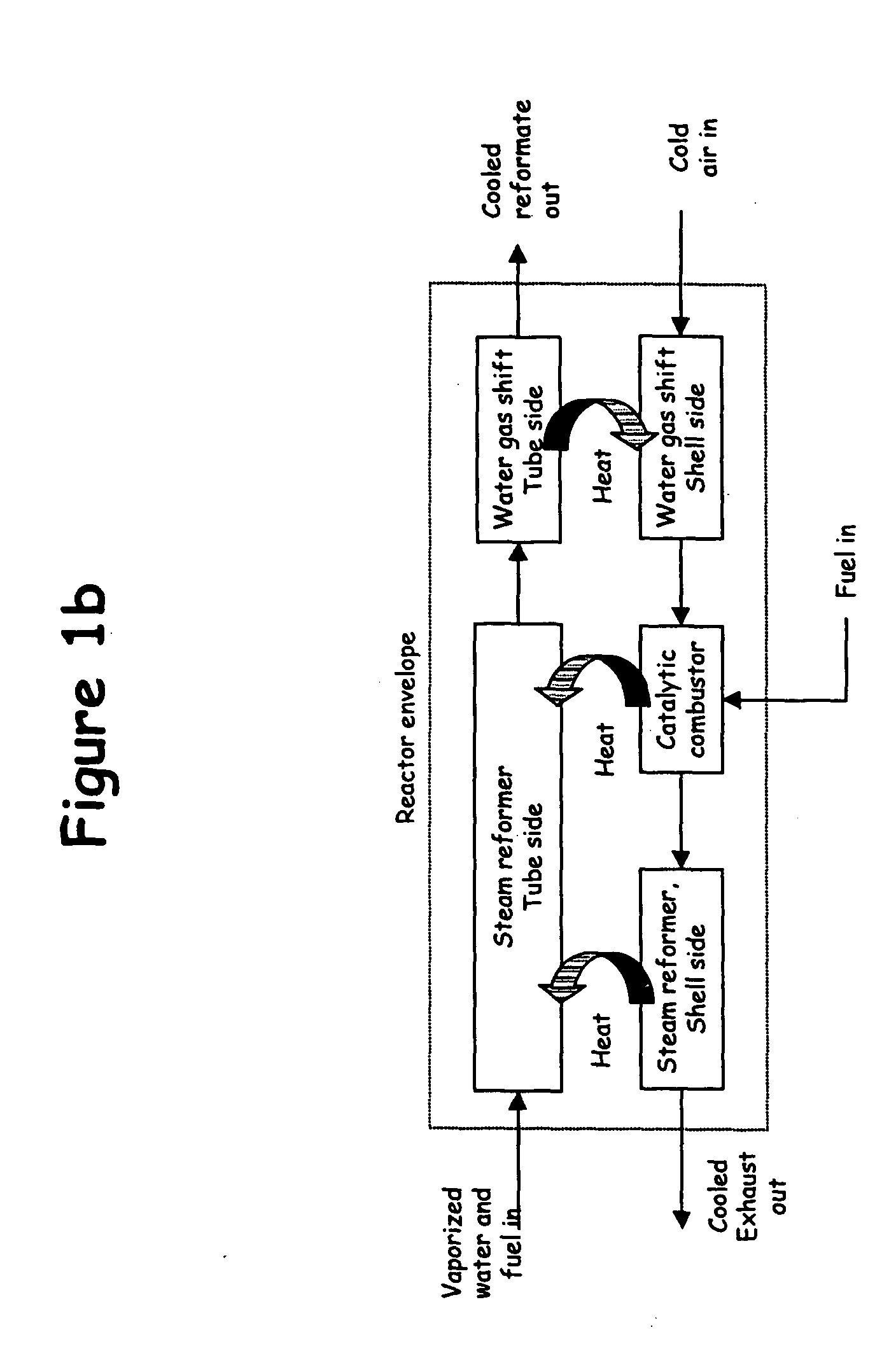

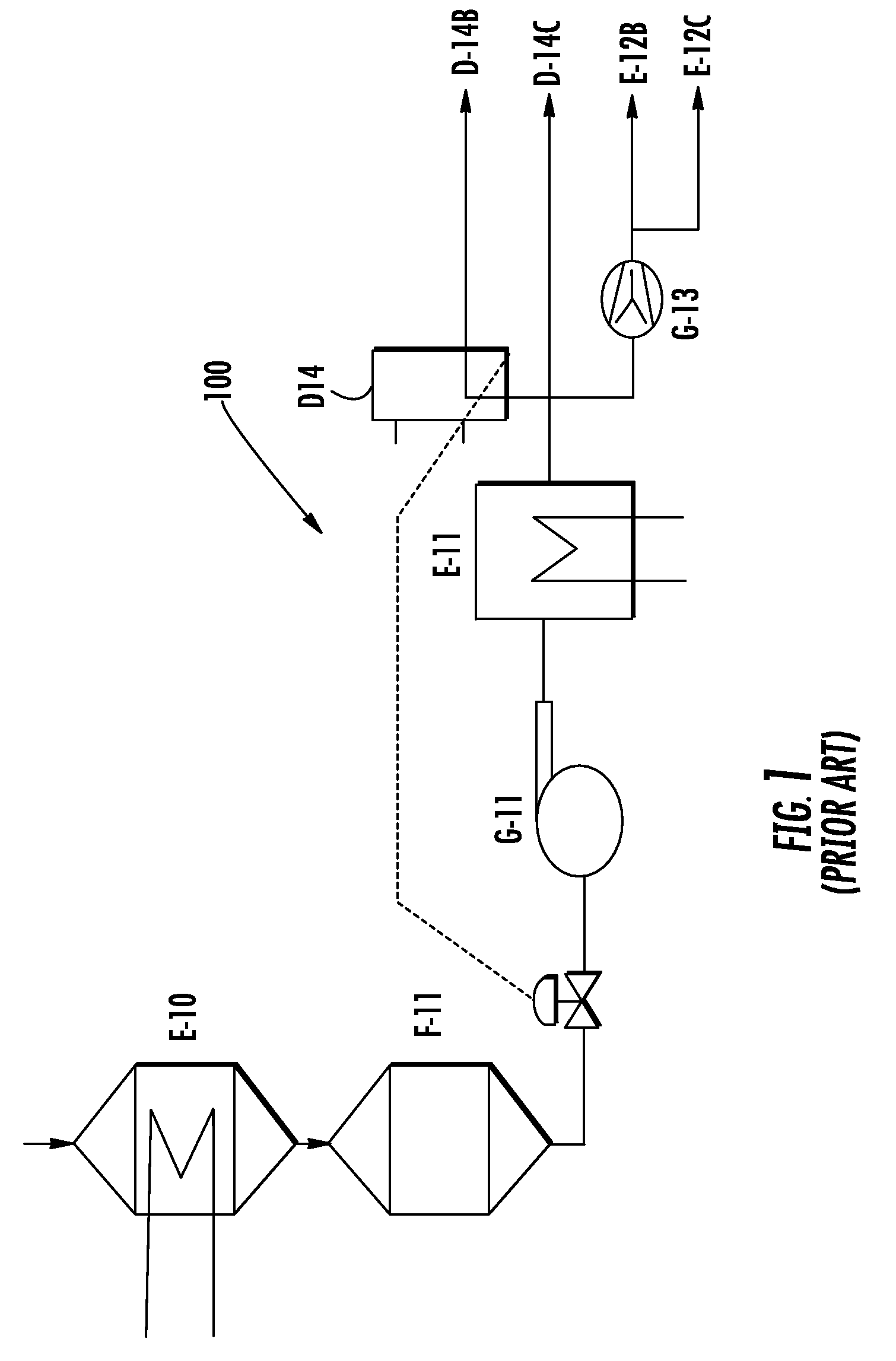

System for hydrogen generation through steam reforming of hydrocarbons and intergrated chemical reactor for hydrogen production from hydrocarbons

InactiveUS20050097819A1Avoid problemsCost efficientHydrogenHydrogen/synthetic gas productionSteam reformingEngineering

The present invention provides a reactor, which includes: a unitary shell assembly having an inlet and an outlet; a flow path extending within the shell assembly from the inlet to the outlet, the flow path having a steam reformer section with a first catalyst and a water gas shift reactor section with a second catalyst, the steam reformer section being located upstream of the water gas shift reactor section; a heating section within the shell assembly and configured to heat the steam reformer section; and a cooling section within the shell assembly and configured to cool the water gas shift reactor section. The present invention also provides a simplified hydrogen production system, which includes the catalytic steam reforming and subsequent high temperature water gas shift of low-sulfur (<100 ppm by mass) hydrocarbon fuels followed by hydrogen purification through the pressure swing adsorption (PSA). The integrated reactor offers significant advantages such as lower heat loss, lower parts count, lower thermal mass, and greater safety than the many separate components employed in conventional and is especially well-suited to applications where less than 15,000 standard cubic feet per hour of hydrogen are required. The improved system also may be started, operated and shut down more simply and quickly than what is currently possible in conventional systems. The improved system preferably employs active temperature control for added safety of operation. The hydrogen product is of high purity, and the system may be optionally operated with a feedback control loop for added purity.

Owner:H2GEN INNOVATIONS INC

Chemical reactor

InactiveUS7033553B2Tight controlReduce backmixingPhysical/chemical process catalystsChemical/physical/physico-chemical processesWorking fluidChemical reactor

A reactor comprises a reaction zone, optionally containing a catalyst bed, and heat exchange means inoperative contact with the reaction zone, e.g. embedded in a catalyst bed, and arranged so as to received reactants for heat exchange purposes, wherein the heat exchange means is formed from a plurality of superposed metal plates wherein fluid flow channels have been formed, according t a pre-determined pattern, the channel-bearing plates being aligned during superposition to define discrete heat exchange pathways respectively for reactant and working fluids, and the said plates are diffusion bonded together.

