Patents

Literature

132results about How to "Optimize operating parameters" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Central air conditioning system optimizing method and system based on mathematic model

InactiveCN104713197ASave electricityOptimize operating parametersMechanical apparatusSpace heating and ventilation safety systemsCentral air conditioningElectric energy

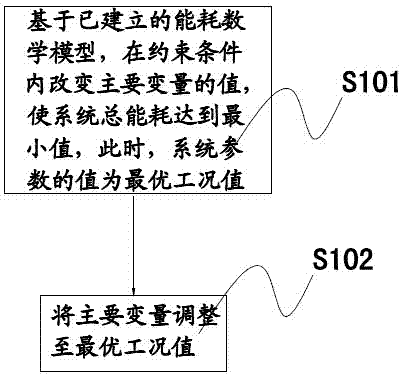

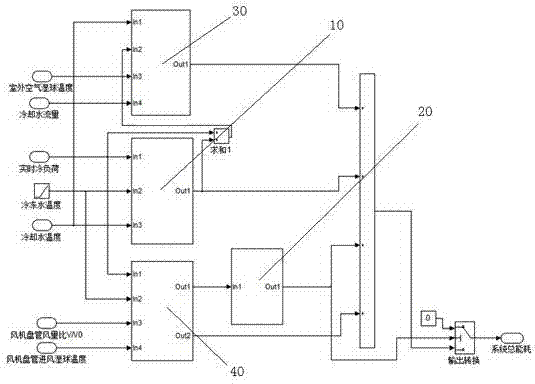

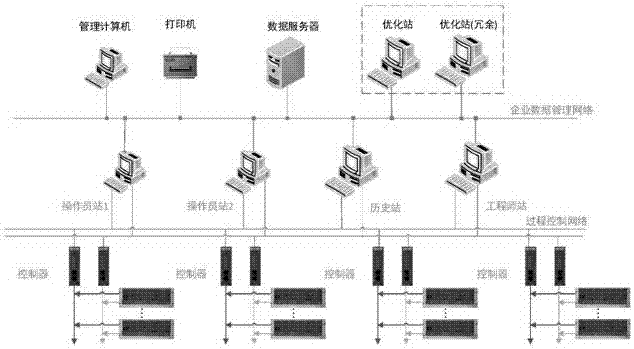

A central air conditioning system optimizing method based on a mathematic model includes the following steps of changing values of main variables within constraints on the basis of the established energy consumption mathematic model so that the total energy consumption of a system can reach the minimum, wherein at the moment, the parameter value of the system is the optimal working condition value; adjusting the main variables to the optimal working condition value. Meanwhile, the invention provides the central air conditioning system optimizing system based on the mathematic model. The system comprises a processing module and a dispatching module. The processing module changes the values of the main variables in the constraints on the basis of the established energy consumption mathematic model so that the total energy consumption of the system can reach the minimum, and at the moment, the parameter value of the system is the optimal working condition value. The dispatching module is used for adjusting the main variables to the optimal working condition value. By means of the method and system, running parameters of a central air conditioning system can be optimized, the central air conditioning system runs under the optimal working condition, and electric energy is saved.

Owner:GUANGDONG URBAN & RURAL PLANNING & DESIGN INST

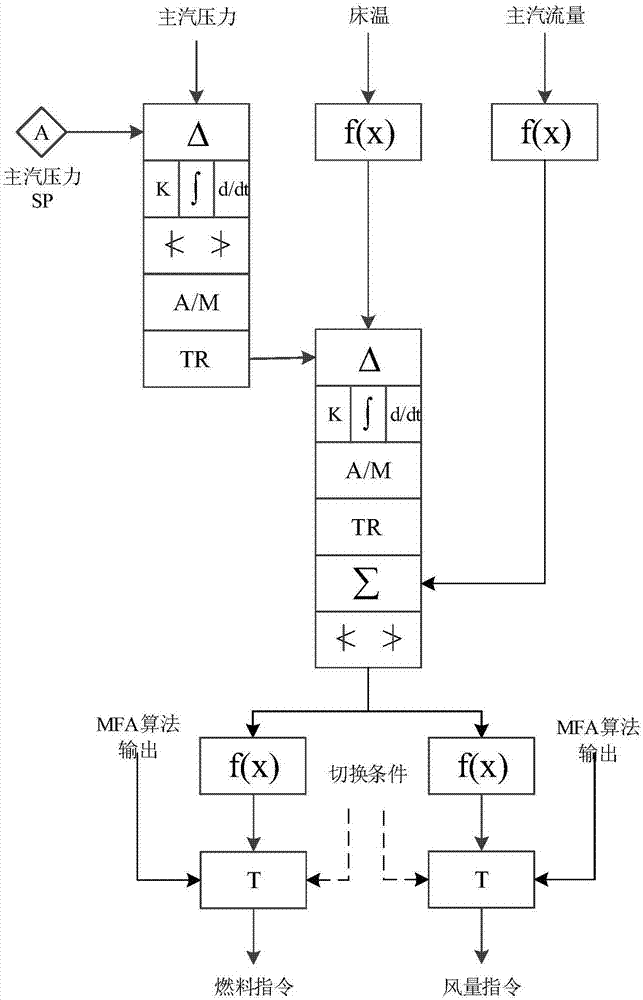

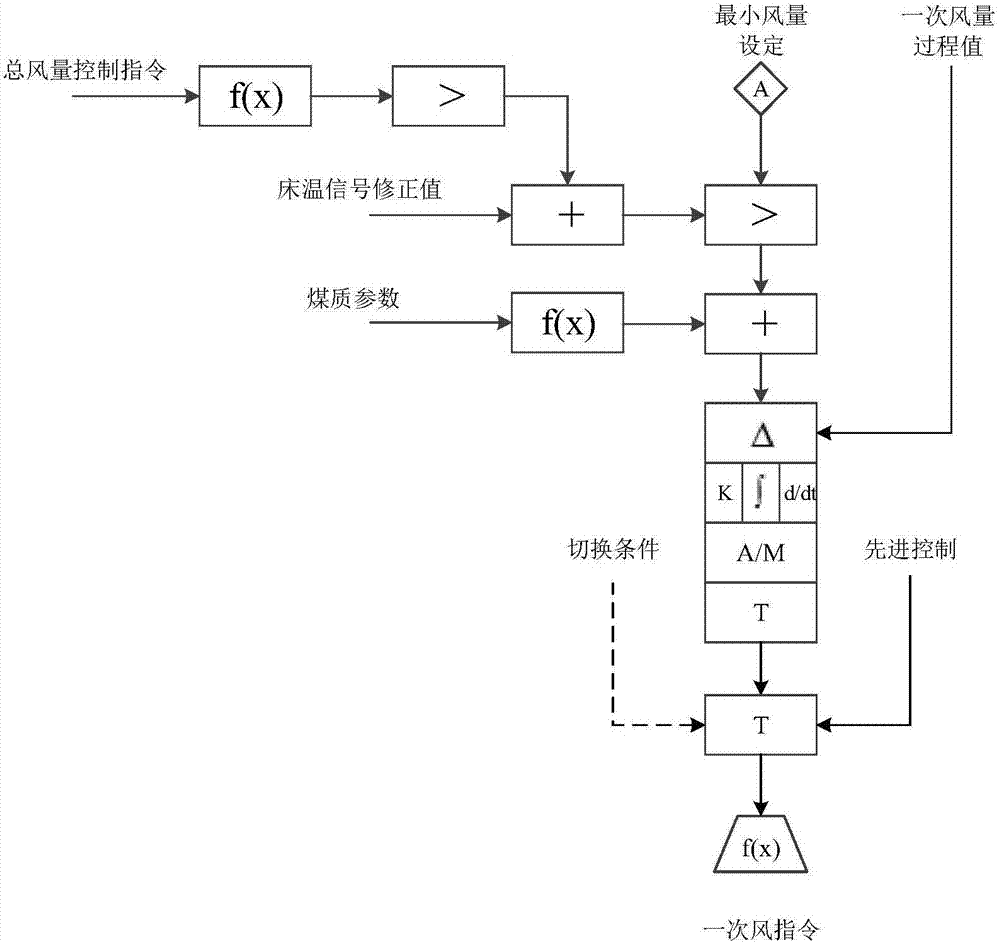

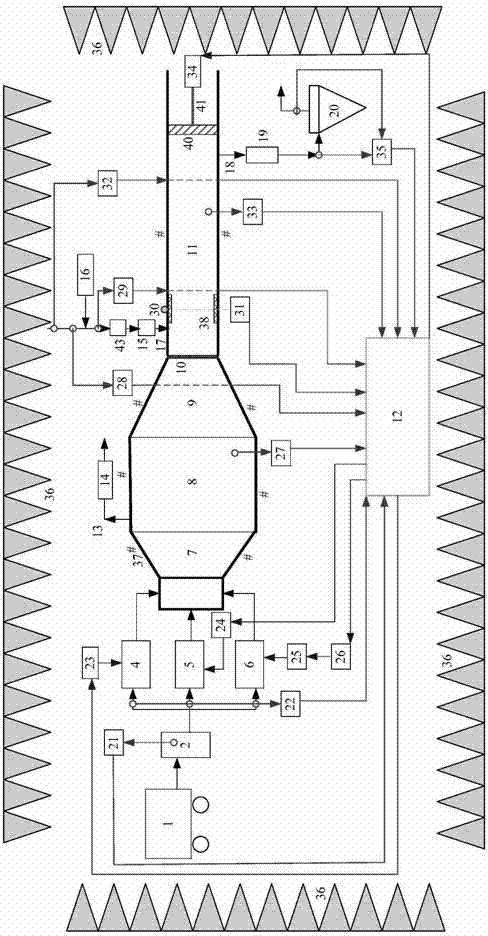

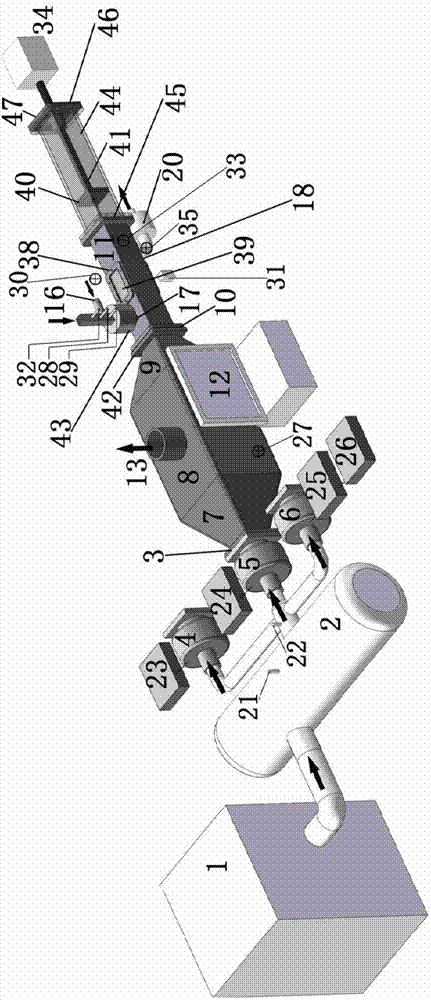

Fluidized bed boiler control and combustion optimization system

ActiveCN107023825AOptimize operating parametersImprove controlFluidized bed combustionApparatus for fluidised bed combustionFluidized bedOxygen content

The invention discloses a fluidized bed boiler control and combustion optimization system. The problem that a fluidized bed boiler system is not easy to control for a long time is solved. According to a method, a control strategy of combining an advanced control algorithm and a conventional control algorithm is adopted, and continuous, economical and stable operating of the boiler system is guaranteed; multivariable model-free adaptive control is adopted, and decoupling control of the fuel quantity and the air supply quantity over the bed temperature under the variable load work condition is achieved; and a nerual network technique is adopted for building a boiler combustion prediction model, online calculation of the boiler efficiency and NOX and SOX emissions is achieved, a multi-objective optimization function is constructed according to the prediction result, a combustion self-optimization algorithm is adopted, the flue gas oxygen content and the bed temperature are optimized constantly so as to adapt to work condition changes, and a fluidized bed boiler can operate in an optimal combustion area.

Owner:XIAN IBL TECH DEV +1

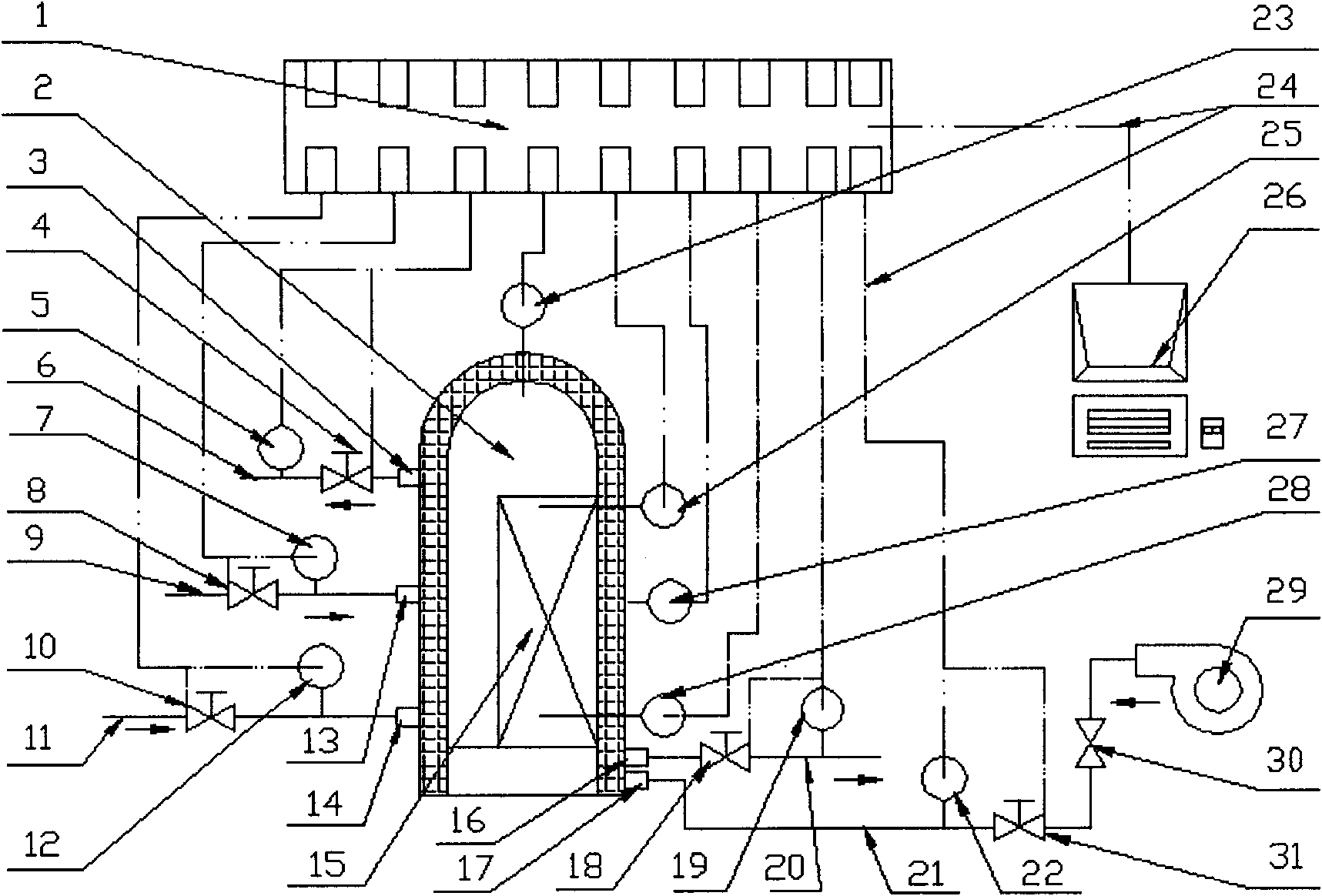

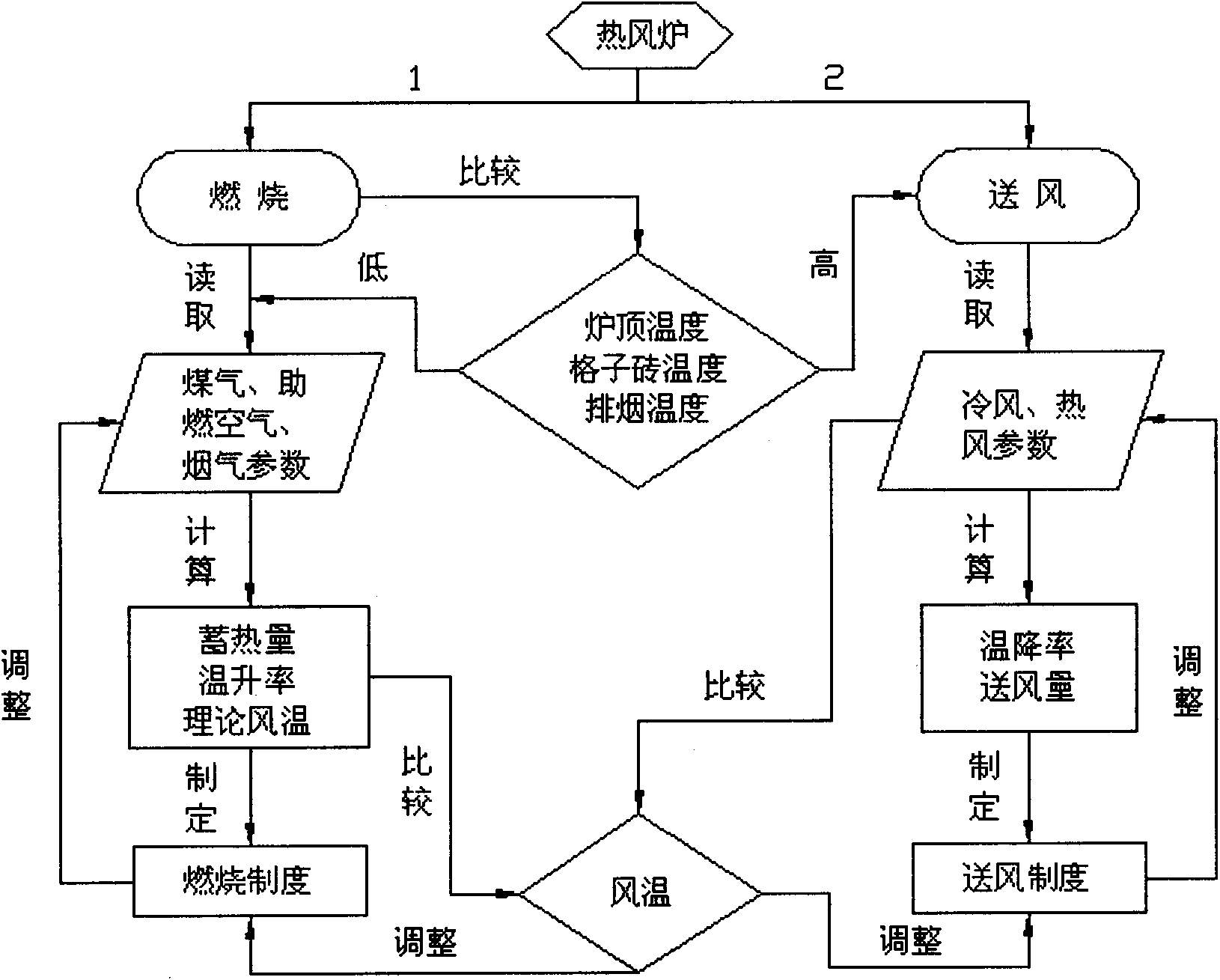

Constant wind temperature control system for hot blast stove

ActiveCN101892338ARegulating pressureAdjustable temperatureBlast furnace detailsHeating stovesBrickAir volume

The invention provides a constant wind temperature control system for a hot blast stove, comprising the hot blast stove (2), a detection element, a regulating valve, a data acquisition unit (1) and a computer (26). The control method of the control system comprises the following processes: detection of fluid parameters and valve location signals, data acquisition, data transmission, data comparison and data correction and control adjustment, wherein the detection element and the regulating valve are arranged in a pipeline, and temperature measuring equipment is arranged on the surface of a stove body. Specific steps are as follows: dynamically calculating parameters such as the heat storage capacity of checker bricks, temperature-rise ratio, theoretical wind temperature and the like during the combustion process, and carrying out on-line adjustment of parameters such as combustion air and gas flow, preheating temperature and the like; controlling direction change of the hot blast stove by the highest setting temperature of the checker bricks, a stove top and fume; and during the air supply period, taking hot blast temperature control as a target to determine an air supply curve and air supply time. The method based on calculation of dynamic balance of on-line energy of the hot blast stove effectively controls the heat storage capacity of the checker bricks of the hot blast stove, adjusts air supply quantity and air supply time, and ensures stable output of wind temperature of the hot blast stove.

