Patents

Literature

15229 results about "Solid phases" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Solid phase (plural solid phases) (physics) One of the three fundamental structural phases of matter in which the cohesive force of matter is strong enough to keep the molecules or atoms in the given positions, restraining the thermal mobility.

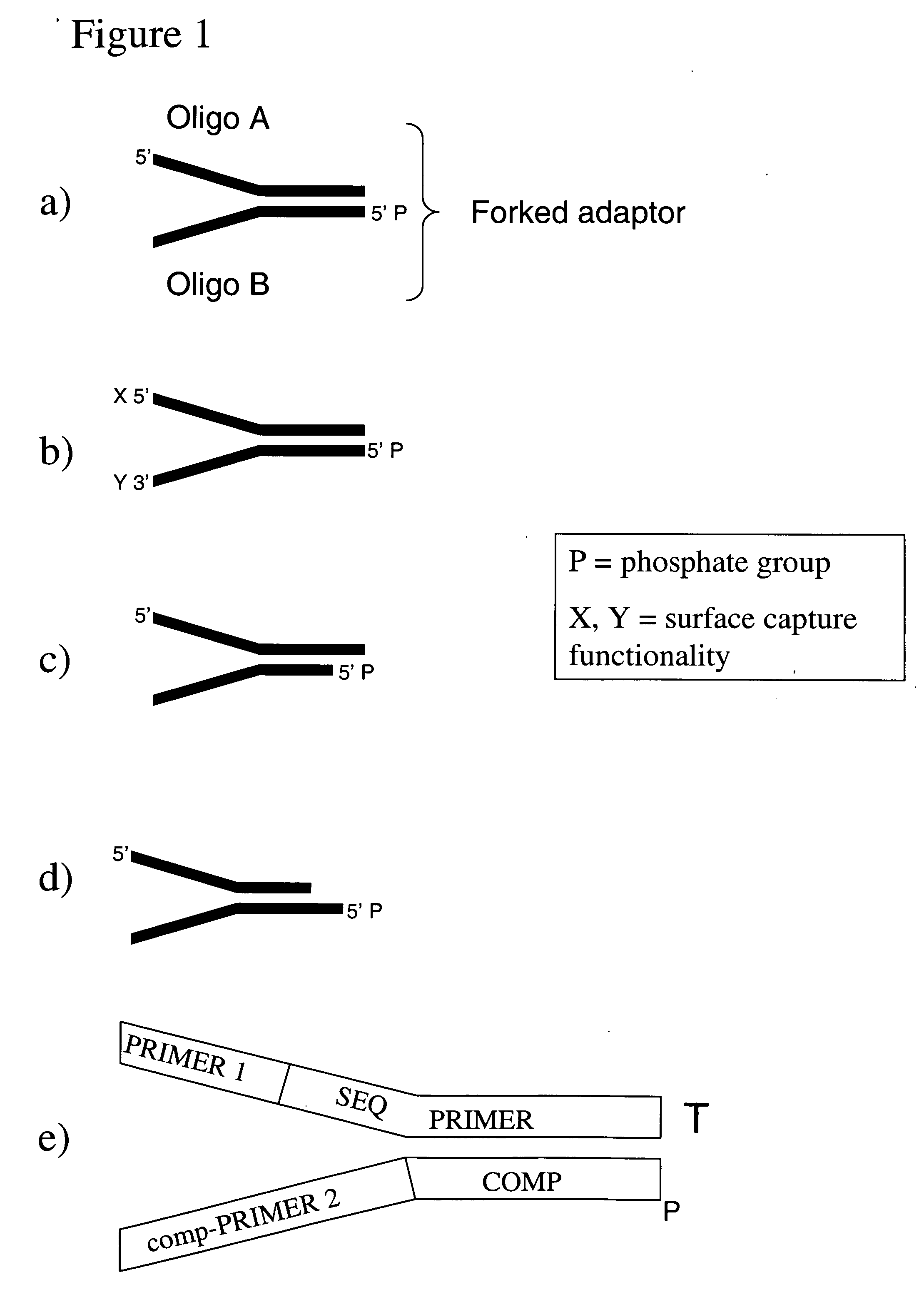

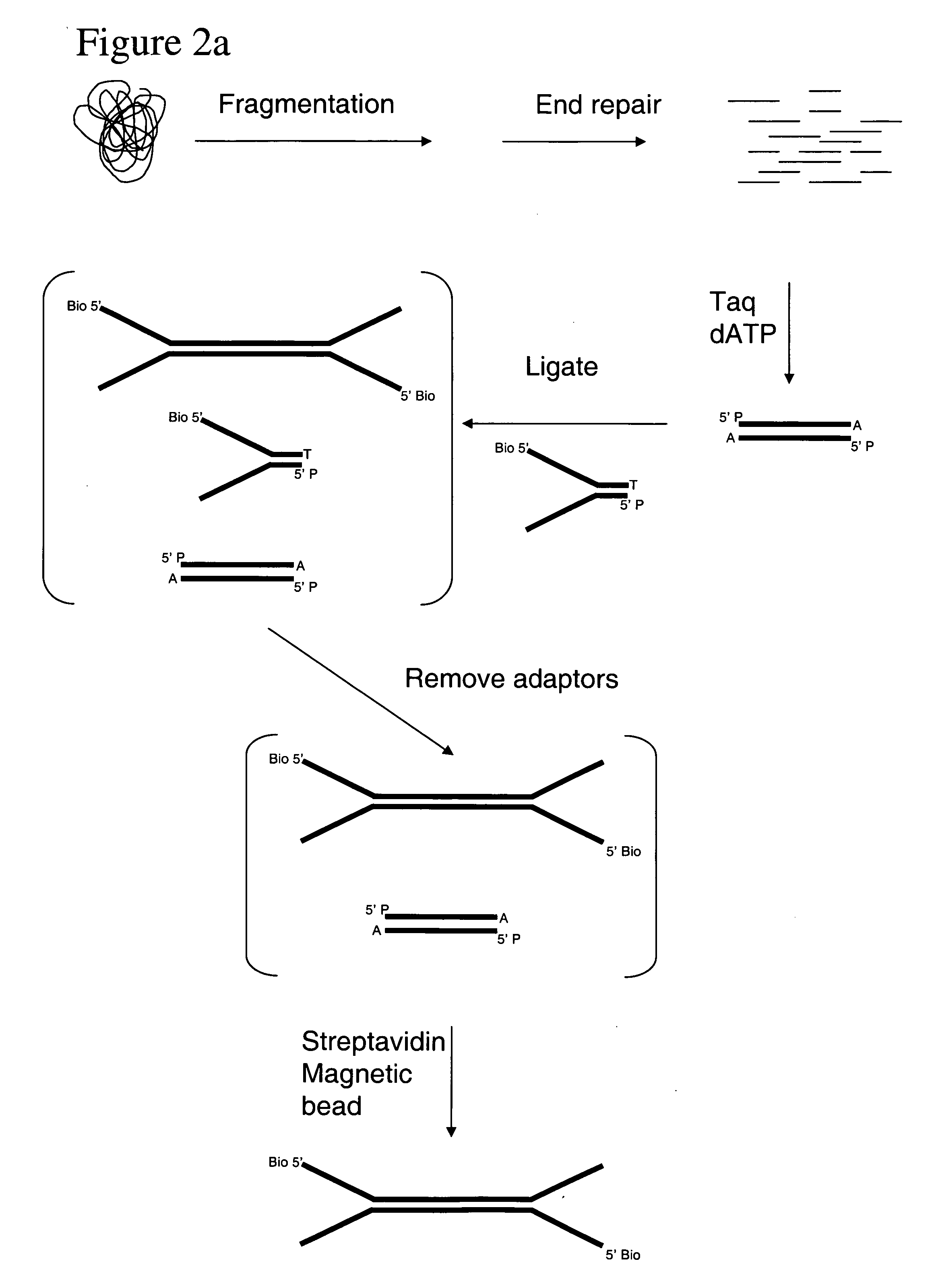

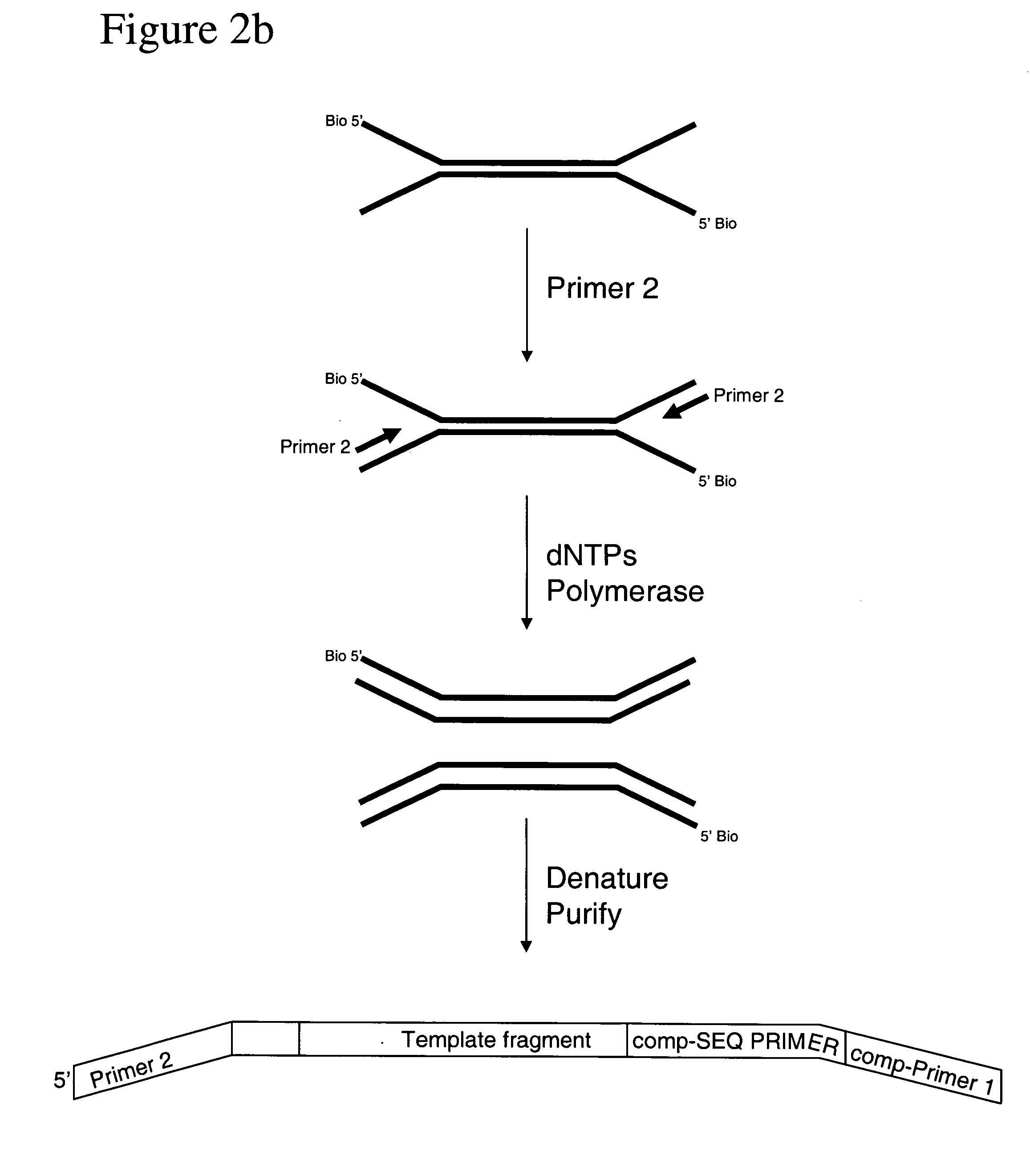

Method of preparing libraries of template polynucleotides

The present invention relates to a method for preparing a library of template polynucleotides and use thereof in methods of solid-phase nucleic acid amplification. More specifically, the invention relates to a method for preparing a library of template polynucleotides that have common sequences at their 5′ ends and at their 3′ ends.

Owner:ILLUMINA CAMBRIDGE LTD

Laundry multi-compartment pouch composition

InactiveUS20090011970A1Improve bleaching effectEasy to useDetergent materialsDetergent compounding agentsSolid componentWater soluble

This invention relates to a laundry pouch made from a water-soluble film and having at least two compartments, containing a solid component and a liquid component, wherein the solid phase contains a peroxide source and the liquid phase contains bleach activator. The present invention also relates to a method for treating laundry by placing the pouch, according to the present invention, in the drum of the washing machine.

Owner:THE PROCTER & GAMBLE COMPANY

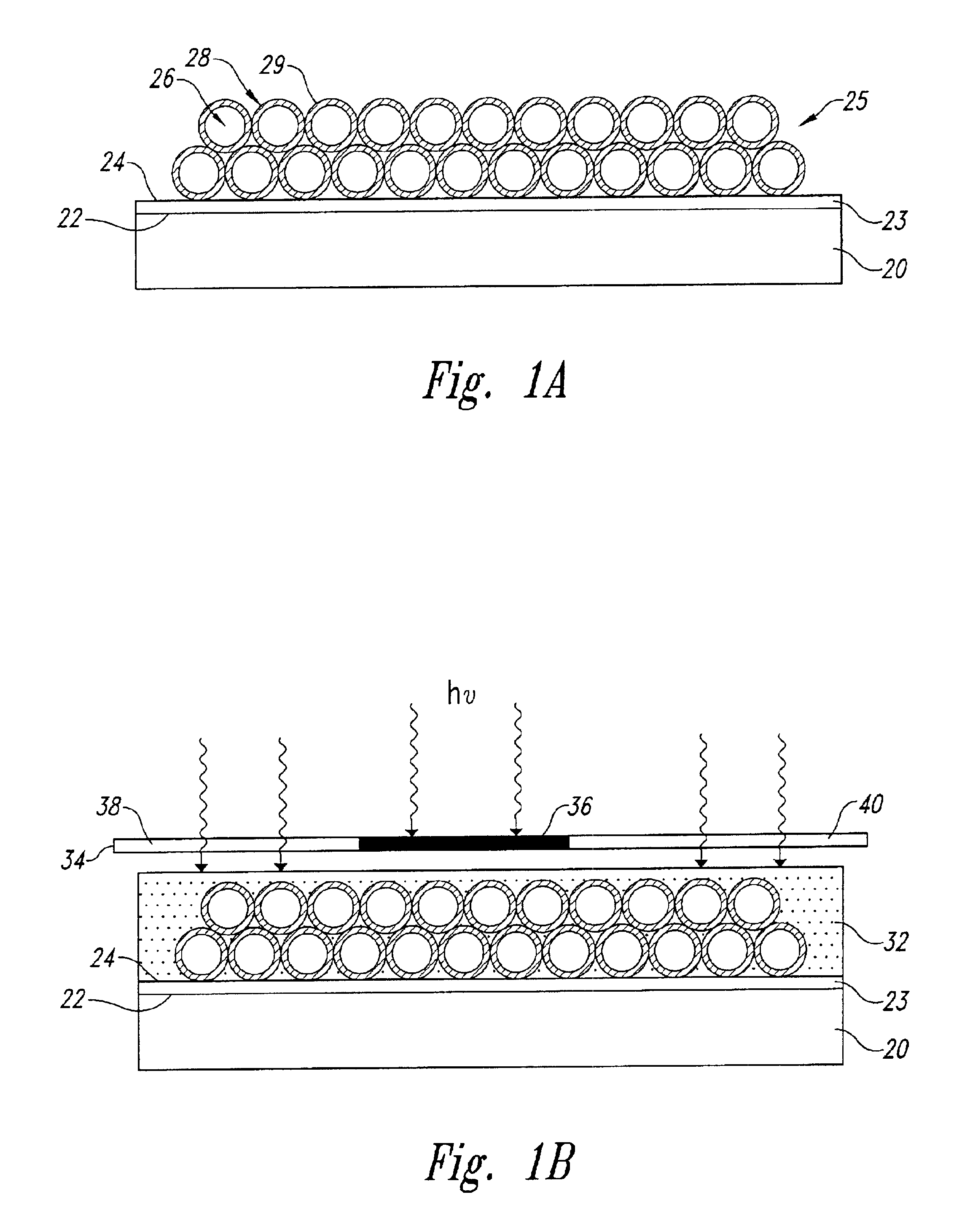

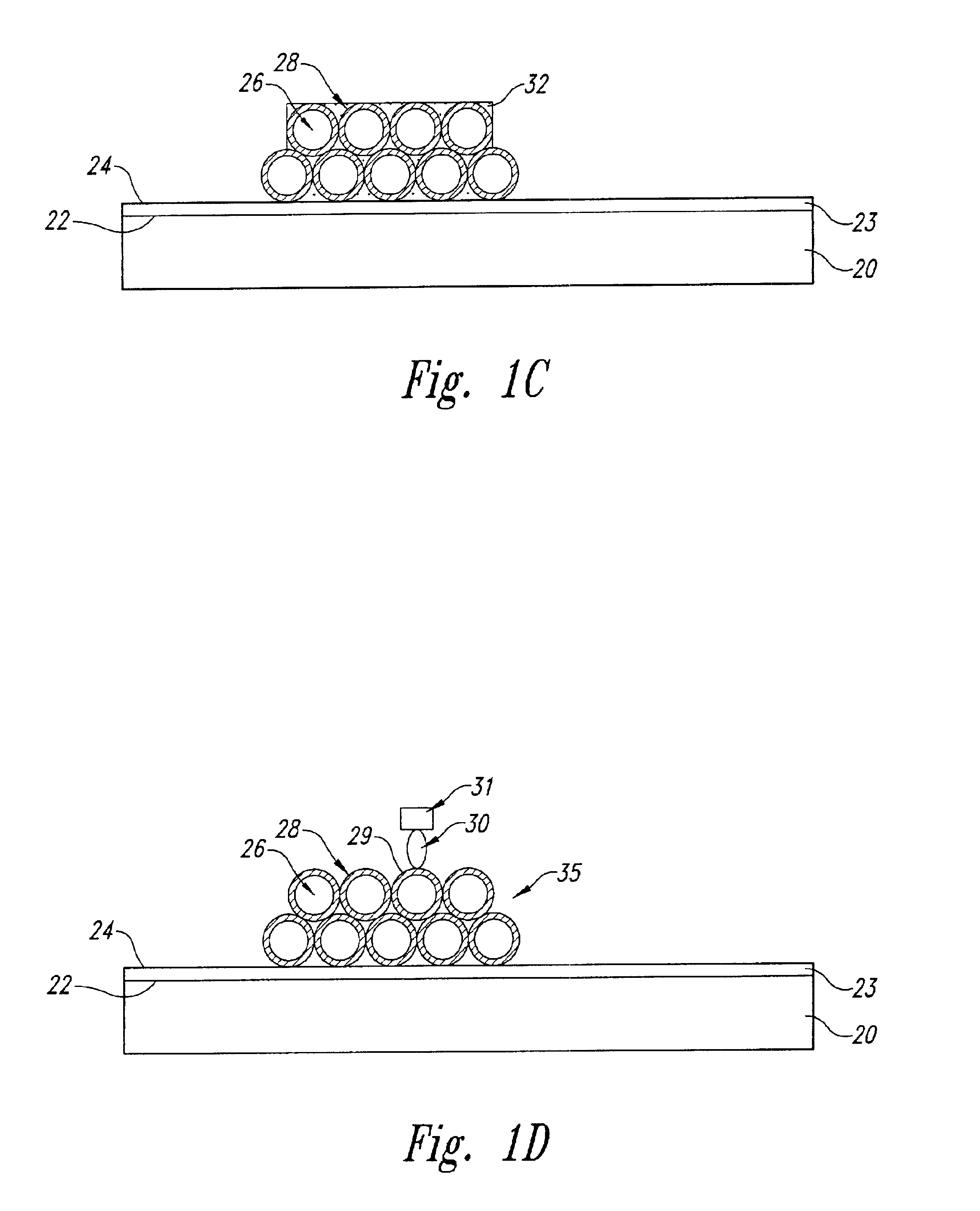

Apparatus for preparing a solid phase microparticulate composition

InactiveUS6042792ALow costImproved substantivityCosmetic preparationsComponent separationWaxMicroparticle

Described are controlled, time-release microparticulate active and bioactive compositions (including perfuming compositions) for targeted delivery to services such as skin, hair and fabric and the environment proximate thereto, where the active and bioactive materials have a calculated log10P values of between 1 and 8 (P being the n-octanol-water partition coefficient). Such compositions include the active or bioactive material in single phase, solid solution in a wax or polymer matrix also having coated thereon and / or containing a compatible surfactant. Also described are processes and apparatus for preparing such compositions and processes for using same. Furthermore, certain component(s) of the aforementioned compositions in combination with one another are novel, and other components have novel uses in increasing fragrance substantivity.

Owner:INTERNATIONAL FLAVORS & FRAGRANCES

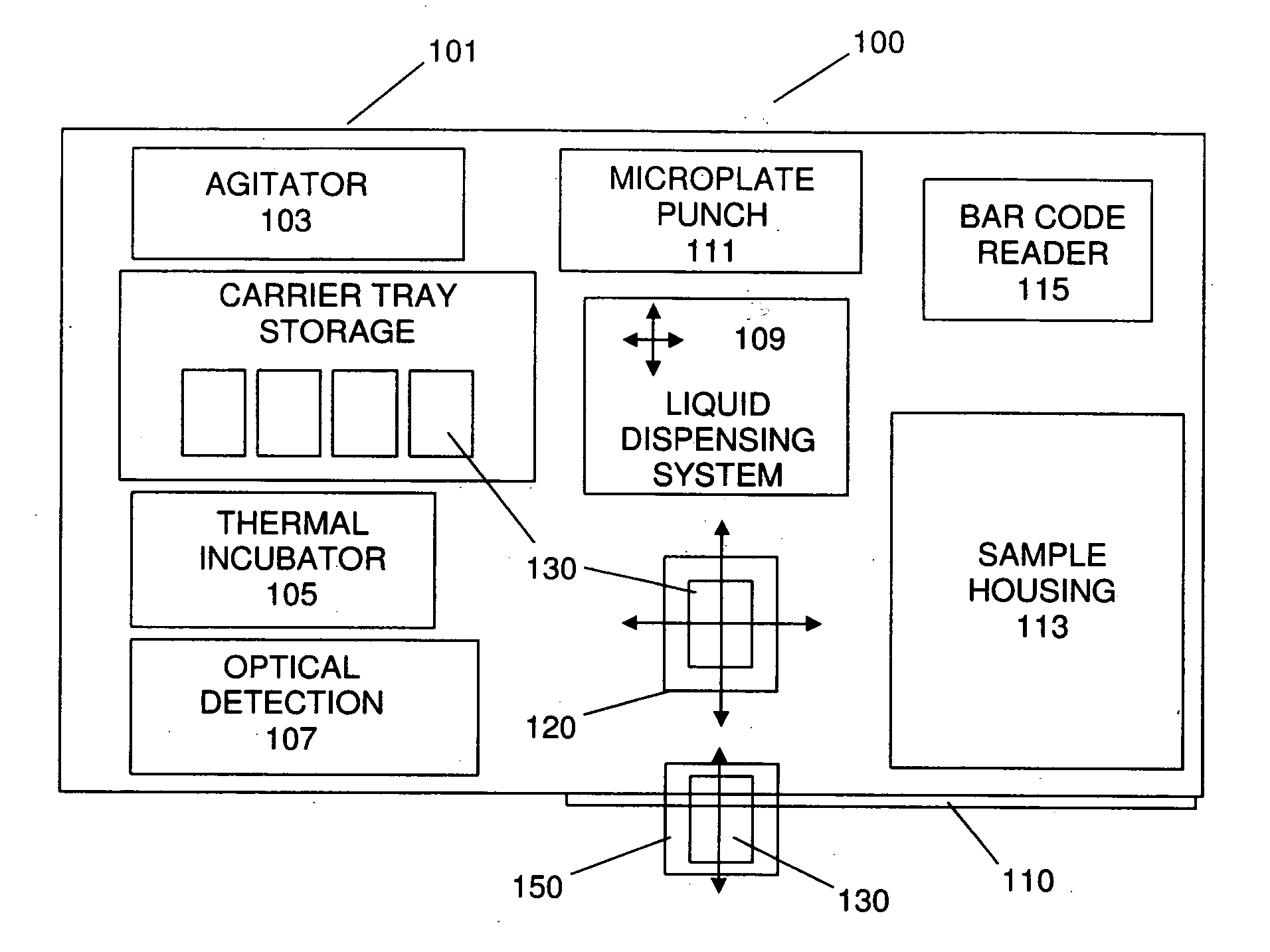

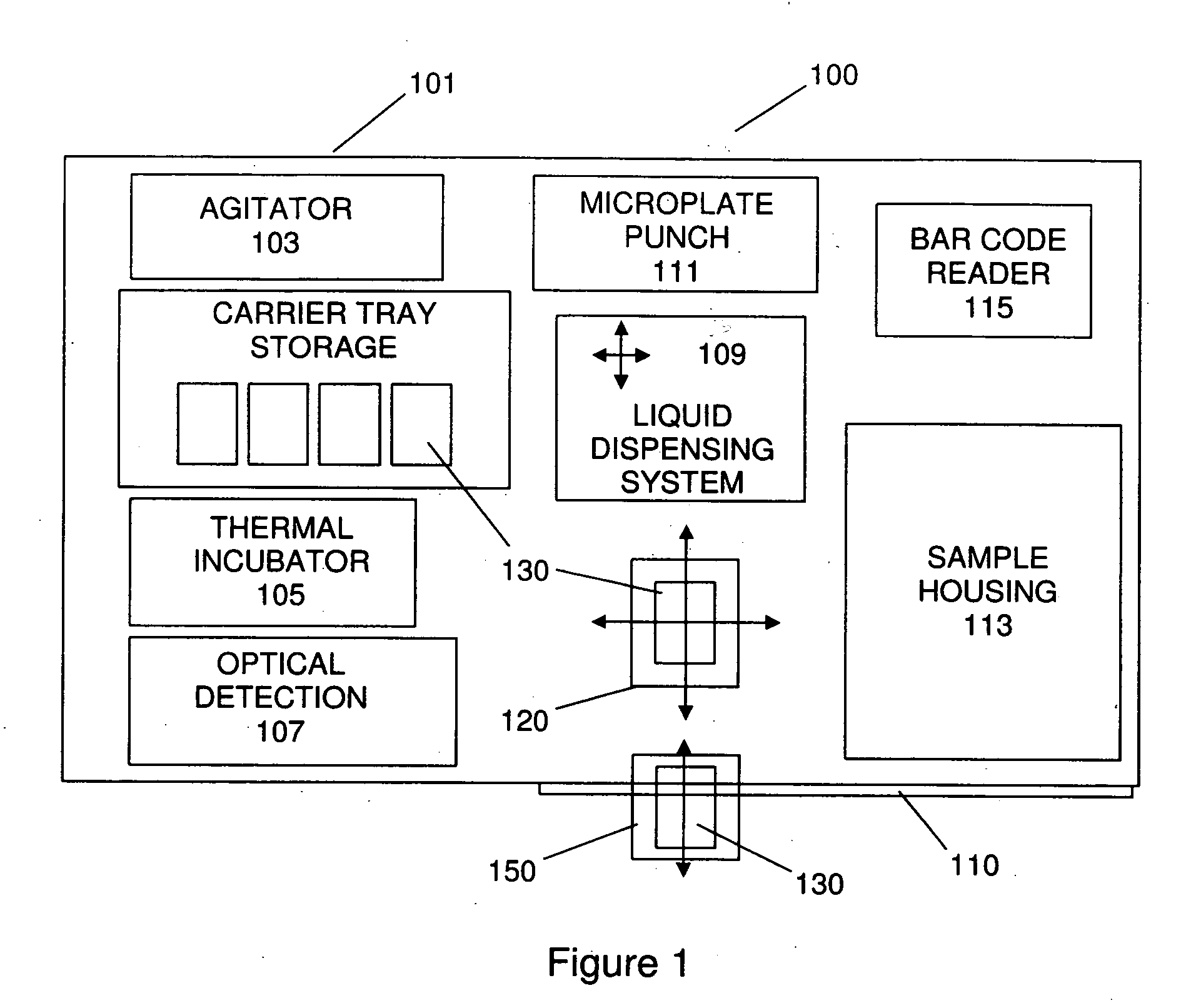

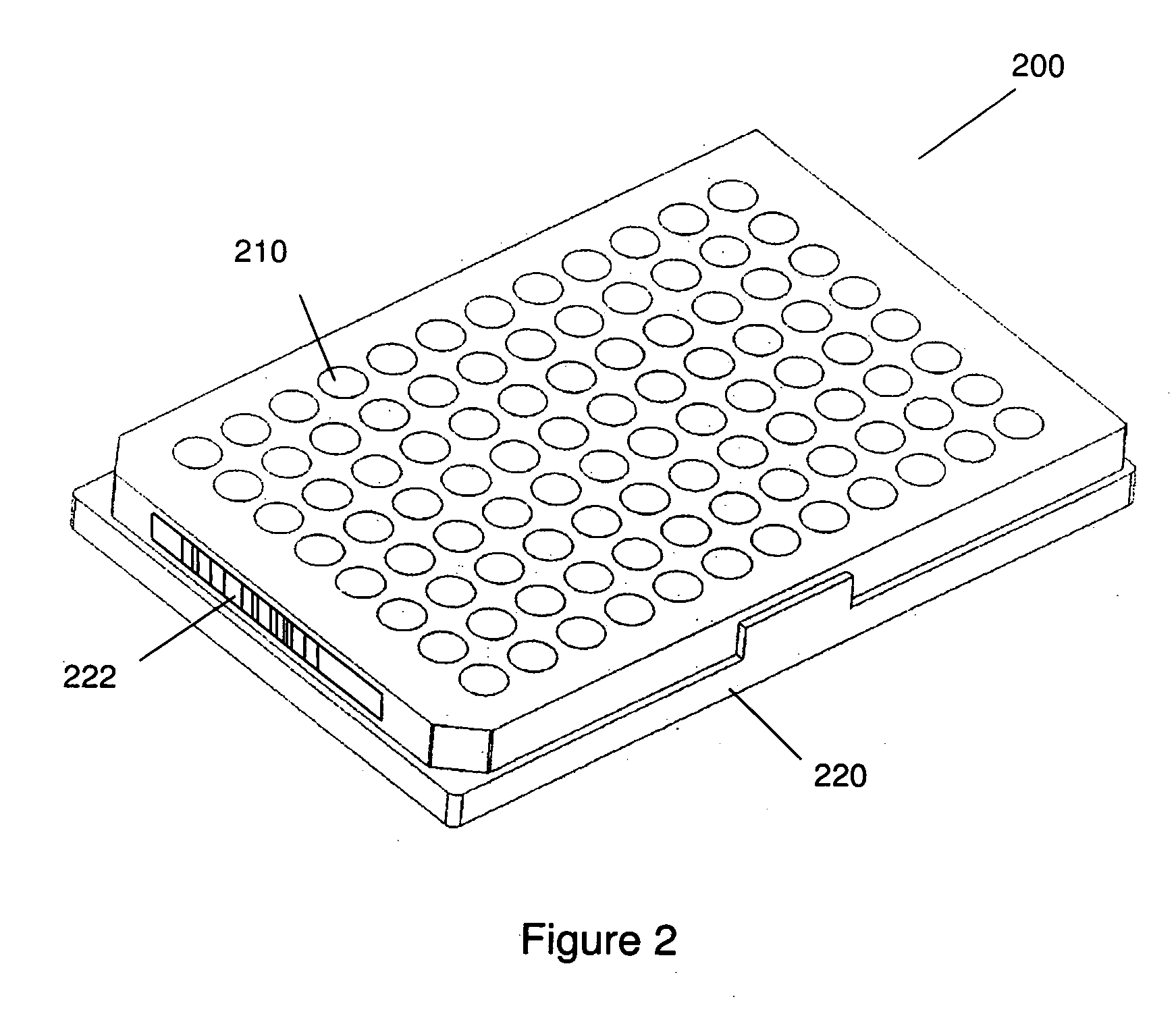

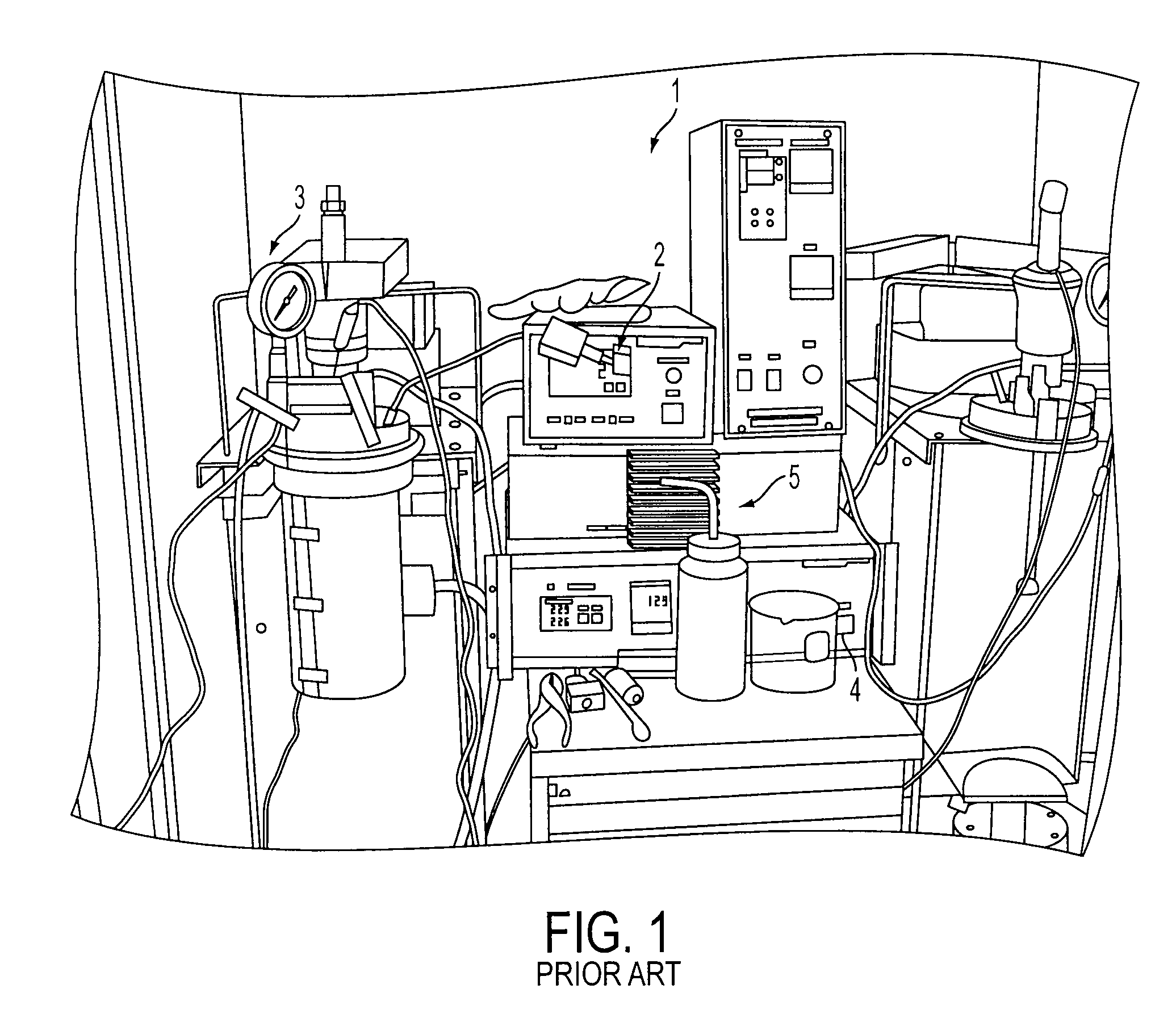

Automated analyzer

InactiveUS20060210435A1Minimal operator involvementEasy loadingBioreactor/fermenter combinationsBiological substance pretreatmentsLiquid-crystal displayBarcode

The present invention provides a bar-code driven, completely automated, microplate-based analyzer system for performing chemical, biochemical or biological assays. The analyzer is a modular, bench-top instrument that compactly integrates subsystems for sample dispensing, liquid handling, microplate transport, thermal incubation, vortexing, solid phase separation and optical reading. An internal processor is included for automating the instrument, and a user interface to facilitate communication with the operator via a touch-sensitive liquid-crystal display (LCD), and communicating with a remote network via multiple protocols. The analyzer includes firmware resident within the processing system and the user interface allows the operator to select pre-defined assay batch protocols and the user interface is configured in such as way so as to restrict an operator from programming the firmware.

