Patents

Literature

425results about How to "Improve bleaching effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Laundry multi-compartment pouch composition

InactiveUS20090011970A1Improve bleaching effectEasy to useDetergent materialsDetergent compounding agentsSolid componentWater soluble

This invention relates to a laundry pouch made from a water-soluble film and having at least two compartments, containing a solid component and a liquid component, wherein the solid phase contains a peroxide source and the liquid phase contains bleach activator. The present invention also relates to a method for treating laundry by placing the pouch, according to the present invention, in the drum of the washing machine.

Owner:THE PROCTER & GAMBLE COMPANY

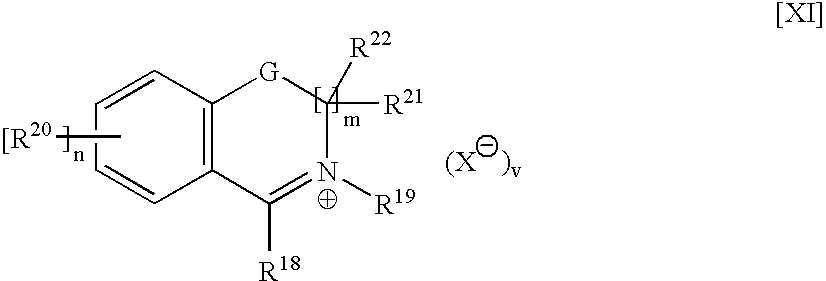

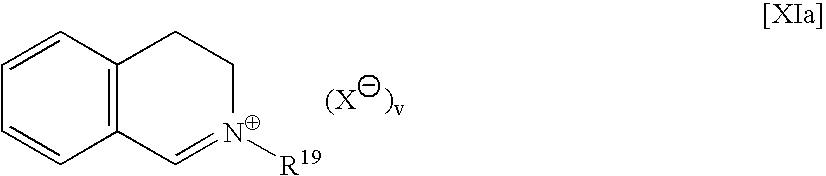

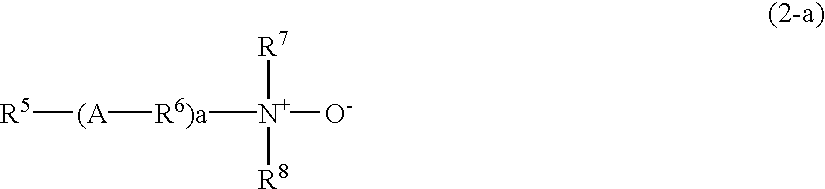

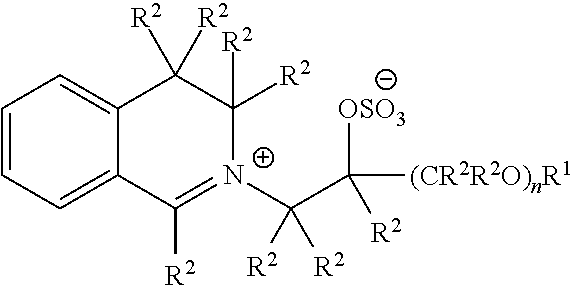

Stable formulation components, compositions and laundry methods employing same

InactiveUS6903060B1Improve stabilitySuperior emission lifetimeIsocyanic acid derivatives preparationNon-ionic surface-active compoundsBleachOrganocatalysis

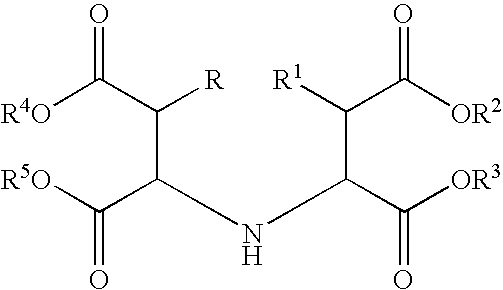

The present invention relates to formulation components, such as organic catalyst compounds having increased stability, compositions and laundry methods employing such organic catalyst compounds. More particularly, this invention relates to organic catalysts compounds such as quaternary imine bleach boosting compounds, quaternary oxaziridinium bleaching species, modified amines and amine oxides, compositions and laundry methods employing such organic catalyst compounds.

Owner:THE PROCTER & GAMBLE COMPANY

Laundry multi-compartment pouch composition

InactiveUS20100190677A1Improve stabilityImprove bleaching effectOrganic/inorganic per-compounds compounding agentsDetergent materialsSolid componentWater soluble

Laundry multi-compartment pouch made from a water-soluble film and having at least two compartments. The pouch of the present invention comprises a composition containing a solid component and a liquid component, wherein the solid component contains a peroxide source and a mixture of specific polymer.

