Patents

Literature

779results about How to "Easy to dye" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Denier/superfine denier nylon master granule, preoriented yarn (POY) and draw textured yarn (DTY) stretch yarn and preparation method thereof

ActiveCN101724265AHigh tensile strengthImprove mixing performanceMelt spinning methodsMonocomponent polyamides artificial filamentYarnEngineering

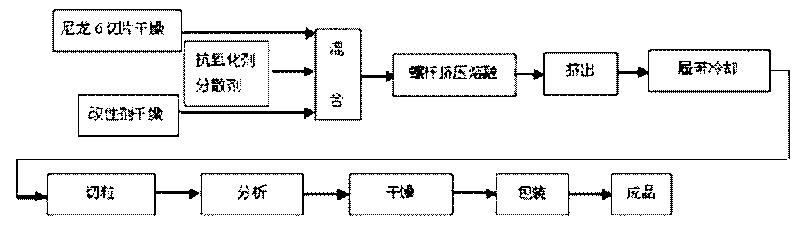

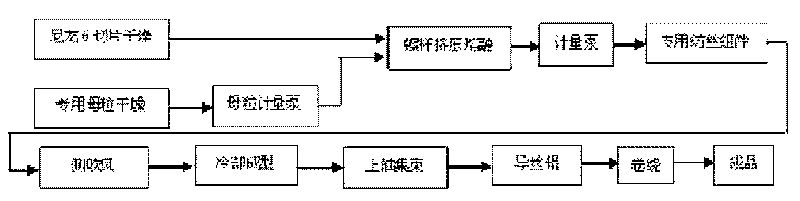

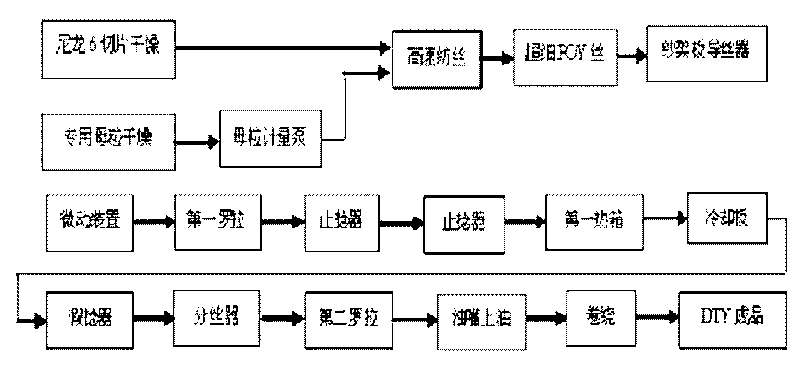

The invention belongs to the field of spinning materials. Firstly, the invention provides a fine denier / superfine denier nylon master granule prepared by proportionally adding a modifying agent, an antioxidant and a dispersant to nylon 6 sliced sheets according to the proportion, melting, mixing and extruding, and the modifying agent is a metallic salt which can take effect on nylon base; The fine denier / superfine denier nylon master granule and the nylon 6 sliced sheets are proportionally mixed, melted and spun, and the fine denier / superfine denier nylon POY is prepared by cooling, oiling, bundling and coiling; and the POY is textured to obtain the DTY. The invention provides the fine denier / superfine denier nylon POY of which the filament size is 0.3-0.8dtex, the filament size of the DTY is 0.25-0.70dtex, which fills the vacancy that the fine denier / superfine denier nylon POY and the DTY are produced by the conventional yarn-spinning process at home and abroad.

Owner:HANGZHOU NORMAL UNIVERSITY

Fire retardant cotton nonwoven fabrics and manufacture method thereof

InactiveCN101307528AImprove flame retardant performanceGood anti-melting effectHeating/cooling textile fabricsNon-woven fabricsCardingPolymer science

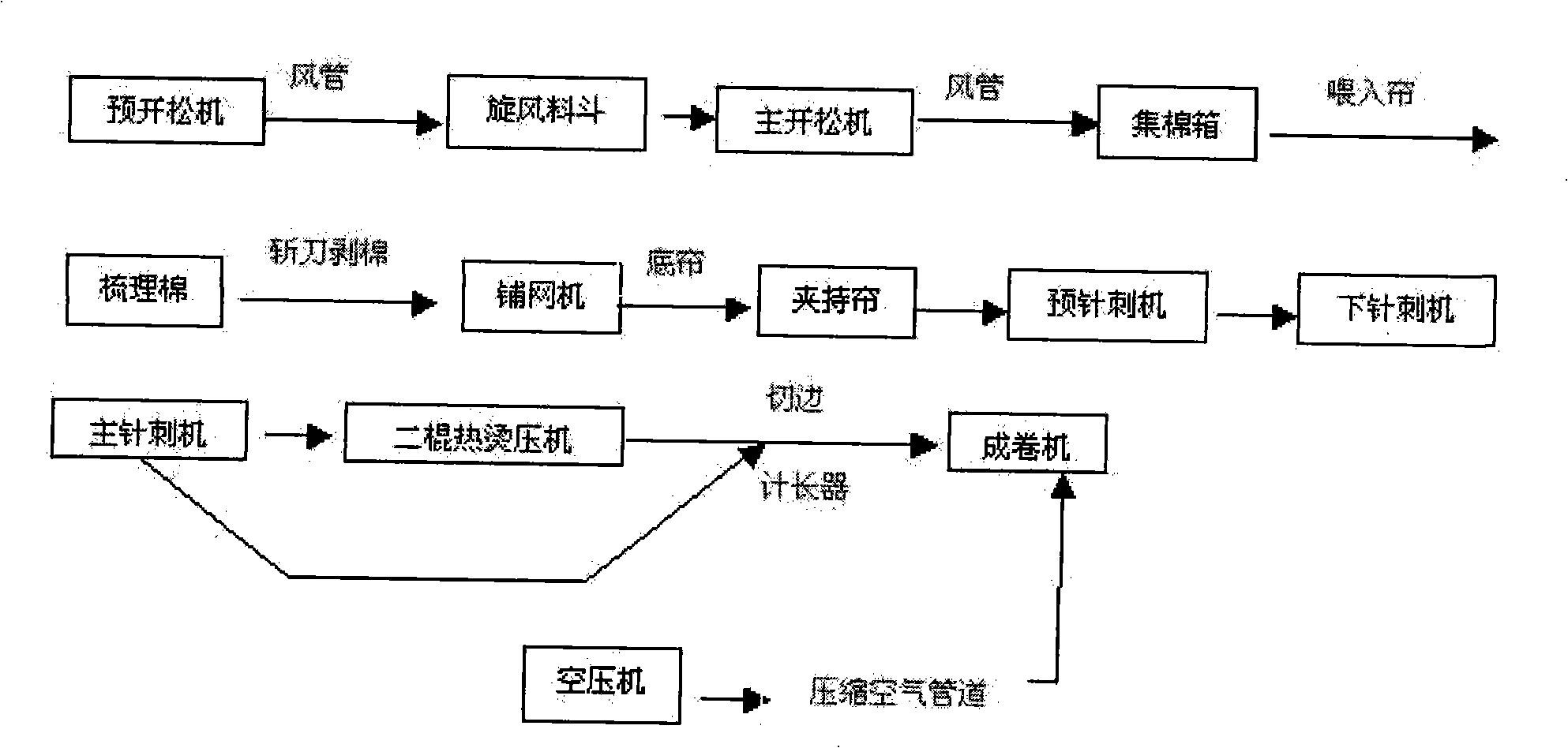

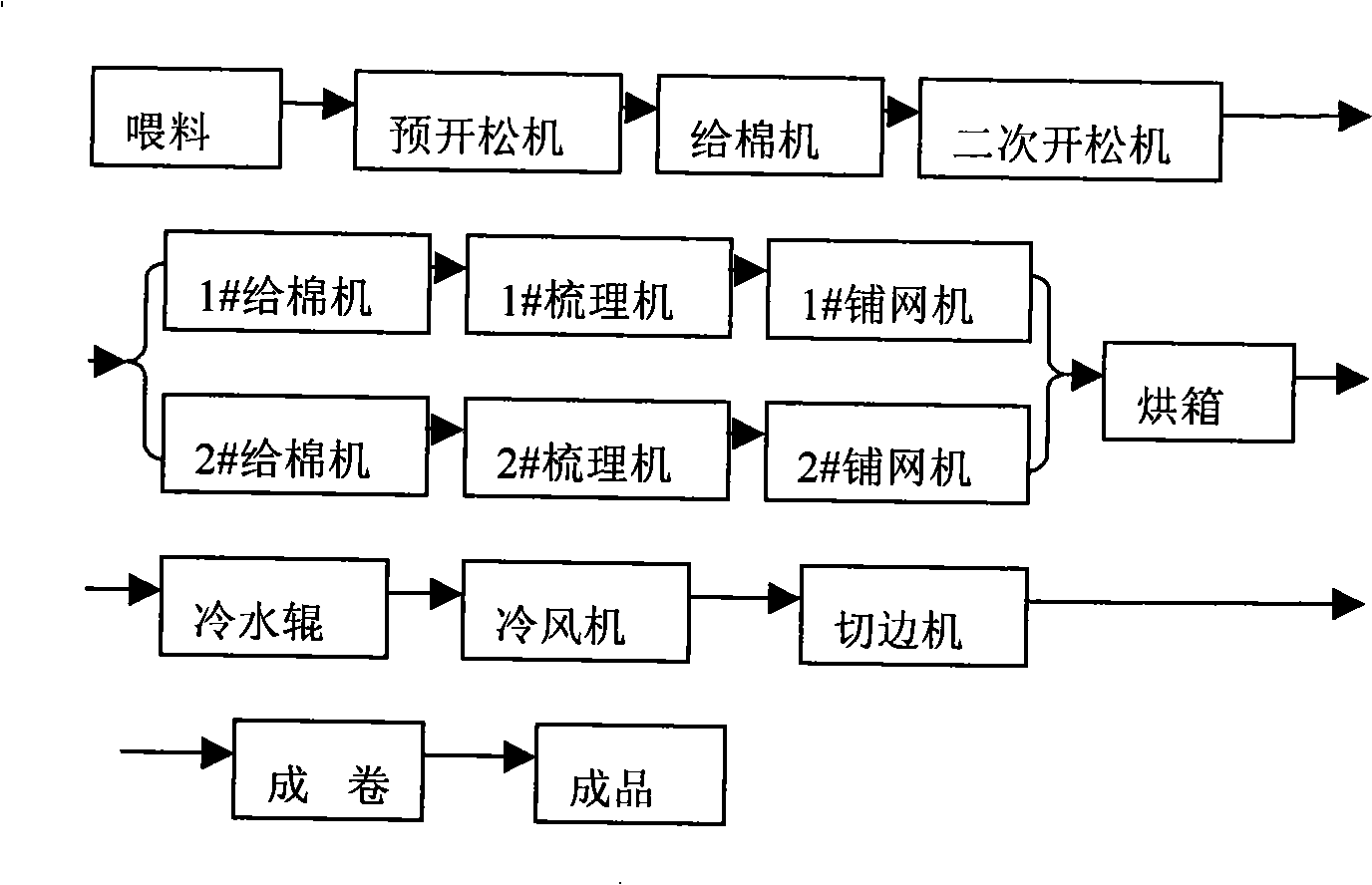

The invention discloses an flame retardant non-woven cotton fabric, comprising anti-fcell flame retardant fiber and washing / washing composite hot melting short fiber, wherein, the weight percentage of the anti-fcell flame retardant fiber is between 70 and 90 percent, the balance is the washing / washing composite hot melting short fiber; the two fibers are stuck into an integrated whole by the hot wind heating and / or are penetrated together by prickling fibers to combine into the non-woven fabric. The method for producing the non-woven cotton fabric comprises the processes of mixing, opening, carding, mesh placing, moulding processing, etc. The moulding processing method has the needle point method and the through-air method. The flame retardant non-woven cotton fabric adopts the prescription of mainly taking the anti-fcell flame retardant fiber and solves the problems of the flammability of the terylene, dropping of the fusion and the flammability of the viscose. The washing / washing composite hot melting short fiber is added to increase the caking coefficient so that the fibers are conglutinated evenly. The unique processing flow ensures that the inflaming retarding non-woven cotton fabric has high tension intensity and anti-breakage intensity as well as certain elasticity and bulkiness.

Owner:DONGGUAN LIANYING NONWOVEN TECH

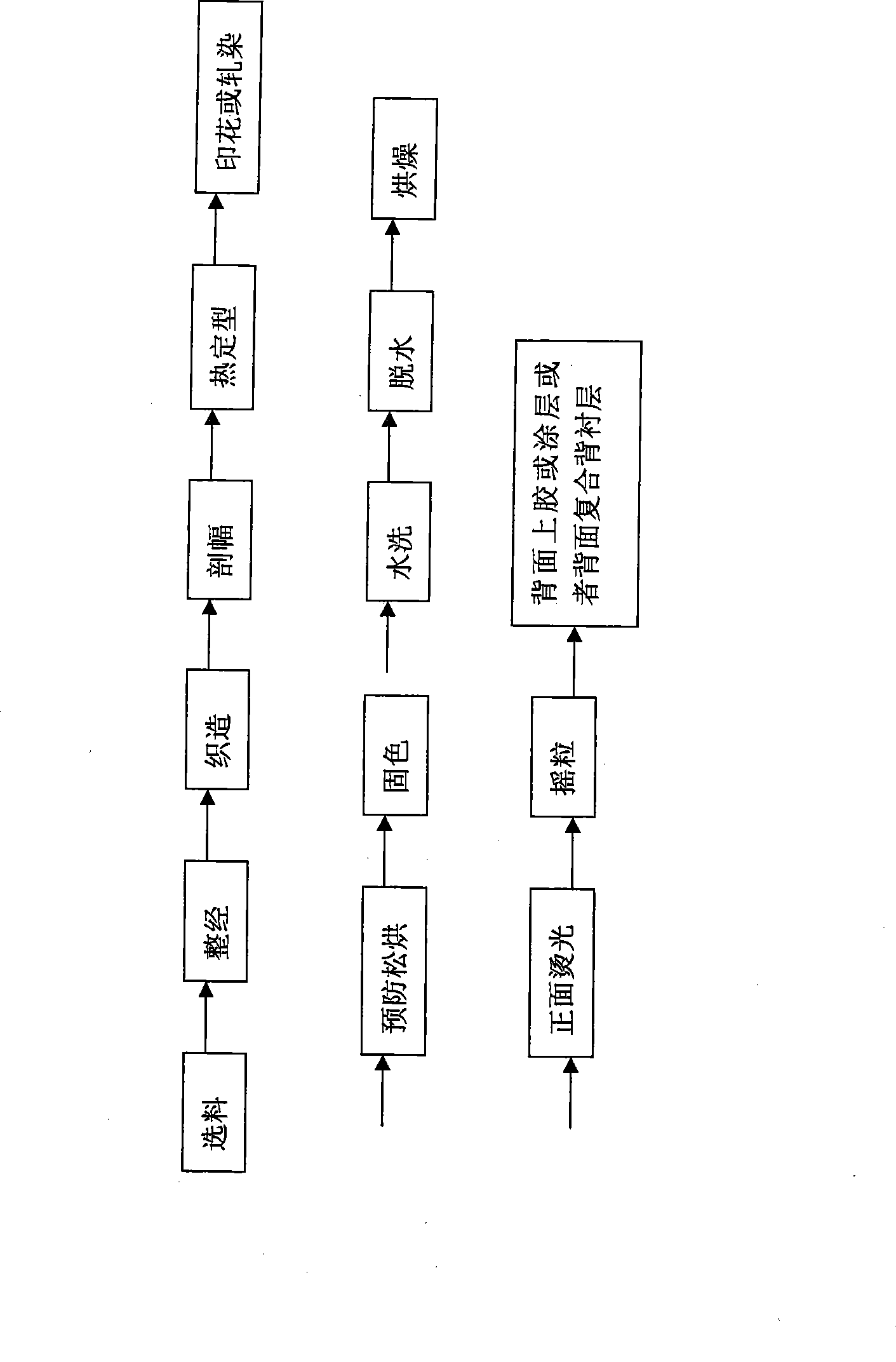

Pigment dyed colored cloth production method

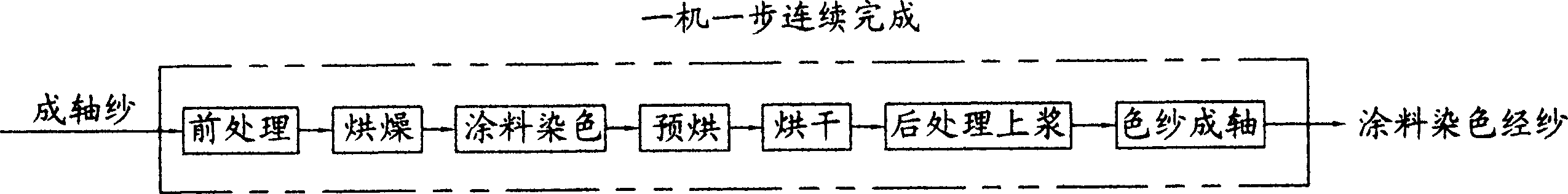

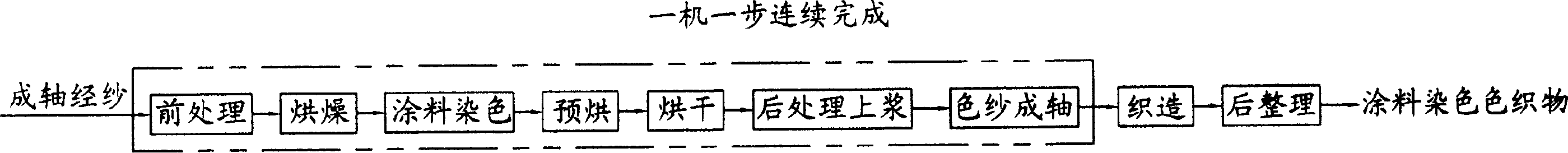

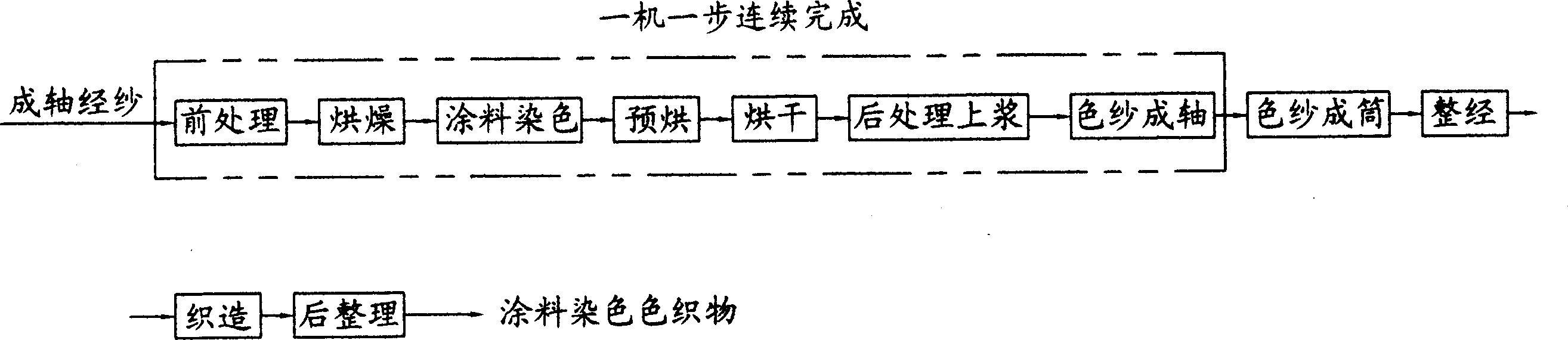

InactiveCN1884659AQuality improvementGood processing depthSucessive textile treatmentsSingeingSewageEnergy consumption

The invention discloses a manufacturing method of paint dyeing weaver with oxford textile, chambray and denim, which comprises the following steps: predisposing warp; drying; dyeing; predrying; drying; after-treating; shafting warp; weaving; dressing; finishing one step by one machine continually. The invention satisfies large batch and scale manufacturing request, which is fit for producing original paint dyeing and other pain dyeing weaver product.

