Patents

Literature

8635results about How to "Compact design" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

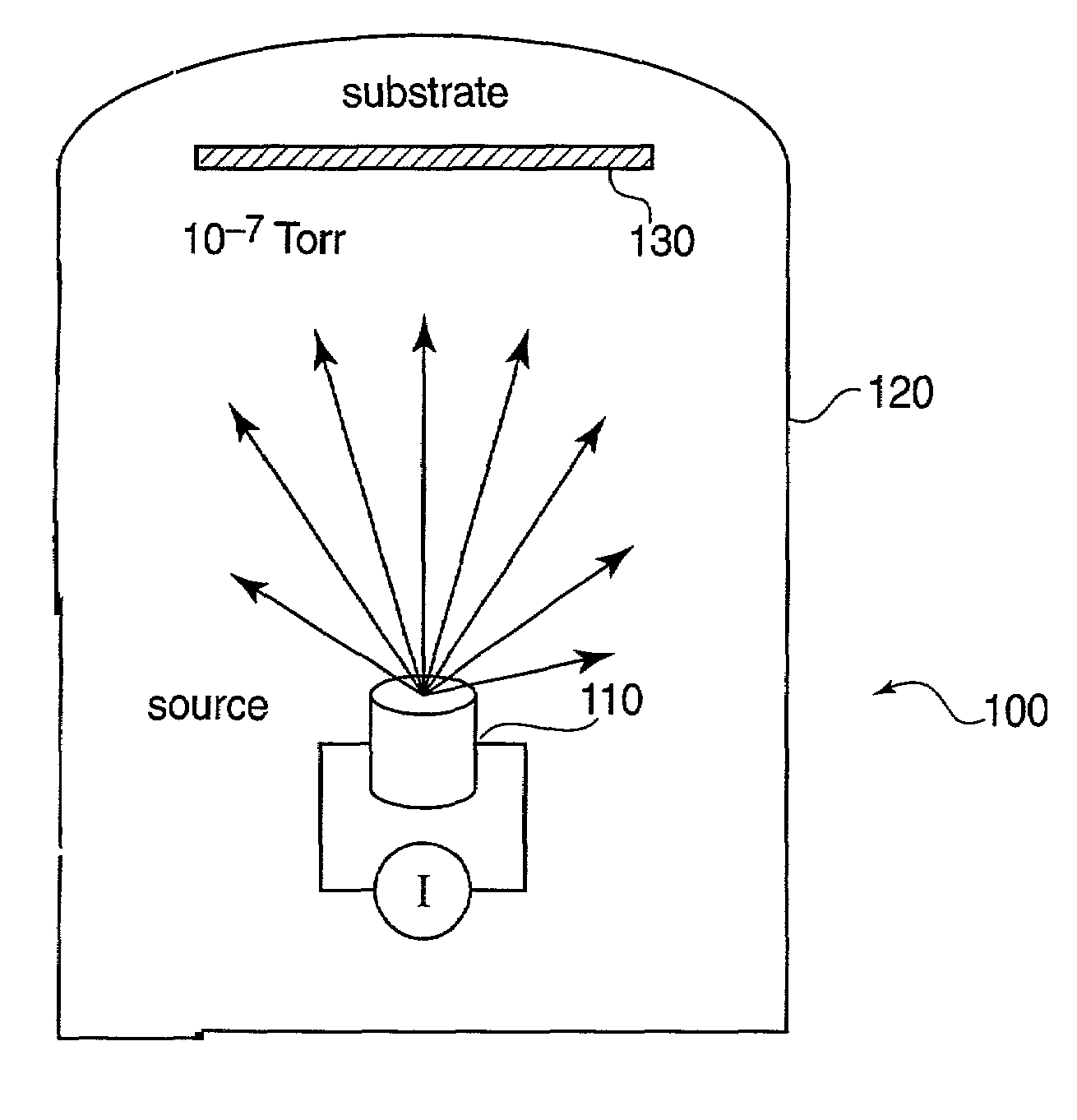

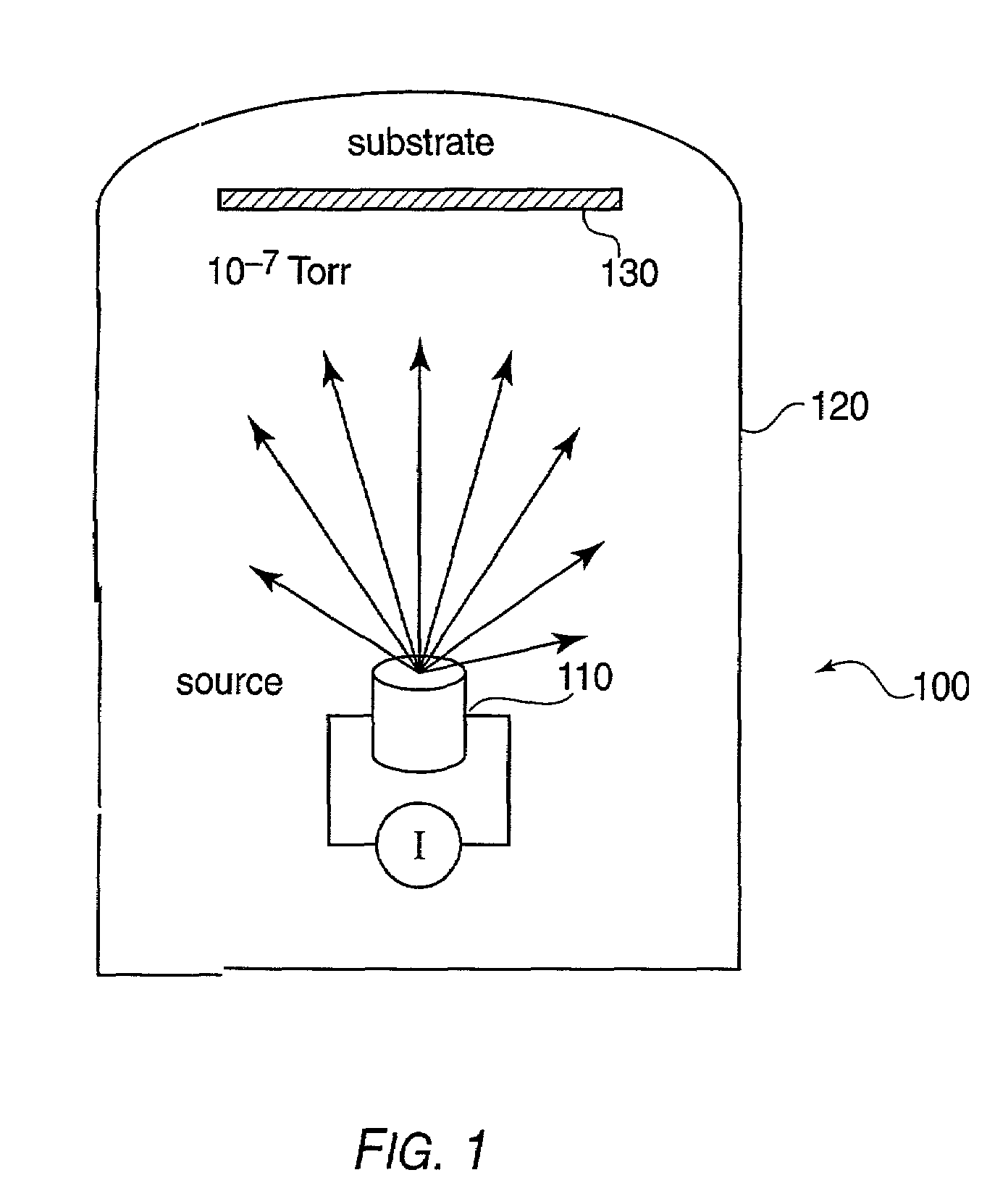

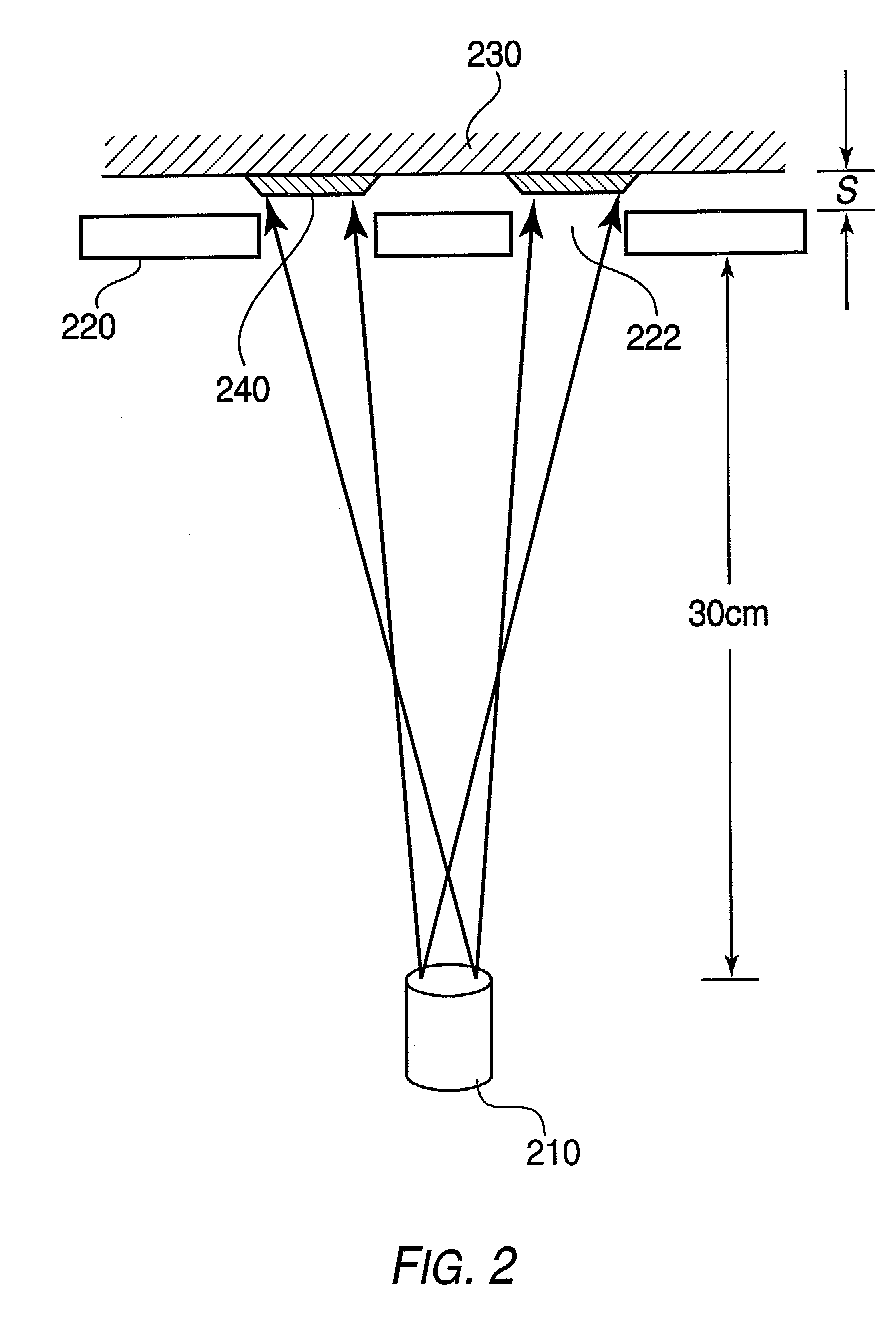

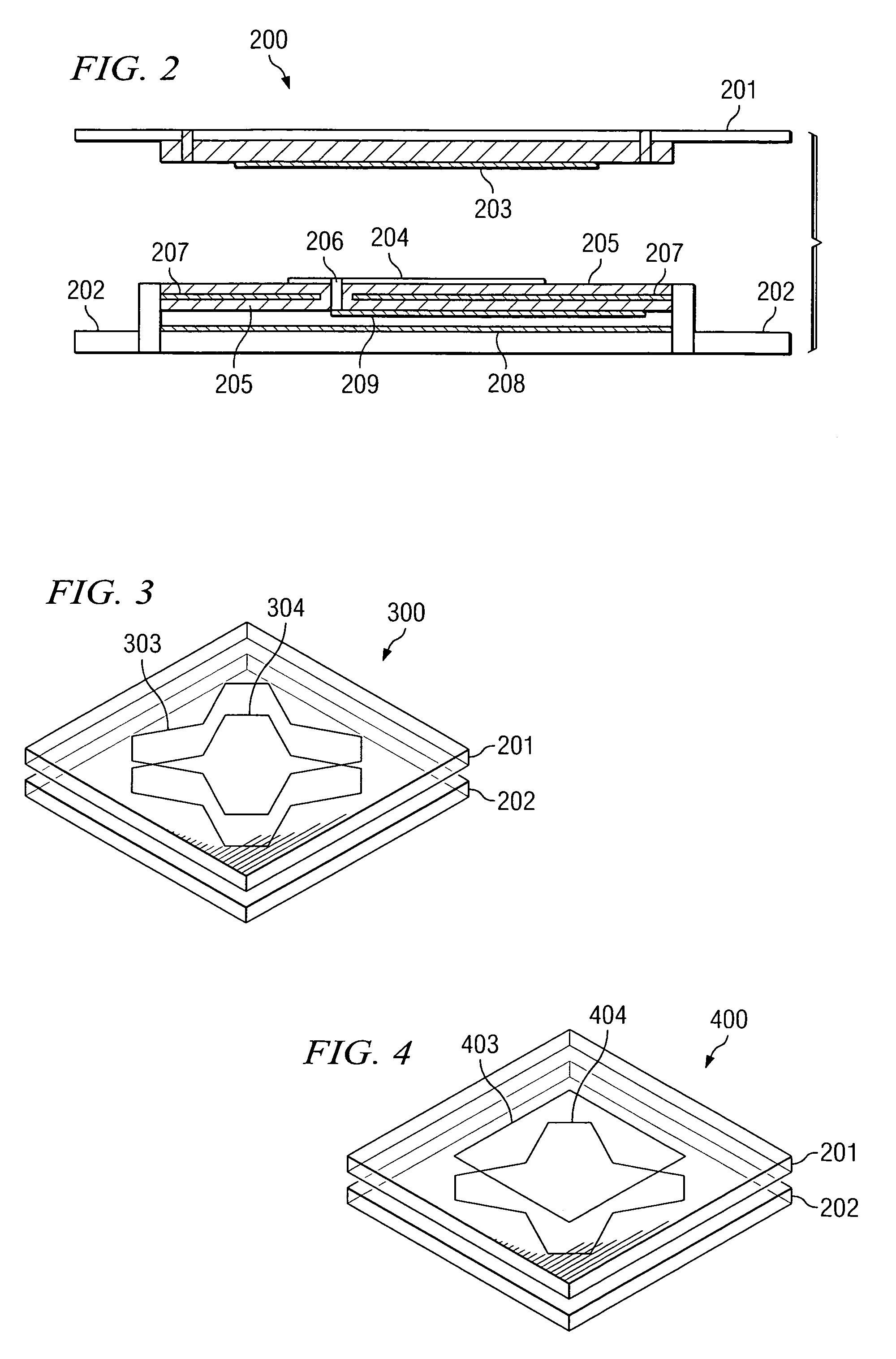

Process and apparatus for organic vapor jet deposition

ActiveUS7431968B1Good directionSharp pixelVacuum evaporation coatingSputtering coatingOrganic filmVacuum chamber

A method of fabricating an organic film is provided. A non-reactive carrier gas is used to transport an organic vapor. The organic vapor is ejected through a nozzle block onto a cooled substrate, to form a patterned organic film. A device for carrying out the method is also provided. The device includes a source of organic vapors, a source of carrier gas and a vacuum chamber. A heated nozzle block attached to the source of organic vapors and the source of carrier gas has at least one nozzle adapted to eject carrier gas and organic vapors onto a cooled substrate disposed within the vacuum chamber.

Owner:THE TRUSTEES FOR PRINCETON UNIV

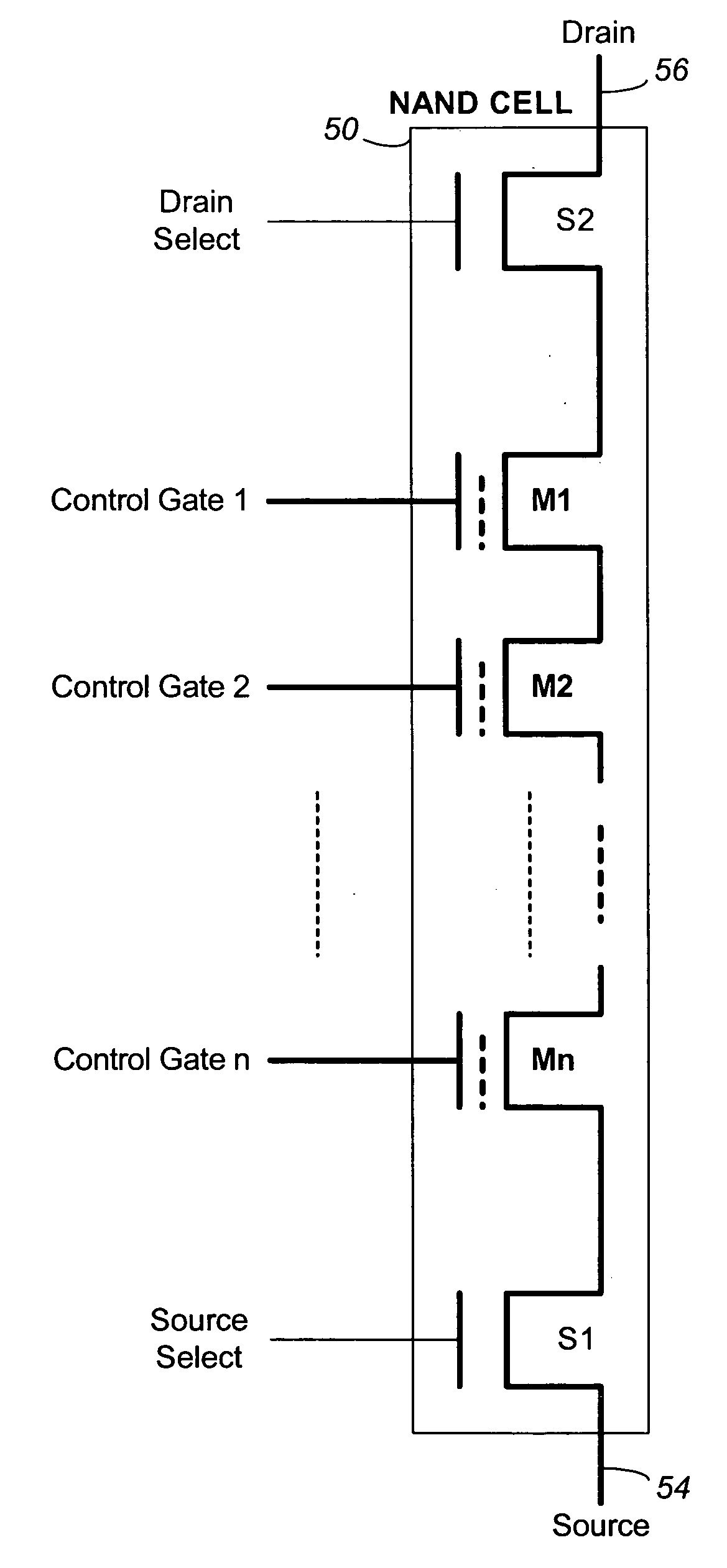

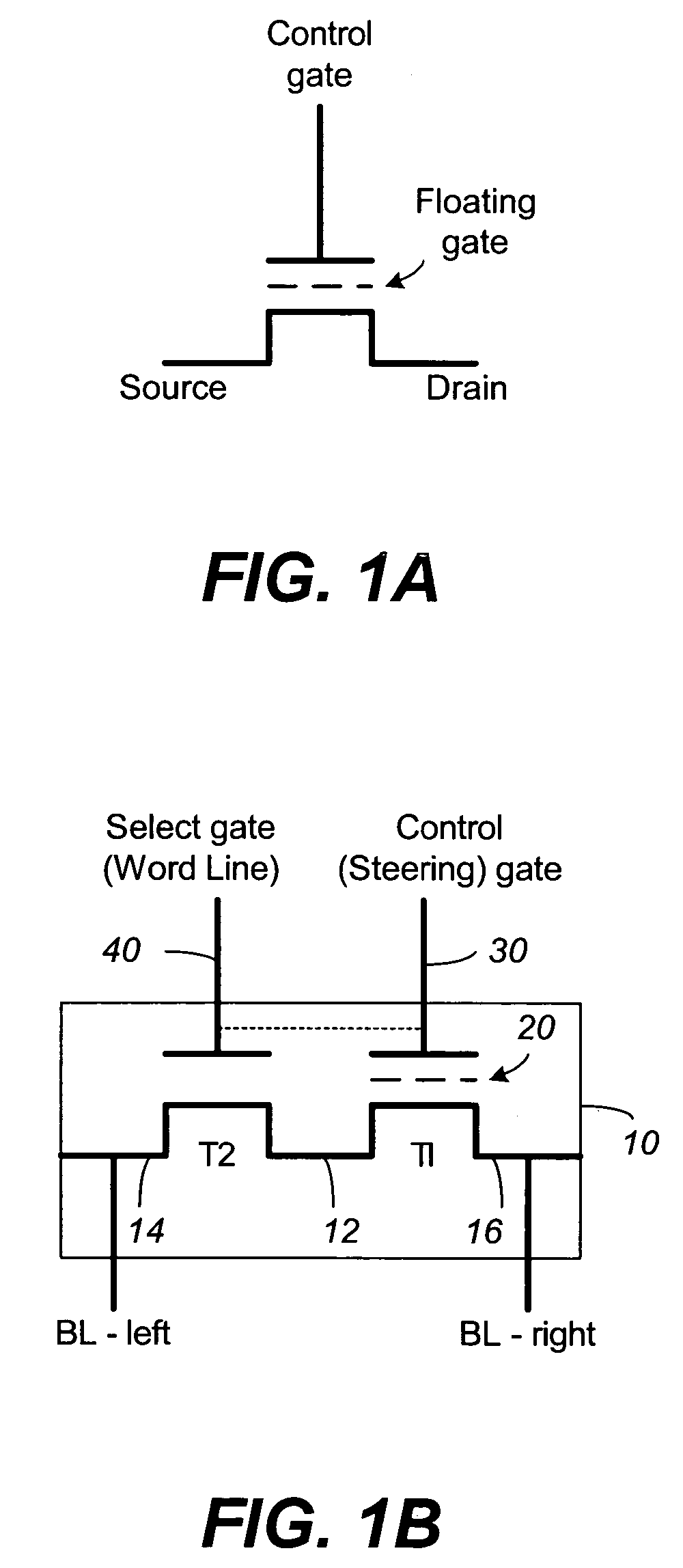

Non-volatile memory and method with shared processing for an aggregate of read/write circuits

InactiveUS20060140007A1Maximum versatilityMinimal componentRead-only memoriesDigital storageAudio power amplifierAssociative processor

A non-volatile memory device capable of reading and writing a large number of memory cells with multiple read / write circuits in parallel has an architecture that reduces redundancy in the multiple read / write circuits to a minimum. The multiple read / write circuits are organized into a bank of similar stacks of components. Redundant circuits such as a processor for processing data among stacks each associated with multiple memory cells are factored out. The processor is implemented with an input logic, a latch and an output logic. The input logic can transform the data received from either the sense amplifier or the data latches. The output logic further processes the transformed data to send to either the sense amplifier or the data latches or to a controller. This provides an infrastructure with maximum versatility and a minimum of components for sophisticated processing of the data sensed and the data to be input or output.

Owner:SANDISK TECH LLC

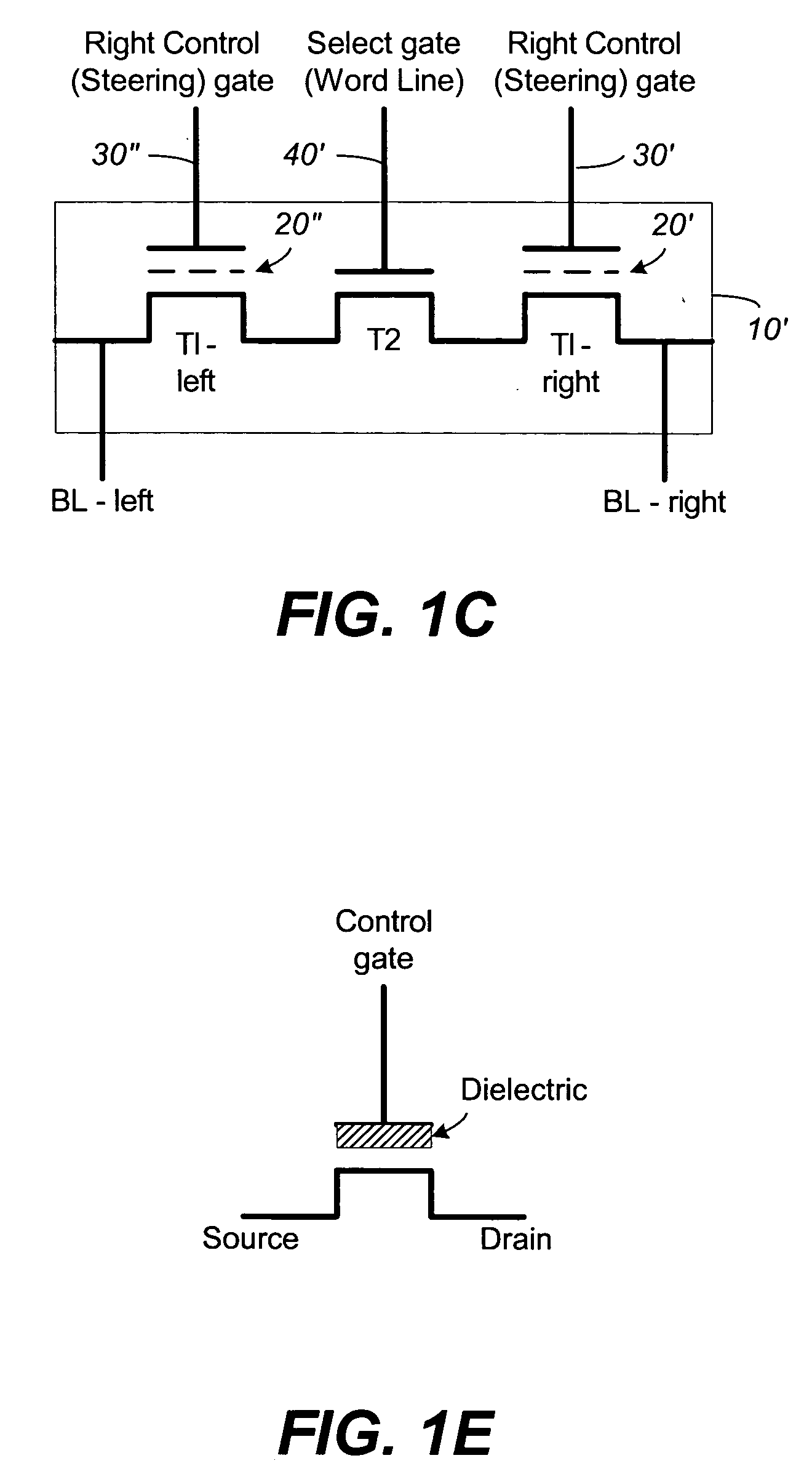

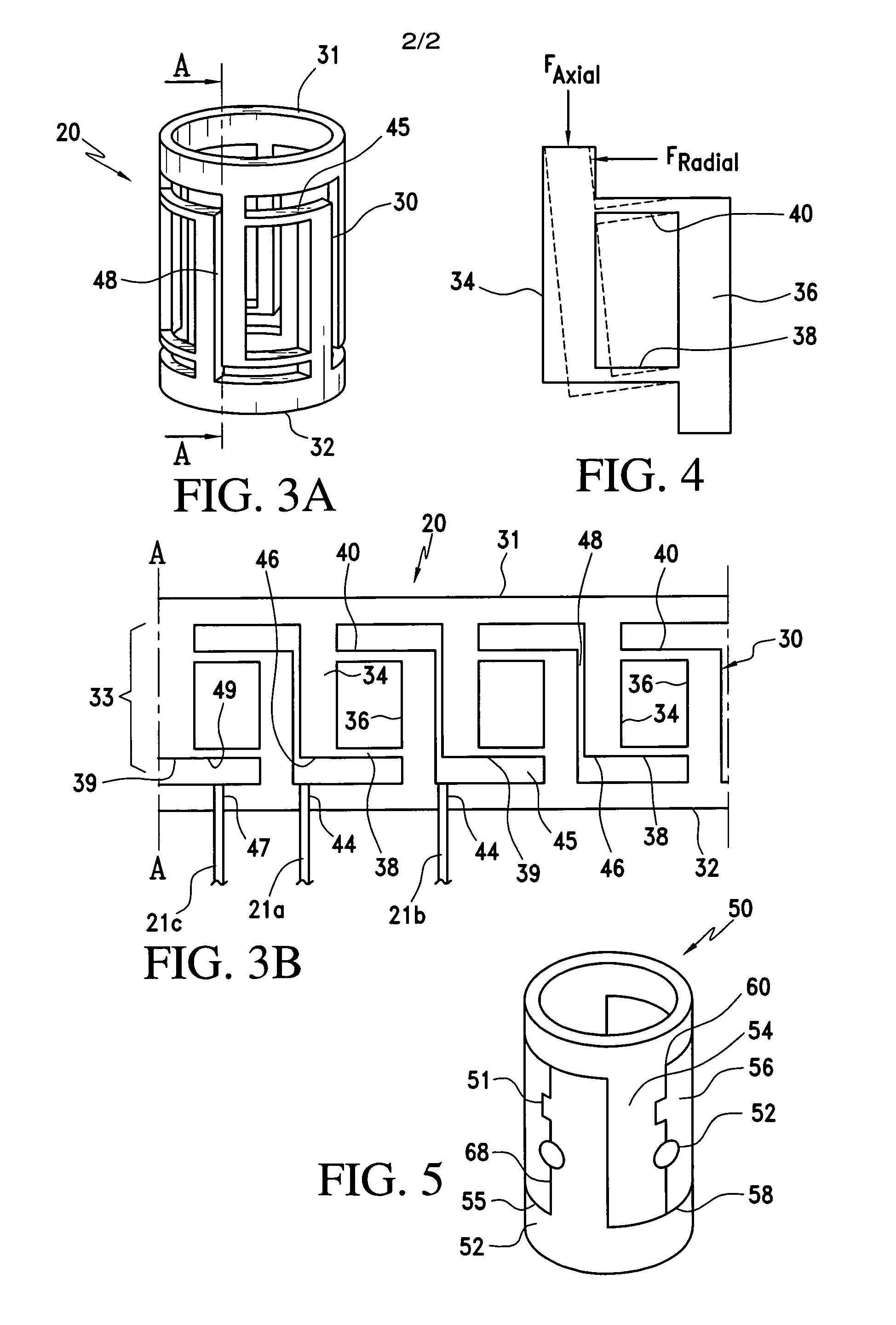

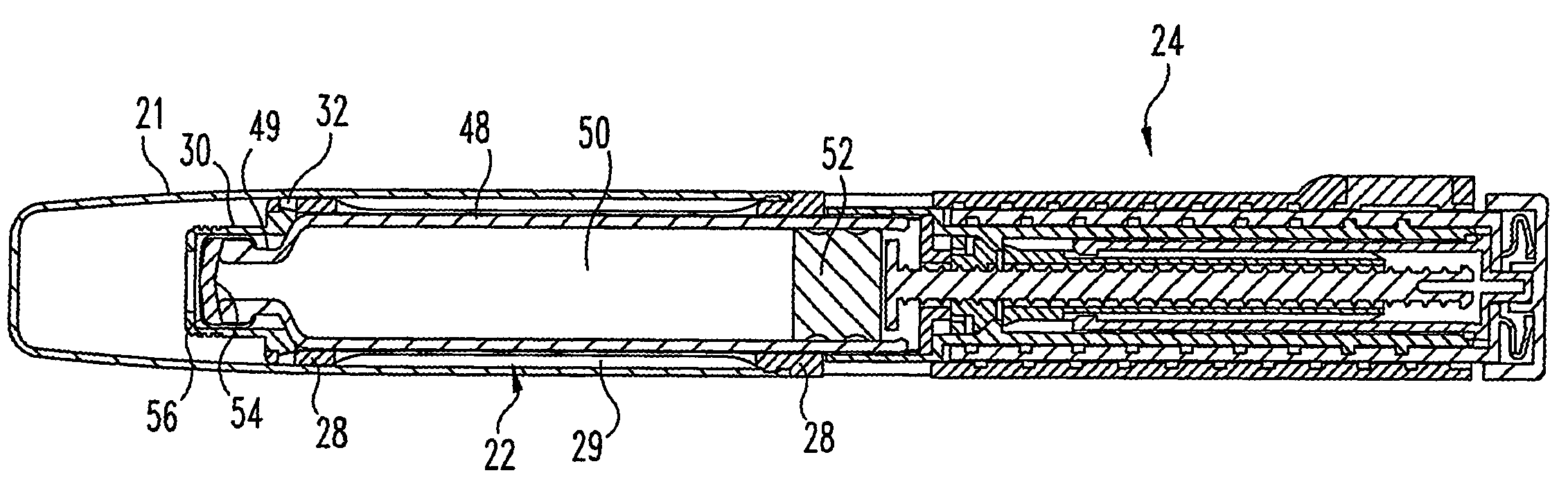

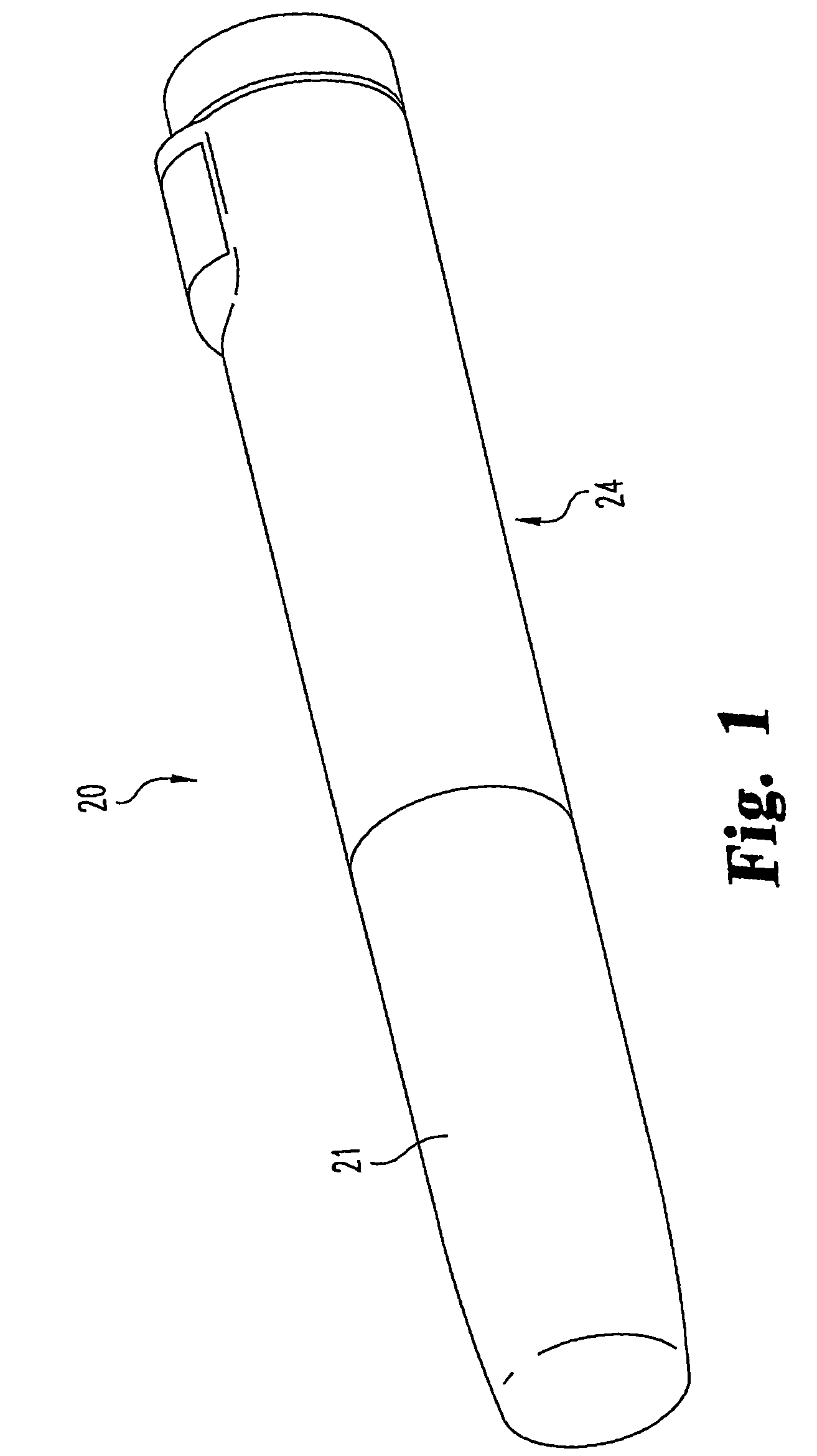

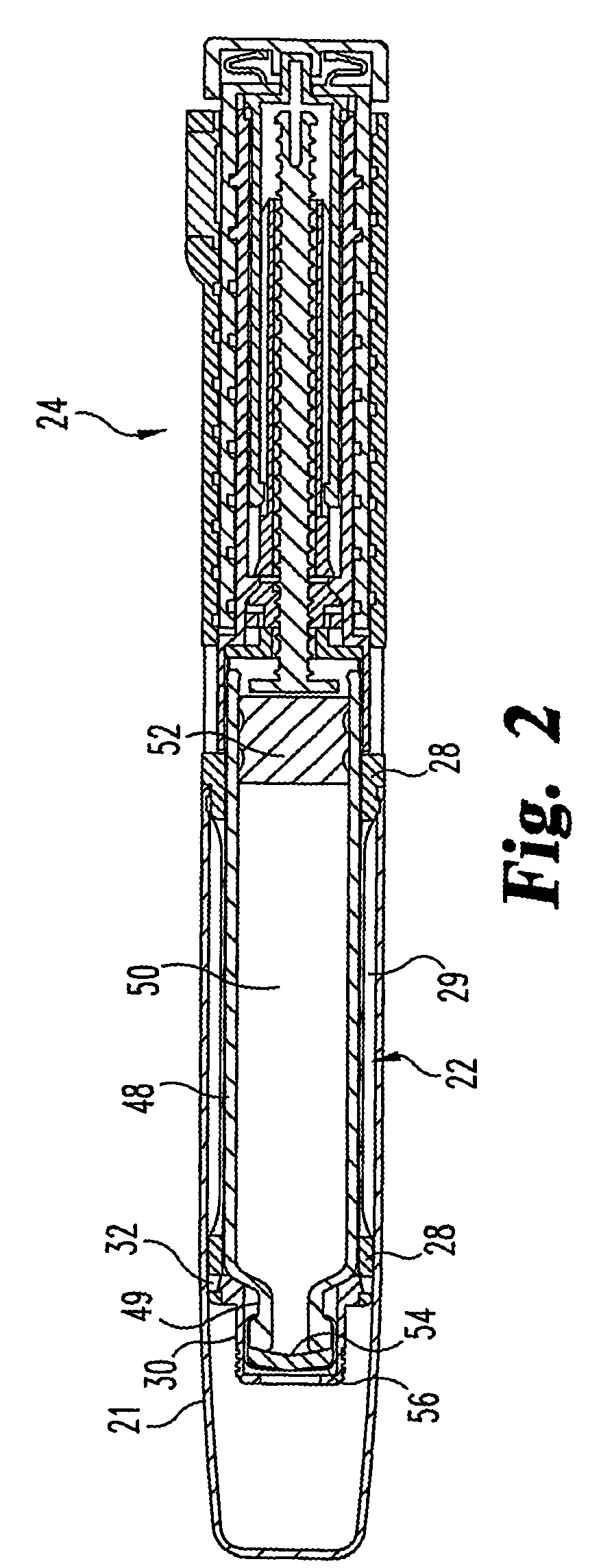

Catheter having tri-axial force sensor

ActiveUS20080009750A1Plenty of spaceFacilitate speedElectrocardiographySurgical instrument detailsAxial forceContact force

A catheter for diagnosis or treatment of a vessel or organ is provided in which a flexible elongated body includes a tri-axial force sensor formed of a housing and a plurality of optical fibers associated with the housing that measure changes in the intensity of light reflected from the lateral surfaces of the housing resulting from deformation caused by forces applied to a distal extremity of the housing. A controller receives an output of the optical fibers and computes a multi-dimensional force vector corresponding to the contact force.

Owner:ST JUDE MEDICAL INT HLDG SARL

Medication dispensing apparatus with triple screw threads for mechanical advantage

A medication dispensing apparatus that provides a mechanical advantage. During dose preparing, a nut rotating element (410) and a screw element (368) are in a first axial arrangement such that a screwing motion of the nut rotating element and screw element relative to the apparatus housing that moves the elements a first axial distance from a home position screws a nut (364) along a drive member threaded shaft (362) a second axial distance different than the first axial distance. During dose dispensing, the nut rotating element and the screw element are in a second axial arrangement, whereby a screwing motion of the screw element relative to the housing back toward the home position advances a plunger (366) in the distal direction to axially advance the nut and thereby the drive member and a fluid container piston to dispense medicine.