Owner:THE PROCTER & GAMBLE COMPANY

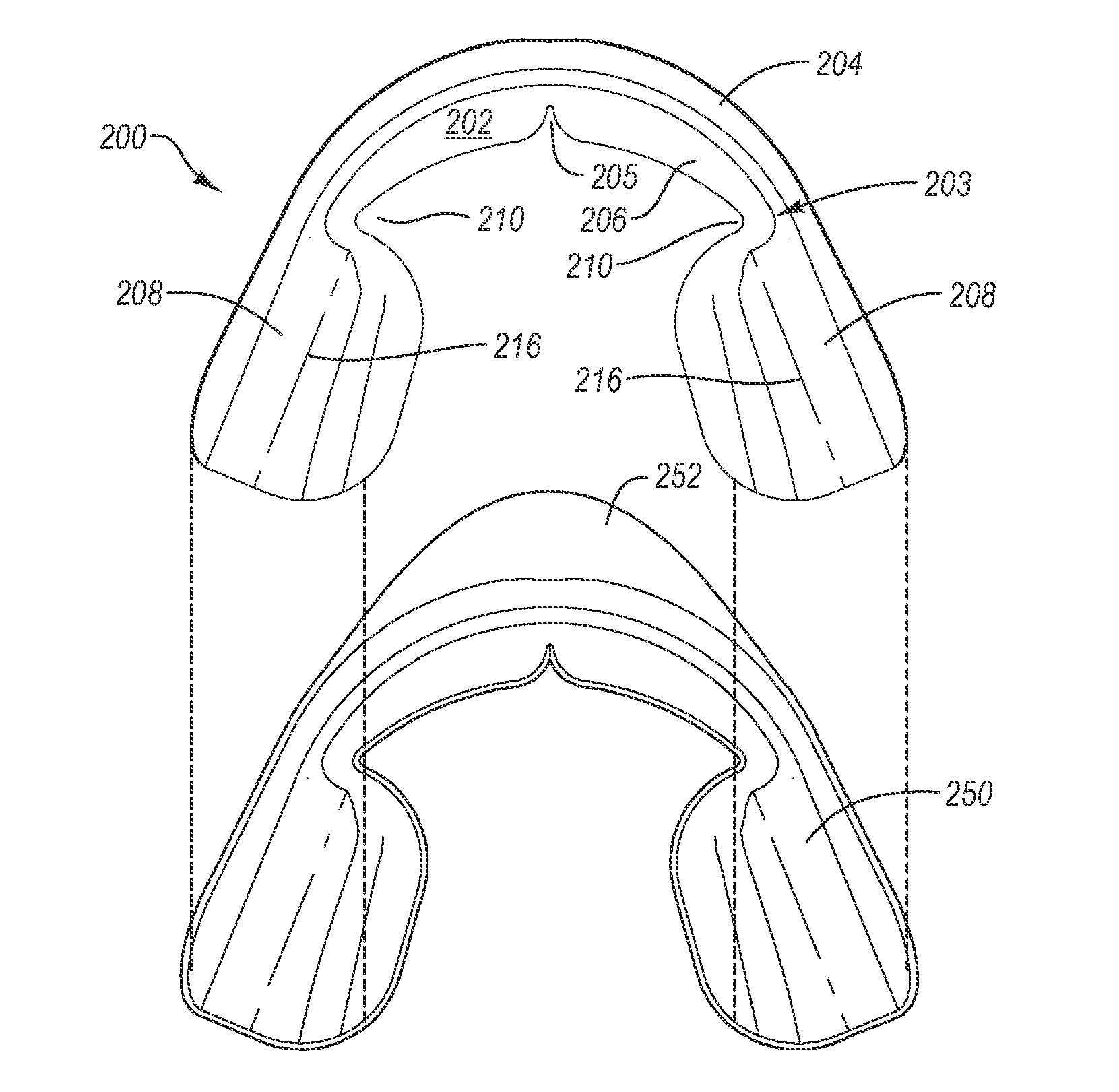

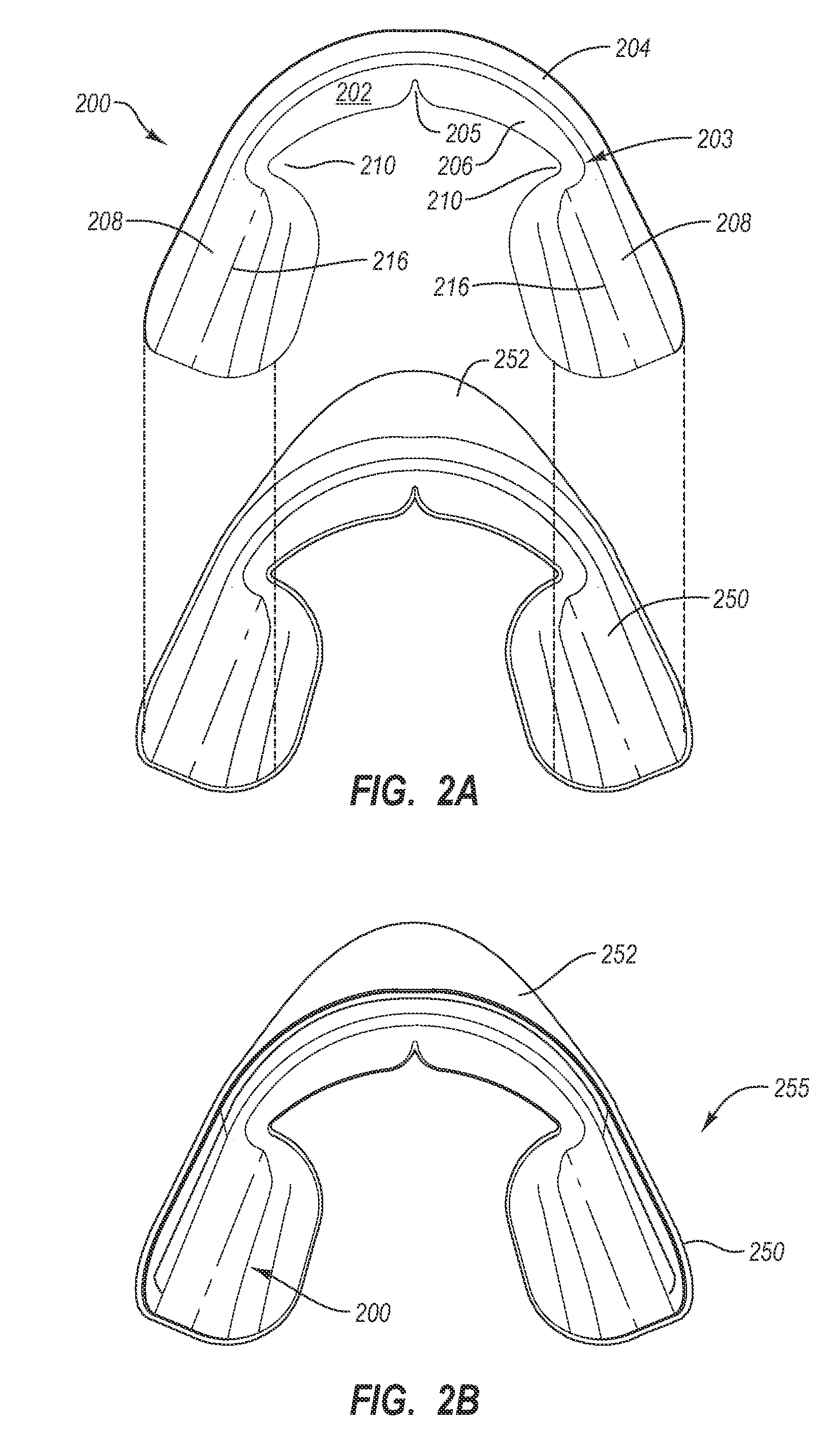

Chemically activated dental bleaching trays

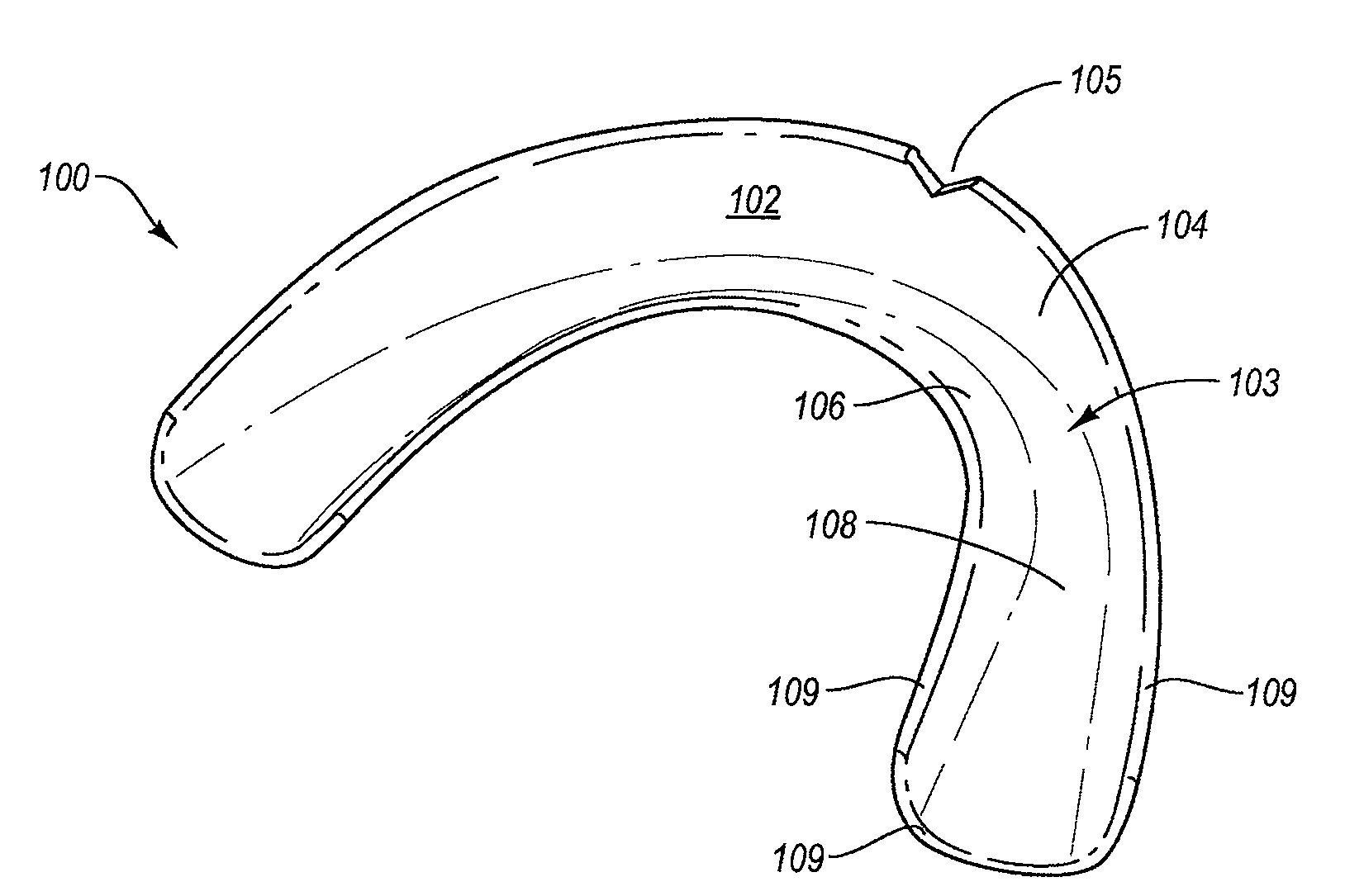

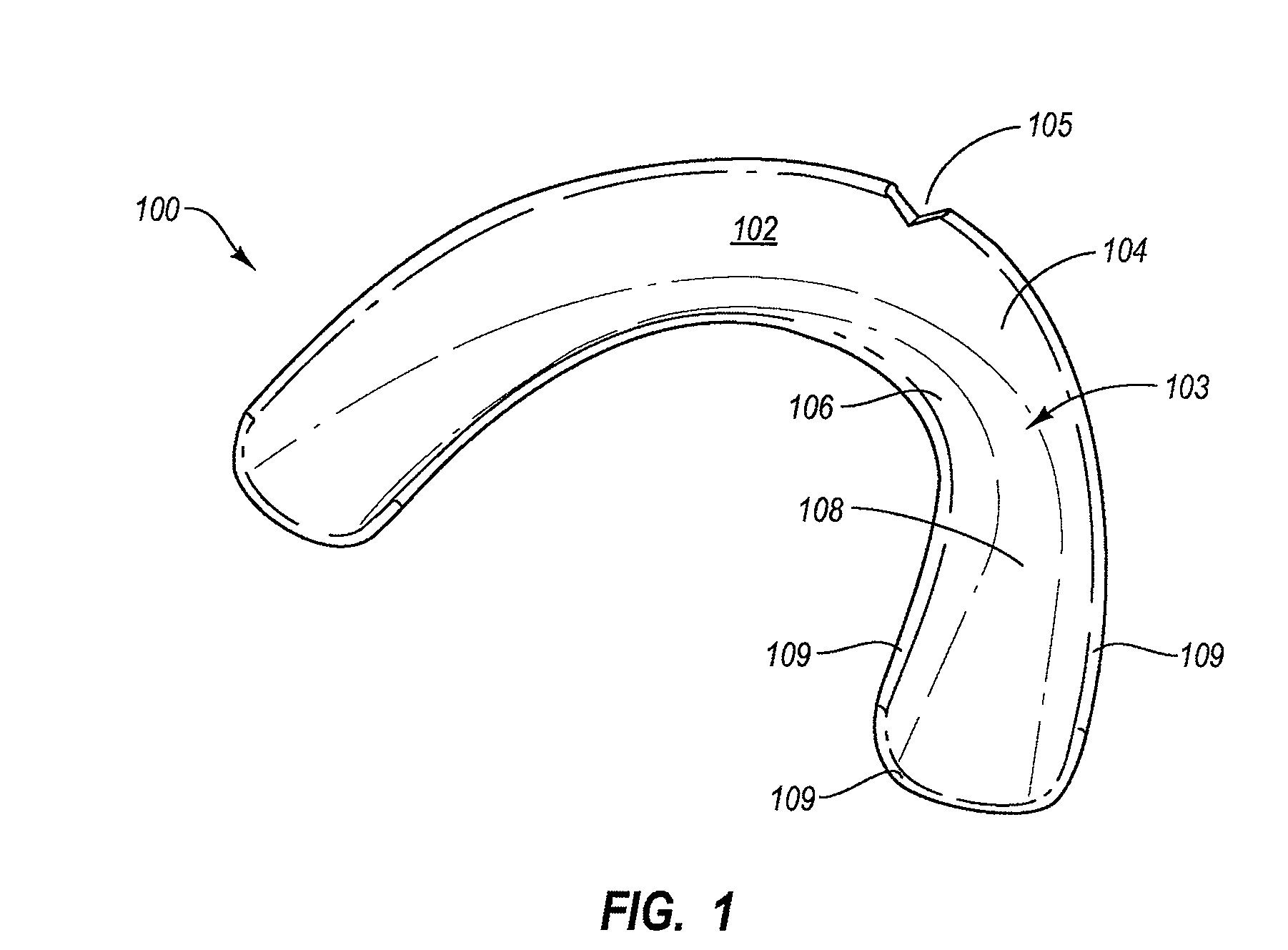

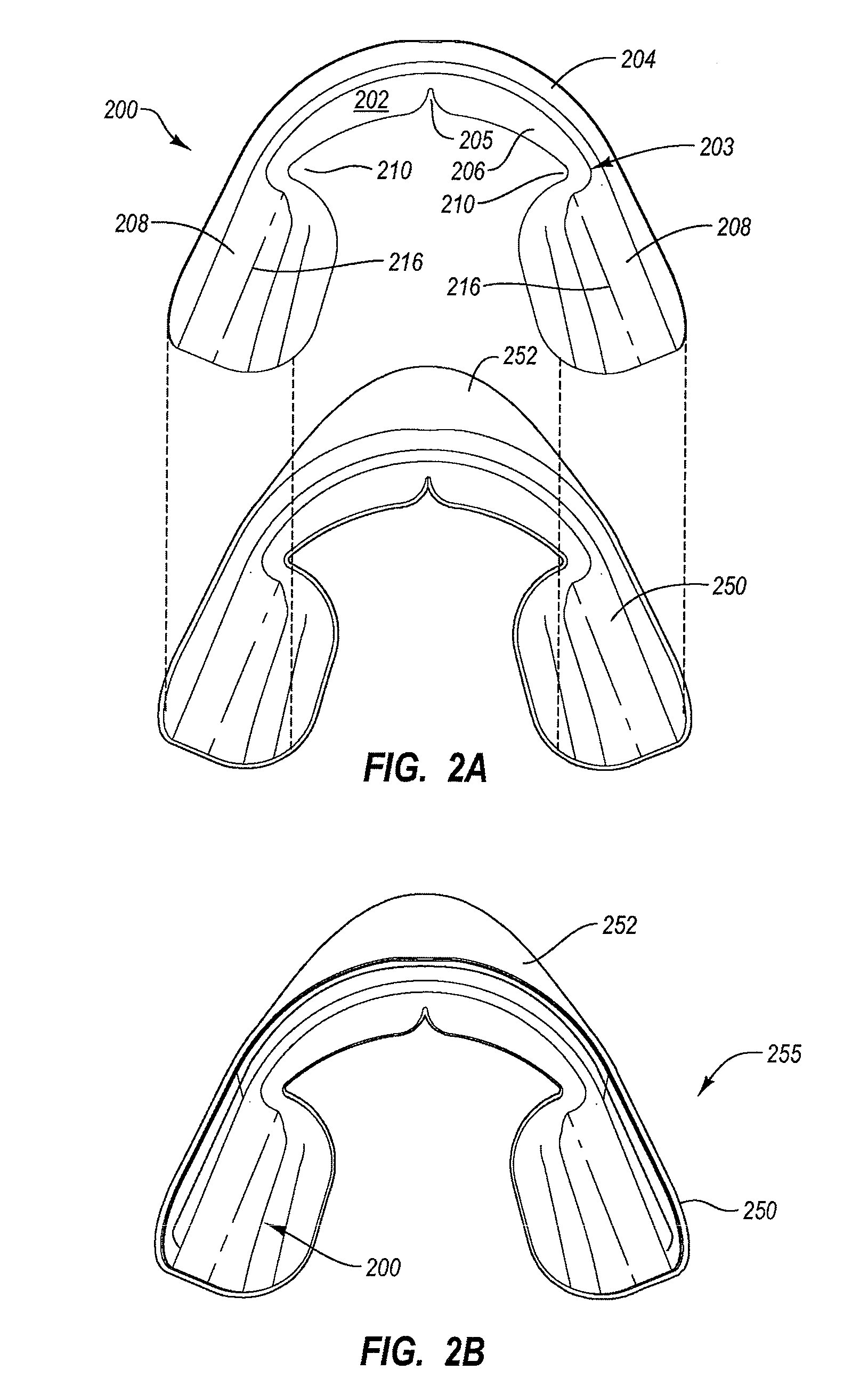

Dental treatment trays and strips used to deliver a dental bleaching composition to a person's teeth are formed from a moisture resistant barrier material and include a bleaching agent destabilizer disposed on an inner treatment surface of the barrier layer that is positioned against the person's teeth during use. The bleaching agent destabilizer may be compounded with the moisture resistant material or otherwise disposed relative to the barrier layer so that at least some destabilizer is positioned on the inner treatment surface of the tray or strip so as to contact the dental bleaching composition during use.

Owner:ULTRADENT PROD INC

Mildly Alkaline, Low-Built, Solid Fabric Treatment Detergent Composition Comprising Perhydrolase

InactiveUS20110257063A1Improve bleaching effectImprove the level ofInorganic/elemental detergent compounding agentsNon-surface-active detergent compositionsPhosphateLotion

A solid fabric treatment detergent composition including: (i) detersive surfactant; (ii) perhydrolase; (iii) substrate for perhydrolase; (iv) source of hydrogen peroxide; (v) from 0 wt % to 10 wt % zeolite builder; (vi) from 0 wt % to 10 w % phosphate builder; and (vii) optionally, from 0 wt % to 10 wt % silicate salt, wherein the upon dilution in de-ionized water to a concentration of 1 wt % at 20° C., the composition has a pH in the range of from 7.6 to 8.8.

Owner:THE PROCTER & GAMBLE COMPANY

Detergent Composition

ActiveUS20090325840A1Good bleaching propertyImprove bleaching effectInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsKetoneBleach activator

A hard surface detergent composition is provided, said composition comprising a peroxygen bleach capable of exhibiting bleaching properties at a pH of below 9, and an amino ketone or derivative thereof bleach activator, and wherein a 1% wt solution in distilled water at 25° C. of the composition has a pH lower than 9. Potassium monopersulphate is the preferred bleach compound and diethyl amino acetone or derivative thereof is the preferred bleach activator. The compositions exhibit good bleaching performance at pHs of less than 9.