Owner:常州市森容纺织品有限公司

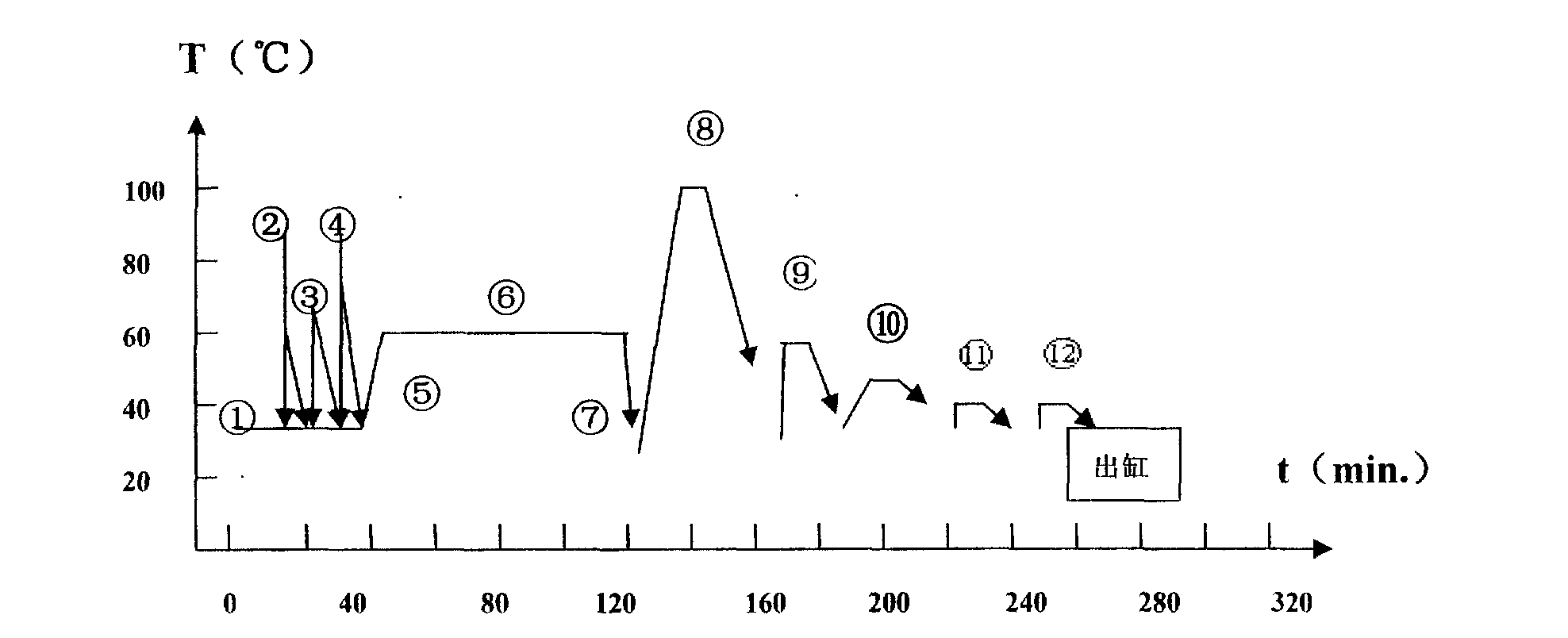

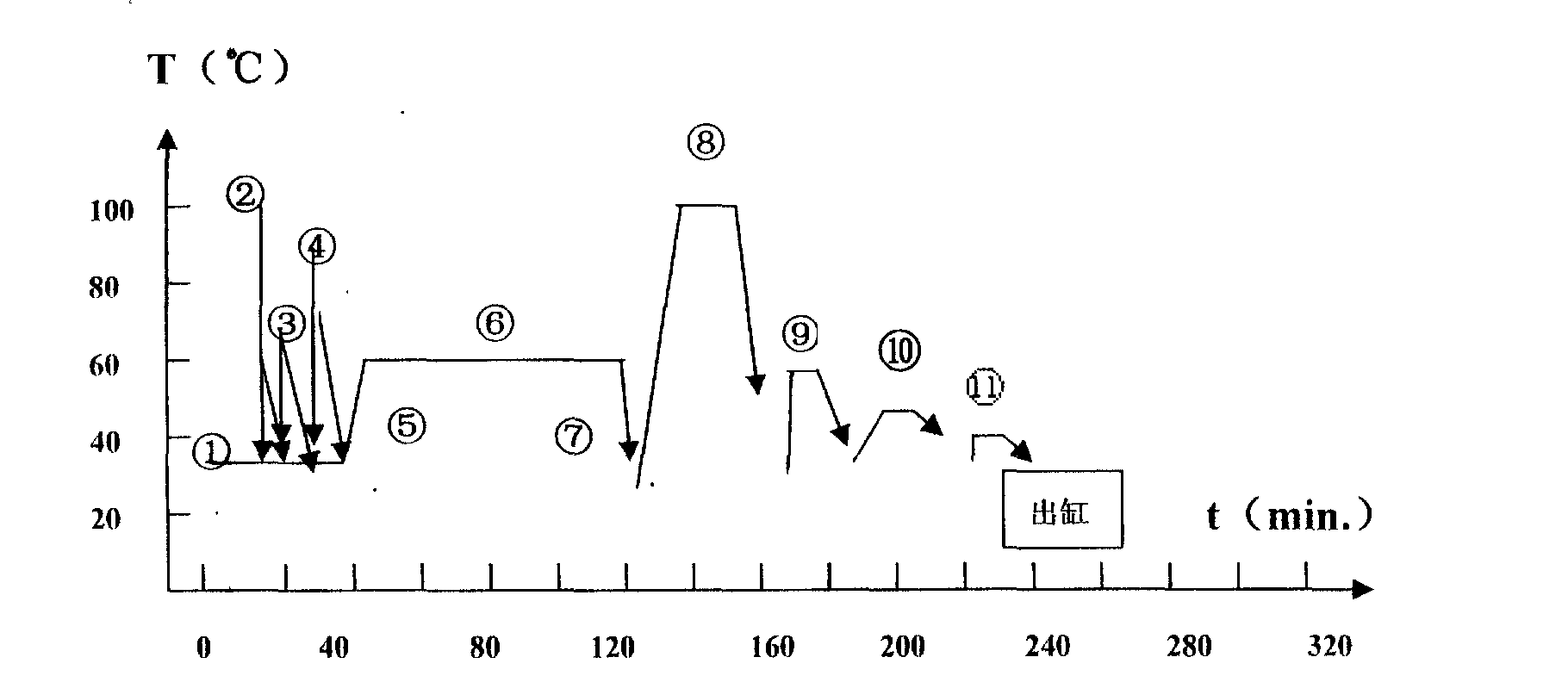

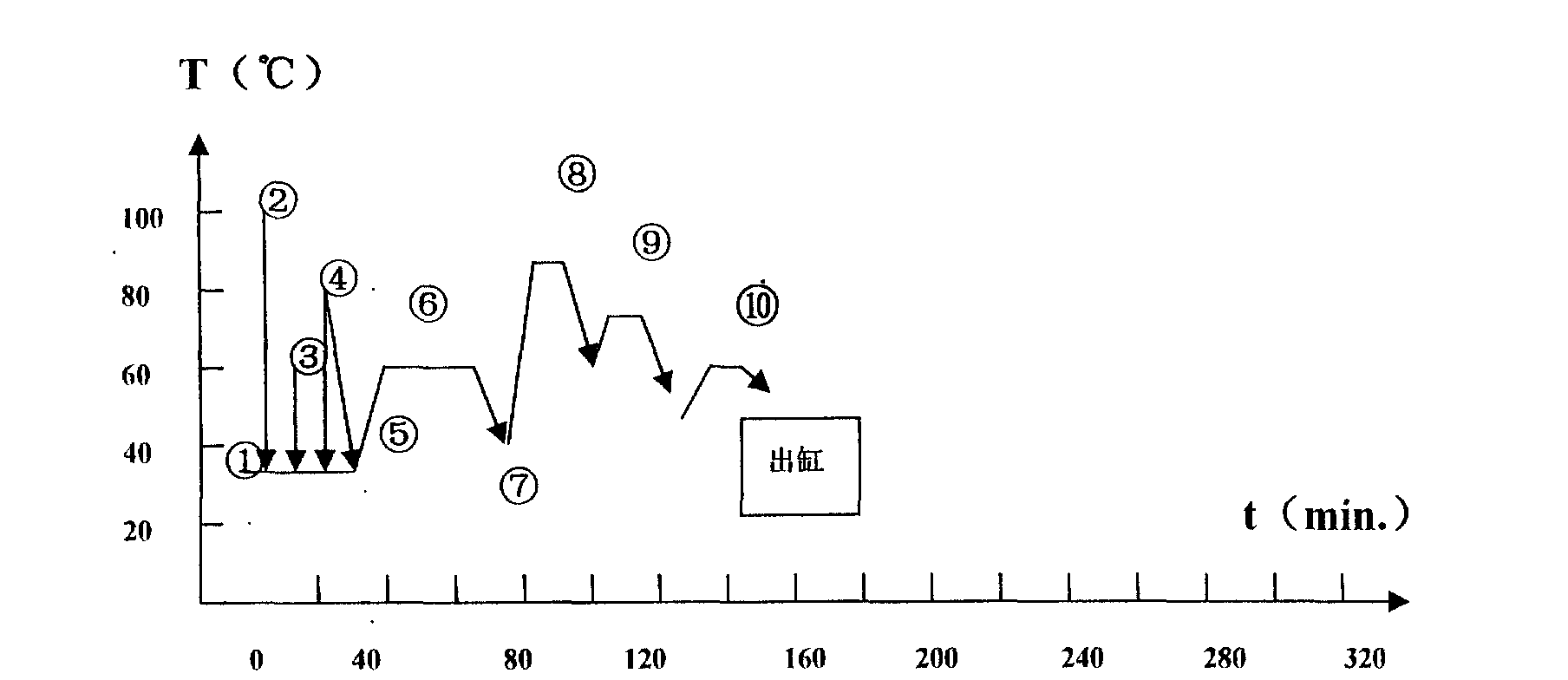

Reactive dye ultra-short rapid dyeing and fixation technology method

The invention relates to a reactive dye ultra-short rapid dyeing and fixation technology method. The method is realized by effectively minimizing auxiliary time such as feeding, shortening and optimizing post-processing processes, especially carrying soap boiling (one bath color mending) only once in advance to the greatest extend, merging washing, using less hot water and controlling the use of water aiming at various substances to be dyed according to dyeing requirements and the conditions of normal or abnormal and with the help of various accessory ingredients, thereby the reactive dye normal or abnormal dyeing conditions (especially mediate high color with a dye usage higher than 1percent of o. W. f) by the single one bath process, the multifunction composite one bath process, or the like, comprising pre-processing, dyeing, polishing with enzyme, and color mending, and even the pre-processing and the whole dyeing procedure in conventional equipment in an ultra-low bath ratio limit state can be completed well within 2.5-8h. The effects of thorough energy saving and emission reduction, efficiency increasing and consumption reduction, cleaner production and environmental protection are achieved.

