Patents

Literature

429results about How to "Plenty of space" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

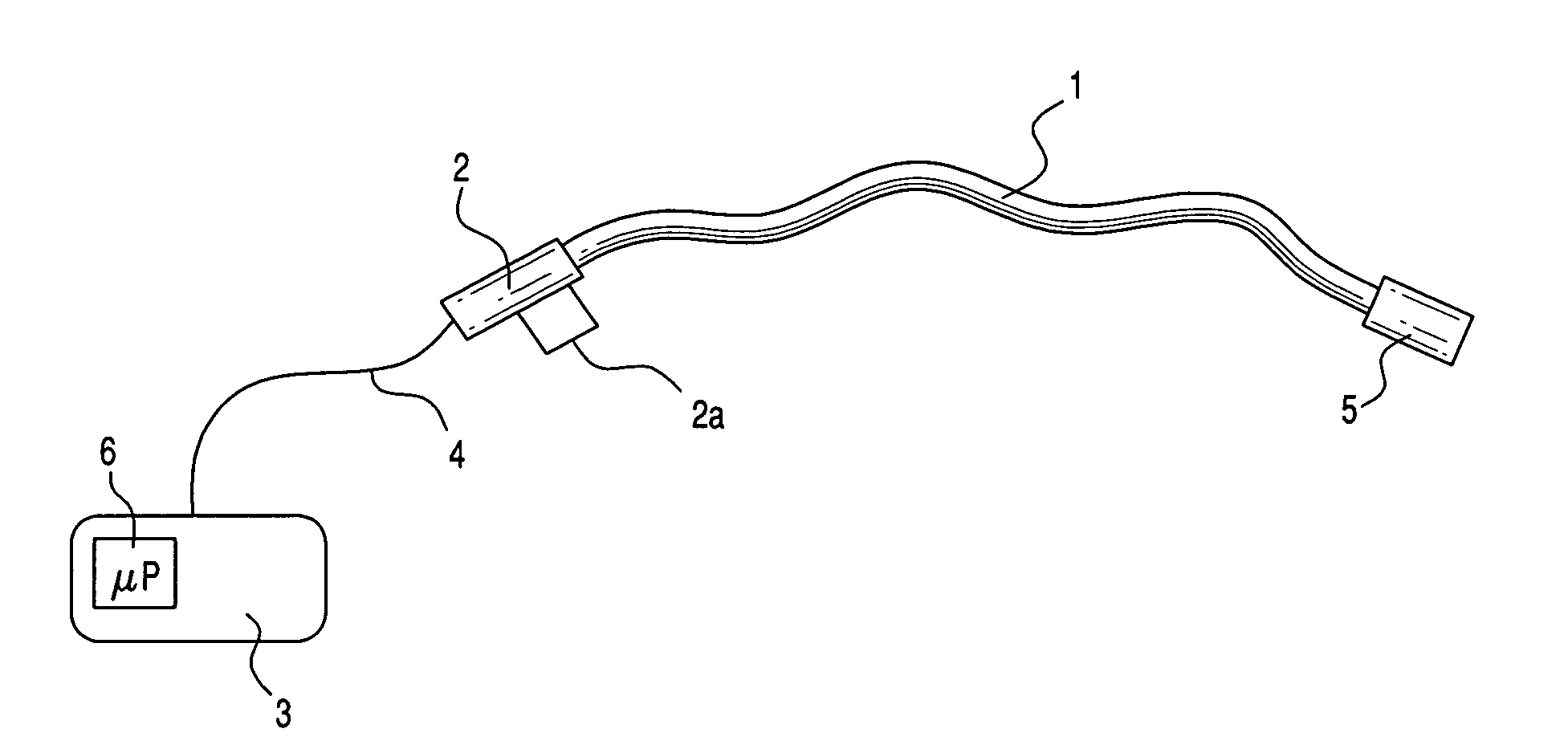

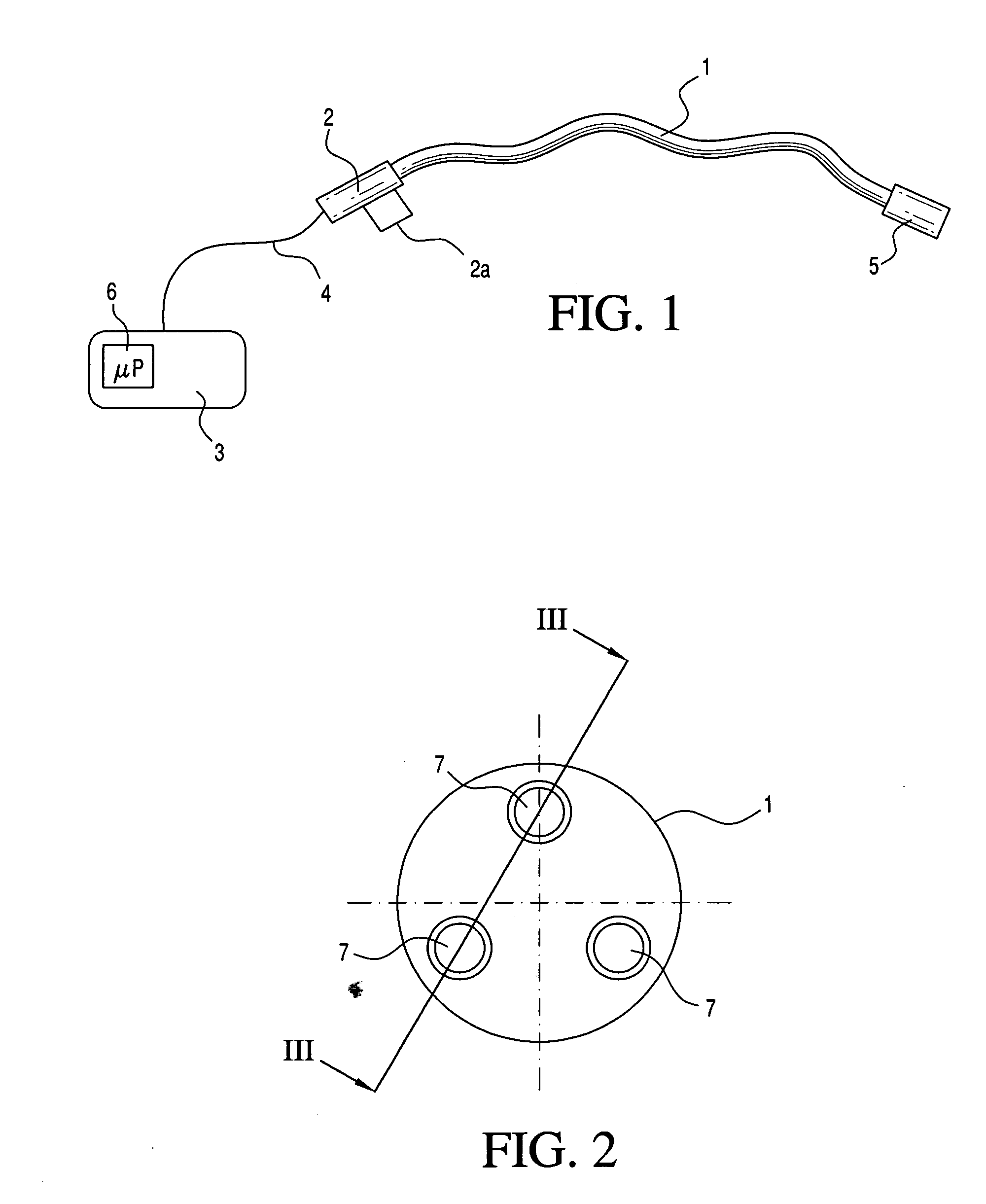

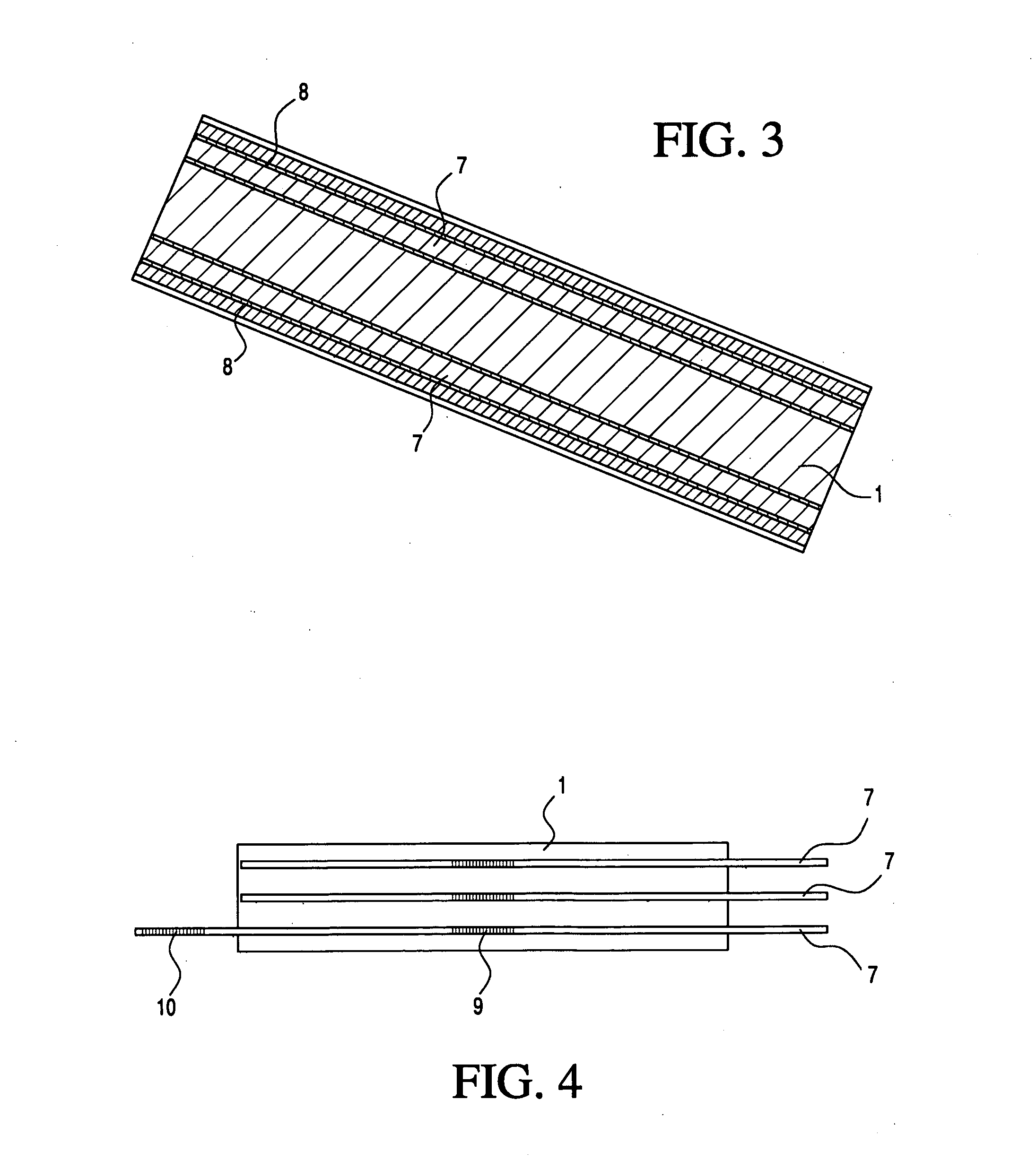

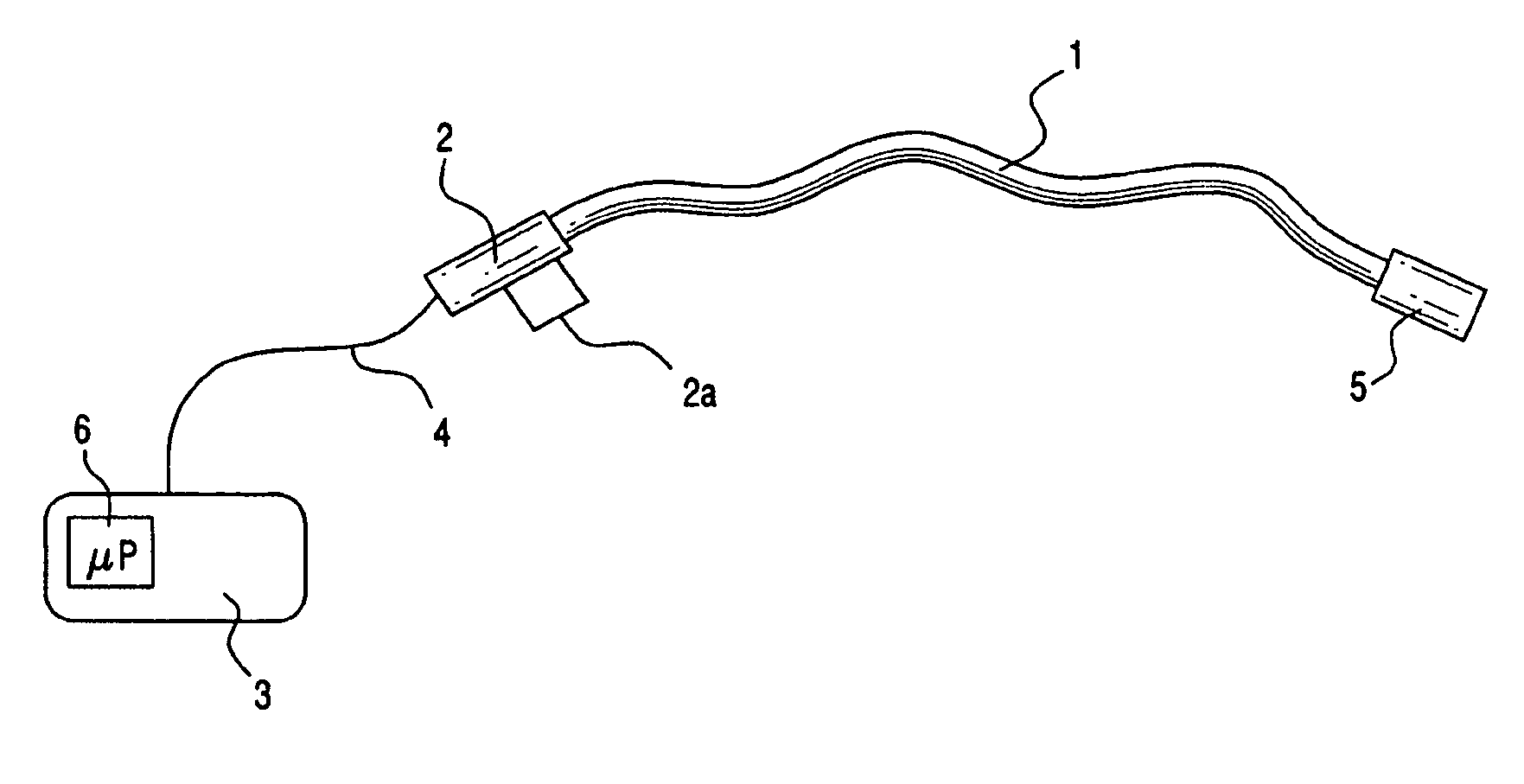

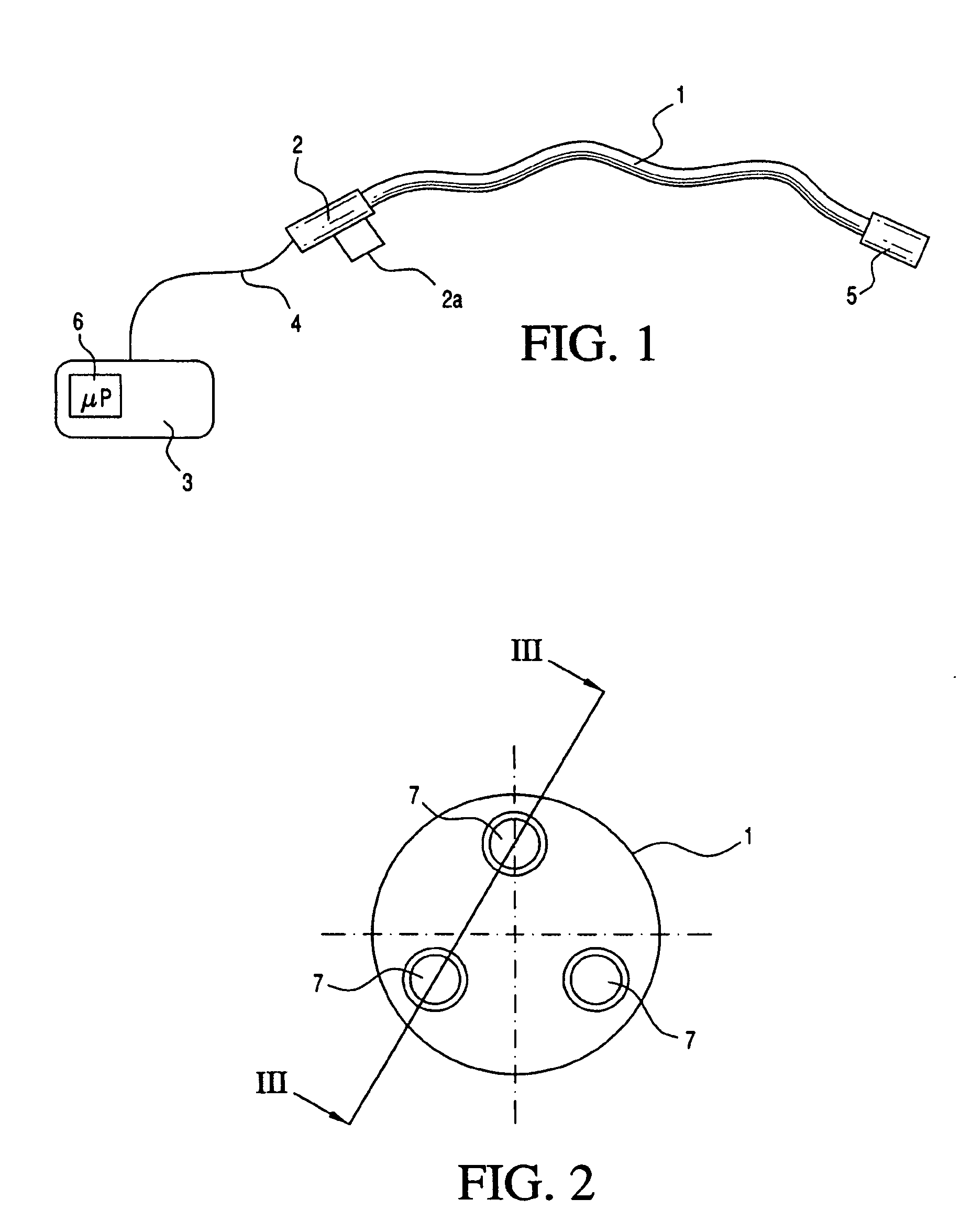

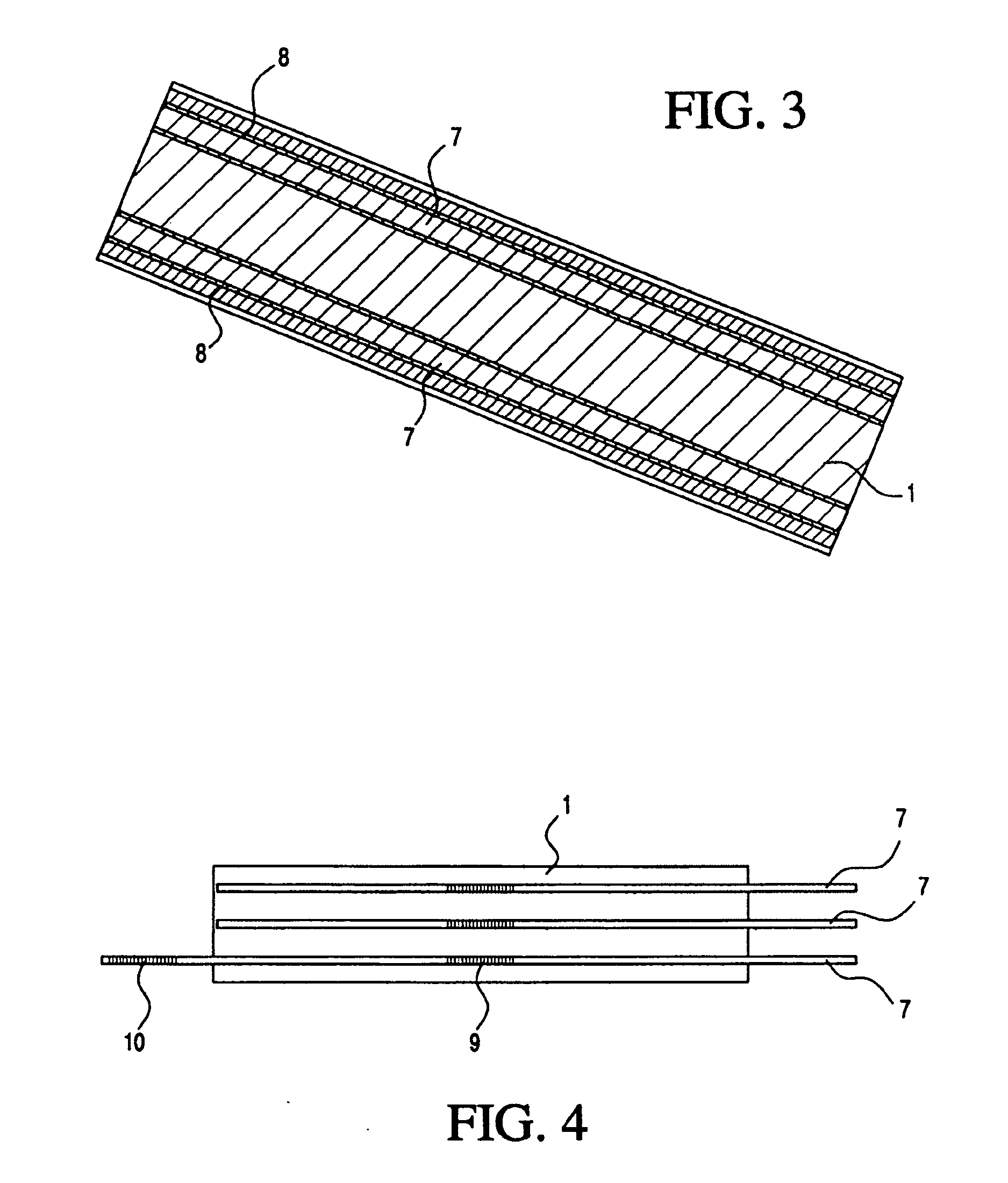

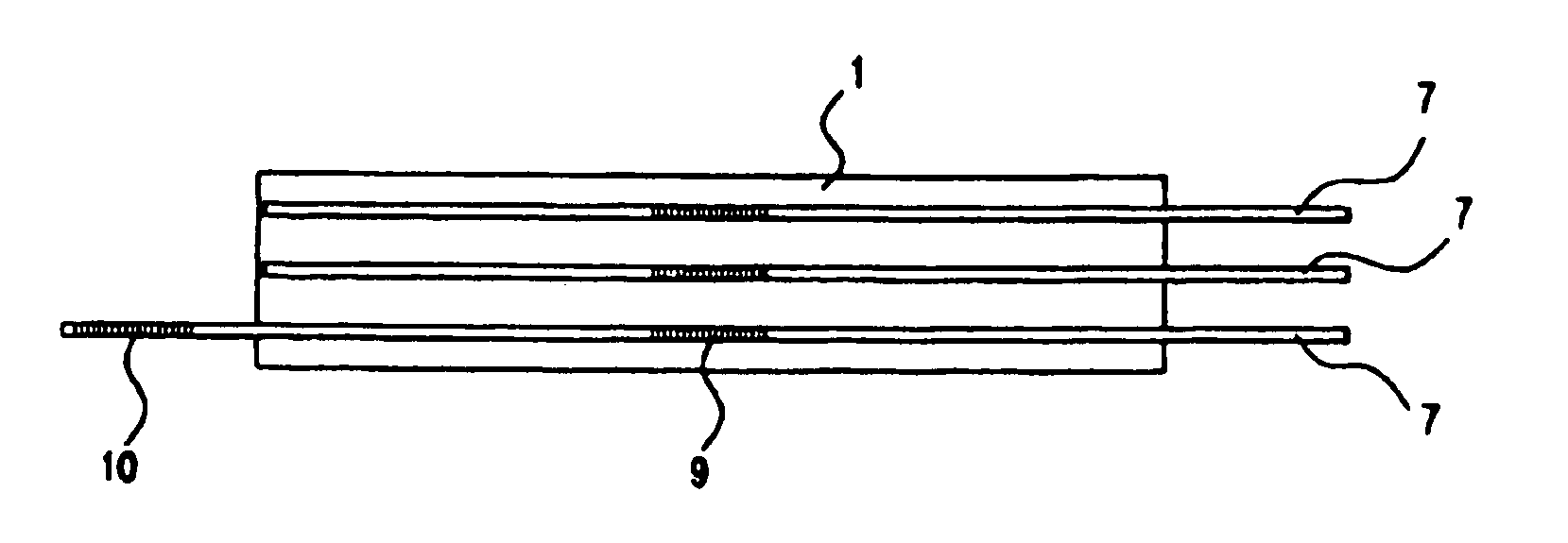

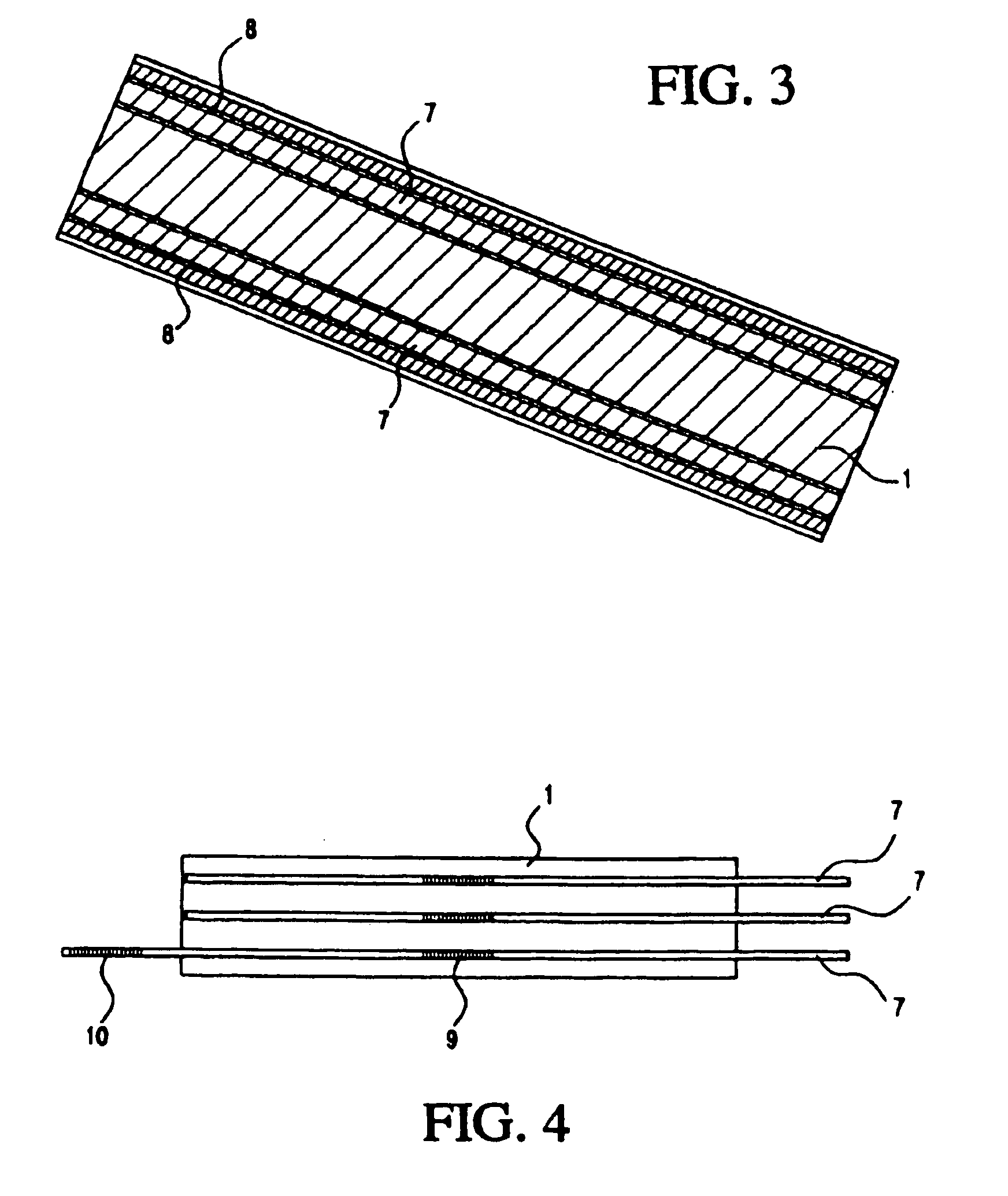

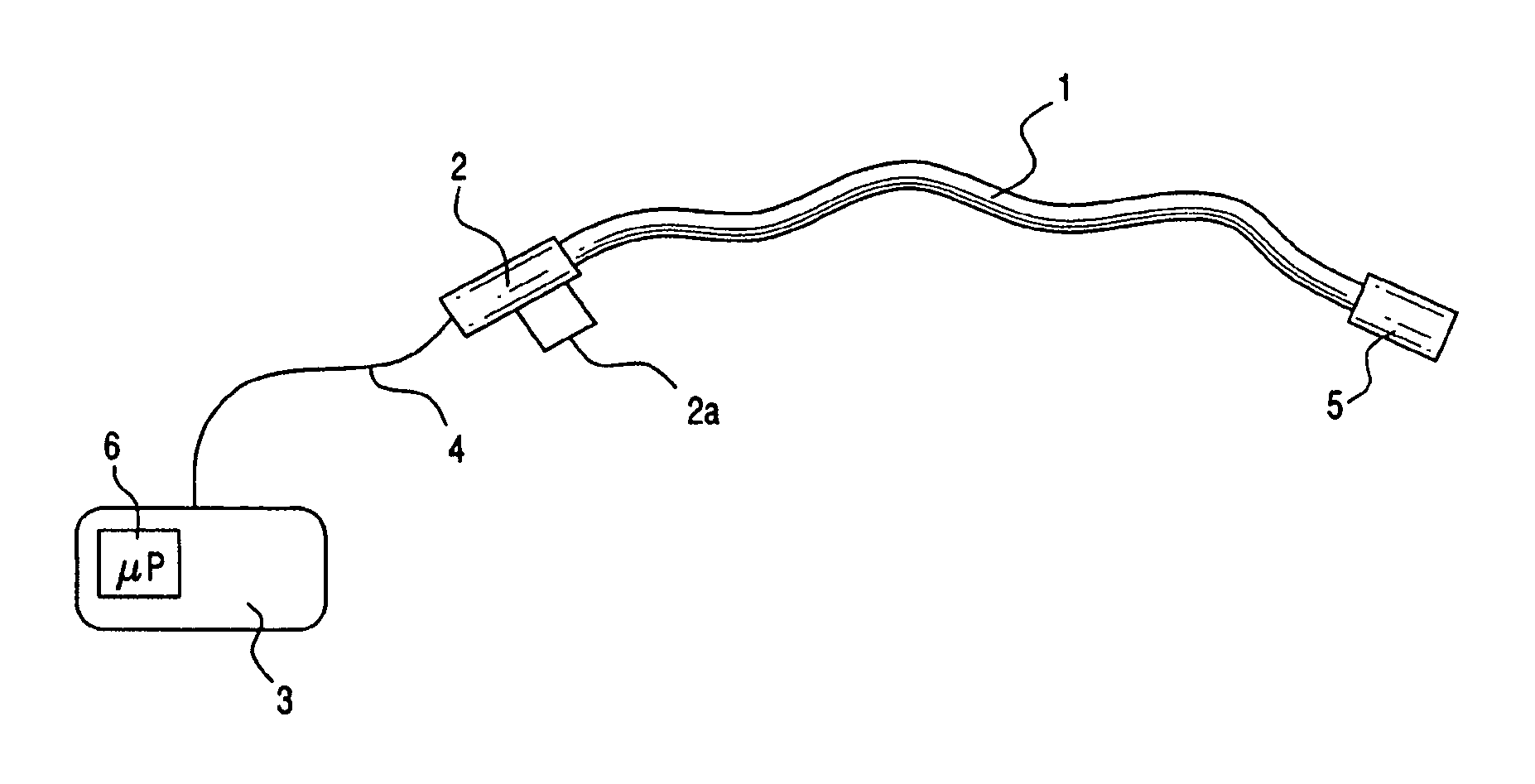

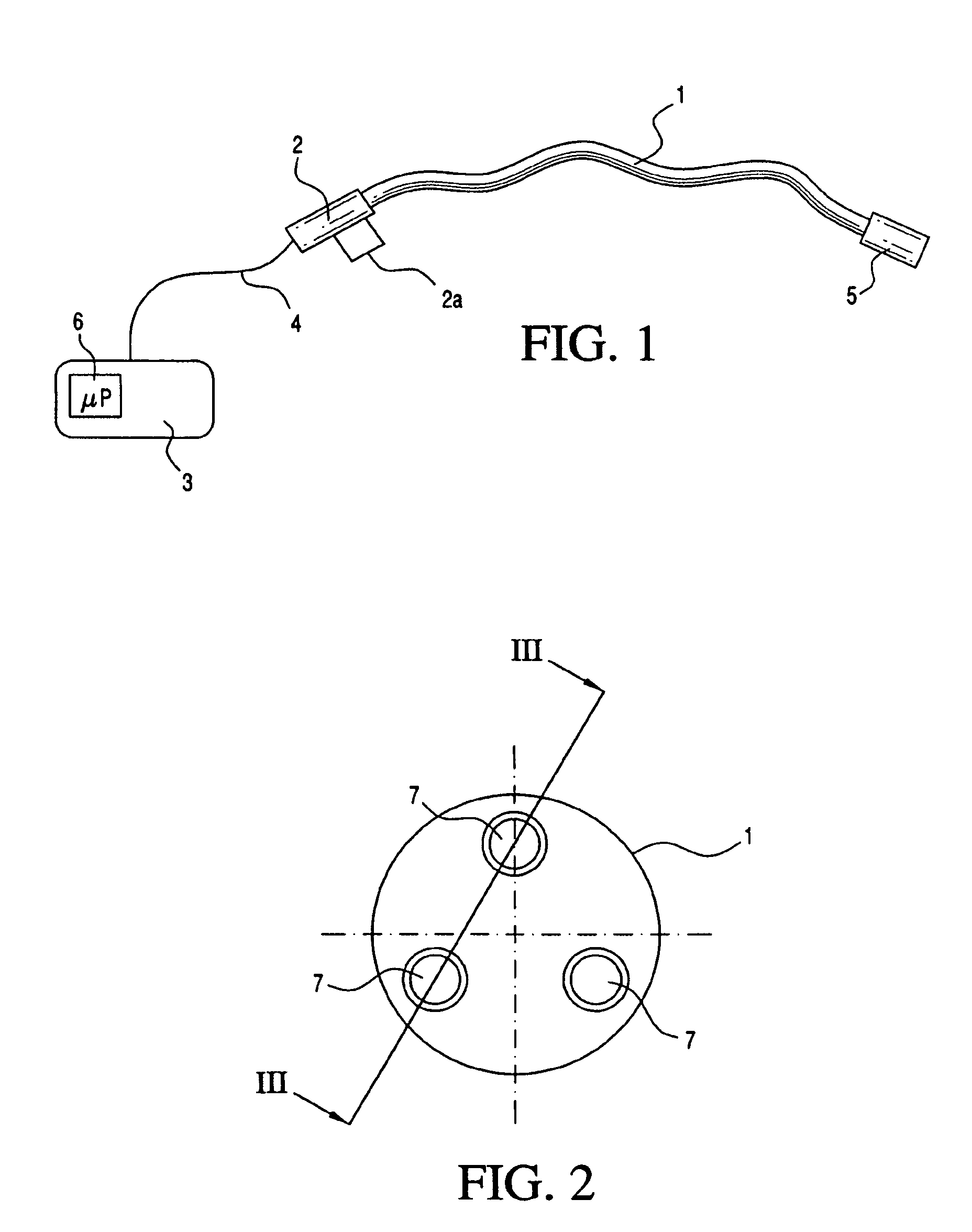

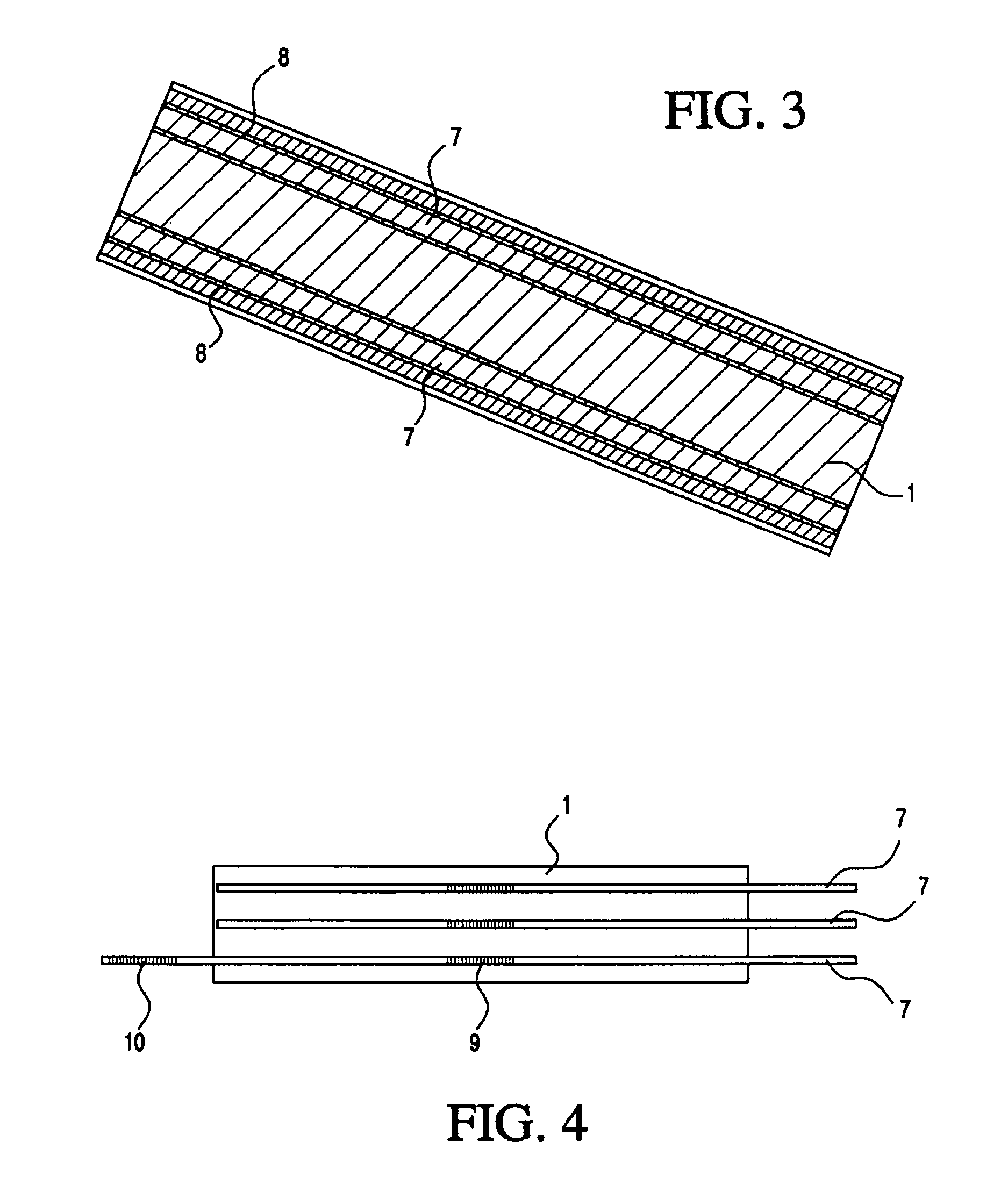

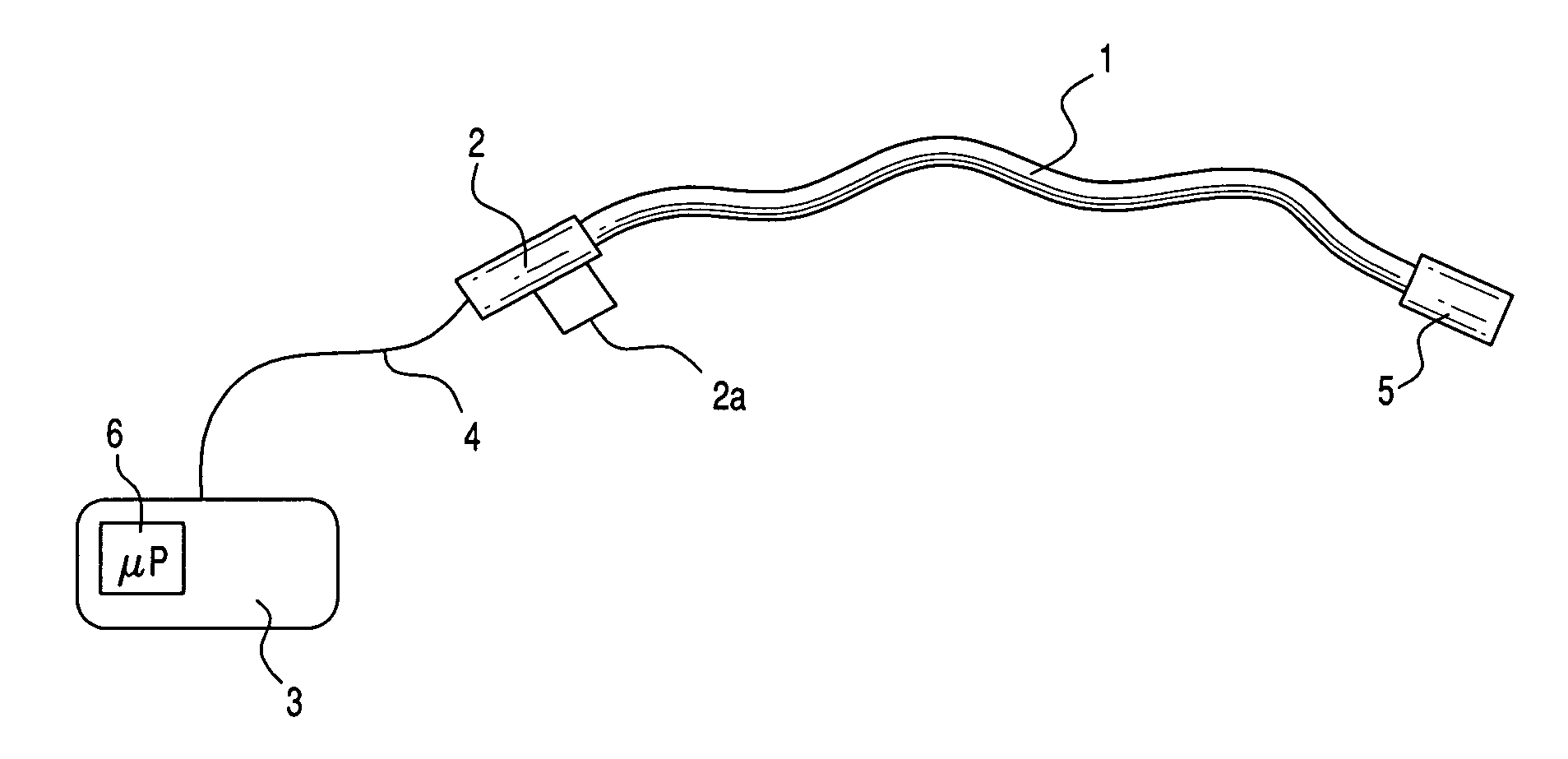

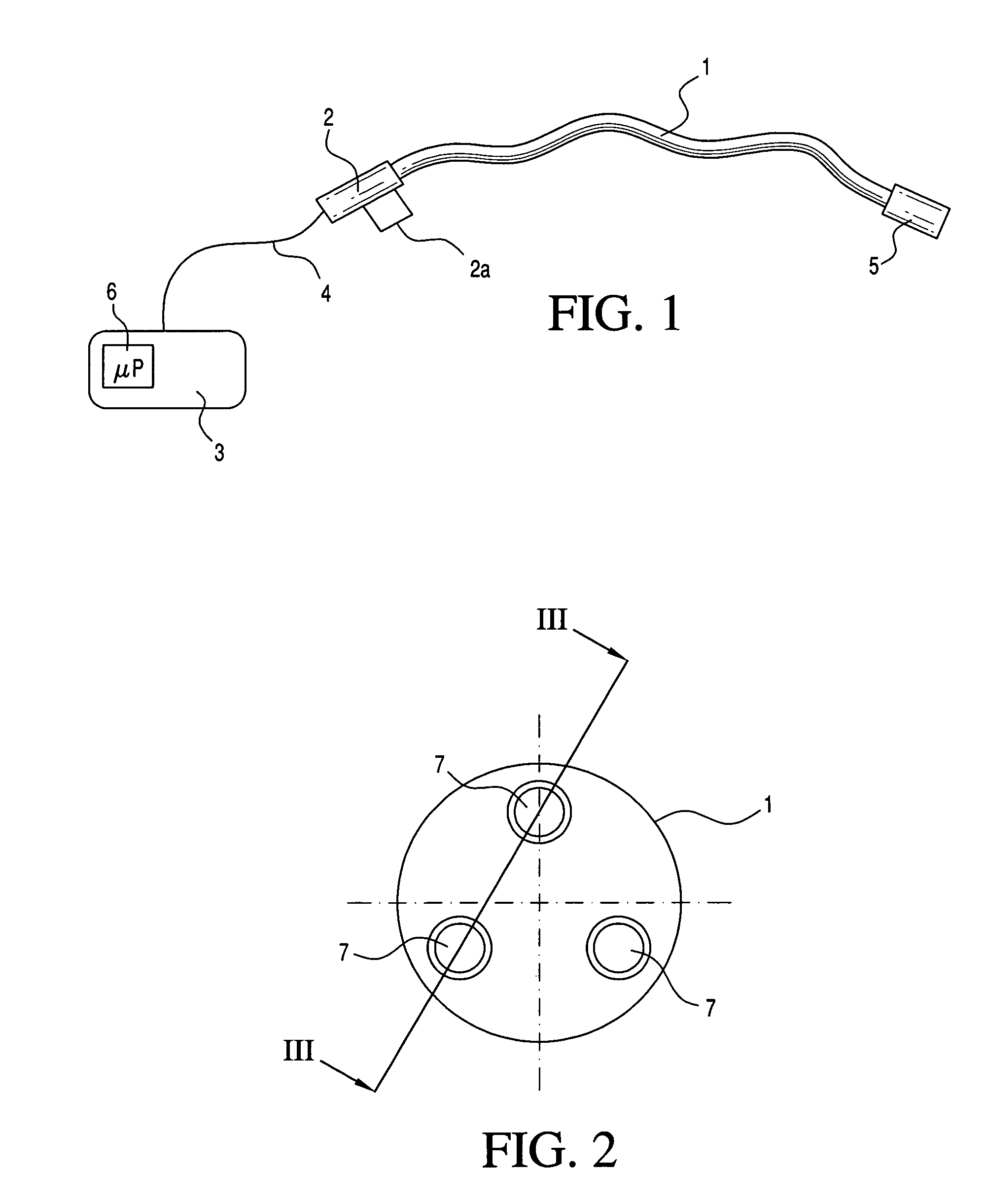

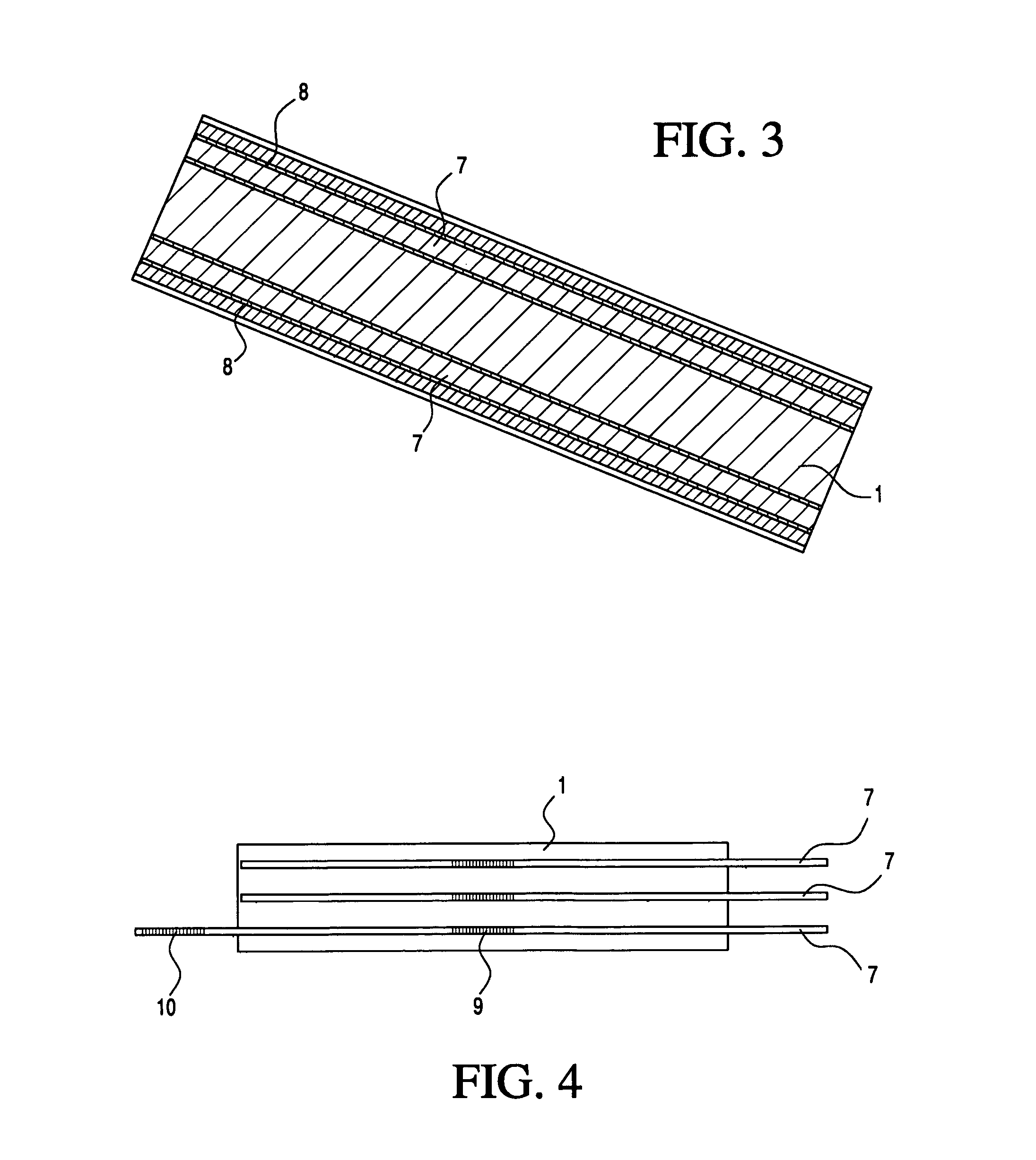

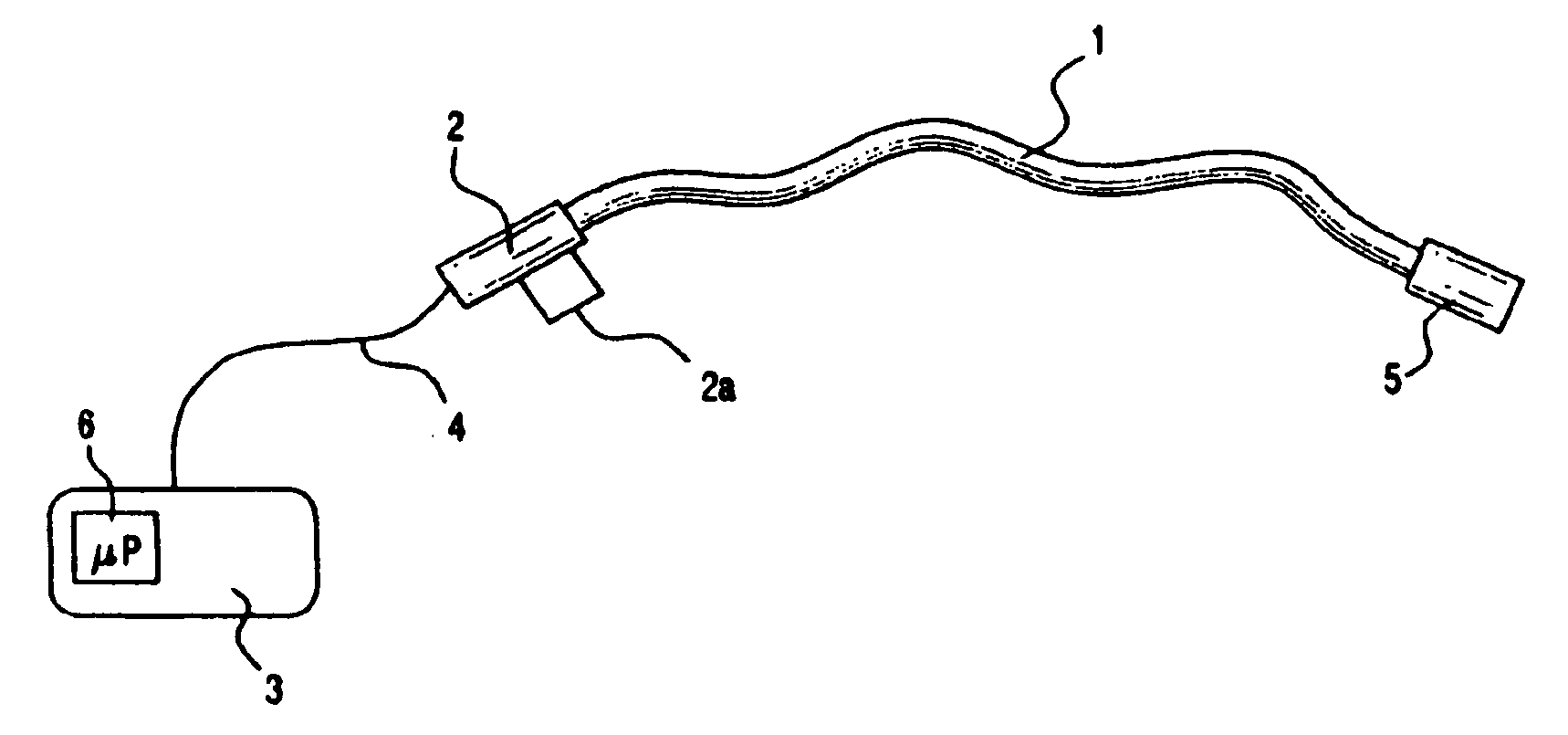

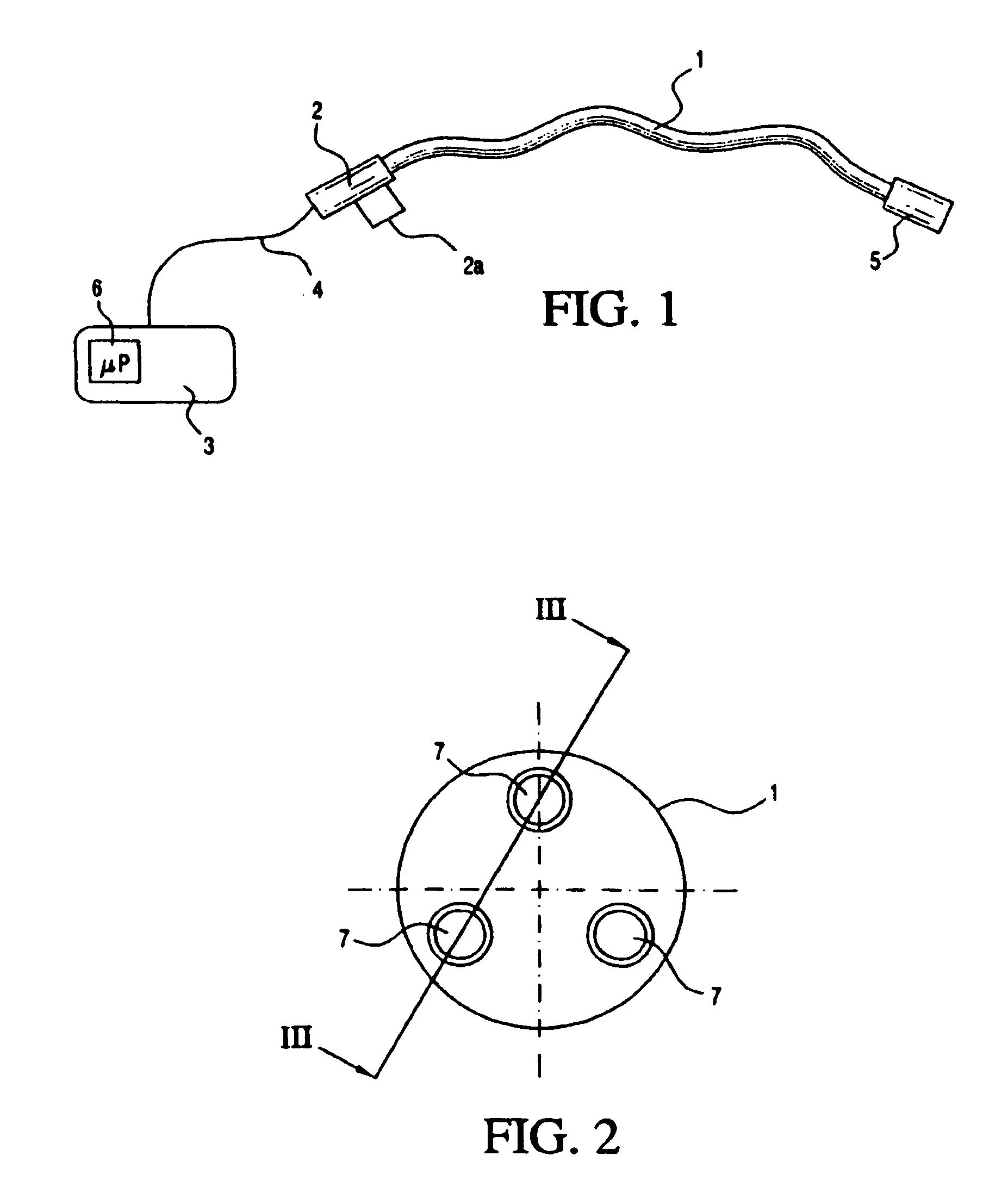

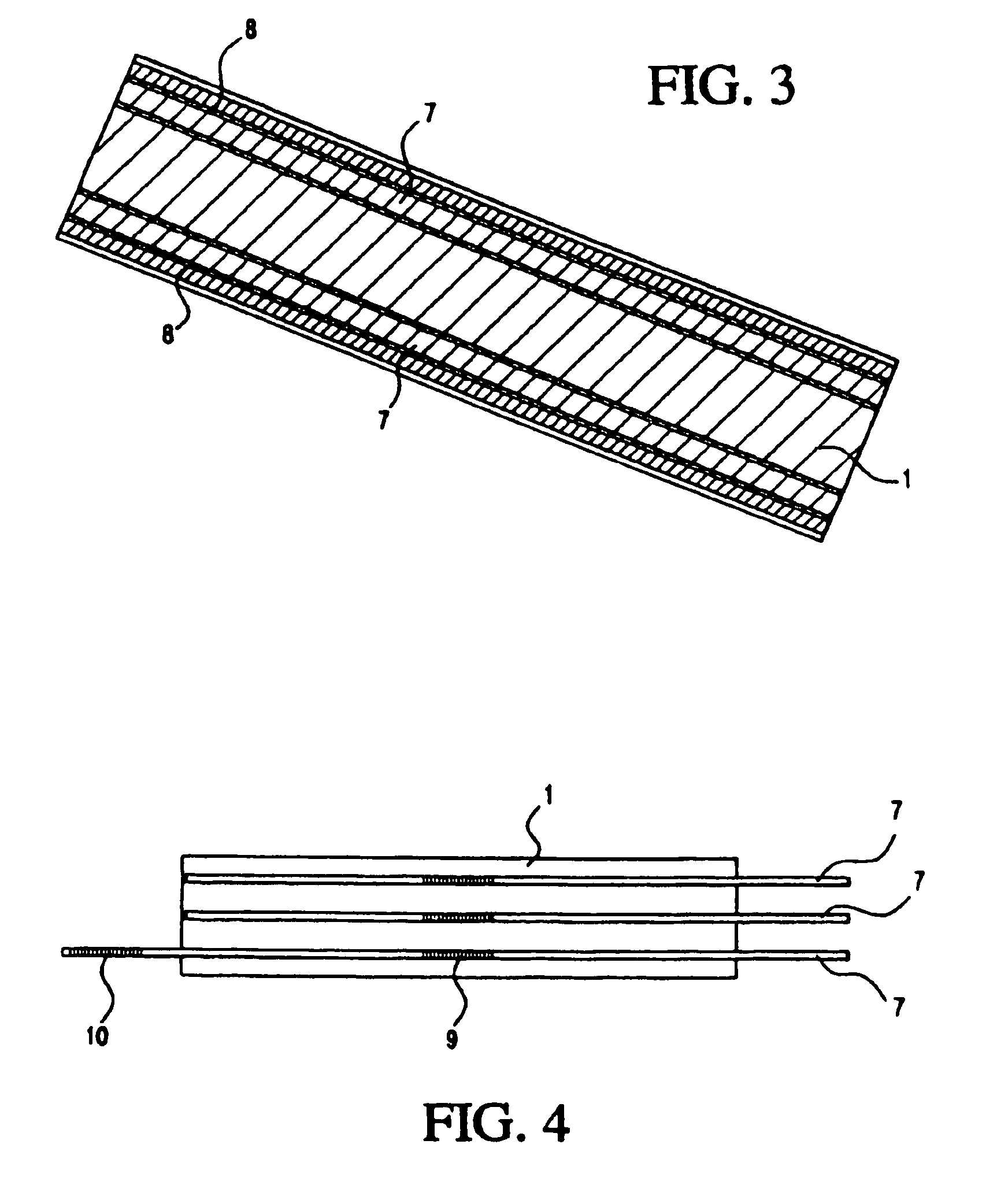

Medical apparatus system having optical fiber load sensing capability

ActiveUS20060200049A1Facilitate speedHelp accuracyStrain gaugePerson identificationRobotic systemsProcess logic

Apparatus is provided for diagnosing or treating an organ or vessel, wherein a deformable body having at least two optical fiber sensors disposed in a distal extremity thereof is coupled to processing logic programmed to compute a multi-dimensional force vector responsive to detected changes in the optical characteristics of the optical fiber sensors arising from deflection of the distal extremity resulting from contact with the tissue of the wall of the organ or vessel. The force vector may be used to facilitate manipulation of the deformable body either directly or automatically using a robotic system.

Owner:ST JUDE MEDICAL INT HLDG SARL

Medical apparatus system having optical fiber load sensing capability

ActiveUS20070060847A1Reduces sensor artifactReduction factorStrain gaugePerson identificationLoad sensingEngineering

Apparatus is provided for diagnosing or treating an organ or vessel, wherein a device having at least two optical fiber sensors disposed in a distal extremity thereof is coupled to processing logic programmed to compute a multi-dimensional force vector responsive to detected changes in the optical characteristics of the optical fiber sensors arising from deflection of the distal extremity resulting from contact with the tissue of the wall of the organ or vessel. The force vector may be used to facilitate manipulation of the catheter either directly or automatically using a robotic system.