Owner:RECKITT BENCKISER VANISH BV

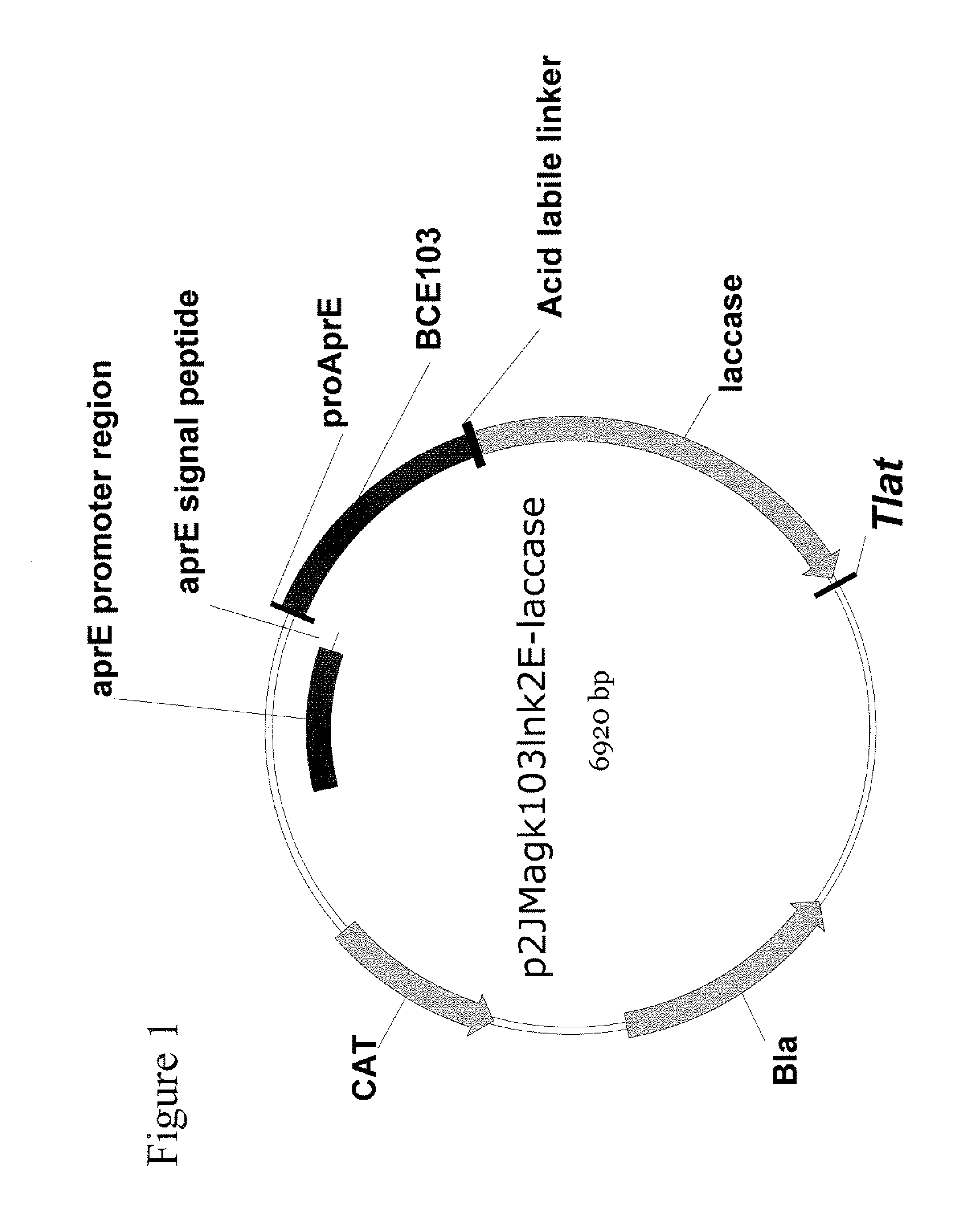

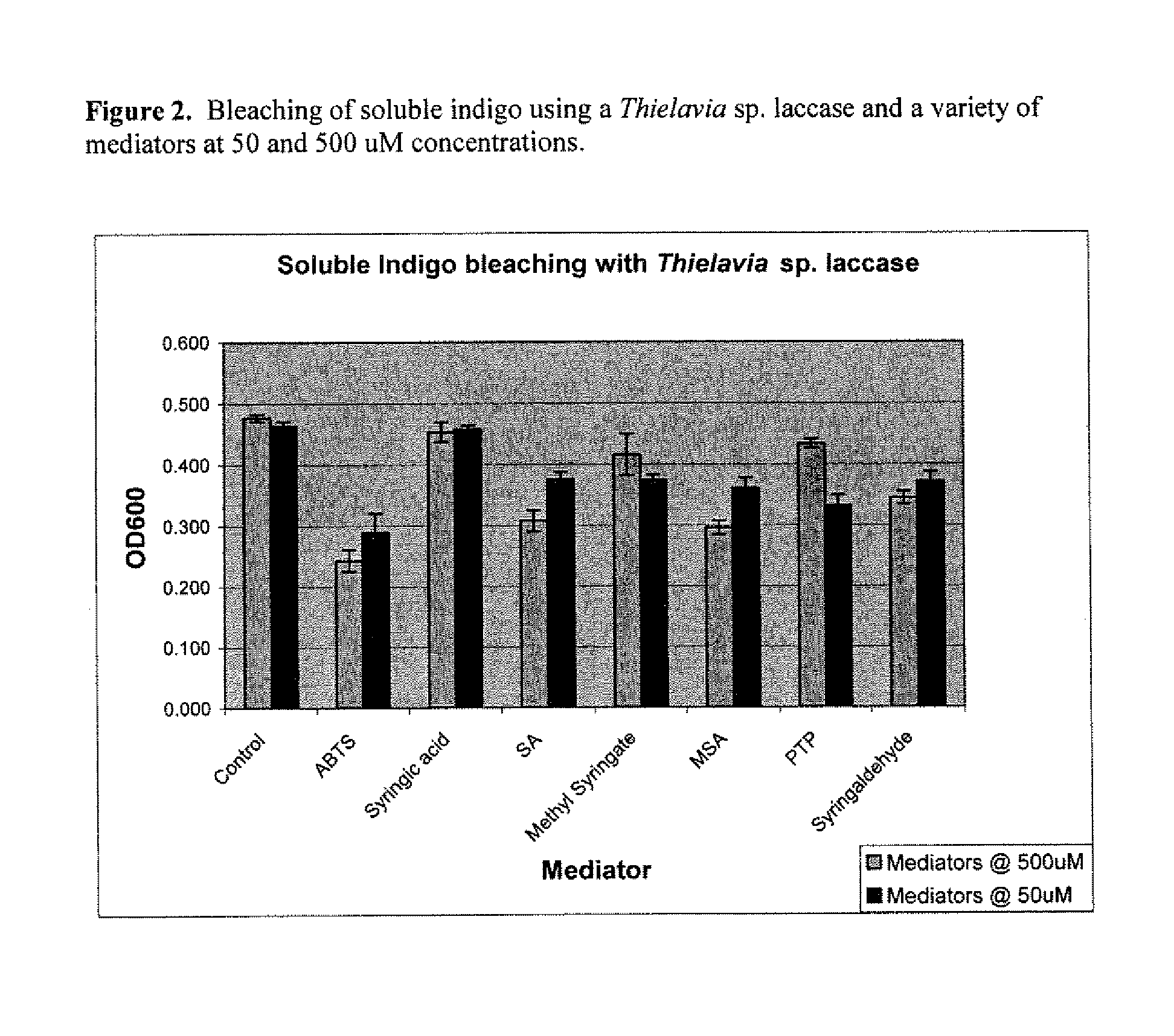

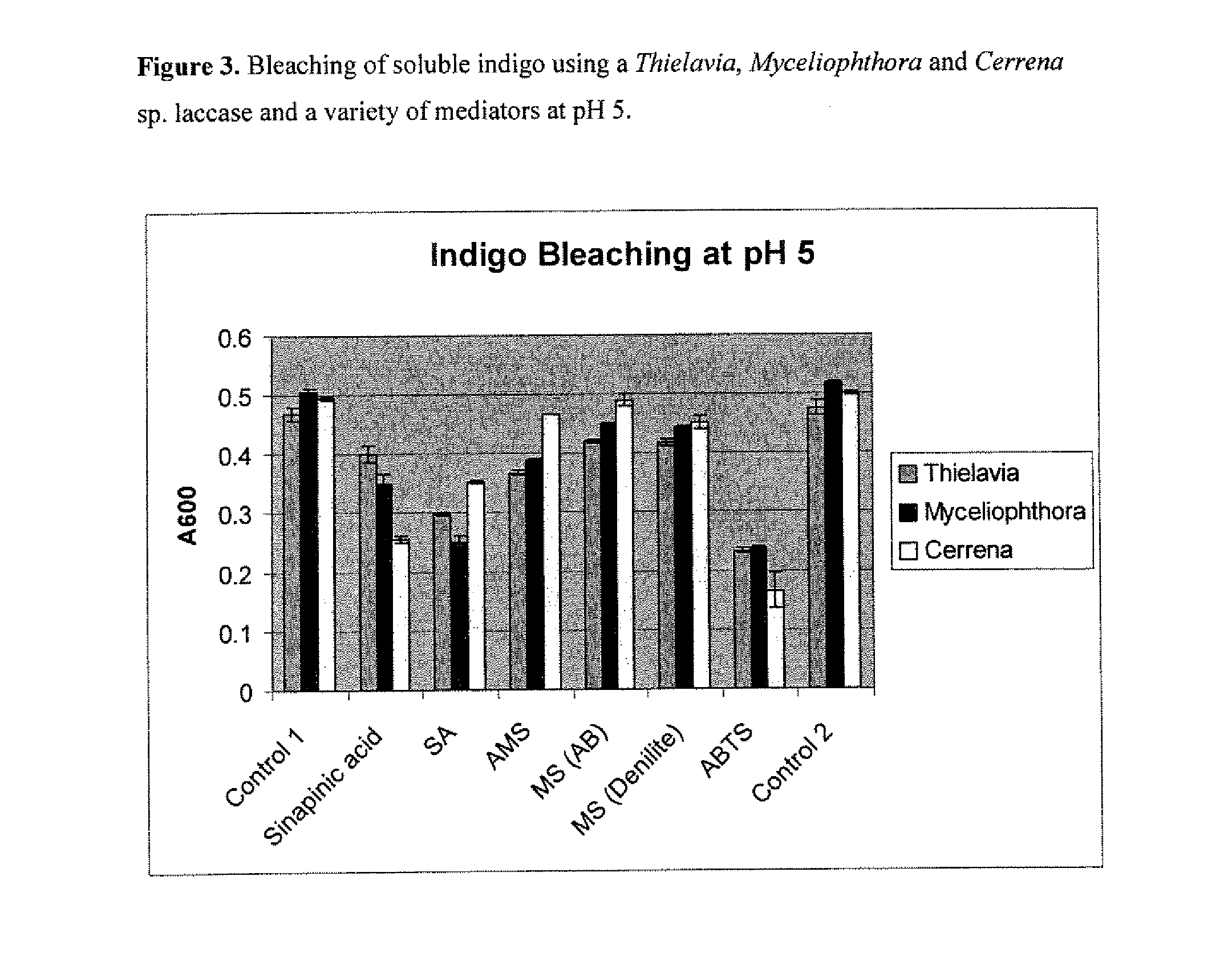

Laccase mediators and methods of use

ActiveUS20080189871A1Improve stabilityImprove bleaching effectFibre treatmentBleaching apparatusCombinatorial chemistryImproved method

Novel laccase mediators, including carboxyamido and cyano derivatives of 2,6-dimethoxyphenol that exhibit improved hydrolytic stability and good bleaching performance. The novel laccase enzymes may be employed in conjunction with the 2,6-dimethoxyphenol derivatives of this invention to provide an improved method for bleaching denim fabrics.

Owner:DANISCO US INC

Textile hydrogen peroxide bleaching stabilizer

InactiveCN101643997AHigh whitenessNo rough and hard feelFibre treatmentBleaching apparatusInorganic saltsMechanical equipment

The invention relates to a textile hydrogen peroxide bleaching stabilizer, comprising the following components: chelating agent, surfactant, magnesium inorganic salt, sodium silicate, scale inhibitionand dispersion agent and water. The scale inhibition and dispersion agent is polyepoxysuccinic acid or sodium salt thereof and has good scale inhibiting dispersing property to silicon so that silicate scale can not deposit and adhere to the surface of fabric; the bleached product has ideal whiteness and no harsh and hard handfeel and can not pollute the inner wall of mechanical equipments.

Owner:LIAONING FIXED STAR FINE CHEM

Two-agent type liquid bleaching compositions

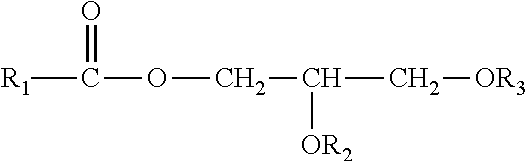

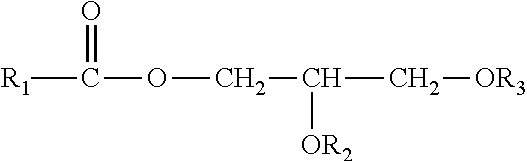

InactiveUS20030119697A1Improve bleaching effectReduce usageNon-surface-active detergent compositionsOrganic/inorganic per-compounds compounding agentsHydrogen peroxideDosage form

To provide two-agent type liquid bleaching compositions having excellent bleaching effect even if a mixing ratio of the two agents varies, great usability, and no problem in storage stability, two-agent type liquid bleaching compositions contains an agent A and an agent B filled and held in separate chambers of a container and comprises the agent A made of constituents containing 0.1 to 10% by weight of hydrogen peroxide and water and provided with certain buffering capacity, and the agent B made of constituents containing an alkali agent and water and provided with certain buffering capacity.

Owner:KAO CORP

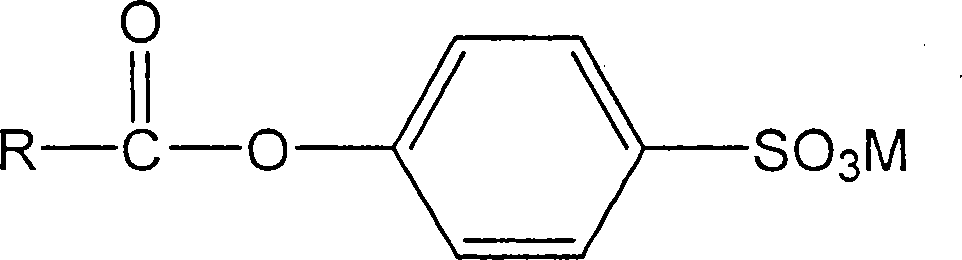

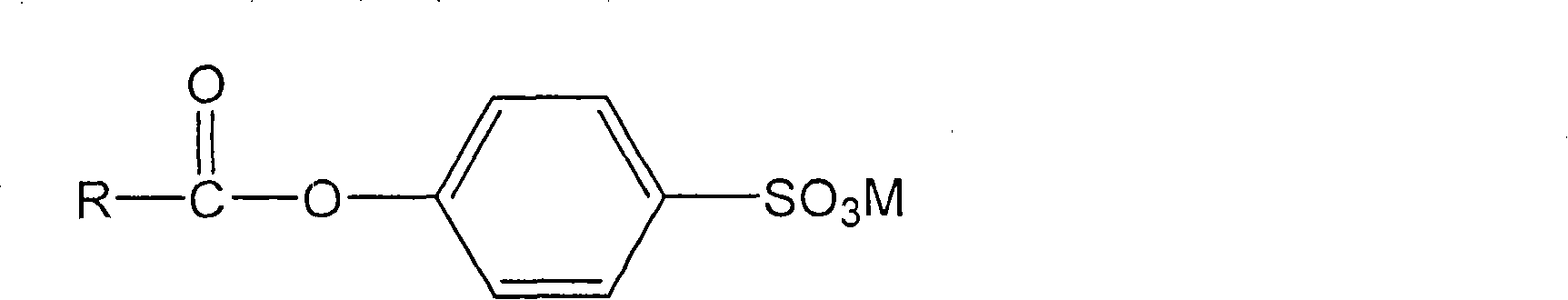

Cold-pad-batch method for textile materials

InactiveCN101135113AAchieve the bleaching effectAvoid damageTextile storage in wounded formFibre treatmentEngineeringBatch method

The present invention discloses process of cold padding, stacking and actively bleaching fabric. The process includes through steps, including one step of compounding bleaching solution and padding, one step of winding and stacking, and one step of hot water washing and cold water washing. The present invention adopts alkanoylxy benzene sulfonate bleaching activator, hydrogen peroxide / activator bleaching system, and cold padding and stacking treatment to reach excellent fabric bleaching effect. Compared with traditional bleaching technology, the present invention has the advantages of excellent fabric bleaching effect, lowered alkali consumption, reduced stacking time, less fabric damage, raised production efficiency and environment friendship.

Owner:ZHEJIANG SCI-TECH UNIV

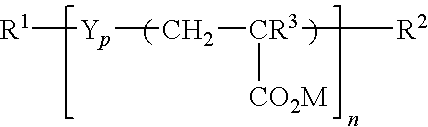

Stabilizing agent for peroxide-bleaching procedure and methods of bleaching a fiber material by using same

InactiveUS6120556AImprove bleaching effectImprove efficiencyOrganic/inorganic per-compounds compounding agentsBleaching apparatusFiberBleach

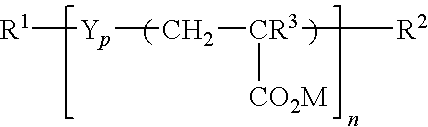

A stabilizing agent for peroxide-bleaching procedure includes (A) a component including a homopolymer or copolymer of alpha -hydroxyacrylic acid or water soluble salt or polylactone of the homo- or co-polymer, (B) a component including a homopolymer or copolymer of acrylic acid, methacrylic acid and / or maleic acid and water-soluble salt of the homo- or co-polymer, (C) a component including DTPA, TTHA or water-soluble salt thereof and optionally (D) a component including a water-soluble inorganic Mg salt and is used to pretreat a fiber material with a pretreating liquid containing the stabilizing agent before bleaching with peroxide, or to bleach the fiber material by a bleaching liquid containing a peroxide bleaching agent and the stabilizing agent.

