Patents

Literature

74results about How to "Achieve in situ regeneration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

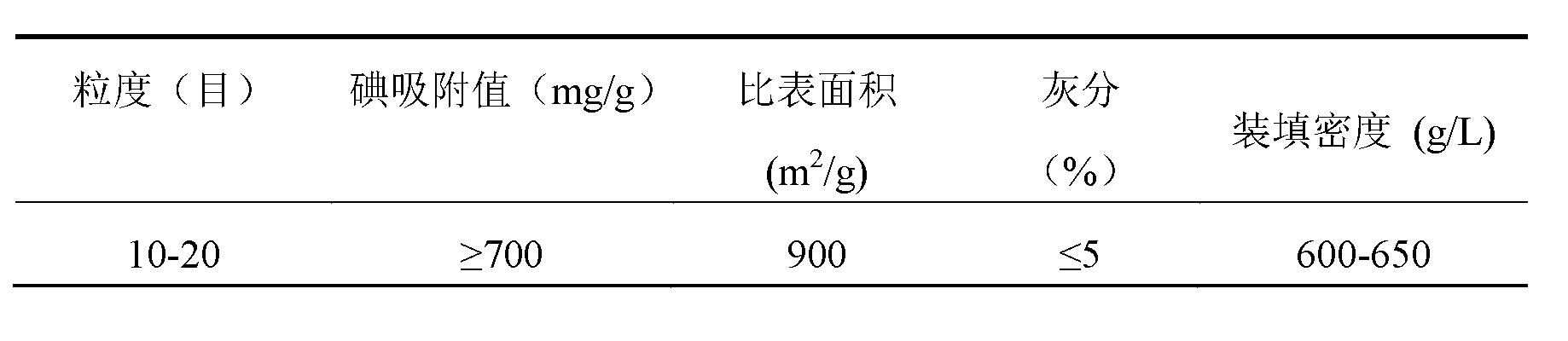

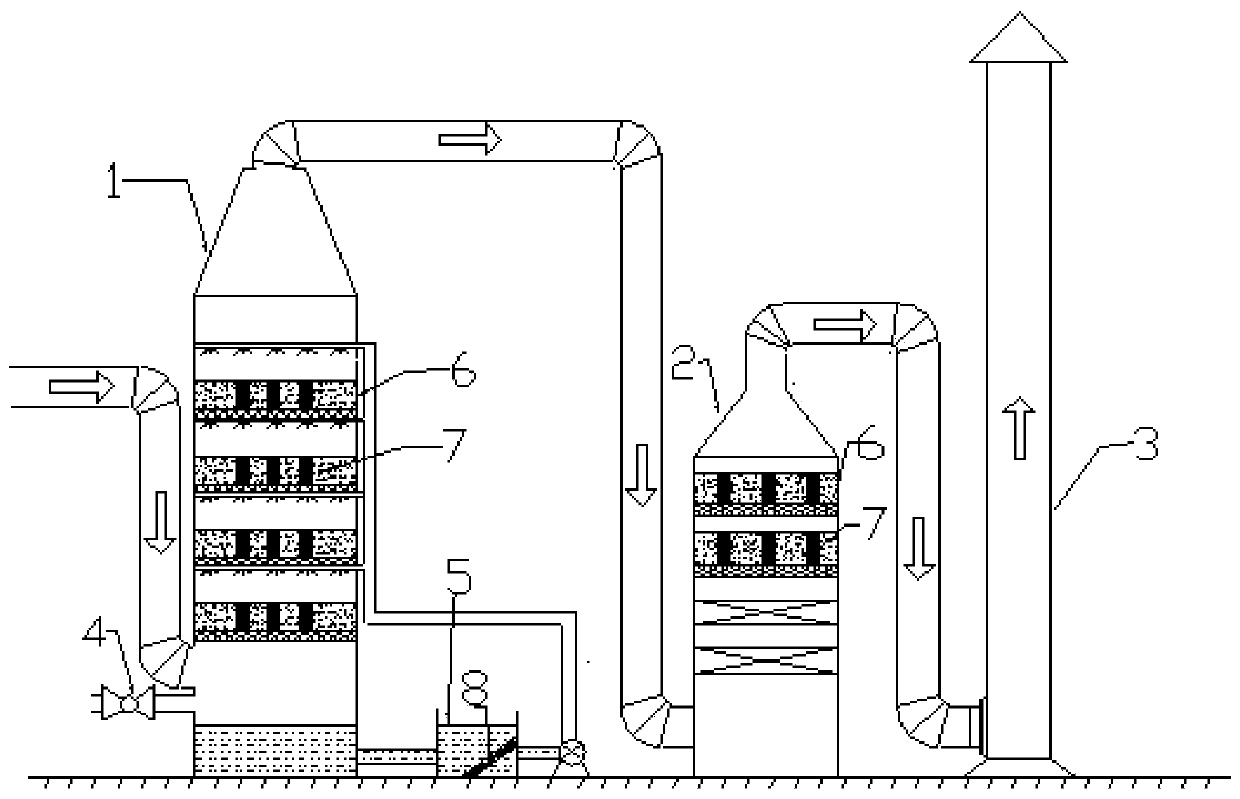

Desulfurization and denitrification process utilizing microwave to intermittently irradiate activated carbon

InactiveCN102489107AReduce lossesAchieve in situ regenerationDispersed particle separationSulfur preparation/purificationActivated carbonPtru catalyst

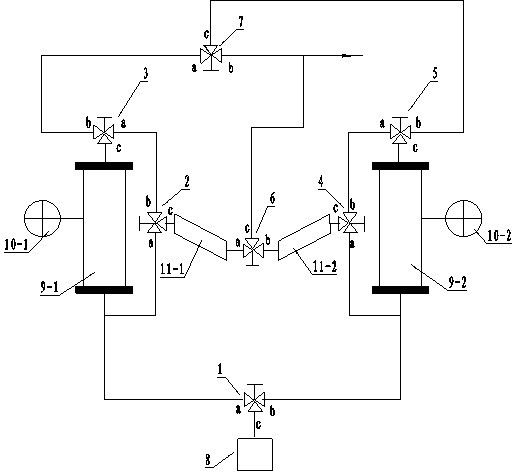

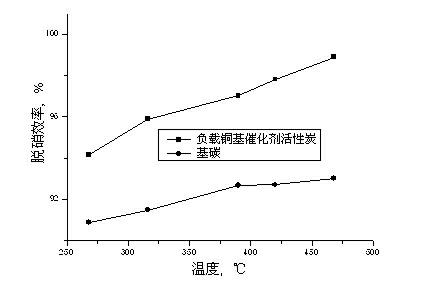

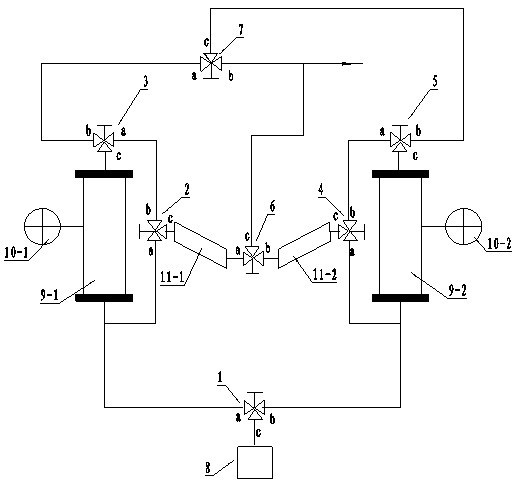

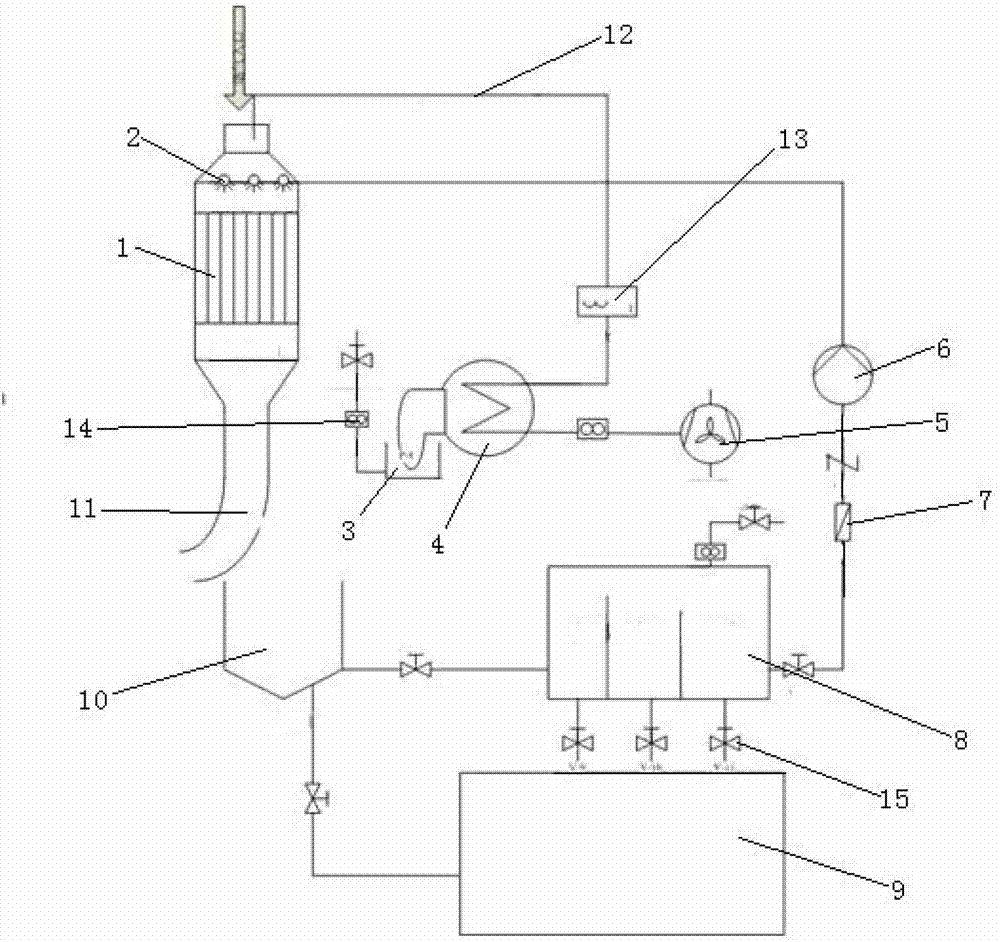

Disclosed is a desulfurization and denitrification process utilizing microwave to intermittently irradiate activated carbon. Two or more adsorption beds filled with activated carbon particles are used for adsorbing or implementing microwave irradiation to flue gas of boilers alternatively. Flue gas is delivered into one of the adsorption beds by an induced draft fan, then the adsorption bed begins to run, and sulfur and nitric oxides in the flue gas are adsorbed by the activated carbon. After the activated carbon in the adsorption bed in running is saturated, the adsorption bed is in a regenerating state so as to be reused. The flue gas is delivered into the other adsorption bed beginning to run so as to be adsorbed, activated carbon particles of the regenerating adsorption bed are irradiated by microwave, sulfur and nitric oxides adsorbed on the surface of the activated carbon are quickly reduced and decomposed into elemental sulfur and nitrogen gas under high temperature, and the different adsorption beds are switched between the running state and the regenerating stage alternatively. Metal oxide is used as a reduction reaction catalyst so as to reduce reduction and decomposition temperature and loss of carbon. By the desulfurization and denitrification process, energy consumption of microwave irradiation can be reduced greatly, loss of carbon can be decreased, and in-situ regeneration of activated carbon is realized. In addition, the desulfurization and denitrification process has the advantages of fine desulfurization and denitrification effect, short time for regeneration of activated carbon, low cost for desulfurization and denitrification, high recovery rate, easiness in industrialized implementing and the like.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Method for catalytically degrading adsorbed organic pollutants through microwave ultraviolet coupled radiation

ActiveCN102701310ASave microwave timeSave energyWater/sewage treatment by irradiationDispersed particle separationSorbentUltraviolet lights

The invention relates to a method for catalytically degrading adsorbed organic pollutants through microwave ultraviolet coupled radiation, belonging to the technical field of pollution control technologies. The invention solves the problems that the consumption level of the traditional adsorbent is high and secondary solid pollutants are produced by using an adsorption method, and overcomes the defects that the microwave-assisted photocatalytic oxidation water treatment and waste gas treatment method is high in energy consumption, easy for generation of thermal pollution and incomplete in degradation of pollutants. In the method, an adsorbent is used to enrich organic matters in waste water and waste gas; a porous wave-adsorbing catalyst for adsorbing the organic matters is placed in a quartz reactor; air with the humidity being 30-100% is introduced into the quartz reactor via an air intake pipe, the microwave ultraviolet reaction time is adjusted to be 10-60 min, and the microwave power is 100-2000 W; and a microwave oven is started, a non-polar ultraviolet lamp is excited by microwaves to generate ultraviolet light, and organic matters are thoroughly mineralized under the combined action of the microwaves, the ultraviolet light and the catalyst. The method is used for treating the organic matters in the waste water and the waste gas.

Owner:HARBIN INST OF TECH

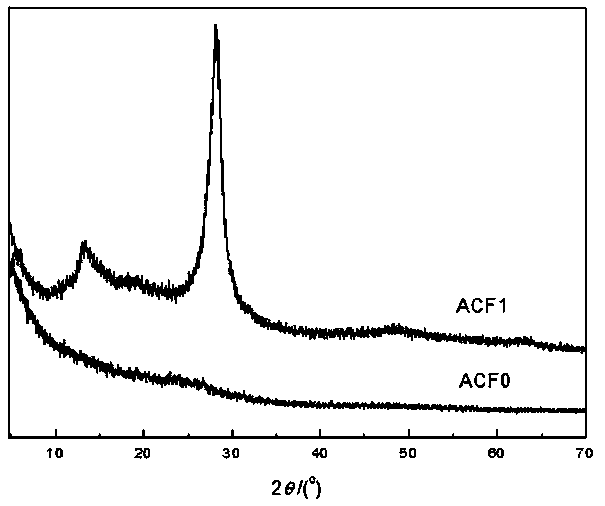

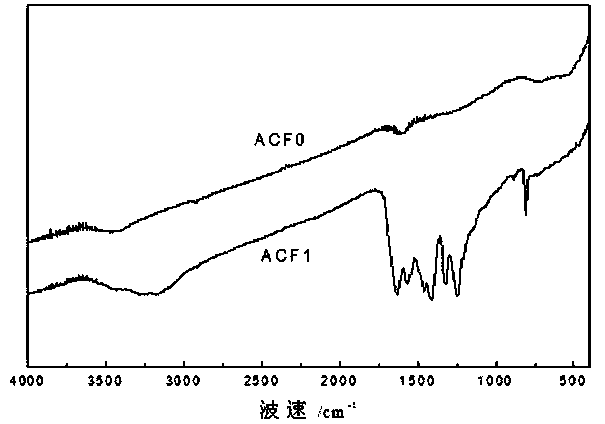

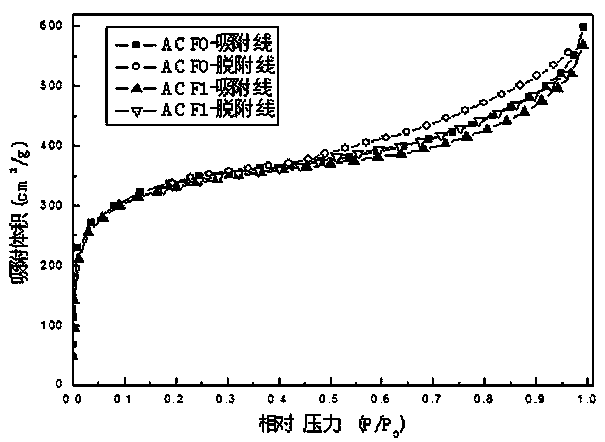

Electrochemical method for preparing activated carbon fibers with photocatalysis function

InactiveCN103769050AWith adsorption functionWith photocatalytic functionPhysical/chemical process catalystsOther chemical processesFiberActivated carbon

The invention discloses a preparation method for activated carbon fibers with a photocatalysis function. The activated carbon fibers for immobilizing graphite phase carbon nitride are prepared by an electrochemical deposition method by taking activated carbon fibers, dicyanodiamine, N,N-dimethylformamide and the like as main raw materials. The activated carbon fibers have an adsorption function and the photocatalysis function. Under a condition of darkness or insufficient light, pollutants can be purified under the adsorption function of the activated carbon fibers; under a condition of sufficient light, the pollutants can be purified under the adsorption function and the photocatalysis function; in-situ regeneration of the adsorption function of the activated carbon fibers can be realized; labor, resource and financial consumption of a regeneration process is greatly reduced. Successful research on the activated carbon fibers has an important significance for relieving of insufficience of activated carbon fiber supply in China.