Owner:ST JUDE MEDICAL INT HLDG SARL

Medical apparatus system having optical fiber load sensing

ActiveUS20110087112A1Reduces sensor artifactReduction factorStrain gaugeCatheterProcess logicOptical property

Apparatus is provided for diagnosing or treating an organ or vessel, wherein a device having at optical fiber contact force sensors disposed in a distal extremity thereof and a deflection mechanism configured to deflect the elongate body at a location proximal of the distal extremity. The optical fiber contact force sensors are configured to be coupled to processing logic programmed which computes a force vector responsive to detected changes in the optical characteristics of the optical fiber contact force sensors arising from deflection of the distal extremity resulting from contact with the tissue of the wall of the organ or vessel.

Owner:ST JUDE MEDICAL INT HLDG SARL

Medical apparatus system having optical fiber load sensing capability

ActiveUS8075498B2Facilitate speedHelp accuracyStrain gaugePerson identificationLoad sensingEngineering

Owner:ST JUDE MEDICAL INT HLDG SARL

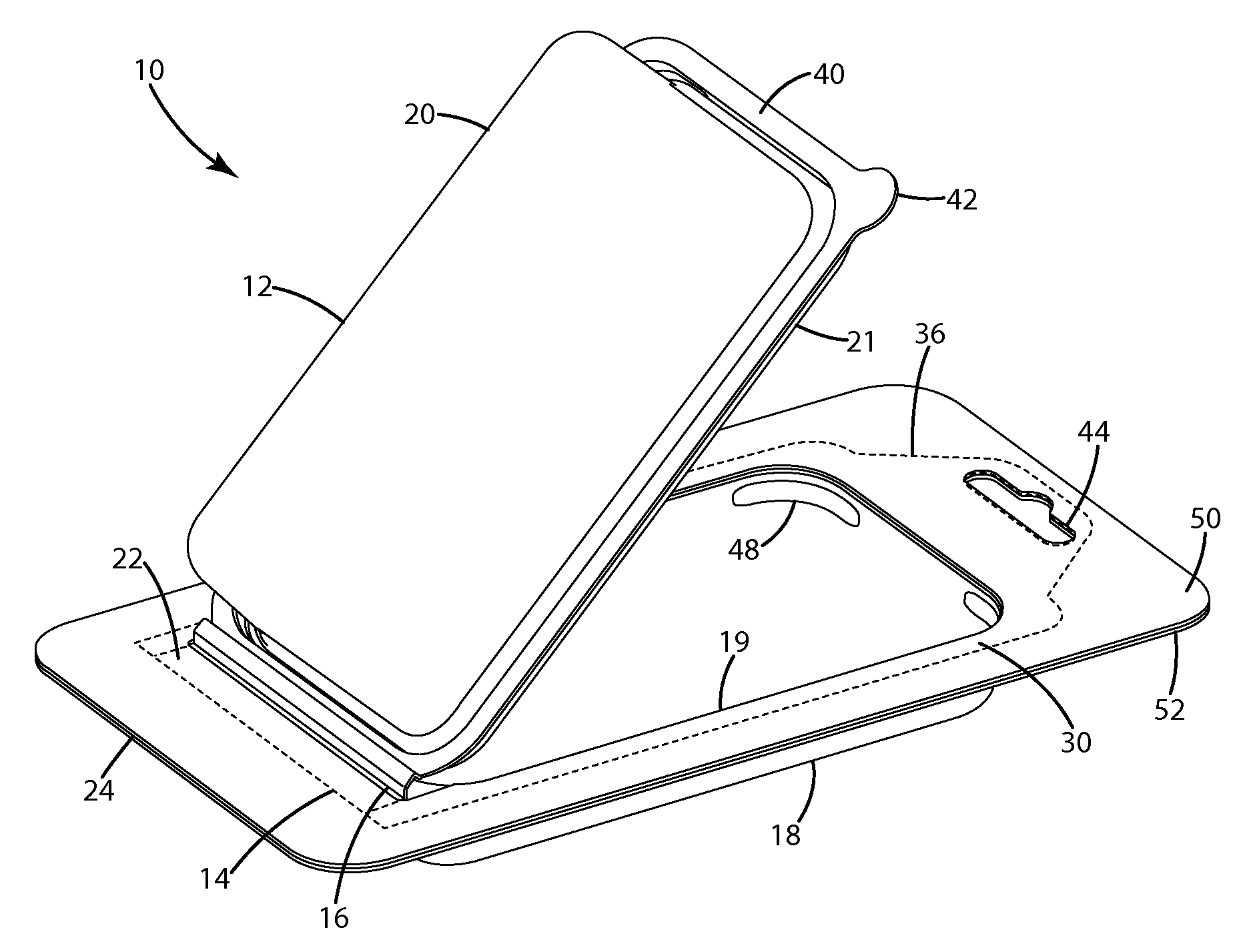

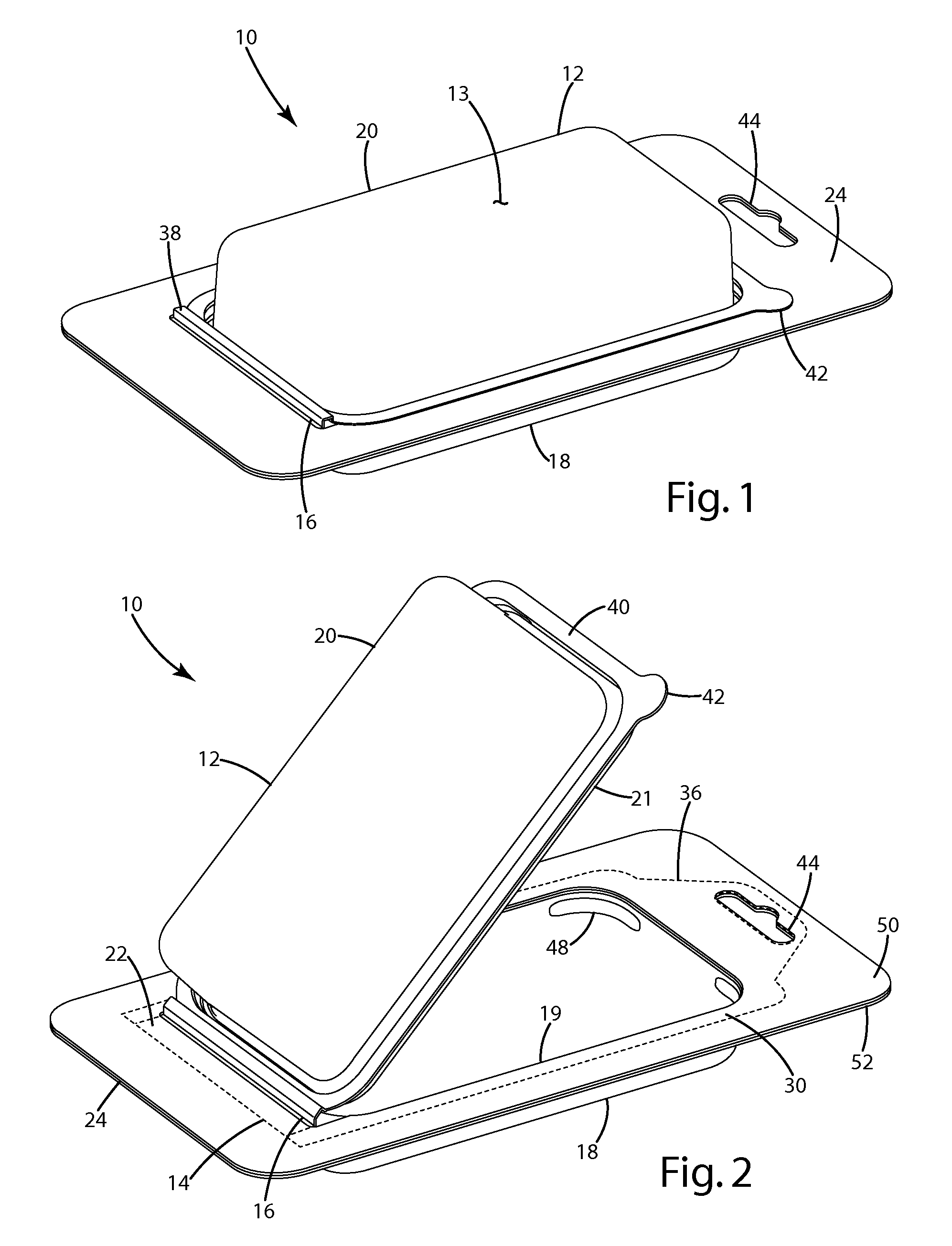

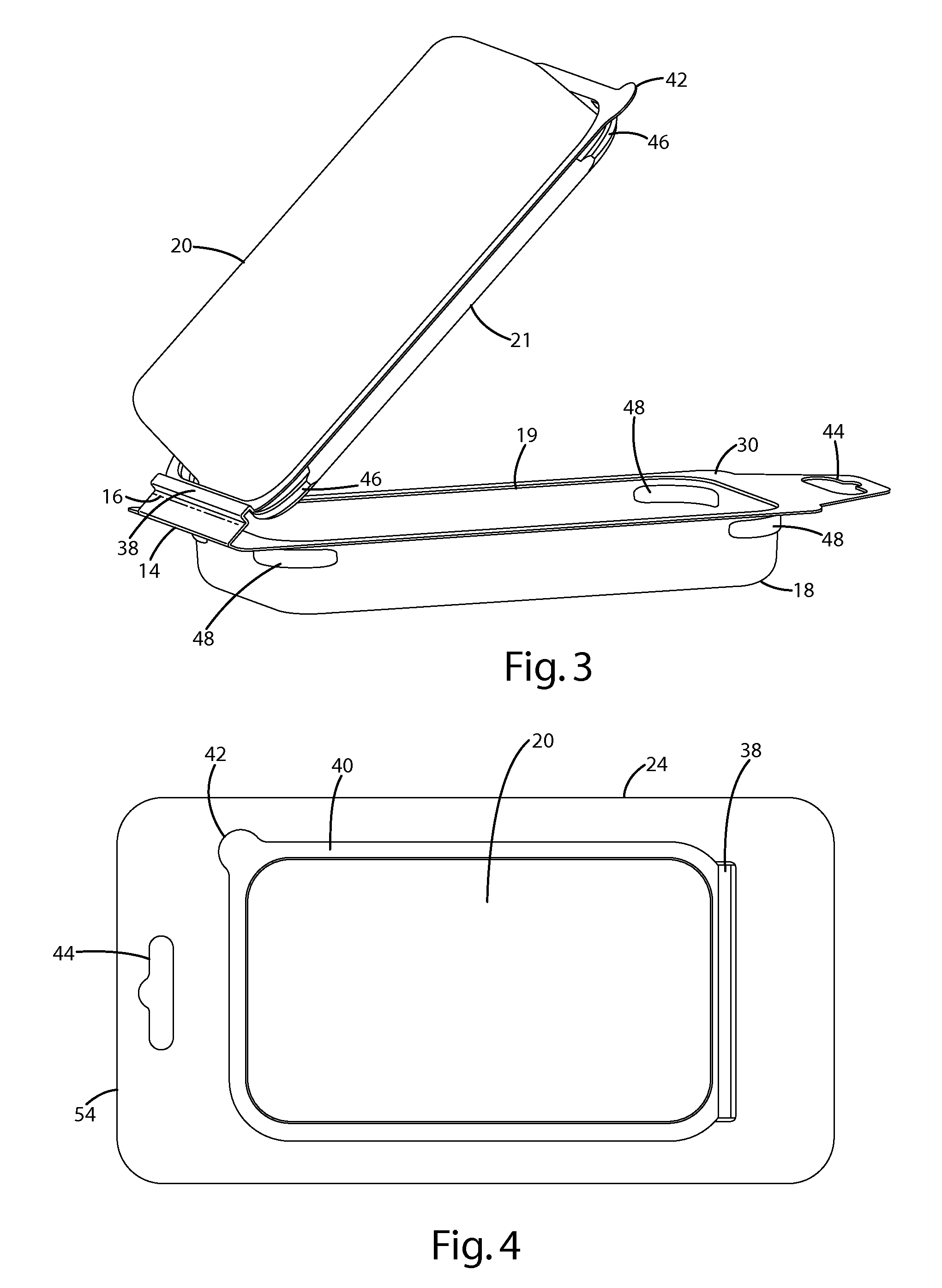

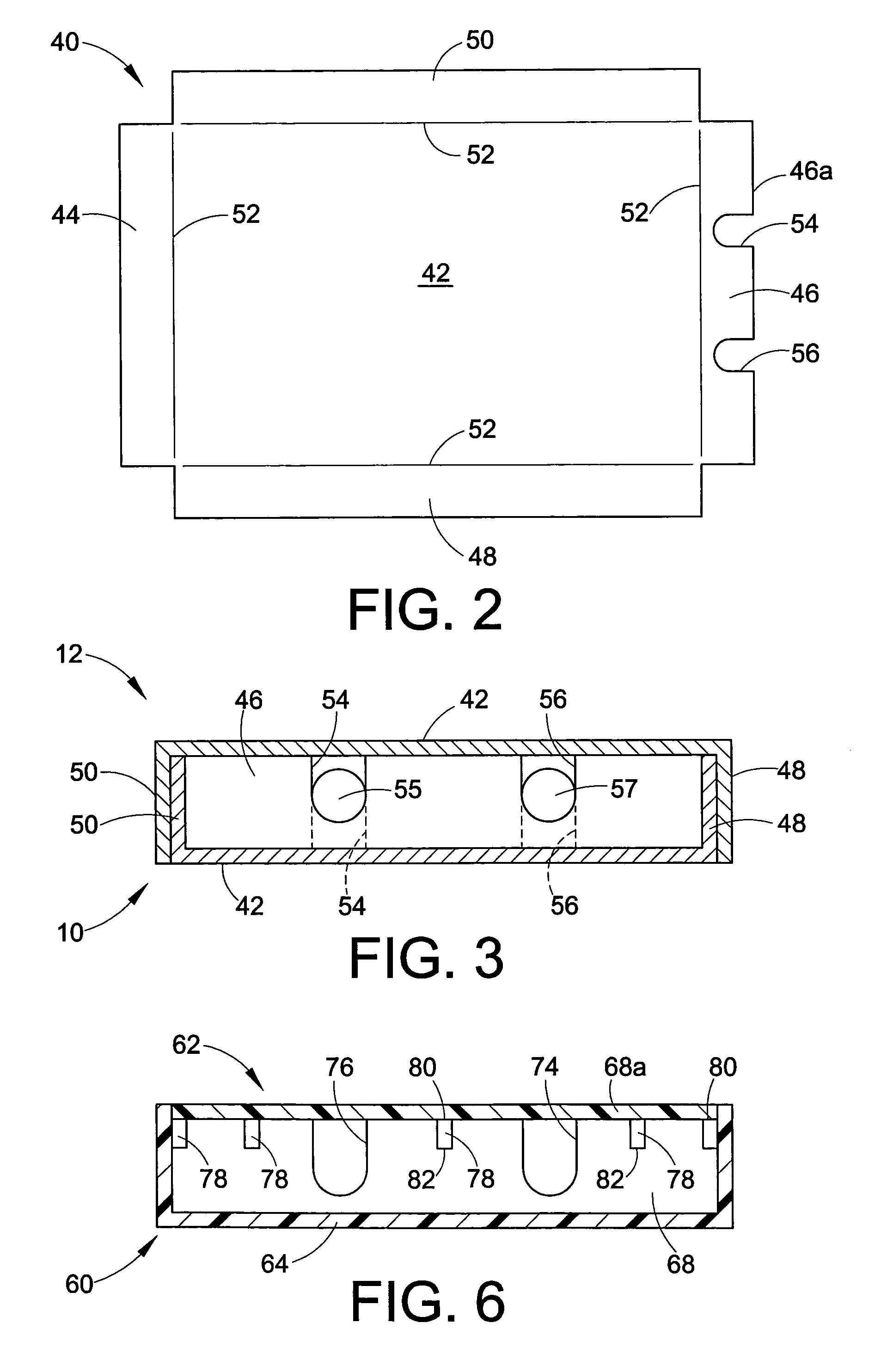

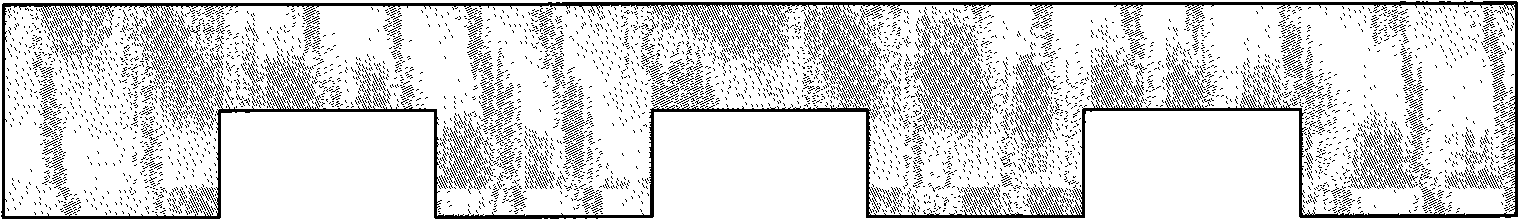

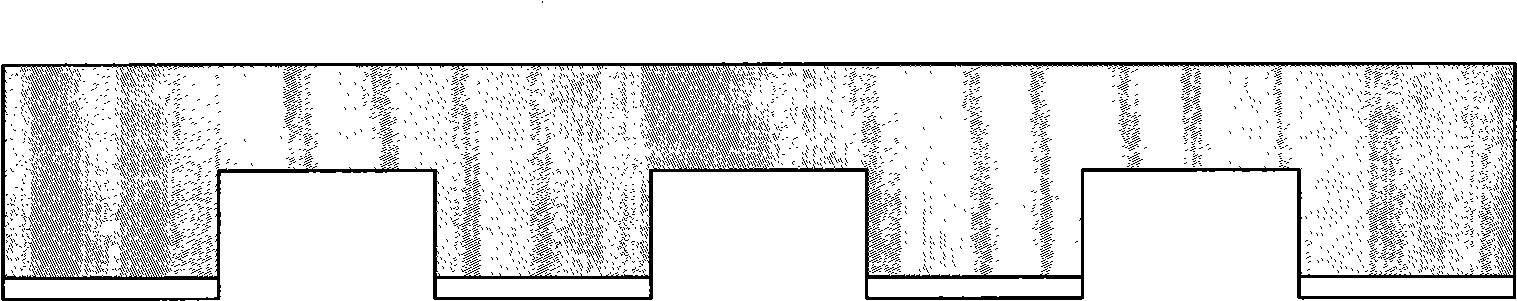

Double hinge display package and method of use

InactiveUS7931148B2Secure retentionEasy to manufactureOther accessoriesLidsDisplay deviceEngineering

A clamshell package for supporting an article is provided including a covered manufacturing hinge adapted to divide the clamshell into first and second parts adapted to form a cavity. The first and second parts partially overlap to form a flange adjacent the manufacturing hinge. The second part includes an uncovered operating hinge, about which the second part is adapted to pivot away from the first part to an open position. The clamshell package includes a panel adapted to engage the manufacturing hinge and flange to retain the manufacturing hinge in a folded position, with the panel being spaced from the operating hinge.

