Exhaust gas purification system

a technology of exhaust gas purification system and filter, which is applied in the direction of physical/chemical process catalysts, metal/metal-oxide/metal-hydroxide catalysts, and separation processes. it can solve the problems of reducing fuel economy, small amount of heat from hc combustion supplied to the catalyst to the filter, and low flow rate of exhaust gas in the downstream oxidation catalyst. , to achieve the effect of quick regenerating the filter and preventing an increase in fuel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 2

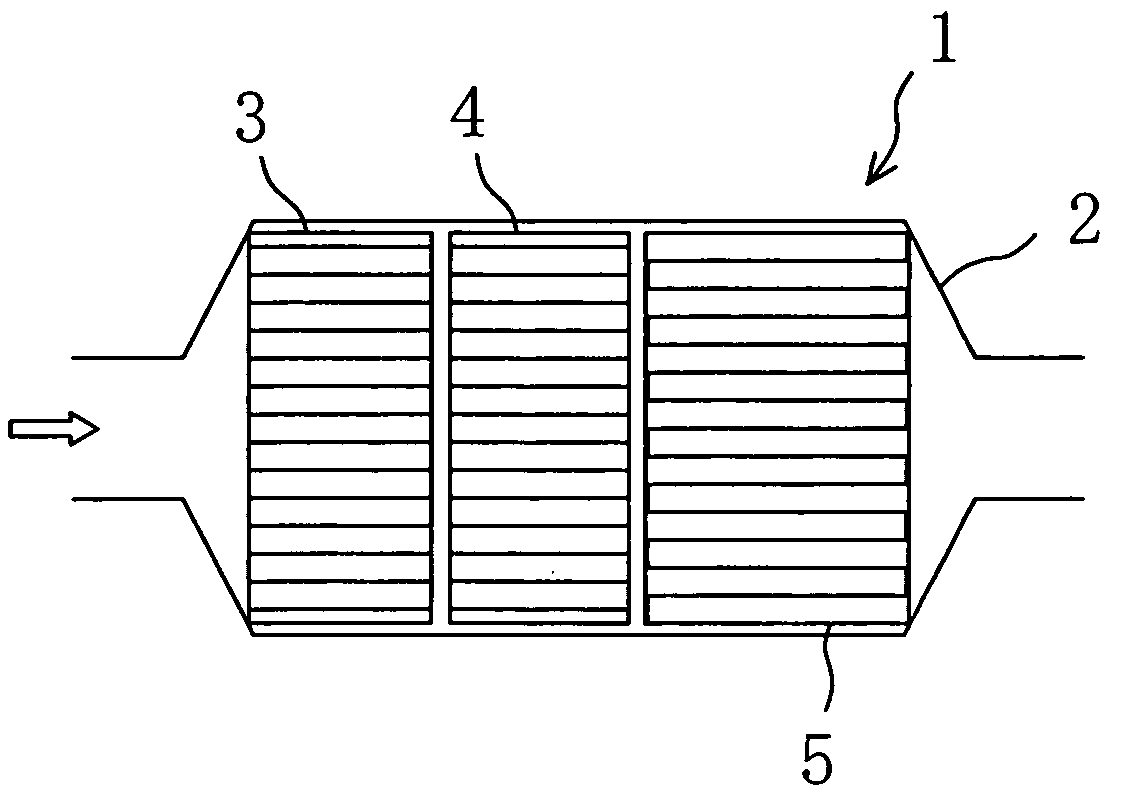

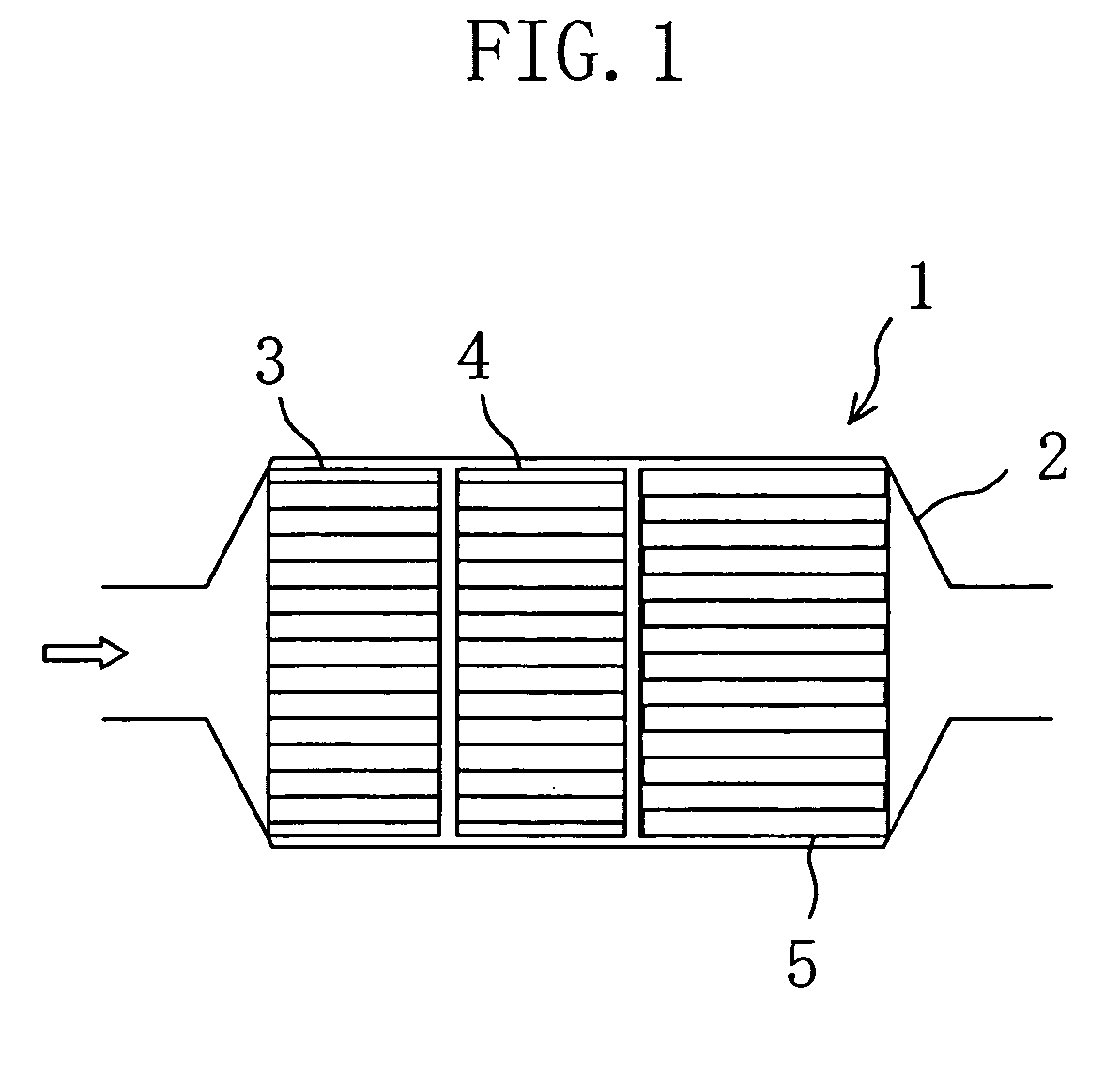

[0035] Both the upstream catalyst 3 and the downstream catalyst 4 are lean-NOx catalysts. The catalytic material is made of active alumina, CeO2, barium (Ba) serving as a NOx storage component and platinum (Pt) serving as a catalytic metal. Each catalyst was made by mixing active alumina and CeO2 in a mass ratio of 1:1 to prepare a support material and supporting Pt and Ba on the support material. As a support for each of the upstream and downstream catalysts 3 and 4 was used a cordierite honeycomb support of the same type as in Example 1.

[0036] Further, for the upstream catalyst 3, the support material obtained by mixing active alumina and CeO2 in a mass ratio of 1:1 was supported by 60 g / L on the honeycomb support. For the downstream catalyst 4, the same support material was supported by 180 g / L on the honeycomb support. Therefore, the downstream catalyst 4 contains a larger amount of support material per unit area of wall surfaces of each cell in the honeycomb support than the u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com