Owner:FUJIAN AGRI & FORESTRY UNIV

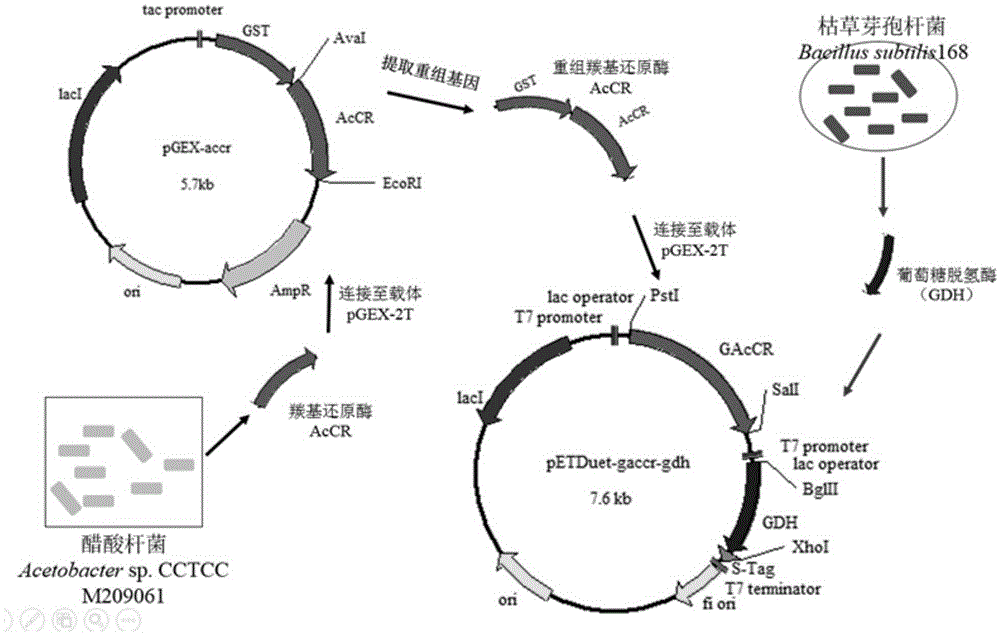

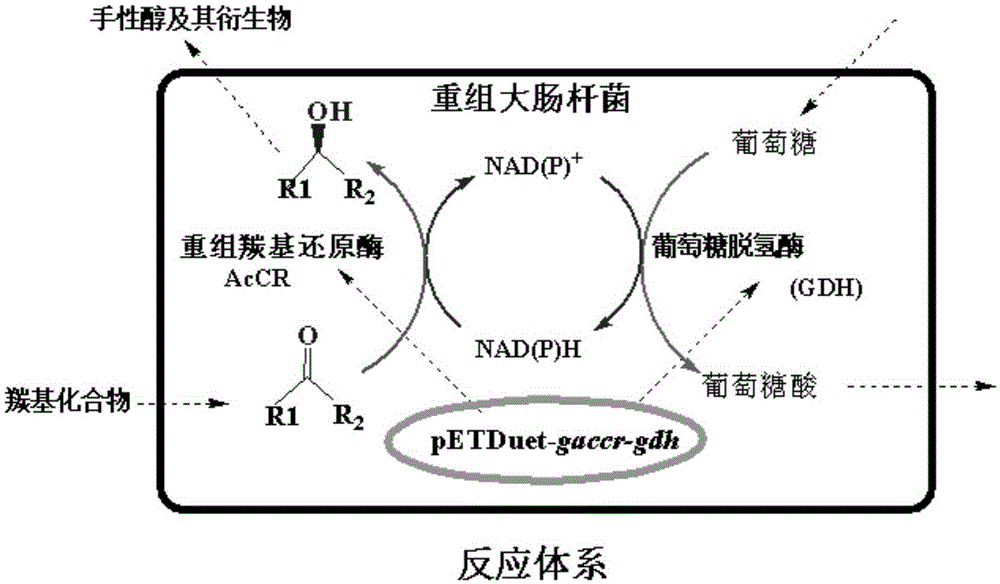

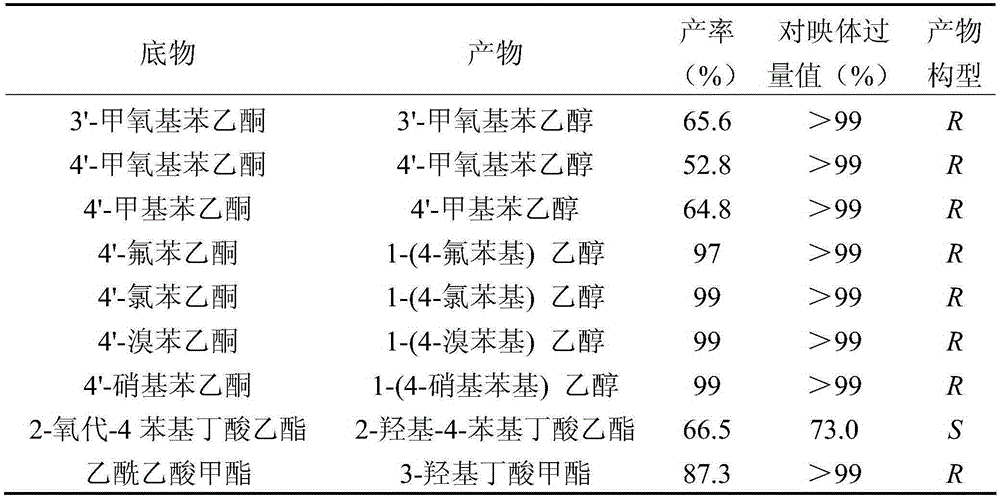

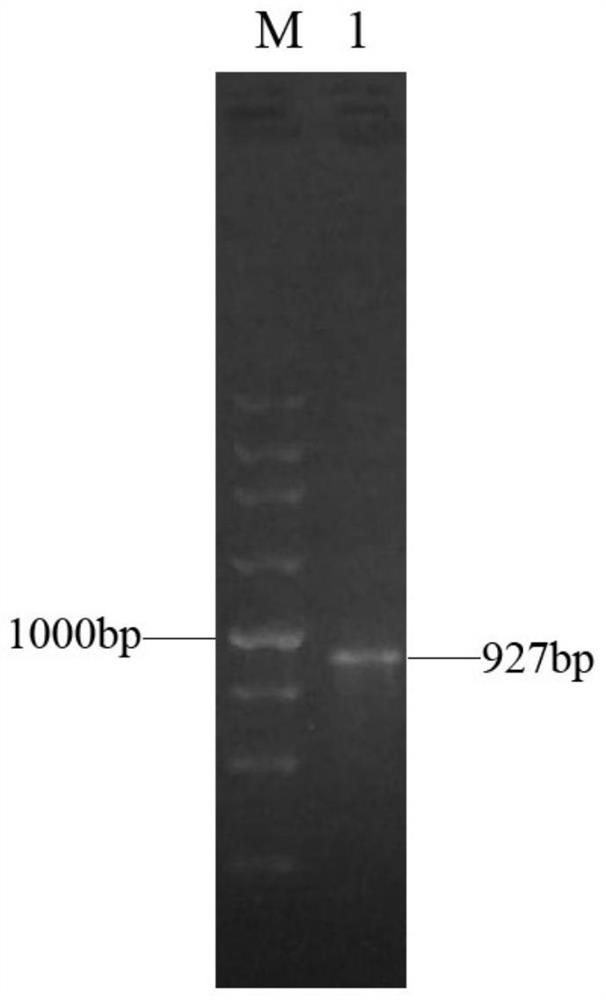

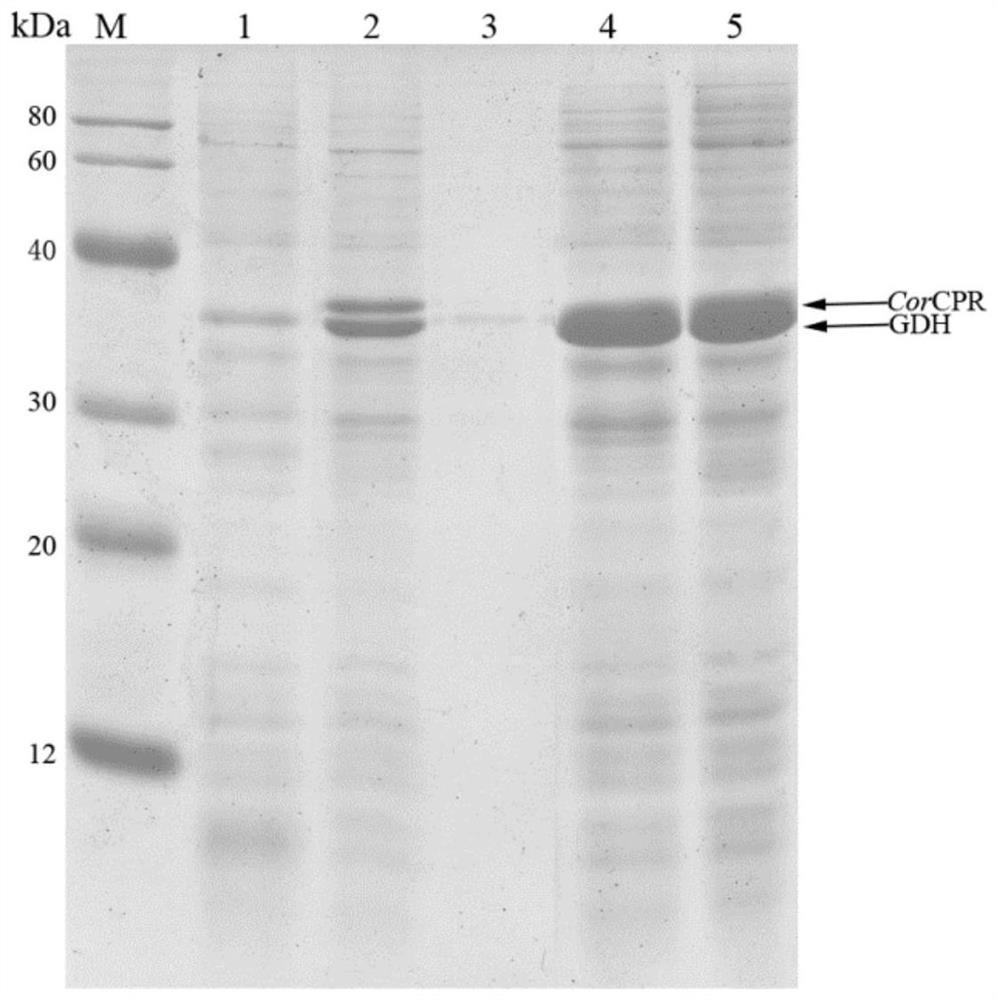

Carbonyl reductase AcCR and encoding gene and application thereof

InactiveCN105349503ACan be catalyzed to generateAchieve in situ regenerationBacteriaMicroorganism based processesAlcoholEnantiomer

The invention belongs to the technical field of gene engineering and particularly relates to carbonyl reductase AcCR and an encoding gene and application thereof. The amino acid sequence of the carbonyl reductase AcCR is shown as SEQ ID NO.1. The nucleotide sequence of the gene for encoding the carbonyl reductase AcCR is shown as SEQ ID NO.2. The carbonyl reductase AcCR comes from bacillus aceticus XZY003 and can catalyze 13 carbonyl compounds to generate corresponding chiral alcohol of single enantiomers. The carbonyl reductase AcCR and glucose dehydrogenase GDH are co-expressed in a prokaryotic expression system or a eukaryotic expression system, the biological reaction process of biological catalytic conversion is conducted through the carbonyl reductase, in-situ regeneration of coenzyme is achieved, production cost is greatly reduced, the optical purity of an obtained product is high, the reaction process is efficient, and conditions are moderate.

Owner:SOUTH CHINA UNIV OF TECH

Plant in-situ regeneration method and application thereof in genetic transformation

InactiveCN102599052AAchieve in situ regenerationAchieve genetic transformationHorticulture methodsPlant tissue culturePlant rootsBud

The invention belongs to the biology and biological technical field, and discloses a plant in-situ regeneration and agrobacterium transformation method. Agrobacterium is coated on a wound of a plant root stock, a callus which is generated by inducing a plant in-vitro tissue on a culture medium is used as a scion, and the scion is grafted onto the root stock through a cleft graft method. Root stock wound cells can realize in-situ organ regeneration under the induction of an exogenous callus, so that a transgenic regeneration bud can be obtained. Compared with the traditional plant genetic transformation method combining the tissue culture, a one-by-one genotype fumbling tissue culture condition can be avoided, a novel technological platform can be provided to the genetic transformation of plants, meanwhile, a novel plant regeneration system is established, and a research system is provided to the study of plant development biology.

Owner:SHENYANG AGRI UNIV

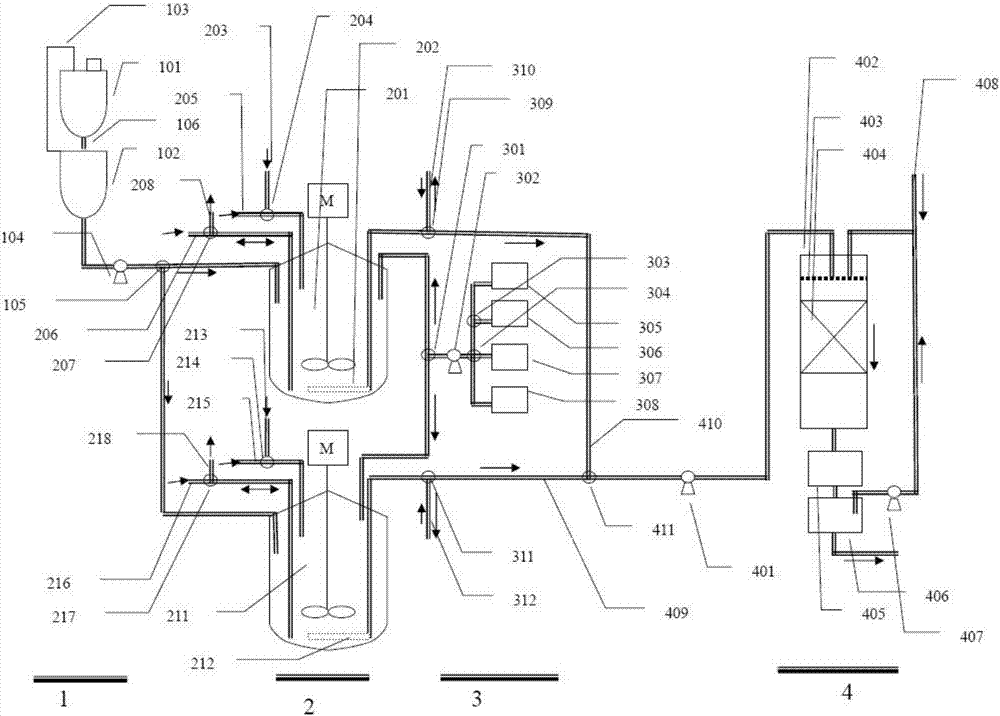

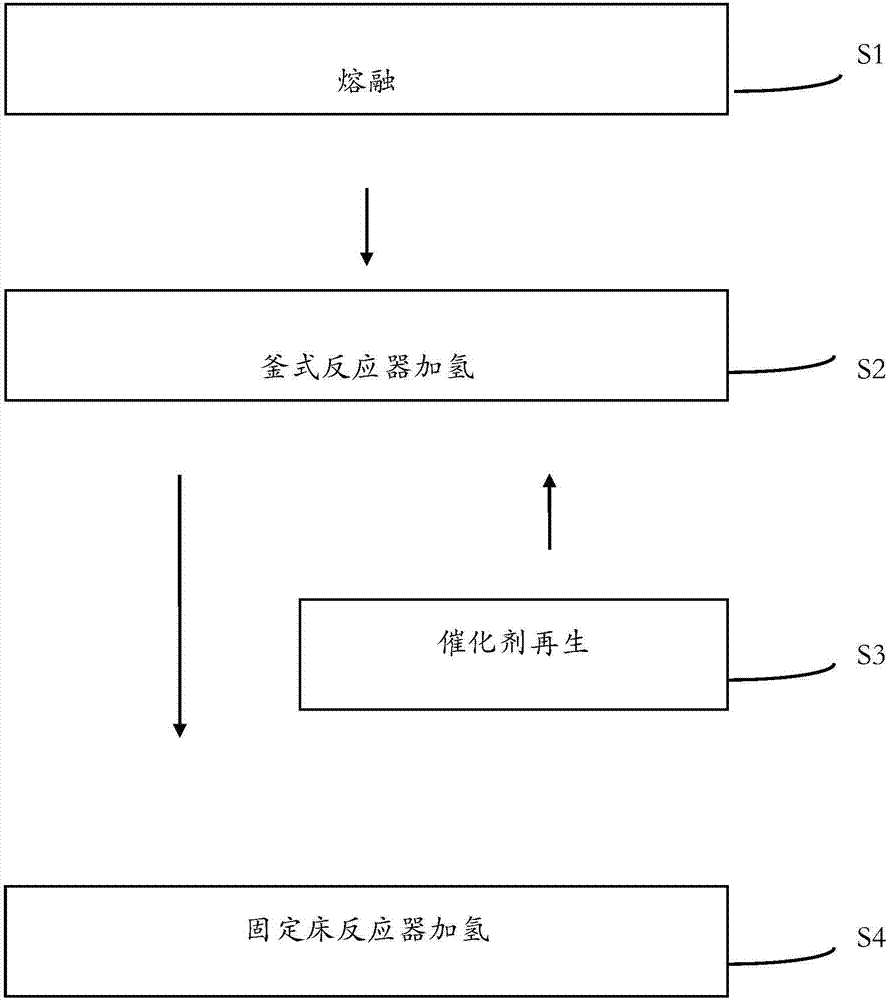

Continuous catalytic hydrogenation production and catalyst regeneration device and method

ActiveCN106866429AAchieve in situ regenerationExtended use timeOrganic compound preparationChemical recyclingAutomatic controlHydrogenation reaction

The invention discloses a continuous catalytic hydrogenation production and catalyst regeneration device, which is used for realizing hydrogenation product continuous production and reaction kettle hydrogenation catalyst in-situ regeneration. The device comprises a fusing section, a reaction kettle hydrogenation section, a catalyst regeneration section and a fixed bed reactor hydrogenation section which are connected through pipelines and are sealed, wherein the reaction kettle hydrogenation section comprises two high-pressure hydrogenation reaction kettles in parallel connection; the catalyst regeneration section and one high-pressure hydrogenation reaction kettle form a catalyst in-situ regeneration system. The device has the advantages that the automatic control on the continuous production of hydrogenation products, and the in-situ regeneration treatment of a reaction kettle hydrogenation catalyst can be realized, so that the use time of the catalyst can be prolonged; the catalyst loss is reduced; the production flow process is shortened; the energy consumption is reduced; the production efficiency is improved; the hydrogenation products with high quality and high yield can be produced. The invention also discloses a continuous catalytic hydrogenation production and catalyst regeneration method.

Owner:SHANGHAI XUNKAI NEW MATERIAL TECH

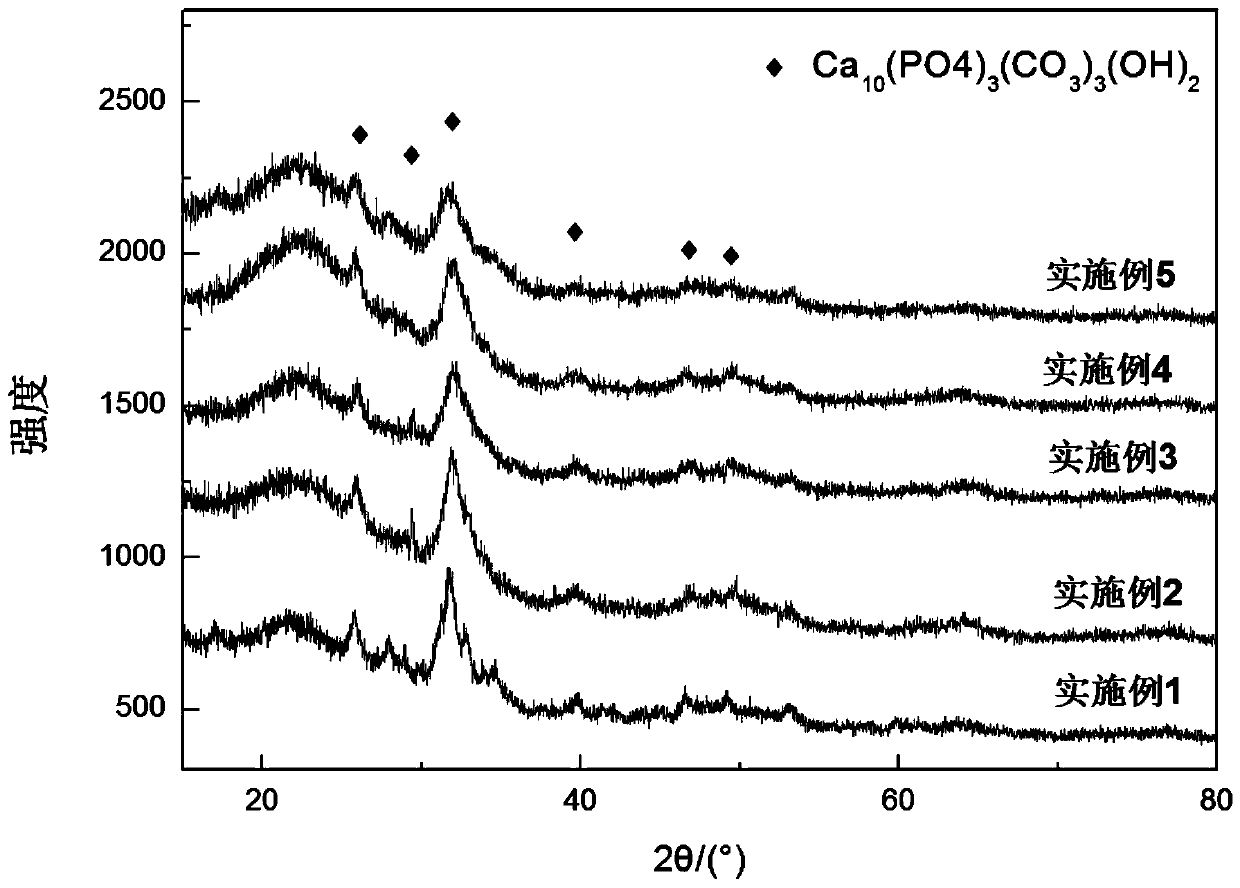

Bone cement based on bio-based polyurethane composite degradable material and preparation method thereof

ActiveCN110124111APromote degradationGood biocompatibilityTissue regenerationProsthesisFiberBone cement

The invention discloses a bone cement of a bio-based polyurethane composite degradable material, which is composed of a solid phase powder material and a liquid phase composite, wherein the solid phase powder mainly comprises inorganic powder and / or a prepolymerized organic filler insoluble in a polyurethane monomer, doped reinforcing fibers and other functional powders. The liquid phase compositemainly comprises a bio-based polyurethane prepolymer and a liquid phase monomer diluent. The liquid phase composite is slowly added to the solid phase powder material, and the materials are sufficiently mixed and solidified to form the bone cement. The bone cement can completely replace the bone cement such as PMMA, calcium phosphate and calcium sulfate on the market, and has excellent biologicalactivity and the ability to promote new bone formation. After injecting into the human bone defect site, the mechanical properties are excellent, the polymerization reaction produces less heat, and the bone cement degradation rate is matched with the new bone formation inducing speed, and the autologous bone in-situ regeneration is achieved to ensure stable and controllable bone increment.

