Patents

Literature

75 results about "Multivariable model" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The multivariate model is a popular statistical tool that uses multiple variables to forecast possible outcomes. Research analysts use multivariate models to forecast investment outcomes in different scenarios in order to understand the exposure that a portfolio has to particular risks.

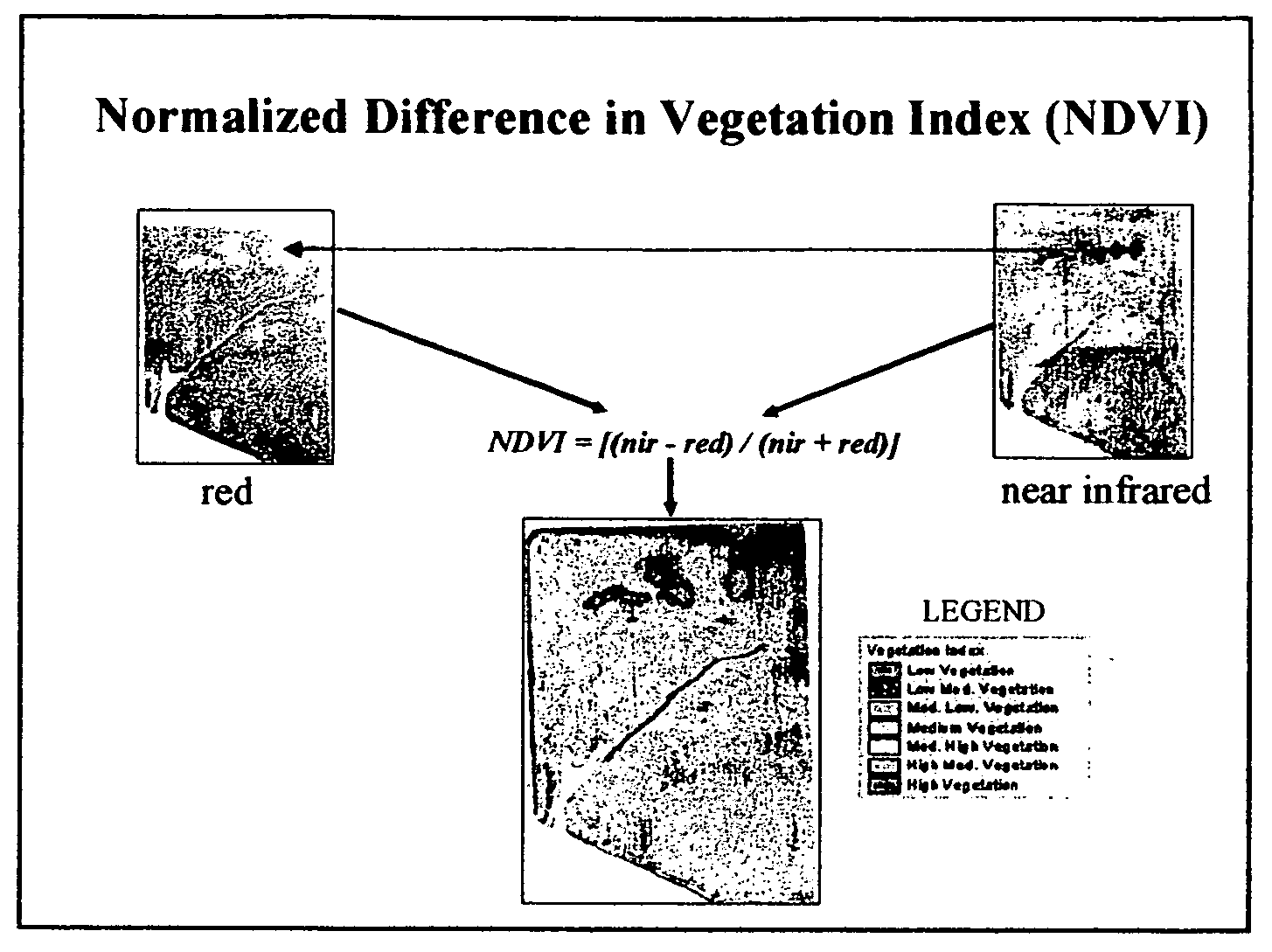

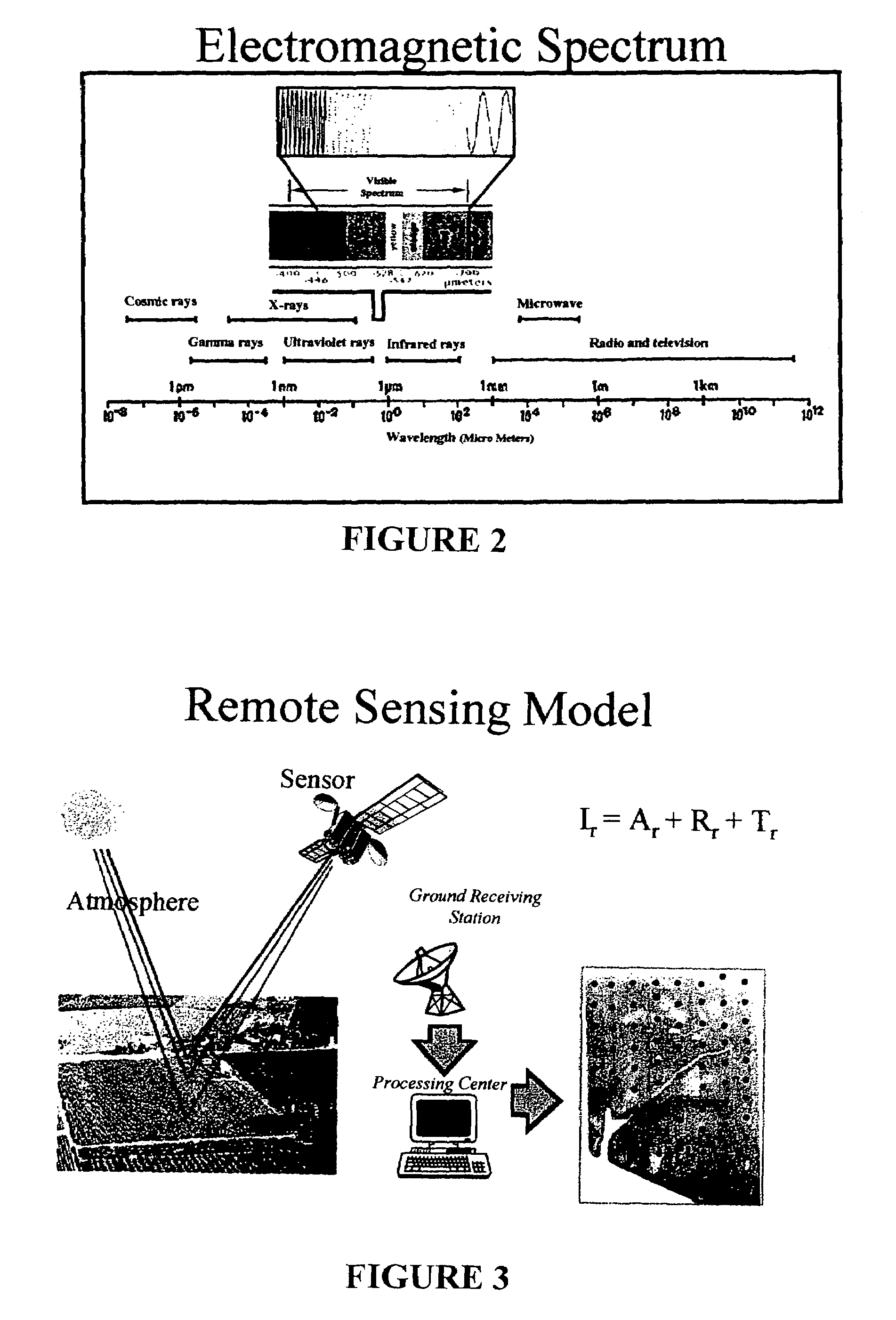

Multi-variable model for identifying crop response zones in a field

InactiveUS7058197B1Increased leaf areaEliminate the effects ofImage enhancementImage analysisVegetationGrowing season

An computer implemented apparatus and method are disclosed for defining areas of a field in which a crop or other vegetation is grown based on their selective ability to grow such vegetation through a growing season, or some shorter preselected time period. The method includes making a number of temporally separated measurements through air borne imaging of a field, registering the data to the geography of the field and each other, normalizing the data including converting the data to a vegetative index indicative to the presence of vegetation in the field, comparing the data to identify clusters of like value, and classifying the clusters and images to learn how the different field areas responded in growing vegetation through the season. With this method, the field may be segregated into a number of like areas called crop response zones which exhibit similar vegetative growth characteristics as an aid to a grower in his decision making regarding how to maximize yield in his field.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

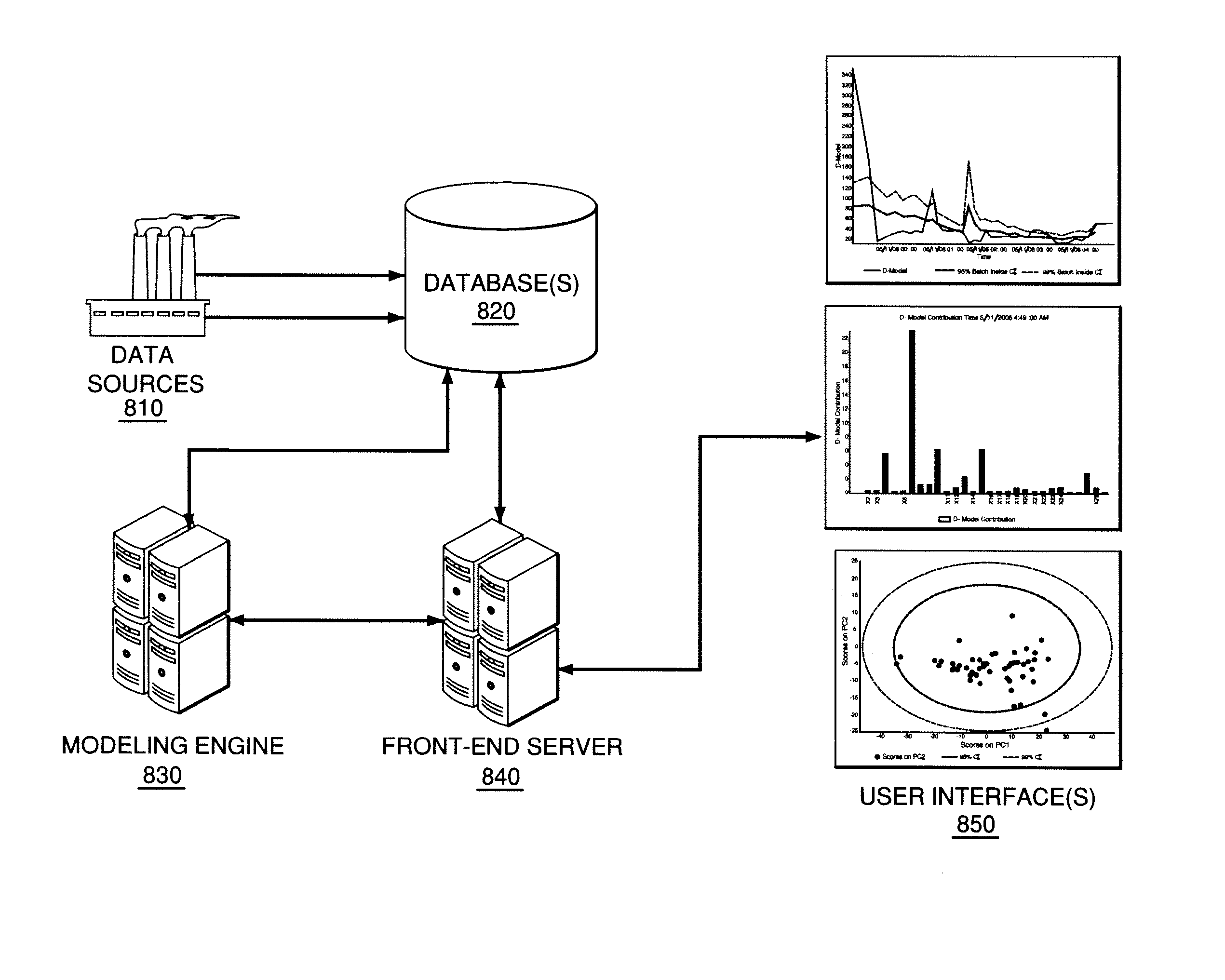

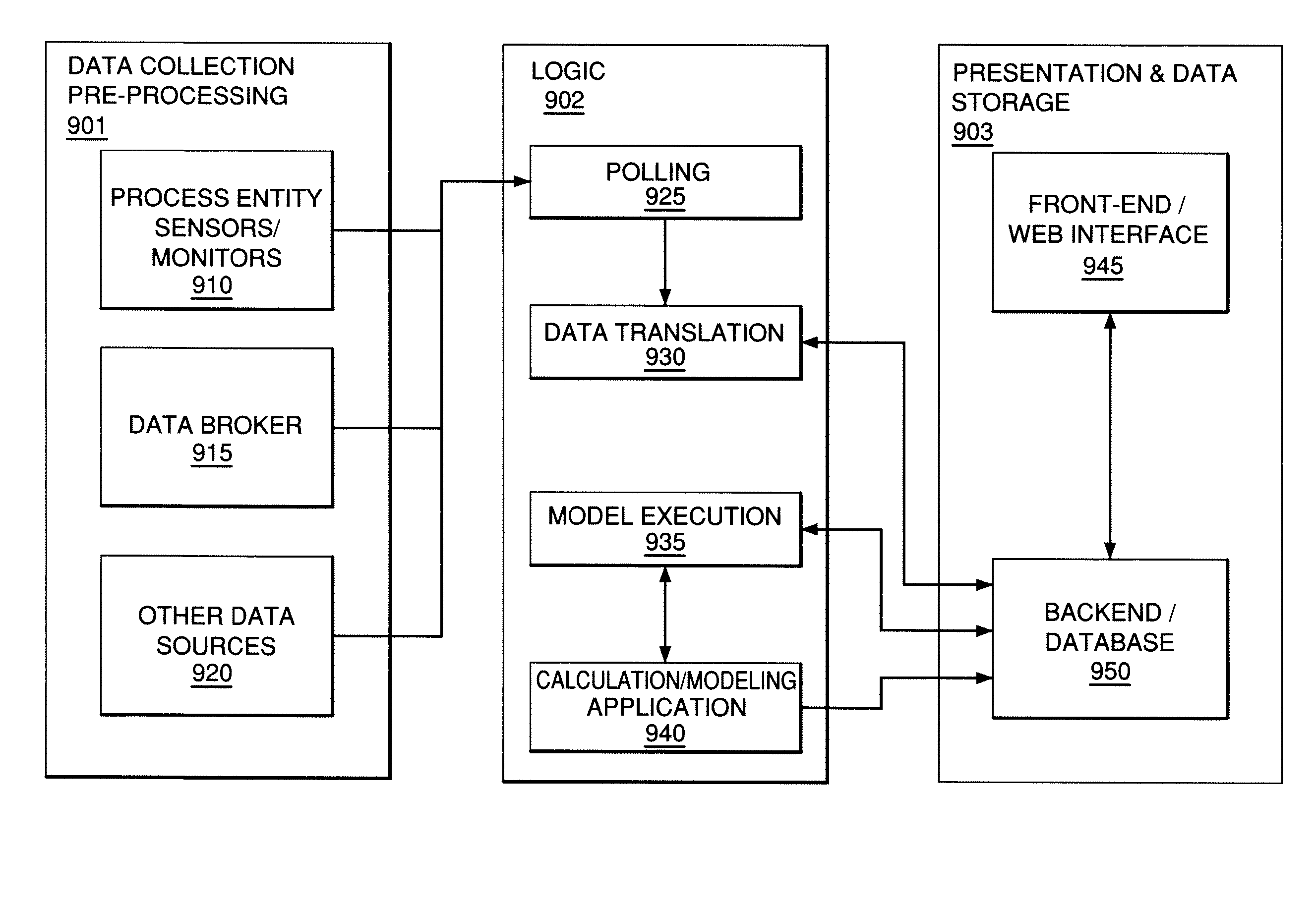

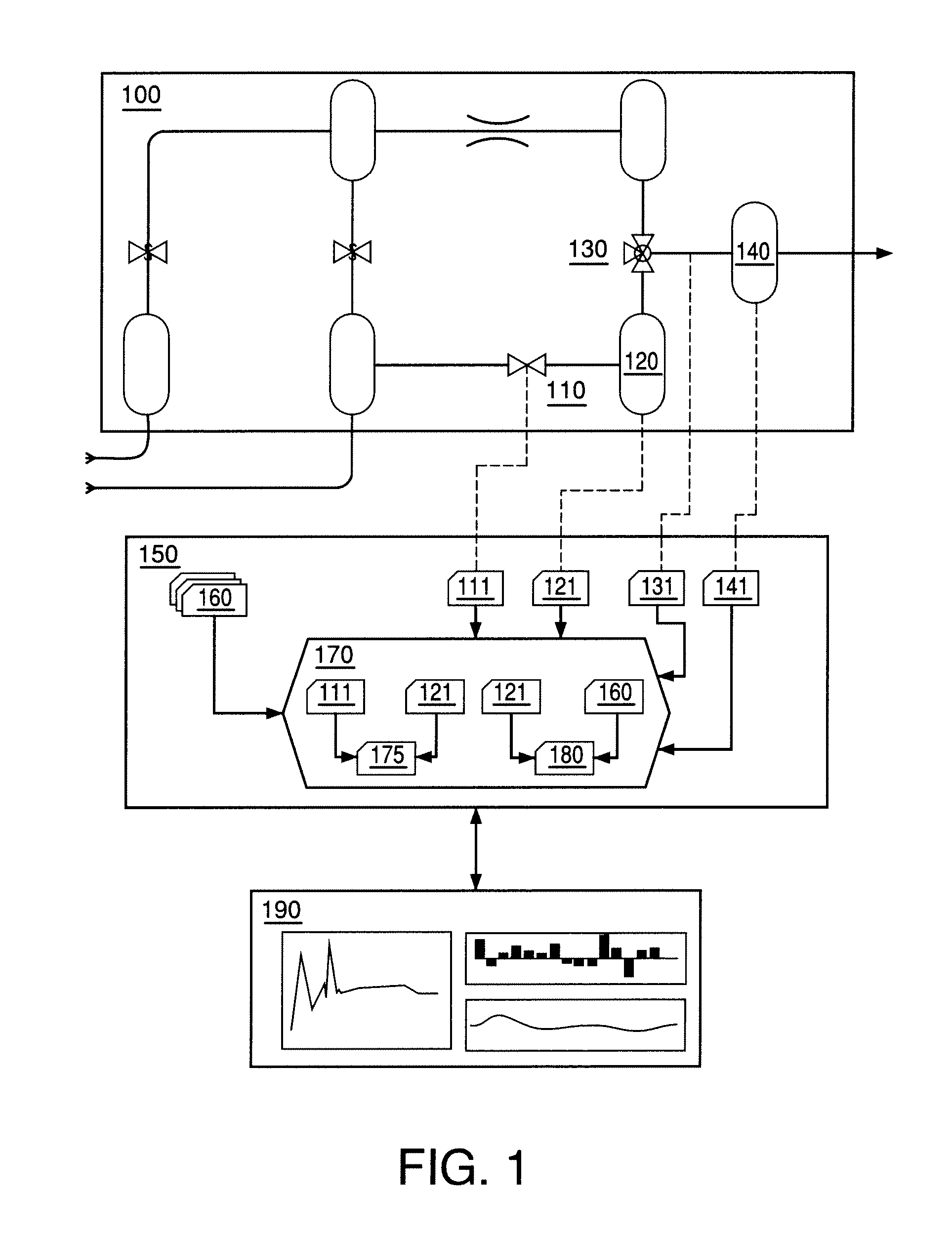

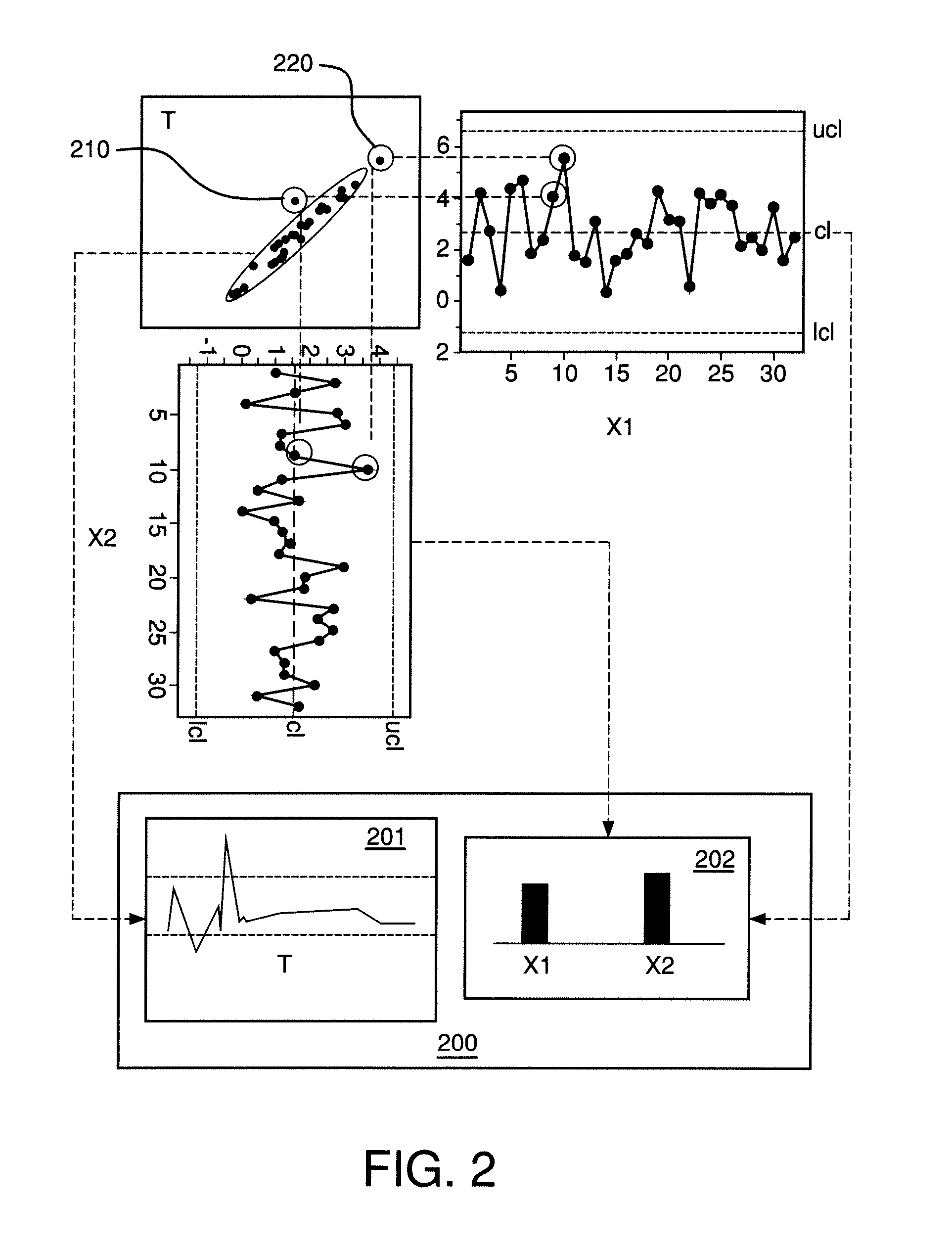

System And Method For Process Monitoring

ActiveUS20080109090A1Electric signal transmission systemsElectric testing/monitoringMonitoring systemHuman–computer interaction

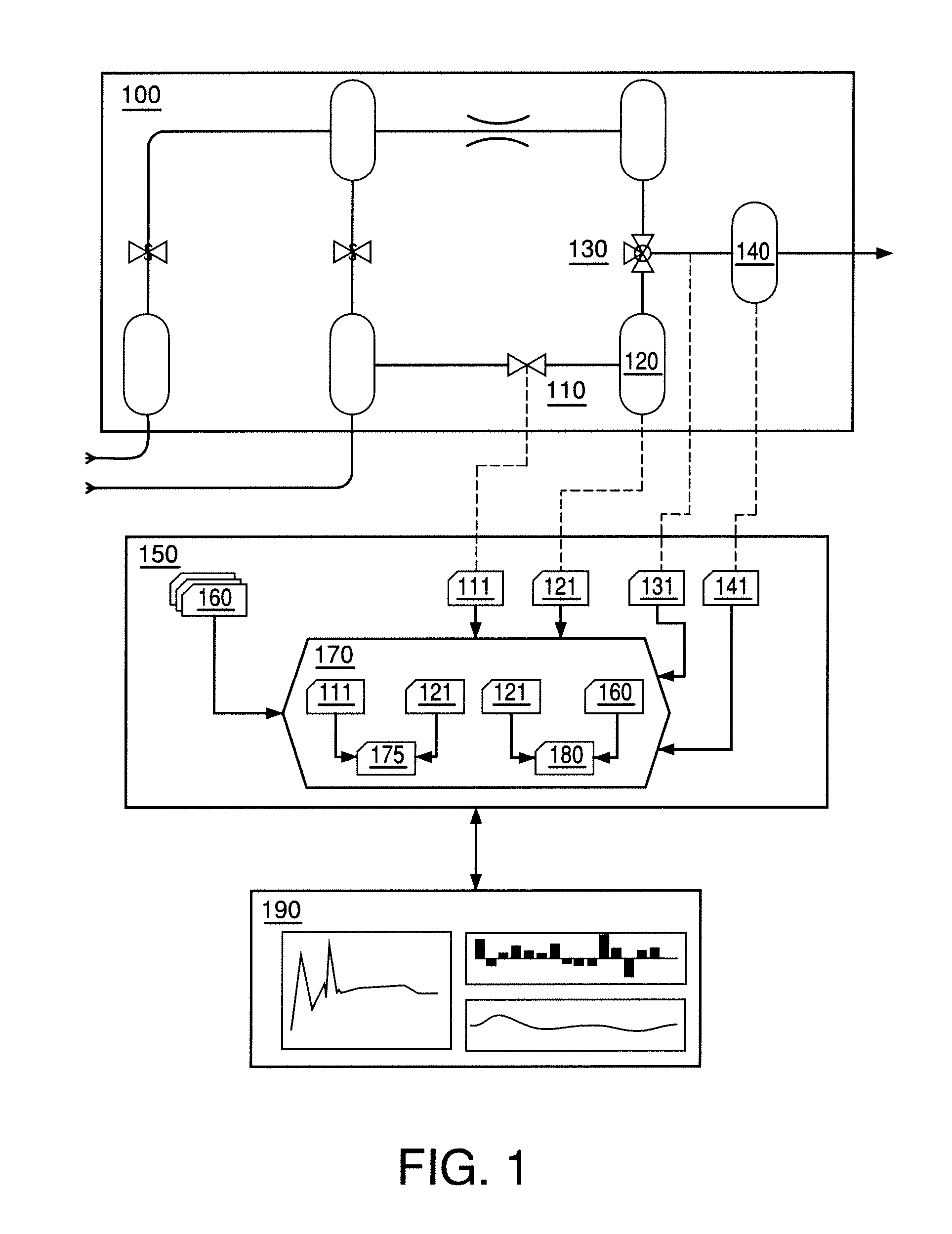

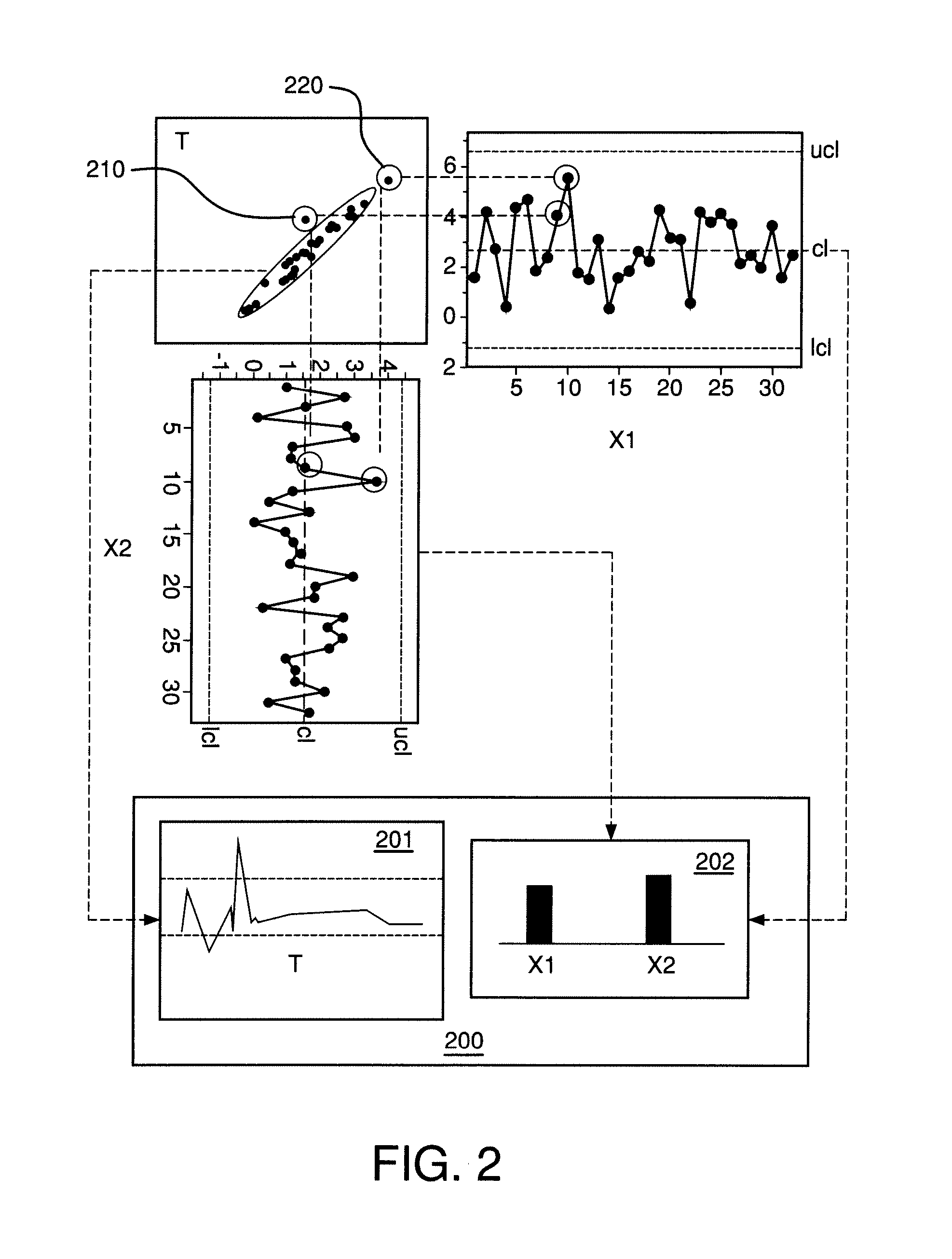

Systems and methods are provided that allow a user to monitor, diagnose, and configure a process. A user interface may be presented that displays data received from process monitors, sensors, and multivariate models. The user interface may be interactive, allowing a user to select which composite and multivariate models are displayed. The user interface and multivariate model may be constructed and updated in real time. The user interface may present various data and interfaces, such as a representation of a composite variable in a multivariate model, a representation of the contribution of process variables to the composite variable, and a representation of a subset of the process variables. The user may select a point of the composite variable for analysis, and the interface may indicate the contribution and values of process variables at the selected point. The interface may be transmitted to a remote user.

