Patents

Literature

765results about How to "Small heat capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

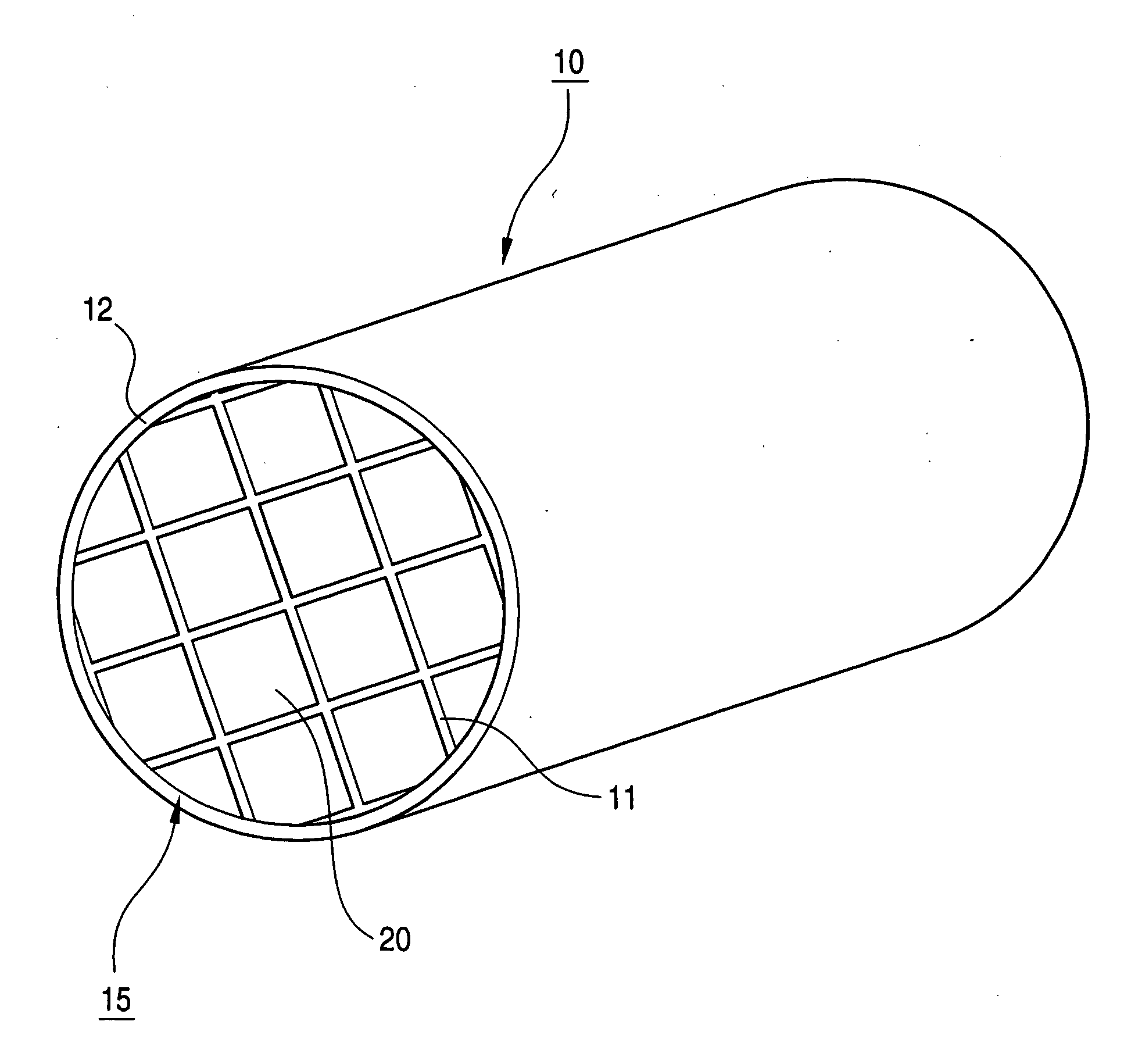

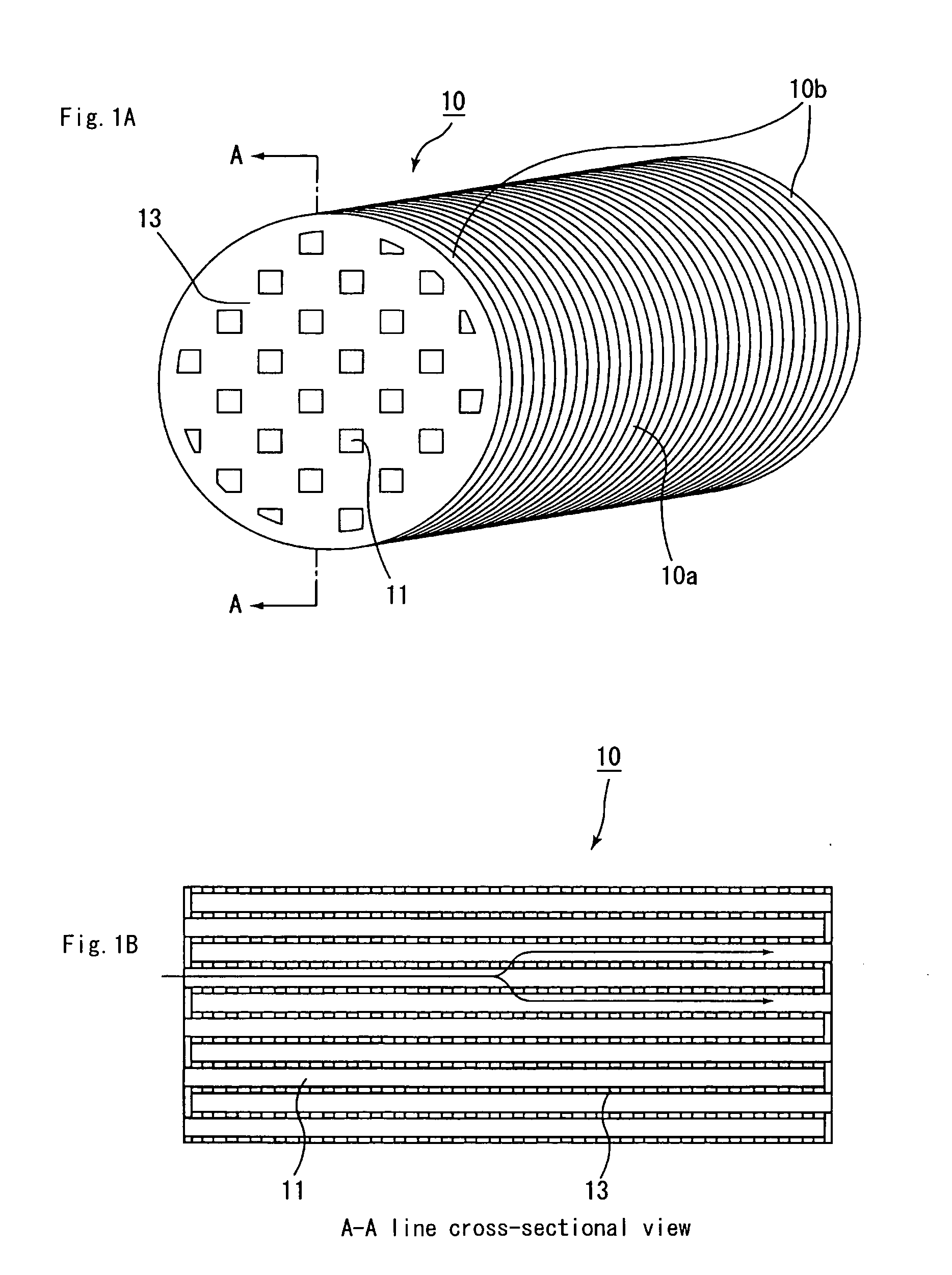

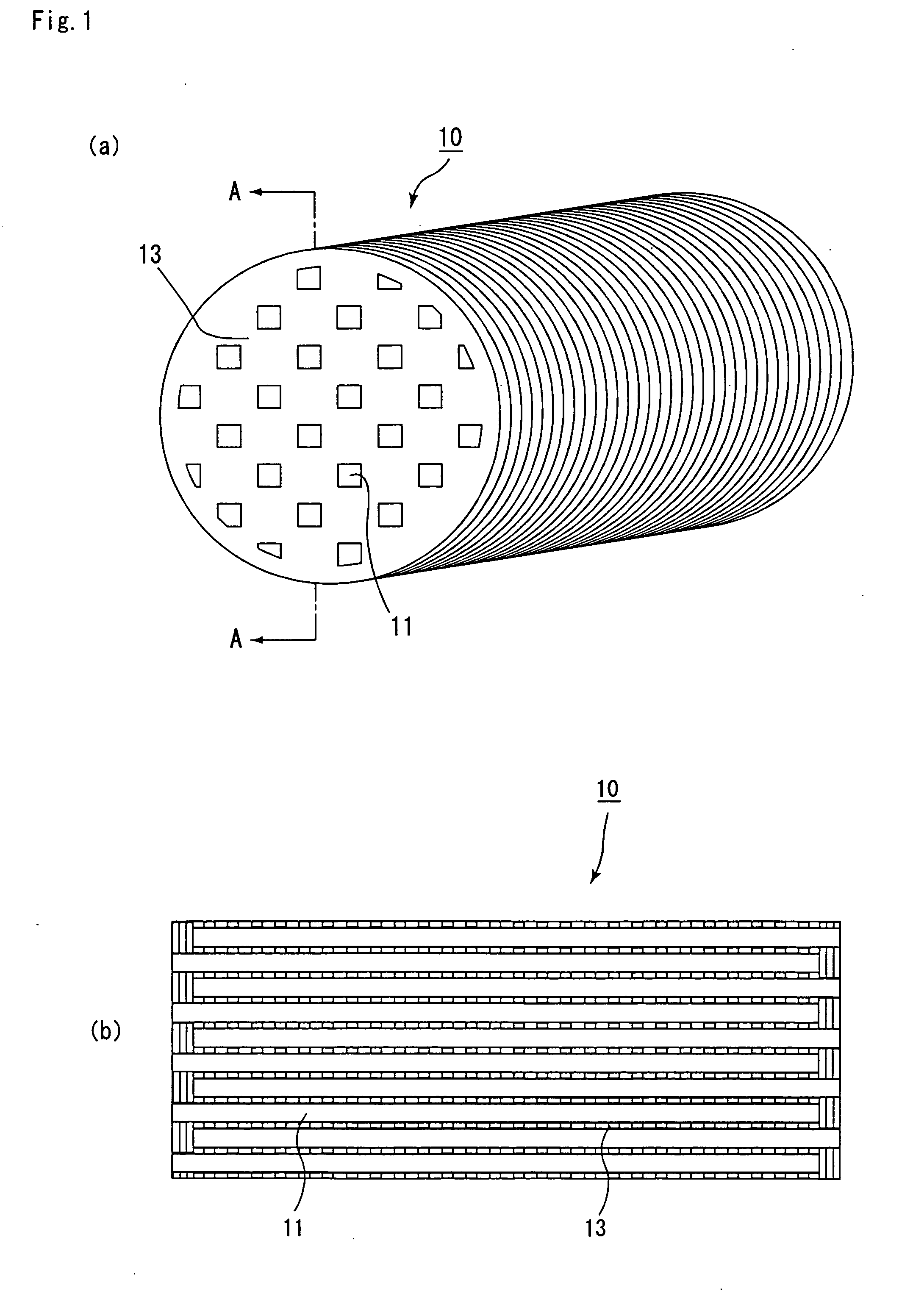

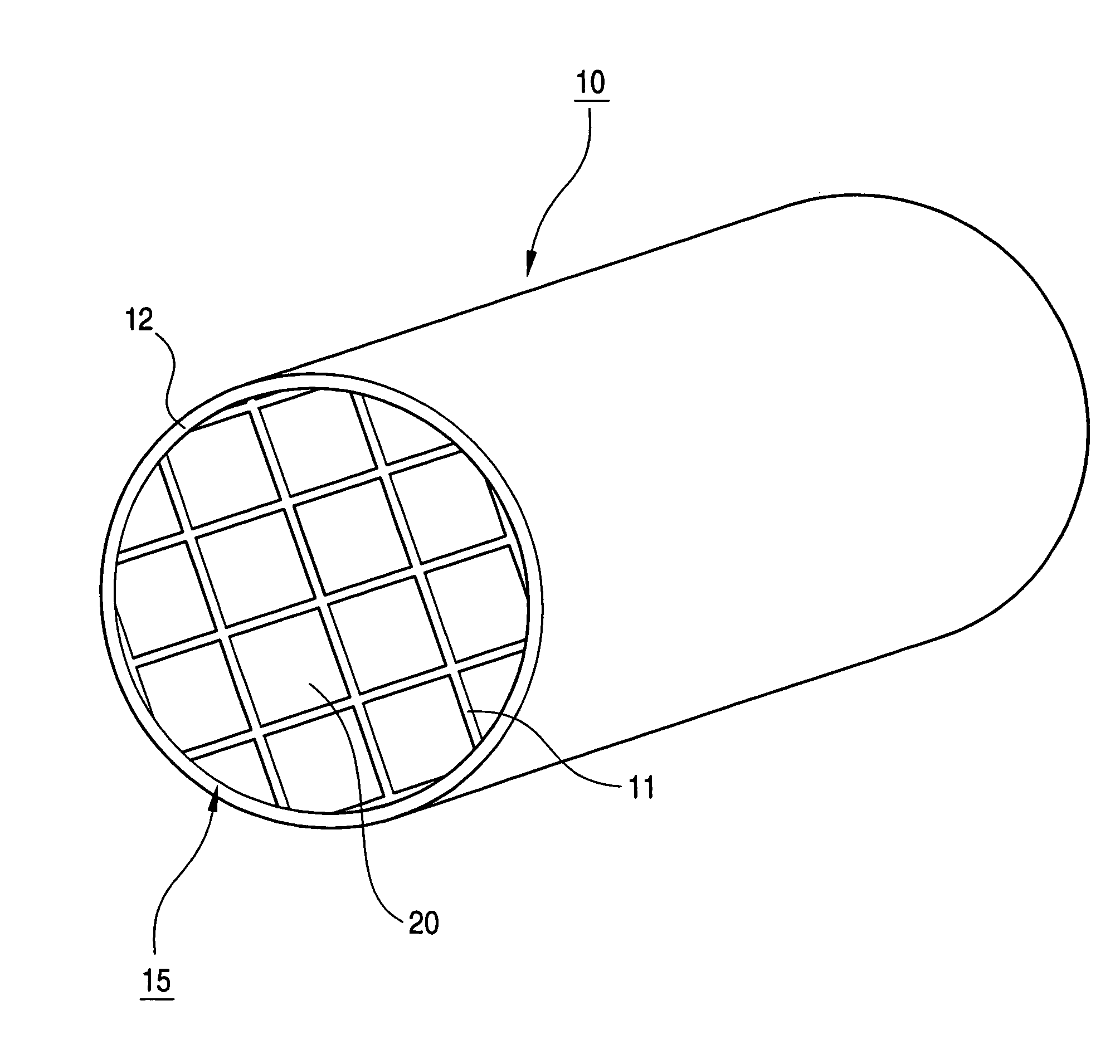

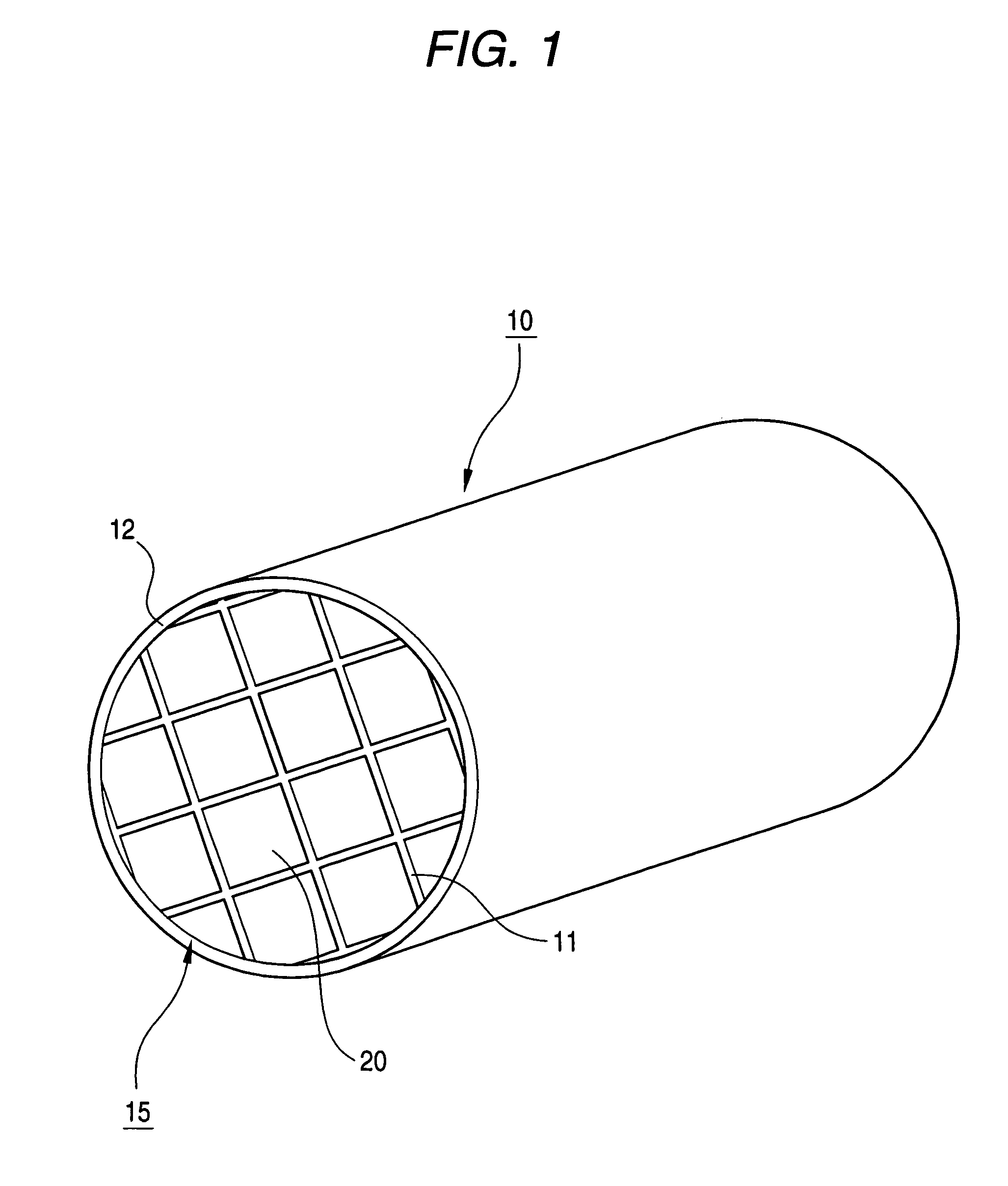

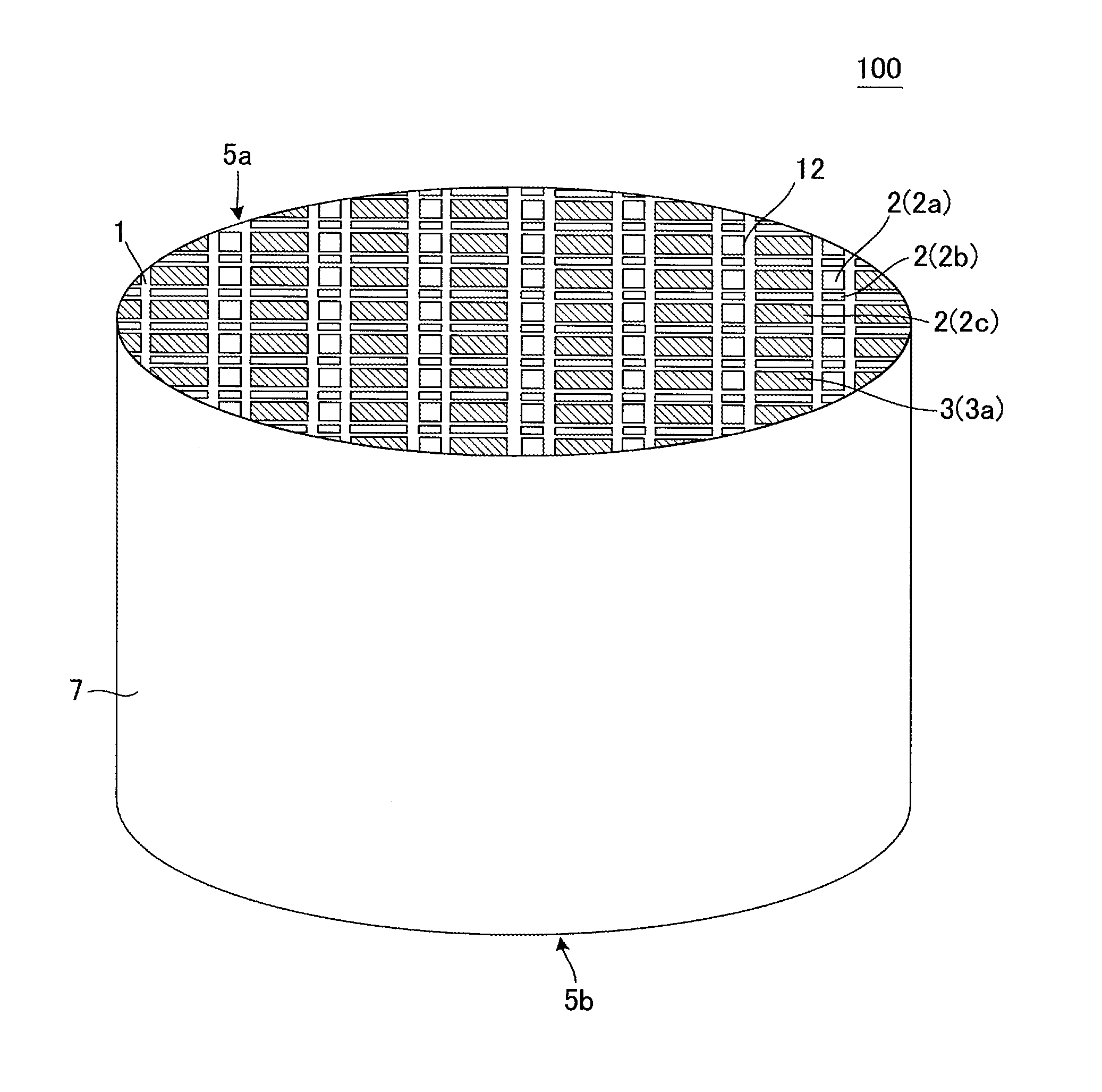

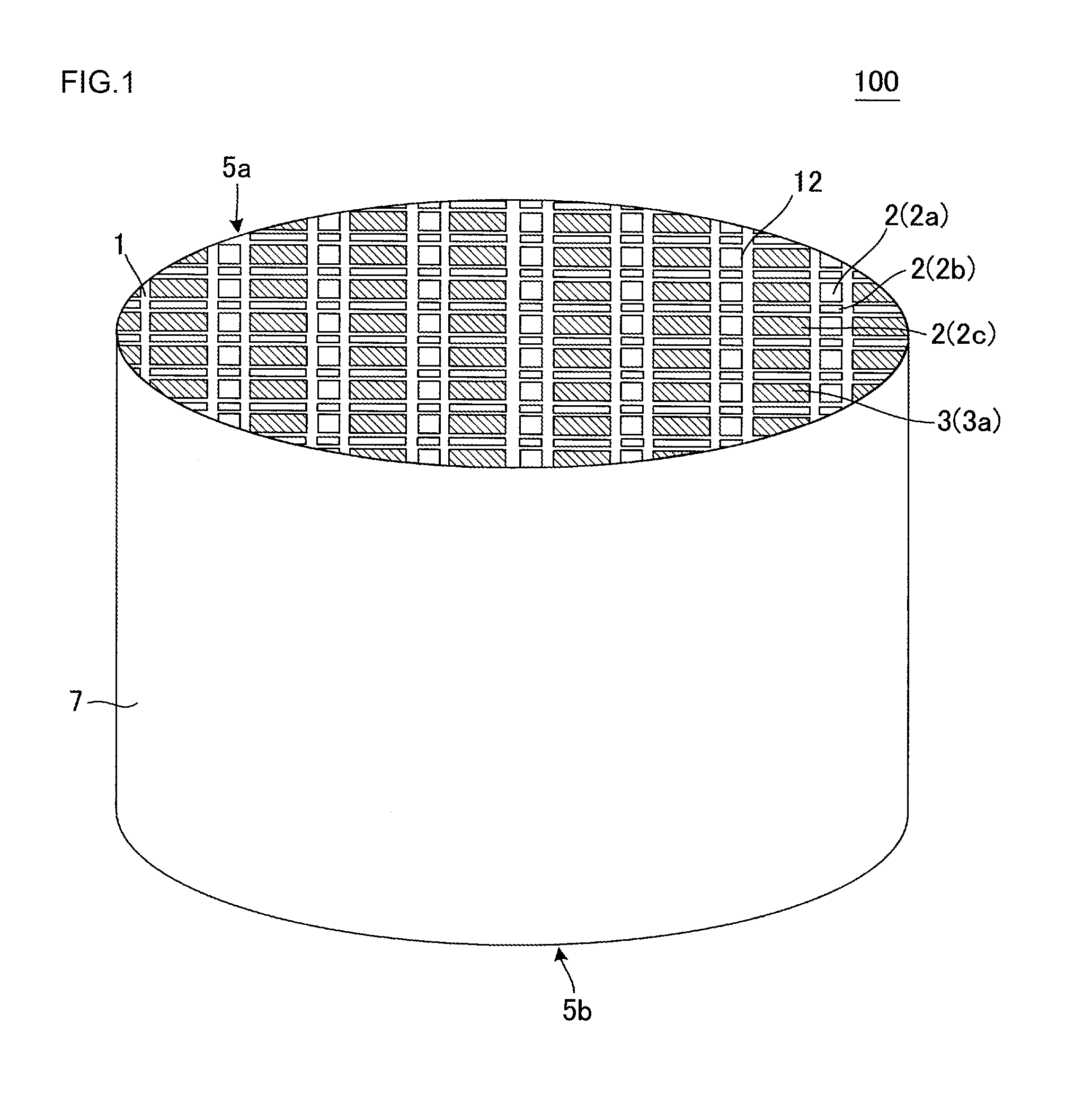

Honeycomb structure

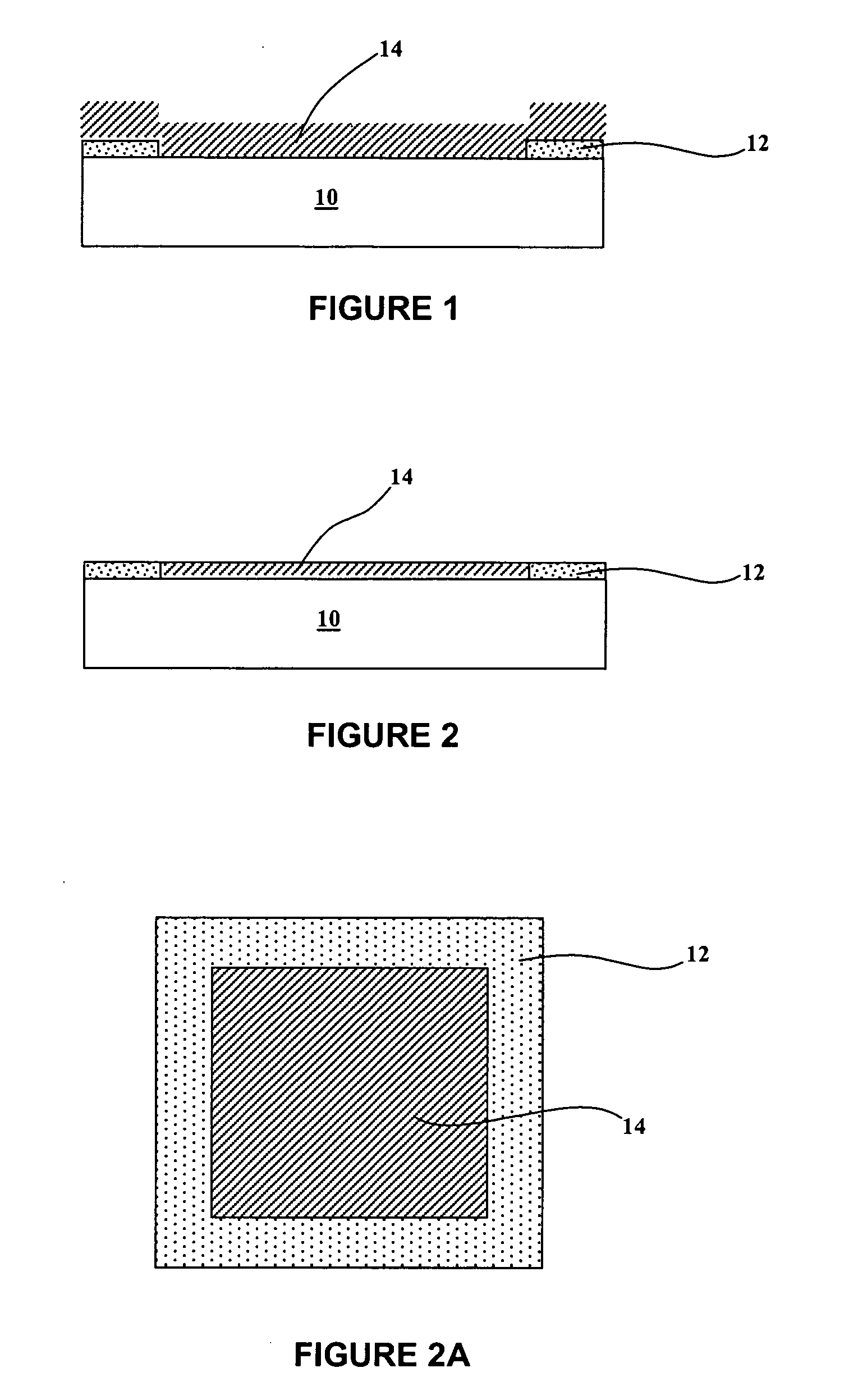

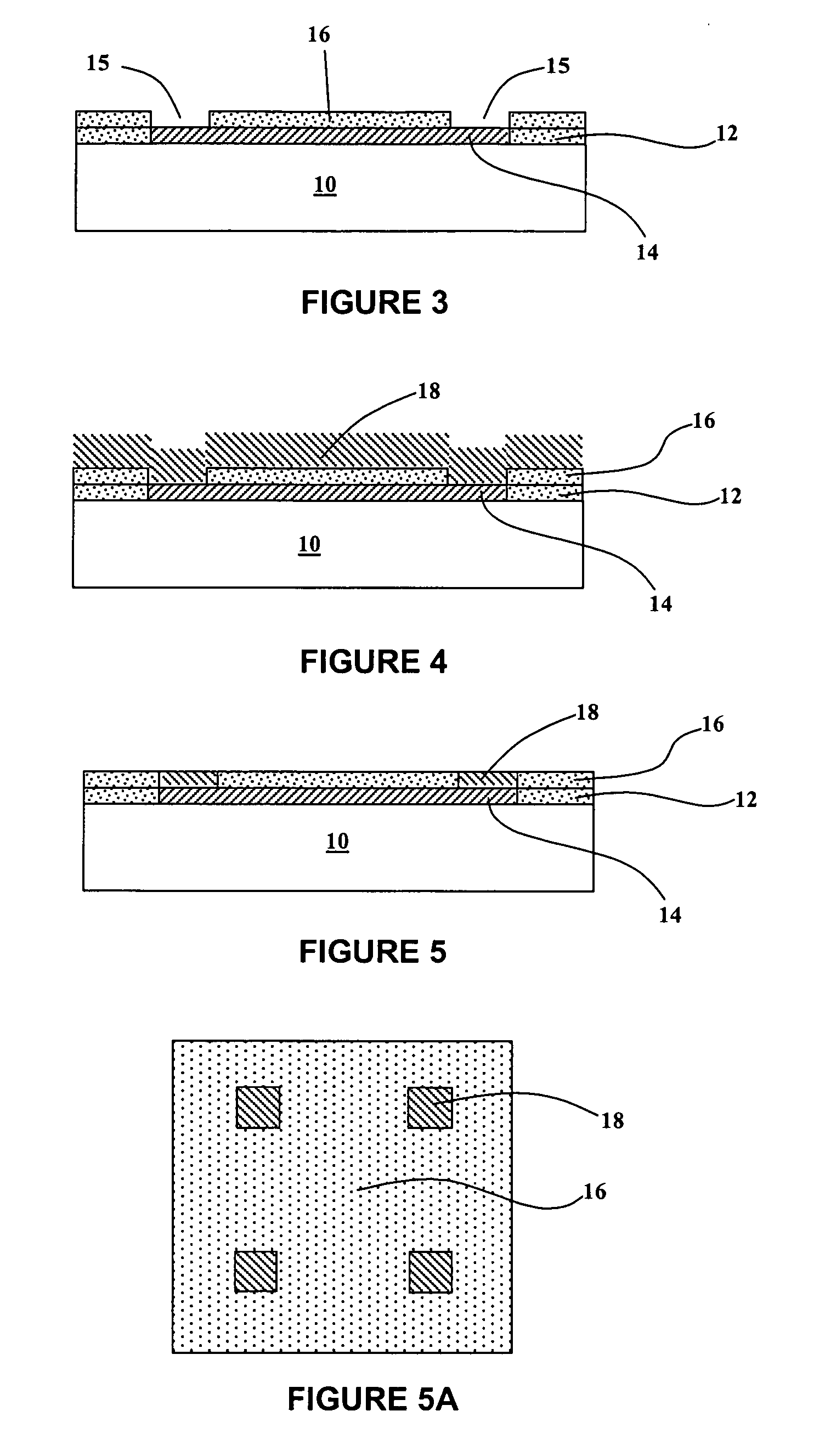

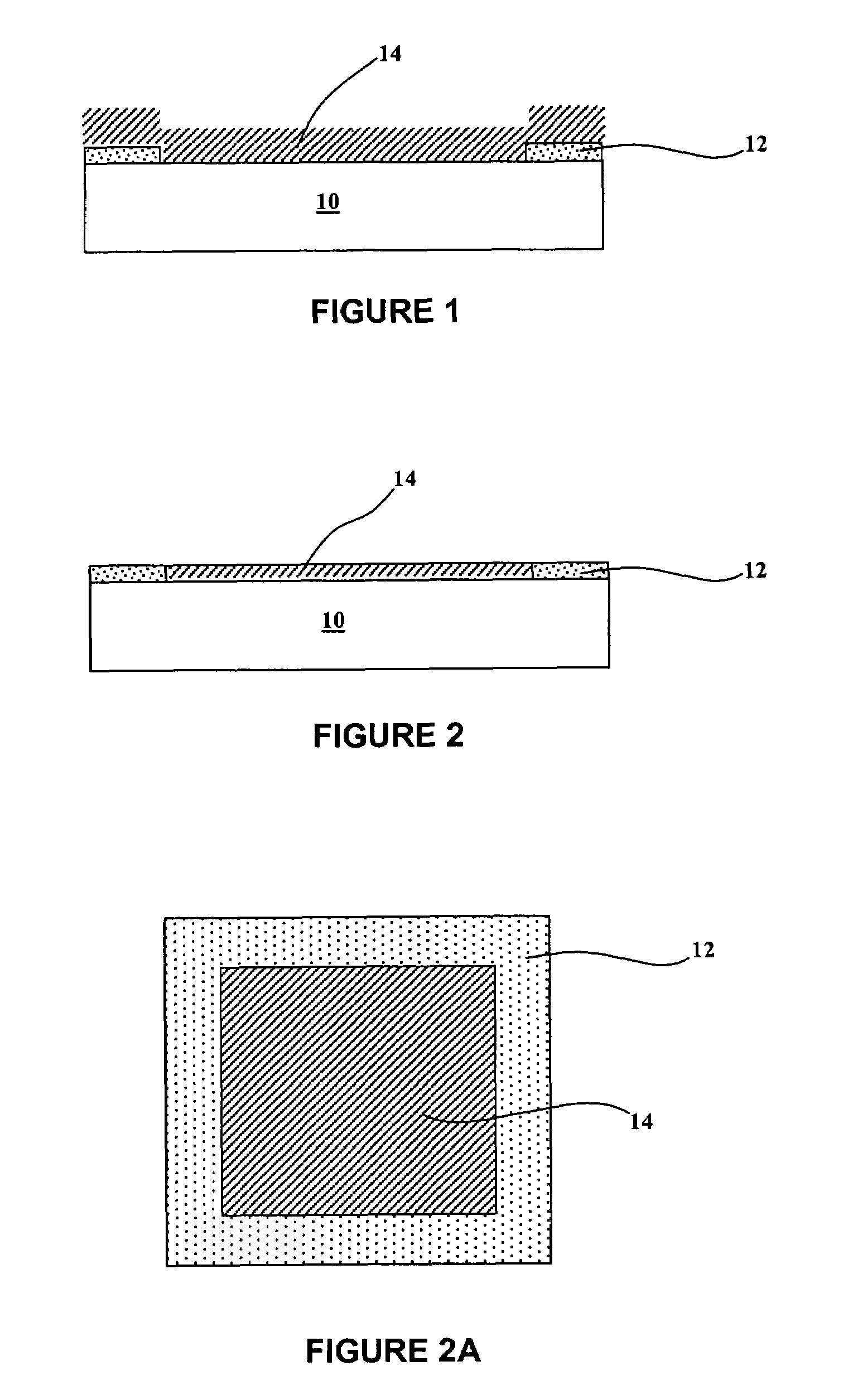

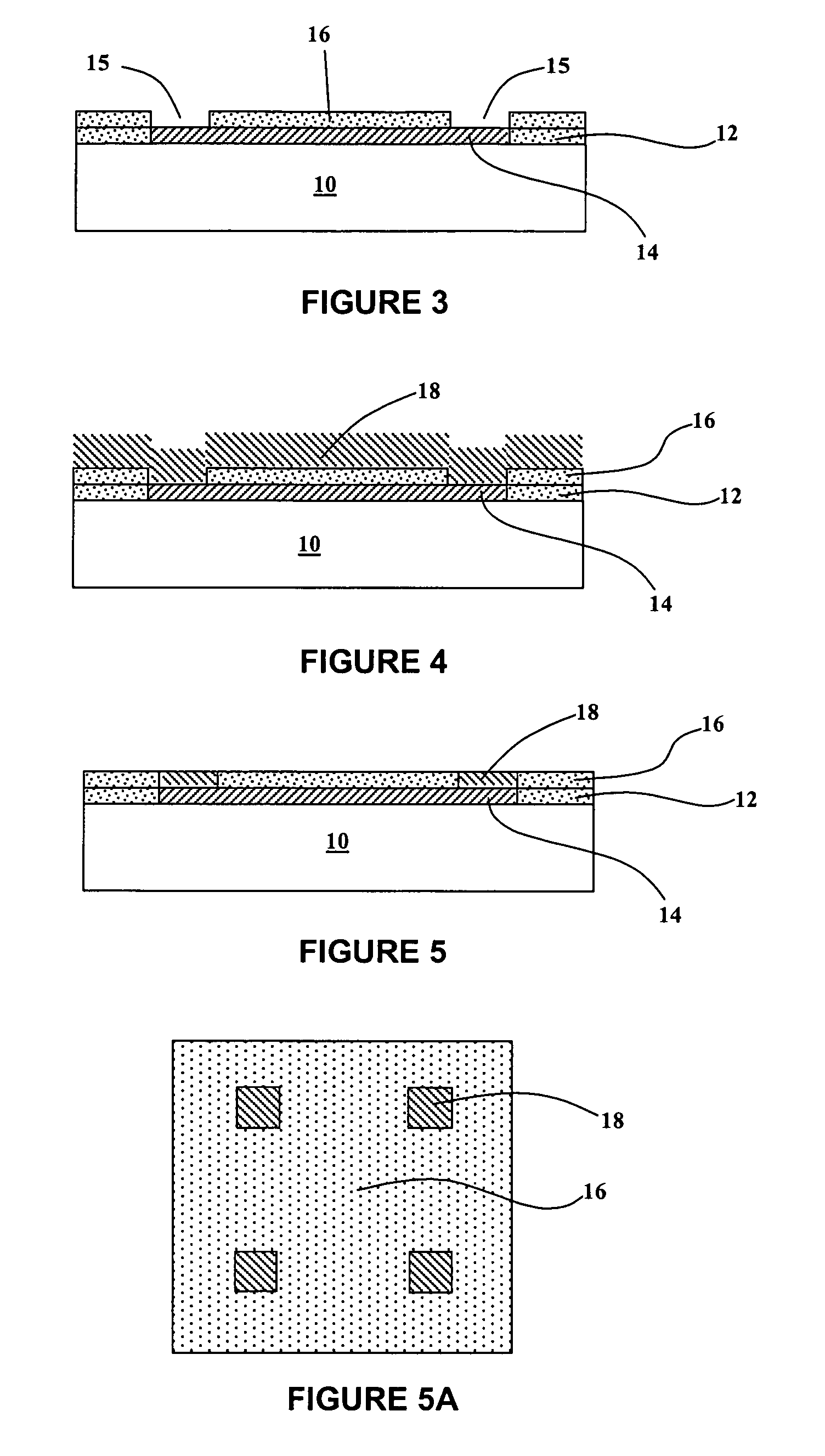

ActiveUS20060230732A1Light weightSmall heat capacityDispersed particle filtrationOther chemical processesApparent densityYoung's modulus

A honeycomb structure including a plurality of porous ceramic members which are bonded through an adhesive layer, each of the porous ceramic members has a plurality of cells, which are arranged in parallel while being separated by cell walls. The