Owner:SHOUGANG CORPORATION

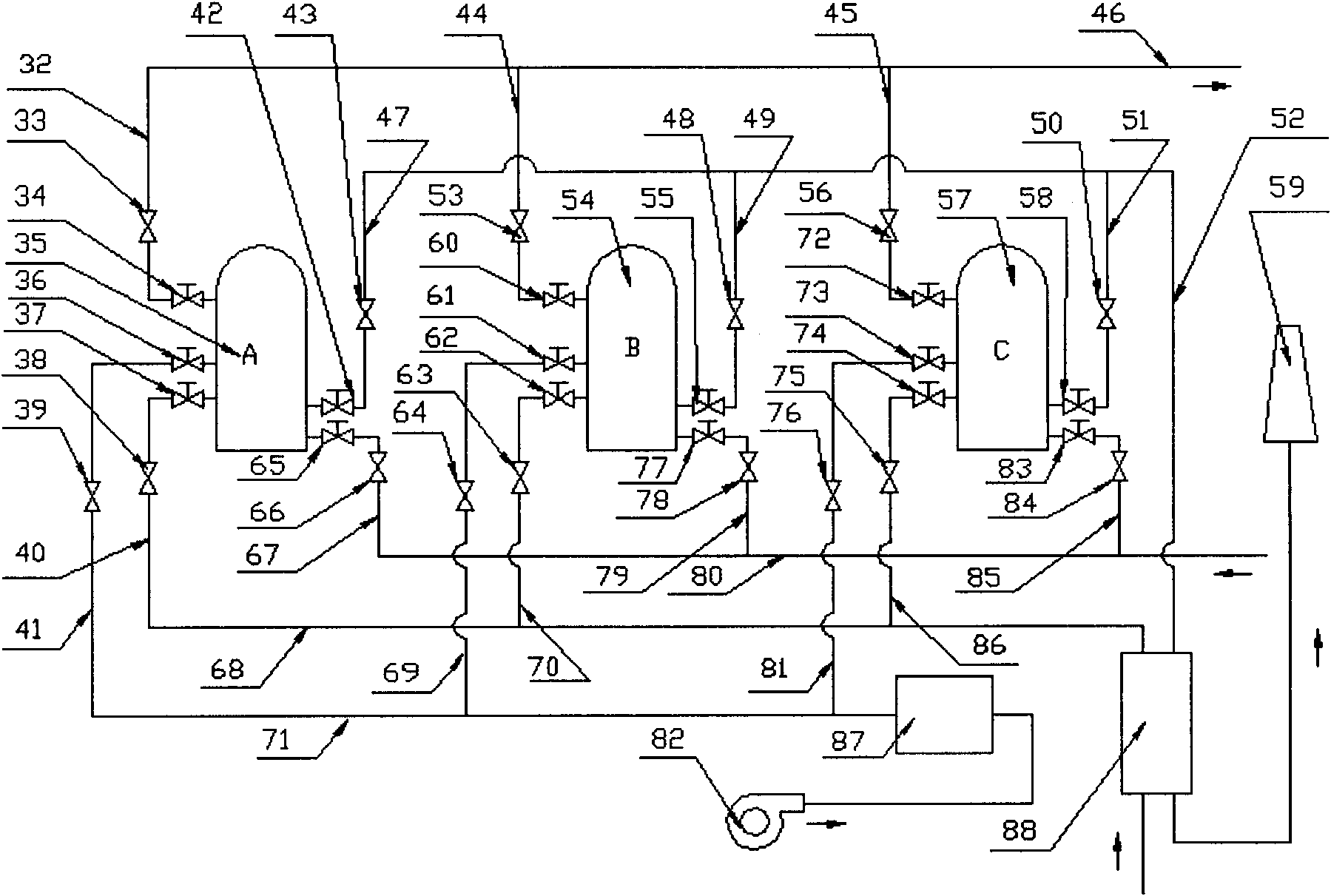

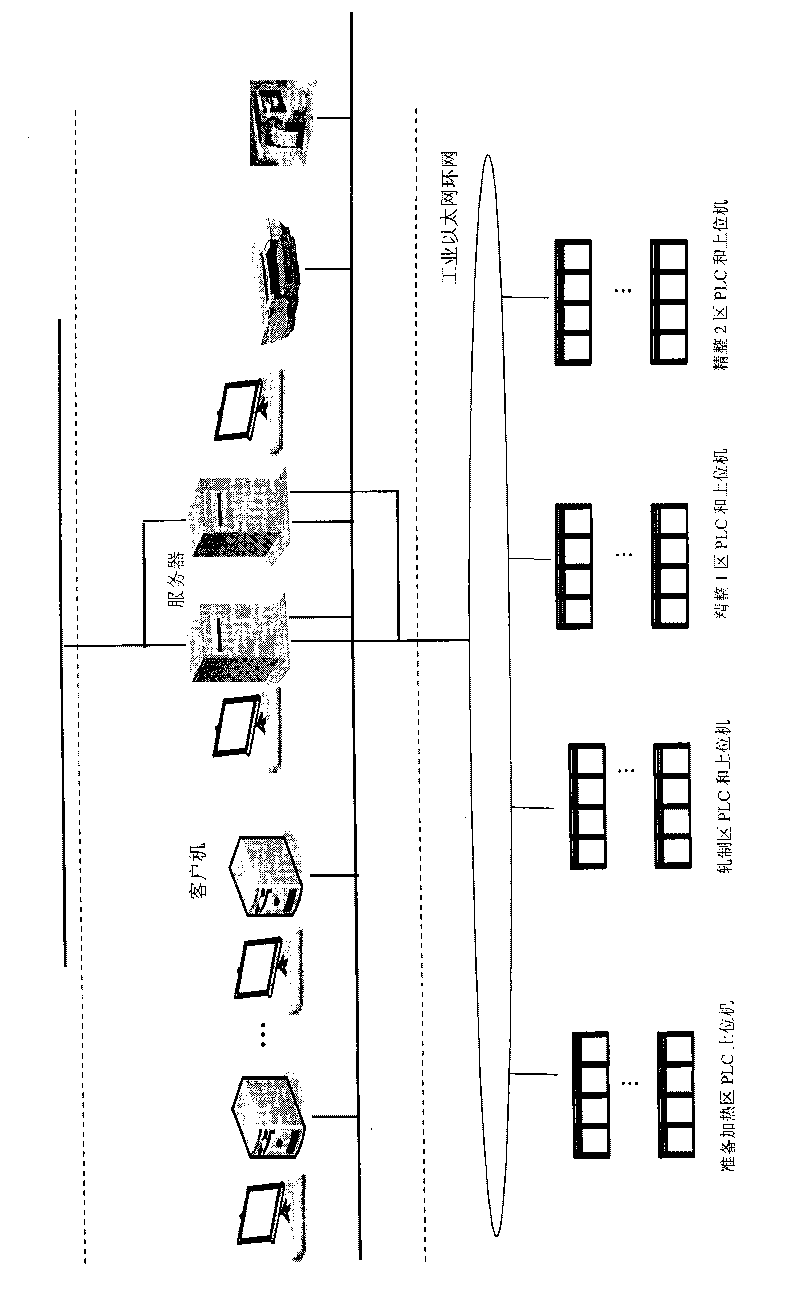

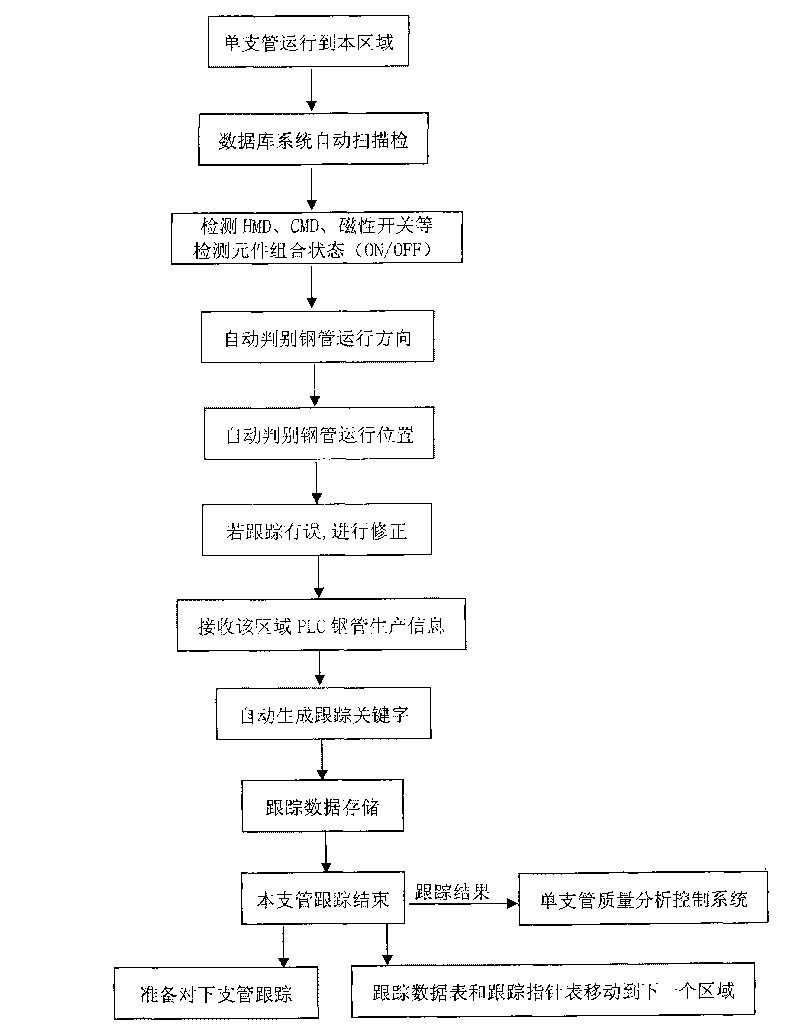

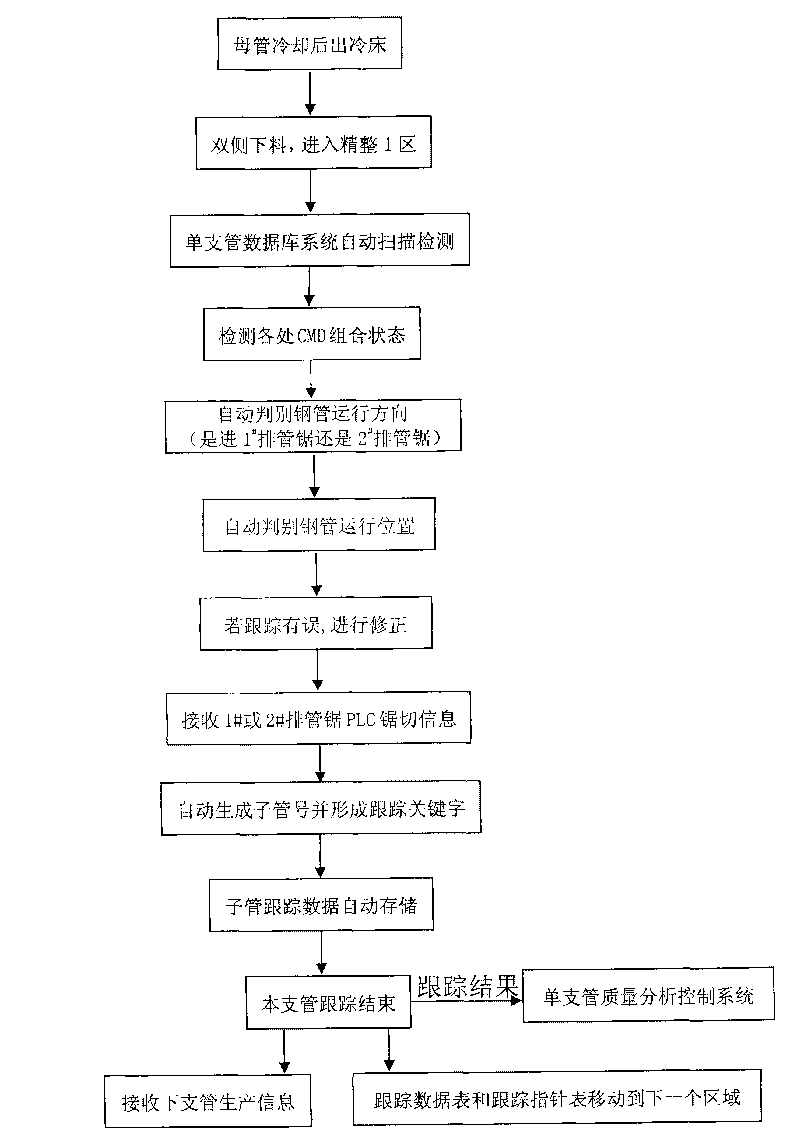

Seamless steel tube production process information tracking method

ActiveCN101751021AOptimize operating parametersImprove product qualityTotal factory controlProgramme total factory controlElectrical controlSteel tube

The invention discloses a seamless steel tube production process information tracking method, which carries out equipment electrical control partition and single branch pipe tracking partition on a production line; an added seamless steel tube production process information acquisition device is provided with a QAS device, an on-line steel tube jet printing machine, an on-line steel tube label making machine and an off-line steel tube number reading recognition machine; primary PLC of all the single equipment of the production and upper computers thereof are connected onto a server by Ethernet, and a database system is built; and the server visits the primary PLC in the single equipment of each area in an OPC manner by the Ethernet, and visits the upper computer of the single equipment of each area in a database manner. The invention solves the problem that the existing seamless steel tube production can only realize batch tracking, realizes the real-time track record of real running positions of each steel tube during the whole process from the on-line of the raw material tube blank to the off-line of the finished steel tube in the seamless steel tube production, the original setting information of each single equipment and the practical production information, and satisfies the practical requirements of users and manufactures on single steel tube production information tracking.

Owner:鞍钢集团工程技术有限公司

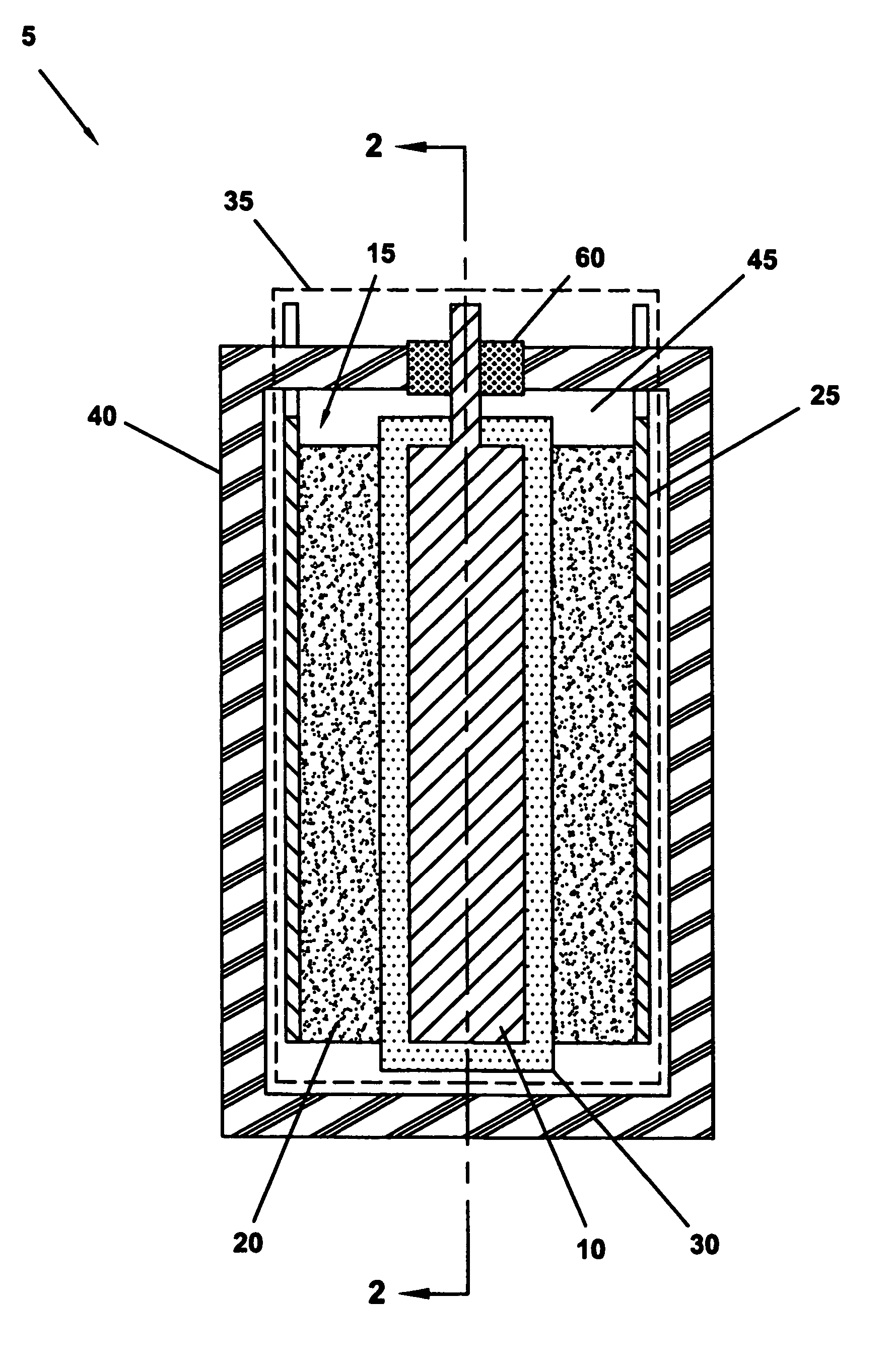

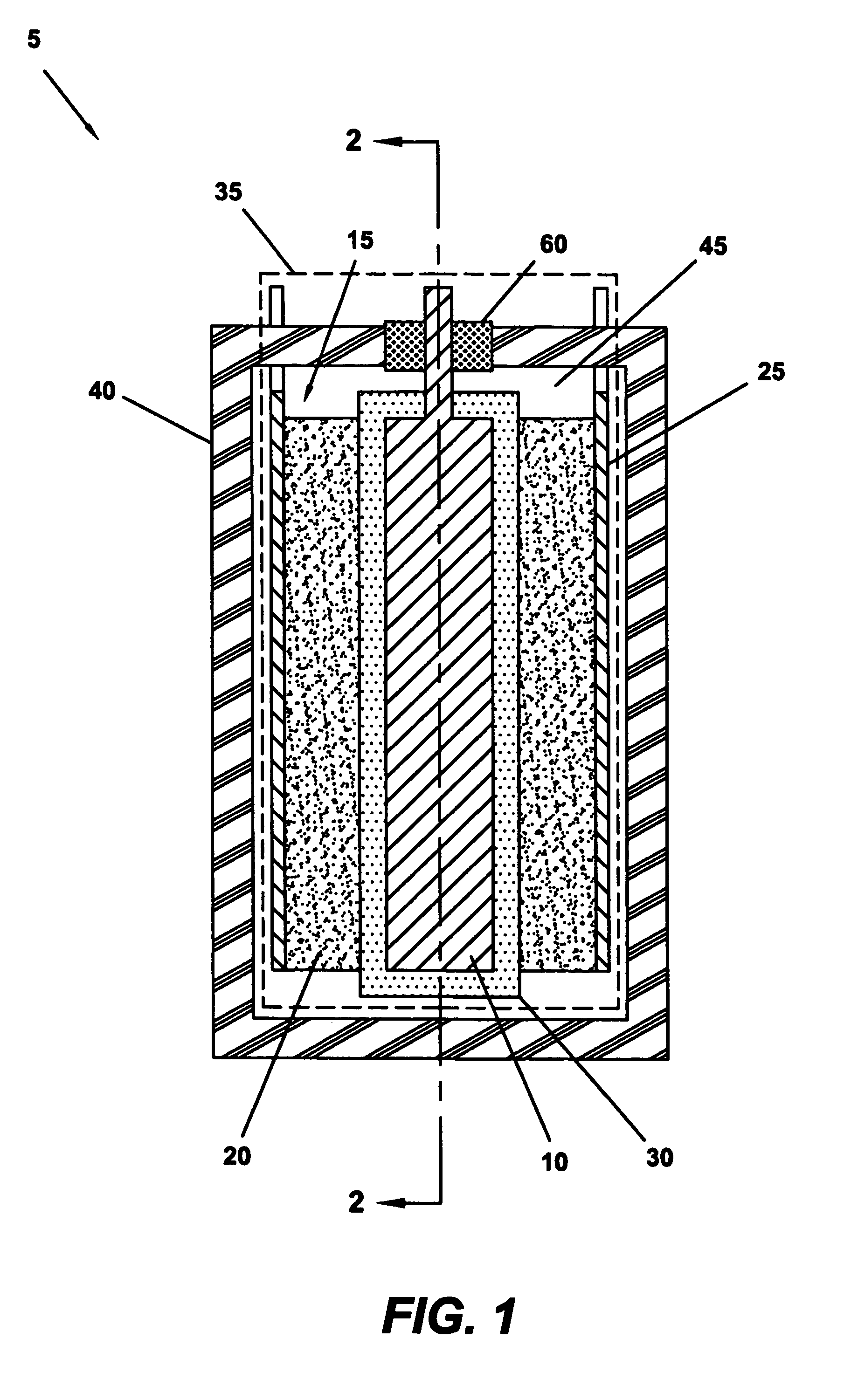

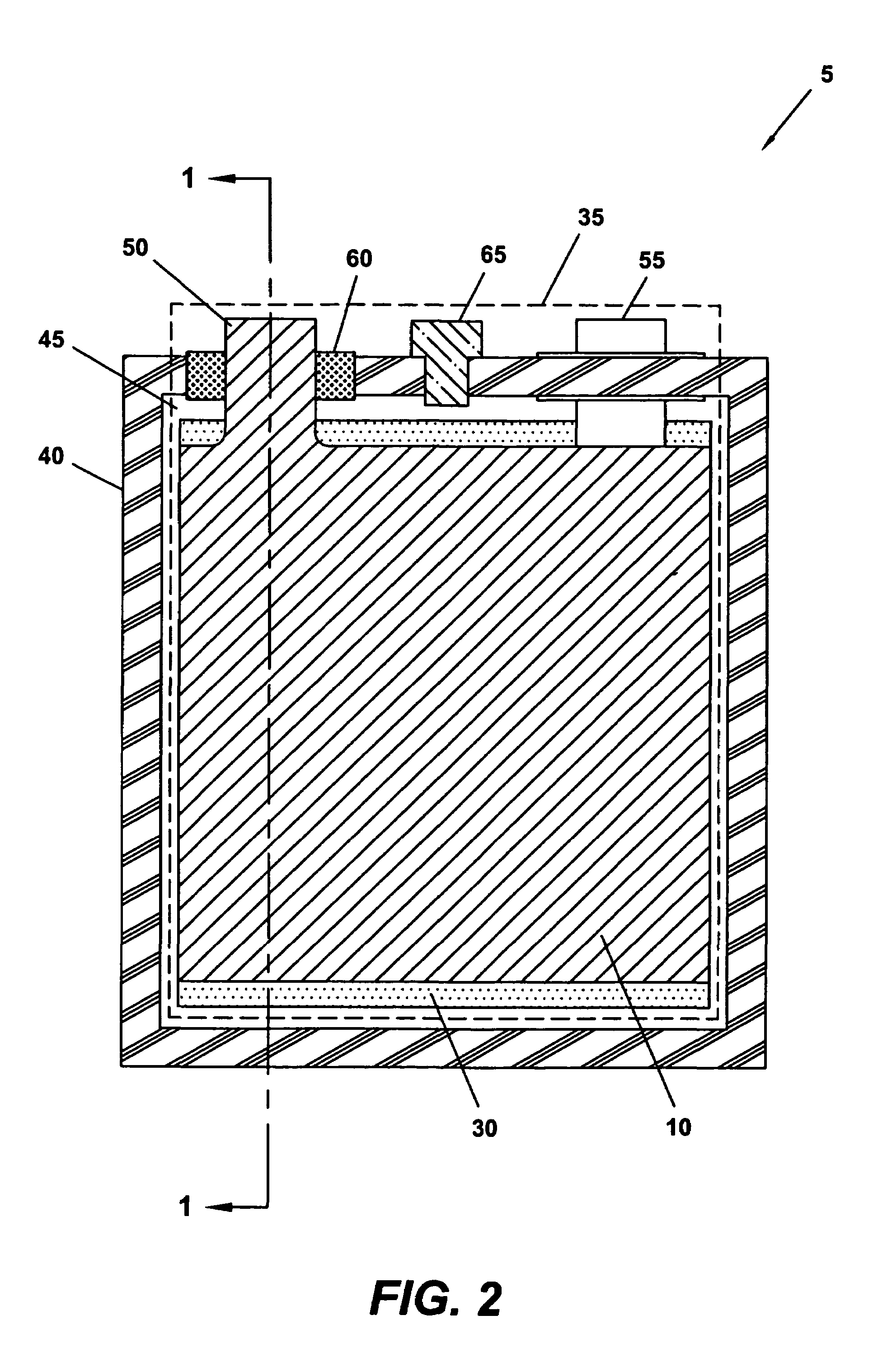

Heterogeneous electrochemical supercapacitor and method of manufacture

InactiveUS7312976B2Increase discharge powerHigh specific power characteristicHybrid capacitor electrolytesHybrid capacitor electrodesHydrogenEngineering

Owner:UNIVERSAL SUPERCAPACITORS LLC

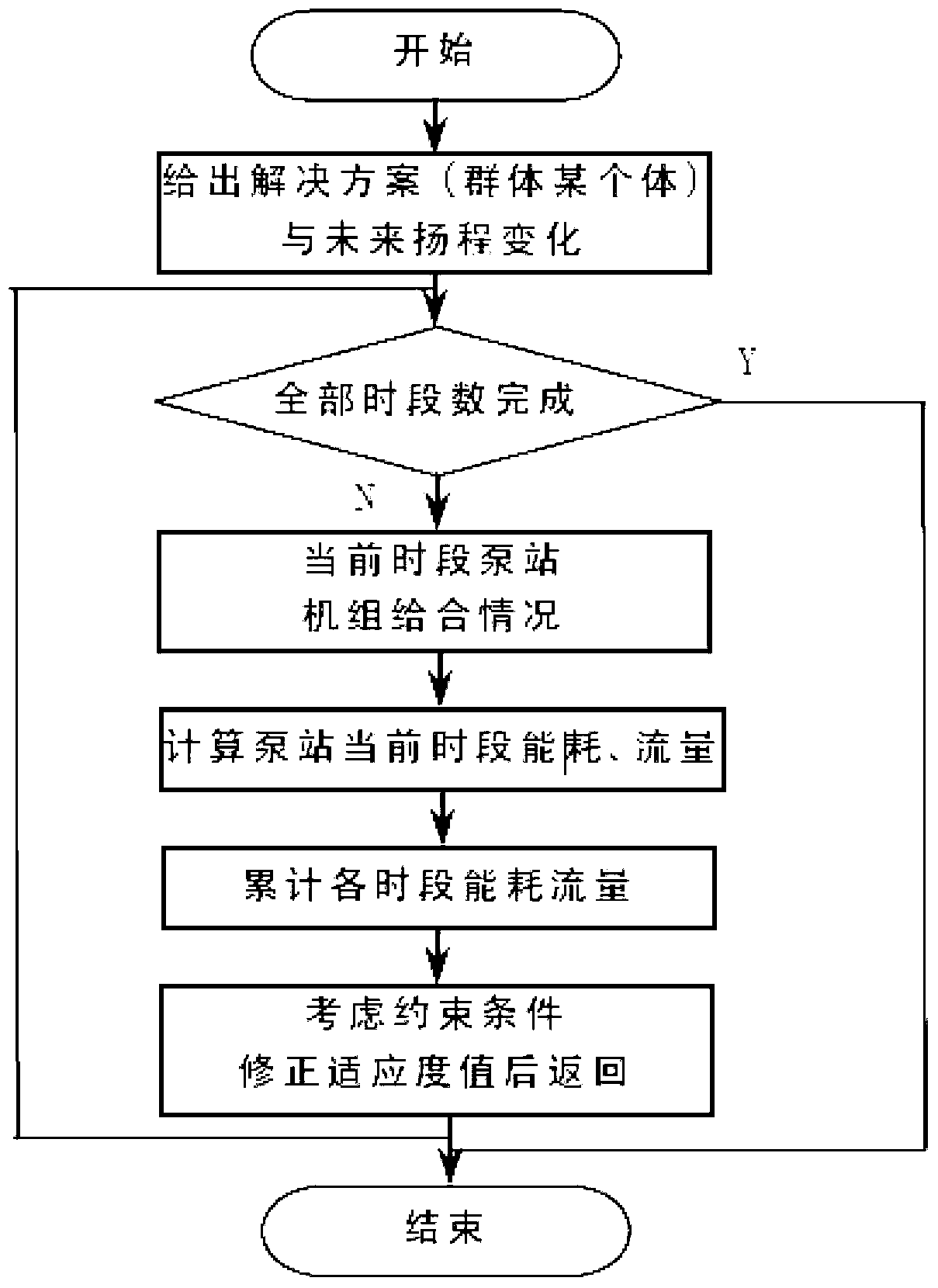

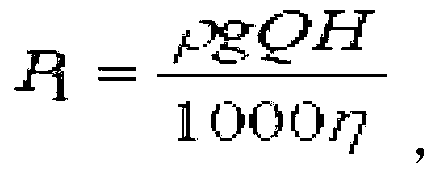

Optimal scheduling method for single-stage pump station

InactiveCN103277291AReduce energy consumptionOptimize operating parametersPump controlPositive-displacement liquid enginesMotor speedMathematical model

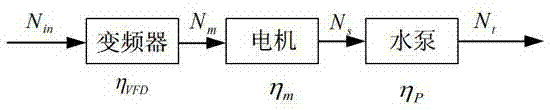

The invention relates to an optimal scheduling method for a single-stage pump station. The optimal scheduling method comprises the following steps: establishing mathematical models according to water pump energy consumption and water pump performance and optimizing pump station running parameters; establishing a mathematical model according to water pump energy consumption influencing factors including water pump flow and lift, and obtaining functional relations between the water pump energy consumption and every influencing factor; establishing a mathematical model according to water pump performance influencing factors including water pump flow, lift, efficiency, motor speed, upstream and downstream water level difference of the pump station and resistance factors of a system pipeline, and obtaining functional relations between the water pump performance and every factor; and adjusting the pump station by combination with the mathematical models established according to the water pump energy consumption and the water pump performance and specific changes of the real-time parameters. According to scientific management optimization technology and scheduling decisions, the water pump performance and motor efficiency factors are considered comprehensively, minimum of energy consumption of the pump is achieved for a goal of minimum of total power consumption of a pump station unit on the premise that the required flow of every time period and the lift are met.