Owner:AIR PROD & CHEM INC

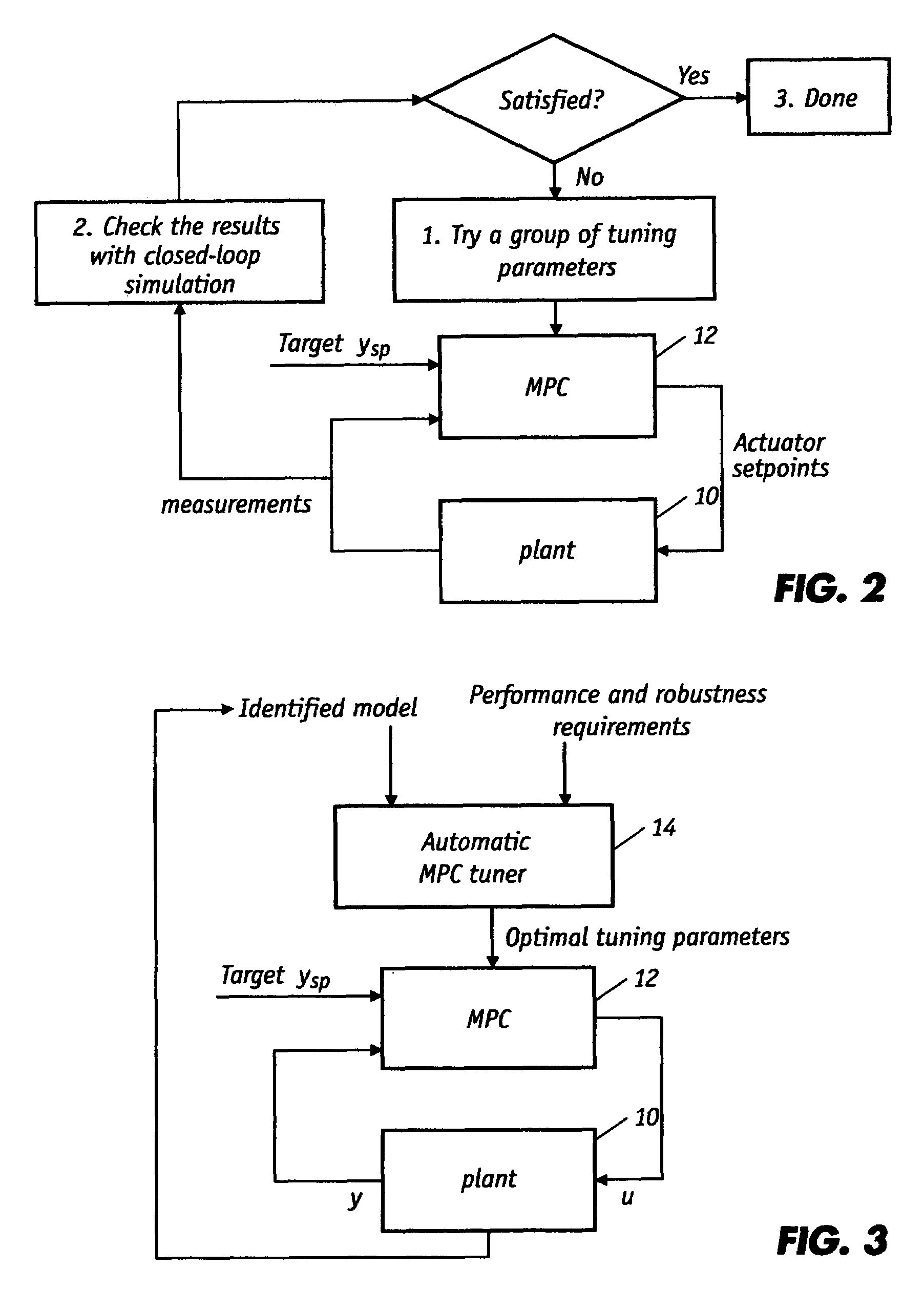

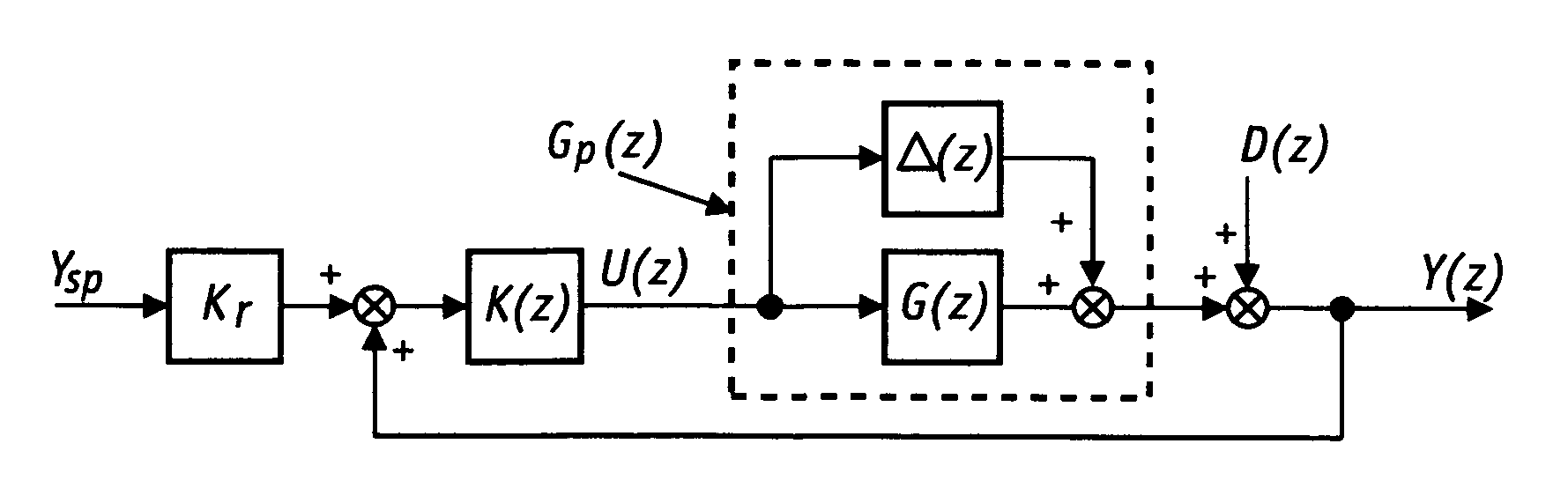

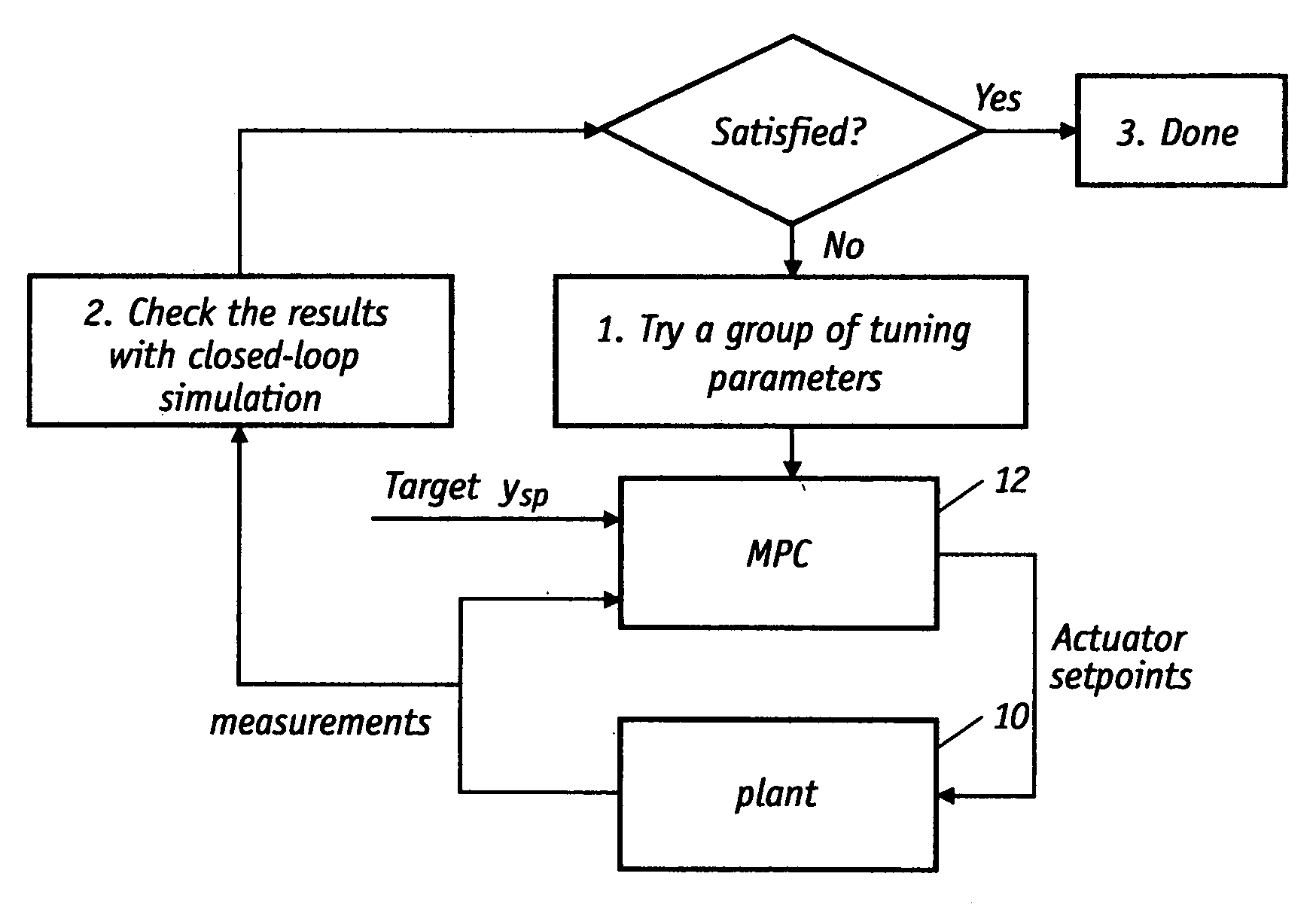

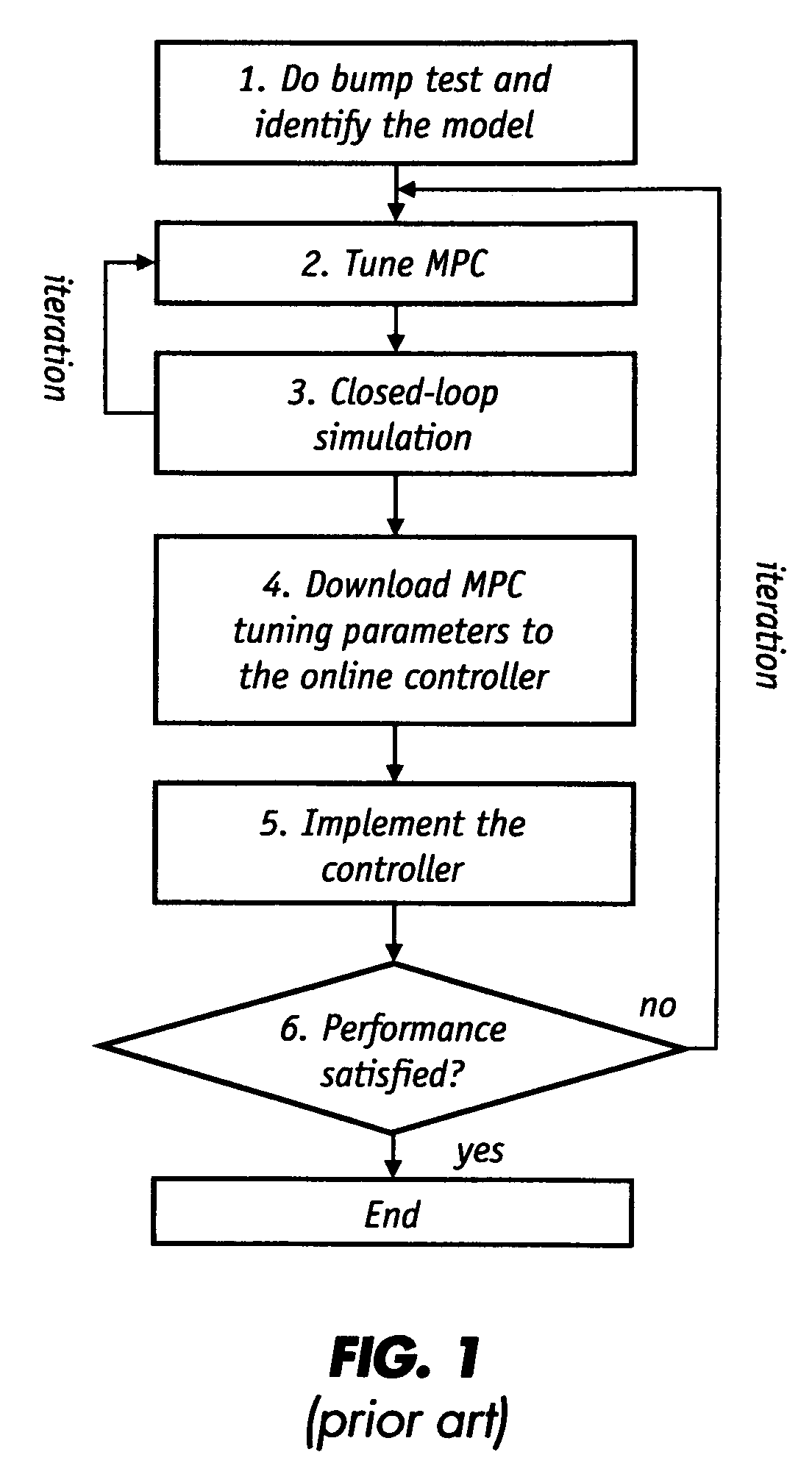

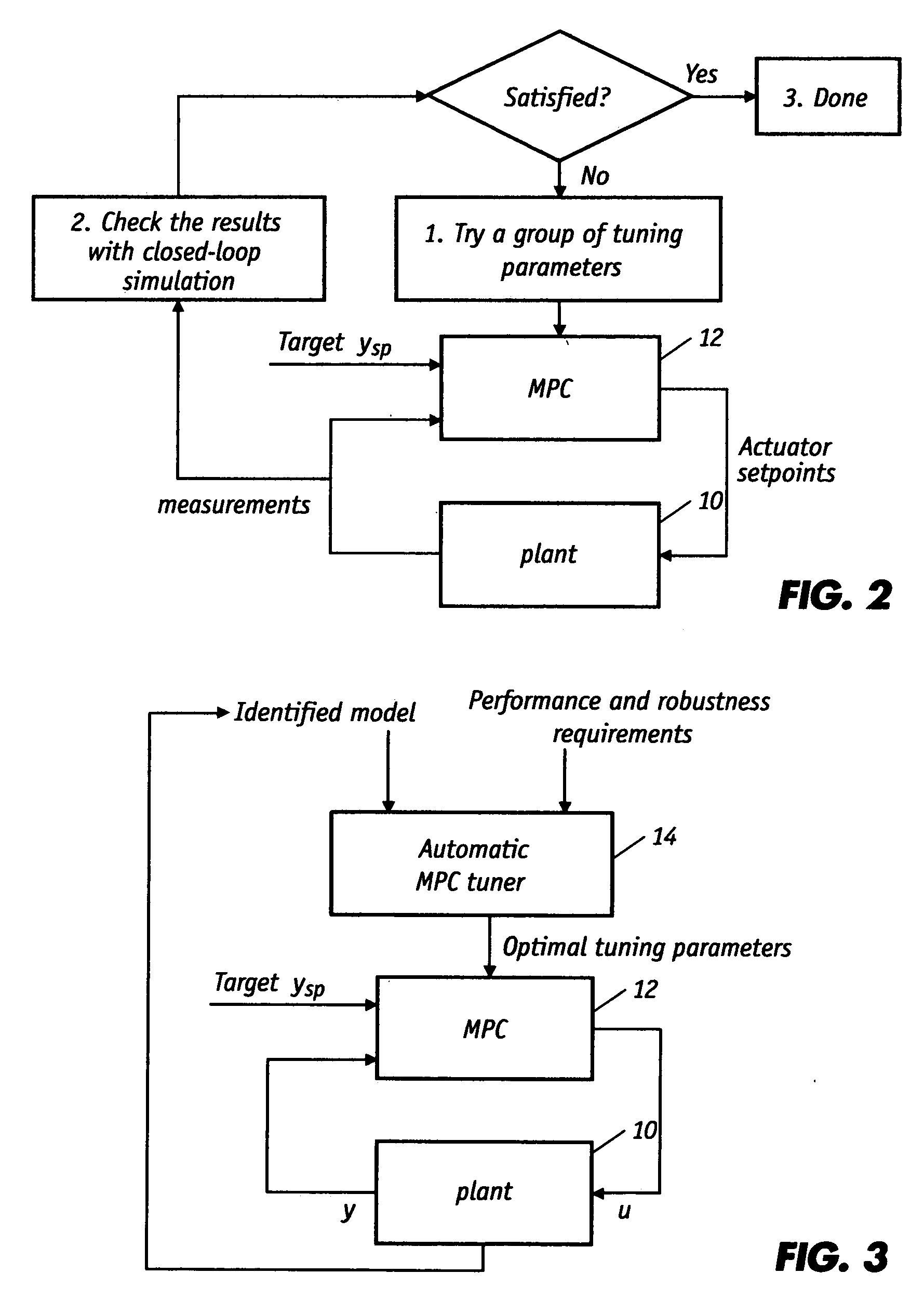

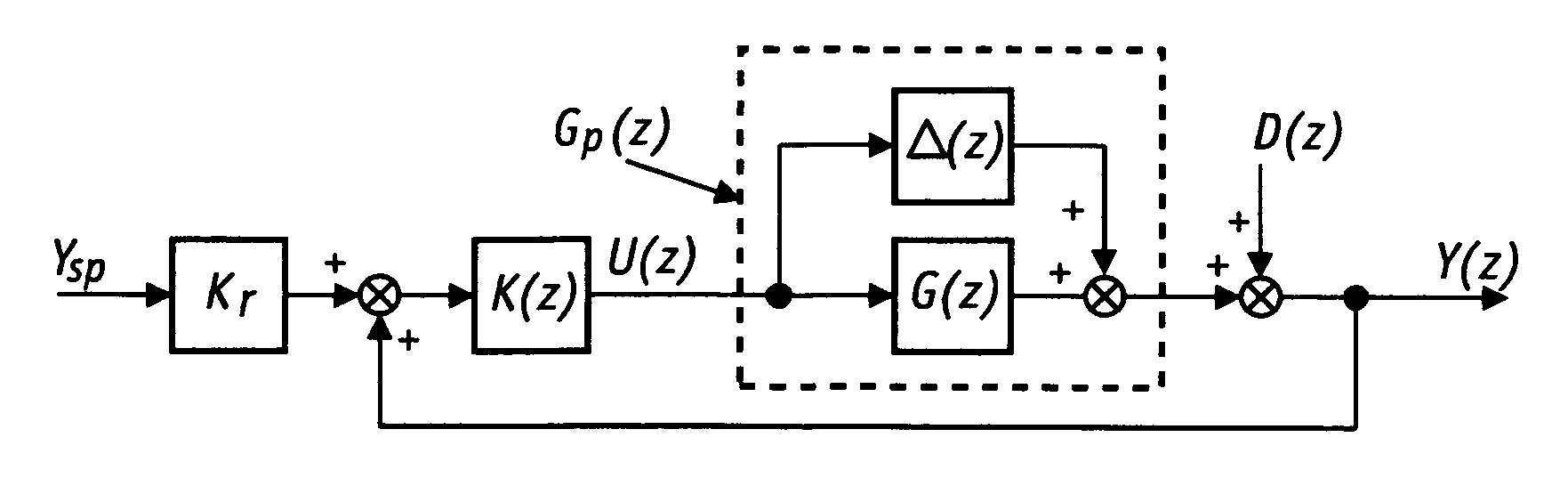

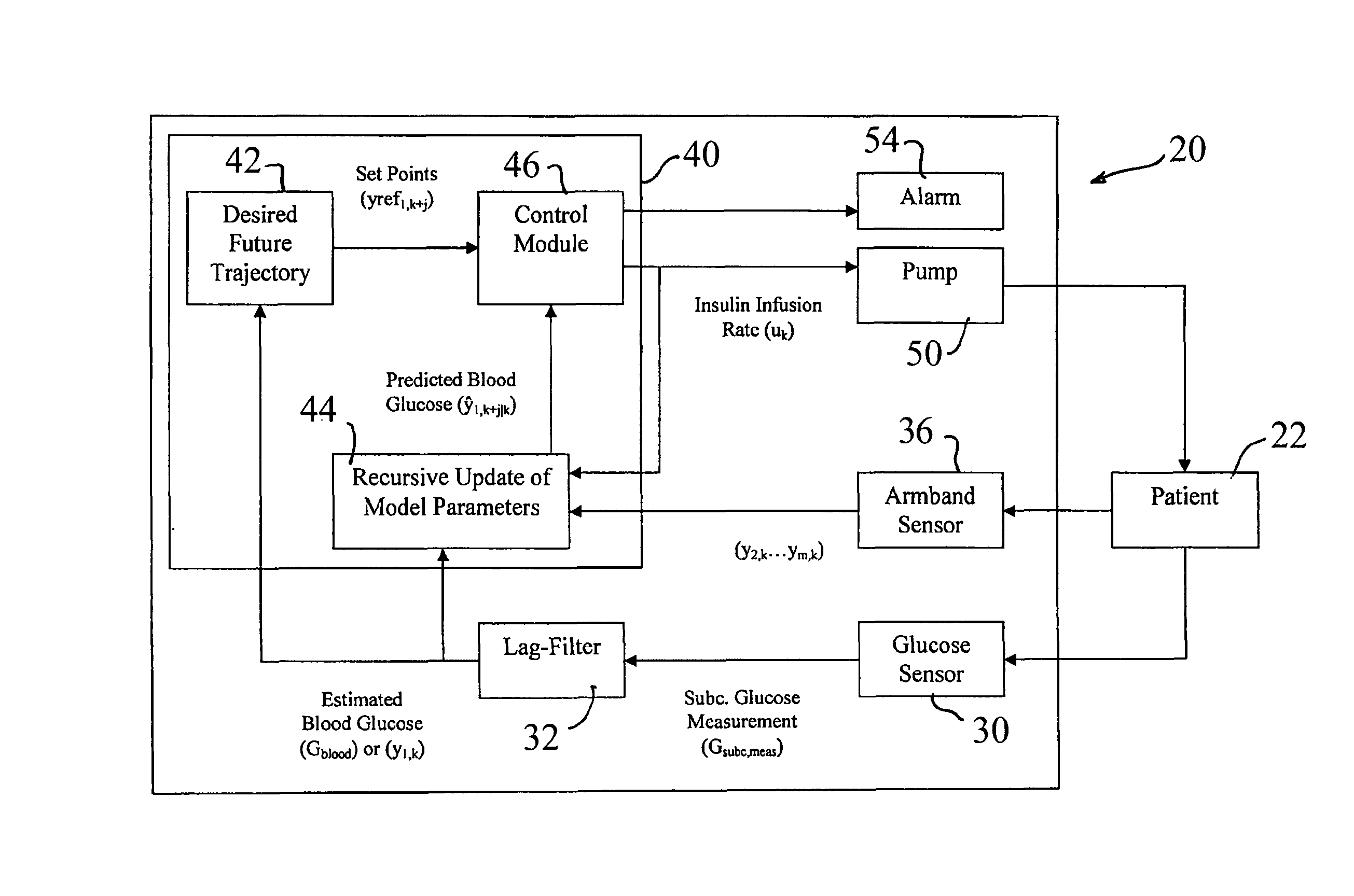

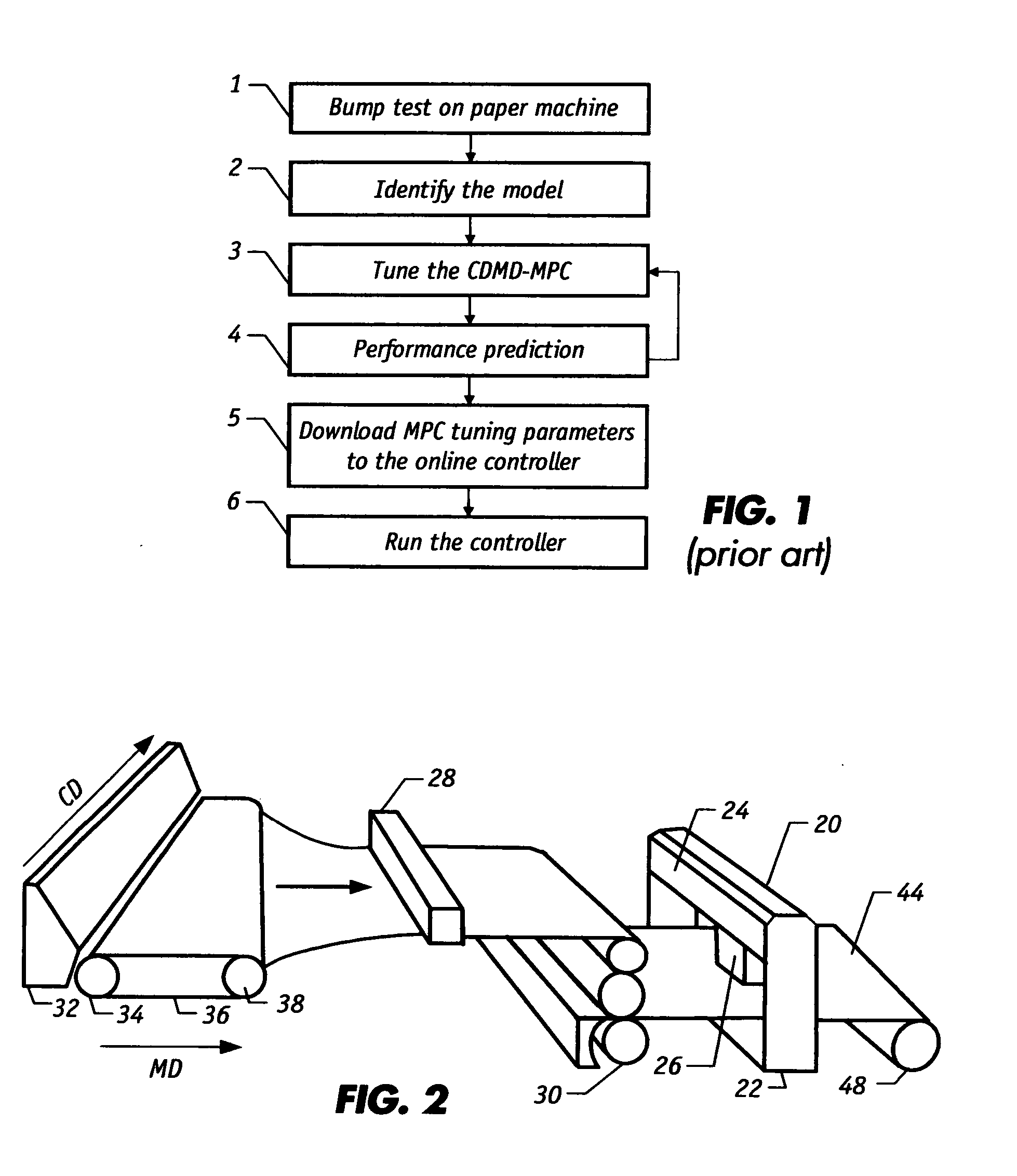

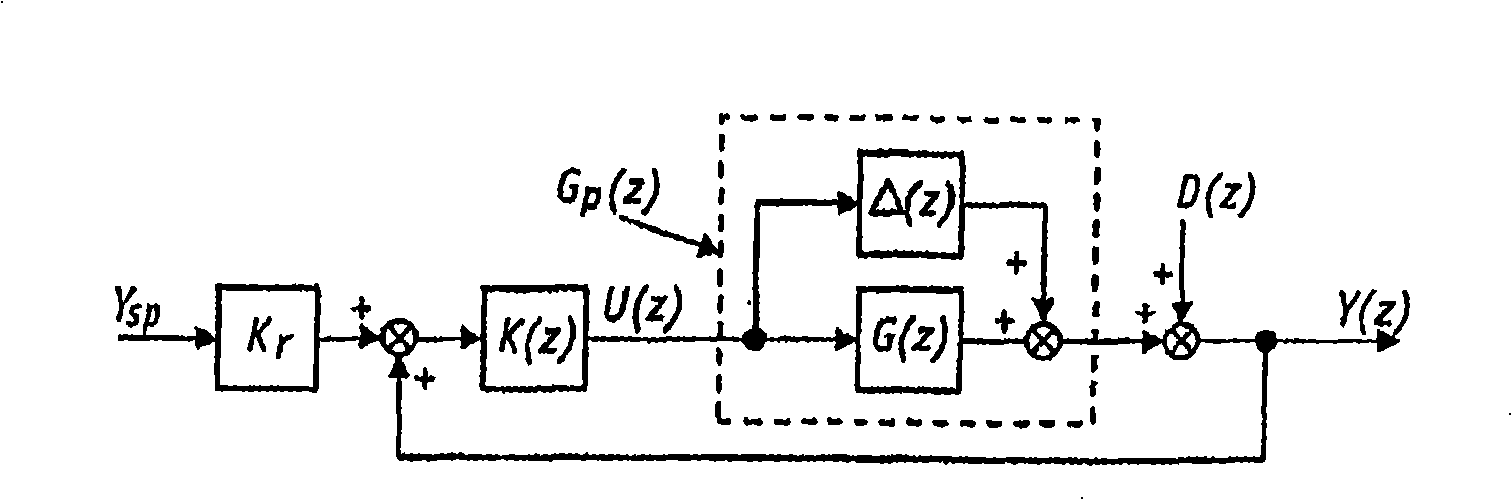

Automatic tuning method for multivariable model predictive controllers

ActiveUS7577483B2Fast and reliableDigital computer detailsElectric controllersRobustificationPredictive controller

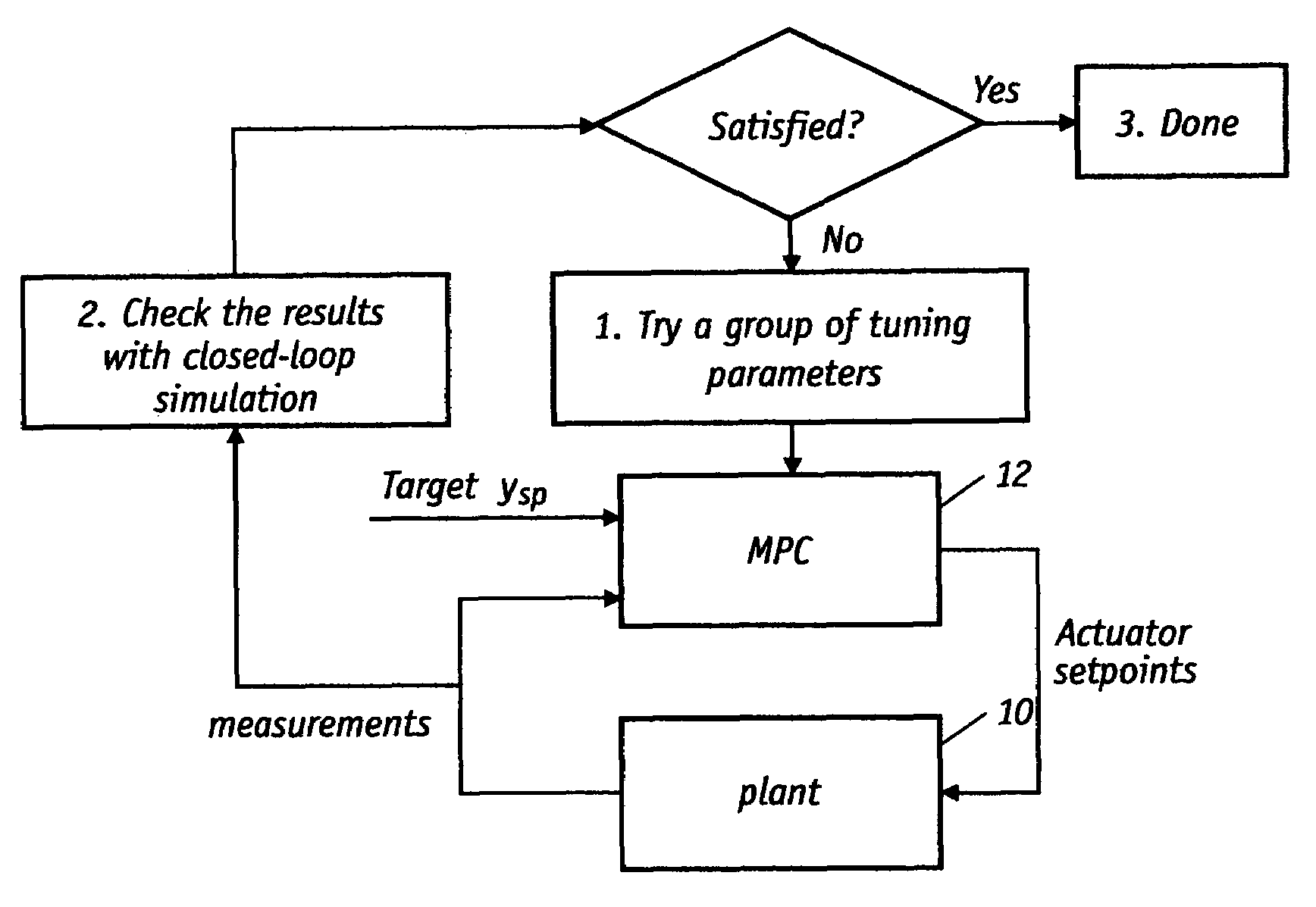

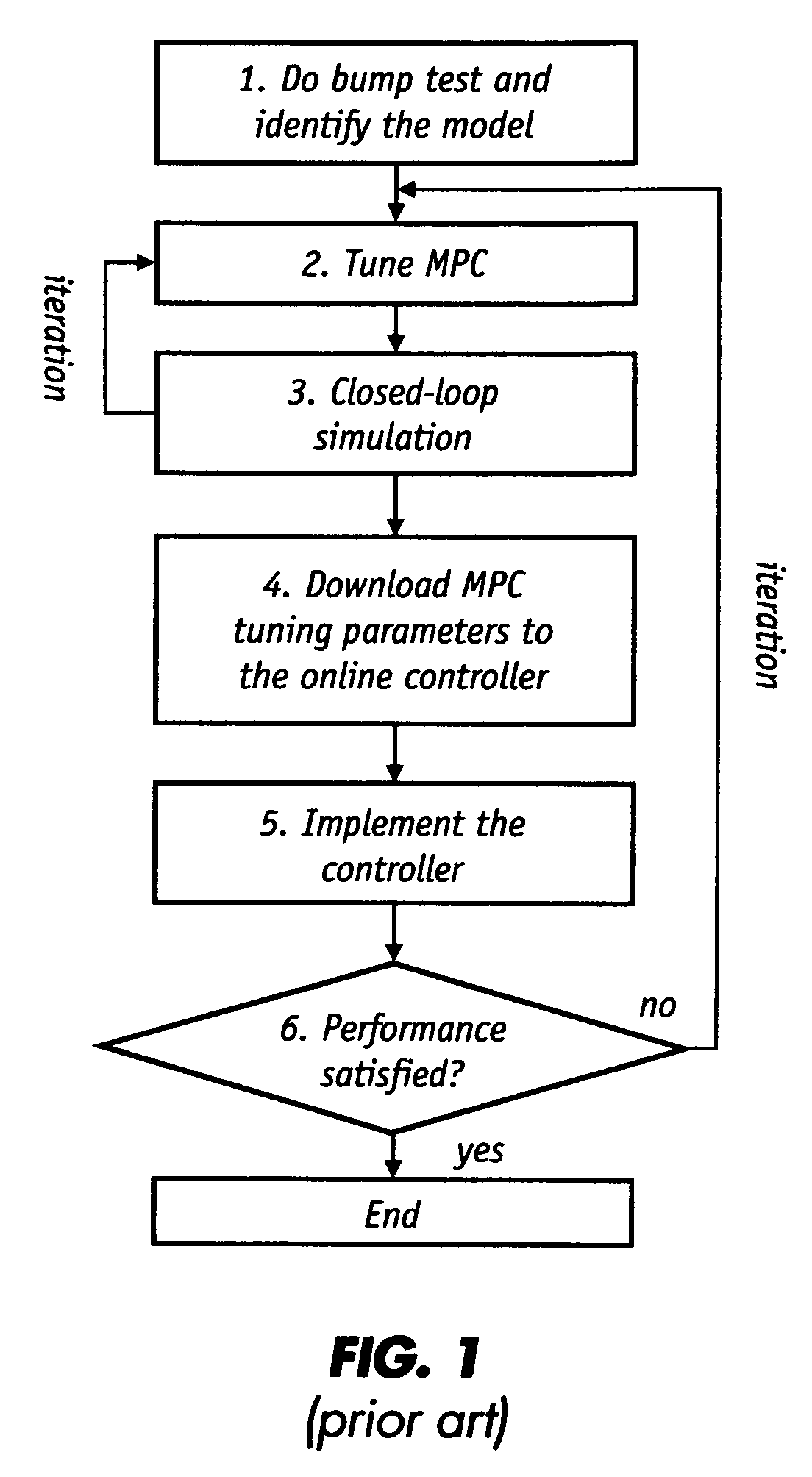

A fast and reliable technique for tuning multivariable model predictive controllers (MPCs) that accounts for performance and robustness is provided. Specifically, the technique automatically yields tuning weights for the MPC based on performance and robustness requirements. The tuning weights are parameters of closed-loop transfer functions which are directly linked to performance and robustness requirements. Automatically searching the tuning parameters in their proper ranges assures that the controller is optimal and robust. This technique will deliver the traditional requirements of stability, performance and robustness, while at the same time enabling users to design their closed-loop behavior in terms of the physical domain. The method permits the user to favor one measurement over another, or to use one actuator more than another.