Owner:DISPLAY PACK

Medical apparatus system having optical fiber load sensing capability

ActiveUS8182433B2Facilitate speedHelp accuracyStrain gaugePerson identificationRobotic systemsProcess logic

Owner:ST JUDE MEDICAL INT HLDG SARL

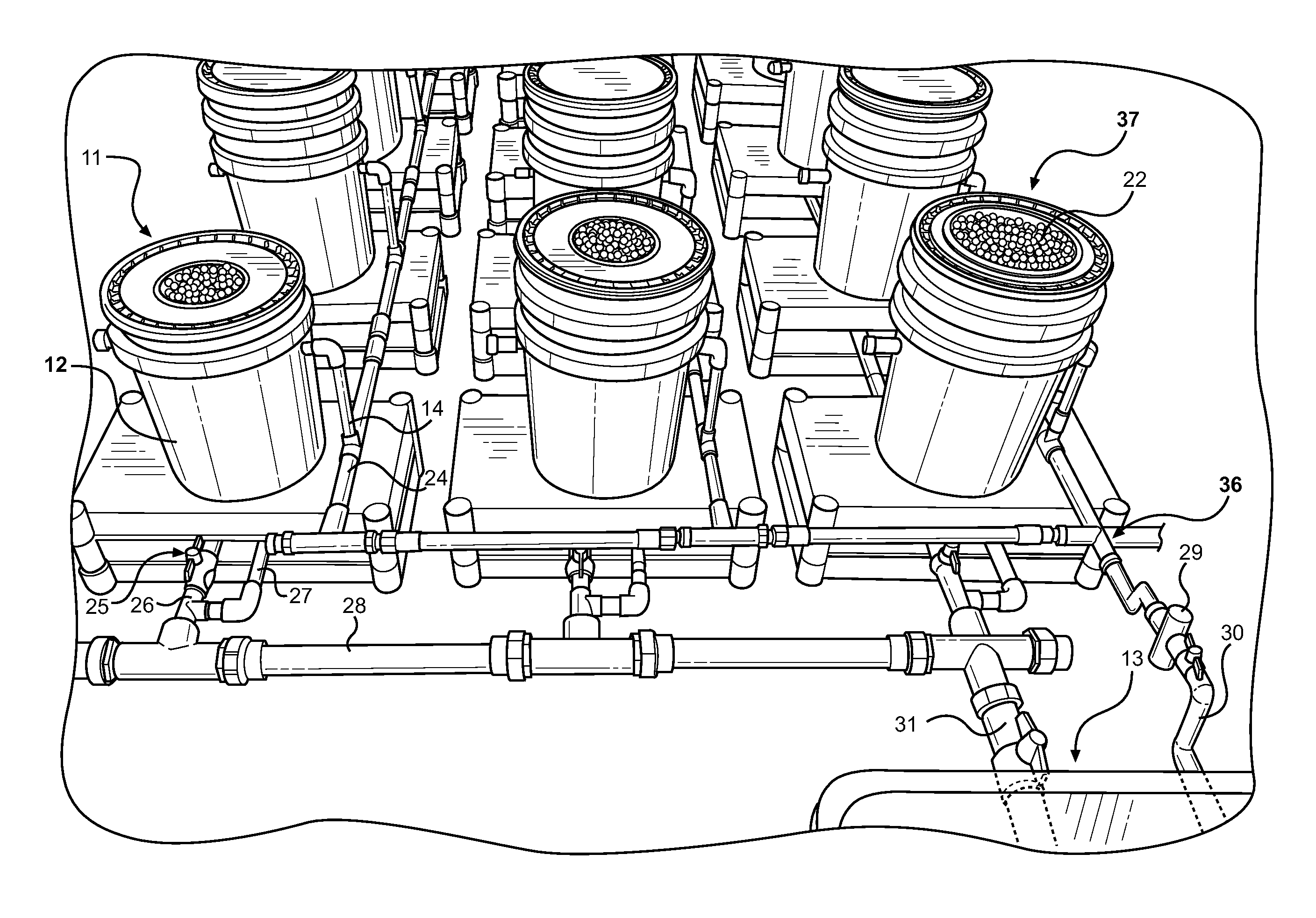

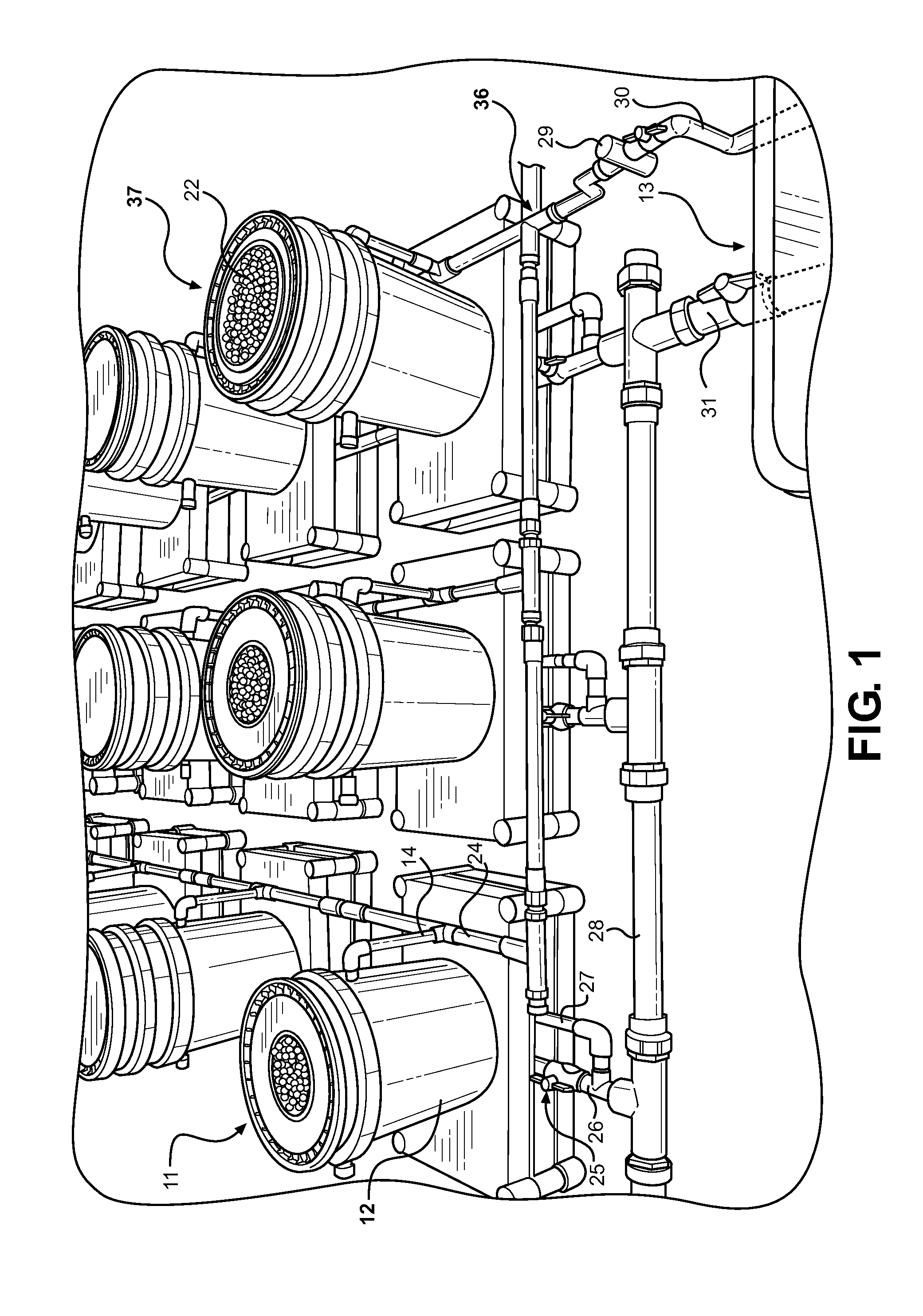

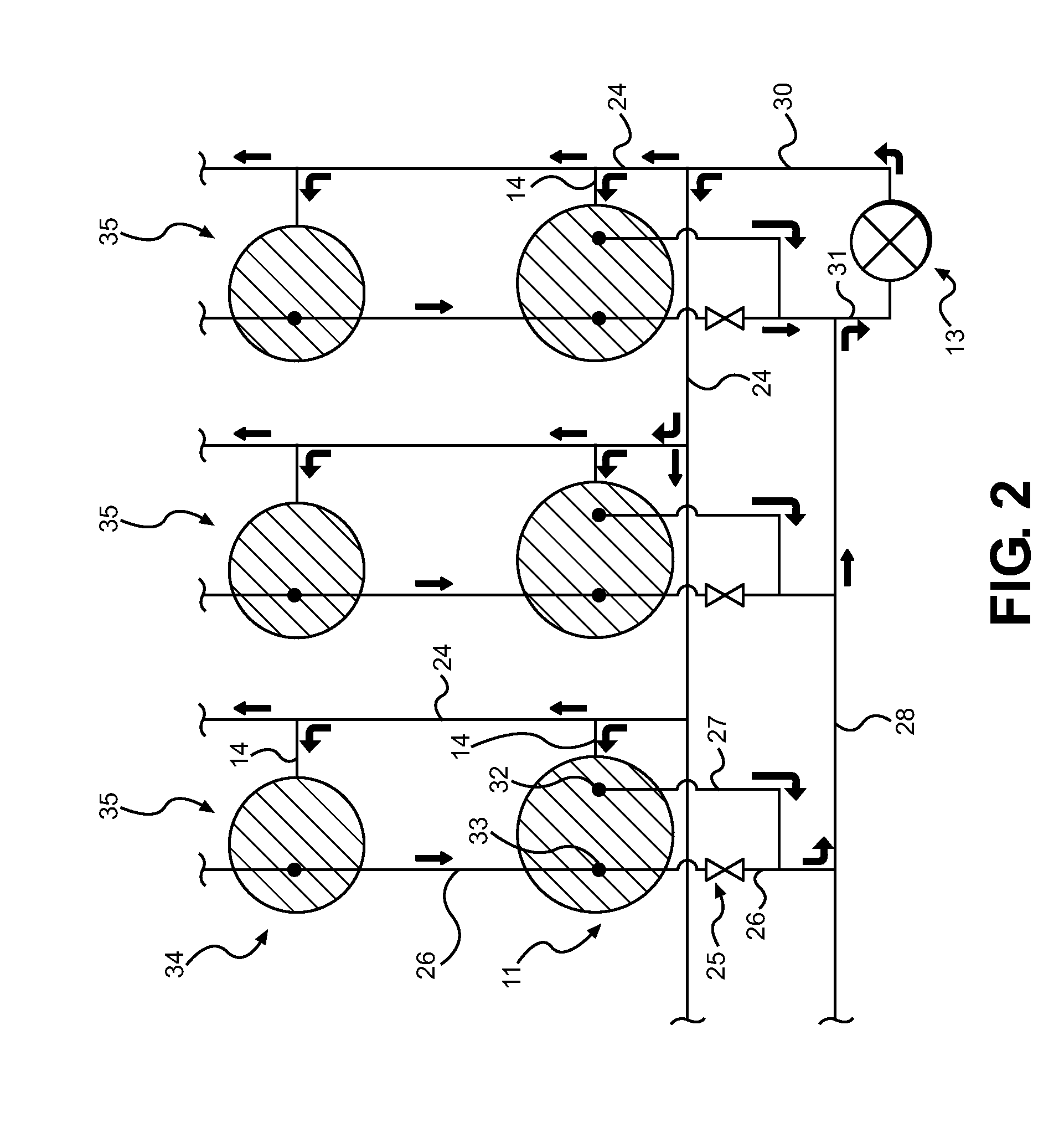

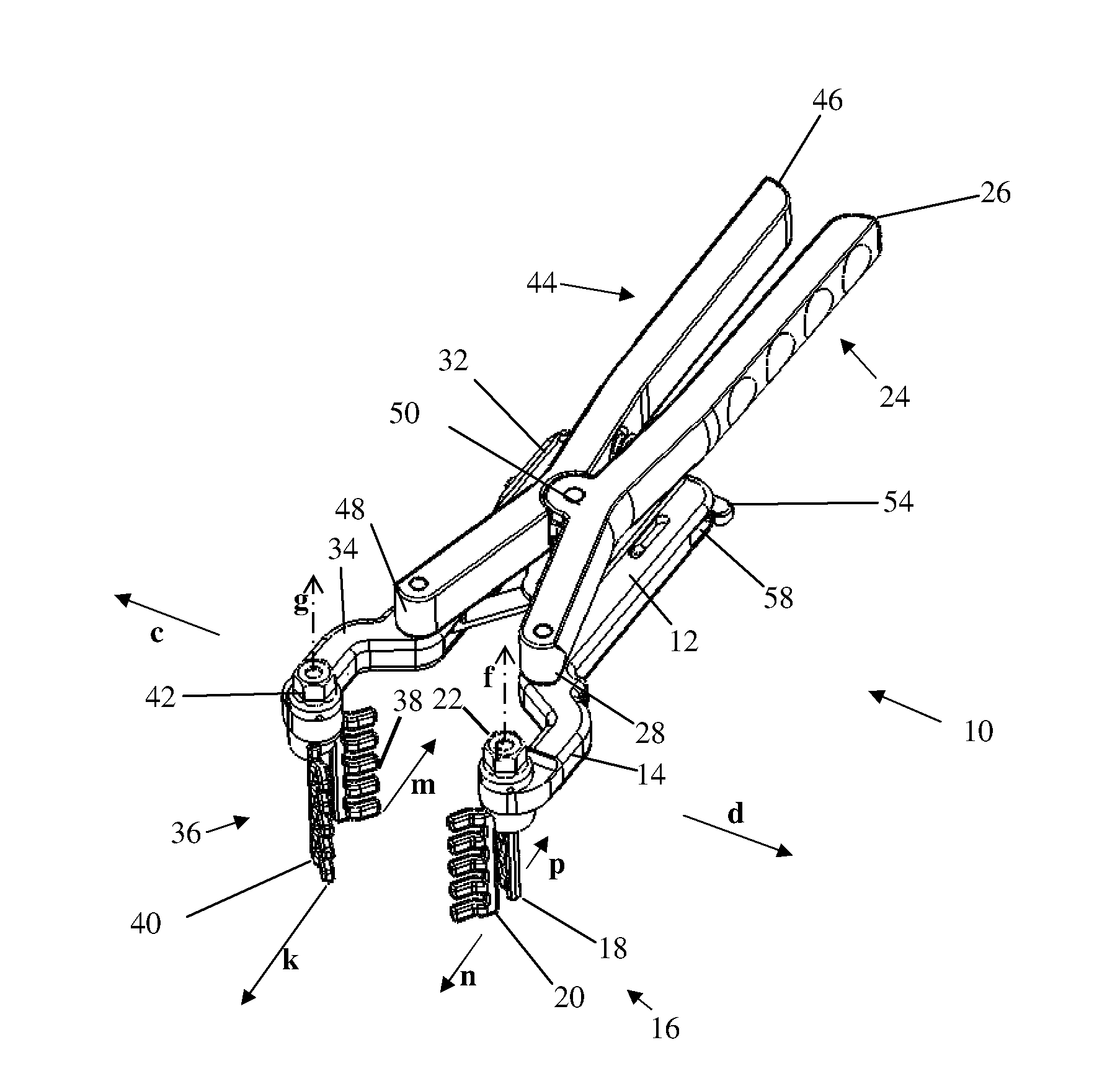

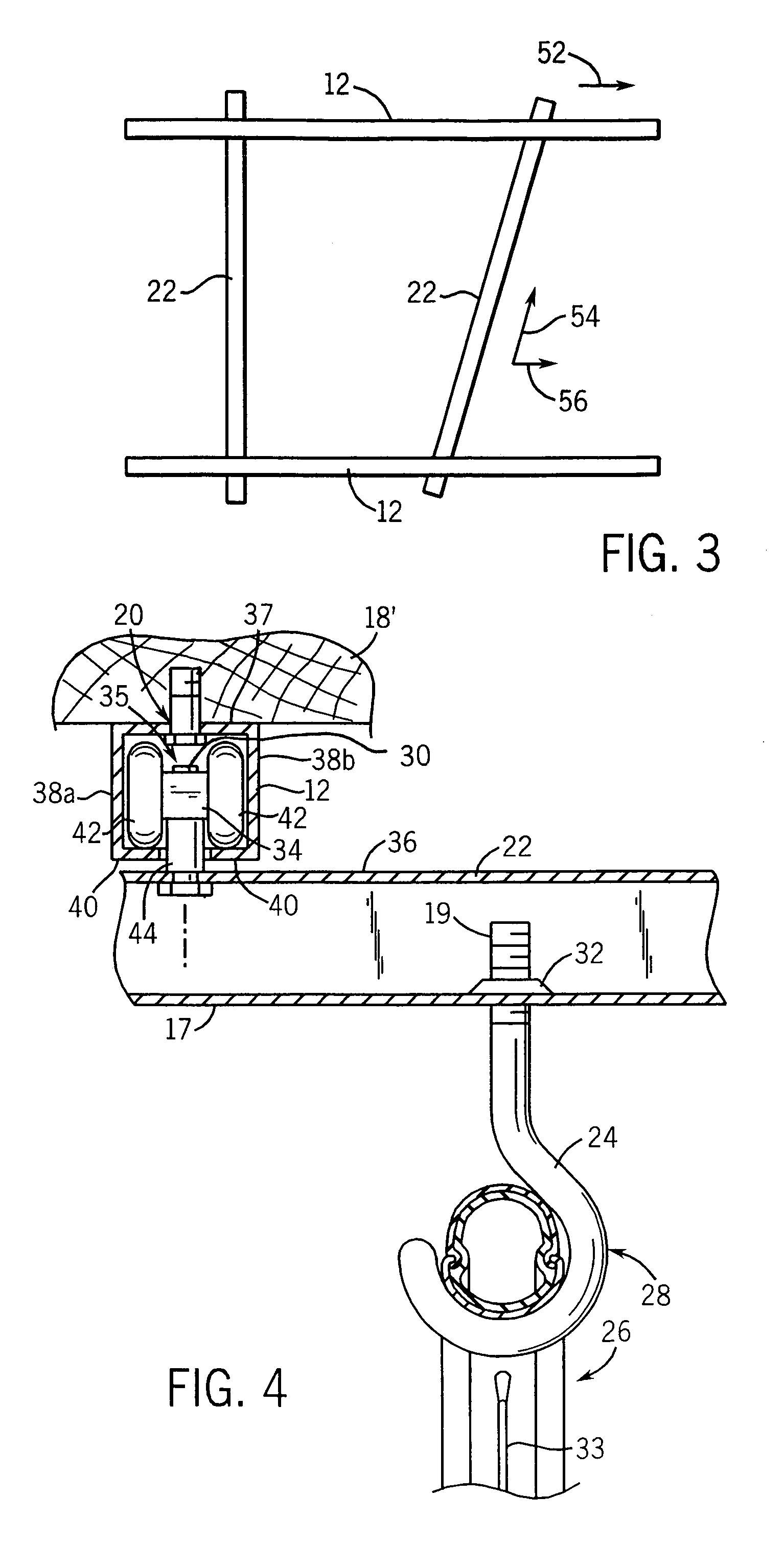

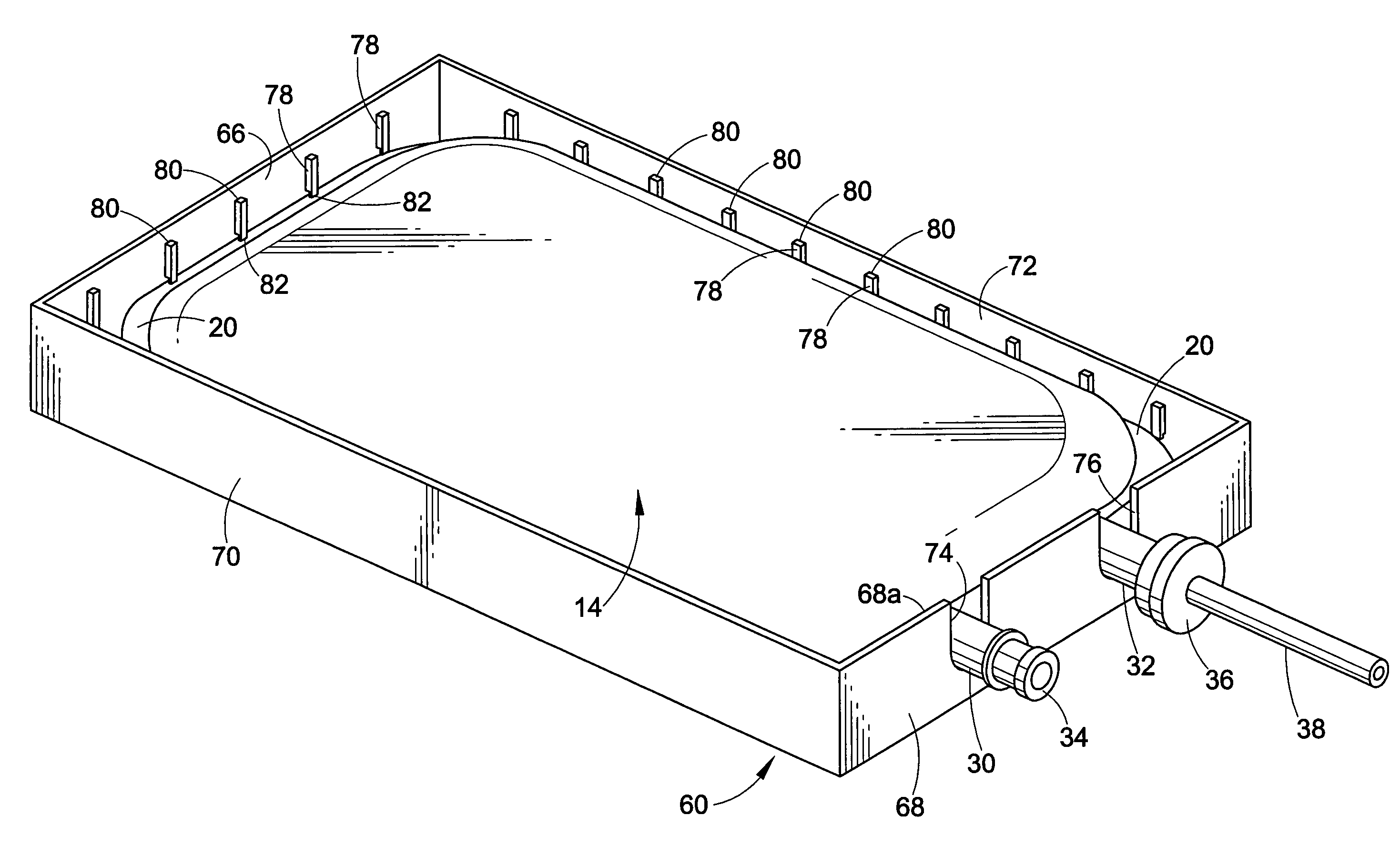

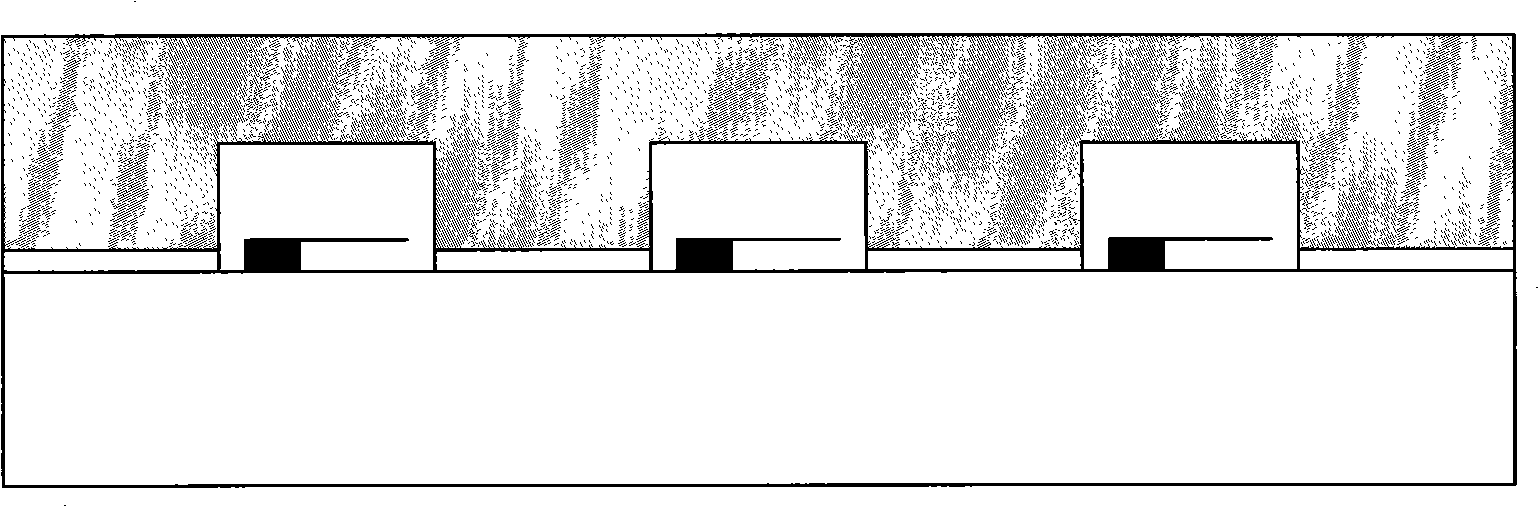

Aeroponic System and Sprayer Device for Improved Plant Growth and Aeration

ActiveUS20120005957A1Effective drainageReduce heat transferDust removalFire preventionPlant rootsSprayer

An aeroponic growing system, double T-shaped sprayer design and method for cultivating larger plant crops and increasing harvest frequency. The system comprises a series of aeroponic growing units, each of which supports a plant's roots within an enclosure. The enclosure houses a sprayer, an interior volume of plant nutrient solution and a plumbing system for accepting and distributing the aqueous water-nutrient solution. The internal sprayer is a double T-shaped mister that sprays an atomized mist directed from a first set of nozzles onto the plant roots, along with a second set of nozzles directed toward the base of the enclosure to aerate the interior volume of plant nutrient solution. The T-shaped mister provides circumferential coverage of the plant roots, while the aeration of the plant nutrient solution provides an aerated solution that accelerates plant growth through a hybrid process of Nutrient Film Technique (NFT) called a Hyperactive Aeroponic Shallow Water Culture (HAS Culture). Several interconnected aeroponic growing units may be stationed in a parallel grid to provide ample space for rapid growth of crops, while supplying the water and nutrient solution through a network of pipes and tubes between units.