Owner:MEGGIT (UK) LTD

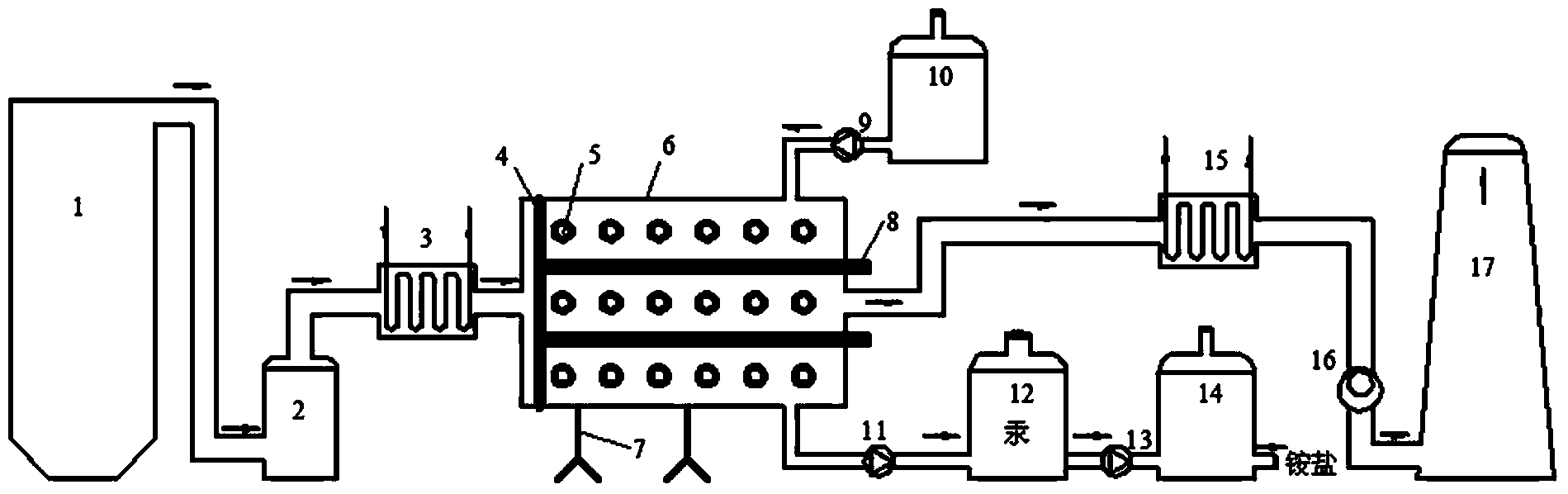

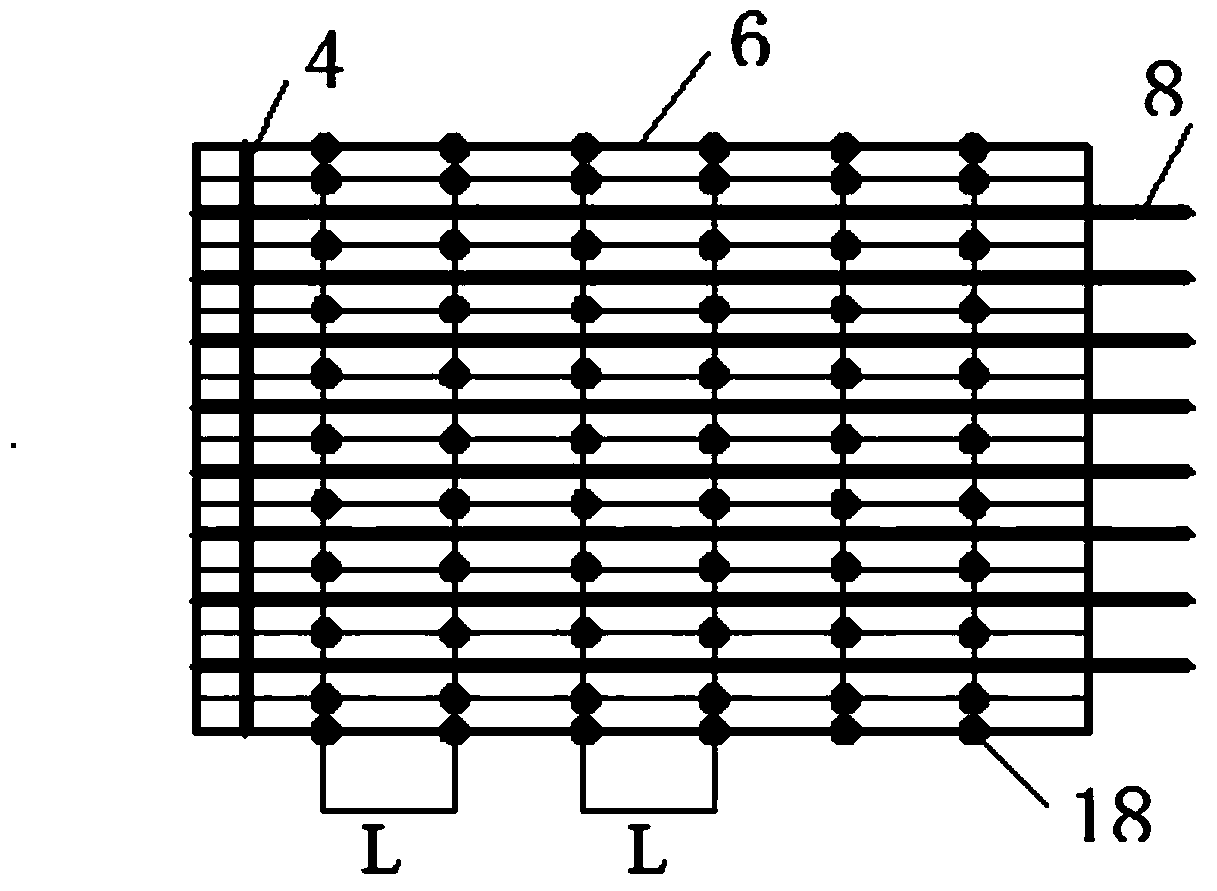

System and method for desulfurizing, denitrifying and removing mercury based on photoactivation ammonium persulfate

ActiveCN103638796ALow investment costLow running costDispersed particle separationAir quality improvementSulfate radicalsResource utilization

The invention discloses a system and a method for desulfurizing, denitrifying and removing mercury based on photoactivation ammonium persulfate. The system is mainly provided with a boiler or kiln, a deduster, a flue gas temperature regulator, a photochemistry reactor, a liquid spraying system as well as a byproduct post-processing system. Flue gas discharged from the boiler or kiln enters the photochemistry reactor arranged on a flue channel after being subjected to dedusting and temperature regulation, and an ammonium persulfate solution from the liquid spraying system is sprayed into the photochemistry reactor in a mist form; an UV (ultraviolet) lamp in the photochemistry reactor emits UV light to perform catalytic decomposition on ammonium persulfate, releases sulfate radical free radicals with high oxidizing property (SO4-.), and meanwhile oxidizes and removes SO2, NOx and mercury in the flue gas. Oxidized products are subjected to resource utilization after being processed by the byproduct post-processing system. The method has the prominent advantages that the method can be used for removing multiple pollutants in coal burned flue gas synchronously, has no secondary pollution during removing, and can be used for transforming aging units and the like, and the system is a novel flue gas purifying system with a wide application prospect.

