Internal transient film heat-flow sensor of fuel cell

A heat flow sensor and fuel cell technology, used in fuel cells, fuel cell additives, material thermal development, etc., can solve the problem that the fuel cell heat flow density cannot be accurately reflected, the sensor positions cannot be accurately unified, and the fuel cell overall performance degradation and other problems, to achieve the effect of convenient and rapid disassembly and assembly of batteries, accurate measurement, and avoidance of fuel leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The accompanying drawings are specific embodiments of the present invention;

[0032] Below in conjunction with accompanying drawing, the content of the present invention is described in further detail:

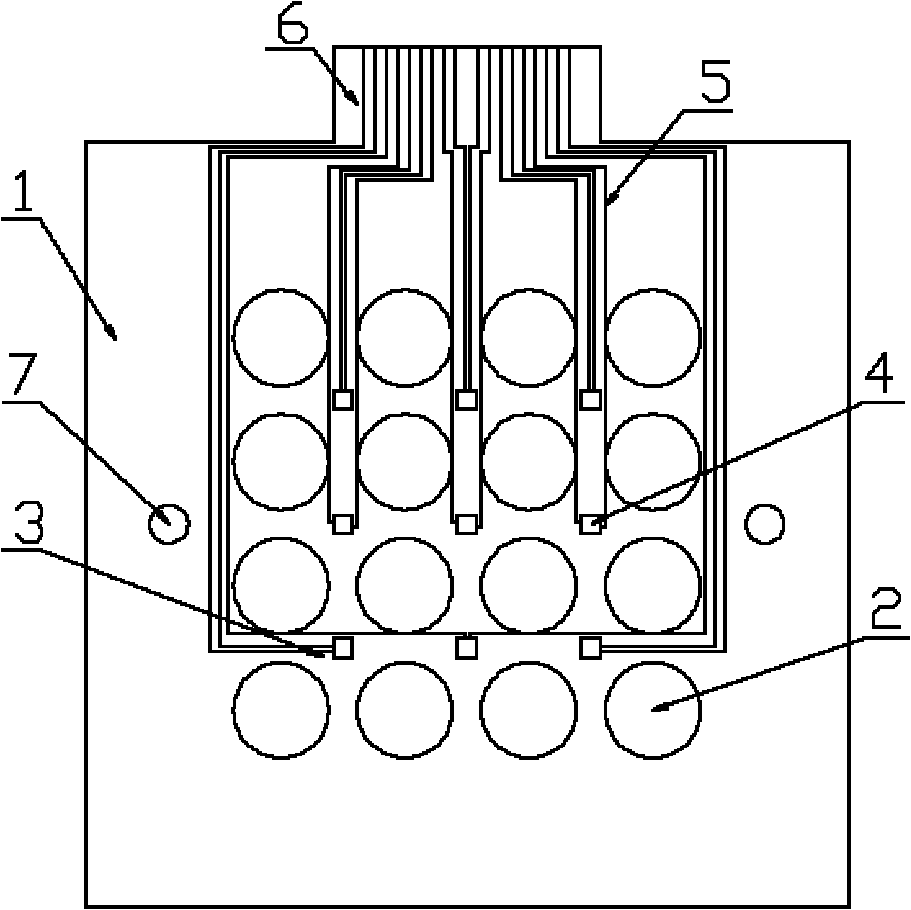

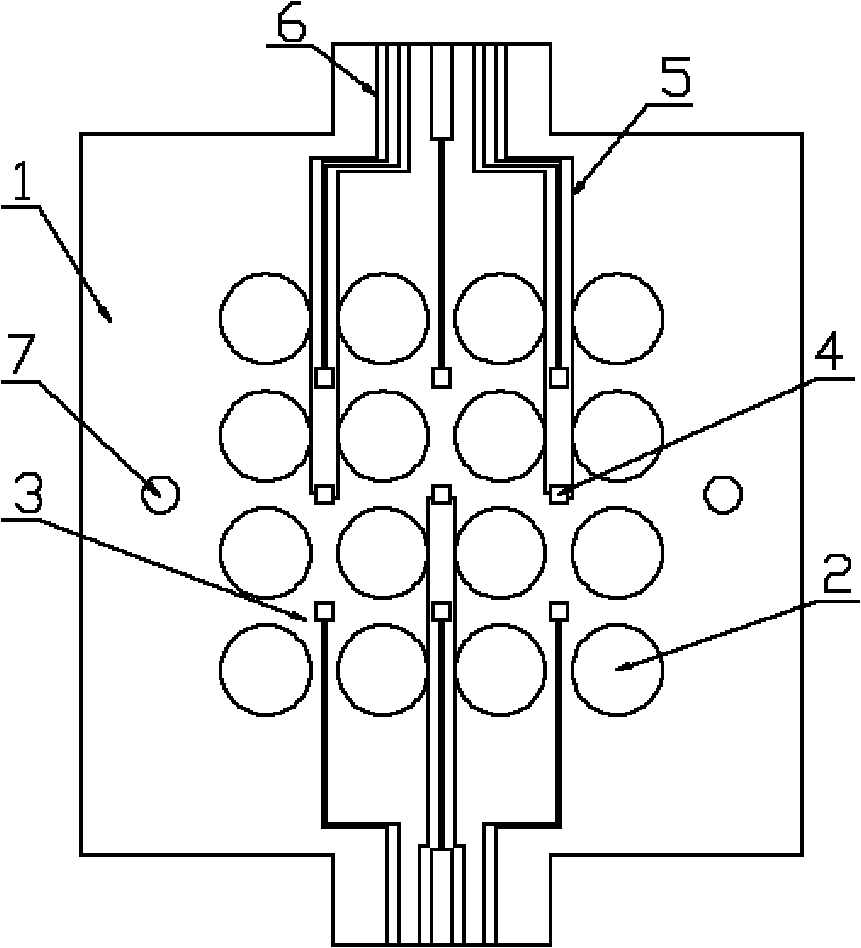