Owner:DOWNS SR THOMAS J

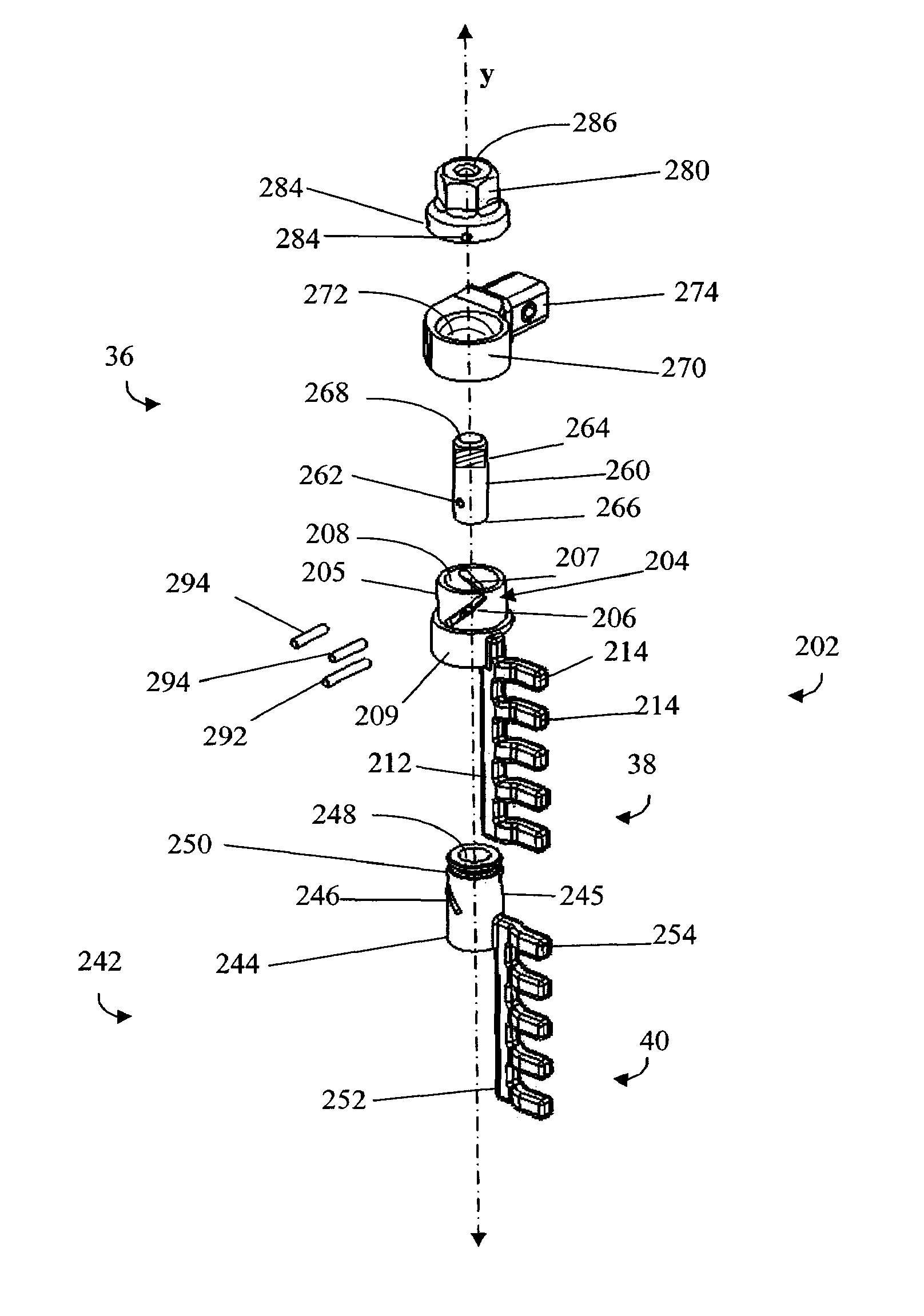

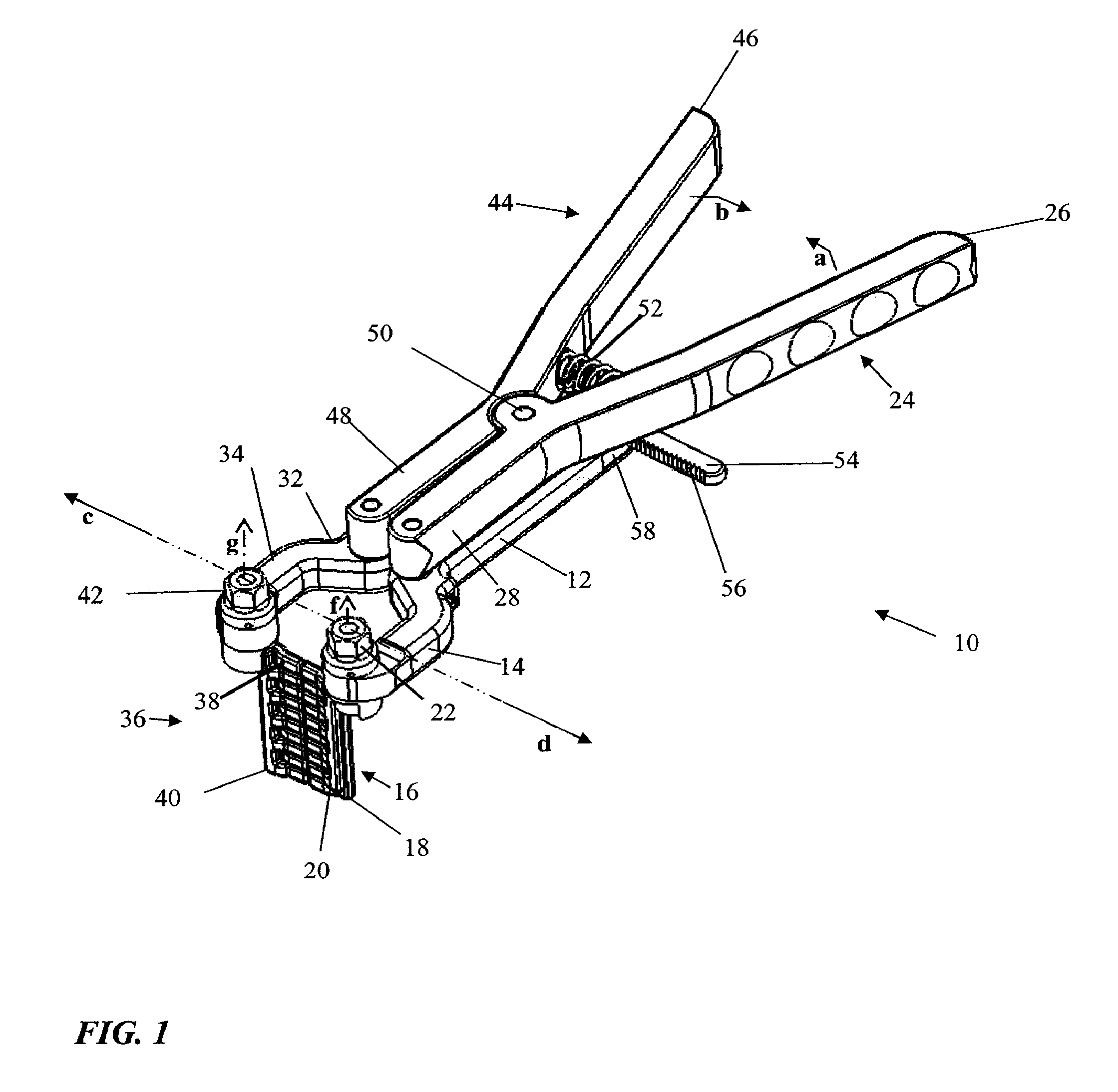

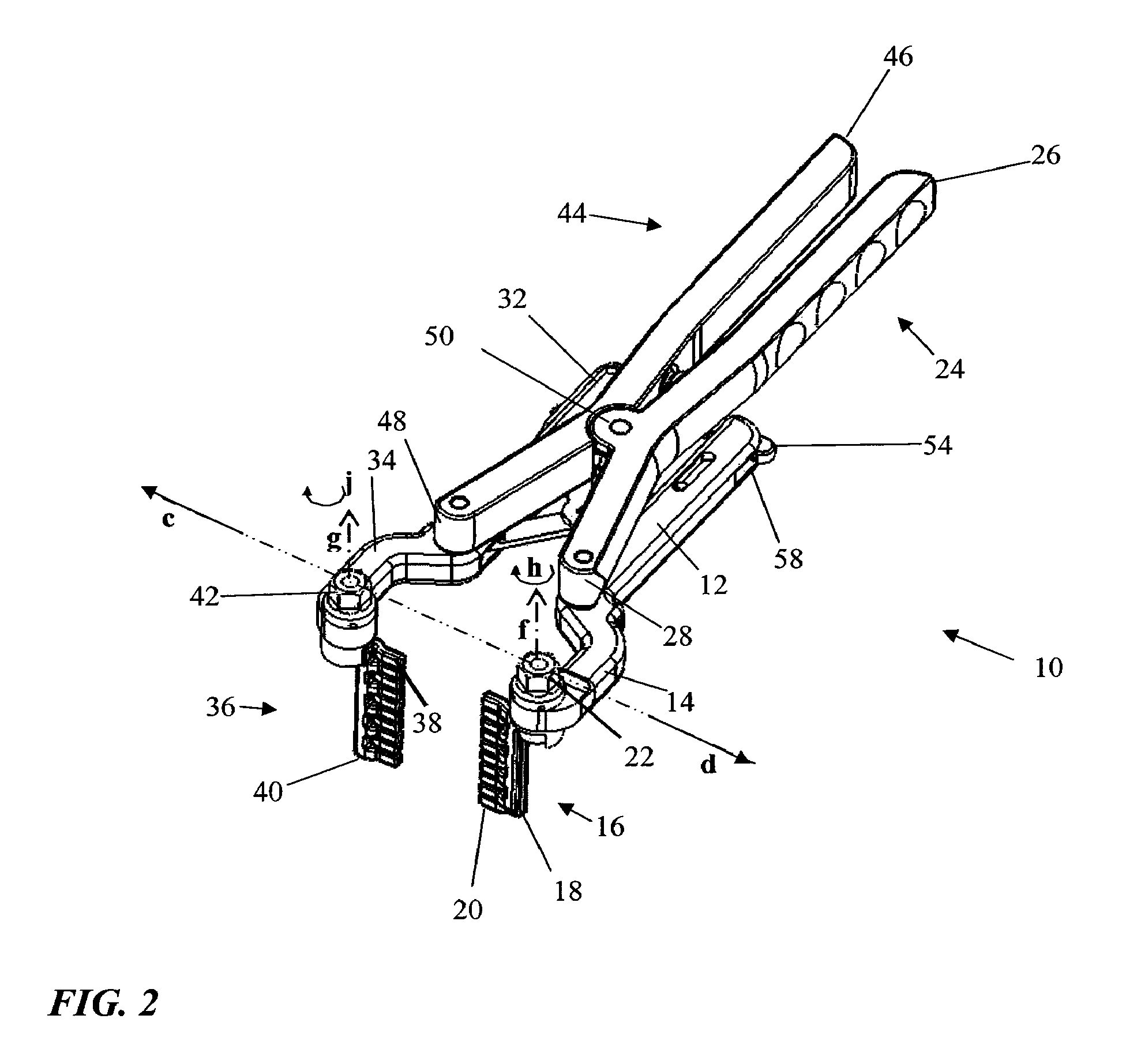

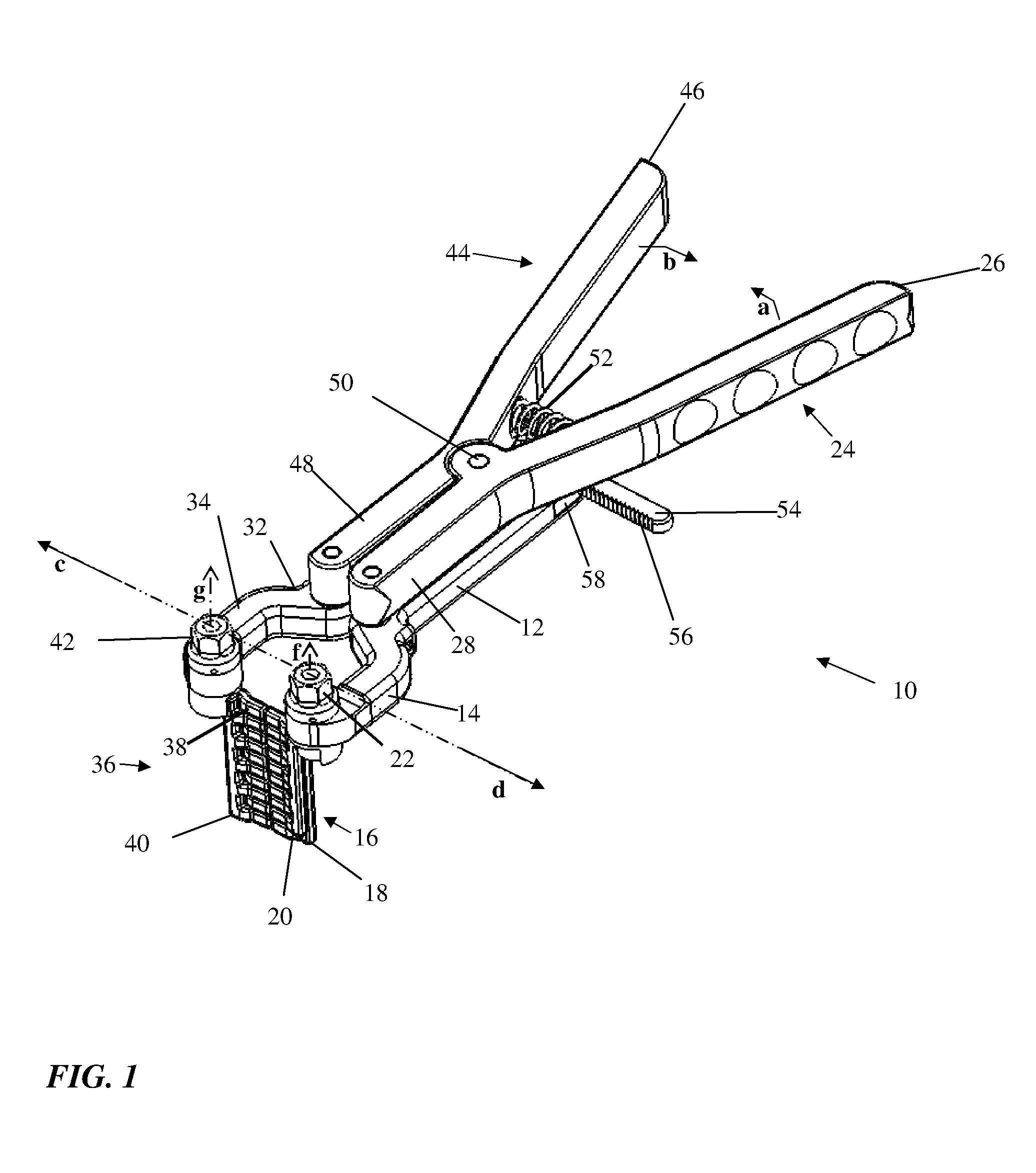

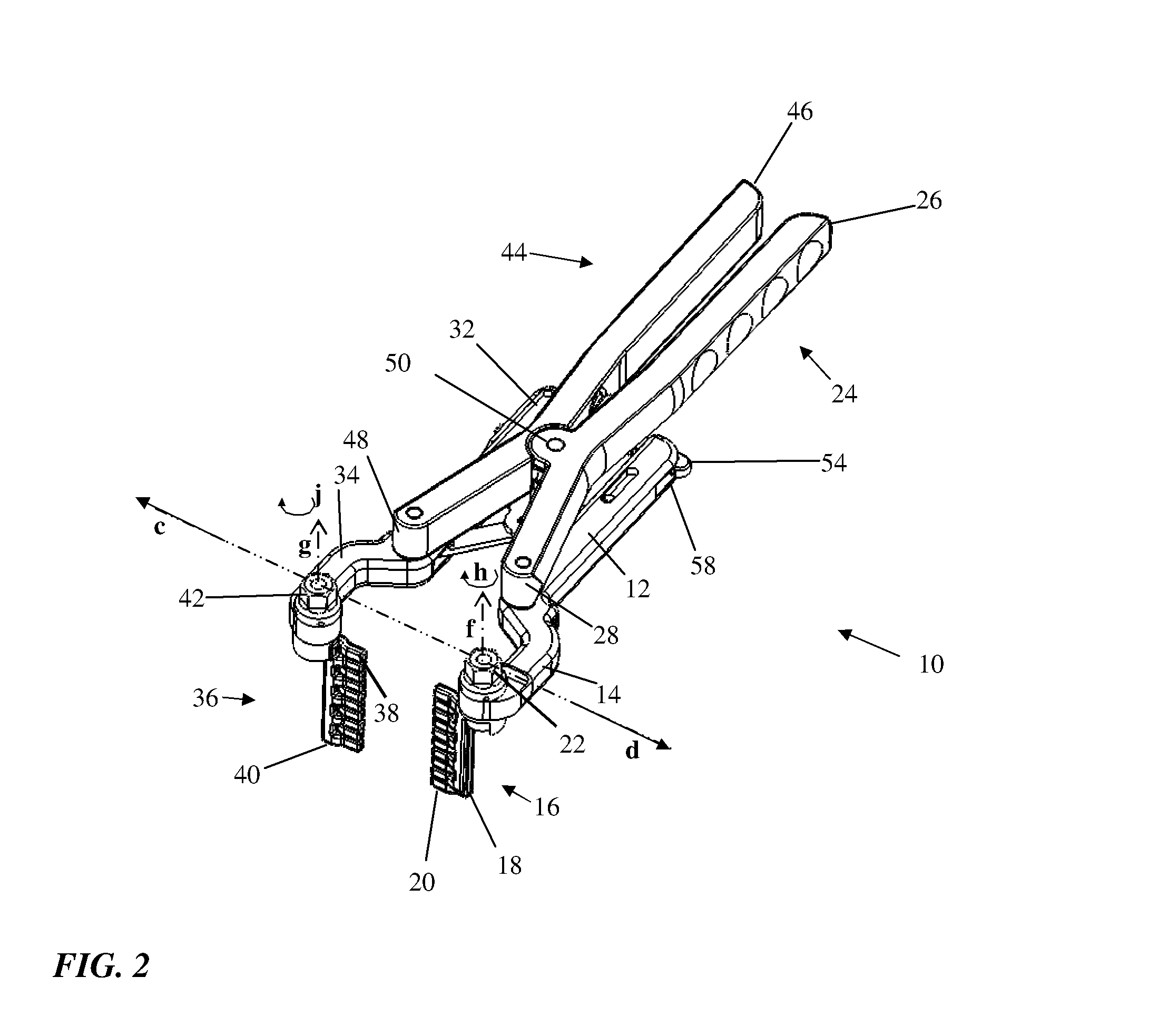

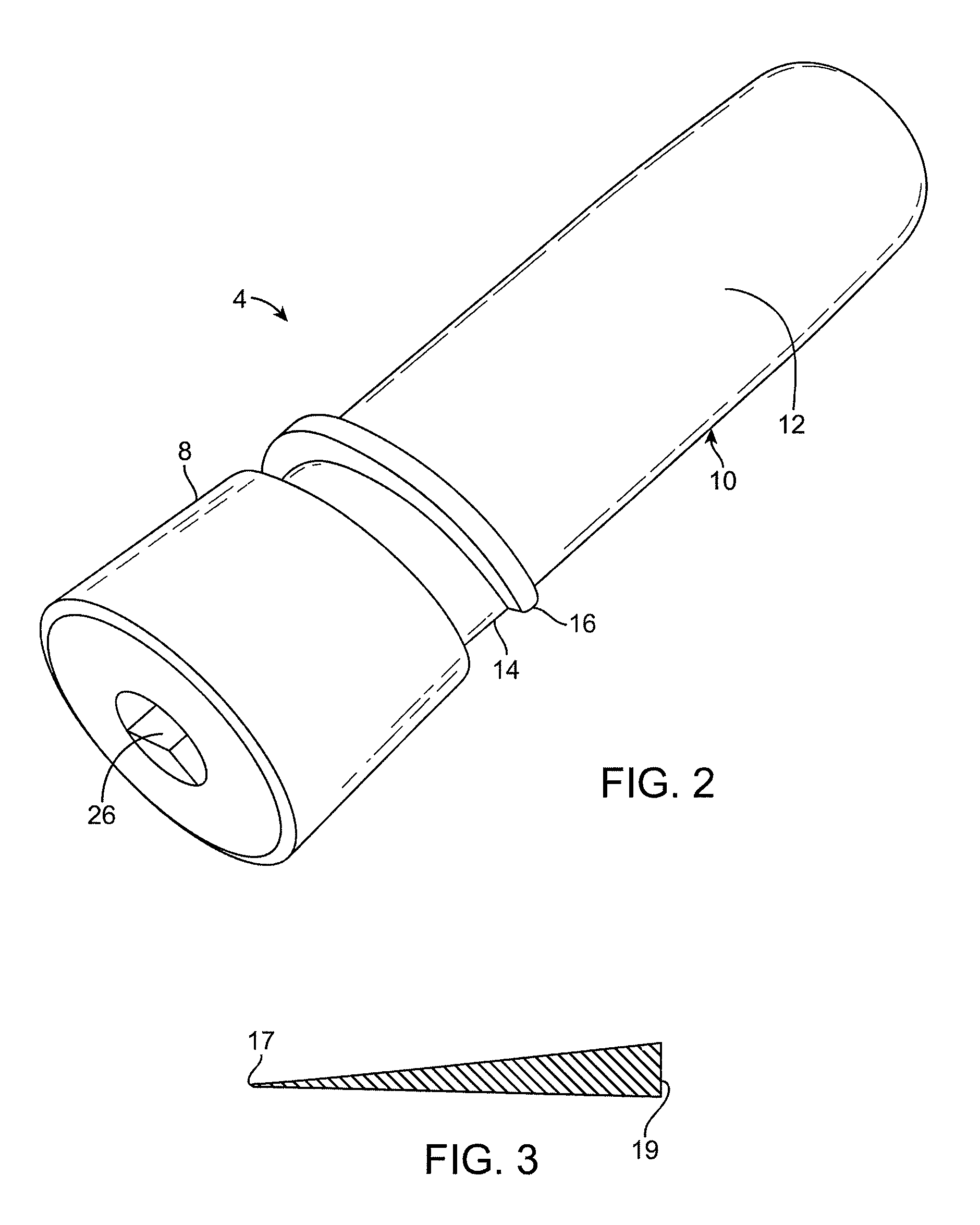

Surgical tissue retractor

Owner:SPINAL ELEMENTS INC

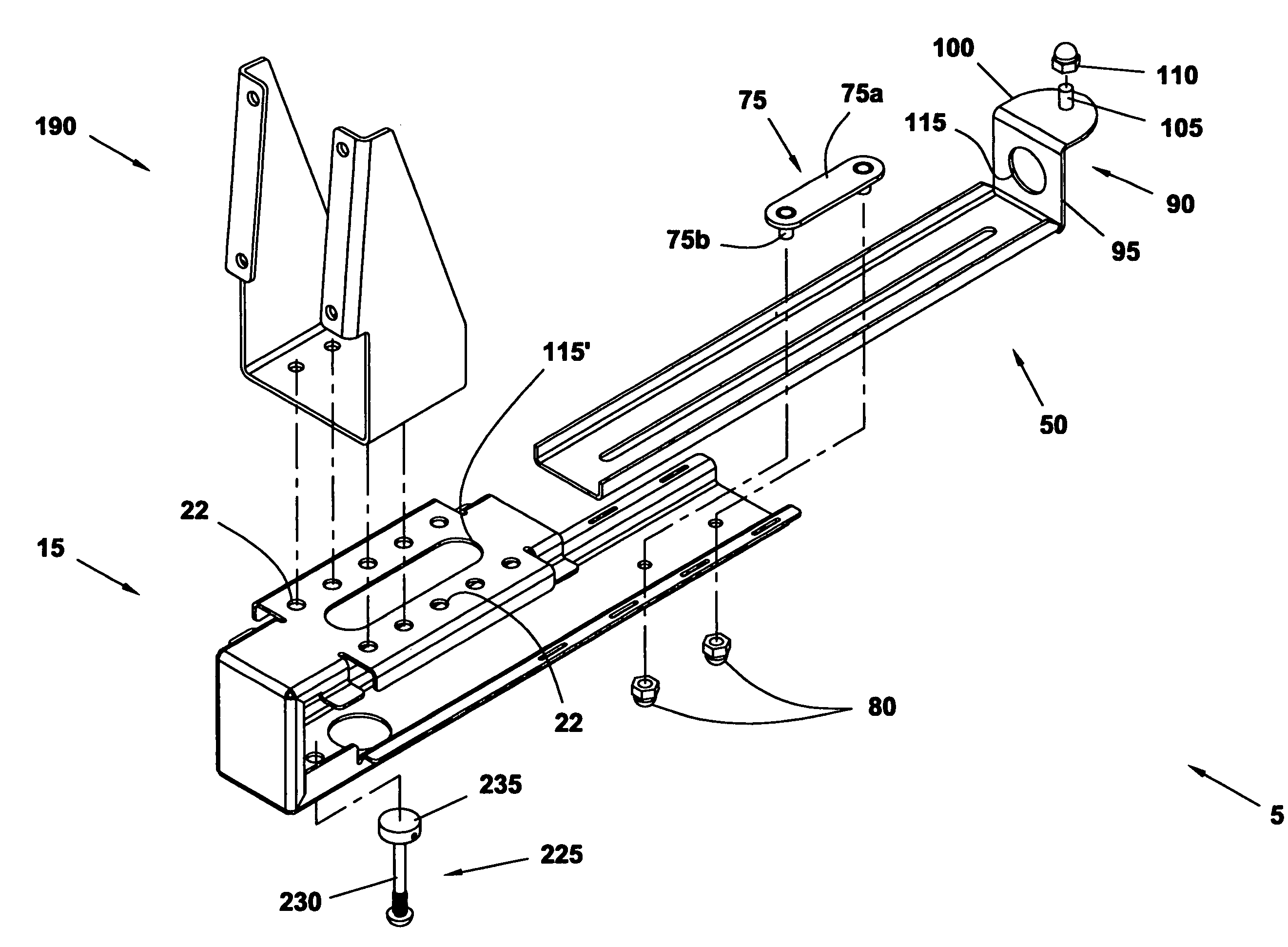

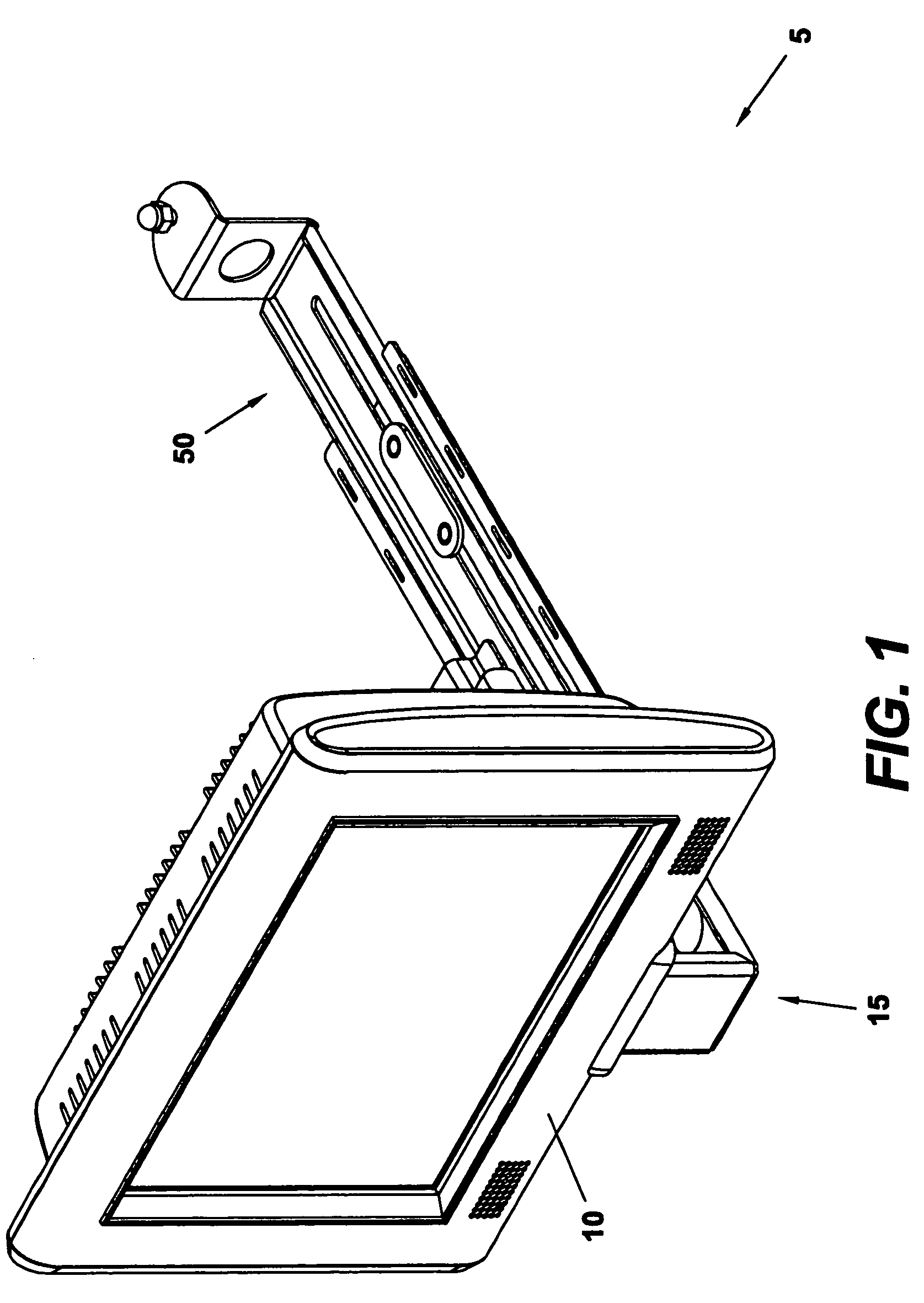

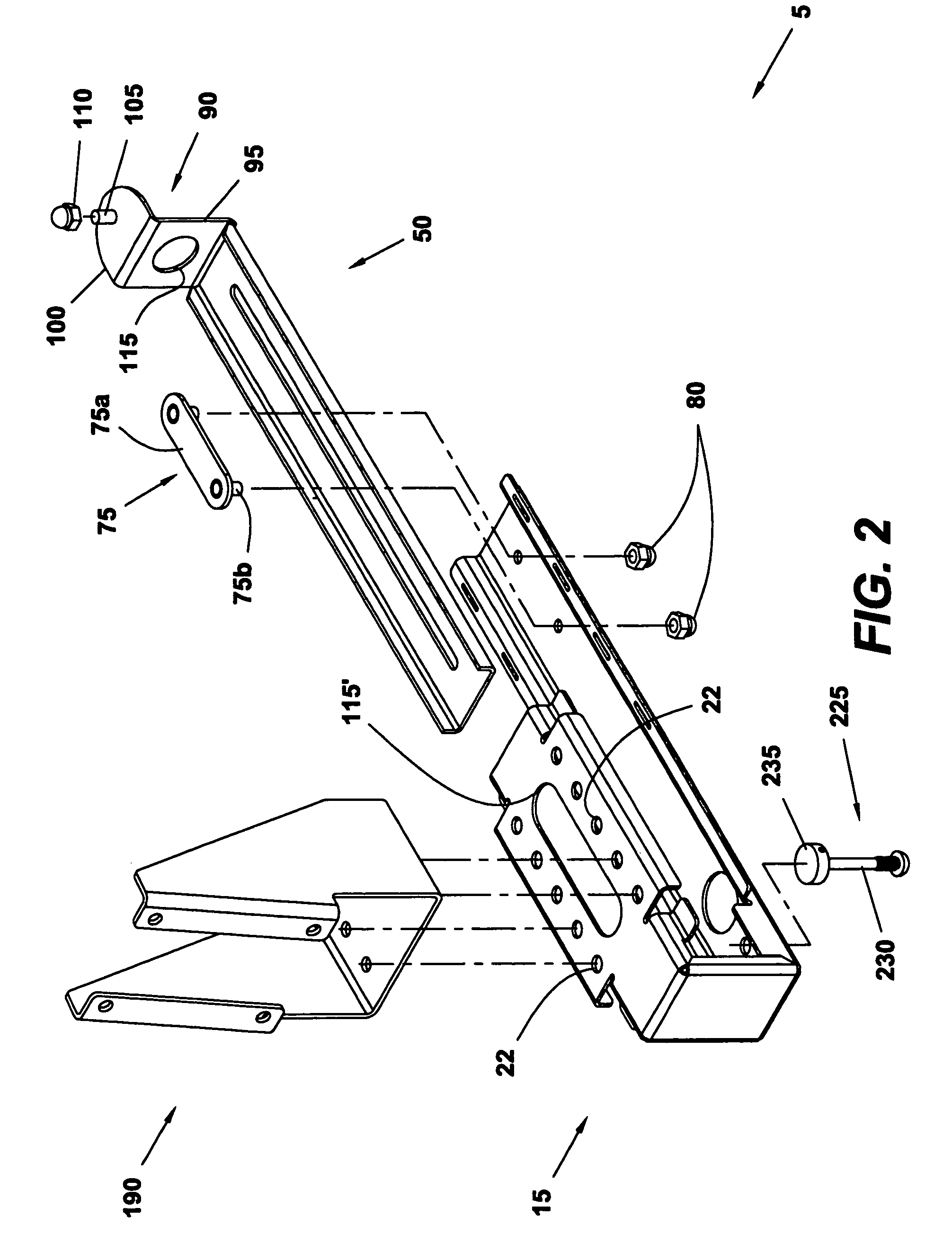

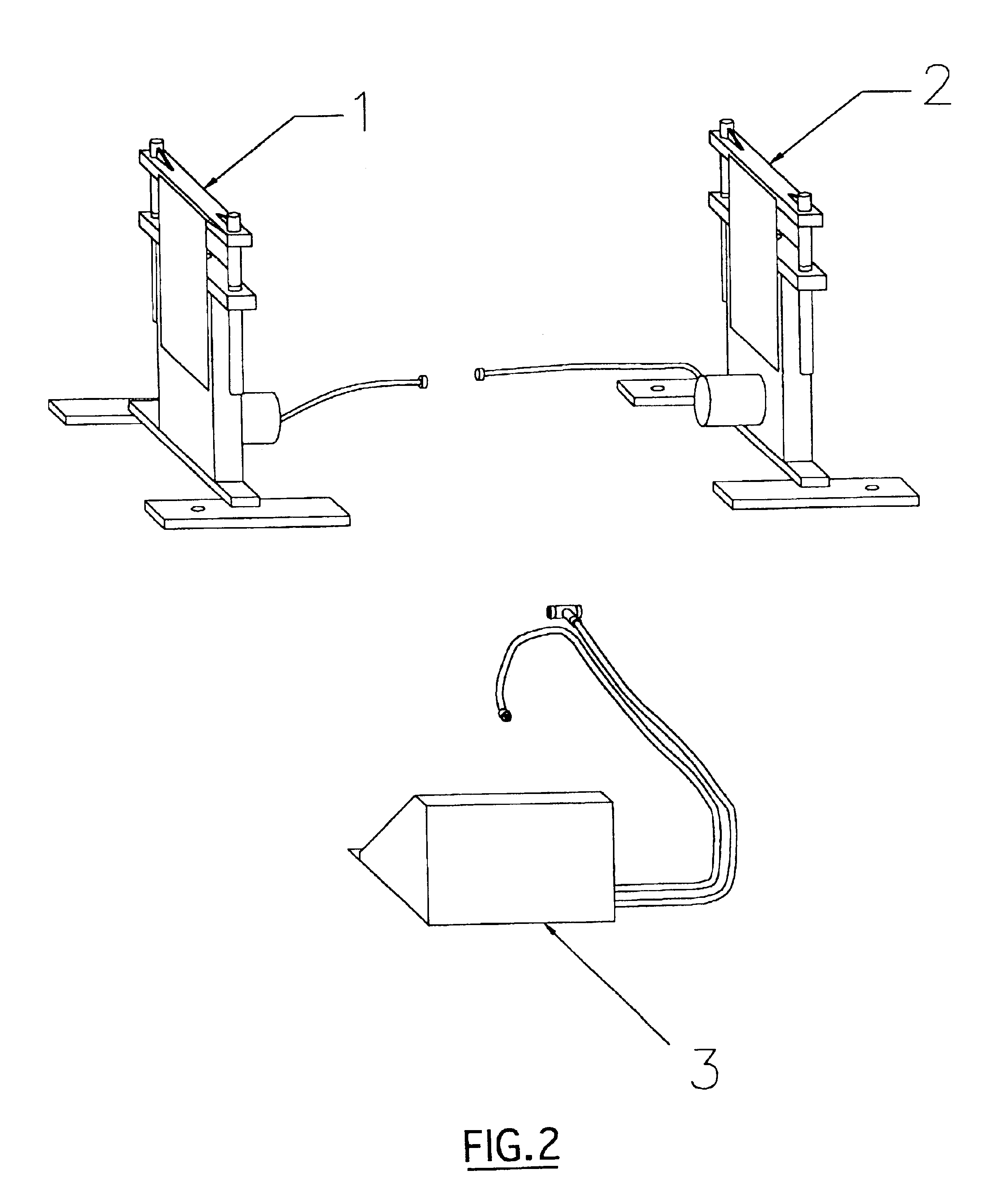

Adjustable bracket assembly for shelf-mounted electronic display device

InactiveUS7316378B1Easy to installGood adhesionCurtain suspension devicesStands/trestlesEngineeringDisplay device

An adjustable bracket assembly for mounting an electronic display device to a shelf, such as, for example, a shelf of a retail store. The adjustable bracket assembly allows for the mounting of an electronic display device to shelving of different width and does not require any alteration of the shelving. The electronic display device may be mounted at different locations with respect to the shelf. The design of the adjustable bracket assembly preferably allows for useable shelf space to exist behind the electronic display device once it is installed to the shelf. The adjustable bracket assembly may also allow for attachment of a printer, or a printer housing.

Owner:MICRO INDS CORP

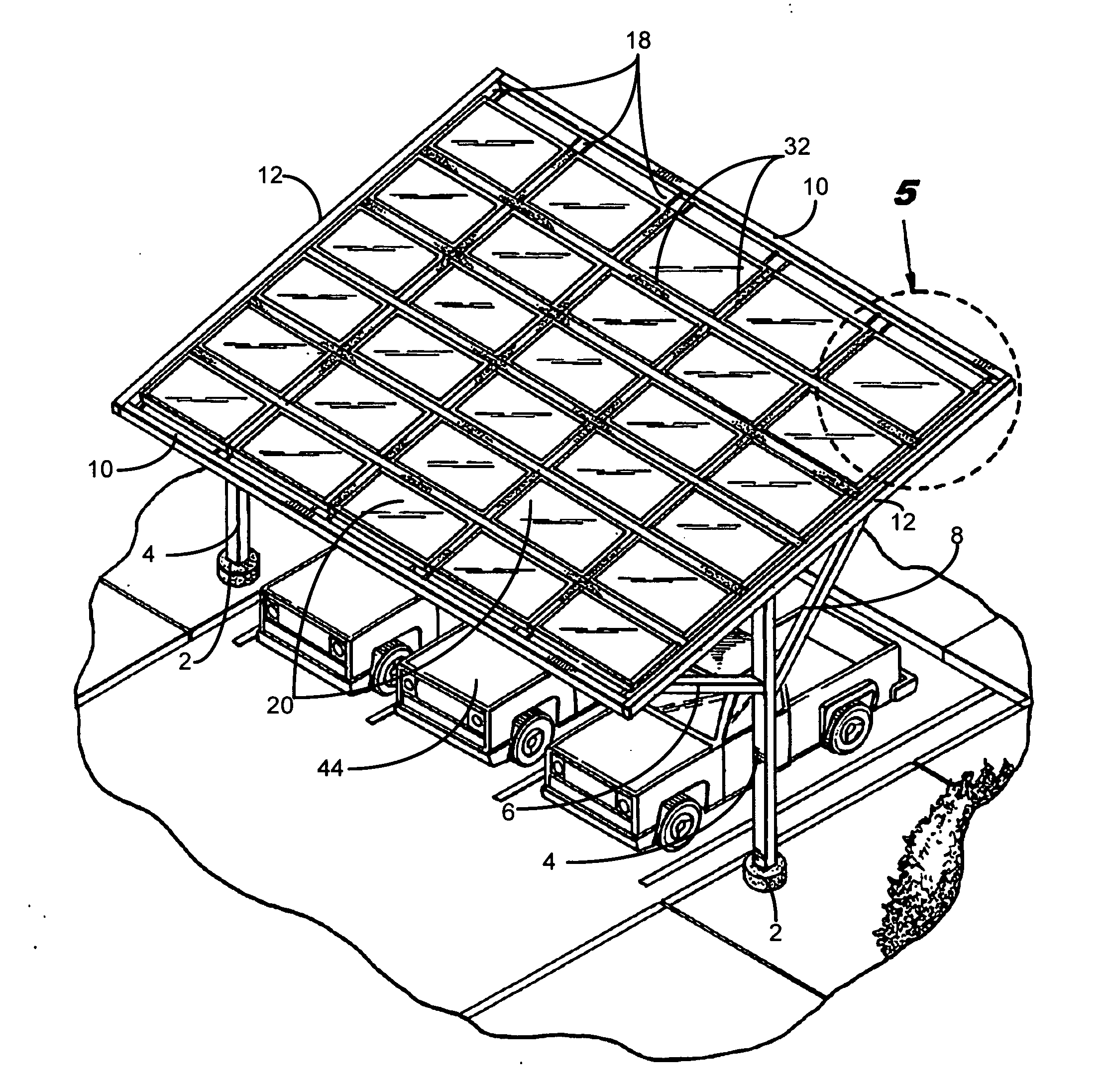

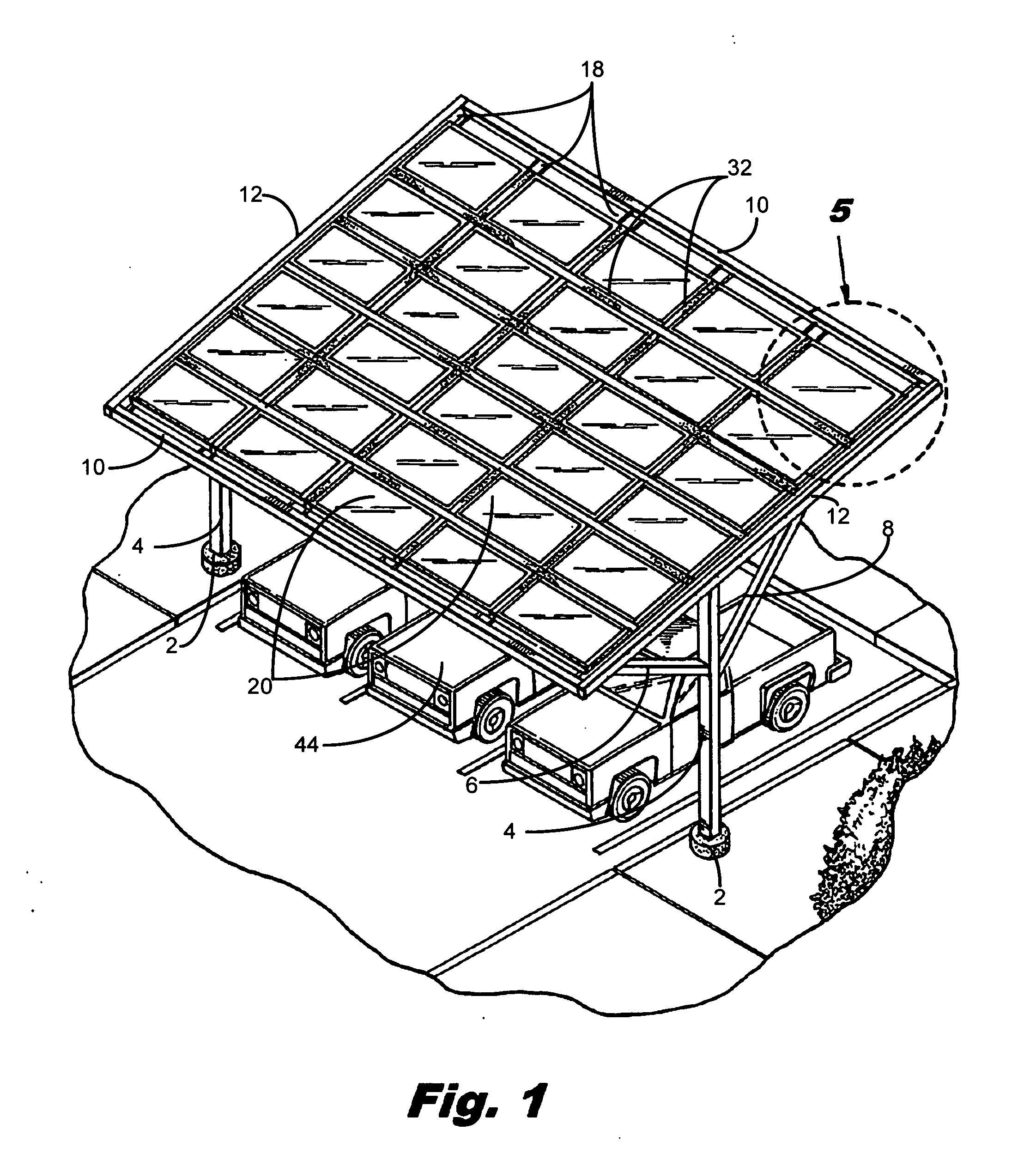

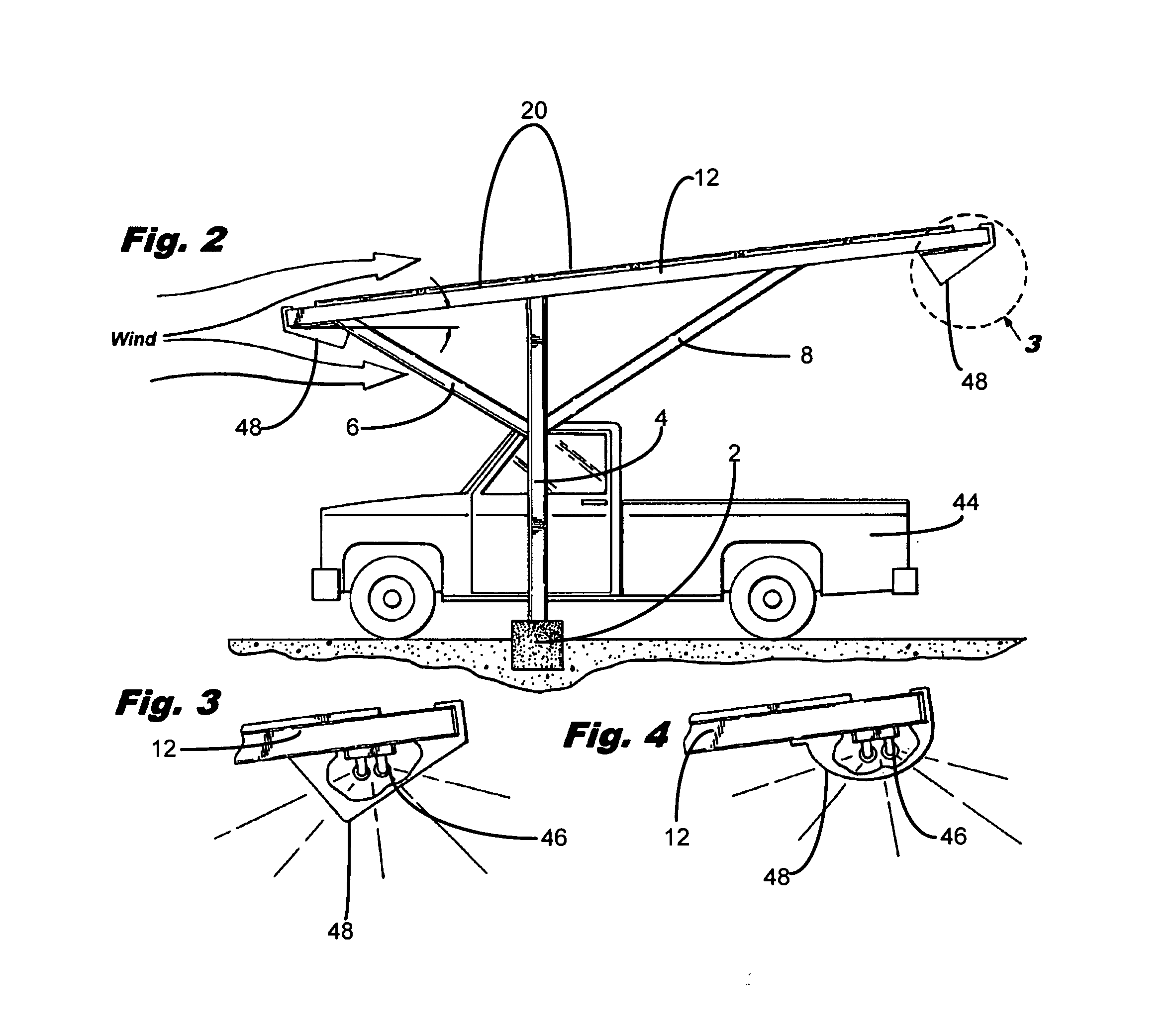

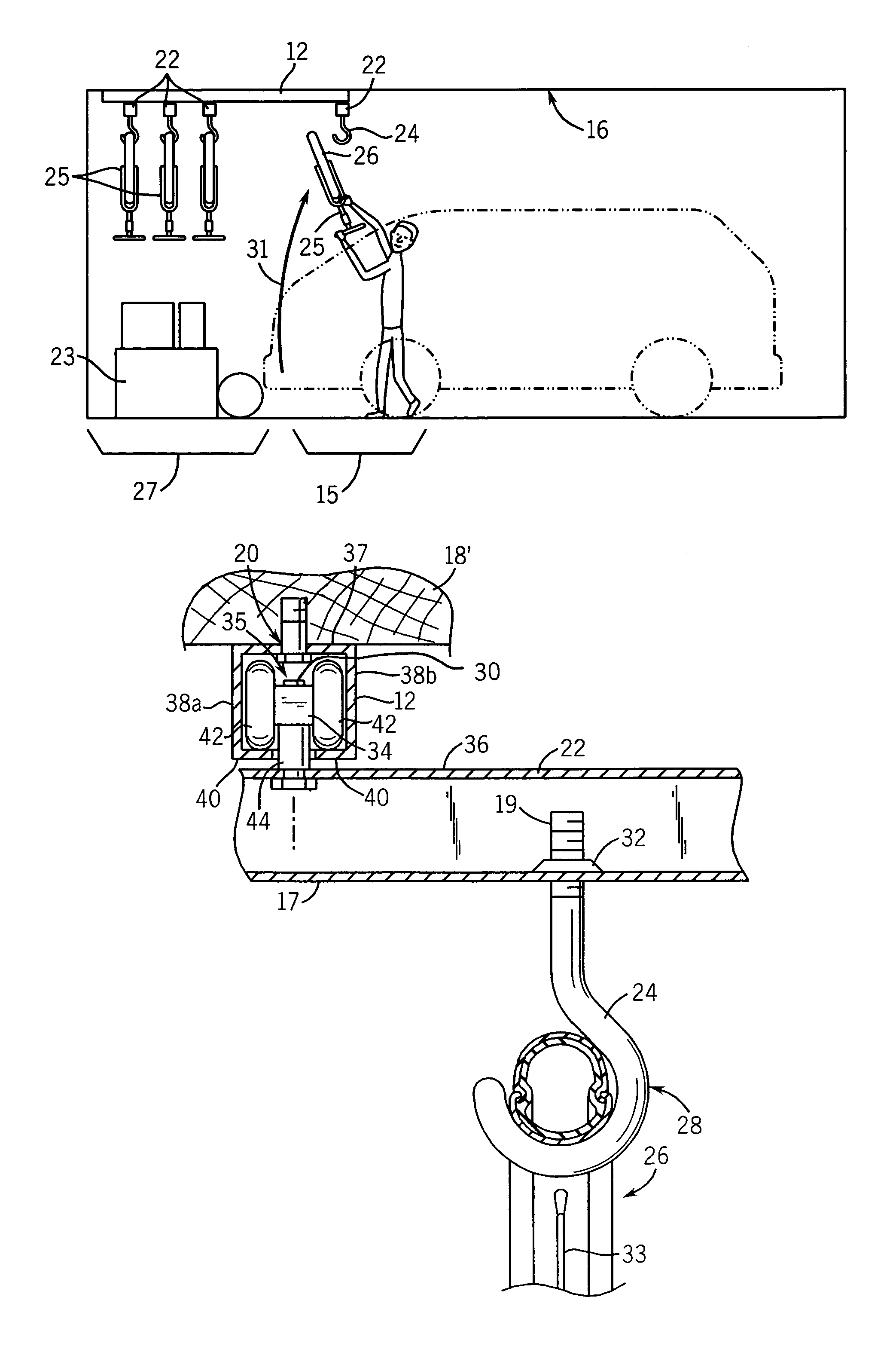

Cabled matrix for cantilevered photovoltaic solar panel arrays, apparatus and deployment systems

InactiveUS20110290305A1High strength-to-weight ratioProlong lifePhotovoltaic supportsSolar heating energyDistal portionCoupling

A cable reinforced matrix to support a solar panel array comprising array bracing beams which define a perimeter including longitudinal array bracing beams and latitudinal array bracing beams with coupling apertures at various points along the latitudinal array bracing beams; cable couplings at opposite points along the latitudinal array bracing beams; cabling traversing the latitudinal array bracing beams; solar panels atop the cabling; longitudinal I-beams; latitudinal I-beams; interpanel I-beam(s); grommets along the cabling; grommet clips; grommet clip fasteners; panel fasteners; columns at either end of the longitudinal array bracing beams; a first cantilever support post extending from the column to the distal portion of the longitudinal array bracing beam; a second cantilever support post extending from the column to the proximal portion of the longitudinal array bracing beam; a footing at the bottom of each column; and dampening / stabilizing element(s) to mitigate vibration and uplift.