Owner:BEIJING BEST LIFE REGENERATIVE MEDICINE TECH CO LTD

Biological preparation method of (R)-1-(2-trifluoromethylphenyl)ethanol

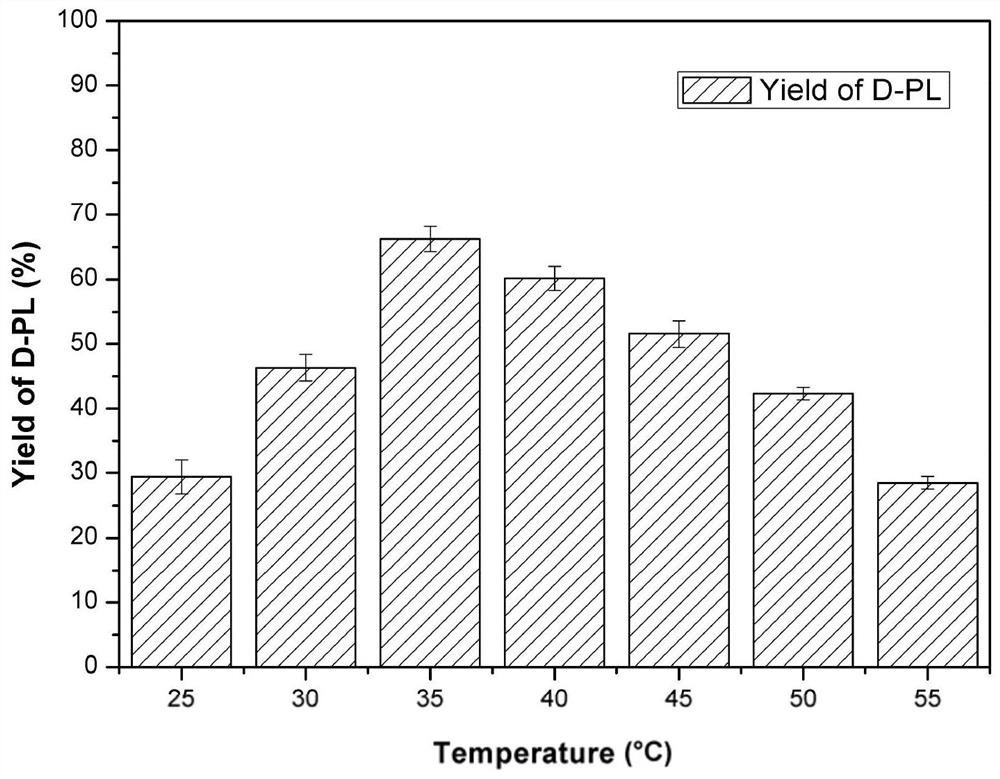

ActiveCN107746861AHigh stereoselectivitySimple processFungiMicroorganism based processesPhosphoric acidTrifluoromethyl

The invention discloses a biological preparation method of (R)-1-(2-trifluoromethylphenyl)ethanol. The method comprises the following steps: taking a wet thallus obtained by carrying out fermentationculture on geotrichum candidum ZJPH1704 as a biological catalyst and taking 2-trifluoromethylacetophenone as a substrate; carrying out biological reduction reaction in a phosphoric acid buffering solution with the pH (Potential of Hydrogen) of 5.8 to 8.0 under the condition that the temperature is 25 DEG C to 40 DEG C and the speed is 200rpm; after the reaction is finished, carrying out separationand purification on a reaction solution to obtain the (R)-1-(2-trifluoromethylphenyl)ethanol. According to the method disclosed by the invention, when the concentration of the substrate is 10mmol / L,the yield of the product (R)-1-(2-trifluoromethylphenyl)ethanol is 92.31 percent and the e.e. value is greater than 99 percent; the product has better catalysis efficiency. Compared with a reported conversion strain, the stereoselectivity and the yield of converting the catalytic conversion substrate 2-trifluoromethylacetophenone of the strain into the product are relatively high.

Owner:ZHEJIANG UNIV OF TECH

Preparation method and application of dark light catalytic non-photo-catalyst/activated carbon fiber composite material

InactiveCN104437452AUninterrupted adsorptionUninterrupted adsorption degradationBiocidePhysical/chemical process catalystsActivated carbonAdhesive

The invention belongs to the field of novel materials and photocatalysis and particularly relates to a preparation method and application of a dark light catalytic non-photo-catalyst / activated carbon fiber composite material. The dark light catalytic non-photo-catalyst / activated carbon fiber composite material is characterized by comprising a non-photo-catalyst, an activated carbon fiber raw material, an adhesive and water. The preparation method comprises the following steps: cutting the activated carbon fiber to required size and perforating; weighing the non-photo-catalyst, and adding water to form a non-photo-catalyst solution; preparing a chitin powder adhesive; spray coating the non-photo-catalyst solution onto the surface of the activated carbon fiber, drying, spray coating the adhesive onto the surface of the coated non-photo-catalyst solution to fix the adhesive on the surface of the activated carbon fiber, and drying. The dark light catalytic non-photo-catalyst / activated carbon fiber composite material can purify pollutants through adsorption and catalysis functions under dark light or sufficient light, the formaldehyde degradation efficiency within 1 hour reaches 99.9%, the load is firm, the specific surface area is high, and the composite material can be regenerated in situ under sunlight exposure or at low temperature of 60 DEG C.

Owner:SICHUAN AGRI UNIV

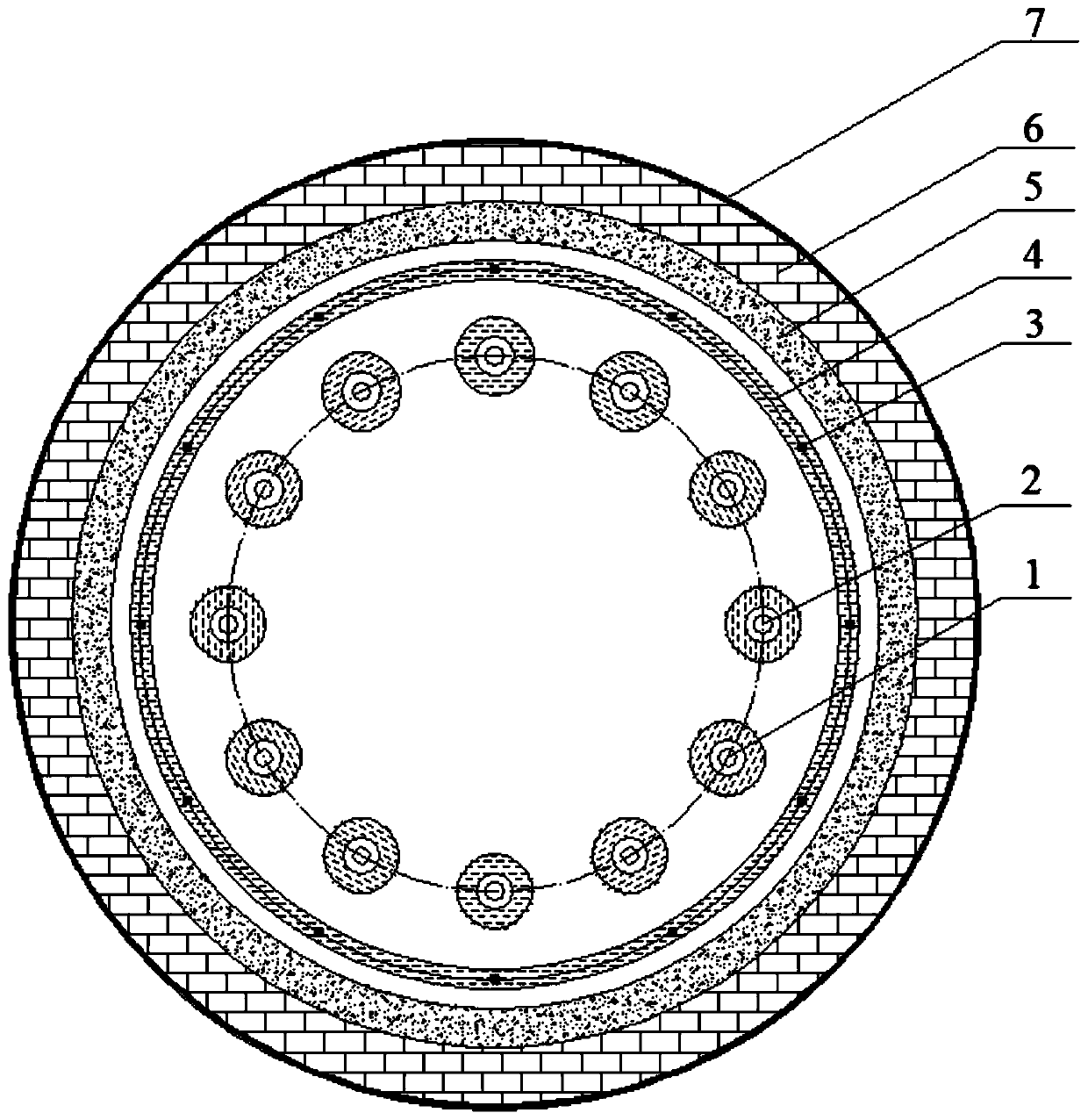

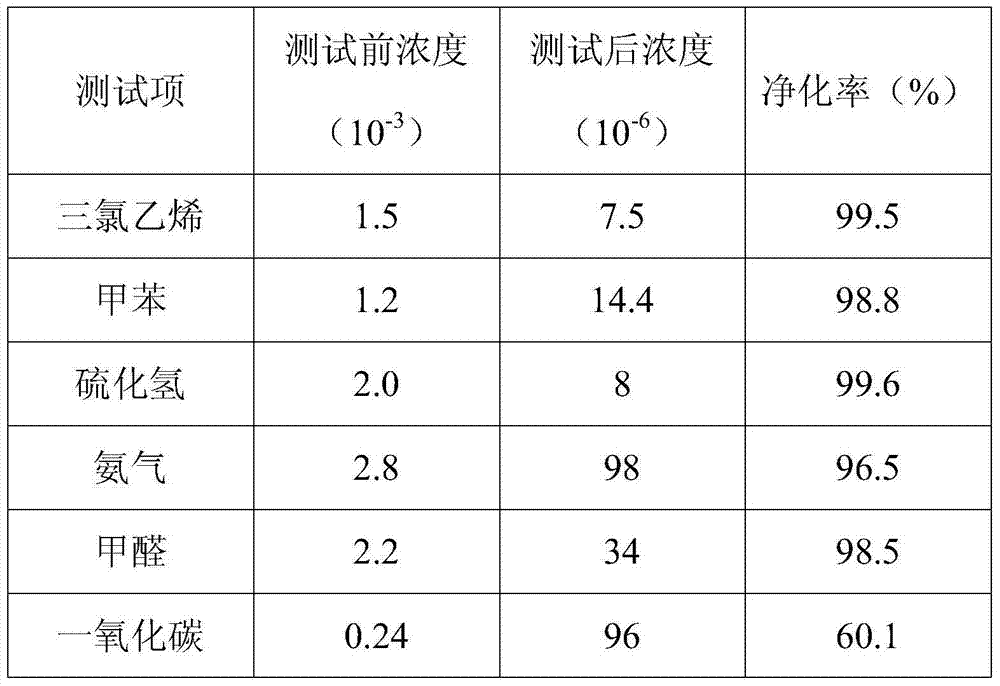

In-situ regenerable adsorption photocatalysis and ozone synergistic purification method and device for VOCs

ActiveCN110152481AEfficient purificationGuaranteed adsorption effectGas treatmentDispersed particle separationFiberActivated carbon

The invention relates to an in-situ regenerable adsorption photocatalysis and ozone synergistic purification method and device for VOCs. The device comprises annularly-distributed ultraviolet lamp tubes and heating lamp tubes arranged in the device, the periphery of the ultraviolet lamp tubes and the heating lamp tubes is corona generation electrode electric purifying wires, and the corona generation electrode electric purifying wires are wound by a wire holder assembled in an annular installation frame to form annular arrangement; an activated carbon fiber adsorption layer loading with a photocatalyst, an ozone catalyst layer and a dust collecting electrode are sequentially arranged at the outer side of the corona generation electrode electric purifying wires, the activated carbon fiber adsorption layer, the ozone catalyst layer and the dust collecting electrode are attached together to form a barrel structure, and the outermost-layer outer-side dust collecting electrode forms a device skeleton and has a metal mesh structure. After the technical solution provided by the invention is adopted, the VOCs can be effectively removed, the purification efficiency is higher, at the same time, decomposition products of the VOCs can be effectively desorbed, and the purification efficiency can be restored in time.

Owner:ACAD OF ENVIRONMENTAL PLANNING & DESIGN GRP CO LTD NANJING UNIV

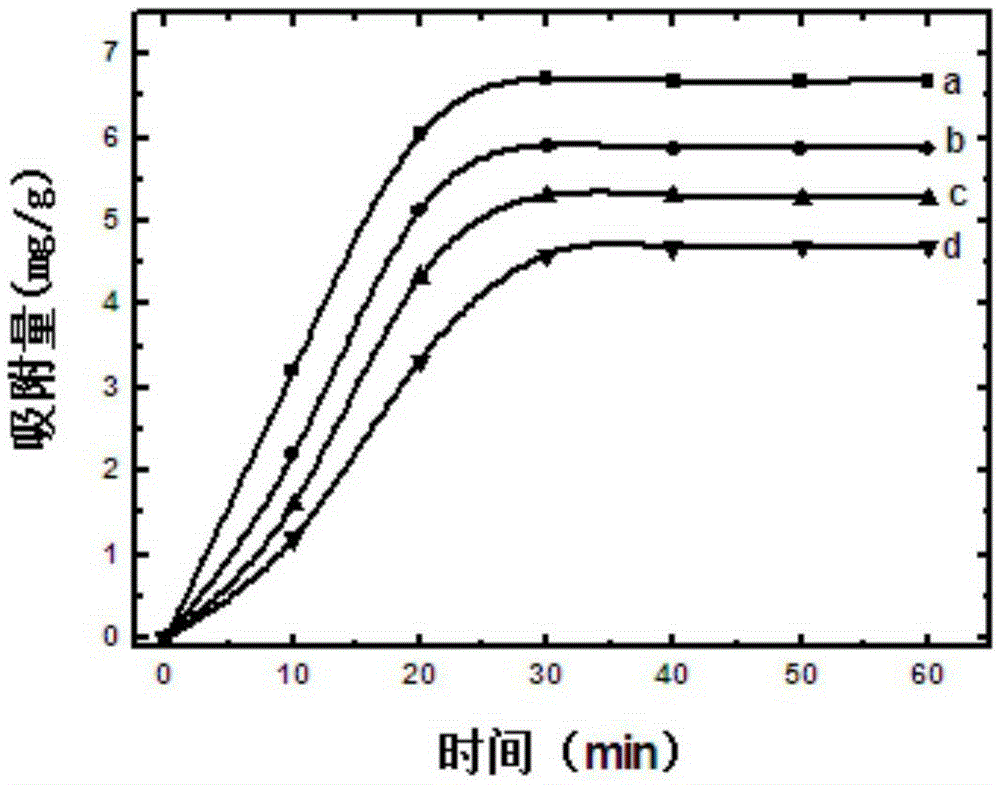

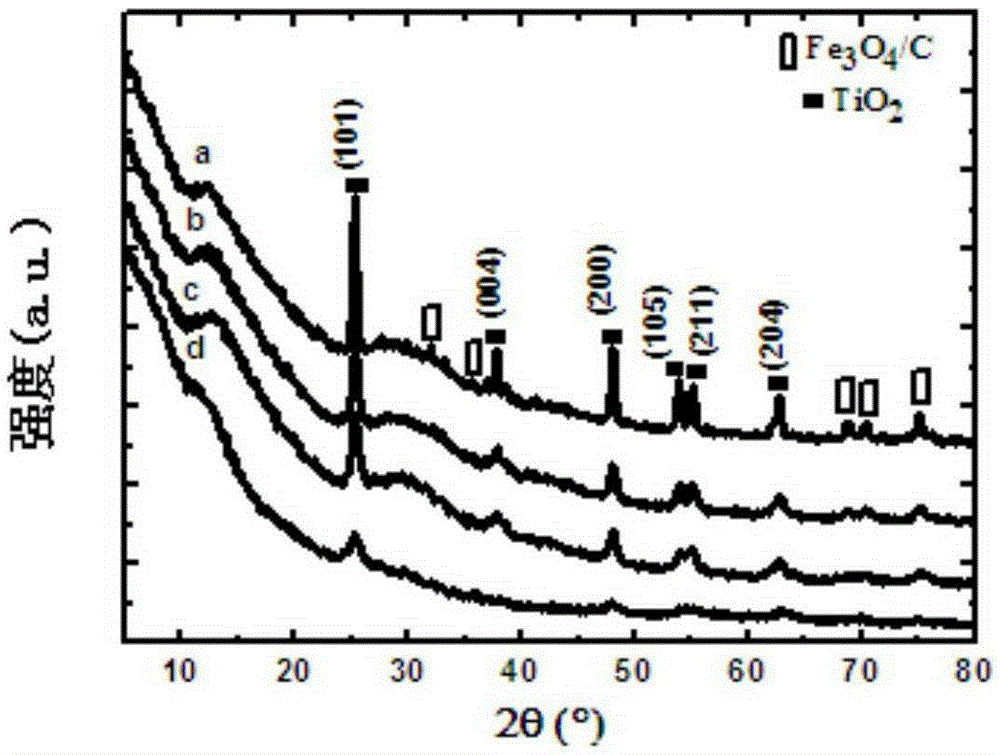

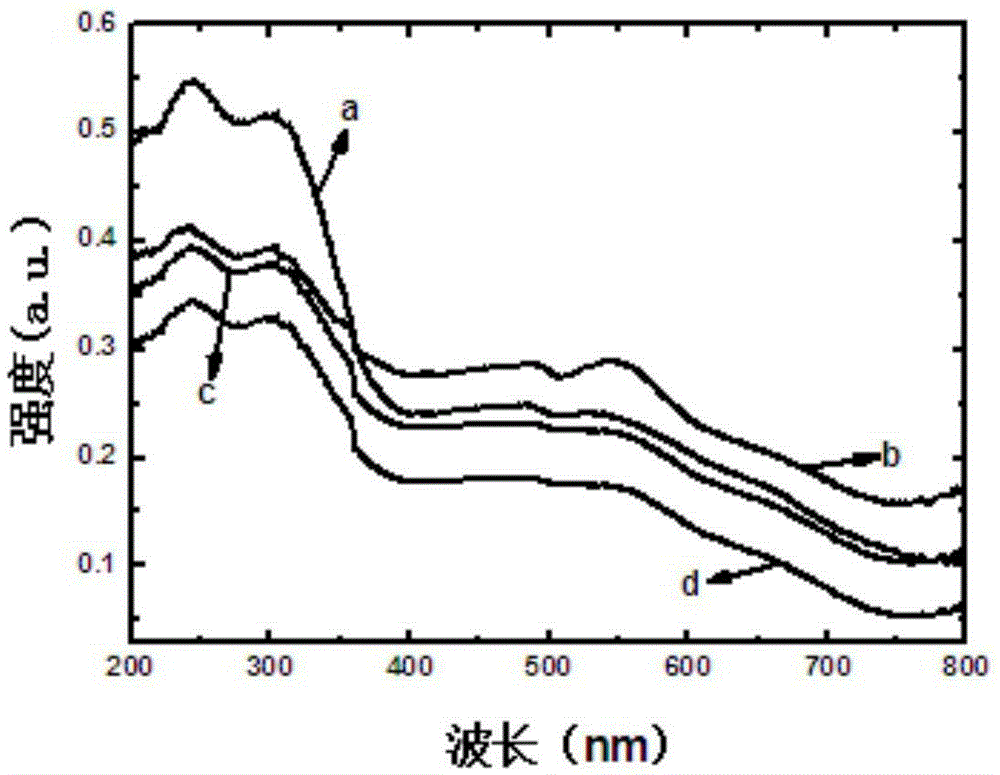

Magnetic TiO2/Fe3O4/C composite photocatalyst, and preparation method and application thereof

InactiveCN105289609AMagneticHigh recovery rateWater/sewage treatment by irradiationWater contaminantsTube furnacePhysical chemistry

A provided preparation method for a magnetic TiO2 / Fe3O4 / C composite photocatalyst comprises the following steps: preparing magnetic Fe3O4 / microzyme; preparing magnetic TiO2 / Fe3O4 / microzyme, concretely, mixing anhydrous enthanol, deionized water and concentrated hydrochloric acid to obtain a mixed solution A, performing enclosed stirring on anhydrous ethanol and tetrabutyl titanate at 40 DEG C to obtain a mixed solution B, adding the mixed solution A into the mixed solution B drop by drop, then performing enclosed stirring, then opening the plug, starting to introducing N2 for protection, observing the sol, adding Fe3O4 / microzyme after the sol is formed, observing the gel, taking out the sample after the gel is formed, stopping to introduce N2, and performing ageing and drying on the sample, so as to obtain magnetic TiO2 / Fe3O4 / microzyme; and preparing magnetic TiO2 / Fe3O4 / C, concretely, putting the magnetic TiO2 / Fe3O4 / microzyme into a tubular furnace, calcining at a temperature of 300-600 DEG C for 1-5 h, controlling the heating rate to be 1-2 DEG C / min, introducing N2 for protection in the whole calcining process, and cooling, so as to obtain the product magnetic TiO2 / Fe3O4 / C. The preparation method is simple in operation and relatively low in cost, and is a green environment-friendly efficient processing technology.

