Bone cement based on bio-based polyurethane composite degradable material and preparation method thereof

A technology for degrading materials and bone cement, which is used in tissue regeneration, medical science, prosthesis, etc. It can solve the problems of insufficient degradation rate capability, insufficient mechanical strength of bone cement, and inability to achieve autologous bone in situ regeneration, and achieve good biodegradation. The effect of good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

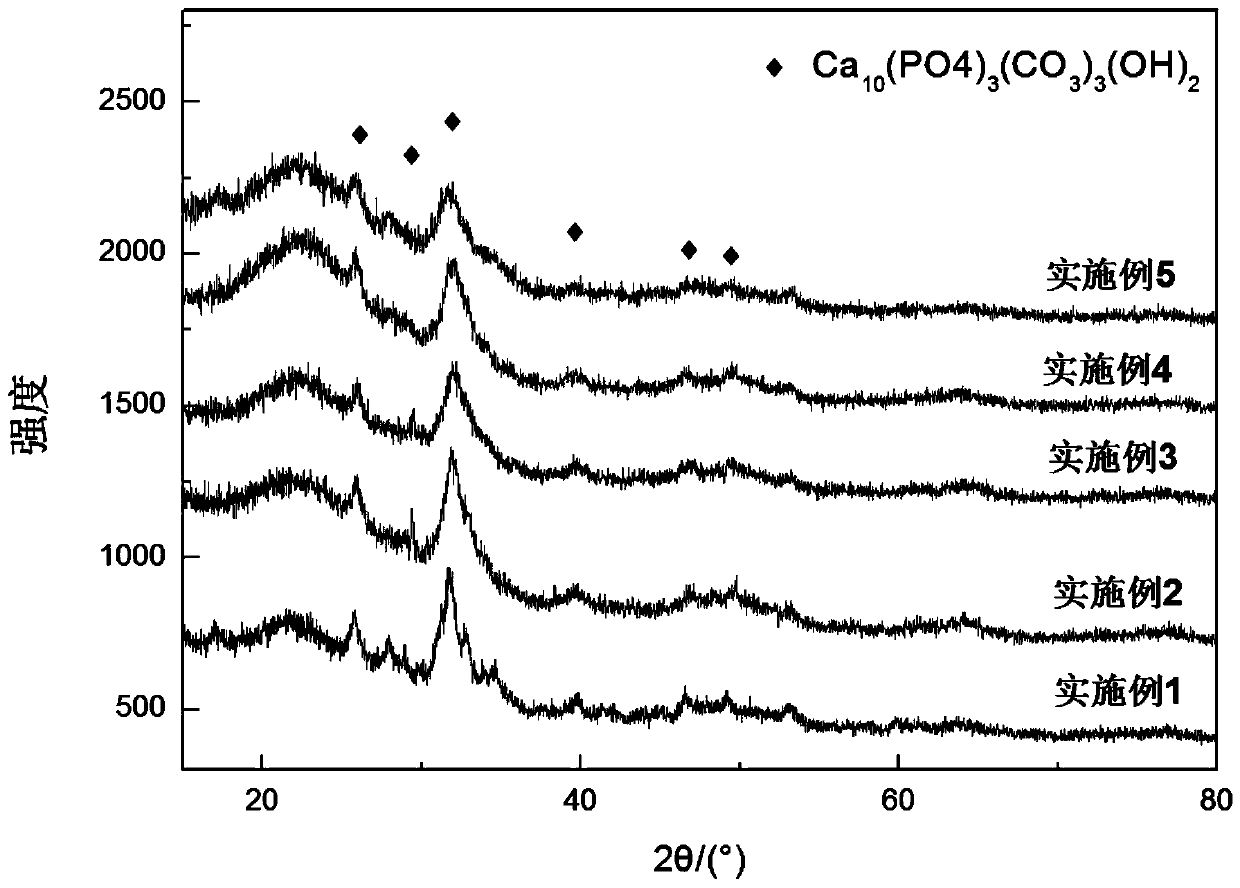

Examples

Embodiment 1

[0065] Prepare solid phase powder materials, bio-based polyurethane prepolymers, accelerators, initiators, polymerization inhibitors and other raw materials.

[0066] (1) The solid phase powder material accounts for 50% of the bone cement raw material mass sum, and the solid phase powder material of this embodiment is only the Regesi regenerated silicon material (that is, the Regesi regenerated silicon material accounts for 100% of the solid phase powder material gross weight ), in an environment of 25°C, the Regesi regenerated silicon powder material is screened for particle size, and the Regesi regenerated silicon powder body with a particle size of 10 μm-60 μm is used for subsequent use, and then the coupling agent KH570 (the molecular formula of KH570 is: CH 2 =C(CH 3 )COOC 3 h 6 Si(OCH 3 ) 3 ) Surface modification of the screened solid phase powder material, the specific modification method is as follows:

[0067] After ultrasonically mixing the solid phase powder, a...

Embodiment 2

[0086] Prepare solid phase powder materials, bio-based polyurethane prepolymers, accelerators, initiators, polymerization inhibitors and other raw materials.

[0087] (1) Solid-phase powder materials account for 50% of the total mass of bone cement raw materials. Weigh various powder materials according to the formula of solid-phase powder materials below, and measure the particle size of various powder materials in an environment of 25°C. Screening, select powder materials with a particle size of 10 μm-60 μm for use, and then use a coupling agent to carry out surface modification treatment on the screened solid phase powder materials. The specific modification method is as follows: modify the solid phase powder materials separately and then mix them, and use the same method as in Example 1 for modification.

[0088] According to mass percentage, the ingredients of solid phase powder materials are as follows:

[0089]

[0090](2) The initiator benzoyl peroxide and accelera...

Embodiment 3

[0096] Prepare solid phase powder materials, bio-based polyurethane prepolymers, accelerators, initiators, polymerization inhibitors and other raw materials.

[0097] (1) The solid phase powder accounts for 50% of the total mass of the bone cement. According to the mass proportion of each powder in the solid phase, the particle size of the powder material is screened in an environment of 25°C, and the particle size of the solid powder is optimized. : 10μm-60μm, use the coupling agent to modify the surface of the screened solid phase powder. The specific modification method is as follows: modify the solid phase powder materials separately and then mix them, and use the same method as in Example 1 for modification.

[0098] According to mass percentage, the ingredients of solid phase powder materials are as follows:

[0099] 45S5 bioactive glass powder 74%

[0100] Bioactive Glass 58S Reinforcing Fiber 5%

[0101] Hydroxyapatite 21%

[0102] (2) The initiator benzoyl peroxid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com