Owner:HOFFMANN STEVE +2

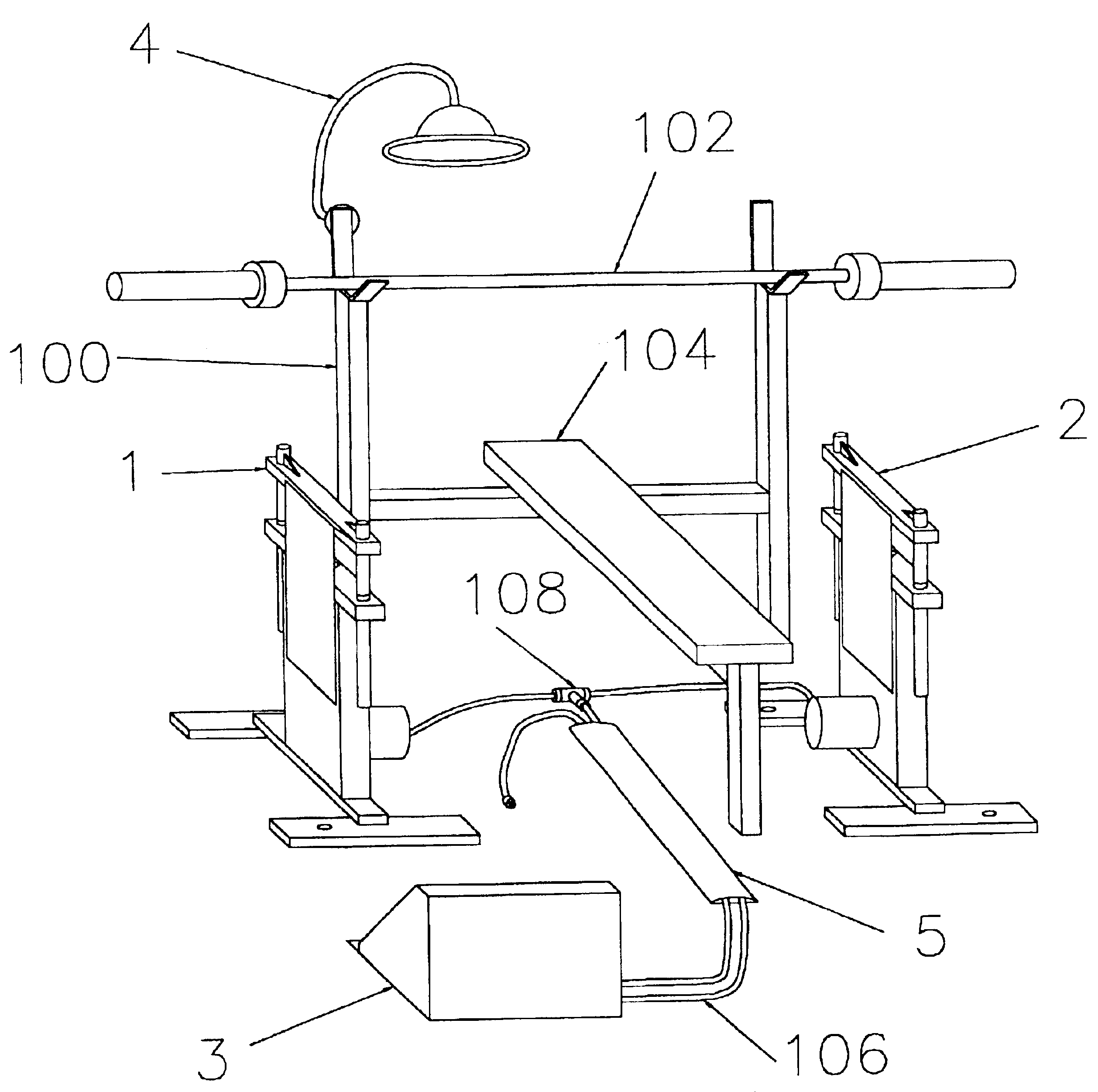

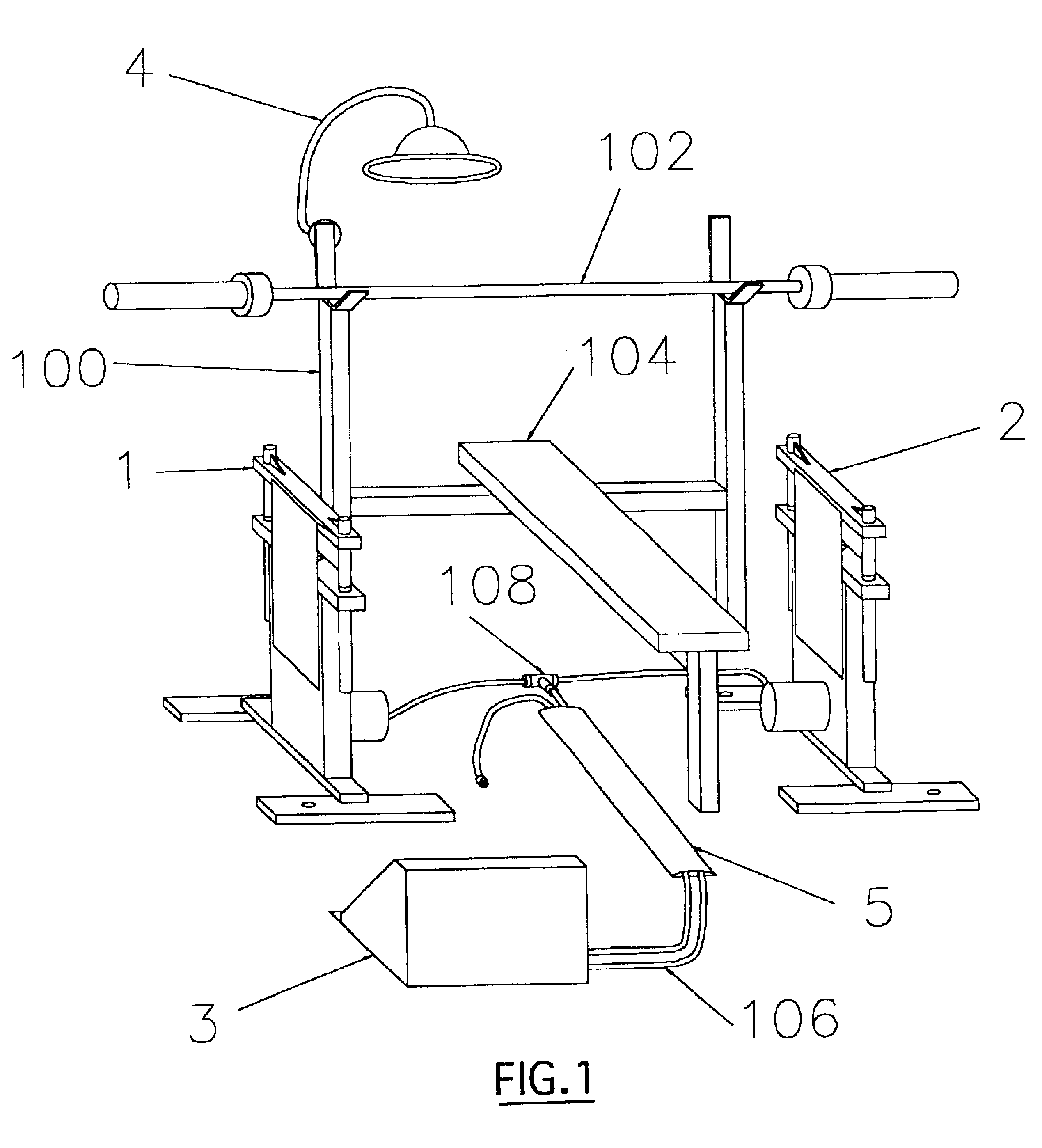

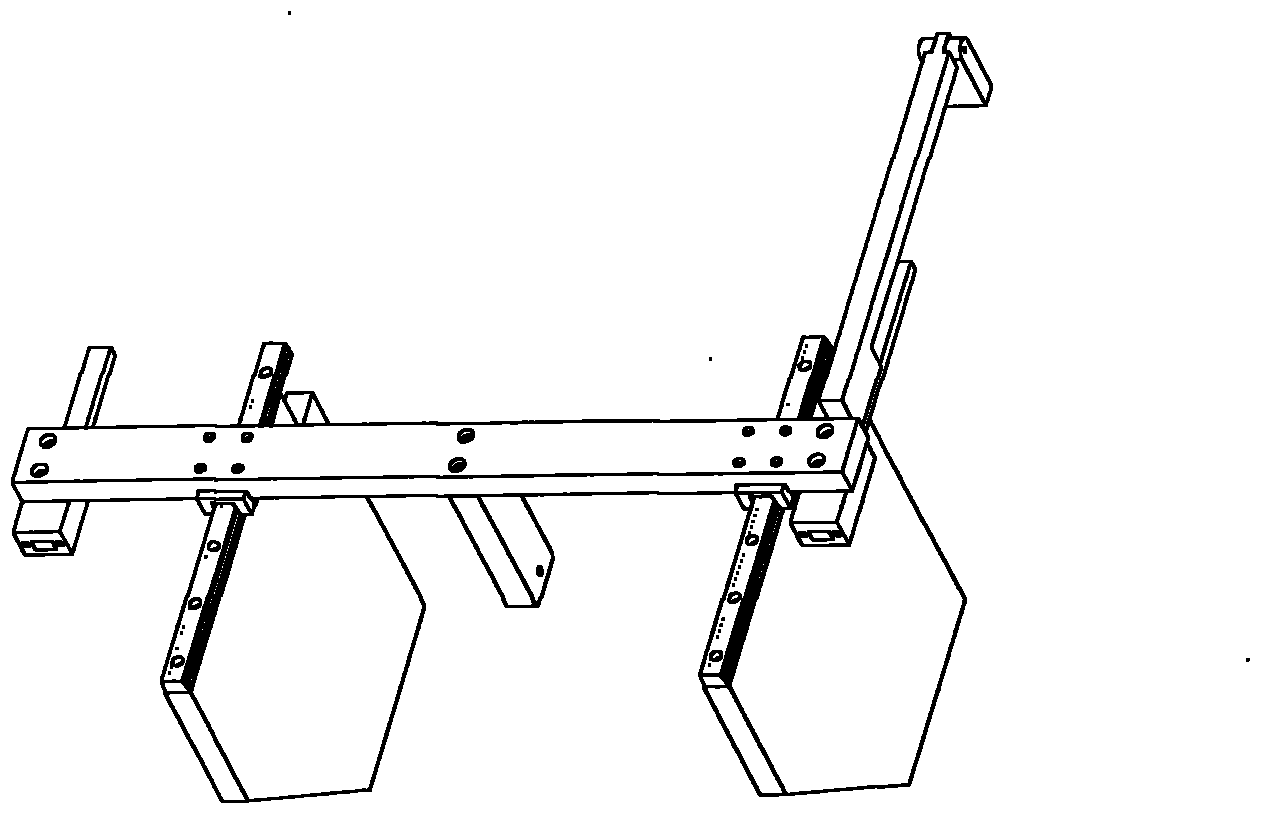

Self-spotting bench press apparatus for progressive lift distance training

InactiveUS6926648B2Satisfy safety performance requirementsPlenty of spaceDumb-bellsStiltsVertical motionBench pressing

A self-controlled modular bench press apparatus for progressive lift distance training including a pair of stands each with an upper translating assembly for vertical, incremental movement selectable by the user during exercise with no barbell attachments. The stands fit underneath the barbell and accommodate off-center loading of the barbell. Each stand includes a linear motion actuator to provide for the vertical movement and a quick connect / disconnect controller enables the user to provide input to each electrically controlled linear motion actuator to translate the upper translating assembly in an independent but parallel manner.

Owner:CONCEPTS 2000

Method of using a surgical tissue retractor

ActiveUS20120149991A1Easy to viewEasy to returnJoint implantsSurgical forcepsEngineeringSmall incision

Owner:SPINAL ELEMENTS INC

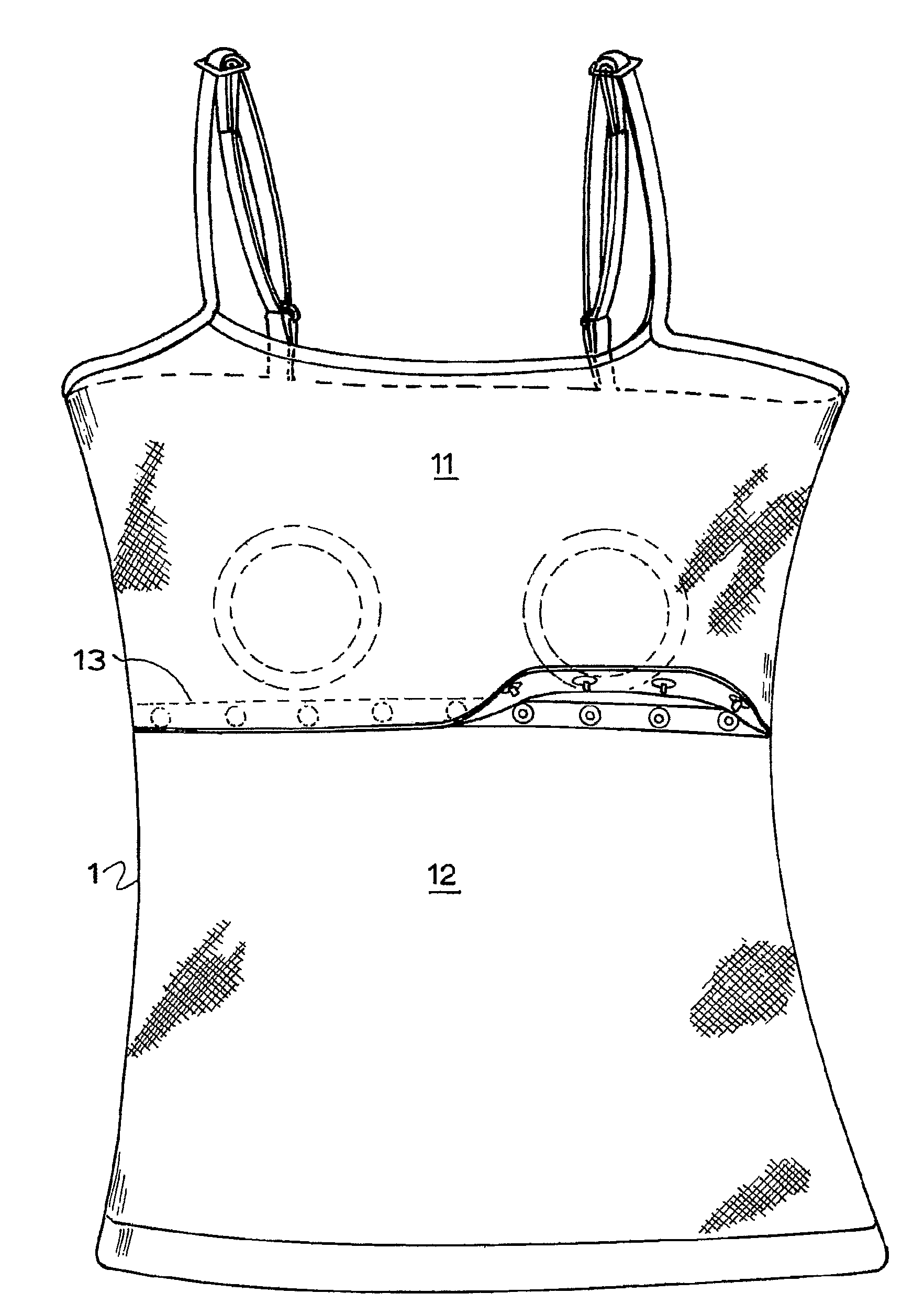

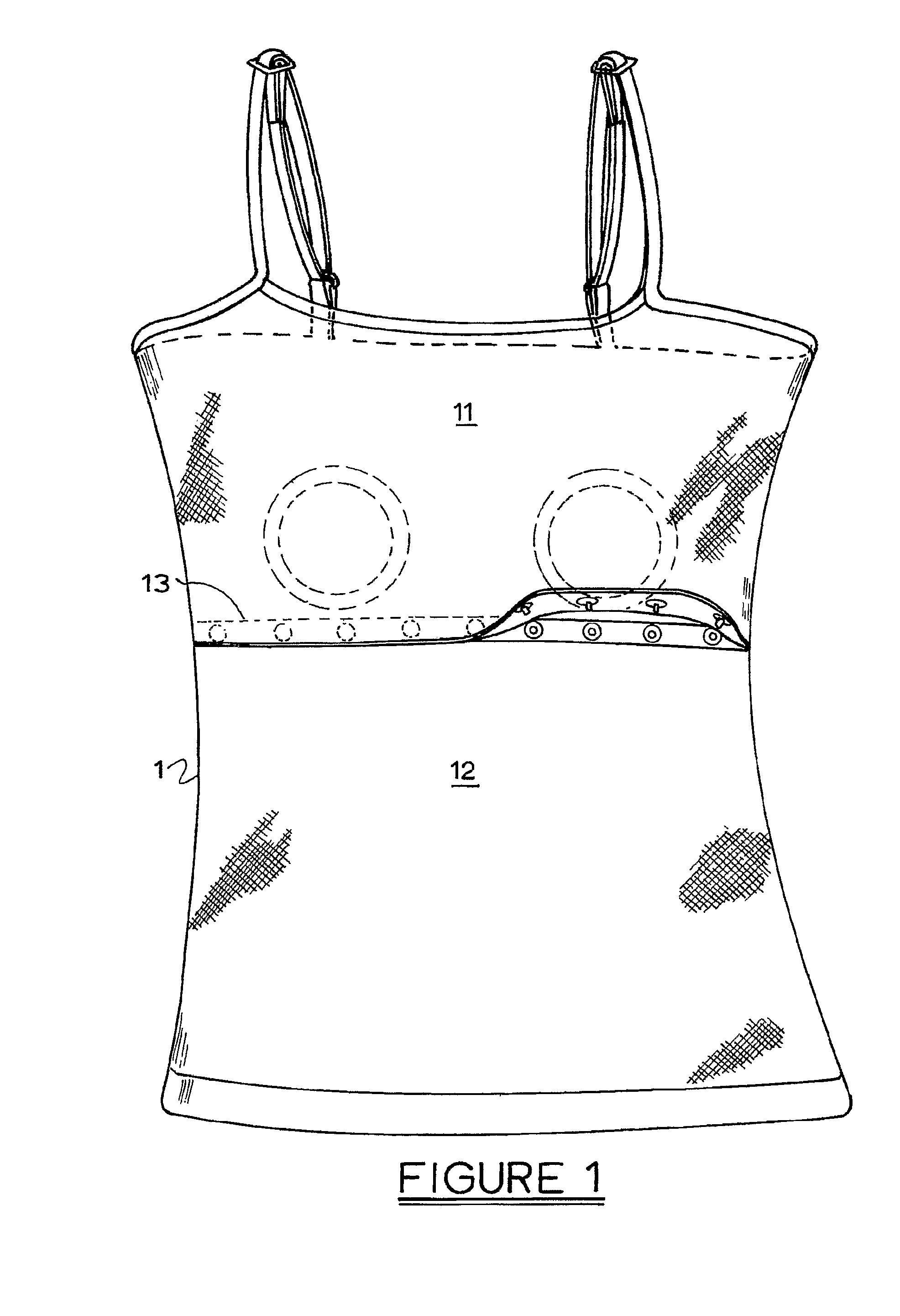

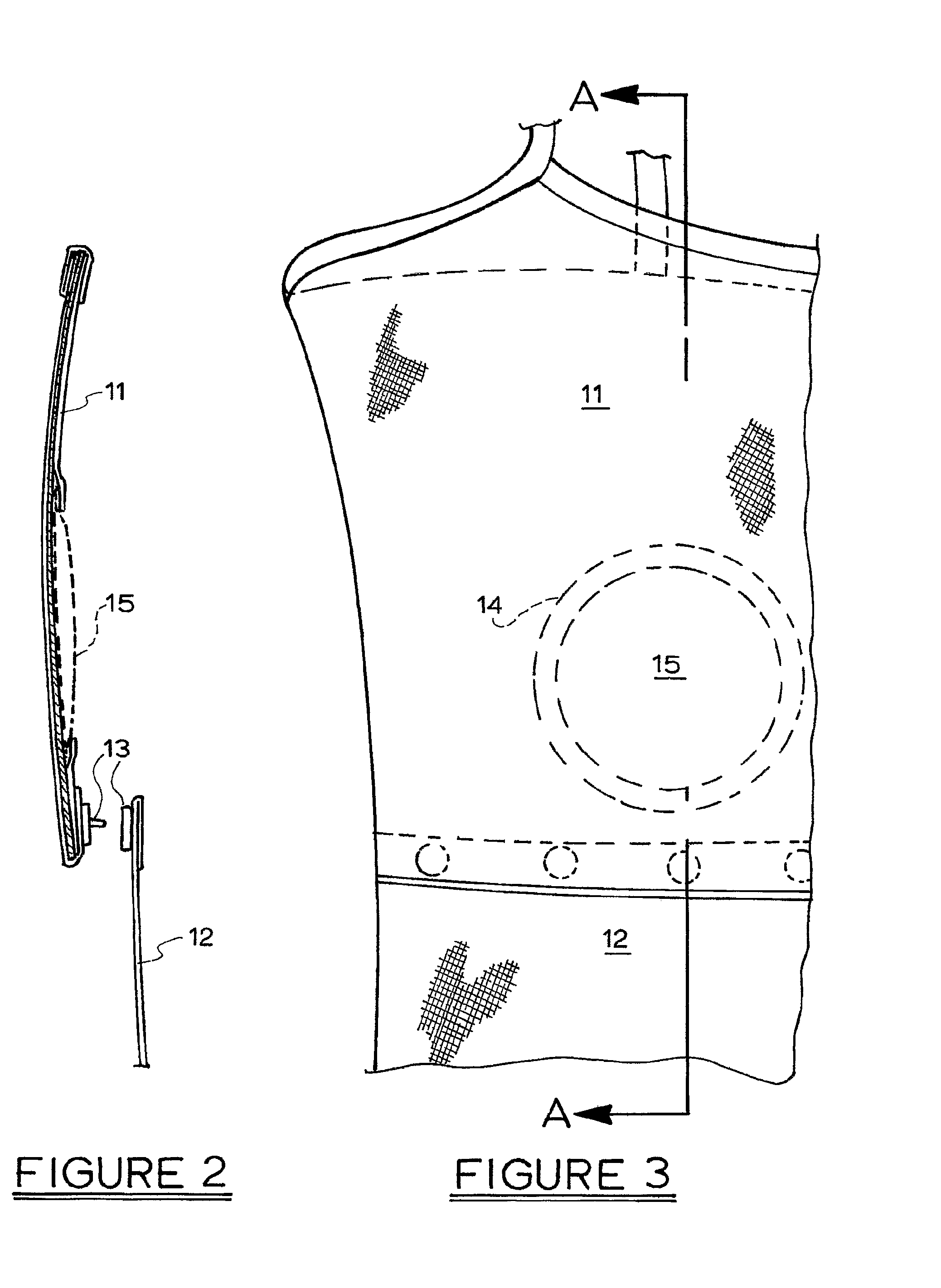

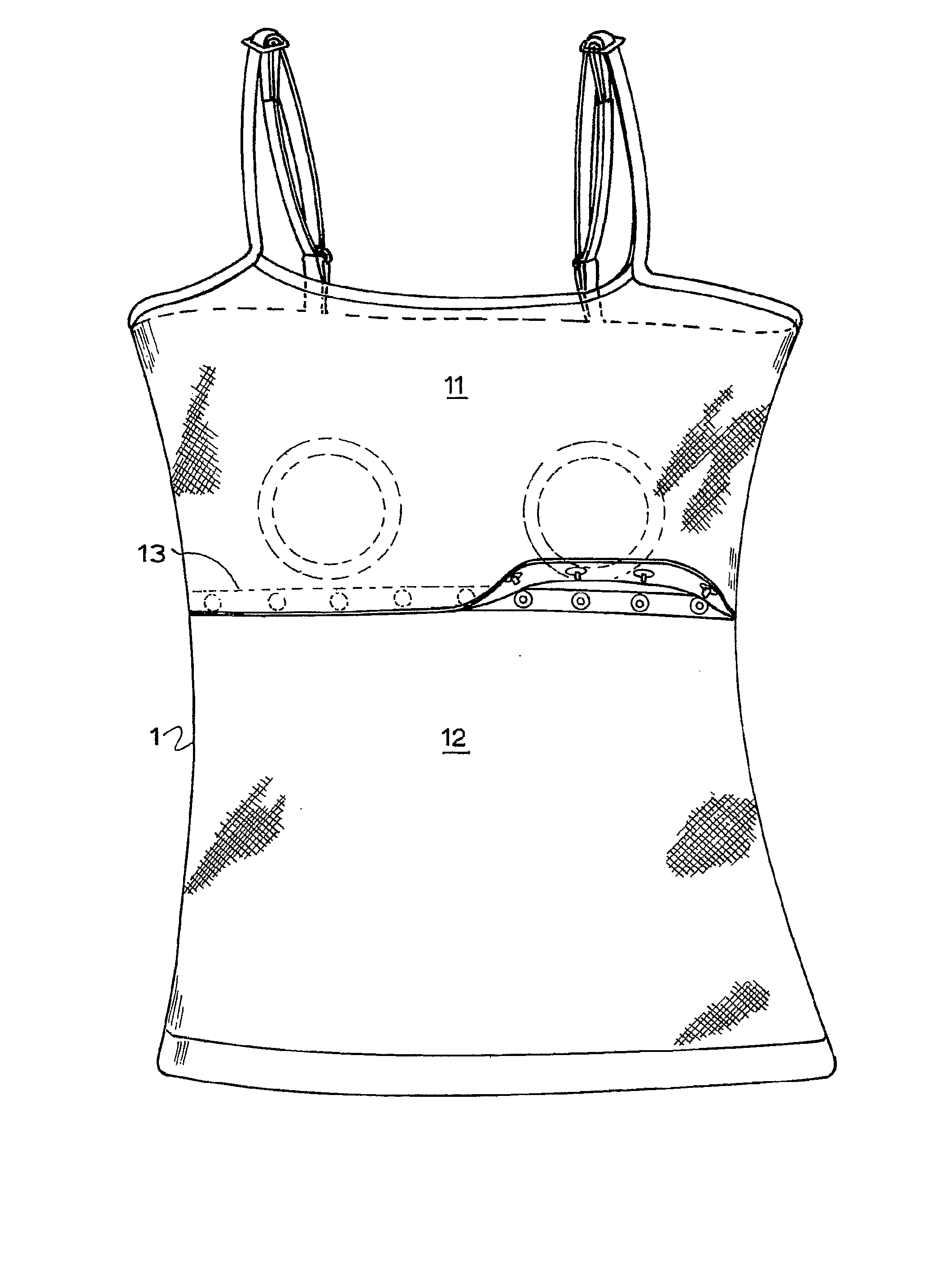

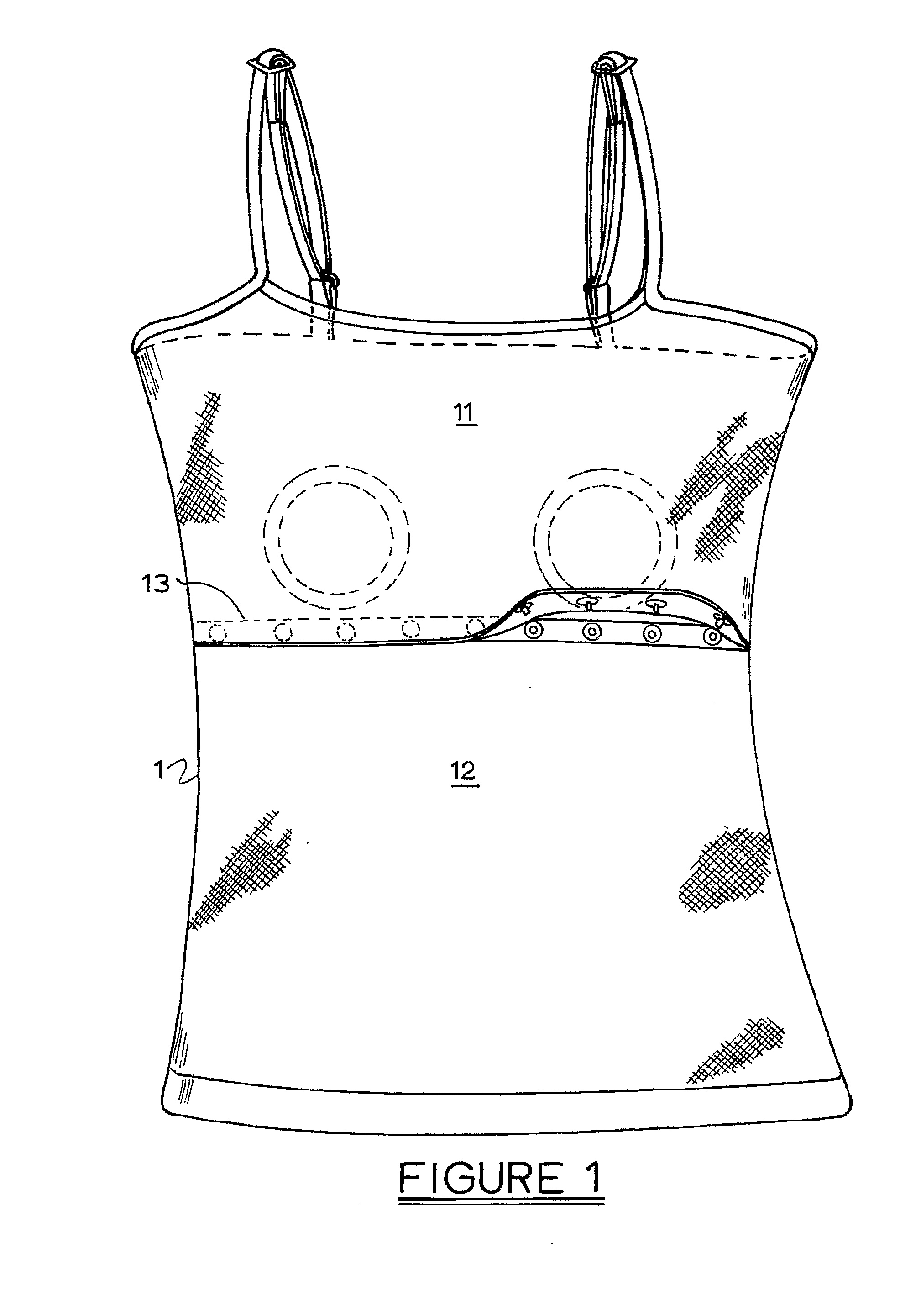

Nursing garment

InactiveUS7448090B2Easy to openEasy to closeBrassieresMaternity clothingBiomedical engineeringFront panel

Owner:FRESH IDEAS AUSTRALIA

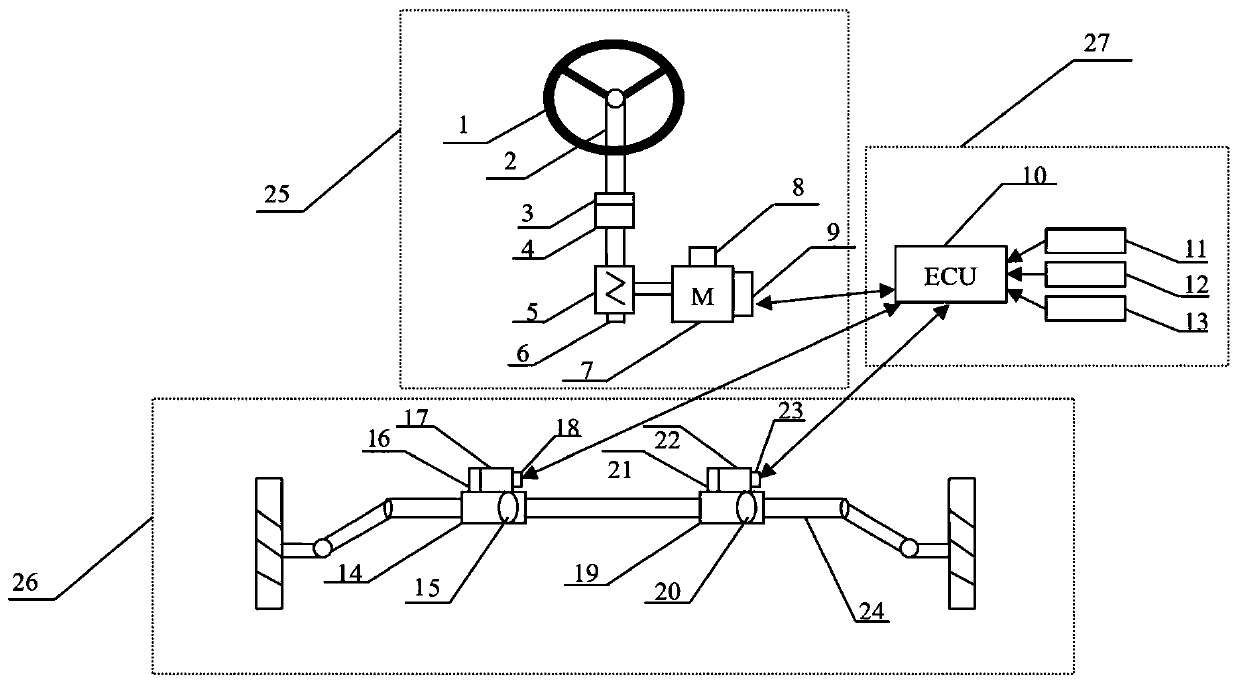

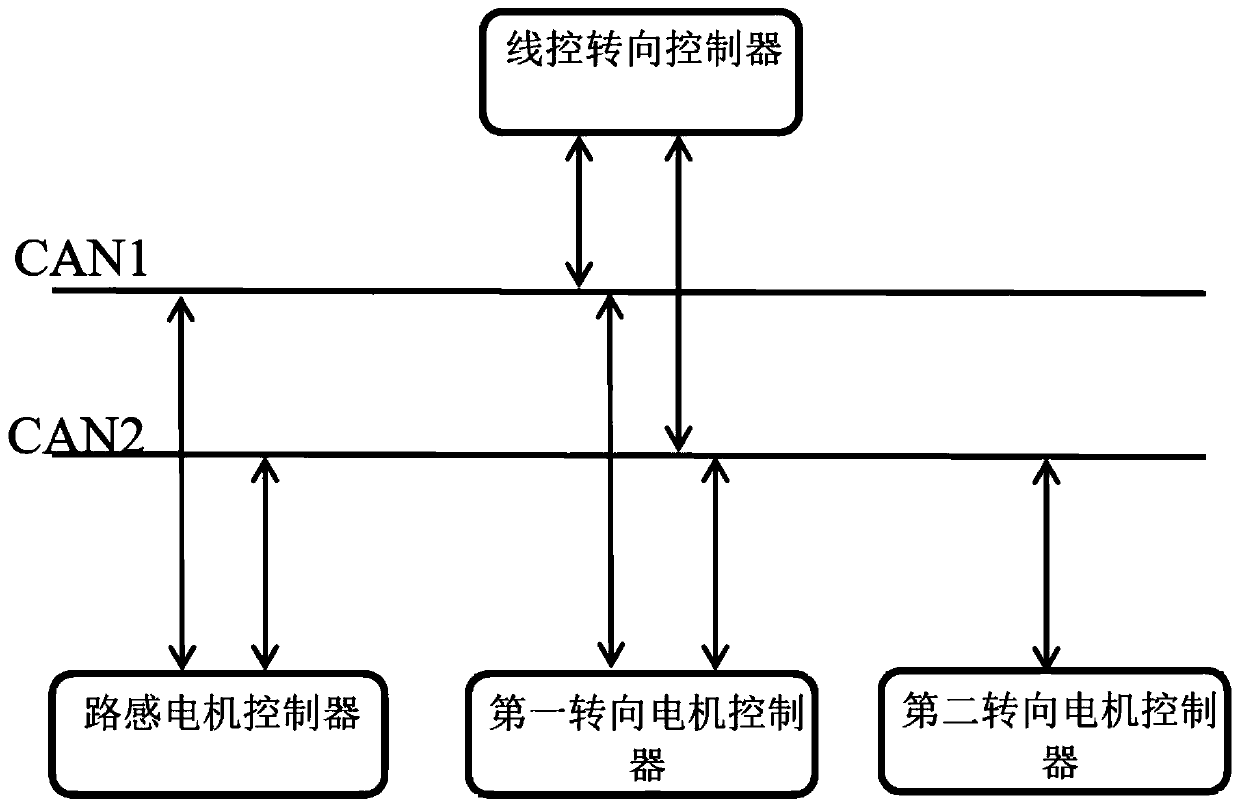

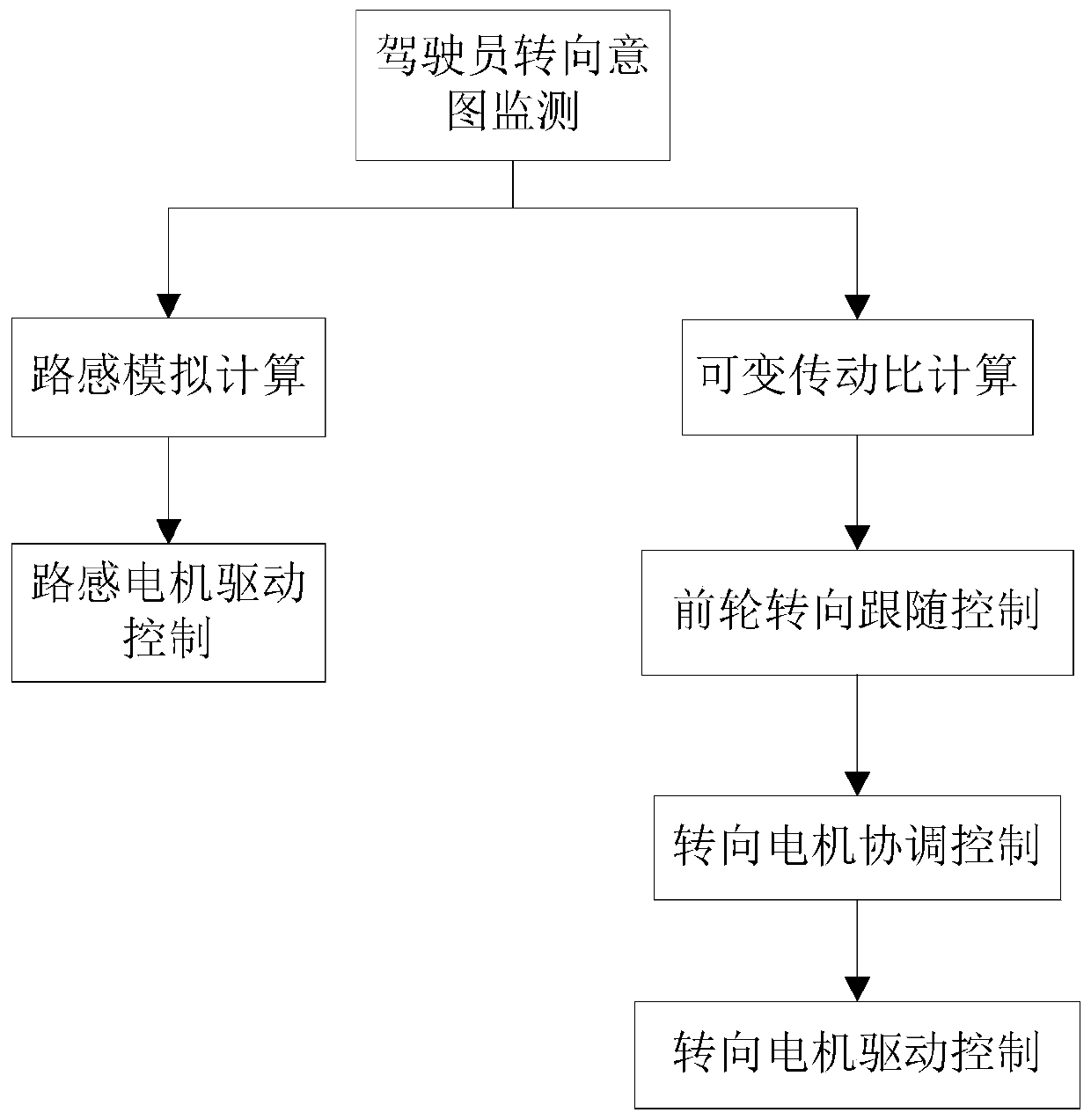

SBW (steer-by-wire) device with redundancy function and control method

PendingCN109808764AEnsure safetySave spaceMechanical steering gearsElectrical steeringEngineeringMotor controller

The invention discloses an SBW (steer-by-wire) device with a redundancy function and a control method. The SBW device with the redundancy function comprises a road feel simulation actuator, a steeringactuator and an SBW control module, wherein the steering actuator comprises a first gear-rack mechanism, a first rack travel sensor, a first steering motor controller, a first steering motor, a firststeering motor rotor position sensor, a second gear-rack mechanism, a second rack travel sensor, a second steering motor controller, a second steering motor, a second steering motor rotor position sensor and a steering engine. By means of the redundant first steering motor and first steering motor controller as well as the redundant second steering motor and second steering motor controller, theSBW system can still steer normally once a fault occurs, and safety of passengers in a vehicle is guaranteed.