Owner:JIANGSU UNIV

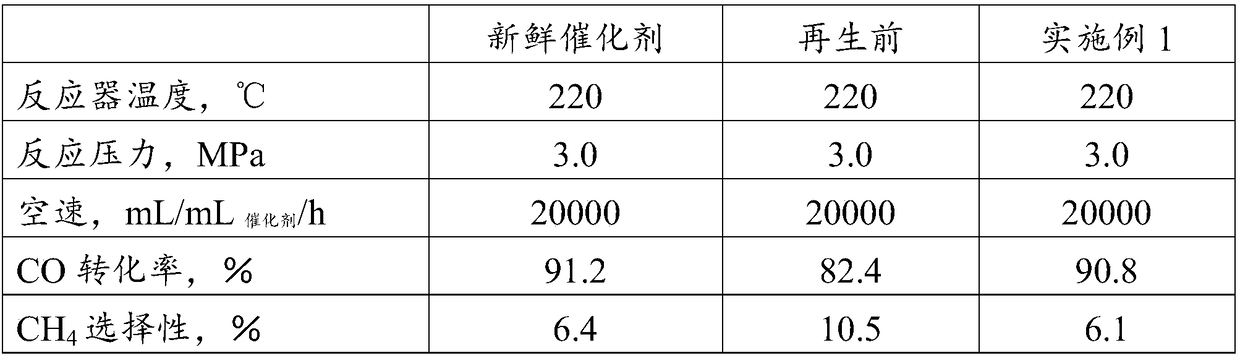

Regeneration method of microchannel reactor Fischer-Tropsch synthesis catalyst

ActiveCN109201074AAvoid destructionOmit washing stepsCatalyst regeneration/reactivationLiquid hydrocarbon mixture productionMaterial consumptionCobalt

The invention relates to a regeneration method of a microchannel reactor Fischer-Tropsch synthesis catalyst. The method includes: firstly using an inert gas to replace synthesis gas in a reactor, thenunder a cracking reaction condition, carrying out cracking reaction on the macromolecular hydrocarbon adsorbed by a Fischer-Tropsch synthesis catalyst to obtain methane and light hydrocarbon, and then conducting oxidation and reduction. The method provided by the invention achieves regeneration of the cobalt-based Fischer-Tropsch synthesis catalyst in the microchannel reactor, the physicochemicalproperties and catalytic performance of the regenerated catalyst are similar to those of fresh catalysts, and the regeneration process has low energy consumption and low material consumption.

Owner:CHINA PETROLEUM & CHEM CORP +1

Composite diatom purification particles and preparation method thereof

InactiveCN108435139AEasy to useExtend the lifespanBiocideGas treatmentSodium bicarbonateDecomposition

The invention relates to the technical field of diatom and discloses composite diatom purification particles. The composite diatom purification particles are prepared from raw materials in parts by weight as follows: 40-60 parts of diatomite, 6-14 parts of zeolite powder, 3-5 parts of dodecy dimethyl benzyl ammonium bromide, 2-5 parts of sodium bicarbonate, 3-7 parts of a photocatalyst, 1-3 partsof nano photocatalytic titania, 1-2 parts of antibacterial powder, 3-5 parts of nano tourmaline powder, 3-5 parts of infrared functional powder and 1-3 parts of titanium dioxide. According to the composite diatom purification particles and a preparation method thereof, zeolite powder is added and has adsorption capability for pollutants in the air, nano photocatalytic titania has adsorption and decomposition functions on pollutants in the air, the antibacterial powder can effectively remove bacteria, nano tourmaline powder has higher negative ion production and far infrared emittance and is matched with the infrared functional powder to release negative oxygen ions and far infrared rays while cleaning air, and the cleaning effect of the composite diatom purification particles on the pollutants in the air is improved through adsorption and decomposition.

Owner:温州德润日用品有限公司

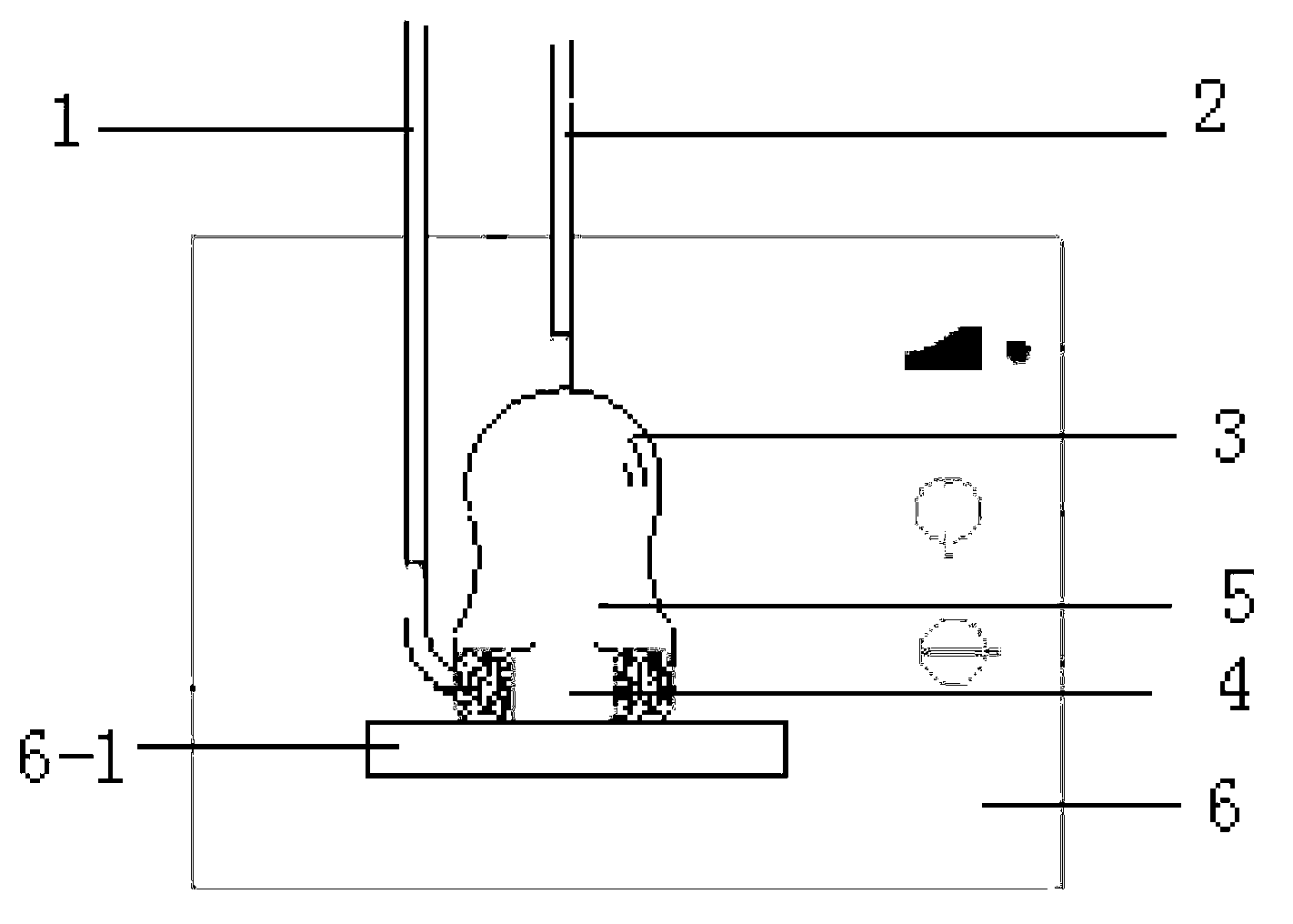

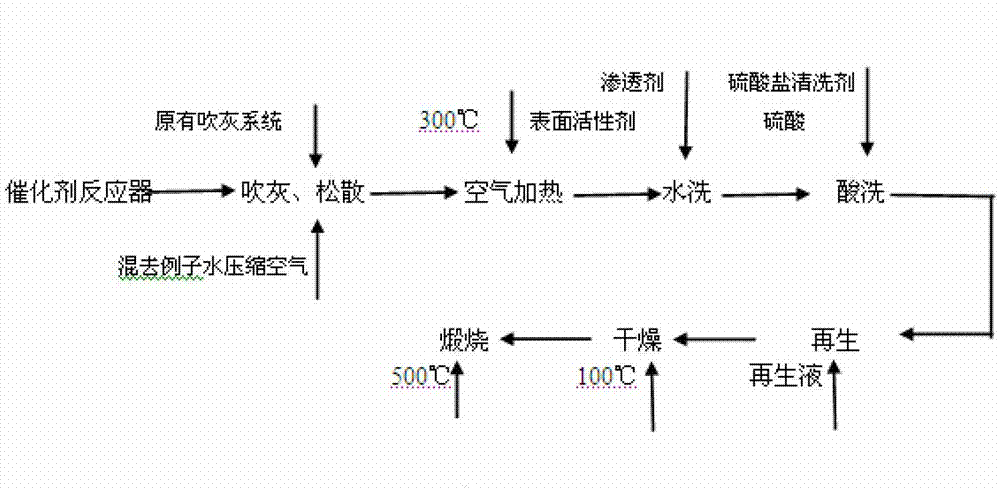

In-situ regeneration device and method for glass kiln SCR denitration catalyst

InactiveCN105435864AAchieve in situ regenerationAvoid pollutionDispersed particle separationCatalyst regeneration/reactivationLiquid wastePollution

The invention relates to an in-situ regeneration device for a glass kiln SCR denitration catalyst, which comprises a denitration reactor, wherein the denitration reactor is connected with a washing device, a hot air conveying device and a dosing device; the dosing device is connected with a waste liquid collection device; the washing device is connected with the dosing device to form a circulation circuit. The in-situ regeneration device can be used for achieving in-situ regeneration of the denitration catalyst, and is high in regeneration efficiency, and meanwhile capable of preventing pollution of a regeneration solution to the environment, reducing the waste of regeneration solution and reducing the regeneration cost.

Owner:FUJIAN ZIJIN ENVIRONMENT ENG TECH

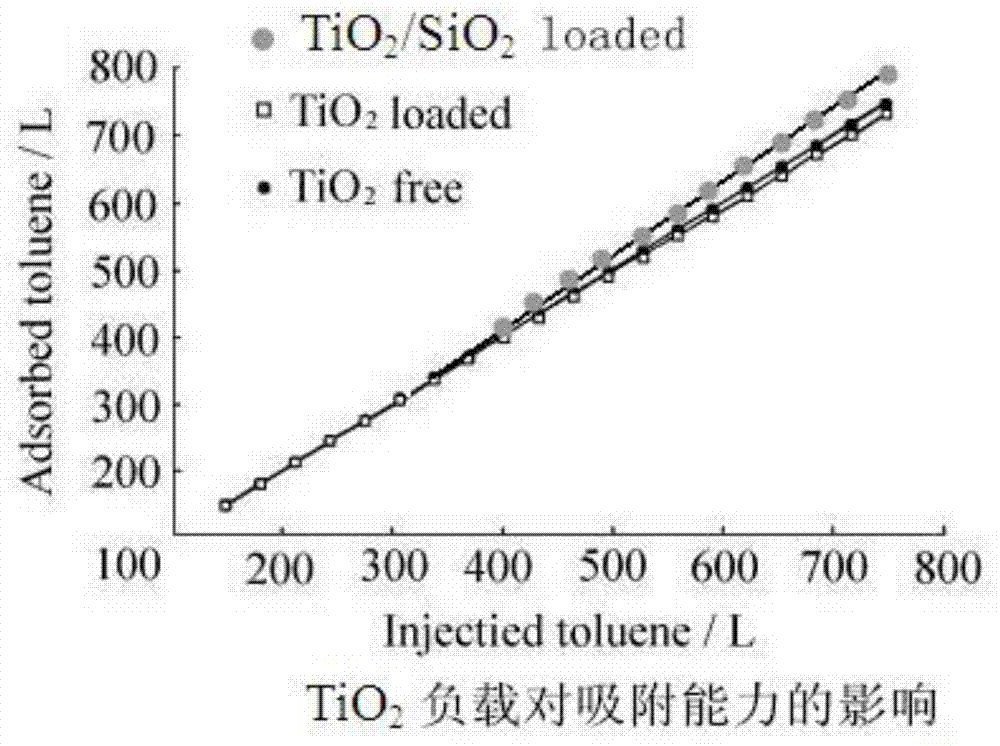

Indoor cleaning photocatalyst and preparation method thereof

ActiveCN104772133AIncrease oxidation rateInhibition releasePhysical/chemical process catalystsOther chemical processesFiberUltraviolet

The invention discloses an indoor cleaning photocatalyst and a preparation method thereof. The photocatalyst is prepared from active carbon fiber, mesoporous silica and nano titanium dioxide, wherein the active carbon fiber and the mesoporous silica are used as a composite double carrier and the nano titanium dioxide is loaded on the composite double carrier, so that ultraviolet can directly act on the TiO2 photocatalyst. The light utilization rate is increased, the speed of photocatalytic degradation reaction is expedited and the speed of full oxidation of pollutants is increased.

Owner:河北纳诺新材料科技有限公司

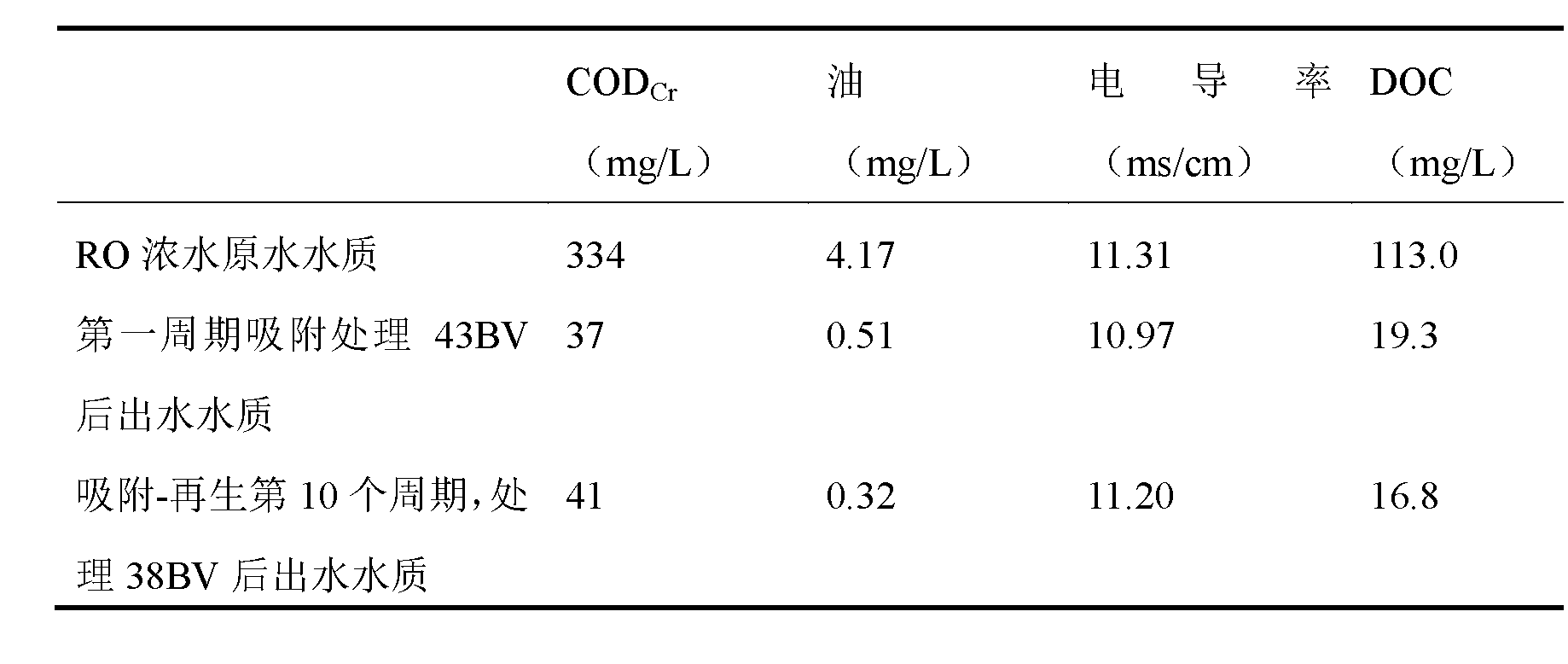

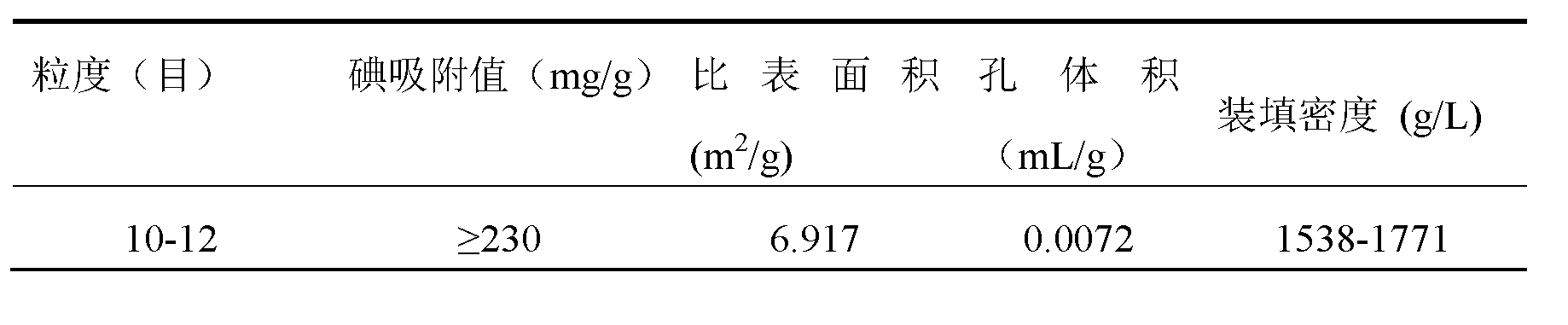

Method for reverse osmosis concentrated water by adsorption-regeneration circular treatment

ActiveCN103214056ARealize automatic controlLess investmentWater/sewage treatment by sorptionAfter treatmentChemical oxygen demand

The invention discloses a method for reverse osmosis concentrated water by adsorption-regeneration circular treatment, belonging to the field of advanced wastewater treatment. An adsorption-regeneration combination treatment process is adopted, the advanced treatment problem of reverse osmosis concentrated water is solved, the COD (Chemical Oxygen Demand) of inlet water is 150-300mg / L, the COD of the outlet water is less than or equal to 50mg / L after treatment. According to the combination process, adsorption treatment is adopted as the main, an electrochemistry regeneration manner is adopted to recover the adsorption capacity on a saturation adsorption material, the adsorption-regeneration combination treatment process is realized, and the treatment cost of the reverse osmosis concentrated water is greatly reduced.

