Patents

Literature

1055 results about "Oil mist" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Oil mist refers to oil droplets suspended in the air in the size range 1~10 μm.

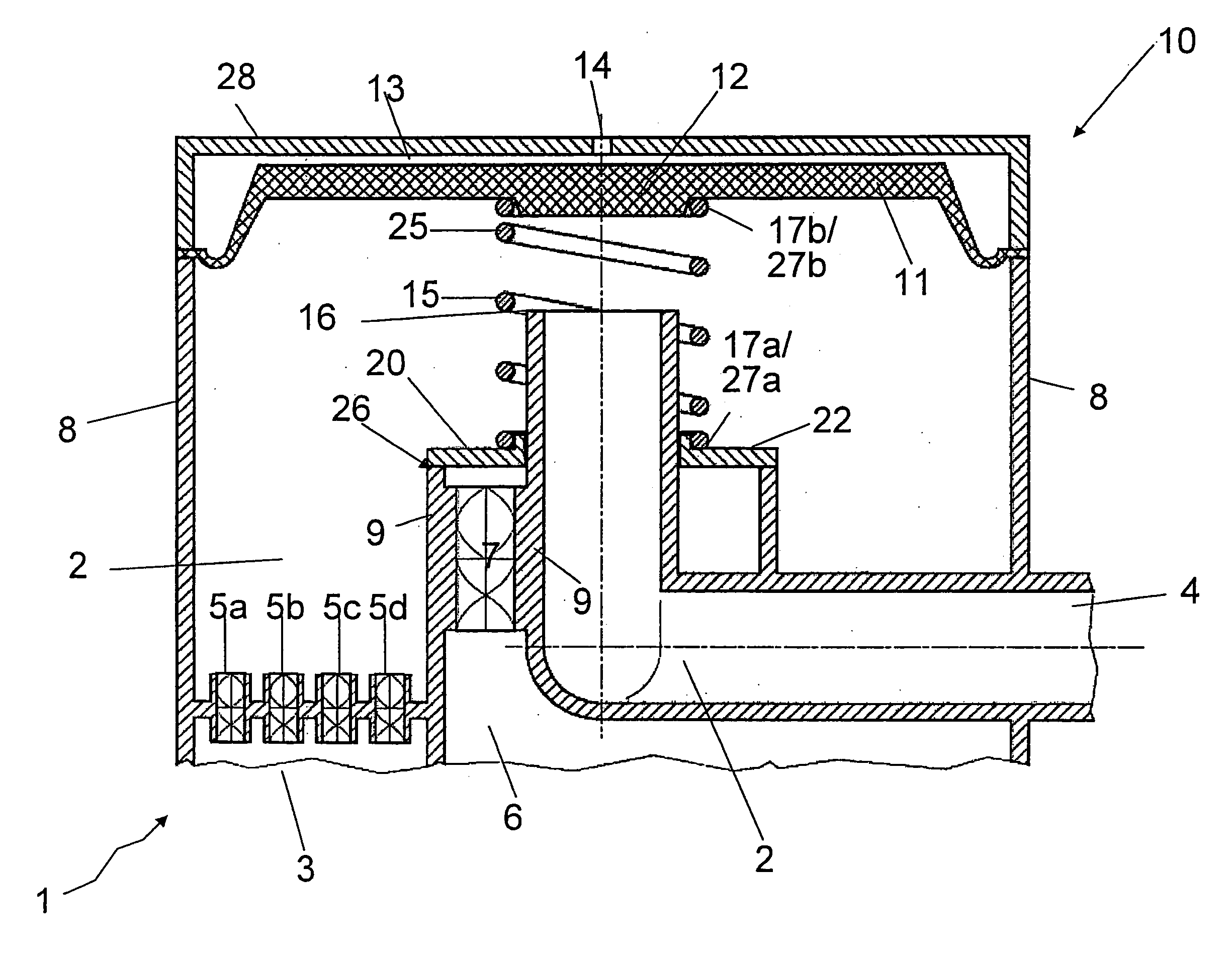

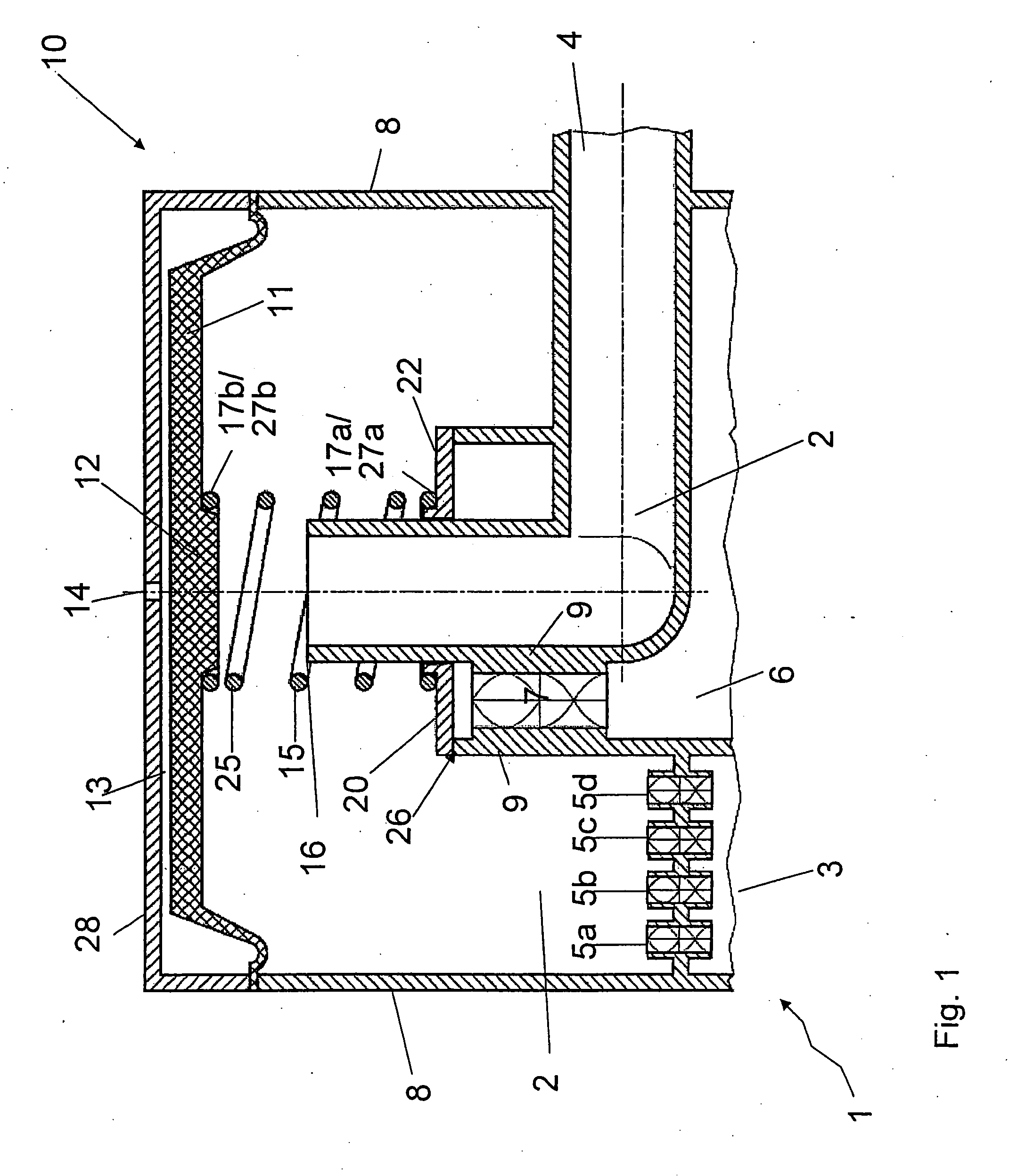

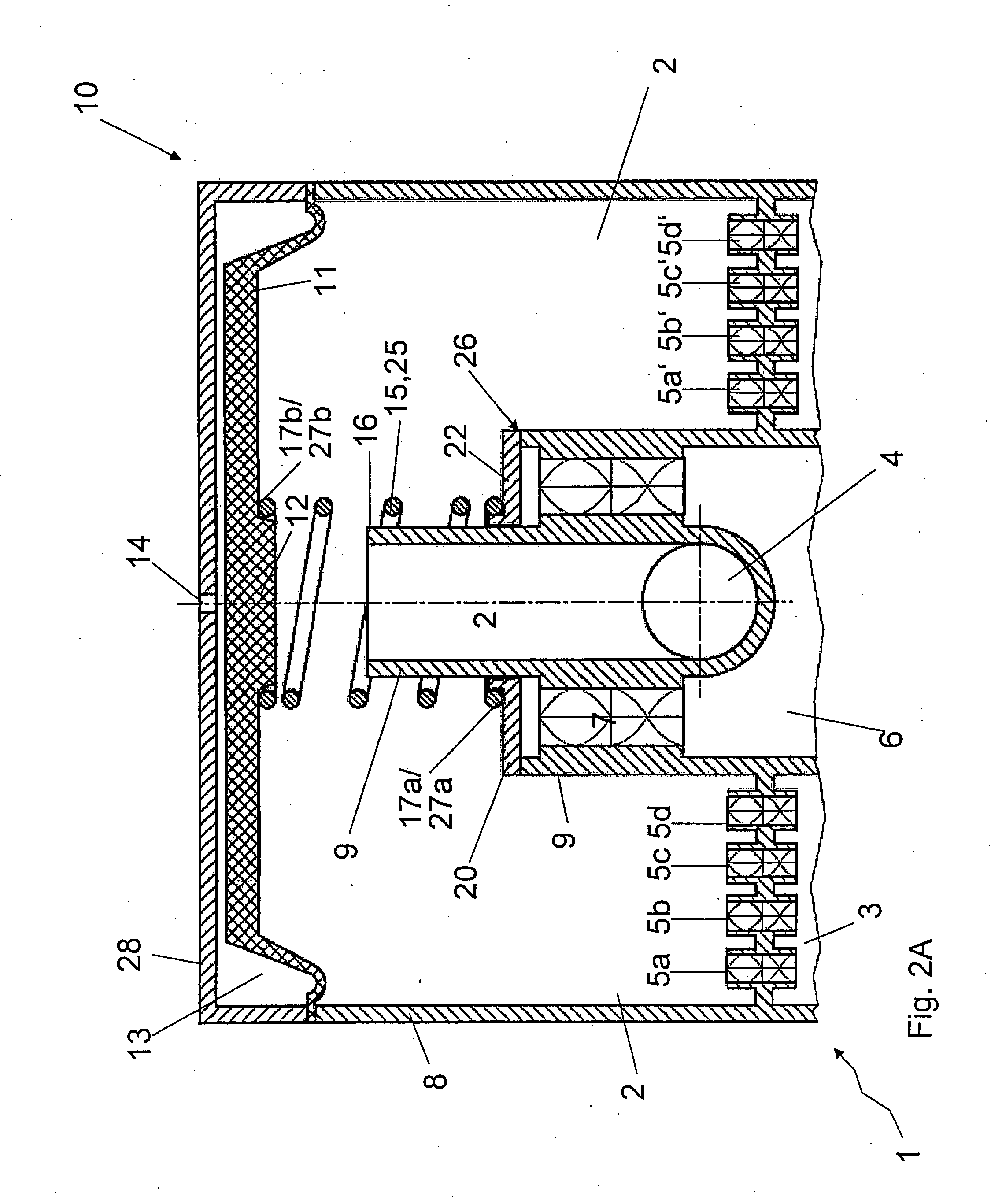

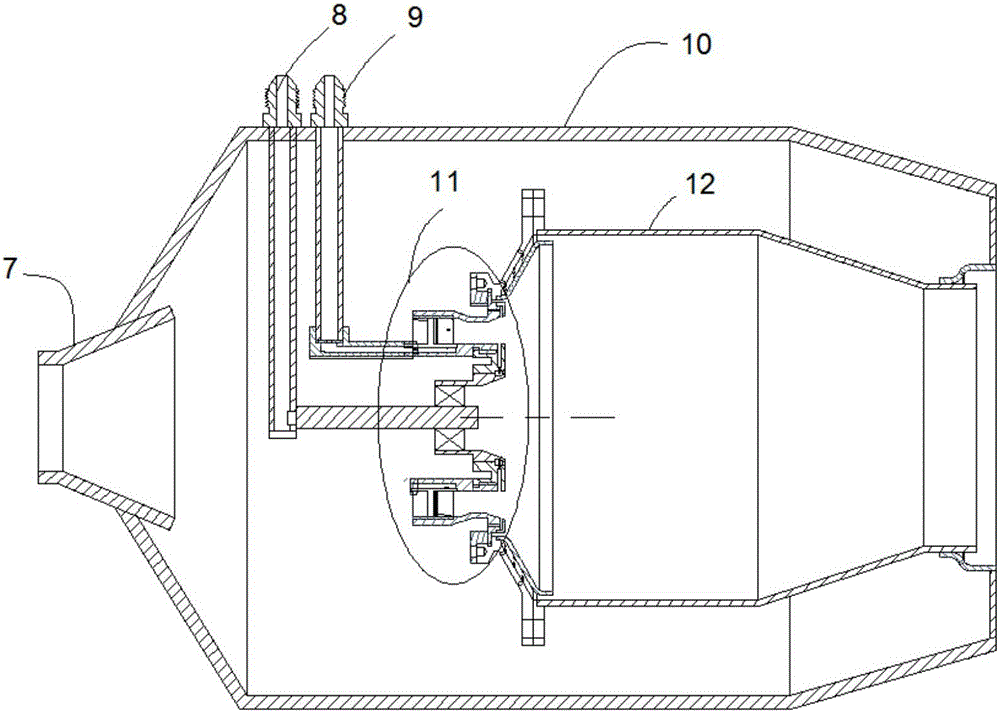

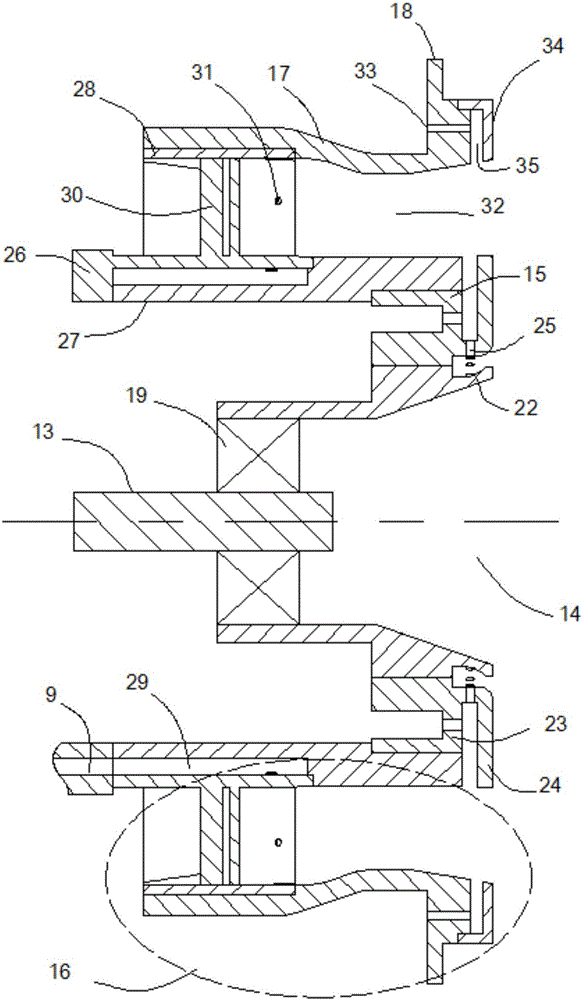

Separator for separating oil mist from the crankcase ventilation gas of an internal combustion engine, and functional module and internal combustion engine comprising a separator

ActiveUS20100180854A1Increase speedEasy to separateCombination devicesLubrication of auxillariesExternal combustion engineEngineering

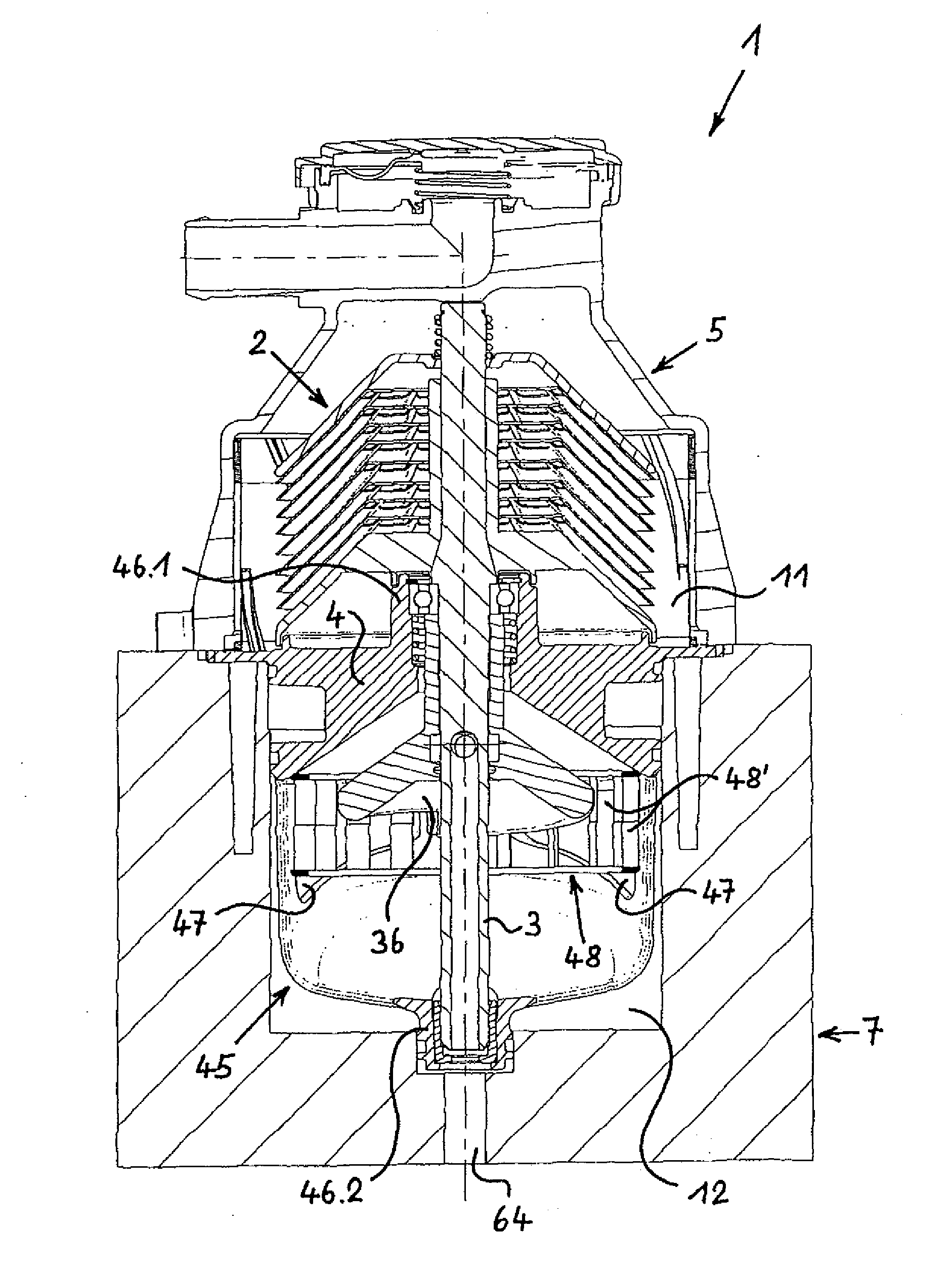

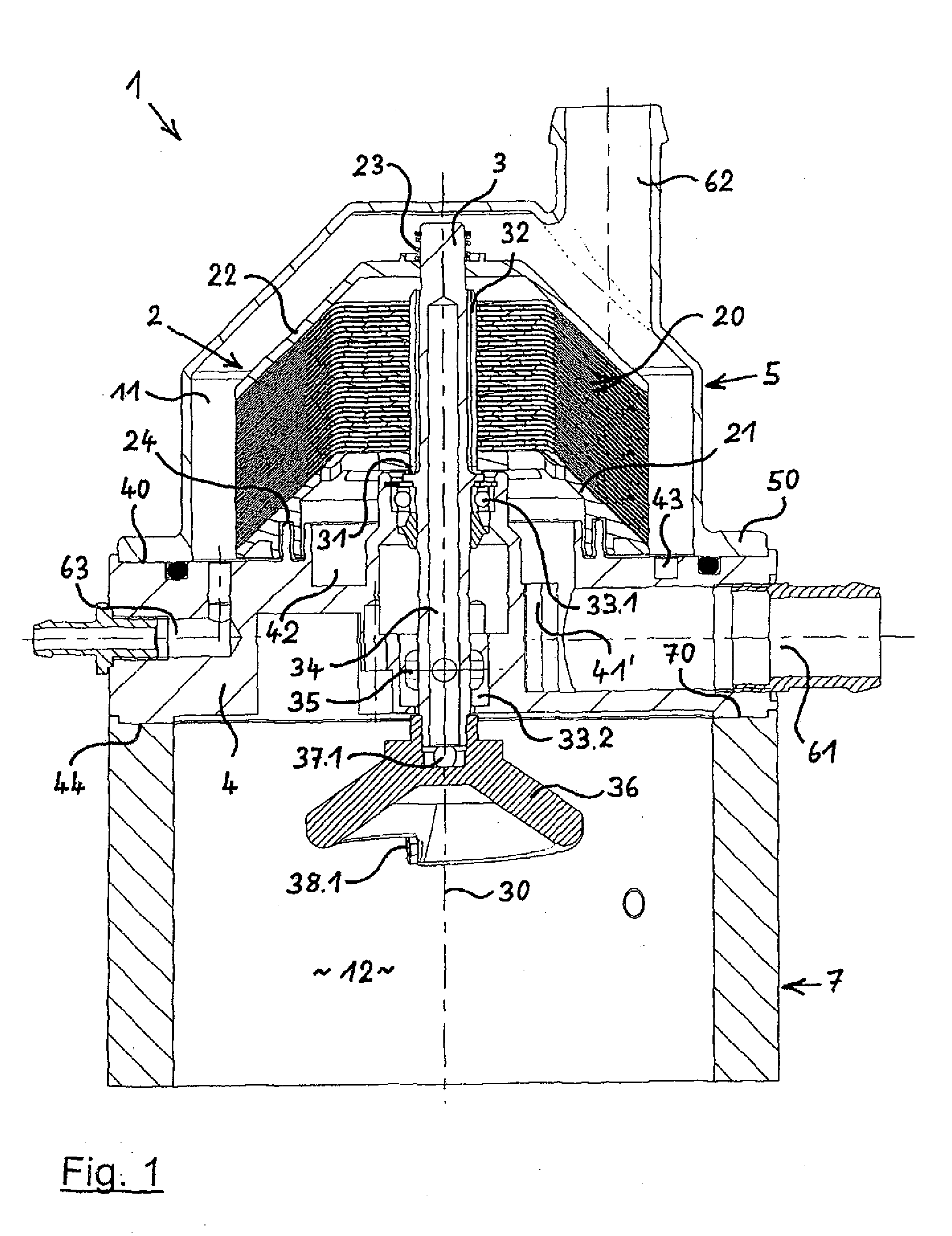

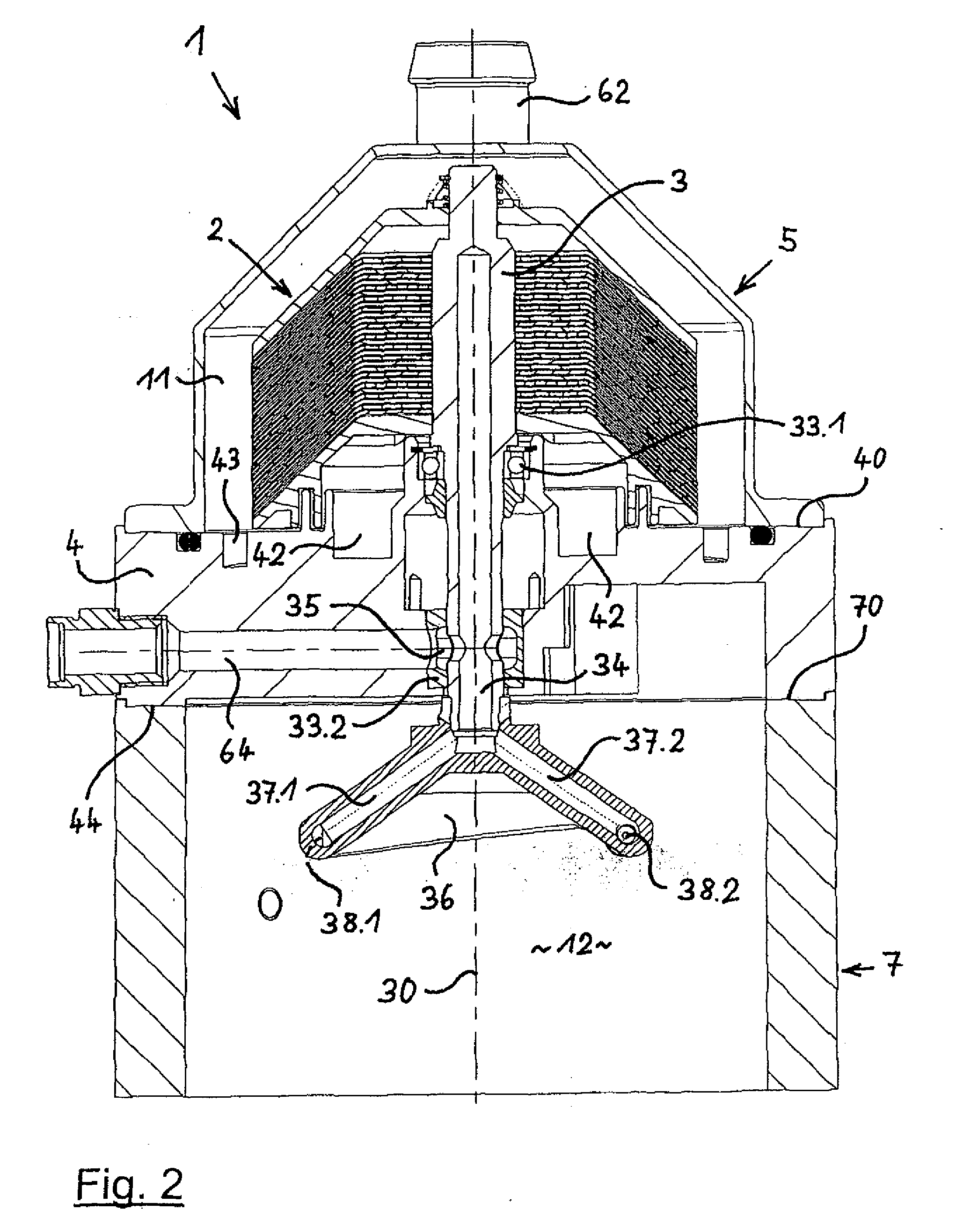

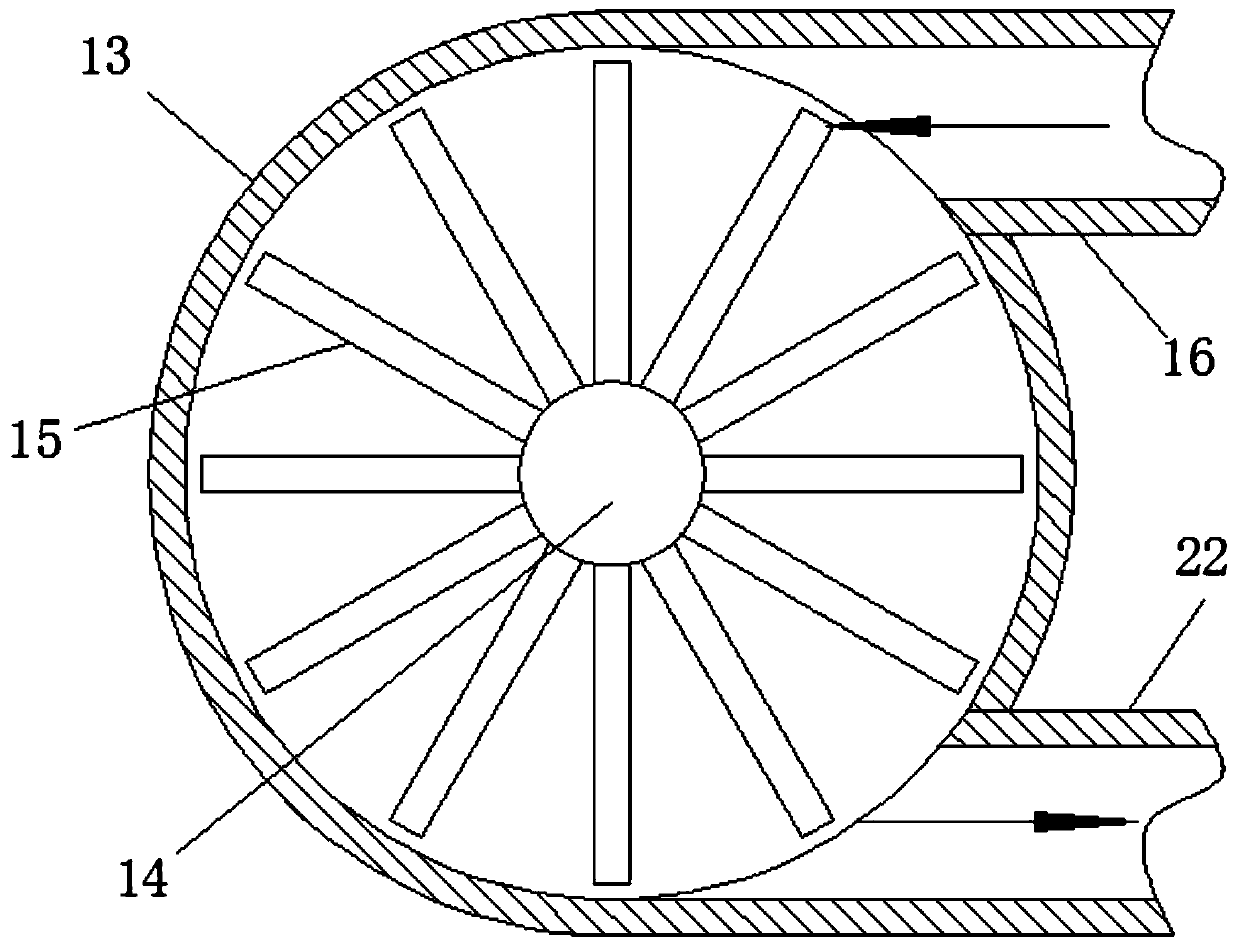

A separator for separating oil mist from the crankcase ventilation gas of an internal combustion engine, especially of a motor vehicle. The separator includes a gas purification chamber inside which a rotatably mounted centrifugal rotor is arranged. The gas purification chamber has a crude gas inlet, a pure gas outlet, and an oil outlet. The crankcase ventilation gas can be conducted into a radially internal zone of the centrifugal rotor via the crude gas inlet, while pure gas that is liberated from oil mist can be discharged from the gas purification chamber via the pure gas outlet, and oil separated from the gas can be discharged from the gas purification chamber via the oil outlet. The separator further includes a rotary drive for the centrifugal rotor. The rotary drive is disposed in a drive chamber of the separator, can be operated using pressurized lubrication oil of the internal combustion engine, and is connected to the centrifugal rotor by means of a shaft extending from the drive chamber into the gas purification chamber, from which the drive chamber is separated. The rotary drive is formed by at least one thrust nozzle which is connected to the shaft and to which the pressurized lubrication oil of the internal combustion engine can be fed. The separator includes at least one part of a base that forms the separation between the gas purification chamber and the drive chamber and extends into the drive chamber, the part of the base being fitted with a seat for a bearing of the shaft. The bearing is located at a distance from the centrifugal rotor.