Owner:NIPPON PEROXIDE

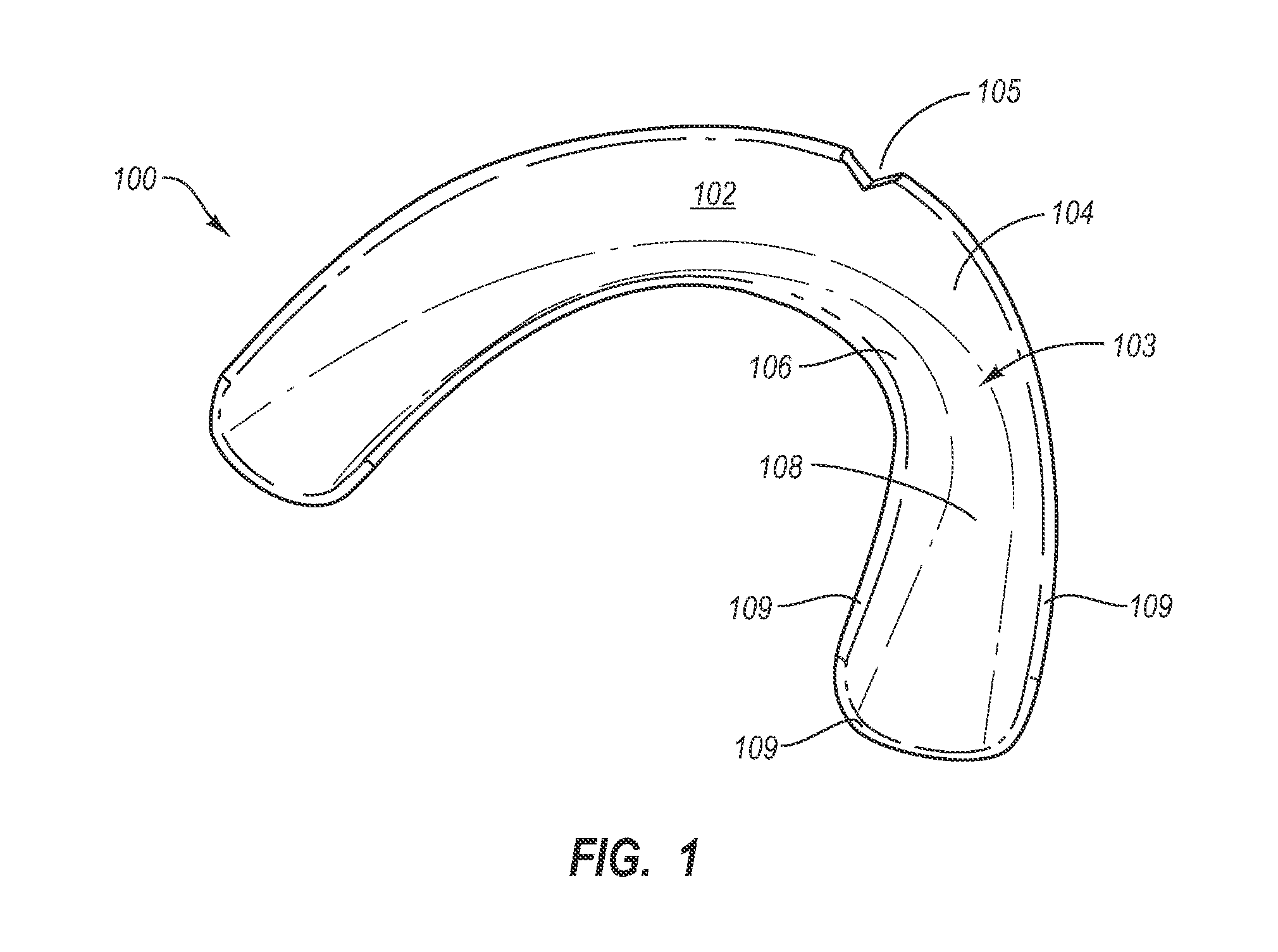

Portable Simultaneous Tooth Prophylaxis And Bleaching System

InactiveUS20120258418A1Reduce paste splatterExtend working lifeTooth pluggers/hammersSomatoscopeRubber CupTooth polishing

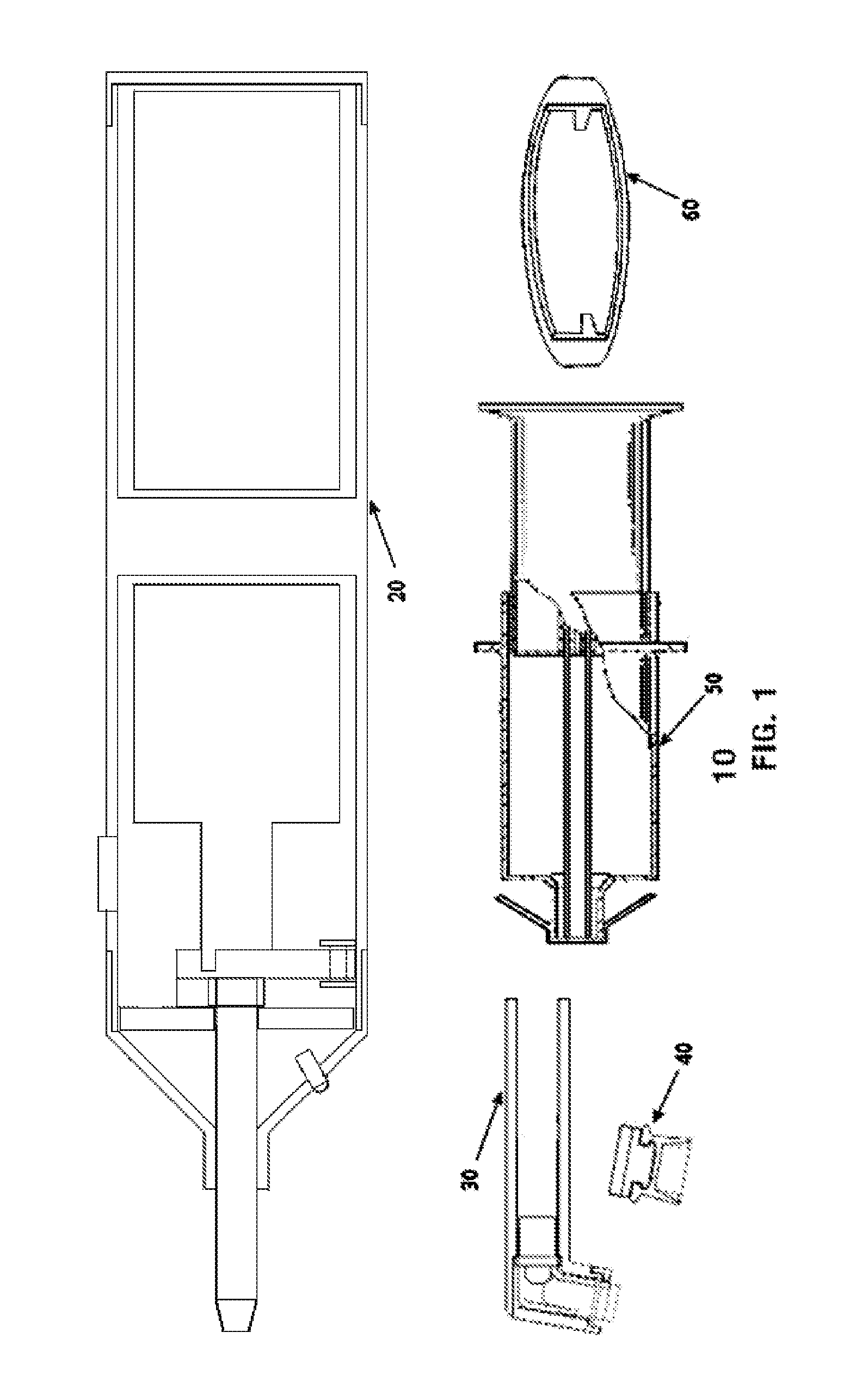

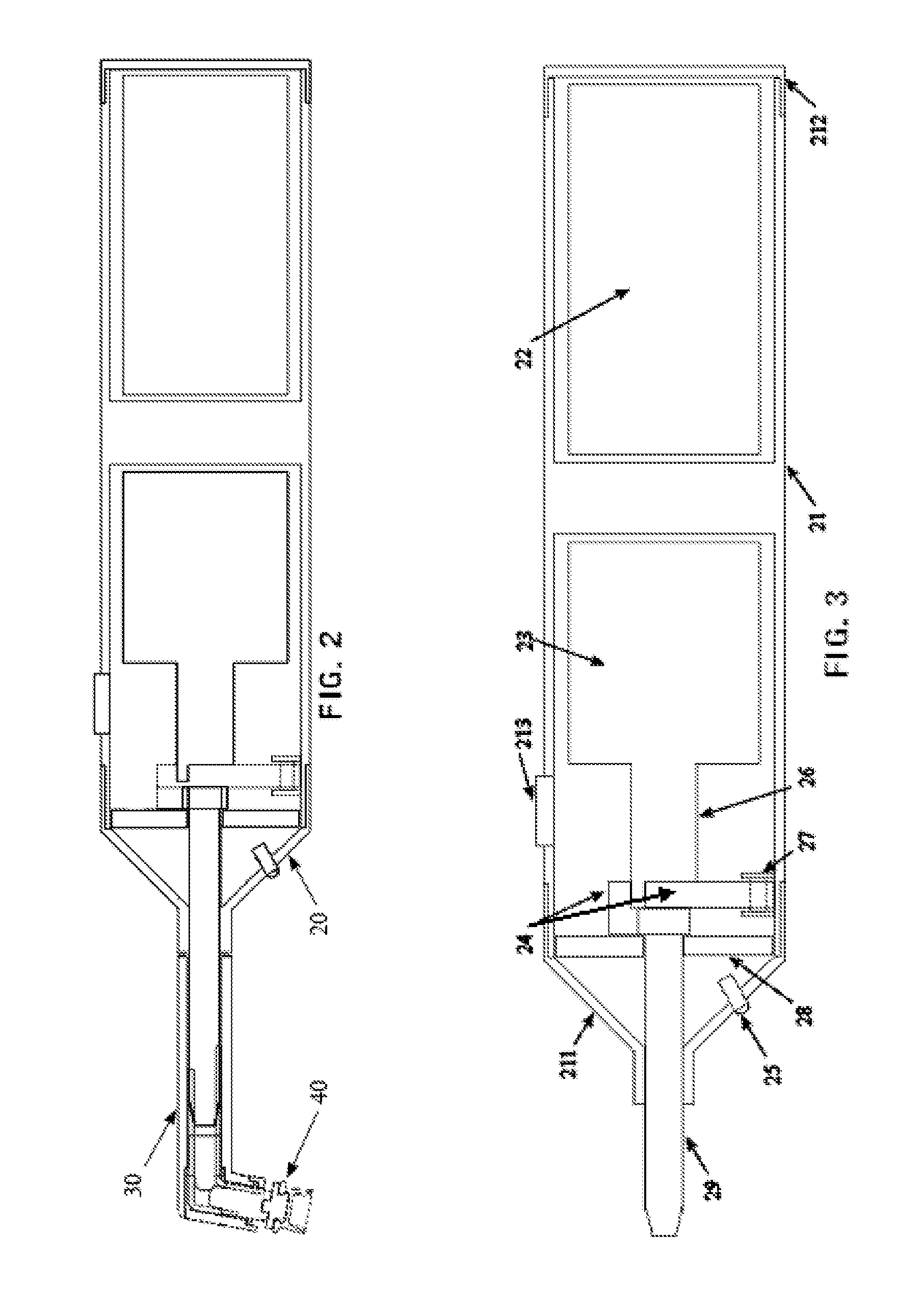

A portable dental prophylaxis and bleaching system is provided for simultaneous tooth polishing and bleaching. It includes an oscillatory driving handpiece, a dental angle with a disposable rubber cup assembly, a dual-component dispenser, and a disposable mouthpiece. The battery-powered handpiece transforms a continuous rotation through a driving cam into a rotary oscillation which is then transferred through the attached dental angle to the rubber cup with an obtuse angle at its distal output end. The dispenser is operated manually to correctly apportion and mix the dual treatment materials into the rubber cup. In order to provide longer shelf life and effective bleaching action, the treatment materials are maintained at optimal pH values in separate compartments within the dispenser before use. The disposable mouthpiece is shaped for easy access to the user's teeth while protecting the gum surfaces. The system can be used both in dental clinics and at home.

Owner:SHEN FEIMO

Method for producing sodium fatty acid methyl ester sulfonate

ActiveCN101759612AAvoid coexistenceReduce dosageSulfonic acids salts preparationSolventFatty acid methyl ester

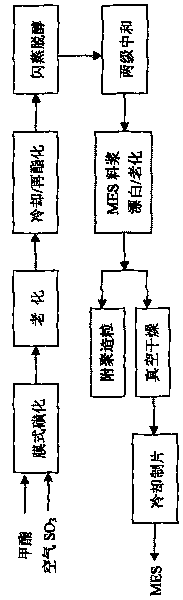

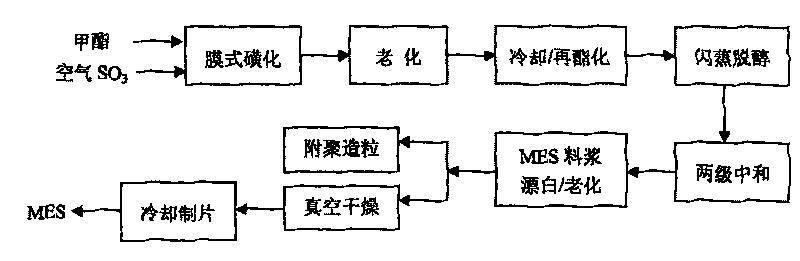

The invention relates to a surfactant used in the production of washing powder, in particular to a method for producing sodium fatty acid methyl ester sulfonate, which solves the problem that the prior art cannot realize continuous, stable industrialized mass production. Hydrogenated palm-methyl stearate is adopted as material, and is sulfonated by SO3 gas on a multi-tube film reactor, steps, such as aging, reesterification, dealcoholization, neutralization, bleaching and vacuum drying, are then sequentially carried out, so that sodium fatty acid methyl ester sulfonate product is obtained, the content of MES is more than 80 percent, the content of disodium salt is less than 5 percent, the content of free oil is less than 2.5 percent, the content of sodium methyl sulfate is less than 8 percent, and color is less than 60 klett(5 percent A.M). Because highly selective catalyst is added in the aging process, the production of deep-colored by-product is reduced; because the reesterification reaction and the bleaching reaction are separately carried out, the safety of reaction is enhanced, and the consumption of methanol as solvent is greatly reduced; because vacuum dealcoholization is carried out before sulfoacid neutralization, industrialized operation can be easily carried out, and meanwhile, the safety problem of methanol in the subsequent bleaching step is eliminated.

Owner:南风化工(运城)集团有限公司

Dental treatment devices

InactiveUS20110171606A1Increase bleachingQuick releaseTeeth fillingTeeth cappingParaffin waxActive agent

Dental treatment trays or strips include a moisture-resistant barrier layer that is flexible so as to conform to a plurality of differently-sized and shaped dental arches during use. The moisture-resistant barrier layer comprised of wax, paraffin wax and / or polyolefin. The dental treatment device also includes a substantially solid dental treatment composition adapted so as to be initially substantially dry to the touch and so as to become sticky and adhesive to dental tissue when moistened. The substantially solid dental treatment composition includes at least one adhesive agent and at least one active agent, such as a dental bleaching agent.