Owner:SHANGHAI EAST PUMP AUTOMATION CO LTD

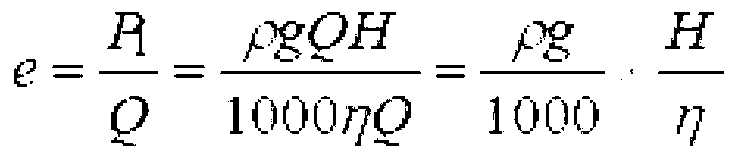

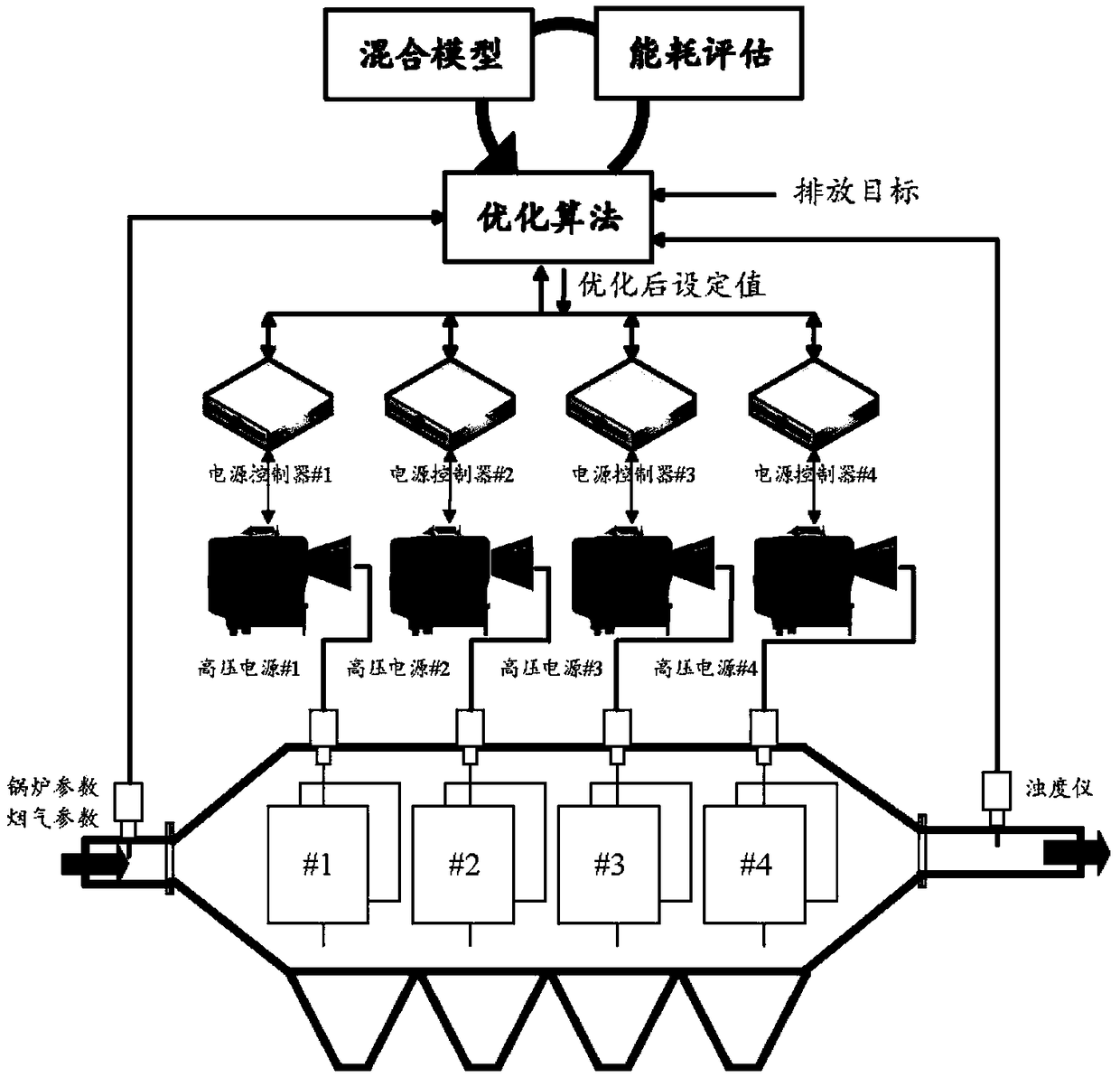

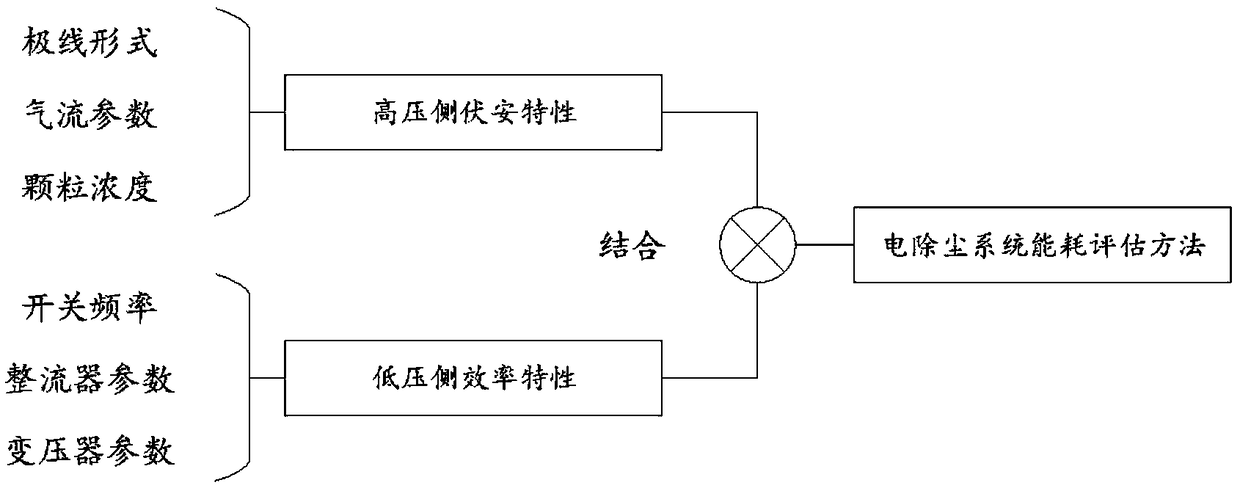

Electric dust removal system optimization control method based on hybrid model

ActiveCN108940596AOptimize operating parametersGuaranteed Emission ReliabilityEnergy industryElectric supply techniquesParticulatesElectricity

The invention relates to an electric dust removal system optimization control method based on a hybrid model. The optimization control method comprises a modeling method mixing electric dust removal system mechanism and data, an electric dust removal system variable working condition energy consumption evaluation method and a system operation multi-parameter optimization method based on a group intelligent algorithm; wherein through the modeling method mixing electric dust removal system mechanism and data, the particulate matter removal mechanism of the electric dust removal system is organically combined with the actual operation data, so that the accurate prediction of the outlet concentration under the variable working condition of the electric dust removal system is realized; throughthe electric dust removal system variable working condition energy consumption evaluation method, the change rule of system energy consumption under different parameters is obtained; and through the system operation multi-parameter optimization method based on a group intelligent algorithm, the methods are combined to obtain the optimal energy injection strategy under the specific emission targetand the variable operation working condition. According to the method, the operation strategy of the electric dust removal system is innovated from the theory, the framework and the algorithm layer, the problems of low model precision, even model mismatch, large energy consumption evaluation error, difficulty in operation parameter optimization and the like brought by the variable working condition, the multi-electric field, the multi-pole matching mode and the like are solved, so that reliable energy-saving and efficient removal of particulate matters in industrial flue gas is realized.

Owner:ZHEJIANG UNIV

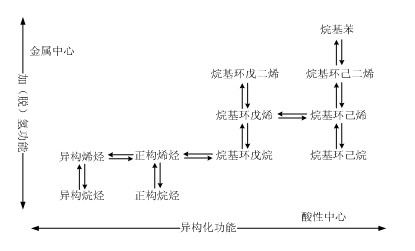

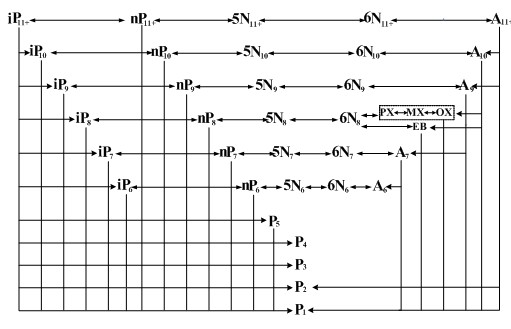

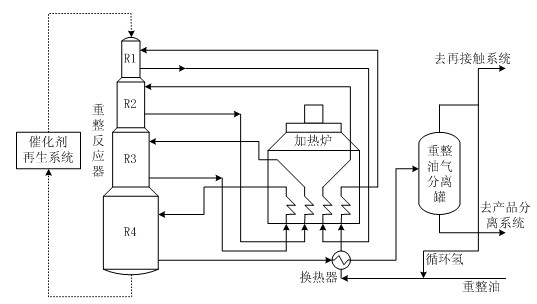

A 38 Lumped Reactor Modeling Method for Continuous Reforming Unit

ActiveCN102289579AHigh precisionEliminate production bottlenecksCatalytic naphtha reformingSpecial data processing applicationsBroyden fletcher goldfarb shannoTest analysis

The invention discloses a modeling method for a 38-lumping continuous reforming device reactor. The modeling method comprises the following steps of: 1) subdividing a reaction material into 38 lumping components; 2) constructing a reforming reaction network comprising 86 reactions; 3) building a reforming reaction dynamical model equation group on the basis of the reaction network by combining a reactor structure; 4) accumulating an influence of catalyst inactivation to estimation of each reforming reaction dynamical parameter, determining 86 model parameters, and estimating the model parameters by adopting a method combined with a gradient descent method and a broyden fletcher goldfarb shanno (BFGS) variable scale optimization algorithm based on an industrial data sample. On the basis ofa dynamic mechanism of reforming reaction, the precision of a reforming model is improved by fully using an advanced computer technology and a test analysis condition and the simulation of a reforming device is closer to the actual reaction, so that an instruction having a practical significance is provided for eliminating the production bottleneck and optimizing each operating parameter, and theeconomic benefit of the device can be enhanced.

Owner:ZHEJIANG UNIV

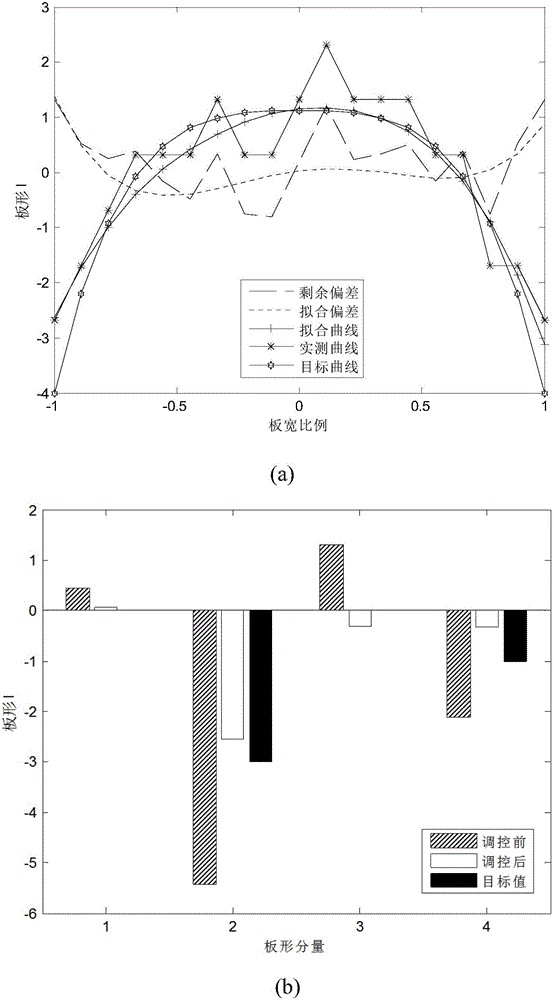

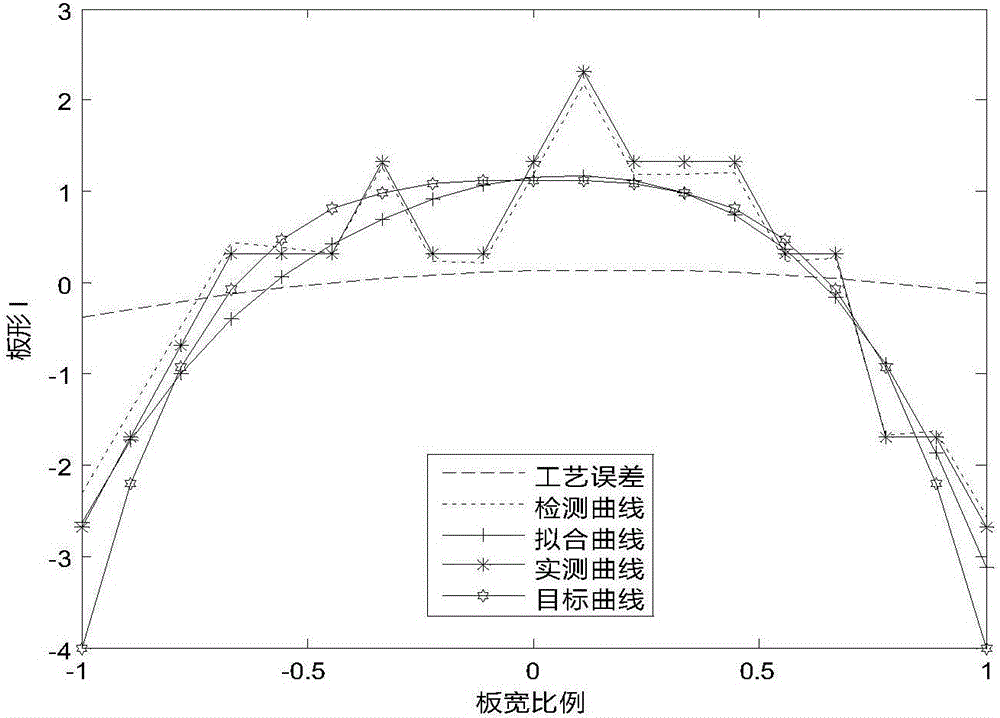

Intelligent setting method for on-line target strip shape of cold rolling strip

ActiveCN105689405AReduce shape deviationFacilitate the realization of intelligent settingsMeasuring devicesMetal rolling arrangementsLegendre polynomialsEngineering

The invention discloses an intelligent setting method for the on-line target strip shape of a cold rolling strip. The intelligent setting method comprises the following steps that a strip shape curve is divided into an original strip shape detection curve, a technology error strip shape compensation curve and a target strip shape curve, wherein the original strip shape detection curve and the technology error strip shape compensation curve are overlaid to form an effective actually-measured strip shape curve which is called the effective strip shape curve for short, and the target strip shape curve only needs to consider a strip shape control target for the follow-up process requirement; an on-line strip shape target curve is built on the basis of a quartic Legendre polynomial, the self-balanced constraint condition requirement (that is, the transverse integration in the width direction of the strip is zero) of the residual stress deviation of the rolled strip in the width direction of the strip is met, the target is clear, and the function is explicit; and a target strip shape standard curve library is built on the basis of an intelligent algorithm, the optimal parameter of the on-line target strip shape is obtained, and the control precision of the strip shape is ensured.

Owner:河北燕赵蓝天板业集团有限责任公司

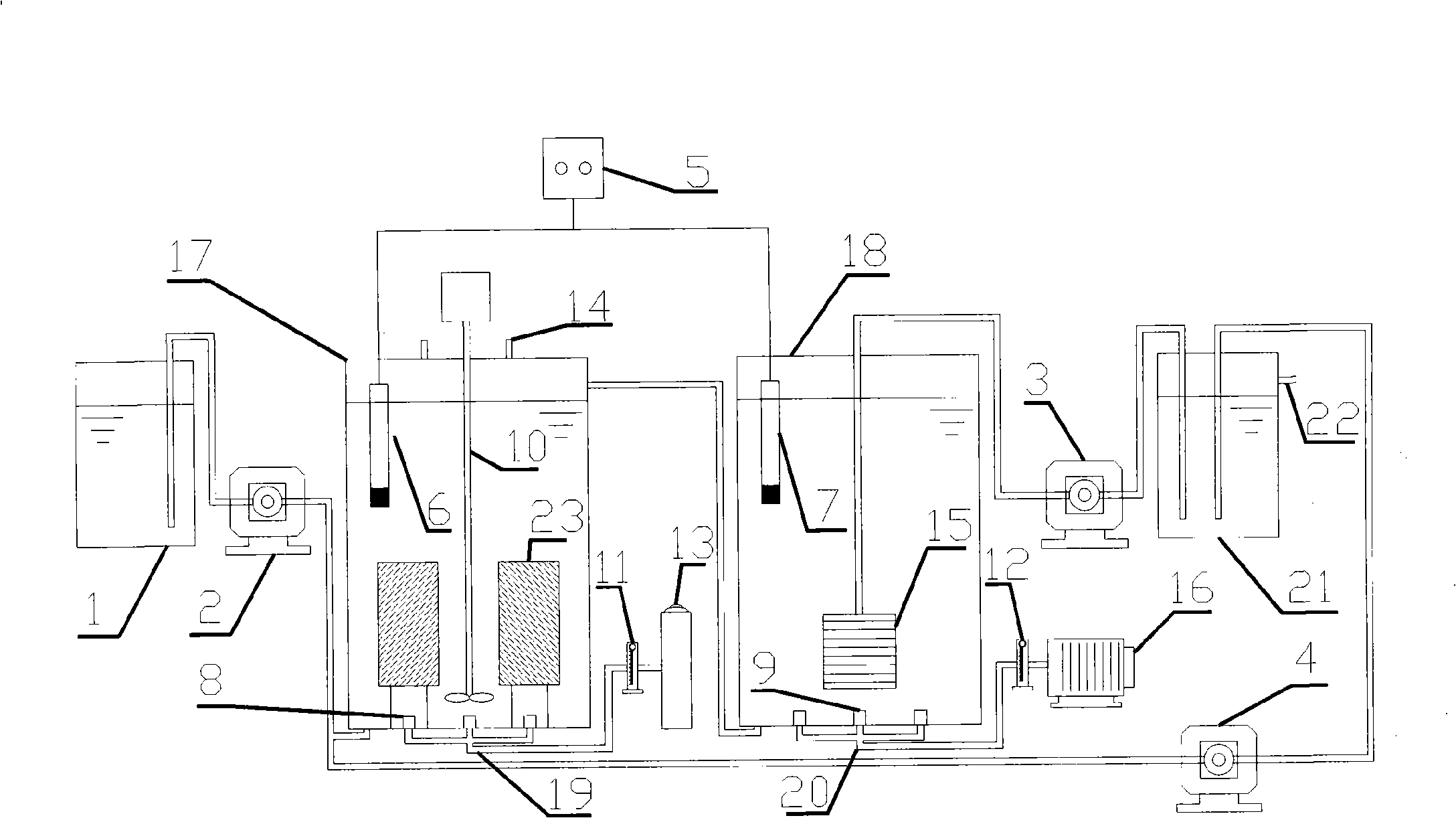

Inverted denitrification process film bioreactor

InactiveCN101302059AGood adhesionPromote growthTreatment with aerobic and anaerobic processesPorosityFiber

The invention provides a novel inverted denitrogenation membrane bioreactor, which belongs to the water treatment equipment technical field. The invention is characterized in that the inverted denitrogenation membrane bioreactor consists of non-woven fabric padding, reaction vessels, an aeration device, a temperature control device and a membrane component. An anaerobic ammonium oxidation reaction vessel is a closed device with anaerobic ammonium oxidation bacterium adopting non-woven fabric for attachment growth; a nitrosification reaction vessel is an open device with effluent adopting membrane effluent. Non-woven fabric which has a larger extent of porosity (the aperture is 3 micrometres) and a roughened surface is suitable for the attachment of the anaerobic ammonium oxidation bacterium which grow slowly, and has low cost and light weight; and the membrane component adopts a hollow fibrous membrane (the material is polypropylene, the average aperture is 0.1 micrometre, and the membrane area is 0.2 m<2>). The inverted denitrogenation membrane bioreactor has the advantages that: the attachment of microorganism is excellent, and stromata and gas-liquid-solid three-phase are mixed evenly, thereby easily achieving the required operating parameter, and saving cost and operating expense. The reactor is applicable to a process which performs anaerobic ammonium oxidation and nitrosification in succession, and is a novel biological denitrogenation reactor with wide market application prospect.

Owner:DALIAN UNIV OF TECH

A coating-treatment surface modification method for ultrahigh molecular weight polyethylene fibers

InactiveCN105544180AOptionalUniform concentrationFibre typesUltrasonic/sonic fibre treatmentFiberPolymer science

The invention belongs to the field of materials and particularly relates to a coating-treatment surface modification method for ultrahigh molecular weight polyethylene fibers and fabric of the fibers. To improve adhesion properties of an interface between a resin substrate and the ultrahigh molecular weight polyethylene fibers as well as the fabric thereof and to eliminate or weaken timeliness of material surface plasma treatment, the surface of the ultrahigh molecular weight polyethylene is treated with low-temperature plasma and the fibers or the fabric are then immediately dipped into a coating solution containing epoxy resin, cyanate esters, bismaleimide resin, and the like so as to artificially introduce a designable "composite material interface layer" before compositing the ultrahigh molecular weight polyethylene fibers and the resin substrate, thus enhancing interface adhesive strength with the resin substrate and improving comprehensive properties.