Owner:CHINA FIRST AUTOMOBILE

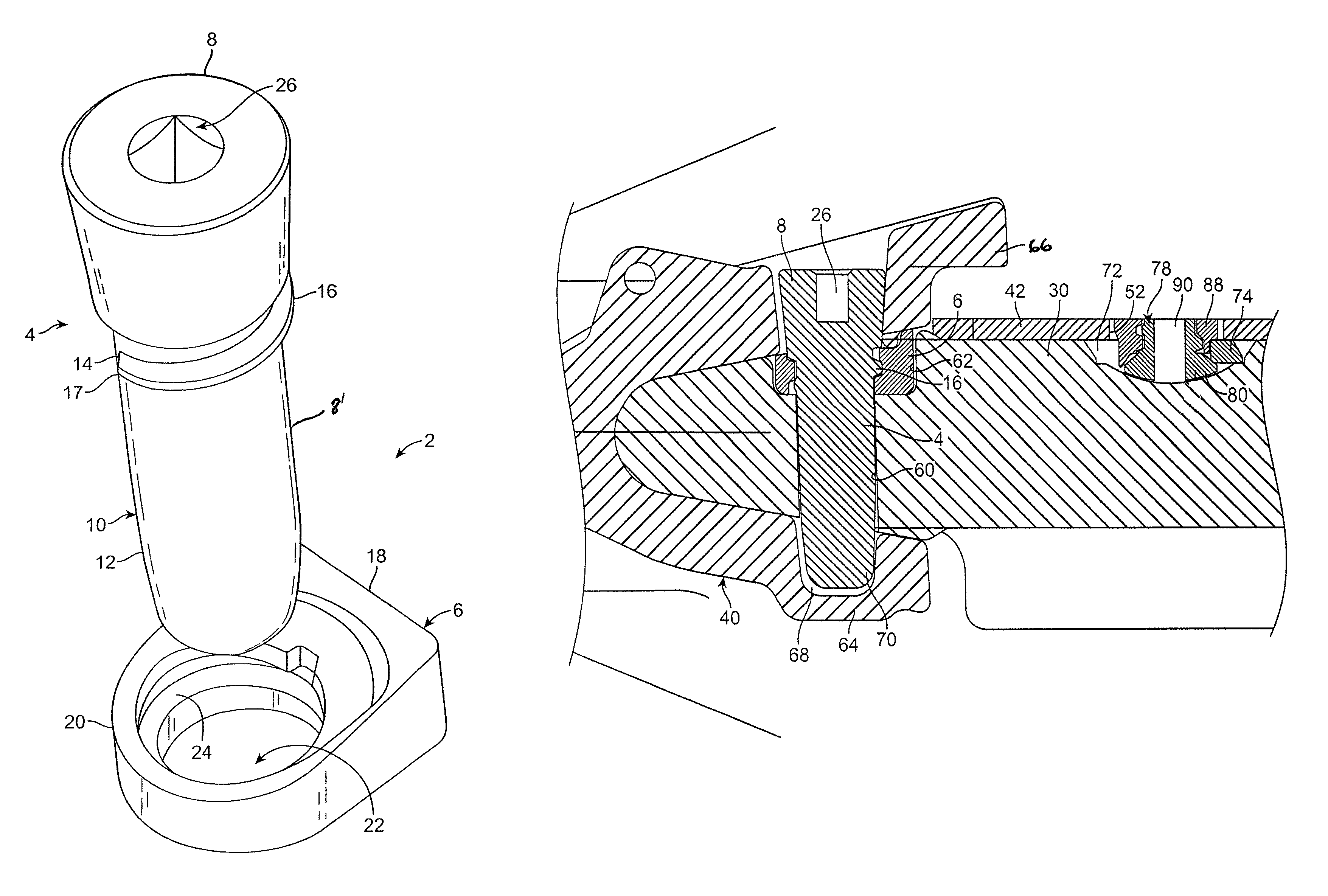

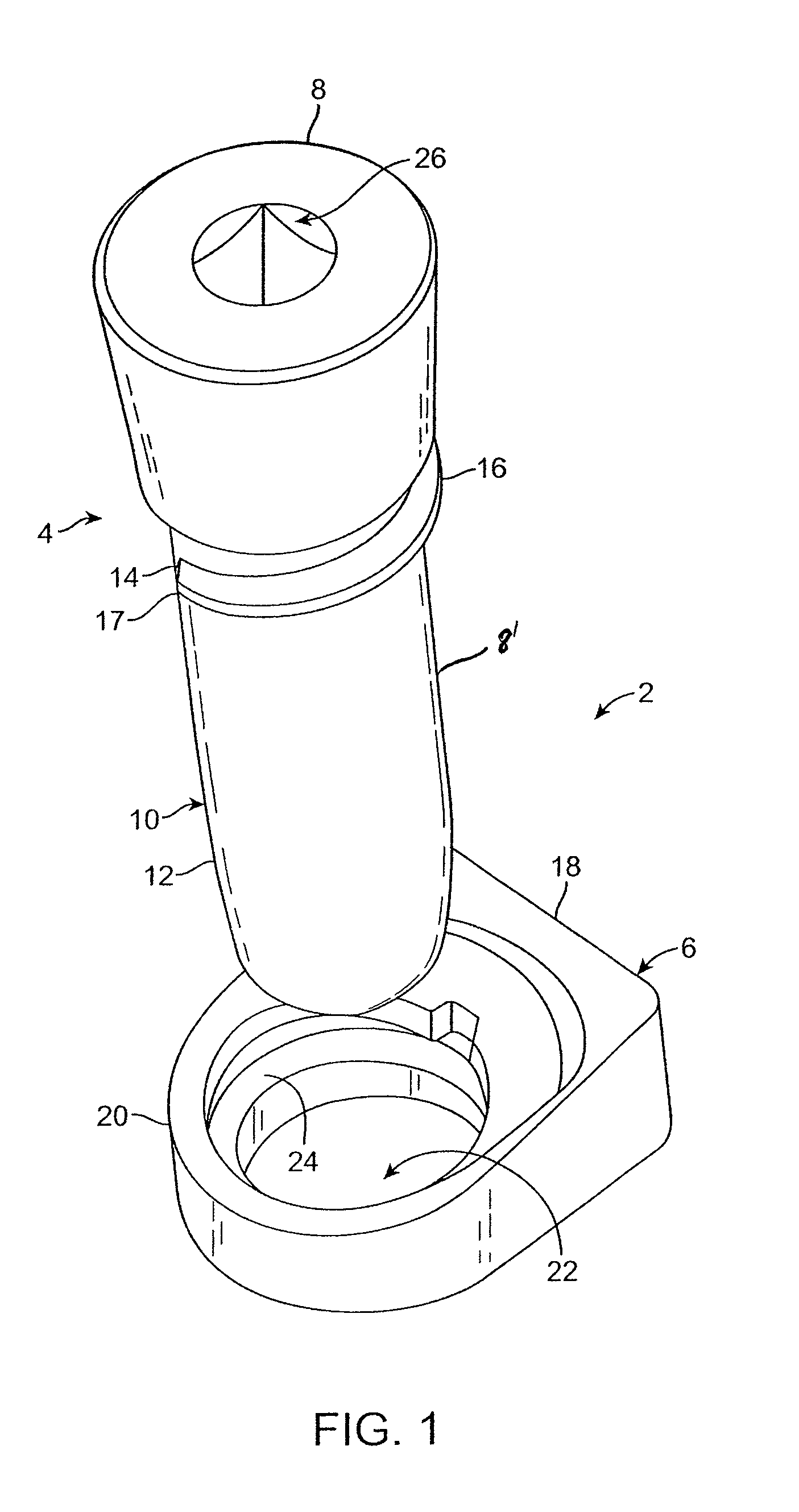

Quick release screw connector for earth-moving equipment

A connector for earth-moving equipment subjected to contact with earth, abrasive materials and the like has a nut with a body and a hole extending through the body. A bolt with a shank adapted to extend into the hole has an enlarged head at one end of the shank. Cooperating thread formations are defined on the shank and in the hole. The thread formations have cooperating matching cross-sections that decrease from a vicinity of the head of the screw towards the other end of the screw and that extend over a circumference of less than 360° and typically of no more than 270°. The connector is adapted to connect various components, including teeth and adapters, to each other and to lips at the front end of earth moving buckets and the like.

Owner:BERKELEY FORGE & TOOL

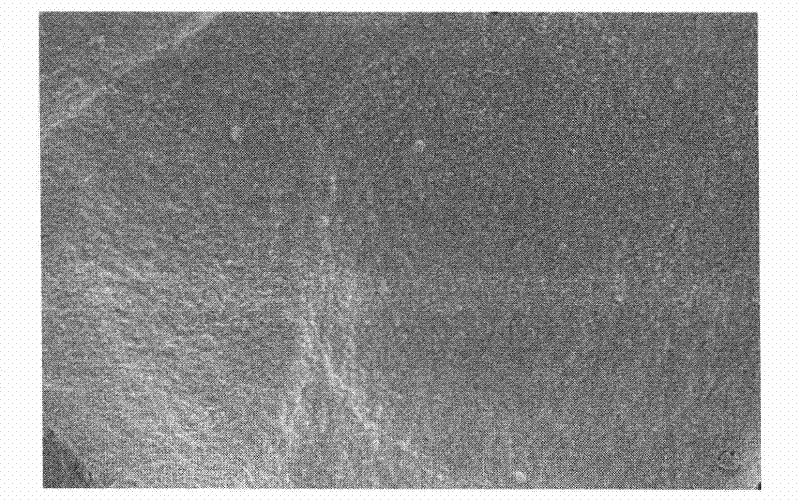

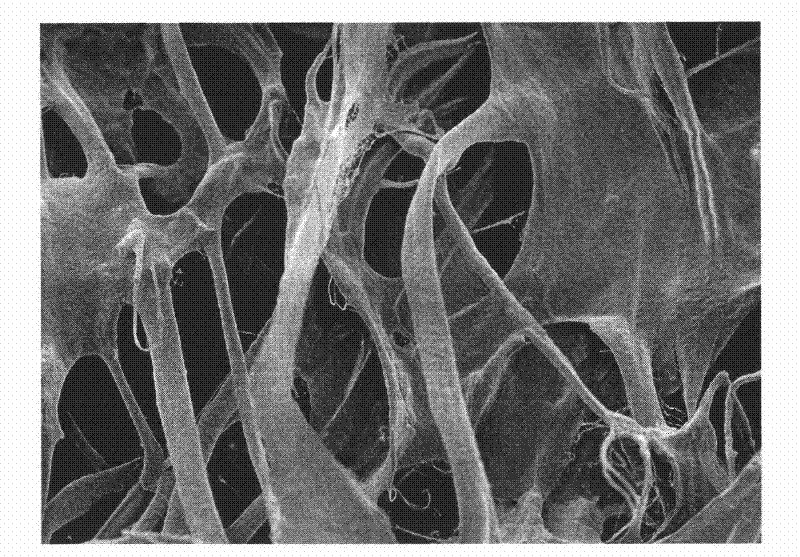

Bone tissue regeneration guiding membrane and preparation method thereof

A bone tissue regeneration guiding membrane. The invention employs an antigen-extracted mammal tissue membrane, which has a double layer structure of a compact layer and a loosening layer. The compact layer is formed by tightly arranged collagen fibers, and an external side of the compact layer is composited with a collagen coating containing active polypeptides; the loosening layer is formed by interlaced collagen fibers and is composited with ossification active factors. The prepared guiding membrane can prevent soft tissue from evolving and promote new bone formation, has good biological compatibility, hydrophilism and bone induction capability, and can be completely degraded in body without generation of harmful substances. Besides, the guiding membrane has an effect of isolating cell evolving, a characteristic of slow degradation and a longer retaining time in body than a current guiding membrane prepared from natural high-molecular polymer, and can provide enough time and space for new bone growth. The method of the invention is simple, and raw materials have wide sources and low prices, so that the method is suitable for large-scale industrial production and beneficial to lowering medical costs and mitigating patient burdens.

Owner:SHAANXI BIO REGENERATIVE MEDICINE CO LTD

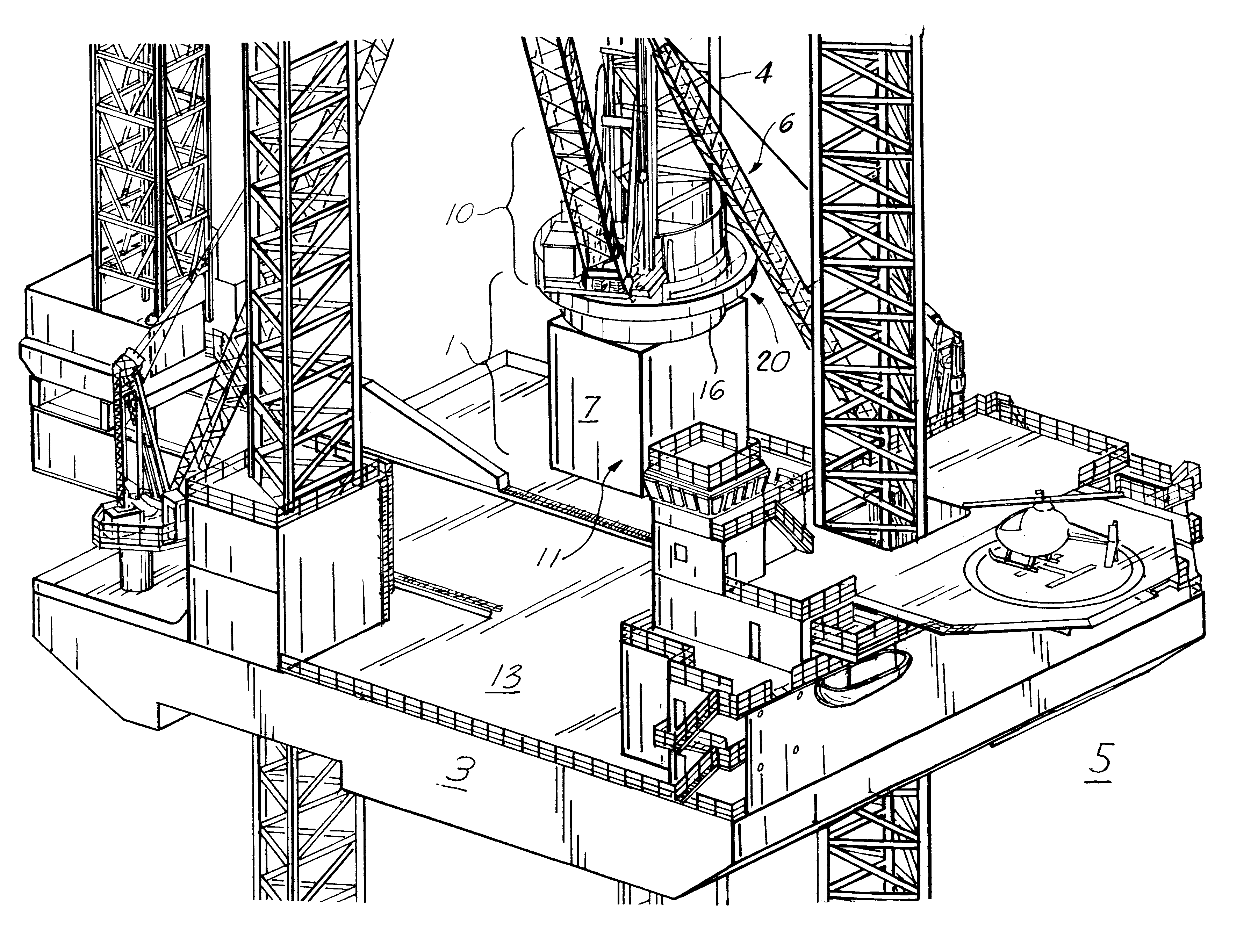

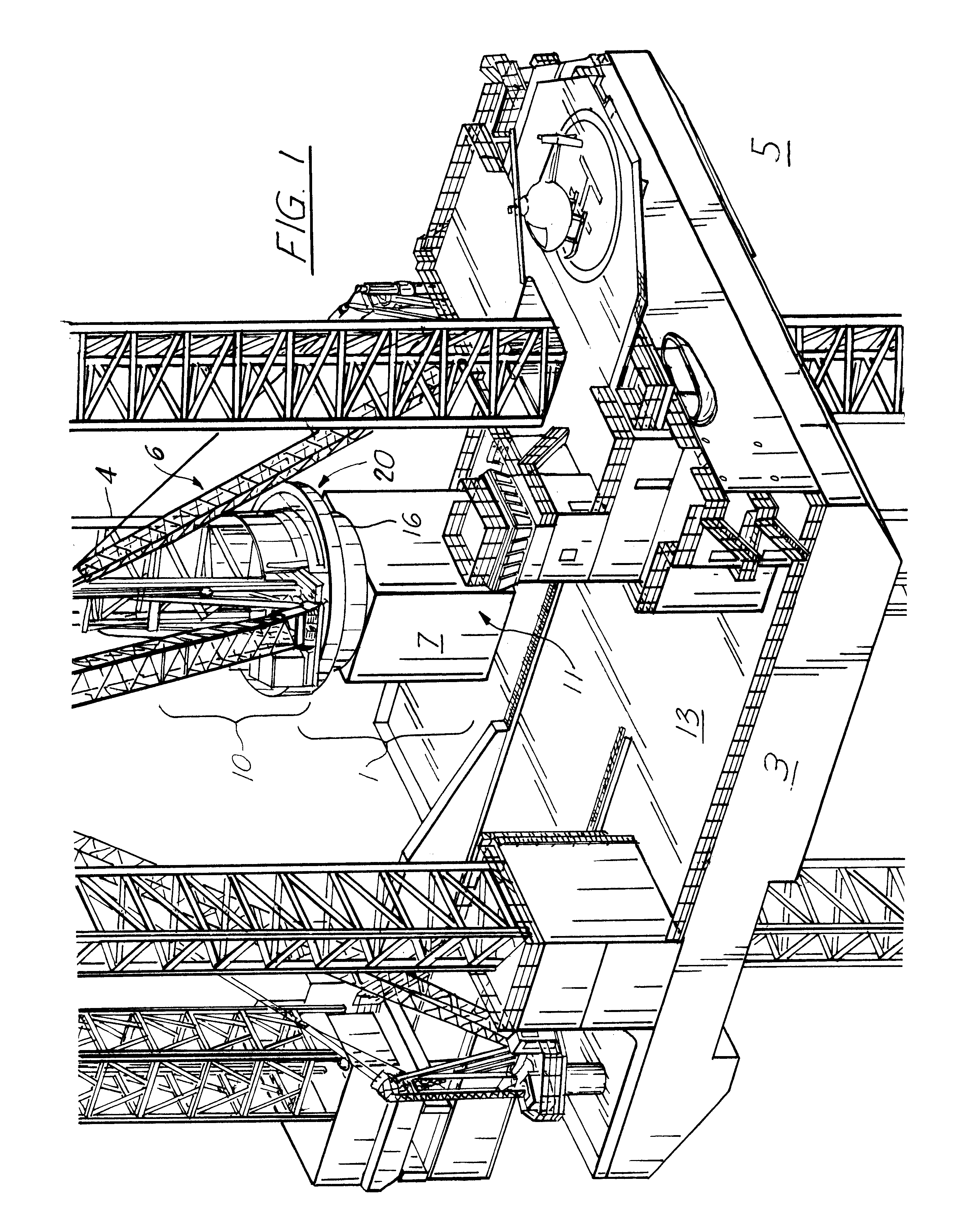

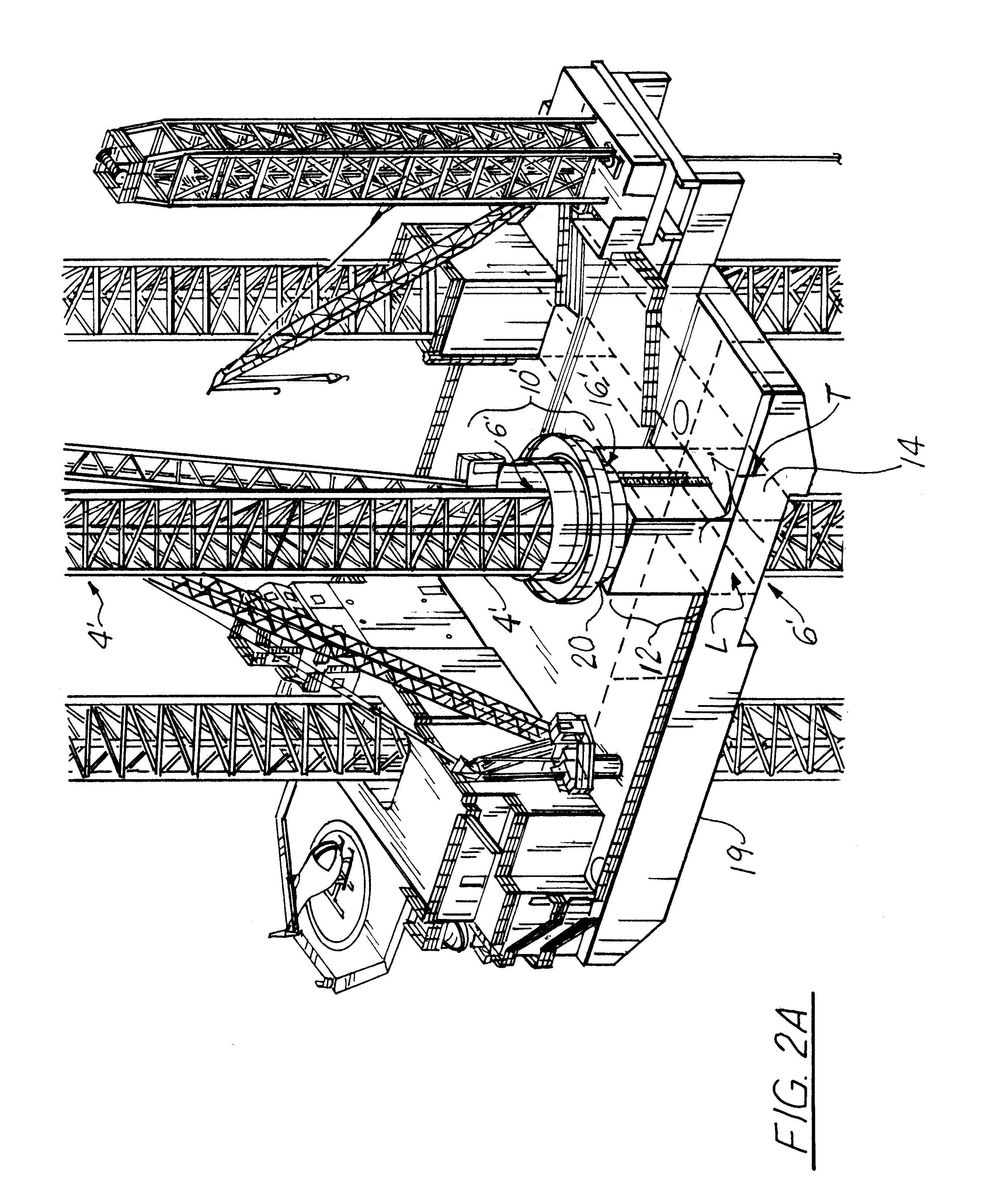

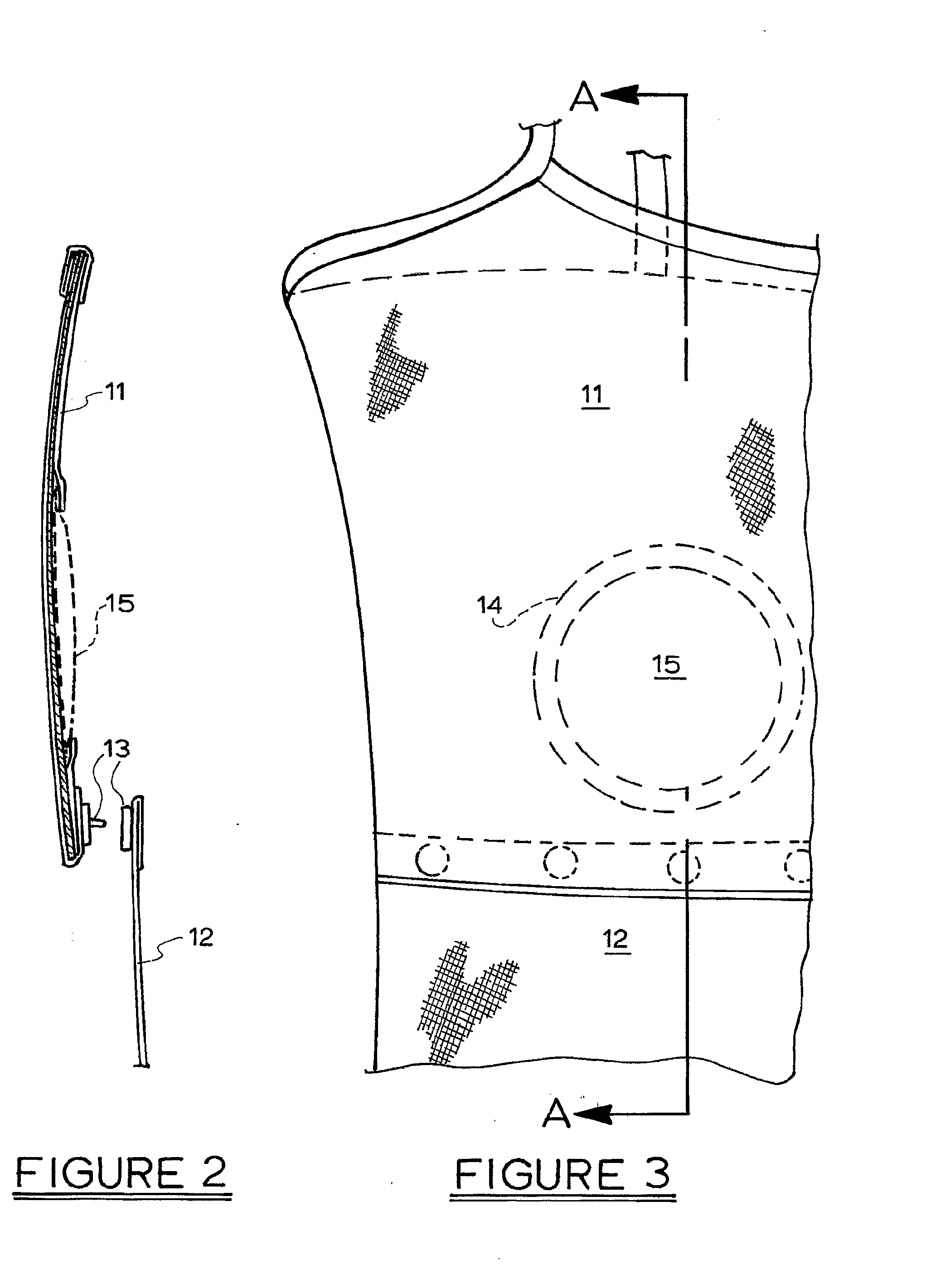

Elevated crane support system and method for elevating a lifting apparatus

InactiveUS6607331B2Save spaceImprove abilitiesArtificial islandsDrilling rodsSupporting systemMarine engineering

Owner:THE LEVINGSTON

Medical apparatus system having optical fiber load sensing capability

ActiveUS8894589B2Facilitate speedHelp accuracyStrain gaugePerson identificationProcess logicOptical property

Apparatus is provided for diagnosing or treating an organ or vessel, wherein a device having at optical fiber contact force sensors disposed in a distal extremity thereof and a deflection mechanism configured to deflect the elongate body at a location proximal of the distal extremity. The optical fiber contact force sensors are configured to be coupled to processing logic programmed which computes a force vector responsive to detected changes in the optical characteristics of the optical fiber contact force sensors arising from deflection of the distal extremity resulting from contact with the tissue of the wall of the organ or vessel.

Owner:ST JUDE MEDICAL INT HLDG SARL

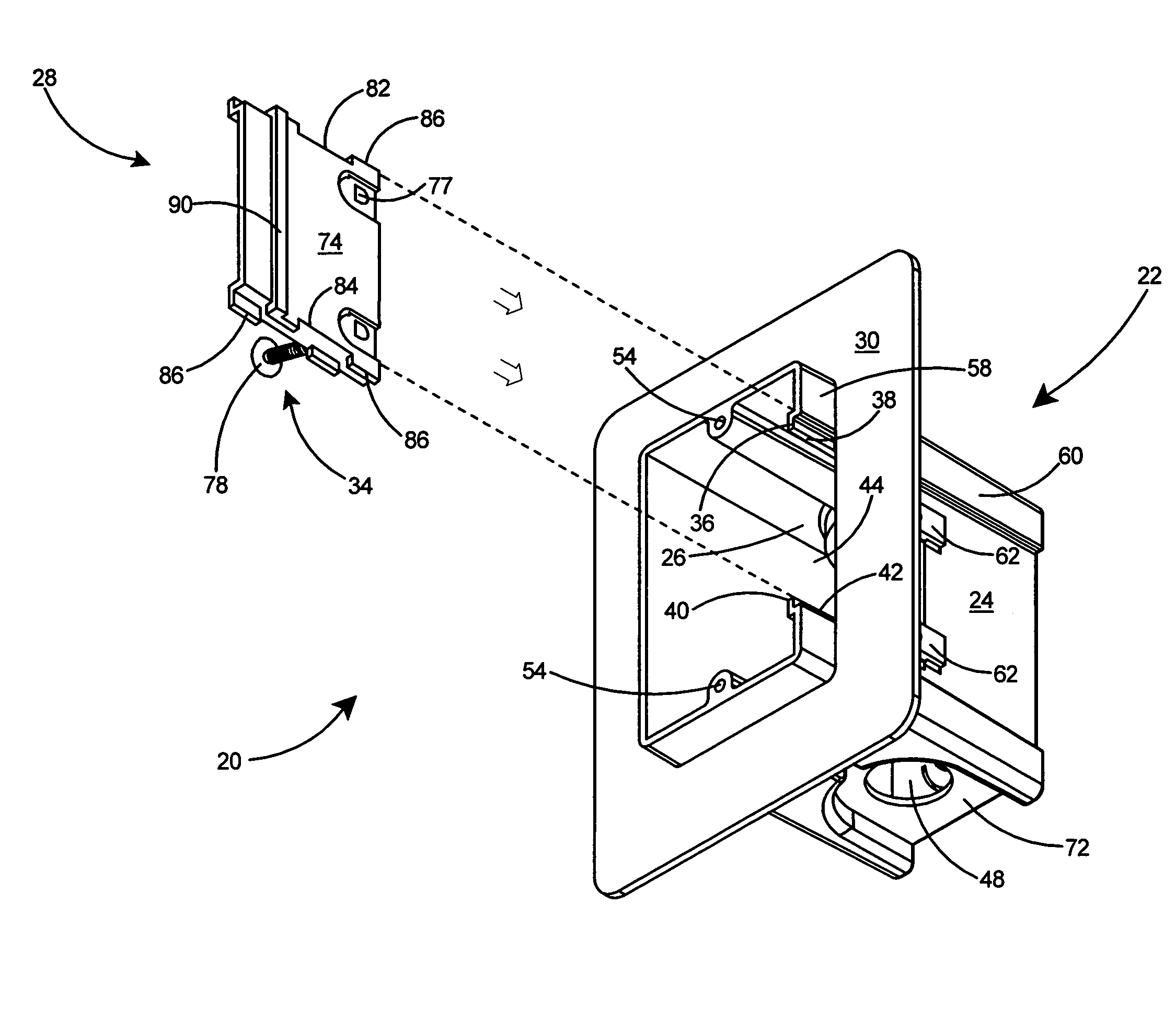

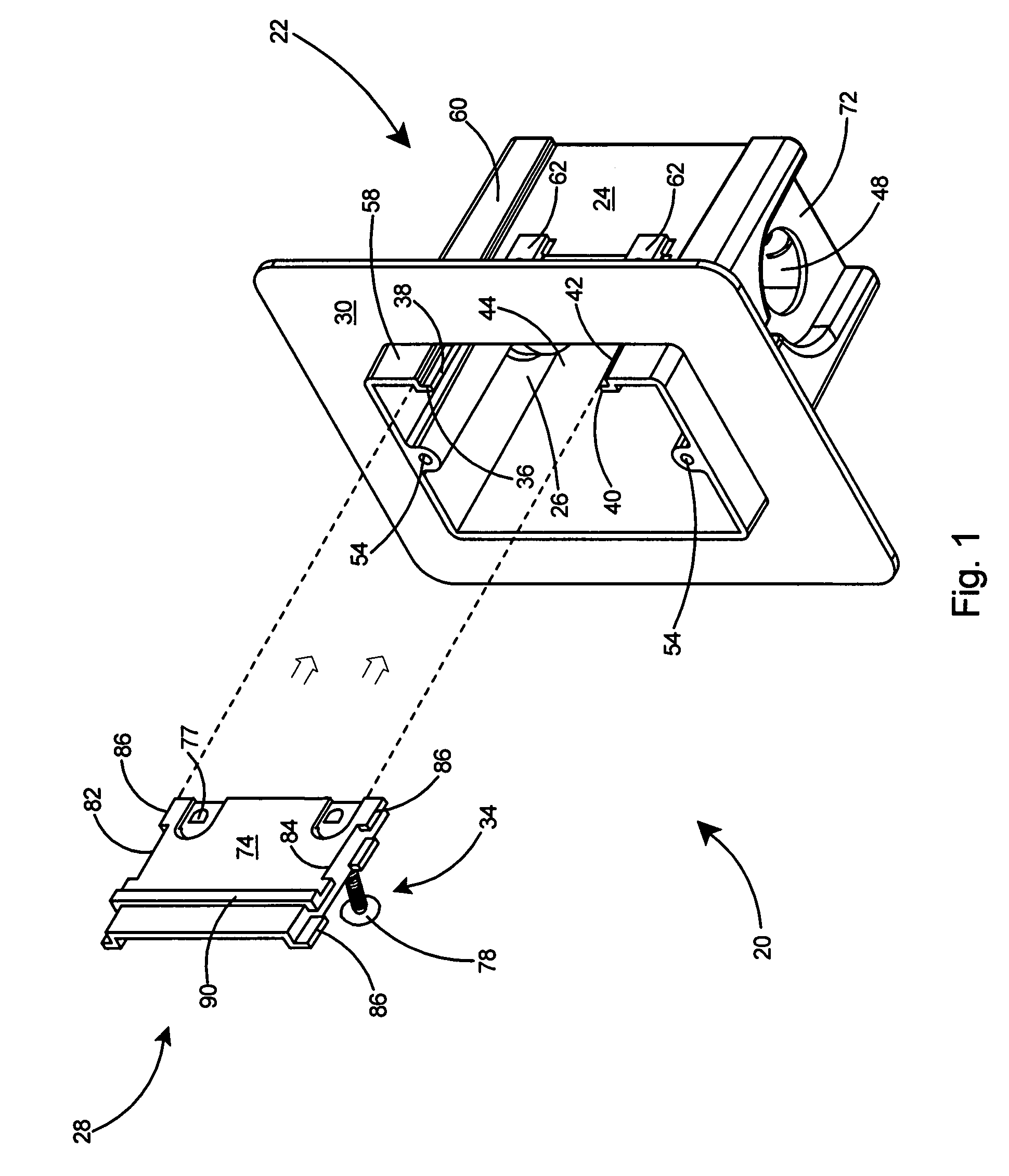

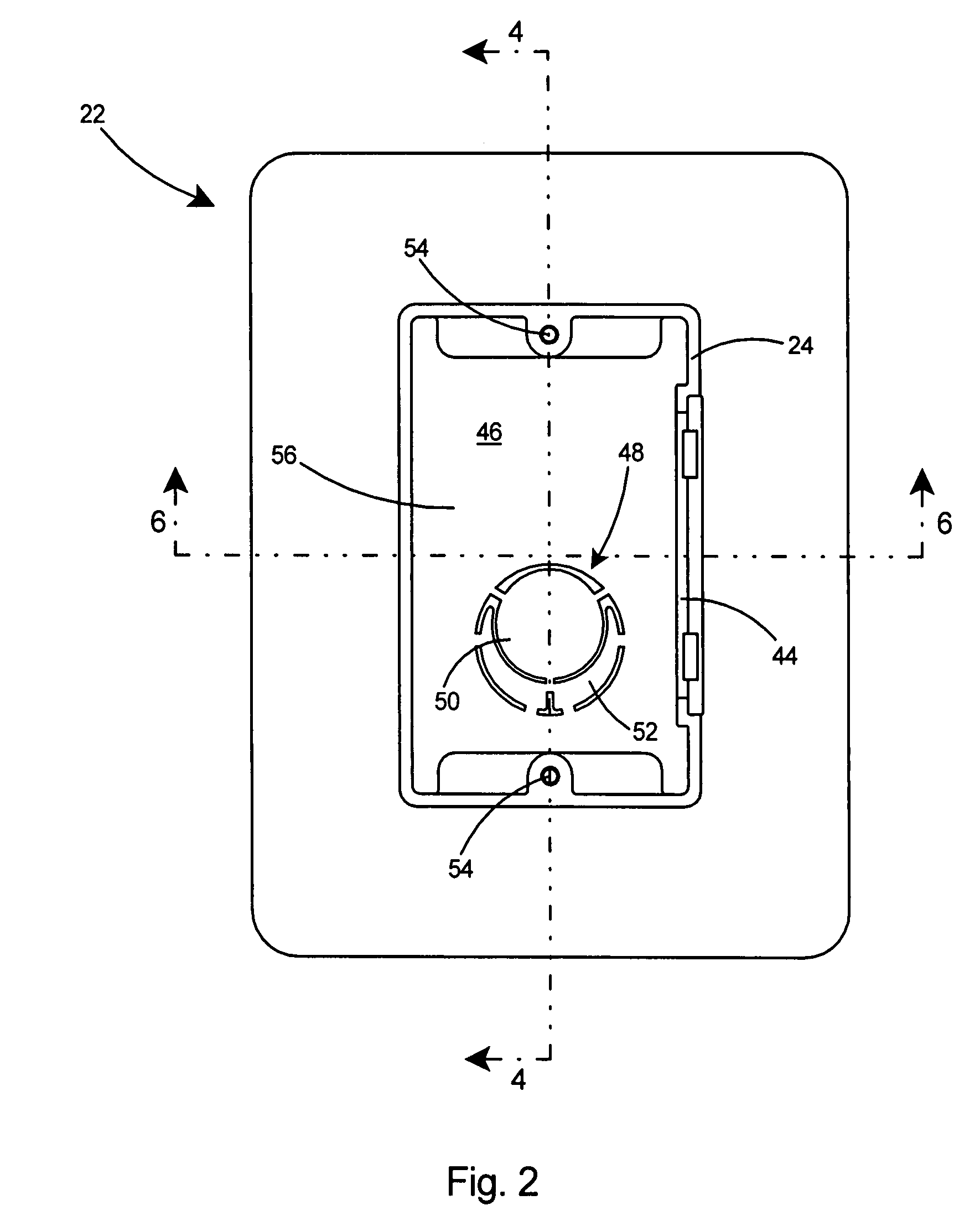

Electrical box assembly with internal mounting arrangement and flange to seal against air infiltration

ActiveUS7307212B1Minimize open areaImprove sealingCouplings bases/casesGaseous cathodesVapor barrierEngineering

An electrical box with sidewalls having a front edge and a flange extending transversely from the sidewalls at a set distance from the front edge. Knockouts in the sidewalls include multiple removable sections, which can be removed selectively as desired to create large or small openings for electrical cables. The sidewalls of the electrical box include an opening therein and a panel that can be inserted into the opening. The panel includes an internal mounting arrangement with captive fasteners for securing the electrical box to a stud. The flange provides a sealing surface for contacting the vapor barrier surrounding the box and thereby seals around the periphery of the electrical box. Duct seal is applied around the periphery of the cables at the knockout areas to provide an airtight seal for the electrical cables entering the electrical box.