Owner:HONEYWELL ASCA INC

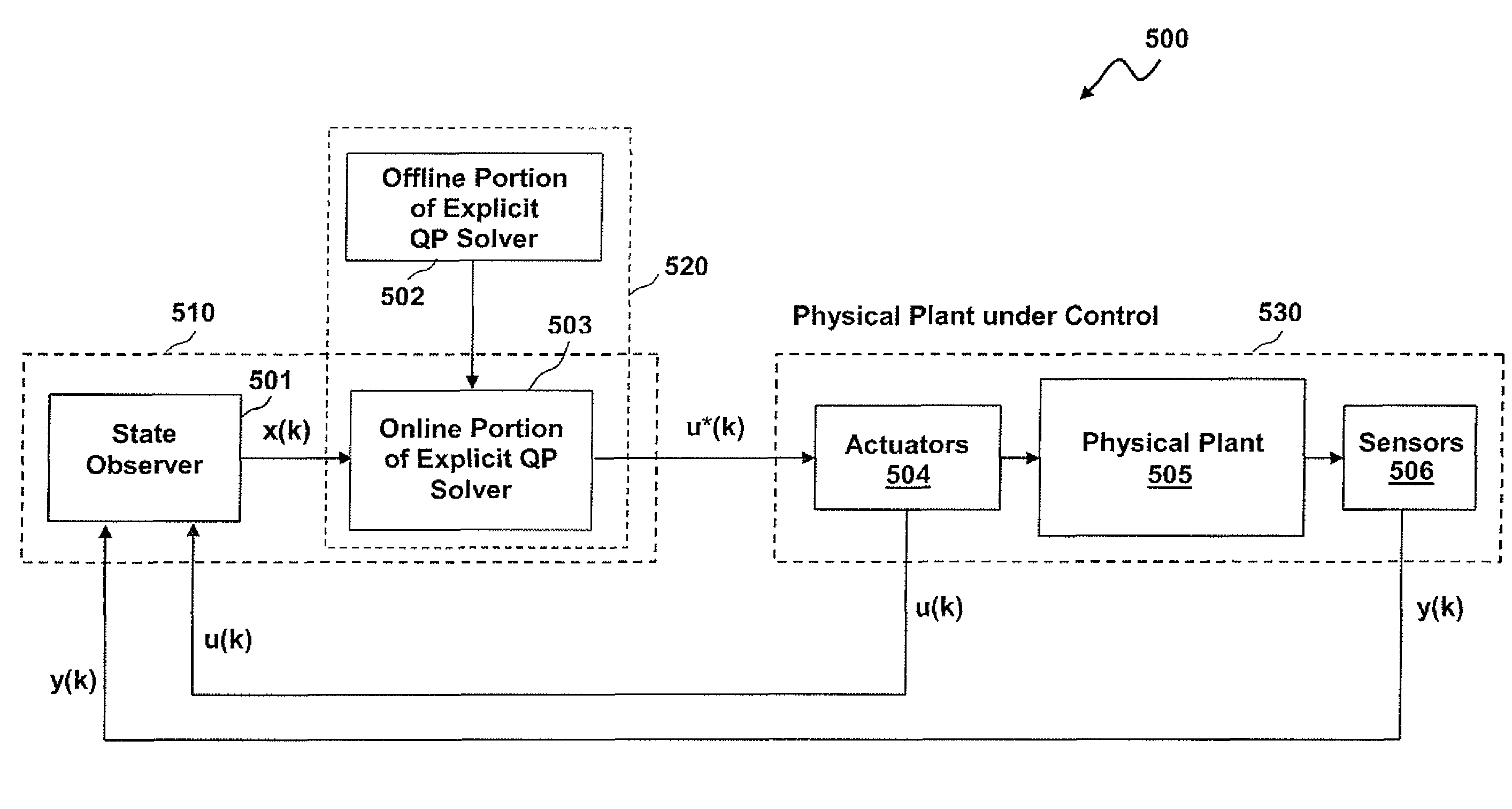

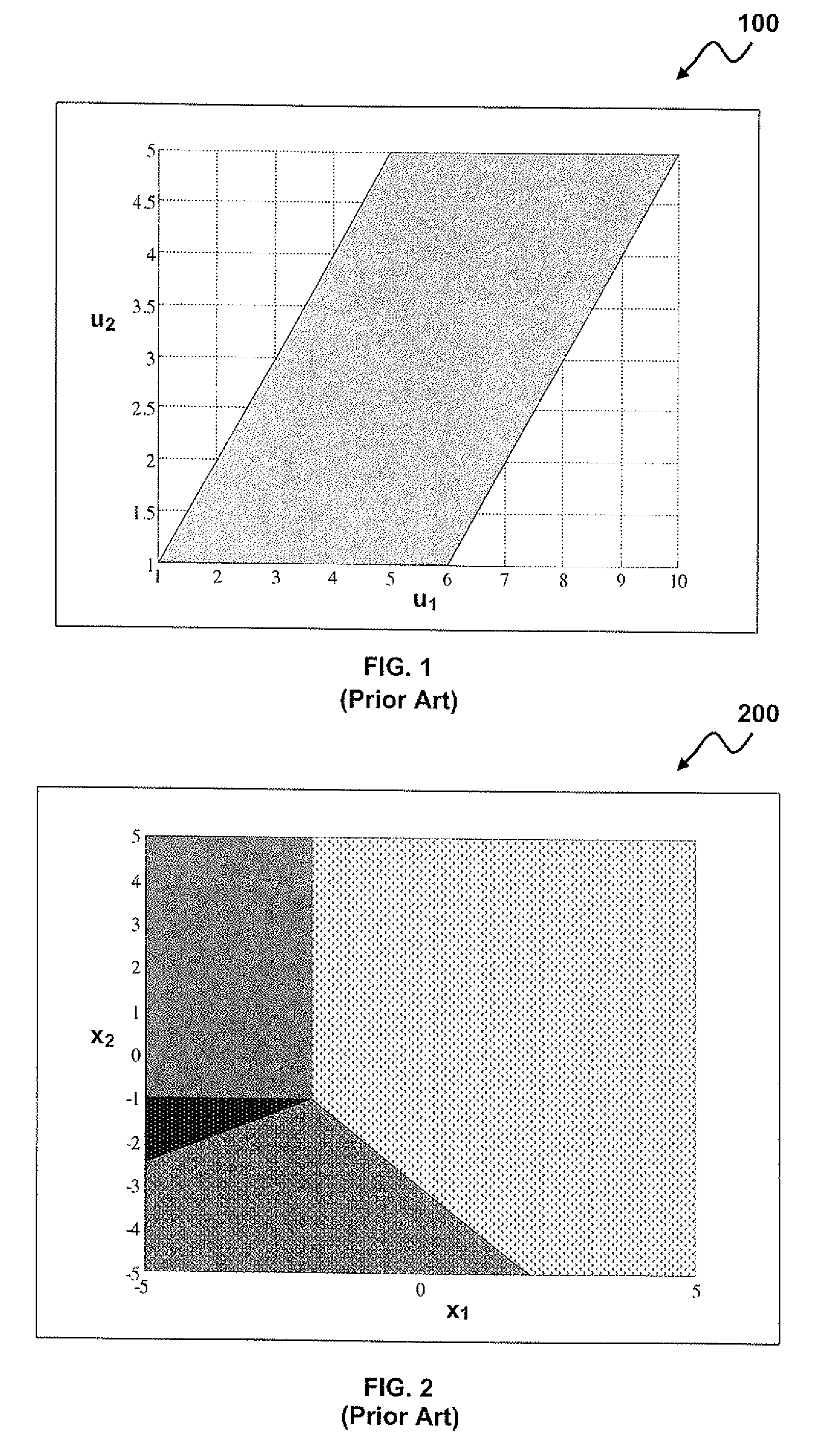

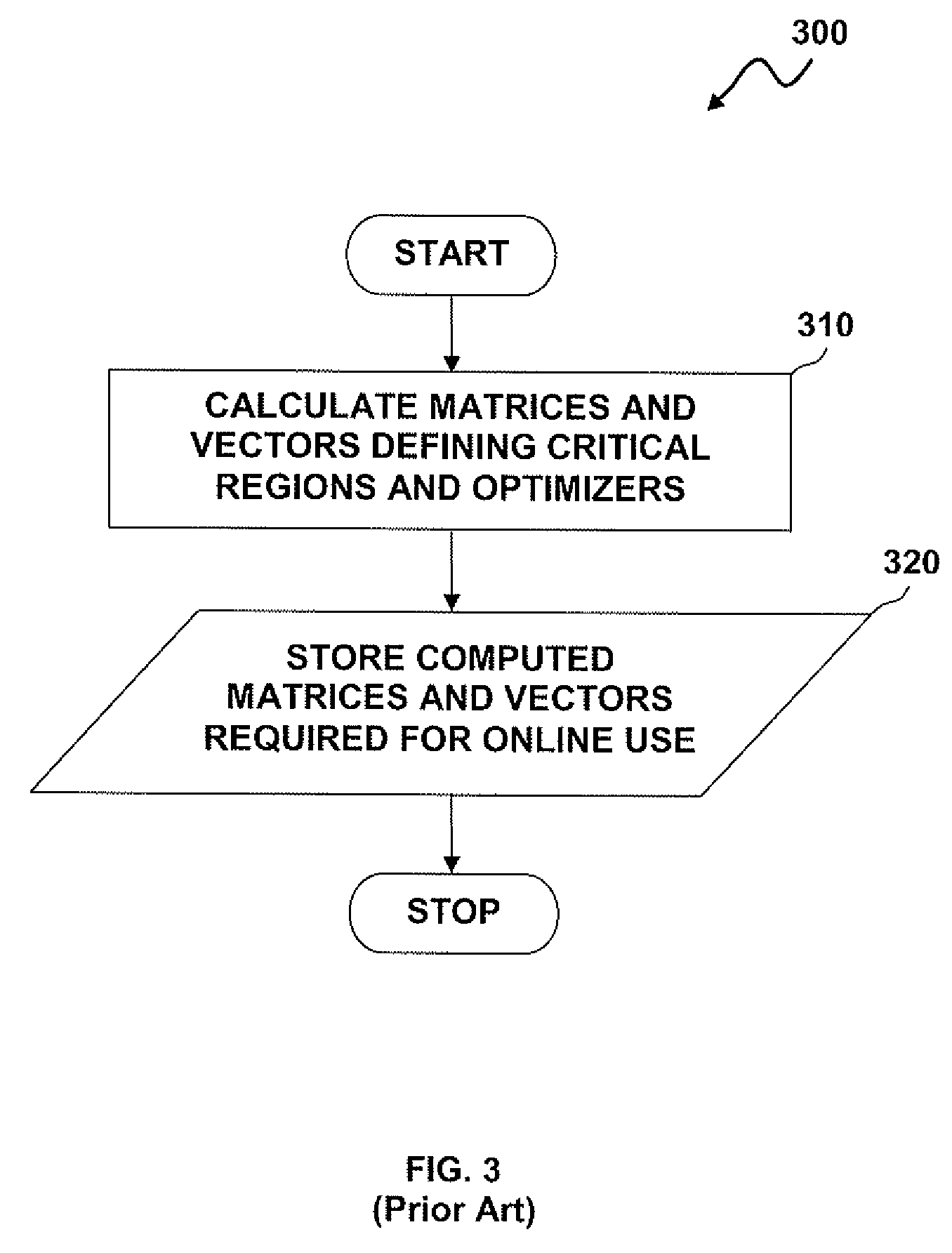

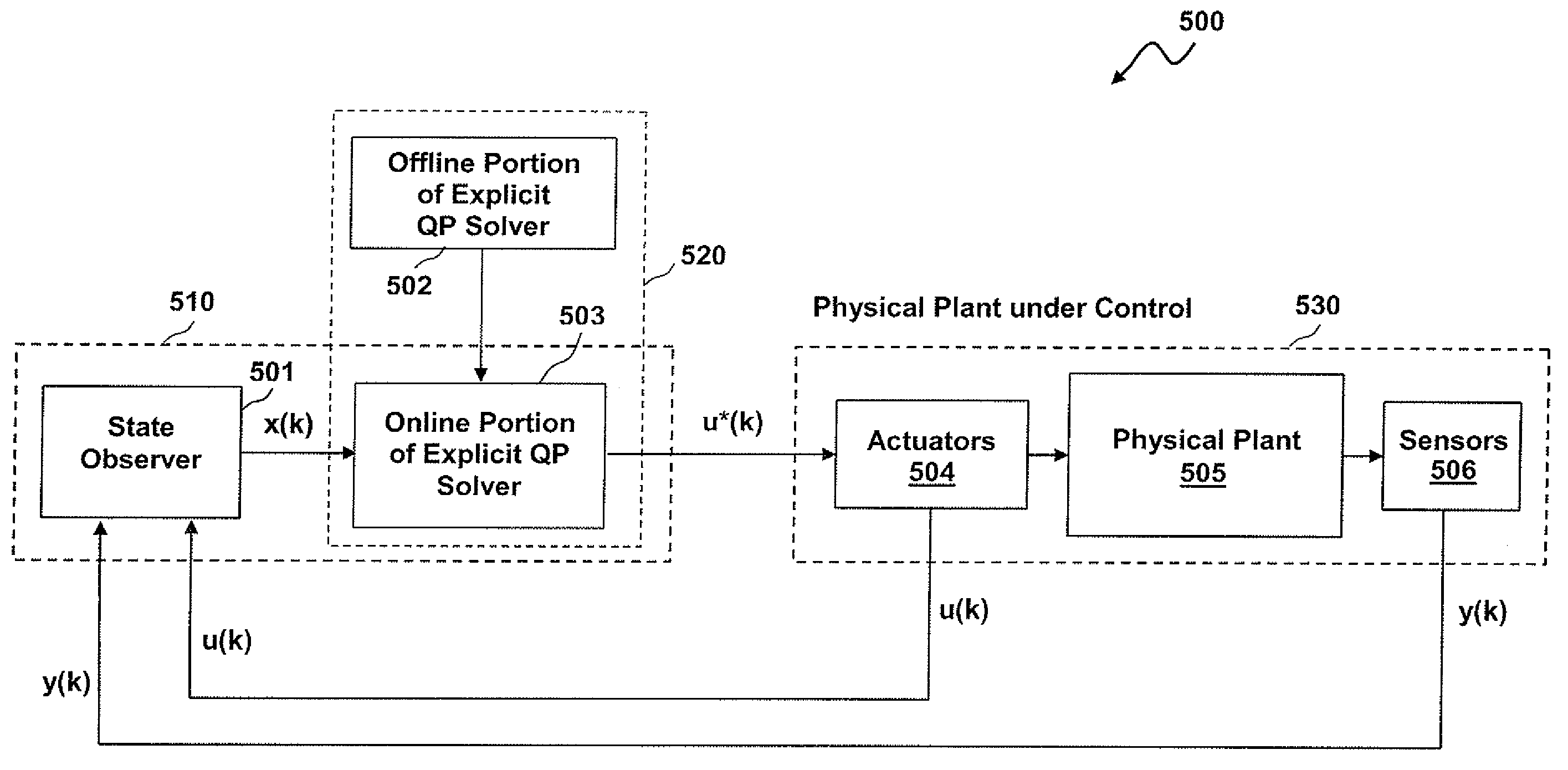

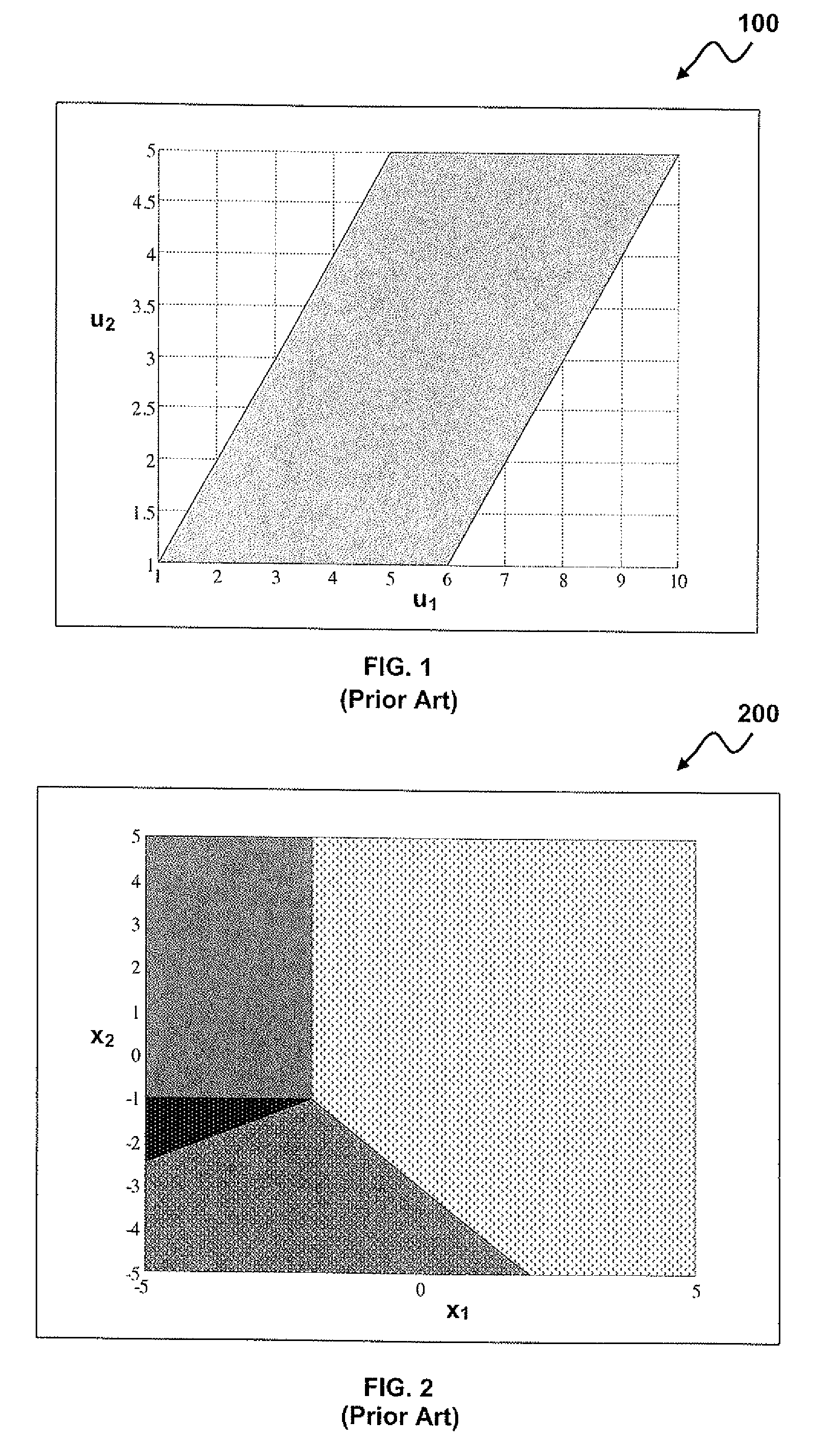

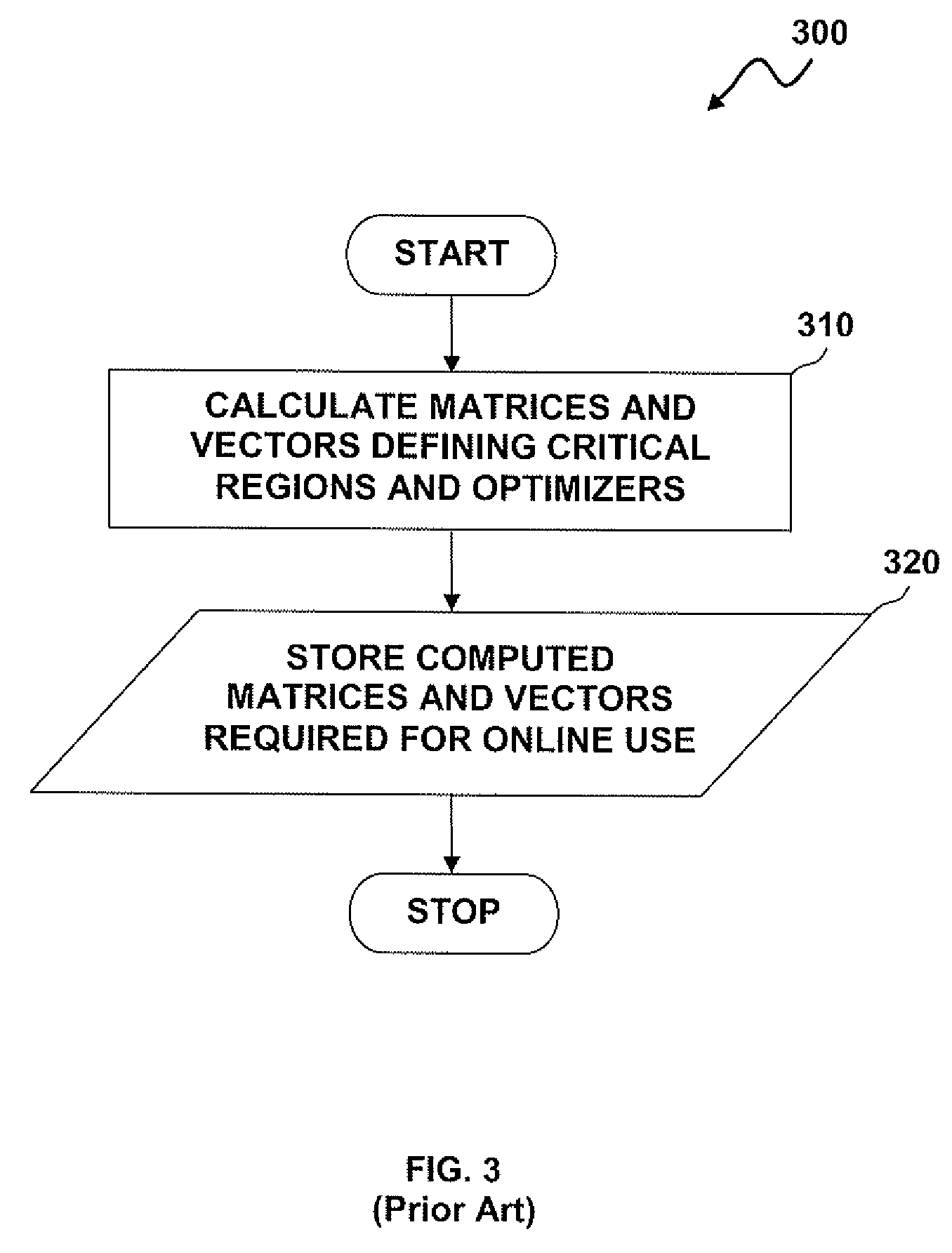

Methods and systems for the design and implementation of optimal multivariable model predictive controllers for fast-sampling constrained dynamic systems

ActiveUS8078291B2Minimize the numberReduce searchComputation using non-denominational number representationAdaptive controlAlgorithmPredictive controller

Methods and systems for the design and implementation of optimal multivariable MPC controllers for fast-sampling constrained dynamic systems utilizing a primal-dual feasibility approach and / or a graph approach. The primal-dual feasibility approach can compute and store matrices defining constraints of quadratic programming problems in an off-line part in order to calculate vectors of Lagrange multipliers and an optimizer. Then primal-dual feasibility can be checked in an on-line part using the Lagrange multipliers and the optimizer can provide a unique optimal solution for the constrained dynamic system. The graph approach can compute and store the matrices and the vectors, and also prepare and store a structure of directed graph in off-line part. An optimizer for a given parameter vector can be determined in on-line part using the directed graph, the matrices and the vectors.