Owner:ELI LILLY & CO

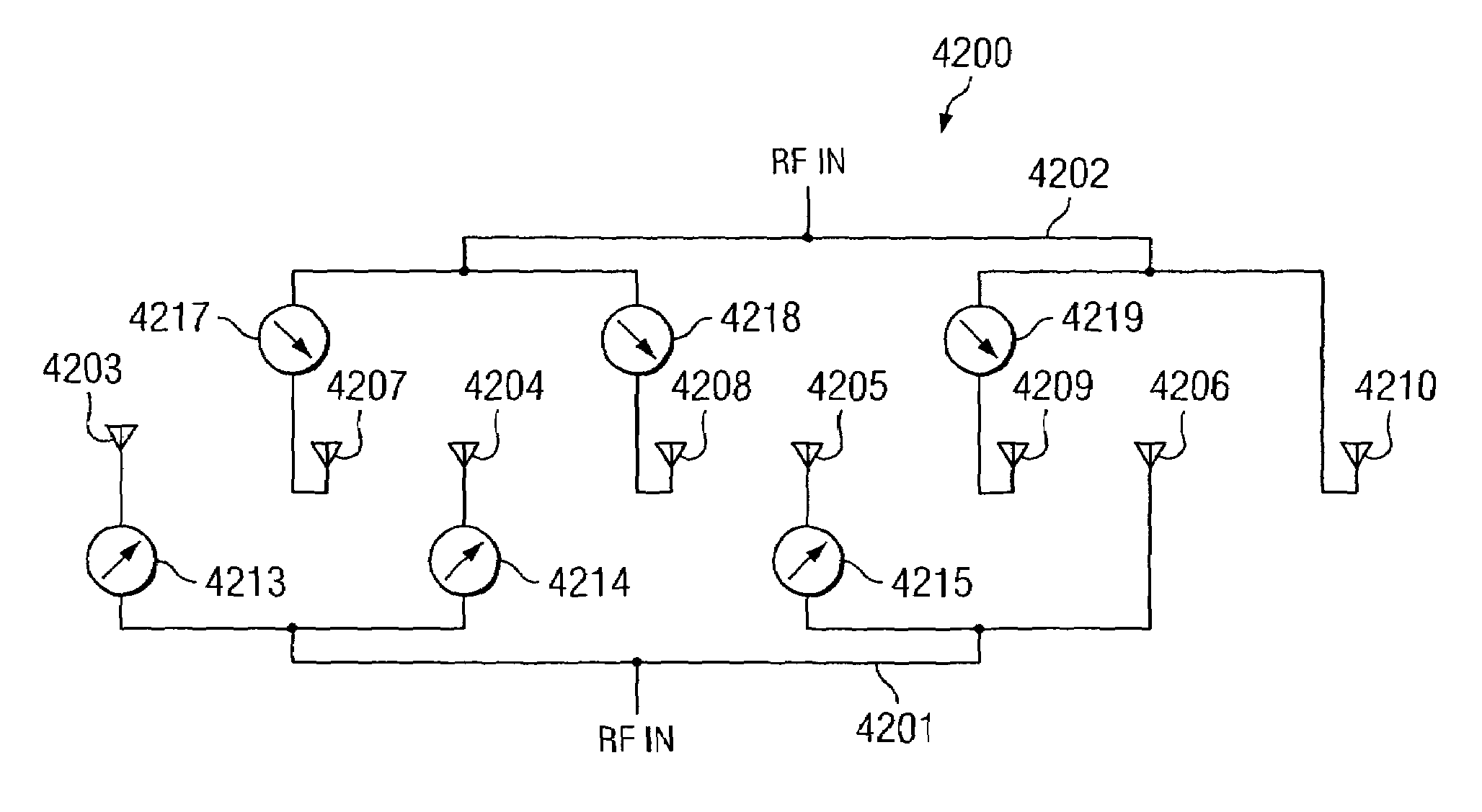

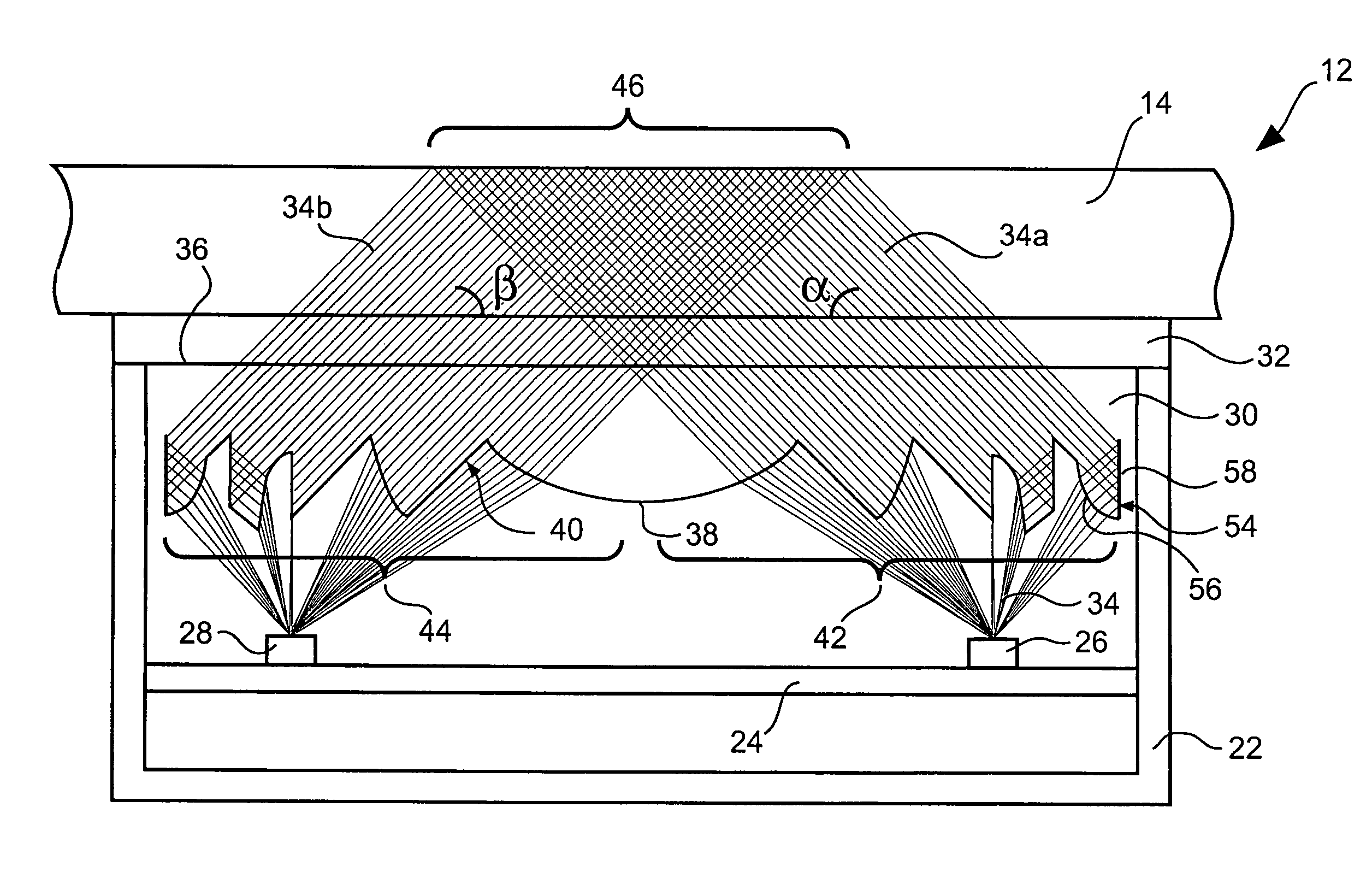

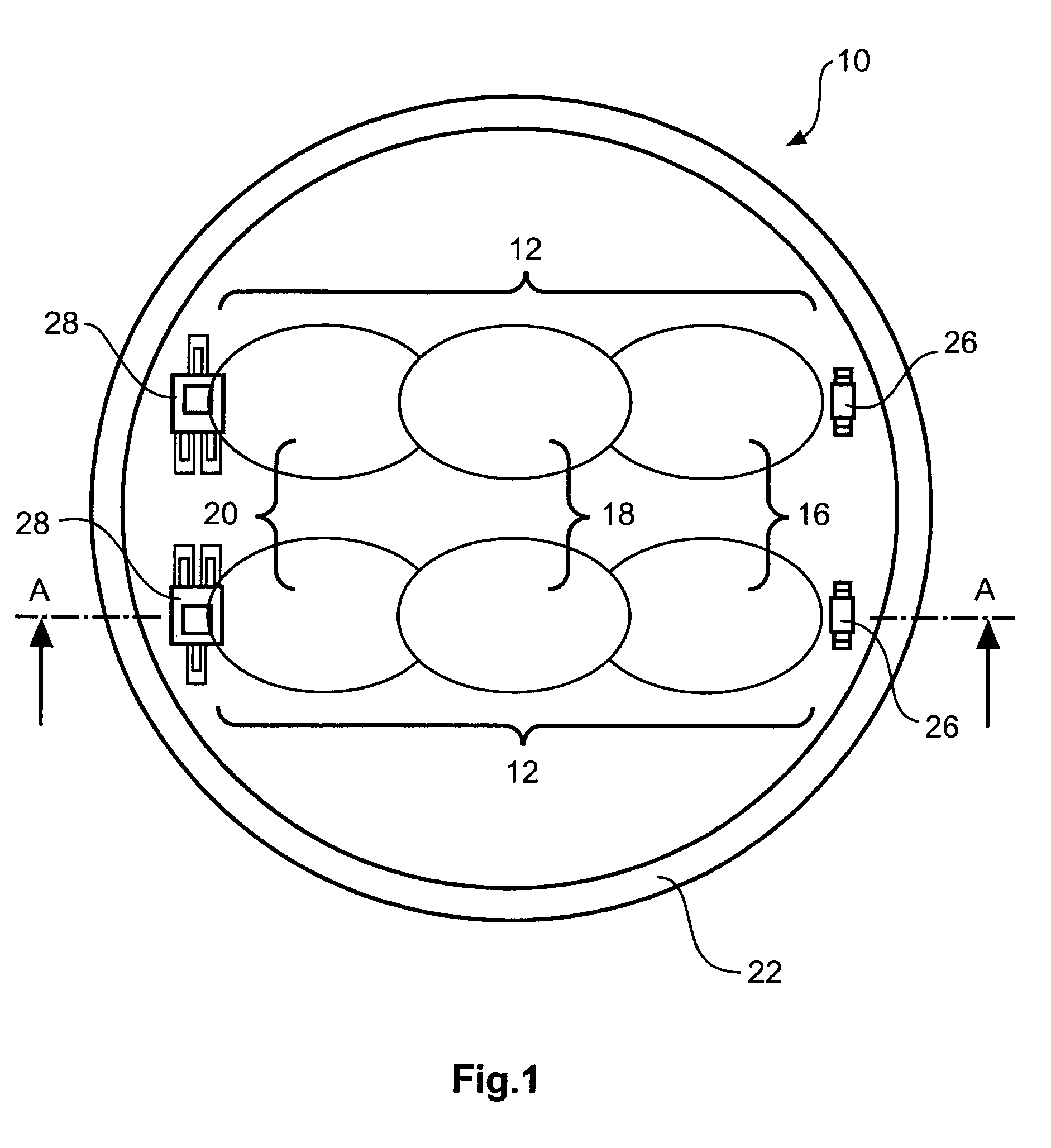

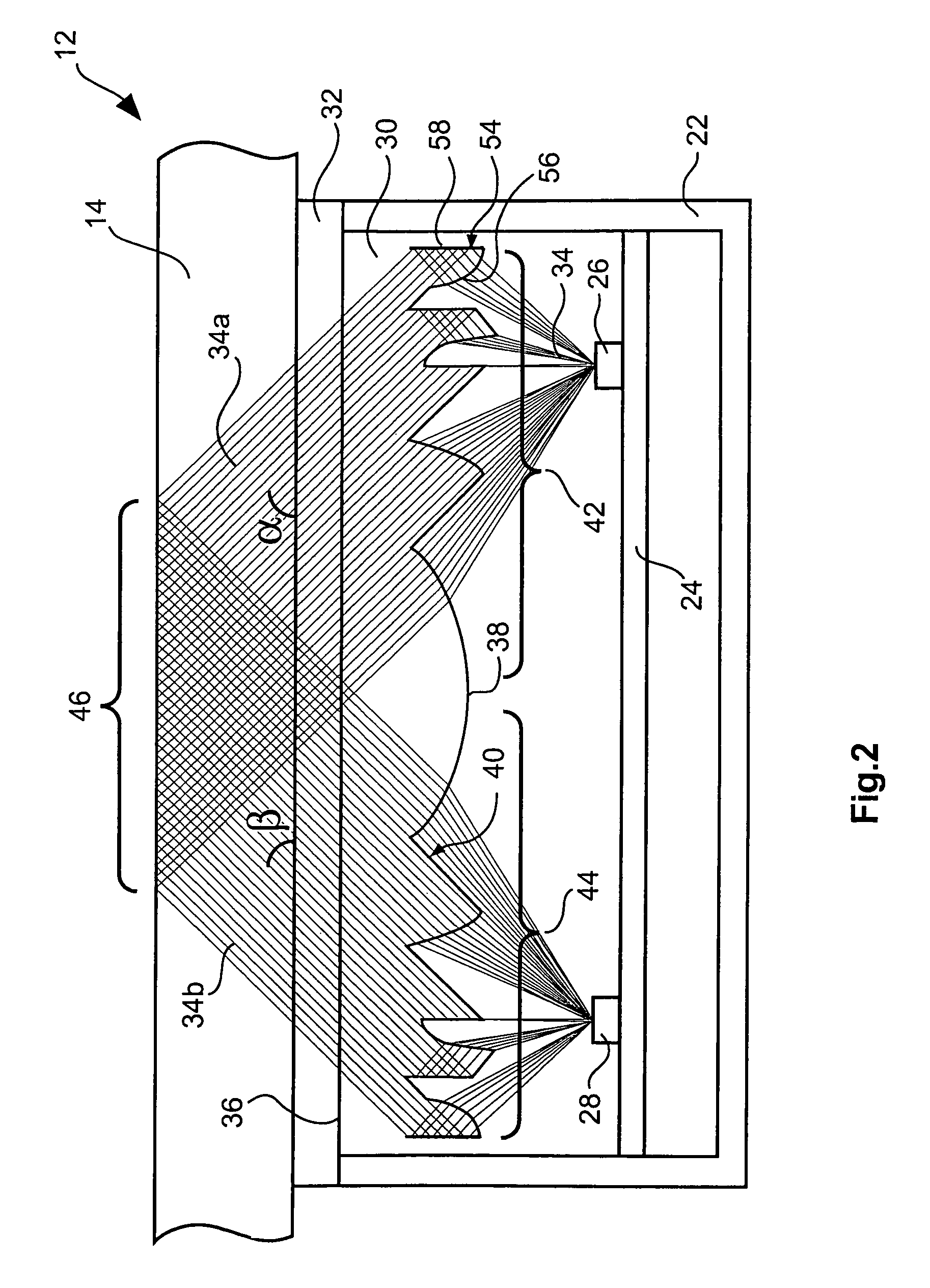

Low cost multi-beam, multi-band and multi-diversity antenna systems and methods for wireless communications

ActiveUS7075485B2Low costImprove performanceSimultaneous aerial operationsAntenna supports/mountingsMulti bandCommunications system

Systems and methods for employing switched phase shifters and a feed network to provide a low cost multiple beam antenna system for wireless communications. The present systems and methods may also facilitate multi-band communications and employ multi-diversity. The present systems and methods allow communication systems to achieve enhanced performance for communication or other services such as location tracking. The present systems and methods may employ switched phase shifters, multiple diversity antennas and / or a feed network having a multi-layer construction to provide an antenna system with low losses, low external component count and / or which is thin and compact.

Owner:HONG KONG APPLIED SCI & TECH RES INST

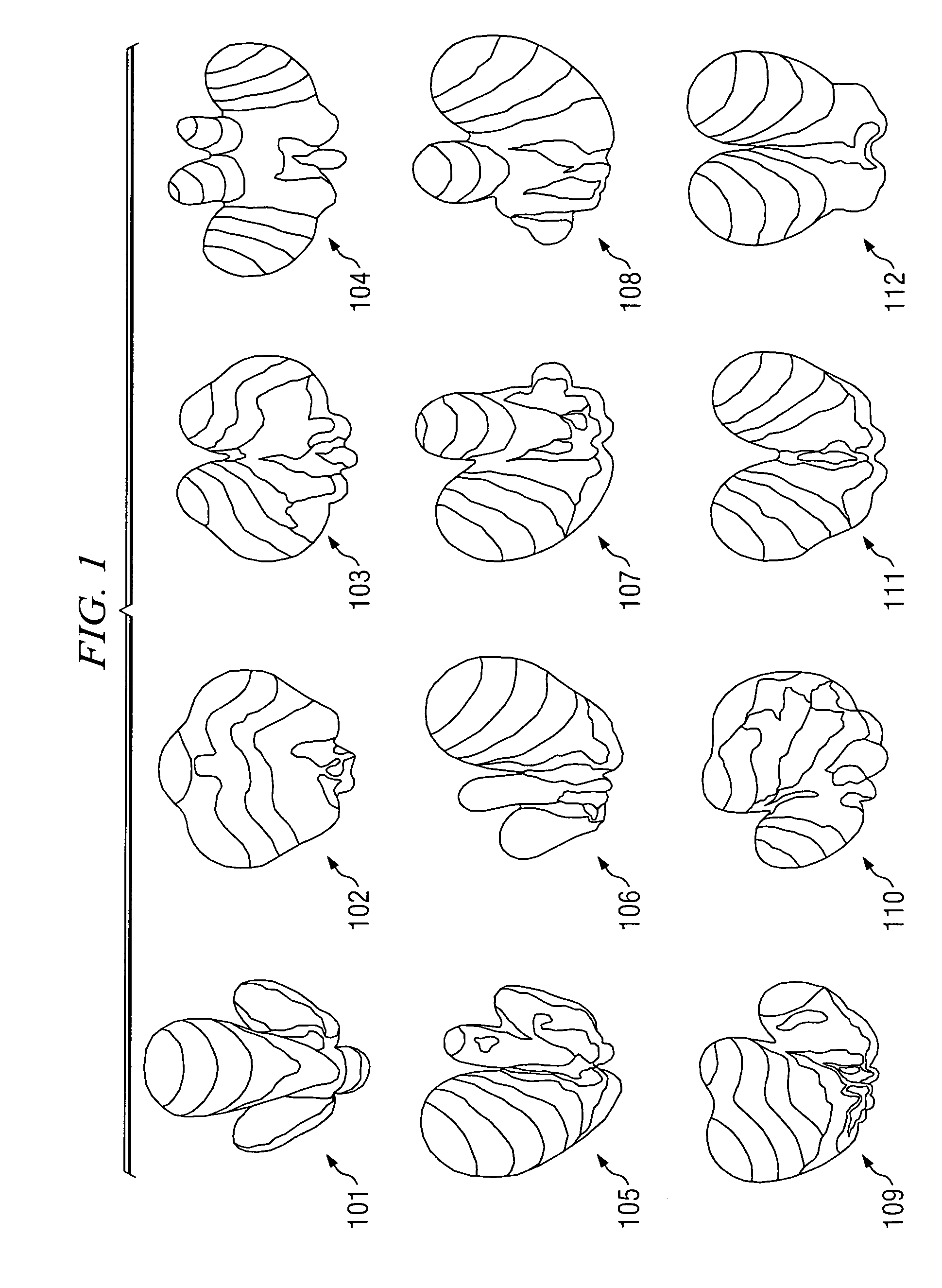

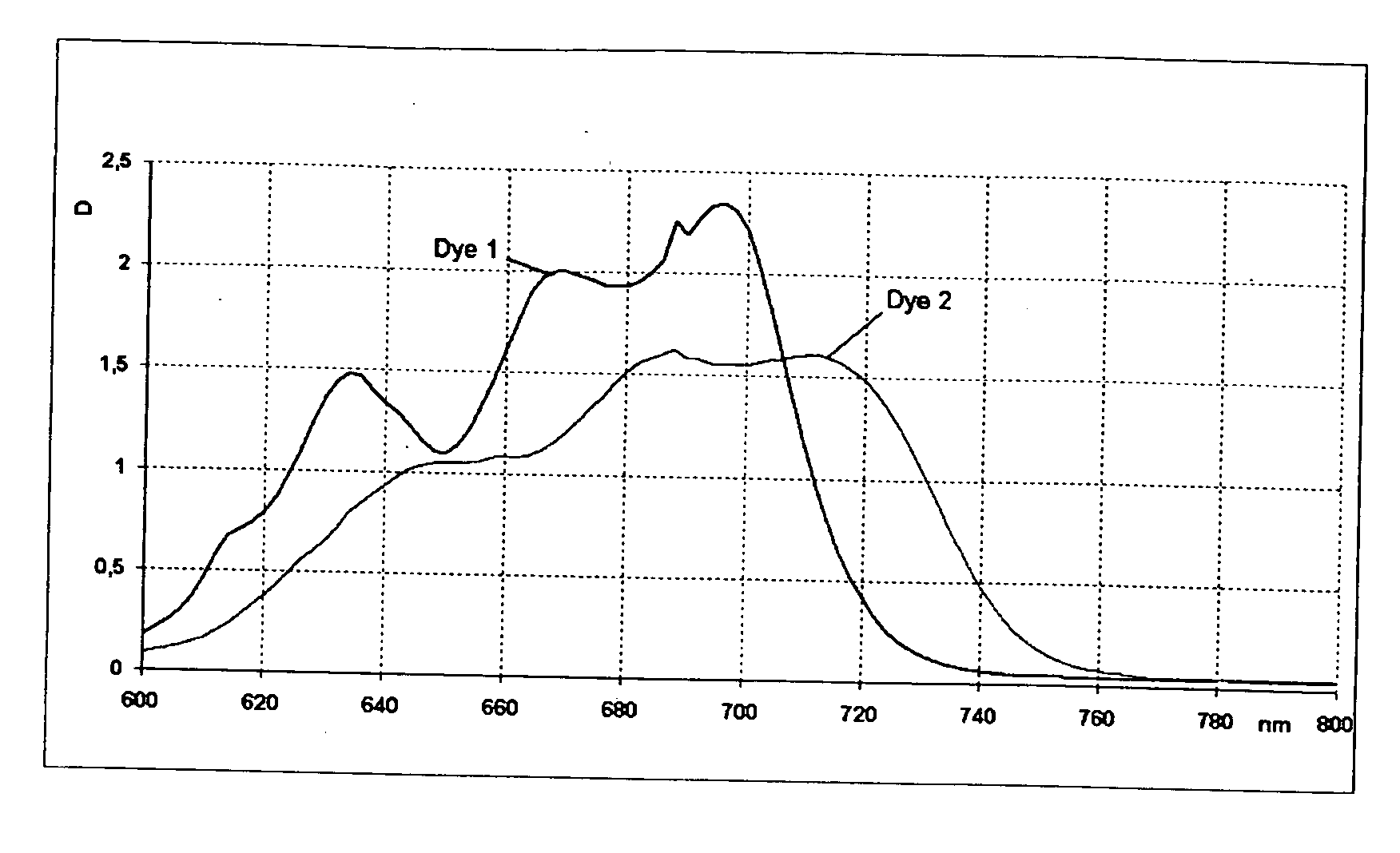

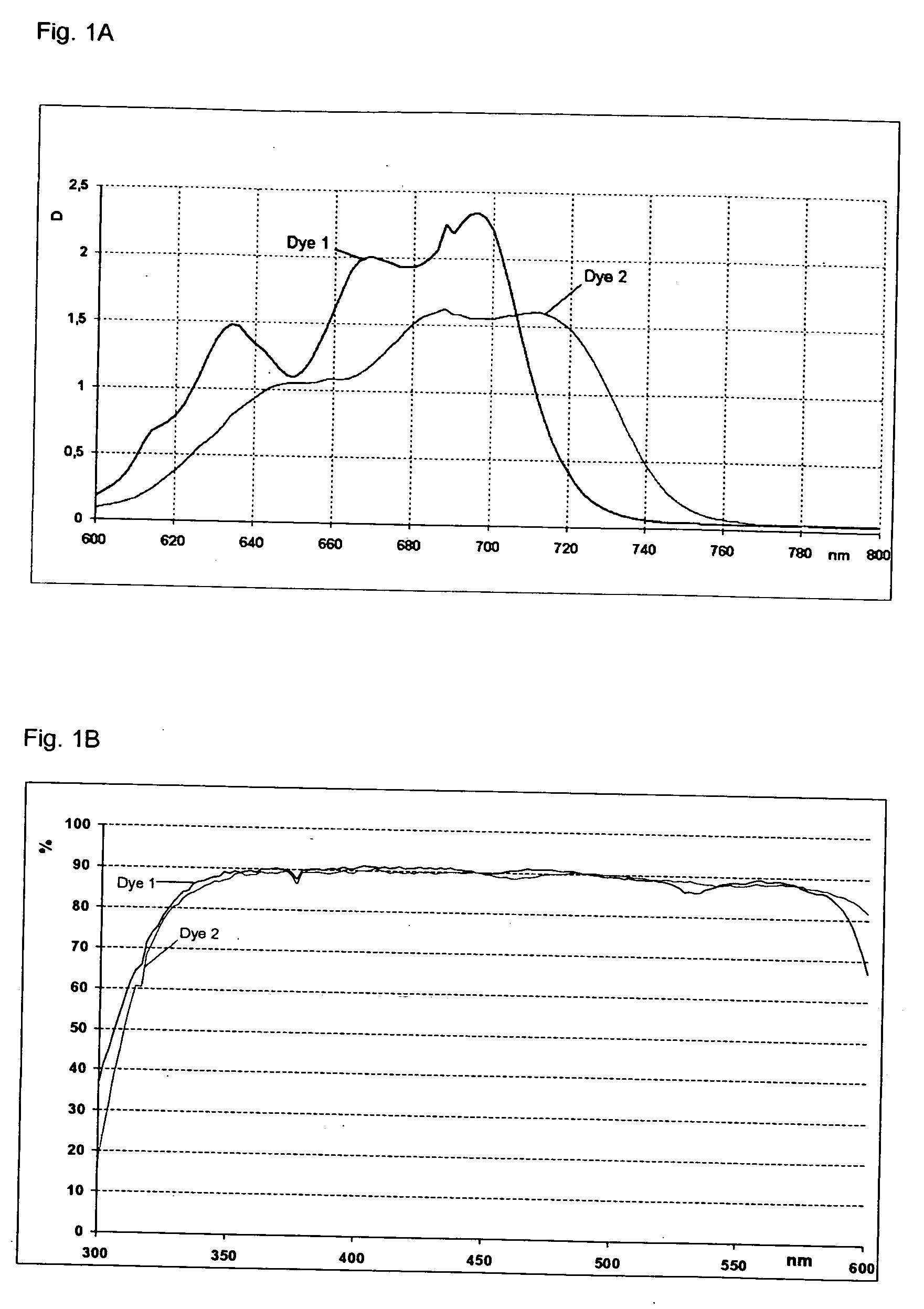

Device provided with a dedicated dye compound

InactiveUS20060030738A1Low costCompact designPhosphorus organic compoundsOptical elementsCompound aDigital converter

A device comprises at least one organophosphonium transition metal dye or is provided with a filter, comprising at least one organophosphonium transition metal dye, wherein, in a particular embodiment said device is selected from the group consisting of a scanner, a digitizer, a display and a photographic device.

Owner:ROCKWELL SCI LICENSING +2

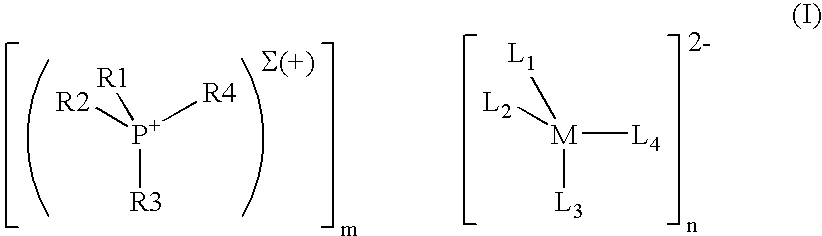

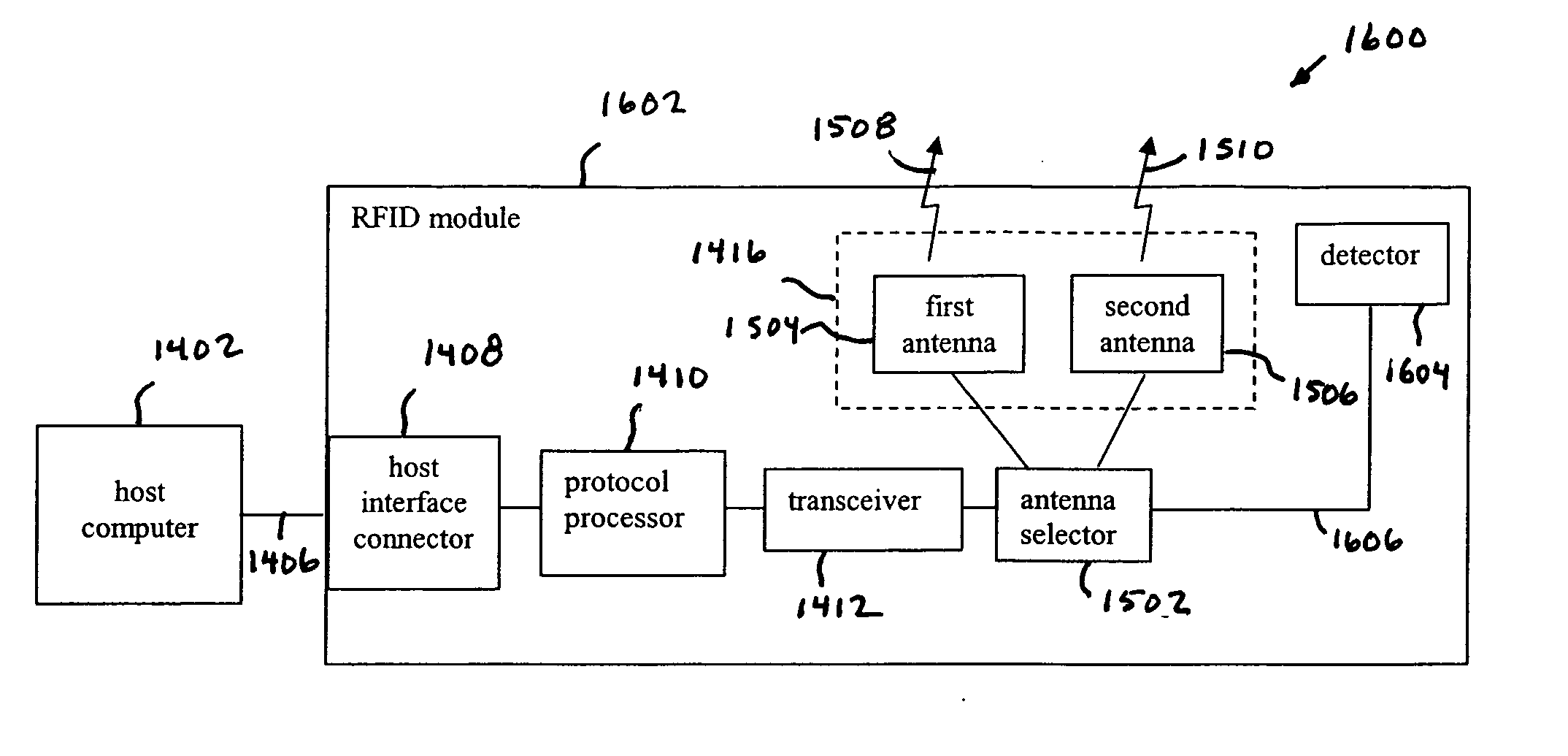

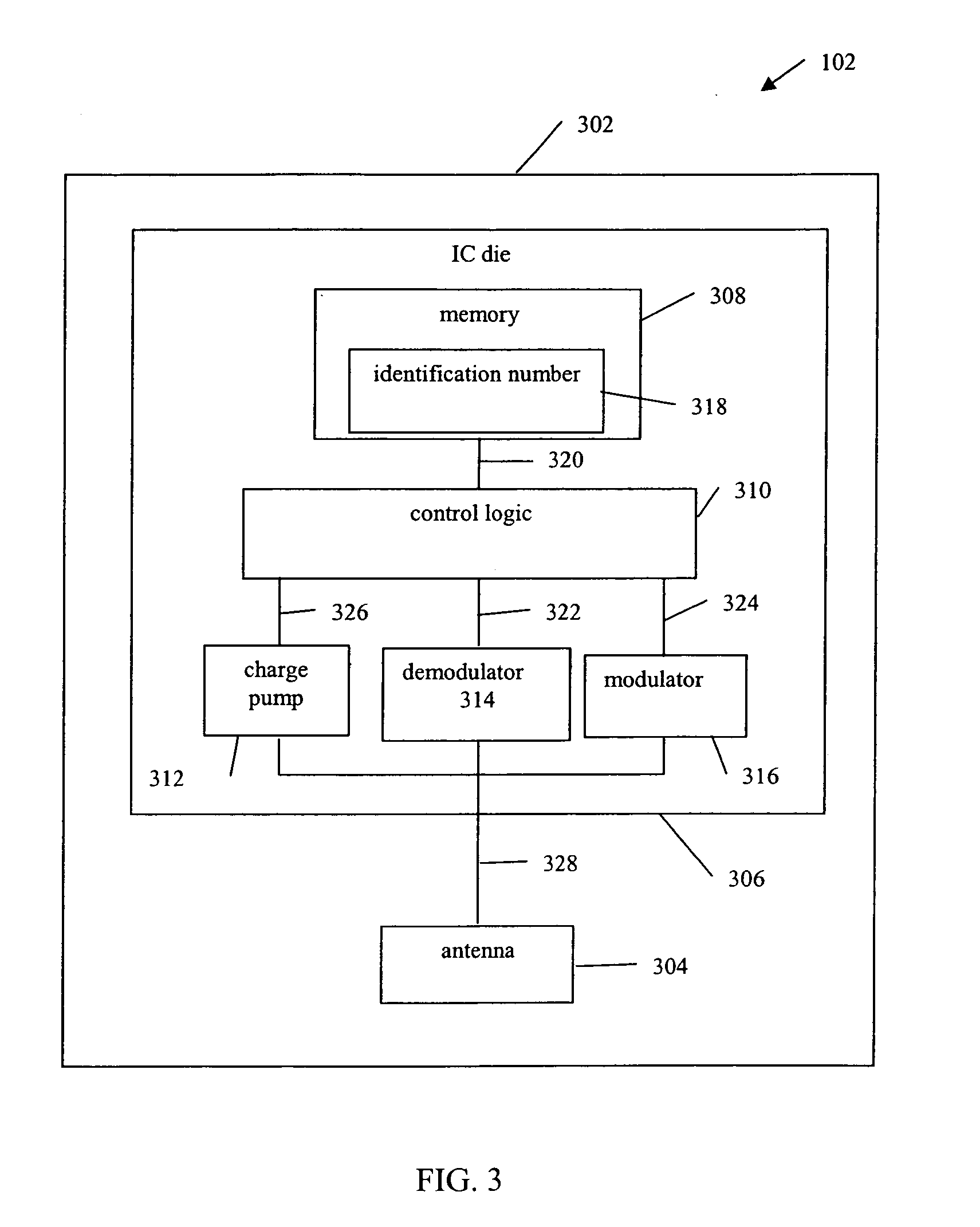

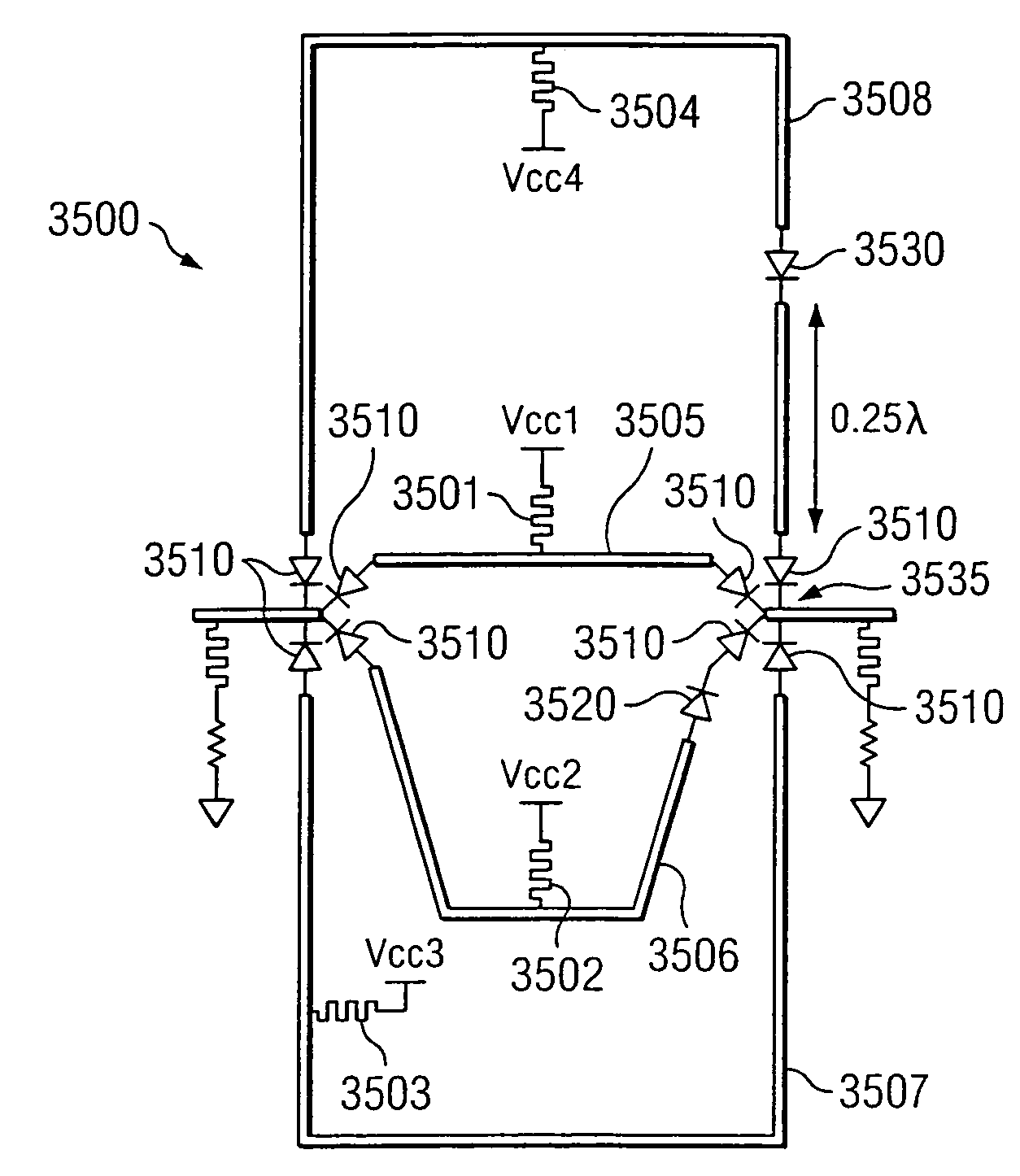

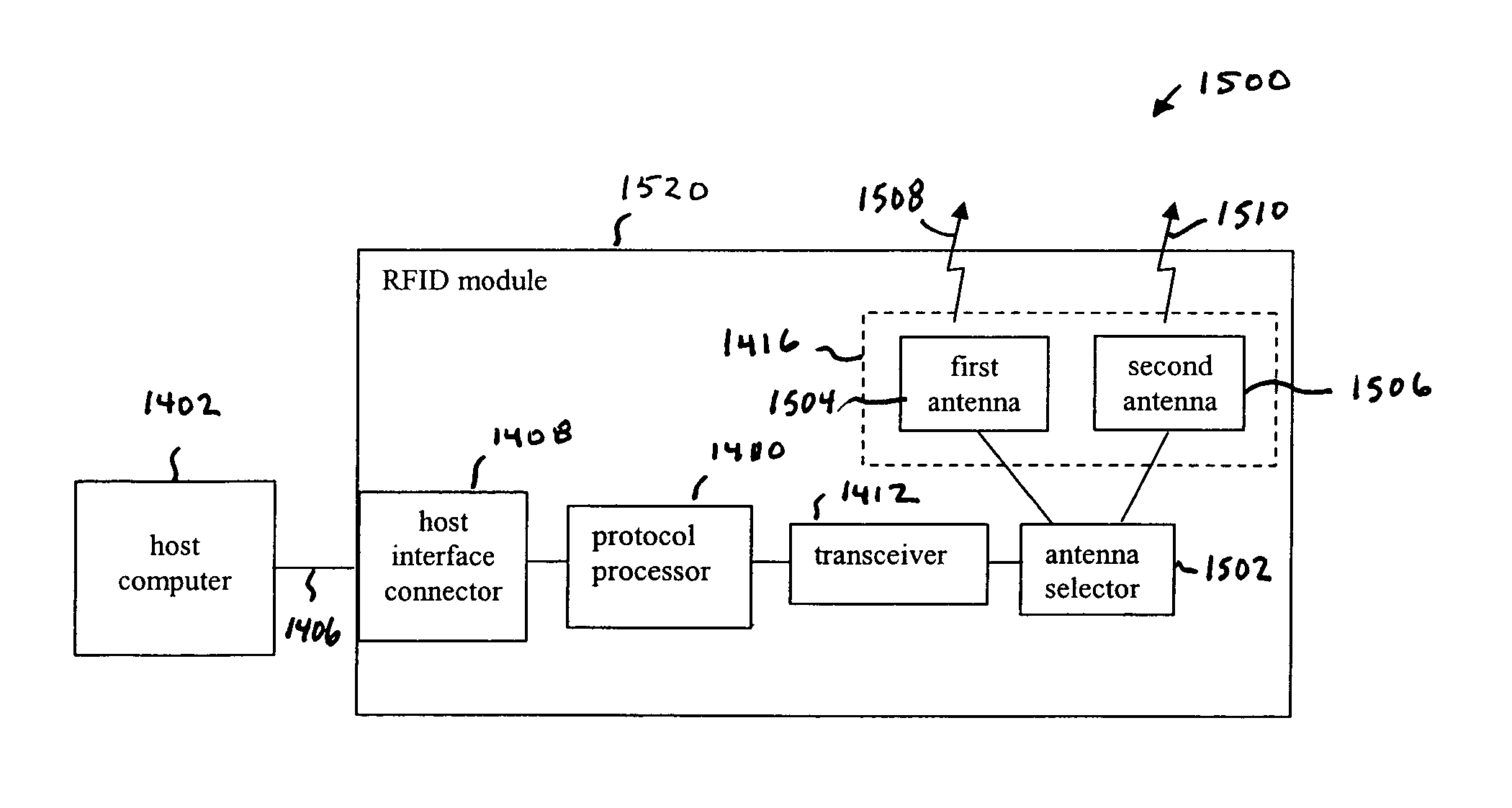

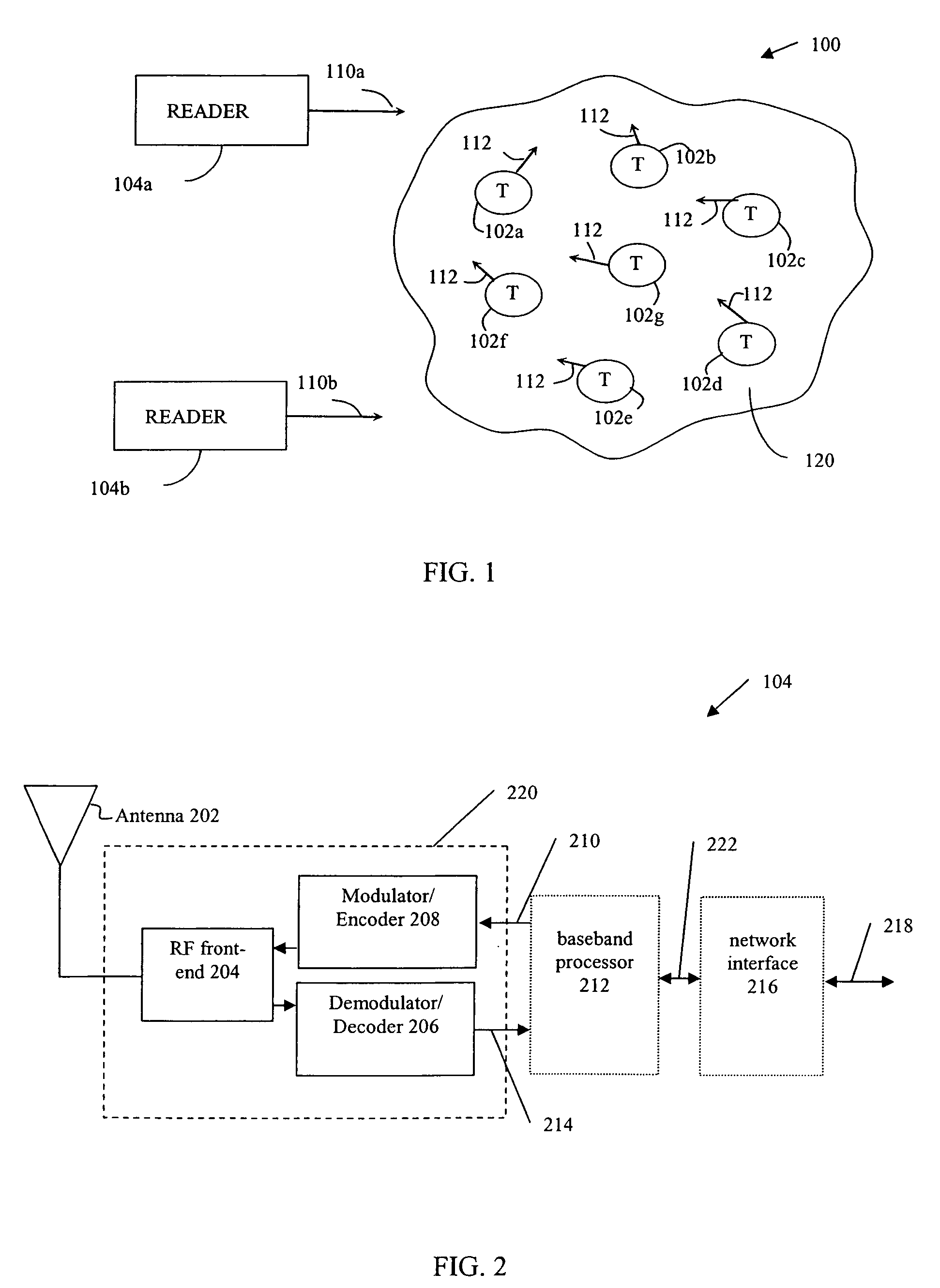

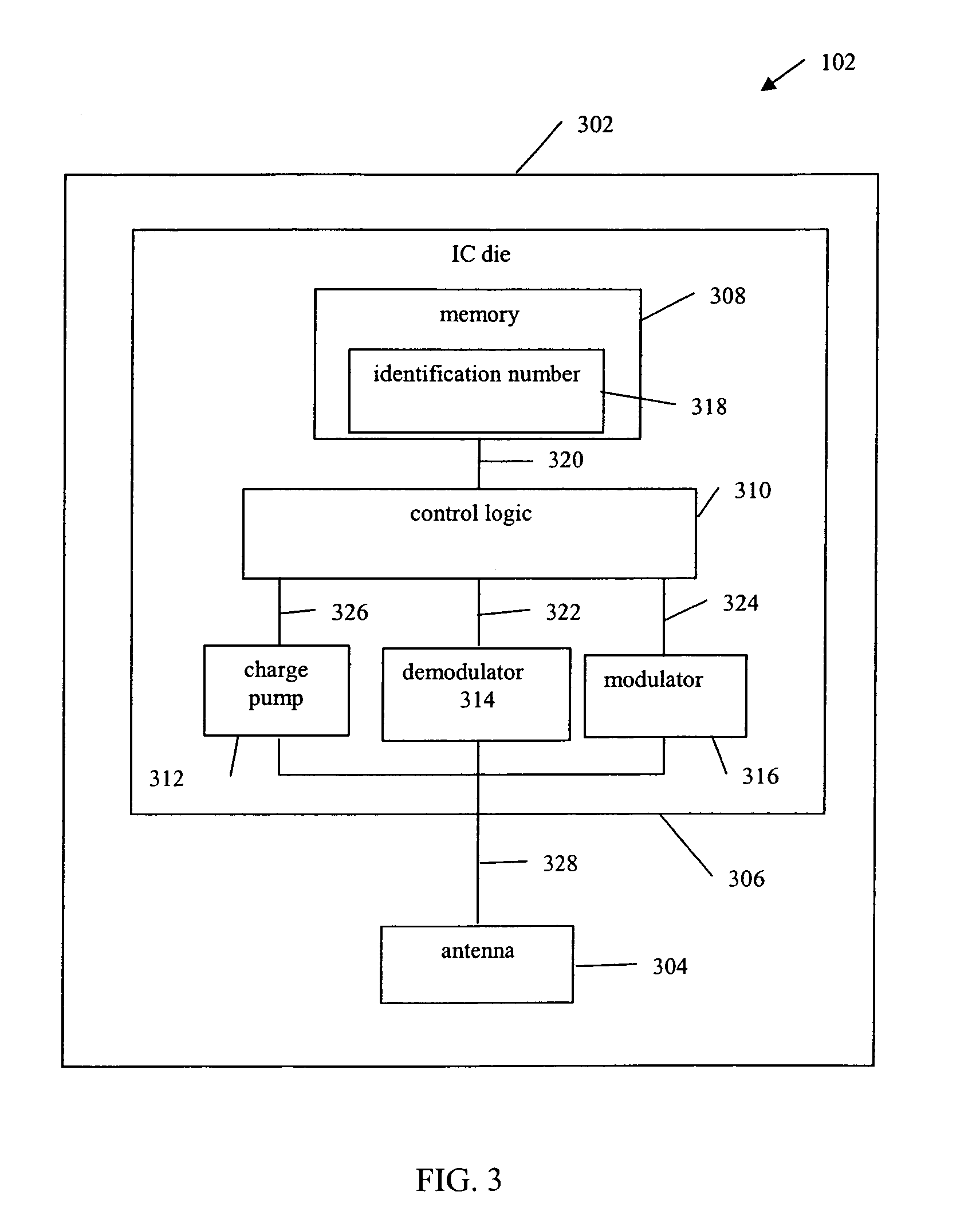

Single frequency low power RFID device

ActiveUS20070222609A1Compact designEnhance short range readNear-field transmissionMemory record carrier reading problemsTransceiverAcoustic wave