Owner:ARLINGTON INDS

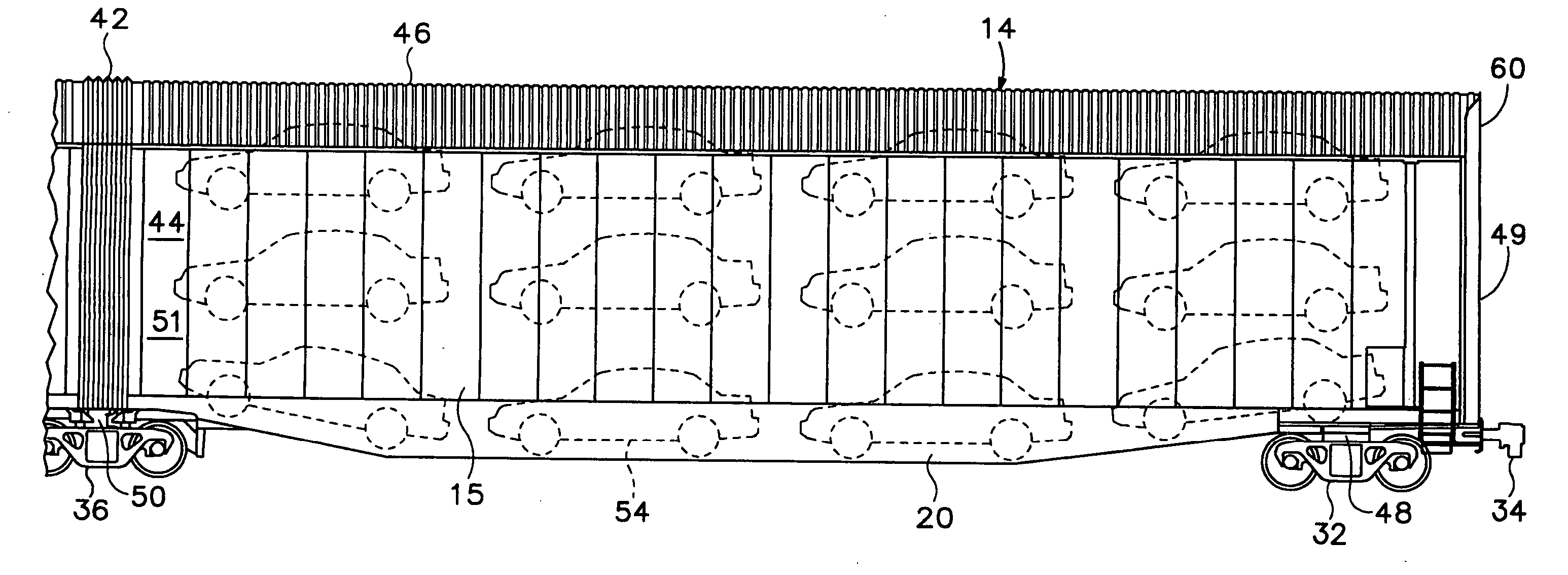

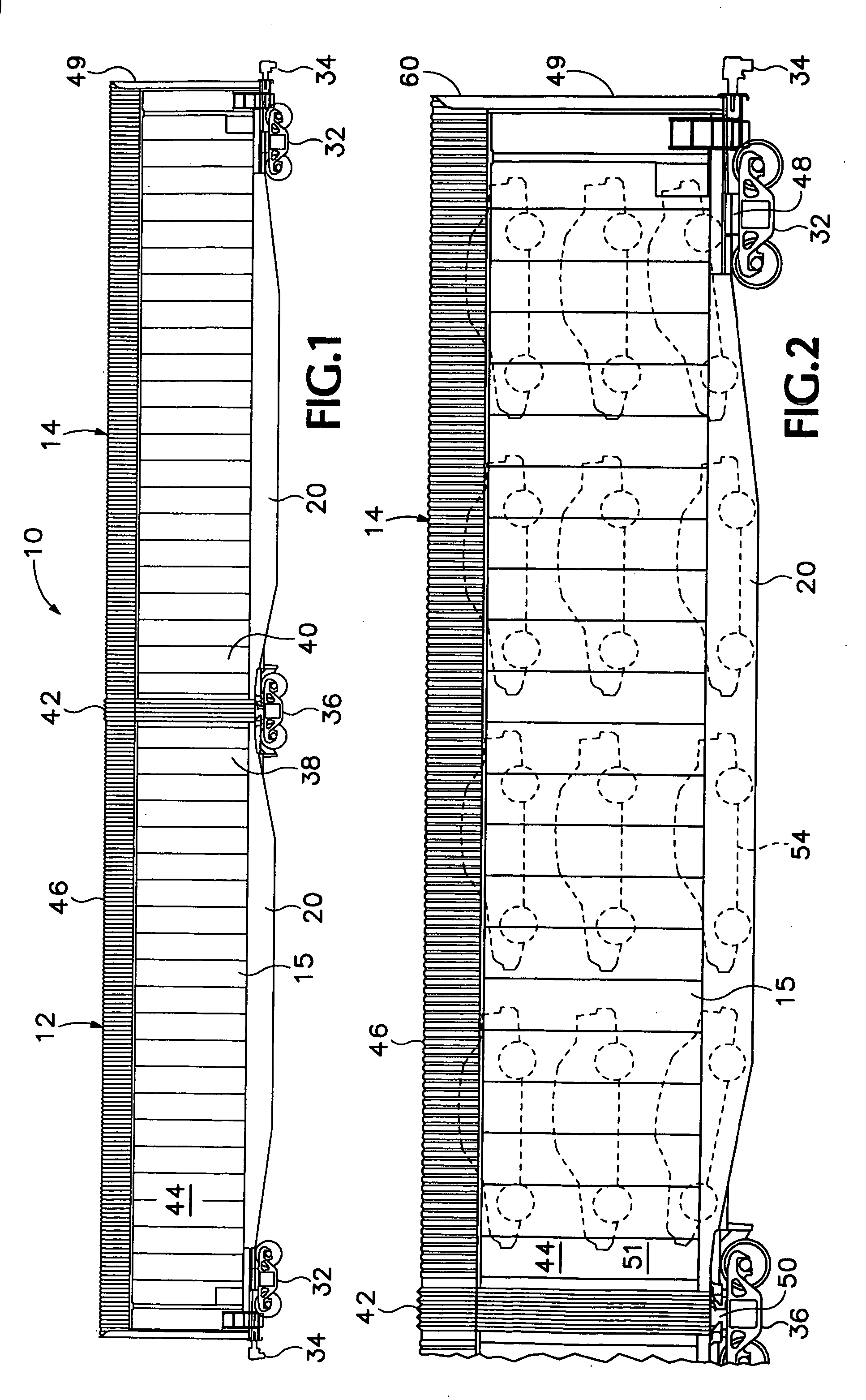

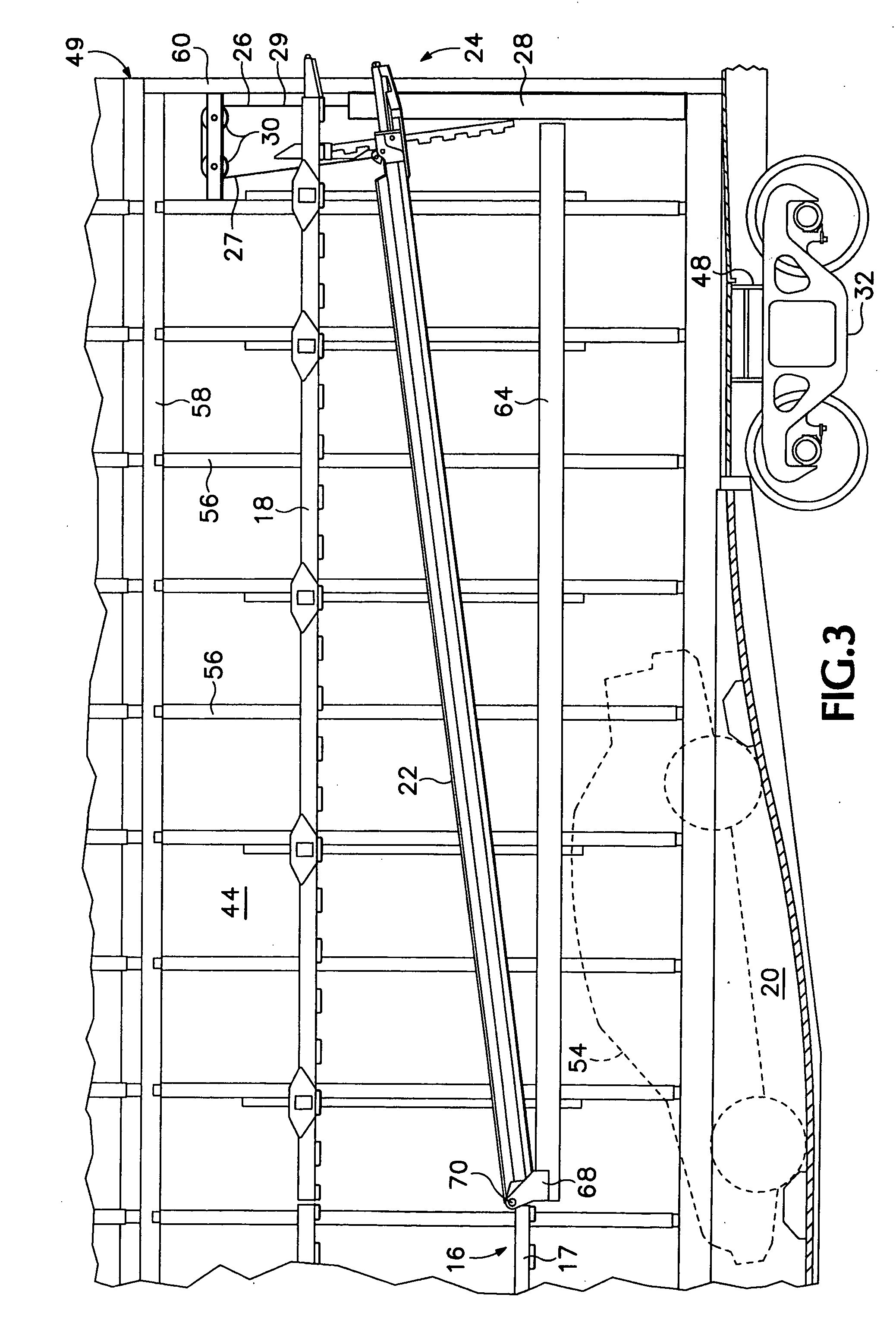

Counterbalanced deck for railroad freight car

A railroad car includes a body having a pair of side walls and at least a pair of parallel horizontal support beams extending along the side walls at substantially the same height. A movable end portion of a deck built as a lightweight composite structure may pivot with respect to the pair of support beams. A respective counterbalance apparatus is arranged between each of the pair of side walls and the movable deck portion at a location spaced apart from the pivot axis so as to provide a lifting force acting on the movable end portion to urge it to pivot upward about the pivot axis.

Owner:GUNDERSON

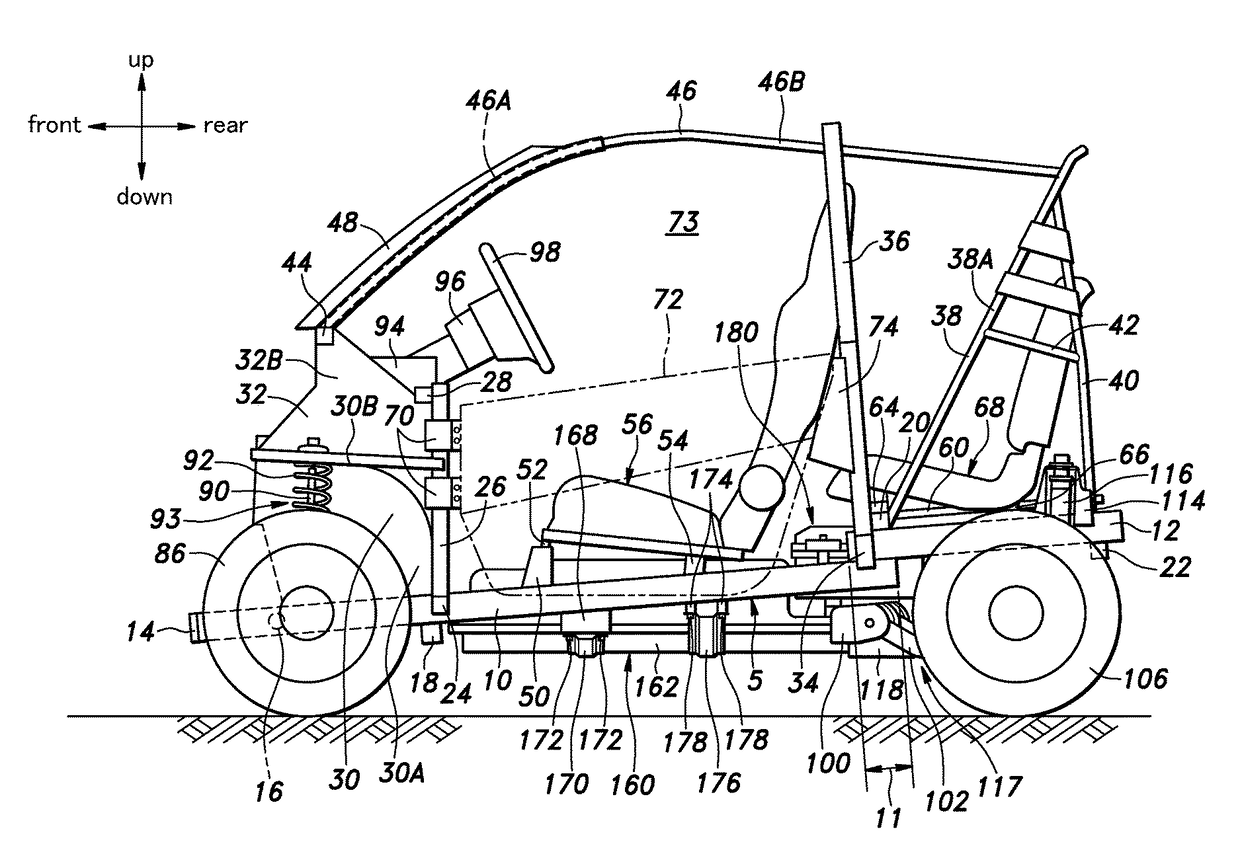

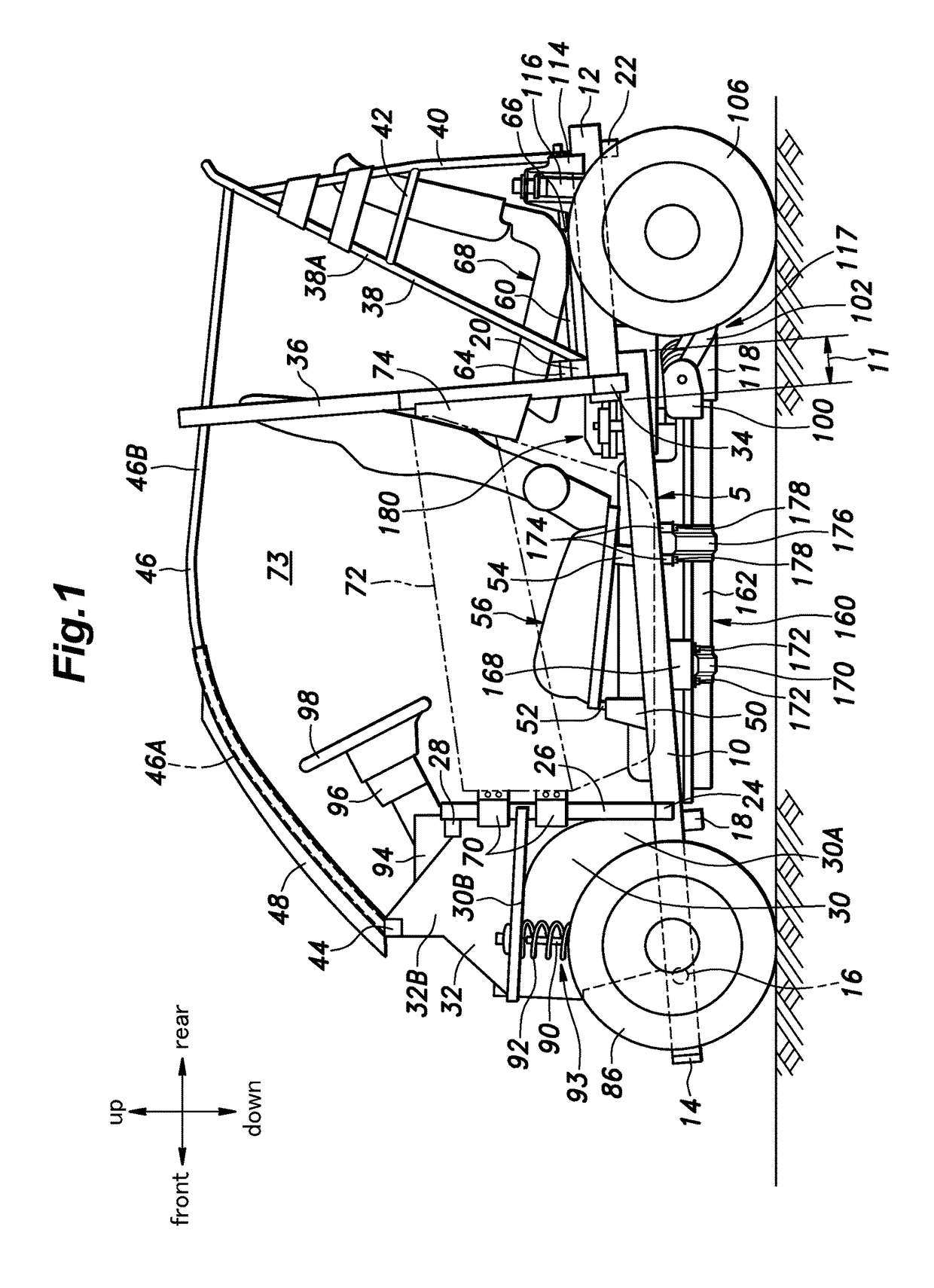

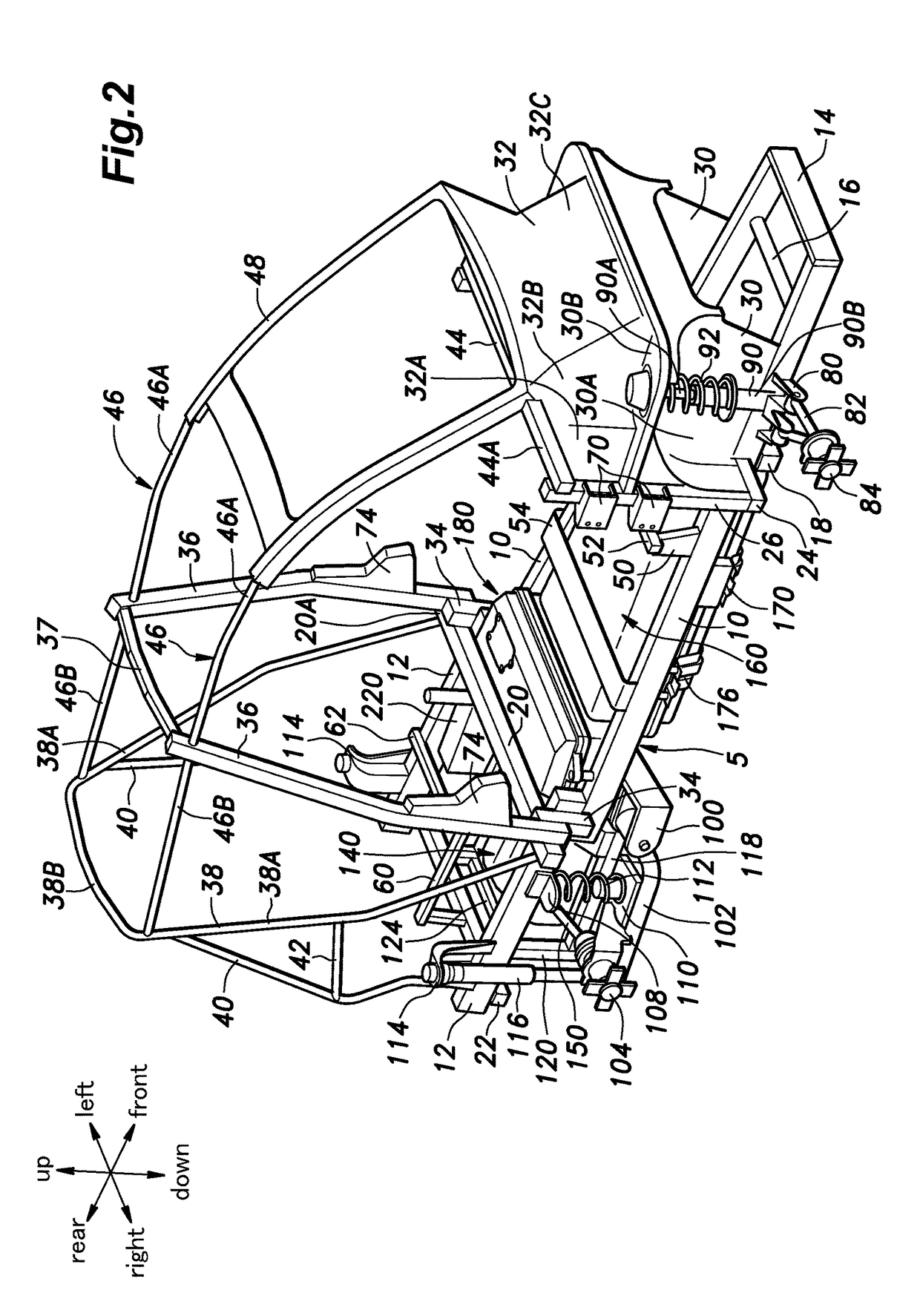

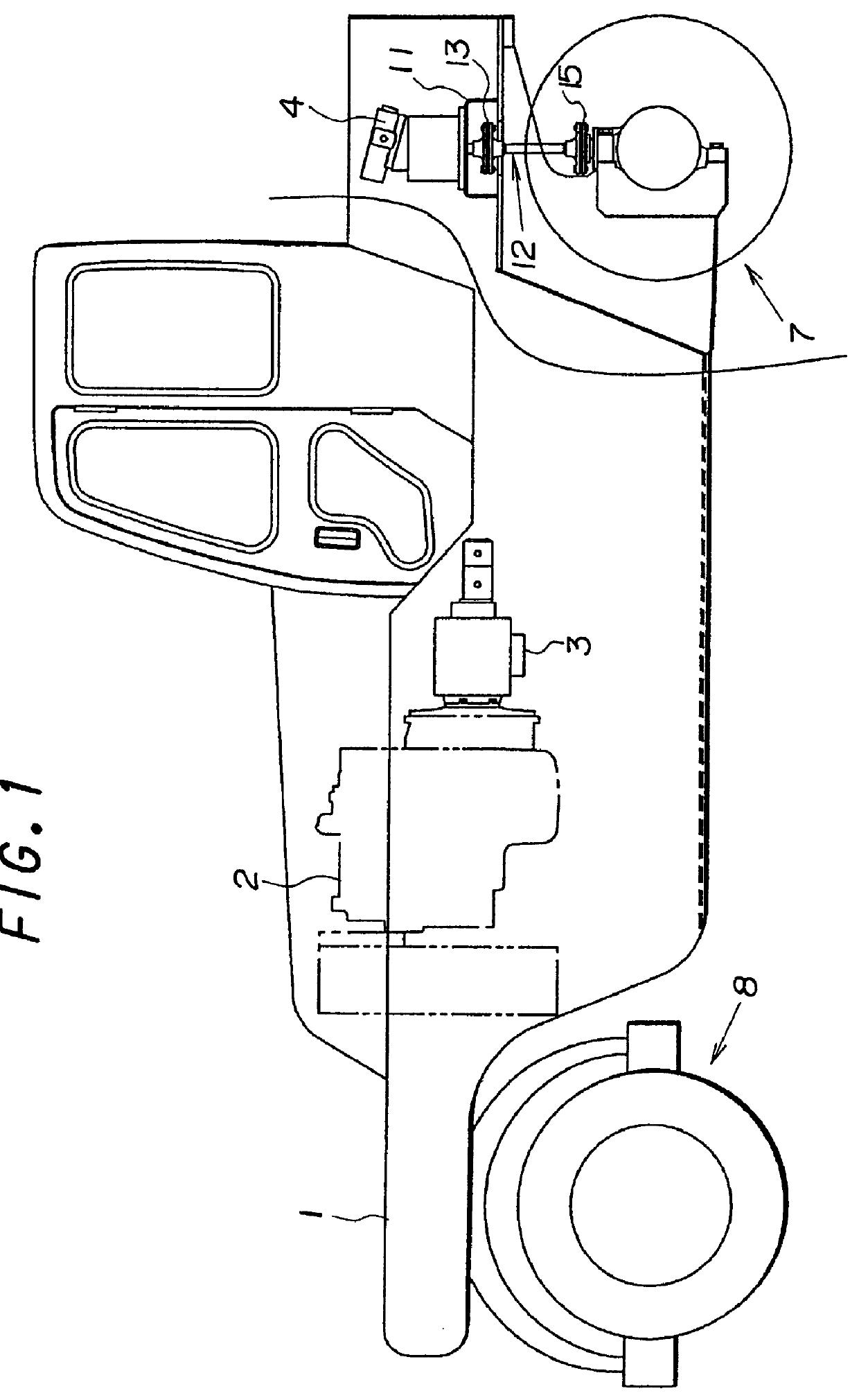

Four wheel vehicle

ActiveUS20170225715A1Plenty of spaceIncrease widthUnderstructuresVehicle sub-unit featuresEngineeringSide impact

The four wheel vehicle uses an electric motor (142) for driving the vehicle and a battery unit (160) for supplying electric power to the electric motor. The lower chassis (5) of the vehicle includes a pair of front side frames (10) extending linearly in a fore and aft direction with an upward slant and a progressively increasing lateral mutual spacing from a front part thereof to a rear part thereof and a plurality of cross members (14, 16, 18) connecting the front side frames to each other. The battery unit is positioned between the two front side frames such that the battery unit overlaps with the front side frames in side view. Thereby, the battery unit can be effectively protected from side impacts.

Owner:HONDA MOTOR CO LTD

Nursing Garment

InactiveUS20080000004A1Easy to openEasy to closeBrassieresMaternity clothingBiomedical engineeringFront panel

A nursing garment in which the front panel is divided into upper and lower sections whereby the upper section is overlaps and is attached to the lower section via a detachable seam extending horizontally across the front of the garment below the breast. Optionally nursing pads are placed into annular pockets.

Owner:FRESH IDEAS AUSTRALIA

High density bicycle storage system

A ceiling mount bicycle rack provides for easy loading through the use of downwardly transversely opening wheel hooks that may receive the tires of a bicycle when flipped about the bicycle's upper structure by a user through a gentle arc. After installation on the rack, the bicycle may be slid along longitudinal tracks for storage in a more compact configuration in a less accessible location.

Owner:FERRON WILLIAM J

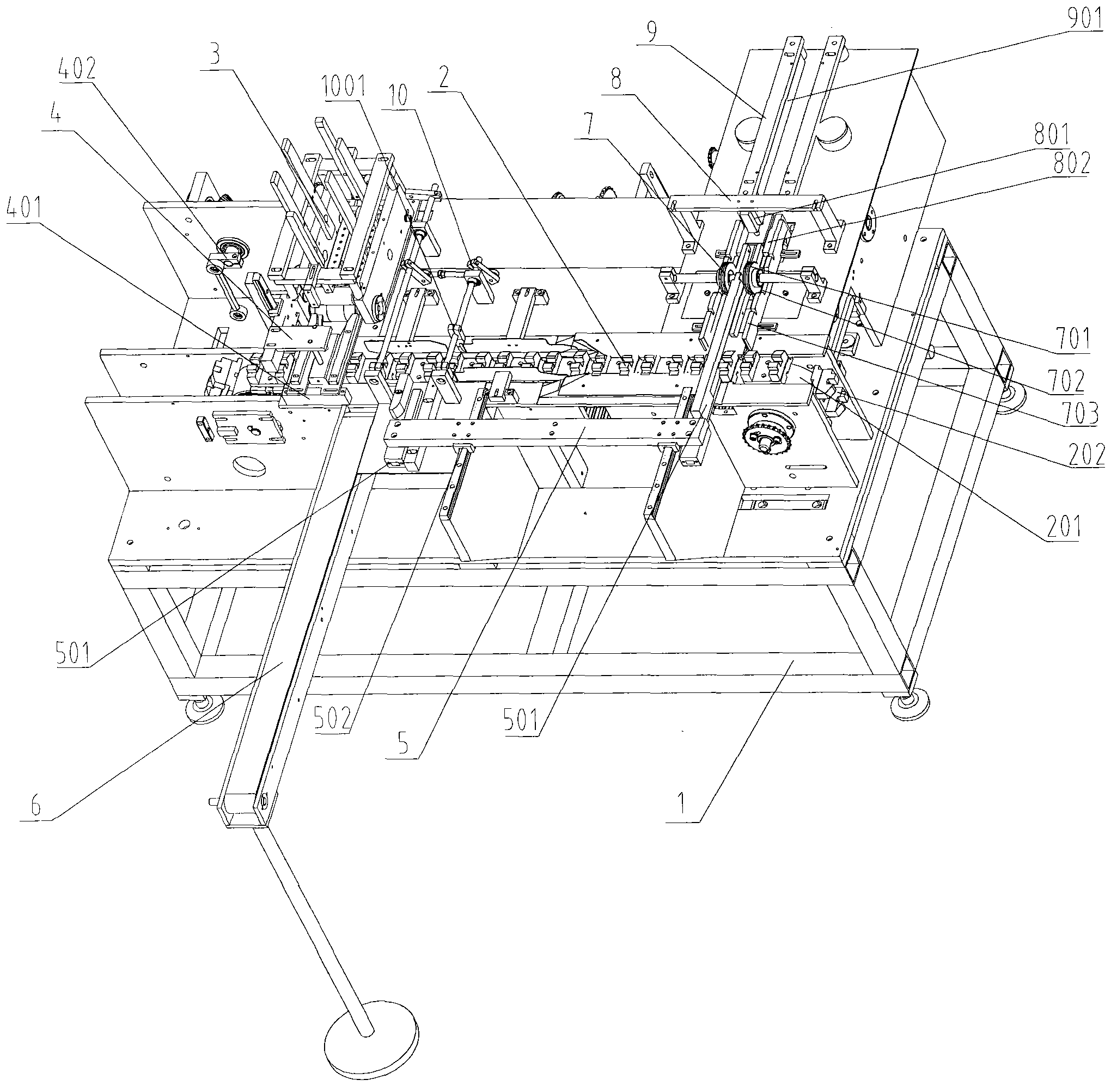

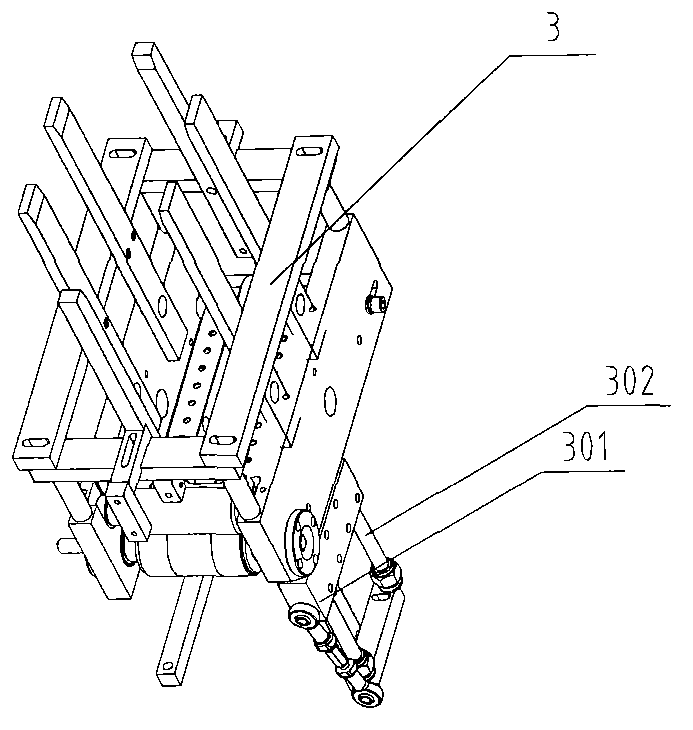

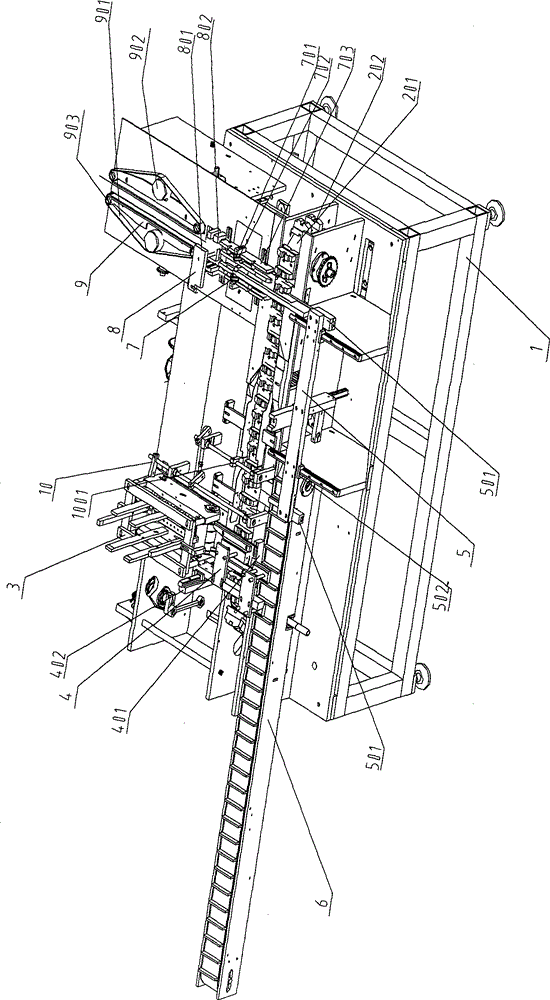

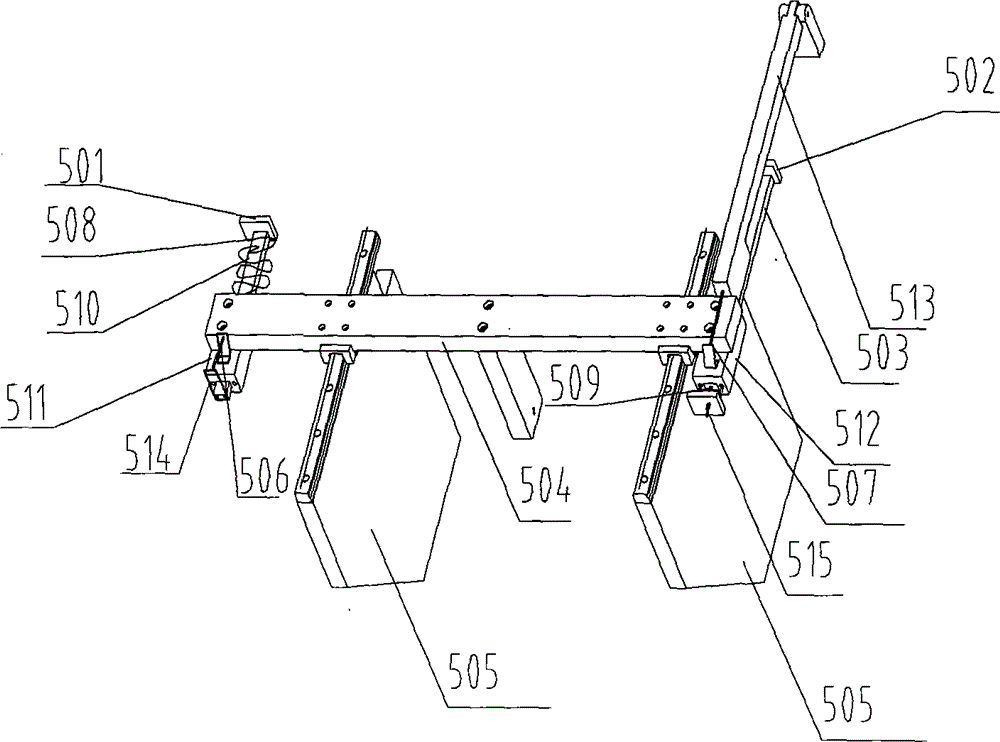

Tea-leaf boxing machine

ActiveCN103183140AGuaranteed success rateEliminate the problem of inaccurate positioningIndividual articlesDrive shaftPulp and paper industry

A tea-leaf boxing machine comprises a rack, as well as a paper box bin component, an air suction mechanism, a paper box forming module component, a paper box pressure block component, a paper box lug folding mechanism, a feeding mechanism, a material incoming and box outgoing push mechanism, a box gluing mechanism, a paper box shaping mechanism and an intermittent indexing drive device which are mounted on the rack, wherein the paper box bin component comprises a paper box bin and a paper box pressure block which are located on the same straight line, and the paper box pressure block is located above paper box forming modules; the air suction mechanism is arranged below the paper box bin component, and connected with a first rocker arm of a main transmission shaft; and the paper box forming module component comprises the paper box forming modules and a synchronous belt, the paper box forming modules are uniformly distributed on the synchronous belt, and the synchronous belt is connected with the intermittent indexing drive device. The invention provides the tea-leaf boxing machine which can perform mechanization packing, reduce the cost, and improve the efficiency.