Owner:HENGST WALTER

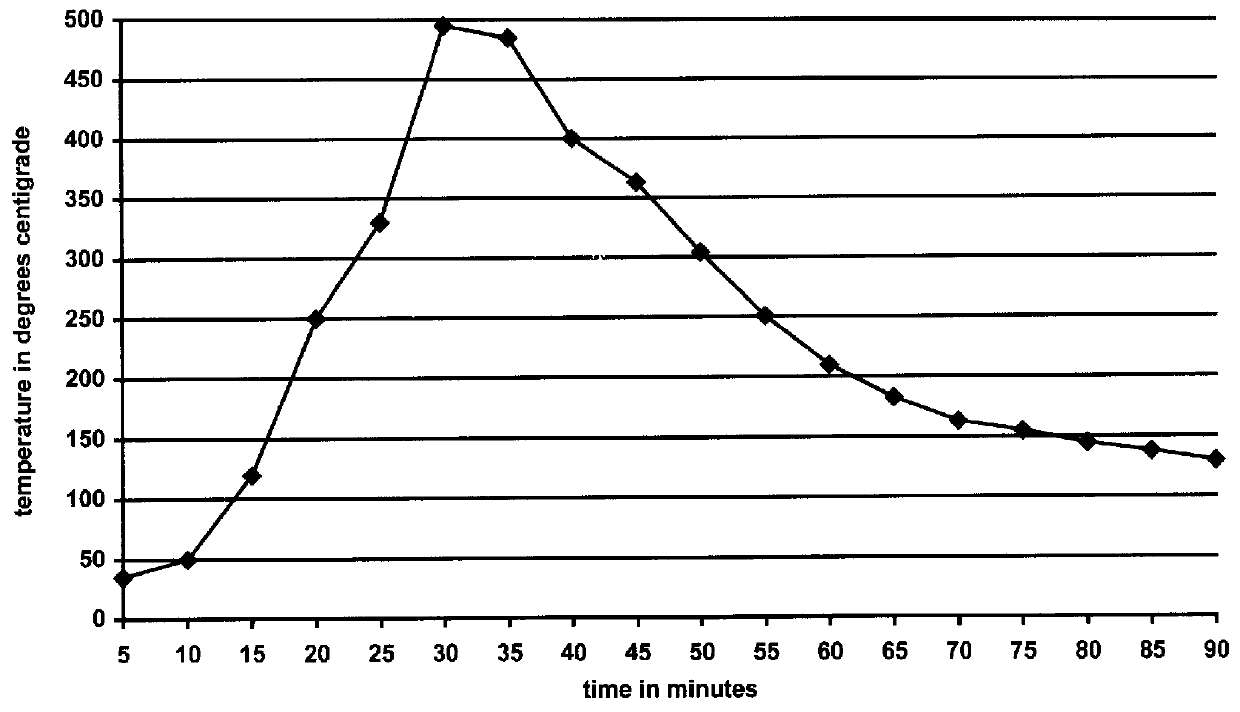

Process for pyrolyzing tire shreds and tire pyrolysis systems

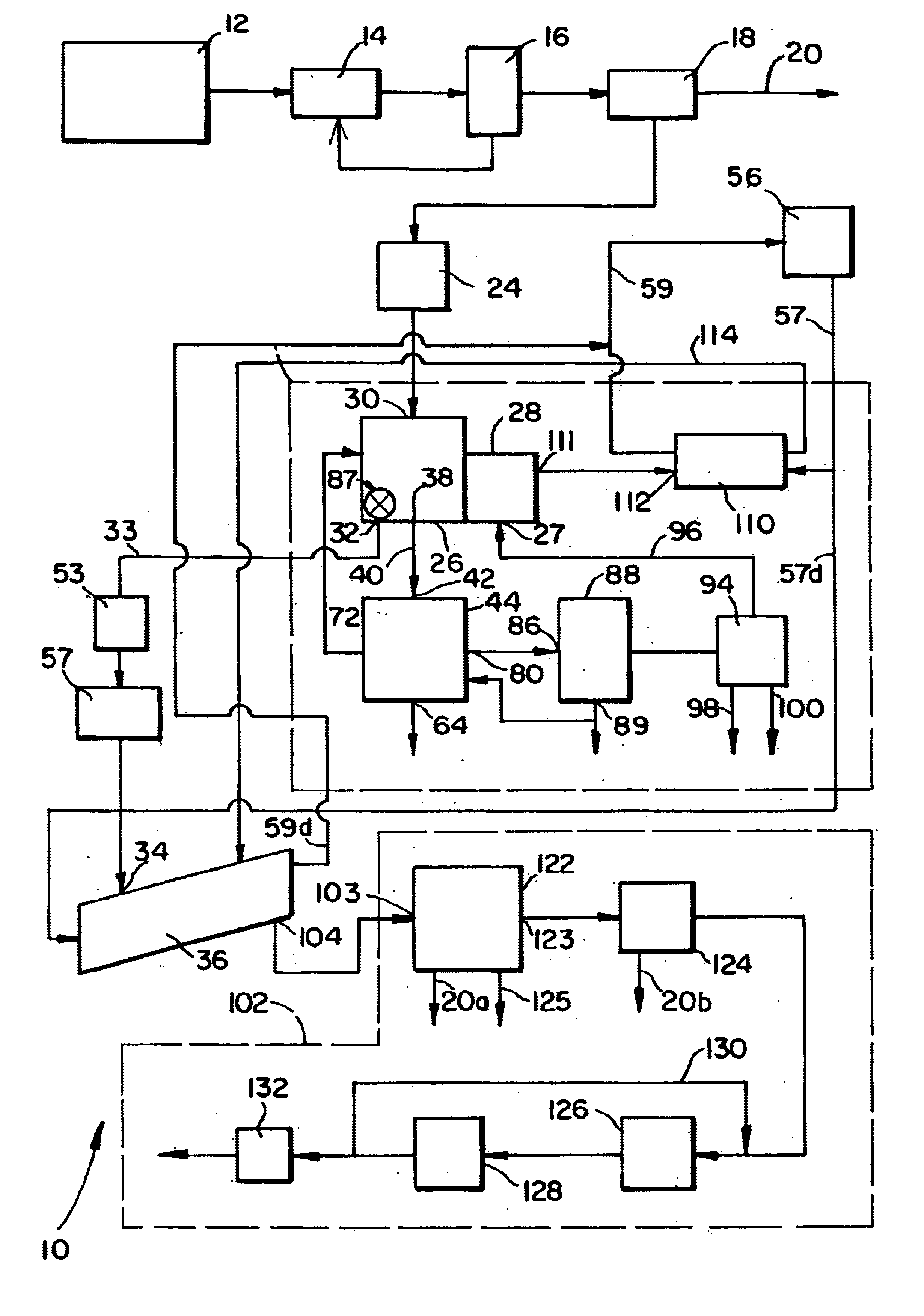

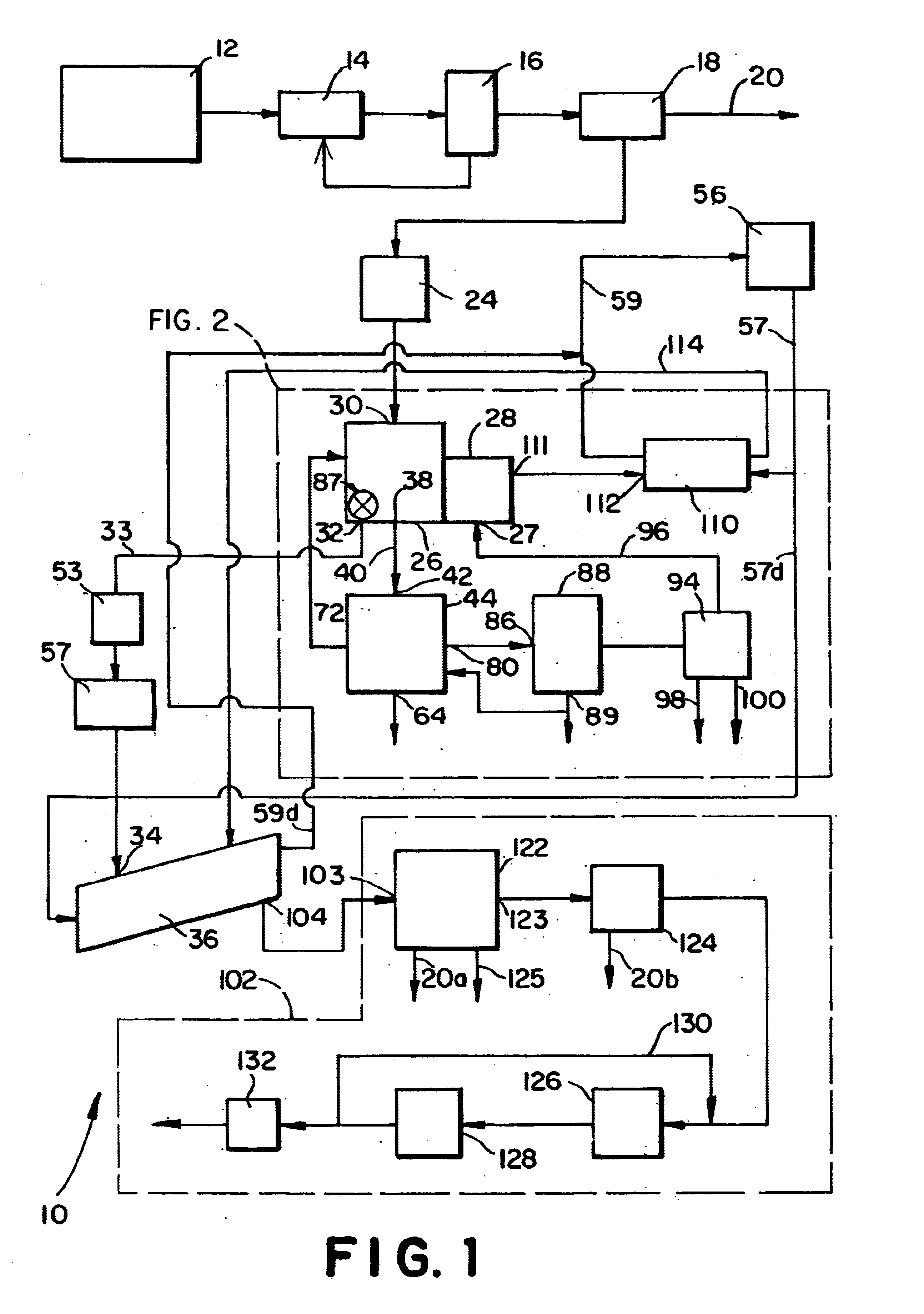

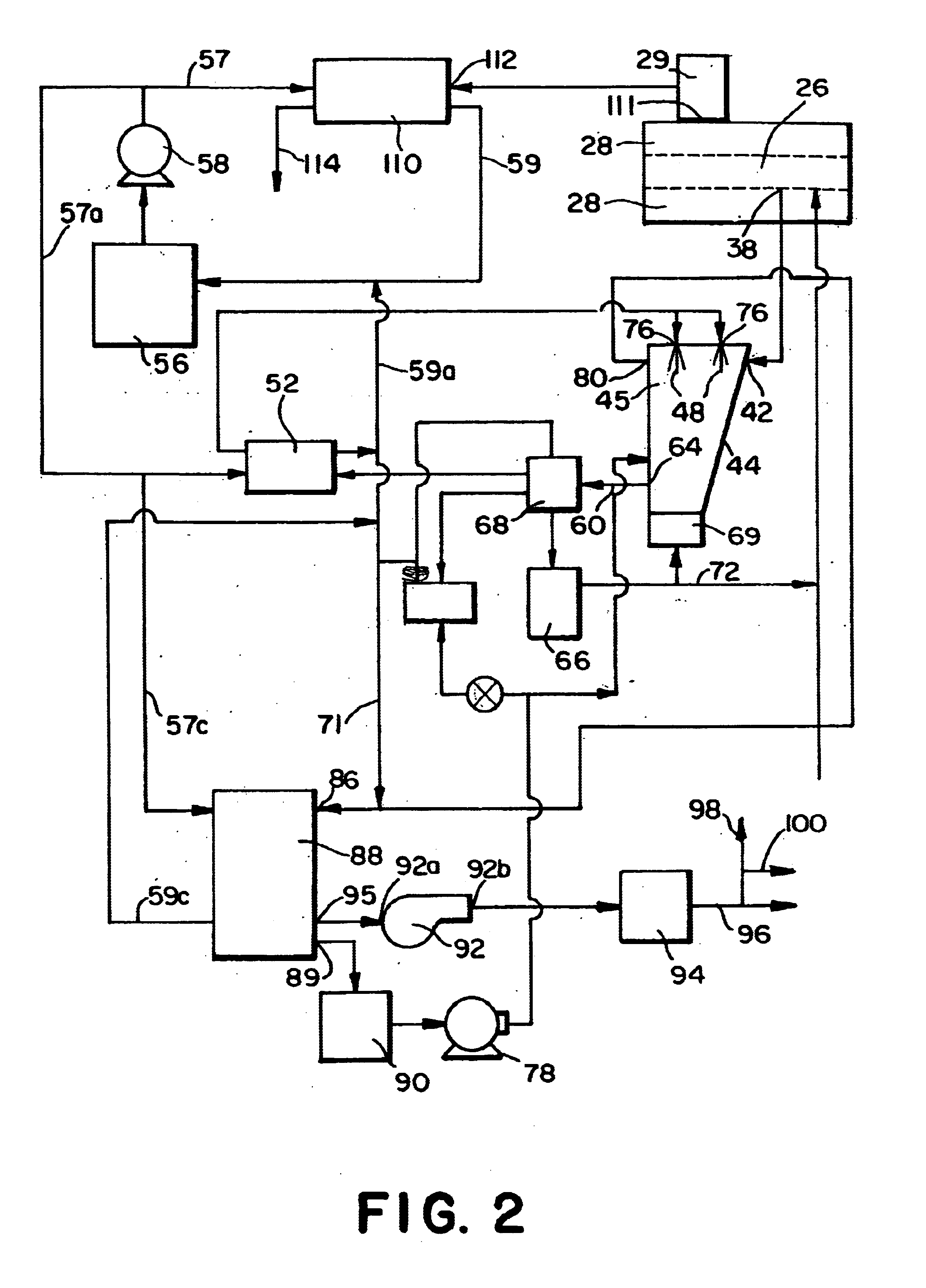

Tire pyrolysis systems and processes are provided which include feeding tire shreds to a pyrolysis reactor, pyrolyzing the shreds in a pyrolysis reactor to produce a hydrocarbon-containing gas stream and carbon-containing solid, removing the carbon-containing solid from the reactor, directing the hydrocarbon-containing gas stream into a separator, contacting the hydrocarbon-containing gas stream with an oil spray in the separator thereby washing particulate from the hydrocarbon-containing gas stream and condensing a portion of the gas stream to oil, removing and cooling the oil from the separator, directing non-condensed gas from the gas stream away from the separator, and directing a portion of the cooled oil removed from the separator to an inlet of the separator for use as the separator oil spray. A process is also provided in which solids from the pyrolysis reactor are directed to an auger having a pressure which is greater than the pressure in the pyrolysis reactor, and in which non-condensed gas from the gas stream after condensing a portion of the gas is directed to at least one burner in heat exchange relation with the pyrolysis reactor, and burned to heat the reactor and generate an effluent flue gas, a portion of which effluent flue gas is cooled and injected into the auger which is a trough auger in one embodiment.

Owner:RENAISSANCE ENERGY GROUP

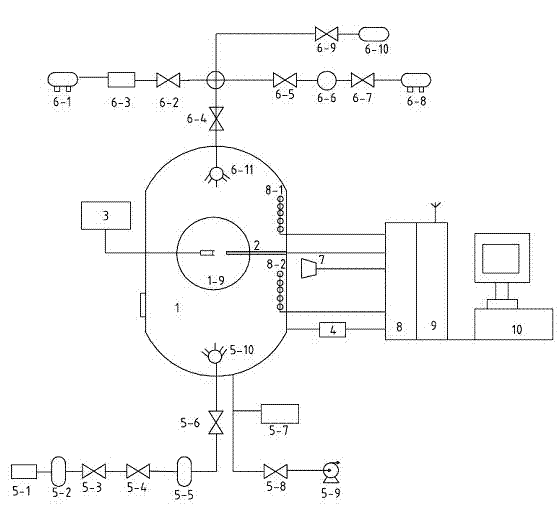

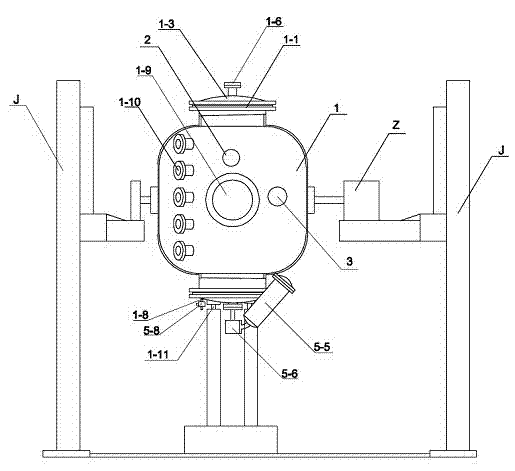

Experiment device and experiment method for gas cloud combustion, explosion simulation and inerting, inhibition

ActiveCN102879416ARealize the separation of man and machineEasy to installMaterial exposibilityExperimental testingData synchronization

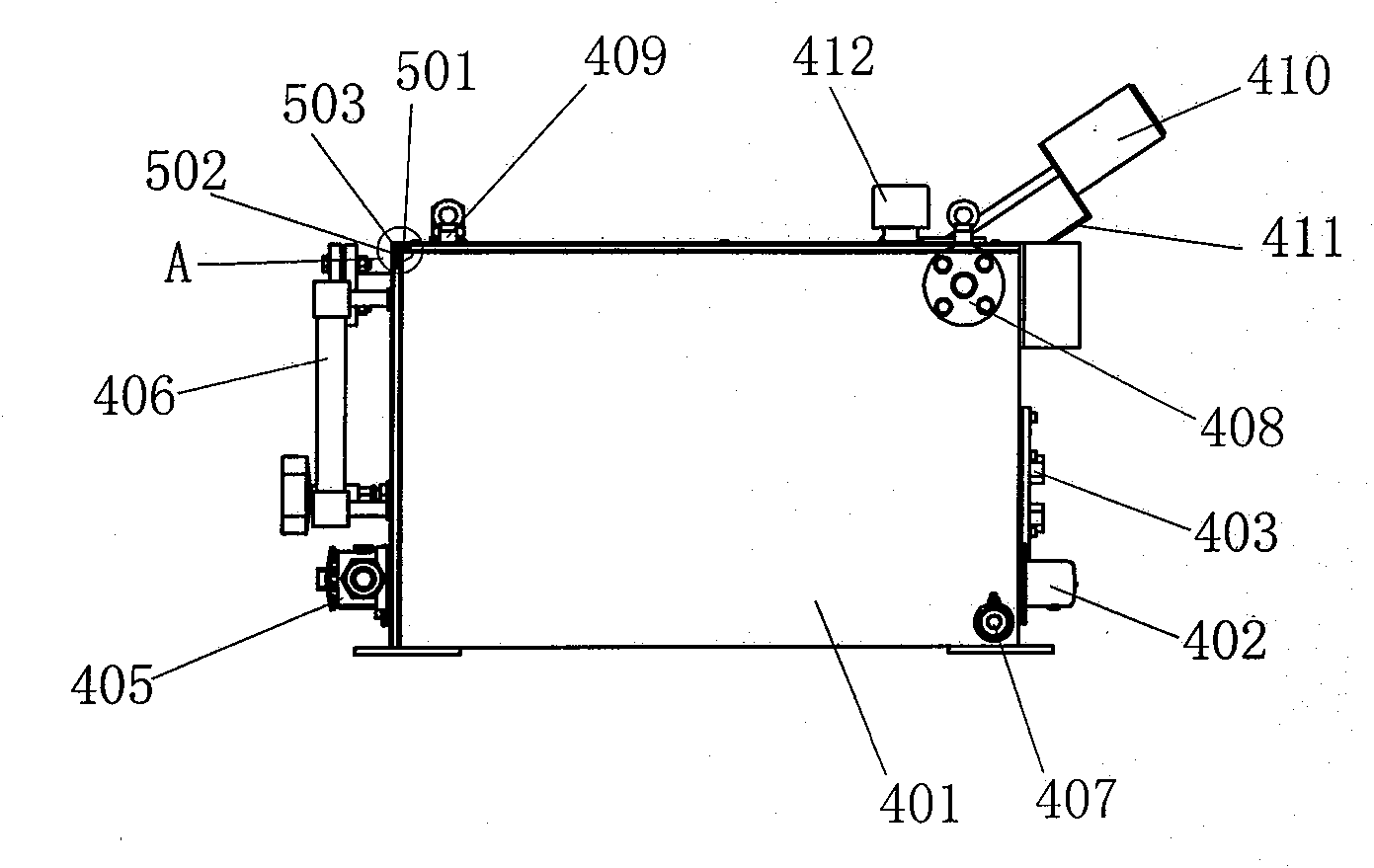

The invention relates to the technical field of fire hazard safety, and especially relates to an experiment device and an experiment method for gas cloud combustion, explosion simulation and inerting, inhibition. The device comprises an experiment test system composed of an explosion experiment container tank, a flame and explosion pressure radial propagation detection device, an ignition device, a generated gas sampling analyzer, and a high-speed schlieren and data acquisition, a sample introduction system, a combustion explosion inerting inhibition system, and a control system composed of wireless synchronous control and computer remote monitoring, and is a multifunctional comprehensive experiment platform device. The invention realizes 180-degree rotation of the tank, data synchronous acquisition, gas distribution and sample introduction with precise proportions, synchronous and delayed multimode ignition and inhibition system ejection; wireless and wired data transmission is adopted for control; man-machine separation of the tank and the controlling person is realized; safety and reliability of data transmission are guaranteed; combustion or explosion and inerting and inhibition experiments of various experiment samples such as gas cloud, dust, oil mist, and the like can be carried out when the tank is in a vertical or horizontal state.