cells extend in a longitudinal direction of the honeycomb structure. In the honeycomb structure, the following relationship is satisfied: 2≦B≦100 / 3×A−10 / 3 (1) where A (g / cm3) designates apparent density of the porous ceramic members, and B (GPa) designates Young's modulus of the adhesive layer.

Owner:IBIDEN CO LTD

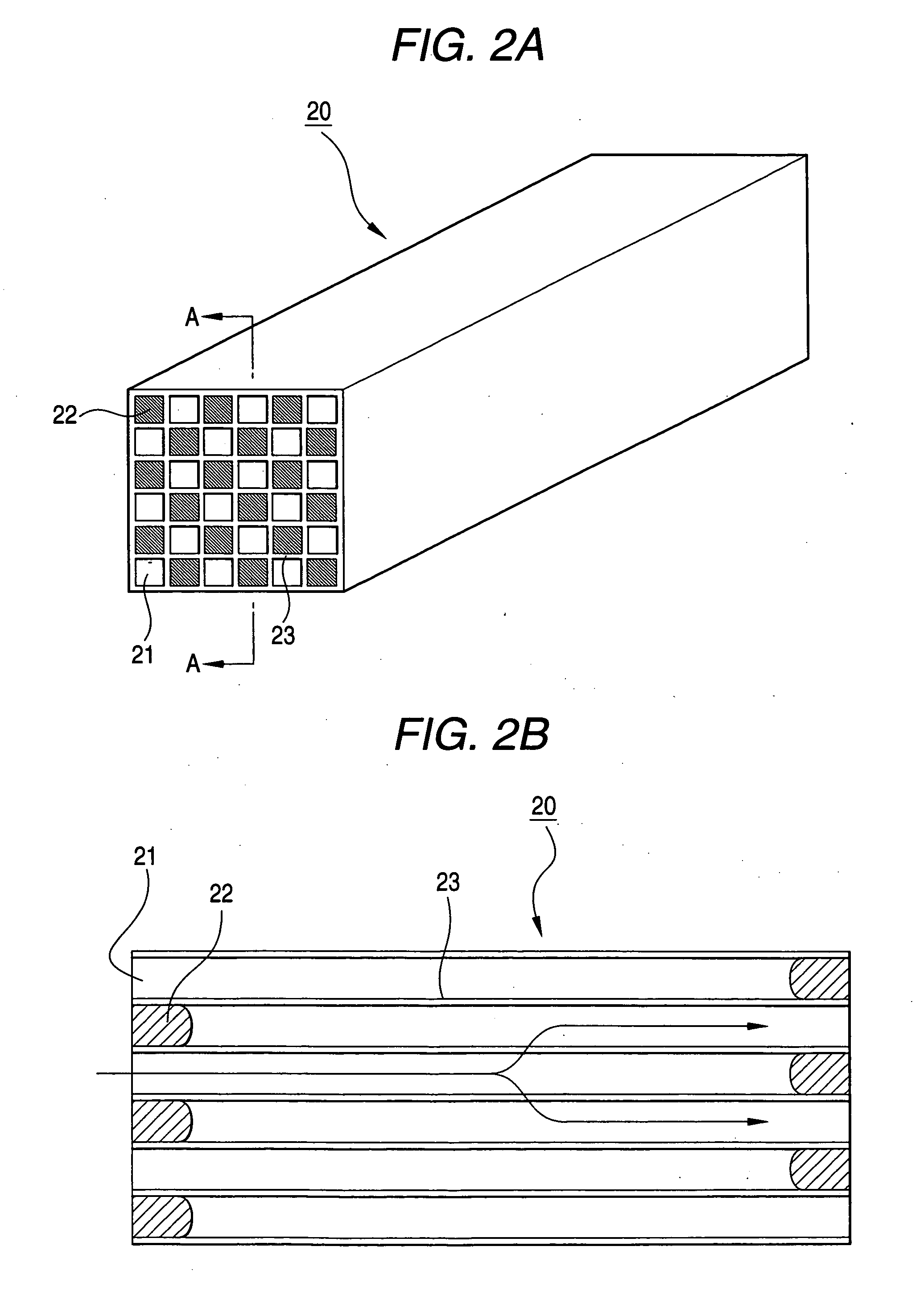

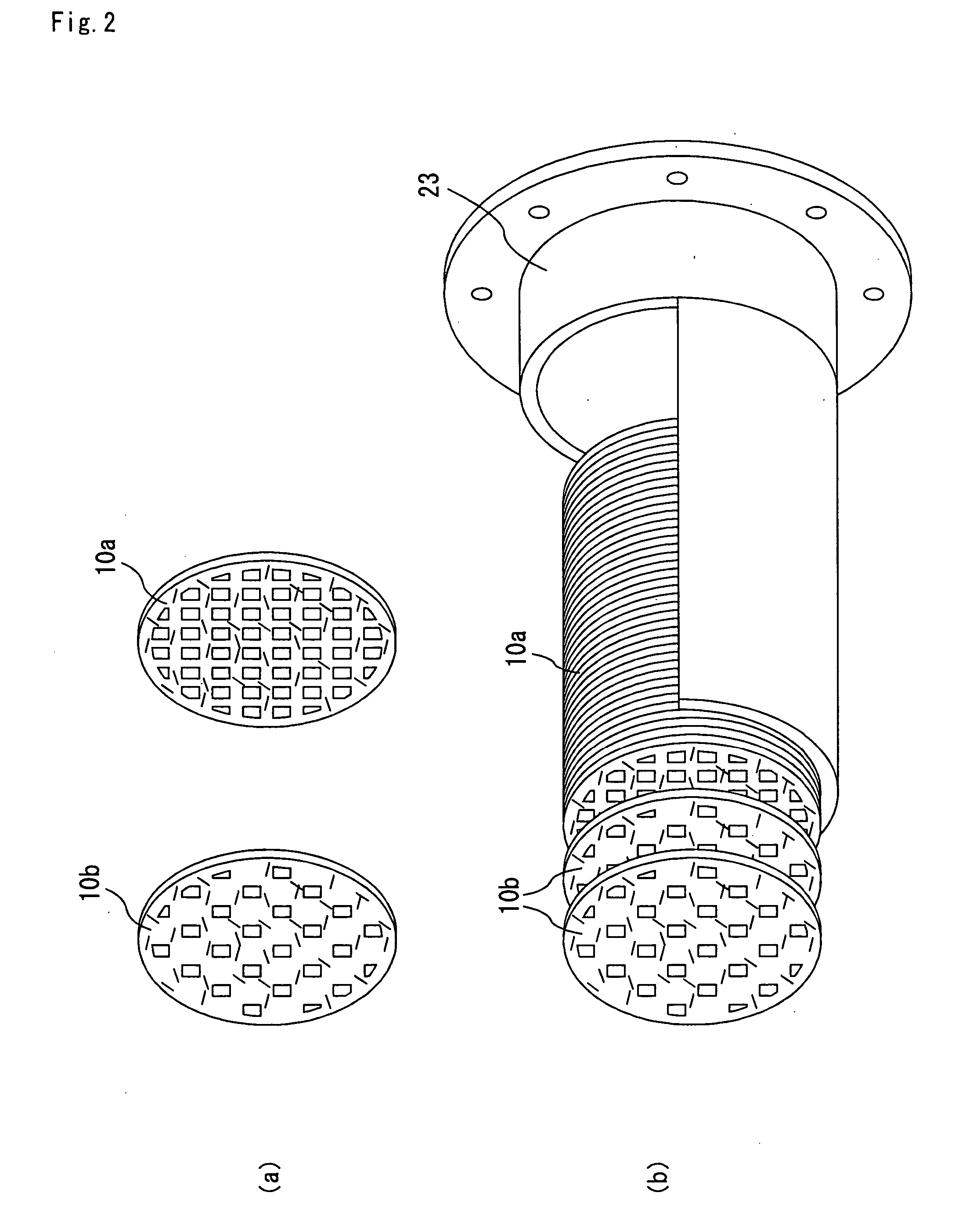

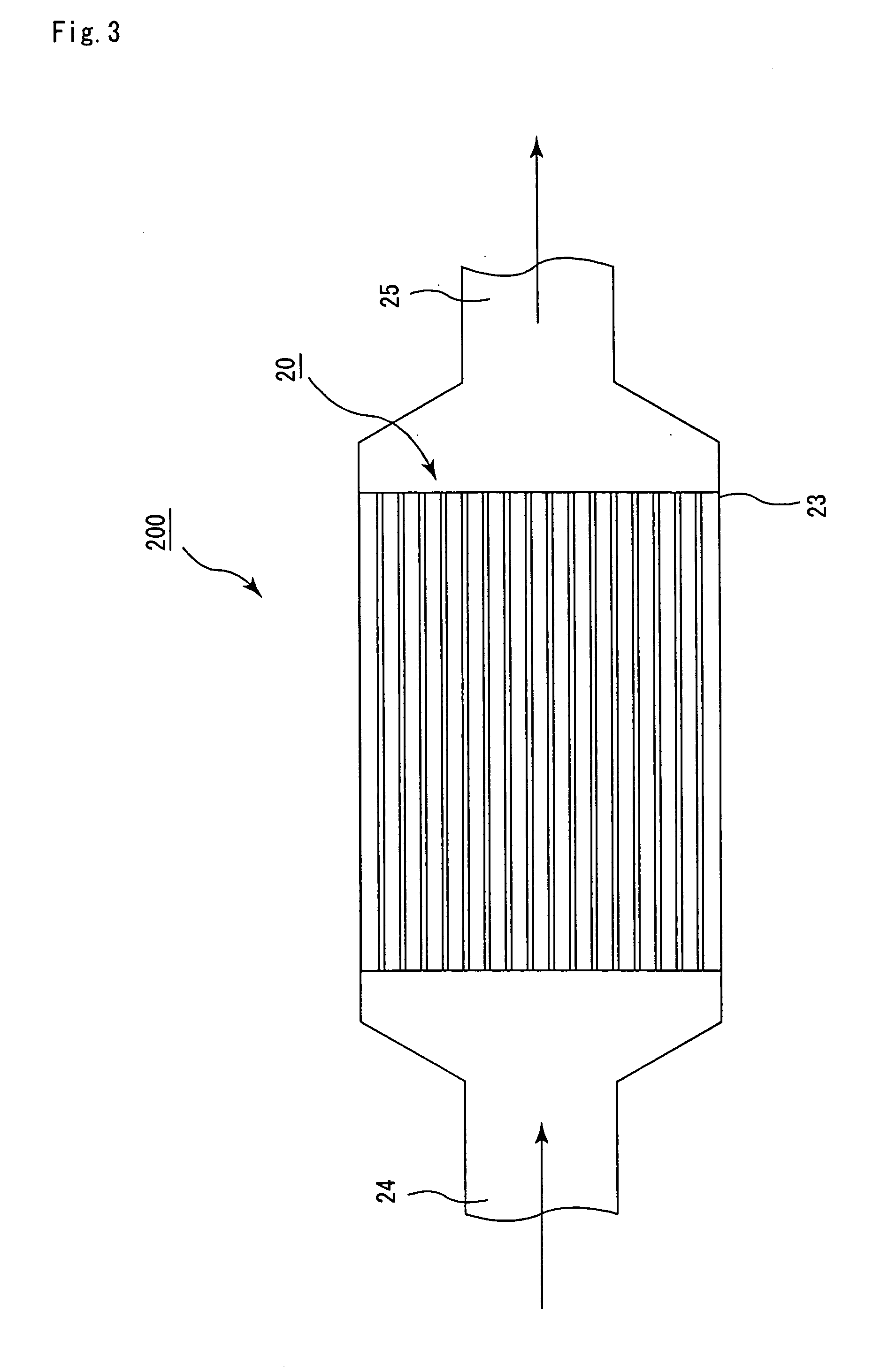

Honeycomb structured body and exhaust gas purifying device

InactiveUS20070020155A1Simple processReduce the temperatureCombination devicesGas treatmentApparent densityEngineering

A honeycomb structured body of the present invention comprises a plurality of cells placed in parallel with one another in a longitudinal direction with a cell wall therebetween, wherein an oxide catalyst is supported on at least one portion of the cell wall, and the honeycomb structured body has an apparent density of about 0.7 g / cm3 or less.