Owner:JIANGSU UNIV

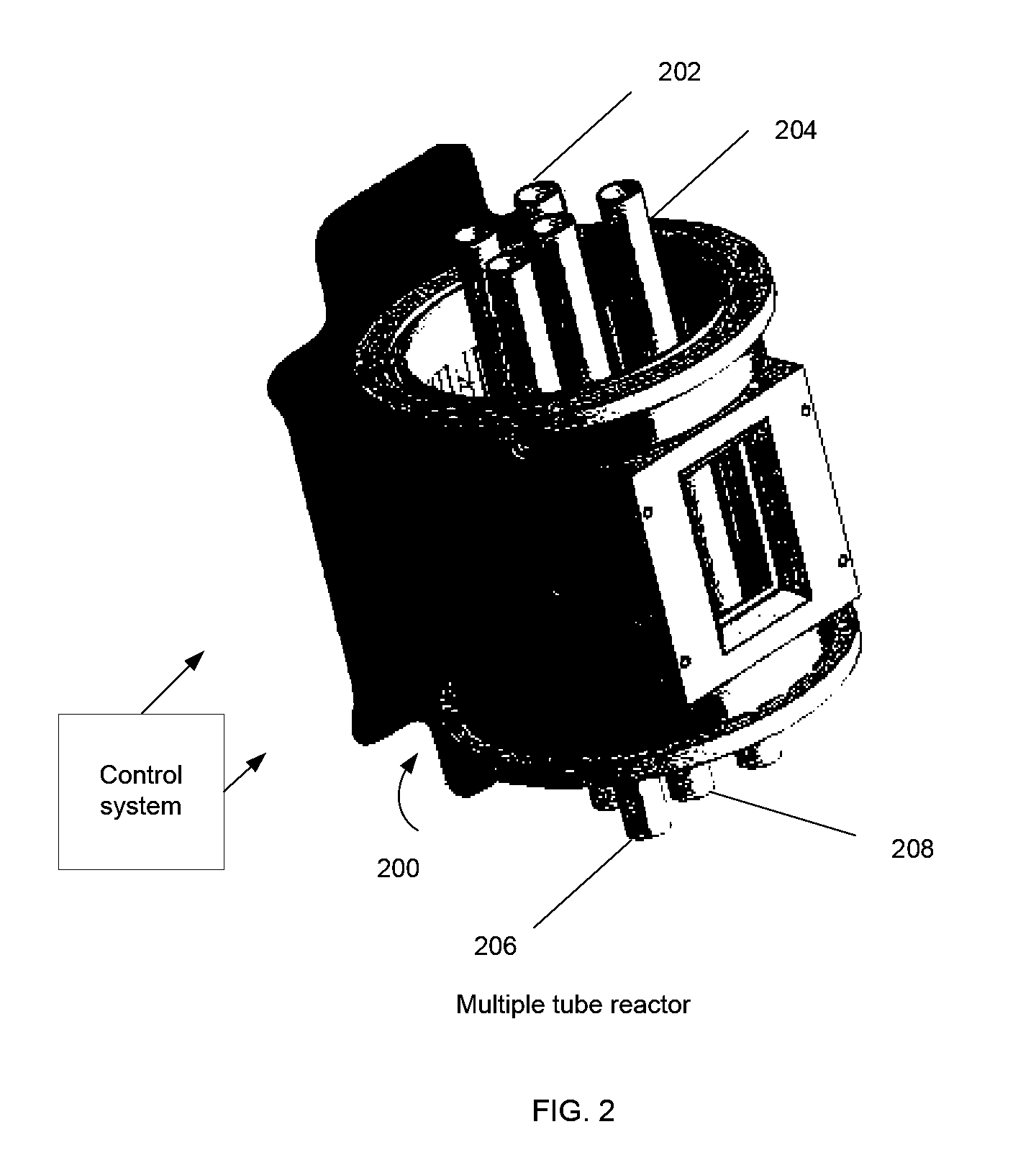

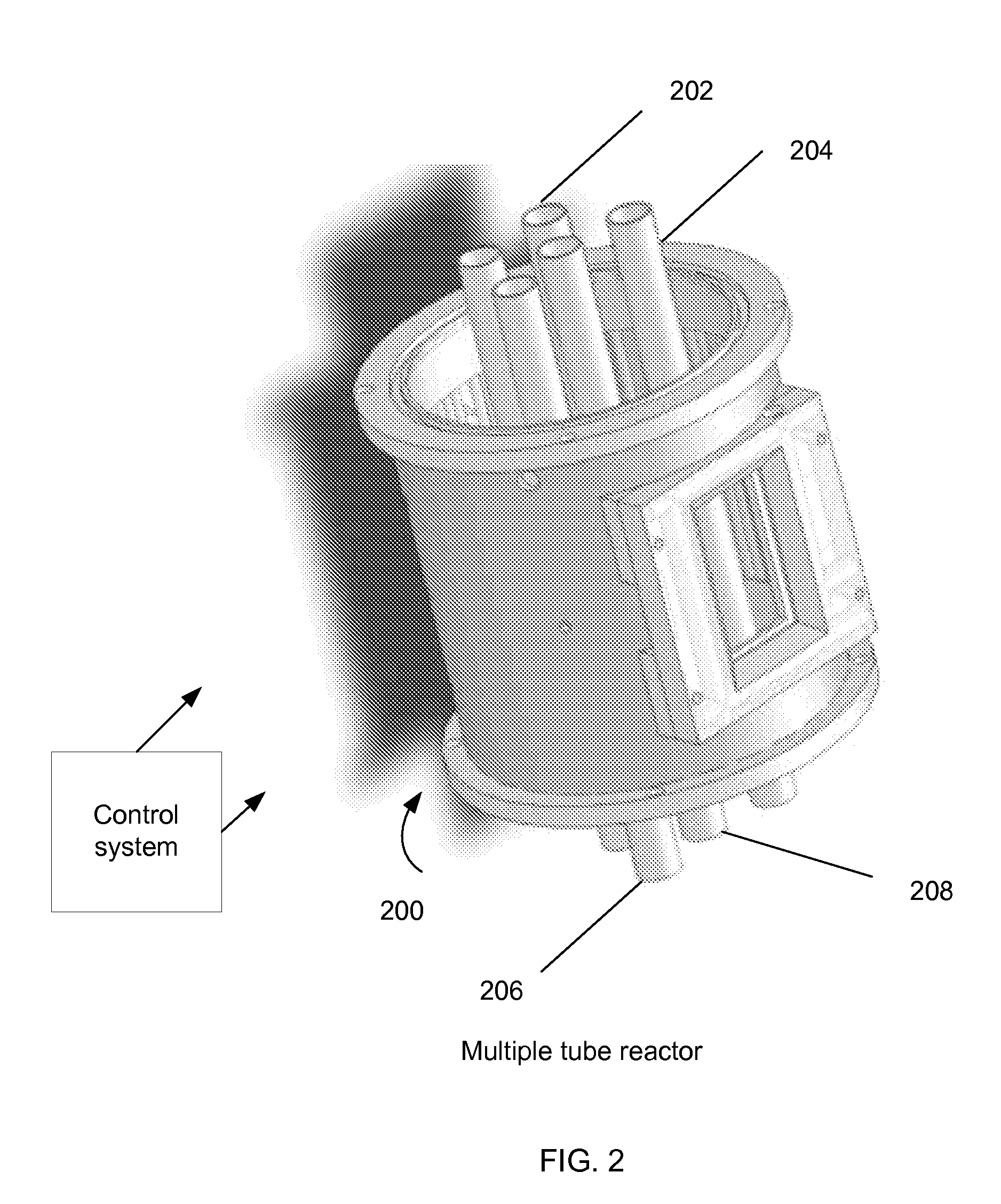

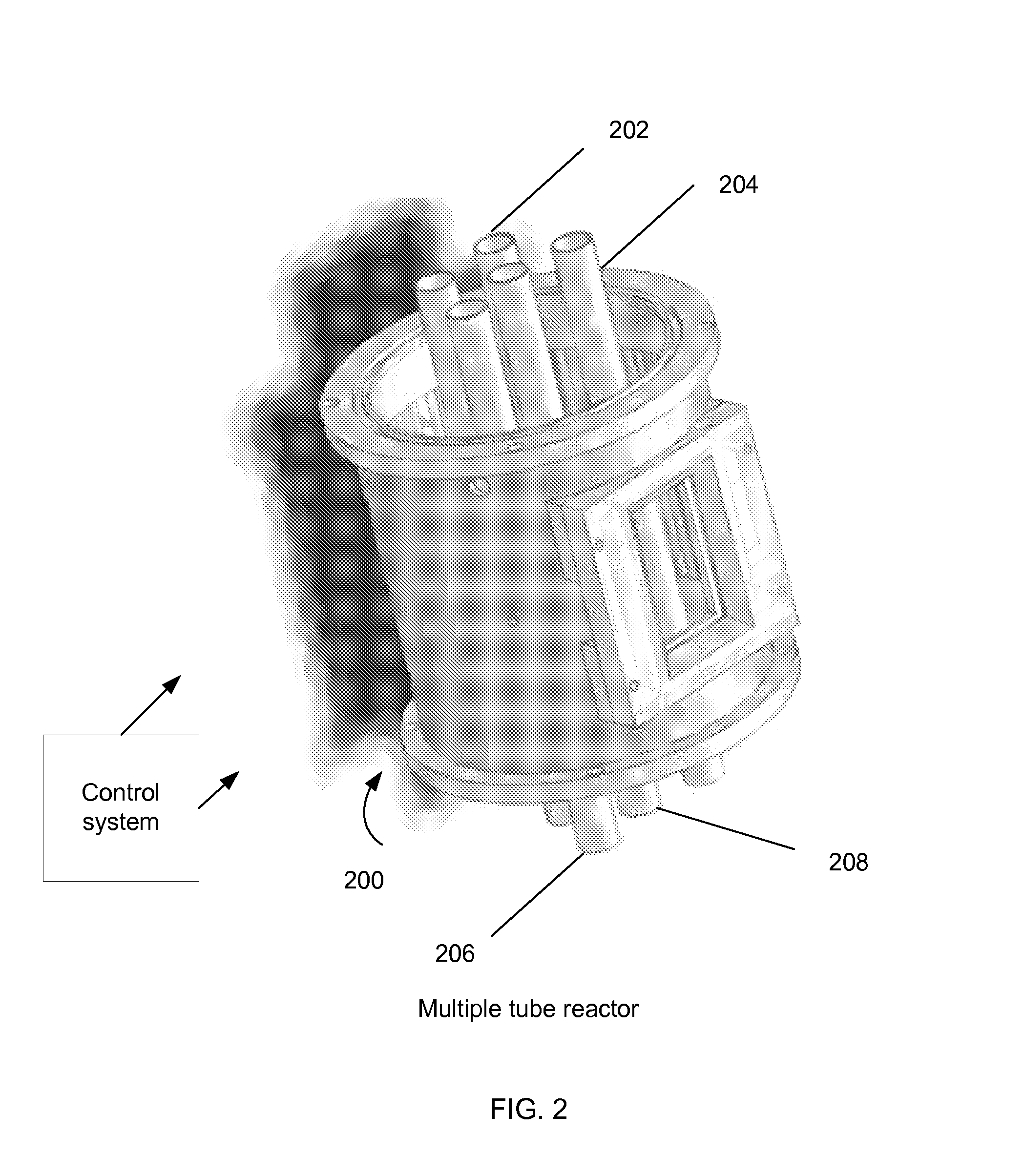

Systems and methods for reactor and receiver control of flux profile

InactiveUS20100242352A1Improve availabilityProcess control/regulationSolar heating energyChemical reactionChemical reactor

A method, apparatus, and system for a solar-driven chemical reactor are disclosed, including a solar thermal receiver aligned to absorb concentrated solar energy. Some embodiments include a solar driven chemical reactor that has multiple reactor tubes. Some embodiments include one of 1) one or more apertures open to an atmosphere of the Earth or 2) one or more windows, to pass the concentrated solar energy into the solar thermal receiver. This energy impinges on the multiple reactor tubes and cavity walls of the receiver and transfer energy by solar radiation absorption and heat radiation, convection, and conduction. In this way, the energy causes reacting particles to drive the endothermic chemical reaction flowing in the reactor tubes. The design of the multiple reactor tubes and solar thermal receiver can be adapted per a solar flux profile to take advantage of variations in the concentrations of solar flux in the profile.

Owner:SUNDROP FUELS

Chemical reactor for gas phase reactant catalytic reactions

InactiveUS6984363B2Lower overall pressure dropSufficient reactionCombination devicesChemical/physical/physico-chemical microreactorsPorosityChemical reaction

The present invention is a chemical reactor for catalytic chemical reactions having gas phase reactants. The chemical reactor has reactor microchannels for flow of at least one reactant and at least one product, and a catalyst material wherein the at least one reactant contacts the catalyst material and reacts to form the at least one product. The improvement, according to the present invention is: the catalyst material is on a porous material having a porosity that resists bulk flow therethrough and permits molecular diffusion therein. The porous material further has a length, a width and a thickness, the porous material defining at least a portion of one wall of a bulk flow path through which the at least one reactant passes.

Owner:BATTELLE MEMORIAL INST

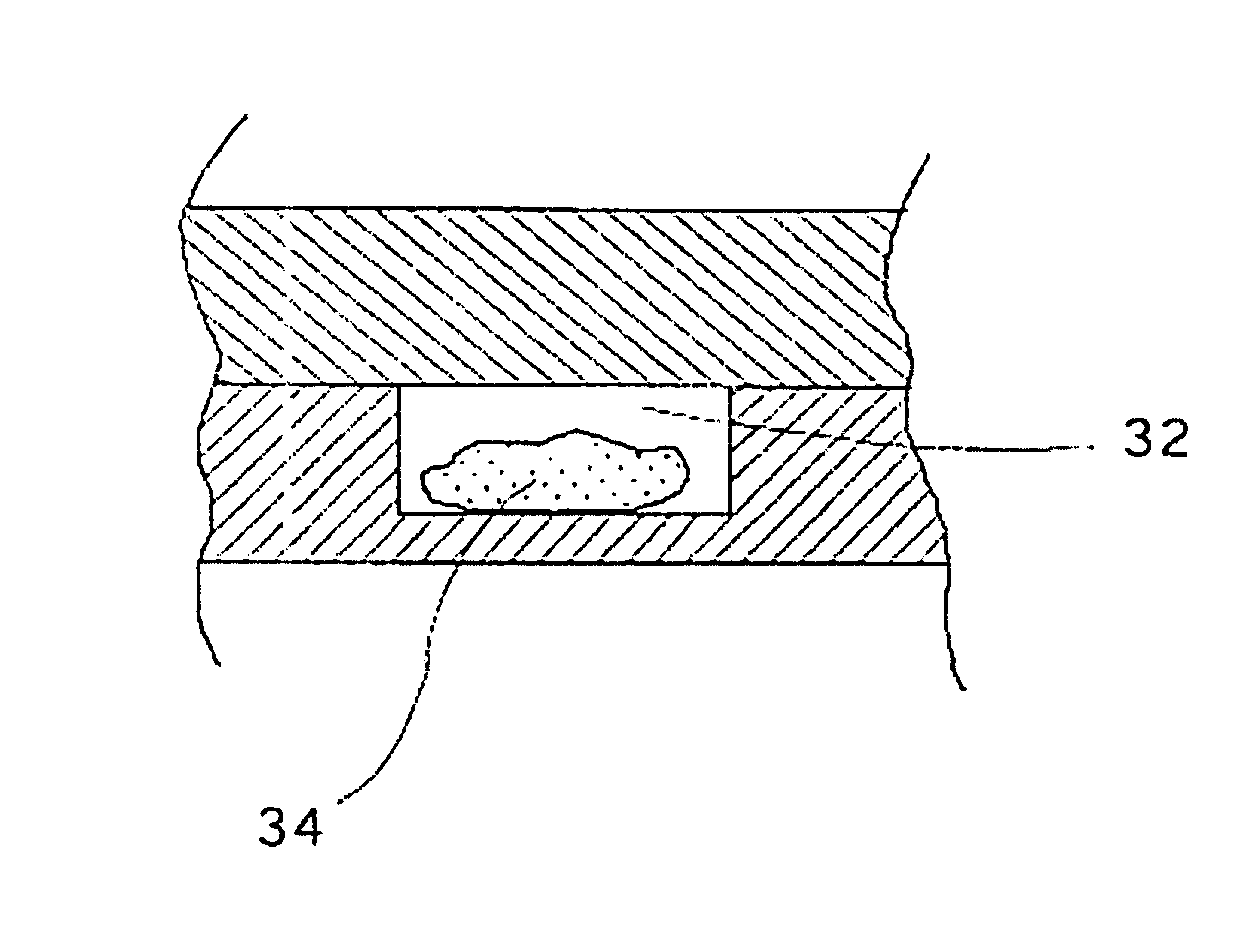

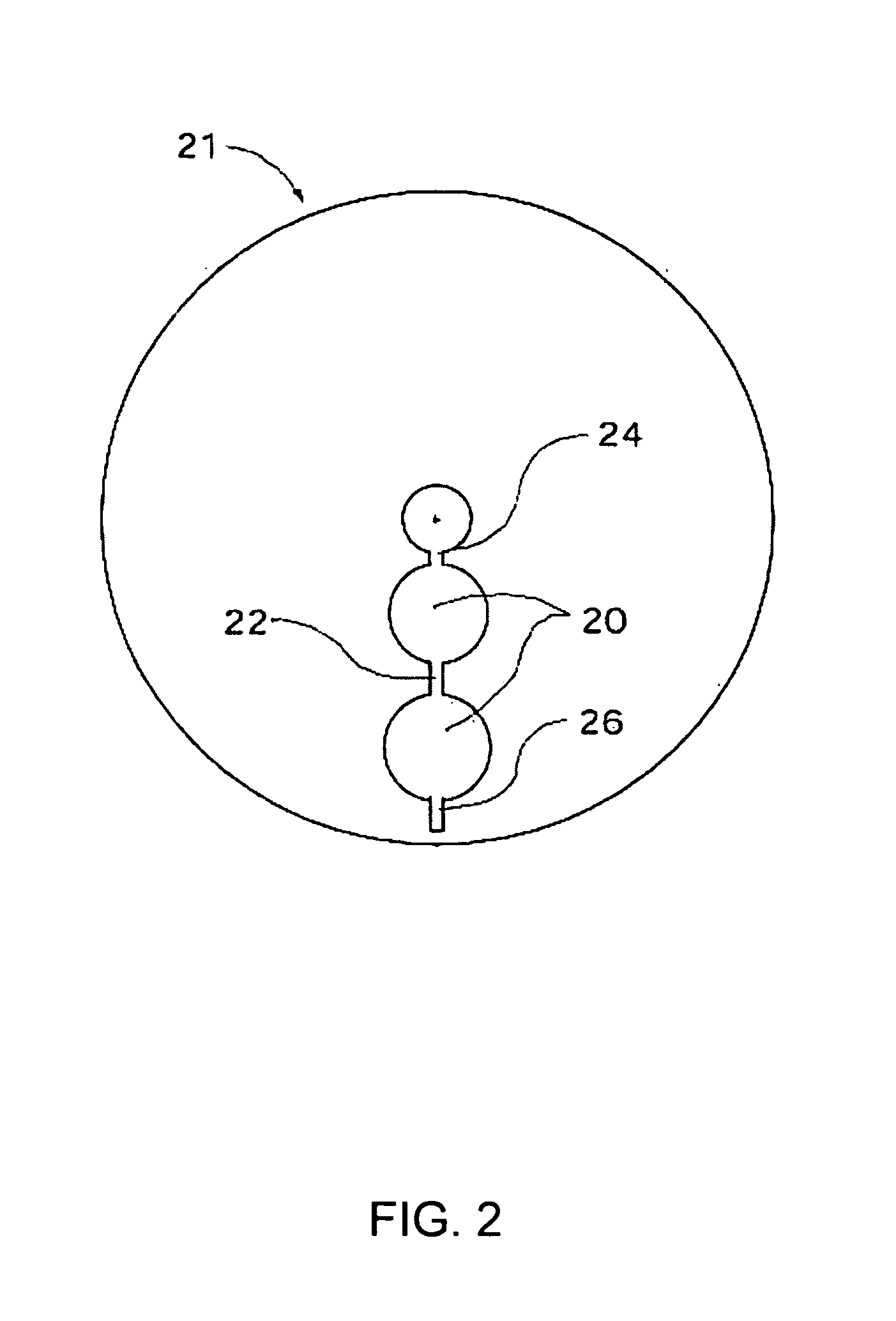

Polymer valves

The invention relates to a method of controlling flow of liquids in a micro channel structure. It comprises providing in said micro channel structure plugs (34) of polymer material in said structure, said polymer material in a first state blocking said channel from liquid flow, and in a second state providing a free path-way (32) for liquid flow. Energy is selectively applied so as to cause said polymer to enter a desired one of said first or second states. It also relates to a micro channel valve system, comprising a plurality of such plugs (34). Additionally it comprises a chemical reactor, comprising a plurality of micro chambers interconnected by micro channels, having a valve system according to the invention.

Owner:GYROS

Water soluble nanoparticles of hydrophilic and hydrophobic active materials and an apparatus and method for their production

InactiveUS7081450B2Readily bioavailableReduce manufacturing costBiocidePowder deliveryFood additiveWater insoluble

This invention provides a soluble nano-sized particles formed of a core (water-insoluble lipophilic compound or hydrophilic compound) and an amphiphilic polymer and which demonstrated improved solubility and / or stability. The lipophilic compound within the soluble nano-sized soluble (“solu-nanoparticles”) may consist of pharmaceutical compounds, food additives, cosmetics, agricultural products and veterinary products. The invention also provides novel methods for preparing the nano-sized soluble particles, as well as a novel chemical reactor for manufacturing an inclusion complex comprising the nano-sized soluble particles.