Owner:吉林市宏源科学仪器有限公司

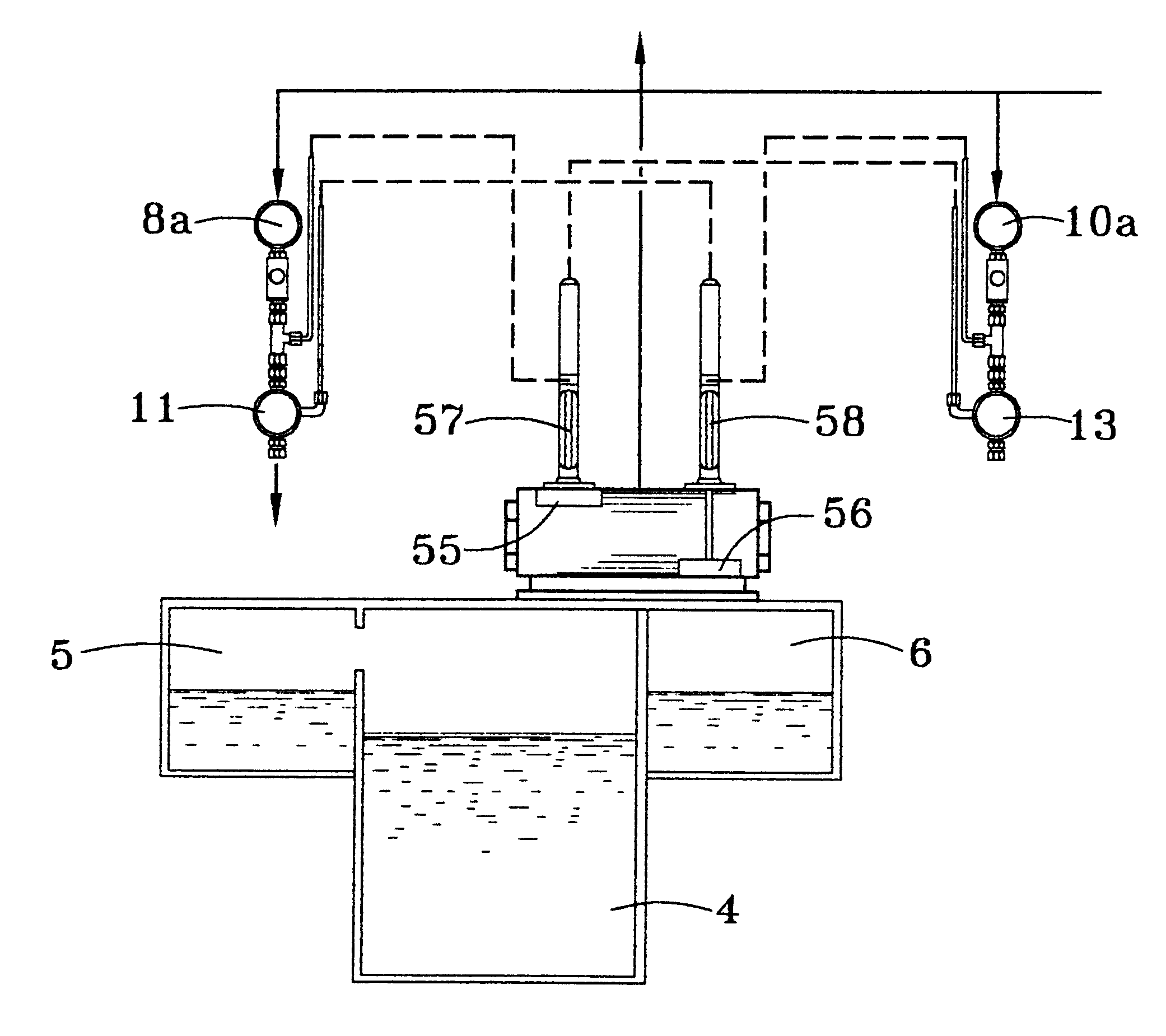

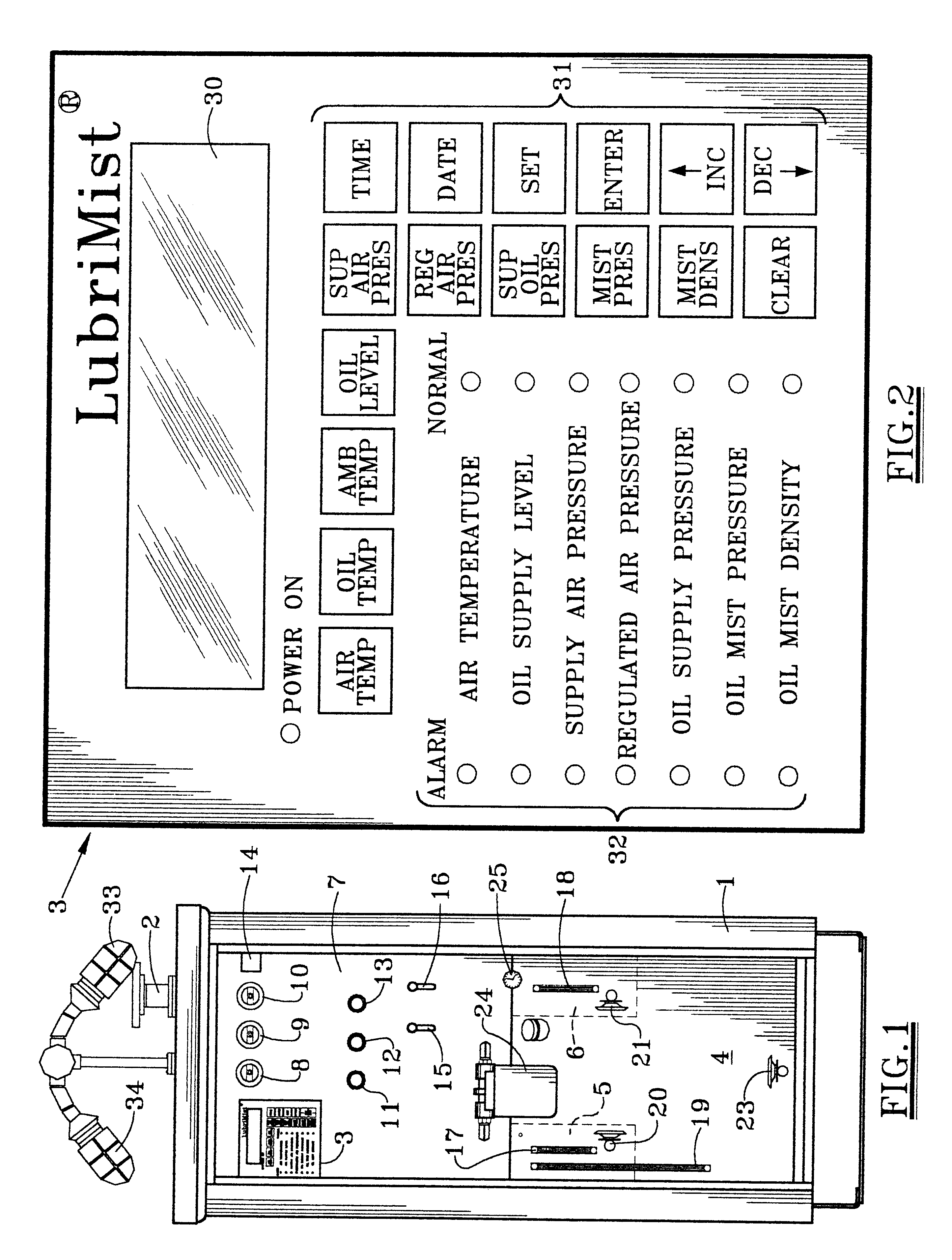

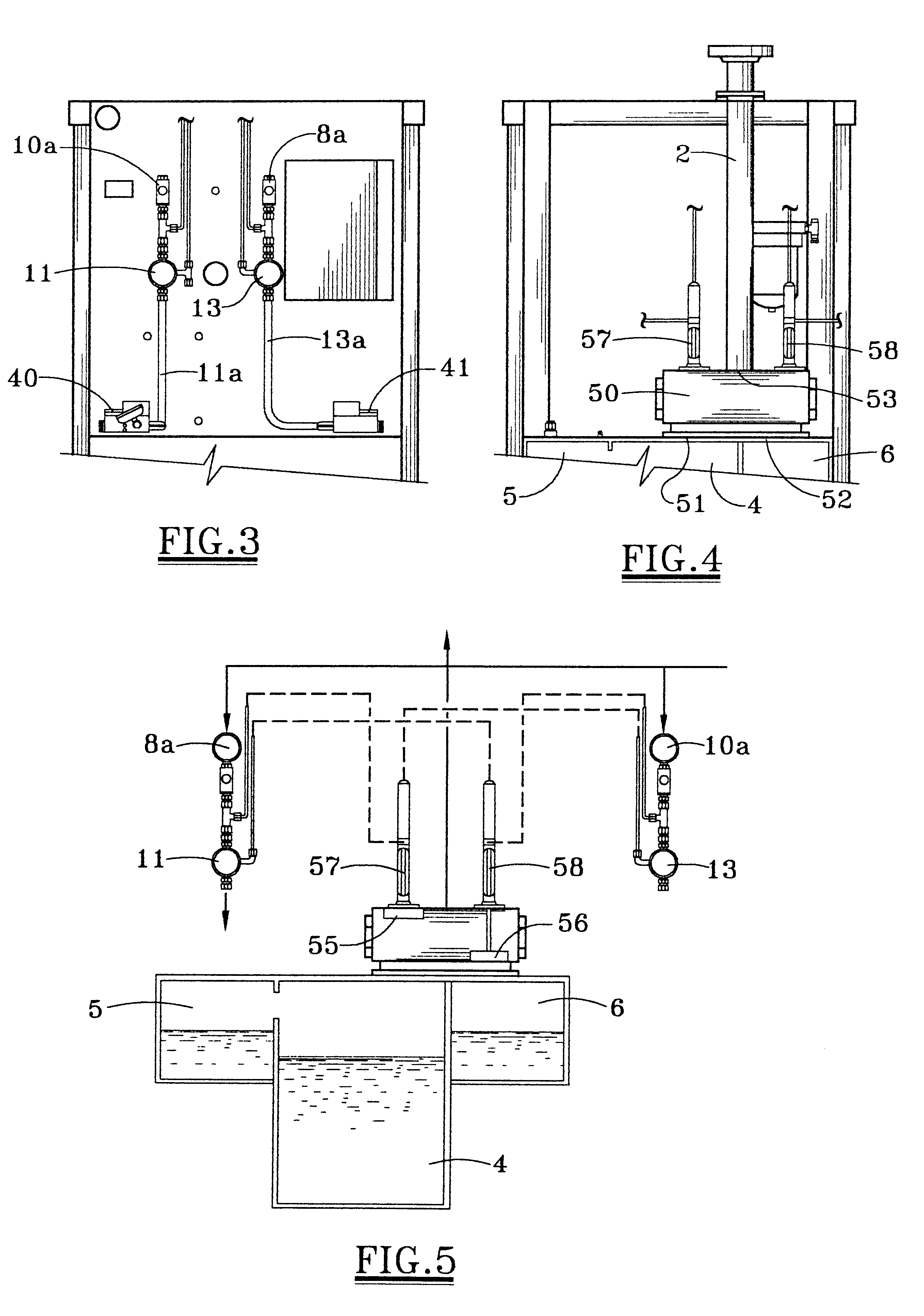

Oil mist generating system

An improved oil mist generating system in which air and oil are supplied to a mist generator in which the air and oil are combined to form oil mist. The system is characterized in that the oil is alternately provided by a main oil reservoir and an auxiliary oil reservoir each of which is provided with a mist generator. Each mist generator is operatively associated with a control device for alternatively activating one of the mist generators while deactivating the other. Also disclosed is an oil mist generator which includes a heater manifold extending into an oil reservoir heating both air and oil prior to entry into a mist head in which the air and oil are combined to form an oil mist. Air and oil are introduced into the mist head through plates which are removable for replacement by plates of different sizes, allowing oil mist capacity to be changed.

Owner:CIRCOR RELIABILITY SERVICES CO

Process for dust removing, cooling and tar oil recovering of pyrolysis coal gas

The invention discloses a process for dust removing, cooling and tar oil recovering of pyrolysis coal gas. The process adopts an overheater, a high-temperature dust remover, an accident quench tower, a waste heat recovering boiler, an indirect cooling device and an electrical tar precipitator which are connected in sequence, and comprises the following steps: pyrolysis coal gas is fed into the overheater to be cooled to 400-700 DEG C, fed into the high-temperature dust remover to be subjected to dust removing, fed into the waste heat recovering boiler to be cooled to 50-100 DEG C and condensed to separate out water and tar oil, fed into the indirect cooling device to be cooled to 10-30 DEG C and further condensed to separate out water and tar oil, and finally fed into the electrical tar precipitator, so that the carried tar oil mist and water mist are recovered. According to the process, dust particles in the coal gas are removed by high-performance dust removing equipment before condensing of tar oil, so as to prevent tar oil and dust separated out through condensation in the coal gas cooling process from being mixed together, improve the quality of tar oil and avoid the problems of equipment blockage and high dust content of tar oil.

Owner:ZHEJIANG UNIV

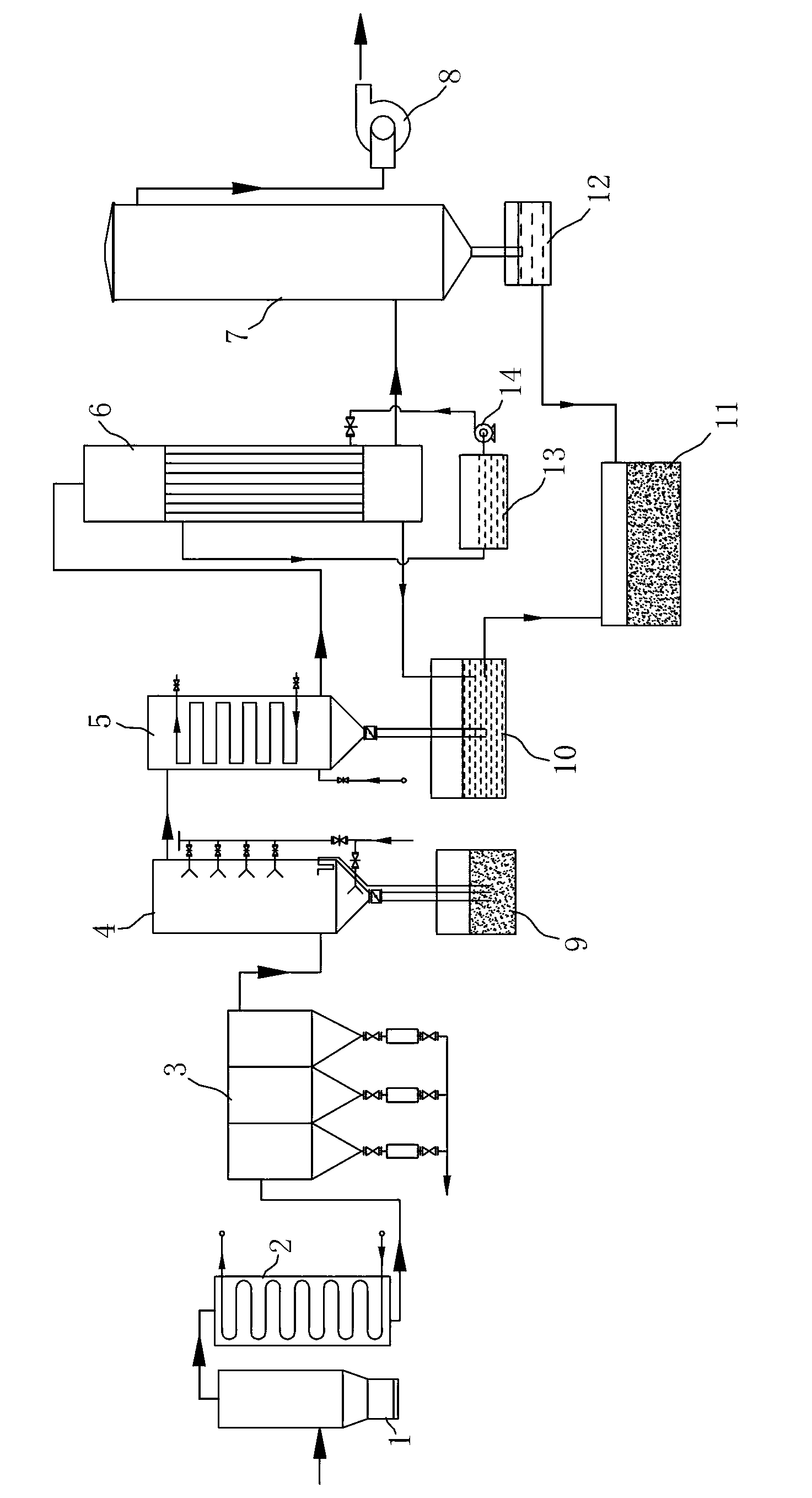

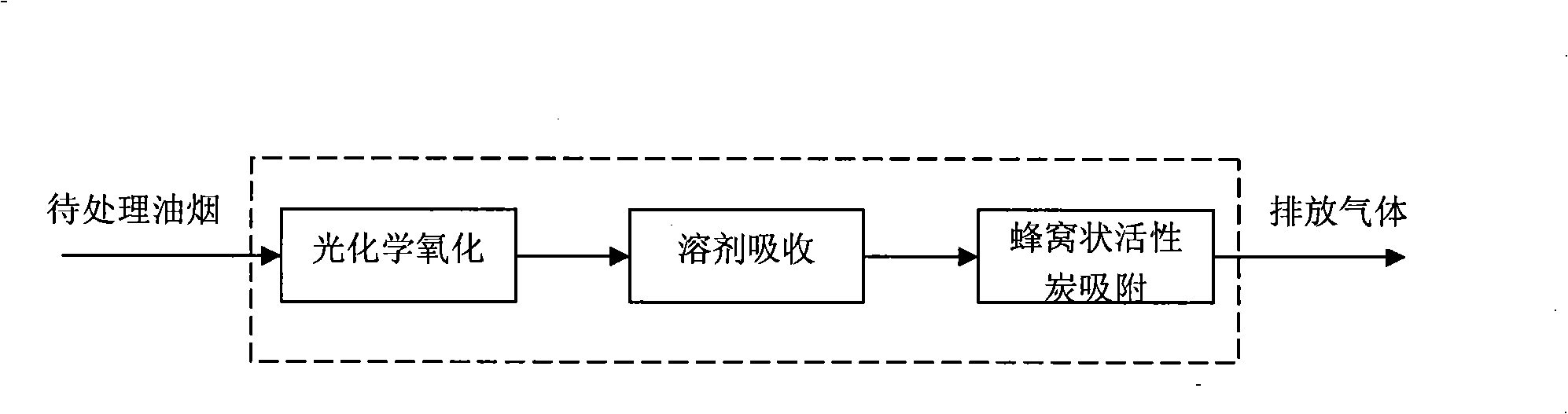

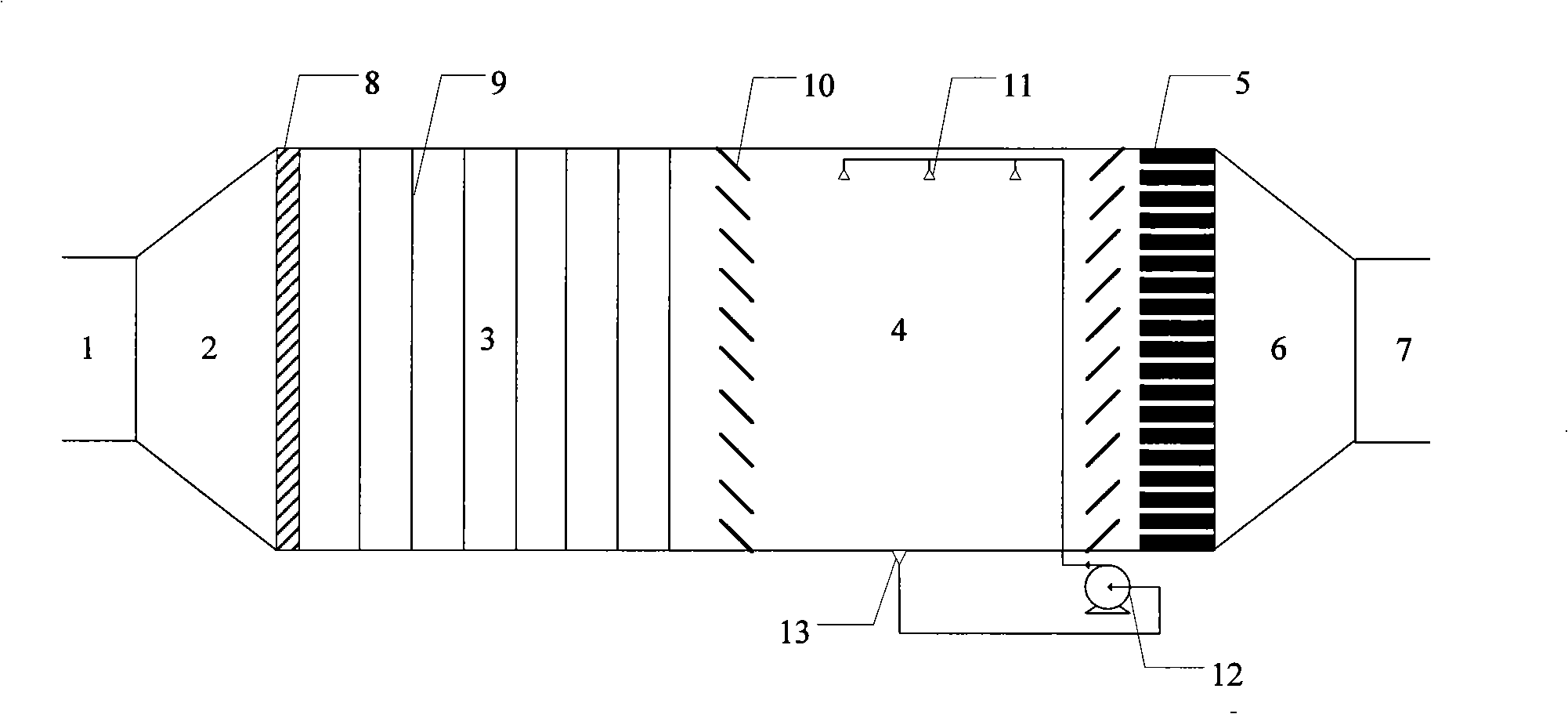

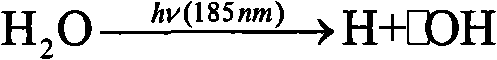

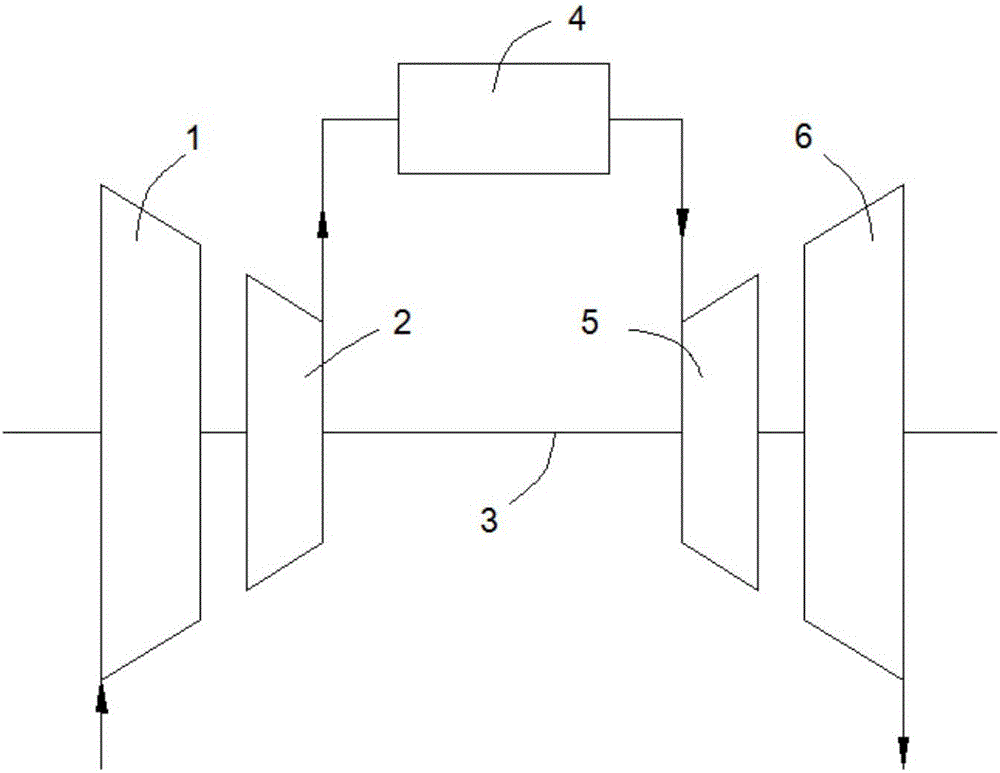

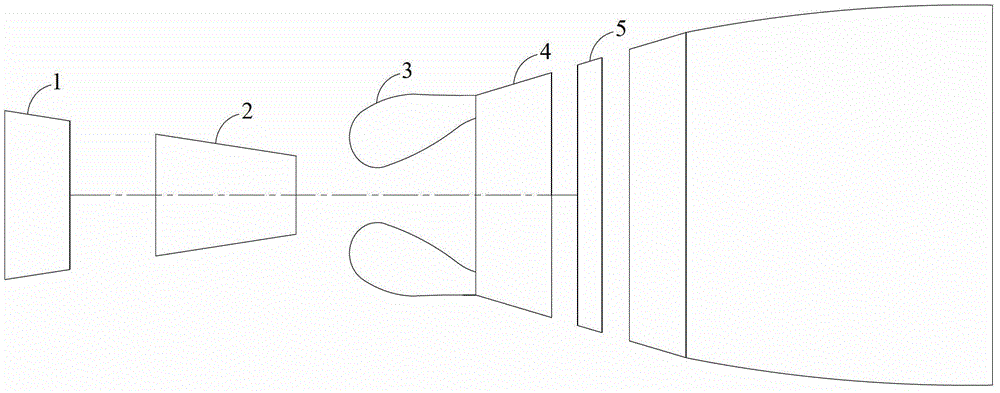

Method and device for removing oil mist and volatile organic matter in oil smoke

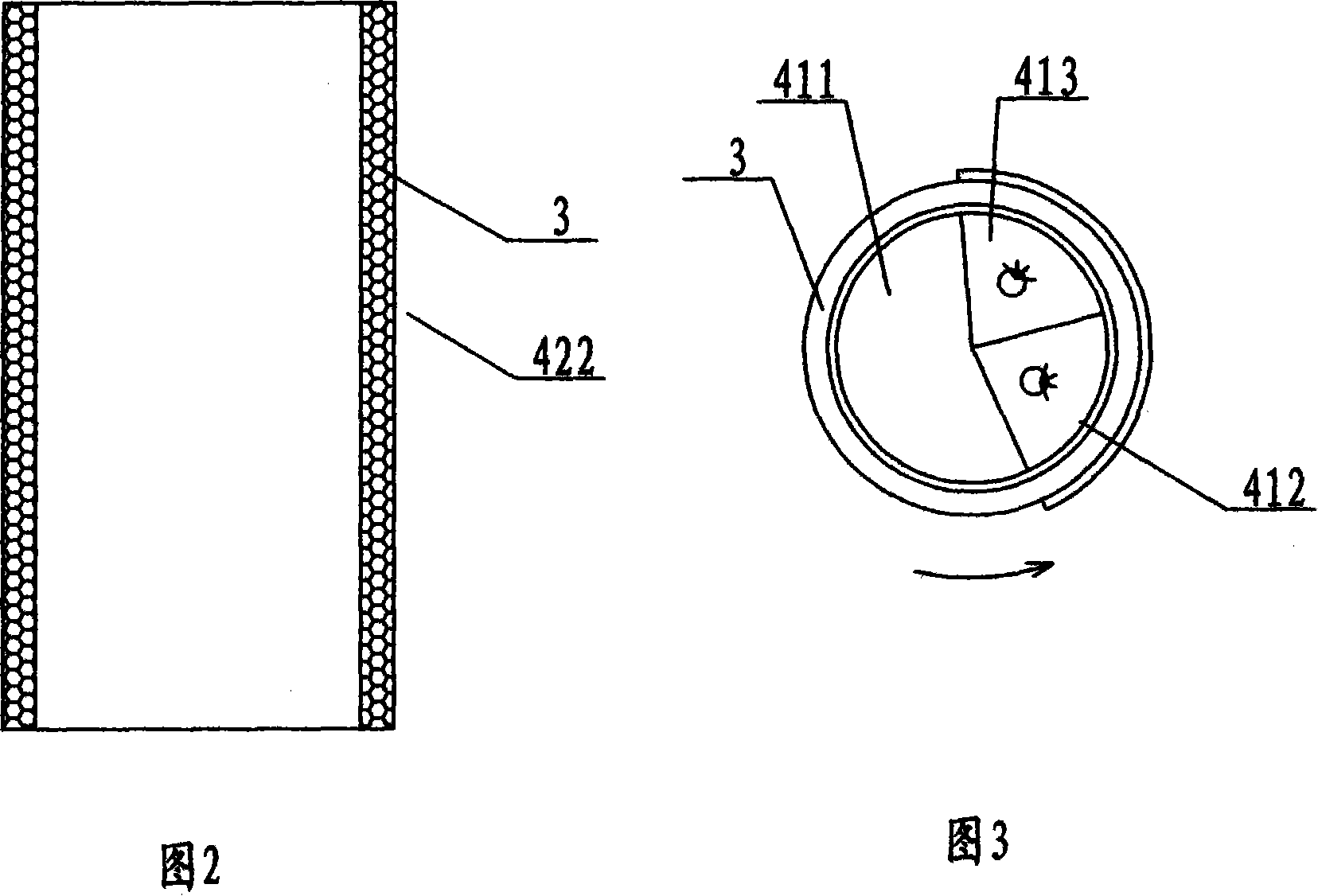

ActiveCN101327400AImprove economyImprove purification efficiencyDispersed particle separationKetoneHoneycomb like

The present invention relates to a method for eliminating the oil mist and the volatile organic matter in the oil smoke and a device thereof, and belongs to the catering oil smoke purification field. The method comprises the steps of ultraviolet photochemical oxidation, wet-method water spraying and honeycomb-shaped active carbon absorption. The main body of the device is a cylindrical container or a prismatic container, and is arranged on an oil smoke exhaustion pipeline, and is provided with an inlet adjusting section 2, a photochemical oxidation section 3, a spraying absorption section 4, a honeycomb-shaped active carbon absorption section 5 and an outlet adjusting section 6, which are arranged in turn. Three steps are matched with each other, thus effectively overcoming the weaknesses that the photochemical oxidation purification produces multiple aldehyde ketone category intermediate products, and produces a great amount of ozone and has low purification efficiency for individual pollutant composition; the oil smoke that is purified with the method of the present invention exceeds the national standard, and is free from influencing the people; the method can be widely used for the catering operation units such as the restaurant, etc. and has low installation and operation expense, and is safe and reliable.

Owner:TSINGHUA UNIV

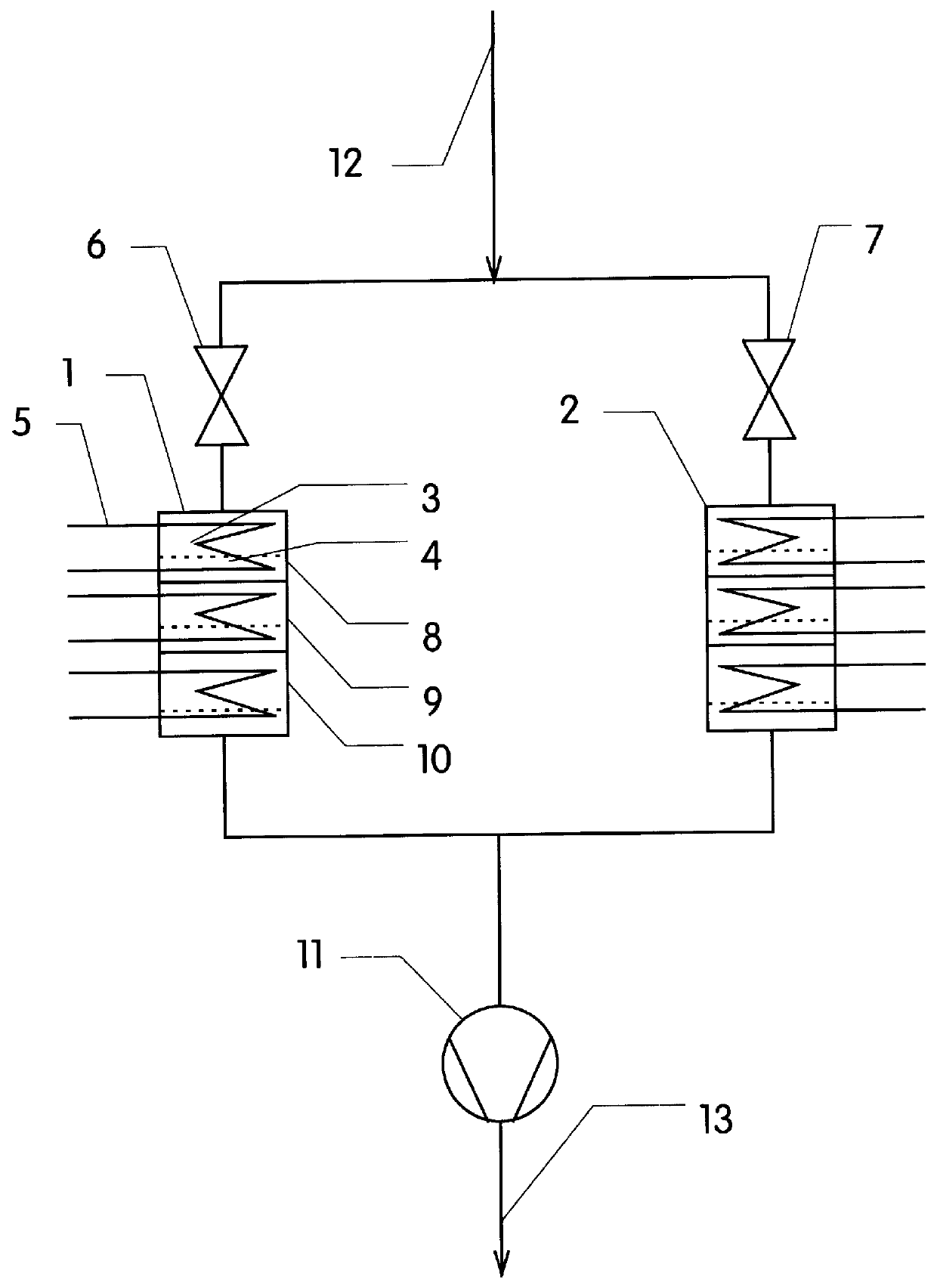

Process for oxidative exhaust gas cleaning

A process is provided for destroying organic contaminants, such as oil mists from workshop rooms, formaldehyde and aromatics, out of exhaust gases by passing the exhaust gas through two reactors connected in a parallel arrangement to a contaminated exhaust gas inlet. Each of the two reactors is equipped with a plurality of serially arranged reaction zones, wherein each reaction zone contains an upstream catalyst (such as a commercial wire knit catalyst); a downstream absorbent (such as Y zeolite or H-ZSM) and a heater. A major portion of the contaminated exhaust gas is passed through one of the two reactors, while, simultaneously, a minor portion of the contaminated exhaust gas is passed through the other reactor. After a period of time, the exhaust gas flow rate through the two reactors is reversed so that a major portion of the exhaust gas now flows through the reactor that previously had a minor portion of the exhaust gas flowing through it and a minor portion of the exhaust gas now flows through the reactor that previously had a major portion of the exhaust gas flowing through it, so that the process is cyclical in this manner. When a major portion of the exhaust gas flows through a reactor, the hydrocarbon contaminants are sorbed into the absorbent. When a minor portion of the exhaust gas flows through a reactor, the reactor is heated to the catalyst light-off temperature so that the contaminants within the exhaust gas and the contaminants released from the absorbent are catalytically destroyed in a downstream catalyst in an adjacent downstream reaction zone.