Owner:GARRETT TRANSPORATION I INC

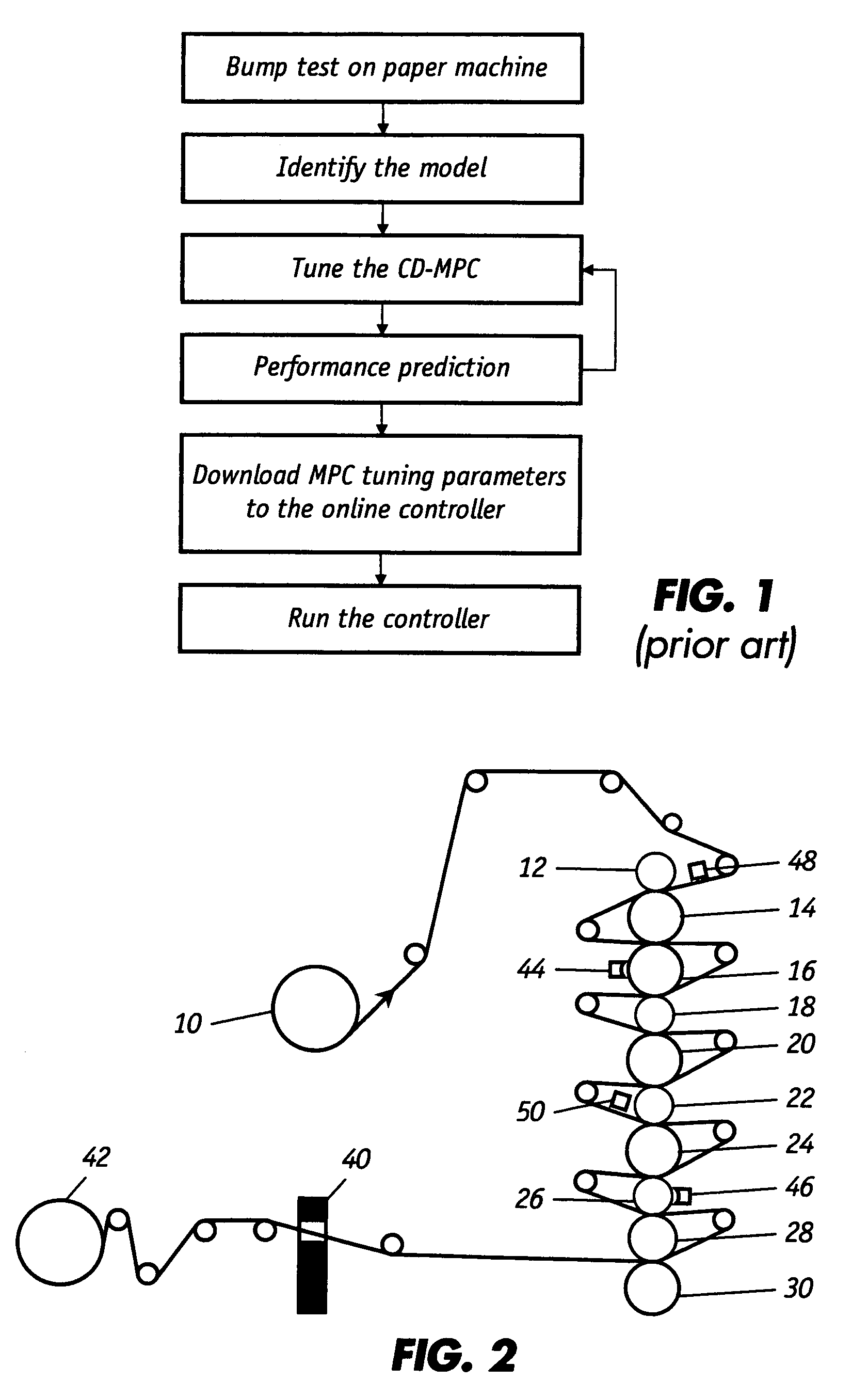

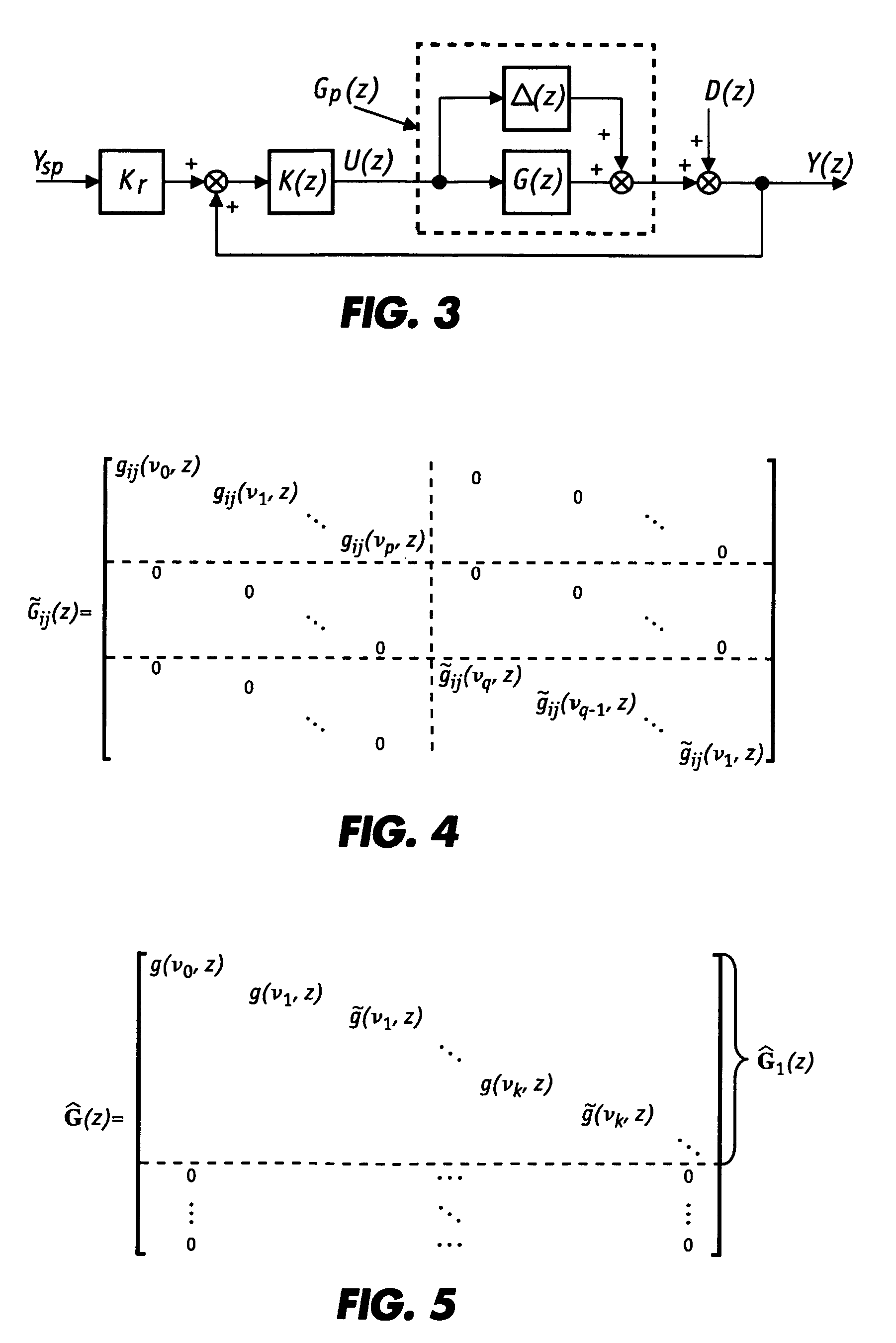

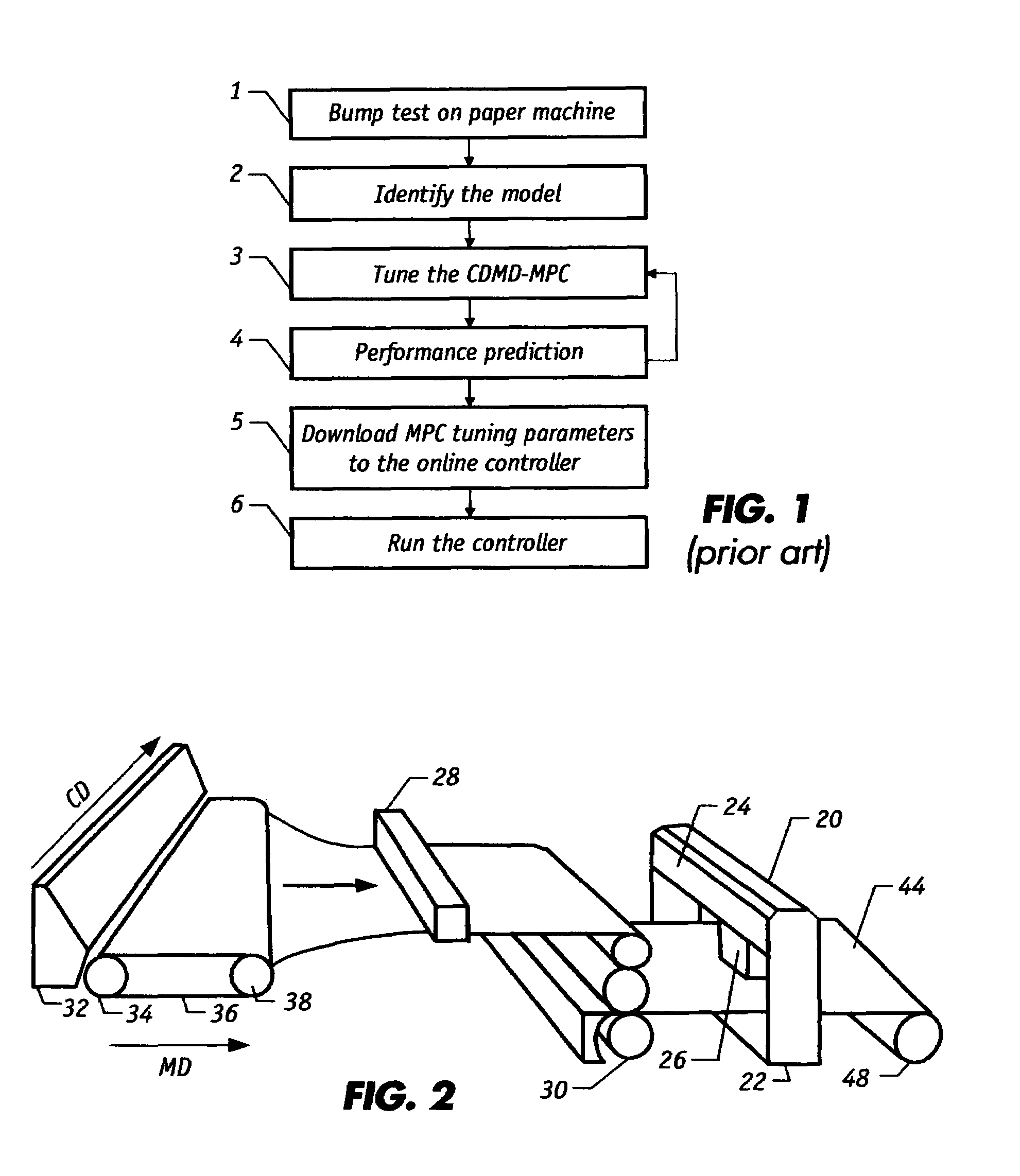

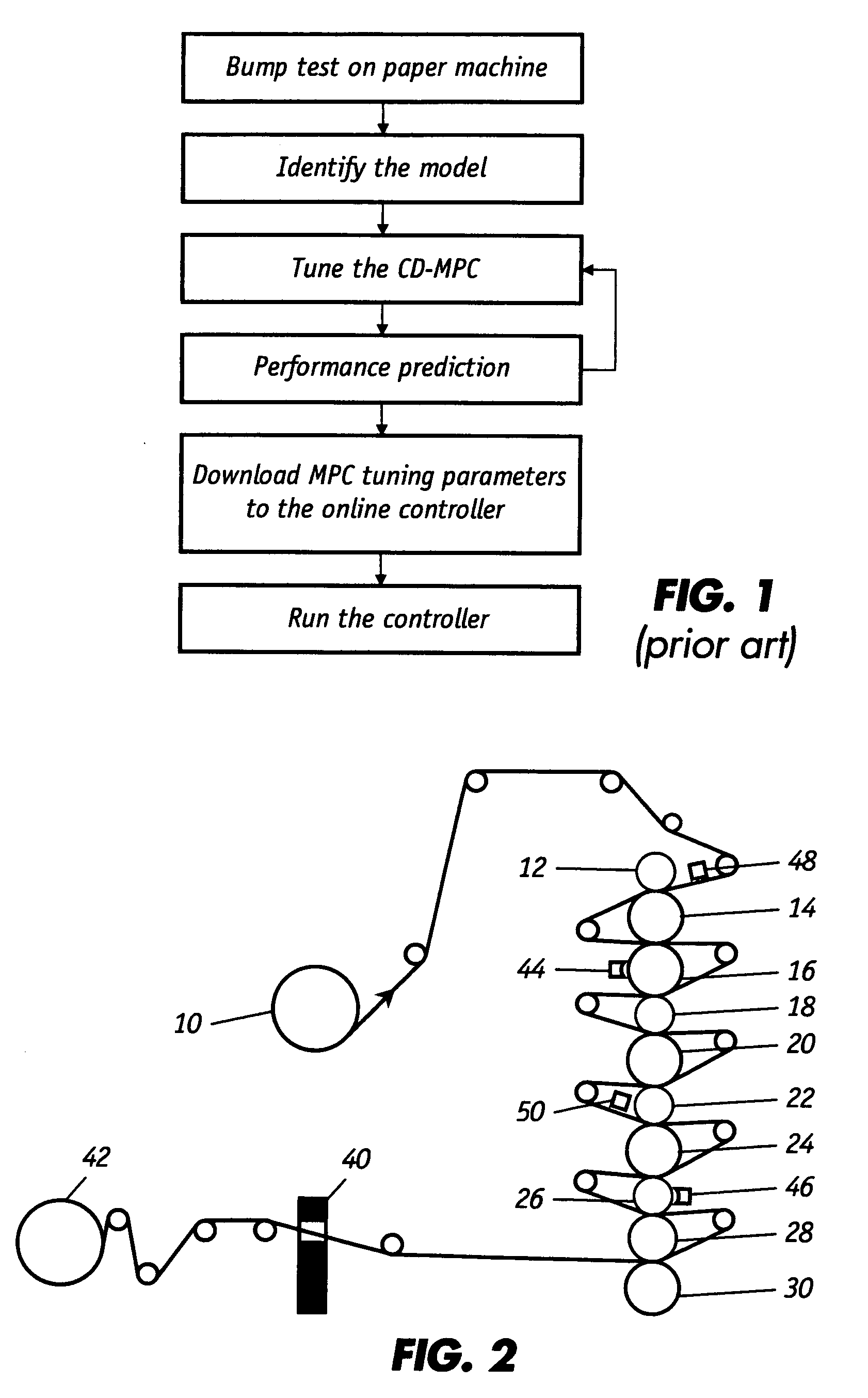

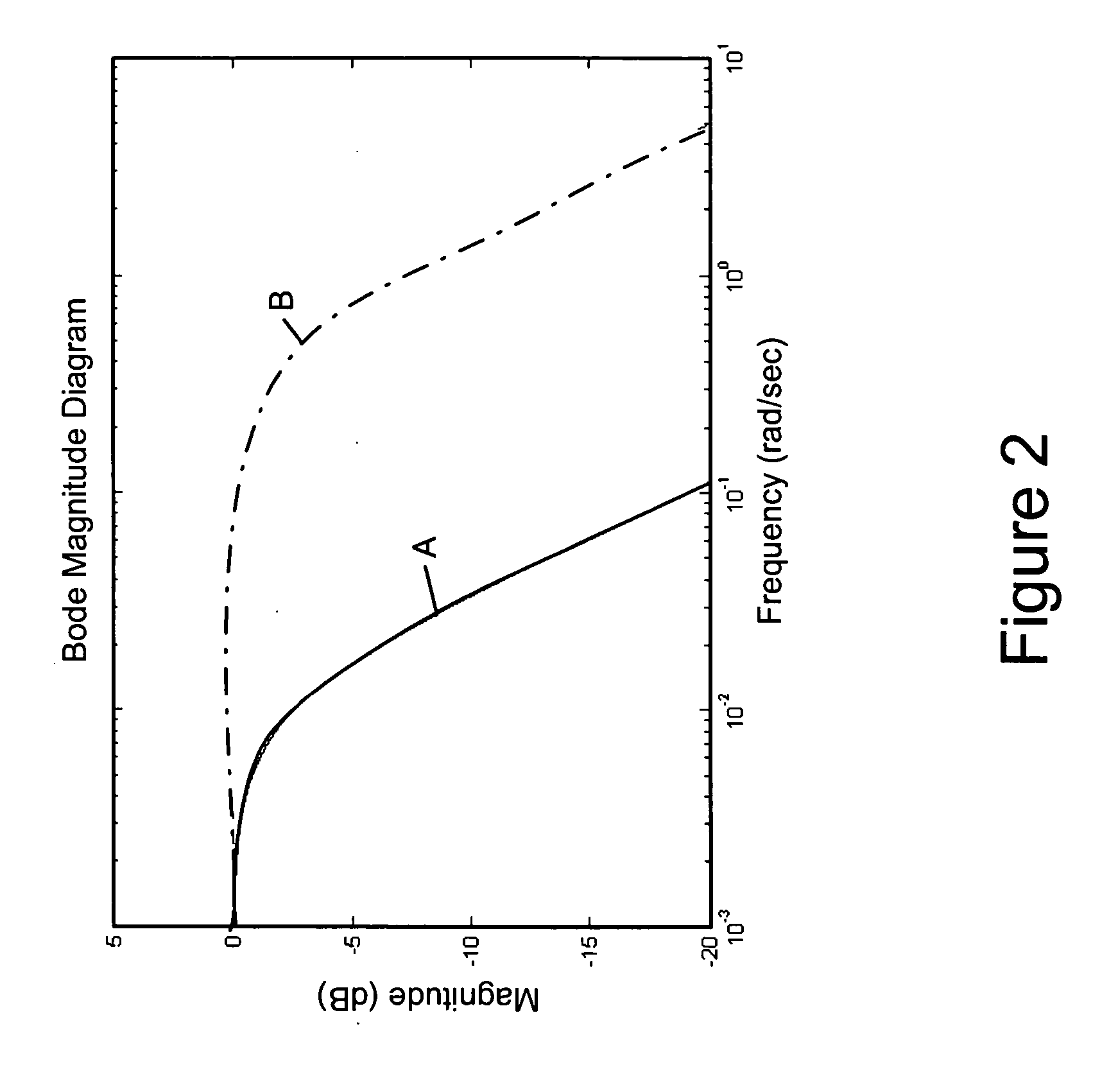

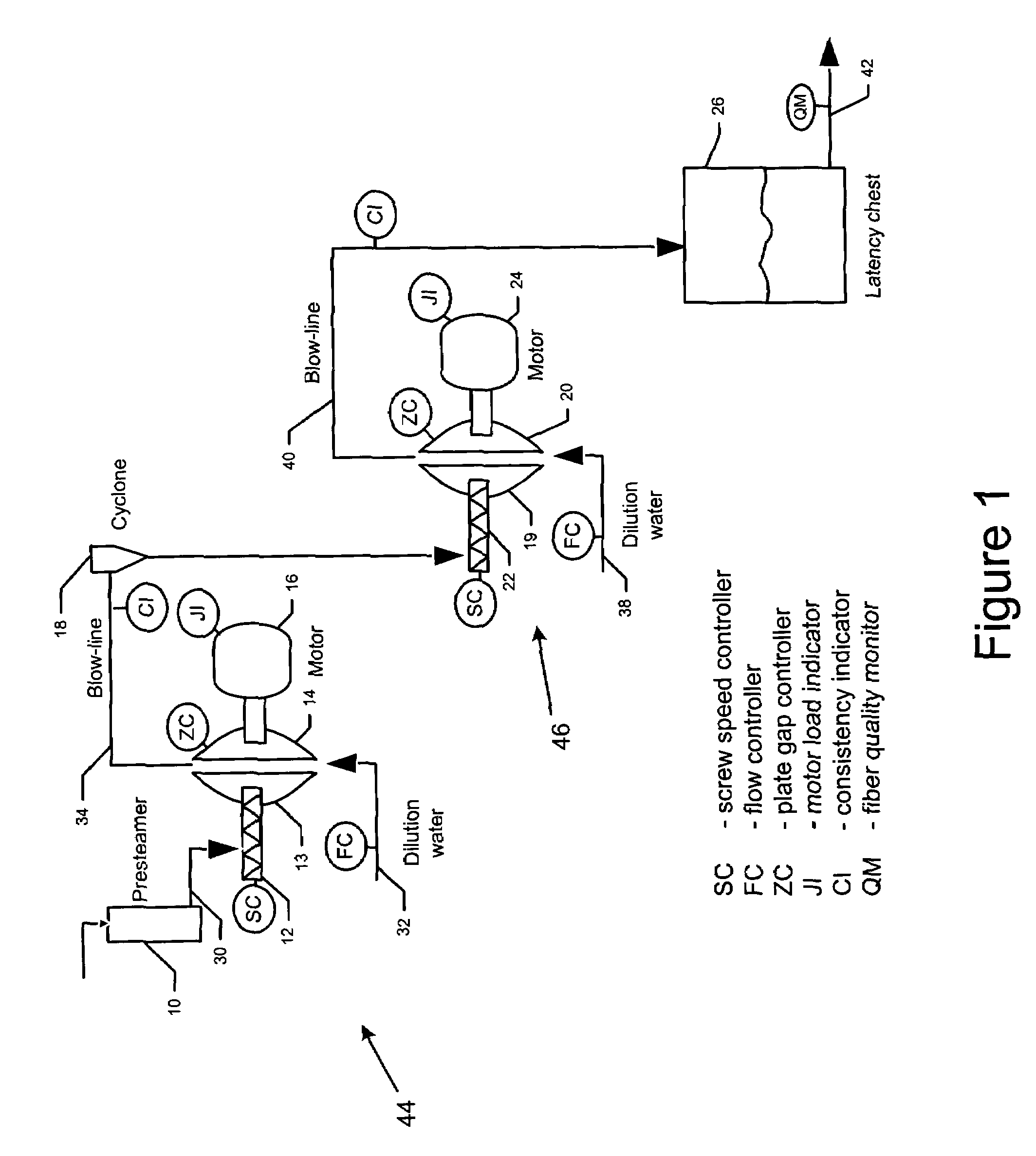

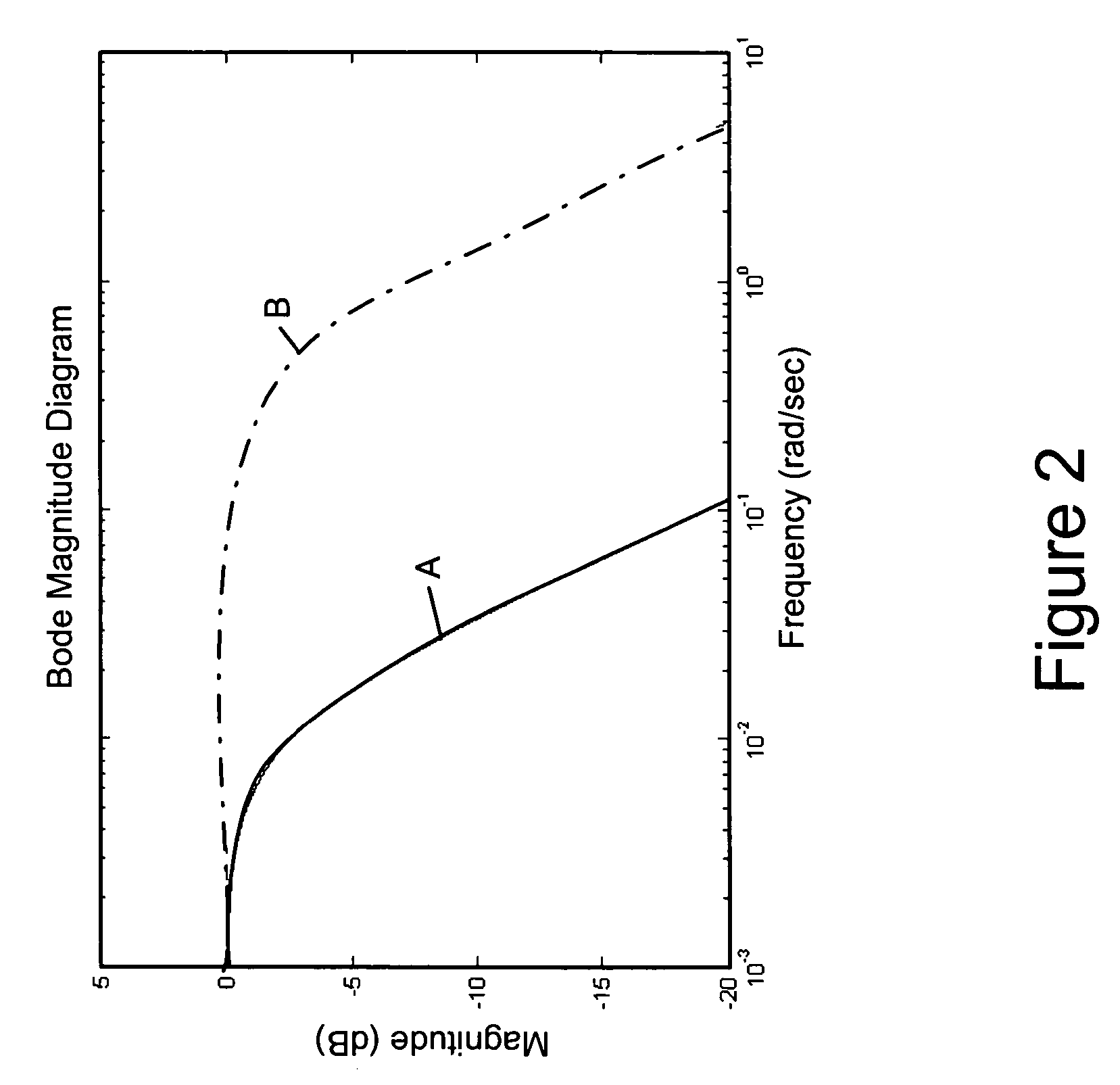

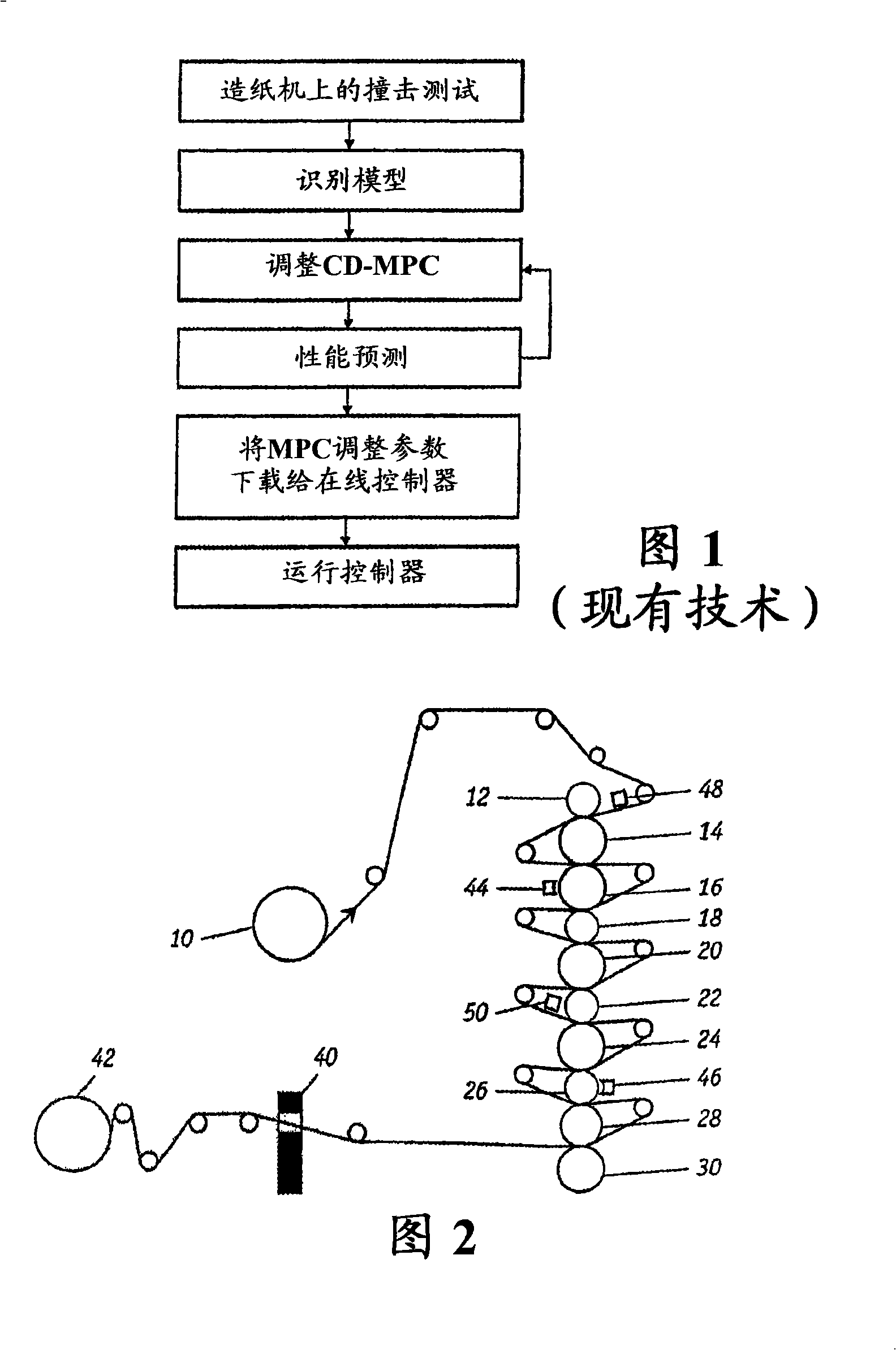

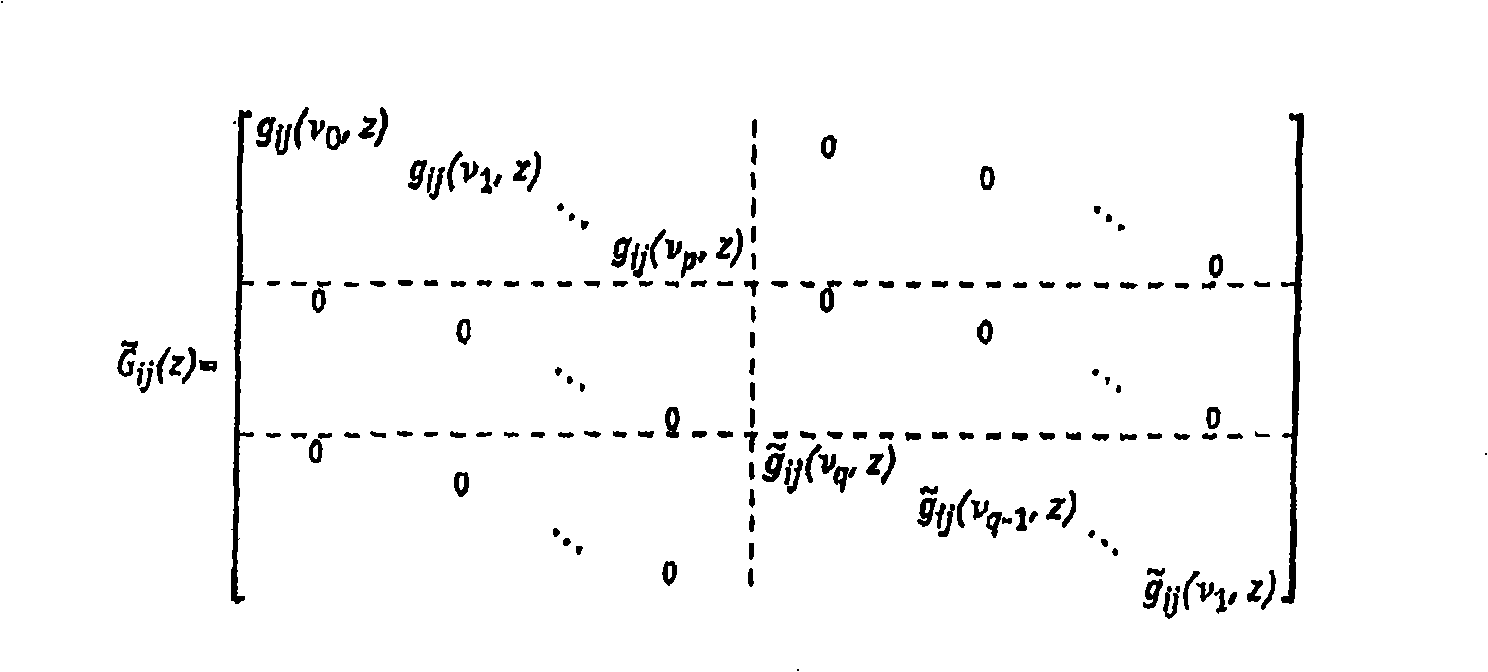

Automated tuning of large-scale multivariable model predictive controllers for spatially-distributed processes

ActiveUS7650195B2Analogue computers for chemical processesDigital computer detailsPredictive controllerClosed loop

An automated tuning method of a large-scale multivariable model predictive controller for multiple array papermaking machine cross-directional (CD) processes can significantly improve the performance of the controller over traditional controllers. Paper machine CD processes are large-scale spatially-distributed dynamical systems. Due to these systems' (almost) spatially invariant nature, the closed-loop transfer functions are approximated by transfer matrices with rectangular circulant matrix blocks, whose input and output singular vectors are the Fourier components of dimension equivalent to either number of actuators or number of measurements. This approximation enables the model predictive controller for these systems to be tuned by a numerical search over optimization weights in order to shape the closed-loop transfer functions in the two-dimensional frequency domain for performance and robustness. A novel scaling method is used for scaling the inputs and outputs of the multivariable system in the spatial frequency domain.

Owner:HONEYWELL ASCA INC

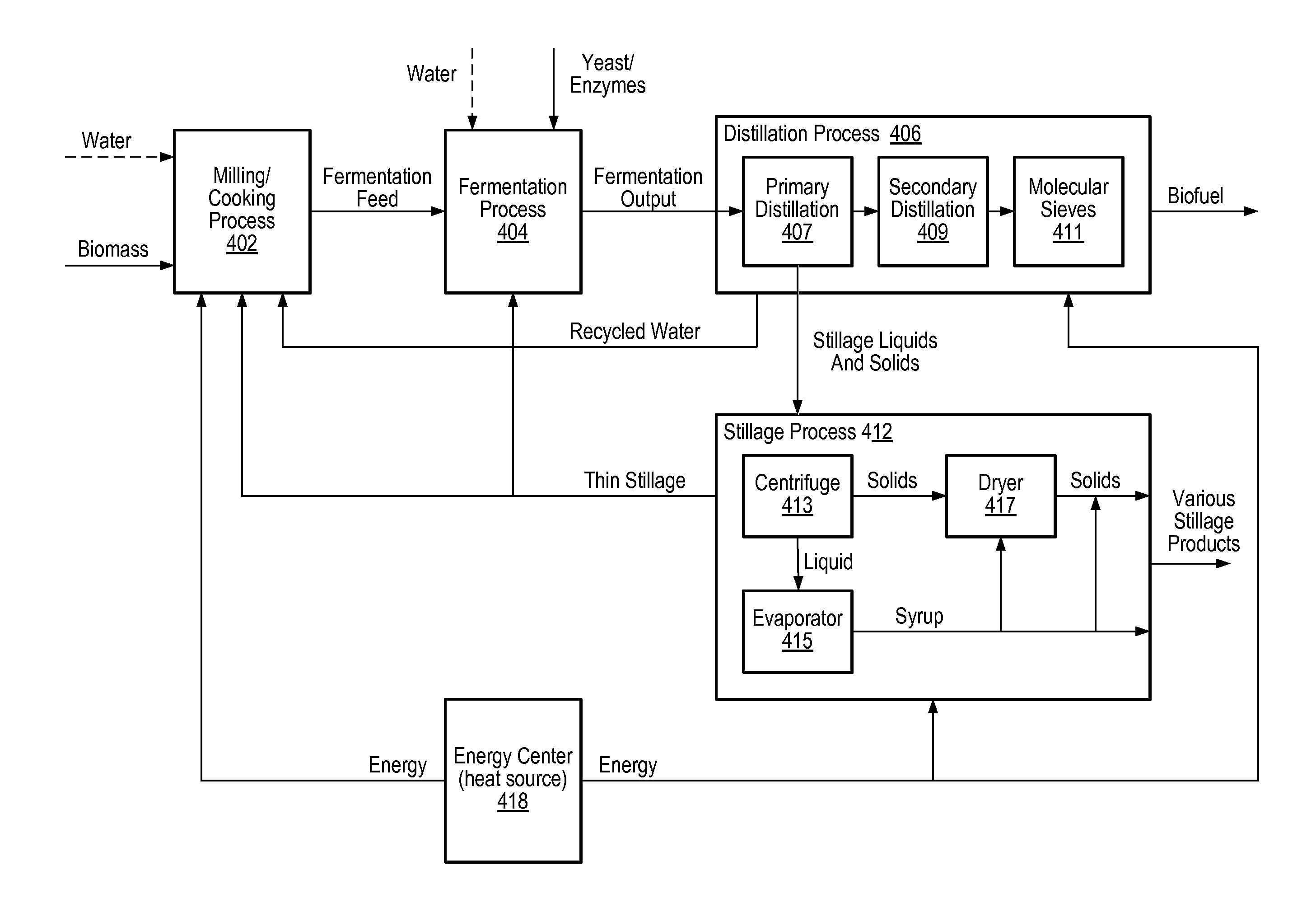

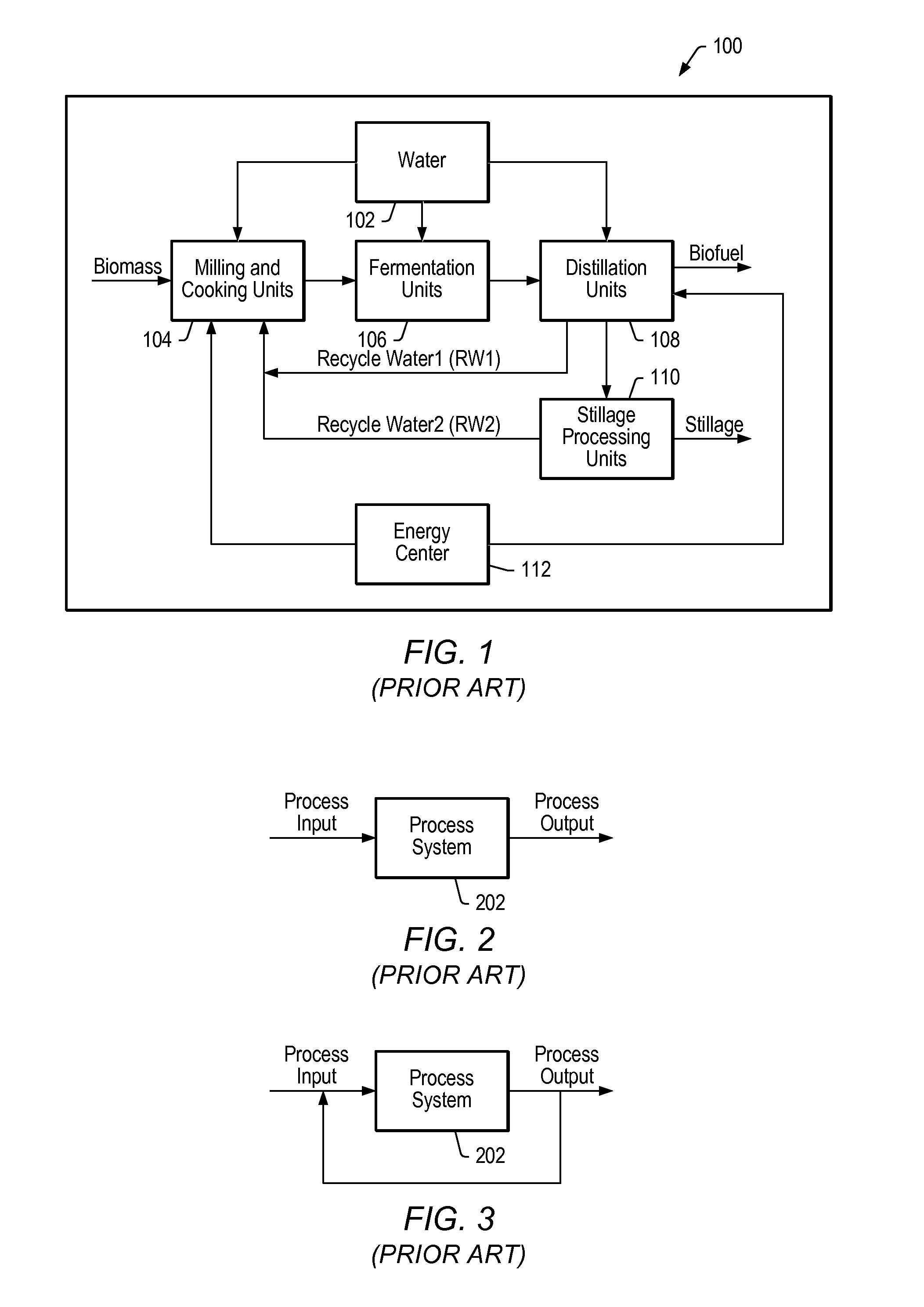

Integrated model predictive control of distillation and dehydration sub-processes in a biofuel production process

ActiveUS20080103748A1Efficiently manipulatedBioreactor/fermenter combinationsAnalogue computers for chemical processesProcess systemsProduction rate

System and method for integrated management of a biofuel distillation process and a biofuel dehydration process of a biofuel production process, comprising a dynamic multivariate model-based controller coupled to a dynamic multivariate predictive model. The model is executable to: receive distillation and dehydration process information including biofuel compositions, receive an objective for biofuel production output from the distillation and dehydration processes, e.g., target product composition, production rate, and / or feed rate, and generate model output comprising target values for a plurality of manipulated variables related to the distillation and dehydration processes in accordance with the objective. The controller is operable to dynamically control the biofuel production process by adjusting the plurality of manipulated variables to the model-determined target values in accordance with the objective for biofuel production.

Owner:ROCKWELL AUTOMATION TECH

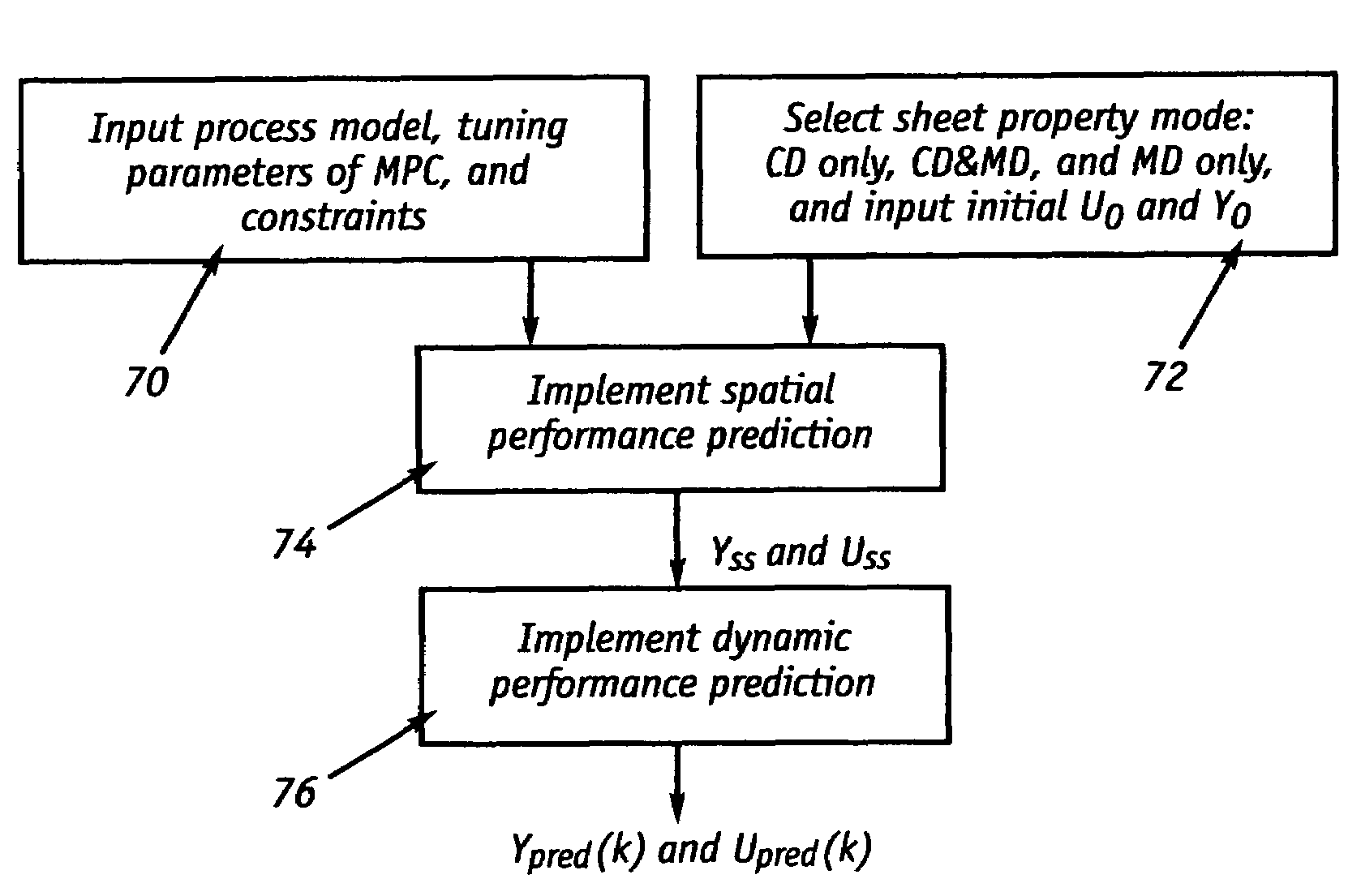

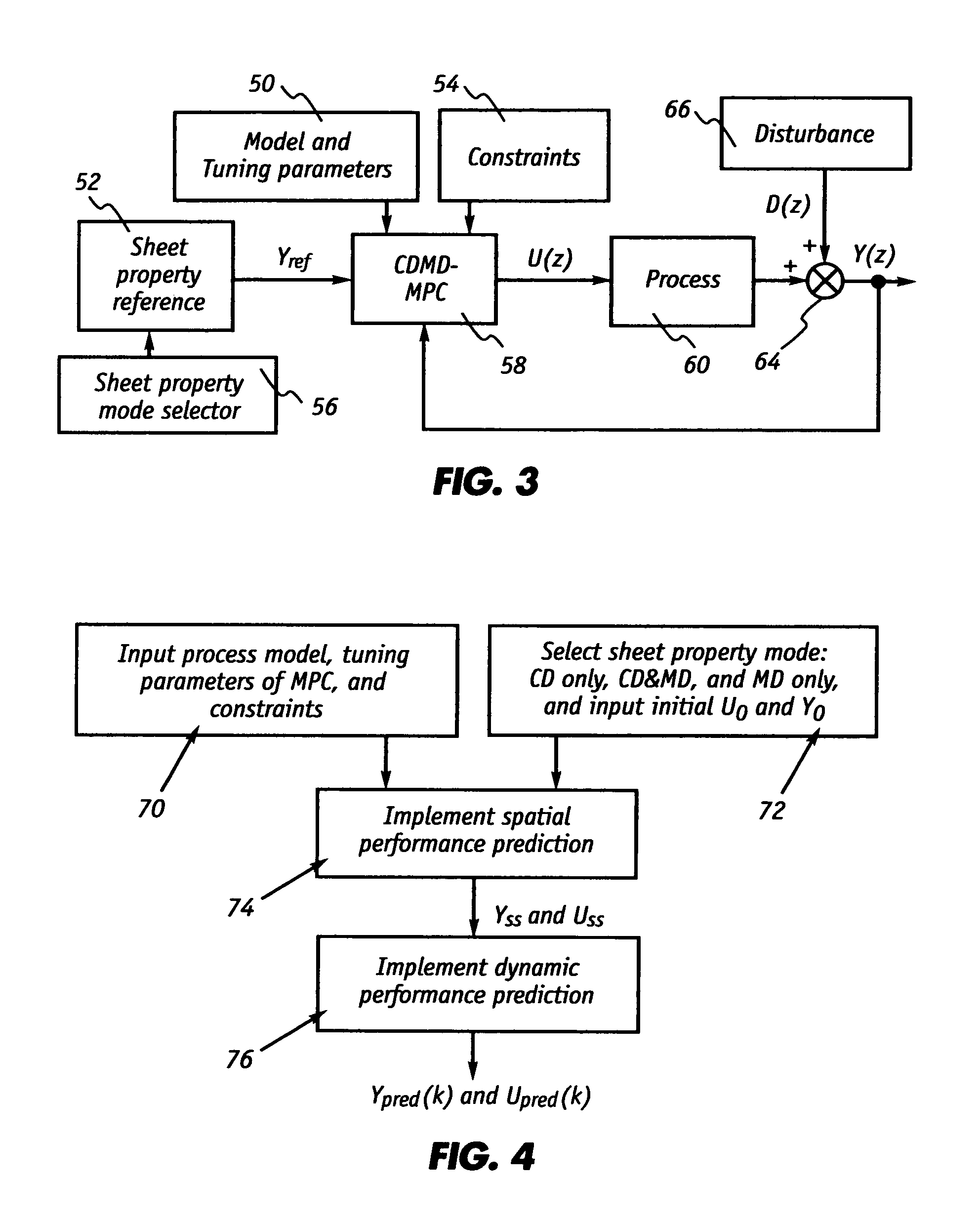

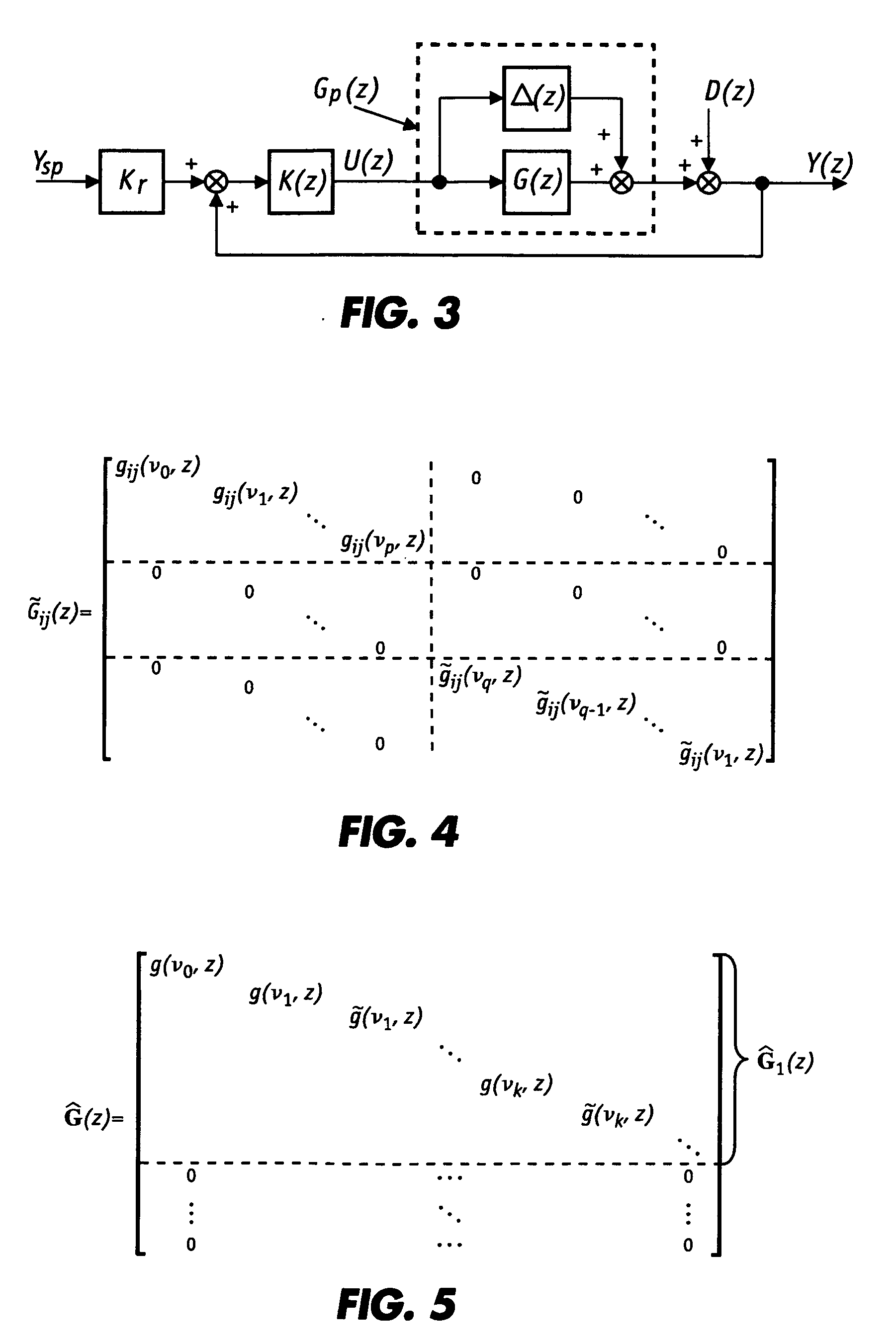

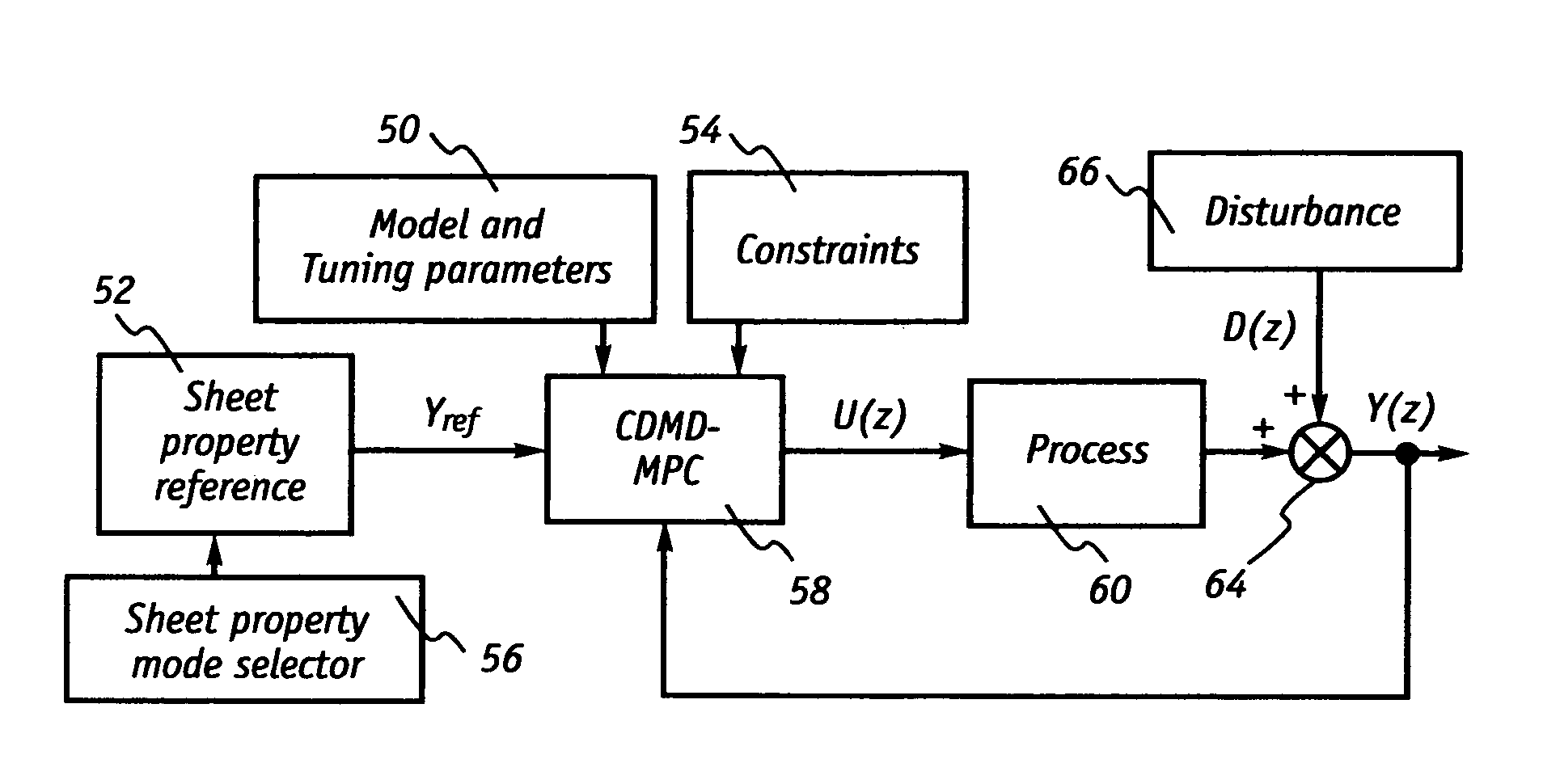

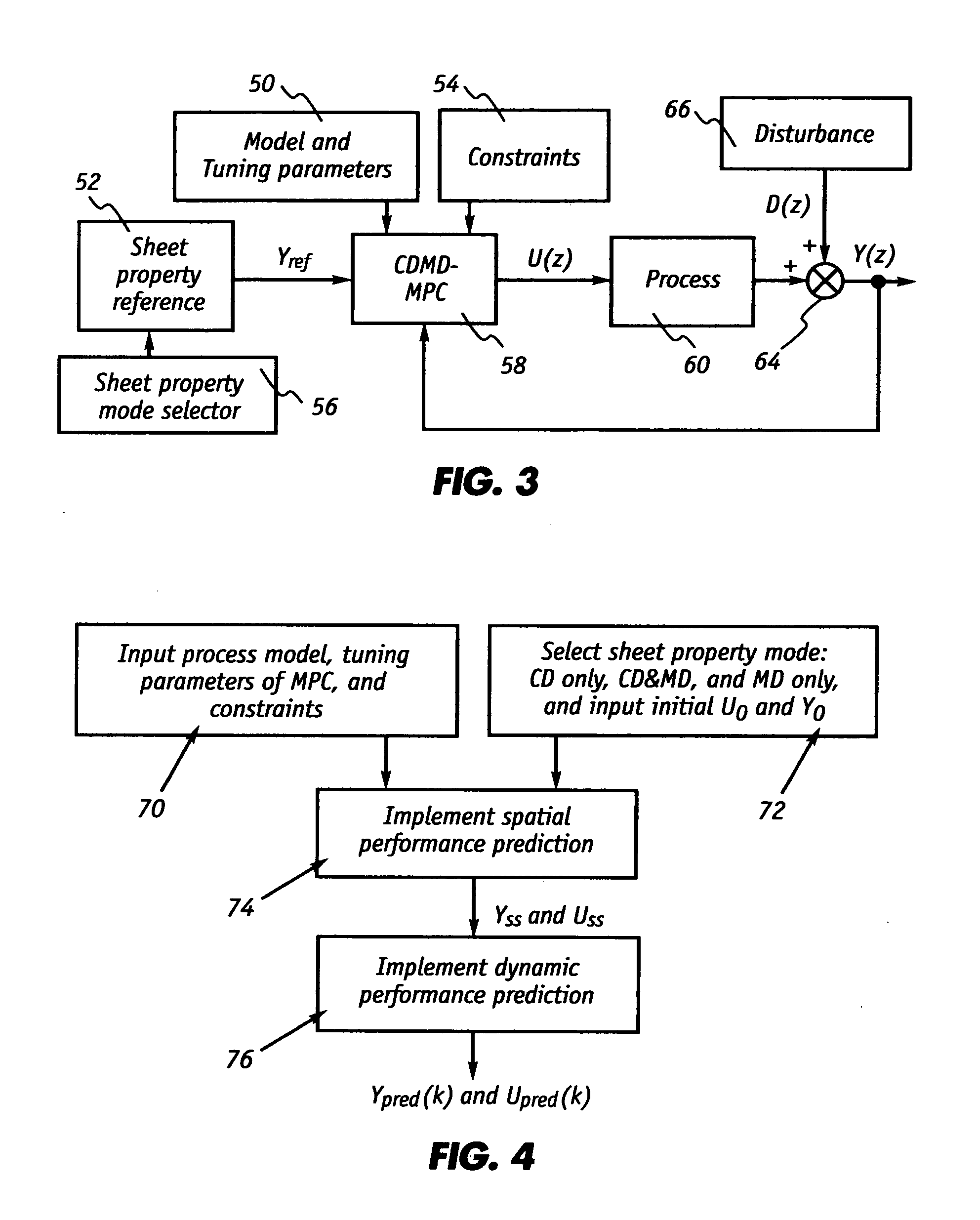

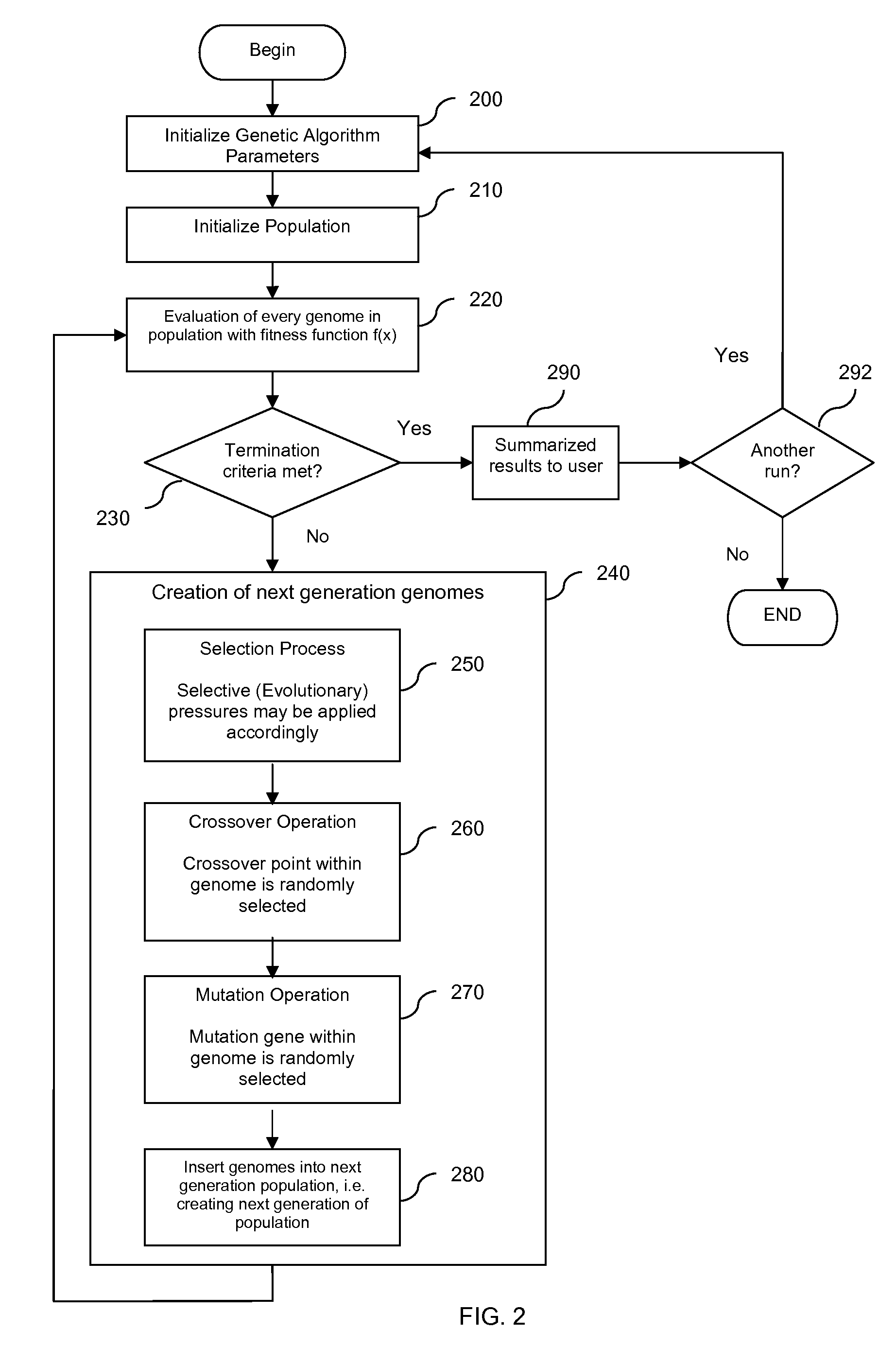

Fast performance prediction of multivariable model predictive controller for paper machine cross-directional processes

ActiveUS7454253B2Efficient solutionMinimize the differenceElectric/magnetic detection for well-loggingDigital differential analysersPredictive controllerActuator

A technique for fast performance prediction of multivariable model predictive controllers (MPC) for large-scale spatially-distributed dynamic systems is provided. When operating an MPC for a two-dimensional sheetmaking process, the controller's performance can be separated into spatial performance and dynamic performance. The steady-state spatial performance for different sheet property modes is first predicted, thereafter, the dynamic performance is predicted on the basis of the steady-state actuator profiles. During the steady-state spatial performance prediction, the original MPC's cost function is approximated to be a steady-state cost function. Then the steady-state measurement profiles and the actuator profiles are calculated through the steady-state cost function. The actuator profiles in time series can be efficiently solved by minimizing the difference between the actuator profiles and the steady-state actuator profiles in the face of constraints. Finally, the model can be employed to expeditiously compute the measurement profiles in times series.