Owner:SOLUBEST +1

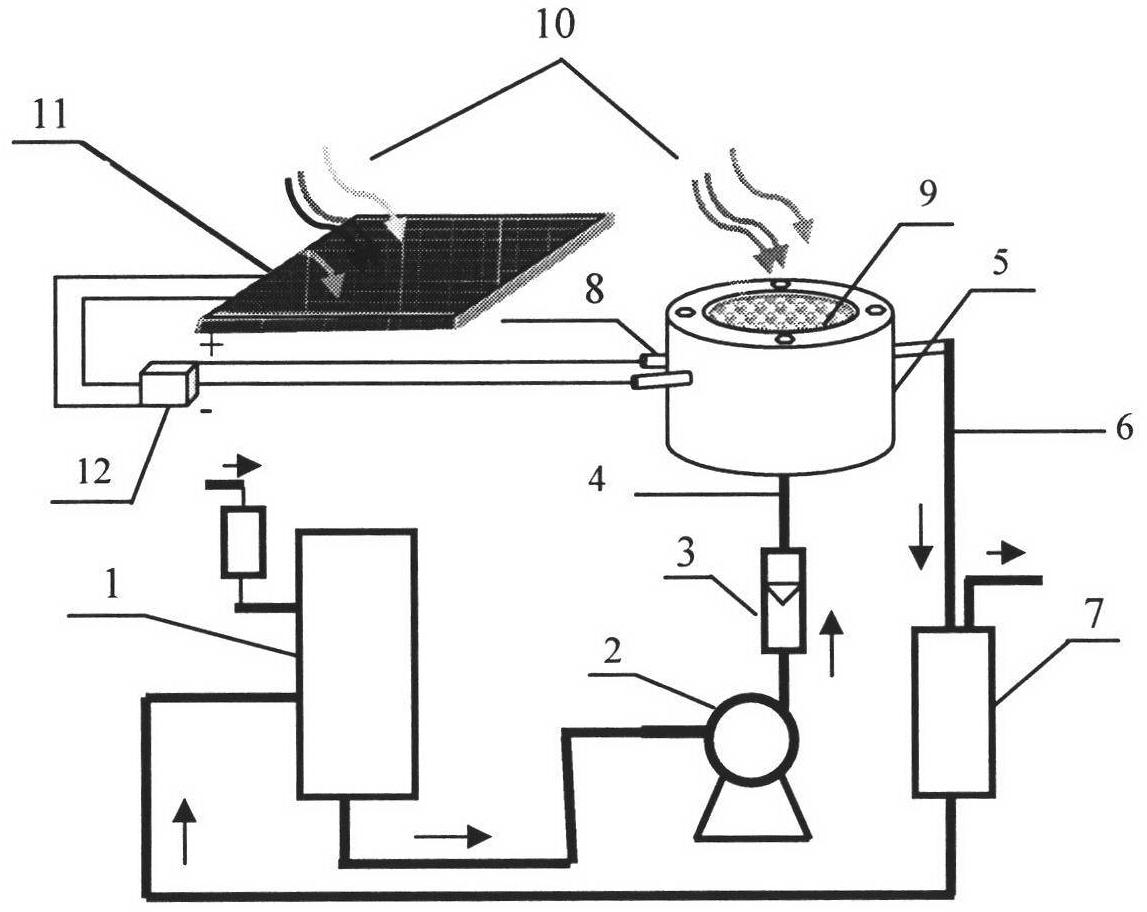

Organic wastewater treatment film reactor utilizing sunlight-assisted electro-catalysis

InactiveCN102603037AAccelerated adsorption/desorption rateThe actual user interface increasesWater/sewage treatment by irradiationEnergy based wastewater treatmentPhoto assistedPorous channel

The invention relates to an organic wastewater treatment film reactor utilizing solar energy photo-assisted electro-catalysis, which comprises a storage tank of water to be processed, a flow controllable constant flow pump, a photoelectric chemical reactor, a clear water storage tank and a solar battery component, wherein a photo anode and a cathode are correspondingly arranged in the reactor; the photo anode takes a porous metal membrane as a base body, and a TiO2 nano tube or a TiO2 mesoporous membrane is formed on the surface of a porous titanium membrane (net) by an electrochemical anisotropic etching technology; a porous channel film is used as the base body; a metal oxide coating electrode with high electrochemical catalytic activity and high electrical conductivity is prepared by a dipping film-forming method, simultaneously, by doping and modifying operations, the electrode material has photo catalytic activity and the reaction efficiency is improved. The reactor integrates electrochemistry, photocatalysis and film separation technologies; the three technologies are coupled to enhance a synergistic effect; the wastewater treatment efficiency can be improved; a solar component is adopted as a power supply; the clean solar energy is utilized to the maximal degree, and the organic wastewater treatment film reactor has social benefits of reducing environment load and economic benefits of reducing cost.