Owner:JENOPTIK KATASORB

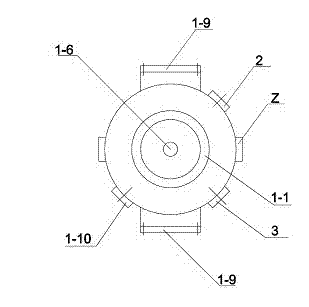

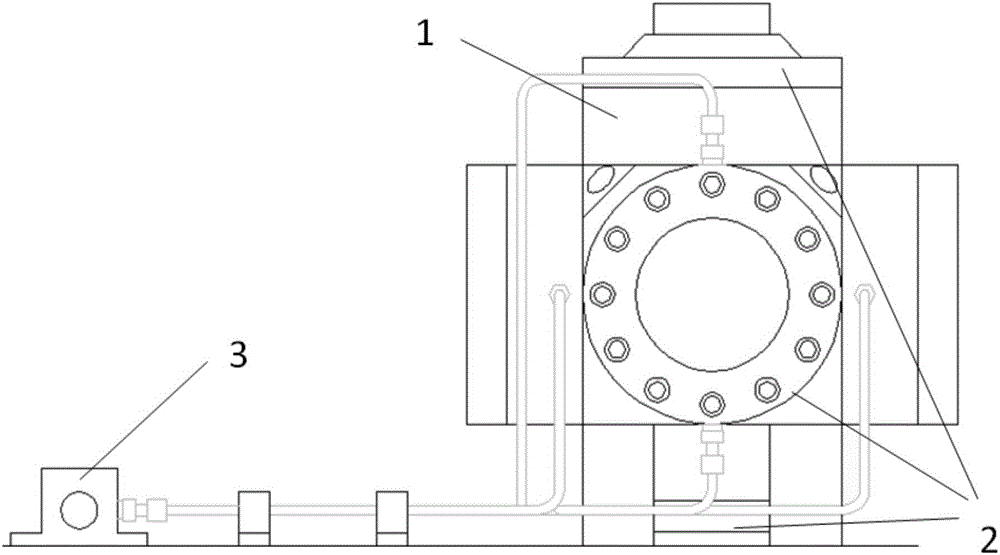

Functional spraying and combustion visualization measuring constant volume bomb

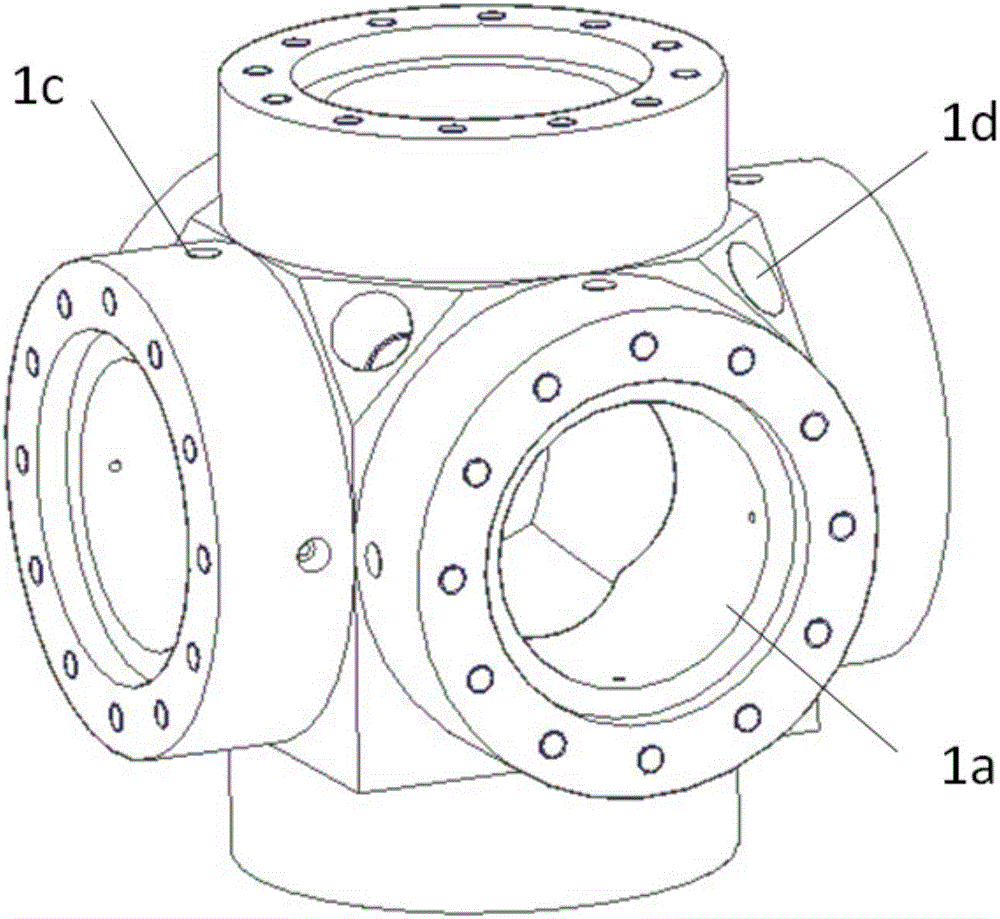

ActiveCN106441912AMeet the design requirementsCompact structureInternal-combustion engine testingEvaporationInlet pressure

The invention provides a functional spraying and combustion visualization measuring constant volume bomb. The constant volume bomb includes a bomb body and 6 windows provided on the bomb body. The axes of all windows intersect at the center of the constant volume bomb so as to form a measurement region. The windows can be provided with adaptive covers having different functions. The constant volume bomb is designed to have multiple sealing, such that the constant volume bomb can withstand extreme pressure and temperature loads, and the large range of warm pressing can be adjusted. The constant volume bomb is designed to have adaptors which ensure the constant volume bomb can use various types of sensors. The bomb body is provided with a plurality of air inlet guide holes thereon, which can ensure stabilization of air inlet pressure and keep the measurement region unaffected, and also keep quartz windows from being polluted by oil mist and combustion products, thus achieving on-going measurement. According to the invention, the constant volume bomb can provide flexible light path arrangement for one or a group of multiple measurement technologies of shadow / schlieren, laser induced flourescense, particle imaging velocity measurement and spectrum temperature measurement, etc. The constant volume bomb has tight structure, can research spray atomization, evaporation, air blending, gas mixture distribution, combustion and process product characteristics, etc, has a wide range of measurement parameters, and has universality.

Owner:HARBIN ENG UNIV

Low oil mist gear grinding oil composition

ActiveCN101701163AHigh viscosity indexExcellent antioxidant stabilityAdditivesBase-materialsGear grindingEcological environment

The invention discloses a low oil mist gear grinding oil composition, belonging to the field of metalworking liquid. The composition according to the invention is composed of the following components by weight percent: 70-81% of refined mineral oil, 10-20% of synthesized fatty acid ester oiliness agent, 5-10% of sulfulrized fatty acid ester, 0-3% of phosphate, 0.3-1.0% of oil mist inhibitor and 0.01-0.1% of antifoaming agent; in the composition, the polymer of oil mist inhibitor is innovatively introduced by means of the coordinate proportioning of the refined mineral oil and the fatty acid ester oiliness agent as main component, thus enhancing lubricity, quickening the sedimentation of the oil mist and effectively reducing the concentration of the oil mist in the operating environment, and in addition, lubricating agent and anti-abrasive agent are scientifically proportioned and used, so the composition contains no chlorine which does harm to ecological environment and human body, has strong universality, can be used for processing black and non-ferrous metals and is non-corrosive to copper, therefore, the composition according to the invention not only imparts excellent processing performance to gear grinding oil, but also effectually improves oil mist environment, which is favorable for environmental protection and body health of operating staff.

Owner:BOER TECH WUHAN

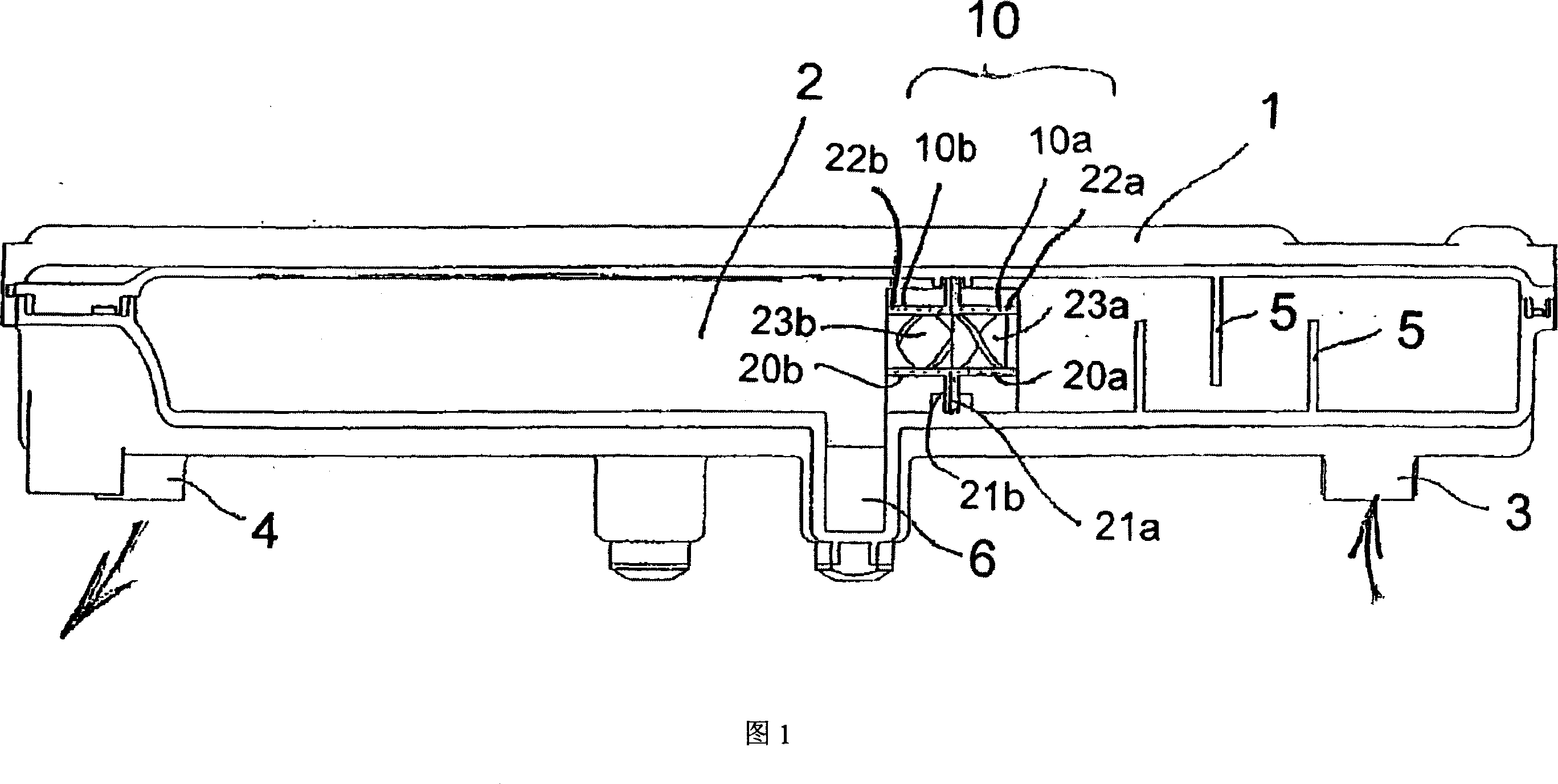

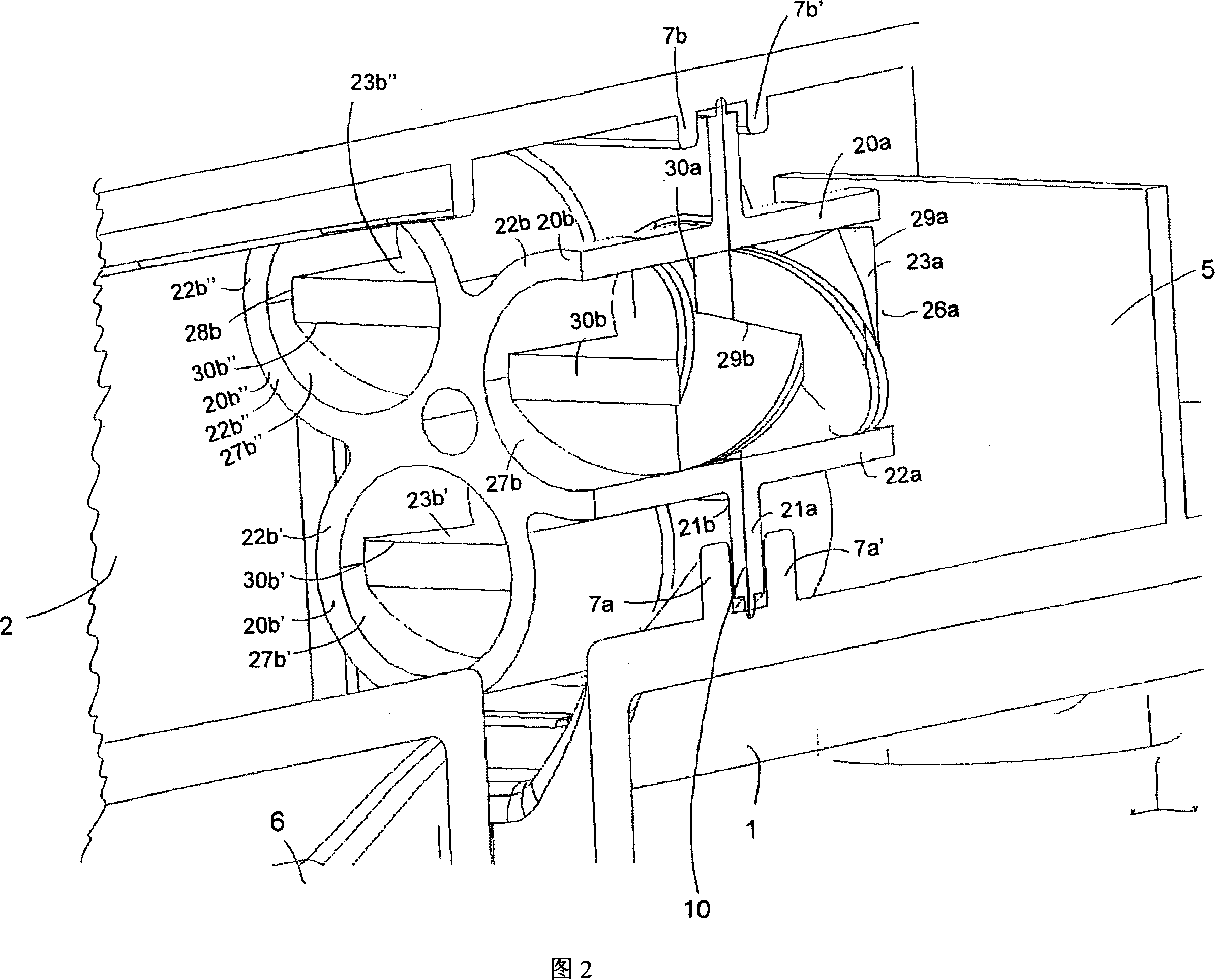

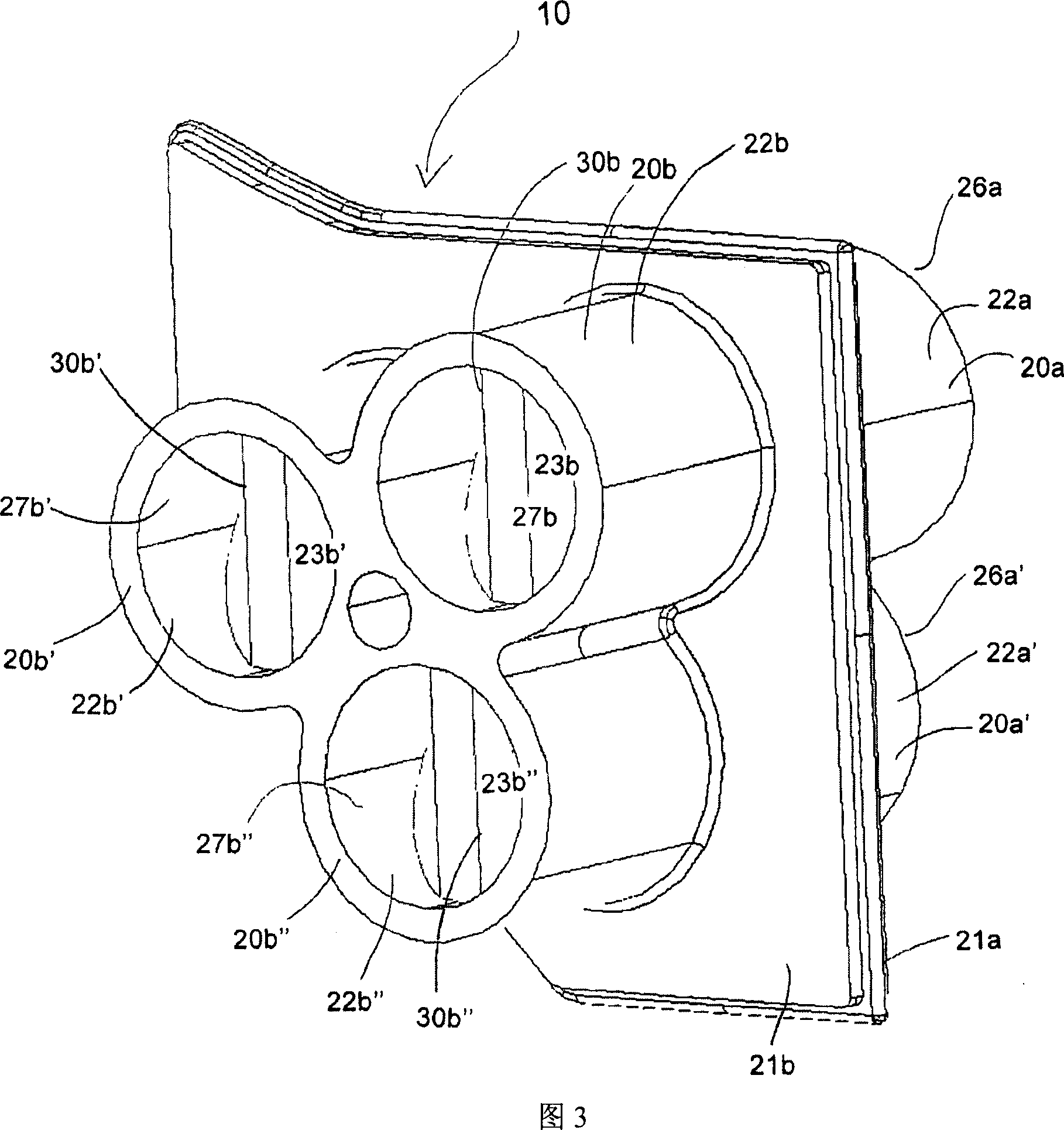

A fluid separation device

InactiveCN1925902AEasy to modularizeReduce in quantityFuel cell auxillariesDispersed particle separationEngineeringSpiral flow

The present invention relates to a fluid separation device (10) for separating fluid, oil and oil spray from a gas. This fluid separation device (10) comprises a base carrier (21) in which fluid separator elements (20) in the form of flow-through tubes with worm-like segments (23) arranged therein, are integrated. The worm-like segments (23) at the same time form spiral flow paths (25) for the gas. They have a maximal length of half a pitch of the worm-like segment (23) so that the base carrier (21) together with the associated fluid separator elements (20) may be formed as one piece. Several base carriers may be arranged one after the other in a manner such that individual fluid separator elements of various base carriers form a common flow path for the gas.