Owner:NOVX SYST CANADA

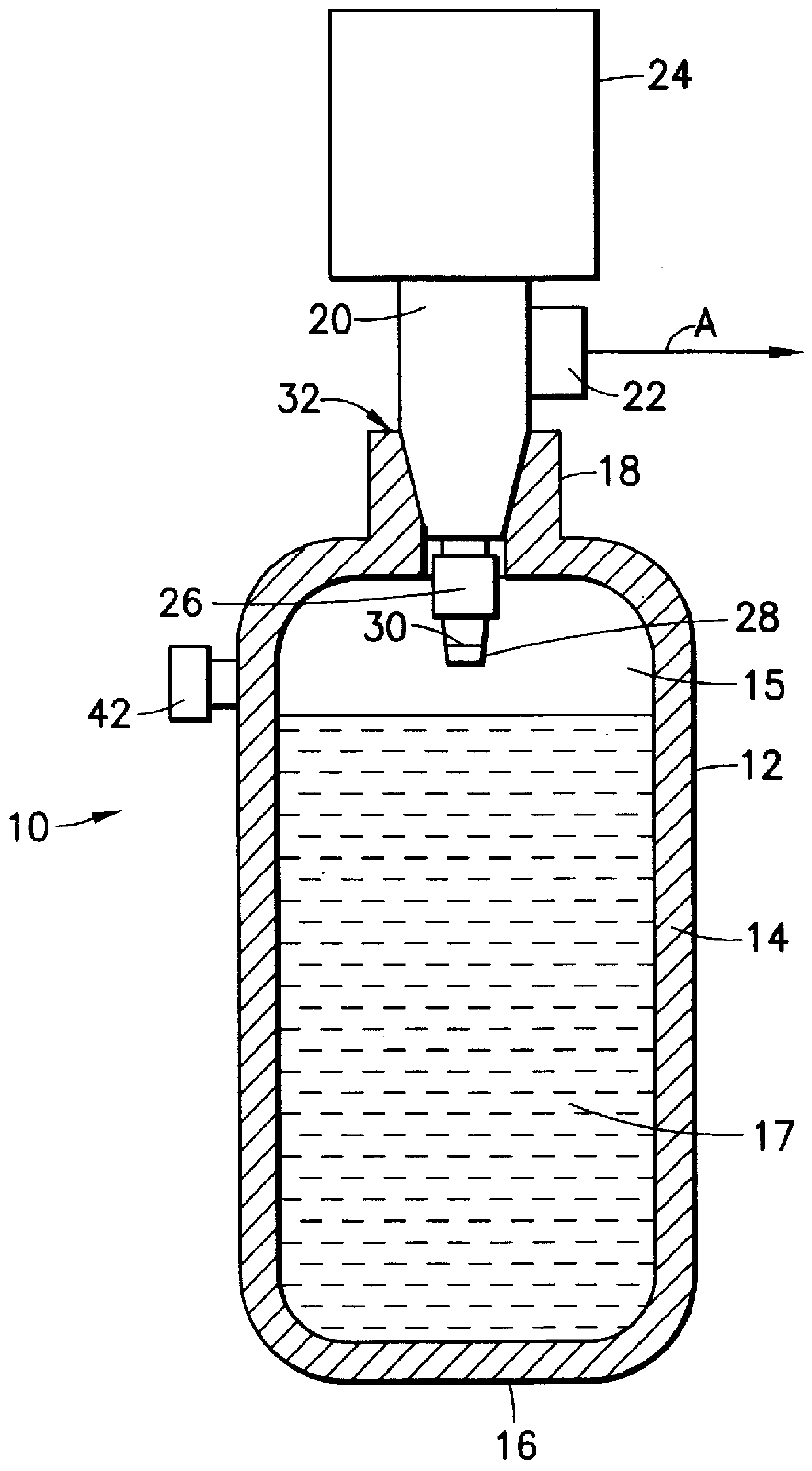

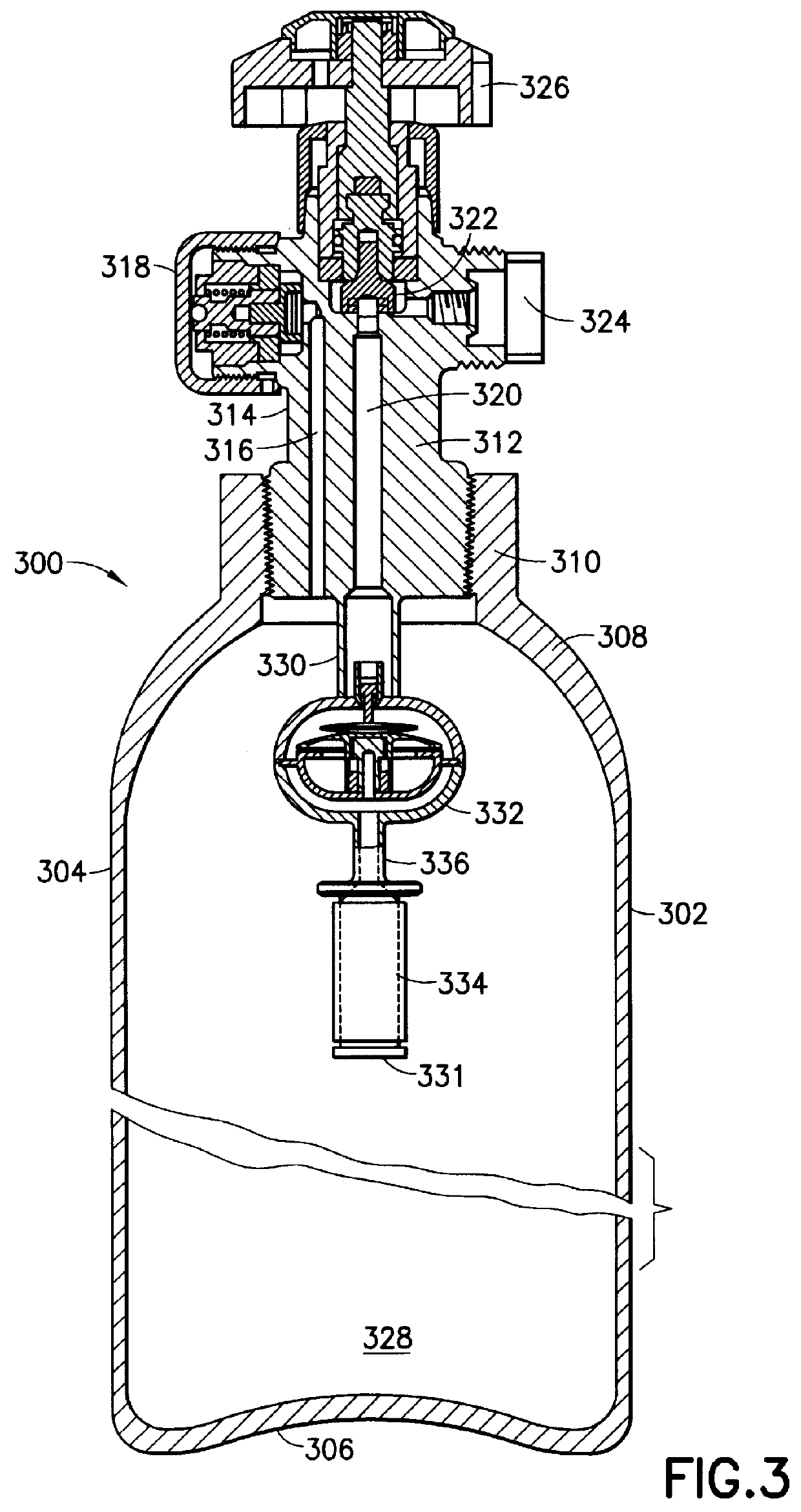

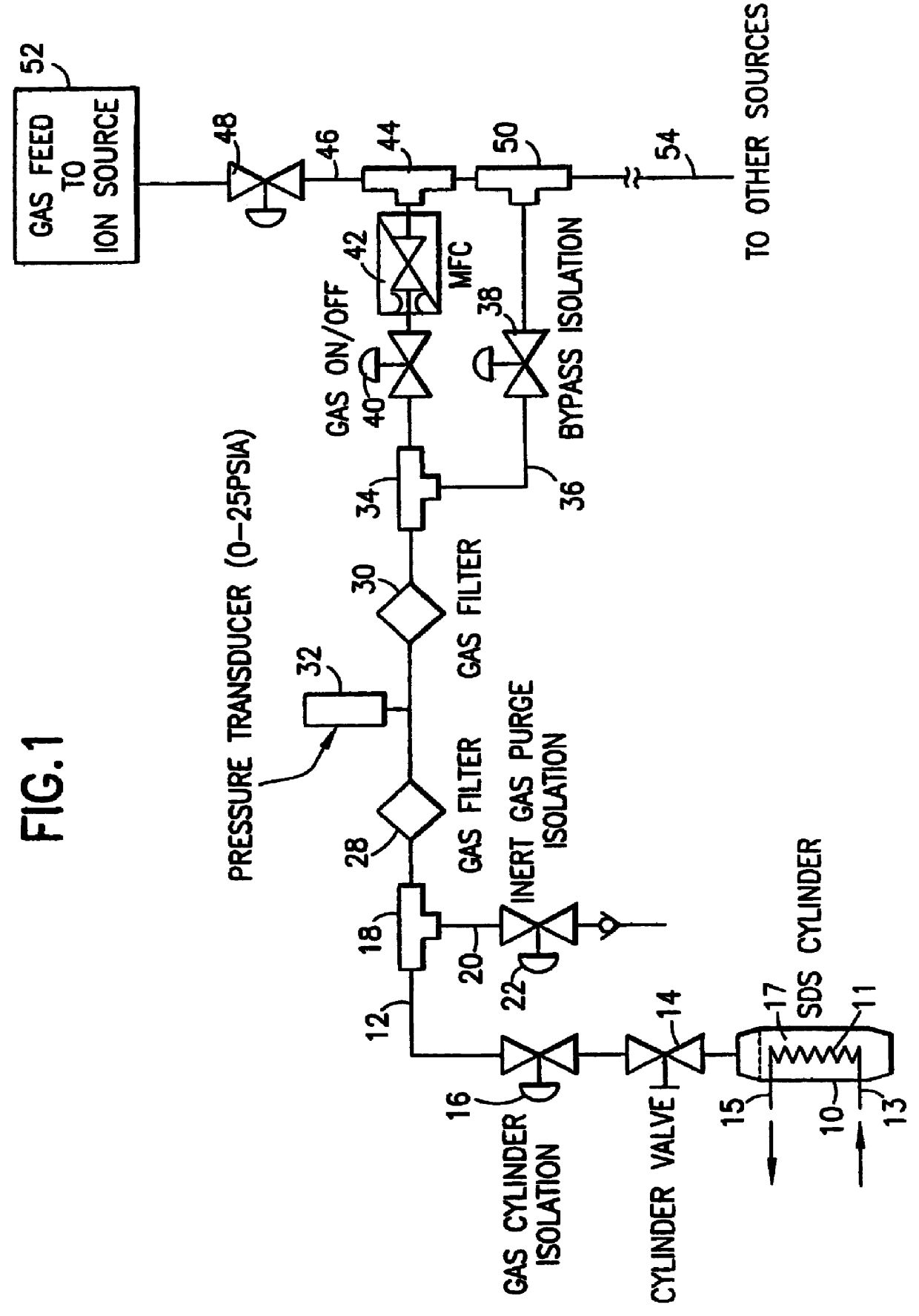

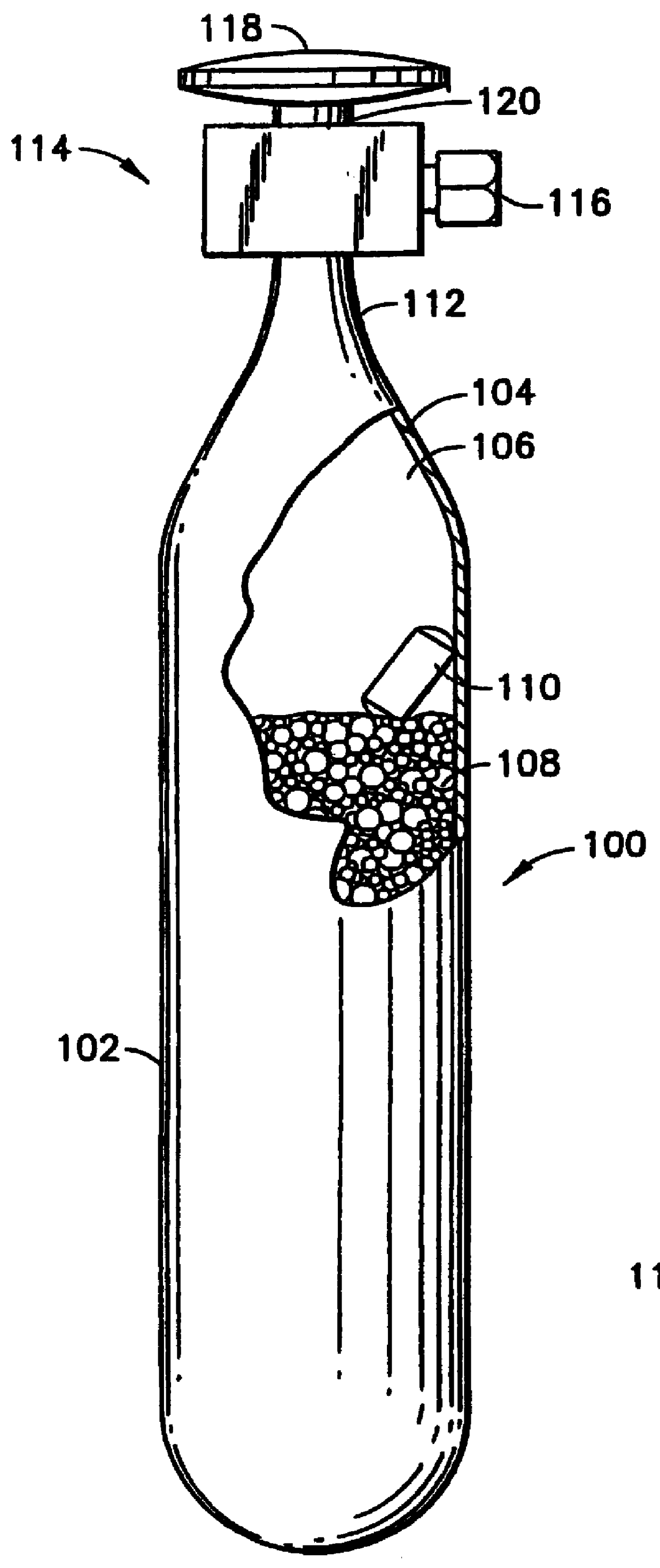

Fluid storage and dispensing system

InactiveUS6089027ACostPerformanceContainer filling methodsVacuum evaporation coatingSingle stageSorbent

A fluid storage and dispensing system comprising a vessel for holding a fluid at a desired pressure. The vessel has a pressure regulator, e.g., a single-stage or multi-stage regulator, associated with a port of the vessel, and set at a predetermined pressure. A dispensing assembly, e.g., including a flow control means such as a valve, is arranged in gas / vapor flow communication with the regulator, whereby the opening of the valve effects dispensing of gas / vapor from the vessel. The fluid in the vessel may be constituted by a liquid that is confined in the vessel at a pressure in excess of its liquefaction pressure at prevailing temperature conditions, e.g., ambient (room) temperature. In another aspect, the vessel contains a solid-phase sorbent material having sorbable gas adsorbed thereon, at a pressure in excess of 50 psig. The vessel may have a >1 inch NGT threaded neck opening, to accommodate the installation of an interior regulator.

Owner:ENTEGRIS INC

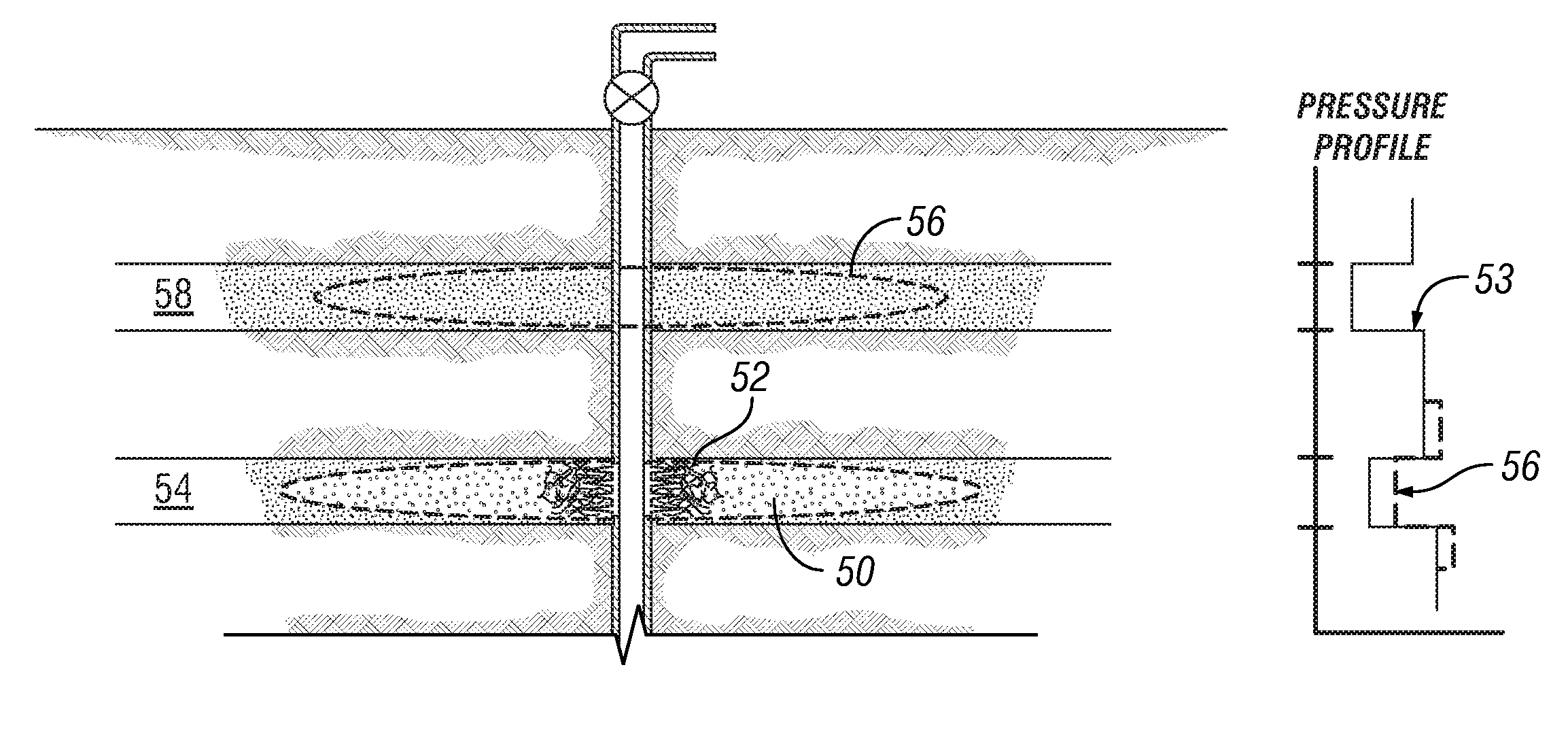

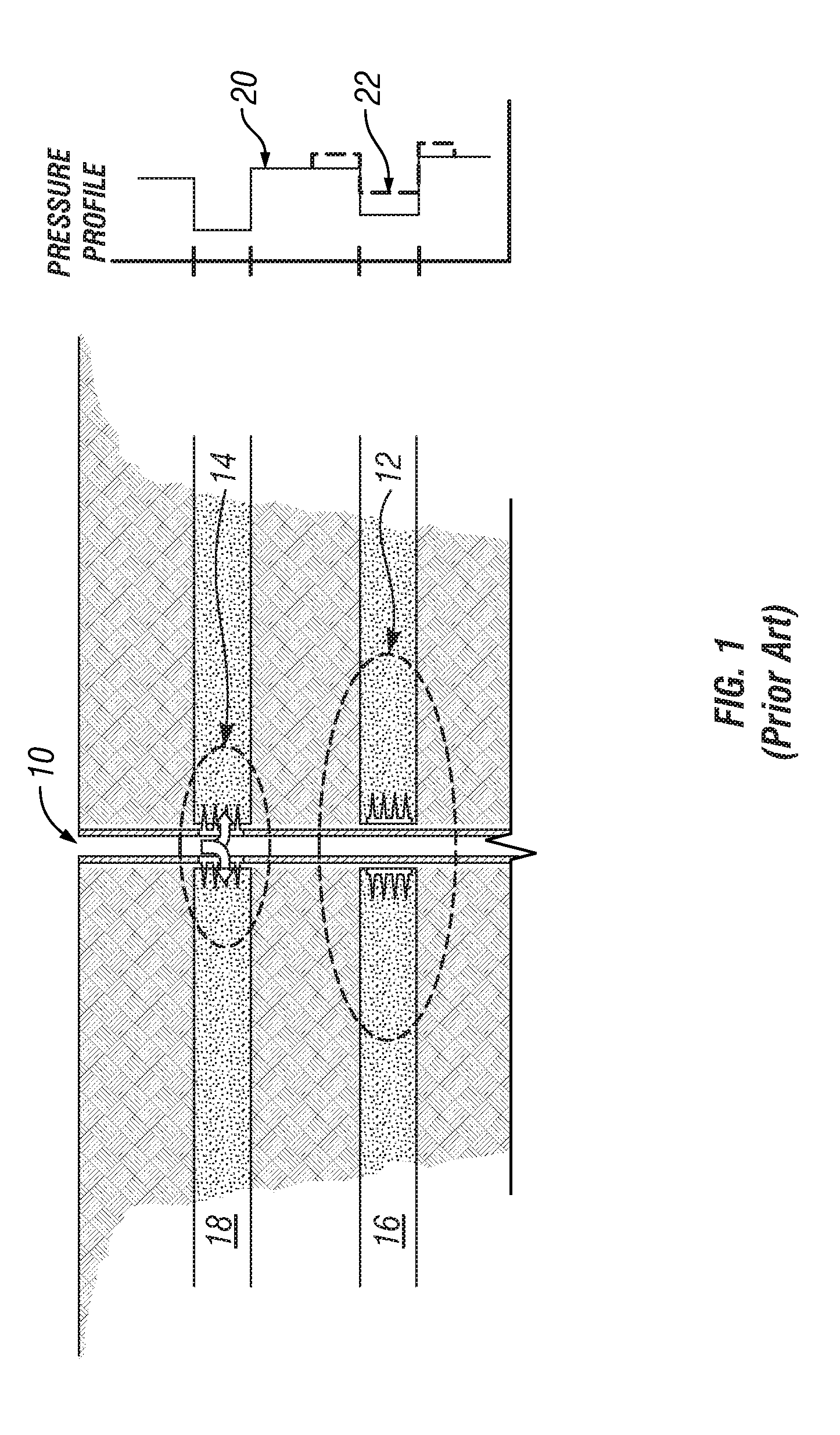

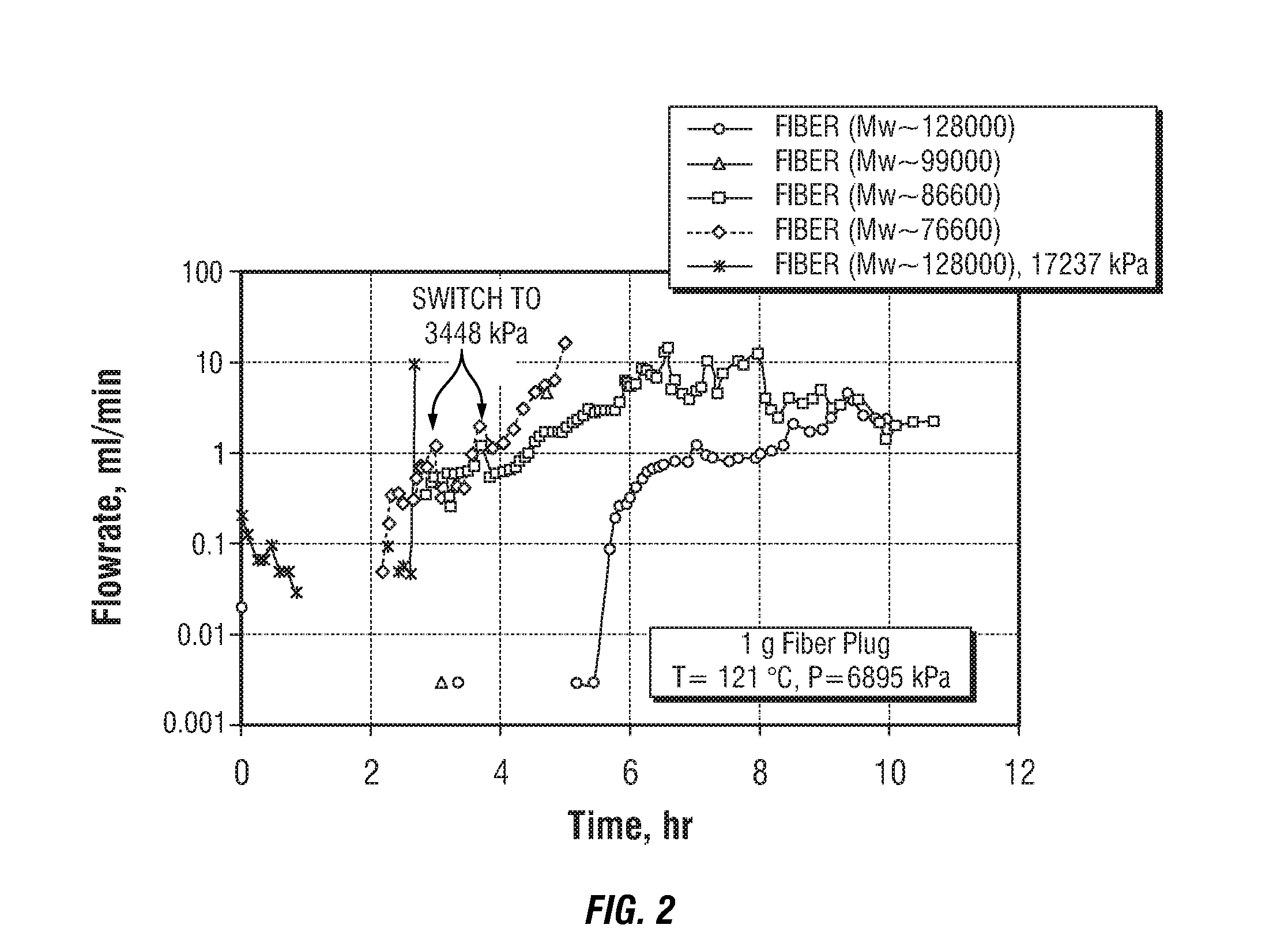

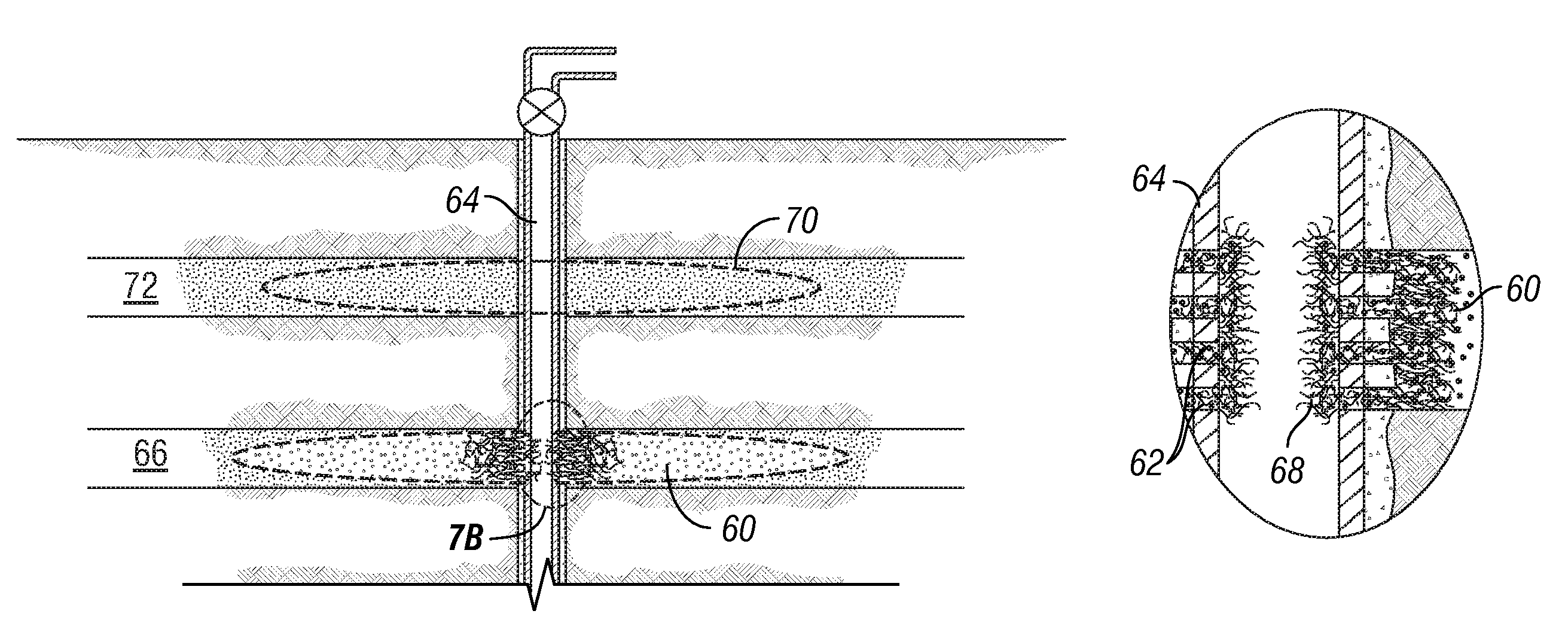

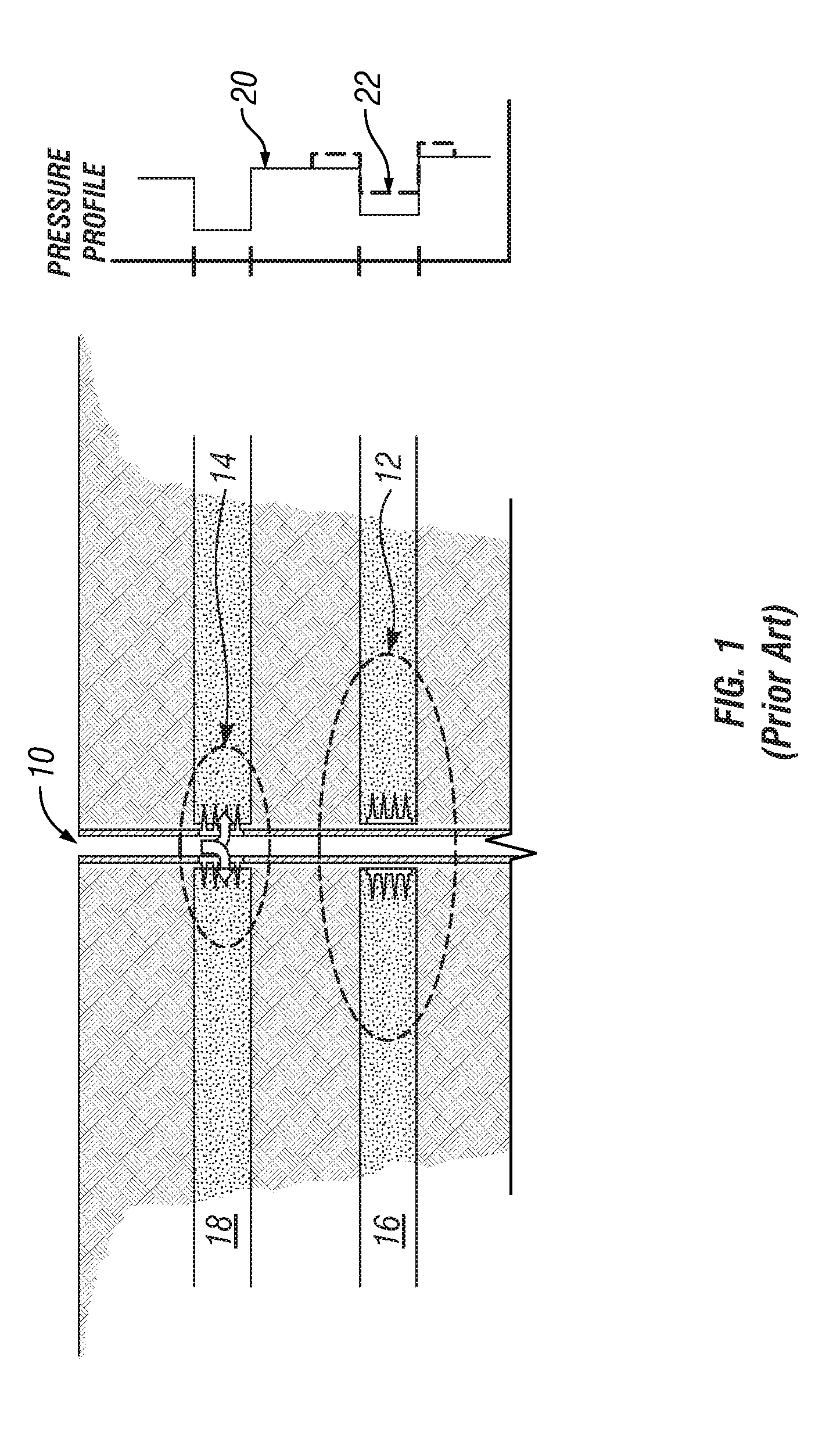

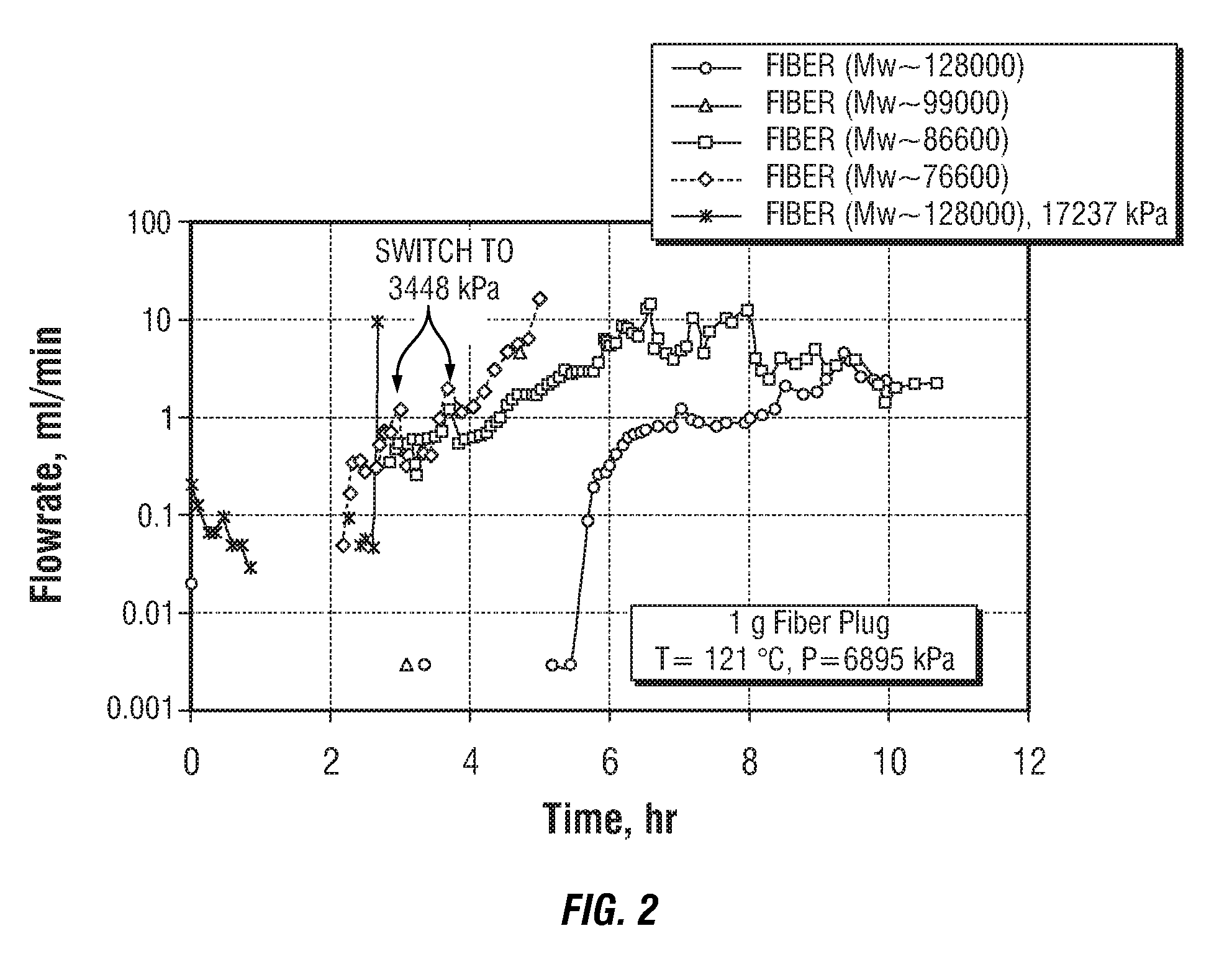

Degradable Material Assisted Diversion

Degradable material assisted diversion (DMAD) methods for well treatment, DMAD treatment fluids, and removable plugs for DMAD in downhole operations. A slurry of solid degradable material is injected into the well, a plug of the degradable material is formed, a downhole operation is performed around the plug diverter, and the plug is then degraded for removal. Degradation triggers can be temperature or chemical reactants, with optional accelerators or retarders to provide the desired timing for plug removal. In multilayer formation DMAD fracturing, the plug isolates a completed fracture while additional layers are sequentially fractured and plugged, and then the plugs are removed for flowback from the fractured layers. In DMAD fluids, an aqueous slurry can have a solids phase including a degradable material and a fluid phase including a viscoelastic surfactant. The solids phase can be a mixture of fibers and a particulate material.