Methods, systems, and apparatuses for a reader transceiver circuit are described. The reader transceiver circuit incorporates a frequency generator, such as a surface acoustic wave (SAW) oscillator. A reader incorporating the reader transceiver circuit is configured to read a tag at very close range, including while being in contact with the tag. The transceiver can be coupled to various host devices in a variety of ways, including being located in a RFID reader (e.g., mobile or fixed position), a computing device, a barcode reader, etc. The transceiver can be located in an RFID module that is attachable to a host device, can be configured in the host device, or can be configured to communicate with the host device over a distance. The RFID module may include one or more antennas, such as a first antenna configured to receive a magnetic field component of an electromagnetic wave and a second antenna configured to receive an electric field component of an electromagnetic wave. The RFID module may include a detector that is configured to determine if the RFID module is positioned in proximity to an object, such as a RFID tag. The detector may operate as a trigger for the RFID module, to enable or trigger a function of the RFID module.

Owner:SYMBOL TECH LLC

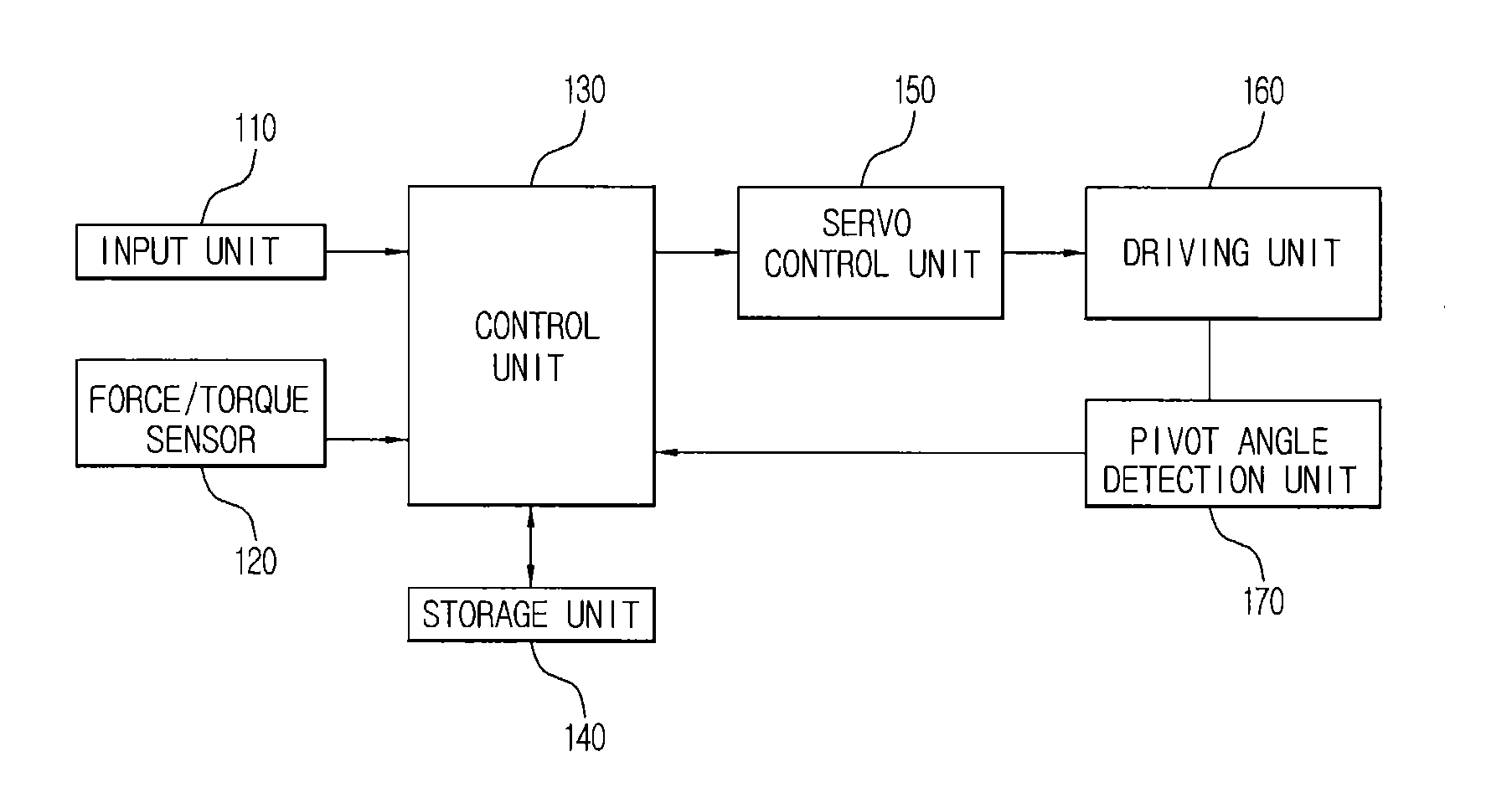

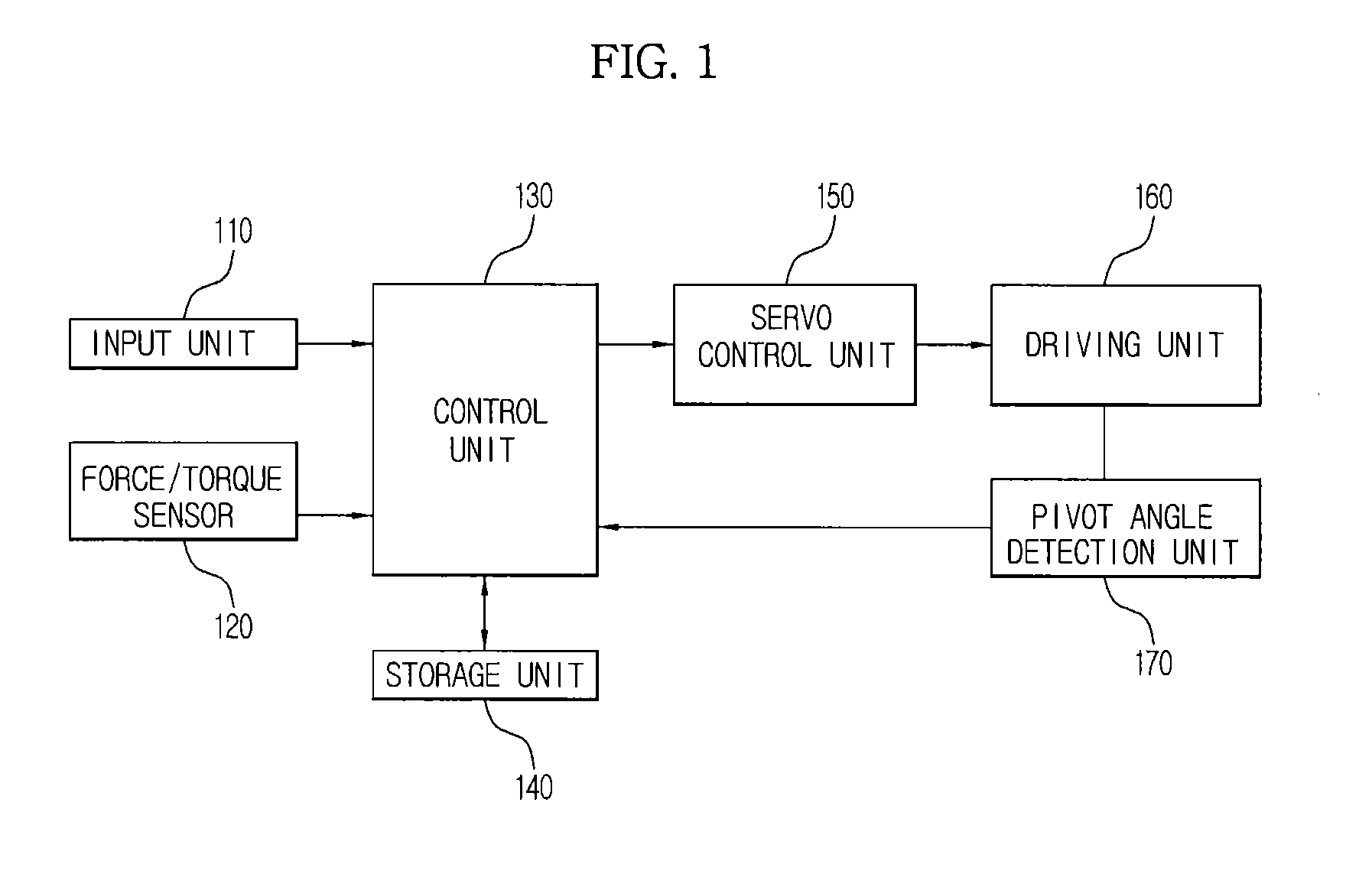

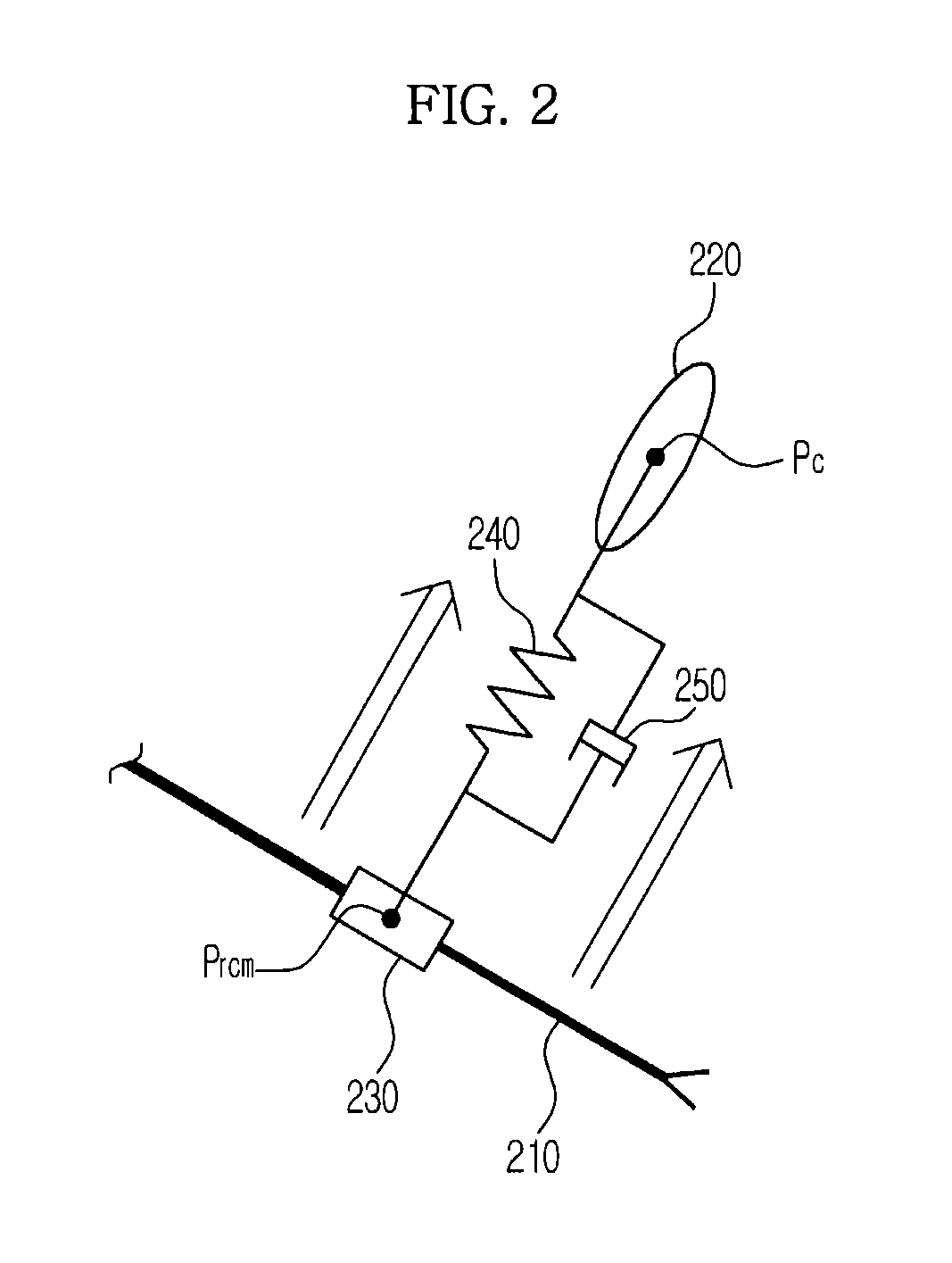

Surgical robot and control method thereof

InactiveUS20130116706A1Lower the volumeCompact designProgramme-controlled manipulatorDiagnosticsSurgical robotEngineering

A method for controlling a surgical robot includes calculating an external force acting on a robot arm mounted with a surgical instrument, filtering the external force acting on the robot arm when a central point of an incision is set, calculating a virtual force to enable the surgical instrument which is positioned away from the central point of the incision to return to the central point of the incision, and applying the calculated virtual force to the filtered external force, to control movement of the robot arm. As a result, it is possible to compactly design the surgical robot and thereby reduce the volume of the surgical robot.

Owner:SAMSUNG ELECTRONICS CO LTD

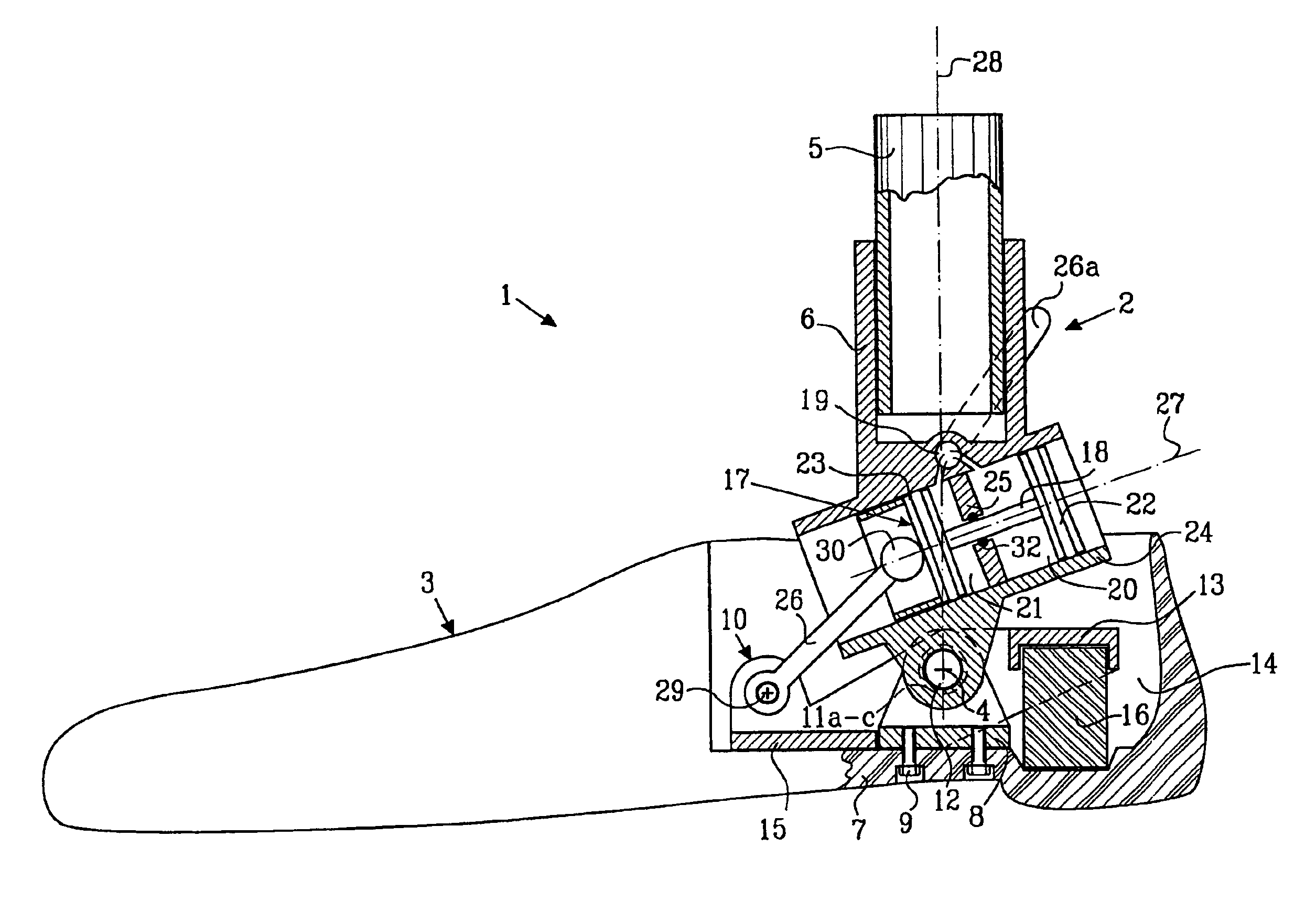

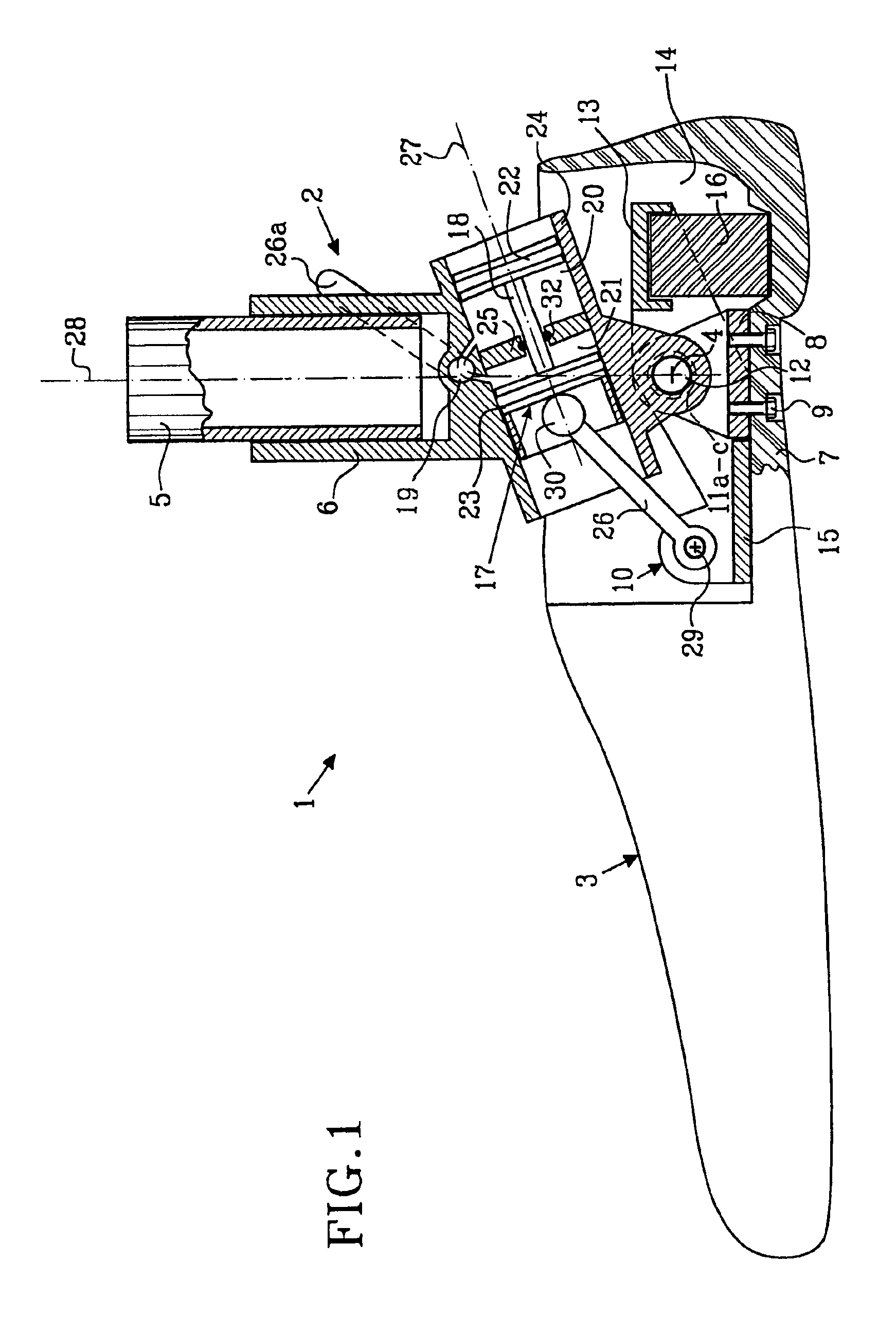

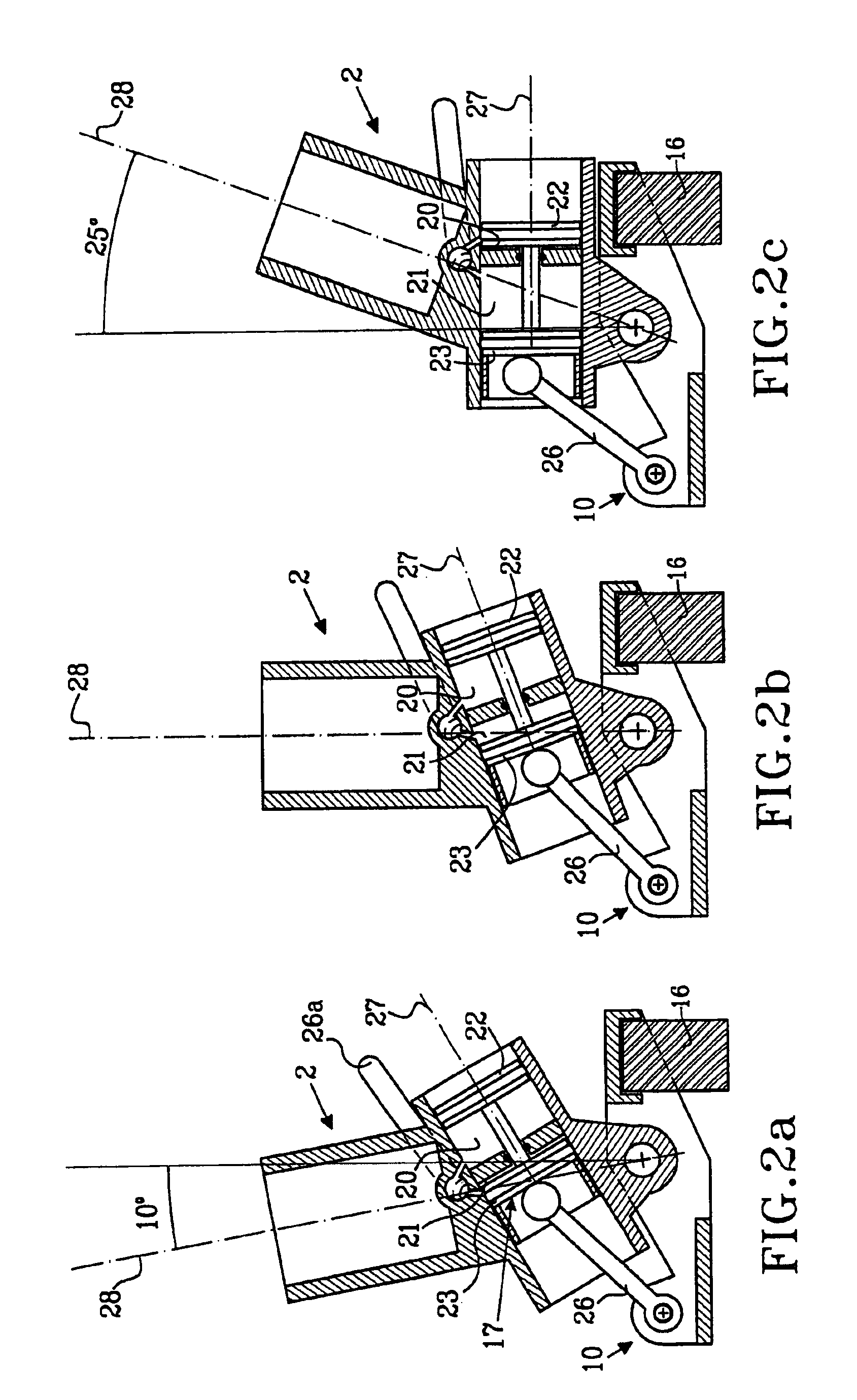

Device in a leg prosthesis

InactiveUS6855170B2Simple geometryReduce manufacturing costArtificial legsPhysical medicine and rehabilitationLeg prosthesis

A device in a leg prosthesis which via a pivot axle is connected to the leg prosthesis, wherein first means are arranged to permit a limited rotation of the foot with respect to the leg prosthesis from an initial position, in which the leg prosthesis and the foot have a certain angle with respect to each other and second means are arranged to permit a stepless adjustment of the angle between the prosthesis and the foot in the initial position.

Owner:GRAMTEC INNOVATION

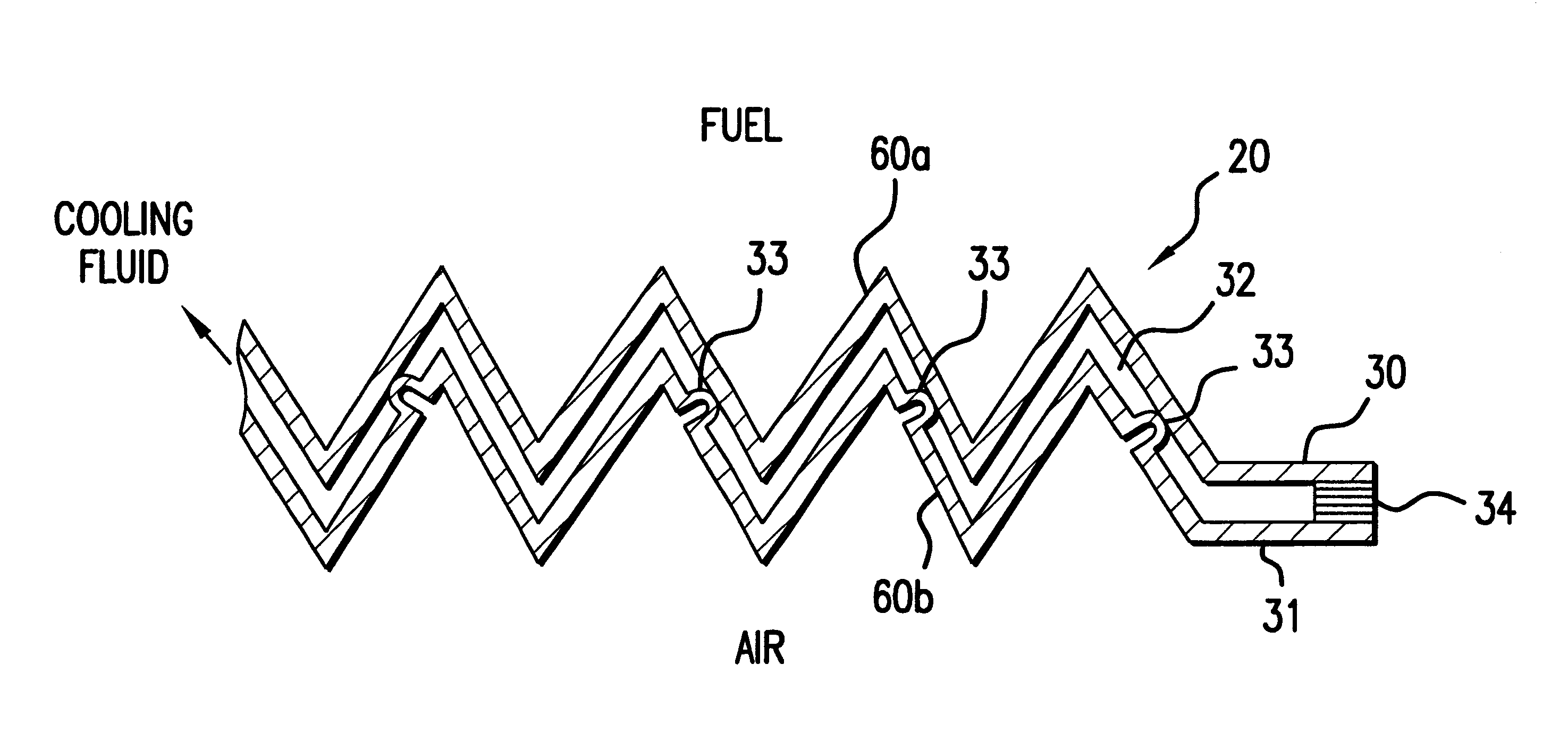

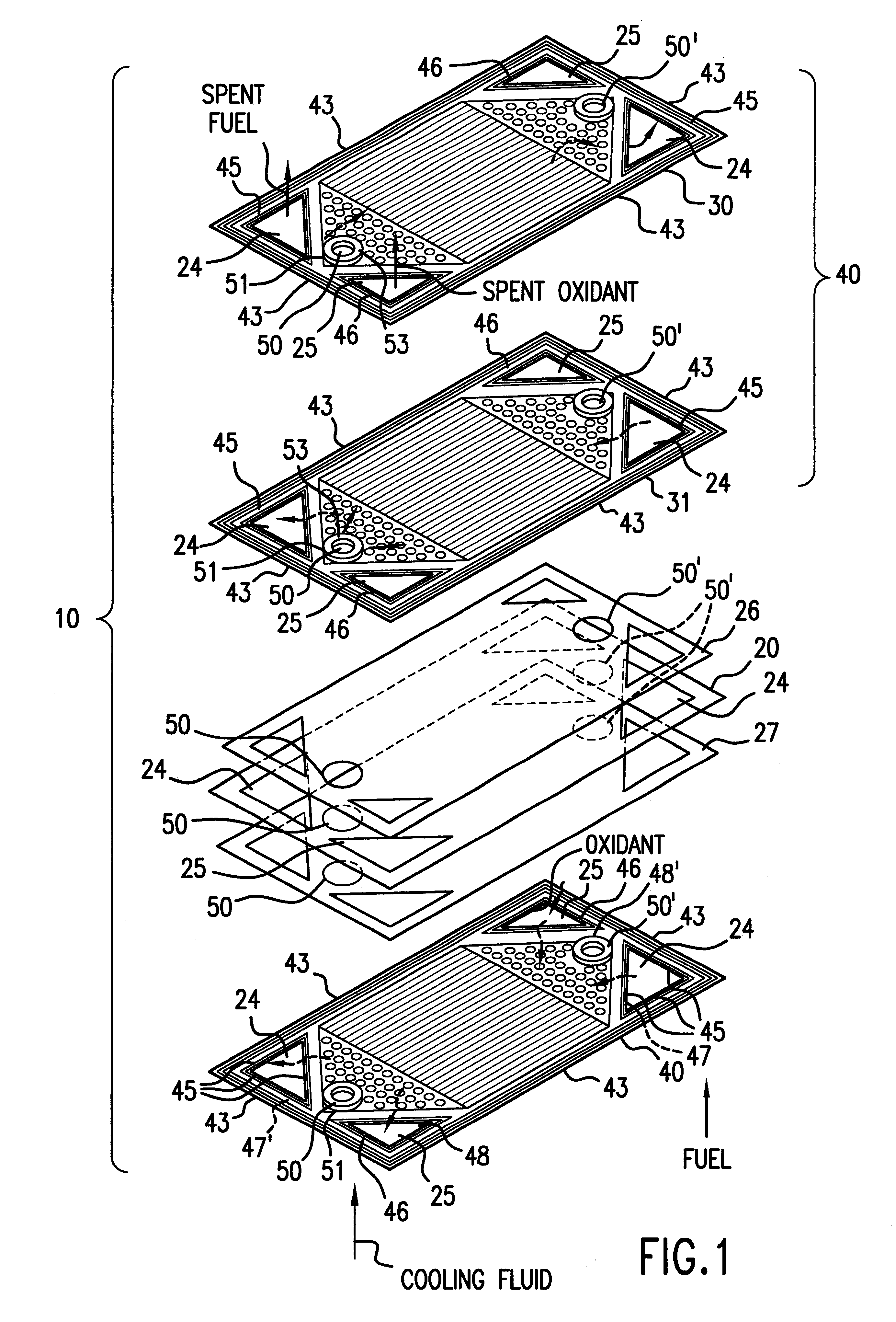

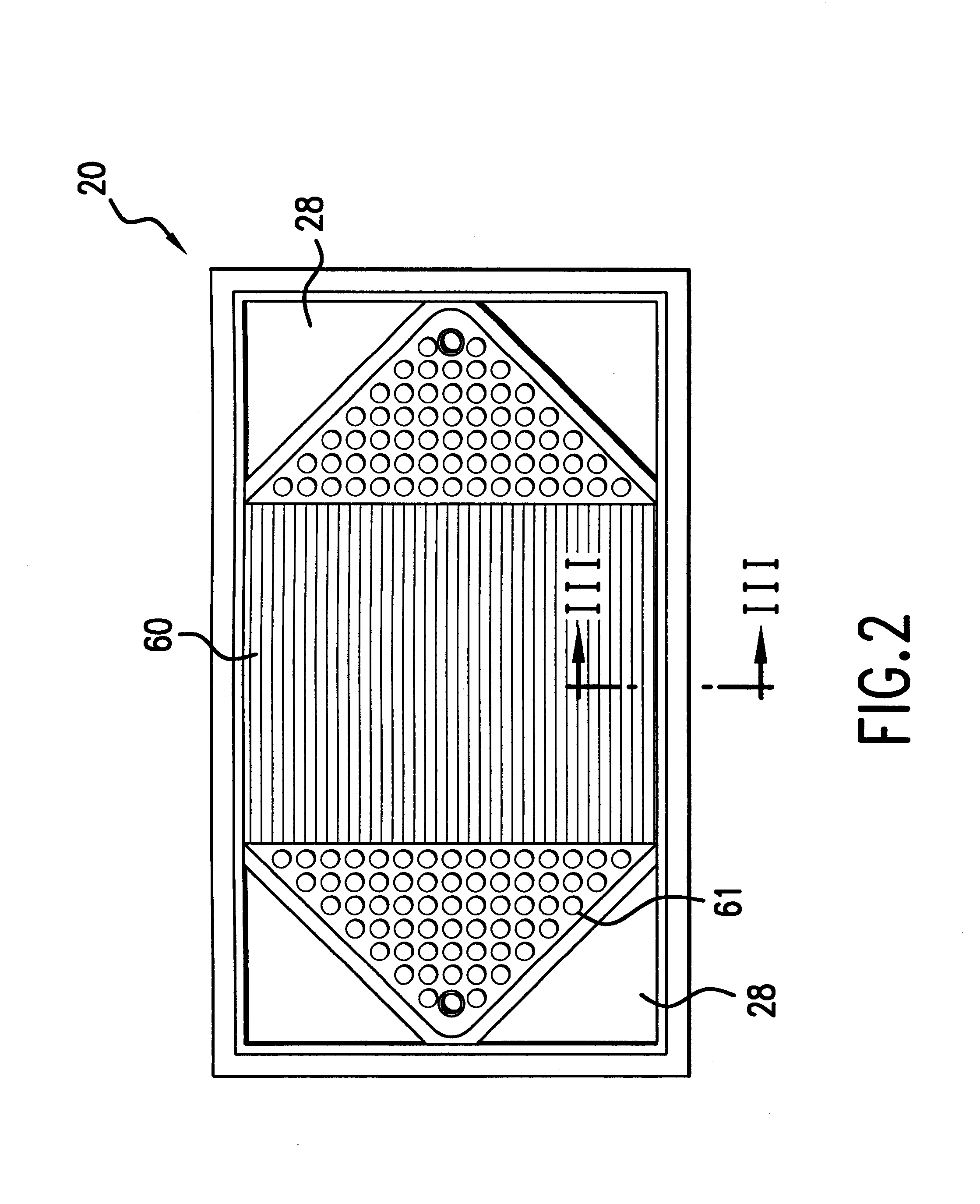

Sheet metal bipolar plate design for polymer electrolyte membrane fuel cells

InactiveUS6261710B1Compact designIncrease the number ofSolid electrolytesFuel cells groupingPolymer electrolytesFuel cells

A separator plate for a polymer electrolyte membrane fuel cell stack constructed of at least two coextensive sheet metal elements shaped to promote the distribution of reactant gases to the electrodes of the fuel cell units of the fuel cell stack. The coextensive sheet metal elements are nestled together and form a coolant flow space therebetween.

Owner:INST OF GAS TECH

Low cost multi-beam, multi-band and multi-diversity antenna systems and methods for wireless communications

InactiveUS7525504B1Low costImprove performanceSimultaneous aerial operationsAntenna supports/mountingsMulti bandCommunications system

Systems and methods for employing switched phase shifters and a feed network to provide a low cost multiple beam antenna system for wireless communications. The present systems and methods may also facilitate multi-band communications and employ multi-diversity. The present systems and methods allow communication systems to achieve enhanced performance for communication or other services such as location tracking. The present systems and methods may employ switched phase shifters, multiple diversity antennas and / or a feed network having a multi-layer construction to provide an antenna system with low losses, low external component count and / or which is thin and compact.