Owner:HONEYWELL ASCA INC

System and method for process monitoring

ActiveUS7606681B2Electric signal transmission systemsElectric testing/monitoringMonitoring systemHuman–computer interaction

Systems and methods are provided that allow a user to monitor, diagnose, and configure a process. A user interface may be presented that displays data received from process monitors, sensors, and multivariate models. The user interface may be interactive, allowing a user to select which composite and multivariate models are displayed. The user interface and multivariate model may be constructed and updated in real time. The user interface may present various data and interfaces, such as a representation of a composite variable in a multivariate model, a representation of the contribution of process variables to the composite variable, and a representation of a subset of the process variables. The user may select a point of the composite variable for analysis, and the interface may indicate the contribution and values of process variables at the selected point. The interface may be transmitted to a remote user.

Owner:AIR PROD & CHEM INC

Automatic tuning method for multivariable model predictive controllers

ActiveUS20070276512A1Fast and reliableDigital computer detailsElectric controllersClosed loopPredictive controller

A fast and reliable technique for tuning multivariable model predictive controllers (MPCs) that accounts for performance and robustness is provided. Specifically, the technique automatically yields tuning weights for the MPC based on performance and robustness requirements. The tuning weights are parameters of closed-loop transfer functions which are directly linked to performance and robustness requirements. Automatically searching the tuning parameters in their proper ranges assures that the controller is optimal and robust. This technique will deliver the traditional requirements of stability, performance and robustness, while at the same time enabling users to design their closed-loop behavior in terms of the physical domain. The method permits the user to favor one measurement over another, or to use one actuator more than another.

Owner:HONEYWELL ASCA INC

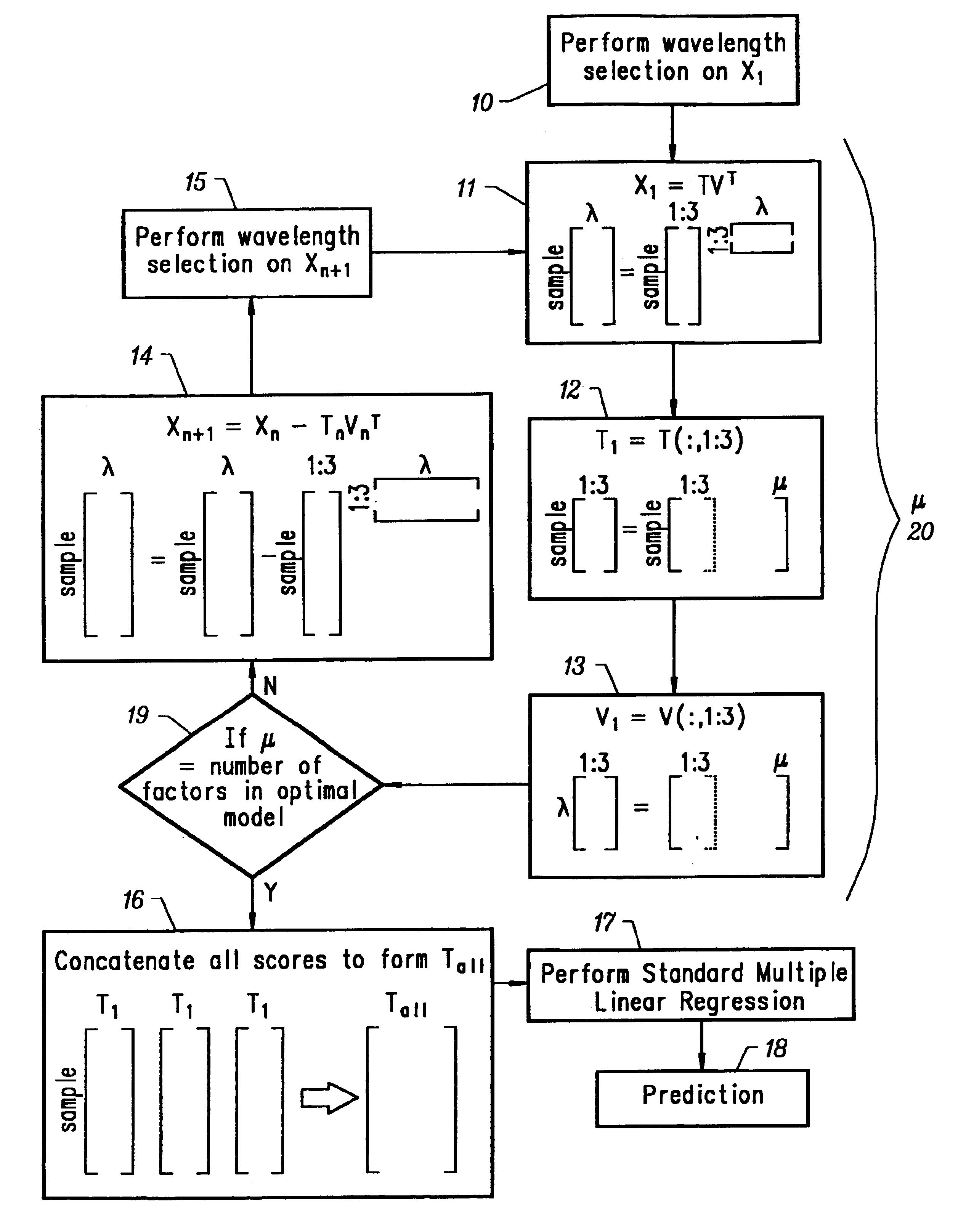

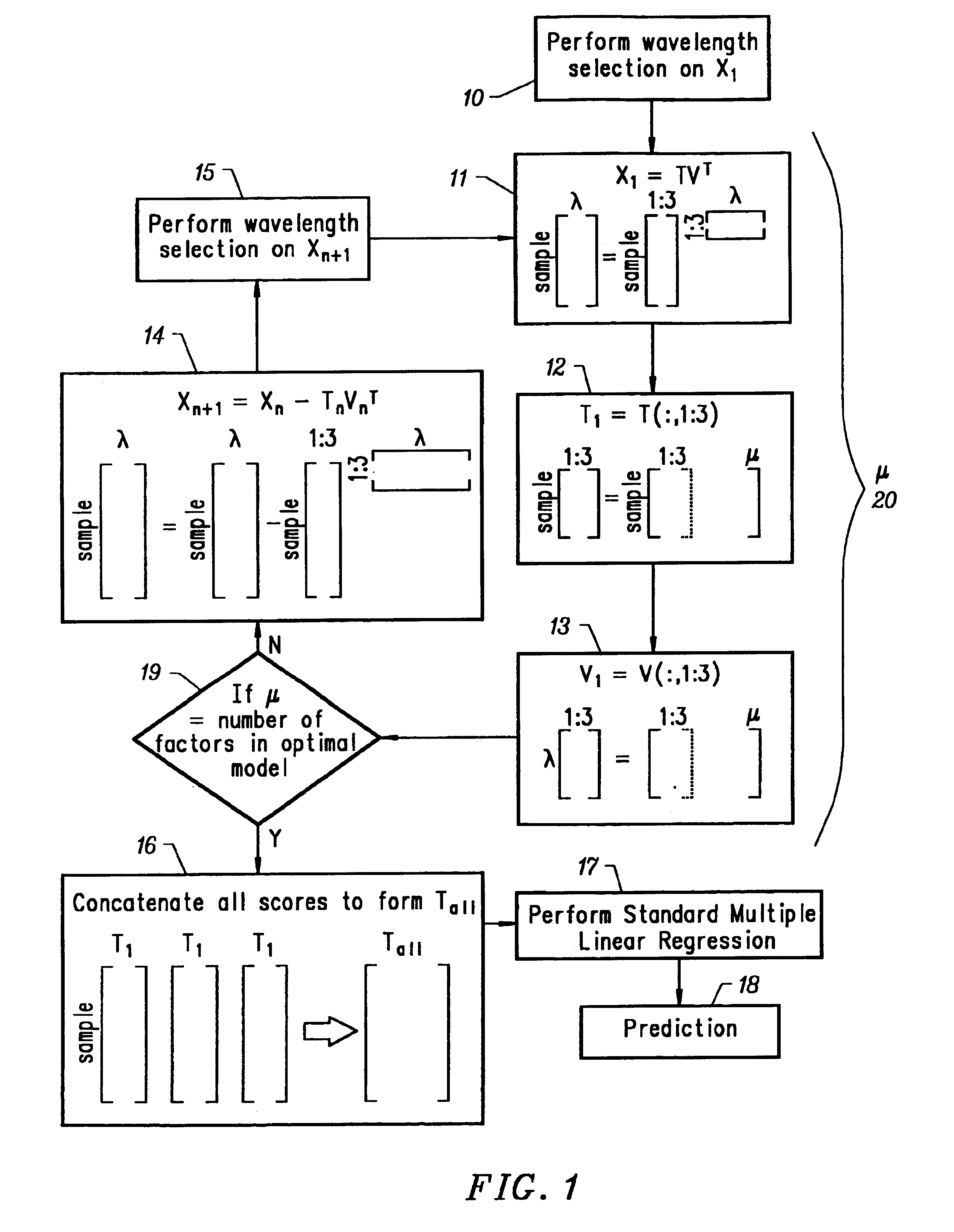

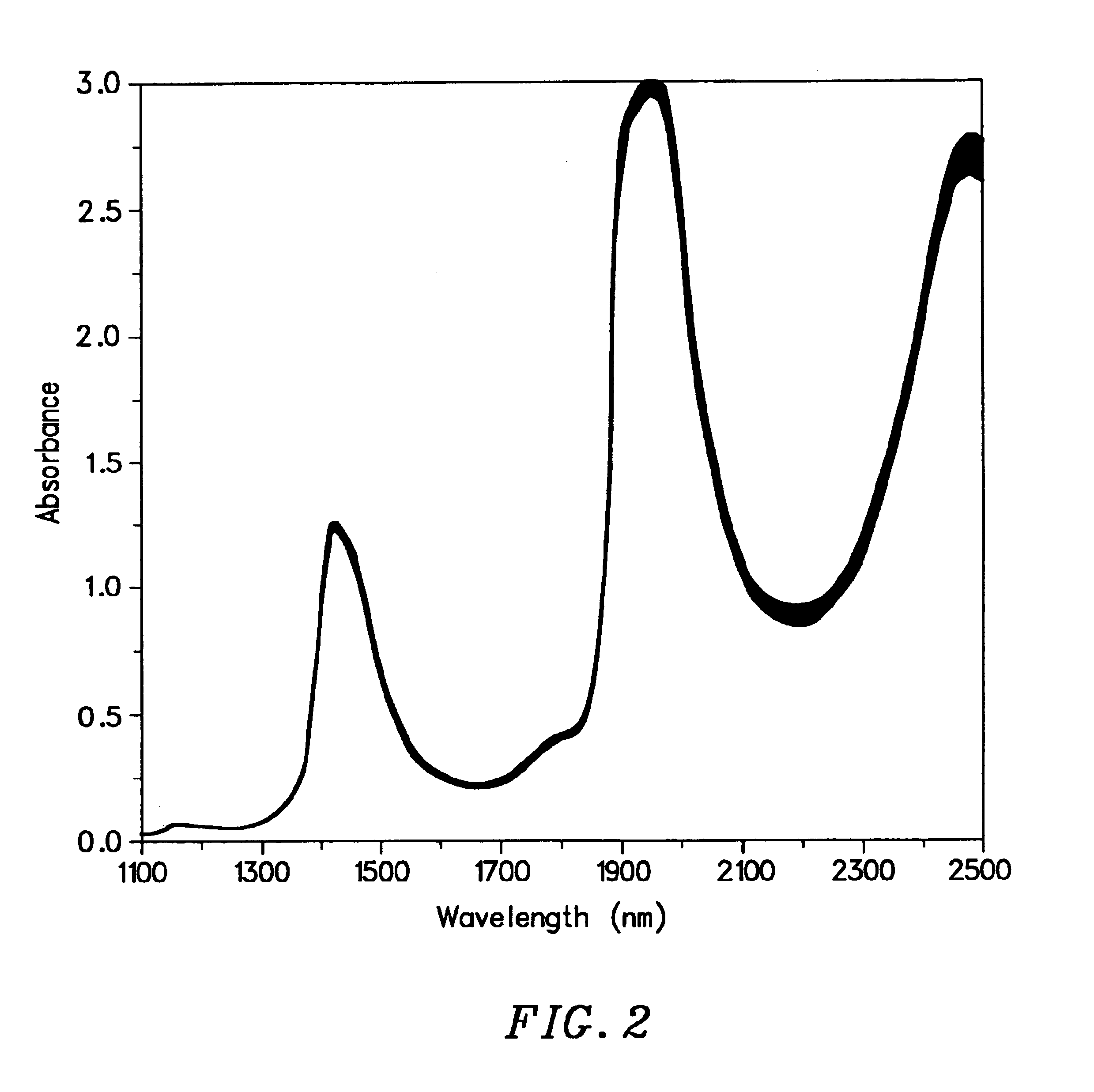

Combinative multivariate calibration that enhances prediction ability through removal of over-modeled regions

InactiveUS6871169B1Analogue computers for chemical processesComputation using non-denominational number representationTarget analysisAnalyte

A novel multivariate model for analysis of absorbance spectra allows for each wavelength or spectral region to be modeled with just enough factors to fully model the analytical signal without the incorporation of noise by using excess factors. Each wavelength or spectral region is modeled utilizing its own number of factors independently of other wavelengths or spectral regions. An iterative combinative PCR algorithm allows a different number of factors to be applied to different wavelengths. In an exemplary embodiment, a three-factor model is applied over a given spectral region. The residual of the three-factor model is calculated and used as the input for an additional five-factor model. Prior to the additional five factors being applied, some of the wavelengths are removed. This leads to a three-factor model over the first region and an eight-factor model over the second region. This analysis of residuals can be repeated such that a one to n factor model could be applied to any given wavelength, or rather any number of factors may be employed to model any given frequency or spectral region. A method of predicting concentration of a target analyte from sample spectra applies a calibration developed using the inventive PCR algorithm to a matrix of sample spectral to generate a vector of predicted concentrations for the target analyte.

Owner:GLT ACQUISITION

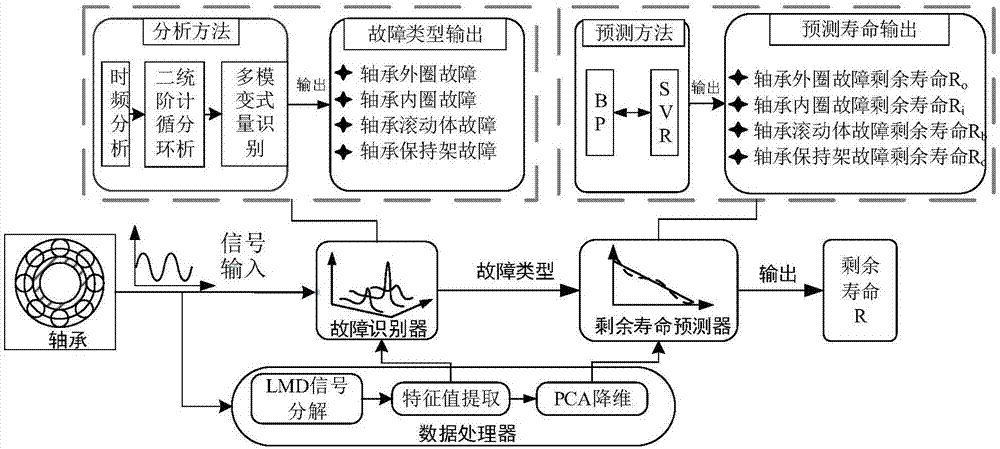

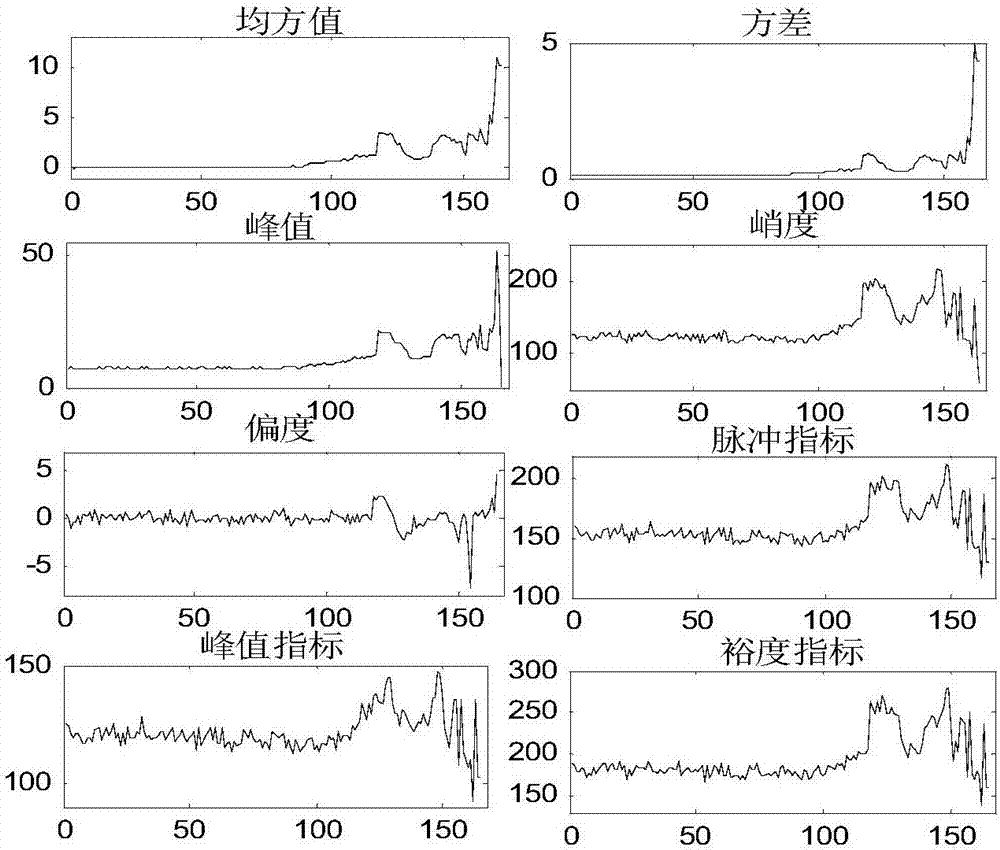

Fault diagnosis-based rail transit vehicle bearing residual life prediction method

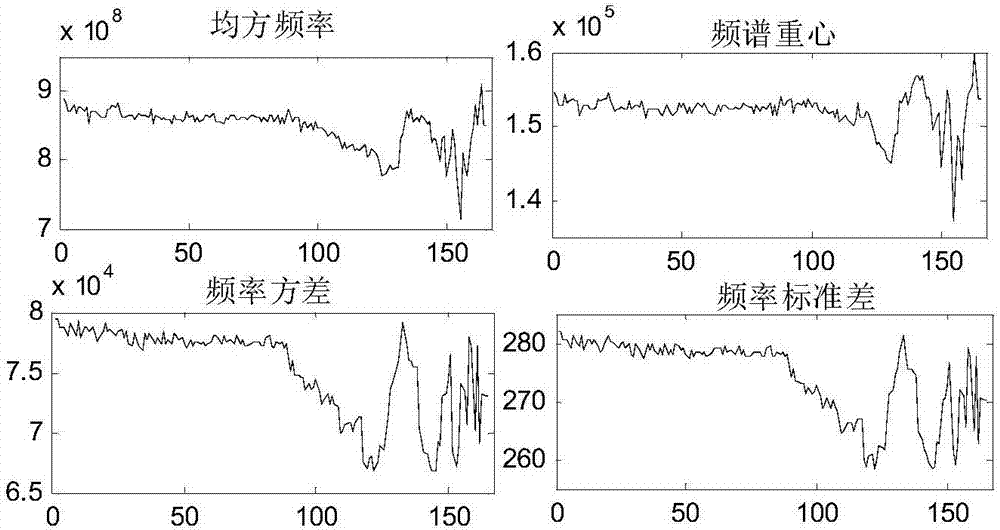

ActiveCN107144428AImprove health status monitoringHard to getMachine bearings testingFeature extractionComputer science

The invention discloses a fault diagnosis-based rail transit vehicle bearing residual life prediction method. The method includes the following steps that: S100, multi-angle feature extraction and fusion are performed; S200, cyclostationary theory-based fault diagnosis is performed; S300, multi-variable model training is performed, so that multi-variable model-based fault isolation is realized; and S400, based on a semi-supervised algorithm, a BP neural network algorithm and a support vector regression algorithm are used in combination to perform fault diagnosis-based residual life prediction. With the fault diagnosis-based rail transit vehicle bearing residual life prediction method of the invention adopted, fault detection, fault isolation and residual life prediction at the early stage of the fault of a bearing are realized, and a basis is provided for the formulation of vehicle bearing maintenance decision making.

Owner:BEIJING JIAOTONG UNIV

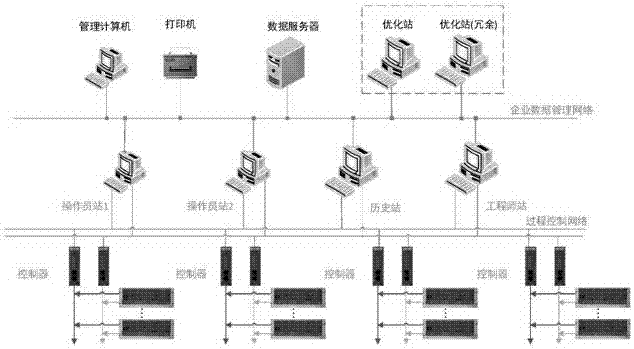

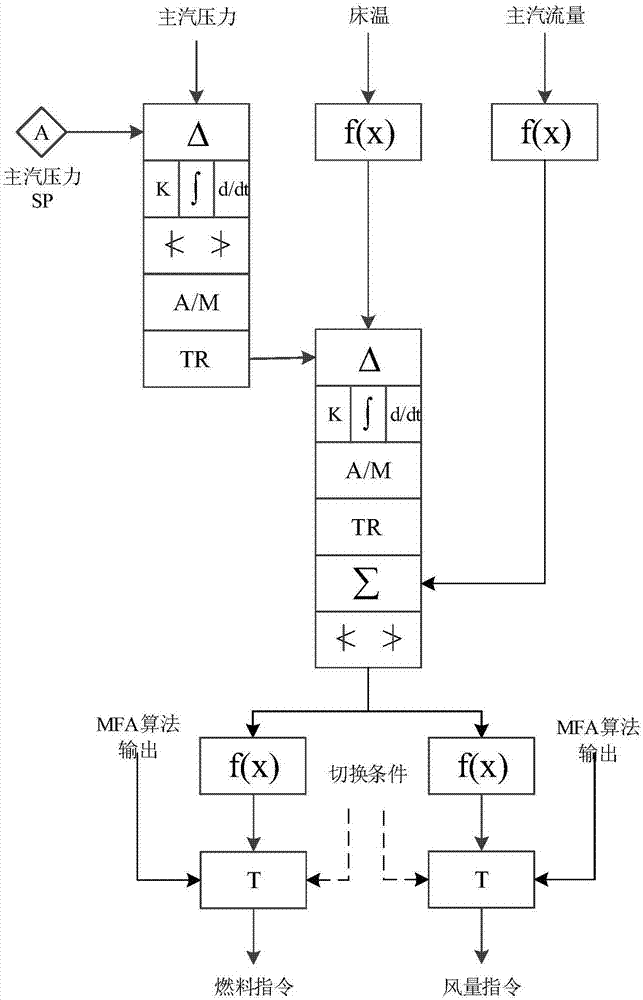

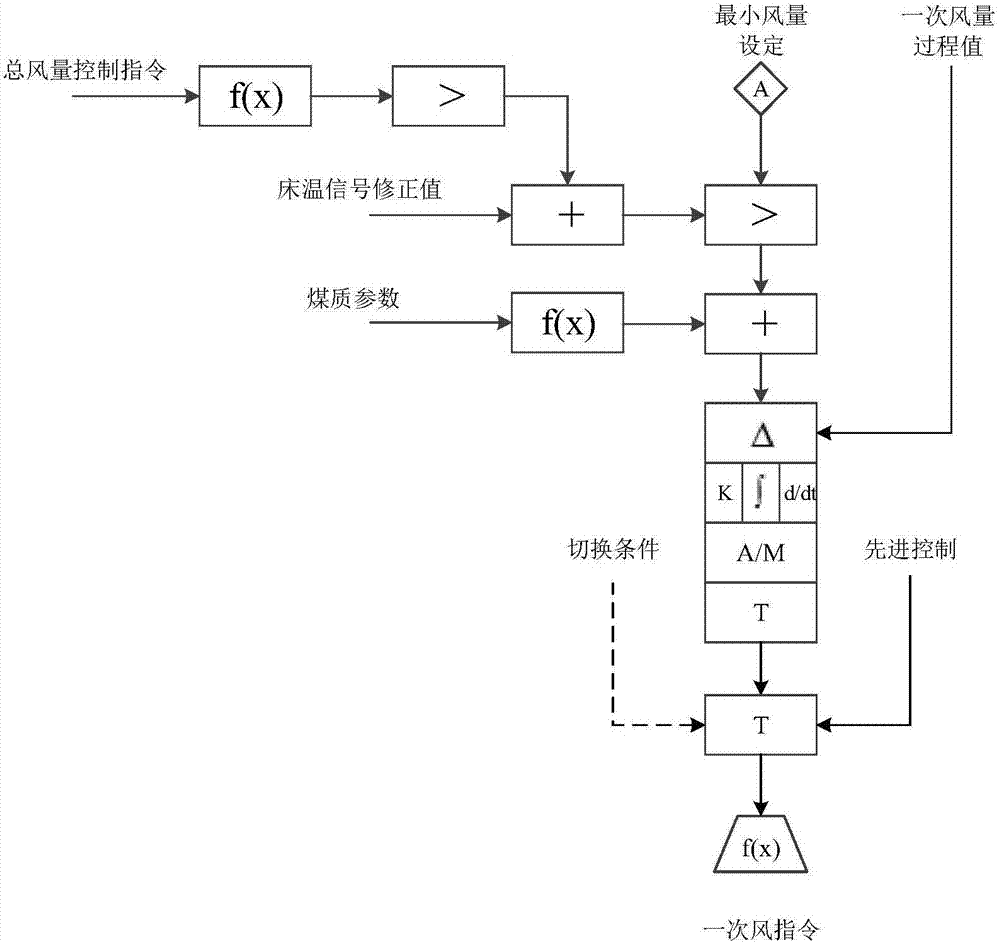

Fluidized bed boiler control and combustion optimization system

ActiveCN107023825AOptimize operating parametersImprove controlFluidized bed combustionApparatus for fluidised bed combustionFluidized bedOxygen content

The invention discloses a fluidized bed boiler control and combustion optimization system. The problem that a fluidized bed boiler system is not easy to control for a long time is solved. According to a method, a control strategy of combining an advanced control algorithm and a conventional control algorithm is adopted, and continuous, economical and stable operating of the boiler system is guaranteed; multivariable model-free adaptive control is adopted, and decoupling control of the fuel quantity and the air supply quantity over the bed temperature under the variable load work condition is achieved; and a nerual network technique is adopted for building a boiler combustion prediction model, online calculation of the boiler efficiency and NOX and SOX emissions is achieved, a multi-objective optimization function is constructed according to the prediction result, a combustion self-optimization algorithm is adopted, the flue gas oxygen content and the bed temperature are optimized constantly so as to adapt to work condition changes, and a fluidized bed boiler can operate in an optimal combustion area.

Owner:XIAN IBL TECH DEV +1

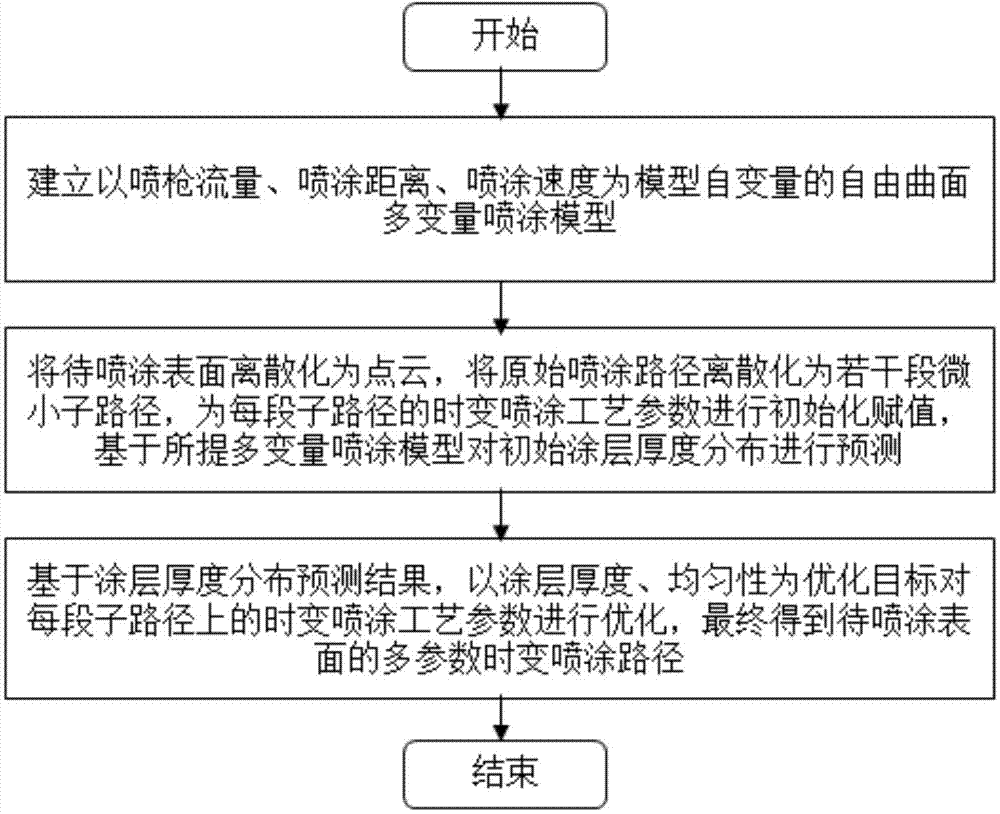

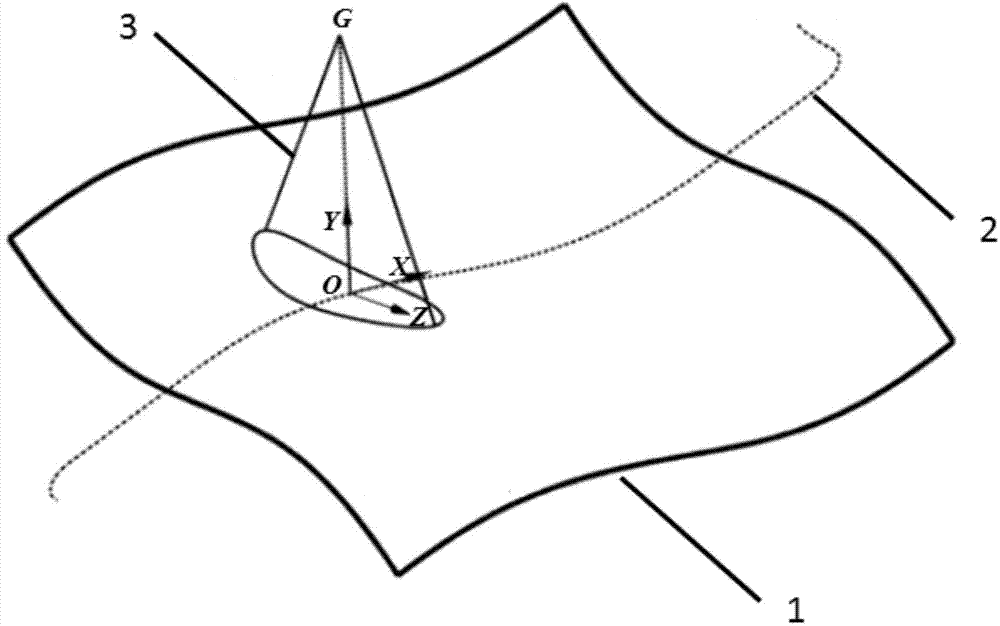

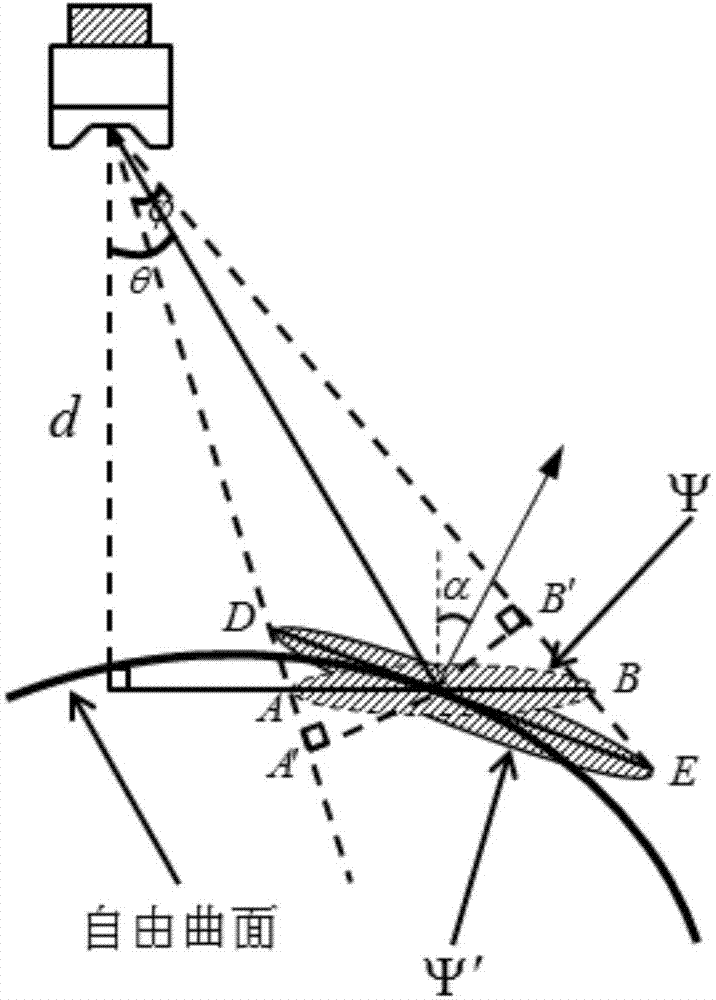

Multi-parameter time-varying robot spraying method

ActiveCN104324861AImprove efficiencyImprove spray qualityLiquid surface applicatorsSpraying apparatusFree formEngineering

The invention relates to a multi-parameter time-varying robot spraying method which comprises the following steps: firstly, establishing a free-form surface multivariable spraying model which uses flow of a spraying gun, a spraying distance and a spraying speed as model independent variables; then discretizing an original spraying path into a plurality of sections of minute sub paths, distributing initial values of time-varying spraying process parameters to each sub path and on the basis of the established multivariable spraying model, predicting distribution of an initial coating thickness; next, on the basis of a prediction result on distribution of the coating thickness, carrying out combined optimization on the time-varying process parameters to obtain the optimal process parameters on each section of sub path and finally, obtaining a multi-parameter time-varying spraying path of a surface to be sprayed. According to the method disclosed by the invention, various process parameters are used as variables; by the multivariable spraying model and a free-form surface coating thickness predicting method, the optimal process parameters on the sub paths of the discretized spraying path are obtained; dynamic optimization of the process parameters is implemented; the multi-parameter time-varying robot spraying method has the important effect of improving spraying operation efficiency, quality and safety of a robot.

Owner:清研同创机器人(天津)有限公司

Automated tuning of large-scale multivariable model predictive controllers for spatially-distributed processes

ActiveUS20070100476A1Digital computer detailsAnalogue computers for chemical processesClosed loopPredictive controller

An automated tuning method of a large-scale multivariable model predictive controller for multiple array papermaking machine cross-directional (CD) processes can significantly improve the performance of the controller over traditional controllers. Paper machine CD processes are large-scale spatially-distributed dynamical systems. Due to these systems' (almost) spatially invariant nature, the closed-loop transfer functions are approximated by transfer matrices with rectangular circulant matrix blocks, whose input and output singular vectors are the Fourier components of dimension equivalent to either number of actuators or number of measurements. This approximation enables the model predictive controller for these systems to be tuned by a numerical search over optimization weights in order to shape the closed-loop transfer functions in the two-dimensional frequency domain for performance and robustness. A novel scaling method is used for scaling the inputs and outputs of the multivariable system in the spatial frequency domain.