Owner:SCHLUMBERGER TECH CORP

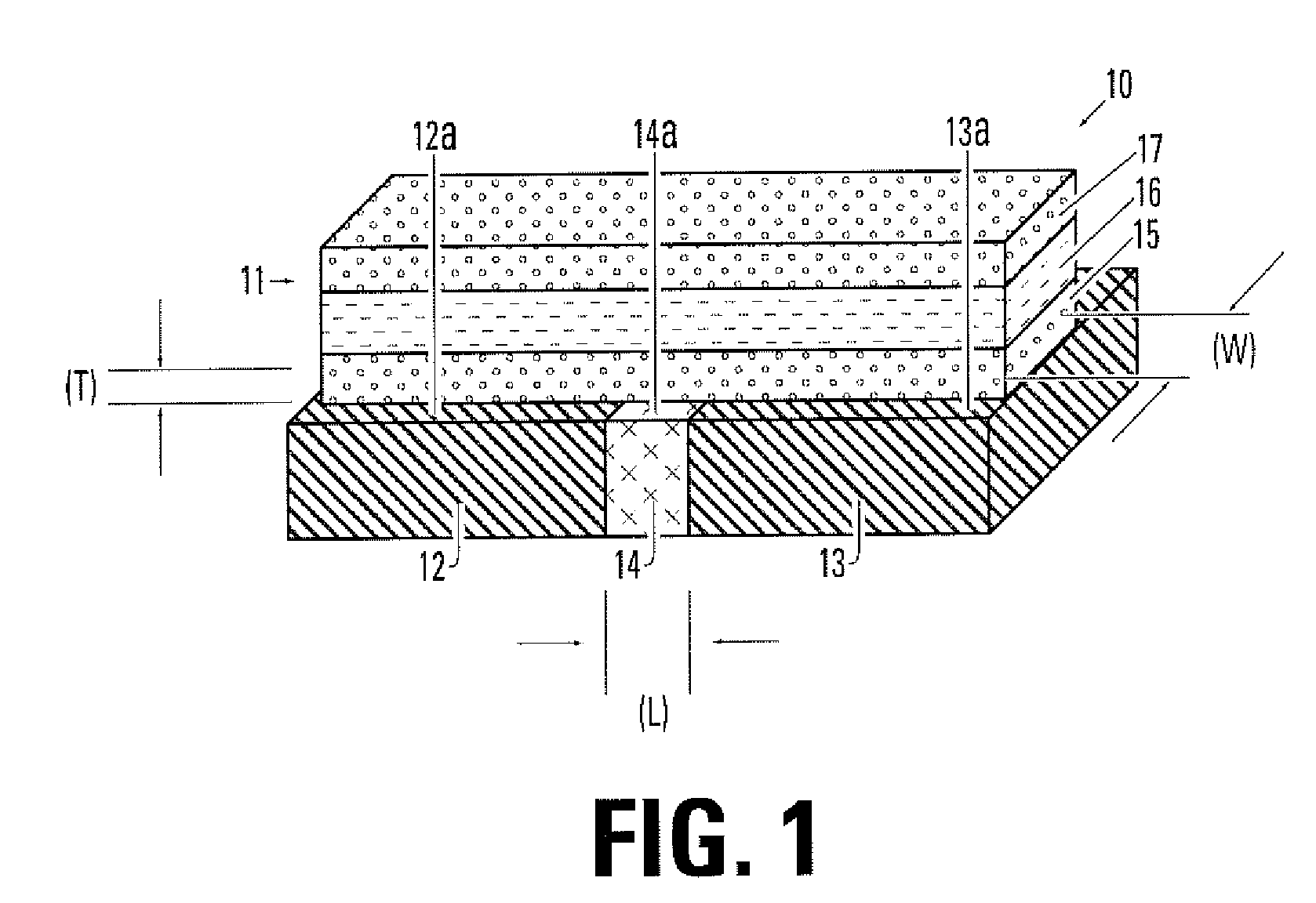

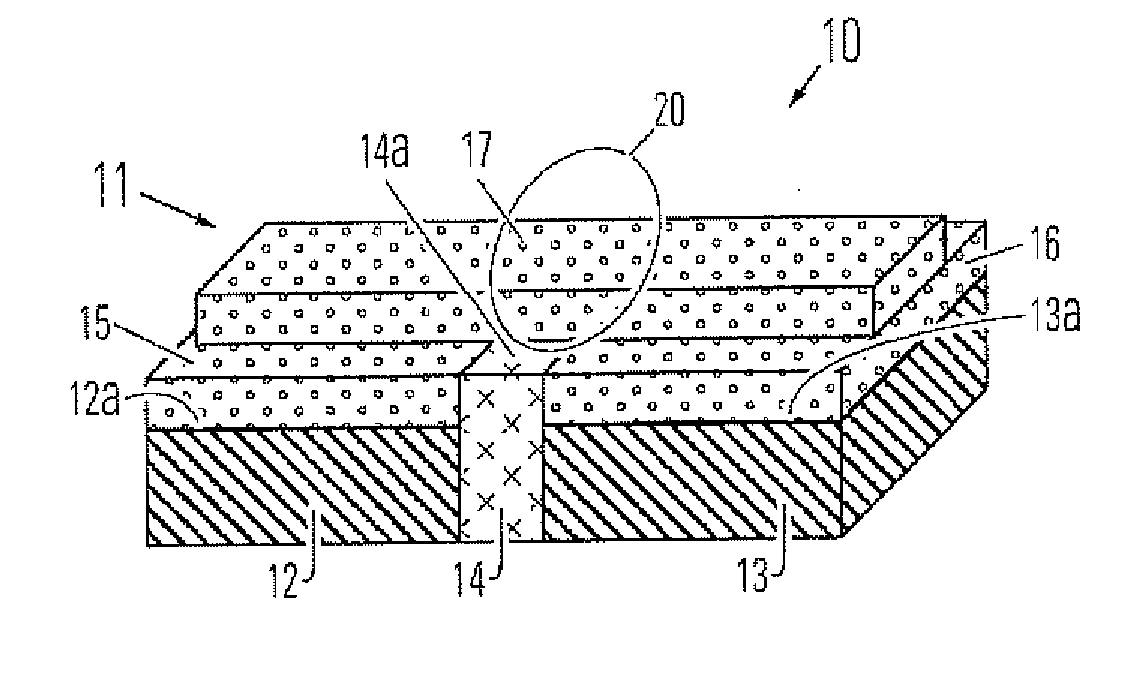

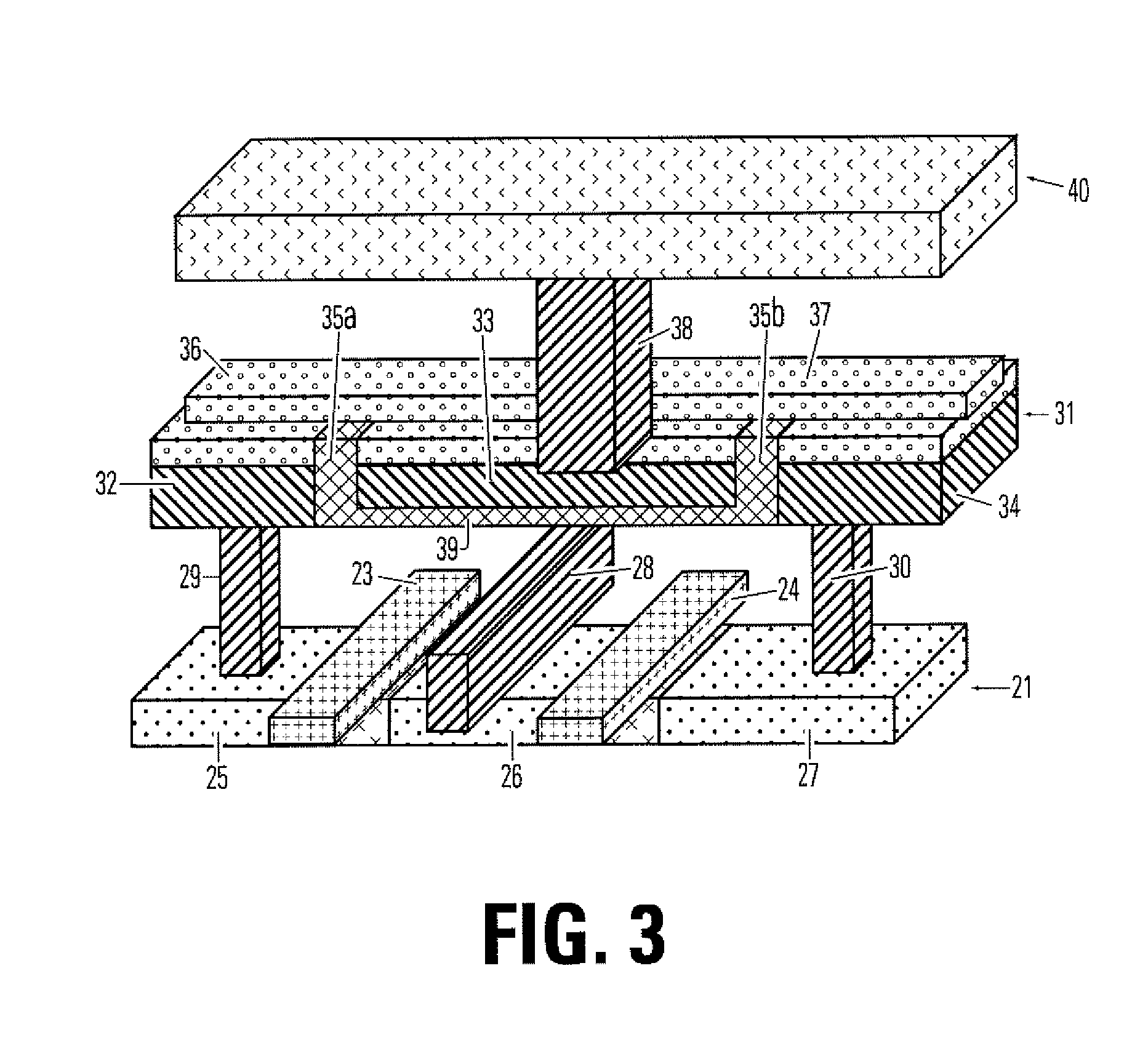

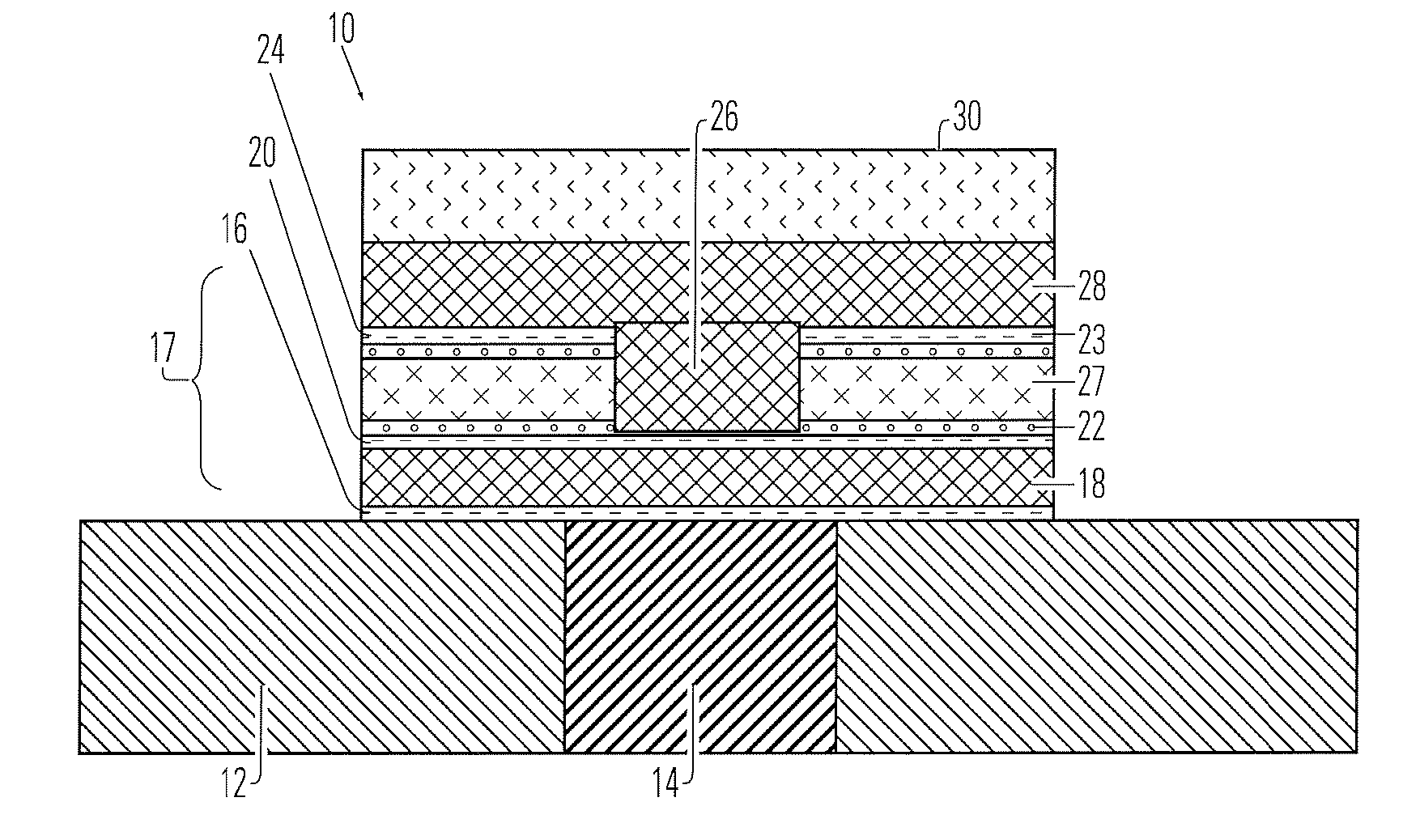

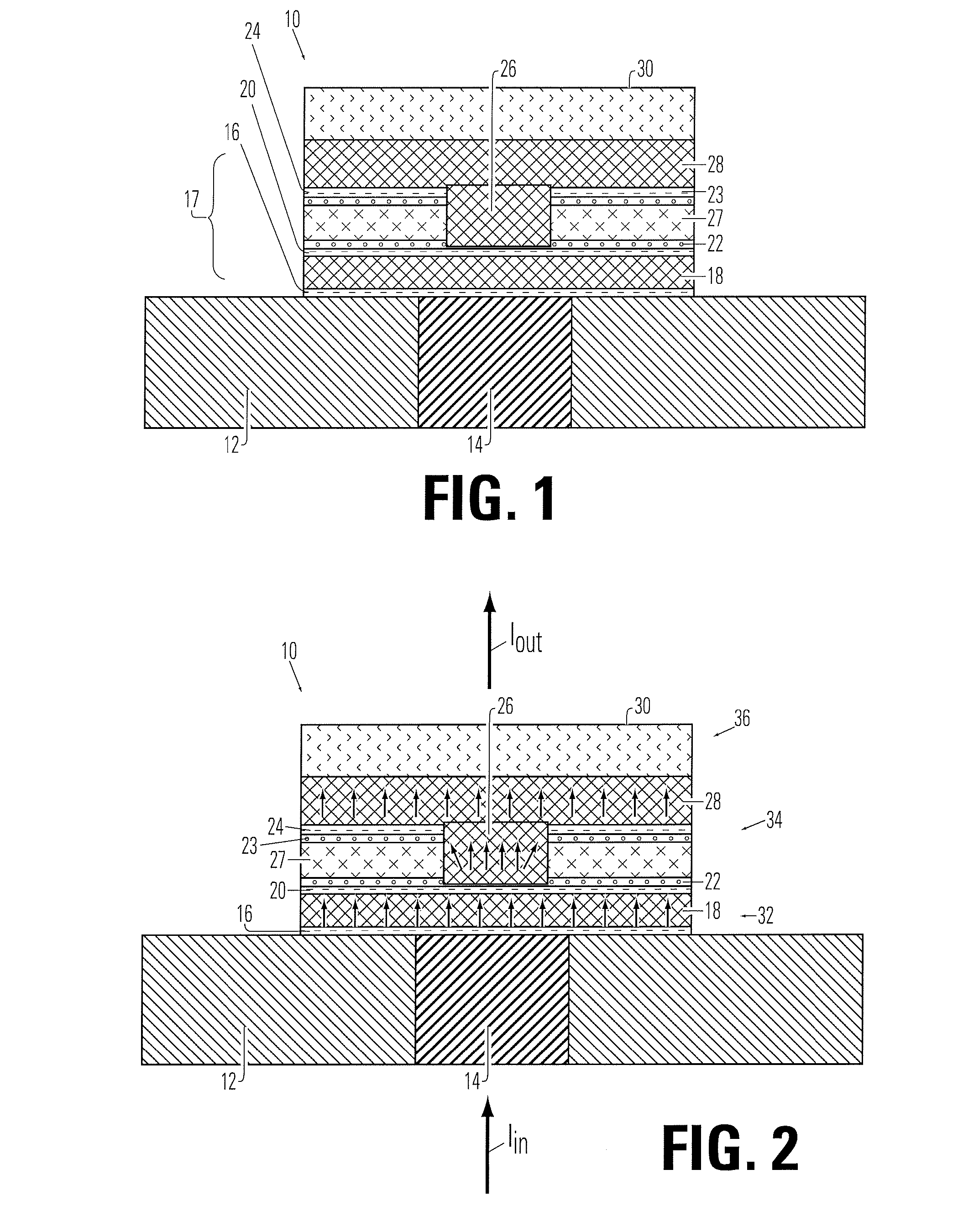

I-shaped phase change memory cell

A memory device includes two electrodes, vertically separated and having mutually opposed contact surfaces, between which lies a phase change cell. The phase change cell includes an upper phase change member, having a contact surface in electrical contact with the first electrode; a lower phase change member, having a contact surface in electrical contact with the second electrode; and a kernel member disposed between and in electrical contact with the upper and lower phase change members. The phase change cell is formed of material having at least two solid phases, and the lateral extent of the upper and lower phase change members is substantially greater than that of the kernel member. An intermediate insulating layer is disposed between the upper and lower phase change members adjacent to the kernel member.

Owner:MACRONIX INT CO LTD

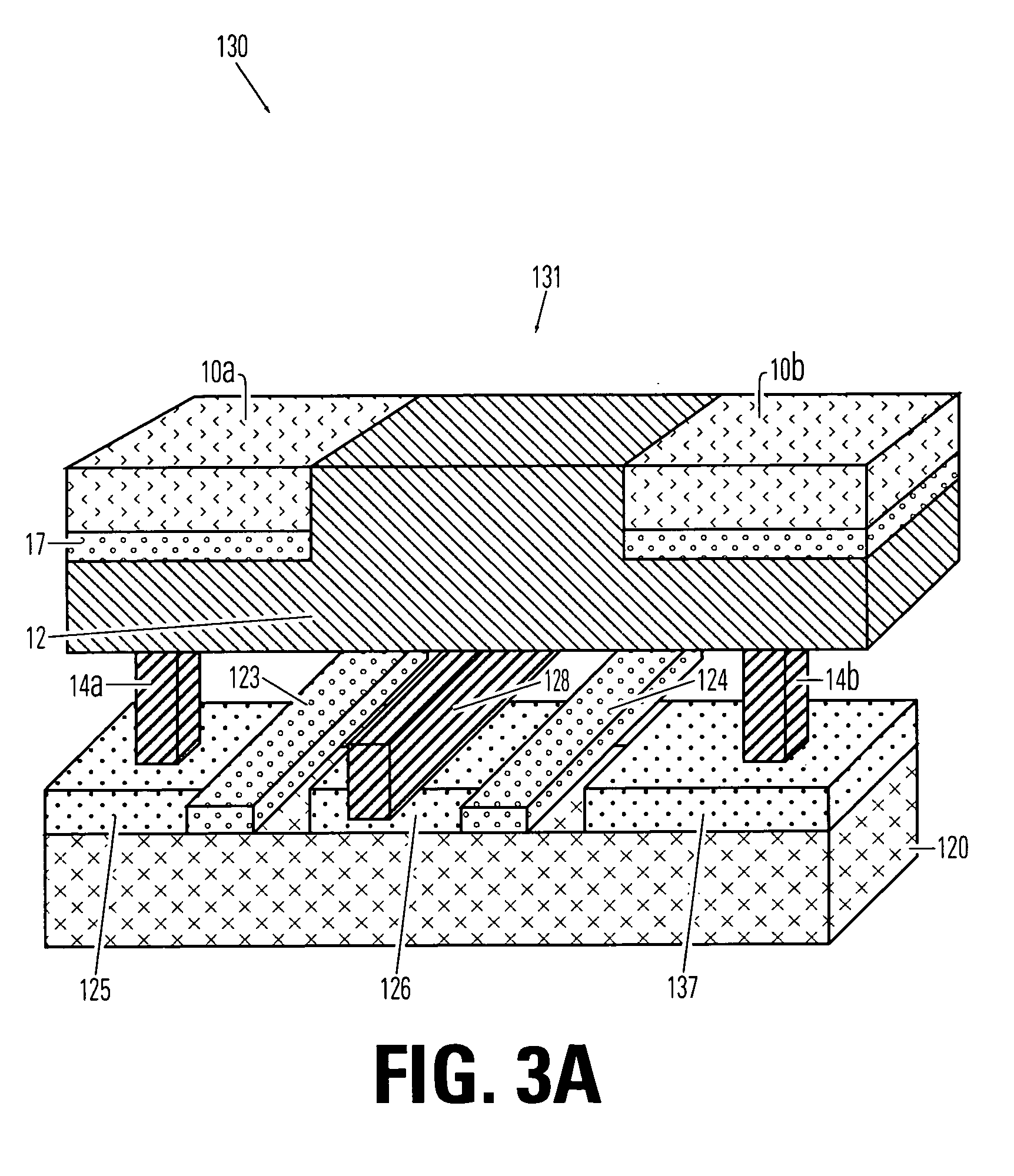

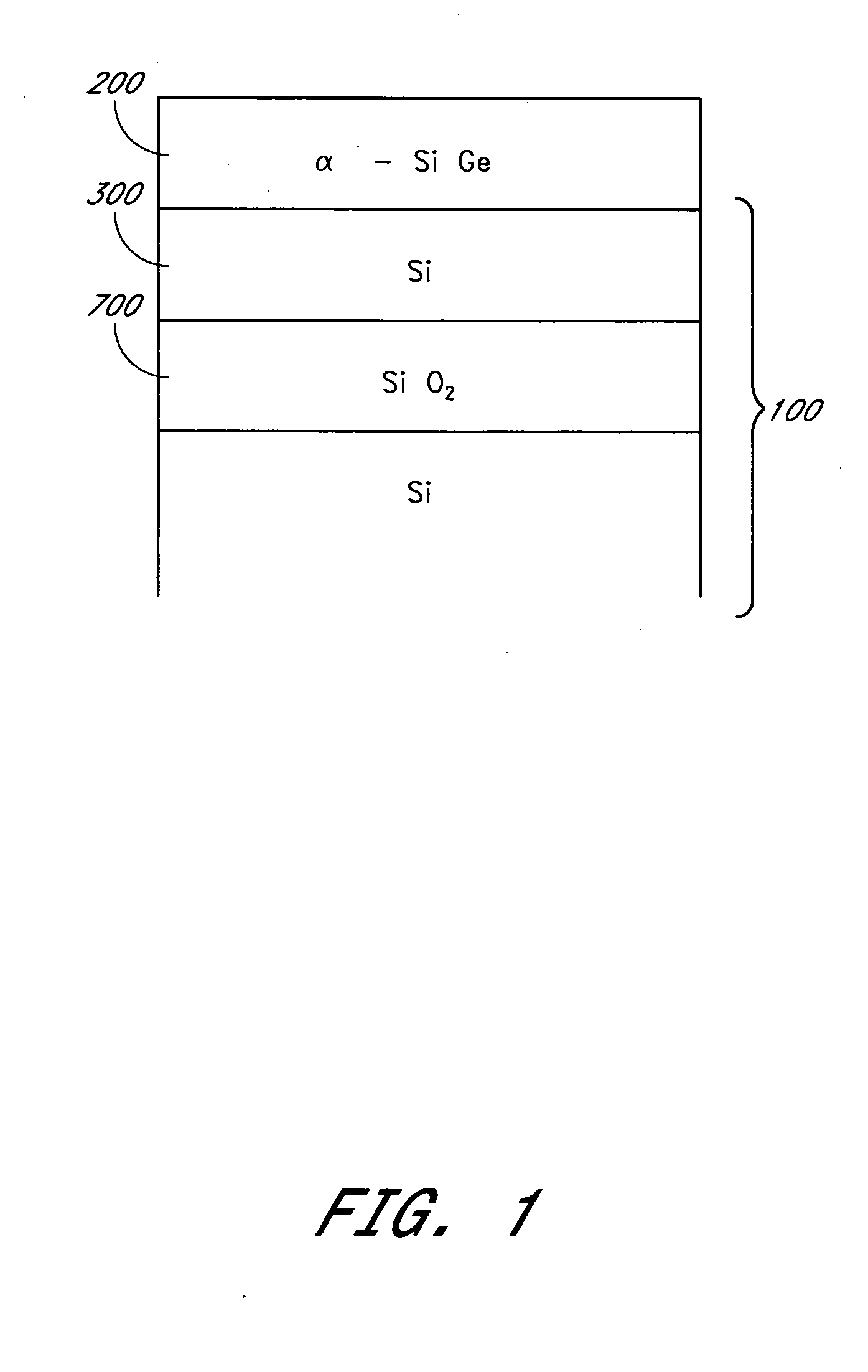

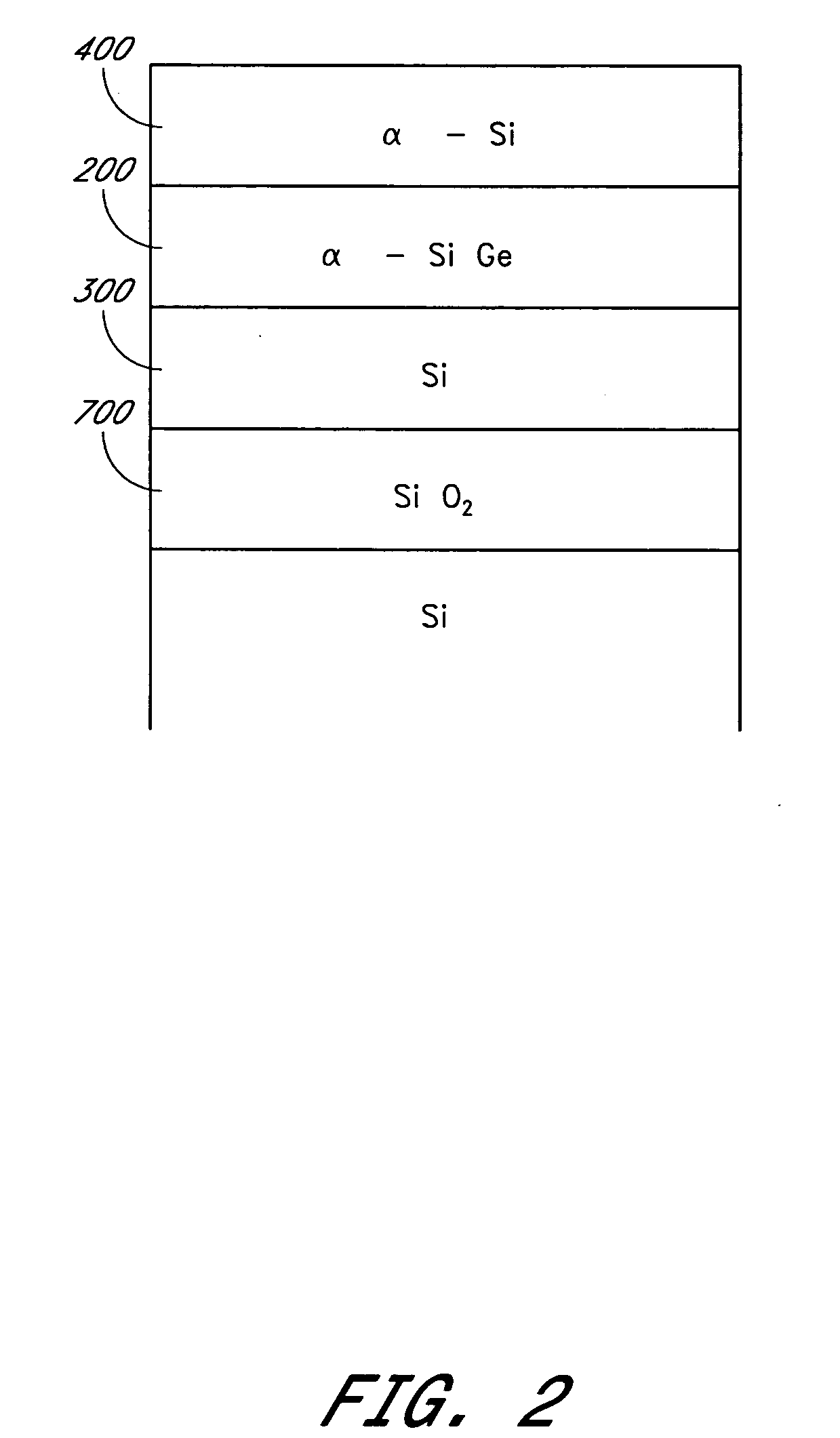

Deposition of silicon germanium on silicon-on-insulator structures and bulk substrates

Methods are provided for producing SiGe-on-insulator structures and for forming strain-relaxed SiGe layers on silicon while minimizing defects. Amorphous SiGe layers are deposited by CVD from trisilane and GeH4. The amorphous SiGe layers are recrystallized over silicon by melt or solid phase epitaxy (SPE) processes. The melt processes preferably also cause diffusion of germanium to dilute the overall germanium content and essentially consume the silicon overlying the insulator. The SPE process can be conducted with or without diffusion of germanium into the underlying silicon, and so is applicable to SOI as well as conventional semiconductor substrates.