Owner:REINZ DICHTUNGS

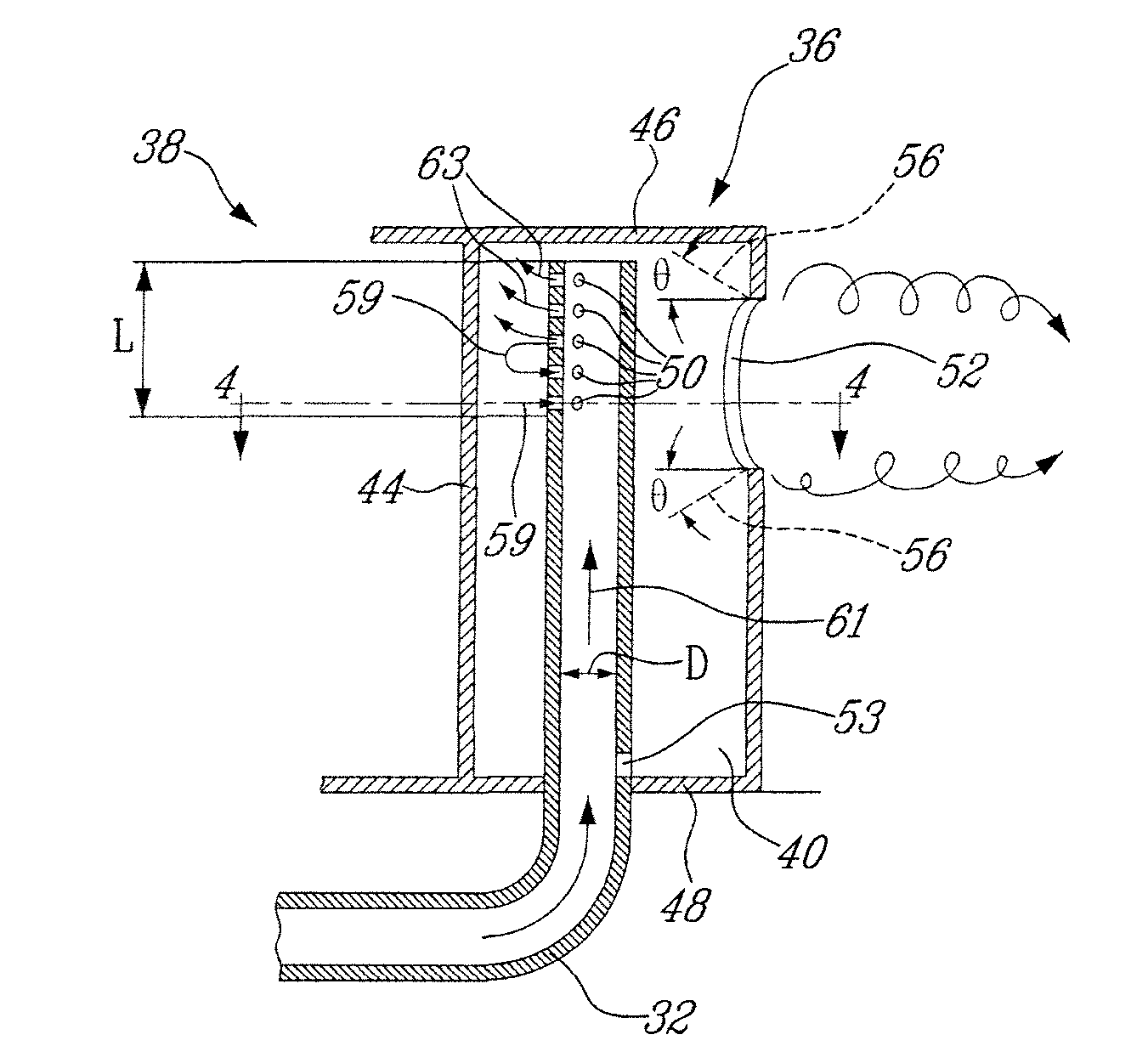

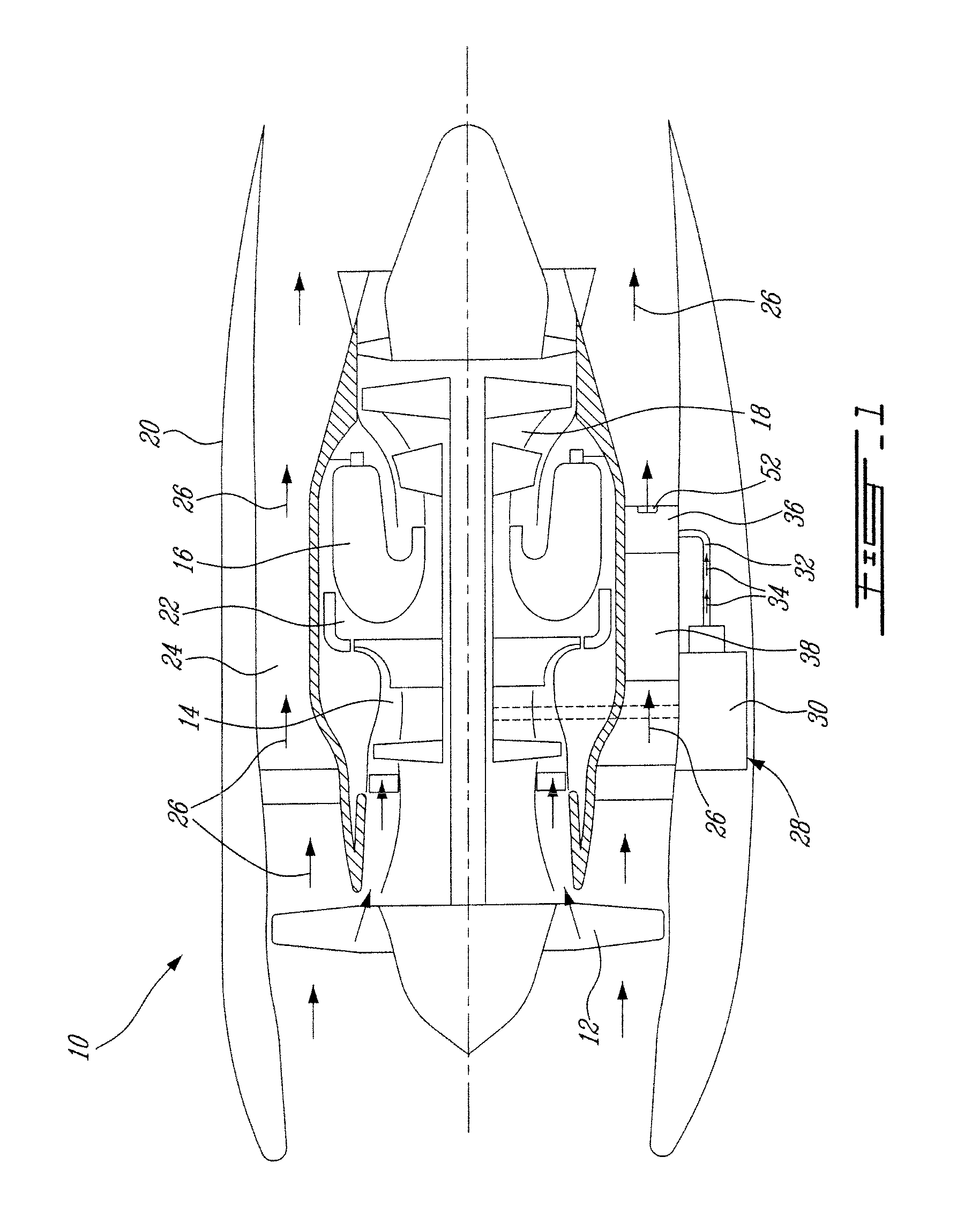

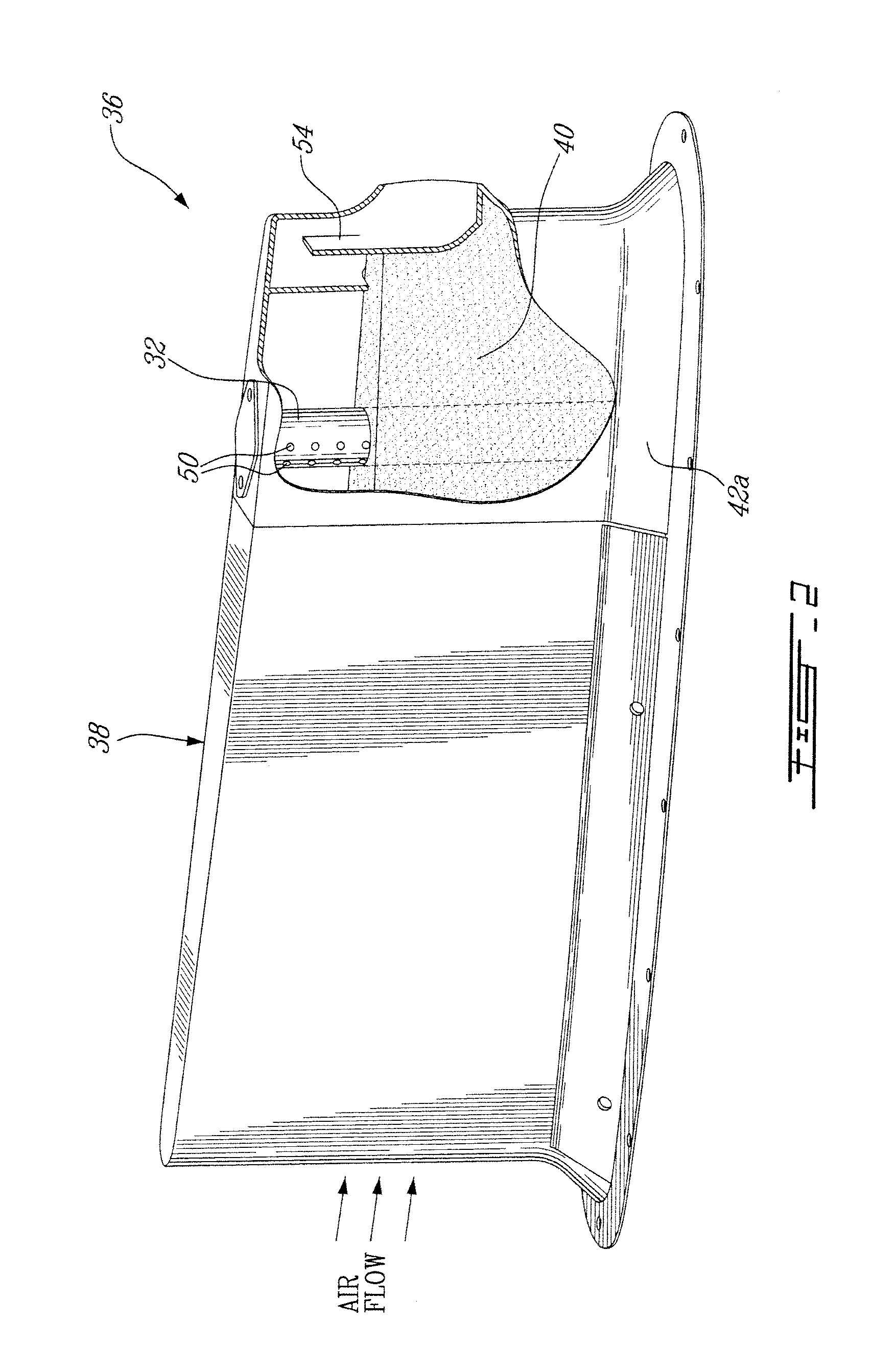

Gas turbine engine breather exhaust oil collector

A gas turbine engine oil system has an air-oil separator for removing air from an air / oil mixture. A breather tube is connected to an exhaust of the air-oil separator for receiving hot air removed from the air / oil mixture in the air-oil separator. The gas turbine engine oil separator exhaust is directed in a cooled oil collector to cause the oil mist remaining in the air at the exit from the engine air-oil separator to condensate. The oil condensate is returned back into the engine oil system.

Owner:PRATT & WHITNEY CANADA CORP

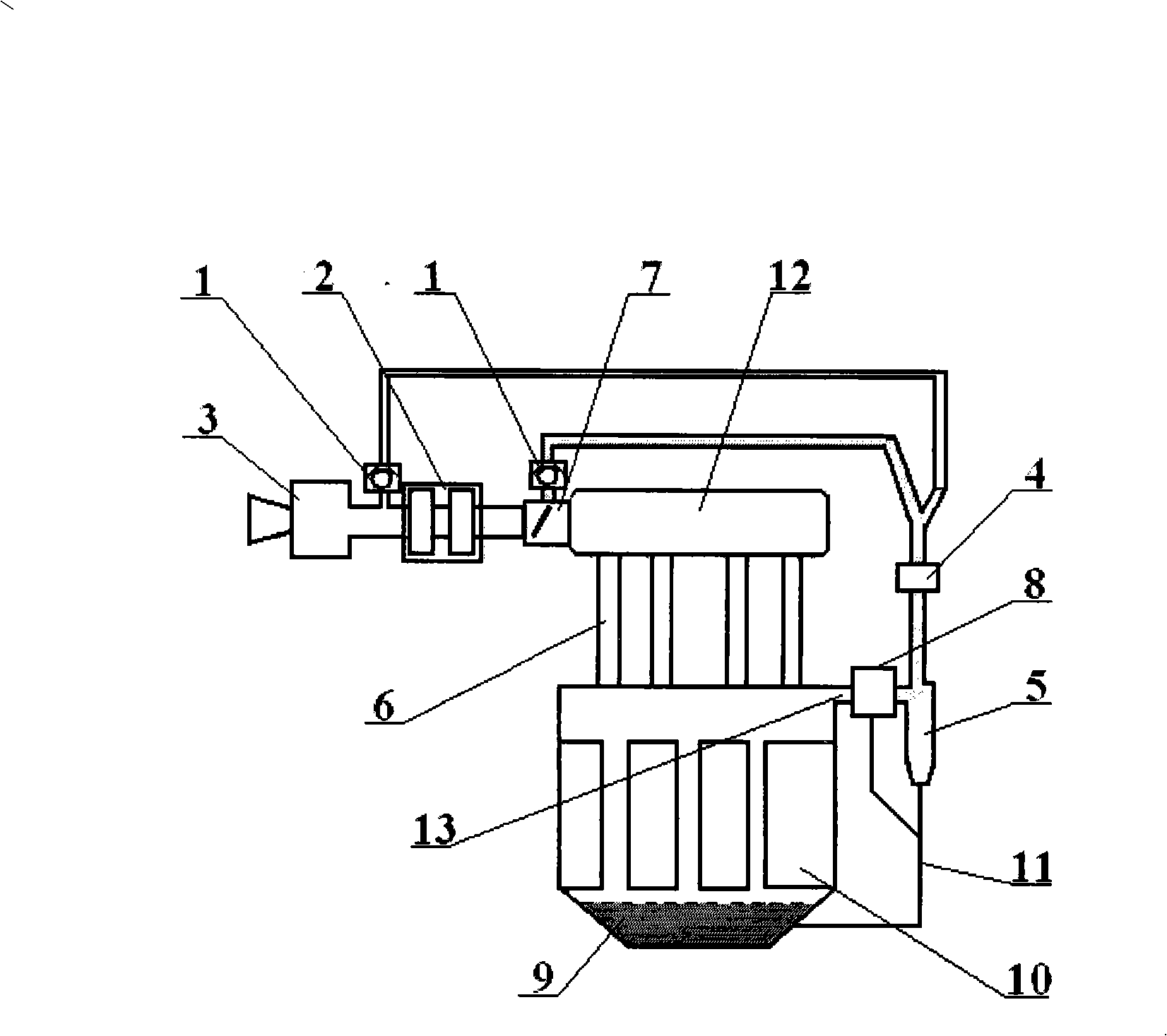

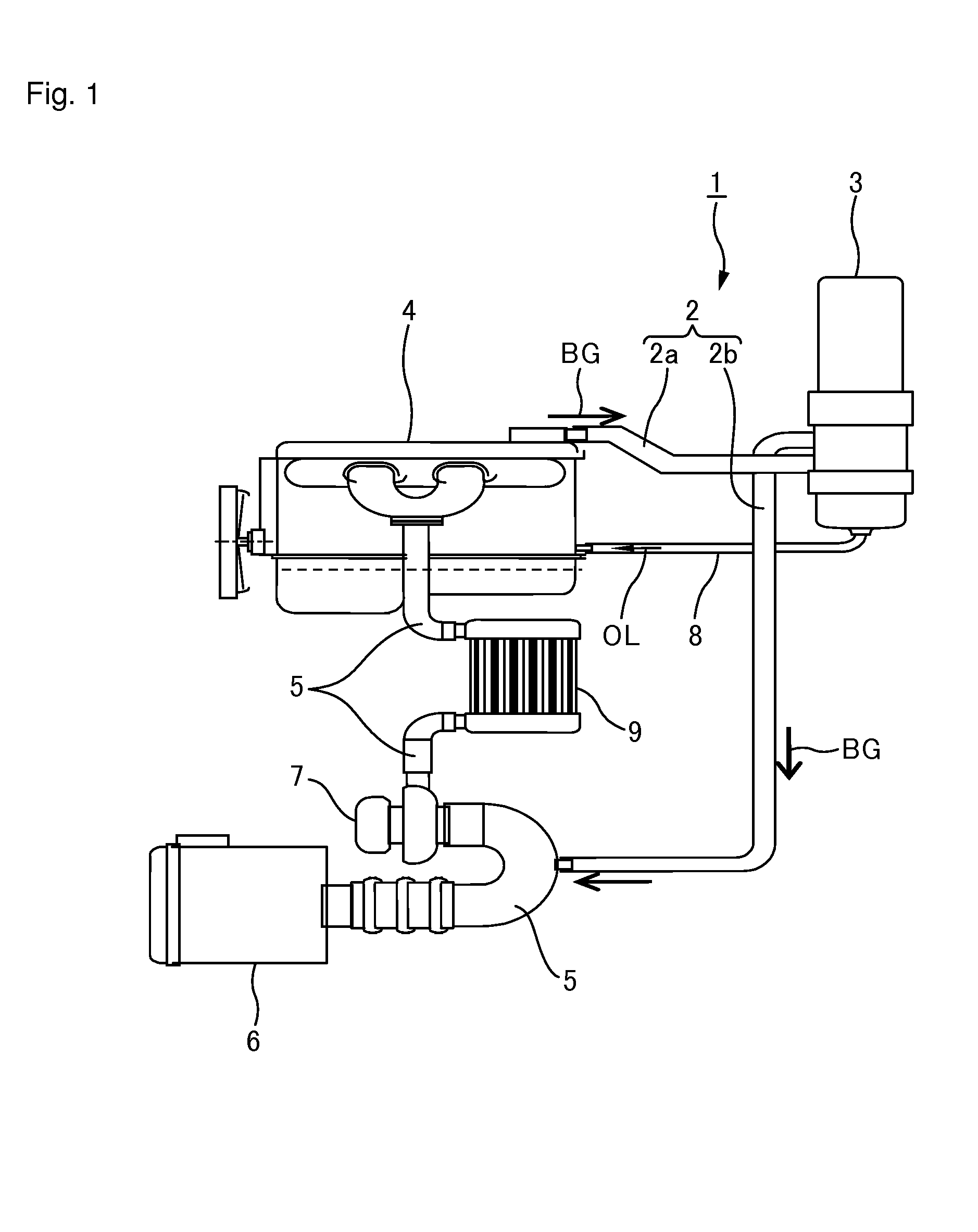

Engine crankcase oil gas separation system and its oil gas separation method

InactiveCN101260819AIncrease liquid contentImprove separator effectMachines/enginesCrankcase ventillationLiquid stateIntercooler

The invention discloses an oil-gas separating system of an engine crankcase, which is arranged in a ventilation system of the engine crankcase and comprises an oil-gas separator (5) connected with an oil-gas outlet (13) of a crankcase; a gas outlet of the oil-gas separator (5) is communicated with a pipeline in a gas inlet end of a gas inlet main pipe (12); an intercooler (8) is arranged on a pipeline connected with the oil-gas outlet (13) of the crankcase and the oil-gas separator (5). The technical proposal is adopted on the basis of the ventilation system of the crankcase, the middle cooling part is arranged for cooling high-temperature mixed oil gas from the crankcase. With the temperature dropping, oil in the high-temperature mixed oil gas is changed from a gaseous state to a liquid state, thereby improving liquid content of the mixed oil gas. Part of the oil gas can be directly condensed and separated in the intercooler; liquid oil mist can be separated in the later oil-gas separation to improve the effect of the oil-gas separator.

Owner:CHERY AUTOMOBILE CO LTD

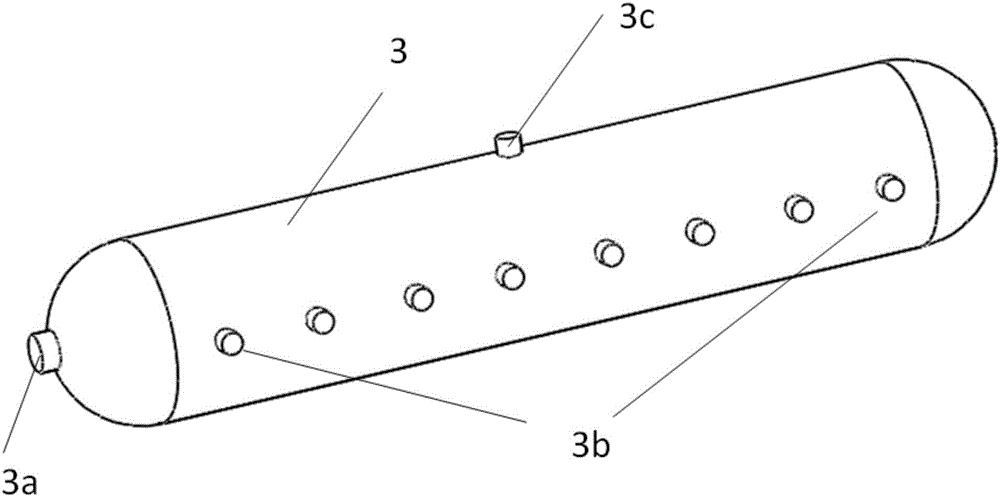

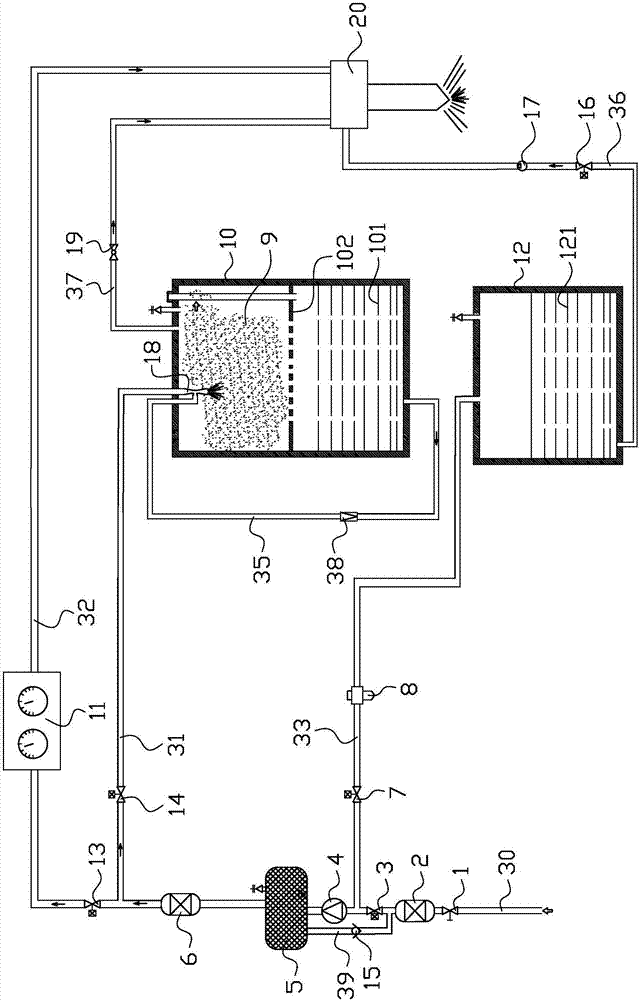

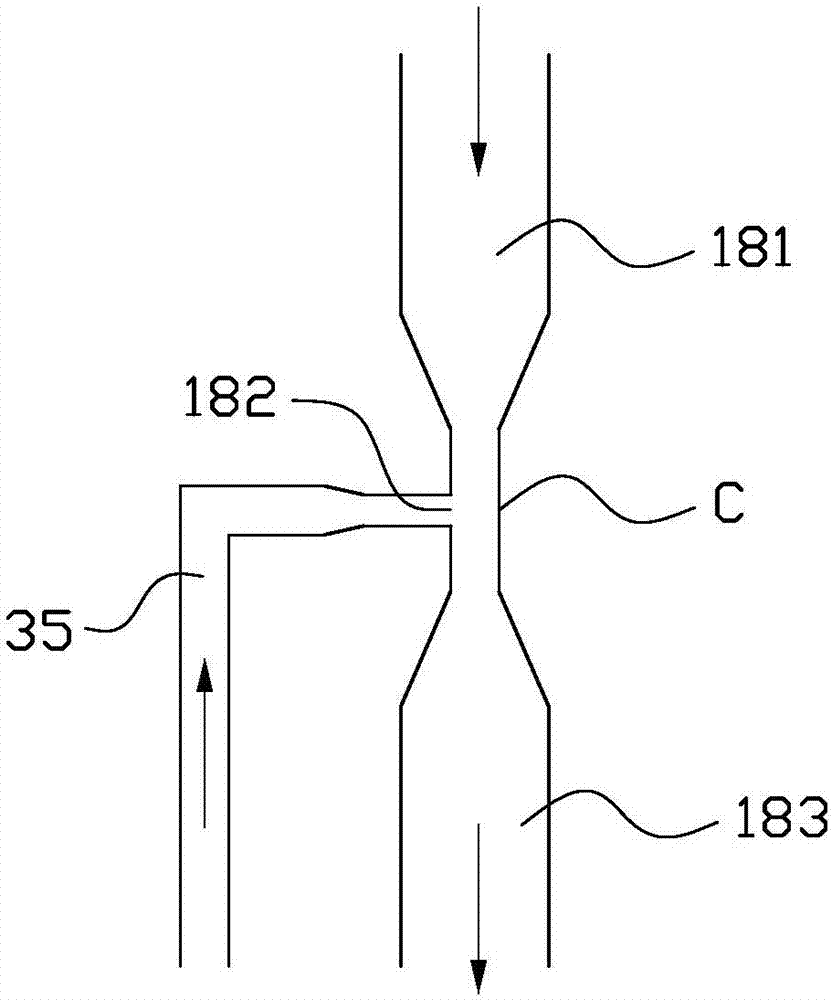

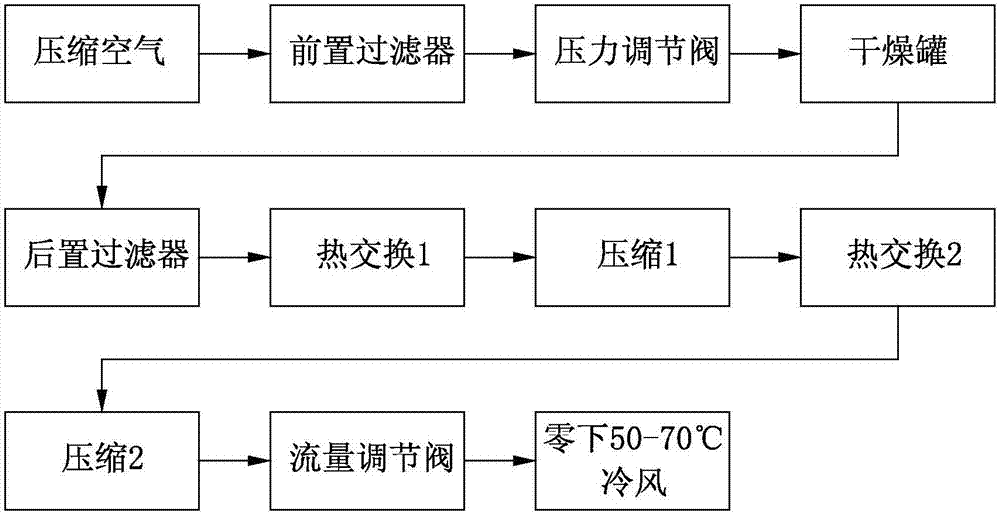

Low temperature water mist and oil mist cutting cooling lubrication supply system

ActiveCN106863002AImprove permeabilityExtend your lifeMaintainance and safety accessoriesAviationSprayer

The invention discloses a low temperature water mist and oil mist cutting cooling lubrication supply system. A Venturi atomization sprayer is arranged at the upper portion of an inner cavity of an atomization chamber, an air inlet of the Venturi atomization sprayer is connected to the outlet end of an air tank through a first air conveying pipe, an eddy atomization sprayer comprises an eddy pipe and an oil-water mixing sprayer, the eddy pipe is connected to the outlet end of the air tank through a second air conveying pipe, and a compression refrigerator is arranged on the second air conveying pipe; the oil-water mixing sprayer is connected with the water tank through a water pipe, and is connected with the atomization chamber through an oil mist conveying pipe; and cold air refrigerated through the compression refrigerator and the eddy pipe is mixed with oil mist coming from the atomization chamber and water coming from the water tank at the position of the oil-water mixing sprayer. By means of the system, advantages of low-temperature cold air and composite spraying mist are combined, and therefore when a cutter is used for machining difficultly-machined materials such as the titanium alloy, the high-temperature alloy and the aviation composite material, the cutting temperature is rapidly decreased, the machining process is more efficient, and the service life of the cutter is prolonged.