Owner:罗海航 +1

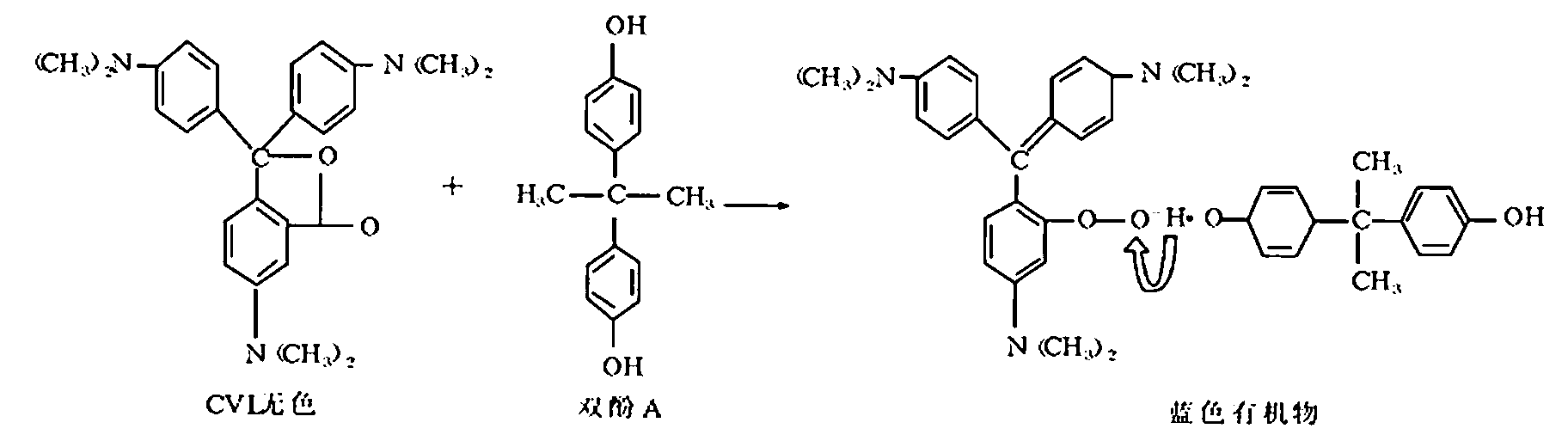

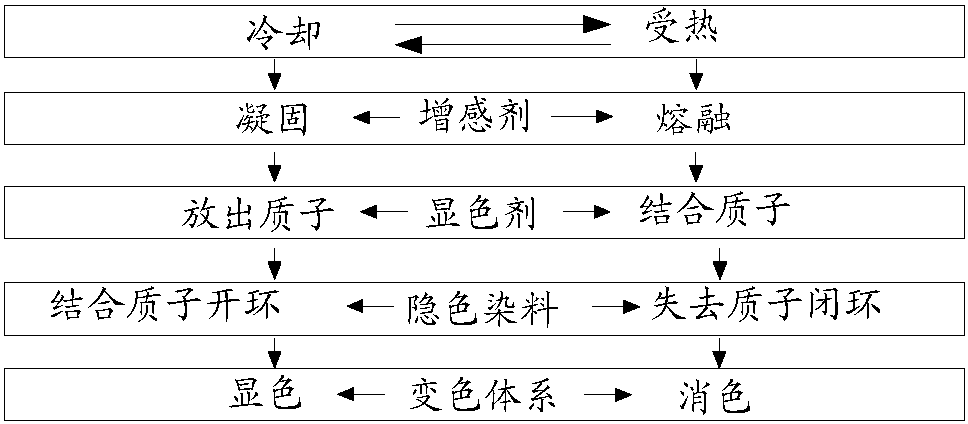

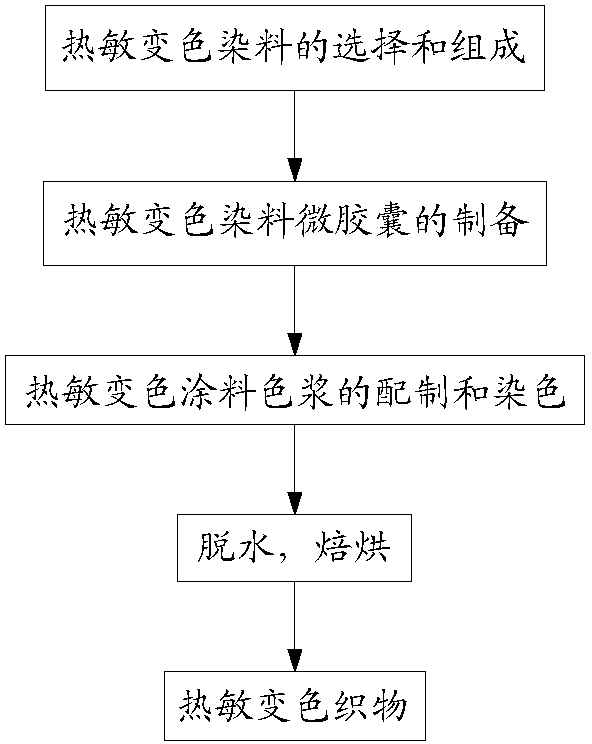

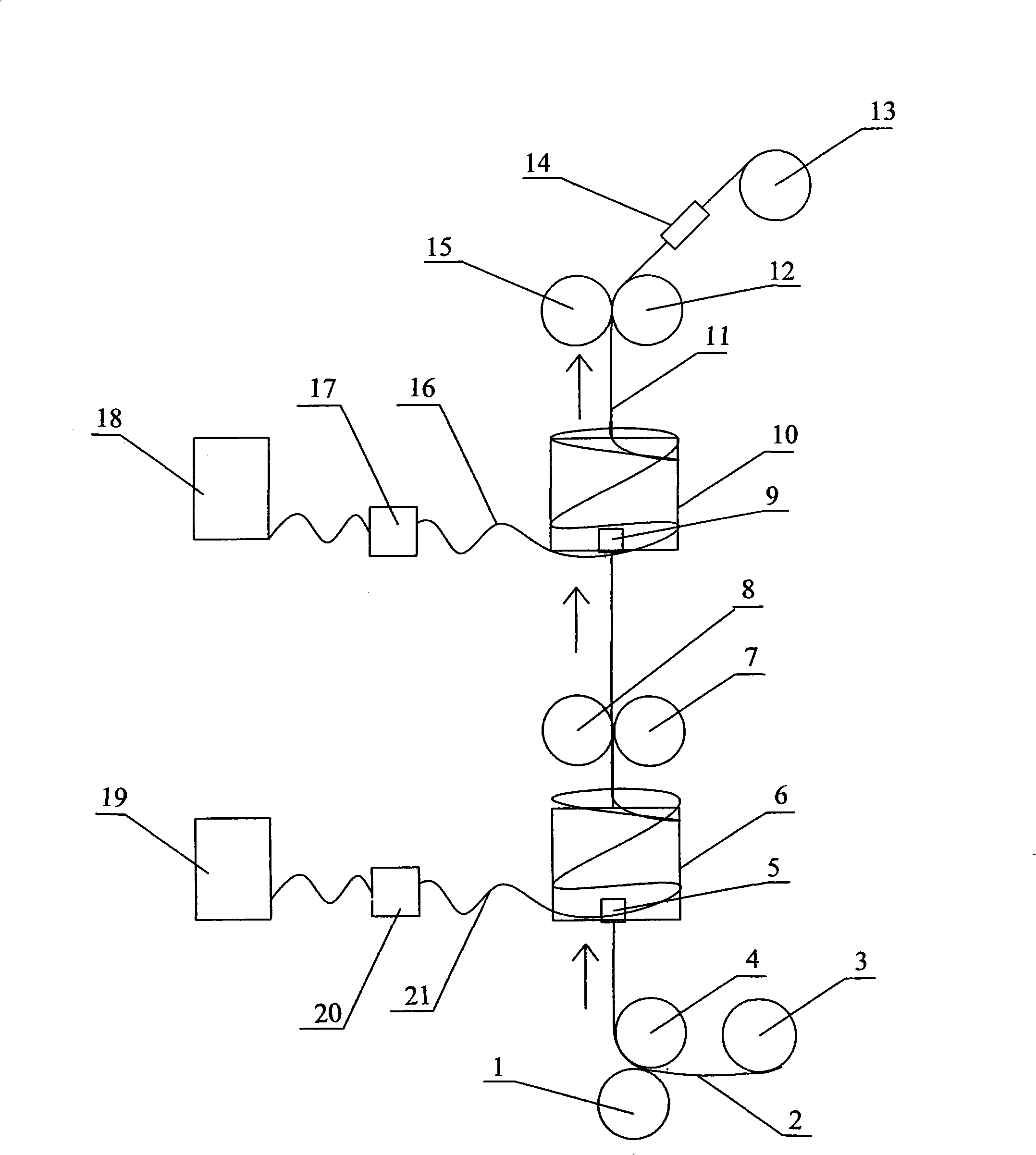

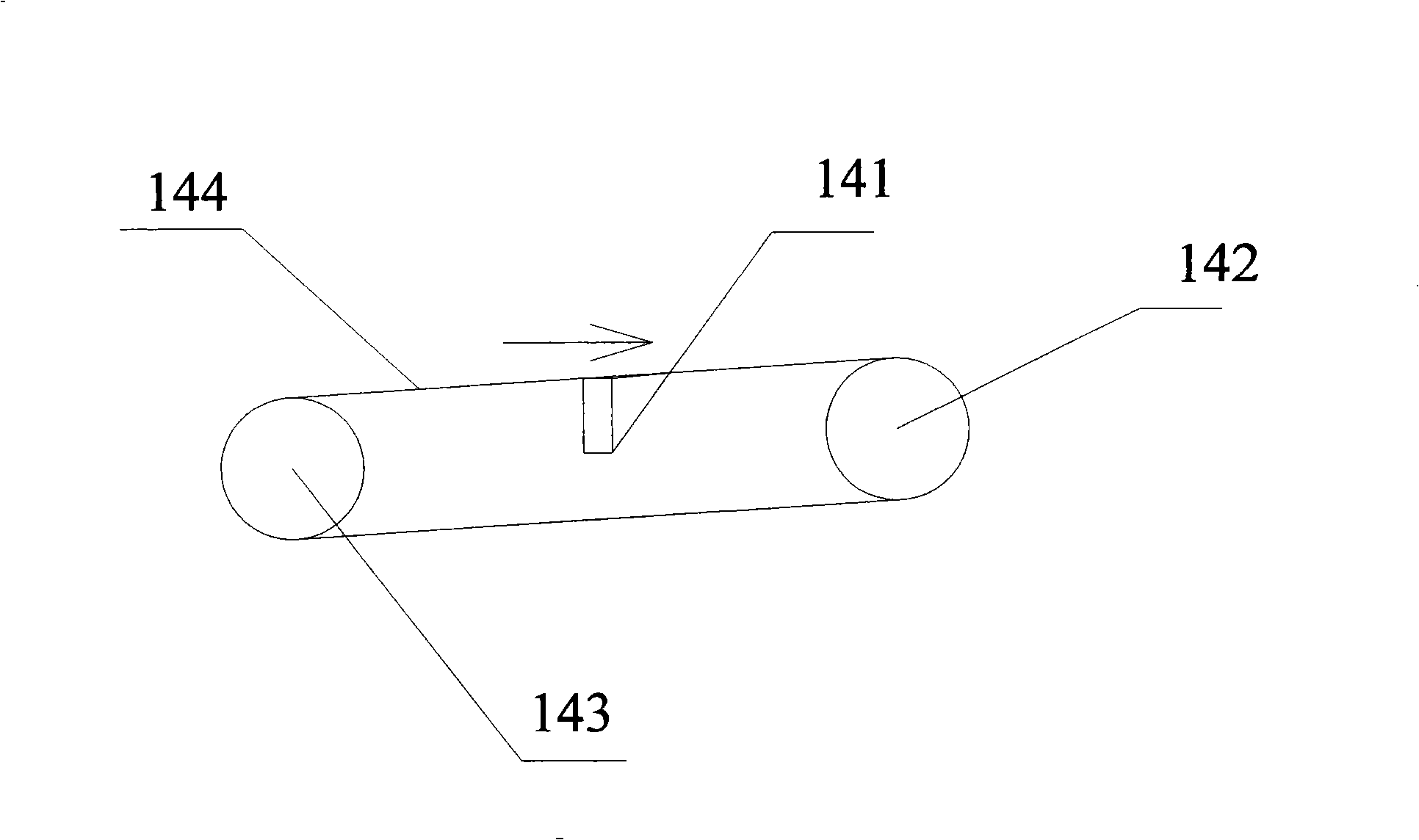

Temperature-sensitive color-changing paint dyeing technology of textile fabrics

InactiveCN103225212AObvious color differenceImprove qualityDyeing processMicroballoon preparationPolyesterFiber

Owner:FUJIAN ZHONGHE

Liquid ammonia modified method of cotton fibriia and yarn

InactiveCN101413213AGood flexibilityImprove curling effectLiquid/gas/vapor removal by centrifugal forceTextile treatment by pouringYarnVegetable fibers

The invention provides a method for modifying cotton and long vegetable fiber or yarn by ammonia liquid, which comprises the following steps: firstly, drying pre-treatment of raw materials; secondly, ammonia leaching of the raw materials in a hermetical treatment tank; thirdly, spin-drying of the raw materials subjected to ammonia leaching when a creel is twirled; fourthly, drying of the raw materials subjected to spin-drying by ammonia flow when the creel rotates slowly; fifthly, flushing of the raw materials which are dried by the ammonia flow by airflow when the creel rotates slowly; and so on. The method keeps the inherent advantages of the cotton, the long vegetable fiber and the yarn, overcomes the defects of the cotton, the long vegetable fiber and the yarn, increases softness, crimp tendency and fluffiness of the cotton, the long vegetable fiber and the yarn, improves the dye-uptake rate, the leveling property and the showy dye level, and further solves the problems of energy conservation, efficiency improvement and environmental protection.

Owner:上海业安纺织科技有限责任公司

Dissimilar materials double-layer superpacket center thread and manufacturing method thereof

InactiveCN101328637AGuaranteed wrapping tensionFeel comfortableContinuous wound-up machinesYarnYarnFiber

The invention discloses an abnormal material dual-layer composite clad yarn, which comprises an upper fiber-wrapped clad material layer, a lower fiber-wrapped clad material layer and a clad yarn layer which is positioned in the middle, wherein, the clad yarn layer adopts chemical fiber filament clad yarns and fiber-wrapped clad materials with different materials to be compositely processed into a dual-layer composite clad yarn. The invention also discloses a method for manufacturing the dual-layer composite clad yarn. The dual-layer composite clad yarn has the characteristics of comfortable hand feeling, large strength and toughness of chemical fiber filaments of the sandwich layer, burliness and durability, and high performance and use value.