Owner:IBIDEN CO LTD

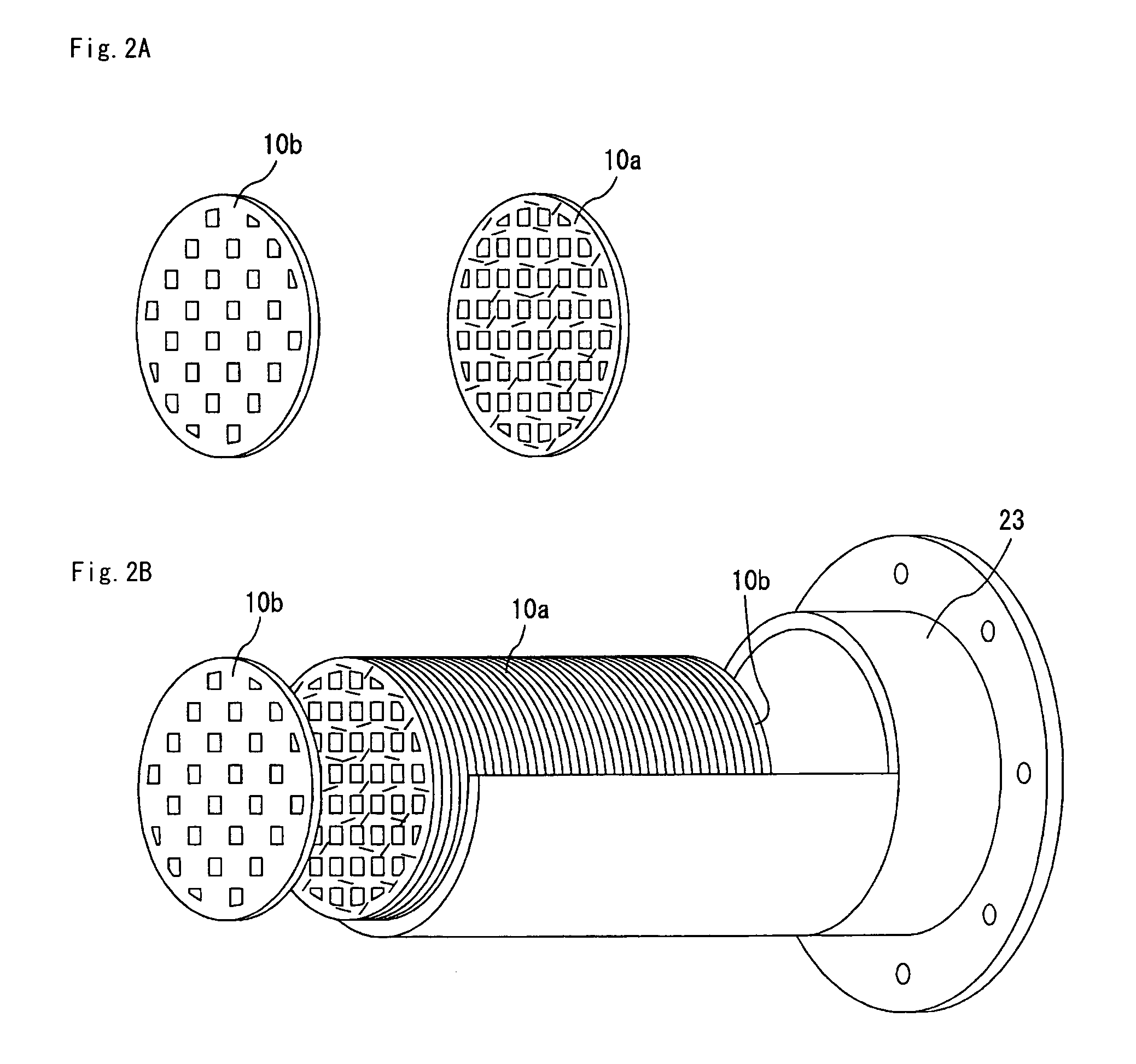

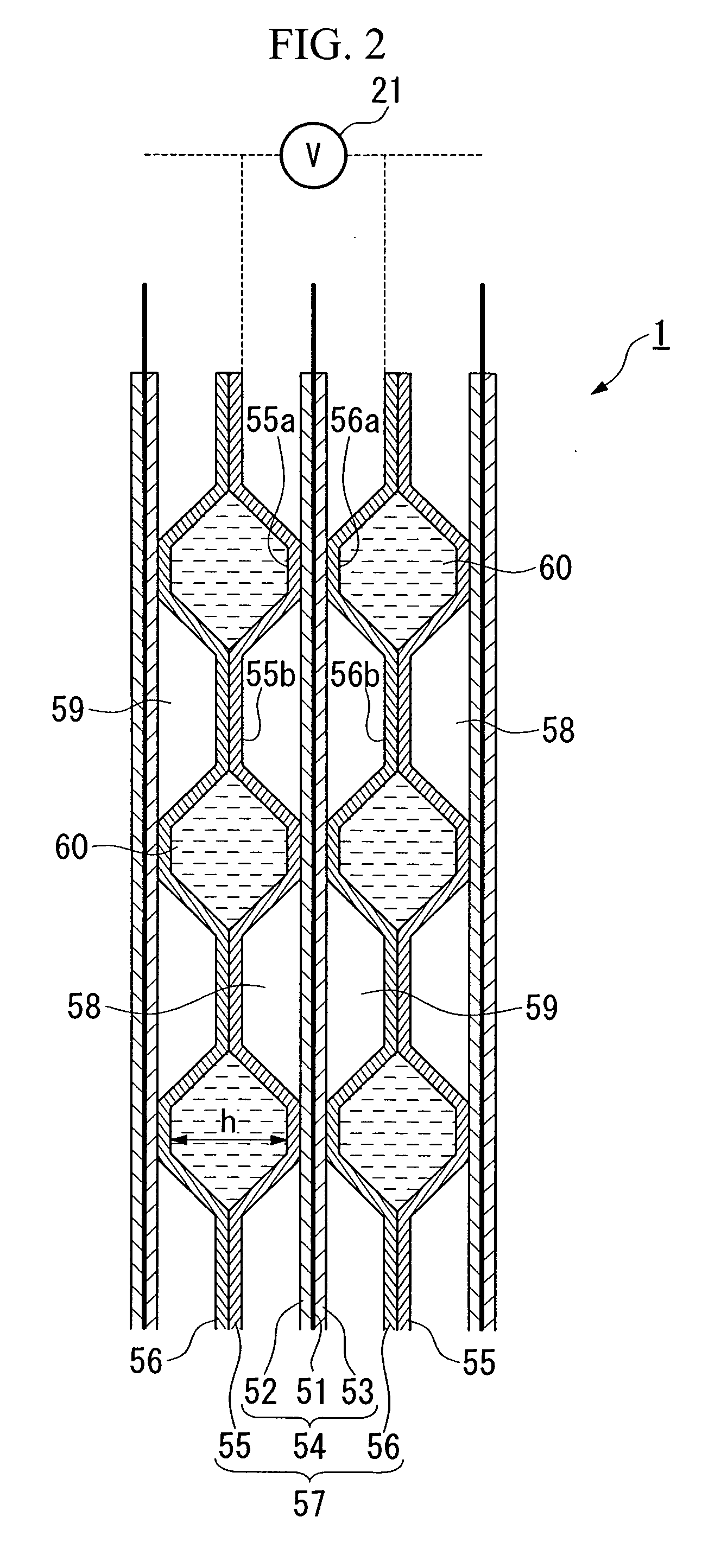

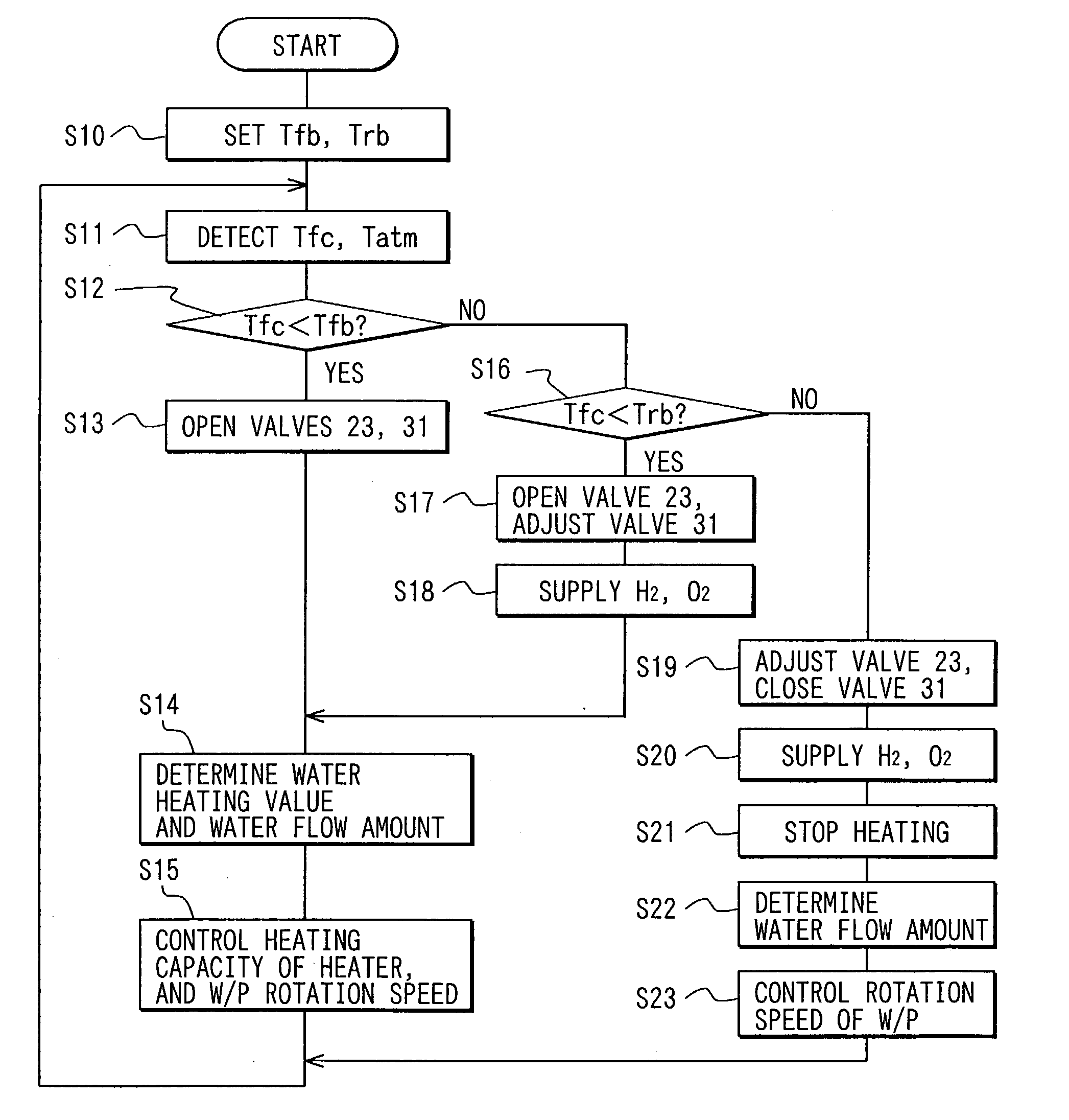

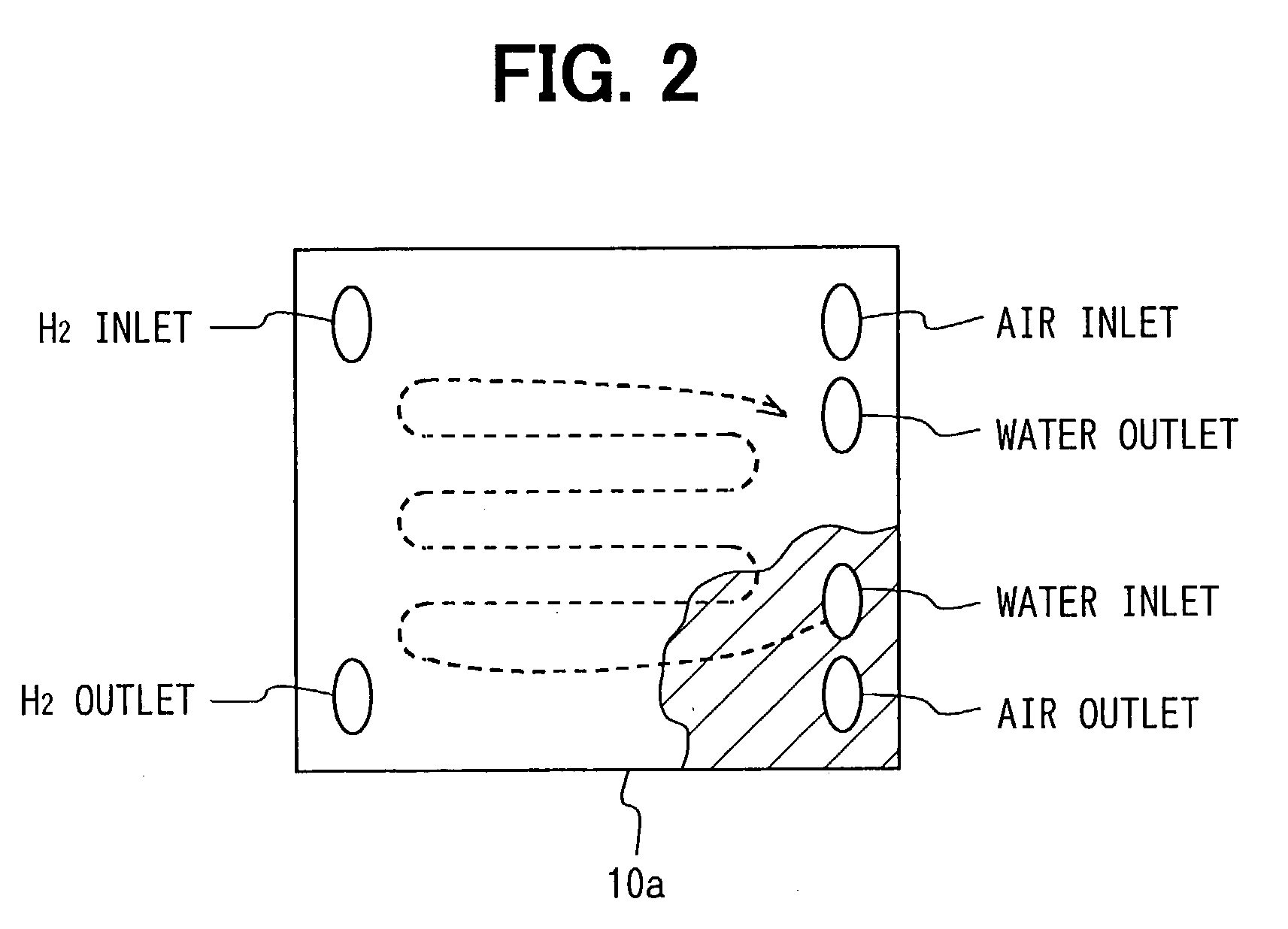

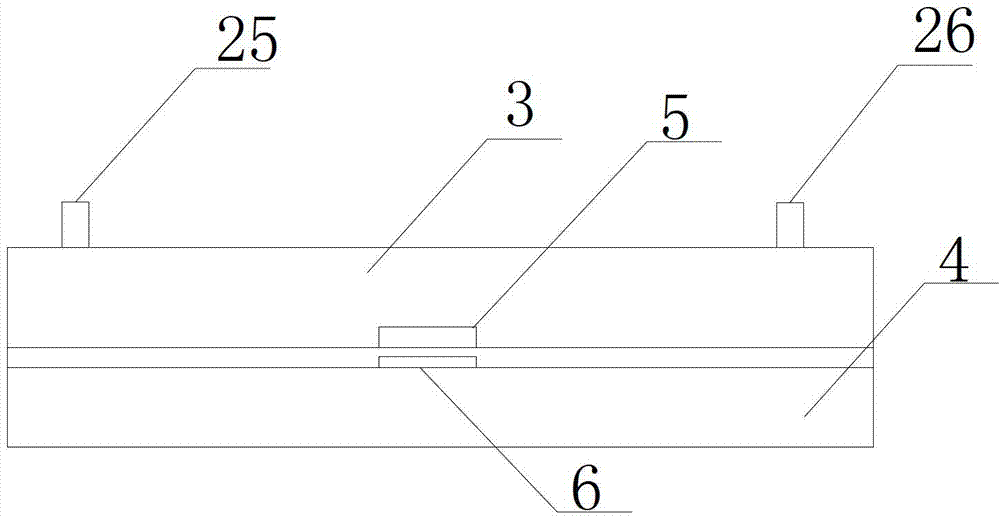

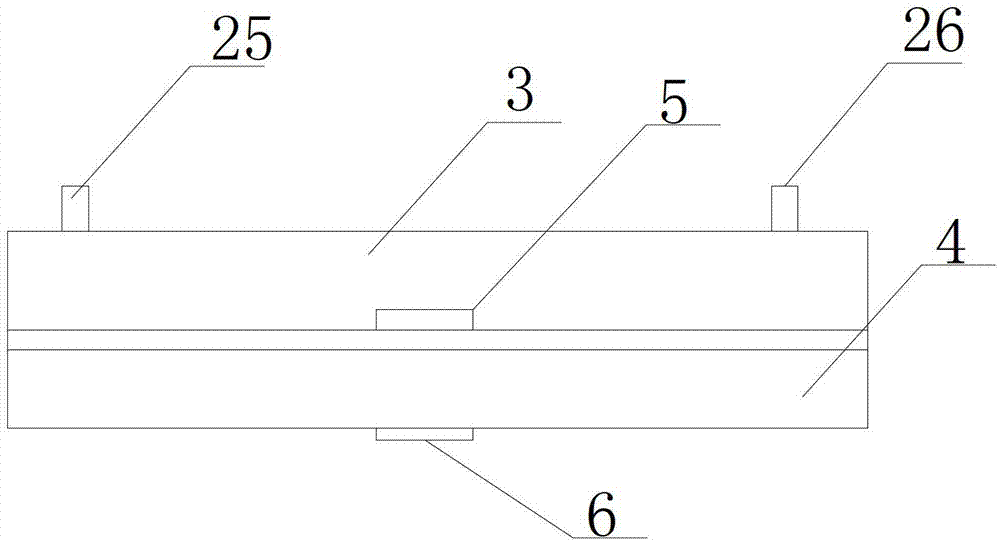

Method and system for starting up fuel cell stack at subzero temperatures, and method of designing fuel cell stack

InactiveUS20050053810A1Shorten warm-up timeSmall heat capacityFuel cells groupingFuel cell auxillariesPolymer electrolytesFuel cells

A method of starting up at a subzero temperature a solid polymer electrolyte fuel cell stack that is formed by stacking a plurality of layers of separators and membrane electrode assemblies having a solid polymer electrolyte membrane and electrodes. The method includes a step of using a solid polymer electrolyte fuel cell stack in which the separators are made from metal and have a cross-sectional waveform structure, and a space that is formed between at least a portion of the separators and separators that are placed adjacent to this portion of the separators is used as a coolant flow passage.

Owner:HONDA MOTOR CO LTD

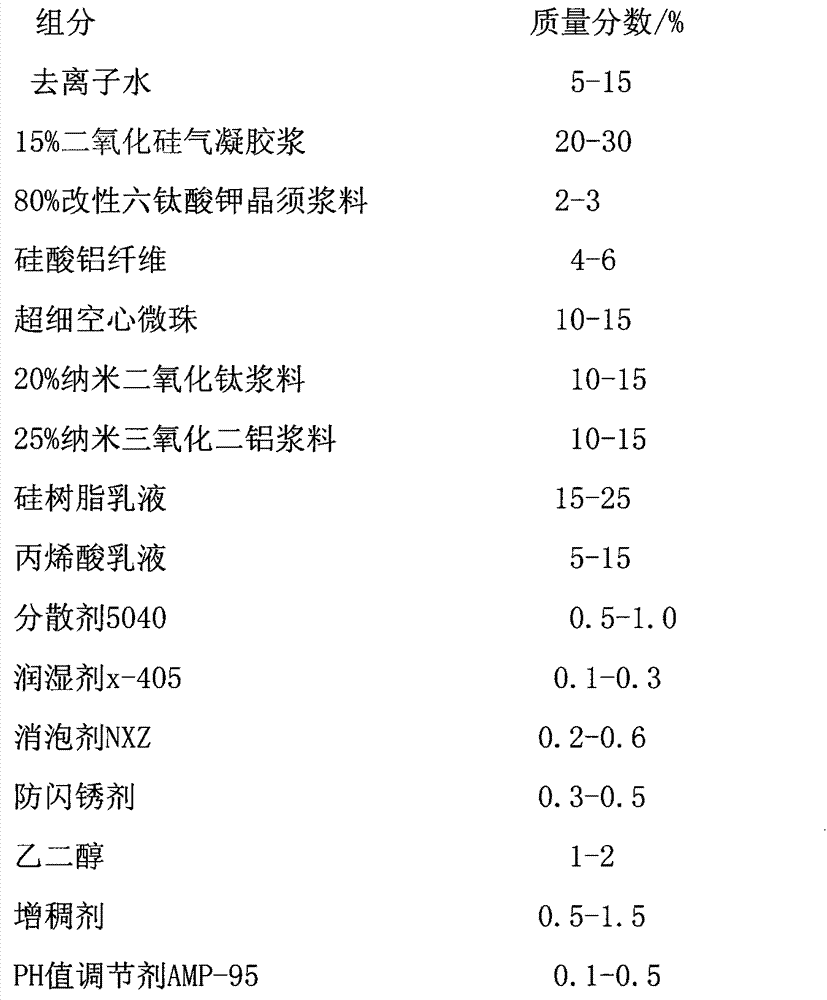

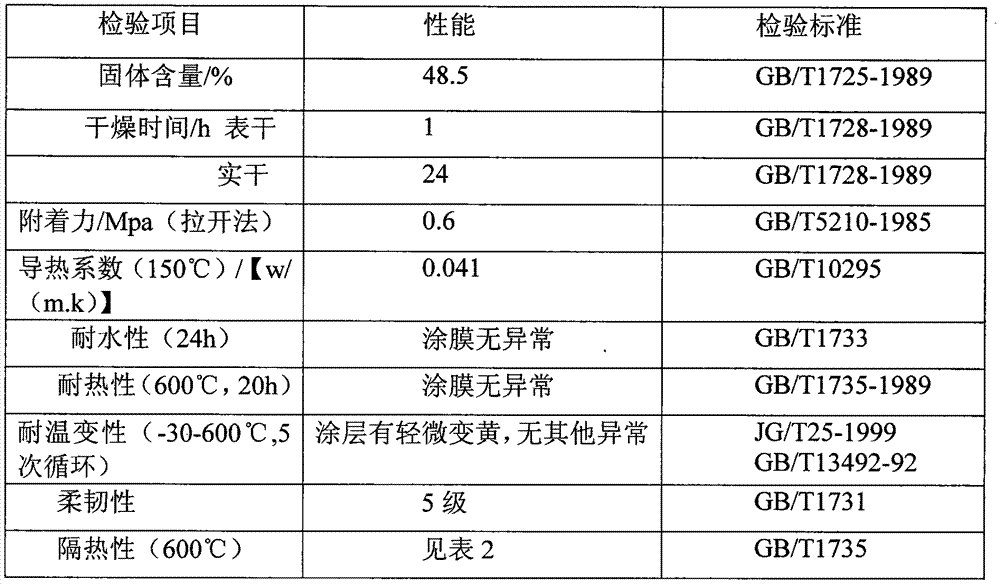

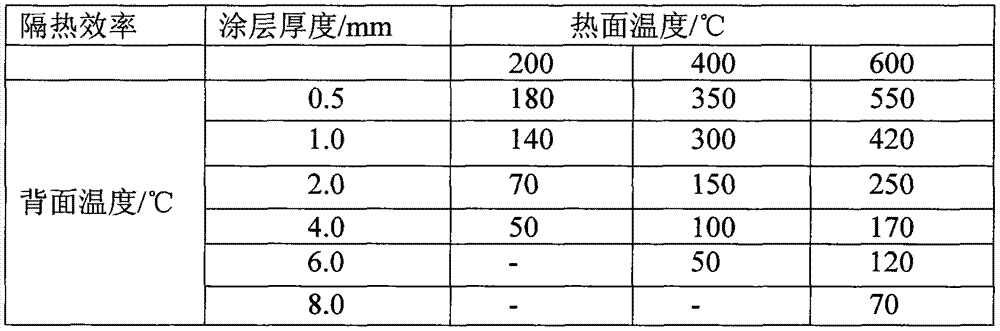

Nanometer high temperature resistant thermal insulation and prevention coating

The invention discloses a nanometer high temperature resistant thermal insulation and prevention coating. SiO2 aerogel, modified potassium hexatitanate whisker, aluminum silicate fiber, ultra-fine cenosphere, nanometer TiO2 and nanometer Al2O3 are used as a thermal insulation filler. A vacuum thermal insulation layer is formed by nano porous structures of SiO2 aerogel and cenosphere. The aluminum silicate fiber is used as a reinforcing and toughening material. The infrared shading performance of potassium hexatitanate whisker, nanometer TiO2 and nanometer Al2O3 are used as a thermal radiation shielding layer. A silicon resin emulsion and an acrylic emulsion are compounded to be an adhesive. Therefore, the nanometer 600 DEG C temperature resistant thermal insulation and prevention coating is prepared with matching of a variety of functional additives. The nanometer high temperature resistant thermal insulation and prevention coating has the characteristics of scumbling, thermal insulation, waterproofing, anti-crack, anti-corrosion, high temperature resistance, weather-proofing, durability and the like and is applicable to the field of industrial high temperature resistant thermal insulation energy conservation.

Owner:株洲中铁中南制造有限公司

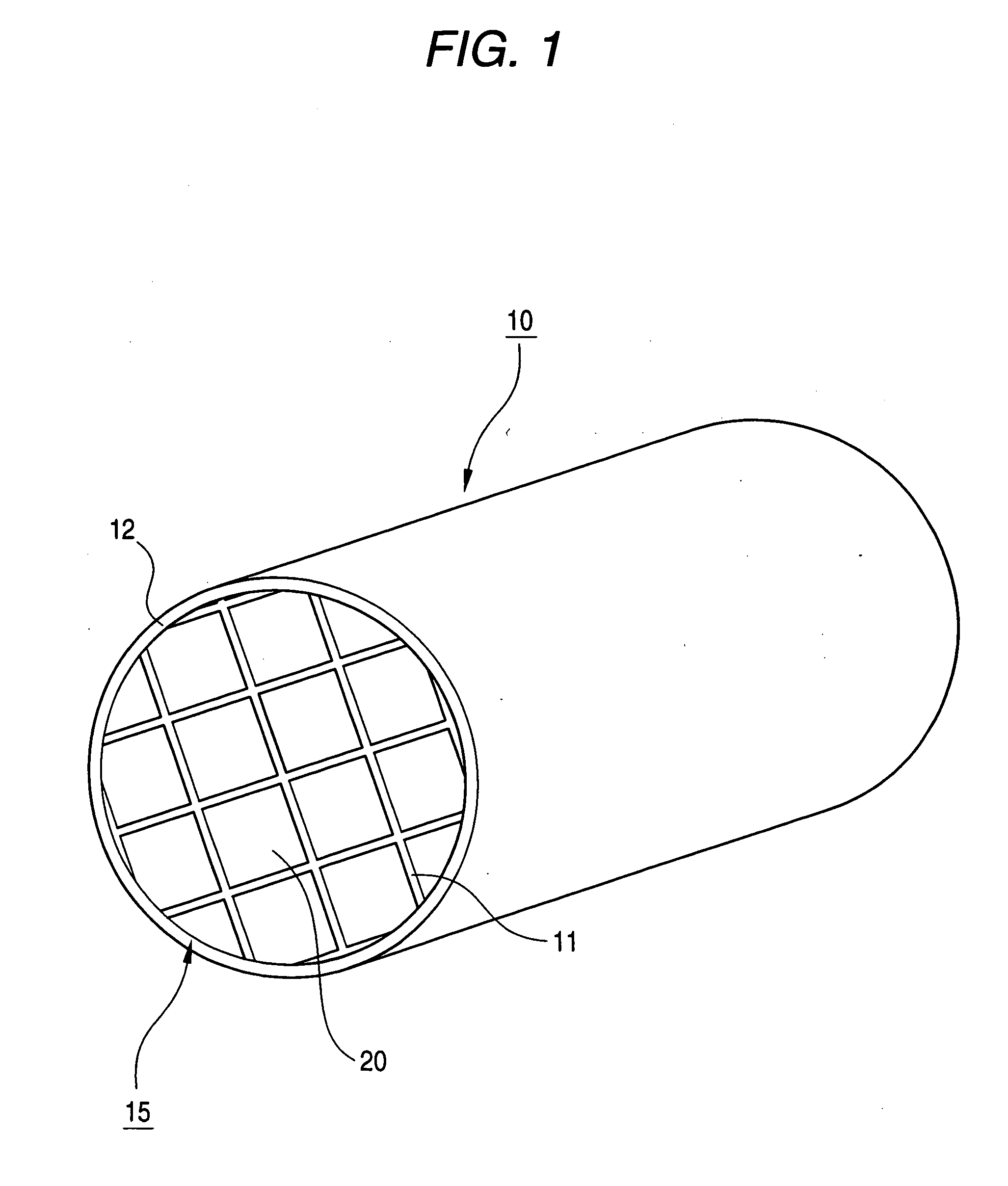

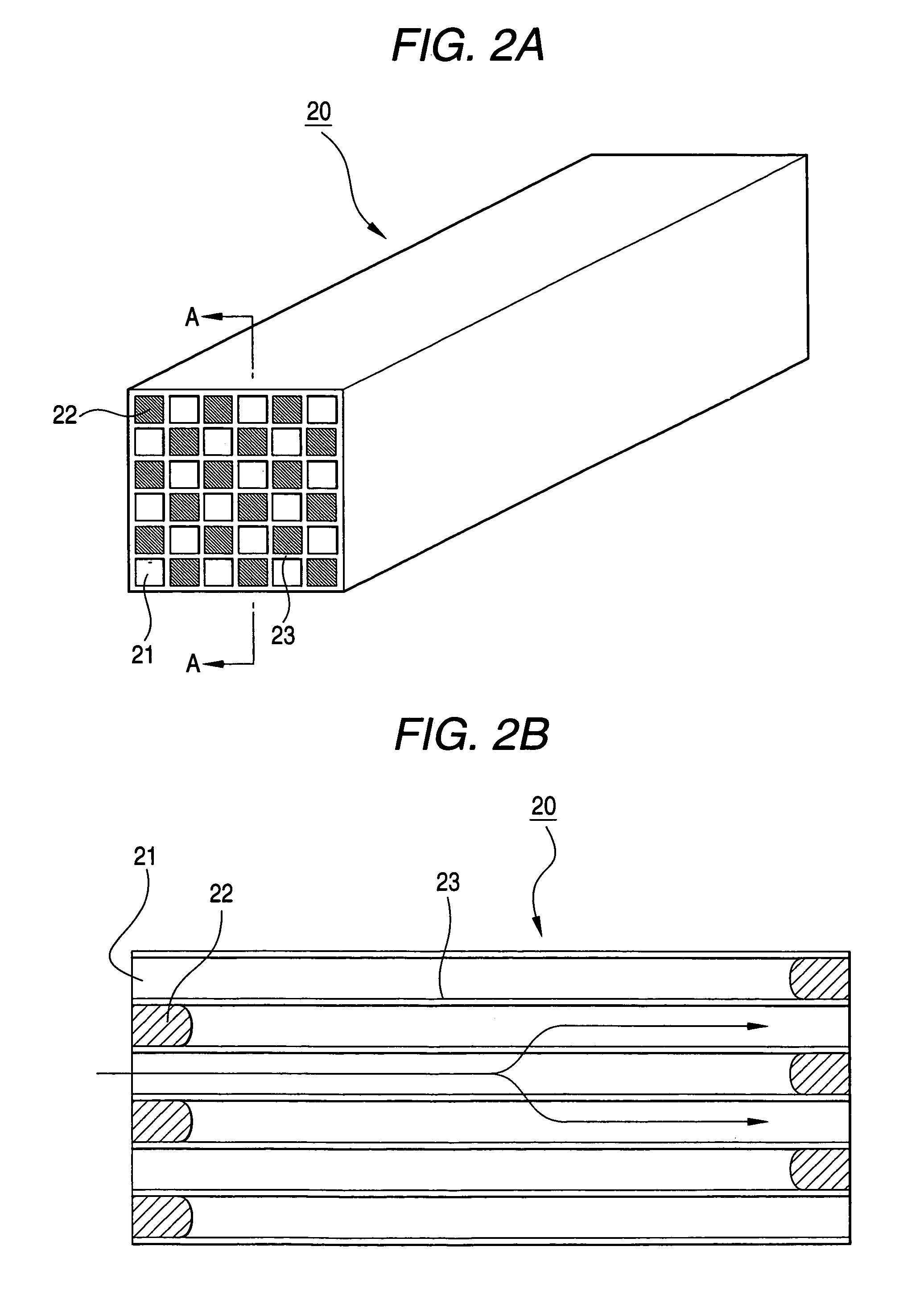

Honeycomb structural body

InactiveUS20050266991A1Improve purification functionReduce initial pressure lossCombination devicesAuxillary pretreatmentFiberToxic gas

An object of the present invention is to provide a honeycomb structural body for use in a filter, which can be provided with a large amount of catalyst, can suppress an increase in pressure loss upon collecting particulates, can have a high particulate collecting capability and can efficiently carry out a regenerating process and a toxic gas purifying process. The honeycomb structural body of the present invention is a pillar-shaped honeycomb structural body that is mainly composed of inorganic fibers and has a structure in that a large number of through holes are placed in parallel with one another in the length direction with a partition wall interposed therebetween. Herein, the inorganic fibers, which form the honeycomb structural body, are arranged in such a manner that more fibers are aligned along a face perpendicular to the forming direction of the through holes rather than aligned along a face in parallel with the forming direction of the through holes.

Owner:IBIDEN CO LTD

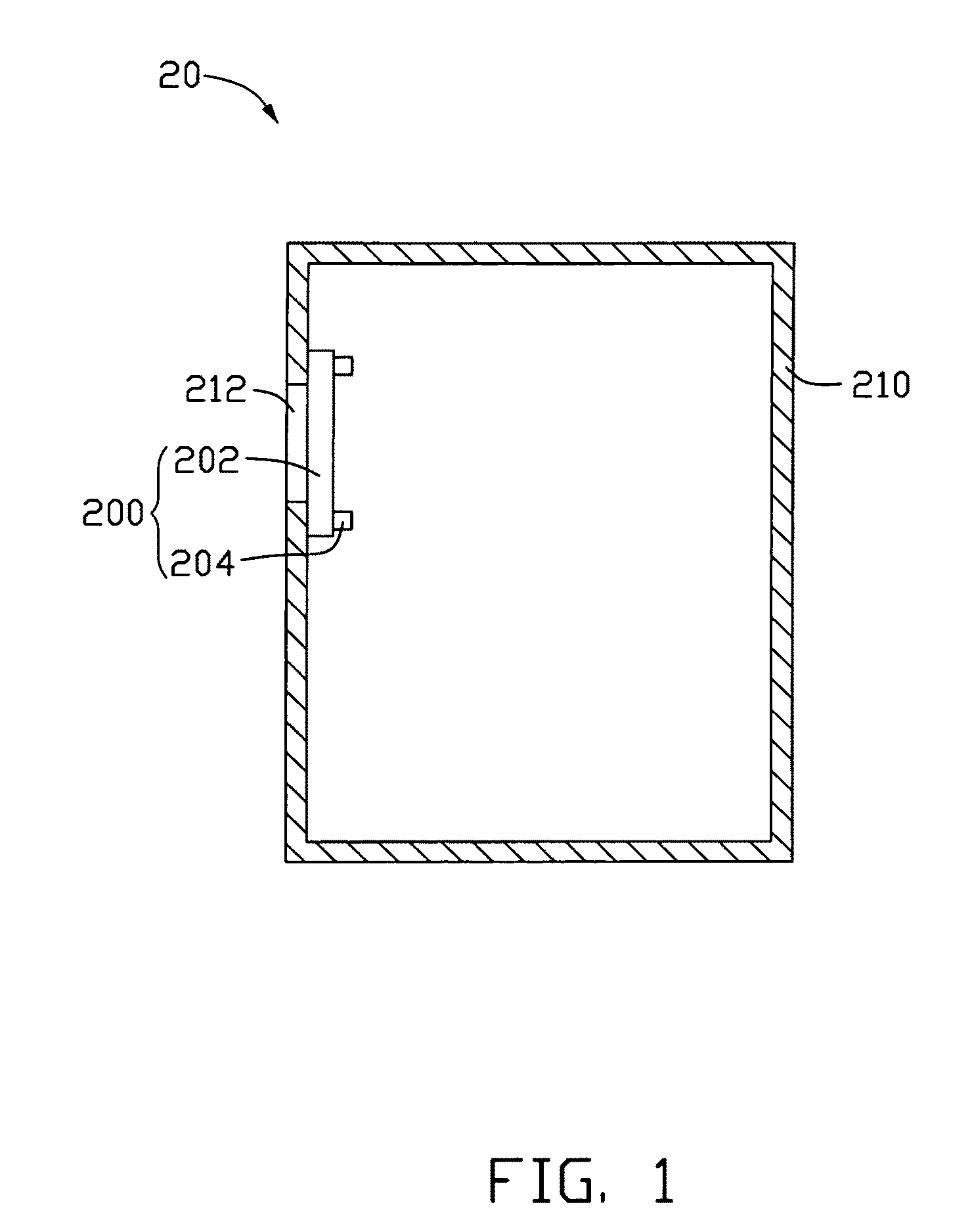

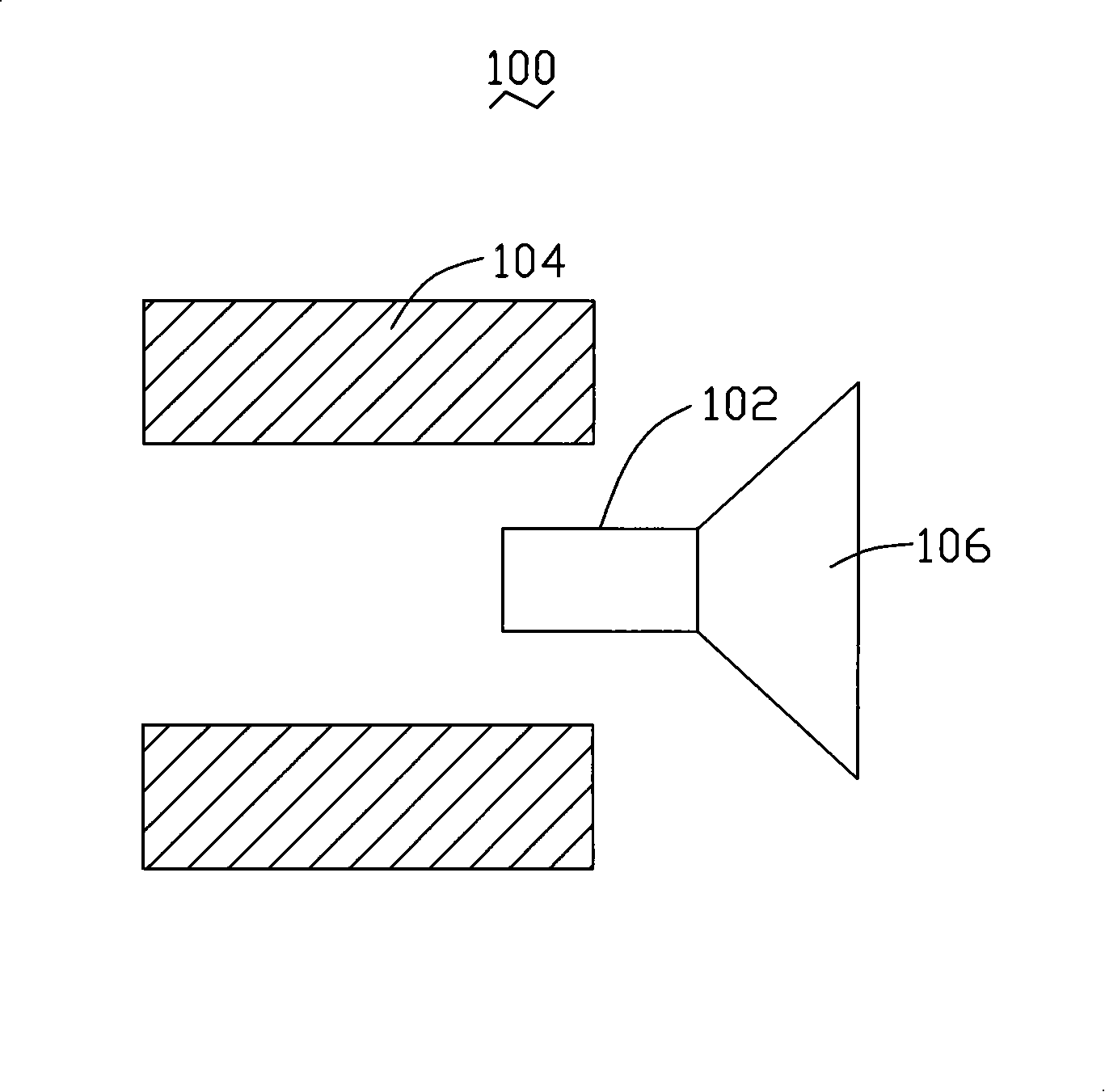

Loudspeaker

ActiveUS20100046784A1Small heat capacityIncrease the areaElectrothermic-effect transistorTransducer casings/cabinets/supportsCarbon nanotubeEngineering

A loudspeaker includes an enclosure and at least one sound wave generator disposed in the enclosure. The sound wave generator includes at least one carbon nanotube structure. The carbon nanotube structure is capable of converting electrical signals into heat. The heat is transferred to a medium and causes a thermoacoustic effect.