Owner:DG ARMORINE ENERGY EFFICIENT & ECO FRIENDLY TECH

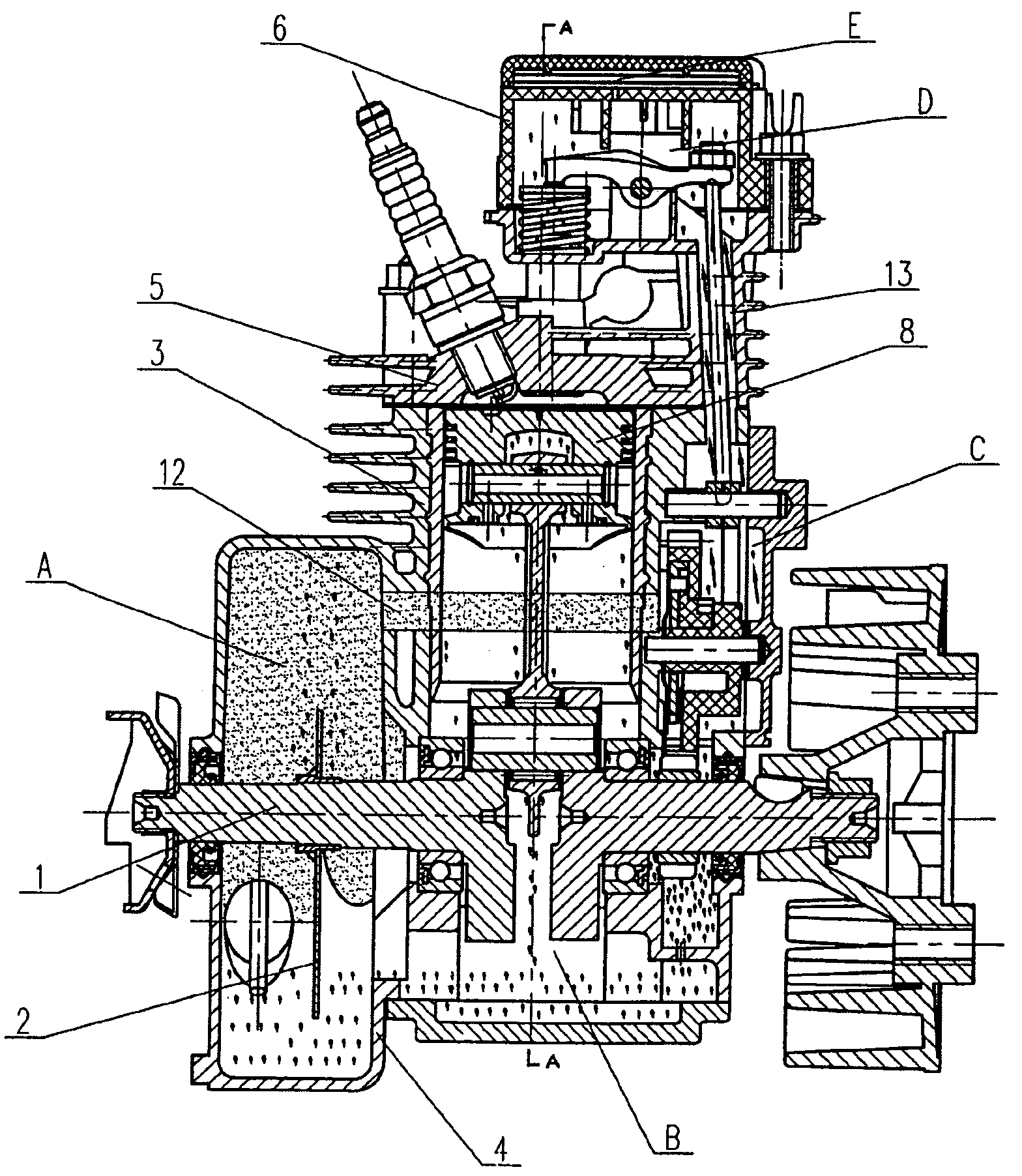

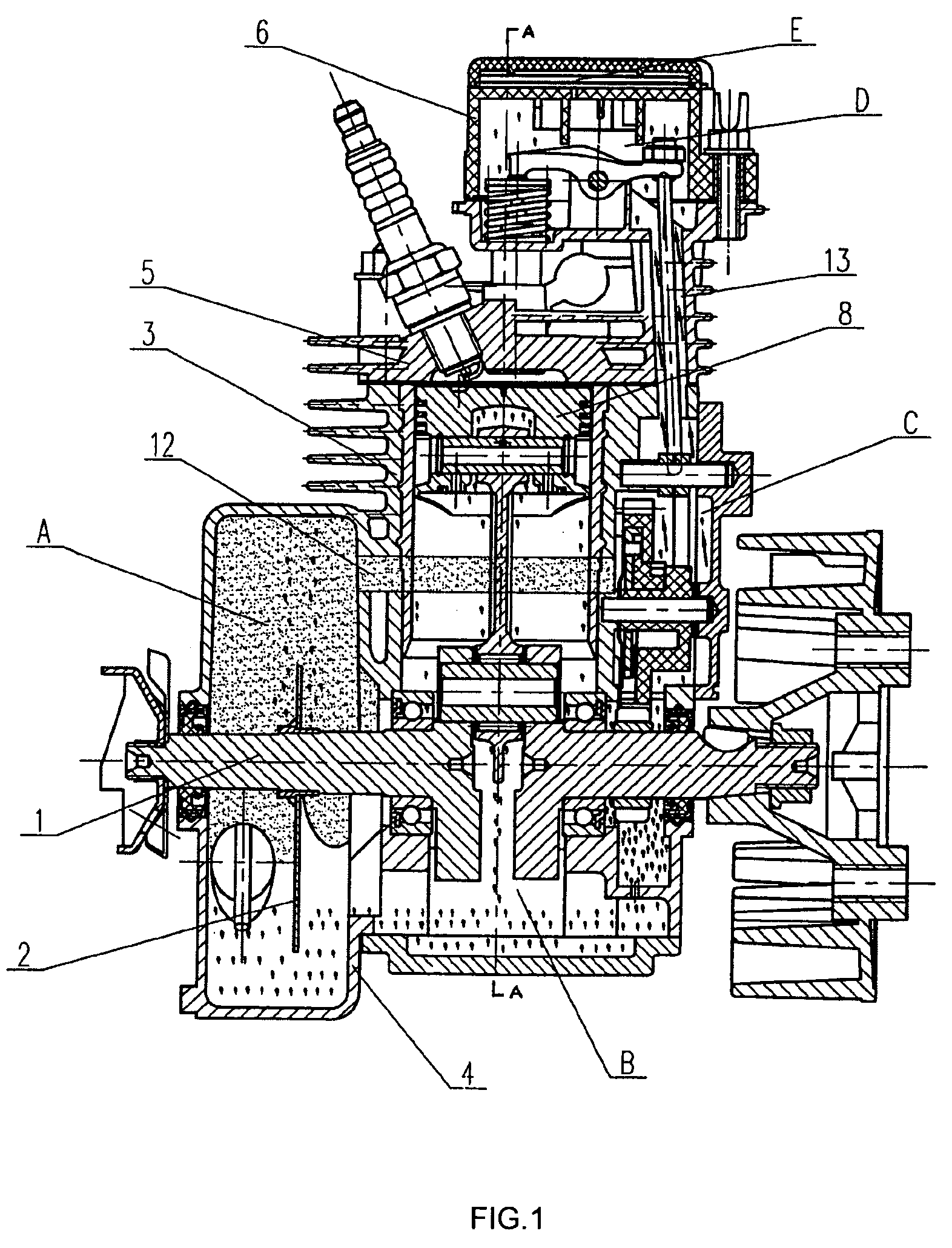

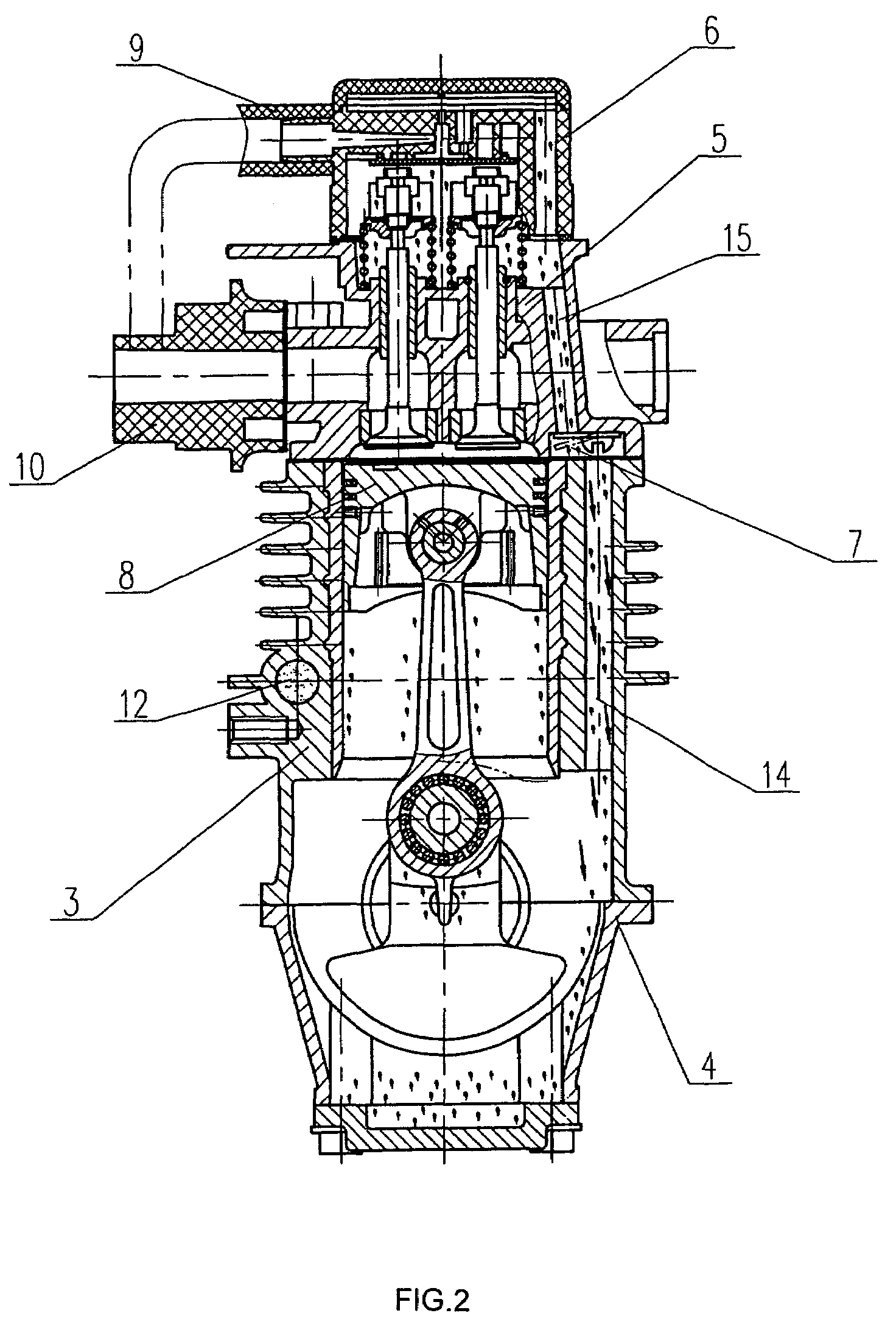

Small four-stroke gasoline engine with oil mist lubrication

InactiveUS7243632B2Easy constructionImprove mobilityLubrication of auxillariesDrip or splash lubricationImpellerReciprocating motion

The present invention relates to a small four-stroke gasoline engine with oil mist lubrication. The lubrication oil way of the engine includes a crankshaft chamber B, a camshaft chamber C, an upper rocker arm chamber D and a condensation chamber E. The camshaft chamber C communicates with the upper rocker arm chamber D via a tappet cavity 13. The upper rocker arm chamber D communicates with the condensation chamber E. An oil mist chamber A is surrounded by an upper case body 3 and a lower case body 4 at the side of the crankshaft chamber B, the bottom of the oil mist chamber A communicates with the crankshaft chamber B. An oilsplash impeller 2 is fixed on a crankshaft, which extends into the oil mist chamber A. An oil way 12 is provided on the upper case body 3 between the oil mist chamber A and the camshaft chamber C. An oil return way 15 is provided on a cylinder head assembly 5. An oil return way 14 is provided on the upper case body 3. An upper interface of the oil return way 15 communicates with the upper rocker arm chamber D, a lower interface of the oil return way 15 communicates with the oil return way 14, and a lower interface of the oil return way 14 communicates with the crankshaft chamber B. The conventional lubricating mode is changed by the structure of the invention, which makes use of the pressure change during the reciprocating movement of a piston assembly 8 to attain the circulation of oil. The structure is simple, reliable in operation and has small consumption in power.

Owner:HU JI RONG NO

Adaptive oil separator

InactiveUS20080105494A1Improve control characteristicsEasy to separateCombustion enginesCrankcase ventillationEngineeringPressure difference

An oil mist separator has a pressure regulator valve which is located in the blow-by line downstream of the oil mist separator element in the flow direction of the gas. The pressure regulator valve has a bias so that it opens above a specified pressure difference between the blow-by line and a neighboring chamber. Located around the oil mist separator element is a bypass line which has a bypass valve. The bypass valve has a bias that causes the bypass valve to close below a specified pressure difference between the suction side and the pressure side of the oil mist separation element. The pressure regulator valve and the bypass valve are connected with each other so that the pressure regulator valve, as it closes, increases the bias of the bypass valve.

Owner:DANA AUTOMOTIVE SYST GRP LLC

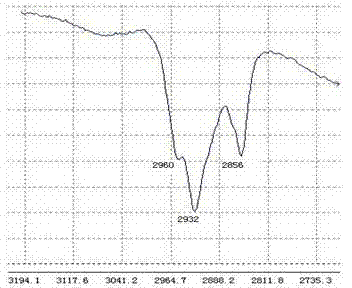

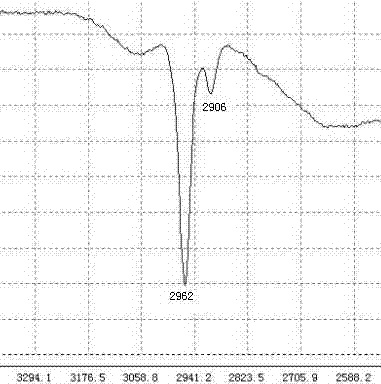

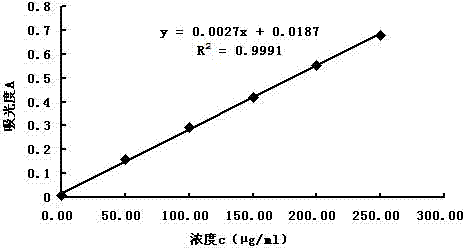

Method for determination of concentration of mineral oil mist in workshop air

InactiveCN102854167AReduce distractionsSmall precisionColor/spectral properties measurementsInfrared SpectrophotometryGlass fiber

The invention provides a method for determination of a concentration of mineral oil mist in workshop air. The method comprises the following steps of collecting an oil mist sample form air by an ultrafine glass fiber membrane, carrying out extraction by 10mL of CCl4, directly carrying out detection by an infrared spectrophotometer by scanning in a range of 2700 to 3200cm<-1> to obtain the maximum absorption peak as a sample measurement wave number, and subtracting the absorbance at the wavelength of 3200cm<-1> from the absorbance of the maximum absorption peak to quantify a concentration of mineral oil mist in the oil mist sample. The method is accurate and fast, produces a small interference, has high sensitivity, precision less than 10%, accuracy less than 10% and a detection limit of 2.0 microgrammes per milliliter, and satisfies detection and research requirements. The method provided by the invention fills in the blank of infrared spectrophotometry-based determination of mineral oil mist in workshop air.

Owner:浙江中一检测研究院股份有限公司

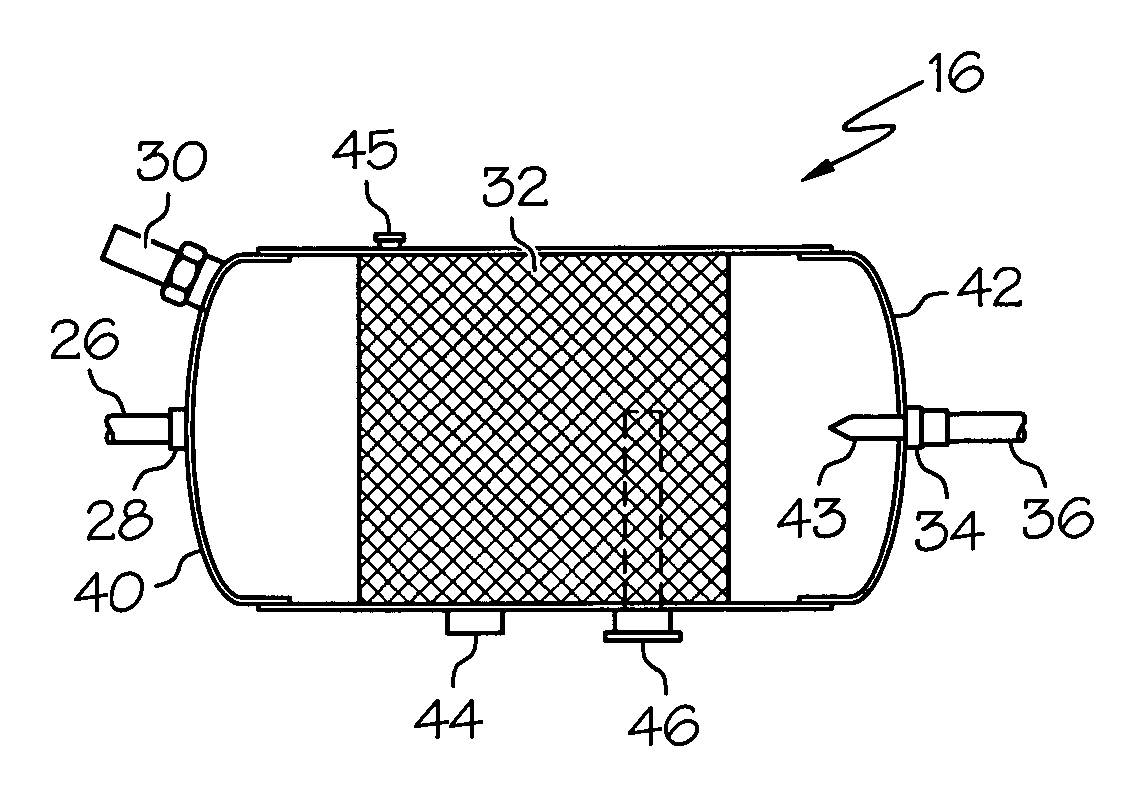

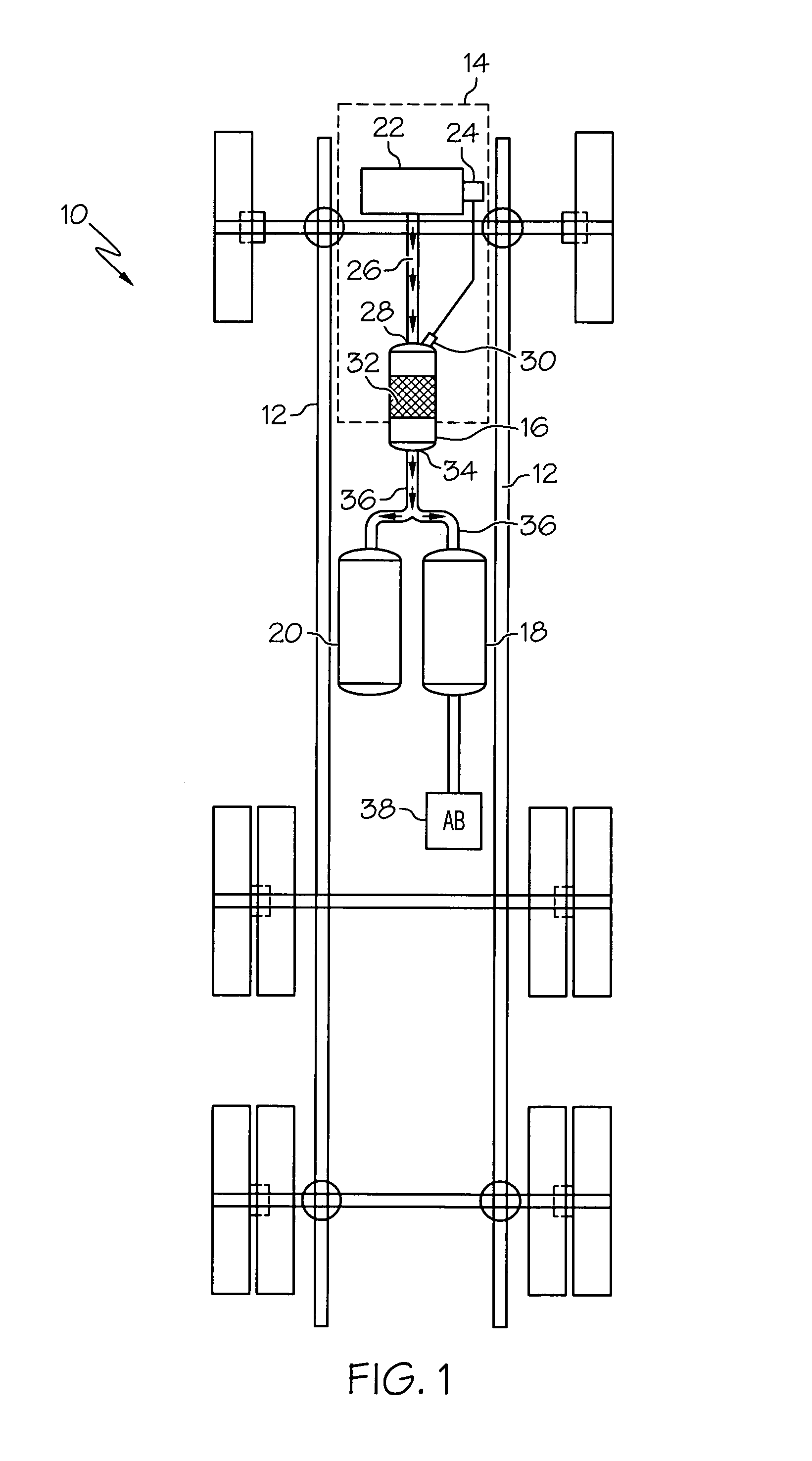

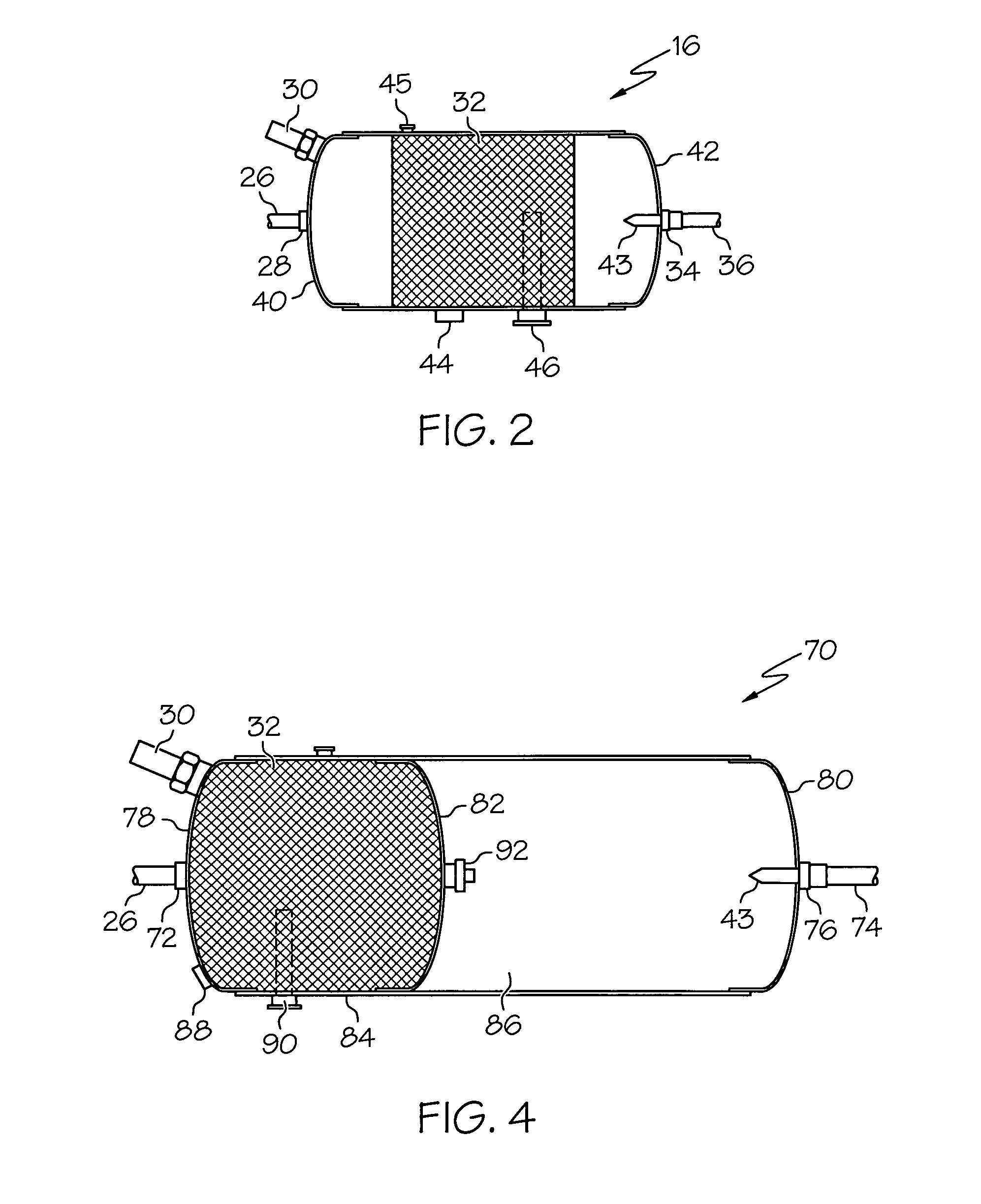

Water and oil mist elimination apparatus for a vehicular compressed air storage system

A moisture removal apparatus for a vehicular compressed air storage system includes a canister of mist-eliminating mesh that collects moisture and oil droplets in the air and exhausts them through a gravity drain. The mesh coalesces droplets of both water and oil vapor in the air stream, and is not contaminated by either. The mist eliminating canister can be a stand-alone device through which compressed air is delivered to a pressure tank, or may be integrated into a pressure tank for space efficiency.

Owner:JOHNSON WELDED PRODS

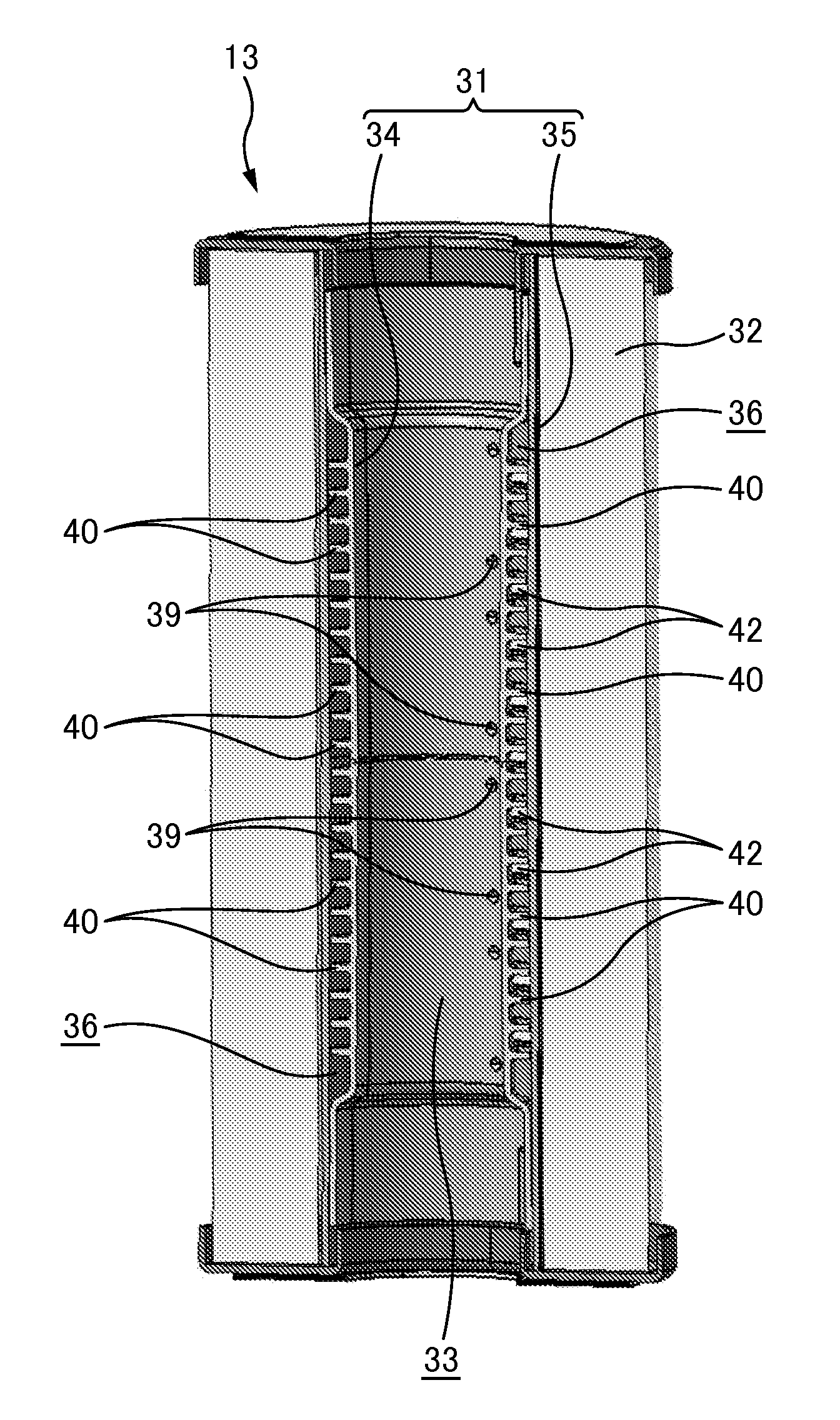

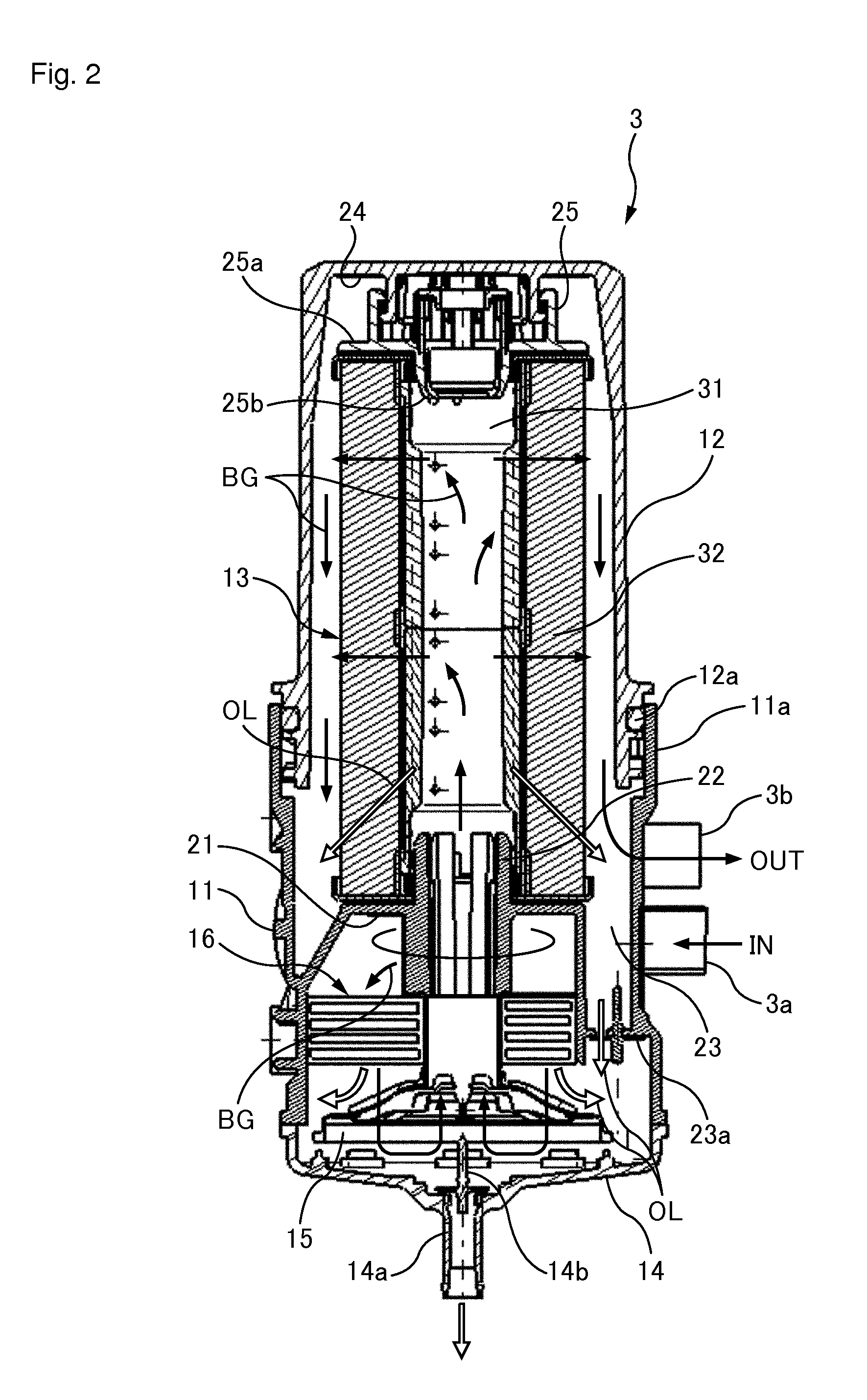

Oil mist separator

ActiveUS20130205726A1Improve performanceCombination devicesAuxillary pretreatmentDouble tubeOil mist

[Problem to be Solved]To enhance the performance for separation of oil mist from blow-by gas.[Solution]A filter element 13 which is to be attached to an oil separator unit 3 includes a core 31. This core is a double tube having an internal cylindrical member 34 and an external cylindrical member 35, and a space between the internal cylindrical member and the external cylindrical member is used as a separation chamber 36. An injection hole 39 for injecting blow-by gas while increasing its flow velocity is provided in the internal cylindrical member. A surface which is an inner wall surface of the external cylindrical member and which faces the injection hole is a spraying surface onto which the blow-by gas injected from the injection hole is sprayed. Moreover, an opening for oil discharge from which oil OL condensed on the spraying surface is discharged, and an opening for discharge from which the blow-by gas from which oil mist has been separated is discharged are provided in the core.