Owner:HONEYWELL ASCA INC

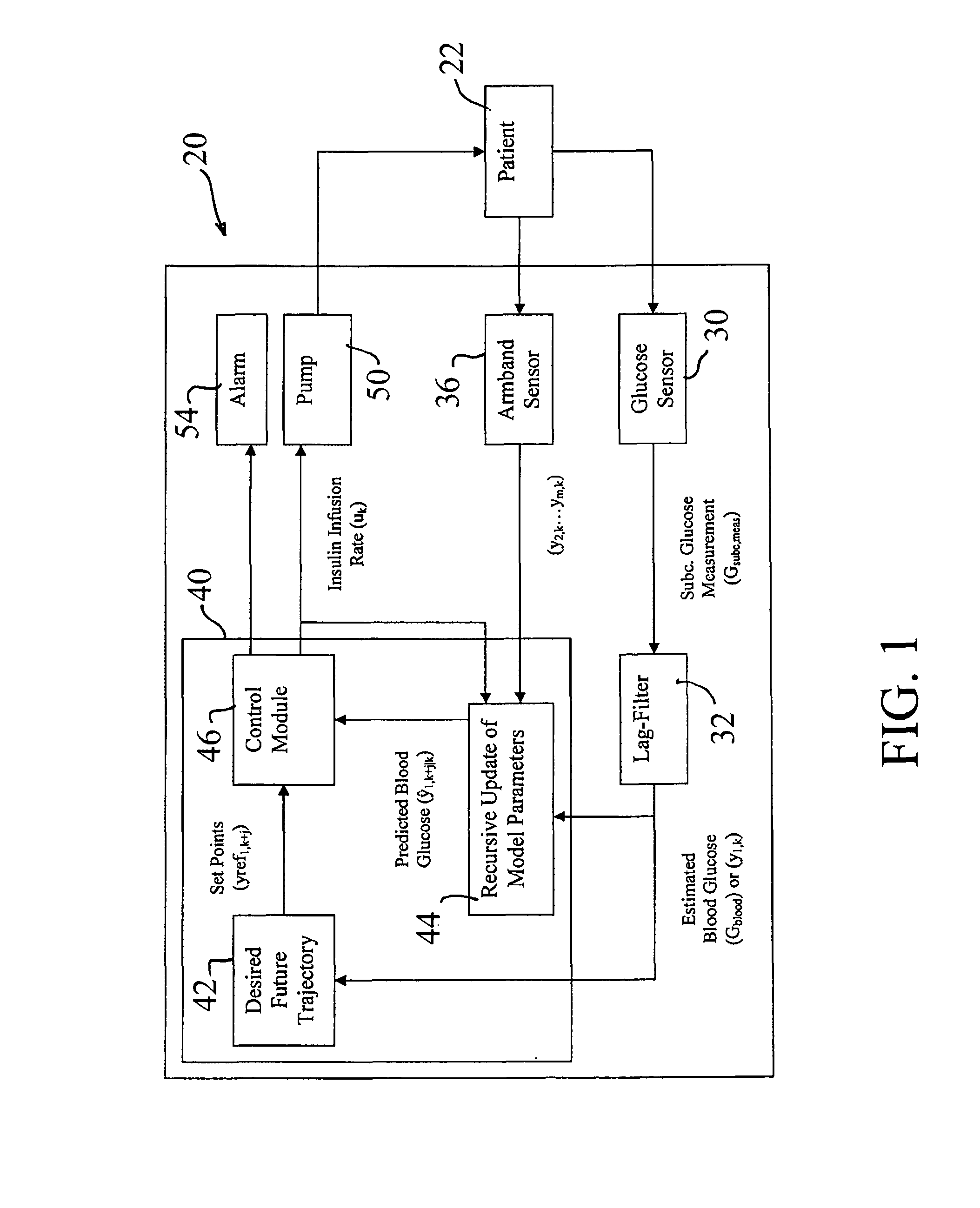

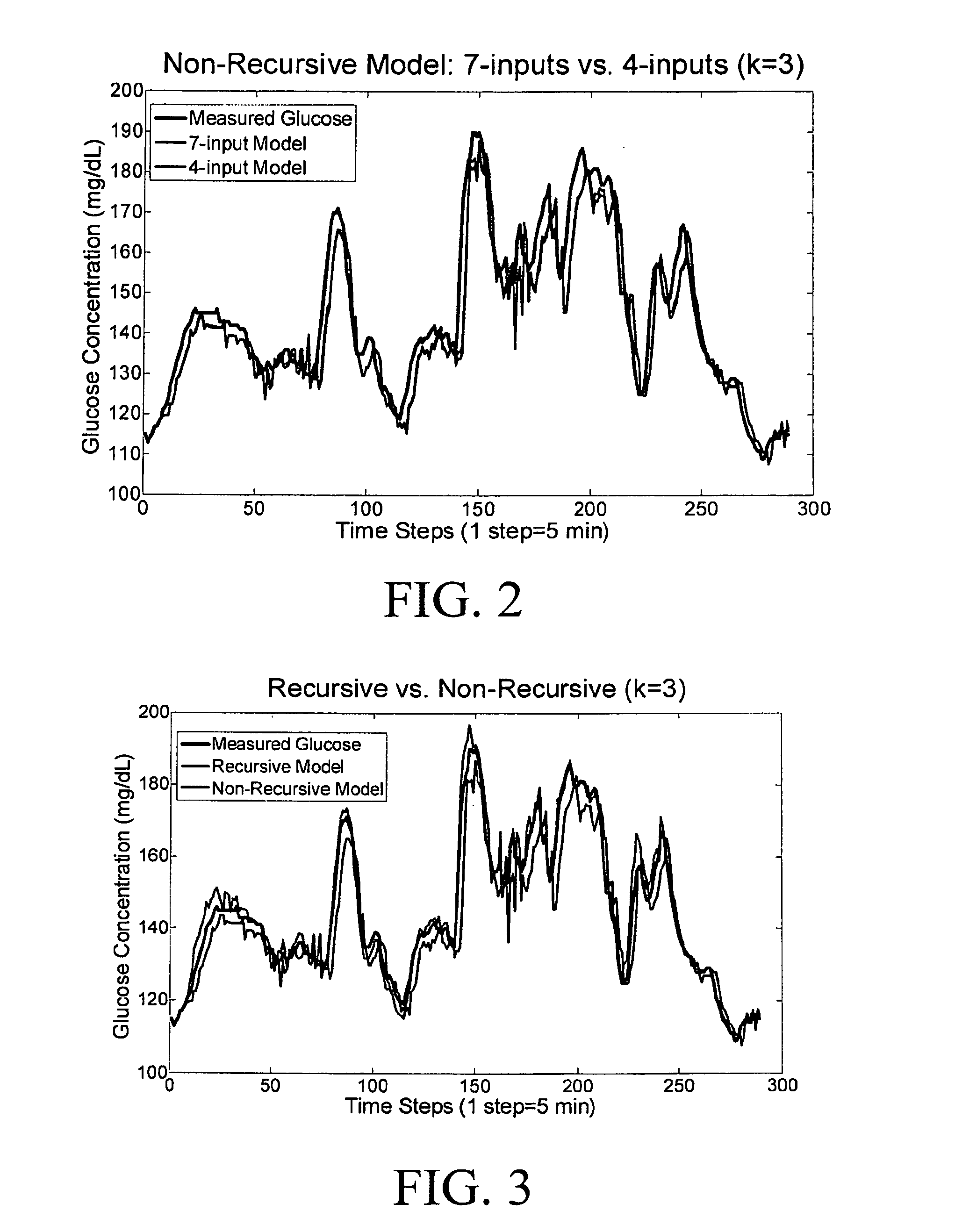

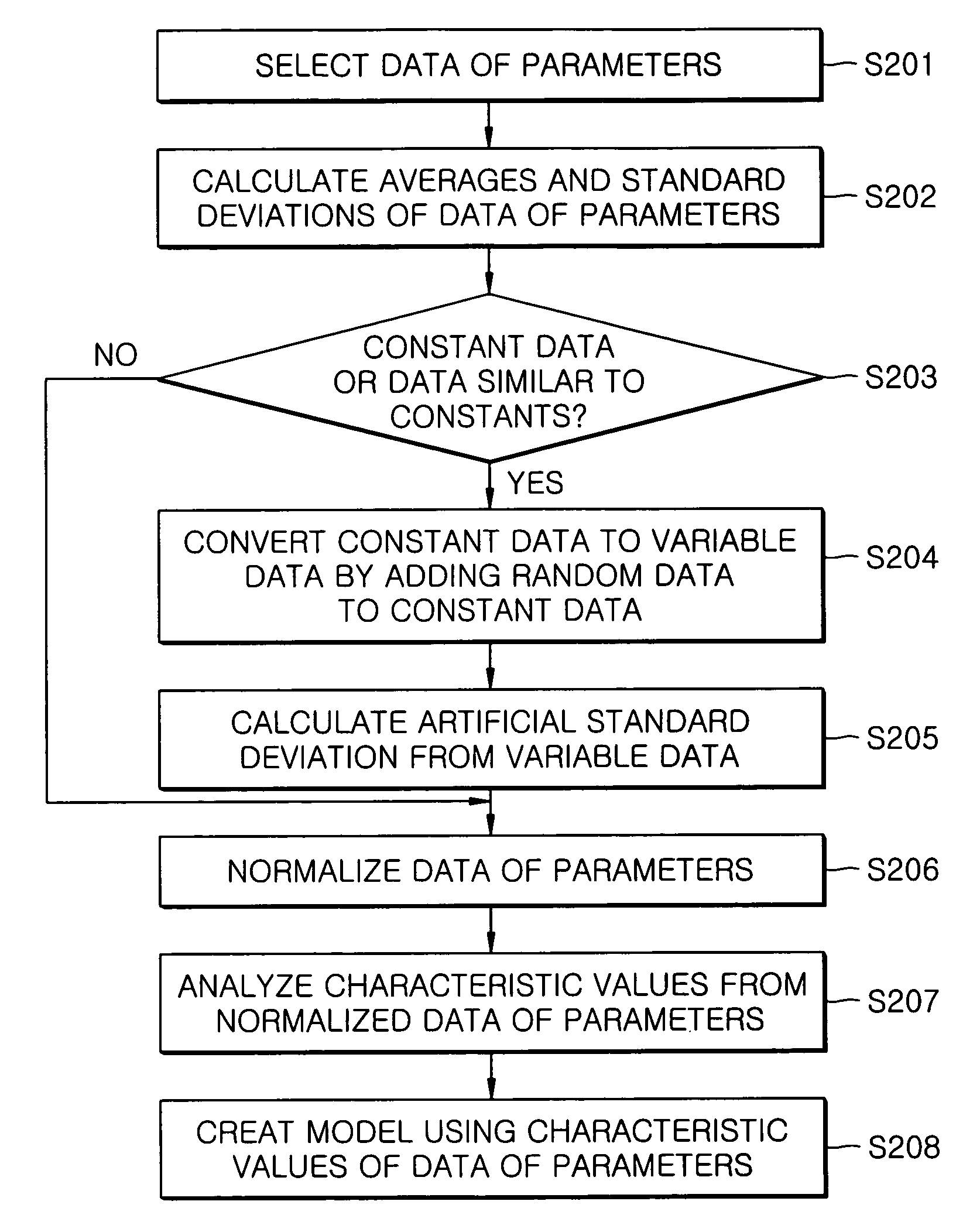

Automatic insulin pumps using recursive multivariable models and adaptive control algorithms

ActiveUS8690820B2Reduce errorsMore time to take precautionary measuresDrug and medicationsMedical devicesGlucose sensorsPhysiologic States

A method and device for monitoring or treating patient glucose levels. The device includes a glucose sensor for measuring a glucose level of a patient, a physiological status monitoring system for measuring at least one physical or metabolic variable of the patient, and an automatic controller in communication with the glucose sensor and the physiological status monitoring system. The controller includes a prediction module for automatically predicting a future glucose level using data measured by the glucose sensor and the physiological sensor.

Owner:ILLINOIS INSTITUTE OF TECHNOLOGY

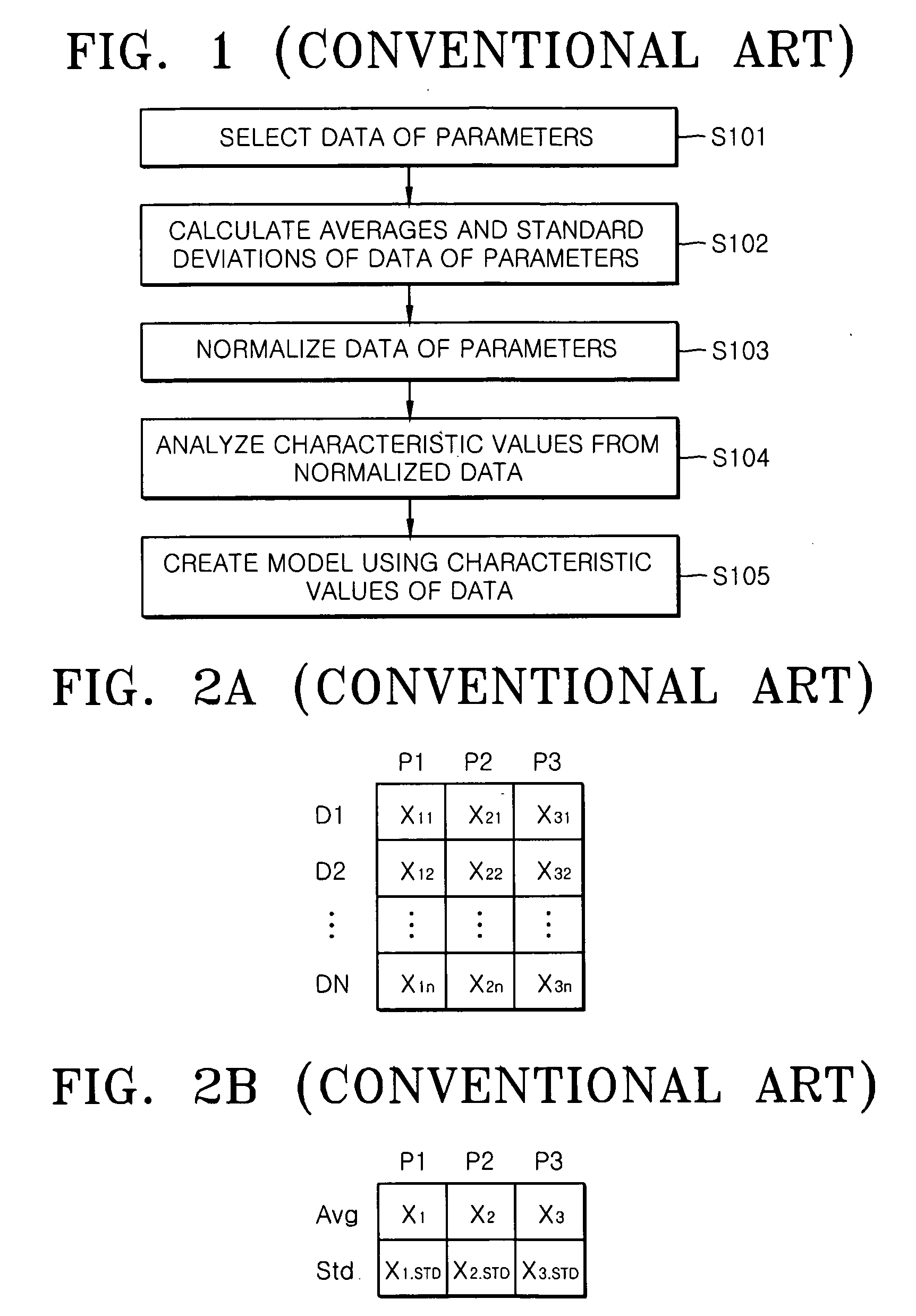

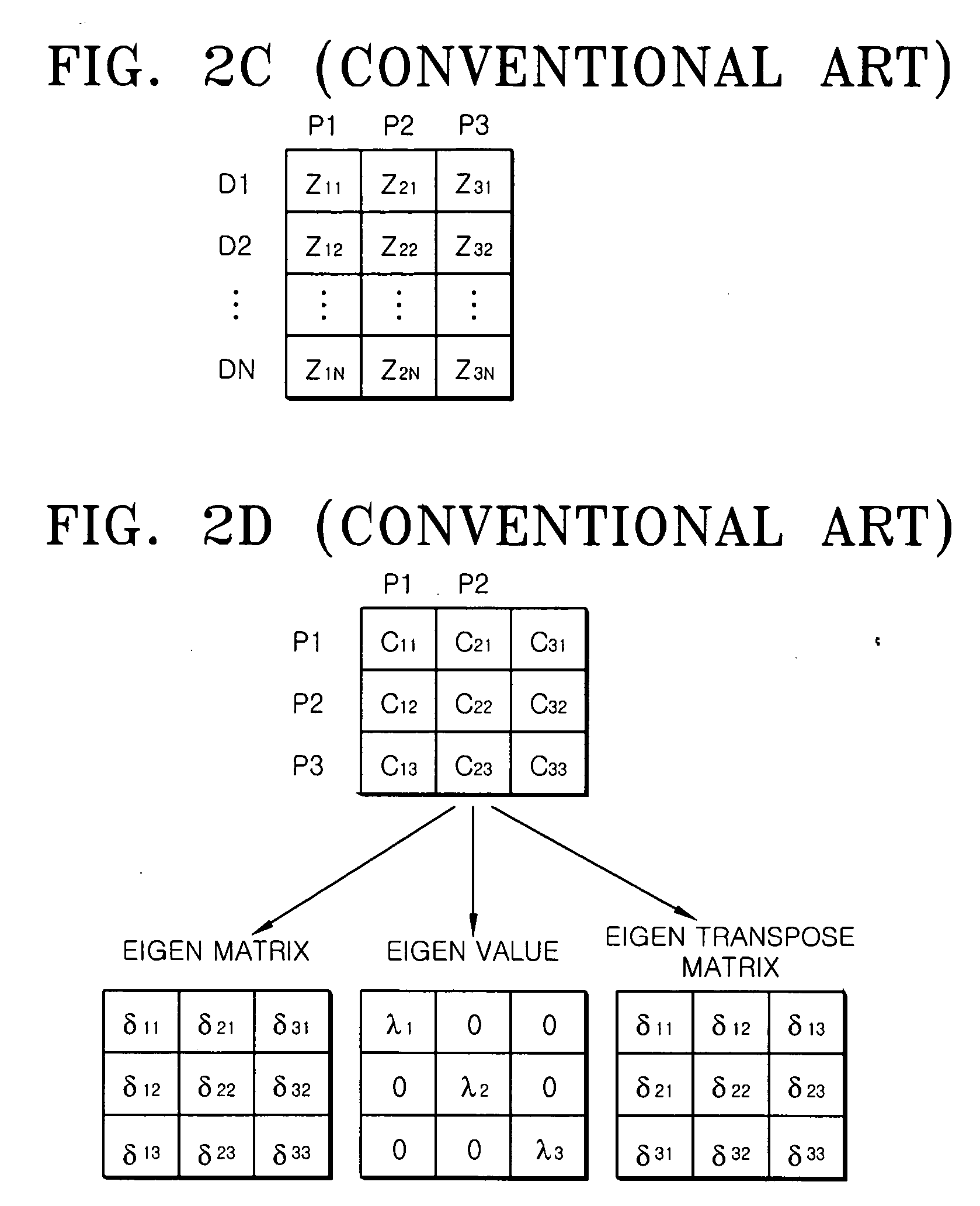

Method and apparatus for modeling multivariate parameters having constants and same pattern and method of fabricating semiconductor using the same

InactiveUS20070038418A1Guaranteed uptimeSimulator controlSemiconductor/solid-state device manufacturingNormalized numberComputer science

Example embodiments of the present invention relate to a multivariate modeling method, a method of fabricating semiconductors using a semiconductor fabricating facility and a multivariate model creating apparatus. Other example embodiments of the present invention relate to a method and apparatus for modeling multivariate parameters having constants and the same pattern and a semiconductor fabricating method of detecting whether a semiconductor fabricating facility is operating normally using the multivariate modeling method. In a multivariate modeling method according to example embodiments of the present invention, data of parameters are selected during a modeling period. Averages and standard deviations of the data of the parameters may be calculated. It may be determined whether the data of the parameters contain non-random data. If the data of the parameters do not contain non-random data, the data may be normalized using the averages and standard deviations of the data of the parameters. If the data of the parameters contain non-random data, random data may be added to data of a parameter containing the constants or the data similar to constants among the parameters. The data may be normalized by calculating an artificial standard deviation of the random data added data of the parameter. Characteristic values of the parameters may be analyzed from the normalized data. A model may be created based on the characteristic values.

Owner:SAMSUNG ELECTRONICS CO LTD

Methods and systems for the design and implementation of optimal multivariable model predictive controllers for fast-sampling constrained dynamic systems

ActiveUS20090254202A1Minimize the numberSaveMathematical modelsComputation using non-denominational number representationGraphicsDirected graph

Methods and systems for the design and implementation of optimal multivariable MPC controllers for fast-sampling constrained dynamic systems utilizing a primal-dual feasibility approach and / or a graph approach. The primal-dual feasibility approach can compute and store matrices defining constraints of quadratic programming problems in an off-line part in order to calculate vectors of Lagrange multipliers and an optimizer. Then primal-dual feasibility can be checked in an on-line part using the Lagrange multipliers and the optimizer can provide a unique optimal solution for the constrained dynamic system. The graph approach can compute and store the matrices and the vectors, and also prepare and store a structure of directed graph in off-line part. An optimizer for a given parameter vector can be determined in on-line part using the directed graph, the matrices and the vectors.

Owner:GARRETT TRANSPORATION I INC

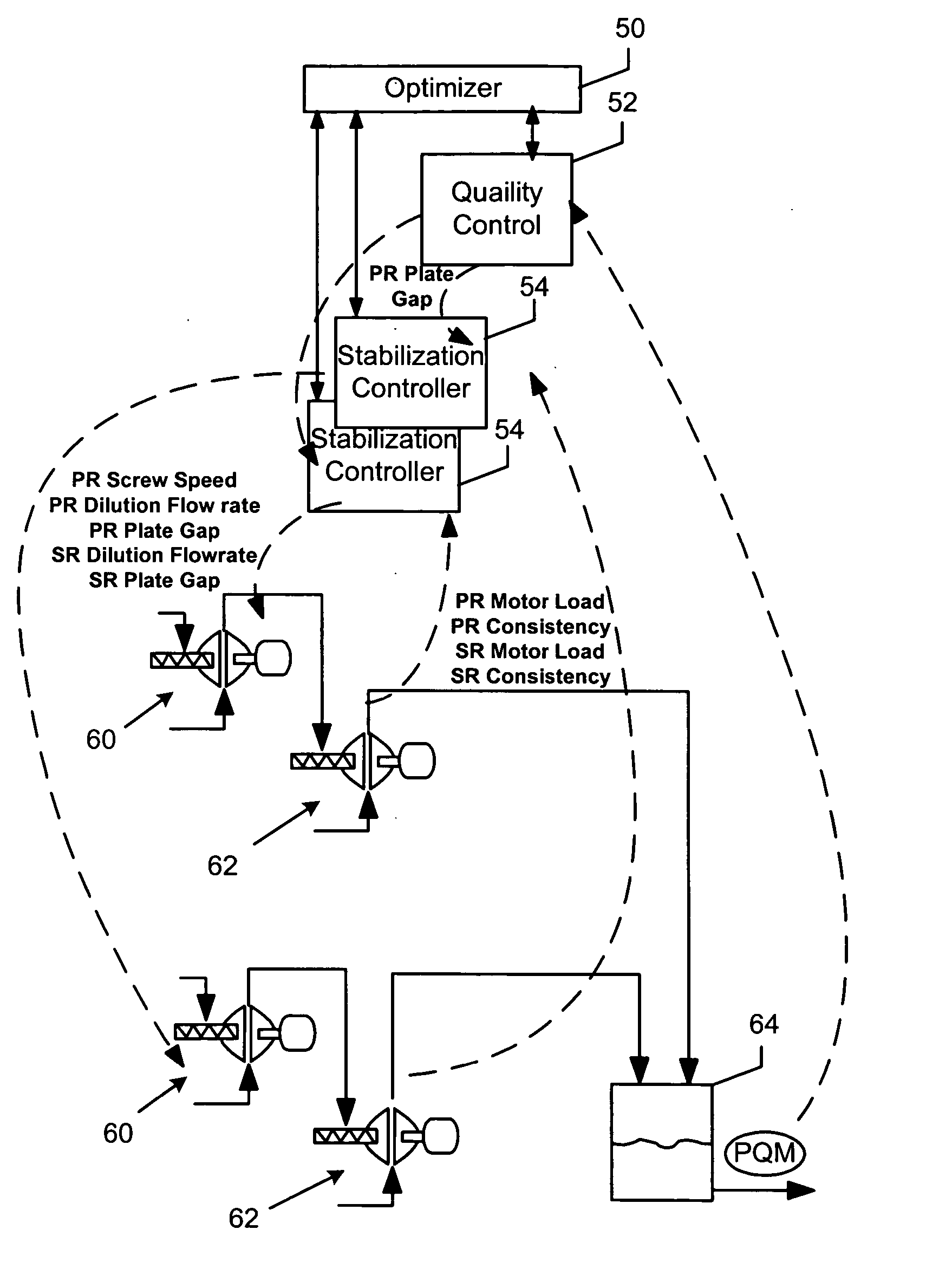

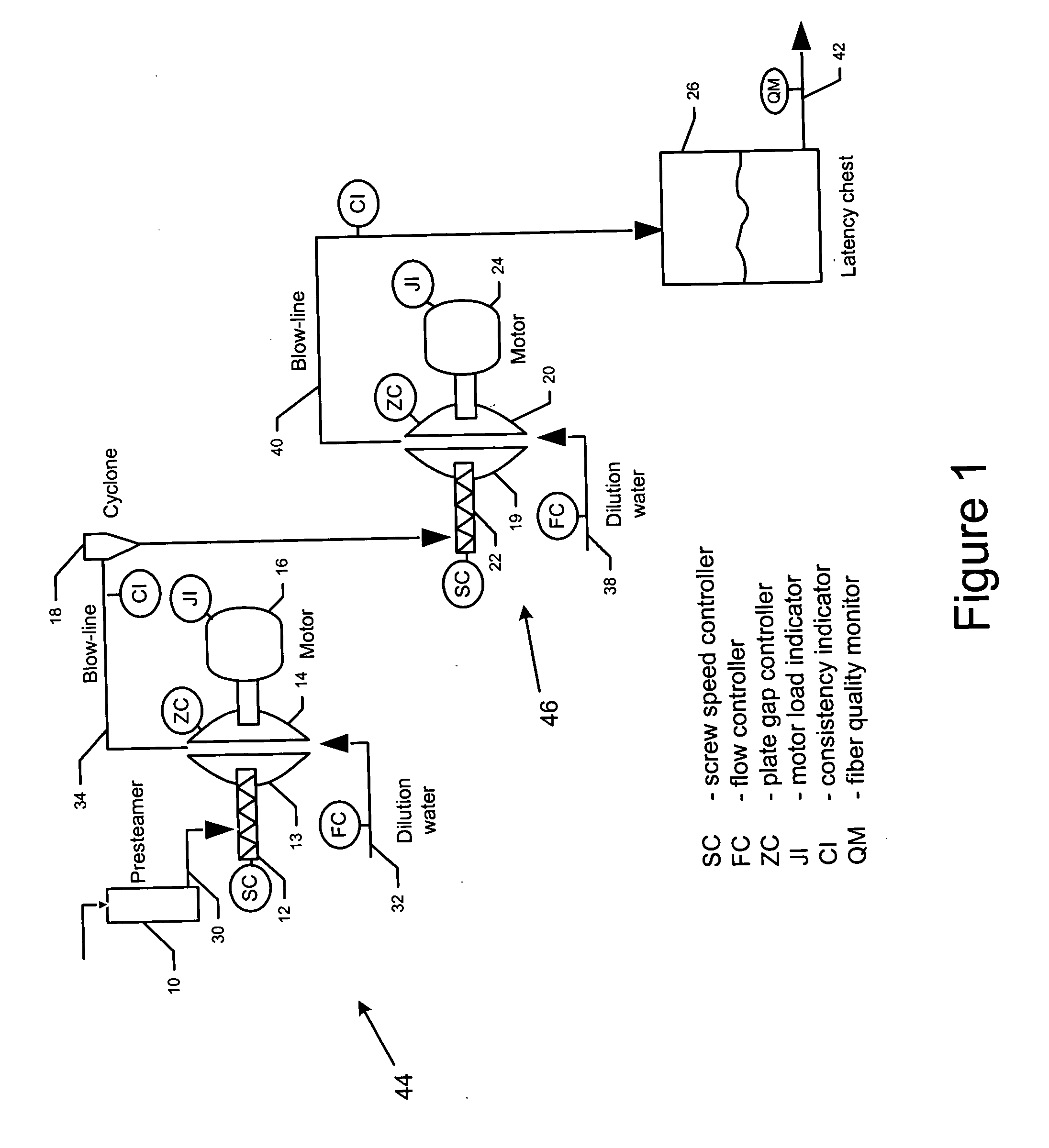

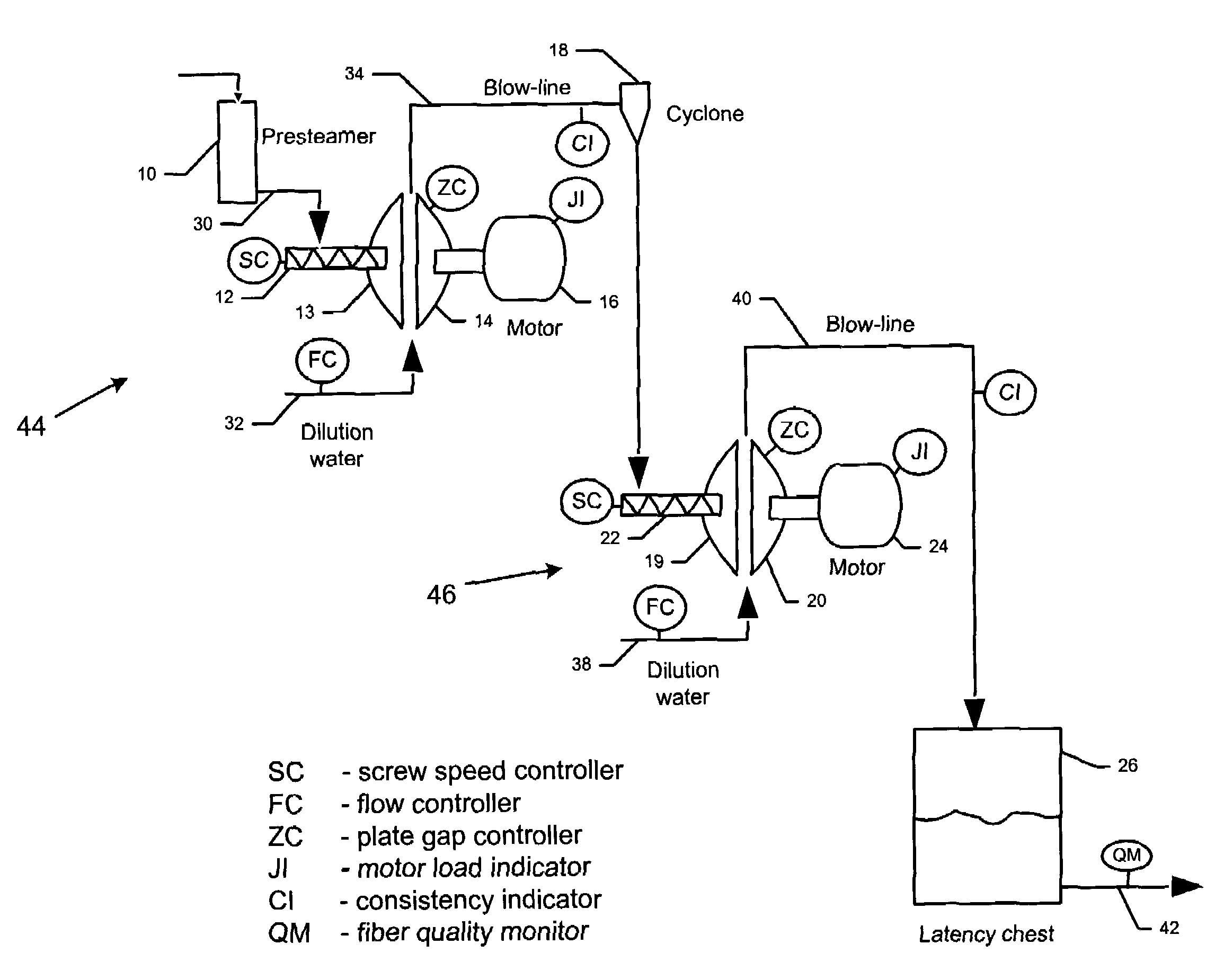

System and method for controlling a thermo-mechanical wood pulp refiner

ActiveUS20050263259A1Improve throughputReduce energy useBeating/refining control devicesComputer controlFiberQuality optimization

Thermomechanical pulp is an important process for producing fibrous mass used in papermaking. A two-level control strategy that stabilizes and optimizes the refining process has been developed. The Stabilization layer consists of a multivariable model predicative range controller that regulates the refiner line operations. The Quality Optimization layer provides the pulp quality control as measured by an online pulp quality (freeness, fibre length) sensor. This control startegy leverages the natural decoupling in the process. The modular design technique is able to handle multiple refiner lines that empty into a common latency chest. A global optimizer is also used to integrate and coordinate the two layers for enhanced constraint handling.

Owner:HONEYWELL INT INC

Fast performance prediction of multivariable model predictive controller for paper machine cross-directional processes

ActiveUS20070239310A1Efficient solutionMinimize the differenceElectric/magnetic detection for well-loggingDigital differential analysersPredictive controllerEngineering

A technique for fast performance prediction of multivariable model predictive controllers (MPC) for large-scale spatially-distributed dynamic systems is provided. When operating an MPC for a two-dimensional sheetmaking process, the controller's performance can be separated into spatial performance and dynamic performance. The steady-state spatial performance for different sheet property modes is first predicted, thereafter, the dynamic performance is predicted on the basis of the steady-state actuator profiles. During the steady-state spatial performance prediction, the original MPC's cost function is approximated to be a steady-state cost function. Then the steady-state measurement profiles and the actuator profiles are calculated through the steady-state cost function. The actuator profiles in time series can be efficiently solved by minimizing the difference between the actuator profiles and the steady-state actuator profiles in the face of constraints. Finally, the model can be employed to expeditiously compute the measurement profiles in times series.