Owner:NANJING UNIV OF TECH

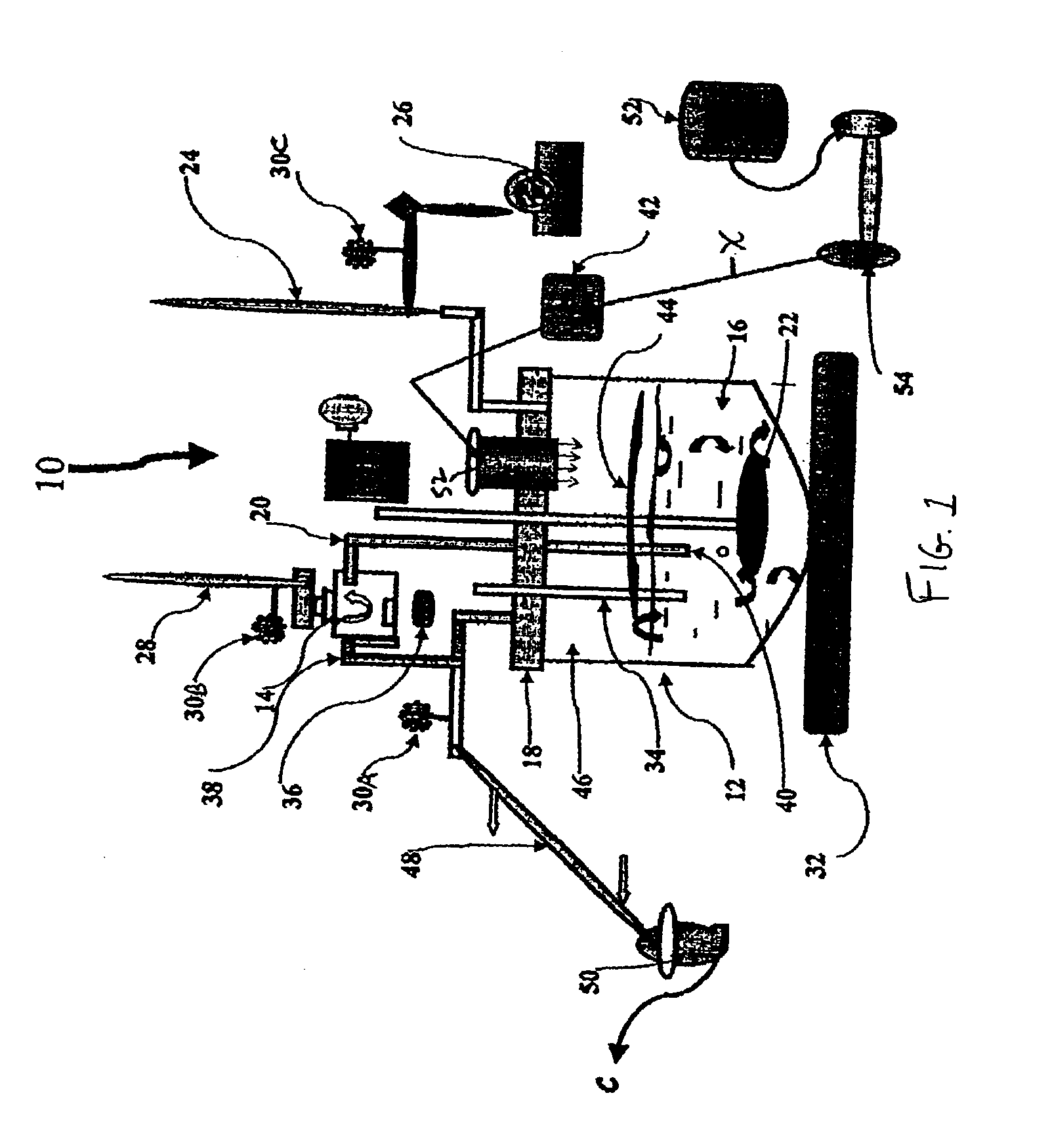

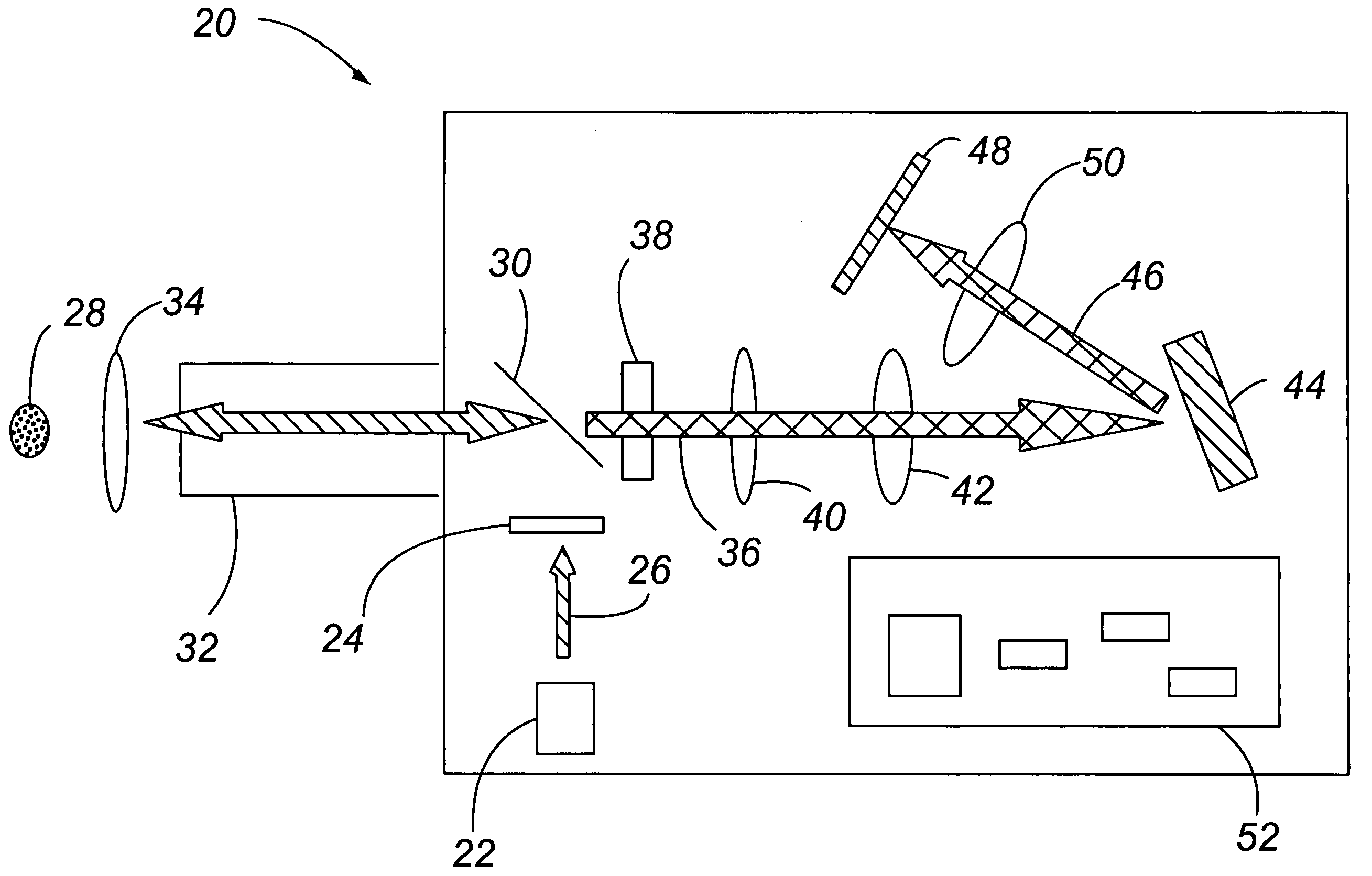

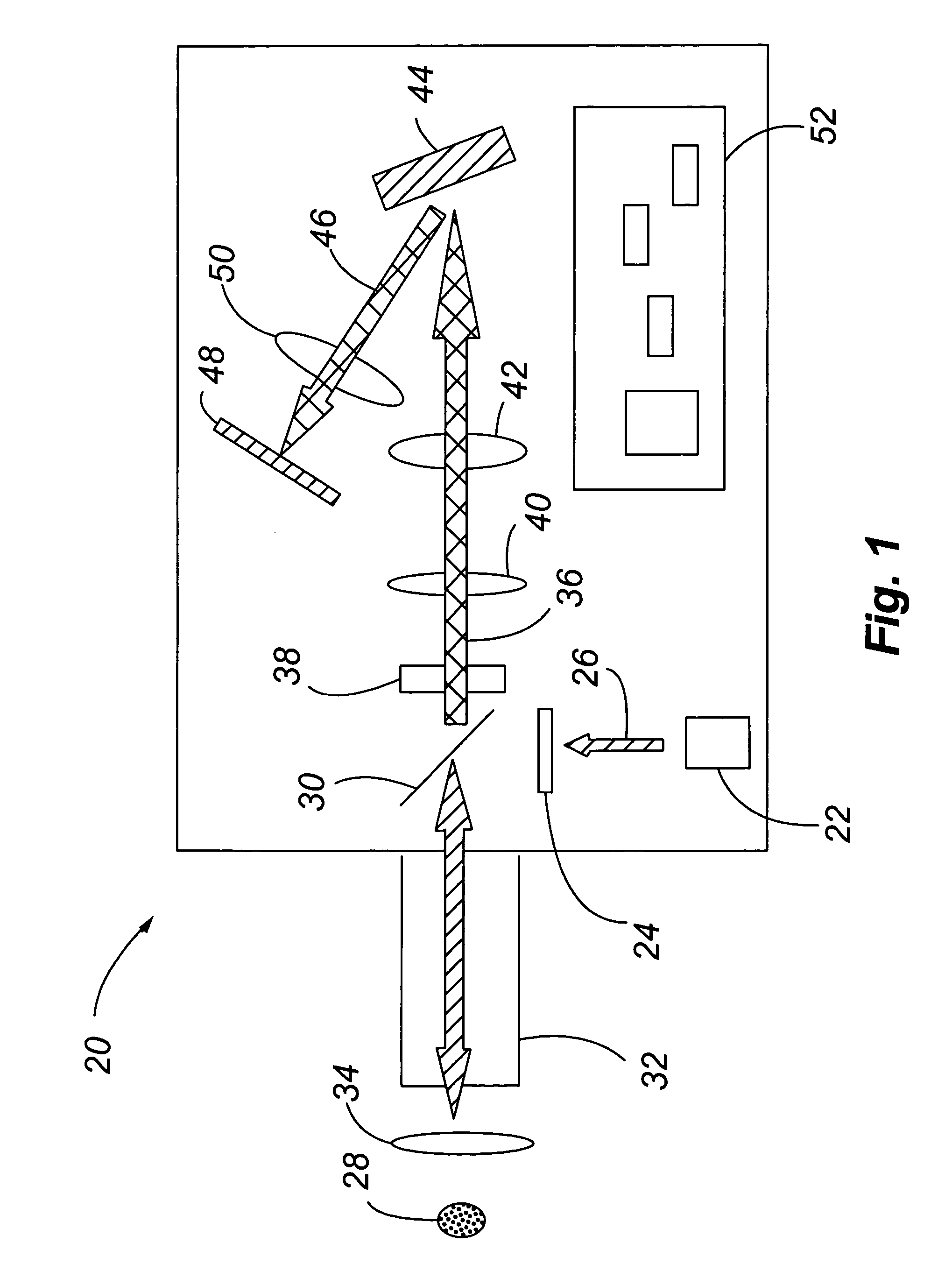

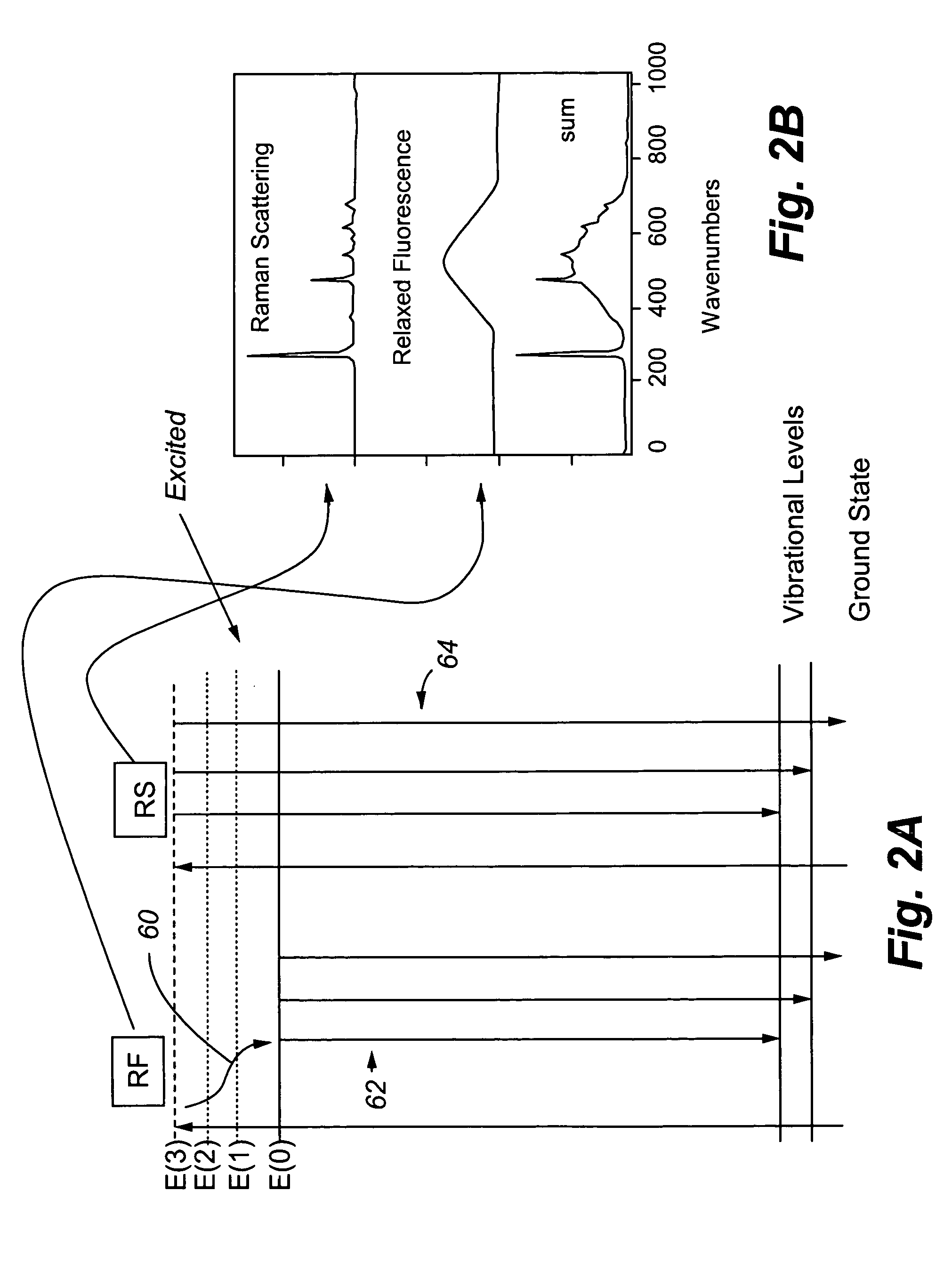

Raman spectrometer

A system, method and apparatus for taking a Raman spectrum of a sample is disclosed. In one embodiment, for example, an integrated Raman spectrometer is provided. In another embodiment, a portable Raman spectrometer is provided. In another embodiment, a Raman spectrometer is provided comprising a collimated beam tube for transmitting excitation radiation to an external optical system, such as a microscope, a telescope or a camera lens. In another embodiment, a method for correcting a Raman spectrum for background interference is provided. In yet another embodiment, a method for rejecting fluorescence in a Raman spectrometer is provided. A chemical reactor comprising a built-in Raman detector for monitoring a chemical reaction in a reaction chamber of the reactor is also provided.