Owner:鲁建国

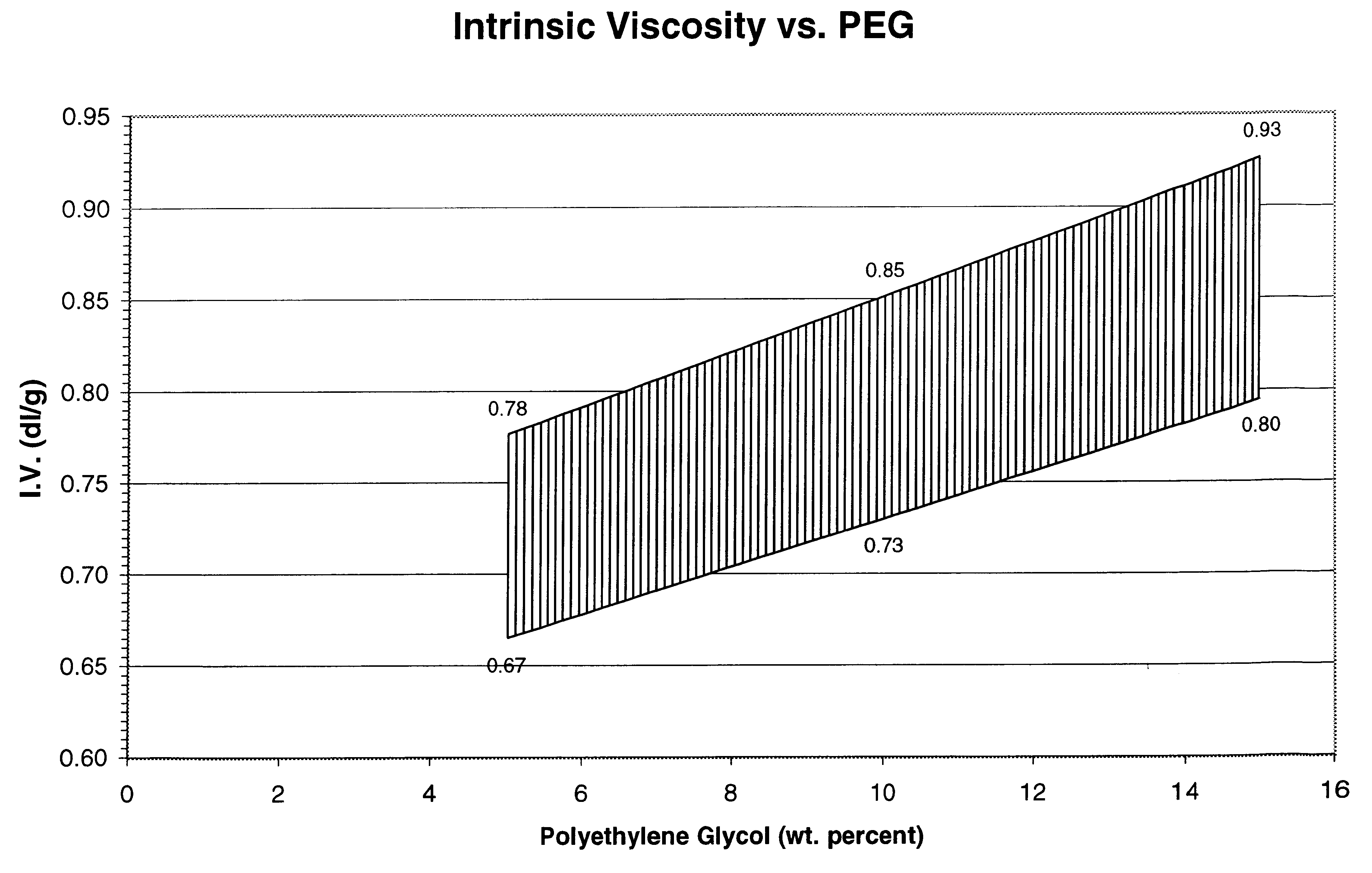

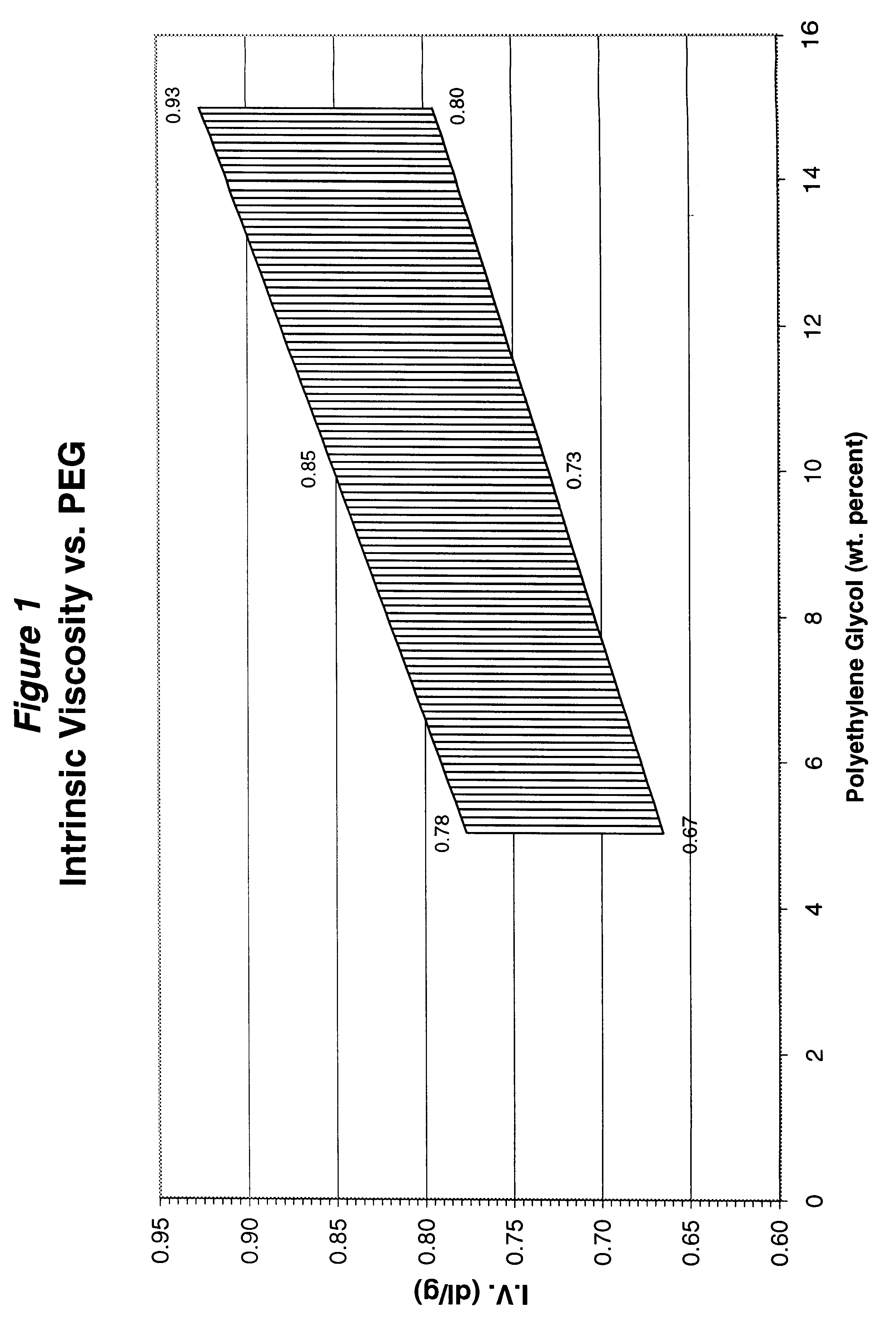

Polyethylene glycol modified polyester fibers and method for making the same

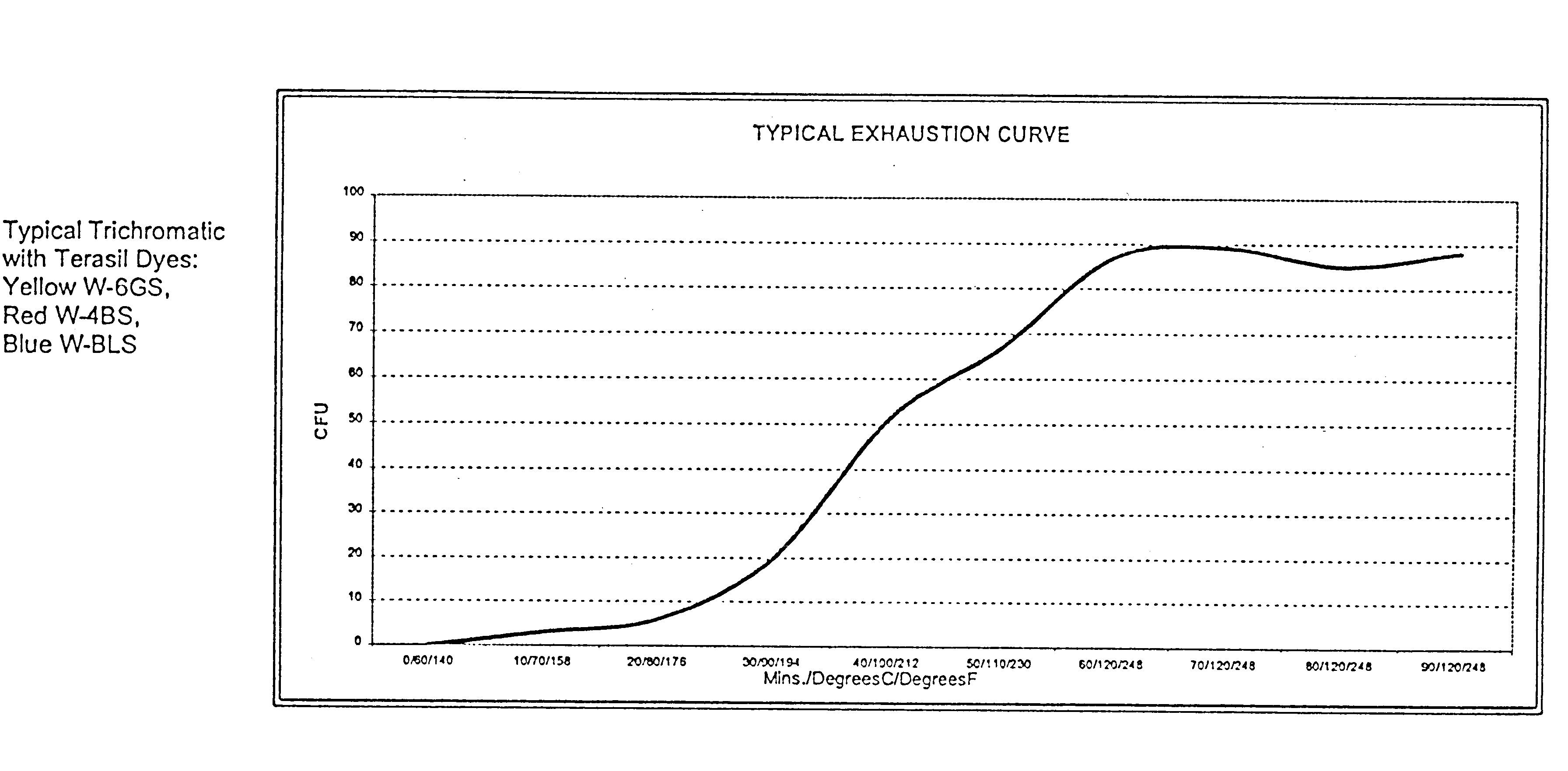

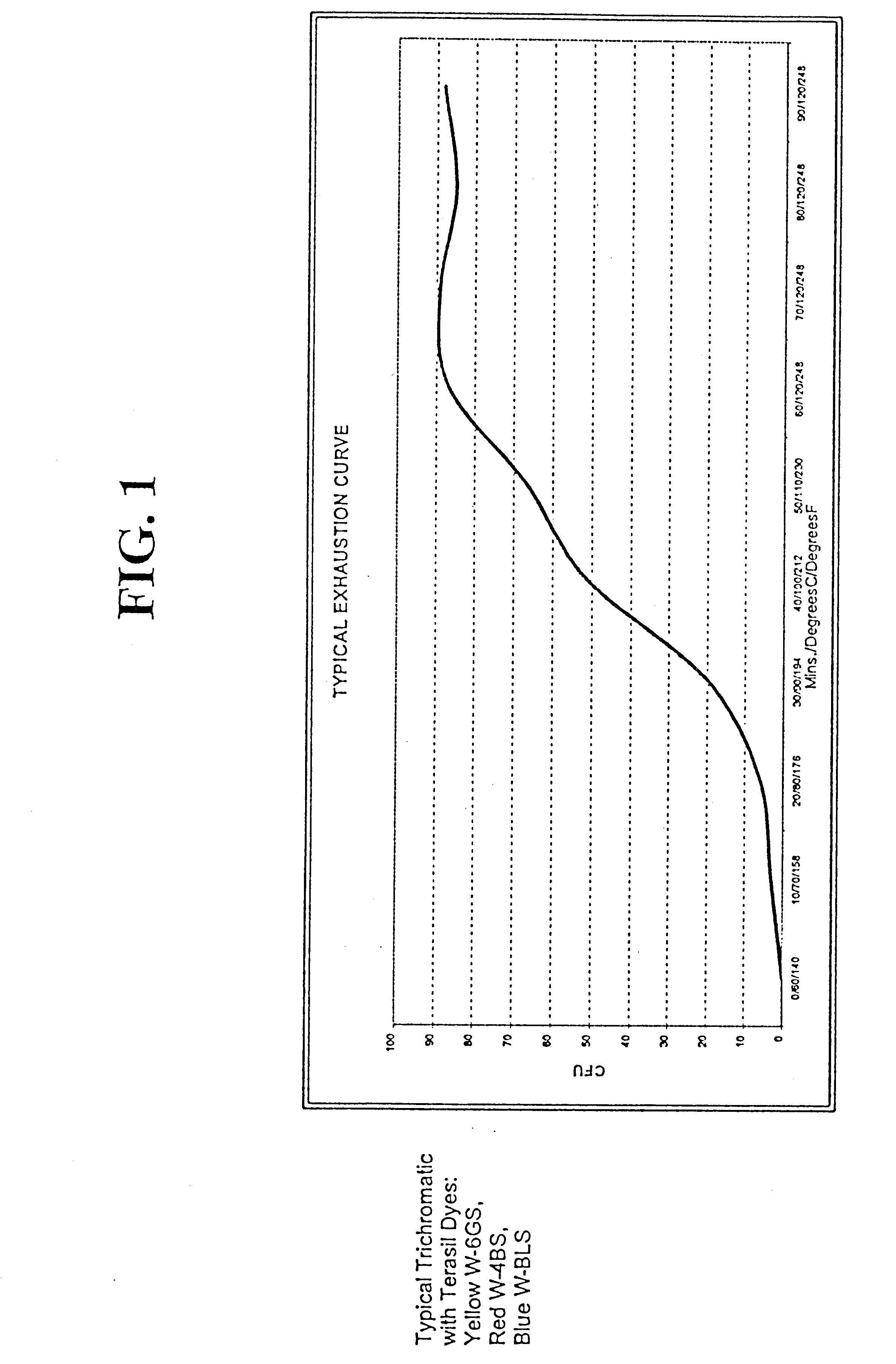

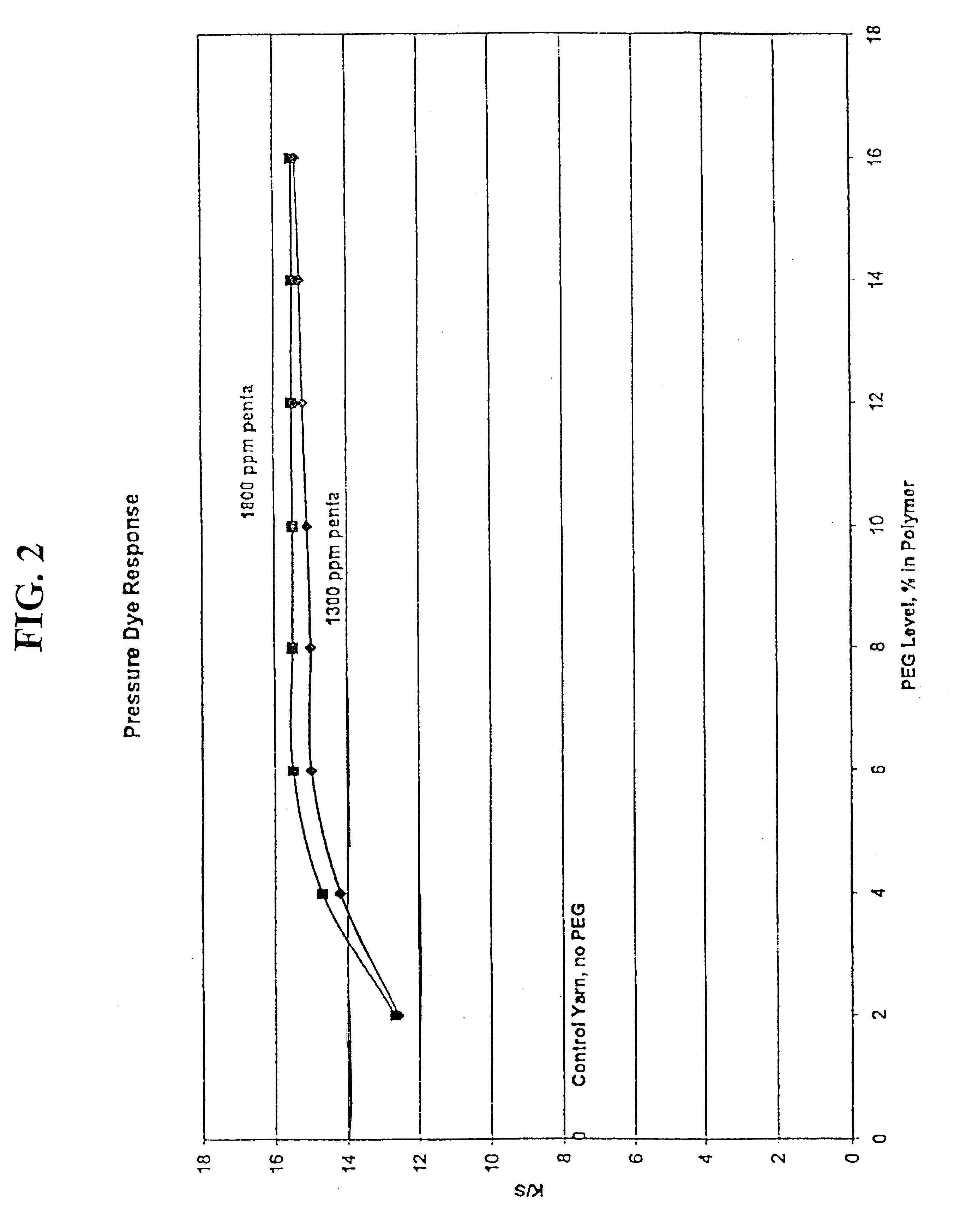

InactiveUS6623853B2Easy to dyeEnhance dye uptakeMonocomponent polyetheresters artificial filamentAnimal housingYarnFiber

Disclosed is a method of copolymerizing polyethylene glycol (PEG) and branching agent into polyethylene terephthalate (PET) to achieve a polyethylene glycol-modified polyester composition that can be spun into filaments. Fabrics made from fibers formed from the copolyester composition possess wicking, dyeability, and tactility properties that are superior to those of fabrics formed from conventional polyethylene terephthalate fibers of the same yarn and fabric construction. Also disclosed are polyethylene glycol modified copolyester compositions, fibers, yarns, and fabrics.

Owner:FIBER IND INC

Natural vegetable dye textile dyeing and printing technique

InactiveCN101368341AEasy to dyeGood health effectBiochemical fibre treatmentDry-cleaning apparatus for textilesColour fastnessEngineering

The invention relates to a dyeing and printing technique to dye fabrics with natural plant dyestuff, including the following steps: (1) pretreatment, (2) soaping, (3) pre-mordant dyeing, (4), dyeing, (5) washing, (6) post-treatment, (7) washing, and (8) drying. The dyeing and printing technique adopts pollution-free natural plant dye and addition agent and requires no metal mordant during the dyeing process, and the dyeing and printing technique is ecological and produces no harmful gas or volatile substance, so the dyeing and printing technique is nontoxic and is environment-friendly. The product indexes accord with EU Oko-Tex Standard 100 and reach the standard of modern ecological textiles. The dyed fabric has excellent color fastness and good UV screening property. Production shows that the dyeing and printing technique totally satisfies the requirements of industrialized production of fabrics dyed and printed with plant dyestuff. The dyeing and printing technique suits technological development trend and the requirement of the change of consumer product market and has obvious environmental, social and economic benefits.

Owner:殷大卫

Method for preparing regenerated cellulose fibers from plant fibrous pulp of reeds and stalks

InactiveCN101736426AHigh strengthGood hygroscopicityArtificial filaments from cellulose solutionsWet spinning methodsPolymer sciencePlant fibre

The invention relates to a method for preparing regenerated cellulose fibers from plant fibrous pulp of reeds and stalks. The method is the solvent method, and comprises the following steps of: preparing 8 to 15 mass percent spinning solution of the regenerated cellulose fibers by adopting the direct method or indirect method; and spinning the obtained spinning solution of the regenerated cellulose fiber. The method has the advantages of simple process, little pollution, and good performance of the fiber prepared by the method. The regenerated cellulose fiber of reeds, stalks and the like, prepared by the method, has the advantages of high strength, softness, smoothness, good moisture absorbing property, convenient dyeing and the like.