Owner:ULTRADENT PROD INC

Wood surface bleaching technology and its special-purpose apparatus

InactiveCN101121278AReduce bleaching effectImprove bleaching efficiencyWood treatment detailsOXALIC ACID DIHYDRATEOxalate

A bark bleaching process; the steps are as follows that hydrogen peroxide, sodium hydroxide, sodium silicate and magnesium chloride are taken in I bleacher according to a certain proportion to make bleaching liquid: the bark is encased in a bark bleaching frame and the frame is soaked in the bleacher; a pump is adopted to continuously circulate the bleaching liquid in the bleacher; at the same time, steam is input for heating the bleaching liquid and the temperature is kept constant between 60 to 70 Celsius degrees; the constant temperature is kept for 4 to 6 hours; the bark bleaching frame is taken out of the in I bleacher and put into II bleacher filled with oxalic acid solution; a liquid compulsory circulation device is used to make the liquid in the bleacher continuously circulate; the bark bleaching frame is taken out after the frame is soaked for continuous 30 minutes; the bleaching frame is washed with pressed clean water and the drying treatment is implemented at last. The present invention also discloses a special bark bleaching frame and snakelike parting strip for angle steel welding. The present invention boasts of low investment on equipment, high production efficiency and excellent bleaching effect.

Owner:CHENGDU CANYA WOOD IND

Heavy pure cotton fabric cold padding and stacking pretreatment method

ActiveCN103088645AExcellent desizingExcellent and refinedPhysical treatmentBiochemical fibre treatmentPretreatment methodTherapeutic effect

The invention discloses a heavy pure cotton fabric enzyme padding and stacking pretreatment process after normal pressure plasma treatment, and belongs to the technical field of dyeing and finishing pretreatment. The technological process comprises the following steps of: carrying out the normal pressure plasma treatment on the singed heavy pure cotton grey fabric; carrying out refining enzyme liquid padding on the fabric; then stacking at room temperature; then carrying out oxygen bleaching and low alkali mercerization; and finally sufficiently rinsing to complete the pretreatment process of the heavy pure cotton fabric. According to the method, the process has the characteristics of being good in treatment effect, little in fabrics strength damage, high in quality, soft in hand feeling, high in capillary effect and good in glossiness; the method provides a condition of high color yield for the subsequent dyeing and printing processing; the process operation is simple and high in controllability; the treated waste water, the pH value and the energy consumption of the process are far lower than the treated waste water, the pH value and the energy consumption of the traditional strong base scouring process; and the process is a clean production process meeting the environmental protection requirement, so that the sewage treatment burdens of enterprises are greatly reduced, the process is very high in social benefit and market prospect, and the process conditions are optimized.

Owner:浙江肯特科技股份有限公司

Gel for bleaching and whitening teeth

InactiveCN101507689AReduce allergic symptomsImprove bleaching effectCosmetic preparationsToilet preparationsAnti-Allergic AgentsAdhesive

The invention discloses gel for bleaching and whitening teeth, which comprises two parts, namely whitening gel and catalyzing gel, wherein the mixture ratios of the whitening gel and the catalyzing gel are respectively that: the whitening gel consists of the following raw materials in percentage by weight: 5 to 40 percent of peroxide, 10 to 80 percent of humectant, 0.5 to 3.0 percent of adhesive, 1.0 to 10.0 percent of stabilizing agent, 1.0 to 10 percent of anti-allergic agent, and the balance being purified water; and the catalyzing gel consists of the following raw materials in percentage by weight: 10 to 80 percent of humectant, 0.5 to 3.0 percent of adhesive, 0.01 to 1 percent of catalyst, 0.1 to 1 percent of preservative, 0.8 to 2 percent of essence, and the balance being purified water. During the use, the whitening gel and the catalyzing gel are mixed evenly according to the proportion of 4: 1, and are directly coated on the surfaces of the teeth. The gel for the bleaching and whitening the teeth has the characteristics of obvious bleaching effect, stability, and durability, can effectively reduce allergic symptoms of the teeth during the whitening treatment, and is suitable for the whitening treatment of the teeth under various conditions.

Owner:南昌普洋科技有限公司

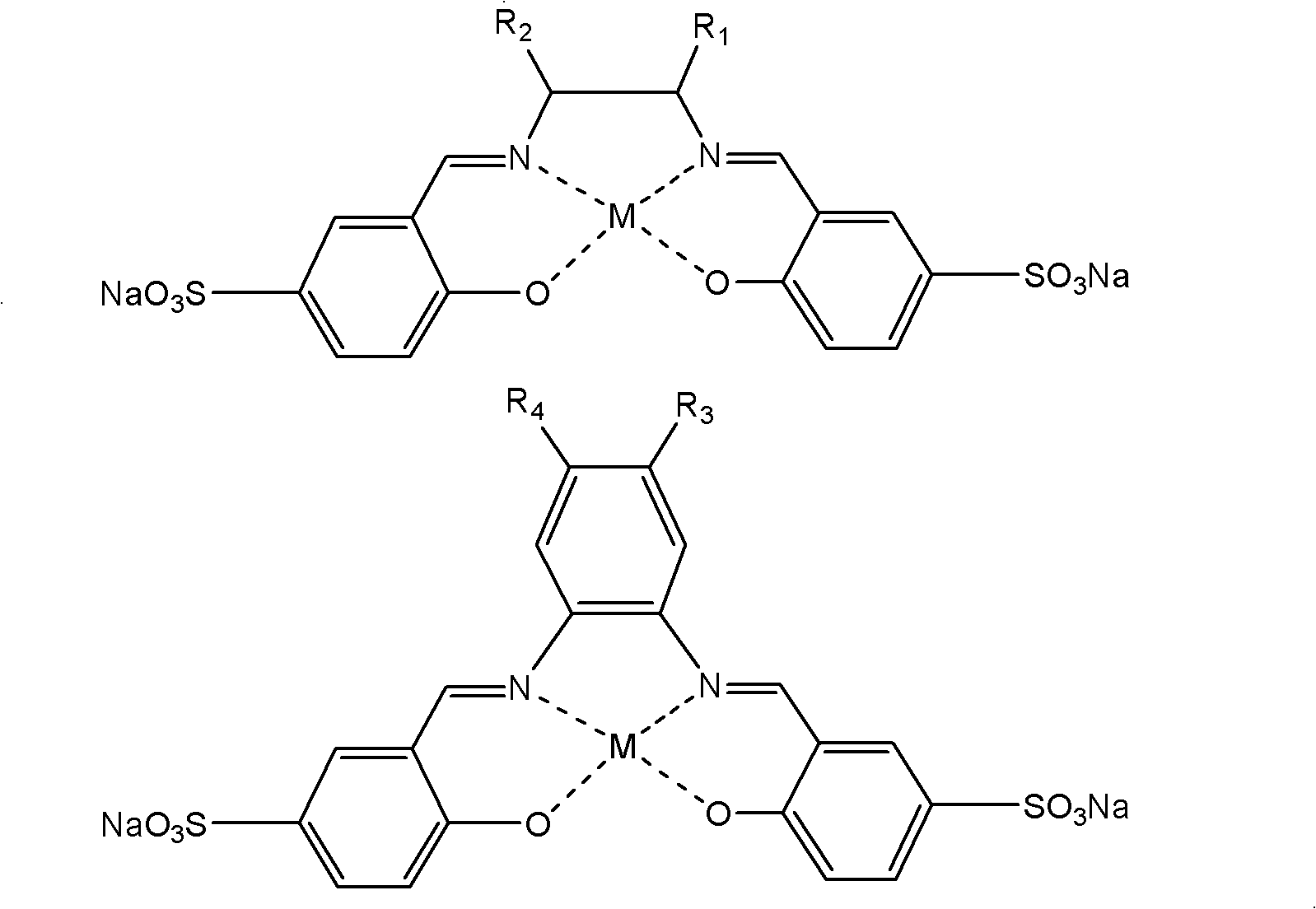

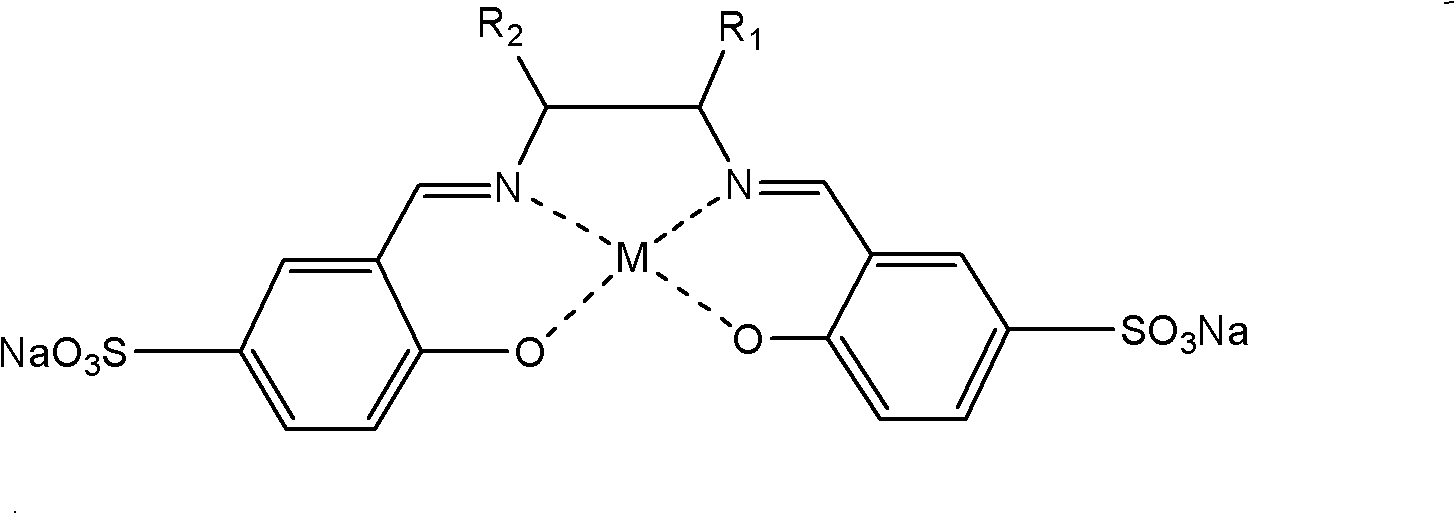

Method for low-temperature activated bleaching by using Schiff base metal complexes

ActiveCN101922109AReduce stacking timeAchieve the bleaching effectBleaching apparatusNuclear chemistryCoordination complex

The invention relates to a method for low-temperature activated bleaching by using Schiff base metal complexes, belonging to the field of methods for low-temperature activated bleaching. The method comprises the following steps: (1) taking the Schiff base metal complexes, 20-50g / L of H2O2, penetrating agents and stabilizing agents and then mixing the substances to obtain bleaching operating fluid with pH value of 7-11; (2) padding the fabrics in the bleaching operating fluid; and (3) carrying out cold pad-batch or steaming on the padded fabrics and then washing the fabrics with water. The method is simple, low in cost, high in production efficiency, environment-friendly, energy-saving and suitable for industrialization and reduces the bleaching temperature, shortens the stacking time and reduces the fabrics damage under the premise of achieving good bleaching effect.

Owner:DONGHUA UNIV

Mechanical alkaline pulping method using hydrogen dioxide from raw material of grass family

InactiveCN1519427AGood strength performanceHigh whitenessChemical/chemomechanical pulpNon-woody plant/crop pulpLignin peroxidaseSewage

A process for mechanically preparing the alkaline hydrogen peroxide pulp from raw straw materials includes such steps as immersing raw straw materials in hot water, squeezing for dewatering, chemical pretreating, grinding, enzyme treating with the solution of semi-cellulase or the solution of semi-cellulase and lignin peroxidase, chemical pretreating, and grinding. The resultant pulp features high whiteness and strength and easy treatment of its sewage.