Owner:TSINGHUA UNIV +1

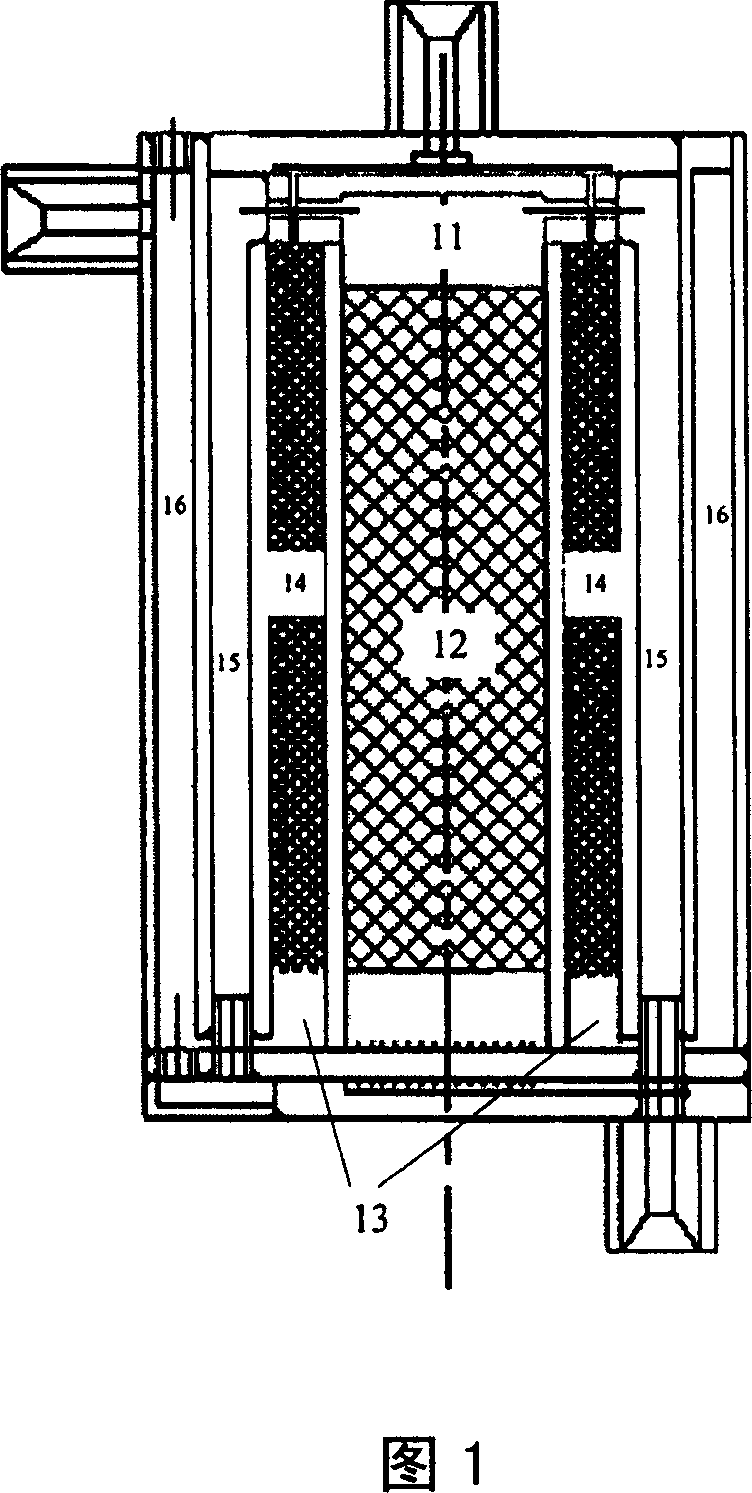

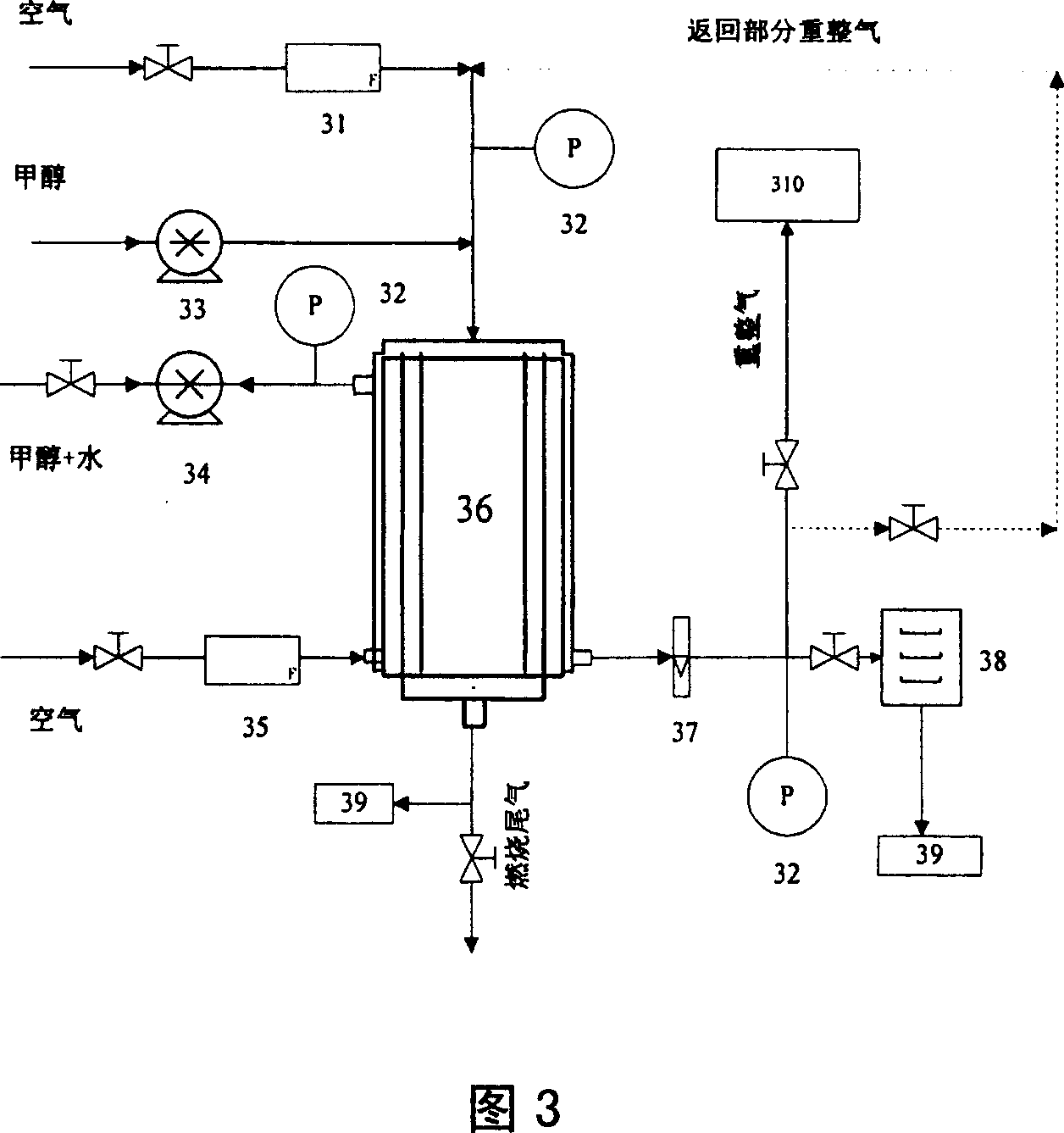

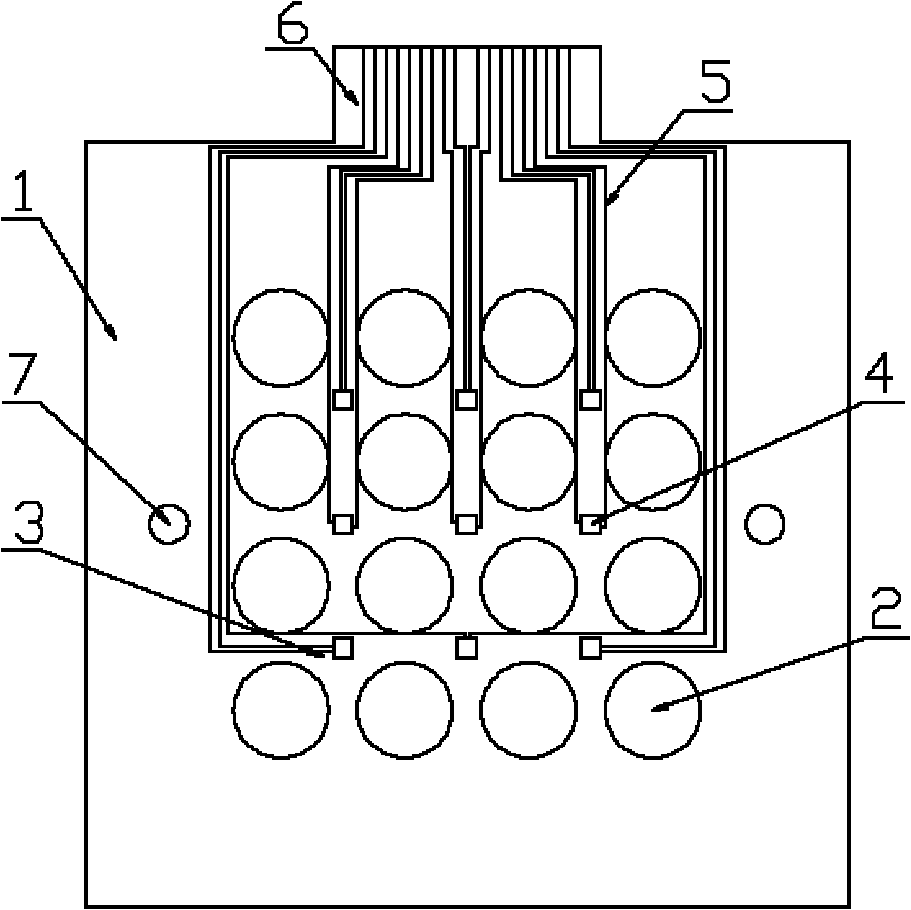

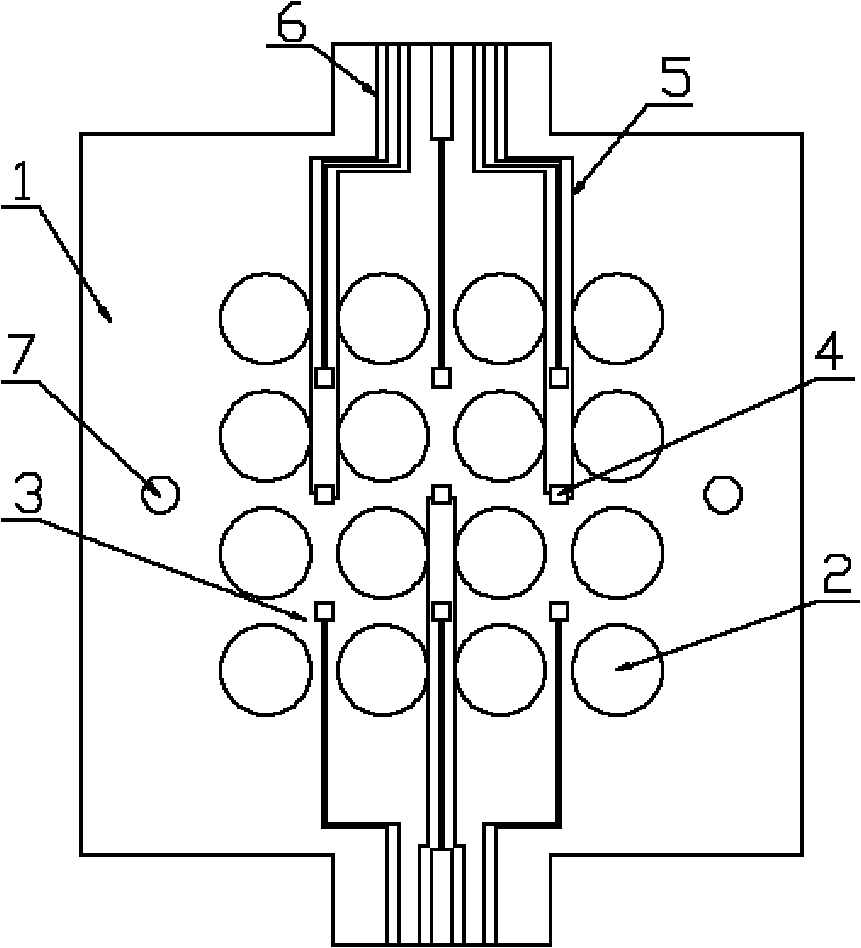

Mini reforming hydrogen-preparation reactor

InactiveCN101054160ARapid reforming hydrogen production reactionEven air distributionHydrogenHydrogenFuel cells

A minitype reactor for reforming hydrogen, which main part has telescopefeed structure, comprising a burning offgas heat exchange cavity, a reforming offgas heat exchange cavity, a burning cavity and a reforming cavity in sequence from outside; a fuel inlet is arranged communicating with the burning cavity; a reforming material inlet is arranged communicating with a built-in cavity of the burning offgas heat exchange cavity; reforming material liquid is preheated in the built-in cavity of the burning offgas heat exchange cavity then supplied into a built-in cavity of the reforming offgas heat exchange cavity; reforming material liquid flows in built-in cavities, burning offgas and reforming offgas exchange heat via tube wall of built-in cavities and flow oppose to reforming material liquid; a reforming air inlet is arranged, mixture gas of reforming air mixing with gas phase vaporized in the reforming offgas heat exchange cavity is supplied into the reforming cavity to process reforming hydrogen reaction. The catalytic burning reaction and reforming reaction of the invention has advantages of temperature easy to be control, stable running, easy operation; compact structure; the invention is suit for hydrogen source system of 10-500 W fuel cell minitype electrical source.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Zirconium oxide foam ceramic filter

InactiveCN101164657AImprove high temperature stabilityImprove impact performanceFiltration separationCeramicwarePolyvinyl alcoholMethyl cellulose

The present invention relates to a zirconium oxide foamed ceramic filter. It is made up by adopting the following steps: using zirconium oxide, aluminium oxide, calcium oxide and yttrium oxide to form ceramic powder, adding methyl cellulose, polyvinyl alcohol and water to prepare slurry, using soft polyurethane foamed plastics as carrier, impregnating said carrier with said slurry, extruding to obtain blank material, drying and sintering so as to obtain the invented zirconium oxide foamed ceramic filter. The invented foamed ceramic filter has good high-temperature stability and thermal shocking resistance in the high-temperature molten steel, does not contaminate alloy and can obtain good filtering purification effect.

Owner:晋城市富基新材料股份有限公司

Honeycomb structure

ActiveUS7556666B2Reduce the temperatureLight weightCombination devicesAuxillary pretreatmentApparent densityYoung's modulus

A honeycomb structure including a plurality of porous ceramic members which are bonded through an adhesive layer, each of the porous ceramic members has a plurality of cells, which are arranged in parallel while being separated by cell walls. The cells extend in a longitudinal direction of the honeycomb structure. In the honeycomb structure, the following relationship is satisfied:2≦B≦100 / 3×A−10 / 3 (1)where A (g / cm3) designates apparent density of the porous ceramic members, and B (GPa) designates Young's modulus of the adhesive layer.

Owner:IBIDEN CO LTD

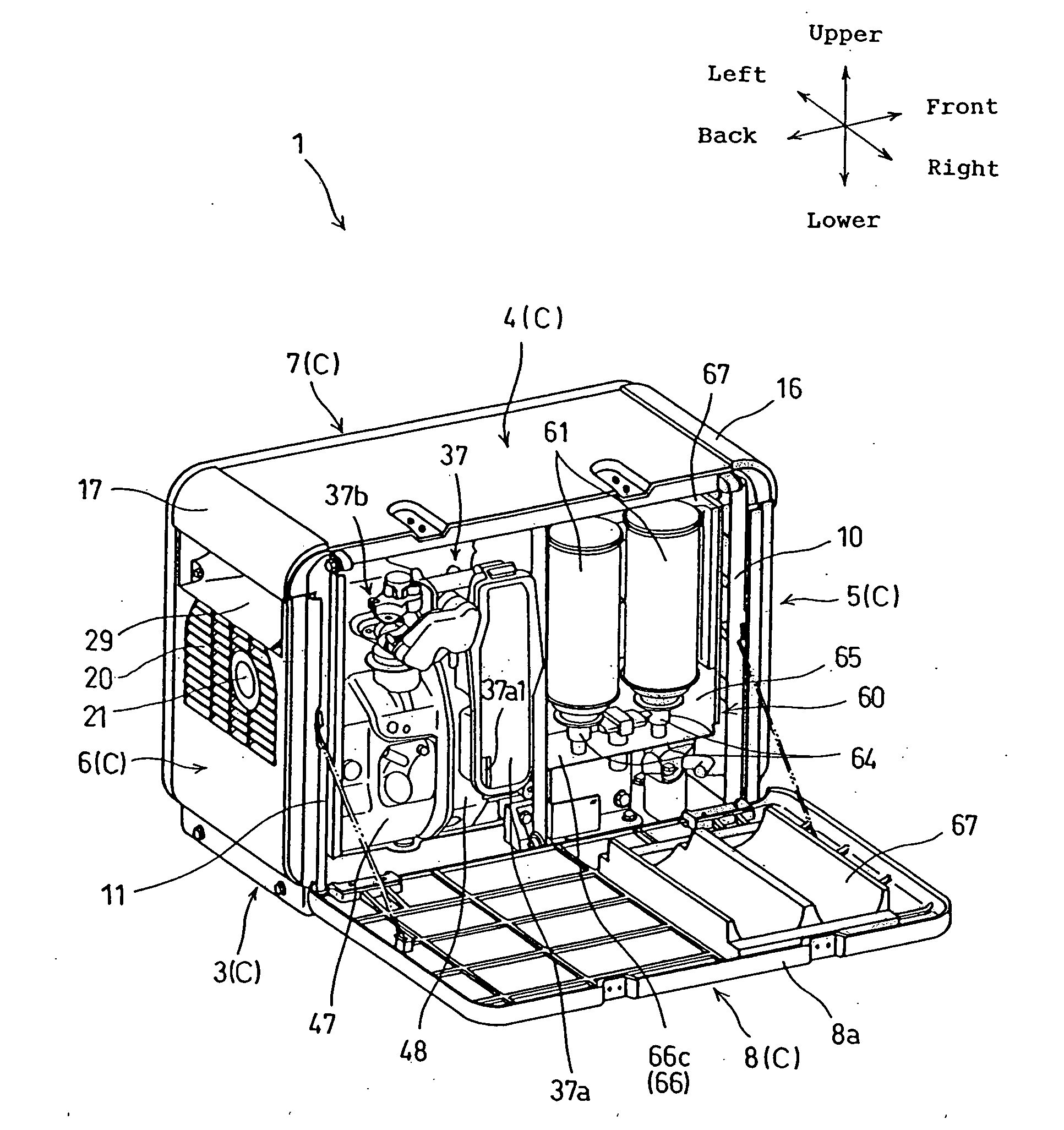

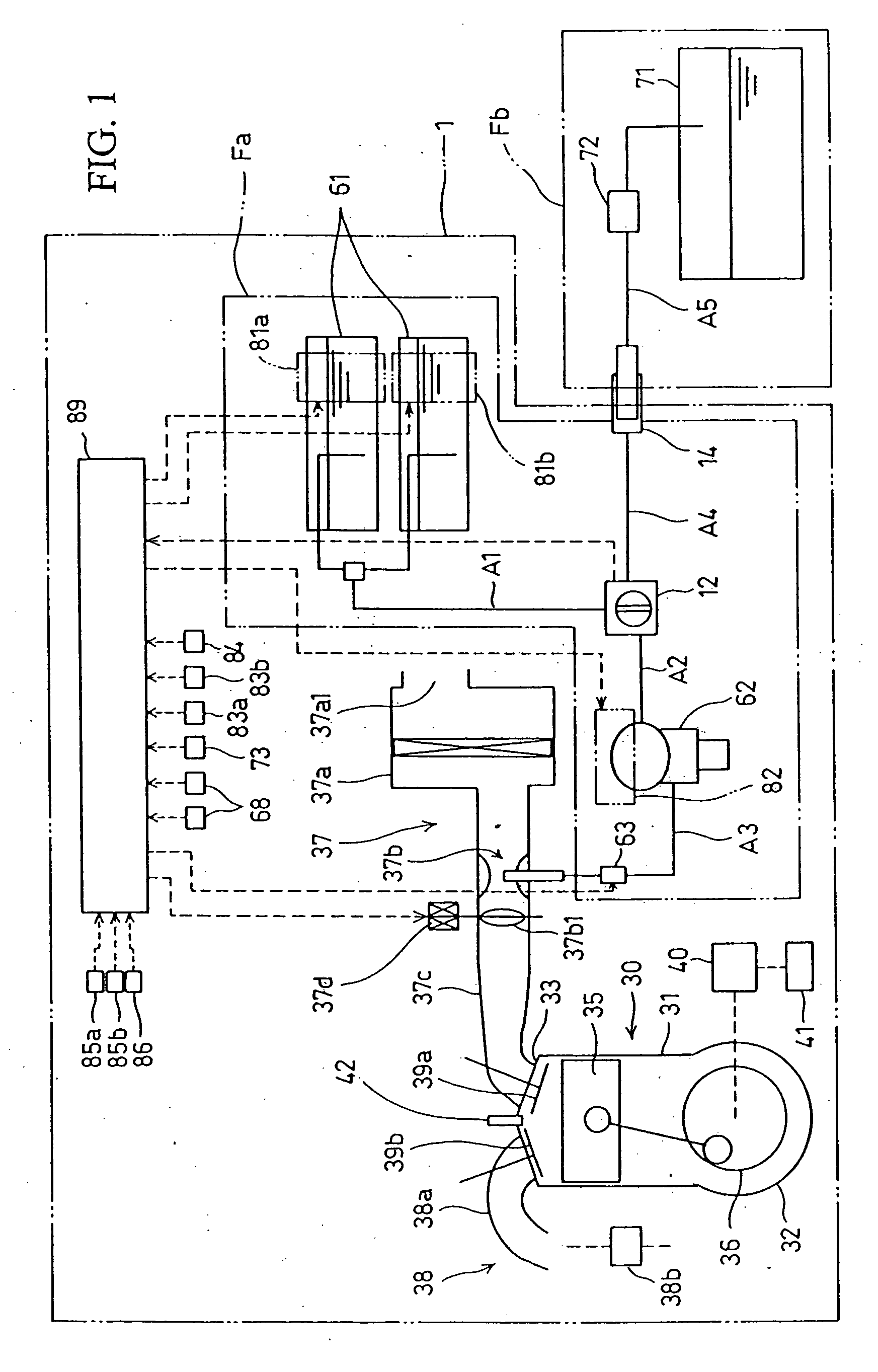

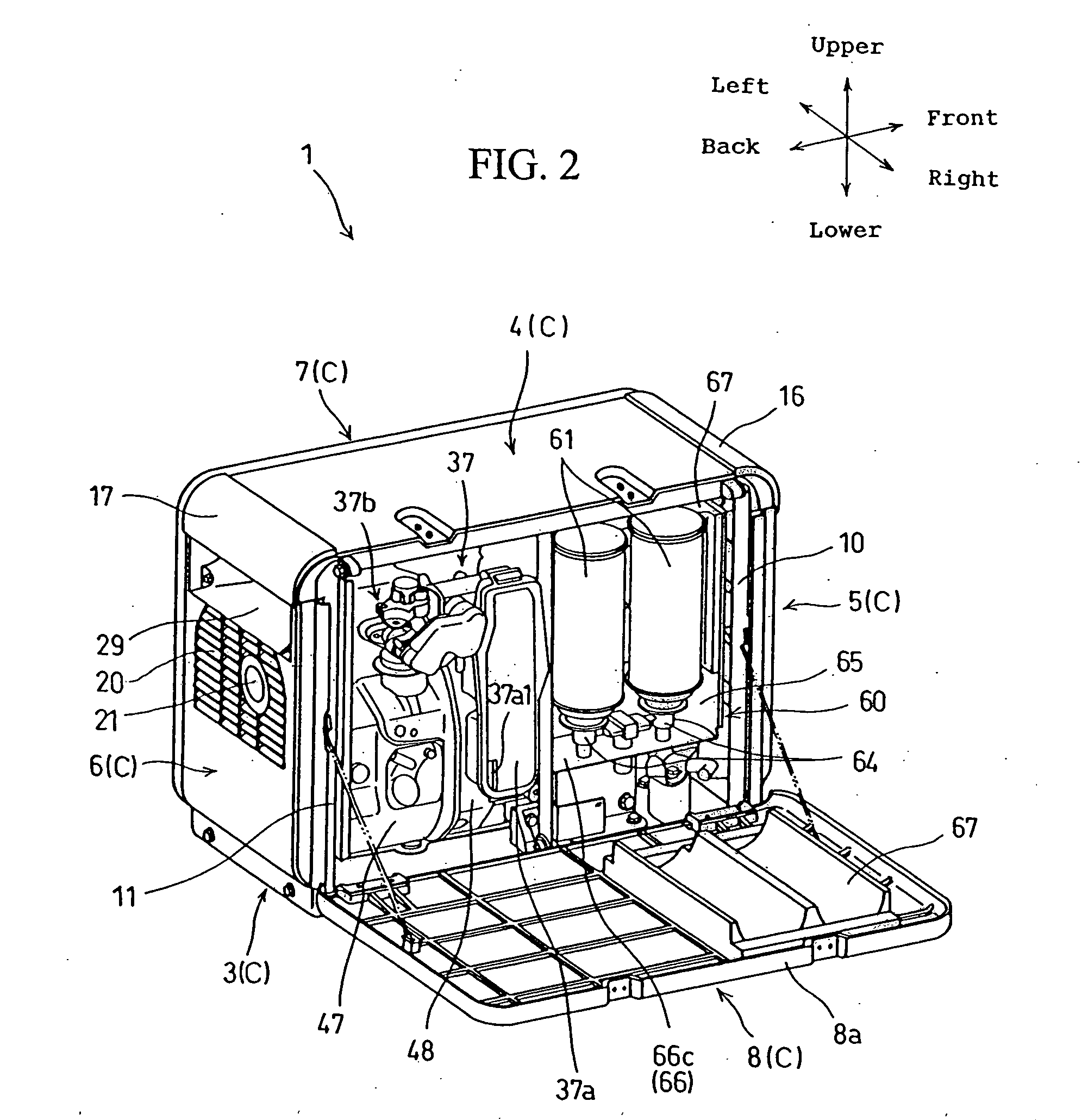

Engine operated generator

InactiveUS20070137591A1Heat dissipating structure can be in smallSmall heat capacityInternal combustion piston enginesAir coolingBottleFuel gas

An engine operated generator is provided with an engine, a generator driven by the engine, and a power control unit for controlling the power generated by the generator. A fuel gas stored in fuel bottles set in a case for the engine operated generator, is supplied to the engine though a fuel pressure regulator. The fuel bottles and the fuel pressure regulator are disposed adjacent to the power control unit to enable heat exchange with the power control unit provided with an inverter. Thus, heat is mutually utilized between the power control unit and at least one of the fuel bottles as fuel receptacles and the fuel pressure regulator.

Owner:HONDA MOTOR CO LTD

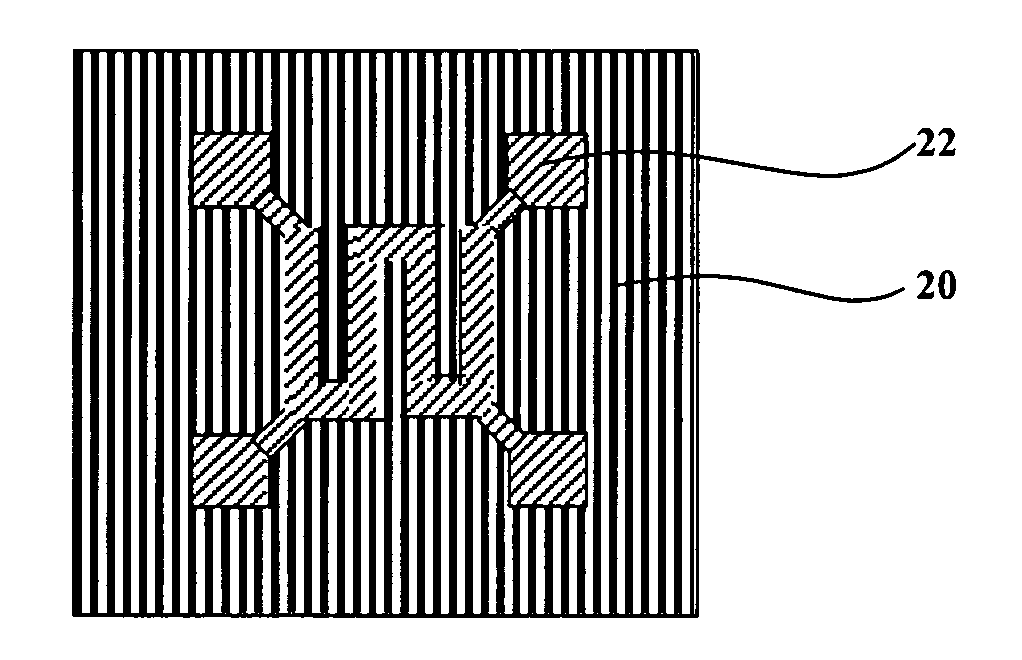

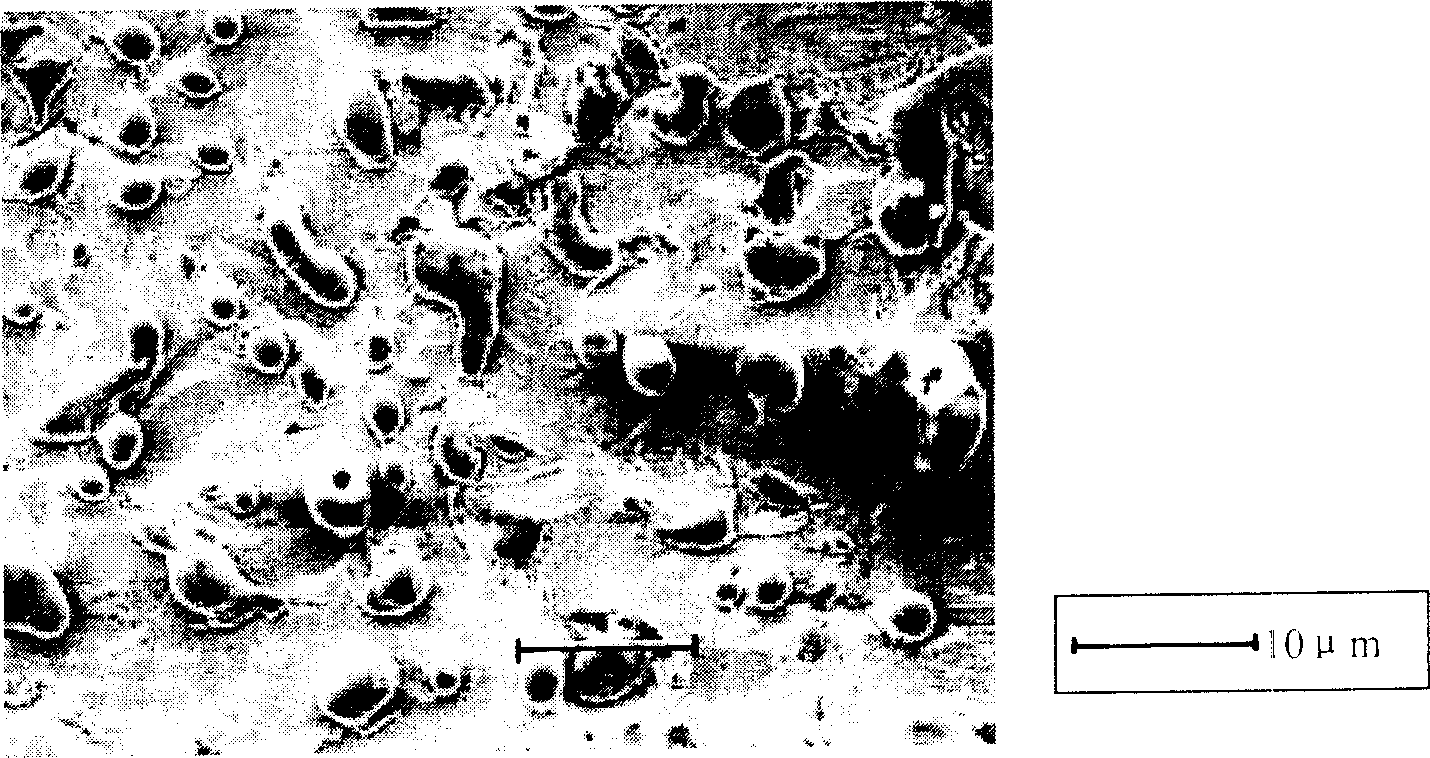

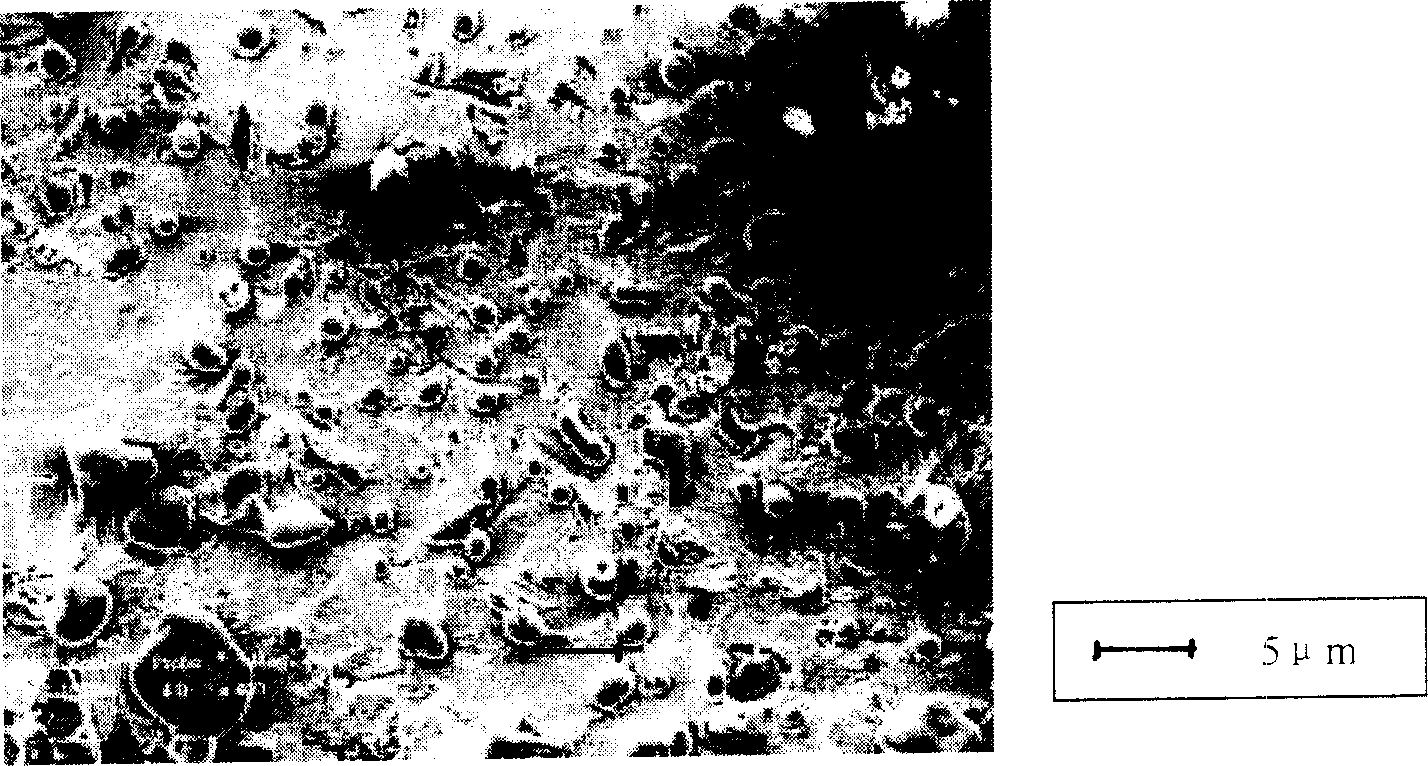

Nickel-coated free-standing silicon carbide structure for sensing fluoro or halogen species in semiconductor processing systems, and processes of making and using same

InactiveUS20040163444A1High resistivitySmall heat capacityAnalysing fluids using sonic/ultrasonic/infrasonic wavesComponent separationHalogenNickel alloy

A (MEMS)-based gas sensor assembly for detecting a fluorine-containing species in a gas containing same, e.g., an effluent of a semiconductor processing tool undergoing etch cleaning with HF, NF3, etc. Such gas sensor assembly in a preferred embodiment comprises a free-standing silicon carbide support structure having a layer of a gas sensing material, preferably nickel or nickel alloy, coated thereon. Such gas sensor assembly is preferably fabricated by micro-molding techniques employing sacrificial molds that are subsequently removable for forming structure layers.