Owner:HONEYWELL ASCA INC

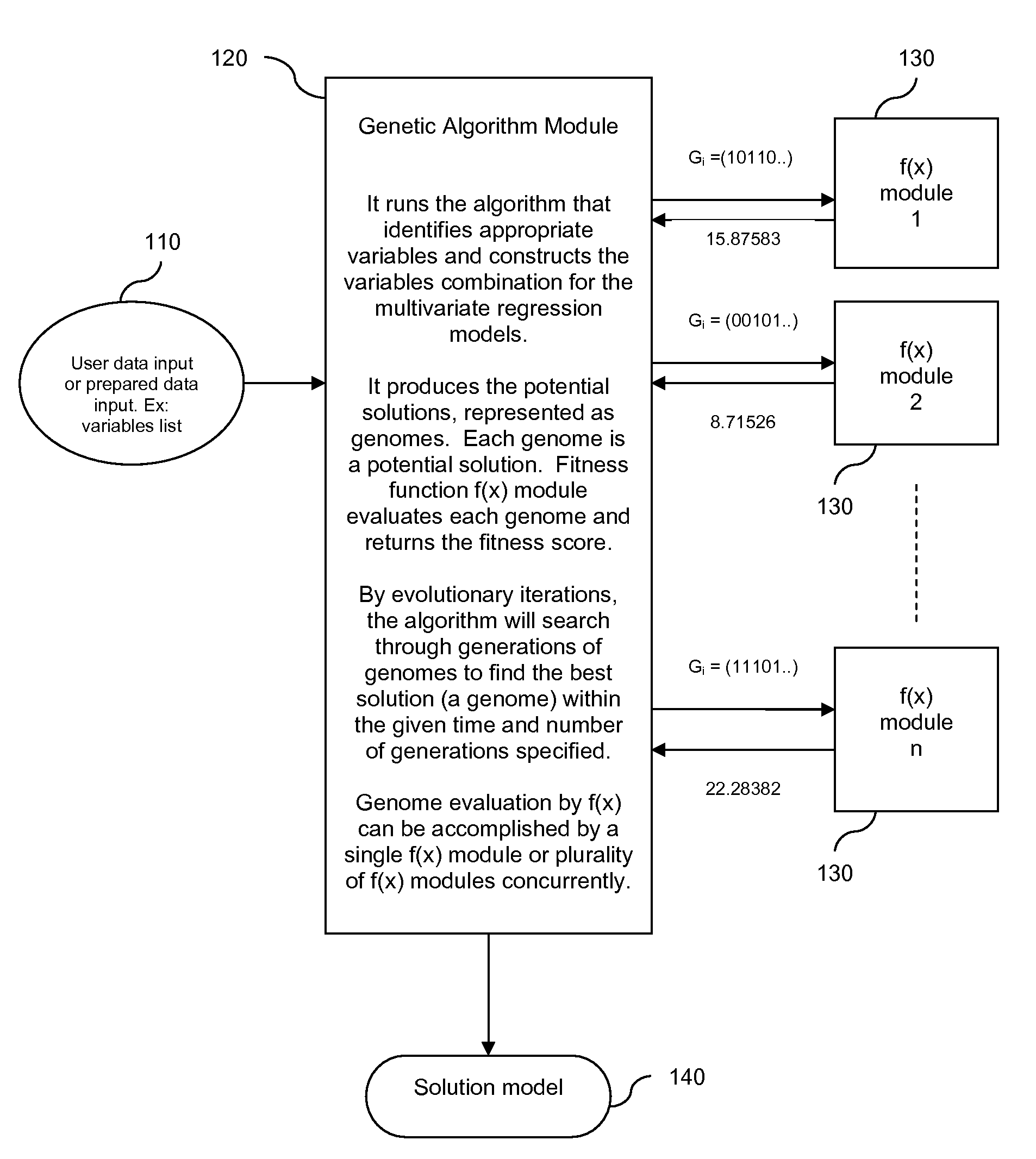

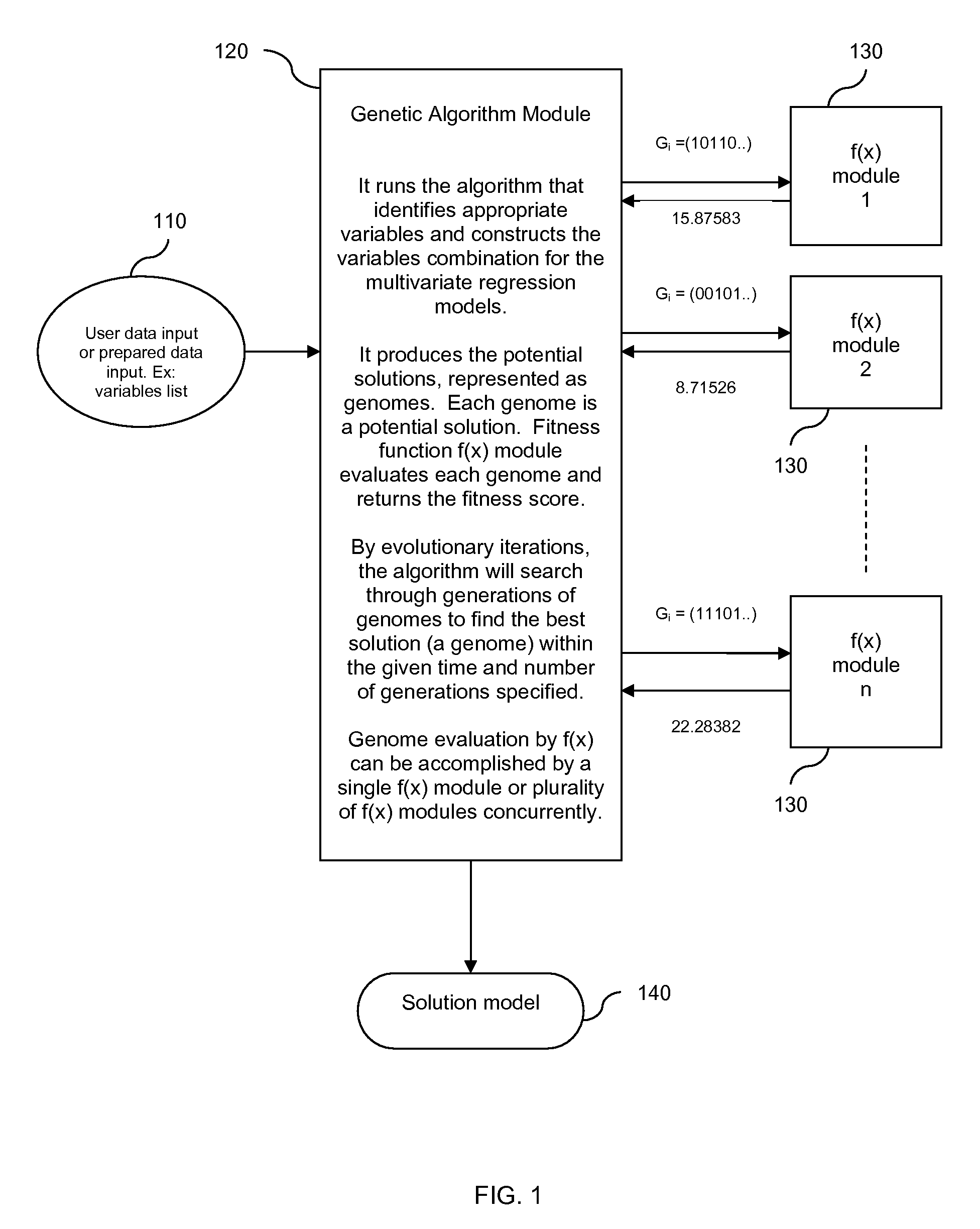

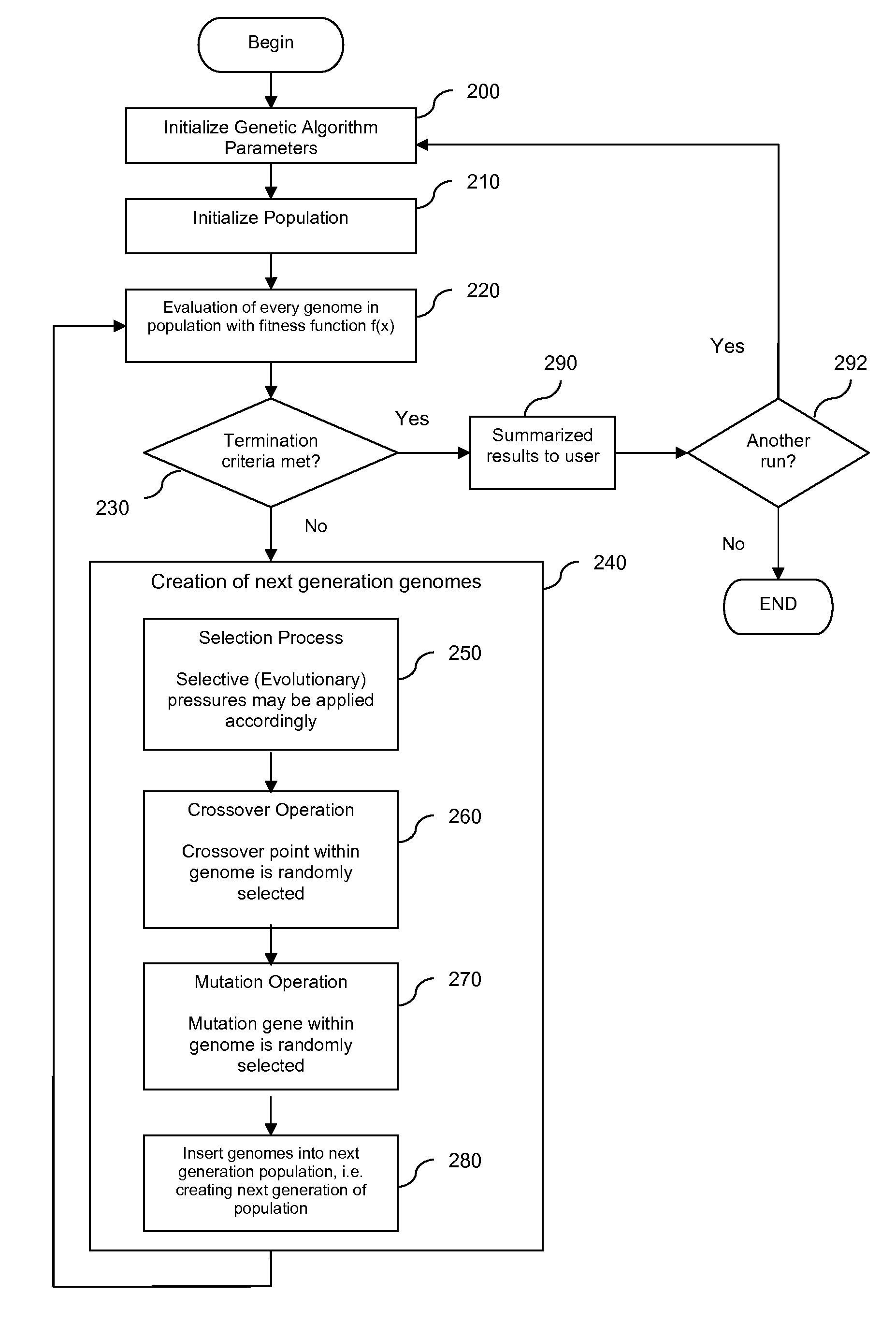

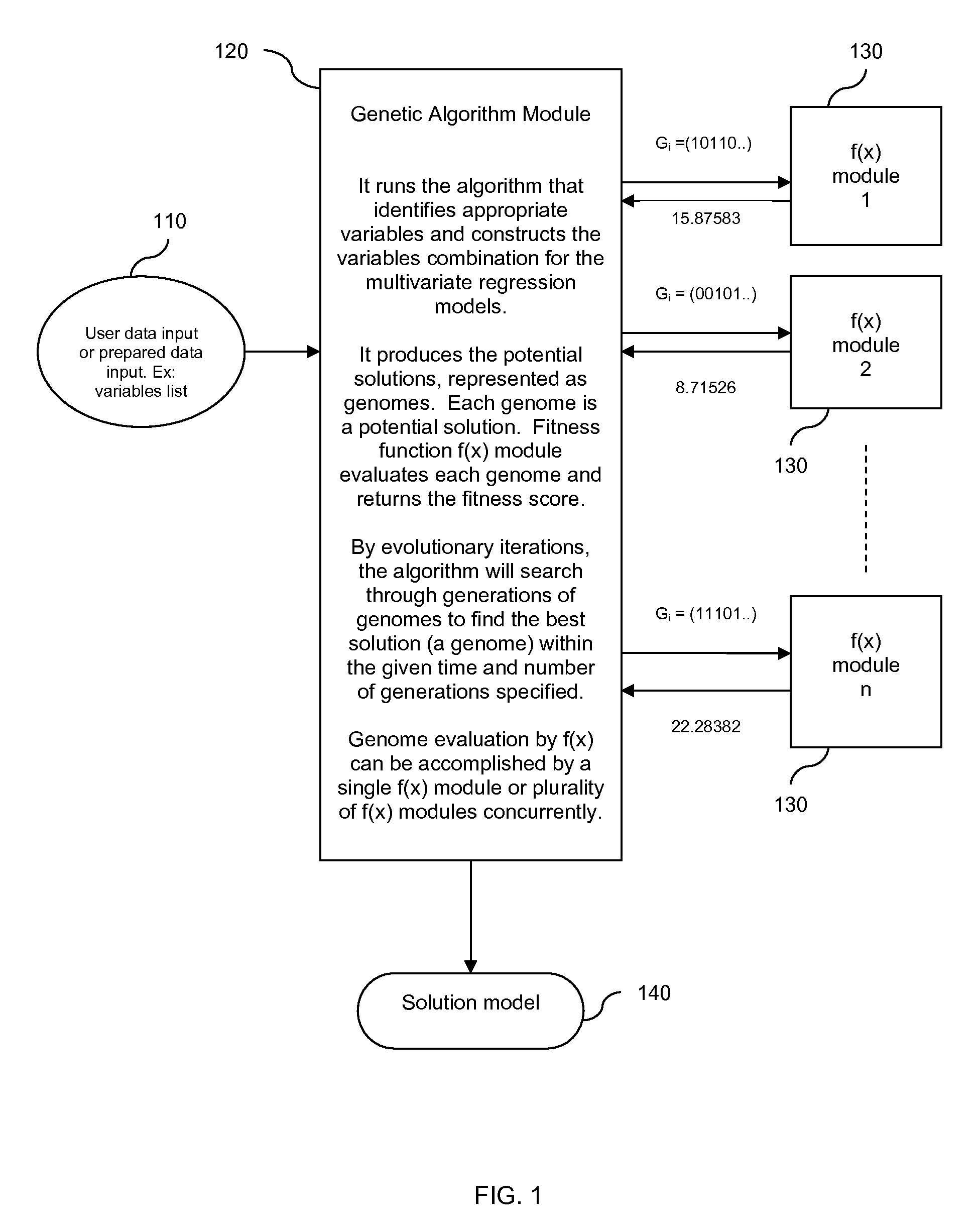

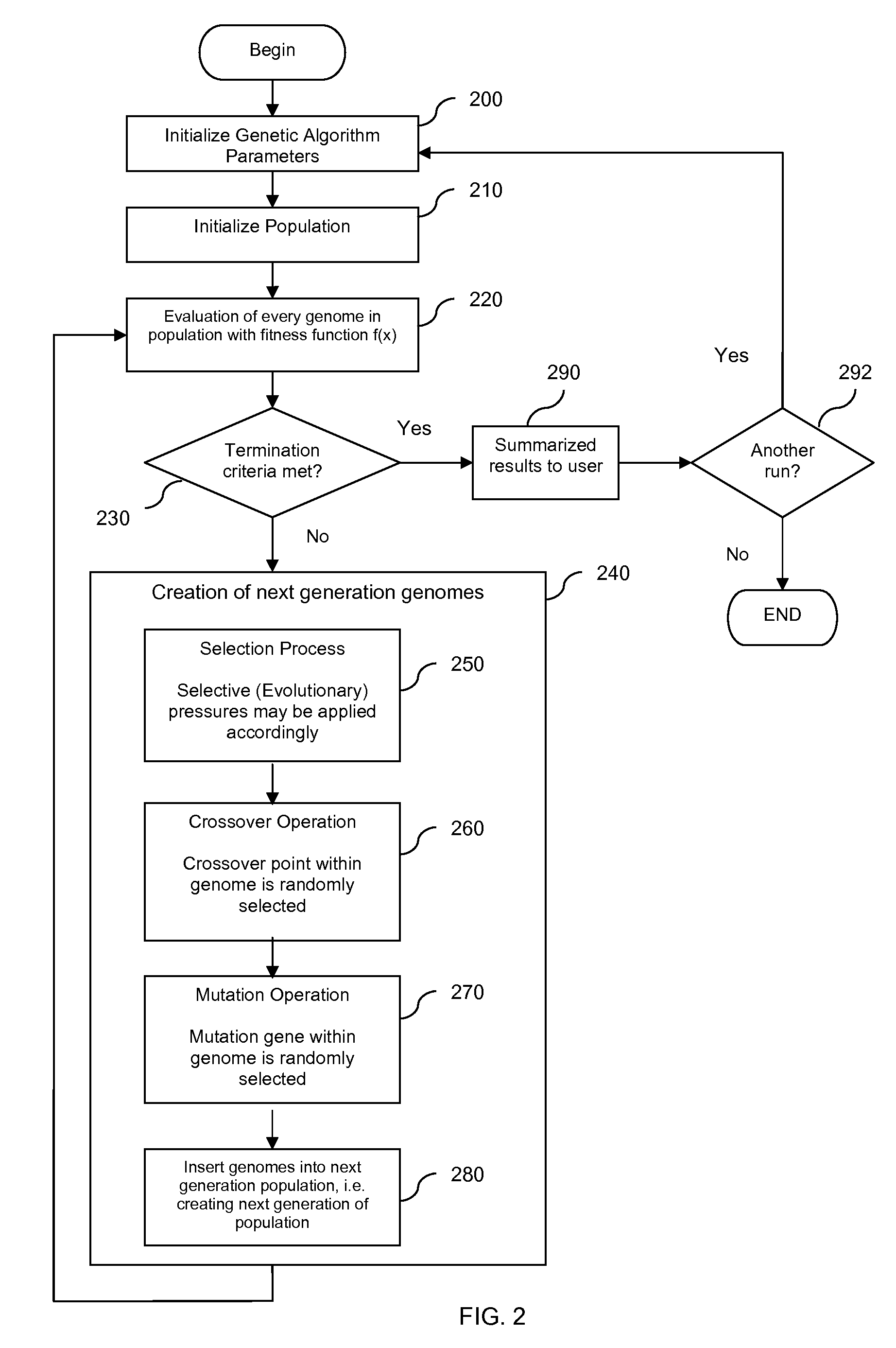

Adaptive Multivariate Model Construction

InactiveUS20080222061A1Increase powerImprove predictive performanceDigital computer detailsElectric digital data processingExplanatory powerMembership testing

The present embodiment is able to find the optimal or near optimal variables composition of multivariate models by an evolutionary process within acceptable amount of time and resources that are less than using full variables permutation methodology. Subjected to any data, it adaptively identifies and constructs the most effective combination of the relevant variables to achieve one or more objectives. The objective could be for high explanatory power, high predictive power, response measure, or other objectives that the user defines. The present embodiment solves the sequential F-test problem by conducting non-sequential and non-linear search. The algorithm also solves partial F-test dilemma by evaluating all candidate variables membership intact, maintaining fidelity of full variables membership test throughout its permutation. Furthermore, the stochastic nature of the algorithm neutralizes the prejudices of manual decisions in variables identification and membership construction.

Owner:SOETJAHJA HENDRA

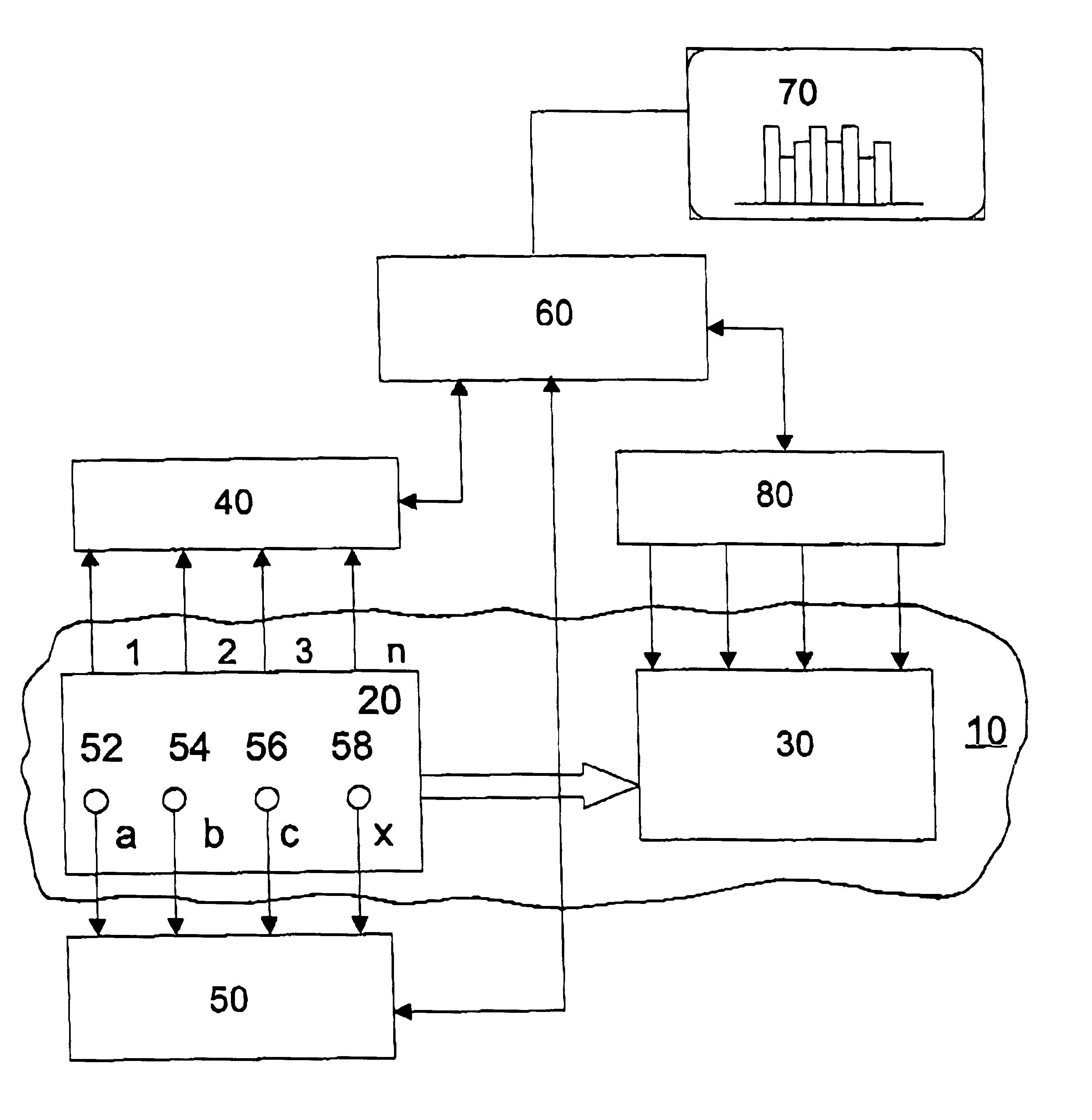

Method and device for controlling an essentially continuous process

InactiveUS6597959B1Minimizes rejectionQuality improvementSampled-variable control systemsDigital differential analysersProcess engineeringEngineering

A method and a device for controlling a process (10), having at least two sub-processes (20, 30), by tracking, processing and correcting variables for the product, the production means and / or any process media throughout the process line. The process flow for the first sub-process (20) is divided into slices, each slice representing a specific volume of process flow. At least some of the measured and sampled variable values are related to its specific slice volume. Any variable value obtained is processed using a control and processing, unit (60) with means for receiving, information on variable values on-line, means for presenting (70) the process flow through the production units, means for dividing the process flow into slices, means for processing a variable value obtained, including means for relating, the variable value to is specific slice volume, means to develop one or more multivariate models based on variable values for a multiple of slice volumes and means to combine the multivariate model with a processed variable value for a specific slice volume to predict a variable value and / or a quality variable for subsequent second sub-process (30). Corrective actions are executed in the subsequent second sub-process (30) based on a processed variable value from the first sub-process (20) using, actuating, means (80) for execution of corrective action.

Owner:ABB (SCHWEIZ) AG

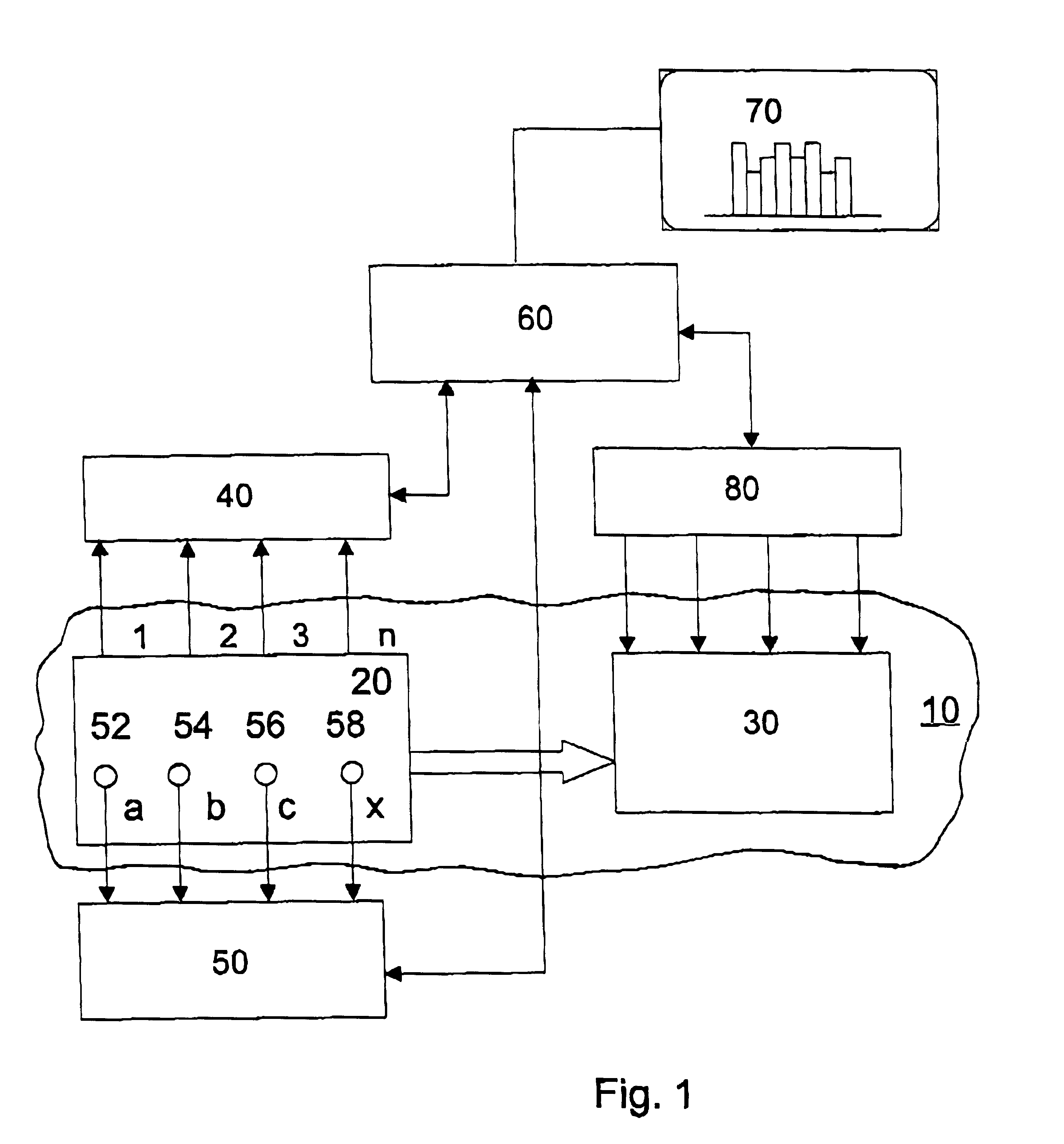

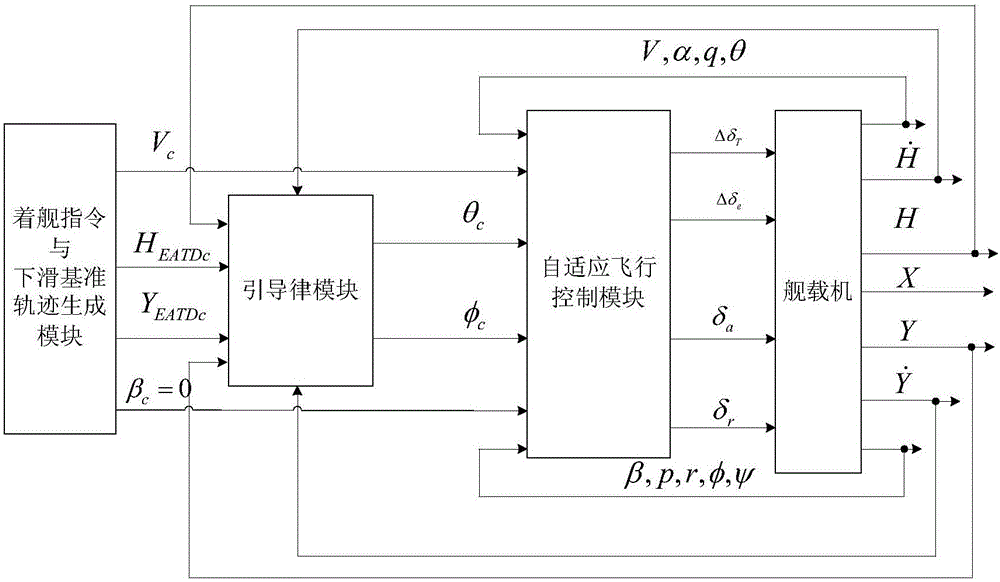

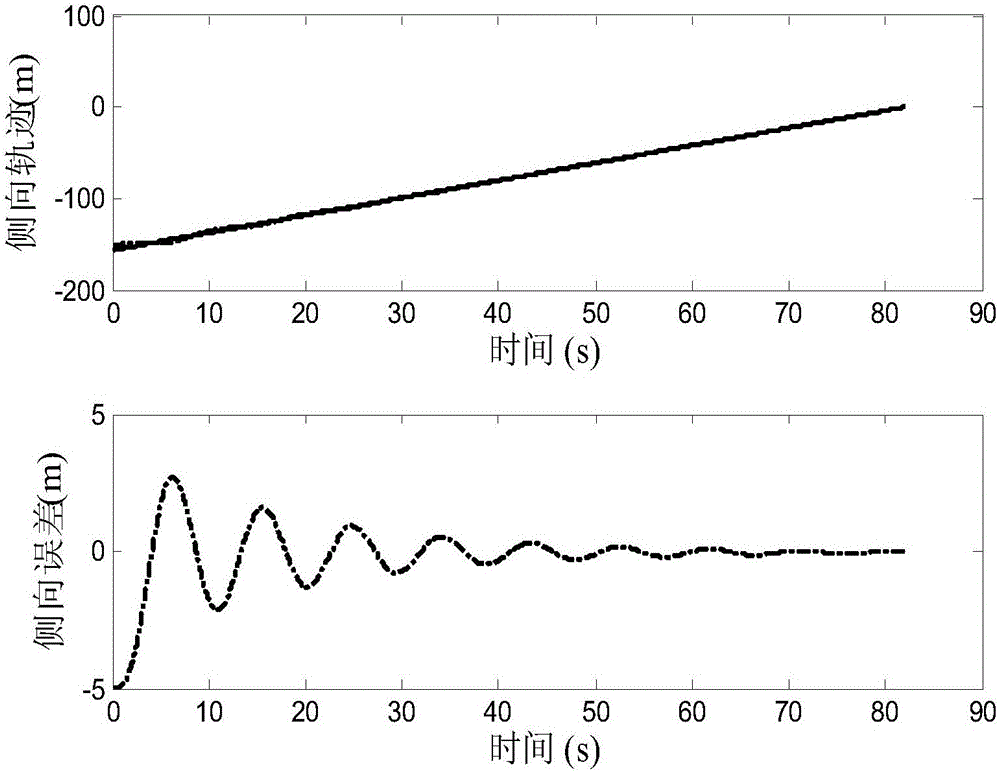

Adaptive automatic carrier landing guide control system of fixed-wing unmanned carrier-based aircraft

InactiveCN106292293ASolve the landing control problemSimplify design stepsAttitude controlPosition/course control in three dimensionsControl systemControl signal

The invention discloses an adaptive automatic carrier landing guide control system of a fixed-wing unmanned carrier-based aircraft. The adaptive automatic carrier landing guide control device comprises a carrier landing instruction and glide reference track generating module, a guide law module and an adaptive flight control module. The carrier landing instruction and glide reference track generating module is used for generating three-dimensional reference glide track signals, speed instruction signals and side slide instruction signals, outputting the three-dimensional glide reference track signals to the guide law module and outputting the speed instruction signals to the adaptive flight control module; the guide law module is used for generating a pitch angle instruction and a roll angle instruction which are two guidance instructions and outputting the two guidance instructions to the adaptive flight control module; the adaptive flight control module is used for generating flight control signals for the unmanned carrier-based aircraft by the aid of multivariable model reference adaptive control algorithms. The adaptive automatic carrier landing guide control system has the advantages that the unmanned carrier-based aircraft can precisely trace glide reference tracks by the aid of the adaptive automatic carrier landing guide control system, and accordingly carrier landing tasks can be successfully accomplished.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

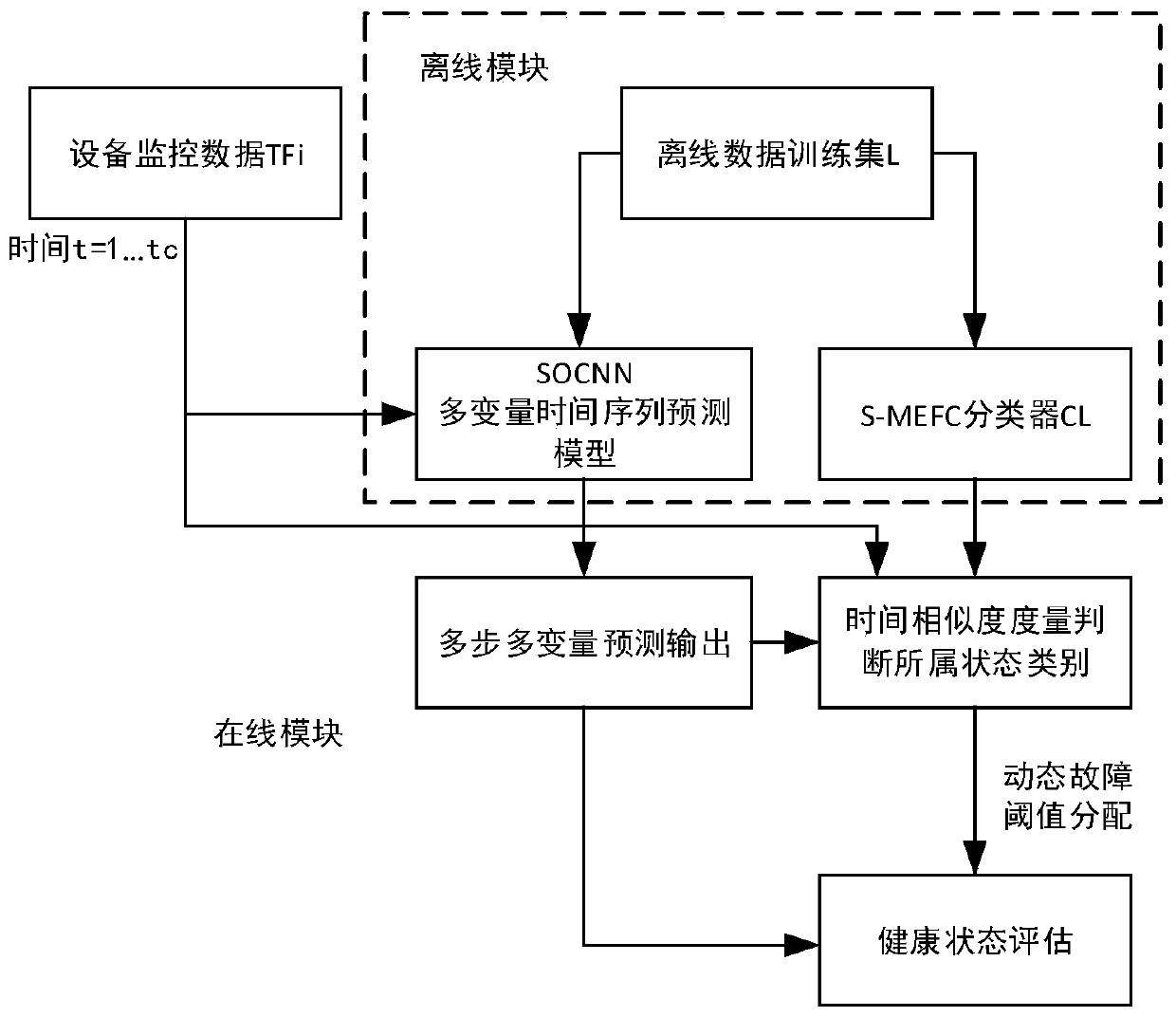

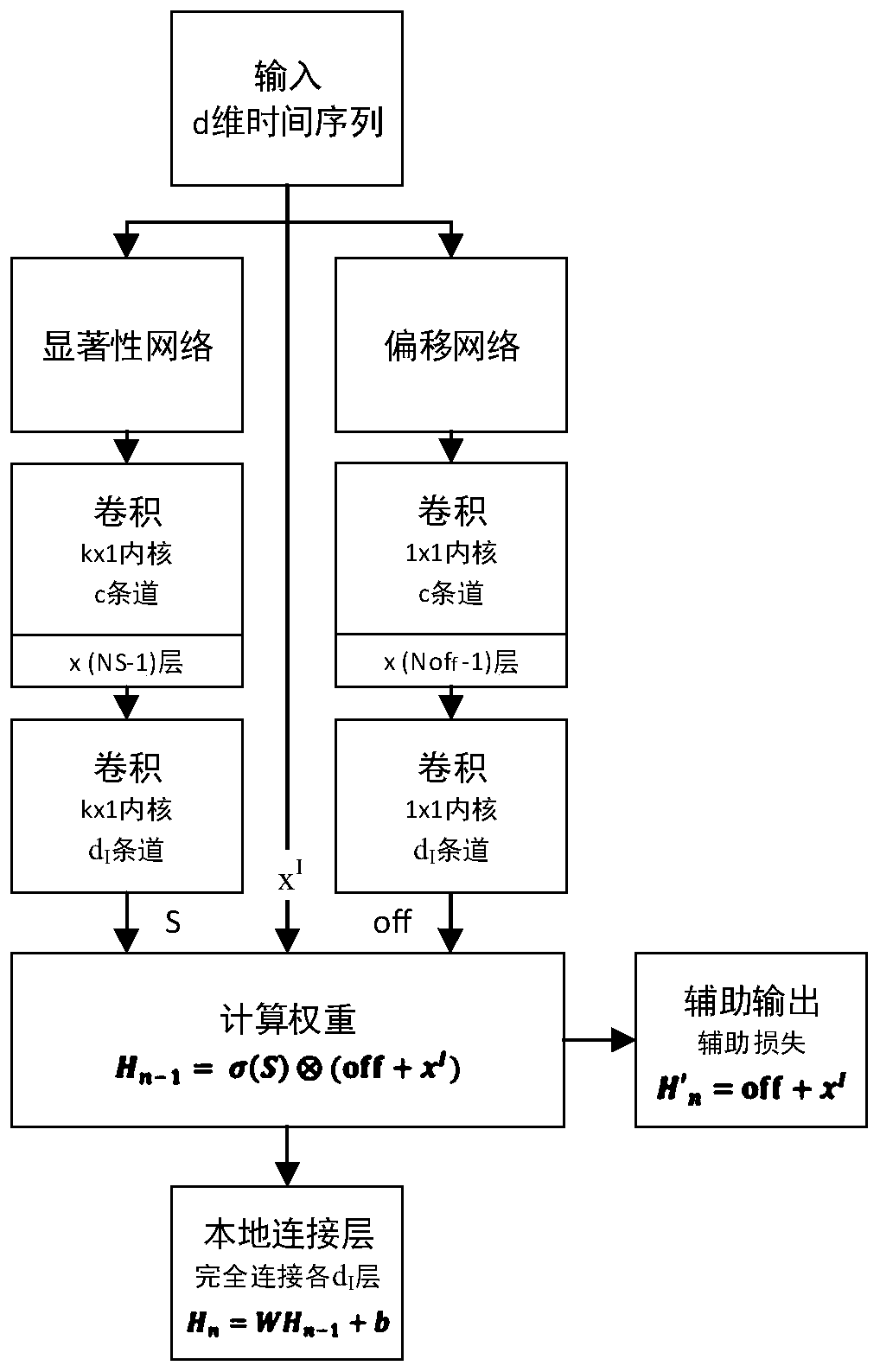

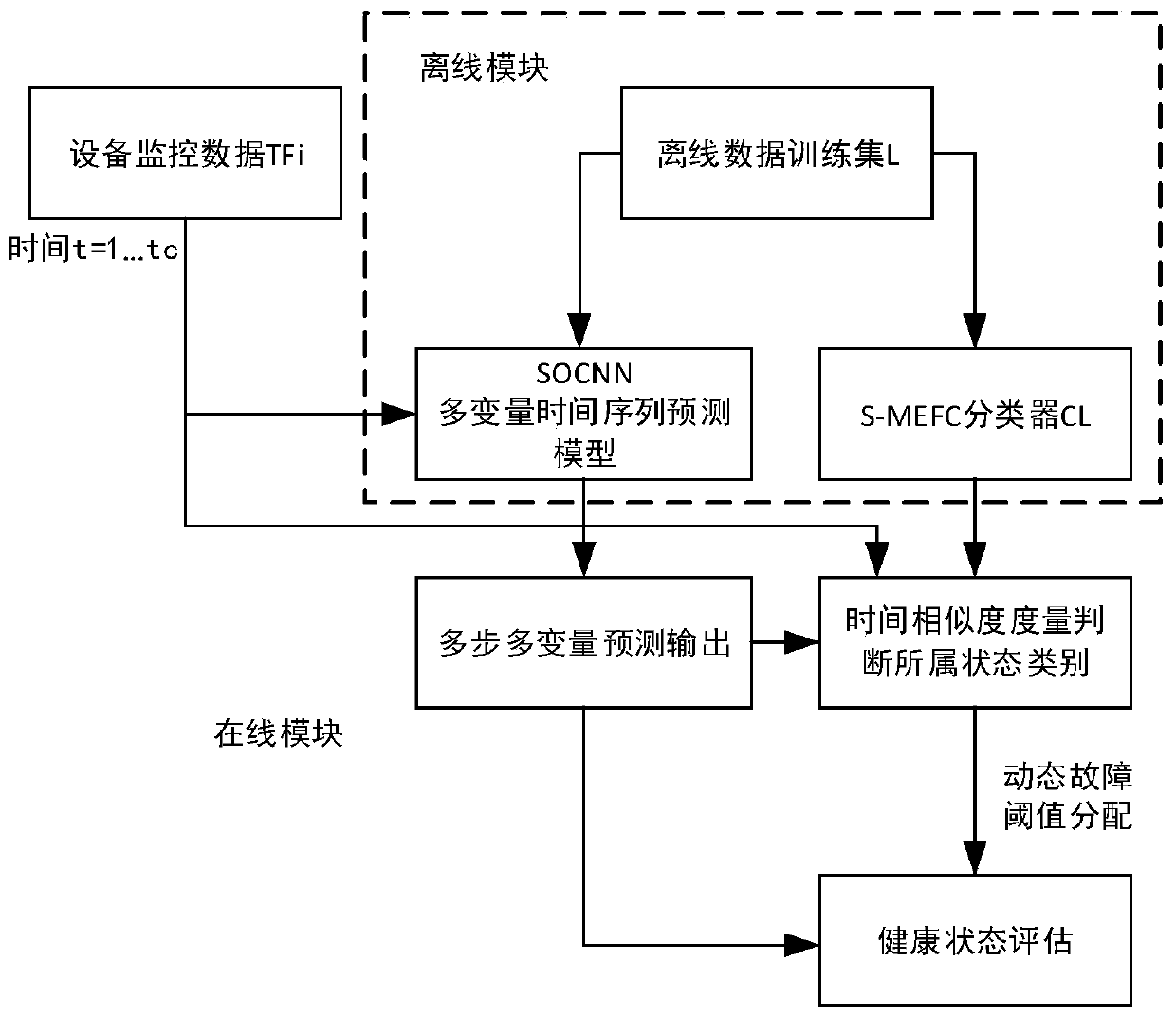

A multivariate-based equipment dynamic health state assessment method

ActiveCN109711453AHigh precisionImprove generalization abilityCharacter and pattern recognitionSimulationFuzzy clustering

Owner:GUANGDONG UNIV OF TECH

Adaptive multivariate model construction

InactiveUS8073790B2Increase powerImprove predictive performanceDigital computer detailsElectric digital data processingExplanatory powerComputer science

The present embodiment is able to find the optimal or near optimal variables composition of multivariate models by an evolutionary process within acceptable amount of time and resources that are less than using full variables permutation methodology. Subjected to any data, it adaptively identifies and constructs the most effective combination of the relevant variables to achieve one or more objectives. The objective could be for high explanatory power, high predictive power, response measure, or other objectives that the user defines. The present embodiment solves the sequential F-test problem by conducting non-sequential and non-linear search. The algorithm also solves partial F-test dilemma by evaluating all candidate variables membership intact, maintaining fidelity of full variables membership test throughout its permutation. Furthermore, the stochastic nature of the algorithm neutralizes the prejudices of manual decisions in variables identification and membership construction.