Owner:CHINA NAT OFFSHORE OIL CORP +1

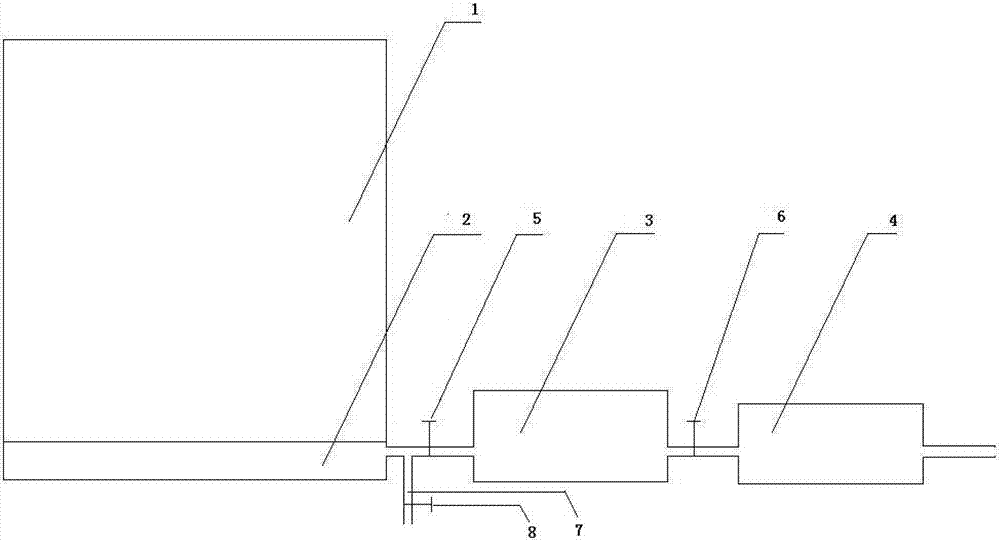

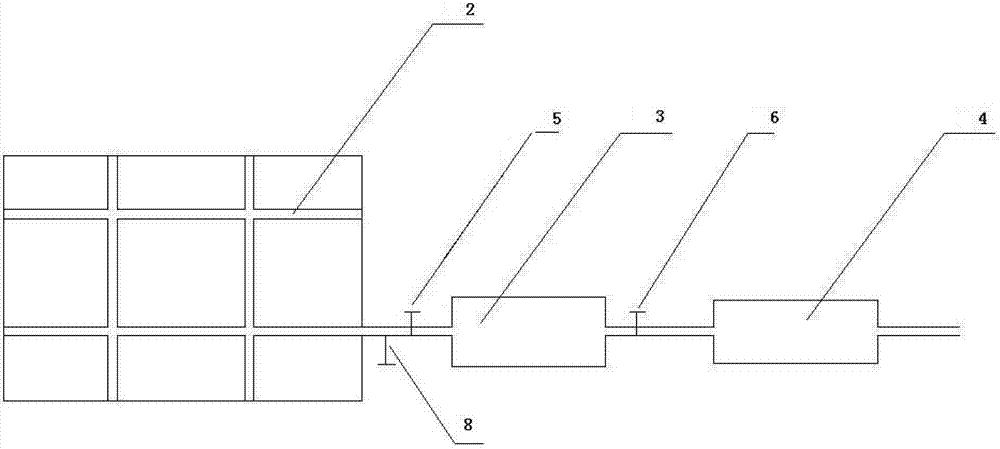

Device for regenerating spherical hydroxyapatite for defluorination

ActiveCN102728333AGood regeneration performanceAchieve regenerationOther chemical processesWater contaminantsApatiteProcess engineering

The invention provides a device for regenerating spherical hydroxyapatite for defluorination. The device comprises a defluorination reactor (1), a steam supply device (2), a steam generation device (3) and a water softener (4), wherein the steam supply device (2) is arranged at the bottom of the defluorination reactor (1); and the steam supply device (2), the steam generation device (3) and the water softener (4) are connected sequentially. According to the device for regenerating spherical hydroxyapatite for the defluorination, spherical hydroxyapatite is regenerated in a mode that steam is used for heating; the device has the characteristics of rapidness and high efficiency; and furthermore, the regeneration effect is improved greatly.

Owner:HOHAI UNIV

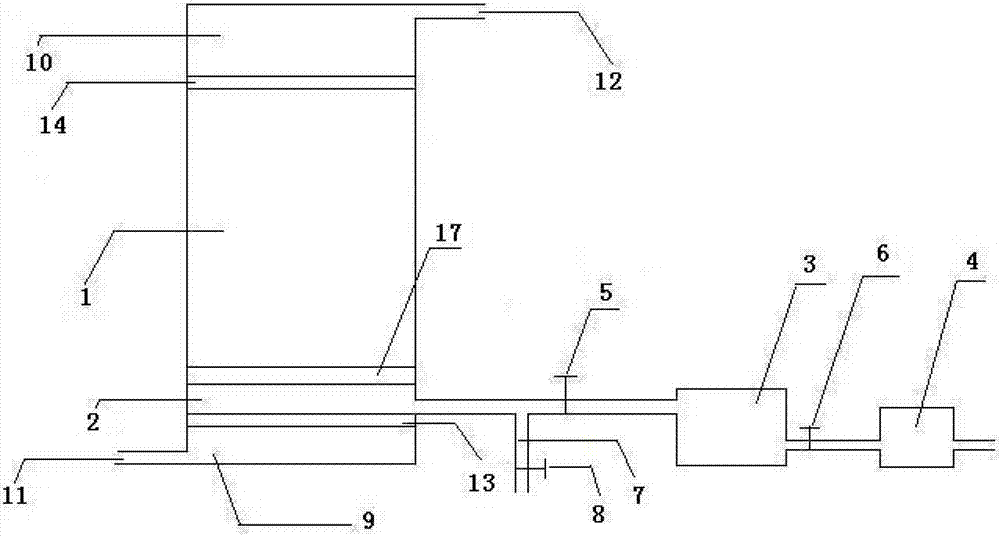

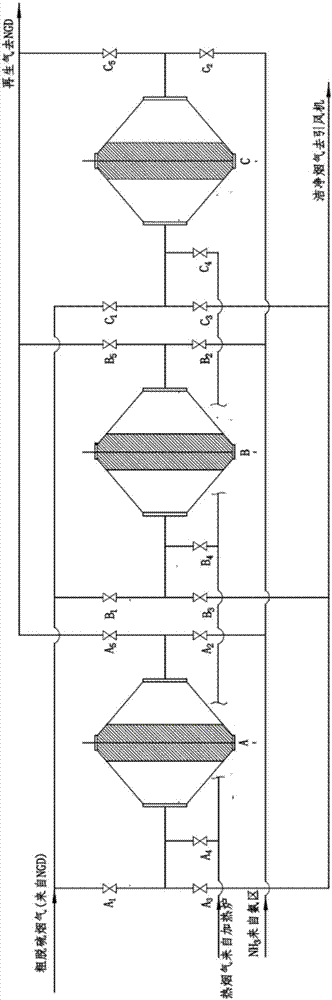

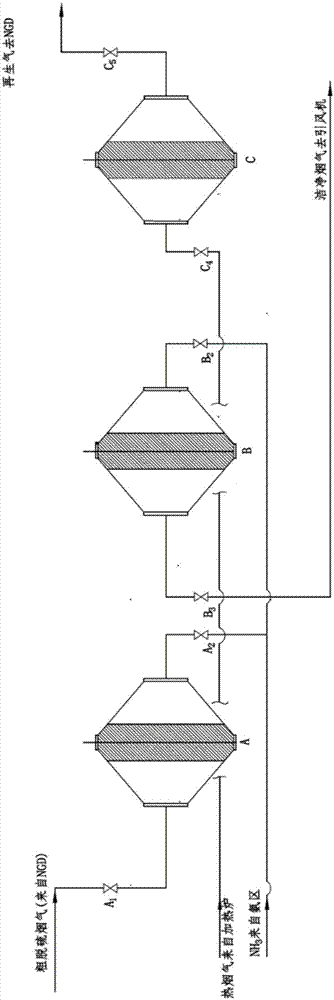

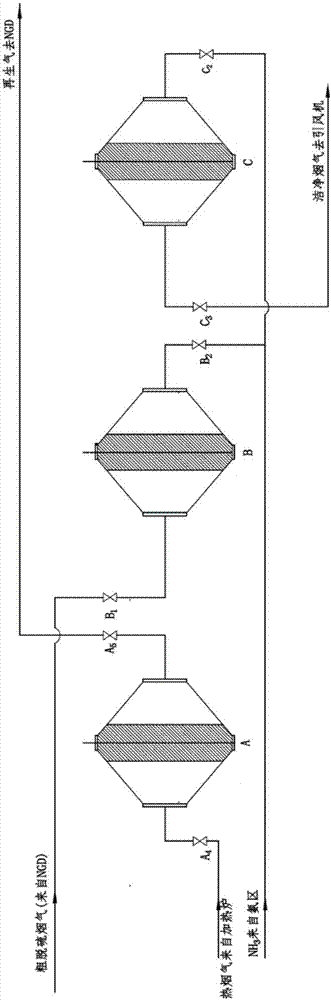

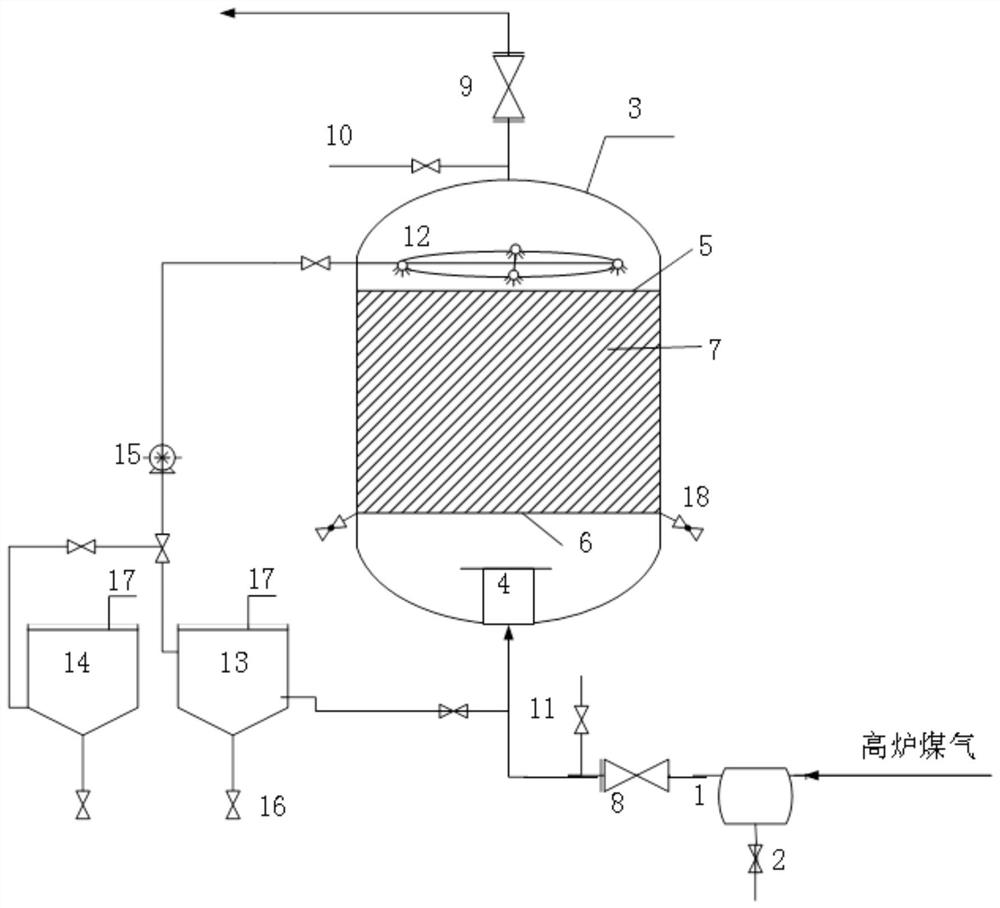

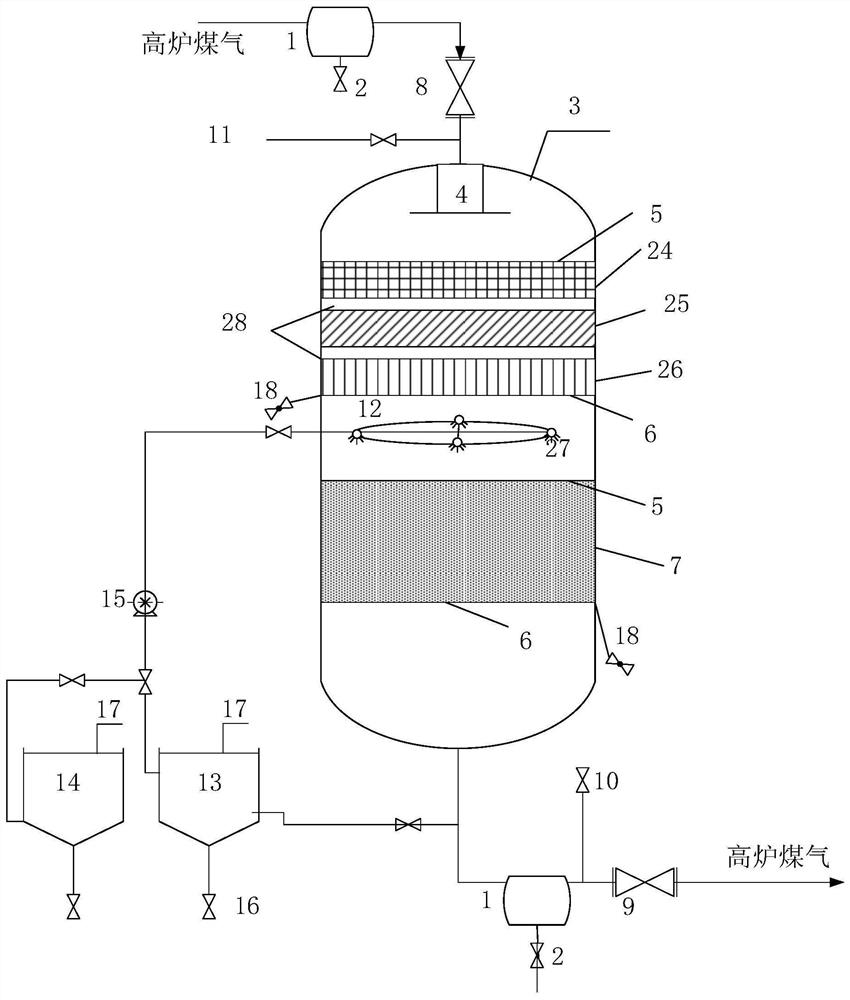

Low-temperature carbon-based combined desulfurization and denitrification flue gas system and use method thereof

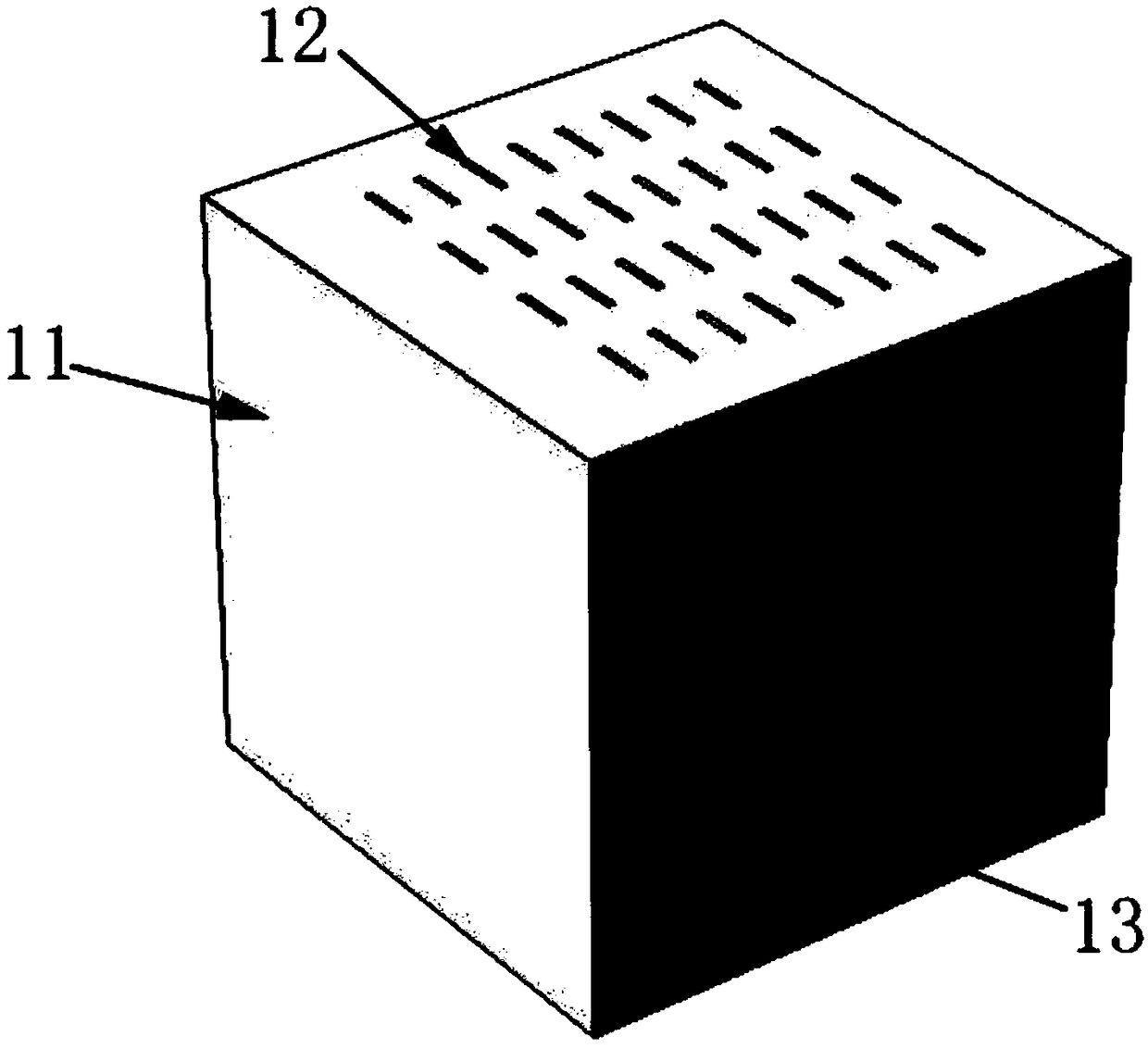

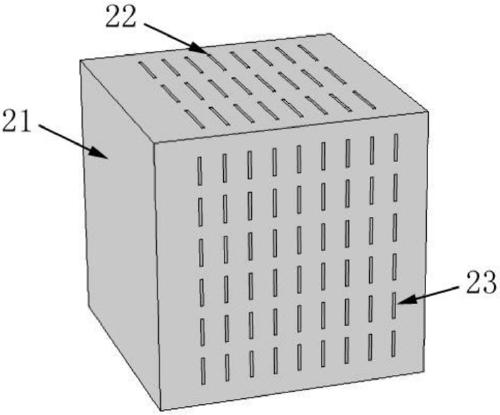

PendingCN107321135AReduce the impactIncrease the windward areaGas treatmentDispersed particle separationActivated carbonFlue gas

The invention relates to a low-temperature carbon-based combined desulfurization and denitrification flue gas system and a use method thereof. The system comprises a first reactor, a second reactor and a third reactor and the reactors have the same structures. Each one of the first reactor, the second reactor and the third reactor comprises a central carbon-based bed, left and right air distribution grilles and left and right gas collection tanks in the outer side. The carbon-based bed is filled with an activated carbon material. The system utilizes the three same reactors and has functions of fine desulfurization, denitration and regeneration. The fine desulfurization and denitratio processes are connected in series and are connected to the regeneration process in parallel and the processes are carried out simultaneously so that in-situ regeneration is really realized. The reactor comprises the central carbon-based bed, left and right air distribution grilles and left and right gas collection tanks. The bed has a large windward area so that uniform gas distribution in the work and regeneration processes is guaranteed and a floor space is reduced. The system further improves the desulfurization and denitrification performances of the activated carbon material.