Owner:ENTEGRIS INC

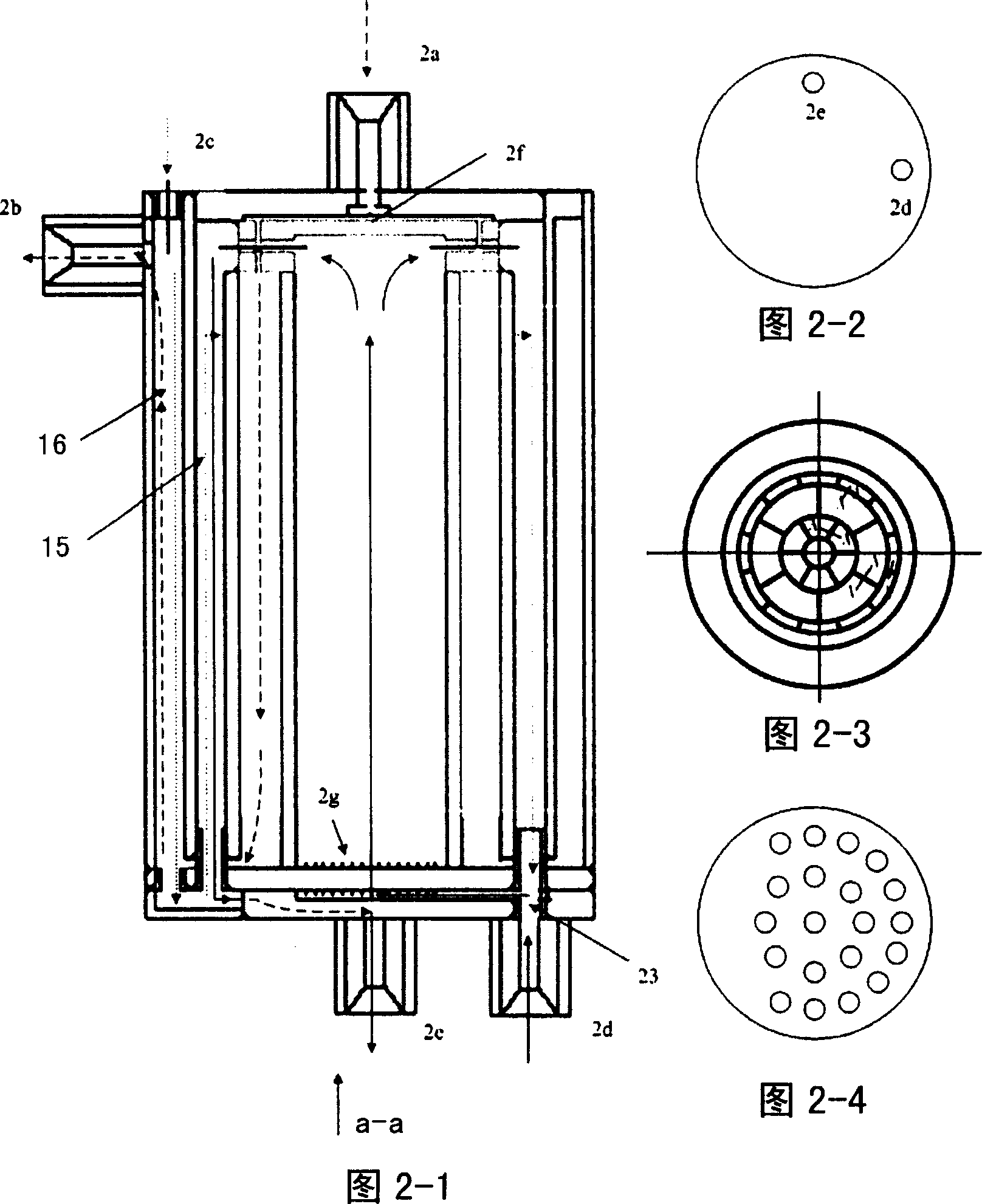

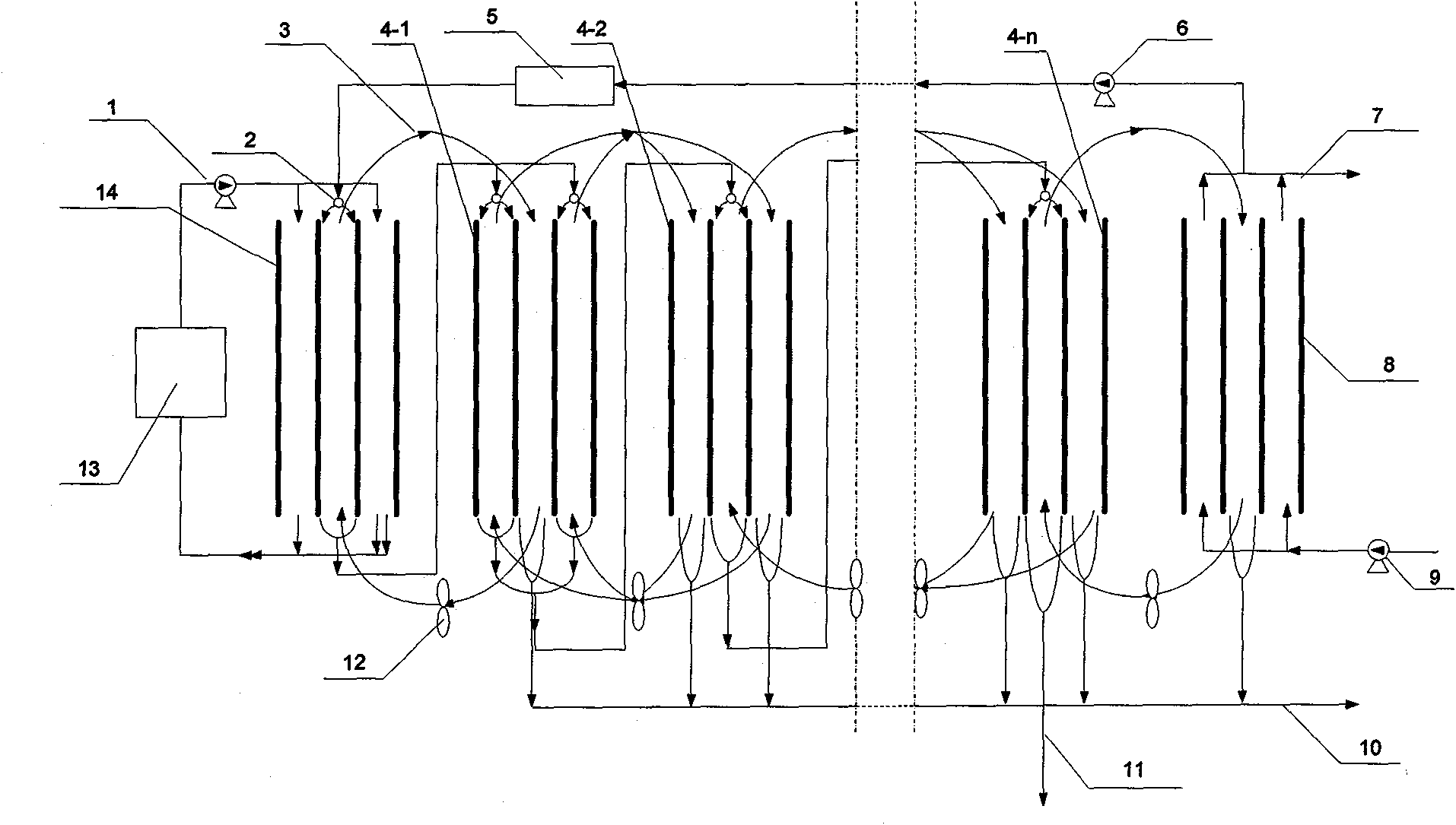

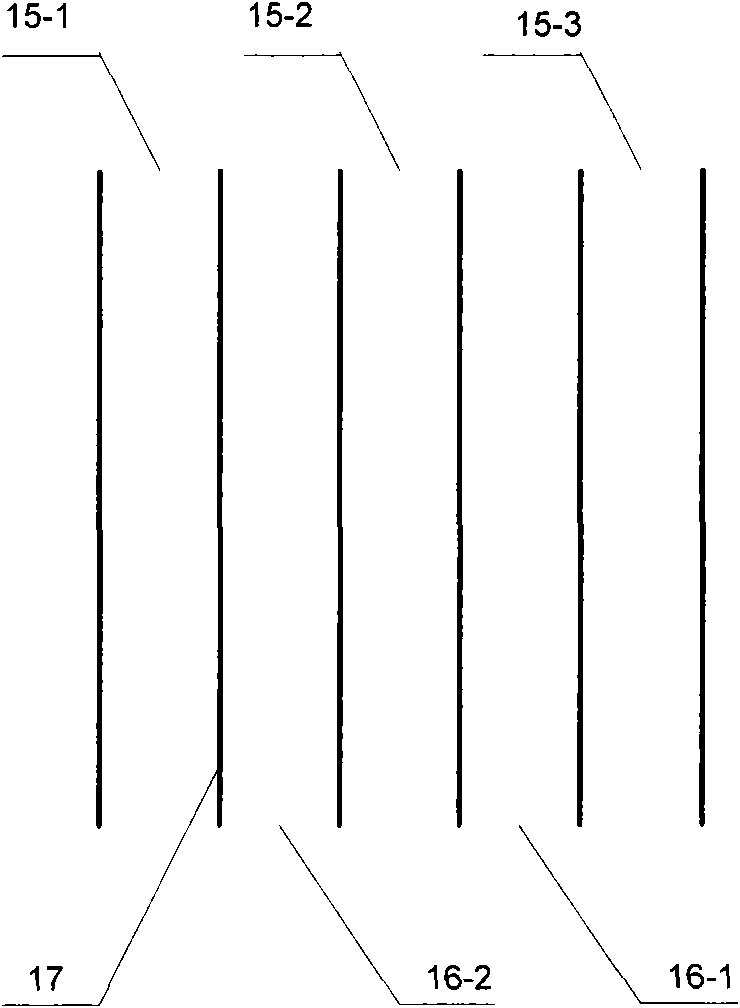

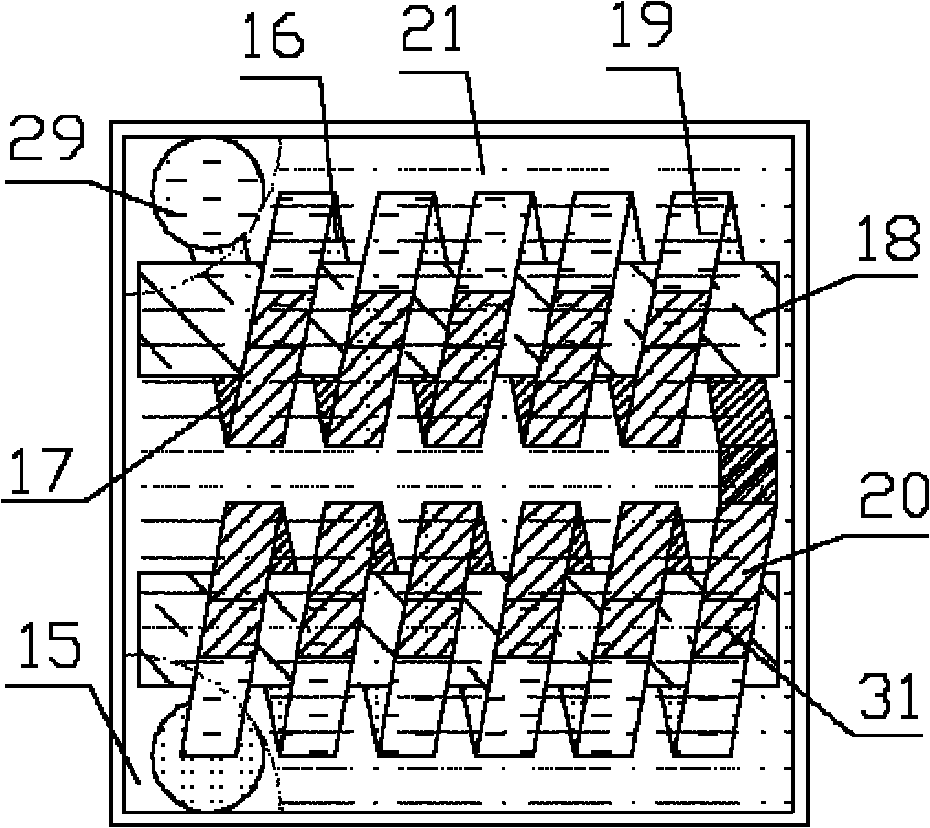

Constant-pressure multiple-effect evaporation condensation sea water desalination device with air medium

InactiveCN101921036AReduce consumptionImprove performanceSeawater treatmentMultistage water/sewage treatmentWater desalinationEnergy recovery

The invention discloses a constant-pressure multiple-effect evaporation condensation sea water desalination device with an air medium, which mainly comprises a low-and-medium temperature heat source (13), a first-stage heating evaporator (14), an evaporation condenser (4) and a last-stage condenser (8). The first-stage heating evaporator (14), the evaporation condenser (4) and the last-stage condenser (8) are installed in sequence closely, and the low-and-medium heat source (13) and the first-stage heating evaporator (14) are connected together. The first-stage heating evaporator (14), the evaporation condenser (4) and the last-stage condenser are all formed by combining a plurality of heat exchange plates which are arranged from left to right in sequence, and a gap is reserved between every two adjacent heat exchanging plates to form a flow channel for heat exchange fluid. By adopting the plate-type heat exchange principle, the sea water desalination device realizes multiple-effect air humidification and dehumidification evaporation and condensation for sea water desalination under constant pressure. Heat and moisture transfer is performed between sprayed sea water and overflowing air, and the condensation latent heat of fore effect heat and moisture air can be absorbed at the same time, and therefore, energy recovery is realized and the fore effect heat and moisture air can be condensed to obtain fresh water.

Owner:GUANGDONG FIVESTAR SOLAR ENERGY

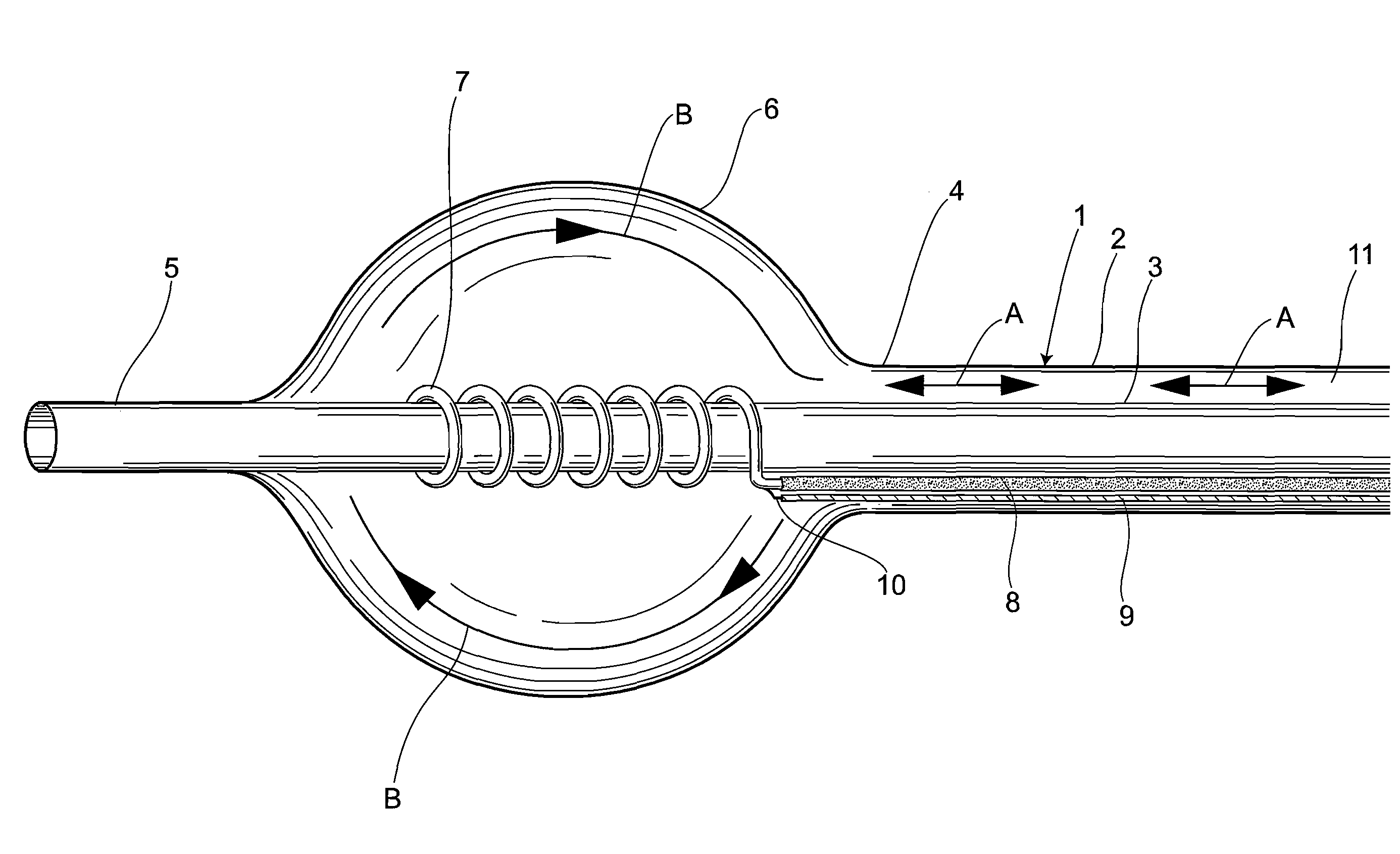

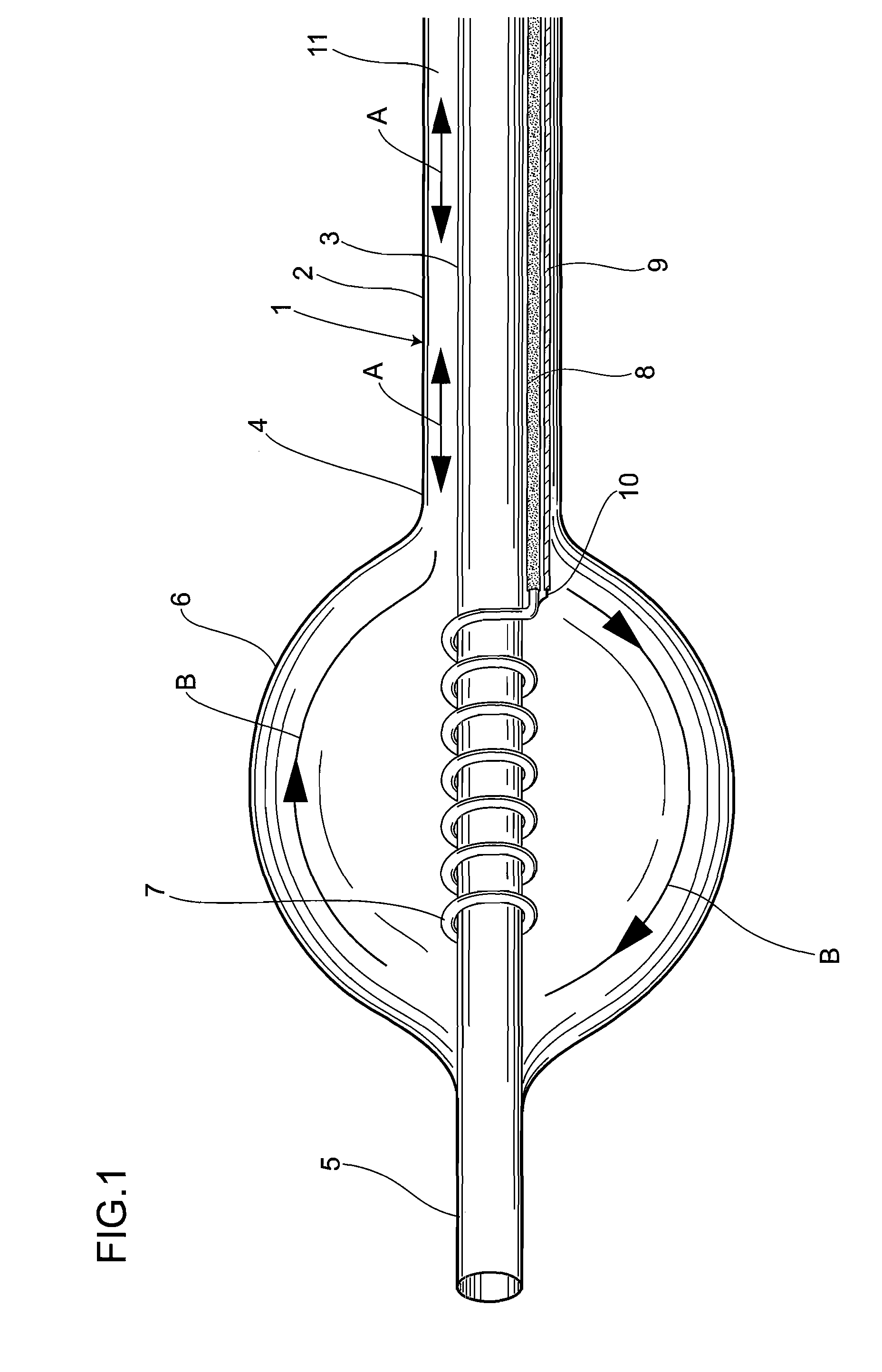

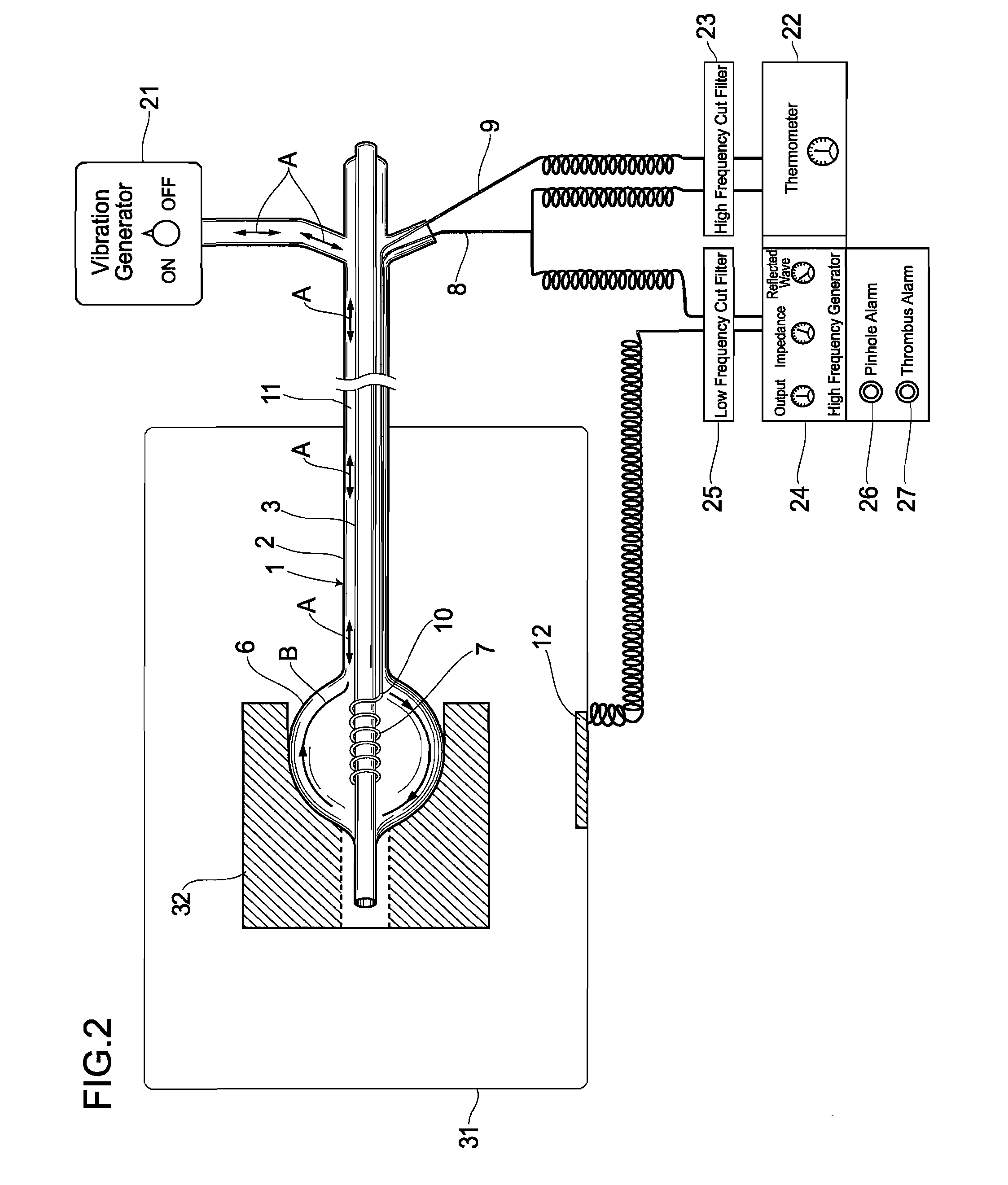

Radiofrequency thermal balloon catheter system

InactiveUS20080172050A1Small heat capacityAccurately and instantaneously detectedSurgical instruments for heatingAutomatic controlMiniaturization

A radiofrequency thermal balloon catheter system which is accurate in the detection temperature, capable of miniaturization compared to conventional systems, reliably detecting pinholes and adhesion of thrombi. A thermocouple is composed of a radiofrequency transmission line and a single metal wire joined to the distal end thereof. A coiled electrode is formed in a coil shape by extending the distal end of the radiofrequency transmission line. The distal end of the metal wire is brought into pin-point connection with the proximal end of the coiled electrode. A radiofrequency generator monitors the radiofrequency output, total impedance, and reflection waves, while supplying the coiled electrode and a counter electrode plate with a radiofrequency of 1 to 5 MHz, and automatically controls the radiofrequency output, so that the temperature of the coiled electrode can be kept at a target value.

Owner:JAPAN ELECTEL

Fabricated prestressed heat-resistant cement concrete pavement and construction process thereof

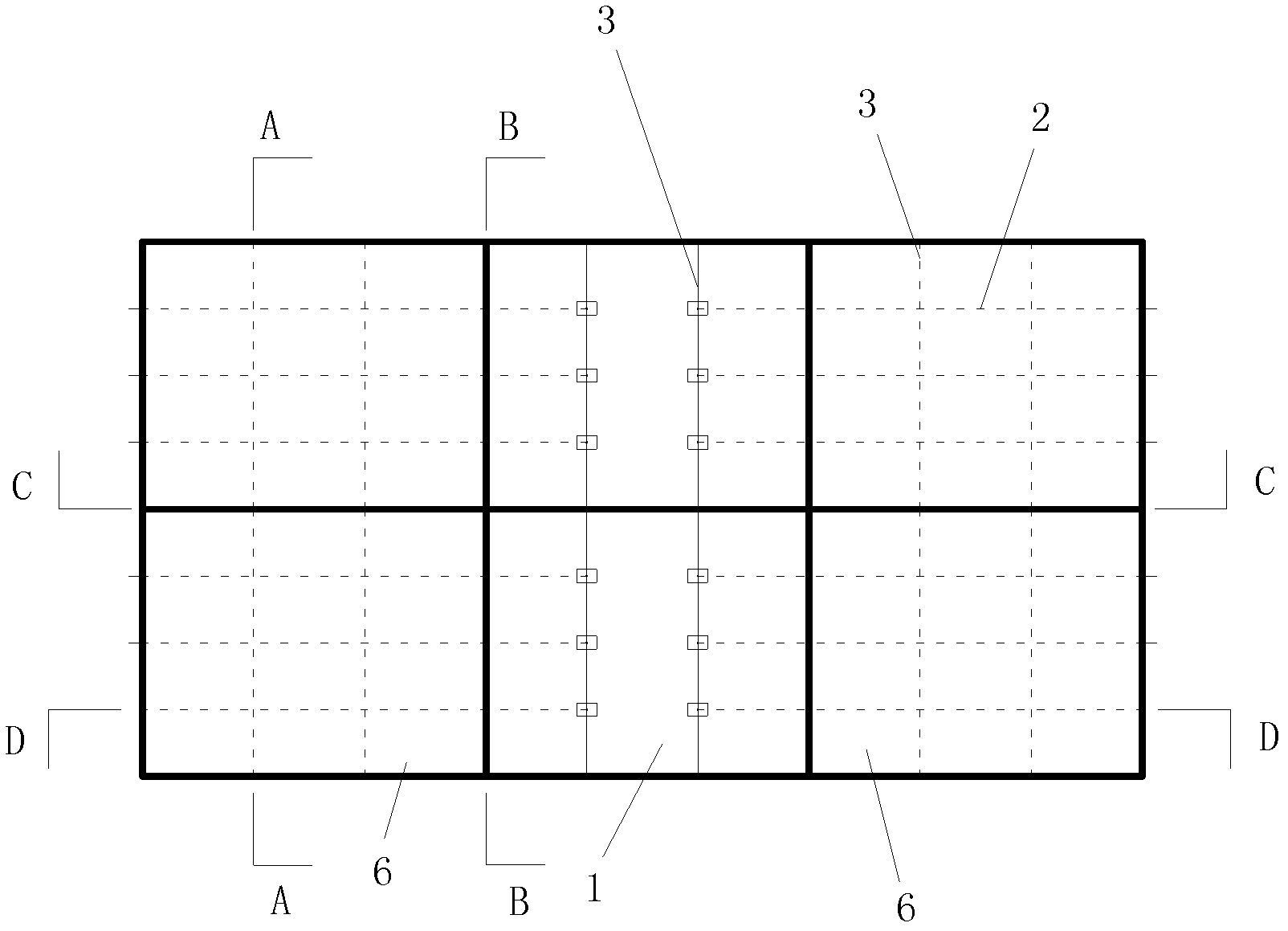

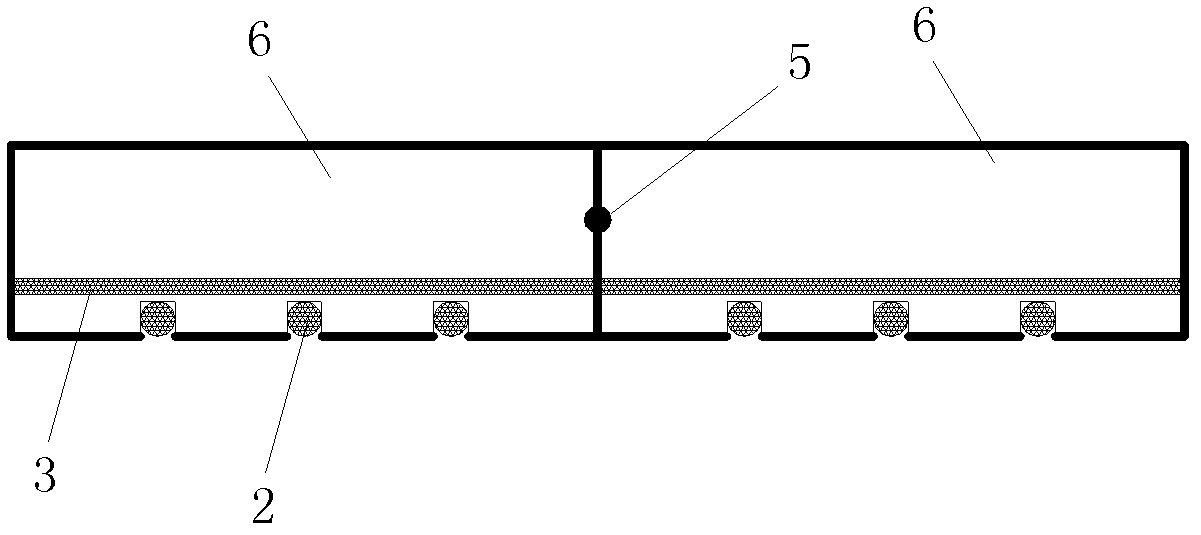

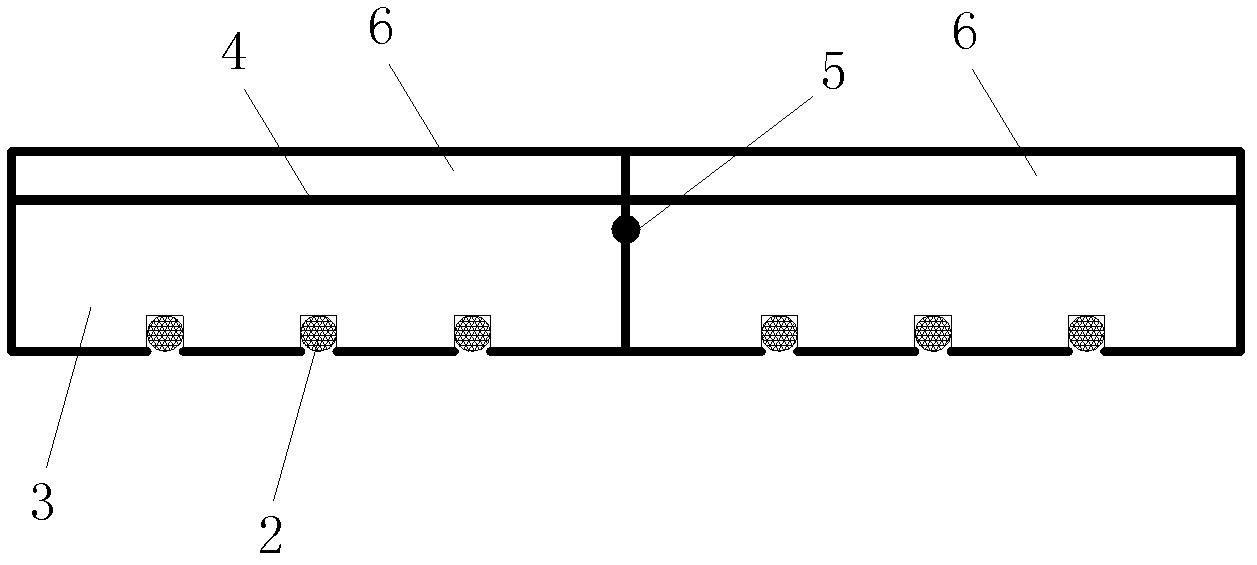

ActiveCN102535295AReasonable structural designEasy to laySingle unit pavingsPaving detailsHeat resistancePre stress

The invention discloses a fabricated prestressed heat-resistant cement concrete pavement and a construction process thereof. The pavement is formed by splicing a plurality of fabricated prestressed heat-resistant pavement plates which are parallelly paved and connected into a whole through transverse prestressed steel stranded wires, wherein each fabricated prestressed heat-resistant pavement plate comprises a fabricated prestressed pavement plate which consists of a plurality of pavement plate blocks connected through connecting plates, and a vermiculite concrete heat-resistant paving layer which is paved on the fabricated prestressed pavement plate; each pavement plate block comprises a plurality of common plates which are connected into a whole through longitudinal prestressed steel stranded wires; and the connecting plates and the common plates are cement concrete prefabricated plate blocks. The construction process comprises the following steps of: 1, prefabricating the cement concrete prefabricated plate blocks; 2, transporting the cement concrete prefabricated plate blocks; and 3, paving the pavement. The pavement is reasonable in structural design, convenient to construct, low in input cost and short in construction period, and has heat resistance, construction quality is easy to ensure, and various practical problems of the traditional fabricated cement concrete pavement can be solved.