Owner:INST OF CHEM CHINESE ACAD OF SCI

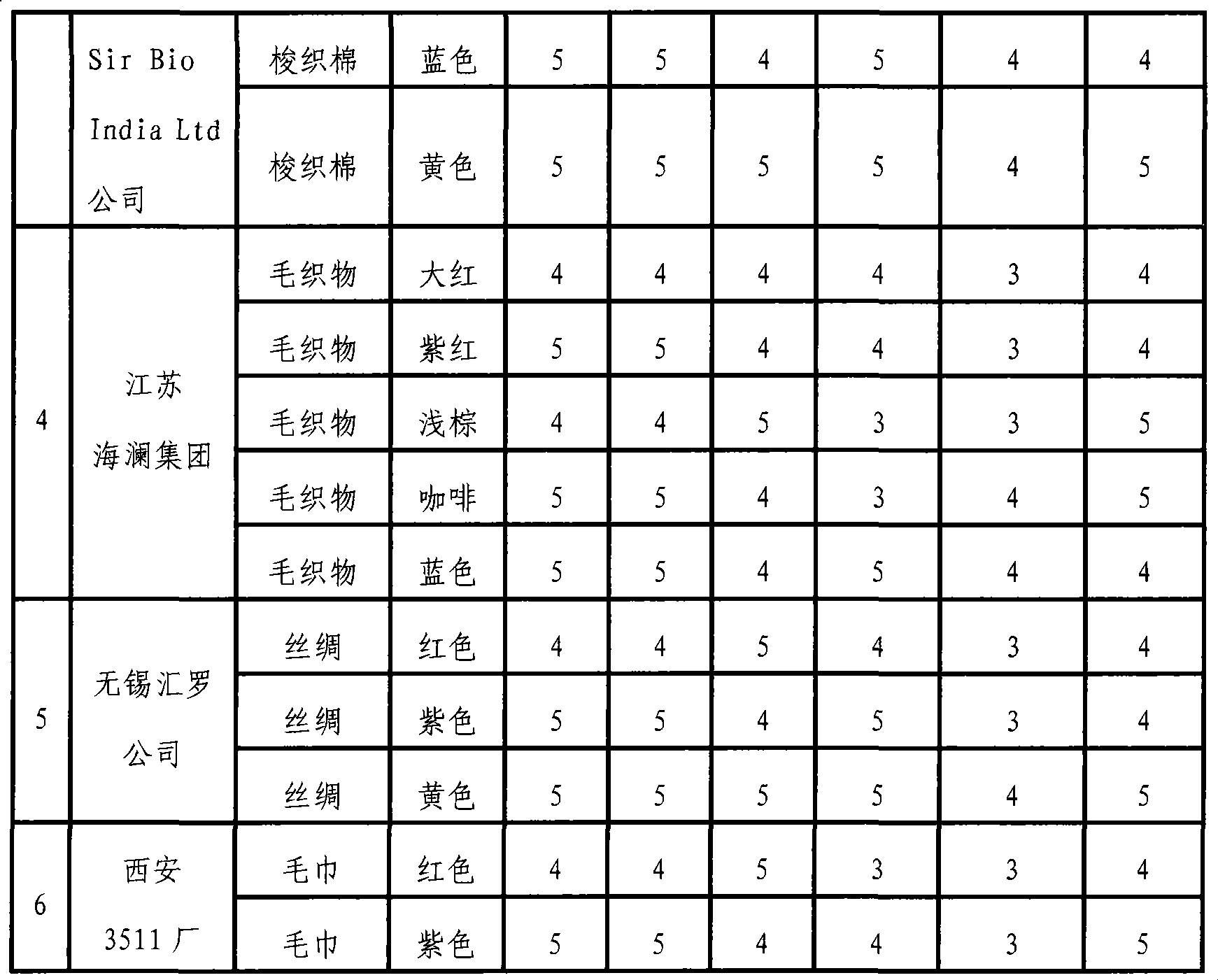

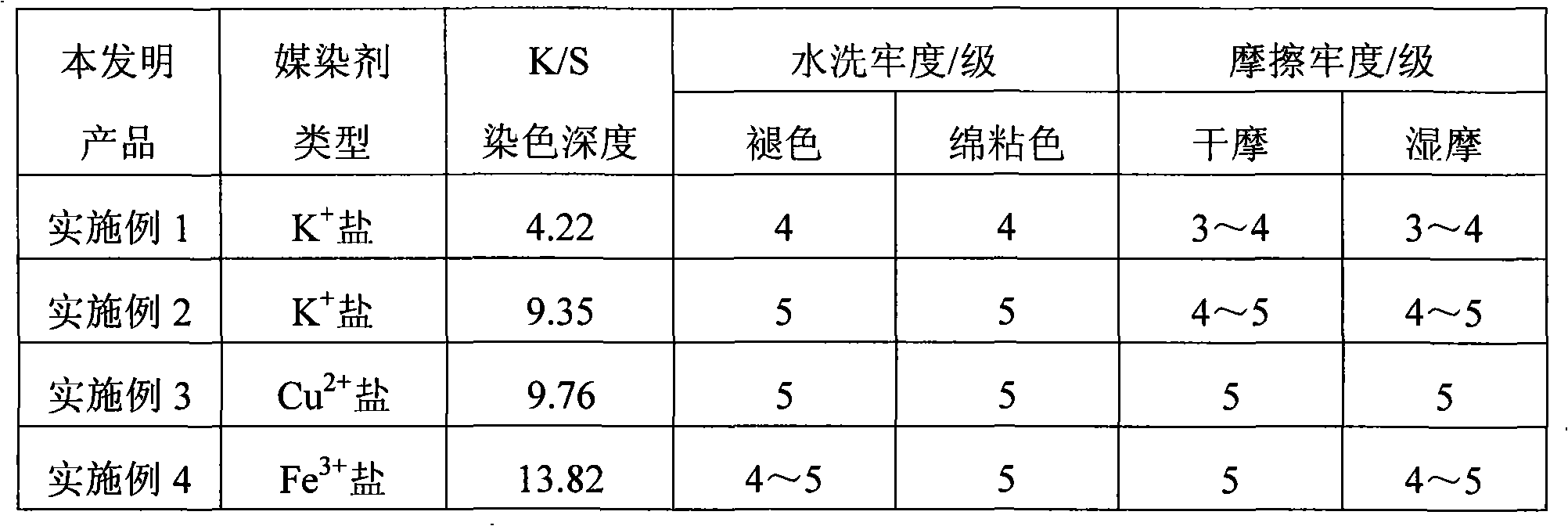

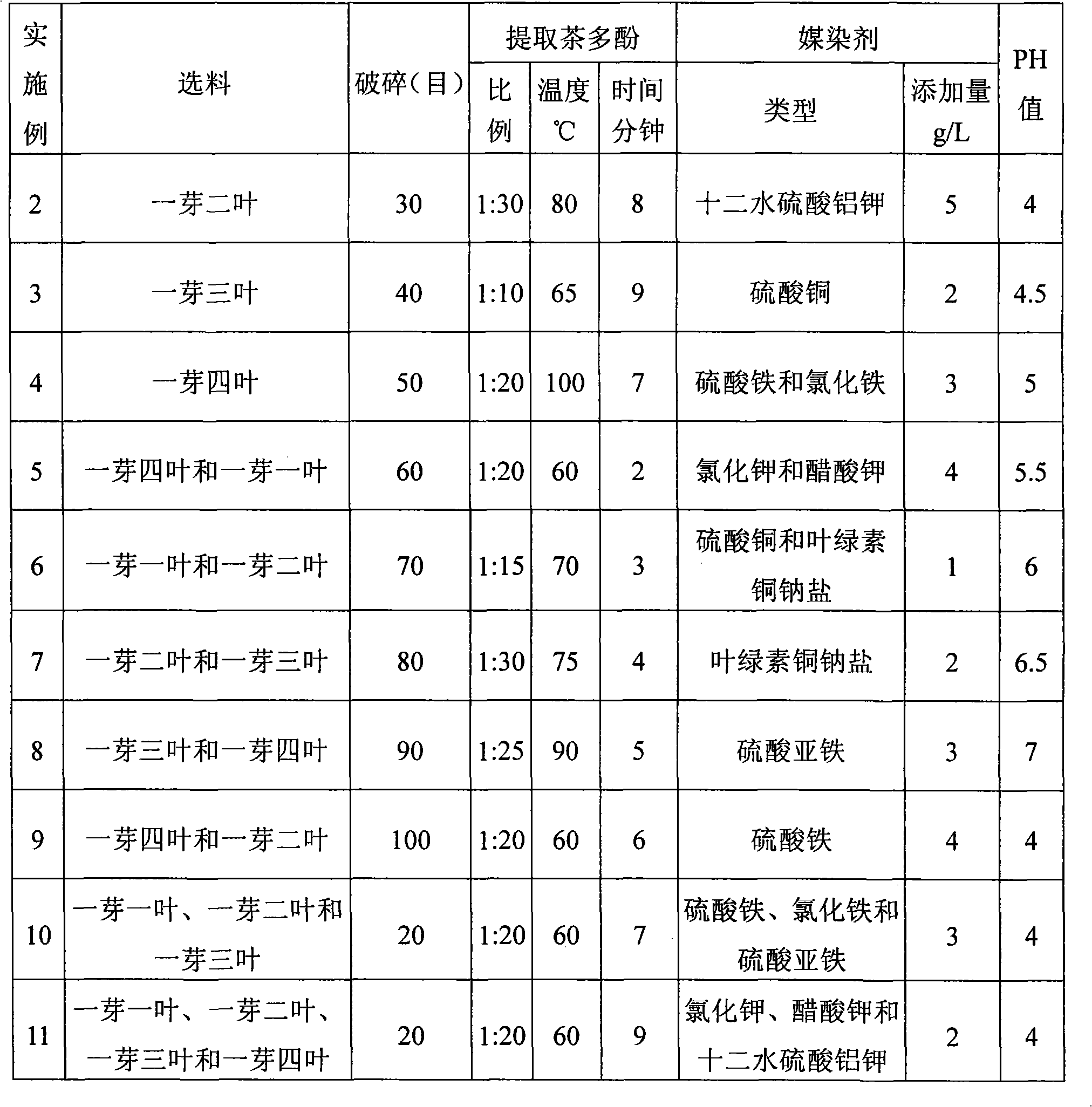

Natural staining agent, preparation thereof and application thereof to silk dyeing

The invention provides a natural coloring agent, which is characterized in that: the fresh tea leaves are used as material to extract tea polyphenol, and then the extraction liquid of the tea polyphenol is added with mordant agent, so as to form the natural coloring agent. As the natural coloring agent has rich color, good dyeing effect, good dyeing fastness (in particular wash fastness), and low production cost, the natural coloring agent has wide application, and strong practicality. The natural coloring agent also provides a preparation method of natural dyeing agent and an application at the aspect of silk fabric dyeing.

Owner:CHONGQING ACAD OF AGRI SCI

Fire retardant viscose short filament and its production technology

InactiveCN1904156AGood hygroscopicityComfortable to wearMonocomponent cellulose artificial filamentStaple fibre formationFire hazardFire retardant

One kind of short flame-resistant viscose fiber: the raw material and percent by weight are: Cellulose filament 66.7-76.9%, flame-resistant 15-20%, aqueous8-13%, oil emulsion 0.10-0.30%. With the technique of fermenting , soaking, squeezing, smashing, experienced, alkali filament cooling and transportation, etiolution, dissolution, filtration, ripening, deaeration, filtration, spins inpouring, spinning, two baths, one draft, two drafts, three roller beaming, cutting-off, concise (rough steam boiling, sour laundering, one laundering, desulphurization, two laundering, blanching, three and four laundering and PH value regulation, oil bath), drying( wet pine, wet drying delivers, A section drying, blooms pine, B section drying, dry delivery), fine blooms pine, packing, the system results in the non-toxic environmental protect, non spontaneous combustion, non burning without flames, evacuation extinguished without fire hazard, and low burning smoking density. It has good spinnability, stable permanent being flame-resistant, fine soft performance.

Owner:唐山三友集团化纤有限公司

Polyethylene glycol modified polyester fibers and method for making the same

InactiveUS6291066B1Easy to dyeImprove dyeing effectProtective fabricsMonocomponent polyetheresters artificial filamentFiberYarn

Disclosed is a method of copolymerizing polyethylene glycol (PEG) and branching agent into polyethylene terephthalate (PET) to achieve a polyethylene glycol-modified polyester composition that can be spun into filaments. Fabrics made from fibers formed from the copolyester composition possess wicking, drying, stretching, abrasion-resistance, flame-retardancy, static-dissipation, dyeability, and tactility properties that are superior to those of fabrics formed from conventional polyethylene terephthalate fibers of the same yarn and fabric construction. Also disclosed are polyethylene glycol modified copolyester compositions, fibers, yarns, and fabrics.

Owner:FIBER IND INC

Warp knitting terylene ginning velvet carpet and method of processing the same

InactiveCN101476207AIncrease elasticityGood hygroscopicityWarp knittingHeating/cooling textile fabricsEngineeringMildew

The invention provides a warp knitting terylene polar fleece carpet which belongs to the terylene fibre product technique field. The carpet includes a flocked yarn and a bottom yarn, the flocked yarn is made of 500-780dtex DTY terylene continuous yarn with 80-100 pieces per meter network, the bottom yarn is made of 167-333dtex FDY terylene yarn, a flocked surface height of the flocked yarn is 5-12mm, wherein, single yarn denier of the DTY terylene continuous yarn is more than or equal to 3.5dtex. The carpet has advantages that processing technique is shortened, production process is more environmentally friendly and cleaning, and cost is lower; the carpet has high impact resistance, better elasticity and hygroscopic property, abrasive resistance is second only to chinlon, high heat and solarization resisting property, no-mildew, no-moth-eaten, easy to dye or print, portable and easy to clean; the carpet is rich in polar sphere sense, has strong third dimension and flexible pattern, the carpet color is novel and shibui, has better visual effect that is suitable to be placed in high class hotel guest room, white-collar apartment, high class chamber, hotel aisle and household bathroom.

Owner:常熟市锦绣经纬编有限公司

Production technology of viscose extinction monofilament

InactiveCN103215680AImprove spinnabilitySoft touchSpinnerette packsArtificial filaments from viscoseInlet channelExtinction

The invention relates to a production technology of viscose extinction monofilament. The production technology takes cellulosic fiber pulp as a raw material and obtains viscose extinction monofilament through preparation of a spinning solution, injection before spinning, spinning and aftertreatment, and specifically comprises the following steps of: (A) preparing the spinning solution from the cellulosic fiber pulp through steeping, ageing, yellowing, dissolving, defoaming and filtering; (B) adding a titanium dioxide solution into the spinning solution so that the weight ratio of titanium dioxide to alpha cellulose content in the spinning solution reaches (0.5-5.0):100; and uniformly mixing and feeding for spinning; (C) feeding the spinning solution into a spinning machine, and enabling the spinning solution to pass through a spinneret orifice of a single-hole spray head under pressure, and solidifying and molding the formed viscose trickle to form raw silk strips, wherein the spray head is stretched by +60% to +80%, and an inlet channel of the spinneret orifice is in a parabola shape; and (D) performing aftertreatment: performing desulfurization, bleaching, oiling and drying on the raw silk strips to obtain the viscose flat monofilament. According to the production technology provided by the invention, the filament number of the prepared viscose monofilament is 50-6,000D, the strength is high over 75CN, and the requirements on dyeing, weaving and finished product taking are met; and moreover, the viscose extinction monofilament has gentle color and an extinction effect.