Owner:CHINA COAL RES INST CCRI ENERGY SAVING TECH CO LTD +1

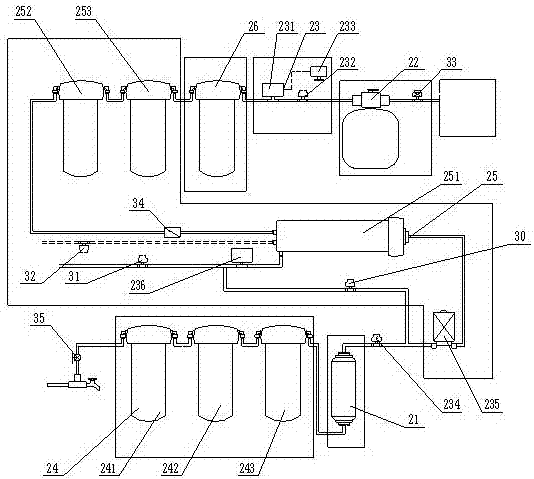

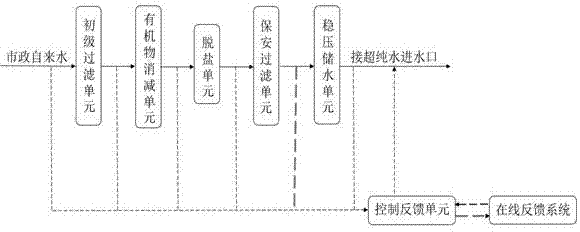

Pretreatment equipment for water supply of ultra-pure water machine

ActiveCN107162079AImprove water qualityGuaranteed stabilityWater treatment parameter controlWater/sewage treatment by irradiationElectricityWater storage tank

The invention discloses pretreatment equipment for water supply of an ultra-pure water machine. The equipment comprises a pretreatment system and a water storage system, wherein the pretreatment system comprises a water treatment reactor; the water storage system comprises a water storage tank; a water inlet end of the water treatment reactor is communicated and connected with a tap water pipe; a valve switch is also arranged on a water pipeline between the tap water pipe and the water treatment reactor; a water outlet end of the water treatment reactor is communicated and connected with a water inlet end of the water storage tank; a water outlet end of the water storage tank is communicated and connected with a water inlet end of the ultra-pure water machine; the equipment further comprises a control feedback unit; the control feedback unit comprises an electromagnetic valve and a resistivity monitoring device; the resistivity monitoring device and the electromagnetic valve are connected in series with a water pipeline between the water treatment reactor and the water storage tank; the electromagnetic valve is located on a water outlet side of the resistivity monitoring device; the resistivity monitoring device and the electromagnetic valve are electrically connected with an on-line feedback system. The equipment can improve influent quality of the ultra-pure water machine and prolong the service life of the ultra-pure water machine.

Owner:CHONGQING XINHE QIYUE TECH CO LTD

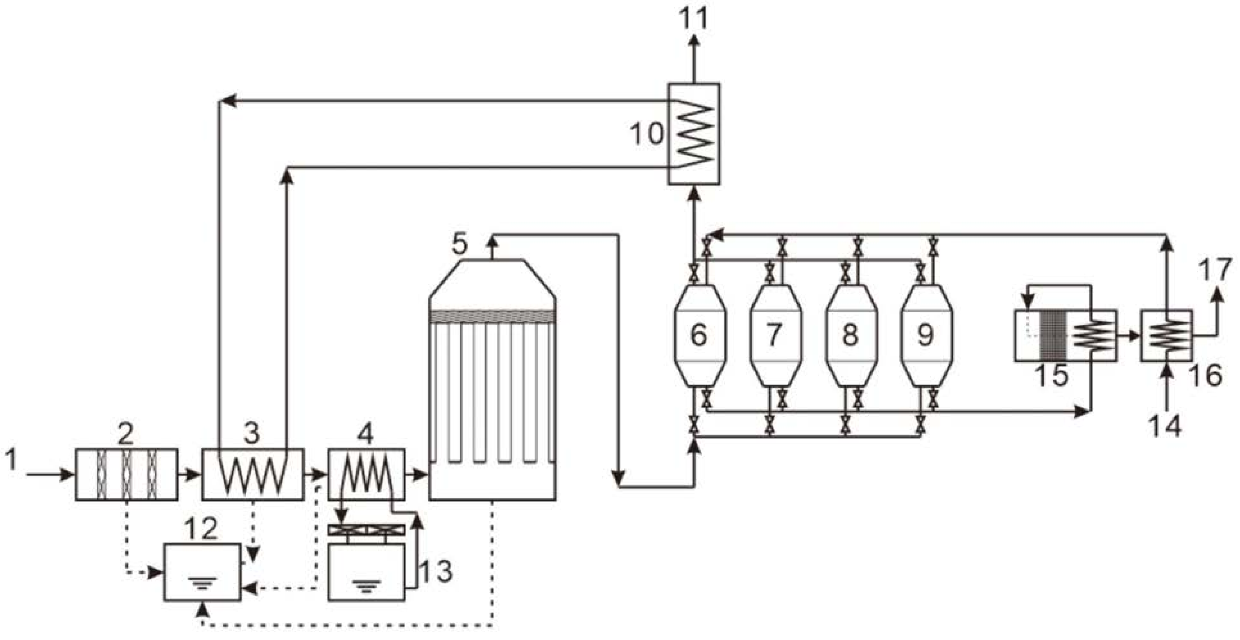

Equipment for removal of multiple pollutants in waste gas of setting machine and in-situ regeneration of adsorbent and method of equipment

The invention relates to equipment for removal of multiple pollutants in waste gas of a setting machine and in-situ regeneration of an adsorbent. The equipment includes a dust-removing oily fume-removing device, a flue gas de-whitening device, a VOC adsorption regeneration device and an oil-water separation device; the dust-removing oily fume-removing device comprises a filter and a wet electrostatic precipitator, the flue gas de-whitening device includes a first-stage gas-water heat exchanger, a third-stage gas-water heat exchanger, a second-stage gas-water heat exchanger, and a water coolingtower, the VOC adsorption regeneration device includes an adsorption tank, a catalytic burner and a gas-gas heat exchanger, and the oil-water separation device includes an oil-water separator; an inlet of the filter is connected with the waste gas of the setting machine; an inlet of the first-stage gas-water heat exchanger is connected with an outlet of the filter, and the first-stage gas-water heat exchanger is connected with the third-stage gas-water heat exchanger located at an outlet of the adsorption tank. The equipment has the following beneficial effects: 1) simultaneous removal and ''de-whitening'' of the multiple pollutants are realized; 2) the generation amount of waste water is reduced; and 3) the adsorbent is regenerated in situ.

Owner:ZHEJIANG TIANDI ENVIRONMENTAL PROTECTION TECH CO LTD +1

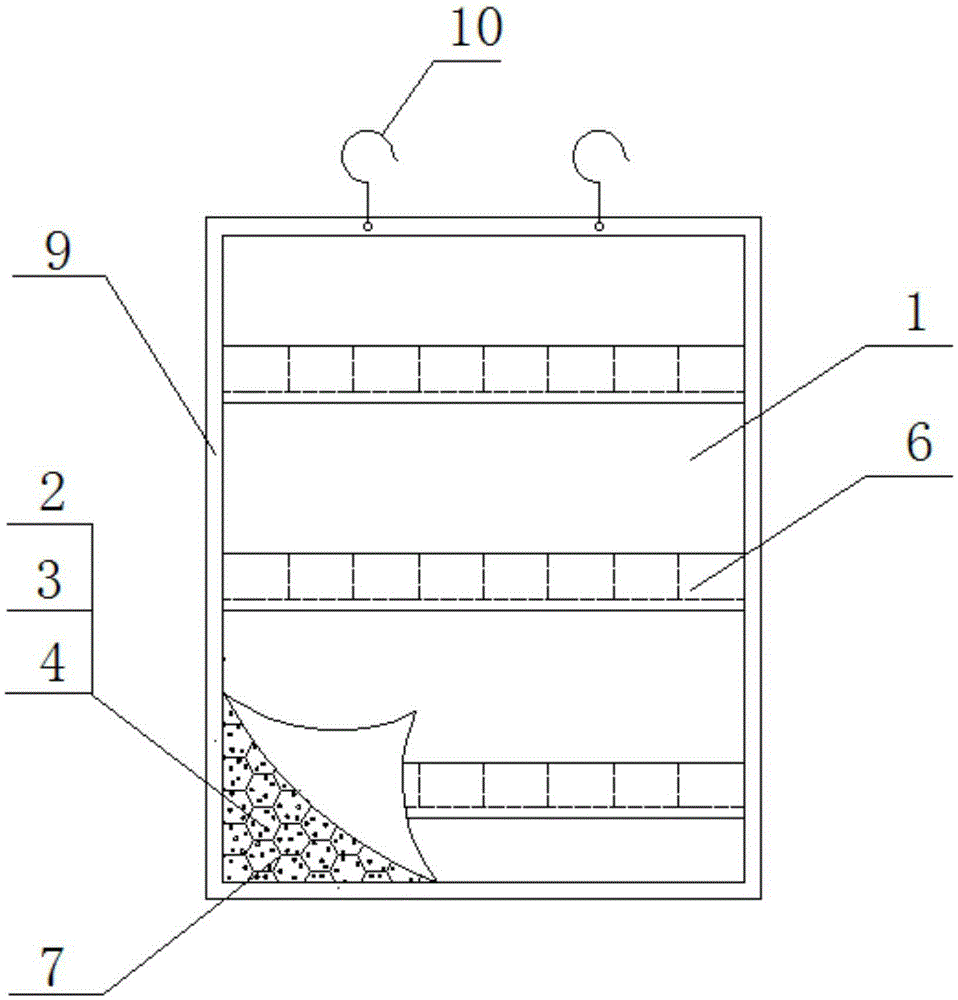

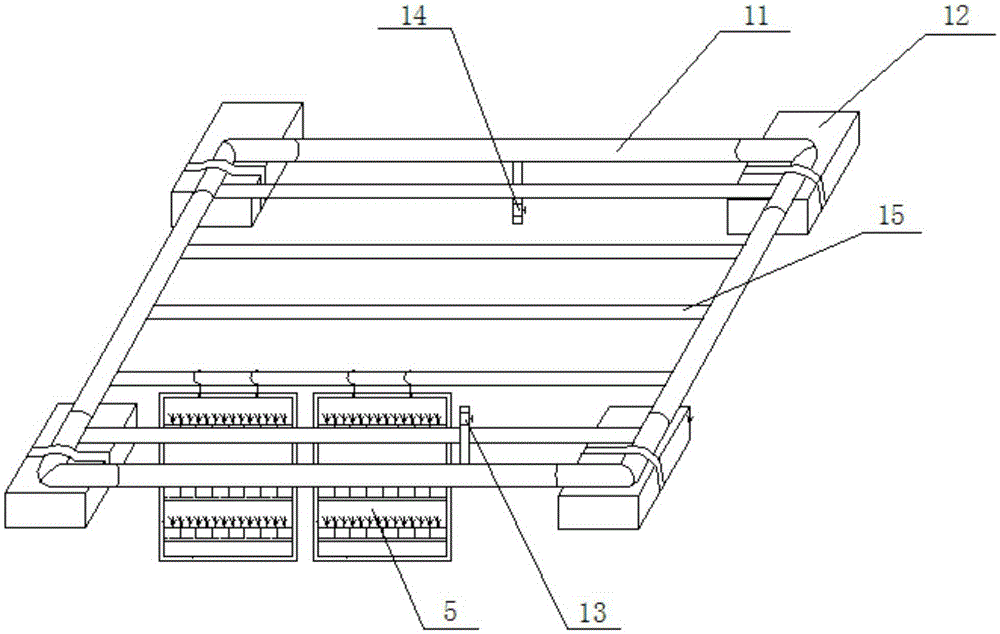

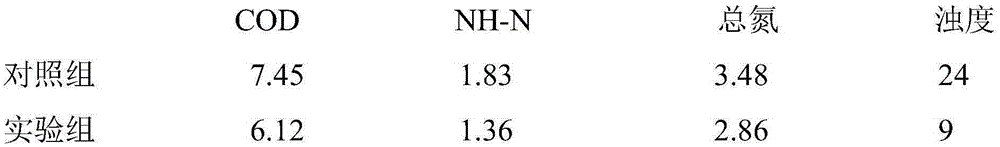

Suspension type ecological restoration plate and multi-medium artificial mattress comprising same

ActiveCN105399220AEfficient decomposition and removalAchieve in situ regenerationBiological treatment apparatusFiberEngineering

The invention relates to a suspension type ecological restoration plate and a multi-medium artificial mattress comprising the same. The suspension type ecological restoration plate is an ecological restoration apparatus, which comprises functions of multi-medium adsorption, microbial degradation, and rapid growth of submerged plants. In the prior art, the ecological bag is used, the area of wall of pool for submerge plants is limited, rooting is difficult on the wall, and the growth of submerged plants is influenced. The provided ecological restoration plate can solve the problems mentioned above. The ecological restoration plate comprises a frame and a suspension ring and also comprises a chemical fiber silk screen, granular active carbon, zeolite particles, degradable starch particles, a plurality of plant bags, and a beehive plate; the beehive plate is arranged in the frame, granular active carbon, zeolite particles, and degradable starch particles are filled in a beehive arranged on the beehive plate, the chemical fiber silk screen is arranged on two surfaces of the beehive plate, and the plant bags are stitched on the external surface of the chemical fiber silk screen. The multi-medium artificial mattress comprises a mattress support, a floating body, a valve, a rod, and a suspension type ecological restoration plate. The suspension type ecological restoration plate is hung on the rod.

Owner:山西卫安环保科技股份有限公司

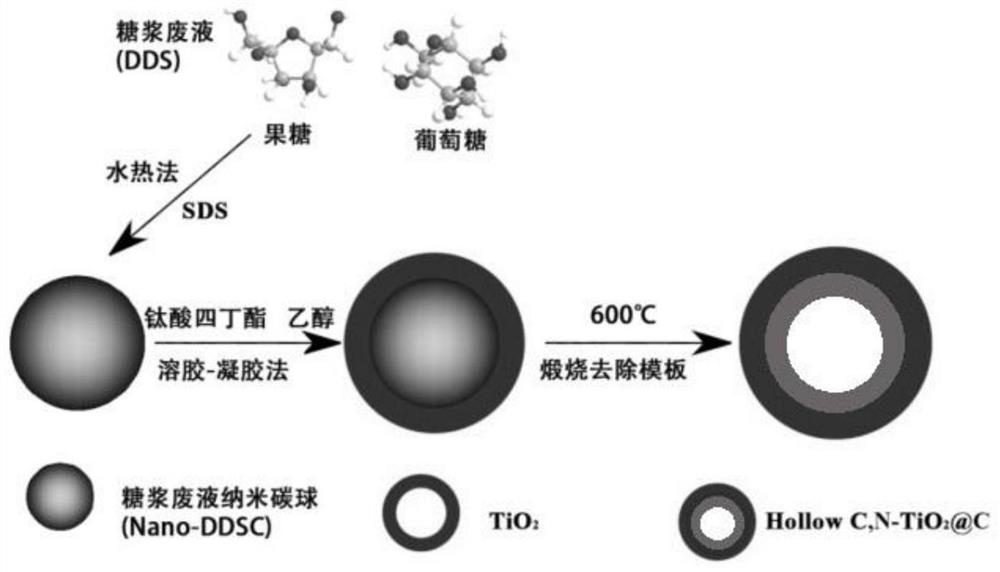

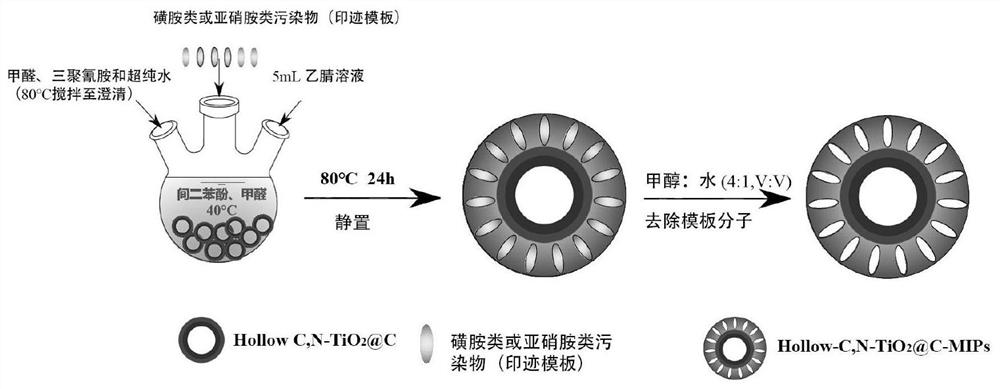

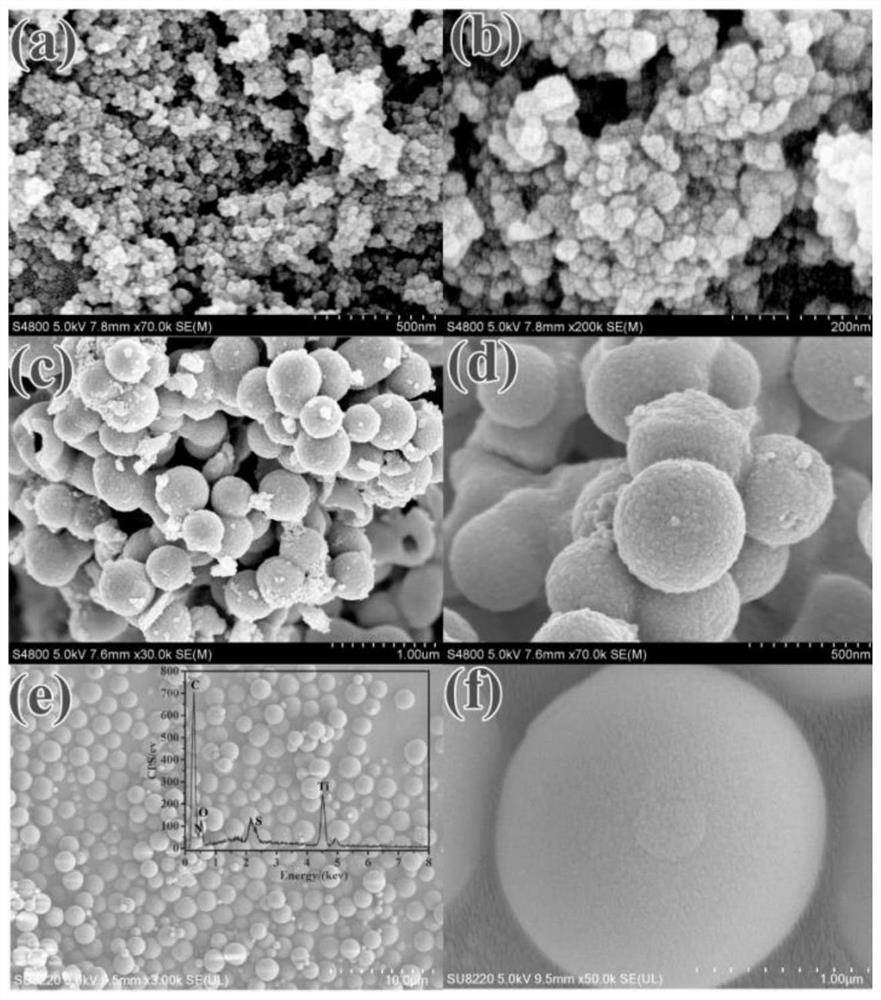

Preparation method of targeted adsorption in-situ regeneration hydrophilic nano molecularly imprinted material