Owner:ASM IP HLDG BV

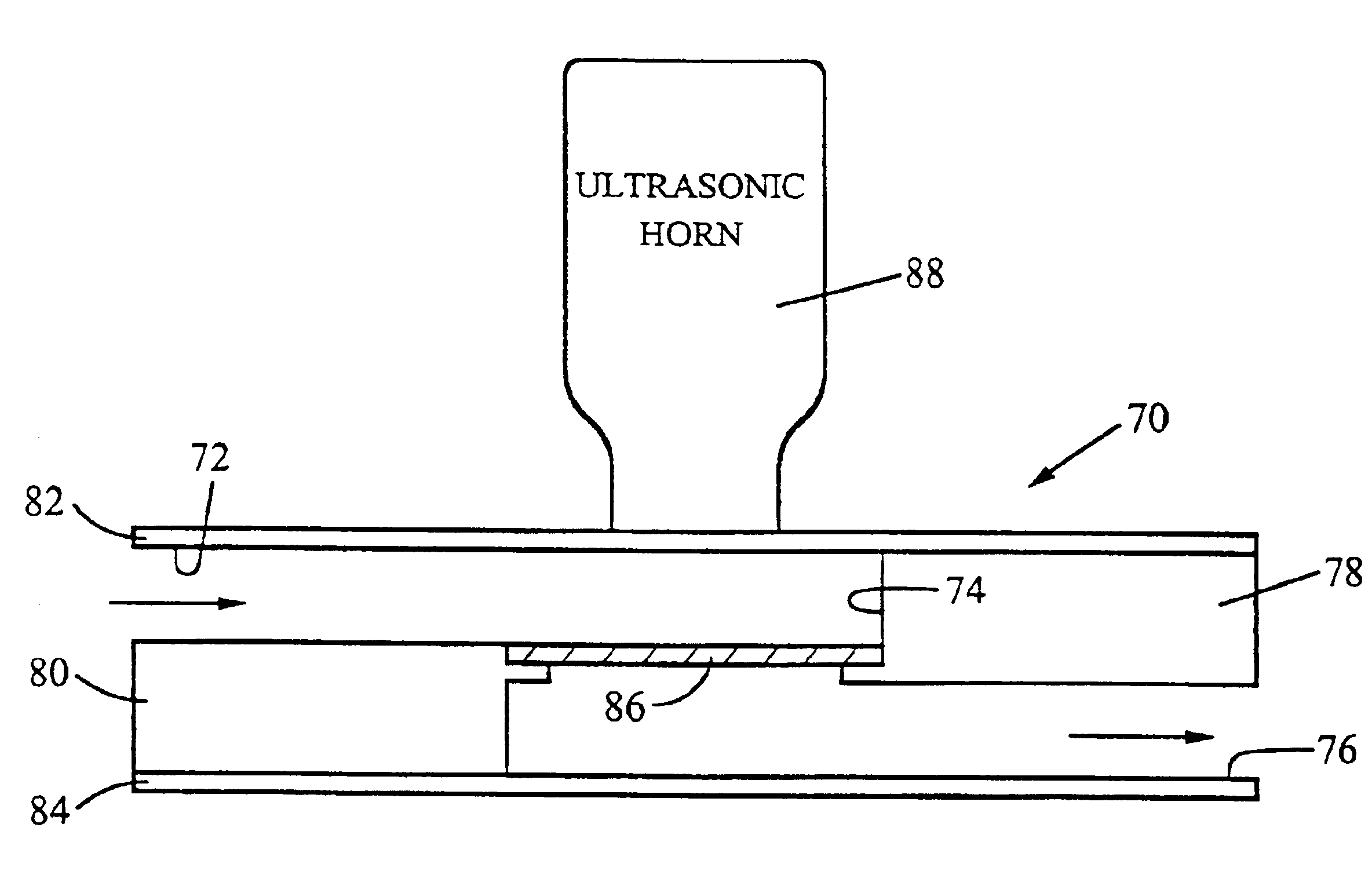

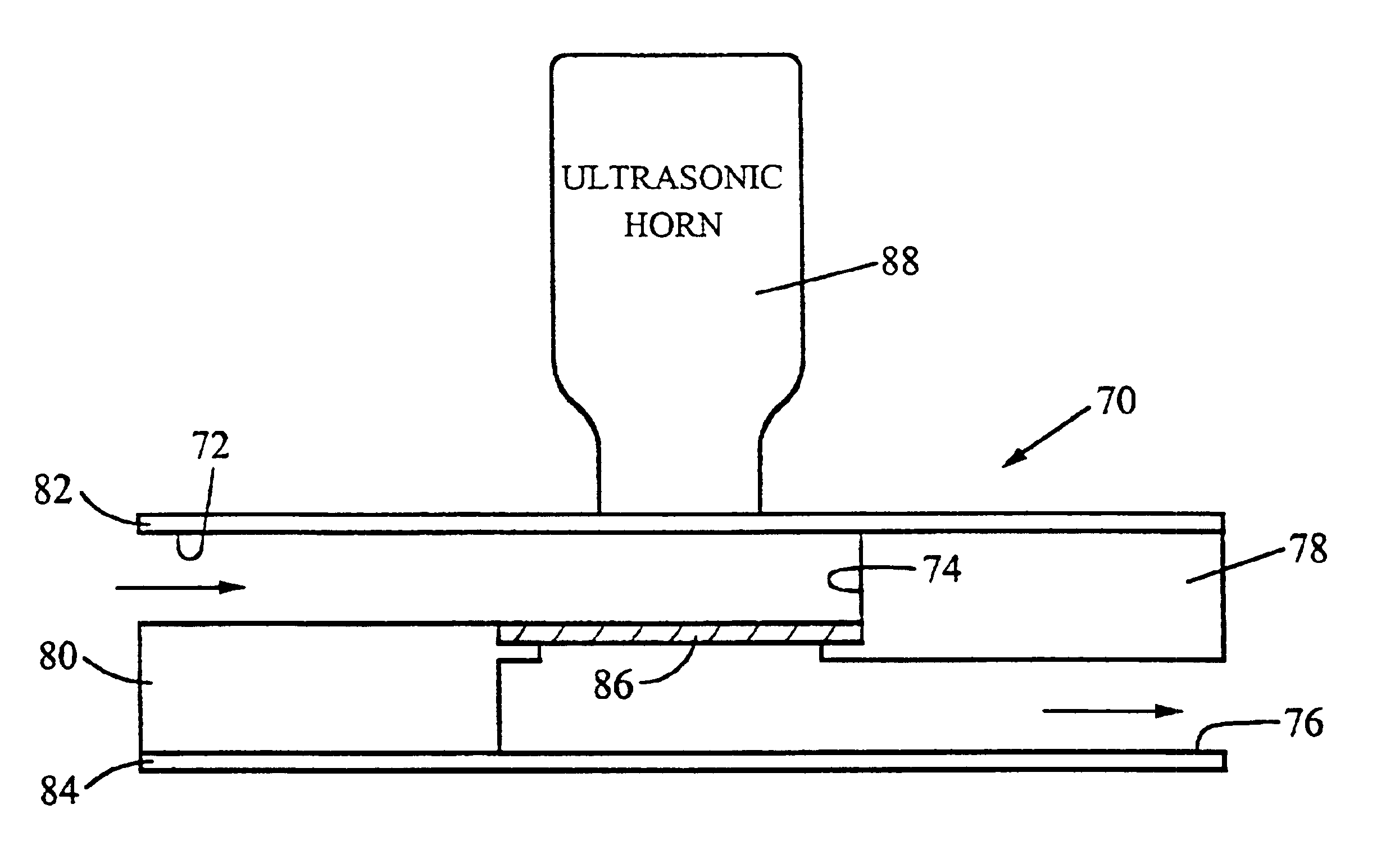

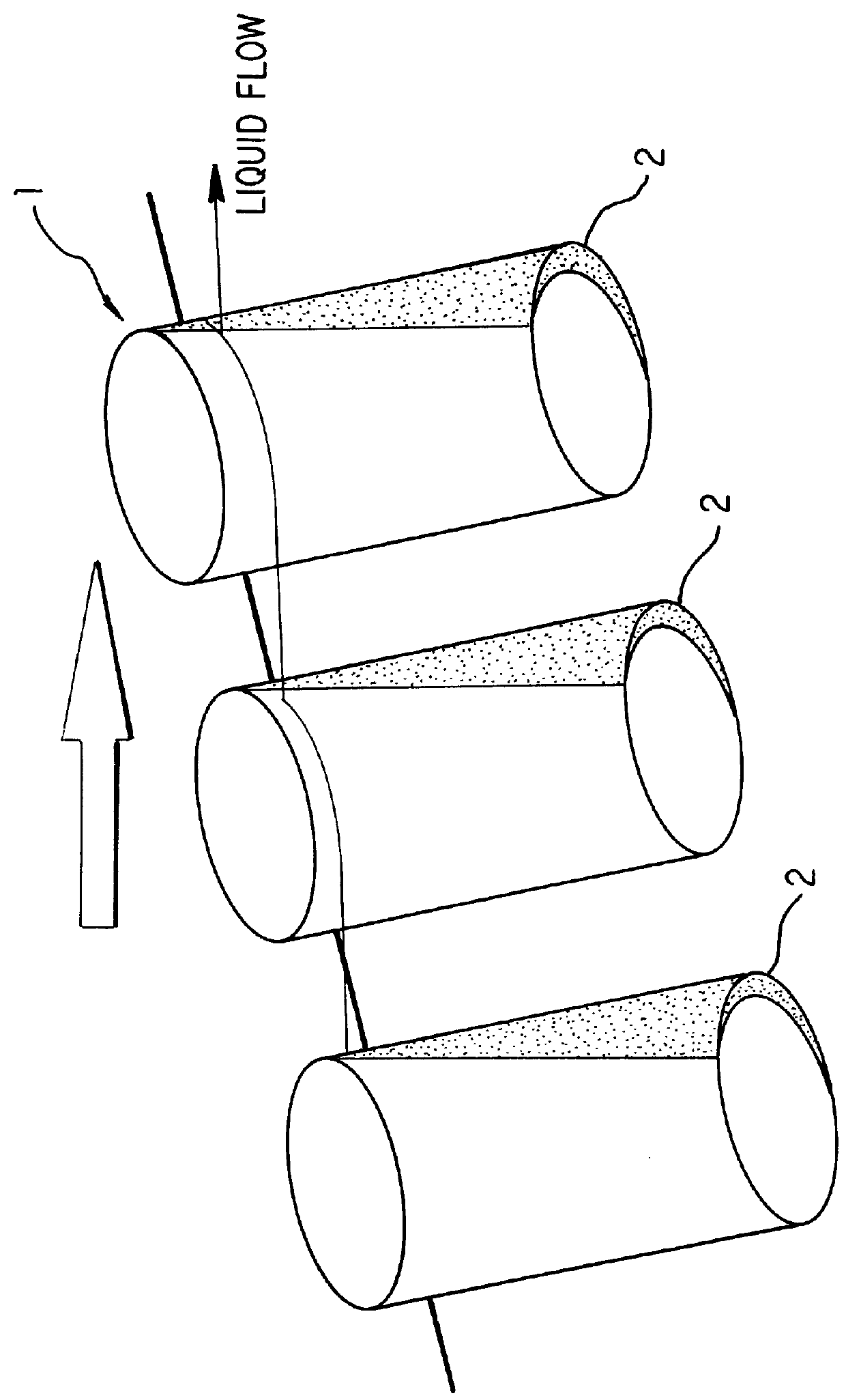

Device for lysing cells, spores, or microorganisms

InactiveUS6878540B2Improve convenienceImprove efficiencyBioreactor/fermenter combinationsBiological substance pretreatmentsMicroorganismSpore

A device for use with an ultrasonic transducer to lyse components of a fluid sample comprises a cartridge having a lysing chamber, an inlet port in fluid communication with the lysing chamber, and an outlet port for exit of the sample from the lysing chamber. The inlet and outlet ports are positioned to permit flow of the sample through the lysing chamber, and the chamber contains at least one solid phase for capturing the sample components to be lysed as the sample flows through the chamber. The lysing chamber is defined by at least one wall having an external surface for contacting the transducer to effect the transfer of ultrasonic energy to the chamber.

Owner:CEPHEID INC

Device and method for lysing cells, spores, or microorganisms

InactiveUS6887693B2Simple designImprove efficiencyBioreactor/fermenter combinationsBiological substance pretreatmentsSporeMicroorganism

A device for lysing components (e.g., cells, spores, or microorganisms) of a fluid sample comprises a cartridge having a lysing chamber for receiving the sample and having at least one solid phase in the lysing chamber for capturing the sample components to be lysed. An ultrasonic transducer is coupled to a wall of the lysing chamber to transfer ultrasonic energy to the captured sample components.

Owner:CEPHEID INC

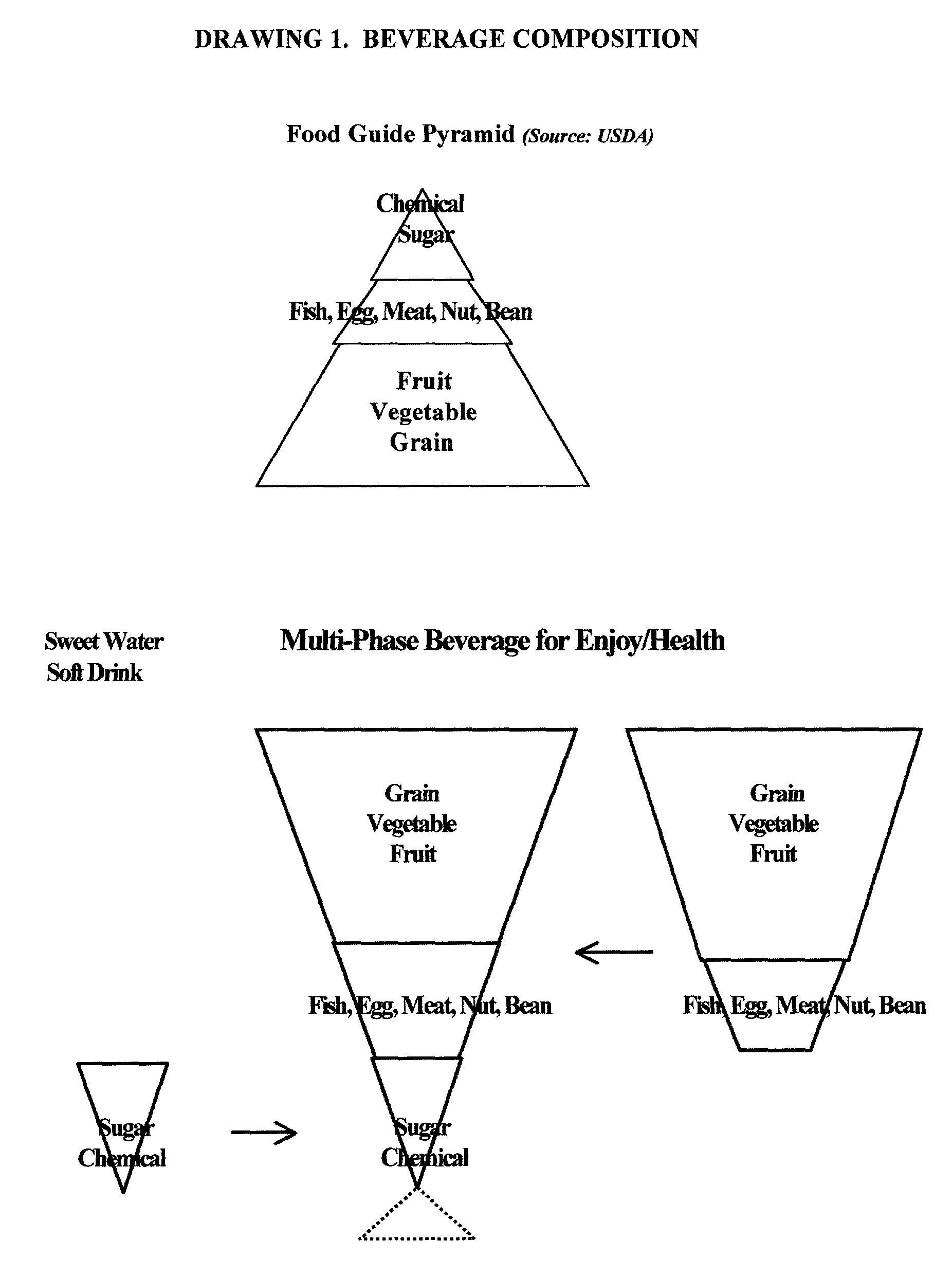

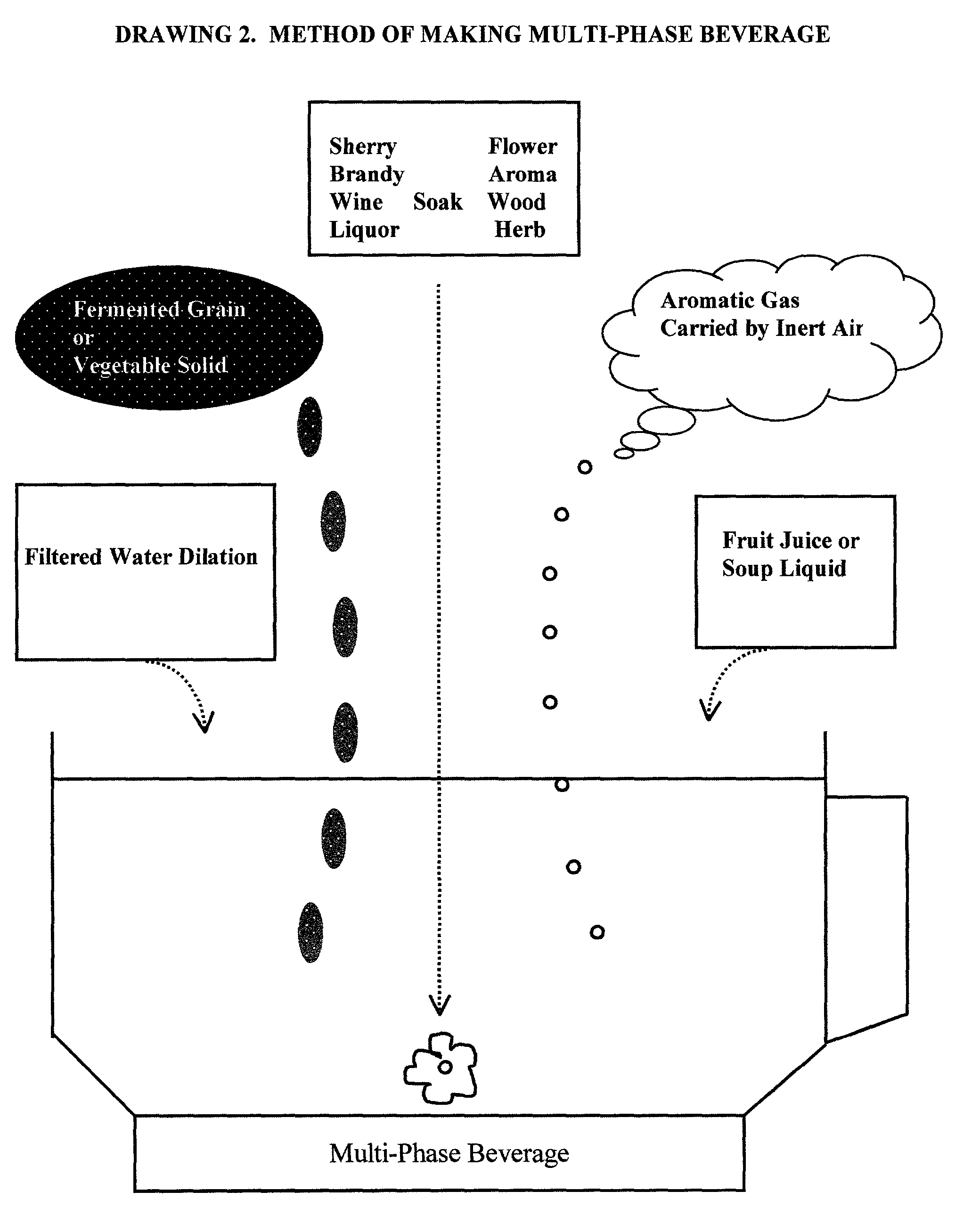

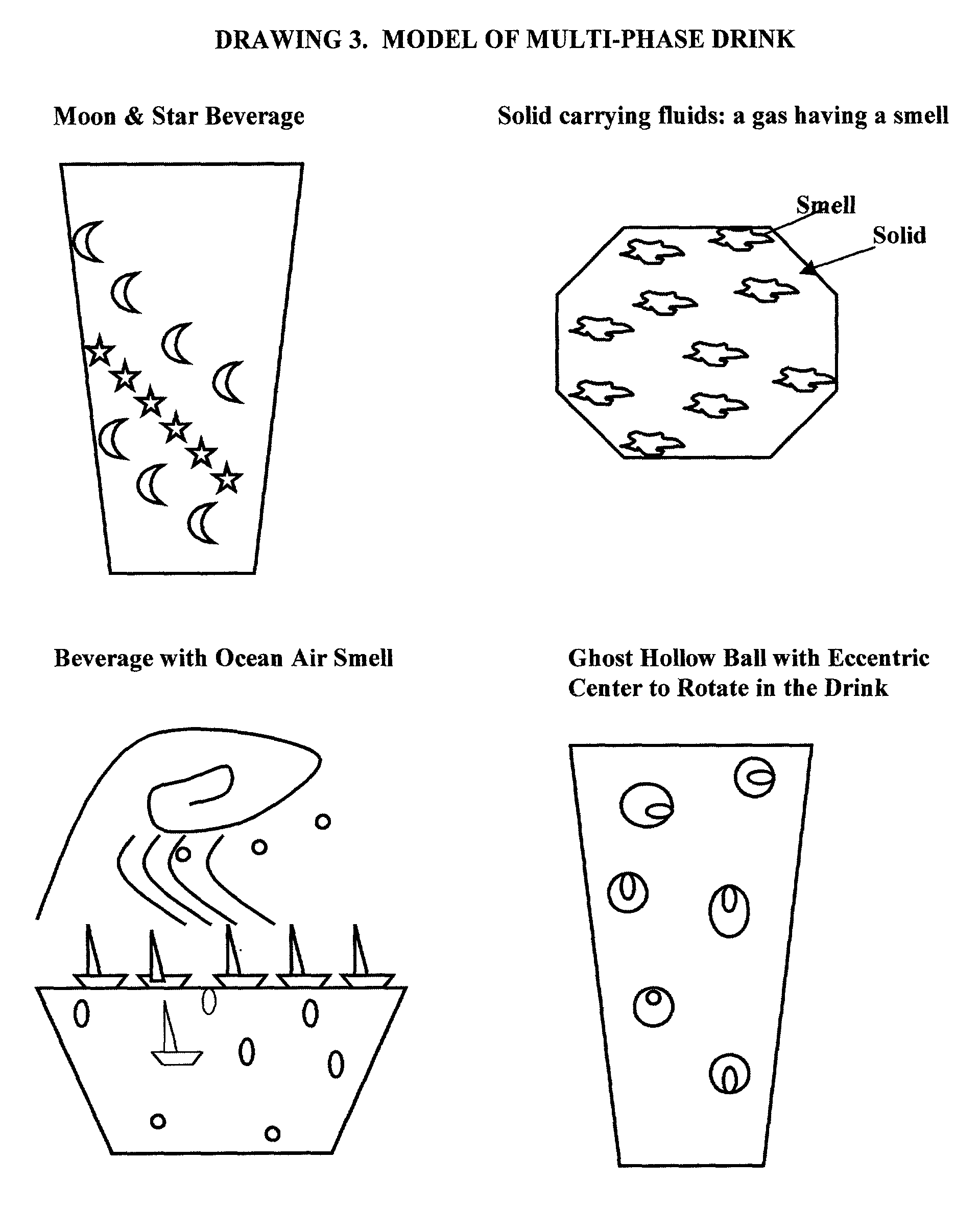

Multi-phase food & beverage

A method of making, combining, and using a balanced multi-phase food mixture and a multi-phase beverage made thereof is incorporated into carbonated herb beverage, aerated tea, fast fermented grain drink, amino acid flavored beverage, alcohol soaked cocktail drink, and aerated vegetable beverage. The liquid phase comprises total small molecular mineral and sugar up to 350 mOsm, pH 3.5-7.8, sweetener up to 7 wt %, alcohol up to 3 wt %, protein up to 30 wt %, fiber 20-37 gram per 2000 calories, at least 30% of calories are derived from complex carbohydrate, and up to 5% by volume gas, which will release a meaningful smell when being consumed. The solid phase includes at least 10% by weight plant mix, complex carbohydrate, protein, fat, and a combination thereof The beverage is natural and balanced referred to physiological body composition for normalizing body composition and fluid metabolism toward optimal body fitness with increased sensory experience and satiety.

Owner:ZHAO IRIS GINRON

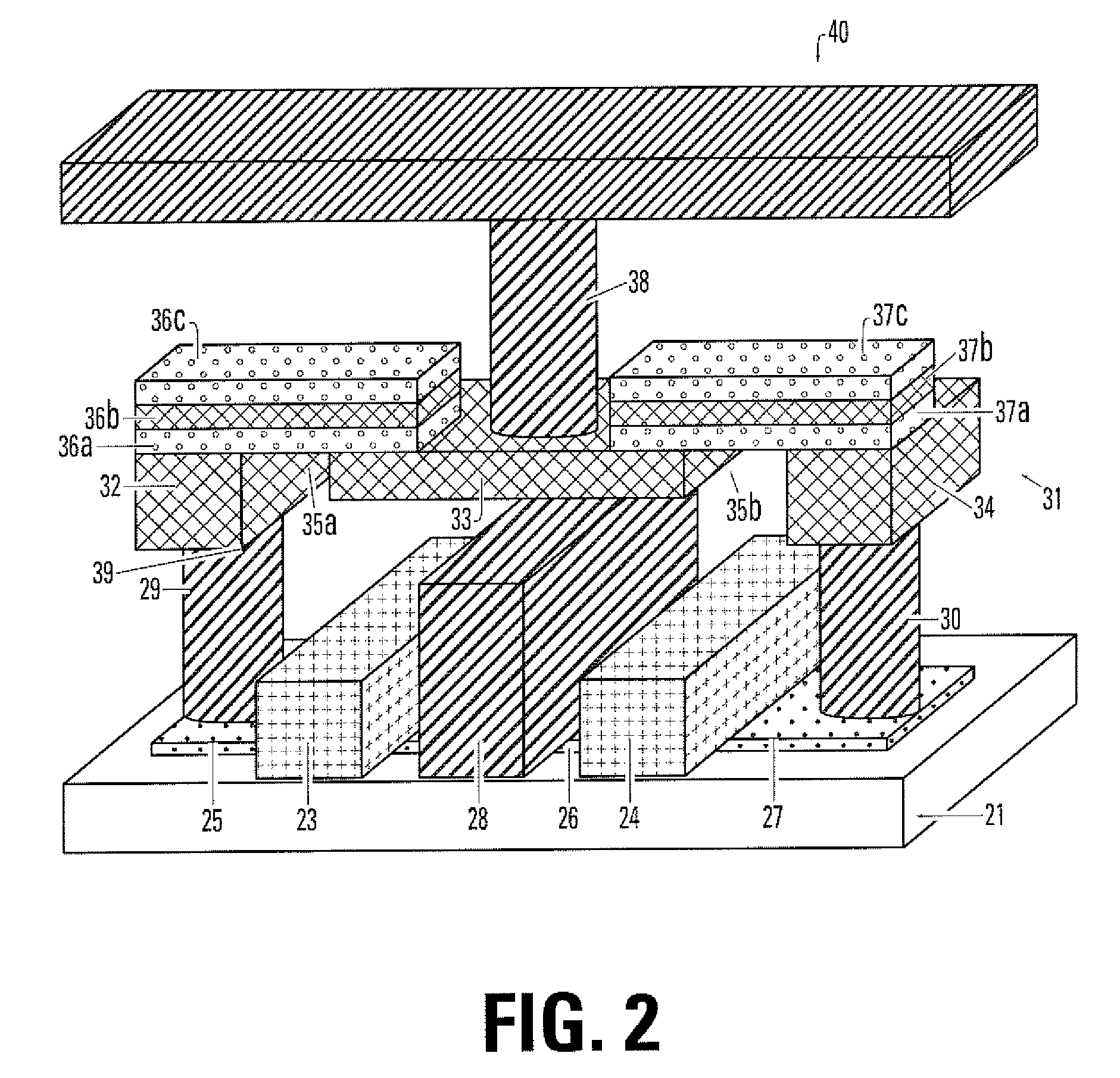

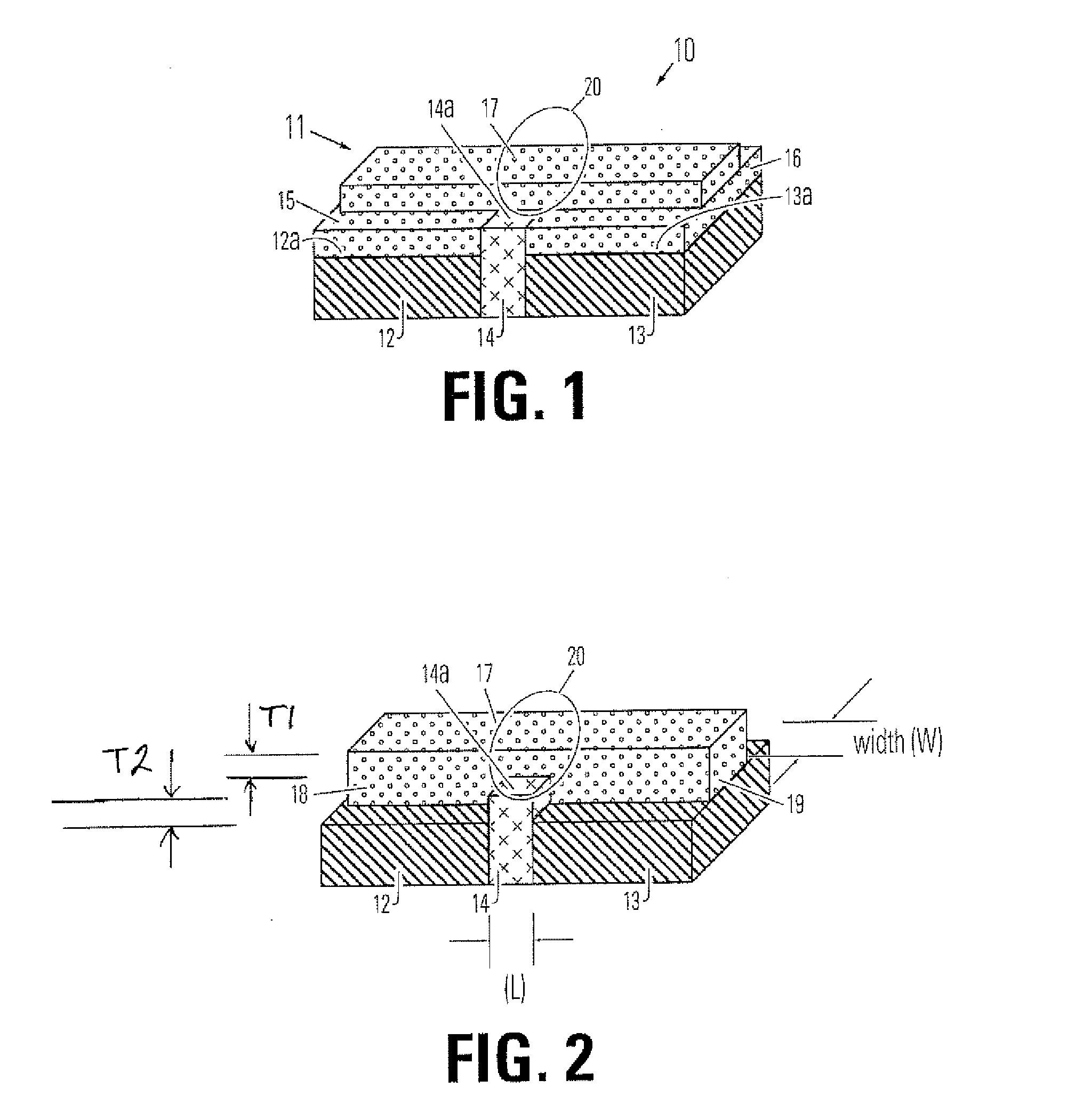

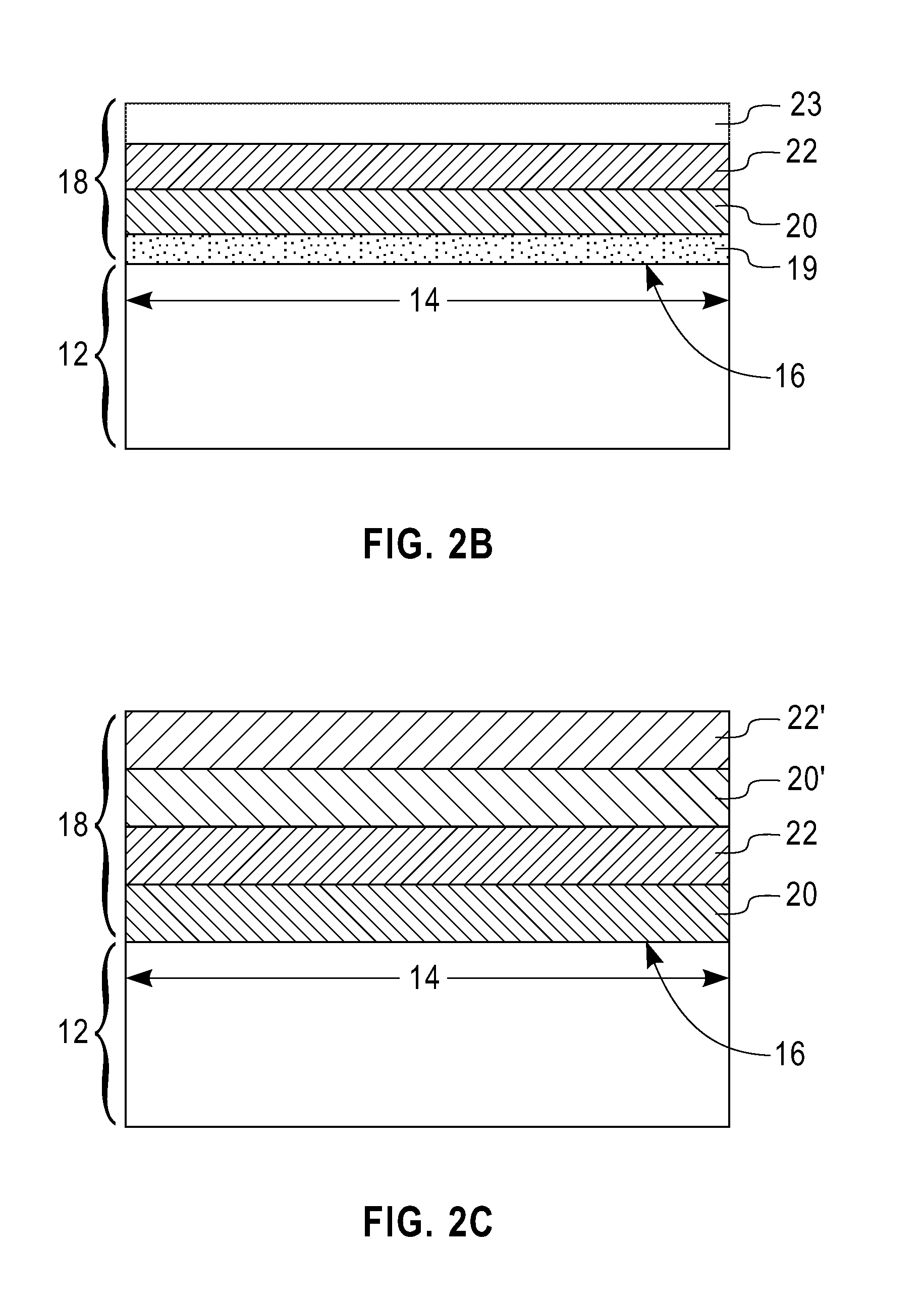

Thin film fuse phase change cell with thermal isolation layer and manufacturing method

ActiveUS20060284214A1Simple structureReduce power consumptionSolid-state devicesDigital storageThermal isolationEngineering

A memory device comprising a first electrode having a top side, a second electrode having a top side and an insulating member between the first electrode and the second electrode. The insulating member has a thickness between the first and second electrodes near the top side of the first electrode and the top side of the second electrode. A bridge of memory material crosses the insulating member, and defines an inter-electrode path between the first and second electrodes across the insulating member. An array of such memory cells is provided. The bridge comprises an active layer of memory material on the first side having at least two solid phases and a blanket of thermal insulating material overlying the memory material having thermal conductivity less than that of an overlying electrically insulating layer.

Owner:MACRONIX INT CO LTD

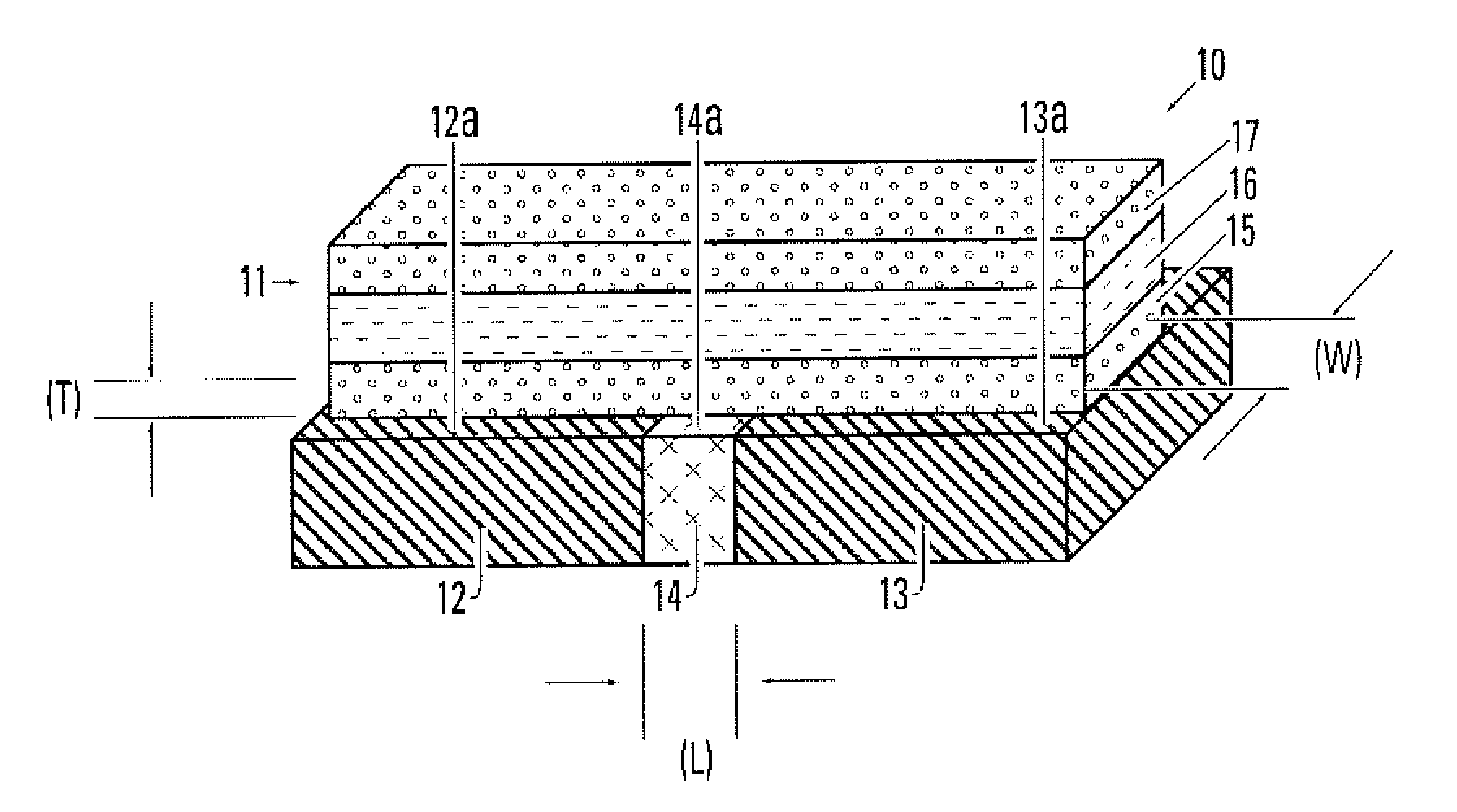

Thin Film Fuse Phase Change Cell with Thermal Isolation Pad and Manufacturing Method

ActiveUS20070131922A1Simple structureSmall reset currentSolid-state devicesSemiconductor/solid-state device manufacturingThermal isolationEngineering

A memory device comprising a first electrode having a top side, a second electrode having a top side and an insulating member between the first electrode and the second electrode. The insulating member has a thickness between the first and second electrodes near the top side of the first electrode and the top side of the second electrode extends outwardly from the top sides of the first and second electrodes defining a wall of insulating material having top side. A bridge of memory material crosses the insulating member over the top of the wall, and defines an inter-electrode path between the first and second electrodes across the insulating member. An array of such memory cells is provided. The bridge comprises an active layer of memory material on the top side of the wall, having at least two solid phases and a layer of thermal insulating material overlying the memory material having thermal conductivity less than a thermal conductivity of the first and second electrodes.