Owner:YIBIN HIEST FIBER +2

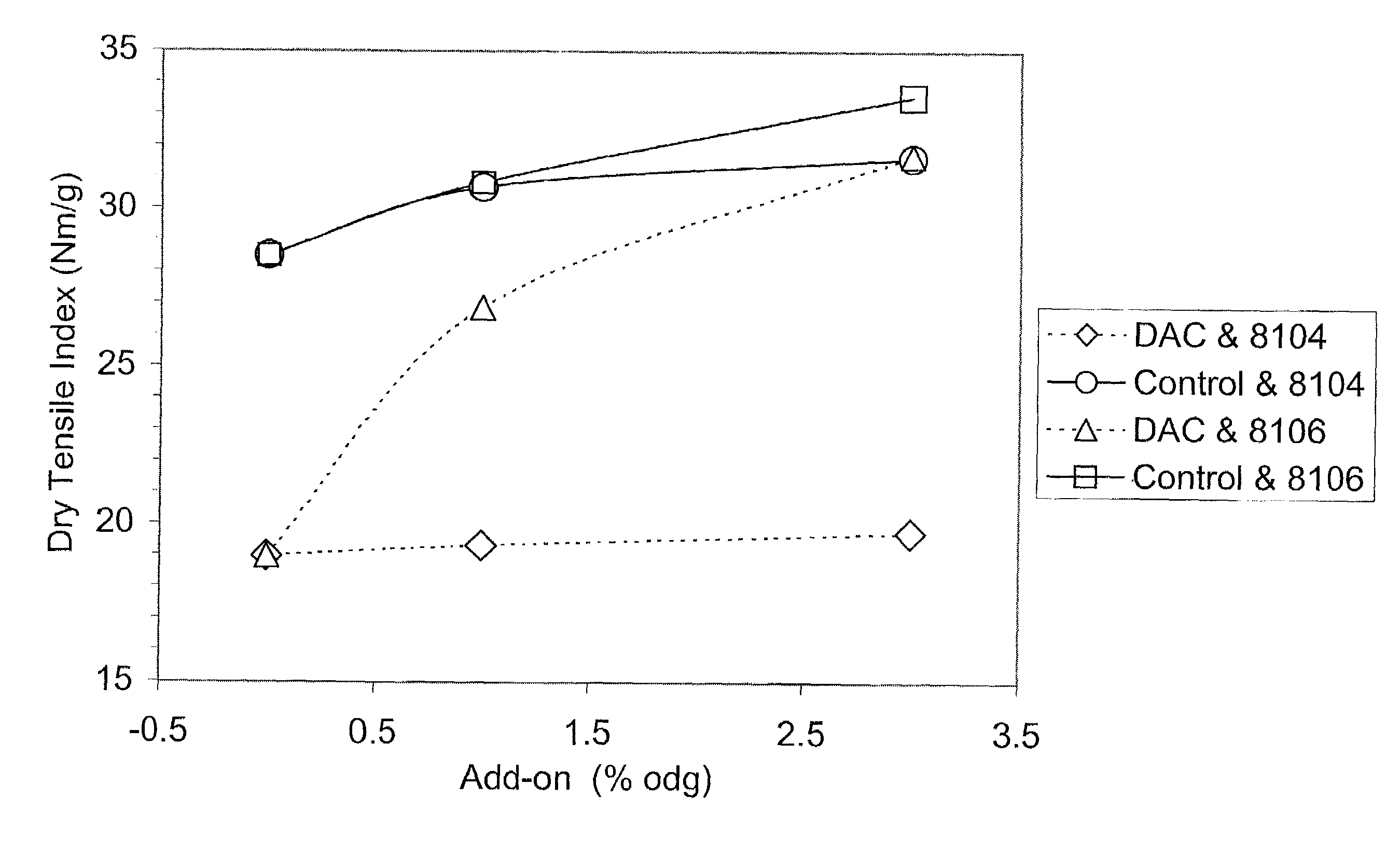

Polyvinylamine treatments to improve dyeing of cellulosic materials

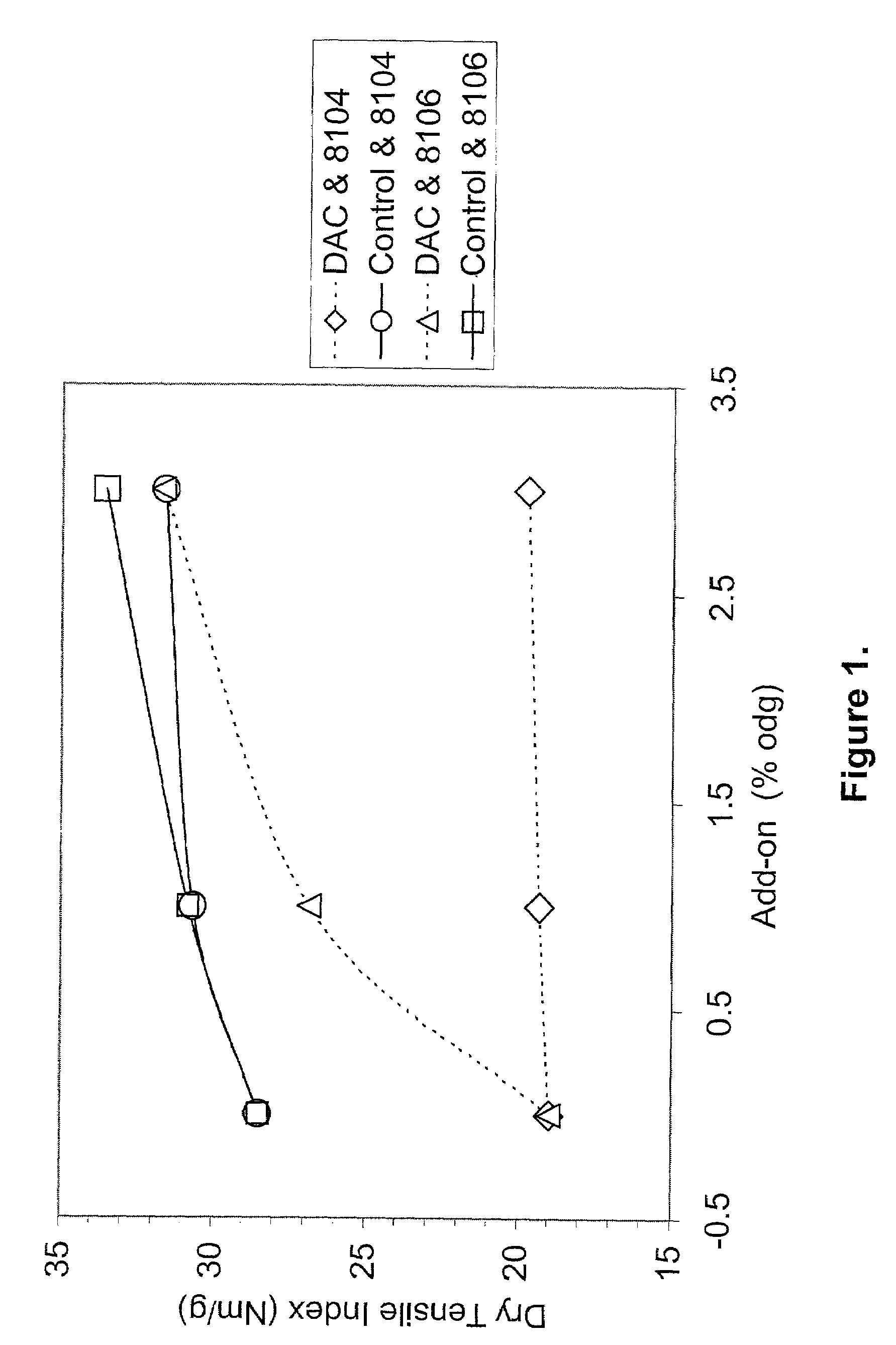

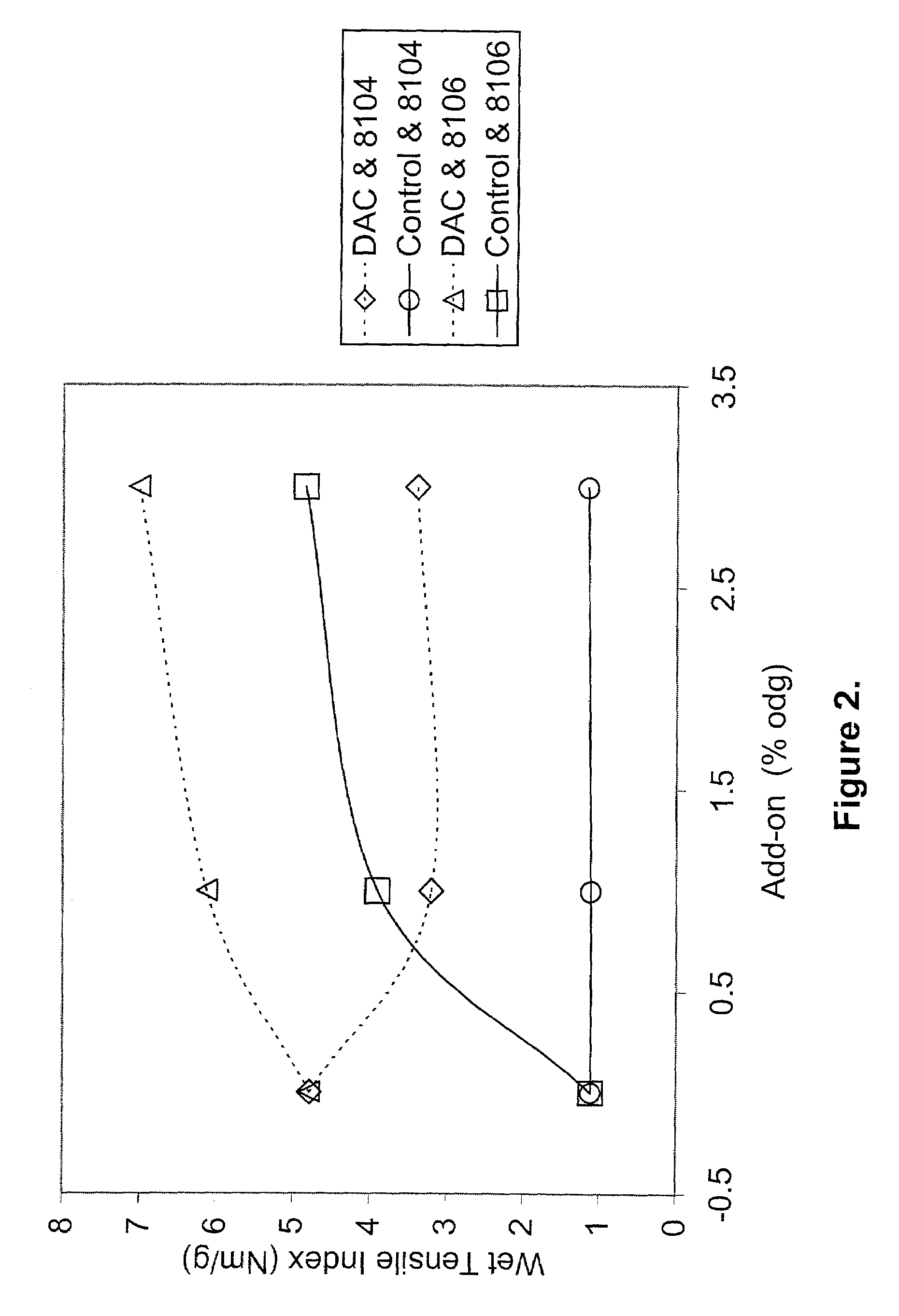

InactiveUS7214633B2Improve wet strengthEasy to dyeDecorative surface effectsFibre treatmentCellulosePolymer interaction

Textile materials, including paper webs, treated with a polyvinylamine polymer and a second agent that interacts with the polyvinylamine polymer is disclosed. The second agent added with the polyvinylamine polymer can be, for instance, a polymeric anionic reactive compound or a polymeric aldehyde-functional compound. When incorporated into a paper web, the combination of the polyvinylamine polymer and the second agent provide improved strength properties, such as wet strength properties. In an alternative embodiment, the polyvinylamine polymer and the second polymer can be applied to a textile material for increasing the affinity of the textile material for acid dyes.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Bi-component sheath-core composite high-stretch fiber and preparation method thereof

ActiveCN101845686AEasy accessImprove dyeing effectConjugated synthetic polymer artificial filamentsStretch-spinning methodsPolytetramethylene terephthalatePolytrimethylene terephthalate

The invention provides a bi-component sheath-core composite high-stretch fiber. The bi-component is a polyester component and a polyamide component respectively, wherein the polyamide component forms an outer sheath part; the polyester component forms an inner core part; the outer sheath part is coated around the inner core part; and the polyester component may be one or more of a cationic normal-pressure dyeable polyester, a polytrimethylene terephthalate and a polybutylene terephthalate. As the bi-component sheath-core composite high-stretch fiber provided by the invention utilizes a polyester of which a molecular chain has flexible branched chains, such as the cationic normal-pressure dyeable polyester, the polytrimethylene terephthalate, the polybutylene terephthalate and the like, the prepared composite fiber is looser, and dyes can enter the fiber more easily to achieve higher dying performance under a conventional dying condition. The invention also provides a preparation method for the bi-component sheath-core composite high-stretch fiber.

Owner:厦门象屿兴泓特种材料有限公司

Low-temperature dyeing process of fiber fabric

ActiveCN103966867AGuaranteed functionAvoid damageFibre treatmentDyeing processFiberProcess engineering

The invention provides a low-temperature dyeing process of a fiber fabric. The low-temperature dyeing process comprises the processes of pretreatment, pre-sizing, dyeing, reduction clearing, fixing, softening treatment, drying, sizing, calendaring and rolling. In the dyeing process, the highest temperature does not exceed 100 DEG C, mild dyeing is carried out by using a gradual warming method and pH value regulation is carried out through a buffer solution, so that a proper acid environment required during the dyeing is satisfied and the dyeing effect is excellent; during the dyeing, a leveling agent is added to ensure that the dyeing is uniform; anhydrous sodium sulphate is added to postpone the dyeing process of the pigment and the temperature rises slowly at the same time, so that the uniform dyeing is ensured; a smoothing agent is added to prevent the scratching and local fibrillation; a penetrant and a diffusant are added to ensure that the penetration and the diffusion of the dyeing are relatively good; by means of the strict control in the aspects of temperature, acid, auxiliaries, time and the like, the low-temperature dyeing process of the fiber fabric has the advantages that the dyeing firmness is high, the dyeing is uniform, the dyeing stability is good and the effect is excellent at low temperature.

Owner:绍兴洁彩坊印染有限公司

Traditional Chinese medicine preparation for treating herpes simplex keratitis

InactiveCN103800485ARealize the purpose of treating herpes simplex virus keratitisGood curative effectSenses disorderAnthropod material medical ingredientsDandelionPeppermints

The invention relates to a traditional Chinese medicine preparation for treating herpes simplex keratitis. The traditional Chinese medicine preparation is prepared from the following raw pharmaceutical materials in parts by weight: 18-22 parts of honeysuckle flower, 18-22 parts of radix isatidis, 18-22 parts of dandelion, 18-22 parts of hooked uncaria, 13-17 parts of red peony root, 13-17 parts of selfheal spike, 13-17 parts of folium isatidis, 8-12 parts of forsythia fruit, 8-12 parts of herba schizonepetae, 8-12 parts of ledebouriella root, 8-12 parts of scutellaria root, 8-12 parts of balloon flower root, 8-12 parts of bupleurum root, 8-12 parts of cicada slough, 8-12 parts of chrysanthemum flower, 3-7 parts of peppermint and 3-7 parts of licorice root. The traditional Chinese medicine preparation has the advantages of good treatment effect, high effect taking speed, no toxic and side effects and low recurrence rate.

Owner:周比冠

Simplified thin-layer liquid-based cytology detection method

InactiveCN1967196ACheap methodGood effectMicrobiological testing/measurementSurgical needlesLiquid base cytologyCervical cells

The invention discloses a simple thin liquid-based cytology examine method applied for the gynecological examination, the cervical cancer general examine and the cervical cancer preceding lesion of selected crowd, the steps including: using the cervical cells brush and the scraper to collect samples, put samples in the liquid-based cell preservation solution, add base liquid cell processing solution, oscillate, centrifugally separate, take and discard the supernatant samples liquid, using adding samples gun to assimilate sediment samples, smear, sheet drying, using 95% ethanol marinate or spray for fixed, washing and dyeing. The invention has simple method, small steps, high positive detection rate, low misdiagnosis rate, low cost, and it can effectively eliminate the red blood cells, mucus and other interference components from the cervical cytology detection specimens, with good sheet-producing result.

Owner:绵竹市人民医院

Conductive fiber and its preparation method

InactiveCN101086088AHigh strengthImprove conductivityElectroconductive/antistatic filament manufactureFilament/thread formingPolyesterConductive polymer

The invention relates to a conductive fiber and its preparation method. The conductive fiber has core-skin composite structure, the core layer is polyester and the cortical layer is polypropylene with containing conductive components, the skin-core ratio is 2:8-8:2; the quality percentage formula of cortical layer is: polypropylene 70-80%, nano-conductive powder 20 - 30%; said nano-conductive powder is tin oxide doped with antimony, the average diameter is not more than 0.1 micron, the resistance value is 10 omega.cm, its surface is treated and the treatment agents includes 3 - 10% coupling agent, 2 - 5% dispersing agent and 0.01- 0.1% anti-oxidant agent, said coupling agent is mono-alkoxylation catalyst barium ester or chloropropylated methoxyl silicon alky coupling agent; said dispersing agent is low molecular polyethylene wax; said anti-oxidant agent is four[ beta -(3',5'-di- tertiary-butyl- hydroxyl phenyl) ethylformic acid] pentaerythrite ester. The preparation method first prepares conductive polypropylene parent granule according said formula in the invention, then prepares conductive fiber through melting spinning technology.

Owner:CHINA PETROLEUM & CHEM CORP +1

Pretreatment liquid for direct injection of polyester fiber through dispersive ink and direct injection digital printing process

The invention discloses a pretreatment liquid for direct injection of polyester fiber through dispersive ink and a direct injection digital printing process. The pretreatment liquid comprises, by mass, 0.2-5 parts of thickener, 1-10 parts of dispersion promoter, 2-5 parts of sodium chloride and 76-95 parts of water. The pretreatment liquid is semi-thick liquid, polyester fabric after going through impregnation or padding treatment liquid is dried, injection printing of dispersive dye ink is performed, high-temperature steaming baking is performed for color fixing after drying, water washing is performed, and then drying is performed to obtain a printing finished product. The pretreatment liquid is simple to prepare, convenient to use and suitable for direct injection process digital printing of all fabric high in polyester content, and the pretreatment liquid is easy to wash away after printing, so that hand feel of fabric is unaffected. Conventional heat transfer printing is replaced by the dispersive direct injection process, and transfer printing paper is not used, so that the direct injection digital printing process is environment-friendly. The pretreatment liquid can effectively prevent ink from spreading around on the polyester fabric, so that patters are ensured to be exquisite and lines are ensured to be clear after printing; color yield rate is high, printing is saturated and bright in color, and visual three-dimensional sense is high.

Owner:深圳市墨库图文技术有限公司

Dyeing process for elastic polyester-polyurethane fabric

InactiveCN101046064AEasy to dyeNo pollution in the processFibre treatmentDyeing processColour fastnessDisperse dye

The dyeing process for elastic polyester-polyurethane fabric includes one dyeing step and one reducing and cleaning step. The dyeing step using disperse dye, ammonium acetate and dyeing assistant is performed in certain bath ratio and at certain temperature. The reducing and cleaning step using sodium hydrosulfite, sodium hydroxide and cleaning assistant is performed in certain bath ratio. The dyeing process can dye polyester component well at low temperature dyeing condition, and has well dyeing on polyurethane component and high color fastness.