Owner:HONG KONG APPLIED SCI & TECH RES INST

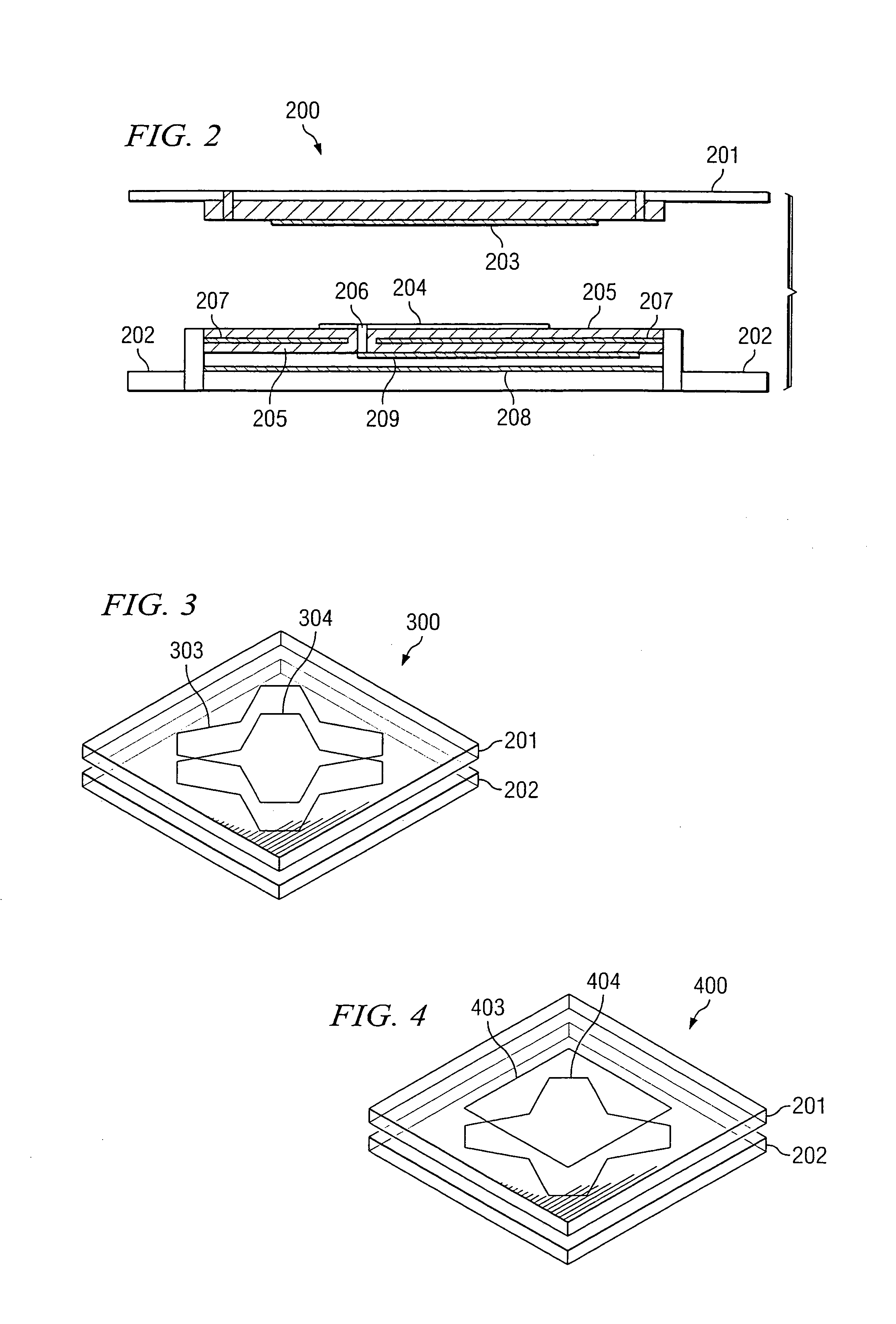

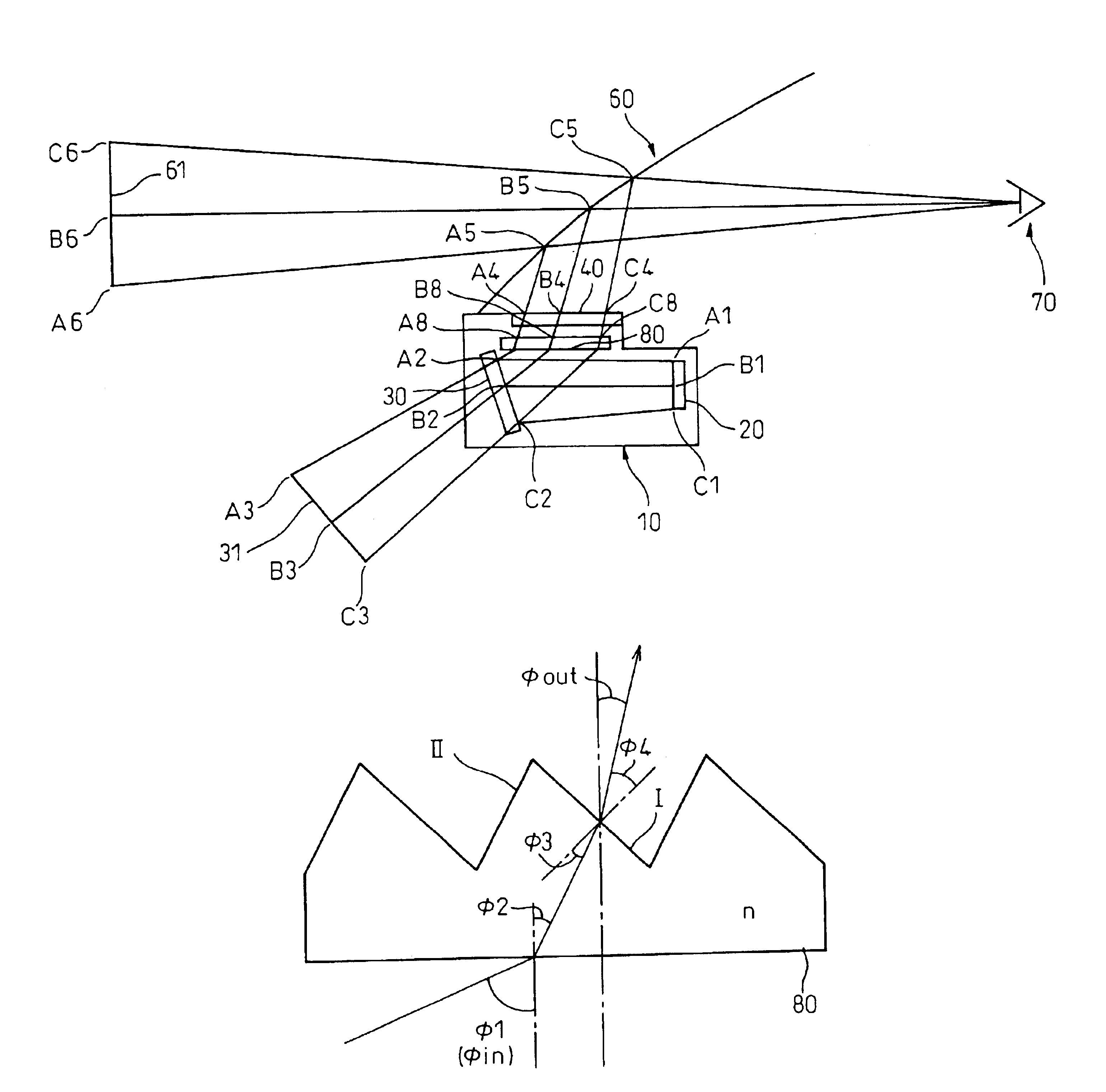

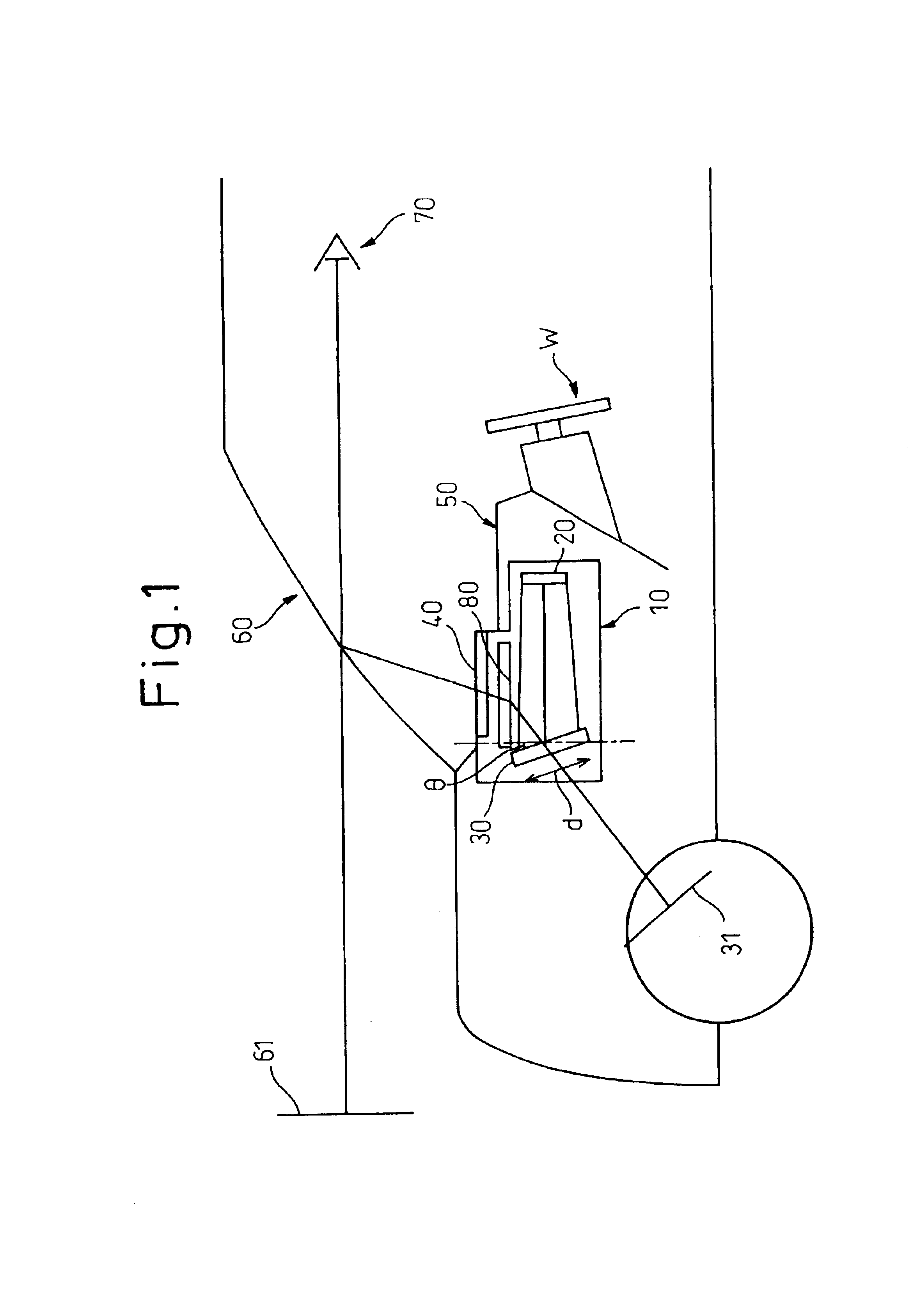

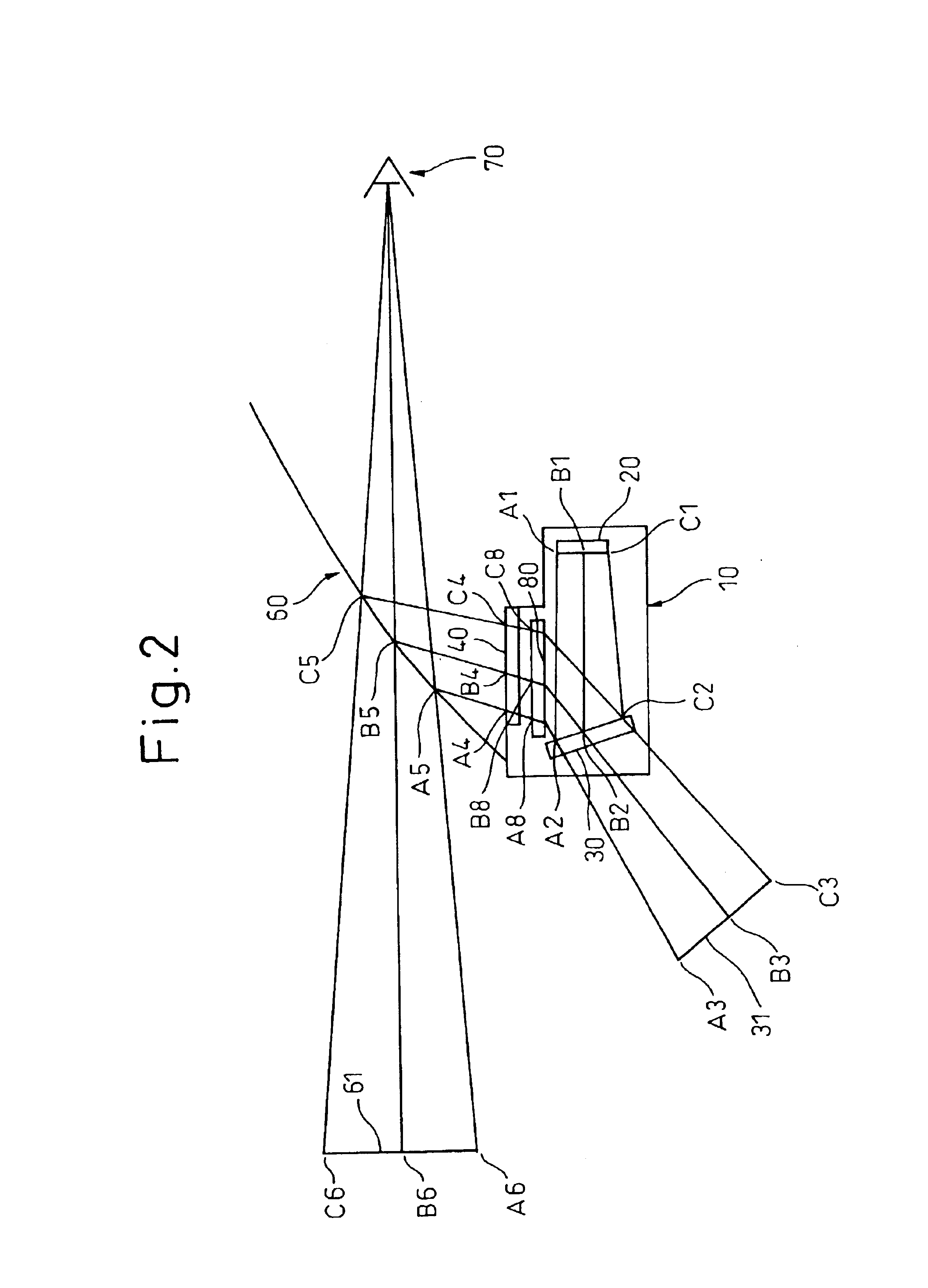

Optical sensor device for detecting wetting

InactiveUS7751054B2Small thicknessIncrease the areaScattering properties measurementsPhotoelectric discharge tubesFresnel lensElectrical conductor

An optical sensor device (10) is able to be coupled to a window (14), in particular to a windscreen of a motor vehicle. The optical sensor device (10) comprises a sensor unit (12), which includes a emitter (26), a receiver (28) and a light conductor unit (30). By the light conductor unit (30), a light beam (34) emitted by the emitter (26) is coupled into the window (14), coupled out of the window (14) and directed onto the receiver (28). The light conductor unit (30) includes Fresnel lens regions and associated reflecting regions.

Owner:TRW AUTOMOTIVE ELECTRONICS & COMPONENTS GMBH & CO KG

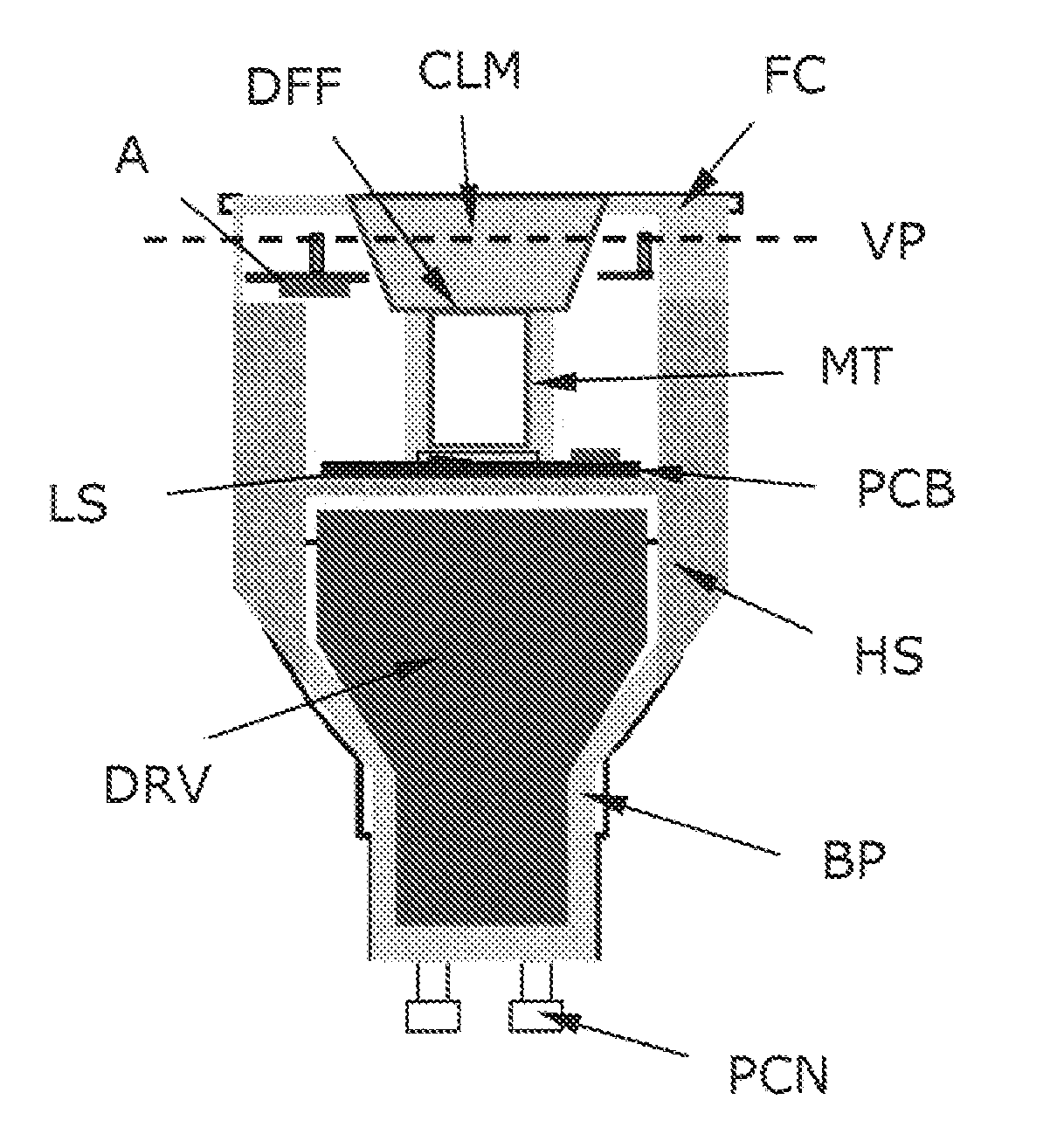

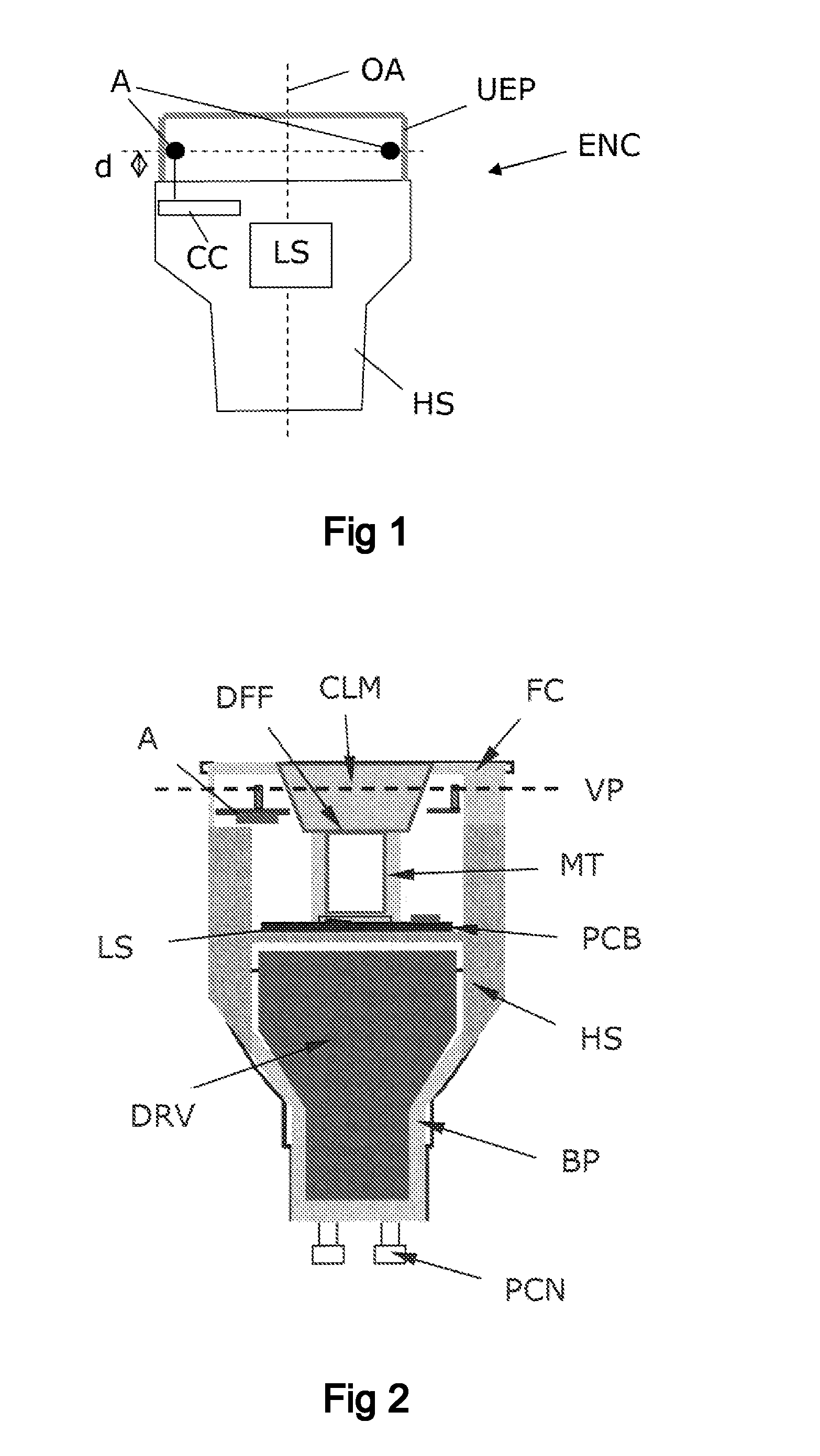

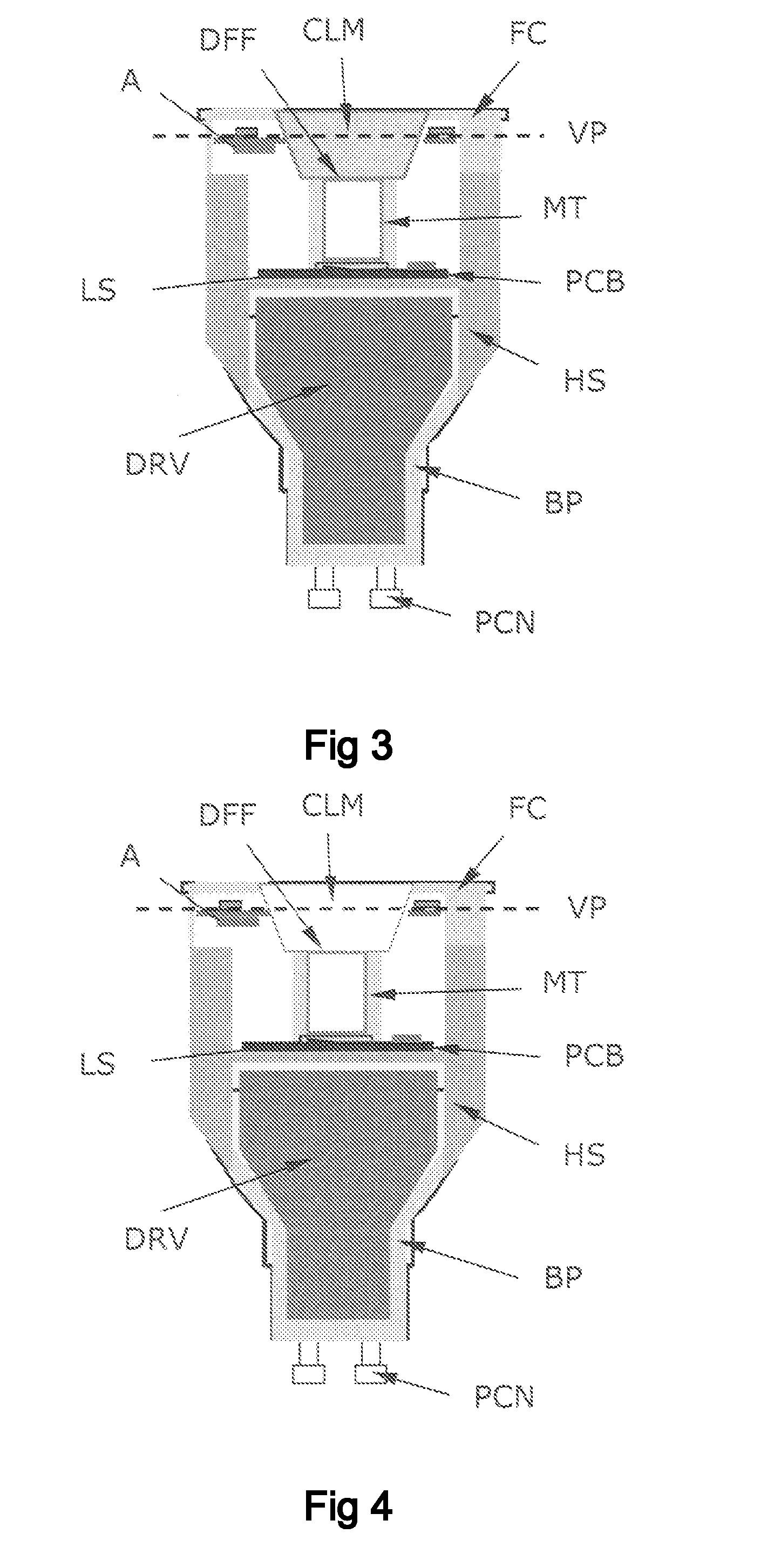

Lighting device with built-in RF antenna

ActiveUS20120274208A1Remove unavoidable heat dissipationSmall sizeLight source combinationsPoint-like light sourceRemote controlOptical axis

A lighting device, such as a replacement lighting device, comprising a light source (LS), e.g. LEDs, for producing light along an optical axis (OA). A heat sink (HS) made of a material with an electrical resistivity being less than 0.01 Ωm, e.g. a metallic heat sink being a part of the housing, transports heat away from the light source (LS). A Radio Frequency (RF) communication circuit (CC) connected to an an antenna (A) serves to enable RF signal communication, e.g. to control the device via a remote control. Metallic components, including the heat sink (HS), having an extension larger than 1 / 10 of a wavelength of the RF signal are arranged below a virtual plane (VP) drawn orthogonal to the optical axis (OA) and going through the antenna (A). Hereby a compact device can be obtained, and still a satisfying RF radiation pattern can be obtained. The antenna can be a wire antenna or a PCB antenna, e.g. a PIFA or a IFA type antenna. In a special embodiment the antenna is formed on a ring-shaped PCB with a central hole allowing passage of light from the light source. Preferably, the antenna is positioned at least 2 mm in front of the heat sink (HS).

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

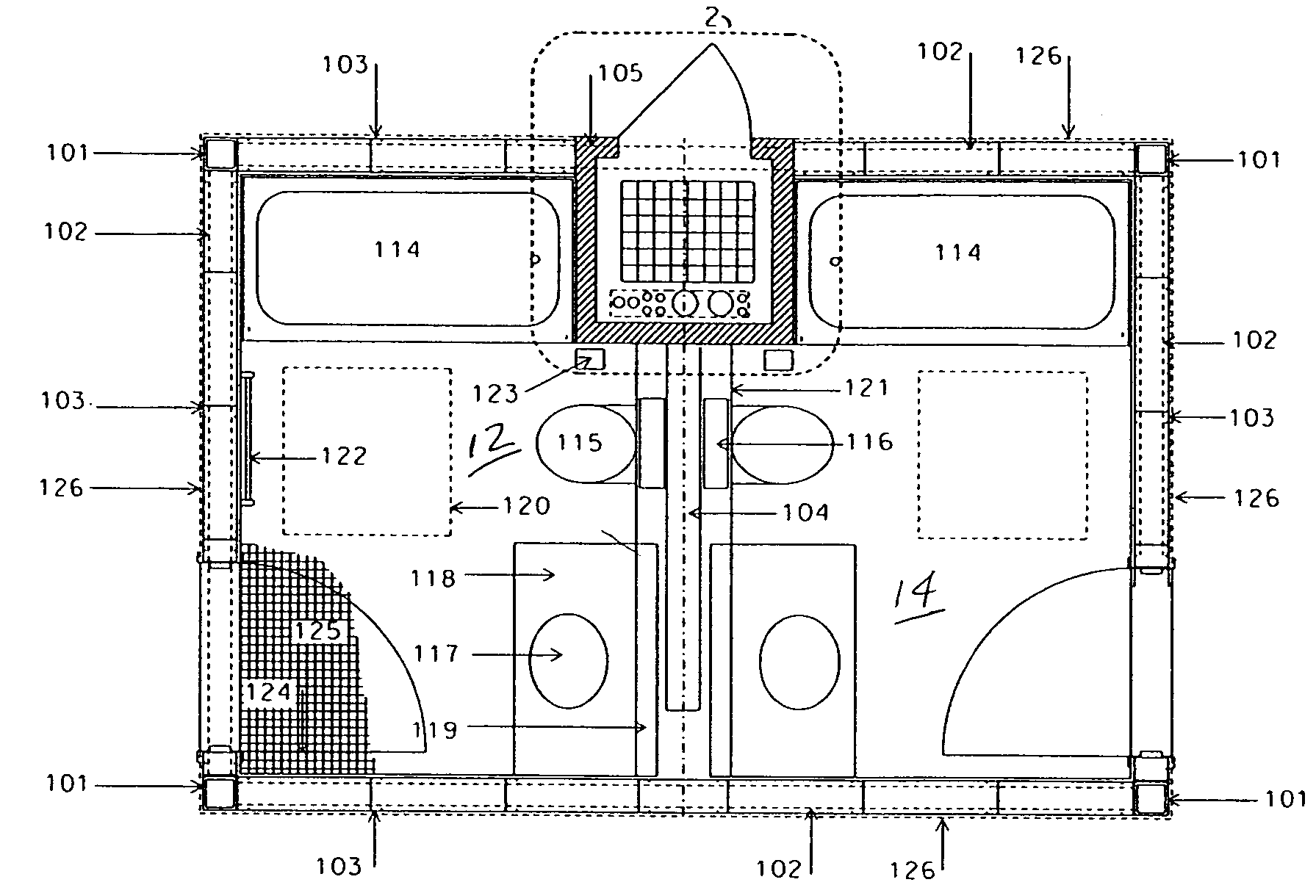

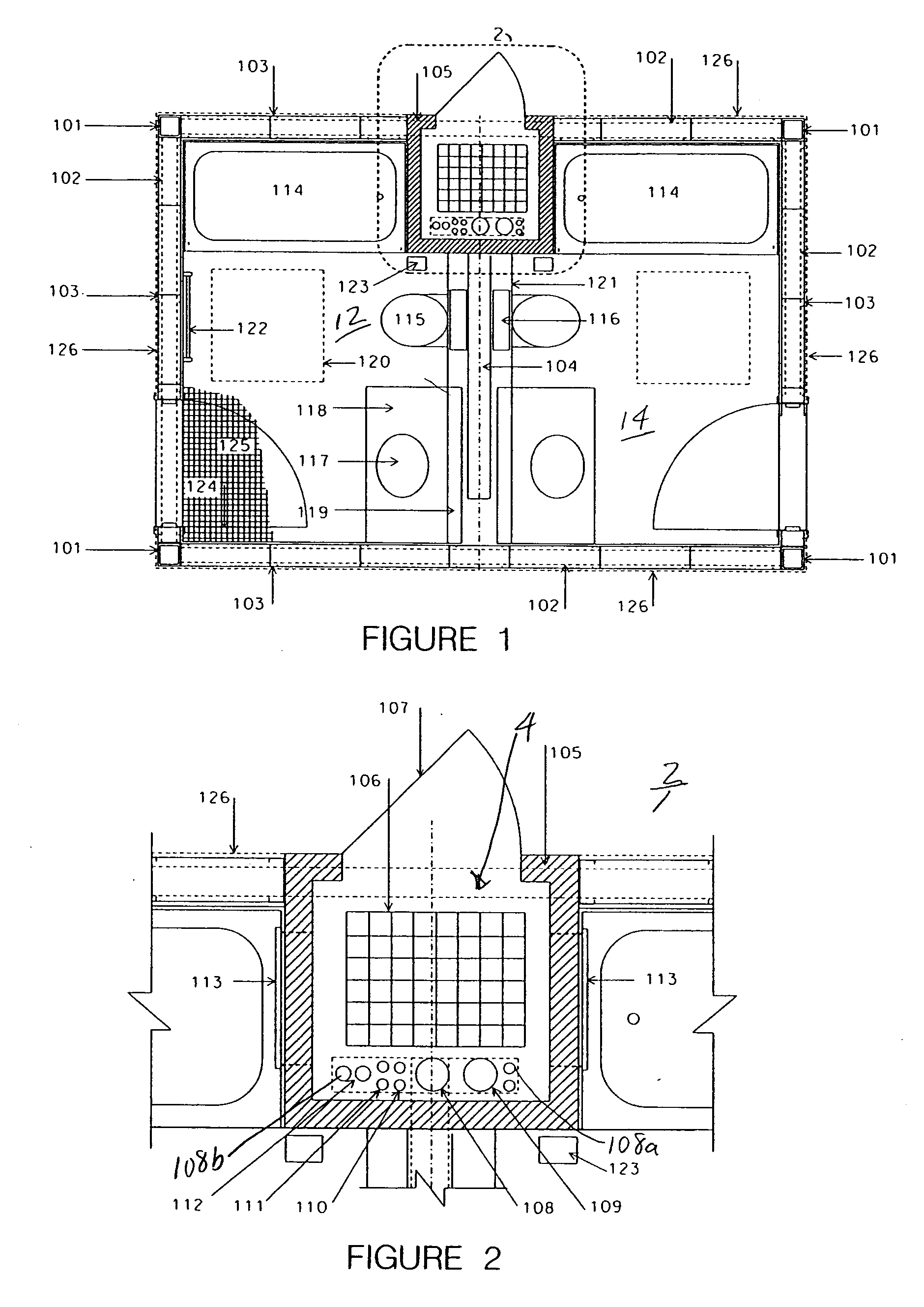

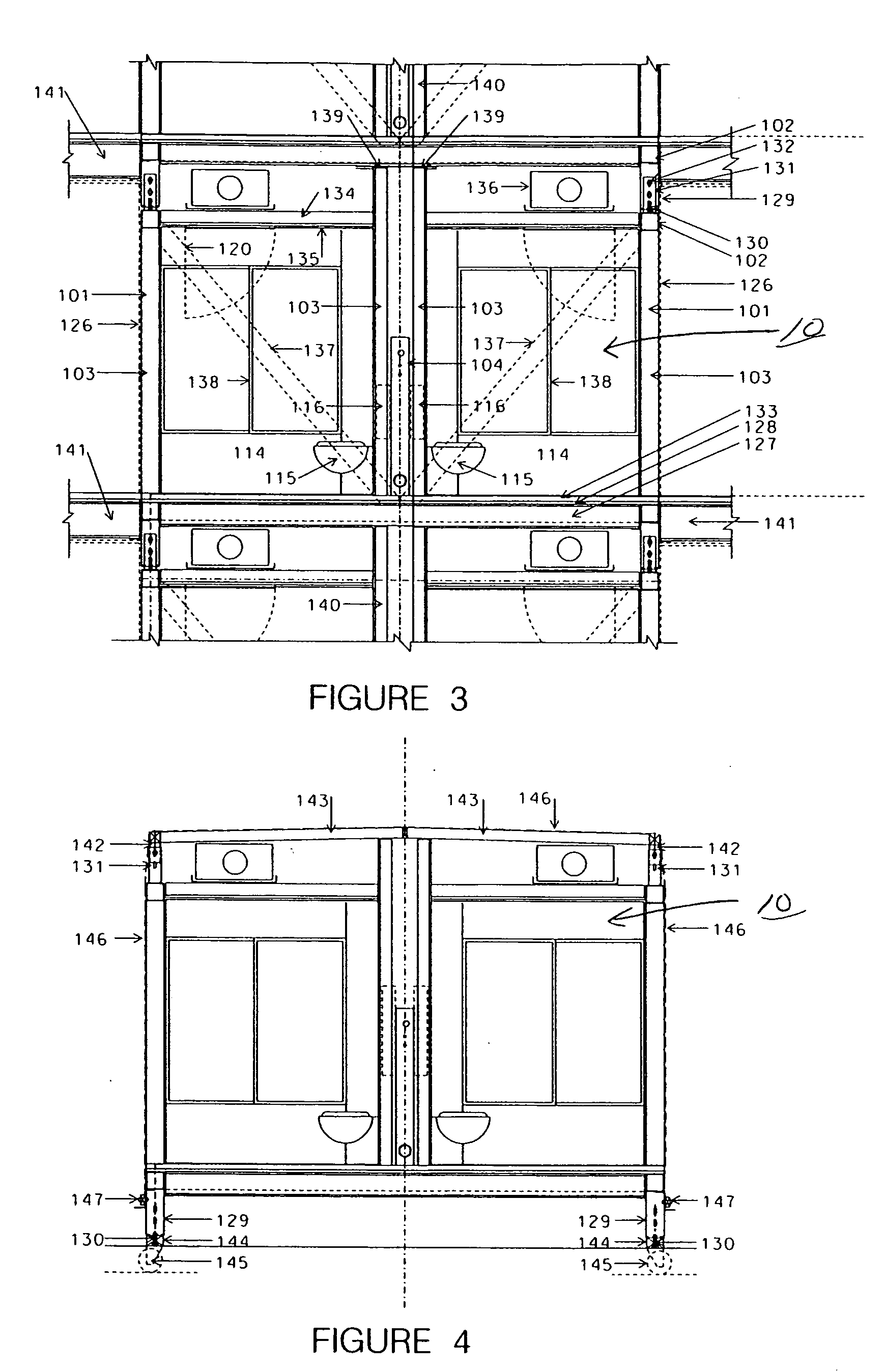

Pre-fabricated building modules and method of installation

InactiveUS20050108957A1Low costCompact designSpecial buildingExtraordinary structuresVentilation shaftPrefabrication

A pre-fabricated building module containing components of a typical multi-story housing project and a corresponding method of installation. Each module is configurable to provide one of a variety of room and dual-room layouts. The module's design allows for road transportation and installation by a tower crane typically found in most multi-story construction projects. Module embodiments are provided for enabling drop-in, stack-in, or slide-in installation in most buildings. Each module is preferably stackable with another module of the same type and configured to provide a predetermined amount of support for loads in the surrounding structure. Each module preferably provides all necessary mechanical and electrical components including their section of risers and ventilation shaft, as well as fixtures, fittings, appliances, cabinets, etc. except for the exterior cladding of perimeter walls which are designed for on-site installation. Each module preferably includes panelized interior cladding for built-in room items enabling sub-assembly prefabrication.