Owner:SHANDONG UNIV

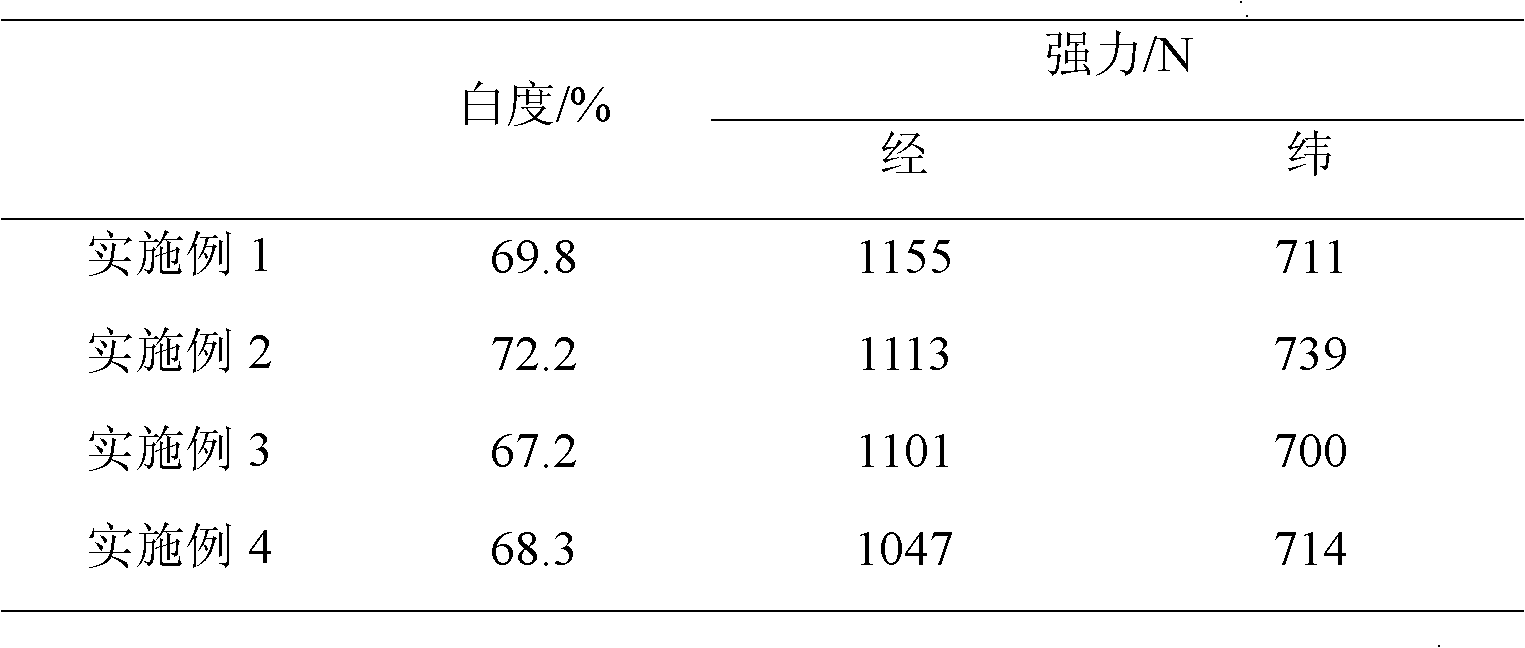

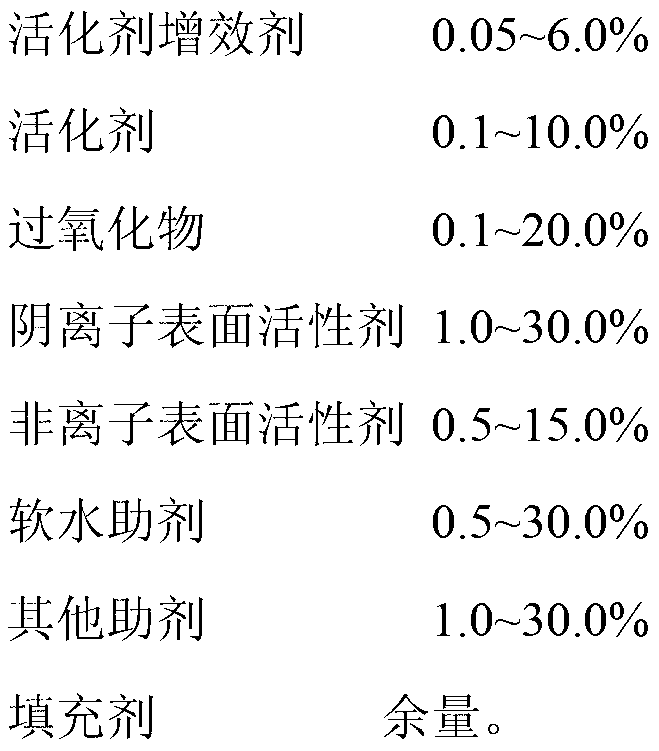

Detergent composition containing low-temperature bleaching and activation system

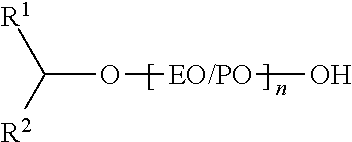

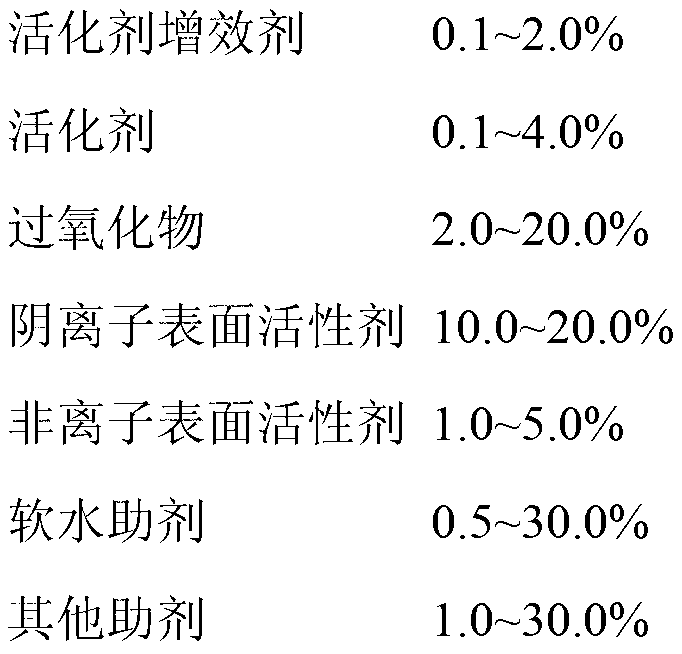

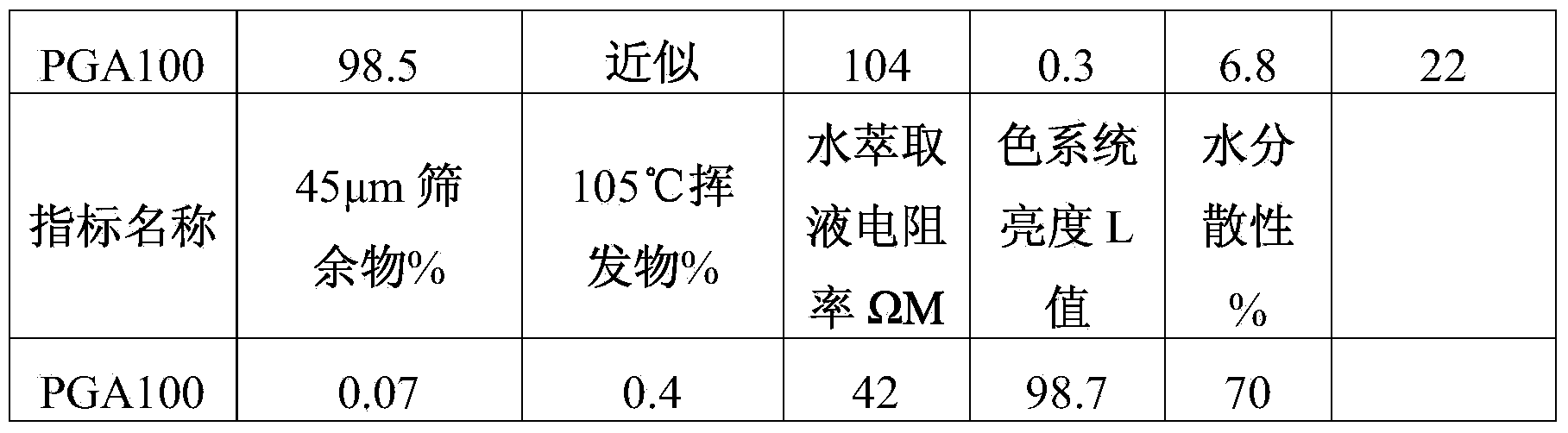

InactiveCN103131552AImprove stabilityReduce the effective bleaching temperatureOrganic detergent compounding agentsSurface-active detergent compositionsBiological activationPeroxide

The invention discloses a detergent composition containing a low-temperature bleaching and activation system, which is prepared from the following components in percentage by mass: 0.05-6.0% of activation agent synergist, 0.1-10.0% of activation agent, 0.1-20.0% of peroxide, 1.0-30.0% of anionic surfactant, 0.5-15.0% of nonionic surfactant, 0.5-30.0% of soft water assistant, 1.0-30.0% of other assistants and the balance of filler. According to the invention, the novel activation synergist is added into the detergent composition, so that the activation efficiency of the conventional activation agent is greatly enhanced; and the detergent composition has favorable bleaching and washing effect at a low washing temperature.

Owner:GUANGZHOU LIBY

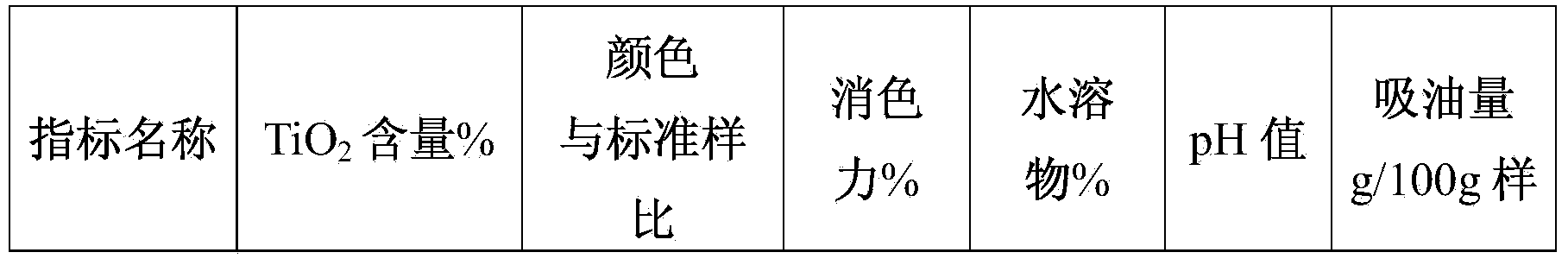

Bleaching method of metatitanic acid in titanium dioxide production by sulfuric acid method

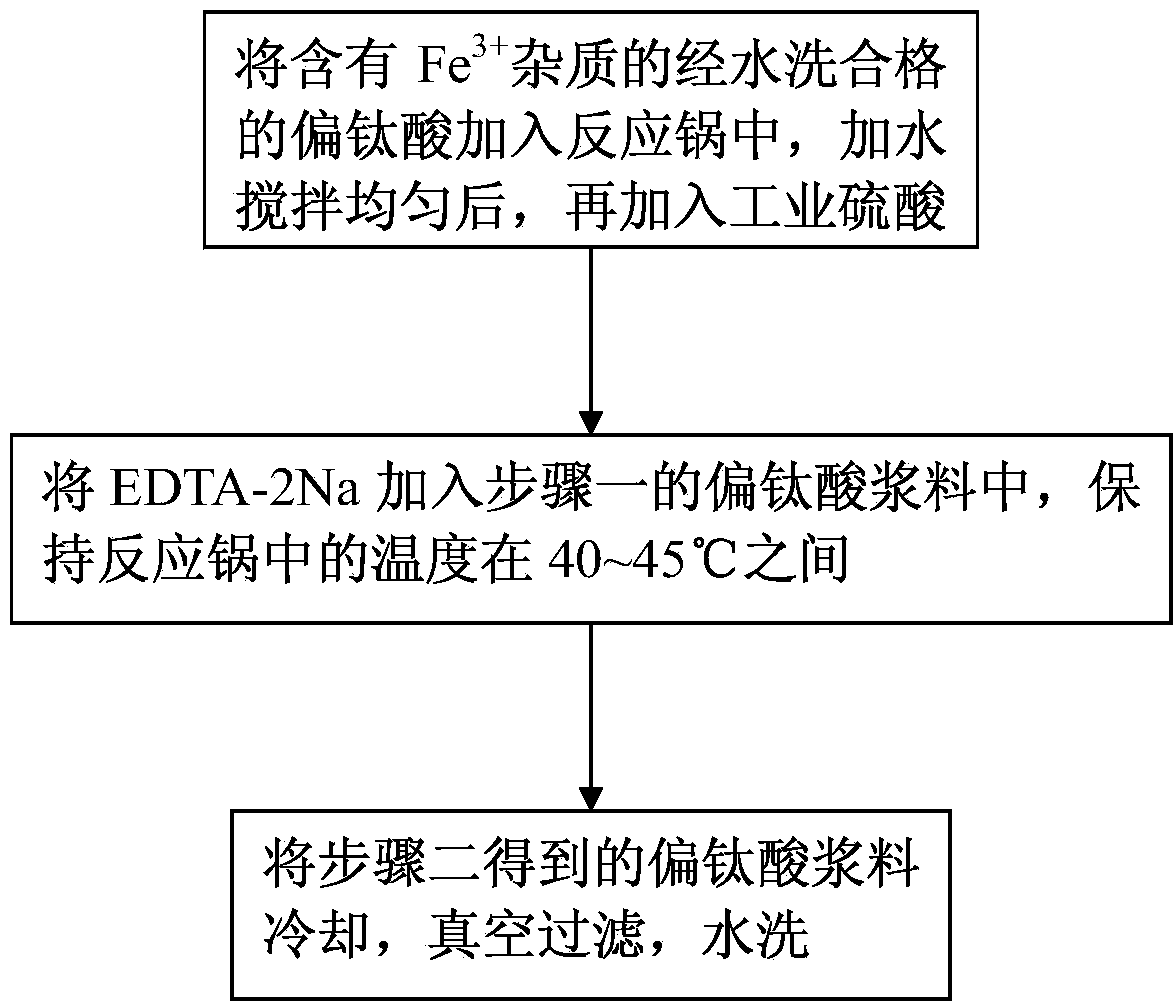

The invention relates to the production field of titanium dioxide and particularly relates to a bleaching method of metatitanic acid in titanium dioxide production by a sulfuric acid method. The bleaching method comprises the following steps: a step I of adding metatitanic acid which is qualified by water-washing and contains Fe<3+> impurities into a reaction pan, and adding industrial sulfuric acid after adding water and uniformly stirring; a step II of adding EDTA (Ethylene Diamine Tetraacetic Acid)-2Na into the metatitanic acid sizing agent of the step I, and keeping the temperature in the reaction pan between 40 DEG C and 45 DEG C; a step III of cooling the metatitanic acid sizing agent obtained in the step II, vacuum-filtering and water-washing. The invention provides a bleaching method of metatitanic acid in titanium dioxide production by a sulfuric acid method, which is simple in process, easy to realize, little in sulfuric acid dosage, low in operating environment, short in bleaching time, free from residue pollution and good in bleaching effect.

Owner:CNMC GUANGXI PGMA

ECF bleaching technology of fast growing poplar by NaOH-AQ pulp biochemical method

The invention discloses an ECF bleaching technology of fast growing poplar by a NaOH-AQ pulp biochemical method. The technology provided by the invention is characterized by comprising the following steps: (1) steaming: taking fast growing poplar chips, stewing the fast growing poplar chips in a digester to obtain virgin pulp, washing and screening to obtain paper pulp; (2) xylanase pretreatment; and (3) ECF bleaching: bleaching the above paper pulp which has undergone enzyme treatment, wherein the bleaching process is ODED and comprises steps of: oxygen delignification or reinforced oxygen delignification is firstly carried out on the paper pulp which has undergone enzyme treatment; after oxygen delignification, the paper pulp is washed and D-stage chlorine dioxide bleaching is then carried out; after D-stage chlorine dioxide bleaching, the paper pulp is washed and then E stage is performed; and after E stage, the paper pulp is washed and secondary D stage is carried out. According to the invention, xylanase is used to pretreat the paper pulp, and then bleaching is performed by the ODED bleaching process so as to obtain the paper pulp with higher whiteness and viscosity. Under the condition that the total dosage of ClO2 is 1%, the whiteness of bleached pulp reaches up to 88.6% ISO as the highest level and to 88.1% ISO as the lowest level.

Owner:QILU UNIV OF TECH

Pre-processing technology of alginate fibre fabric

InactiveCN101392441AWon't be lostEasy to dyeBiochemical fibre treatmentFibre typesFiberPolymer science

The invention provides a preliminary treatment technology of a seaweed fiber fabric, which belongs to the processing technology in the printing and dyeing production field of the textile. The technology includes the following steps: adding water in a water tank, placing the seaweed fiber fabric into the water which is heated, adding 301L nerbanase, penetrant CWA and Kier boiling agent 88ECO into the water and evenly mixing the mixture to form treating fluid, rotating the seaweed fiber fabric in the treating fluid for 15-17 circles, then draining the treating fluid from the water tank, adding water into the water tank for a plurality of times, and placing the seaweed fiber fabric into the water which is heated for a plurality of times for processing so as to finish the pre-treatment process. The treated seaweed fiber fabric can reach the desizing grade requirement of semi-finished seaweed fiber fabrics, and the metal cations and alginate in the seaweed fiber fabrics can not be lost and the physical property or the physical index can not be destroyed during the subsequent dyeing and finishing process; good dyeing or bleaching effect can be obtained in the next dyeing and finishing process if the process is complete.