ActiveCN111659438AReduce dosageEasy to operateWater/sewage treatment by irradiationWater treatment compoundsBinding siteSulfanilamide

The invention relates to the field of molecularly imprinted materials, and discloses a preparation method of a targeted adsorption in-situ regeneration hydrophilic nano molecularly imprinted material.The preparation method comprises the following steps: preparing multi-group nano carbon spheres from syrup wastewater, synthesizing carbon and nitrogen co-doped nano TiO2 carbon spheres on the surfaces of the nano carbon spheres in situ by adopting a sol-gel method, and calcining to remove cores to form a hollow structure, thereby enhancing the yield and specific surface area of the surface molecularly imprinted polymer, and having multiple binding sites and high mass transfer rate; using sulfanilamide and nitrosamine pollutants as target molecules, using resorcinol and melamine as bifunctional monomers, using a formaldehyde aqueous solution and TiO2 as double cross-linking agents, and using acetonitrile i as a pore-forming agent to form a carbon nanosphere surface molecularly imprinted hollow material so that the specific surface area of the molecularly imprinted material is increased, higher targeted adsorption capacity is achieved, operation is easy, and the use amount of chemicalagents is small; with the use of C, N-TiO2 photocatalytic material in the material, visible light is directly utilized to catalyze and degrade target molecules, and in-situ regeneration and repeated utilization of the molecularly imprinted material are realized.

Owner:MINNAN NORMAL UNIV

A kind of genetic recombination engineering bacteria and its application in the catalytic synthesis of d-pantolactone

ActiveCN110452861BImprove catalytic stabilityAchieve in situ regenerationBacteriaMicroorganism based processesEscherichia coliNucleotide

Owner:HANGZHOU NORMAL UNIVERSITY

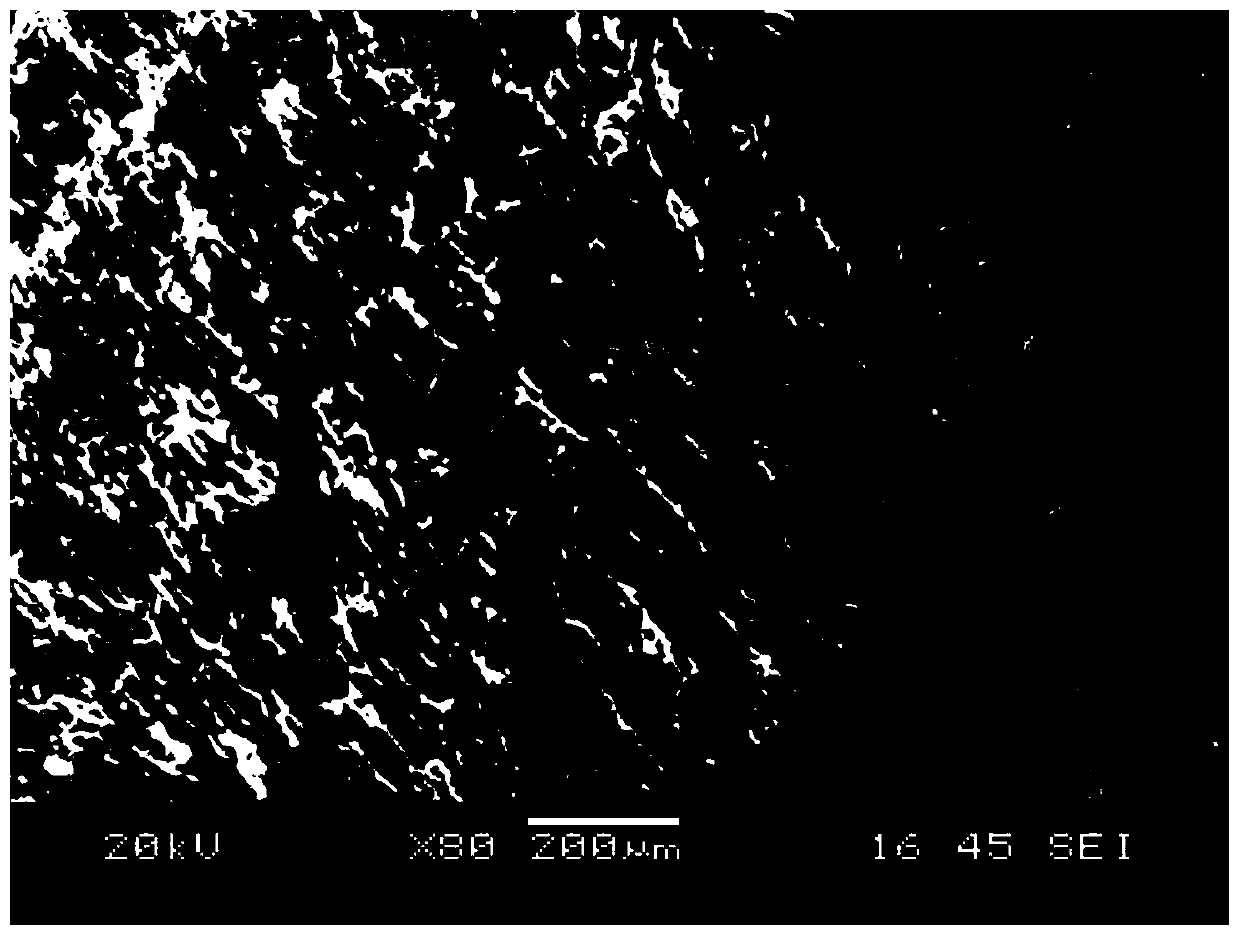

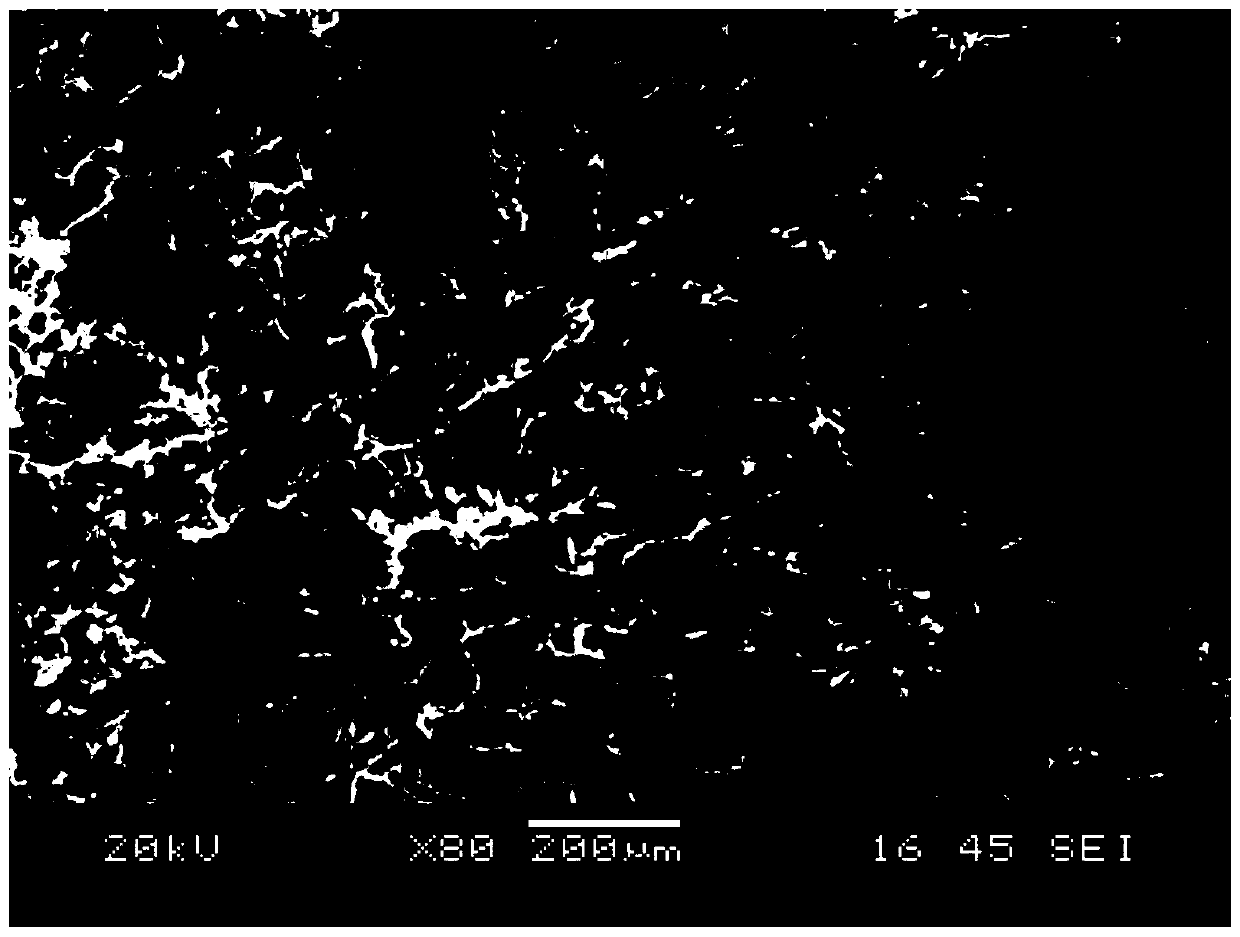

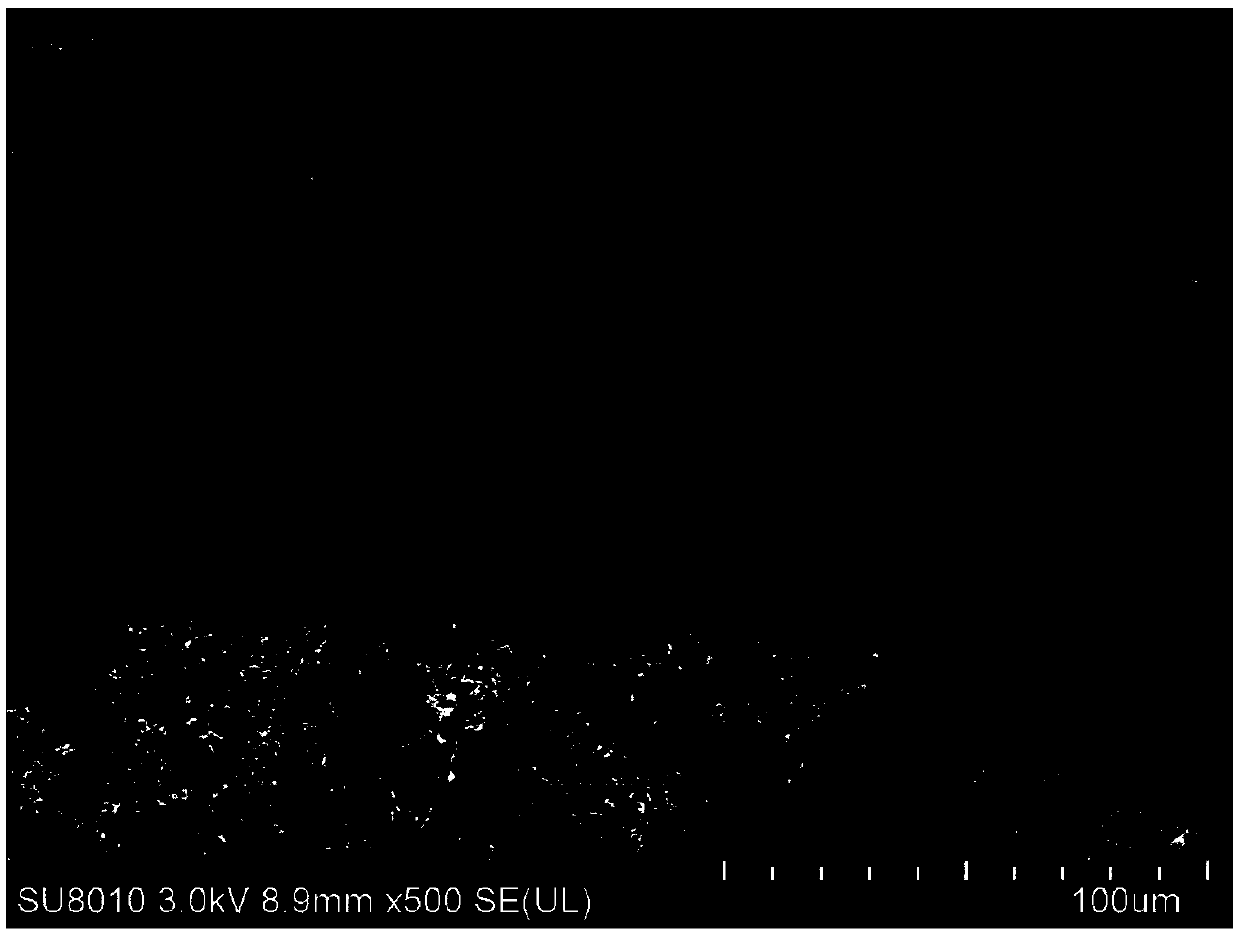

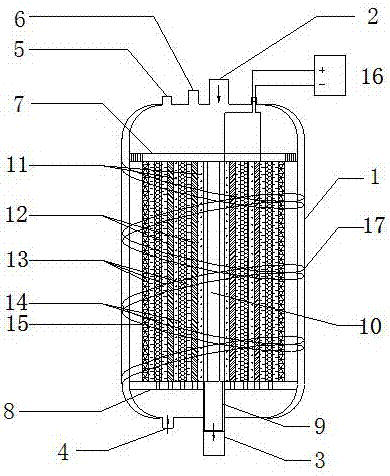

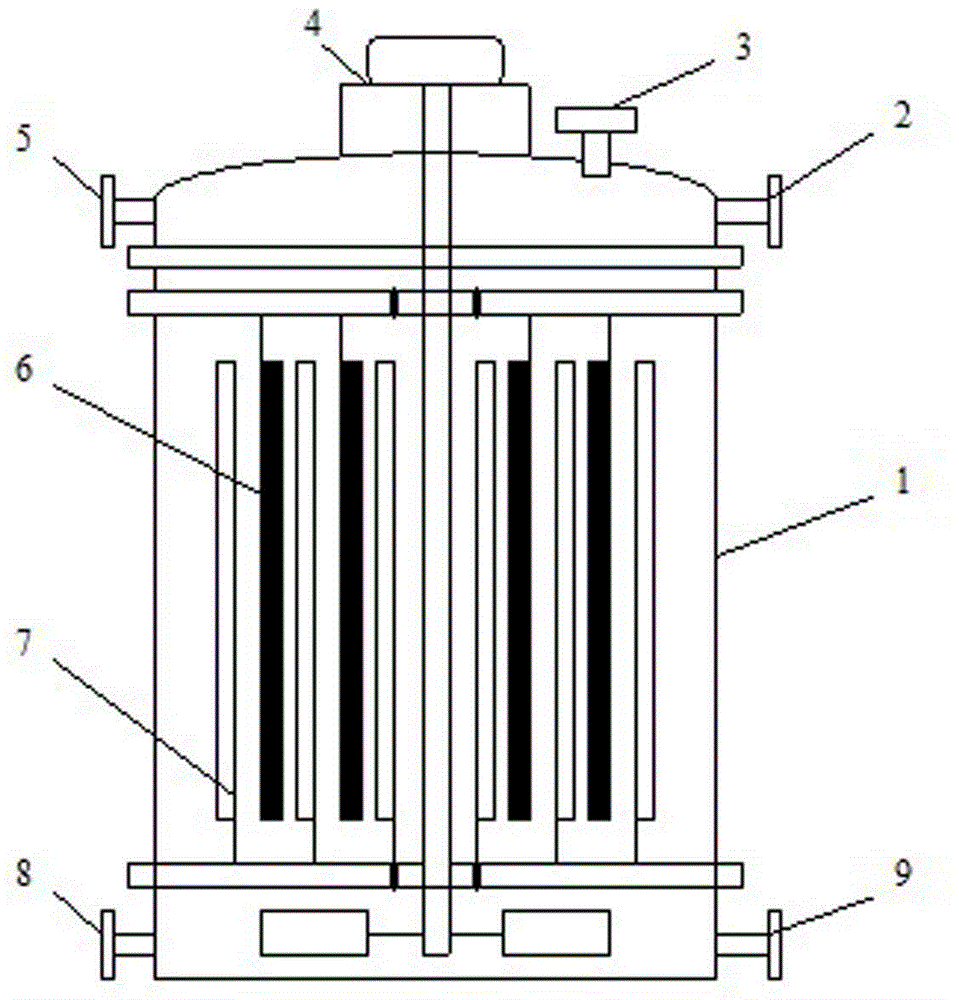

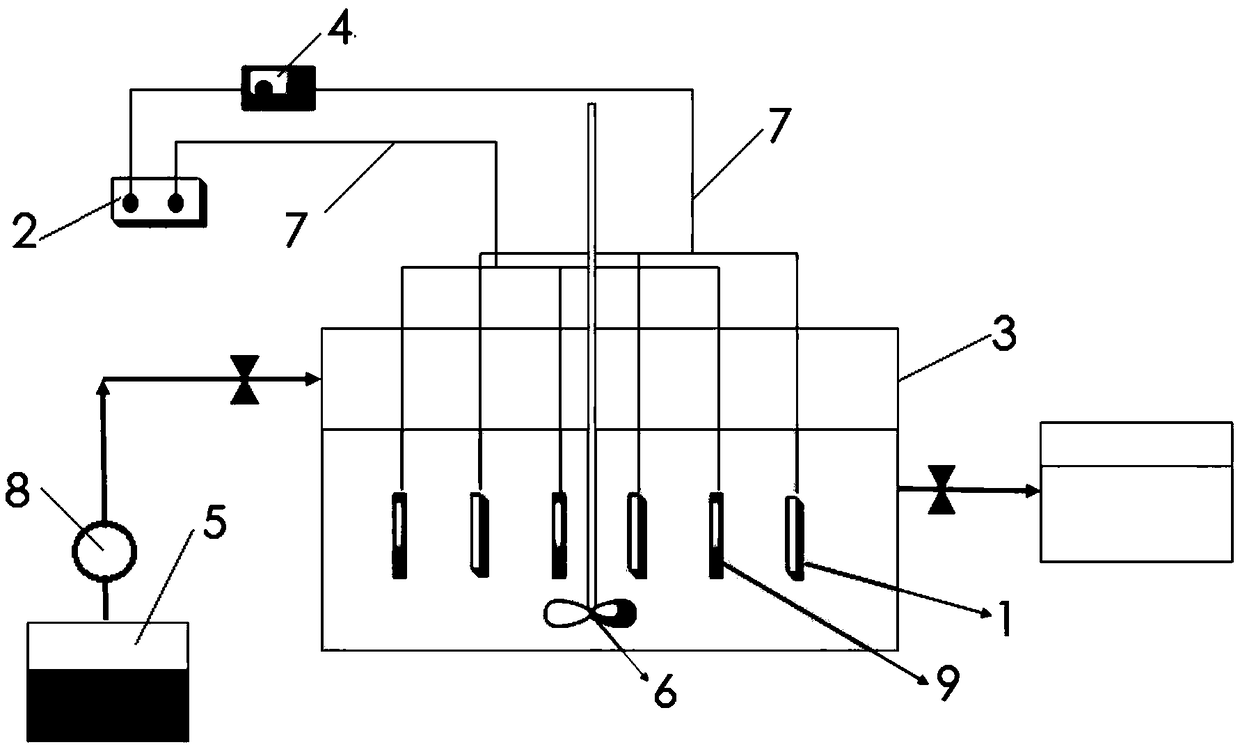

Activated carbon fiber for treating oily wastewater as well as regeneration method and device of activated carbon fiber

ActiveCN103435132BAdjustable number of groupsEasy to install and replaceWater/sewage treatmentElectrochemical responseElectrolysis

The invention discloses a method and device for treating oily wastewater with activated carbon fiber and its regeneration method and device. Specifically, the method disclosed in the invention uses an electrochemical reaction device in which activated carbon fiber felt is used as the anode and mesh-shaped titanium metal is used as the cathode. The combination of adsorption-electrolysis-desorption of oil in oily wastewater and regeneration of activated carbon fibers was studied. This electrochemical reaction device is composed of a reactor, an electric mixer and an externally connected regulated DC power supply. The reactor is equipped with multiple sets of detachable anodes and cathodes. The anode is composed of activated carbon fiber felt as the main body and titanium-based metal oxide as the support. The net-like pure titanium metal is the cathode electrode, and the anode and cathode groups are alternately connected by wires. The power supply and the number of electrode groups can be disassembled to increase or decrease, and the number of electrode groups can be adjusted according to the processing requirements. Compared with the existing technology, the method of the present invention realizes the integration of activated carbon fiber electrochemical treatment of oily wastewater and its in-situ regeneration technology, prolongs the regeneration cycle, reduces the process flow and secondary pollution, is easy to operate and control, and is convenient industrial applications.

