Fine particle emission reduction device of burning energy system based on acoustic agglomeration principle

An energy system, a technology for fine particulate matter, applied in auxiliary pretreatment, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of limited emission reduction effect and scale, low sound field intensity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

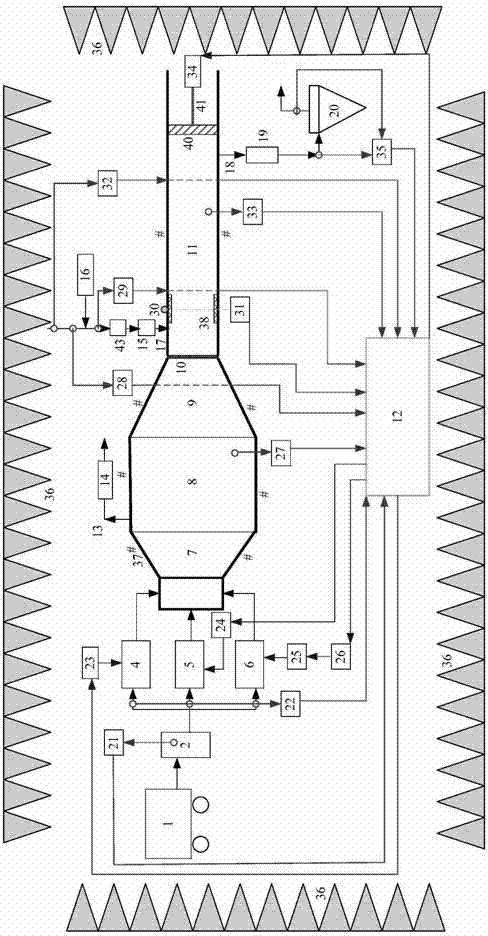

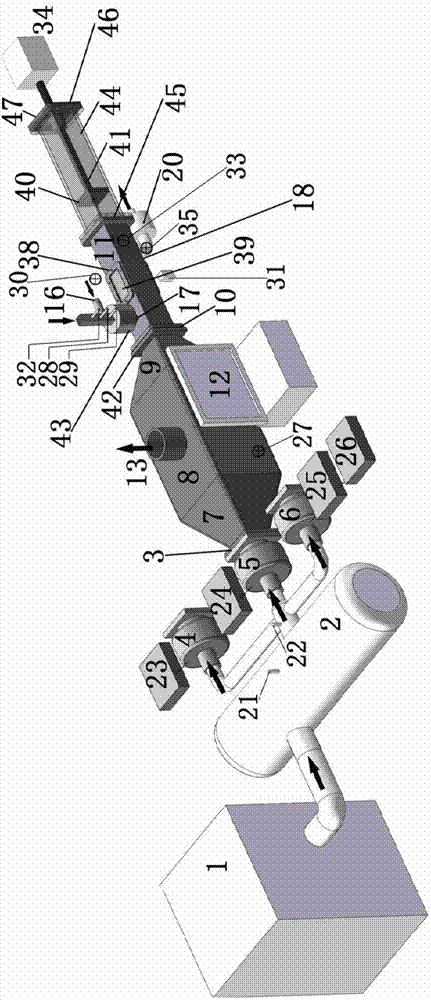

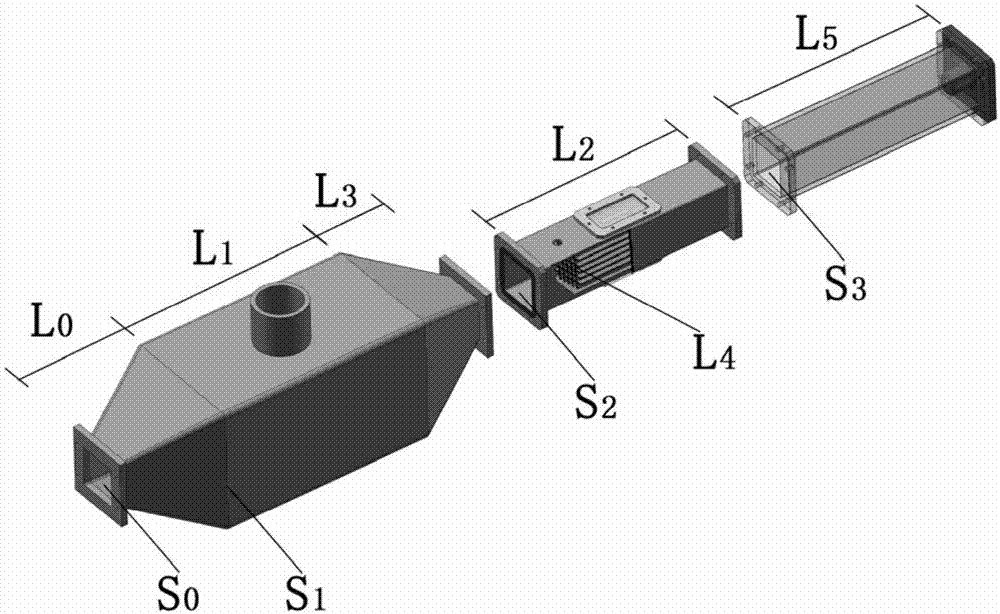

[0057] The working principle of the emission reduction device of the present invention is combined with figure 1 A brief description is as follows:

[0058] The high-pressure airflow provided by the high-pressure airflow source 1 (air compressor or high-pressure air supply source) enters the high-pressure air mixing chamber 2. After the pressure of the high-pressure airflow is stabilized in the high-pressure air mixing chamber, it is selected to enter the high-pressure cyclone according to the determined optimal working condition. Flute 4, resonant type strong sound generator 5 or modulated airflow sound source 6, in the above-mentioned airflow sound source, the high-pressure airflow energy is converted into strong sound waves; the strong sound waves pass through the horn 7 (the horn-shaped line can be straight, hyperbolic or exponential) Line) enters the cross-sectional section 8 of the coupling cabin and the contraction section 9 of the coupling cabin, passes through the so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com