Owner:SCIAPS +2

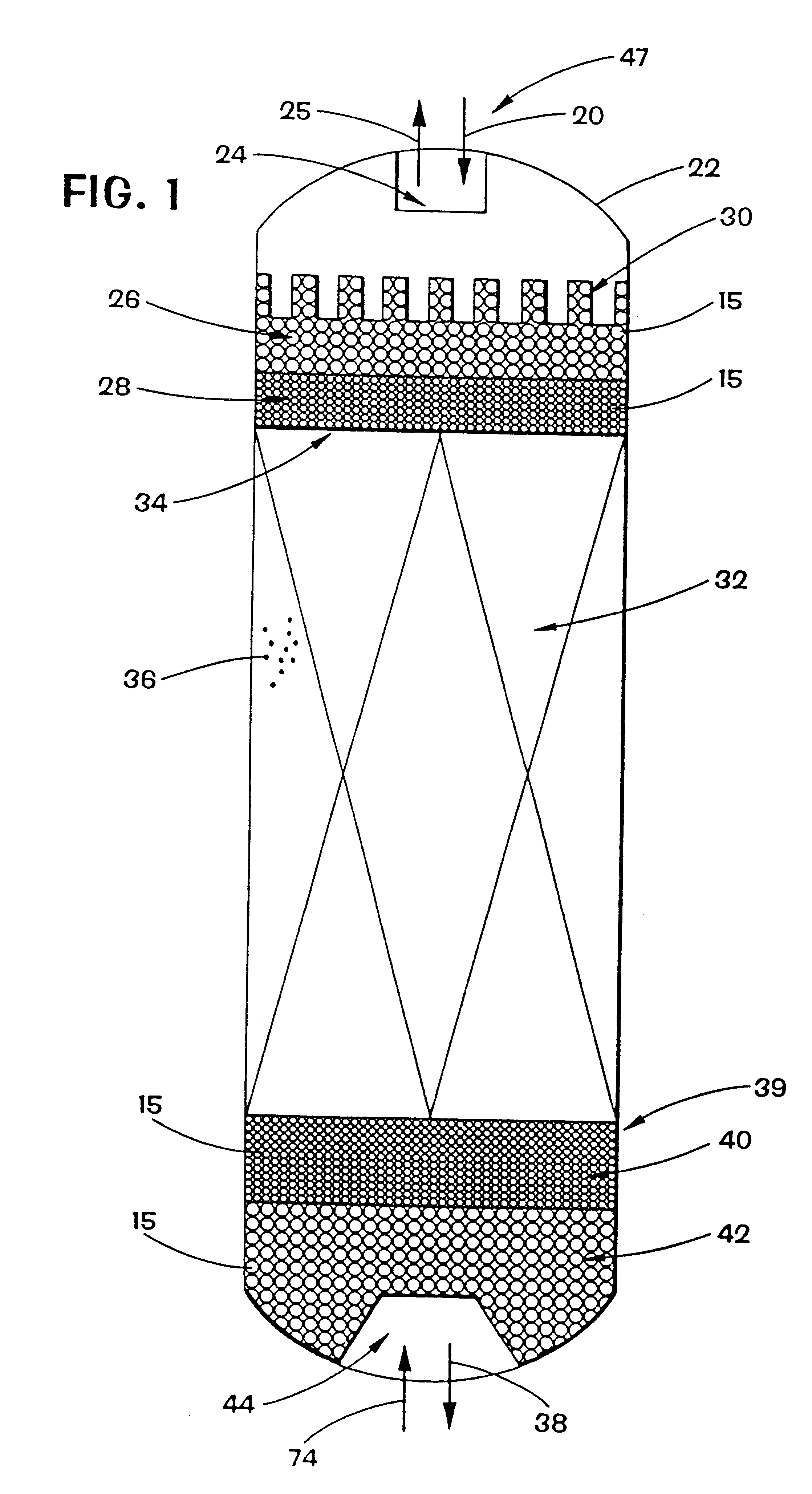

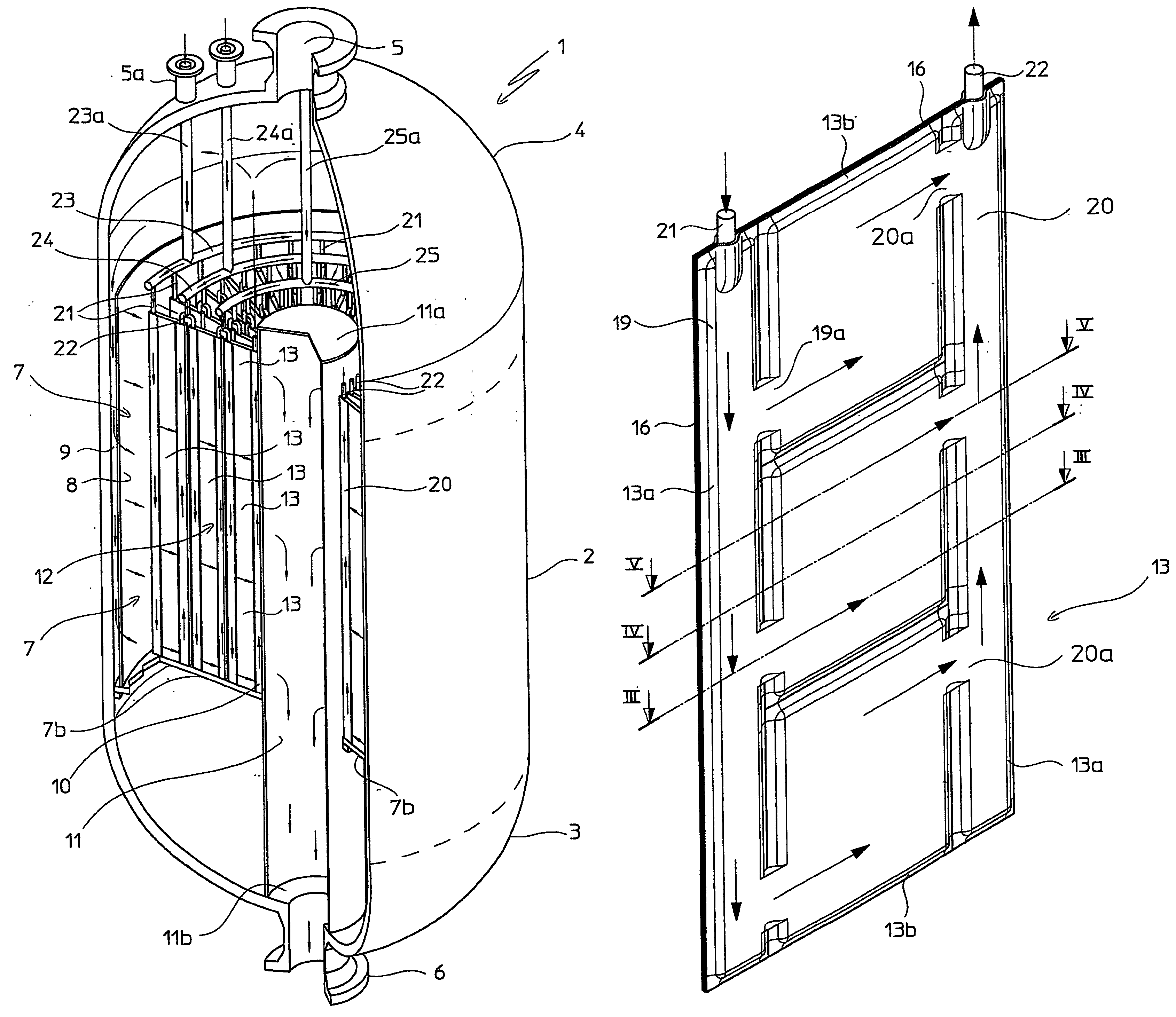

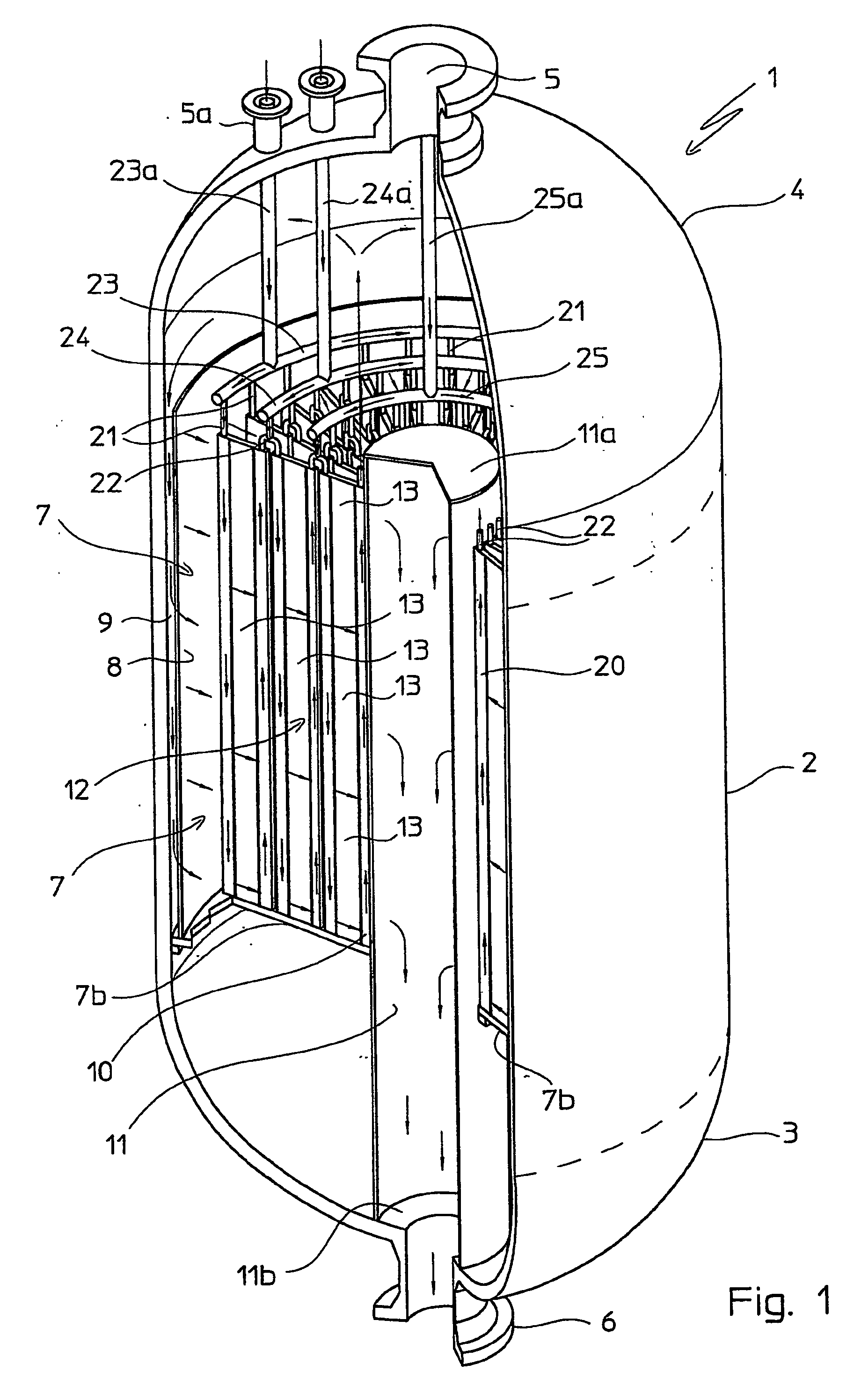

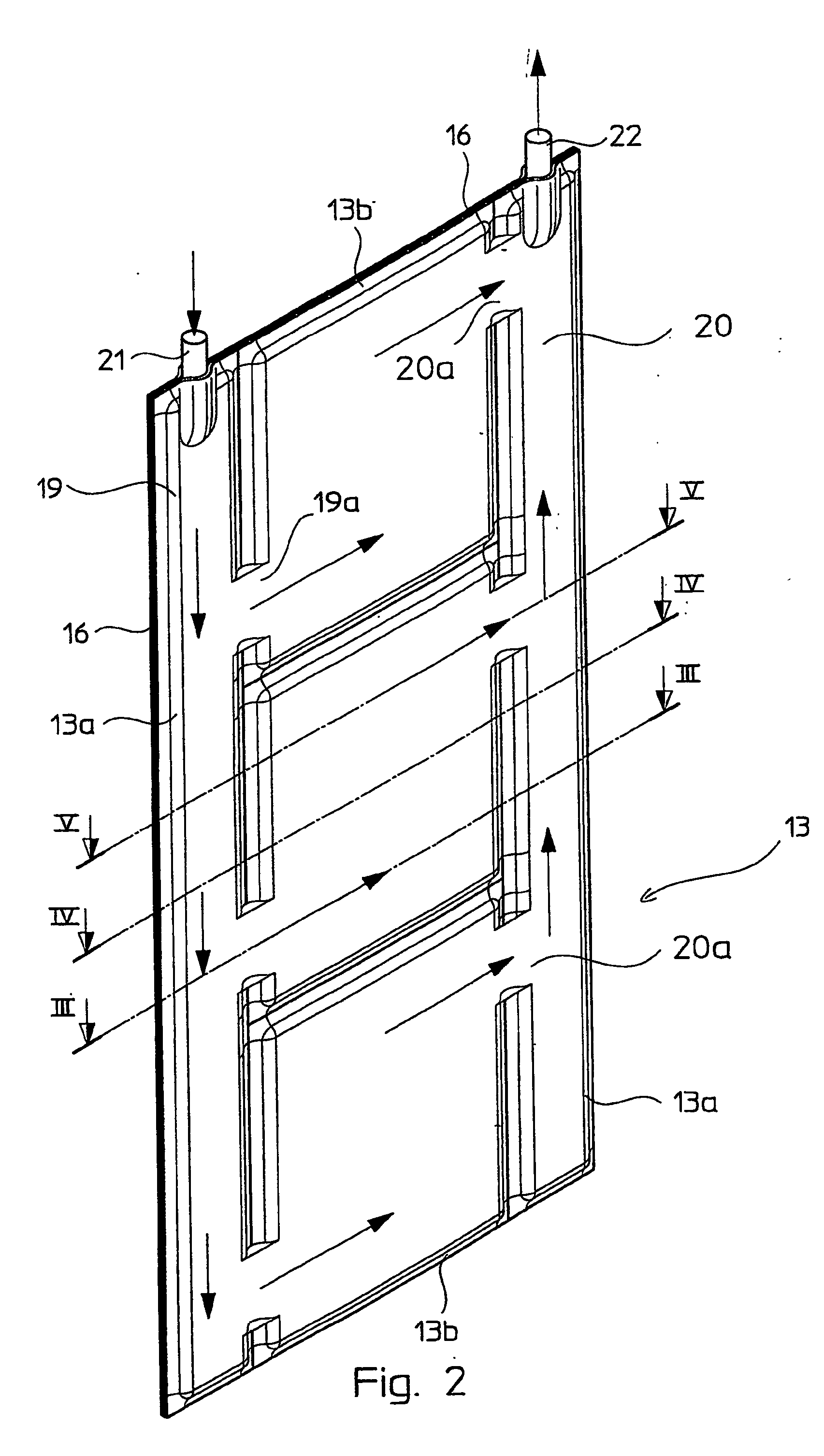

Heat exchange unit for isothermal chemical reactors

InactiveUS20050061490A1Chemical/physical/physico-chemical stationary reactorsHeat exchanger casingsWorking fluidChemical reactor

A heat exchange unit for isothermal radial or axial-radial chemical reactors (1), with an overall configuration which is substantially annular and cylindrical having a passage (11) with a predetermined diameter running through it axially, is distinguished in that it comprises a plurality of substantially rectangular, flattened box-shaped heat exchangers (13), distributed in many coaxial and concentric arrays, defining in the unit (12) a plurality of radial alignments with a substantially radial arrangement, and wherein the exchangers (13) have long sides (13a) parallel to the axis of the unit (12) and short sides (13b) extending radially, each of the exchangers (13) comprising an inner chamber (17), intended to be passed through by an operating heat exchange fluid, at least one distributor pipe (19) and at least one collector pipe (20) of the operating fluid, associated with two respective opposing sides (13a) of the exchanger (13) and extending along them, the pipes (19, 20) being in fluid communication, on the one side, with the chamber (17) through at least one opening (19a, 20a) formed therein and, on the other side, with the outside of the exchanger (13), through respective inlet and outlet fittings (21, 22) for the operating fluid.