Owner:北京中能环科技术发展有限公司

Plant in-situ regeneration method and application thereof in genetic transformation

InactiveCN102599052BAchieve in situ regenerationAchieve genetic transformationPlant tissue cultureHorticulture methodsPlant rootsBud

Owner:SHENYANG AGRI UNIV

Desulfurization and denitrification process utilizing microwave to intermittently irradiate activated carbon

InactiveCN102489107BReduce lossesAchieve in situ regenerationDispersed particle separationSulfur preparation/purificationActivated carbonPtru catalyst

A method of a microwave intermittently liquid activated carbon desulfurization and denitrification. It is used to adsorb or microwave radiation treatment of boiler flue gas with two or more adsorption beds equipped with activated carbon particles., The adsorption bed enters the working state, and the sulfur nitrogen oxide in the flue gas in the activated carbon has the activated carbon inhalation of the active carbon suction to be saturated after the working state.The smoke adsorption of the bed, the recycled recycled state adsorption bed adopts microwave liquid liquid carbon particles, and sulfur nitrogen oxides that are adsorbed on the surface of the activated carbon surface are quickly restored to monocular sulfur and nitrogen by charcoal at high temperatures.Alternate cycle.In order to reduce the reduction of degradation temperature and reduce carbon loss, metal oxides were used as a reaction catalyst.The present invention can greatly reduce the energy consumption of microwave radiation, reduce the loss of carbon, and achieve the regeneration of activated carbon in situ. It has the characteristics of good removal effect, short activated carbon regeneration time, low removal cost, high recovery rate, and easy industrialization implementation.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

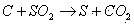

A Fe3O4/Ag@Si three-dimensional composite electrode, a preparation method thereof and an advanced oxidation integrated technical system

ActiveCN108751378AAchieve in situ regenerationRealize the use effectWater contaminantsWater/sewage treatment using germicide/oligodynamic-processComposite electrodeElectrolysis

The invention relates to a Fe3O4 / Ag@Si three-dimensional composite electrode, a preparation method thereof and an advanced oxidation integrated technical system, and belongs to the technical field ofenvironmental functional material synthesis and sewage treatment. The composite electrode is prepared through growing three-dimensional dendritic elemental silver on P-type boron-doped monocrystallinesilicon and loading the three-dimensional dendritic elemental silver with Fe3O4. The composite electrode is used for electrolysis and catalysis of persulfates and organic pollutants in water can be removed through advanced oxidation.

Owner:南大盐城环境工程有限公司

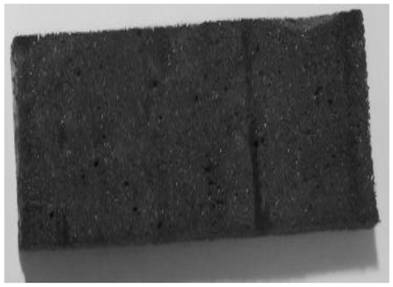

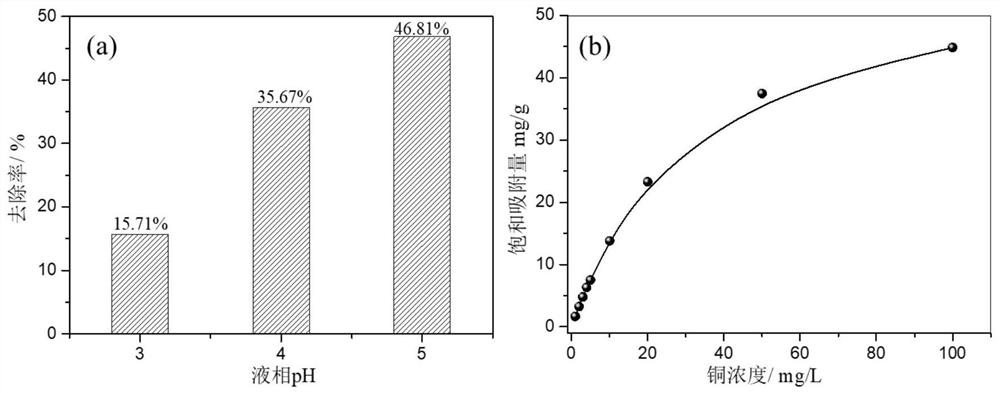

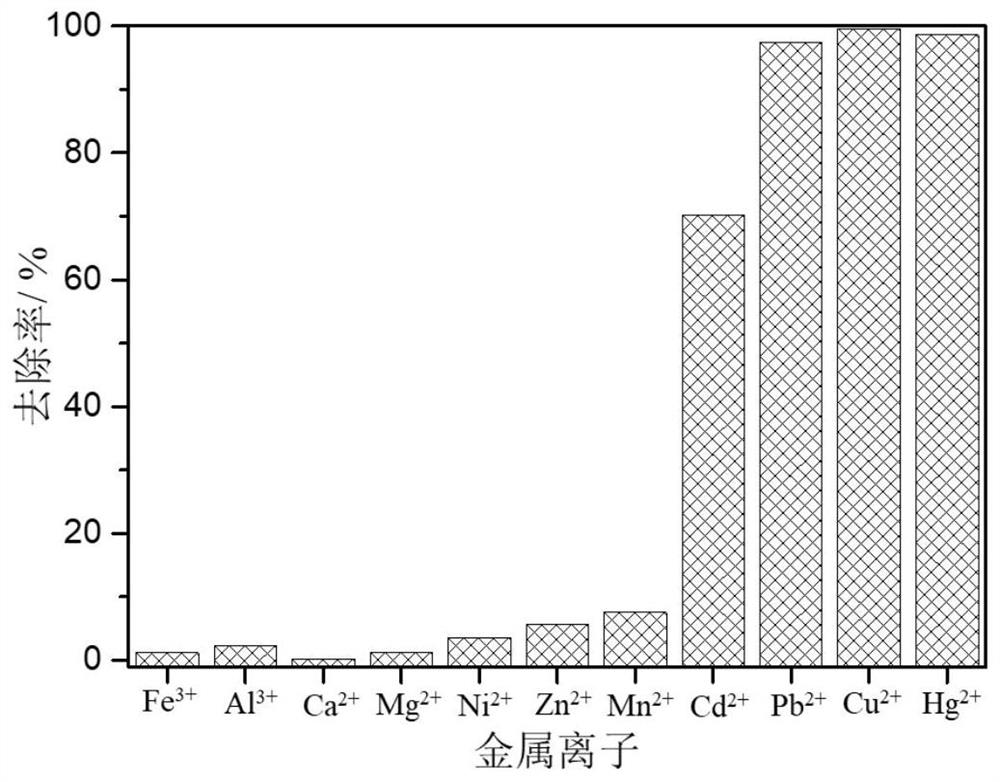

Selective heavy metal ion adsorption material and preparation method and application thereof

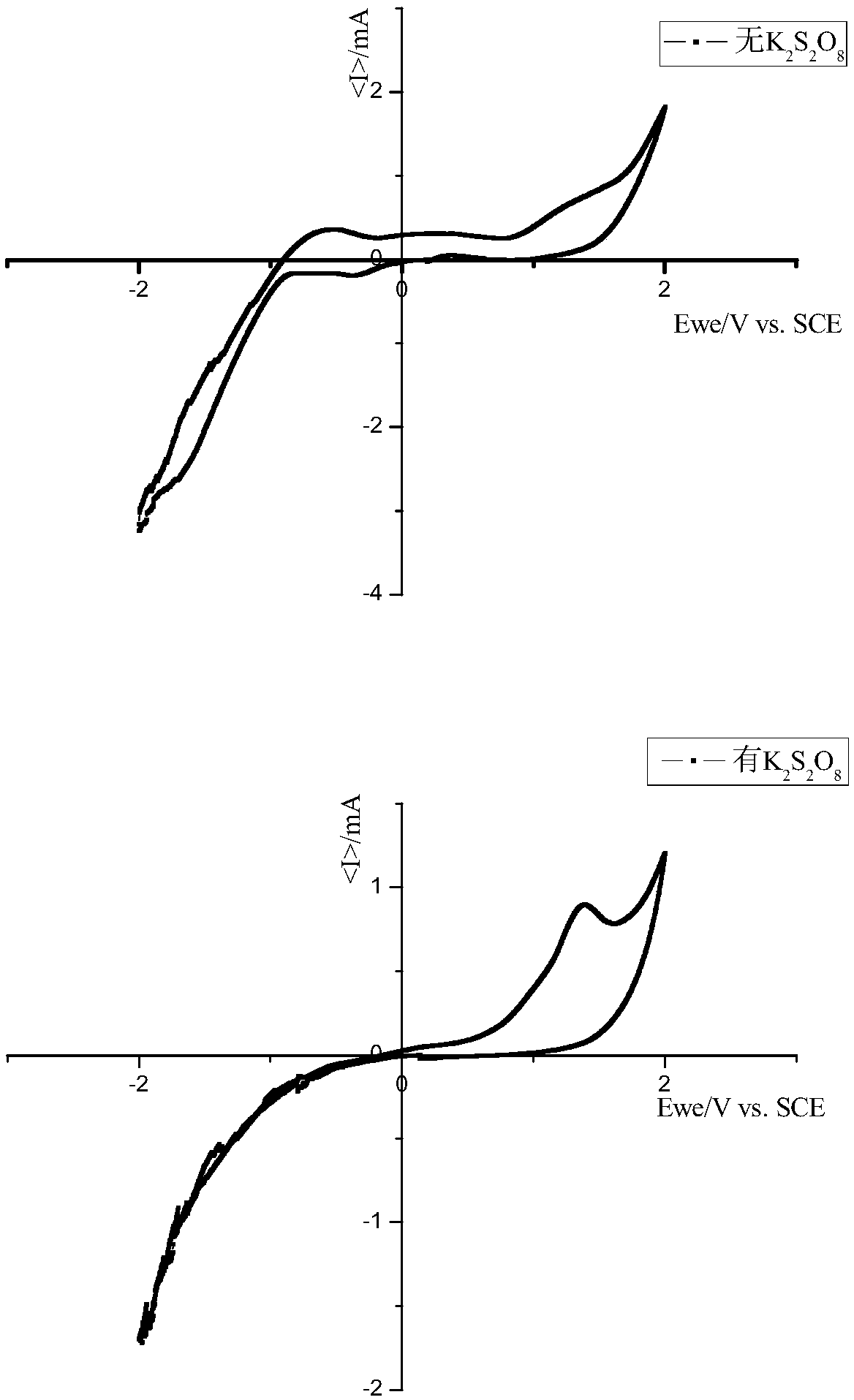

ActiveCN111672487AHigh selectivityGood choiceOther chemical processesWater contaminantsAcrylonitrileElectrochemical anodization

The invention discloses a selective heavy metal ion adsorption material polyacrylonitrile-sulfur@melamine sponge which is prepared by forming a polyacrylonitrile-sulfur polymer through a high-temperature polymerization reaction of polyacrylonitrile and sulfur and fixing polyacrylonitrile-sulfur in a melamine sponge skeleton structure through a hot solvent bonding method. The polyacrylonitrile-sulfur@melamine sponge has selective adsorbability, the removal rate of copper in copper-containing wastewater is high, an electrolytic tank is formed by the polyacrylonitrile-sulfur@melamine sponge, a cathode, an anode and an electrolyte solution, copper-sulfur efficient separation is carried out through an electrochemical anodic oxidation reaction to regenerate an adsorption material, and copper deposition recovery is carried out through a cathodic reduction reaction. Environment-friendly, efficient and low-cost up-to-standard treatment and resource recycling of copper in copper-containing wastewater are achieved, the preparation raw materials are wide in source, cheap and easy to obtain, the preparation process is simple, and large-scale production is facilitated.

Owner:CHINA UNIV OF MINING & TECH

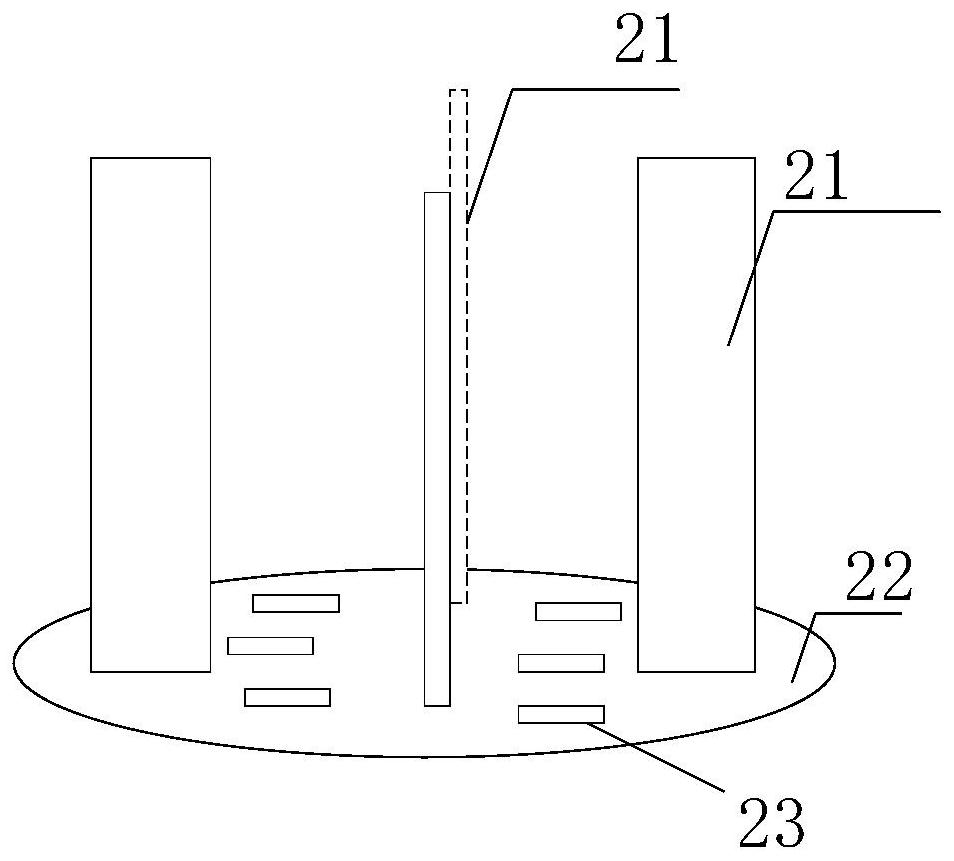

Device and method for converting organic sulfur in blast furnace gas and method for regenerating organic sulfur conversion catalyst

ActiveCN114130187AReduce pressure dropImprove conversion efficiencyDispersed particle separationCatalyst regeneration/reactivationPtru catalystPhysical chemistry

The invention relates to the technical field of blast furnace gas desulfurization, in particular to a blast furnace gas organic sulfur conversion device and method and an organic sulfur conversion catalyst regeneration method. The conversion device comprises a reactor containing a gas distributor and at least one catalyst bed layer, a spraying regeneration system and at least one liquid collection bag, the catalyst bed layer comprises an organic sulfur conversion catalyst bed layer, the spraying regeneration system is used for cleaning and / or regenerating the catalyst bed layer, and the liquid collection bag is used for collecting the organic sulfur conversion catalyst bed layer. The liquid collecting bag is used for collecting water in the blast furnace gas and optional liquid for cleaning and / or regenerating the catalyst bed layer; wherein the ratio of the height of the catalyst bed layer to the diameter of the reactor is (0.1-2): 1. The conversion device provided by the invention can significantly reduce the pressure drop of blast furnace gas passing through the catalyst bed layer, improve the conversion efficiency of organic sulfur, and realize in-situ regeneration of the organic sulfur conversion catalyst, thereby ensuring long-term stable operation of the blast furnace gas conversion device.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for treating coating waste gas by manganese-loaded expanded graphite adsorption coupled catalytic ozonation

InactiveCN111068513AMany surface active sitesStrong oxidation abilityGas treatmentDispersed particle separationParticulatesCatalytic oxidation

The invention discloses a method for treating coating waste gas by manganese-loaded expanded graphite adsorption coupled catalytic ozonation, and is characterized in that the coating waste gas is introduced into a wet oxidation spray washing tower taking the manganese-loaded expanded graphite as a filler; ozone is introduced at the same time, adsorbing and catalyzing are carried out on the ozone to oxidize VOCs by utilizing manganese-loaded expanded graphite to mineralize the VOCs into carbon dioxide and water, and particles in the waste gas are removed by utilizing the washing and agglomeration effects of spray water which is used for dissolving the ozone and has chemical oxidation activity; then the waste gas enters a demisting purification tower of a manganese-loaded expanded graphite packing layer to remove fog drops brought out of a spray washing tower, the VOCs removal rate is further increased through the adsorption and catalytic oxidation effects of manganese-loaded expanded graphite, and finally the waste gas is discharged through a discharge tower. The removal rate of VOCs reaches 98% or above, the removal rate of particles reaches 99.5% or above, and secondary pollutionis avoided. The manganese-loaded expanded graphite is stable in adsorption and catalytic performance and can be used for a long time.

Owner:DONGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com