Owner:MACRONIX INT CO LTD

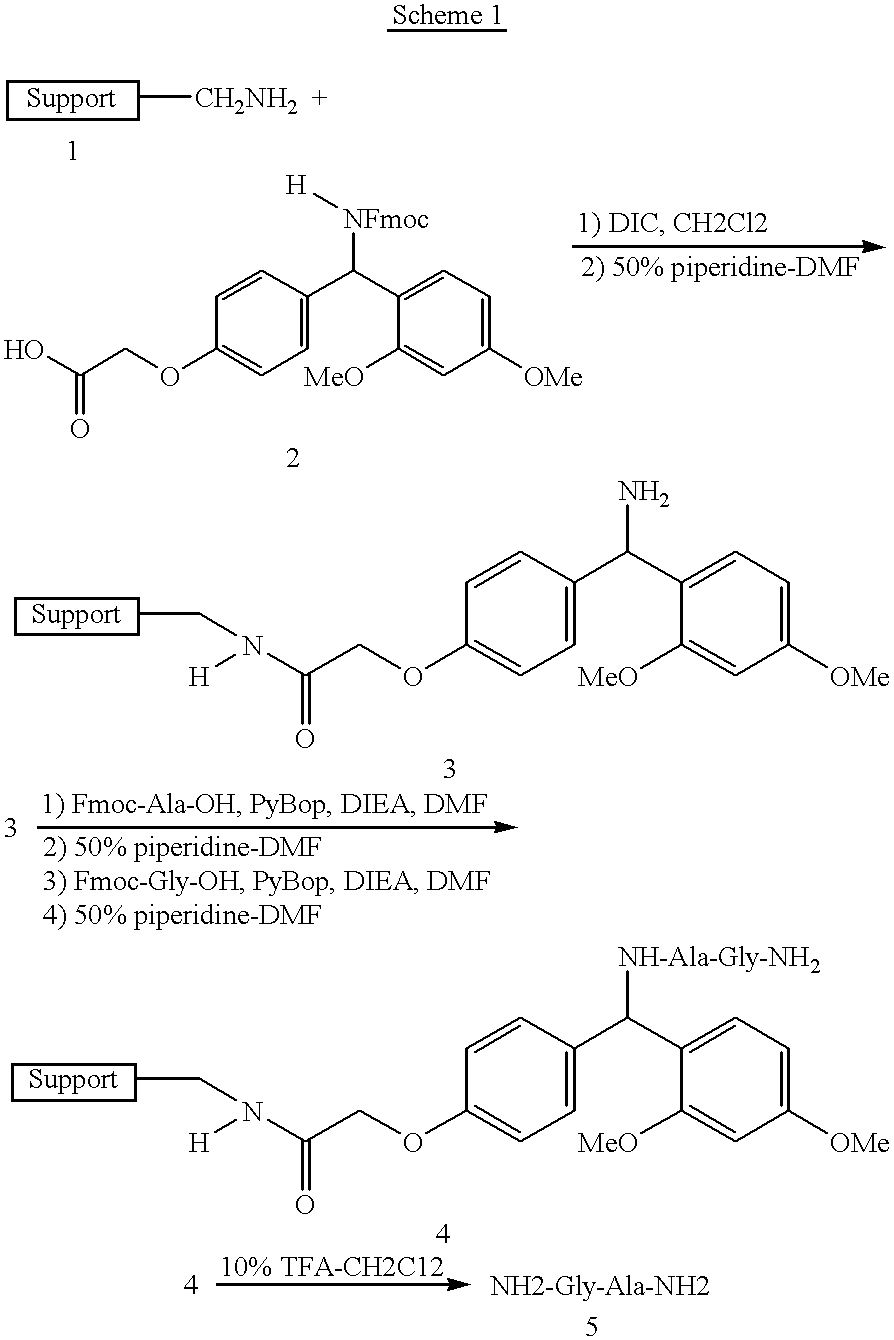

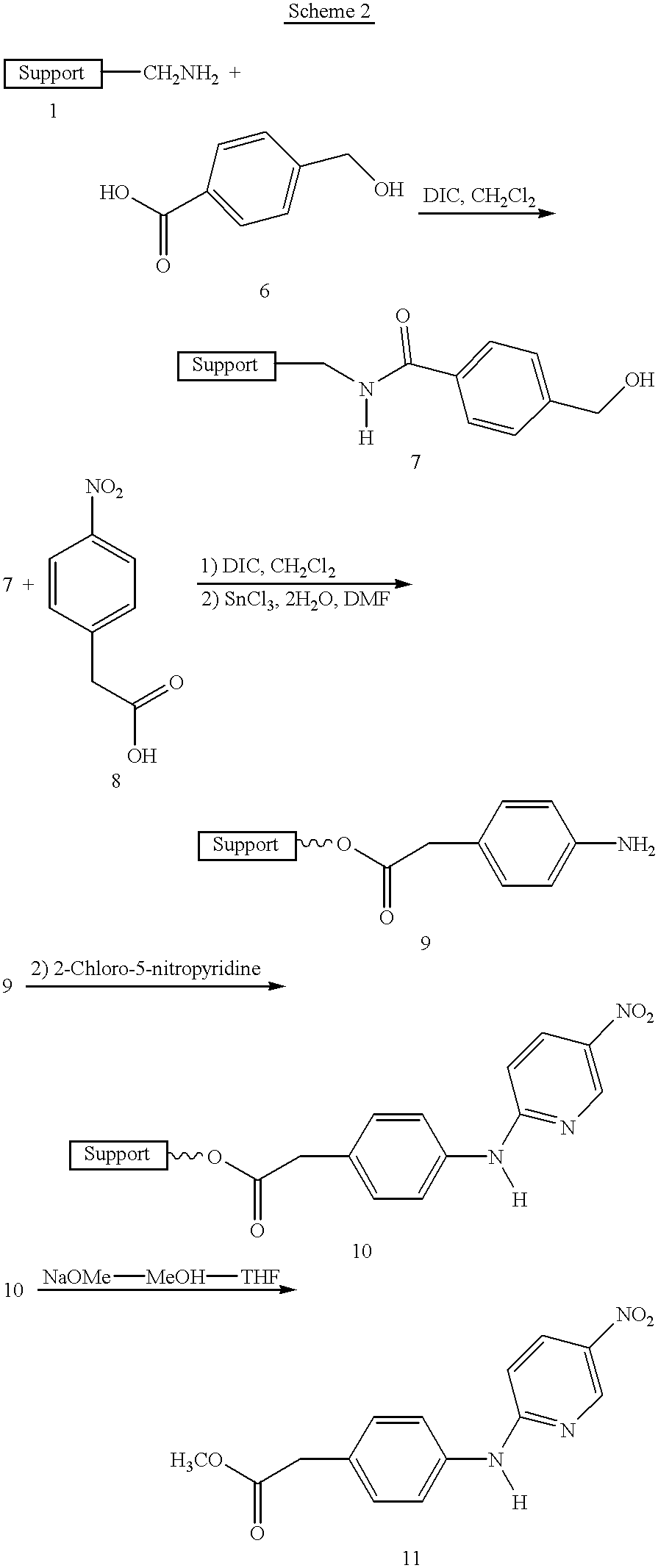

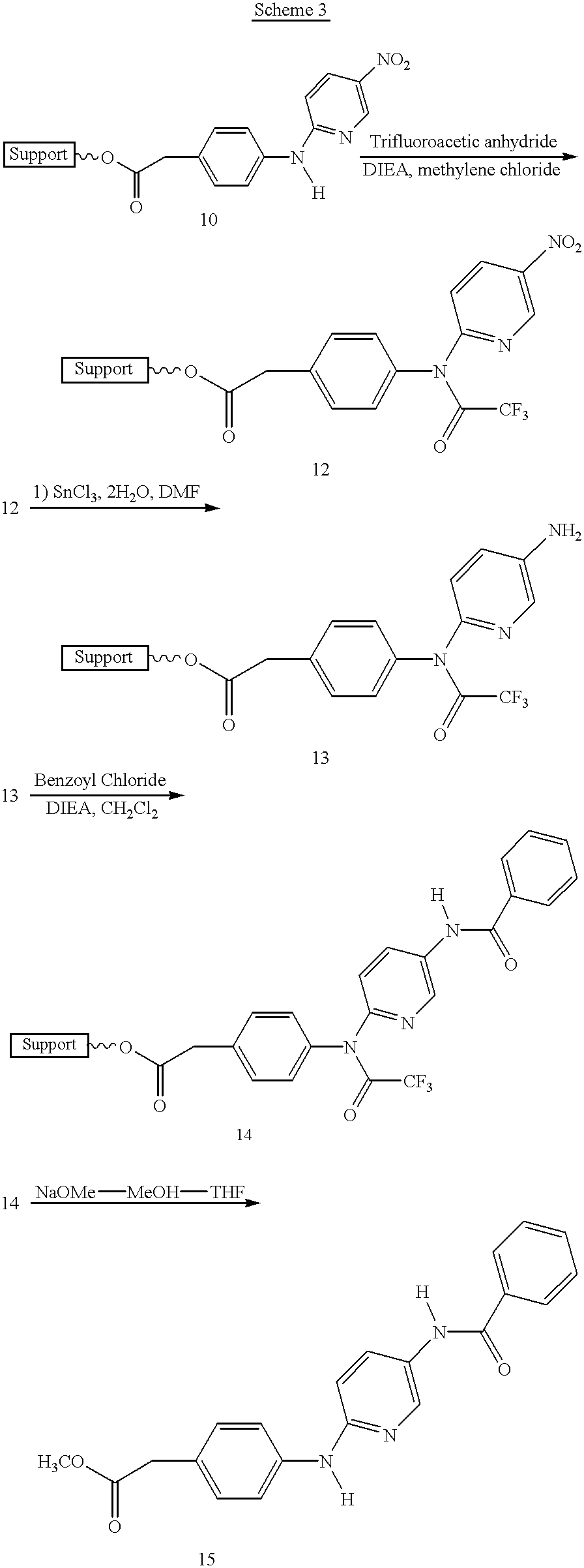

Topologically segregated, encoded solid phase libraries comprising linkers having an enzymatically susceptible bond

The invention relates to libraries of synthetic test compound attached to separate phase synthesis supports. In particular, the invention relates to libraries of synthetic test compound attached to separate phase synthesis supports that also contain coding molecules that encode the structure of the synthetic test compound. The molecules may be polymers or multiple nonpolymeric molecules. Each of the solid phase synthesis support beads contains a single type of synthetic test compound. The synthetic test compound can have backbone structures with linkages such as amide, urea, carbamate (i.e., urethane), ester, amino, sulfide, disulfide, or carbon-carbon, such as alkane and alkene, or any combination thereof. Examples of subunits suited for the different linkage chemistries are provided. The synthetic test compound can also be molecular scaffolds, such as derivatives of monocyclic of bicyclic carbohydrates, steroids, sugars, heterocyclic structures, polyaromatic structures, or other structures capable of acting as a scaffolding. Examples of suitable molecular scaffolds are provided. The invention also relates to methods of synthesizing such libraries and the use of such libraries to identify and characterize molecules of interest from among the library of synthetic test compound.

Owner:AVENTIS PHARMA INC

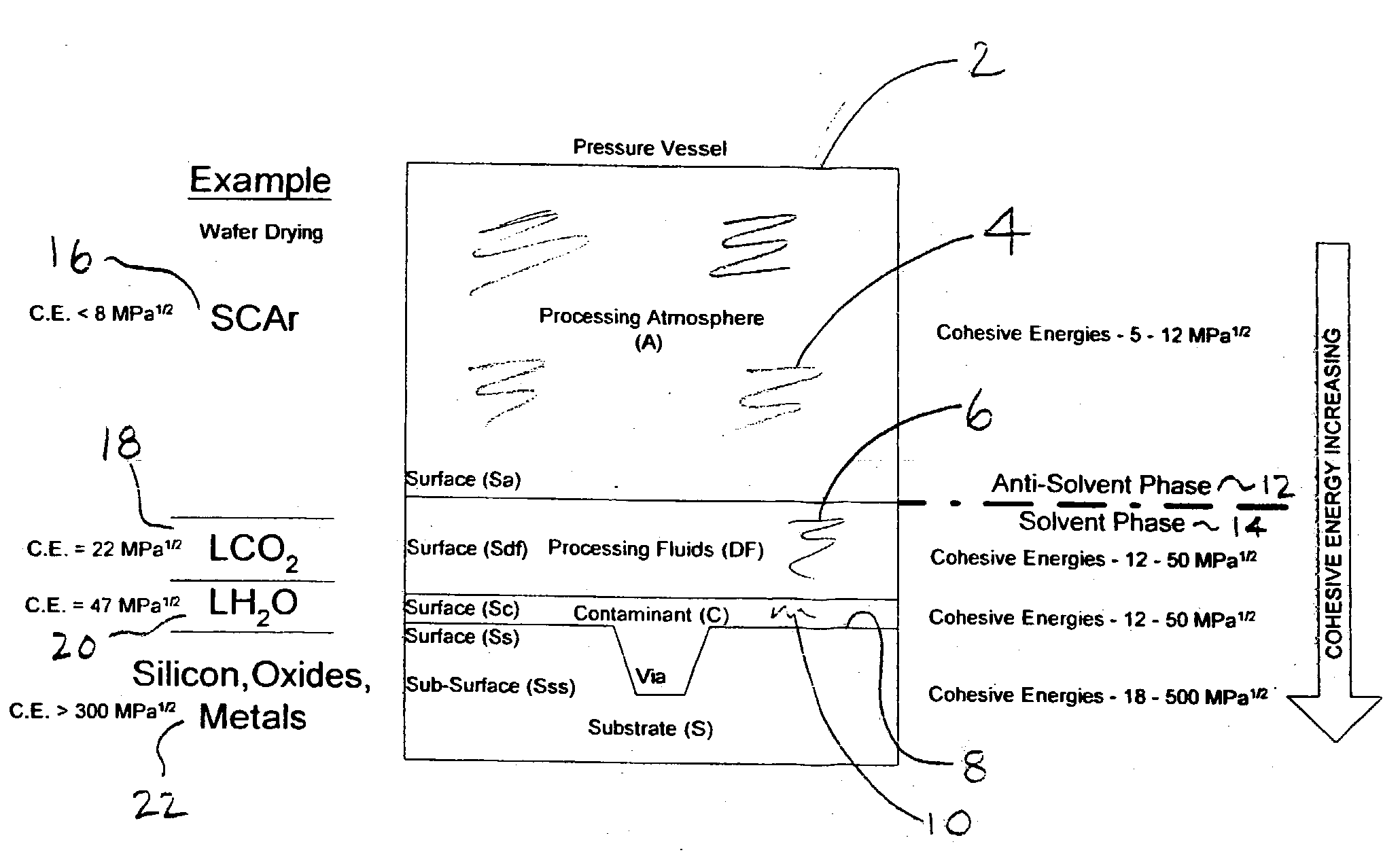

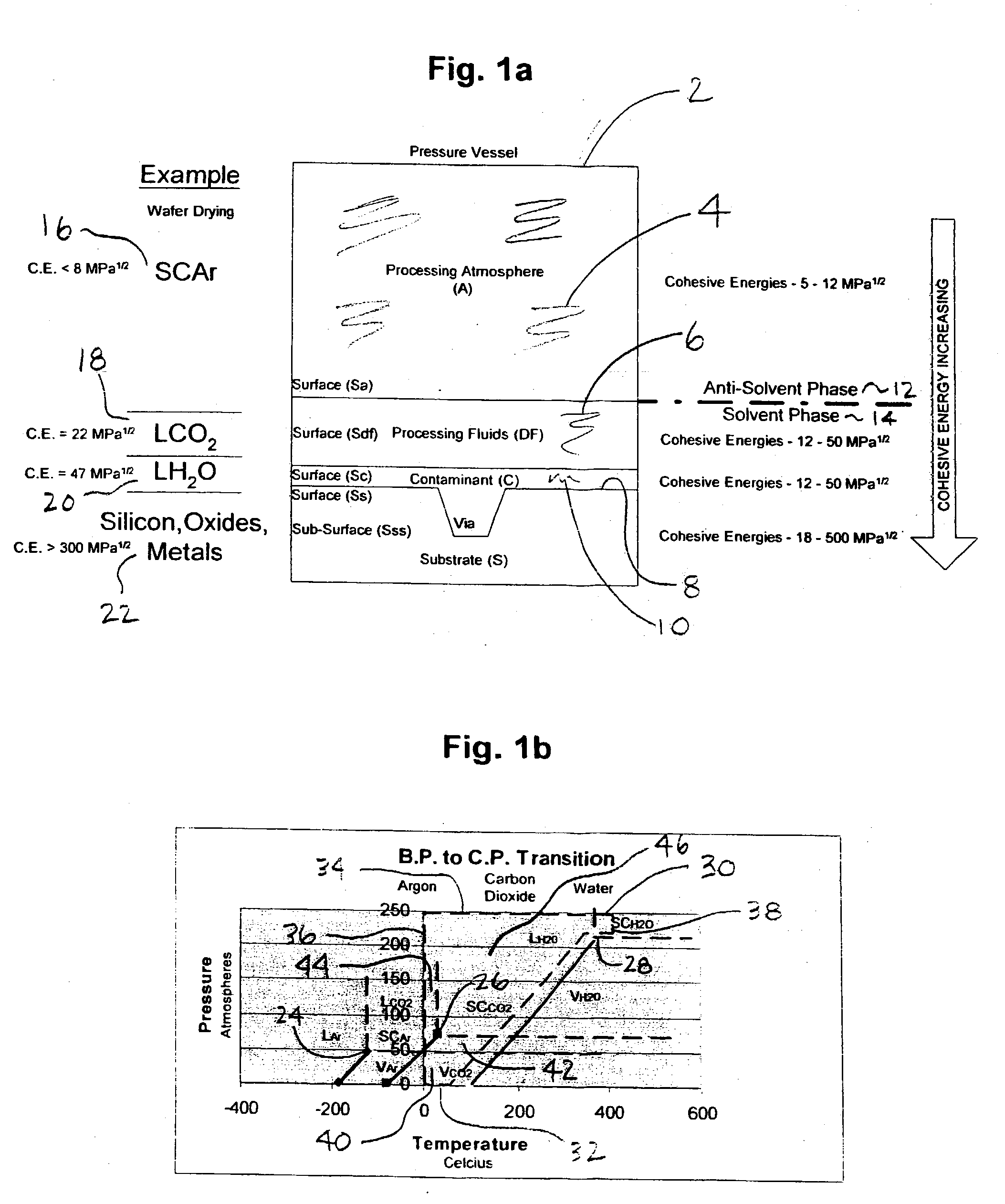

Precision surface treatments using dense fluids and a plasma

InactiveUS20040003828A1Reduce the temperatureEasy to separateElectric discharge tubesElectrostatic cleaningSolventSolid phases

The present invention is a method, process and apparatus for selective cleaning, drying, and modifying substrate surfaces and depositing thin films thereon using a dense phase gas solvent and admixtures within a first created supercritical fluid antisolvent. Dense fluids are used in combination with sub-atmospheric, atmospheric and super-atmospheric plasma adjuncts (cold and thermal plasmas) to enhance substrate surface cleaning, modification, precision drying and deposition processes herein. Moreover, conventional wet cleaning agents such as hydrofluoric acid and ammonium fluoride may be used with the present invention to perform substrate pre-treatments prior to precision drying and cleaning treatments described herein. Finally, dense fluid such as solid phase carbon dioxide and argon may be used as a follow-on treatment or in combination with plasmas to further treat a substrate surface.

Owner:JACKSON DAVID P

Ceramic slurry preparation and 3D (three dimensional) printing light curing molding method

ActiveCN106810215ALow viscosityHigh solid contentAdditive manufacturing apparatusCeramic shaping apparatusFlexural strengthVolumetric Mass Density

The invention provides a ceramic slurry preparation and 3D (three dimensional) printing light curing molding method. 25-85vol% of ceramic powder and 15-75vol% of an optical resin premix solution are mainly involved, and the method includes: A), preparation of the optical resin premix : namely stirring a low polymer, a reactive diluent, a photoinitiator, a dispersing agent, a photosensitizer and a sensitizer according to a certain proportion under intermediate speed for 0.5-3 hours to enable the components to be mixed evenly; B), placing the premix solution and the ceramic powder in a ball mill according to certain volume for ball-milling for 5-15 hours to prepare the ceramic slurry high in solid content and low in viscosity; subjecting the ceramic slurry to curing molding layer by layer gradually on a 3D light curing molding machine to obtain a ceramic green body prior to aftertreatment of drying, degreasing, sintering and the like to obtain ceramic part. The method is high in preparation molding precision and free of molds to prepare complex structure parts, the ceramic product can reach more than 92% in density, 320-1750MPa in flexural strength and 1800-4500MPa in compression strength.

Owner:重庆摩方科技有限公司

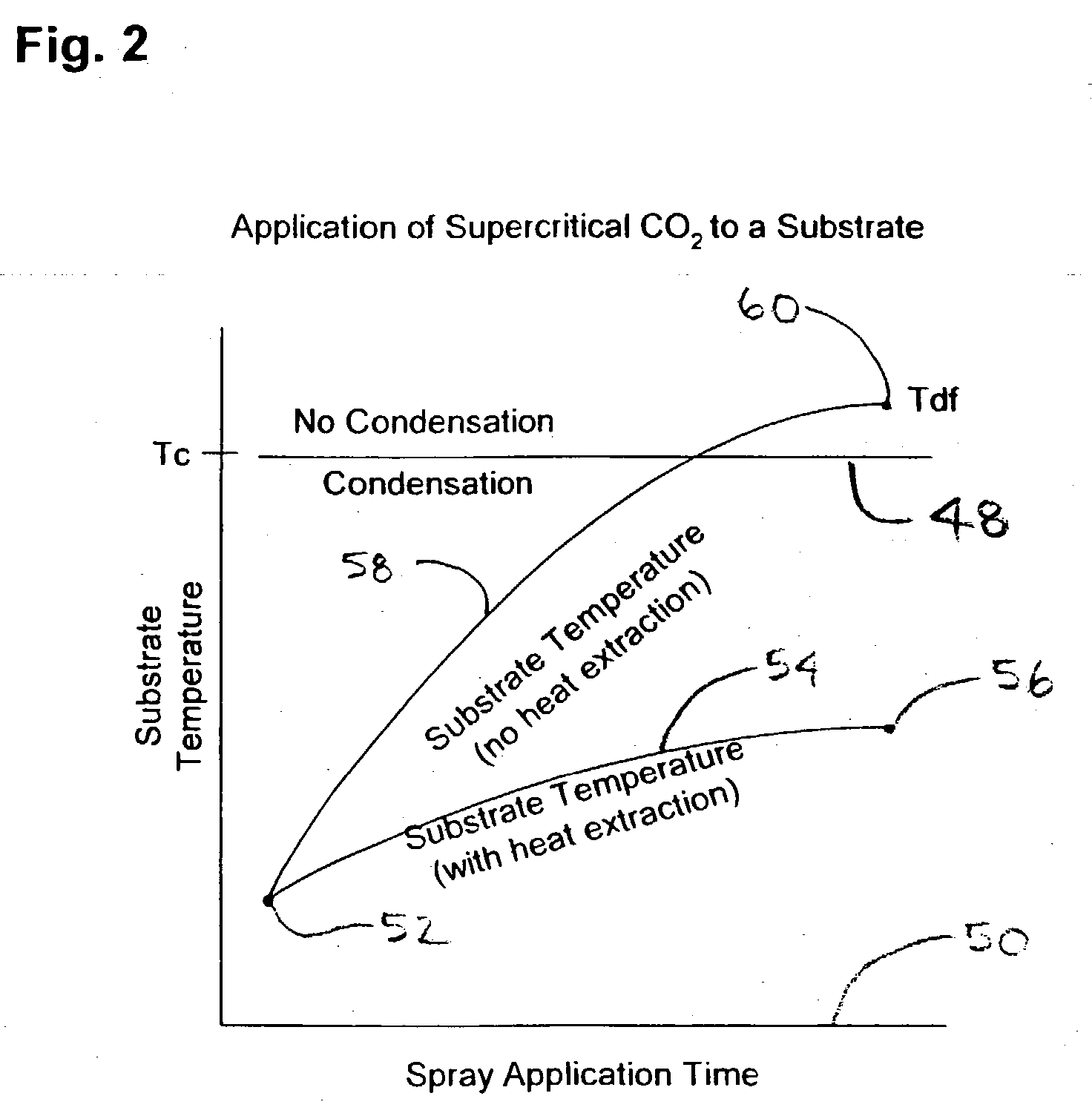

Methods and apparatus for drug delivery involving phase changing formulations

InactiveUS20020004063A1Cleanly peeled from the skinMaintenance of such surfaceSalicyclic acid active ingredientsAnaestheticsPharmaceutical formulationSoft solids

This invention relates to an apparatus and method of drug delivery on a human body surface. The formulation comprises a drug, a conversion agent capable of converting the formulation from a less solid phase to a coherent, soft, solid phase, and a vehicle medium or carrier for the drug and conversion agent. The drug formulation is applied to this human body surface in its less than solid phase and is subsequently converted to a soft solid phase while the drug is being delivered through the human body surface. After delivery of the drug is complete, the soft solid formulation can be removed or peeled from the body surface as a coherent solid formulation. The drug formulation provides control over drug delivery rates and allows the formulation to be removed without leaving a messy, residual formulation on the body surface.

Owner:CRESCITA THERAPEUTICS INC

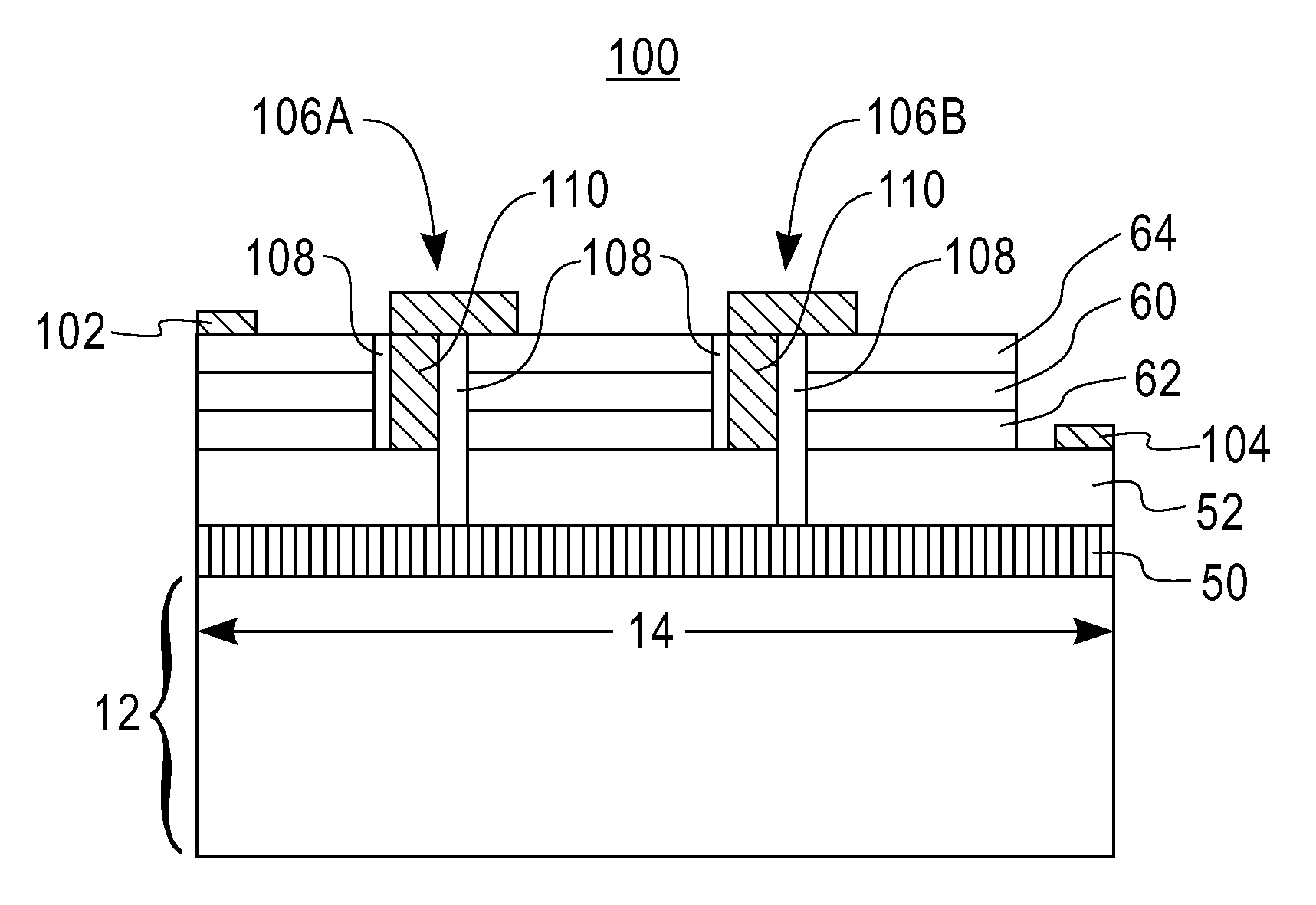

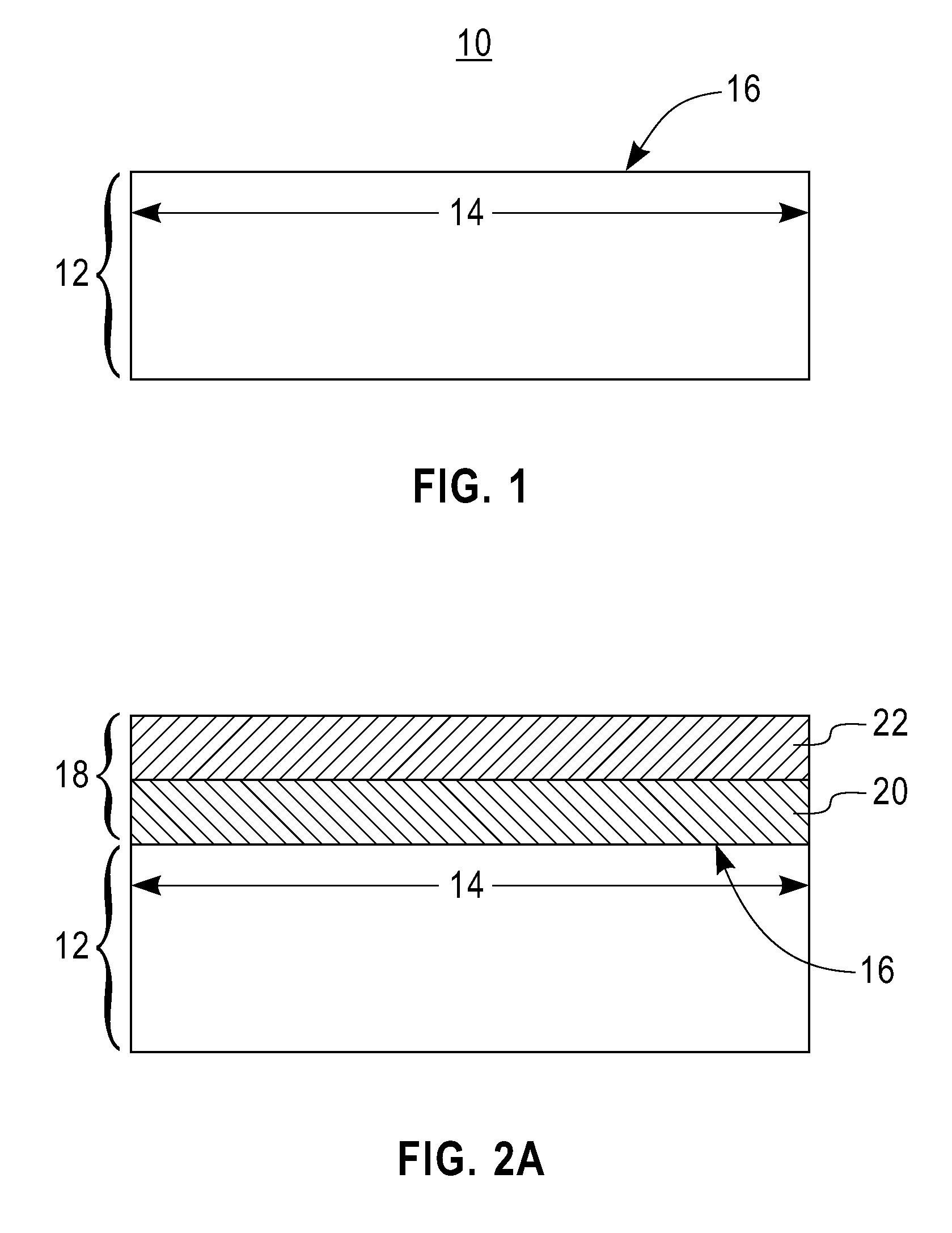

Low cost soi substrates for monolithic solar cells

InactiveUS20100221867A1Reduce defect densityFinal product manufactureSemiconductor/solid-state device manufacturingSoi substrateSingle crystal

A lost cost method for fabricating SOI substrates is provided. The method includes forming a stack of p-type doped amorphous Si-containing layers on a semiconductor region of a substrate by utilizing an evaporation deposition process. A solid phase recrystallization step is then performed to convert the amorphous Si-containing layers within the stack into a stack of p-type doped single crystalline Si-containing layers. After recrystallization, the single crystalline Si-containing layers are subjected to anodization and at least an oxidation step to form an SOI substrate. Solar cells and / or other semiconductor devices can be formed on the upper surface of the inventive SOI substrate.