Owner:QUESADA JORGE DE

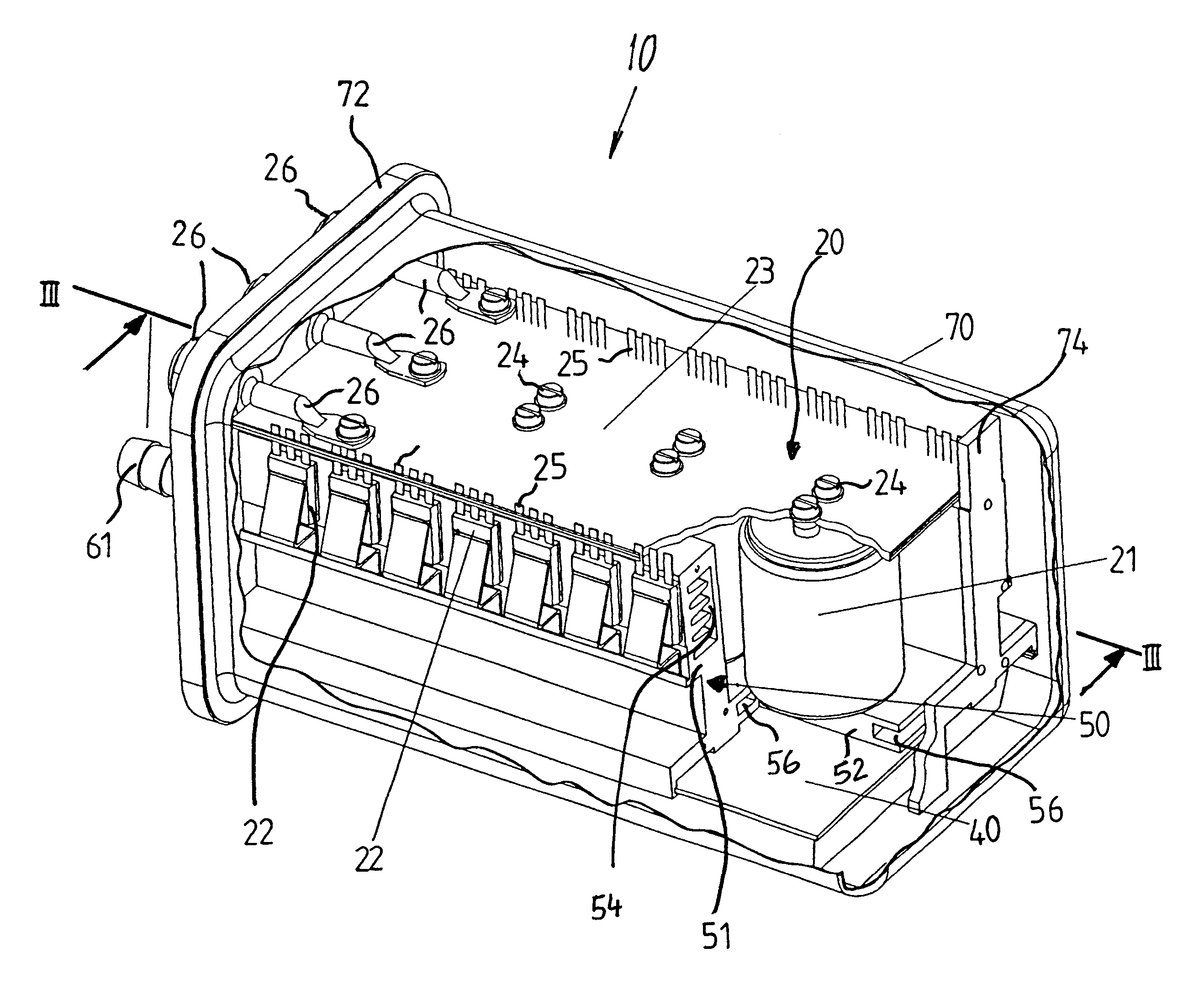

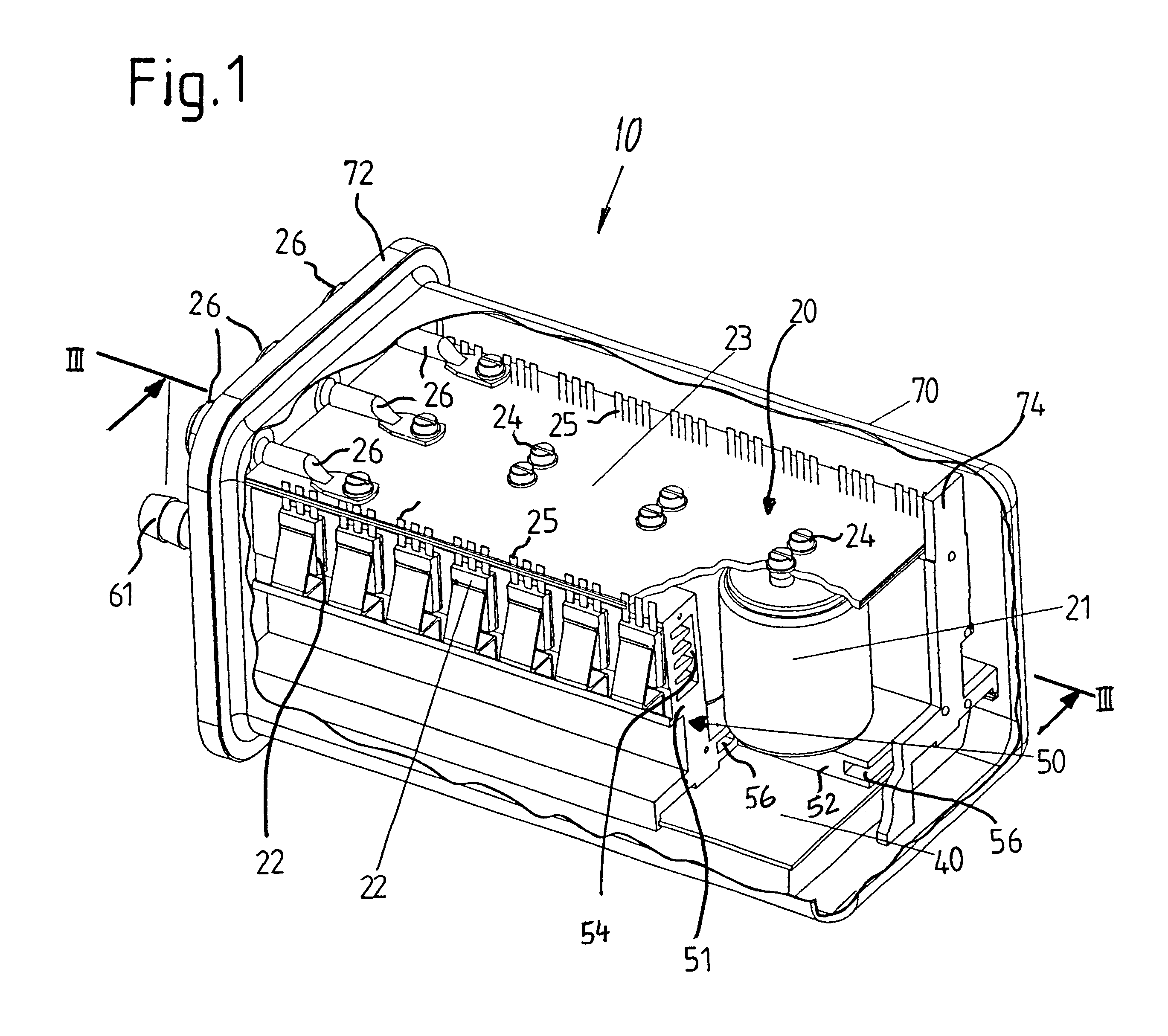

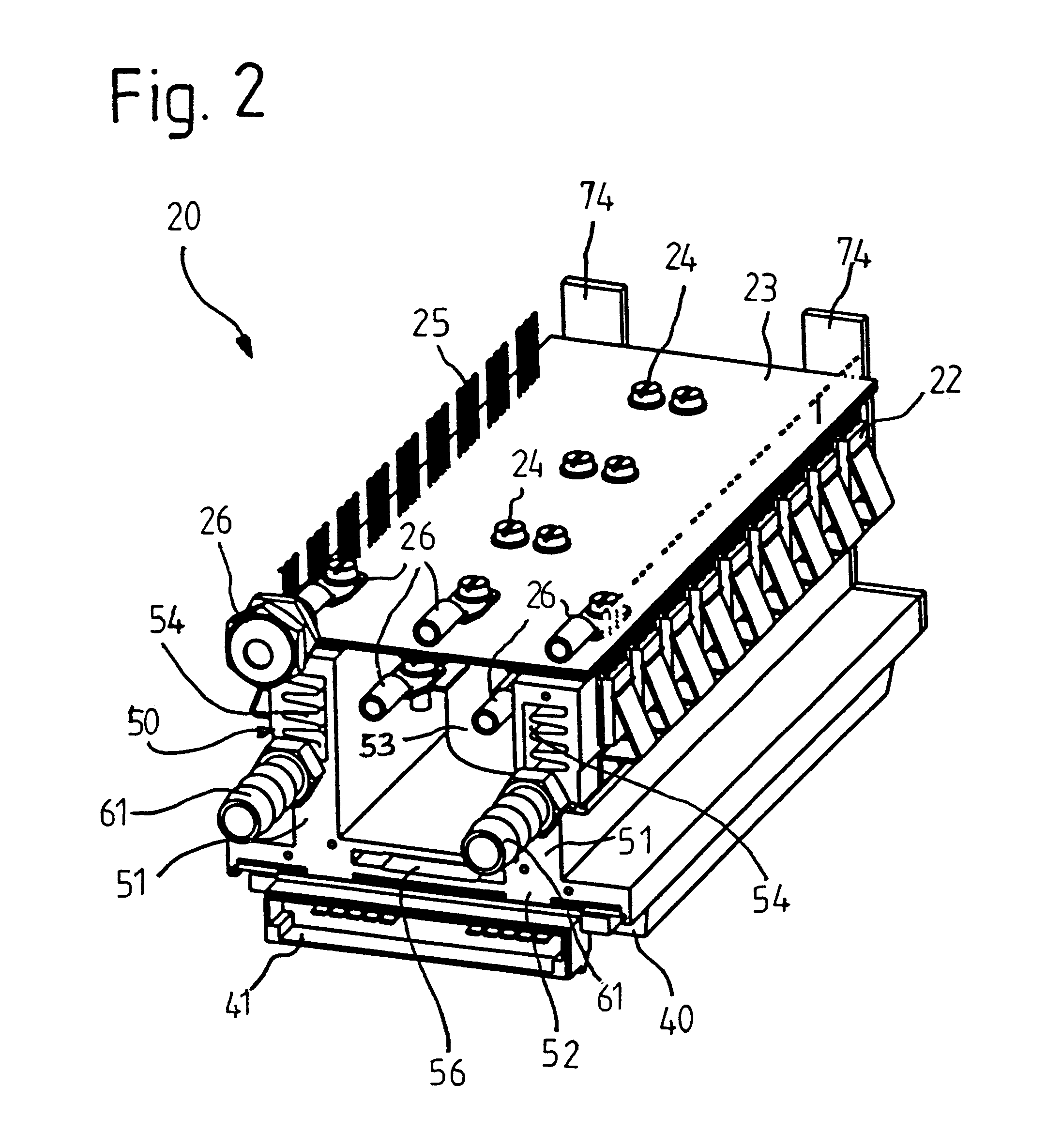

Power electronics device for controlling an electric machine

InactiveUS6326761B1Small space requirementCompact designElectronic commutation motor controlMotor/generator/converter stoppersElectric machineEngineering

A power electronics device for controlling an electric machine including a power section arranged within a housing which can be closed via a cover element. The power section has a plurality of capacitors and a plurality of power semiconductors which are connected to a power bus bar. In addition, a control device is provided for controlling the power electronics device. The capacitors, power semiconductors, and control device are cooled via a cooling device which is formed as a profile having an essentially U-shaped cross section. The cooling device has two lateral limbs and a base region through which cooling ducts are arranged. A suitable cooling medium flows through the cooling ducts and the ends of the cooling ducts opposite the housing cover are closed by a covering element. The capacitors, the power semiconductors and the control device are connected to the cooling device such that thermal exchange occurs between these components and the cooling device.

Owner:ZF FRIEDRICHSHAFEN AG

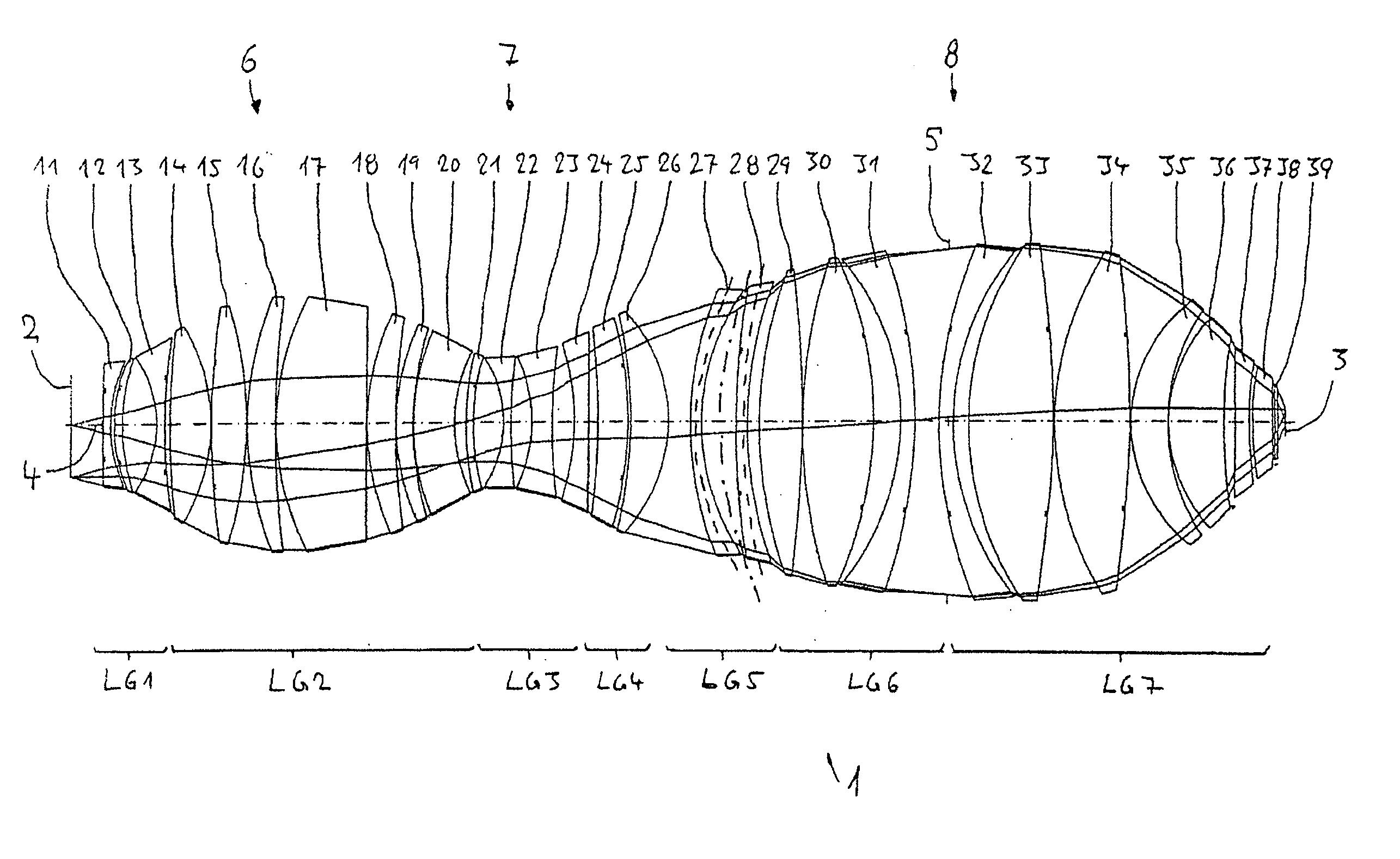

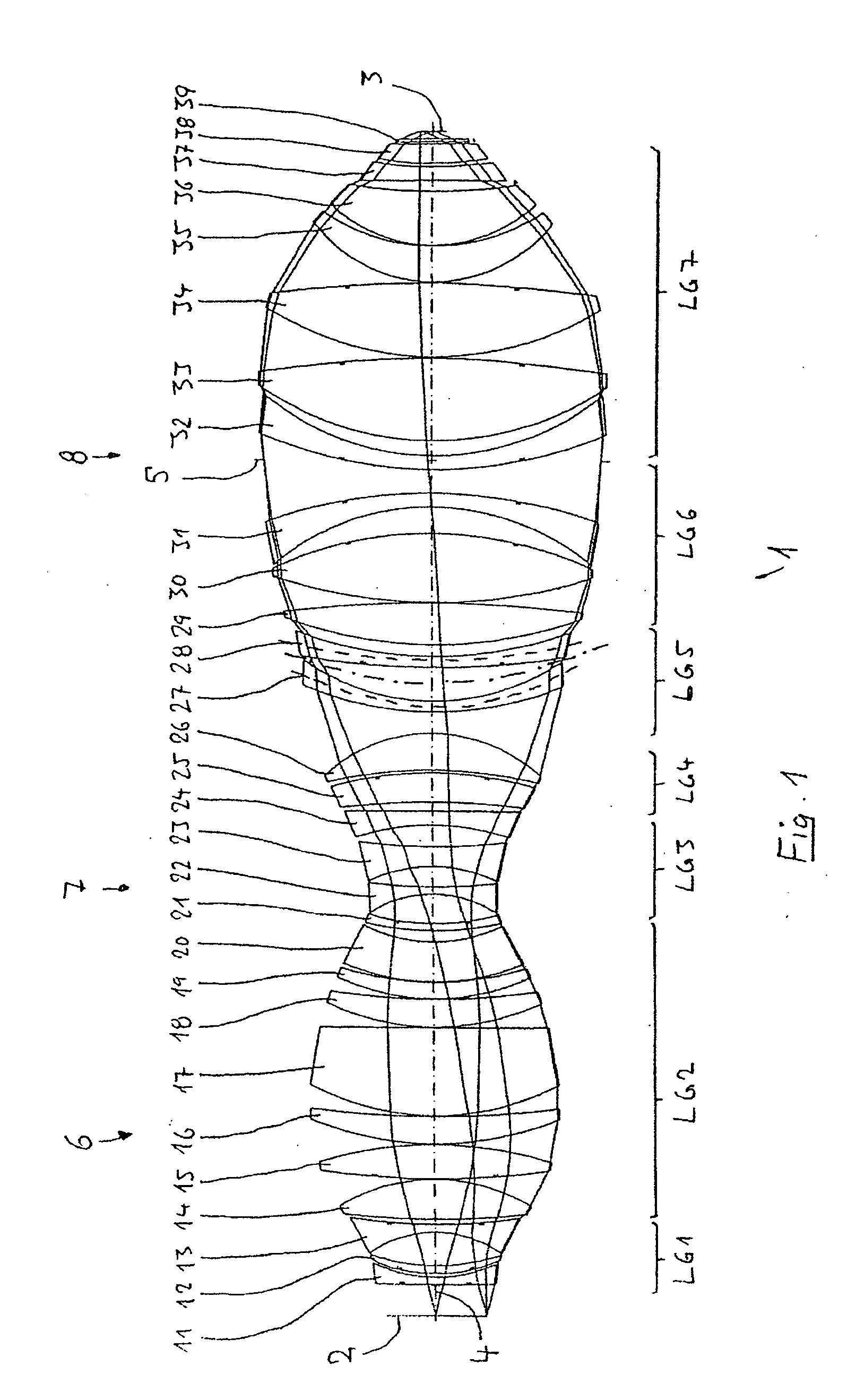

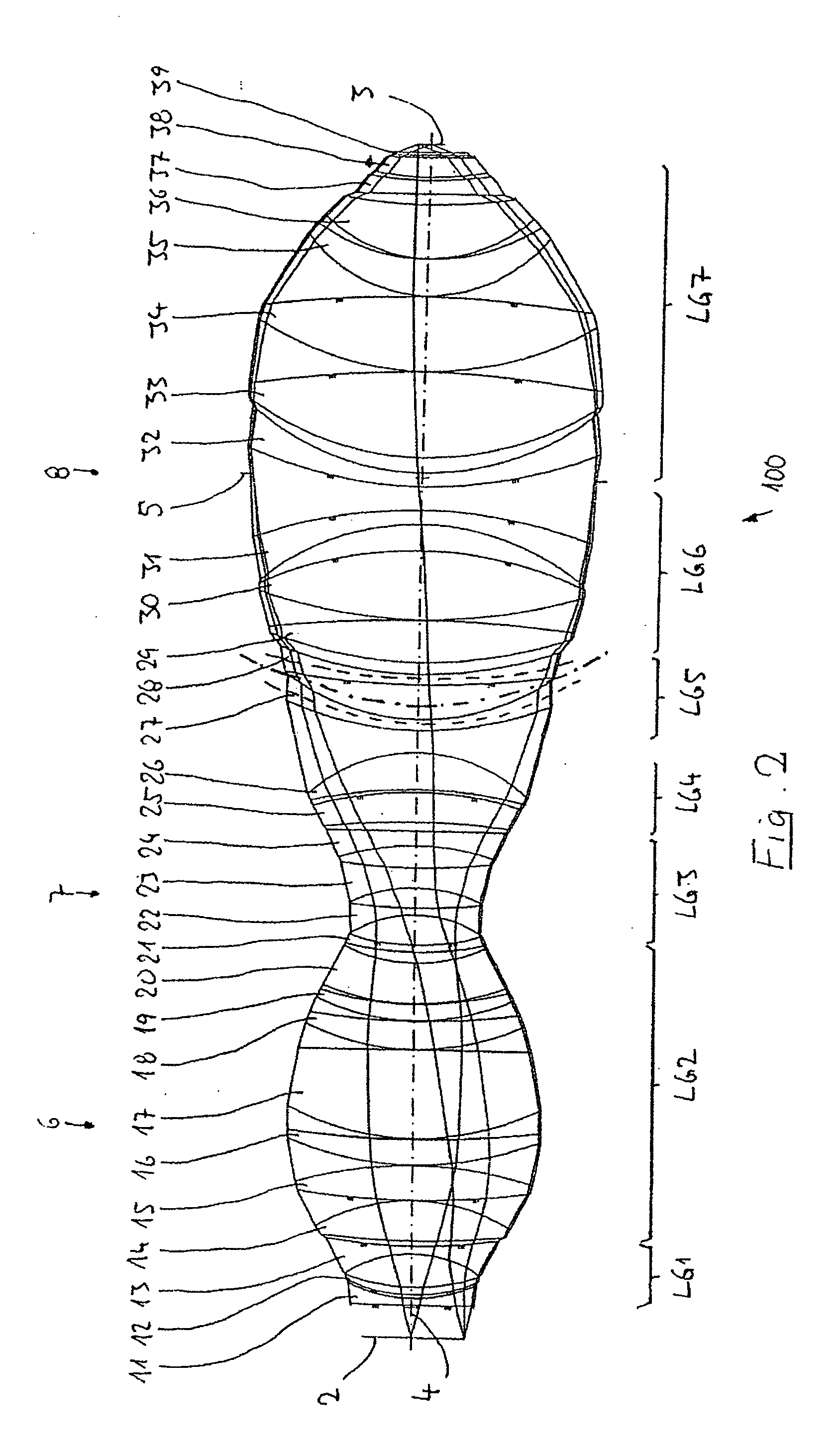

Very-high aperture projection objective

InactiveUS20050111108A1High image-side numerical apertureImproved chromatic correctionPhotomechanical exposure apparatusMicrolithography exposure apparatusHigh numerical apertureImage plane

A very-high aperture, purely refractive projection objective is designed as a two-belly system with an object-side belly, an image-side belly and a waist (7) situated therebetween. The system diaphragm (5) is seated in the image-side belly at a spacing in front of the image plane. Arranged between the waist and the system diaphragm in the region of divergent radiation is a negative group (LG5) which has an effective curvature with a concave side pointing towards the image plane. The system is distinguished by a high numerical aperture, low chromatic aberrations and compact, material-saving design.

Owner:CARL ZEISS SMT GMBH

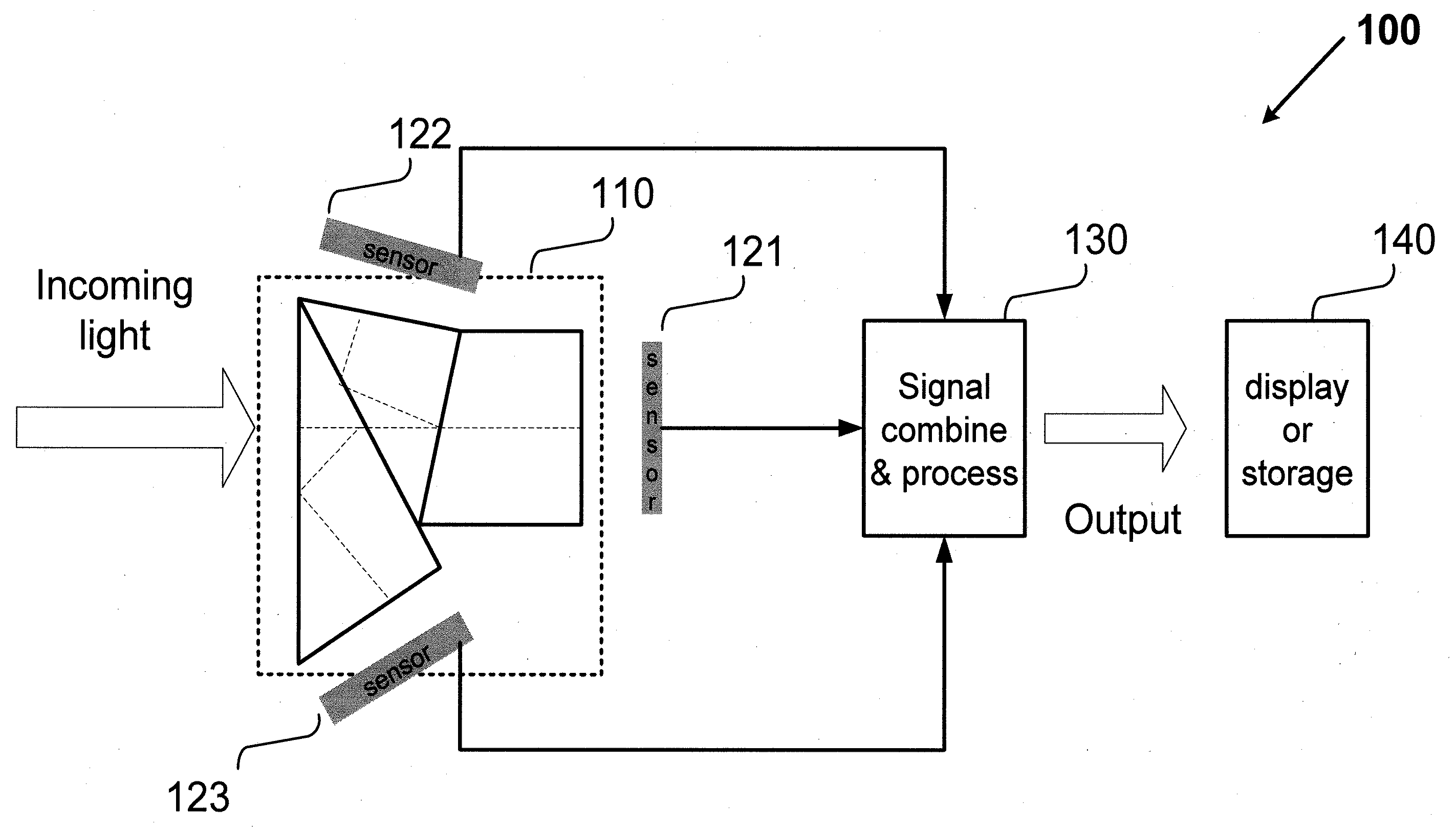

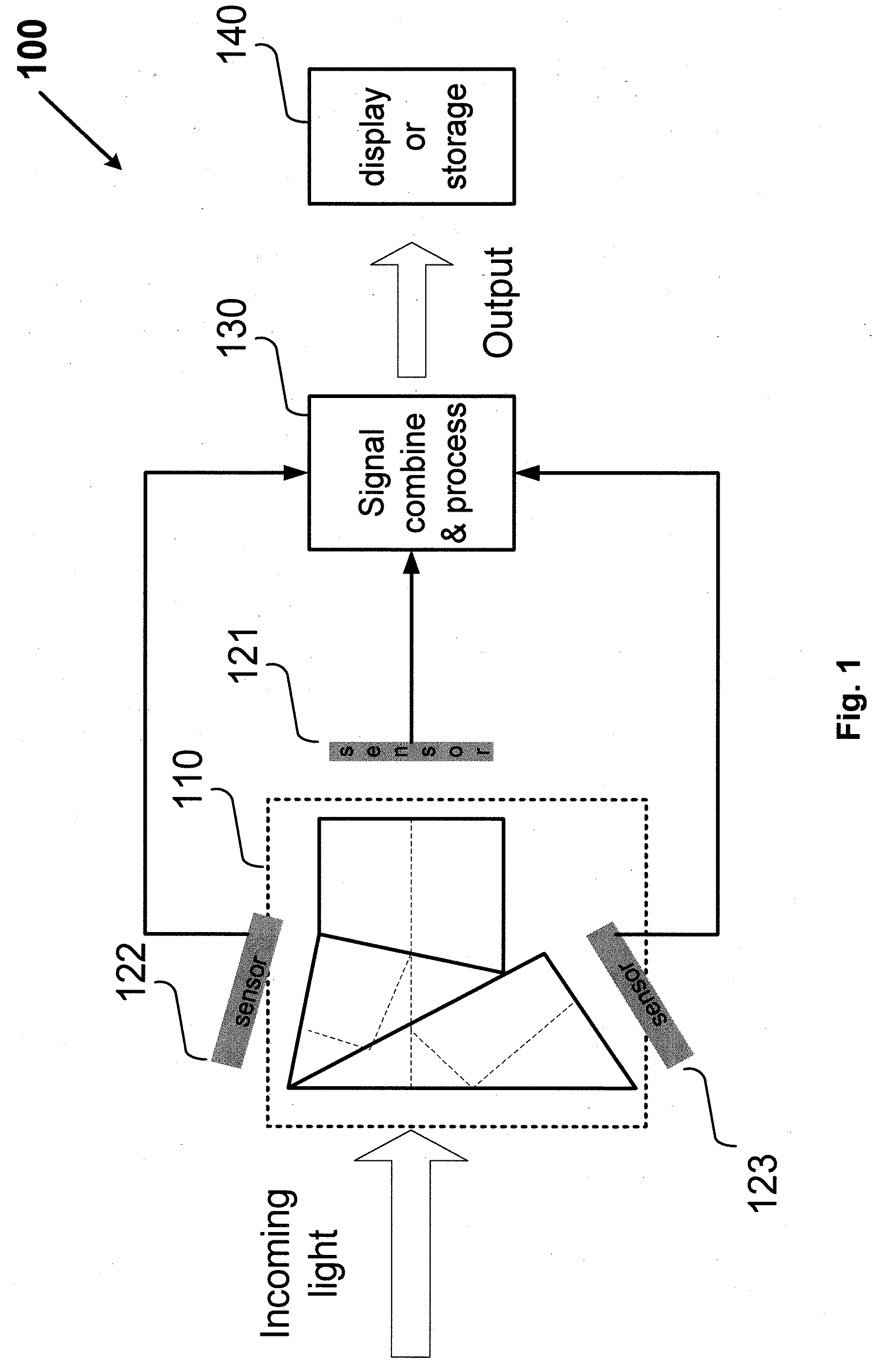

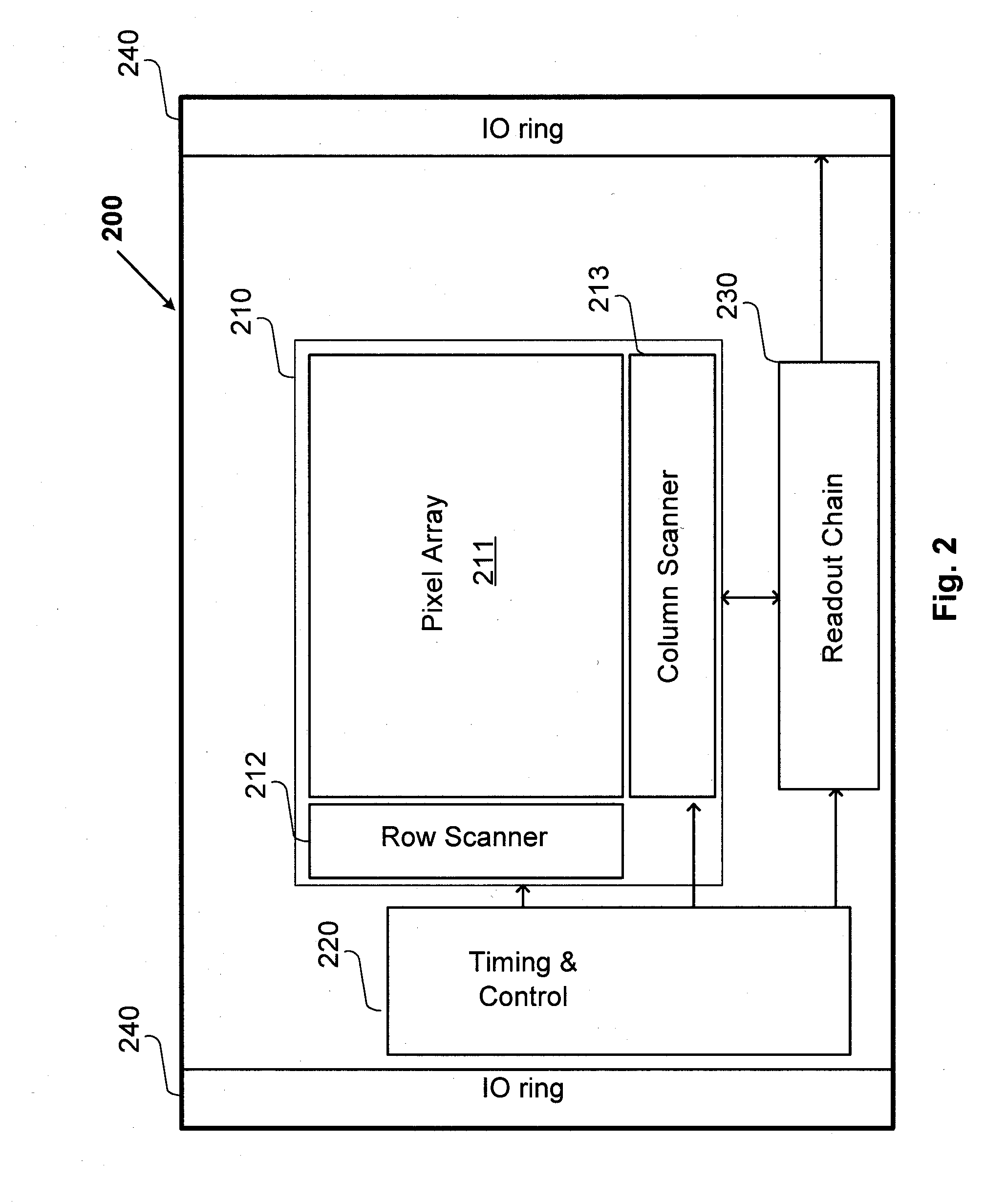

Camera system with multiple pixel arrays on a chip

ActiveUS20090135245A1Compact designEasy to makeTelevision system detailsPulse modulation television signal transmissionTelecommunications linkDigital storage

A camera system uses one or more image sensor IC chips each having multiple pixel arrays on the same semiconductor substrate (i.e., “multiple pixel arrays on a chip”). In one embodiment, such a camera system includes: (a) optical components that create multiple images in close physical proximity of each other (e.g., within a few millimeters or centimeters); and (b) a single sensor substrate (“chip”) containing multiple 2-dimensional pixel arrays that are aligned to capture these multiple images, so as to convert the multiple images into electrical signal. The pixel arrays can be manufactured using a CCD or a CMOS compatible process. For manufacturing reasons, such a chip is typically two centimeters or less on a side. However, large chips can also be made. Optional electronic components for further signal processing of the captured images may be formed either on the sensor chip (i.e., in a “system-on-a-chip” implementation), or in a separate back-end application specific integrated circuit (ASIC). In addition, digital storage components, display elements, and wired or wireless communication links may also be included in any suitable combination to allow review and further processing of the captured images.

Owner:CAPSO VISION INC

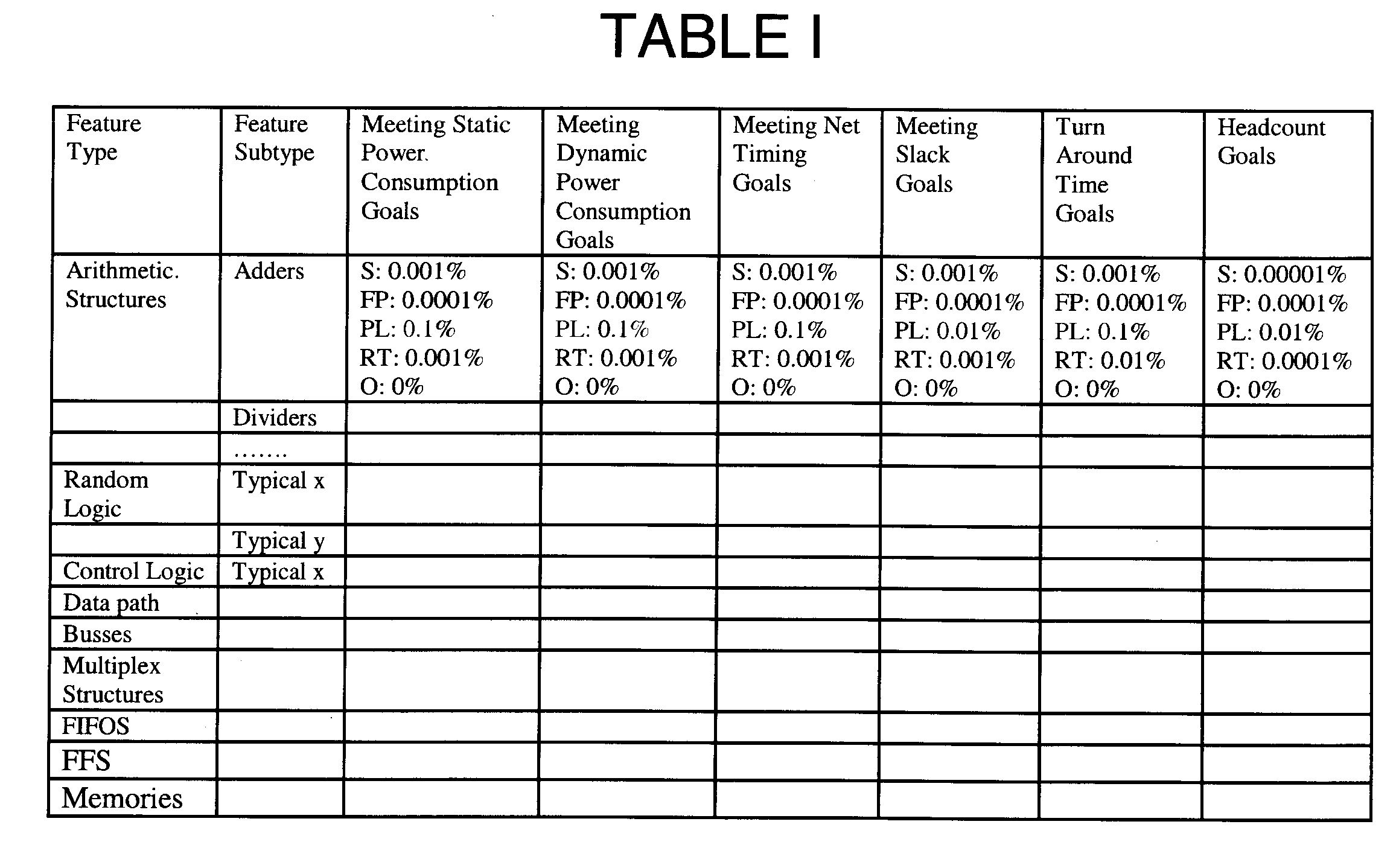

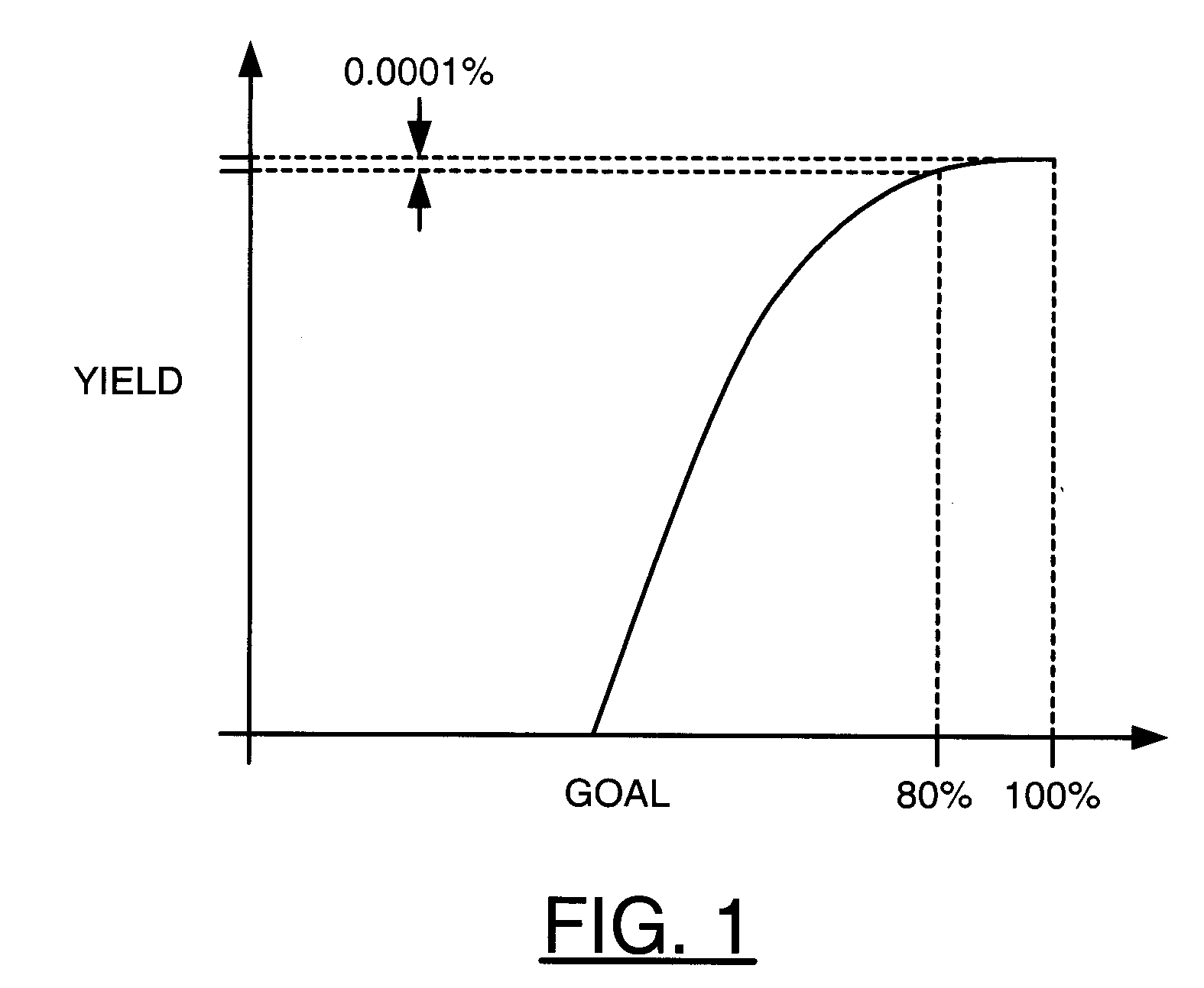

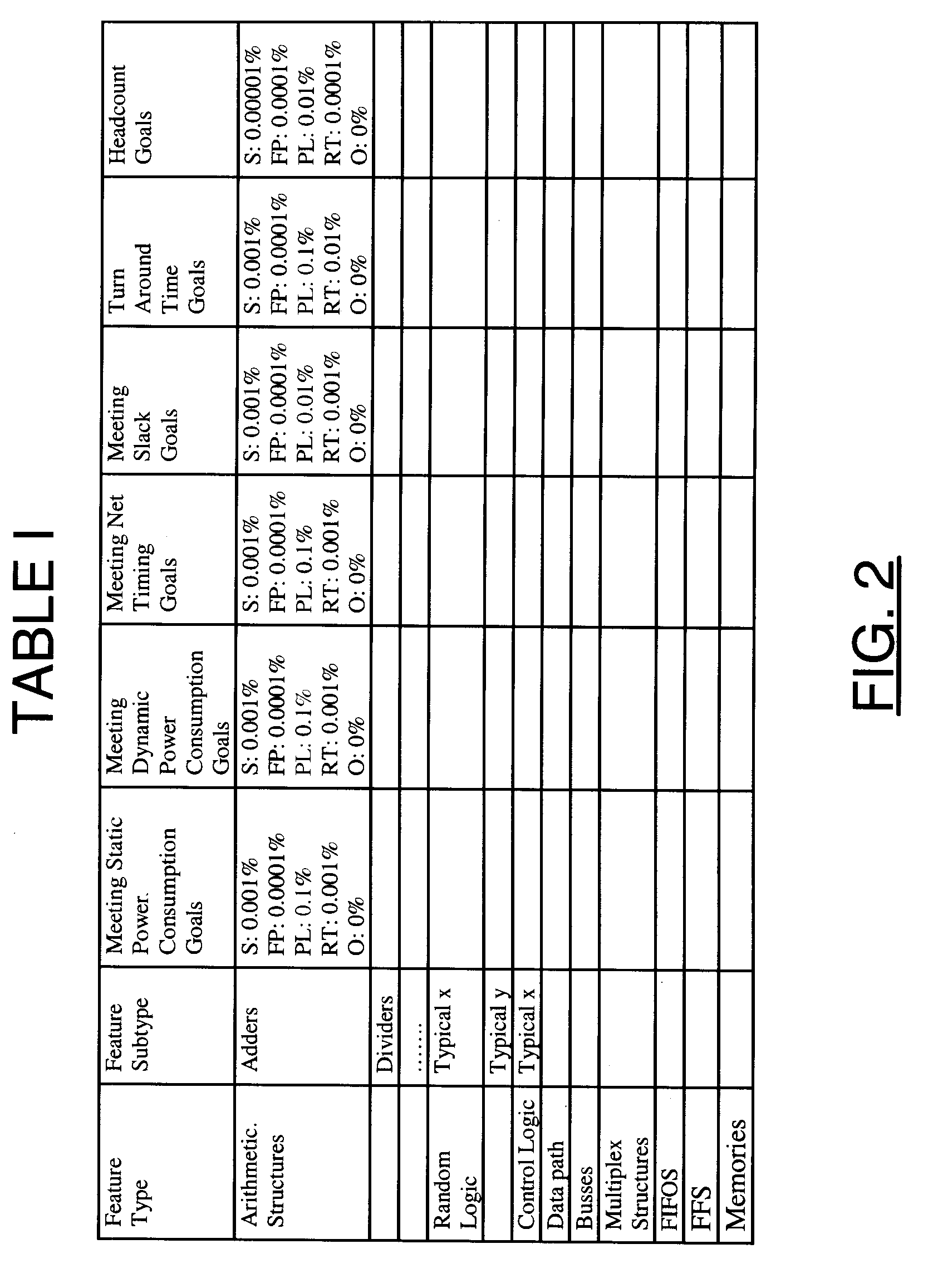

Statistical design closure

A method of statistical design closure is disclosed. The method generally includes the steps of (A) reading statistical data from a database, the statistical data defining a plurality of chip yield improvements, one of the chip yield improvements in each one of a plurality of design closure categories respectively, the chip yield improvements capturing historically trends based on a plurality of previous projects, (B) calculating a plurality of targets of a current design closure project based on the statistical data, one of the targets in each one of the design closure categories respectively and (C) generating a resource report to a user that indicates a plurality of resources expected to be used the current design closure project.