Owner:HUAFANG

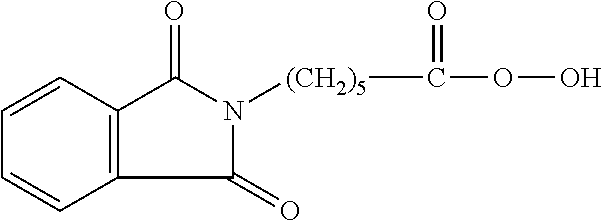

Mildly Alkaline, Low-Built, Solid Fabric Treatment Detergent Composition Comprising Phthalimido Peroxy Caproic Acid

ActiveUS20110021406A1Improve bleaching effectInorganic/elemental detergent compounding agentsDetergent dyesPhosphateLotion

A solid fabric treatment detergent composition having: (i) detersive surfactant; (ii) phthalimido peroxy caproic acid; (iii) from 0 wt % to 10 wt % zeolite builder; (iv) from 0 wt % to 10 wt % phosphate builder; and (v) optionally from 0 wt % to 10 wt % silicate salt, wherein the upon dilution in de-ionized water to a concentration of 1 wt % at 20° C., the composition has a pH of from 7.6 to 8.8.

Owner:THE PROCTER & GAMBLE COMPANY

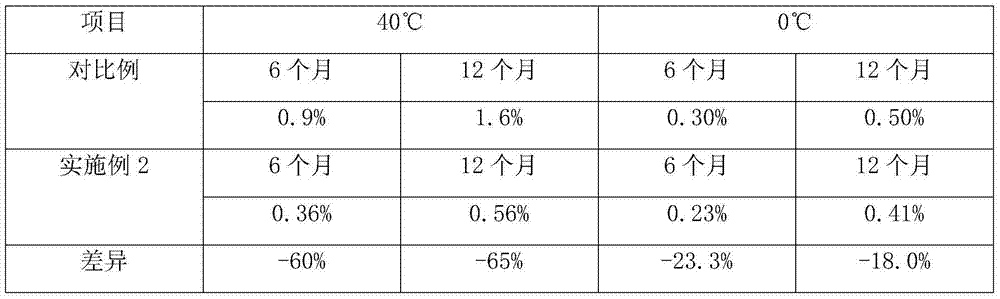

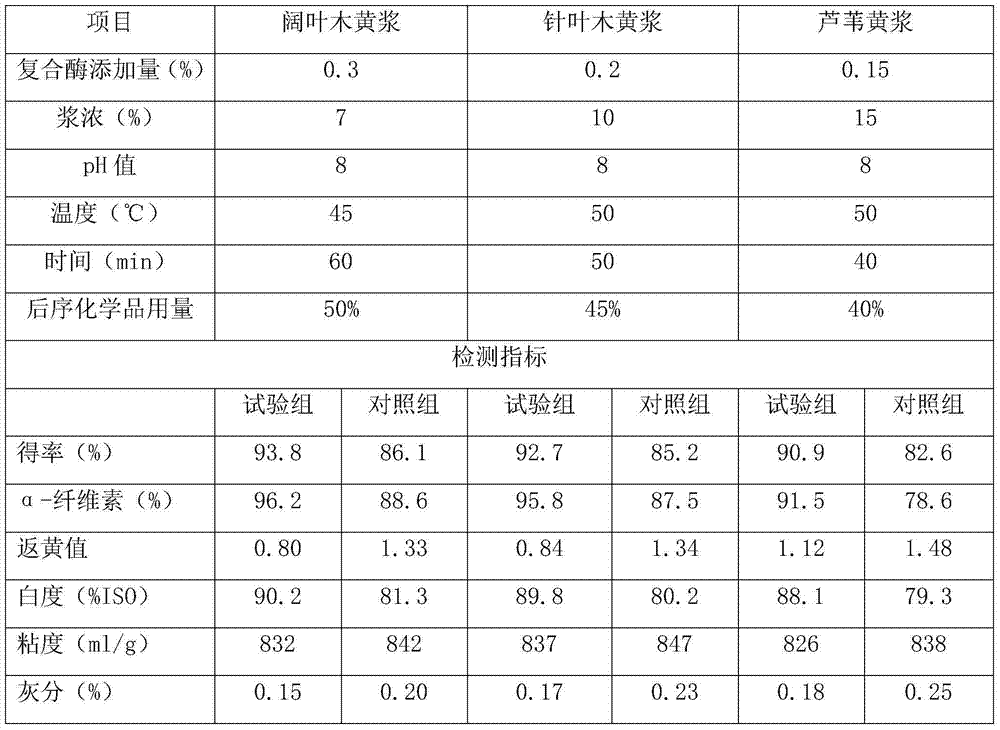

Bleaching compound enzyme for papermaking and preparation method of bleaching compound enzyme

The invention discloses a bleaching compound enzyme for papermaking and a preparation method of the bleaching compound enzyme. The bleaching compound enzyme for papermaking, which has the advantages of complete enzyme system, good bleaching effect, easiness in preservation and good storage stability, is prepared by taking high temperature-resistant alkaline xylanase as main raw material, scientifically compounding a thermophilic bacillus culture, laccase and a medium thereof, dextranase, EDTA (ethylenediaminetetraacetic acid), a protecting agent, an activator, mannose, lipase, tannase, pectase, a whiteness stabilizer, a nonionic surfactant, an antioxidant and the like, completely retaining paper pulp cellulose and simultaneously dissolving out and degrading lignin to the greatest extent. The bleaching compound enzyme disclosed by the invention can significantly improve yield and quality of paper pulp against broad-leaf wood, coniferous wood and reed yellow slurry, and the whiteness is improved by 10.94%, 11.97% and 11.10% respectively; the yellow index is reduced by 39.84%, 37.31% and 24.32% respectively; the amount of conventional chemical products can be saved by 50-60%; and the purposes of reducing cost and protecting an environment are finally achieved.

Owner:黄冈晨鸣浆纸有限公司

Low-quality potash feldspar iron removal purification method

InactiveCN108083288AFacilitate dissociationIn line with rapid developmentAluminium silicatesPurification methodsPotassium

The invention relates to a low-quality potash feldspar iron removal purification method. According to the method, firstly, potassium feldspar is crushed to be made into particles; then, the potassiumfeldspar particles are ground into sand powder by a ball milling process; next, the obtained sand powder is screened; next, magnetic selection is performed by using a multistage strong magnetic selection machine; finally, the potassium feldspar sand powder subjected to the magnetic selection is subjected to acid washing in sulphuric acid by a microwave hydrothermal method; the high-quality and high-purity potassium feldspar sand powder is obtained. The purification process meets the requirement of domestic industries of glass, ceramics, enamel and the like on high-whiteness potash feldspar sand powder; in addition, the microwave hydrothermal technology is applied to the potash feldspar ore purification aspect; the characteristics of high production efficiency, low energy consumption, harmlessness, no pollution and the like are realized; the method belongs to a green and environment-friendly iron removal purification process.

Owner:洛南县大秦钾矿有限公司

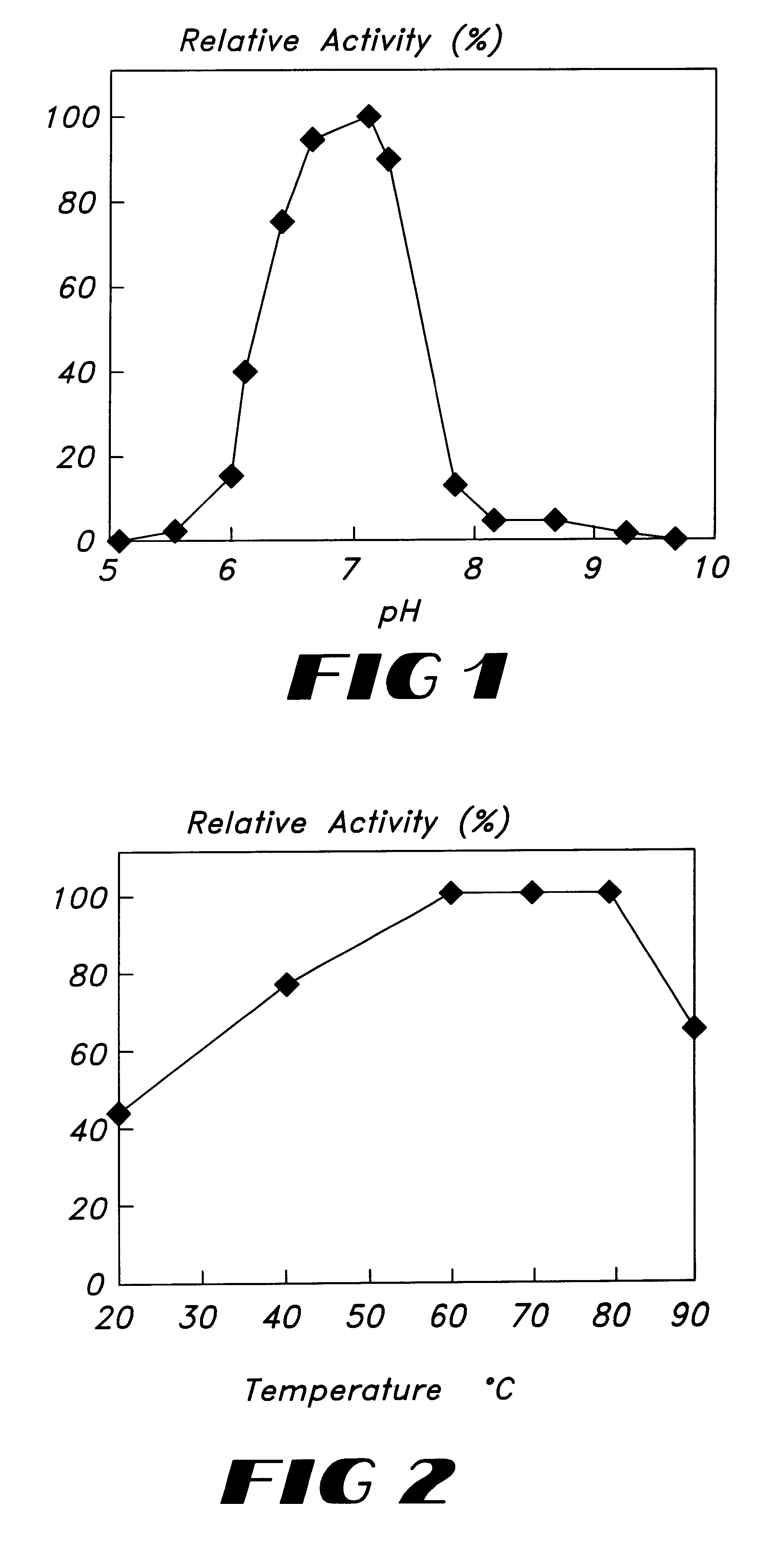

Bacterial polyphenol oxidase from bacillus for use in oxidation of colored substances

InactiveUS6184014B1Efficient of substanceEfficient oxidationOrganic detergent compounding agentsBacteriaBacteroidesFiltration

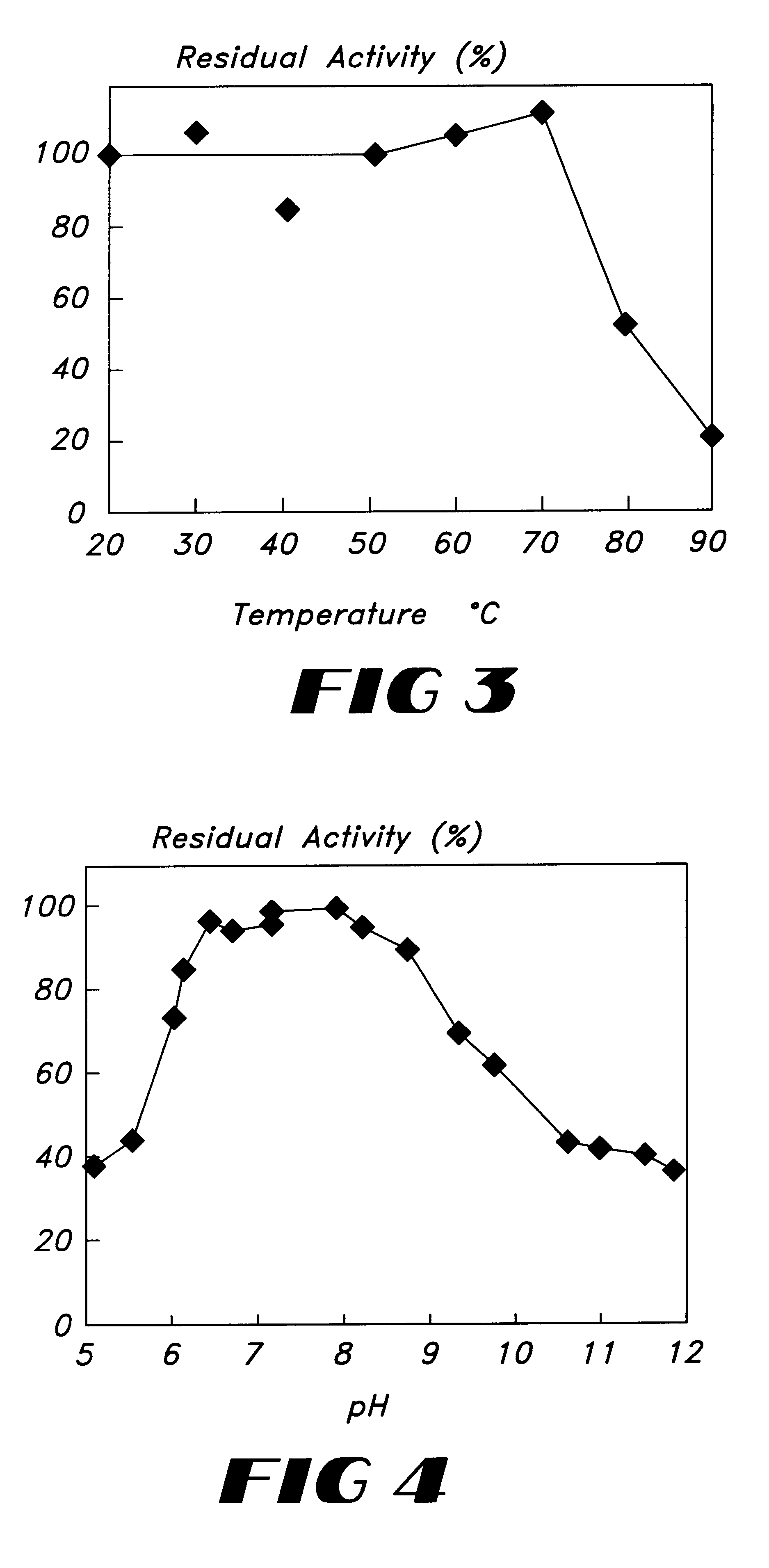

The present invention provides polyphenol oxidases from bacteria, particularly from the genus Bacillus including, without limitation, B. licheniformis, B. natto, and B. sphaericus, In some embodiments, the polyphenol oxidase has an optimum reaction pH of about 7; an optimum reaction temperature between 60° C. and 80° C.; and a molecular weight of 51,000 measured by gel filtration chromatography. The enzymes of the invention are useful for oxidizing and / or bleaching a variety of substrates.