Owner:CHANGAN UNIV

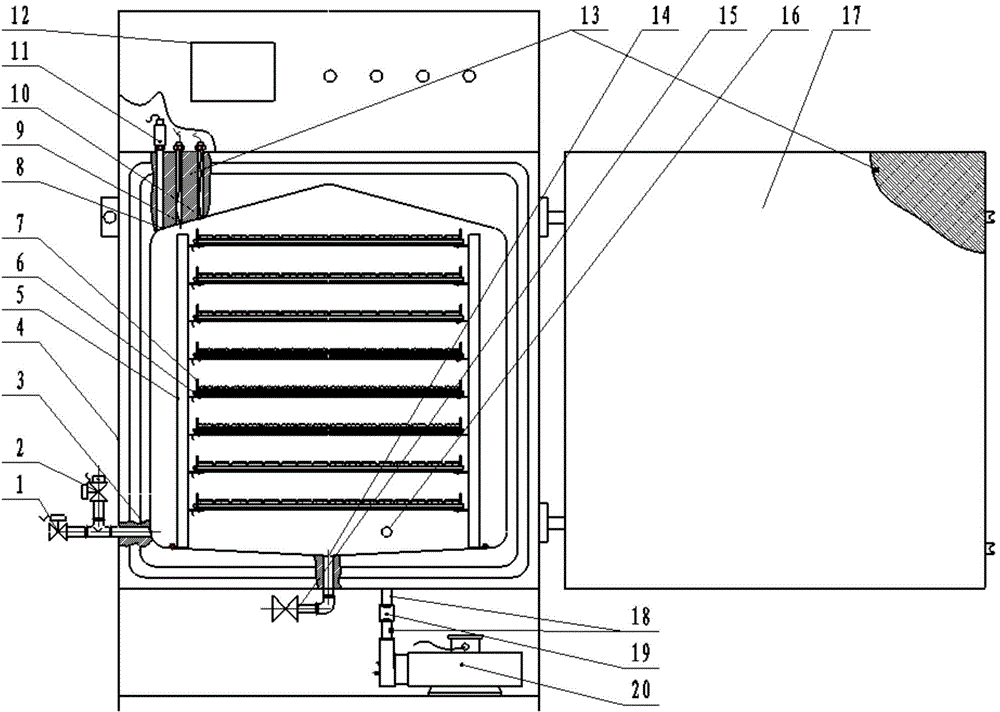

Flat plate type vacuum pulsation drying machine

ActiveCN104596207ANo damageReduce consumptionDrying using combination processesDrying machines with local agitationSoft materialsPulp and paper industry

The invention belongs to the technical field of agriculture product processing, and particularly relates to a flat plate type vacuum pulsation drying machine. The flat plate type vacuum pulsation drying machine comprises a machine body, a control unit, a material drying unit and a pulsation vacuum unit, wherein the material drying unit is provided with multiple layers of material shelves. According to the flat plate type vacuum pulsation drying machine disclosed by the invention, a heating part adopts special electric heating plates, so that the processing is simple and convenient, the cost is low, the heating temperature is uniform, and the manufacturing cost, the using cost and the maintaining cost of the drying machine are greatly reduced; through a hierarchical control mode, corresponding heating plates can be opened according to actual processing amount, so that the energy consumption is reduced; meanwhile, soft material trays are adopted, so that the contact conditions between the material trays and the heating plates are remarkably improved, the quality of dried products can be effectively ensured, and the problem that the soft material trays are inconvenient to move is overcome by using a dedicated material tray shovel to assemble and disassemble the material trays; in addition, the flat plate type vacuum pulsation drying machine belongs to static drying, the breakage of materials cannot be caused; the processing and loading capacity of equipment can be effectively increased by virtue of a multi-layer structure.

Owner:CHINA AGRI UNIV

Glass ceramic coating produced on metal carrier and its producing method

InactiveCN1899997AImprove ductilityNot easy to fall offCatalyst carriersCatalyst protectionCopper oxideAluminium oxide

The present invention belongs to the field of automobile tail gas purifying technology, and is especially glass ceramic coating on metal or alloy carrier of automobile tail gas purifying treater and its preparation process. The oxides of the glass coating include silica in 25-65 wt% and boron oxide in 5.0-27 wt%, except the mixture of other 3-9 oxides selected from 17 kinds of oxides, including sodium oxide, potassium oxide, lithium oxide, aluminum oxide, calcium oxide, etc. The glass coating on the metal carrier can raise the mechanical strength and reaction activity of the catalyst effectively, and this results in saving in active component and lowered cost.

Owner:JILIN UNIV

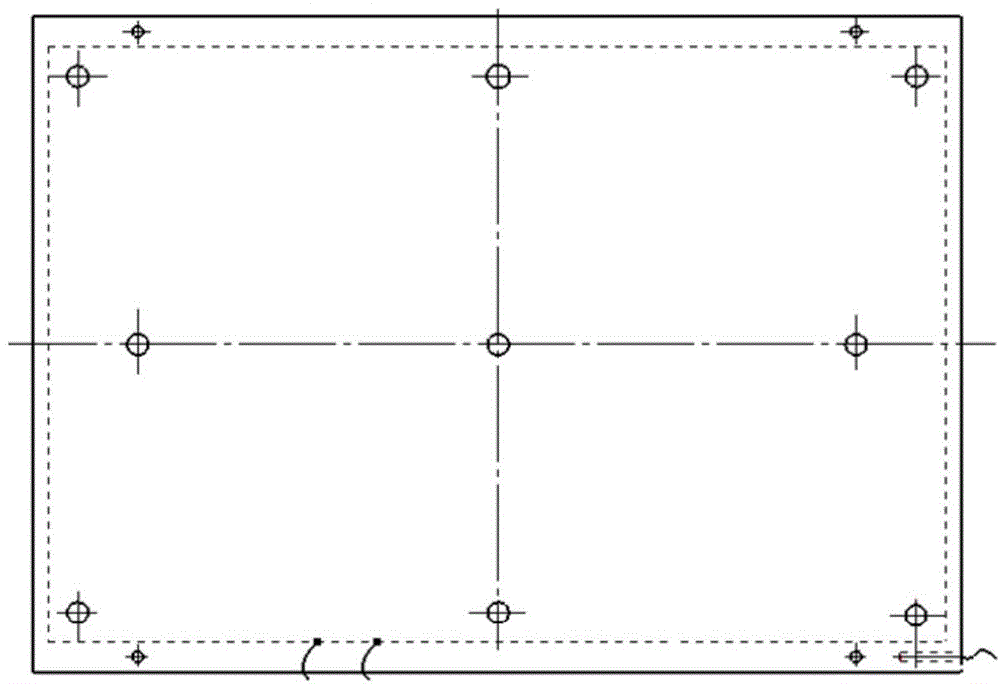

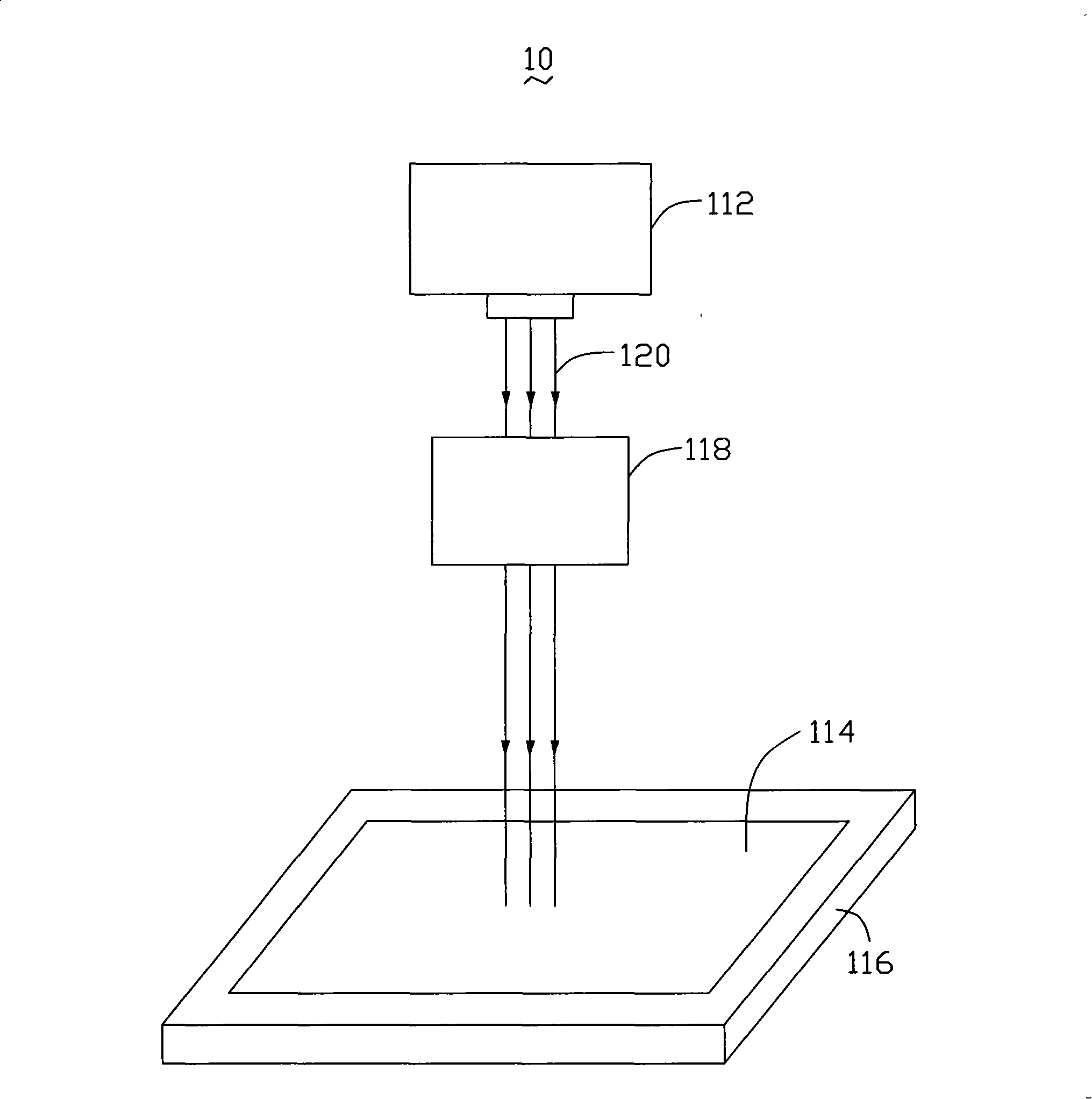

Internal transient film heat-flow sensor of fuel cell

ActiveCN102175339ASimple structureEasy to useFinal product manufactureMaterial heat developmentEngineeringSilicon dioxide

The invention discloses a method for measuring internal heat-flow density distribution of fuel cells. In the method, a certain number of film heat-flow meters are arranged by employing a vacuum film coating technology on ribs between adjacent flow paths of a fuel cell graphite flow field board so as to measure the internal heat-flow density distribution of fuel cells. A single film heat-flow meter is formed by evaporating seven films on the rib of the graphite flow field board; the clad layers of the film heat-flow meter are determined according to the shape of a mask; a silica insulating layer is coated on the first layer; metal film thermocouples are coated on the second and third layers; a silica heat resistance layer is coated on the fourth layer; the metal film thermocouples are coated on the fifth and sixth layers; and a protective layer of a measuring head of the heat-flow meter is coated on the seventh layer. The wire of the film heat-flow meter is extended to the edge of the flow field board by the printing circuit technology on the rib of the graphite flow field board, and provided with a standard wiring access connected with an external circuit. The measuring method is simple, the processing and manufacturing are easy, the measurement is accurate, and the use is convenient.

Owner:BEIJING UNIV OF TECH

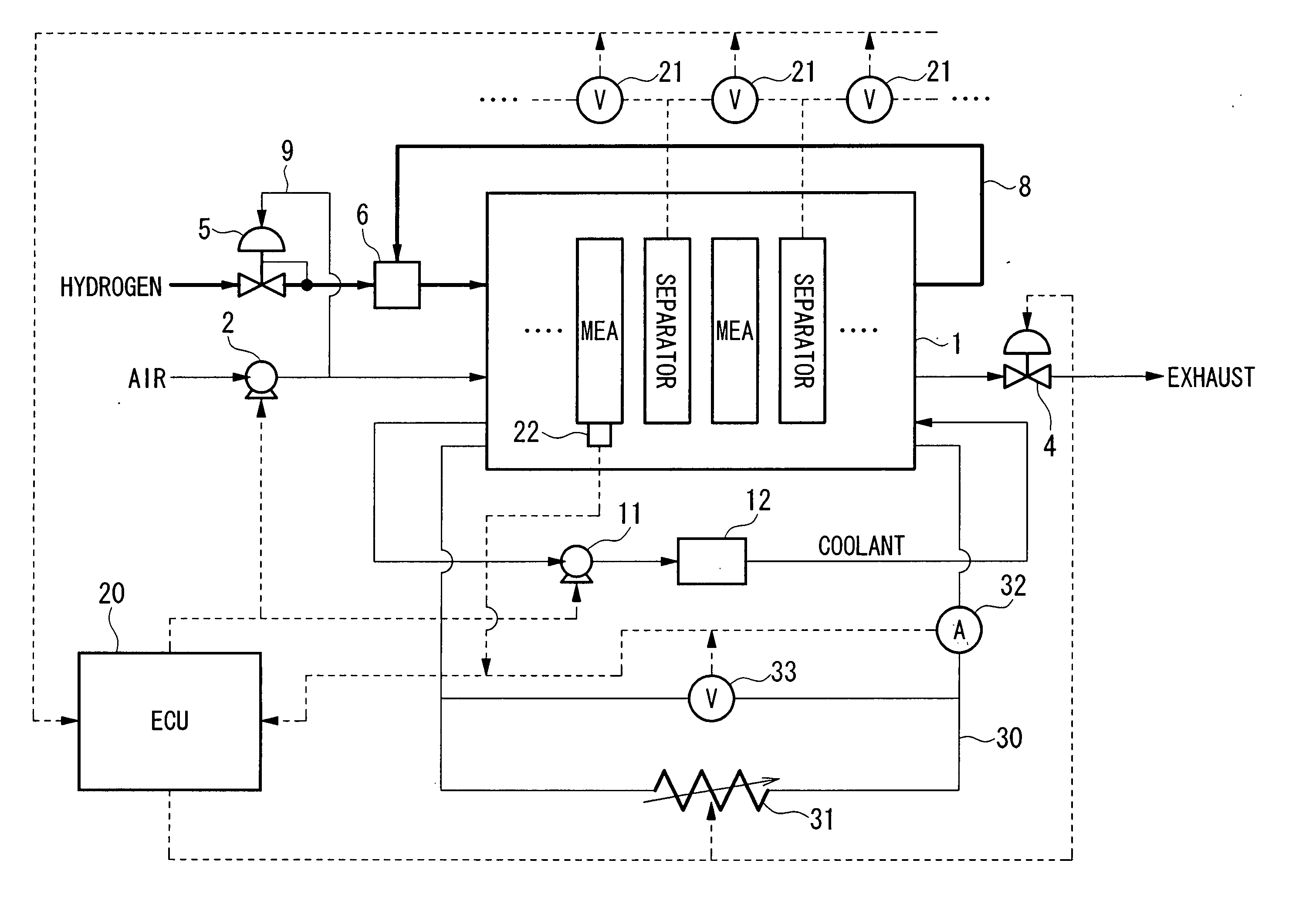

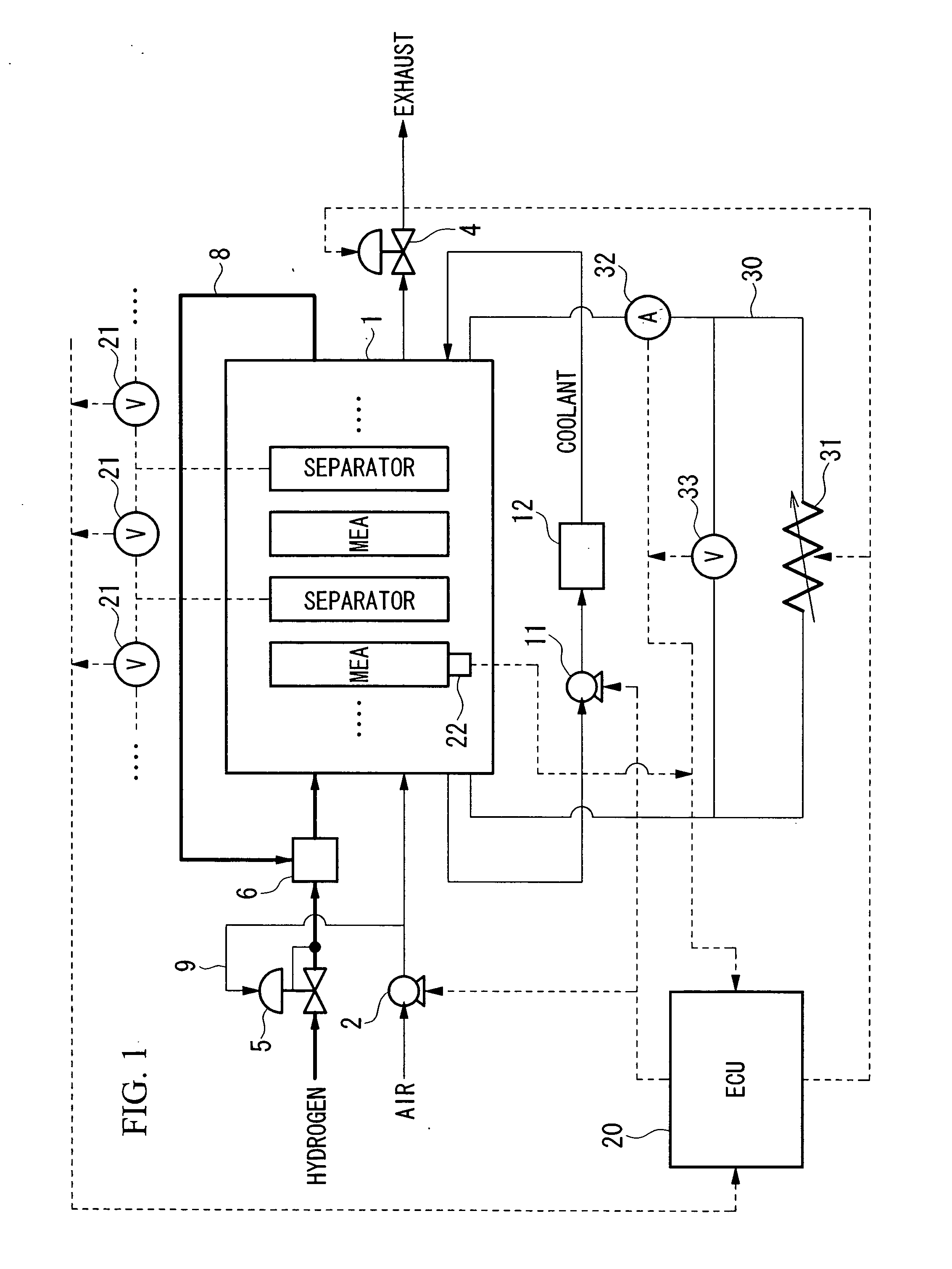

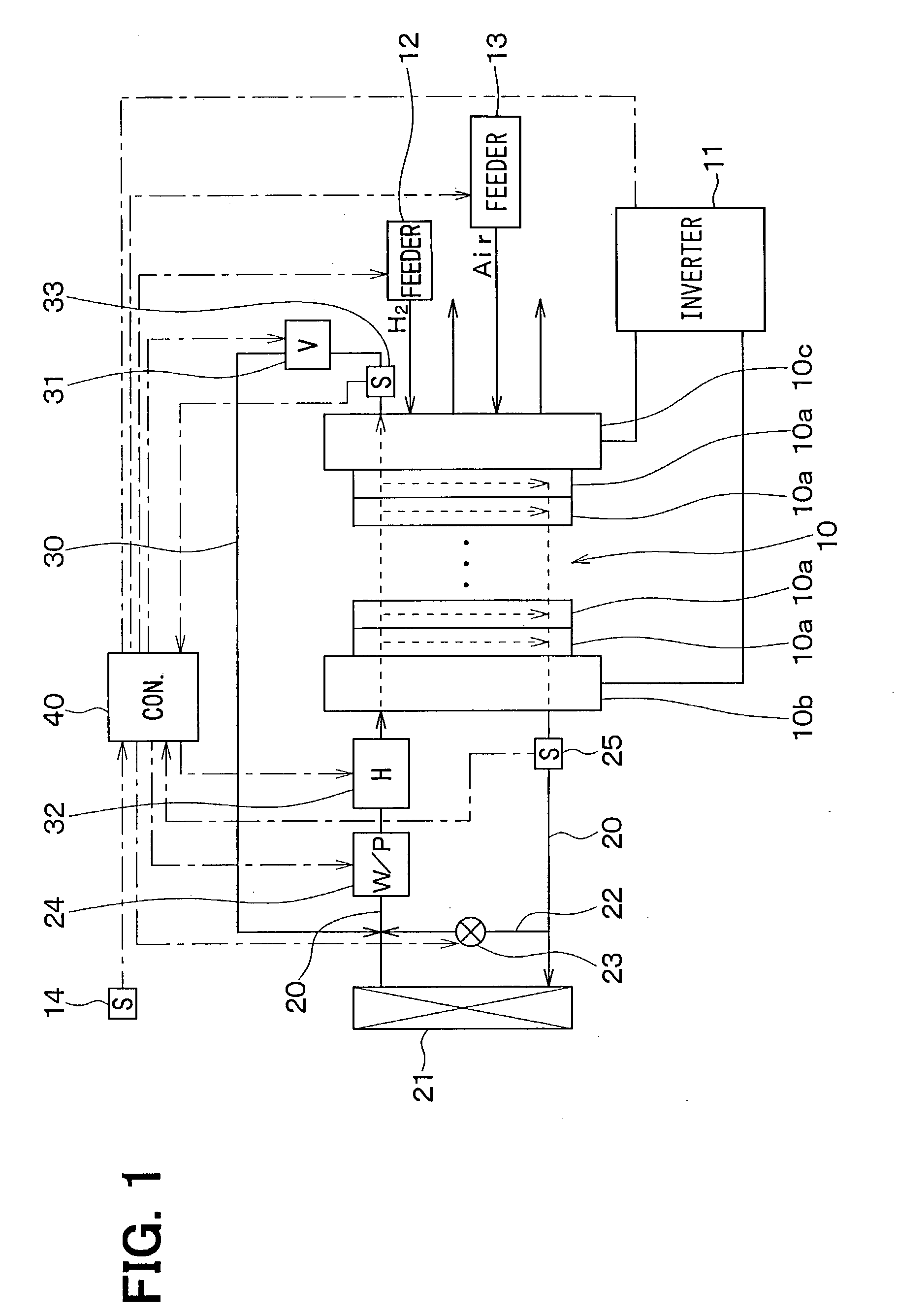

Fuel cell system

InactiveUS20030165725A1Small sizeHeating up fastFuel cells groupingFuel cell auxillariesFuel cellsEngineering

In a fuel cell system, a fuel cell includes plural stacked cells, a circulation passage for circulating a thermal medium to the fuel cell. The fuel cell has therein a plurality of thermal medium passages through which the thermal medium flows, and the thermal medium passages are provided such that the thermal medium from the circulation passage independently flows through the thermal medium passages. The thermal medium passages in the fuel cell have inlet portions from which the thermal medium is introduced, and outlet portions from which the thermal medium is discharged. In the fuel cell system, at least one-side portions among the inlet portions and the outlet portions are provided independently. Accordingly, a circulation area of the thermal medium in the fuel cell can be selectively changed, and a part of the fuel cell can be effectively heated to generate electrical power in this part.

Owner:DENSO CORP

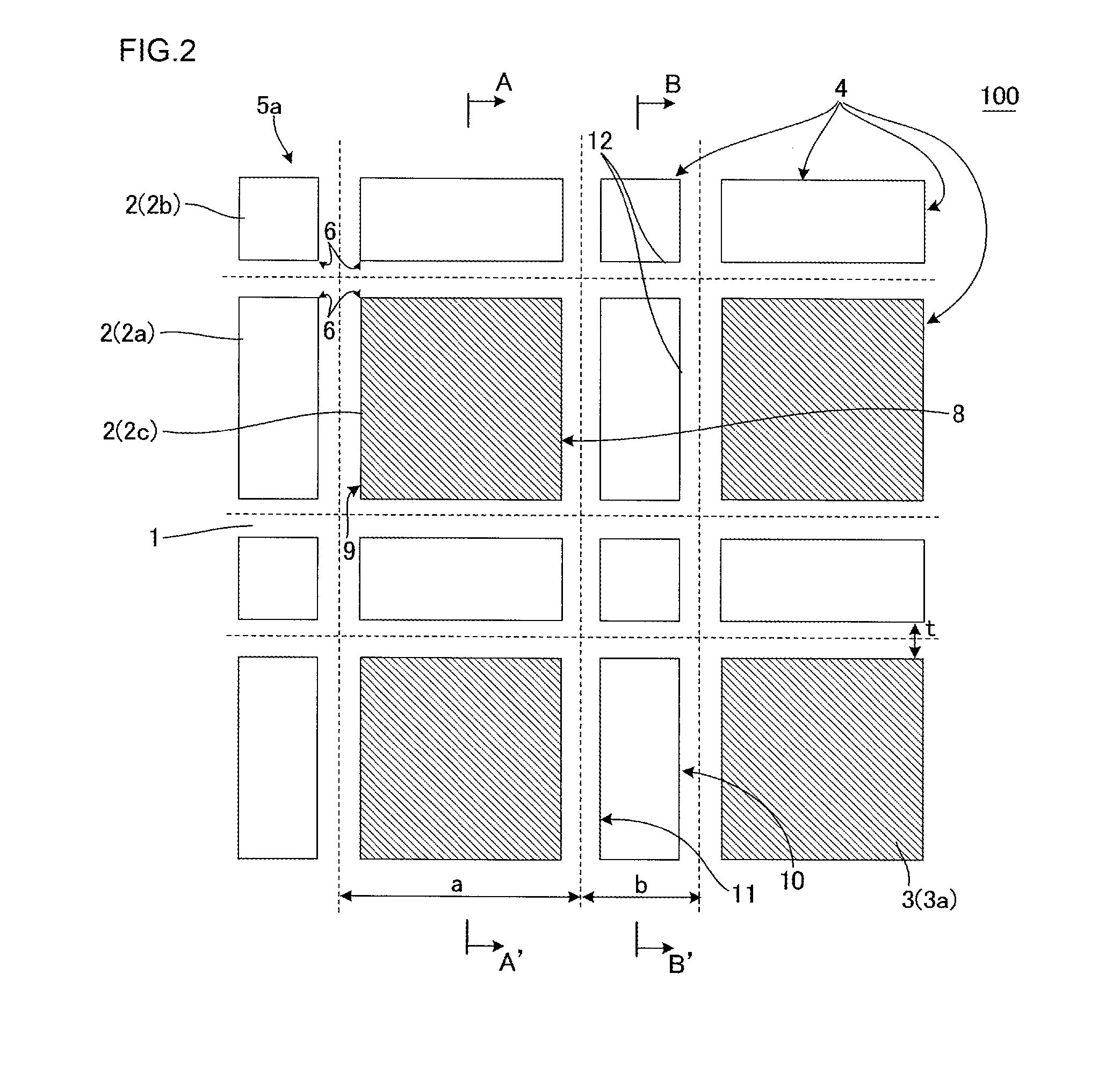

Honeycomb filter

ActiveUS20160067653A1Efficiently regenerateImprove ignitabilityCombination devicesGas treatmentHoneycombUnit volume

In a cross section perpendicular to a central axis direction of the honeycomb substrate, cells are arranged so that a periphery of an inlet plugged cell is surrounded with four rectangular outlet plugged cells and four square outlet plugged cells, and in the cross section, a partition wall center distance a, a partition wall center distance b and a partition wall thickness t satisfy the following equation (1). Additionally, an amount of a catalyst per unit volume of partition walls which is loaded onto the partition walls defining the rectangular outlet plugged cells and the inlet plugged cells is larger than an amount of a catalyst per unit volume of the partition walls which is loaded onto the partition walls defining the rectangular outlet plugged cells and the square outlet plugged cells.0.95<b / at<1.90 (1)

Owner:NGK INSULATORS LTD

Magnesium oxide foam ceramic filter

InactiveCN100536986CImprove high temperature stabilityImprove filtration and purification effectFiltration separationCeramicwareBoron carbideSlurry

The invention relates to a magnesia foam ceramic filter with special high-temperature chemical stability, which is composed of magnesia, boron The high-quality polyurethane foam is used as the carrier, impregnated with the above slurry, extruded to form a billet, dried and sintered to obtain a magnesia foam ceramic filter. The ceramic foam filter of the present invention has good high-temperature stability in the magnesium alloy melt, does not pollute the alloy, has good filtration and adsorption capacity for oxidation inclusions and flux inclusions in the magnesium alloy melt, and has a good filtration and purification effect and is heat-resistant. Small capacity, no need to preheat when using, small fluid resistance, large filtration capacity, through the filtration and purification test of metal magnesium and magnesium alloy melt, all performances are good.