Owner:TOKYO ROKI

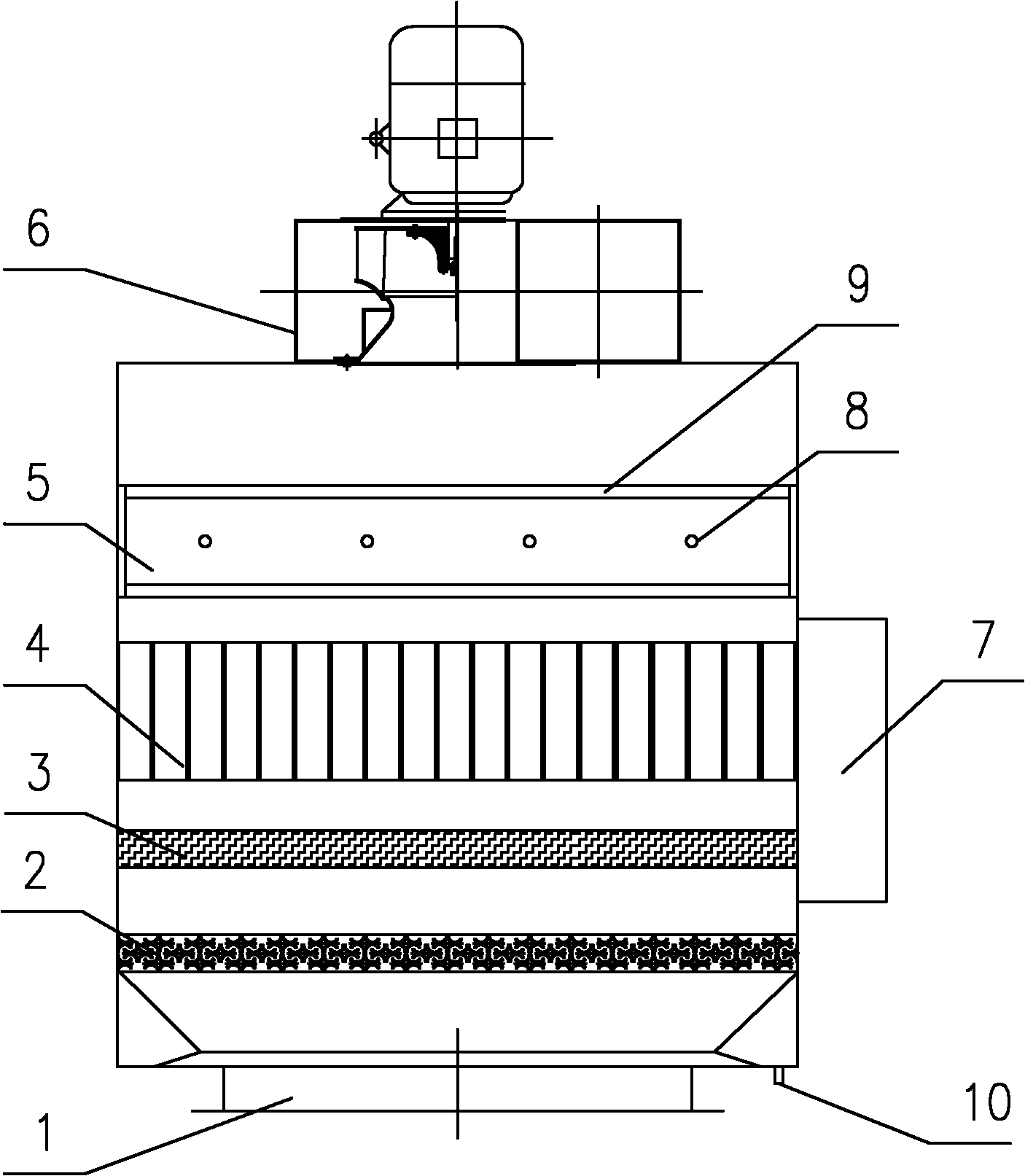

Kitchen oil mist and lampblack purifier

InactiveCN102252357AReduce power consumptionReduce energy consumptionCombination devicesDomestic stoves or rangesLow temperature plasmaLiving environment

The invention discloses a kitchen oil mist and lampblack purifier, which comprises a sealed purifier shell and an electric cabinet arranged outside the shell; the shell comprises an oil mist and lampblack suction port and an air outlet; an oil collecting groove primary filter plate, a fiber filter screen, a low-temperature plasma purifier and a photocatalyst purifier are sequentially arranged between the oil mist and lampblack suction port and the air outlet in the shell; and a fan is arranged on the air outlet. Through the purifier, oil mist and lampblack can be regularly, hierarchically and systematically trapped and collected, so that the oil mist and the lampblack are finally fully cracked, removed and purified and can also be instantaneously sterilized; the kitchen oil mist and lampblack purifier meets the environmentally-friendly emission requirement, and is simple in structure, low in investment, low in energy consumption, economic and feasible; and the kitchen oil mist and lampblack purifier provides a clean and healthy working and living environment for repast personnel and neighborhoods, and is suitable for lampblack and oil mist discharge purification treatment of the catering industry.

Owner:AEROSPACE KAITIAN ENVIRONMENTAL TECH CO LTD

Oil, water and solid multi-phase separation method for natural gas

InactiveCN101721875ASimplify traditional craftSolution to short lifeCombination devicesGaseous fuelsCycloneEngineering

The invention discloses an oil, water and solid multi-phase separation method for natural gas. The method is characterized in that: a shell is a horizontal tank structure; the horizontal tank is partitioned into four sections, namely a gas inlet water-washing region (19), a cyclone separation region (20), a coalescing separation region (21) and a tail end mist catching region (22); fluid produced by a gas well in the gas inlet water-washing region (19) enters the gas inlet water-washing region (19) through a gas inlet distributing pipe (1) of a multi-phase separator, and a solid phase and an oil phase in the gas can be separated rapidly; a large amount of saturated water is separated in the cyclone separation region (20) via a cyclone (4); saturated water mist and oil mist remaining in the gas are conglomerated once again by a coalescer (5) in an oil-water coalescing section of the coalescing separation region (21); and condensate oil and the water mist in the gas are fully removed by catching in the tail end mist catching region (22), and is finally discharged from a gas outlet (16) on the top of the tail end mist catching region (22). The method has small floor area, low investment and convenient maintenance, can not only simplify the process, but also achieve the aim of deep dehydration.

Owner:XIAN TIANXIANG ENERGY TECH

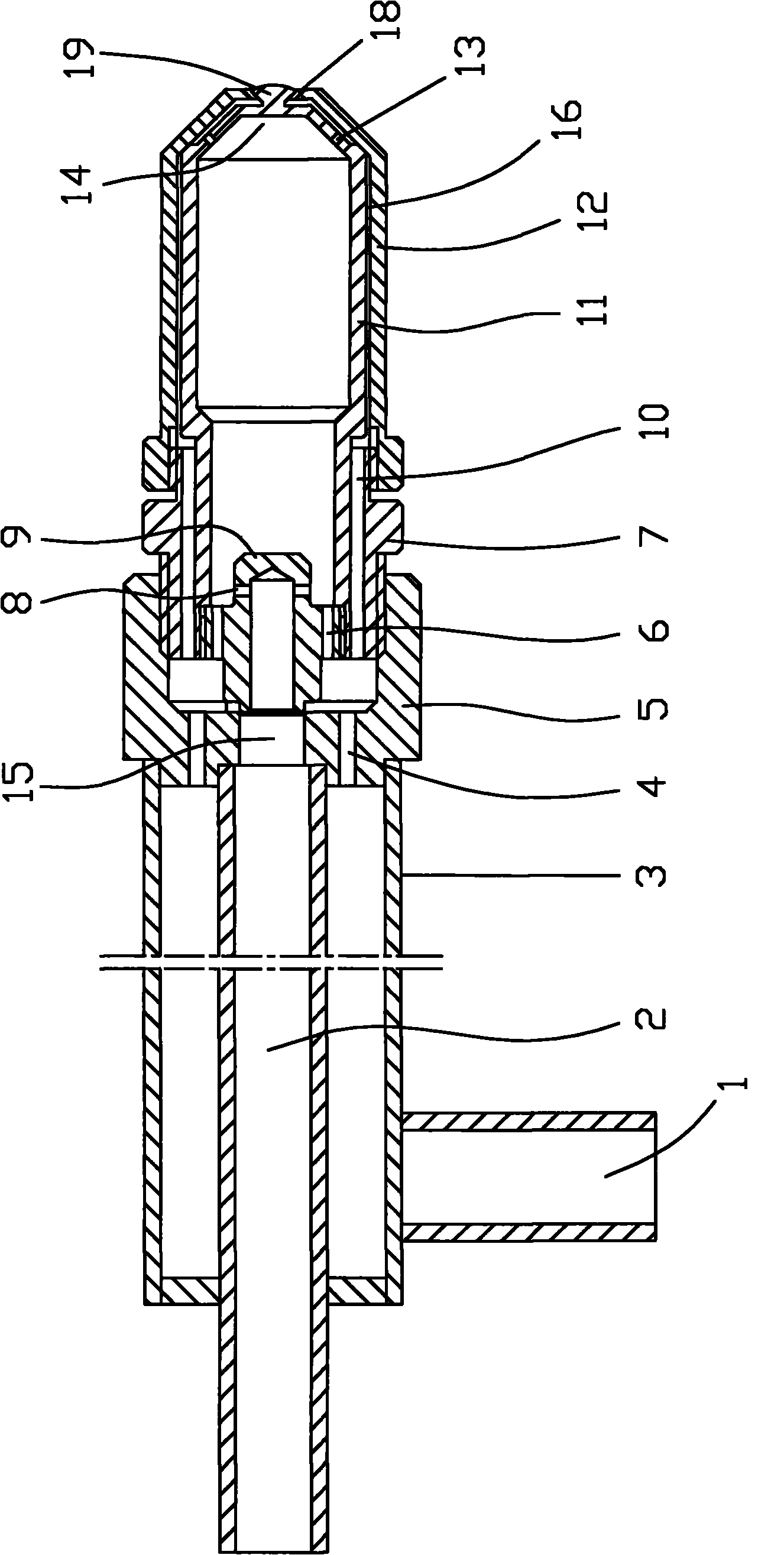

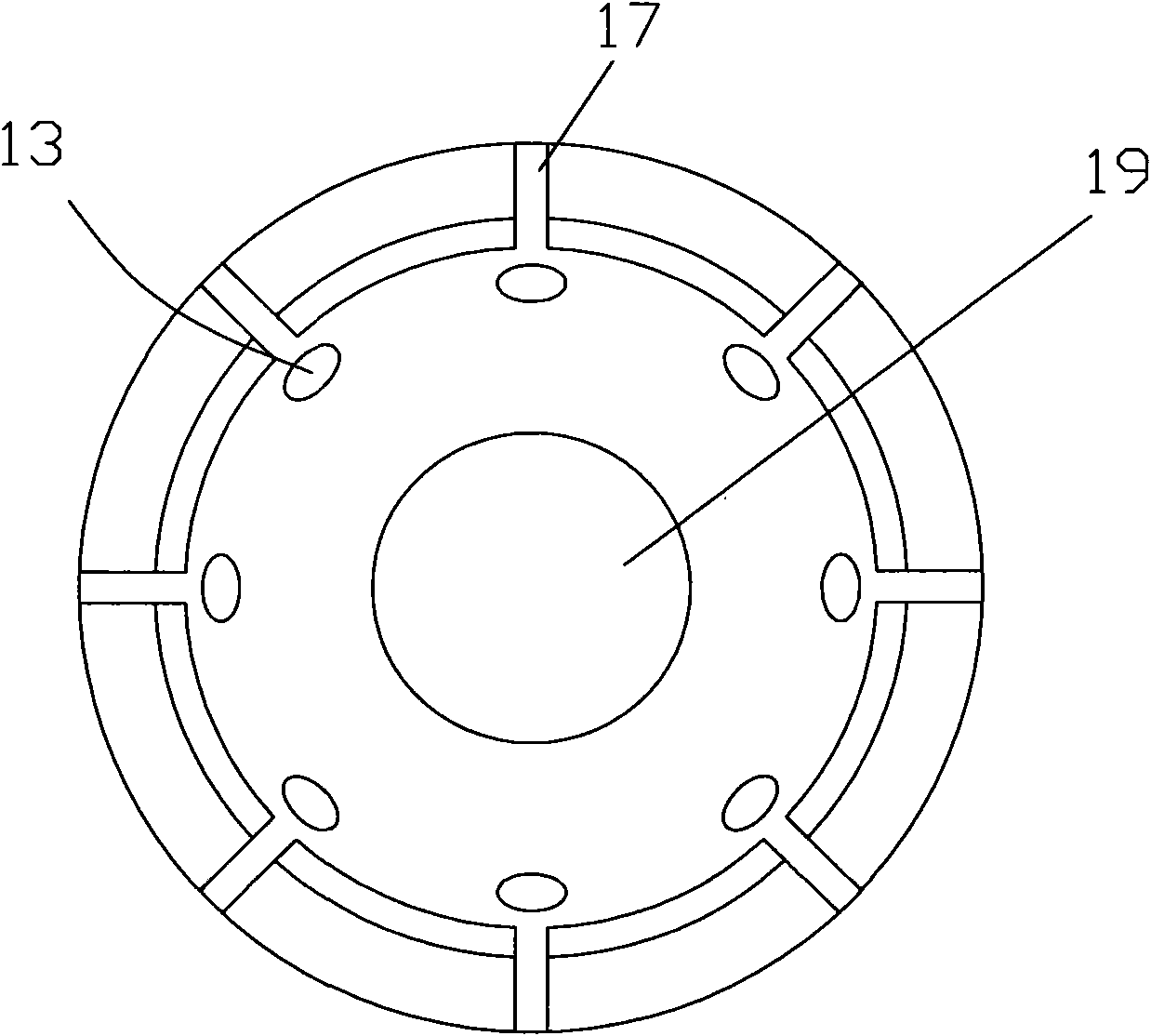

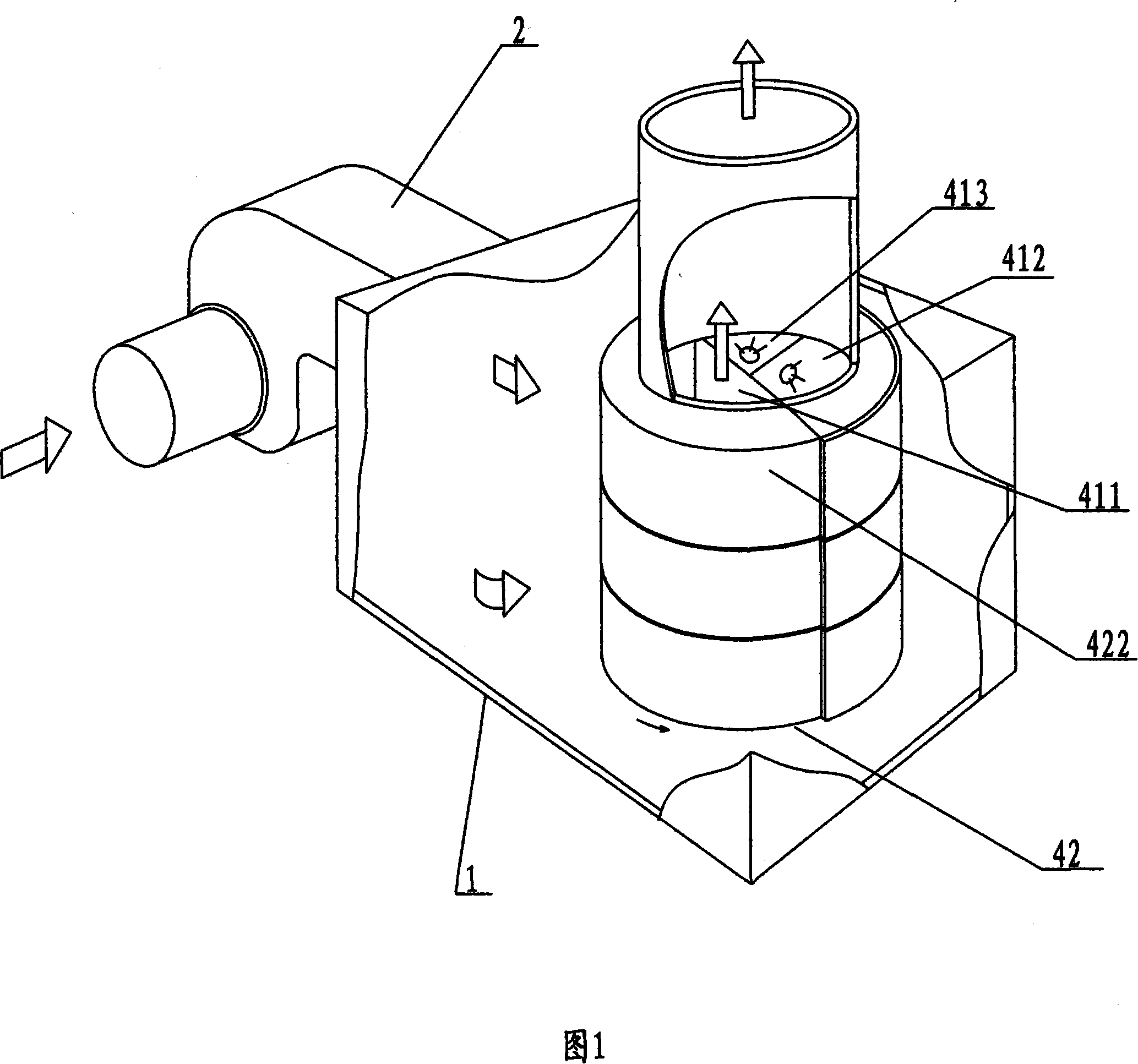

Low-pressure oil film breaking and atomizing technology and device thereof

The invention discloses low-pressure oil film breaking and atomizing technology and device thereof. The low-pressure oil film breaking and atomizing technology is characterized in that fuel oil and an auxiliary gas are formed into gas-liquid two-phase fluids, the gas-liquid two-phase fluids are jetted into a furnace cavity through an oil gun, and the jetted gas-phase fluids enable a formed oil film to be broken by overcoming the surface tension of the jetted gas-phase fluids so as to realize the superfine atomization of the fuel oil; the outlet of a circular jet hole is provided with a secondary transverse ultrasonic air flow, the jet direction of the secondary transverse ultrasonic air flow is perpendicular to that of the circular jet hole, and the secondary transverse ultrasonic air flow further impacts initially-atomized fuel oil jetted from the circular jet hole to carry out secondary breakage and atomization on the fuel oil. The invention has the advantages of smaller average diameter of an oil drop, high penetrating capability of oil mist, good adjustability of an atomized taper angle and very little change of the average dimension of the oil drop when the viscidity of the fuel oil is enhanced or the ejection force of the oil gun is smaller; and in addition, the invention only needs lower fuel oil pressure of 0.4-0.5 MPa, thereby lowering the pressure of a fuel oil system, reducing the electricity consumption of an oil pump and saving the plant electrical consumption.

Owner:艾佩克斯科技(北京)有限公司

Oil mist removing method with automatic cleaning and device thereof

The invention relates to an oil and smoke removing method and device with automatic cleaning function. The method is that: adopt a rotating structure to drive a filtering rotaing barrel made of filtering material to rotate and make the filtering material cycle through an air process zone, a liquid cleaning zone and an air back flushing zone in sequence; on the air process zone, the filtering material filters the oil and smoke in the air, the air after processed can be discharged out directly; on the liquid cleaning zone, adopting cleaning agent and spaying device to force the oil and smoke separated from the filtering material; on air back flushing zone, using high pressure air to blow away the cleaning agent remained on the filtering material. The device mainly comprises: a shell, a blower, filtering material and a rotating structure, the rotating structure comprises a wheel carrier, a filtering rotating barrel and a motor, the motor drives the filtering rotating barrel to rotate, the filtering material can rotate in the air process zone, the liquid cleaning zone and the air back flushing zone according to the pre-set speed. The device can work continuously and be under the situation of high efficiency and low flow resistance for a long time, which doesn't need manual regular cleaning and saves time and labour.

Owner:马军

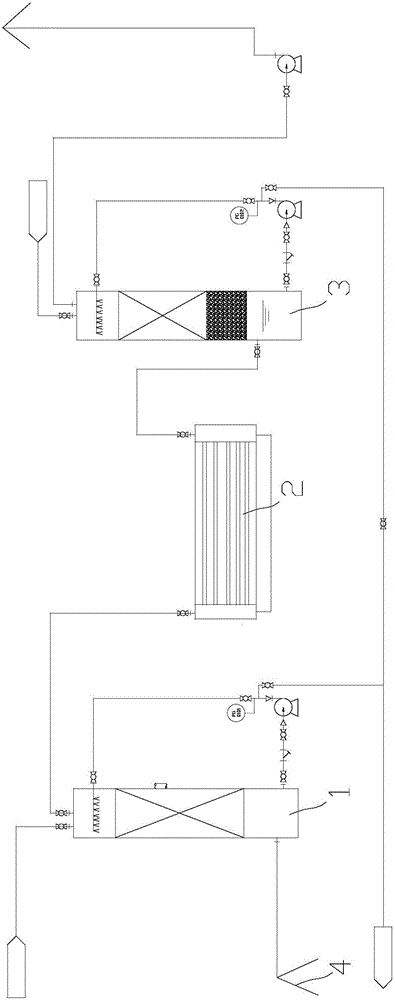

Organic exhaust gas degradation method and device

InactiveCN105964136APromote degradationFlexible adjustment of process parametersGas treatmentUsing liquid separation agentDecompositionCatalytic oxidation

The invention discloses an organic exhaust gas degradation method and device. The organic exhaust gas degradation method comprises the steps that particles and oil mist in exhaust gas are removed, and then the exhaust gas is delivered into a photocatalytic oxidation reactor; a catalyst is exposed to ultraviolet irradiation, the exhaust gas is directly subjected to splitting decomposition on the surface of the catalyst, meanwhile hydroxyl radicals and ozone are produced, and organic exhaust gas is further oxidized; non-decomposed exhaust gas is delivered into a catalytic oxidation scrubbing tower and is further subjected to oxidative decomposition under the combined action of the catalyst and an oxidizing agent. The device comprises a gas inlet pipeline, a gas outlet pipeline, a pretreatment tower, the photocatalytic oxidation reactor and the catalytic oxidation scrubbing tower. The organic exhaust gas degradation method thoroughly decomposes organic pollutants under the combined action of photocatalytic oxidation and catalytic oxidation scrubbing and does not produce secondary pollution.

Owner:ZHEJIANG QICAI ECO TECH CO LTD

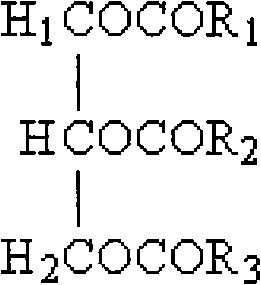

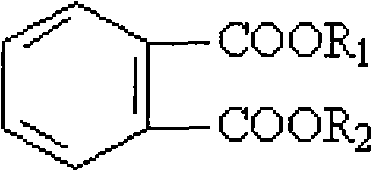

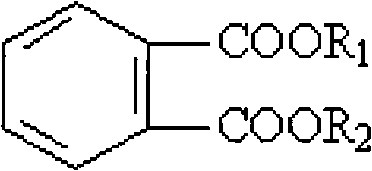

Cold rolling oil composition and use thereof

The invention relates to a cold rolling oil composition and use thereof, which is mainly used for solving the problems of heavy oil mist in a workshop after rolling as well as poor surface cleanness and poor annealing cleanness after rolling in the prior art. The cold rolling oil composition comprises the following components in parts by weight: a) 1-20 parts of aromatic acid diester, b) 1-25 parts of fatty acid monoester, c) 0.01-5 parts of a fog resistant agent and d) 50-97.99 parts of base oil; and the structural formula of the aromatic acid diester is shown in the specification, wherein R1 and R2 are chosen from alkyl groups with 3-8 carbon atoms. By means of the technical scheme, the problems are better solved; and the cold rolling oil composition can be applied to industrial production of stainless steel thin plates with 2B and BA high-precision grades.

Owner:CHINA PETROLEUM & CHEM CORP

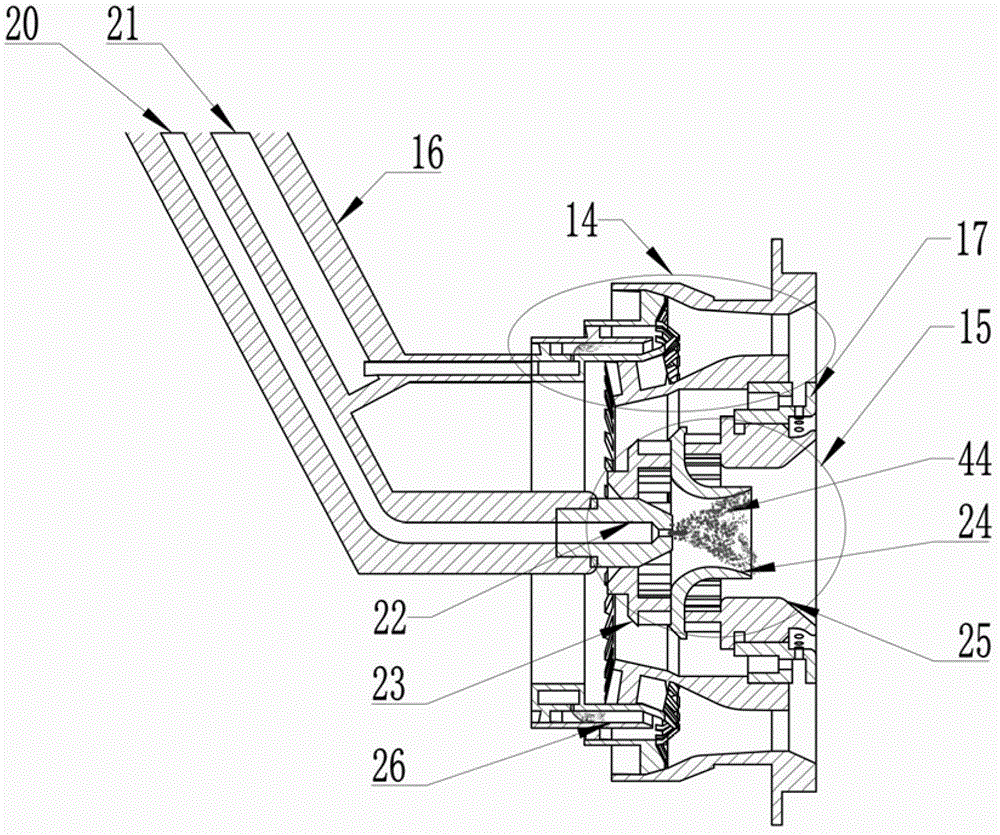

Low-emission combustion chamber for spraying oil through holes in primary combustion stage blades

ActiveCN106123033ASufficient convenience for afterburningImprove distributionContinuous combustion chamberCombustion chamberFuel oil

The invention relates to the technical field of gas turbines, and discloses a low-emission combustion chamber for spraying oil through in primary combustion stage blades. One or more radial primary combustion stage oil through holes are formed in each primary combustion stage blade at the head of the combustion chamber. One or more primary combustion stage oil spray holes are formed in the side of each primary combustion stage blade. The primary combustion stage oil spray holes communicate with the primary combustion stage oil through holes in the corresponding primary combustion stage blades. Fuel oil enters the primary combustion stage blades along a primary combustion stage fuel oil supply circuit, a primary combustion stage oil collection chamber and the primary combustion stage oil through holes in sequence, and is sprayed out from the primary combustion stage oil spray holes to form primary combustion stage oil mist with a helical track. The primary combustion stage oil mist is mixed with air flow in a primary combustion stage channel to form an oil-air mixture, and the oil-air mixture enters a flame tube to participate in the combustion, so that blending of fuel oil and air flow is enhanced, the radial distribution uniformity of fuel oil is improved, and nitrogen oxide emission of the combustion chamber under a large working condition can be reduced remarkably; and besides, the primary combustion stage oil spray holes are far from the inner wall surface of the primary combustion stage channel, so that the condition that fuel oil is attached to the wall surface is avoided.

Owner:BEIHANG UNIV

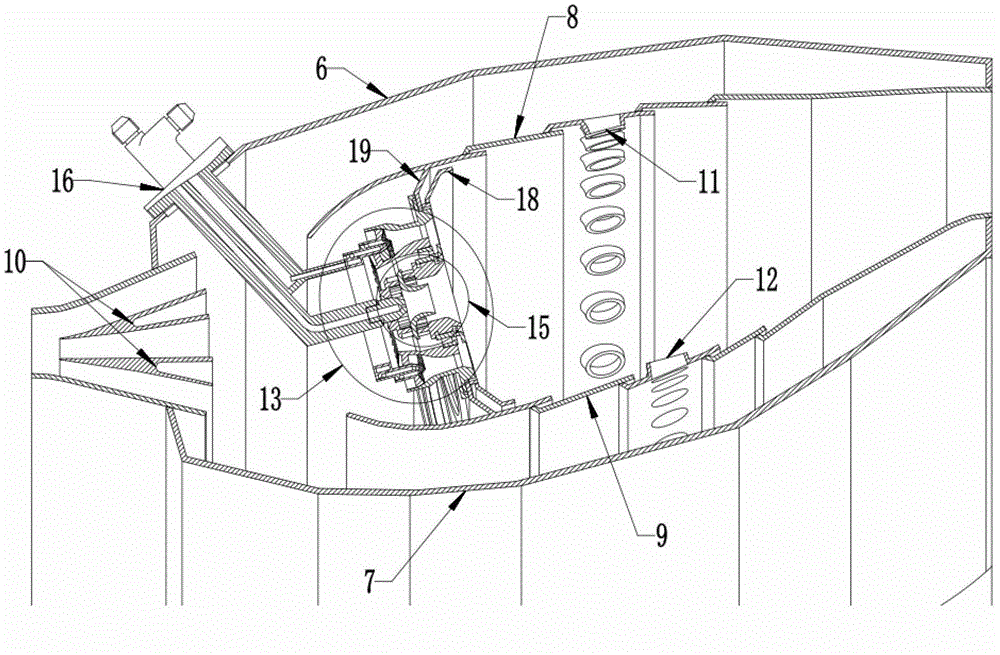

Single-oil passage pre-diaphragm type staggered plate primary combustion stage premixing and pre-vaporizing low-pollution combustor

ActiveCN103335333AReduce pollutionPollution discharge is beneficial toContinuous combustion chamberCombustion chamberSingle stage

The invention relates to a single-oil passage pre-diaphragm type staggered plate primary combustion stage premixing and pre-vaporizing low-pollution combustor, which adopts a single-annulus cavity structure, a central staged combustion method is adopted by the combustor, a combustor head is divided into a pre-combustion stage and a primary combustion stage, the combination of diffusion combustion and swirling premixed combustion is adopted by the pre-combustion stage, and while the stability of combustion is guaranteed, pollutant emission under the low working condition is reduced; and a premixing and pre-vaporizing combustion method is adopted by the primary combustion stage, so that the combustion of pollutants can be effectively reduced. The primary combustion stage is a single-stage oil passage, fuel oil can form an oil film on a pre-diaphragm plate, the oil film is atomized, vaporized and mixed with the air under the action of two streams of swirls, the formed oil-air mixture is radially mixed additionally under the function of the staggered plates, uniform oil-air mixture is formed under the swirling effect of an internal swirler and an external swirler, the pre-diaphragm plate can help to enhance the circumferential uniformity of the oil mist, while the radial mixing and diffusion of the oil mist are enhanced by the staggered plates, consequently, uniform oil-air mixture can be formed at the outlet of the primary combustion stage, and the combustion of pollutants can be reduced.