Owner:CASALE SA

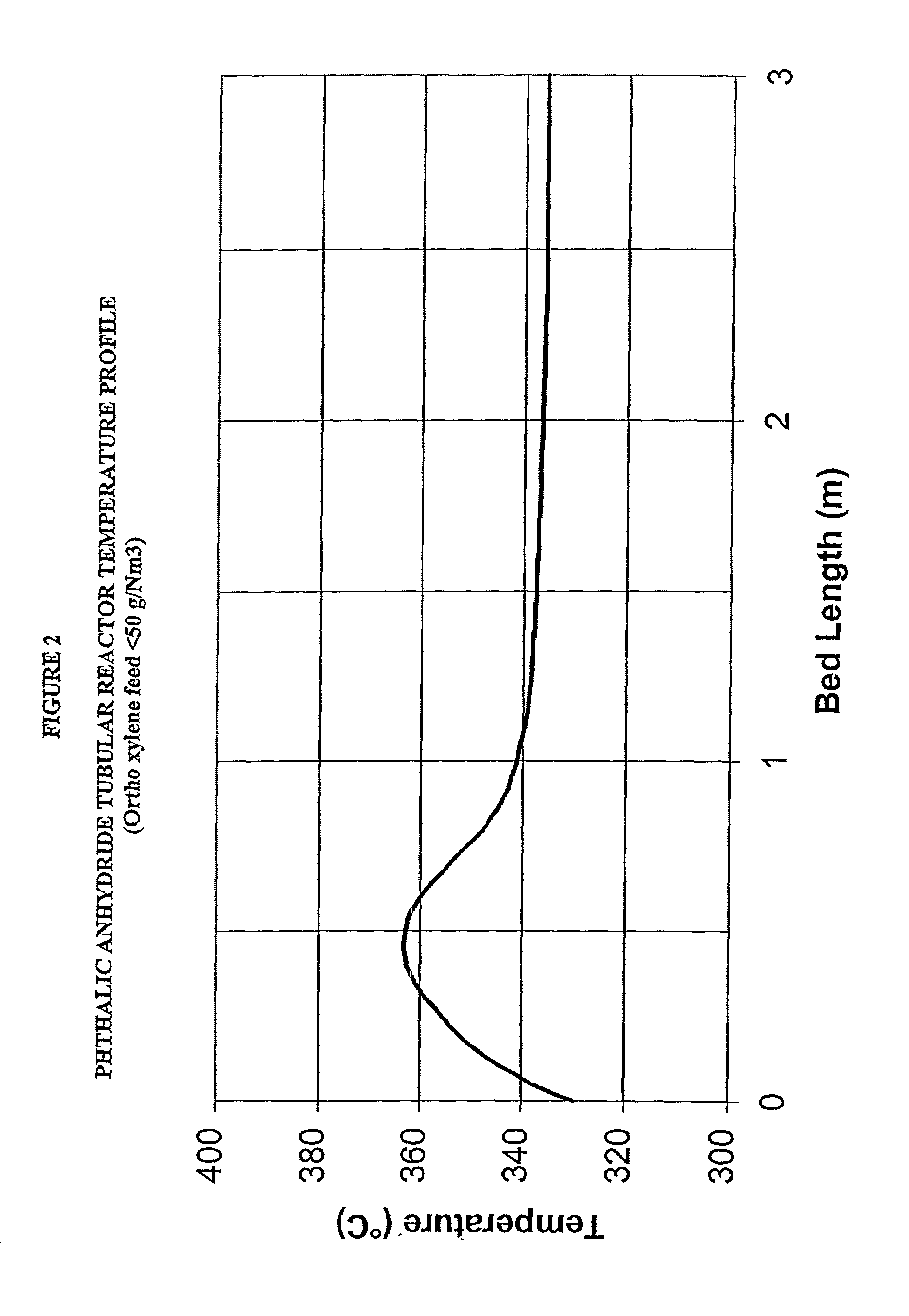

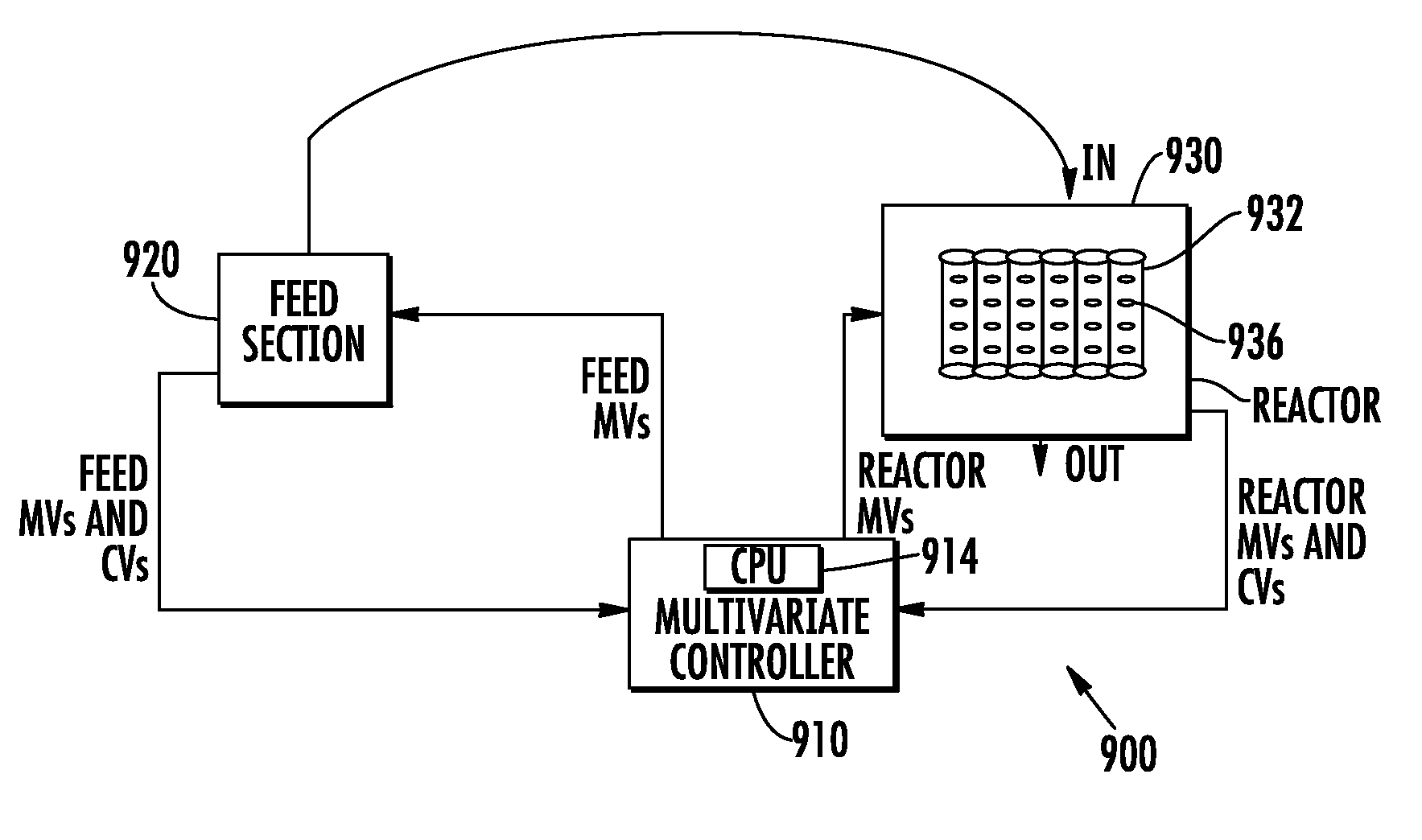

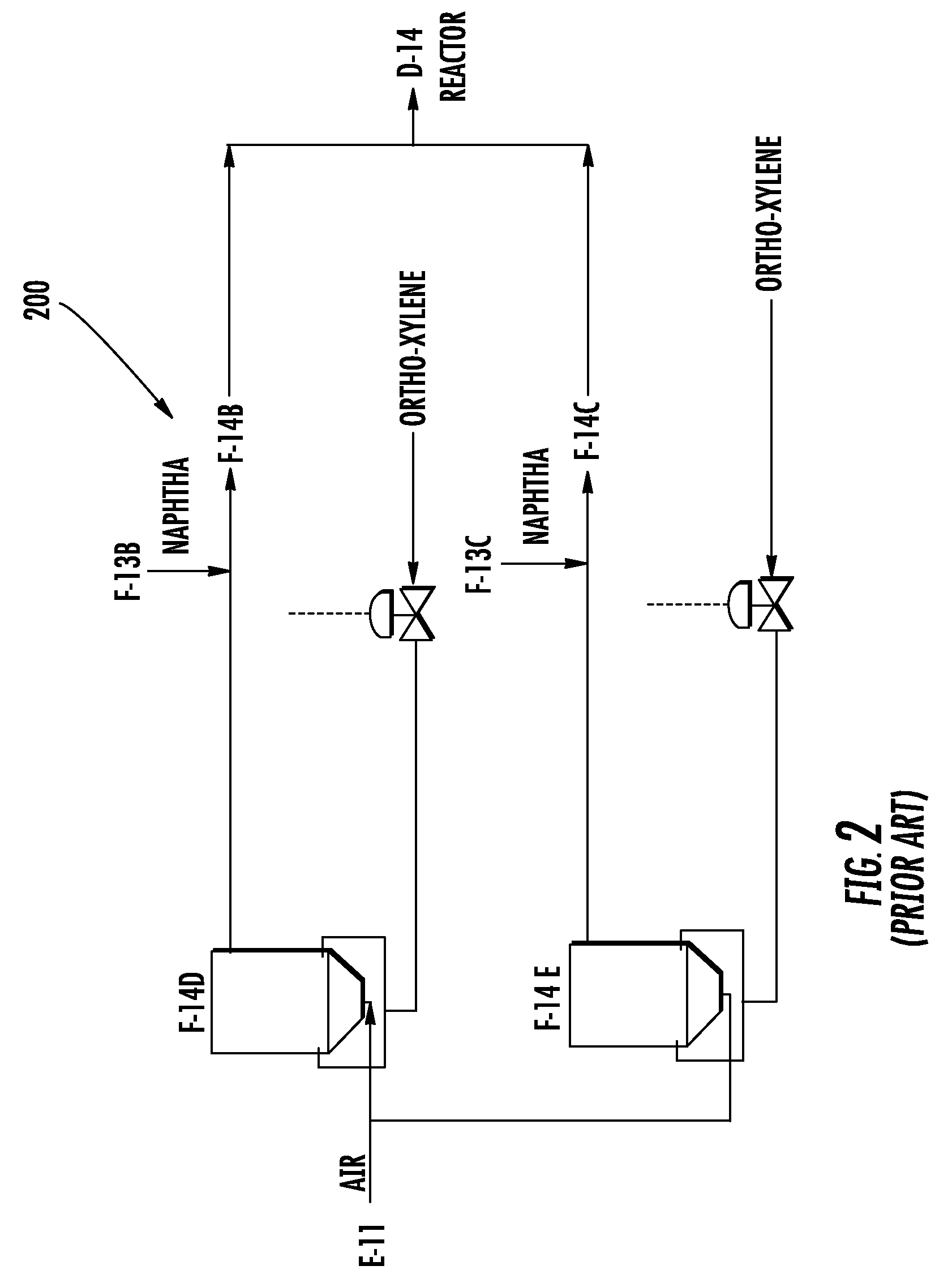

Multivariable process controller and methodology for controlling catalyzed chemical reaction to form phthalic anhydride and other functionalized aromatics

InactiveUS8060258B2Increase productivityMinimizing flow rateSampled-variable control systemsGaseous chemical processesChemical reactionChemical reactor

A multivariable method and process controller is for controlling a catalyzed chemical reaction to form phthalic anhydride (PA), produced by a production unit including a chemical reactor having a plurality of pipes connected in parallel having inner surfaces affixed with at least one solid catalyst. The reactor implements a process for forming PA by receiving flows of reagents including at least one oxidizable substituted aromatic and an oxygen including source gas at one or more inlets of the reactor. A dynamic multivariable model for the process represents the effects of moving a plurality of manipulated variables (MVs) including a flow of the oxygen including source gas and a flow or temperature of the oxidizable substituted aromatic on controlled variables (CVs) including a temperature at a plurality of positions along a length of the pipes. During the process, a first parameter related to performance of the catalyst in producing PA and a second parameter including a temperature at one or more of the plurality of positions in measured. Using the dynamic model, the temperature in the plurality of positions along the length of the reactor are automatically adjusting based on at least the first measured parameter, which permits the temperature profile to be adjusted to compensate for ageing of the catalyst to improve production efficiency.

Owner:HONEYWELL INT INC

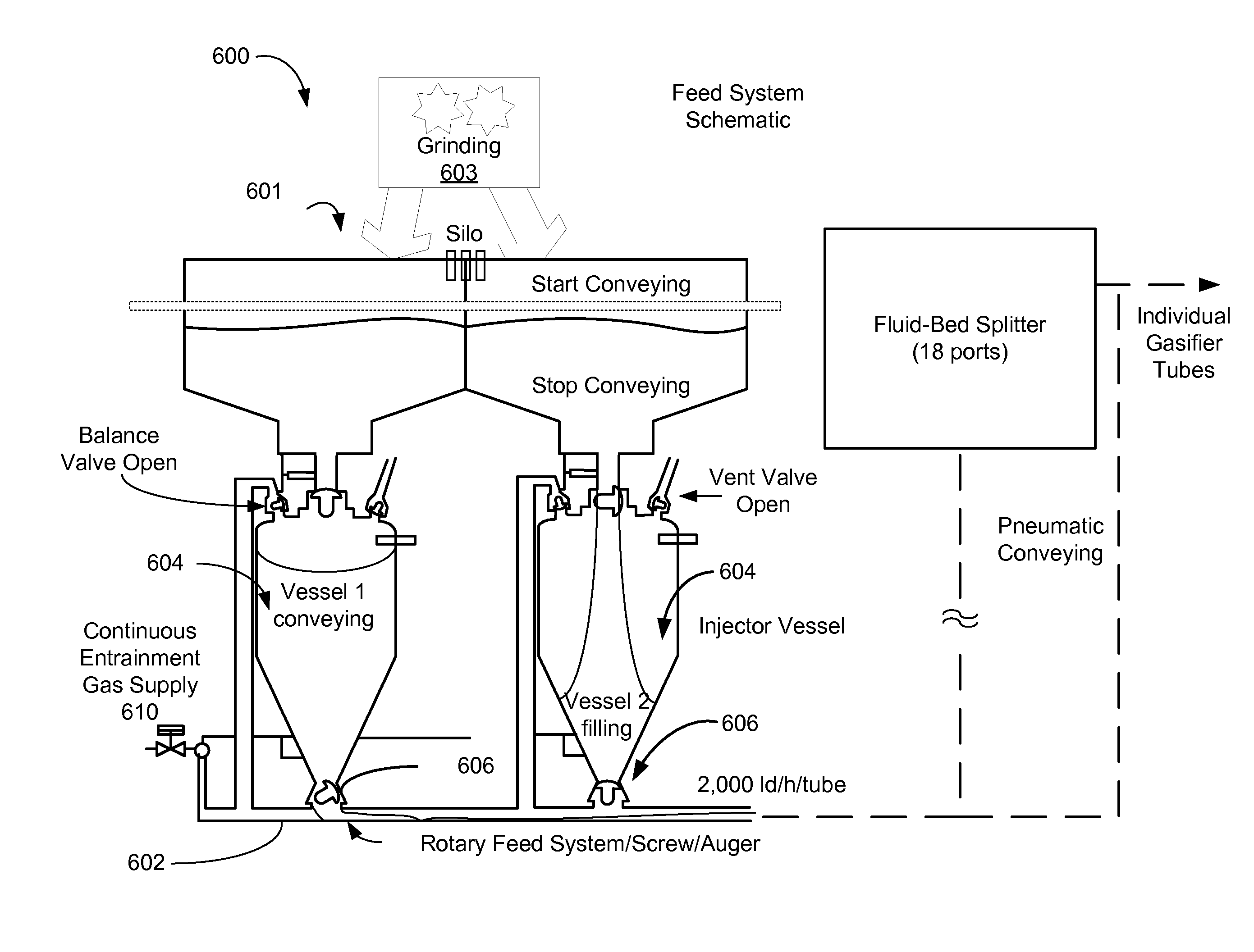

Systems and methods for reactor chemistry and control

InactiveUS20100242354A1Process control/regulationSolar heating energyChemical reactionChemical reactor

A method, apparatus, and system for a solar-driven chemical plant that manages variations in solar energy are disclosed. Some embodiments include a solar thermal receiver to absorb concentrated solar energy, a solar driven chemical reactor contained within the solar thermal receiver, and an entrained gas biomass feed system that uses an entrainment carrier gas and supplies a variety of biomass sources fed as particles into the solar driven chemical reactor. Inner walls of the solar thermal receiver and the chemical reactor can be made from materials selected to transfer energy. Some embodiments include a control system that may be configured to balance the gasification reaction of biomass particles with the available concentrated solar energy and additional variable parameters including, but not limited to, a fixed range of particle sizes, temperature of the chemical reactor, and residence time of the particles in a reaction zone in the chemical reactor.