Owner:晋城市富基新材料股份有限公司

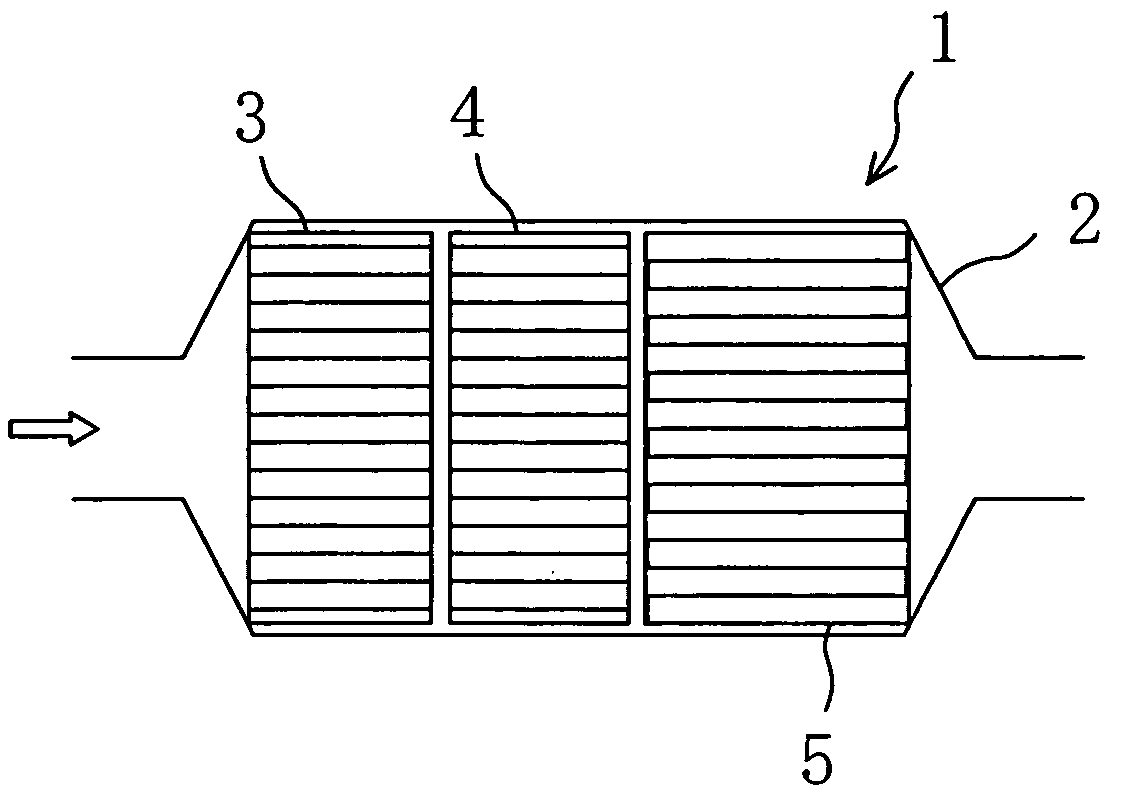

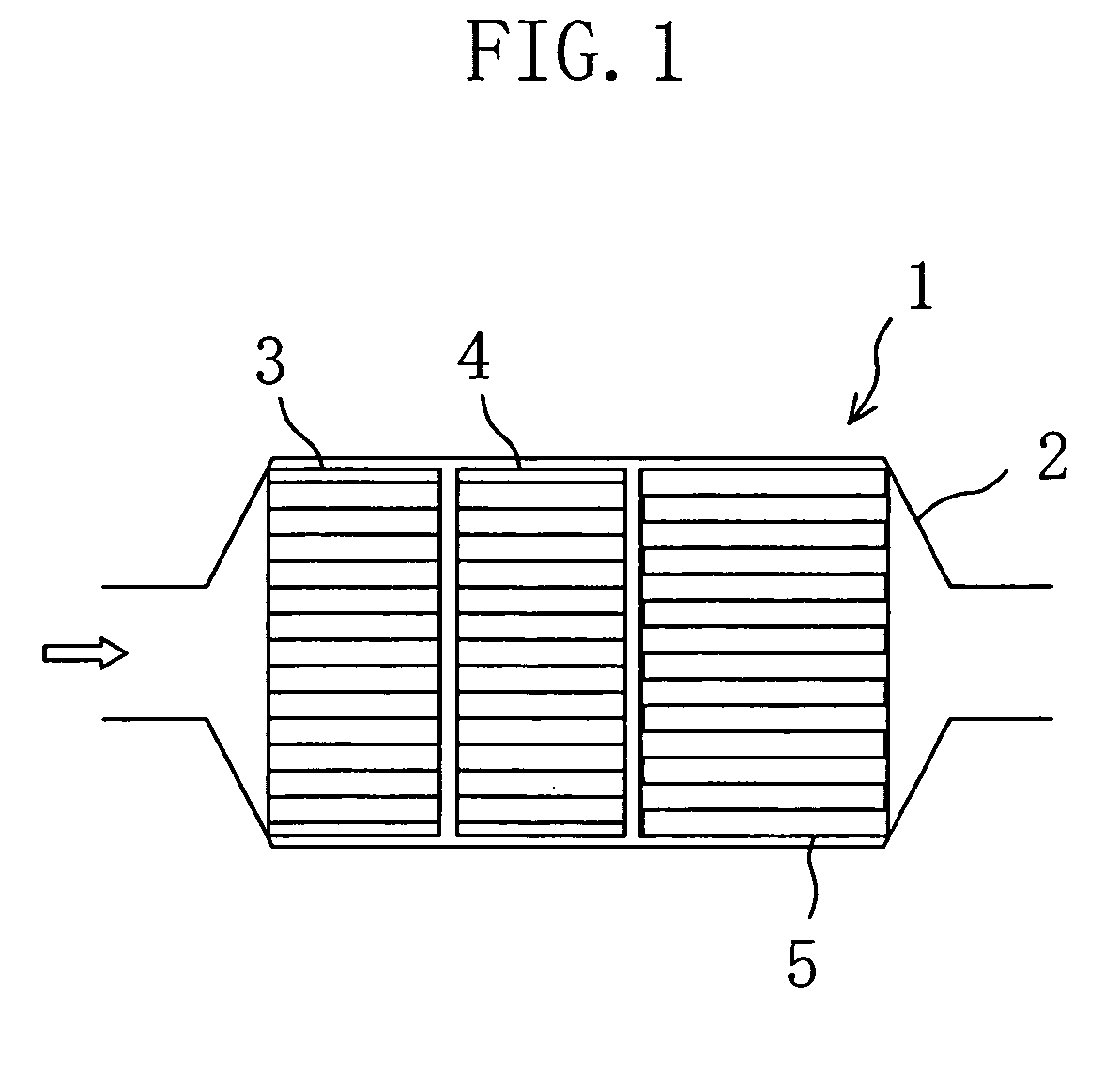

Exhaust gas purification system

InactiveUS20060059900A1Fast regenerationIncrease fuel consumptionInternal combustion piston enginesExhaust apparatusParticulatesExhaust fumes

An upstream catalyst (3) and a downstream catalyst (4) are disposed upstream of a particulate filter (5) in an exhaust passage of a diesel engine. The downstream catalyst (4) has a larger amount of support material for supporting catalytic metal than the upstream catalyst (3). This enhances the efficiency of oxidation reactions of HC in the catalysts to raise the temperature of exhaust gas flowing into the filter (5).

Owner:MAZDA MOTOR CORP

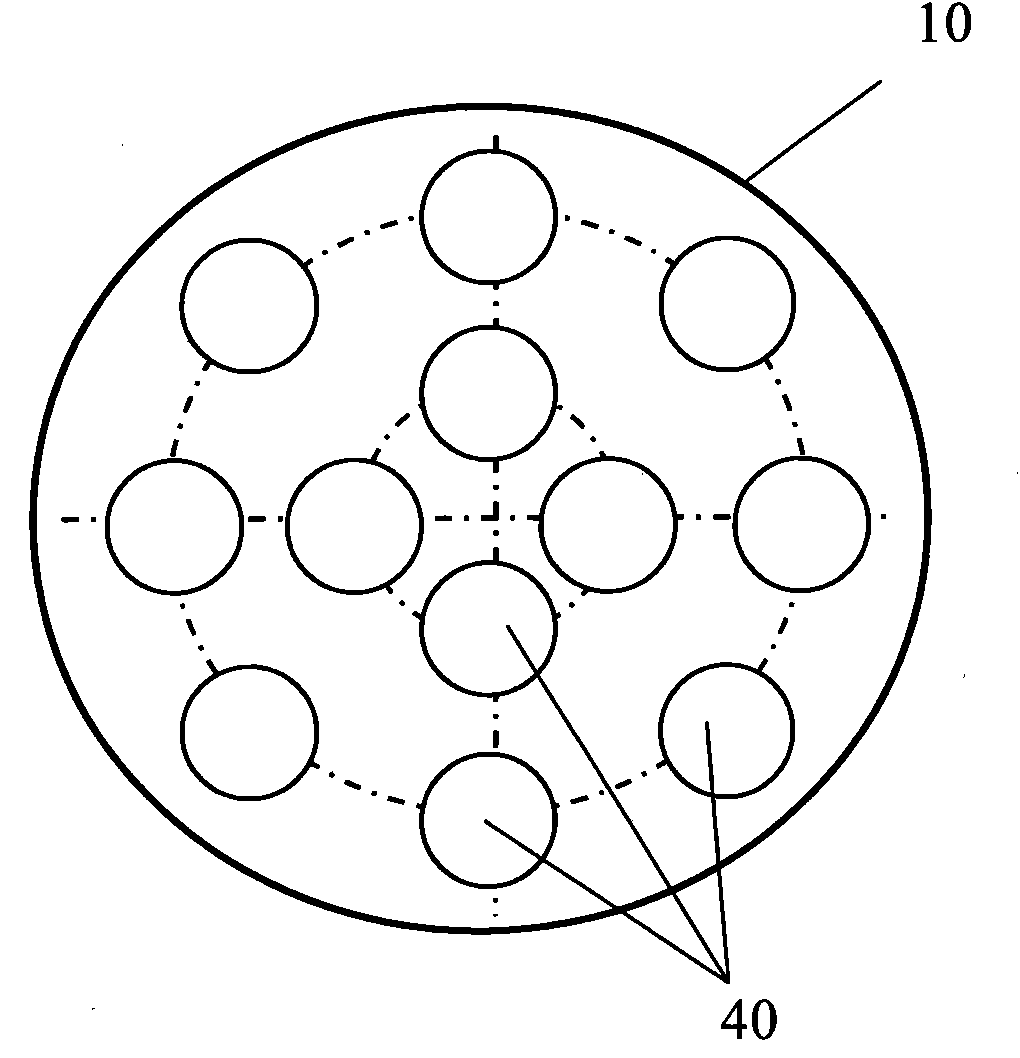

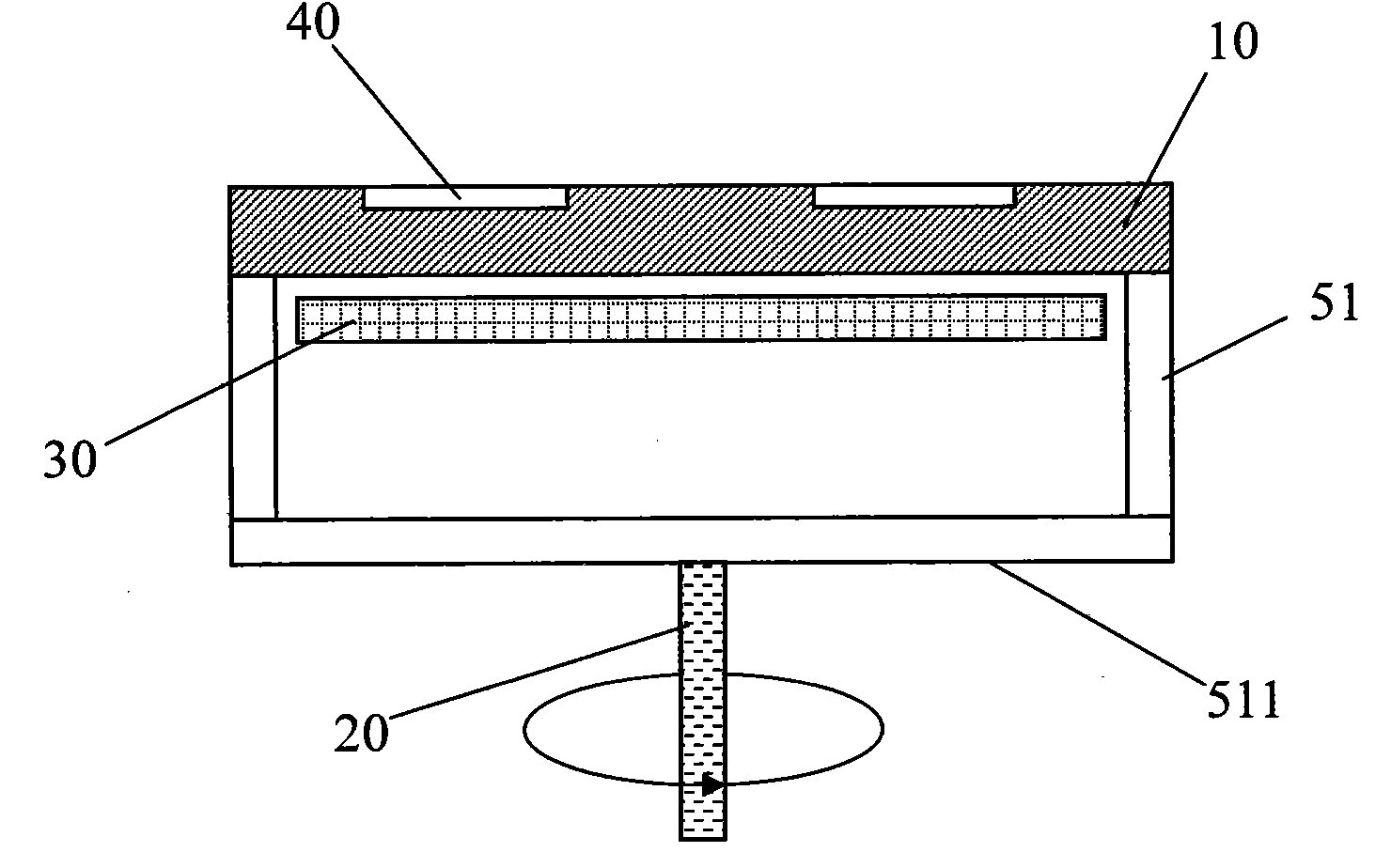

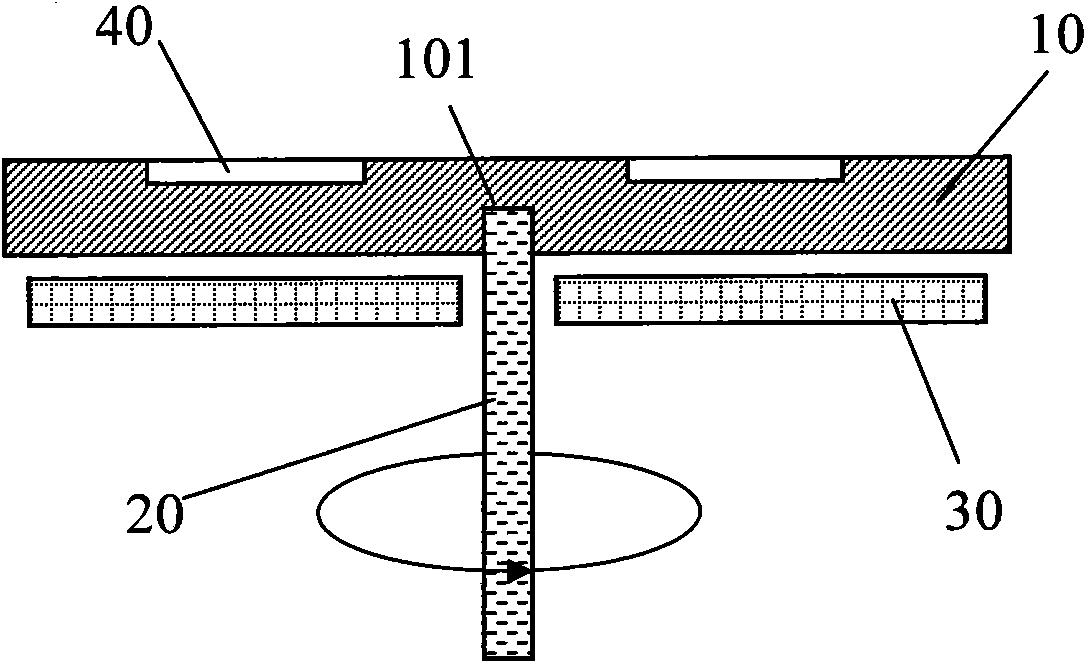

Epitaxial wafer tray and support and rotation connecting device matched with same

ActiveCN101922042AUniform gas concentrationReduce replacementSemiconductor/solid-state device manufacturingFrom chemically reactive gasesDrive shaftEngineering

The invention relates to an epitaxial wafer tray for an MOCVD (Metal Organic Chemical Vapor Deposition) reaction cavity and a support and rotation connecting device matched with same. When the tray is mechanically loaded and unloaded, and a rotating shaft projecting outward from the center of the bottom of the tray is inserted into a counter bore on the top of a drive shaft perpendicular to the rotating shaft. Respectively arranged contact surfaces parallel to the surface of the tray or contact surfaces on the corresponding side face are used for supporting the tray, and the friction transmission between the contact surfaces is used for driving the tray to rotate when the drive shaft rotates. The friction transmission is changed into contact transmission by arranging an axial locating slot and a locating key, the rotation of the tray is ensured to be consistent with that of the drive shaft, and the security of the tray under middle-high speed long-term rotation is improved. The projecting tray rotating shaft is easy to process the surfaces contacted by friction, the entire thickness of the tray is not increased under the condition of ensuring the mechanical strength of the corresponding part on the tray, and the heat capacity of the tray is reduced. Thus, the time required by heating and cooling the tray is shortened, and the production efficiency is improved, which is beneficial to quick temperature adjustment and control required by epitaxial reactions.

Owner:JIANGSU ZHONGSHENG SEMICON EQUIP

Micro fluidic chip apparatus by integrating continuous flow PCR and capillary electrophoresis function

InactiveCN102899238AEasy to integrateReduce miniaturizationBioreactor/fermenter combinationsBiological substance pretreatmentsContinuous flowBiology

The invention discloses a micro fluidic chip apparatus by integrating a continuous flow PCR and a capillary electrophoresis function, which comprises a continuous flow type PCR chip and a capillary electrophoresis chip, and is characterized in that an output channel of the continuous flow type PCR chip is directly connected in a sample pool of the capillary electrophoresis chip, a sample introduction channel and a separating channel are provided on the capillary electrophoresis chip, the sample introduction channel and the separating channel present an intersect shape, the top of the sample introduction channel is the sample pool and a sample waste liquid pool, and the top of the separating channel is a buffer liquid pool and a waste liquid pool. The apparatus provided by the invention can enhance the automation degree and whole process operation speed for DNA detection, the operation step is reduced, and the apparatus is convenient for miniaturization and portable performance of the apparatus.

Owner:张影频

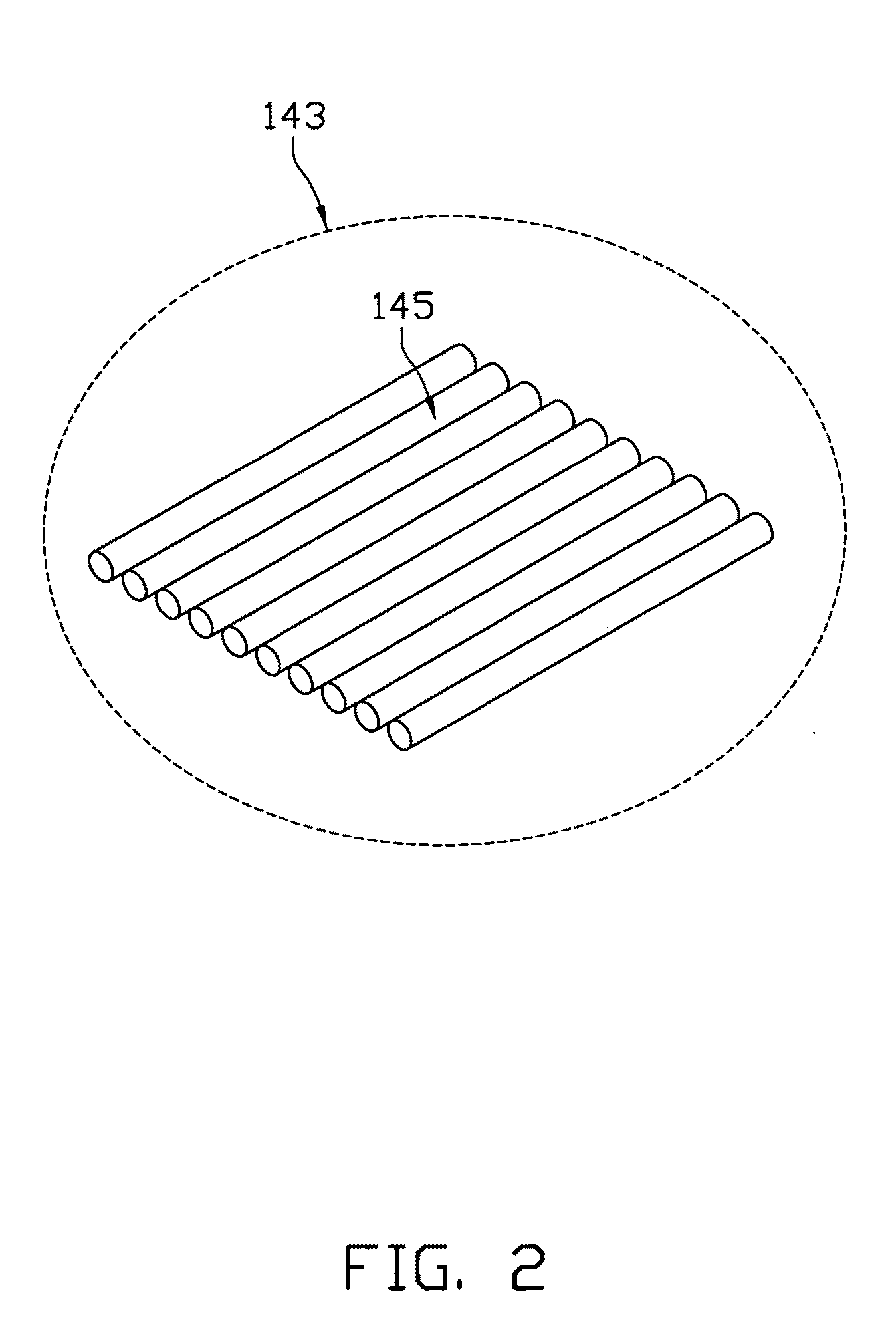

Sounding device

The invention relates to a sounding device comprising an electromagnetic wave signal input device and a sounding element, wherein the sounding element and the electromagnetic wave signal input device are arranged at intervals; the sounding element comprises at least one carbon nano tube film, and the carbon nano tube film includes a plurality of carbon nano tubes which are parallel to each other;and the electromagnetic wave signal input device transmits an electromagnetic wave signal to the carbon nano tube film, thus the carbon nano tube film emits heat by absorbing the electromagnetic wavesignal so as to heat an air medium to send sound waves.

Owner:TSINGHUA UNIV +1

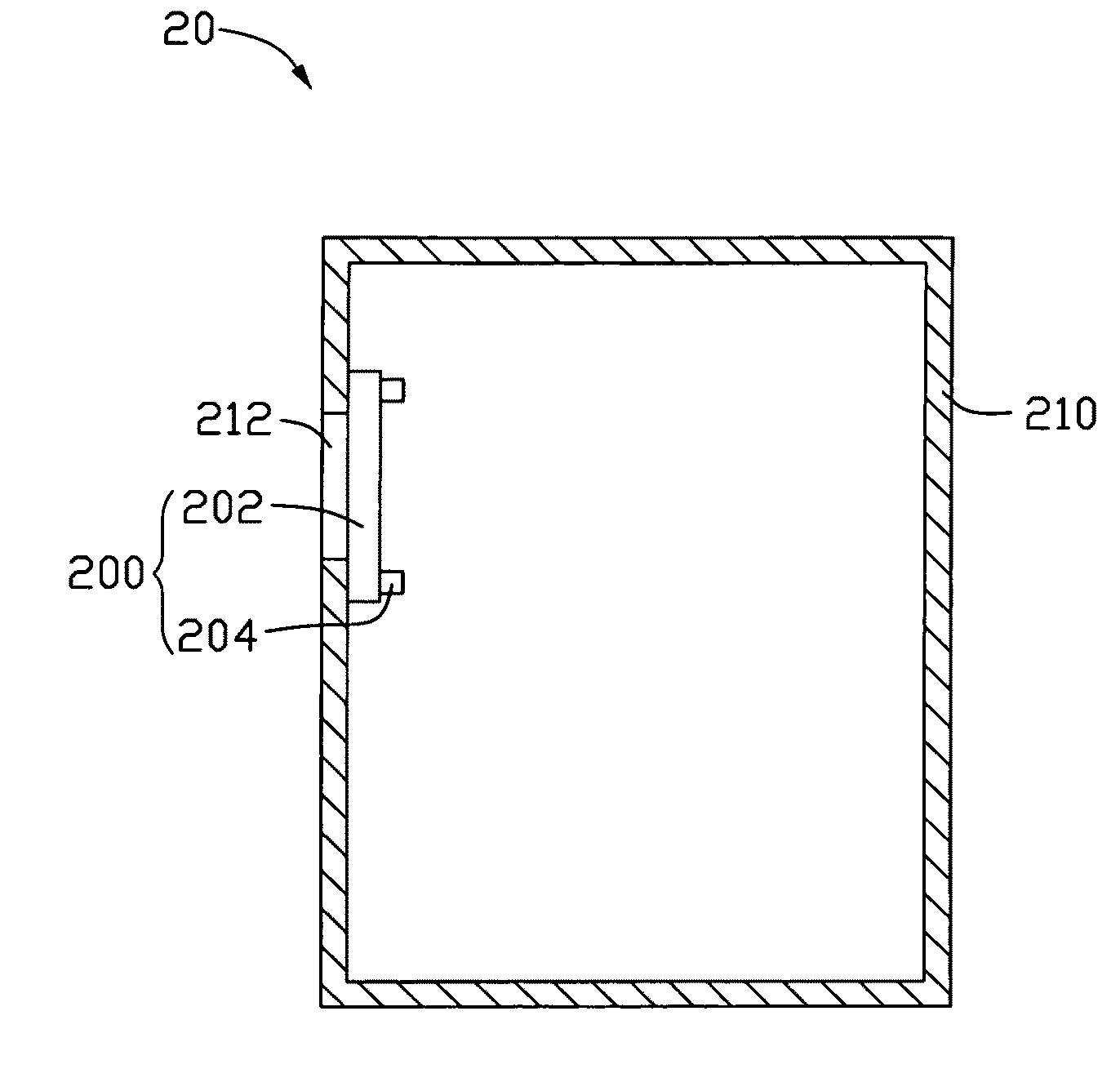

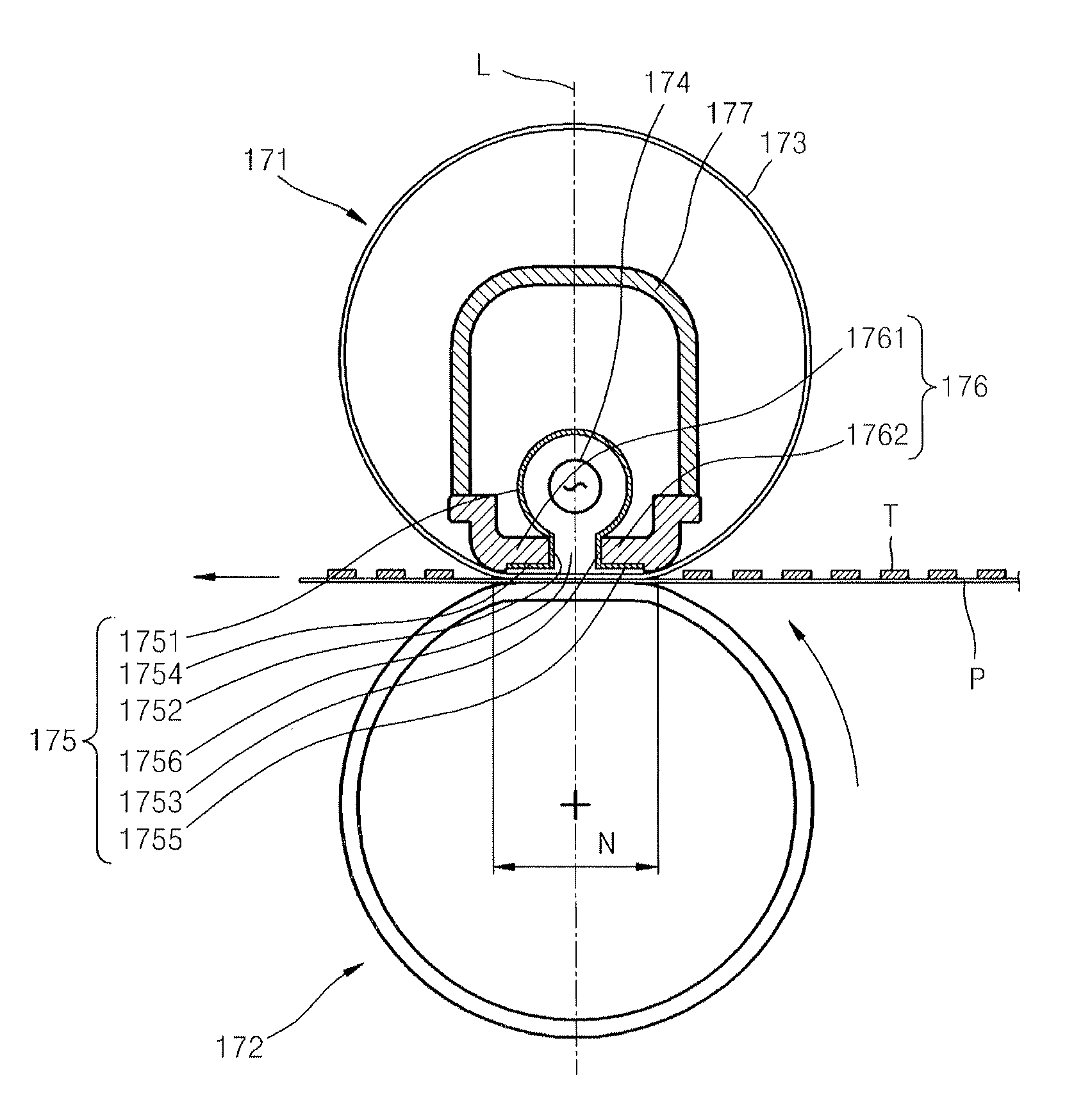

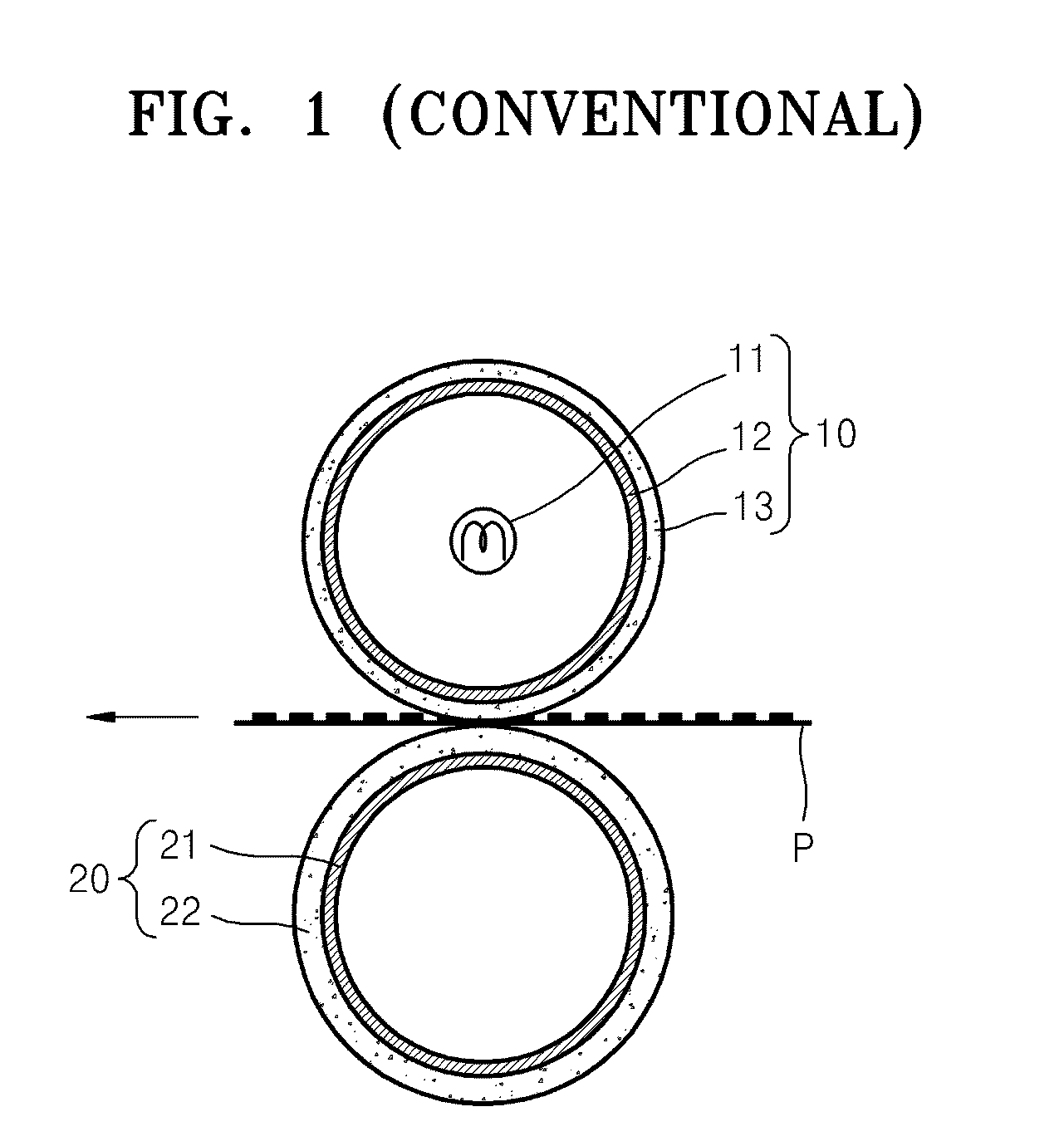

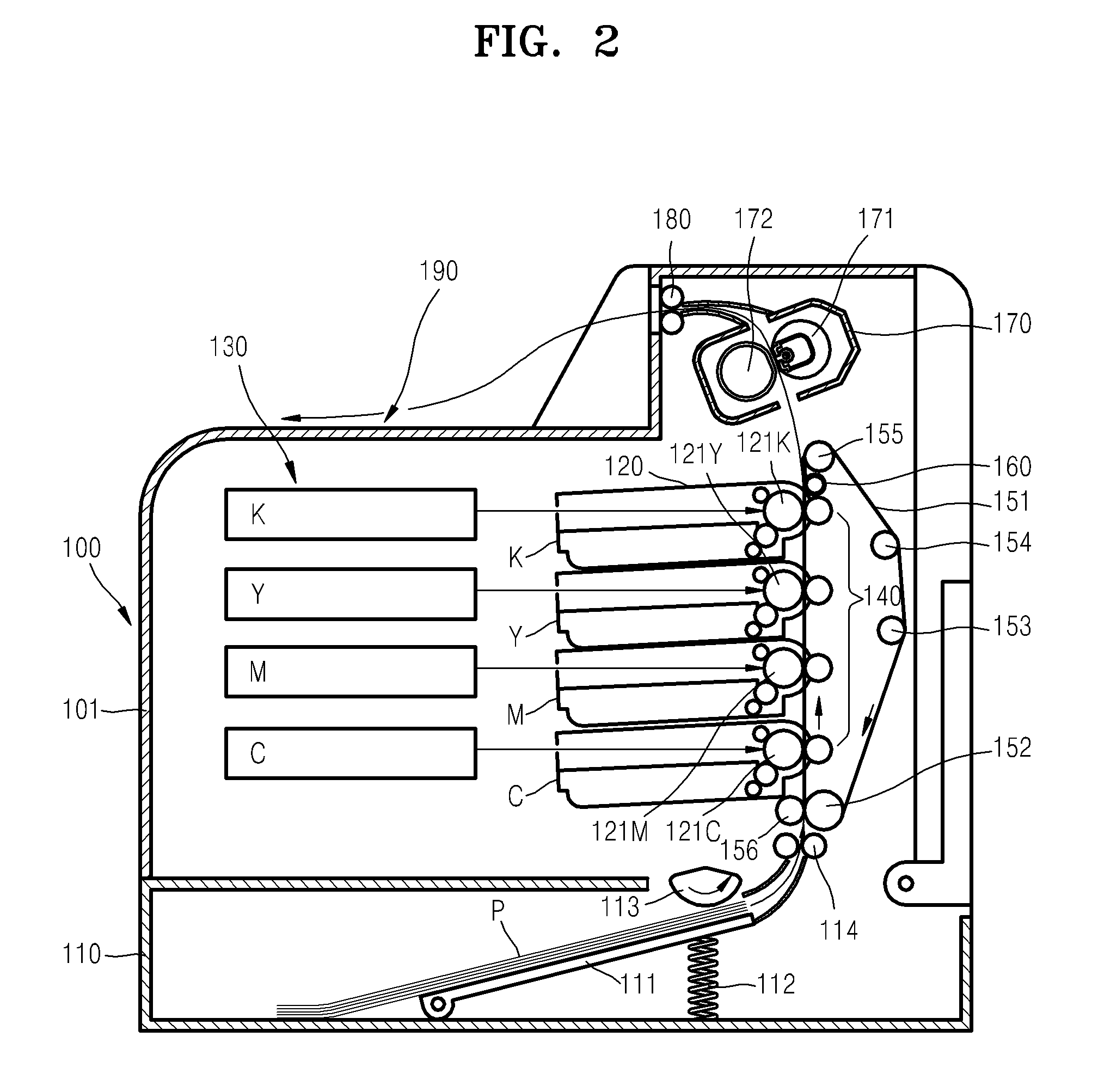

Fusing apparatus and electrophotographic image-forming apparatus having the same

InactiveUS7792476B2Small heat capacityShorten warm-up timeOhmic-resistance heatingElectrographic process apparatusEngineeringMechanical engineering