Owner:NOVOZYMES AS

Production process for purified cotton with high whiteness

The invention discloses a production process for purified cotton with high whiteness. The production process comprises the steps of opening cotton linters by an opener; spraying the cotton linter ribs by using a 25g / L sodium hydroxide solution; squeezing the cotton linter ribs by a squeezer after spraying; putting the squeezed cotton linter ribs in a spherical digester, adding sodium hydroxide with a mass concentration of 3.5-4.0% to carry out alkaline cooking; defibering size after the alkaline cooking; degritting; adding dilute sulphuric acid to carry out acid treatment; adding sodium hypochlorite in the size for bleaching; outputting the size; squeezing the white size; drying the white size and packaging to store. The cotton linter ribs are used as raw materials, partial impurities are removed by opening cotton, removing impurities and cooking the size; cotton fibers wound into balls in the size are dispersed and straighten by the defibering; impurities in the size are further removed by degritting, and thus the quality of the purified cotton is increased and the purified cotton with higher whiteness is obtained.

Owner:杨金福

Amine salt activation of peroxycarboxylic acids

ActiveUS8685112B1Improve performanceEnhance compositionBiocideBleaching apparatusBleach activatorCyclic amines

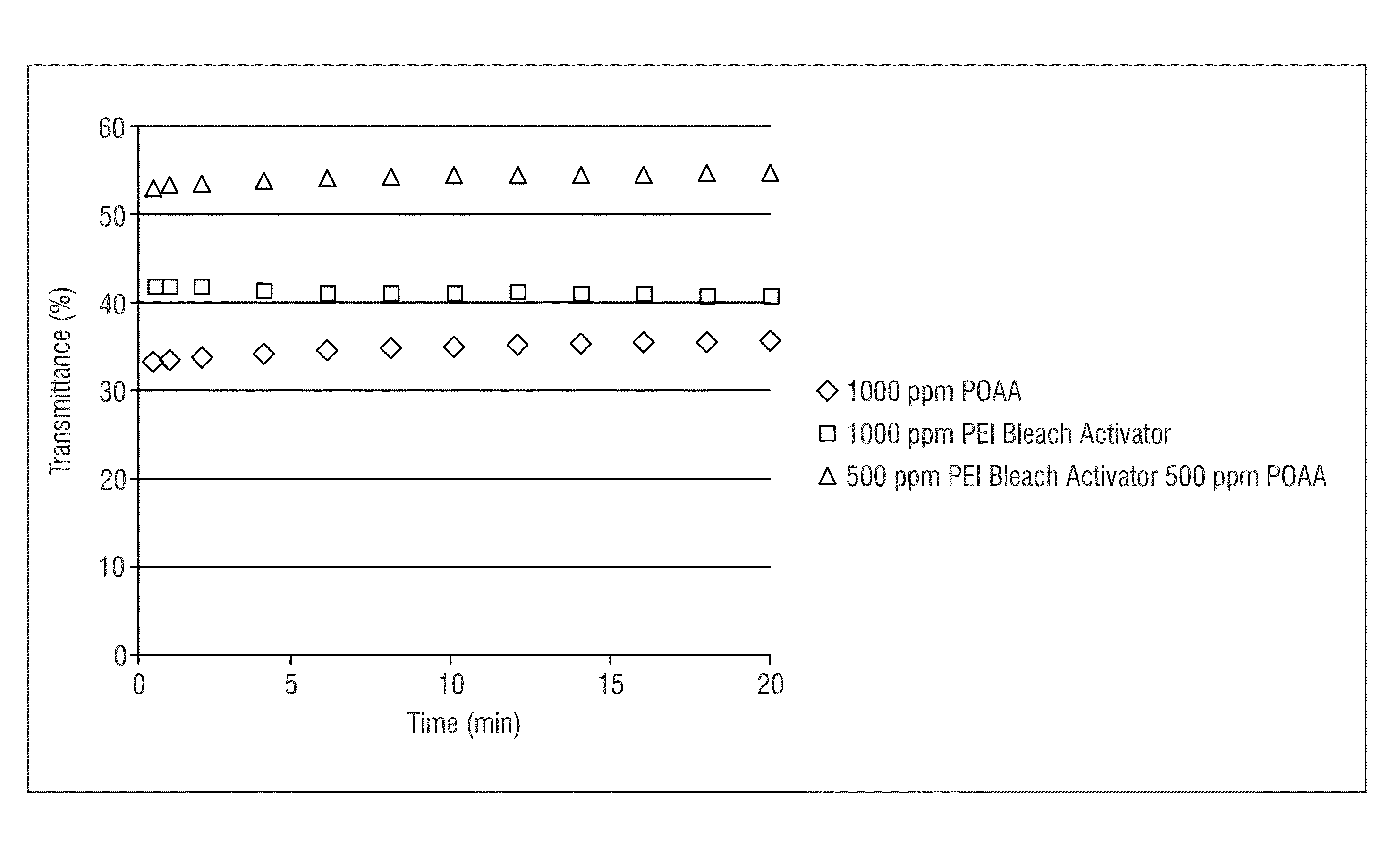

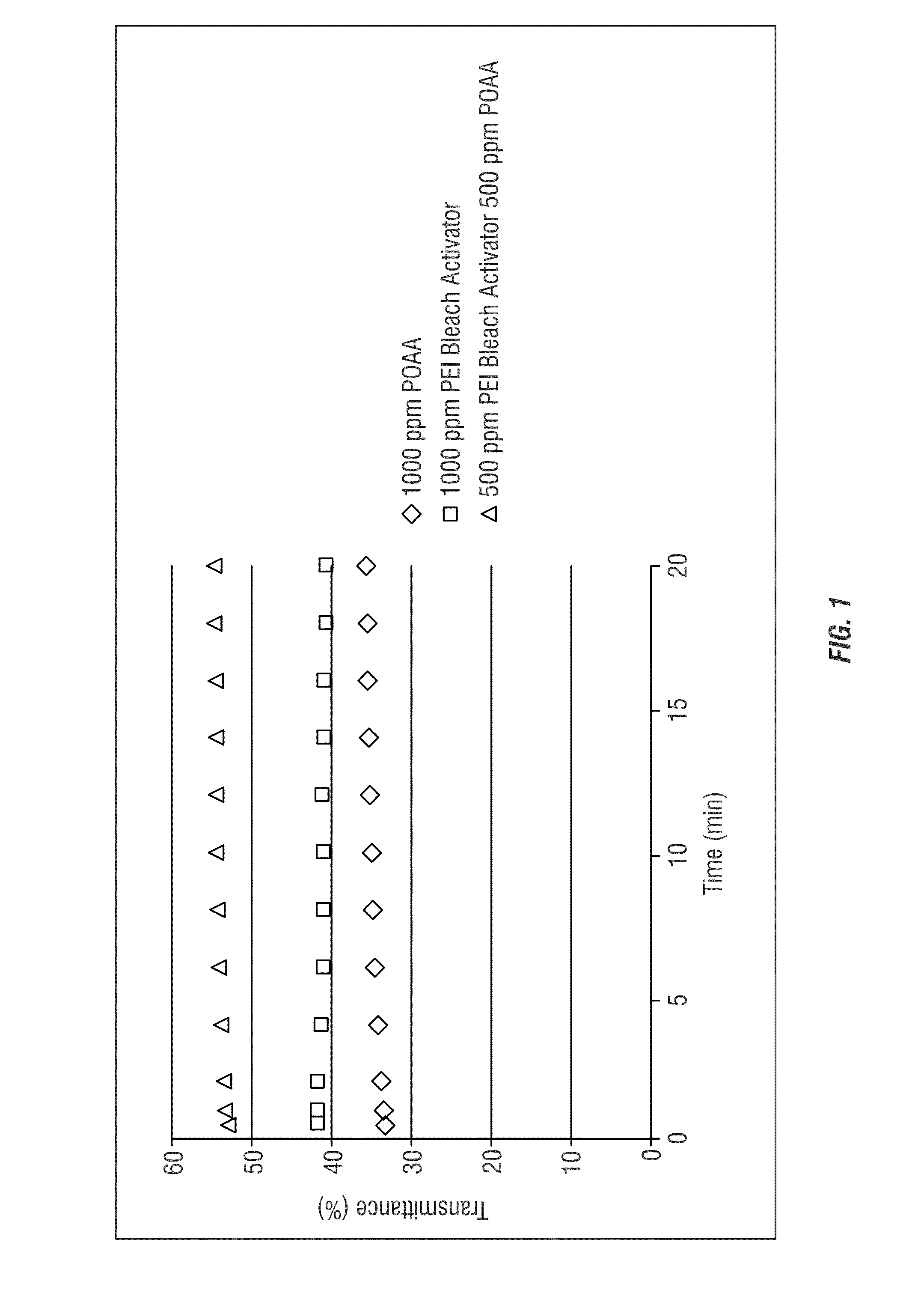

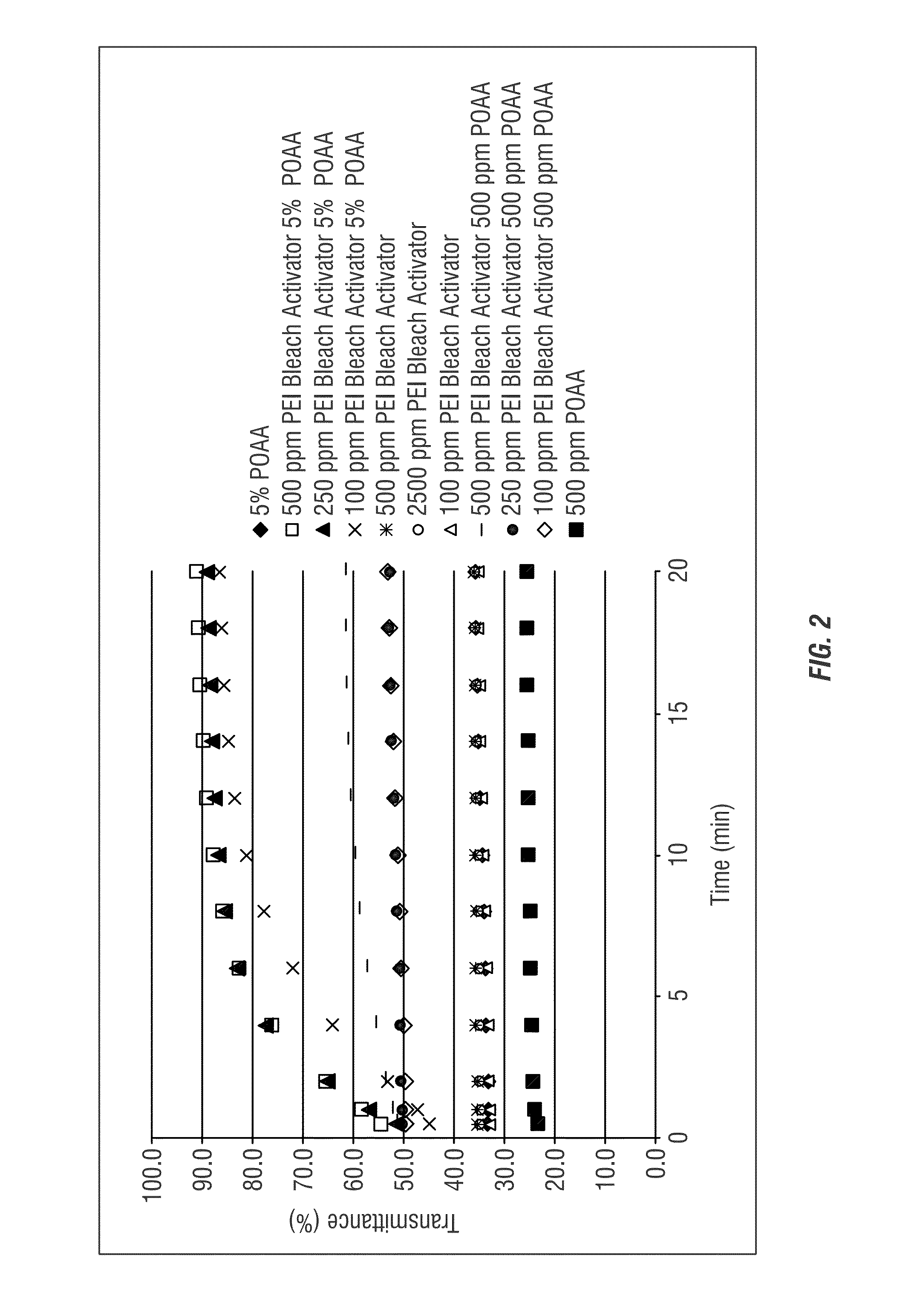

Treated peroxycarboxylic acid bleaching compositions and methods of using the same are provided to enhancing bleaching performance of various peroxycarboxylic acids. Peroxycarboxylic acid peroxycarboxylic acid compositions are combined with non-metal bleach activators, preferably polyethyleneimines. The invention further relates to methods employing the enhanced bleaching compositions.

Owner:ECOLAB USA INC

Method for extracting agar from gracilaria with enzymatic method

The invention discloses a method for extracting agar from gracilaria with an enzymatic method. After gracilaria is soaked, cellulose and protease are added for enzymolysis, and gracilaria slag in enzymatic hydrolysate is filtered; after the gracilaria slag is subjected to bleaching, acidification and washing treatment, an appropriate amount of water is added, water is boiled to 95 DEG C for glue extraction, and enzyme activity is killed; a glue solution is filtered while hot, 95% ethyl alcohol with a volume of two to three times of that of the glue solution is added to the glue solution rapidly, precipitation is centrifuged or filtered, dehydration is performed twice with absolute ethyl alcohol, and drying is performed, so that an agar product is obtained. The main ingredient of agar in gracilaria is separated with a clean and efficient biological enzyme treatment technology, and the defects of a conventional alkali treatment technology are overcome; before glue extraction is performed on gracilaria, sodium hypochlorite is replaced with hydrogen peroxide for bleaching treatment, the bleaching effect is remarkable, and the problems of chloride ion residues and pollution caused by a sodium hypochlorite bleaching method are solved; and finally, agar is rapidly precipitated from the glue solution with a simple, convenient and feasible alcohol precipitation method, the production period is greatly shortened, and the cost is greatly reduced.

Owner:青岛福创环境科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com