Denier/superfine denier nylon master granule, preoriented yarn (POY) and draw textured yarn (DTY) stretch yarn and preparation method thereof

A fine denier nylon and ultra-fine denier technology, applied in the field of DTY elastic yarn, fine denier/ultra-fine denier nylon POY filament, can solve the problems of complexity and long process route, and achieve improved mixing performance, good performance, and increased tensile strength. The effect of tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

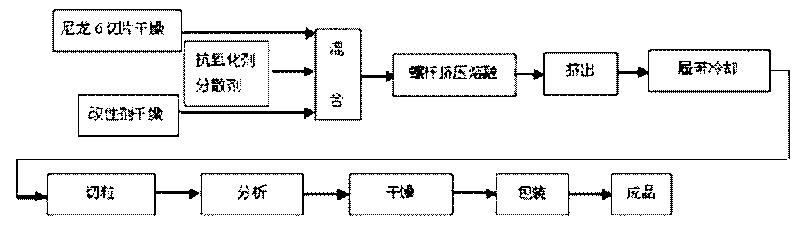

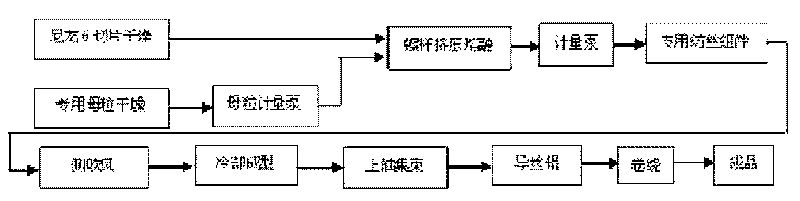

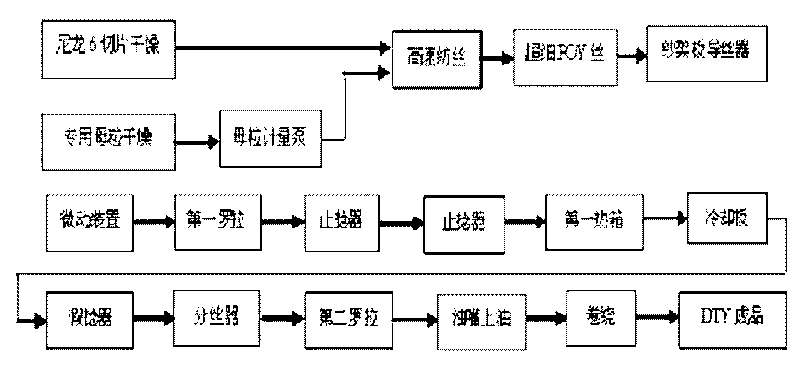

Method used

Image

Examples

Embodiment 1

[0083] Getting the raw materials ready: by weight of nylon 6 slices, take by weight 0.2% antioxidant (mass ratio is 1: 1 antioxidant 1010 and antioxidant 168), 0.3% dispersant (mass ratio is 1: 1 liquid Paraffin and PEG600), 0.8% metal salt MgSO 4 .

Embodiment 2

[0086] Nylon 6 chip after vacuum drying, masterbatch (moisture content 700ppm) is conveyed in twin-screw conventional spinning machine, and nylon chip pump supply rate is 64g / min, and masterbatch pump supply flow rate is 6.4g / min, in melt spinning The wire temperature is 285°C, the screw speed is 22r / min and the screw pressure is 90-100kg / cm 2 Next, the molten mixture is extruded by a screw (including static and dynamic mixers), pumped into the spinneret assembly by metering, filtered through 60-80 mesh sea sand, and then passed through the spinneret hole (the spinneret hole features: Diameter 0.18mm, aspect ratio 3.8) extrusion. Then, in the spinneret ring air blowing device, the temperature of the blown air is 32° C., the humidity is 50%, and the wind speed is 0.3 m / s. The cooled fibers are then clustered and oiled through the oil mist nozzle. The oiling rate is 1.6%. The oil used is a double-distilled water emulsion of nylon oil with a weight fraction of 12%. The rabbit s...

Embodiment 3

[0088] Fine denier / ultrafine denier nylon POY filament passes through the yarn guide, the first roller to the first hot box and is heated at a temperature of 163°C; after the POY filament is heated, it is cooled by the cooling plate, and then enters the false twister for twisting treatment (D The / Y ratio is 1.65, the material of the friction disc is ceramic, and the assembly form is 1-5-3); after cooling and false twisting, it enters the second roller for proper drafting (the drafting ratio is 1.25), while increasing the fiber strength, It can also reduce the elongation and fineness of the fiber; then enter the oil nozzle for oiling, and then wind it into a drum package (winding speed is 300m / min), that is, fine denier / ultrafine denier nylon DTY stretch yarn, and its monofilament The fineness is 0.4dtex, the breaking strength is 4.2cN / dtex, the elongation is 28%, the boiling water shrinkage is 7.2%, and the crimp shrinkage is 43%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Monofilament denier | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com