Owner:THE RES INST FOR SPECIAL STRUCTURES OF AERONAUTICAL COMPOSITE AVIC

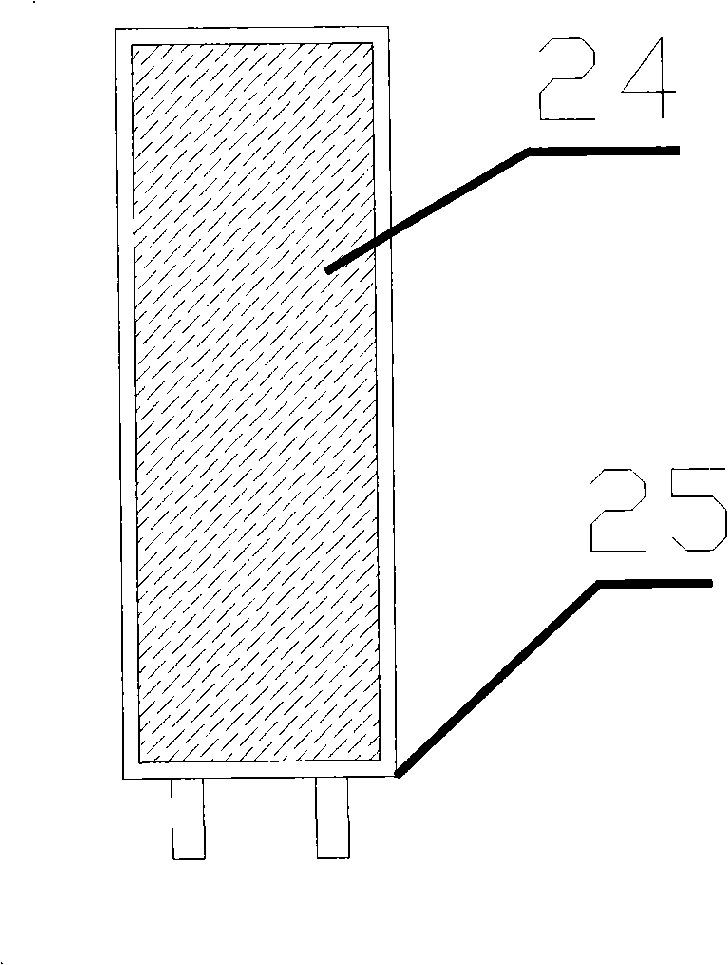

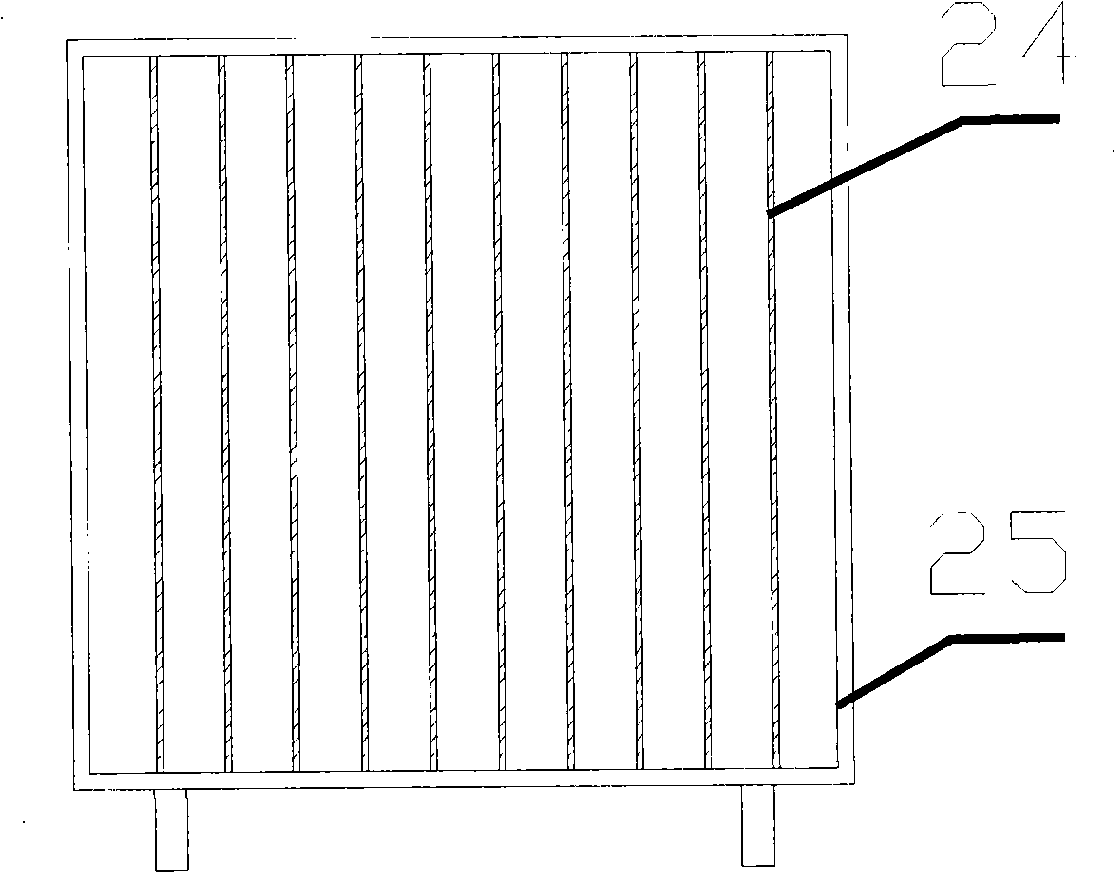

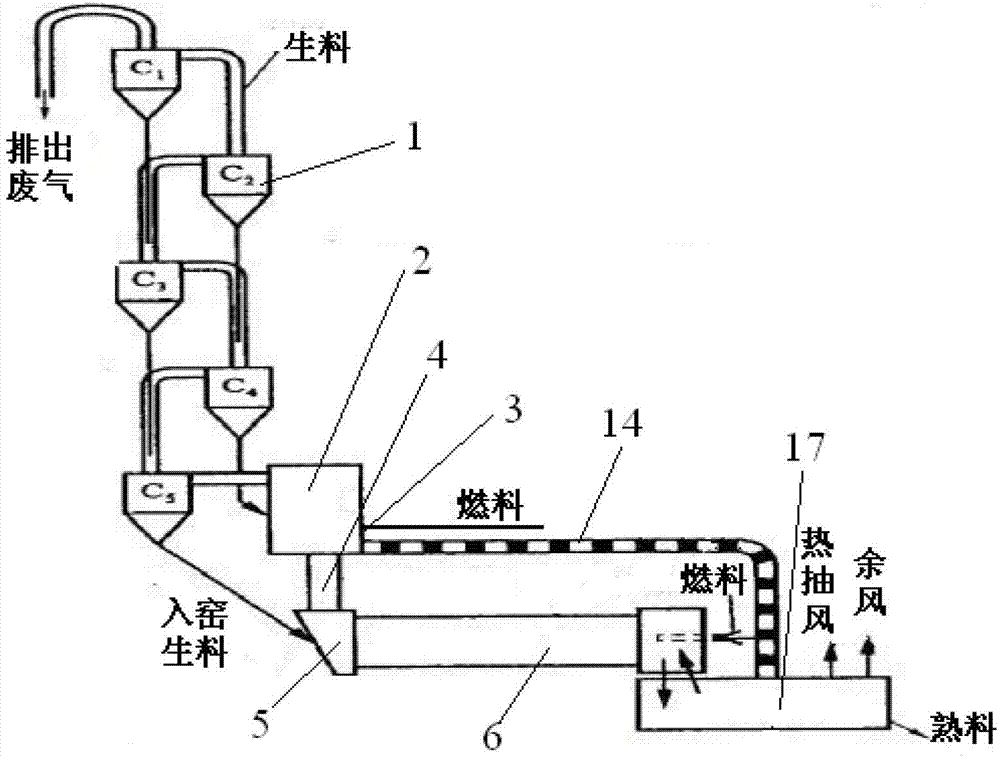

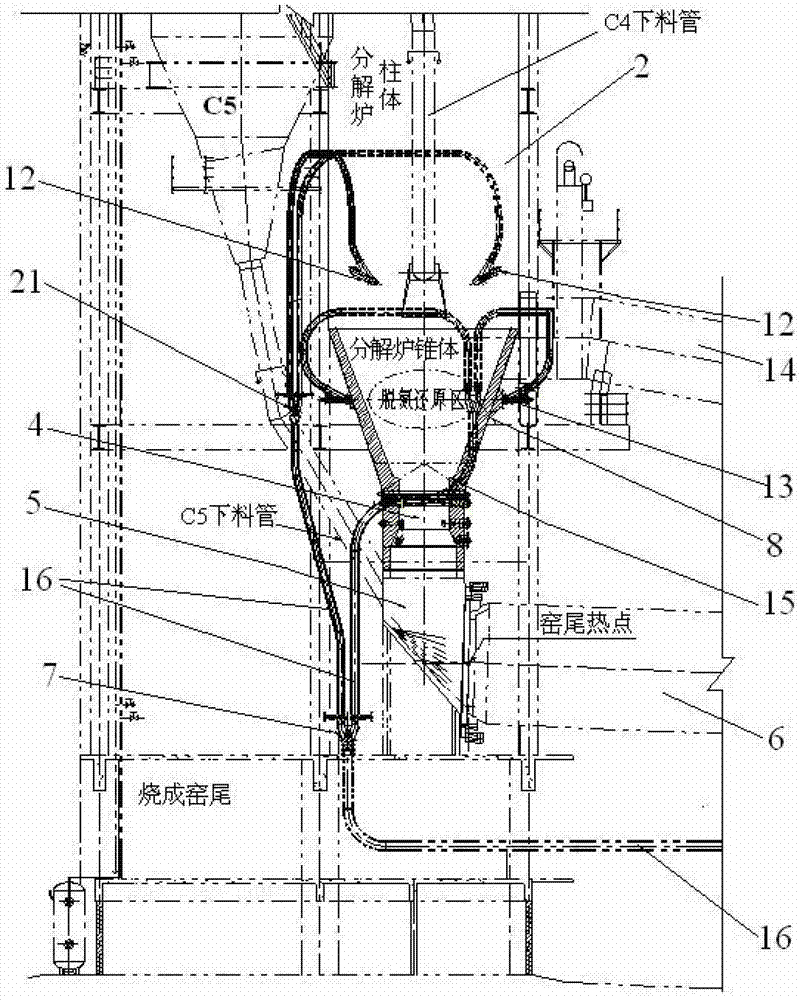

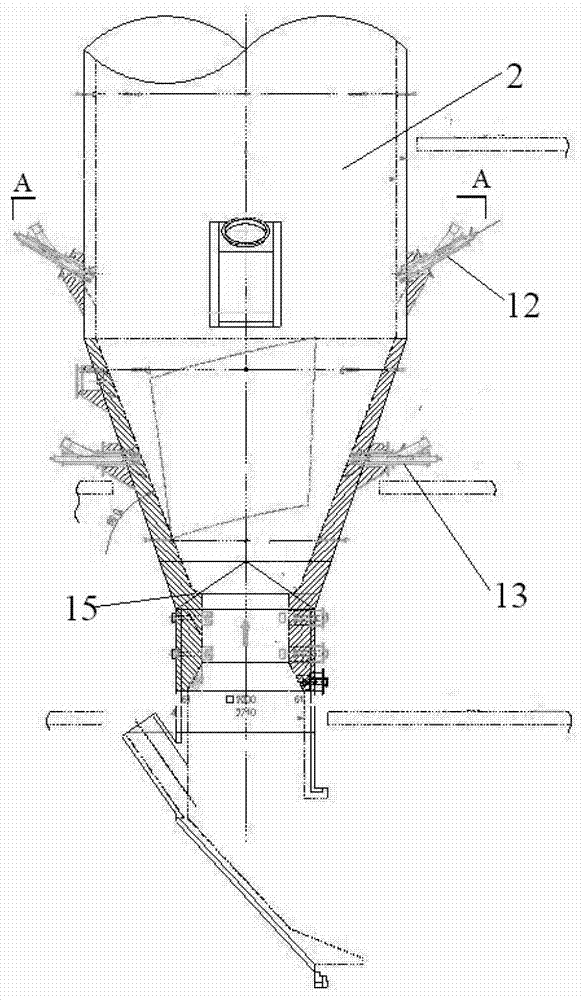

Clinker production line for novel dry process cement kiln and denitration process method for clinker production line

ActiveCN102923979AReduce generationSuppress generationClinker productionProduction lineCoal pipeline

The invention discloses a clinker production line for a novel dry process cement kiln. Pulverized coal in a pulverized coal pipeline which is communicated with the tail of the kiln is divided into two channels by a first pulverized coal distributor, wherein one channel is communicated with a column body on the upper part of a decomposition furnace, and the pulverized coal is divided into two channels again by a second pulverized coal distributor and symmetrically enters the column body on the upper part of the decomposition furnace; and the other channel is communicated with a cone on the lower part of the decomposition furnace, and the pulverized coal is divided into two channels again by the second pulverized coal distributor and symmetrically enters the cone on the lower part of the decomposition furnace. The invention also provides a denitration process method adopted by the production line. By the technical scheme, thermal NOx generated in the kiln is decreased and reduced, and the generation of fuel NOx is inhibited, so that NOx can be effectively reduced from the source; and after process improvement, operation parameters are optimized, the operation quality and stability of the system are promoted, and a certain energy-saving effect is achieved.

Owner:ANHUI CONCH GRP +2

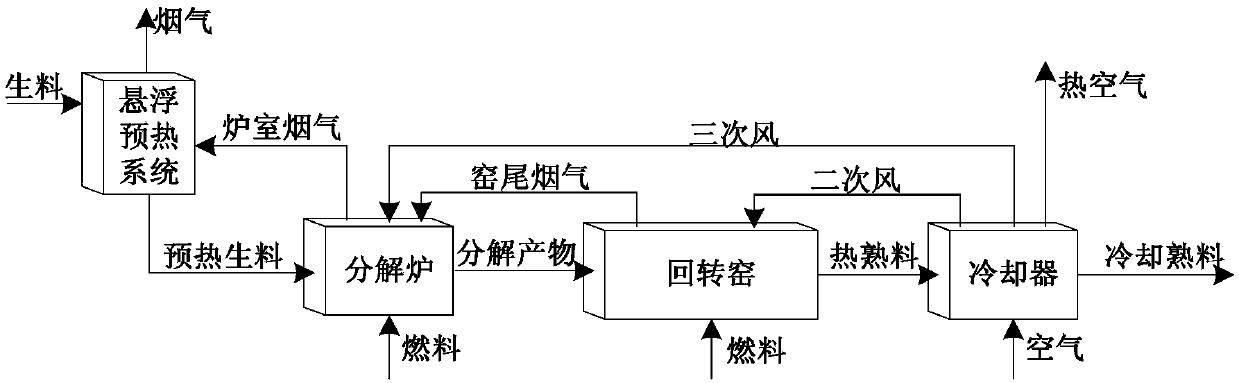

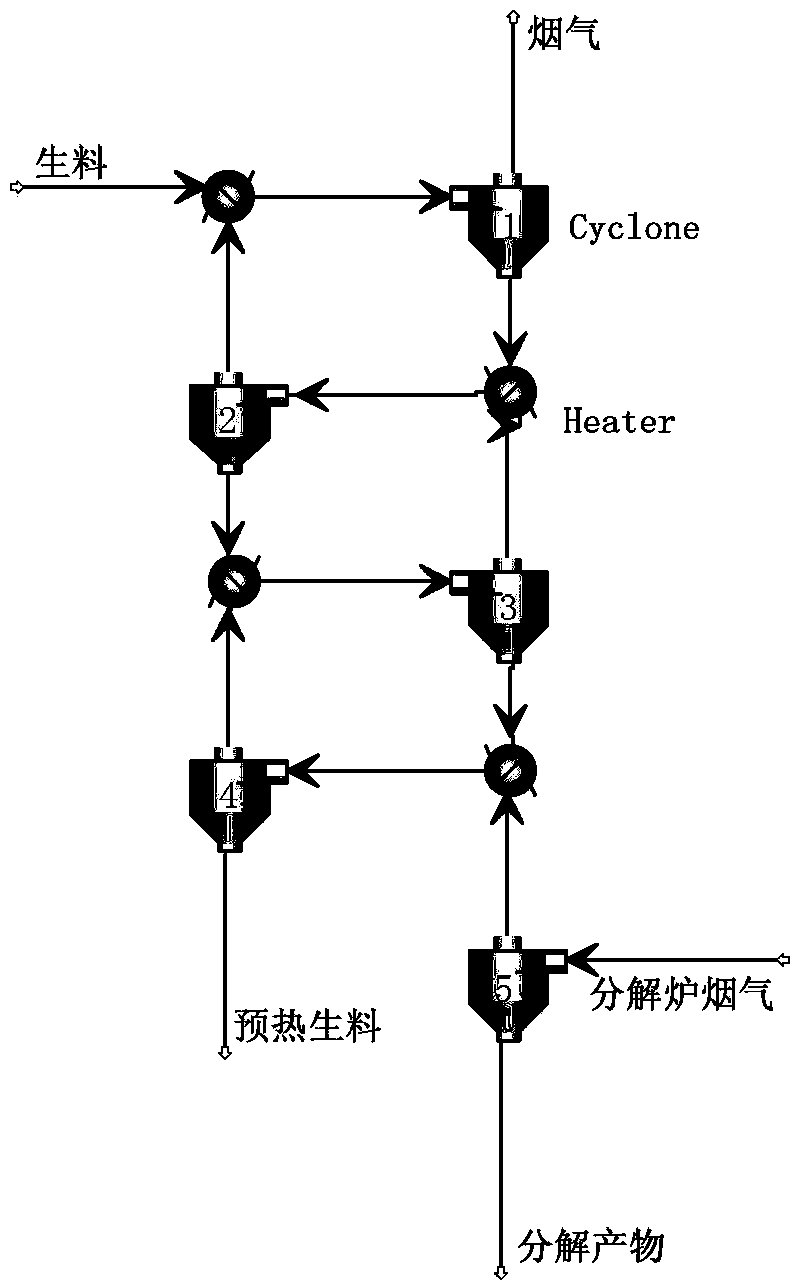

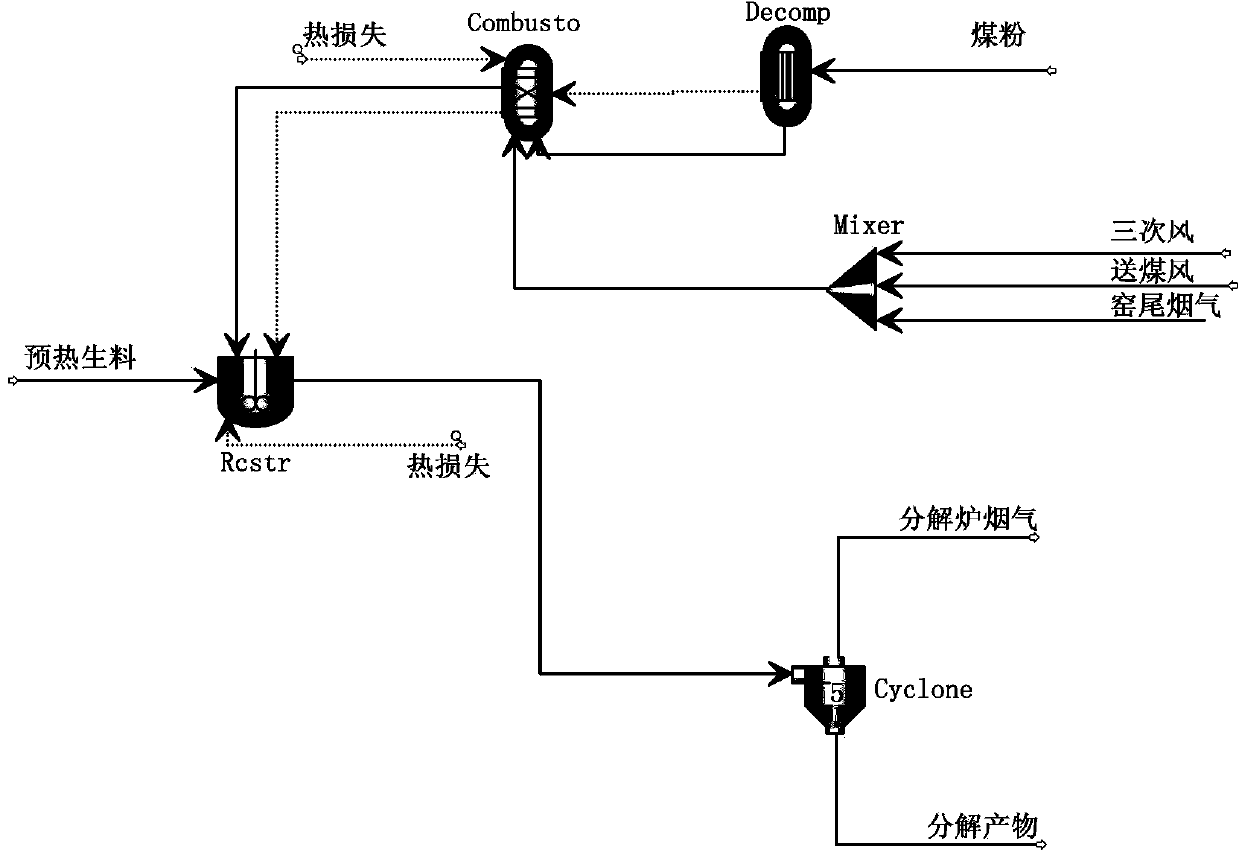

Method for modeling and optimizing cleaner production of cement clinker sintering process

ActiveCN103400196ASimplify the simulation calculation processHelpful for analysisForecastingMaterial balanceHeat conservation

The invention relates to a method for modeling and optimizing cleaner production of a cement clinker sintering process. The method comprises the steps of establishing a cement clinker sintering process model in Aspen Plus software according to a material balance relationship and the heat conservation principle of various working procedures in the cement clinker sintering process; setting and inputting data of the cement clinker sintering process, and operating the model until a simulation result meets an error requirement; selecting corresponding energy saving and emission reduction technologies according to actual production requirements, optimizing the cement clinker sintering process model, and optimizing a clinker sintering method. According to the invention, the steady-state model of the cement clinker sintering process is established based on fundamental principles of substance conservation, energy conservation and macroscopic reaction dynamics, thereby being conducive to describing influences imposed on the process by changes of process parameters and adoption of energy saving and emission reduction technologies.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

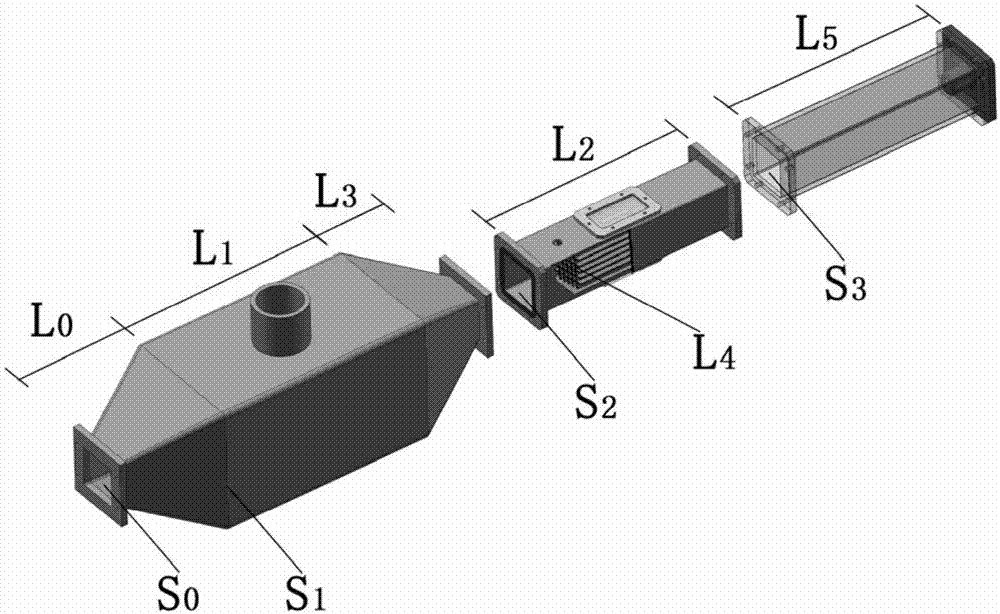

Fine particle emission reduction device of burning energy system based on acoustic agglomeration principle

ActiveCN103877824AAchieving sound condensation emission reductionEnhanced acoustic condensation emission reduction efficiencyAuxillary pretreatmentSound sourcesEngineering

The invention designs a device for realizing acoustic agglomeration emission reduction of fine particles in high-flow flue gas of a burning energy system. The device comprises a high-pressure gas flow source, a high-pressure gas mixing chamber, gas flow sound sources, a horn, a coupling cabin, an agglomeration cabin, an extended cabin, a movable end surface, a conventional dust remover, a data sensing control part, a central measurement and control computer, a sound elimination part and a sound insulation part. According to the device, the three high-power gas flow sound sources are matched with a variable-section pipeline by fully utilizing the principle that the acoustic agglomeration efficiency is sharply improved along with the increment of the sound pressure level; a barrier structure and a gas-sound separation part are introduced, so that the fine particles are quickly agglomerated in the large-size agglomeration cabin under the action of a high-strength and low-harmonic-component planar standing wave sound field; running parameters are adjusted and optimized in a unified manner by virtue of the measurement and control computer; the best transmission efficiency of strong sound waves from generating to acting is realized and the characteristic change of the fine particles is adapted; the whole realization scheme has the advantages of emission reduction efficiency, economical efficiency, applicability, no pollution, extendability and the like.