Owner:毛中水

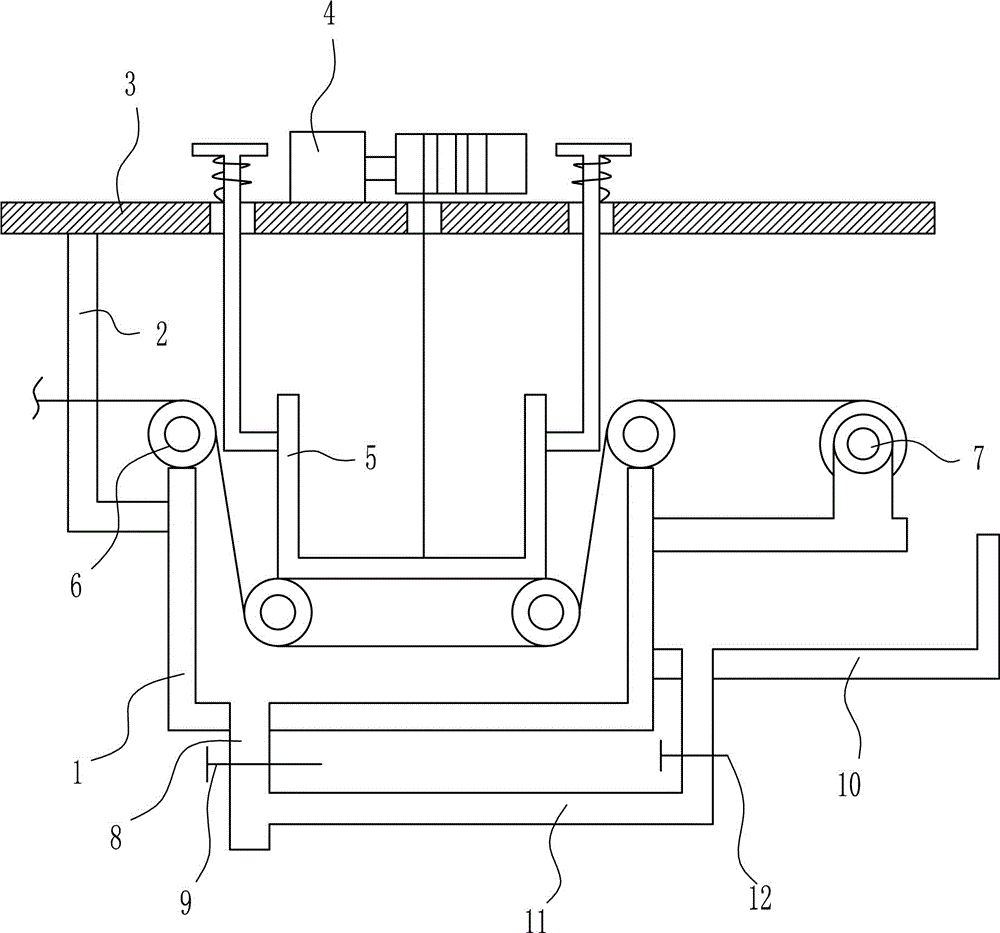

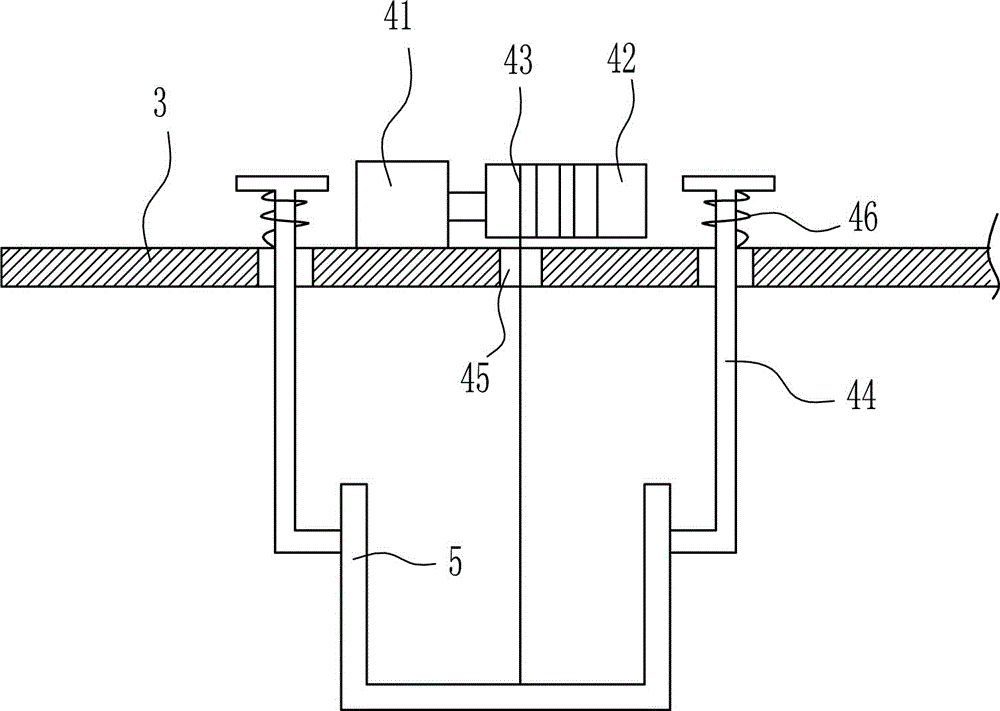

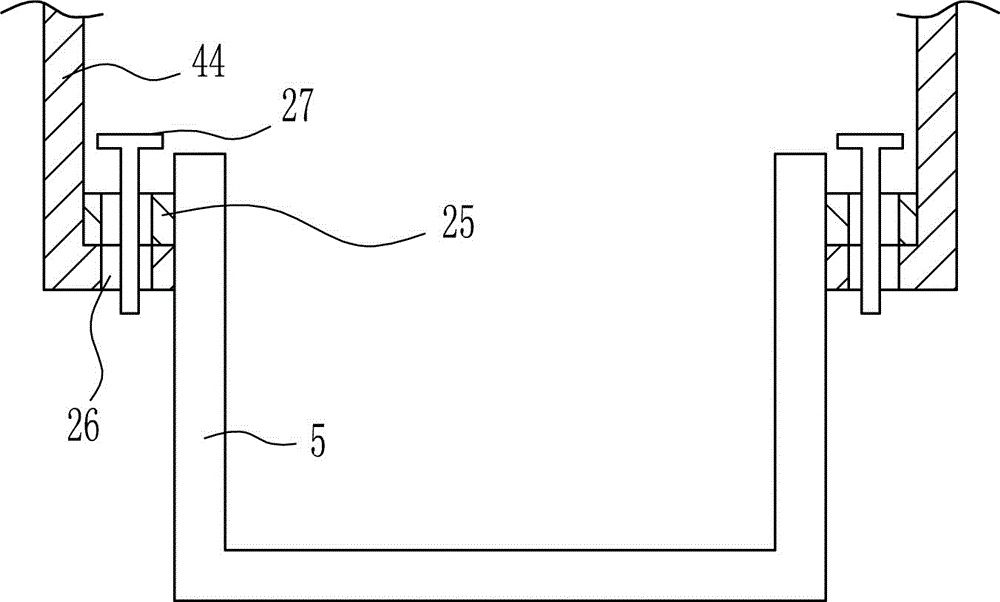

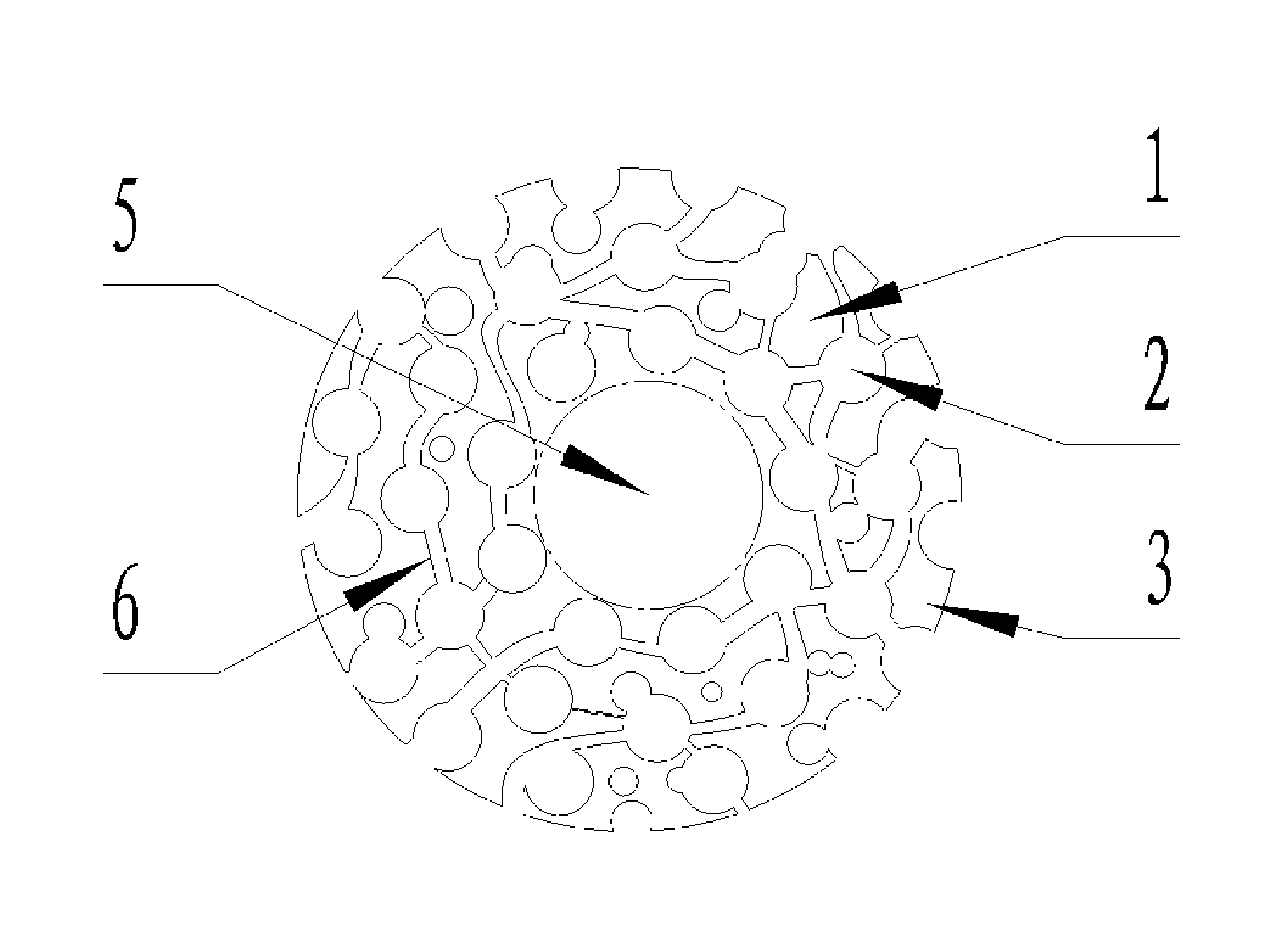

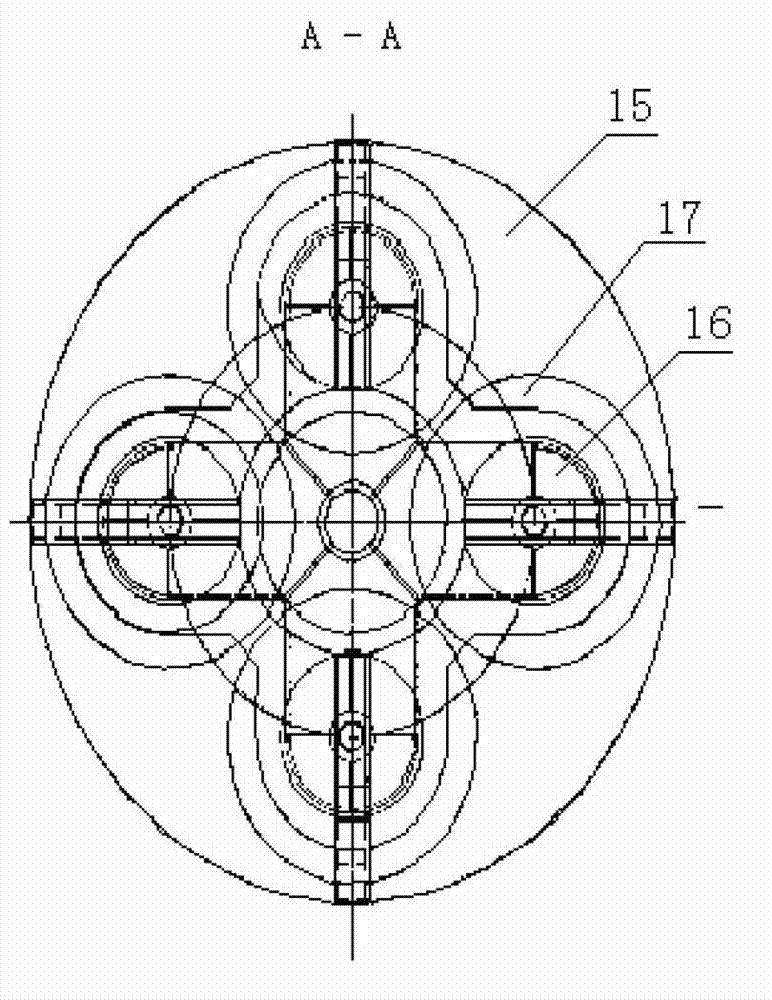

Non-woven lifting dye device for garment production

InactiveCN106835555AEasy to dyeEasy to rewindTextile treatment machine arrangementsTextile treatment carriersNonwoven fabricMechanical engineering

The invention relates to a dye device, particularly relates to a non-woven lifting dye device for garment production, and aims at solving the technical problem of providing a non-woven lifting dye device for garment production, which is capable of flatly putting non-woven into a dye for dyeing. In order to solve the technical problem, the invention provides the non-woven lifting dye device for garment production. The non-woven lifting dye device for garment production comprises a dye box, a connecting rod, a support rod, a lifting mechanism, a lifting frame, a guide roller and the like, wherein the upper part of the left side outside the dye tank is connected with the connecting rod; the top of the connecting rod is connected with the support rod; the support rod is connected with the lifting mechanism; and the lower side of the lifting mechanism is connected with the lifting frame. Through the lifting mechanism, the targets of driving the lifting frame to descend through the lifting mechanism, driving the guide roller at the inner side to descend through the lifting frame and flatly pressing the non-woven into the dye box for dip dyeing through the guide roller at the inner side are achieved.

Owner:绍兴金祥惠纺织印染有限公司

Modified polylactic acid fiber excellent in performance

ActiveCN104818543AImprove heat resistanceEasy to processMelt spinning methodsMonocomponent polyesters artificial filamentCellulose diacetateCellulose acetate

The invention discloses a modified polylactic acid fiber excellent in performance. The modified polylactic acid fiber is prepared by use of a method and the method comprises the steps of adding such raw materials as PDLLA polylactic acid, PLLA polylactic acid, hydroxypropyl starch, cellulose diacetate, nano tourmaline powder, nano talcum powder, chitosan powder and nano montmorillonoid powder to a high-speed mixer, and dispersing at a high speed to obtain a modified polylactic acid mixture, forming a modified polylactic acid master batch from the evenly mixed modified polylactic acid mixture by virtue of melt blending and extruding in a twin-screw extruder, and drying in vacuum, feeding the modified polylactic acid functional master batch slices and the vacuum-dried common polylactic acid slices into the high-speed mixer for evenly mixing, and spinning the mixture by use of a quinquangular spinneret orifice on a melt spinning machine, thereby obtaining the modified polylactic acid fiber.

Owner:CHANGXING YONG XIN TEXTILE PRINTING DYEING

Solid particle for washing and washing method using the same

ActiveUS9315766B2Reduce capacityEasy to dyeInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsSolid particlePolymer

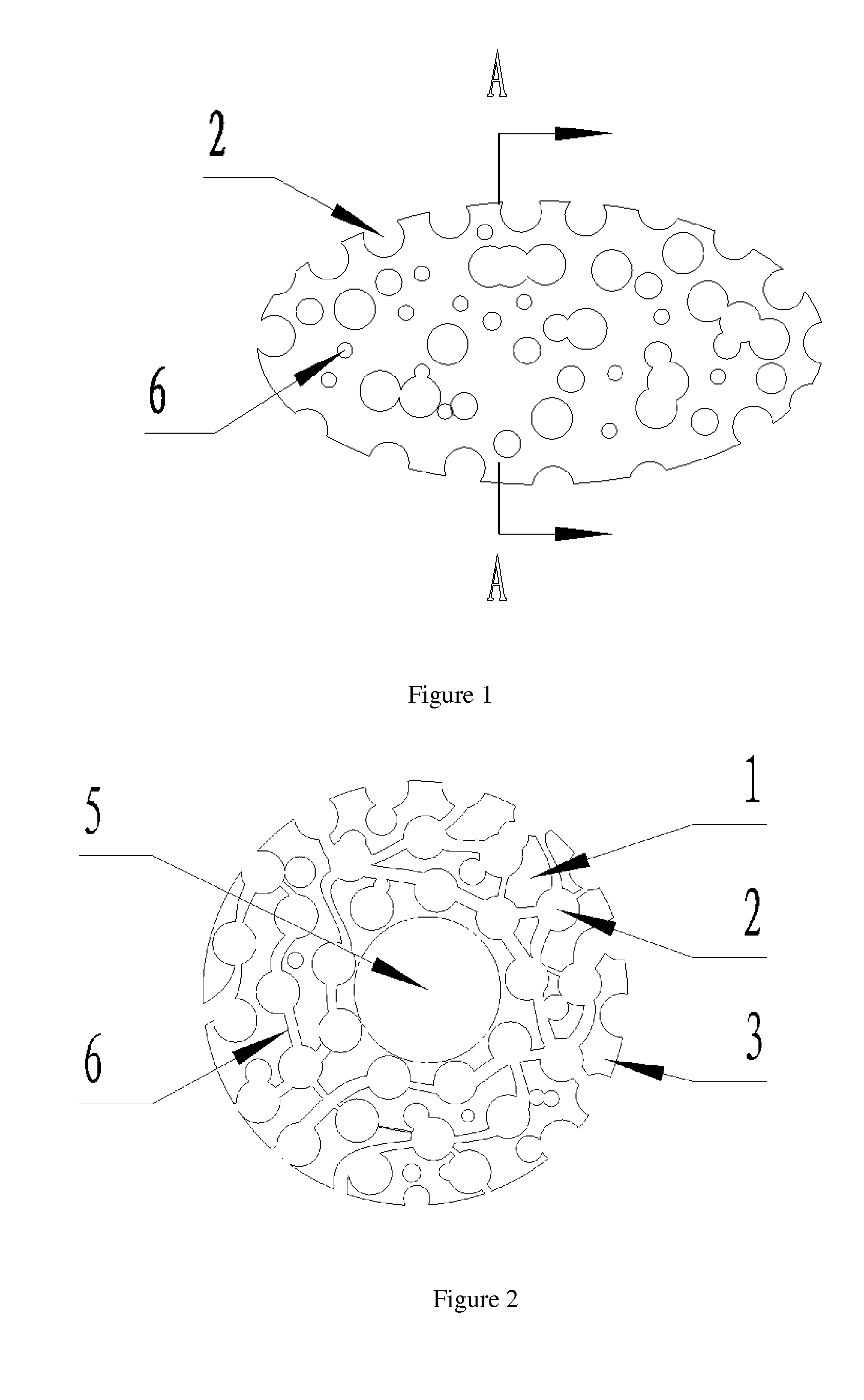

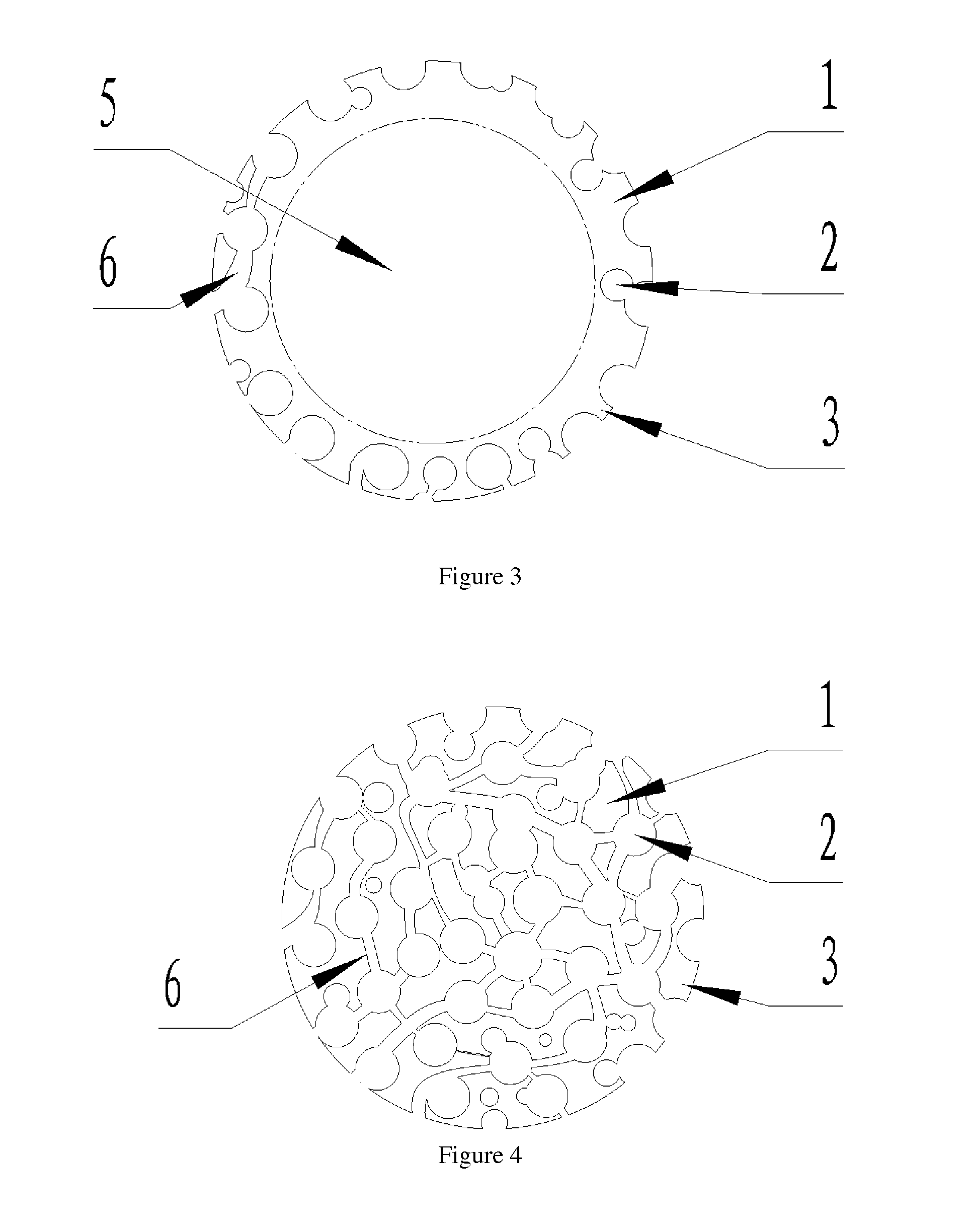

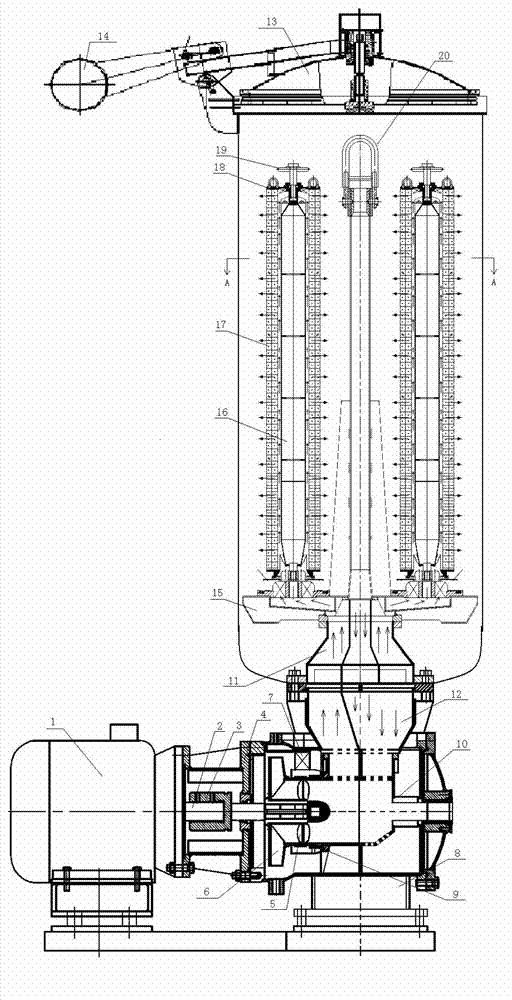

A solid particle for washing and the washing method using the same are provided. The solid particle is a polymer solid particle, wherein open pores are distributed on the solid particle surface. The washing method using the solid particle comprises steps of separating the articles to be washed with the solid particles, rinsing the articles to be washed and drying the articles to be washed.