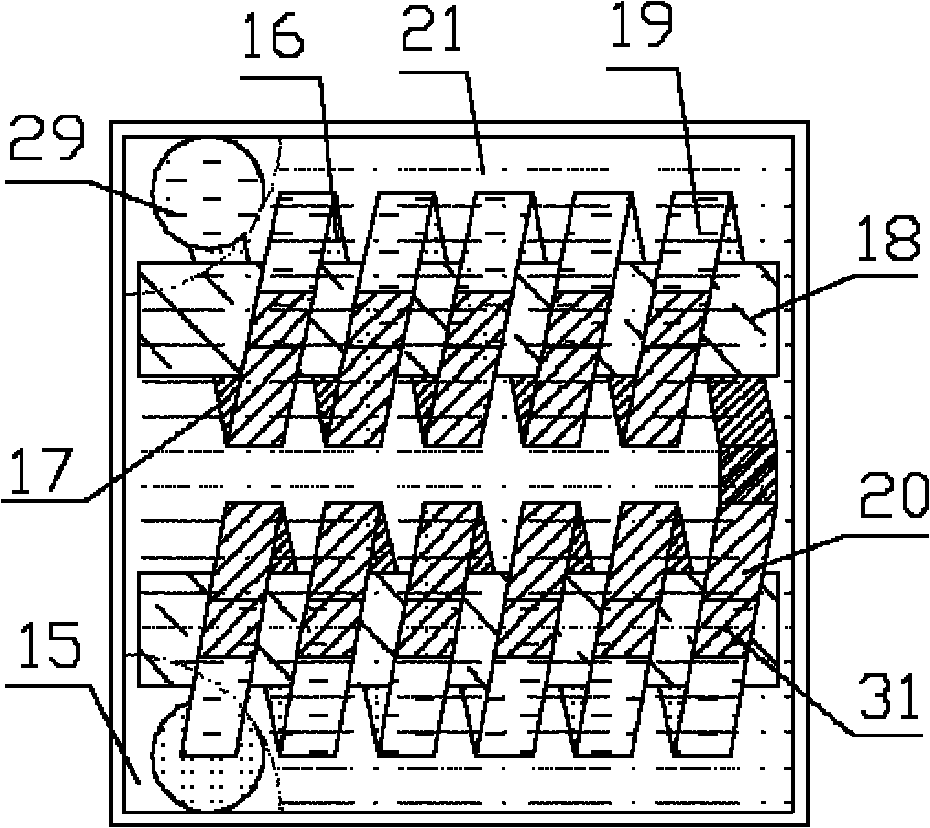

[0033] refer to figure 1 , 2 As shown, the position and number of standard wiring ports of the thin film heat flow sensor on the graphite flow field plate can be set as required. like figure 1 , figure 2 , image 3As shown, the present invention includes a thin film heat flow sensor 4 plated on the ribs 3 between the adjacent flow channels 2 on the graphite flow field plate 1 of the fuel cell, and the lead 5 of the thin film heat flow sensor 4 extends to the edge of the graphite flow field plate 1, The end of the lead wire 5 is provided with a standard wiring port 6 connected to the external circuit, and 7 in the figure is a positioning hole. In the heat flow density measuring device of the present invention, the thin film heat flow sensor 4 and its lead wires 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com