Owner:NAT UNIV OF DEFENSE TECH

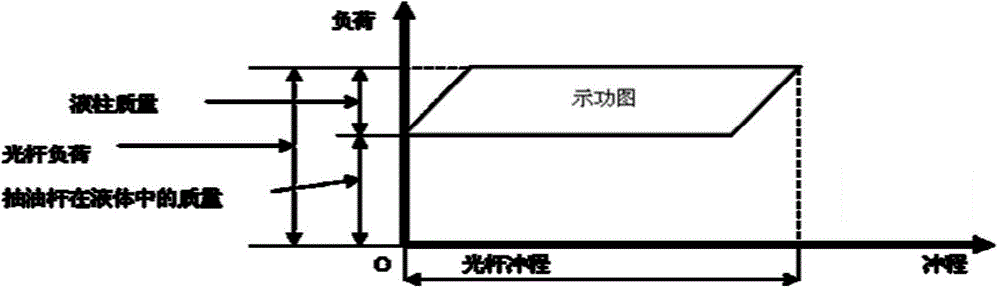

Indicator diagram-based oil pumping machine regulating and controlling method

InactiveCN104570991AAdvantages of regulation methodOptimize operating parametersEnergy industryFluid removalFrequency conversionClosed loop

The invention relates to an indicator diagram-based oil pumping machine regulating and controlling method. The method comprises the following steps: acquiring production parameters of an oil pumping machine well in real time; drawing an indicator diagram of an oil producing well by combining the parameters of the pump hanging, the pump diameter, the stroke, the stroke frequency and the liquid production capacity of an oil well, and calculating the saturation degree of the indicator diagram; performing analysis processing on the data of the indicator diagram and drawing a static load line; solving dynamic fluid level data of the oil well by utilizing dynamic fluid level calculating software; determining the reasonable submergence depth of the oil well according to the dynamic fluid level data of the oil well; performing analysis and calculation on the real-time production parameters of the oil well through a computer to obtain reasonable operating parameters of an oil pumping machine; remotely and intelligently regulating output frequency by utilizing a frequency conversion technology; changing the operating rotating speed of a motor of the oil pumping machine, so that the real-time closed-loop regulation of the working conditions of the oil well is realized. The regulating and controlling method disclosed by the invention is mainly used for optimizing the operating parameters of the oil pumping machine; the operating parameters of the oil pumping machine are regulated in real time; the automatic closed-loop control is realized.

Owner:PETROCHINA CO LTD

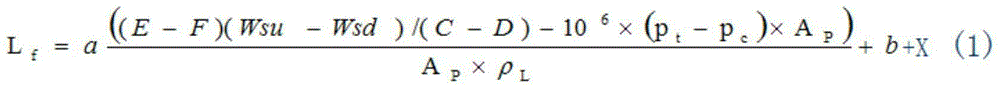

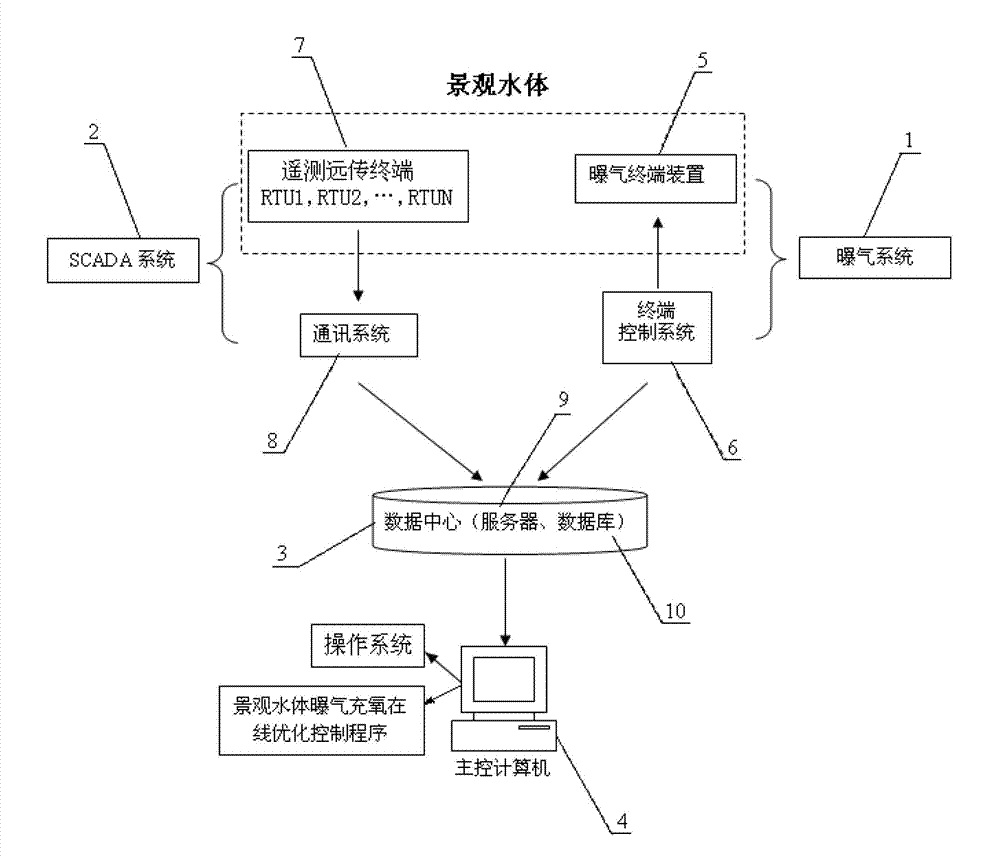

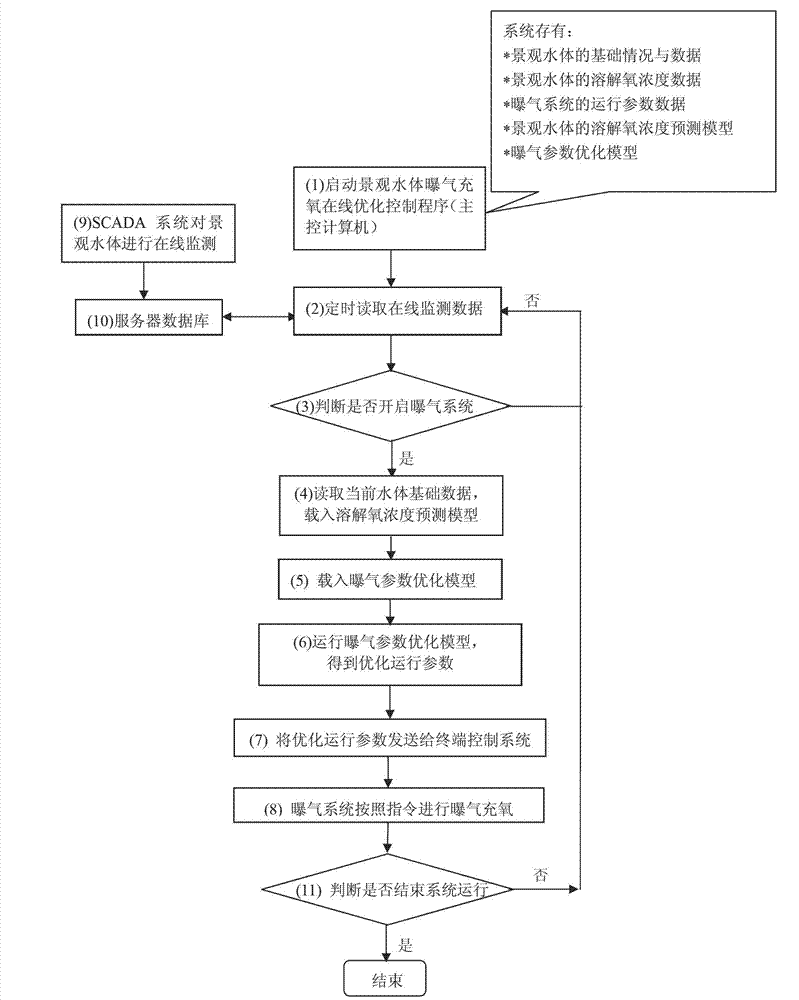

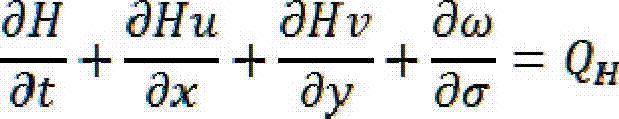

On-line optimization control system for aeration and oxygenation of landscape water body and control method thereof

ActiveCN102968058AEnsure water purification effectImprove operational efficiencyWater aerationSustainable biological treatmentData centerData acquisition

The invention discloses an on-line optimization control system for the aeration and oxygenation of a landscape water body. The system comprises an aeration system, a data acquiring and monitoring system, a data center and a master control computer; the aeration system comprises a plurality of aeration terminal devices and terminal control systems; the data acquiring and monitoring system comprises a plurality of tele-metering tele-transmission terminals and communication systems; the data center comprises a server and a database; and the master control computer stores an on-line optimization control procedure for the aeration and oxygenation of the landscape water body, so that the aeration and oxygenation effect to the water body under different atmosphere and water quality conditions can be evaluated, and the opening, the closing, the aeration quantity and the aeration time of the aeration system can be adjusted and controlled by optimizing the running parameters. According to the invention, the dissolved oxygen concentration and the aeration effect of the landscape water body in the process of aeration under different conditions can be monitored and evaluated, the aeration energy consumption can be reduced by guaranteeing the oxygenation effect and optimizing the running parameters by optimizing the aeration process, and the comprehensive aims of landscape water body water quality keeping, energy saving and consumption reducing can be achieved.

Owner:TIANJIN UNIV

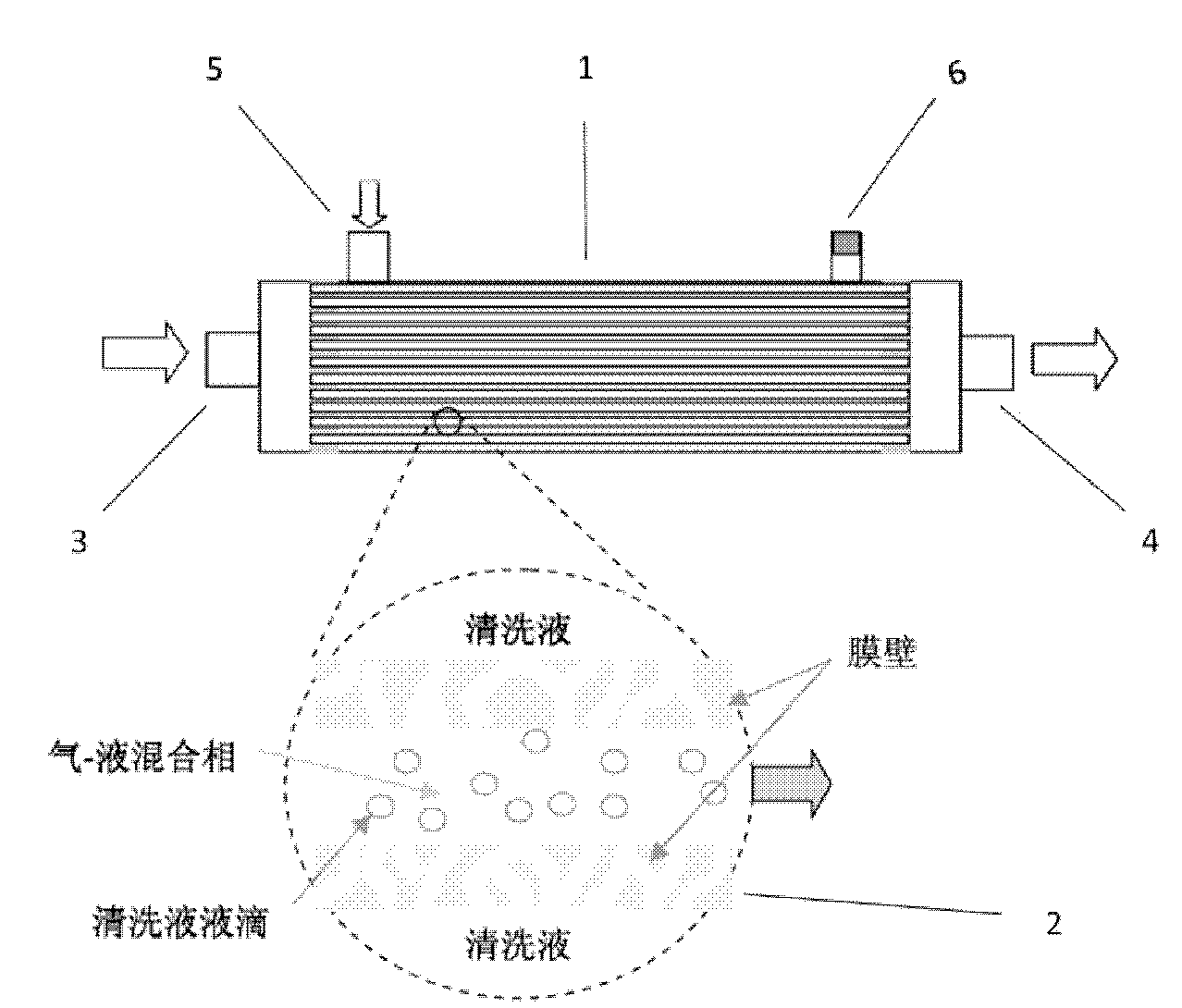

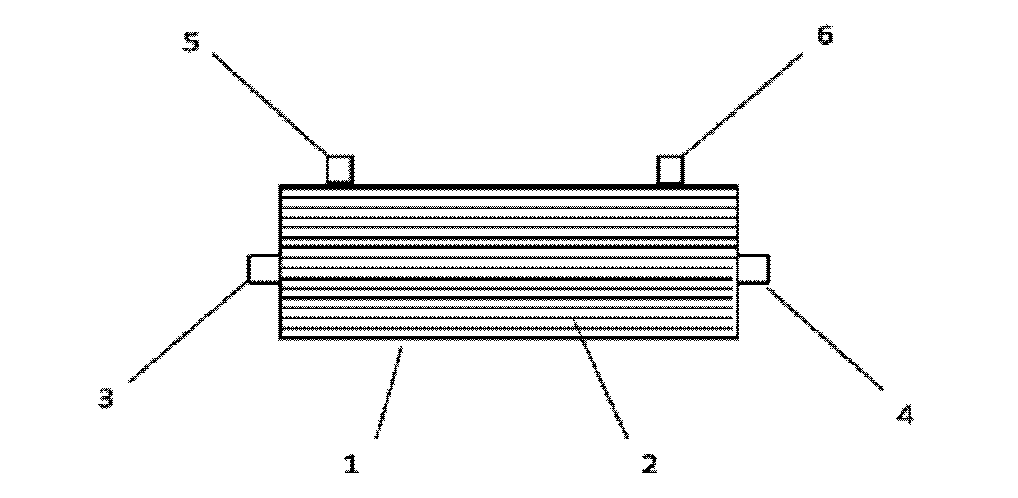

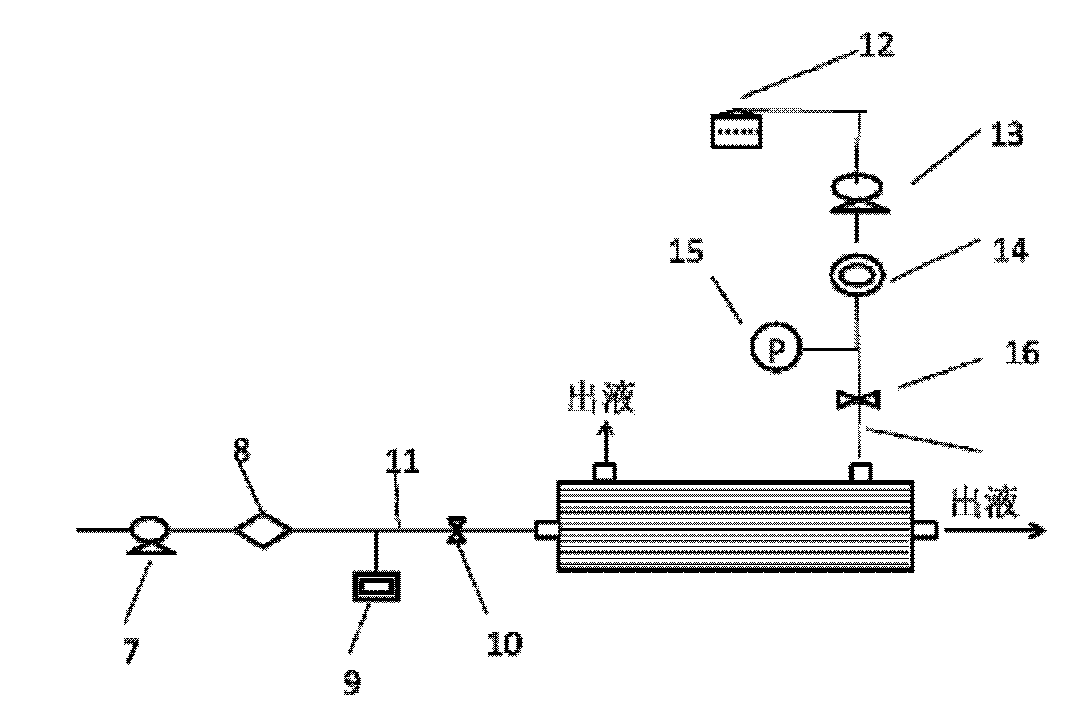

Method for cleaning filtering membrane modules

InactiveCN102145257AEasy to cleanRealization of cleaning optimizationSemi-permeable membranesEnvironmental resistancePhysical chemistry

The invention relates to a method for cleaning filtering membrane modules, which comprises the following steps: high-pressure gas at 0.15MPa-0.5MPa with flow rate of 1L / min-10L / min and cleaning fluid at 10 DEG C-50 DEG C with flow rate of 100mL / min-1000mL / min are respectively applied to two sides of a membrane, the cleaning fluid can permeate through membrane holes under the action of pressure and bring away various contaminants attached to the walls of the membrane holes to the other side, and then is processed into small drops partially at 10m / s by high-pressure gas at the other side, so that great partial shear force is generated to continuously impact the surface of the membrane for impacting, flushing, loosening and separating the various contaminants attached on the surface of the membrane, thereby the effective cleaning effect is achieved. In the method, the specific gas-liquid mixed phase flow is fully utilized to effectively restore the intrinsic separation function of the membrane, so that the service life of the membrane is greatly prolonged and the characteristics of high efficiency, energy conservation and environment protection are achieved.

Owner:SHANGHAI JIAO TONG UNIV

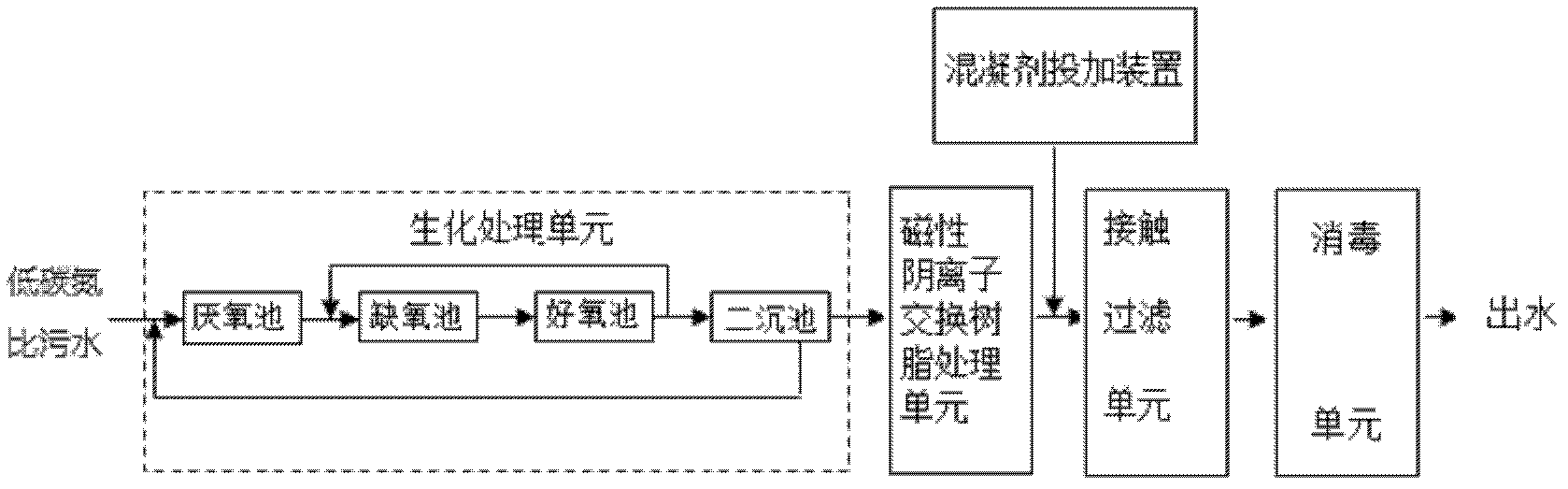

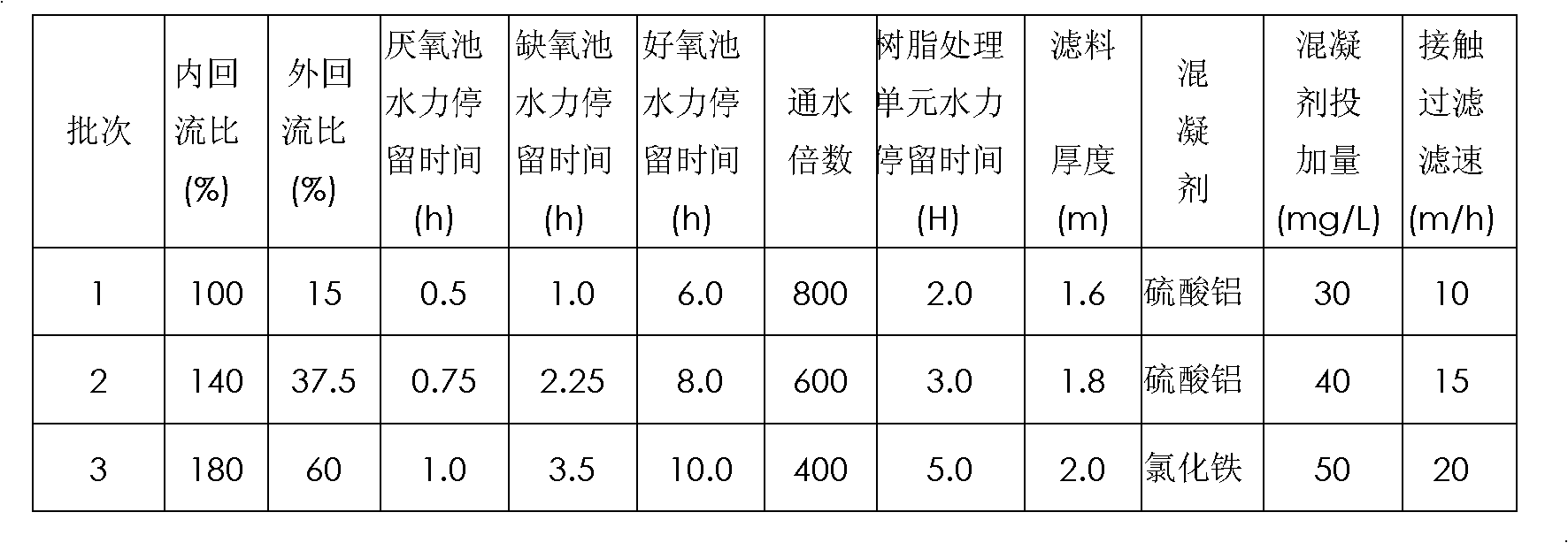

Device and method for treating sewage with low ratio of carbon to nitrogen

ActiveCN102603120ALow costIncrease aerationMultistage water/sewage treatmentWater qualityIon exchange

The invention discloses a device and method for treating sewage with a low ratio of carbon to nitrogen. The device is formed by sequentially connecting a biochemical treatment unit, a magnetic anion exchange resin treatment unit, a contact filtering unit and a disinfecting unit by pipelines in series. According to the method for treating the sewage with the low ratio of the carbon to the nitrogen, the sewage with the low ratio of the carbon to the nitrogen is highly treated through steps of biochemical treatment, ion exchange, contact filtering, disinfection, discharge and the like. The device and the method for treating the sewage with the low ratio of the carbon to the nitrogen, disclosed by the invention, not only is low in technical cost and good in total nitrogen removing effect, but also remarkably strengthen an effect for removing organic matters and suspended matters so as to fully meet the requirement on water quality.