Owner:浙江武义浩伟机械有限公司

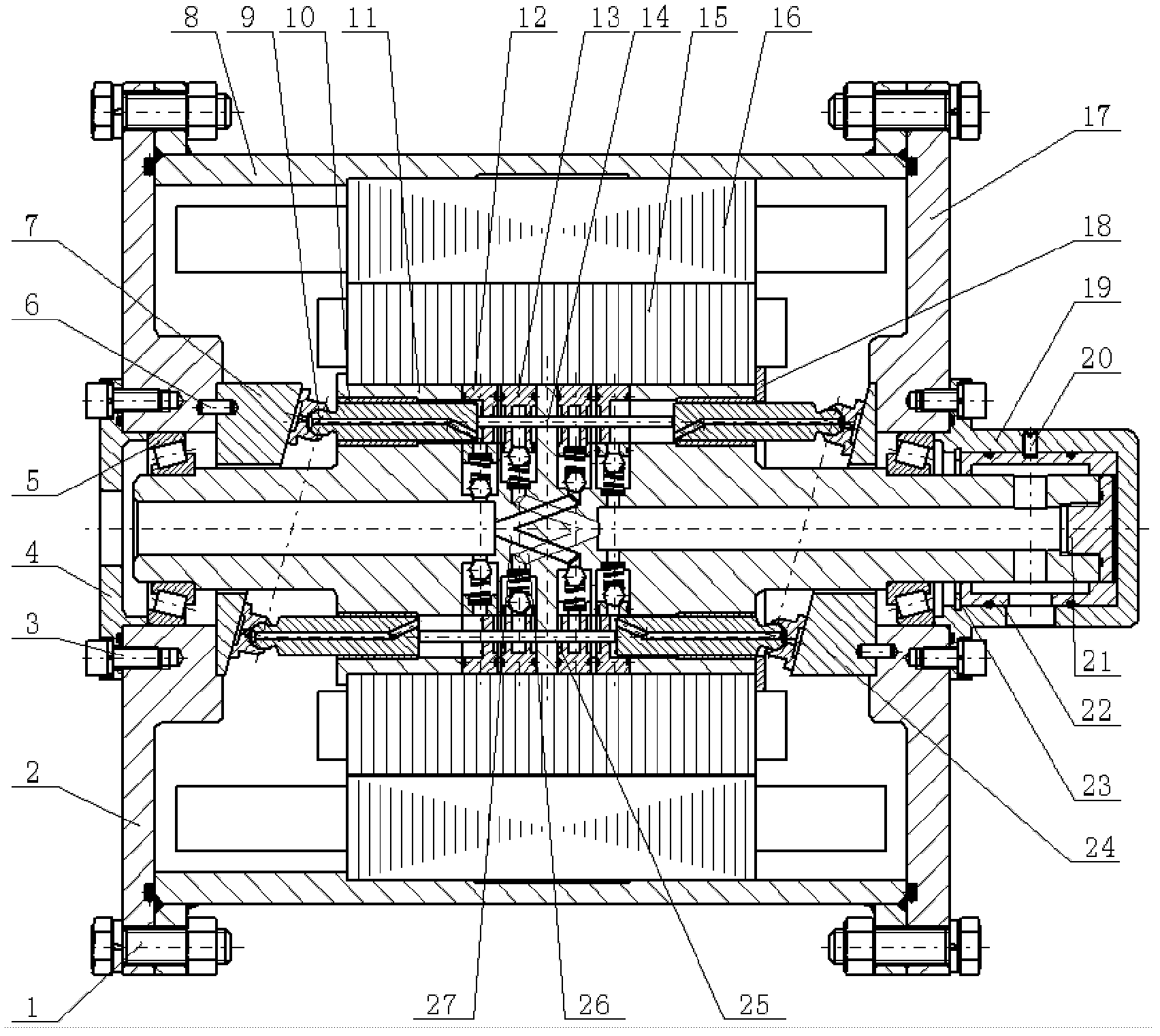

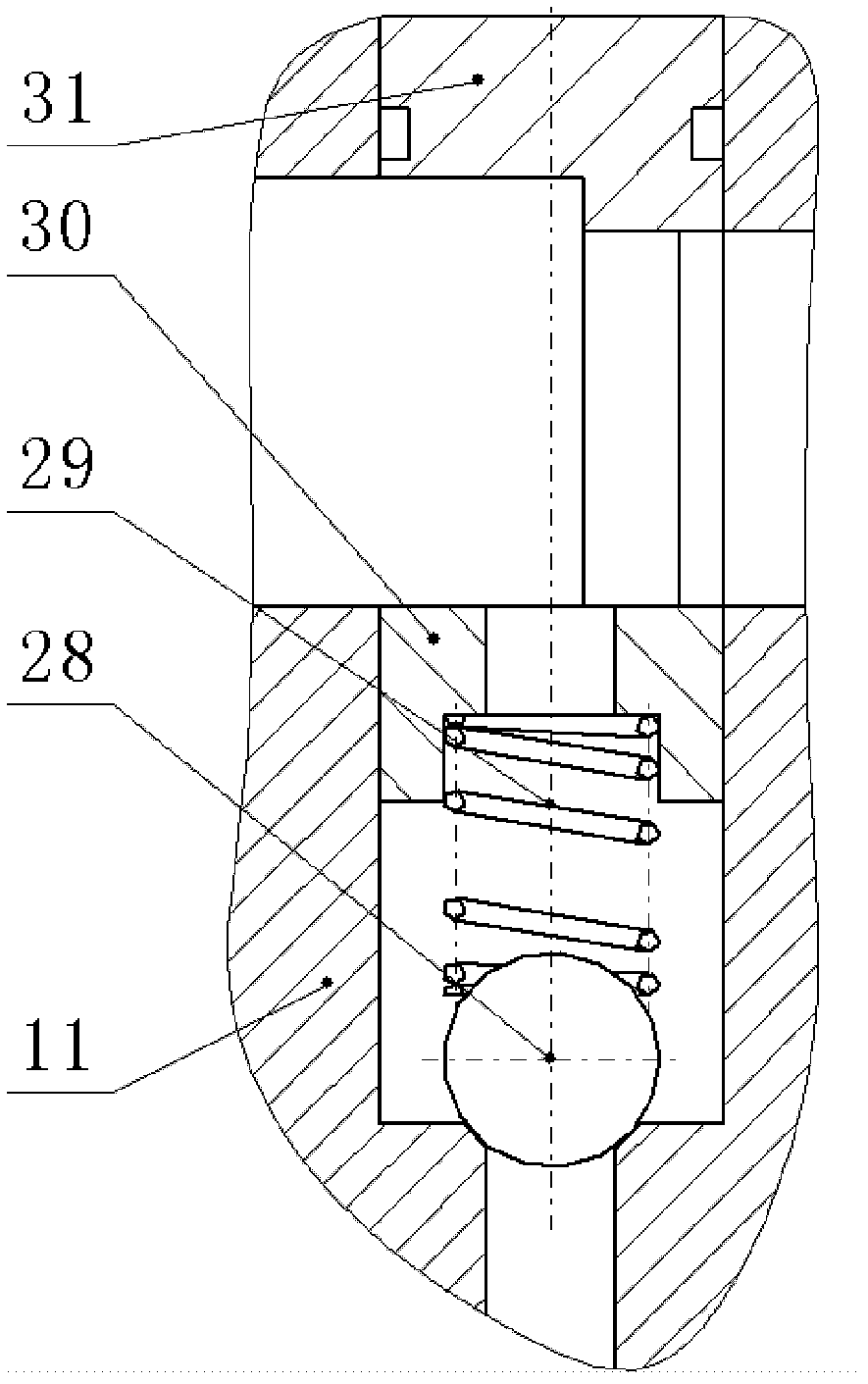

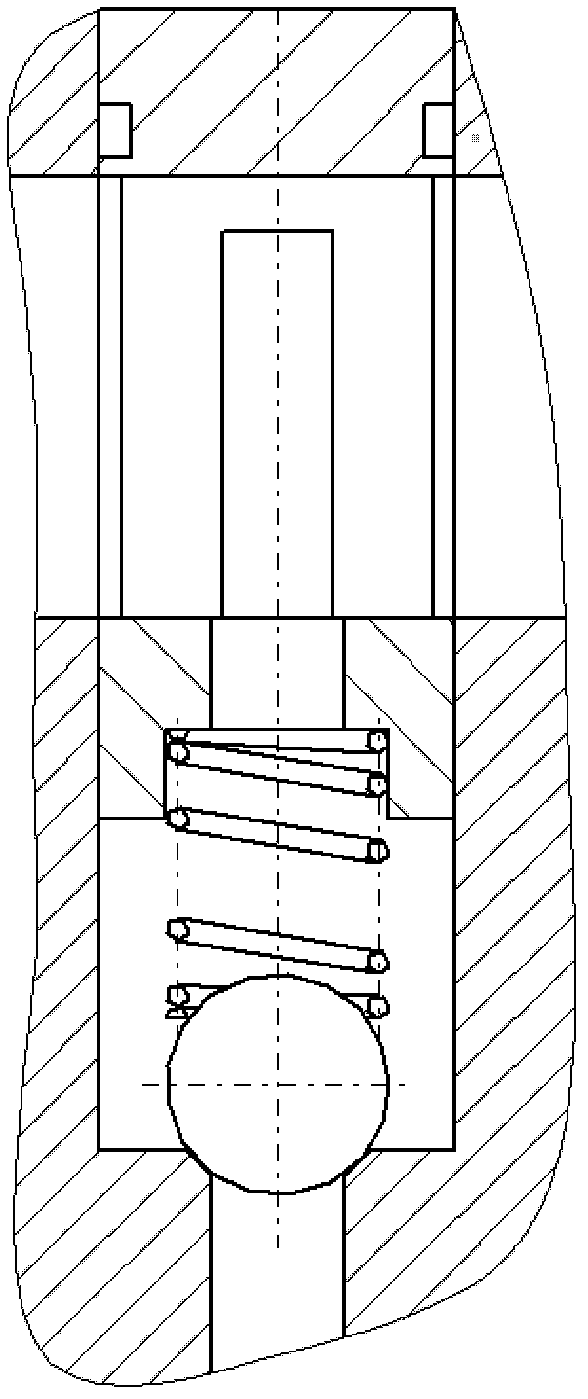

Plunger type motor pump

ActiveCN102619720AReduce intensityReduce stiffnessPositive-displacement liquid enginesMulti-cylinder pumpsEngineeringCylinder block

The invention discloses a plunger type motor pump, and belongs to a plunger pump. The problems of weak strength and low overall power density of a cylinder of the conventional plunger motor pump are solved. According to the plunger type motor pump, a motor stator is assembled in a housing. The two ends of the cylinder are supported in the centers of a left end cover and a right end cover respectively. A motor rotor is sleeved on and fixedly connected with a lug boss on the middle part of the cylinder. N plunger cavities are reserved in each of the left and right end faces of the lug boss of the cylinder. A plunger piston shoe component is arranged in each plunger cavity. Suction and forcing valve components are arranged in correspondence to each plunger piston shoe component on the lug boss of the cylinder. A left swash plate is fixed on the inner side of the left end cover, and a right swash plate is fixed on the inner side of the right end cover. The plate surfaces of the left and right swash plates are parallel. Every two coaxial plunger piston shoe components are pressed against each other through a support rod, and piston shoe heads at the two ends are pressed on the plate surfaces of the left and right swash plates respectively. Reverse thrust generated between the plunger piston shoe components at the two ends and the swash plates and hydraulic acting force in the cylinder are transmitted through the support rods, and internal reacting force is fully utilized, so that the number of the parts is decreased, the overall strength of the pump is strengthened, and the internal space utilization rate of the cylinder is increased.

Owner:HUAZHONG UNIV OF SCI & TECH

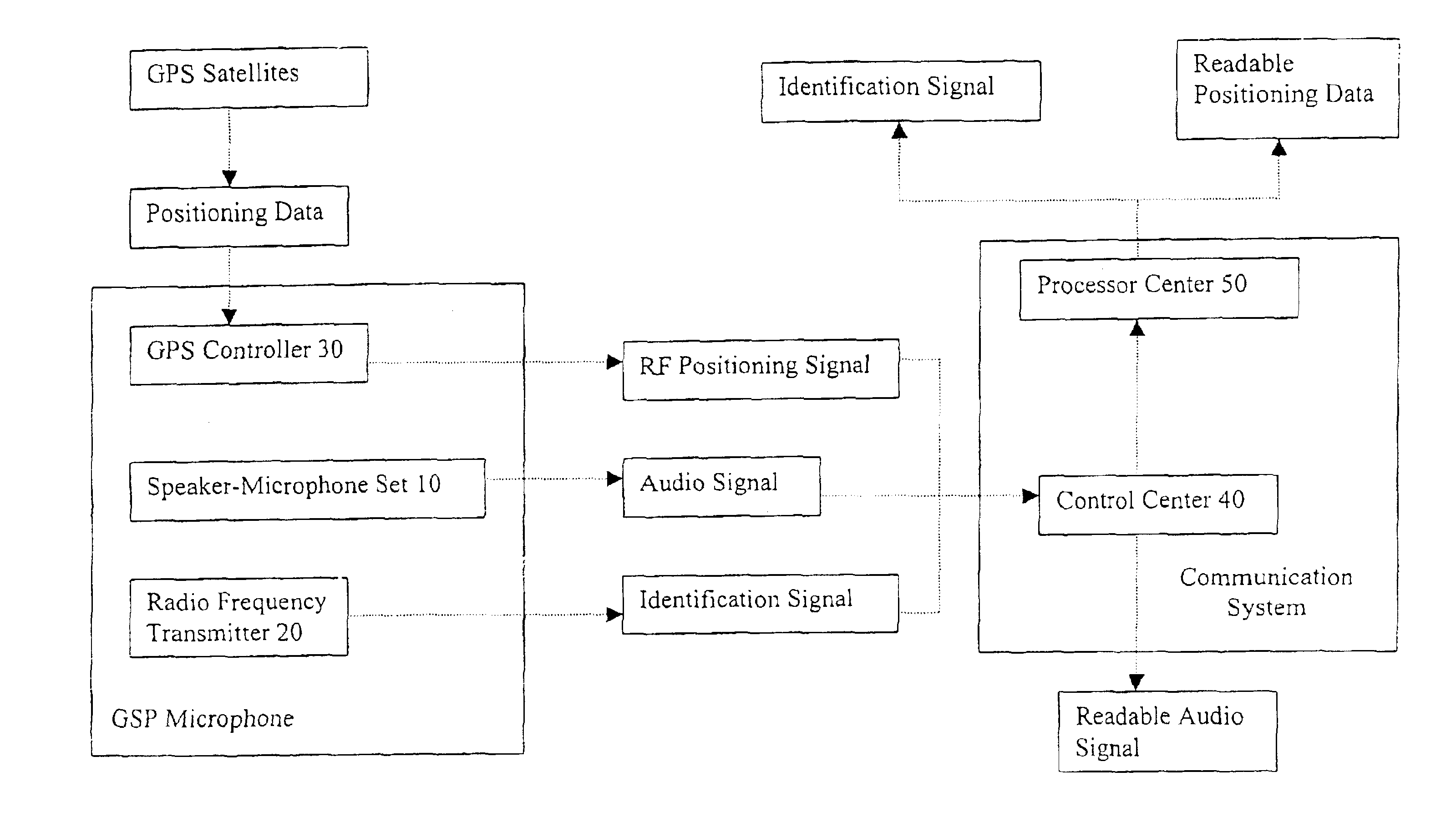

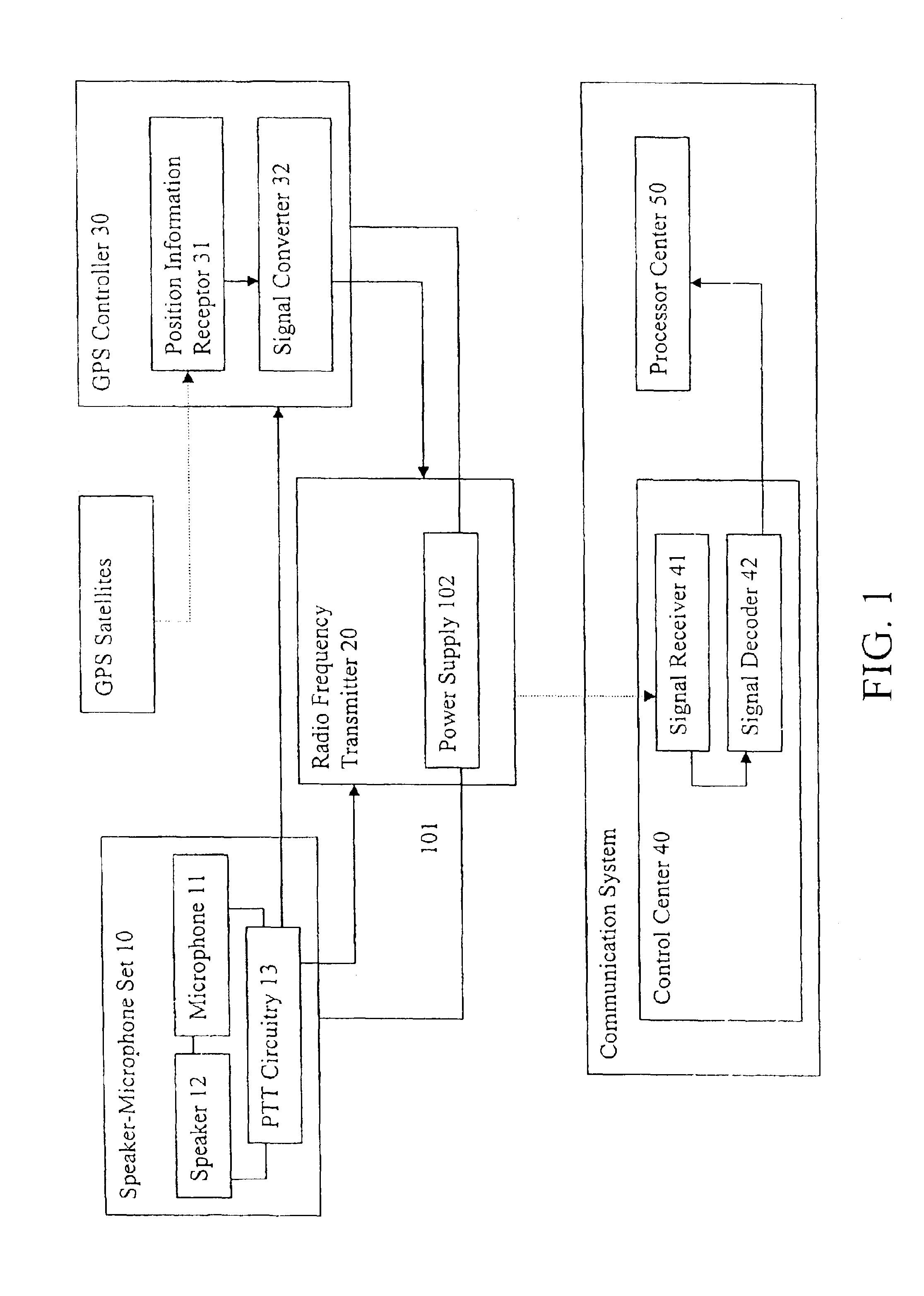

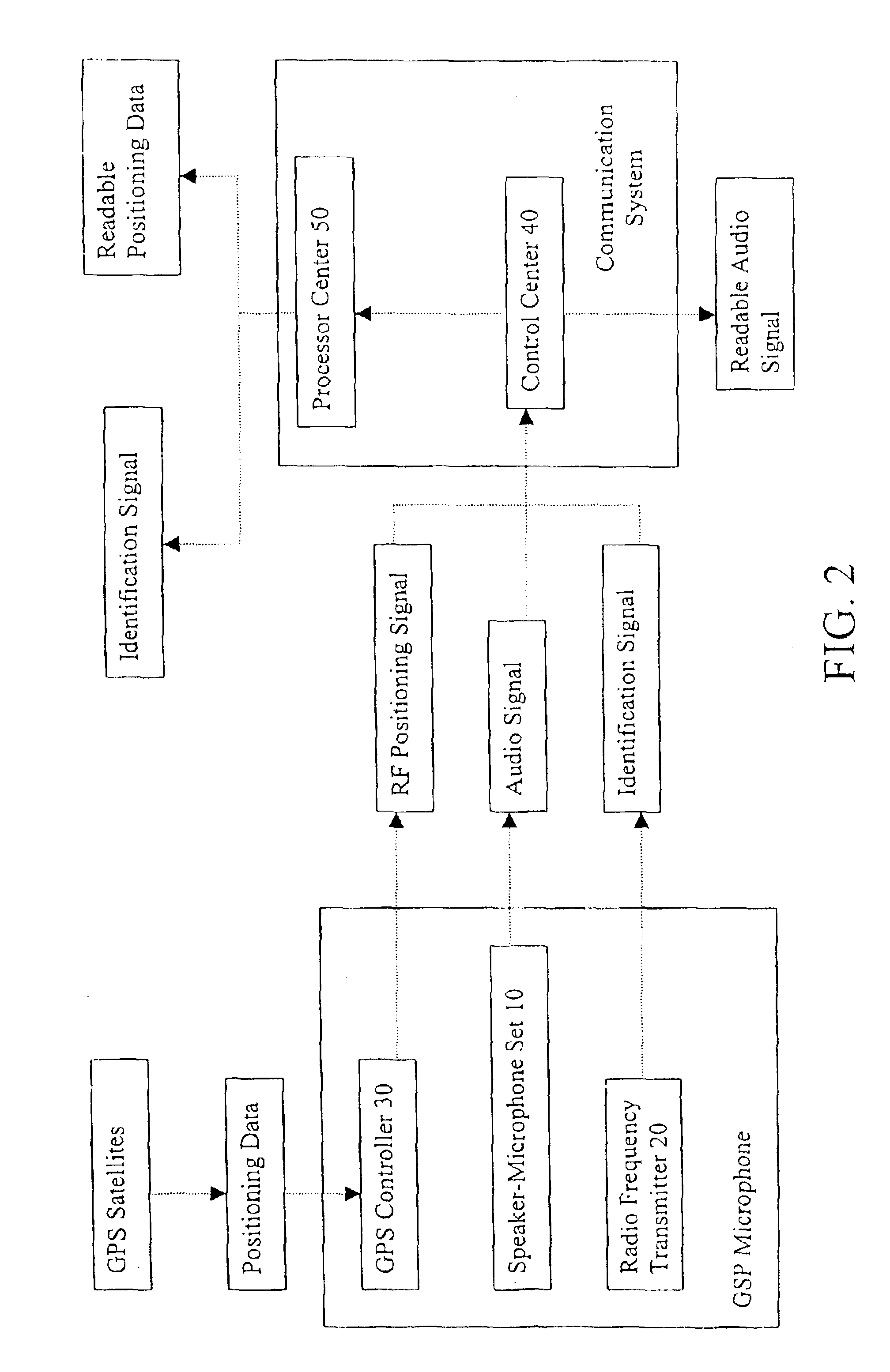

GPS microphone for communication system

InactiveUS6912397B2Reduce manufacturing costPlenty of spaceInstruments for road network navigationBeacon systems using radio wavesElectricityCommunications system

A GPS microphone, which is adapted for incorporating a communication system, includes a speaker-microphone set, a radio frequency transmitter communicatively networked with the communication system through radio frequency signals, and a GPS controller electrically connected with the radio frequency transmitter to encode positioning data into one or more RF positioning signals in form of audio signals wherein when the GPS controller is triggered, the radio frequency transmitter is activated to transmit RF positioning signals to the communication system.

Owner:LIOU HENRY

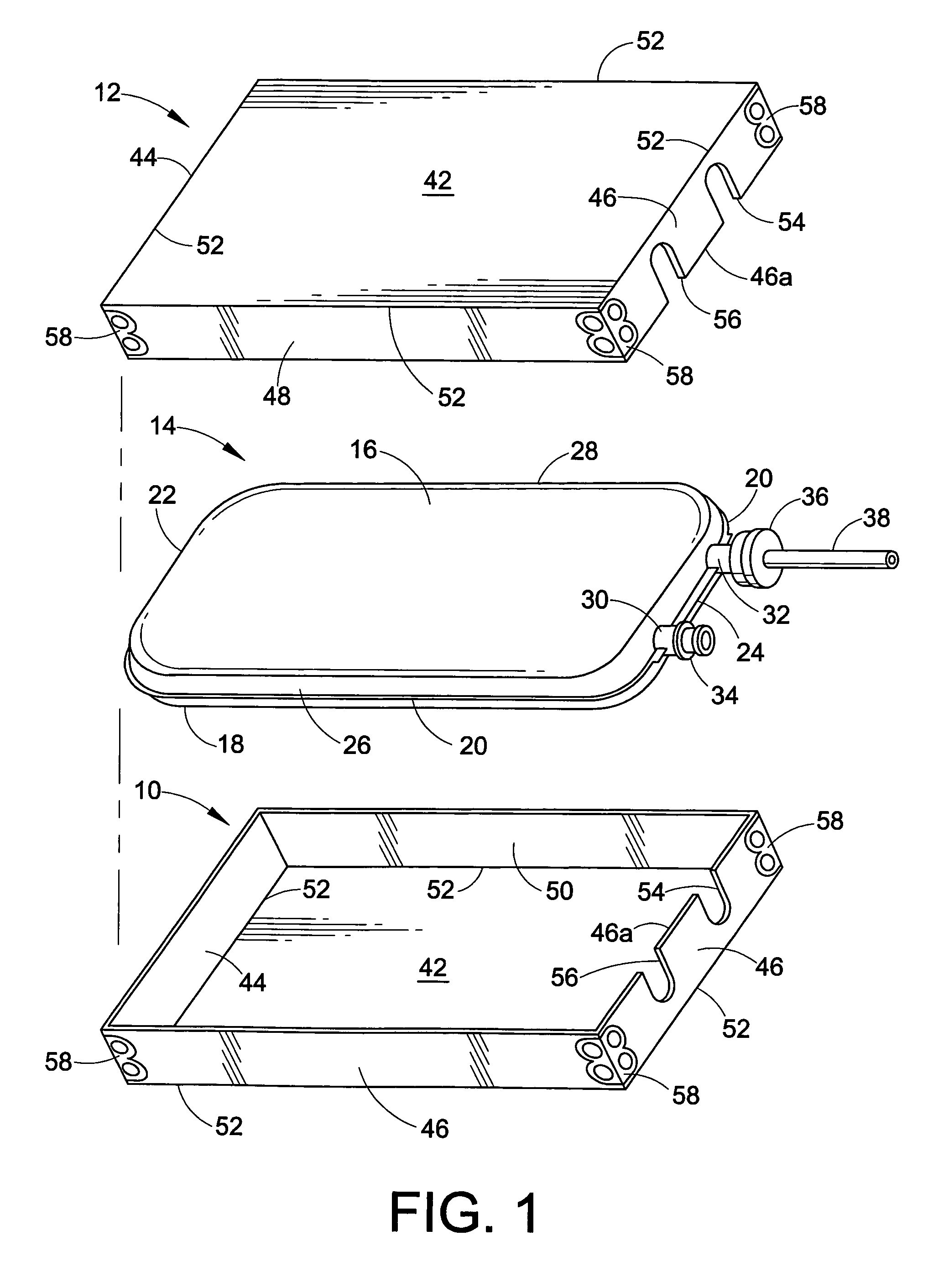

Enclosure for ink reservoir bag

InactiveUS7488059B1Prevents application of excessive pressureLow production costPrintingReservoir bagDelivery system

An enclosure for an ink reservoir bag in an ink delivery system for an ink cartridge comprises a tray and a cover for the tray. The tray includes a bottom wall having opposite ends and opposite sides, end walls extending upwardly from said bottom wall at the opposite ends and side walls extending upwardly from the bottom wall along the opposite sides. One of the end walls of the tray has a pair of openings therethrough between the side walls to receive fill and exit ports of the reservoir bag.

Owner:NU KOTE INT

Low-temperature glass solder bonding and encapsulating method based on disc level glass micro-chamber

InactiveCN101497422AGuaranteed reliabilityLower packaging costsTelevision system detailsPrecision positioning equipmentCMOSFritted glass

The invention discloses a low-temperature glass solder bonding and packaging method based on wafer-level glass microcavities, which comprises the following steps: firstly, utilizing a silk-screen printing process to coat low-temperature glass solder on a packaging contact part of a Pyrex7740 glass substrate provided with a microcavity structure, preliminarily drying the low-temperature glass solder, and making the low-temperature glass solder be cured and cling to the Pyrex7740 glass substrate provided with the microcavity structure; secondly, aligning a Pyrex7740 glass packaging wafer which is cured with the low-temperature glass solder and a silicon substrate wafer comprising an MEMS device or a CMOS circuit, and making the microcavity structure on the Pyrex7740 glass substrate correspond to the position of the MEMS device or the CMOS circuit to be packaged of a silicon substrate; and thirdly, using a clamper to firmly clamp the two aligned wafers, applying the pressure, sintering the glass solder in a specified packaging atmosphere, and cooling the glass solder. The whole process is based on integral processing of the silicon wafer and the Pyrex7740 glass wafer, belongs to a process for manufacturing and packaging a wafer-level MEMS, and has the characteristics of simple method, adjustable packaging space and low cost.

Owner:SOUTHEAST UNIV

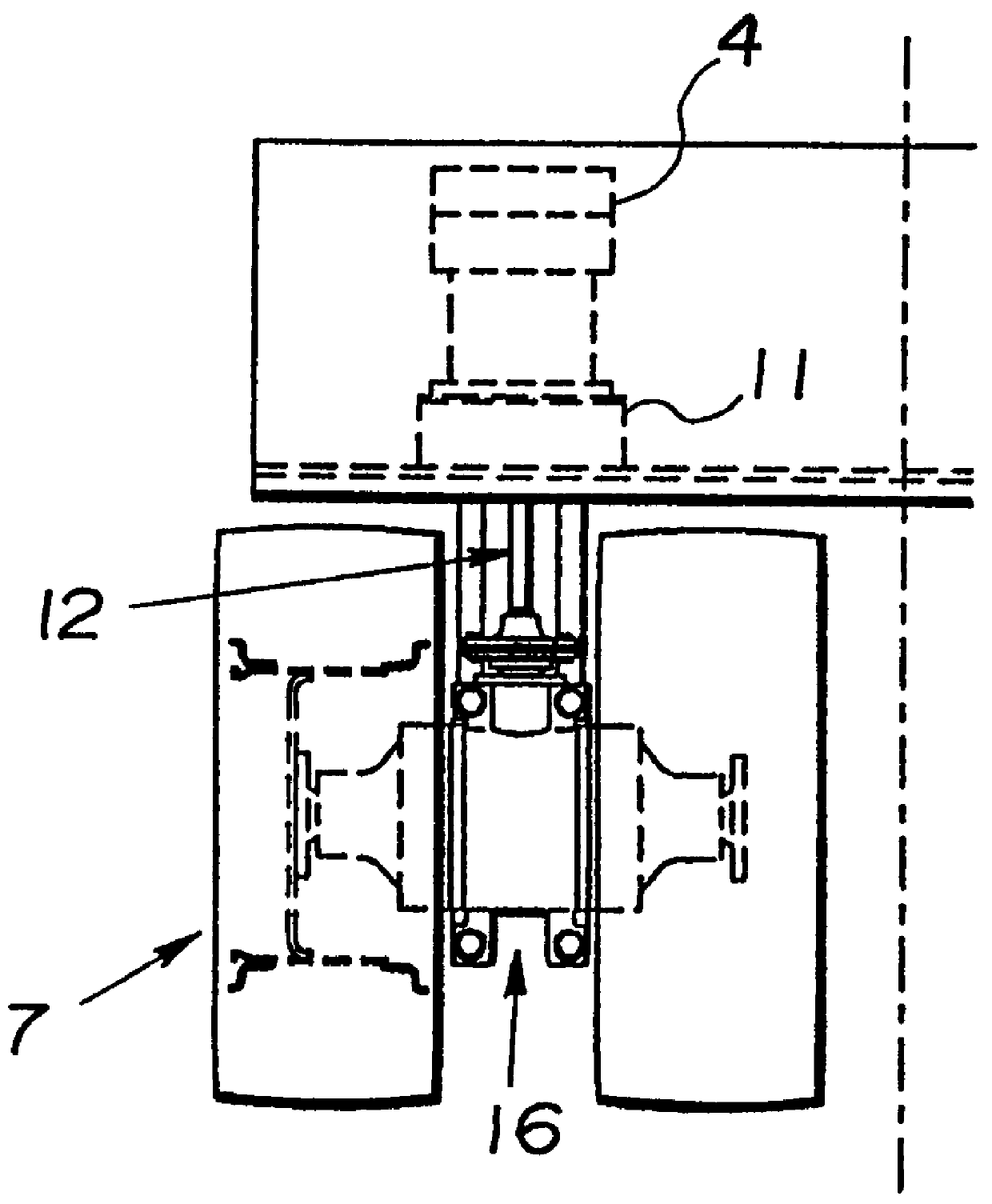

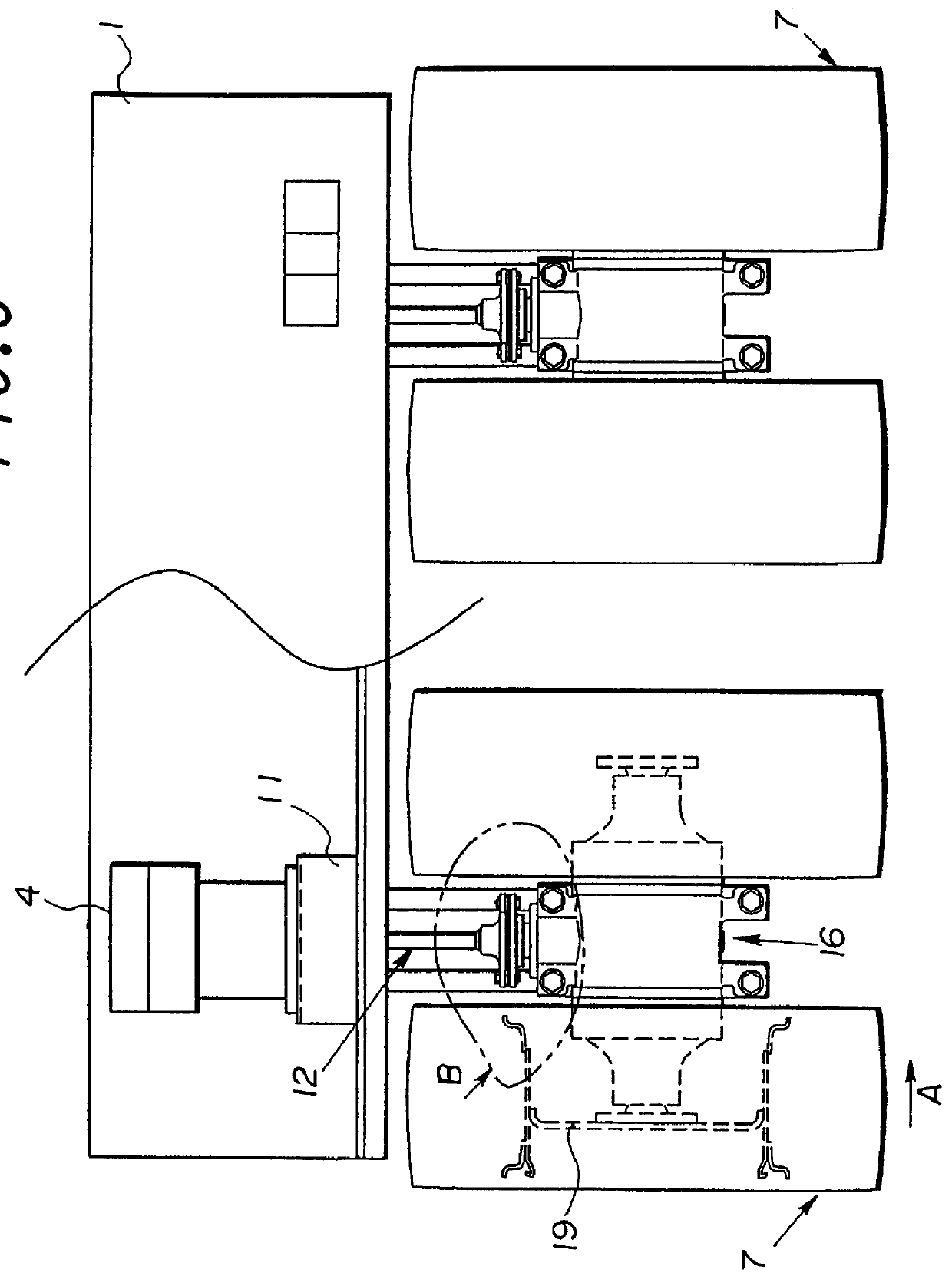

Tired Roller

InactiveUS6105707AReduce speedSmall diameterMotor depositionRoads maintainencePropellerVariable displacement

A tired roller is provided with a prime mover and a speed change unit of the HST type. The speed change unit includes an HST hydraulic pump of the variable displacement type driven by the prime mover and an HST hydraulic motor driven by pressure oil from the hydraulic pump, and can change a rotational speed of the hydraulic motor by varying a delivery rate of pressure oil from the hydraulic pump. Rotation of the hydraulic motor is therefore transmitted at a lower speed to a drive-axle tire train. A propeller shaft is connected to the hydraulic motor without interposition of any speed reduction mechanism, so that the propeller shaft is rotated at a high speed with a low torque. This has made it possible to form the propeller shaft smaller in diameter and hence to arrange it in a narrow space between tires in the drive-axle tire train. Further, the rotation of the hydraulic motor is reduced in speed at an output side of the propeller shaft, thereby making it possible to transmit the rotation in a state increased in rotating torque to the drive-axle tire train.

Owner:DYNAPAC INT

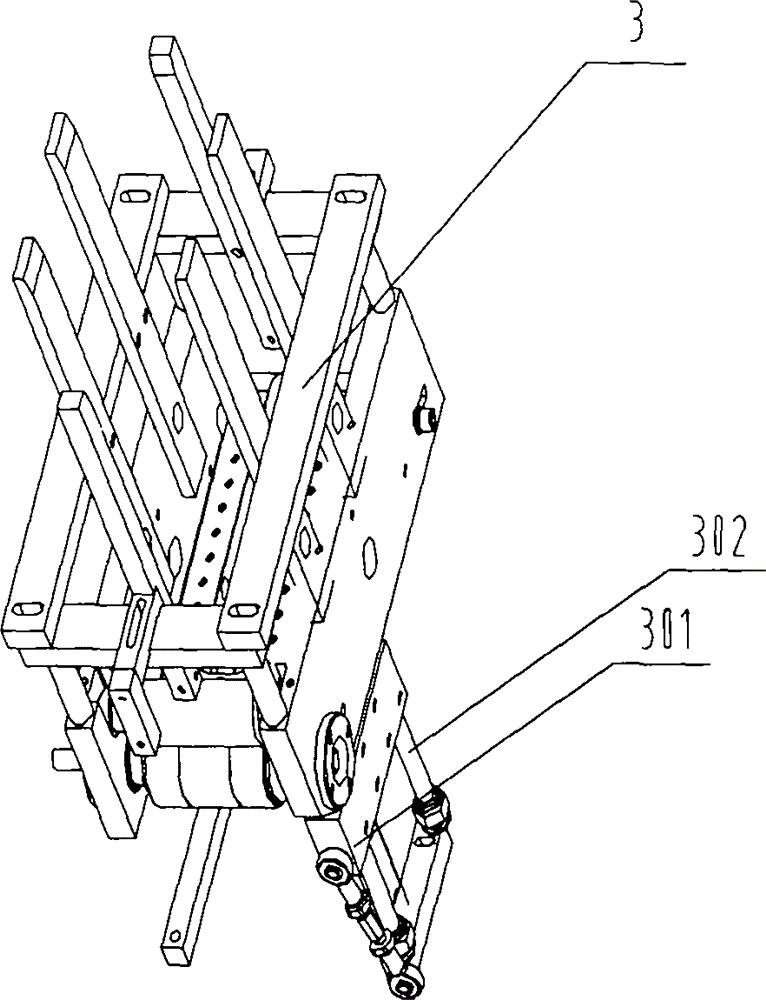

Automatic flat plate box boxing machine

InactiveCN104058132AGuaranteed success rateEliminate the problem of inaccurate positioningPackaging automatic controlCartonEngineering

An automatic flat plate box boxing machine comprises a rack, wherein a feeding mechanism, a mechanism of pushing feed into and pushing boxes out of bins, a carton feed bin, a carton formation mechanism, a lug folding mechanism, an edge folding and tongue folding mechanism, a glue box mechanism, a side wing edge folding device and a transmission mechanism for ejected boxes are arranged on the rack; a carton briquetting component includes a carton briquetting which is arranged right above a groove of a carton formation module; the lug folding mechanism is positioned in front of the carton briquetting component; the edge folding and tongue folding mechanism is arranged in front of the lug folding mechanism; the glue box mechanism is arranged on the box ejecting side of a synchronous belt of the carton formation module; the side wing edge folding device is arranged on one side of a box outlet of the glue box mechanism; the transmission mechanism for ejected boxes is arranged on one side of a box outlet of the side wing edge folding device. The automatic flat plate box boxing machine, provided by the invention, is suitable for a plurality of inclusions, and has higher stability when the boxes are sealed, and higher qualified rate.

Owner:傅会武

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com