Owner:BELL SEMICON LLC

Single frequency low power RFID device

ActiveUS7576657B2Compact designEnhance short range readNear-field transmissionMemory record carrier reading problemsTransceiverAcoustic wave

Methods, systems, and apparatuses for a reader transceiver circuit are described. The reader transceiver circuit incorporates a frequency generator, such as a surface acoustic wave (SAW) oscillator. A reader incorporating the reader transceiver circuit is configured to read a tag at very close range, including while being in contact with the tag. The transceiver can be coupled to various host devices in a variety of ways, including being located in a RFID reader (e.g., mobile or fixed position), a computing device, a barcode reader, etc. The transceiver can be located in an RFID module that is attachable to a host device, can be configured in the host device, or can be configured to communicate with the host device over a distance. The RFID module may include one or more antennas, such as a first antenna configured to receive a magnetic field component of an electromagnetic wave and a second antenna configured to receive an electric field component of an electromagnetic wave. The RFID module may include a detector that is configured to determine if the RFID module is positioned in proximity to an object, such as a RFID tag. The detector may operate as a trigger for the RFID module, to enable or trigger a function of the RFID module.

Owner:SYMBOL TECH LLC

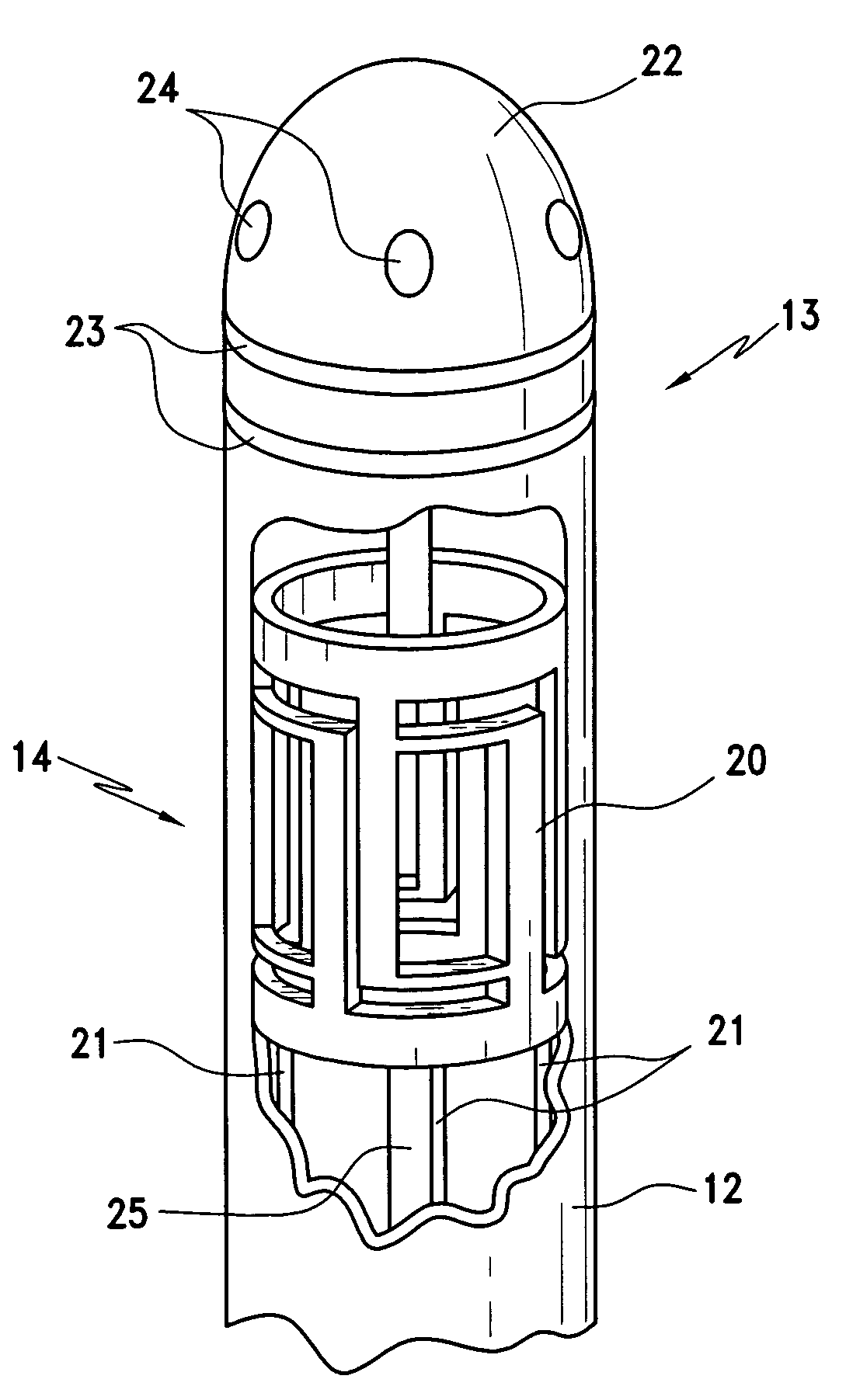

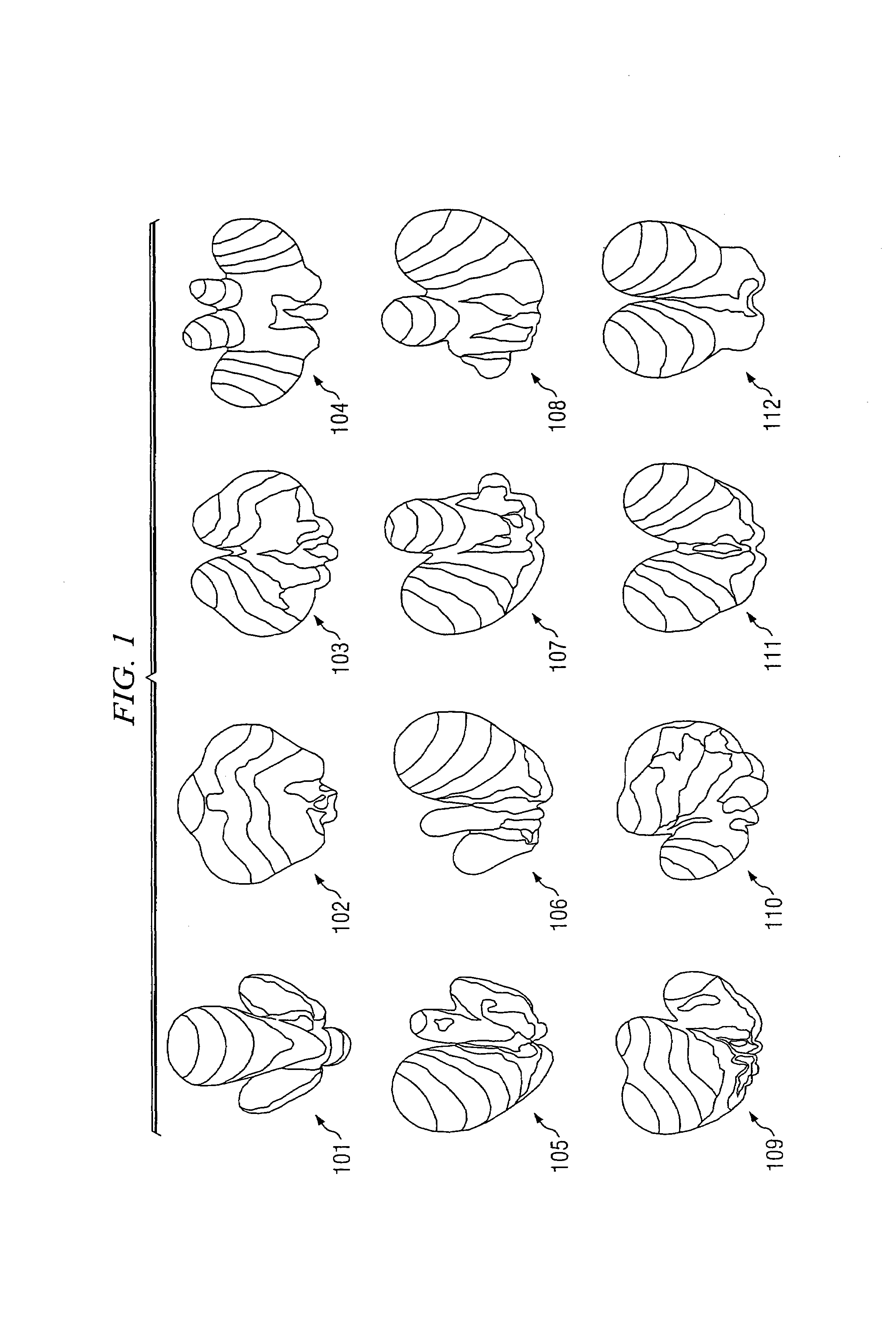

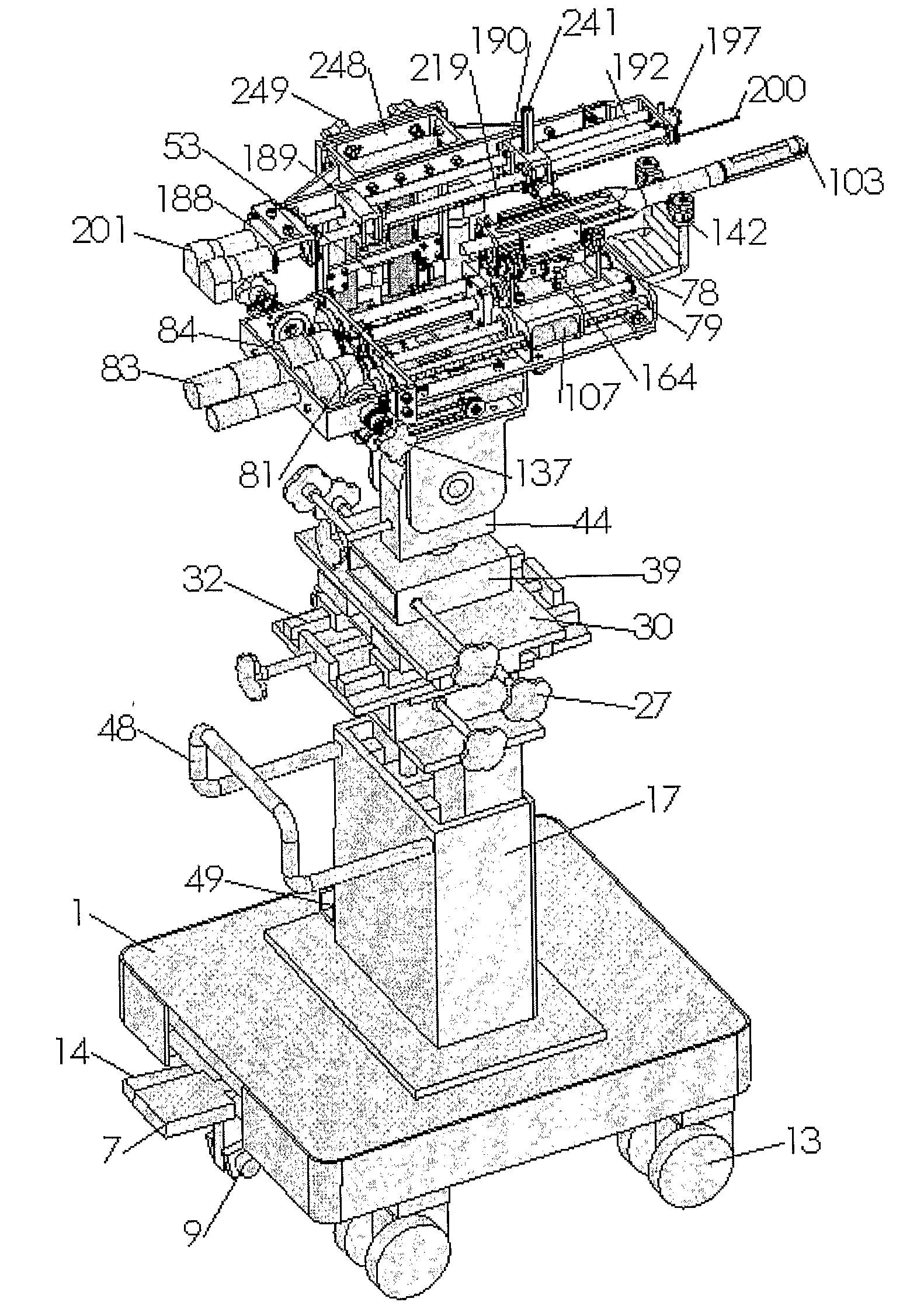

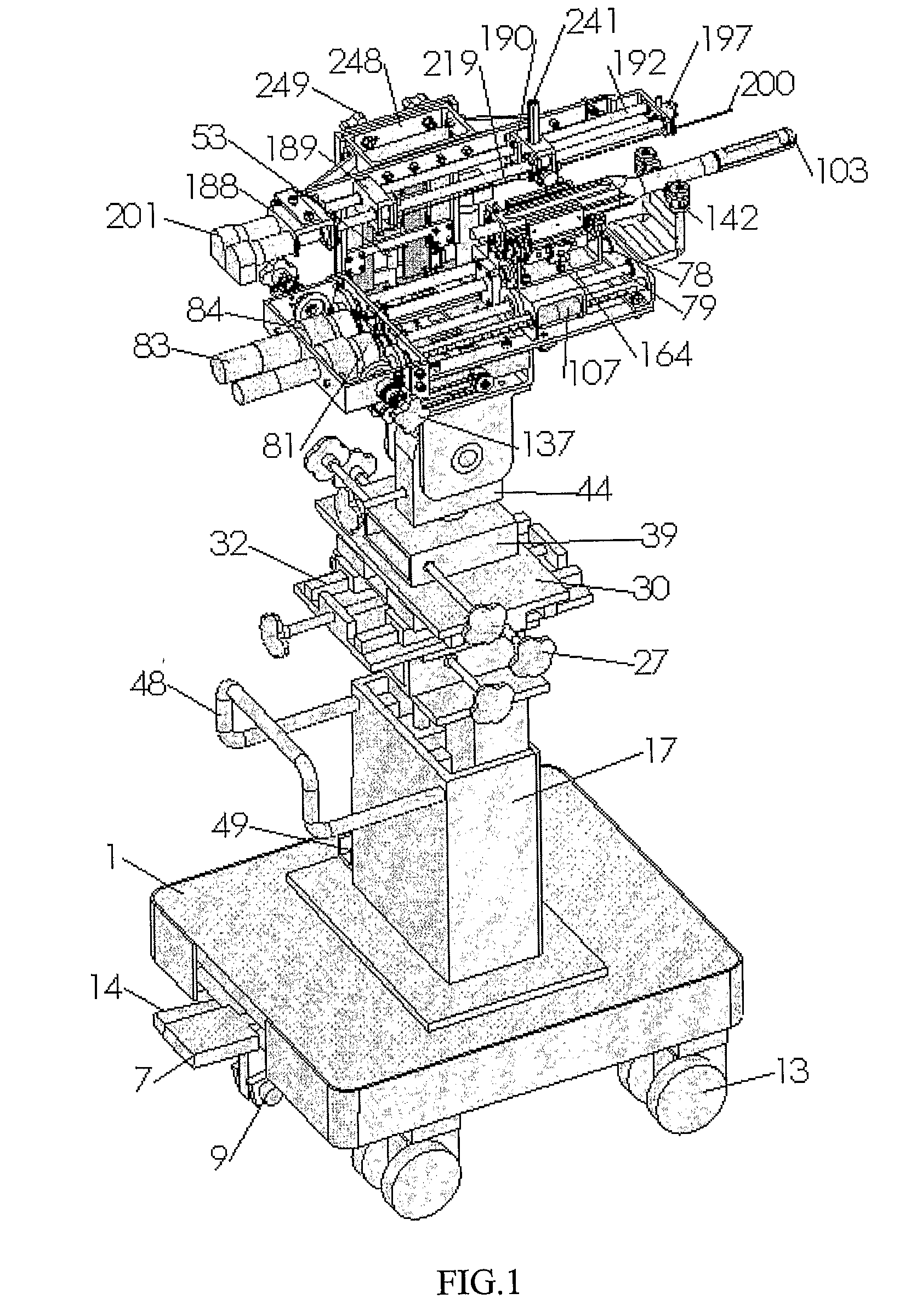

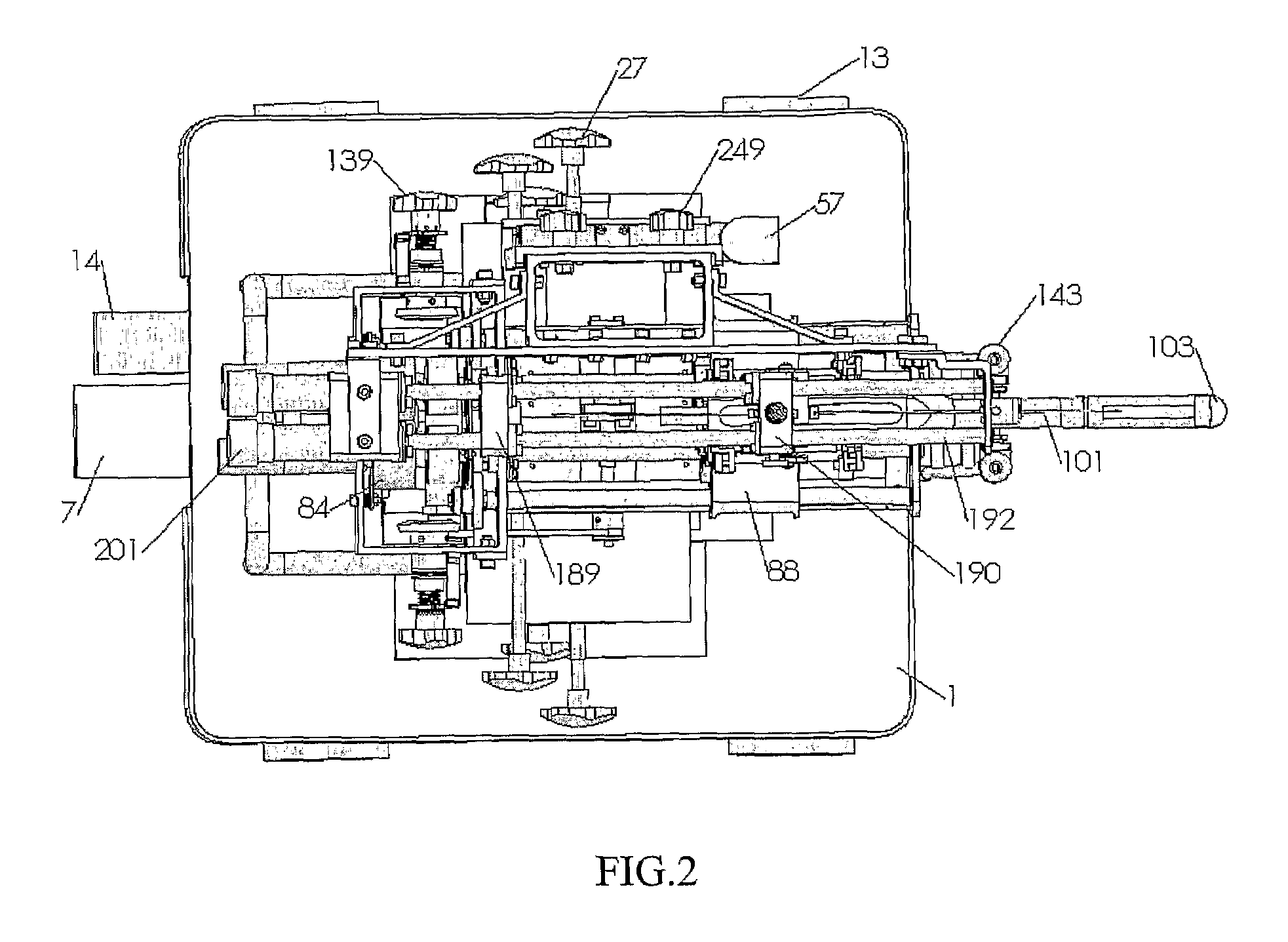

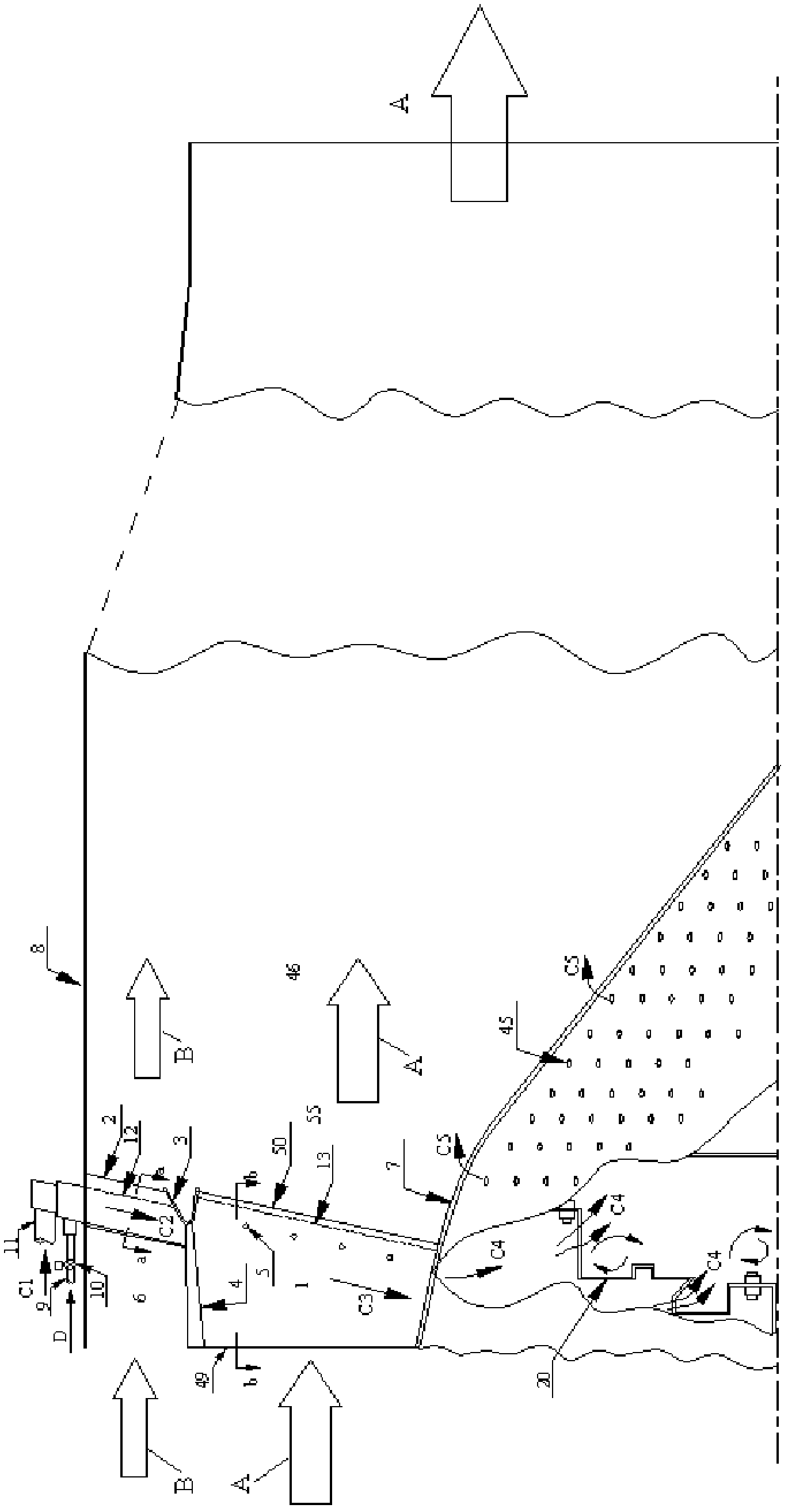

Image-guided therapy delivery and diagnostic needle system

ActiveUS20100036245A1Loading and unloadingSimple structureUltrasonic/sonic/infrasonic diagnosticsSurgeryAdemetionineBending force

An automated system for delivery of seeds or other therapeutic or diagnostic capsules to internal organs of the patient's body for radiation brachytherapy includes a needling mechanism, a 2DOF robot, an ultrasound probe driver, a 5DOF passive platform, and an easy lock cart. The needling mechanism implants radioisotope seeds by its cannula and stylet driven by two moving stages pushed by DC motors with ball screw transmission. Force sensors are included for detecting insertion forces and bending force. In another embodiment, the needle is rotated for insertion into the patient and can also be used for tissue removal for biopsy. The two embodiments are usable together or separately.

Owner:UNIVERSITY OF ROCHESTER

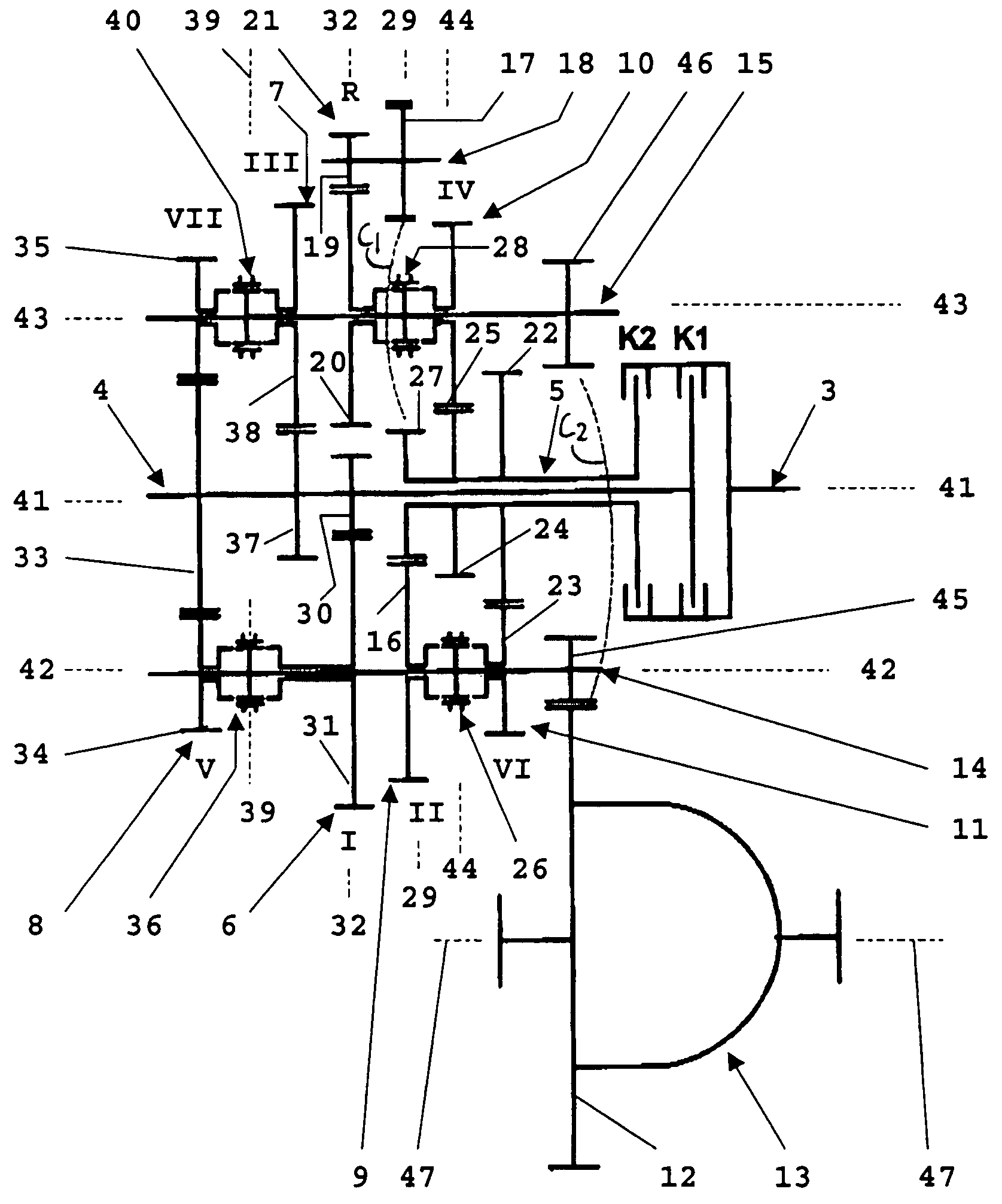

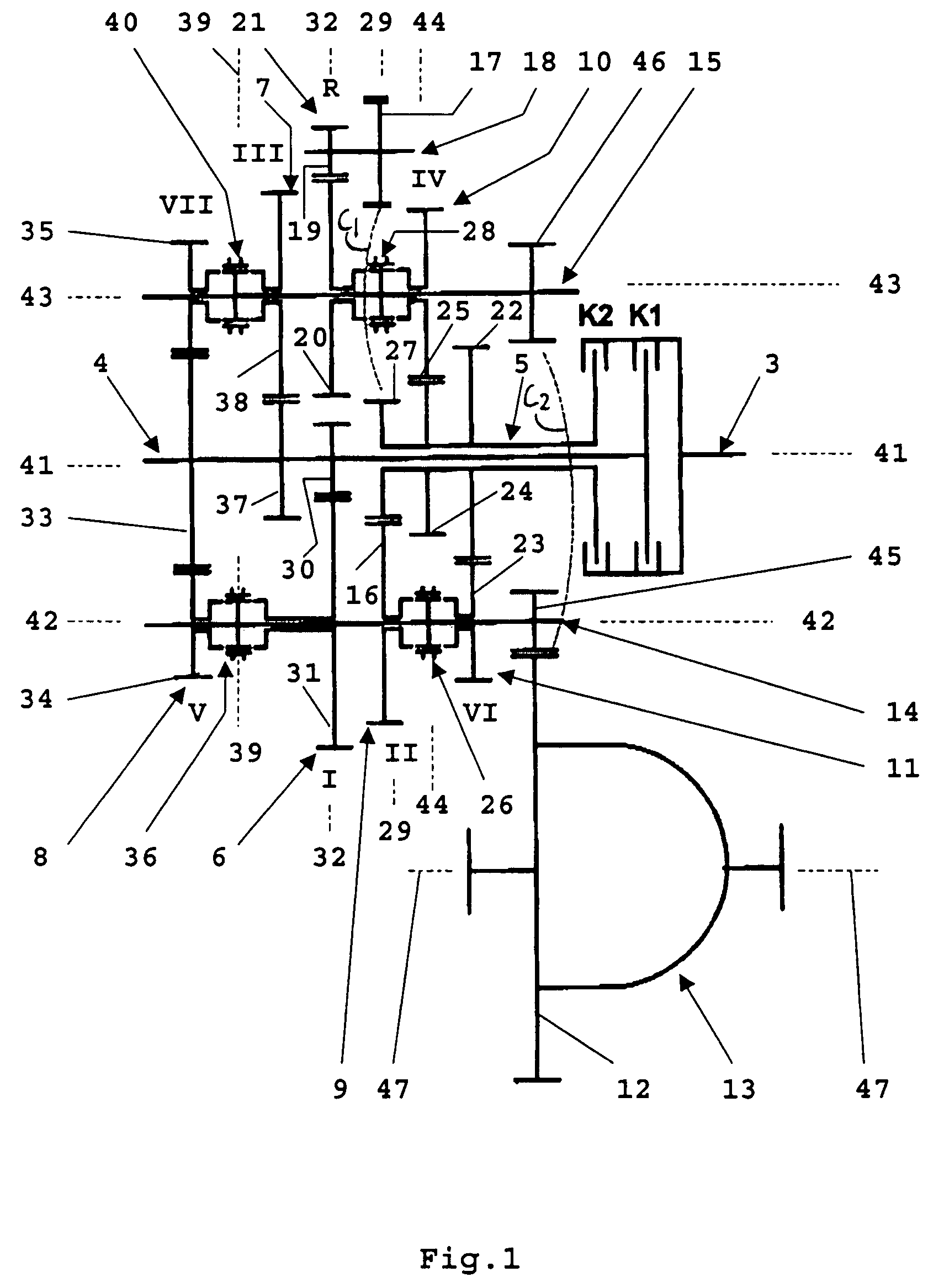

Double clutch transmission

InactiveUS7225696B2Short arrangementCompact designToothed gearingsTransmission elementsJackshaftTransverse engine