Owner:HEWLETT PACKARD DEV CO LP

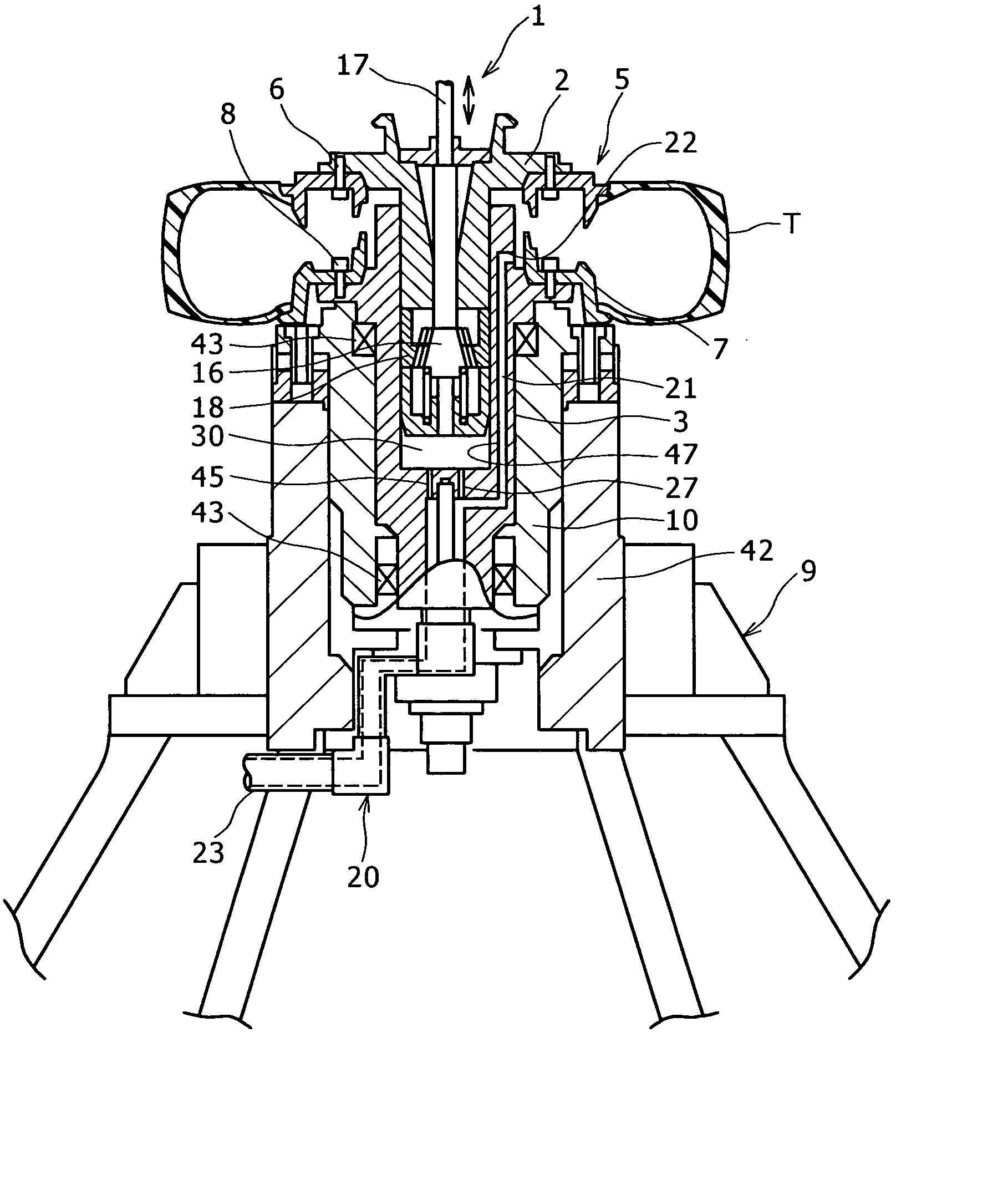

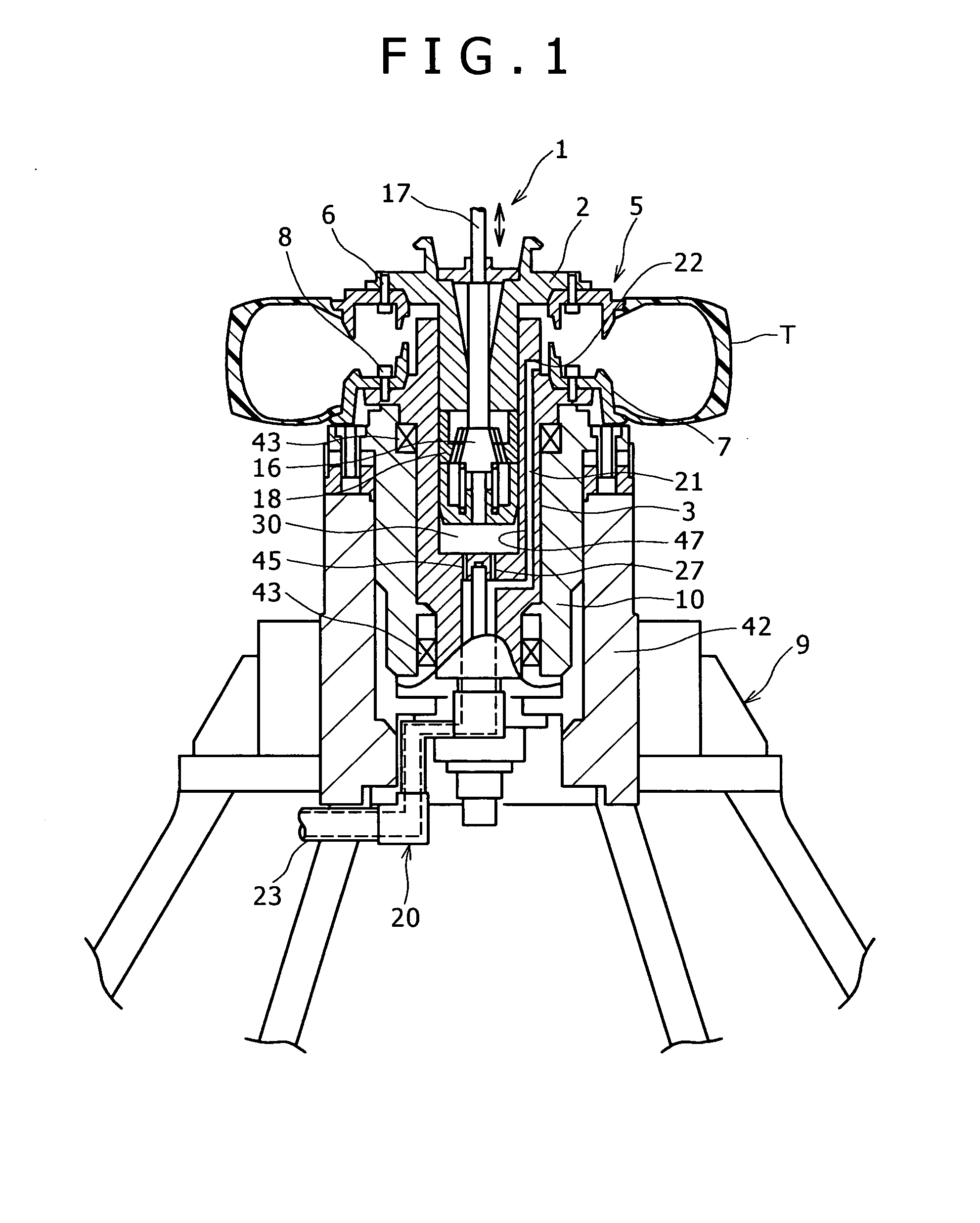

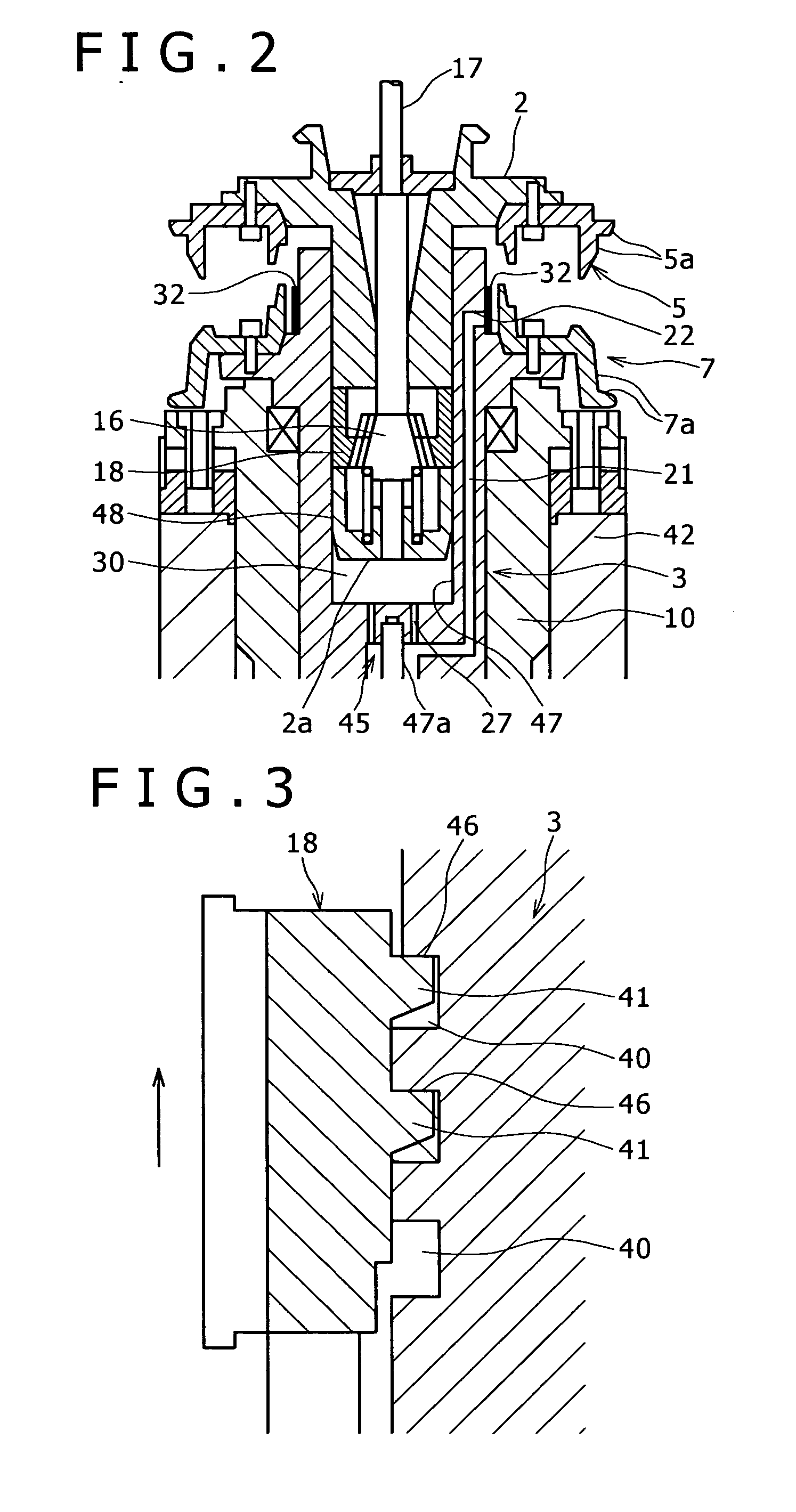

Tire Testing Machine and Axis Misalignment Measuring Method for Tire Testing Machine

InactiveUS20070220964A1Reduce the impactMeasurement resultTyre partsStatic/dynamic balance measurementEngineeringSliding contact

A spindle direction engaging device moves at least one of spindles in a mutually separating direction to closely engage a lock piece or a lock portion in a spindle direction of spindles while the lock piece is locked to the lock portion when a tire is not mounted. A second spindle includes a groove extending in a peripheral direction along an outer periphery thereof in sliding contact with the lock piece; sliding surfaces of the lock piece and the groove are receiving portions formed as flat surfaces to receive separating forces acting on both the spindles. A correction device corrects a gap between an inner ring of the spindle bearing and rolling elements of the spindle bearing, or a gap between an outer ring of the spindle bearing and the rolling elements of the spindle bearing, while the spindle is rotating. Preload bolts include a coolant passage formed by hollowing a corresponding portion passing a mounting hole of a detector, and a coolant can thus be supplied to the coolant passage.

Owner:KOBE STEEL LTD

Nickel-coated free-standing silicon carbide structure for sensing fluoro or halogen species in semiconductor processing systems, and processes of making and using same

InactiveUS7296458B2High resistivitySmall heat capacityAnalysing fluids using sonic/ultrasonic/infrasonic wavesComponent separationCarbide siliconHalogen

A (MEMS)-based gas sensor assembly for detecting a fluorine-containing species in a gas containing same, e.g., an effluent of a semiconductor processing tool undergoing etch cleaning with HF, NF3, etc. Such gas sensor assembly in a preferred embodiment comprises a free-standing silicon carbide support structure having a layer of a gas sensing material, preferably nickel or nickel alloy, coated thereon. Such gas sensor assembly is preferably fabricated by micro-molding techniques employing sacrificial molds that are subsequently removable for forming structure layers.

Owner:ENTEGRIS INC

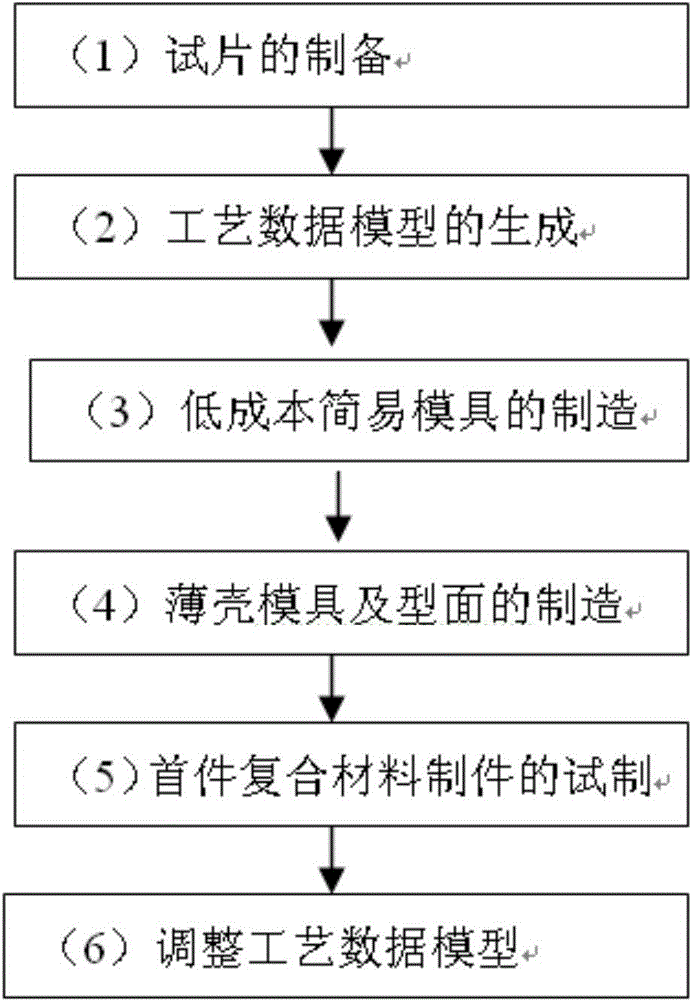

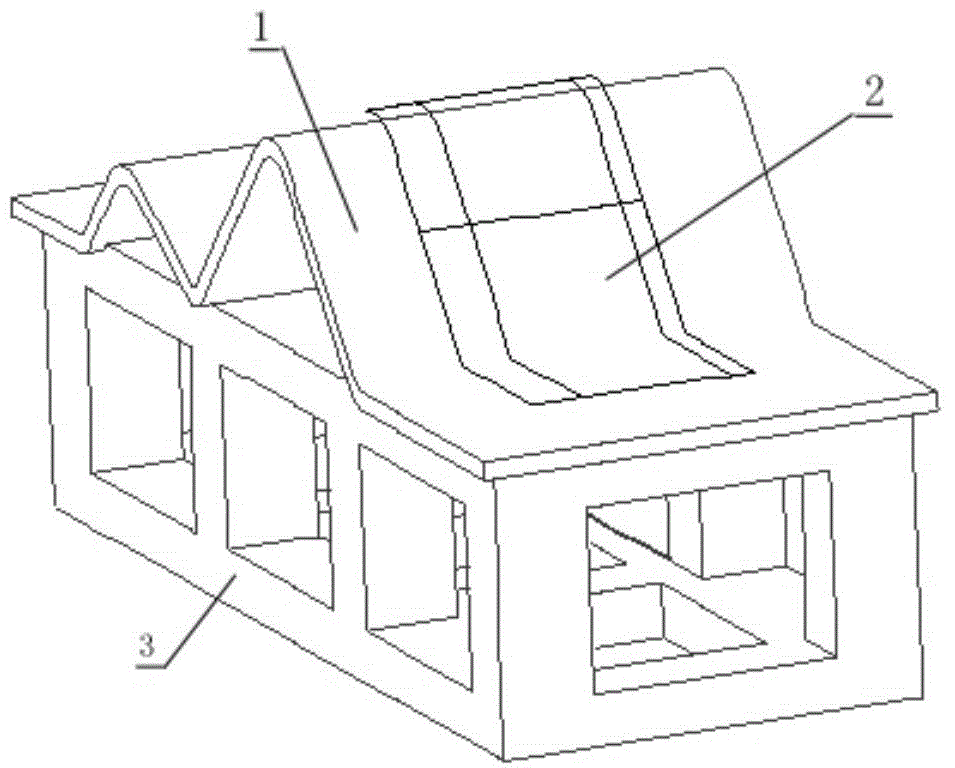

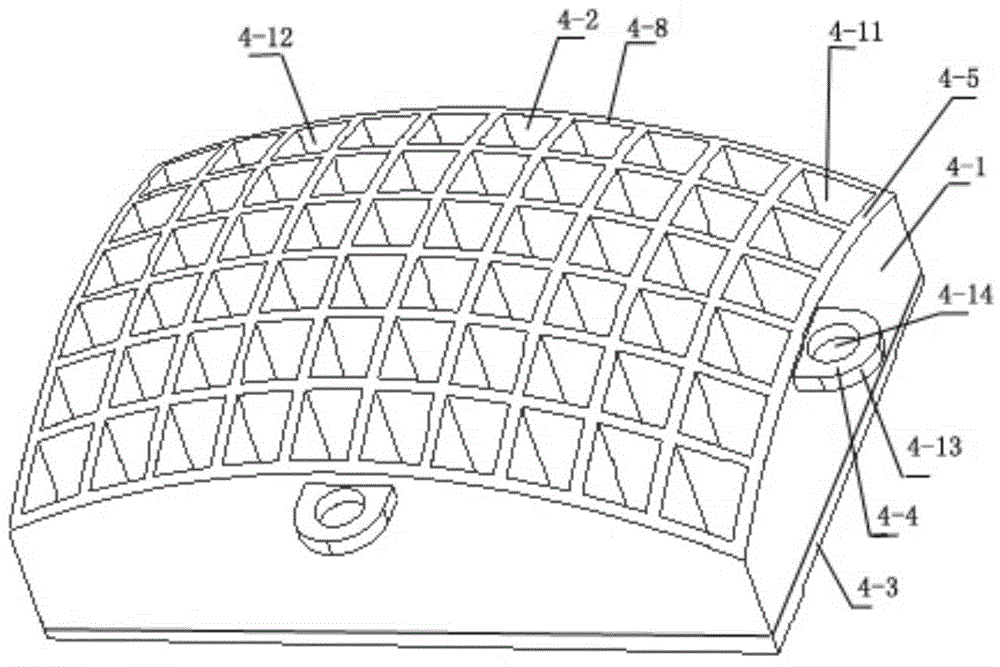

Composite material precision molding tool for airplane and precision molding manufacturing method

The invention relates to a composite material precision molding tool for an airplane and a precision molding manufacturing method. In a single large-scale part composite material molding process, the size precision is affected by many factors such as a mould material and structure, a composite material laying angle, layers and curing processes. The composite material precision molding tool provided by the invention comprises a set of special mould for test piece preparation, a test piece, an easy molding mould, a thin-shell mould and the like; the composite material test piece is prepared on the special test piece preparation mould, a transformative database is built by analyzing the transformation rule of the test piece, and a product digital model is converted into a process digital model by compensating molding errors by using CATIA software. According to the process digital model, a molded surface of the thin-shell mould is manufactured on an easy molding mould transition tool, and the composite material product is manufactured by utilizing the molded surface of the thin-shell mould, so that the molding quality and accuracy of the composite material can be improved, the design difficulty of the molded surface of the mould and the mould manufacturing cost are reduced, the thermal capacity of the mould is effectively reduced, and the optimization of curing reaction is facilitated.

Owner:哈尔滨新科锐工艺装备制造有限公司 +1

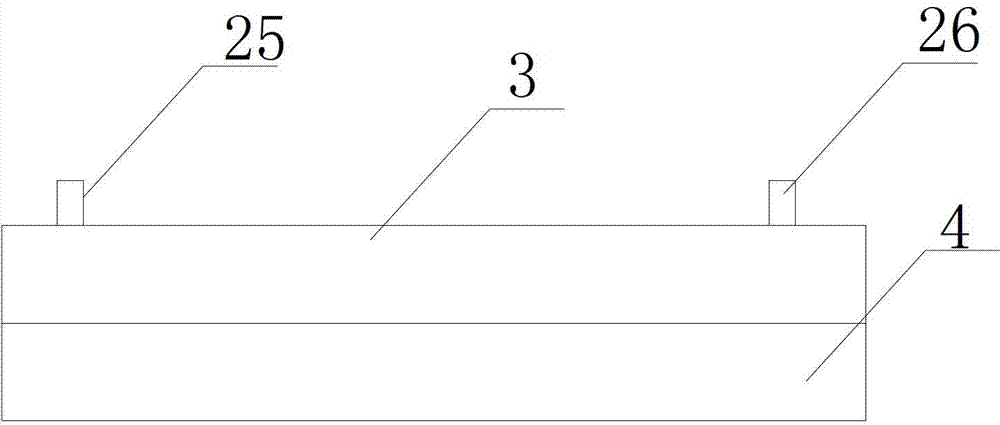

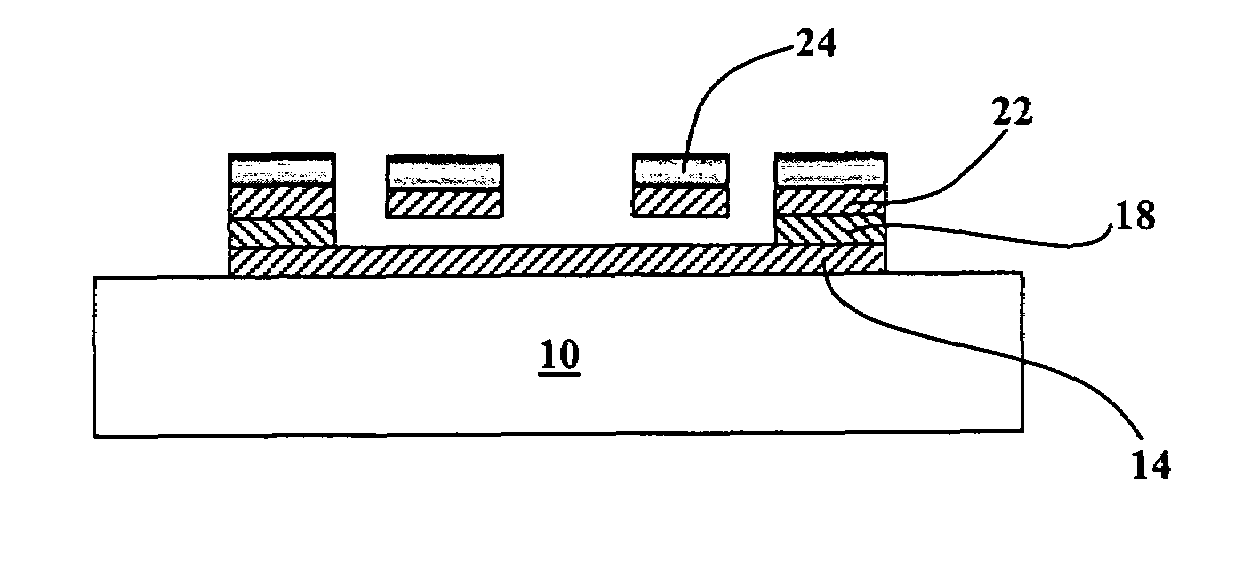

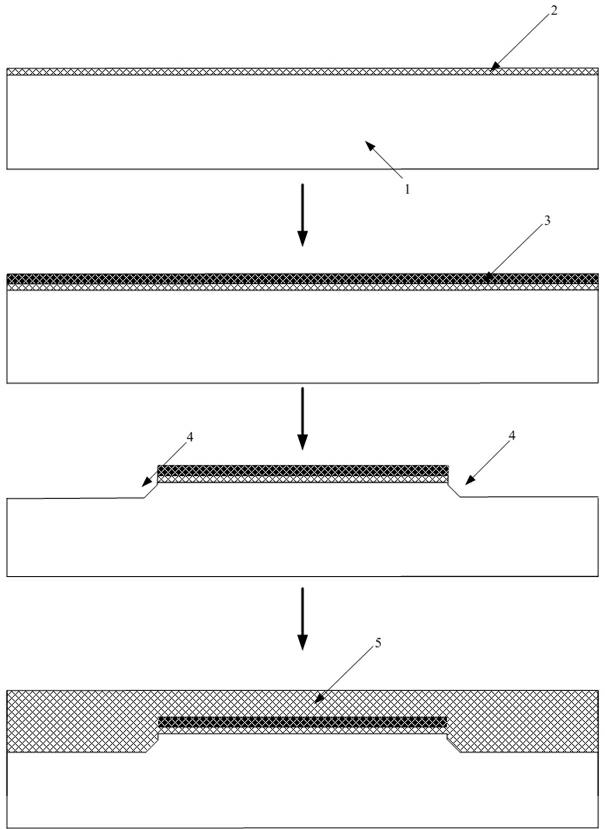

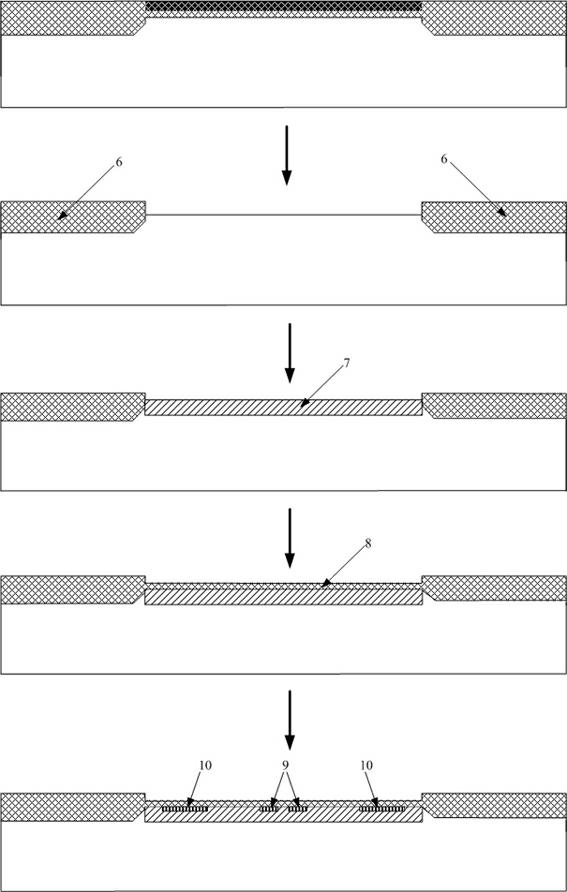

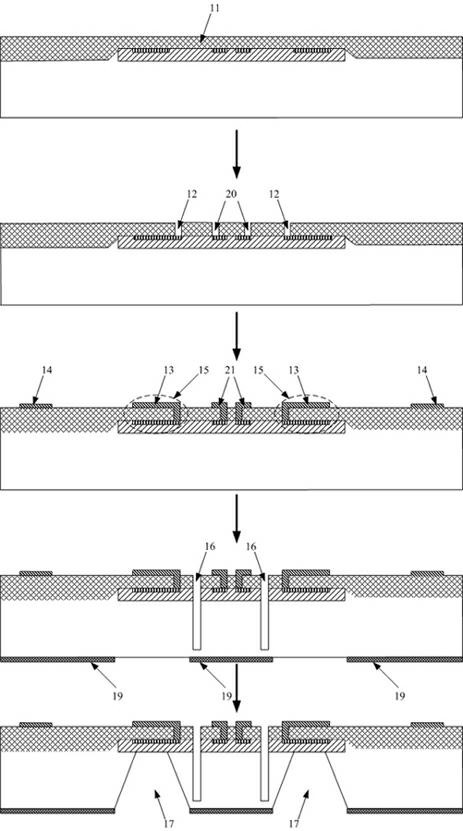

Heat-type wind-speed and wind-direction sensor with heat insulation structure and preparation method thereof

InactiveCN102095888AEnsure consistencyImprove consistencySemiconductor/solid-state device detailsSolid-state devicesBonding processHeat capacity

The invention discloses a heat-type wind-speed and wind-direction sensor with a heat insulation structure, comprising a silicon chip and a ceramic substrate, wherein the silicon chip is positioned above the ceramic substrate; four heating elements and four heat-sensing temperature-measuring elements are symmetrically distributed on the four edges of the upper surface of the silicon chip; a heat insulating groove is arranged between each heating element and each heat-sensing temperature-measuring element; heat insulating cavities are arranged below the heat-sensing temperature-measuring elements at the back of the silicon chip; and a ceramic gold-plating layer and a silicon gold-plating layer are arranged between the silicon chip and the ceramic substrate and are connected by adopting a gold-gold bonding process so as to be used for the heat connection between the silicon chip and the ceramic substrate. In the whole preparation process of the sensor, a standard CMOS (complementary metal-oxide-semiconductor) process is used, the after-treatment process is simple, and the prepared heat-insulating groove and the heat insulating cavities can be used for increasing the sensitivity of the chip effectively, reducing the heat conduction loss of the chip and the heat capacity of the sensor, and reducing the response time of the sensor.

Owner:SOUTHEAST UNIV

Magnesium oxide foam ceramic filter

InactiveCN101164656AImprove protectionEasy to operateFiltration separationCeramicwareBoron carbideMethyl cellulose

The present invention relates to an aluminium oxide foamed ceramic filter with special high-temperature chemical stability. Said aluminium oxide foamed ceramic filter is made up by adopting the following steps: using magnesium oxide, boron carbide and boron trioxide to form ceramic powder, then adding methyl cellulose and water to prepare slurry, using soft polyurethane foamed plastics as carrier, impregnating said carrier with said slurry, extruding to make blank material, drying and sintering so as to obtain the invented magnesium oxide foamed ceramic filter. The invented foamed ceramic filter has good high-temperature stability in the molten magnesium alloy, does not contaminate alloy and possesses good filtering and adsorption efficiency for removing oxide impurity and flux impurity form molten magnesium alloy, so that its filtering purification effect is good.

Owner:晋城市富基新材料股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com