Owner:HOHAI UNIV

Method based on Internet of Things and machine learning and intelligent air conditioners

InactiveCN109882999AReduce wasteOptimize air conditioner operating parametersMechanical apparatusSpace heating and ventilation safety systemsWorking environmentData acquisition

The invention discloses a method based on the Internet of Things and machine learning and intelligent air conditioners. The intelligent air conditioners and the Internet of Things are combined, so that on the one hand, by dividing using areas of the air conditioners, various indoor environment parameters, various outdoor environment parameters and data of the other Internet-of-Things intelligent air conditioners are collected, operation parameters of all the air conditioners are reasonably counted and optimized, thus all the intelligent air conditioners can learn mutually and configure the optimal air conditioner operation parameters according to the Internet of Things; and on the other hand, the optimal air conditioner operation parameters can be updated irregularly, thus a reasonable working environment is set according to an actual regional environment, it is ensured that all the intelligent air conditioners work under the optimal working condition, and energy waste is greatly reduced.

Owner:ZHENGZHOU UNIV

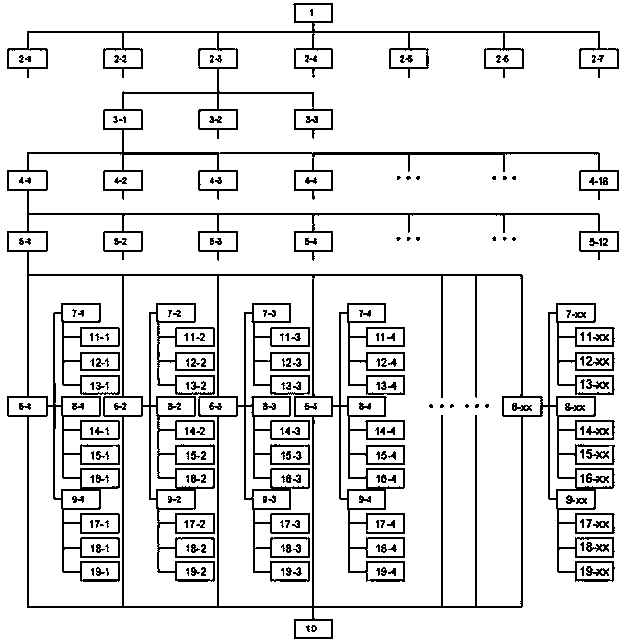

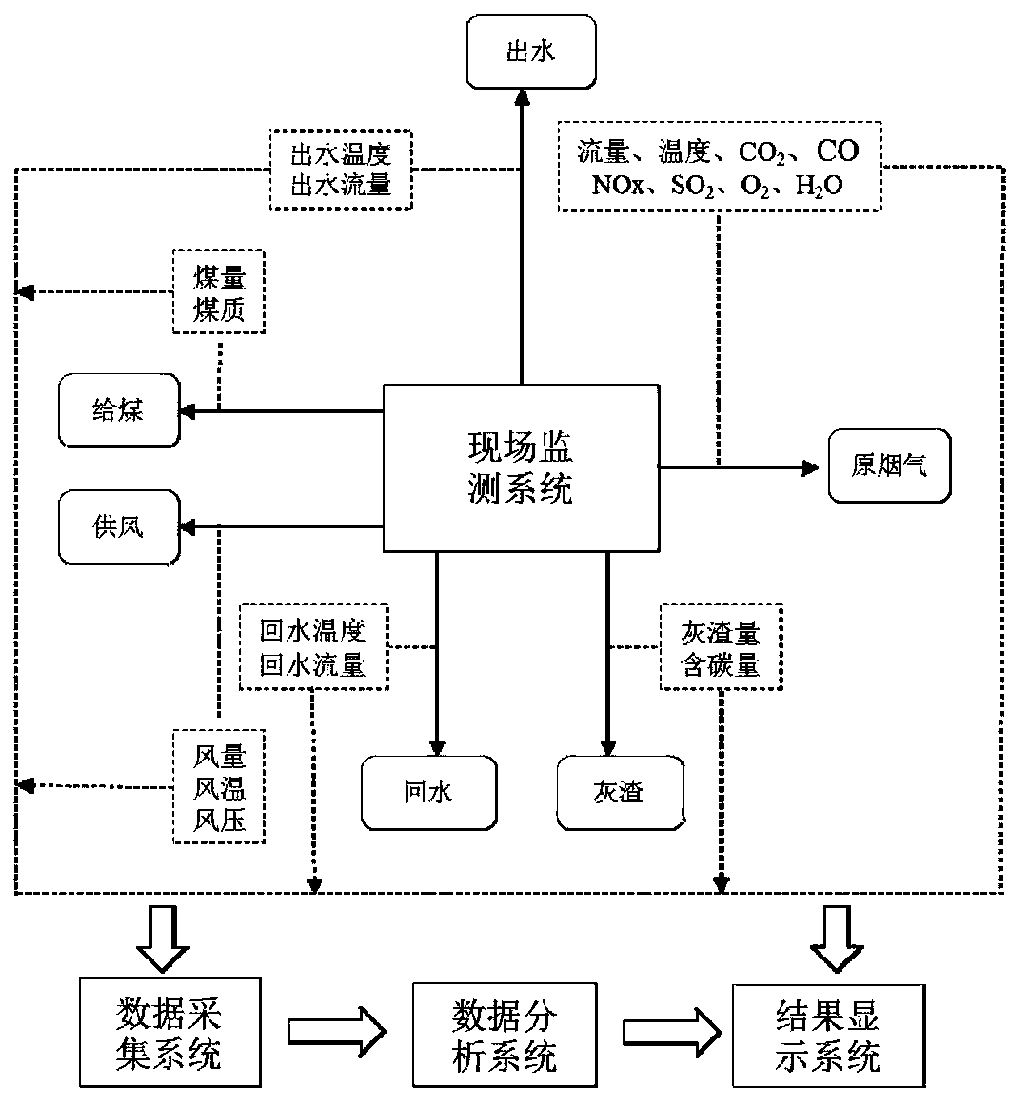

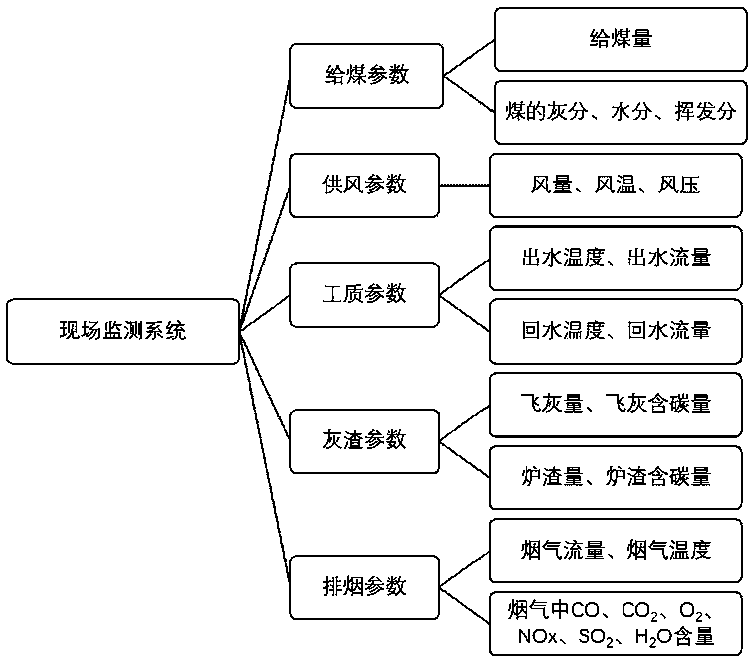

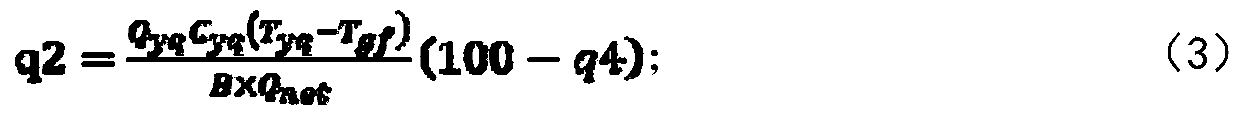

Online monitoring method and system for boiler energy efficiency

InactiveCN109611813ARealize online monitoringOptimize operating parametersFluid heatersBoiler controlCombustionData acquisition

The invention relates to the technical field of boiler running data monitoring, in particular to an online monitoring method and system for boiler energy efficiency. The system comprises a site monitoring system, a data acquisition system, a data analysis system and a result display system. Quick, accurate and real-time recording of the running parameters of a boiler is achieved, and abnormal running parameters are found in time. The thermal efficiency of the boiler is calculated in real time based on the collected parameters, and online monitoring of the running energy efficiency of the boiler is achieved. Users can optimize the running parameters of the boiler in time based on the monitoring data, so that the combustion efficiency is improved, the running cost is reduced, and the purposes of saving energy and reducing emission of the boiler are achieved.

Owner:SHENYANG ACAD OF ENVIRONMENTAL SCI

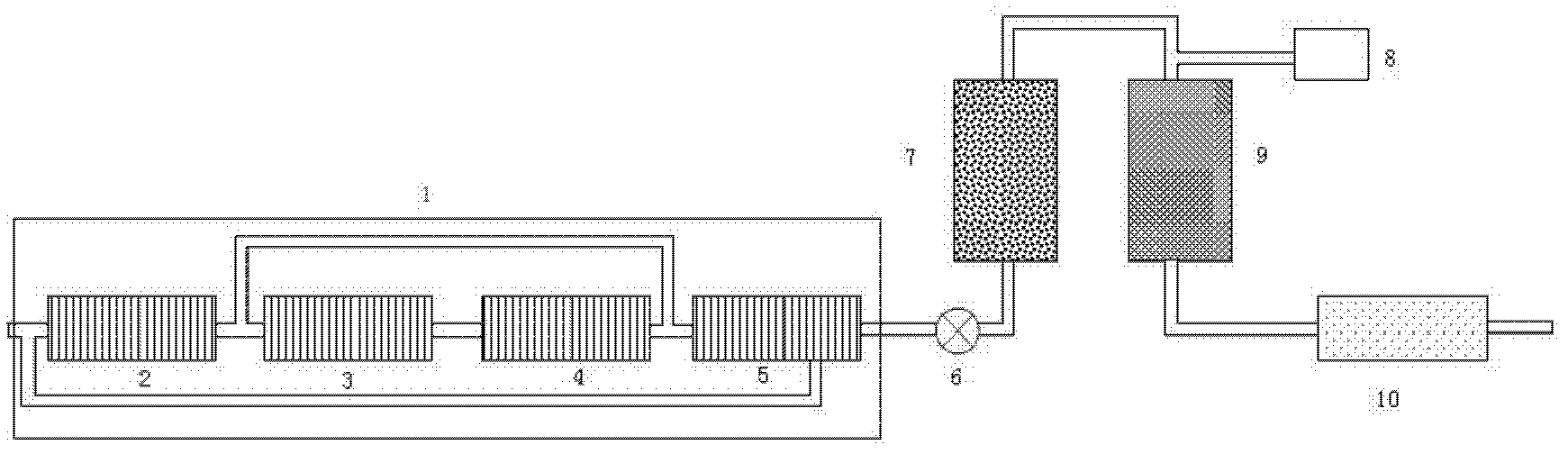

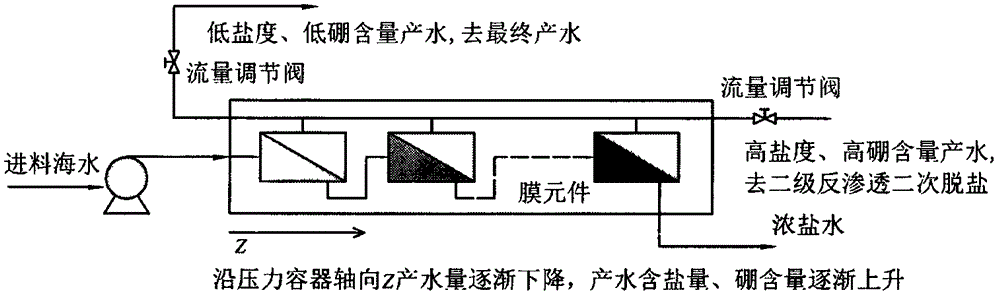

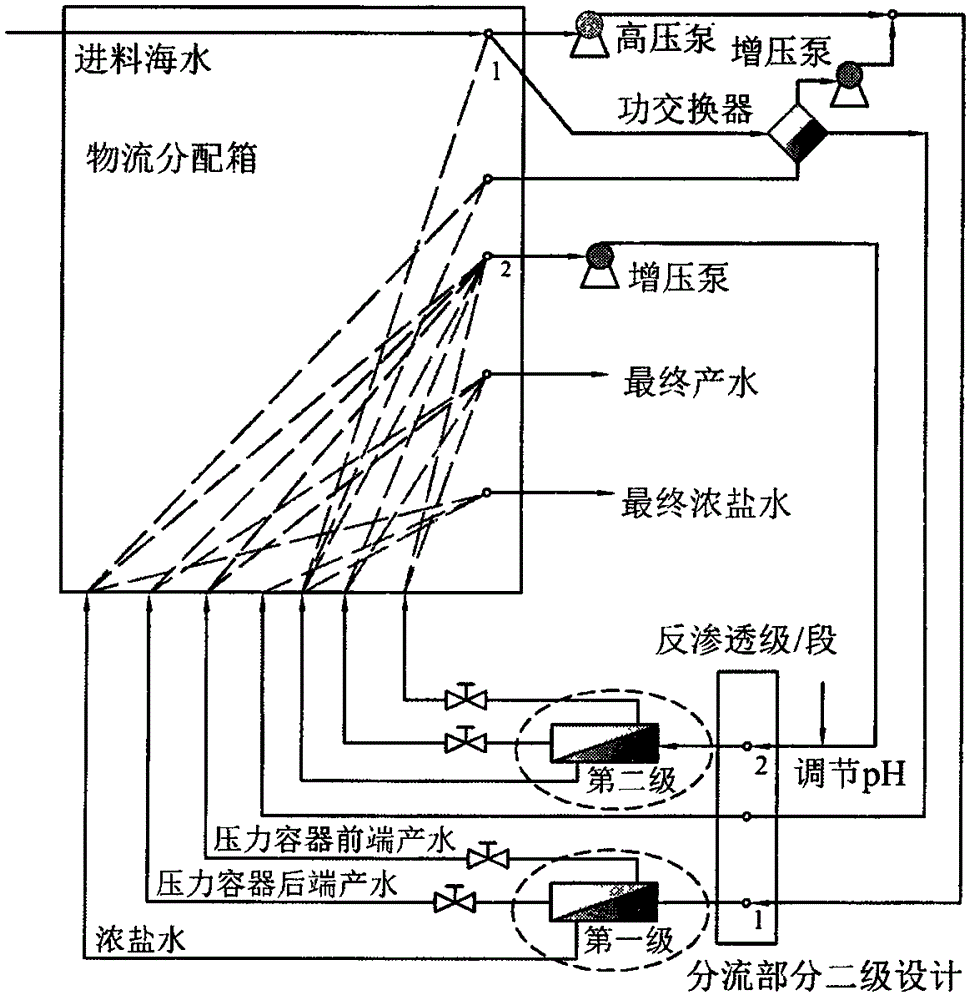

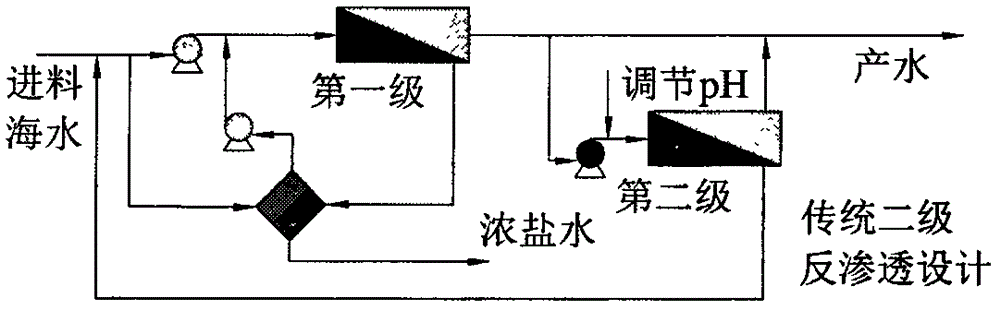

Method for optimizing flow distribution part two-stage type design spiral membrane element reverse osmosis seawater desalination system considering boron removal

InactiveCN105740509ALower water costsReduce energy consumptionGeneral water supply conservationSeawater treatmentWater qualityEngineering

The invention discloses a method for optimizing a flow distribution part two-stage type spiral membrane element reverse osmosis seawater desalination system considering boron removal. According to the method, an accurate model of a reverse osmosis seawater desalination transfer mechanism considering boron removal is established in a strict mechanism mode. The flow distribution part two-stage design is introduced; by utilizing a characteristic that the yield and quality of producing water at the front end of a pressure container are higher than those of producing water at the back end of the pressure container, the producing water at the front end of the pressure container is directly conveyed to final producing water and the producing water at the back end enters a next stage to be treated again; and a flow adjustment valve is added, so that the ratio of outlet water at the two ends can be flexibly adjusted according to an actual condition. A superstructure model of the reverse osmosis system is established, the changes of saline water pressure, concentration and flow in an axial direction of the pressure container as well as the salinity rise caused by saline water mixing in a worker exchange are considered, operation condition constraints are added for ensuring the system to run safely, and a simultaneous solution technology is adopted for solving optimization systems. The method comprehensively considers the influences of various factors on the seawater desalination system to further reduce the water producing cost and energy consumption of seawater desalination and enable the producing water of the system to meet the boron content standard of boron in drinking water. Not only can the reverse osmosis system be designed but also operation parameters can be optimized in a system operation process, so that the method has very good application prospects.

Owner:HEBEI UNIV OF TECH

Chromium-based boiler slag-removing ash-removal coal-saving composition and preparation method thereof

ActiveCN104910996AHigh active specific surface areaHigh hydrogen contentSolid fuelsFuel additivesPetroleumElectric power

The present invention relates to an additive product suitable for coal-fired boilers of electric power, thermal power, petroleum, chemical and metallurgical industries, and particularly relates to a chromium-based boiler slag-removing ash-removal coal-saving composition, and the chromium-based boiler slag-removing ash-removal coal-saving composition consists of the following components in parts by weight: 50 to 65 parts of chromium oxide, 8 to 15 parts of copper oxide, 5 to 9 parts of cerium oxide, 5 to 9 parts of barium molybdate, 7 to 14 parts of cobaltous oxide, 12 to 17 parts of potassium permanganate, 10 to 16 parts of manganese carbonate, 12 to 17 parts of barium carbonate, 8 to 15 parts of titanium dioxide, zinc oxide, 15 to 20 parts of zinc oxide, 6 to 10 parts of potassium chlorate, 6 to 10 parts of potassium perchlorate, 20 to 28 parts of sodium carbonate, 25 to 35 parts of active attapulgite carclazyte and 0.1 to 0.3 part of alkyl glycerol ether sulfonate. The chromium-based boiler slag-removing ash-removal coal-saving composition is an environmentally-friendly product which is efficient in combustion helping, and high in coal saving ratio, can reduce pollution, improve combustion efficiency, and extend the boiler service life, and is convenient to use and stable in performance, and when in use, only the chromium-based boiler slag-removing ash-removal coal-saving composition is added into a fuel to participate in the combustion without equipment transformation.