Owner:DAIMLER AG

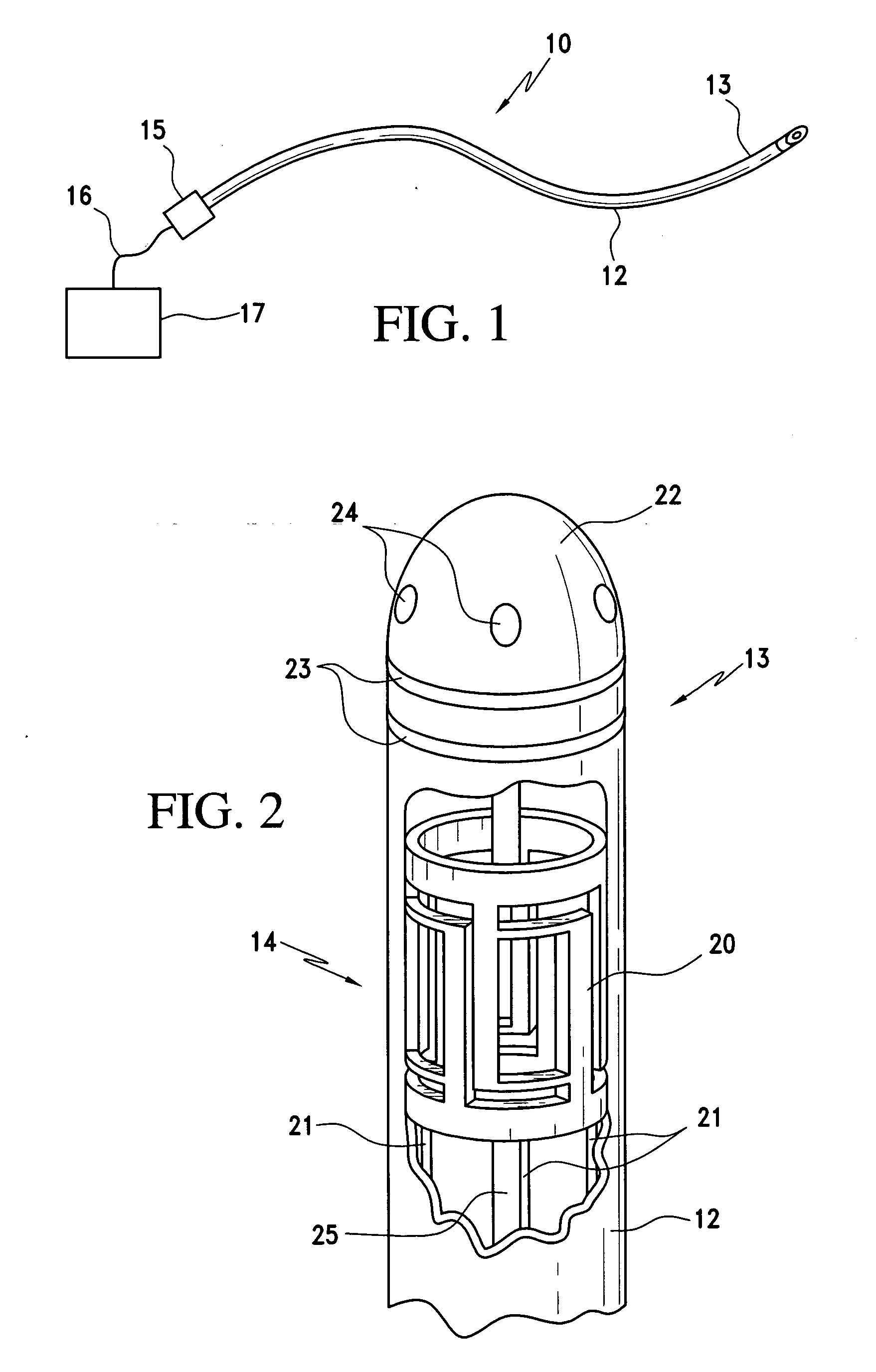

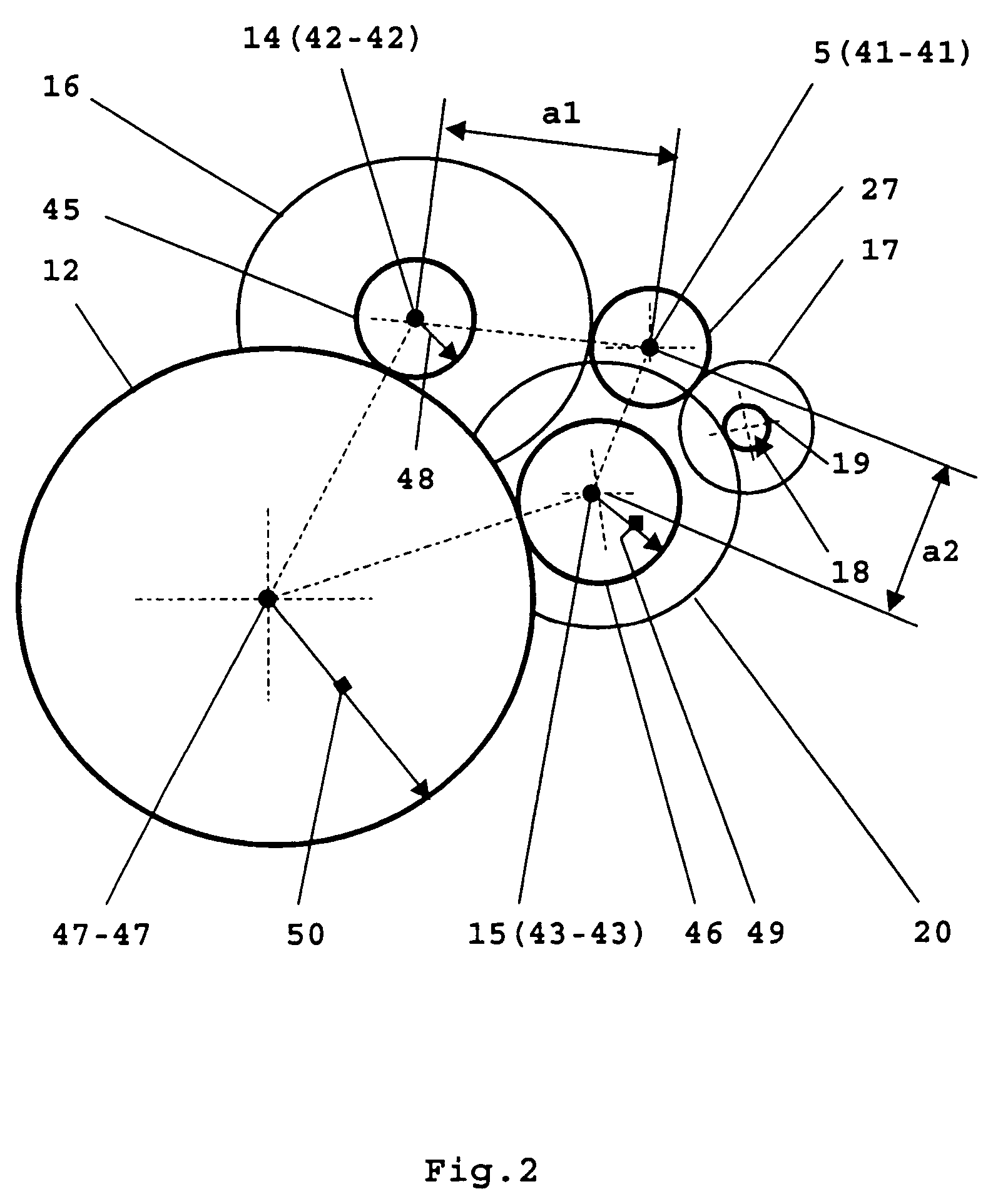

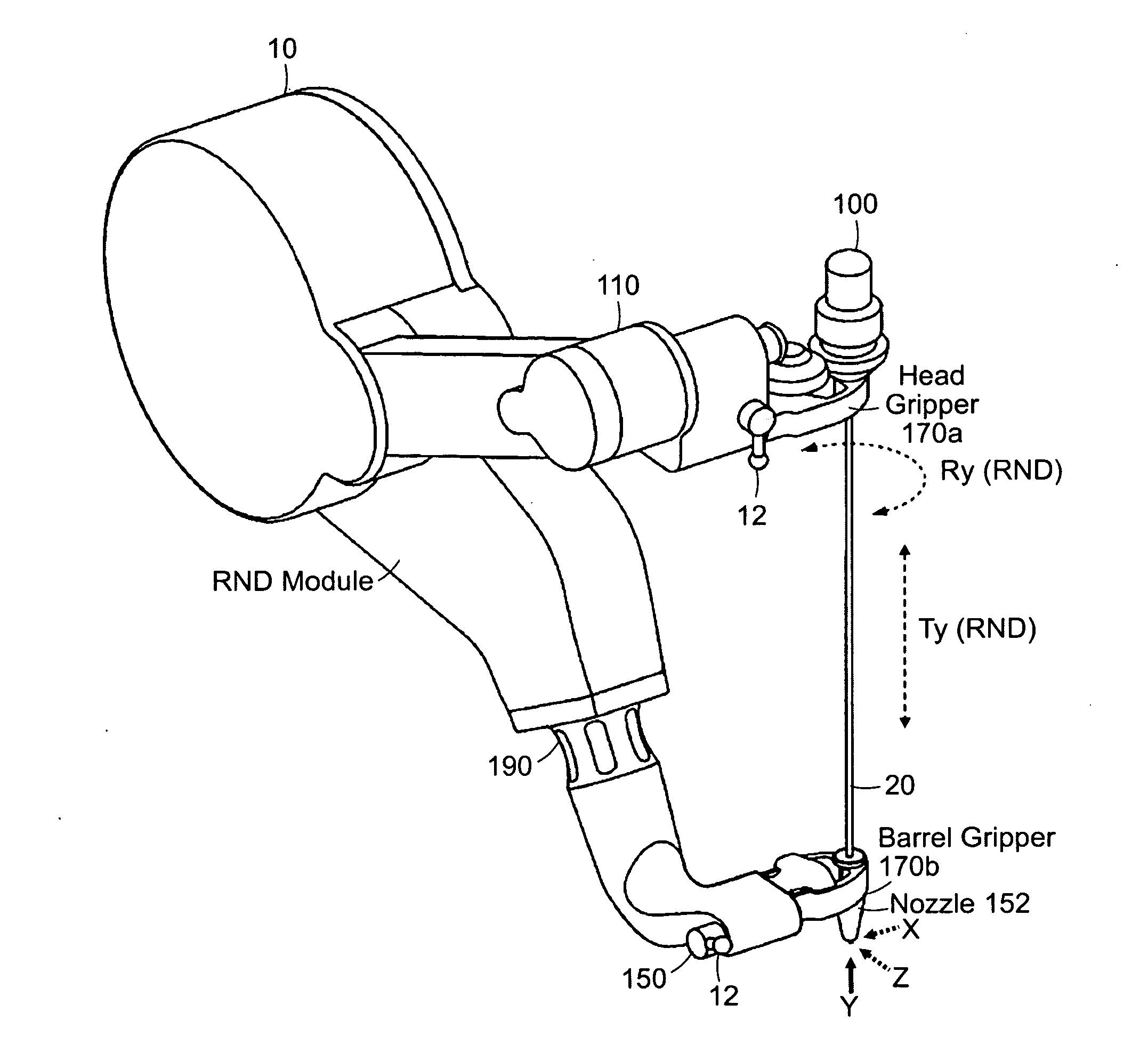

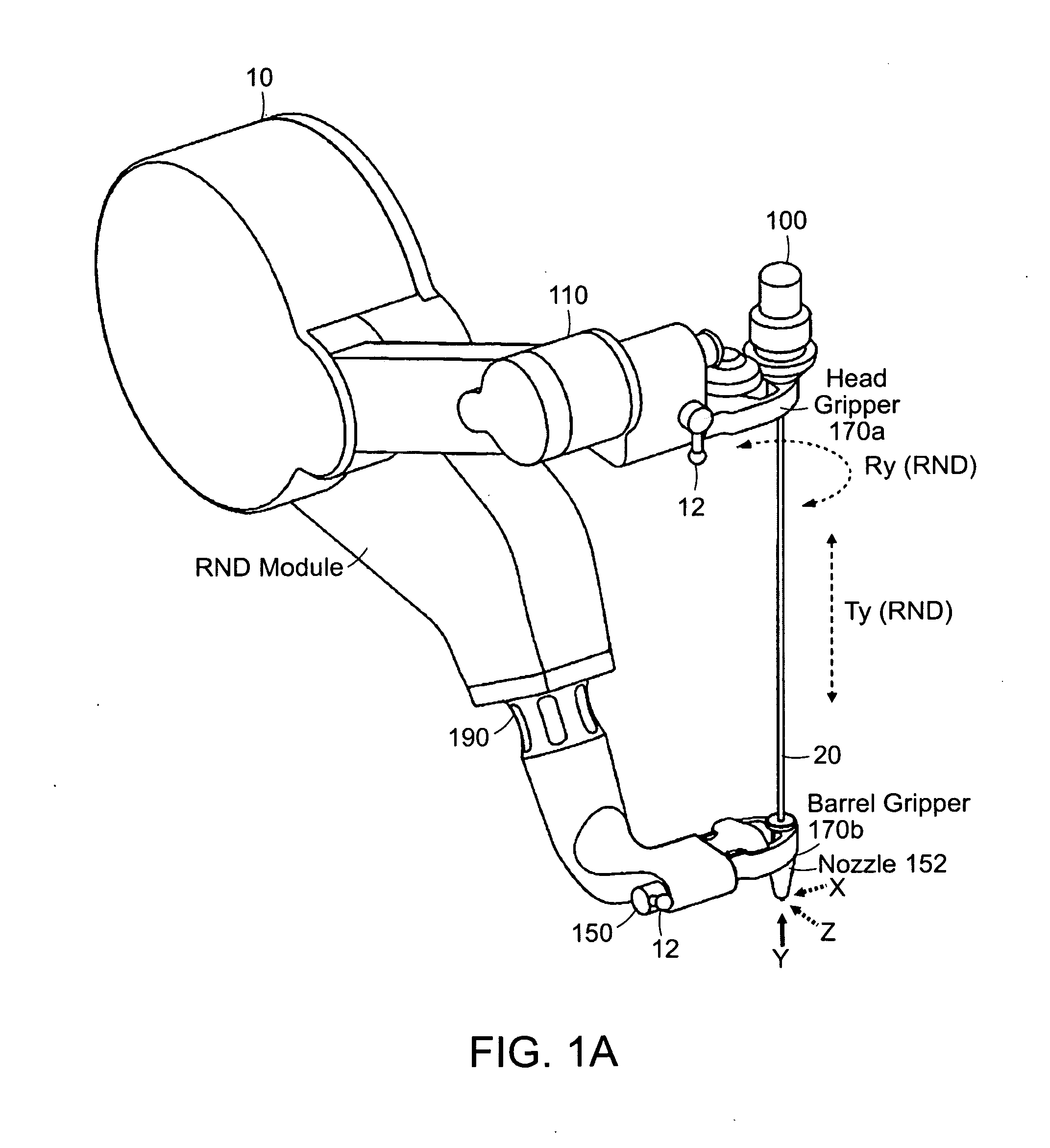

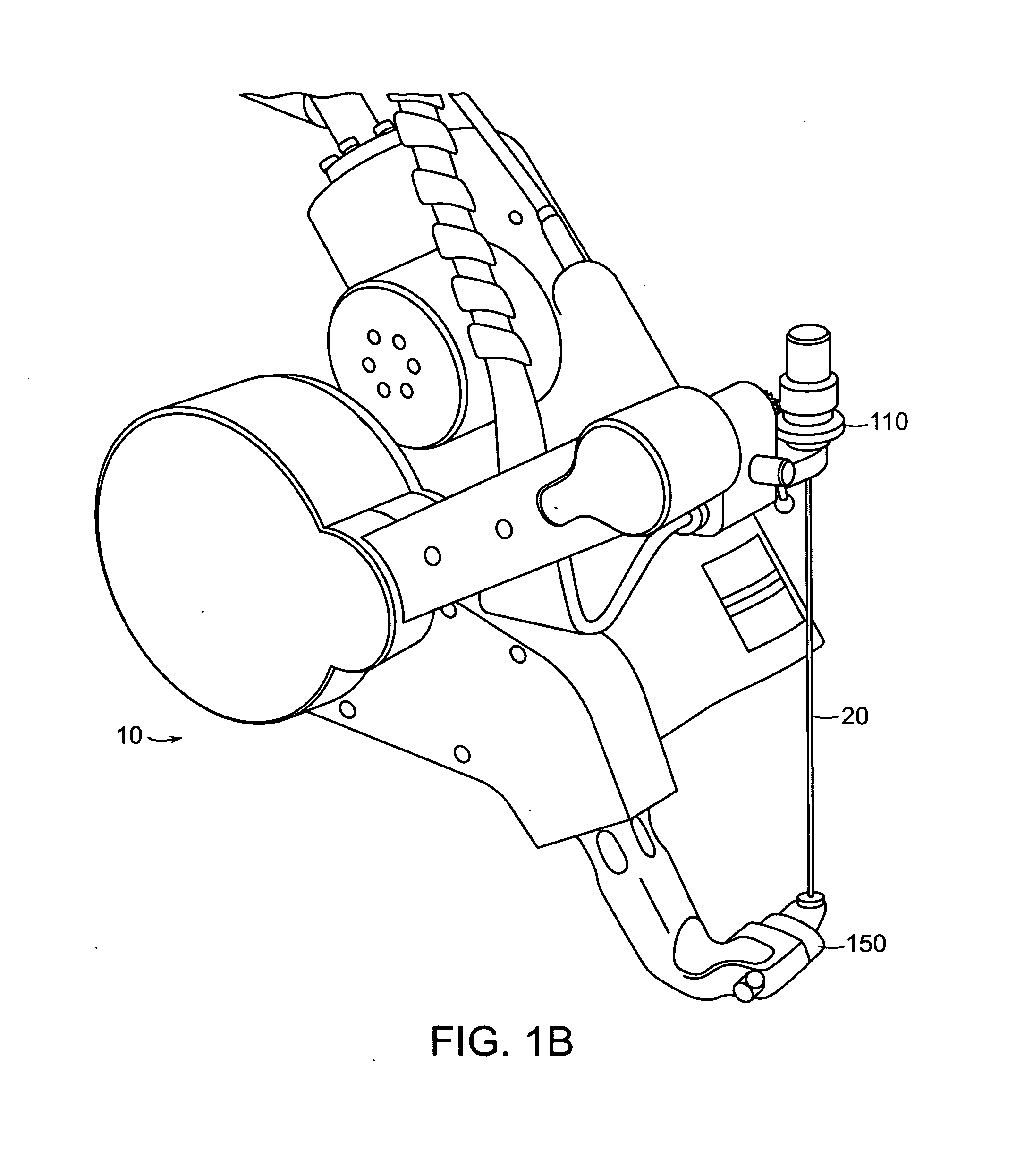

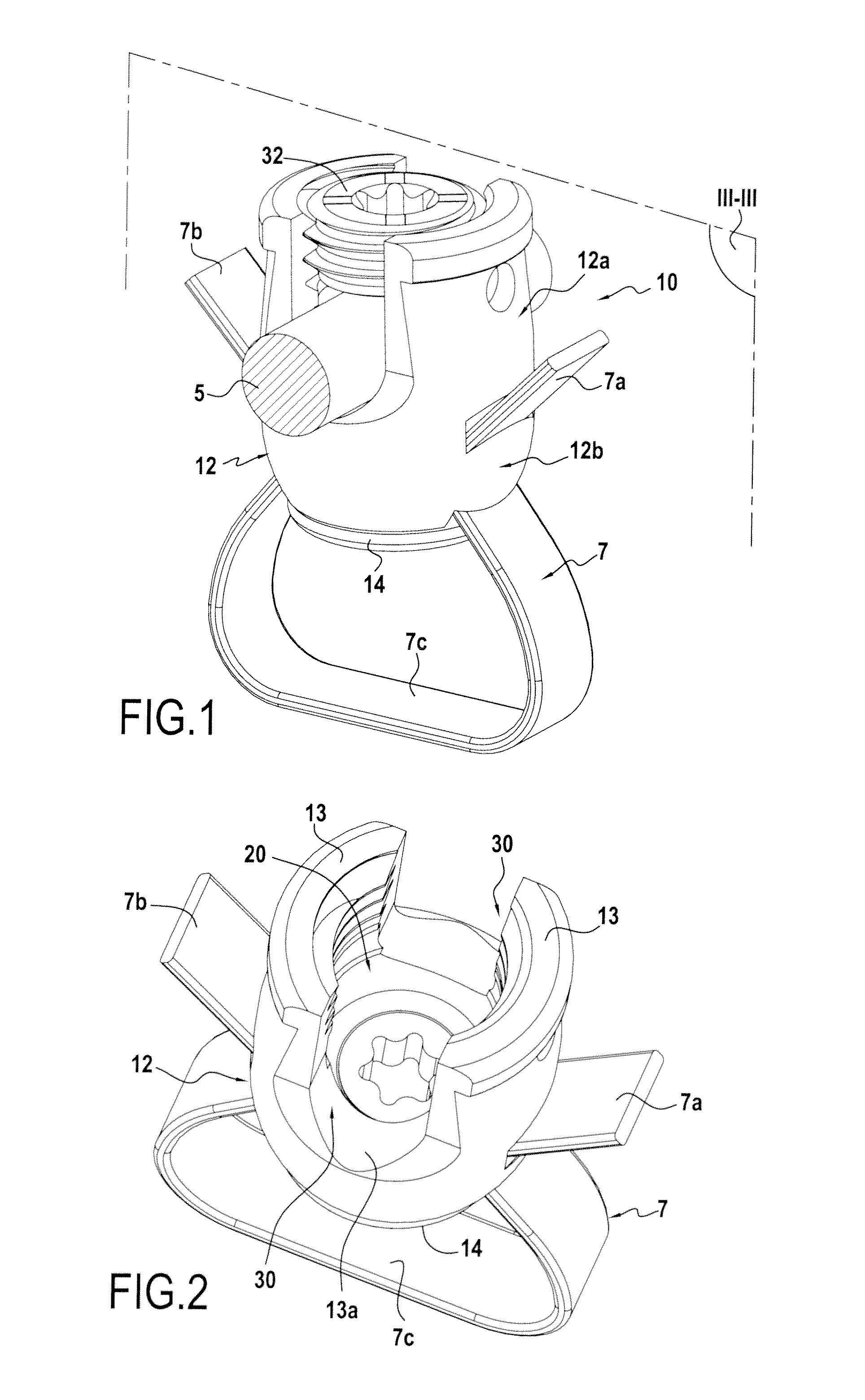

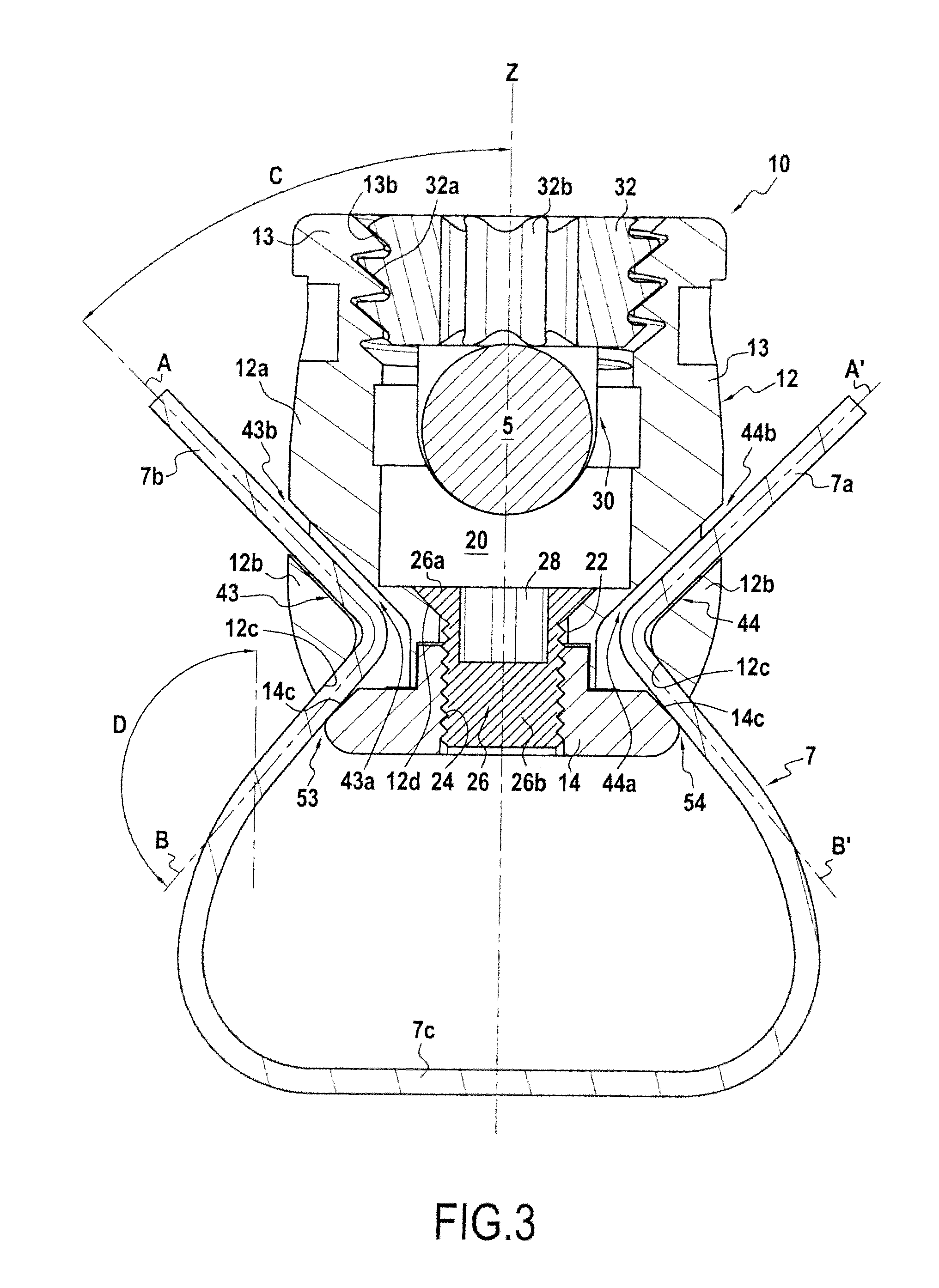

Rotating needle driver and apparatuses and methods related thereto

ActiveUS20100234856A1Reduce insertion forceReduce deformationVaccination/ovulation diagnosticsSurgical manipulatorsAbdominal trocarBiomedical engineering

Featured is a medical instrument driver, a robotic apparatus embodying such a medical instrument driver and methods related thereto for inserting a medical instrument into tissue of a mammal (e.g., human). Such medical instruments include medical needles, biopsy needles, trocars, cutters and introducers. Such a medical instrument driver according to the present invention is configured and arranged so that medical instrument is rotated as it is being moved longitudinally for insertion into the tissue such that the medical instrument is spiraling as it pierces and traverses the tissue to the target area.

Owner:THE JOHN HOPKINS UNIV SCHOOL OF MEDICINE

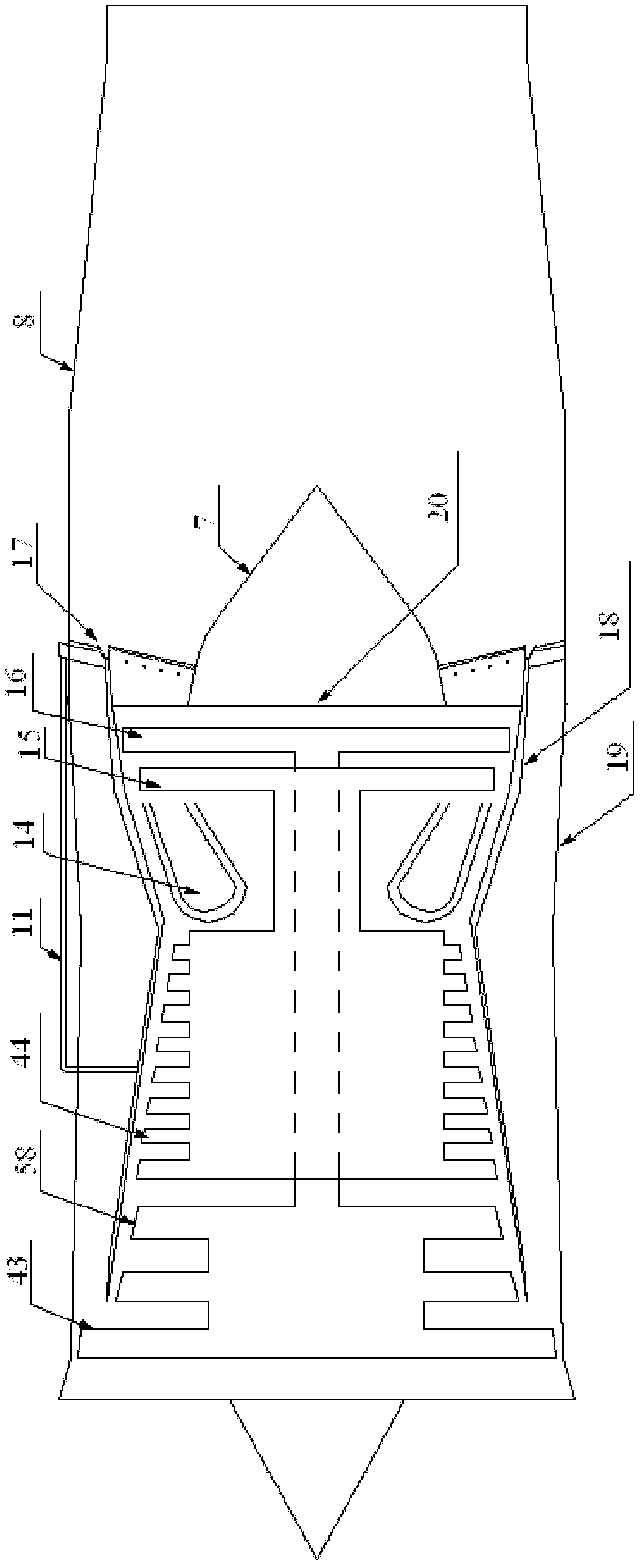

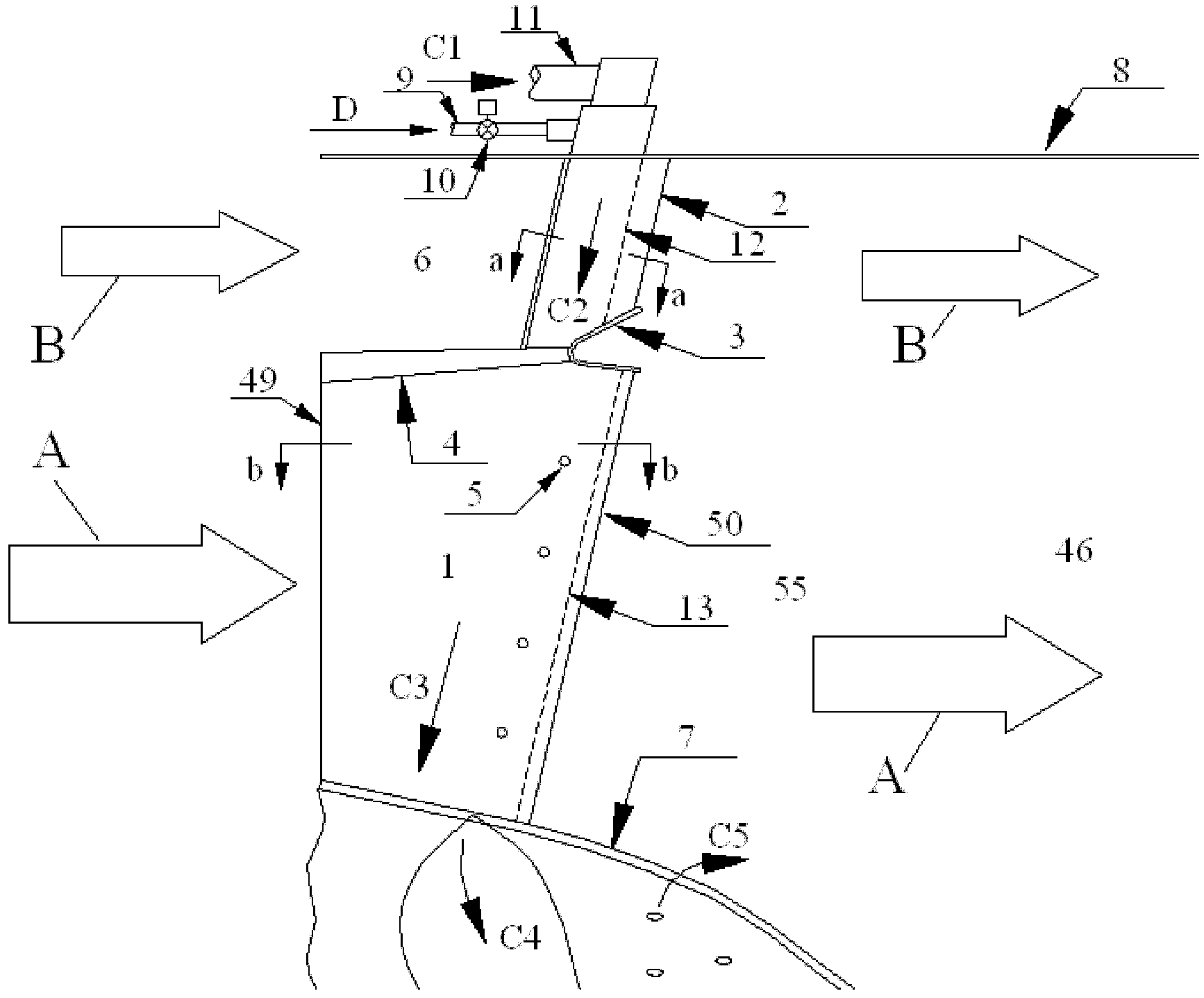

Afterburner integrated with stabilizer and worm wheel rear rectification support plate

InactiveCN102538010ASolve the technical problems of ablationImprove reliabilityContinuous combustion chamberEfficient propulsion technologiesCombustion chamberFuel oil

The invention discloses an afterburner integrated with a stabilizer and a worm wheel rear rectification support plate. A combustion part in the afterburner is integrated with a worm wheel rear load-bearing framework; the worm wheel rear rectification support plate is integrated with an inner culvert flame stabilizer, and cooling air is fed; a fuel oil supply pipe and a fuel oil nozzle are arranged in the rectification support plate; main fuel oil is transversely sprayed out from two sides of the support plate; and duty fuel oil is sprayed out from a groove on the rear surface of the stabilizer to form a duty flame. A pneumatic appearance of an outer culvert flame stabilizer is designed as a V-shaped bluff body, and the cooling air is fed into the outer culvert flame stabilizer; a fuel oil pipeline is arranged in the outer culvert flame stabilizer; the main fuel oil is transversely sprayed by a baffle plate nozzle; and the duty fuel oil is sprayed out from a groove on the rear surface of the outer culvert flame stabilizer. An annular flame stabilizer is arranged between the inner culvert flame stabilizer and the outer culvert flame stabilizer, so that functions of the stabilizer and a flame coupler are realized in a circumferential direction. The internal parts of the afterburner are integrated, so that the part utilization efficiency is improved, and the engine thrust-weight ratio is increased.

Owner:BEIHANG UNIV

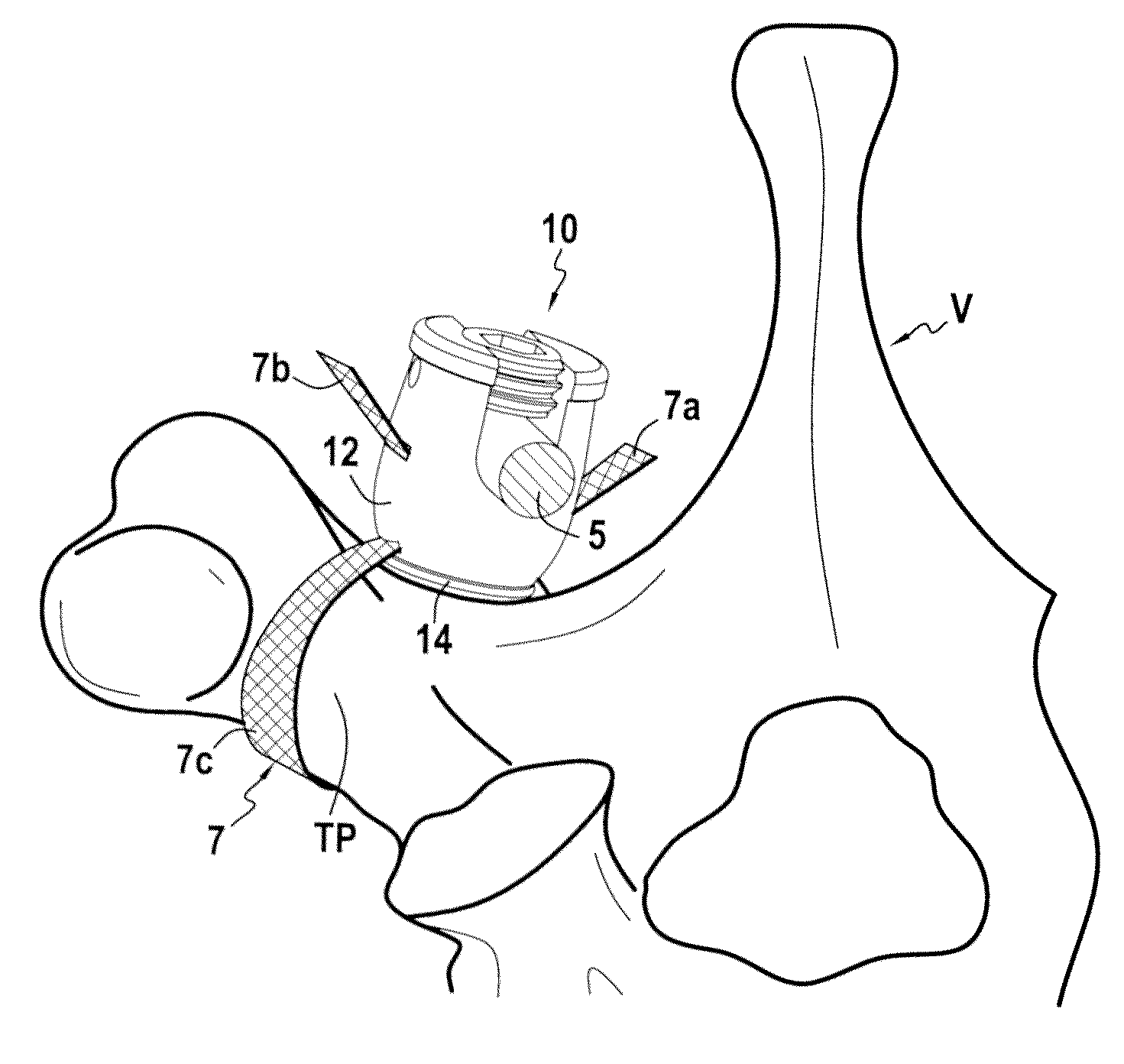

Bone fixing system

InactiveUS20120130373A1Easy to handleRestrict movementInternal osteosythesisJoint implantsOrthodontic ligatureEngineering

This disclosure provides a system for securing a bone to a rod, the system comprising a ligature, a body, and two fasteners. The ligature has two free ends and an intermediate portion therebetween, the intermediate portion being configured to engage a bone. A portion of a rod can be fastened to the body using one of the fasteners. The ligature can be fastened to the body using another one of the fasteners. The two fasteners are distinct from one another and are adapted to fasten two free end portions of the ligature to the body independently from fastening the portion of the rod to the body.

Owner:ZIMMER SPINE INC

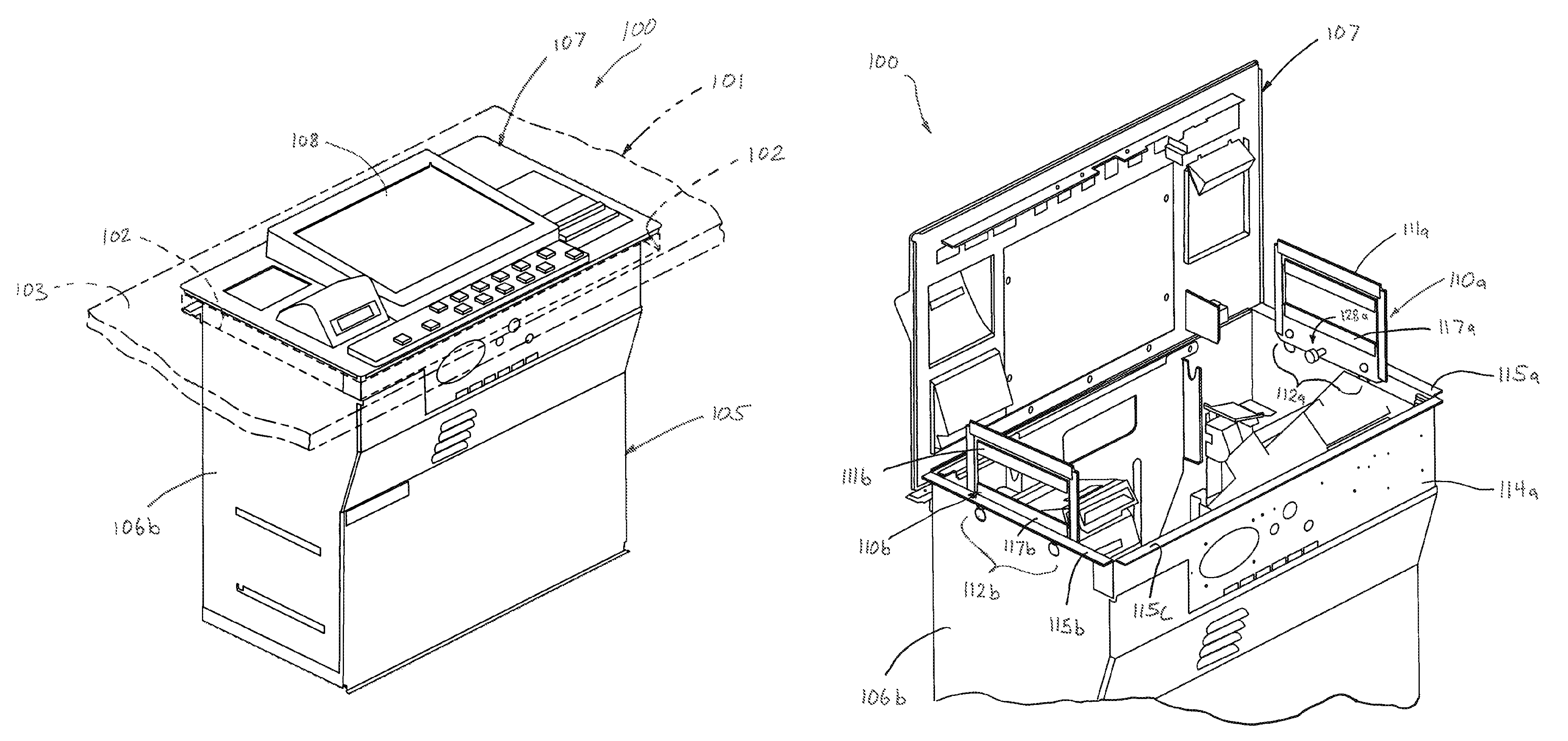

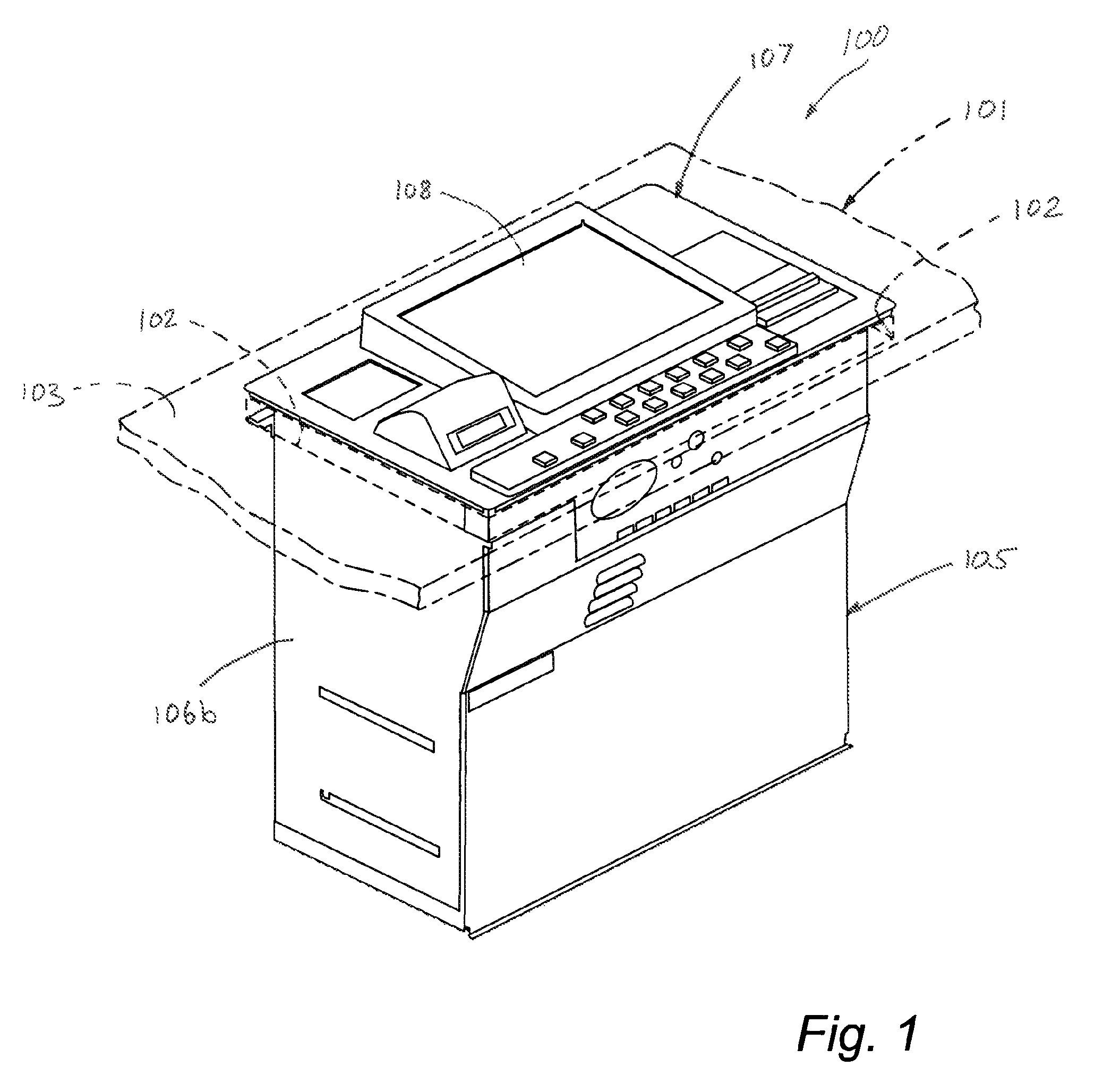

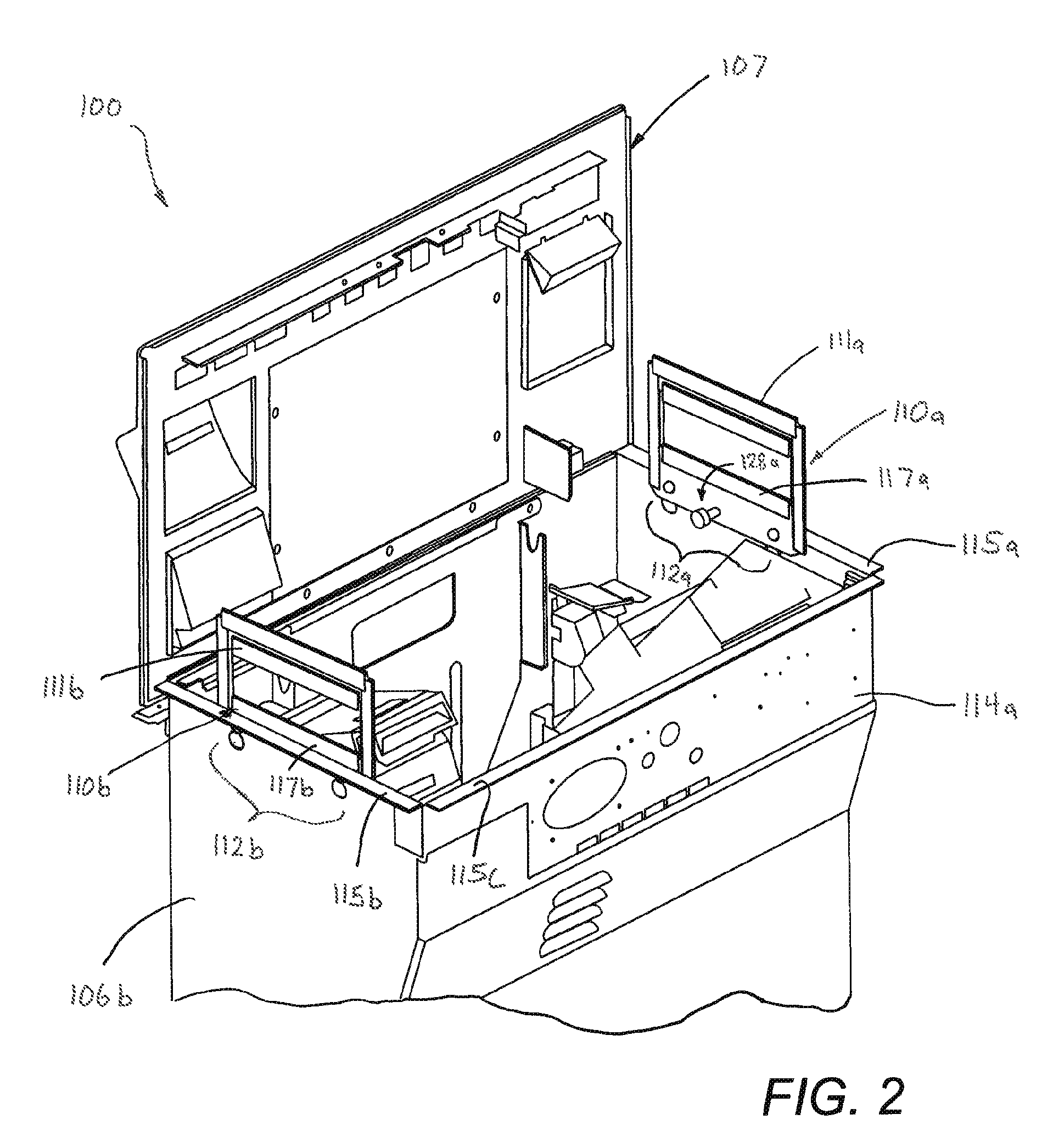

Repositionable handle assemblies for drop-in-bar gaming machines

ActiveUS7938728B2Tight toleranceCompact designCard gamesApparatus for meter-controlled dispensingDisplay deviceMechanical engineering

A “drop-in” style bar top gaming machine that includes a support frame having at least two opposed support walls, and a top panel assembly supporting a display device. The top panel assembly is further configured to cooperate with the support frame for movement between a closed position and an open position, enabling access to the support frame. A handle assembly is provided for each support wall, each of which includes a handle member and a mounting portion that is movably mounted to a corresponding support wall of the support frame between a first position and a second position. In the first position, the handle member is positioned in a manner that enables the top panel to be oriented in the closed position. In the second position, the handle member is exposed in a manner that permits gripping thereof to vertically support and lift the gaming machine assembly.