Owner:XEROS LTD

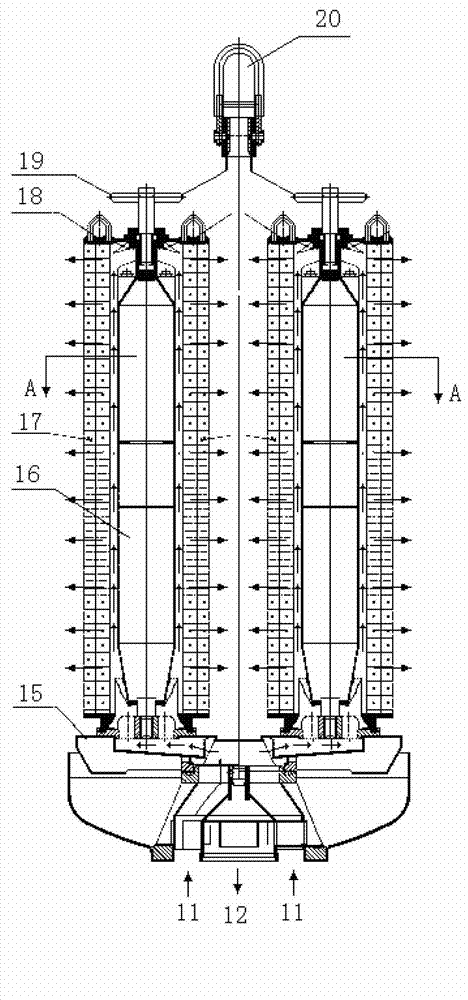

Ultralow liquor ratio zipper dyeing machine and dyeing process thereof

InactiveCN103088574AHollow volume reductionReduced cavity cross-sectional areaPump componentsTextile treatment machine arrangementsPolymer scienceEngineering

The invention discloses an ultralow liquor ratio zipper dyeing machine and dyeing process thereof. The dyeing machine comprises a tube cylinder, a cylinder cover and a zipper warp beam plate frame embedded into the tube cylinder. The zipper warp beam plate frame comprises a zipper plate seat, a hollow water drum, a zipper woven belt, a zipper tube sleeve, a locking bolt, and a zipper frame lifting ring. The lower end of the hollow water drum is fastened on the zipper plate seat, the zipper tube sleeve is sleeved on the outer side of the hollow water drum, and a diversion inlet and a diversion outlet are arranged below the zipper plate seat and connected with an infusion pump through a horn-shaped pipe sleeve. The dyeing process comprises the stages of scouring and bleaching, dyeing and water scrubbing. According to the ultralow liquor ratio zipper dyeing machine and the dyeing process thereof, a lift range required by zipper woven belt dyeing water level can be achieved when the height of dye liquor in the dyeing machine is lower than the zipper plate seat, the effect of ultralow liquor ratio zipper dyeing is achieved, the dyeing machine has a lower dying liquor ratio than a traditional zipper dying machine, and the purposes of saving electric energy, steam and the dye liquor, shortening dyeing and finishing periods, and saving energy and reducing emission are achieved.

Owner:高勋绿色智能装备(广州)有限公司

Flax scribbled yarn and its production

One flax blended yarn and its preparation technology. The blending ratio of the chemical fiber is 20-80:80-20, the Separatist degrees of flax fiber used is more than 2000. the preparation technology is that flax fiber and chemical fiber blend by the equipment of Cotton-cleaning, carding strip, drawing, roving, spinning, finally winding into yarn. The flax fiber and chemical fiber blend in the cleaning cotton disk. Add the equipment of spinning core spun slub Yarn. The beneficial effect of the present invention is: owing to the improvement in the procedure, the blended yarn with multi-fiber and more varieties is available, which satisfy the demand of customers; the Ma in yarn and other fiber are mixed uniformly, which leads to easy dye; the fabrics produced by the mix of Ma yarn and chemical fiber has the following advantages: wrinkle resistant, wear-resistant, can not afford ball, overhanging flexible, antibacterial antibiotics, anti-UV, thin smoothness, cool, breathable, moisture absorption, scattered wet fast, and so on.

Owner:曲阜市锦绣纺织有限公司

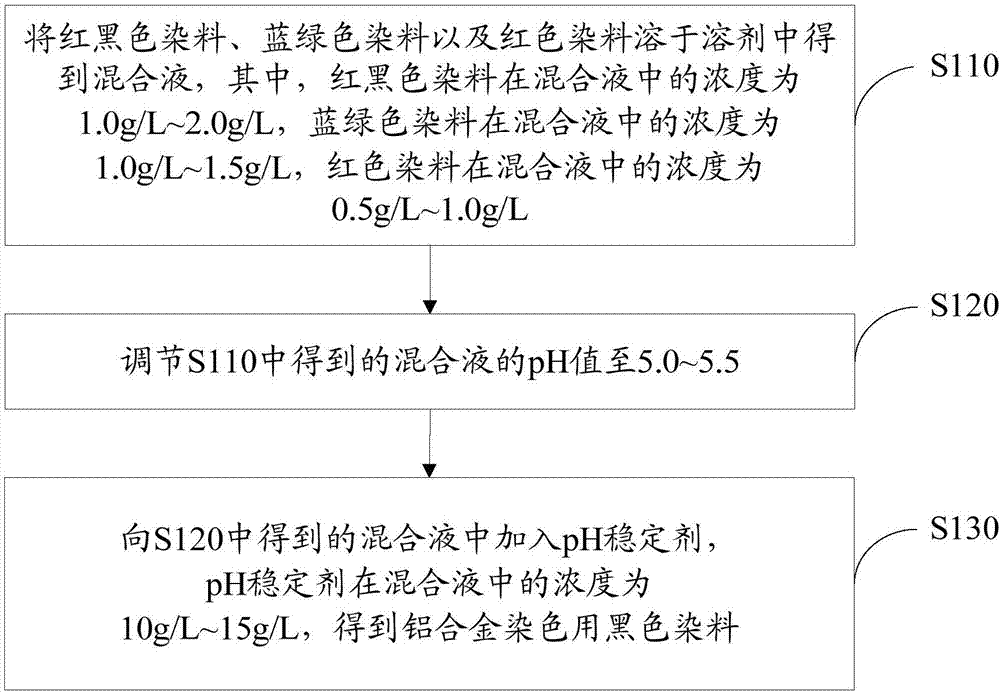

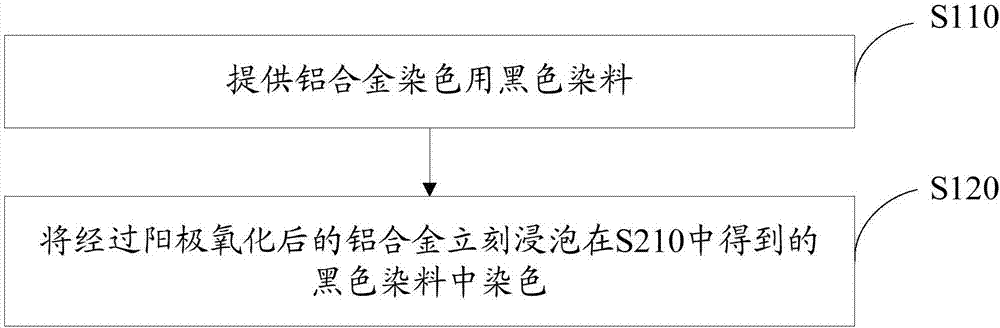

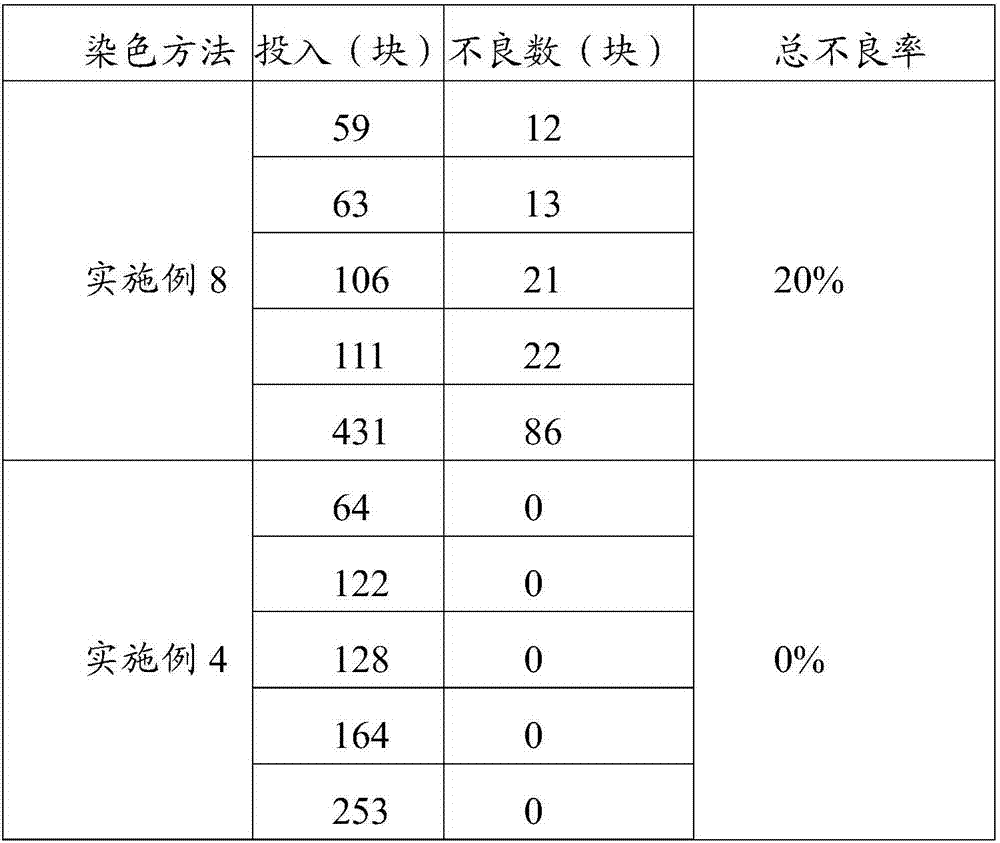

Preparation method of black dyestuff for dyeing aluminum alloy and dyeing method of aluminum alloy

The invention discloses a preparation method of a black dyestuff for dyeing an aluminum alloy and a method for dyeing the aluminum alloy by adopting the black dyestuff. The prepared black dyestuff comprises 1.0g / L to 2.0g / L of a reddish black dyestuff, 1.0g / L to 1.5g / L of a bluish green dyestuff and 0.5g / L to 1.0g / L of a red dyestuff. The inventor accidentally finds out that the black dyestuff, which is formed by mixing the reddish black dyestuff, the bluish green dyestuff and the red dyestuff according to the ratio, regulating the pH (Potential of Hydrogen) value to 5.0 to 5.5, and adding 10g / L to 15g / L of a pH stabilizer, is more suitable for dyeing of the aluminum alloy than a traditional black dyestuff and the aluminum alloy can be easily dyed black. Especially, when the aluminum alloy subjected to anode oxidation is dyed, the mixed black dyestuff can easily dye the aluminum alloy to black with a stable color and coloring durability.

Owner:GUANGDONG EVERWIN PRECISION TECH

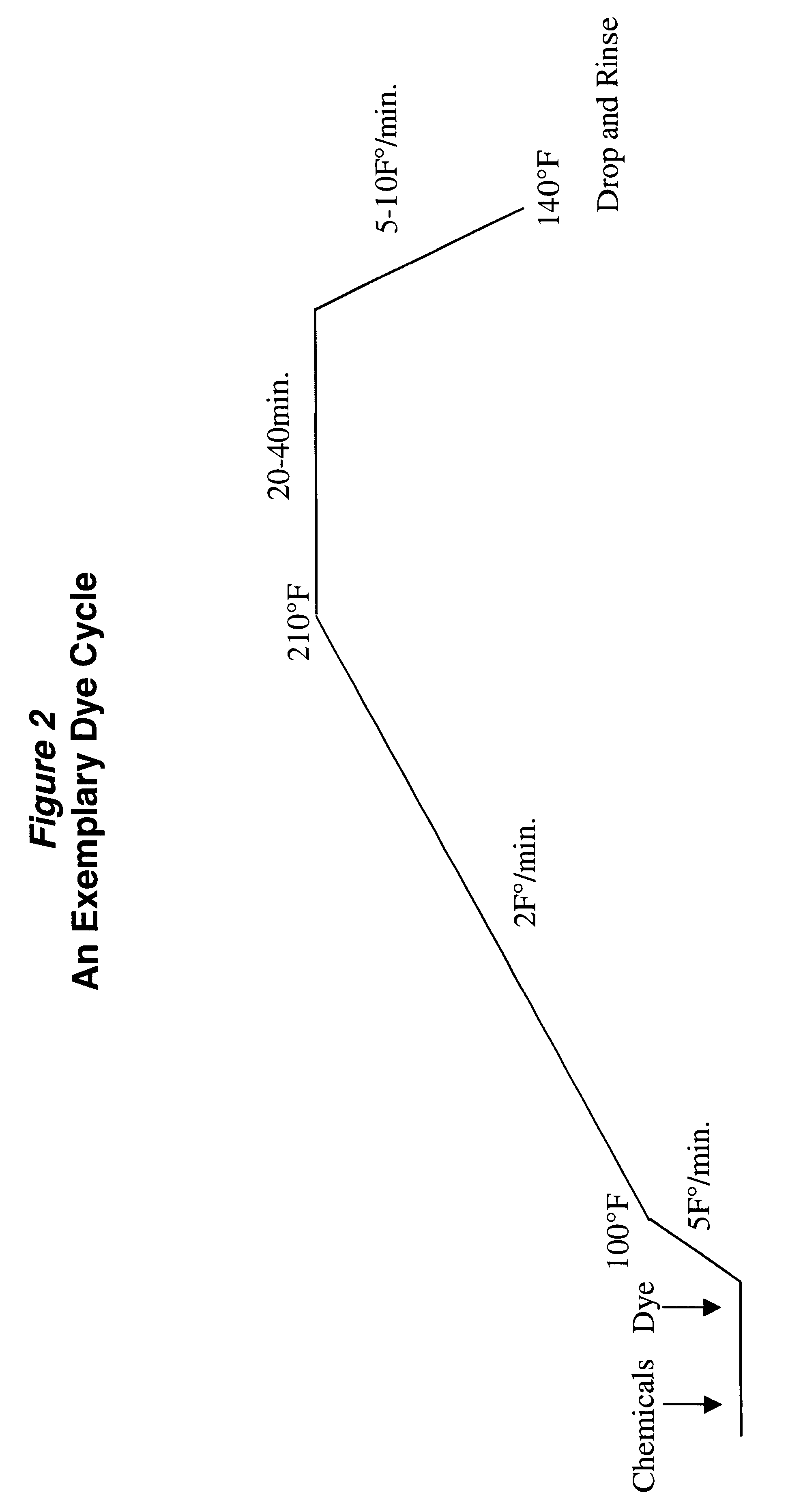

Dye diffusion promoting agents for aramids

Aramid and aramid-blend fabrics are dyed or flame-retardant treated or both dyed and flame-retardant treated using conventional heat dyeing equipment. Amides capable of swelling the aramid fibers at least 1.5% and preferably having 7 to 14 carbon atoms are used as diffusion-promoting agents for dyes, flame retardant agents or both. Odor-free, flame resistant, colored or colored and highly-flame resistant products result.

Owner:SOUTHERN MILLS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com