Owner:GANSU HEIMA PETROCHEM ENG

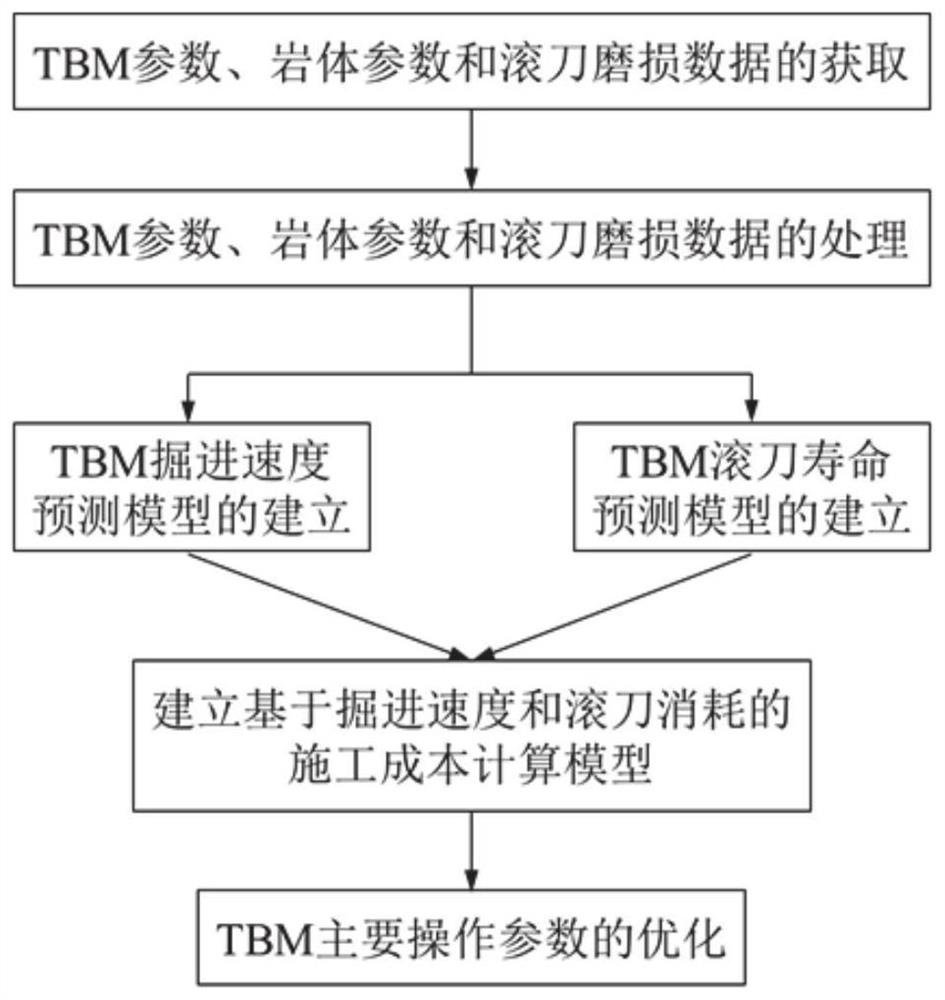

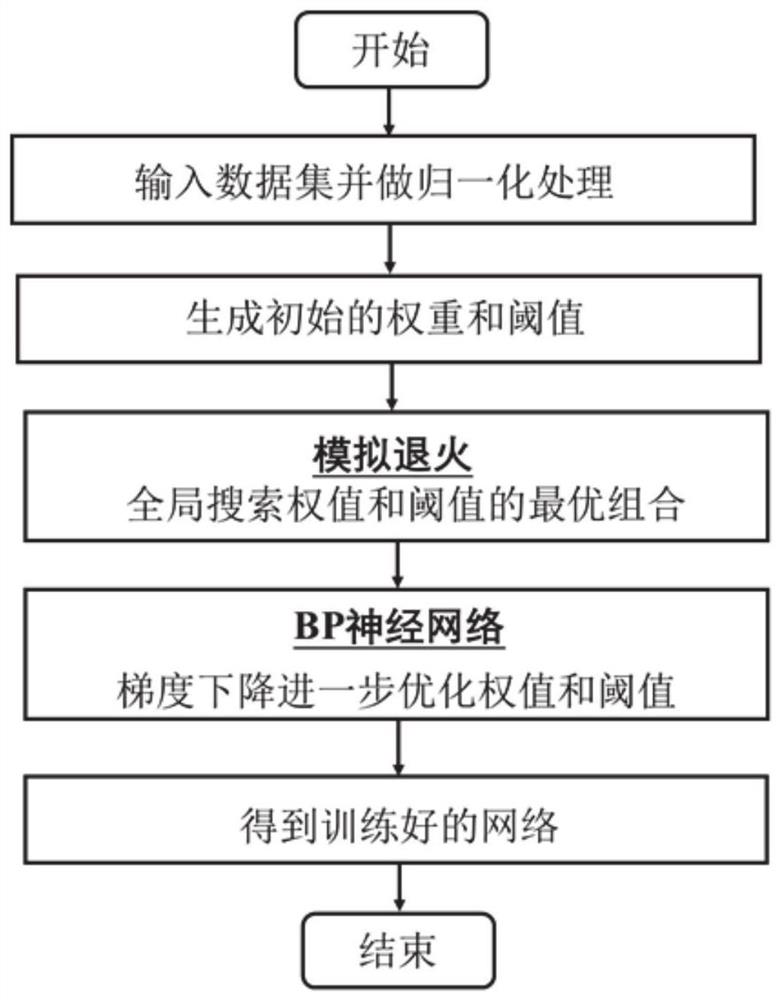

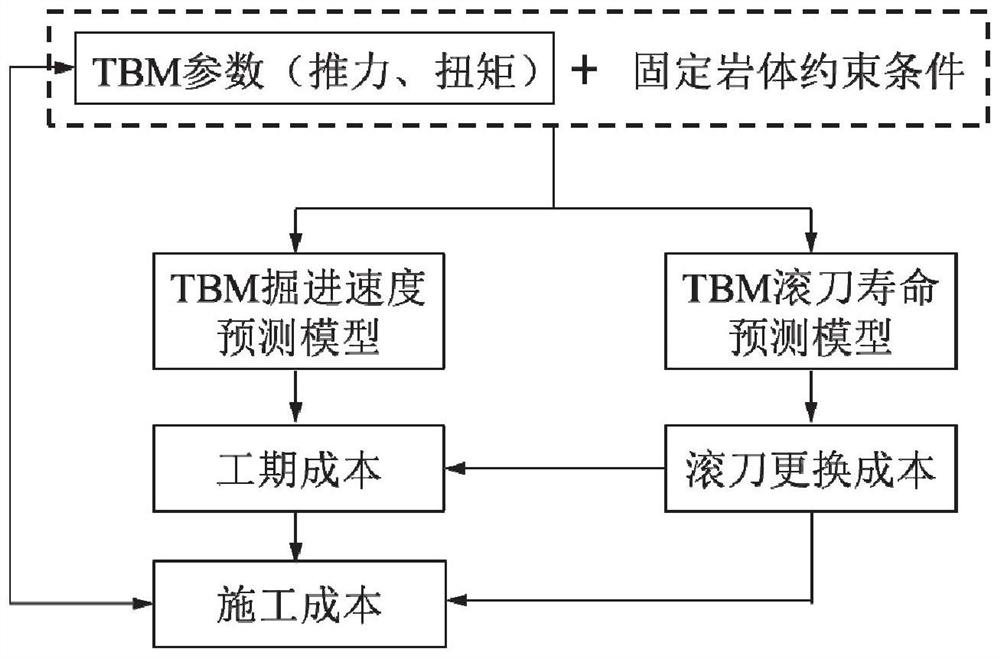

TBM operation parameter optimization method based on optimal tunneling speed and cutter consumption

ActiveCN112196559AHigh precisionConsider comprehensivelyMining devicesTunnelsProcess engineeringTunnel boring machine

The invention provides a TBM operation parameter optimization method based on optimal tunneling speed and cutter consumption, and belongs to the technical field of tunnel boring machine construction.The TBM operation parameter optimization method based on optimal tunneling speed and cutter consumption comprises the following steps of obtaining rock mass parameter data; and taking the obtained rock mass parameter data as the input of a preset construction cost calculation model, and through interpolation fitting, obtaining cutterhead thrust and cutterhead torque when the construction cost is minimum, wherein the preset construction cost calculation model comprises a TBM tunneling speed prediction model and a TBM hob life prediction model. According to the TBM operation parameter optimization method based on optimal tunneling speed and cutter consumption, by combining the TBM tunneling speed prediction model and the hob life prediction model, the relation between a TBM main operation parameter and the construction cost is established, and therefore, the main operation parameter with the optimal construction cost are obtained.

Owner:SHANDONG UNIV

Multistage sand jet perforation and fracture combined operation method adopting coiled tubing and bottom packer

The invention relates to a multistage sand jet perforation and fracture combined operation method adopting coiled tubing and a bottom packer. The method comprises the following steps: 1, coiled tubing wellhead equipment is assembled; 2, a positioner, the packer and a sand jet perforator are connected with the tail end of the coiled tubing sequentially; 3, the coiled tubing is descended into a well; a to-be-fractured horizon is determined, the packer is set, and sealing is examined; 4, after the sealing is examined to be qualified, a pump is started to pump a perforation fluid into the coiled tubing, and the step 4 is executed again if a formation is not perforated until a casing is perforated; 6, the coiled tubing is lifted up and the packer is unset after annulus sand fracture construction, operation is performed from the step 3 when perforation and fracture of next horizon are required, otherwise, the coiled tubing is lifted to a wellhead, and the operation is ended. The method has the advantages of short operation period, flexible and careful stratification, reliable packing and clean shaft after construction and can realize multilayer test and production.

Owner:北京泰坦通源天然气资源技术有限公司 +1

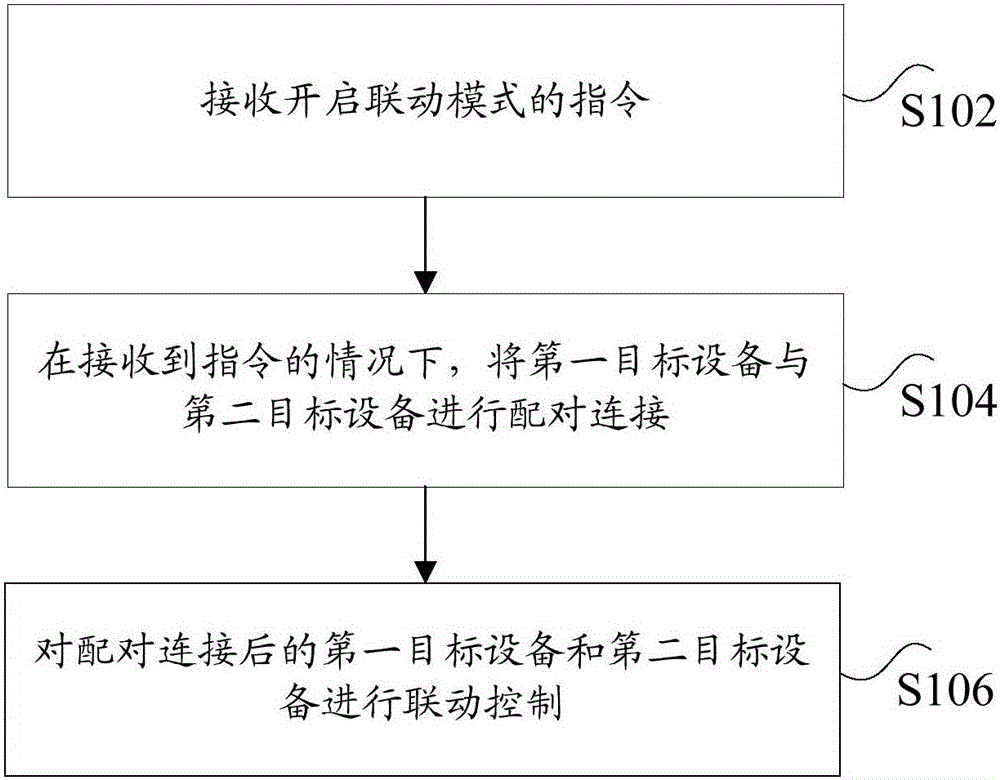

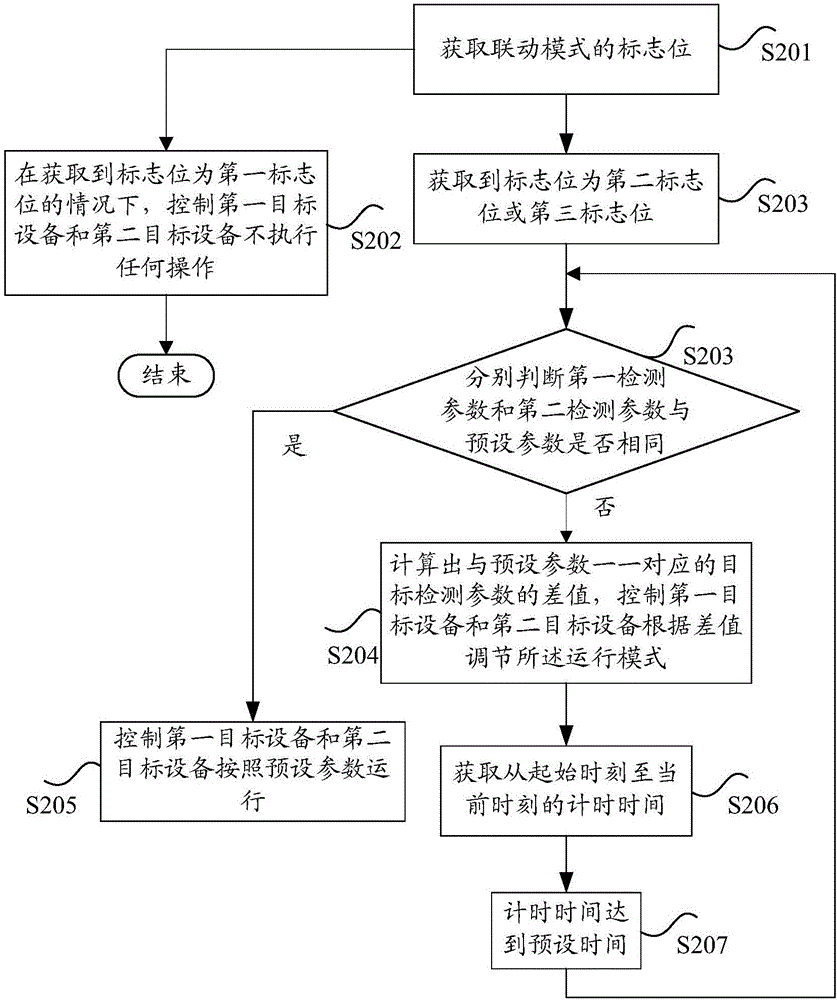

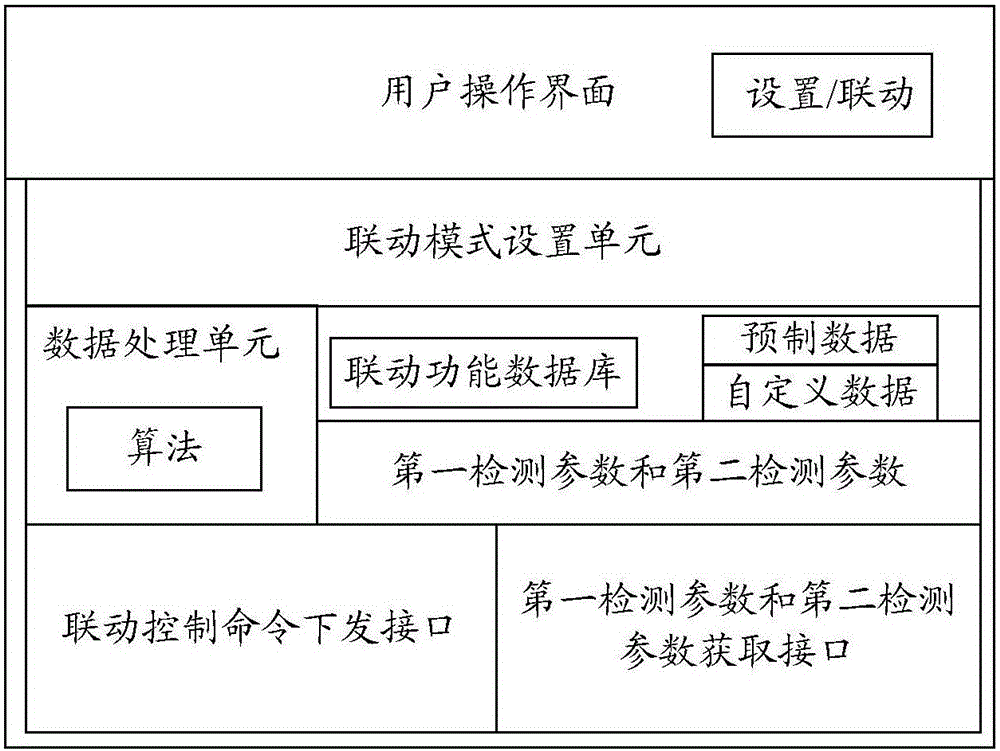

Control method and device of integrated controller

ActiveCN104990231AReduce manual operationsImprove user experienceMechanical apparatusSpace heating and ventilation safety systemsIntegrated controllerEmbedded system

The invention discloses a control method and device of an integrated controller. The method includes the steps that a command for starting a linkage mode is received; under the condition that the command is received, a first target device is connected with a second target device in a paired manner; and linkage control over the first target device and the second target device which are connected in the paired manner is achieved. The control method and device solve the technical problem that in the prior art, the intelligent running efficiency of an air-conditioner and a new draught fan is lower.

Owner:GREE ELECTRIC APPLIANCES INC

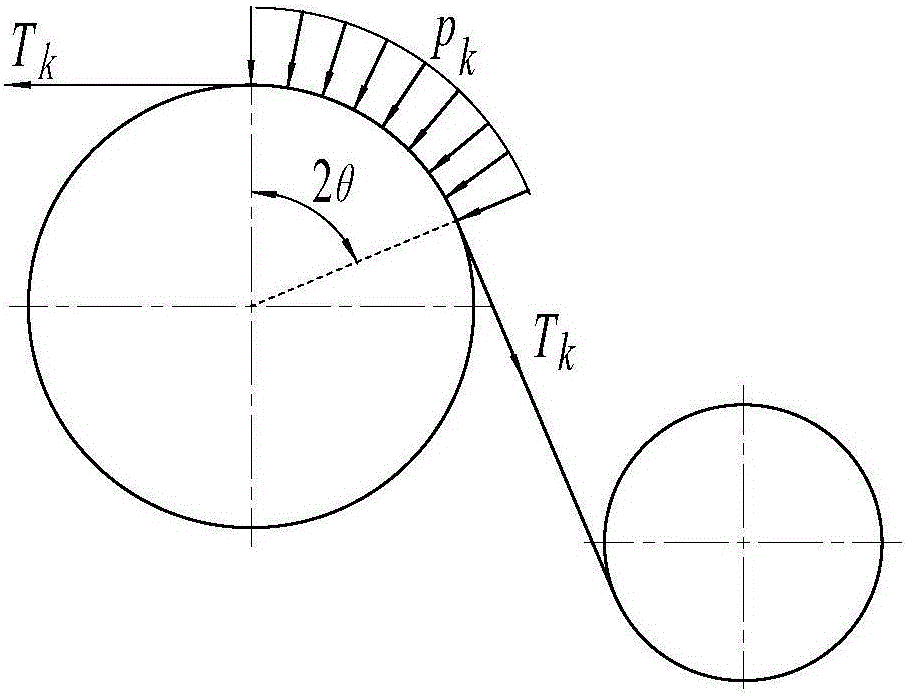

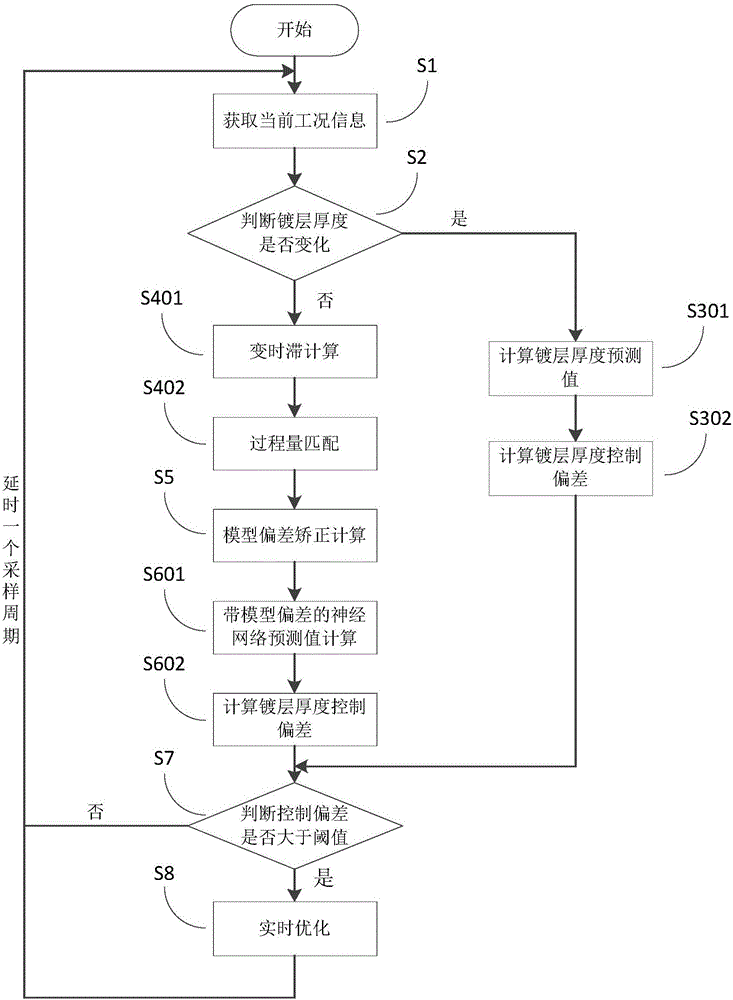

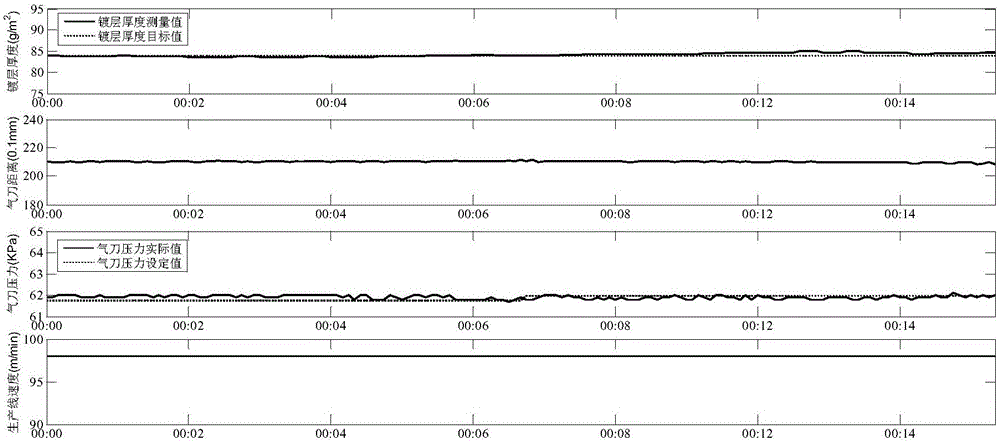

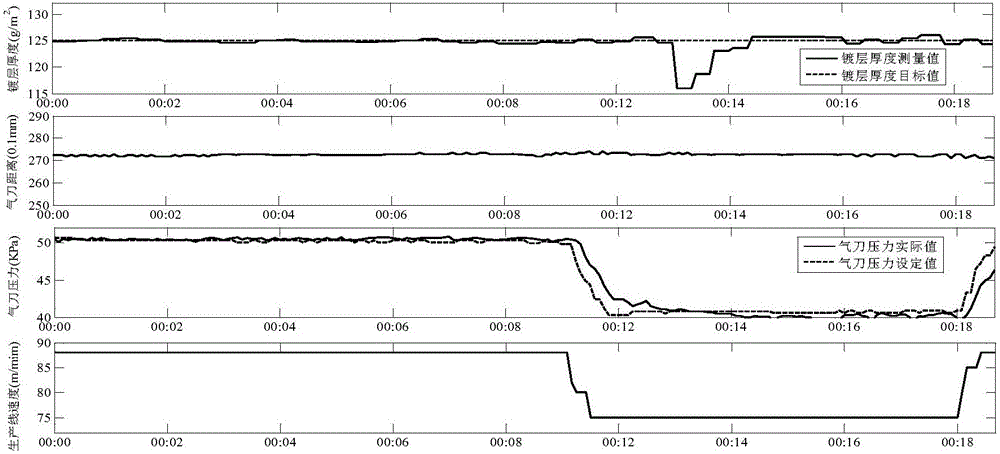

Air knife pressure real-time optimization control method and system in galvanizing process

ActiveCN106637026AStrong nonlinear fitting abilityReflect nonlinear characteristicsHot-dipping/immersion processesEngineeringZinc

The invention relates to an air knife pressure real-time optimization control method in the galvanizing process. On the basis of a plating thickness neural network prediction model, the corresponding error correction based on variable lag time and the real-time optimization technology based on an increment PID algorithm are adopted, and a good anti-interference and follow-up control effect is adopted. When the plating thickness deviates from a set value because of the outside interference, the air knife pressure is optimized in real time based on the difference between a plating thickness predicted value after being subjected to the error correction, and the set value, and the plating thickness is made to be kept nearby the set value; and during product switching, iterative optimization is performed on the air knife pressure based on a plating thickness predicted value not subjected to the error correction, and the plating thickness is made to fast complete the switching process closely along with a changing curve of the set value. According to the pressure real-time optimization control method in the galvanizing process, bad influences caused to the plating thickness by the outside interference are effectively overcome due to the above technology, fast switching between products in different plating thicknesses is achieved, the plating quality fluctuation can be obviously reduced, the excessive zinc consumption is reduced, and the percent of pass of galvanized products is increased.