Owner:IGT

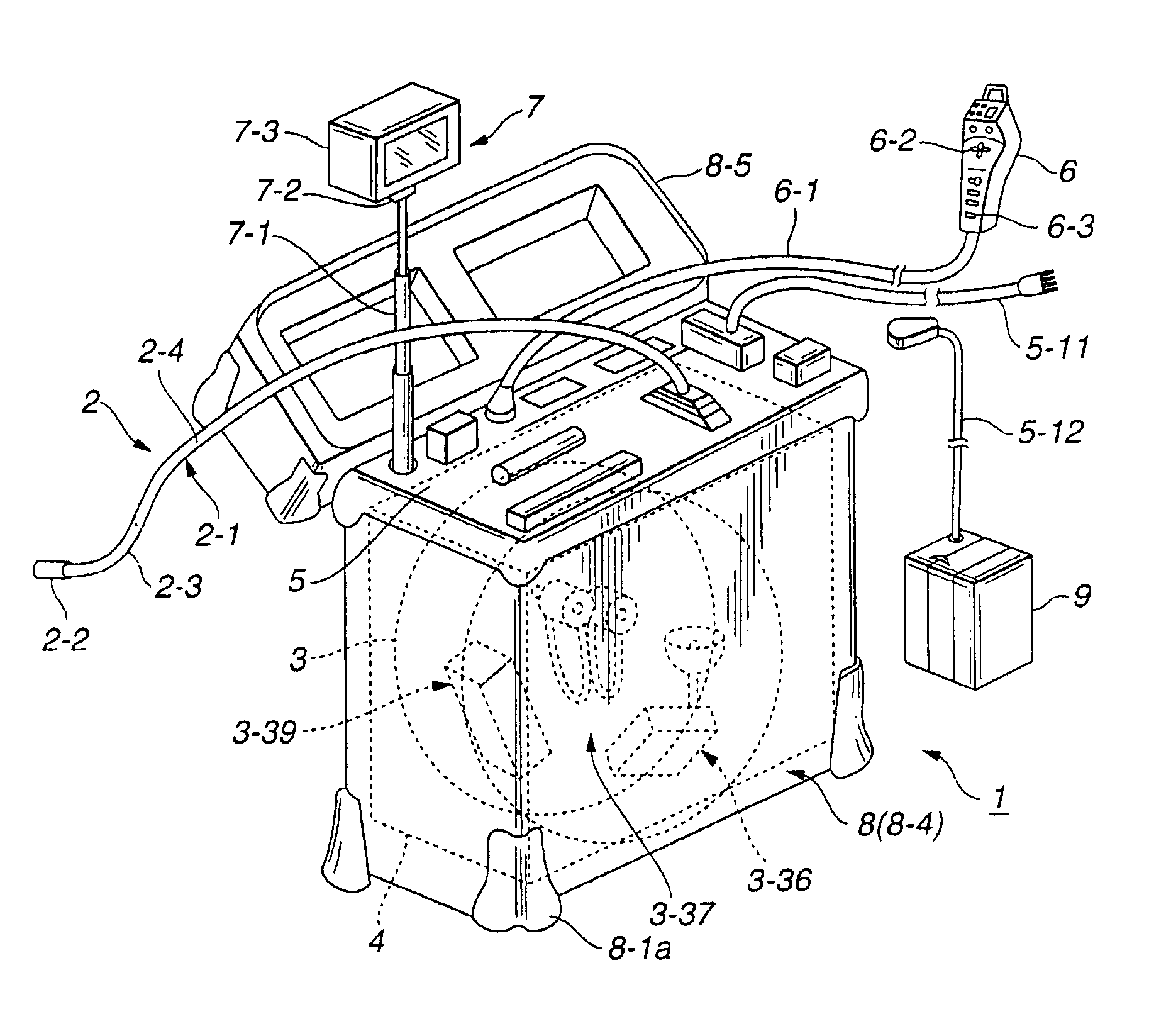

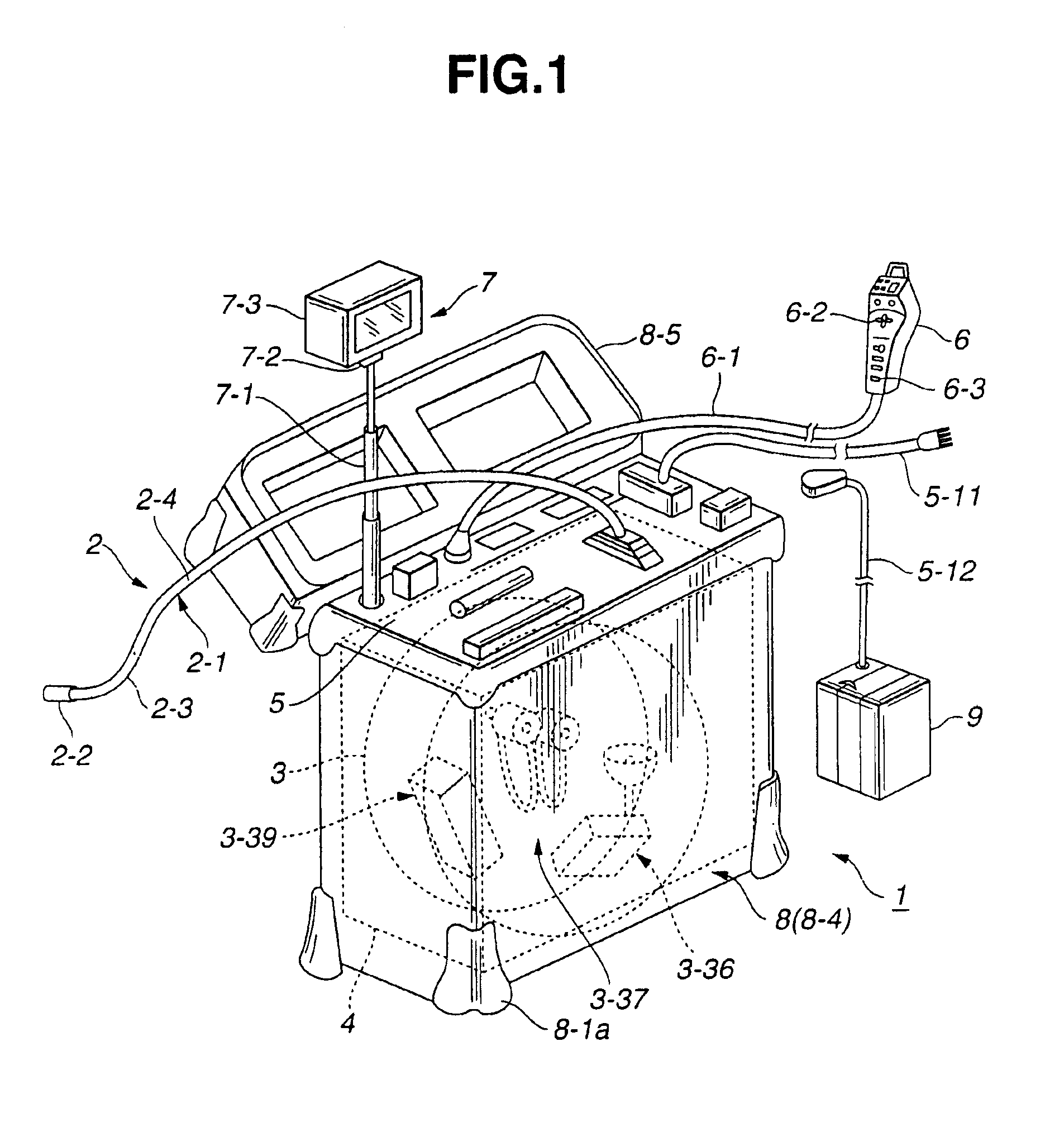

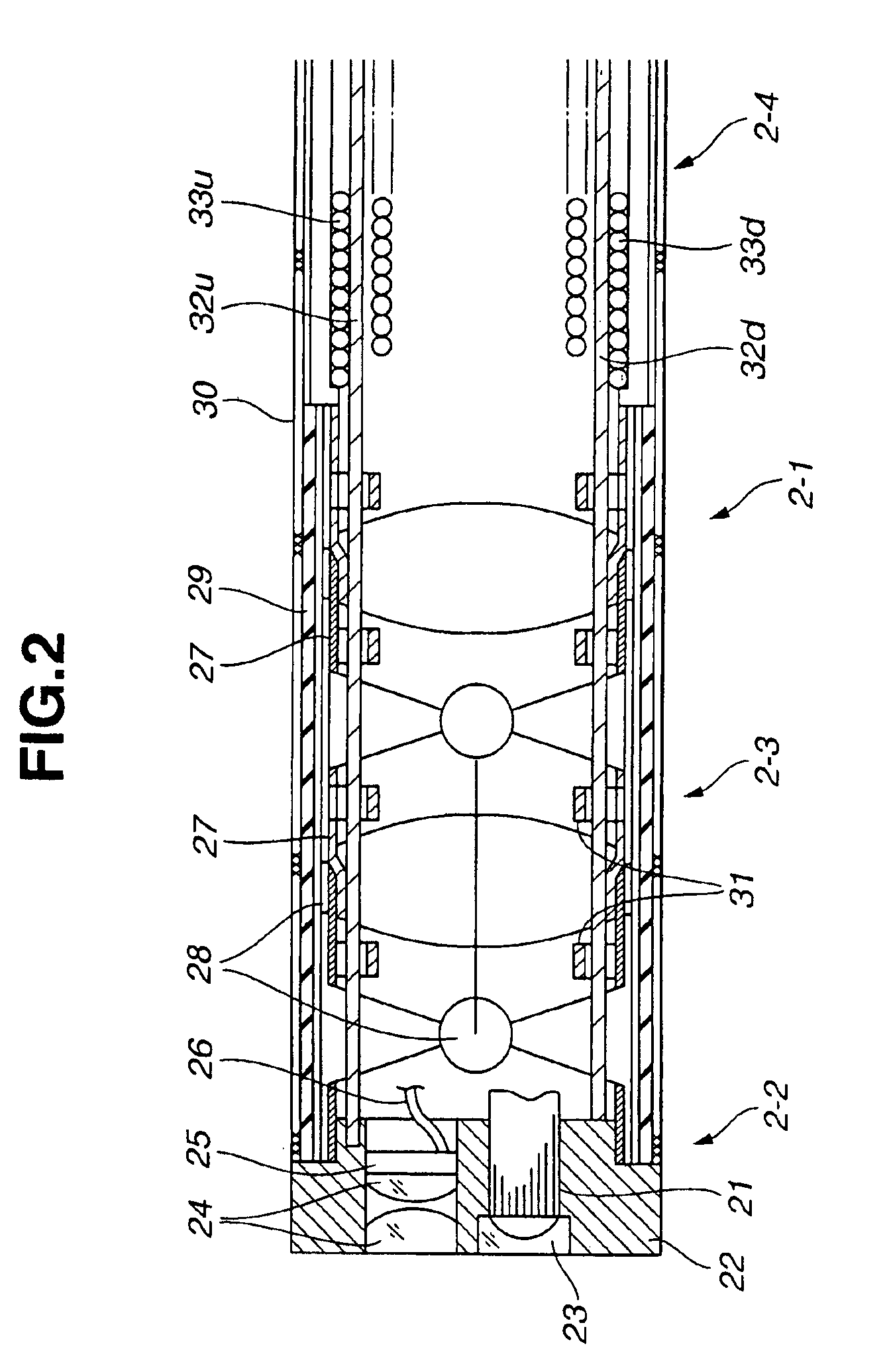

Endoscope apparatus with drum part to wind insertion part therearound

InactiveUS7104951B2Good transportabilityLarge capacitySurgeryEndoscopesMotor driveCamera control unit

According to the present invention, an endoscope system having an insertion member thereof wound about a drum comprises an electronic endoscope, a drum, an angling input unit, a motor-driven angling unit, a camera control unit, a motor-driven angling control circuit unit, and a stowage case. A bending section included in an insertion member of the electronic endoscope is motor-driven to bend, and a solid-state imaging device is incorporated at the tip of the insertion member. The insertion member is wound about the periphery of the drum. The angling input unit is separated from the electronic endoscope, and used to enter a direction of bending in which a user wants to bend the bending section. The motor-driven angling unit is incorporated in the drum, and includes a driving source for driving a driving mechanism that drives the bending section. The camera control unit controls the solid-state imaging device, and includes a signal processor for processing an electric signal sent from the solid-state imaging device to generate a video signal. The motor-driven angling control circuit unit controls the movement of the bending section. The drum is rotatably stowed in the stowage case freely.

Owner:OLYMPUS CORP

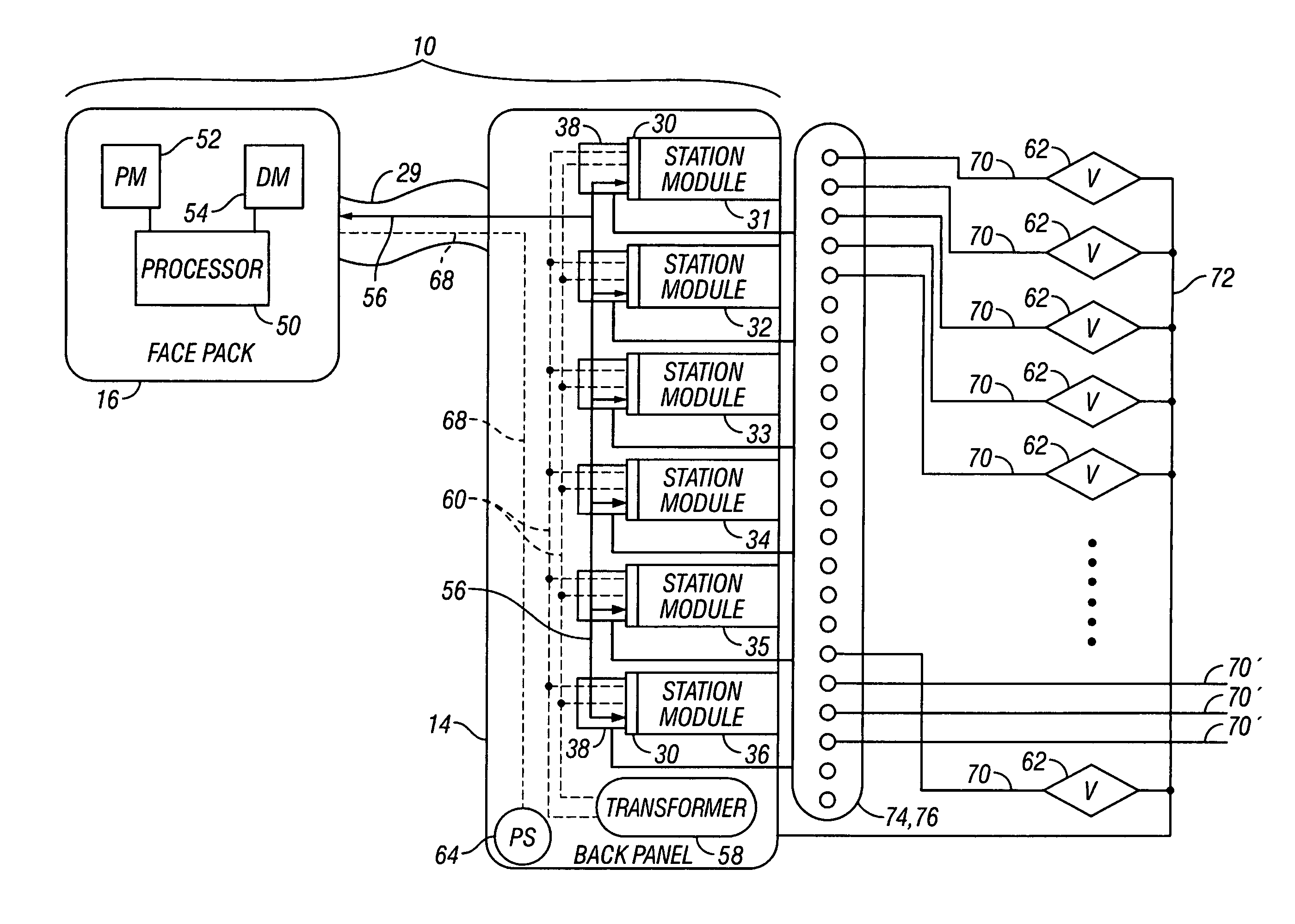

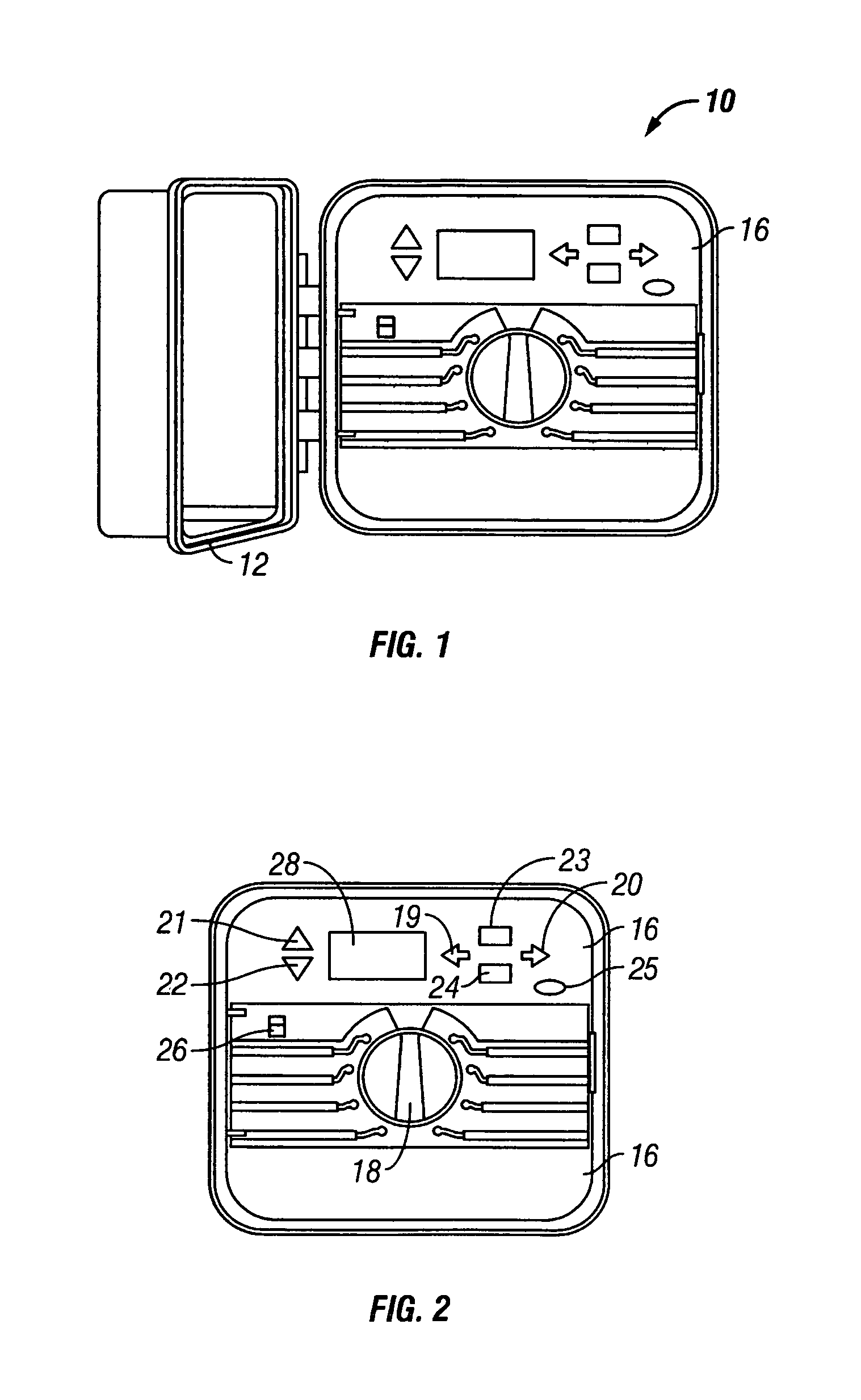

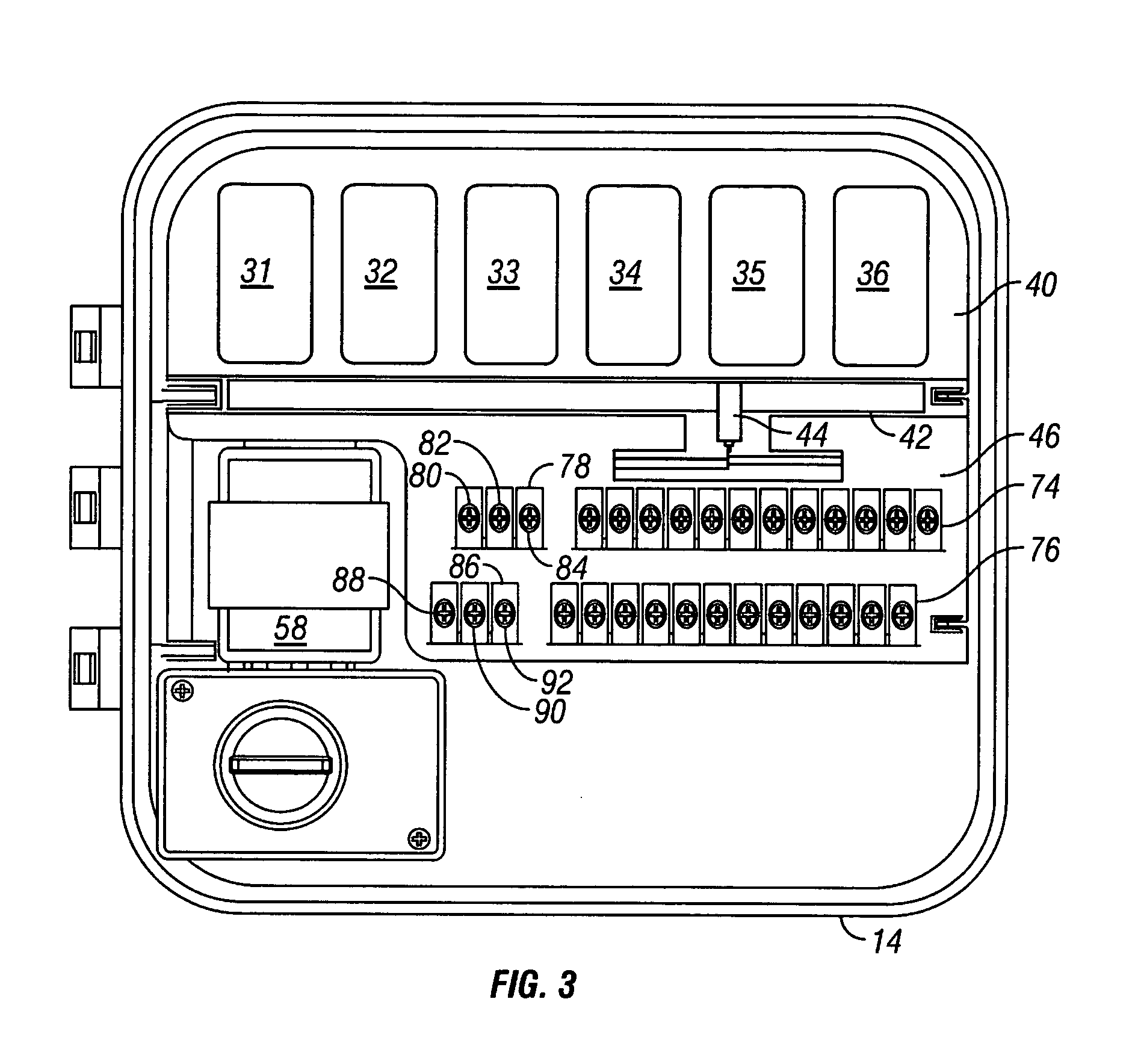

Modular irrigation controller with separate field valve line wiring terminals

ActiveUS7289886B1Compact designEliminate failure problemsSelf-acting watering devicesWatering devicesTelecommunications linkLine tubing

A modular irrigation controller includes a processor capable of executing a stored watering program and controlling a plurality of removable station modules in accordance with the watering program. Each station module includes a station module circuit for opening and closing a plurality of values. A plurality of connectors can mate each mate to establish a communications link between the station modules and the processor. A plurality of terminals are each connectable with a corresponding one of a plurality of field valve lines from the valves. The terminals are mounted separate from the station modules and are connected to the connectors. This allows the irrigation controller to have a more compact design, provides connection terminals for spare field valve lines, and eliminates malfunctions due to erroneous re-connection of field valve lines during station module replacement.

Owner:HUNTER INDUSTRIES

Head-up display

InactiveUS6836369B2Compact designDeterioration in display definitionOptical elementsHead-up displayDisplay device

Owner:DENSO CORP

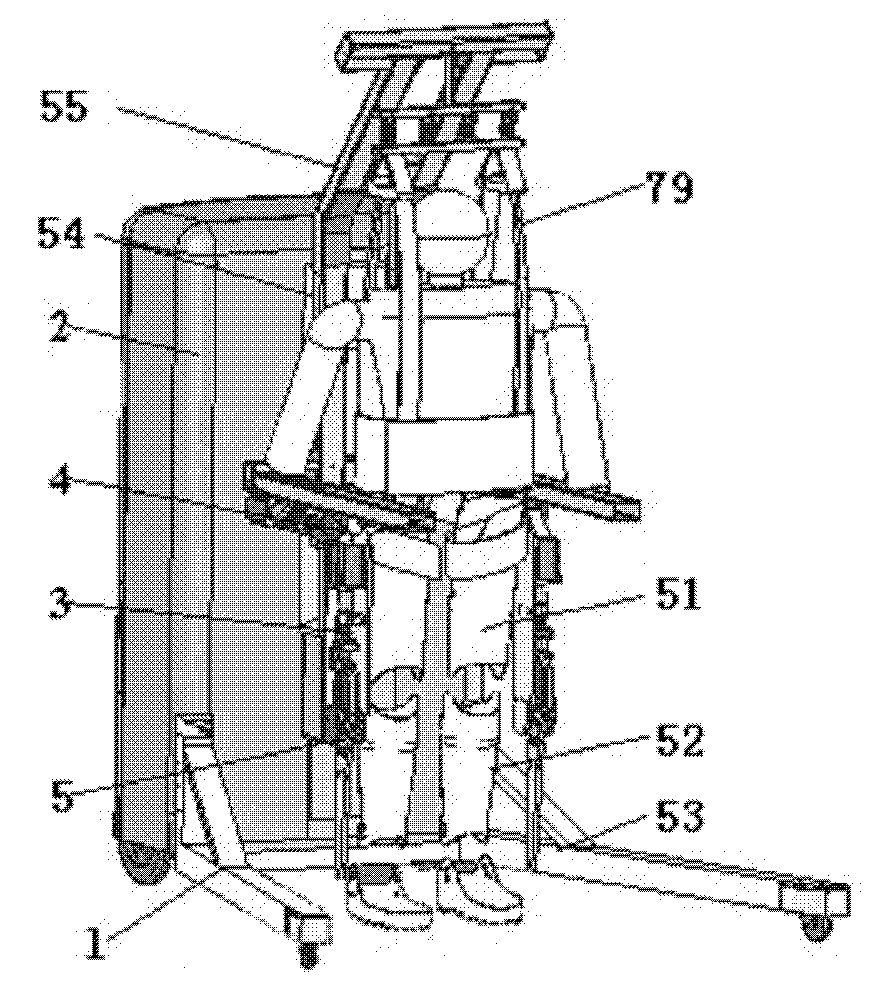

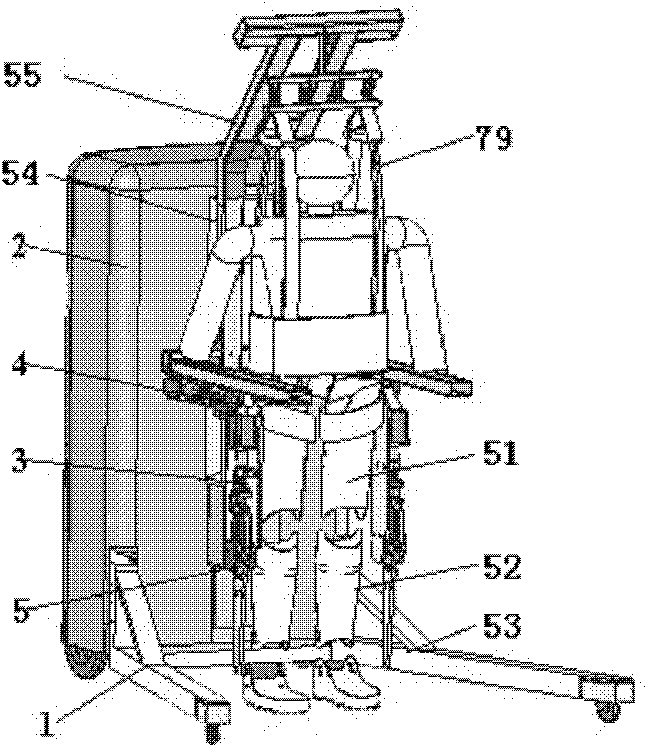

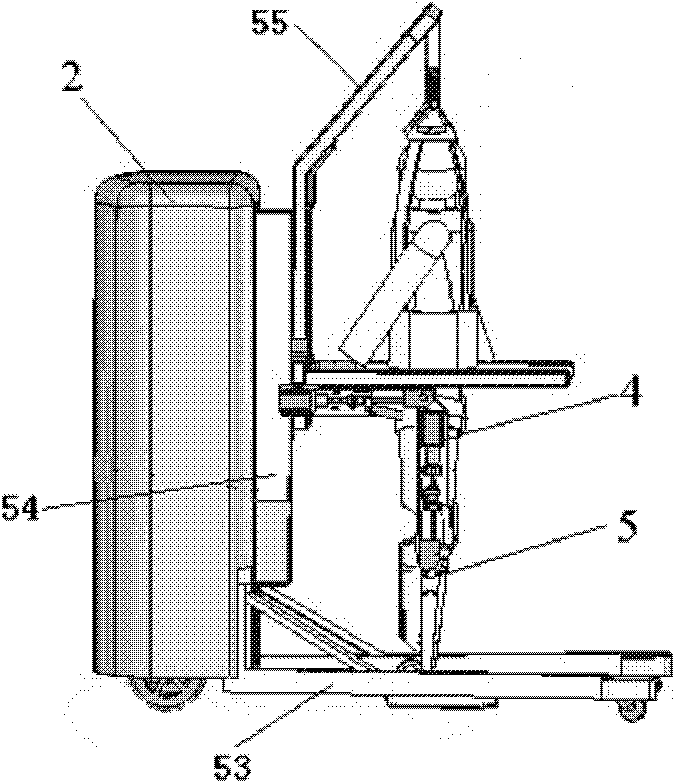

Walking aid exoskeleton rehabilitation robot

InactiveCN101810533ACompact designLarge range of joint rotationChiropractic devicesWalking aidsHuman bodyRehabilitation engineering

The invention discloses a walking aid exoskeleton rehabilitation robot in the technical field of rehabilitation engineering, which comprises a mobile auxiliary mechanism, a control mechanism and an exoskeleton prosthesis mechanism, wherein the mobile auxiliary mechanism is connected with the exoskeleton prosthesis mechanism, and the control mechanism is connected with the mobile auxiliary mechanism and the exoskeleton prosthesis mechanism respectively. The exoskeleton prosthesis mechanism has compact design structure and large rotation range of each joint, and can meet the requirement on actual motion of a human body. By adopting a servo motor to drive, the control precision is high, and the output torque is large; and the mobile auxiliary mechanism rotates under the driving of the servo motor, can freely move, and has higher climbing capacity and movement speed. The height of the mobile auxiliary mechanism is adjusted to be applied to people with different heights. When the patient undergoes gait rehabilitation training, the human gravity center is actively adjusted to accord with the characteristics that the human body is fluctuated along with alternative gait. The mobile auxiliary mechanism also can support the human body, prevent people from tumbling in walking, and guarantee the whole stability.

Owner:SHANGHAI JIAO TONG UNIV

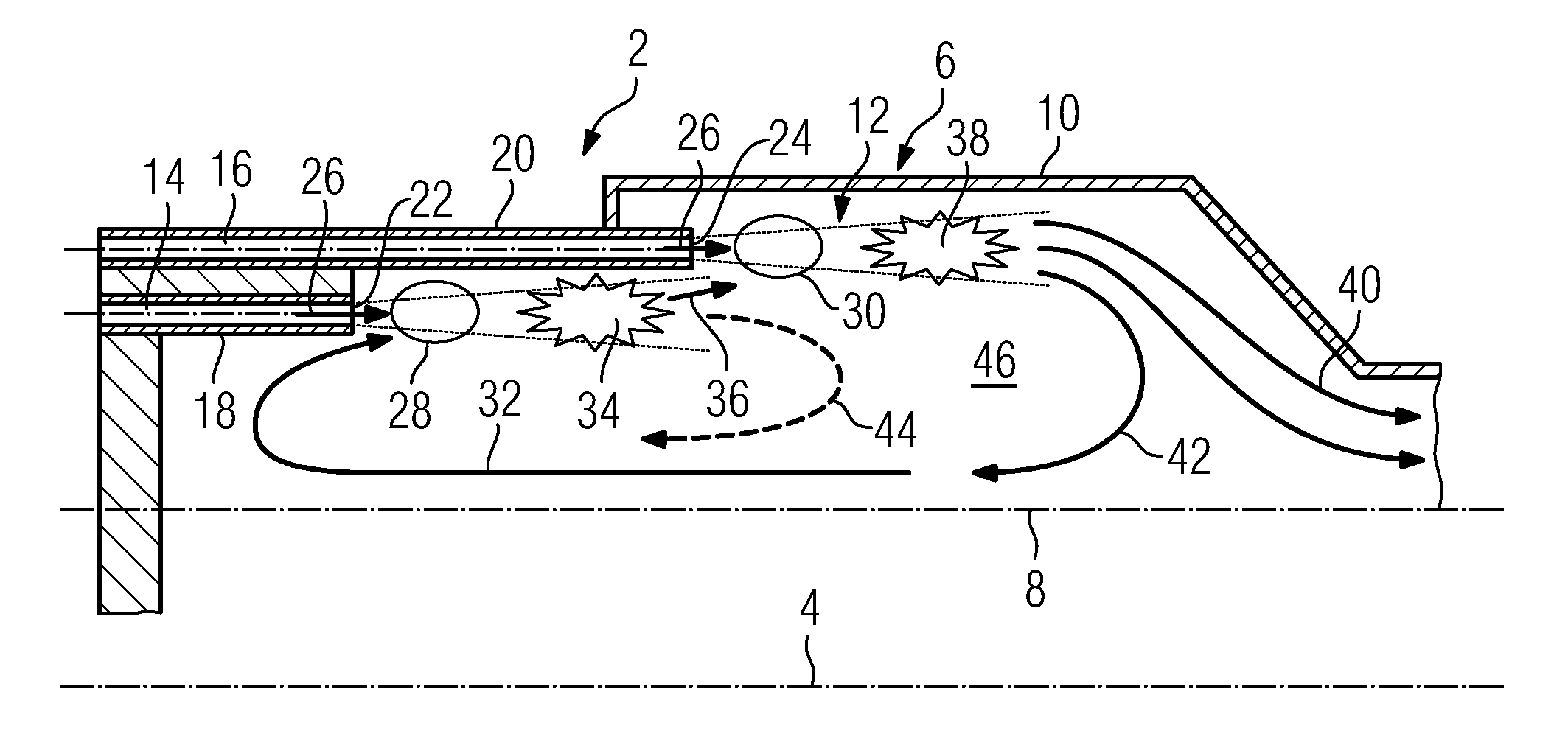

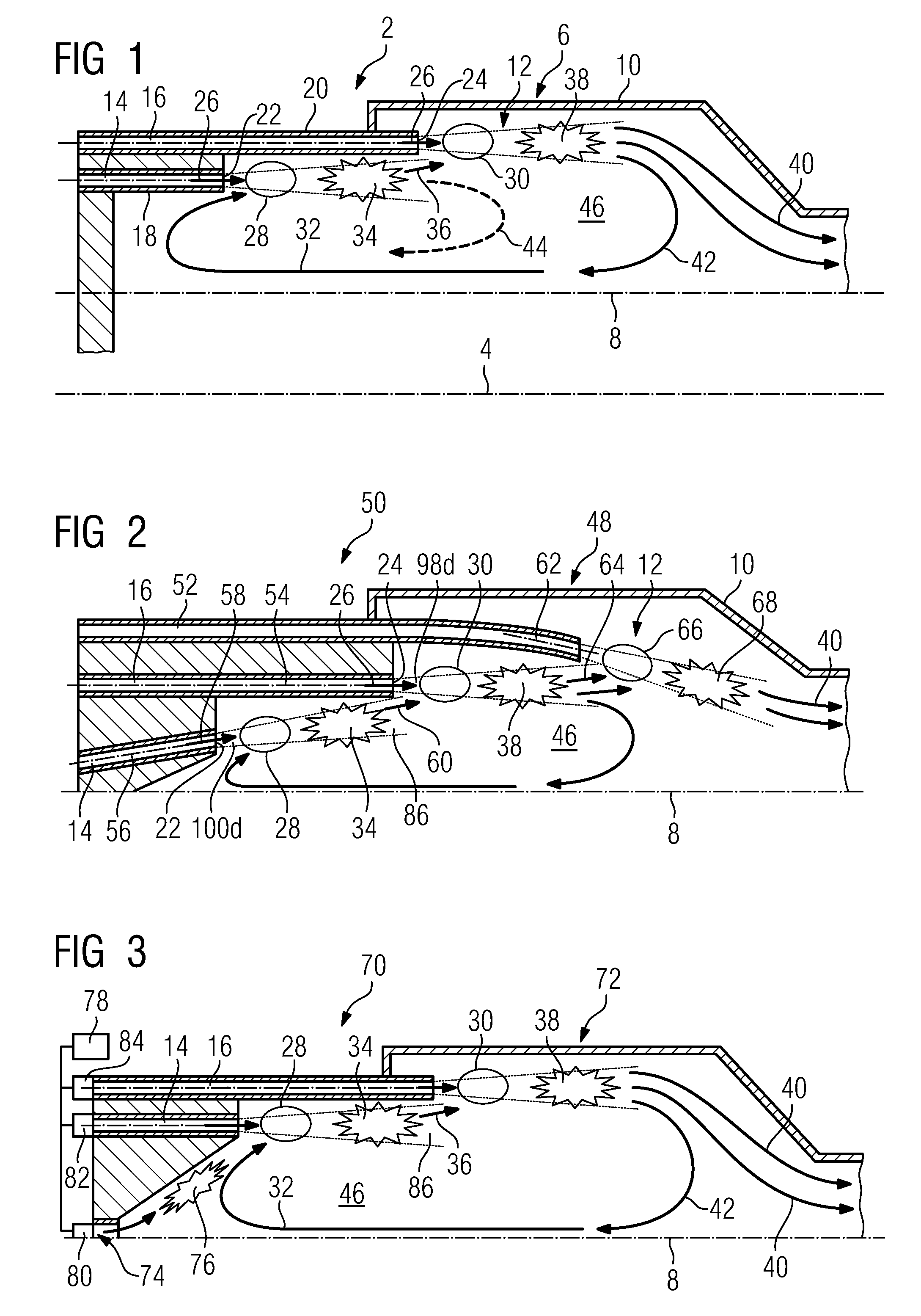

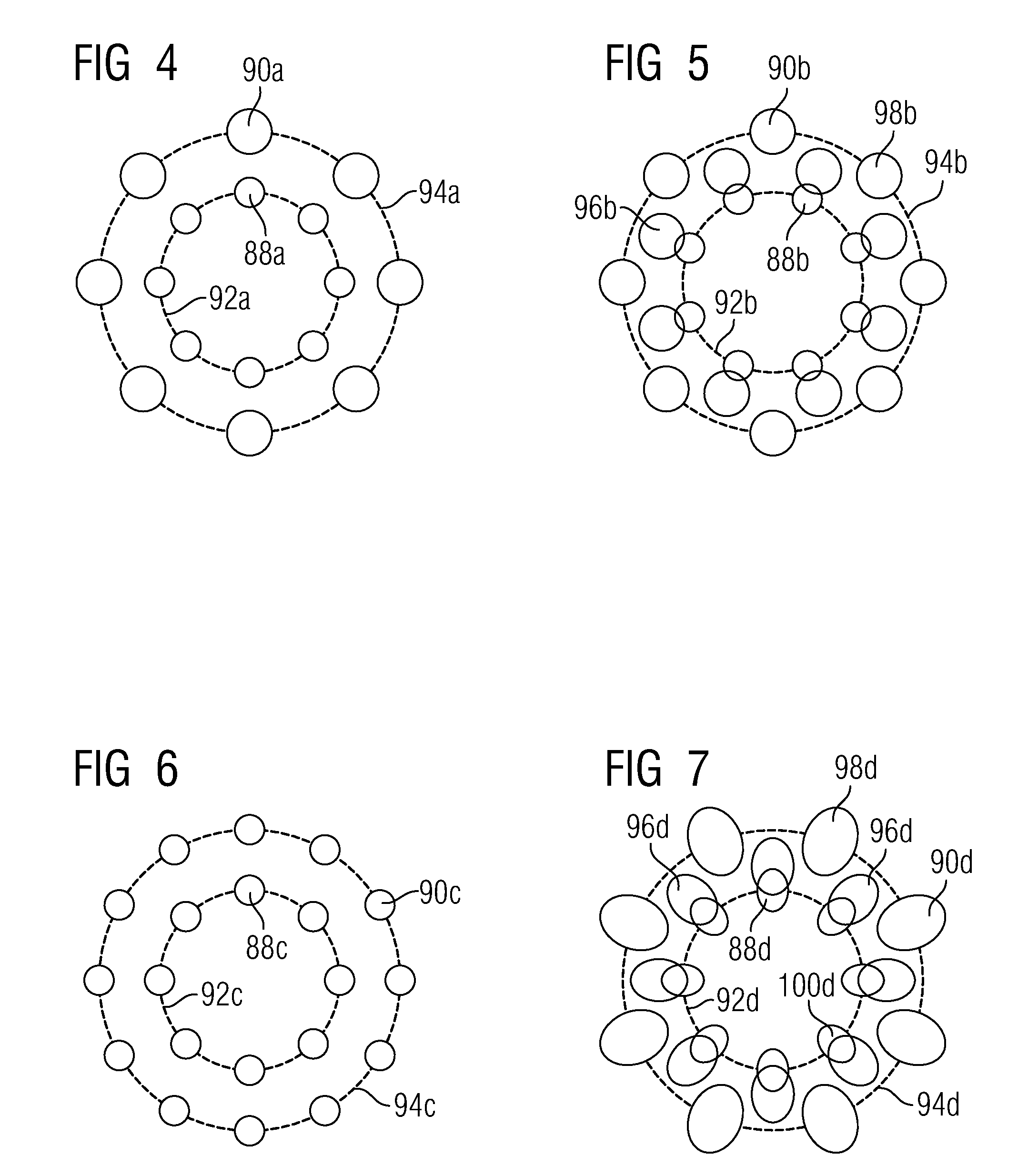

Combustion chamber for a gas turbine

ActiveUS20100058732A1Compact designBroaden applicationContinuous combustion chamberGas turbine plantsCombustion chamberGas turbines

A combustion chamber for a gas turbine is provided. The combustion chamber comprises at least one first and one second jet carrier, of which at least one is provided for injecting an operating gas in the combustion chamber such that waste gas fanned in the flame zone thereof is circulated to a mixing zone of the first jet carrier. In order to achieve a compact combustion chamber, the jet carriers are positioned in relation to each other such that waste gas from the flame zone of the first jet carrier flows directly to the mixing zone of the second jet carrier.

Owner:SIEMENS ENERGY GLOBAL GMBH & CO KG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com