Owner:GLOBALFOUNDRIES INC

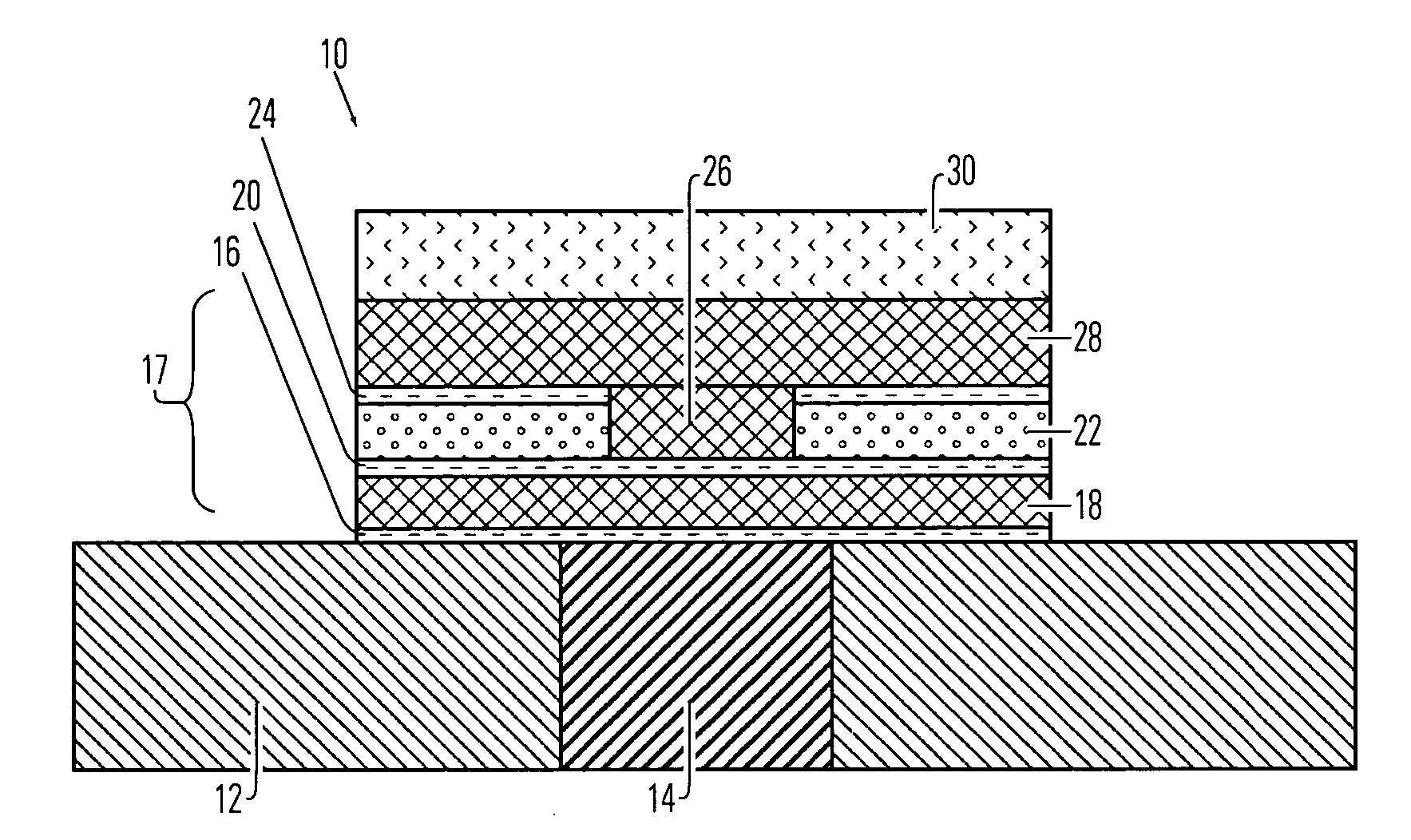

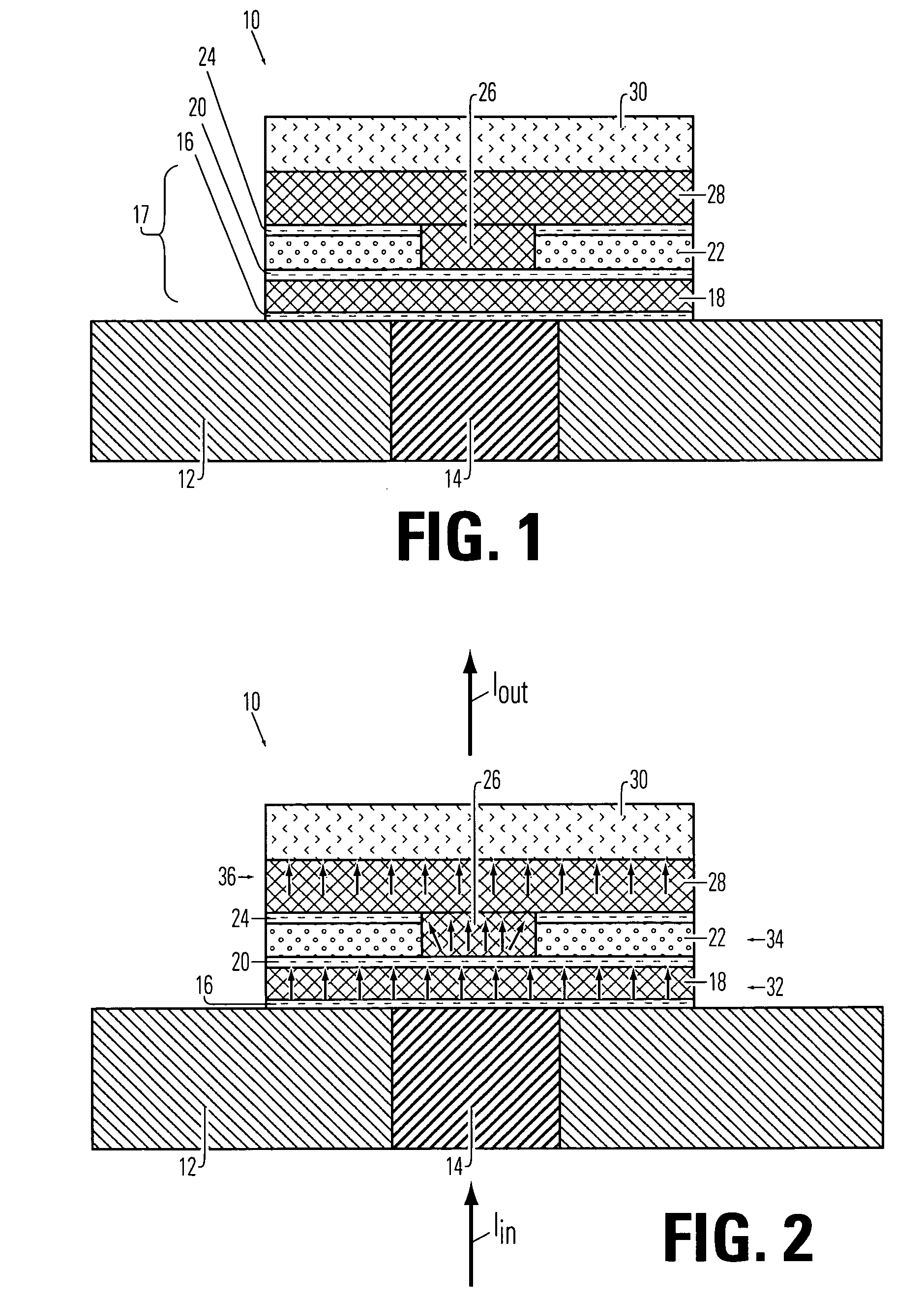

I-shaped phase change memory cell with thermal isolation

InactiveUS20080043520A1Solid-state devicesSemiconductor/solid-state device manufacturingThermal isolationPhase-change memory

A memory device includes two electrodes, vertically separated and having mutually opposed contact surfaces, between which lies a phase change cell. The phase change cell includes an upper phase change member, having a contact surface in electrical contact with the first electrode; a lower phase change member, having a contact surface in electrical contact with the second electrode; and a kernel member disposed between and in electrical contact with the upper and lower phase change members. The phase change cell is formed of material having at least two solid phases, and the lateral extent of the upper and lower phase change members is substantially greater than that of the kernel member. An intermediate insulating layer is disposed between the upper and lower phase change members adjacent to the kernel member.

Owner:MACRONIX INT CO LTD

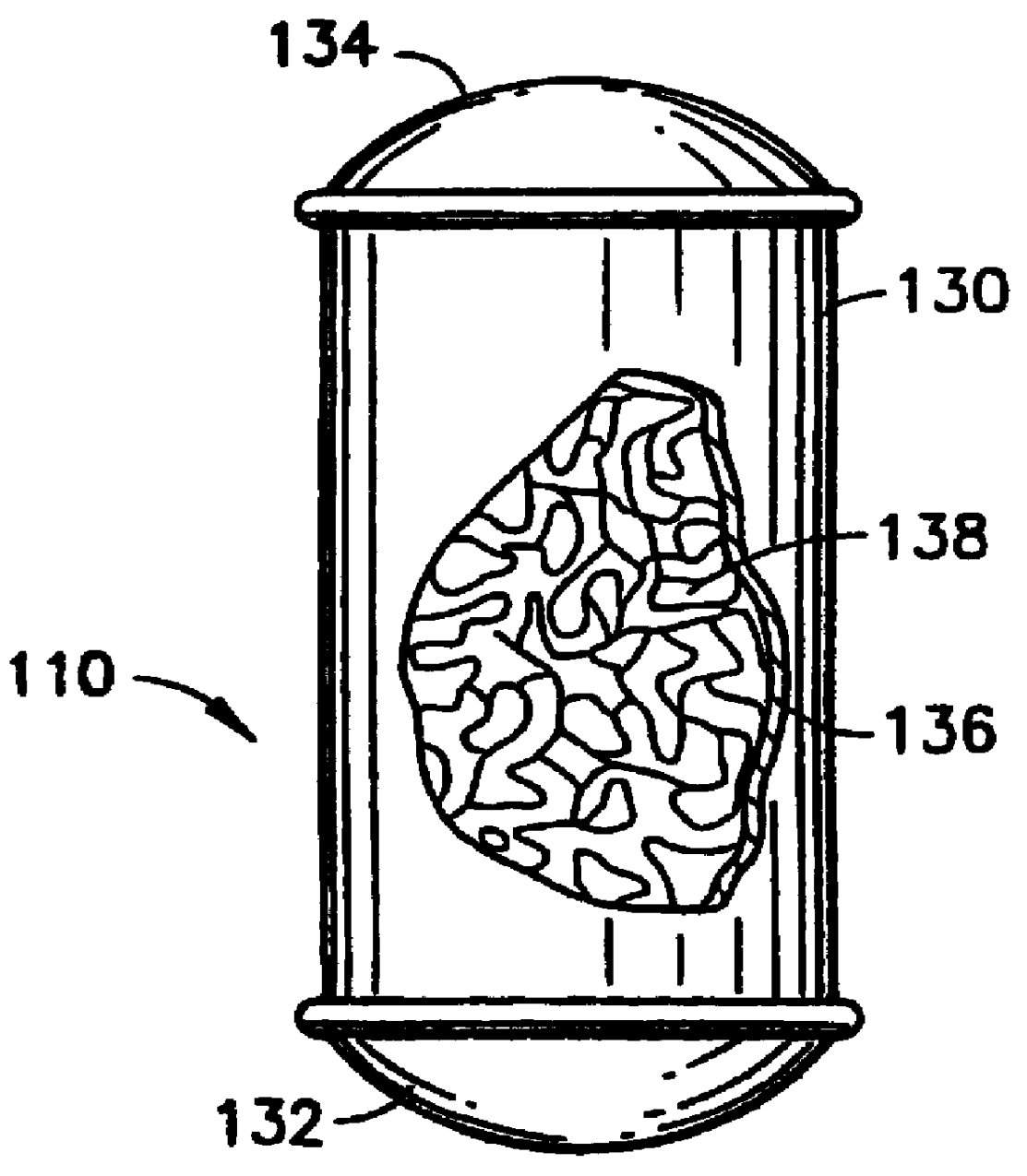

Sorbent-based gas storage and delivery system for dispensing of high-purity gas, and apparatus and process for manufacturing semiconductor devices, products and precursor structures utilizing same

A sorbent-based gas storage and dispensing system, including a storage and dispensing vessel containing a solid-phase physical sorbent medium having a sorbate gas physically adsorbed thereon. A chemisorbent material is provided in the vessel to chemisorb the impurities for gas phase removal thereof in the storage and dispensing vessel. Desorbed sorbate gas is discharged from the storage and dispensing vessel by a dispensing assembly coupled to the vessel. The chemisorbent may be provided in a capsule including an impurity-permeable, but sorbate gas-impermeable membrane, and installed in the vessel at the time of sorbent material loading. Semiconductor manufacturing processes and products manufactured by such processes are described.

Owner:ENTEGRIS INC

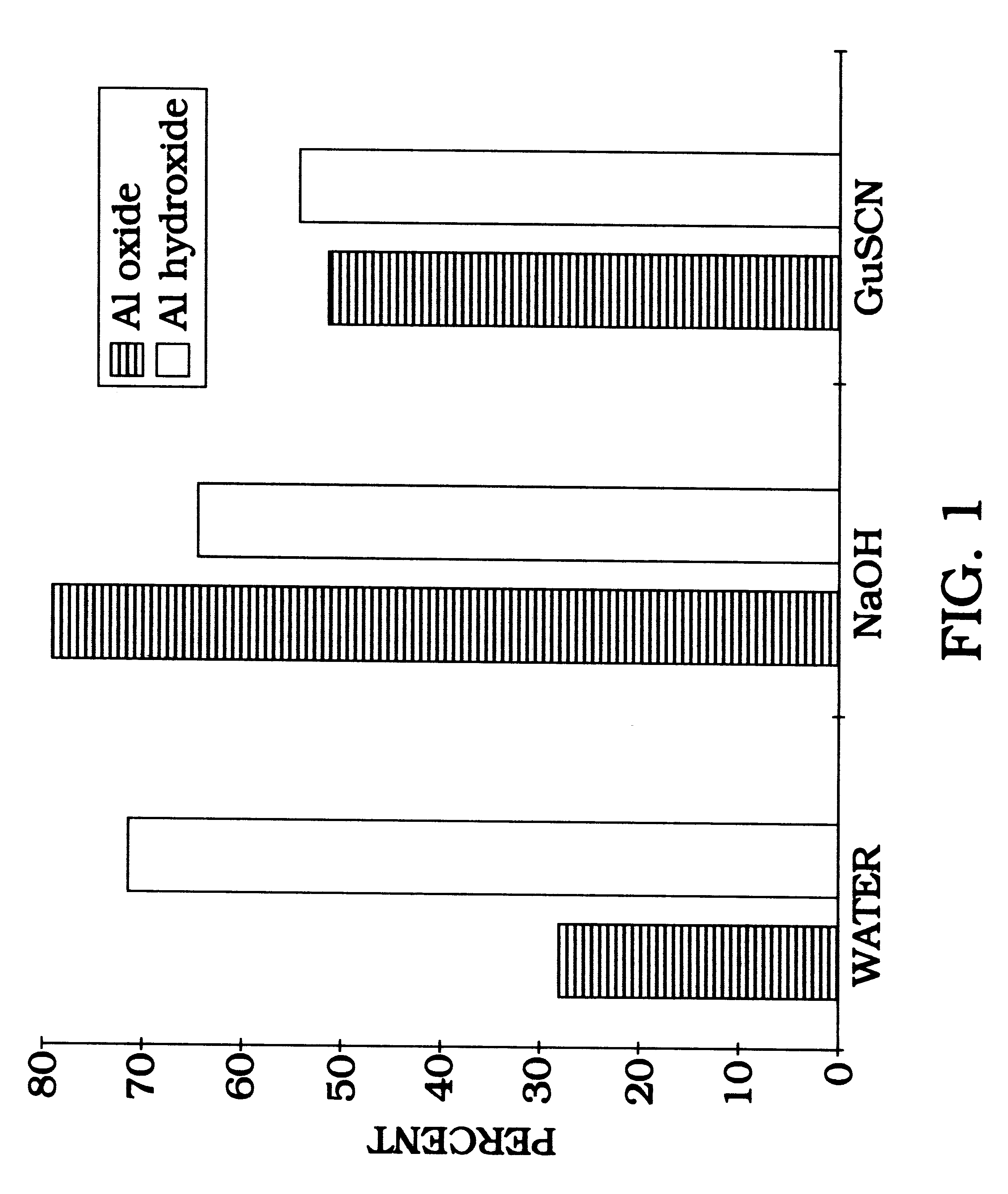

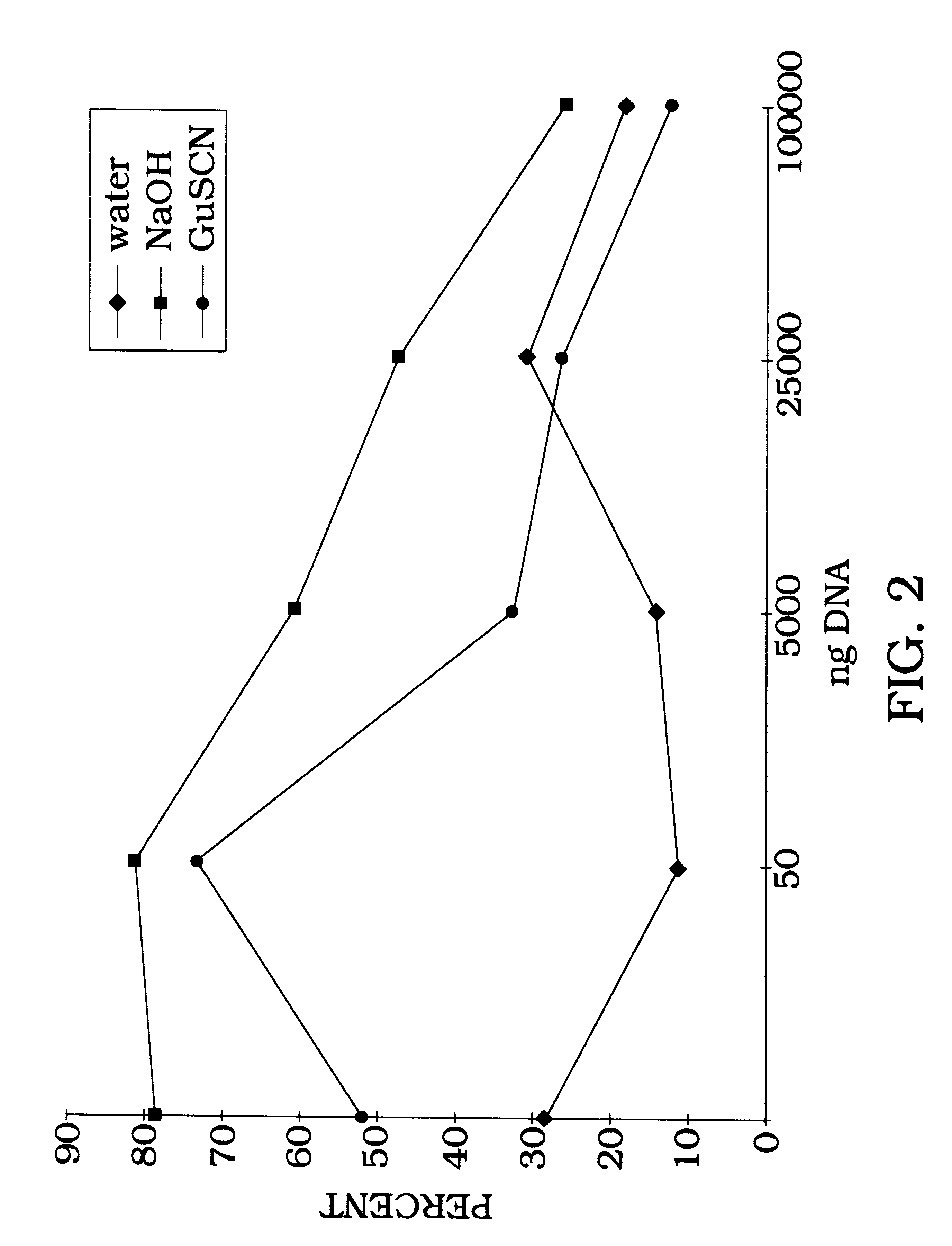

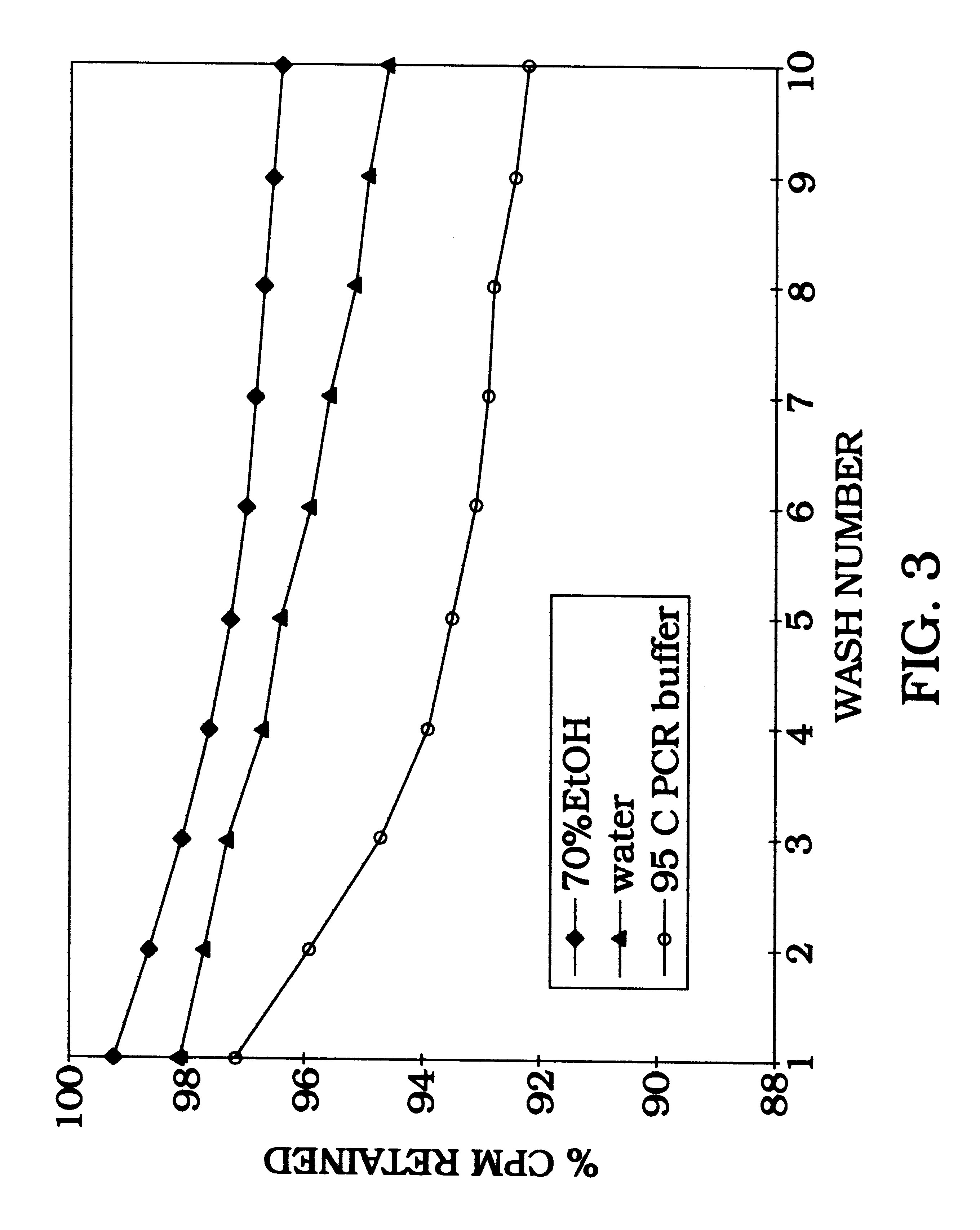

Nucleic acid archiving

InactiveUS6291166B1Overcomes drawbackEasy to cleanBioreactor/fermenter combinationsBiological substance pretreatmentsRepeat analysisBlood plasma

This invention is directed to a process for irreversibly binding nucleic acid to solid phase and corresponding processes for the utilization thereof. Nucleic acid is bound to solid phase matrixes exhibiting sufficient hydrophilicity and electropositivity to irreversibly bind the nucleic acids from a sample. These processes include nucleic acid (double or single stranded DNA and RNA) capture from high volume:low concentration specimens, buffer changes, washes, and volume reductions, and enable the interface of solid phase bound nucleic acid with enzyme, hybridization or amplification strategies. The invention, solid phase irreversibly bound nucleic acid, may be used, for example, in repeated analyses to confirm results or test additional genes in both research and commercial applications. Further, a method is described for virus extraction, purification, and solid phase amplification from large volume plasma specimens.

Owner:APPL BIOSYSTEMS INC

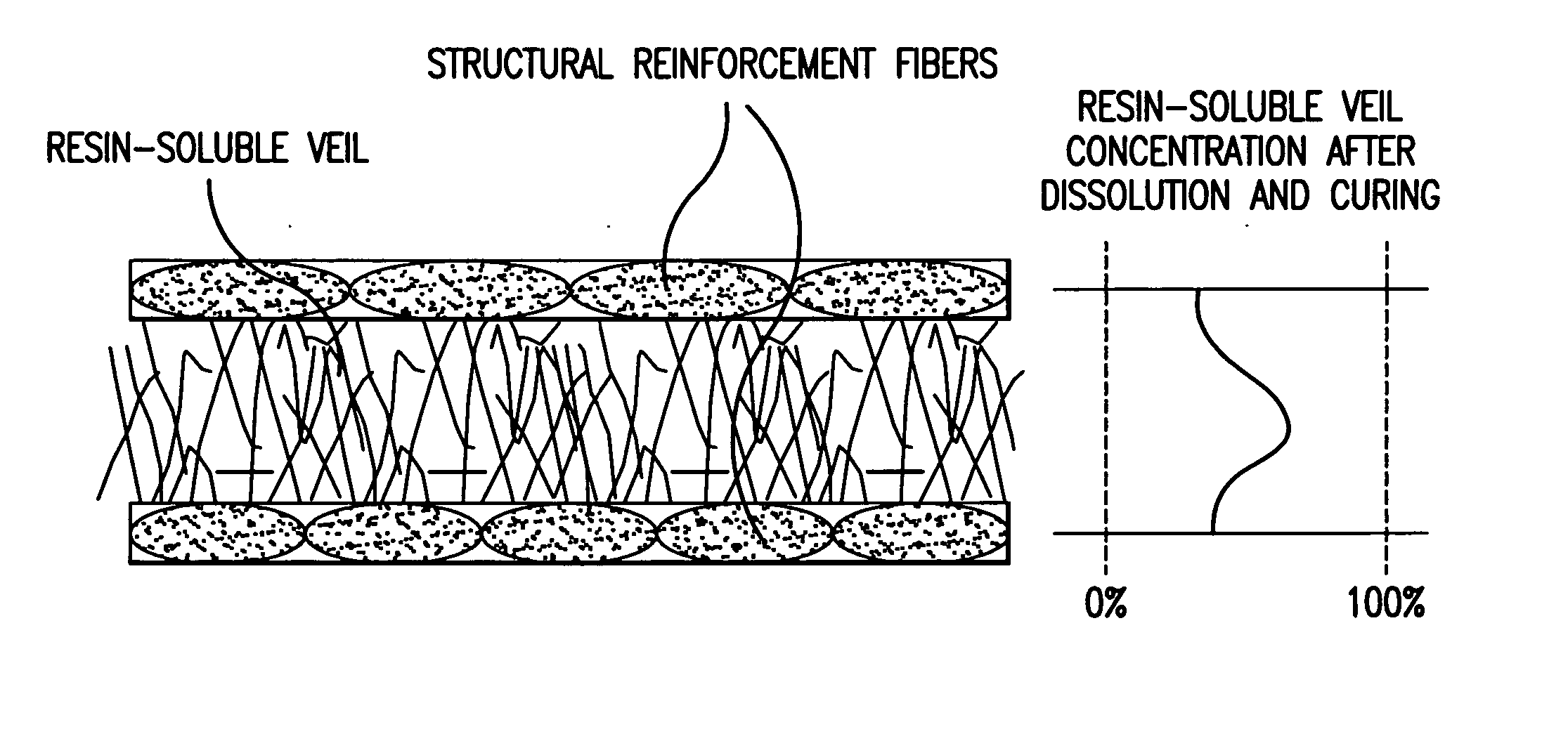

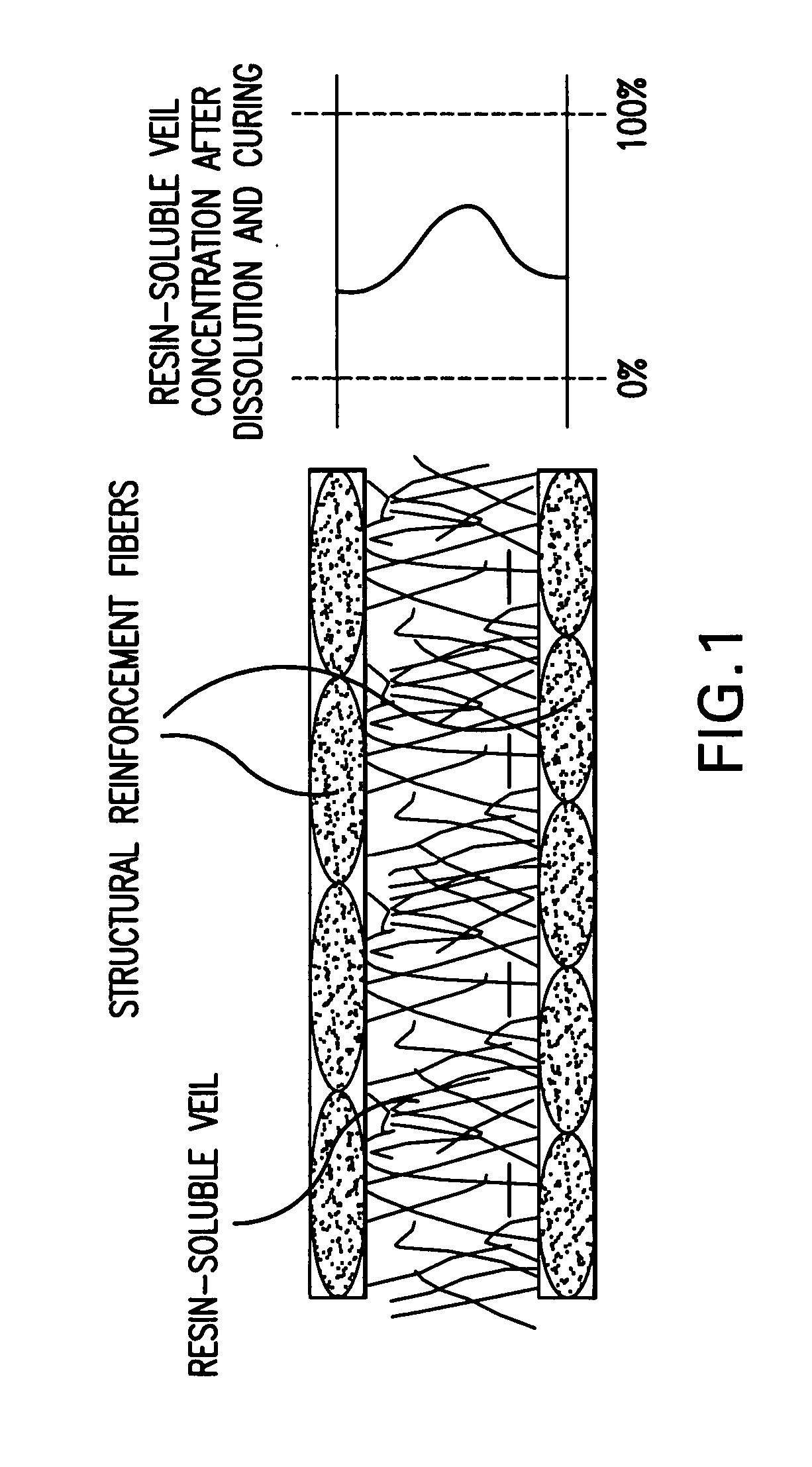

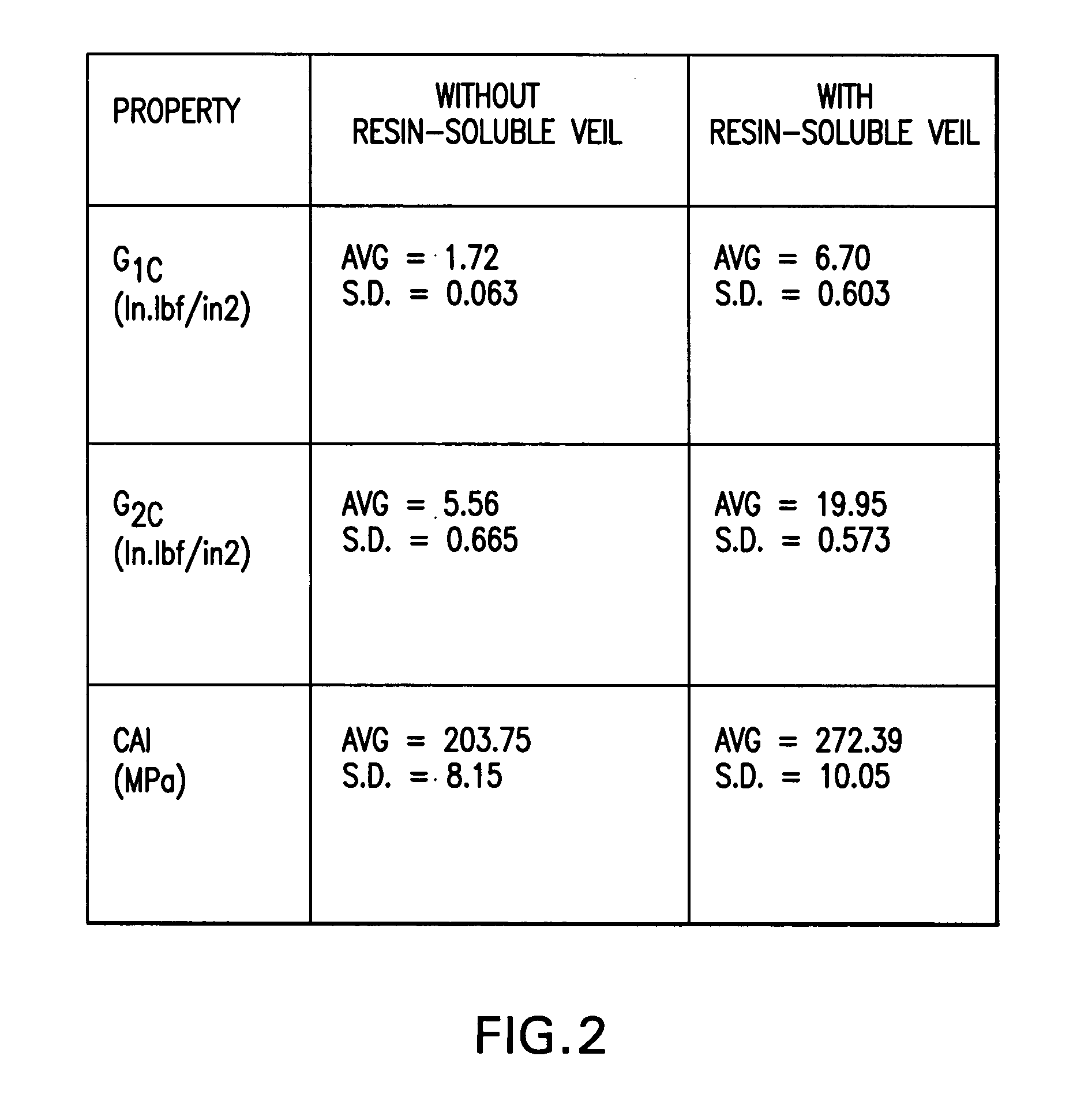

Resin-soluble thermoplastic veil for composite materials

ActiveUS20060252334A1Improve the level ofImprove toughnessWood working apparatusVehicle componentsFiberResin matrix

A resin-soluble thermoplastic polymer veil toughening element for a curable composition wherein the polymer element is a non-woven veil in solid phase adapted to undergo at least partial phase transition to fluid phase on contact with a component of the curable resin matrix composition in which it is soluble at a temperature which is less than the temperature for substantial onset of gelling and / or curing of the curable composition and which temperature is less than the polymer elements melt temperature; a method for the preparation thereof, a preform support structure for a curable composition comprising the at least one thermoplastic veil element together with structural reinforcement fibers, methods for preparation thereof, a curable composition comprising the at least one thermoplastic veil element or the support structure and a curable resin matrix composition, a method for preparation and curing thereof, and a cured composite or resin body obtained thereby, and known and novel uses thereof.