Owner:ZHEJIANG SUPCON RES

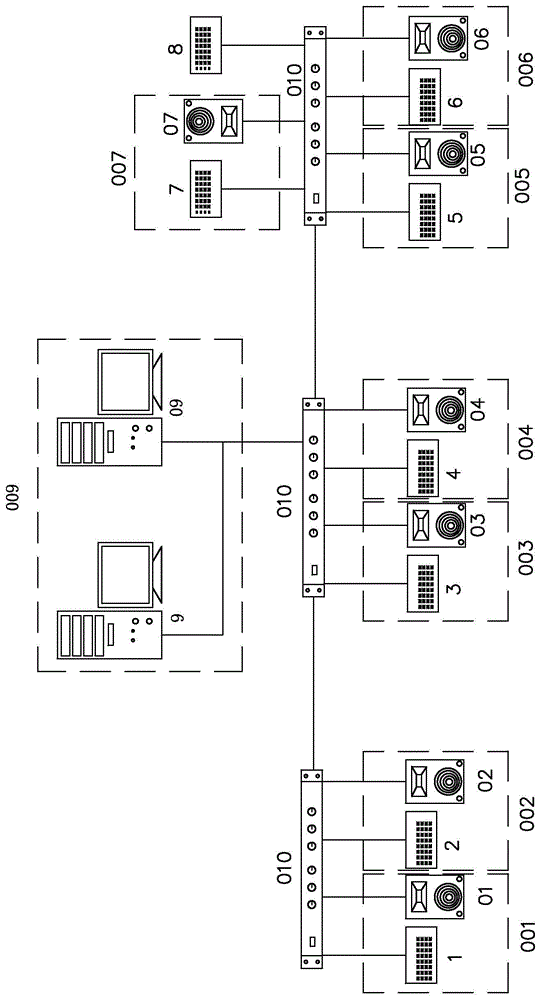

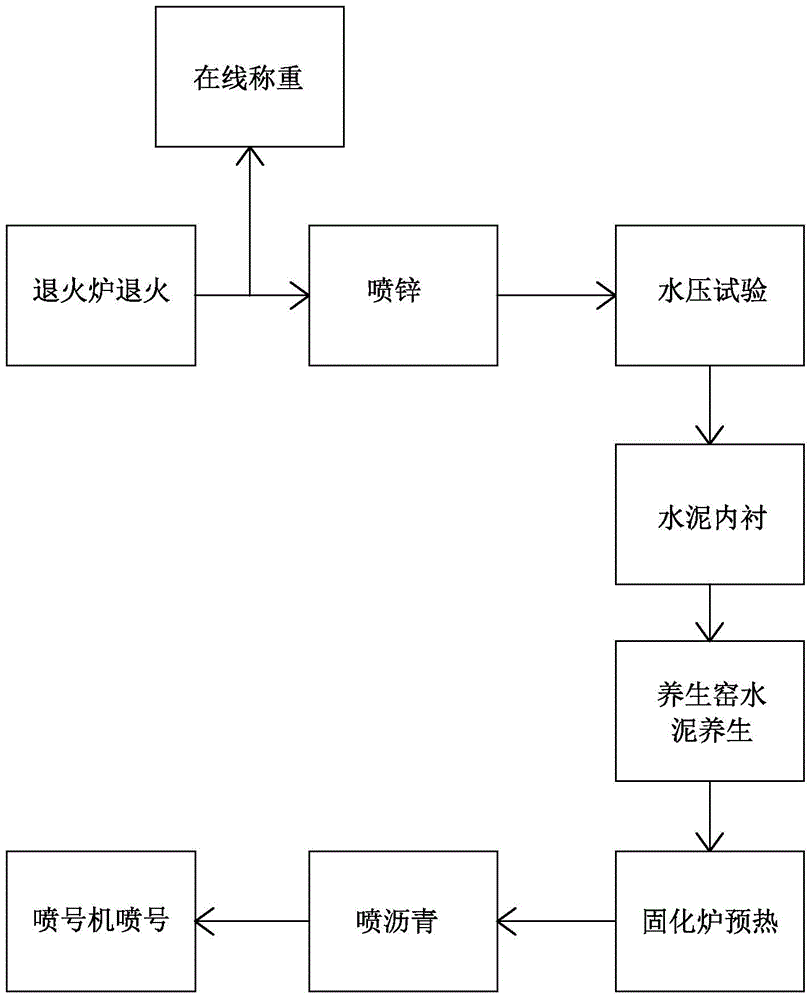

Automatic control system and method for nodular cast iron pipe production process

InactiveCN104794224AReal-time tracking recordEasy to analyze and processData processing applicationsCo-operative working arrangementsAutomatic controlAutomated control system

The invention provides a nodular cast iron pipe production process information tracking system. An automatic control system for a nodular cast iron pipe production process comprises an annealing furnace area, a zinc spraying area, a water pressure area, a cement smearing and lining area, a curing kiln area, a pitch spraying area, a curing oven area, a bulb tube RFID electronic tag, Ethernet interfaces and a server. The annealing furnace area, the zinc spraying area, the water pressure area, the cement smearing and lining area, the curing kiln area, the pitch spraying area and the curing oven area are connected with the server through the Ethernet interfaces. The bulb tube RFID electronic tag is installed on the inner surface of the straight tube portion of a bulb tube bell mouth. The seven areas are used for reading information of the bulb tube RFID electronic tag, and uploading the information to the server. The server is used for accessing the seven areas through the Ethernet, and reading the bulb tube production information stored in the seven areas. The real-time track record of the whole single-bulb tube process production information in nodular cast iron pipe producing is achieved, operating parameters of technology equipment is beneficial to being optimized, and the product quality is improved.

Owner:XINXING DUCTILE IRON PIPES CO LTD

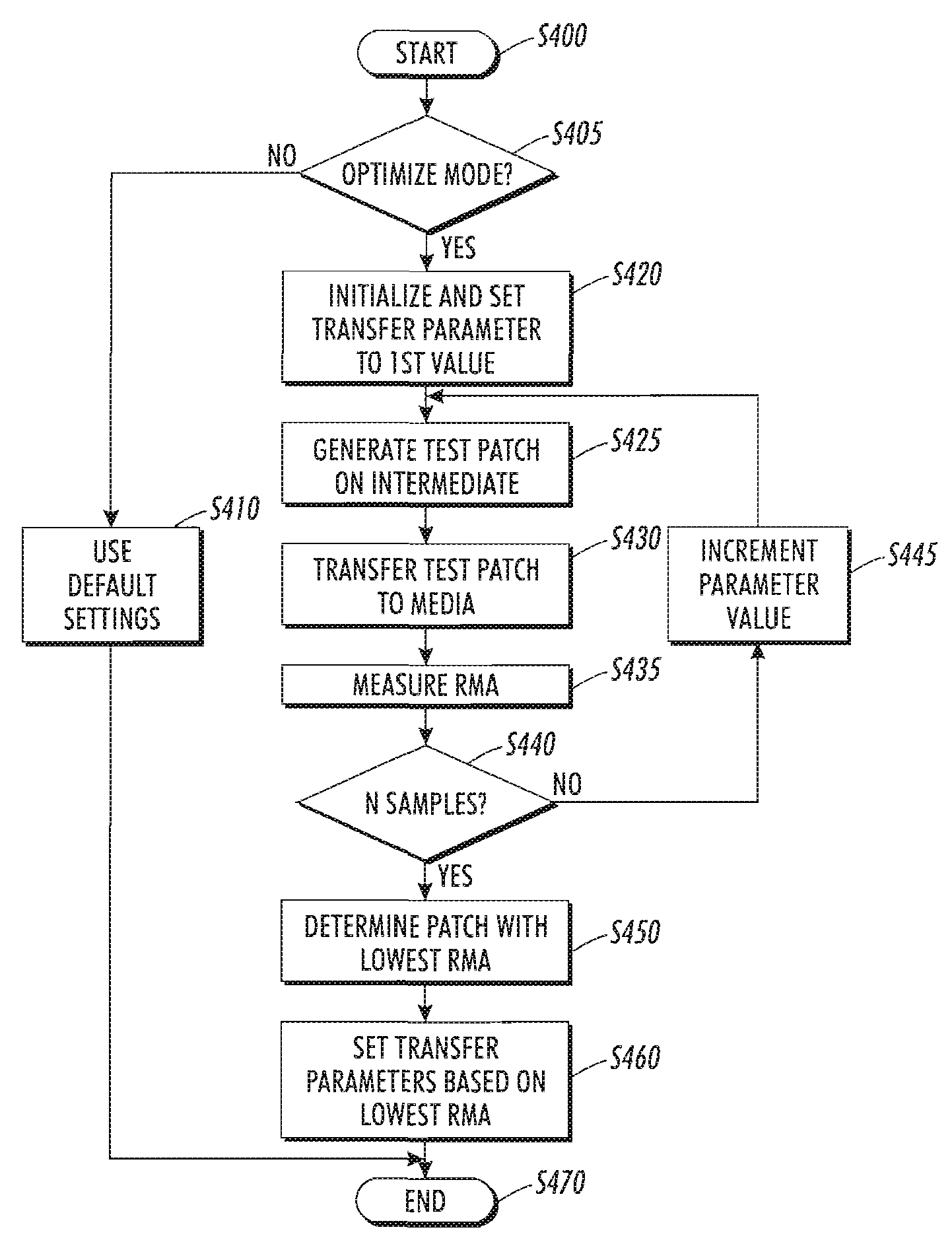

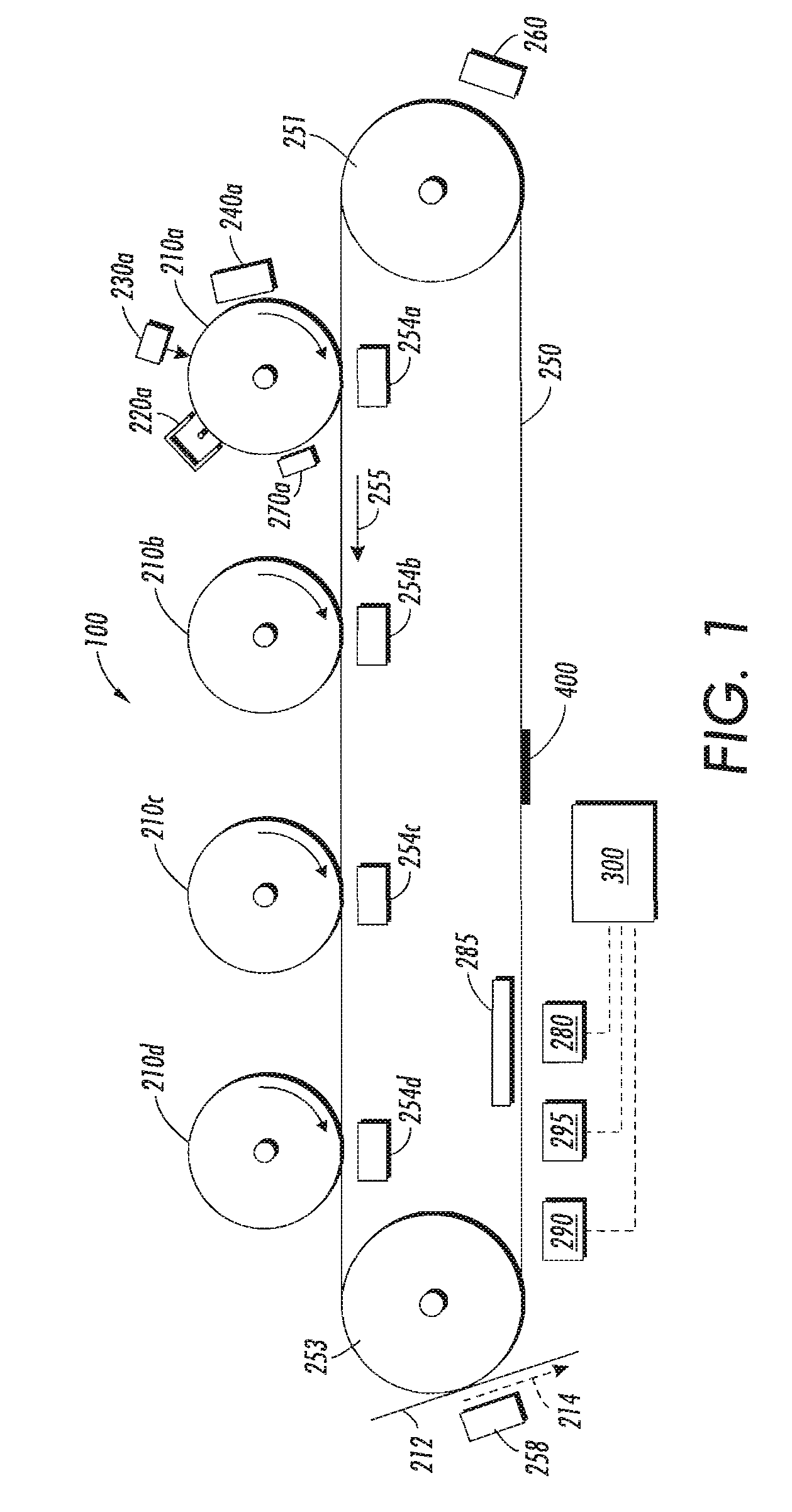

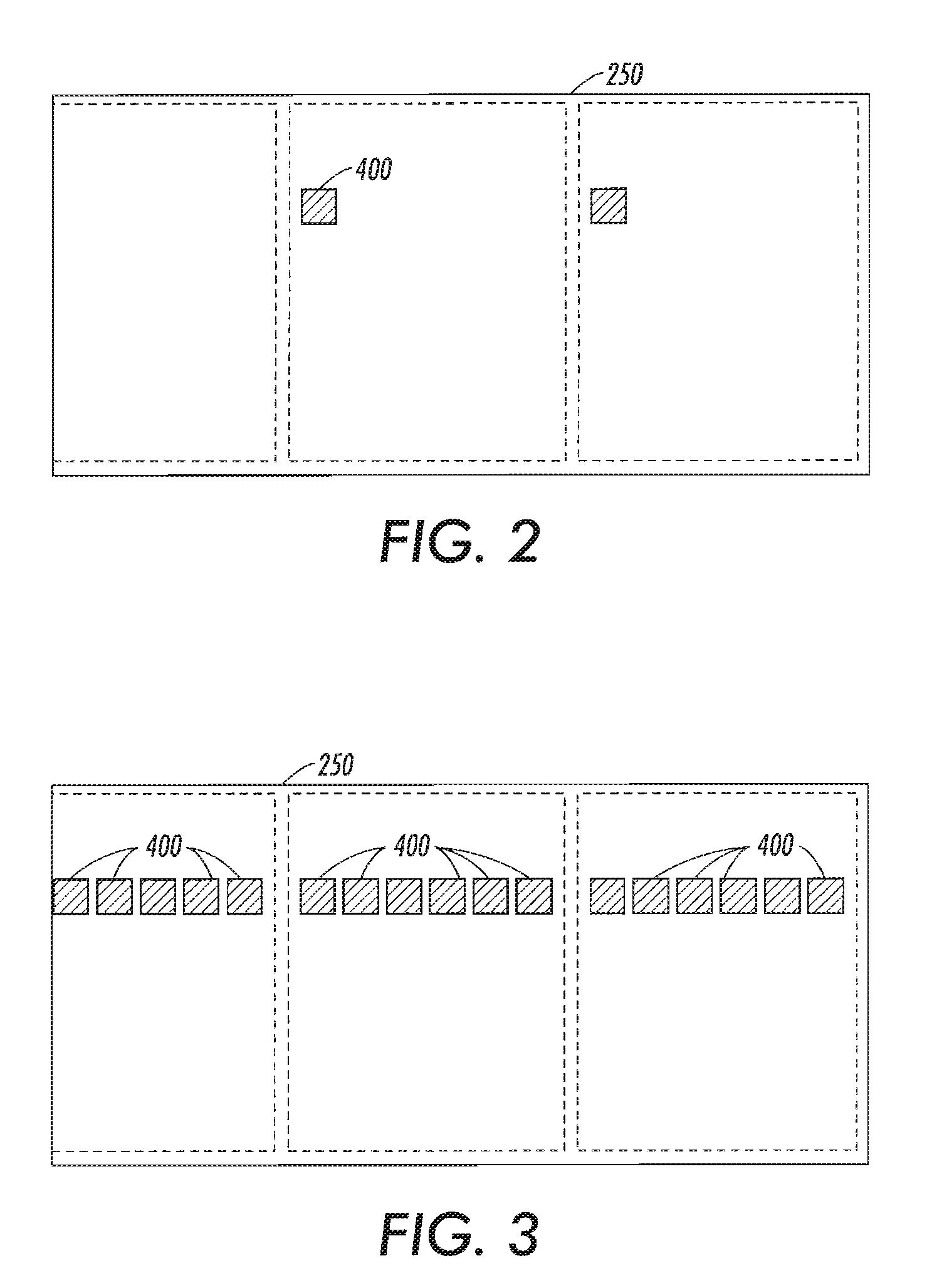

Method and apparatus for optimization of second transfer parameters

InactiveUS7379684B2Improve transmission efficiencyImprove copy qualityElectrographic process apparatusEngineeringArea coverage

Optimization of transfer settings for a given paper and environmental condition is achieved by running a series of prints with varying settings of a transfer parameter such as voltage or current. The mass remaining on the intermediate belt after transfer is monitored for each of the prints. This may be achieved using the same sensor used to monitor and control the developed mass on the intermediate transfer member, such as a transfer belt. A suitable sensor is an Extended Toner Area Coverage (ETAC) mass sensor. Because the control is based on actual conditions for a given paper and environment, it can ensure optimum copy quality over a wide range of papers and conditions, while enabling the minimum target mass per unit area to assure the proper density.

Owner:XEROX CORP

Method for calculating steel ball loading capacity of coal mill in thermal power generation boiler

A method for calculating the steel ball loading capacity of a coal mill in a thermal power generation boiler comprises the steps that the calculation equation of the steel ball loading capacity m of the steel ball coal mill is k4*mk5+k6*mk5-1=k7*I / (Bm*h), wherein m is the steel ball loading capacity of the steel ball coal mill, h is a raw coal blending HGI hardness coefficient of a coal pulverizing system and a boiler combustion system, I is current of the steel ball coal mill, Bm is output of the steel ball coal mill, and k4, k5, k6 and k7 are undetermined coefficients; the problem that in the production site, raw coal blending hardness cannot be obtained can be effectively solved; meanwhile, according to online data of the current and the output of the steel ball coal mill, the steel ball loading capacity of the running steel ball coal mill can be rapidly evaluated, running maintenance persons can be guided to reasonably organize steel ball loading of the coal mill according to the optimum steel ball loading amount of the coal mill, and therefore the output of the steel ball coal mill can be effectively improved; and the current of the steel ball coal mill is controlled, running parameters of the coal pulverizing system can be optimized in an online manner, the economy of the coal pulverizing system of the thermal power generation boiler can be improved, and the effects of saving energy and reducing the consumption are achieved.

Owner:HUADIAN POWER INTERNATIONAL CORPORATION LTD

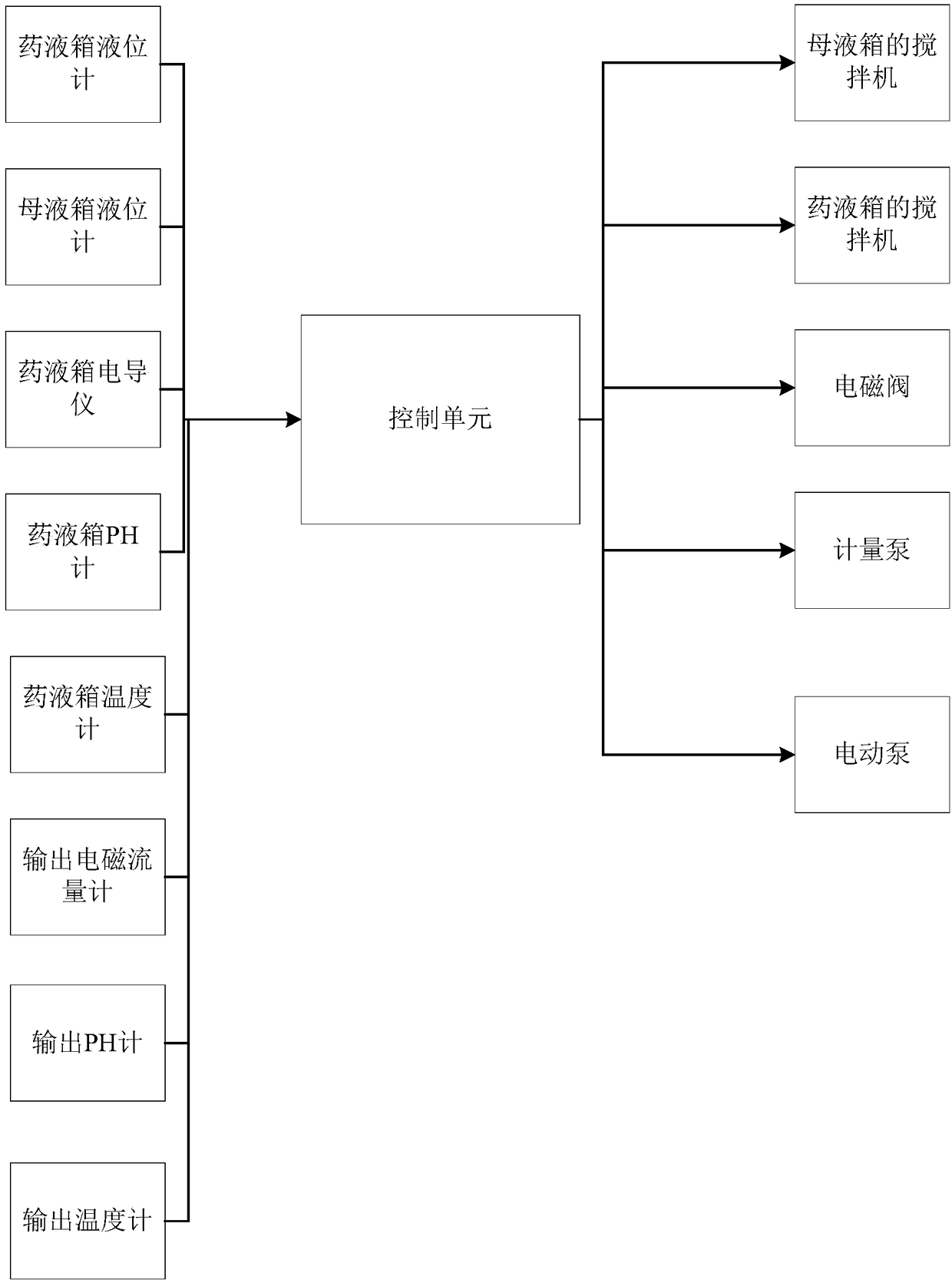

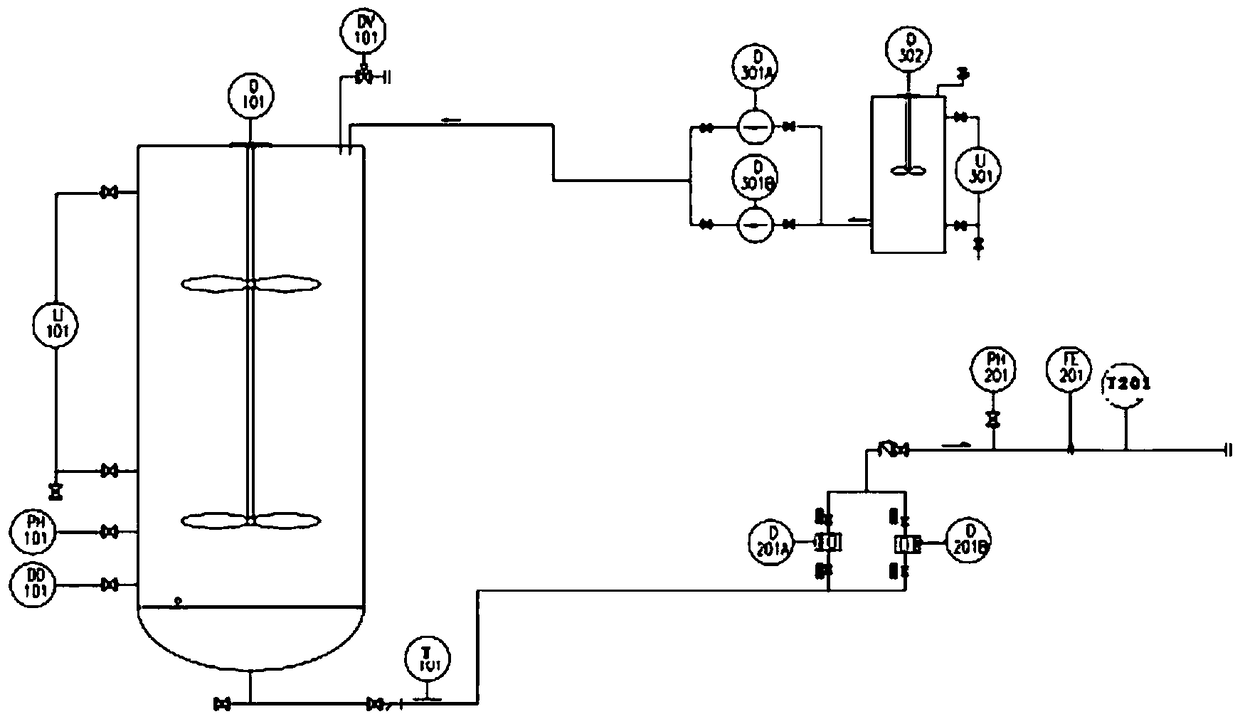

Boiler remote dosing system and method based on data cloud

InactiveCN108958194ARealize real-time automatic monitoringReduce labor intensityRotary stirring mixersTransportation and packagingRemote controlComputer terminal

The invention discloses a boiler remote dosing system and method based on data cloud, and relates to the technical field of remote control. The boiler remote dosing system comprises a plurality of mobile terminals, a cloud server, a background terminal and a plurality of boiler dosing control devices, wherein the mobile terminals are used for inputting target values of various control parameters of a boiler dosing device and transmitting the target values to the cloud server through a wireless network; the cloud server is used for realizing remote connection between the mobile terminals and the controlled boiler dosing device and storage of historical data; the background terminal is used for performing real-time monitoring on the controlled boiler dosing device; and the boiler dosing control device is used for receiving control parameters sent by the mobile terminals and performing automatic dosing on the boiler. The boiler remote dosing system realizes real-time automatic monitoringfor a water system, achieves real-time precision adjustment for the dosing concentration and amount, reduces the labor intensity of operators, saves the labor cost and improves the work efficiency.

Owner:广州长辰农垦科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com