Owner:SOETJAHJA HENDRA

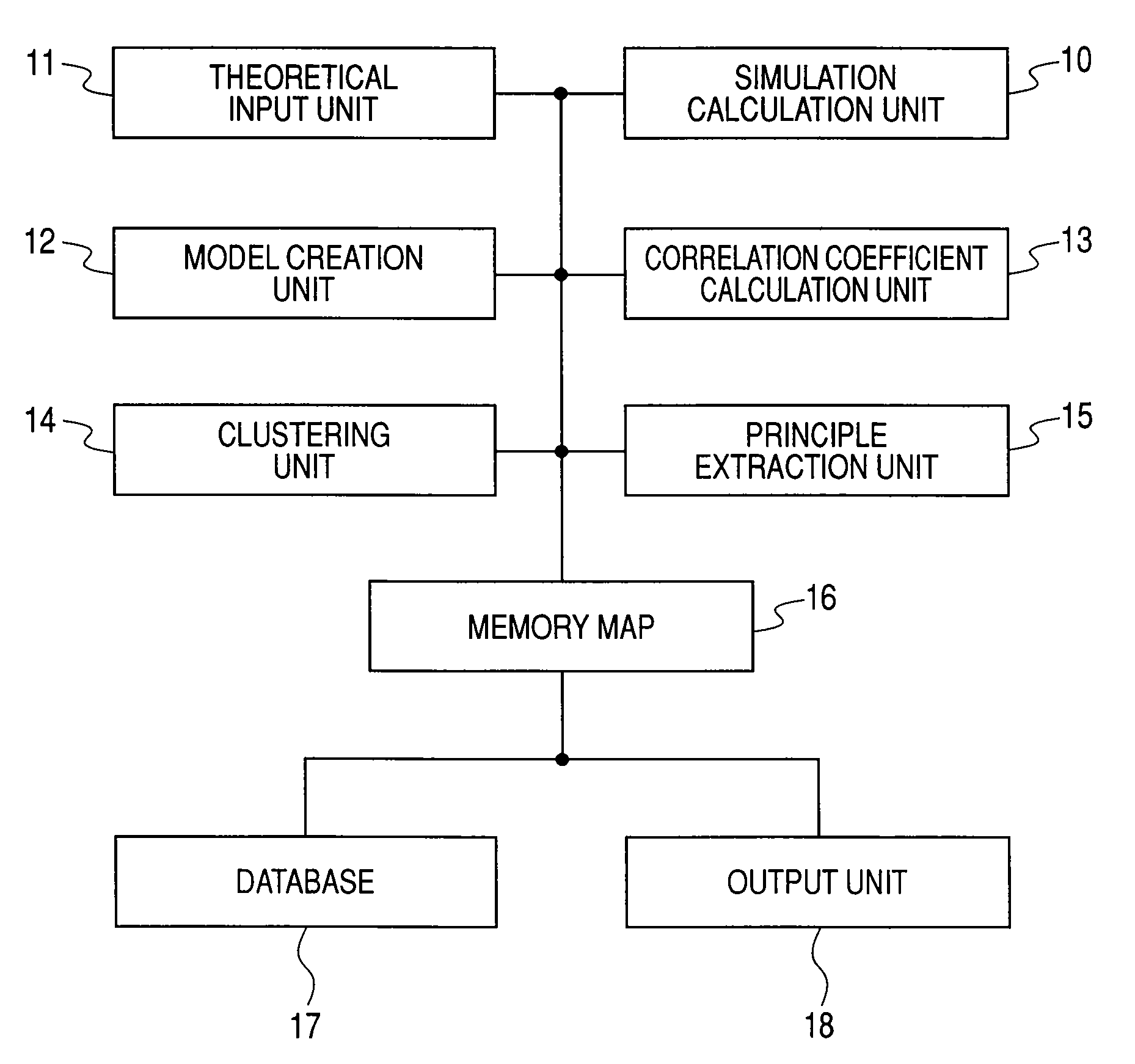

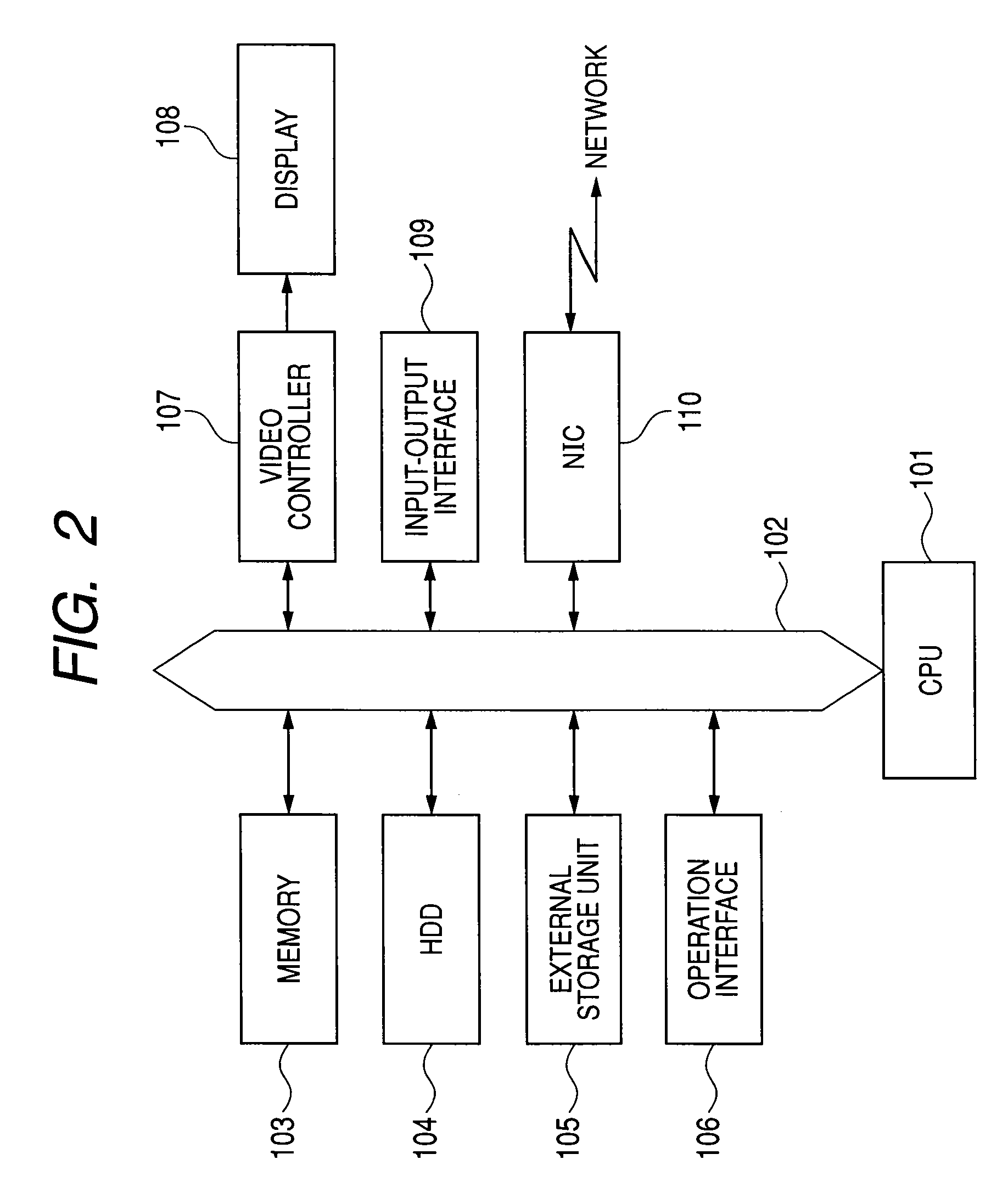

Multi-variable model analysis system, method and program, and program medium

ActiveUS20090132208A1High similarityReduce sensitivityGeometric CADCAD network environmentCorrelation coefficientComputational model

A multi-variable model analysis system comprises a model creation unit for creating a plurality of models individually having a plurality of variables, a characteristic value calculation unit for calculating the characteristic values of the models on the basis of the variables of the models given and for writing the variables and characteristic values of the models, a clustering unit for classifying the plural models having the characteristic values of a high similarity, into an identical cluster; a correlation coefficient calculation unit for calculating the correlation coefficients of the variables of the models in individual clusters and for writing the correlation coefficients in a memory map; and an extraction unit for extracting the variable having a correlation coefficient exceeding a predetermined value in the individual clusters, from the memory map.

Owner:NAT UNIV CORP YOKOHAMA NAT UNIV

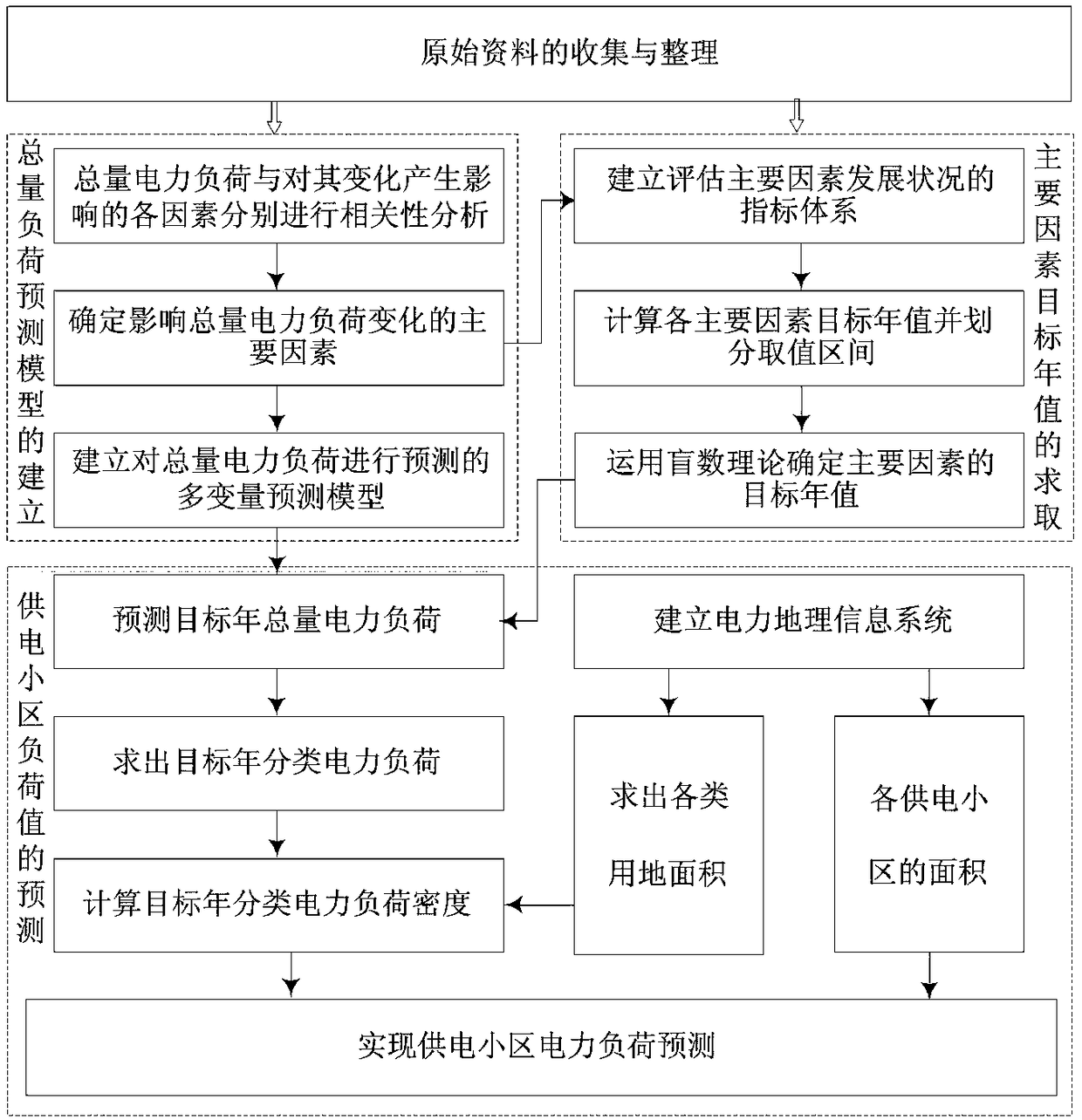

Multivariable model and blind number theory-based spatial load prediction method

The invention discloses a multivariable model and blind number theory-based spatial load prediction method. The method is characterized by comprising the steps of performing correlation analysis on total power loads based on numerous factors influencing changes of the total power loads, and determining main factors influencing the changes of the total power loads in the factors; by applying a multivariable analysis method, building a multivariable prediction model for predicting the total power loads by taking the main factors influencing the changes of the total power loads as input variables; establishing an index system for assessing development states of the main factors influencing the changes of the total power loads, calculating target annual values of the main factors influencing the changes of the total power loads, and predicting the total power loads by adopting the multivariable prediction model; and calculating target annual classified power load values by utilizing totalpower load prediction results, establishing a power geographic information system comprising land use information of to-be-predicted areas, and calculating out classified power load density, thereby obtaining power load values of power supply communities.

Owner:NORTHEAST DIANLI UNIVERSITY

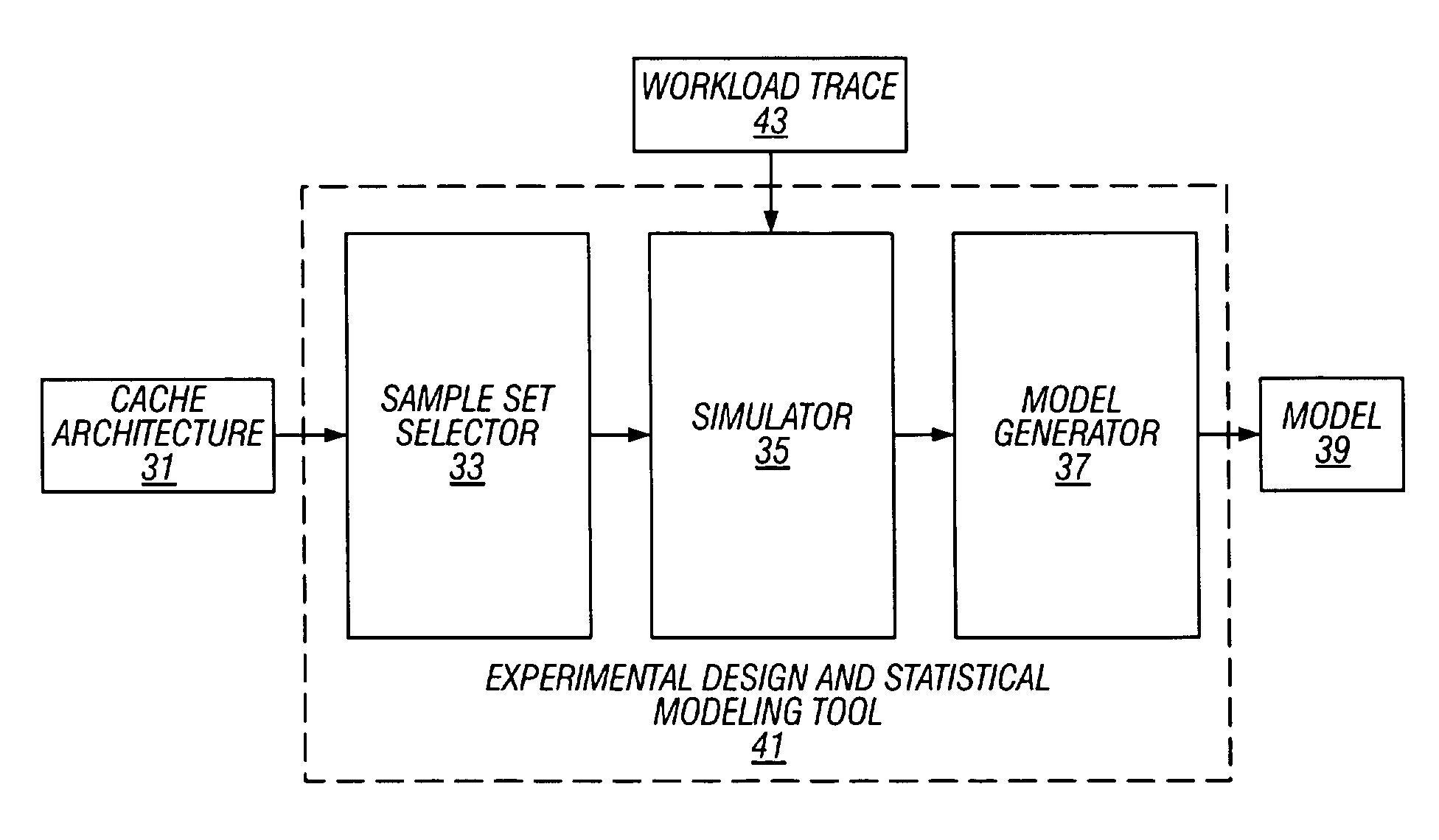

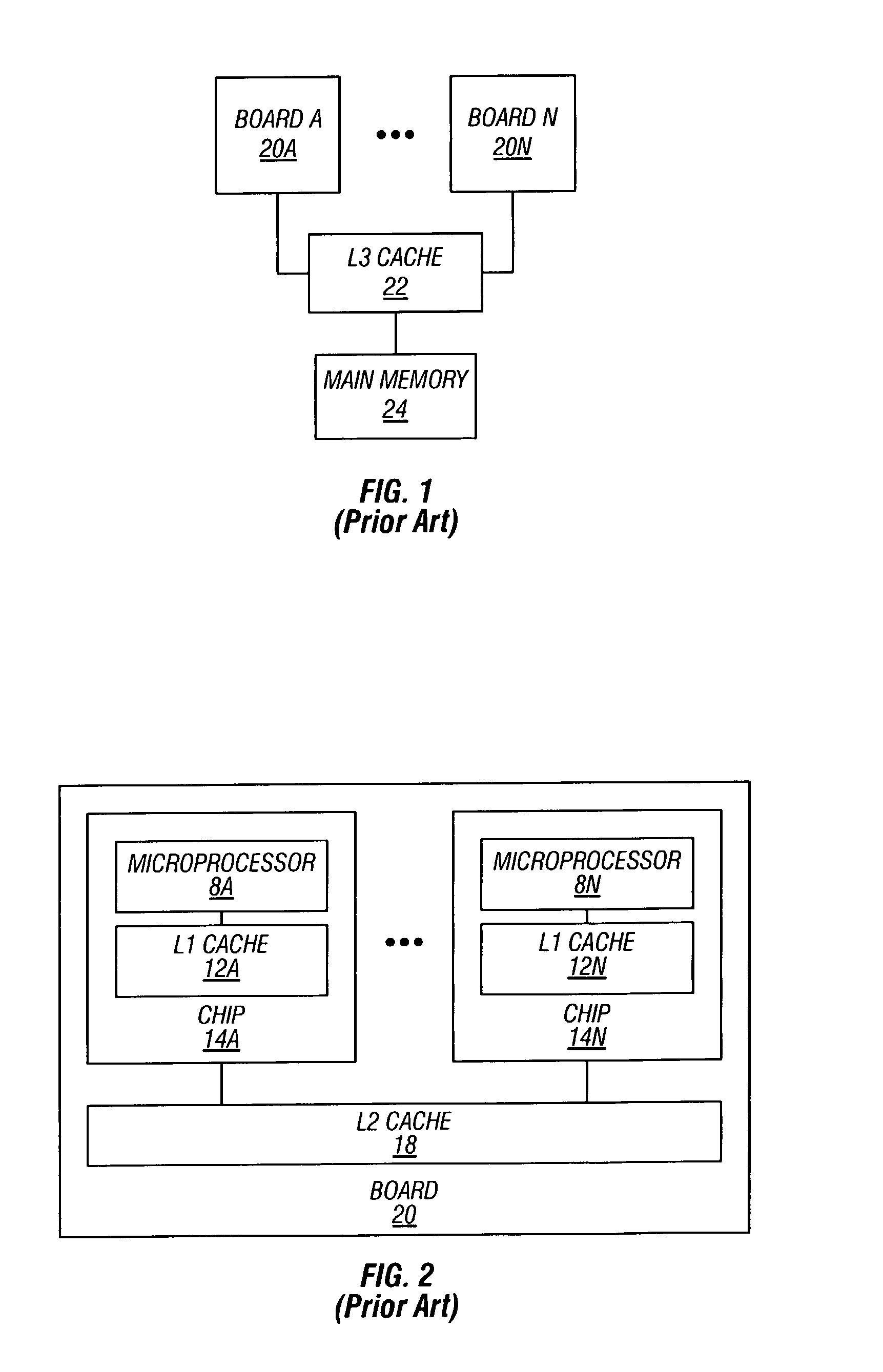

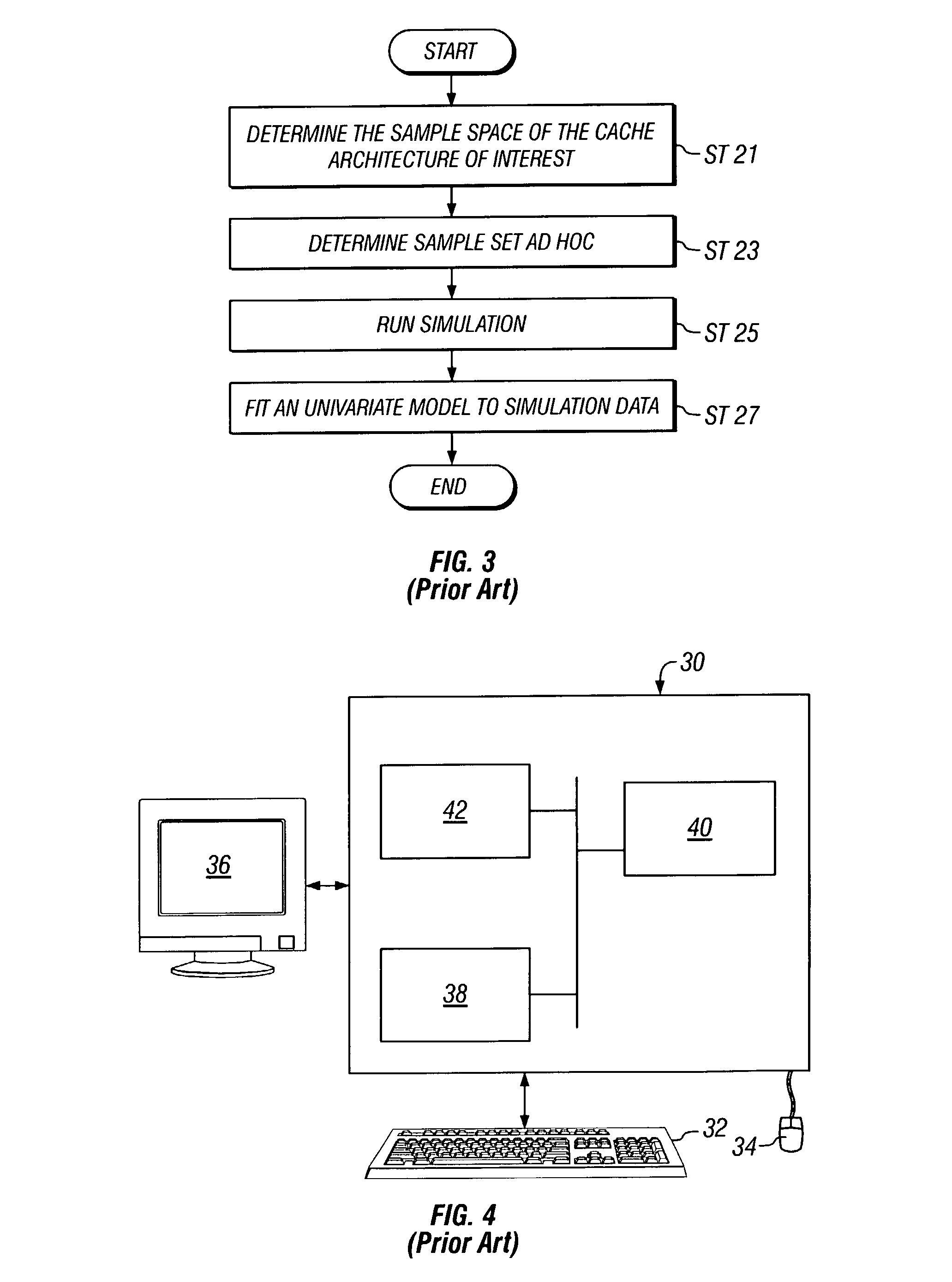

Experimental design and statistical modeling tool for workload characterization

ActiveUS7103517B2Memory adressing/allocation/relocationComputation using non-denominational number representationParallel computingWorkload

A method for a cache architecture simulation includes obtaining a first sample set for the cache architecture using a non-stationary Gaussian field model, performing a cache architecture simulation using the first sample set to produce a first set of simulation data, and fitting a first multivariate model to the first set of simulation data.

Owner:ORACLE INT CORP

System and method for controlling a thermo-mechanical wood pulp refiner

ActiveUS7381303B2Improves overall constraint handling of control strategyImprove throughputBeating/refining control devicesComputer controlFiberProduction line

Thermomechanical pulp is an important process for producing fibrous mass used in papermaking. A two-level control strategy that stabilizes and optimizes the refining process has been developed. The Stabilization layer consists of a multivariable model predicative range controller that regulates the refiner line operations. The Quality Optimization layer provides the pulp quality control as measured by an online pulp quality (freeness, fibre length) sensor. This control startegy leverages the natural decoupling in the process. The modular design technique is able to handle multiple refiner lines that empty into a common latency chest. A global optimizer is also used to integrate and coordinate the two layers for enhanced constraint handling.

Owner:HONEYWELL INT INC

Automated tuning of large-scale multivariable model predictive controllers for spatially-distributed processes

An automated tuning method of a large-scale multivariable model predictive controller for multiple array papermaking machine cross-directional (CD) processes can significantly improve the performance of the controller over traditional controllers. Paper machine CD processes are large-scale spatially-distributed dynamical systems. Due to these systems' (almost) spatially invariant nature, the closed-loop transfer functions are approximated by transfer matrices with rectangular circulant matrix blocks, whose input and output singular vectors are the Fourier components of dimension equivalent to either number of actuators or number of measurements.; This approximation enables the model predictive controller for these systems to be tuned by a numerical search over optimization weights in order to shape the closed-loop transfer functions in the two-dimensional frequency domain for performance and robustness. A novel scaling method is used for scaling the inputs and outputs of the multivariable system in the spatial frequency domain.

Owner:HONEYWELL INT INC

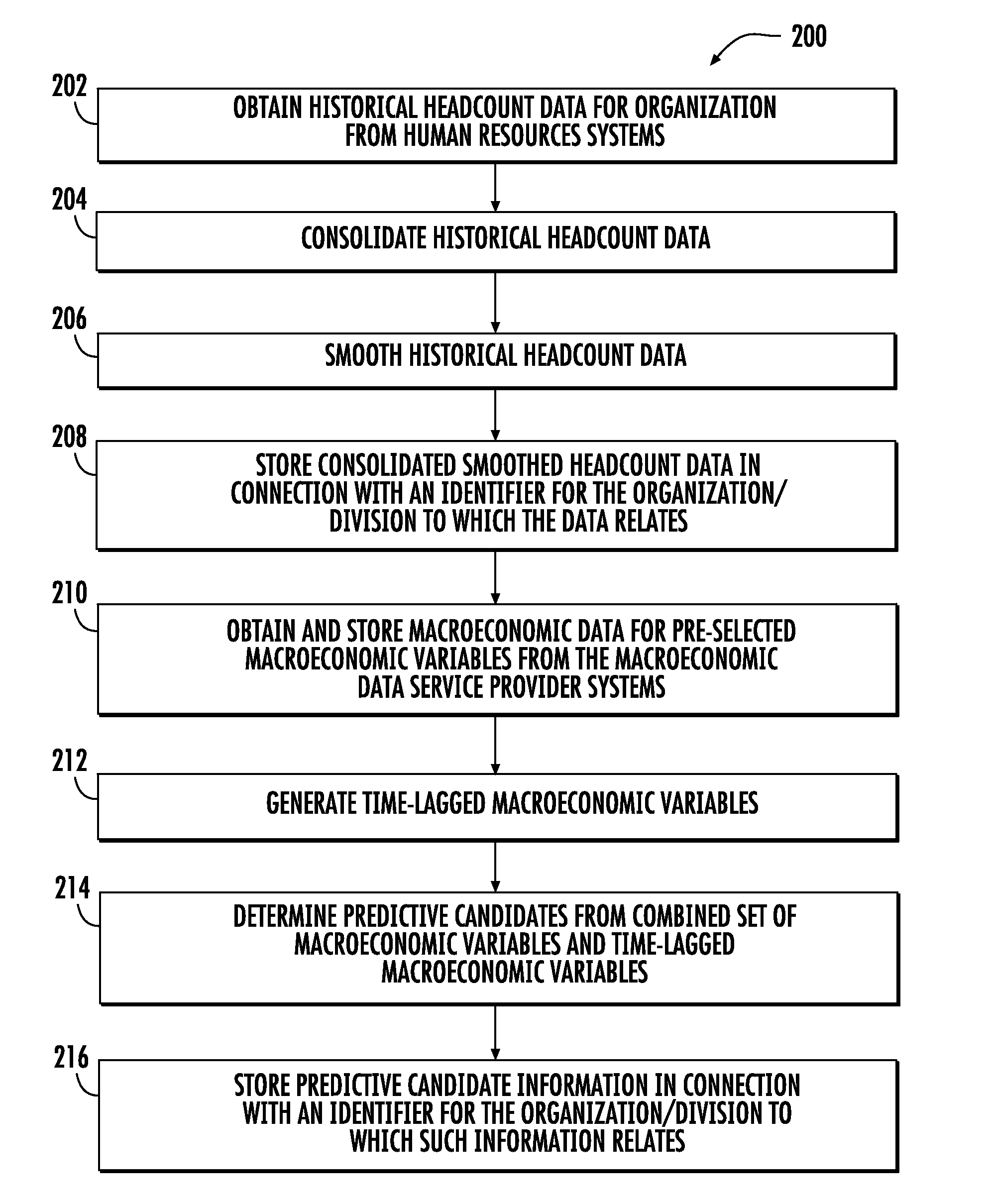

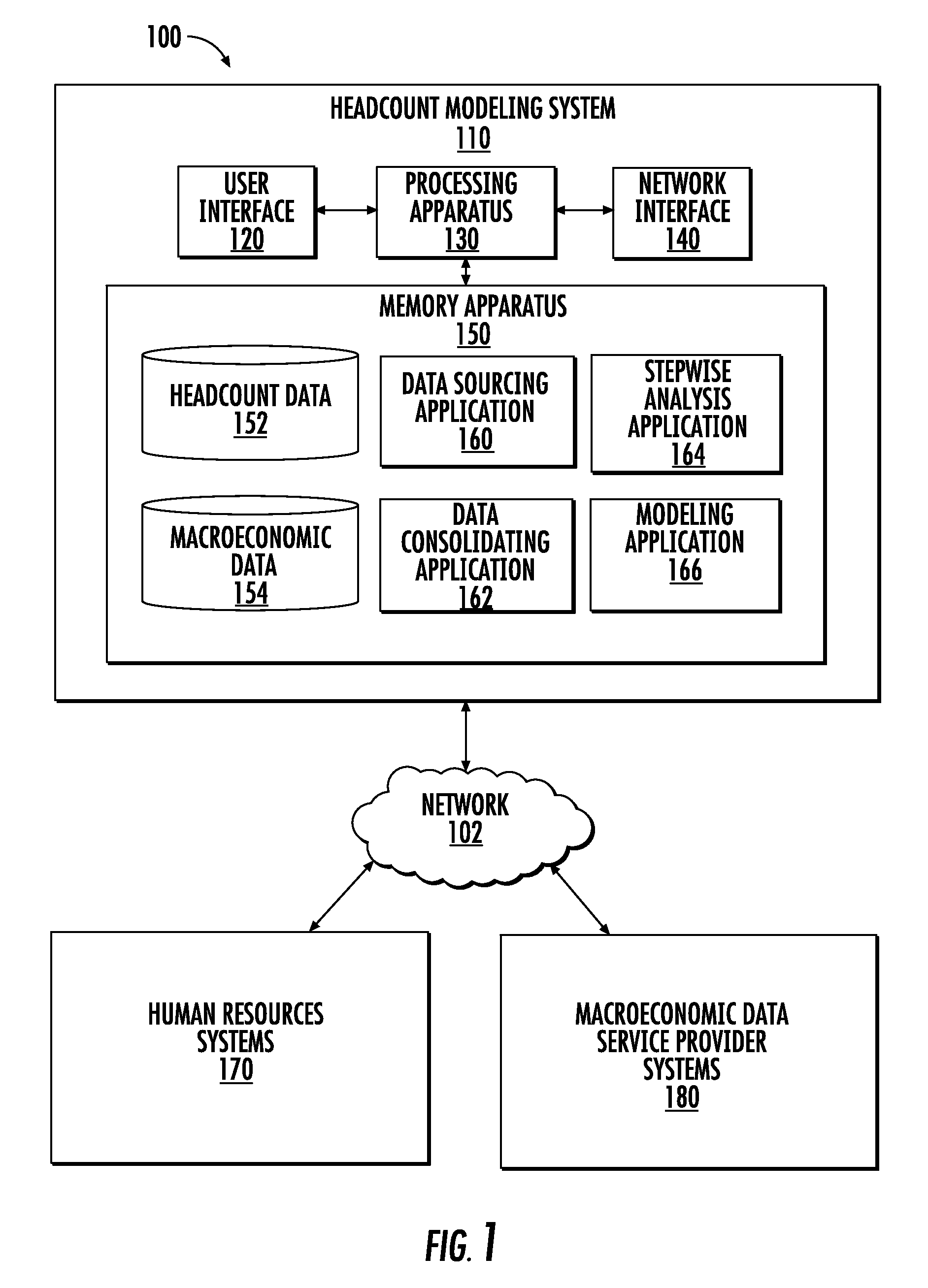

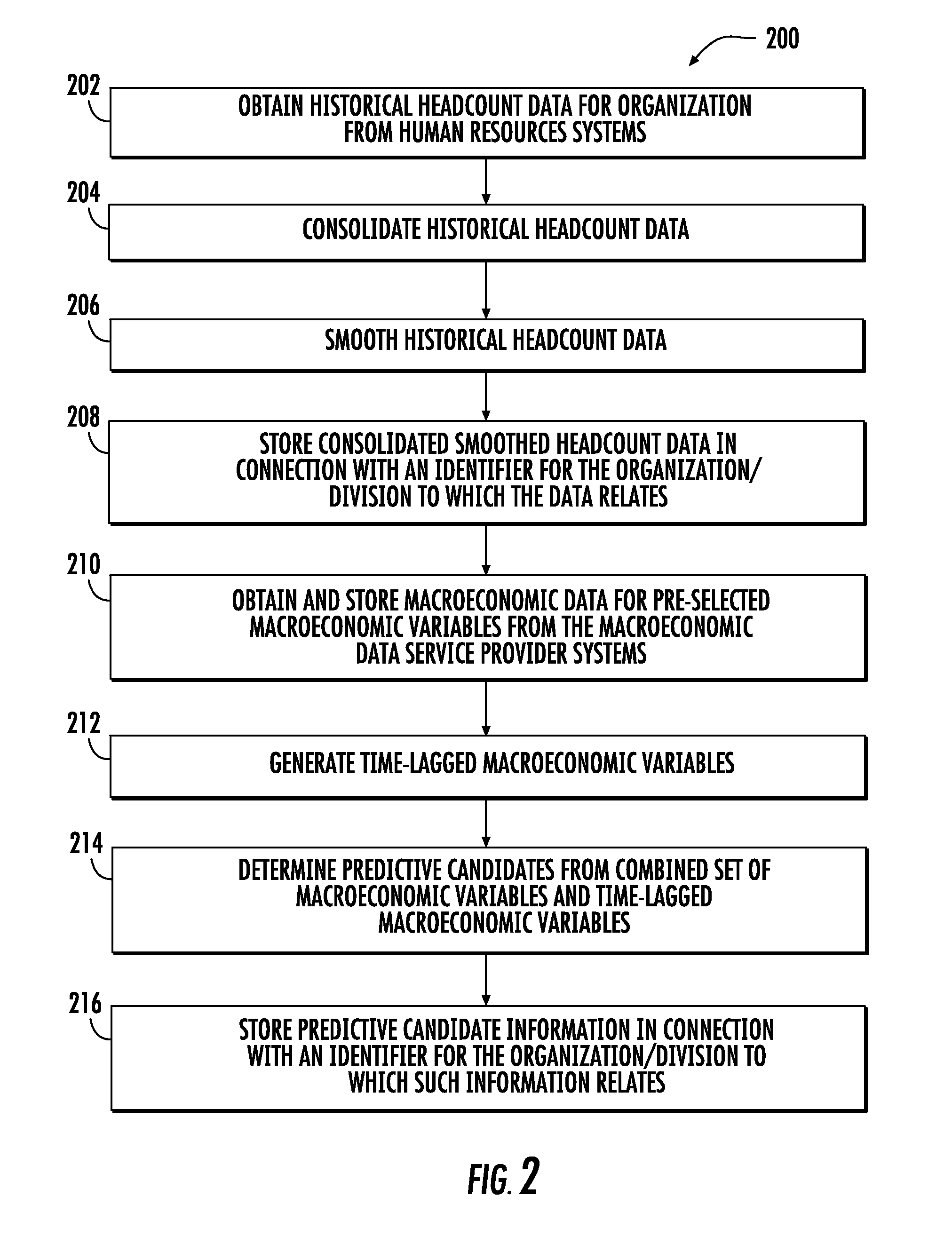

Headcount forecasting system

InactiveUS20110119109A1Remove outliersForecastingRelational databasesLinear regressionBusiness forecasting

Embodiments of the present invention provide systems, apparatuses, methods, and computer program products for forecasting the future headcount of an organization by generating, validating and displaying models of the headcount of an organization or division thereof over time. In some embodiments, at least three different models are generated using stored historical headcount information, including a linear regression model, a multivariate model using macroeconomic variables, and an autoregressive moving average model. In some embodiments, for each of the foregoing types, multiple models are generated and the best model of each type is selected for use in forecasting headcount according to predetermined evaluation criteria.

Owner:BANK OF AMERICA CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com