Owner:CYTEC TECH CORP

Reaction plenum with magnetic separation and/or ultrasonic agitation

InactiveUS6277332B1Easy to runPeptide librariesSequential/parallel process reactionsSolid phasesChemical compound

The inventive apparatus is comprised of a means for producing cavitation in a complex reaction mixture to enhance the yield of the selected reaction product, a means for controlling the temperature of the complex reaction mixture, especially during cavitation, and a means for affecting magnetic separation of paramagnetic beads to which the selected reaction product is attached from the complex reaction mixture. In one embodiment, the compound(s) or molecule(s) is synthesized in situ, and isolated using the inventive apparatus. The apparatus finds use in the fields of solid phase organic synthesis, and for isolation and purification of a selected compound(s) or molecule (s), especially where automation is desired.

Owner:PROTANA

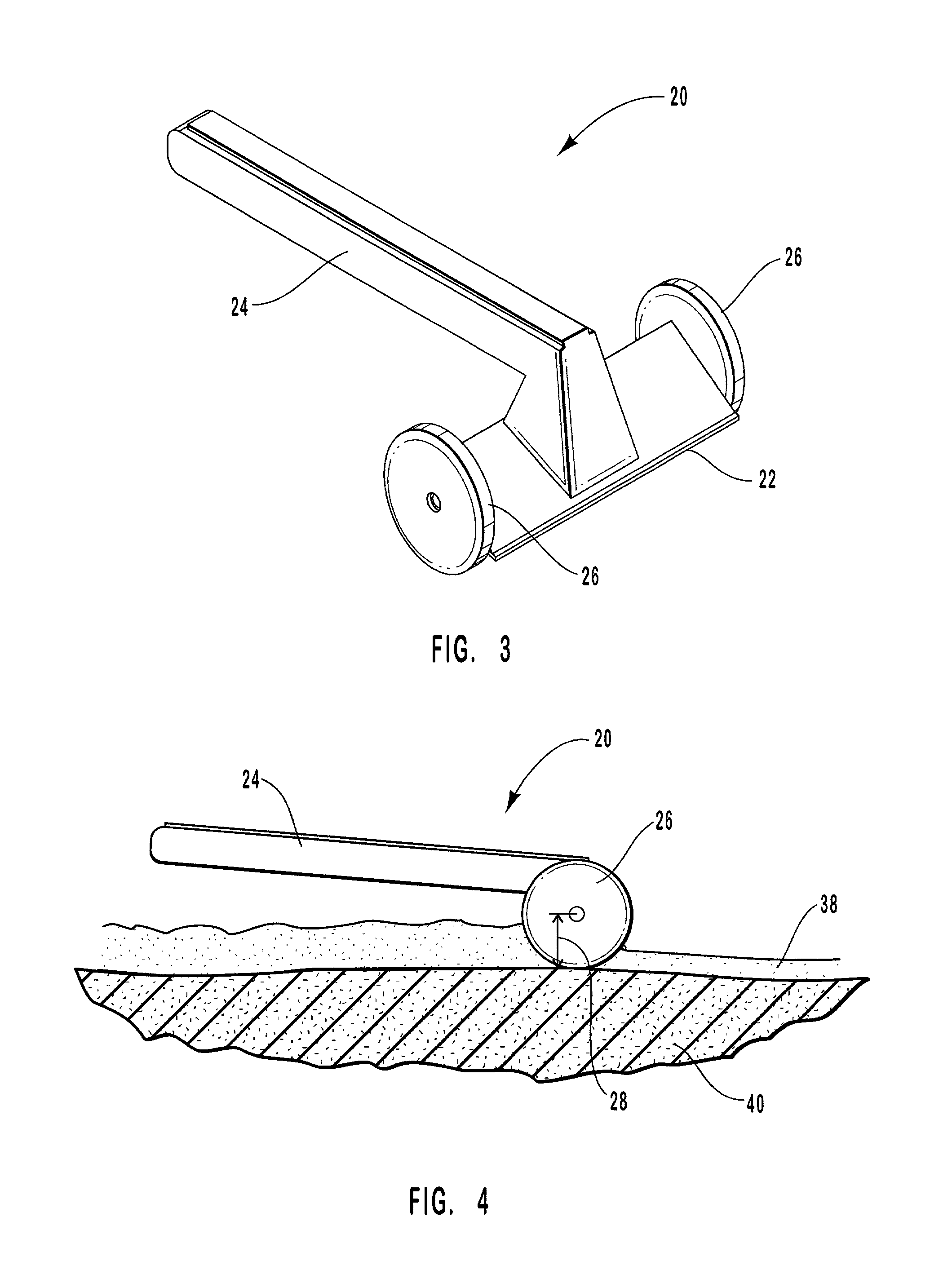

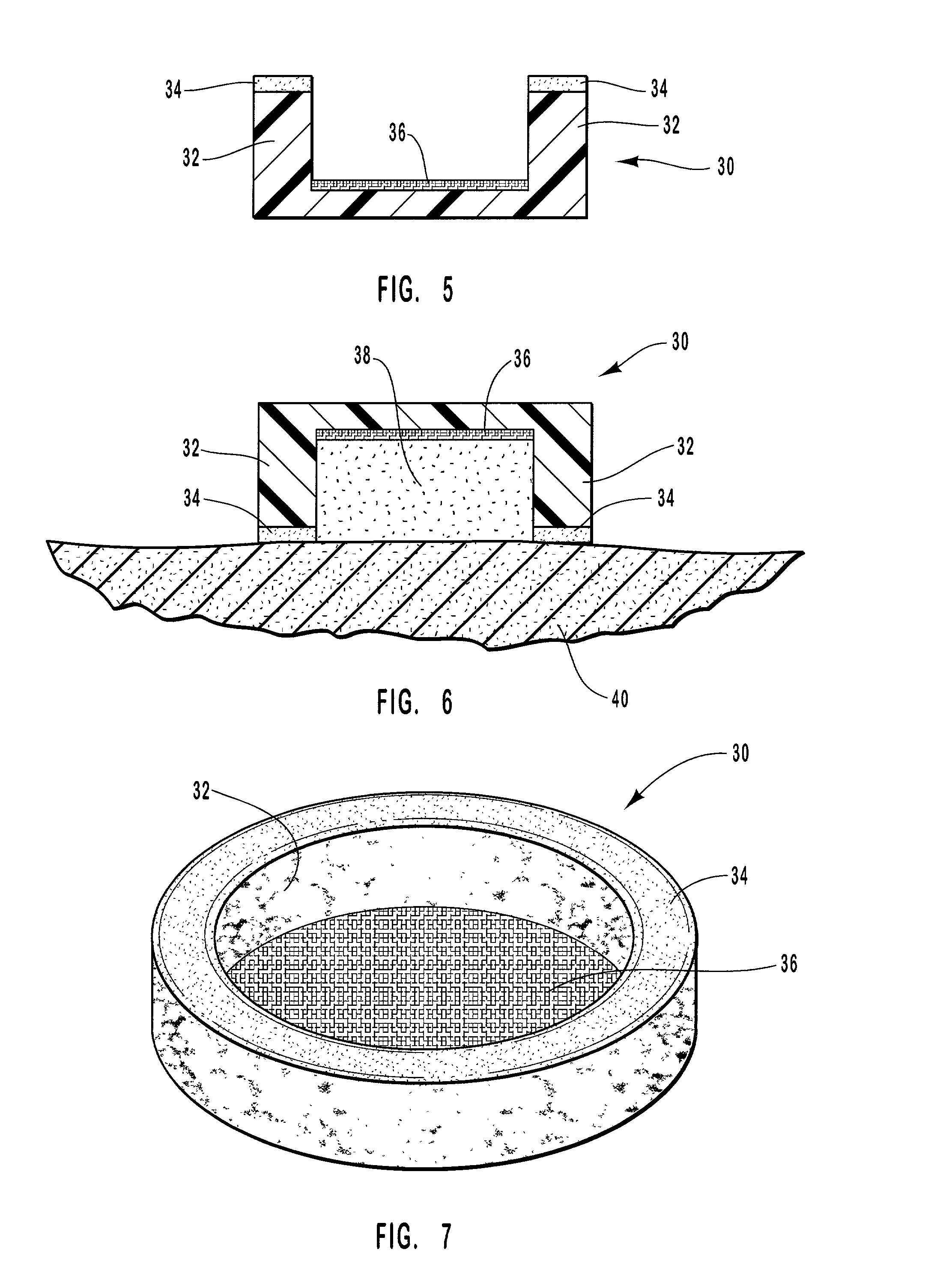

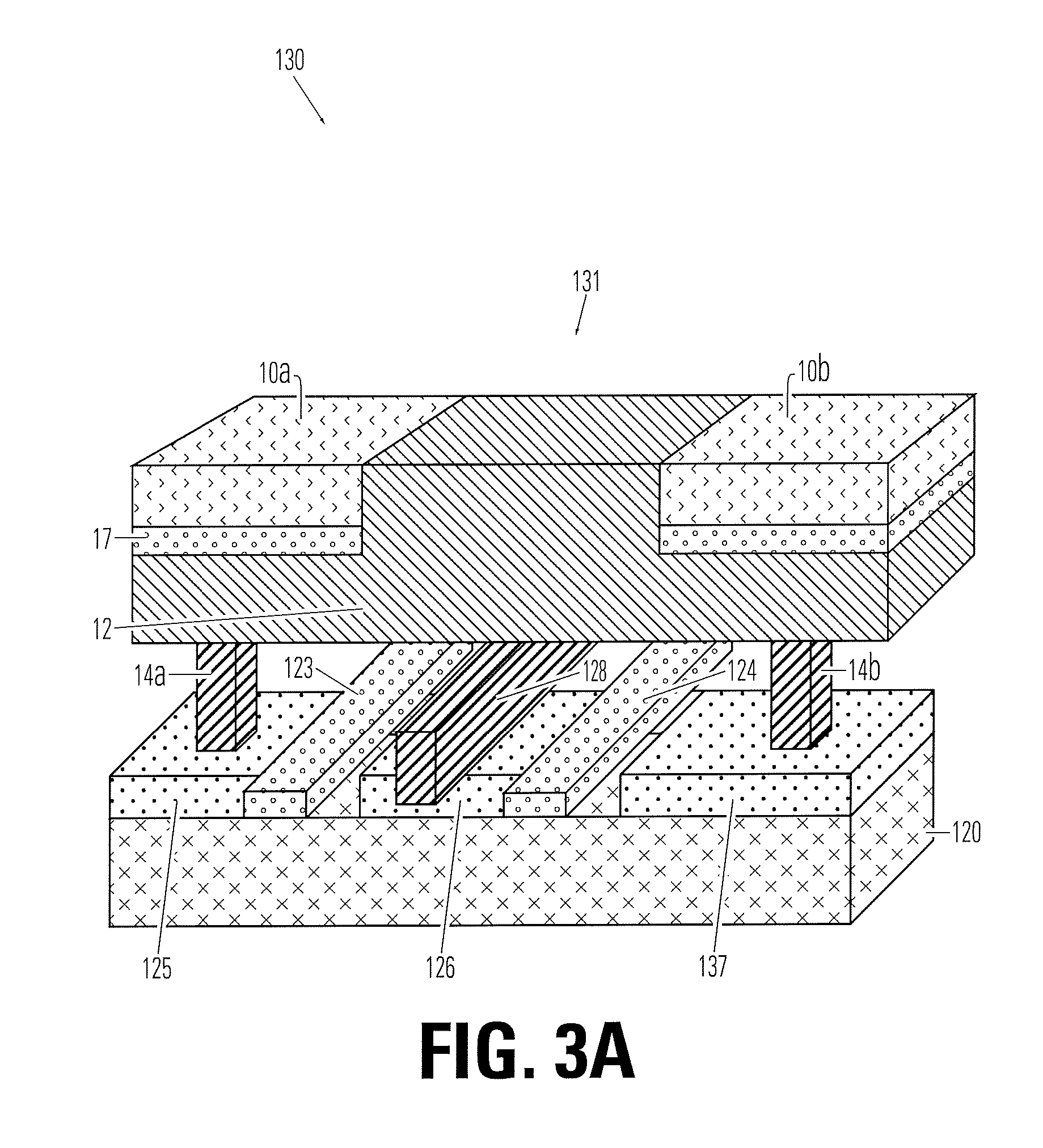

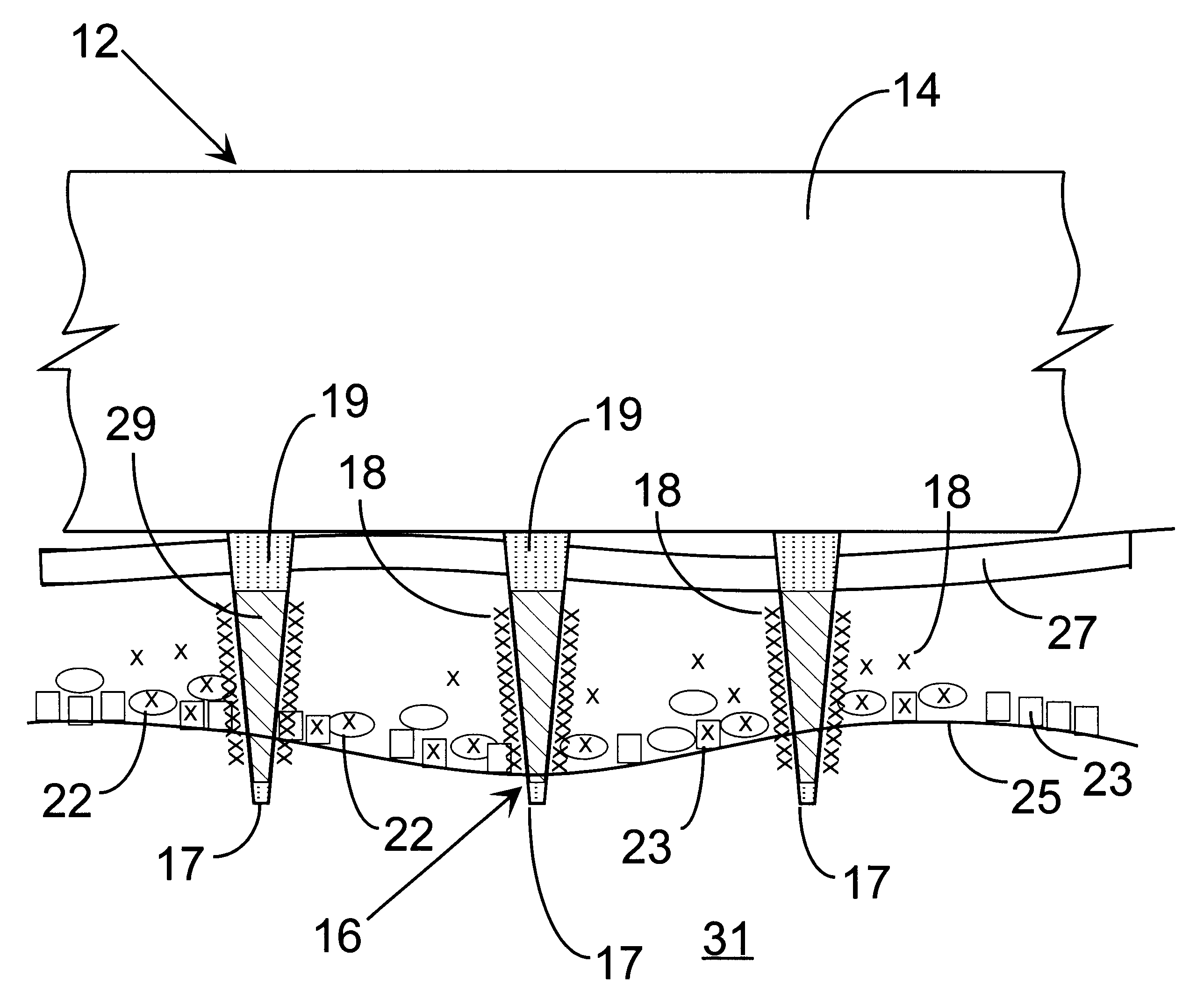

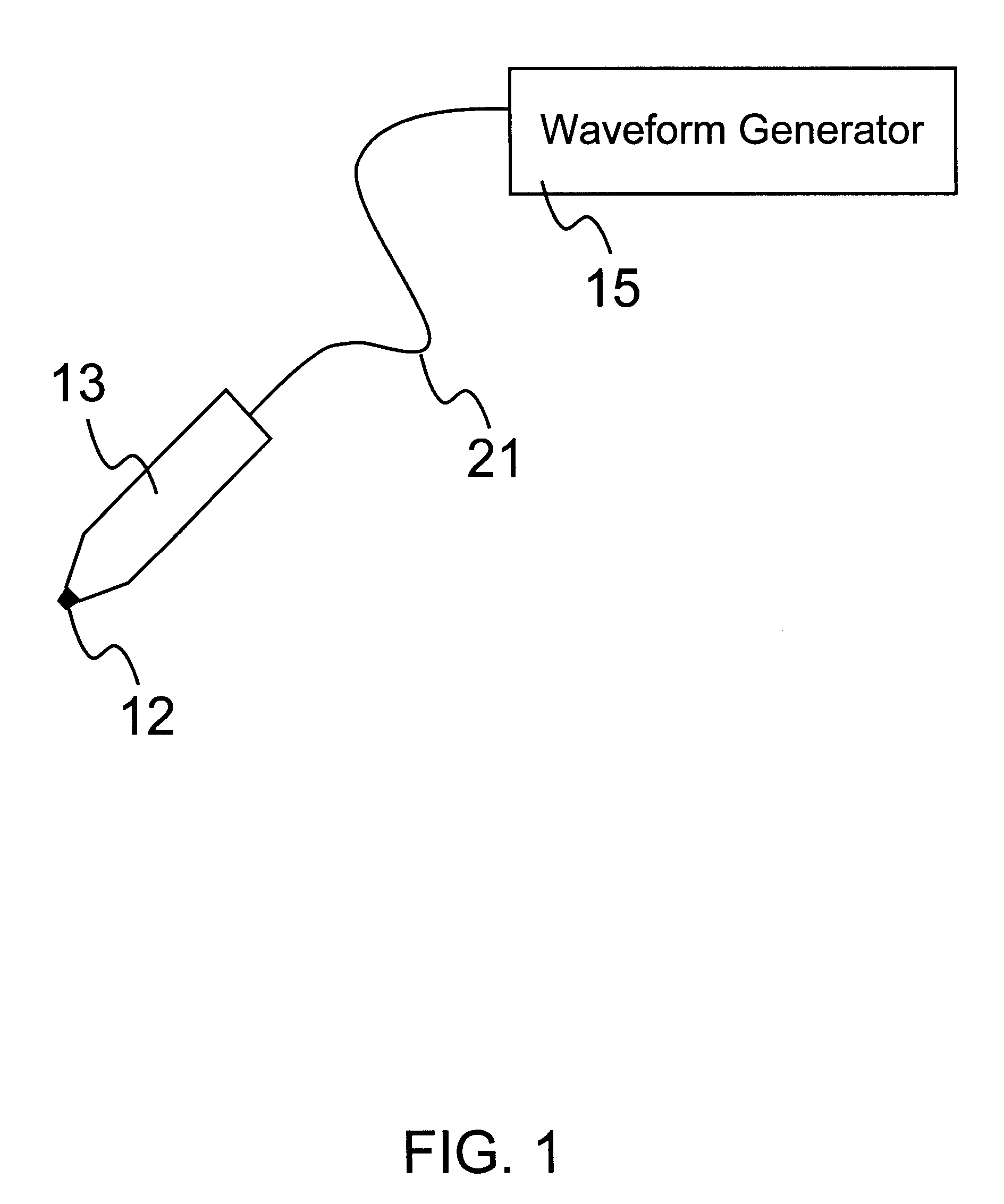

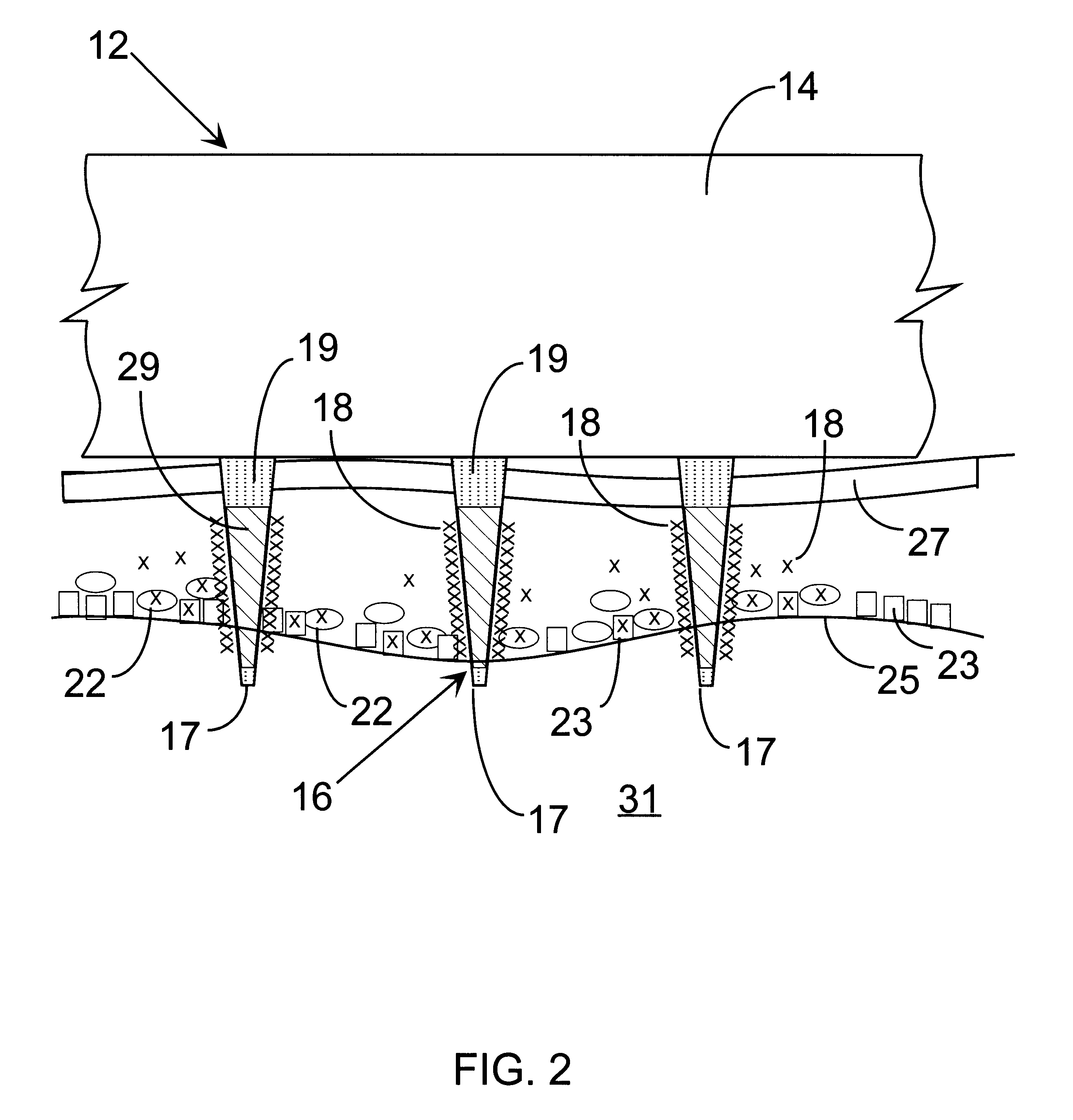

Delivery of macromolecules into cells

InactiveUS6603998B1Raise the threshold voltageReducing pulse widthBioreactor/fermenter combinationsElectrotherapyLangerhan cellA-DNA

An object of the invention is to provide a method for delivery of macromolecules into biological cells, such as Langerhans cells (22) in the epidermis (20) of a patient, which includes the steps of coating electodes (16) in an electrode assembly (12) with solid phase macromolecules to be delivered, such as a DNA, and / or RNA vaccine or a protein-based vaccine, attaching the electrode assembly (12) having the coated electrodes (16) to an electrode assembly holder (13), providing a waveform generator (15), establishing electrically conductive pathways between the electrodes (16), and the waveform generator (15), locating the electrodes (16) such that the biological cells are situated therebetween, such as by penetrating the needle electrode (16) into the epidermis (20) above the epidermal basal lamina, and providing pulse waveform from the waveform generator (15) to the electrodes (16), such that macromolecule on the electrodes (16) is driven off of the electrodes (16), and delivered into the biological cells, such as the Langerhans cells (22).

Owner:CELLECTIS SA

Isolation of proteins

InactiveUS20050176122A1Other chemical processesSolid sorbent liquid separationSpecial classCarboxylic acid

Owner:UPFRONT CHROMATOGRAPHY

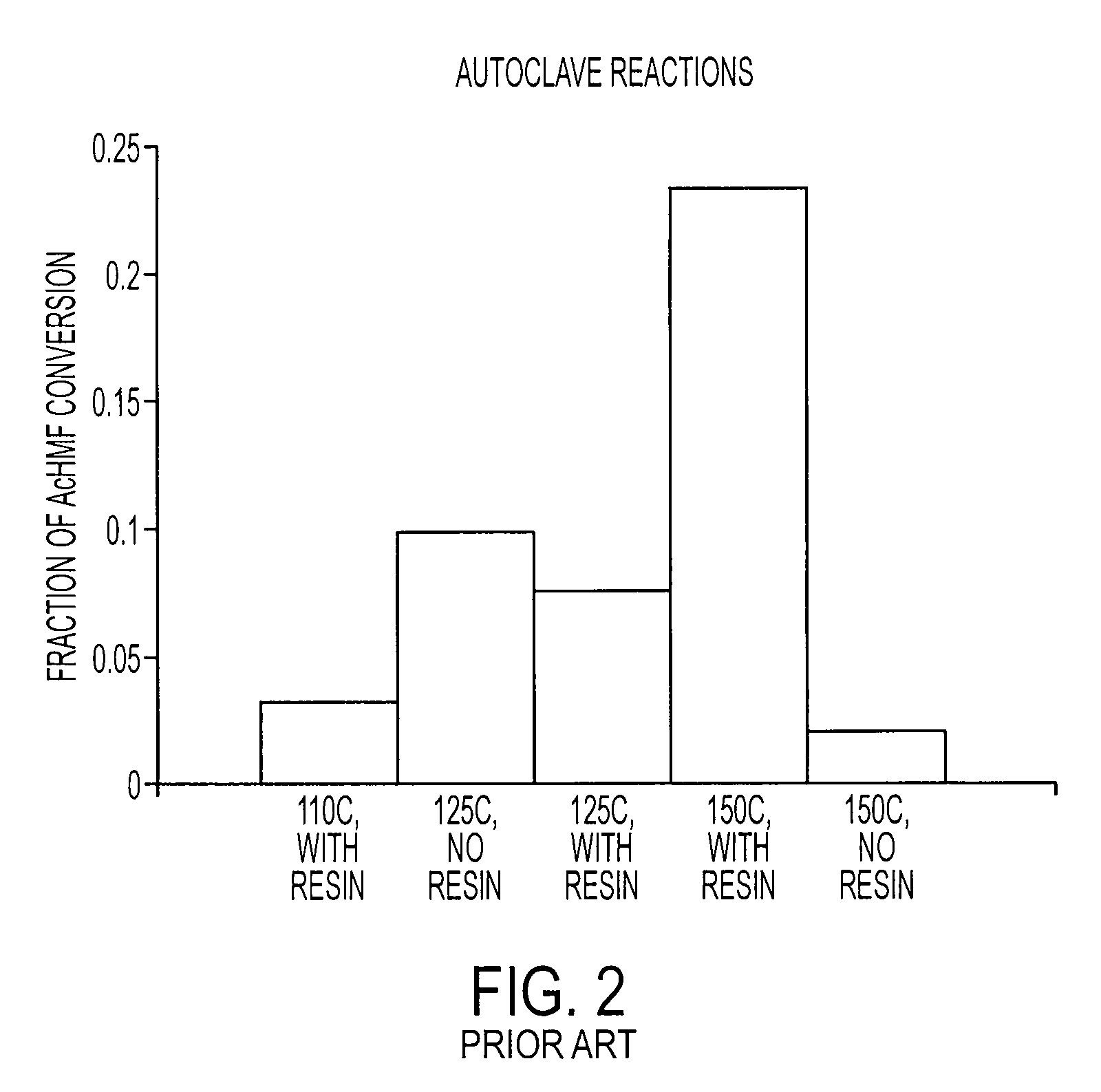

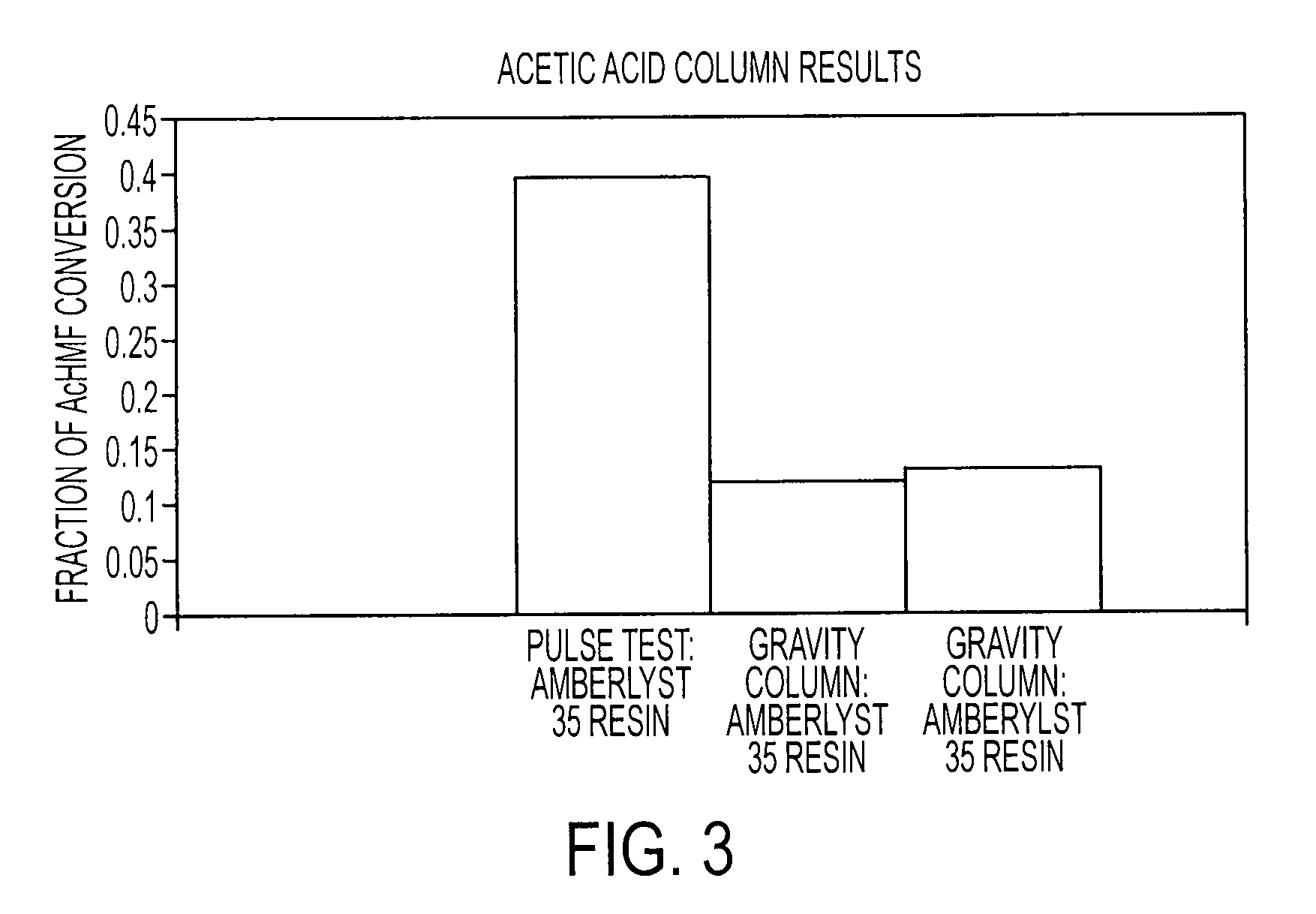

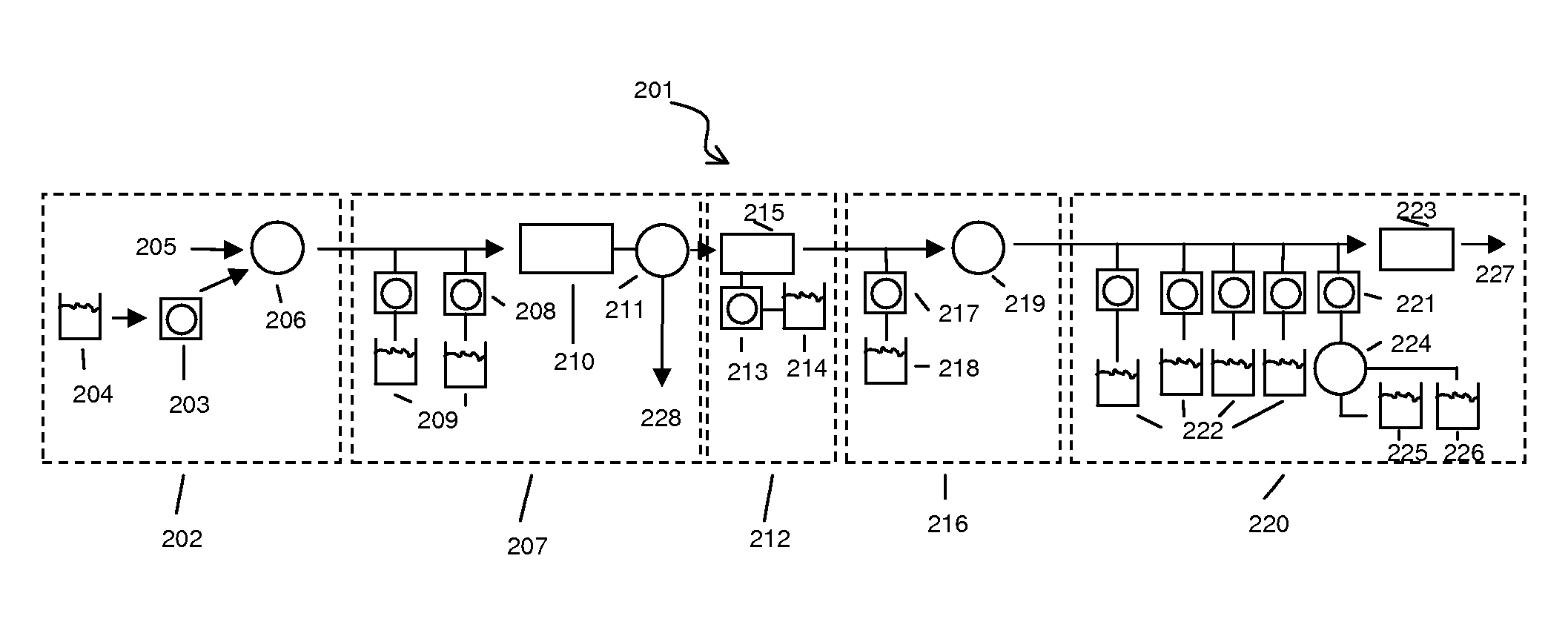

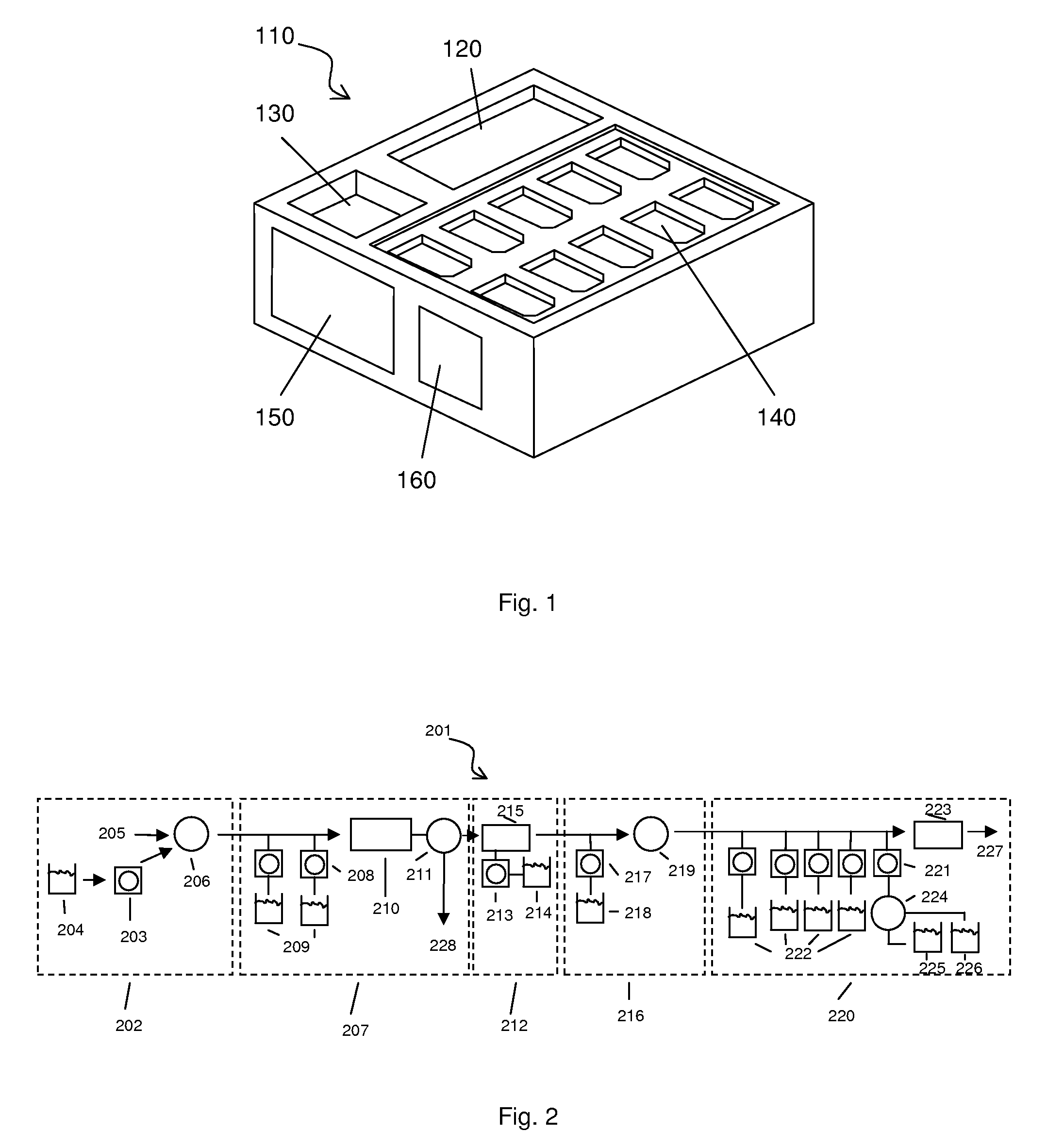

Conversion of carbohydrates to hydroxymethylfurfural (HMF) and derivatives

InactiveUS20090156841A1Increase conversion rateStable formOrganic compound preparationCarboxylic compound preparationMANGANESE ACETATEFuran

A method of producing substantially pure HMF, HMF esters and other derivatives from a carbohydrate source by contacting the carbohydrate source with a solid phase catalyst. A carbohydrate starting material is heated in a solvent in a column and continuously flowed through a solid phase catalyst in the presence of an organic acid, or heated with the organic acid and a solid catalyst in solution to form a HMF ester. Heating without organic acid forms HMF. The resulting product is purified by filtration to remove the unreacted starting materials and catalyst. The HMF ester or a mixture of HMF and HMF ester may then be oxidized to 2,5-furandicarboxylic acid (FDCA) by combining the HMF ester with an organic acid, cobalt acetate, manganese acetate and sodium bromide under pressure. Alternatively, the HMF ester may be reduced to form a furan or tetrahydrofuran diol.