Owner:SUNDROP FUELS

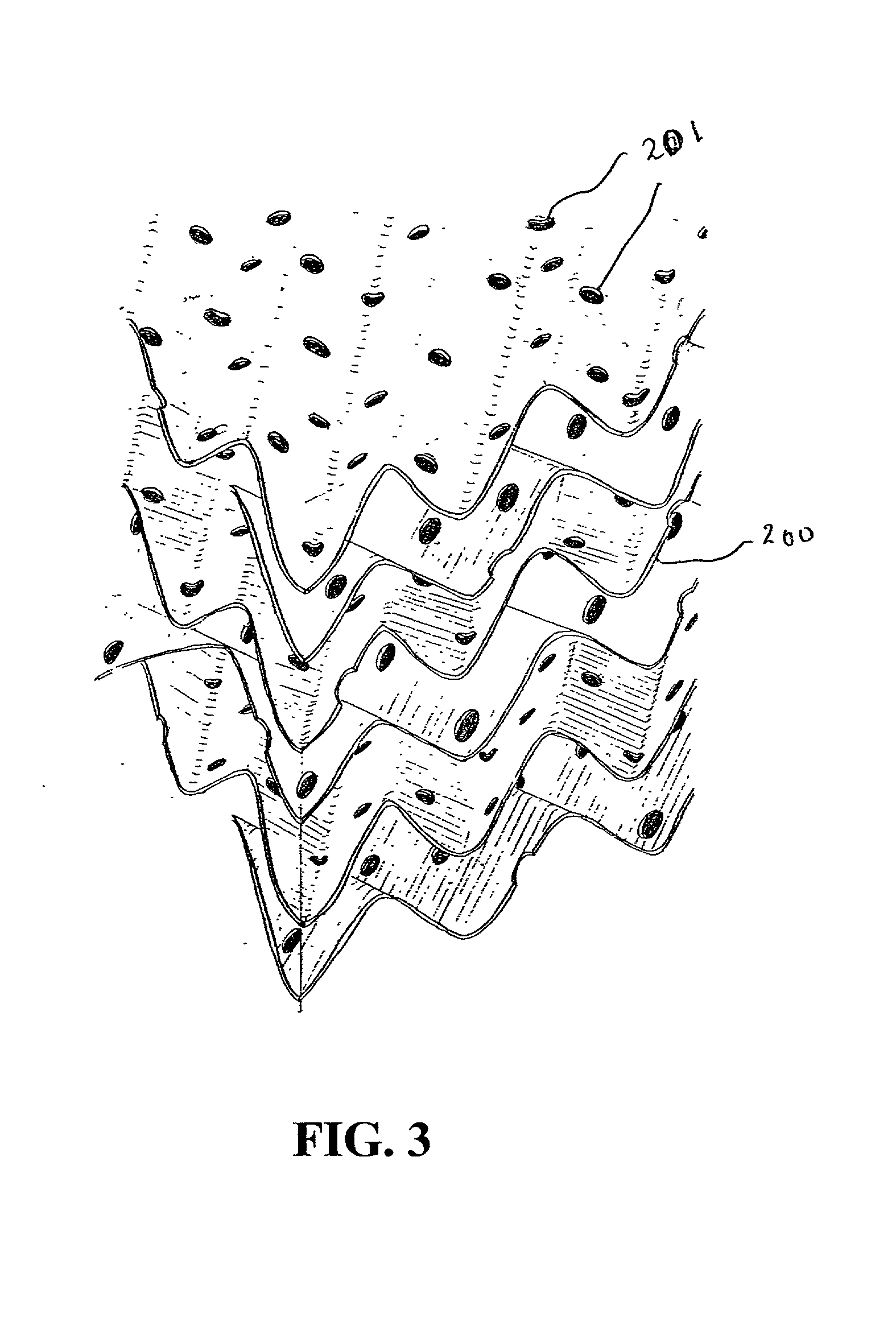

Filtering medium and method for contacting solids-containing feeds for chemical reactors

InactiveUS20010015336A1Increase particulate trappingShorten speedSemi-permeable membranesSolvent extractionOrganic baseChemical reactor

A filtering medium and method for removing contaminants from an organic-based feed stream which includes the use of a layer of ceramic filter units having a plurality of elliptical or trisoidal openings extending therethrough to filter organic-based feed streams and to provide liquid distribution upstream of the catalyst beds.

Owner:CRYSTAPHASE PRODS

Plasma polymerization for encapsulating particles

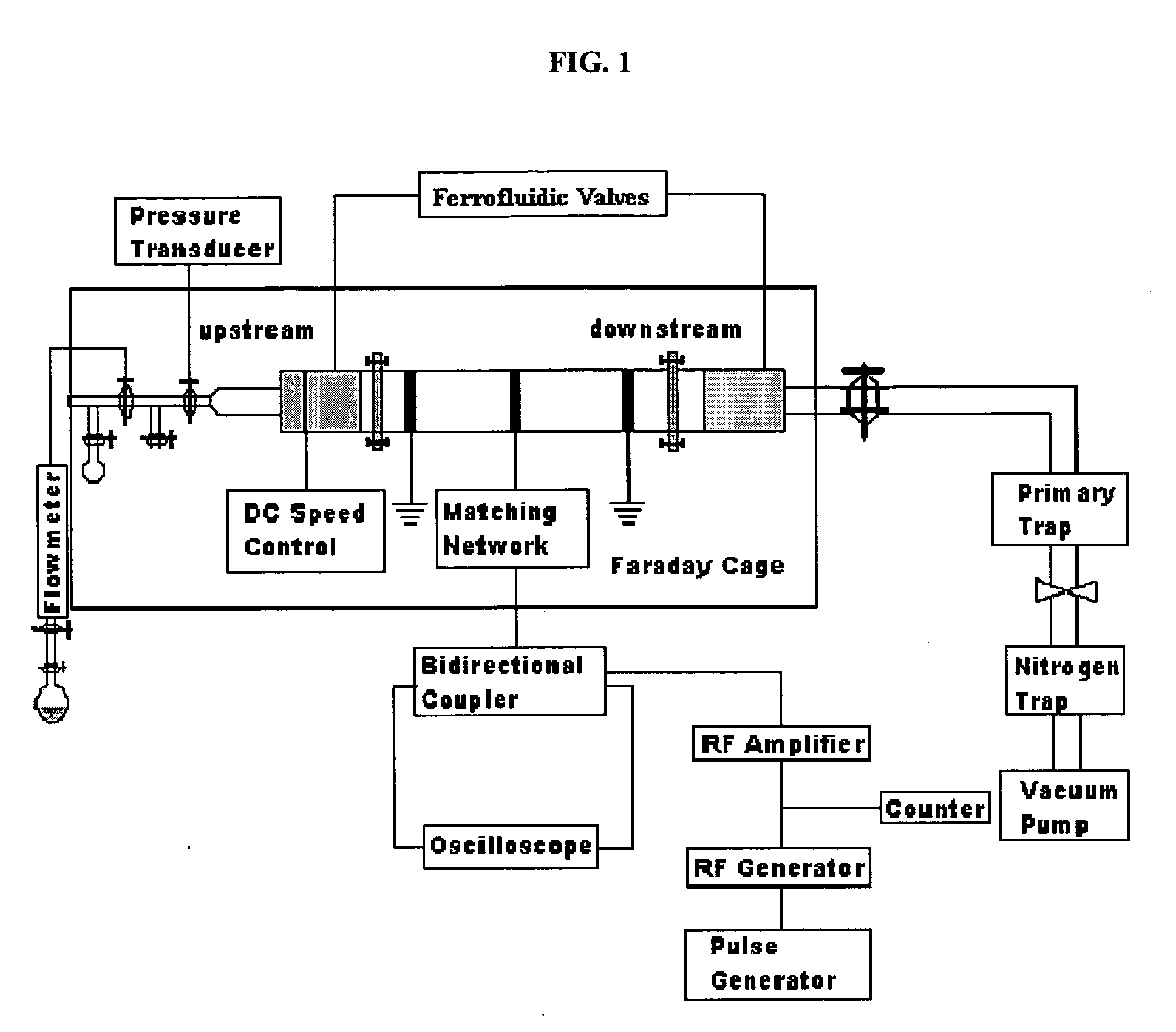

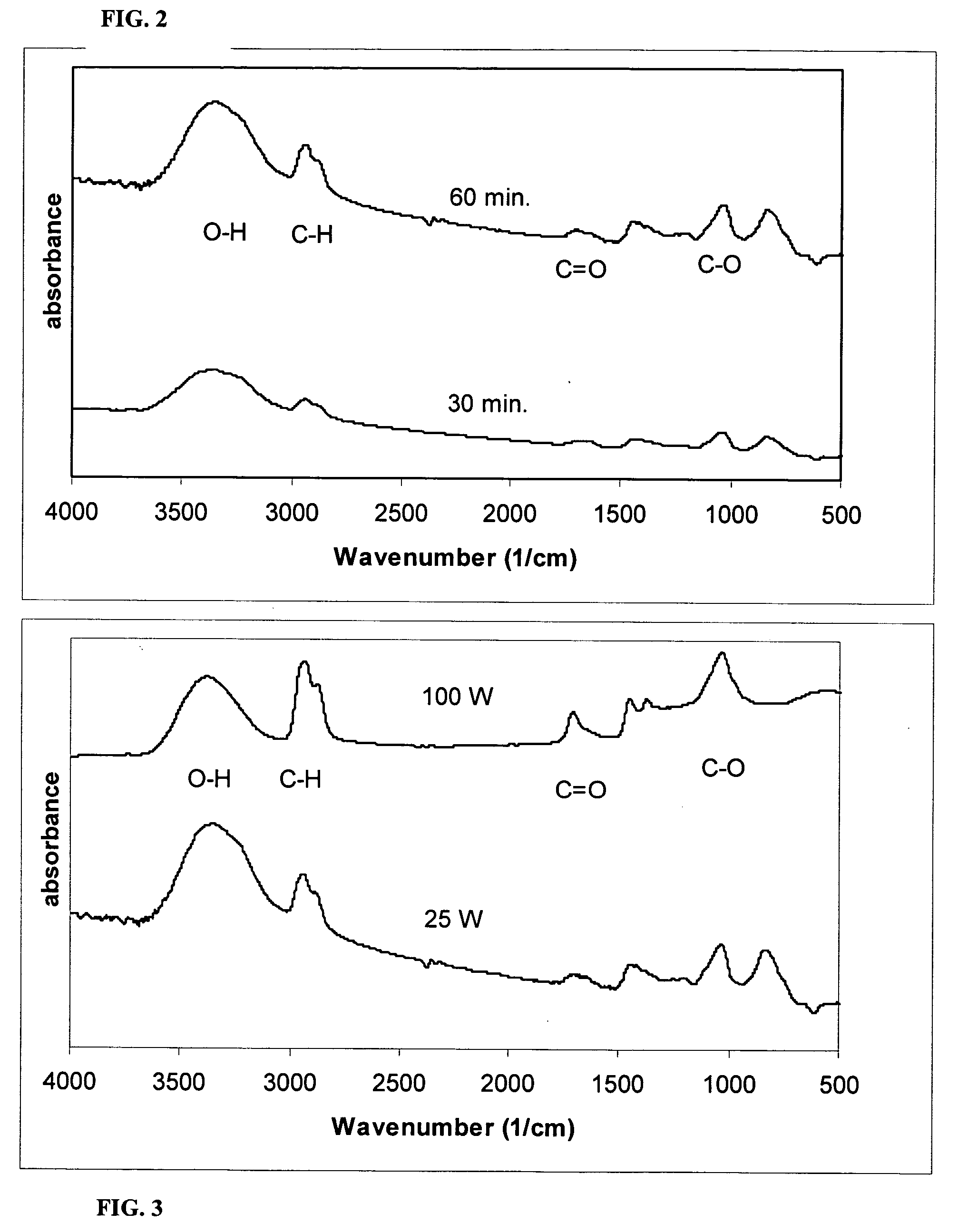

InactiveUS20060045822A1Liquid surface applicatorsChemical/physical/physico-chemical processesChemical reactorCompound (substance)

The present invention includes systems, methods and compositions for the encapsulation of particles. In one form, the system comprises one or more particles, a rotatable reaction chamber in a plasma enhanced chemical reactor to accept one or more particles, and at least one carbonaceous compound to be used in the rotatable reaction chamber, wherein the carbonaceous compound is polymerized onto a surface of one or more particles forming a polymer film encapsulating one or more particles. Using systems, methods, and compositions of the present invention, any particle encapsulated with a degradable or nondegradable polymer film may be introduced and / or released into an environment. The polymer film as well as introduction of encapsulated particles and release therefrom into an environment are controlled by the present invention.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com