Counterbalanced deck for railroad freight car

a rail freight car and counterbalance technology, applied in the direction of railway bodies, axle-box lubrication, wagons/vans, etc., can solve the problems of heavy deck and many operators' difficulty in raising and lowering, and achieve the effect of lightening the weigh

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

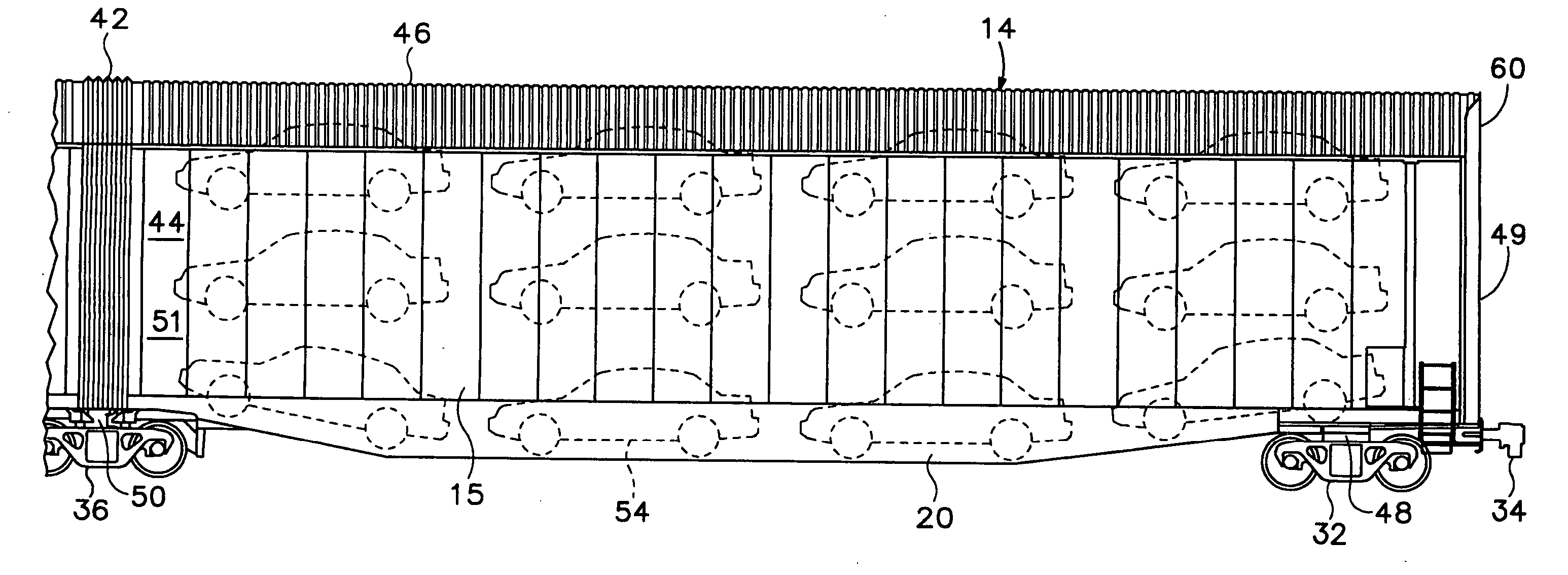

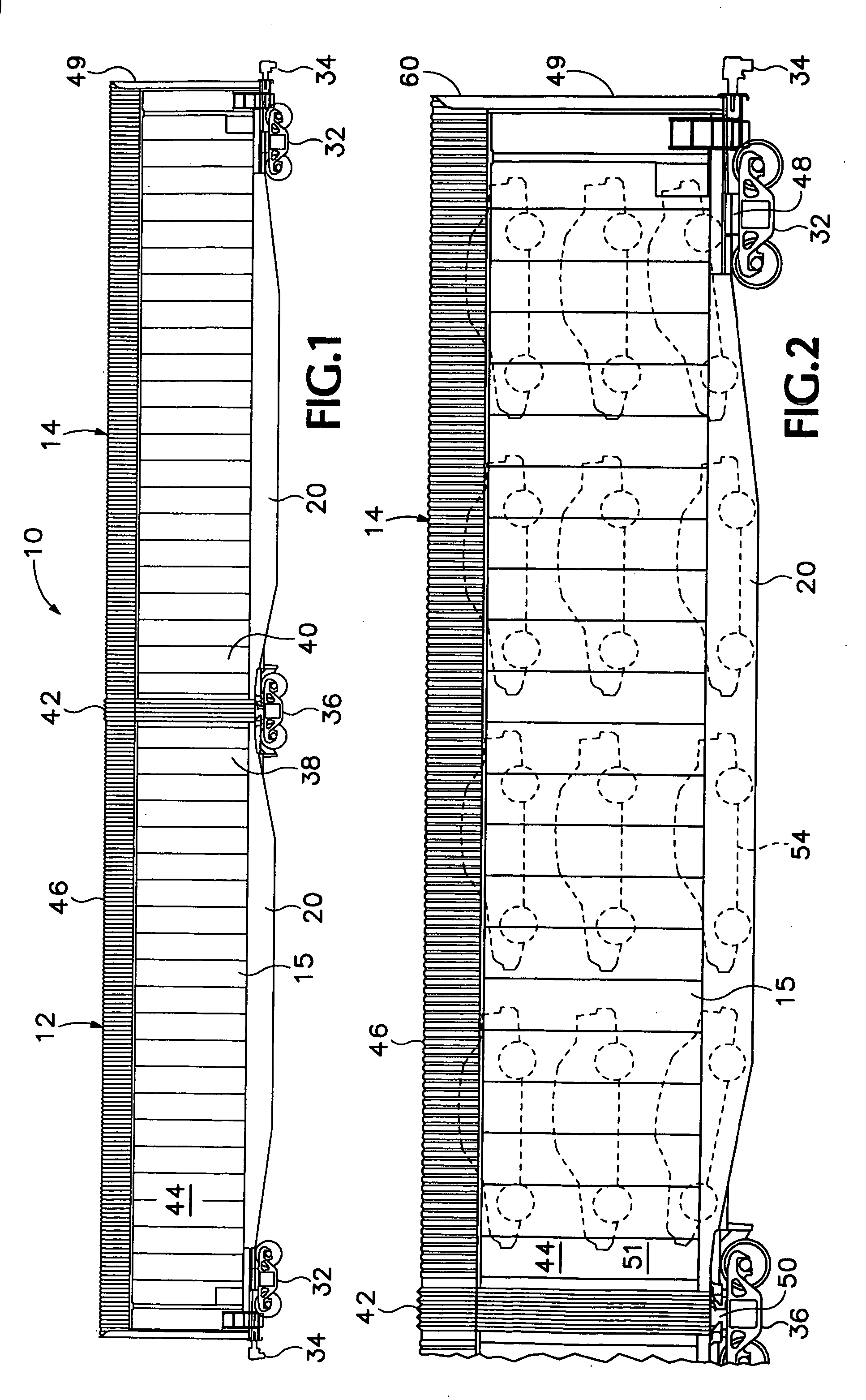

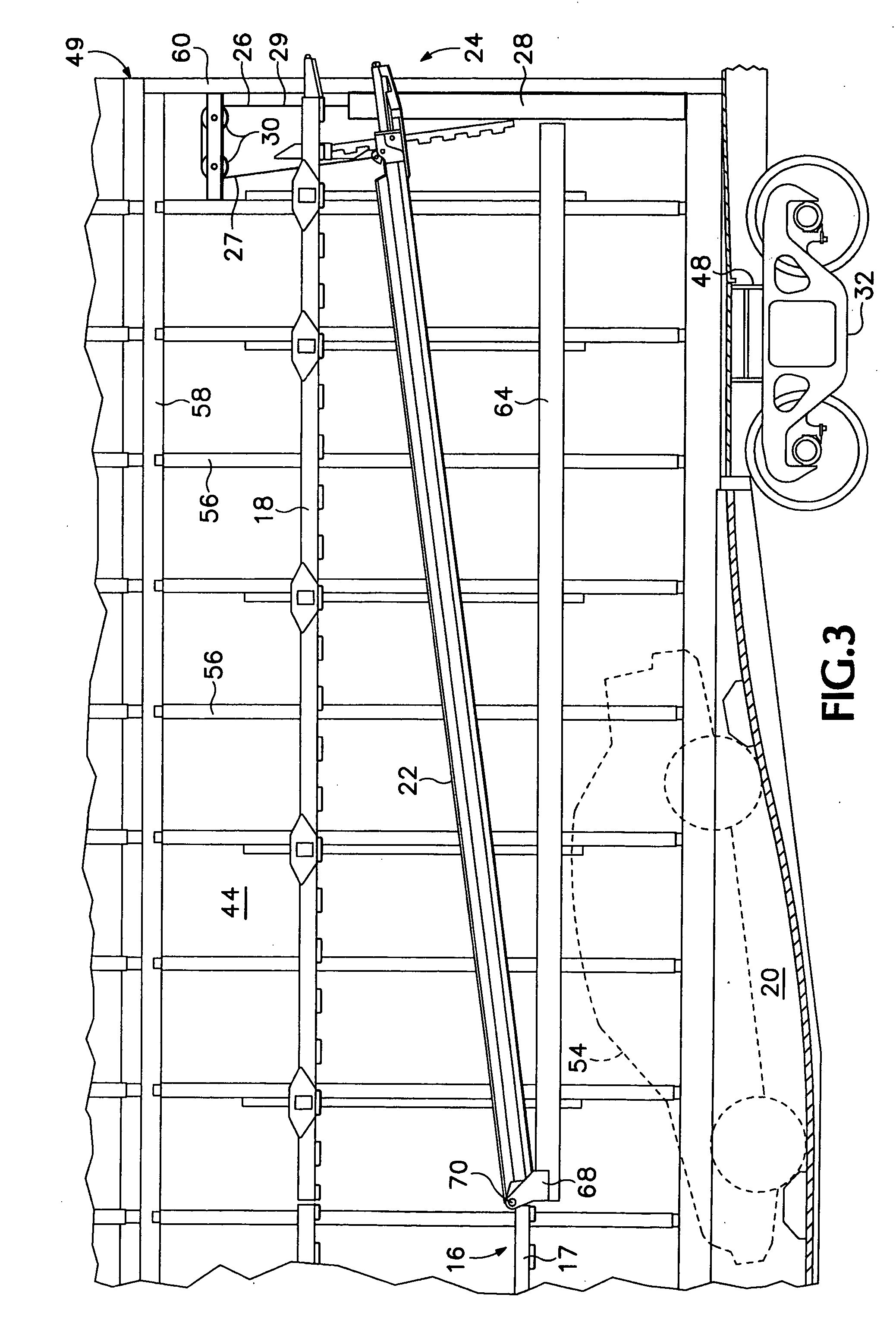

[0032] Referring to the drawings, which form a part of the disclosure herein, FIGS. 1-4 show a multi-unit railroad freight car 10 that incorporates one preferred embodiment of the present invention. The freight car 10 includes two adjacent car units 12 and 14. Each respective car unit 12 and 14, in turn, includes a cargo well 20, a middle deck 16, and an upper deck 18 for selectively supporting and storing automobiles in a tri-level arrangement as shown in FIG. 2. The cargo well 20, the middle deck 16, and the upper deck 18 are sometimes referred to as the “A”, “B”, and “C” decks, respectively. Each deck 16, 18, and 20 preferably has a shape that provides ample strength for supporting motor vehicles, while providing sufficient space to accommodate motor vehicles of the various heights that the car is desired to carry.

[0033] As can be seen in FIGS. 2-3, the automobiles stored on the lowest level of the freight car 10 rest in the respective cargo well 20 of each car unit 12 and 14. I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com