Owner:BEIHANG UNIV +1

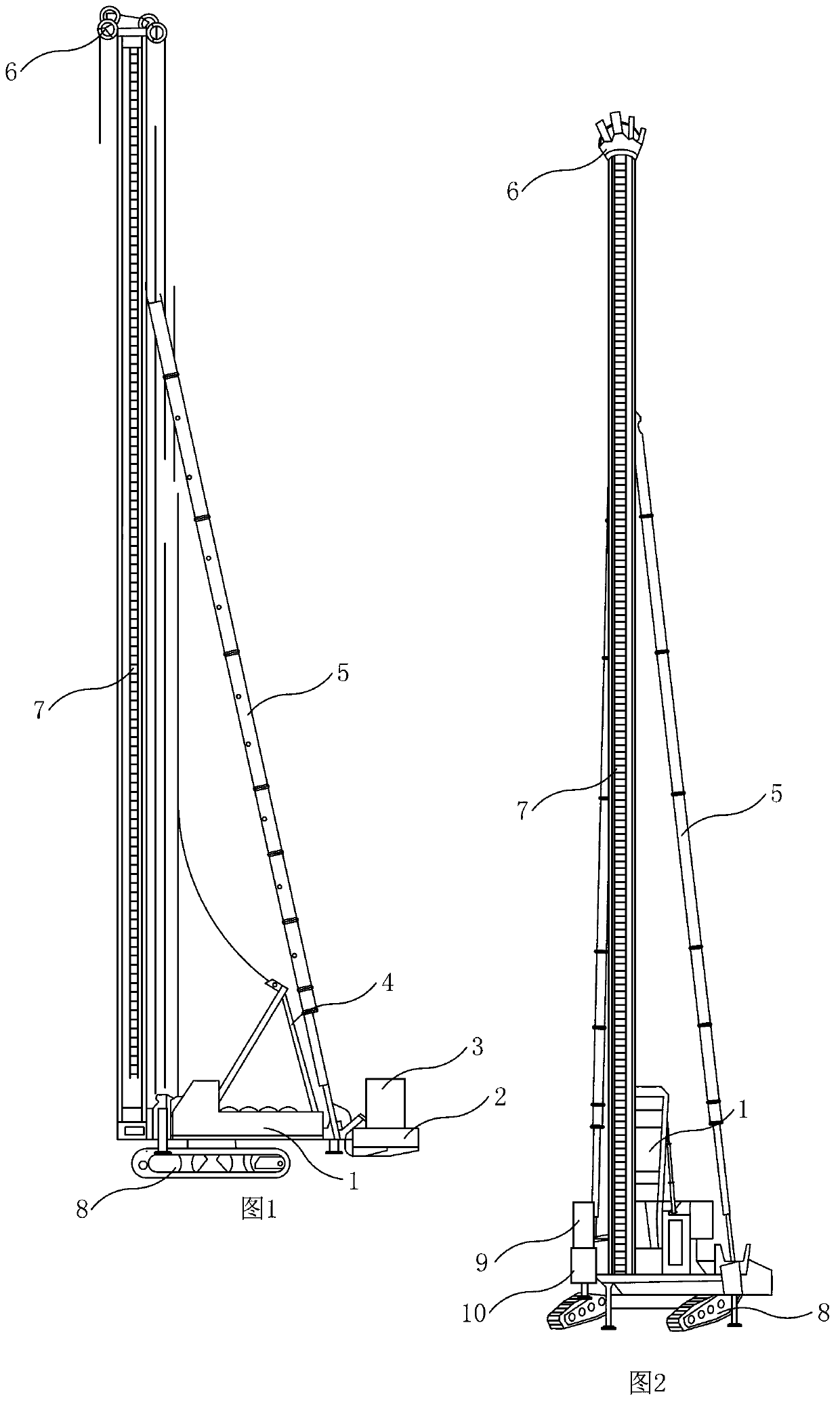

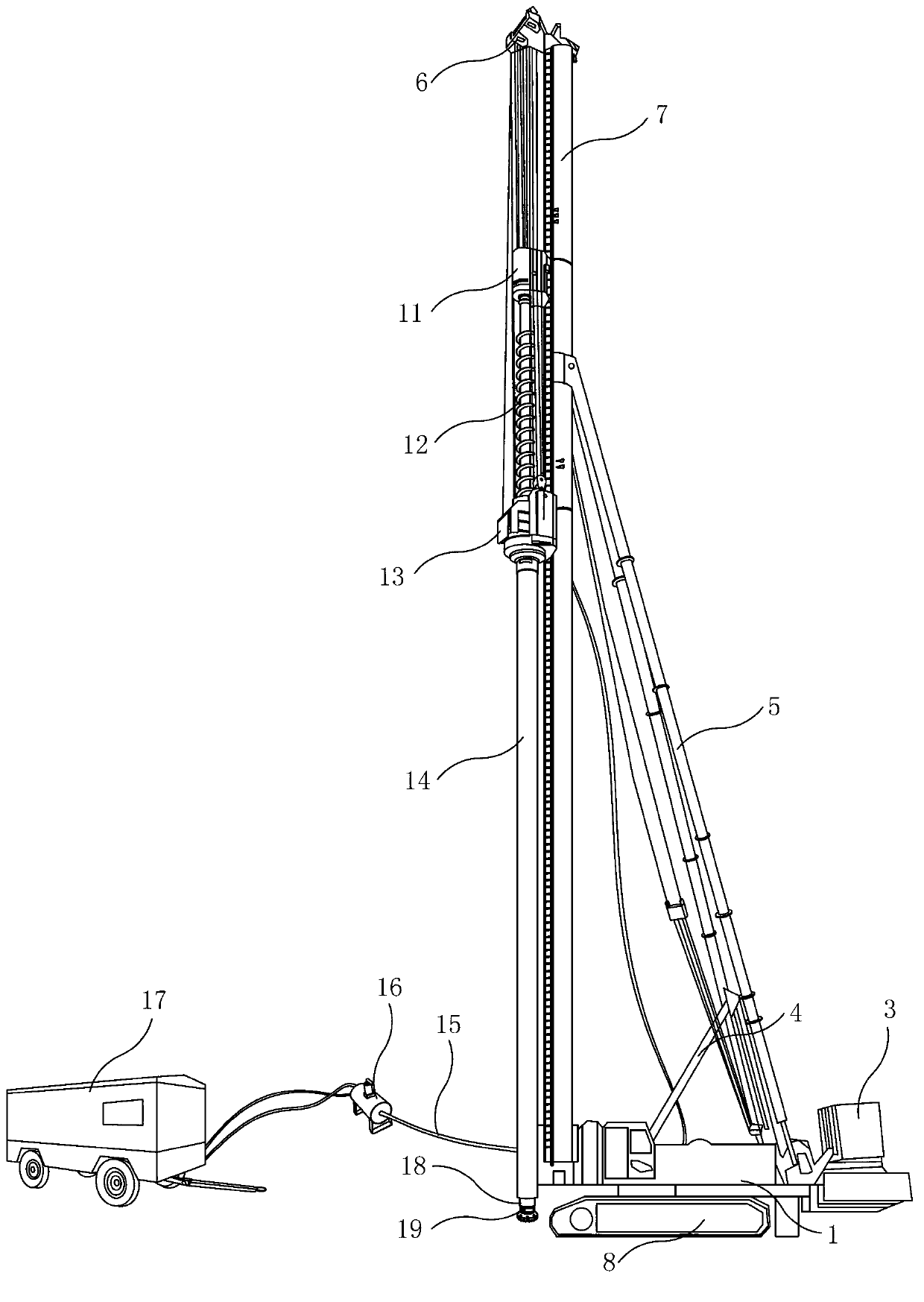

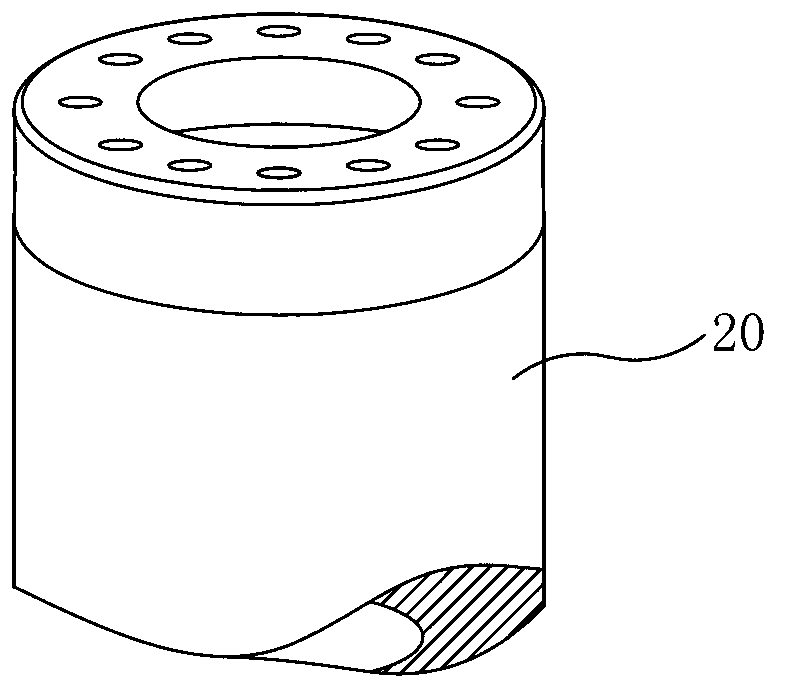

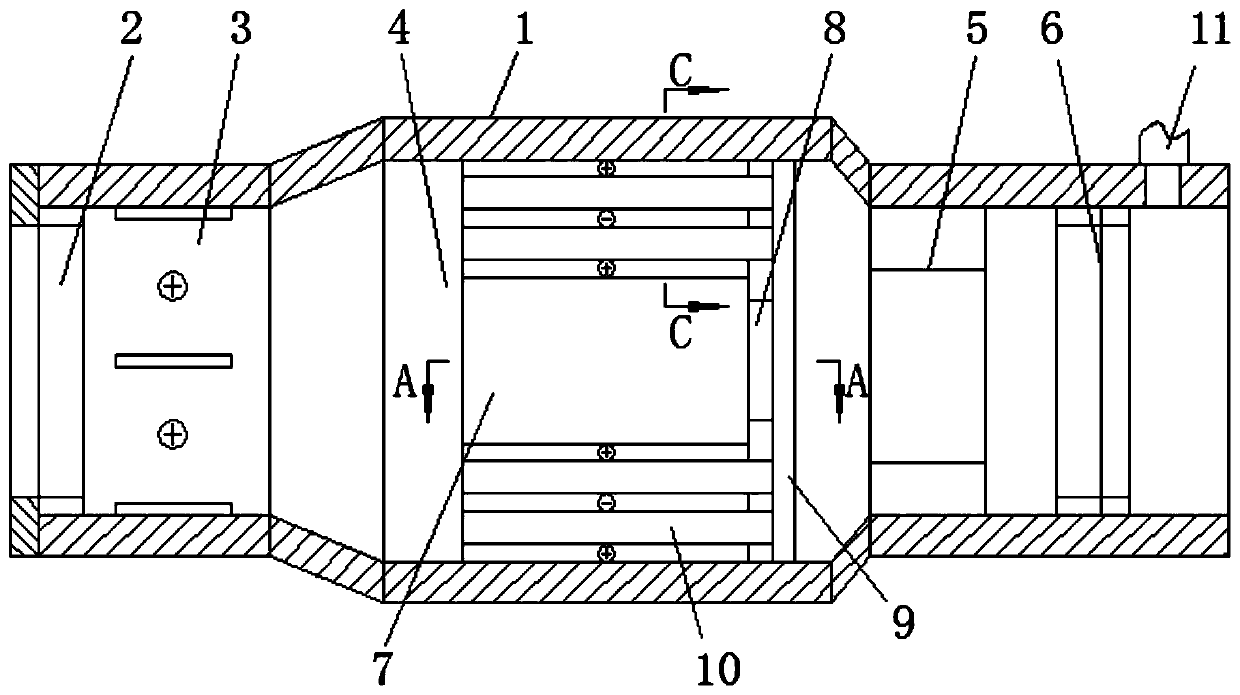

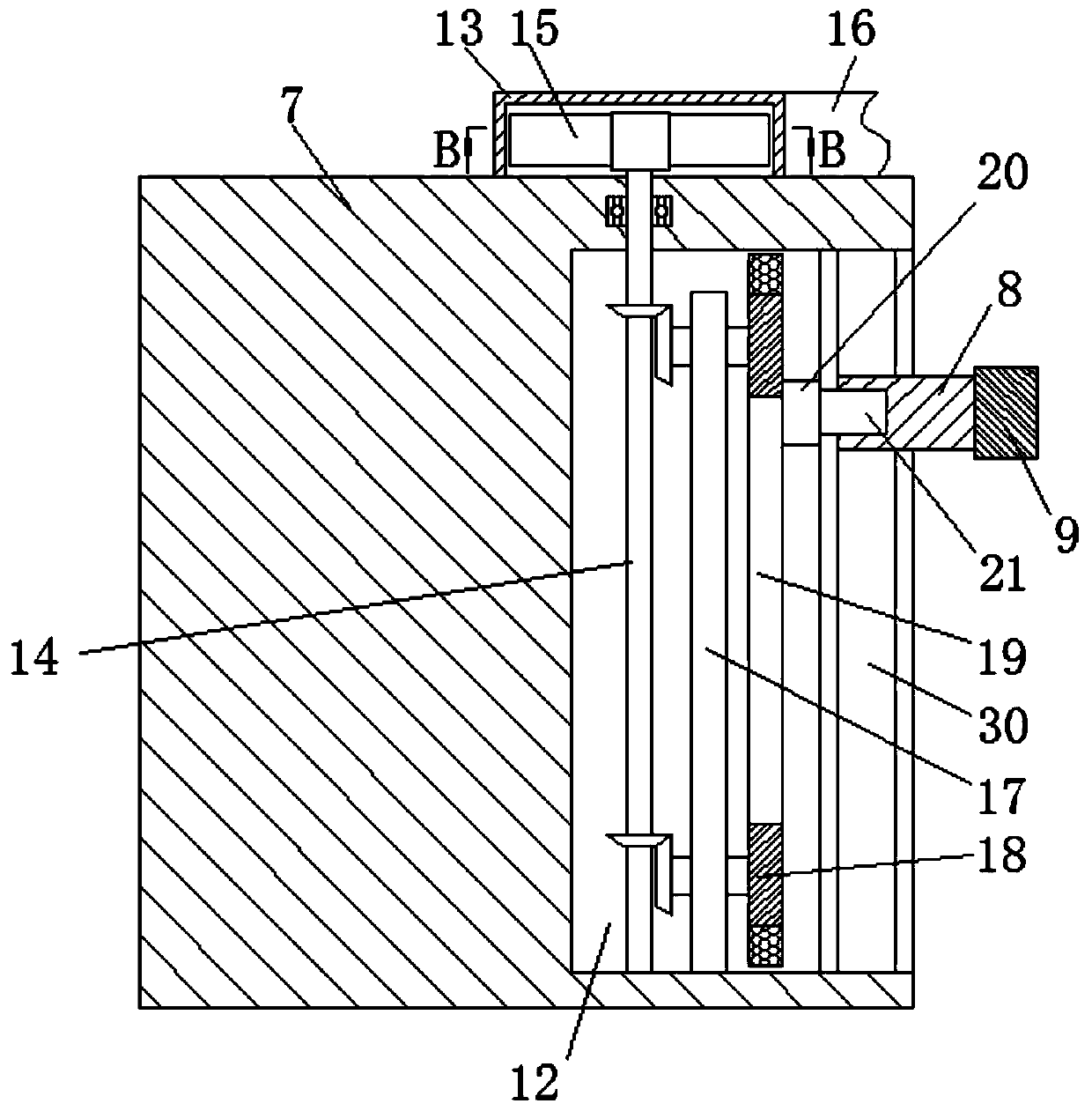

Device for drilling rock and embedding rock-socketed prestressed pipe pile by down-hole hammer and construction method of device

InactiveCN103132908ASolve the technical problem of poor effect of rock-socketed pile plantingBorehole drivesBulkheads/pilesPile capHigh pressure

The invention relates to a device for drilling rock and embedding a rock-socketed prestressed pipe pile by a down-hole hammer and a construction method of the device and aims to solve the problem that existing similar product structures and construction methods are poor. The device comprises a crawler-type pile driver, a casing pipe, an upper power head, a lower power head, a long spiral drill bar, the down-hole hammer, a rock drilling bit, an oil atomizer, an air compressor, an air duct and the like. The device is characterized in that the down-hole hammer is a pneumatic down-hole hammer, high-pressure blast generated by the air compressor sequentially passes through the air duct, the oil atomizer, the air duct and the upper power head and then passes through an air channel of inner holes of the long spiral drill bar to reach to the down-hole hammer, the casing pipe is driven by the lower power head to rotate anticlockwise to be pre-buried in a clay stratum, a gravel layer and a rock stratum, then the pipe pile is placed in the casing pipe, the pipe pile is embedded into the rock stratum, the casing pipe can be slowly pulled out by the crawler-type pile driver, a drop hammer is used for hammering a pile cap or a pile follower of the pipe pile till the pipe pile is fixed in a drill hole, and the pipe pile is organically combined with a rock surface of the rock stratum at the hole bottom. The device is applied to the construction of the rock-socketed prestressed pipe pile.

Owner:宁波市中乾建筑工程有限公司 +1

Electrostatic lampblack purifier

ActiveCN111111927AImprove purification efficiencyReduce maintenance costsExternal electric electrostatic seperatorElectrodes cleaningEnvironmental engineeringParticle adsorption

The invention relates to the field of lampblack purification equipment, in particular to an electrostatic lampblack purifier. The purifier comprises a housing, and a front filtering and purifying device, a high-voltage ionization field, a low-voltage electrostatic adsorption field, an axial flow fan and a rear filtering and purifying device are sequentially arranged in the shell from left to right. The low-voltage electrostatic adsorption field comprises an electrode plate group and a driving box, a driving mechanism and a lifting mechanism are arranged on the driving box, an oil scraping mechanism used for scraping oil stains on the electrode plate group is arranged on electrostatic lampblack purifier utilizes an air flow as driving force to allow the lifting mechanism to drive the oil scraping mechanism to perform oil scraping operation on the electrode plate, so that real-time cleaning of the electrode plate is achieved, the service life of the electrode plate is prolonged, the electrode plate is kept in a stable and efficient oil mist particle adsorption effect all the time, the lampblack purification efficiency is improved, the electrode plate does not need to be disassembledand cleaned, time and labor are saved, and the maintenance cost of the lampblack purifier is greatly reduced.

Owner:北京鑫皓超燃厨具设备有限公司

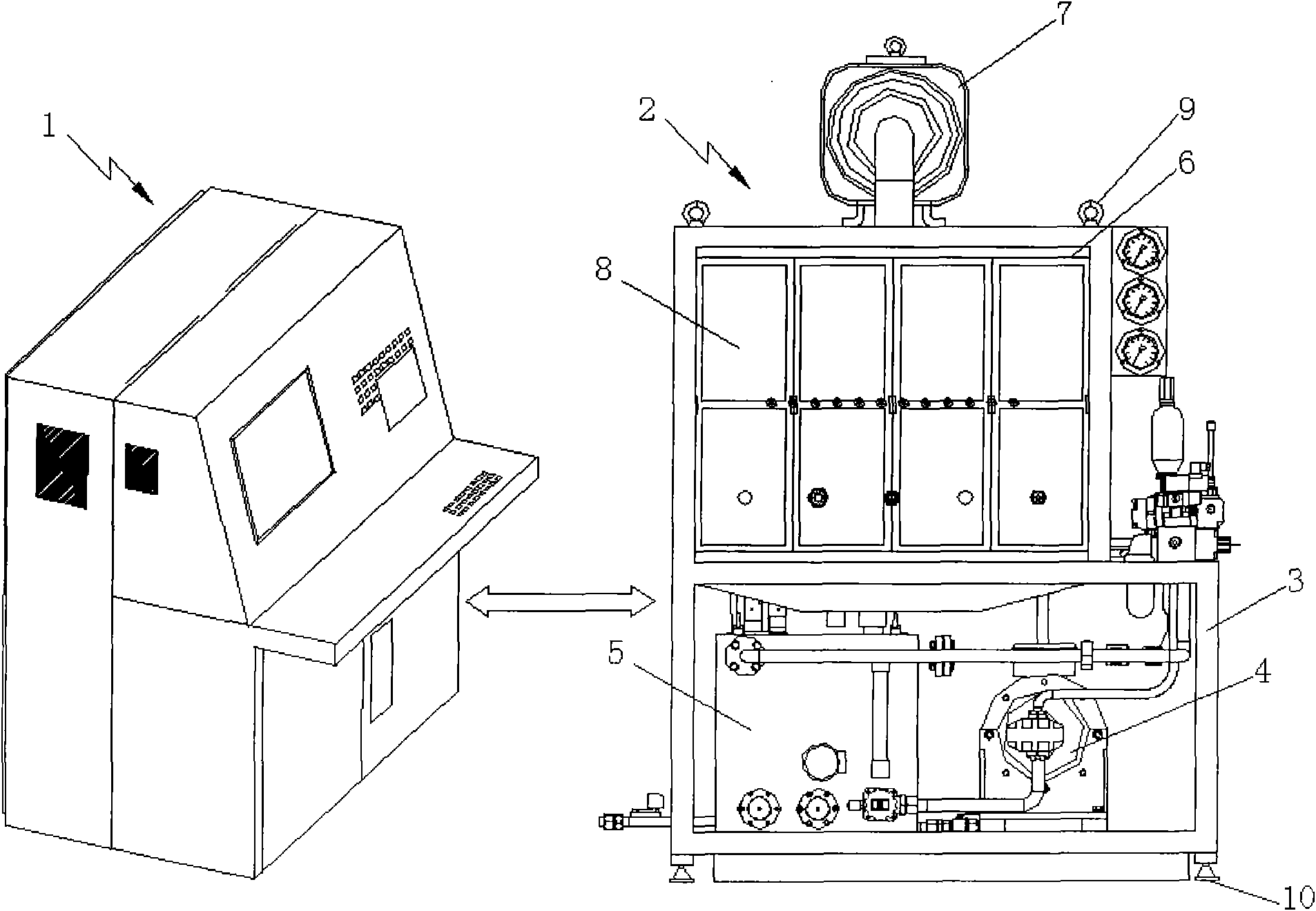

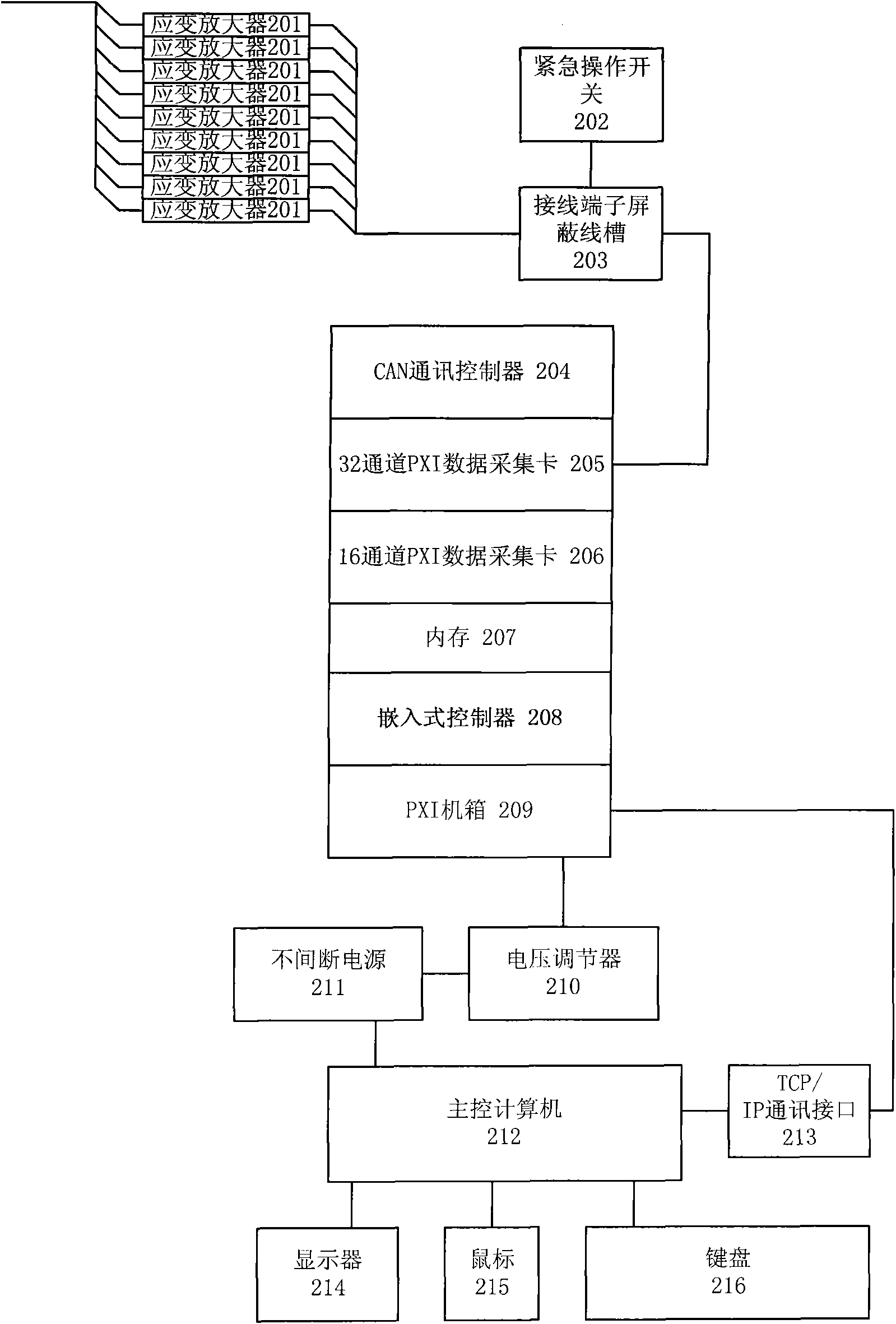

Testing device for CVT (Constant-Voltage Transformer) valve body performance testing

InactiveCN101957258ASimple structureEasy to useMachine gearing/transmission testingFuel tankControl circuit

The invention relates to a testing device for CVT valve body performance testing, which is formed by connecting a controlling machine and a testing machine; the controlling machine comprises an operation table and a control circuit inside the operation table; and the testing machine comprises a framework assembly, a hydraulic system, a hydraulic oil box and a testing cabin, wherein the hydraulic system is connected with the hydraulic oil box and positioned at the bottom of the framework assembly, the testing cabin is positioned at the upper part of the framework assembly, and an oil mist collector is installed at the top of the framework assembly. The invention realizes the performance testing for the pressure, the temperature and the like of an automobile stepless speed-changer valve body by adopting a mechanical-electrical-hydraulic combined mode, has the advantages of simple structure, convenient use and high testing precision, can be used for carrying out automated performance testing on the automobile stepless speed-changer valve body according to testing requirements, reduces the testing expenses and shortens the testing period.

Owner:江苏海超电子技术有限公司

Water-soluble low oil fog anti-rust cutting liquid

InactiveCN101265437AImprove the lubrication effectImprove rust resistanceAdditivesSolubilityPhosphate

The invention relates to a water-soluble low oil mist antirust cutting liquid used for the ferrous and nonferrous metal heavy-duty cutting operation, and the preparation method thereof. The preparation method comprises the following steps: firstly, the low oil mist antirust cutting liquid is prepared; secondly, the low oil mist antirust cutting liquid is added in a reaction vessel as the base oil, and is mixed, heated and warmed up to 60 to 80 DEG C; and then 5 to 15 percent of emulsifying agent, 3 to 10 percent of water solubility phosphate ester and 0.5 to 2 percent of copper / aluminum corrosion inhibitor by the base oil wight are added in sequence; after the completion of feeding, the heating to the reaction vessel is stopped, and the mixed liquor is agitated continuously untill in the uniform and transparent state. The prepared cutting liquid is used after being diluted by adding water, is particularly suitable for metal drilling, threading, gear processing and other heavy-duty cutting operations, and has good extreme pressure lubricating property and anti-rust property. The production cost of the cutting liquid is low, the oil mist is extremely low when in use, and no penetrating odor exists.

Owner:CHANGZHOU XIALEI CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com