Owner:ARCHER DANIELS MIDLAND CO

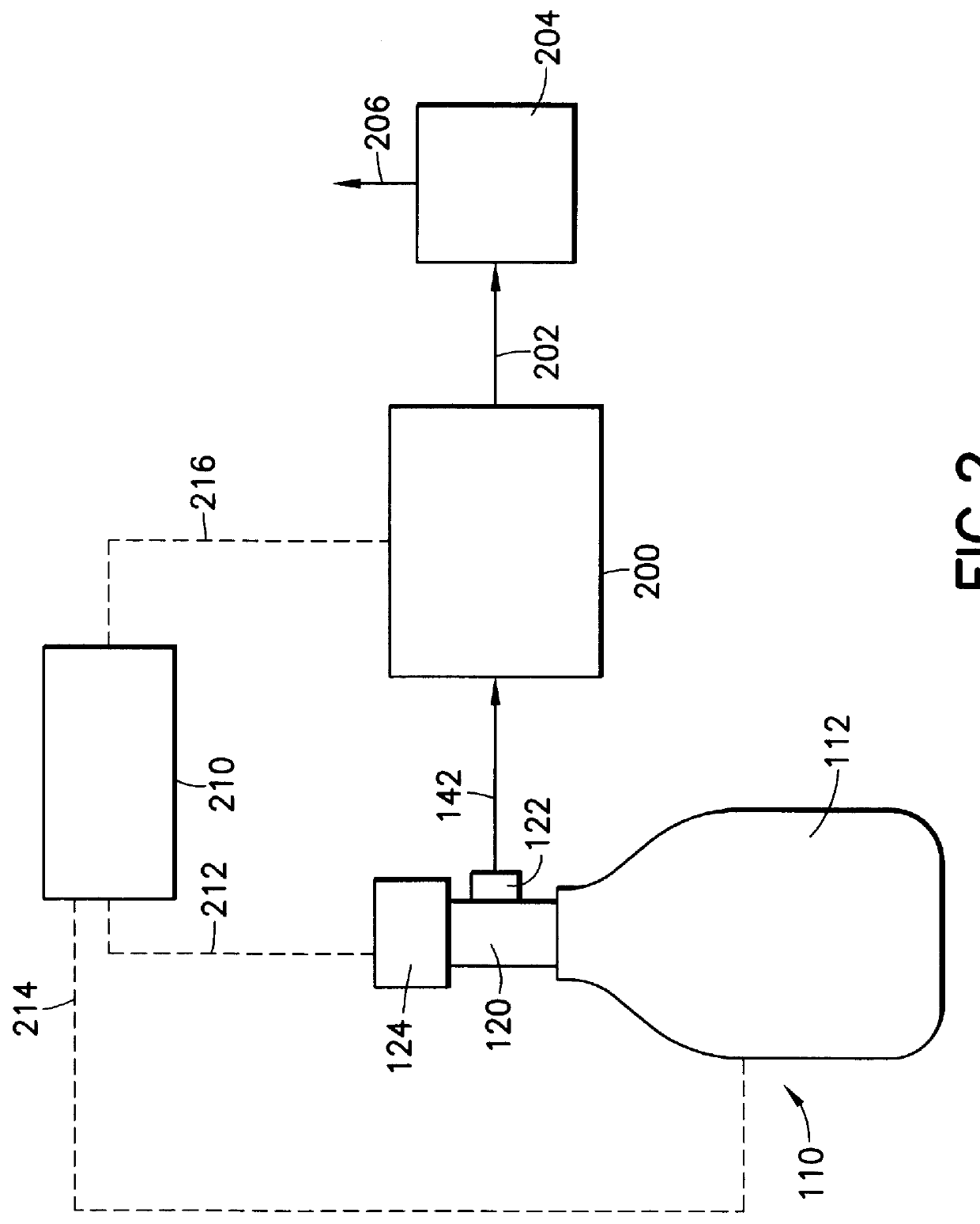

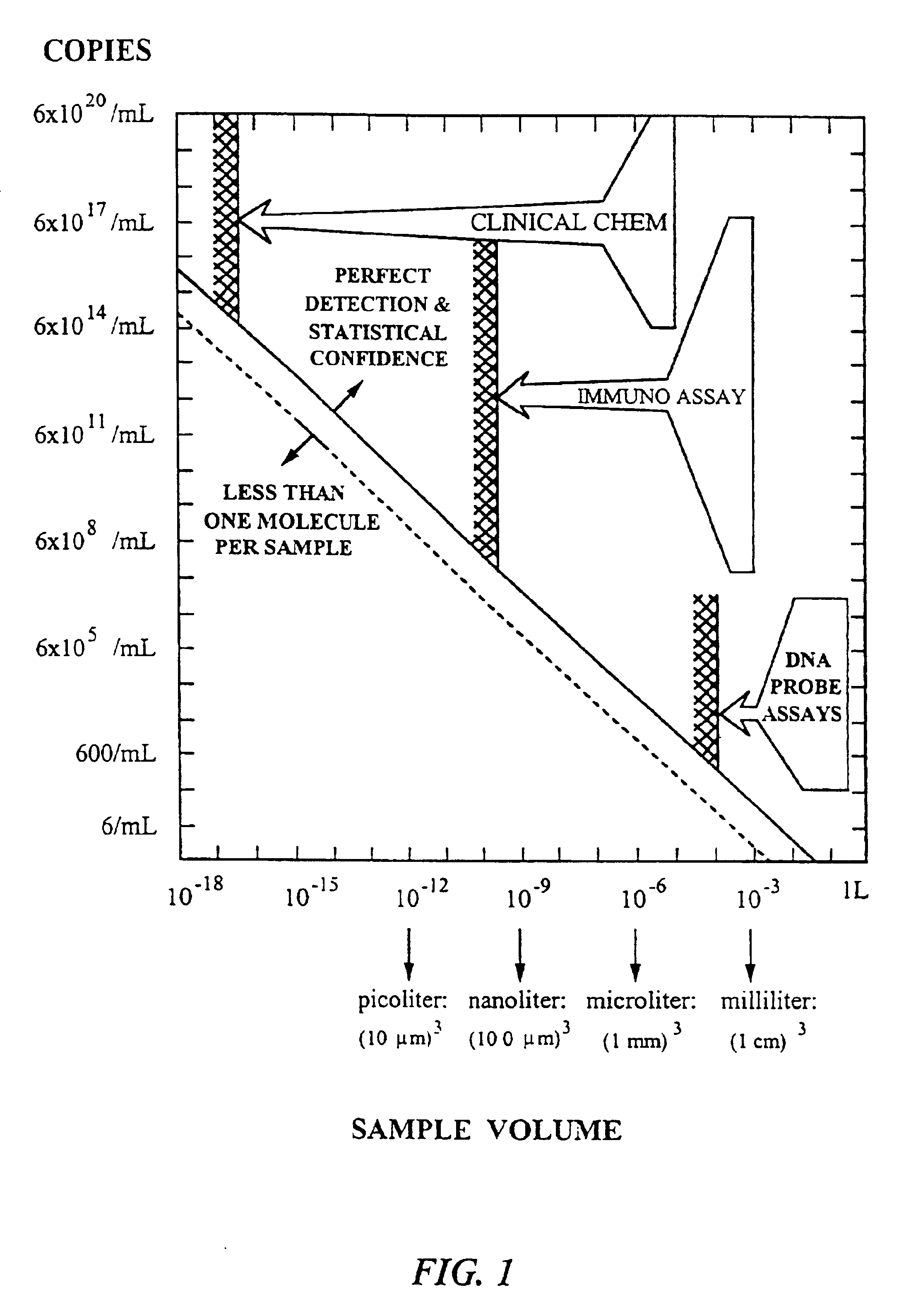

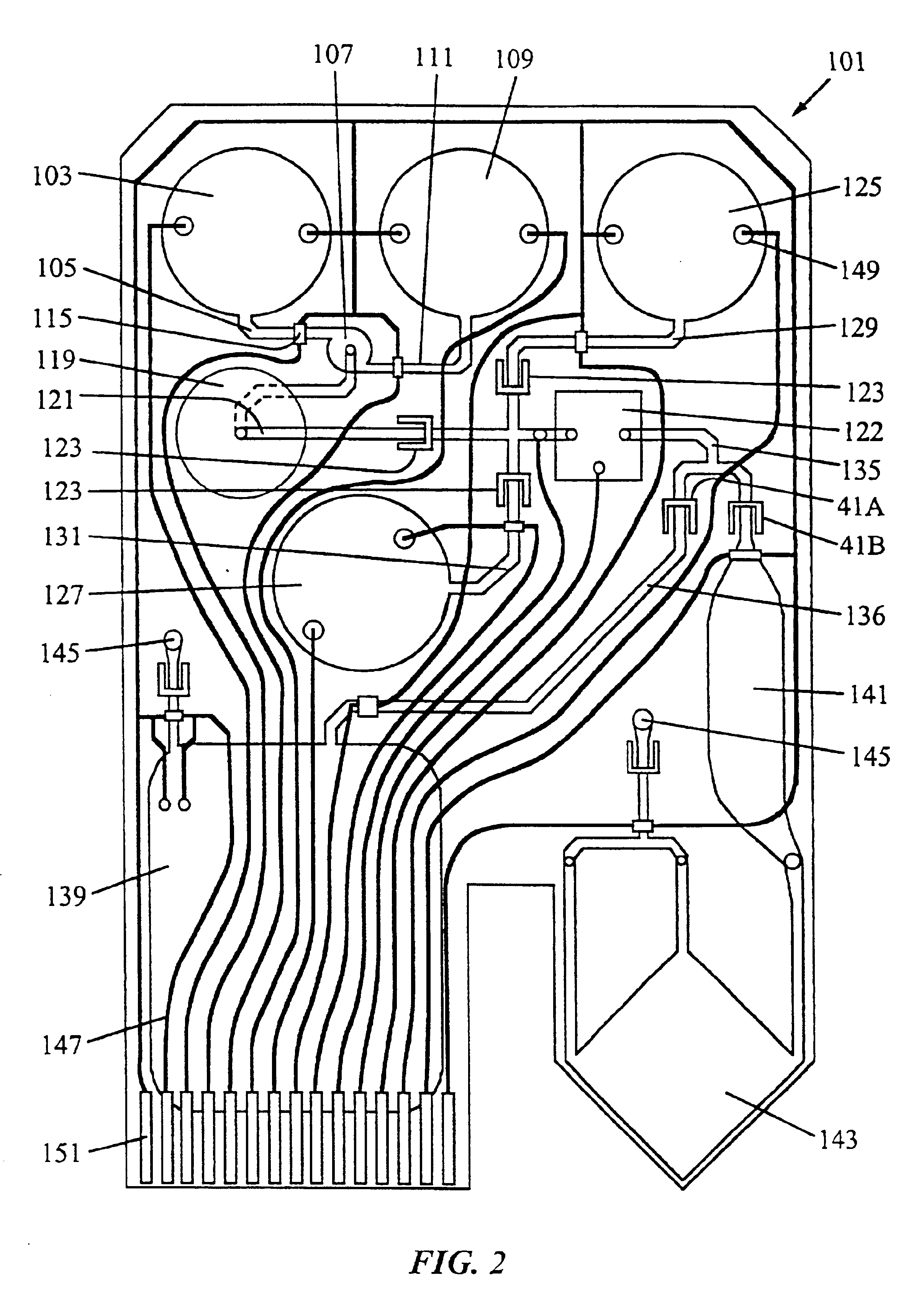

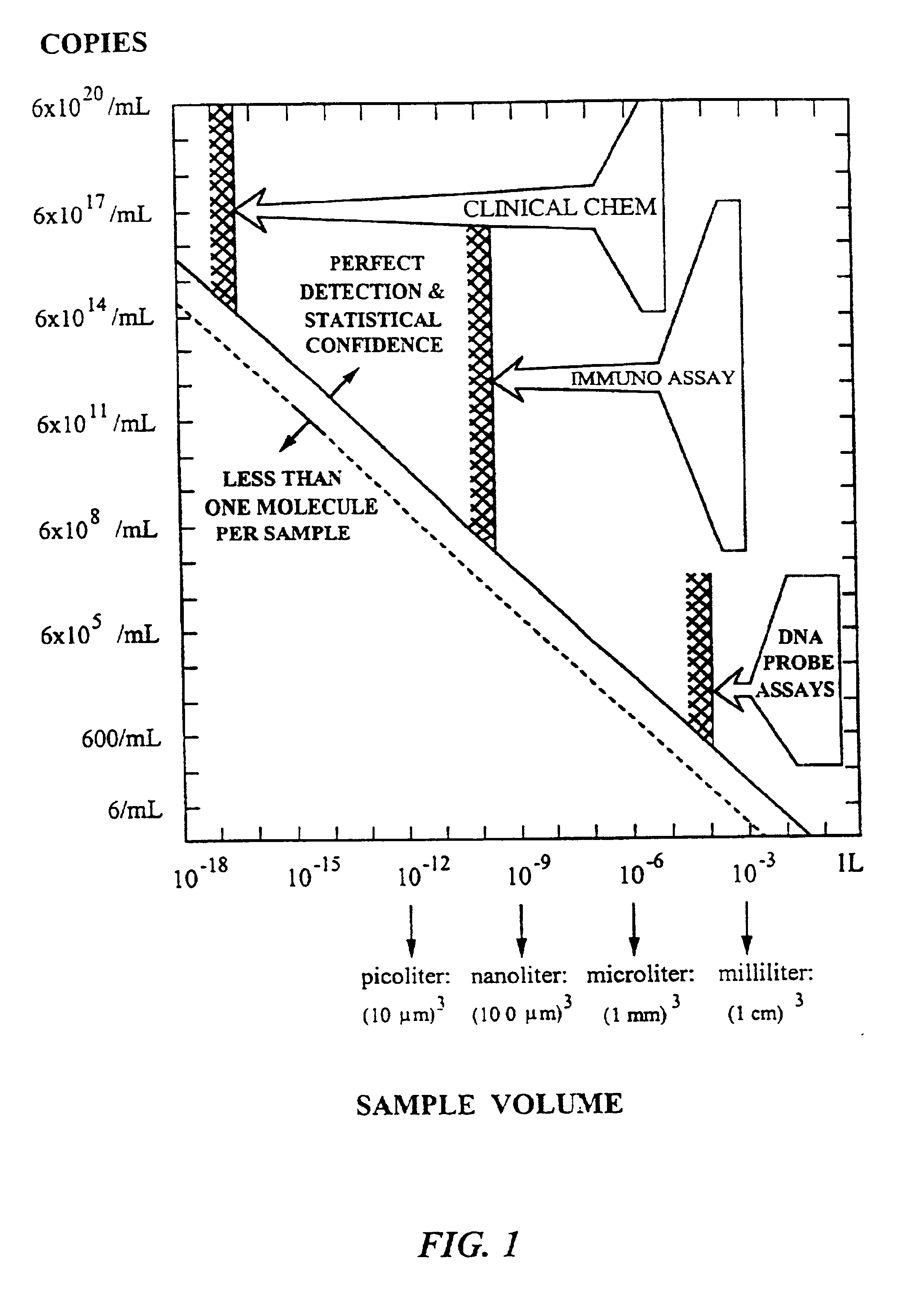

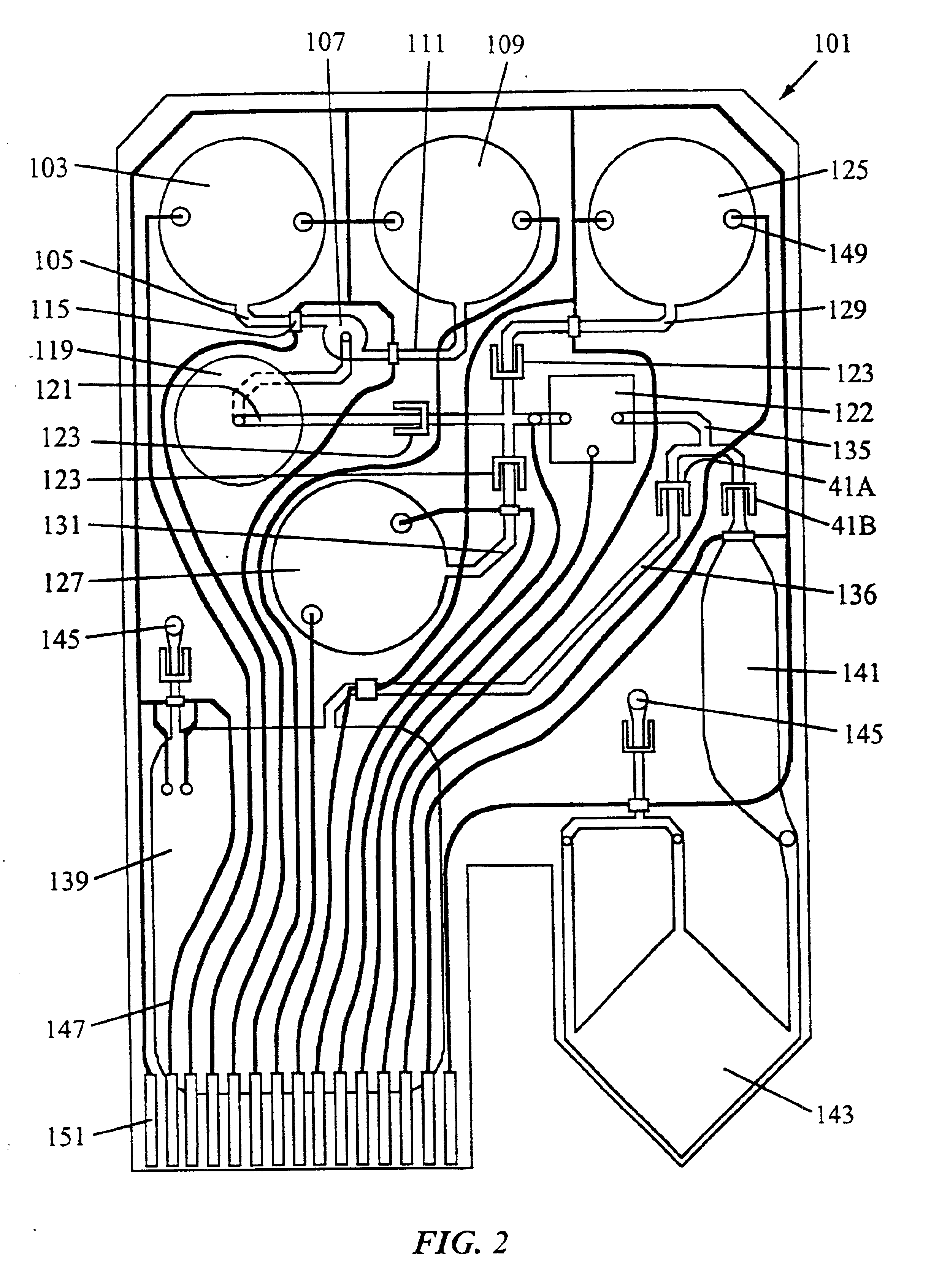

Automated sample-to-microarray system

InactiveUS20070092901A1Bioreactor/fermenter combinationsBiological substance pretreatmentsLysisOligonucleotide

An apparatus having within or as part of a housing; a sample port; a microarray port; a lysis module; a purification module for containing a solid phase for binding of oligonucleotides; a thermocycling module for containing a polymerase chain reaction; a fragmentation module; and a microarray module for holding a microarray and a liquid in contact with the microarray. The apparatus is configured to be coupled to a device for: pumping a liquid through, in order, the lysis, purification, thermocycling, fragmentation, and microarray modules; sonicating any contents of the lysis module; thermocycling the thermocycling module to perform the polymerase chain reaction; heating the fragmentation module to fragment any oligonucleotides contained therein; circulating a fluid over the surface of the microarray; and performing one or more washing or staining steps on the microarray.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

Degradable material assisted diversion

Degradable material assisted diversion (DMAD) methods for well treatment, DMAD treatment fluids, and removable plugs for DMAD in downhole operations. A slurry of solid degradable material is injected into the well, a plug of the degradable material is formed, a downhole operation is performed around the plug diverter, and the plug is then degraded for removal. Degradation triggers can be temperature or chemical reactants, with optional accelerators or retarders to provide the desired timing for plug removal. In multilayer formation DMAD fracturing, the plug isolates a completed fracture while additional layers are sequentially fractured and plugged, and then the plugs are removed for flowback from the fractured layers. In DMAD fluids, an aqueous slurry can have a solids phase including a degradable material and a fluid phase including a viscoelastic surfactant. The solids phase can be a mixture of fibers and a particulate material.

Owner:SCHLUMBERGER TECH CORP

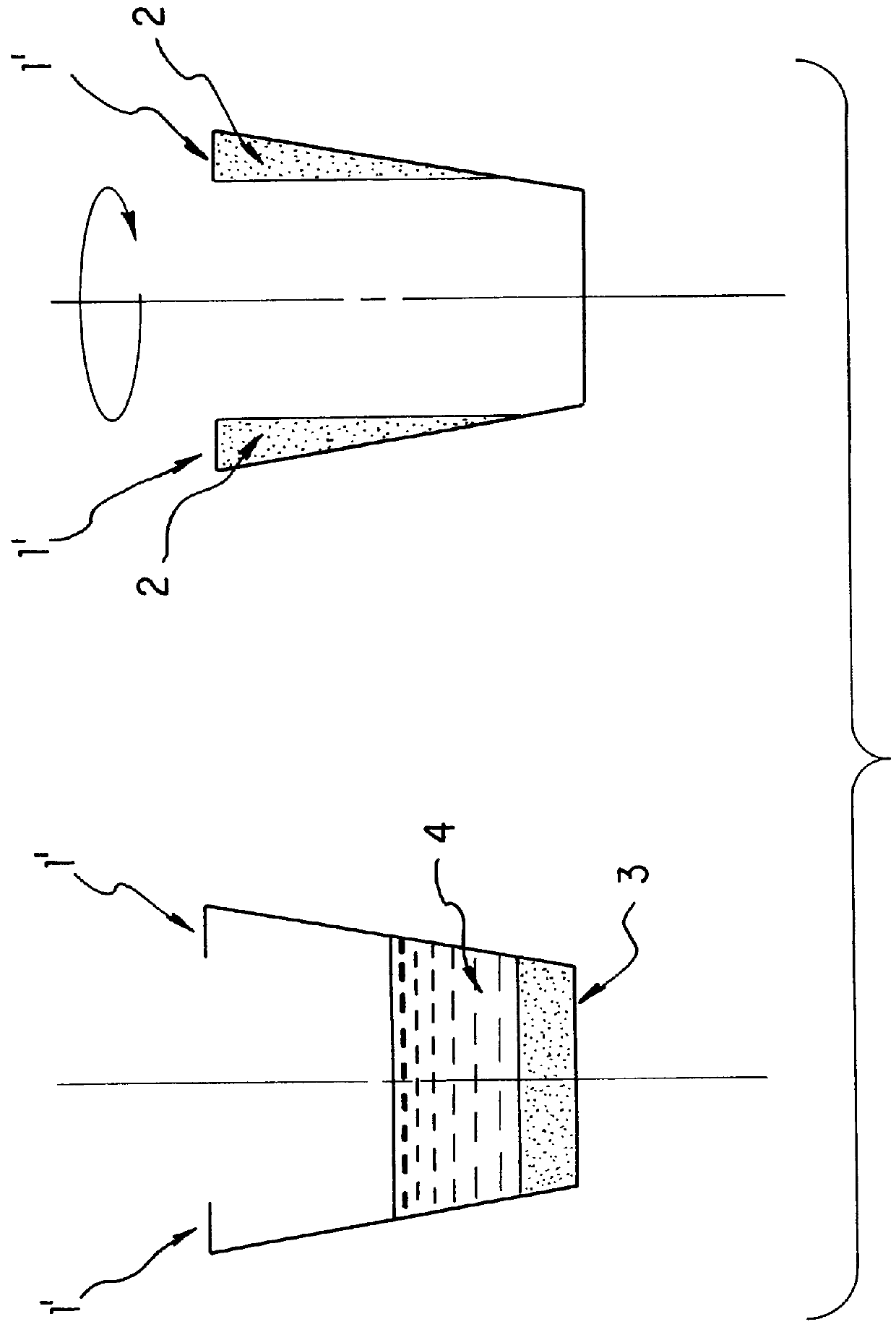

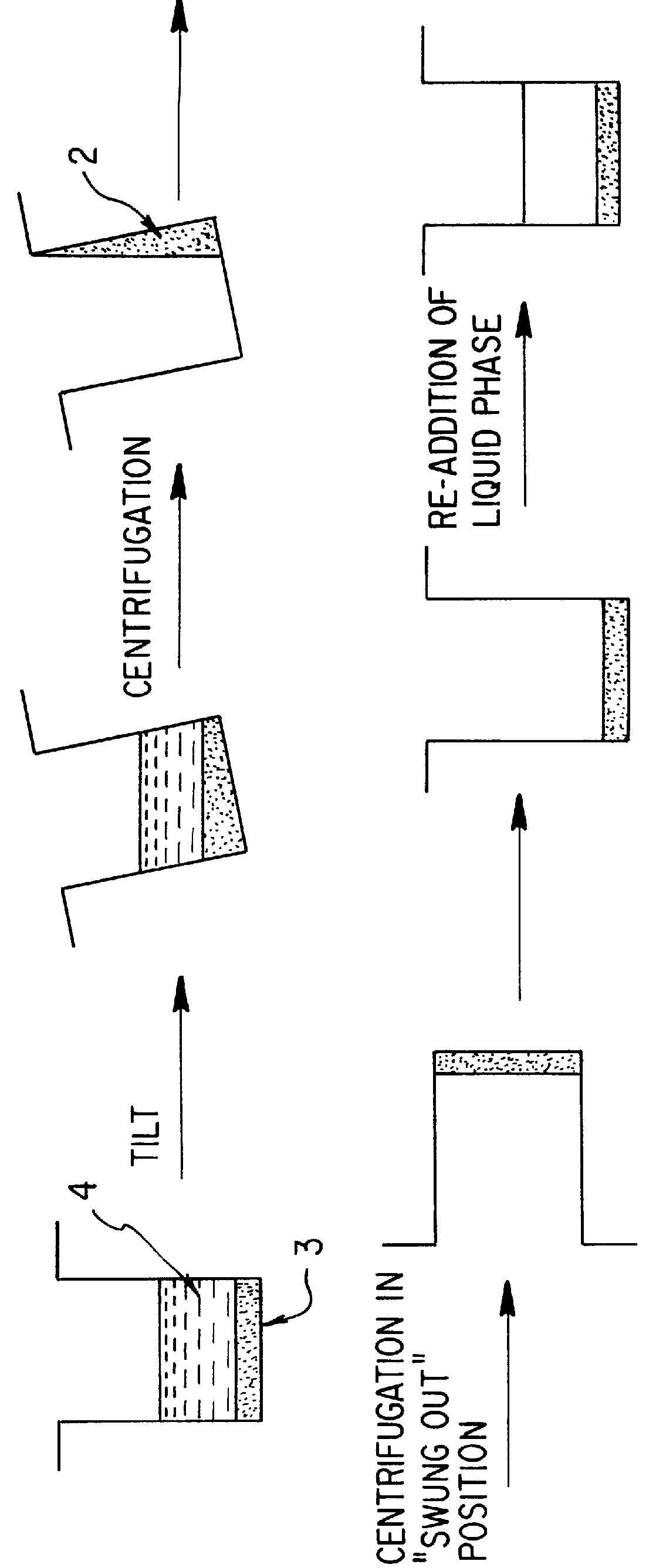

Method for separation of liquid and solid phases for solid phase organic syntheses

InactiveUS6121054ASequential/parallel process reactionsPeptide/protein ingredientsOrganic synthesisMicrotiter plate

A simple, efficient apparatus and method for separation of solid and liquid phases useful in methods of high-throughput combinatorial organic synthesis of large libraries or megaarrays of organic compounds is disclosed. The apparatus and method are useful, whether as part of an automated, robotic or manual system for combinatorial organic synthesis. In a preferred embodiment, an apparatus and method of removal of liquid phase from solid phase compatible with microtiter plate type array(s) of reaction vessels is disclosed.

Owner:BUCYRUS INTERNATIONAL +1

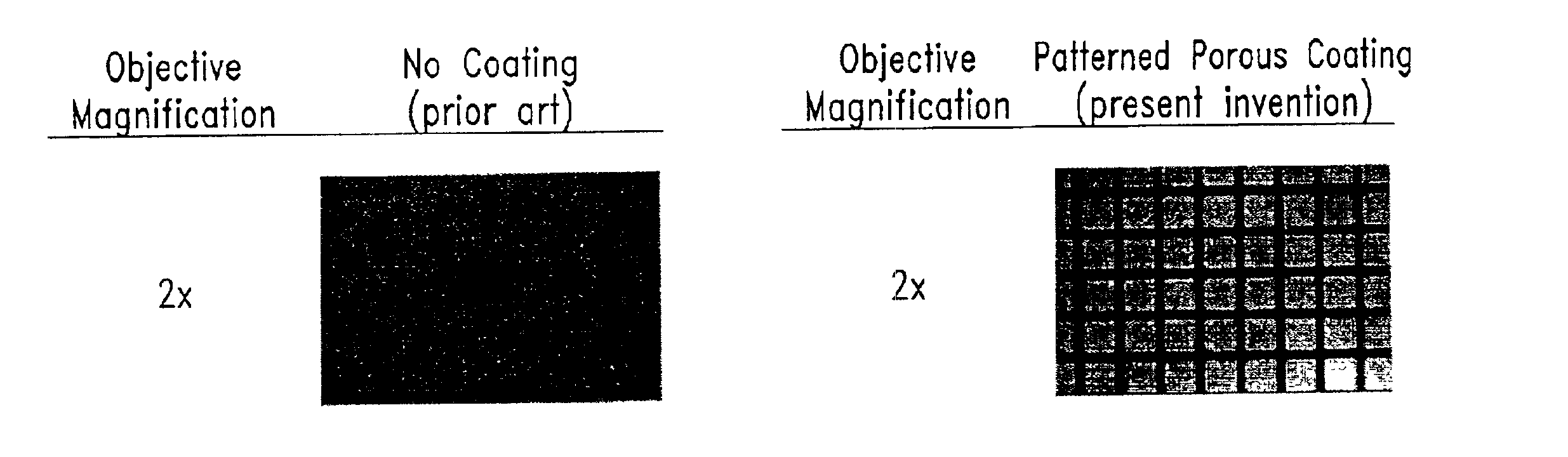

Porous coatings bearing ligand arrays and use thereof

InactiveUS6951682B1Uniform thicknessHigh coating strengthBioreactor/fermenter combinationsMaterial nanotechnologyPorous coatingChemical synthesis

Articles comprising substantially uniform porous coatings, which may be photopatterned, are provided. The use of such porous coatings increases the surface density of attached compounds within, for example, ligand arrays prepared by methods such as regionally selective solid-phase chemical synthesis. Arrays prepared using the porous coatings may be used within a variety of diagnostic and drug discovery assays.

Owner:SYNTRIX BIOSYST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com